Enhanced device for generating hydrogen for use in internal combustion engines

a hydrogen generation and hydrogen technology, applied in the direction of machines/engines, mechanical equipment, instruments, etc., can solve the problems of adverse effects, hydrocarbons, carbon monoxide, carbon dioxide,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

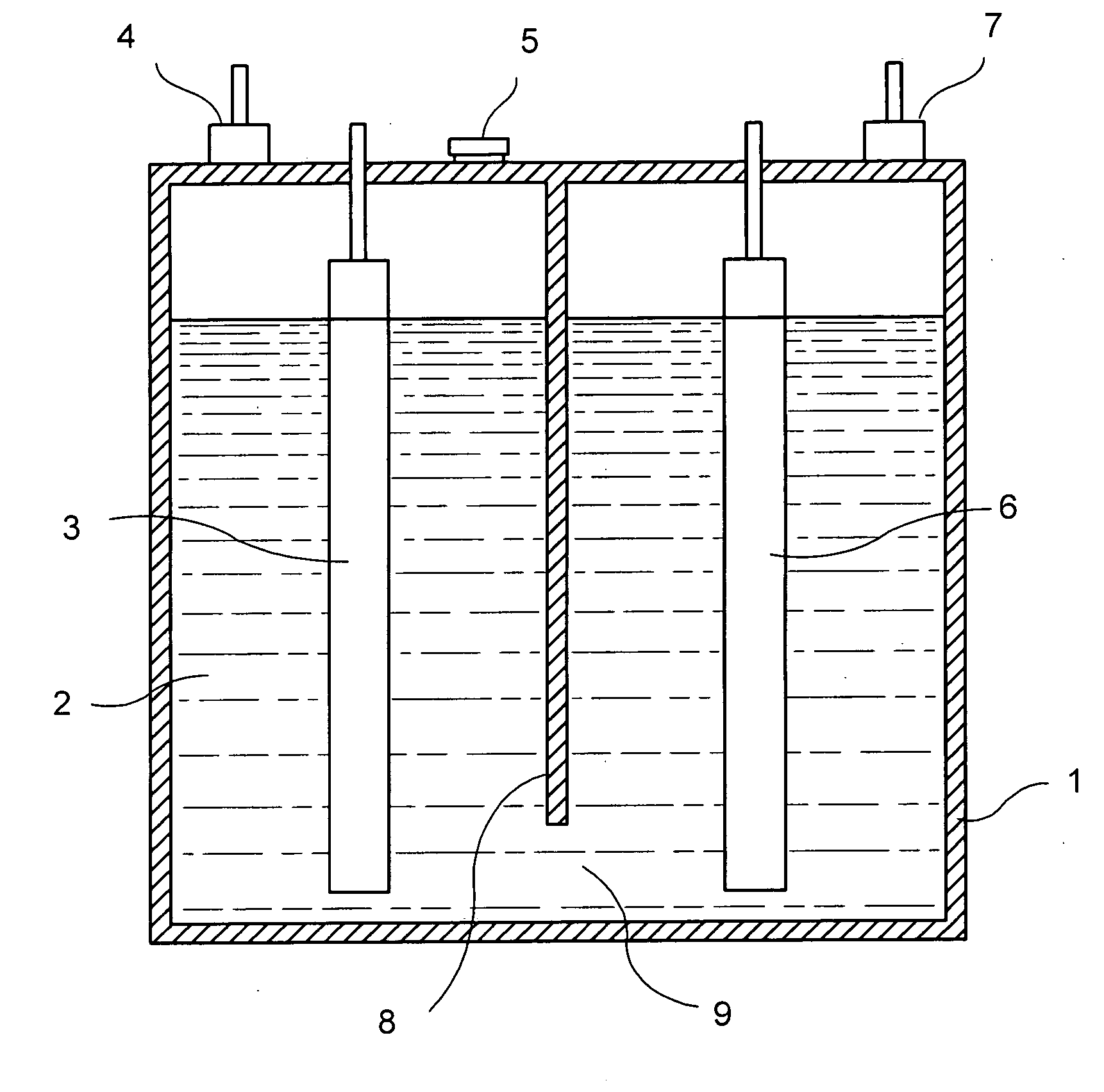

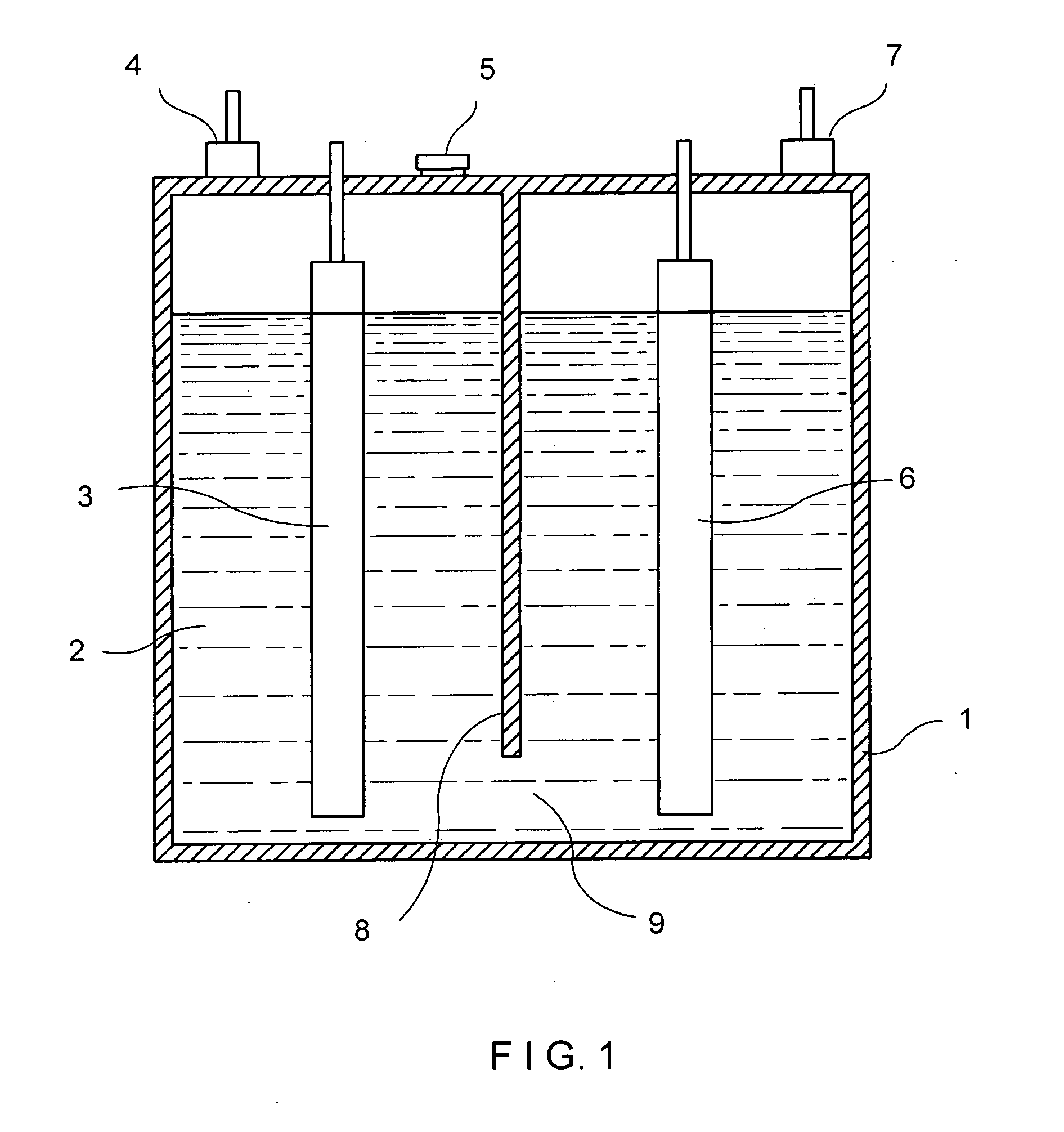

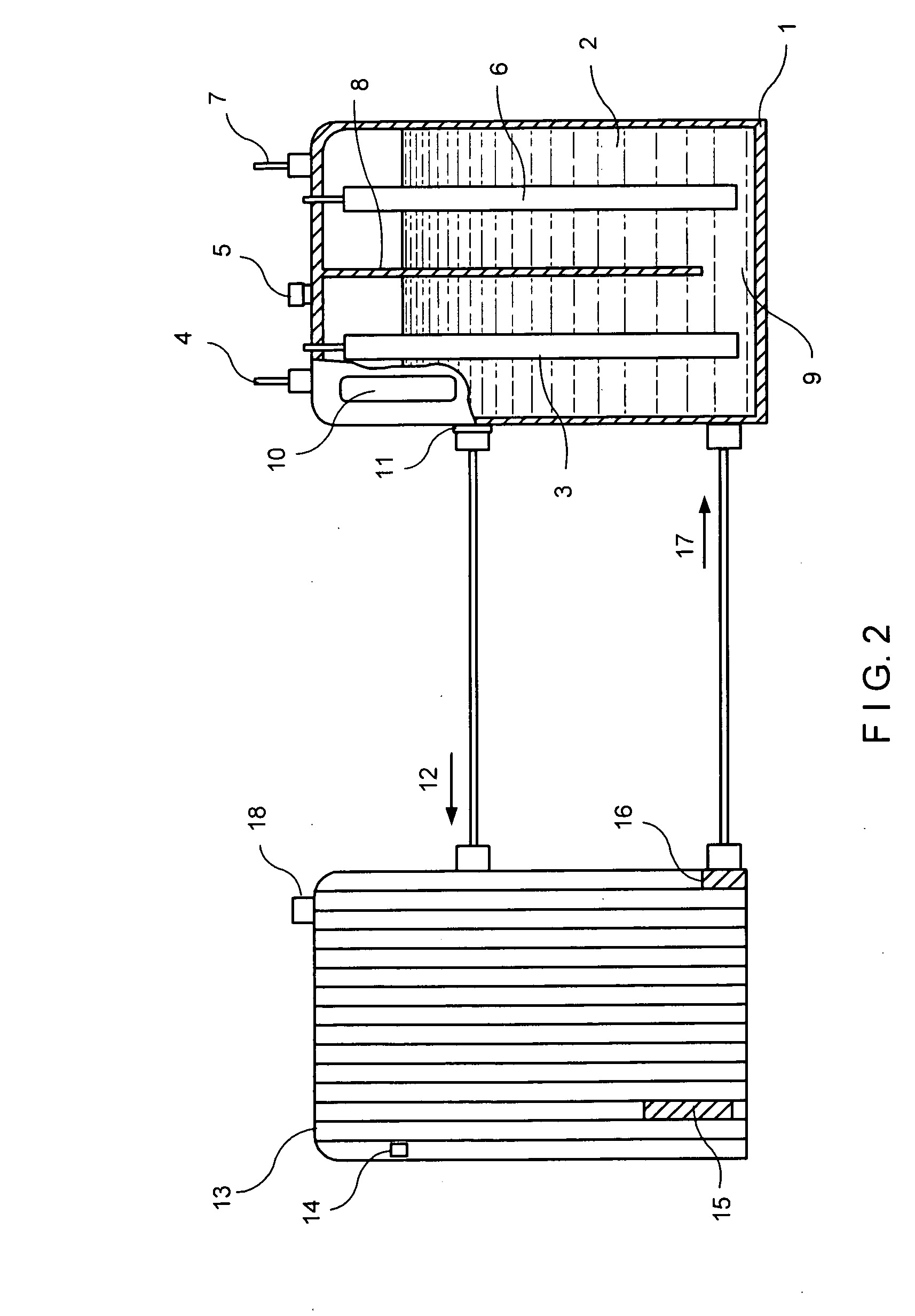

[0035]Turning now to the drawings, in the embodiment shown in FIG. 1, a housing 1 defines a chamber 9 to contain electrolyte fluid 2 introduced through an opening closeable by a fill cap 5. Electrodes in the form of an anode 3 and a cathode 6 are carried by the housing and extend downwardly into the chamber for partial immersion in the electrolyte fluid.

[0036]The positive electrode or anode 3 provides a way for the positive current to come in contact with the electrolyte fluid and the negative electrode 6 provides a place for the negative current to come in contact with the fluid.

[0037]The electrical connectors to the anode and cathode will be described in greater detail and the electrolytes generated by the electrodes in the electrolyte fluid produce oxygen and hydrogen which gases respectively exit through vents 4 and 7. Within the chamber, the oxygen and hydrogen are kept separate by a chamber divider 8.

[0038]The electrolyte fluid 2 is produced by mixing a catalyst with distilled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| operating temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com