Patents

Literature

126results about How to "No backlash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

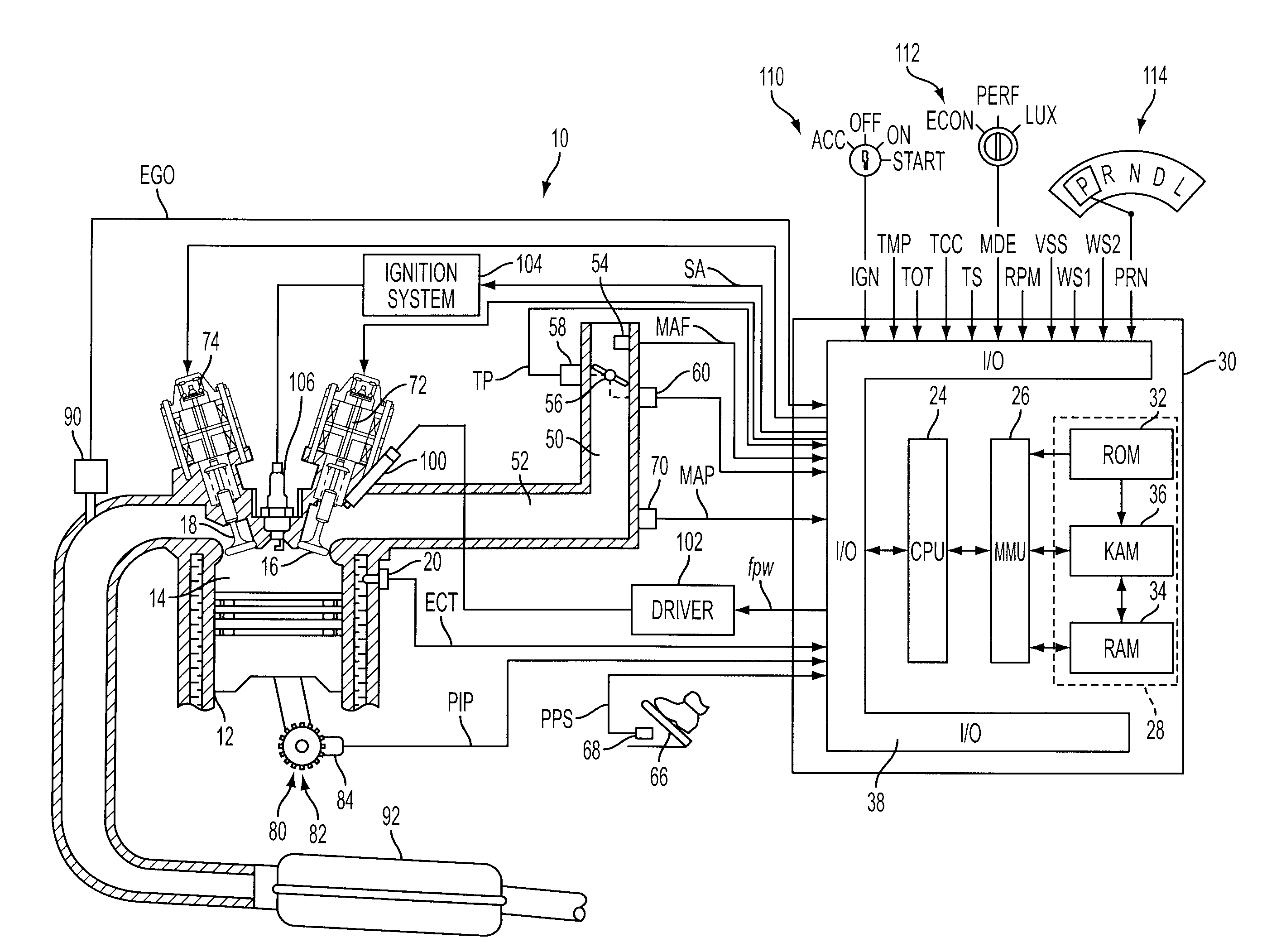

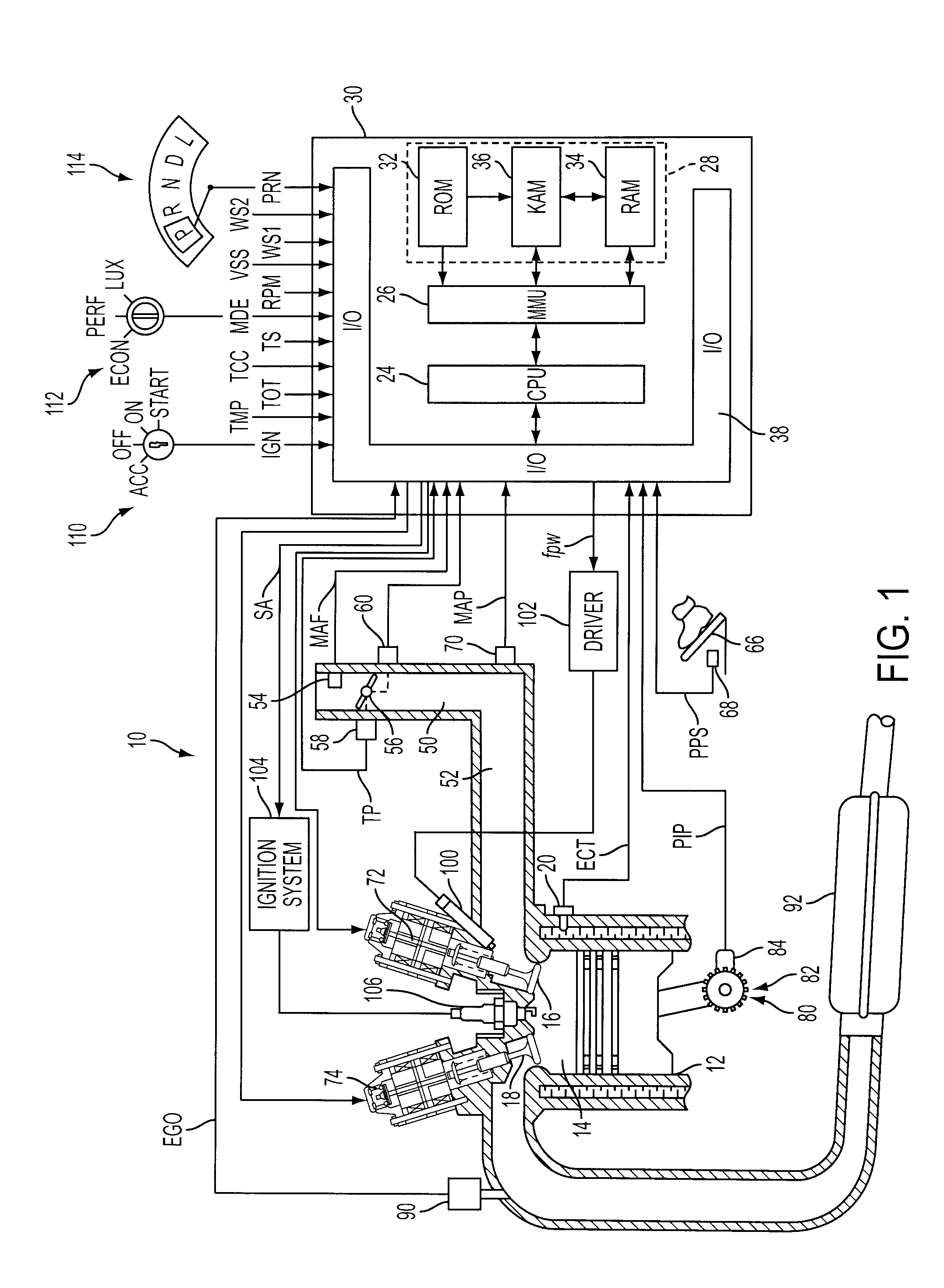

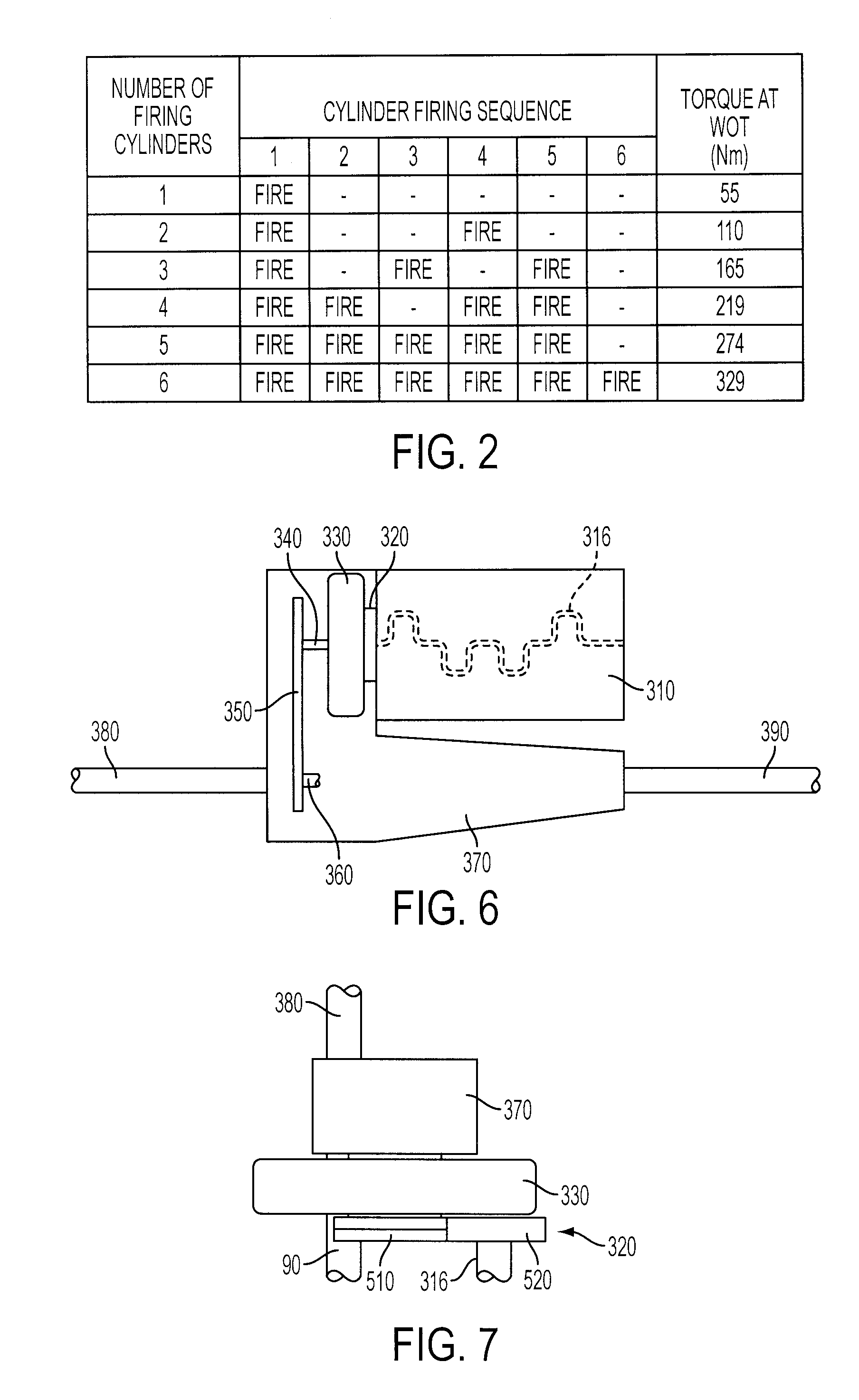

Variable Displacement Engine Operation With NVH Management

InactiveUS20080154468A1Reduce and eliminate torque reactionNo backlashAnalogue computers for vehiclesDigital data processing detailsClose couplingDrivetrain

A system and method for controlling an internal combustion engine operable with a first cylinder firing frequency and a second cylinder firing frequency to reduce or eliminate transmission of torsional vibrations associated with the second cylinder firing frequency to reduce or eliminate constraints on reduced displacement mode operation using a closely coupled drive train component rotating in an opposite direction relative to rotating components of the engine. A close coupling device allows the inertia of the counter-rotating elements to reduce or eliminate the torque reaction of the drivetrain associated with acceleration and deceleration of the engine crankshaft in response to the second cylinder firing frequency in the reduced displacement mode.

Owner:FORD GLOBAL TECH LLC

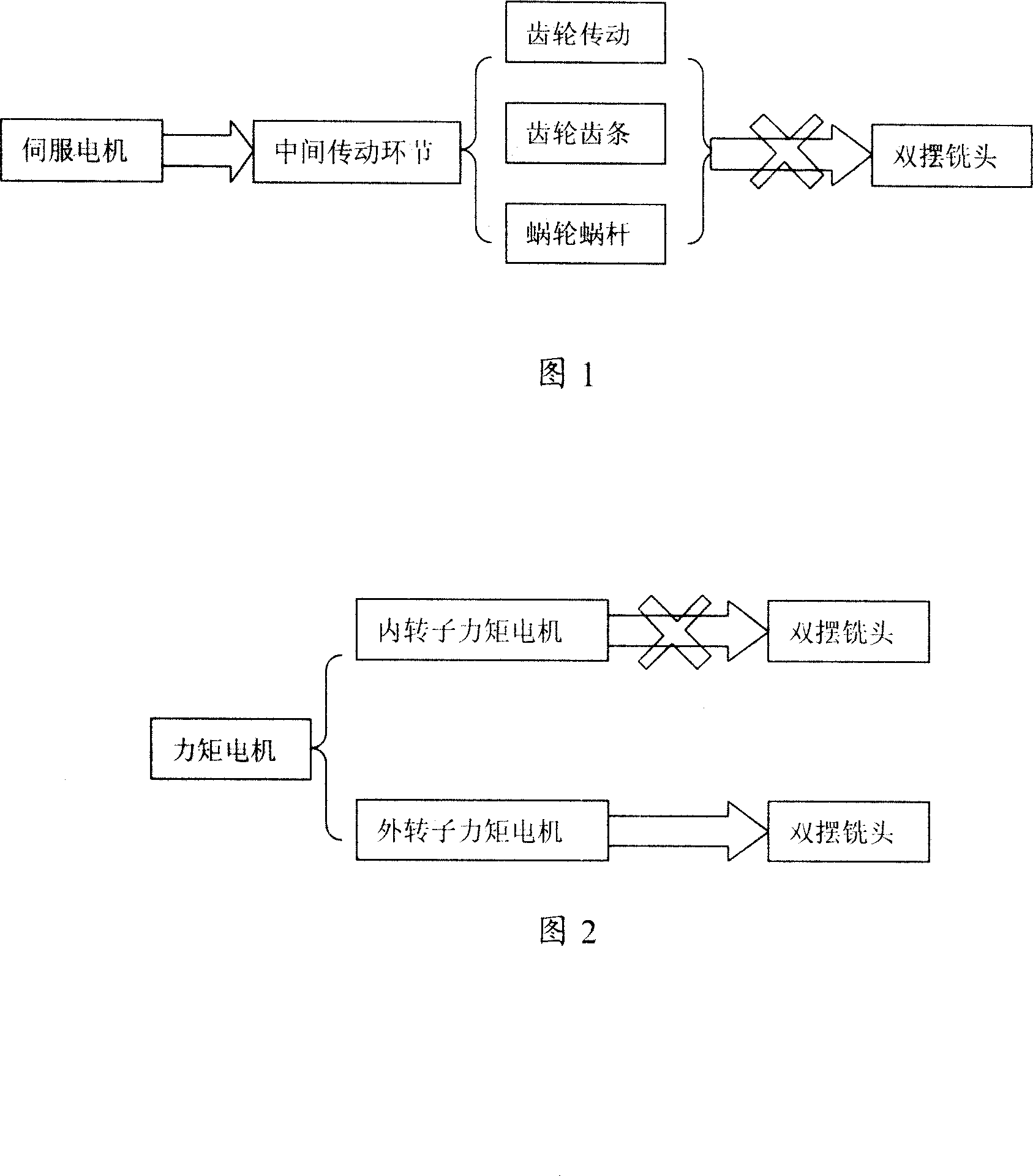

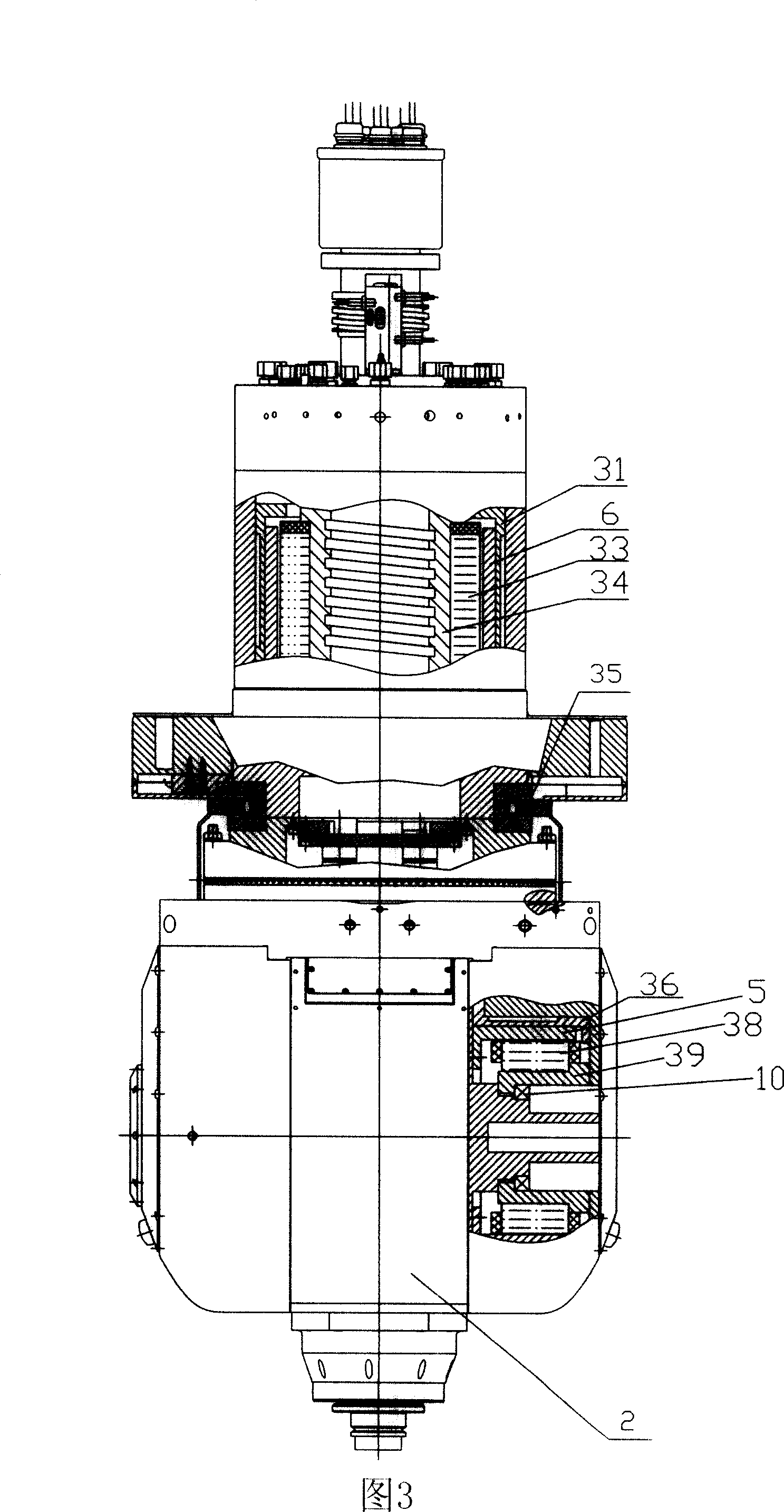

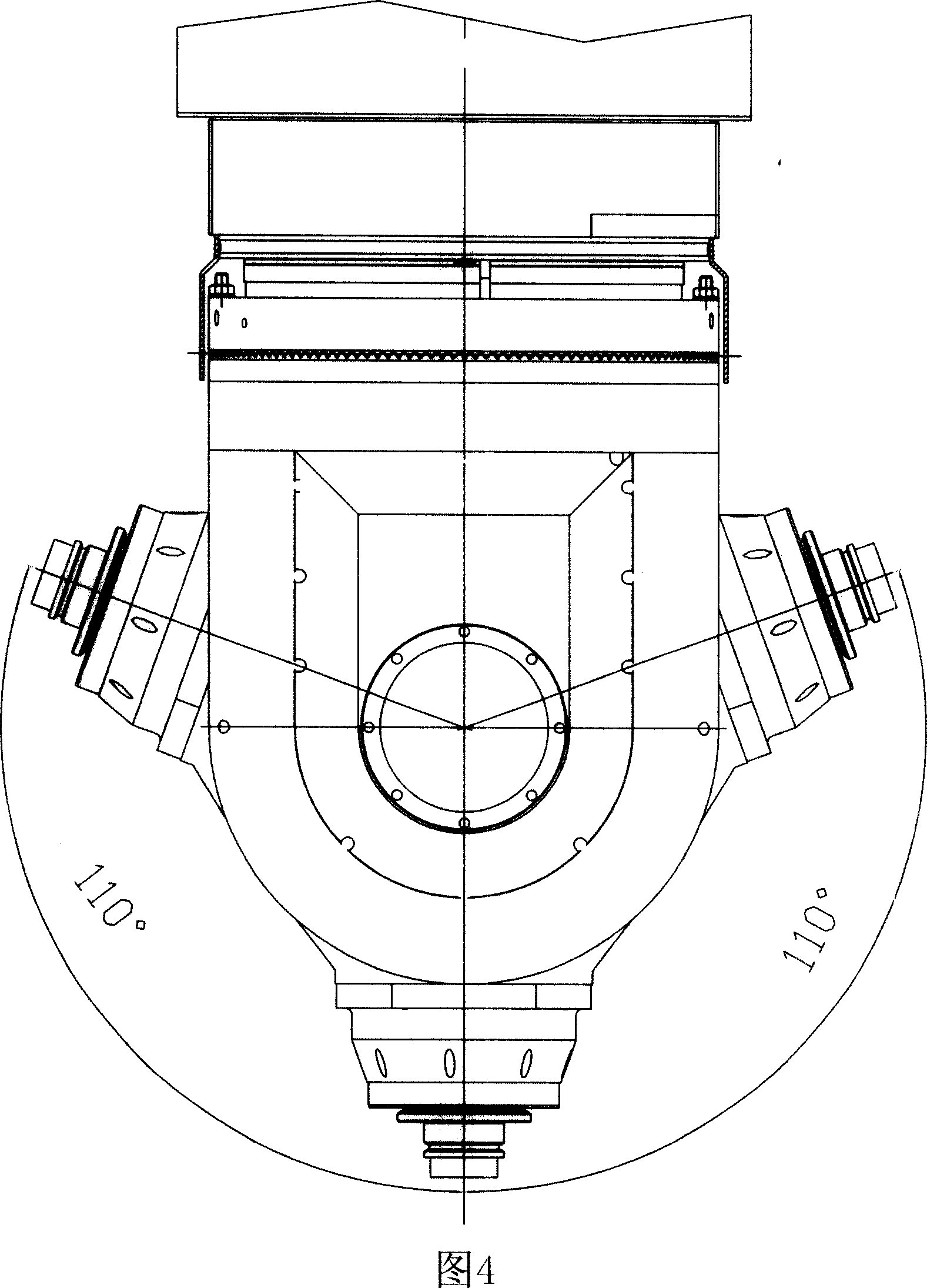

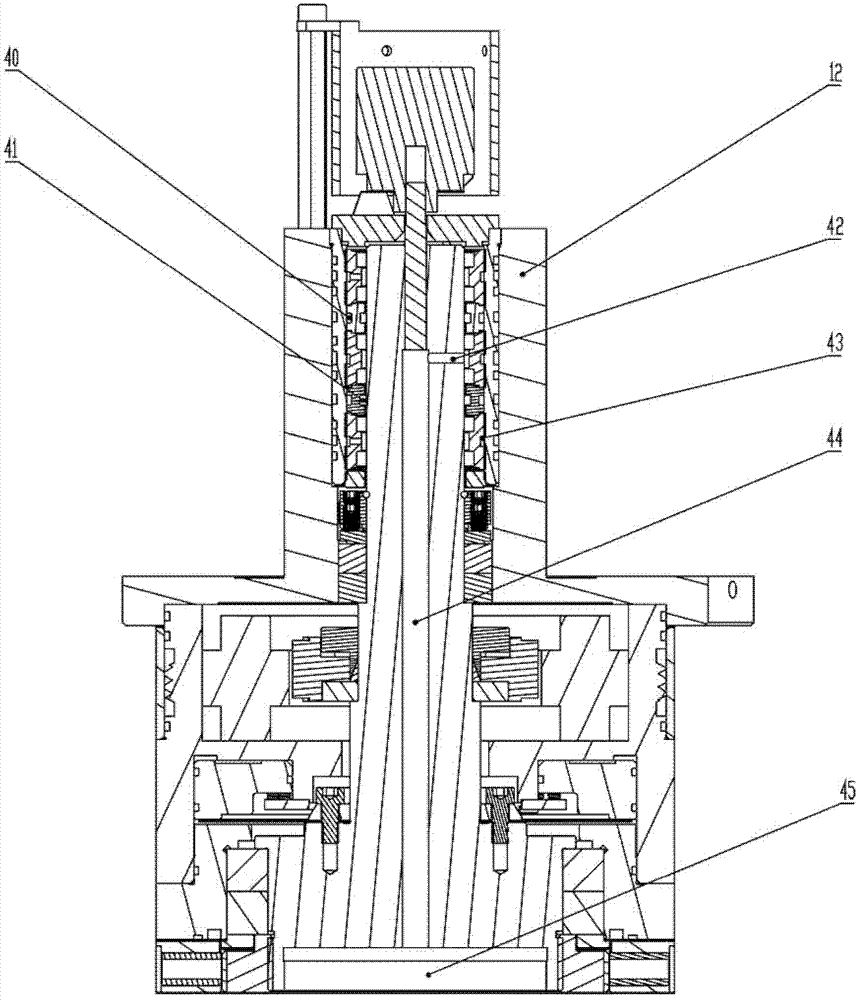

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN101011795AImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

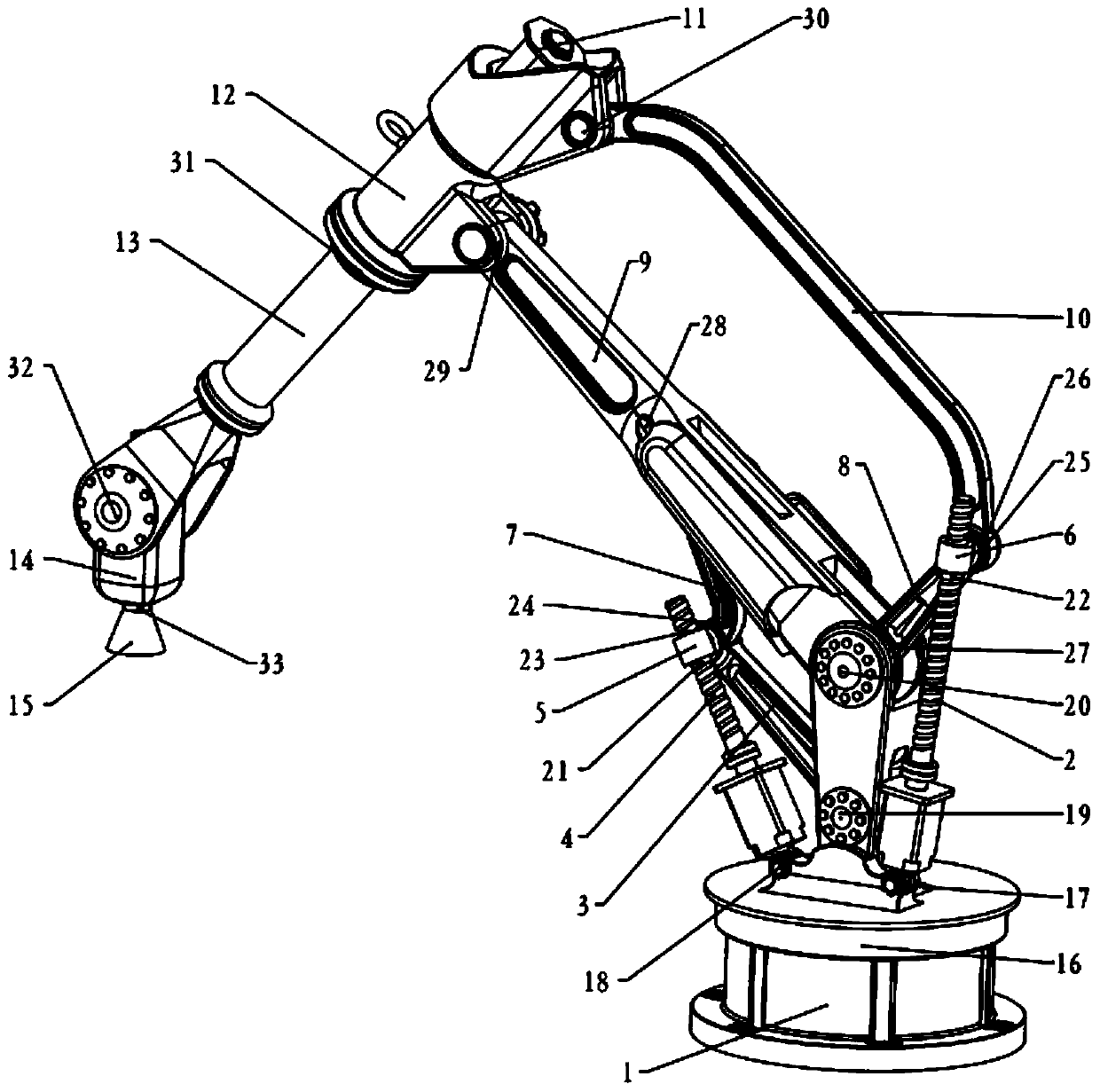

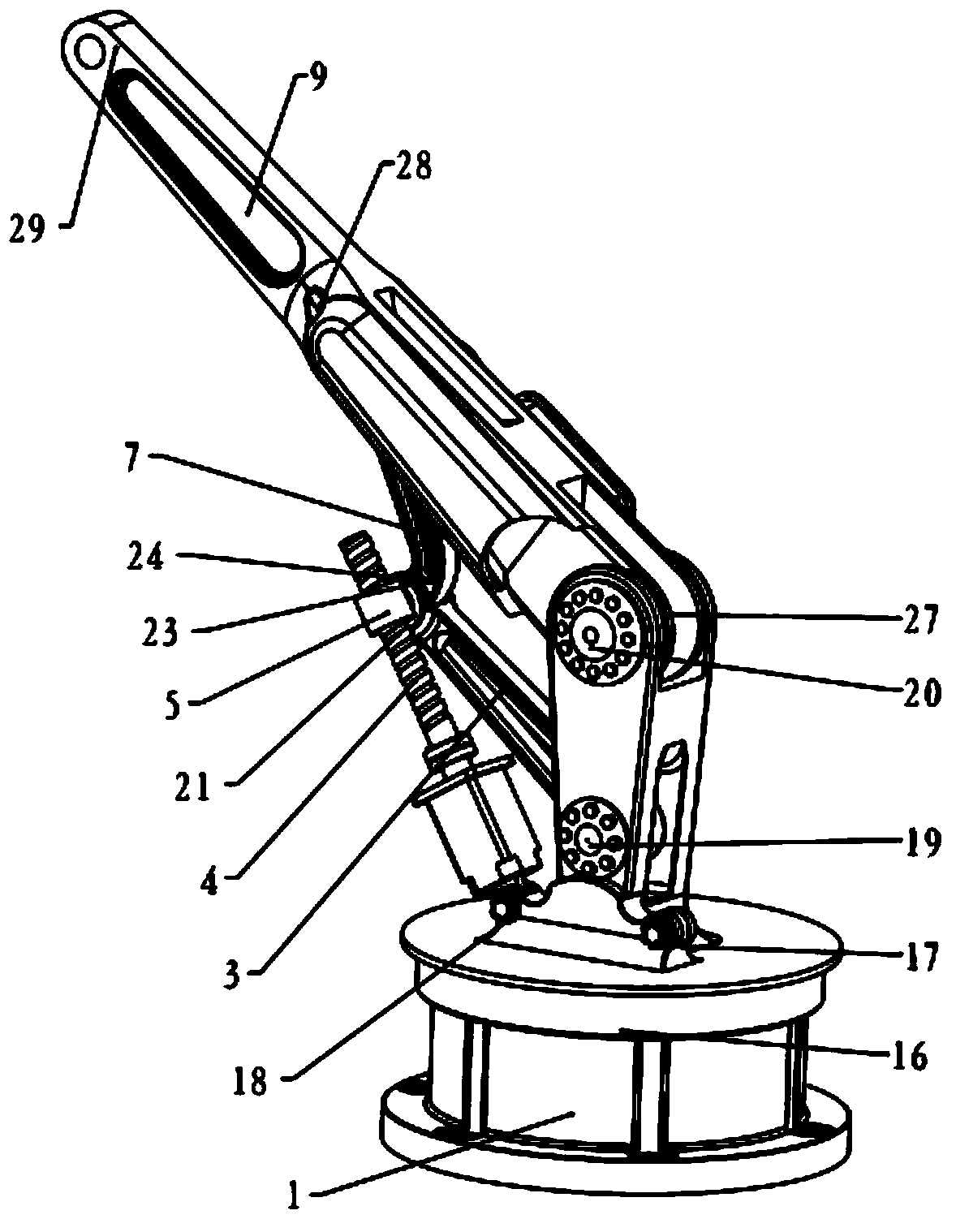

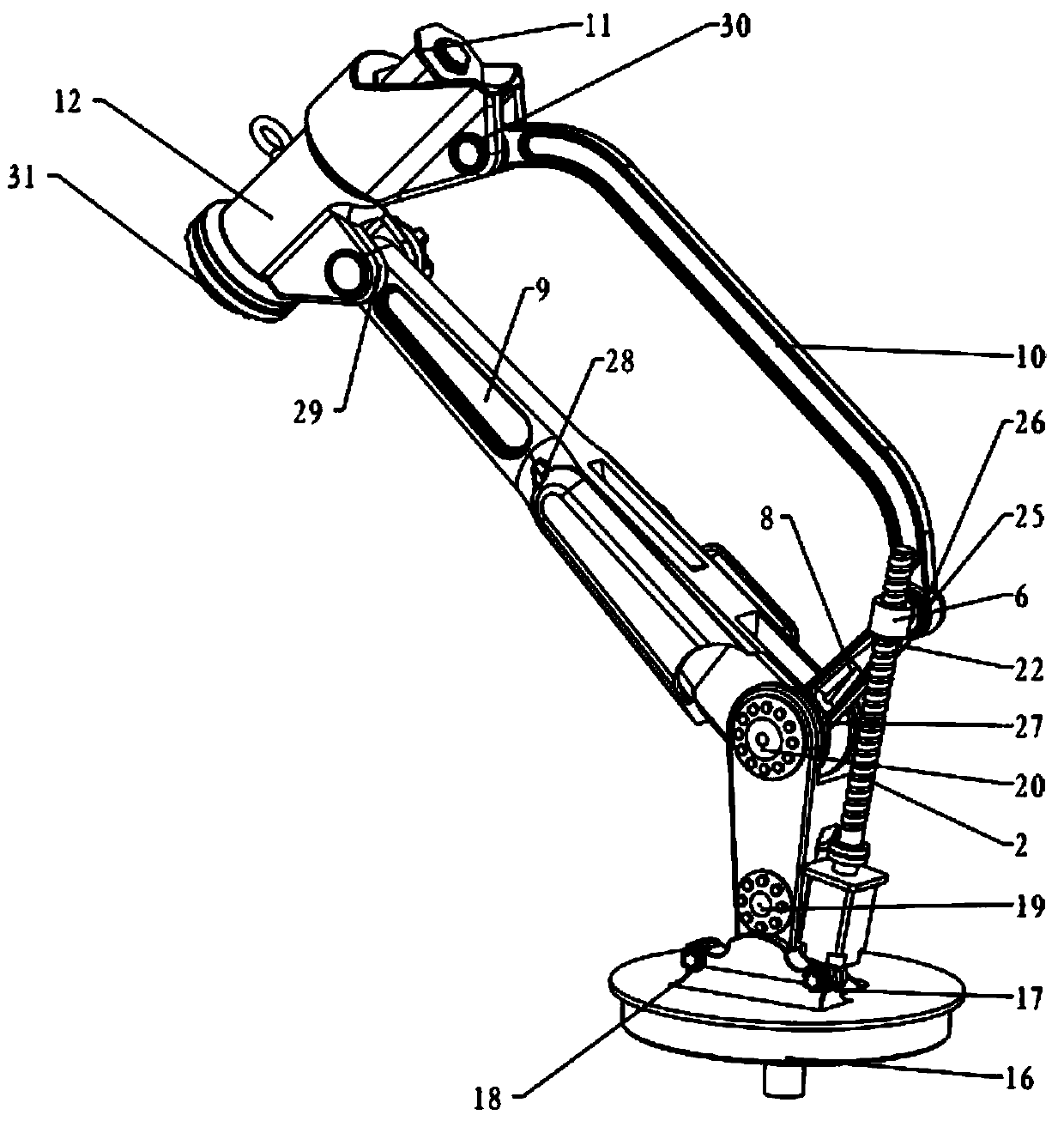

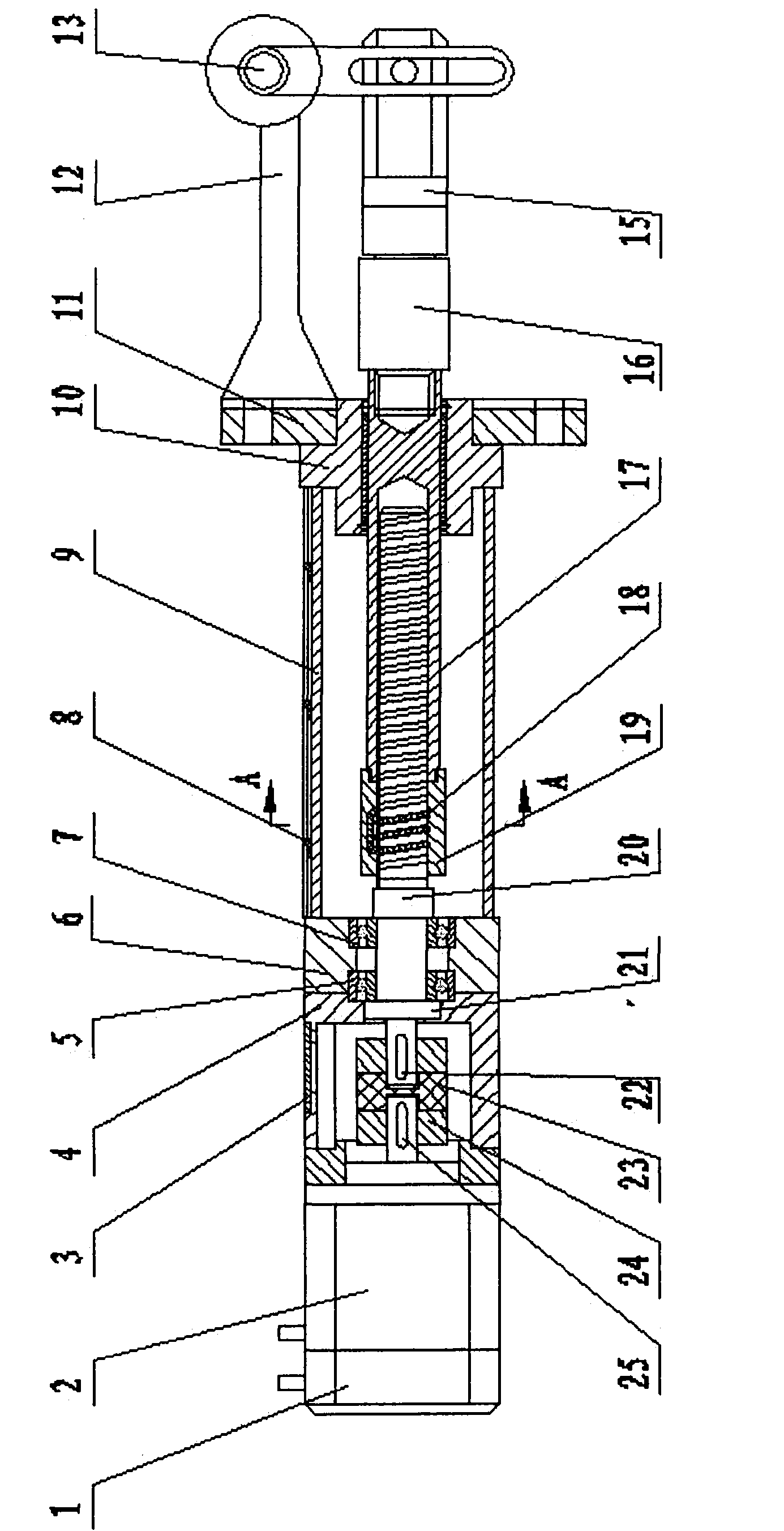

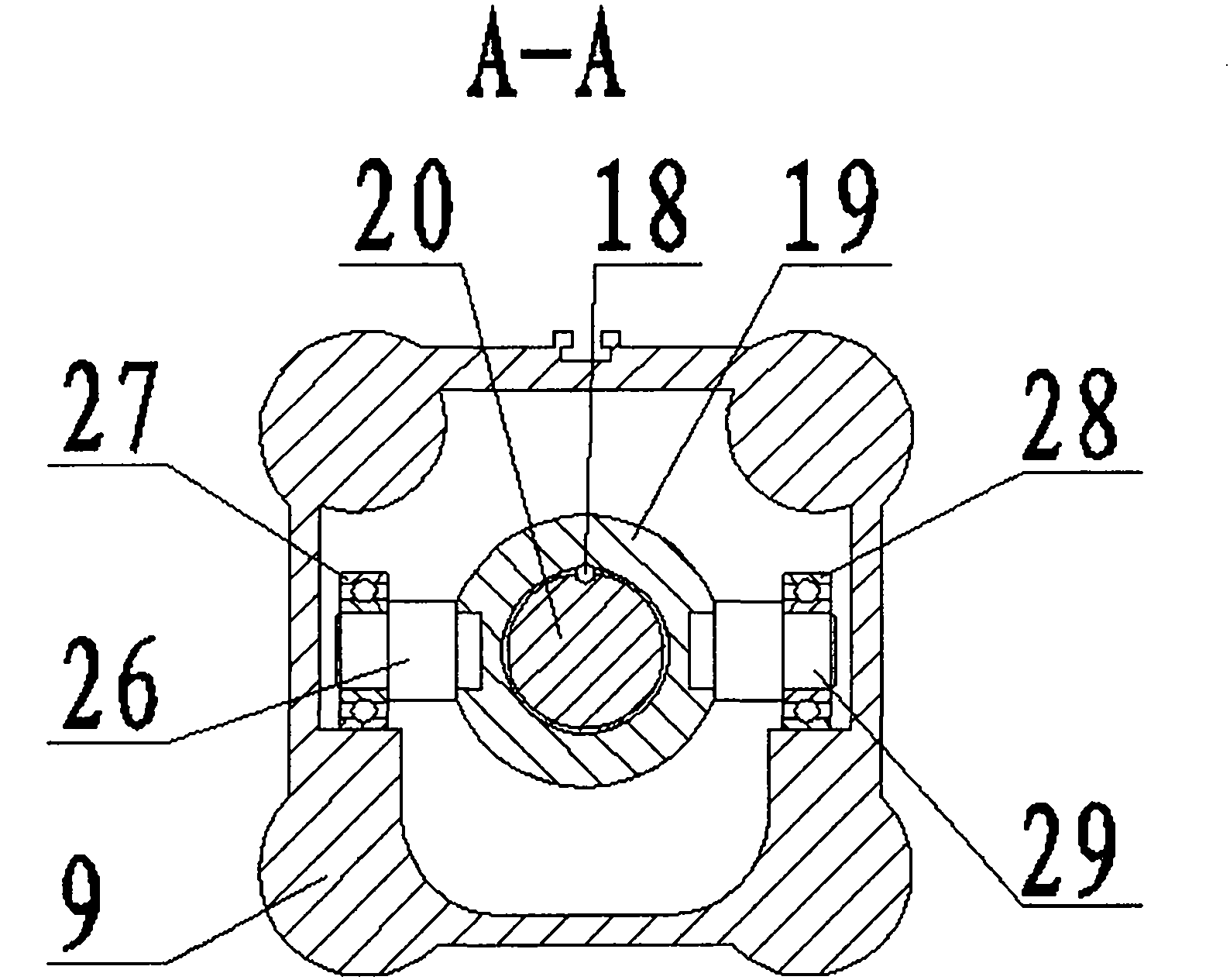

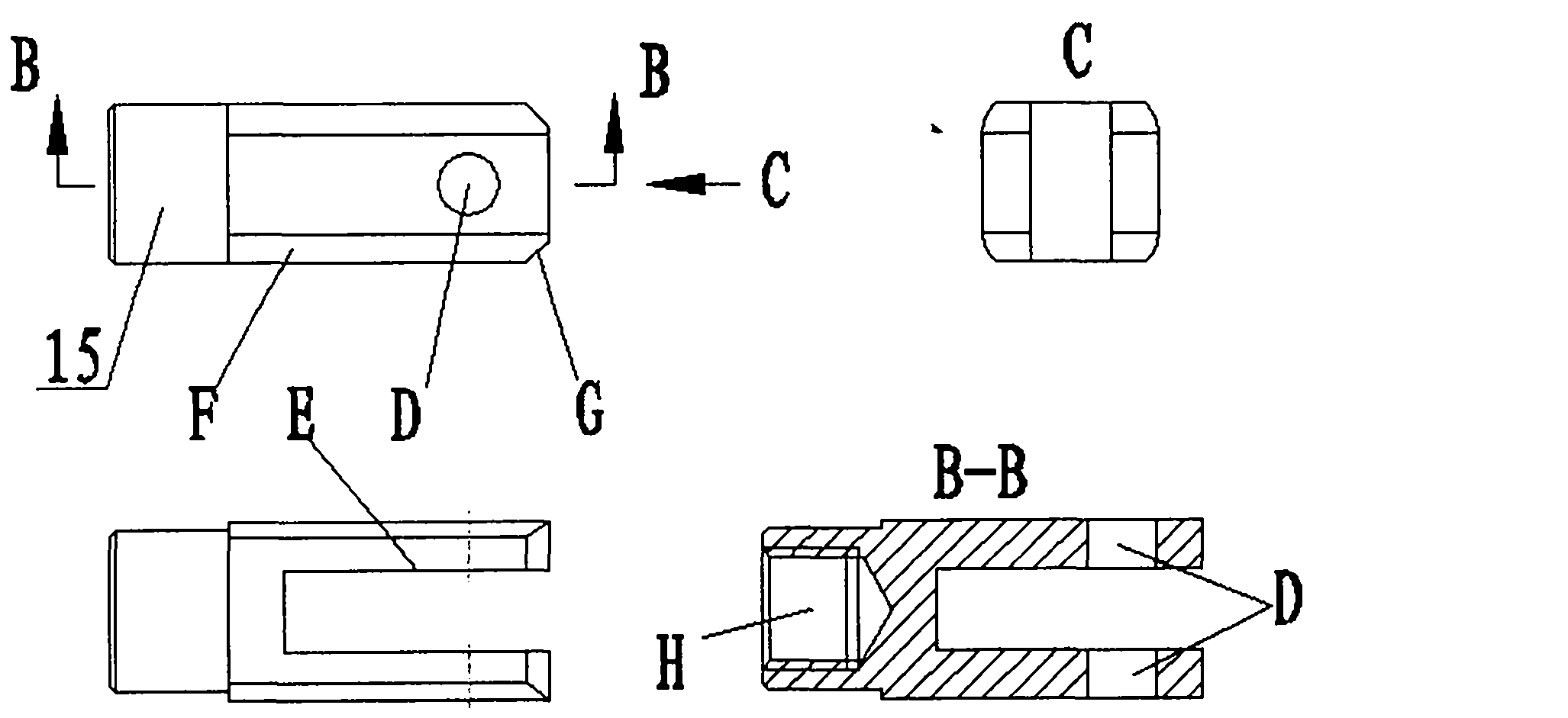

Six-freedom-degree industrial robot with ball screw pair transmission

InactiveCN103737577ARealize two-dimensional translationRealize three-degree-of-freedom attitude adjustmentProgramme-controlled manipulatorBall screw driveDrive motor

The invention relates to a six-freedom-degree industrial robot with ball screw pair transmission. Waist whole circle rotating is achieved through a waist swing mechanism, a shoulder swing mechanism and an elbow swing mechanism form a two-freedom-degree parallel mechanism to achieve two-dimensional horizontal moving, and ball screws are driven by motors arranged on a swing platform respectively. Three mutual-orthometric rotating shafts connected through a front arm rotating mechanism, a wrist swing mechanism and a tool clamping base swing mechanism are driven independently by three motors respectively, and three-freedom-degree gesture adjusting of an executing tail end tool is achieved. The advantage of the large working space of a serial mechanism is kept, ball screw transmission is used, the rigidness of the mechanism is guaranteed, the positions of the driving motors are lowered, good dynamic characteristics are obtained, bearing capacity is large, high-speed or superspeed operation can be easily achieved, and the six-freedom-degree industrial robot has the advantages that side gaps do not exist, rigidness is high, micro-motion feeding can be conveniently achieved, accumulated errors are small, motion accuracy is high, positive and athwart kinematics solving is convenient, and control is convenient.

Owner:GUANGXI UNIV

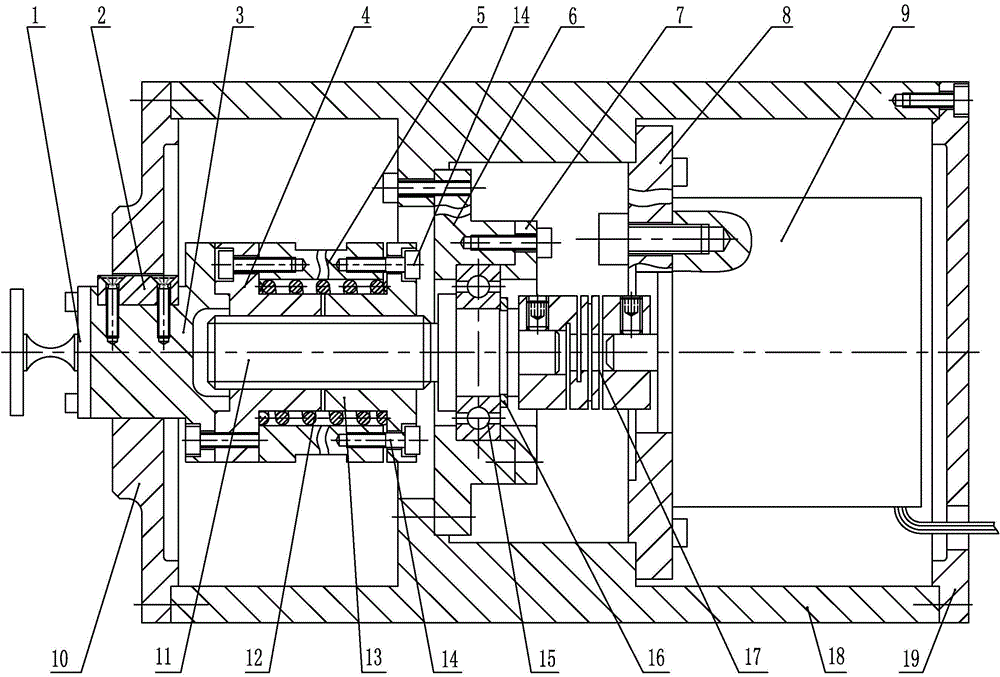

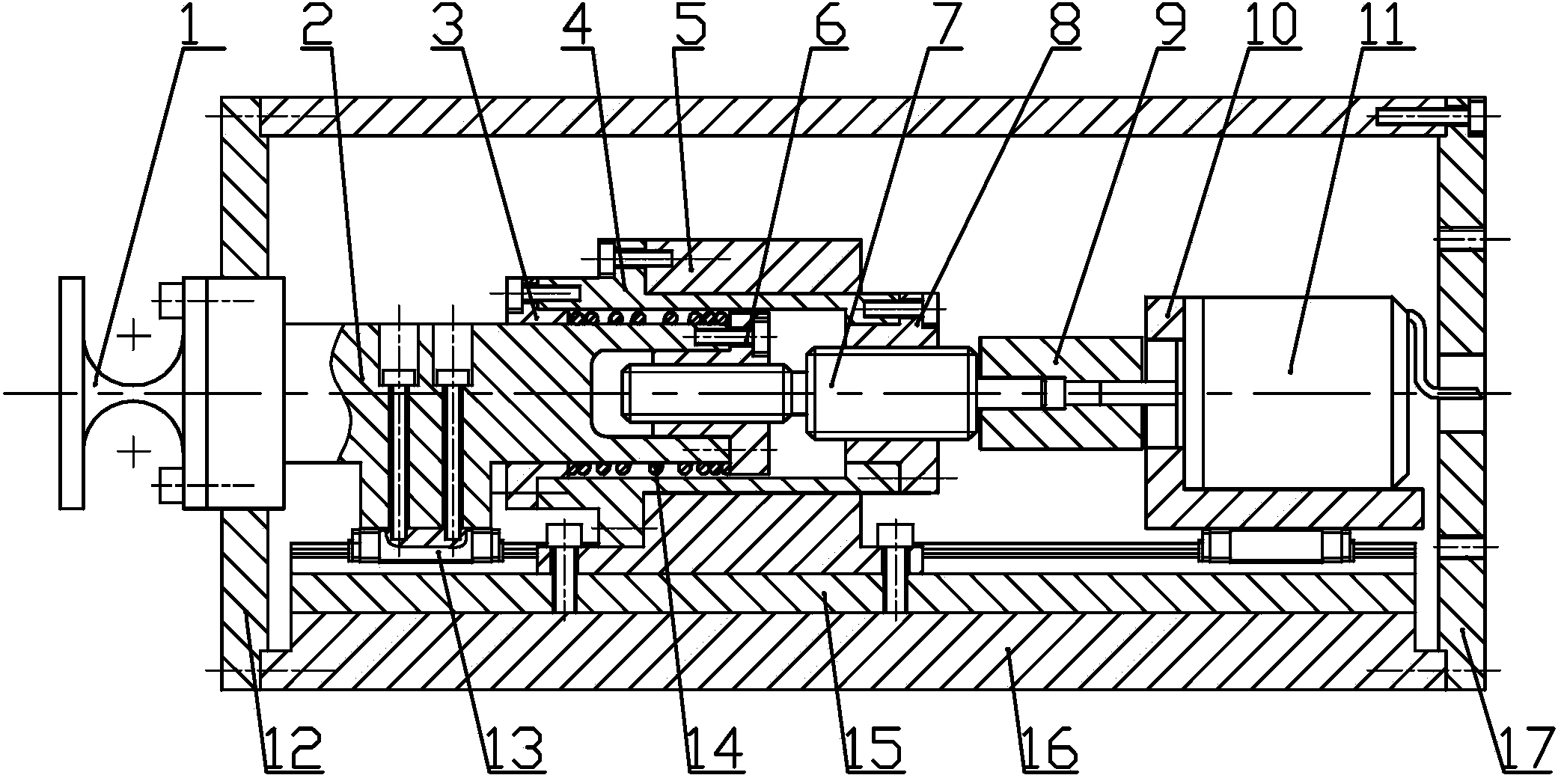

Electric operator for general-purpose mechanical automatic transmission clutch

InactiveCN101852255AHigh control precisionAdjustable control precisionMechanical actuated clutchesGearingGeneral purposeAutomatic transmission

The invention discloses an electric operator for a general-purpose mechanical automatic transmission clutch, which comprises a servo motor, a shell, a coupling, a connector, a front end flange, a back end flange, a bearing, a hinge pin, a ball screw, a pressure sensor, a spacing sensor and a displacement sensor, wherein the front end flange fixes the shell on the clutch bracket; the motor is fixed on the shell; the output shaft of the motor is connected with the screw stem of the ball screw through the coupling; the screw stem drives a screw stem shaft sleeve through balls to drive a push rod to move; and the other end of the push rod is connected with the pressure sensor, thereby finally acting on the driving lever of the clutch, so that the driving lever drives the clutch to move. The invention has the advantages of simple structure, high transmission efficiency, accurate control and the like, is suitable for clutches with different rigidities and movement strokes, and can monitor the movement state of the clutch from different angles. The invention is mainly used in electric operators for clutches in experimental study.

Owner:SHANXI WENZHENG ZHUOYUE AUTOMOBILE ELECTRONICS INJECTION DEVICE CO LTD

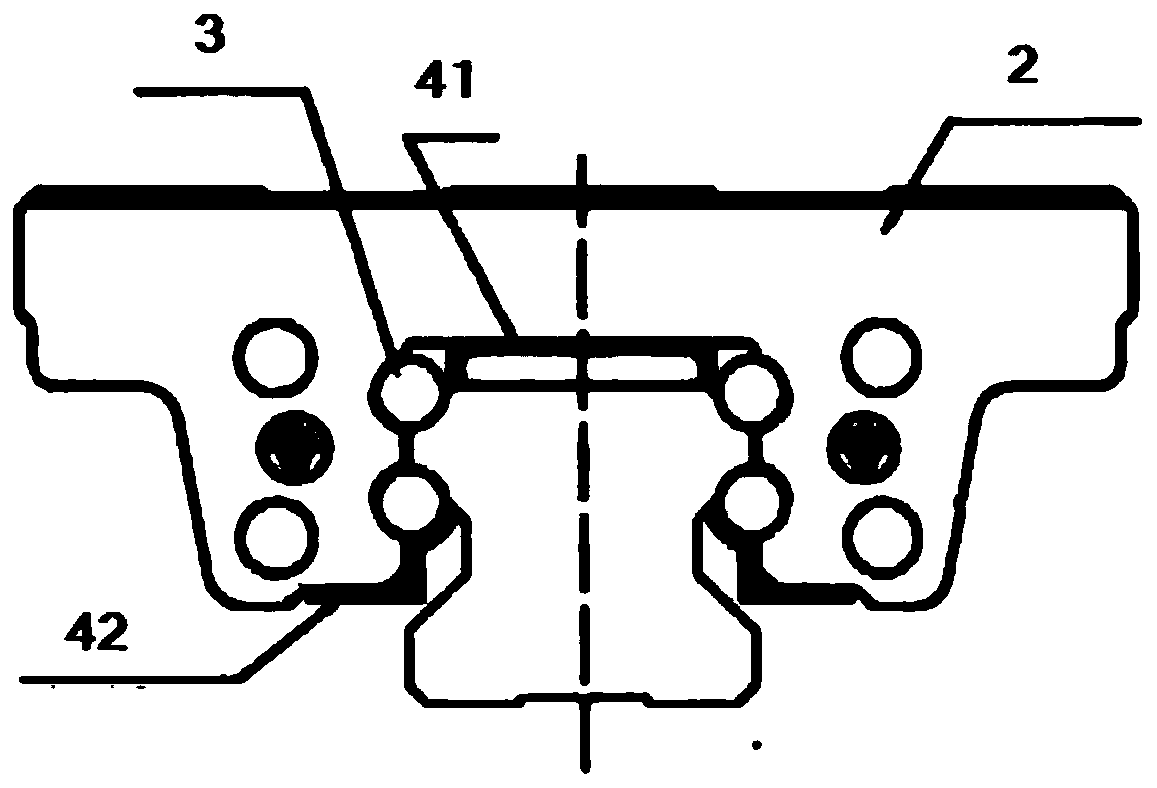

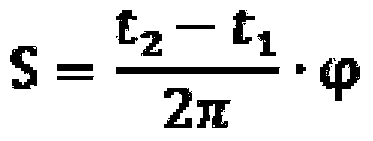

Method for automatically eliminating limited angle gear backlash

InactiveCN104565333AImprove machining accuracyImprove assembly accuracyGearing detailsGear wheelEngineering

The invention discloses a method for automatically eliminating limited angle gear backlash, and aims to provide a compact limited angle gear backlash eliminating mechanism which is simple and compact in structure and capable of realizing gear transmission without backlash, improving gear transmission precision, reducing cost and improving assembling capacity. The technical scheme for implementing the method includes that one of a driving gear and a driven gear which are engaged with each other is divided into a main sector gear and an auxiliary sector gear, a fixed main gear working portion and the loaded auxiliary gear are sectored, a bottom arc of a small end sector of the loaded auxiliary gear fits with a cylindrical surface of a gear rotating shaft cylinder, inclined hole grooves (7) are formed in sectors of the fixed main gear and the loaded auxiliary gear, and gear tension springs (4) keeping a tension state are mounted in the inclined hole grooves, the fixed main gear and the loaded auxiliary gear are connected together by loading the sector of the auxiliary gear through the gear tension springs, and the fixed main gear and the loaded auxiliary gear are mutually staggered to form a certain circumference angle and engaged with the driven gear in opposite directions.

Owner:SOUTH WEST INST OF TECHN PHYSICS

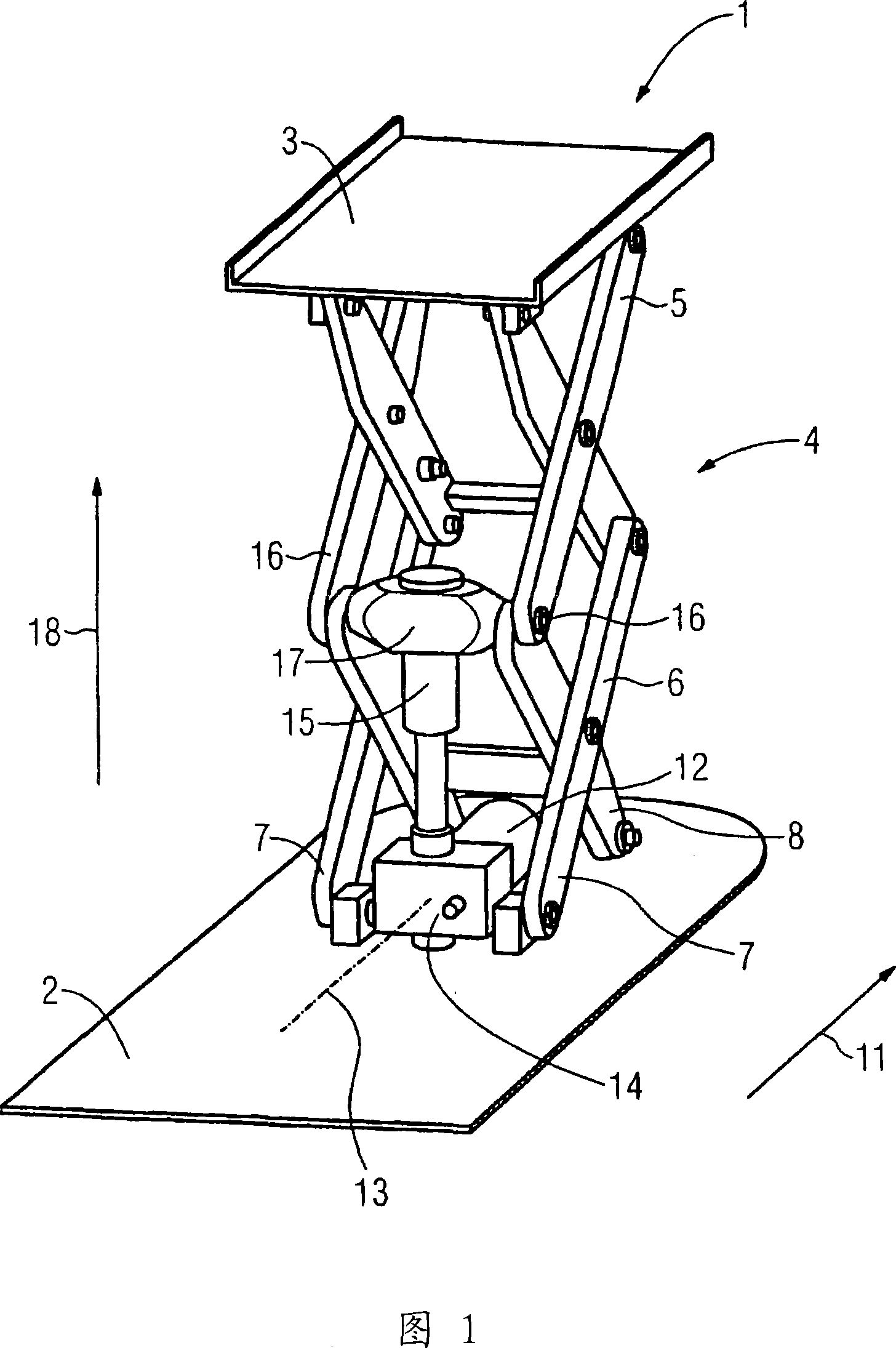

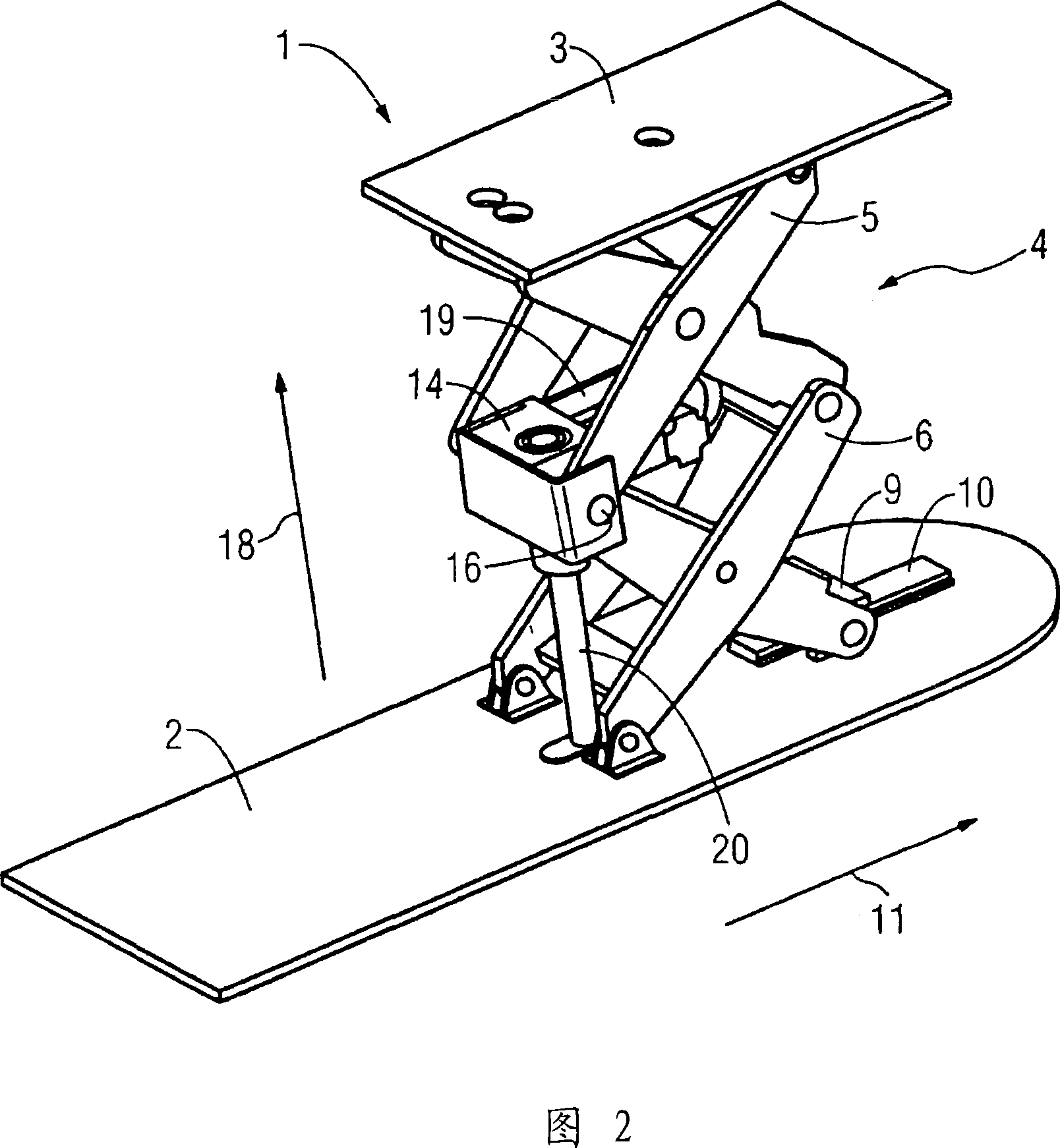

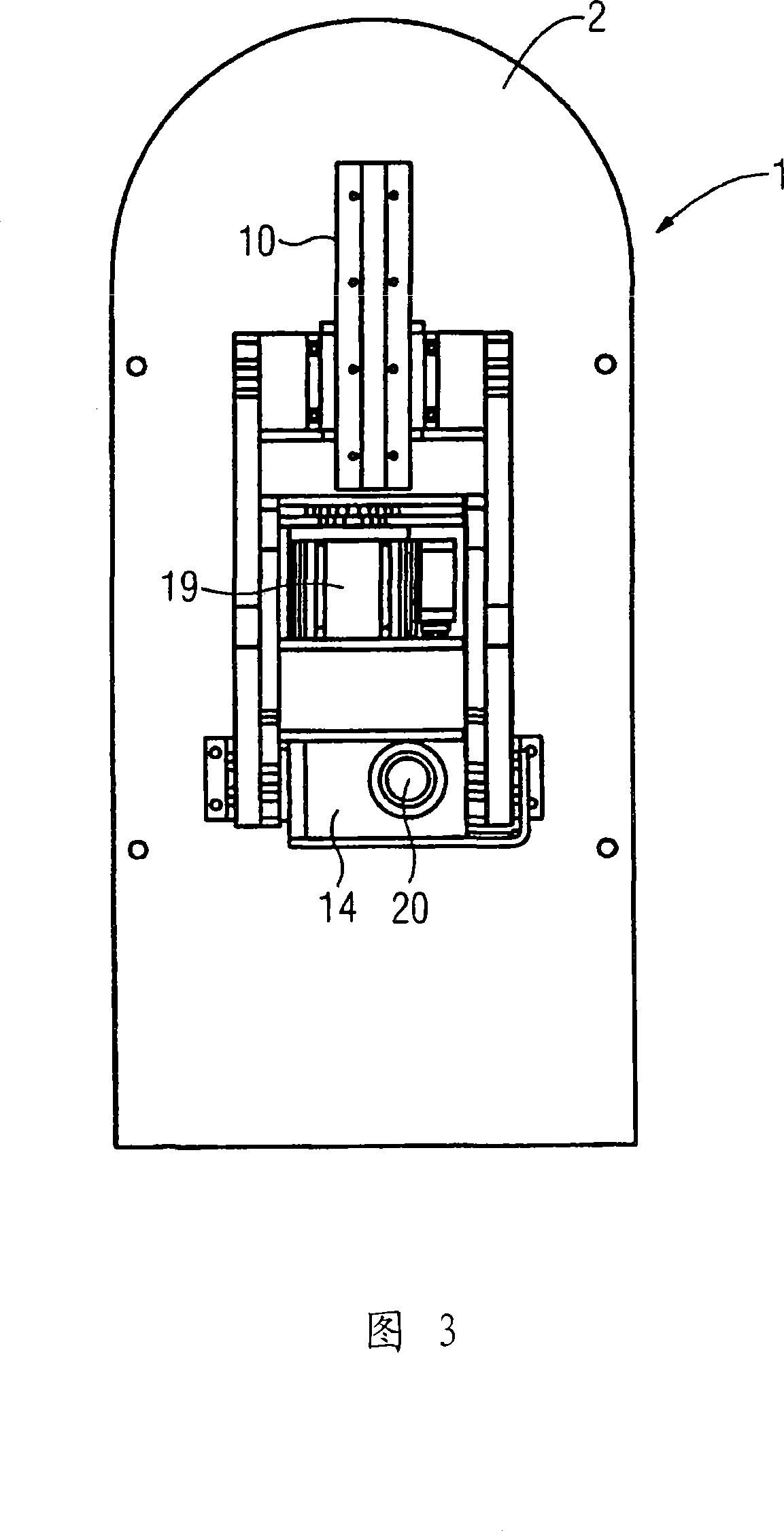

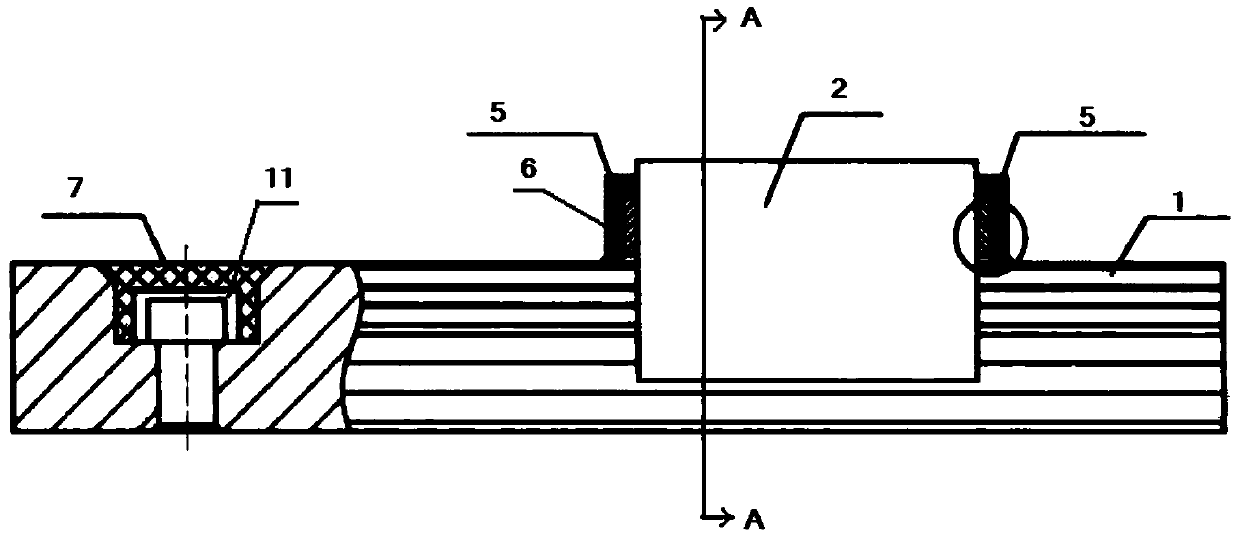

Lifting device

The invention relates to a lifting device (1) comprising a top part (3), a bottom part (2), a lifting rod assembly (4) that connects the top part (3) to the bottom part (2) and is provided with at least two partial rod assemblies (5, 6) which are interconnected via a central joint (16), and a drive unit (12, 14, 15, 19) for adjusting the height of the top part (3). In order to create a particularly simple lifting device, the drive unit (12, 14, 15, 19) grips the central joint (16).

Owner:SIEMENS HEALTHCARE GMBH

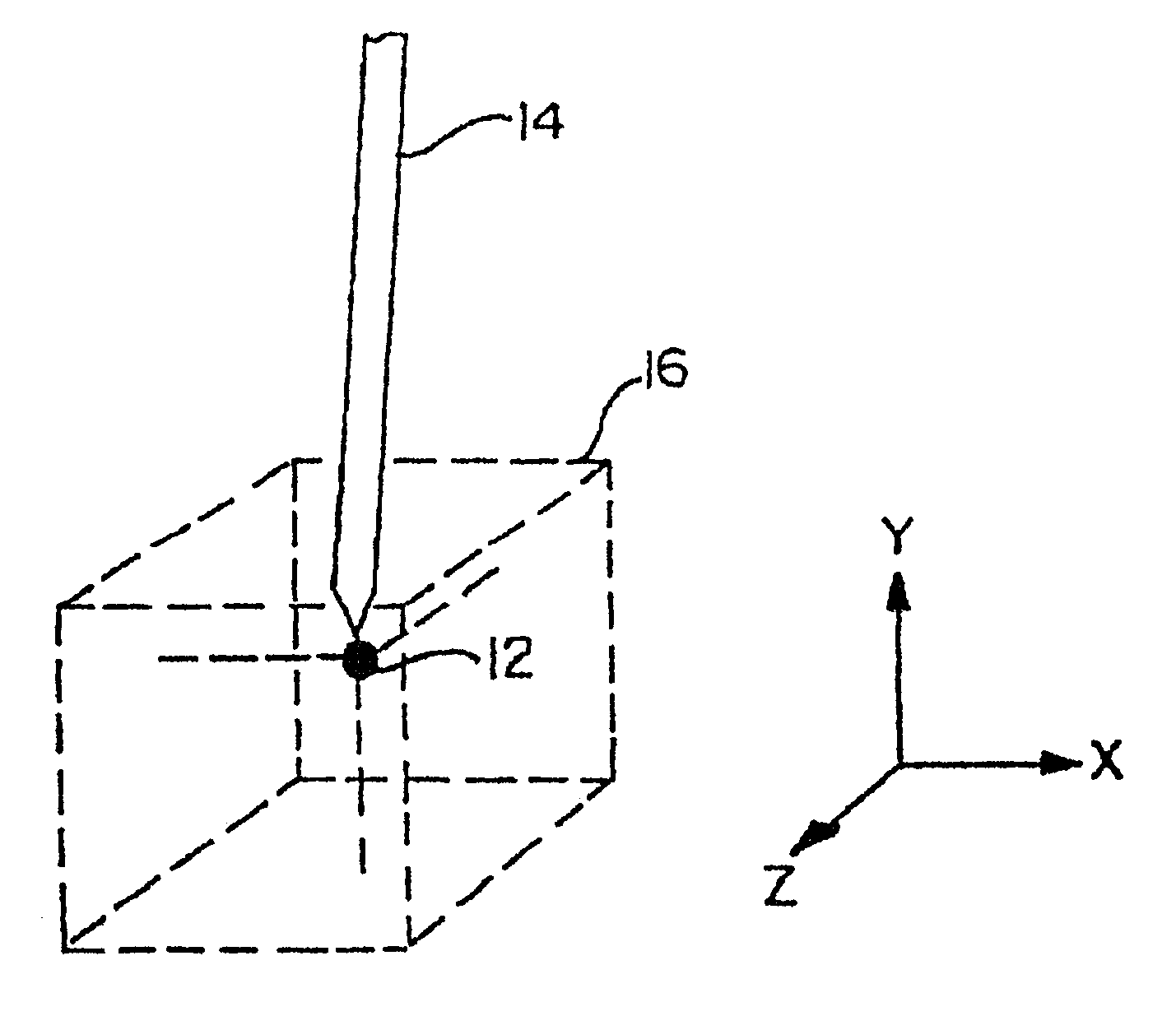

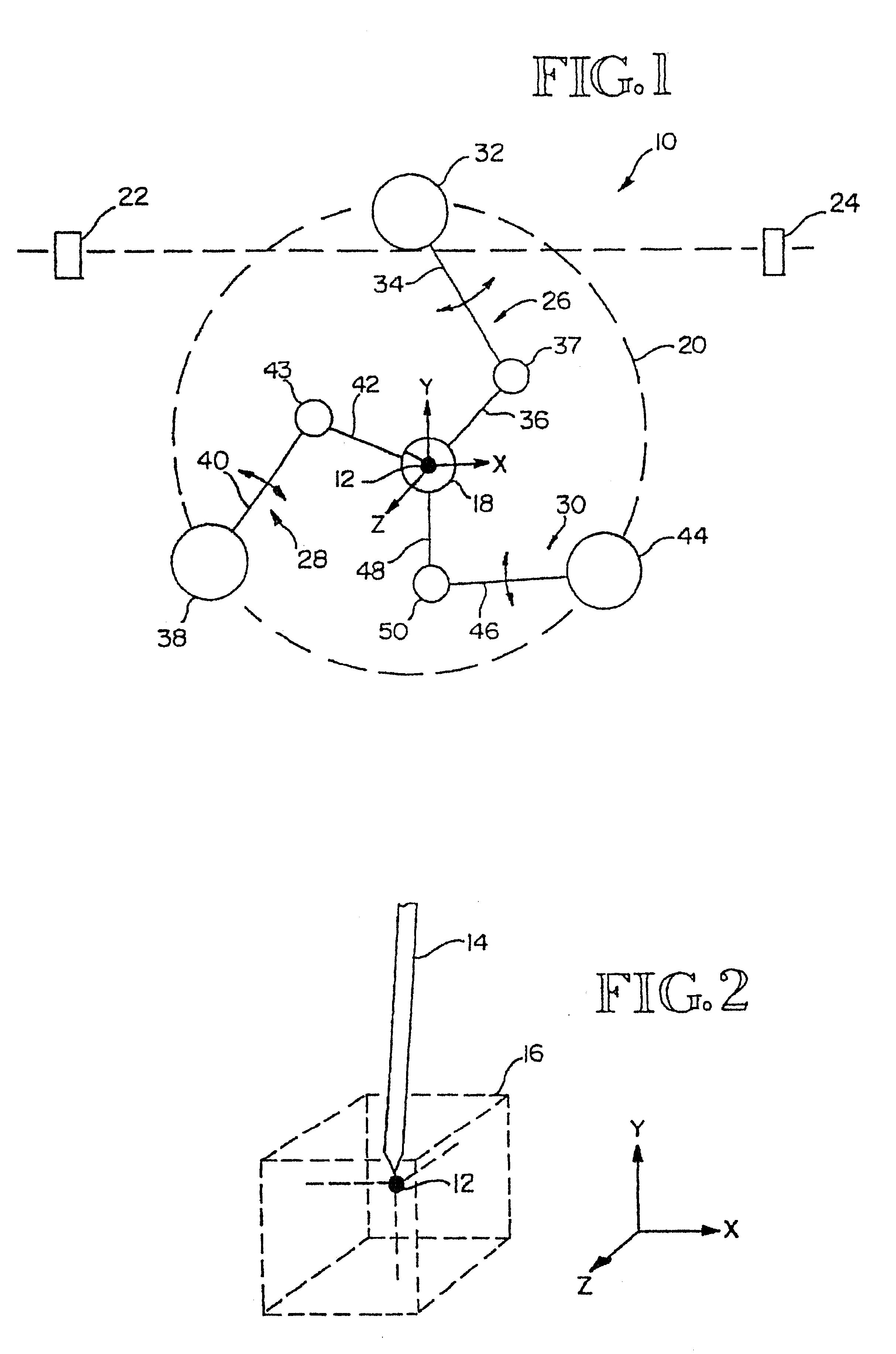

Direct-drive manipulator for pen-based force display

InactiveUSRE37528E1Lower capability requirementsUnacceptable characteristicInput/output for user-computer interactionProgramme-controlled manipulatorEngineeringRotary actuator

A pen-based direct-drive manipulator enables precision manipulation and force display of a control point within three degrees of freedom. The control point exhibits substantially no backlash, very low friction and very low inertia making it useful as a force display. The manipulator also has a very high force generation bandwidth allowing high frequency force components to be displayed. A parallel actuator structure controls motion over two degrees of freedom in a horizontal plane. The parallel structure is a redundant structure including three chains in parallel coupled at the control point. The redundant structure provides a uniform force capability throughout the manipulator workspace. A pair of rotational actuators rotate the parallel structure about an axis to approximate a linear motion along a third axis. The rotational actuators provide a third degree of freedom for the control point. Motion about the third axis is substantially decouple from motion about the horizontal plane.

Owner:IMMERSION CORPORATION

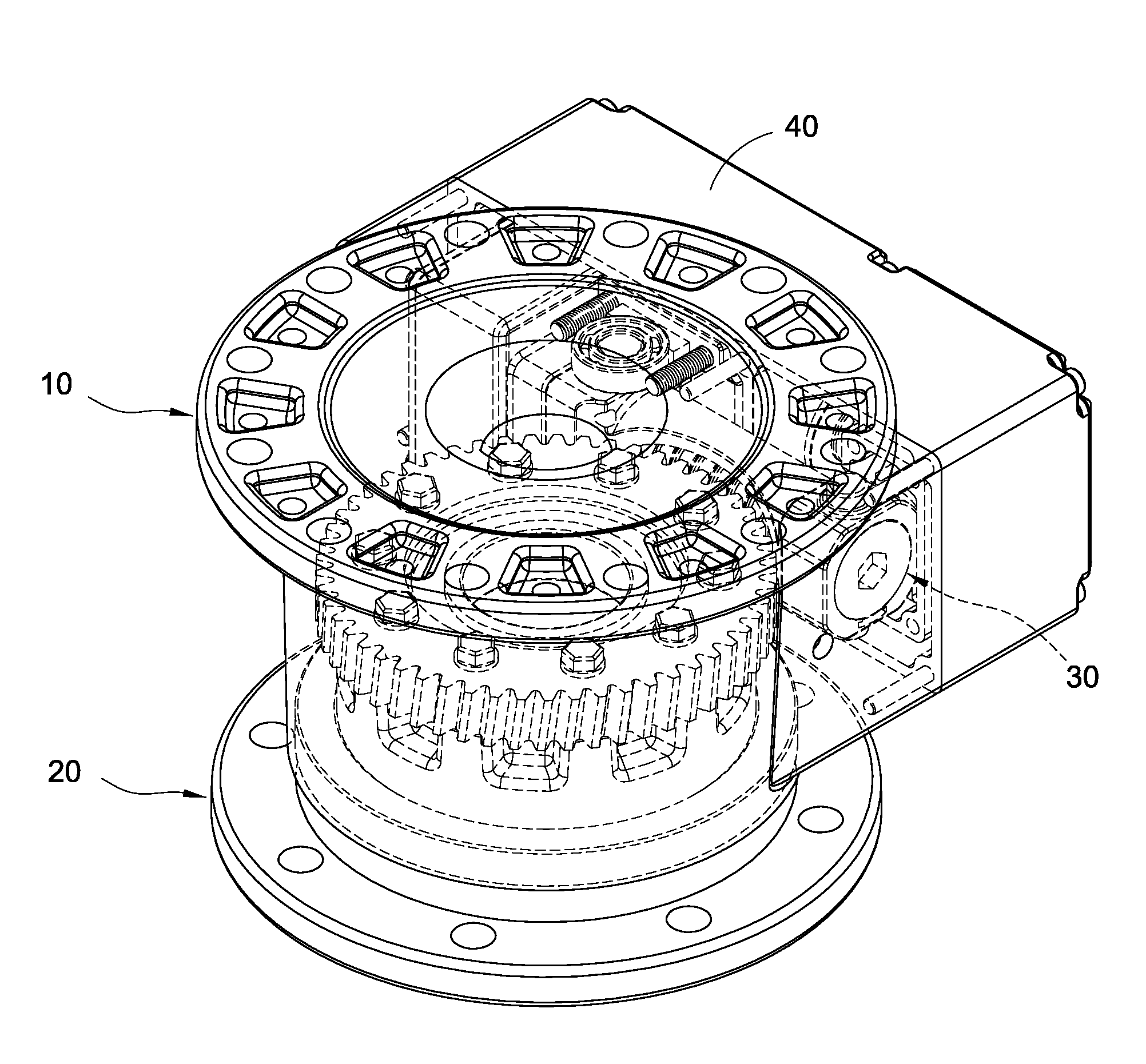

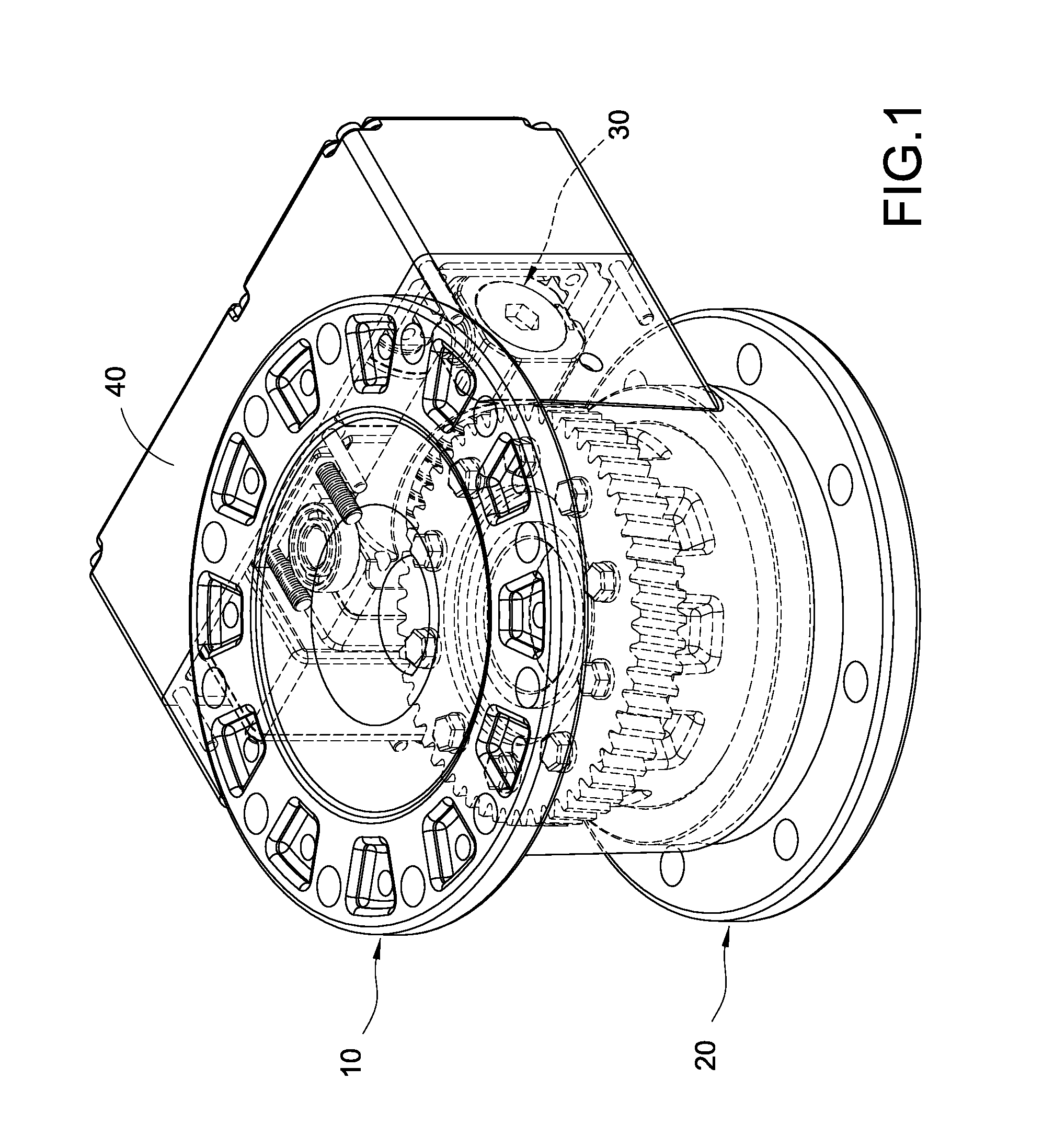

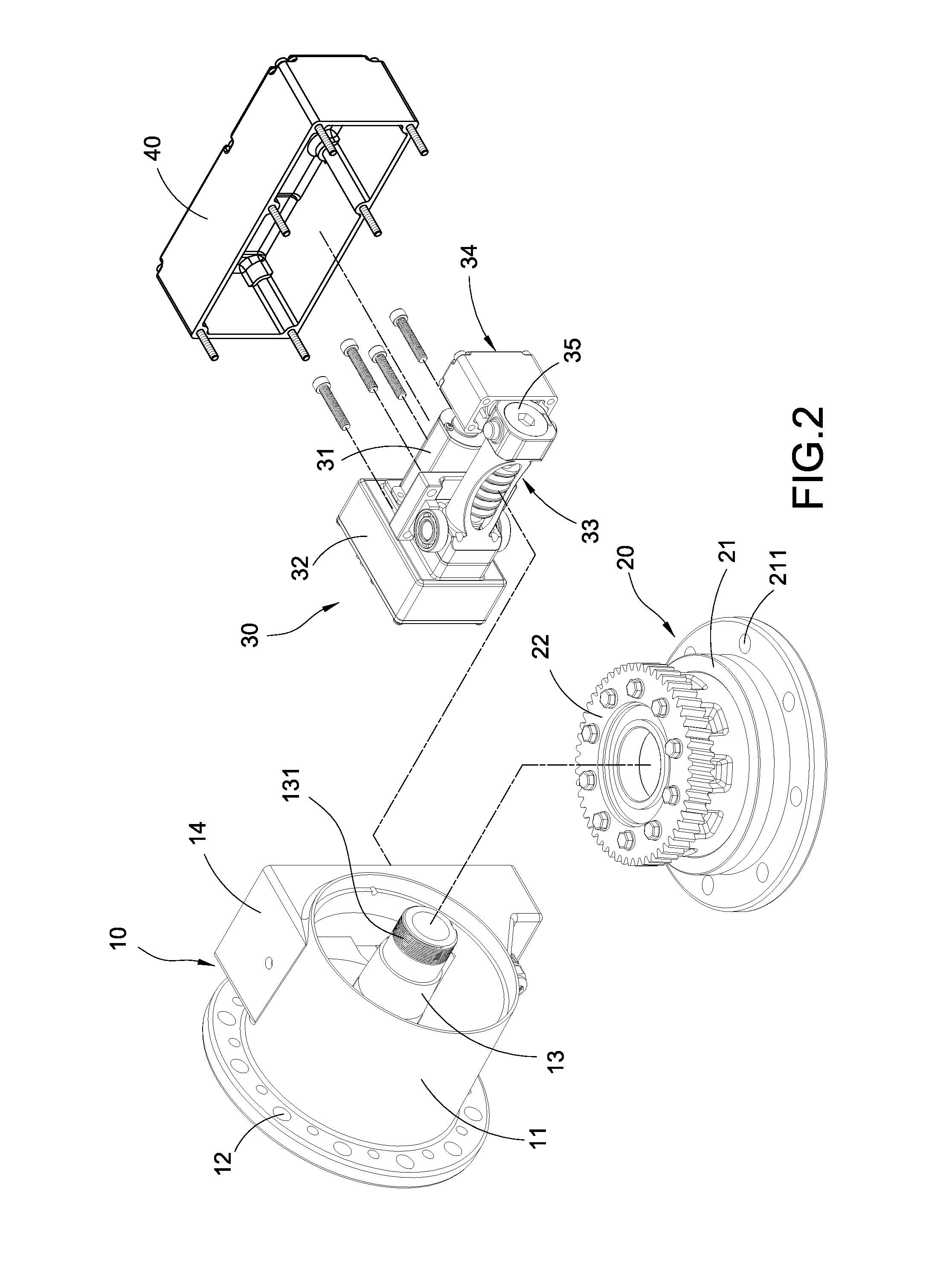

Steering device for use in solar tracking equipment

ActiveUS20160072427A1High rotation accuracyLow costPhotovoltaic supportsSolar heating energyEngineeringSolar energy

Owner:TIMOTION TECH CO LTD

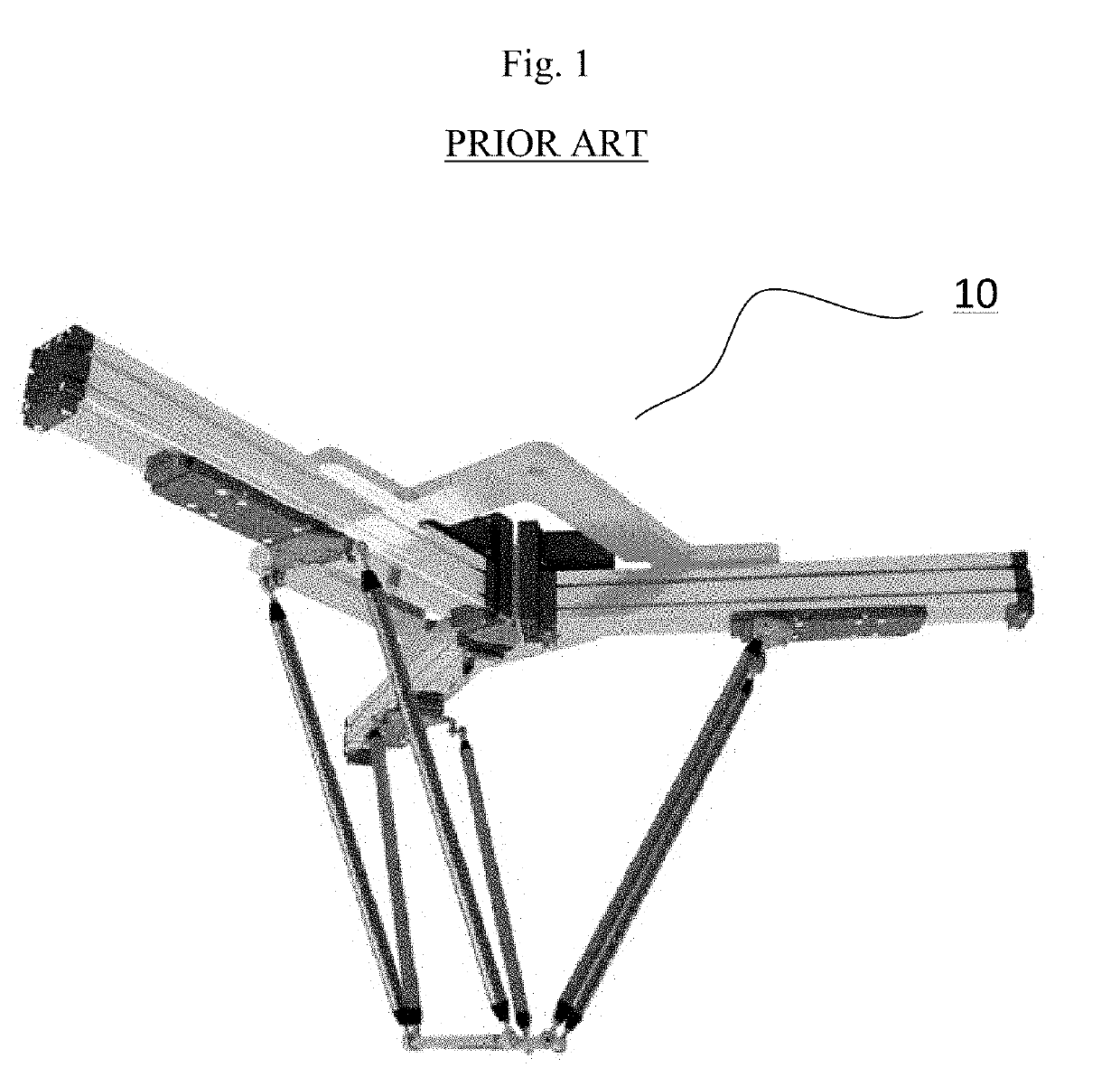

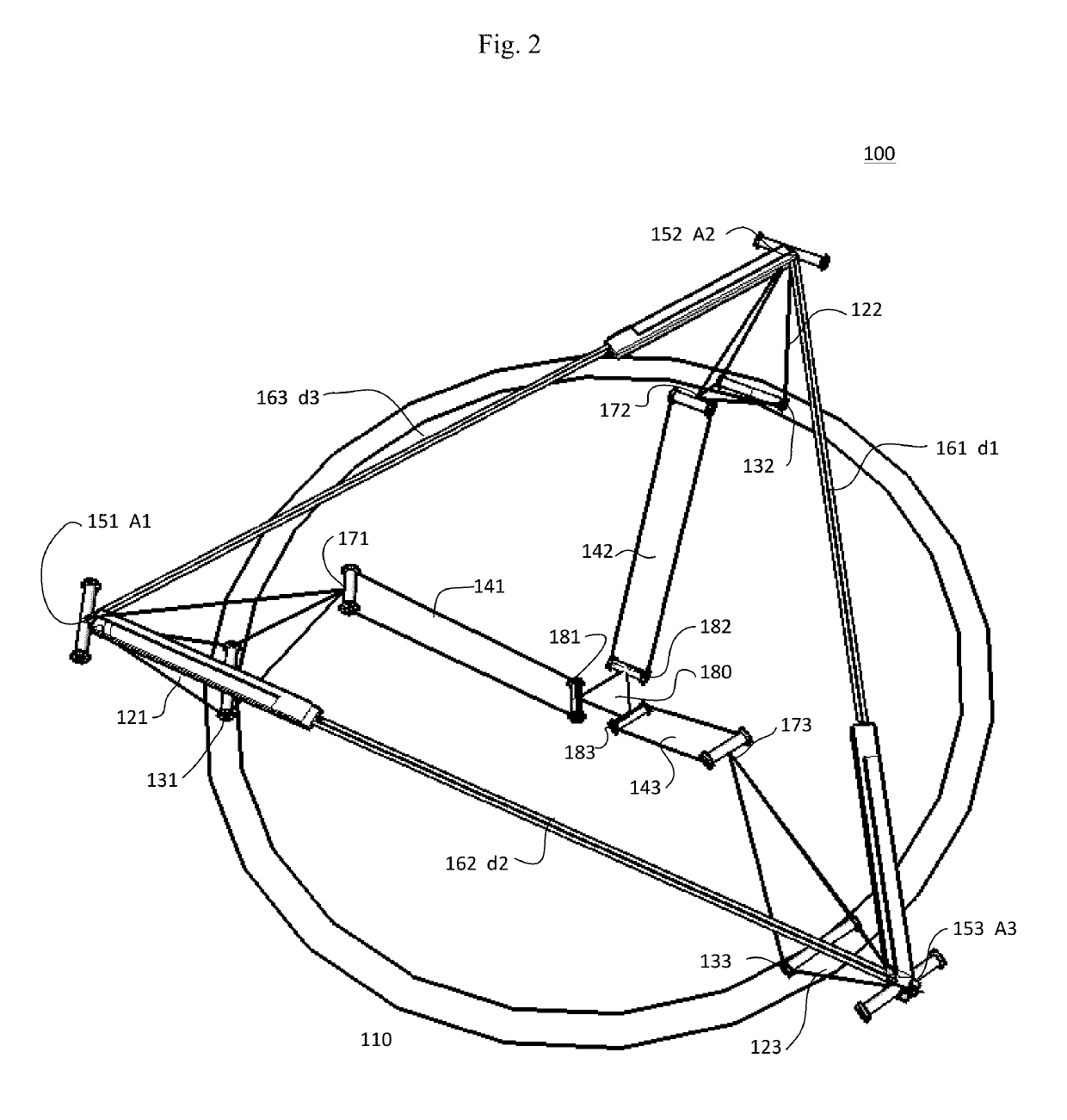

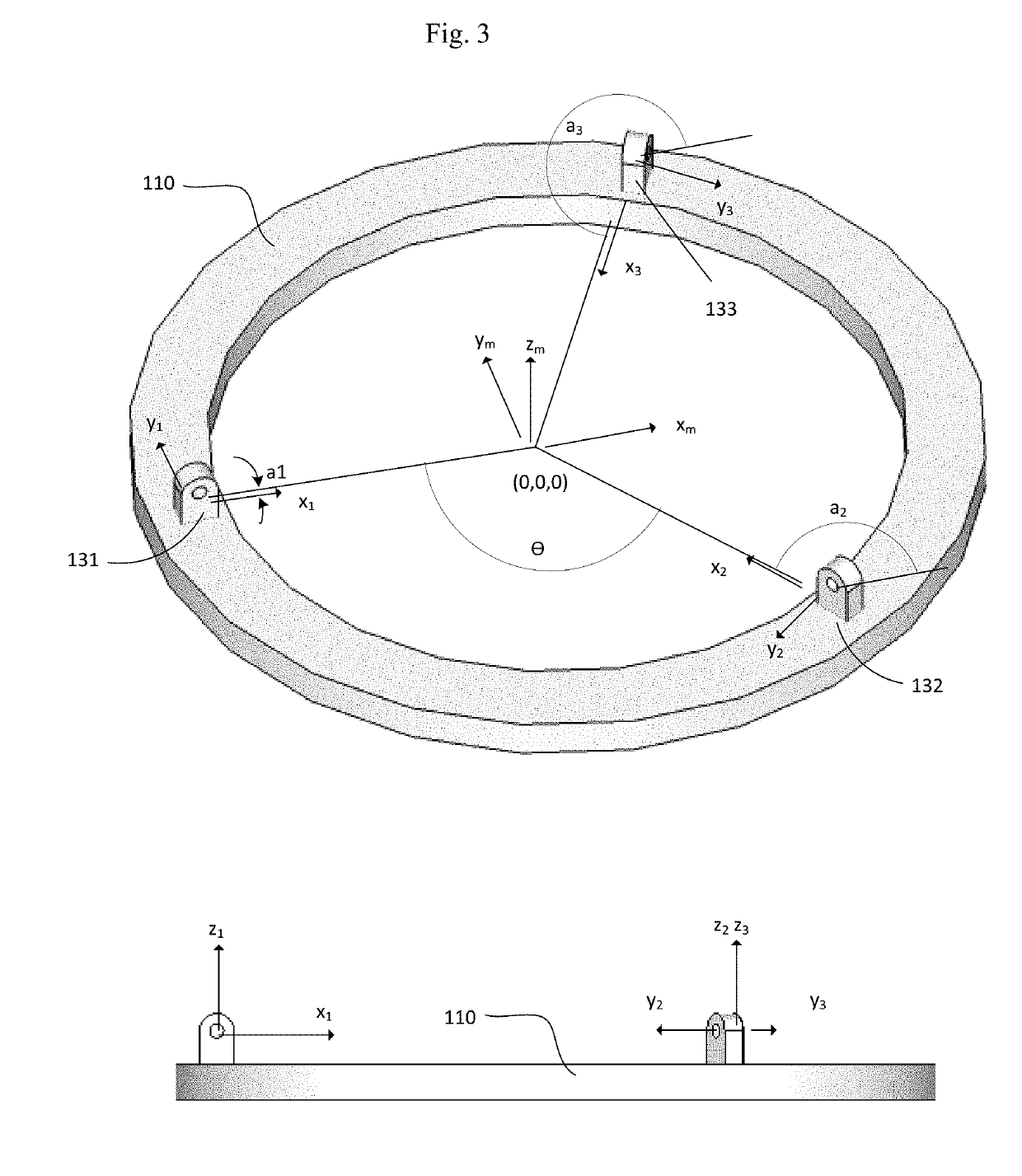

Hybrid delta robot

ActiveUS20190118378A1Inventive design is simpleEasy CalibrationProgramme-controlled manipulatorJointsRobotic armDegrees of freedom

The invention relates to an improved robotic arm apparatus and associated method which improves a robot configured in a “delta” arrangement. The robotic arm apparatus is arranged with three substantially identical movable arm assemblies connected together with three linear actuators in a triangular configuration such that each end of each linear actuator has at least one translational degree of freedom.

Owner:LUDBAN NEIL

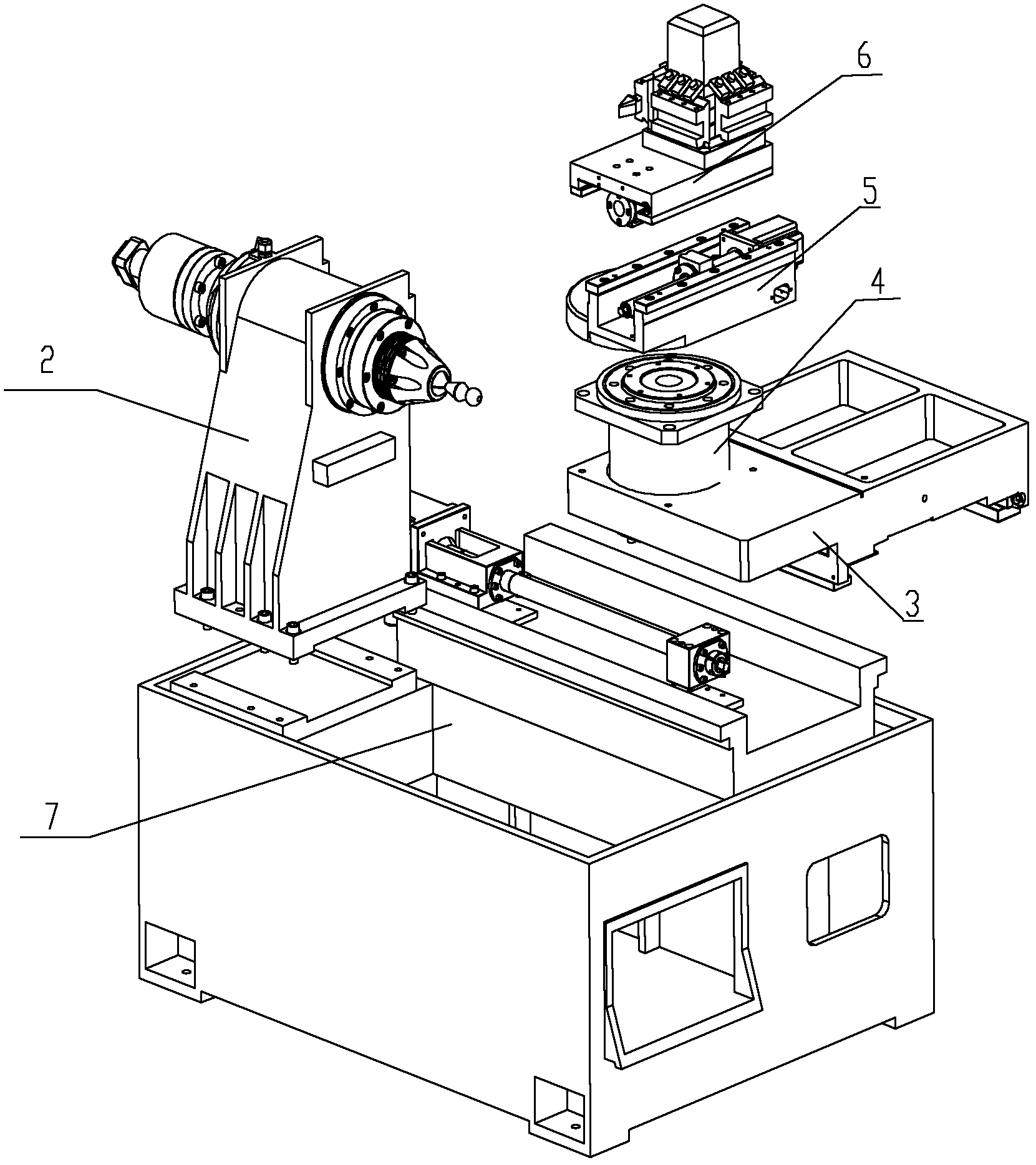

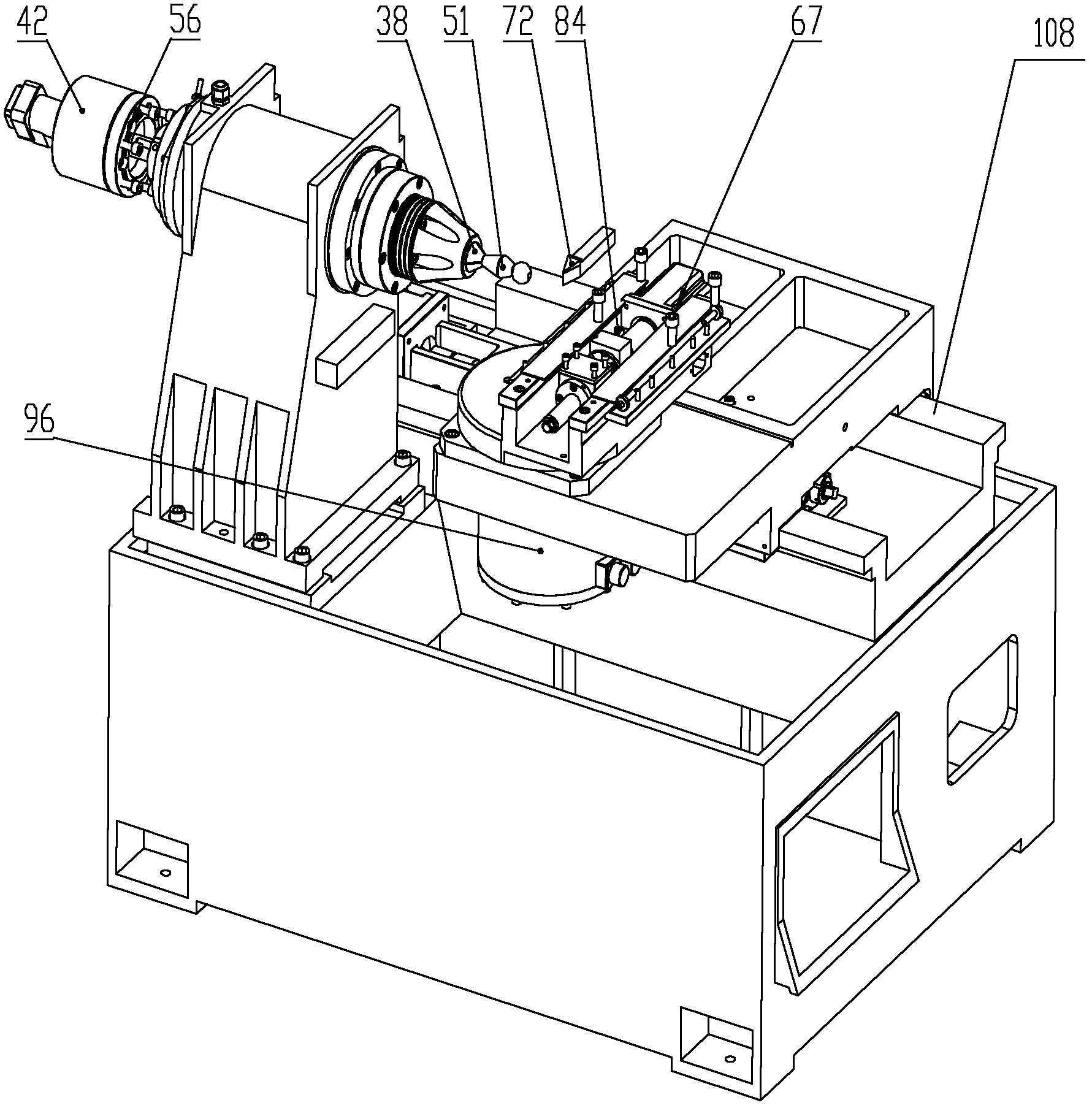

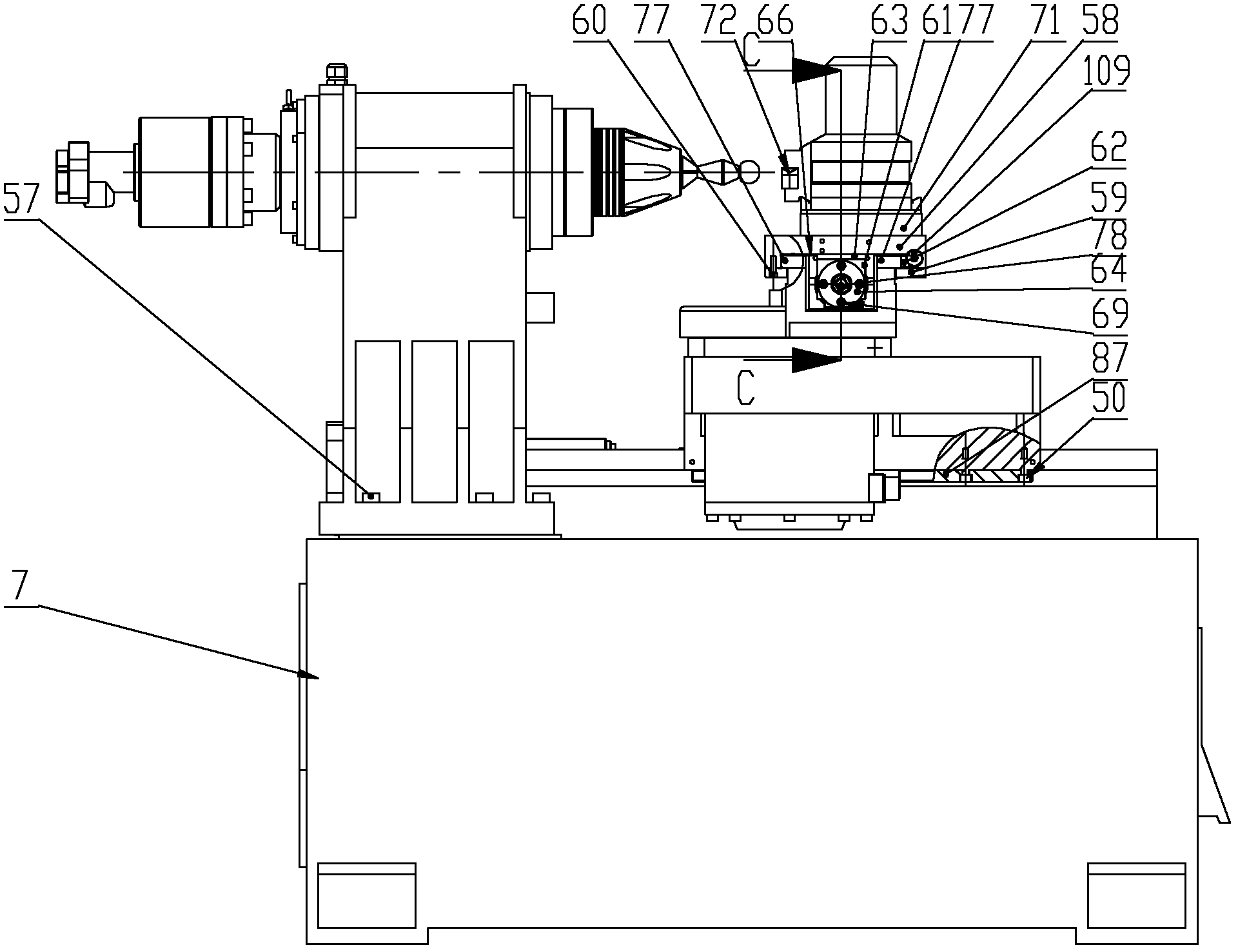

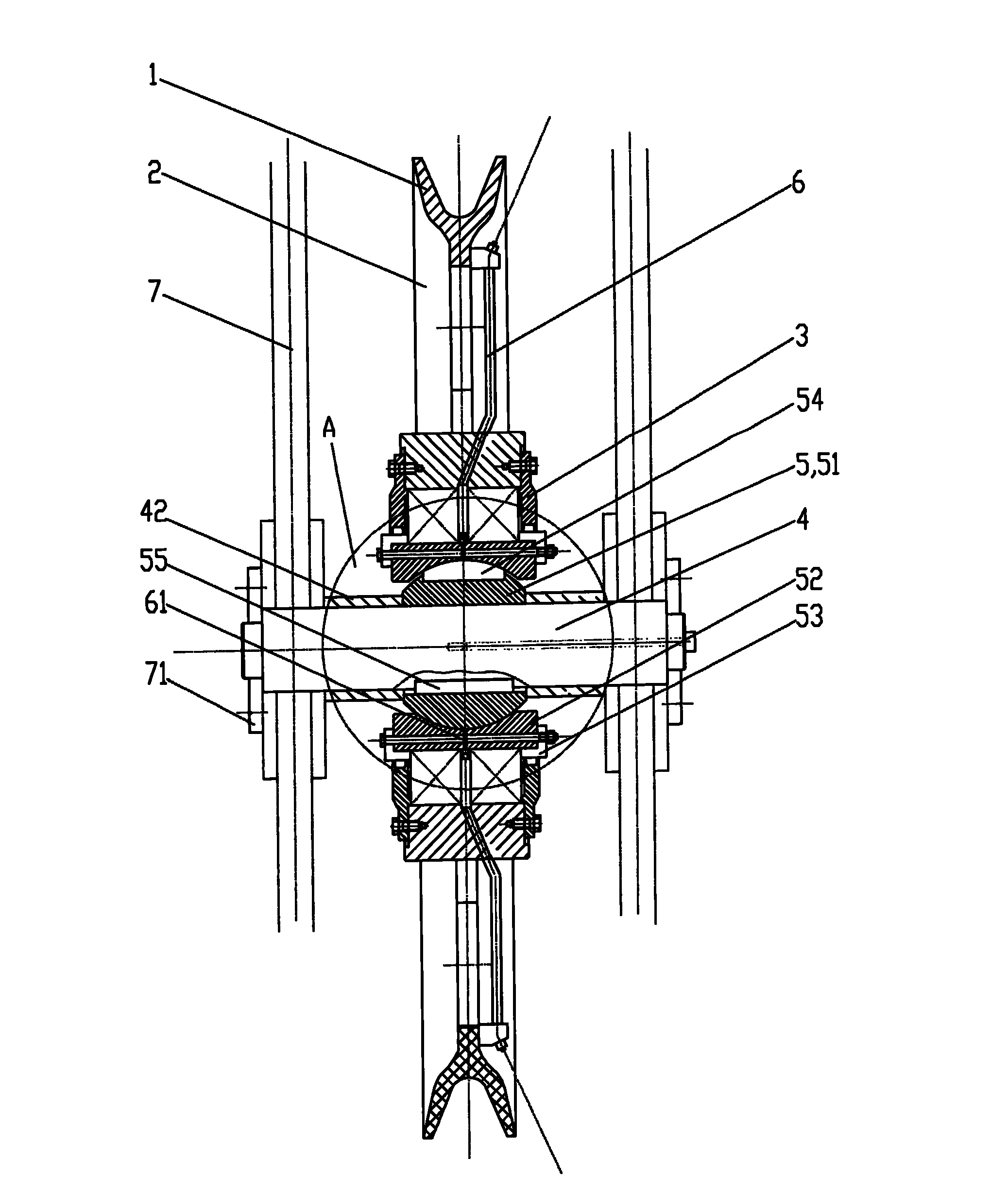

Automatic high-speed precision numerical control machine tool for cutting spherical surface

ActiveCN102366889AImprove machining accuracyReduce processOther manufacturing equipments/toolsLarge fixed membersLinear motionNumerical control

The invention provides an automatic high-speed precision numerical control machine tool for cutting a spherical surface, which is provided with a base, wherein a main shaft device is arranged on one side at the upper part of the base; a saddle dragging plate which does linear reciprocating motion along the axis of the main shaft of the main shaft device is arranged at the upper part of the base, which is positioned at the same side of the main shaft device; a direct-driving type torque motor rotary table device is arranged on the saddle dragging plate; a rotary axis of the direct-driving typetorque motor rotary table device is absolutely intersected with the rotary axis of the main shaft device; the upper end of the direct-driving type torque motor rotary table device is connected with arotary saddle device and drives the rotary saddle device to do rotary reciprocating motion around the axis of the direct-driving type torque motor rotary table device; a tool rest dragging plate device which does linear reciprocating motion along the direction perpendicular to the axis of the main shaft of the main shaft device is arranged at the upper end of the rotary saddle device; and linear motion of the tool rest dragging plate device and rotary motion of the rotary saddle device form cutting motion for workpieces, so that the workpieces clamped at the front end of the main shaft deviceis cut to form a regular spherical shape.

Owner:SHAANXI HALET PRECISION MACHINERY

Linear guide rail pair structure with high dust prevention performance

ActiveCN104006081AHigh movement precisionImprove exercise efficiencyLinear bearingsNutsTongue structureScrap

Owner:上海雄联精密机械配件有限公司

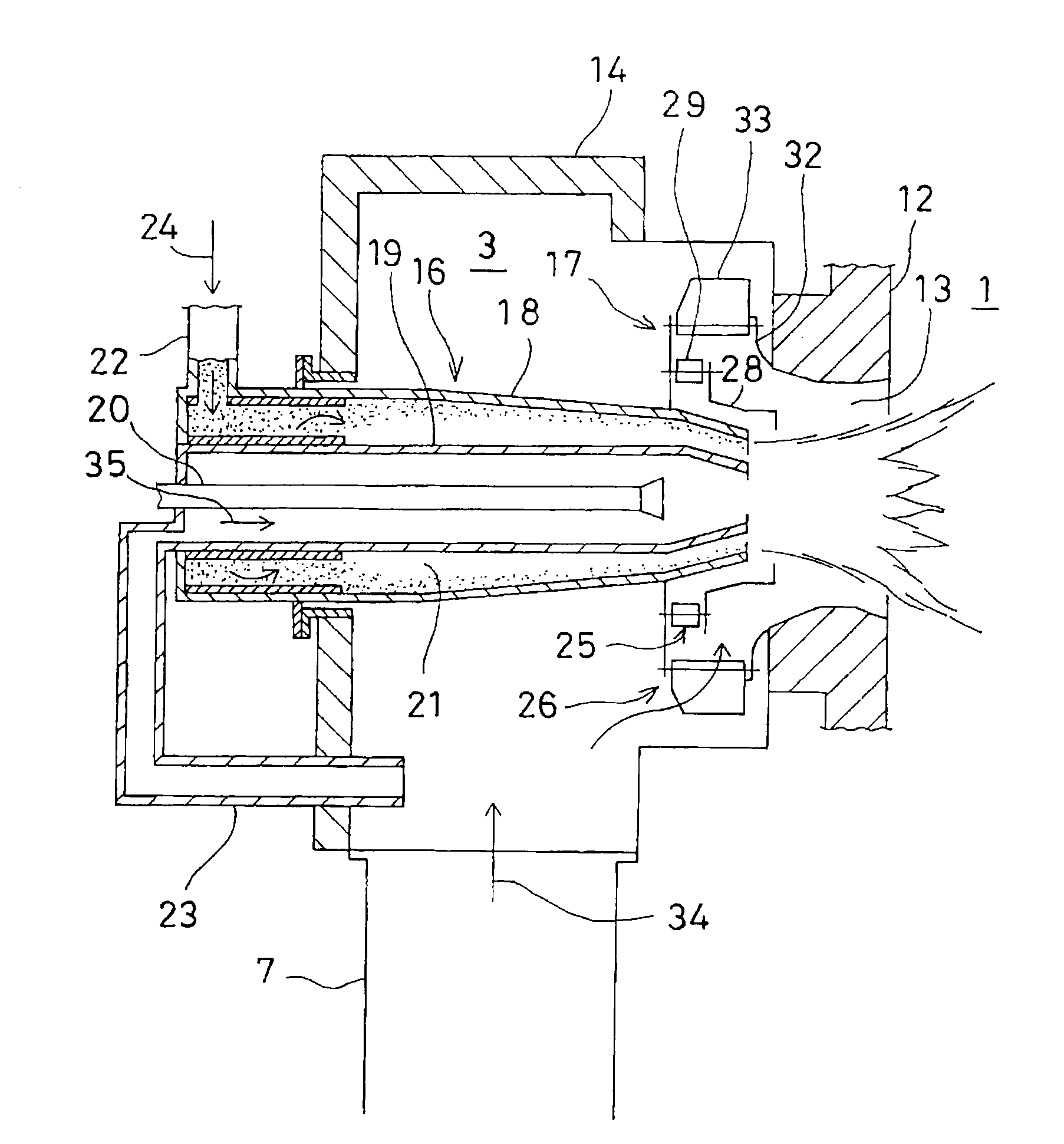

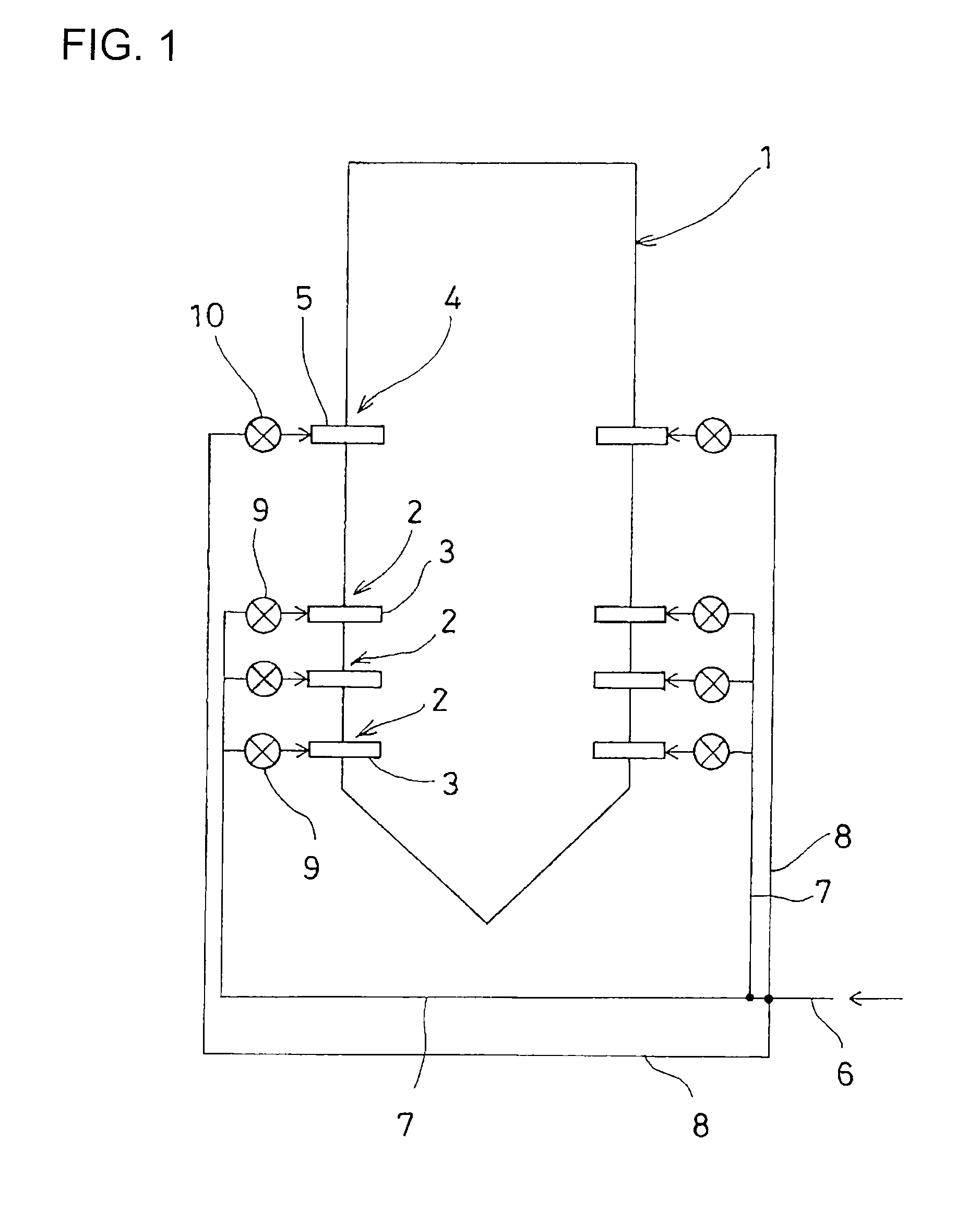

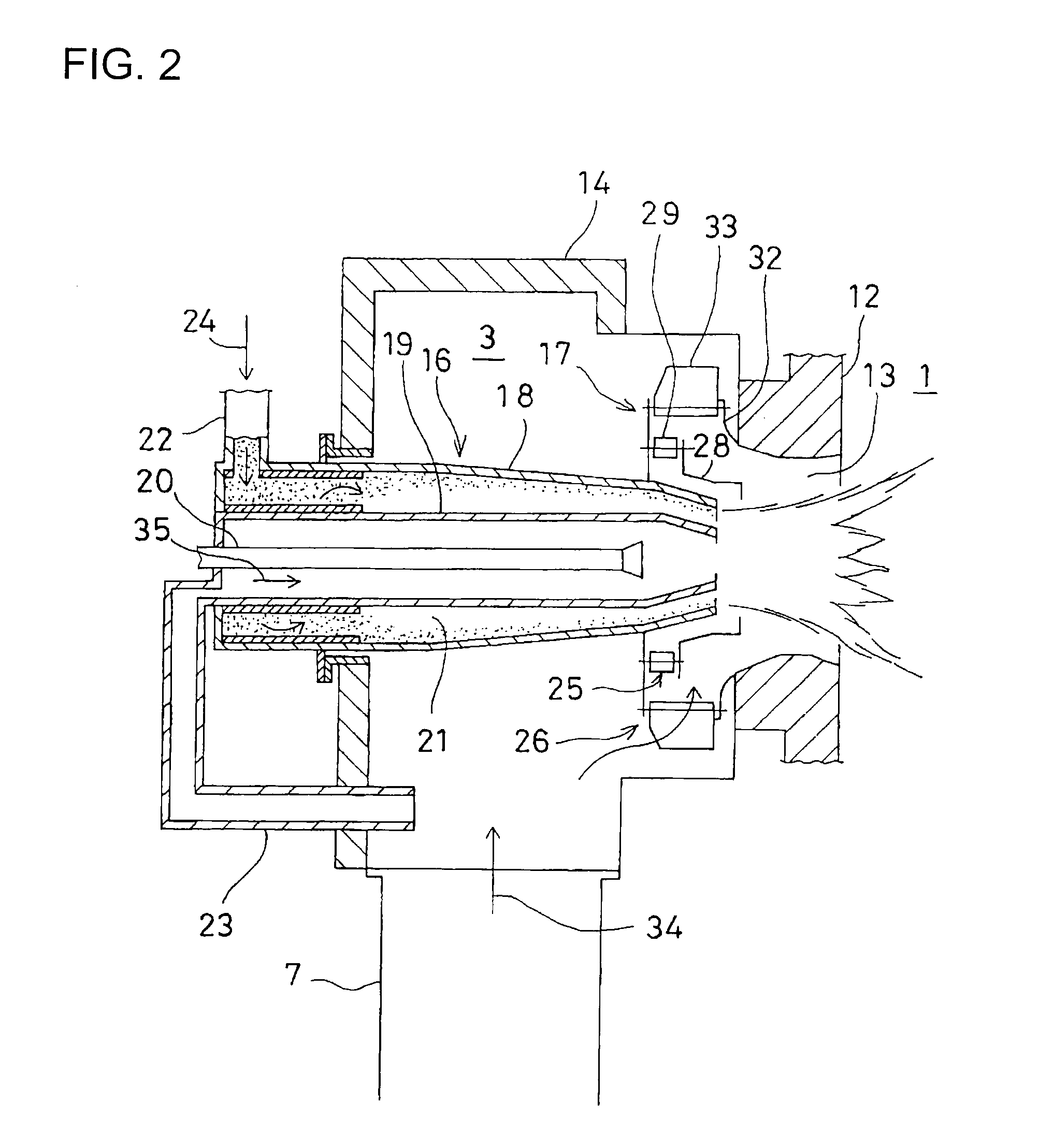

burner

ActiveUS20110139048A1Good benefitReduce manufacturing costCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

A burner is arranged axially of a burner throat on a furnace wall and includes a nozzle body housed in a wind box and with a secondary air adjuster on a leading end of the nozzle body. The adjuster includes an end plate for defining together with a near-furnace side surface of the wind box a cylindrical space opened in an outer circumference thereof, a slide damper axially slidable for surrounding the cylindrical space, air vanes arranged at predetermined intervals and circumferentially of the cylindrical space for swirling a secondary air and drive means and for slide movement of the slide damper.

Owner:IHI CORP

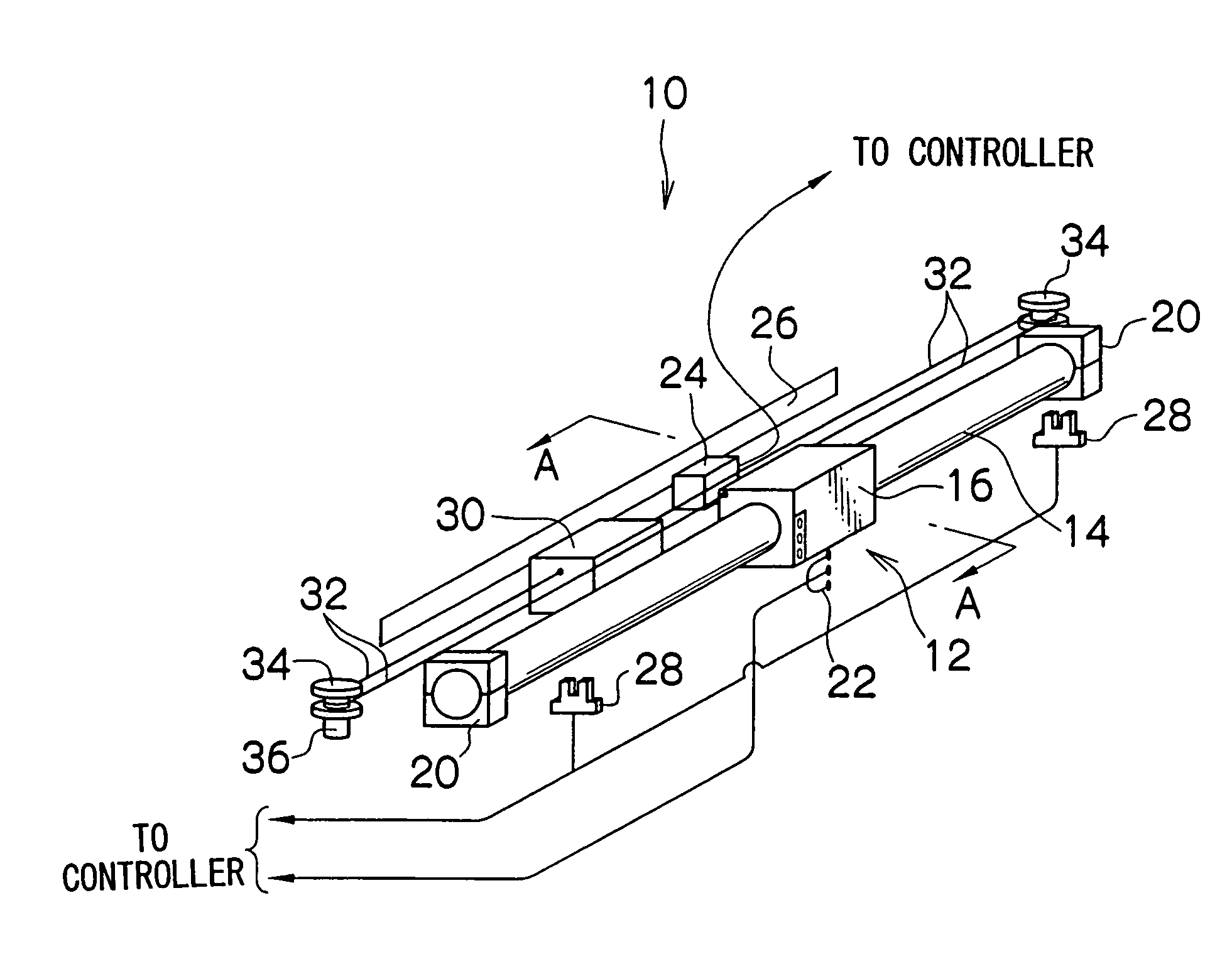

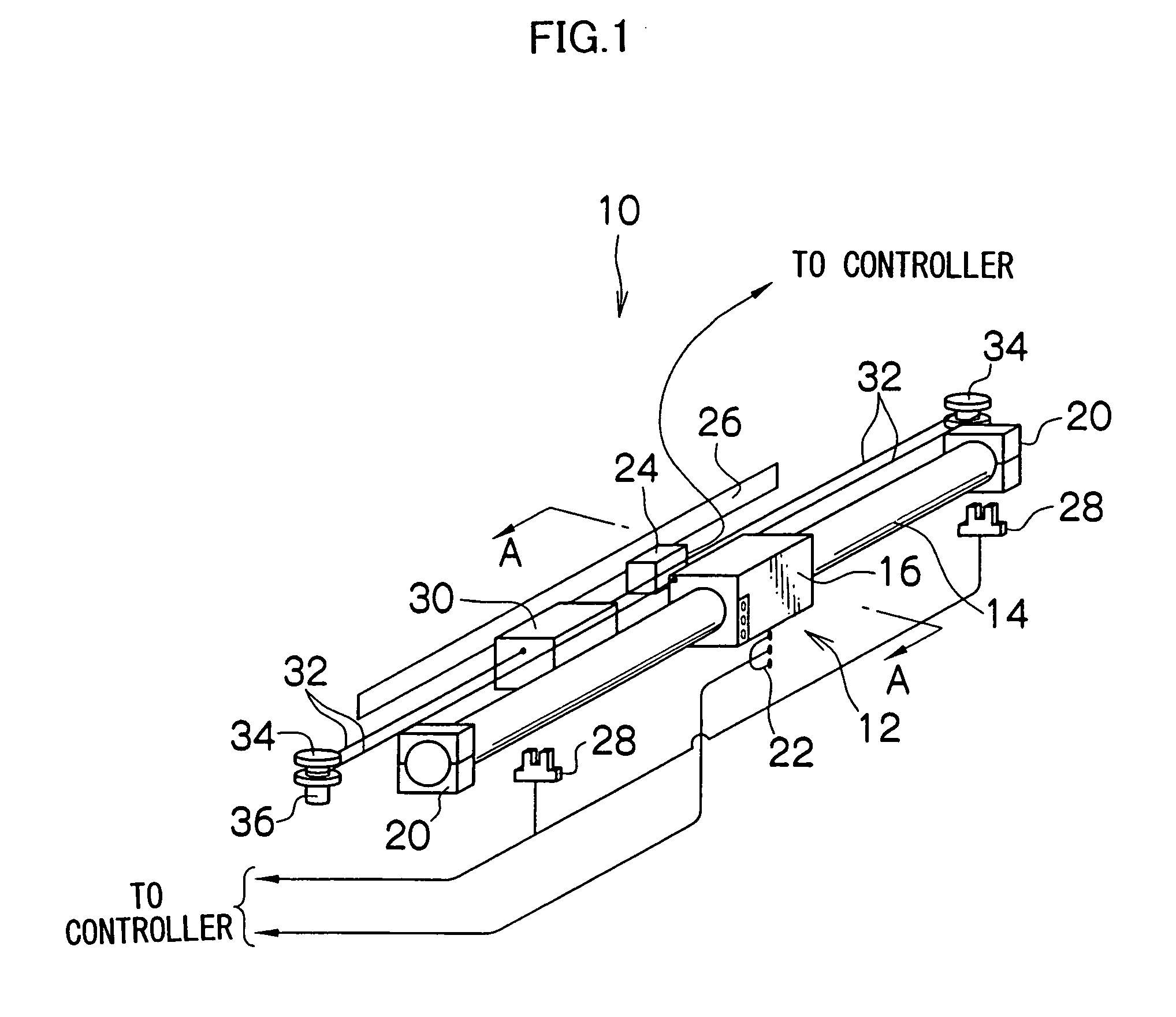

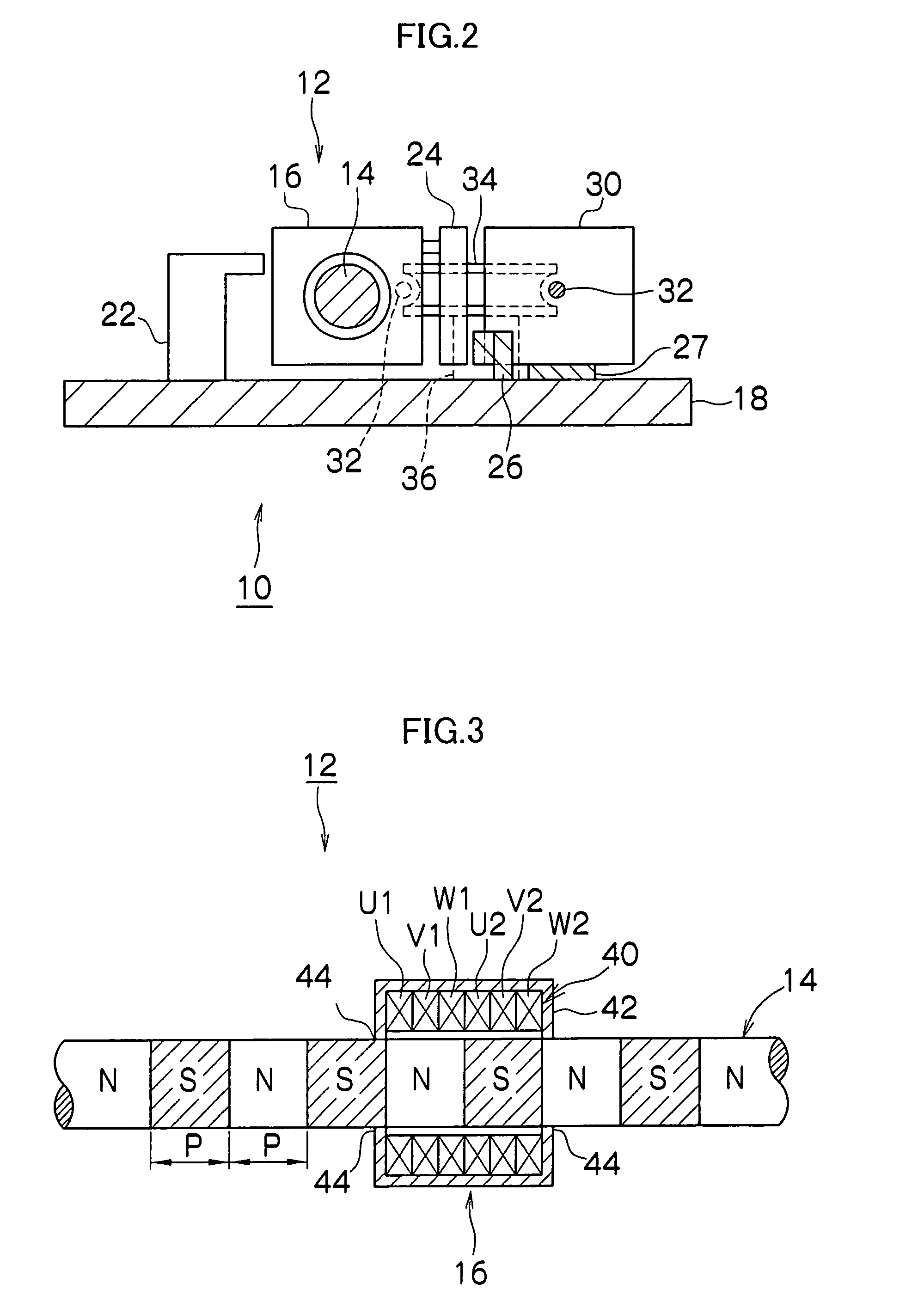

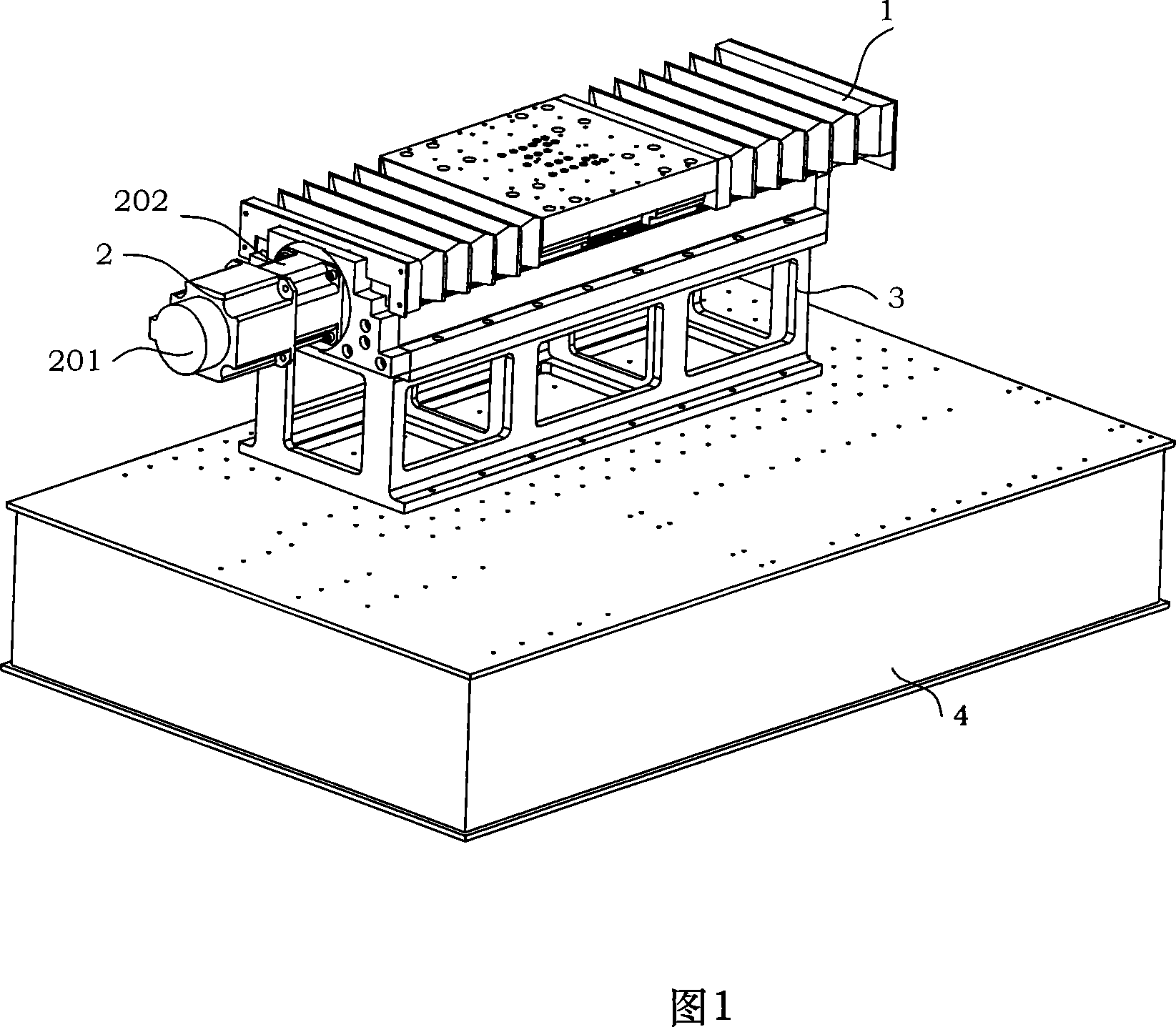

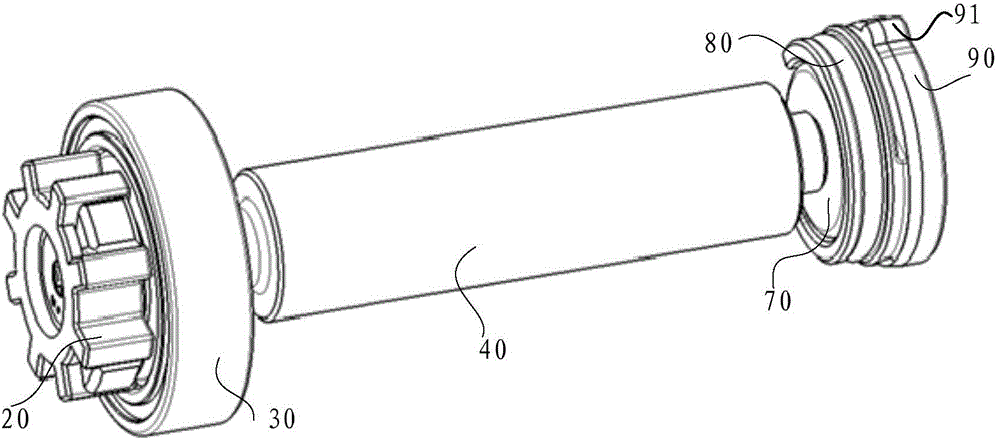

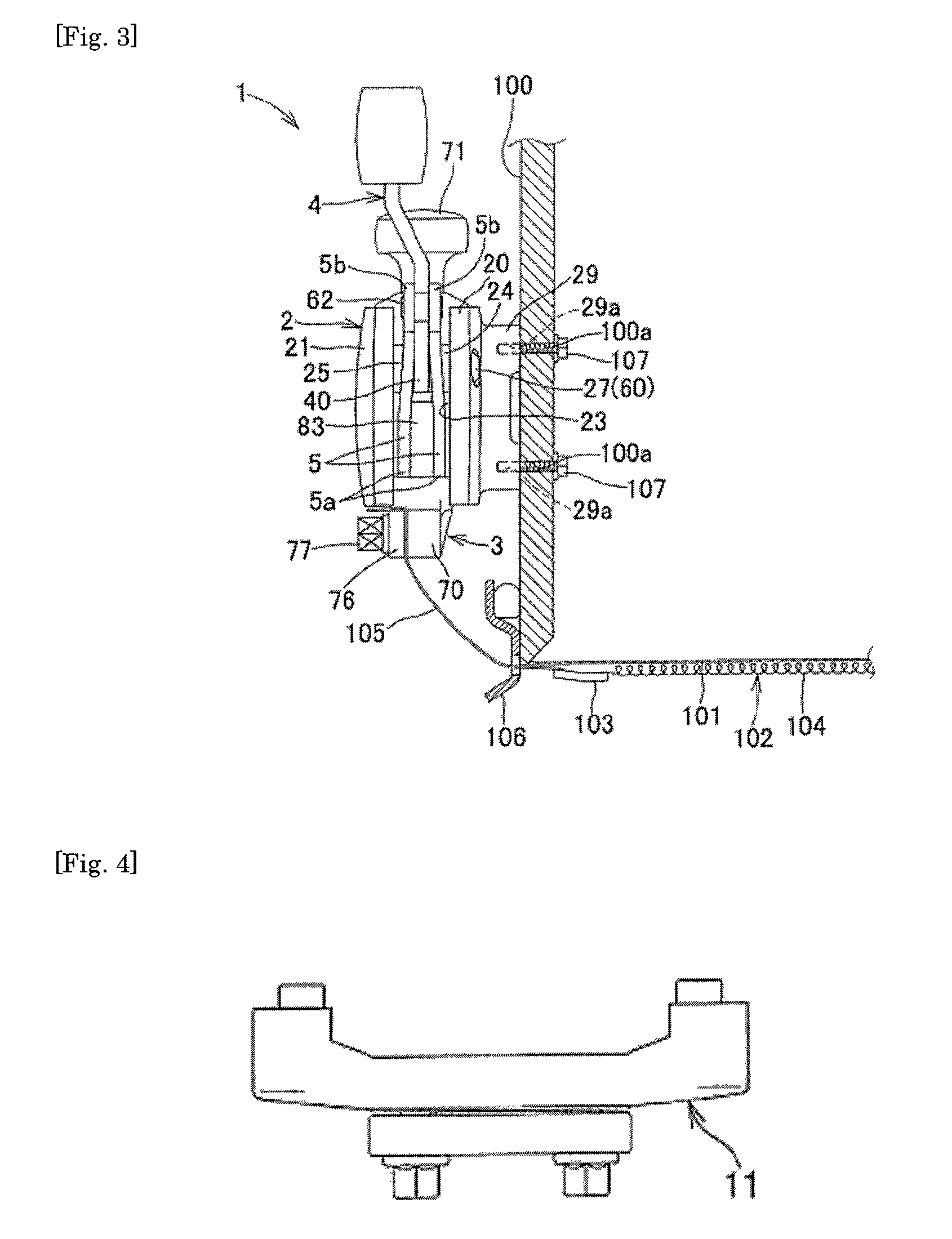

Uniaxial drive unit and surface shape measuring apparatus using the same

InactiveUS7239050B2No worn partsCapabilityMechanical counters/curvatures measurementsMechanical energy handlingEngineeringLinear motor

There is provided a uniaxial drive unit using a linear motor having a fixed part which is a rod-shaped magnet fixed to a unit body and formed so that the N poles and the S poles are arranged alternately; and a moving part which is a ring-shaped member having a coil member, fitted on the fixed part, and capable of moving along the fixed part. A driving section provided so as to be slidable in the uniaxial direction with respect to the unit body is connected to the moving part or a balance weight fixed to the moving part by a winding motion transmission member via a winding motion transmitting support member provided near one end or both ends of the unit body.

Owner:TOKYO SEIMITSU

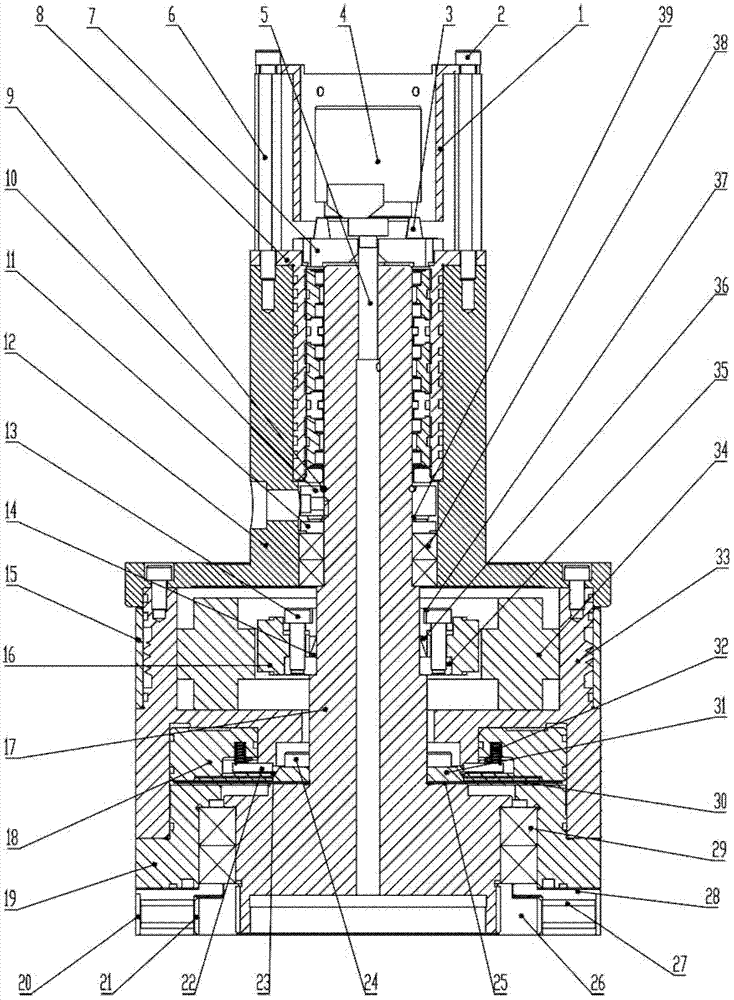

Precise numerical control indexing rotating shaft for electric discharge machining

ActiveCN102773574AHigh precisionHigh servo response performanceElectrical-based auxillary apparatusNumerical controlElectricity

The invention belongs to the field of nontraditional machining, and discloses a precise numerical control indexing rotating shaft for electric discharge machining, which comprises a main shaft body, a permanent magnet alternating current servo torque motor which is connected with the main shaft body, and a grating encoder which is arranged at the upper end of the main shaft body; a brake apparatus is arranged on the main shaft body for controlling the main shaft body to stop rotating; the bottom end of the main shaft body is provided with a power device for supplying power for an electrode which is arranged at the center of the bottom end of the main shaft body; and a main shaft liquid cooing device is arranged on the main shaft body, and the liquid is filled from the outer part of the main shaft body for heat exchanging and flushing of the main shaft body. The precise numerical control indexing rotating shaft and a high-speed rotating shaft are designed into a whole, accessories are not needed to change for the precise indexing machining and the high-speed rotating machining, accordingly, the machining efficiency is improved, and a tool electrode and a workpiece can be automatically changed; and in addition, the precise numerical control indexing rotating shaft adopts an integral structural design and a shortened transmission chain, and has no backlash and higher indexing accuracy and servo response performance.

Owner:北京市电加工研究所有限公司 +1

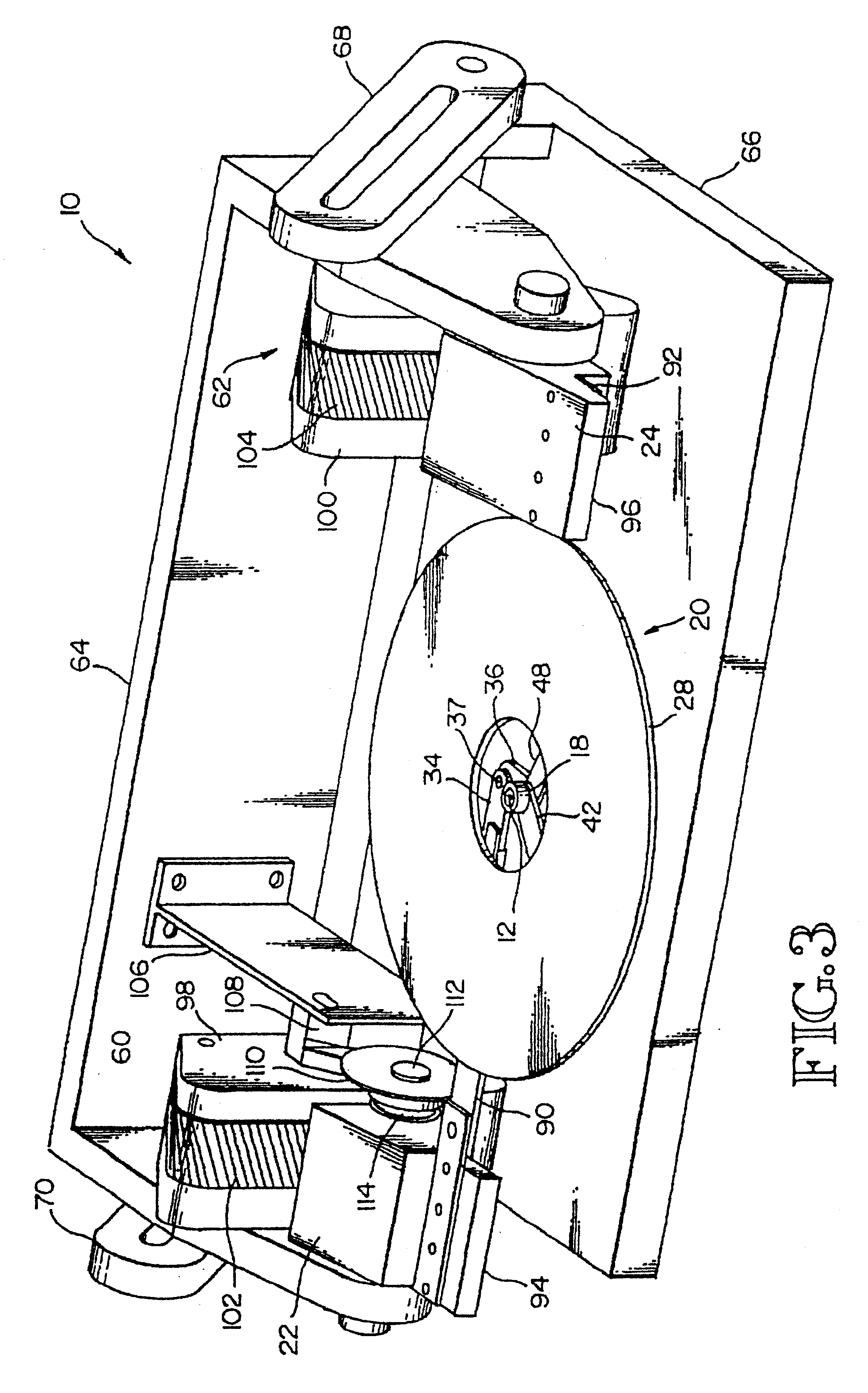

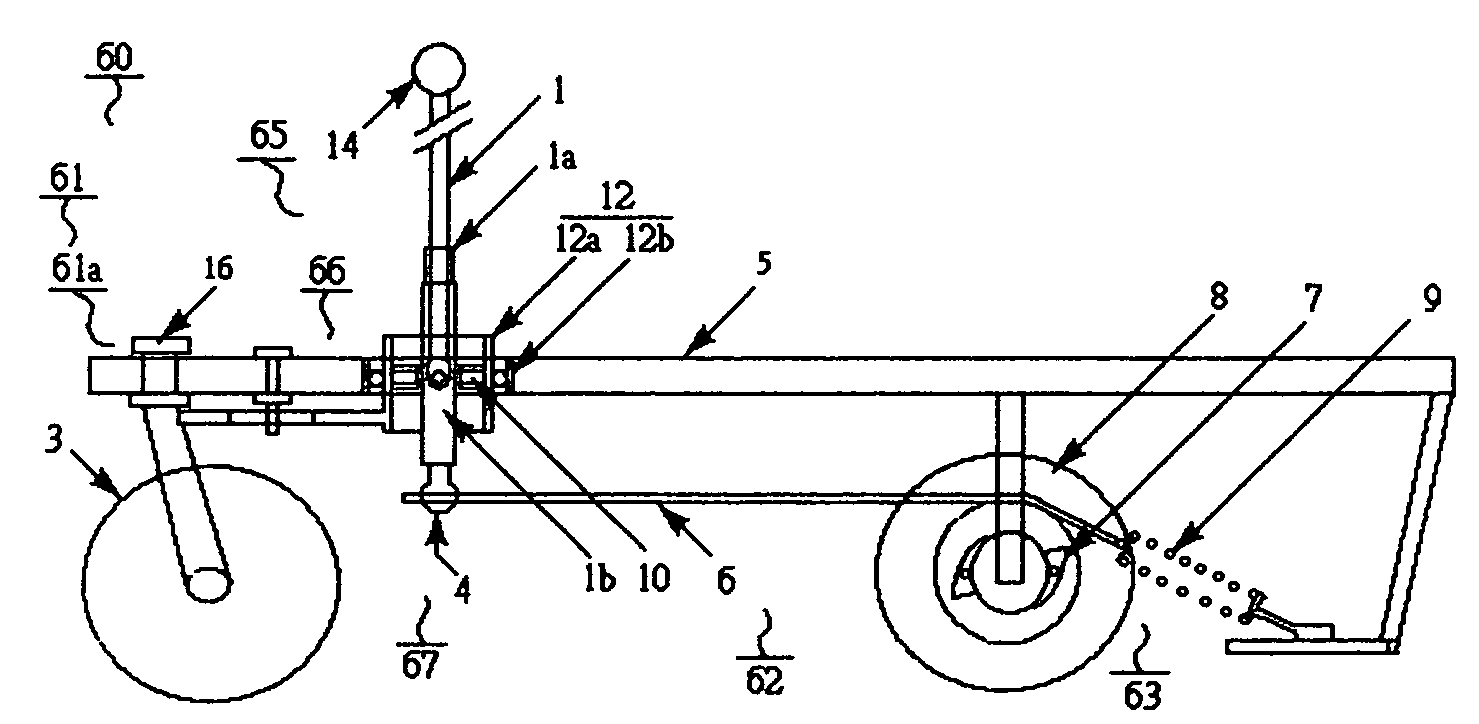

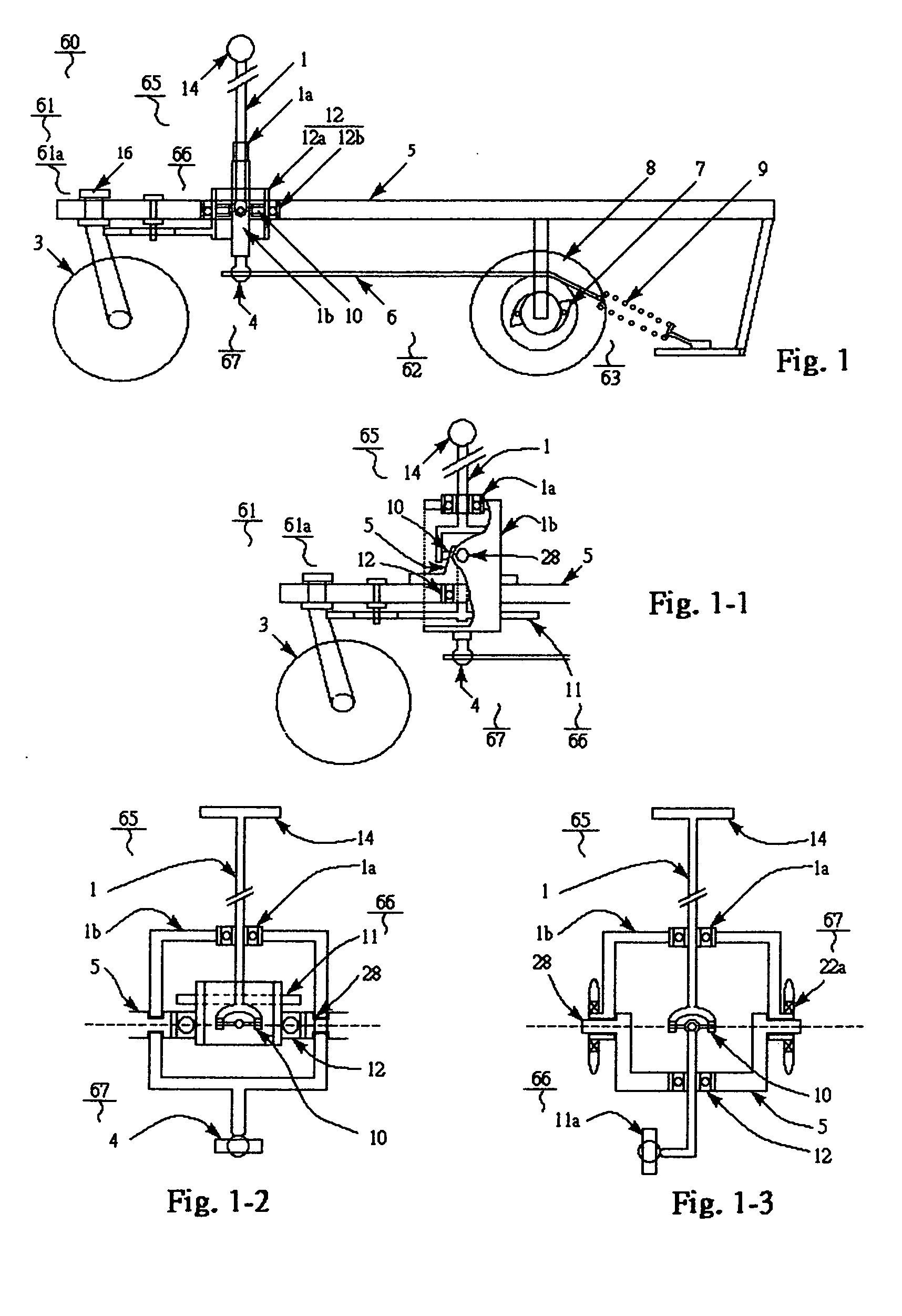

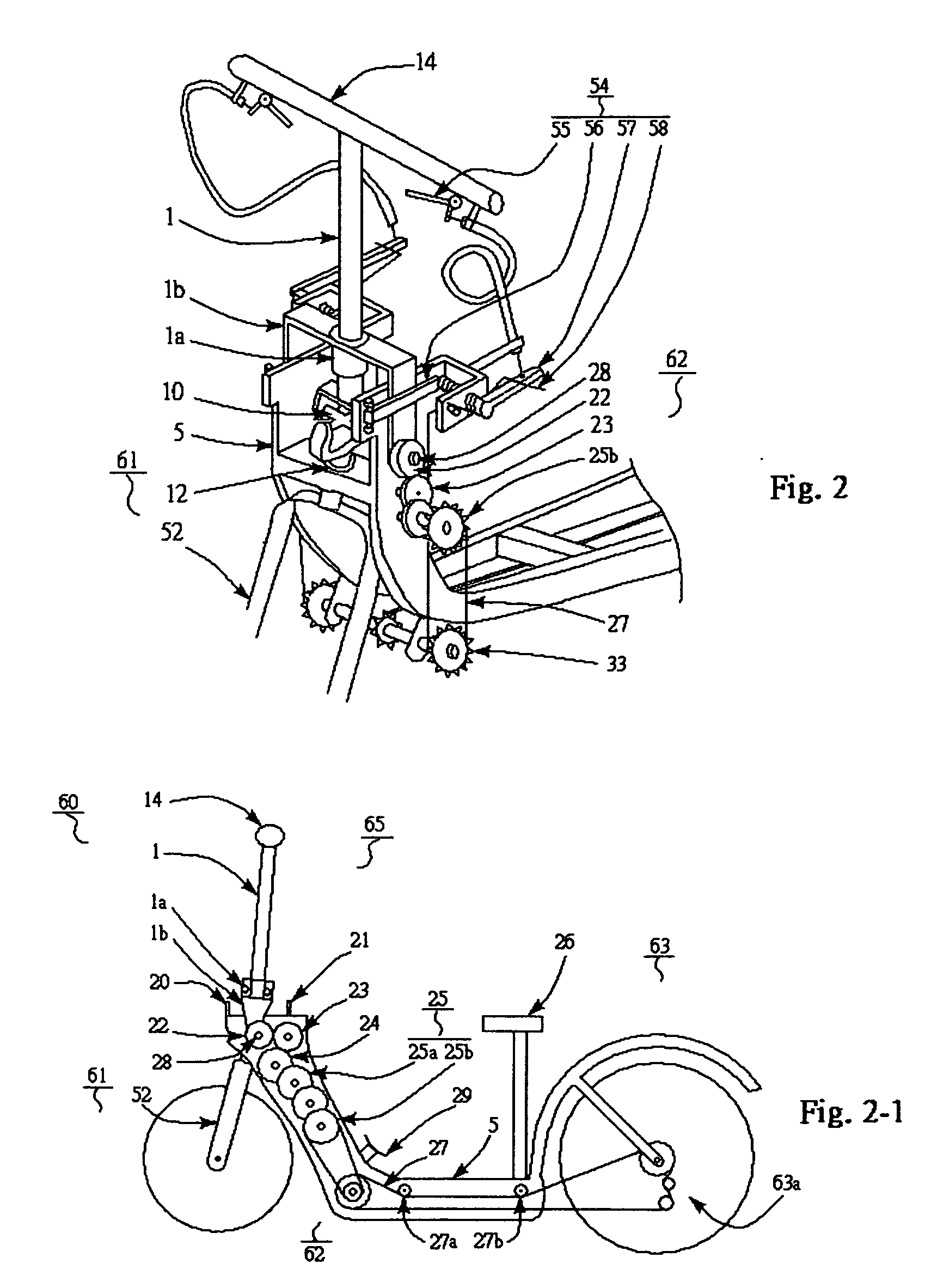

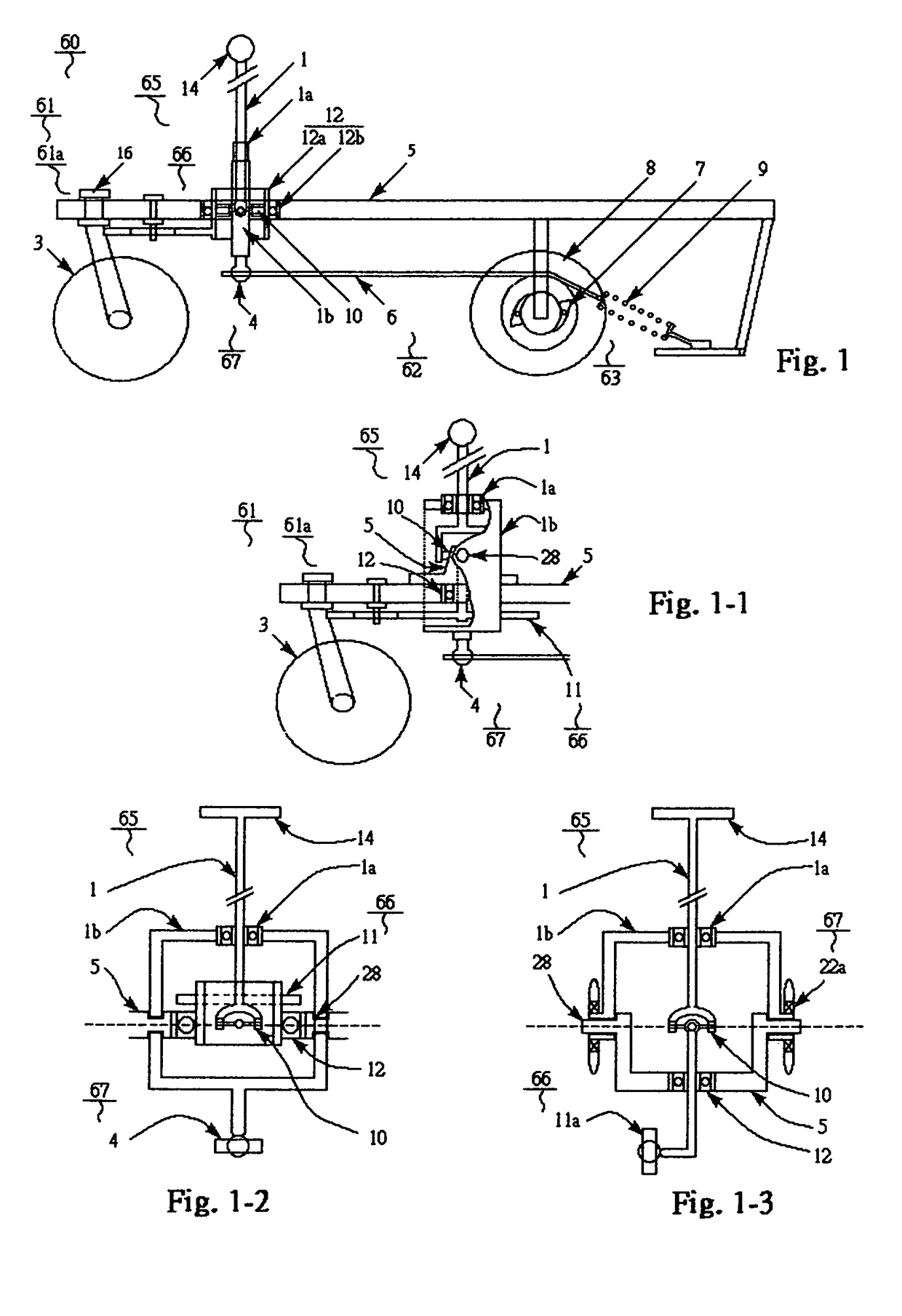

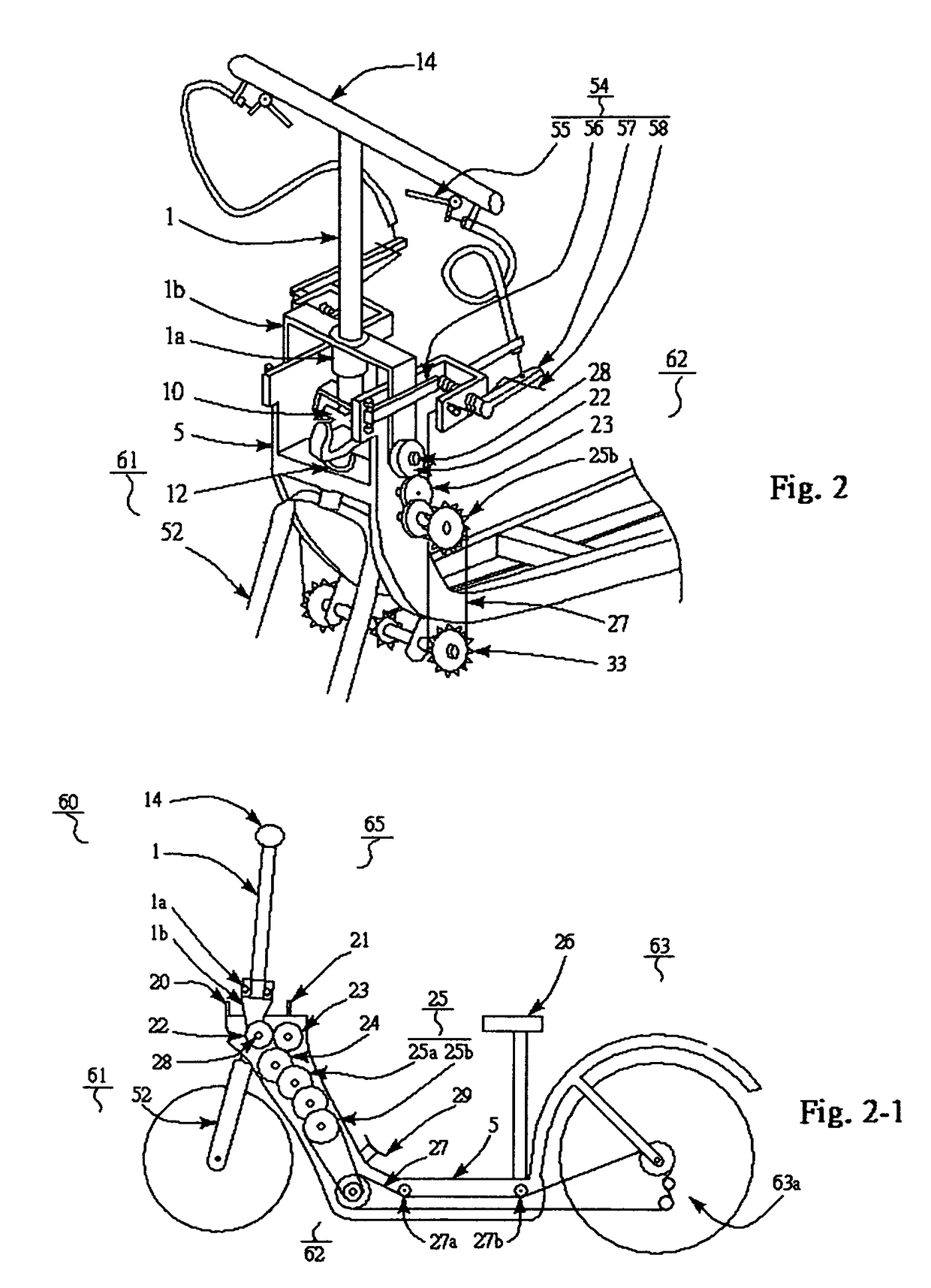

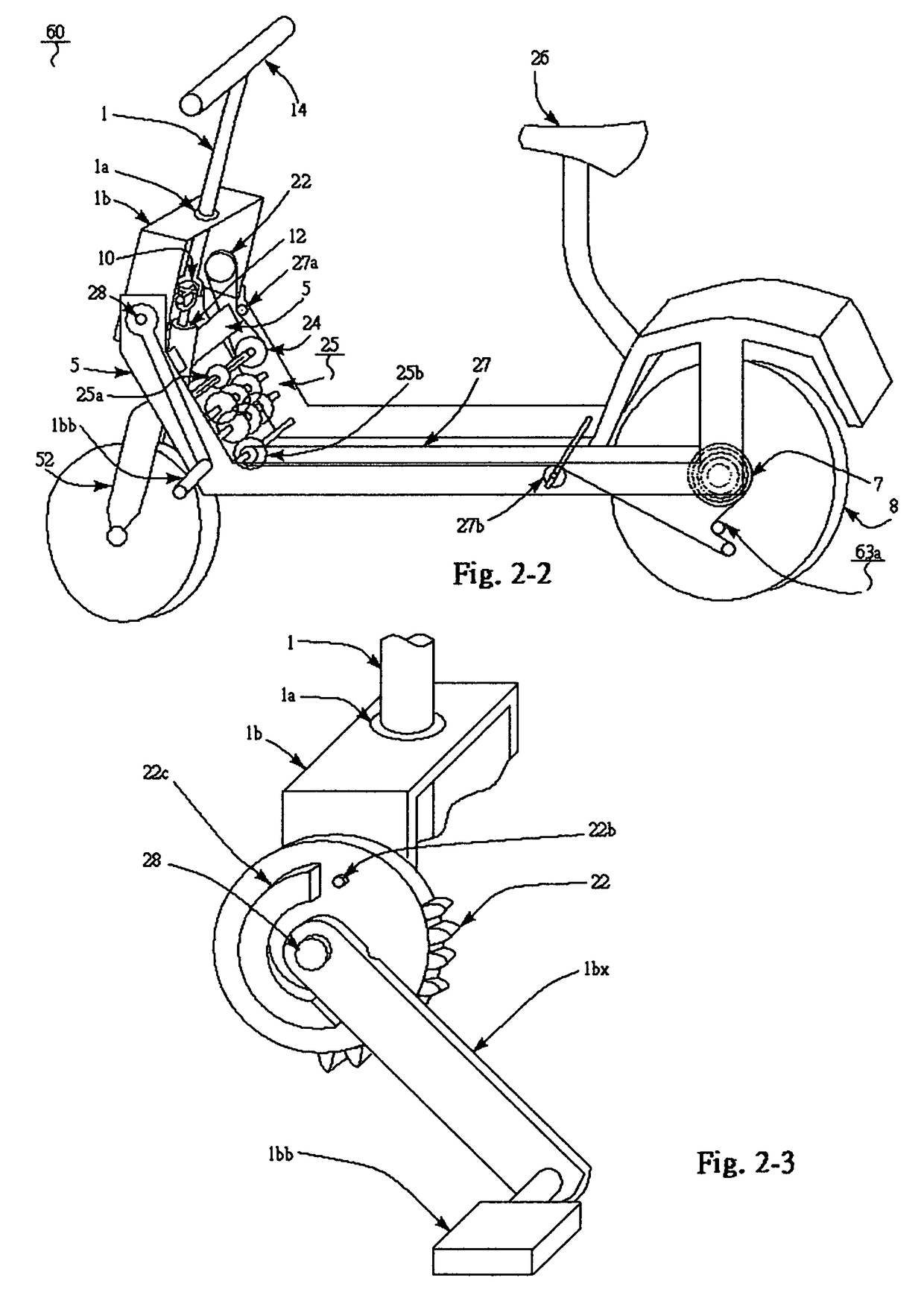

Steering Mechanism for a Push and Pull Vehicle

InactiveUS20090095115A1Rapid responseSustains huge torqueSteering deviceSteering columnsPush and pullVehicle frame

A Steering Mechanism for a Push and Pull Vehicle is to provide a solid turning, fast reaction steering feeling as a regular bicycle steering function, by handlebar turning left or right while still be able to use pulling or pushing action to power a vehicle forward. It contains handlebar at top of swing pole, a turning sleeve on a swing arm to hold swing pole, a frame supported U-joint bearing holds a U-joint which steer vehicle direction, and said swing arm contains a pivot support on vehicle frame and output to drive vehicle forward. So said handlebar is able to swing back and forth on swing arm pivot support to drive vehicle forward and turn left and right on said turning sleeve for steering directions.

Owner:LEE ROCKY JENLON

Steering mechanism for a push and pull vehicle

InactiveUS8118320B2Simple and positive drivingNo backlashSteering deviceSteering columnsPush and pullVehicle frame

A steering mechanism for a push-and-pull vehicle provides a handlebar to be used to steer a vehicle left and right while simultaneously being used to drive the vehicle forward by pushing and pulling action. The handlebar is at the top of a swing pole, the swing pole being held by a turning sleeve on a swing arm pivoted on the vehicle frame. The swing pole connects the handlebar to a frame supported u-joint which is connected to a vehicle steering mechanism. The turning sleeve connects the handlebar and swing pole to the swing arm, the output of the swing arm driving the vehicle forward.

Owner:LEE ROCKY JENLON

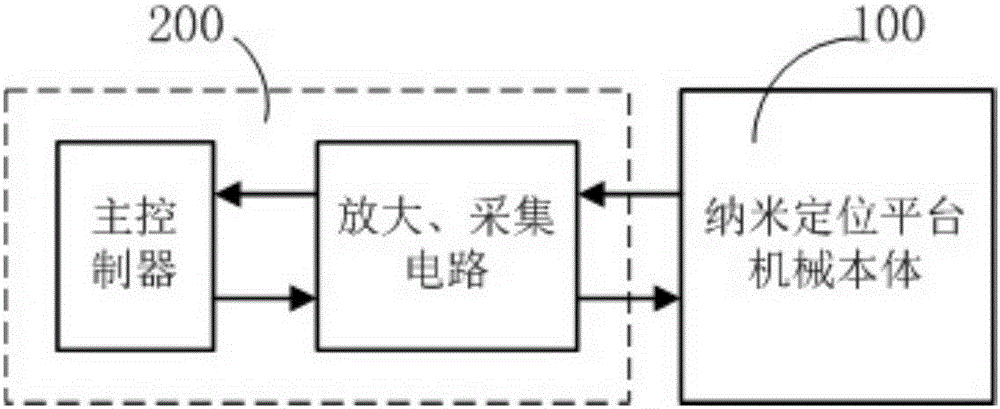

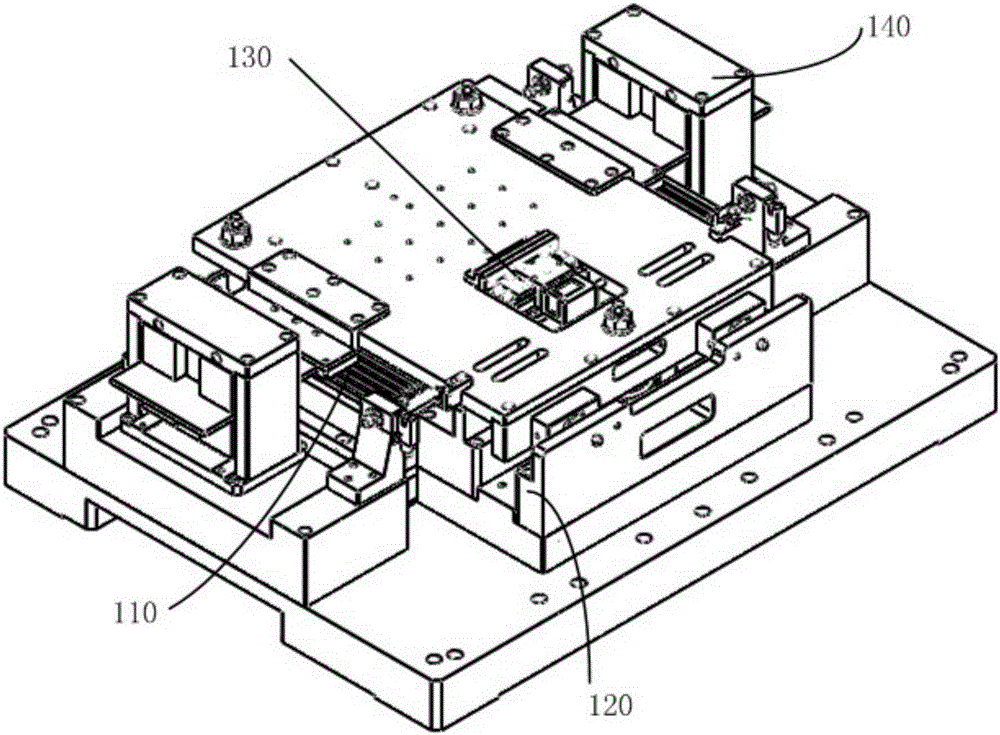

Long-stroke single degree of freedom air-bearing magnetic-drive nano-positioning platform

ActiveCN105202325ASatisfy the large stroke movementFulfil requirementsPiezoelectric/electrostriction/magnetostriction machinesStands/trestlesHysteresisAir bearing

The invention discloses a long-stroke single degree of freedom air-bearing magnetic-drive nano-positioning platform, which comprises a solenoid actuator, an air-bearing guide mechanism, a position sensor module and an eddy current retarder module. The solenoid actuator body consists of two parts of a stator and a rotor; the rotor part is provided with a permanent magnet array; the stator three-phase winding adopts a coreless structure. Degree of freedom in five directions of a positioning platform is constrained by the air-bearing guide mechanism through three air bearings in vertical direction and two lateral air bearings in horizontal direction, so as to enable the positioning platform to perform motion only along one direction. The position sensor module is realized by virtue of a high-precision raster rule. The eddy current retarder module comprises two eddy current retarders which are respectively arranged at the front end and the rear end of the solenoid actuator. The nano-positioning platform disclosed by the invention has the advantages of simple structure, direct drive, zero friction, hysteresis-free, haul back interval-free and the like, and nano-grade positioning resolution is reached in motion strokes from tens of millimeters to hundreds of millimeters.

Owner:SHANGHAI JIAO TONG UNIV

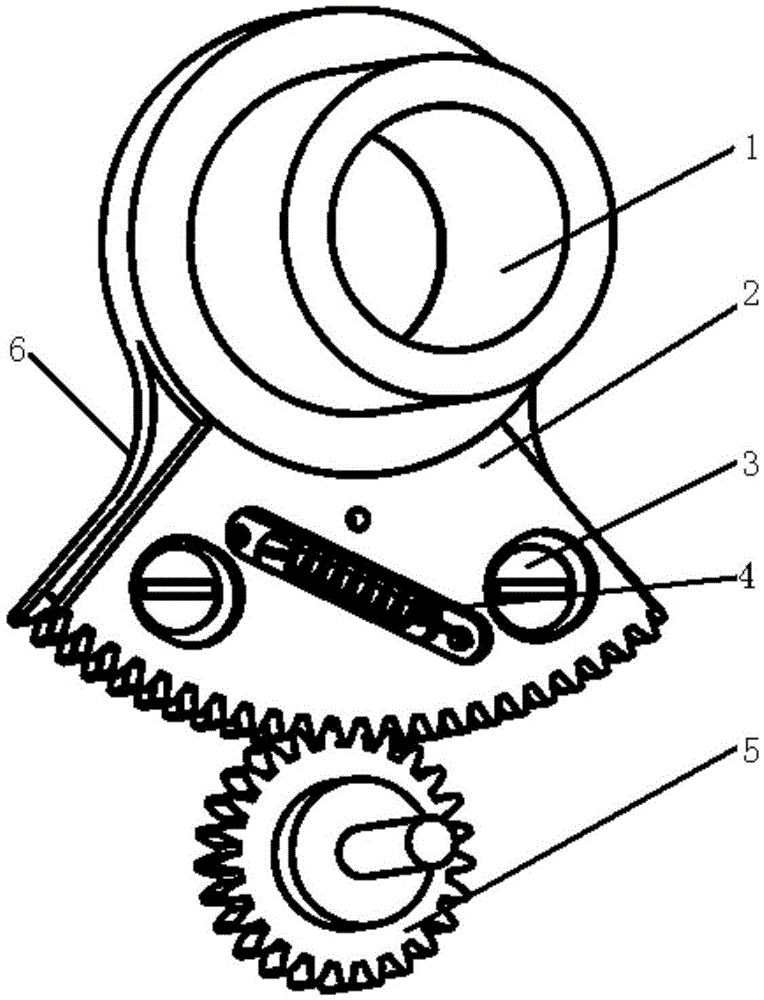

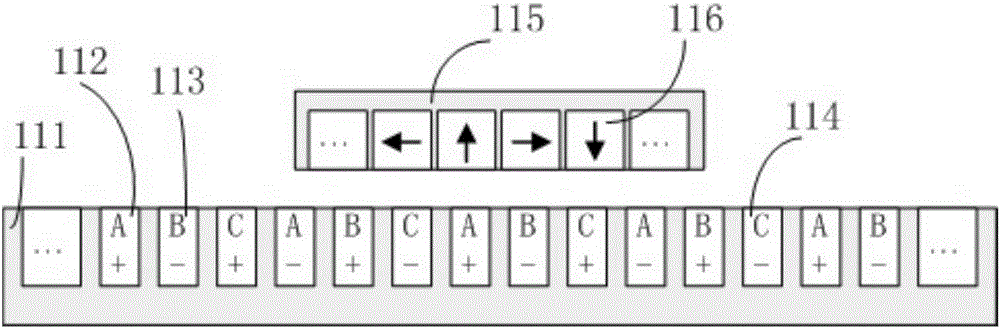

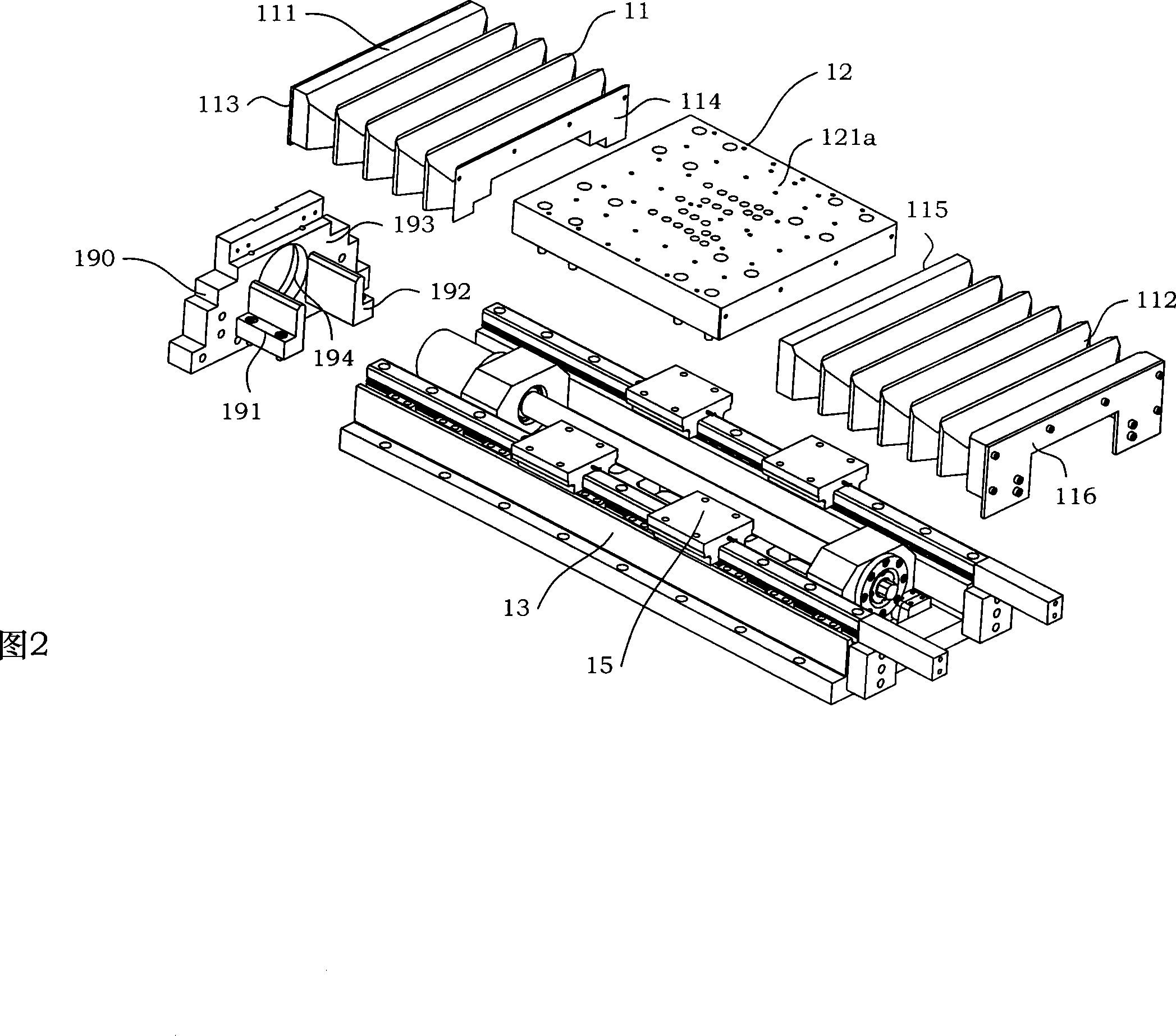

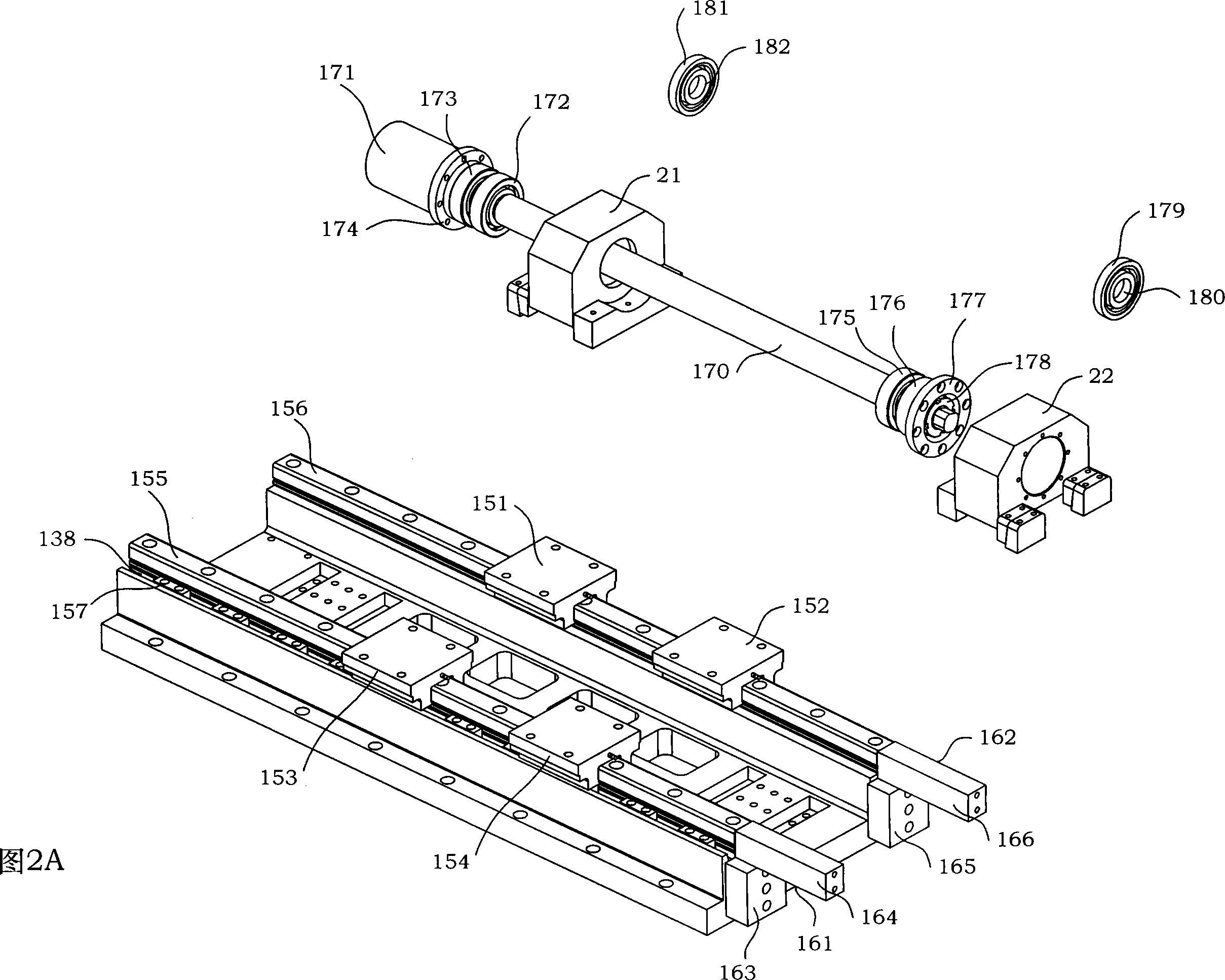

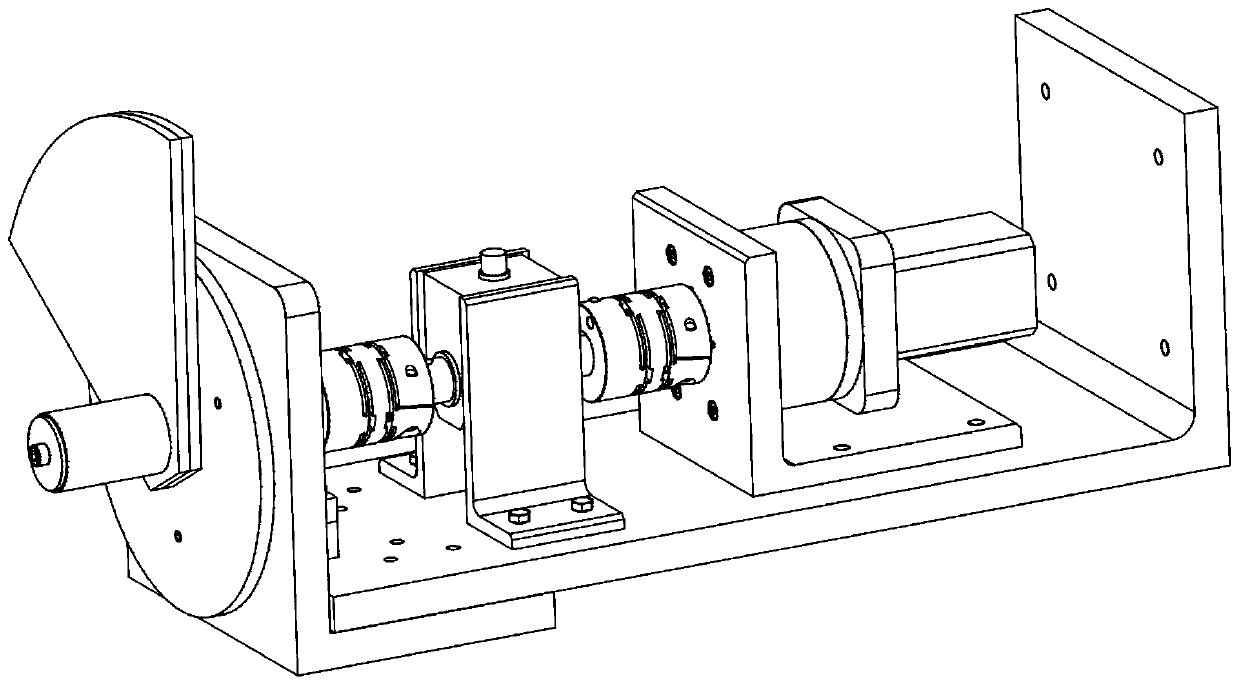

Fiber discharging device suitable for automatic optical fiber winding machine

InactiveCN101169503ALower natural frequencyNot easy to excite vibrationSagnac effect gyrometersCoupling light guidesWinding machineEngineering

The invention relates to a fiber arranging mechanism which is applied to an automatic optical fiber ring coiling machine, and the fiber arranging mechanism is composed of a fiber arranging component (1), a driving component (2) and a platform bracket (3). The lower installing face (302) of the platform bracket (3) is fixedly arranged on a precision platform (4). The upper installing face (301) of the platform bracket (3) is fixed with the slipway base (13) of the fiber arranging component (1). The fiber arranging component (1) is composed of an outer cover (11), a working table (12), the slipway base (13) and a sliding component (15). The fiber arranging mechanism of the invention is applied to the realization of fiber arranging function on various automatic optical fiber ring coiling machines, simultaneously, the invention also can be used in the machines such as optical fiber repeat coiling typed machines and optical fiber selecting machines. A screw lever (170) is driven to rotate by a motor (201), and the working table (12) can be made smoothly to slide on an A guiding rail (155) and a B guiding rail (156). Slight optical fibers can be accurately arranged on a preconcerted light fiber ring through adopting a frame with high stiffness, a prestressed assembling structure and an excellent driving and controlling characteristic in the fiber arranging mechanism.

Owner:BEIHANG UNIV

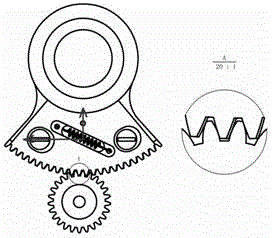

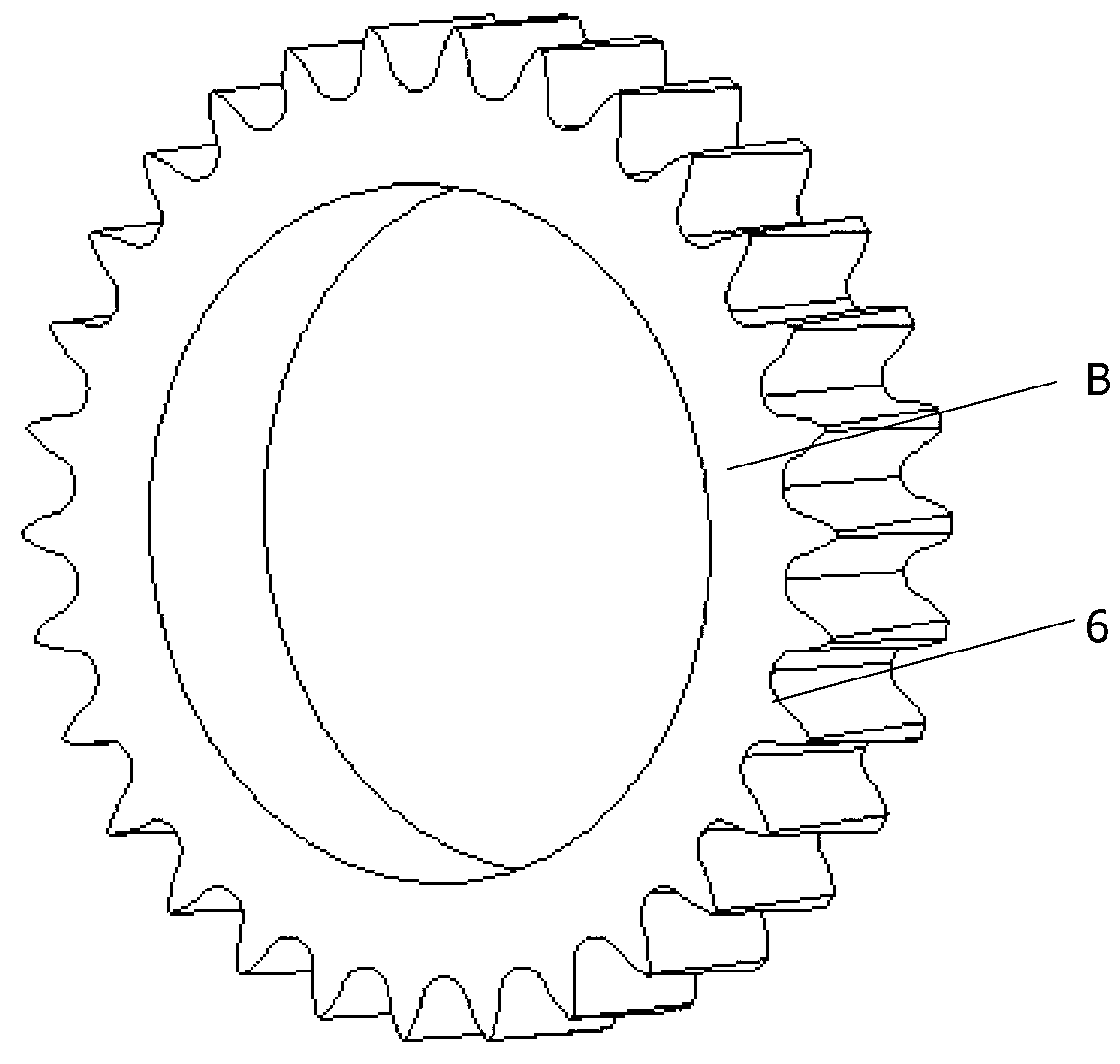

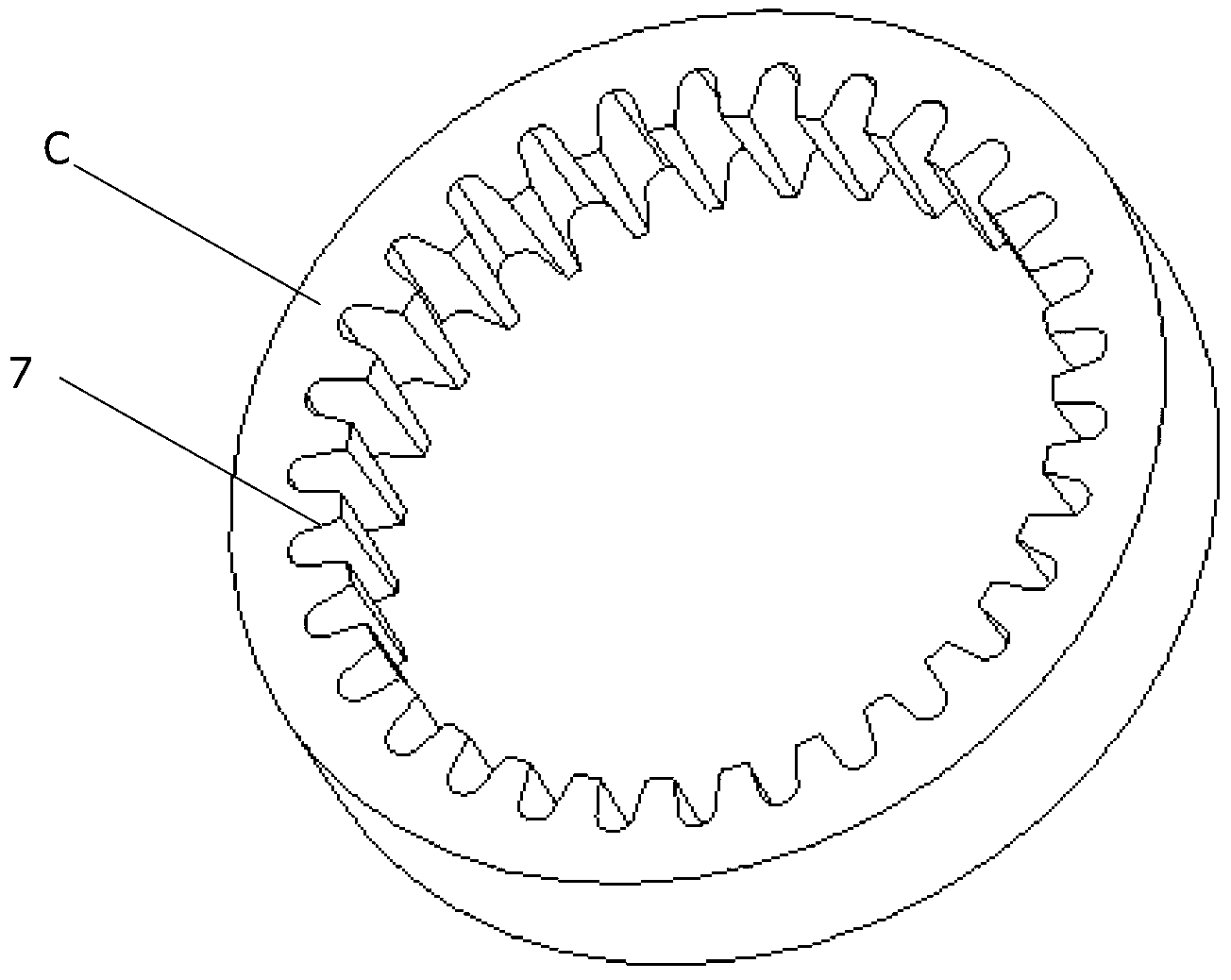

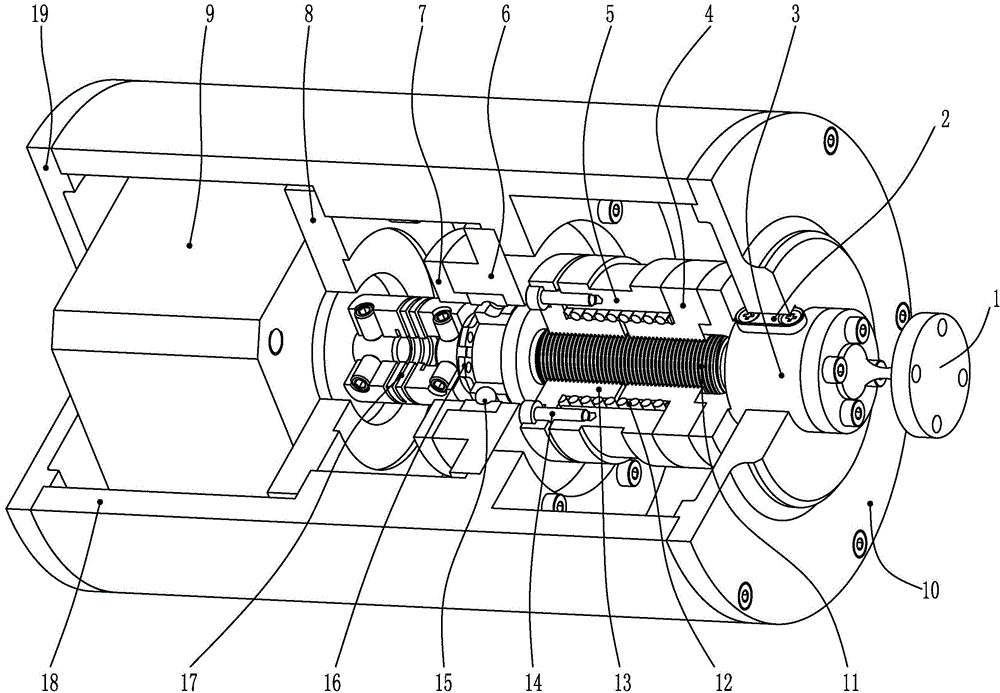

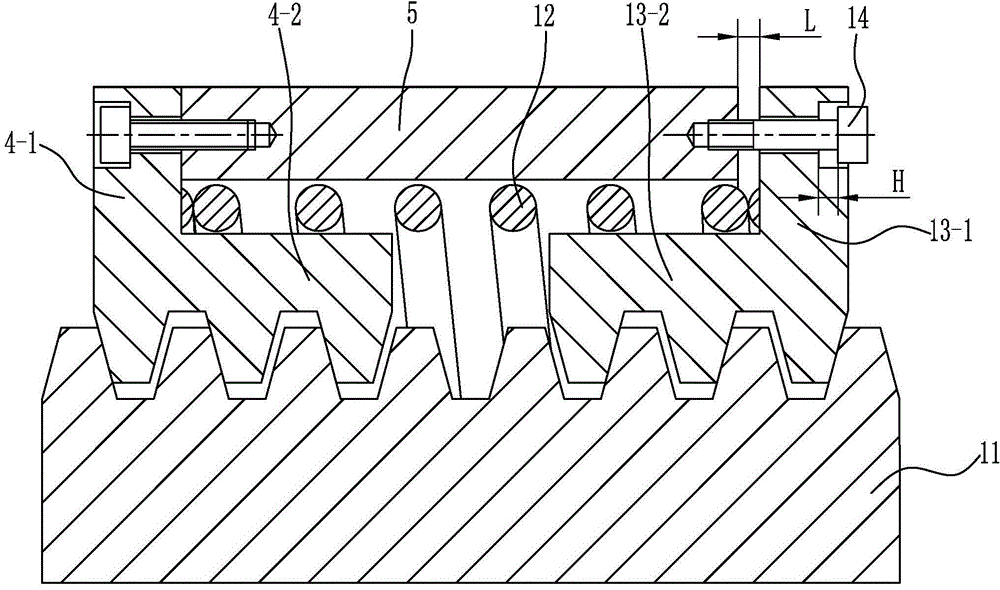

Anti-backlash transmission comprising trochoid gears and roll pins with conical teeth

InactiveCN103062334AImprove interchangeabilityIncrease profitPortable liftingToothed gearingsGear wheelEngineering

The invention relates to an anti-backlash transmission comprising trochoid gears and roll pins with conical teeth. The transmission has two transmission modes, and a pin gear is respectively externally meshed and internally meshed with the corresponding trochoid gears to implement the two transmission modes. The pin gear is provided with a plurality of conical roll pins, and tooth gaps are eliminated by axially pushing the pin gear along the end, which is provided with a small diameter, in a transmission procedure; and the trochoid gears are conical trochoid gears, and the trochoid gears and the pins are meshed to realize zero-backlash power transmission. The pin gear or the trochoid gears is driven by a servo motor to continuously relate, and accordingly a deceleration function or an acceleration function is realized. The anti-backlash transmission is simple in structure, requirements on high-speed and high-precision transmission are met, the tooth gaps generated by abrasion during transmission can be eliminated, the meshing accuracy is guaranteed, and the utilization rate of the roll pins is increased.

Owner:BEIJING UNIV OF TECH

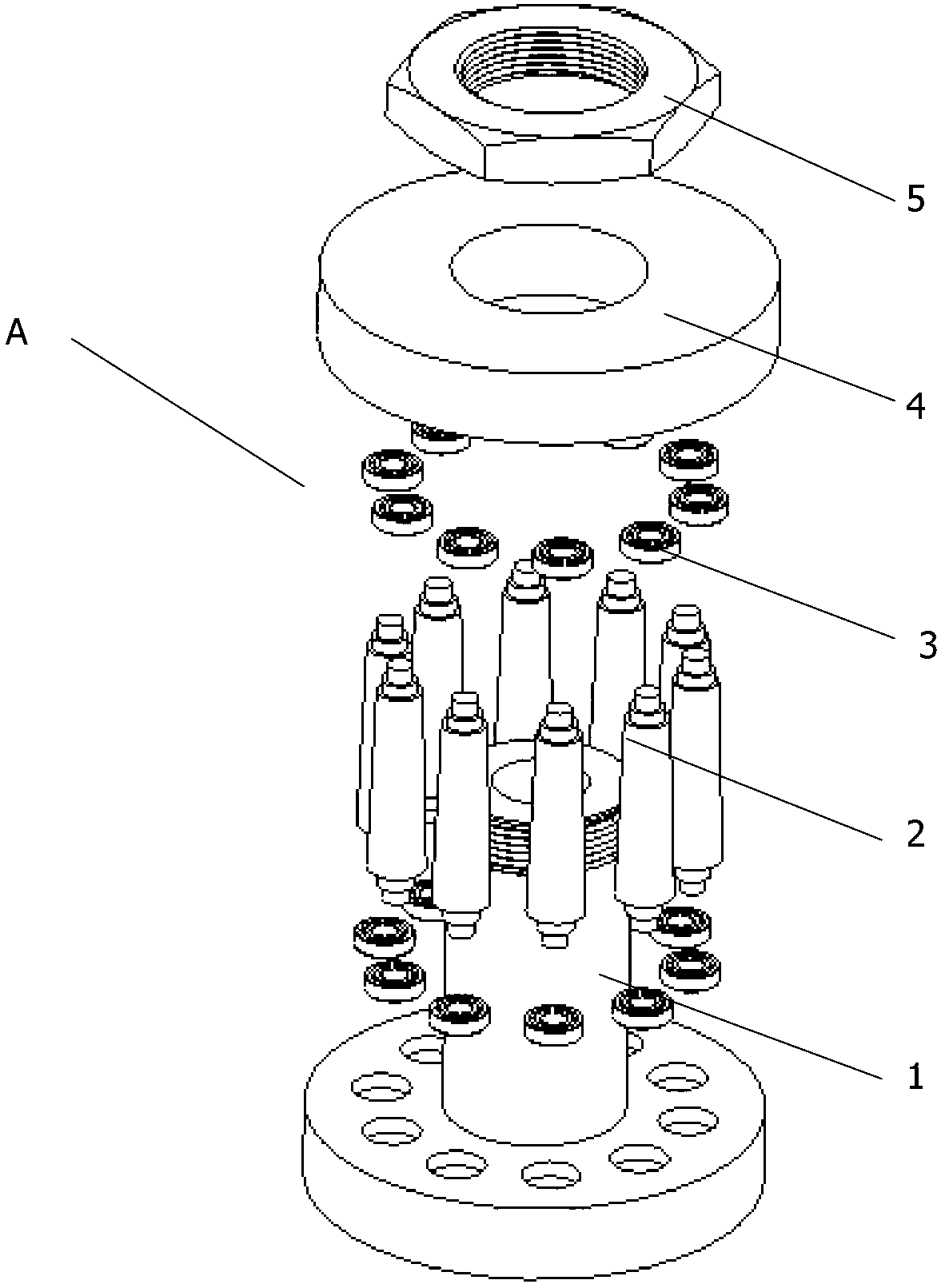

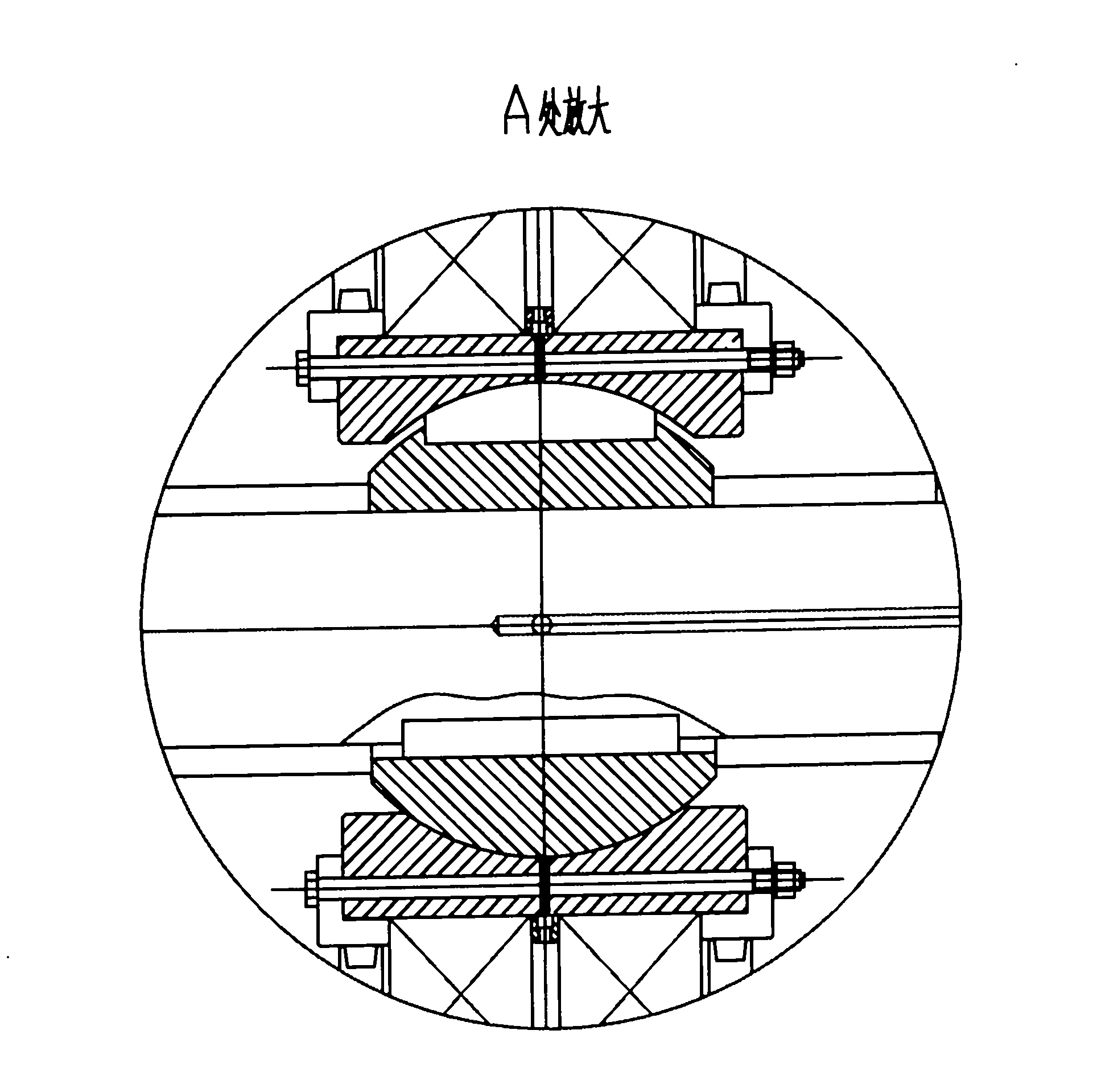

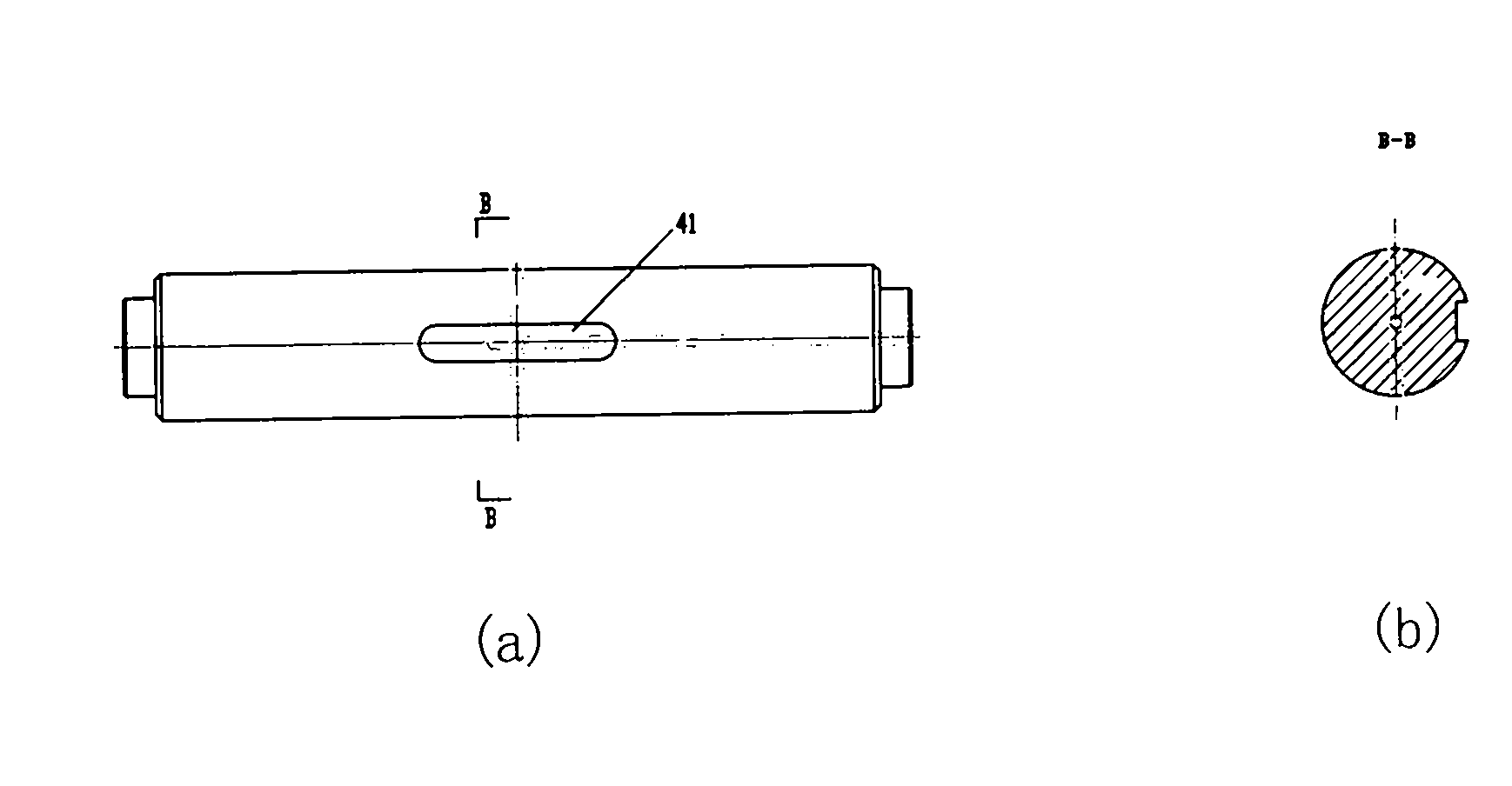

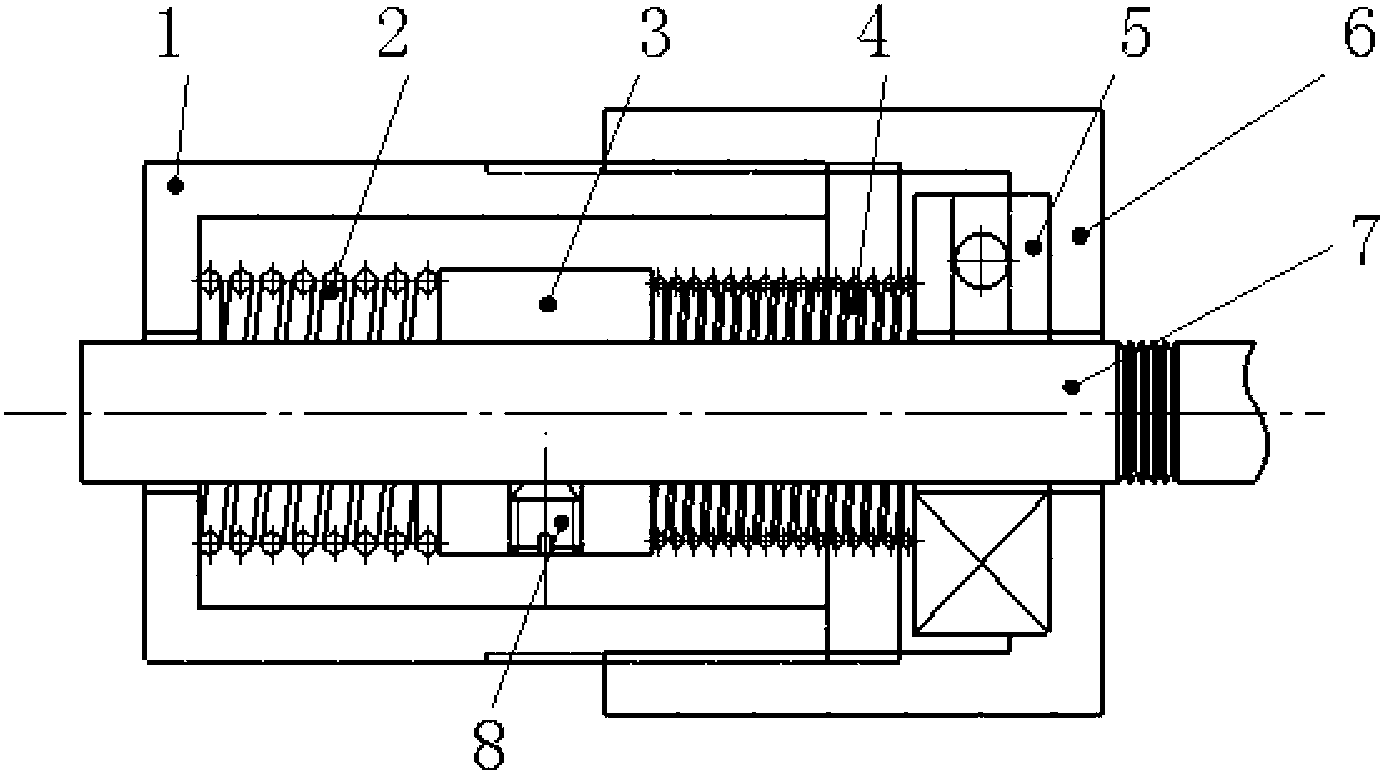

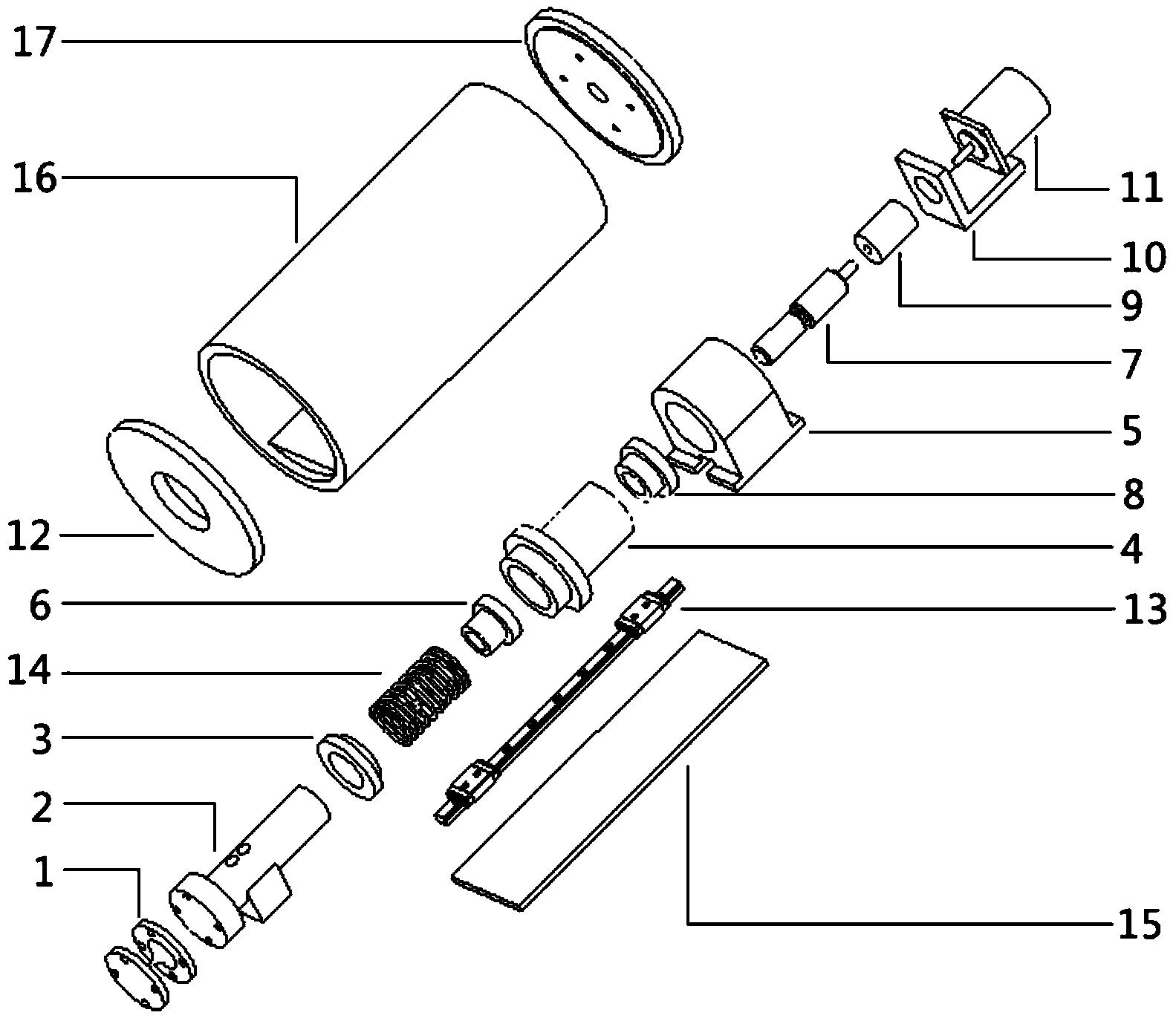

Direct drive type precise micro displacement actuator for polar environment

The invention provides a direct drive type precise micro displacement actuator for a polar environment, and relates to the precise micro displacement actuator. The precise micro displacement actuator aims to solve the problem that no supporting and adjusting mechanism exists for a large spliced mirror surface telescope panel under the polar low-temperature environment. The precise micro displacement actuator comprises a movement supporting mechanism, a drive mechanism and an anti-backlash screw transmission mechanism. The movement supporting mechanism comprises a flexible shaft, an end cover, a shell and a bottom cover. The shell is open at the two ends, and the end cover and the bottom cover are arranged at the two ends of the shell in a covering mode. The drive mechanism comprises an elastic coupling, a motor connection plate and a stepping motor. The anti-backlash screw transmission mechanism comprises a guidance key, a drive rod, a transmission nut, a spring sleeve, a screw rod, pretightening springs, an anti-backlash nut and anti-rotation bolts. The direct drive type precise micro displacement actuator is used for multi-point supporting and adjusting a sub mirror panel of a spliced mirror surface astronomical telescope.

Owner:HARBIN INST OF TECH

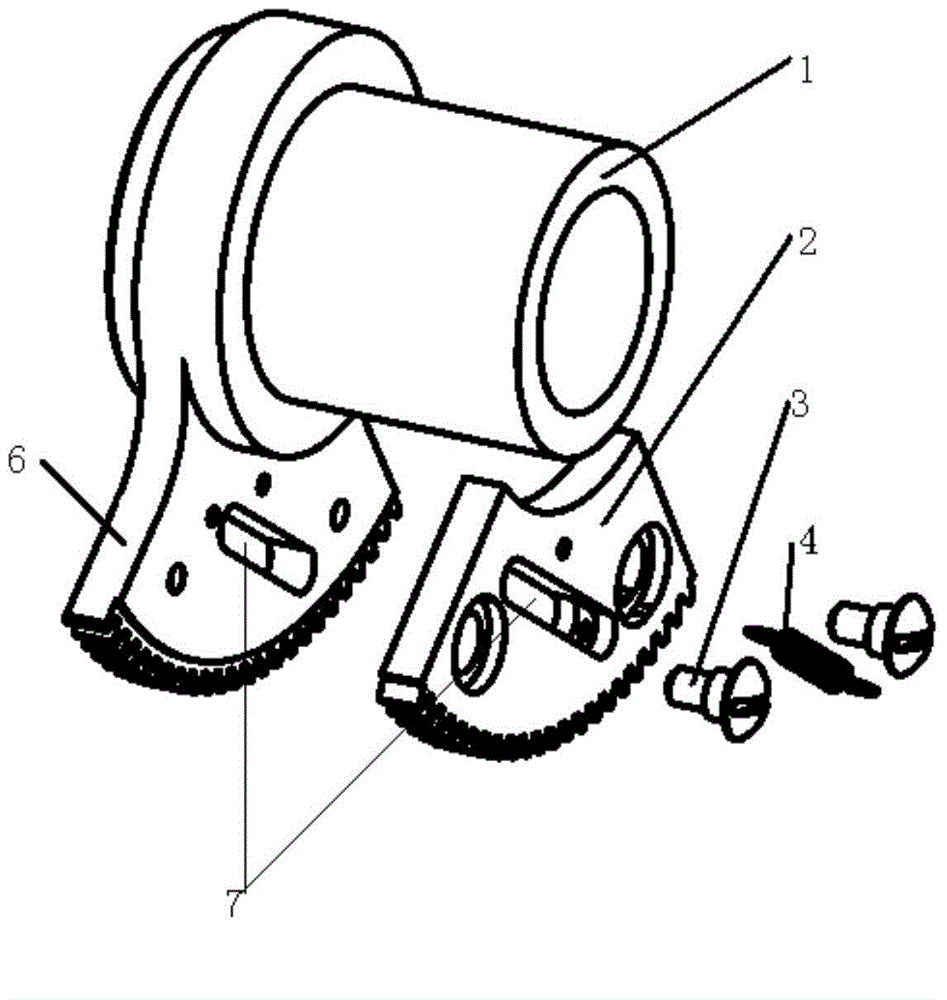

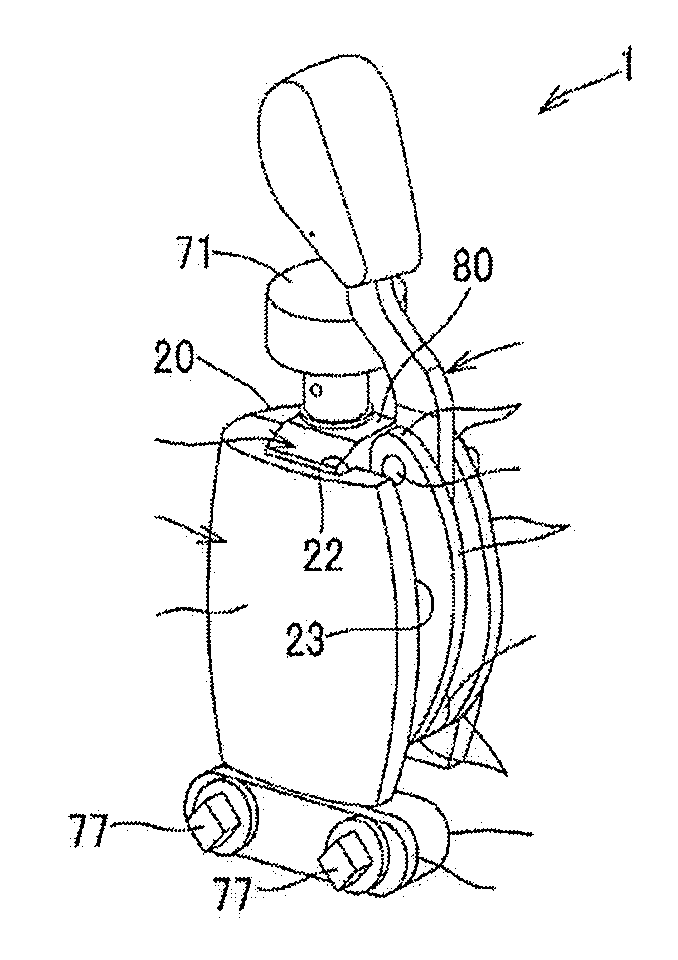

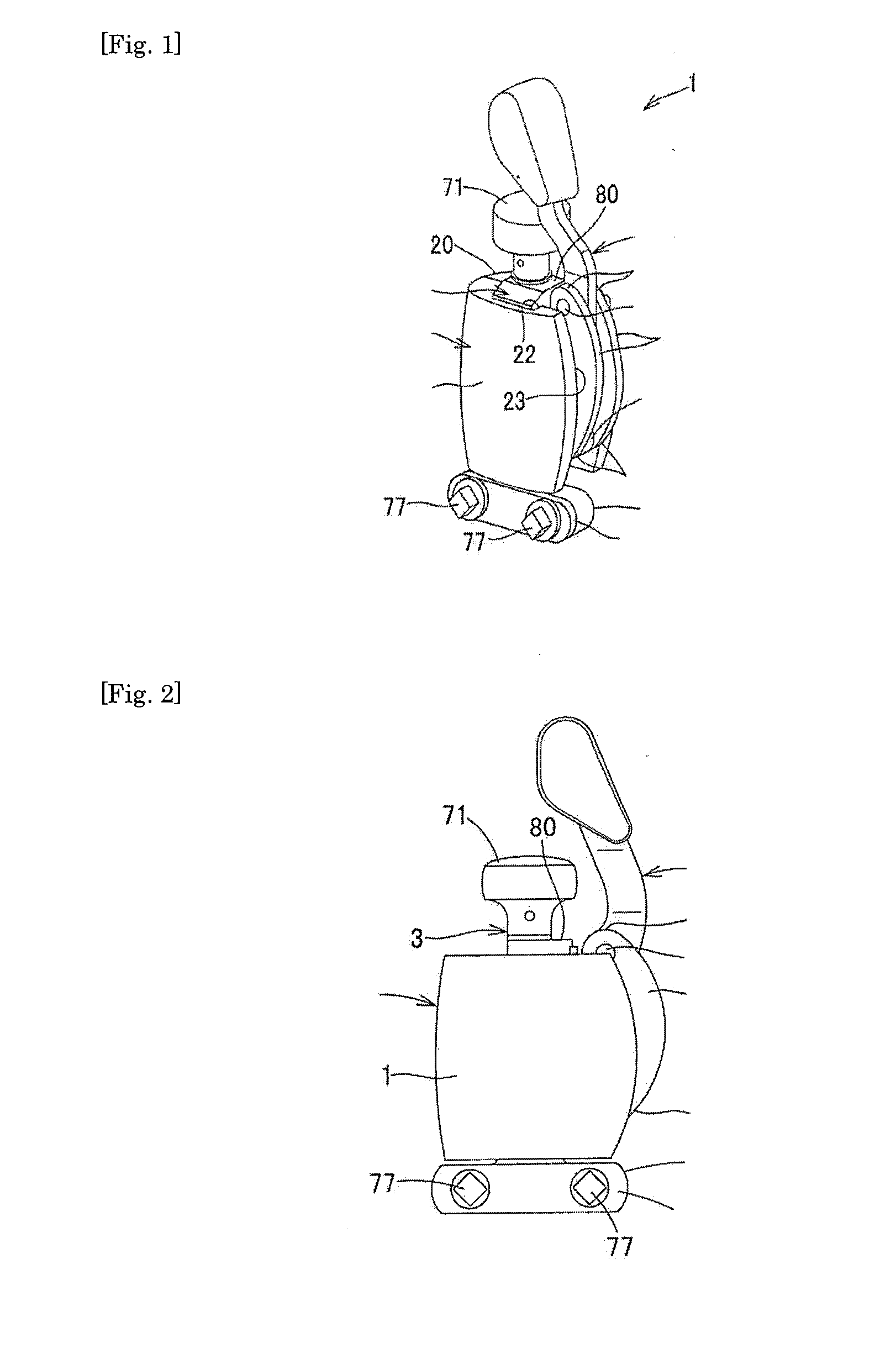

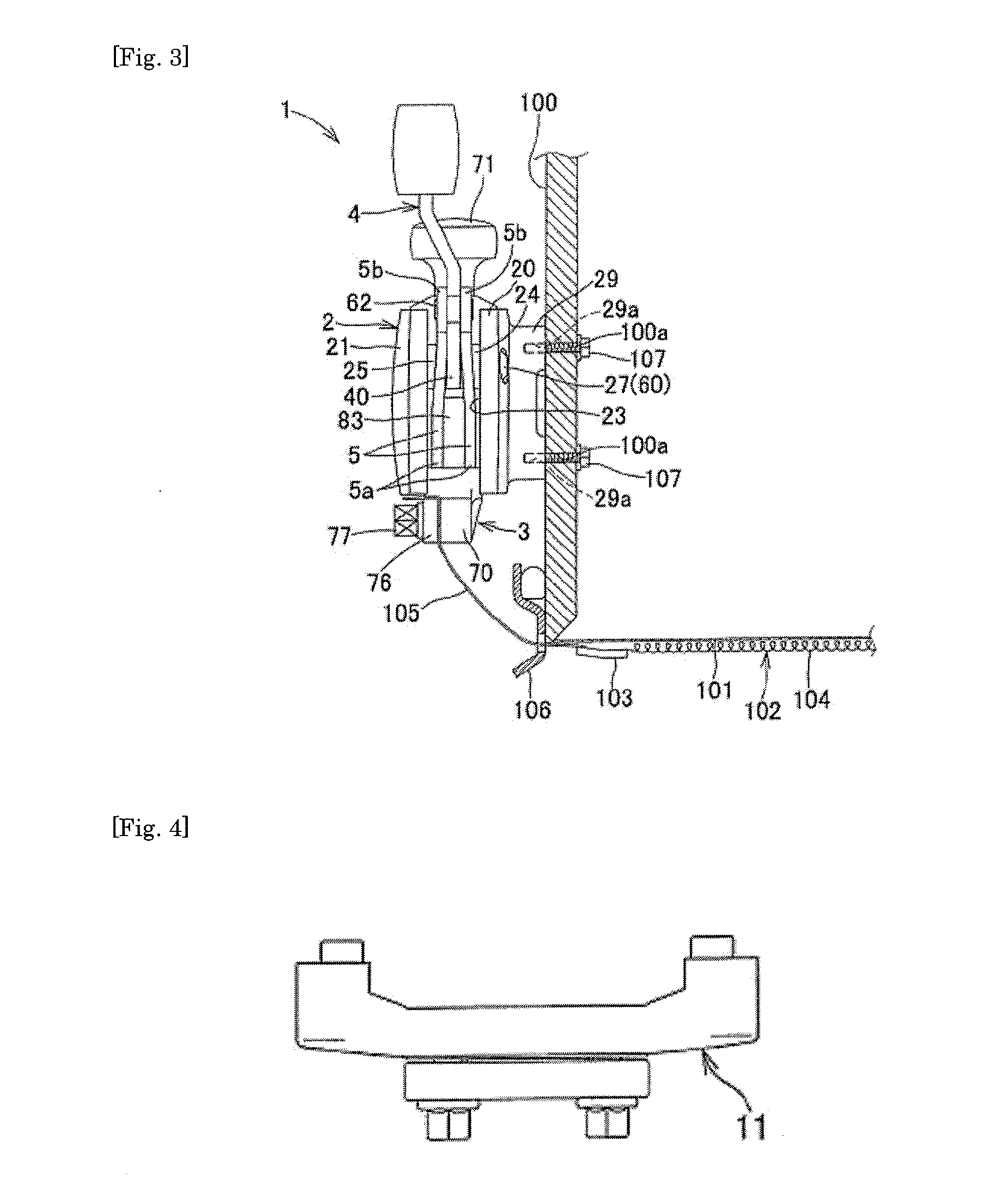

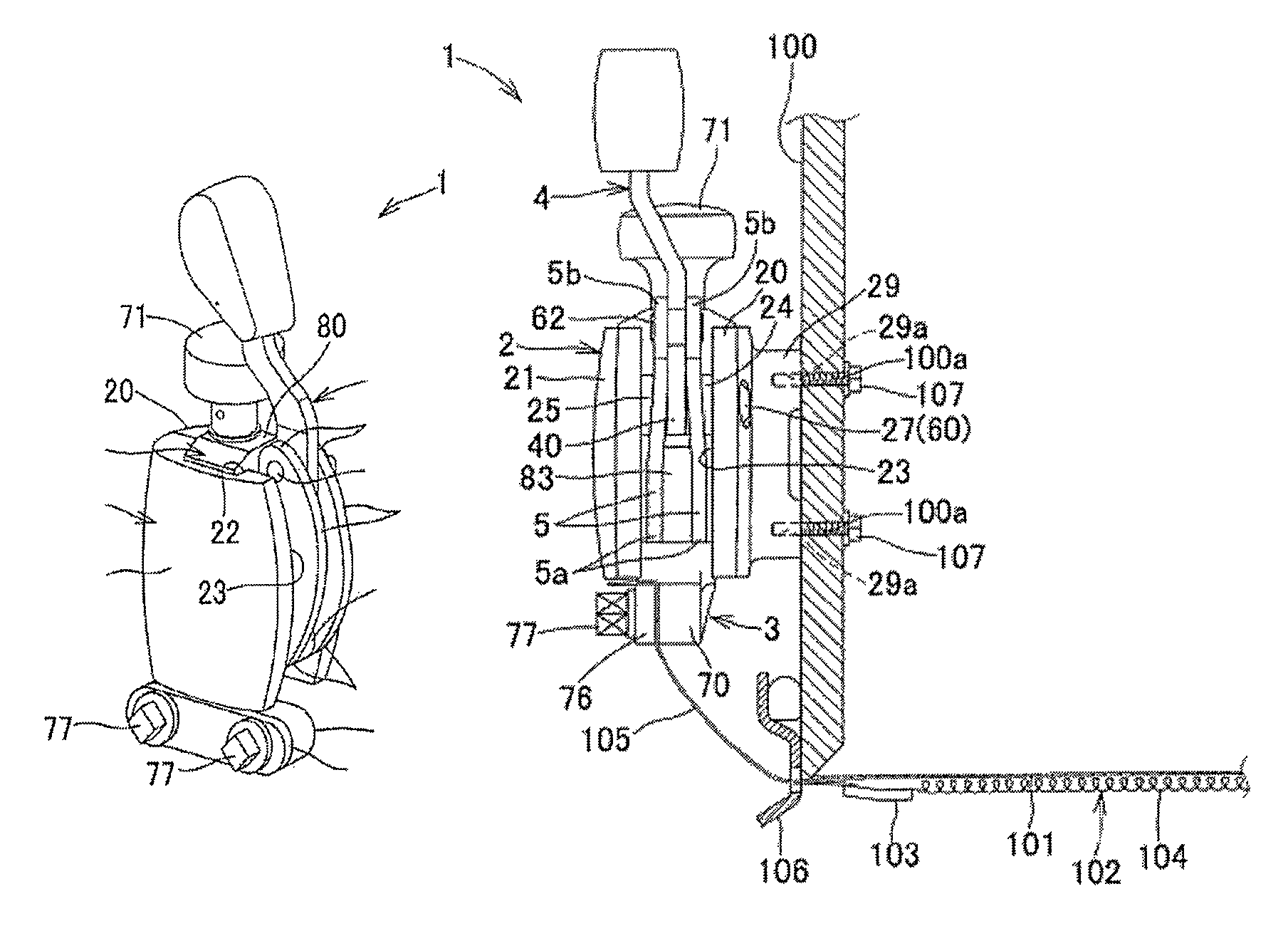

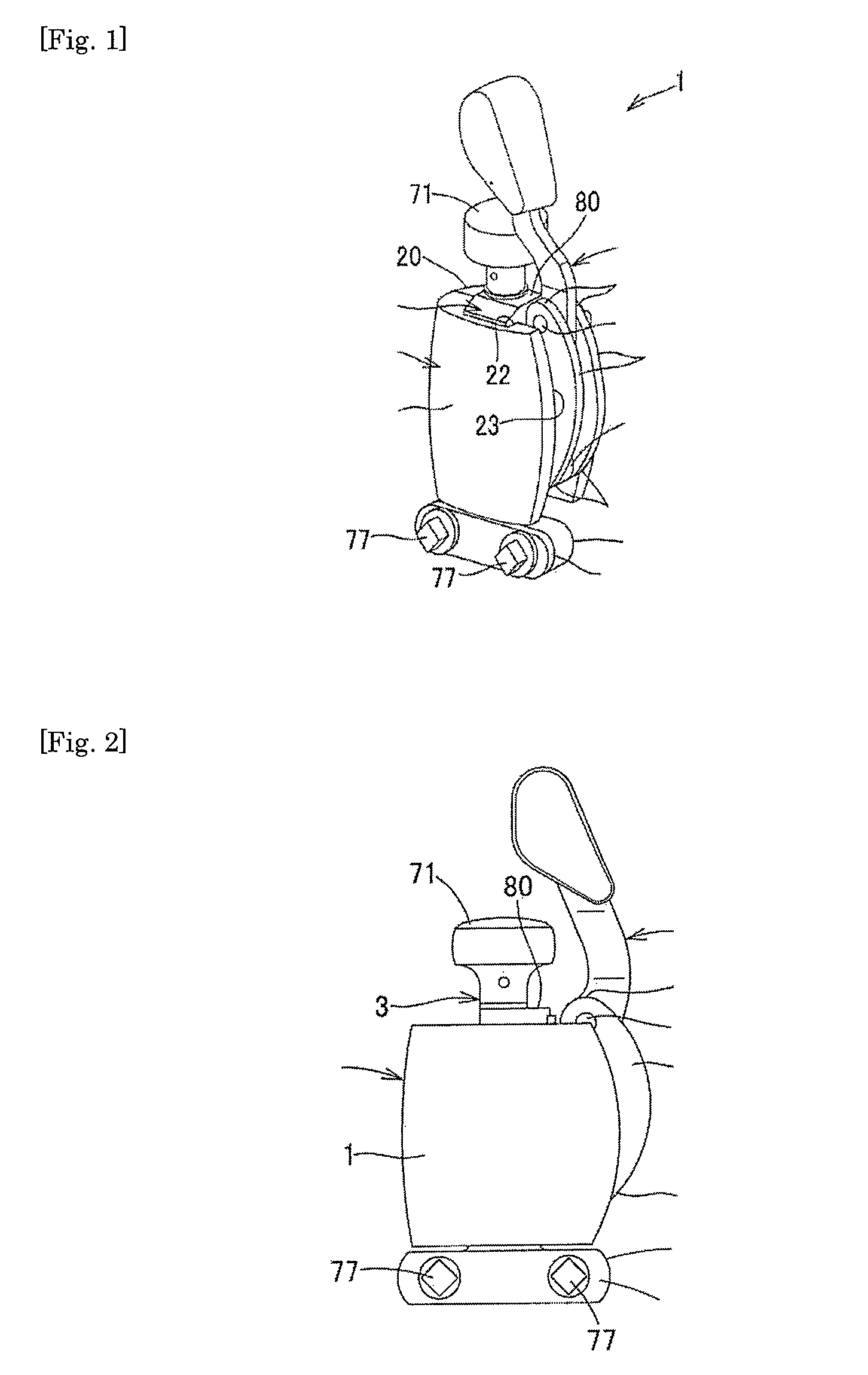

Strainer, and snappy holding structure by the strainer

InactiveUS20110023686A1Easy to operateImprove the sense of operationPercussion musical instrumentsEngineeringMechanical engineering

Intended is to provide a strainer having a switch mechanism, which is hardly rattled by a wear, which can be stably operated by a weak force, which does not load a snare assembly and which can maintain an excellent operation feel, and a snare assembly holding structure which has a reliable clamping force so that it can prevent the looseness of the snare assembly end portion. An operation lever is hinged on its base end side to a base body. A link is turnably connected on its one end side to the lower side portion of a snare assembly holding member, and is likewise turnably connected on its other end side to a midway position of the operation lever. When the operation lever turns upward, the snare assembly holding member is pulled upward through the link. When the operation lever turns downward, the snare assembly holding member is pushed downward.

Owner:SAKAE RHYTHM MUSICAL INSTR

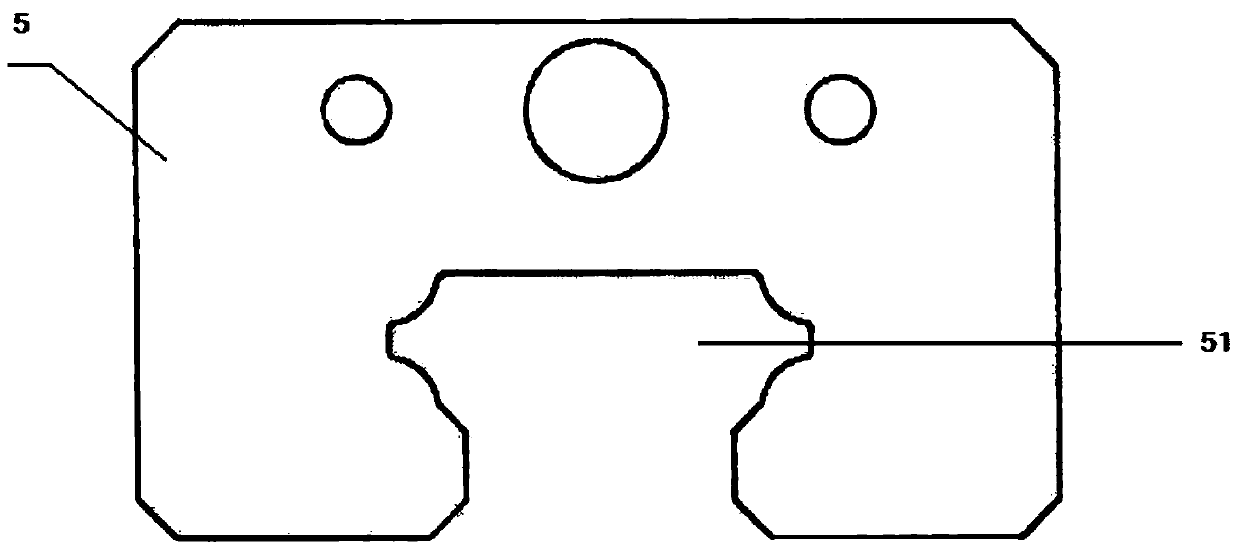

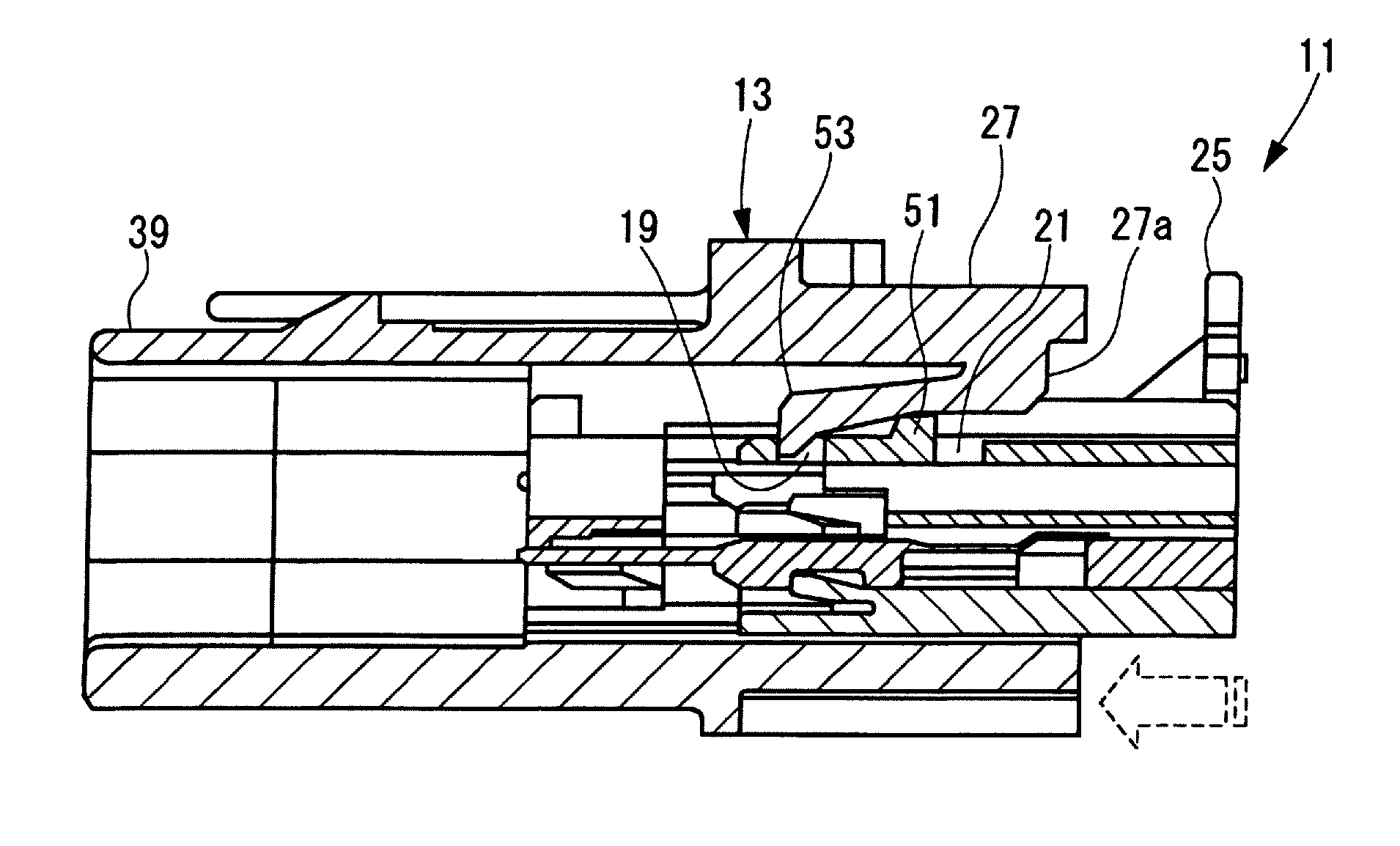

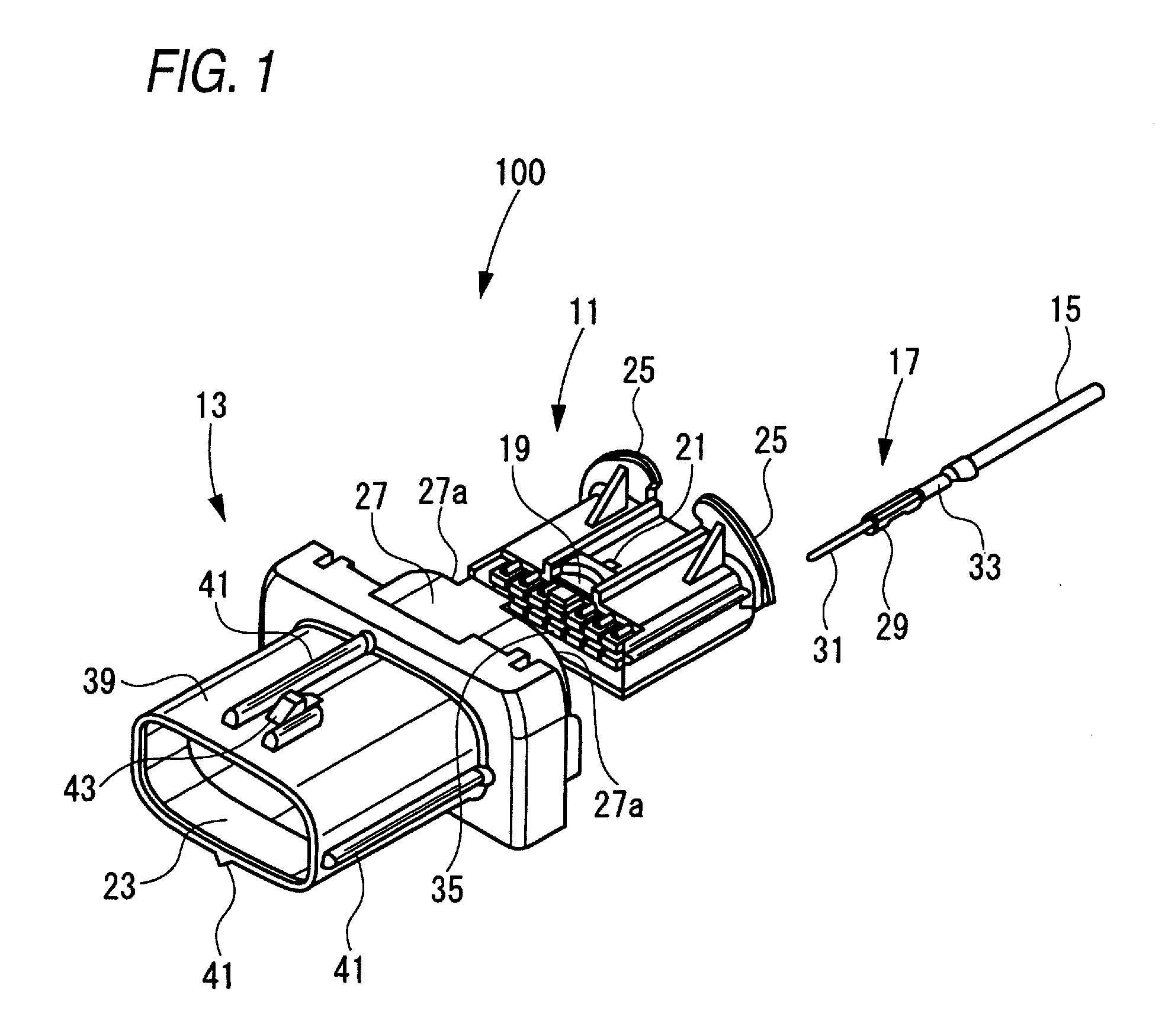

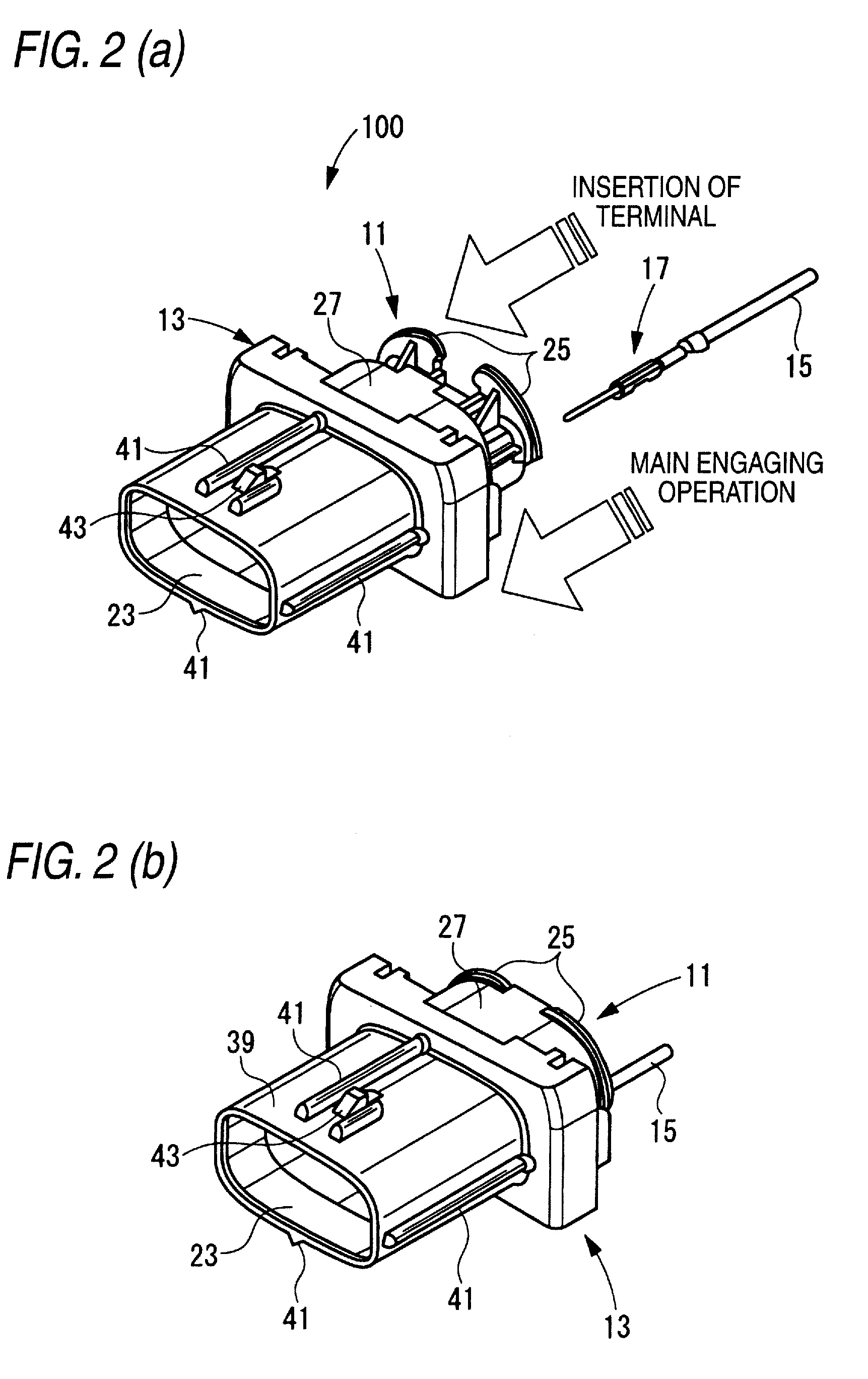

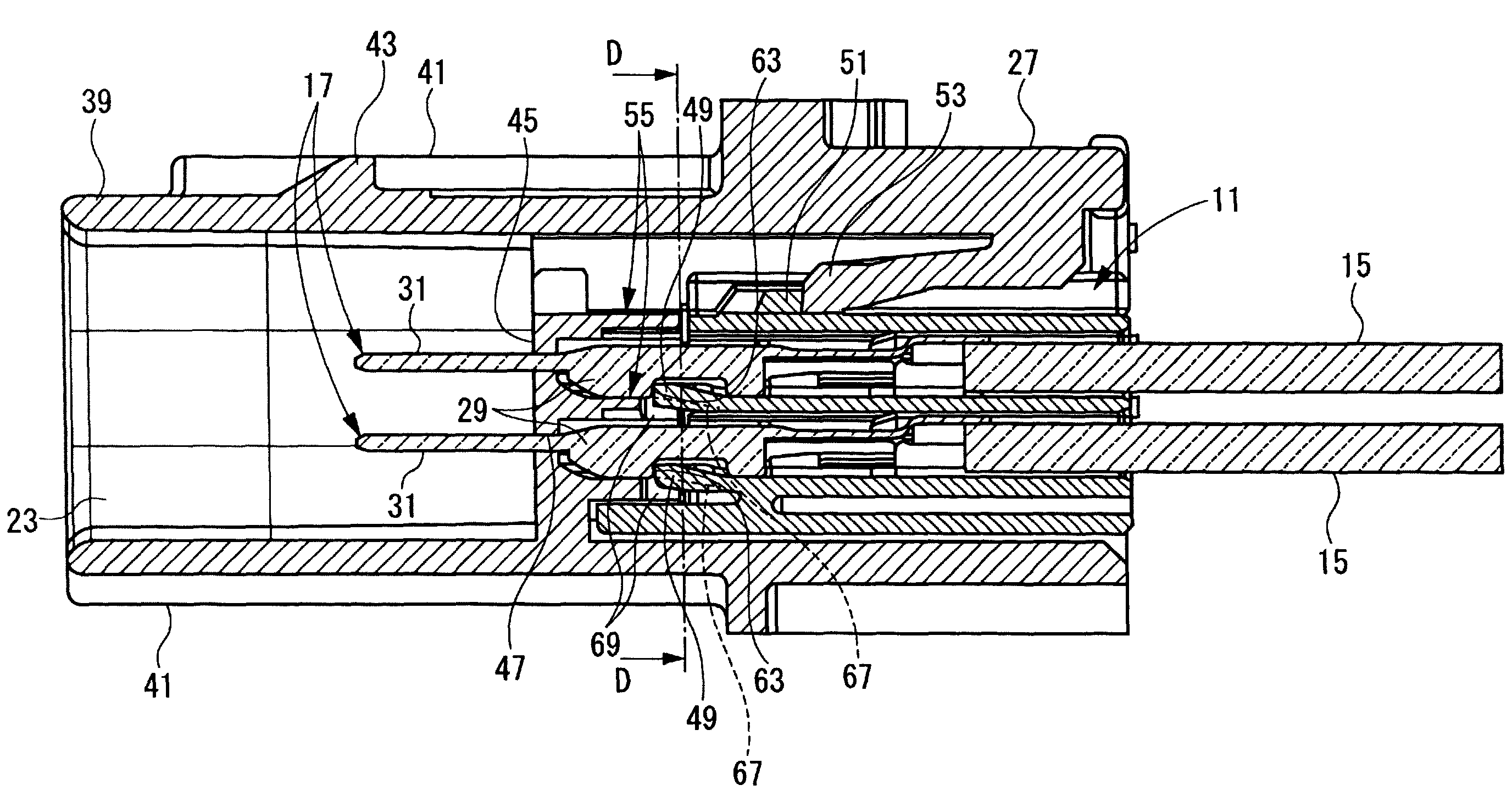

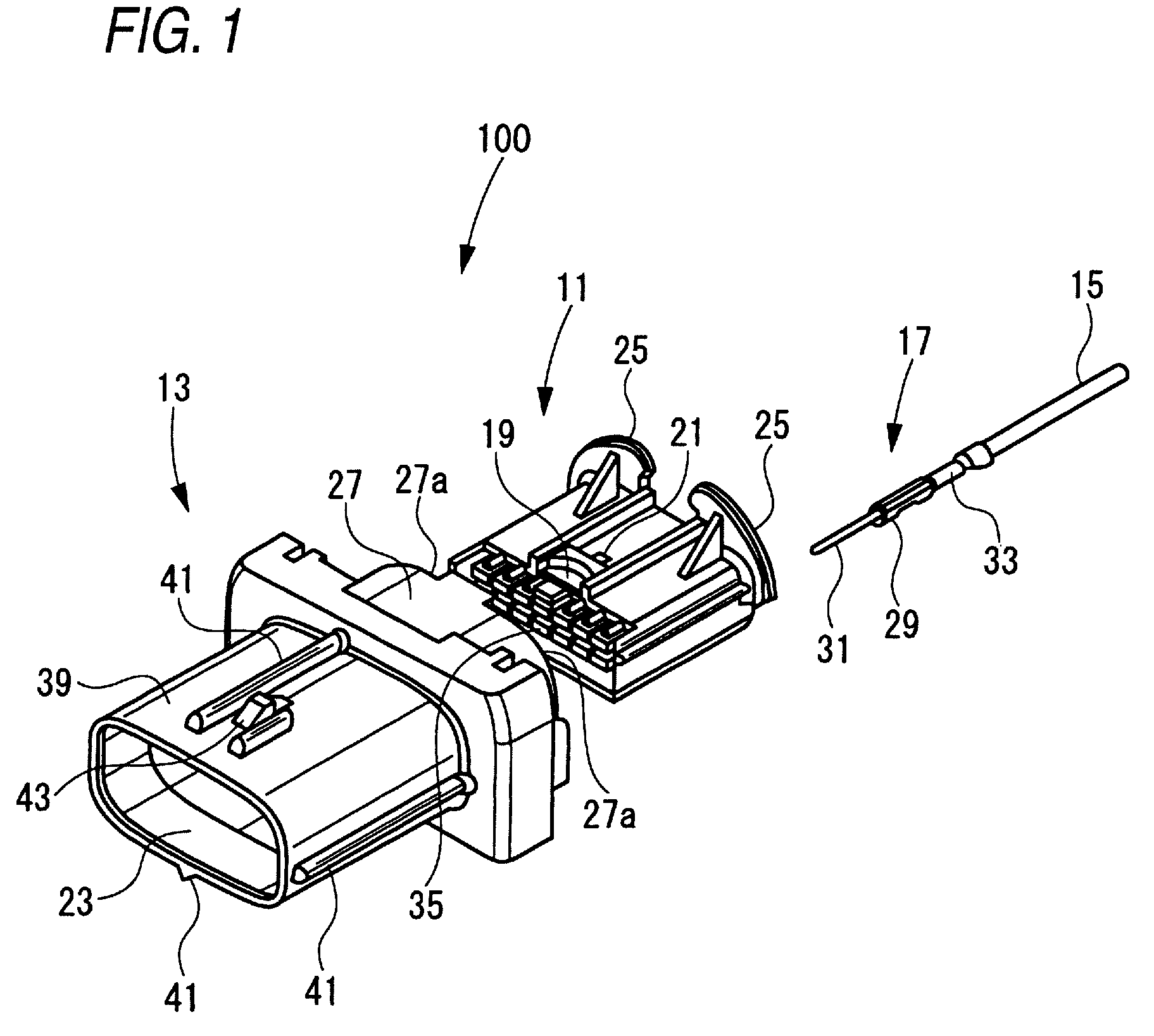

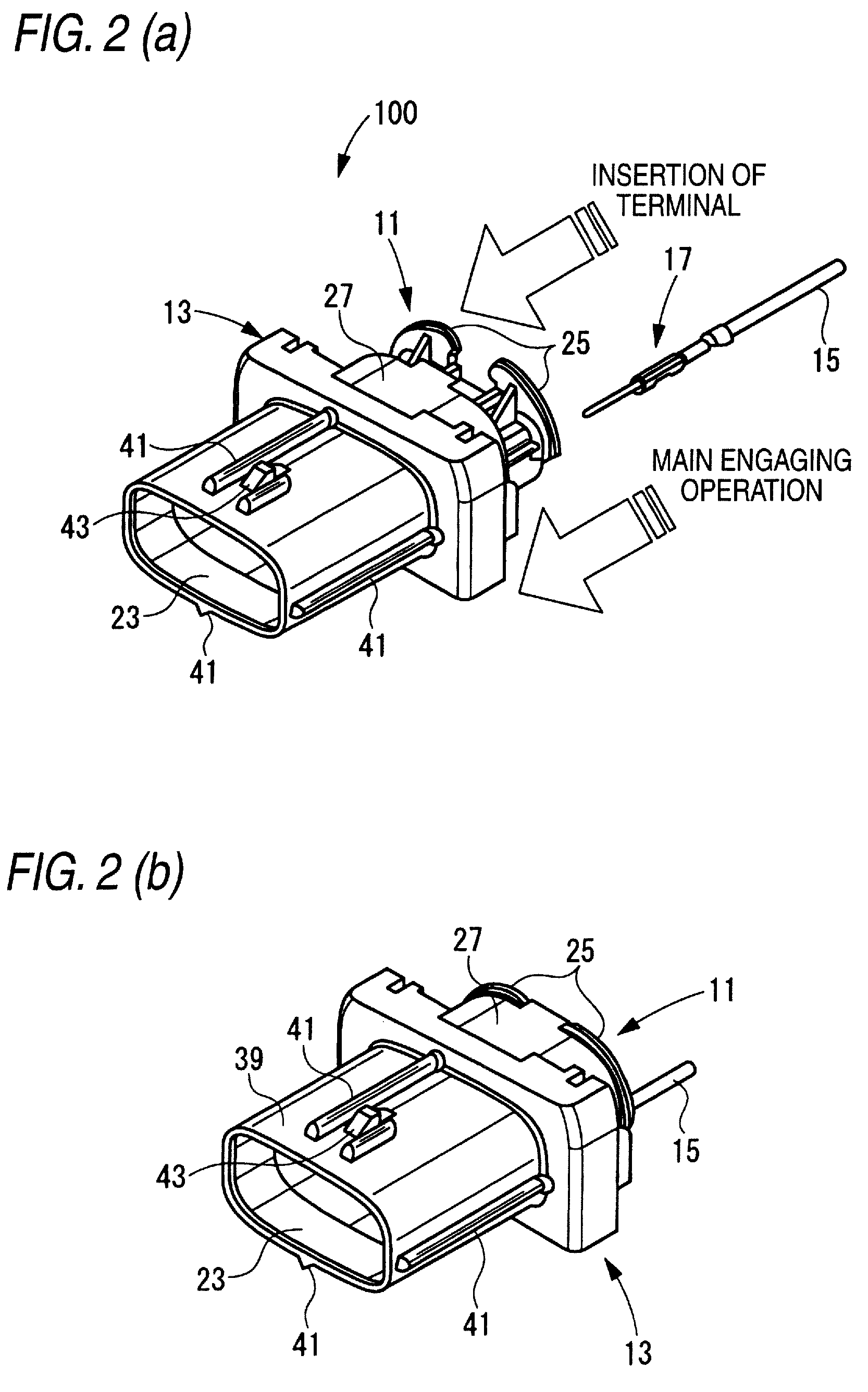

Divided connector

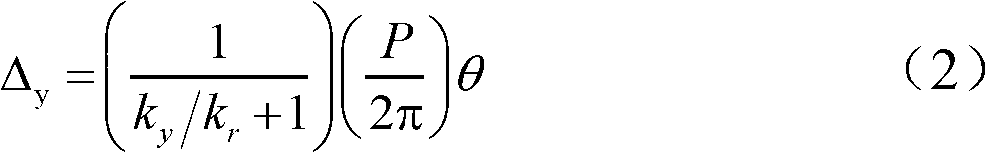

ActiveUS20100136829A1High strengthNo backlashIncorrect coupling preventionSecuring/insulating coupling contact membersEngineeringElectric wire

A divided connector, comprises a terminal having an electric contact part protruding from a main body front part and an electric wire attached under pressure to a main body rear part; an inner housing that allows the terminal inserted into an inner part to be engaged with a terminal engaging piece and attached and the main body front part to protrude from a front end; an outer housing that allows the inner housing inserted into an inner part from a rear part to be engaged with a flexible engaging piece and attached; a terminal positioning regulating wall provided in the outer housing and having a contact part inserting hole for inserting the electric contact part; and a front part positioning frame protruding in the rear surface of the terminal positioning regulating wall correspondingly to the contact part inserting hole to enclose and position the main body front part.

Owner:YAZAKI CORP

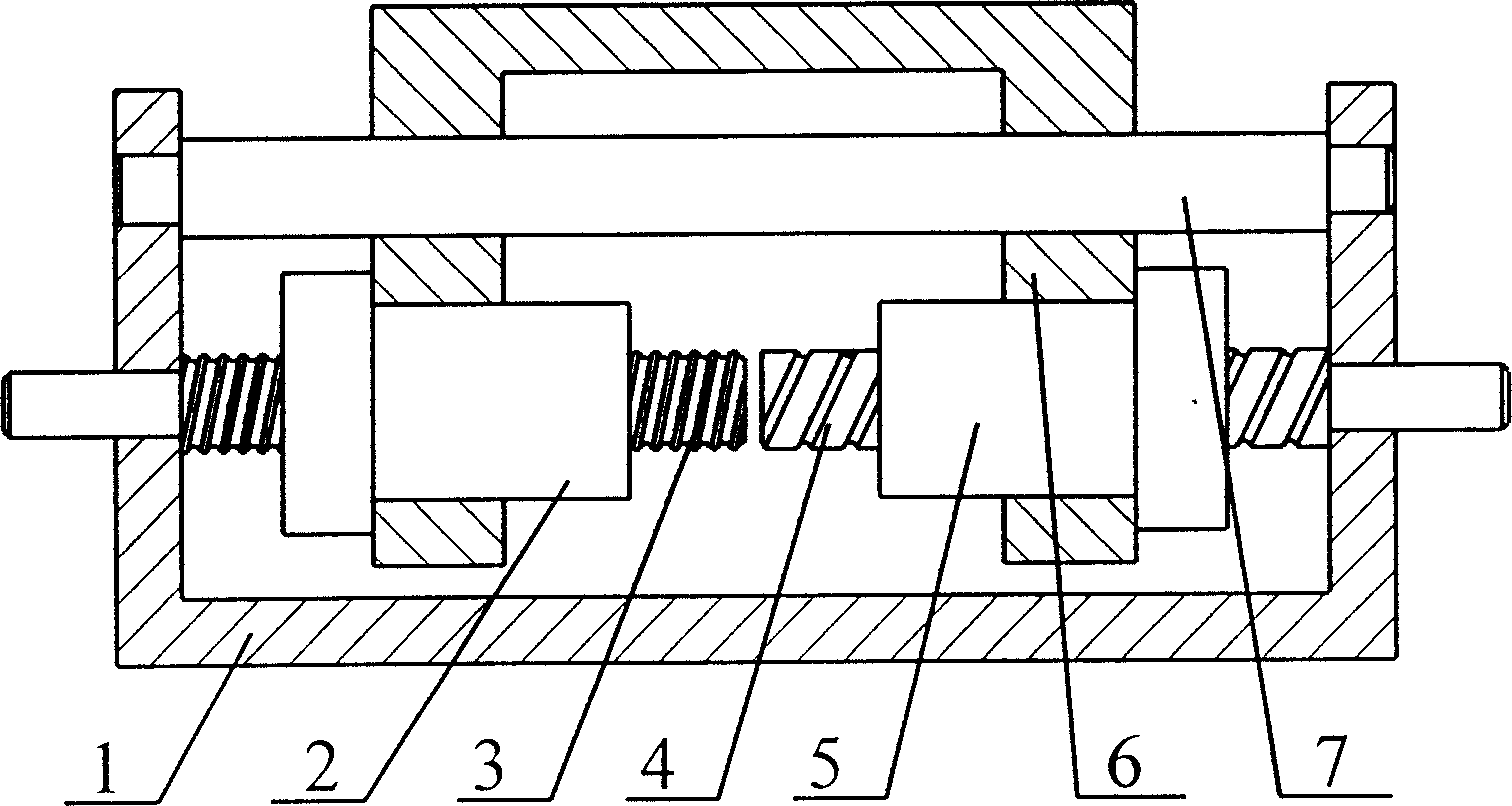

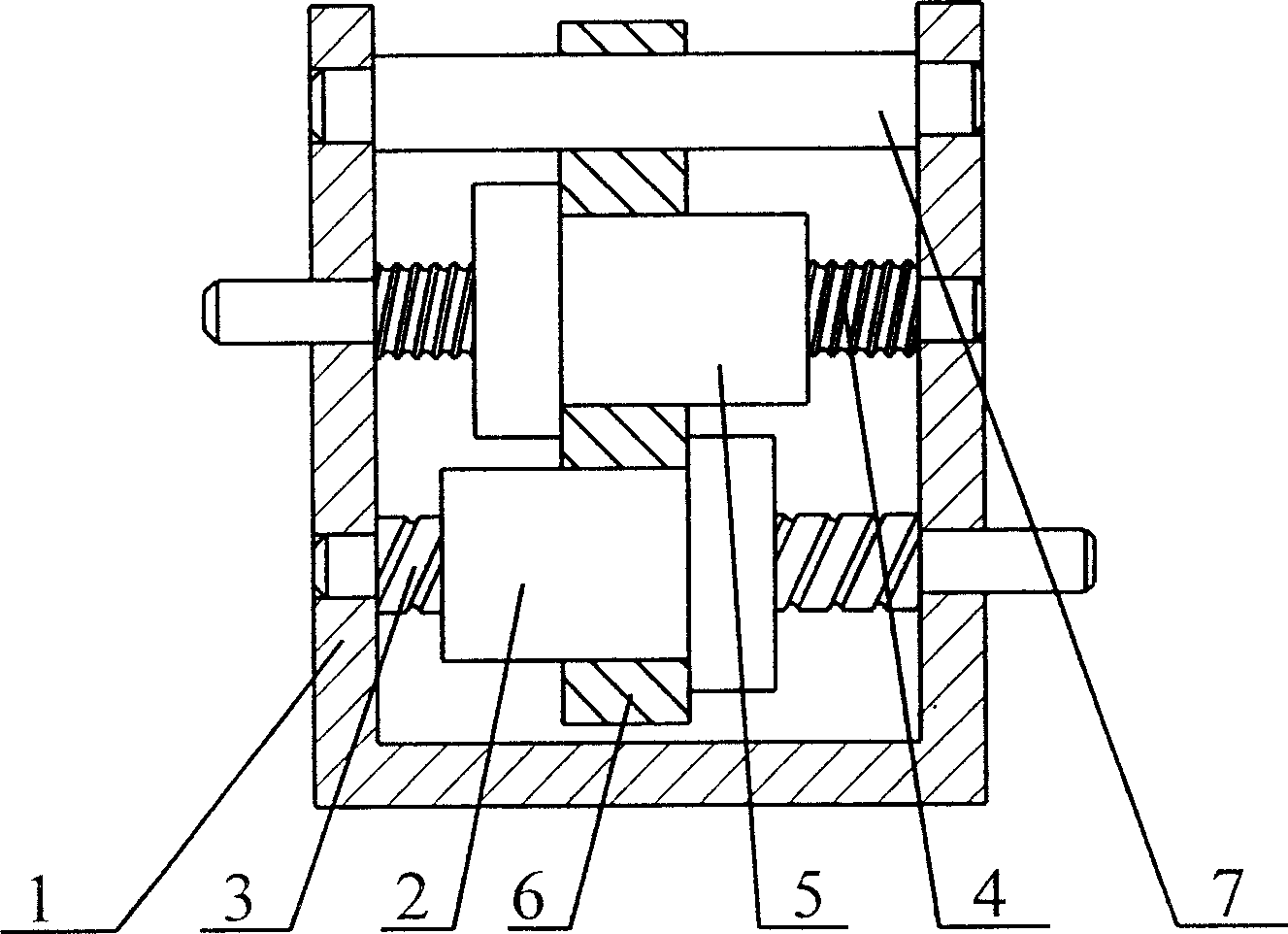

Zero gap speed changing mechanism

InactiveCN1719069AHigh transmission precisionNo backlashGearingGearing detailsEngineeringMetallic Lead

The present invention relates to a gapless speed-changing mechanism, belonging to the field of mechanical transmission. Its structure is characterized by that on its support two rolling screw rods with different leads and guideways are axially parallelly mounted, on said two rolling screw rods respectively are mounted puller nuts, the driving block mounted on the guideway is connected with puller nut, and the axises of two rolling screw rods are coaxial or not coaxial.

Owner:HEBEI UNIV OF TECH

Jib-type crane pulley device

The invention discloses a jib-type crane pulley device which comprises a pulley and a pulley shaft. The pulley comprises a rim with a U-shaped rope groove, a hub, a spoke and a swinging mechanism, wherein the spoke is connected with the rim and the hub, the swinging mechanism comprises an inner ball, a steel ring and a positioning sleeve, the inner ball is sleeved in an inner ring of the steel ring, the ball center of the inner ball is superposed on the circle center of the steel ring which is fixedly connected with the hub by the positioning sleeve, and the inner ball is provided with a pulley shaft hole matched with the pulley shaft which penetrates through the pulley shaft hole of the inner ball of the swinging mechanism and is in rotating connection with the inner ball. When the jib-type crane pulley device is in use, the pulley can wholly swing along with the inclination direction of a hoisted object to constantly keep a force position kept in the center of the pulley so that the rope groove can not be deformed due to unbalanced force, a steel wire is prevented from jumping to cause danger, the deformation of the pulley is effectively lessened in the use process, and the pulley has prolonged service life and is safe to hoist.

Owner:CHANGZHOU CHANGKUANG HOISTING MACHINERY

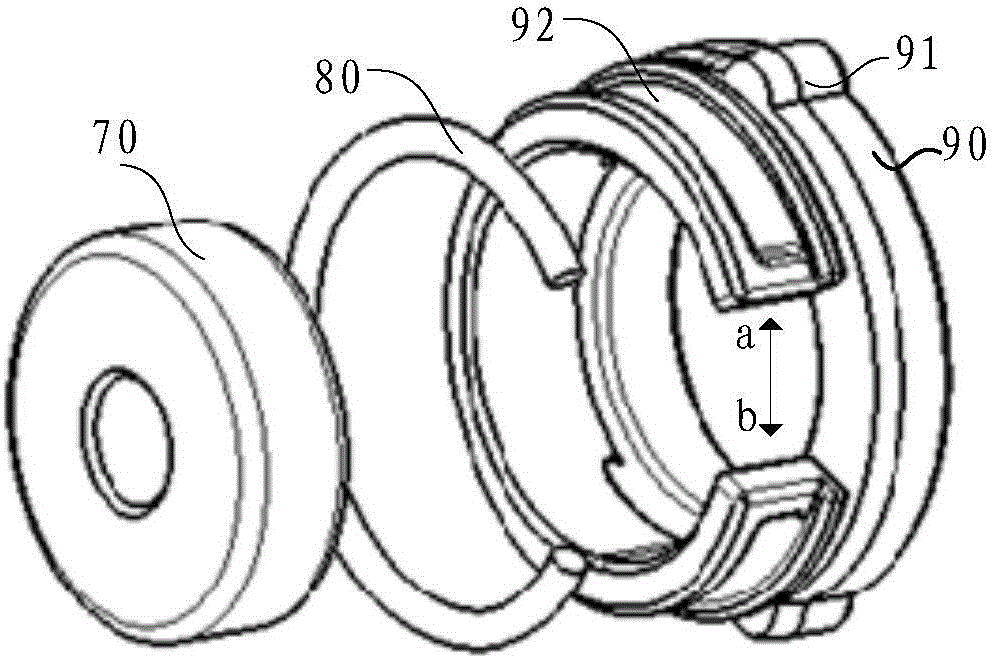

Fine adjustment device for capacitive sensor

InactiveCN102840820AAdapt to the needs of different sensitivitiesSmall amount of fine-tuningUsing electrical meansBall bearingCapacitive sensing

The invention discloses a fine adjustment device for a capacitive sensor. A fixed sleeve, a spring A, a check ring, a spring B, a one-way thrust ball bearing and a fine adjustment sleeve are sleeved on a capacitive probe from front to back in sequence; the check ring is fixedly connected with the capacitive probe; the fixed sleeve and the fine adjustment sleeve are in slidable nesting with the capacitive probe; the fixed sleeve is in threaded connection with the fine adjustment sleeve; one side of the one-way thrust ball bearing is in contact with the spring B, and the other side of the one-way thrust ball bearing is in contact with the bottom surface of the fine adjustment sleeve; and the rigidity of the spring B is less than the rigidity of the spring A. According to the fine adjustment device, smaller fine adjustment can be realized by using a double-spring fine adjustment structure, and no reverse clearance is formed, so that the fine adjustment for the distance between a probe of the capacitive sensor and a tested workpiece is smaller; and the fine adjustment device is more convenient to adjust.

Owner:XIAN UNIV OF TECH

Divided connector for regulating a terminal

ActiveUS7896696B2High strengthNo backlashIncorrect coupling preventionSecuring/insulating coupling contact membersEngineeringElectric wire

A divided connector, comprises a terminal having an electric contact part protruding from a main body front part and an electric wire attached under pressure to a main body rear part; an inner housing that allows the terminal inserted into an inner part to be engaged with a terminal engaging piece and attached and the main body front part to protrude from a front end; an outer housing that allows the inner housing inserted into an inner part from a rear part to be engaged with a flexible engaging piece and attached; a terminal positioning regulating wall provided in the outer housing and having a contact part inserting hole for inserting the electric contact part; and a front part positioning frame protruding in the rear surface of the terminal positioning regulating wall correspondingly to the contact part inserting hole to enclose and position the main body front part.

Owner:YAZAKI CORP

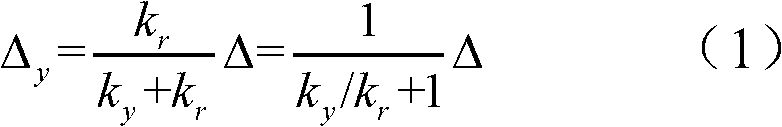

Precision micrometric displacement actuator used under polar region low-temperature environment

The invention provides a precision micrometric displacement actuator used under a polar region low-temperature environment, and relates to the precision micrometric displacement actuator. The precision micrometric displacement actuator solves the problem a supporting and adjusting mechanism suitable for a large-scale segmented mirror telescope under the polar region low-temperature environment does not exist at present. A base plate is mounted in a shell, a rolling linear guide rail is mounted on the base plate, and a left end cap and a right end cap are arranged at the two ends of the shell in a covering mode respectively. A flexible shaft is mounted on a driving rod, a motor seat is mounted on the rolling linear guide rail, and a stepping motor is mounted on the motor seat. One end of a screw rod is connected with the stepping motor through an elastic coupler, a base is mounted on the base plate, and a sleeve is mounted in the base. A first nut is mounted at the left end of the driving rod, a second nut is mounted at the right end of the sleeve, and the other end of the screw rod is screwed on the second nut and the first nut. One end of the driving rod is inserted into the sleeve and is connected with the first nut, and the other end of the screw rod is connected with the flexible shaft. A shaft sleeve is arranged on the driving rod in a sleeved mode, and a pre-tightening spring is arranged on the driving rod in a sleeved mode and is compressed between the first nut and the shaft sleeve. The precision micrometric displacement actuator is used in the segmented mirror telescope.

Owner:HARBIN INST OF TECH

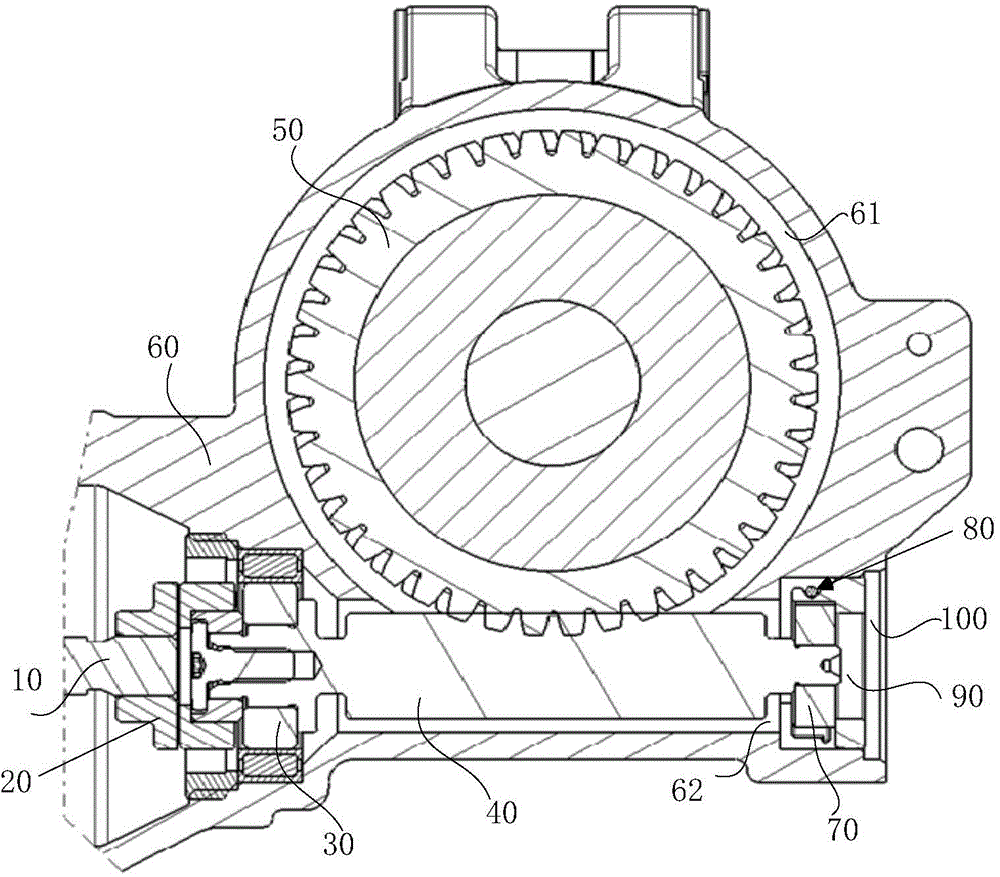

Electric power steering system and vehicle

ActiveCN105564495AAvoid noiseNo backlashElectrical steeringElectric power systemElectric power steering

Provided is an electric power steering system and a vehicle. The electric power steering system comprises a steering gear housing, a worm gear, and a worm. The steering gear housing is internally provided with a worm gear installation cavity and a worm installation cavity. The worm gear is installed in the worm gear installation cavity. The worm is installed in the worm installation cavity. The worm gear and the worm are meshed with each other. One axial end of the worm is provided with a first center distance adjusting mechanism, and the other axial end is provided with a second center distance adjusting mechanism. The first center distance adjusting mechanism and the second center distance adjusting mechanism can make the worm swing deviating the axis of the worm, so as to realize adjustment of the mesh center distance of the worm gear and the worm. Using the electric power steering system can realize mesh center distance of the worm gear and the worm, so that the mesh center distance of the worm gear and the worm is consistent with the center distance of the worm gear installation cavity and the worm installation cavity, and mesh interspace is not generated, so as to prevent to generate noise in a steering process.

Owner:SAIC MOTOR

Strainer, and snappy holding structure by the strainer

InactiveUS7977558B2Easy to operateSimple structurePercussion musical instrumentsEngineeringMechanical engineering

Intended is to provide a strainer having a switch mechanism, which is hardly rattled by a wear, which can be stably operated by a weak force, which does not load a snare assembly and which can maintain an excellent operation feel, and a snare assembly holding structure which has a reliable clamping force so that it can prevent the looseness of the snare assembly end portion. An operation lever is hinged on its base end side to a base body. A link is turnably connected on its one end side to the lower side portion of a snare assembly holding member, and is likewise turnably connected on its other end side to a midway position of the operation lever. When the operation lever turns upward, the snare assembly holding member is pulled upward through the link. When the operation lever turns downward, the snare assembly holding member is pushed downward.

Owner:SAKAE RHYTHM MUSICAL INSTR

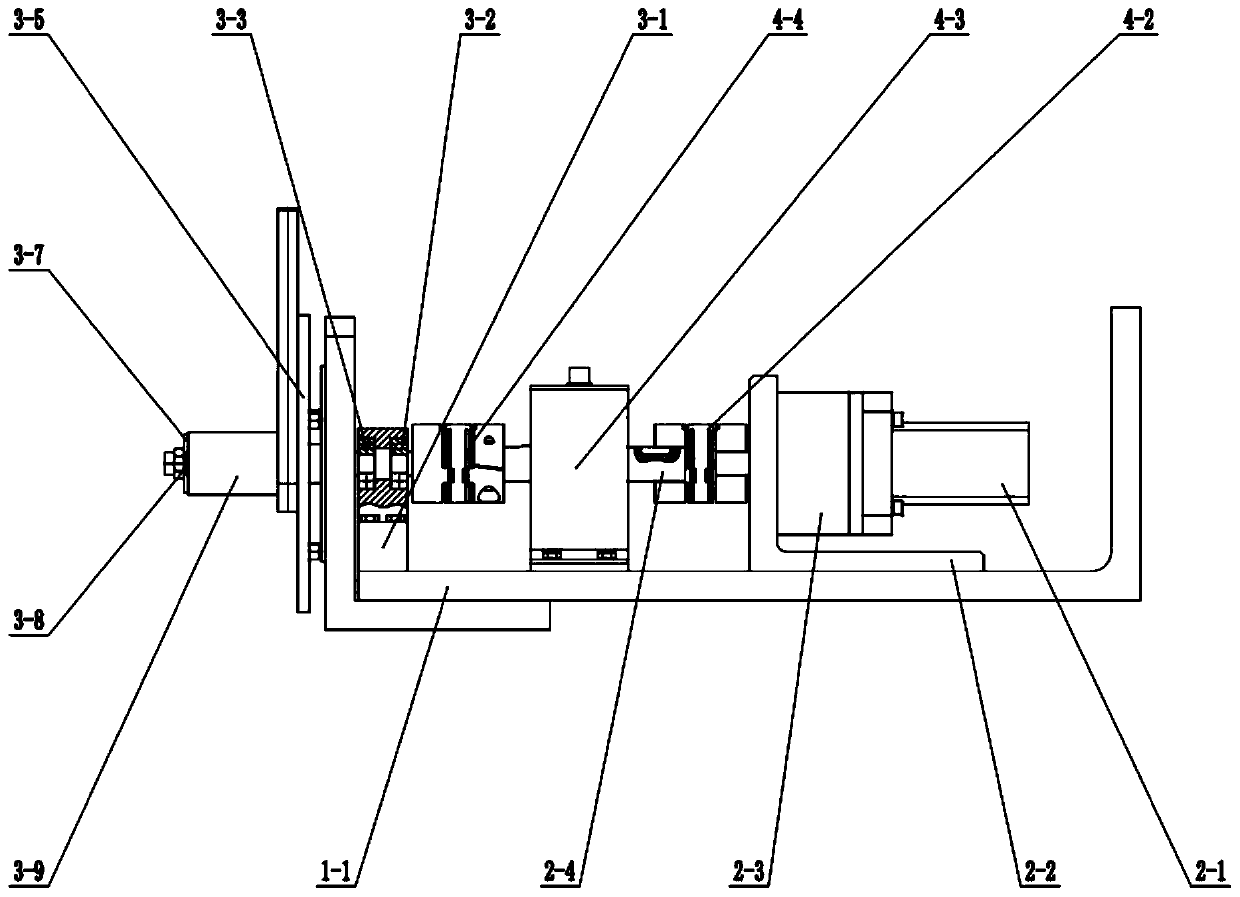

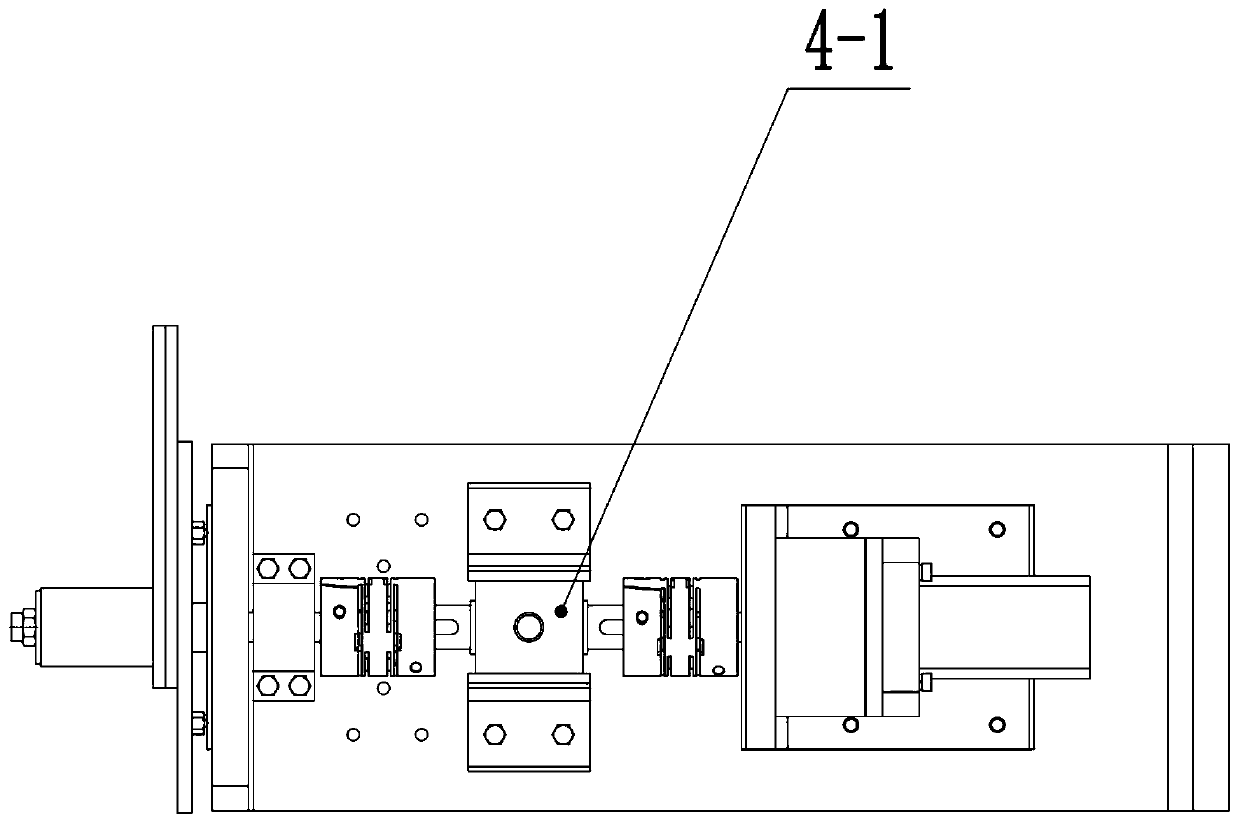

Device and method for measuring friction moment of deep groove ball bearing under gravity or microgravity

ActiveCN110426147AMeasuring frictional torqueCompact structureMachine bearings testingForce sensorsBall bearingDrive shaft

The invention discloses a device and method for measuring the friction moment of a deep groove ball bearing under gravity or microgravity, and relates to the field of bearing friction force measurement. The device comprises a mounting plate, and is characterized in that a torque sensor and an eccentric block are coaxially mounted on the mounting plate; a to-be-tested deep groove ball bearing sleeves a transmission shaft between the torque sensor and the eccentric block; a driving device is mounted on the mounting plate so as to drive the torque sensor to rotate, and the eccentric block is driven to rotate. Accordingly, gravity disturbance of a load is eliminated, the problem that the friction force of the deep groove ball bearing under the microgravity has difficulty in direct measurementis solved, and measurement of the friction force of the deep groove ball bearing under the microgravity is more convenient and accurate.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com