Patents

Literature

5346 results about "Internal combustion engine cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Internal combustion engine cooling uses either air or liquid to remove the waste heat from an internal combustion engine. For small or special purpose engines, cooling using air from the atmosphere makes for a lightweight and relatively simple system. Watercraft can use water directly from the surrounding environment to cool their engines. For water-cooled engines on aircraft and surface vehicles, waste heat is transferred from a closed loop of water pumped through the engine to the surrounding atmosphere by a radiator.

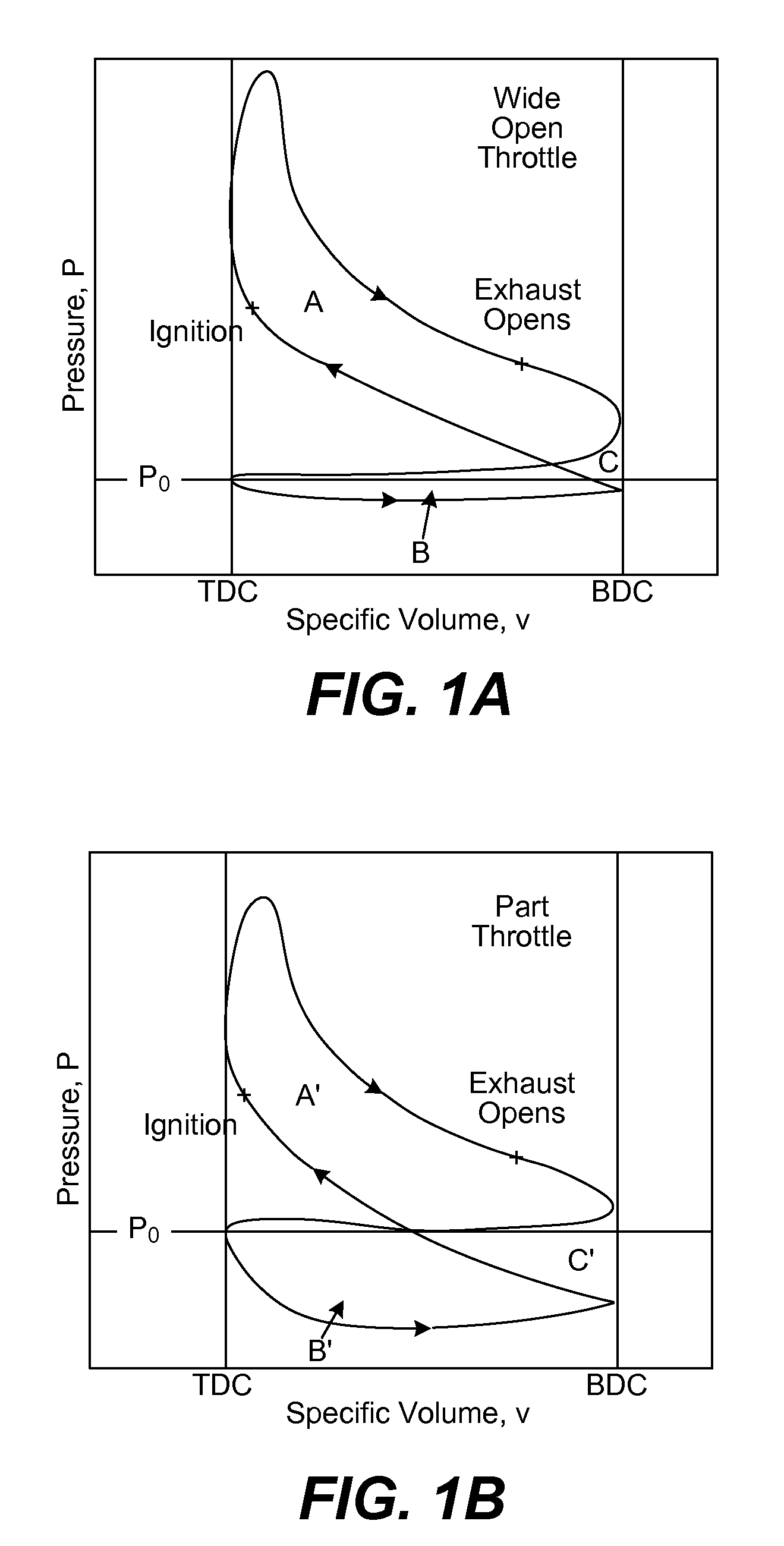

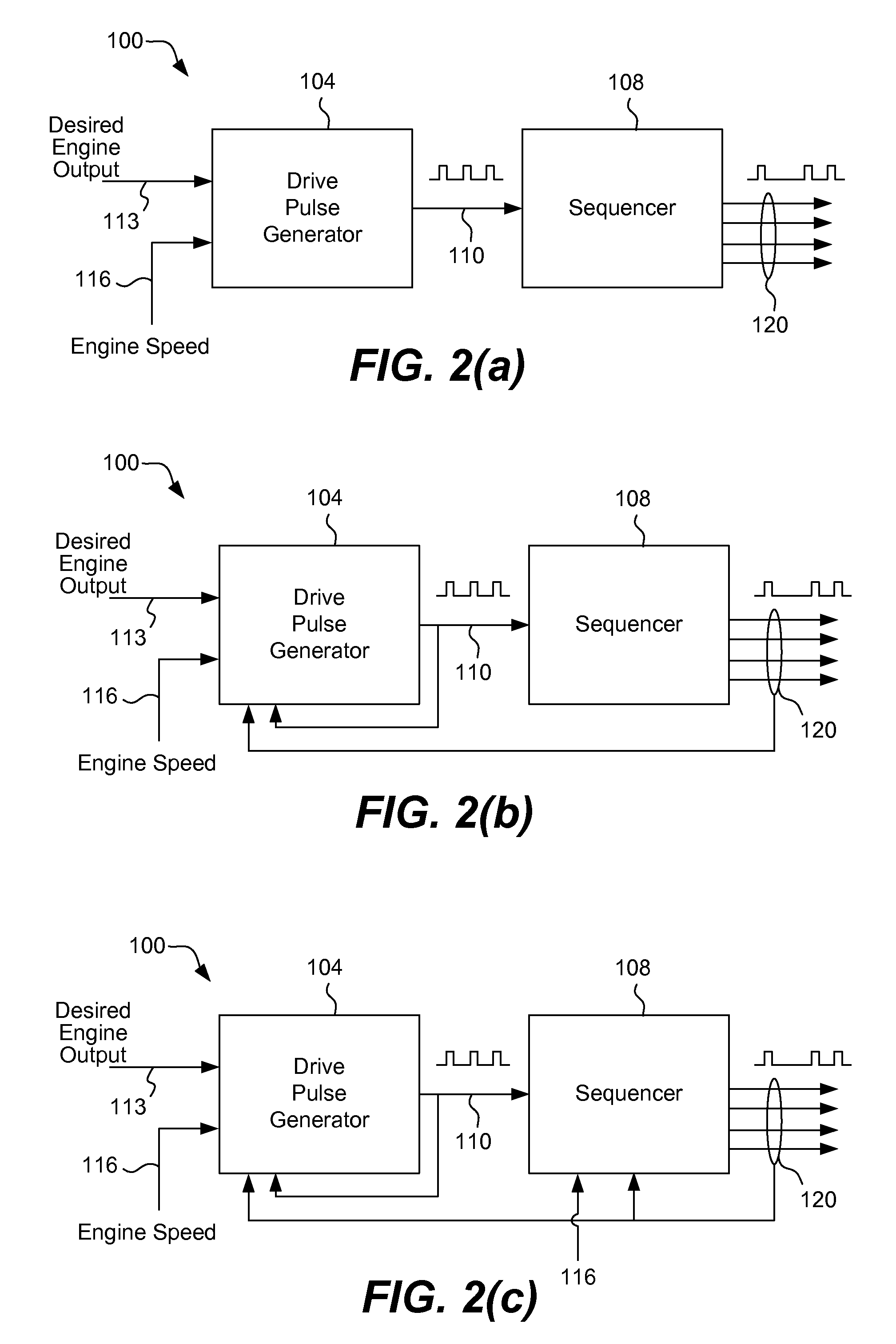

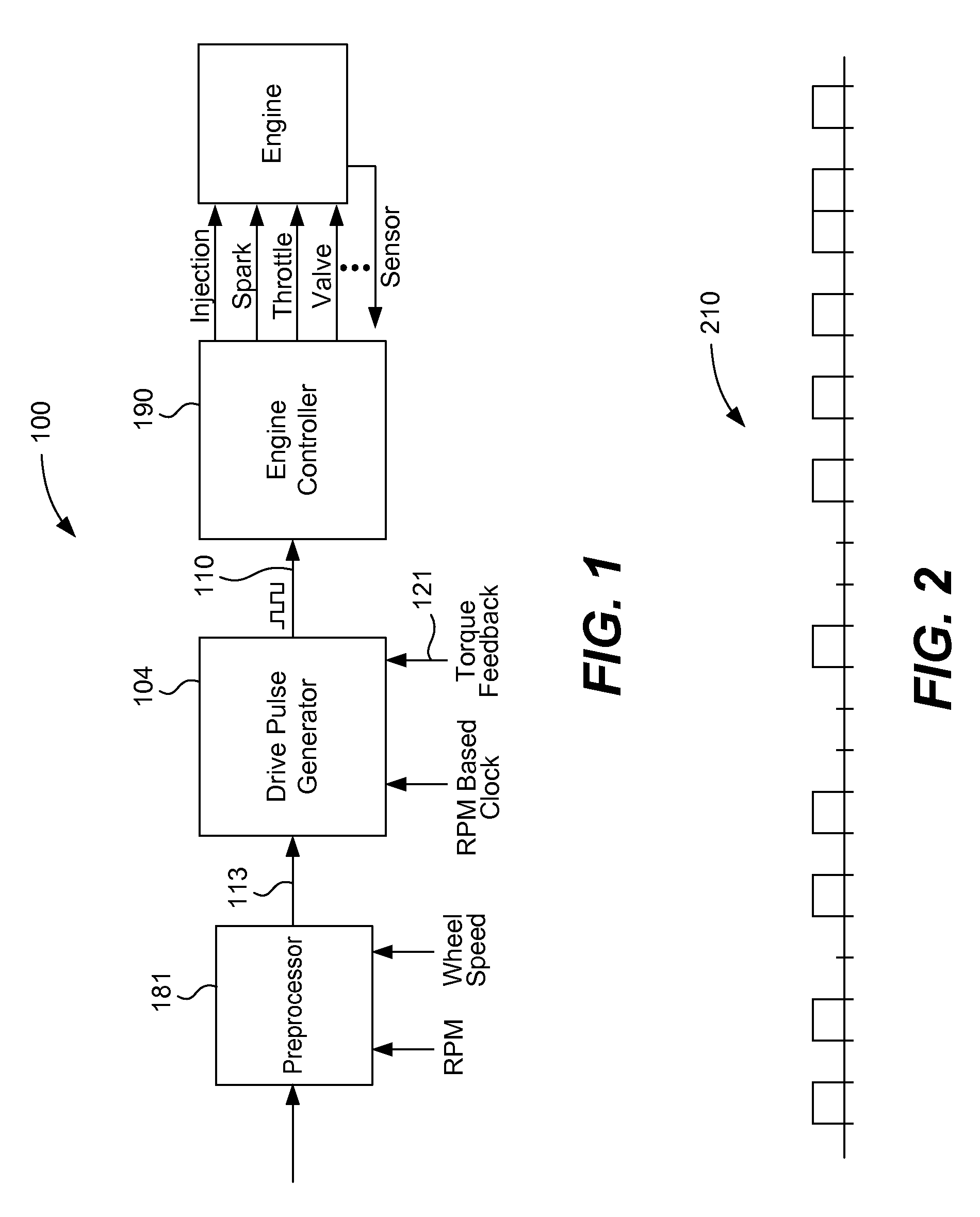

Internal combustion engine control for improved fuel efficiency

ActiveUS7577511B1Smoother and precise controlReduce probabilityElectrical controlInternal combustion piston enginesExternal combustion engineWork cycle

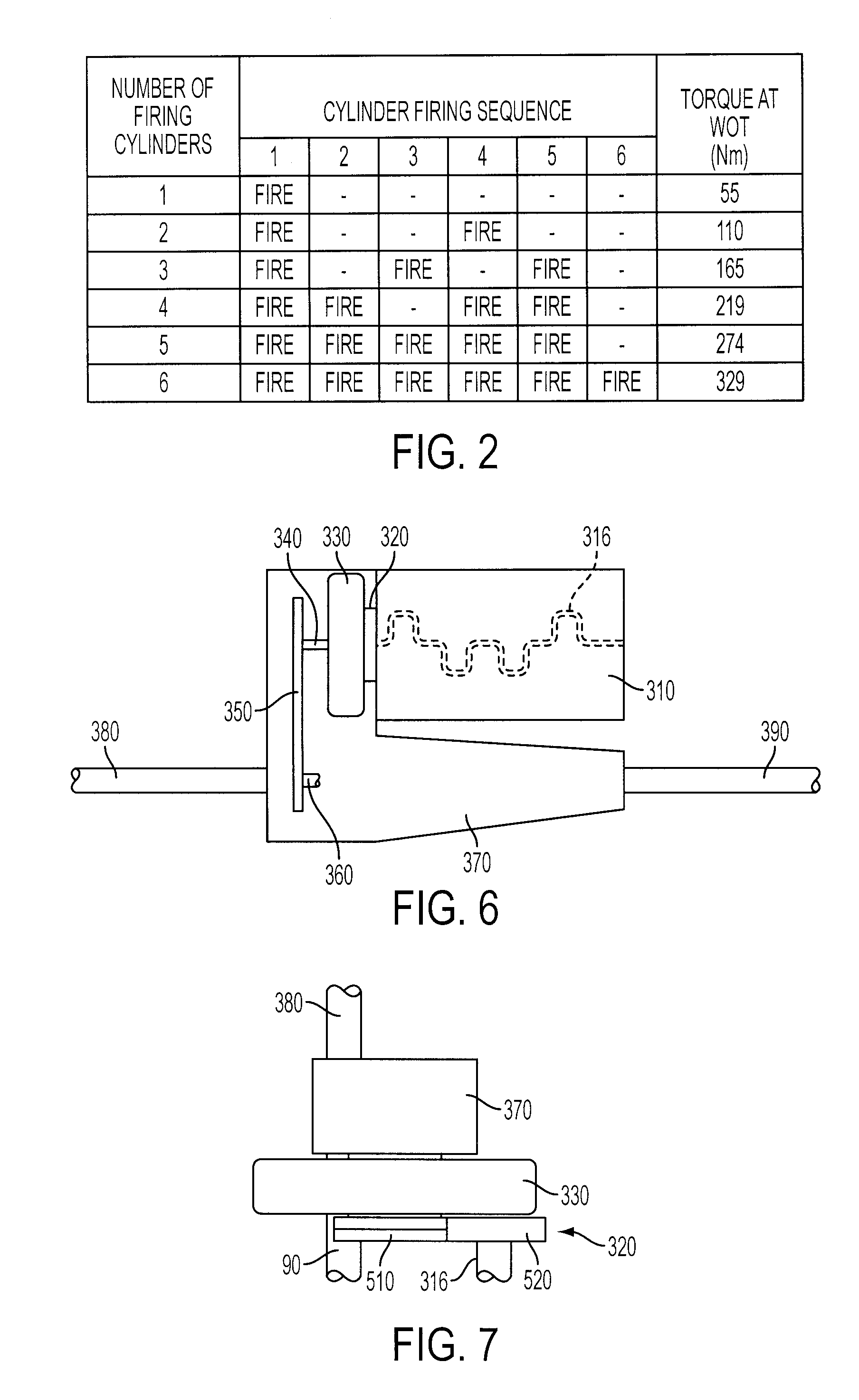

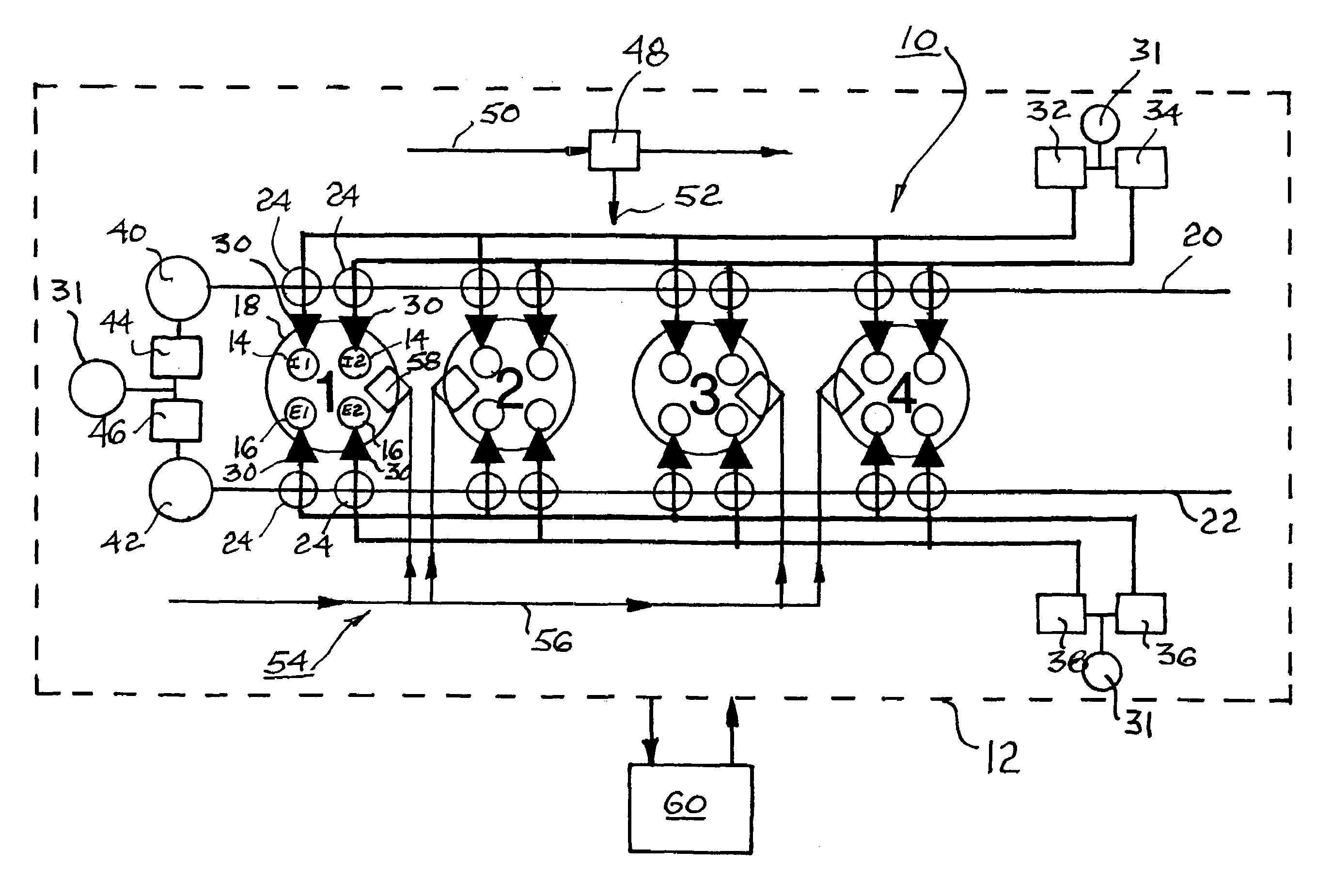

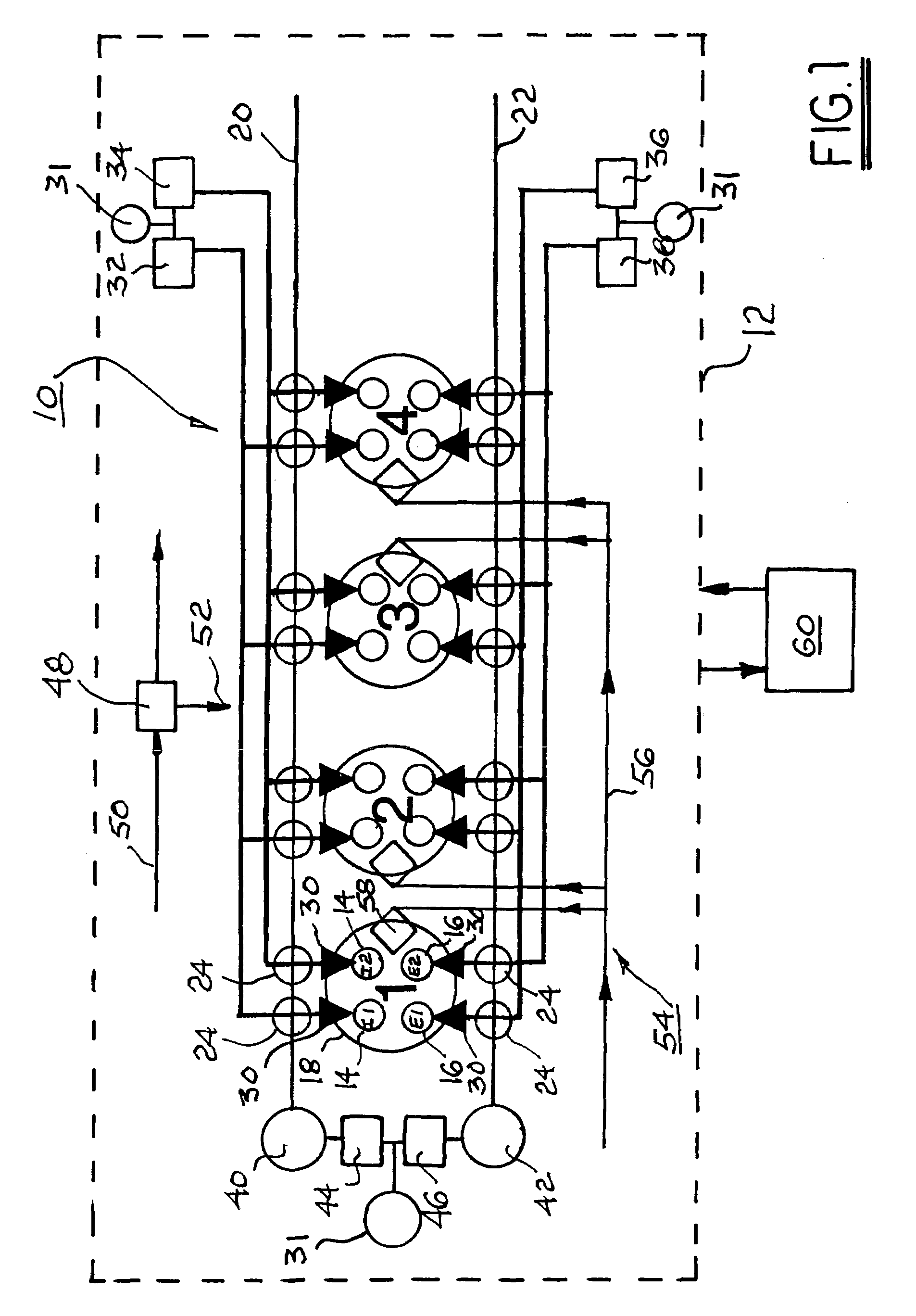

A variety of methods and arrangements for improving the fuel efficiency of internal combustion engines are described. Generally, selected combustion events are skipped during operation of the internal combustion engine so that other working cycles can operate at a better thermodynamic efficiency. In one aspect of the invention, an engine is controlled to operate in a variable displacement mode. In the variable displacement mode, fuel is not delivered to the working chambers (e.g. cylinders) during selected “skipped” working cycles. During active (“non-skipped”) working cycles, a maximum (e.g., unthrottled) amount of air and an optimized amount of fuel is delivered to the relevant working chambers so that the fired working chambers can operate at efficiencies closer to their optimal efficiency. A controller is used to dynamically determine the chamber firings required to provide the engine torque based on the engine's current operational state and conditions. The chamber firings may be sequenced in real time or in near real time in a manner that helps reduce undesirable vibrations of the engine.

Owner:TULA TECH INC

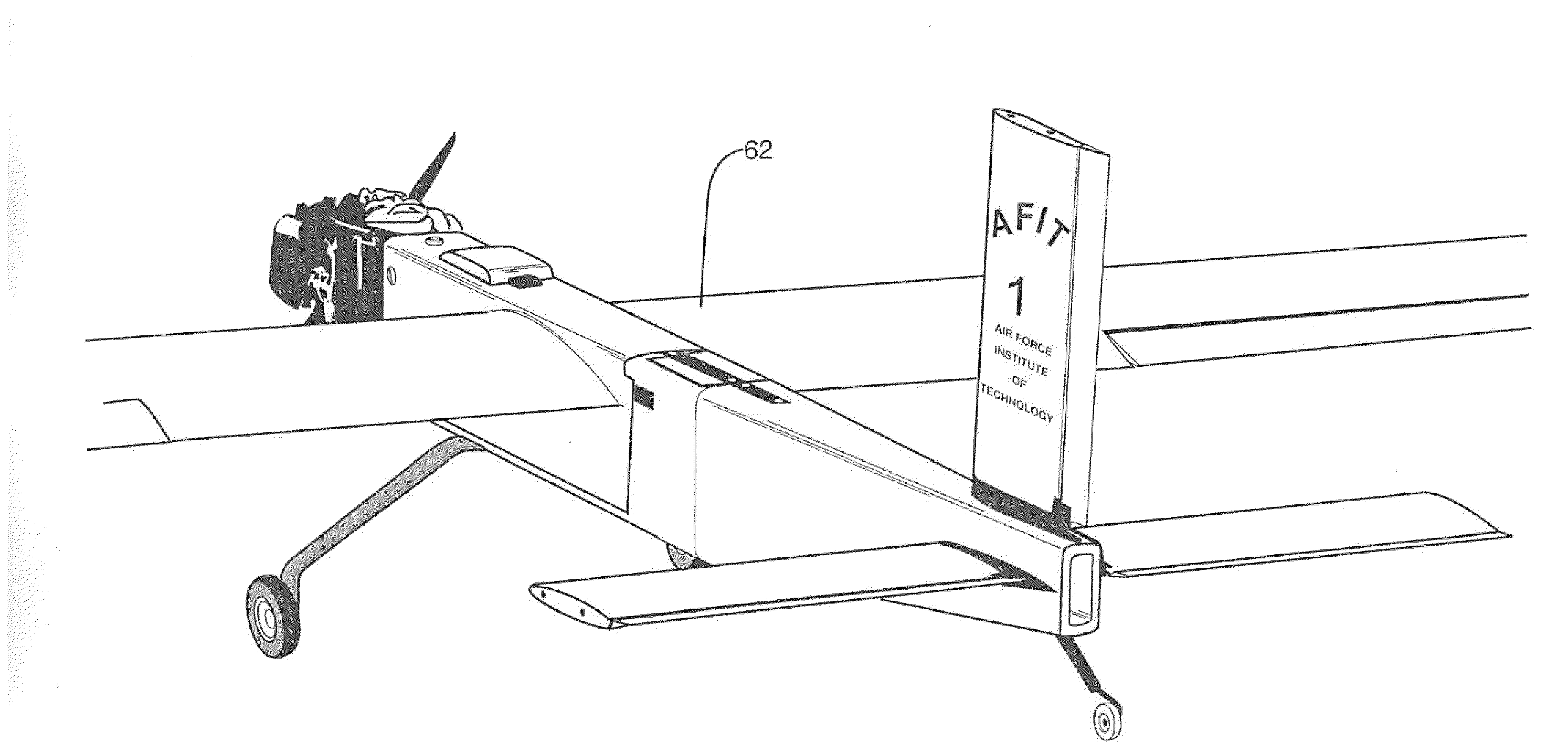

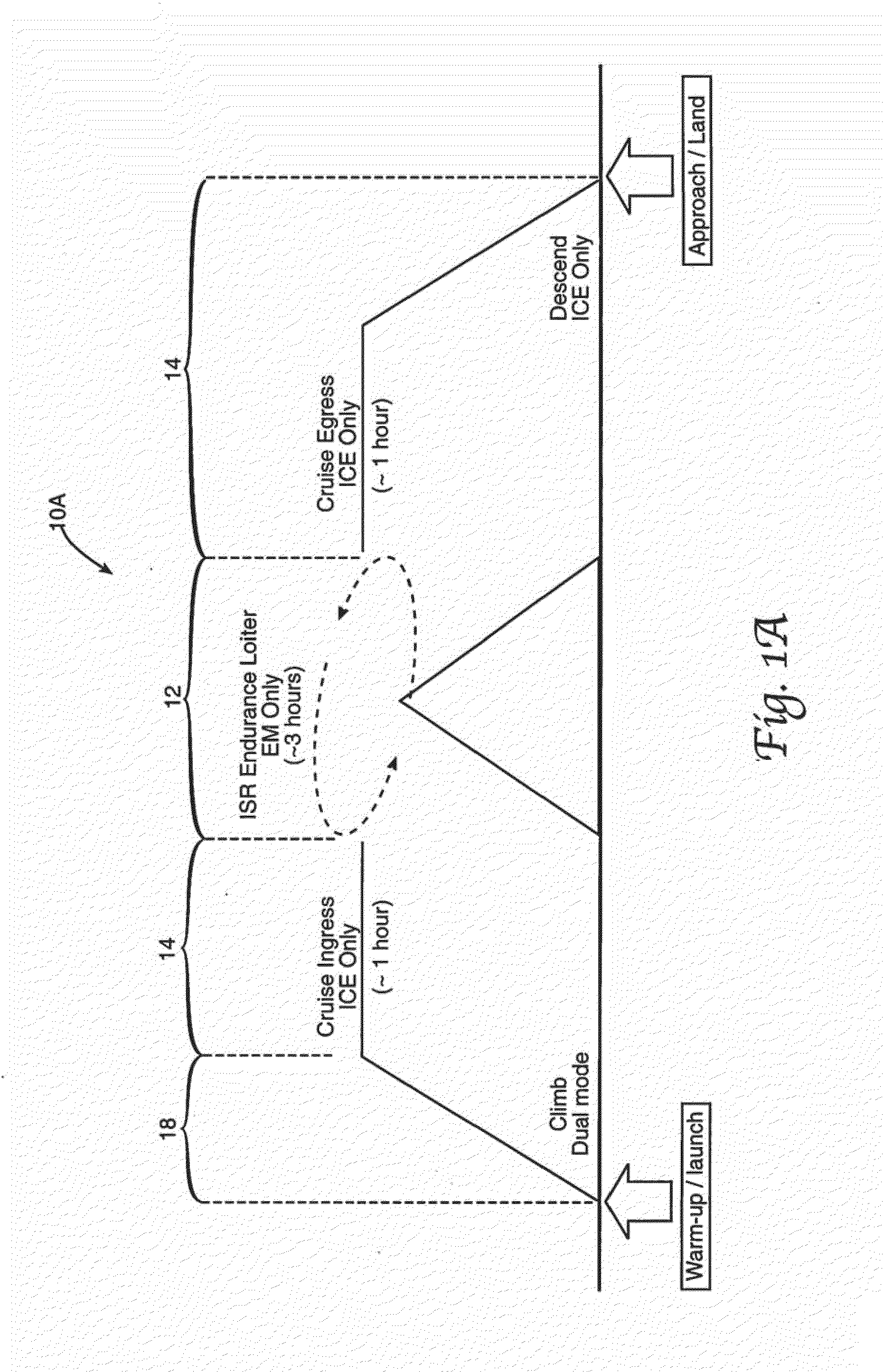

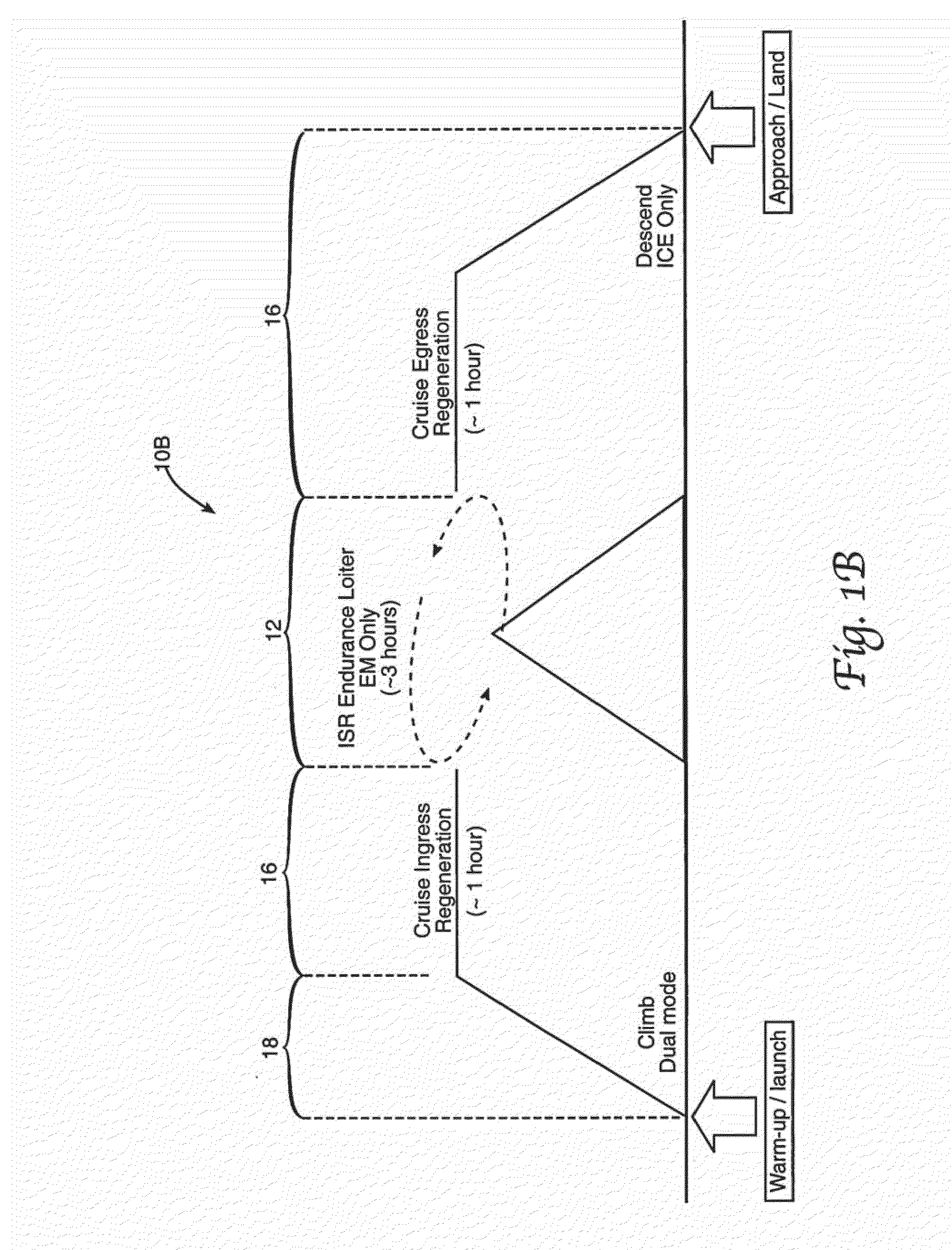

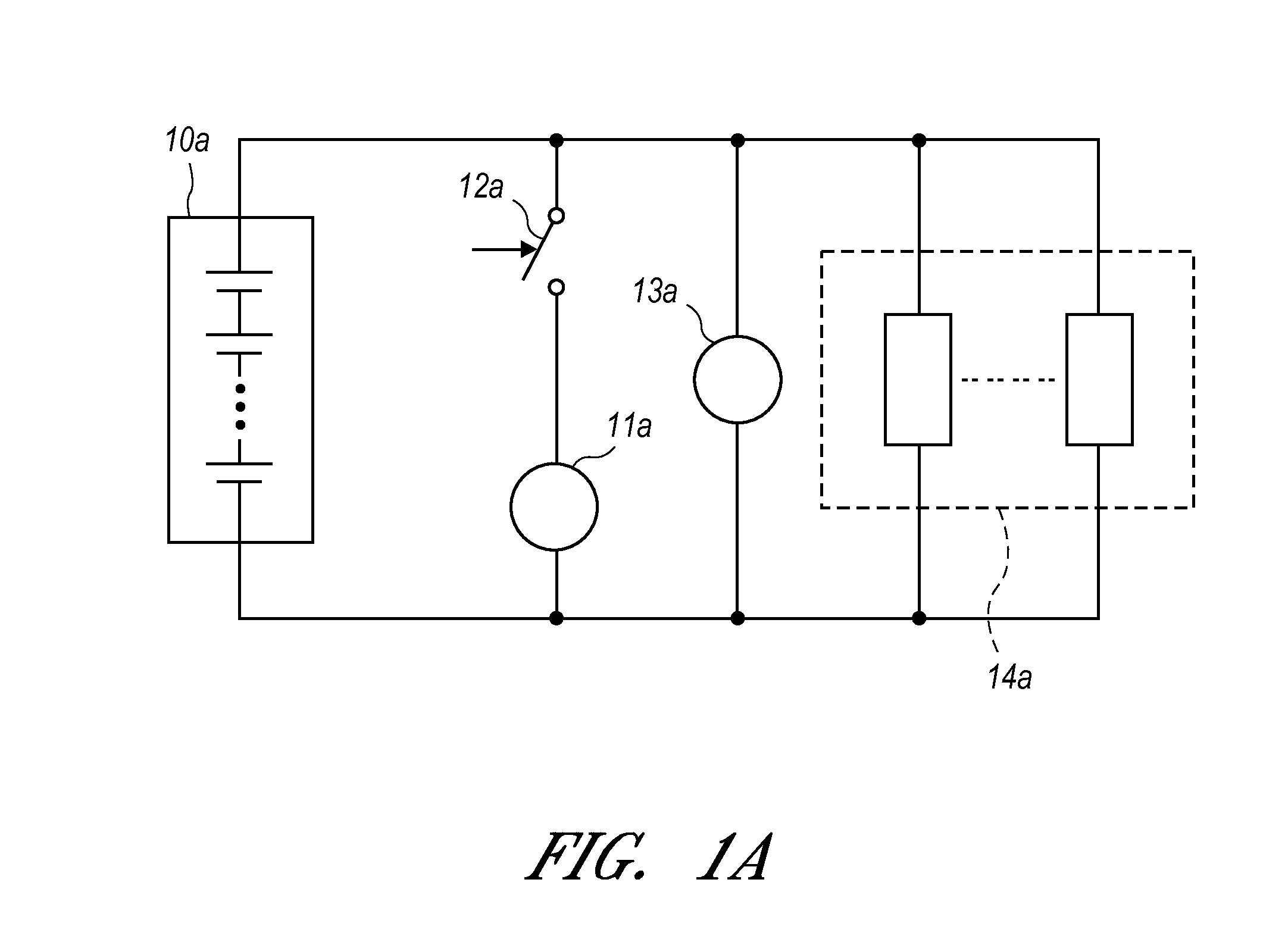

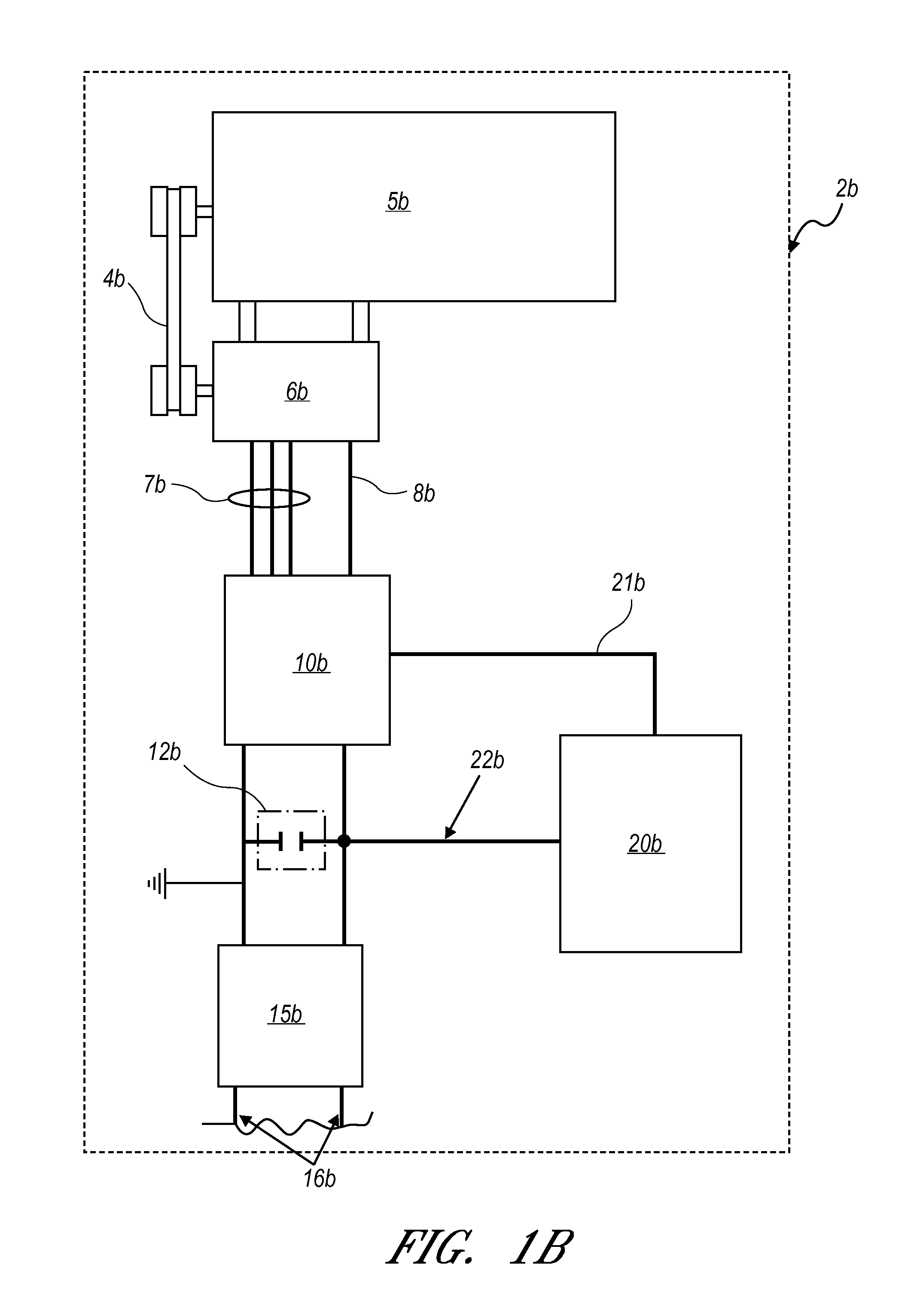

Parallel Hybrid-Electric Propulsion Systems for Unmanned Aircraft

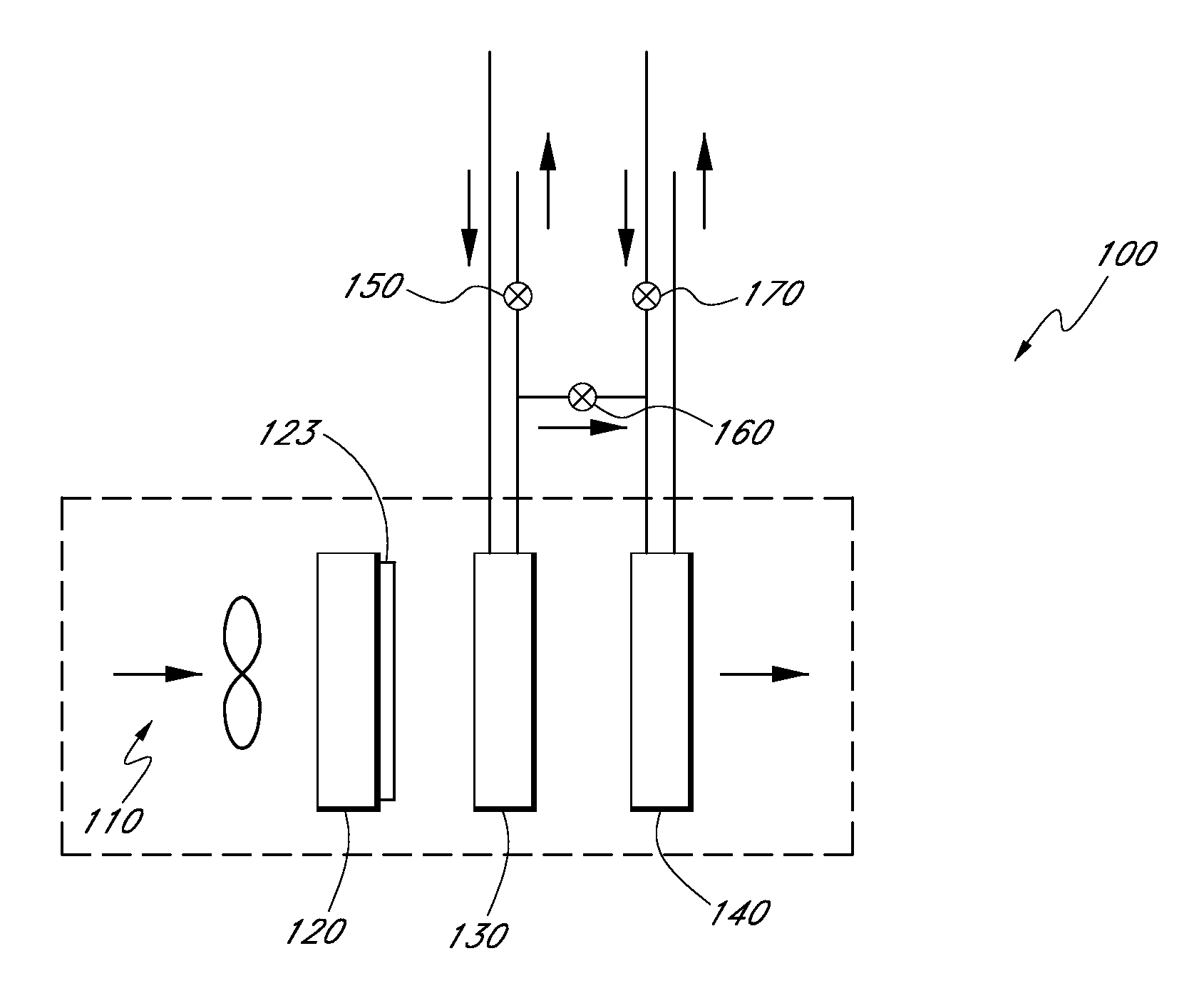

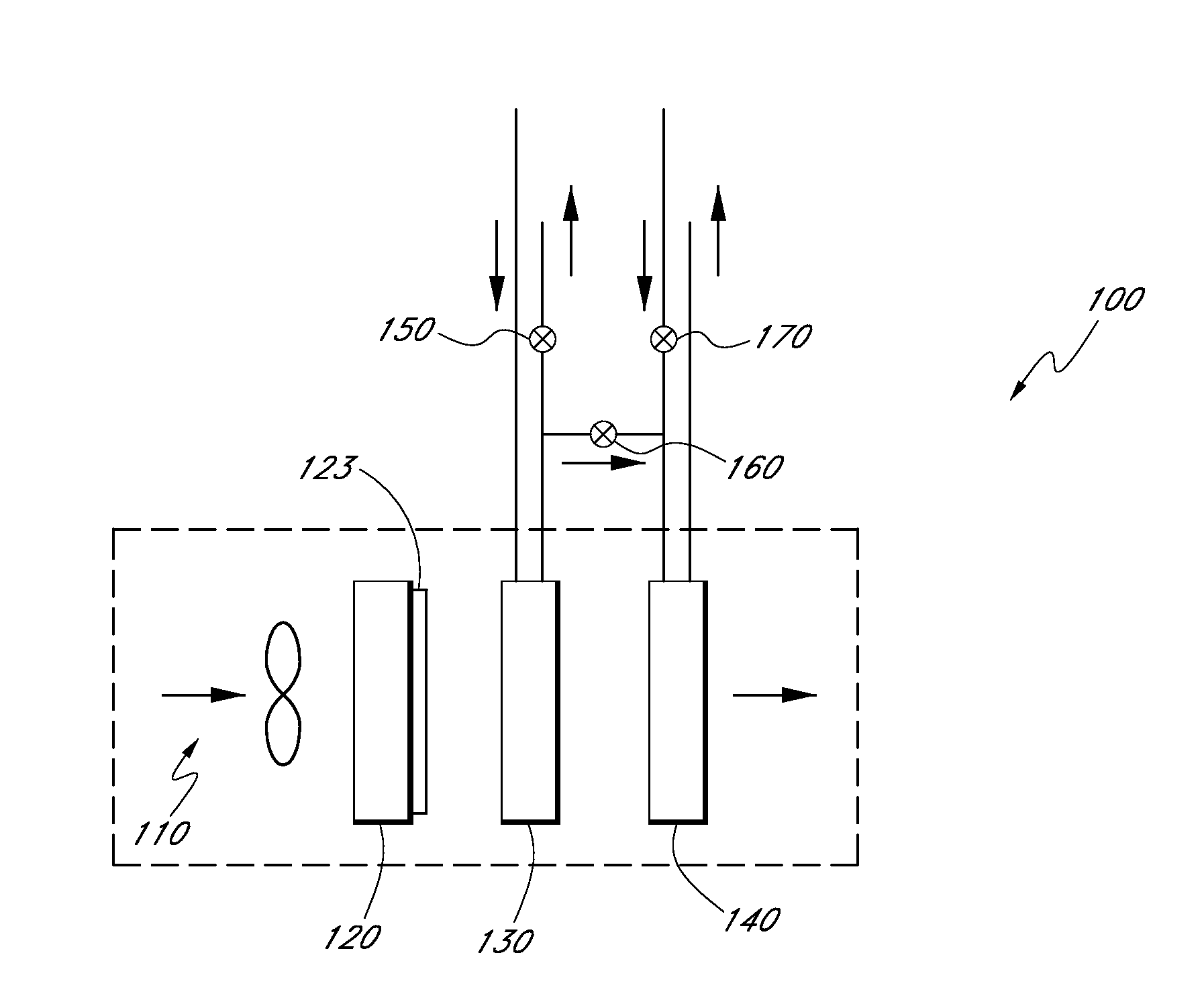

An unmanned air vehicle is provided, which includes an airframe and a parallel hybrid-electric propulsion system mounted on the airframe. The parallel hybrid-electric propulsion system includes an internal combustion engine and an electric motor. A hybrid controller is configured to control both the internal combustion engine and the electric motor. A propeller is connected to a mechanical link. The mechanical link couples the internal combustion engine and the electric motor to the propeller to drive the propeller. An alternate unmanned air vehicle includes a second propeller driven by the electric motor. In this alternate unmanned air vehicle, the internal combustion engine is decoupled from the electric motor.

Owner:GOVERNMENT OF THE UNITED STATES AS REPRESENTD BY THE SEC OF THE AIR FORCE

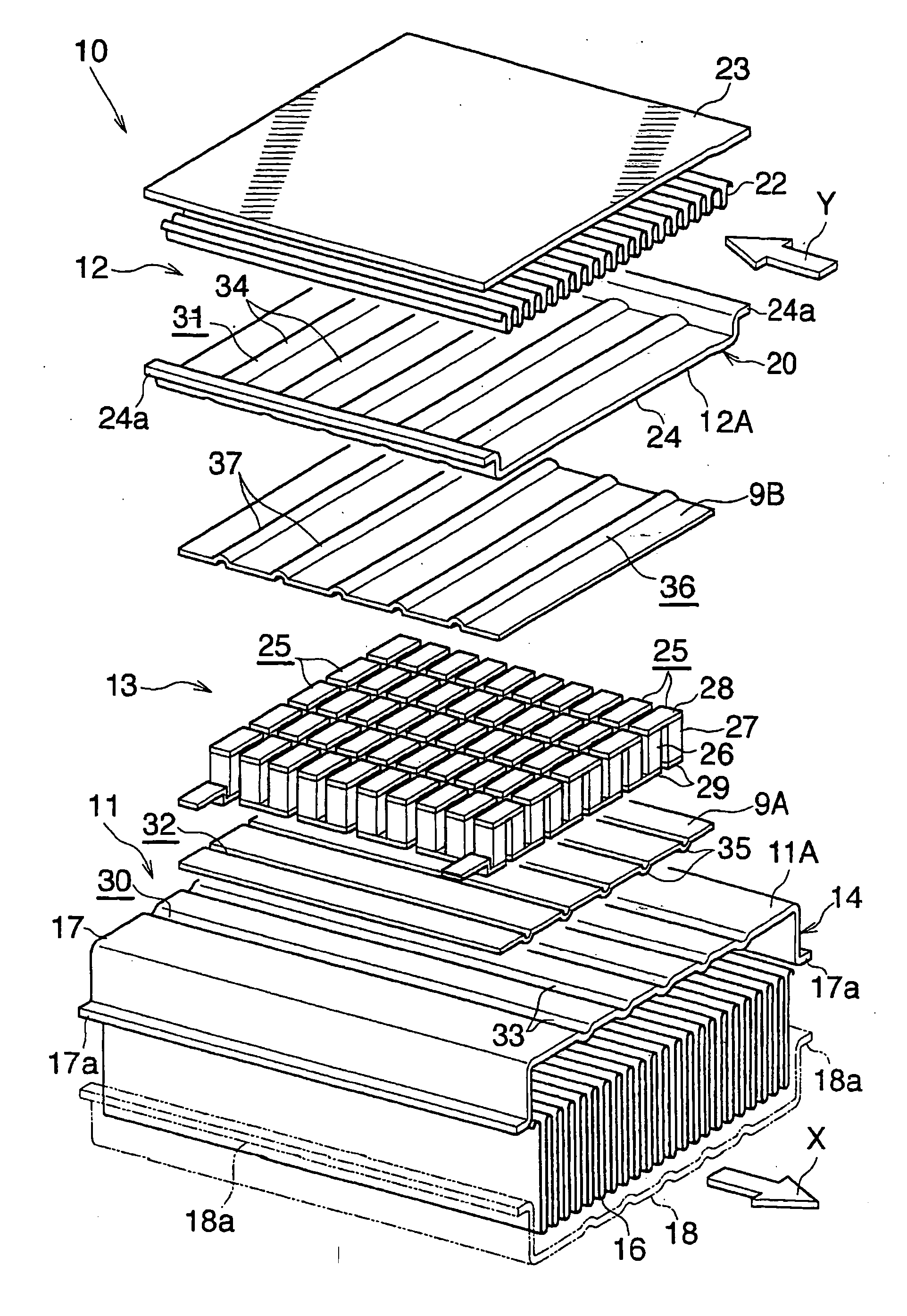

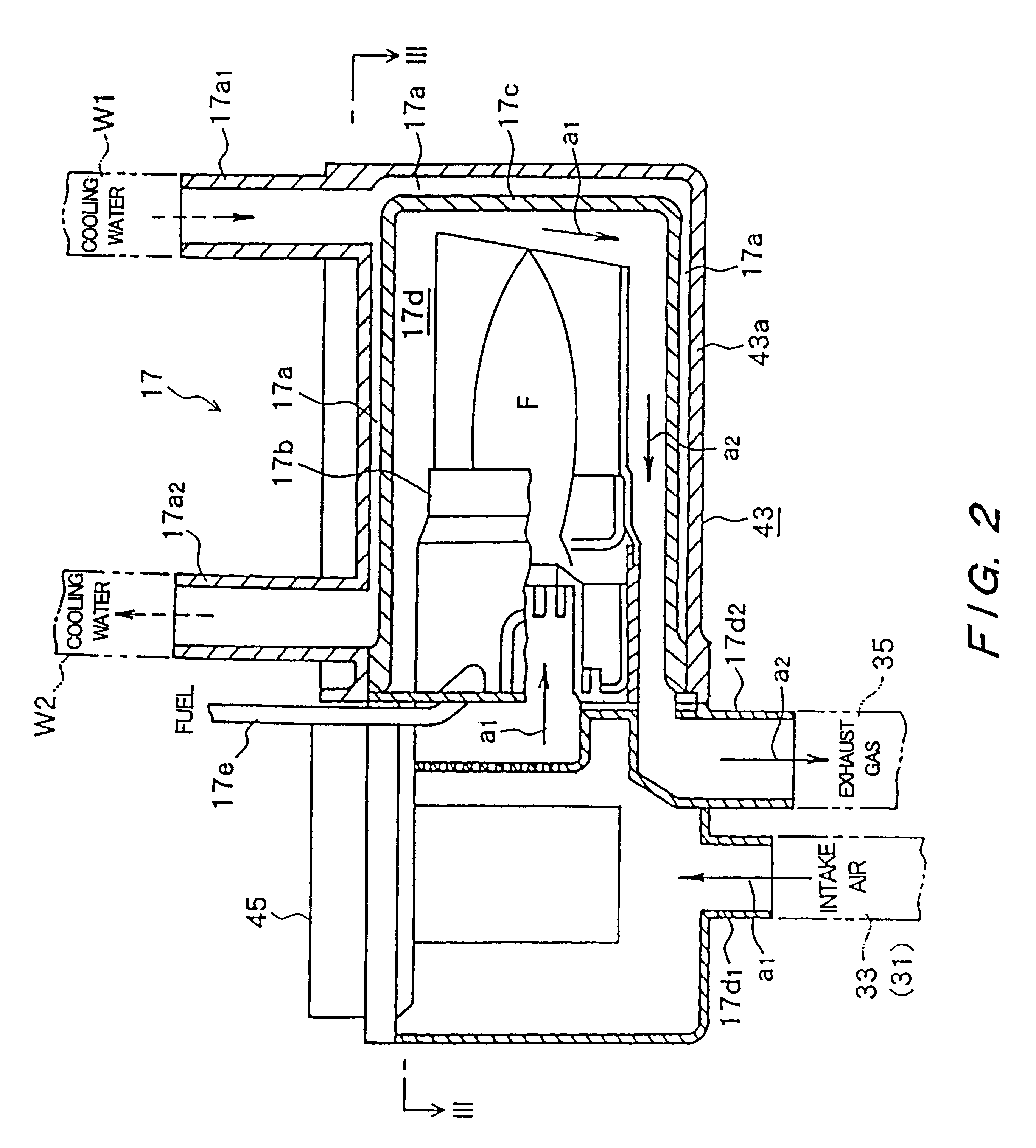

Waste heat recovery system and thermoelectric conversion system

InactiveUS20060157102A1Increase powerImprove efficiencyInternal combustion piston enginesThermoelectric device with peltier/seeback effectWaste heat recovery unitFuel cells

A waste heat recover system includes a mechanism for supplying power by use of a thermoelectric conversion unit, and a mechanism for utilizing heat released from the thermoelectric conversion unit. Heat released from the thermoelectric conversion unit is utilized for, for example, heating, defrosting, defogging, temperature keeping of fuel, temperature keeping of an internal combustion engine, and temperature keeping of a fuel cell. The waste heat recovery system is equipped in, for example, cars, incinerators, fuel cells, and industrial machinery.

Owner:SHOWA DENKO KK

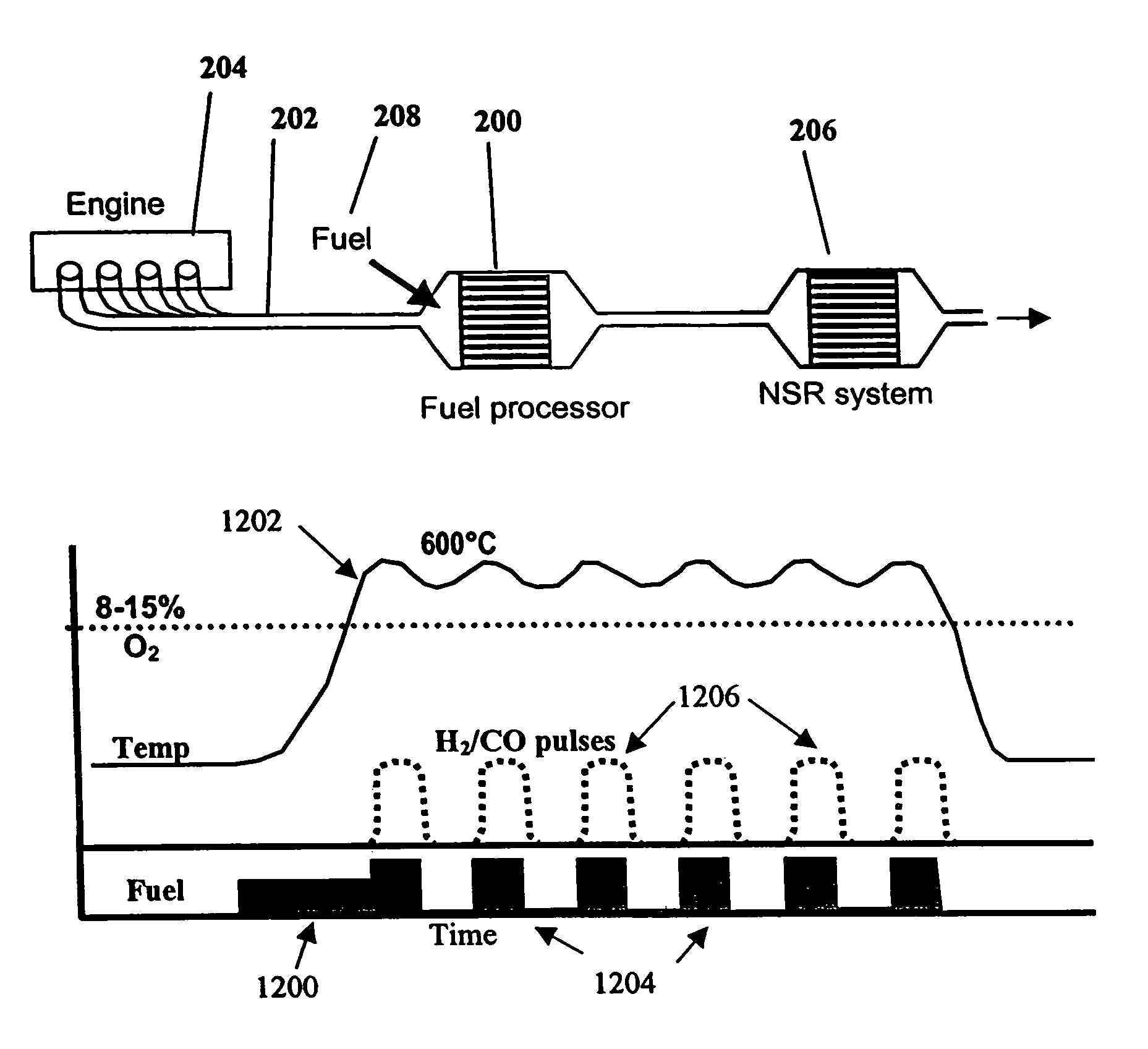

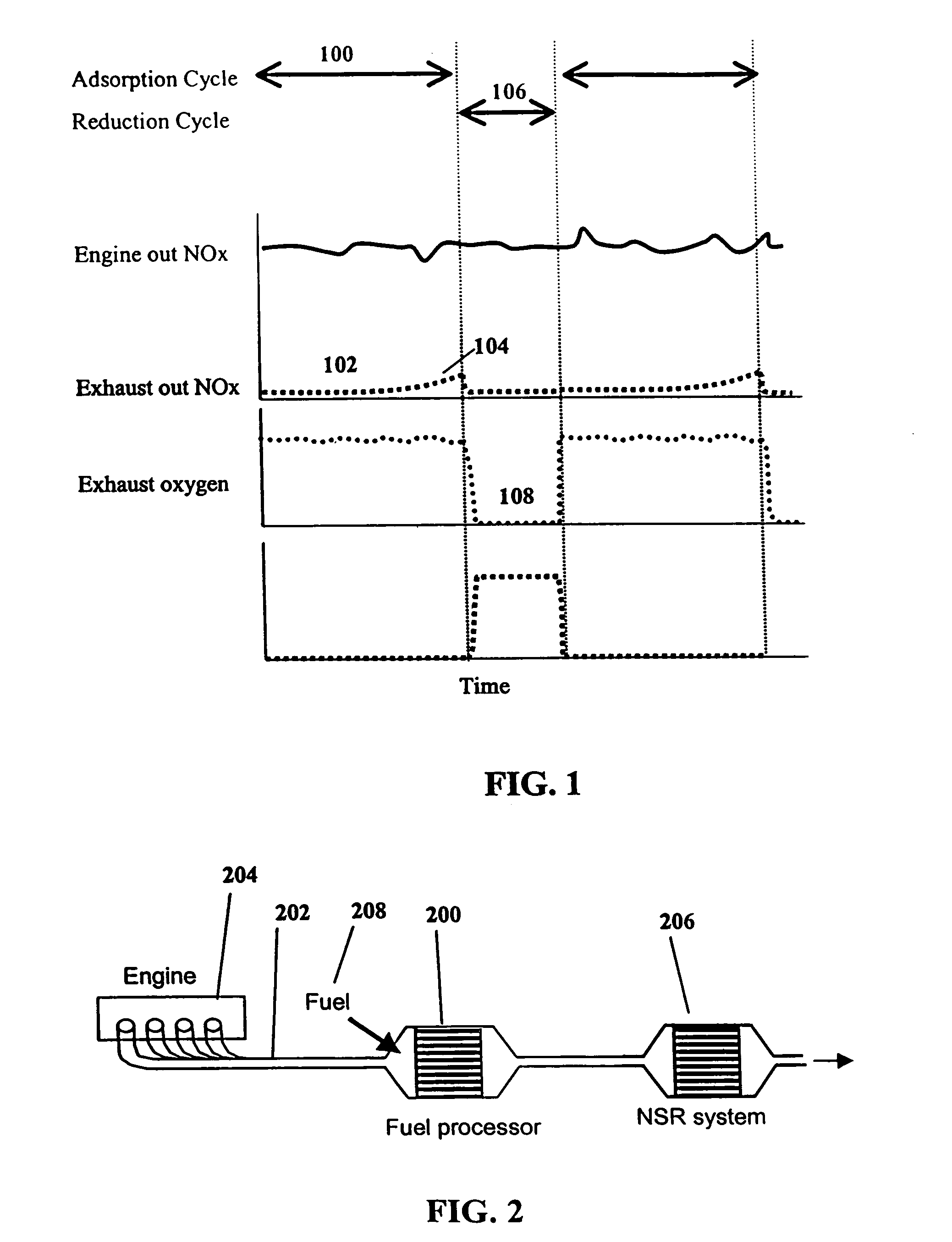

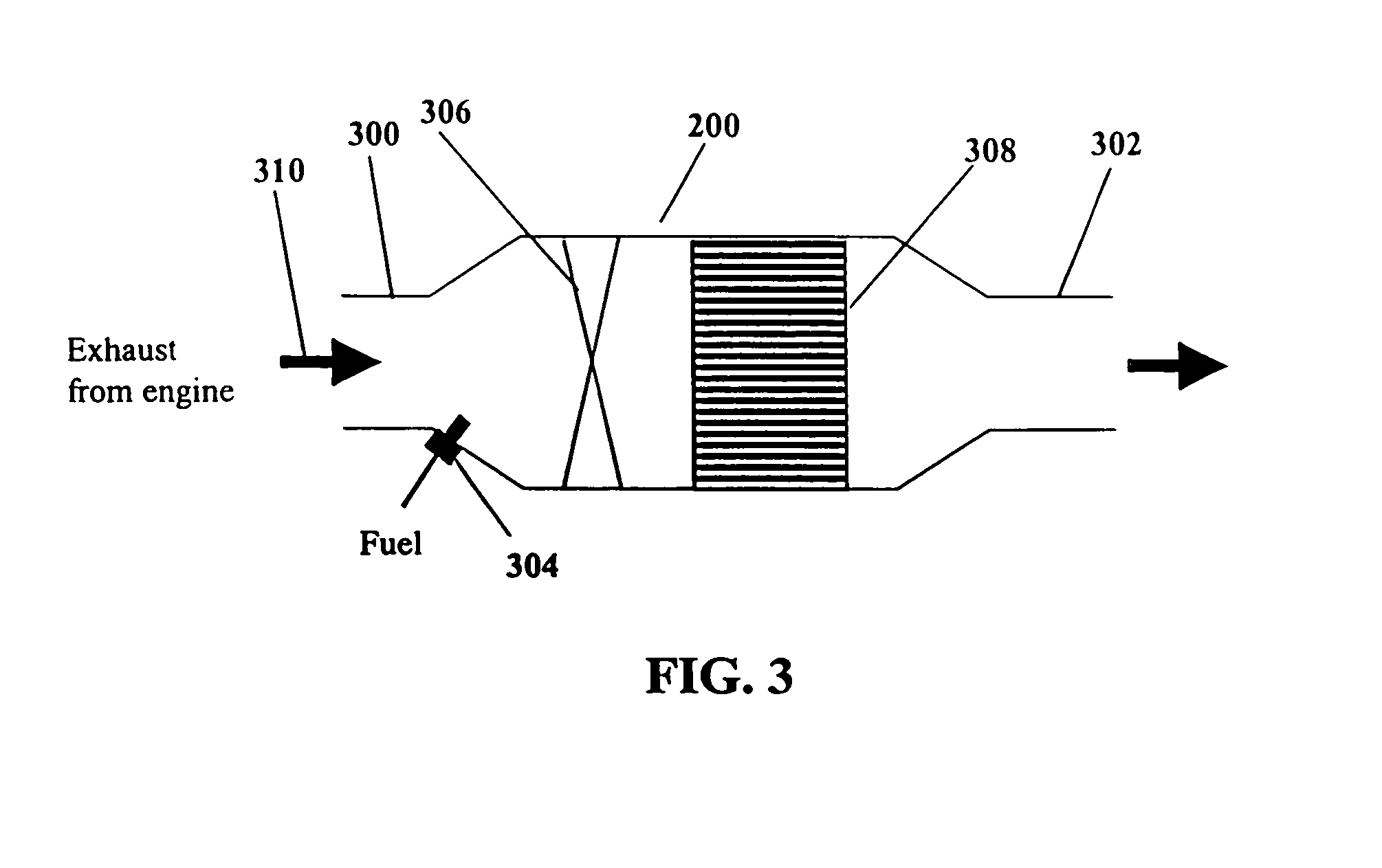

System and methods for improved emission control of internal combustion engines using pulsed fuel flow

InactiveUS7082753B2Save oilReducing greenhouse gas emissionExhaust apparatusCombustion enginesPartial oxidationExternal combustion engine

The present invention provides systems and methods to improve the performance and emission control of internal combustion engines equipped with nitrogen oxides storage-reduction (“NSR”) emission control systems. The system generally includes a NSR catalyst, a fuel processor located upstream of the NSR catalyst, and at least one fuel injection port. The fuel processor converts a fuel into a reducing gas mixture comprising CO and H2. The reducing gas mixture is then fed into the NSR catalyst, where it regenerates the NSR adsorbent, reduces the NOx to nitrogen, and optionally periodically desulfates the NSR catalyst. The fuel processor generally includes one or more catalysts, which facilitate reactions such as combustion, partial oxidation, and / or reforming and help consume excess oxygen present in an engine exhaust stream. The methods of the present invention provide for NSR catalyst adsorbent regeneration using pulsed fuel flow. Control strategies are also provided.

Owner:INT ENGINE INTPROP CO LLC

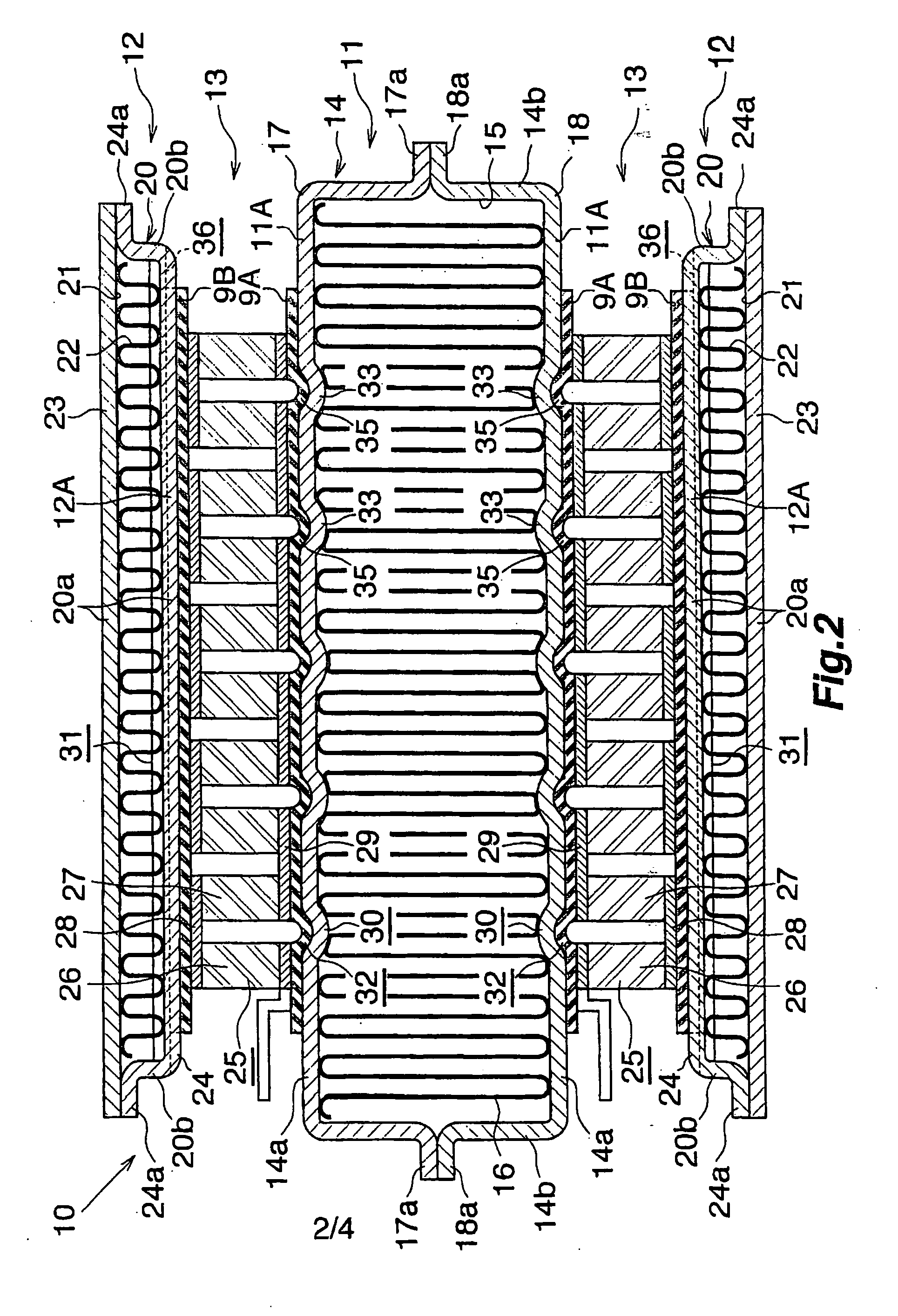

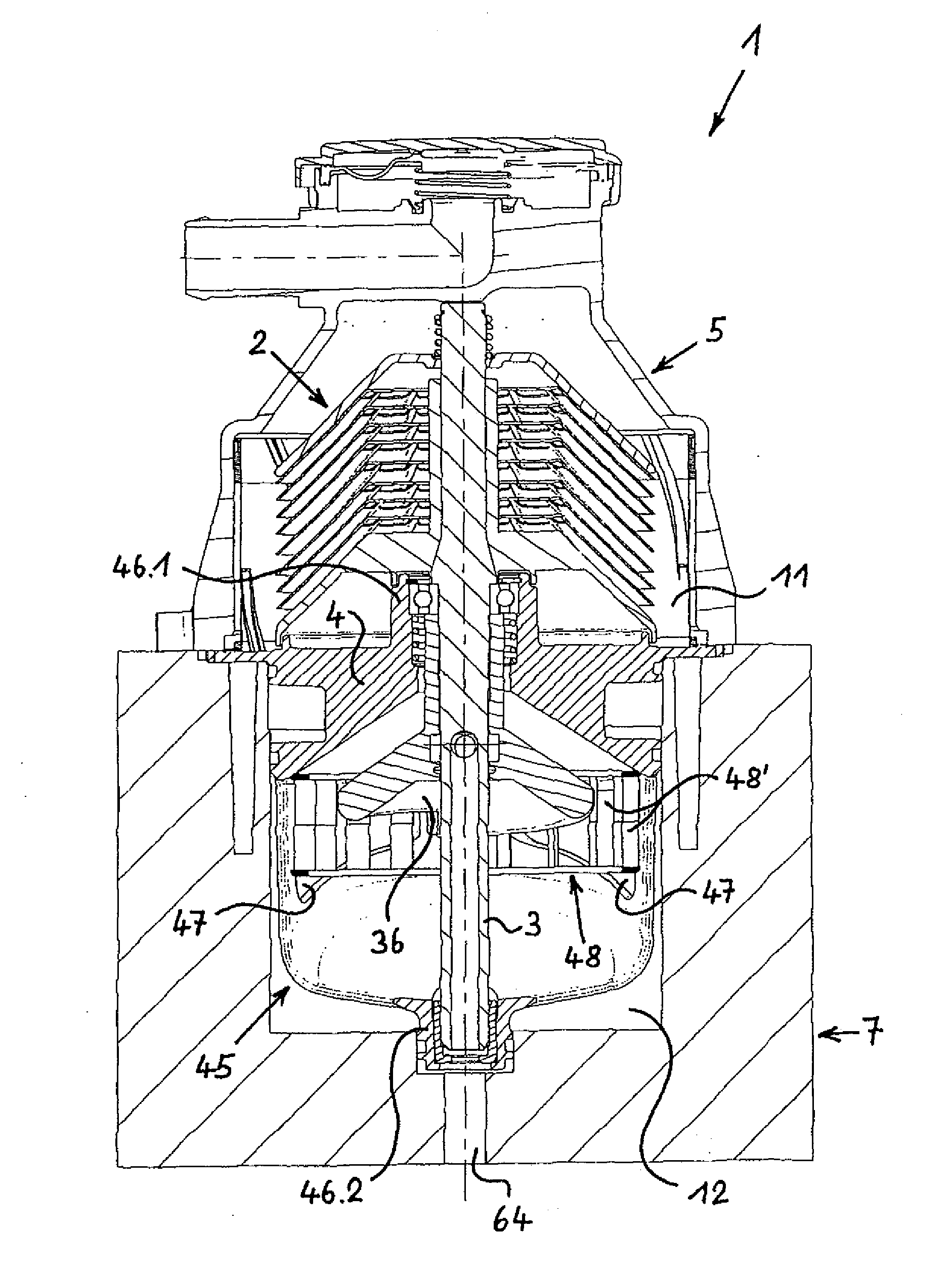

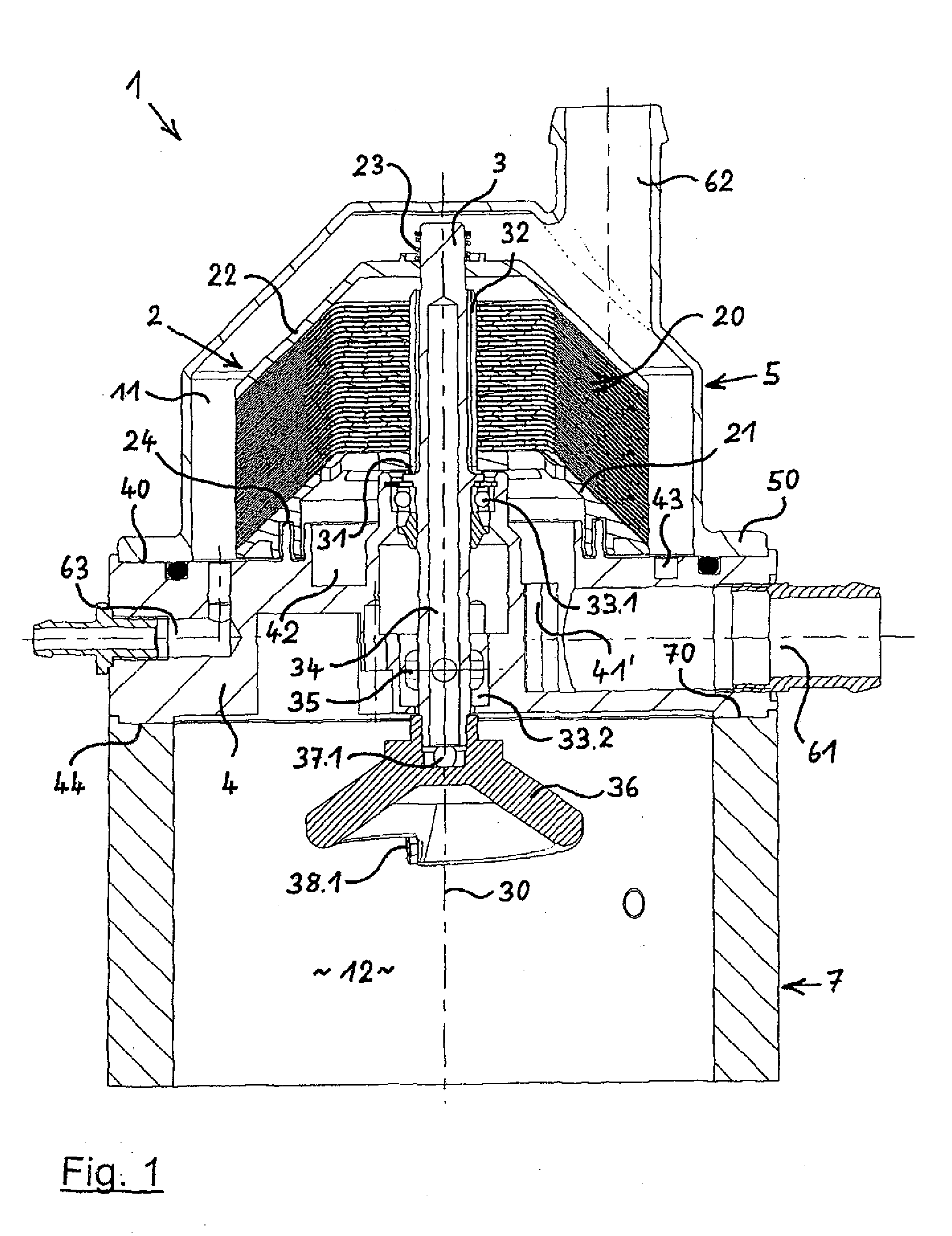

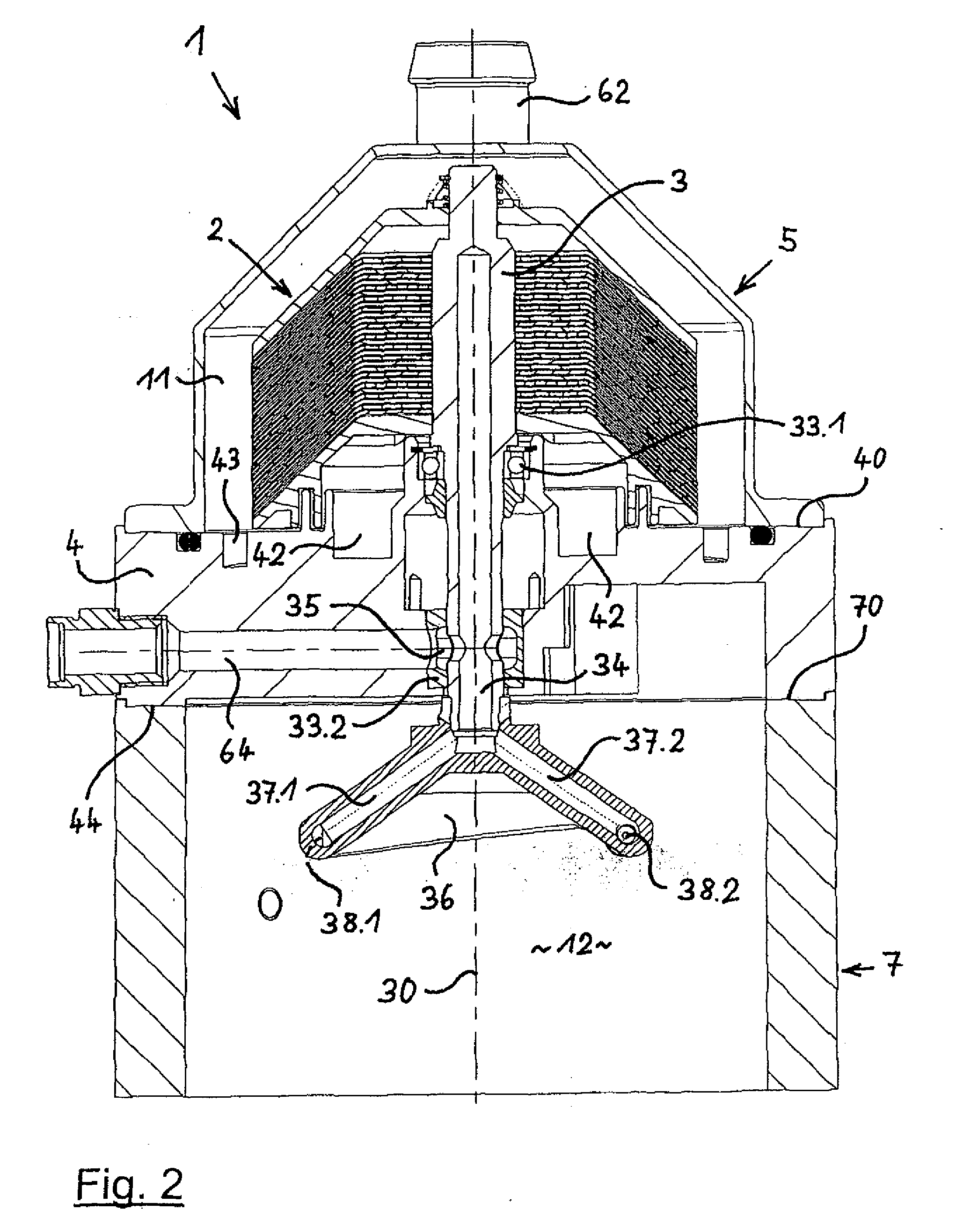

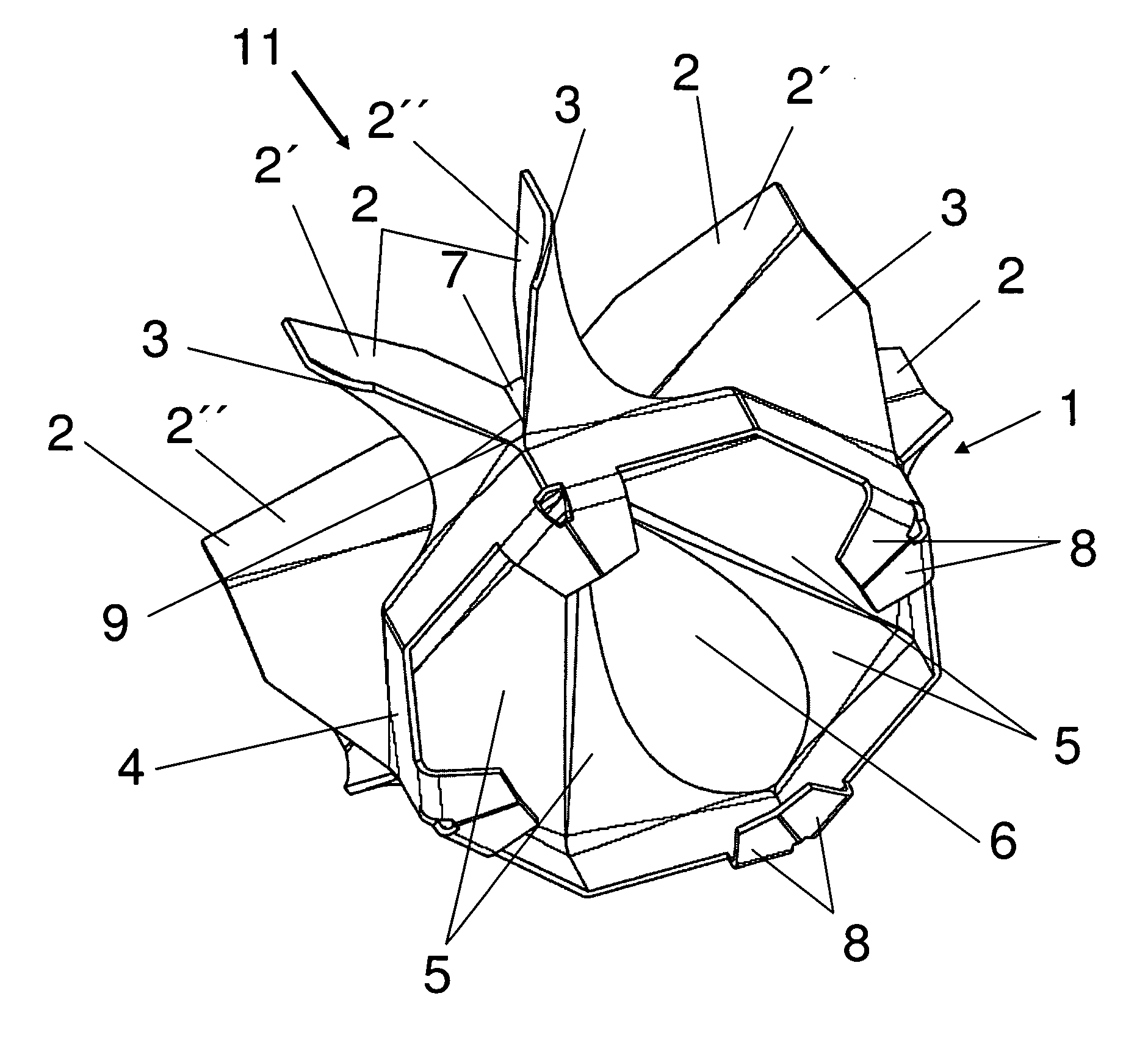

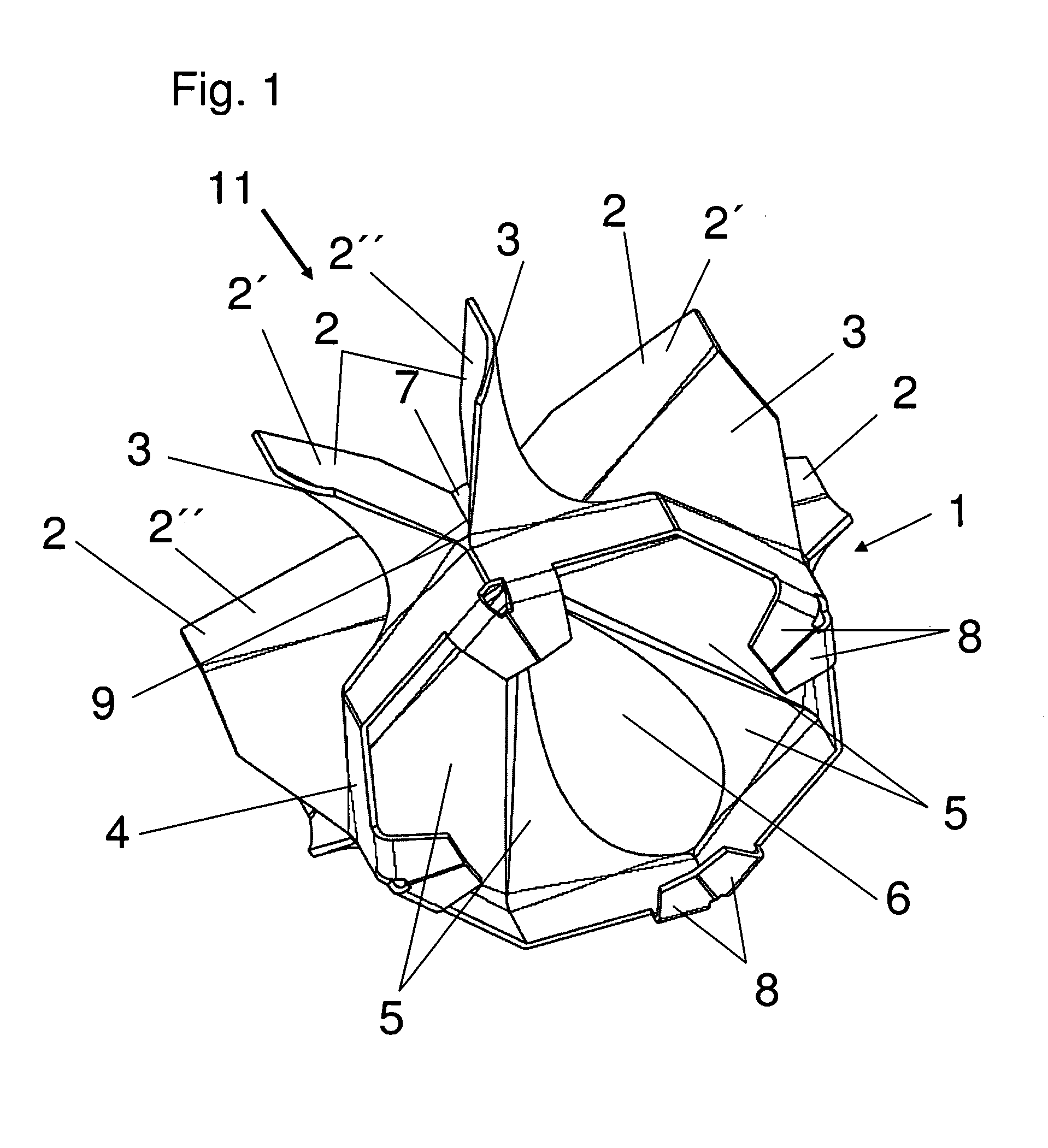

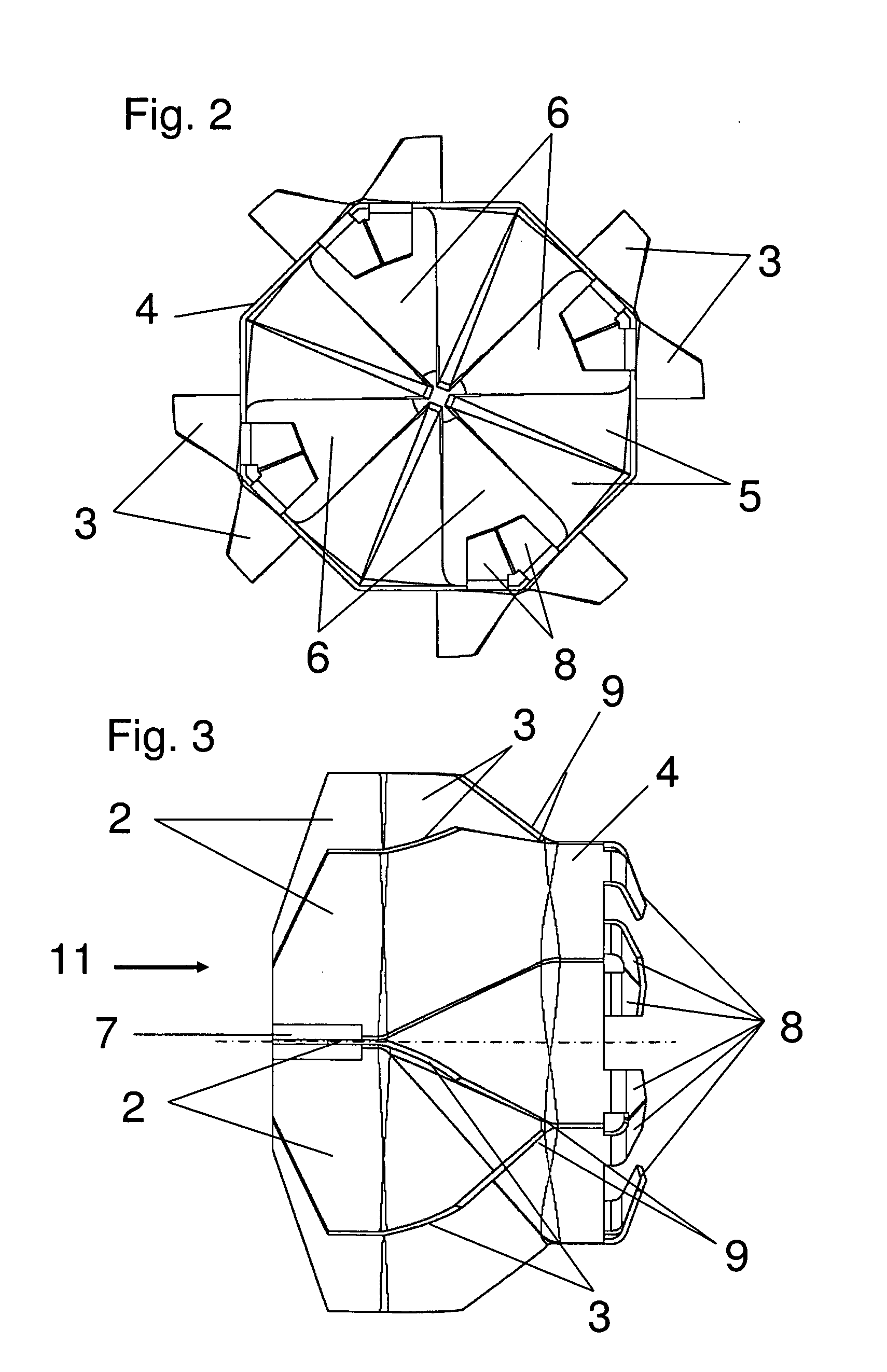

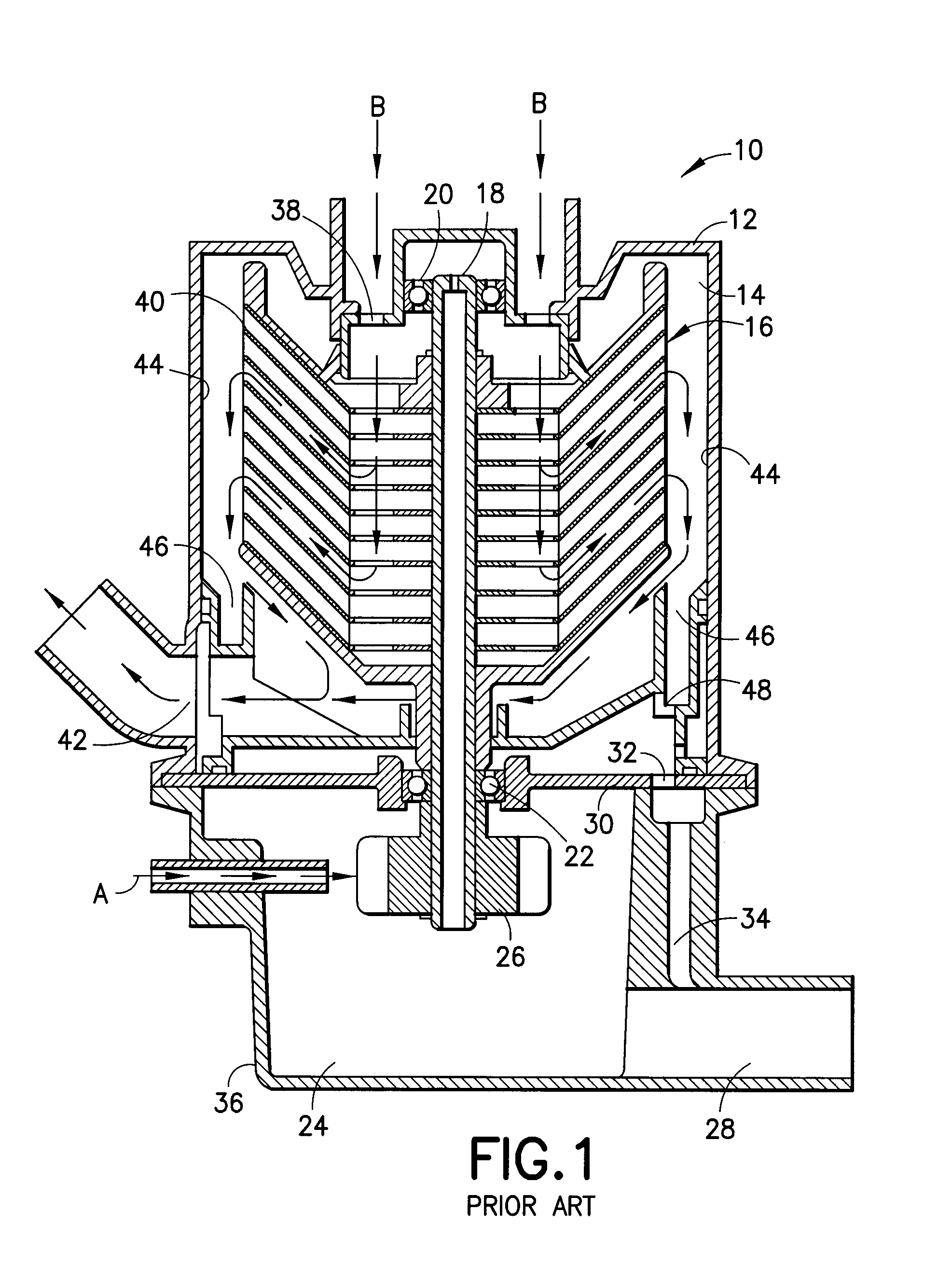

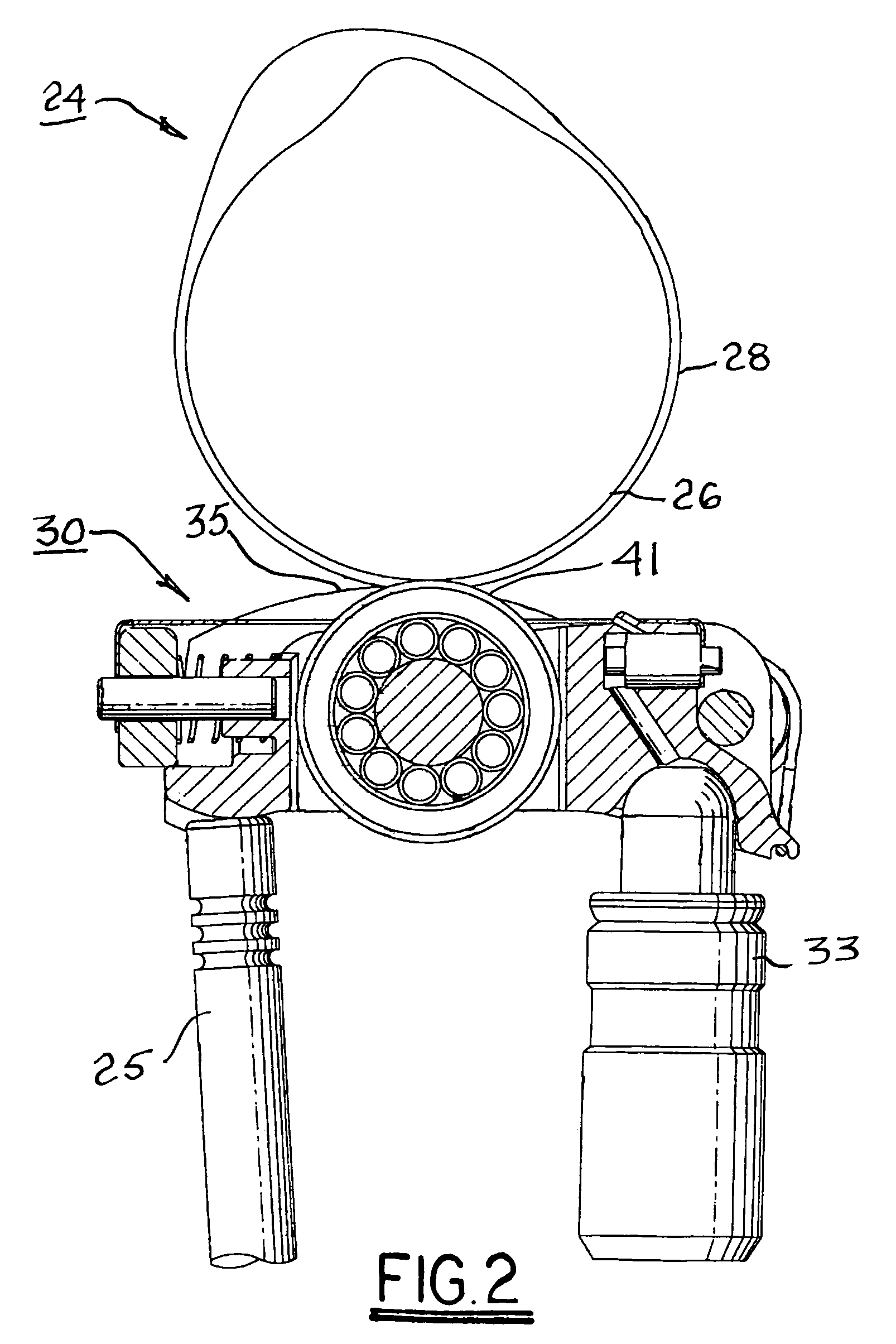

Separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, and functional module and internal combustion engine comprising a separator

ActiveUS20100180854A1Increase speedEasy to separateCombination devicesLubrication of auxillariesExternal combustion engineEngineering

A separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, especially of a motor vehicle. The separator includes a gas purification chamber inside which a rotatably mounted centrifugal rotor is arranged. The gas purification chamber has a crude gas inlet, a pure gas outlet, and an oil outlet. The crankcase ventilation gas can be conducted into a radially internal zone of the centrifugal rotor via the crude gas inlet, while pure gas that is liberated from oil mist can be discharged from the gas purification chamber via the pure gas outlet, and oil separated from the gas can be discharged from the gas purification chamber via the oil outlet. The separator further includes a rotary drive for the centrifugal rotor. The rotary drive is disposed in a drive chamber of the separator, can be operated using pressurized lubrication oil of the internal combustion engine, and is connected to the centrifugal rotor by means of a shaft extending from the drive chamber into the gas purification chamber, from which the drive chamber is separated. The rotary drive is formed by at least one thrust nozzle which is connected to the shaft and to which the pressurized lubrication oil of the internal combustion engine can be fed. The separator includes at least one part of a base that forms the separation between the gas purification chamber and the drive chamber and extends into the drive chamber, the part of the base being fitted with a seat for a bearing of the shaft. The bearing is located at a distance from the centrifugal rotor.

Owner:HENGST WALTER

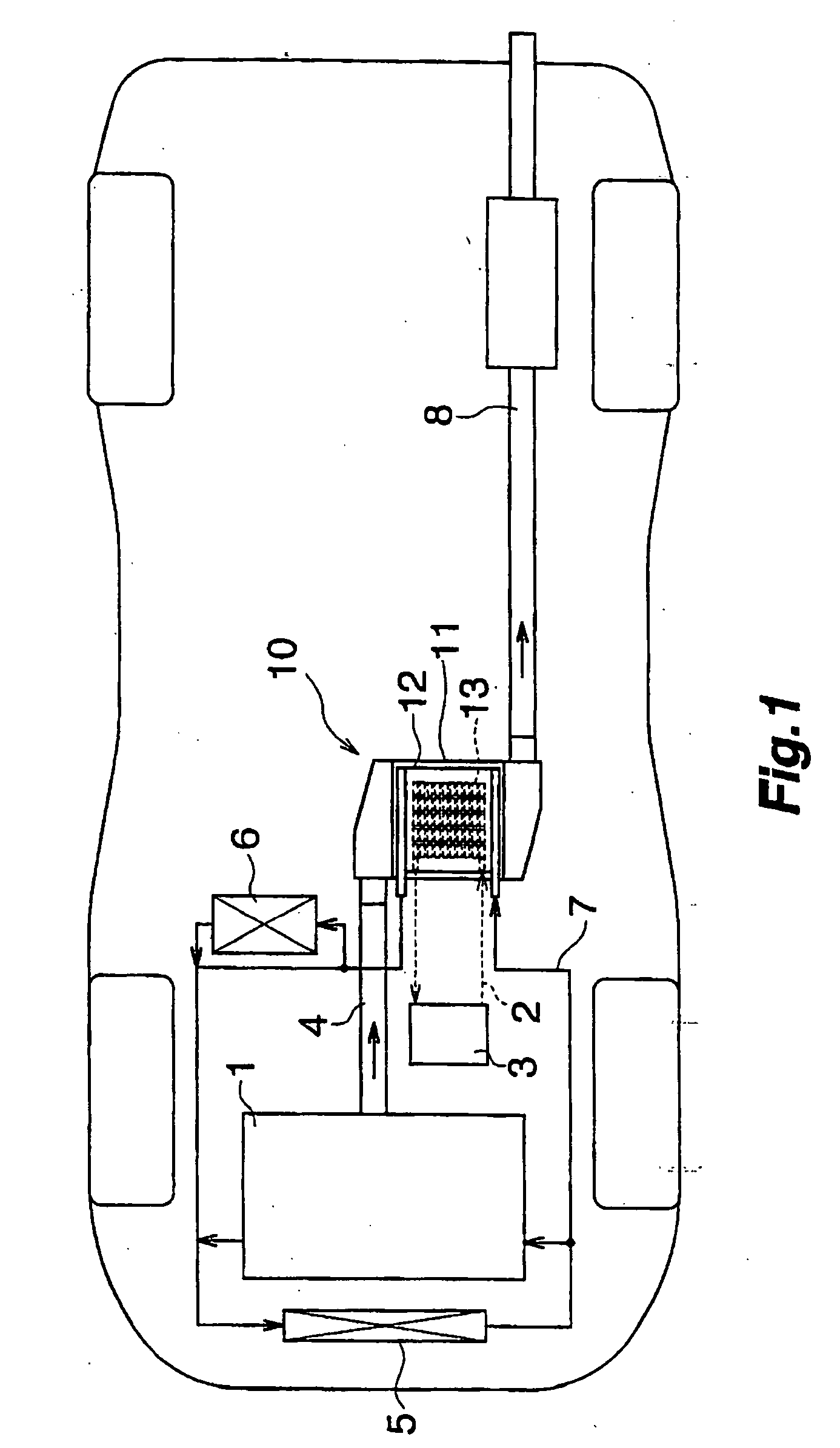

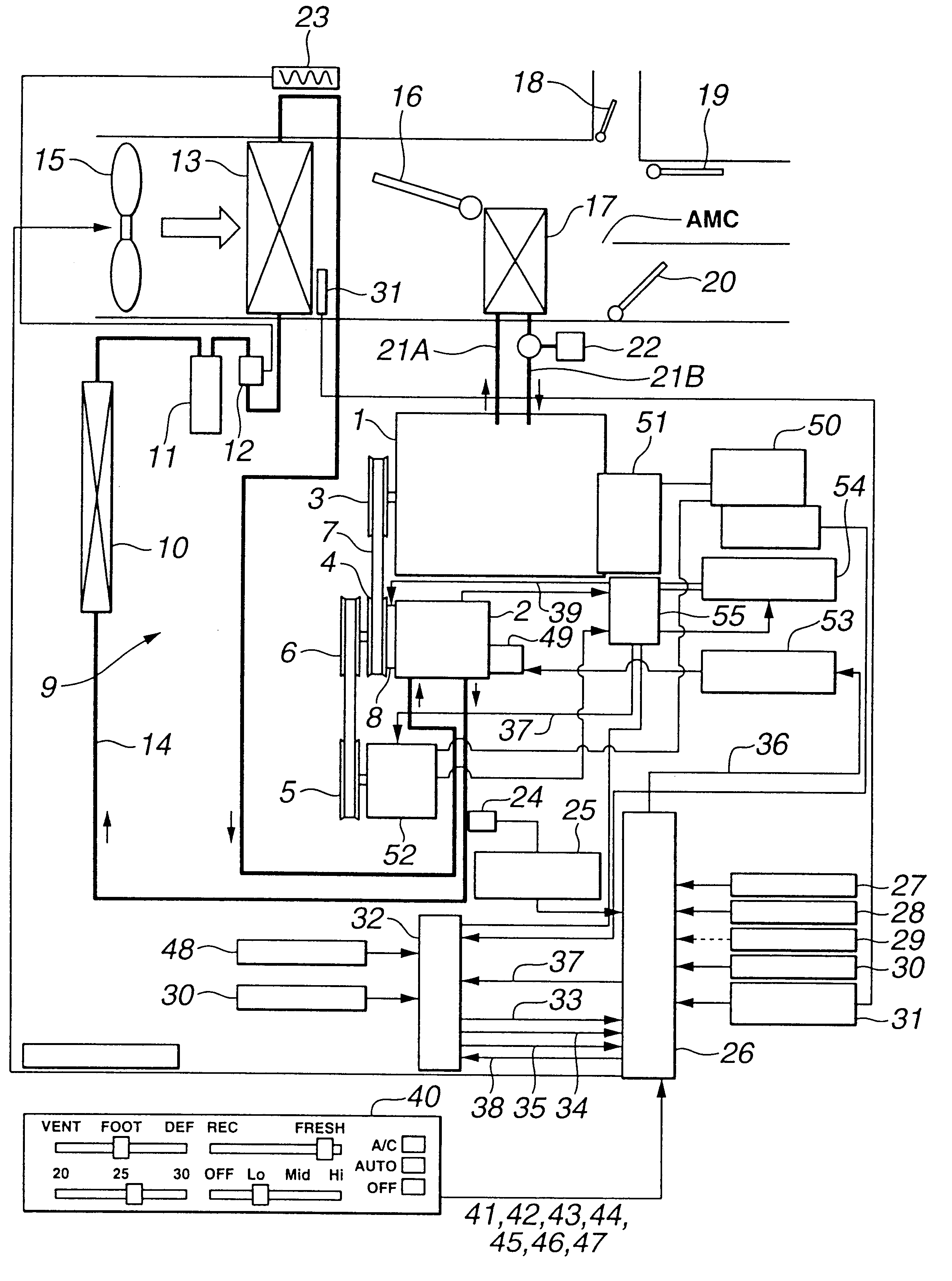

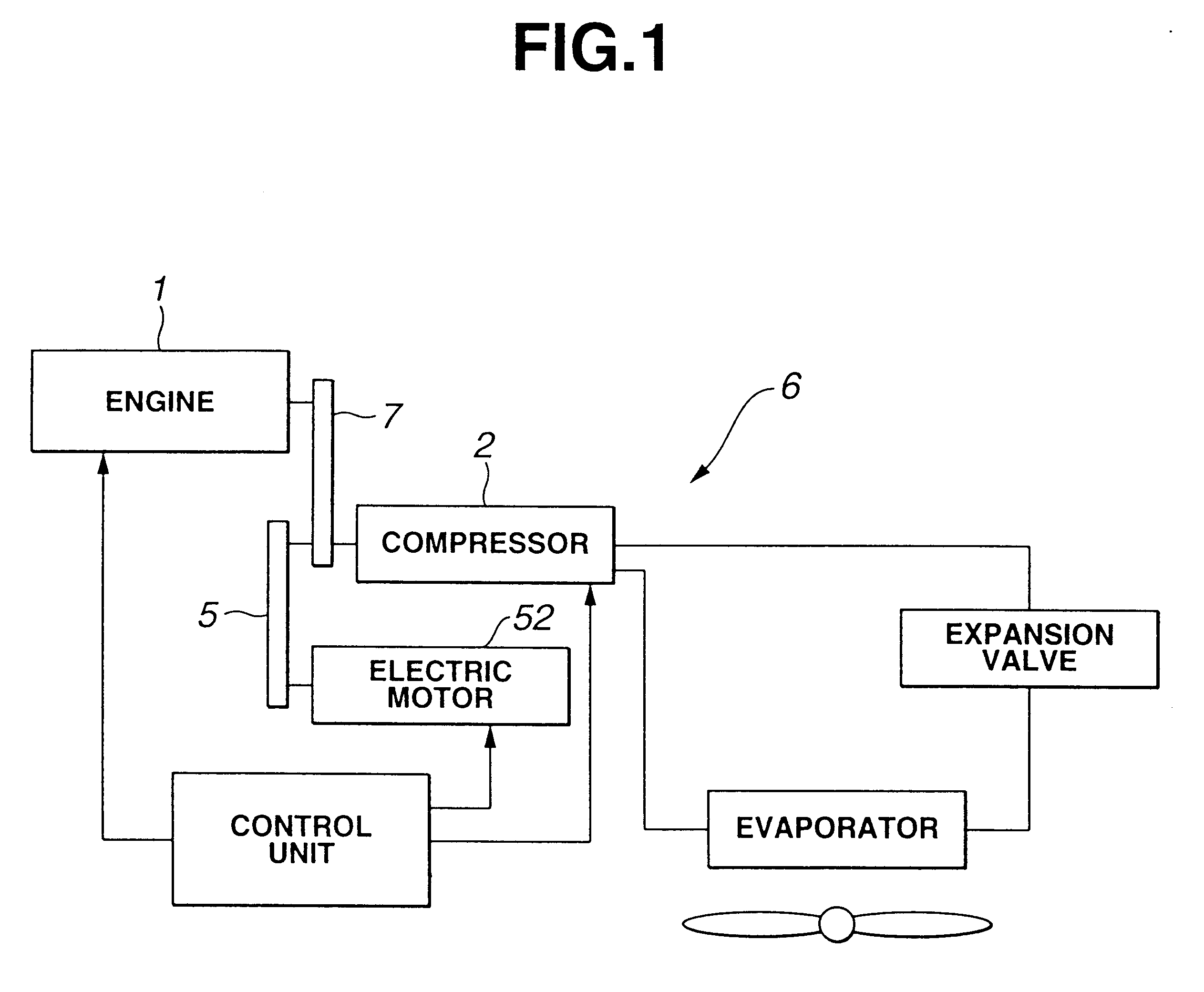

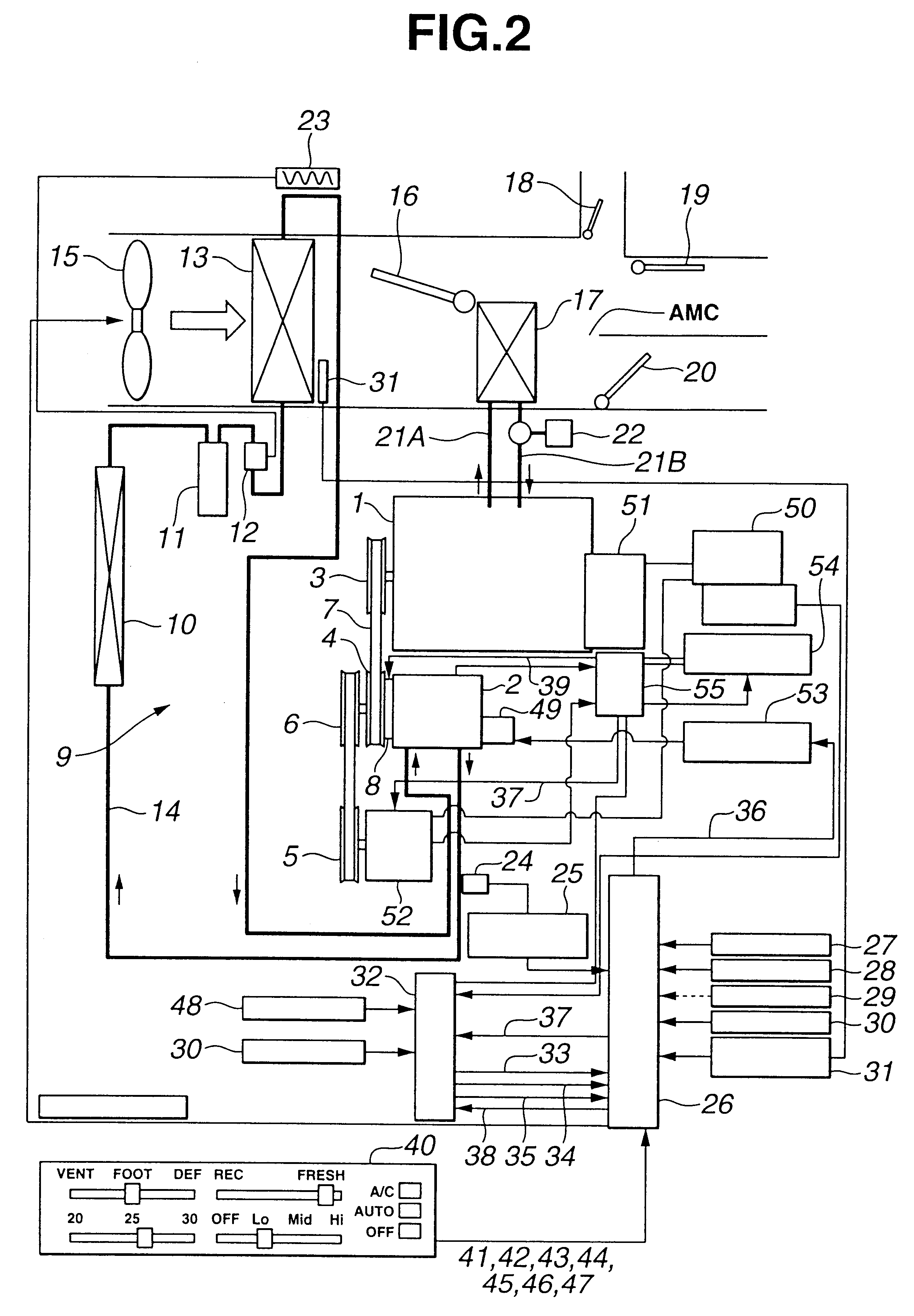

Automotive air conditioning system

An air conditioning system for use in a motor vehicle powered by an internal combustion engine is described. The system comprises an electric motor powered by a battery; a compressor arranged to be powered by at least one of the internal combustion engine and the electric motor; and a control unit that controls the driving of the compressor. The control unit is configured to execute driving the compressor by only the electric motor when the combustion engine is under an idling stop; restarting the combustion engine upon expiration of a first given time from the time when the idling stop has occurred, so that thereafter the compressor is driven by both the combustion engine and the electric motor; and stopping the driving of the compressor by the electric motor upon expiration of a second given time from the restarting of the combustion engine, so that thereafter the compressor is driven by only the combustion engine.

Owner:CALSONIC KANSEI CORP

Variable Displacement Engine Operation With NVH Management

InactiveUS20080154468A1Reduce and eliminate torque reactionNo backlashAnalogue computers for vehiclesDigital data processing detailsClose couplingDrivetrain

A system and method for controlling an internal combustion engine operable with a first cylinder firing frequency and a second cylinder firing frequency to reduce or eliminate transmission of torsional vibrations associated with the second cylinder firing frequency to reduce or eliminate constraints on reduced displacement mode operation using a closely coupled drive train component rotating in an opposite direction relative to rotating components of the engine. A close coupling device allows the inertia of the counter-rotating elements to reduce or eliminate the torque reaction of the drivetrain associated with acceleration and deceleration of the engine crankshaft in response to the second cylinder firing frequency in the reduced displacement mode.

Owner:FORD GLOBAL TECH LLC

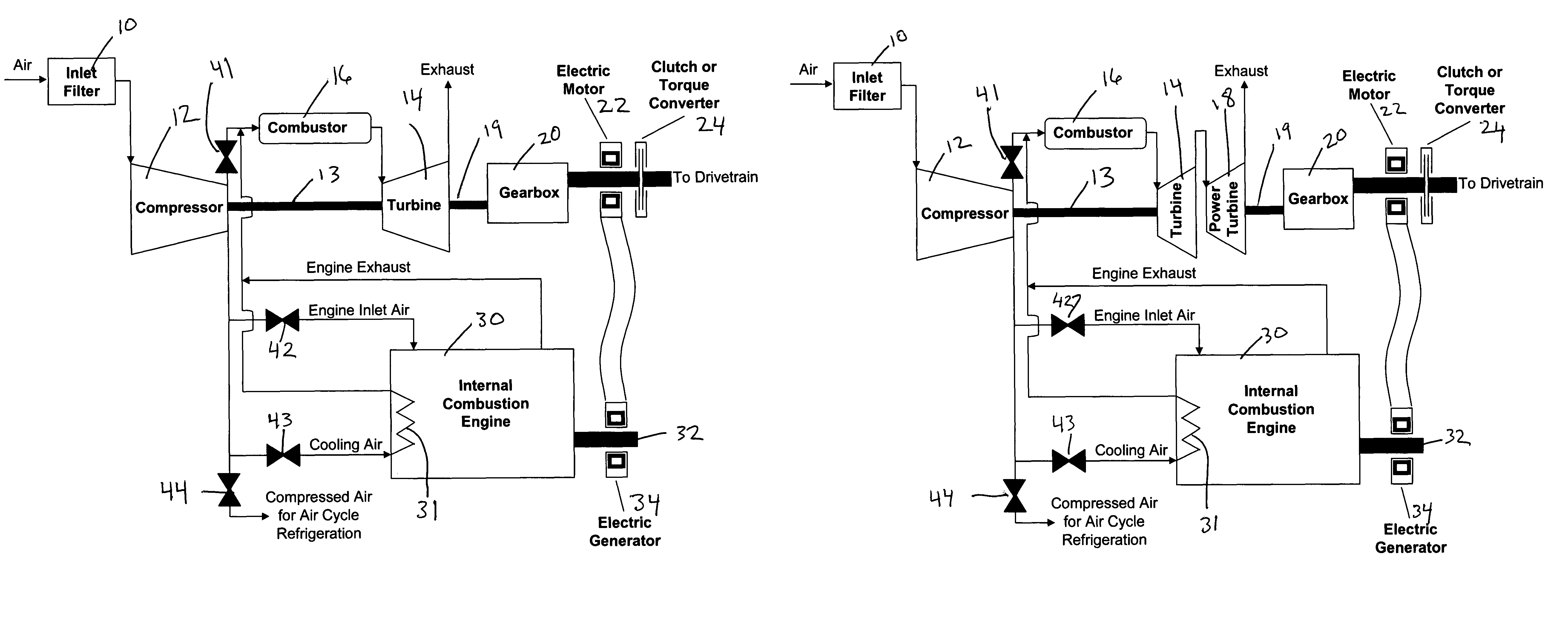

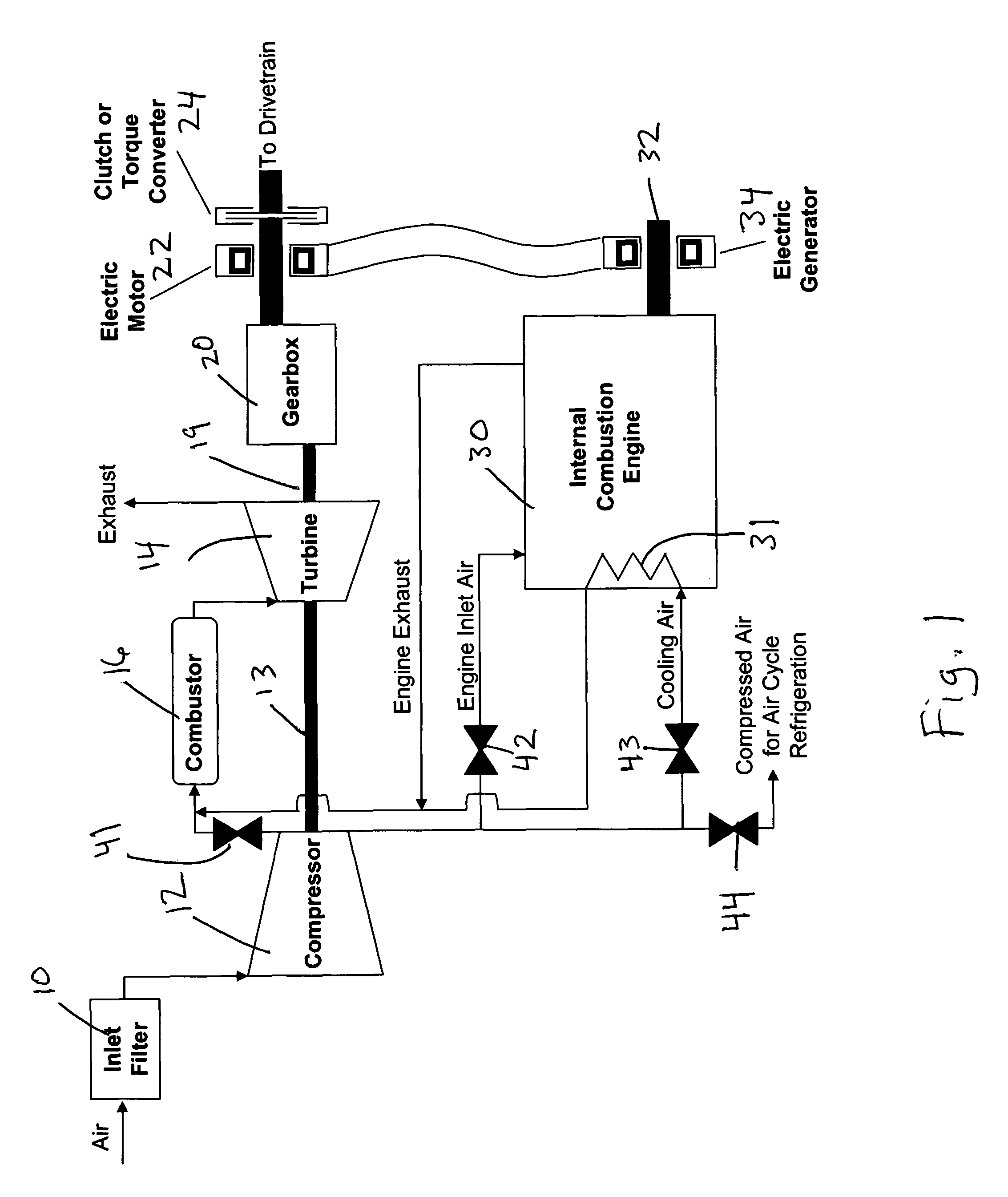

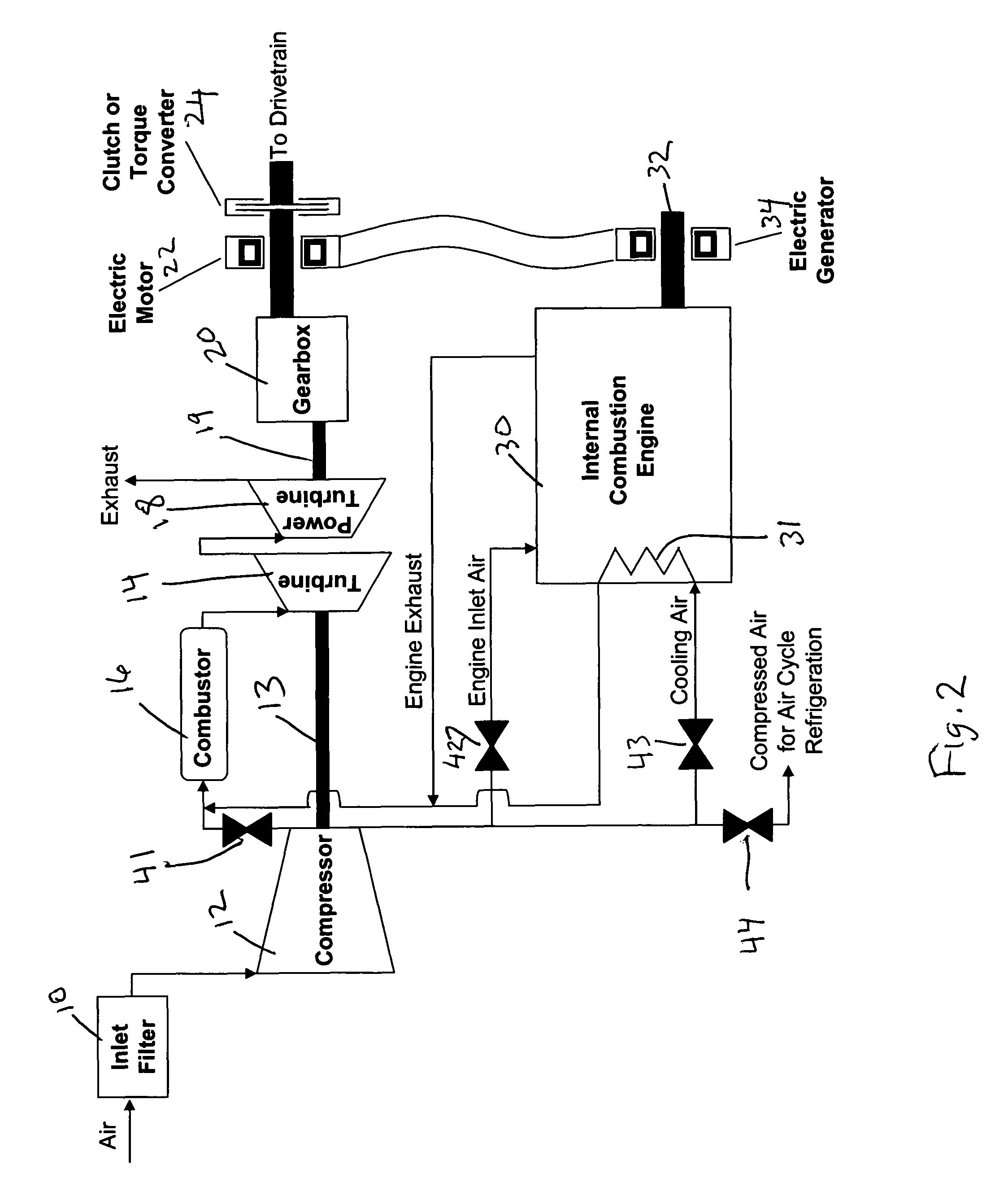

Hybrid gas turbine and internal combustion engine

InactiveUS8141360B1Improve power densityAvoids severe efficiency degradationInternal combustion piston enginesVehicle sub-unit featuresExternal combustion engineFuel efficiency

A hybrid engine having a gas turbine engine and an internal combustion engine, both engines driving a common drive shaft. The compressor delivers compressed air to the combustor and to an inlet of the internal combustion engine, the compressed air picks up heat from the internal combustion engine either from the combustion process or through a heat exchanger, and is delivered to the combustor. When the gas turbine engine is not operating by burning fuel, the heated compressed air from the internal combustion engine is used to maintain the shaft speed sufficient for starting the gas turbine engine without the need to bring the turbine engine up to speed prior to ignition. The apparatus and process of the present invention provides a hybrid engine that is light weight, fuel efficient, and with enough available power for high powered situations.

Owner:FLORIDA TURBINE TECH

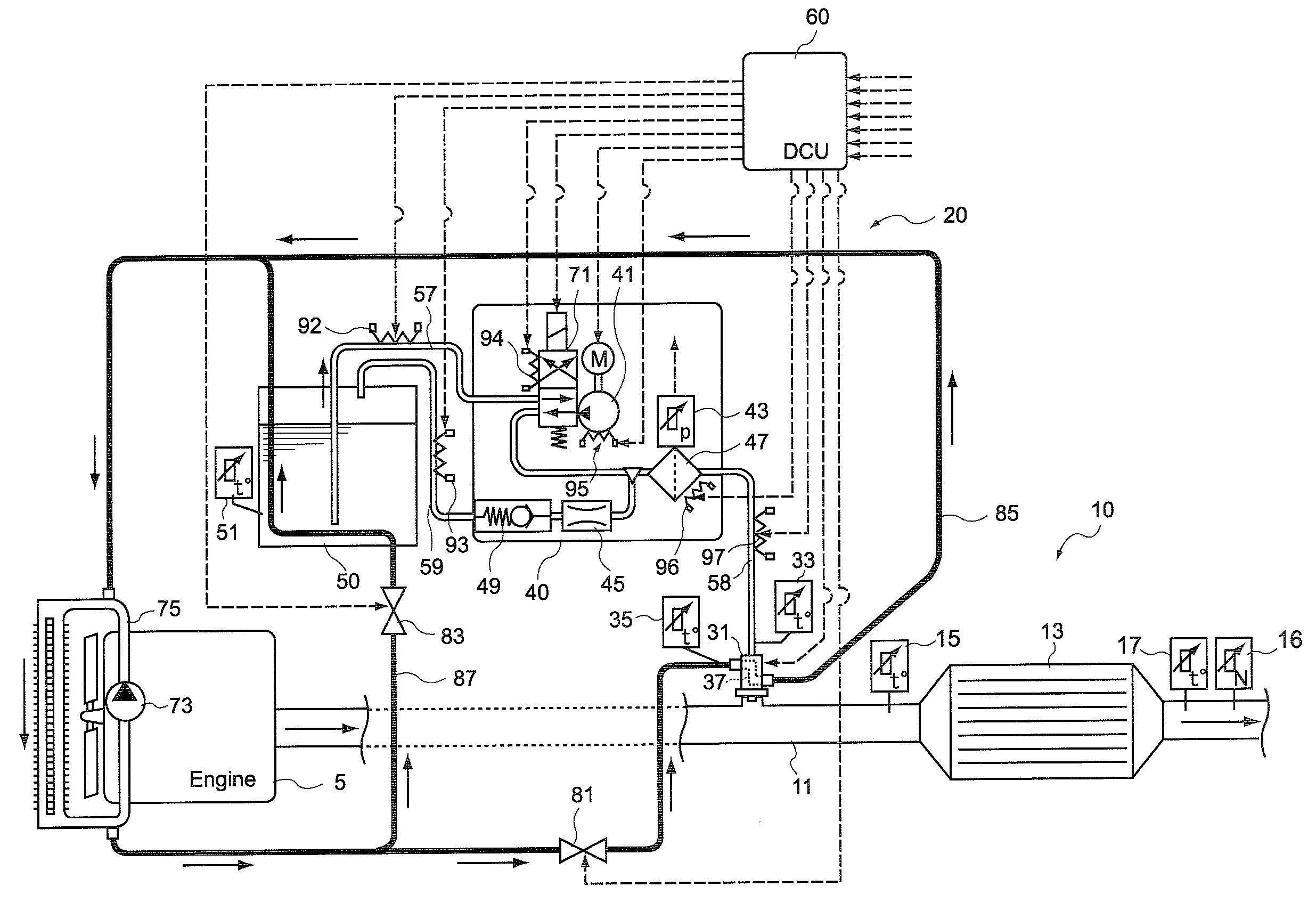

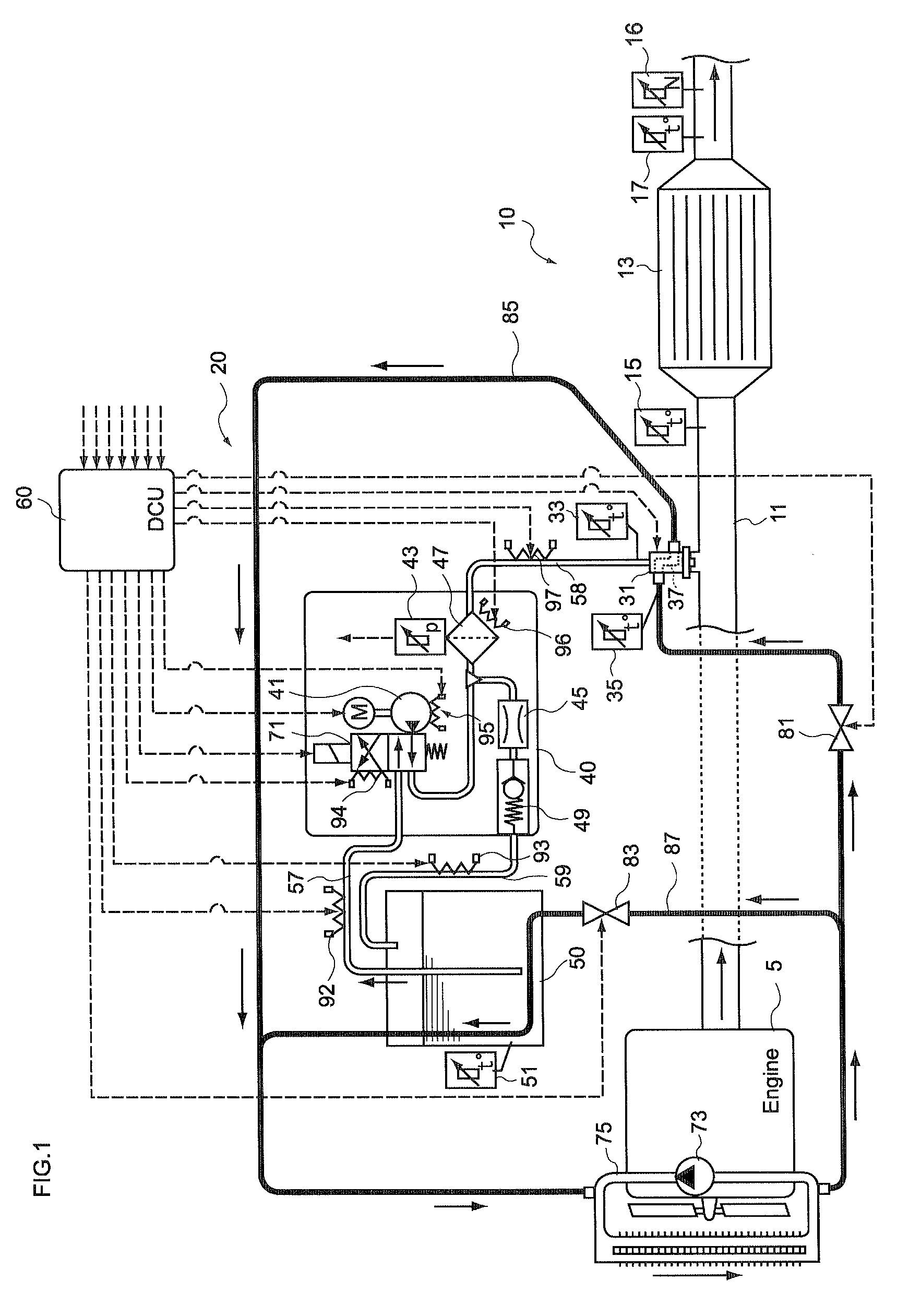

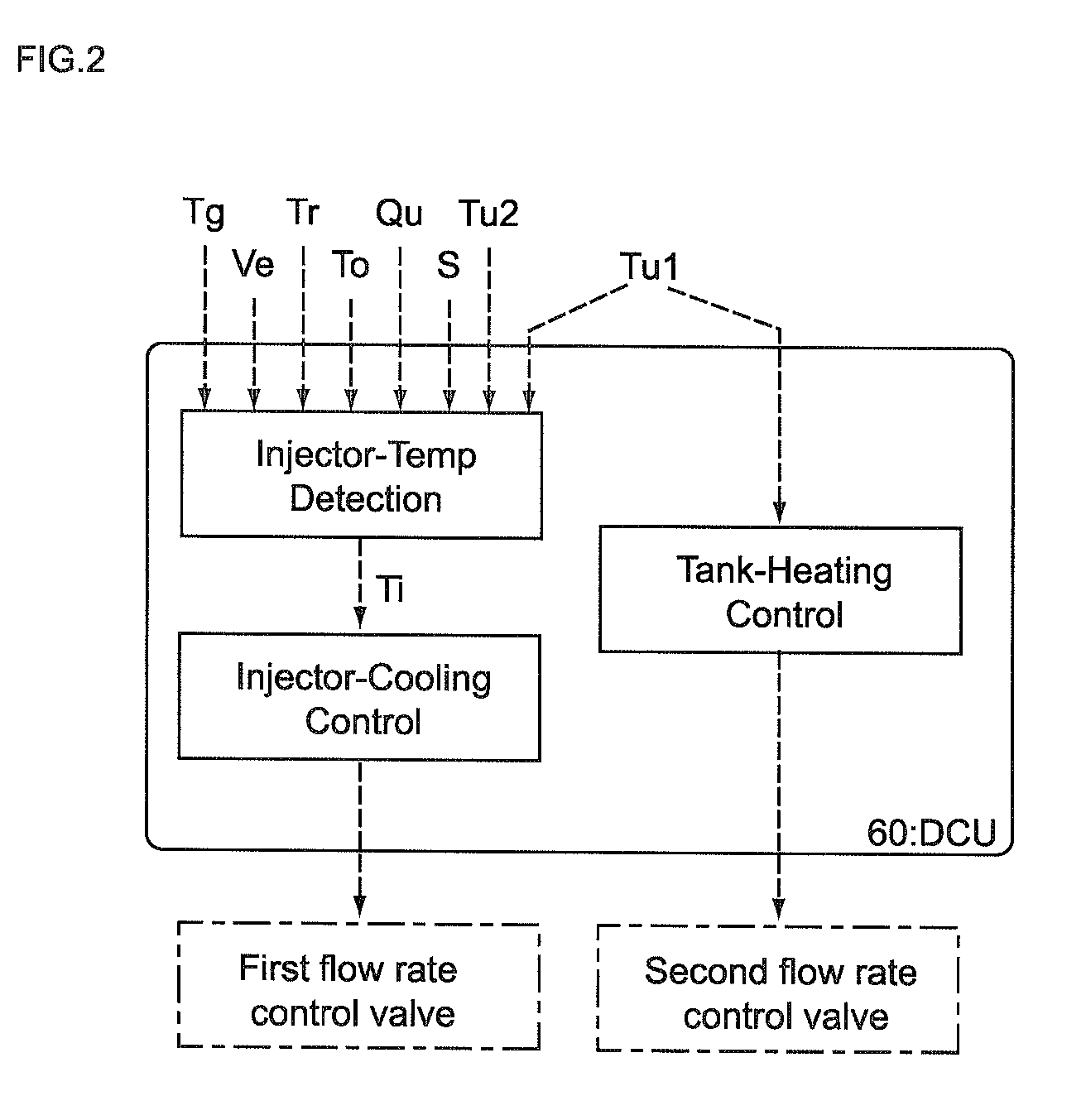

Control unit and control method for reductant supply device

InactiveUS20100242439A1Prevent overcoolingImprove cooling effectLiquid coolingInternal combustion piston enginesEngineeringWater circulation

There are provided a reductant supply device and a control method for the reductant supply device, which can prevent heat damage of a reductant injection valve, and also prevent crystallization of urea solution due to excessive cooling of the solution reductant.The reductant supply device which is used in an exhaust gas purification device that injects and supplies, as a reductant, a urea solution to an exhaust gas upstream side of a reduction catalyst disposed in an exhaust gas passage of an internal combustion engine, and that reduces and purifies nitrogen oxides contained in exhaust gas using the reduction catalyst, the reductant supply device having a reductant injection valve that is fixed to an exhaust pipe on the exhaust gas upstream side of the reduction catalyst, includes: a cooling water circulation passage that circulates at least part of cooling water of the internal combustion engine to cool the reductant injection valve; flow rate control means for adjusting a flow rate of cooling water flowing through the cooling water circulation passage; temperature detection means for detecting a temperature of the reductant injection valve; and control means for controlling the flow rate control means based on the temperature of the reductant injection valve.

Owner:BOSCH CORP

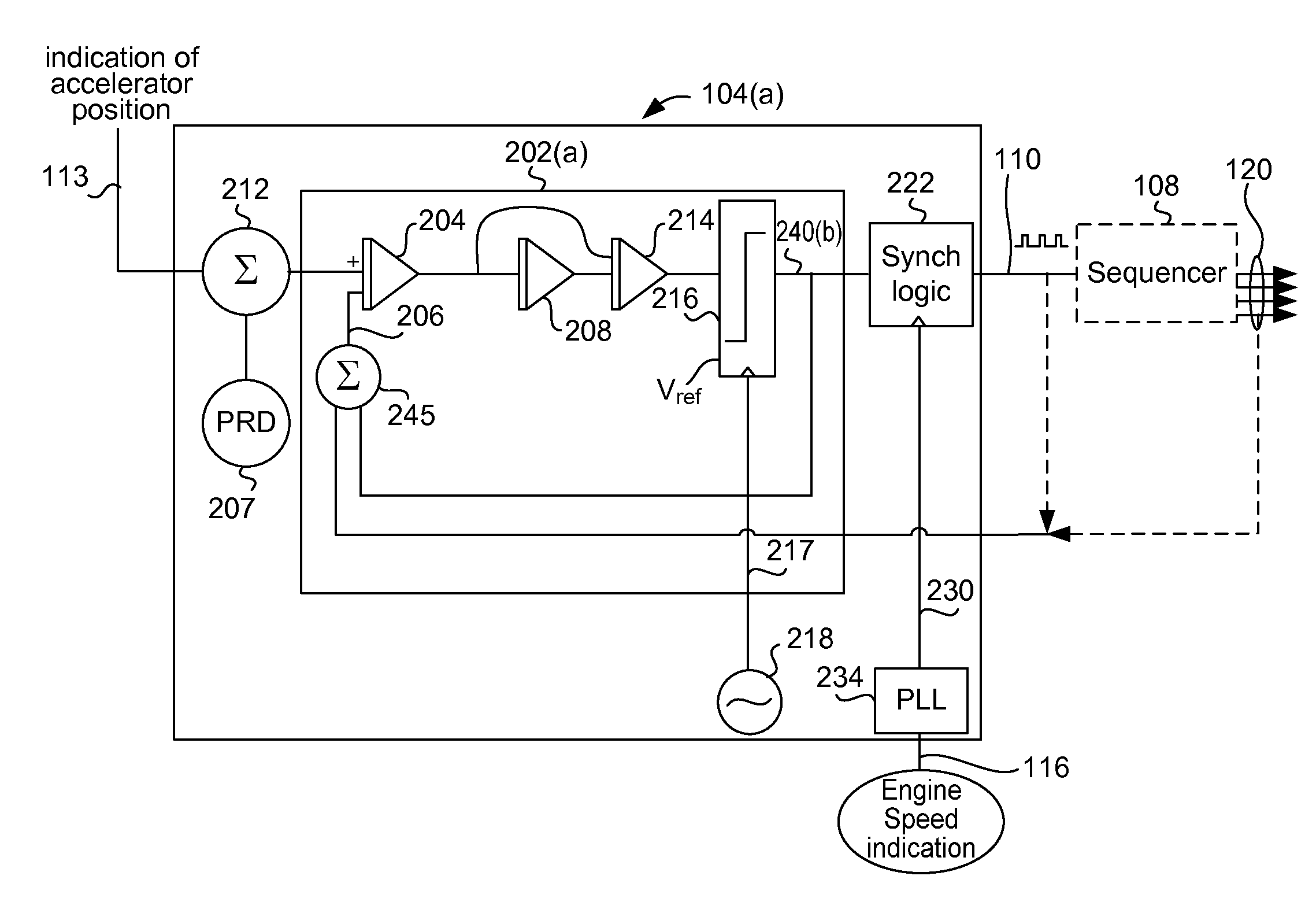

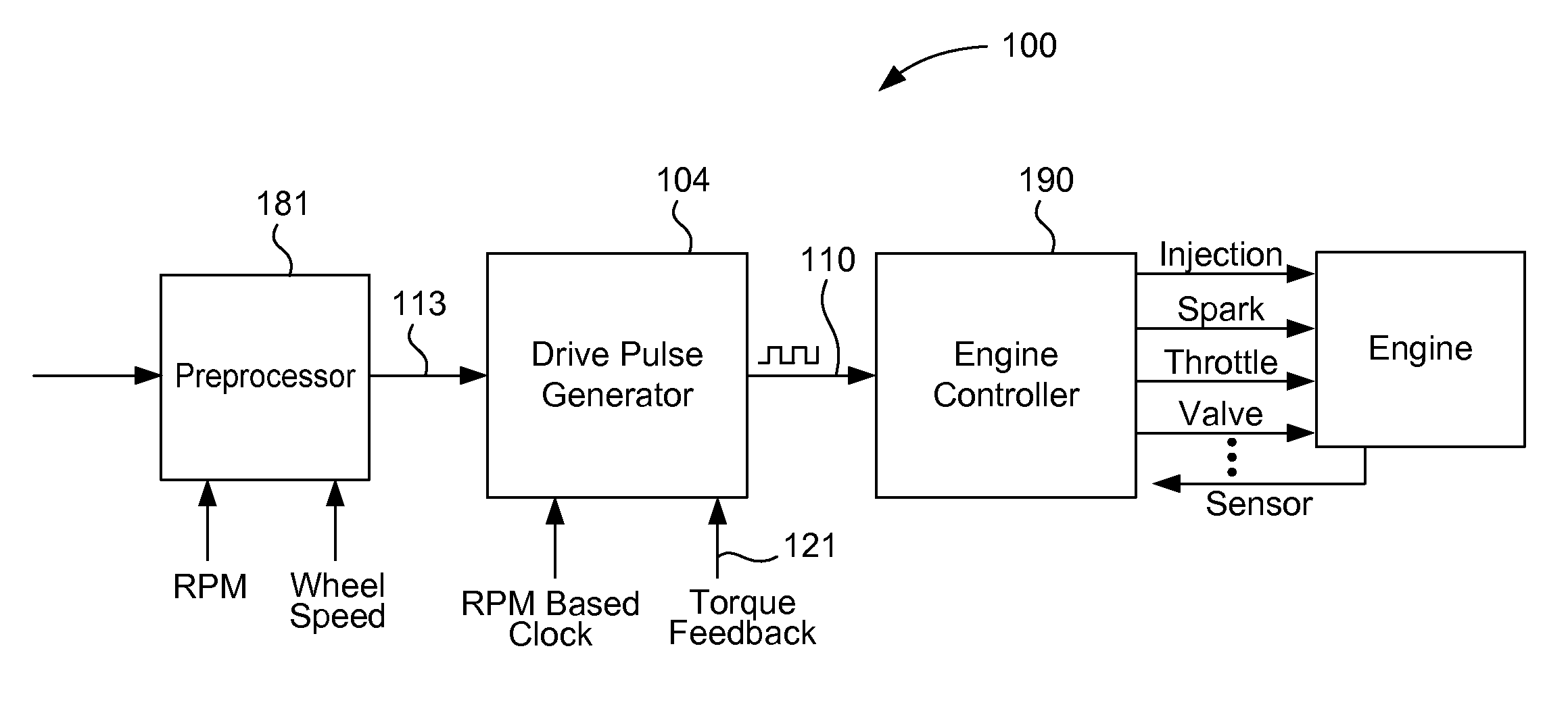

Skip fire internal combustion engine control

ActiveUS8869773B2Reduce generationAnalogue computers for vehiclesElectrical controlFire controlExternal combustion engine

A variety of methods and arrangements for controlling the operation of an internal combustion engine in a skip fire variable displacement mode are described. In general, a firing control unit determines working chamber firings during operation of the engine that are suitable for delivering a desired engine output. In one aspect, the firing control unit is arranged to isolate the generation of firing sequences having frequency components in a frequency range of concern and to alter the firing sequence in a manner that reduces the occurrence of frequency components in the frequency range of concern. In another aspect, a filter is arranged to filter a feedback signal to provide a filtered feedback signal that is used in the determination of the working chamber firings. In preferred embodiments, the frequency characteristics of the filter are variable.

Owner:TULA TECH INC

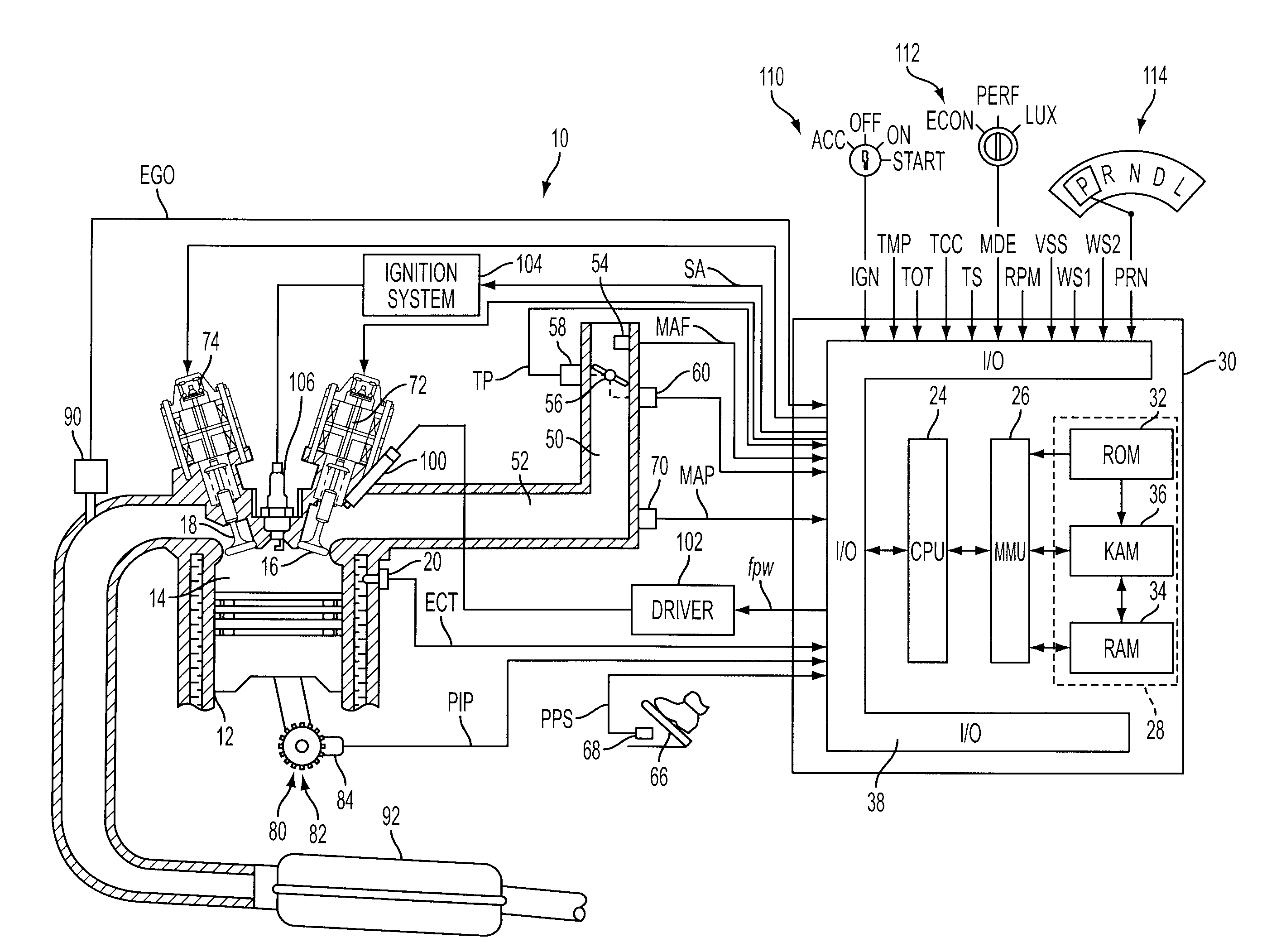

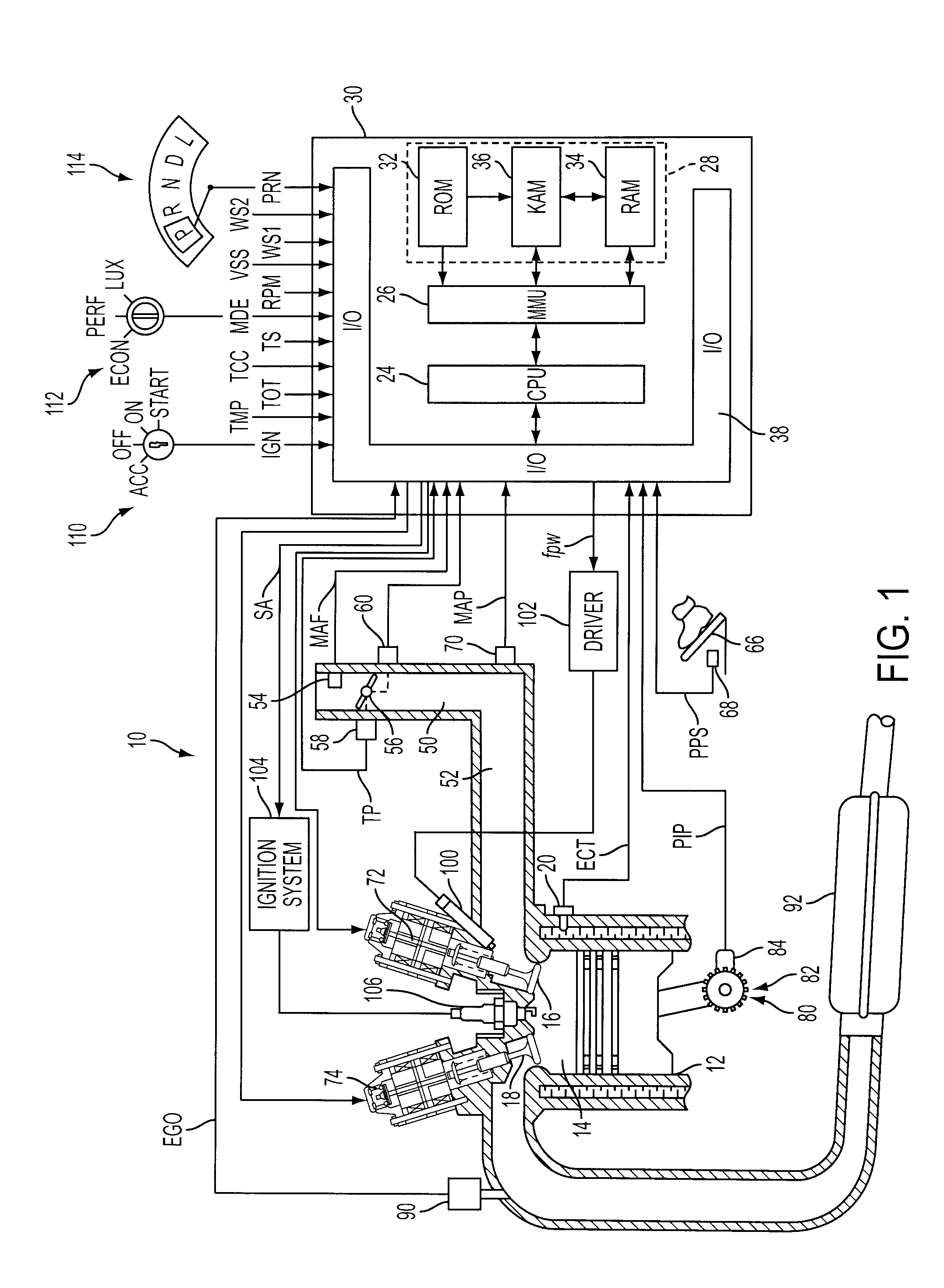

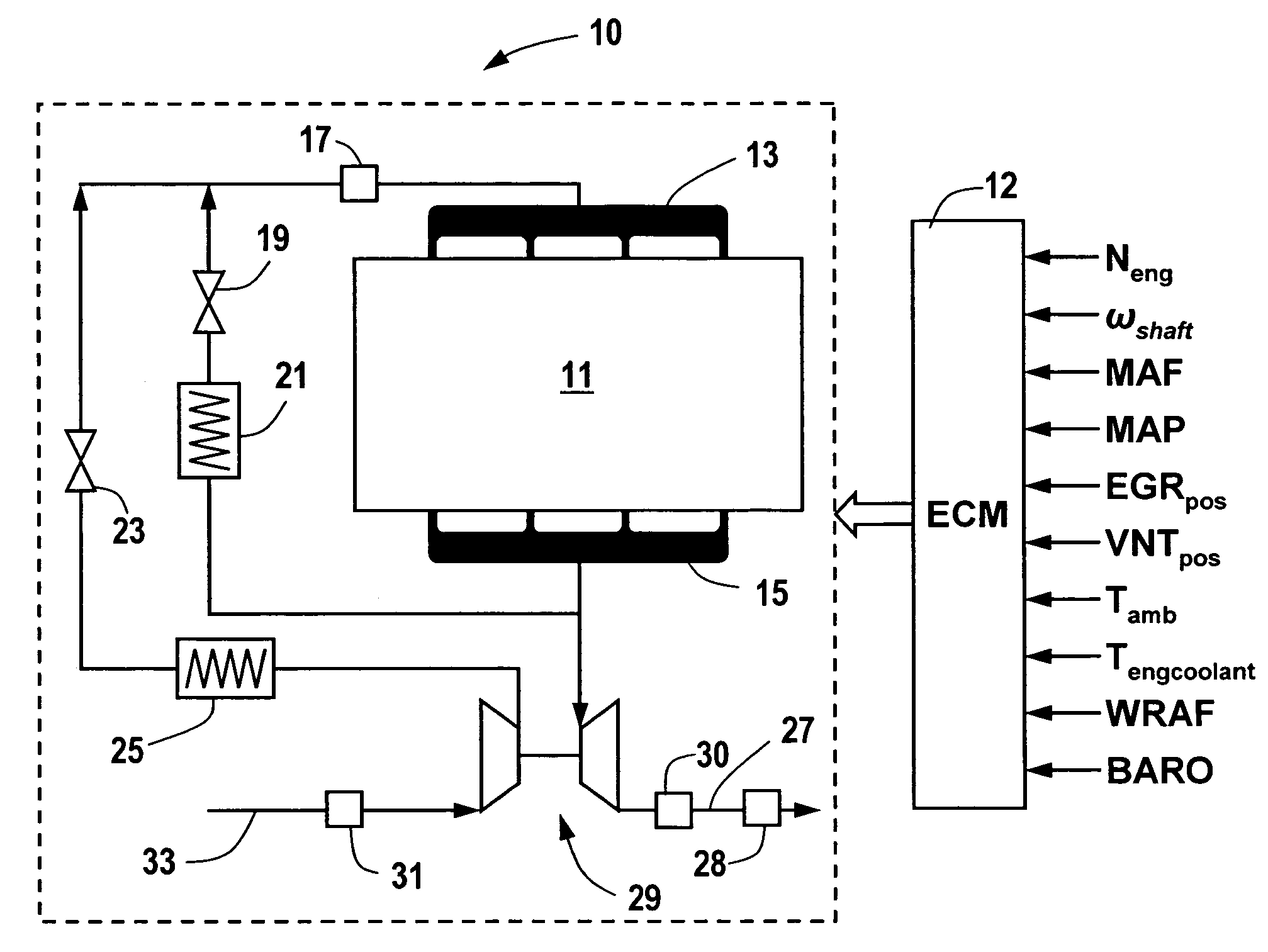

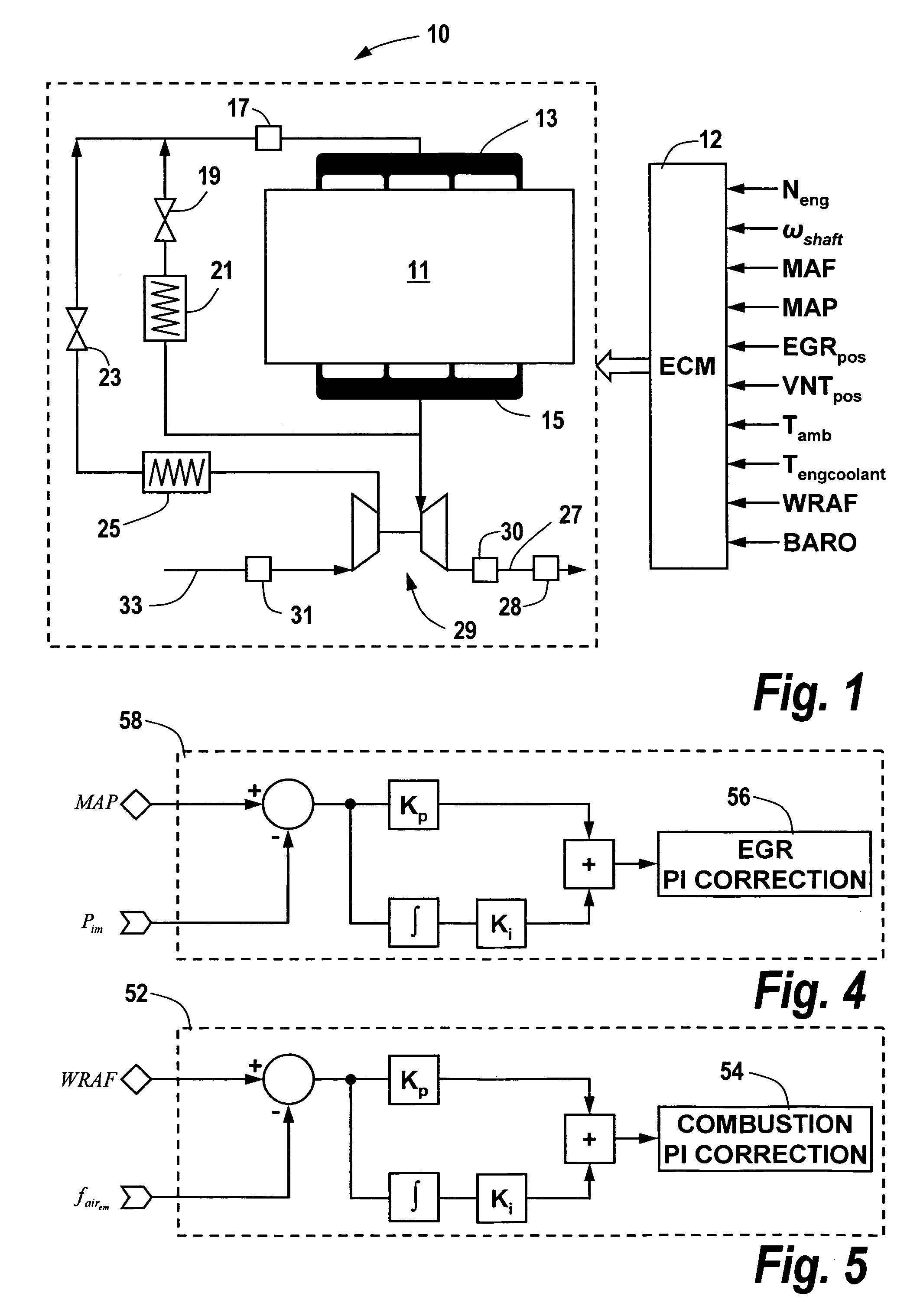

Intake oxygen estimator for internal combustion engine

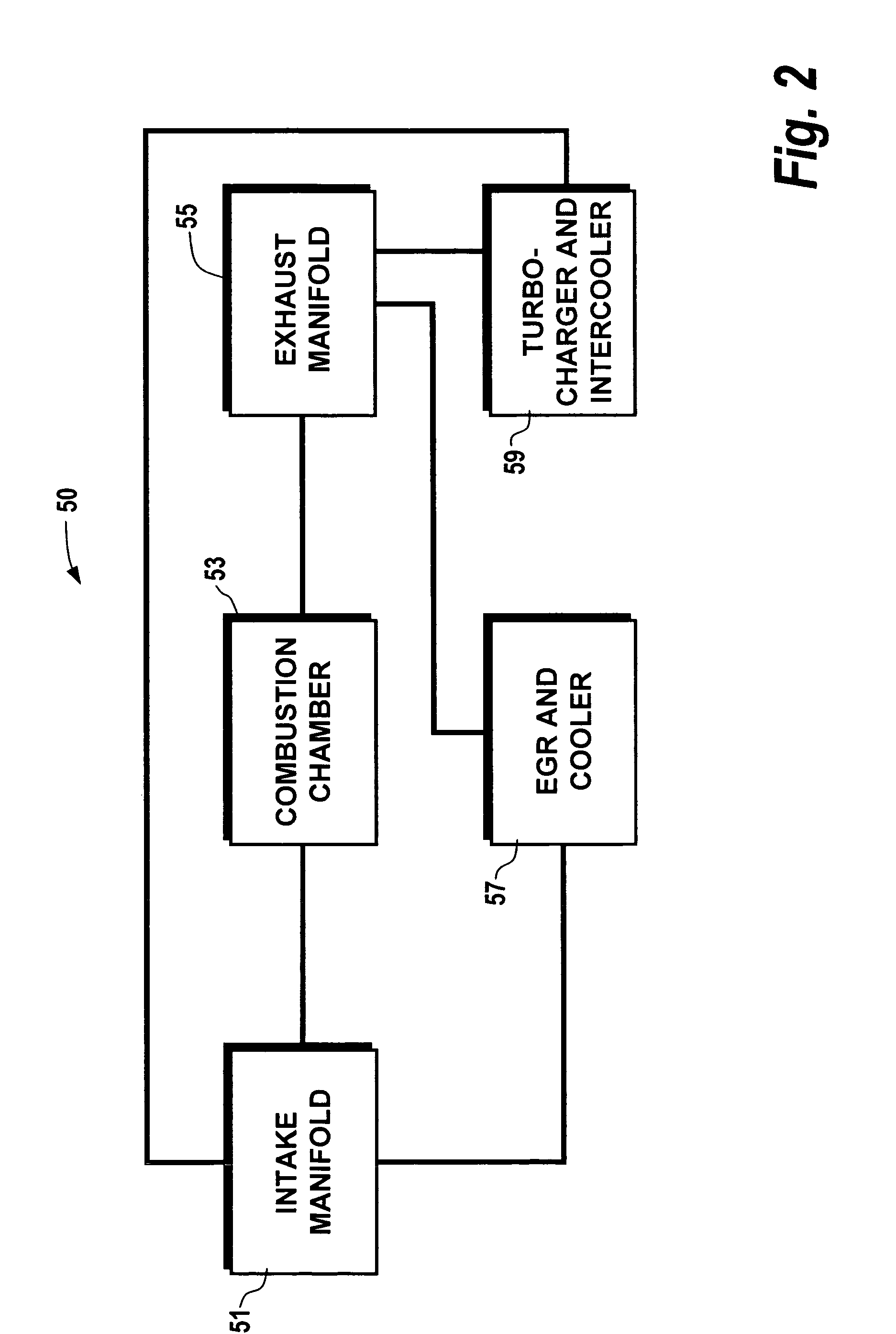

ActiveUS7117078B1Electrical controlDigital data processing detailsExternal combustion engineExhaust gas recirculation

An internal combustion engine system includes an intake manifold, a combustion chamber, an exhaust manifold and exhaust gas recirculation apparatus for recirculating a portion of the exhausted gases from the exhaust manifold to the intake manifold. An estimate intake manifold oxygen concentration is determined from the air fraction within the intake manifold which is determined from an engine system model that provides interdependent air mass fractions at various locations within the engine system.

Owner:GM GLOBAL TECH OPERATIONS LLC

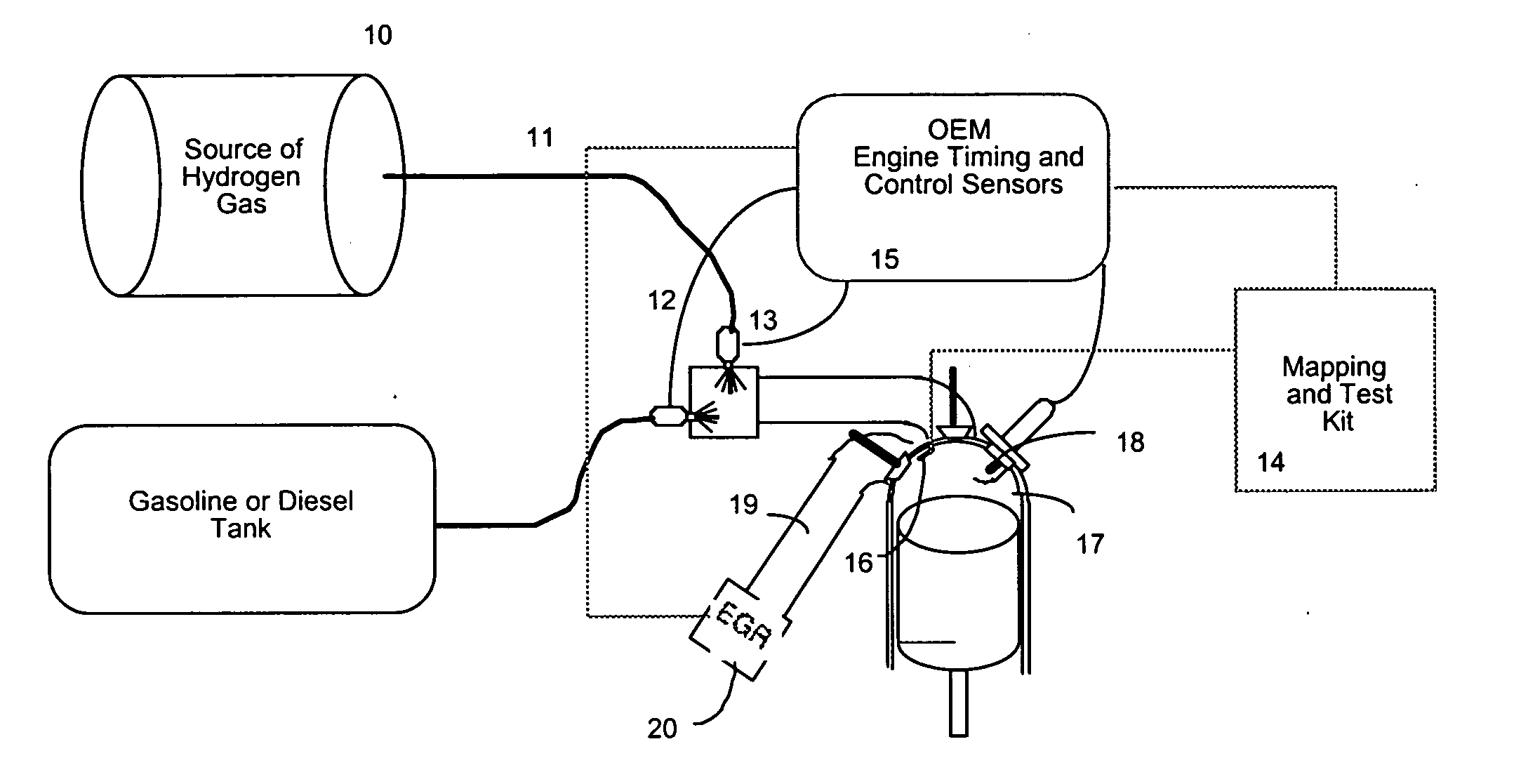

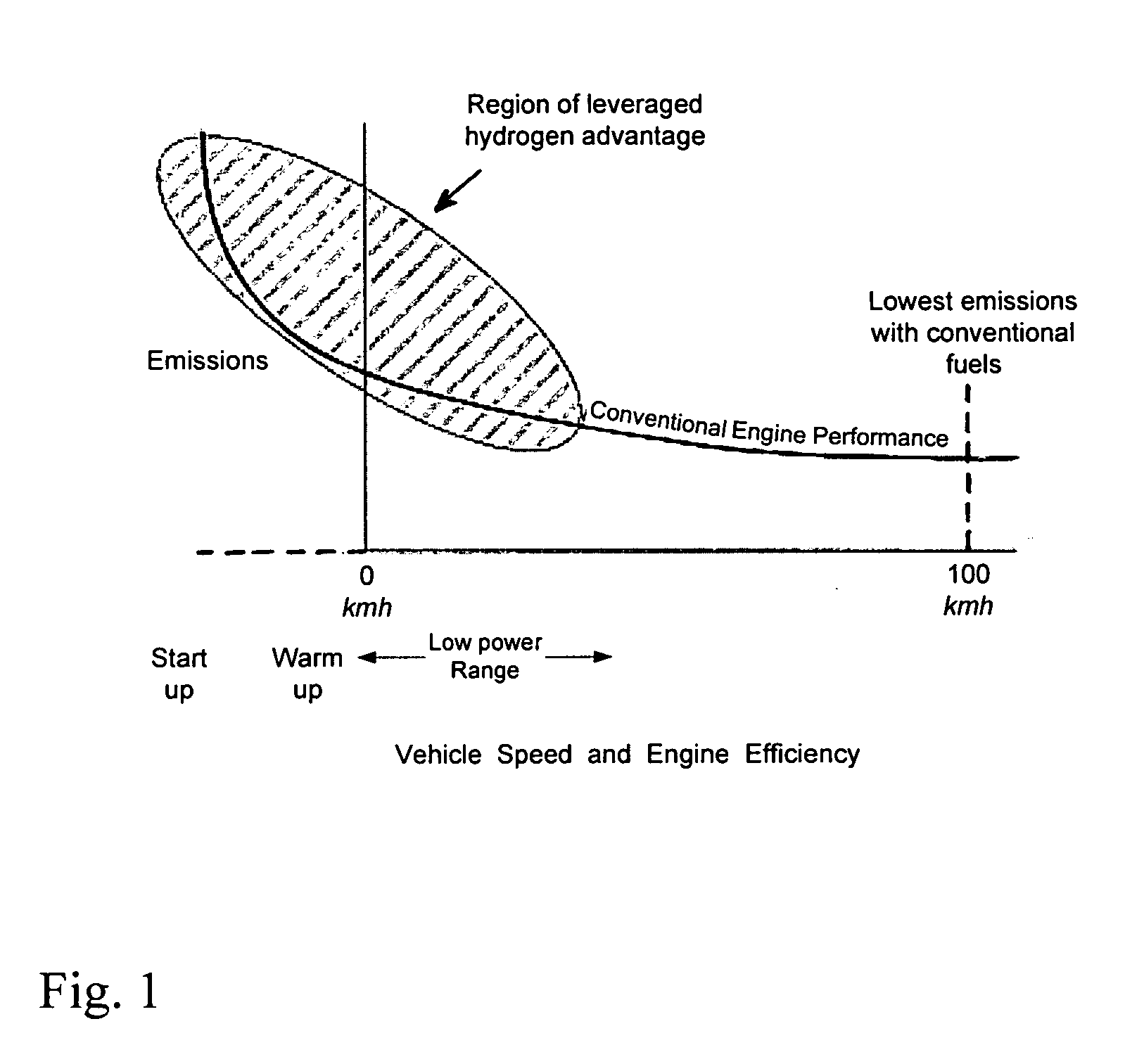

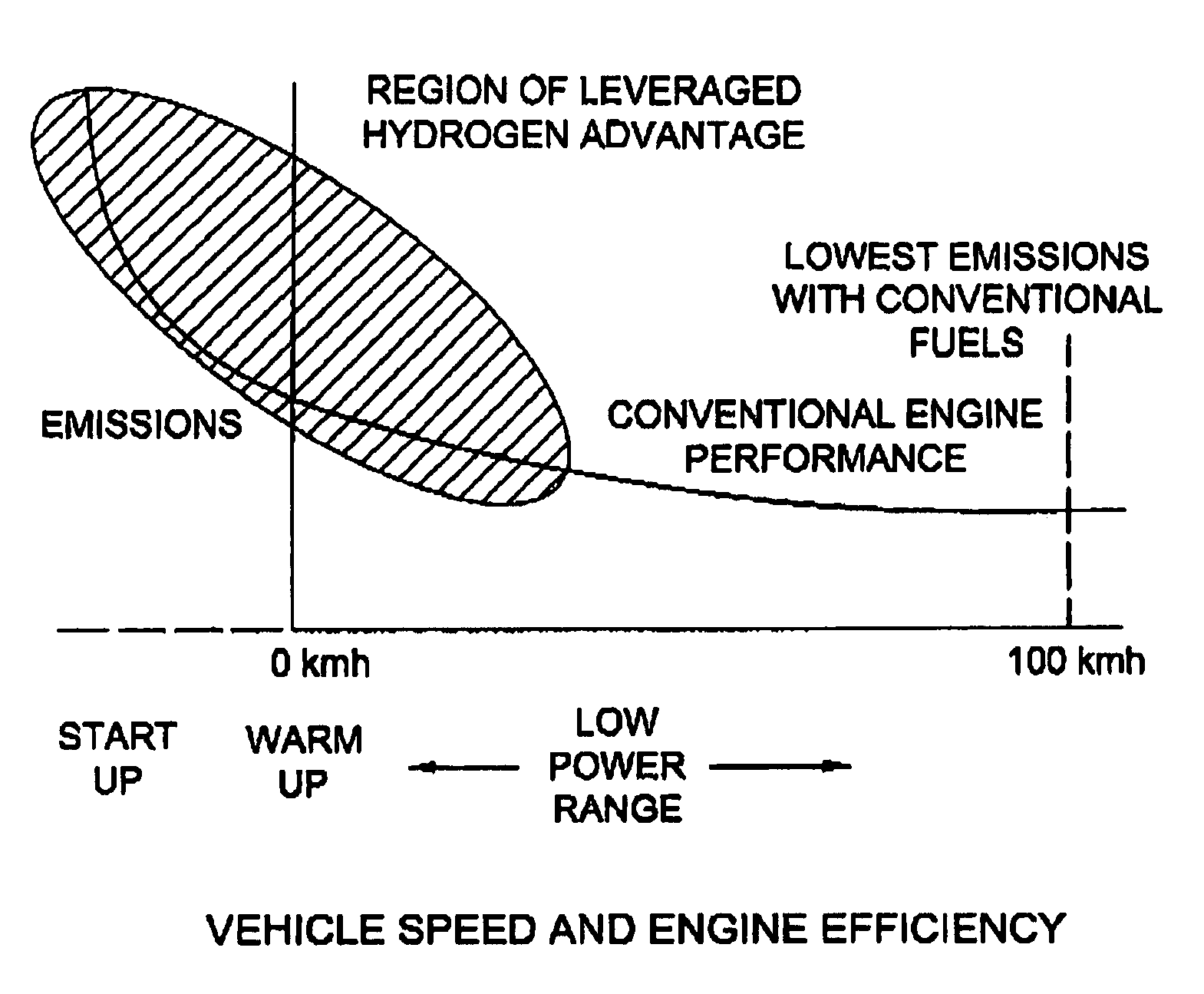

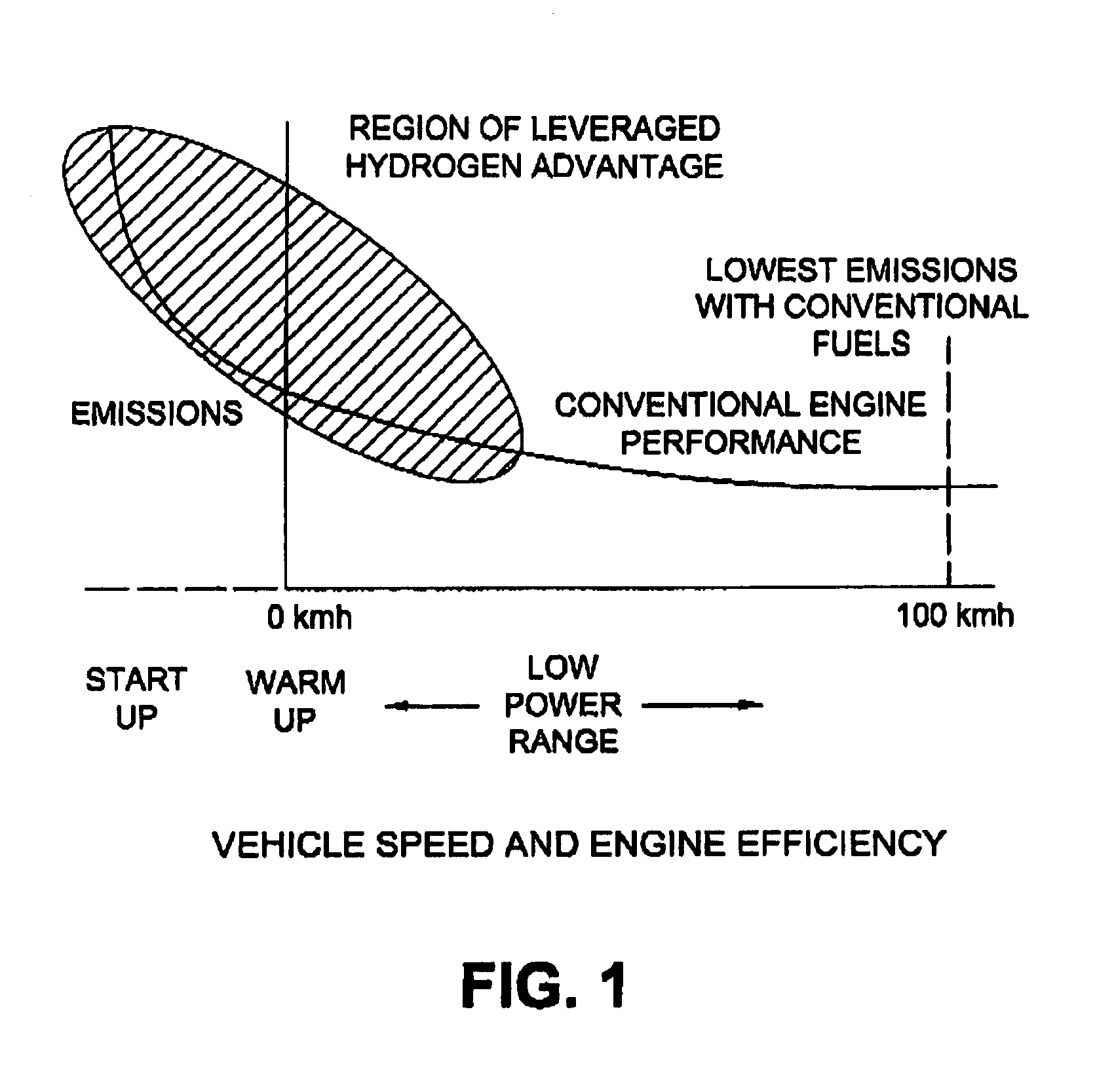

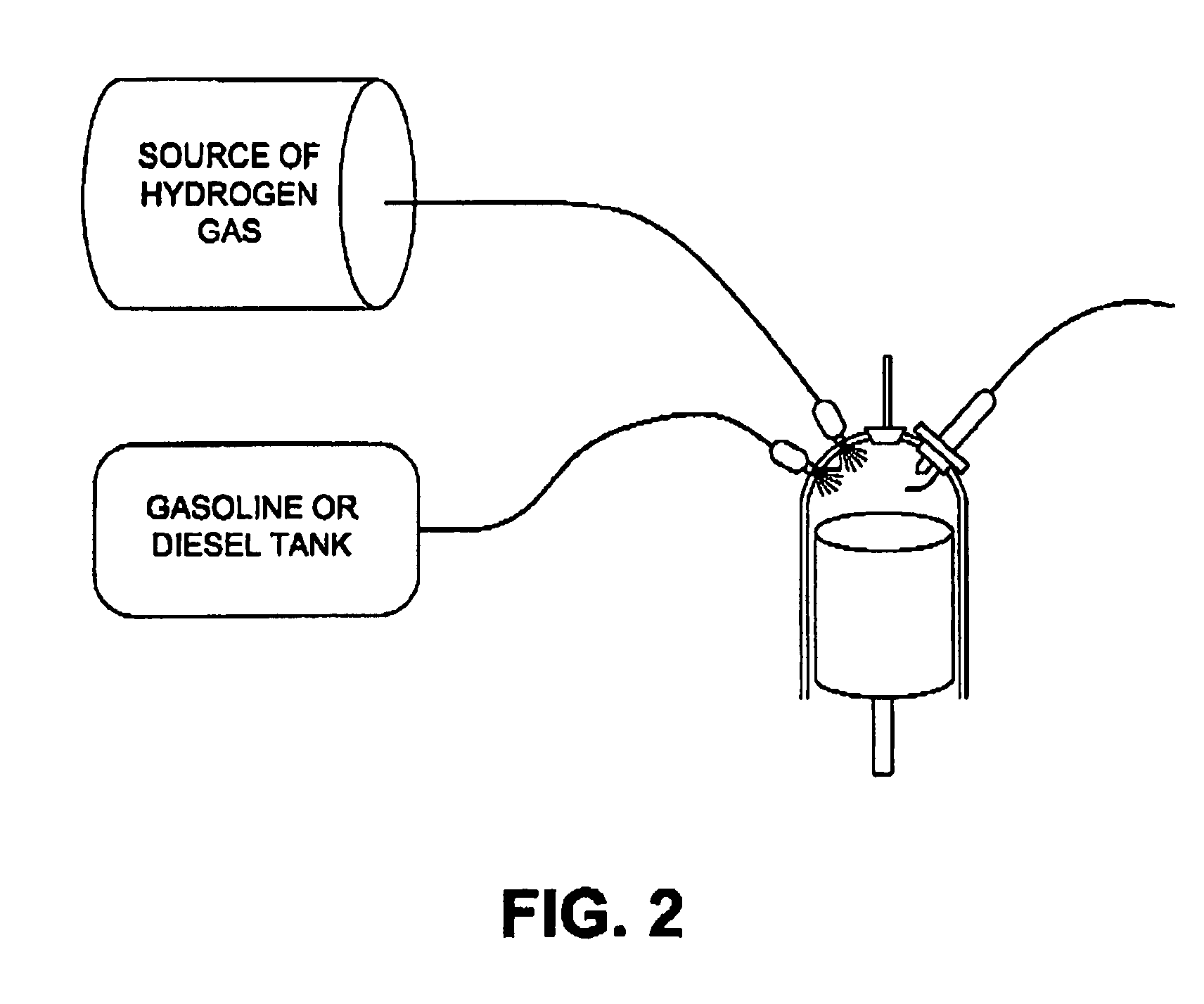

System and method for operating an internal combustion engine with hydrogen blended with conventional fossil fuels

ActiveUS20050229872A1Inexpensively repAccelerate emissionsHydrogenElectrical controlHydrogenExternal combustion engine

A system for retrofitting an internal combustion engine to use a proportion of hydrogen gas and existing fossil fuel is disclosed. The system is comprised of a source of hydrogen gas and means for delivering hydrogen gas to the combustion chamber of the engine. The engine operating parameters are adjusted and the delivery of hydrogen is controlled to provide selective introduction of hydrogen gas throughout the engine's operating cycle. The source of hydrogen gas can comprise an onboard hydrogen reformer, or hydrogen and carbon monoxide can be reformed inside the cylinder from an on board carrier of hydrogen. A single point injector placed at the intake manifold in close proximity to the engine intake valve can be used to mix the hydrogen gas to the air / fossil fuel mixture or sequential injectors can deliver hydrogen in close proximity to each engine intake valve, or directly into each cylinder.

Owner:OREILLY HUGH

Static mixer for an exhaust gas system of an internal combustion engine

InactiveUS20110205837A1Inhibition of turbulent flowAvoid pressure lossFlow mixersExhaust apparatusExternal combustion engineExhaust fumes

A static mixer for an exhaust gas system of an internal combustion engine with which at least two different fluid streams are mixed almost homogeneously after a short mixing distance, and with which back-flow effects and pressure losses are avoided, to the greatest possible extent. Due to the placement of flow guide devices, the inclined front sections of which are disposed alternately facing in different directions, and by the configuration and placement of the fluid passage spaces, which are delimited by guide elements, intensive and homogeneous mixing of two different fluid streams is achieved, while avoiding turbulent flows and pressure losses. Mixing of the fluid streams is supported by guide vanes that are disposed on the flow guide elements in the front region of the central center element, and on a frame that delimits the inclined sections of the flow guide elements.

Owner:IAV INGGES AUTO & VERKEHR

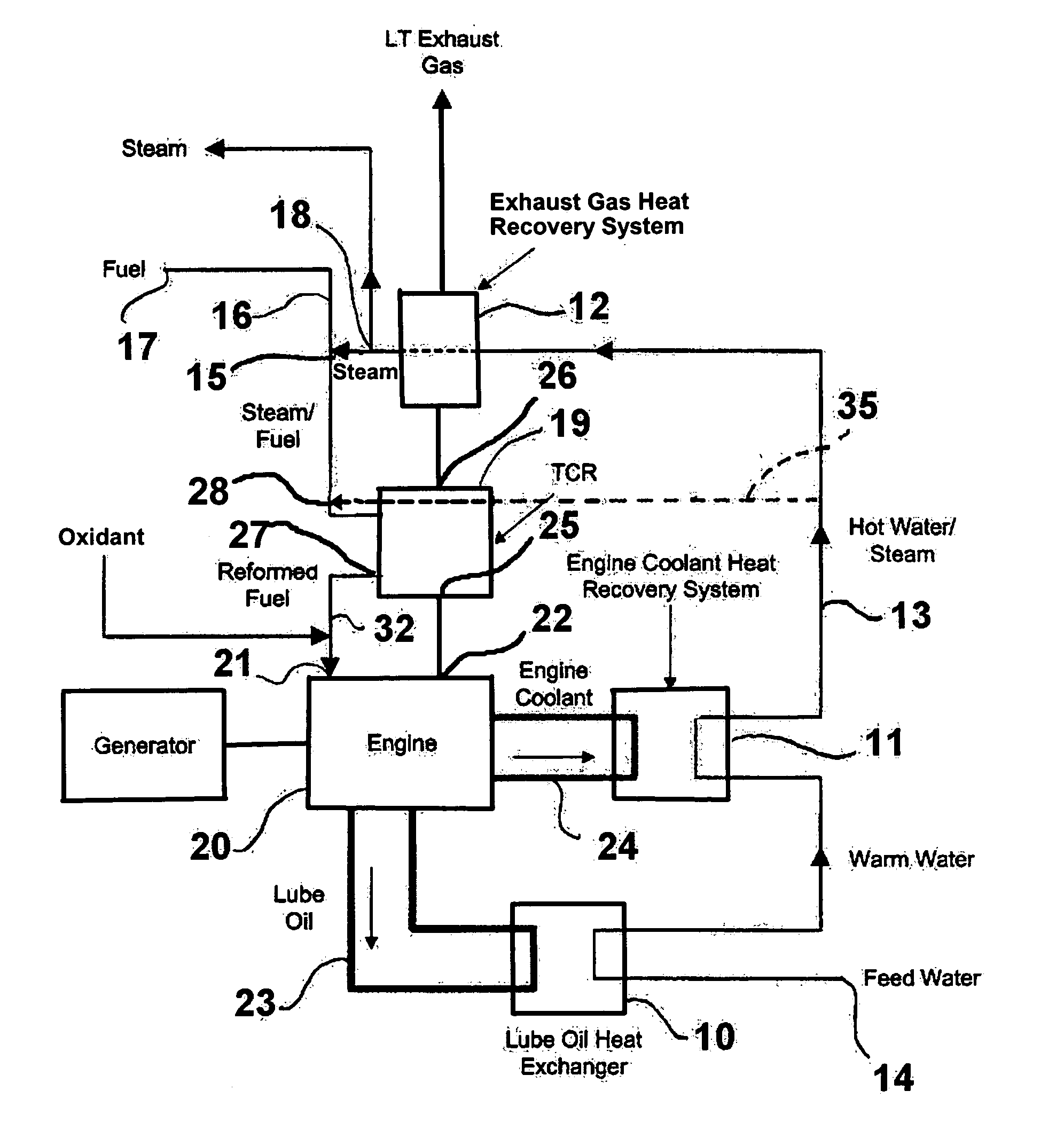

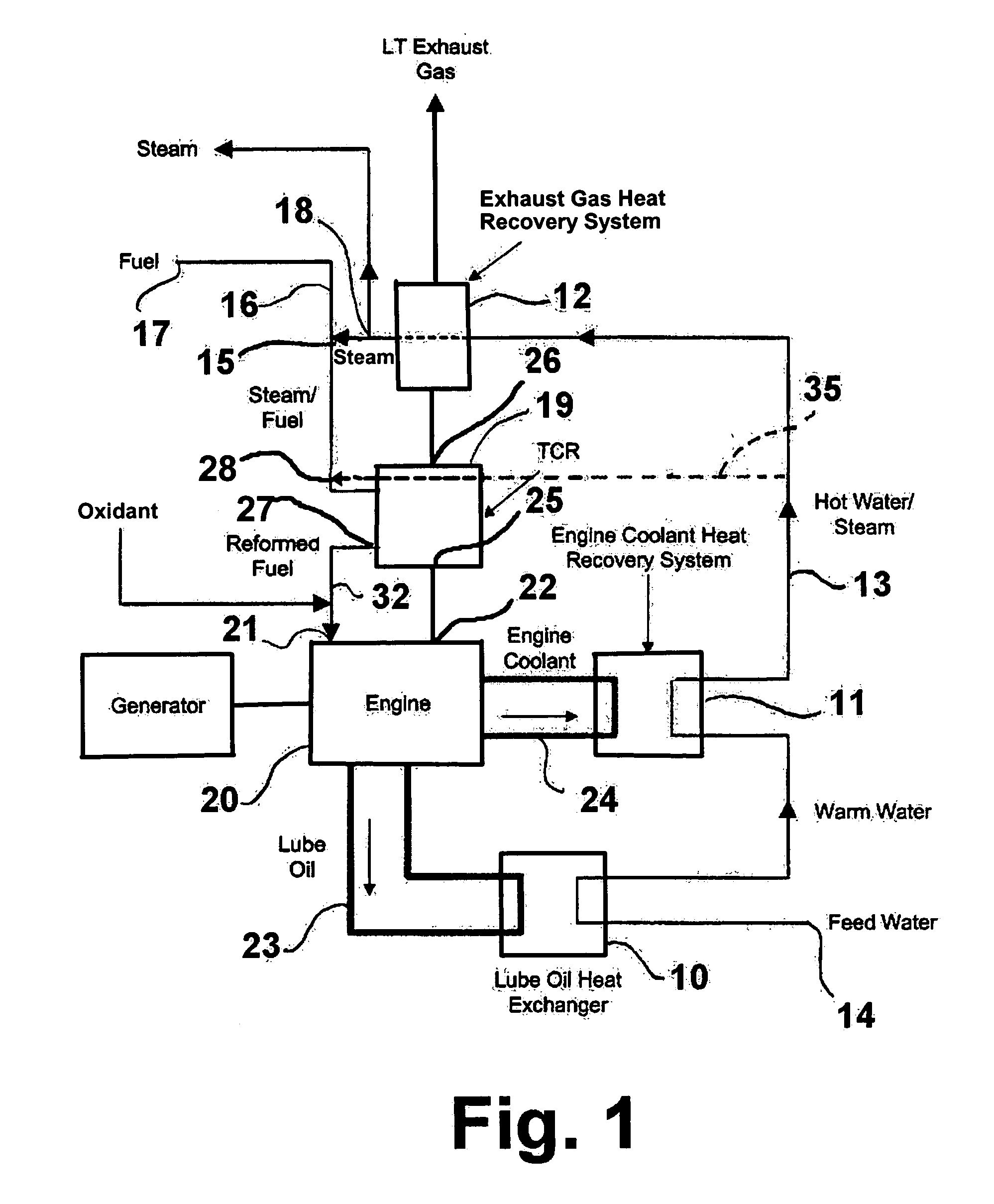

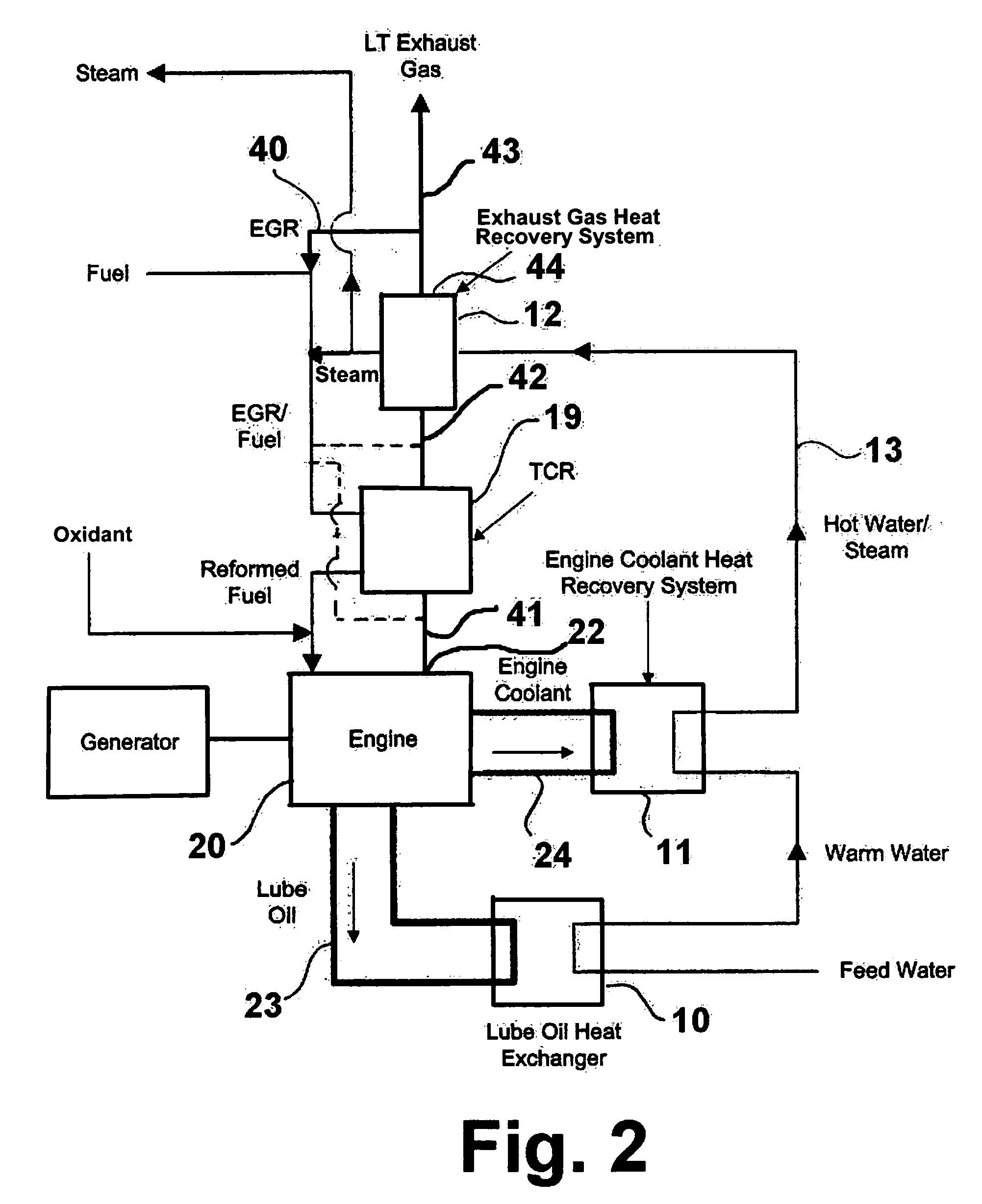

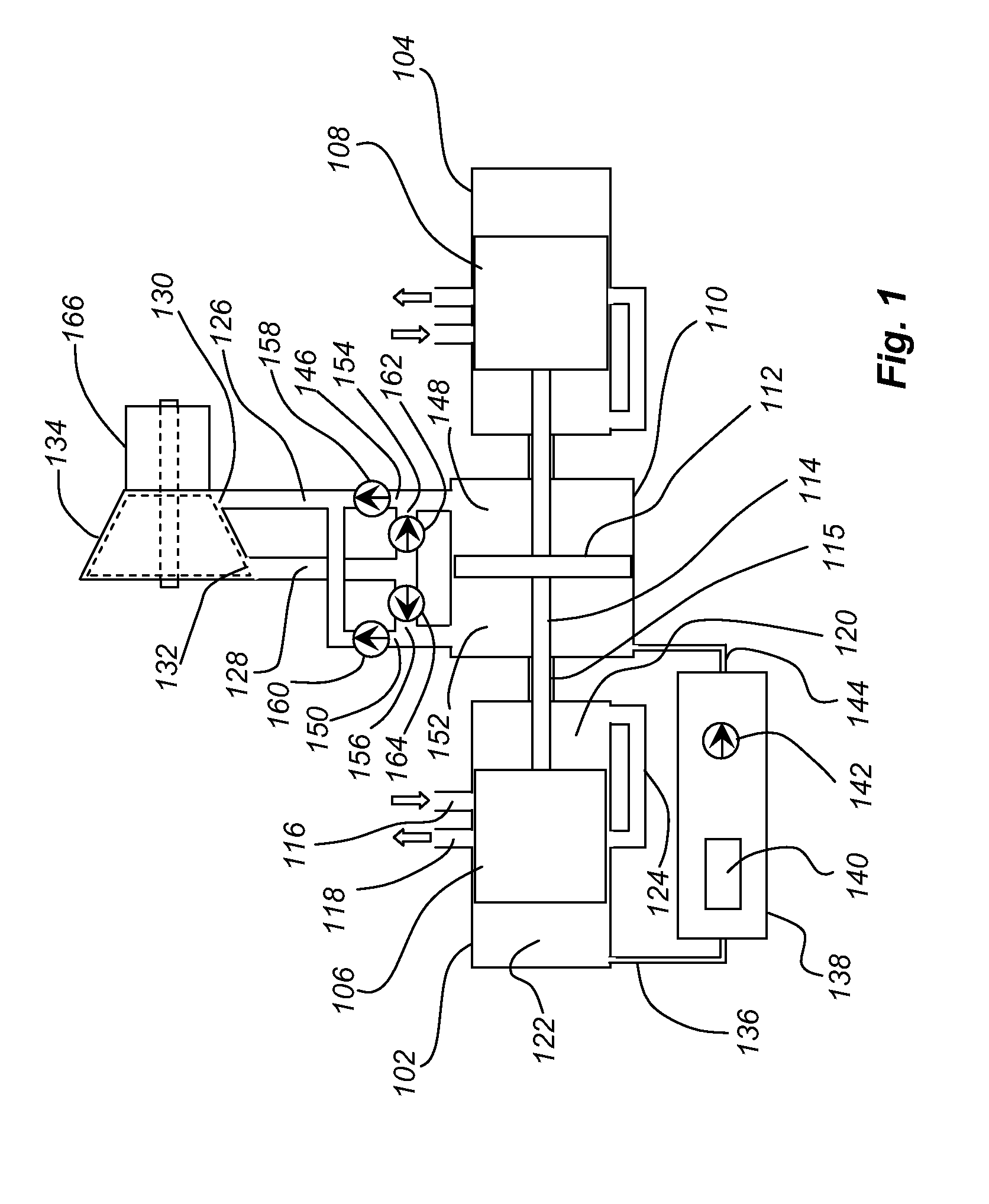

Advanced high efficiency, ultra-low emission, thermochemically recuperated reciprocating internal combustion engine

ActiveUS7210467B2Emission reductionImprove efficiencyInternal combustion piston enginesExhaust apparatusExternal combustion engineEngineering

An apparatus including a reciprocating internal combustion engine and a thermochemical recuperator in which a fuel is reformed. The thermochemical recuperator is heated by exhaust gases from the reciprocating internal combustion engine and steam for the reforming process is produced by passing feed water through an engine lubricating oil heat exchanger, an engine cooling system heat recovery system and an exhaust gas heat recovery system arranged in series.

Owner:GAS TECH INST

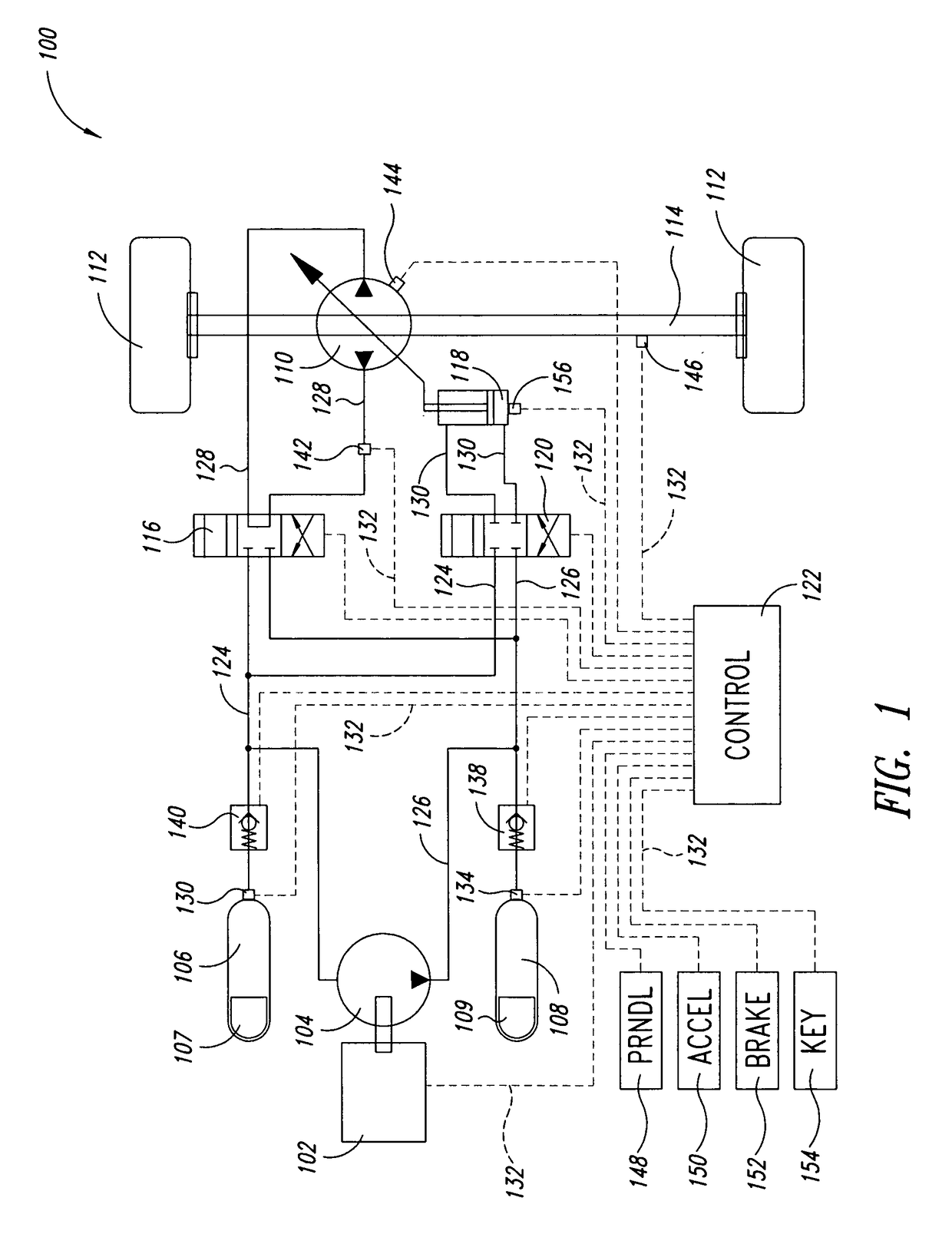

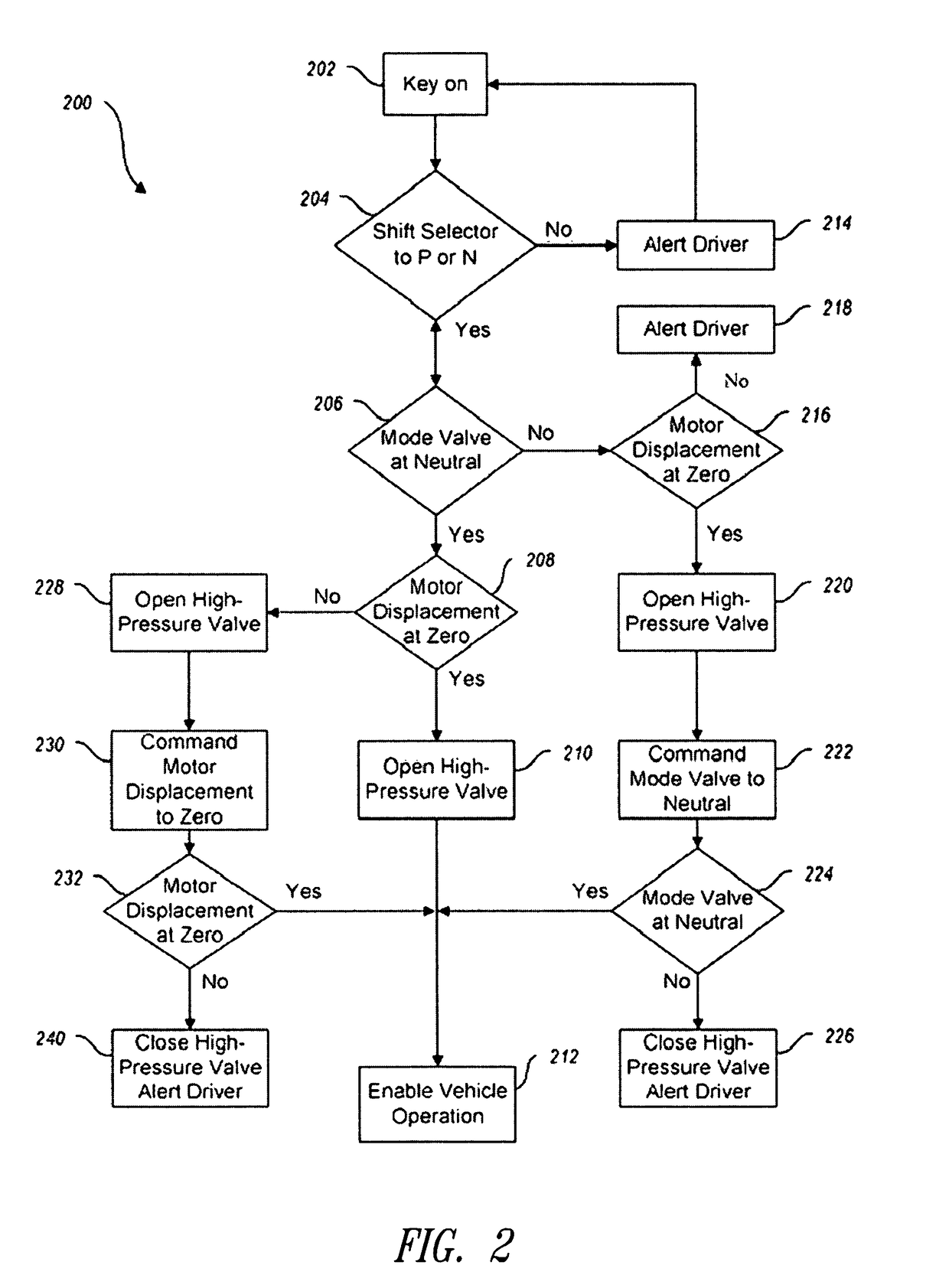

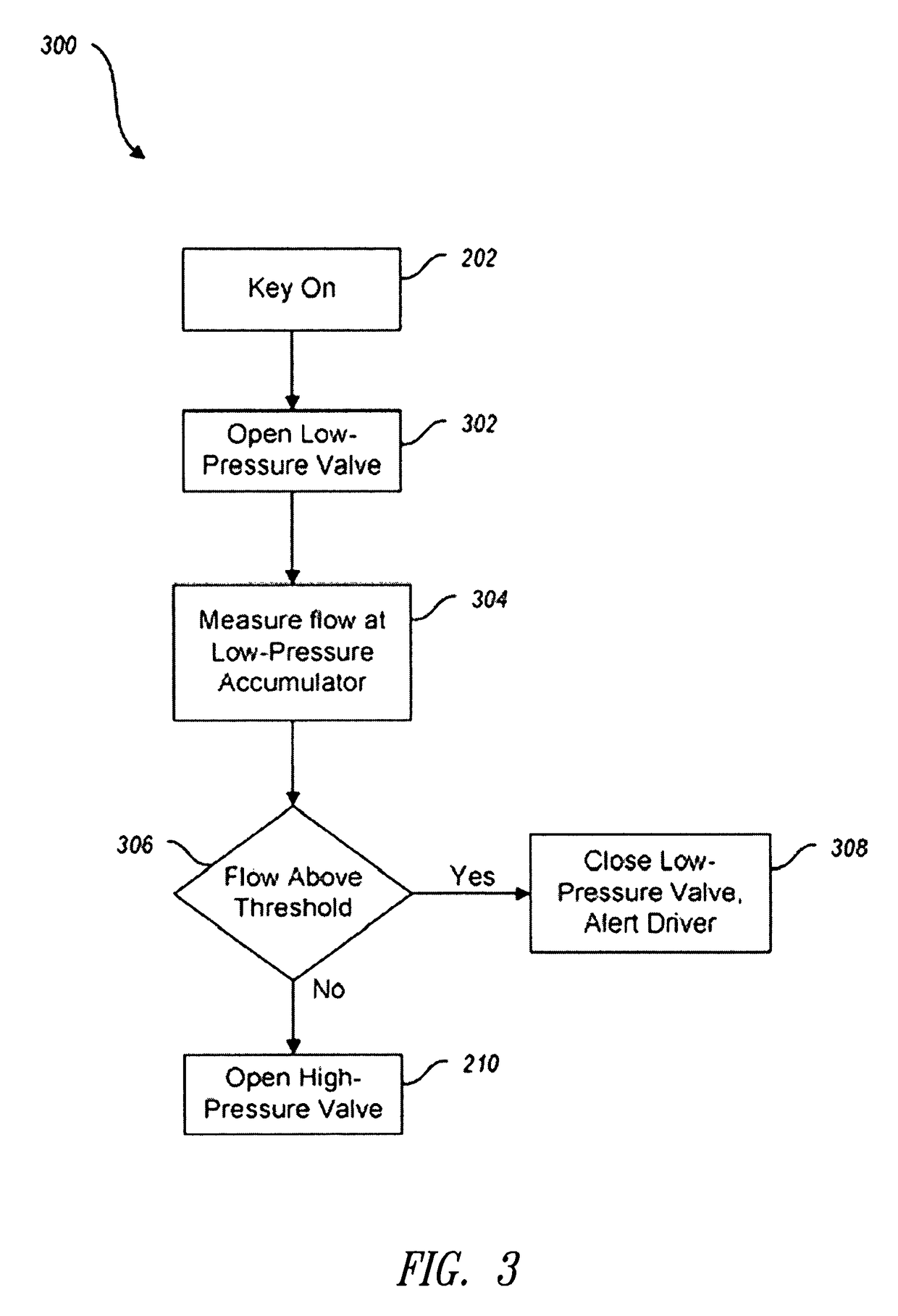

Hydraulic hybrid vehicle method of safe operation

InactiveUS8118132B2Gearing controlPlural diverse prime-mover propulsion mountingExternal combustion engineMode control

Owner:GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTATOR OF THE U S ENIVERONMENTAL PROTECTION AGENCY

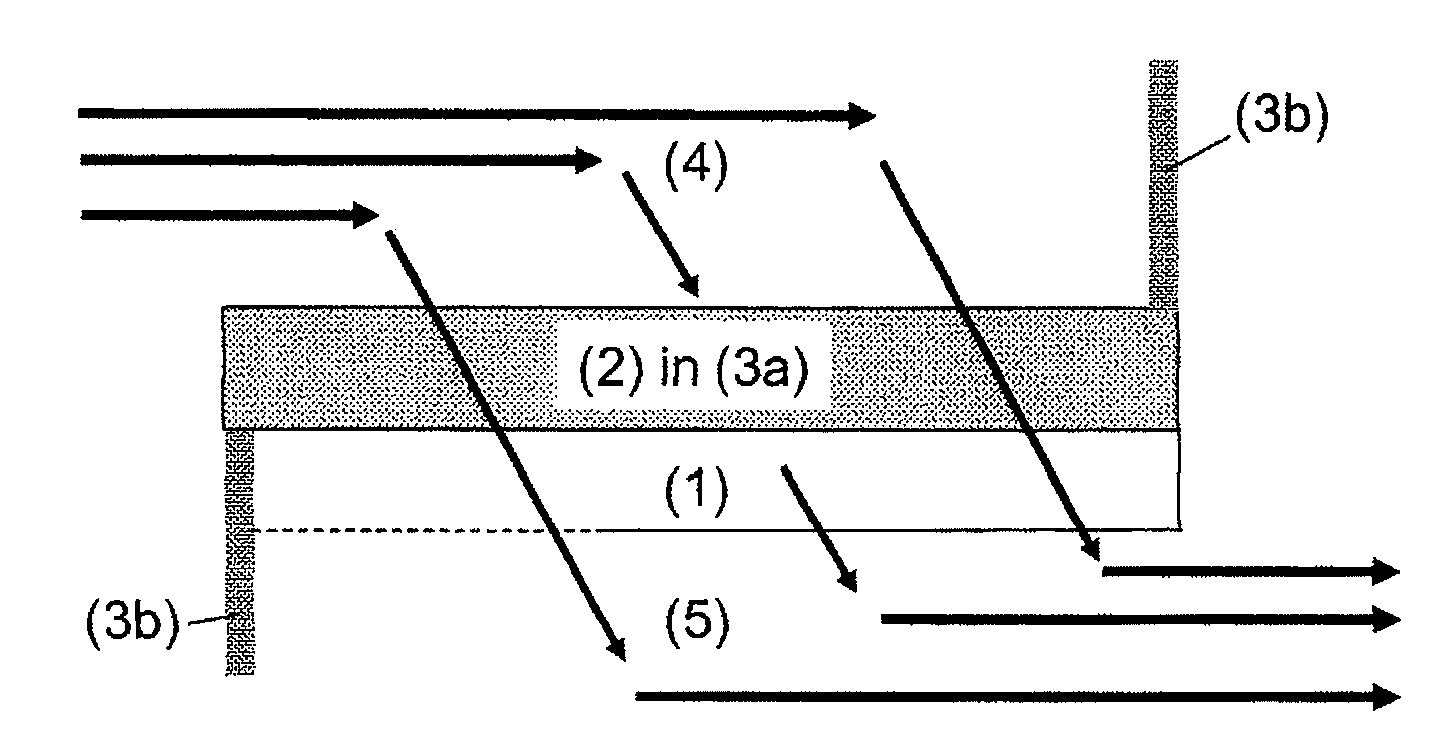

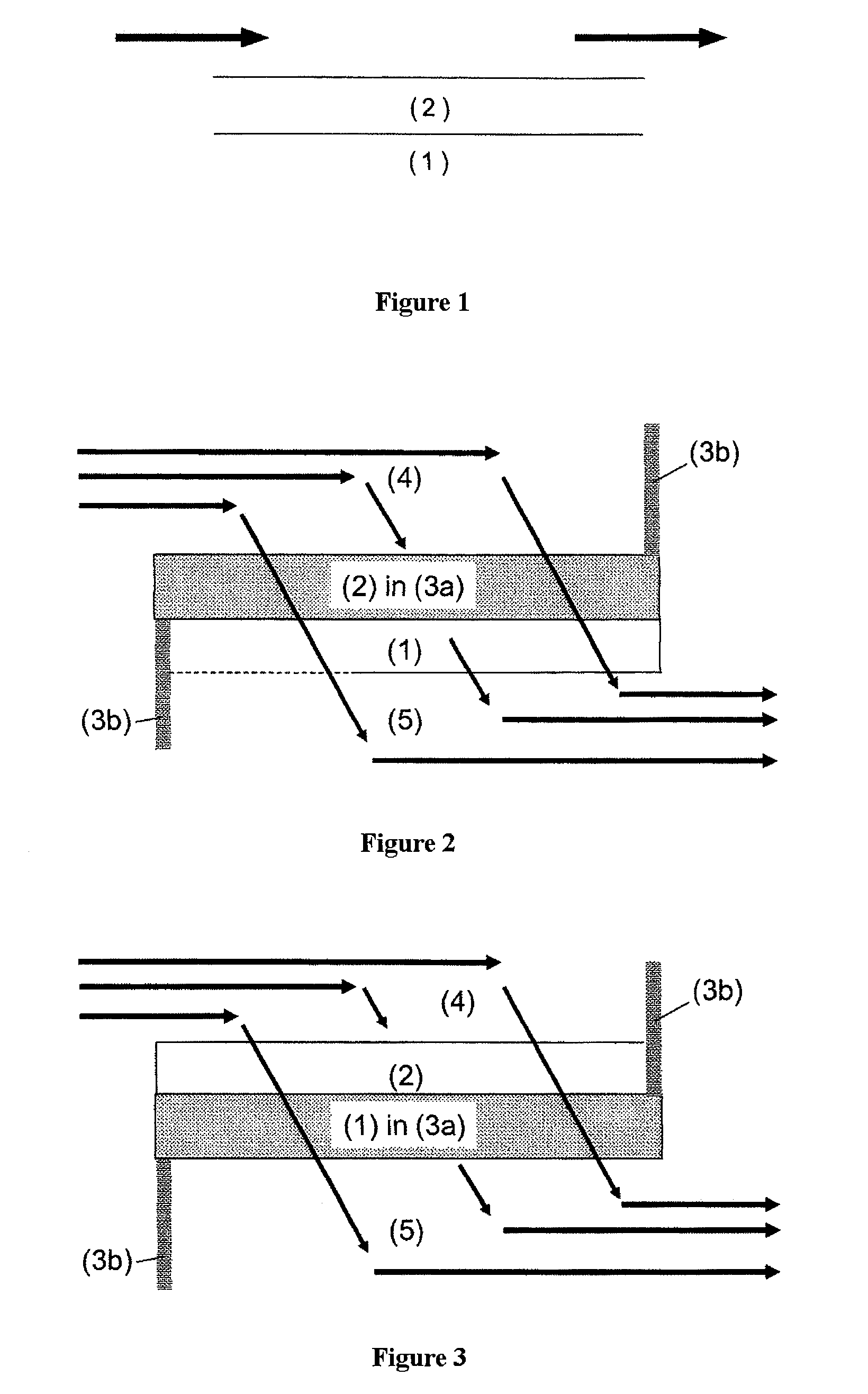

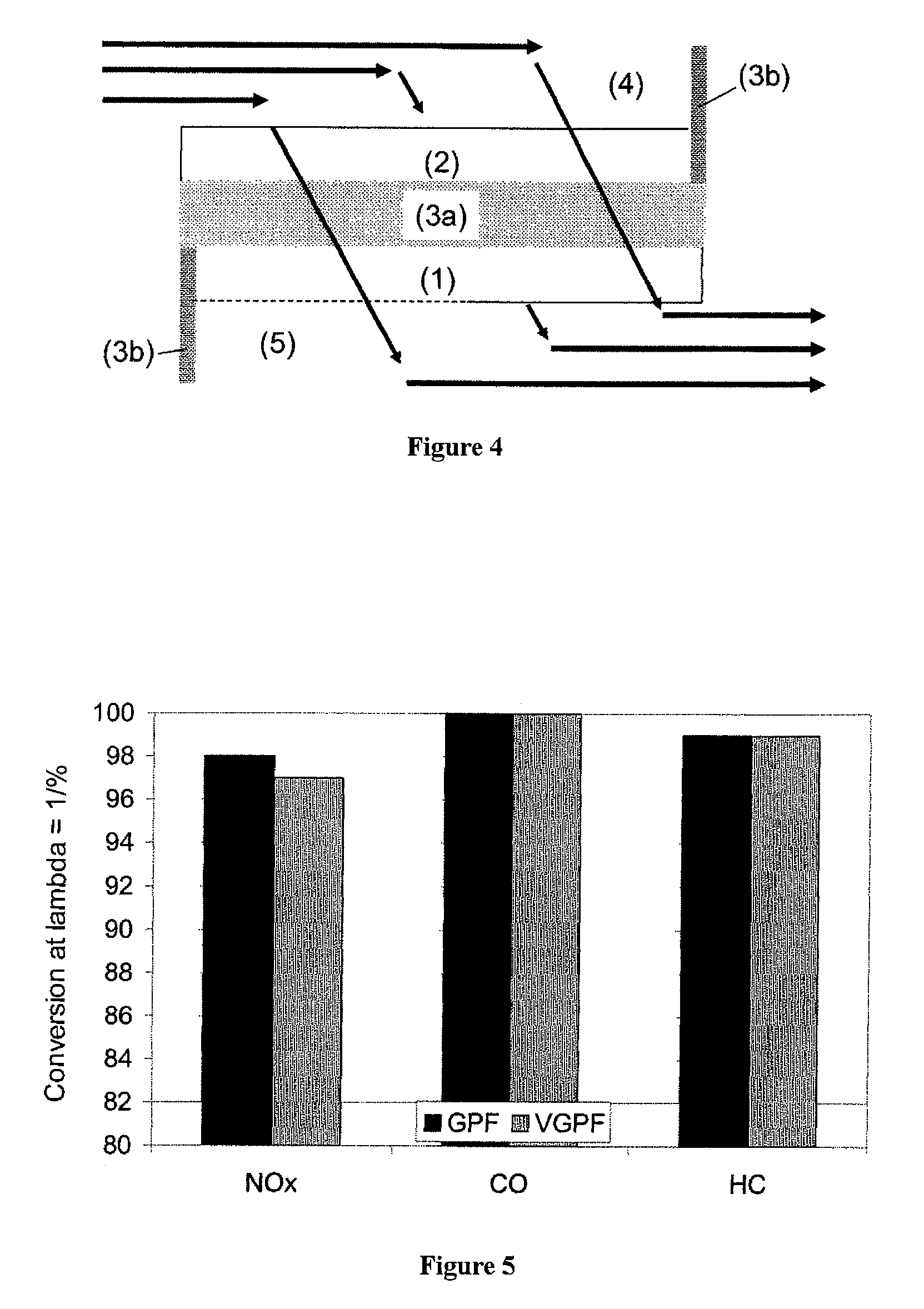

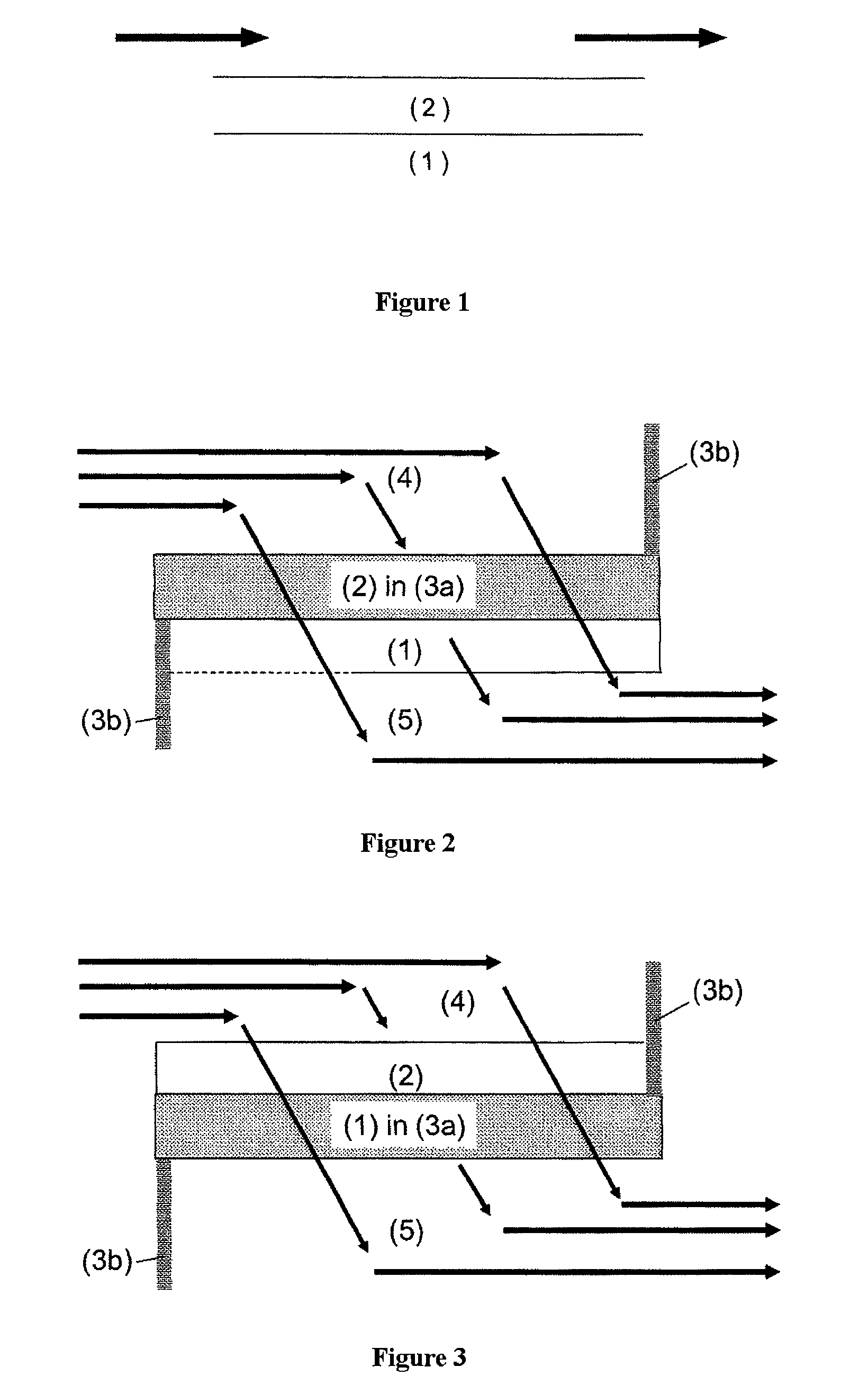

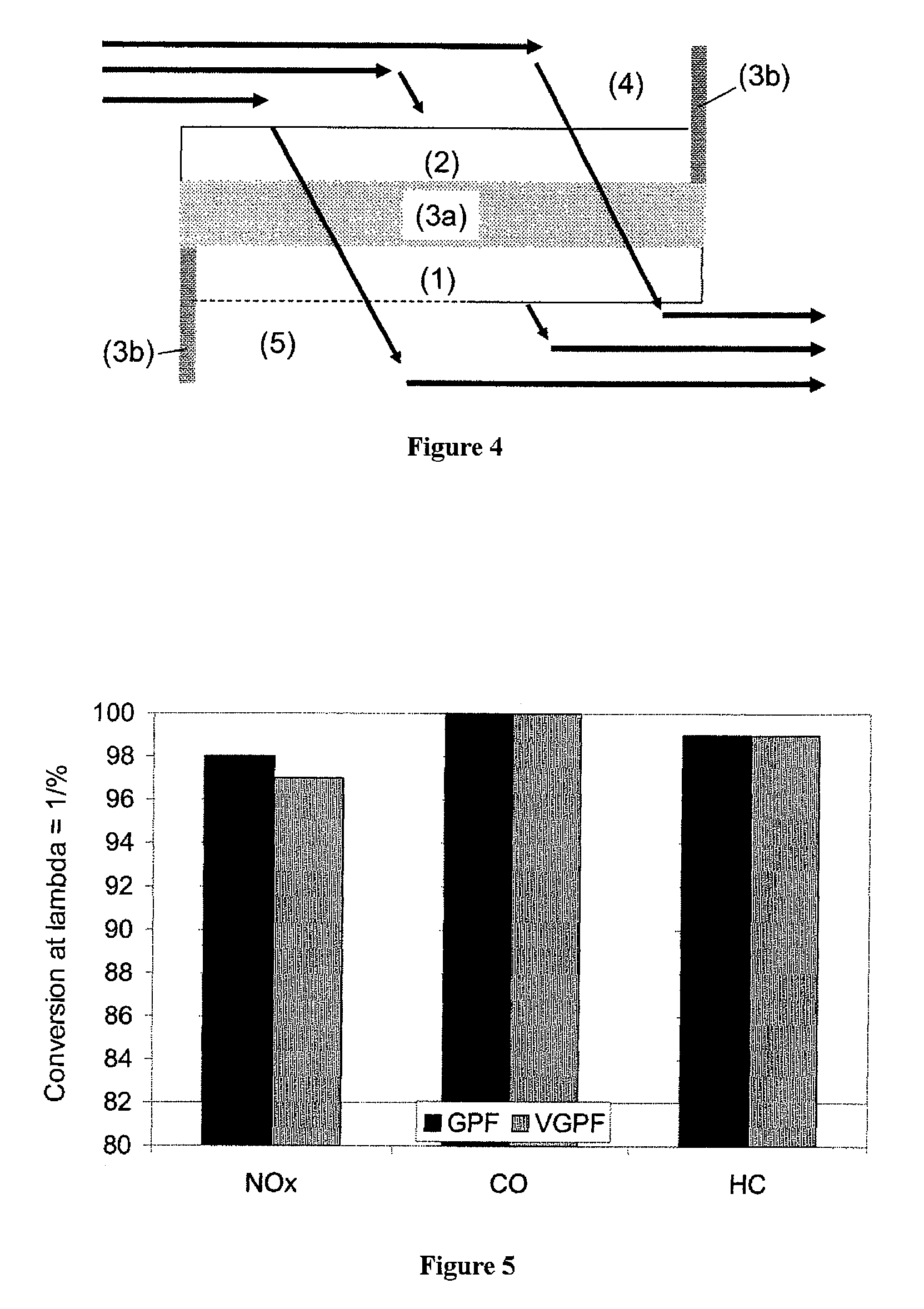

Removal of particulates from the exhaust gas of internal combustion engines operated with a predominantly stoichiometric air/fuel mixture

ActiveUS20090087365A1Sufficient thermal aging stabilityImproved thermal cycling stabilityCombination devicesOrganic chemistryExternal combustion engineEngineering

The exhaust gas of internal combustion engines operated with a predominantly stoichiometric air / fuel mixture contains, as well as the gaseous hydrocarbon (HC), carbon monoxide (CO) and nitrogen oxide (NOx) pollutants, also ultrafine particulates. The introduction of the EU-5 exhaust gas standard in Europe in 2010 will for the first time impose a legal limit to these particulate emissions for gasoline vehicles. Future exhaust gas cleaning concepts for these vehicles must include devices for removing these particulates.A catalytically active particulate filter, an exhaust gas cleaning system and a process for cleaning the exhaust gases of predominantly stoichiometrically operated internal combustion engines are presented, which are suitable, as well as the gaseous CO, HC and NOx pollutants, also for removing particulates from the exhaust gas. The particulate filter comprises a filter body and a catalytically active coating consisting of two layers. Both layers contain alumina. The first layer contains palladium. The second layer contains rhodium. The latter is disposed above the first layer.

Owner:UMICORE AG & CO KG

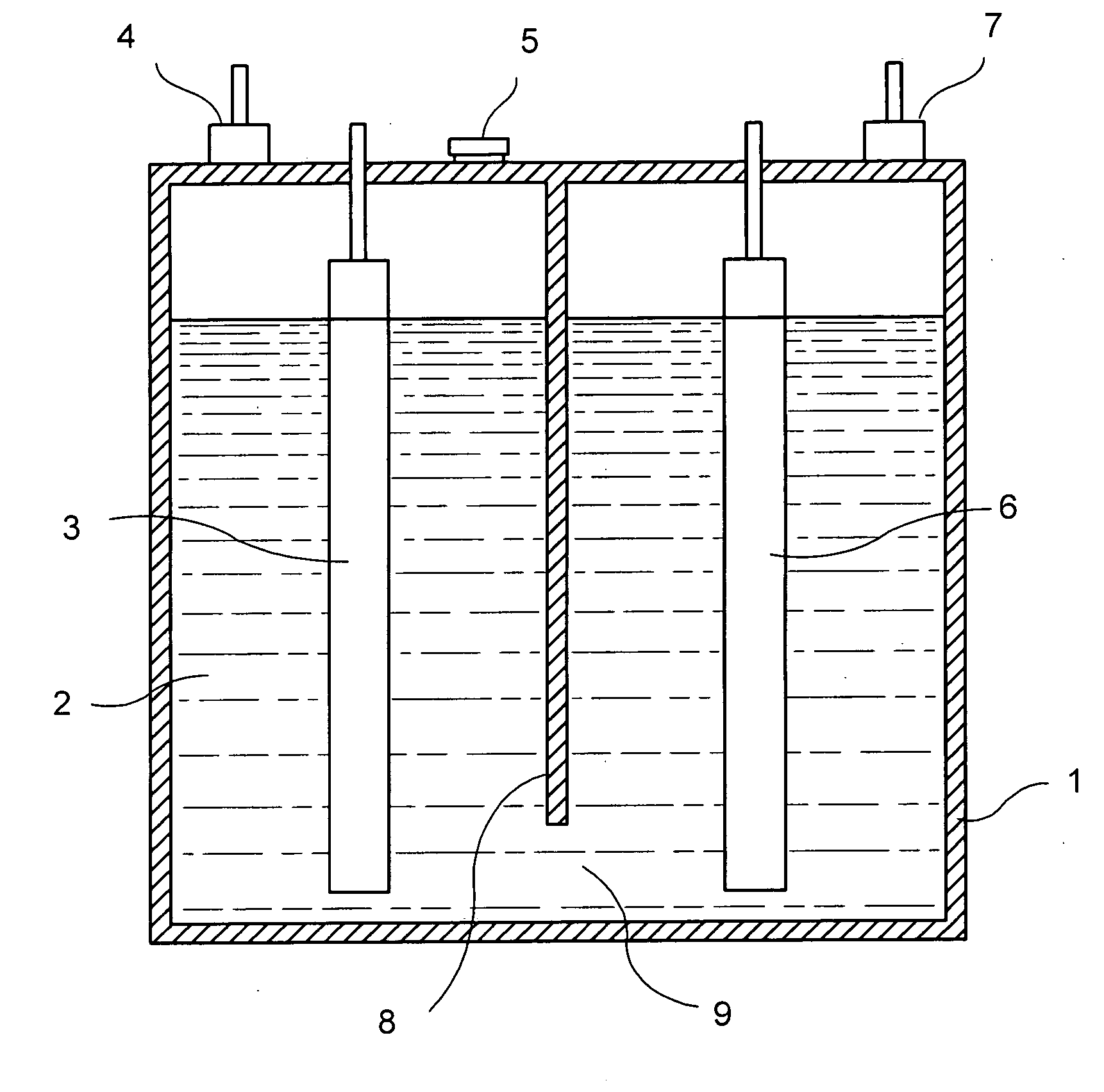

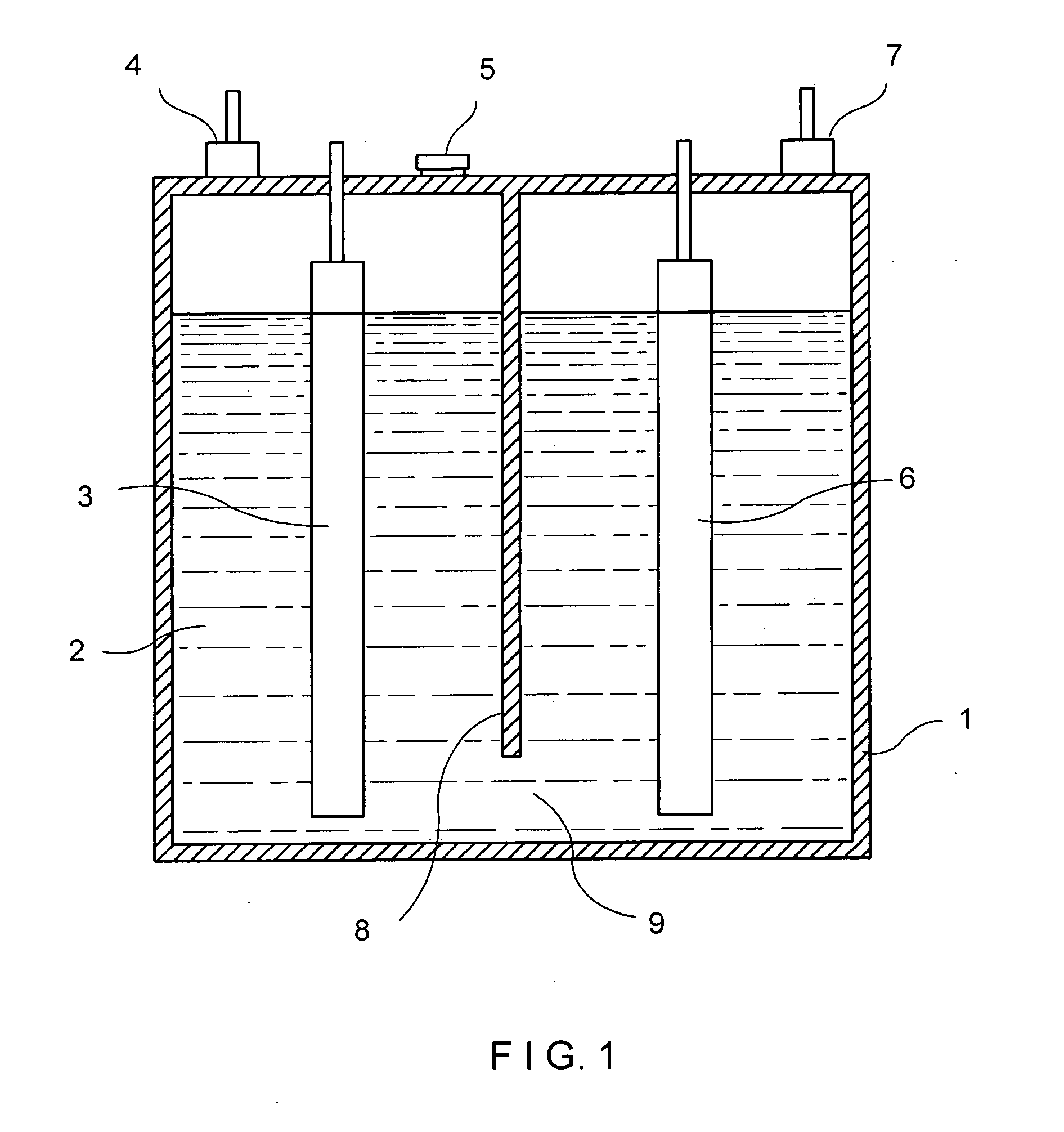

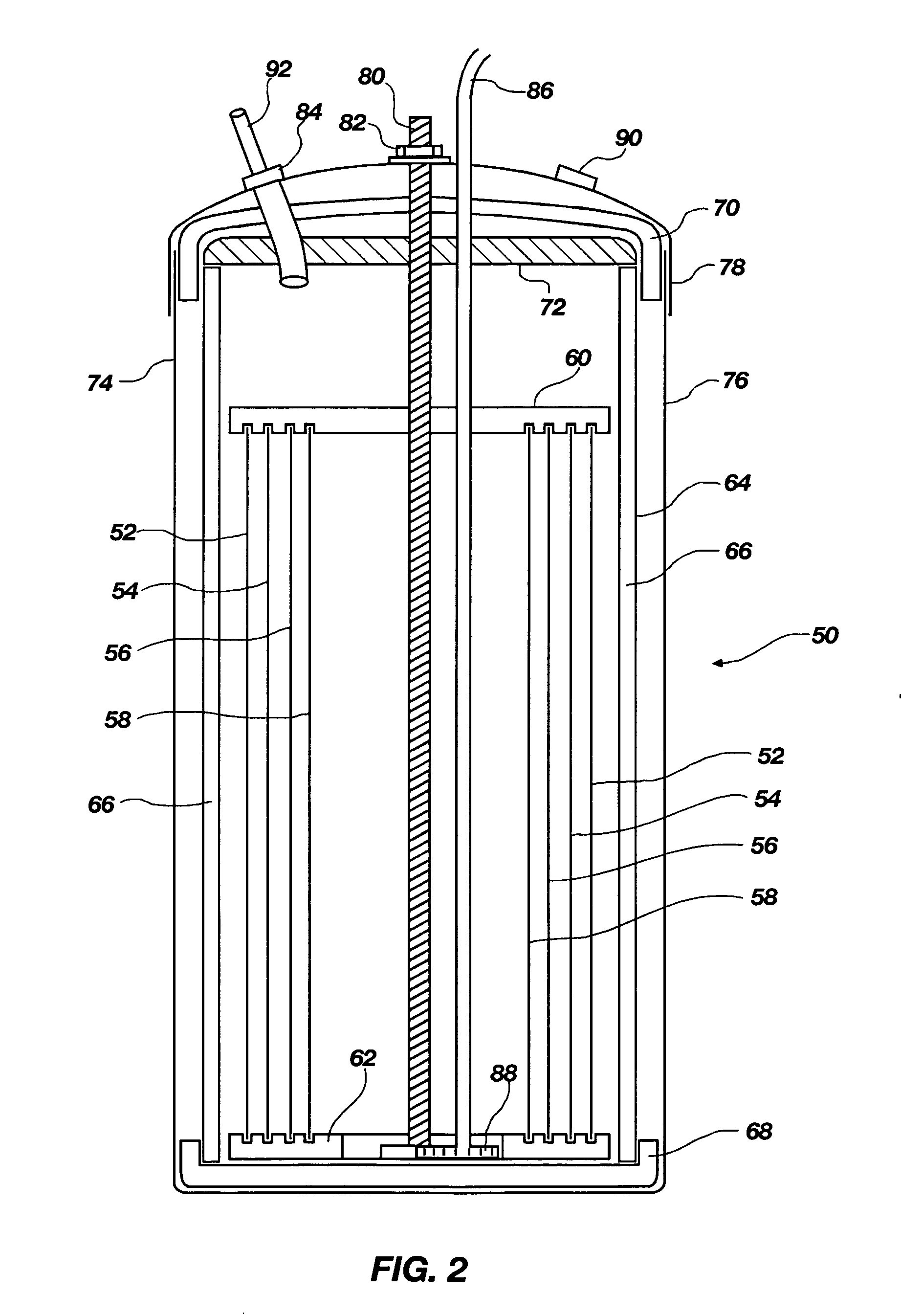

Enhanced device for generating hydrogen for use in internal combustion engines

InactiveUS20080257751A1Facilitate such replenishmentIncrease capacityCellsPhotography auxillary processesElectrolysisHydrogen

An electrolysis conversion system for converting water into hydrogen and oxygen, includes a housing in which are housed electrodes. The electrodes are immersed in an electrolyte and are connected to a positive and negative sides of an energy source. The housing is a non conductive material that has chambers to separate the hydrogen and the oxygen. The present invention further discloses a method of utilizing the electrolyzer in conjunction with the fuel system of an internal combustion engine to improve the efficiency of said internal combustion engines.

Owner:SMOLA MATTHEW M +1

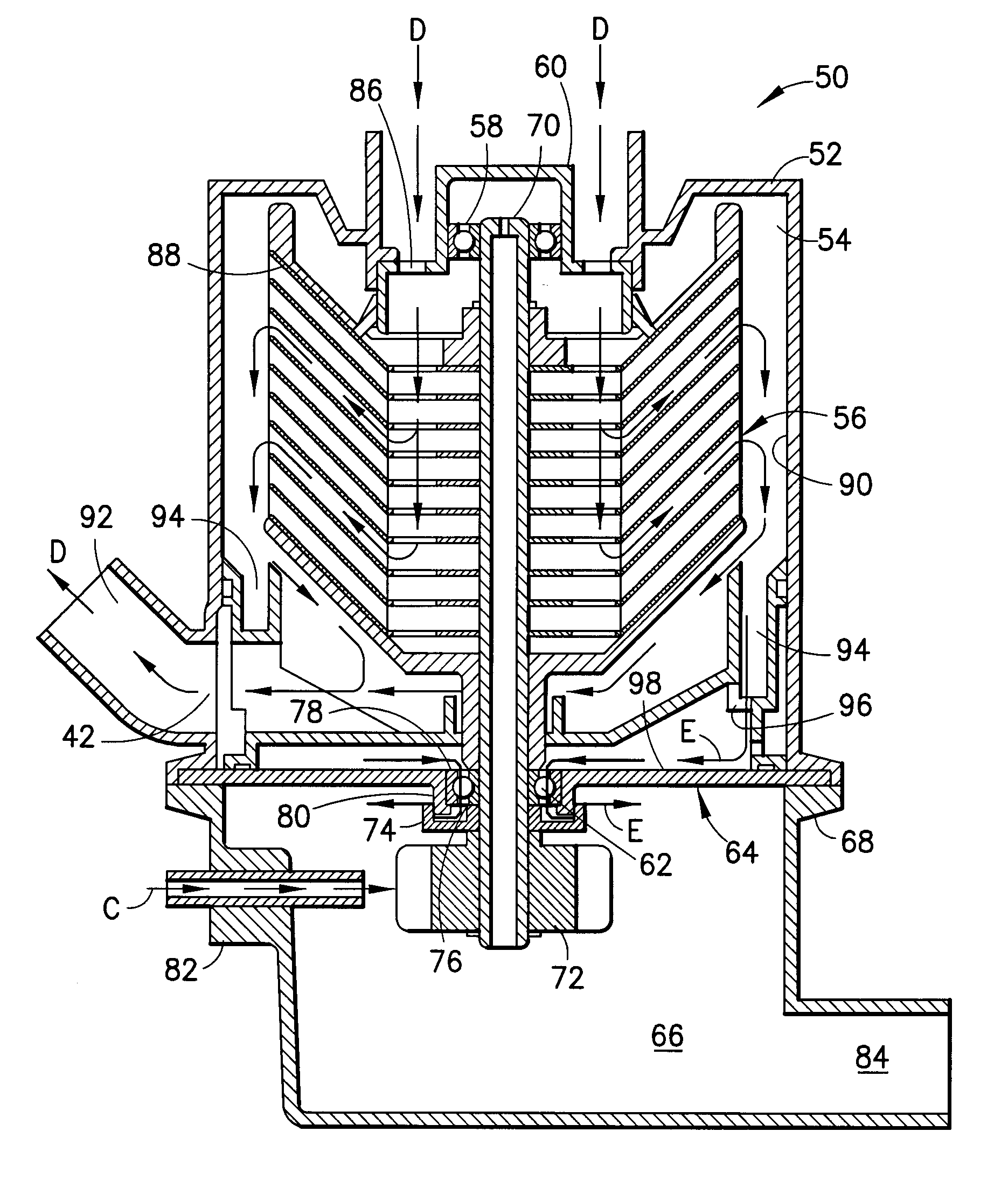

Centrifugal separator for cleaning gas generated by an internal combustion engine and a method for operating the same

ActiveUS7338546B2Minimize potentialUniform pressureCombination devicesAuxillary pretreatmentExternal combustion engineEngineering

In a centrifugal separator for cleaning gases generated by an internal combustion engine a housing defines an interior separation chamber. A centrifugal rotor is coupled for rotation to the housing and extends into the separation chamber. A drainage chamber is positioned adjacent the separation chamber and is delimited therefrom by a partition wall. A flow path is provided through which oil, separated from gases generated by the internal combustion engine and collecting on the partition wall, can travel from the separation chamber to the drainage chamber. A pump wheel is coupled to a shaft portion defined by the rotor and extends radially outwardly therefrom. During operation the oil, upon exiting the separation chamber, contacts the pump wheel. Centrifugal forces generated due to the rotation of the pump wheel cause the oil to be thrown into the drainage chamber. The pump wheel also minimizes the potential for oil resident in the drainage chamber to re-enter the separation chamber.

Owner:ALFA LAVAL CORP AB

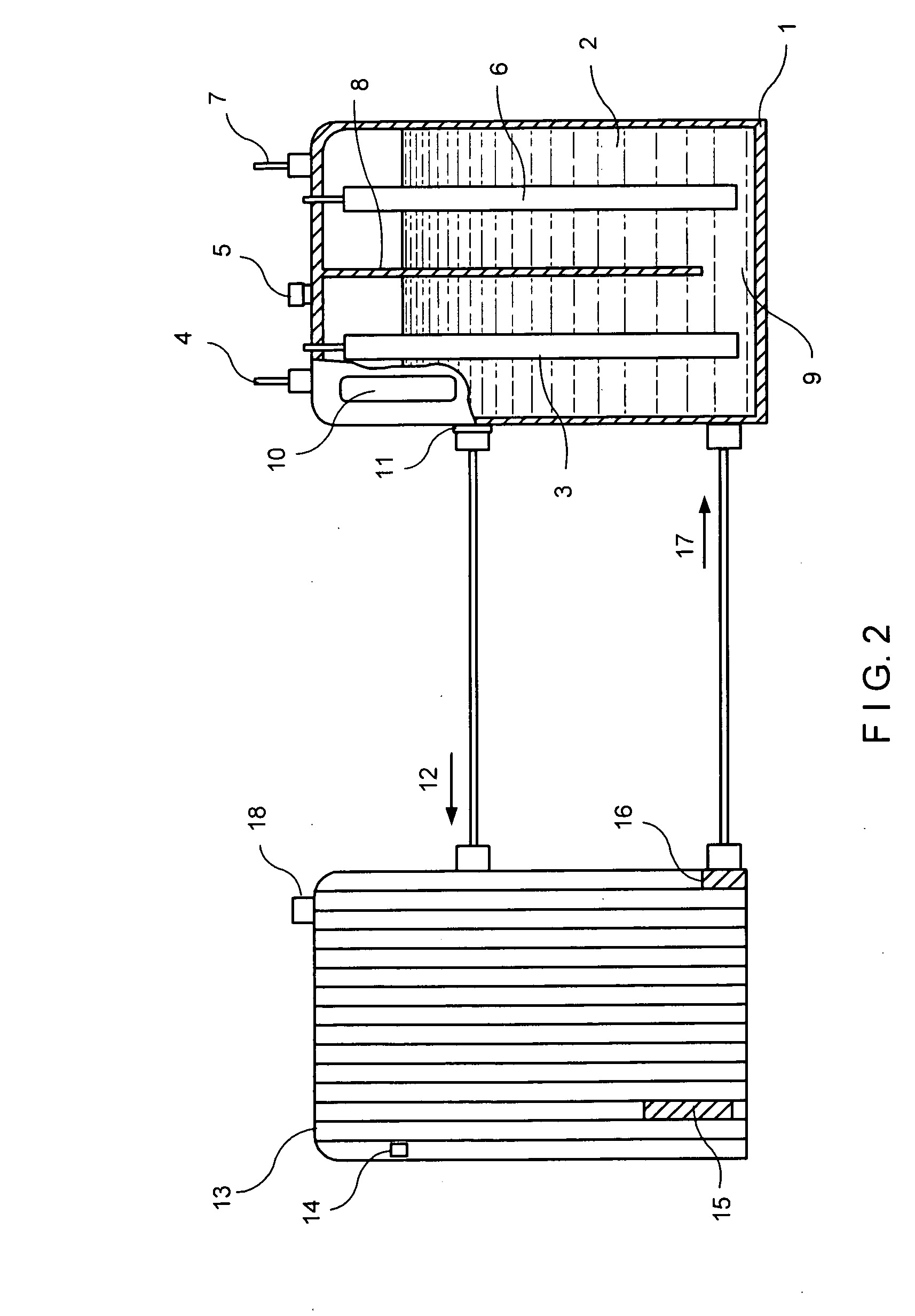

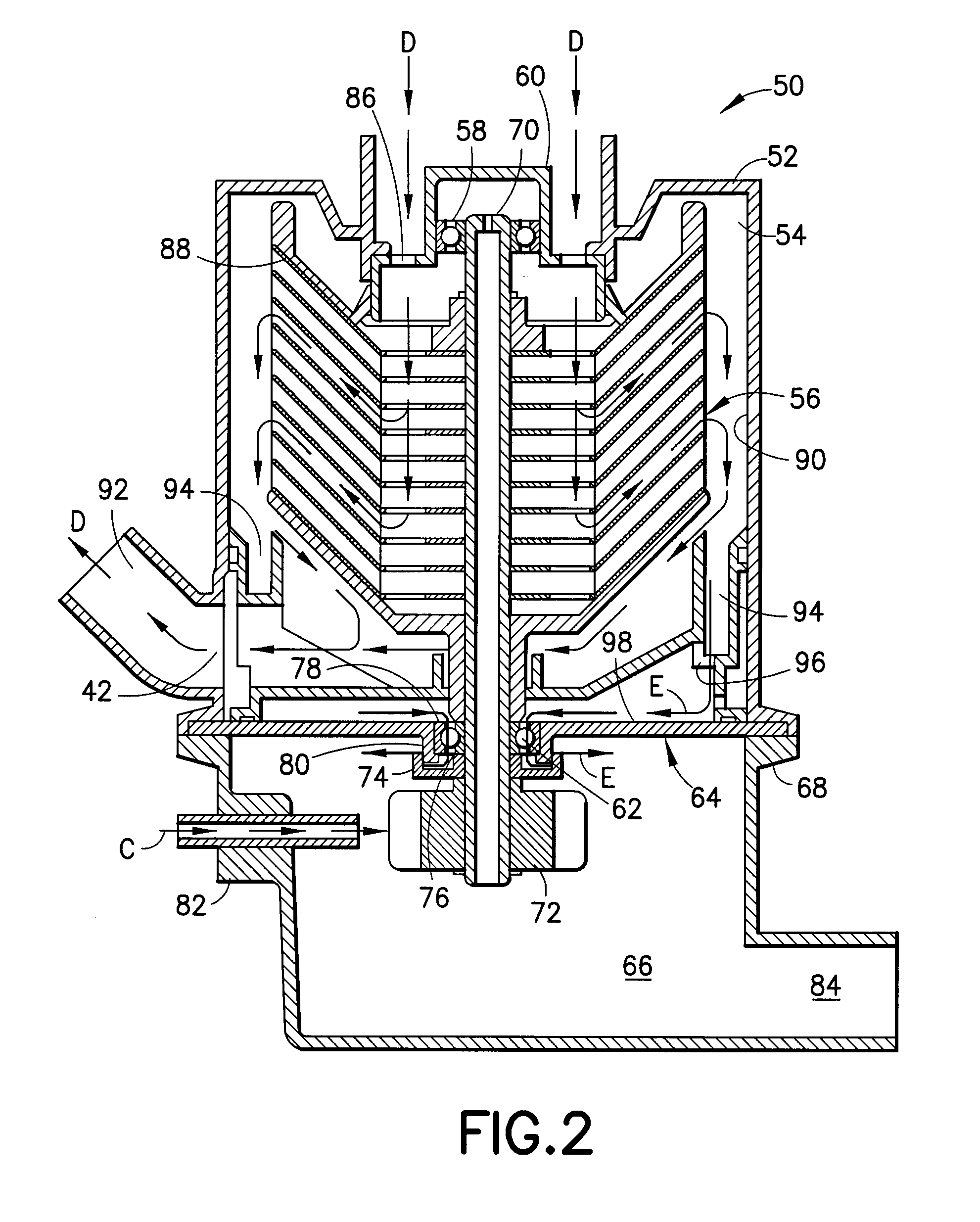

Fuel system for internal combustion engine

InactiveUS20050217991A1Increase flow rateReduces and eliminates contaminantCellsElectrolysisExternal combustion engine

A fuel system is provided for generating hydrogen and oxygen for use in an internal combustion engine to improve combustion efficiency, horsepower, and torque and to decrease emissions. The fuel system has at least one electrolysis cell for generating hydrogen and oxygen by electrolysis of an aqueous solution, a power source for providing electrical power to the electrolysis cell, and a heating and cooling system for maintaining the temperature of the electrolysis cell in a desired range to obtain the desired quantities of hydrogen and oxygen for operation of the internal combustion engine. The invention also includes an electrode array of a plurality of spaced apart electrodes for use in this fuel system and a nonconductive support connected to each of the electrodes to hold the electrodes in place, while leaving adequate room around the electrodes to allow free flow of the aqueous solution between the electrodes. High purity electrolyte and substantially non-reactive electrodes result in improved electrolysis.

Owner:HYDROGEN INNNOVATIONS

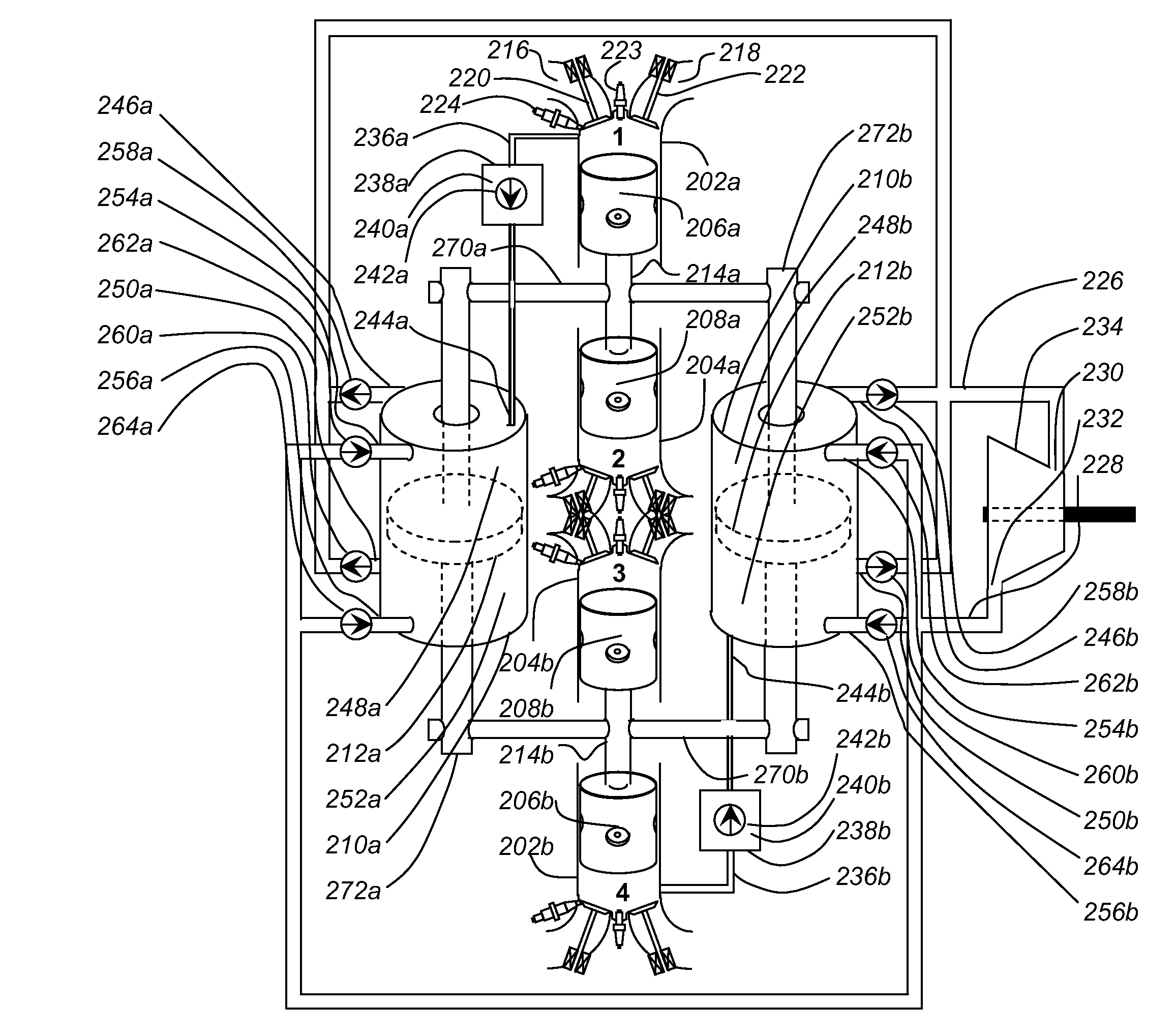

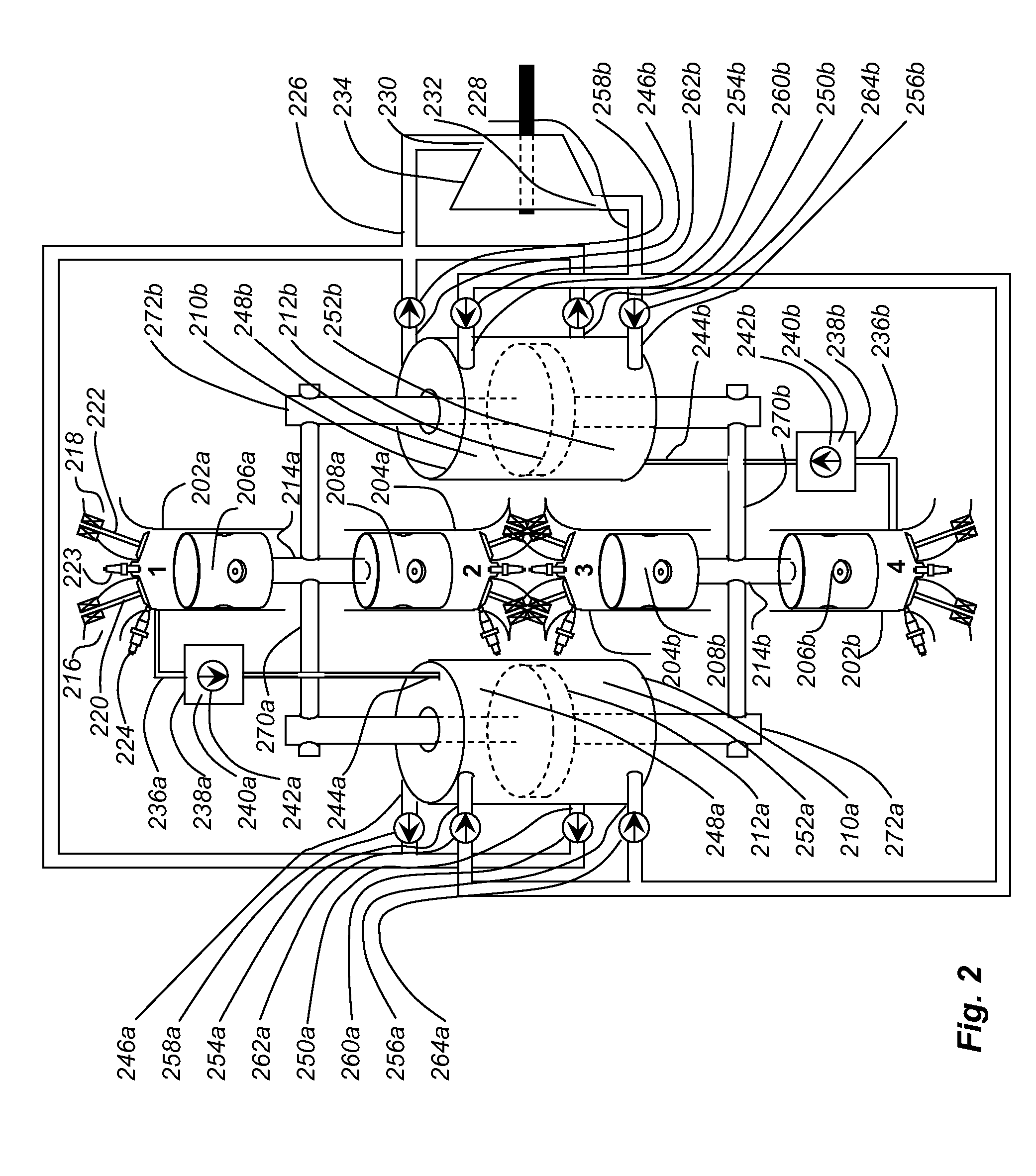

Internal combustion engine driven turbo-generator for hybrid vehicles and power generation

InactiveUS20090179424A1Increased electrical system efficiencyLow costCombustion enginesVehicle sub-unit featuresExternal combustion engineEngineering

A piston compression system converts energy from a conventional combustion cycle engine driving a piston to displace a working gas for flow through a turbine for output power. The working gas is derived by diverting a portion of the charge during combustion at near peak combustion pressure (PCP) into a closed working volume. The working gas is maintained at high pressure within the working volume. The working volume has a first displacement compartment and a second displacement compartment, a supply manifold connected for receiving pressurized working gas alternately from the first and second compartments and connected to an inlet of the turbine, and a return manifold connected to an outlet of the turbine and alternately returning working gas to the second and first compartments. The engine is configured with first and second pistons housed in first and second combustion cylinders respectively powering a first displacing surface for displacement of working gas in the first compartment and a second displacing surface for displacement of working gas in the second compartment.

Owner:INTERNAL COMBUSTION TURBINES

Internal combustion engine air cleaner and adsorption filter

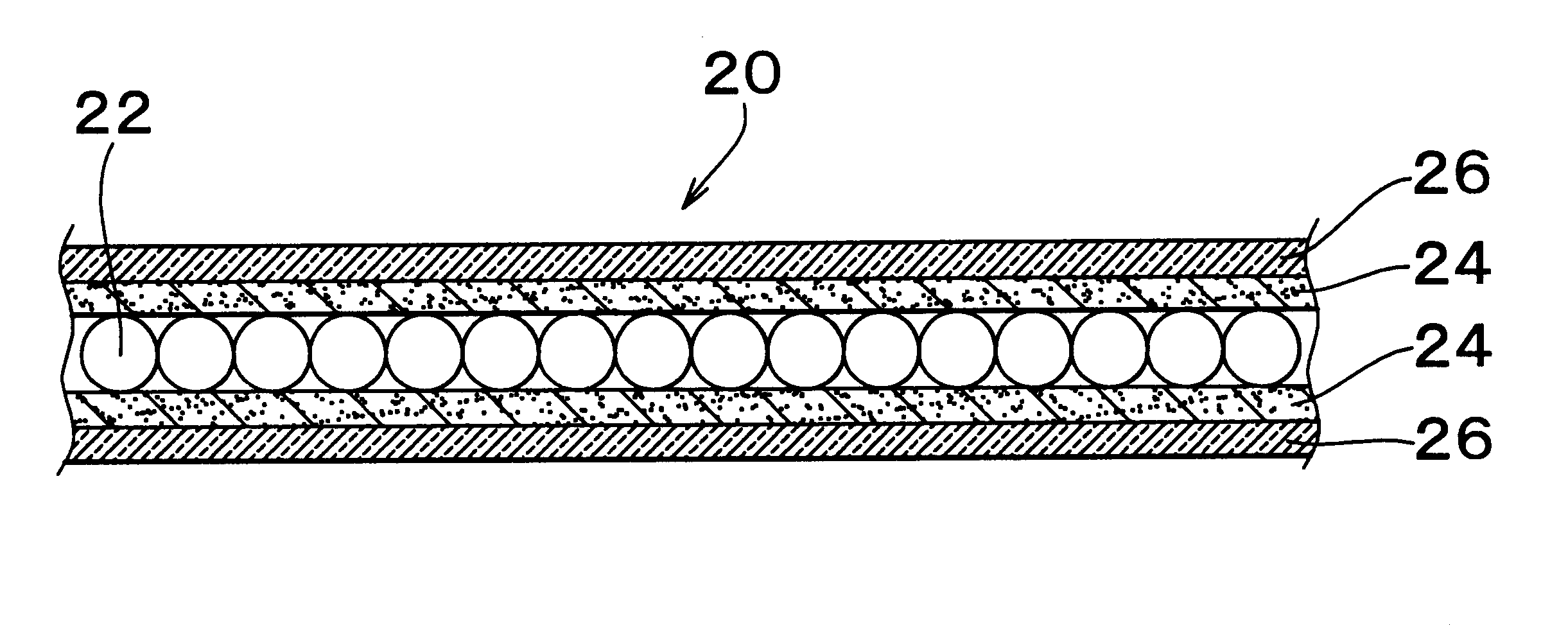

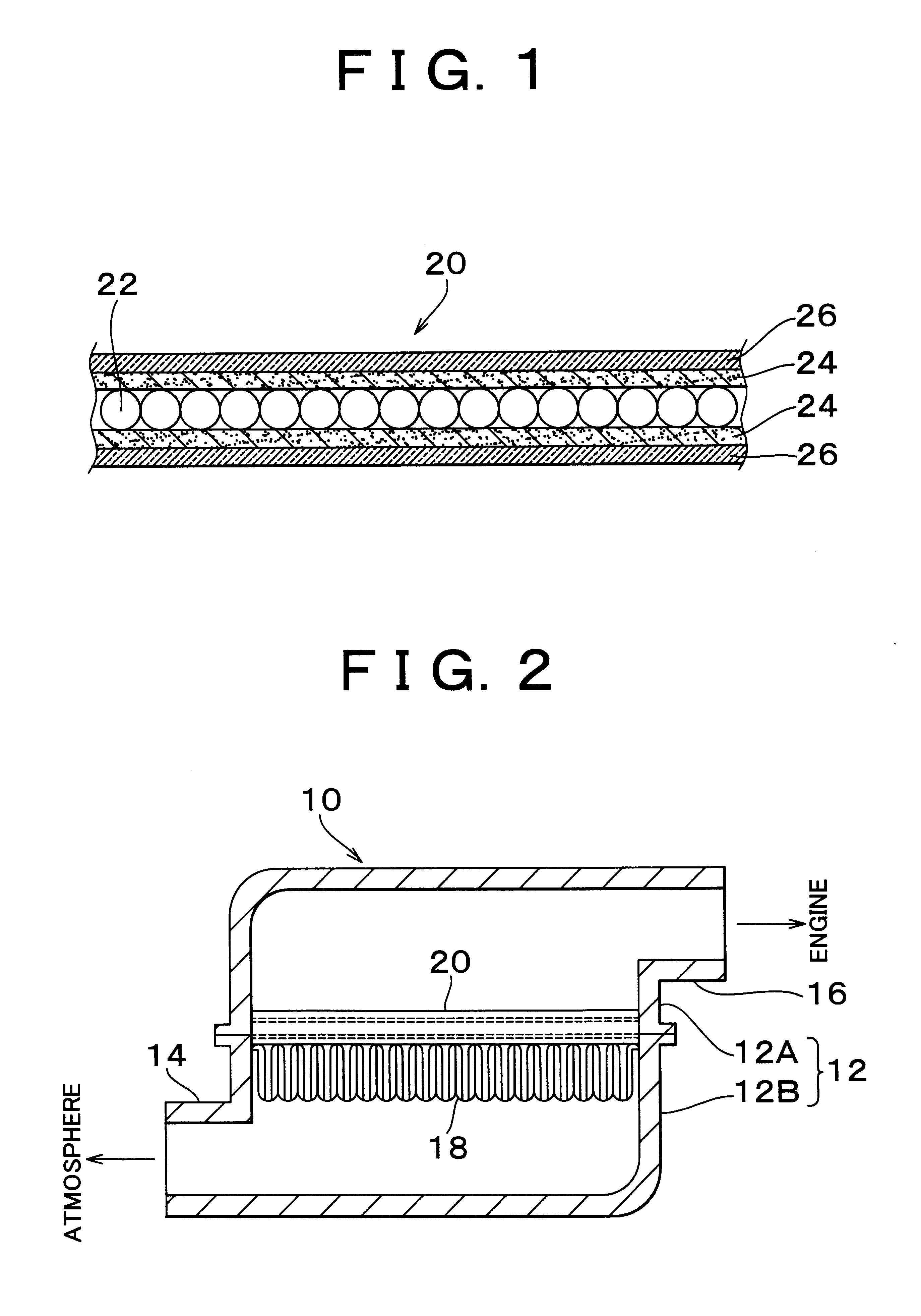

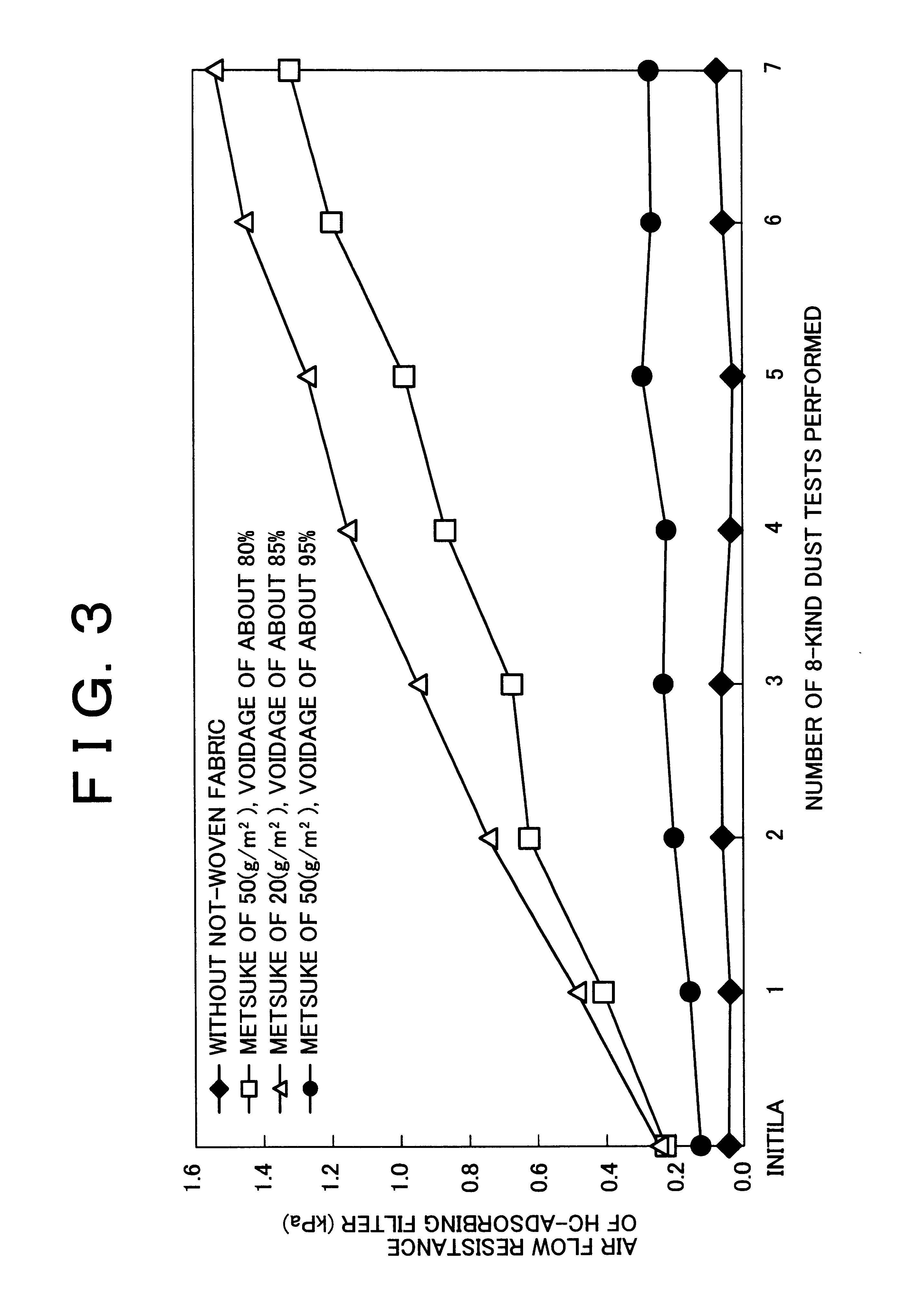

InactiveUS6692555B2Effectively prevent activated carbon powder from falling offImprove abilitiesHuman health protectionCombination devicesActivated carbonParticulates

A sheet-like adsorption filter formed by sandwiching particulate activated carbon with heat-resistant nets and non-woven fabric sheets that have a percentage of void of 90% or higher, is disposed at an internal combustion engine side of a filter element.

Owner:TOYOTA BOSHOKU KK +3

Method and apparatus for optimized combustion in an internal combustion engine utilizing homogeneous charge compression ignition and variable valve actuation

InactiveUS7308872B2Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A valvetrain system mechanization for an internal combustion engine using compression ignition, including homogeneous charge compression ignition, having two intake and one or more exhaust valves per cylinder. The valves are operated by dual overhead camshafts having two-step cams. The intake and exhaust camshafts are provided with phasers for varying the opening and closing of the intake and exhaust valves. A two-step roller finger follower is disposed for each valve between the cam lobes and the valve stem. The two sets of intake and exhaust valves are controlled by separate oil control valves. Swirl of gases may be introduced by mismatching the lifts of the valves. The valve opening times, closing times, lifts, fuel injection, compression ratio, and exhaust gas recirculation may be varied to optimize combustion conditions for a range of engine operating modes.

Owner:DELPHI TECH INC

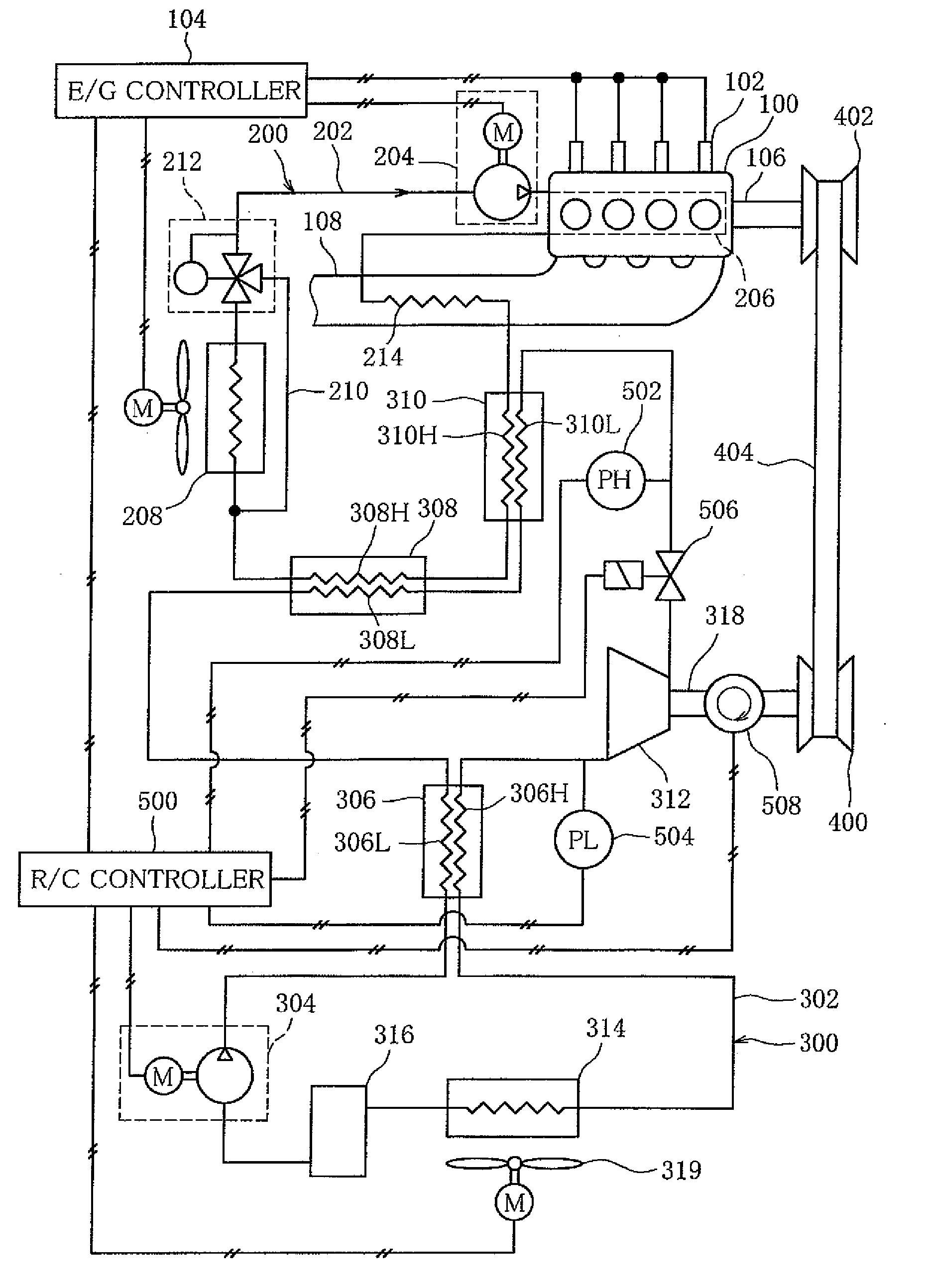

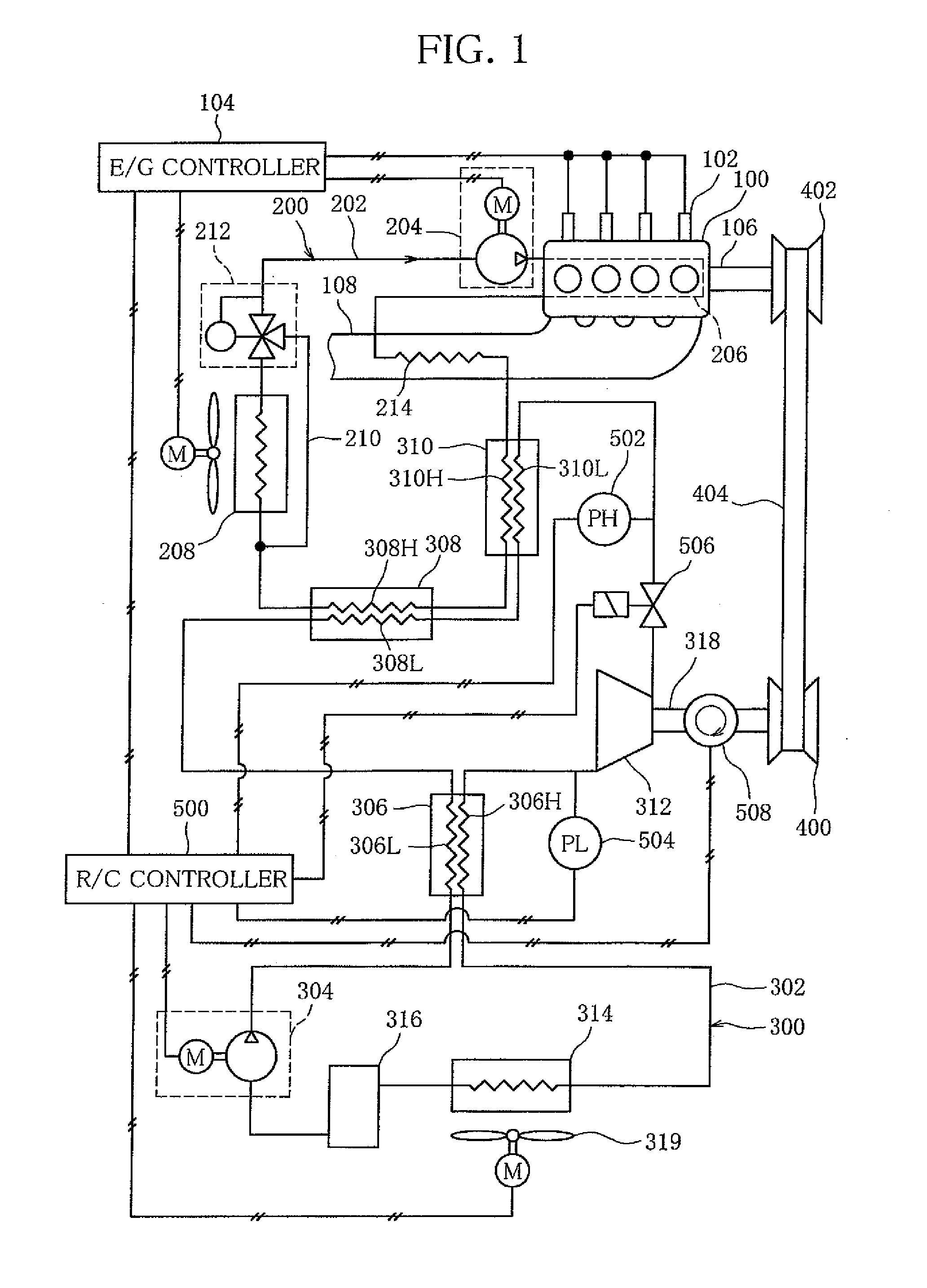

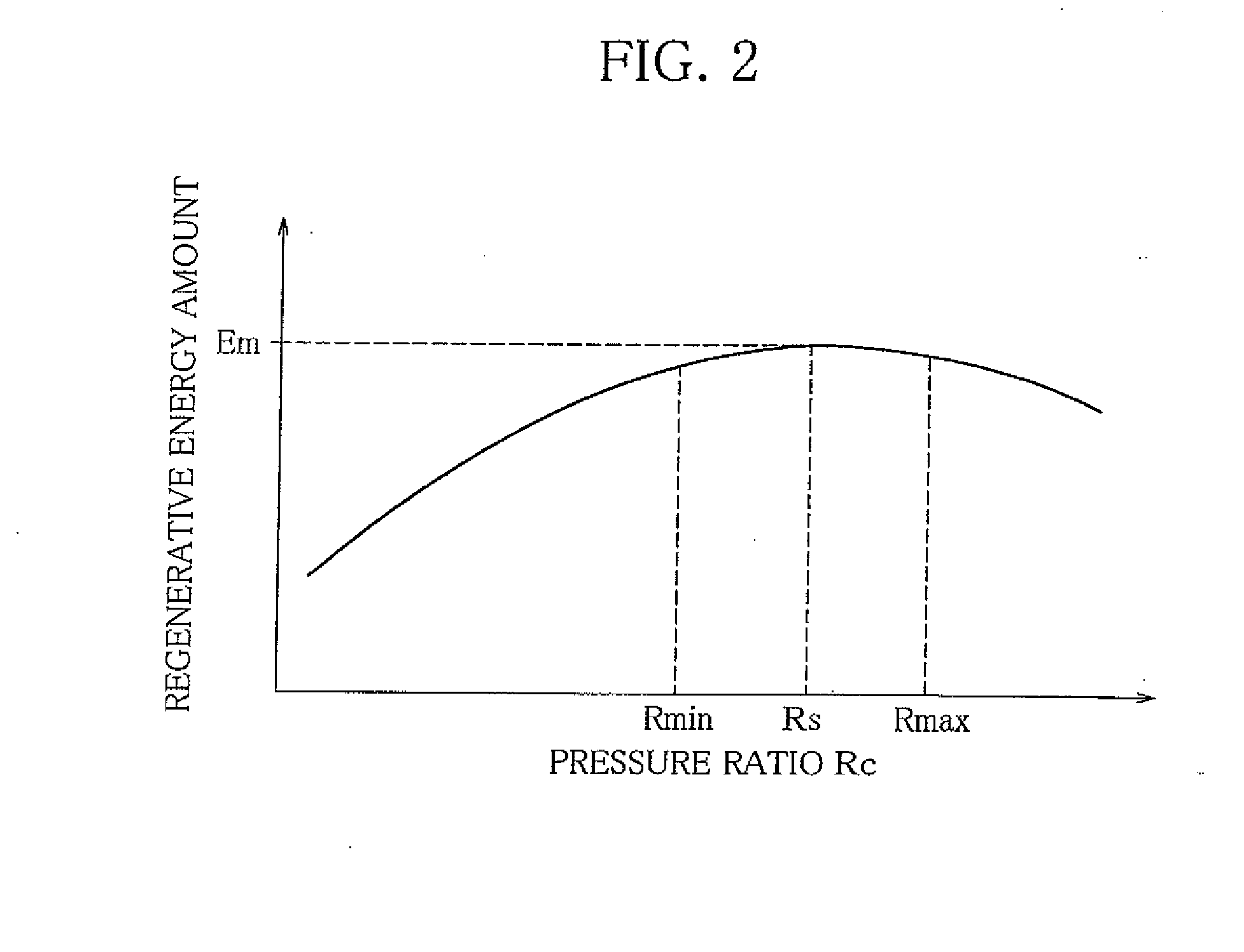

Waste Heat Recovery System of Internal Combustion Engine

InactiveUS20110192163A1Prevent pressure dropReduction in regenerative energy amountInternal combustion piston enginesExhaust apparatusWaste heat recovery unitExternal combustion engine

A waste heat recovery system of an internal combustion engine, in which the amount of regenerative energy transmitted to the internal combustion engine is increased with a simple mechanism. A controller of the waste heat recovery system of an internal combustion engine has at least determination means that makes a determination as to whether it is necessary to increase the pressure of heat-transfer media in a heat exchanger, on the basis of the pressure detected by the high-pressure sensor. When the determination means determines that it is necessary to increase the pressure in the heat exchanger, the controller causes a flow-rate regulating valve (506) to start regulating the flow rate of the heat-transfer media while leaving the pump working. The controller causes the flow-rate regulating valve to continue the regulation at least until the determination means determines that it is not necessary to increase the pressure in the heat exchanger, and then terminates the regulation.

Owner:SANDEN CORP

System and method for operating an internal combustion engine with hydrogen blended with conventional fossil fuels

ActiveUS7290504B2Accelerate emissionsCheap replacementHydrogenElectrical controlOn boardExternal combustion engine

Owner:OREILLY HUGH

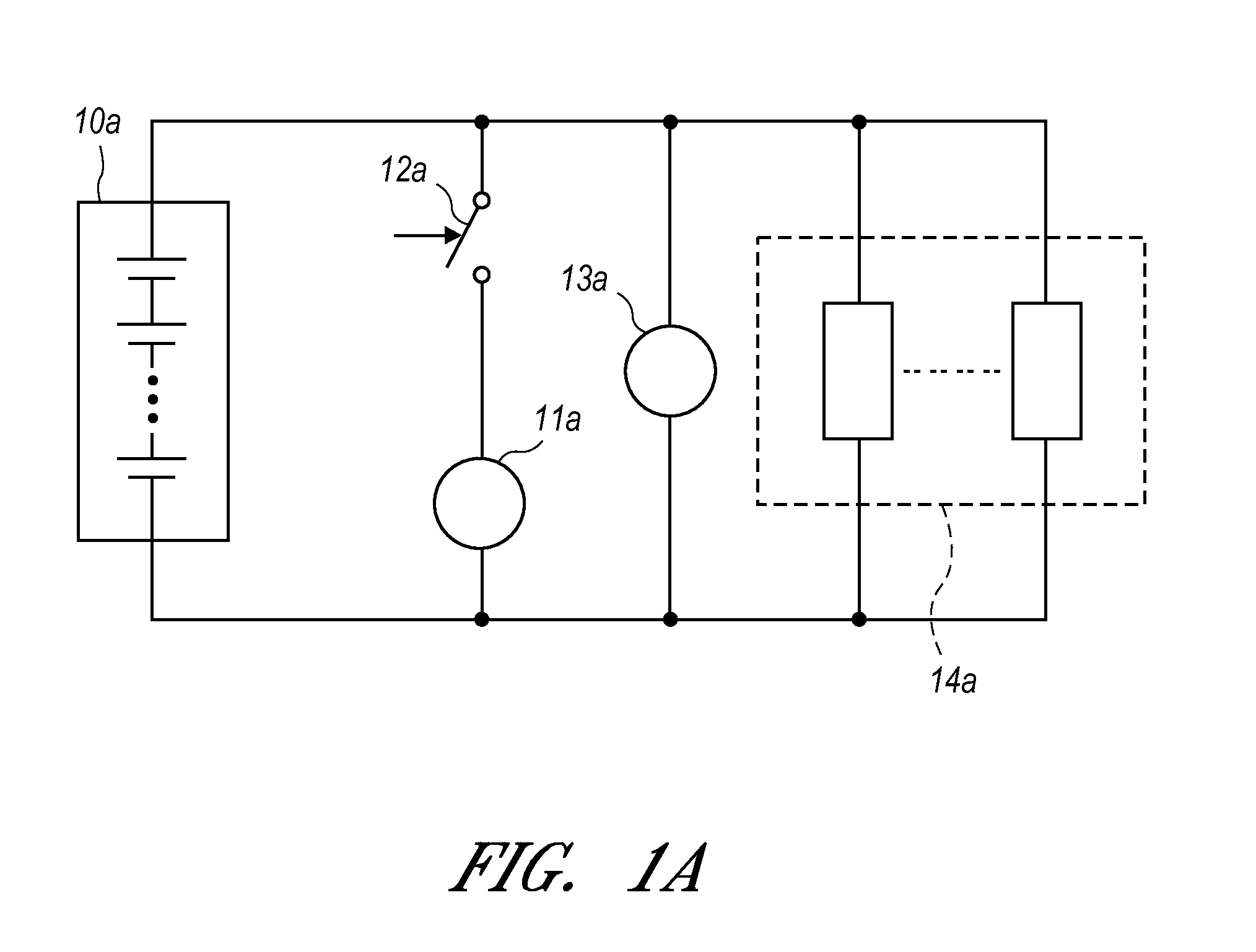

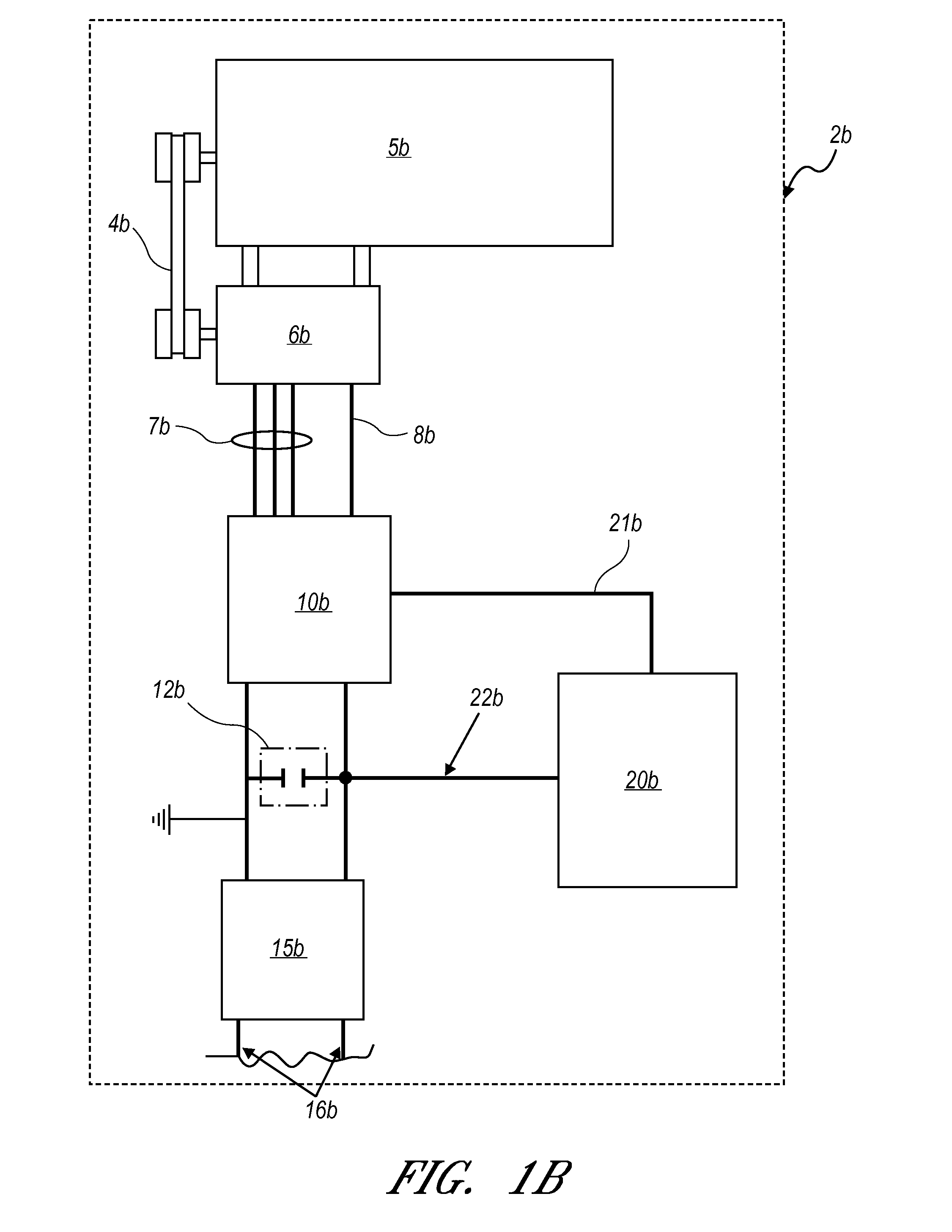

Temperature control systems with thermoelectric devices

InactiveUS20130192272A1Save fuelMachines using electric/magnetic effectsPower to auxillary motorsThermal energyWorking fluid

Temperature control systems and methods can be designed for controlling the interior climate of a vehicle or other the climate of another desired region. The temperature control system for a vehicle can have a thermoelectric system providing heating and / or cooling, including supplemental heating and / or cooling. The thermoelectric system can transfer thermal energy between a working fluid, such as liquid coolant, and comfort air upon application of electric current of a selected polarity. The thermoelectric system can supplement or replace the heat provided from an internal combustion engine or other primary heat source. The thermoelectric system can also supplement or replace cold energy provided from a compressor-based refrigeration system or other primary cold energy source.

Owner:GENTHERM INC

Temperature control systems with thermoelectric devices

InactiveUS20130192271A1Save fuelVehicle heating/cooling devicesMachines using electric/magnetic effectsThermal energyWorking fluid

Temperature control systems and methods can be designed for controlling the interior climate of a vehicle or other the climate of another desired region. The temperature control system for a vehicle can have a thermoelectric system providing heating and / or cooling, including supplemental heating and / or cooling. The thermoelectric system can transfer thermal energy between a working fluid, such as liquid coolant, and comfort air upon application of electric current of a selected polarity. The thermoelectric system can supplement or replace the heat provided from an internal combustion engine or other primary heat source. The thermoelectric system can also supplement or replace cold energy provided from a compressor-based refrigeration system or other primary cold energy source.

Owner:GENTHERM INC

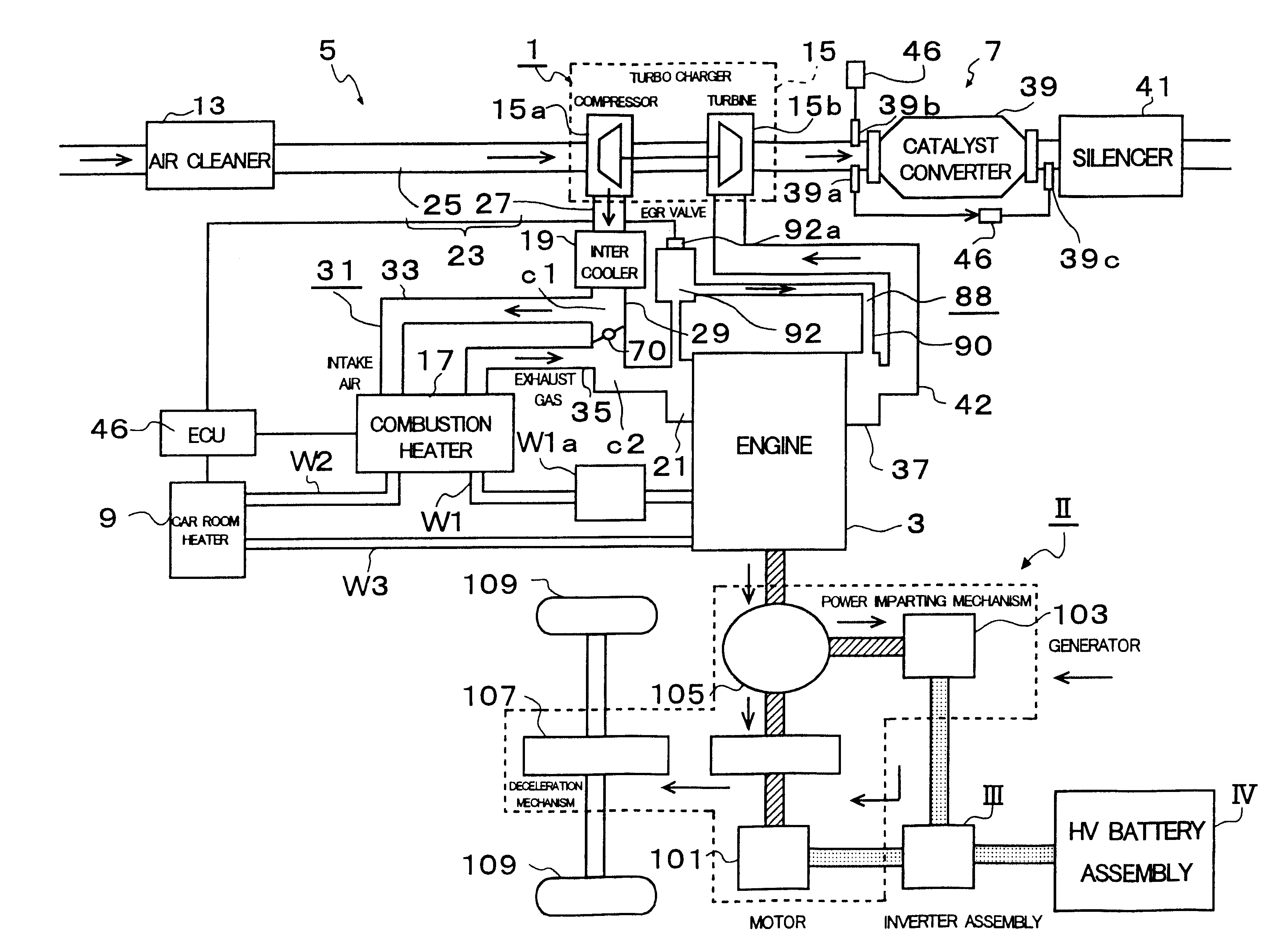

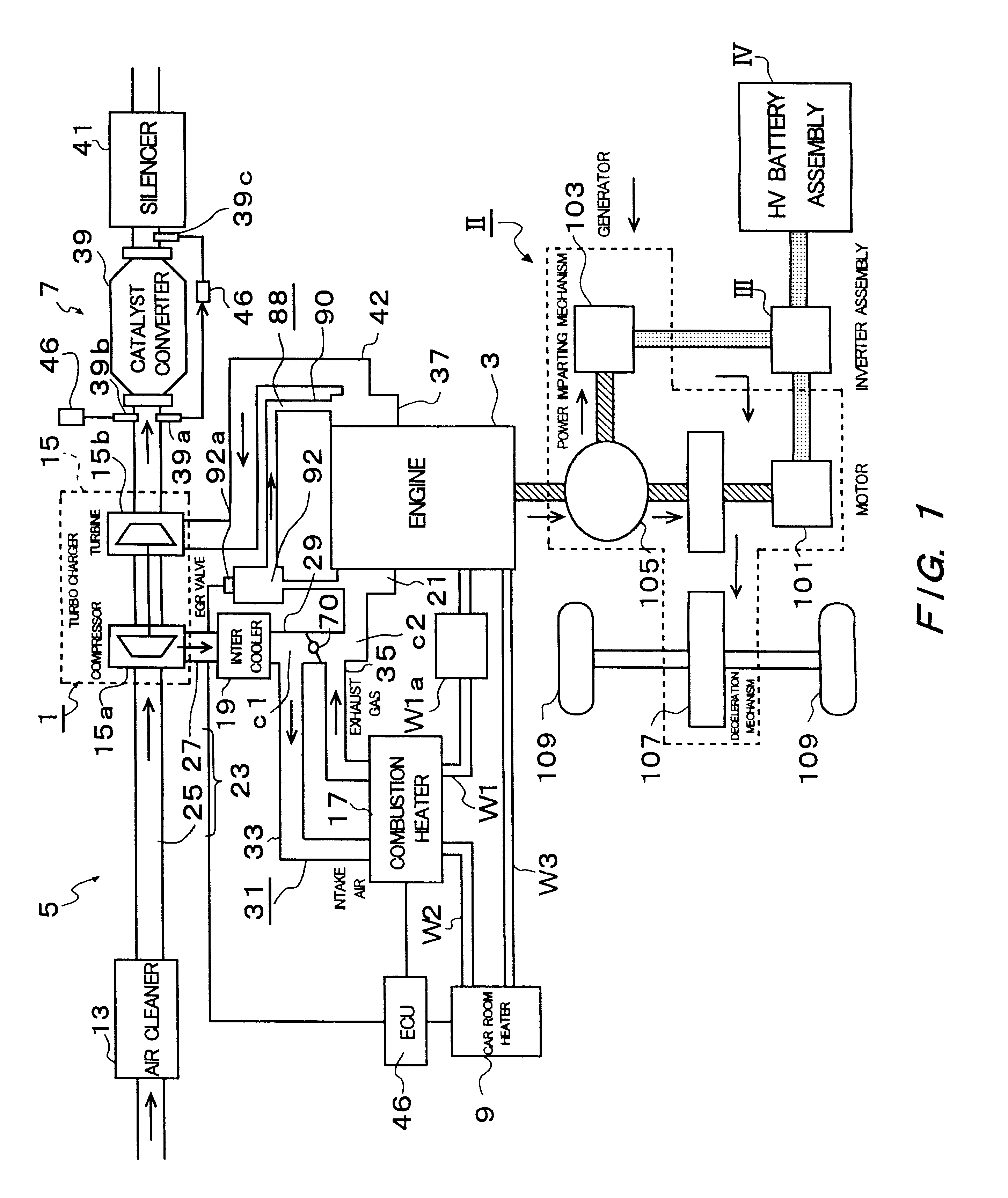

Exhaust emission control system of hybrid car

InactiveUS6266956B1Easy to produceHigh catalytic efficiencyHybrid vehiclesNon-fuel substance addition to fuelHybrid carCombustion

An exhaust emission control system of a hybrid car capable of relieving a load upon an engine fuel injection device by eliminating a use of sub-injection and recovering from S-poisoning as well as purifying an exhaust gas even by eliminating the use of sub-injection. The exhaust emission control system of an internal combustion engine, used for the hybrid car traveled by two types of power sources of a diesel engine and an electric motor, includes a combustion heater as separate body from the engine, a catalyst, provided in an exhaust passageway, for purifying an engine exhaust gas, a combustion gas passageway through which a combustion gas emitted from the combustion heater flows toward the catalyst, and a three-way valve for introducing the combustion gas to the catalyst via the combustion gas passageway or an EGR passageway when the diesel engine is in a stop state and when the electric motor is in a driving state.

Owner:TOYOTA JIDOSHA KK

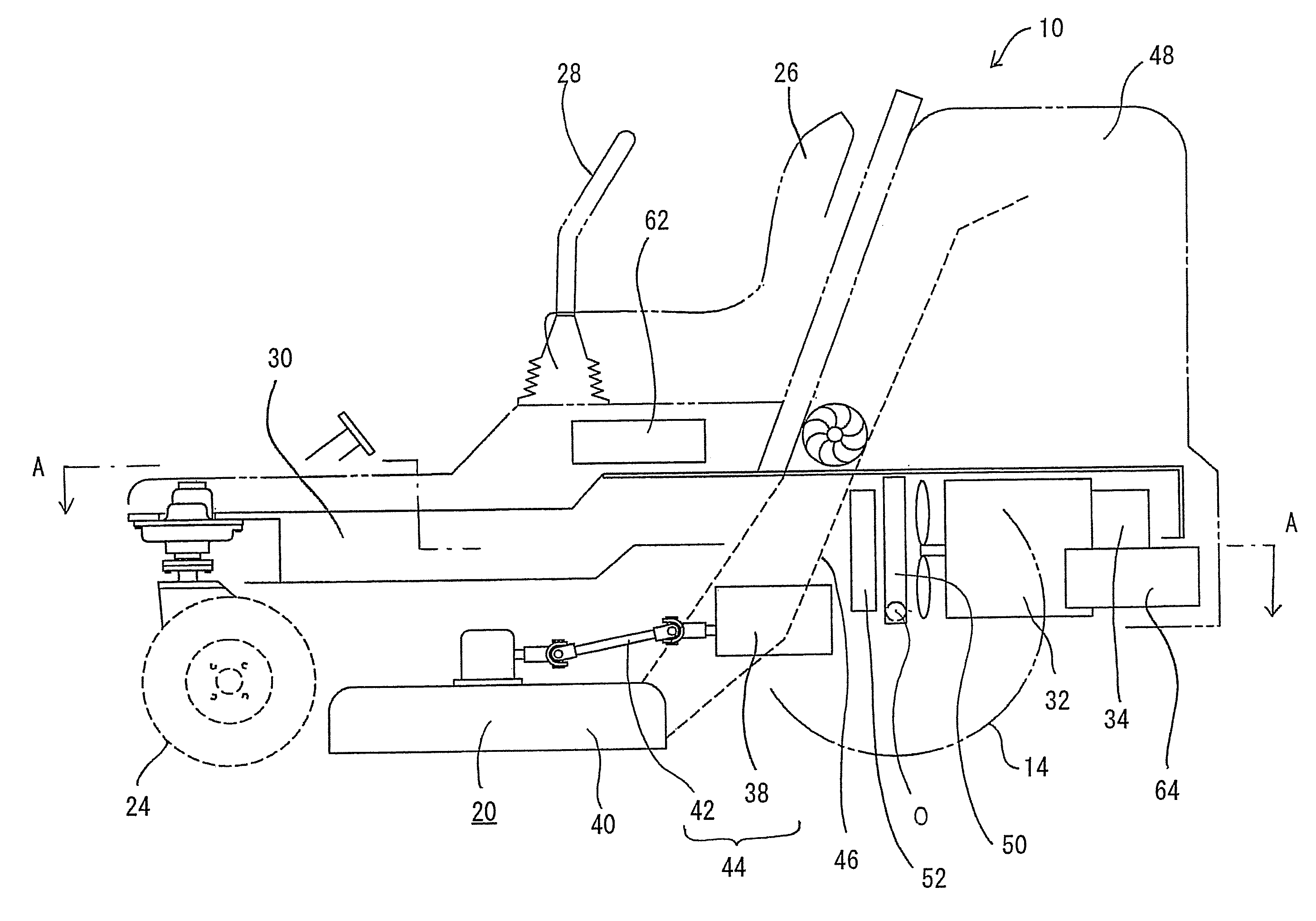

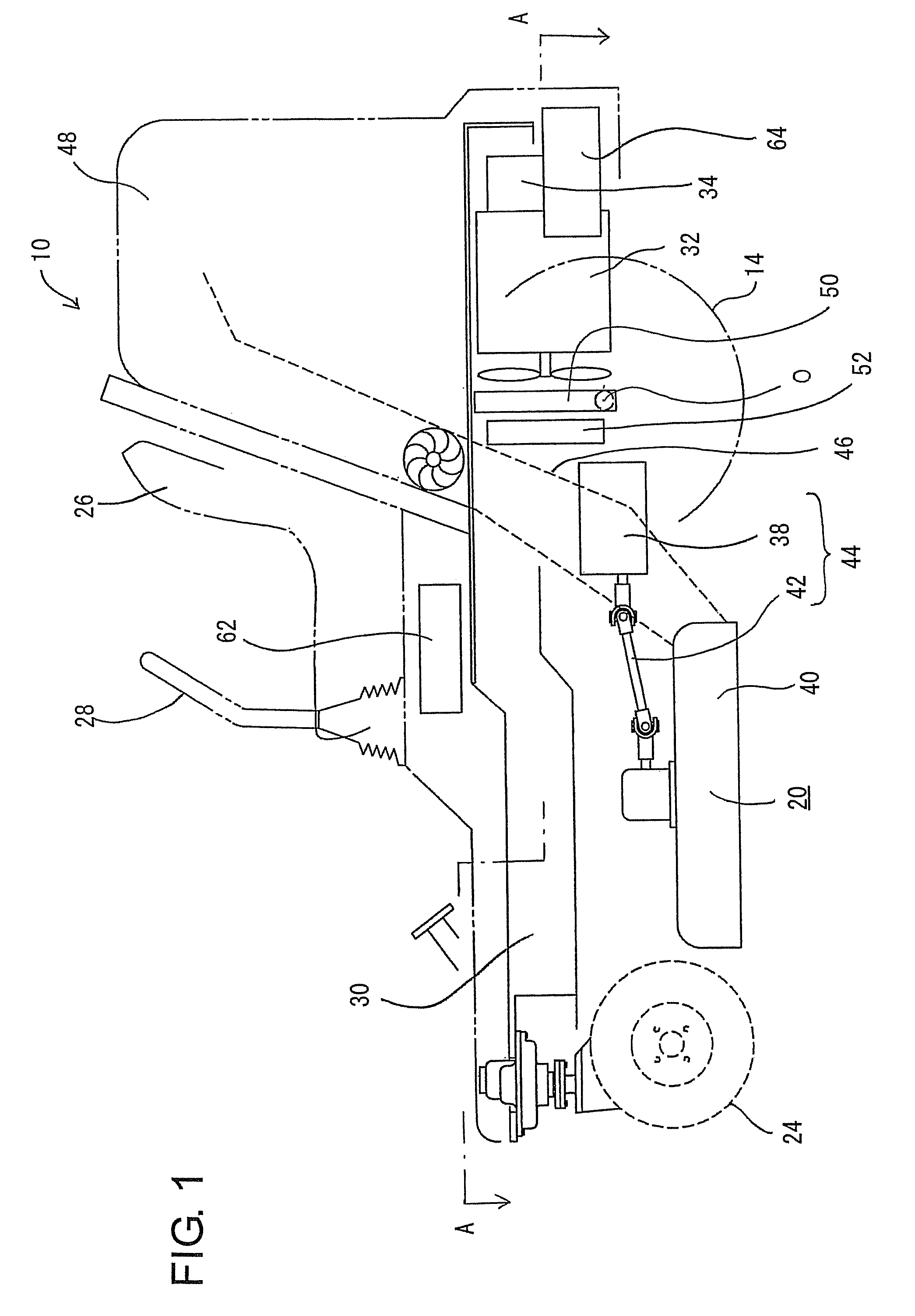

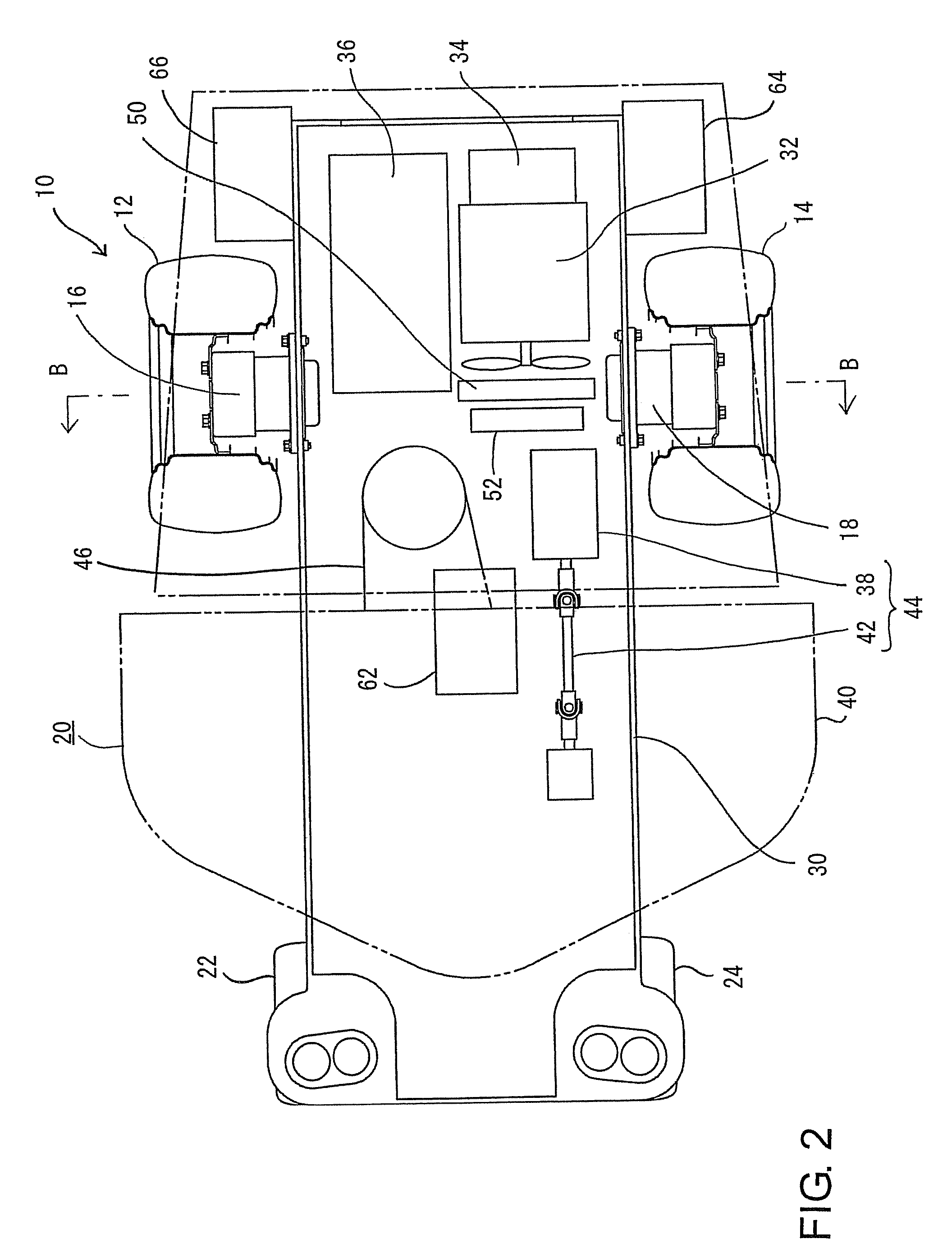

Riding lawnmower vehicle

A riding lawnmower vehicle includes two main drive wheels, at least one caster wheel, an electric traction motor, an internal combustion engine, a generator driven by the internal combustion engine, and a lawnmower. The electric energy generated by the generator can be supplied directly or via an electric accumulator to the electric traction motor. The main drive wheels are independently driven by the electric traction motor, which can operate as a traction power source. When viewed from one end to the other end in the width direction of the vehicle, the internal combustion engine and a secondary battery operable as the electric accumulator overlap each other, and the main drive wheels overlap at least a part of at least one of the internal combustion engine, the generator, the secondary battery, a fuel cell, a capacitor, an inverter, a cooling device, a mower driving motor, and a grass-collecting duct.

Owner:KANZAKI KOKYUKOKI MFG

Removal of particulates from the exhaust gas of internal combustion engines operated with a predominantly stoichiometric air/fuel mixture

ActiveUS8066963B2Eliminate emissionsSmall sizeCombination devicesOrganic chemistryExternal combustion engineChemical measurement

The exhaust gas of internal combustion engines operated with a predominantly stoichiometric air / fuel mixture contains, as well as the gaseous hydrocarbon (HC), carbon monoxide (CO) and nitrogen oxide (NOx) pollutants, also ultrafine particulates. There is disclosed a catalytically active particulate filter, an exhaust gas cleaning system and a process for cleaning the exhaust gases of predominantly stoichiometrically operated internal combustion engines, as well as the gaseous CO, HC and NOx pollutants, also for removing particulates from the exhaust gas. The particulate filter comprises a filter body and a catalytically active coating consisting of two layers. Both layers contain alumina. The first layer contains palladium. The second layer contains rhodium. The latter is disposed above the first layer.

Owner:UMICORE AG & CO KG

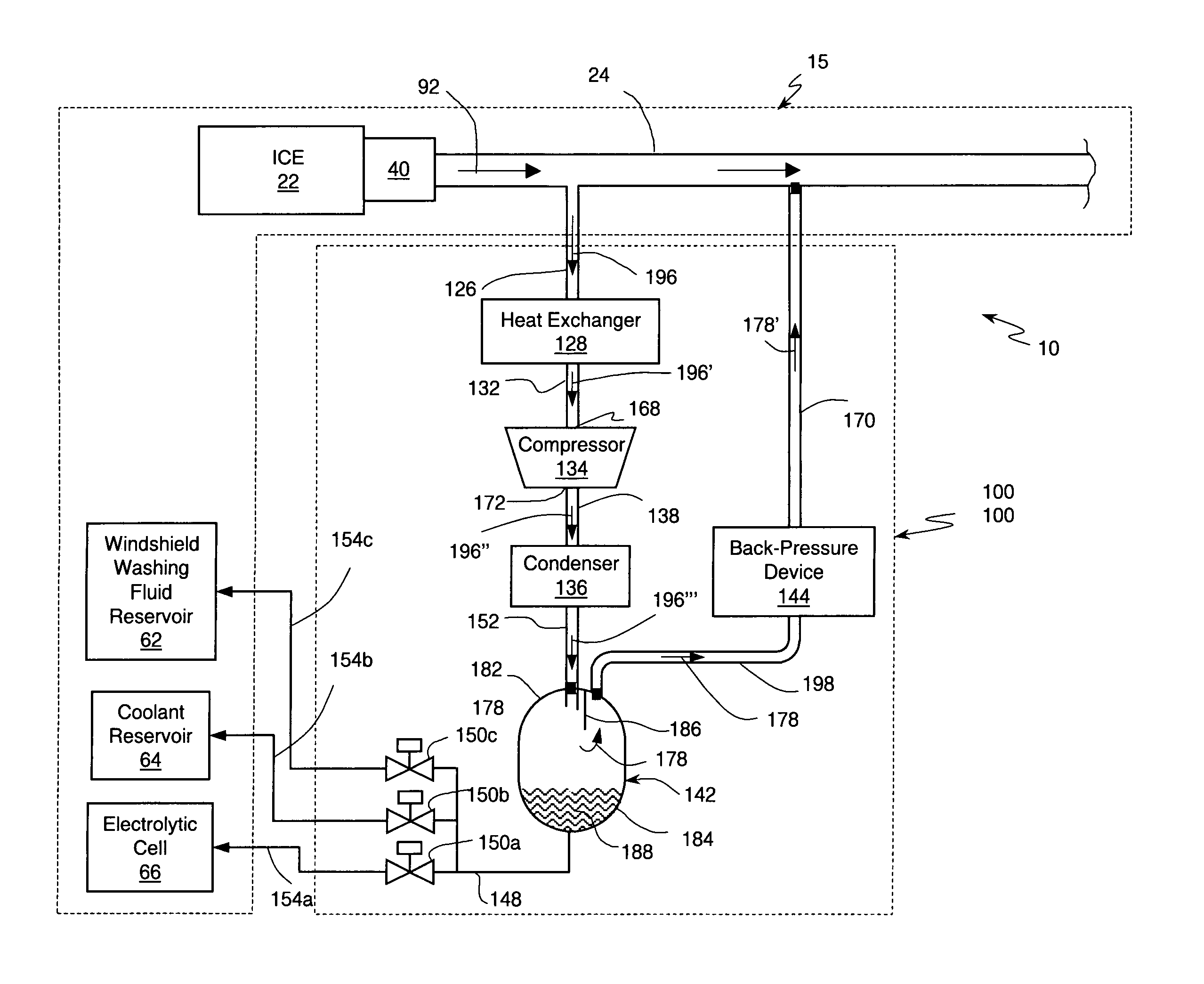

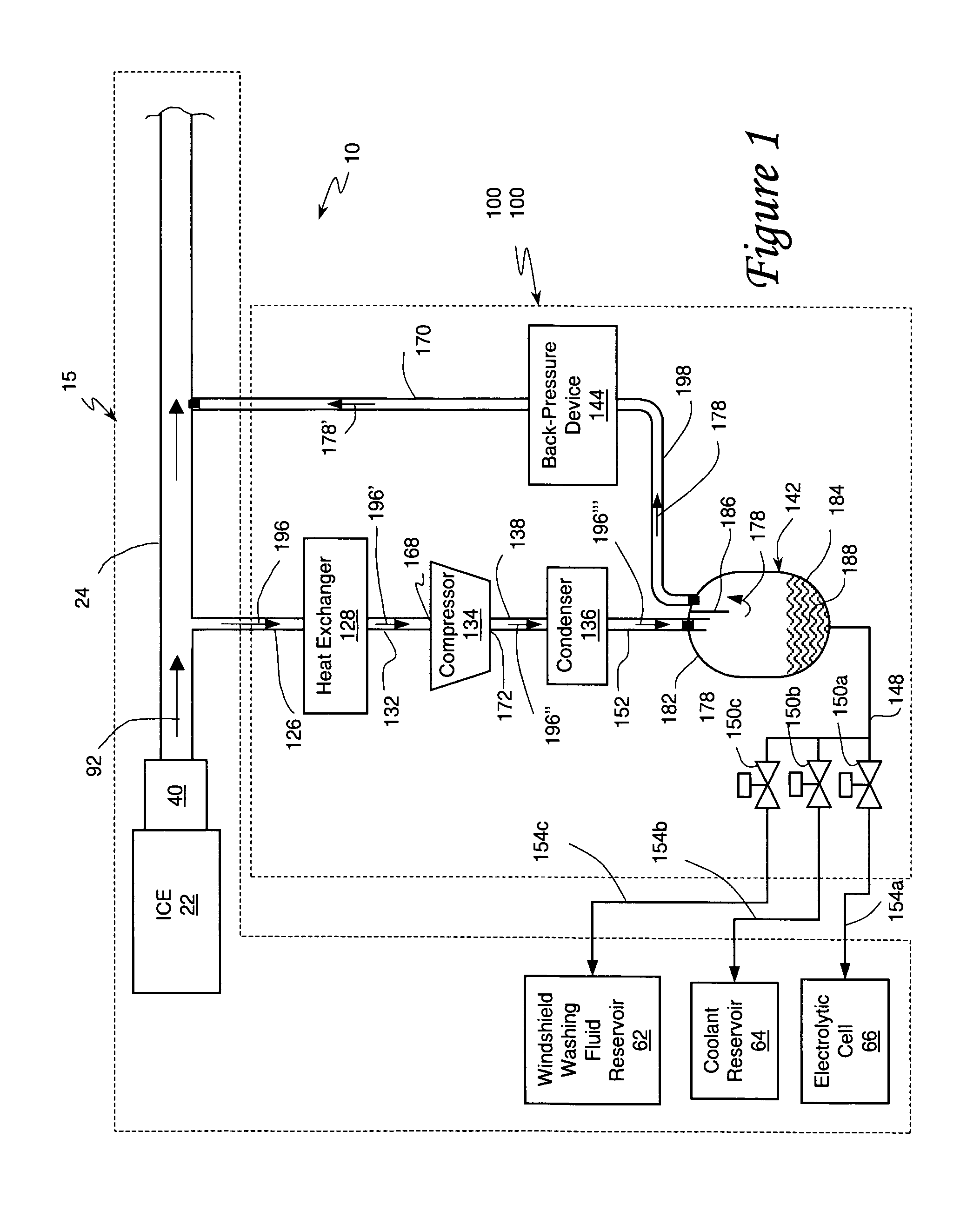

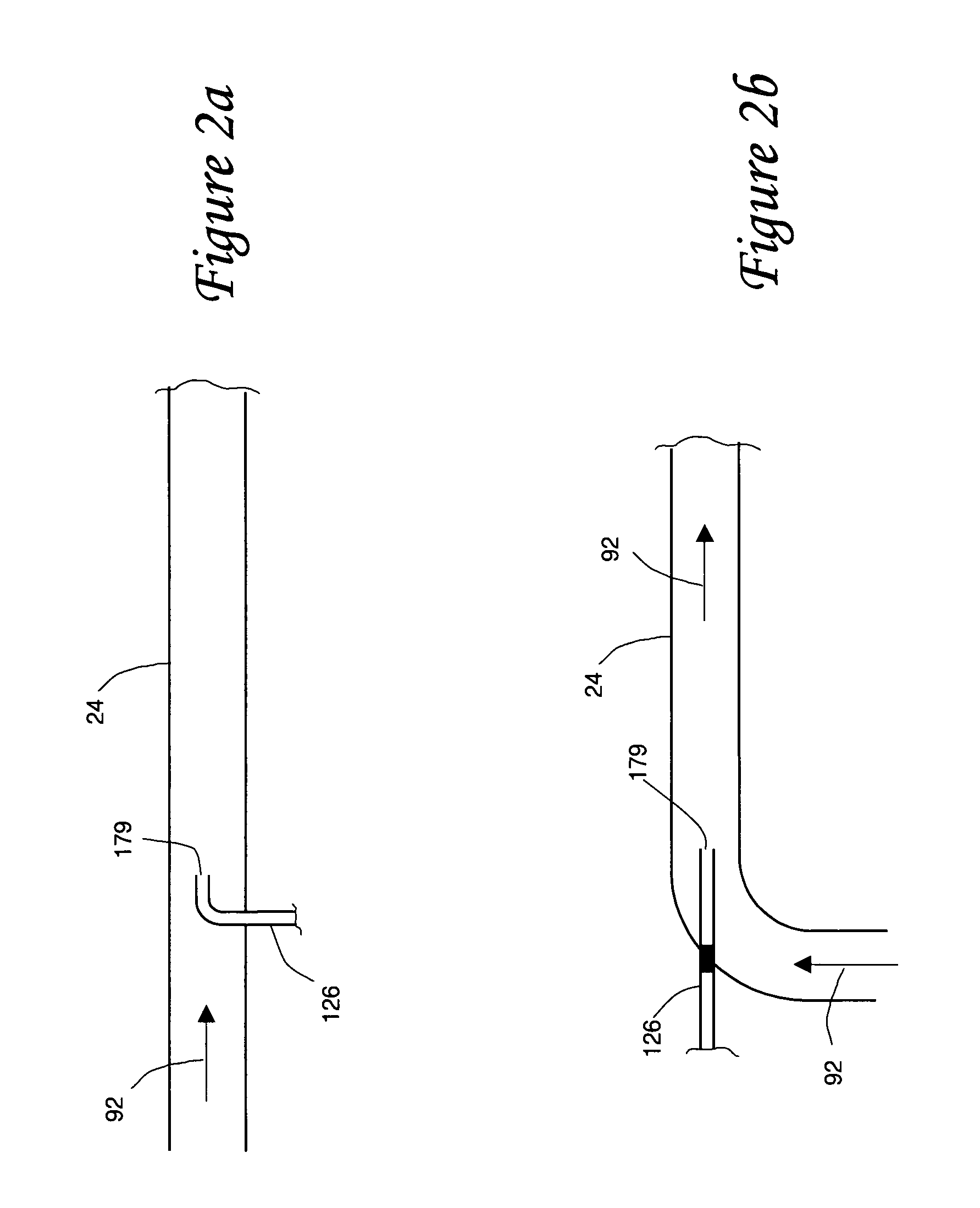

Internal combustion engine/water source system

InactiveUS7302795B2Increase pointsSimple and reliable processNon-fuel substance addition to fuelInternal combustion piston enginesExternal combustion engineWater source

An internal combustion engine system for automotive vehicle wherein liquid water is produced by cooling a portion of exhaust gases at elevated pressure to induce condensation. The use of elevated pressure allows condensation to occur at a higher dew point which is easier to realize with cooling by ambient air. Liquid water condensate is collected and provided to an electrolytic cell for electrolysis into gaseous hydrogen and oxygen. Hydrogen gas generated by the cell is used by the internal combustion engine to reduce internal combustion engine wear and to reduce exhaust pollutants especially during start-up. Alternate uses of the liquid water include a replenishment of engine coolant and window washing fluid.

Owner:VETROVEC JAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com