Patents

Literature

38results about How to "Eliminate elastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

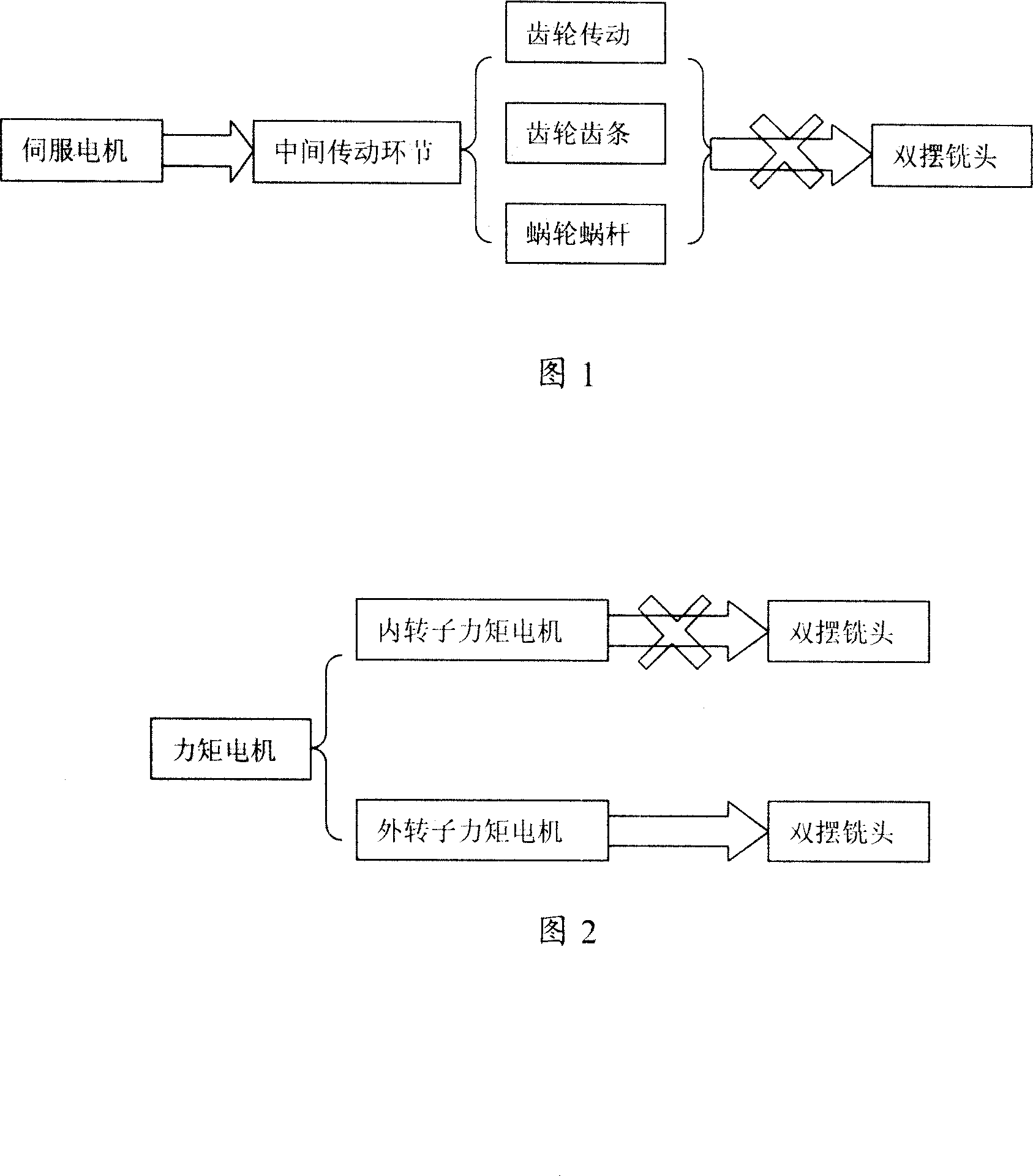

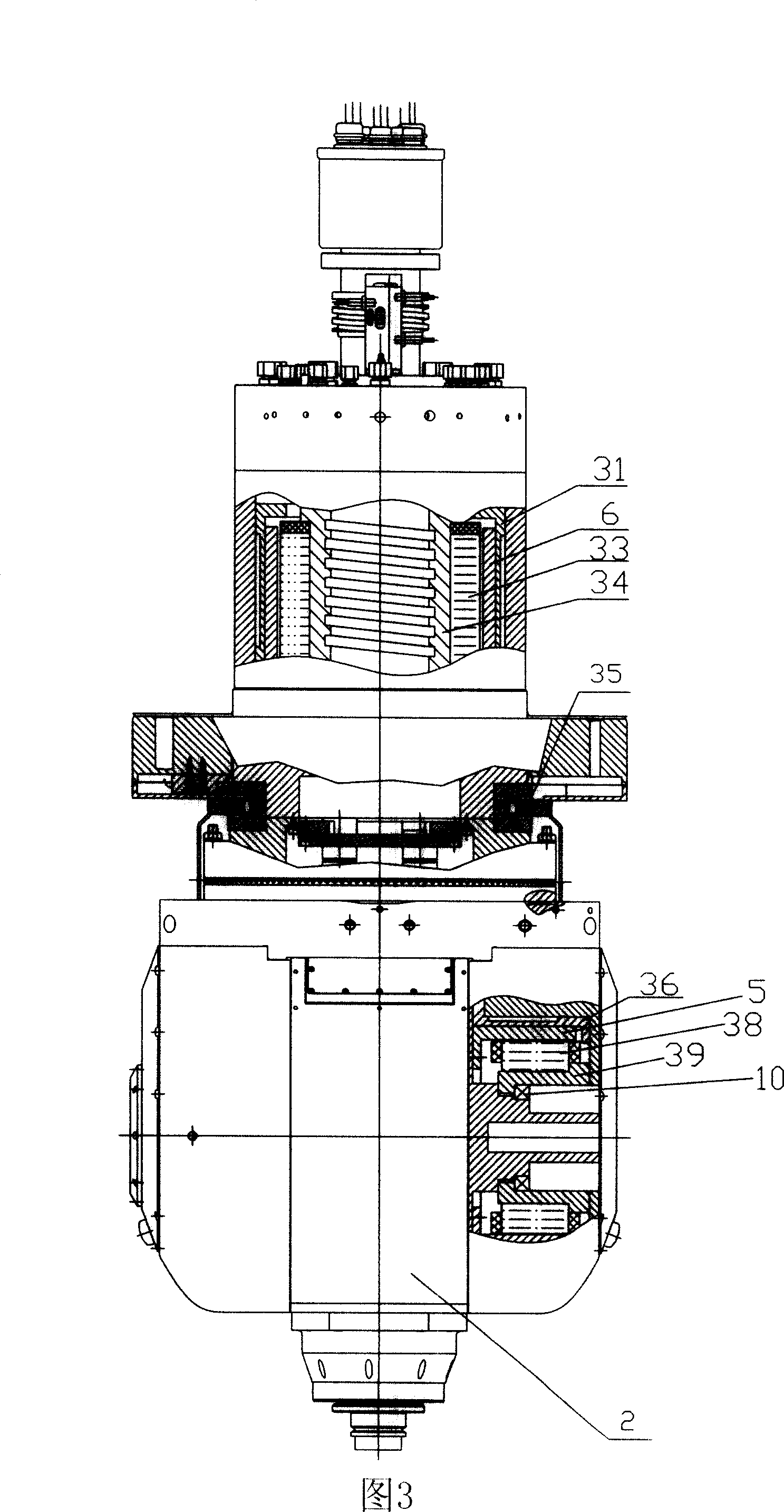

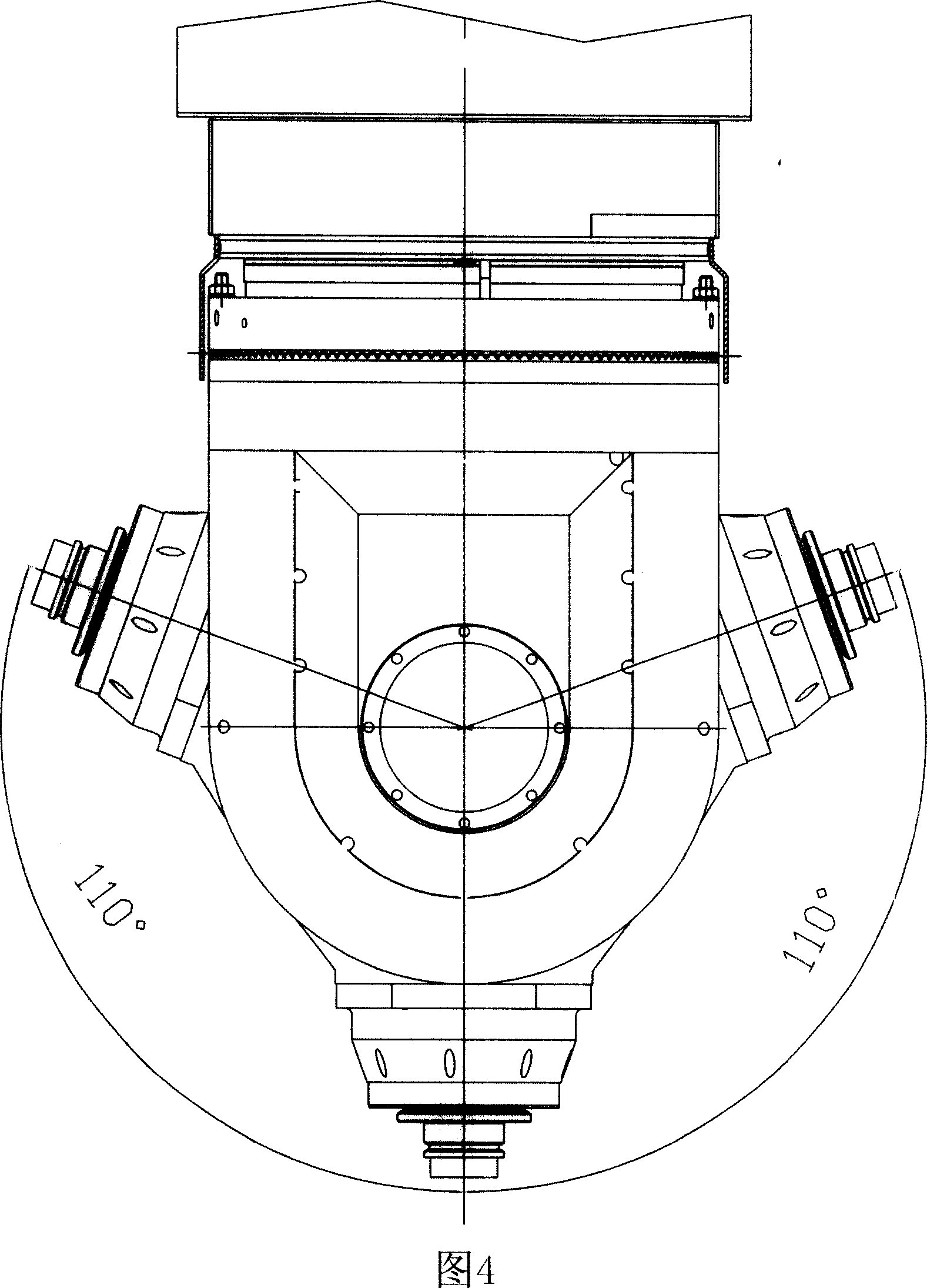

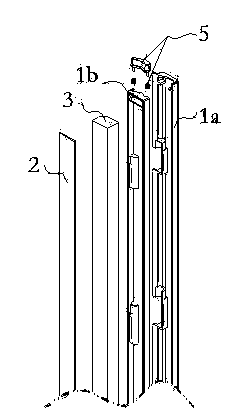

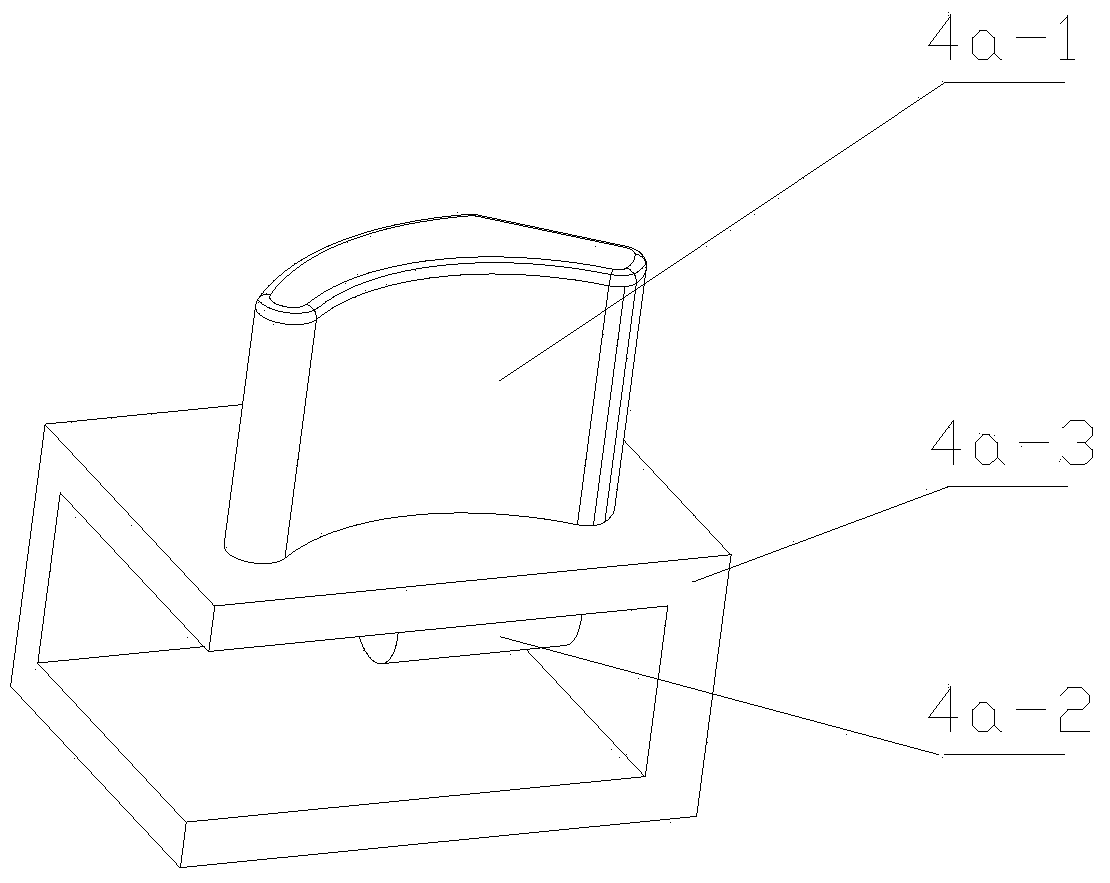

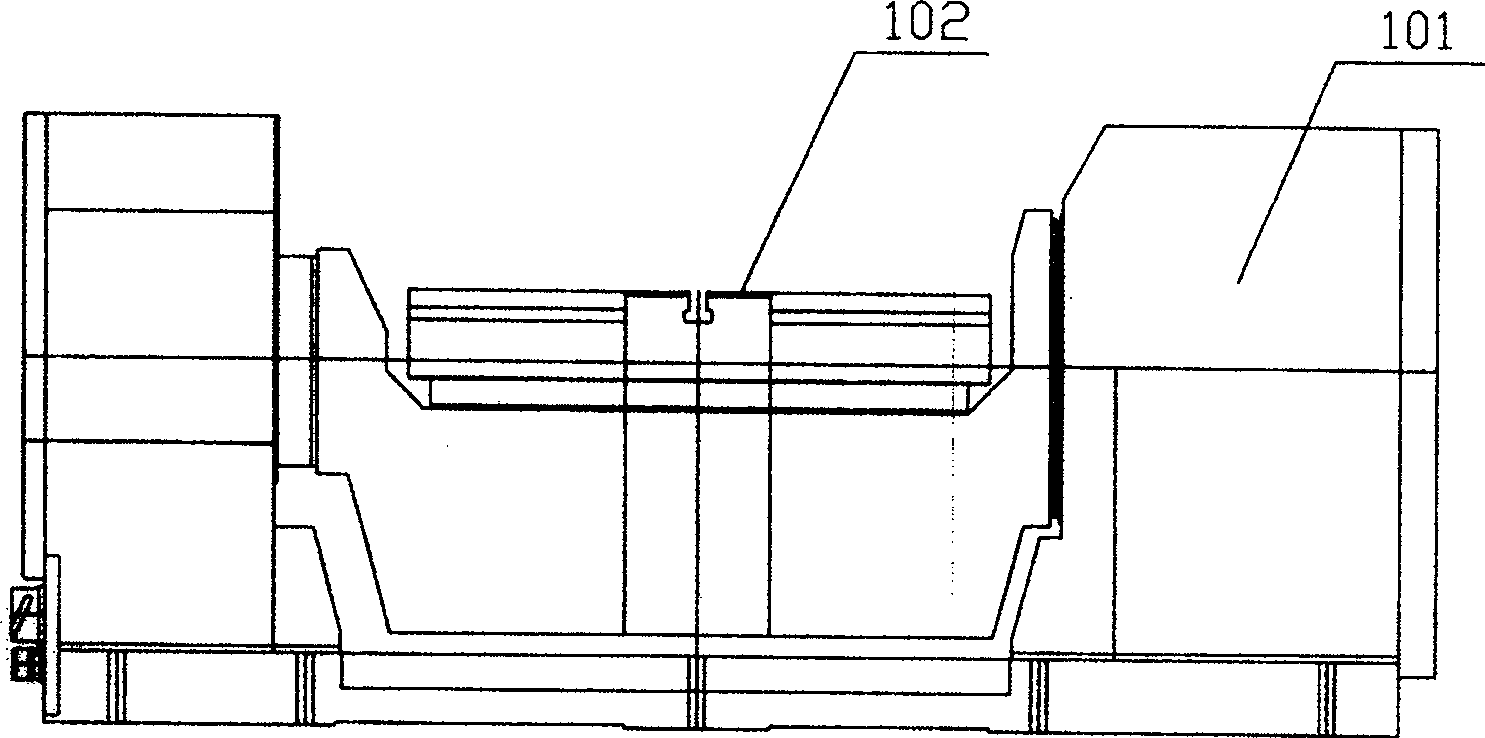

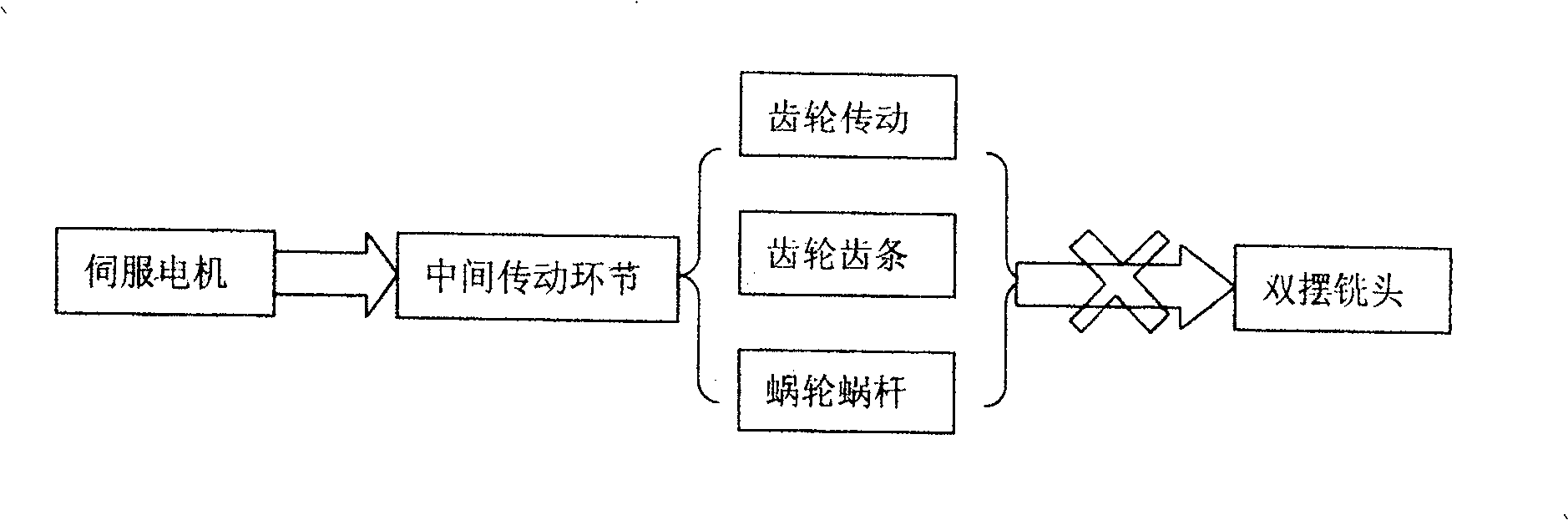

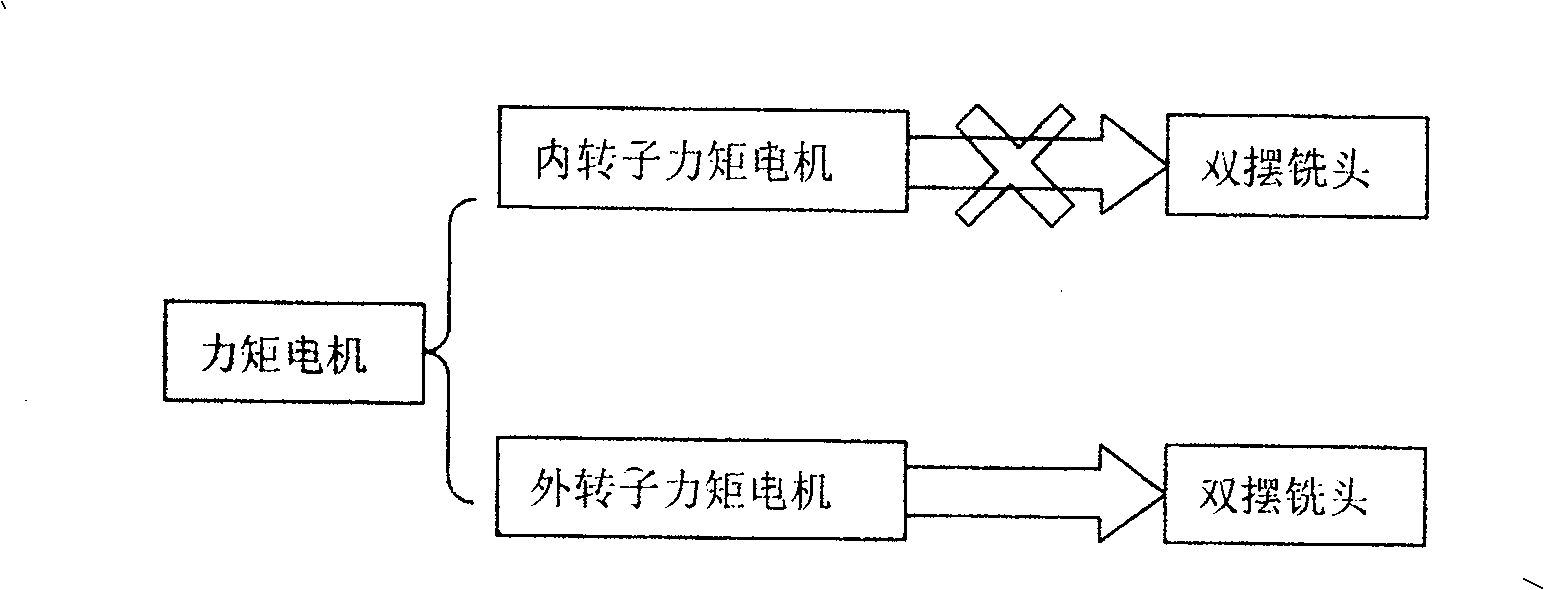

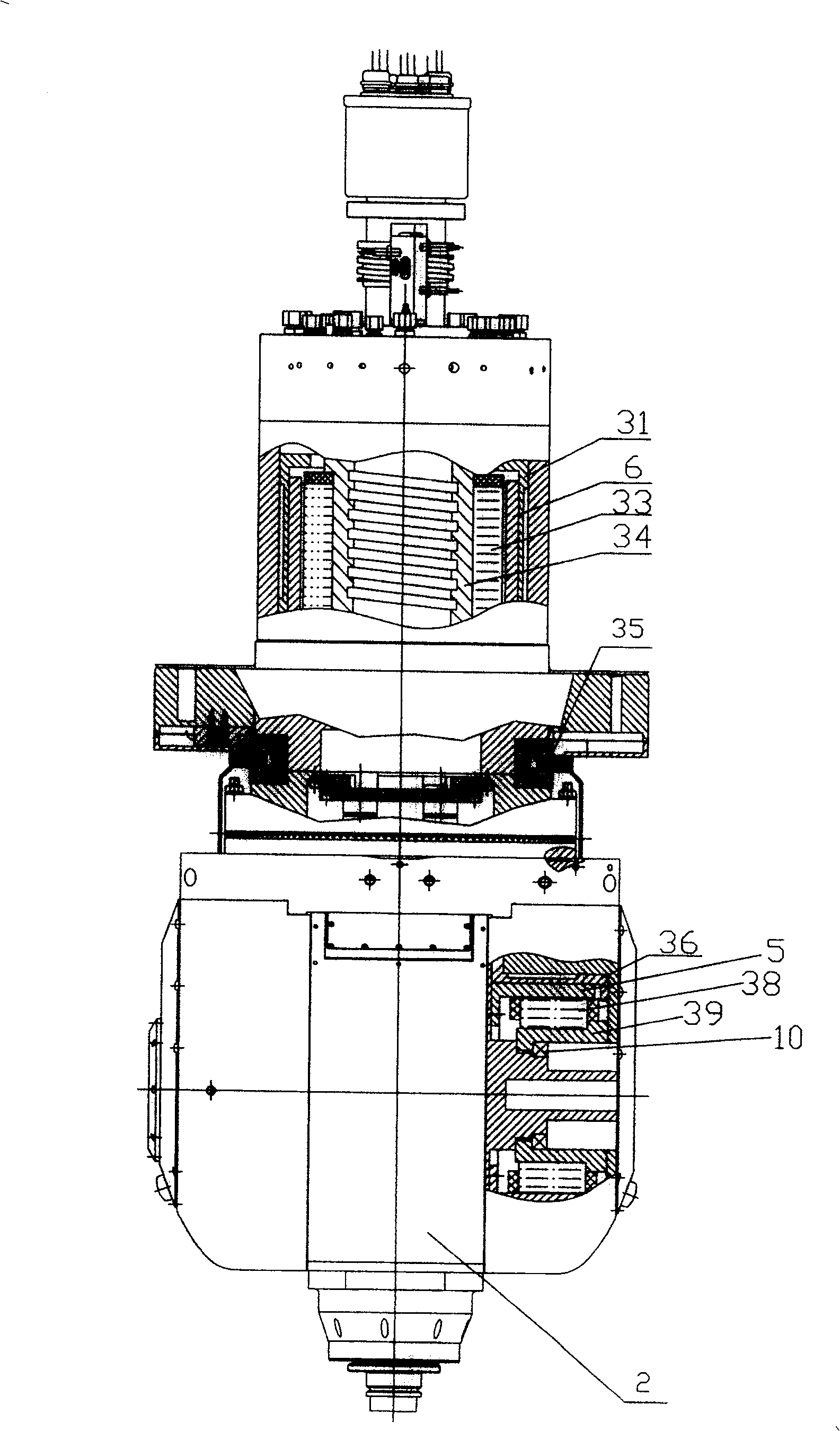

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN101011795AImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

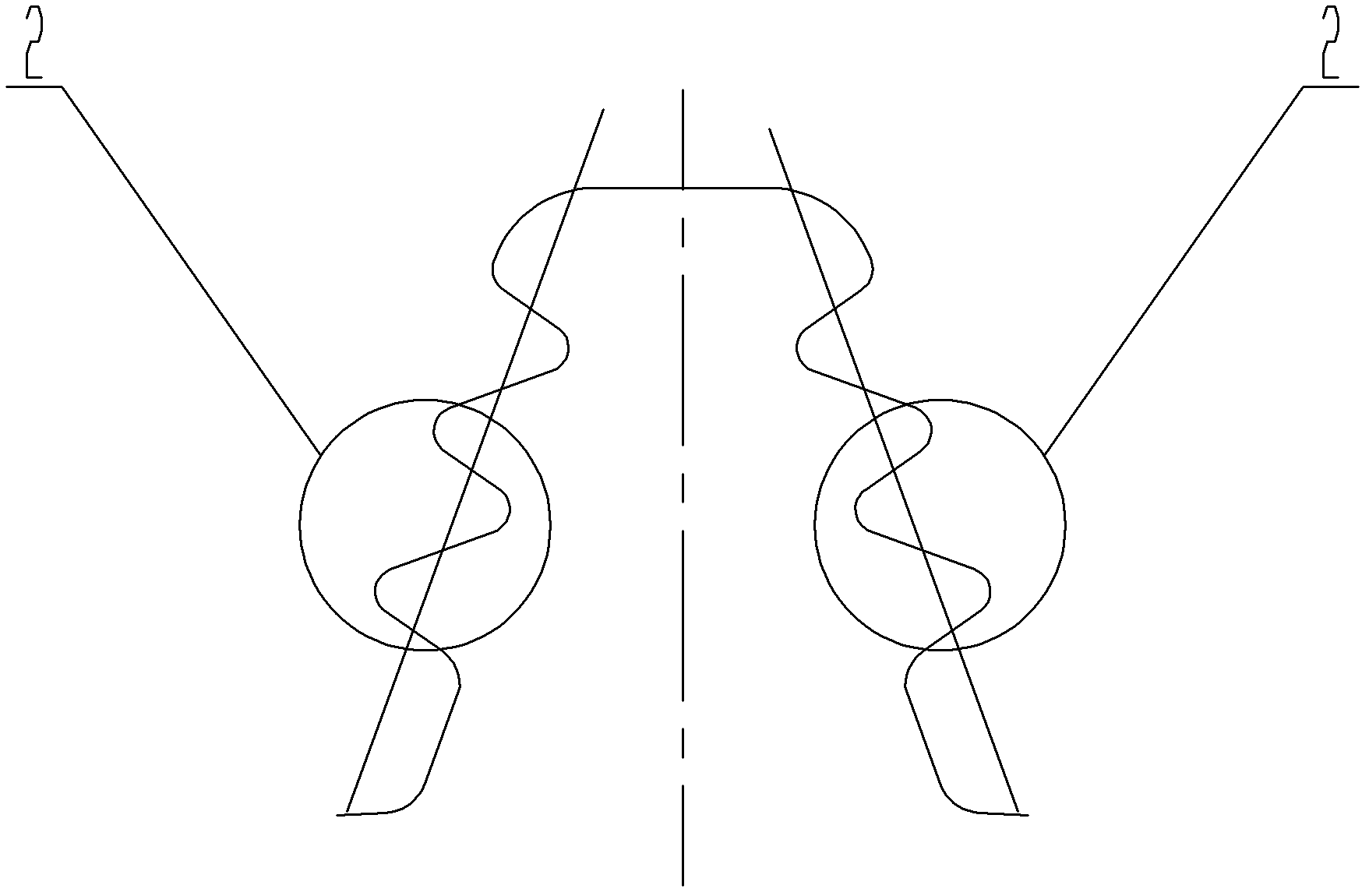

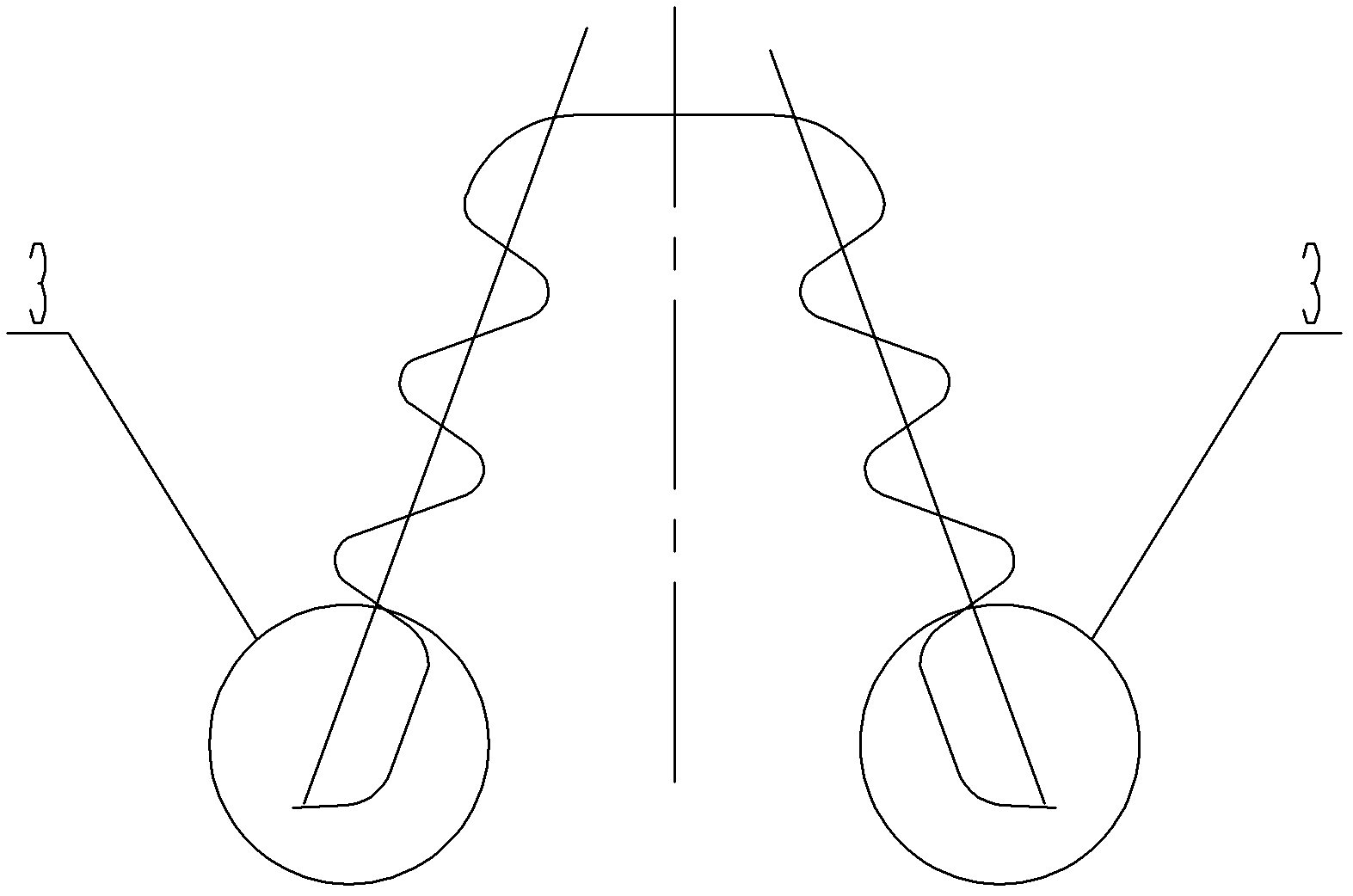

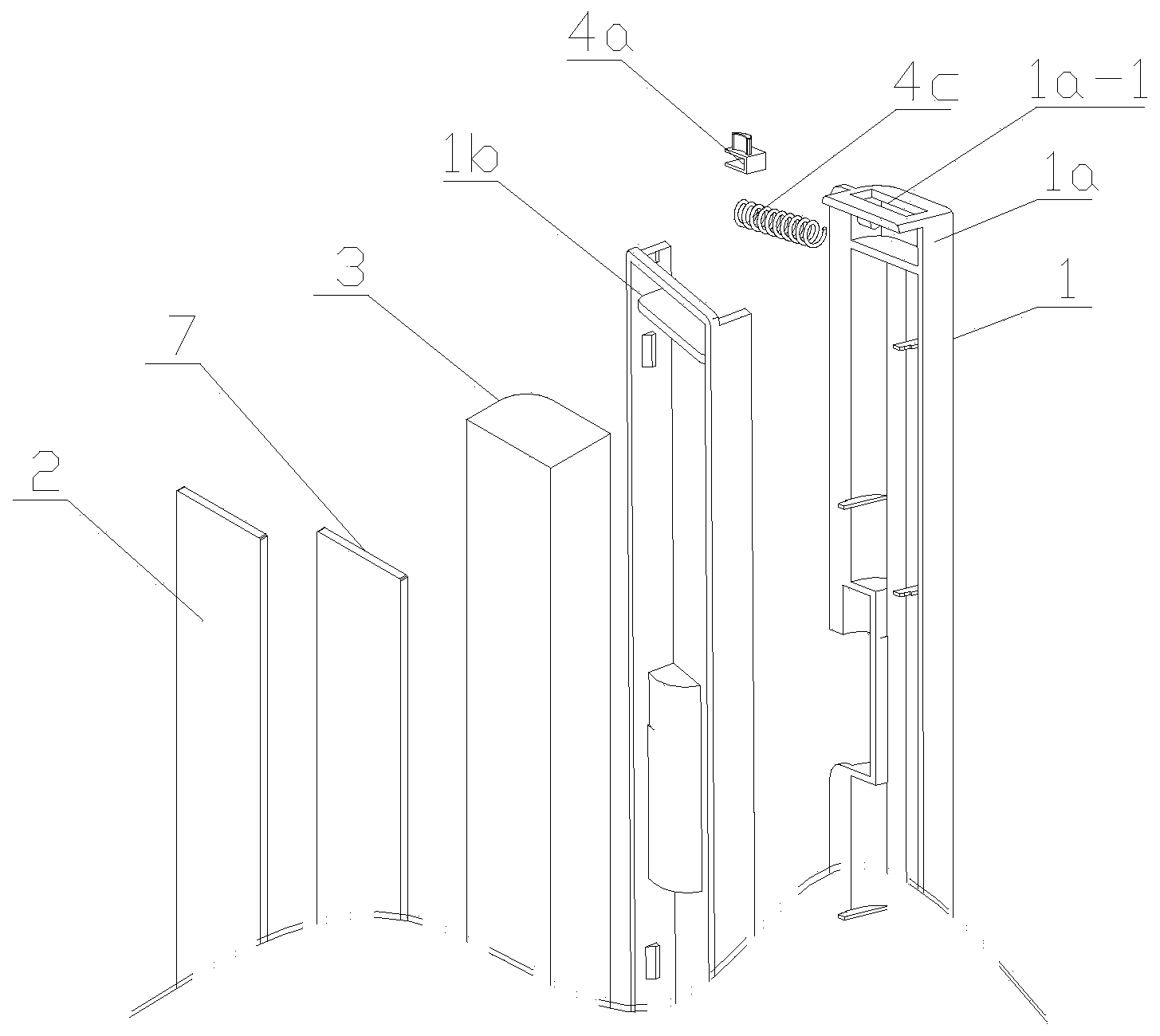

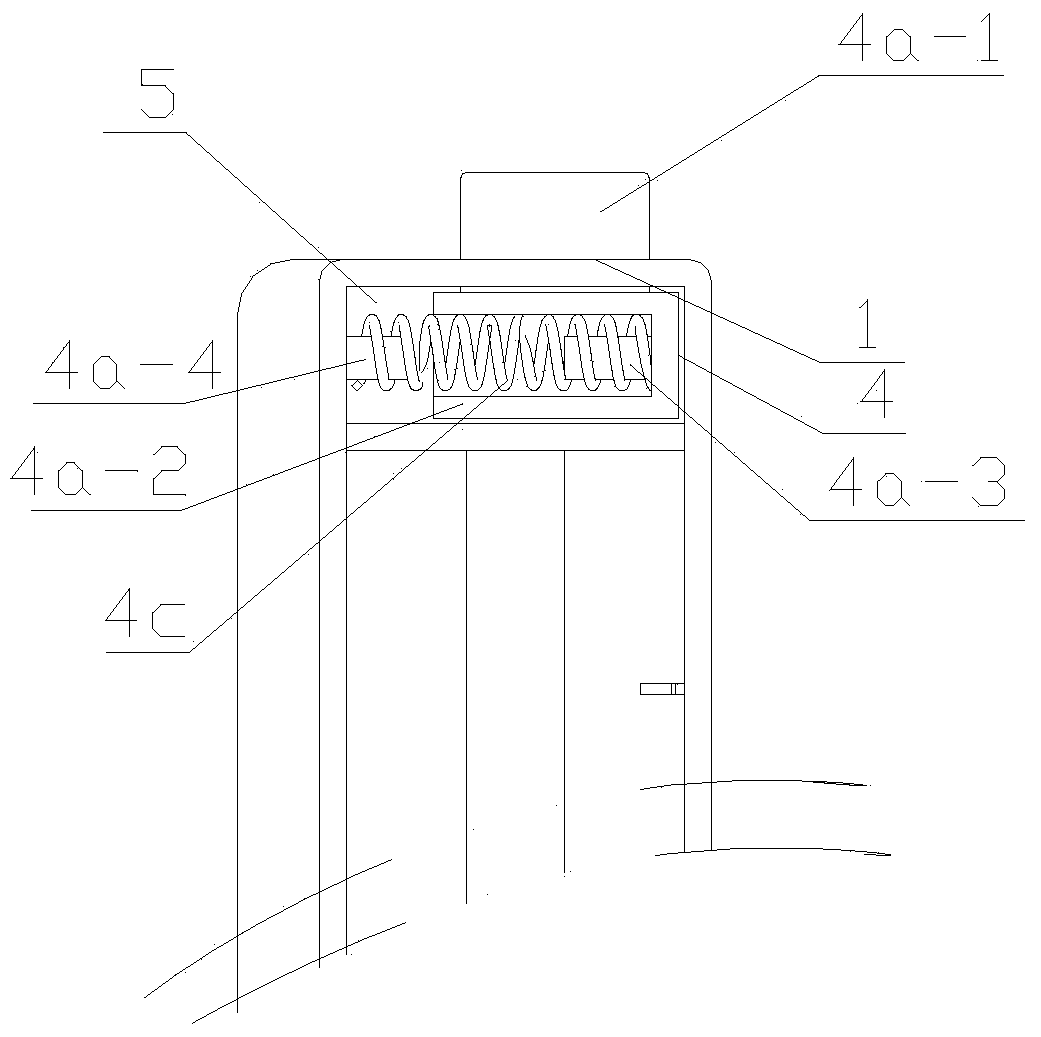

Turnover beam of side-by-side combination refrigerator

InactiveCN103727733ASo as not to damageEliminate elastic deformationLighting and heating apparatusCooling fluid circulationEngineeringRefrigerated temperature

The invention discloses a turnover beam of a side-by-side combination refrigerator. The turnover beam comprises a turnover beam body. The turnover beam body is pivotally connected onto a side wall of an optional door, and a guide seat which can guide to turnover beam body into a horizontal sate when the door is closed is arranged inside the top of a container of the refrigerator; the turnover beam body comprises an outward turnover shell and an inward turnover moving body, the inward turnover moving body can move up and down along an inner cavity of the outward turnover shell, and an elastic guide body which can be in contact with the guide seat is arranged on the top of the inward turnover moving body, and moves downwardly when being squeezed by the guide seat. The turnover beam has the advantages that the turnover beam is provided with the elastic guide body, the elastic guide body moves downwardly when squeezed by the guide seat, accordingly, interference of the guide seat on the turnover beam body can be prevented, the turnover beam does not need to be preliminarily set in a vertical state when the door is closed, and is simple in structure and high in practicality, and the operational convenience can be improved.

Owner:HEFEI SNOWKY ELECTRIC

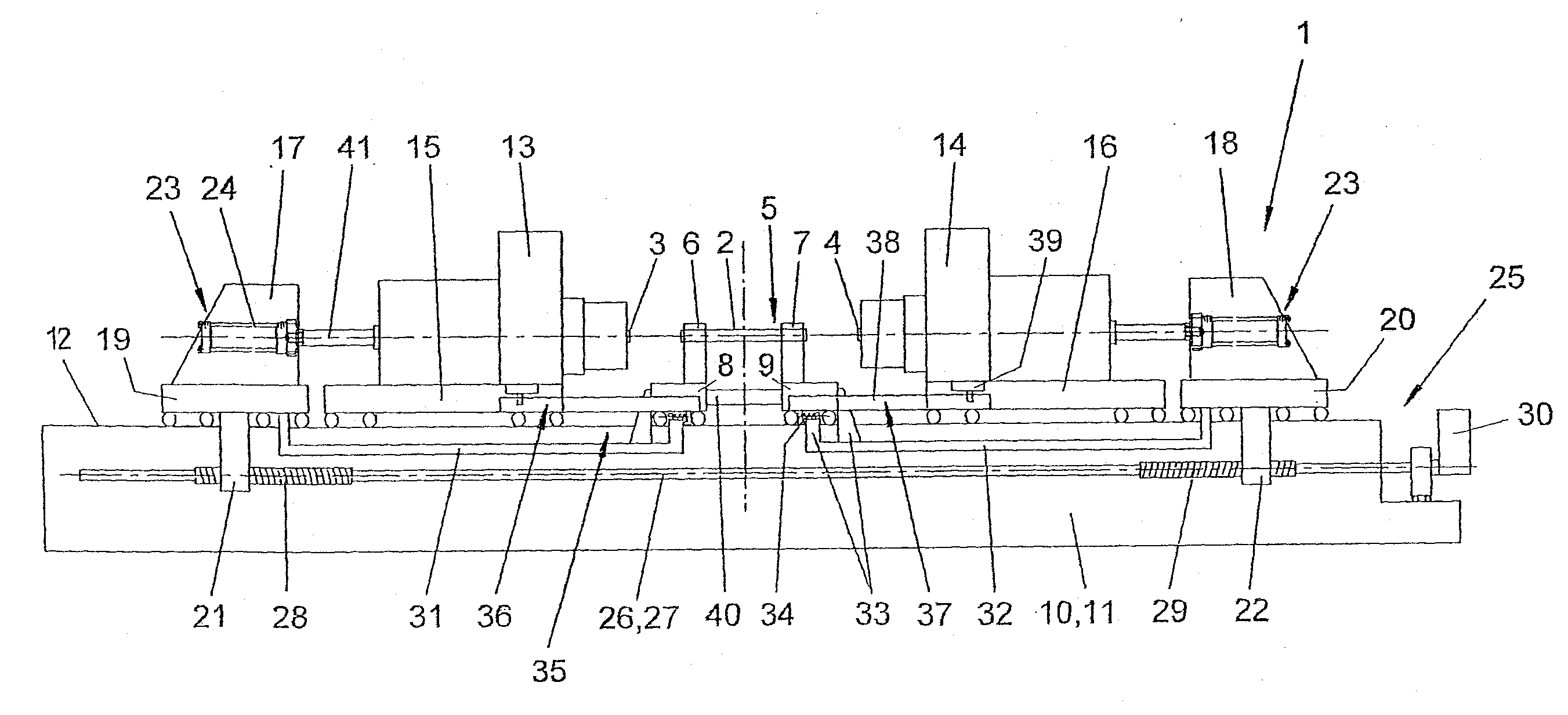

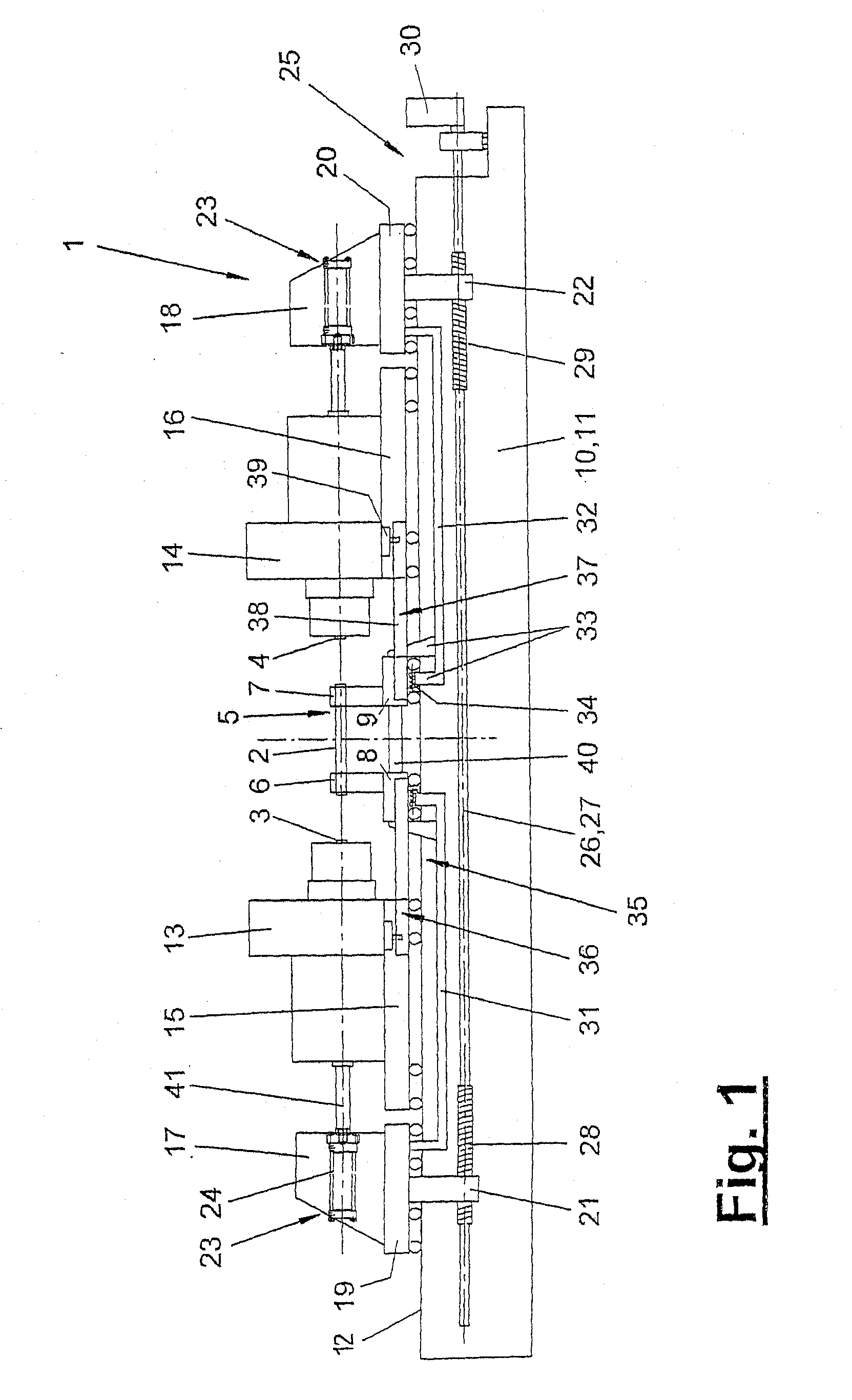

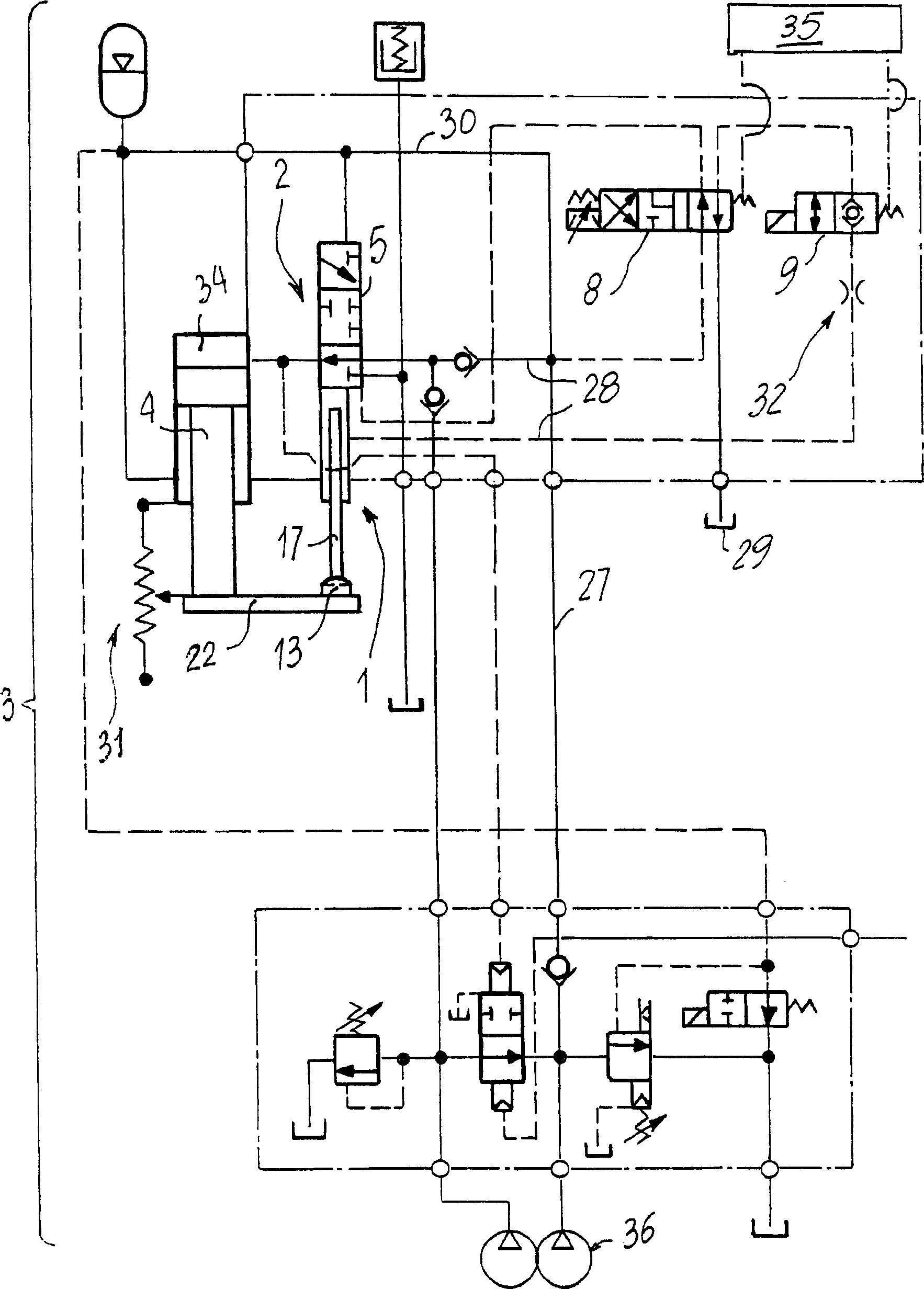

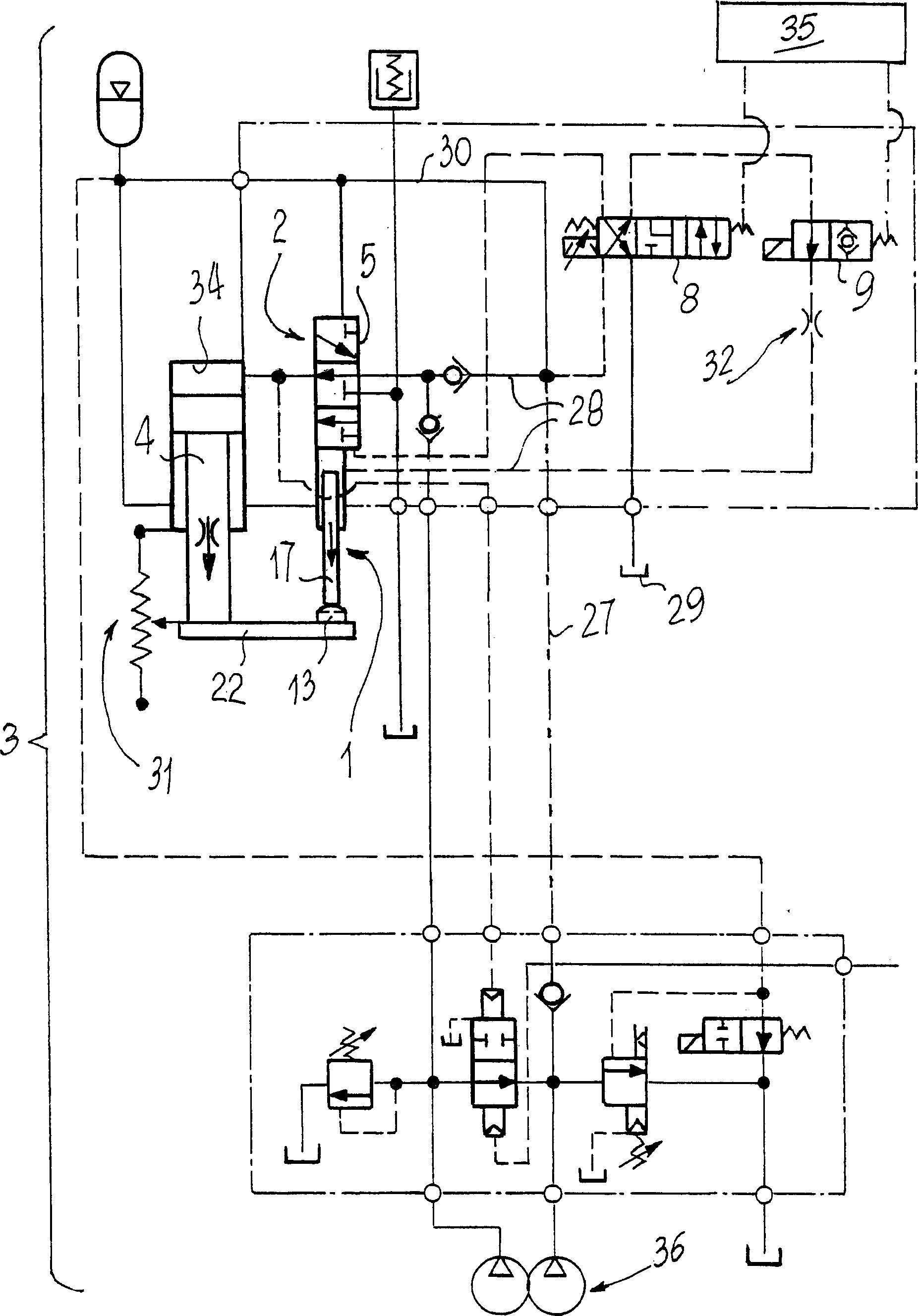

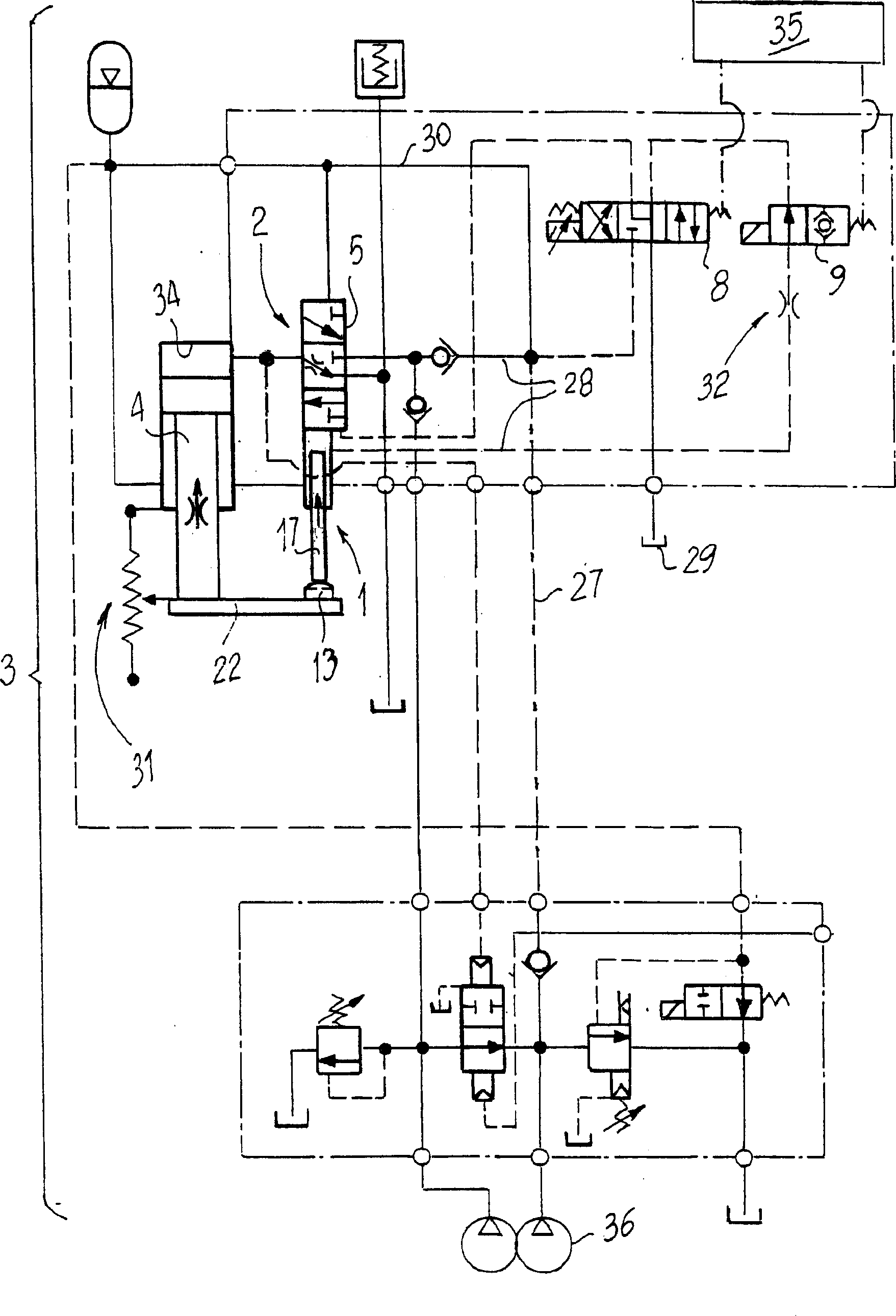

Pressure welding machine and pressure welding method

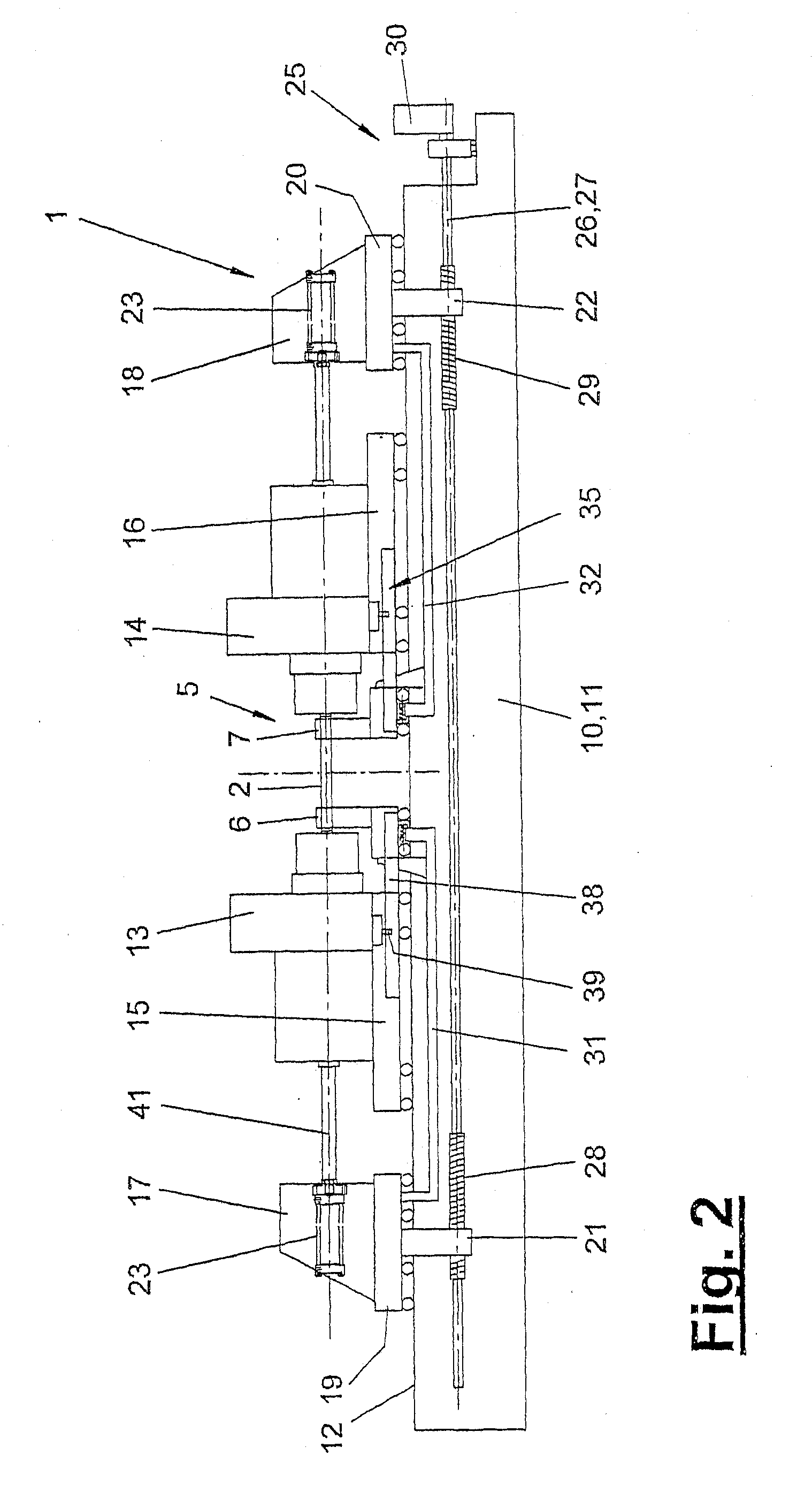

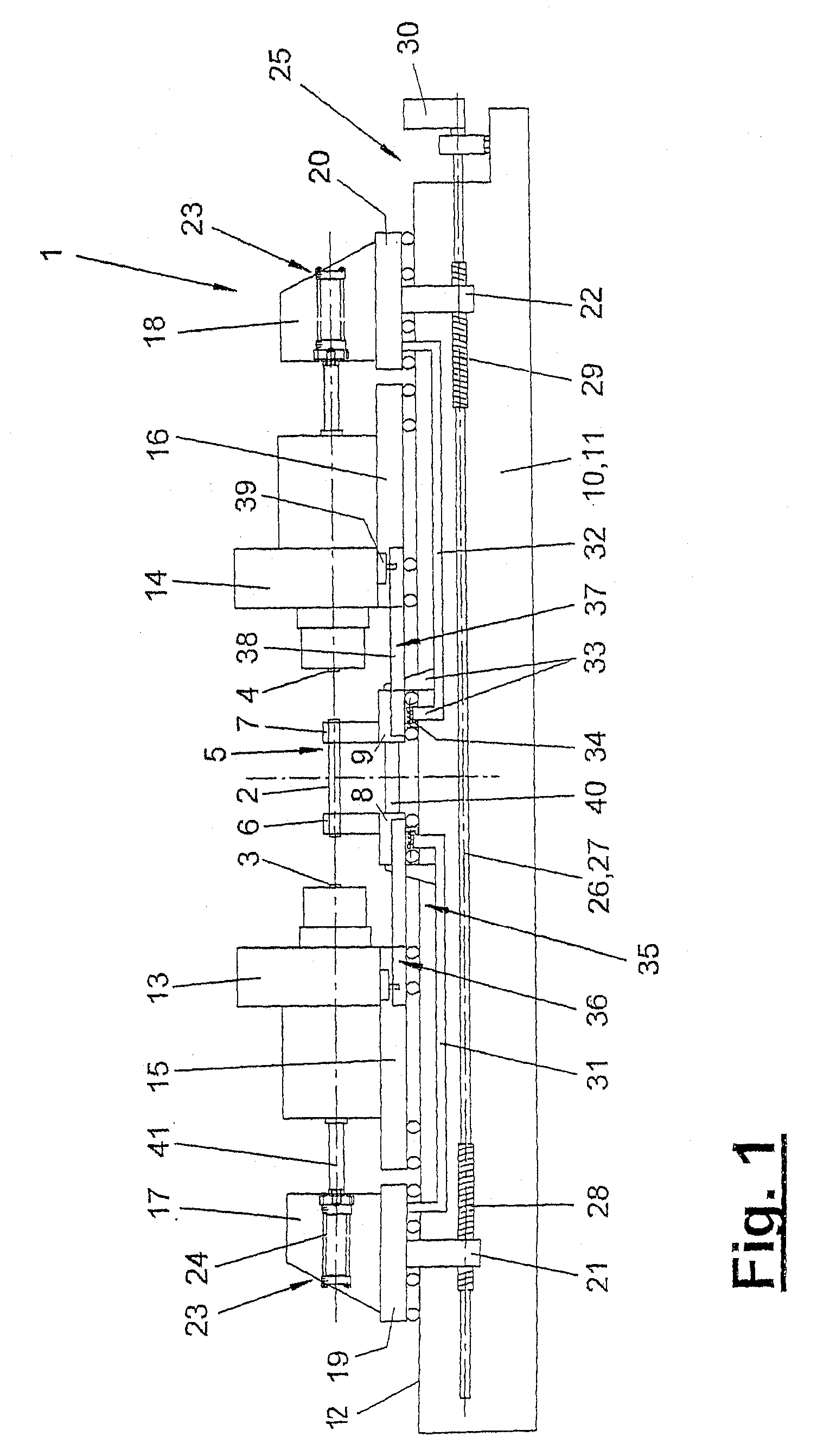

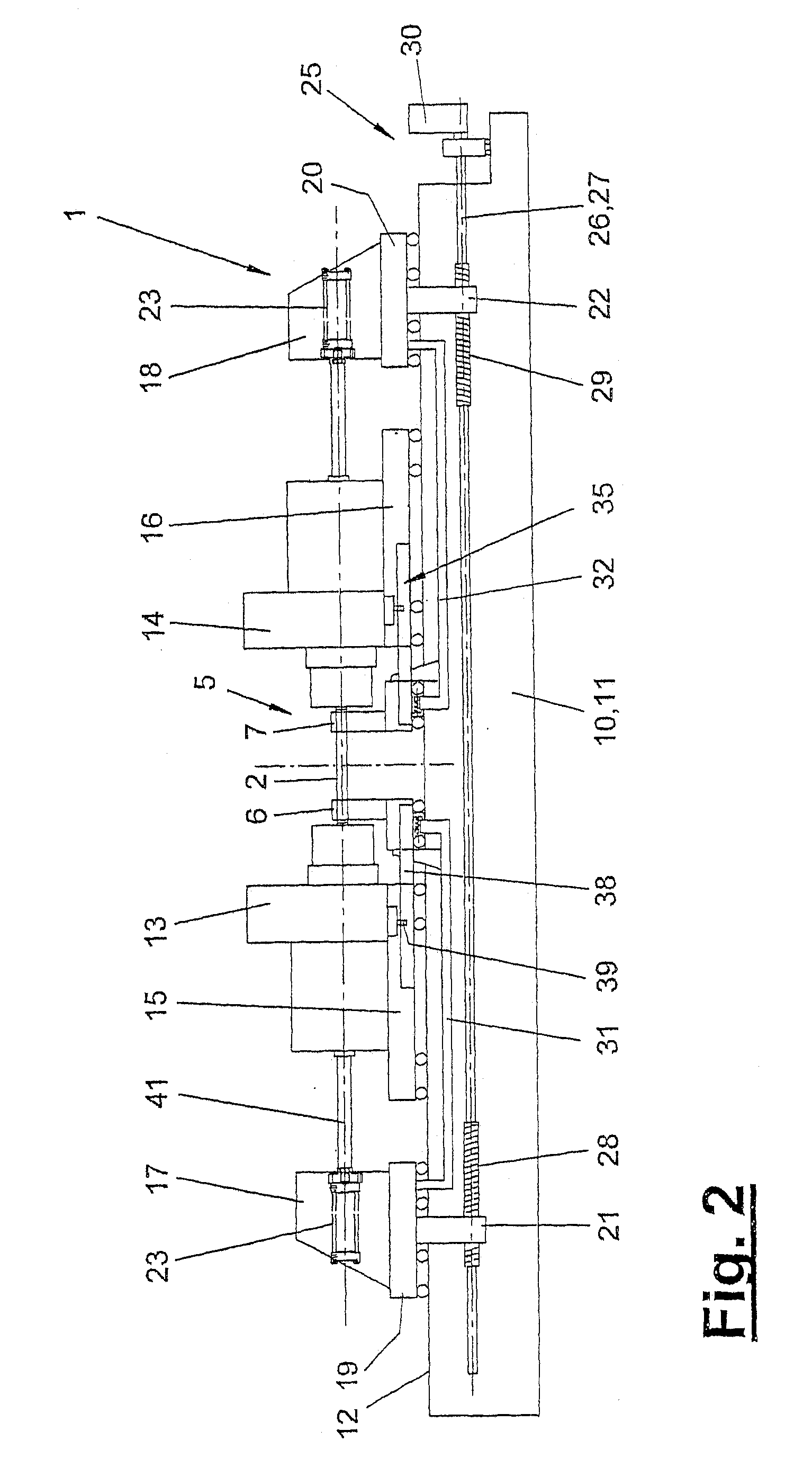

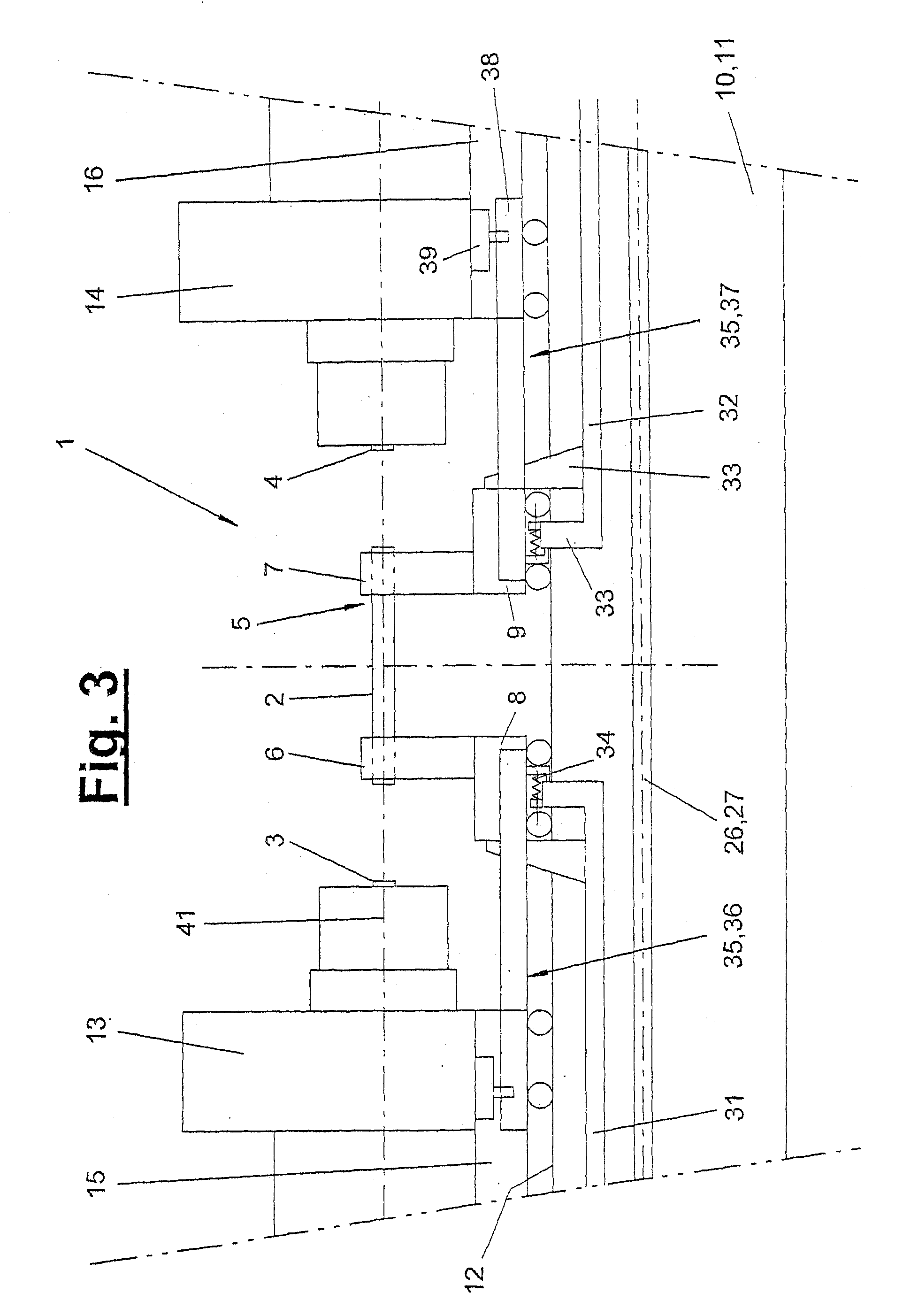

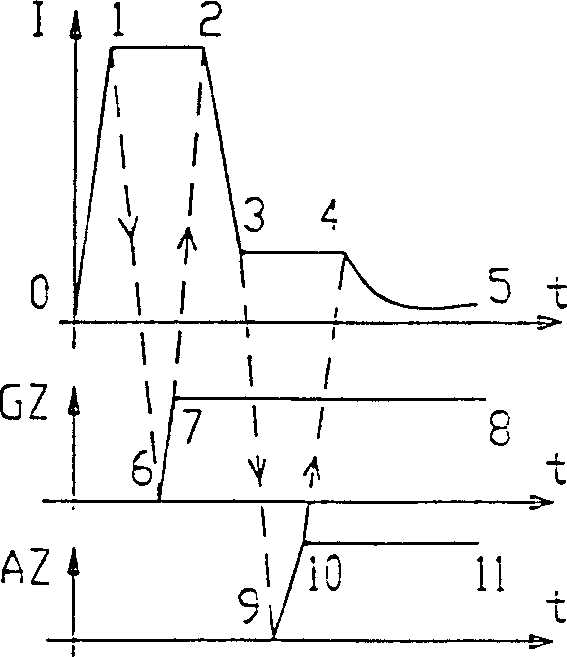

ActiveUS20100206861A1Improve accessibilityReduce loadWelding/cutting auxillary devicesArc welding apparatusFeed driveEngineering

A pressure welding method is provided and a pressure welding machine (1) is provided with a frame (10), two welding heads (13, 14), mobile along a feed axis (41), and two adjusting units (17, 18). The adjusting units (17, 18) include feed drives (23) for the welding heads (13, 14). The two adjusting units (17, 18) are mounted so as to be axially movable (41) on the frame (10) and are interlinked with an adjusting drive (25) by means of a common adjusting element (26) and supported in a closed system of forces while receiving the pressure welding forces, thereby relieving the frame (10). The common adjusting element (26) is configured as a continuous spindle (27) having two self-locking threads (28, 29) that run in opposite directions.

Owner:KUKA SYSTEMS

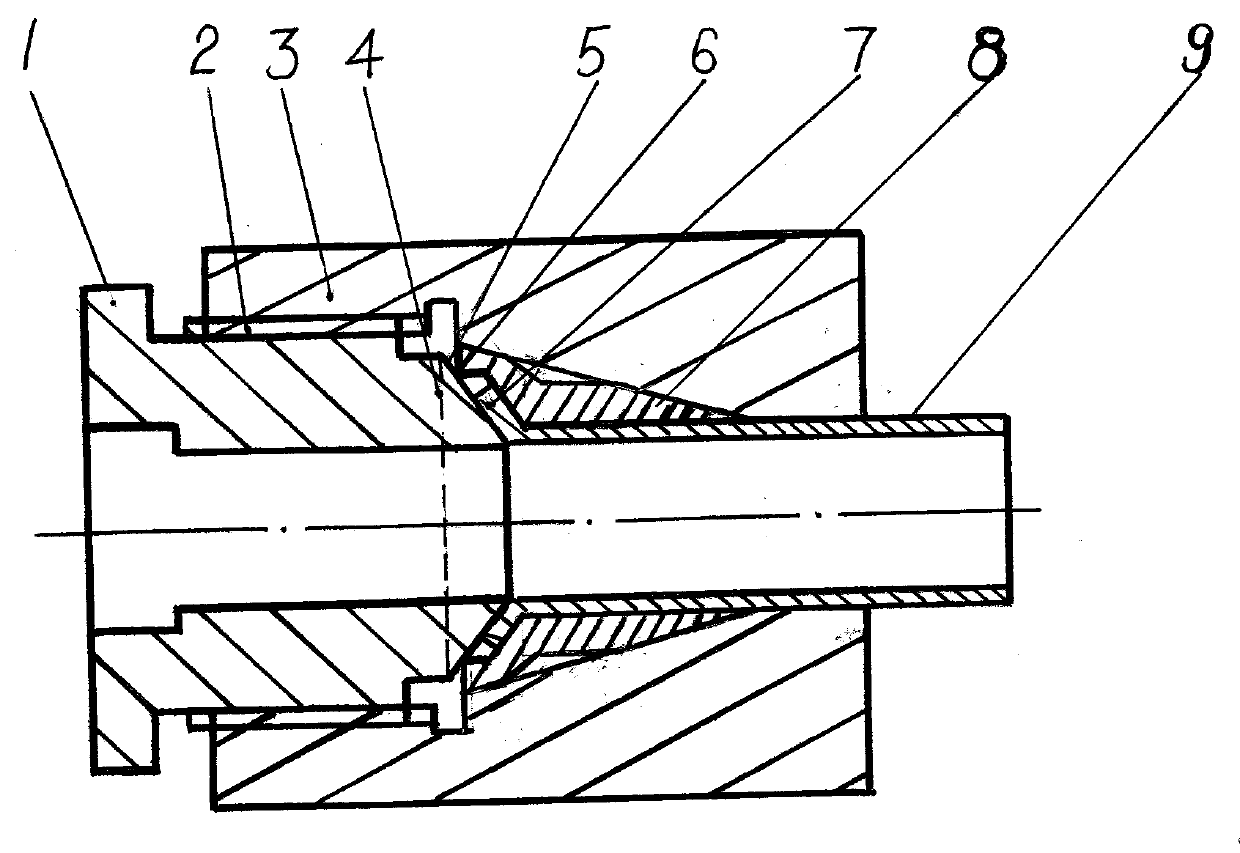

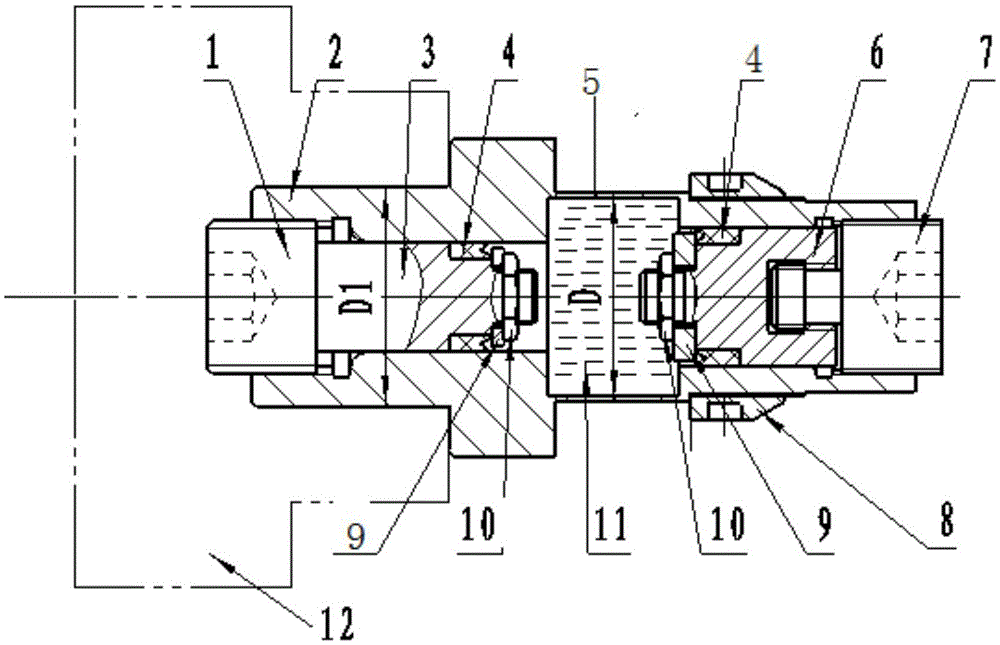

Pipeline connecting pipe fitting

InactiveCN103775761AReduce assembly torqueImprove joint sealing performanceJoints with sealing surfacesThin walledEngineering

A pipeline connecting pipe fitting comprises a nut, a joint, a joint external cone table and a connection pipe horn port and is characterized in that an inner cone hole is formed in the nut, a clamp sleeve for match usage is arranged in the inner cone hole of the nut, the clamp sleeve is provided with a hollow clamp sleeve hole, a clamp sleeve inner cone hole is formed in the bottom of the clamp sleeve hole and consists of a clamp sleeve inner cylinder hole and a clamp sleeve inner cone hole horn groove, the clamp sleeve inner cylinder hole is provided with a seal cone surface, a clamp sleeve hole wall and a clamp sleeve outer cone inclined surface form a clamp sleeve cone inclined angle, the joint outer cone table extrudes the seal cone surface to achieve cone surface sealing, the joint outer cone table extrudes the connection pipe horn port in the clamp sleeve inner cone hole horn groove to achieve horn groove sealing, and the nut inner cone hole extrudes the clamp sleeve to extrude a connection pipe to achieve clamp sleeve sealing. The pipeline connecting pipe fitting has the advantages that seal connection is convenient, seal process requirements are low, seal properties are high, the pipeline connecting pipe fitting can be applied to connection of low-hardness thin-wall metal pipes made of dissimilar materials and can be completely interchanged with connection nuts in the prior art.

Owner:孙海潮

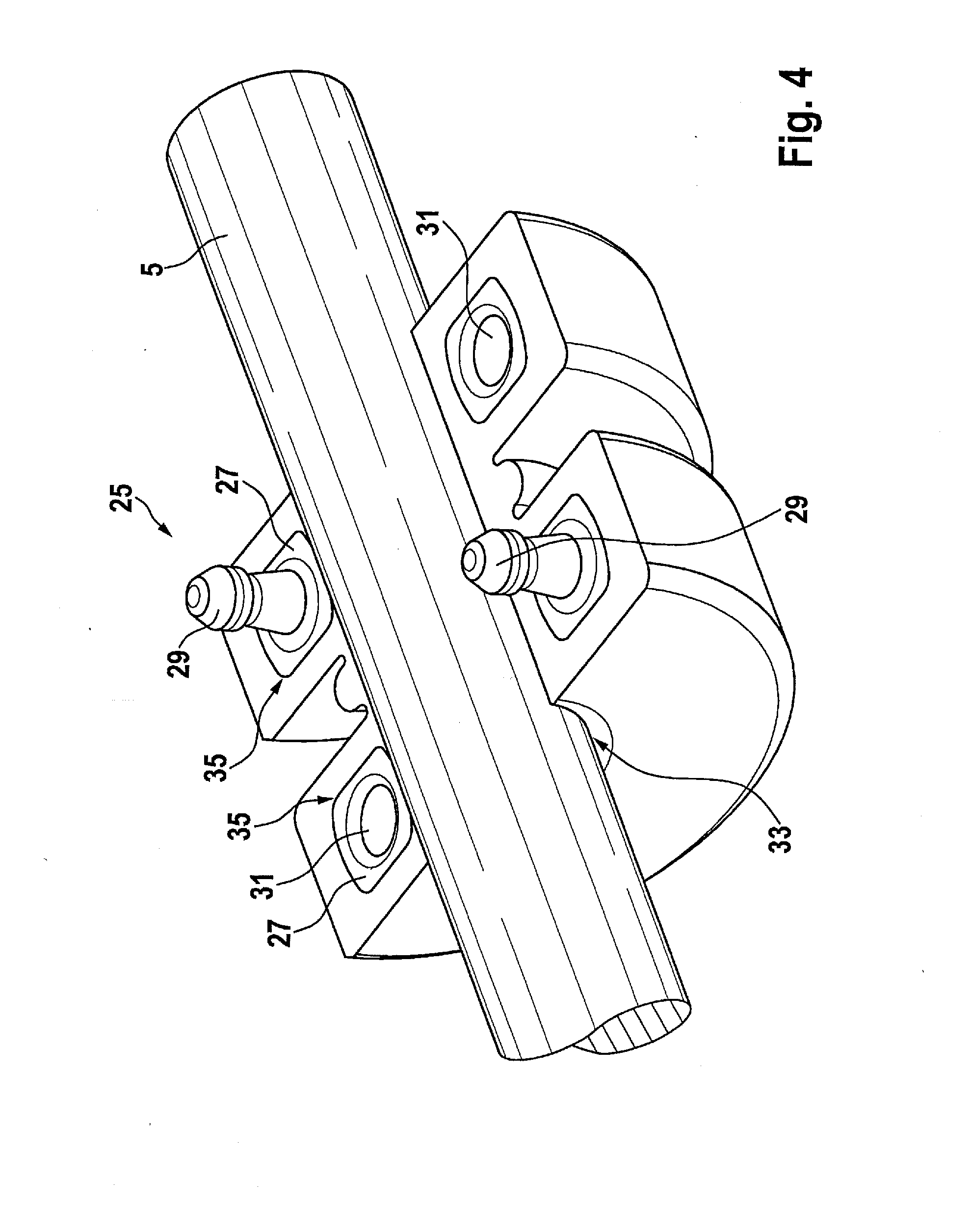

Pressure welding machine and pressure welding method

InactiveUS20070181639A1Less Design WorkLarge working rangeCooking-vessel materialsWelding/cutting auxillary devicesFeed driveSelf locking

The invention relates to a pressure welding method and a pressure welding machine (1) which is provided with a frame (10), two welding heads (13, 14), mobile along a feed axis (41), and two adjusting units (17, 18) comprising feed drives (23) for the welding heads (13, 14). The two adjusting units (17, 18) are mounted so as to be axially movable (41) on the frame (10) and are interlinked with an adjusting drive (25) by means of a common adjusting element (26) and supported in a closed system of forces while receiving the pressure welding forces, thereby relieving the frame (10). The adjusting element (26) is configured as a continuous spindle (27) having two self-locking threads (28, 29) that run in opposite directions.

Owner:KUKA SYSTEMS

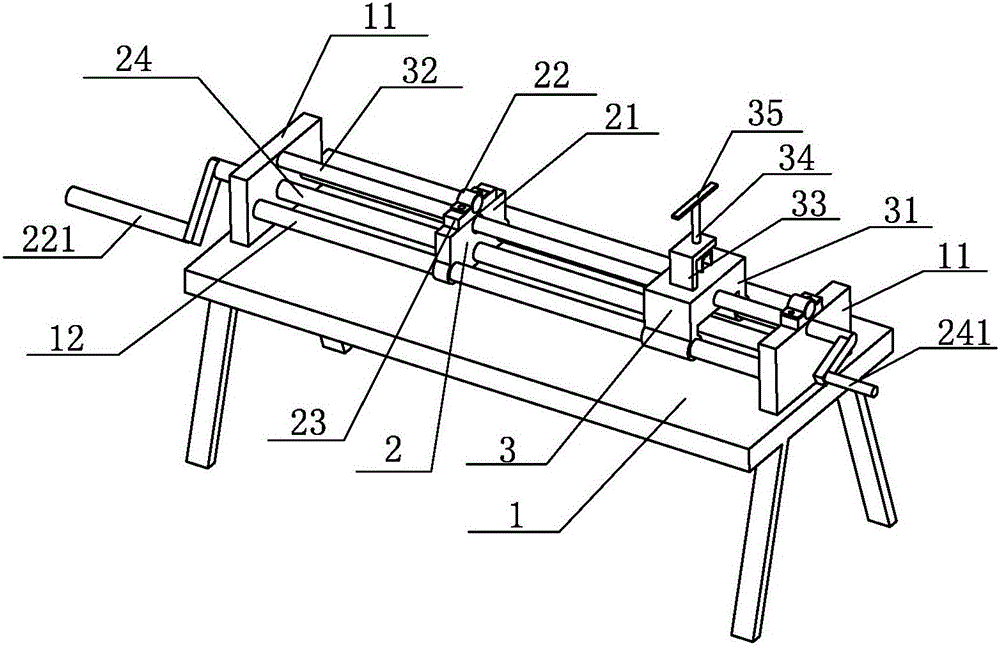

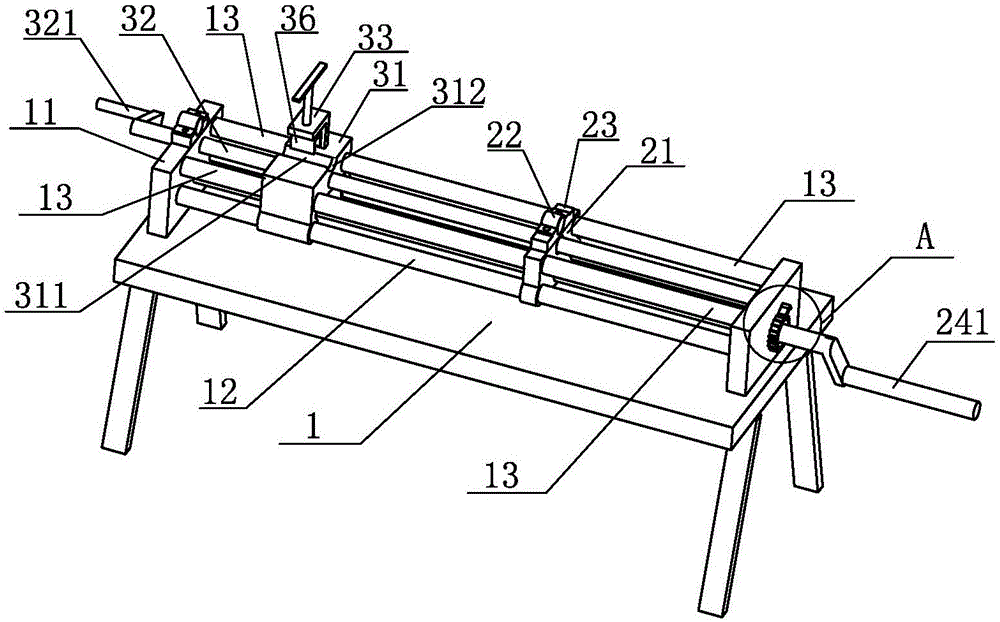

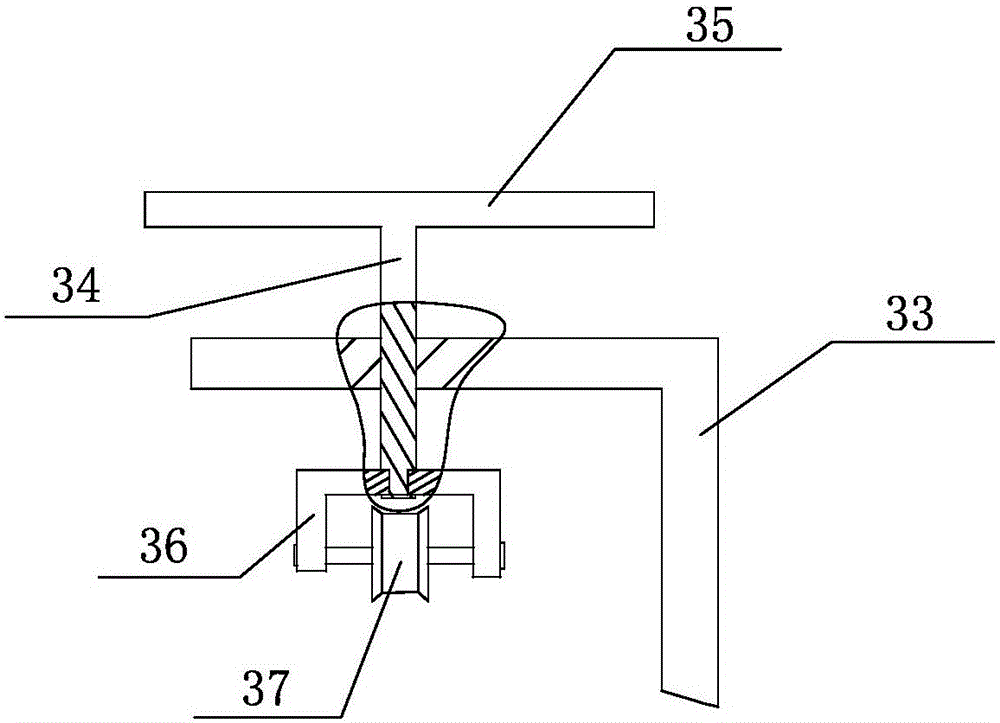

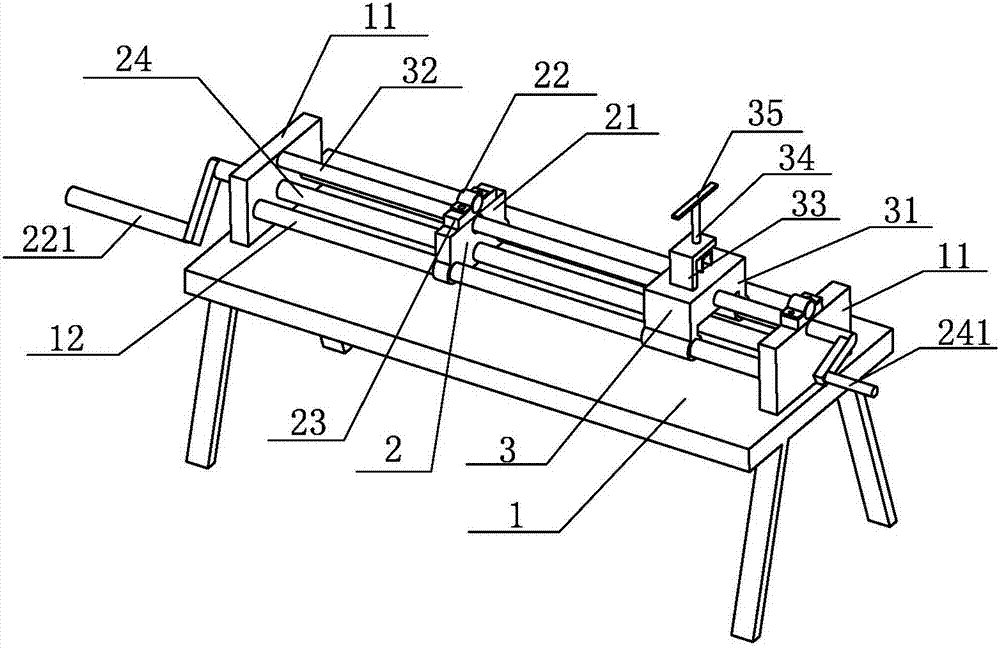

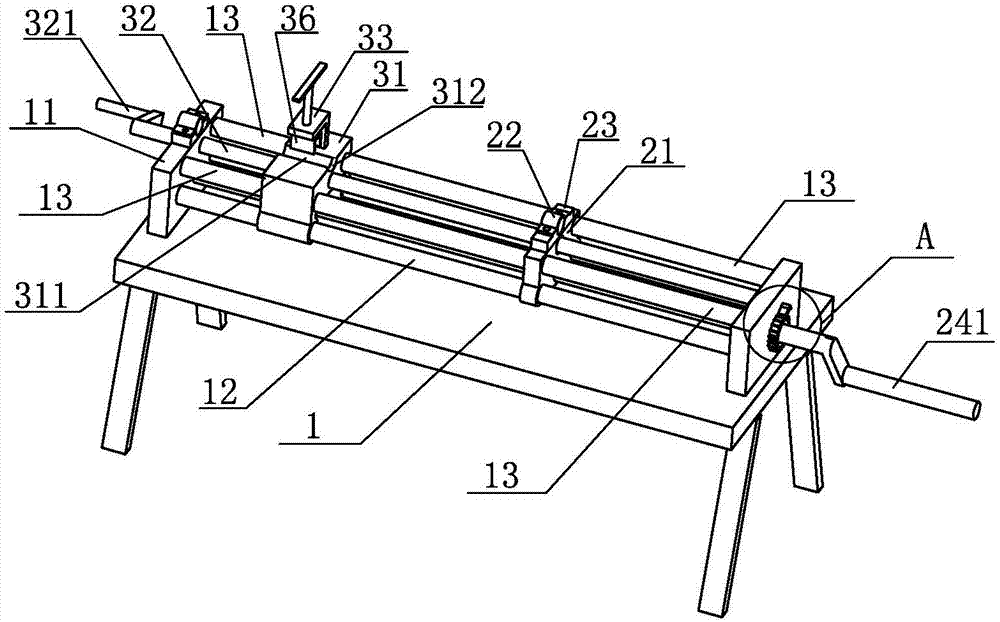

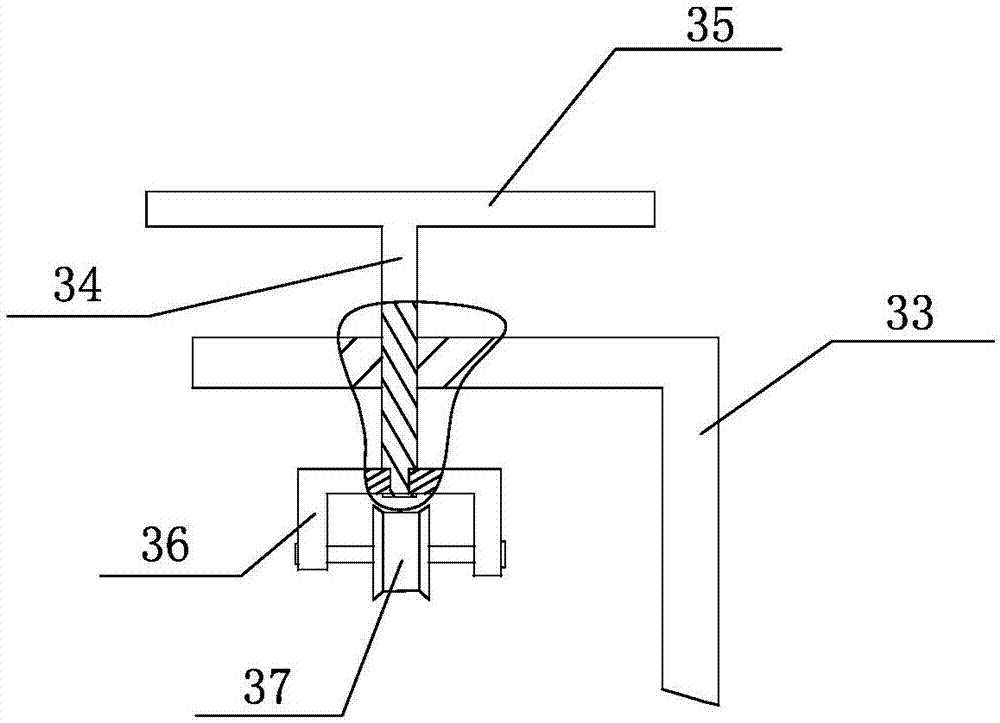

Power transmission wire tensioning and straightening device

InactiveCN106159802AImplementation orientationLarge transmission pullApparatus for overhead lines/cablesEngineeringElectric wire

The invention provides a power transmission wire tensioning and straightening device, which comprises a support frame, a tensioning mechanism and a straightening mechanism, wherein the support frame comprises a support platform; two opposite support vertical plates are arranged at the two ends of the support platform; two mutually parallel first guide rods are arranged between the support vertical plates; the tensioning mechanism comprises a tensioning slide block and a pulling lead screw; the tensioning lead screw is arranged between the two support vertical plates in a sleeving way; the tensioning slide block is arranged on the two first guide rods in a sleeving way; the straightening mechanism comprises a straightening slide block and a compression wheel. The power transmission wire tensioning and straightening device has the advantages that the structure is simple; the operation is convenient; the carrying is easy; during the power transmission line erection, the tensioning mechanism and the straightening mechanism in the power transmission wire tensioning and straightening device can be flexibly used for performing correction treatment on the bent position on a power transmission line, and the goal of fast and efficiently sorting the bent position on the power transmission line can be achieved.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

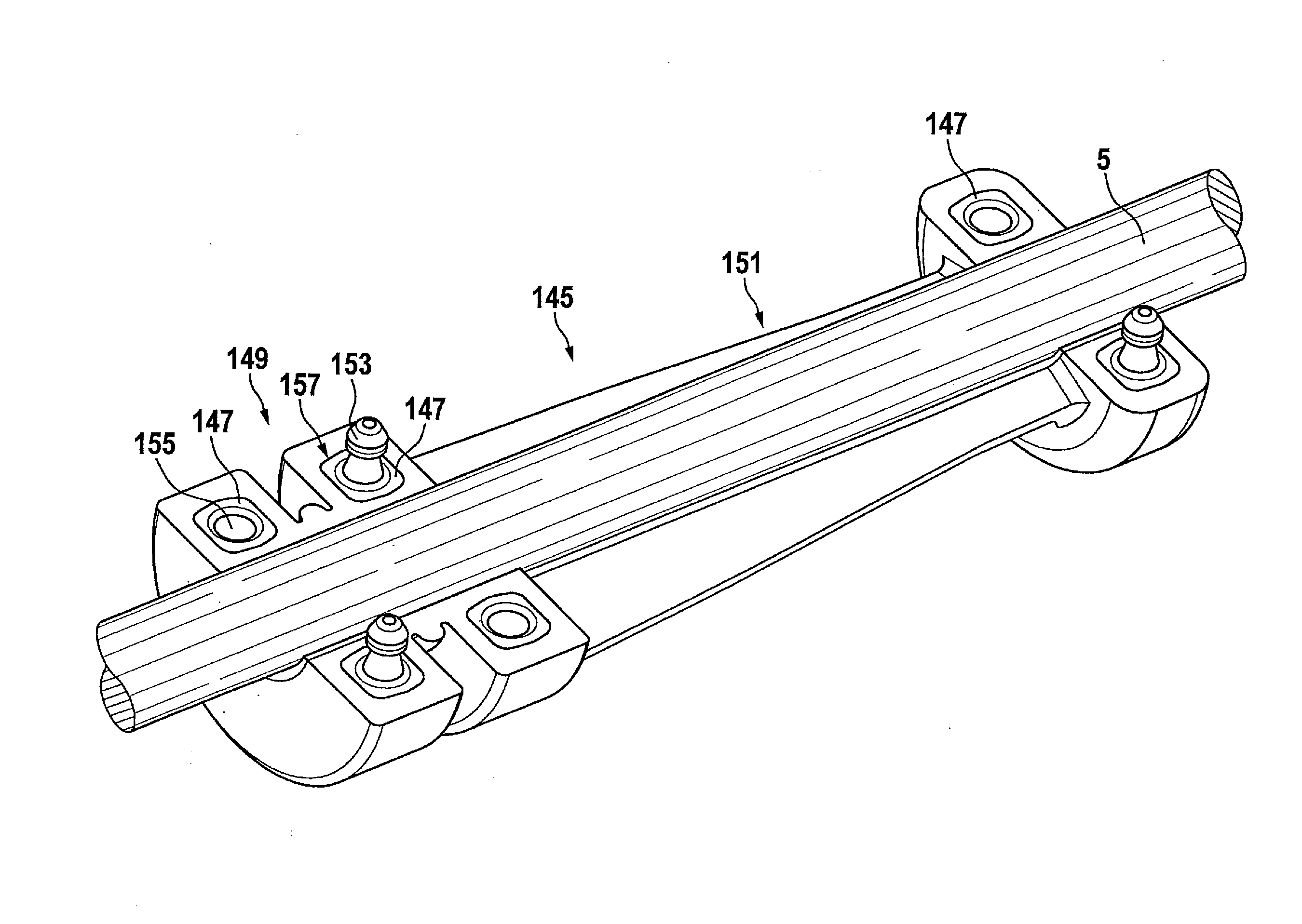

Fastening device for a line and method for fastening a line

InactiveUS20140060922A1Reduce disadvantagesQuick installationElectrical apparatusElectric/fluid circuitThermoplastic elastomerEngineering

A fastening device, e.g., for an electrical cable in a vehicle, has a sleeve which is lockable in a holder and which encloses the line. The sleeve has at least two sleeve subareas which are at least partially separable from one another in such a way that in a preinstalled state the line is inserted into an inner area of the sleeve, and the sleeve subareas are connectable to one another in such a way that in an installed state the line is completely annularly enclosed by the sleeve subareas. Due to the multipart configuration of the sleeve, it is easily mounted on a line. A resistant material such as a thermoplastic elastomer, which is processable with the aid of injection molding, is used for the sleeve.

Owner:ROBERT BOSCH GMBH

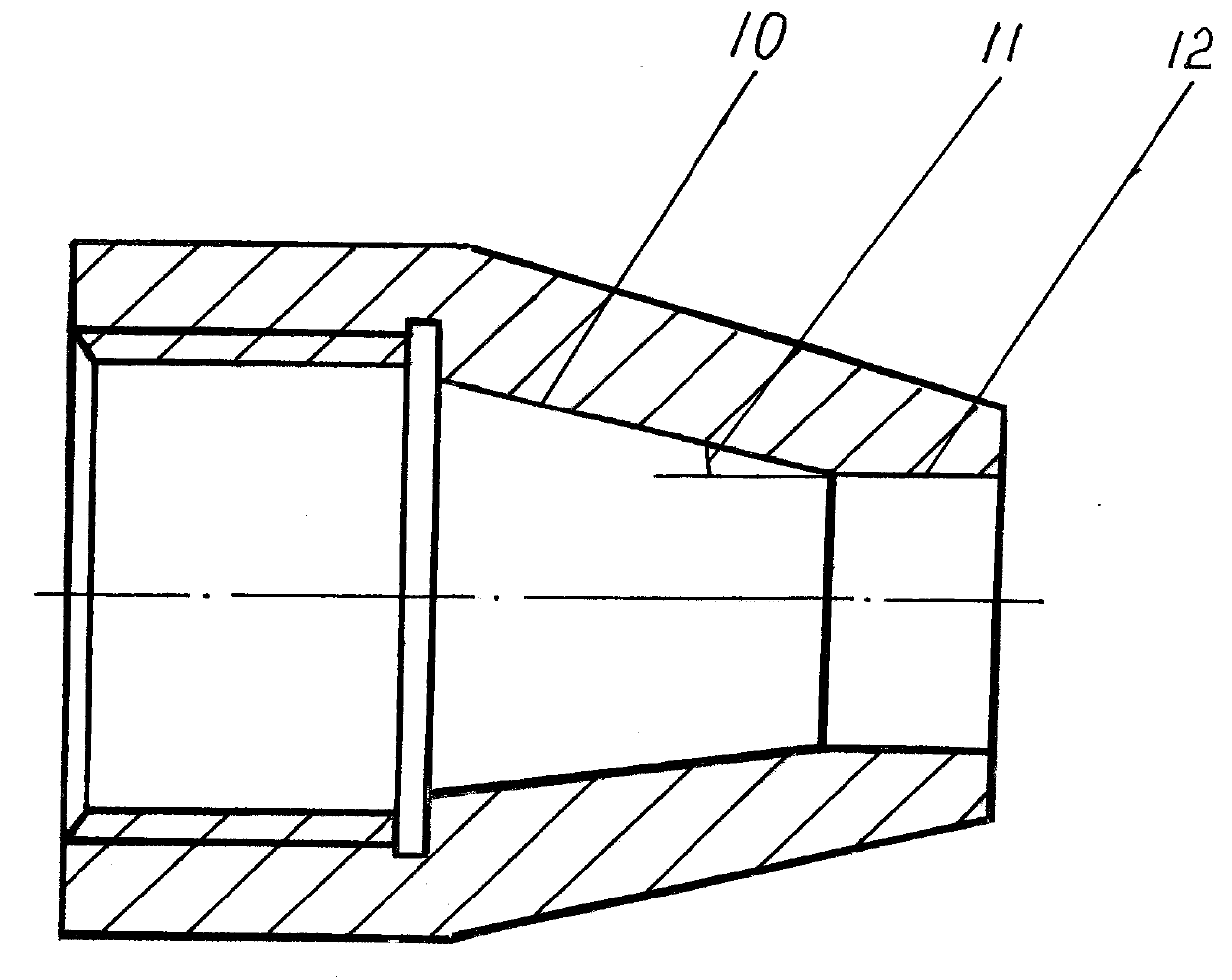

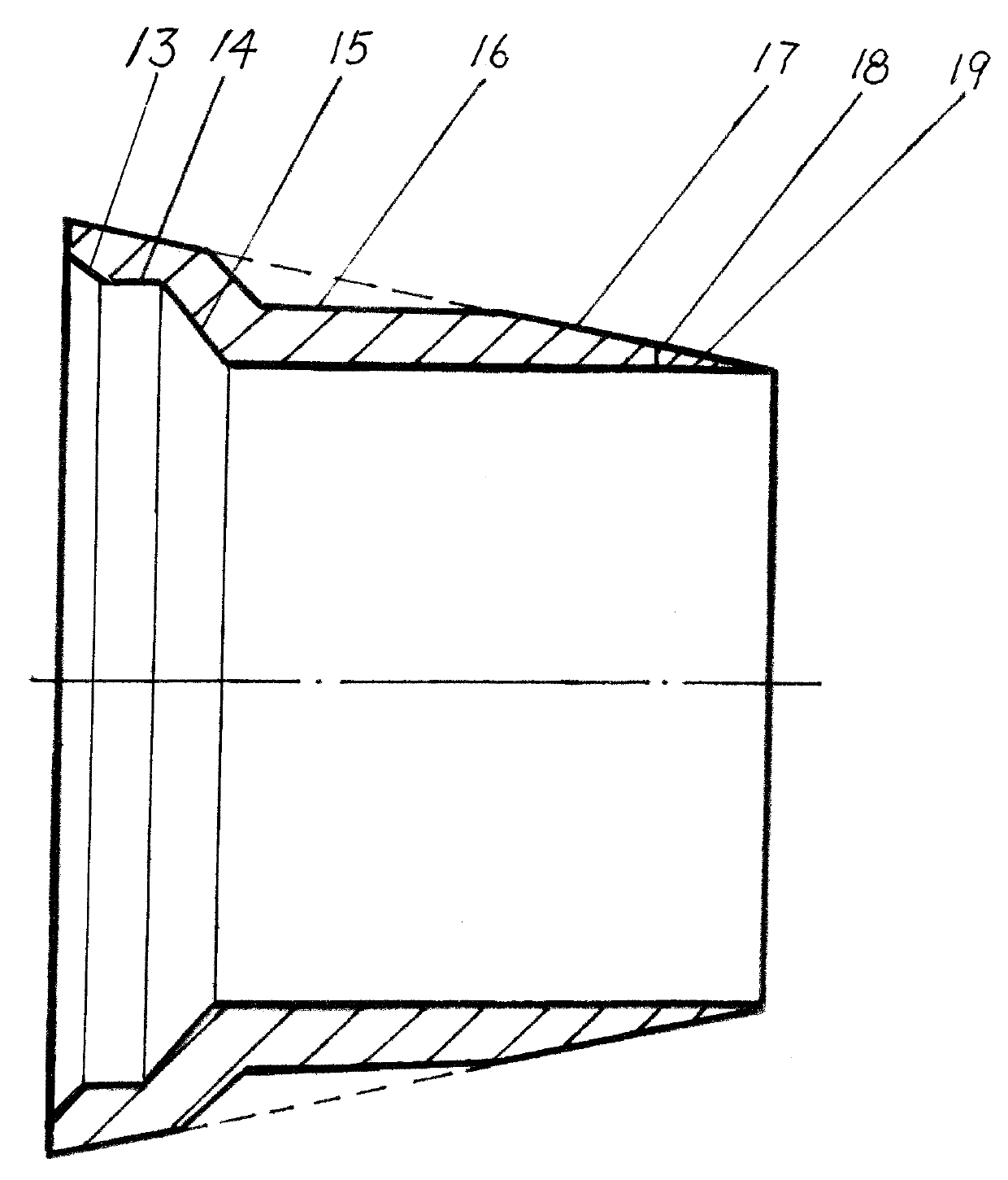

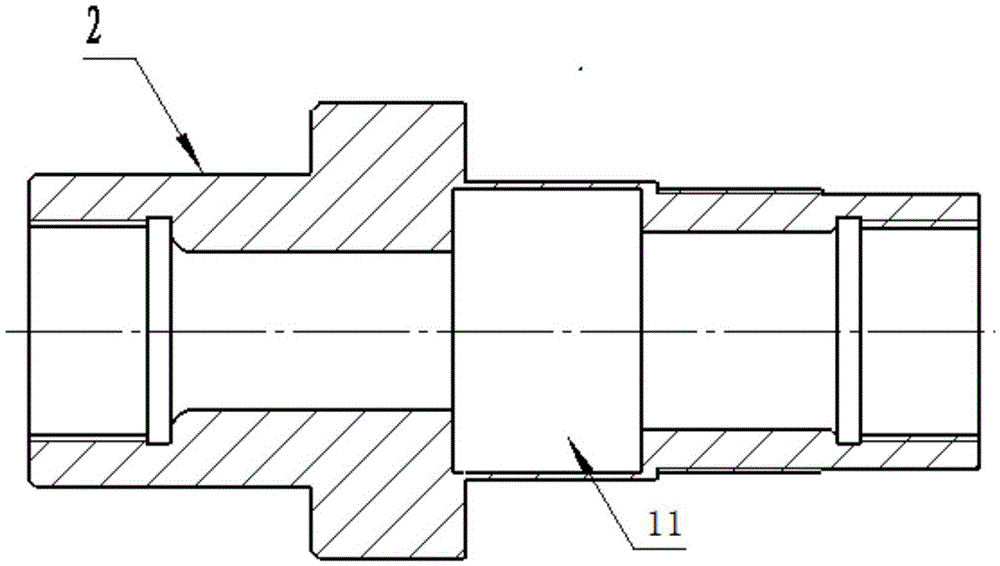

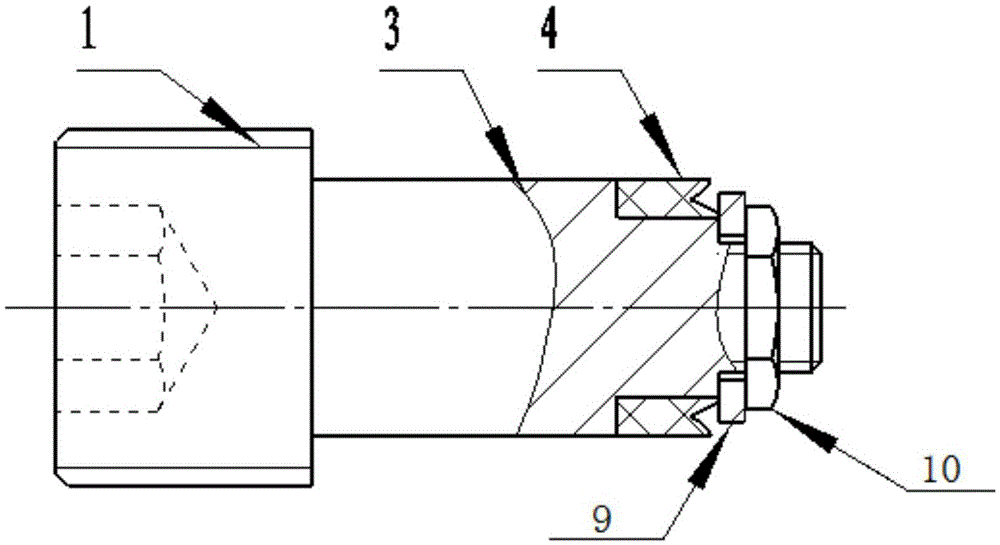

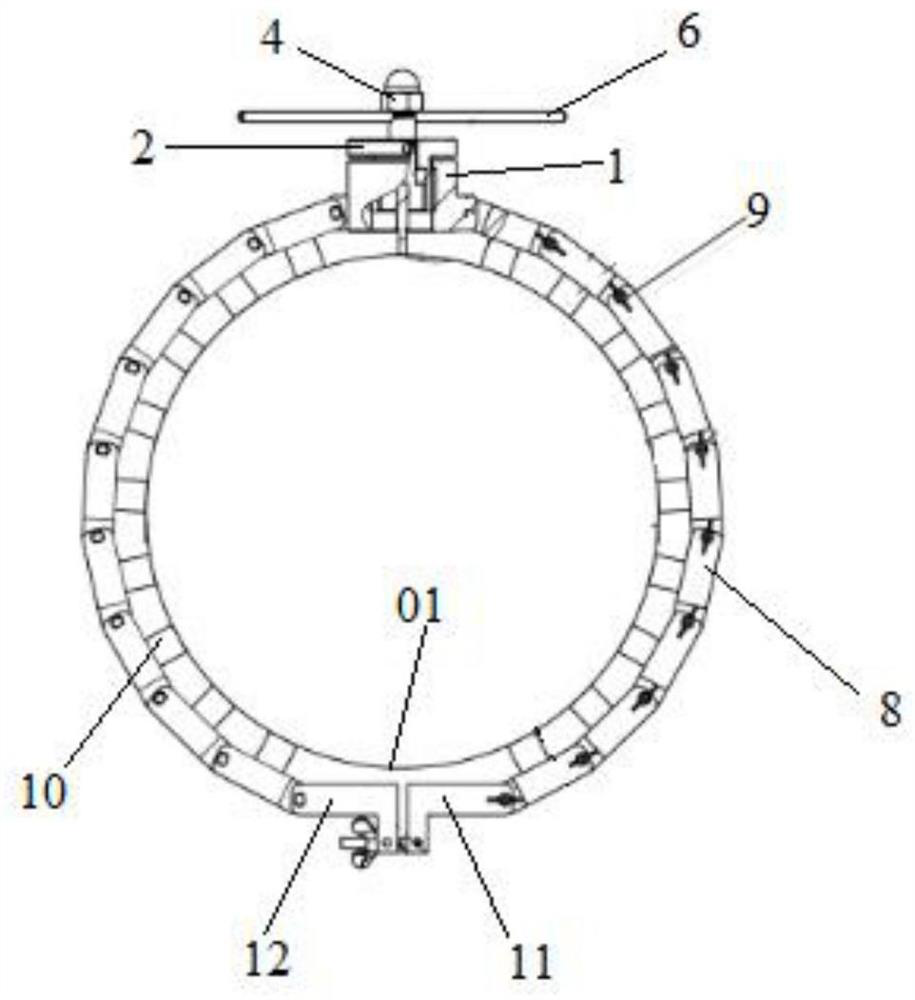

Hydraulic tensioning clamping mandrel for thin-wall shaft sleeve

InactiveCN105458317AReliable positioning and clampingSimple structureExpansion mandrelsEngineeringMachine tool

The invention discloses a hydraulic tensioning clamping mandrel for a thin-wall shaft sleeve. The hydraulic tensioning clamping mandrel is provided with a mandrel body located to the end face of a machine tool chuck or a spring sleeve. A step shaft table for locating the end face of a part to be machined is manufactured on the mandrel body, and step holes for assembling of plungers and a hydraulic oil cavity communicated with the step holes are formed in the two ends. The left pressure adjusting plunger (3) is sealed at the left end of the hydraulic oil cavity from the leftward step hole of the mandrel body (2), the right pressure adjusting plunger (6) is sealed at the right end of the hydraulic oil cavity from the rightward step hole of the mandrel body, and a closed container is formed. The to-be-machined part assembled on a rightward barrel of the mandrel body is clamped between the end face of the step shaft table of the mandrel body and a compressing nut (10) through the compressing nut (10). Sealing screws (7) are screwed down to drive the plungers to move and compress hydraulic oil in the hydraulic oil cavity, and the to-be-machined part clamped on the external circle tensioning mandrel body on the thin wall of the hydraulic oil cavity is expanded through pressure generated by the hydraulic oil cavity under the action of oil pressure. The hydraulic tensioning clamping mandrel is easy to manufacture and high in clamping precision, and a clamping area is stable and reliable in clamping.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

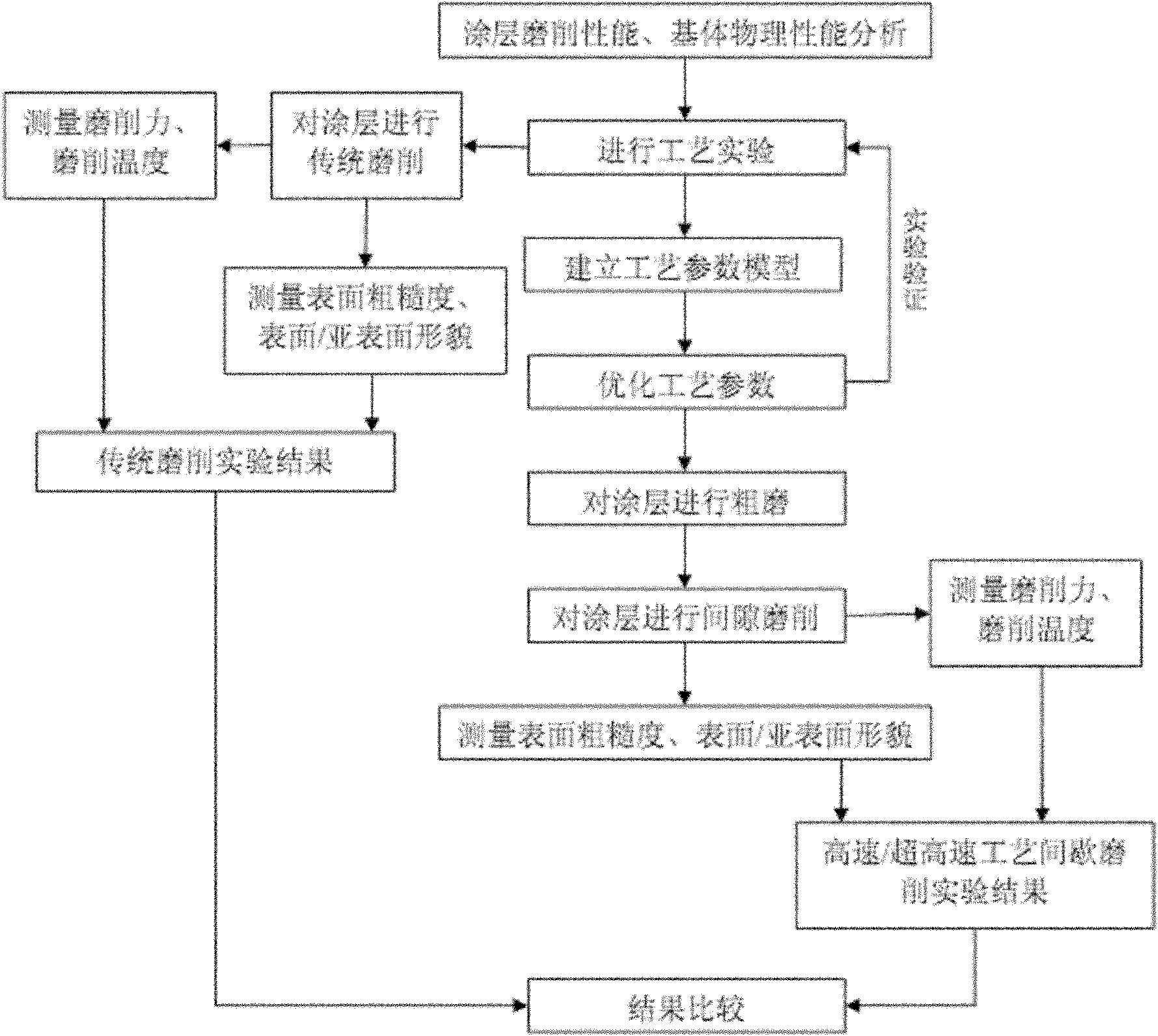

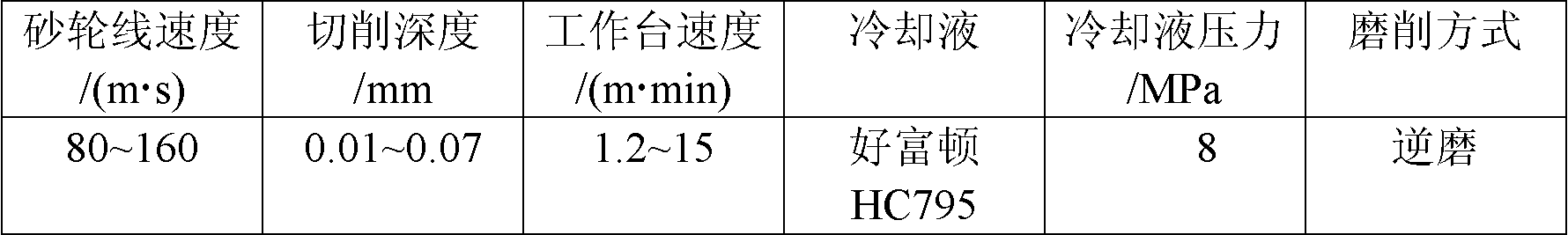

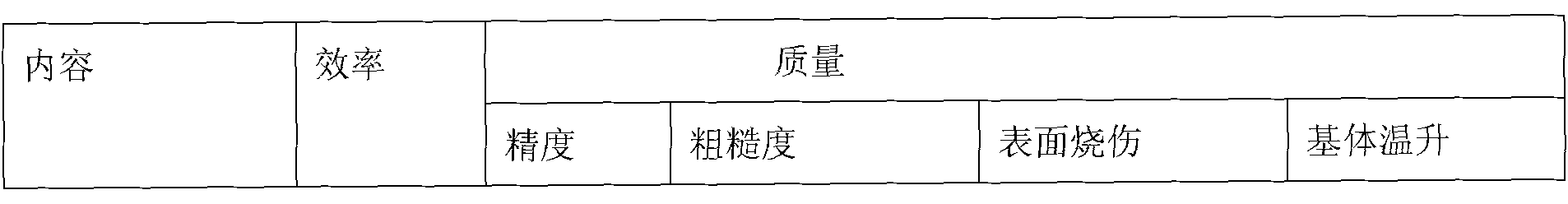

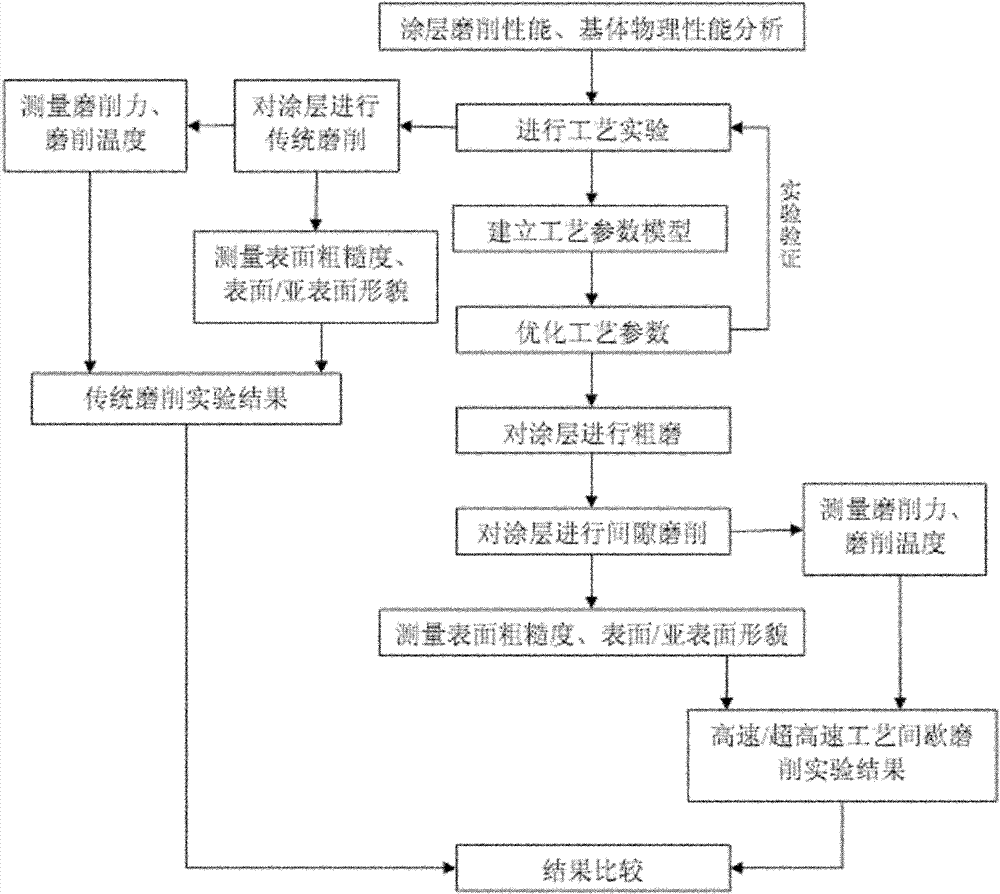

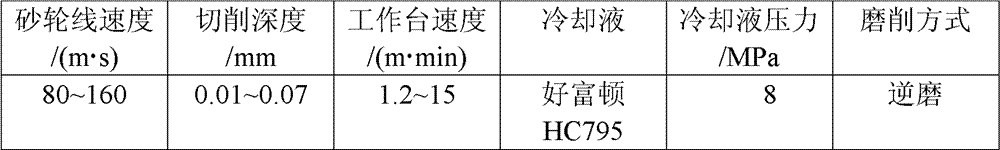

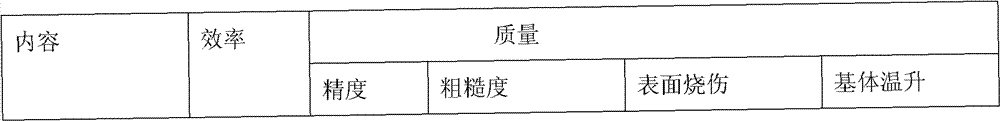

Batch-type grinding method of hard coating material

InactiveCN102085631AHigh removal rateReduce loss costGrinding machinesUltra high speedHigh-speed grinding

The invention relates to a batch-type grinding method of a hard coating material, comprising the following steps: carrying out alternate batch-type grinding by adopting a grinding wheel feeding way and a grinding wheel no-feeding way in the grinding process; when the grinding wheel feeding way is adopted, carrying out high-speed or ultra high-speed grinding; when the grinding wheel no-feeding wayis adopted, carrying out no-load reciprocatory grinding; and after every time of feed grinding of a grinding wheel, carrying out the no-load reciprocatory grinding for 2-20 times according to the actual condition; wherein the high-speed or ultra high-speed grinding comprises that the primary feed grinding depth is 10-15mu m, the feeding speed of an operating platform is 6000-30000mm / min, and the linear speed of the grinding wheel is 80-200m / s. In the invention, variation of the actual grinding depth caused by elastic deformation and heat deformation of the grinding wheel and workpieces can beeliminated to the utmost extent, the heat produced at high-speed grinding can be timely released, and the grinding wheel can maintain to be sharp, thus the material removing rate is improved, the grinding surface burning is effectively reduced, the grinding wheel loss and production cost are greatly reduced, and the good processing quality is obtained.

Owner:HUNAN UNIV

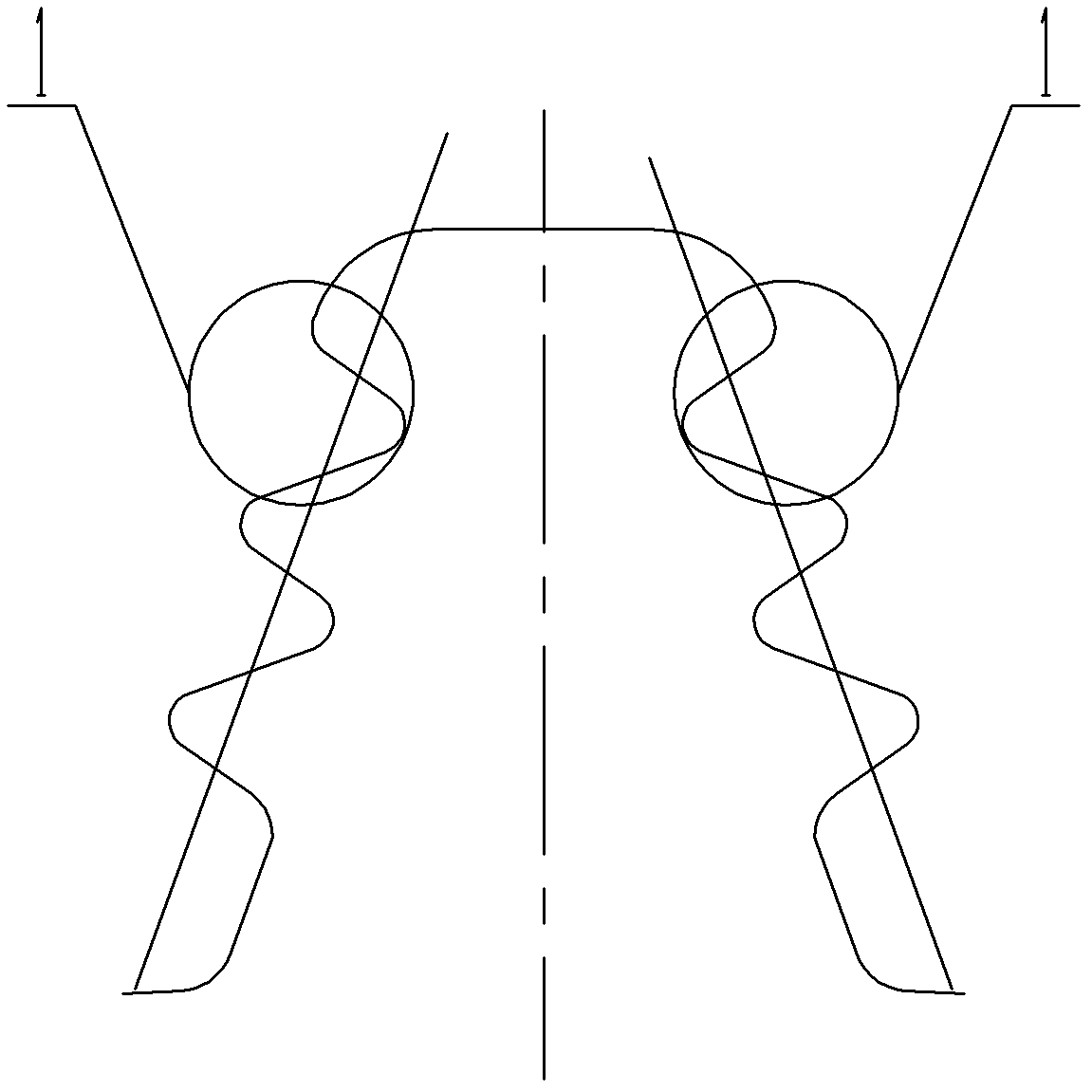

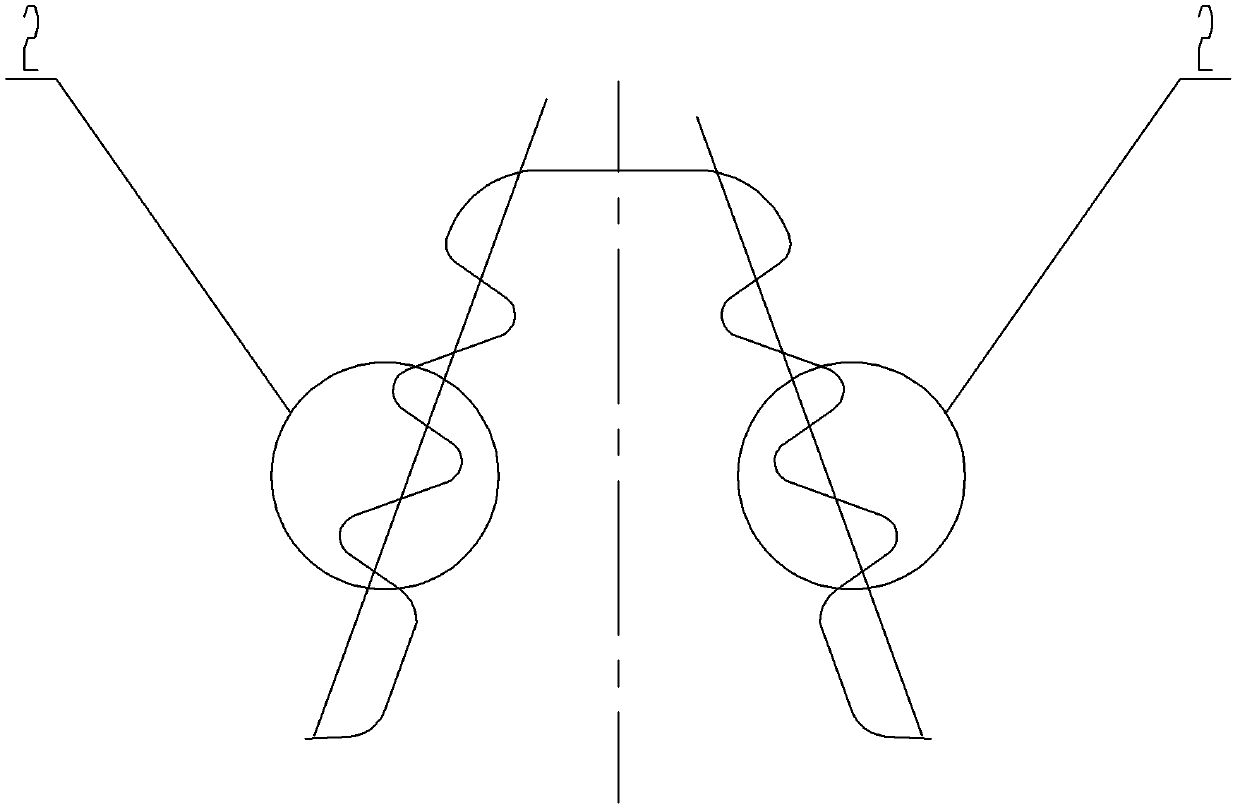

Method for eliminating broaching elastic deformation of high-temperature alloy turbine disk

ActiveCN102350542AEliminate elastic deformationEliminate the effects ofBroaching toolsBroaching machinesNumerical controlMetallurgy

The invention discloses a method for eliminating broaching elastic deformation of a high-temperature alloy turbine disk, relating to a method for eliminating broaching elastic deformation of a turbine disk. The invention aims to solve the problems that the broached part is in a cantilever state during finishing broaching, the entire rigidity is relatively low, the elastic deformation of the turbine disk race is increased and the product quality is influenced when the high-temperature alloy turbine disk broaches a race on a vertical numerical control broaching machine. A method I comprises thefollowing steps of: segmented finishing broaching: firstly, dividing the moulding line of the race of the high-temperature alloy turbine disk to be broached into multiple broaching segments, then performing finishing broaching of each broaching segment, implementing rise per tooth by taking every two of the broach teeth as a group to perform anti-rebound broaching, and performing corrective cutting by use of full-tooth form cutter teeth. A method II is different from the method I in that: the segmented finishing broaching is replaced by the broaching of a finishing broach, wherein the pitch of the finishing broach is equal to the thickness of the high-temperature alloy turbine disk to be broached or is 0.9-1 time of the thickness of the high-temperature alloy turbine disk to be broached. The method disclosed by the invention is used for eliminating the elastic deformation produced by the broaching of the high-temperature alloy turbine disk.

Owner:HARBIN TURBINE

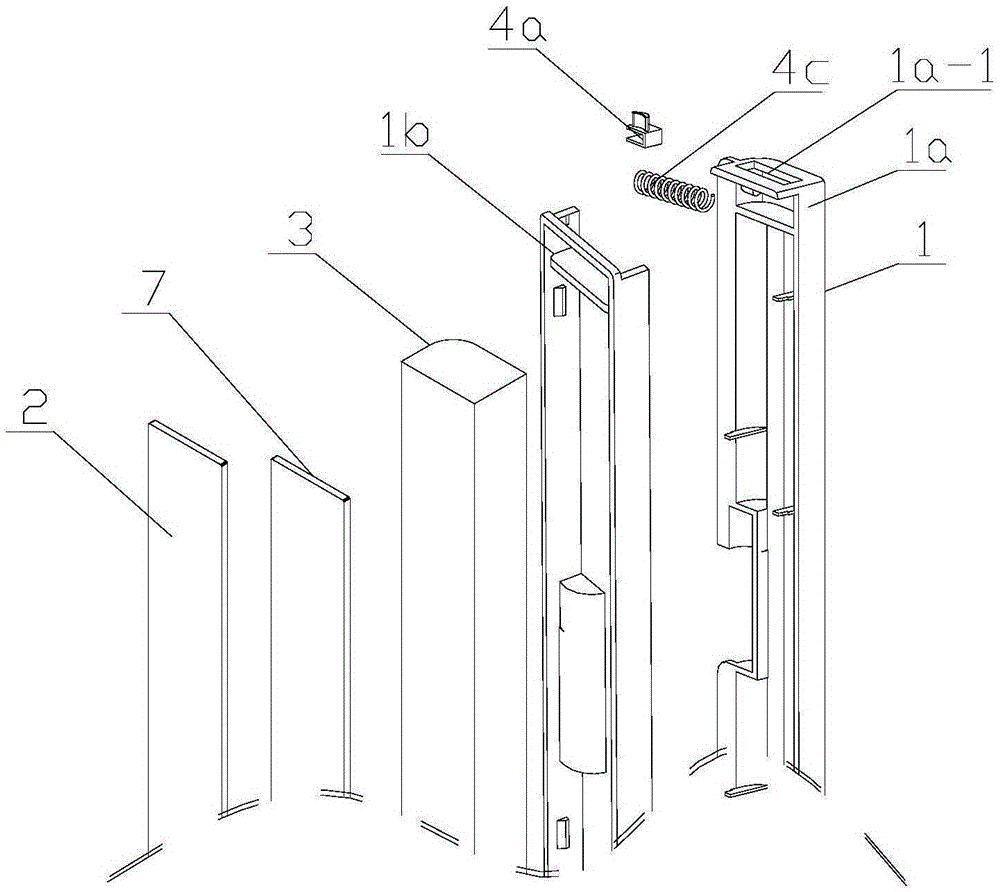

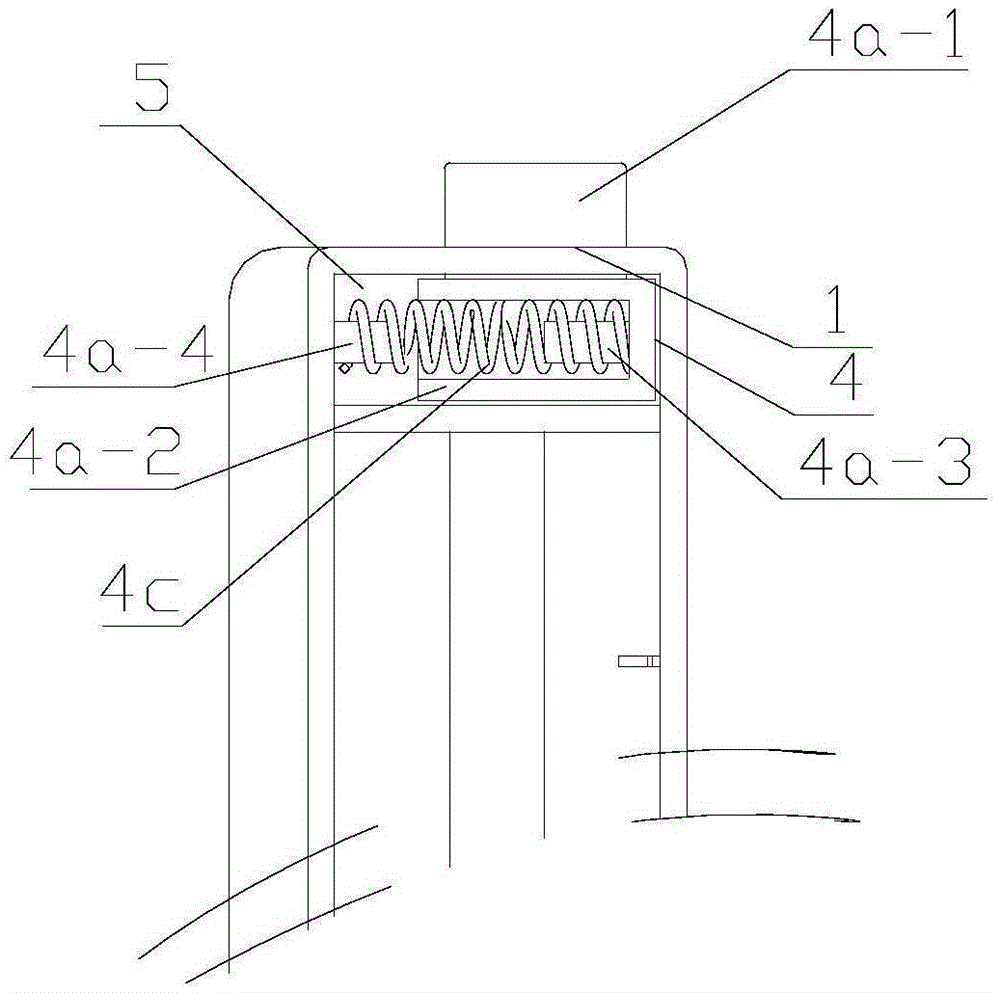

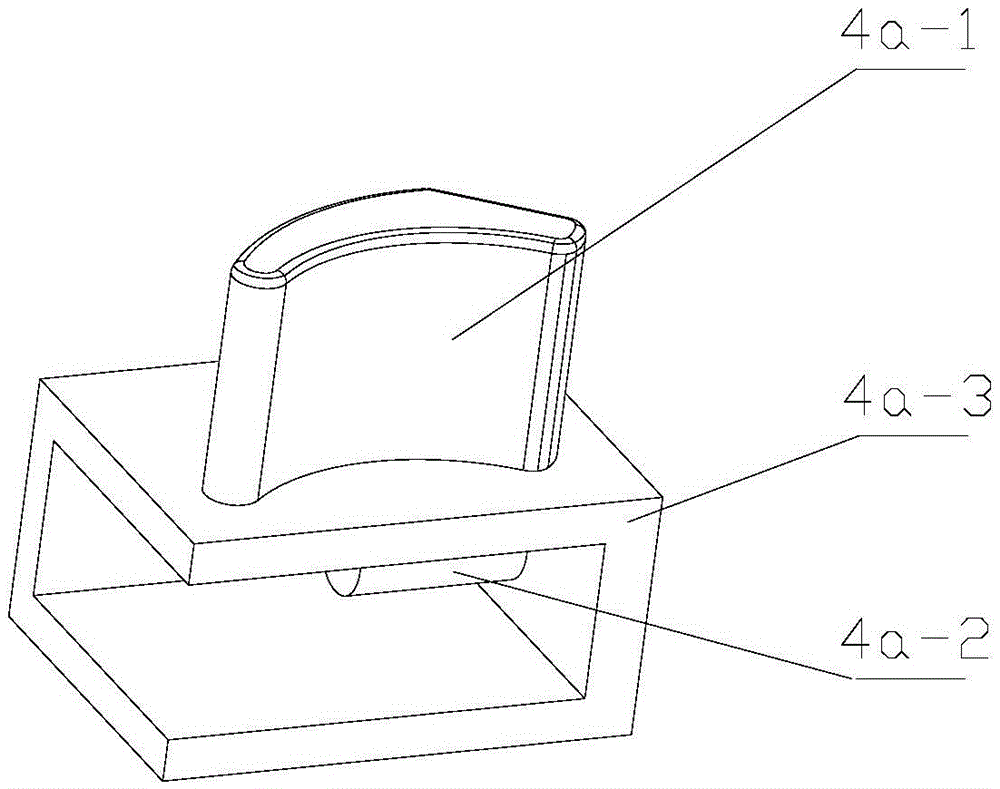

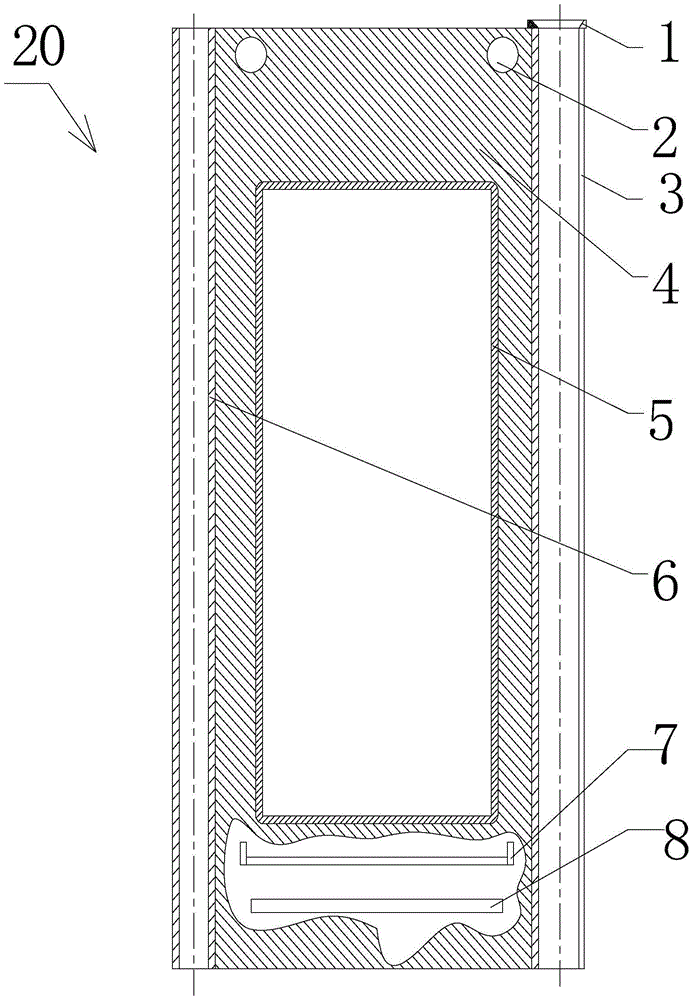

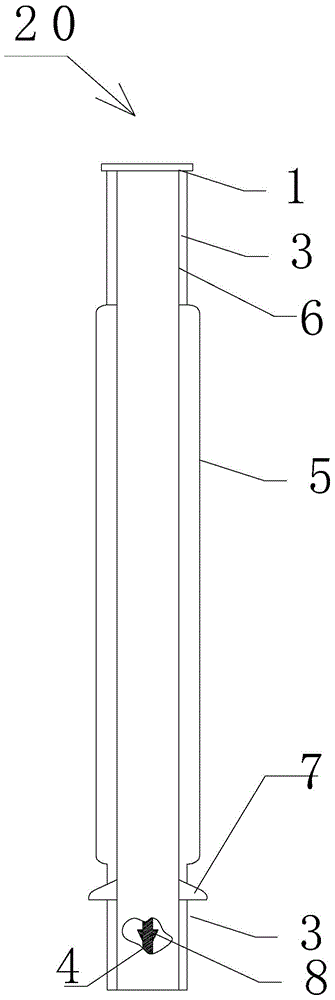

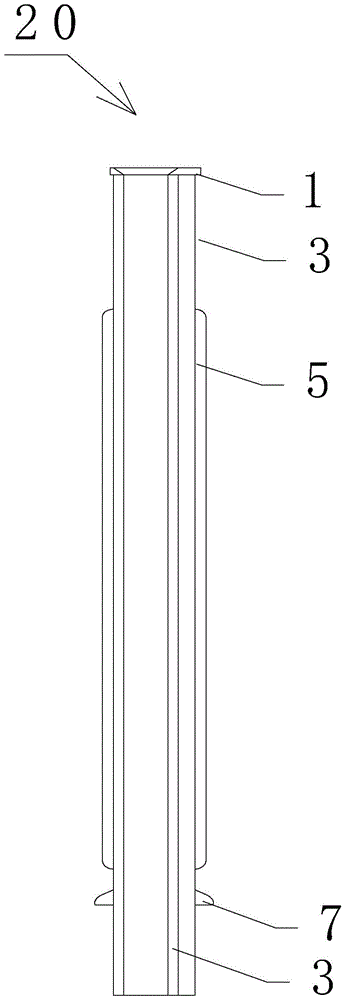

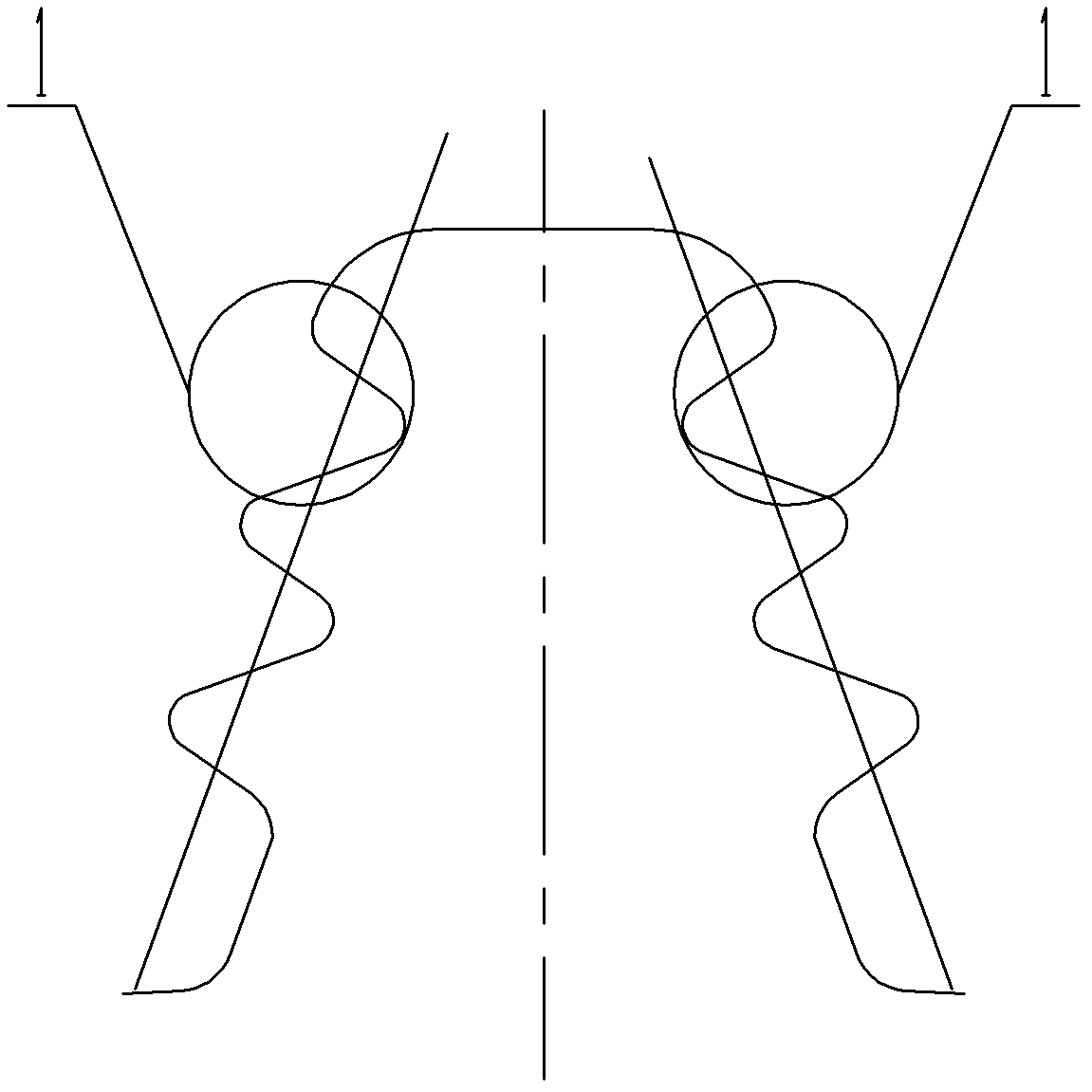

Refrigerator turnover beam

ActiveCN104061743ASo as not to damageEliminate elastic deformationLighting and heating apparatusCooling fluid circulationEngineeringRefrigerated temperature

The invention discloses a refrigerator turnover beam which comprises a turnover beam body. The turnover beam body is connected to the side wall of any door body in a pivoting mode, and a guide seat capable of guiding the turnover beam body to be in a horizontal state when the door bodies are closed is arranged in the top of a container of a refrigerator. The turnover beam body comprises an outward-turnover shell and an inward-turnover beam body arranged in the outward-turnover shell, a containing cavity used for containing a guide support movement assembly is formed between the top inner wall of the outward-turnover shell and the top outer wall of the inward-turnover beam body, the guide support movement assembly comprises the guide support and an elastic piece, the guide support is extruded by the guide seat to move leftwards / rightwards, elastic deformation is eliminated through the elastic piece, and therefore resetting is achieved. The turnover beam body avoids interference of the guide seat, the turnover beam does not need to be set in a vertical state in advance when the door bodies are closed, damage caused by operation errors to a turnover structure is avoided, the structure is simple, and high practicality is achieved.

Owner:HEFEI SNOWKY ELECTRIC

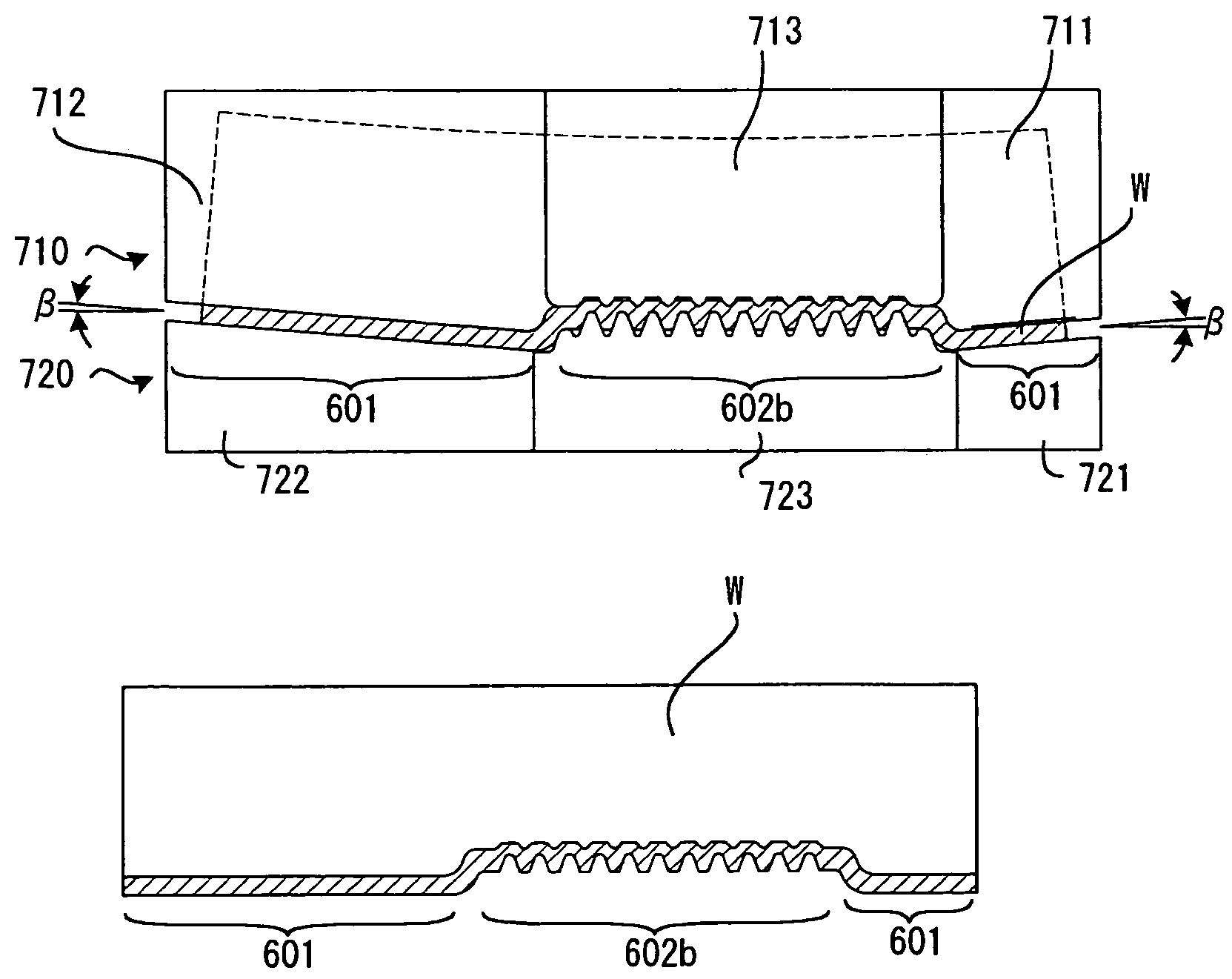

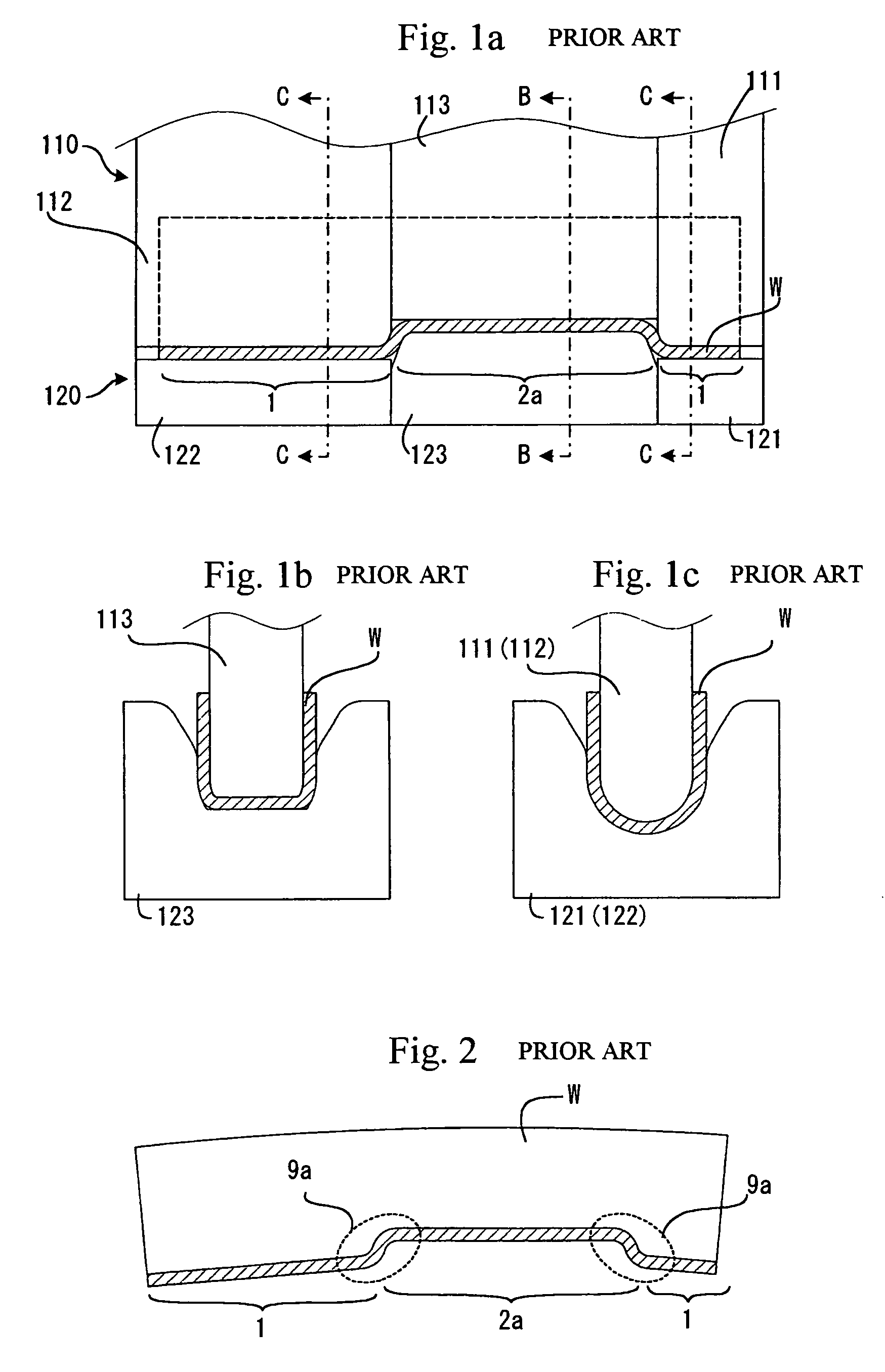

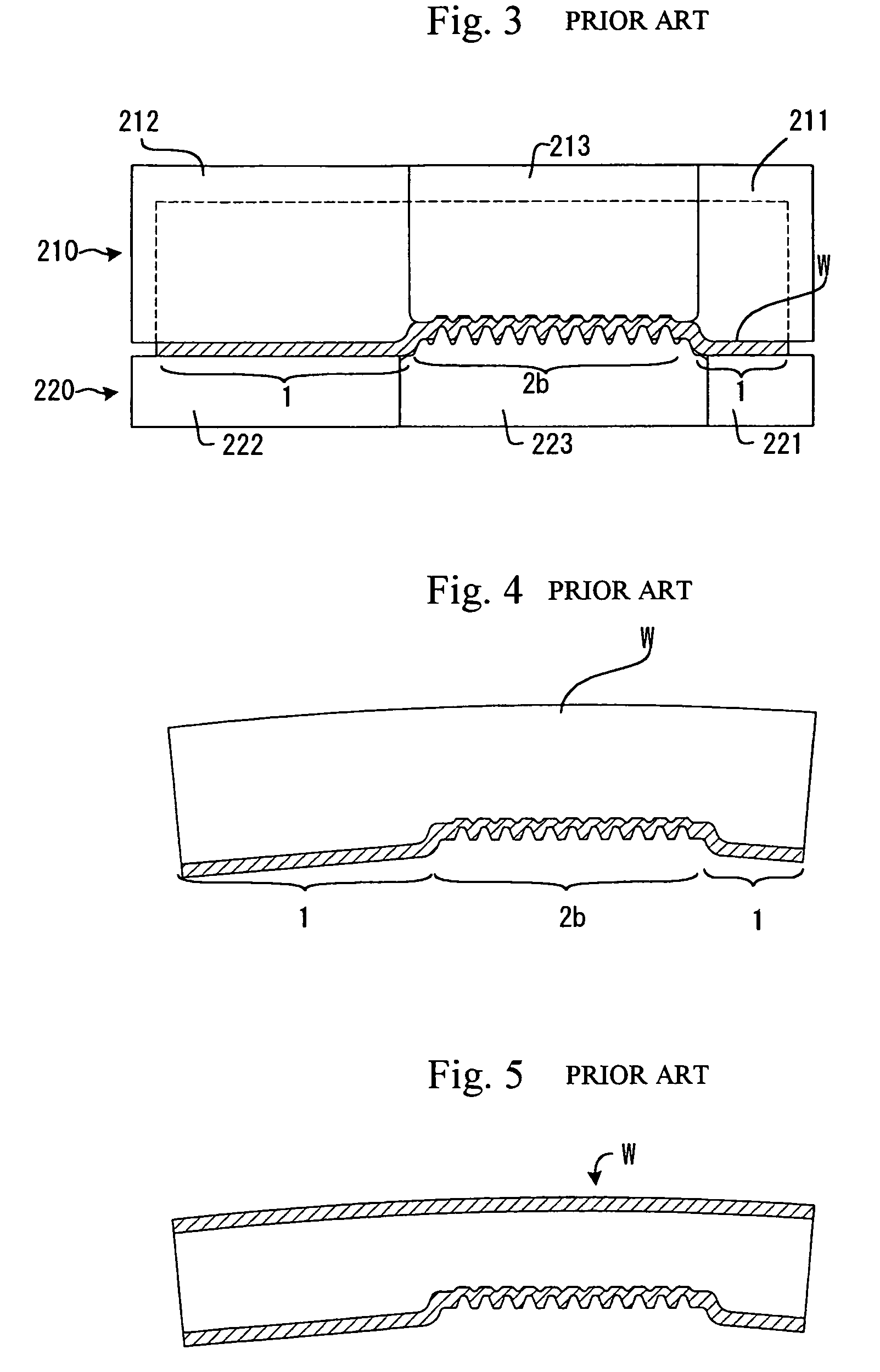

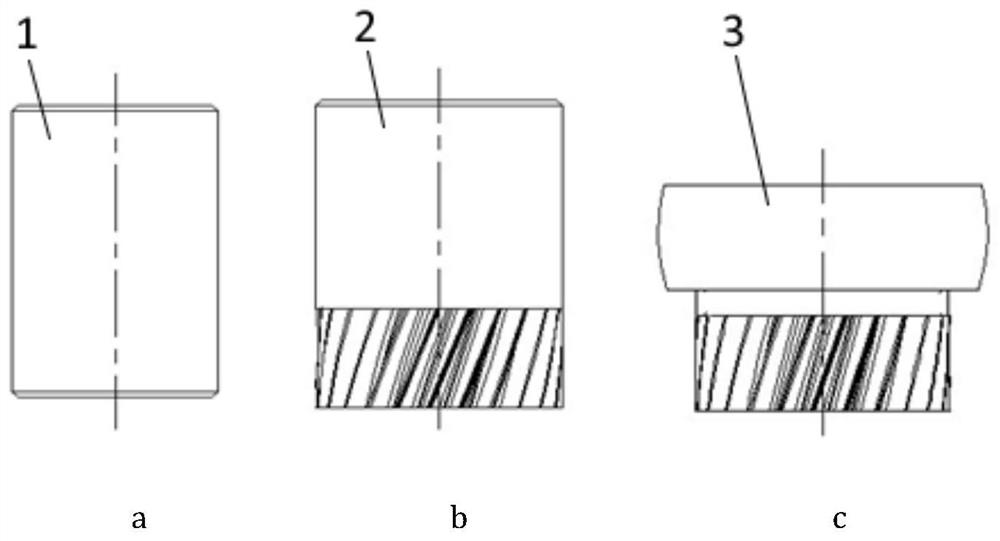

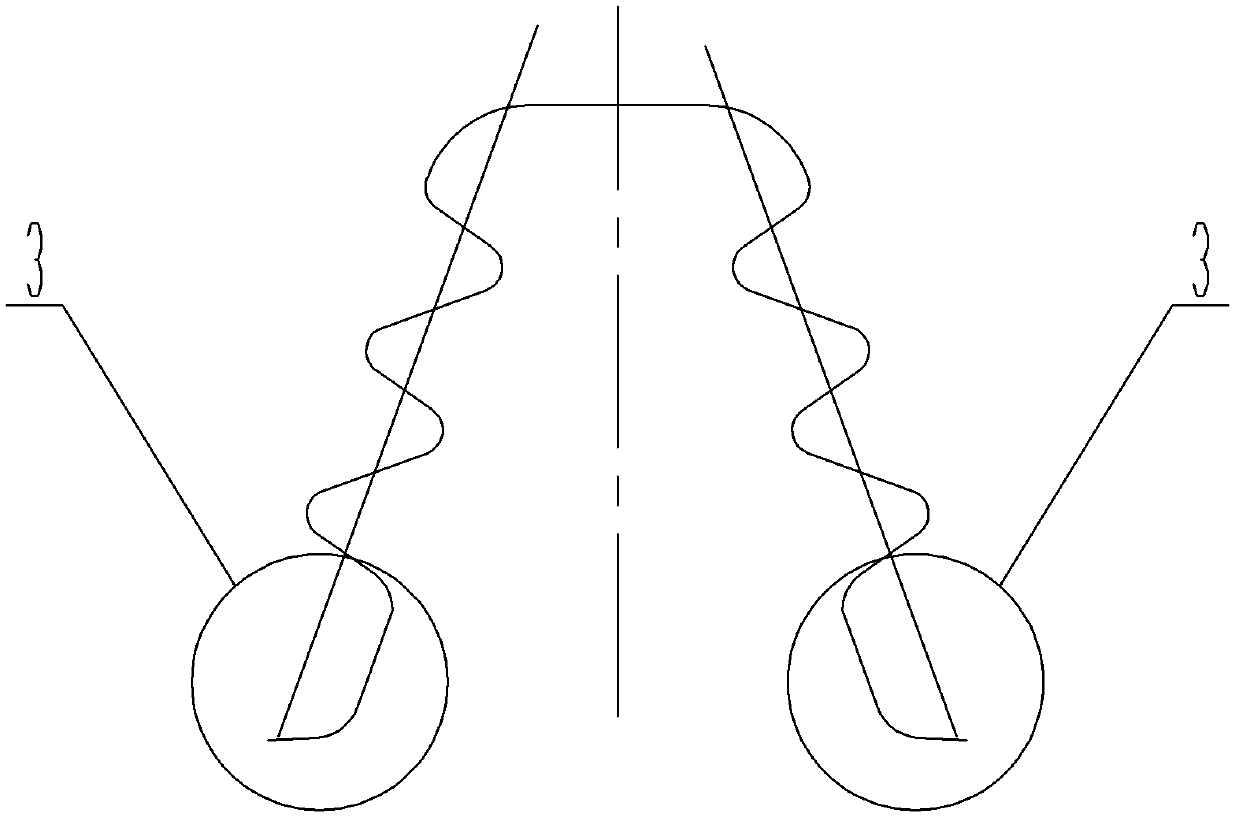

Method for manufacturing a hollow rack shaft

InactiveUS7069764B2Eliminate elastic deformationTelevision system detailsMechanical steering gearsEngineeringMechanical engineering

A hollow rack shaft is manufactured through a first step, a second step and a third step. At the first step, the plate-like workpiece of substantial rectangular shape is press formed into a gutter-like shape. The first die set used at this step is provided with slant die surfaces for canceling elastic recovering generated at the workpiece when the workpiece is removed from the first die set. At the second step, a row of rack teeth is press-formed on the flat bottom portion of the workpiece formed in the first step. The die set used at the second step is provided with a recess for releasing surplus workpiece material within the die clearance at a stroke end of the pressworking. At the third step, each of a pair of legs of the workpiece is bent in a semi-circular shape so as to be butted to each other. At this time, a mandrel is inserted between the legs of the workpiece.

Owner:NSK LTD

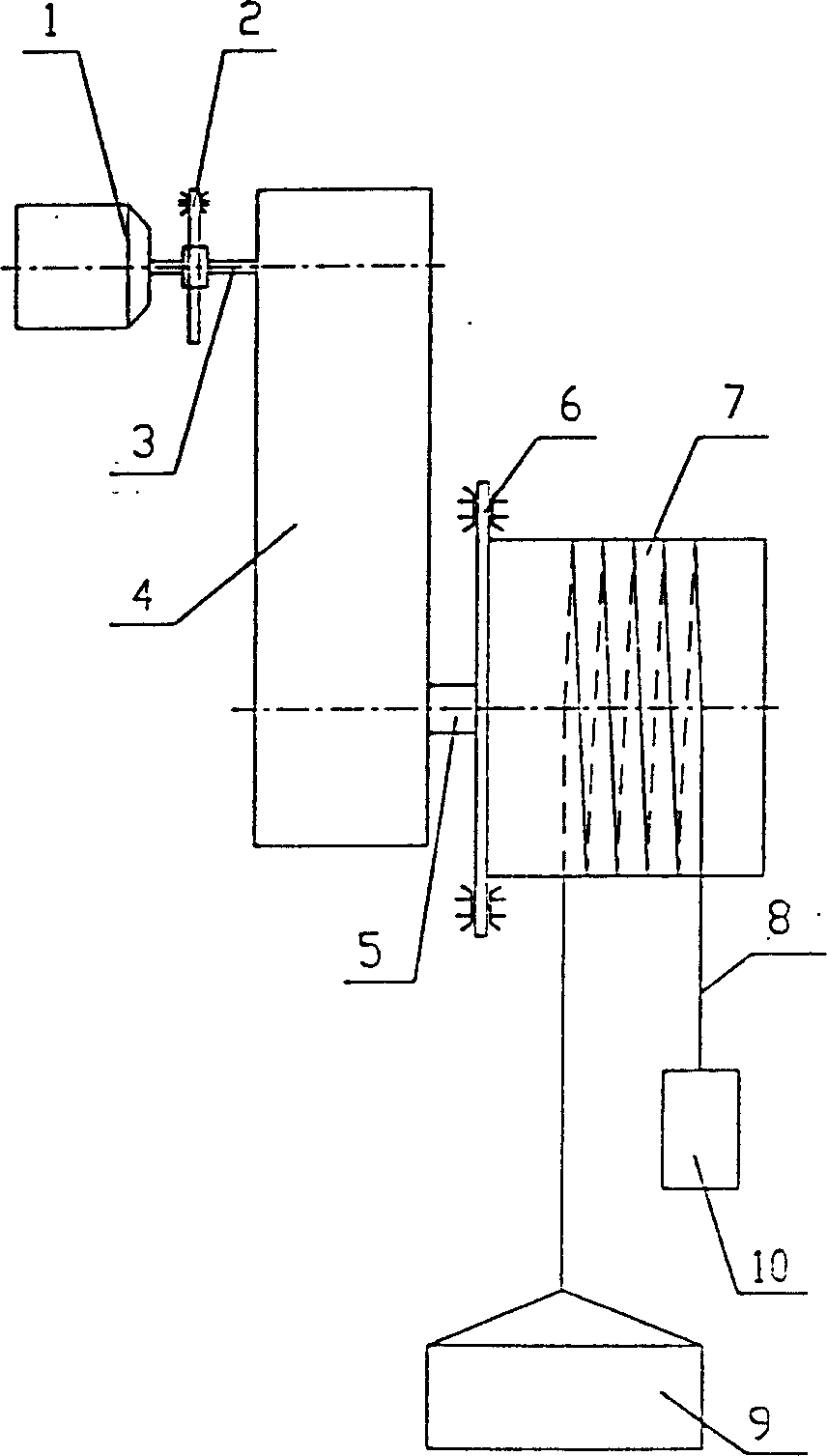

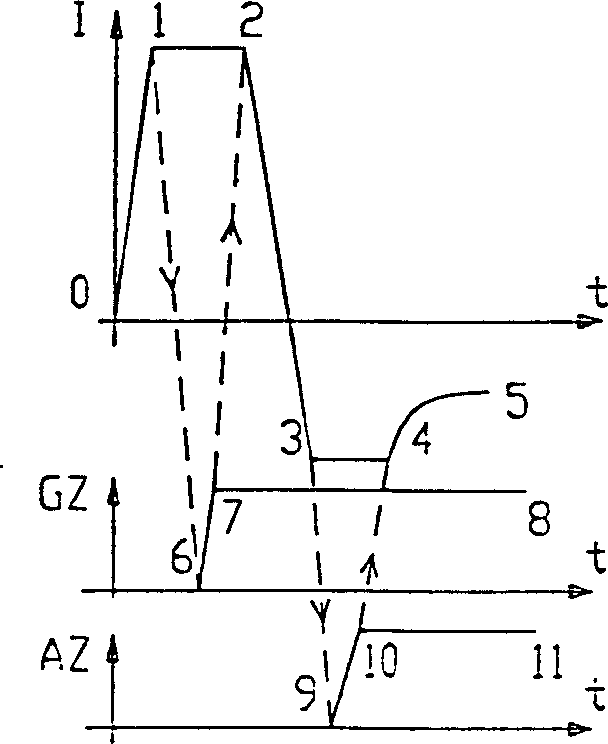

Method of eliminating driving gap and resilient deform in heavy load gearbox

The present invention relates to a method for removing drive gap in heavy-load gearbox and elastic deformation. Said method includes the following steps: using the motor drive current before last operation stop as basis and using it as initial pretorque current for present start, and applying it to motor, starting working brake, converting the pretorque current into the pretorque current required for present operation according to a certain conversion rate, starting safety brake, the motor can be acceleratively started and operated so as to implement present start.

Owner:WUHAN SHIP IND

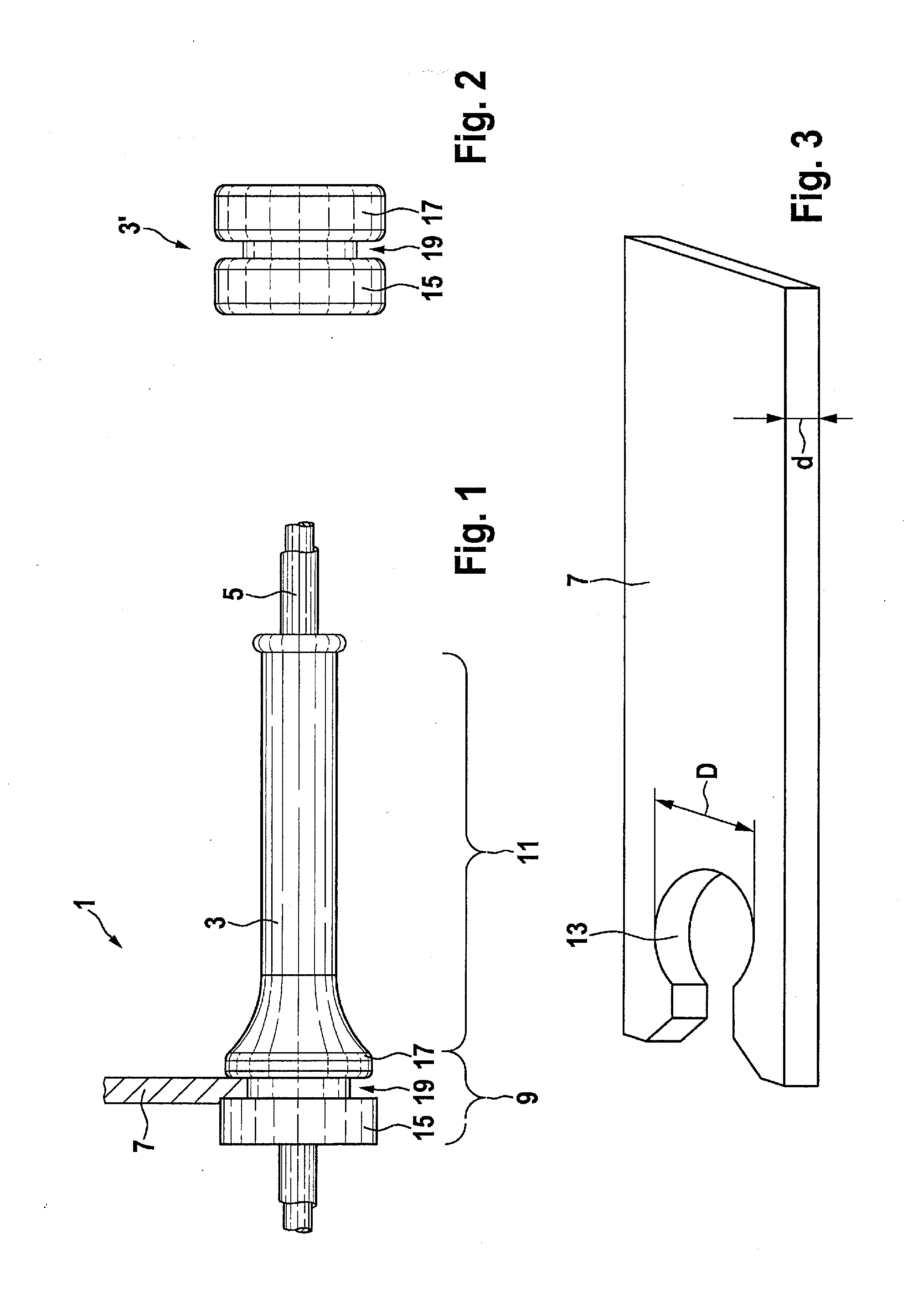

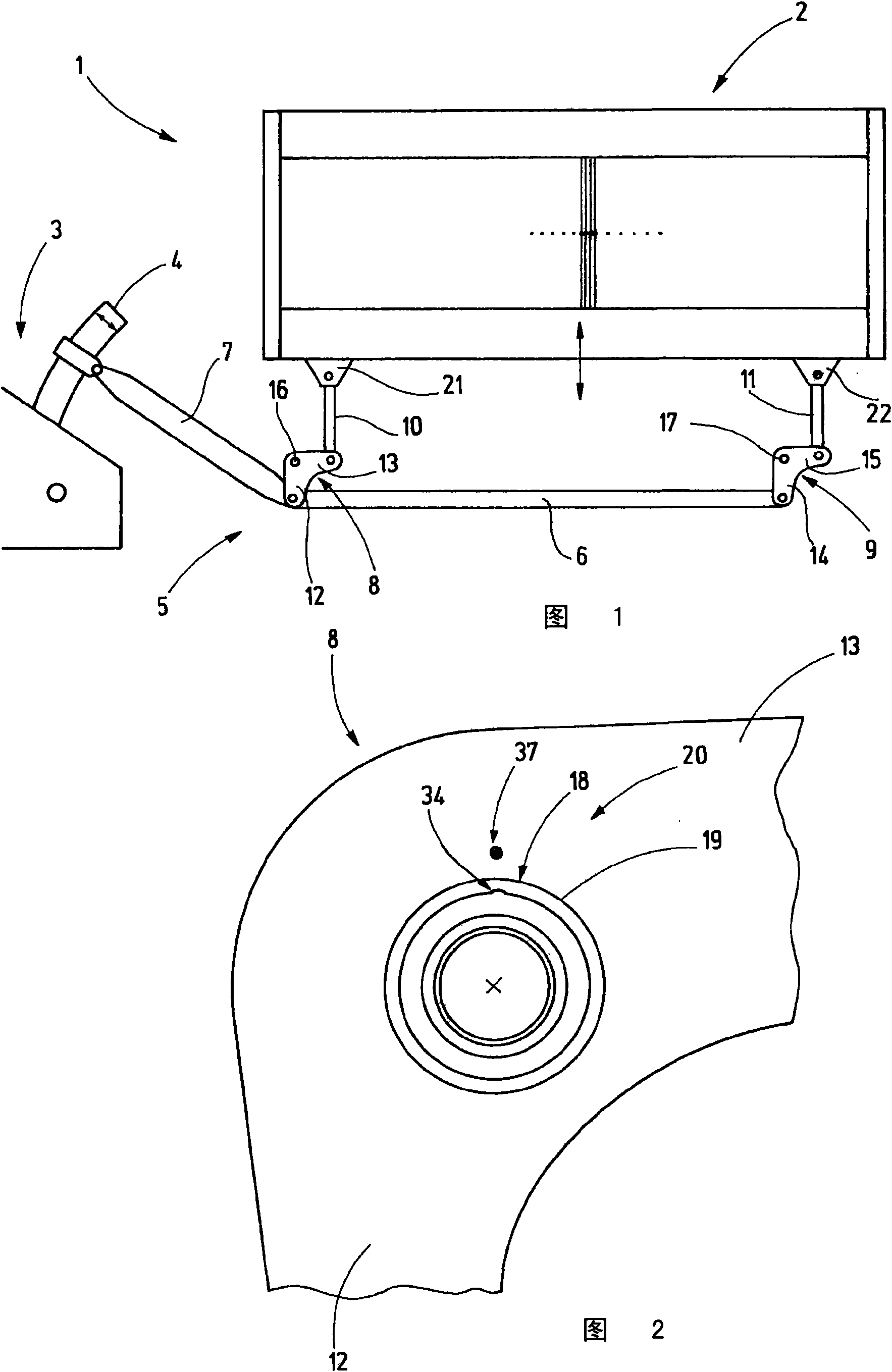

Storage device and beam for loom

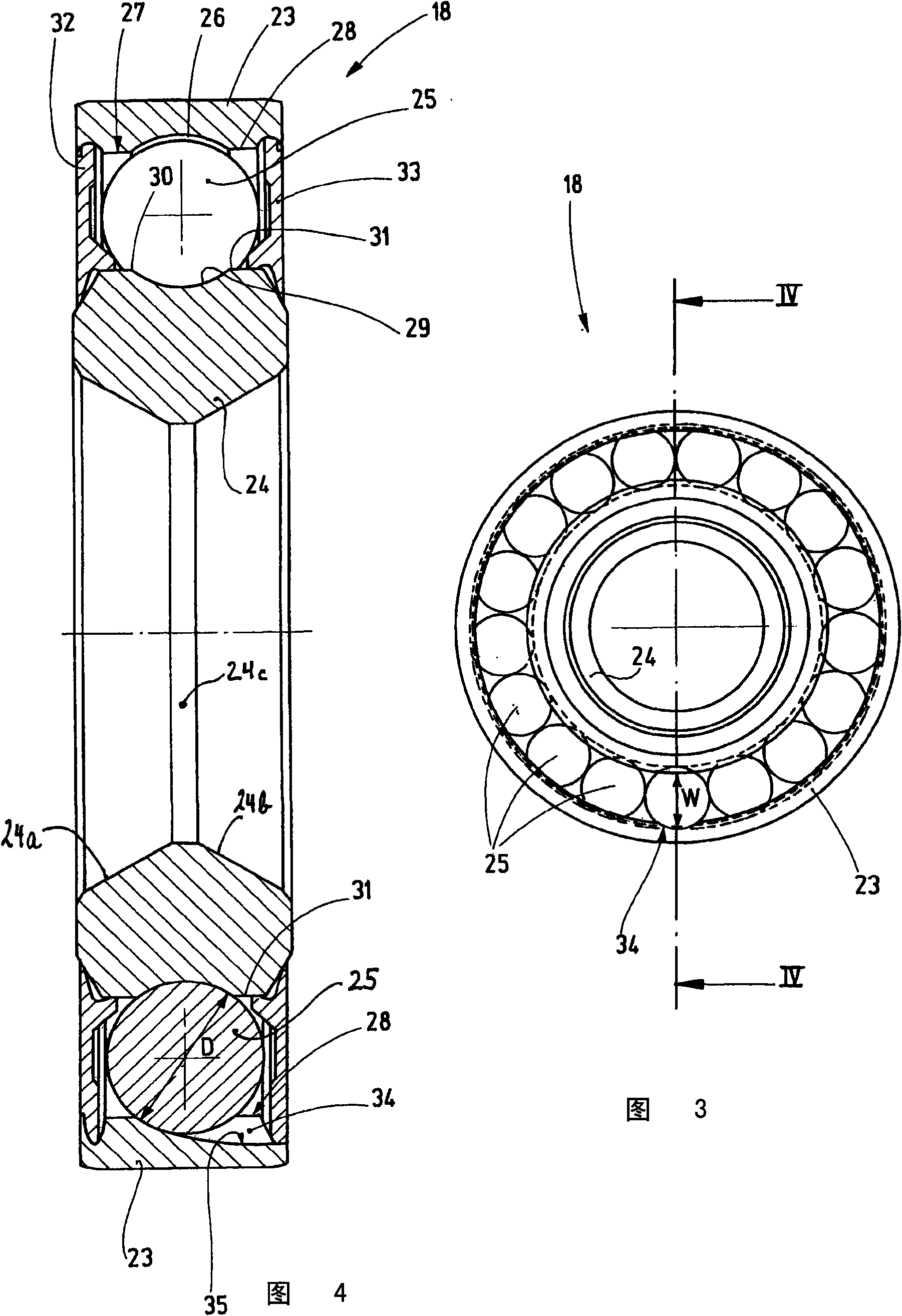

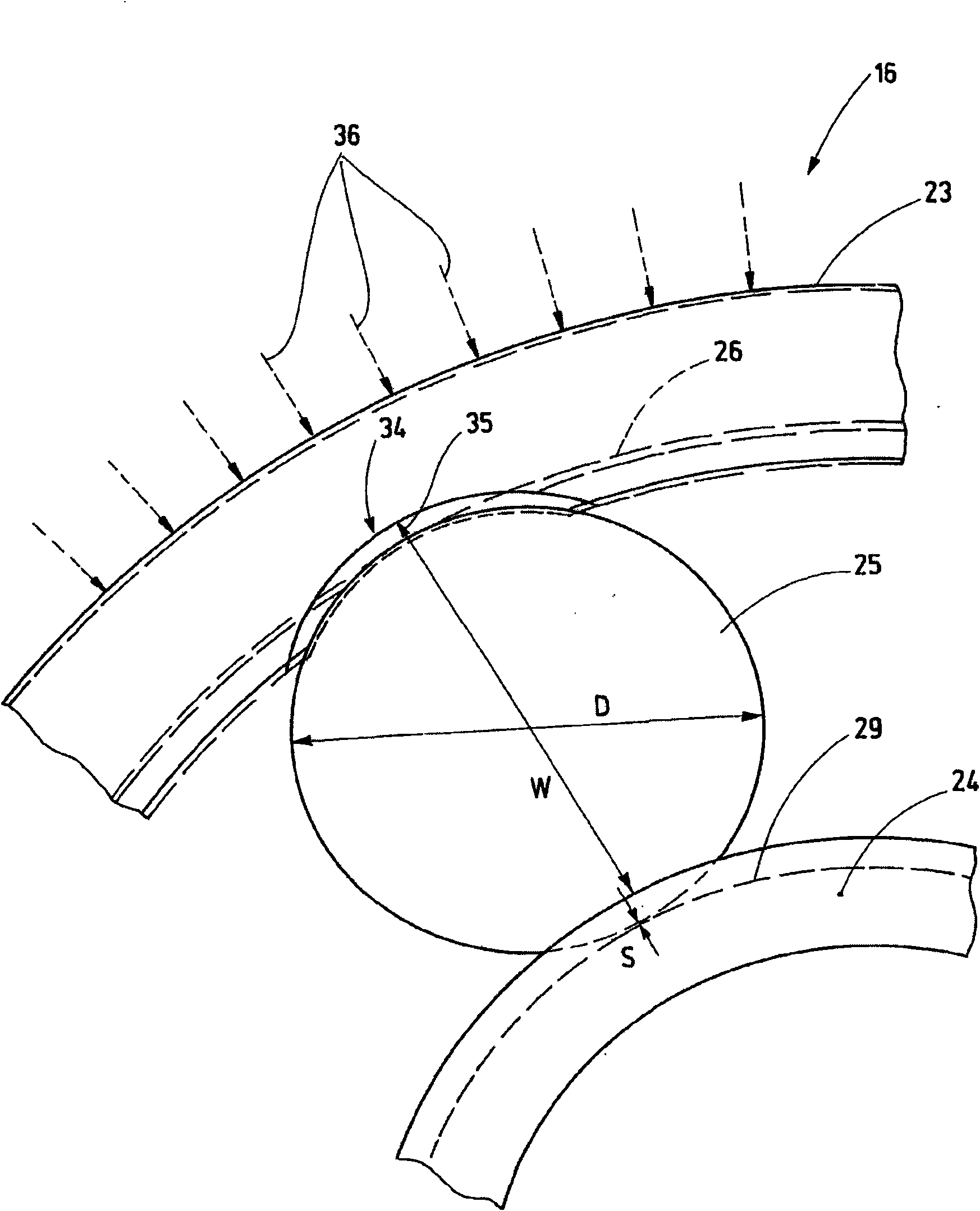

According to the invention, the antifriction bearing (18) needs not to open the outside lane (23). However, the outside lane (23) has a filling groove (34) for keeping unblock when being used. However, the diameter of the filling groove (34) is smaller than the diameter (D) of the ball, thereby the ball (25) does not fall off. In addition, the outside lane (23) of the bearing (18) displays a definite radial elastic. And the antifriction bearing (18) is radially and constrainedly installed through a pressing cooperation, thereby the ball (25) no longer jump out of the bearing (18). In order to assembly antifriction bearing (18) in an accurate angle, the filling groove (34) is out of the range of maximum stress. For this purpose, the filling groove (34) is preferably structured to cause the sealed ring (33) to keep existed and visible.

Owner:GROZ BECKERT KG

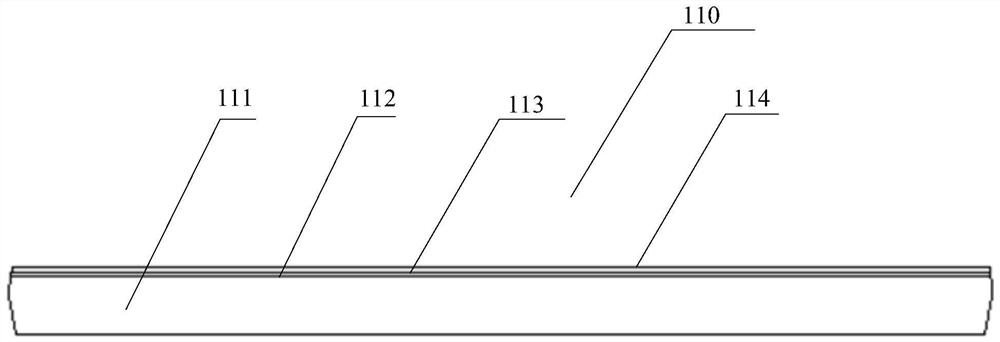

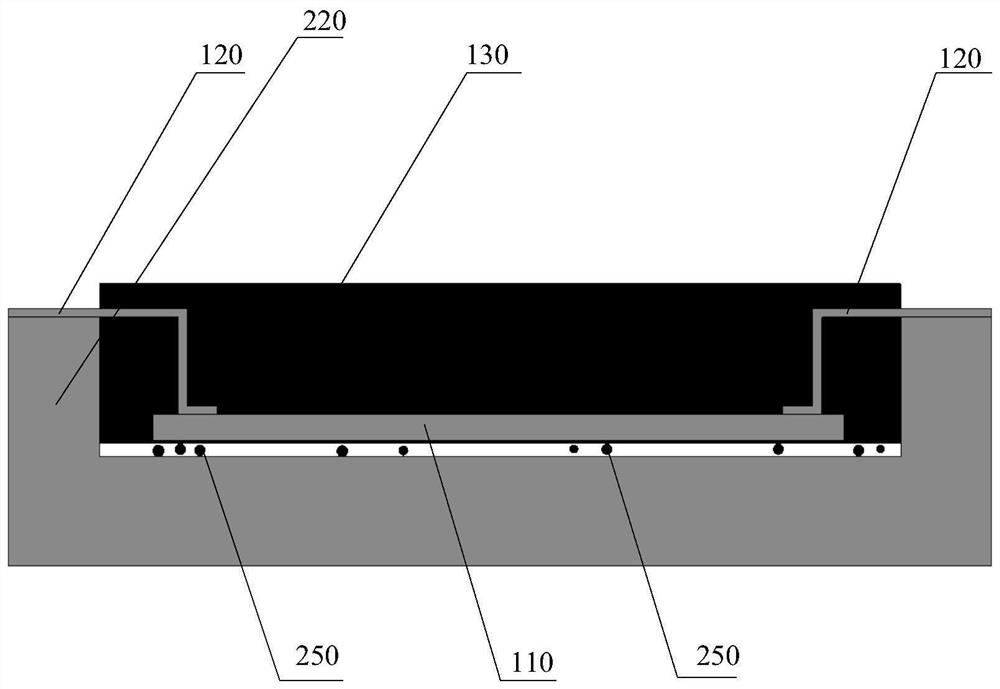

Intelligent power module and packaging method of intelligent power module

PendingCN112510005AReduce stressAvoid Poor PackagingSemiconductor/solid-state device detailsSolid-state devicesStructural engineeringMechanical engineering

The invention discloses an intelligent power module and a packaging method of the intelligent power module. An eliminating structure is arranged on the part, in a sealing layer, of a pin, a stress eliminating structure generates elastic deformation when stress is applied, the stress of stretching force and extrusion force transmitted to a substrate by the pin can be effectively reduced, therefore,the stress finally transmitted to an insulating layer is greatly reduced, the result of poor packaging caused by cracks generated on the insulating layer is avoided, and the yield of packaged finished products is improved.

Owner:广东汇芯半导体有限公司

Transmission line tension straightening device

InactiveCN106159802BImplementation orientationLarge transmission pullApparatus for overhead lines/cablesEngineeringElectric wire

The invention provides a power transmission wire tensioning and straightening device, which comprises a support frame, a tensioning mechanism and a straightening mechanism, wherein the support frame comprises a support platform; two opposite support vertical plates are arranged at the two ends of the support platform; two mutually parallel first guide rods are arranged between the support vertical plates; the tensioning mechanism comprises a tensioning slide block and a pulling lead screw; the tensioning lead screw is arranged between the two support vertical plates in a sleeving way; the tensioning slide block is arranged on the two first guide rods in a sleeving way; the straightening mechanism comprises a straightening slide block and a compression wheel. The power transmission wire tensioning and straightening device has the advantages that the structure is simple; the operation is convenient; the carrying is easy; during the power transmission line erection, the tensioning mechanism and the straightening mechanism in the power transmission wire tensioning and straightening device can be flexibly used for performing correction treatment on the bent position on a power transmission line, and the goal of fast and efficiently sorting the bent position on the power transmission line can be achieved.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

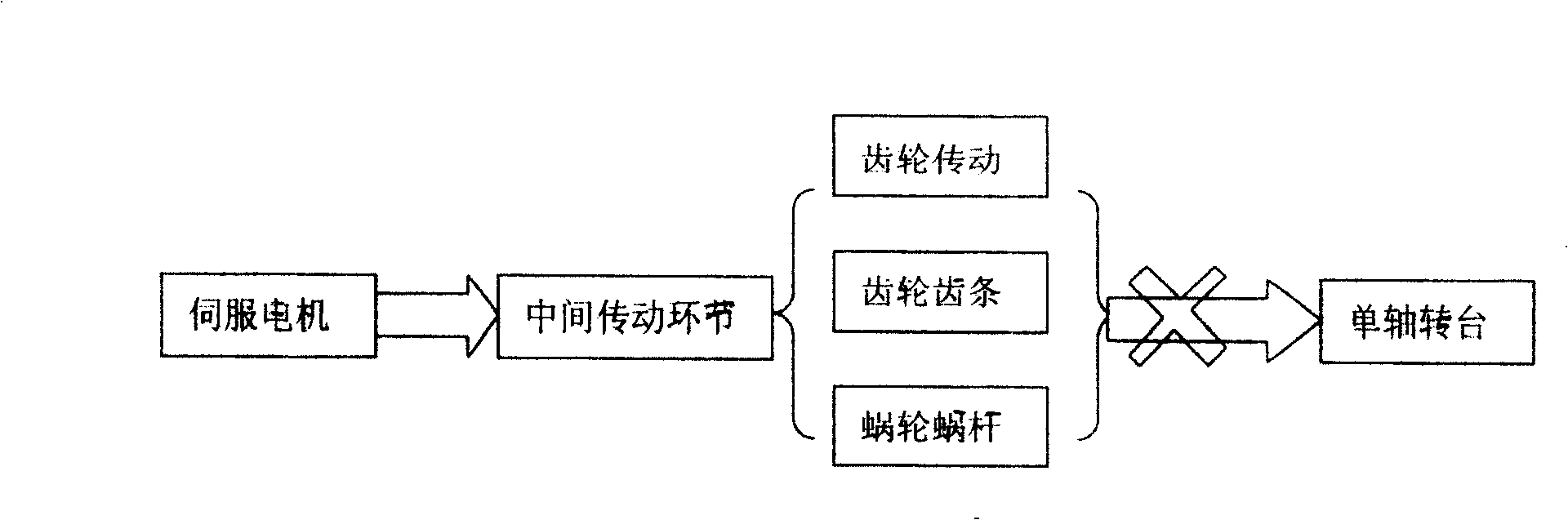

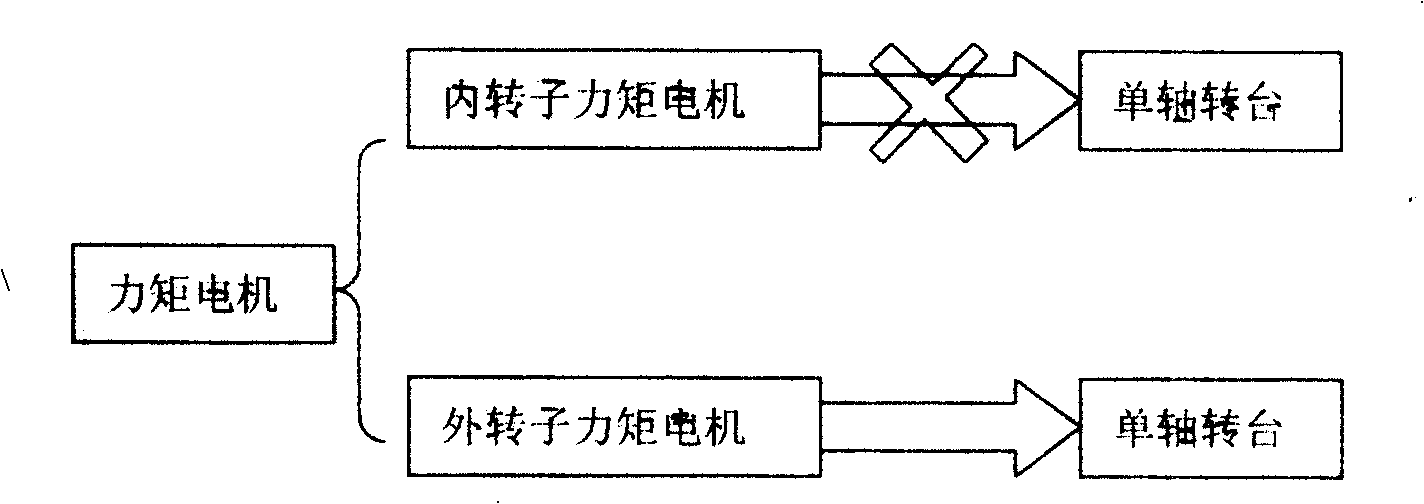

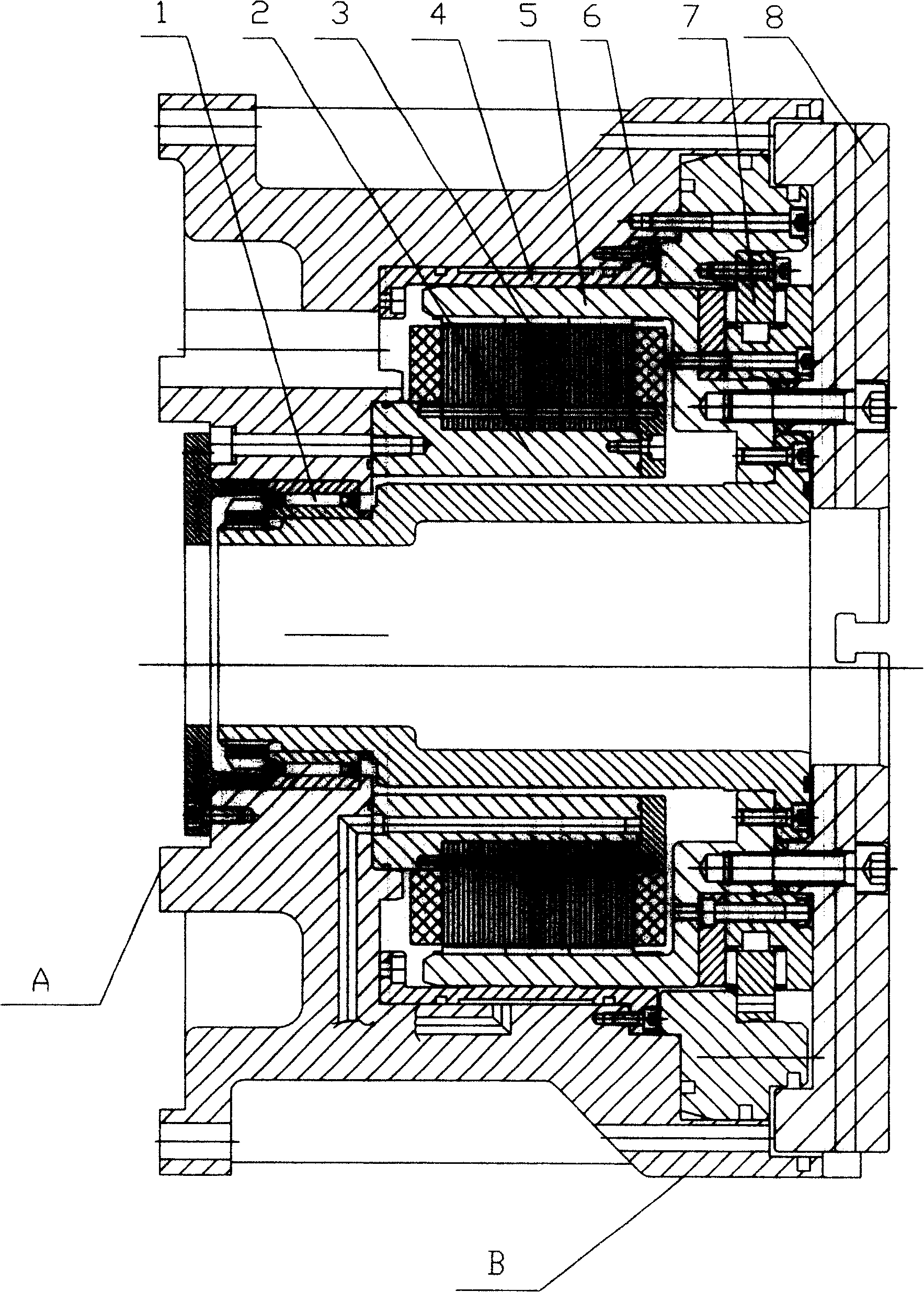

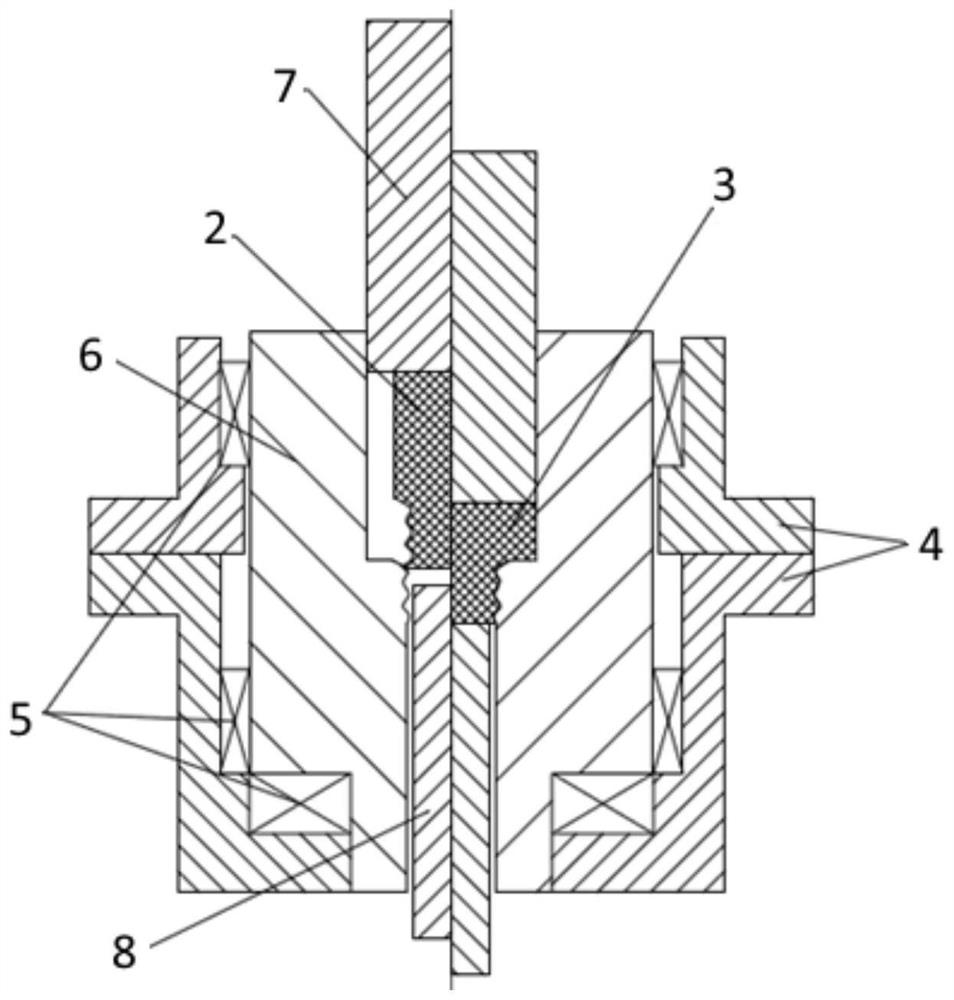

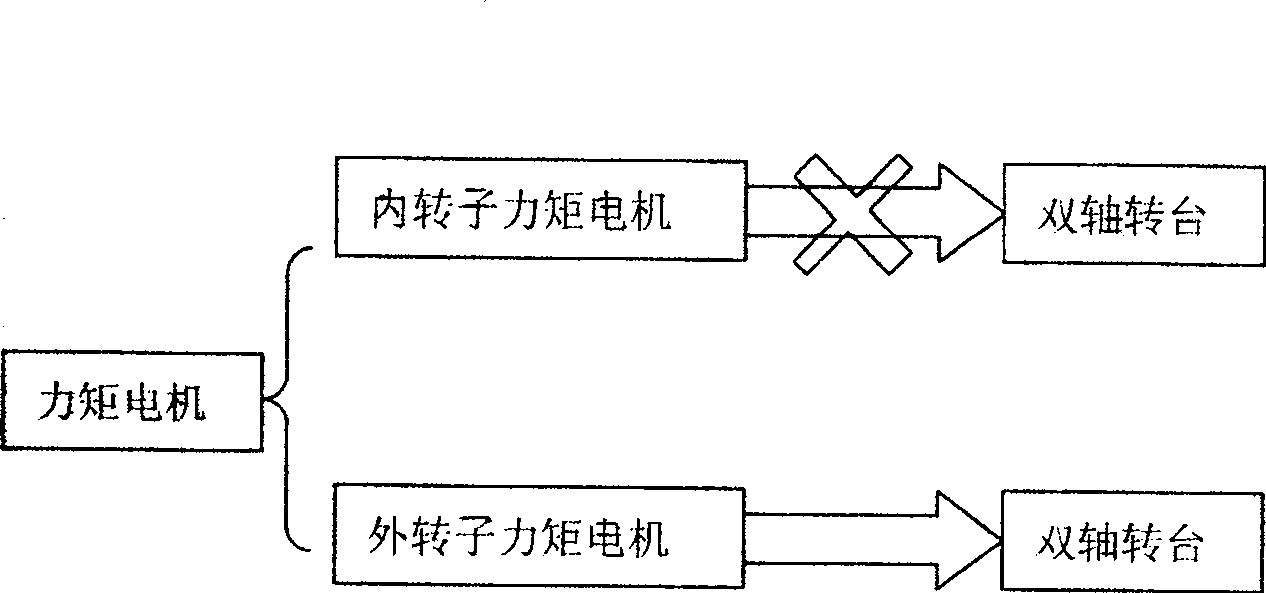

Vertical and horizontal dual-purpose single axle table of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN100421874CImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsMotor driveTorque motor

The invention relates to the vertical and horizontal single shaft rotary bench driven by an alternate permanent syntactic outside rotor torque motor. It directly fixes the bench on the end of the said torque motor rotor, connecting the shell with the inner cold bushing of the stator and the stator of the torque motor, with reduced middle drive linkages, improves the running precision and stability of the rotary bench, with bigger output torque and improved mechanical effect. It simplifies the braking mechanism with bigger clamping area, less drive effect with less size of the outside rotor torque motor under same performance conditions.

Owner:KEDE NUMERICAL CONTROL CO LTD

Cold extrusion forming process of helical gear

InactiveCN112058936AEliminate friction deformationReach the requirement of forming helix angleExtrusion diesRams/plungersFree rotationGear wheel

The invention discloses a cold extrusion forming process of a helical gear. The cold extrusion forming process specifically comprises the following steps: (1) spheroidizing annealing, shot blasting and phosphorus saponification treatment are sequentially conducted on a bar; (2) the bar treated in the step (1) is placed in a cold extrusion die to enable the bar to form a forming blank with a required spiral gear groove; (3) the formed blank in the step (2) is placed in an upset-extrusion forming die, the head of the blank is upset, and a forged piece is obtained; and (4) the forged piece in thestep (3) is subjected to isothermal normalizing treatment, so that the gear meets the technical requirements of products. According to the preparation method, a rotary lower die structure is adopted,a lower die freely rotates under the action of radial force generated when materials flow, and therefore the requirement for forming a spiral angle is met; the extrusion speeds of three strokes are adopted, so that the gear profile of a part is completely filled; and two sets of hydraulic systems are adopted, so that elastic deformation and friction deformation of gear sides caused by demolding are eliminated.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

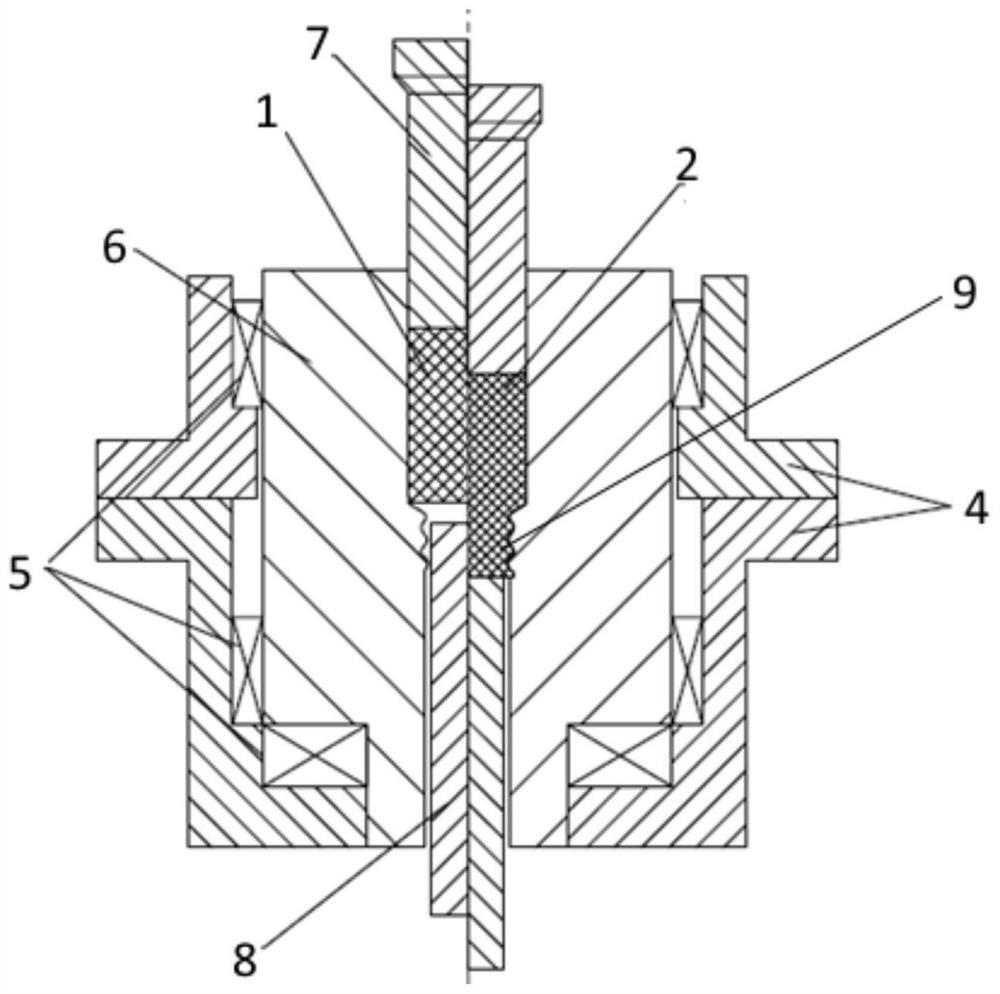

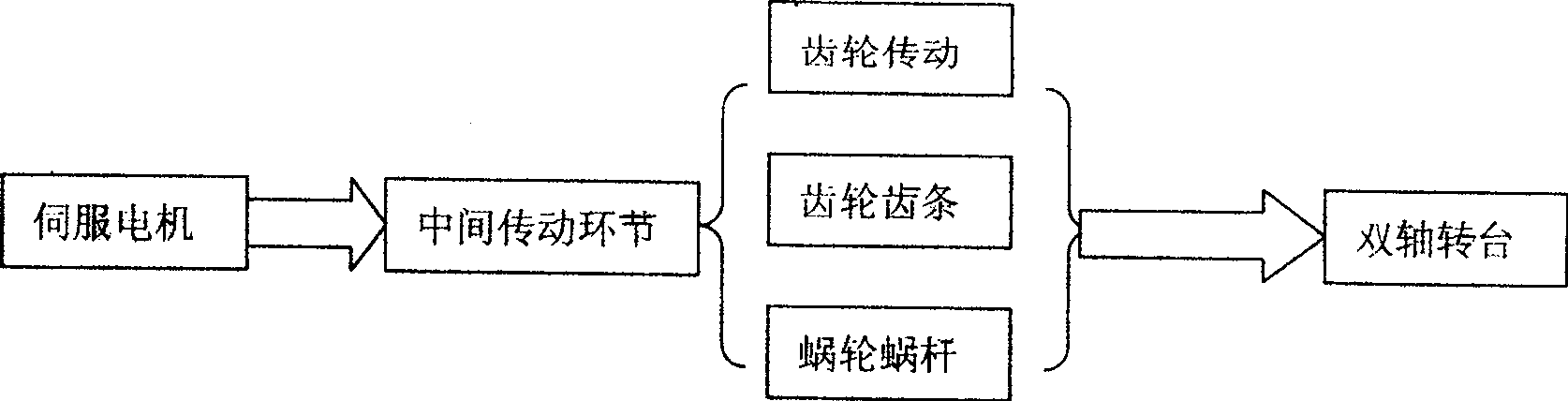

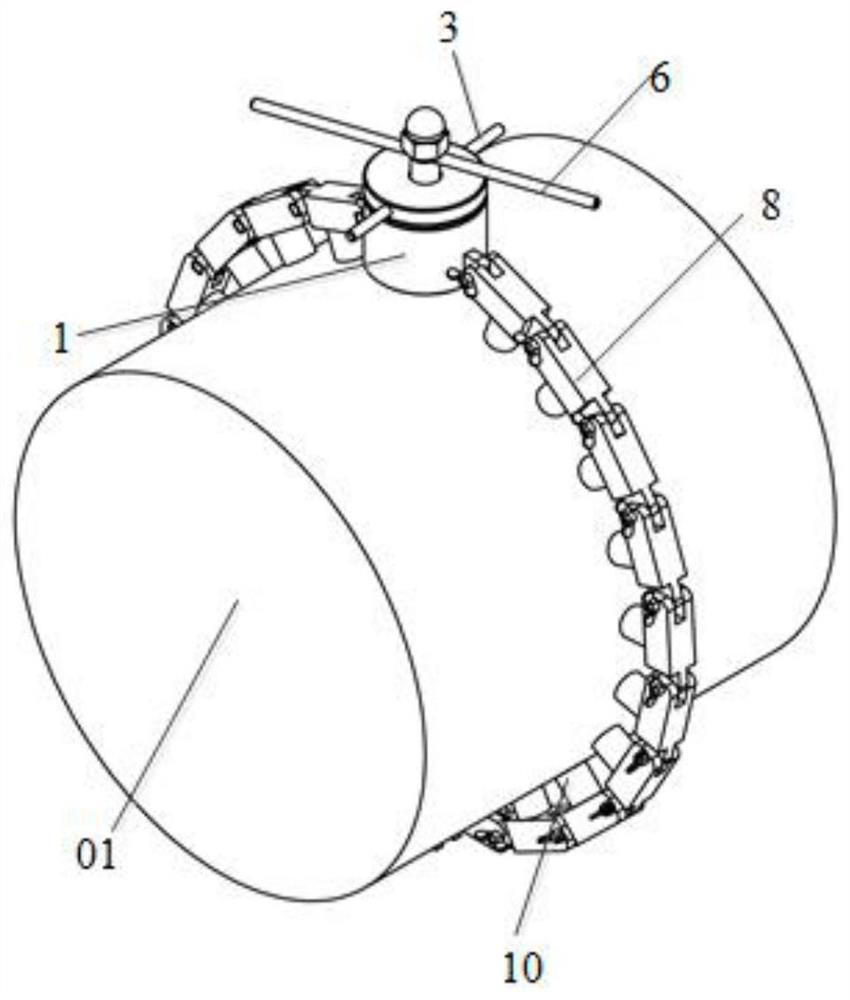

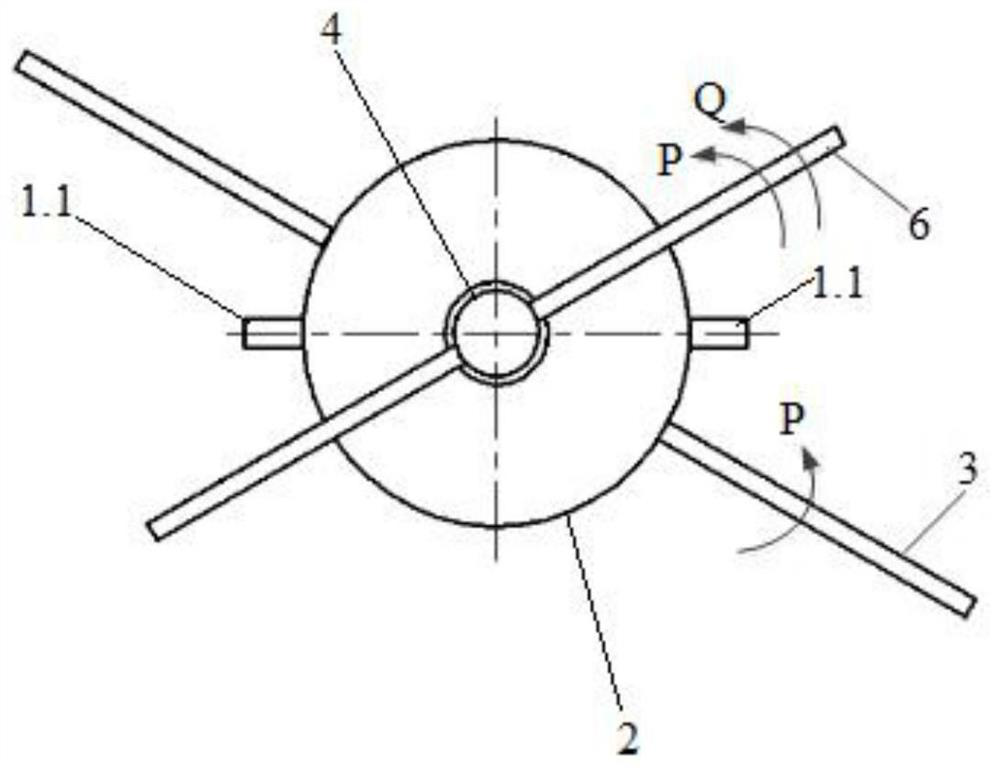

Double axle table driven by AC permanent magnetic synchronization external-rotor-type force moment motor

ActiveCN100467208CImprove running accuracyImprove stabilityEngine sealsMagnetic circuit stationary partsTorque motorEngineering

The biax turntable of an AC permanent magnet syntactic outside rotor torque motor comprises a turntable in the middle with vertical main shaft, turntable at one side of the said turntable with horizontal main shaft connecting with horizontal torque motor and vertical torque motor, oscillating driven by the horizontal torque motor, rotating driven the vertical motor. Saving a lot of middle drive linkage, it improves the running precision and stability of the turntable, with bigger output torque, and improved mechanical returns. It simplifies the braking structure with enlarged clamping area, less effect to the drive and system, smaller size of the outside rotor torque motor.

Owner:KEDE NUMERICAL CONTROL CO LTD

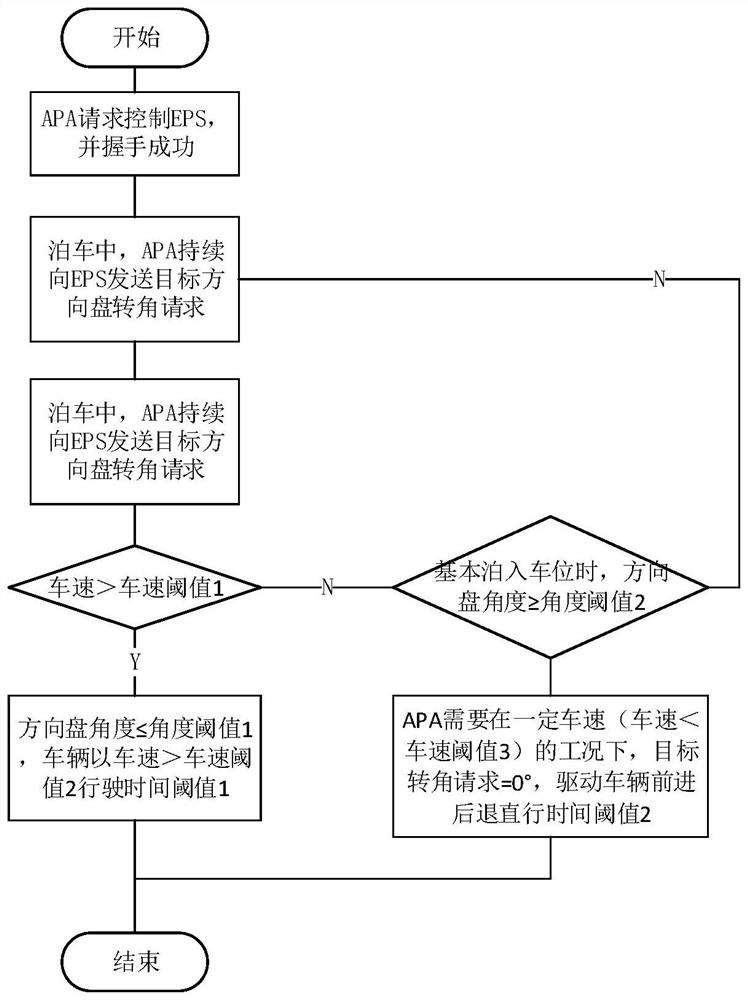

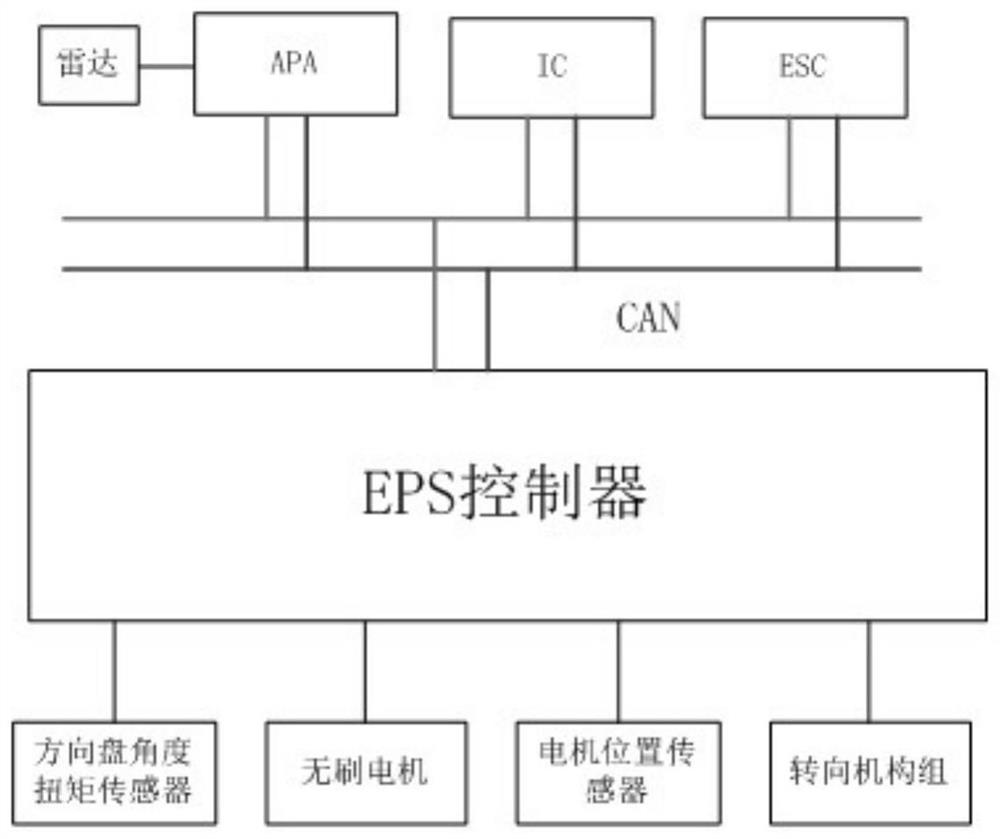

Automatic parking control optimization method and system

PendingCN114475782AEliminate elastic deformationSolve the problem of rebounding at a certain angleSteering partsSteering wheelControl theory

According to the automatic parking control optimization method and system, through control logic optimization of the APA on the EPS, elastic deformation of wheels is eliminated in the dynamic straight moving process of a vehicle, it is guaranteed that a steering wheel is stabilized in the middle position after automatic parking exits, and the problem that after automatic parking is completed, the steering wheel accidentally rebounds by a certain angle from the middle position is solved. It is guaranteed that the steering wheel is stabilized in the middle position after automatic parking quits, and the final control effect and customer experience of the whole parking process are improved.

Owner:DONGFENG MOTOR GRP

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN100475437CImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

A kind of screw removal tool and its use method

ActiveCN113510659BIncrease contact surfaceEven by forceWork holdersMetal-working hand toolsScrew positionClassical mechanics

The invention provides a screw removal tool and a method of using the same. The tool includes a removal mechanism, a clamping mechanism and a locking mechanism. The removal mechanism includes a shaft sleeve and a rotation control assembly. The shaft sleeve is arranged on a device to be The screw position is disassembled, and the rotation control assembly is threadedly connected with the inner wall of the shaft sleeve; the clamping mechanism includes clamping assemblies arranged on the shaft sleeve and located on both sides of the shaft sleeve; the locking mechanism is arranged at a distance from the clamping assembly. on one end of the shaft sleeve. The use method includes step S1 that the clamping member clamps the screw to be disassembled; step S2 locking mechanism circumferentially locks the clamping assembly and the disassembly mechanism on the equipment; step S3 synchronously rotates the rotating handle and loosens the handle to eliminate the clamping assembly Clearance between the device and the device; complete the screw removal operation through step S4. The invention solves the problem that the existing screw removal tool needs to unscrew the screw in advance and use the vacated threaded hole to provide a fulcrum for the tool, the threaded hole is not damaged, and the operation is convenient.

Owner:CHANGSHA AERONAUTICAL VACATIONAL AND TECHNICAL COLLEGE

Lossless surveying and mapping method of enclosed impeller

InactiveCN102434470BEliminate elastic deformationAccurately reproduce the shape of the surfacePump controlNon-positive displacement fluid enginesImpellerPoint cloud

The invention relates to a lossless surveying and mapping method of an enclosed impeller, comprising the following steps: A. select one impeller vane chamber and perform surveying and mapping to the inlet and the outlet of the impeller vane chamber to obtain an inlet and outlet point cloud curve surface; B. fill high-elasticity liquid moulding agents in the impeller vane chamber, take out after solidification and formation to obtain a vane chamber male mold; C. coat parting agents on the male mold and place the male mold into a liquid pond with the same density, and take out after the liquid in the pond is solidified to obtain a vane chamber female mold in the liquid pond; D. perform surveying and mapping to the vane chamber female mold to obtain a vane chamber point cloud curve surface; E. splice the vane chamber point cloud curve surface and the inlet and outlet point cloud curve surface to form an integral vane chamber curve surface and complete the surveying and mapping to the impeller. In the lossless surveying and mapping method of the enclosed impeller, the male mold formed by filling and solidification of the impeller chamber is placed in the liquid with the same density and then is re-solidified to obtain the female mold, so as to basically eliminate the elastic deformation caused by self-gravity and remarkably improve the surveying and mapping precision; moreover, the operation is simple and the technical difficulty is low.

Owner:CHINA SHIPBUILDING INDUSTRY CORPORATION

Improved slide valve in hydraulic copying general pipe for controlling motion of punch hammer in punch

InactiveCN1297753CEliminate elastic deformationImproved Axial AlignmentServomotor componentsServomotorsPunch pressPipe fitting

Improvement in a spool of a copying distributor in a hydraulic circuit for controlling the motion of a cylinder for a hammer in a punching machine, includes a pressurized fluid source in communication with said hydraulic circuit, a distributor body which is connected to said hydraulic circuit through pipe fittings and is formed with pressurised-fluid supply lights and discharge light communicating with said pipe fittings, at least one valve means arranged in said hydraulic circuit to control the said distributor body, a spool slidably mounted in said body and arranged cyclically to open and close the said lights, one operating end of said spool extending outside said distributor body through a calibrated aperture and being arranged to abut against a reference member designed to move rigid with said hammer. The improvement provides for a recess formed in said operating end and having one end thereof blind and its other end open, a pin slidably mounted in said open end and arranged to be displaced therein by pressurised fluid flows controlled by said valve means, and at least one duct formed in said distributor body and arranged to feed pressurised fluid from said fluid source to said recess.

Owner:欧麦克股份公司

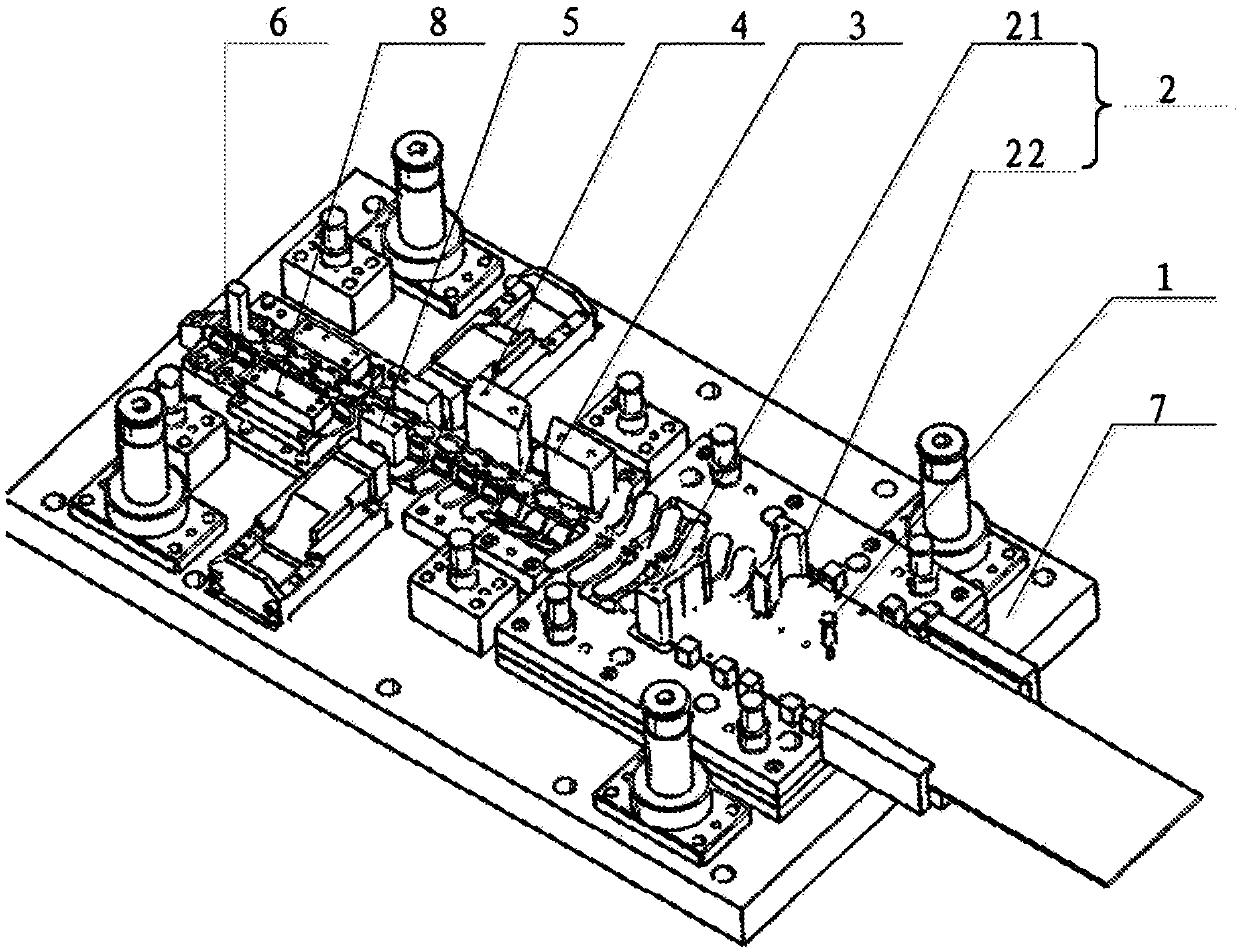

Full-automatic progressive die for hinge shaft

The invention relates to the technical field of machining, and discloses a full-automatic progressive die for a hinge shaft. The progressive die comprises an upper die holder and a lower die holder; aguide hole punching die block, a cutting die block, a semi-forming die block, a full forming die block, a side hole punching die block and a cutting-off die block are sequentially arranged on the upper die holder. The machining procedure of a right front car door lower hinge is subjected to new arrangement, on the basis of ensuring machining precision, the right front car door lower hinge can bemachined in the same machining die, through one machining die, personal losses can be reduced, and machining speed is improved; and the progressive die can effectively solve the problems that the right front car door lower hinge is high in forming cost and complex in process

Owner:HUBEI HONGSHENGCHANG ELECTRONICS CO LTD

refrigerator flip beam

ActiveCN104061743BSo as not to damageEliminate elastic deformationLighting and heating apparatusCooling fluid circulationEngineeringRefrigerated temperature

Owner:HEFEI SNOWKY ELECTRIC

Porous arch bridge water bag pre-pressing construction method

PendingCN114427220AImprove construction qualityEnsure construction safetyBridge erection/assemblySoil preservationTotal stationFraming (construction)

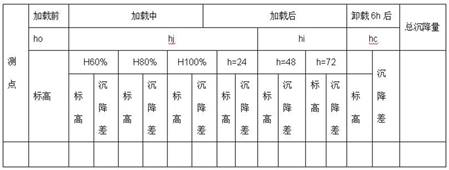

The invention discloses a porous arch bridge water bag pre-pressing construction method which comprises the following steps: S1, pre-pressing control tonnage and load classification are carried out, a pre-pressing coefficient is set to be 1.2, and a pre-pressing balance weight is calculated according to 1.2 times of the upper load of each span; s2, a water bag is adopted for prepressing, and the water bag is filled with water; s3, pre-pressing implementation and observation are carried out; s4, prepressing of a foundation and a support, in the step S3, measurement control points are arranged before prepressing construction, original data of the control points are collected, accurate lofting is conducted on the control points through a total station, the control points are arranged at arch feet, 1 / 8L, 1 / 4L, 3 / 8L and an arch crown, and five points are distributed on each section and distributed on bottom dies on the axis of a bridge and the two sides of an arch ring; according to the water bag pre-pressing construction method for the porous arch bridge, inelastic deformation of the foundation and the full framing of the porous arch bridge can be eliminated, construction safety is ensured, sand or gravel can be completely eliminated after pre-pressing is completed, and resources are saved.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Batch-type grinding method of hard coating material

InactiveCN102085631BHigh removal rateReduce loss costGrinding machinesUltra high speedHigh-speed grinding

The invention relates to a batch-type grinding method of a hard coating material, comprising the following steps: carrying out alternate batch-type grinding by adopting a grinding wheel feeding way and a grinding wheel no-feeding way in the grinding process; when the grinding wheel feeding way is adopted, carrying out high-speed or ultra high-speed grinding; when the grinding wheel no-feeding wayis adopted, carrying out no-load reciprocatory grinding; and after every time of feed grinding of a grinding wheel, carrying out the no-load reciprocatory grinding for 2-20 times according to the actual condition; wherein the high-speed or ultra high-speed grinding comprises that the primary feed grinding depth is 10-15mu m, the feeding speed of an operating platform is 6000-30000mm / min, and the linear speed of the grinding wheel is 80-200m / s. In the invention, variation of the actual grinding depth caused by elastic deformation and heat deformation of the grinding wheel and workpieces can beeliminated to the utmost extent, the heat produced at high-speed grinding can be timely released, and the grinding wheel can maintain to be sharp, thus the material removing rate is improved, the grinding surface burning is effectively reduced, the grinding wheel loss and production cost are greatly reduced, and the good processing quality is obtained.

Owner:HUNAN UNIV

Assembling cofferdams for emergency treatment of oil pipeline leakage in wetlands

The invention provides an assembled cofferdam for leakage emergency treatment of an oil pipeline in a wet land. The assembled cofferdam for leakage emergency treatment of the oil pipeline in the wet land comprises multiple connected cofferdam units. Each cofferdam unit comprises a main board, an air box, a connecting pipe and an opening connecting part, wherein the air box is connected with the main board, the air box is provided with a cavity, and the main board extends out of the air box; the connecting pipe is located outside the air box and connected to the first end of the main board; and the opening connecting part is located outside the air box and connected to the second end of the main board. The adjacent cofferdam units comprise the first cofferdam unit and the second cofferdam unit and the connecting pipe of the first cofferdam unit is connected to the opening connecting part of the second cofferdam unit in a sealed manner. By the adoption of the assembled cofferdam, a leakage accident treatment mode is changed, accident treatment time is saved, accident treatment cost is reduced, the wet land environment damage degree is decreased, cost is low, and the environment-friendly effect is good.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com