Patents

Literature

41results about How to "No axial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

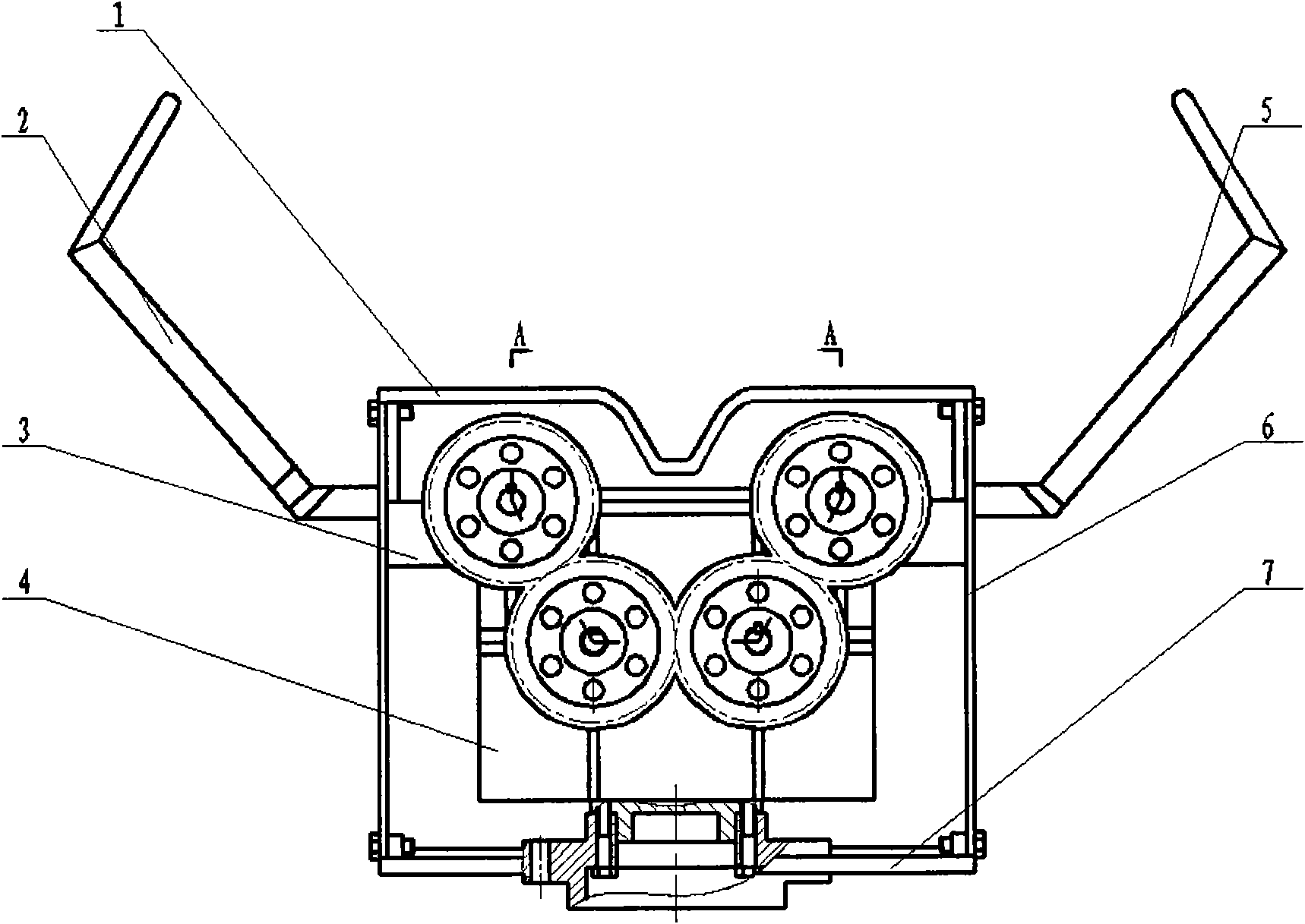

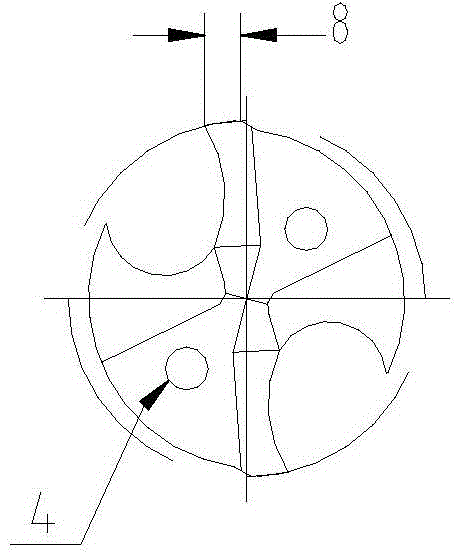

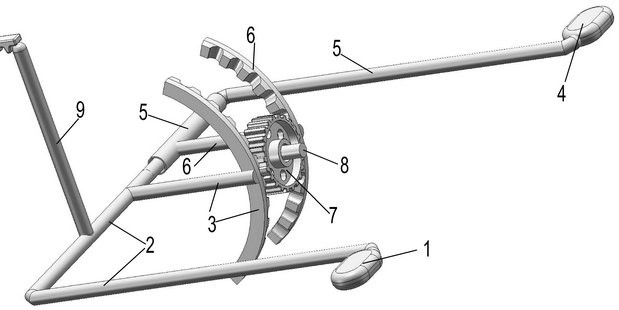

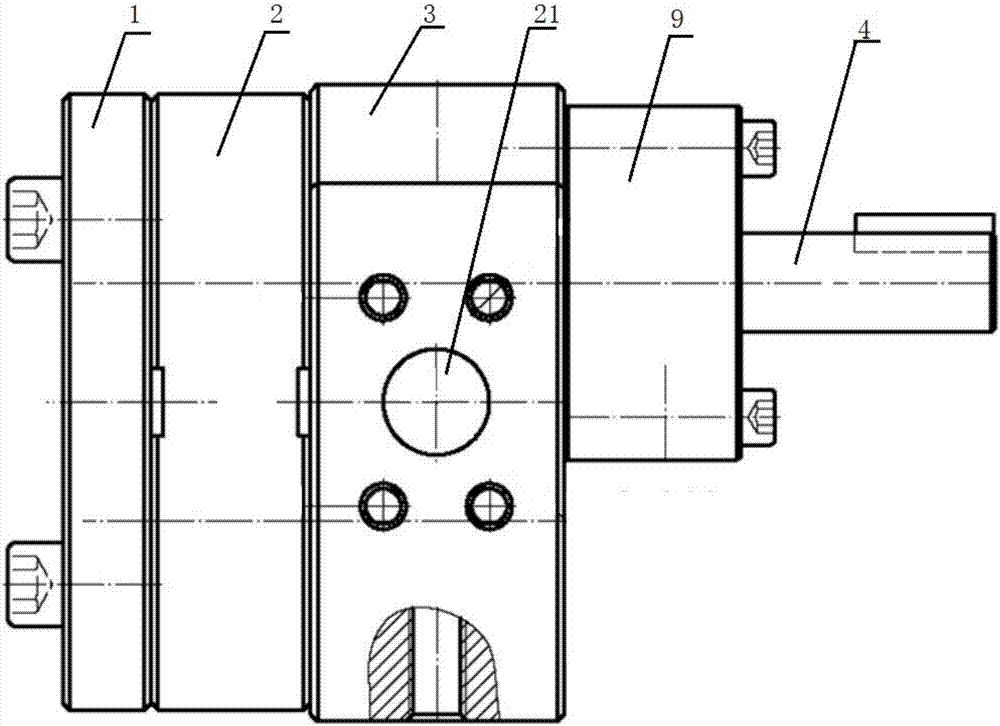

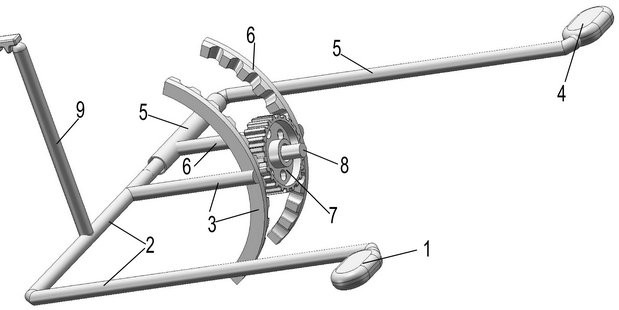

Space robot gripper mechanism

The invention discloses a space robot gripper mechanism, namely an end effector of a mechanical arm, which solves the problems of small gripping range, non-unique locking position, high probability of losing a target during griping and the like existing in the conventional gripper mechanism, greatly simplifies the entire mechanism and also improves the manufacturability. In the mechanism, a palm surface 1, an upper bearing seat 3, a lower bearing seat 4 and a box bottom 7 form a basic frame of the entire mechanism; two finger shafts 9 are arranged in bearing holes between the palm surface 1 and the upper bearing seat 3; two fingers 2 and 5 are fixedly connected with the finger shafts 9; the shaft ends of the two finger shafts are provided with gears 19; a motor 11 and a brake shaft 22 are arranged in through holes between the upper bearing seat 3 and the lower bearing seat 4; the shaft ends of the brake shaft 22 and the motor 11 are provided with gears 21; the gripper box bottom 7 is connected with the bearing seats and an external mechanism through flanges; and a box wall 6 is interconnected with the palm surface 1 and the box bottom 7 to package the entire gripper mechanism. The mechanism has the advantages of compact design, small volume, easiness of machining, convenience in assembly and disassembly and the like.

Owner:BEIJING UNIV OF POSTS & TELECOMM

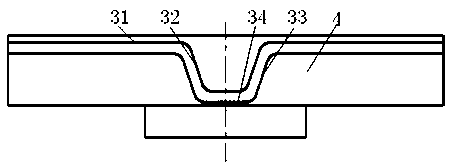

Design method for curved-tooth non-circular gear

ActiveCN105889456AHigh coincidenceImprove carrying capacityGeometric CADPortable liftingDesign methodsAxial force

The invention belongs to the technical field of non-circular gears and discloses a design method for a curved-tooth non-circular gear. The tooth profile of the curved-tooth non-circular gear is designed through a generating gear. The tooth profile equation is solved according to the curved surface of a counterpart rack, the kinematic relation of gear generation and the engagement principle. Compared with a straight gear, the curved-tooth non-circular gear designed through the method is high in contact ratio and bearing capacity. Compared with a bevel gear, the curved-tooth non-circular gear designed through the method does not generate axial force in the transmission process and has low requirements on bearings and installation. Through the arc tooth profile of the curved-tooth non-circular gear, lubricating oil is contained in the tooth surface, and therefore a quite good lubricating condition is achieved.

Owner:WUHAN UNIV OF TECH

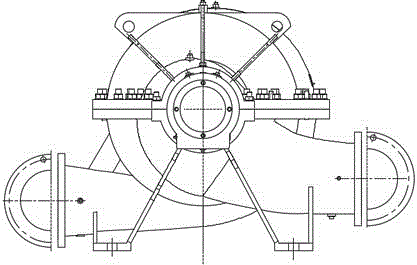

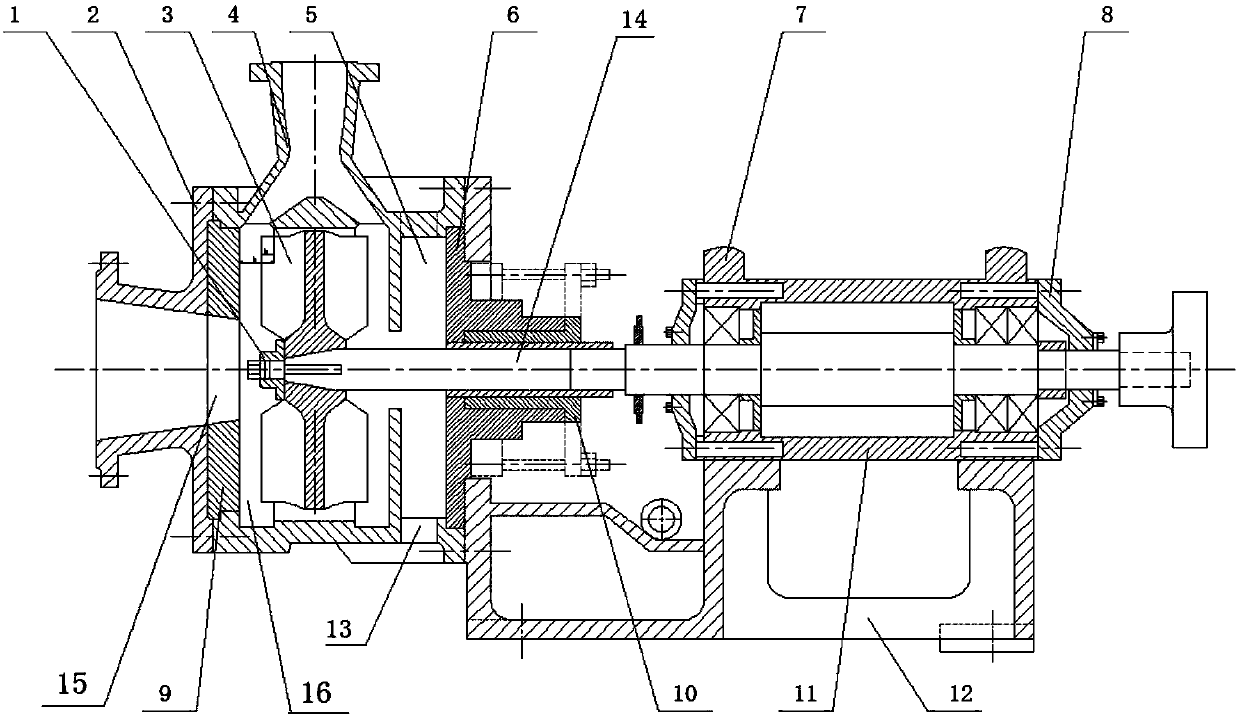

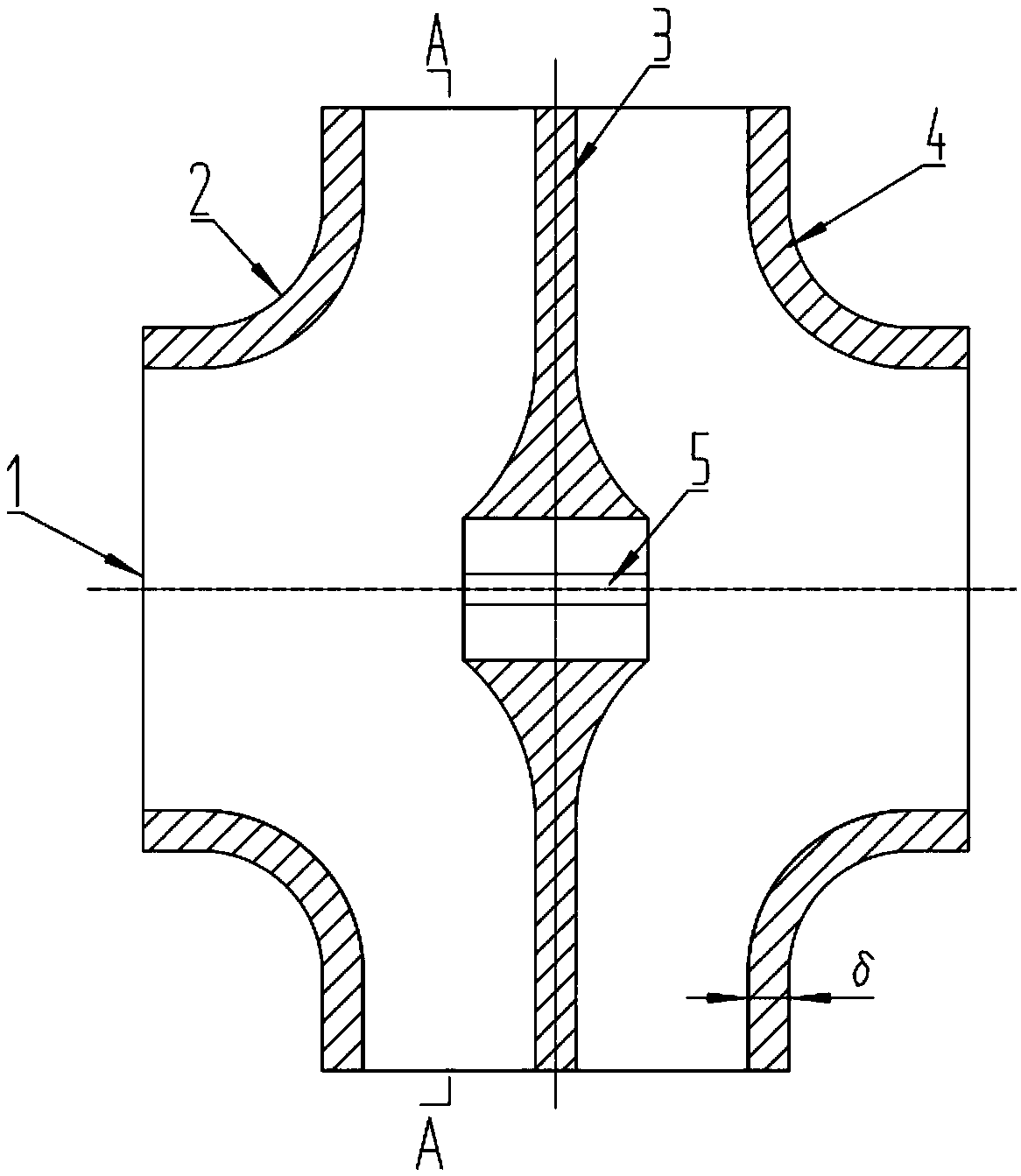

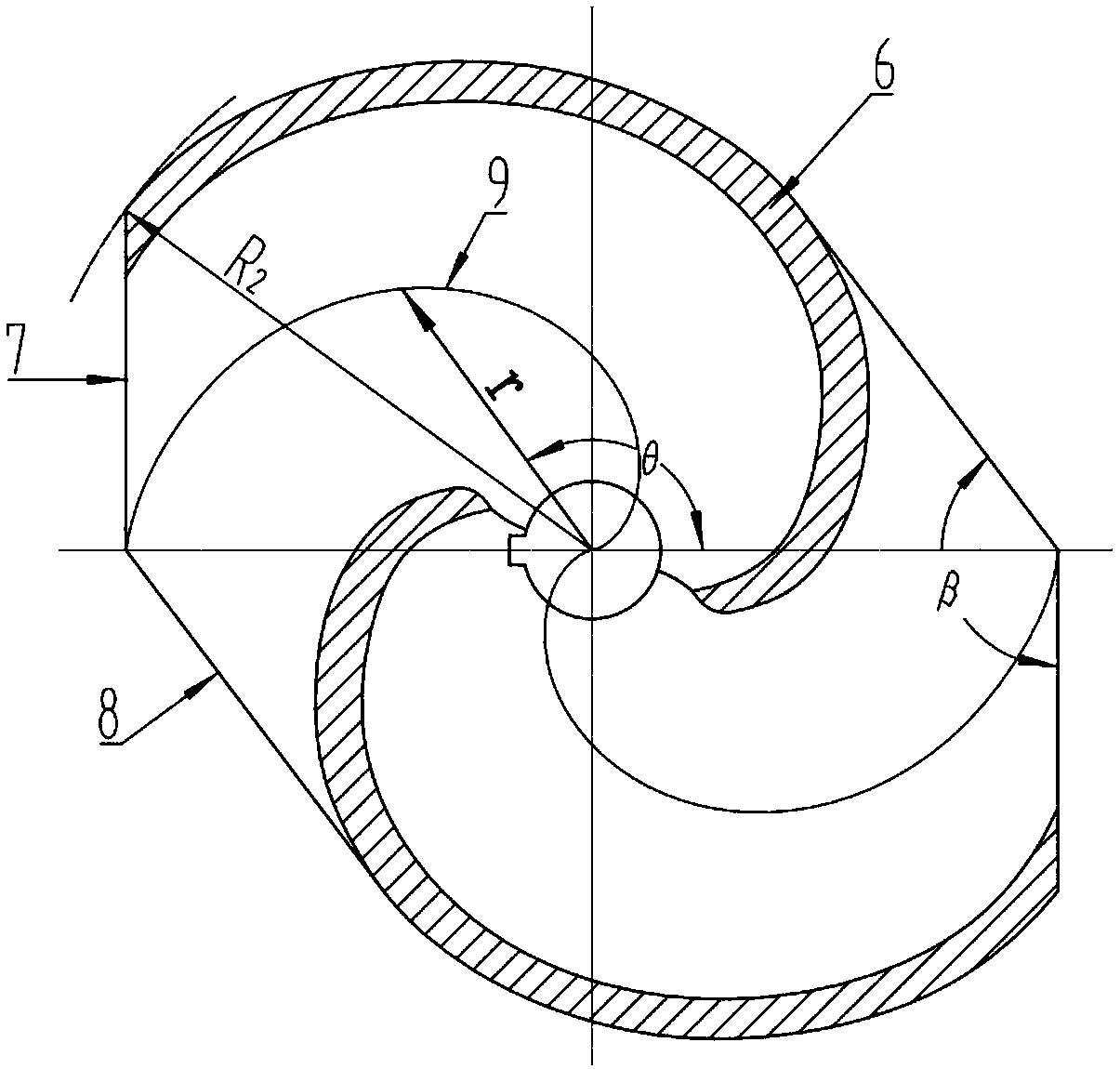

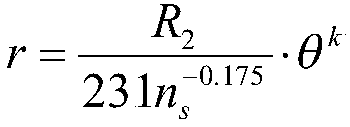

Partial emission pump with low specific speed

ActiveCN101865160AEasy to controlMake up for the shortcomings of unstable working conditionsPump componentsPumpsDrive shaftEngineering

The invention relates to a partial emission pump with a low specific speed, which comprises an inlet component and a shell component. The shell component comprises a shell, an impeller, an inducer, a transmission shaft, a diversion sleeve and a diffusion pipe; the impeller, the inducer, the transmission shaft and the diversion sleeve are arranged in the shell; the diffusion pipe is arranged on the shell and is communicated with the shell; the inlet component comprises an inlet shell and an inlet pipe; the inlet pipe is connected with the inlet shell; the partial emission pump also comprises a throat part arranged on the shell; the shell is communicated with the diffusion pipe through the throat part; and the central line of the diffusion pipe is parallel to the external tangent line of an annular channel on the shell. The invention solves the technical problems of narrow blade outlet, difficult manufacture and processing of the impeller and low efficiency of the centrifugal pump, facilitates the large-scale adjustment of operating conditions, and improves the hydraulic efficiency of the pump.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Process for rolling large-scale rails into miniature type rails and rollers therefor

InactiveCN1546247ALow powerLow running costRollsMetal rolling arrangementsEngineeringMechanical engineering

Owner:周燕雄 +1

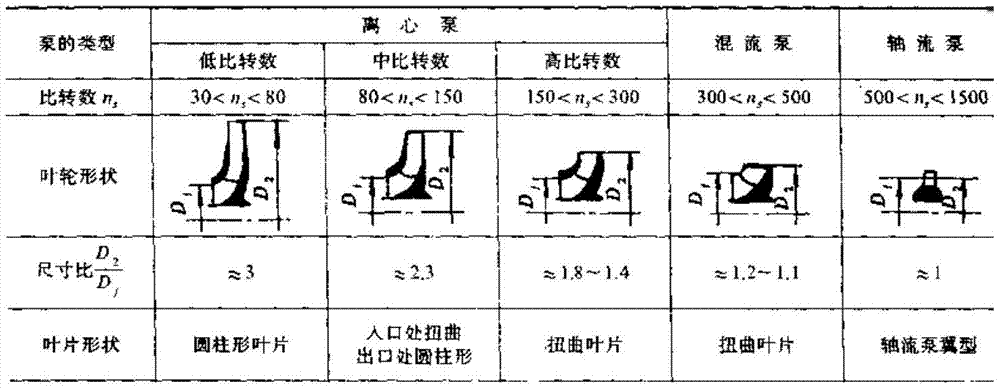

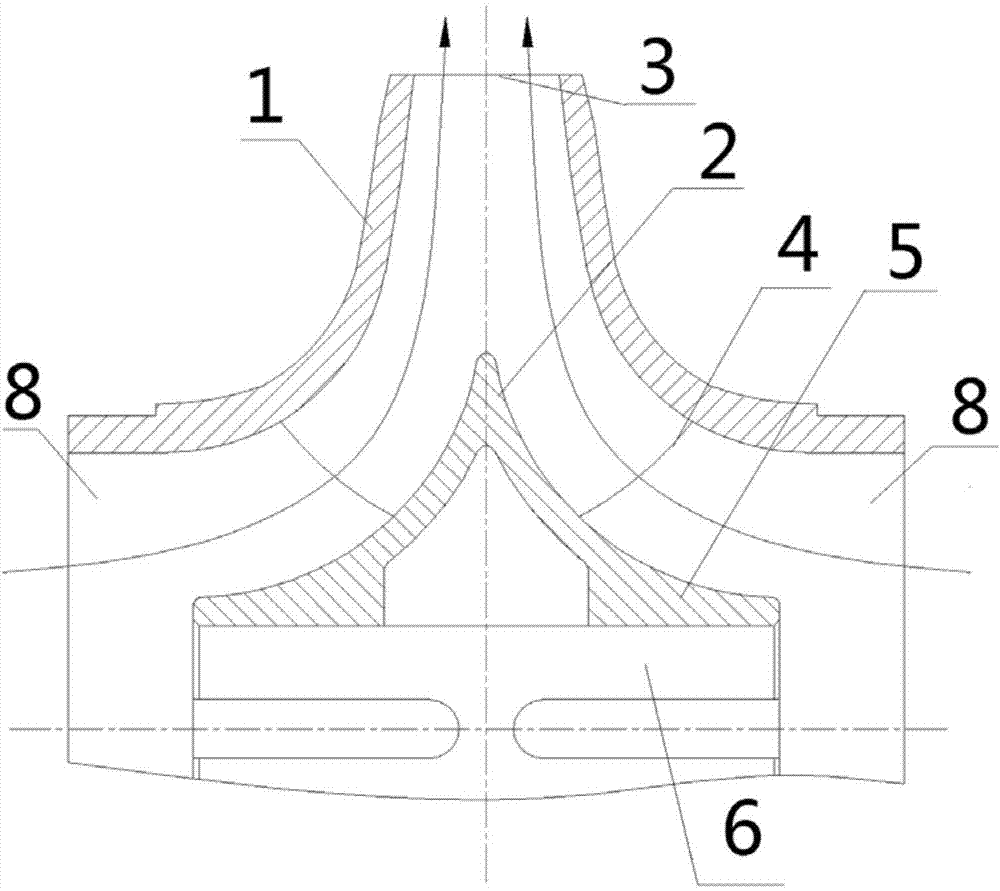

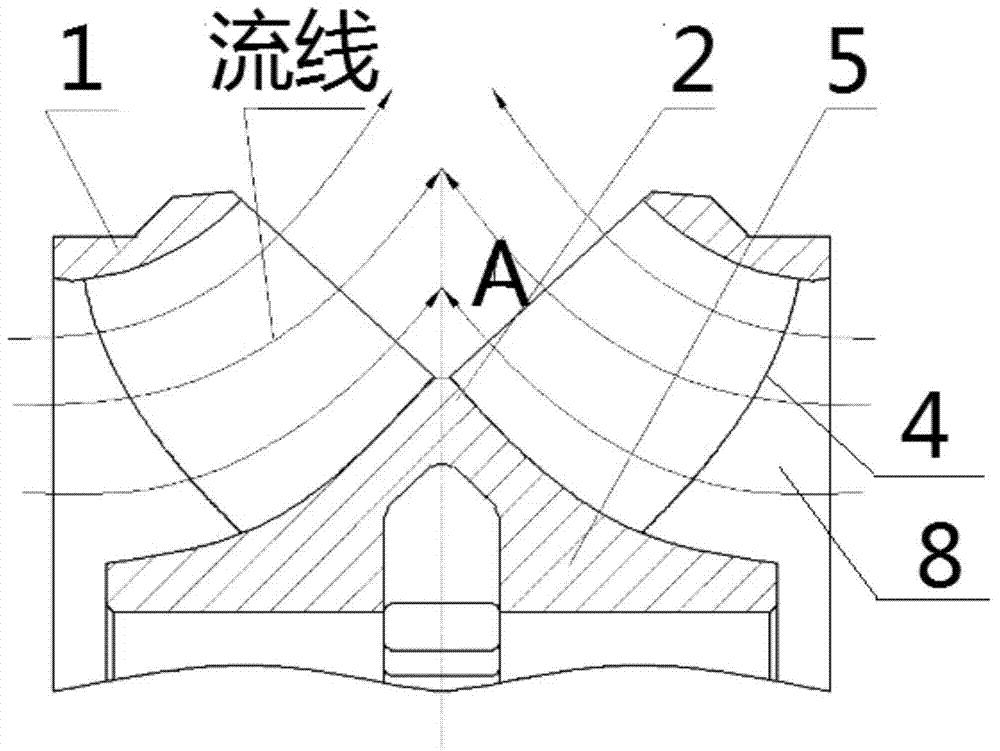

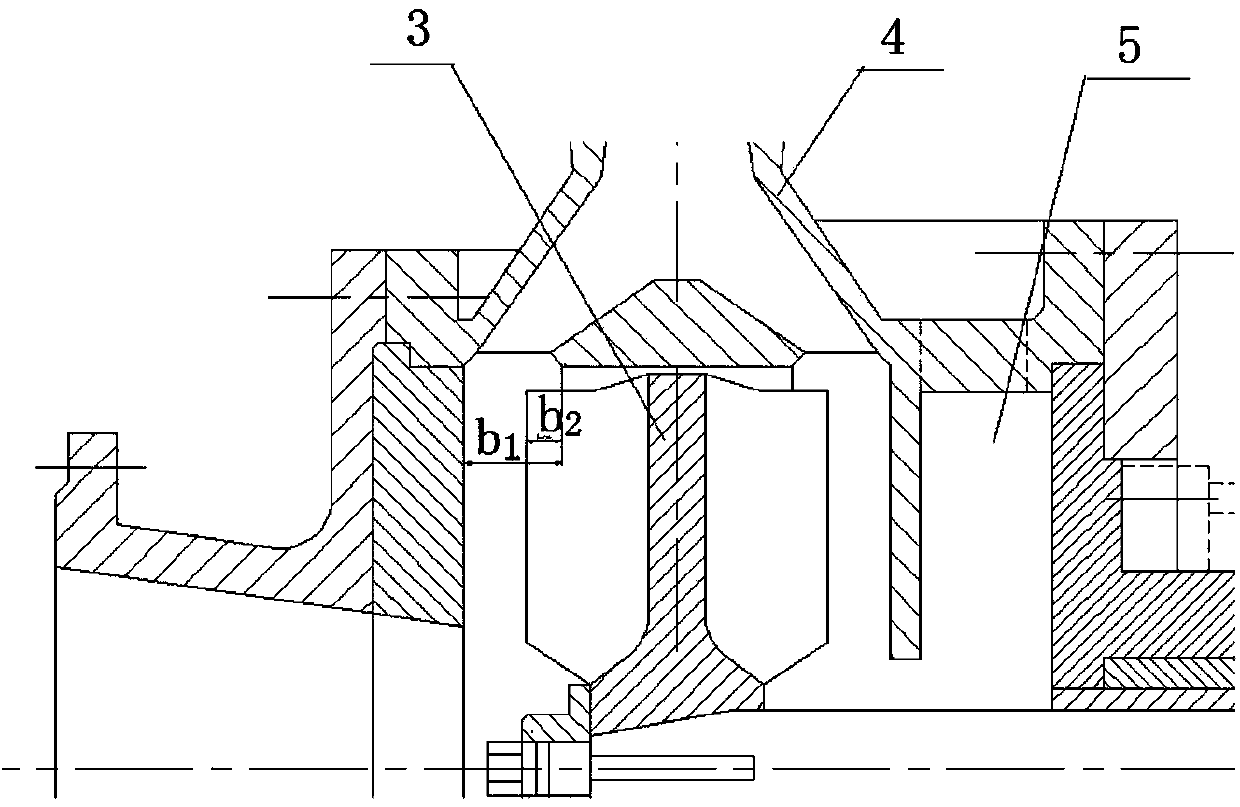

Double-suction impeller

InactiveCN104279180AExpand the specific speed rangeDesign parameters have not changedPump componentsPumpsImpellerAxial force

The invention discloses a double-suction impeller, comprising a front cover board, a rear cover board, blades, a hub and a shaft, wherein the outlet edge of a water outlet is V-shaped; a partition plate which protrudes upwards is arranged on the peak of the V-shape and on the rear cover board; two edges of the partition plate are respectively in an inward concave arc shape; the partition plate is in smooth transition along the runner change shape. According to the double-suction impeller, the specific speed of the impeller is increased, the hydraulic loss is reduced to the maximal extent, and the double-suction impeller is symmetric in structure, free of axial force and stable in operation.

Owner:兰州国器装备制造集团有限公司

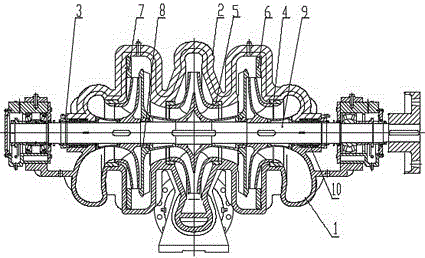

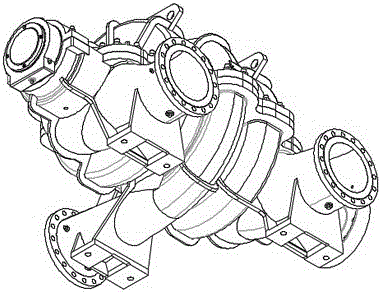

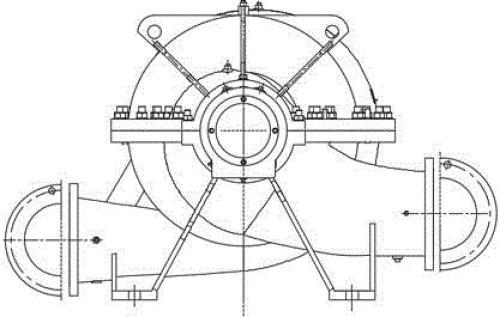

Double-inlet horizontal split centrifugal pump

InactiveCN106122032ALess prone to cavitationStructural symmetryPump componentsRadial flow pumpsEngineeringAxial force

The invention discloses a double-inlet horizontal split centrifugal pump. The double-inlet horizontal split centrifugal pump comprises a pump body and a pump cover; and the pump body and the pump cover are sealed through a filler gland. The double-inlet horizontal split centrifugal pump is characterized in that water sucking ports are respectively formed in two ends of the same side of the pump body; a water outlet is formed in the other side of the pump body, and is positioned in the axial center; primary double-suction impellers and a secondary impeller are arranged in the pump; the water sucking ports are connected with the primary double-suction impellers; the primary double-suction impellers are connected with the secondary impeller; the primary impellers and the secondary impeller are fixed through a sealing ring; and the two primary double-suction impellers are arranged back to back. The centrifugal pump is equivalent to two double-suction pumps connected in parallel for synchronously working; under the same outer diameters of the double-suction pump impellers, the flow lift can be increased by one time; the inlet and the outlet are in the same direction, and are perpendicular to the pump shaft, so that the arrangement and the installation of the pump and the water inlet and outlet pipes are facilitated; and the impellers are symmetrically structured without axial force, and are stably operated.

Owner:湖南长一泵业有限公司

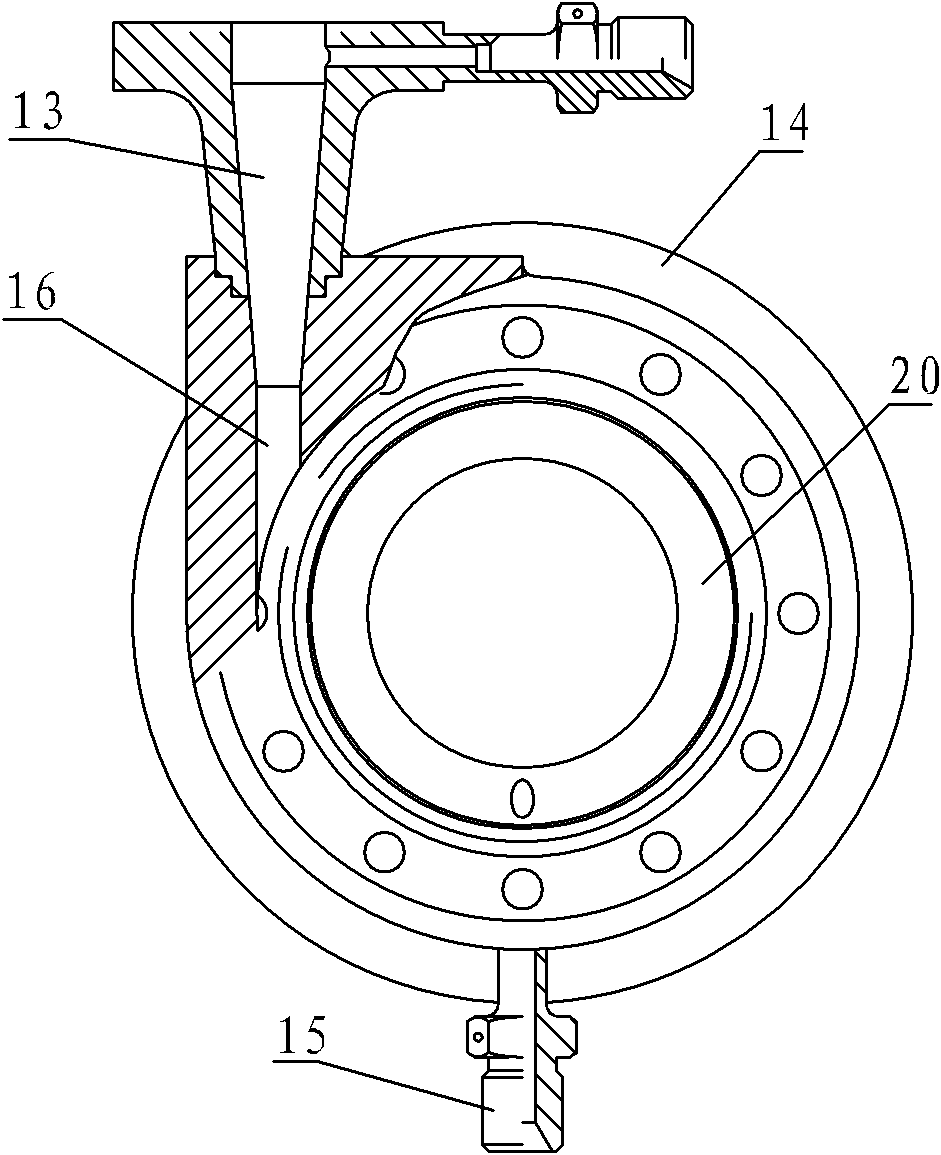

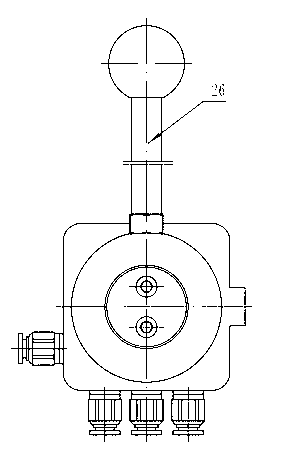

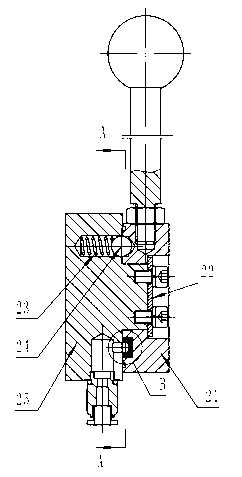

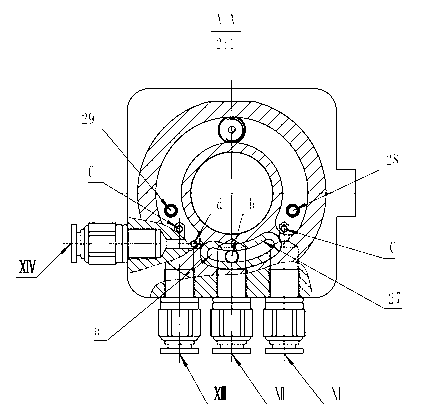

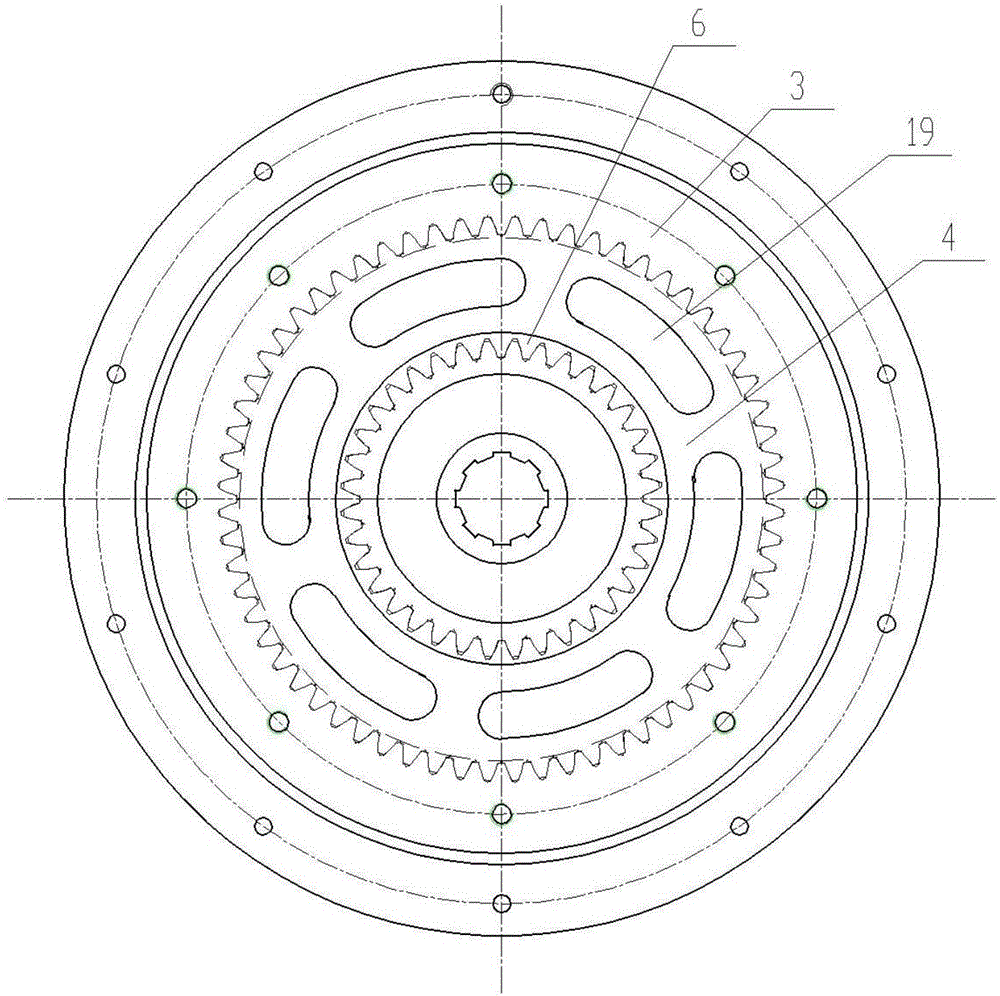

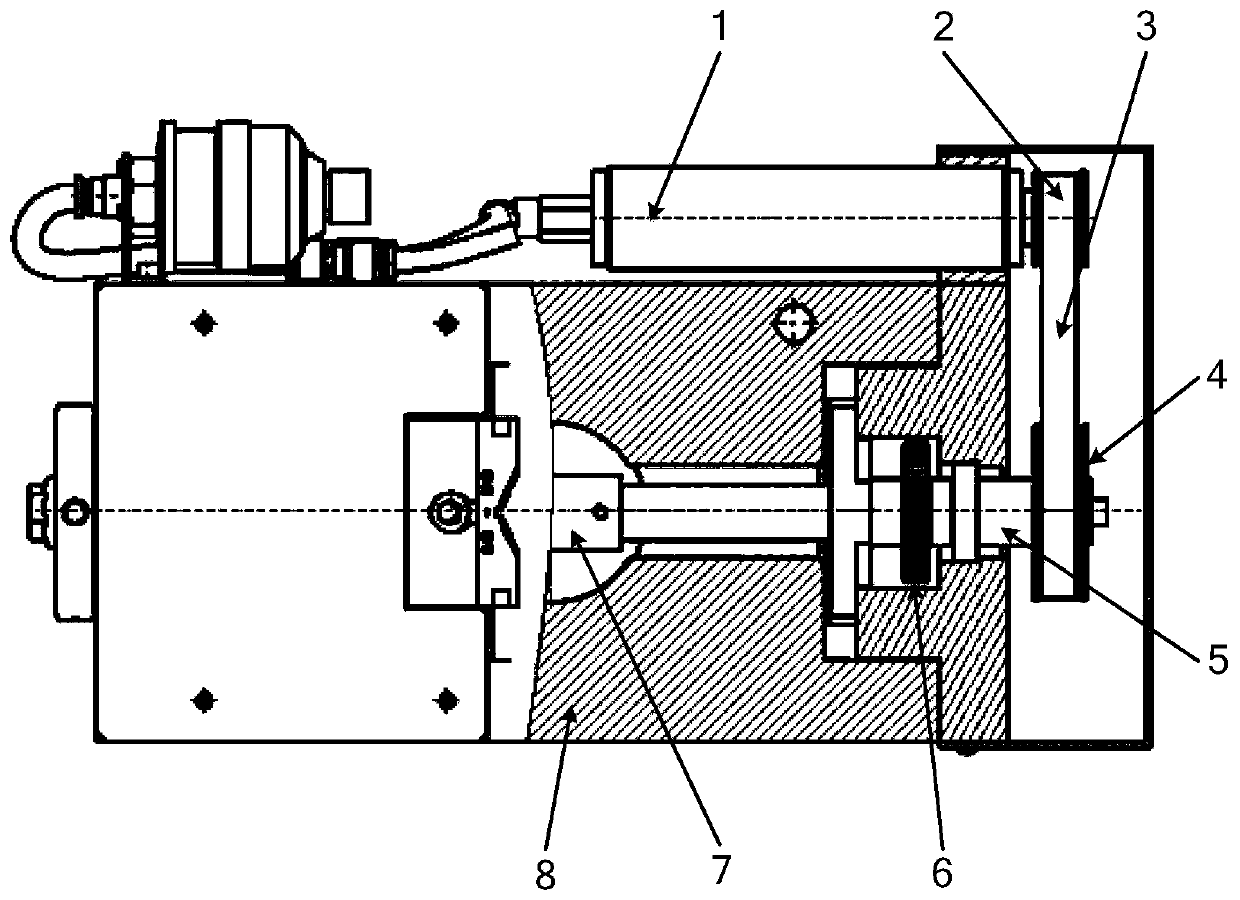

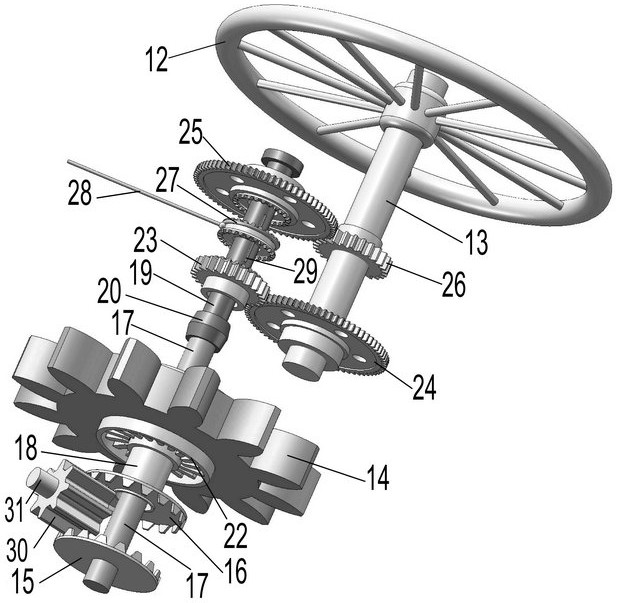

Automatic backlash driving and indexing worktable for gear grinding machine

InactiveCN102728905AAdjust mesh clearanceHigh precision graduationGear-cutting machinesGear teethGear grindingEngineering

The invention relates to an automatic backlash driving and indexing worktable for a gear grinding machine. According to the automatic backlash driving and indexing worktable, the defects that the indexing of a traditional worktable is finished by adopting a pure mechanical driving chain with a complex structure, the structure is relatively complex and the indexing precision is lower are overcome. A worm gear and two worms which are mutually meshed are arranged in a casing; the two worms are mutually parallel; a plane where two worms are positioned is parallel to an axial line of the worm gear; two groups of worm teeth which are respectively meshed with two worms are arranged on the circumference of the worm gear; the two worms comprise a driving worm and a driven worm; the driving worm is connected with the motor; same straight gears are fixed at the same ends of the driving worm and the driven worm; a same idle gear is meshed between the two straight gears; and a hydraulic oil cylinder is connected to the other end of the driven worm. The driven worm is elastically ejected by the hydraulic oil cylinder, the meshed clearance between the worms and the worm gear can be adjusted and the high-precision indexing of the worktable is realized.

Owner:浙江嘉力宝精机股份有限公司

Design method of curved tooth non-circular gear

ActiveCN105889456BHigh coincidenceImprove carrying capacityGeometric CADPortable liftingEngineeringAxial force

The invention belongs to the technical field of non-circular gears and discloses a design method for a curved-tooth non-circular gear. The tooth profile of the curved-tooth non-circular gear is designed through a generating gear. The tooth profile equation is solved according to the curved surface of a counterpart rack, the kinematic relation of gear generation and the engagement principle. Compared with a straight gear, the curved-tooth non-circular gear designed through the method is high in contact ratio and bearing capacity. Compared with a bevel gear, the curved-tooth non-circular gear designed through the method does not generate axial force in the transmission process and has low requirements on bearings and installation. Through the arc tooth profile of the curved-tooth non-circular gear, lubricating oil is contained in the tooth surface, and therefore a quite good lubricating condition is achieved.

Owner:WUHAN UNIV OF TECH

Double-suction impeller and double-suction vortex pump

The invention provides a double-suction impeller and a double-suction vortex pump. The width of a flow channel is staggered by 40 percent to 60 percent through blades on the two opposite faces of the double-suction impeller. The double-suction vortex pump is provided with the double-suction impeller, the width of the blades of the double-suction impeller is 40 percent to 60 percent of the width of an inner cavity of a pump body, the pump body of the double-suction vortex pump is further provided with an auxiliary water inlet chamber, the auxiliary water inlet chamber is located between the inner cavity of the pump body and a packing chamber, and is communicated with the inner cavity of the pump body, an auxiliary water inlet is formed in the auxiliary water inlet chamber, the auxiliary water inlet is a radial inlet, and the inlet direction is parallel to the plane of the impeller. Through the staggered structure of the blades on the two opposite sides of the double-suction impeller, the double-suction impeller can operate more stably, and vibration is reduced. The width of the blades of the double-suction impeller is 40 percent to 60 percent of the width of the inner cavity of the pump body, large impurities can pass through the pump body, and the efficiency and lift of the pump can be guaranteed.

Owner:JIANGSU UNIV

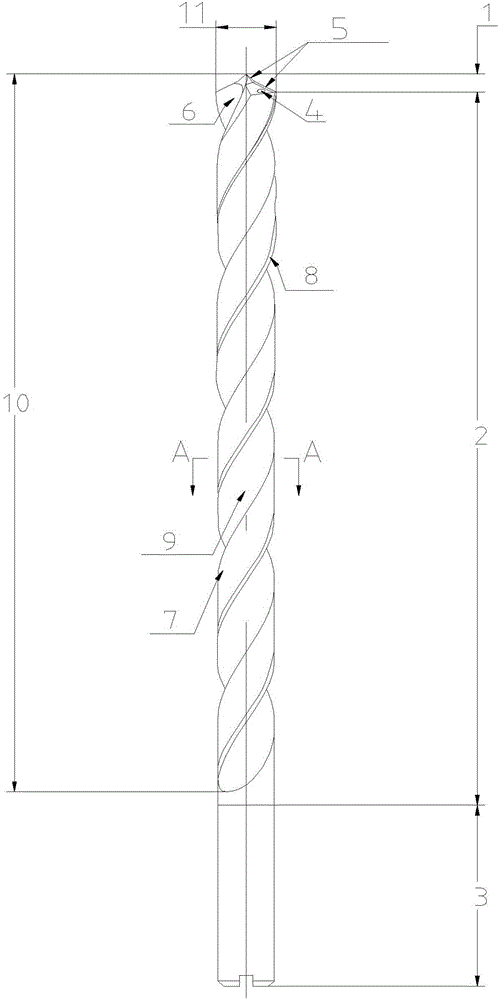

Solid carbide self-centering inner-cooling deep-hole twist drill for ABS valve body

InactiveCN104690342ACompatible with crumbsTaking into account the ability of chip removalTransportation and packagingTwist drillsCarbideEngineering

The invention relates to a solid carbide self-centering inner-cooling deep-hole twist drill for an ABS valve body. A cutter body and a handle part are coaxial cylinders of which the same central axis serves as the center; a spiral chip groove is formed in the cutter body; a solid part except the chip groove is a cutter back; two spiral edge strips are arranged on the cutter back; an inner-cooling hole which spirally penetrates through the cutter body is formed in the front end surface at the head of the cutter body; the intersection line of the chip groove and the cutter back in the radial direction forms an end edge; the end edge is in a double-vertex-angle double-flank-face form; the center position at the 1 / 4-1 / 3 effective edge diameter of the cutter body is a central vertex angle, and the rest are cutting vertex angles; a spiral face of the chip groove, formed by using a cutting edge as a generatrix, is a rake face; the ratio of the axial groove length of the chip groove to the radial effective edge diameter of the cutter body is 10-20; a circular arc of the chip groove is formed by smoothly connecting two circular arcs with different curvature radiuses. The efficient machining and the once feed competition are achieved, and peck drilling is eliminated; the solid carbide self-centering inner-cooling deep-hole twist drill has self-centering capacity, and the requirement on the roughness of an oil way hole of the ABS valve body is met.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

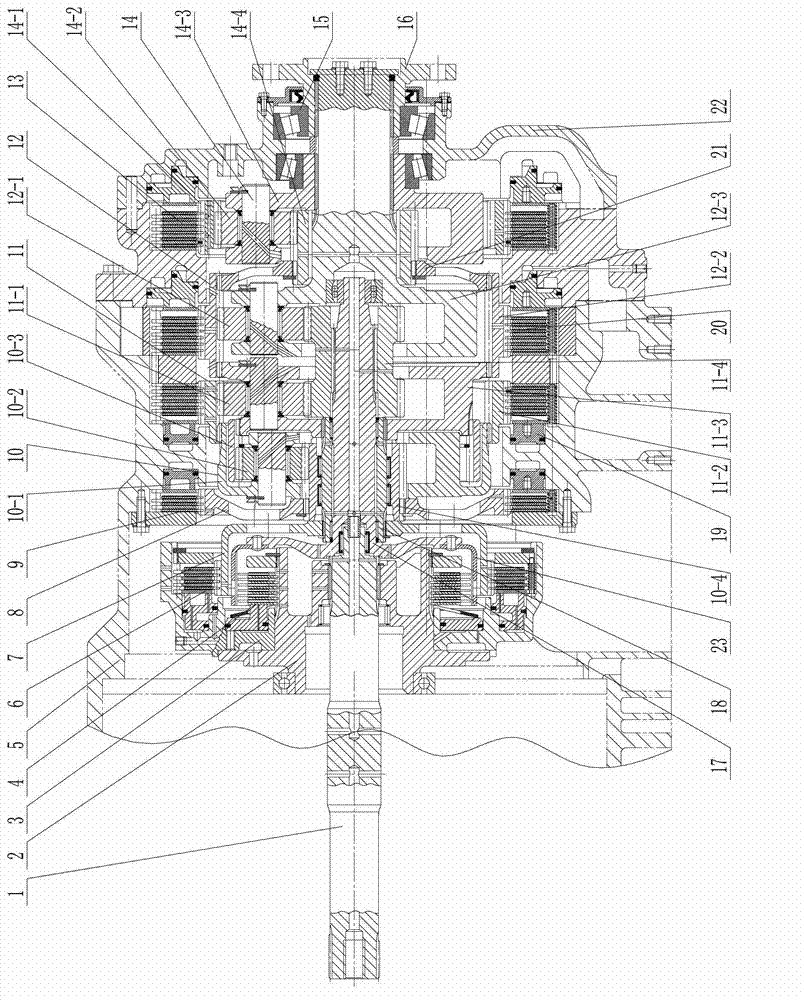

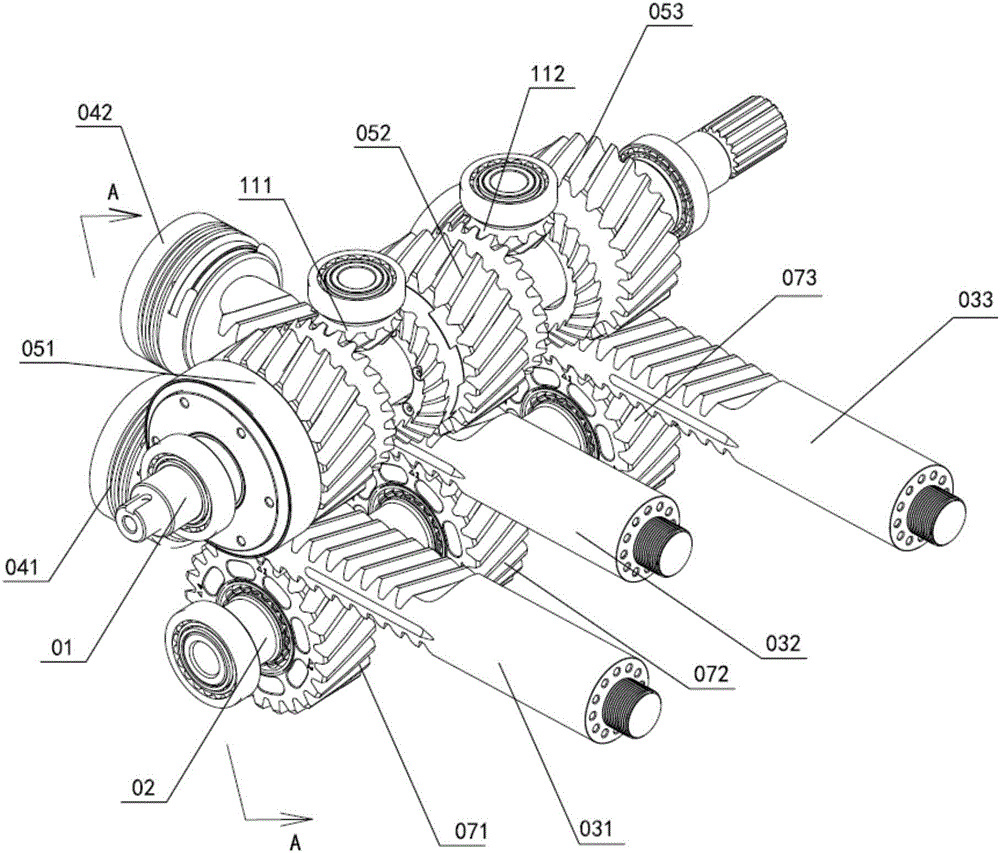

Planetary gear shift mechanism

The invention relates to a planetary gear shift mechanism. An input shaft is connected with a common clutch cylinder through a drive hub. A first clutch is connected with a first shaft. Two sides of the first shaft are supported on the input shaft and a third planet carrier respectively. The first shaft is connected with a common sun gear for a second planet row and a third planet row. A second shaft connected with a second clutch is connected with a second planet carrier through the first shaft. The second planet carrier is respectively connected with a first gear ring row and a third gear ring row. Two ends of a front brake component are connected with a first brake and a first sun gear respectively. A first planet carrier is connected with a second gear ring row of the second planet row. A fourth sun gear is sleeved on an output shaft of the third planet carrier idly. Two ends of a rear connector are connected with the third gear ring row and a fourth sun gear respectively. A fourth planet carrier is connected to an output shaft of the third planet carrier connected with an output disk. The planetary gear shift mechanism is reasonable in layout, compact and simple in structure and convenient to operate and has six forward gears and one reverse gear.

Owner:邓亚民

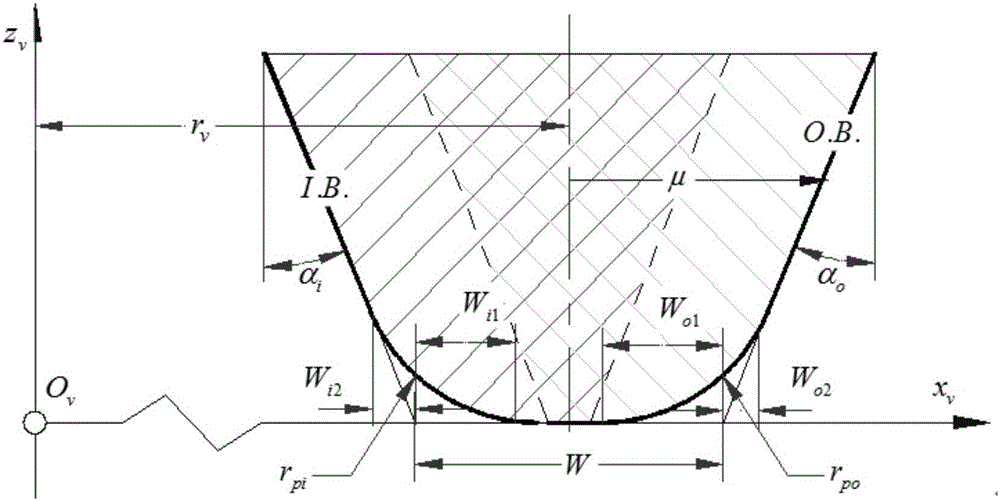

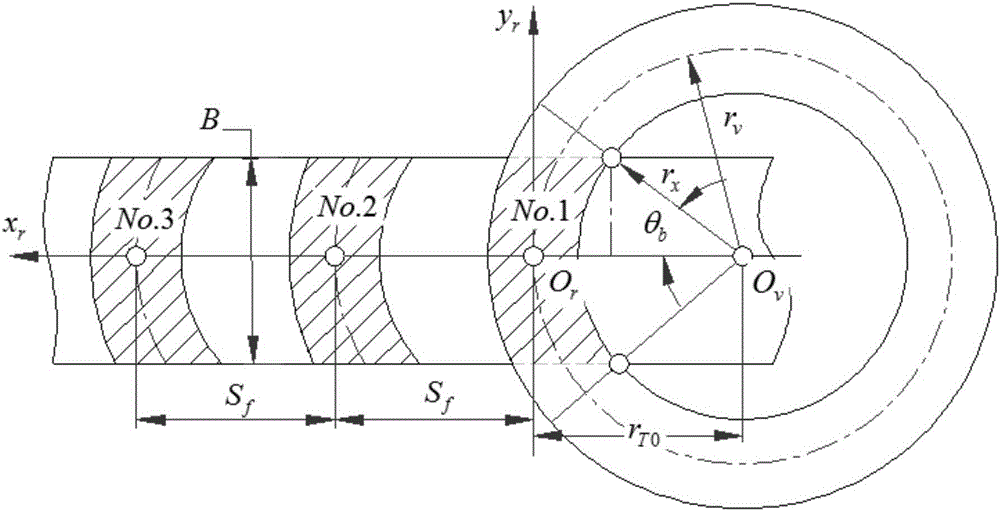

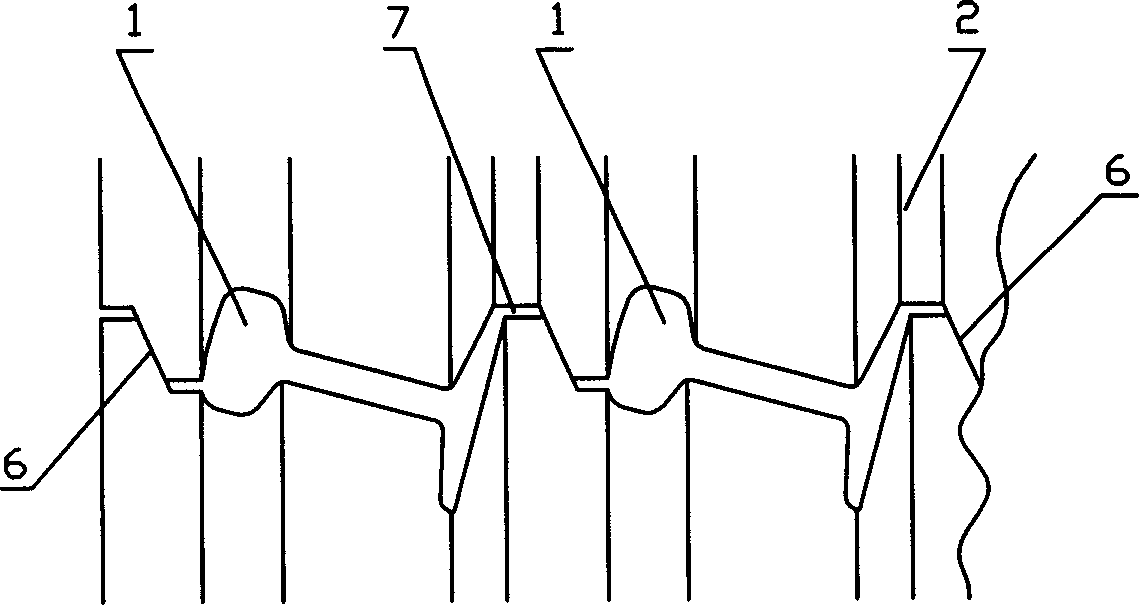

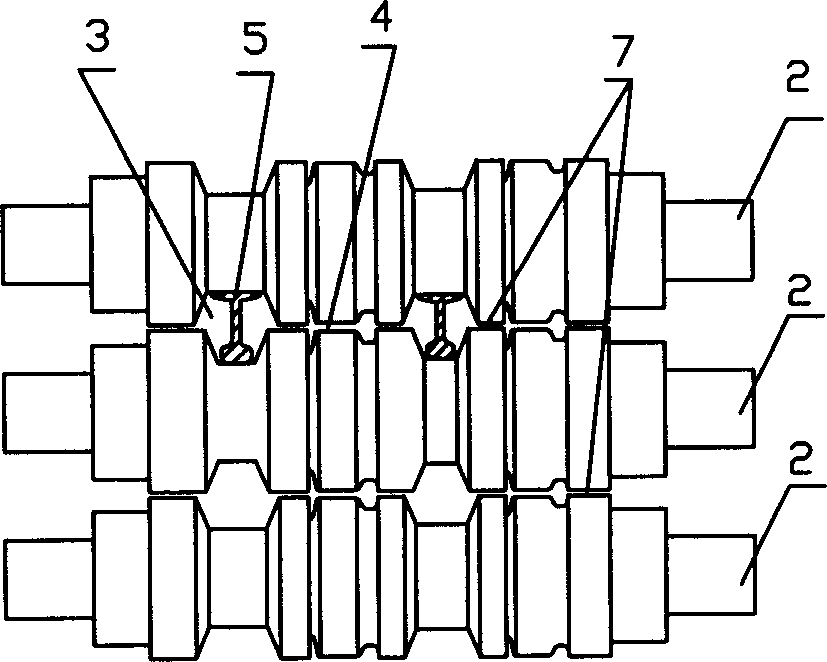

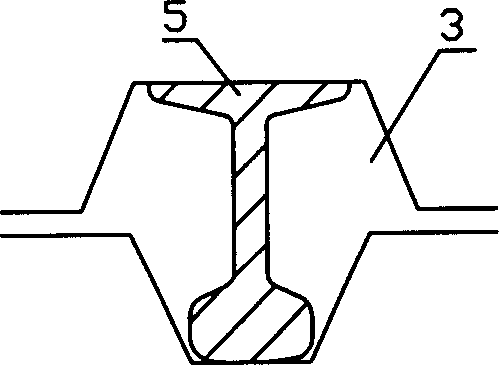

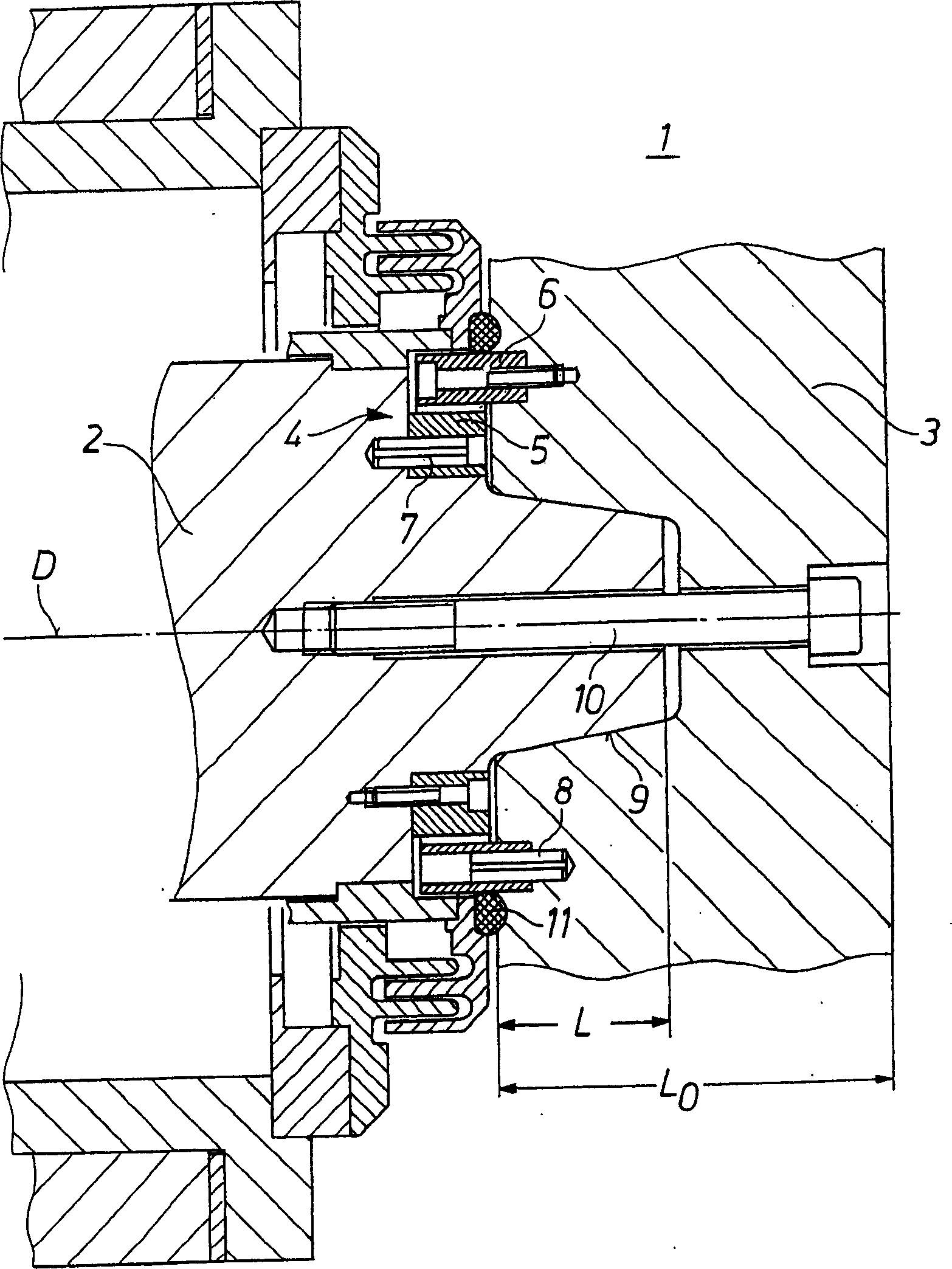

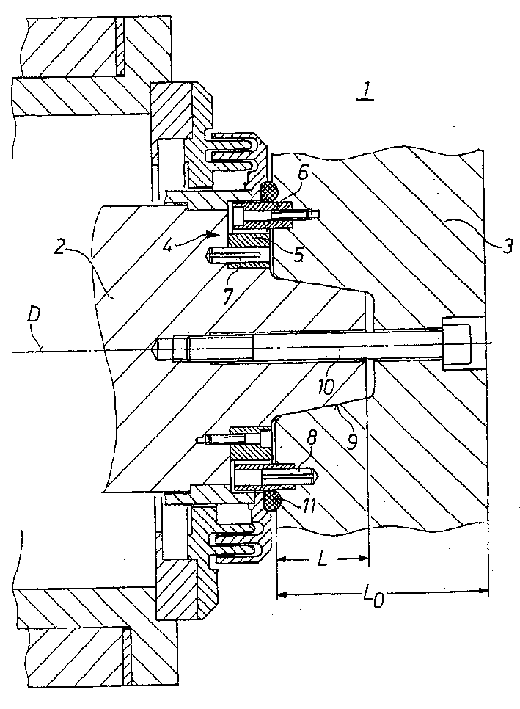

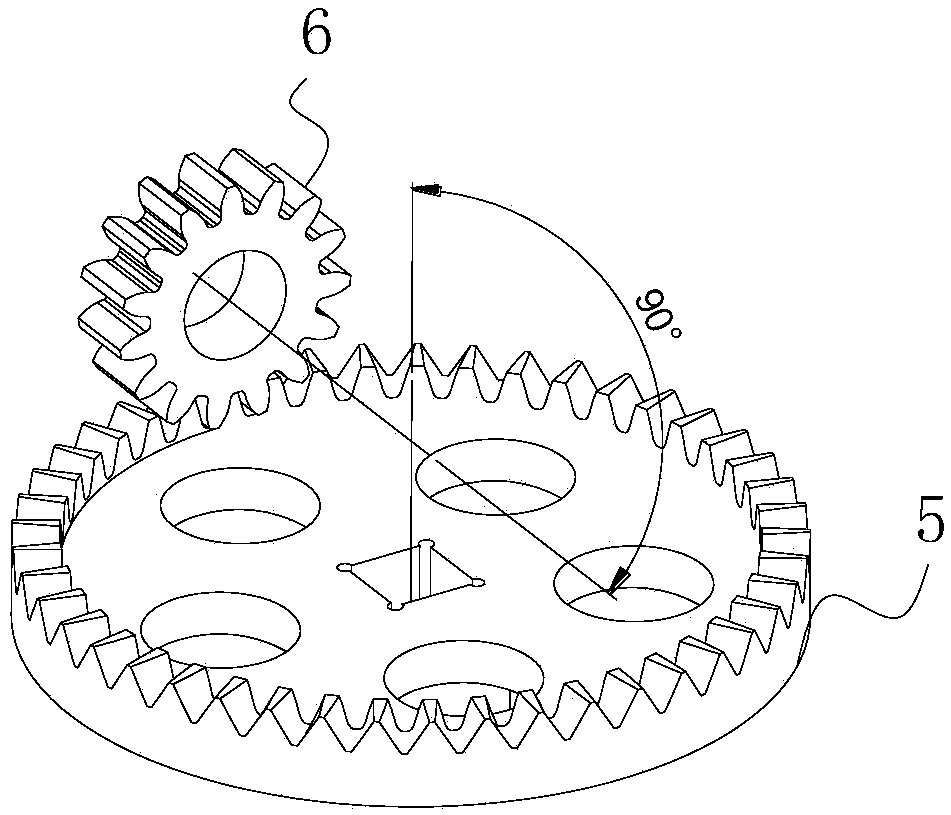

Roller positioning structure of rolling mill

InactiveCN1509824AReduced risk of crackingNo axial forceSkewed roll standMetal rolling stand detailsRolling millEngineering

Roller setup (1) for a rolling mill, especially a planetary inclined rolling mill with roller (3) on roller shaft (2), which is releasably connected to roller (3), has an arrangement (4) between the roller shaft and roller (3) for positive transfer of a drive turning moment from roller shaft (2) to roller (3). Roller setup (1) for a rolling mill, especially a planetary inclined (sic) rolling mill with roller (3) on roller shaft (2), which is releasably connected to roller (3), has a arrangement (4) between the roller shaft and roller (3) for positive transfer of a drive turning moment from roller shaft (2) to roller (3). Arrangement (4) comprises a first gear (5) connected to the roller shaft and a second gear (6) connected to roller (3), and gears (5) and (6) have positive meshing.

Owner:SMS MEER

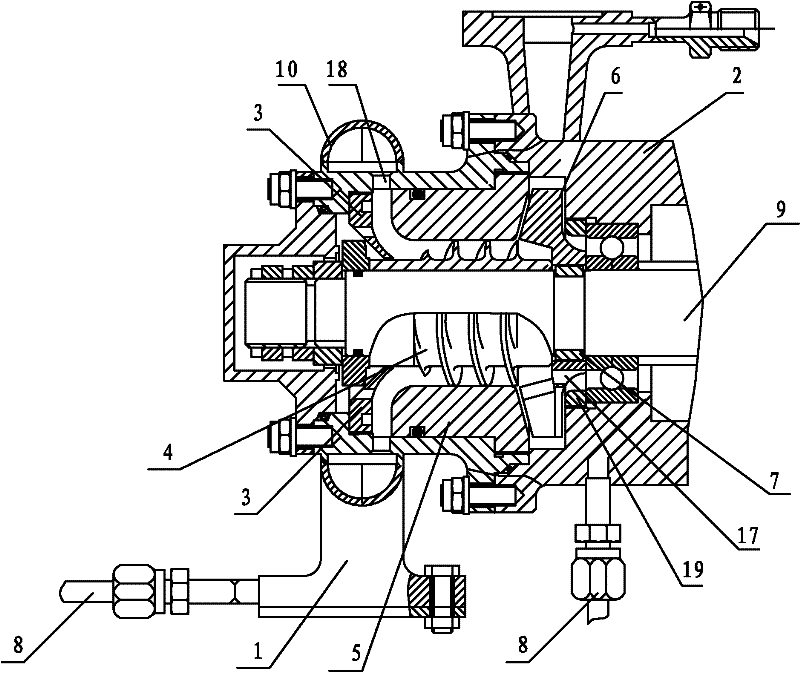

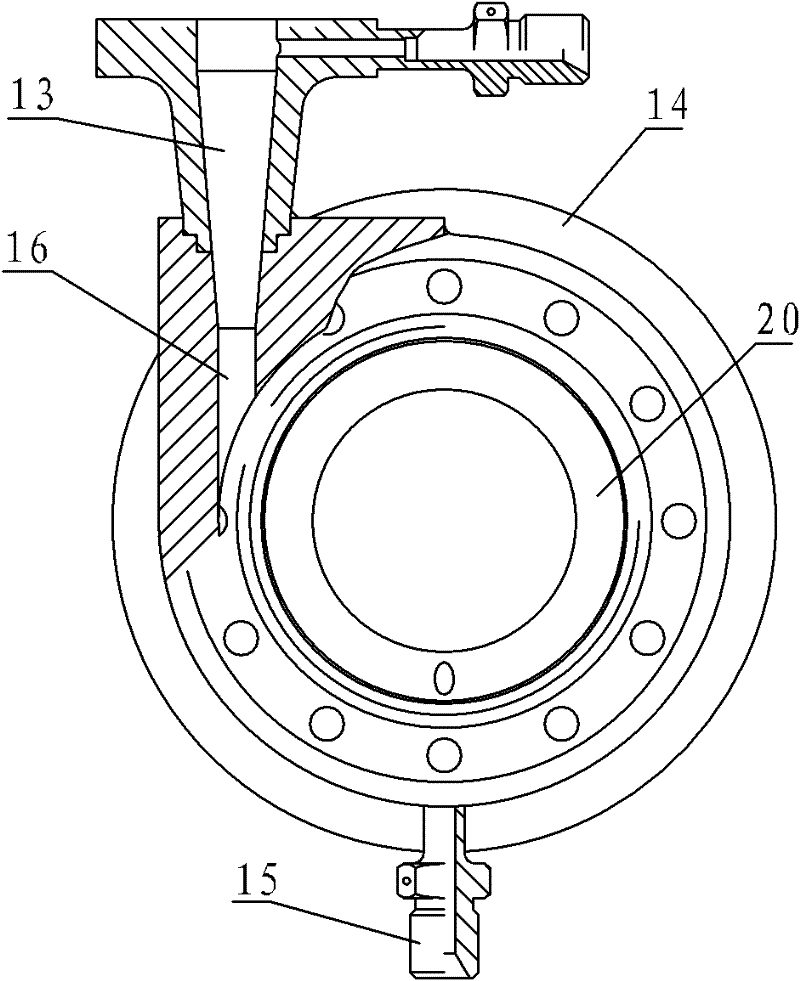

Radial-force-balanced manual control air valve

ActiveCN103234060ASimple structureNo axial forceOperating means/releasing devices for valvesMultiple way valvesRotary valveEngineering

The invention relates to a radial-force-balanced manual control air valve which is reliable in performance and long in service life. The air valve comprises a valve body, a rotary valve spool, a handle, positioning springs, sealing gaskets and air port joints. The handle is connected with the rotary valve spool to be arranged in an inner hole of the valve body, the handle rotates to enable the rotary valve spool to rotate in the inner hole of the valve body, and steel balls fall into positioning grooves C of the valve body respectively under the action of the positioning springs. The two sealing gaskets are symmetrically arranged in an outer circle sealing groove of the rotary valve spool and form two air chambers A with the wall of the inner hole of the valve body, the two air chambers are communicated through air channels, four air channels are opened on the valve body and communicated with outer channels through the air port joints respectively, and reversing positions are determined according to positioning holes to achieve disconnection or connection between the air chambers and the air port channels. The air valve is free of axial force and effects of radial force, light and flexible to operate, reliable in performance and long in service life.

Owner:阜新北鑫星液压有限公司

Series connection non-crankshaft engine transmission mechanism and engine with series connection non-crankshaft engine transmission mechanism

The invention discloses a series connection non-crankshaft engine transmission mechanism which comprises a power shaft and an auxiliary shaft. At least two air cylinder piston rods are arranged between the power shaft and the auxiliary shaft. Air cylinder pistons are arranged at the end heads of the same ends of the air cylinder piston rods correspondingly. One side of each air cylinder piston rod is engaged with a main gear which is arranged on the power shaft in a sleeving manner through a one-way clutch. The combining directions of the one-way clutches are the same. The other side of each air cylinder piston rod is rotationally connected with the auxiliary shaft through a guiding mechanism. Every two adjacent two main gears are in transmission connection through a reverse transmission mechanism. When one air cylinder piston rod acts, the corresponding main gear rotates, and when the combining directions of the one-way clutches are the same, the main gears corresponding to the power shaft enable the power shaft to rotate to output power through the corresponding one-way clutches. Meanwhile, transmission and reversing of power needed by the stroke of the corresponding air cylinder piston rods are achieved by every adjacent two main gears through the corresponding reverse transmission mechanisms. The transmission mechanism belongs to a free piston type, and therefore a variable compression ratio function is achieved.

Owner:朱晓明

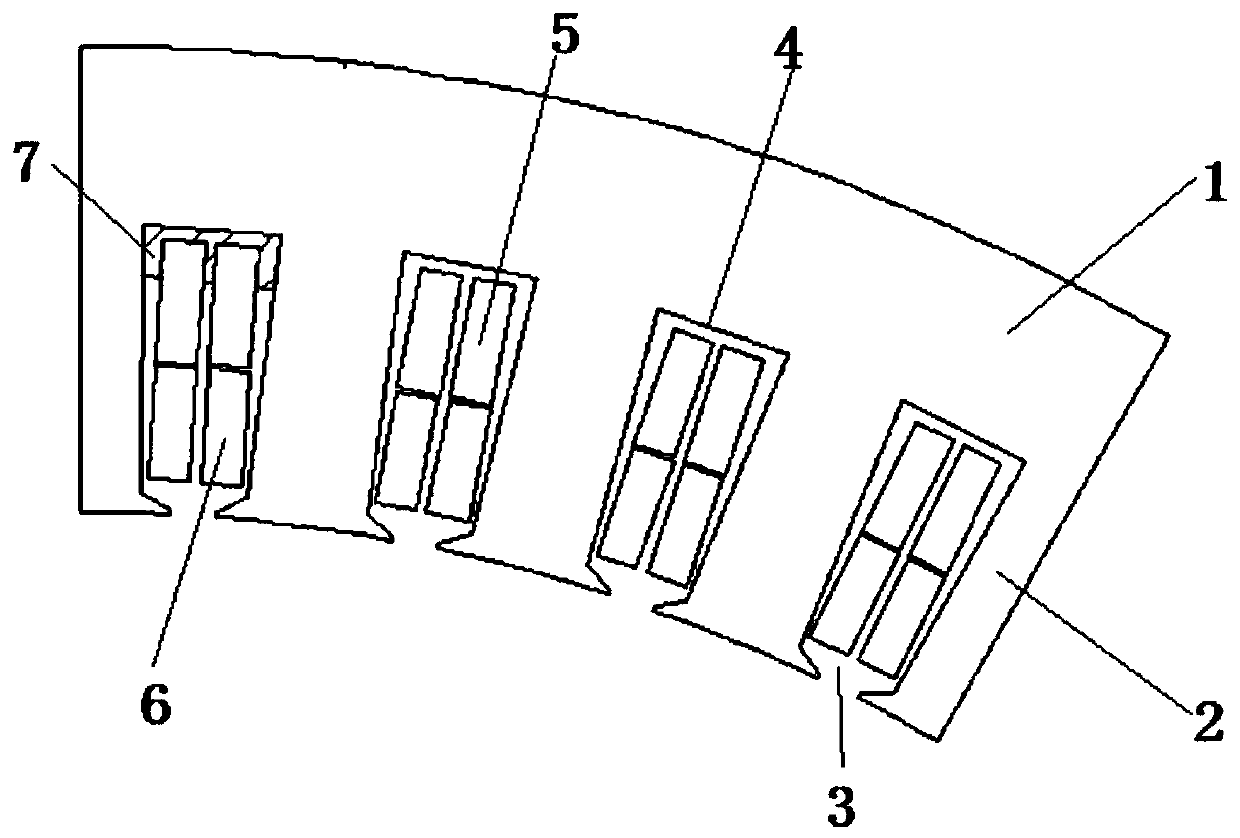

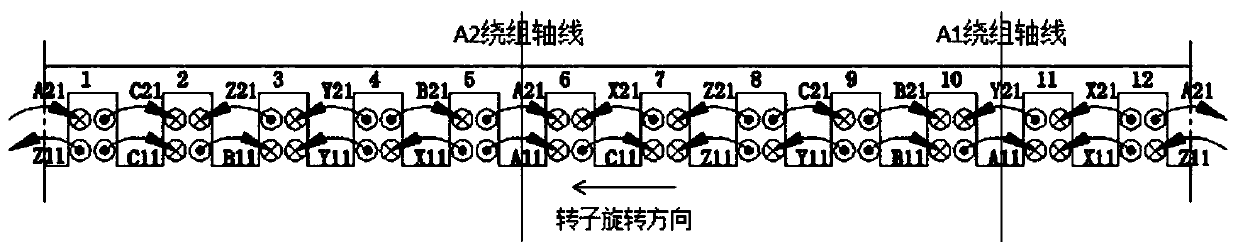

Permanent magnet motor

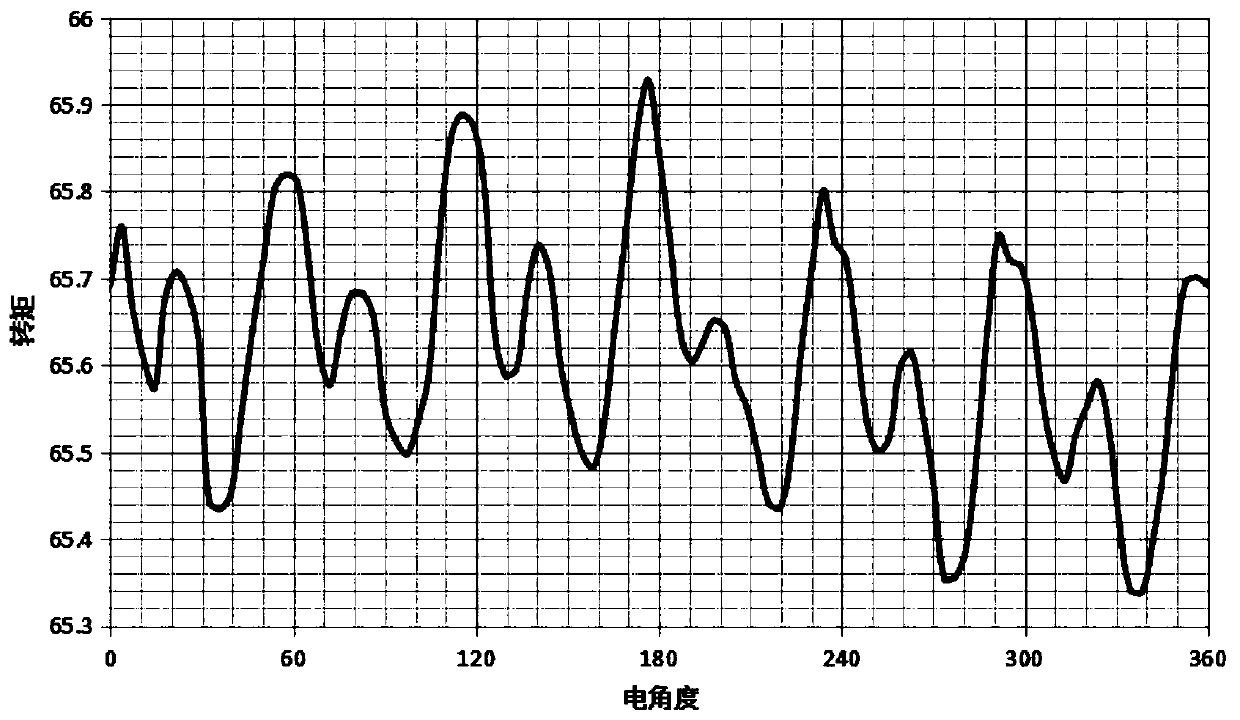

PendingCN111342575AImprove reliabilityExtended service lifeMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machinePermanent magnet motor

A permanent magnet motor belongs to the field of motors. The motor comprises a stator and a rotor; the stator comprises a plurality of stator teeth; stator grooves are formed between adjacent stator teeth. N sets of windings are wound on the stator teeth; each stator slot accommodates the N sets of windings; each set of winding comprises M phases of windings, each phase of winding comprises Z coils, 2N coil edges are accommodated in each stator slot, every two coil edges come from one set of winding, and at least one coil edge in the 2N coil edges and the other coil edge located in the same set of winding are different in phase. According to the invention, a winding form is adopted to replace skewed poles and skewed slots, so the torque ripple is reduced, an axial force is not generated, the reliability of the motor is improved, and the service life of the motor is prolonged.

Owner:大连智鼎科技有限公司

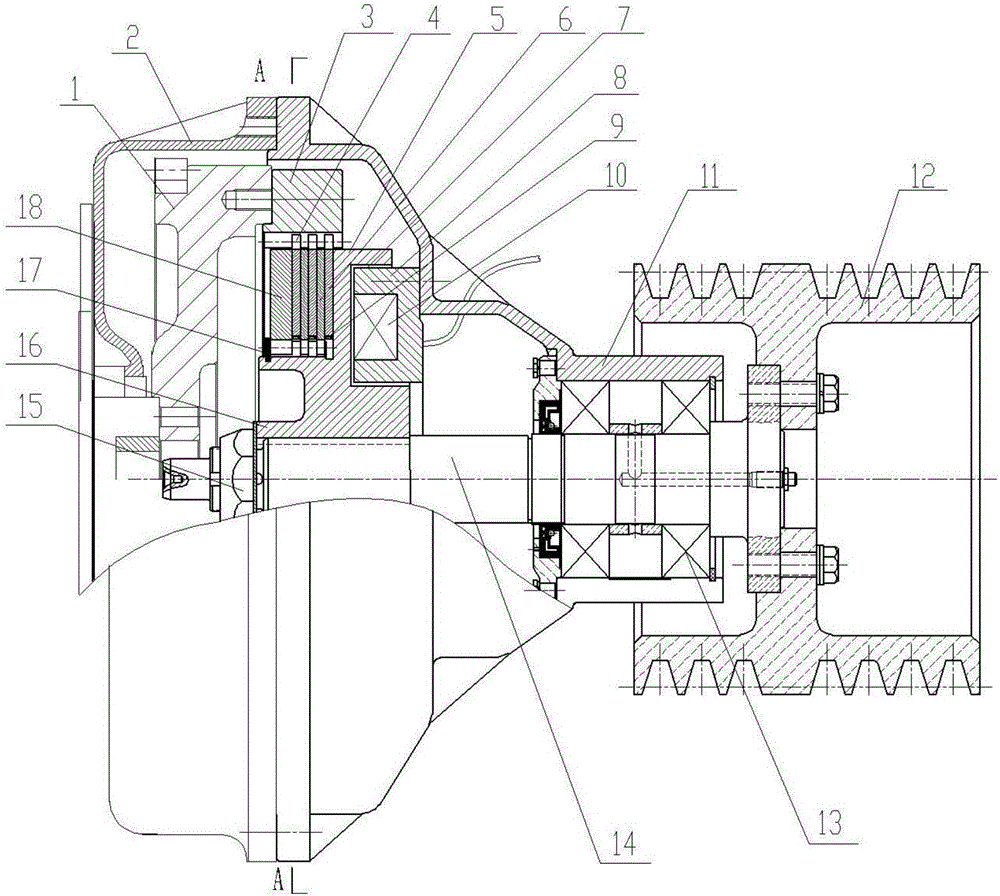

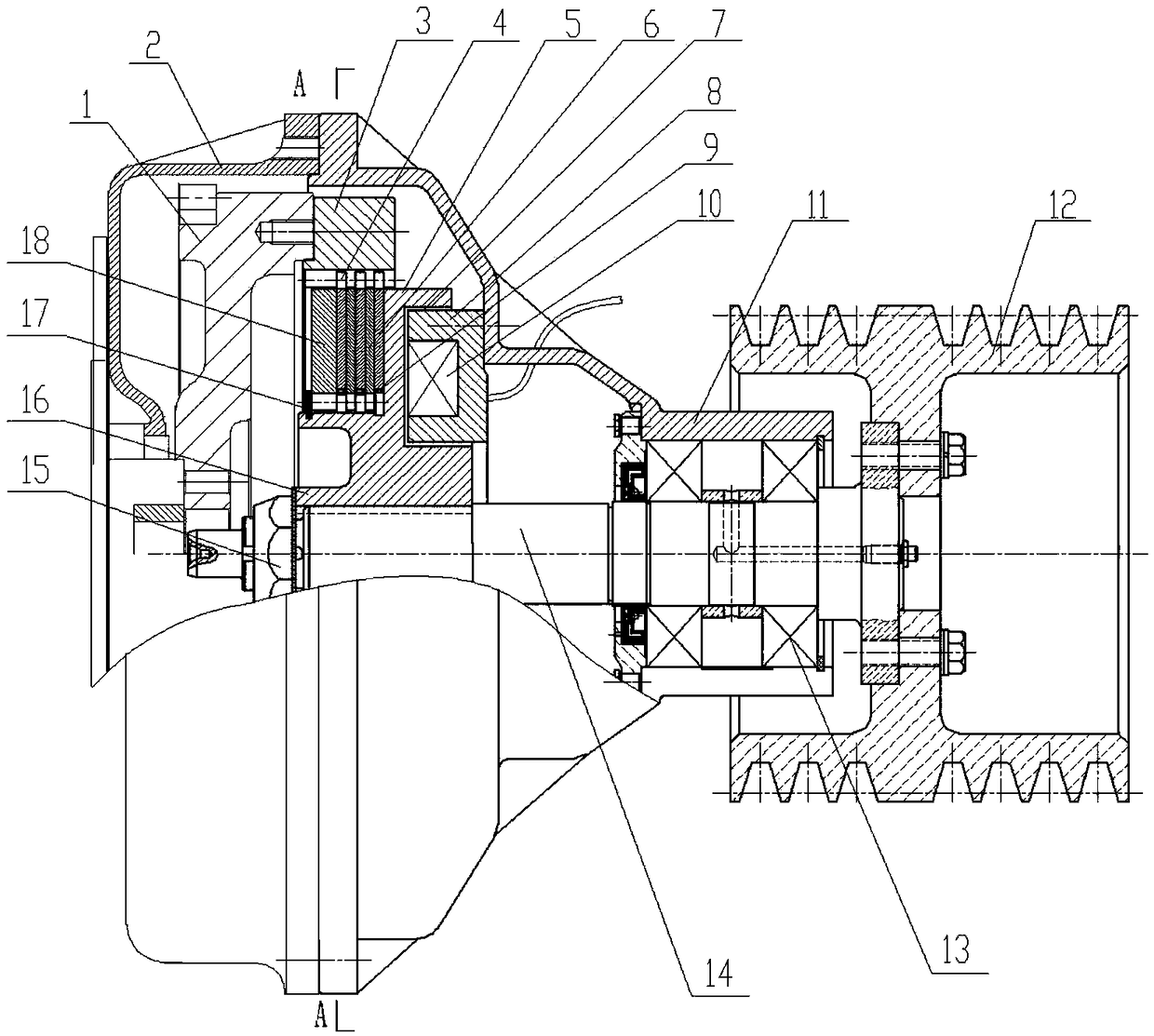

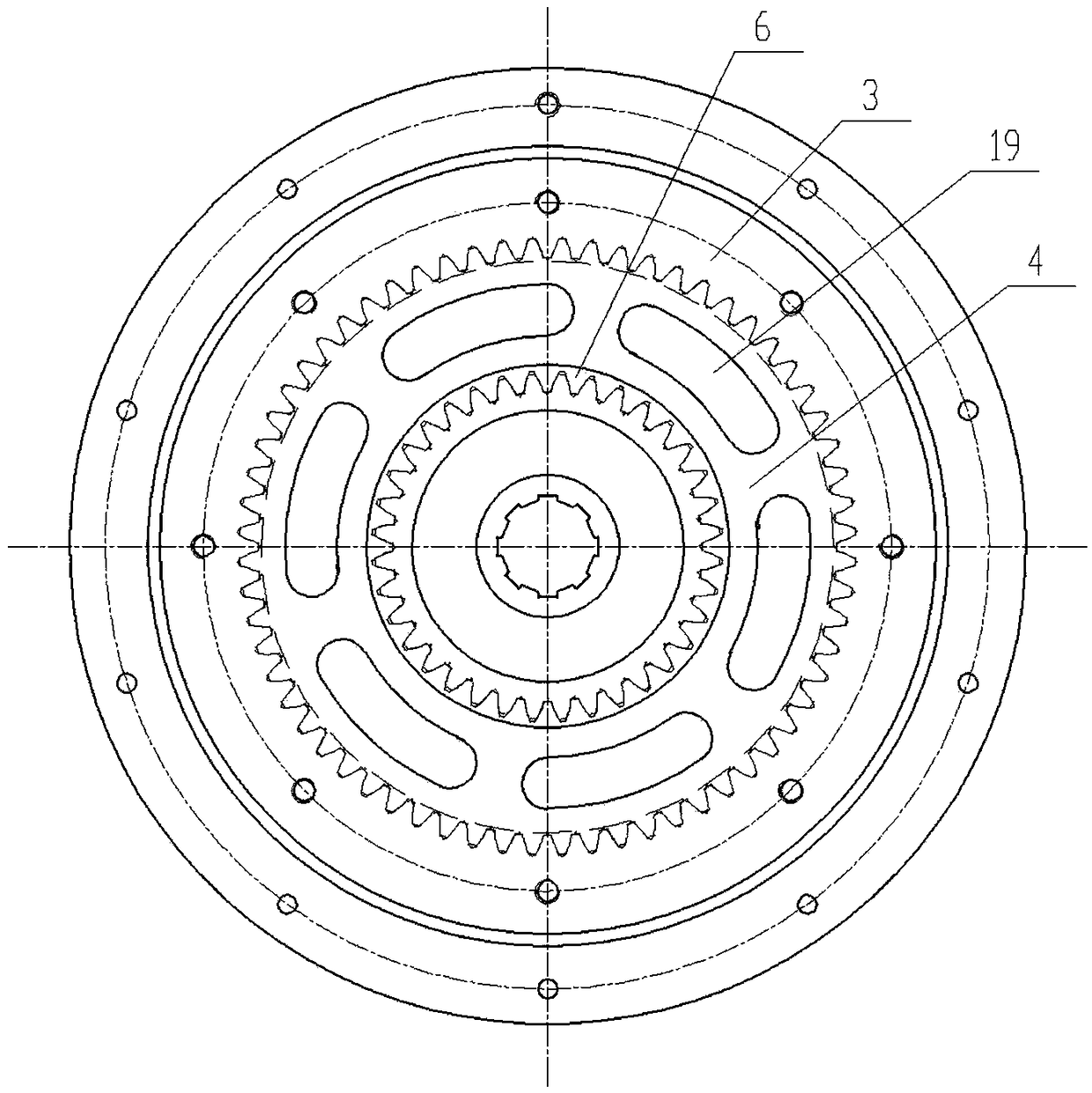

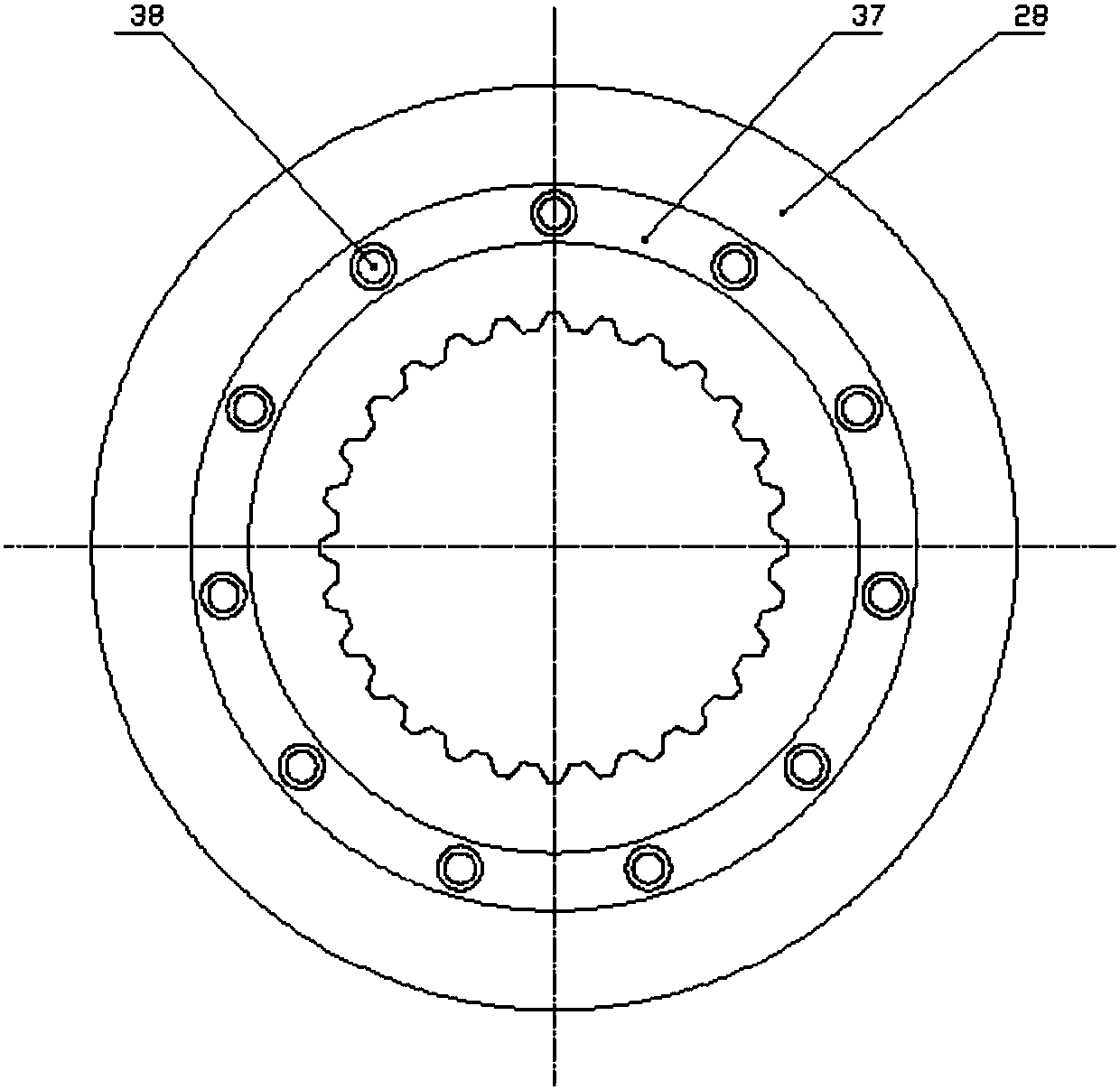

Agricultural-machine engine electromagnetic clutch

ActiveCN106195057AEasy to operate and controlEasy to useMagnetically actuated clutchesElectromagnetic clutchRemote control

The invention discloses an agricultural-machine engine electromagnetic clutch. The agricultural-machine engine electromagnetic clutch comprises a clutch shell. A coil installing sleeve is fixed in the clutch shell, a coil is packaged into an annular groove in the coil installing sleeve, a main shaft is installed in the clutch shell, an outer gear sleeve is connected on the main shaft, and the inner end of the outer gear sleeve is sleeved with an inner armature; an inner gear ring is arranged in the clutch shell and used for being connected with an engine flywheel; a plurality of outer-gear friction plates and a plurality of inner-gear friction plates are arranged between the inner gear ring and the outer gear sleeve, are sequentially arranged at intervals and are engaged with teeth of the inner gear ring and teeth of the outer gear sleeve respectively, the outer end of the teeth of the outer gear sleeve is sleeved with an outer armature, and the outer armature is engaged with the outer gear sleeve through a plurality of teeth and can axially slide along the outer gear sleeve; an output belt wheel is connected to the other end of the main shaft. The agricultural-machine engine electromagnetic clutch has the advantages that operation is easy, remote control of the clutch can be achieved through an electric switch, a gap does not need to be adjusted, the fault rate is low, the service life is long, the structure size is small, and whole machine design is convenient.

Owner:石家庄天人农业机械装备有限公司

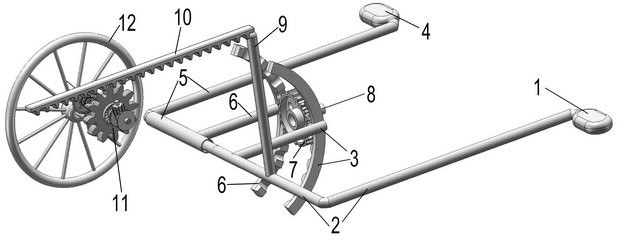

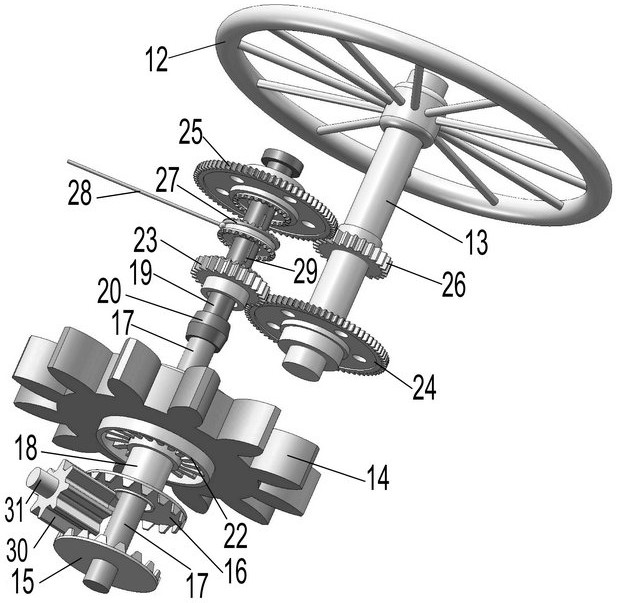

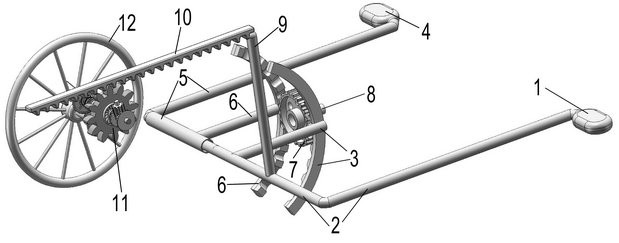

Single-rack transmission bicycle capable of performing reciprocating variable circular motion

ActiveCN113581354AHigh transmission efficiencyReduce vibration and noiseWheel based transmissionRider propulsionCrankLow speed

The invention discloses a single-rack transmission bicycle capable of performing reciprocating variable circular motion. A transmission mechanism of the single-rack transmission bicycle can be used for bicycles, tricycles and other machines capable of achieving transmission through racks, and the single-rack transmission bicycle comprises a left pedal, a right pedal, a left pedal crank, a right pedal crank, a left pedal and right pedal alternating device, a single rack, a reciprocating variable circular device, a speed changing device and a reversing device. The reciprocating variable circular device converts reciprocating motion of the rack into circular motion, the speed change device can achieve high and low speed switching of the circular motion, and the reversing device can achieve reversing without matched actions such as lifting the rack. The bicycle is characterized in that up-and-down motion of the pedal is converted into reciprocating motion of the rack, and then the reciprocating motion is converted into circular motion efficiently with low noise through the reciprocating variable-circumference device; the gear and the rack can be sealed, so that oil stains are reduced, and sufficient lubrication can be realized; the problem of chain falling is avoided; a single rack is equivalent to a large fluted disc of a traditional bicycle, and the stepless speed change function can be achieved.

Owner:董建国

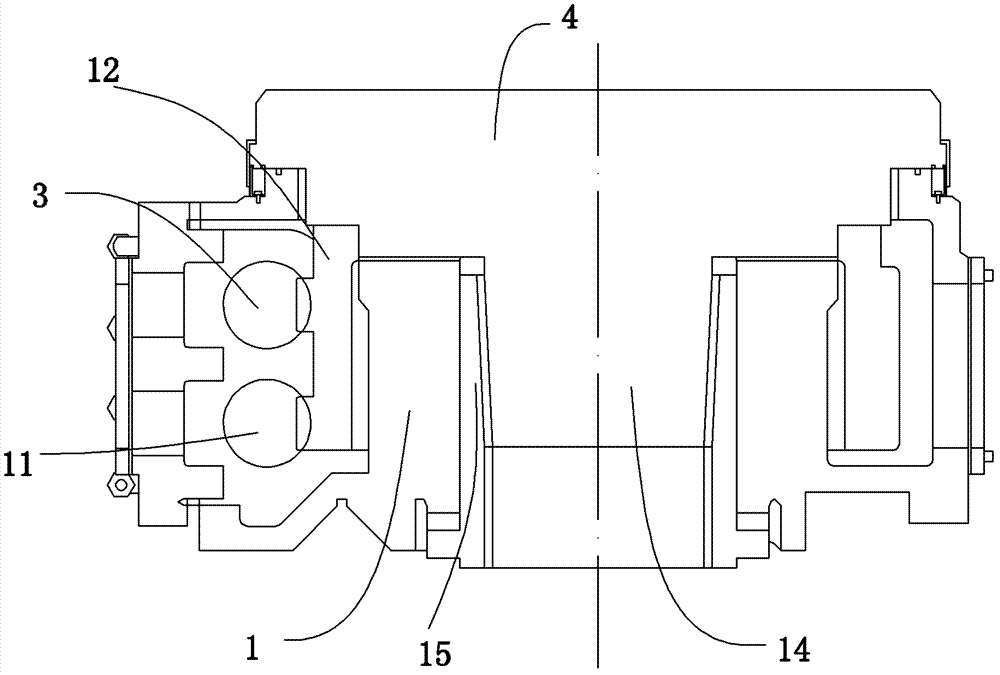

Gear pump with phase dislocation gear compensation structures

InactiveCN106894991AReduce output flow pulsationReduce output pulsation amplitudeRotary piston pumpsRotary piston liquid enginesGear pumpPhase difference

The invention discloses a gear pump with phase dislocation gear compensation structures. The gear pump comprises a pump and two meshing gear trains. The meshing gear trains are arranged in the pump, driving gears of the meshing gear trains are fixed onto spindles, driven gears of the meshing gear trains are mounted on hinge pins, one end of each hinge pin is fixed to the inner side of a front pump plate of the pump, the other end of each hinge pin is fittingly assembled with a rear pump plate of the pump, partition plates are arranged between the adjacent meshing gear trains, the locations of teeth of the gears of the two trains are staggered to form phase difference so as to realize complementary effects. The gear pump has the advantages that pulse waves formed by materials are exactly opposite to one another when the materials are discharged from the gears of the two trains and are compensated by one another after the materials flow together, output flow pulses of the gear pump can be effectively reduced, and accordingly the stability of the gear pump can be obviously improved; output pulse amplitude of existing conventional gear pumps can be effectively lowered to a great extent by the aid of the simplest methods at the lowest cost, and accordingly flow can be stably outputted by the gear pump.

Owner:皮桂庆

Double-inlet horizontal split centrifugal pump

PendingCN114593065ALess prone to cavitationStructural symmetryPump componentsRadial flow pumpsEngineeringCentrifugal pump

The invention discloses a double-inlet horizontal split centrifugal pump which comprises a pump body and a pump cover which are sealed through a packing gland, and is characterized in that a water suction port is formed in each of two ends of the same side of the pump body, a water outlet is formed in the other side of the pump body and located in the axial center, and a first-stage double-suction impeller and a second-stage impeller are arranged in the pump; first-stage double-suction impellers are connected to the water suction openings, then the first-stage double-suction impellers are connected with a second-stage impeller, the first-stage impeller and the second-stage impeller are fixed through a sealing ring, and the two first-stage double-suction impellers are arranged in a back-to-back mode. The centrifugal pump is equivalent to two double-suction pumps which are connected in parallel to work at the same time, and the flow lift can be doubled under the same outer diameter of the double-suction pump impeller; the inlet and the outlet are in the same direction and are perpendicular to the pump shaft, and arrangement and installation of the pump and water inlet and outlet pipes are facilitated; the impeller is symmetrical in structure, free of axial force and stable in operation.

Owner:虞淞

Agricultural machinery engine electromagnetic clutch

ActiveCN106195057BEasy to operate and controlEasy to useMagnetically actuated clutchesElectromagnetic clutchRemote control

The invention discloses an agricultural-machine engine electromagnetic clutch. The agricultural-machine engine electromagnetic clutch comprises a clutch shell. A coil installing sleeve is fixed in the clutch shell, a coil is packaged into an annular groove in the coil installing sleeve, a main shaft is installed in the clutch shell, an outer gear sleeve is connected on the main shaft, and the inner end of the outer gear sleeve is sleeved with an inner armature; an inner gear ring is arranged in the clutch shell and used for being connected with an engine flywheel; a plurality of outer-gear friction plates and a plurality of inner-gear friction plates are arranged between the inner gear ring and the outer gear sleeve, are sequentially arranged at intervals and are engaged with teeth of the inner gear ring and teeth of the outer gear sleeve respectively, the outer end of the teeth of the outer gear sleeve is sleeved with an outer armature, and the outer armature is engaged with the outer gear sleeve through a plurality of teeth and can axially slide along the outer gear sleeve; an output belt wheel is connected to the other end of the main shaft. The agricultural-machine engine electromagnetic clutch has the advantages that operation is easy, remote control of the clutch can be achieved through an electric switch, a gap does not need to be adjusted, the fault rate is low, the service life is long, the structure size is small, and whole machine design is convenient.

Owner:石家庄天人农业机械装备有限公司

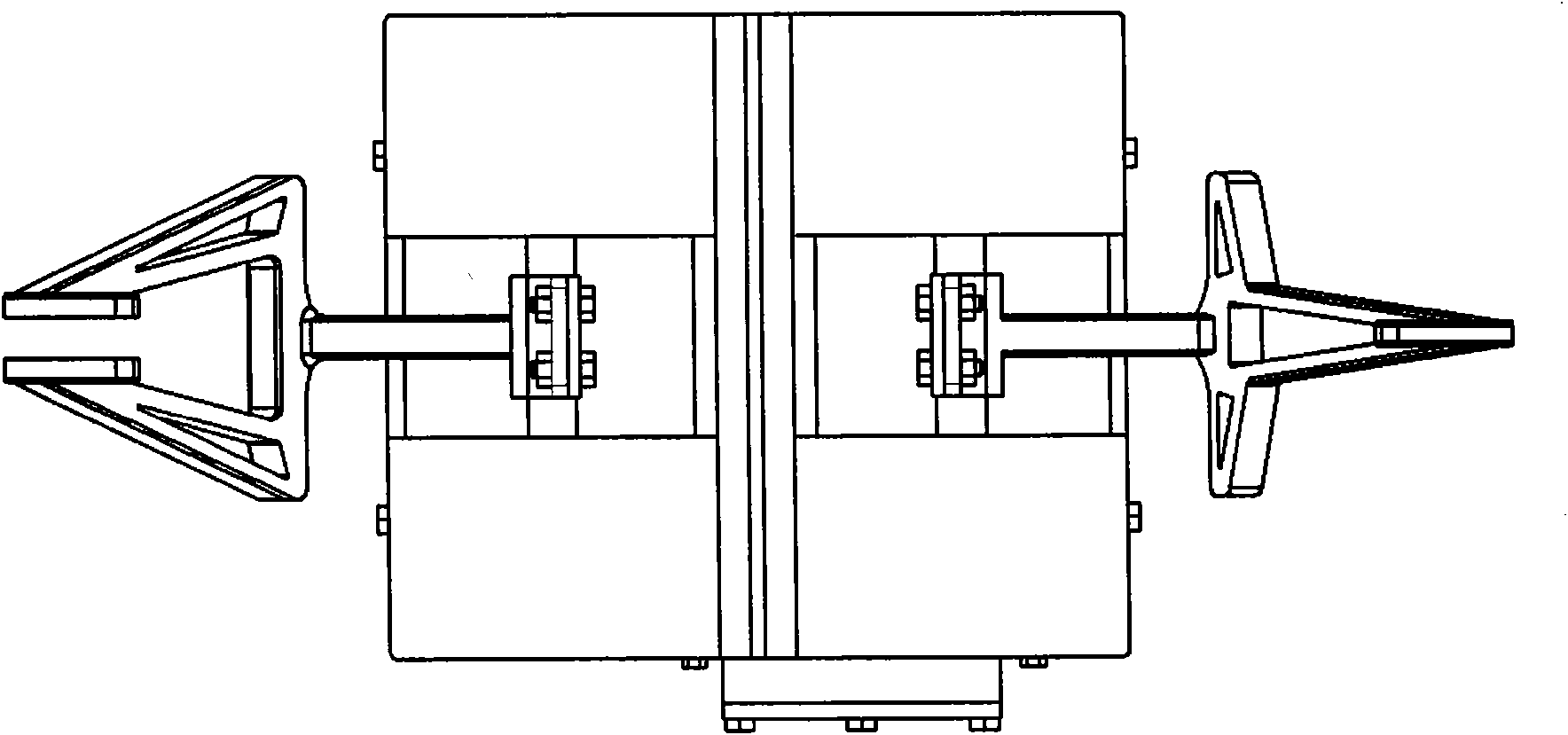

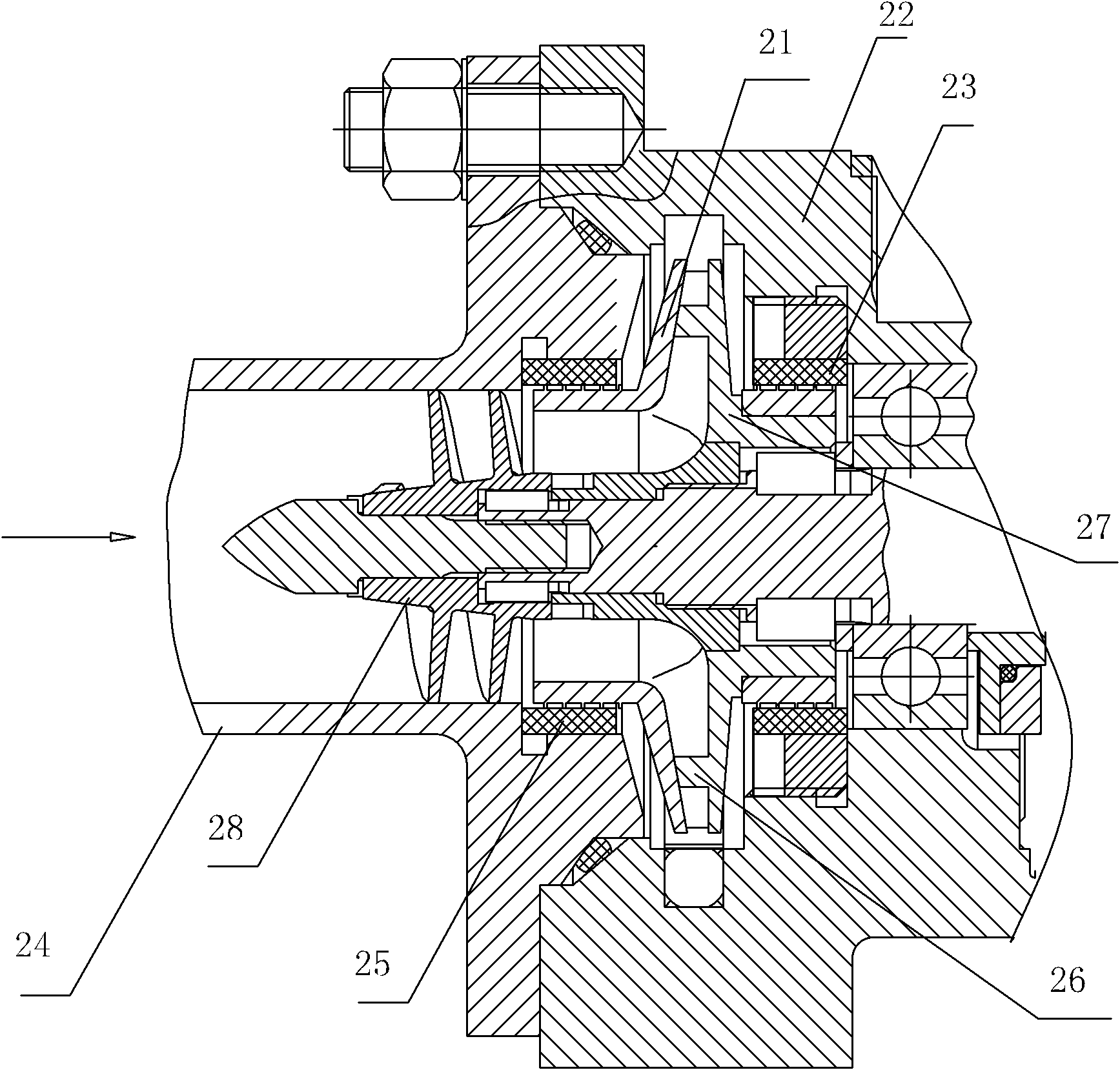

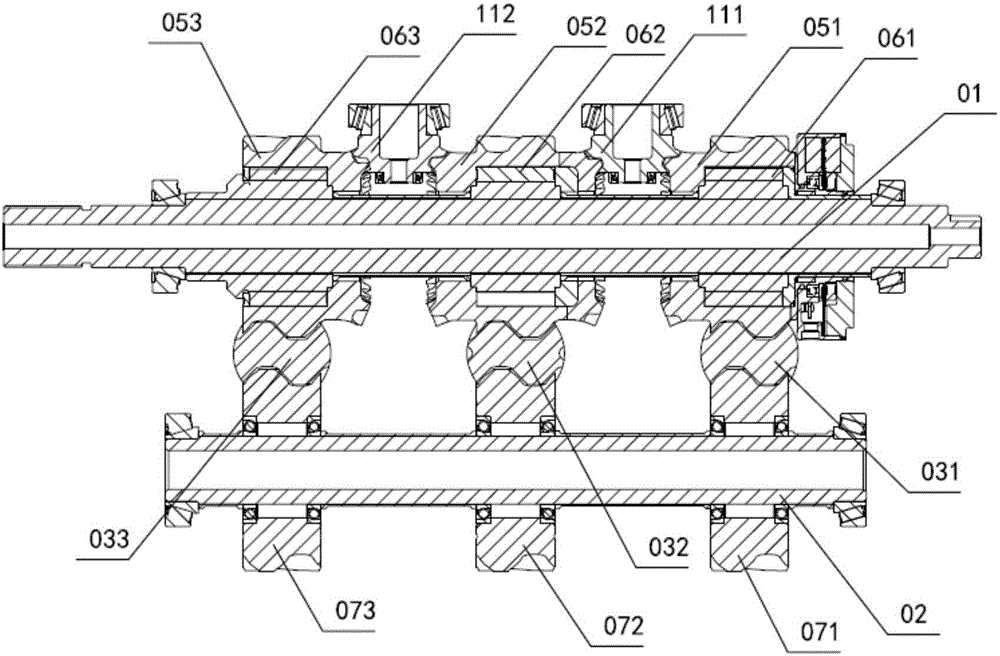

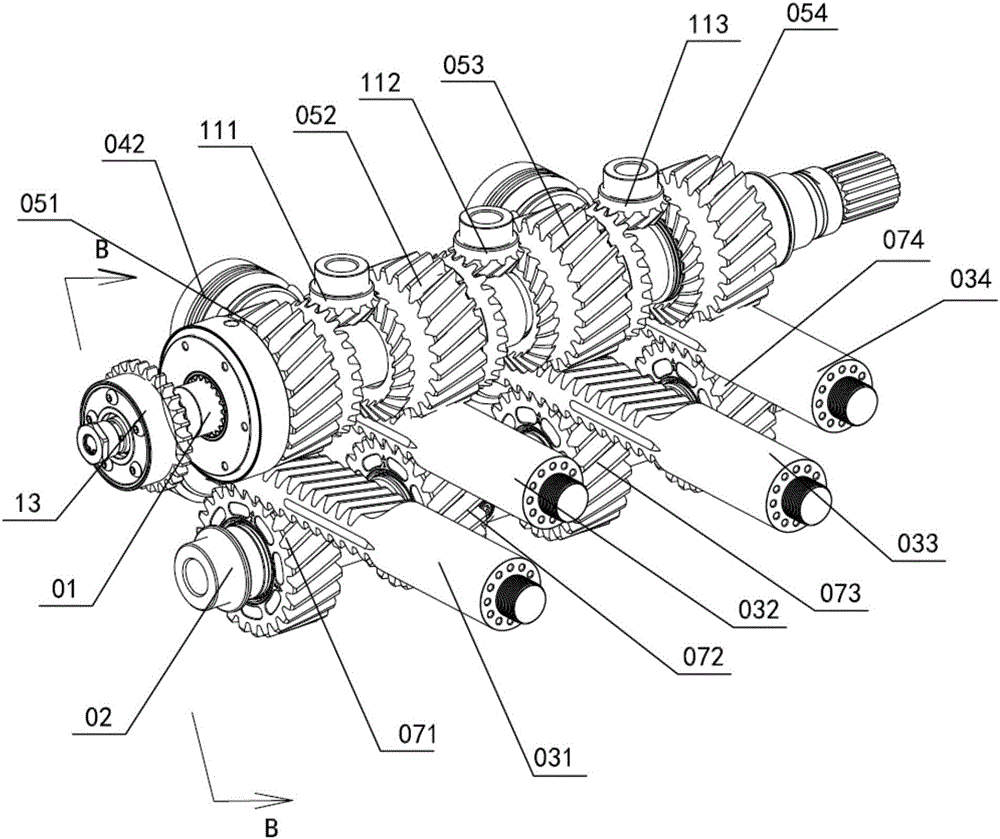

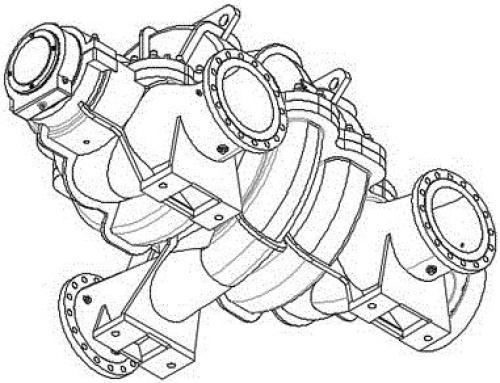

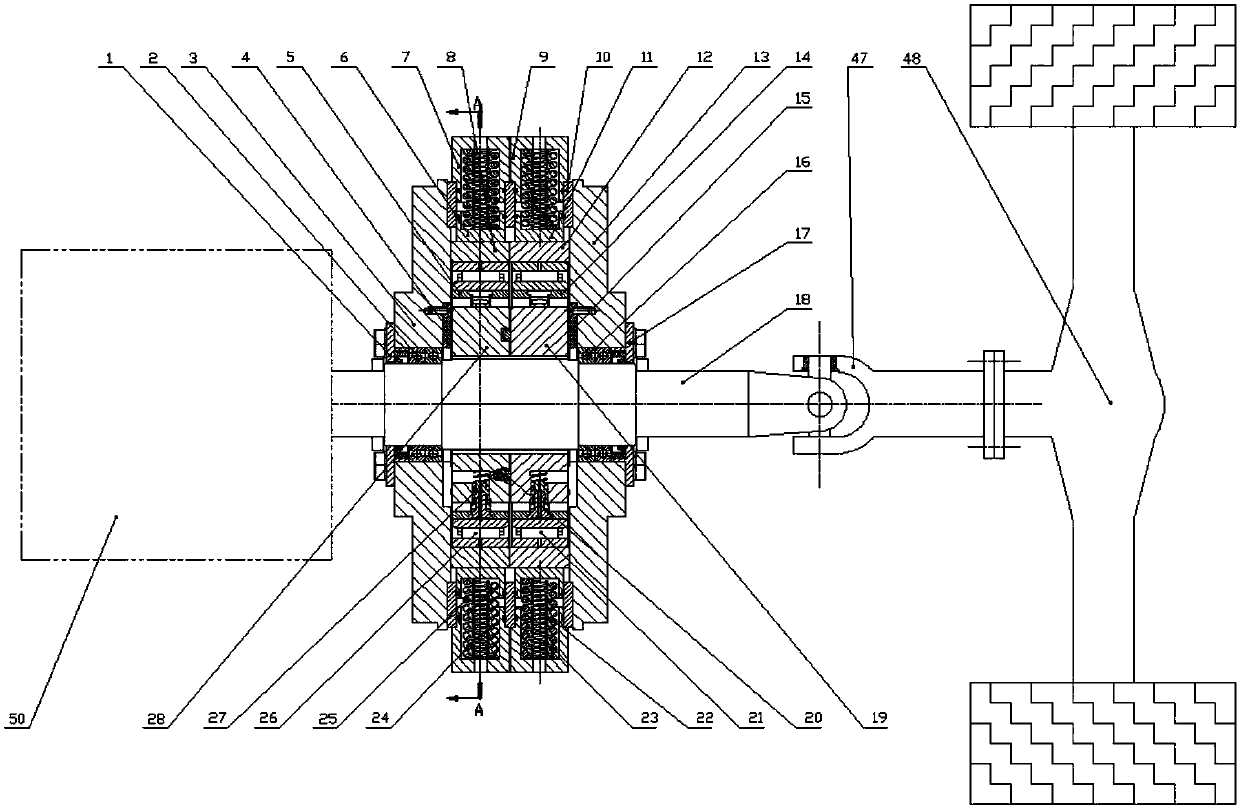

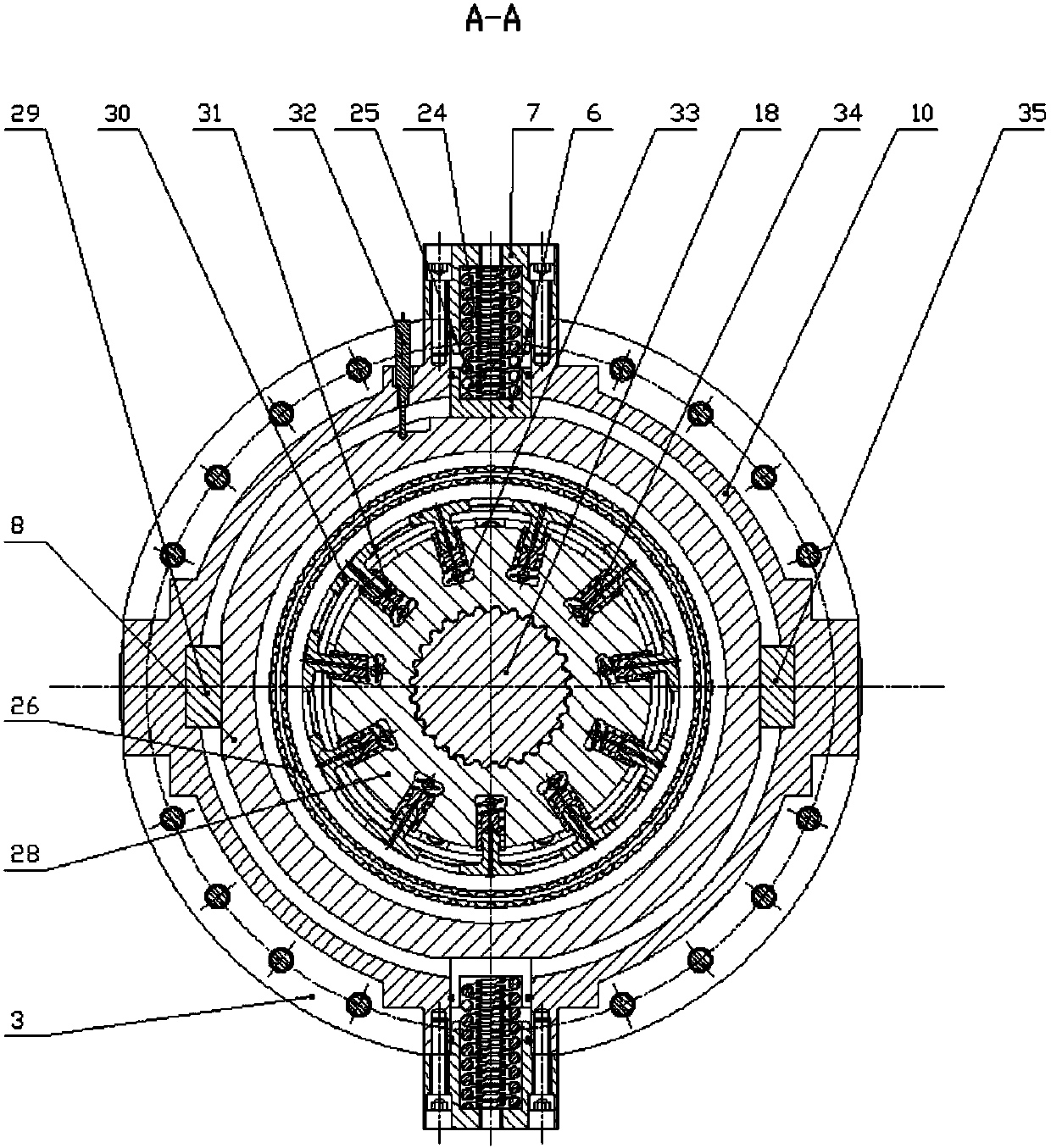

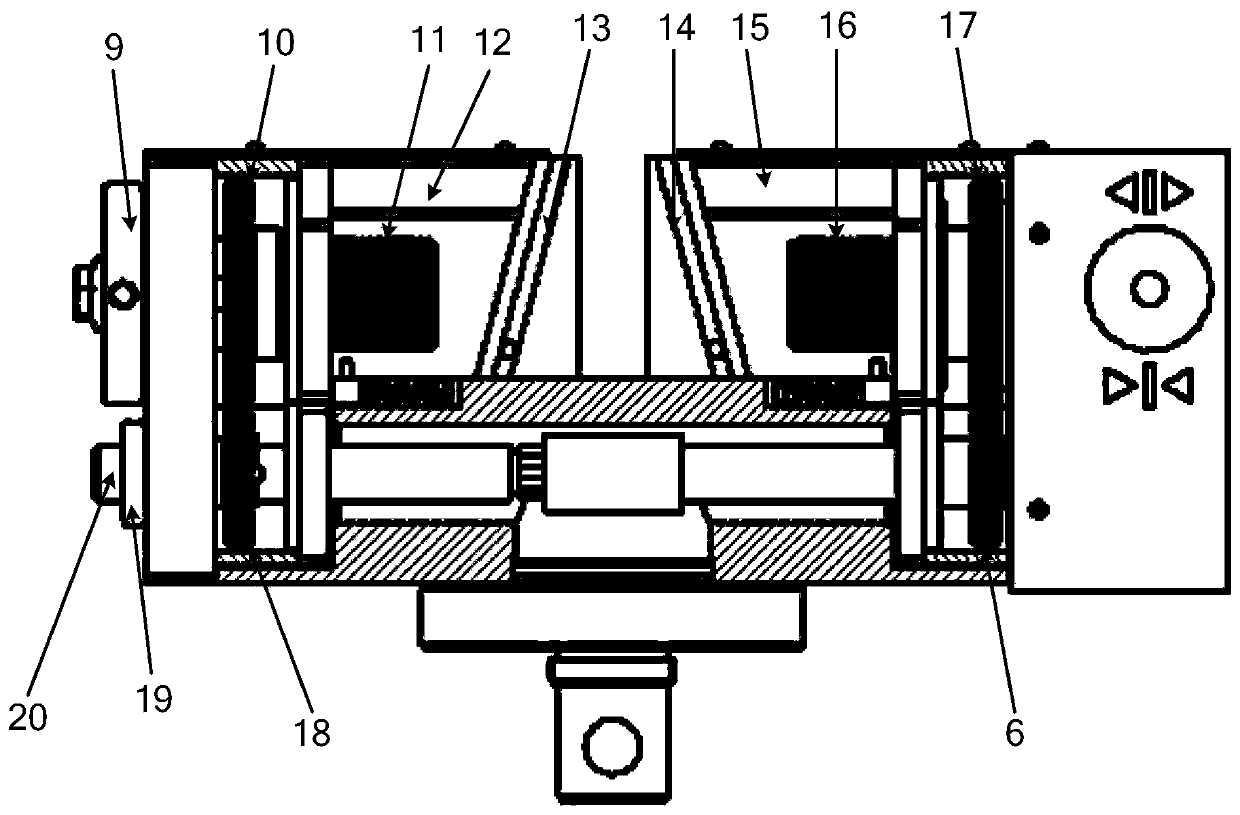

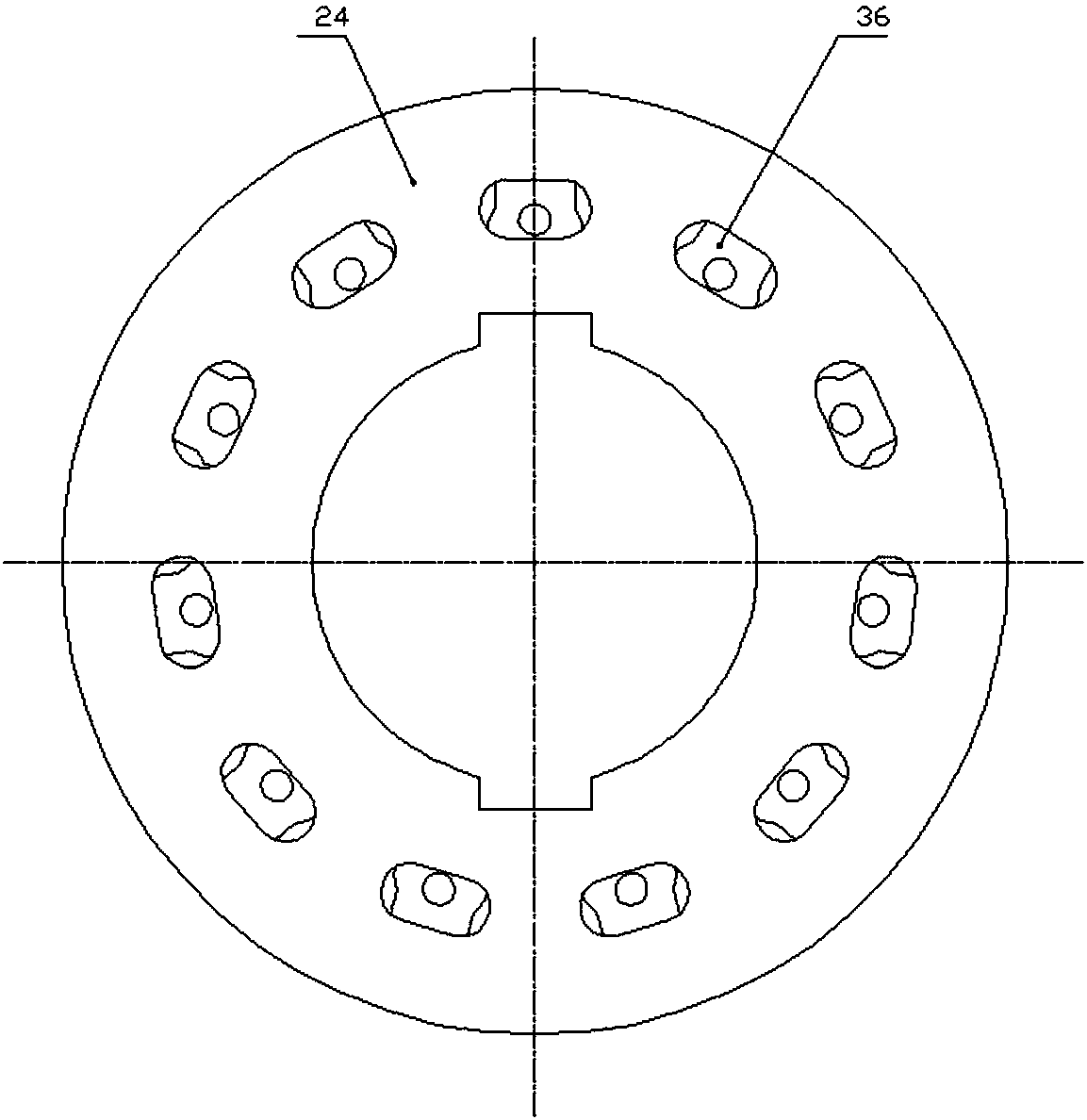

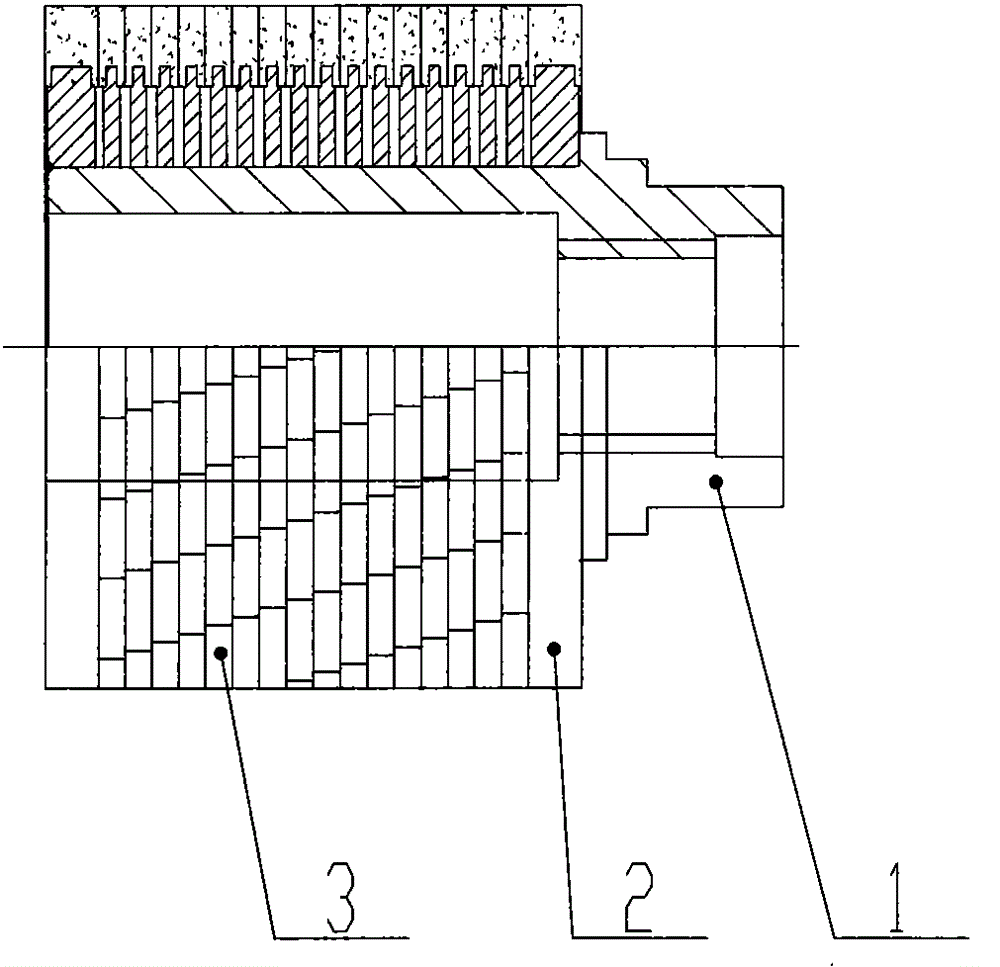

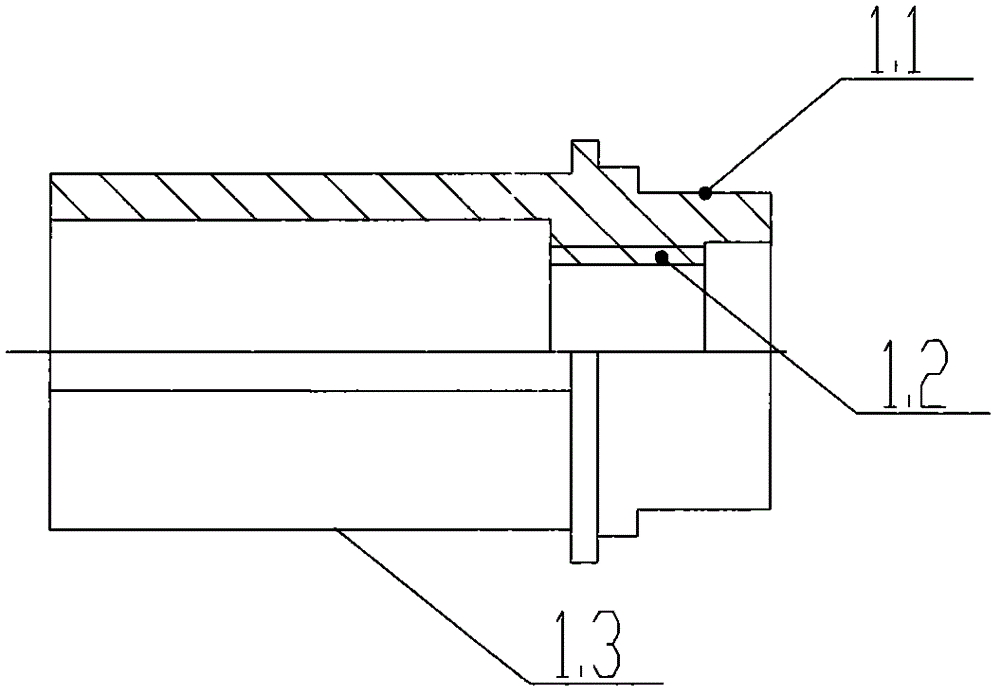

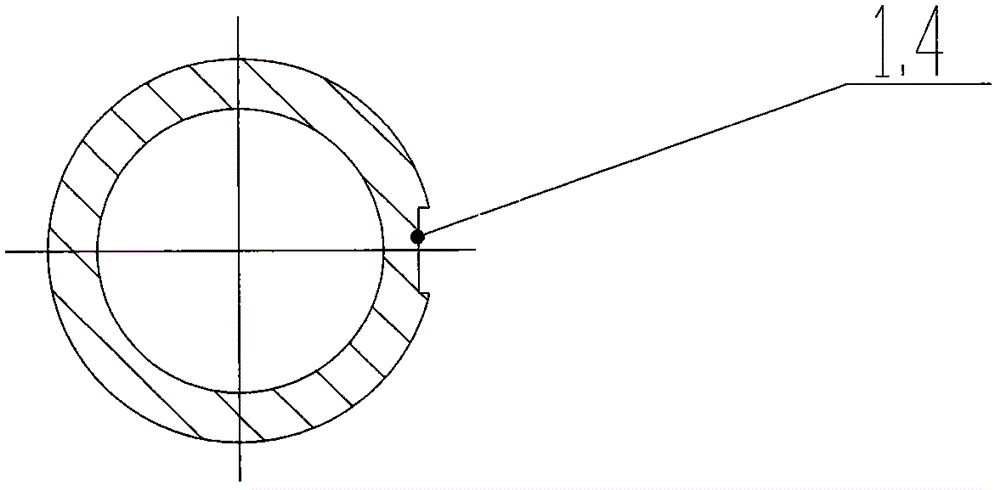

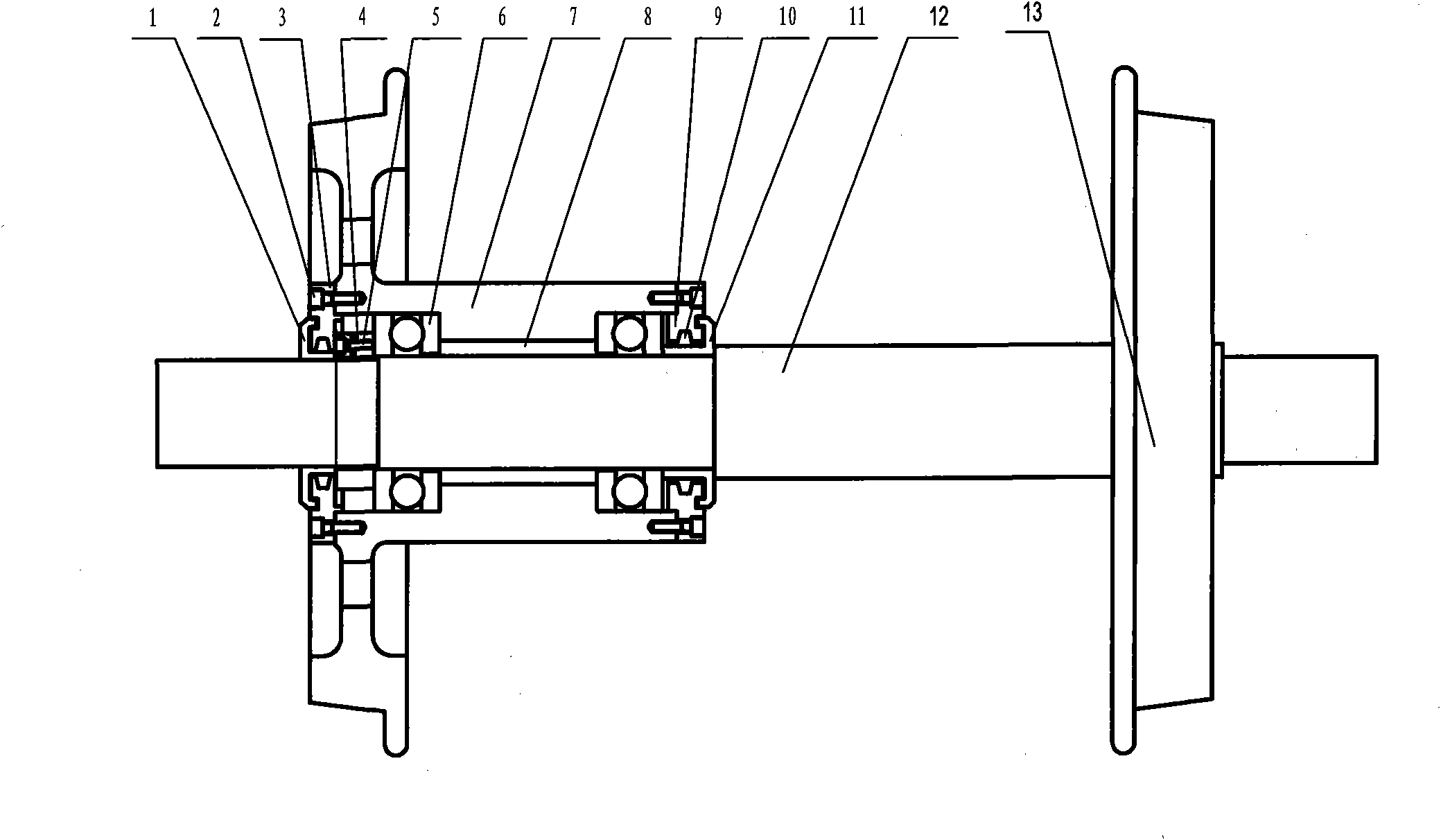

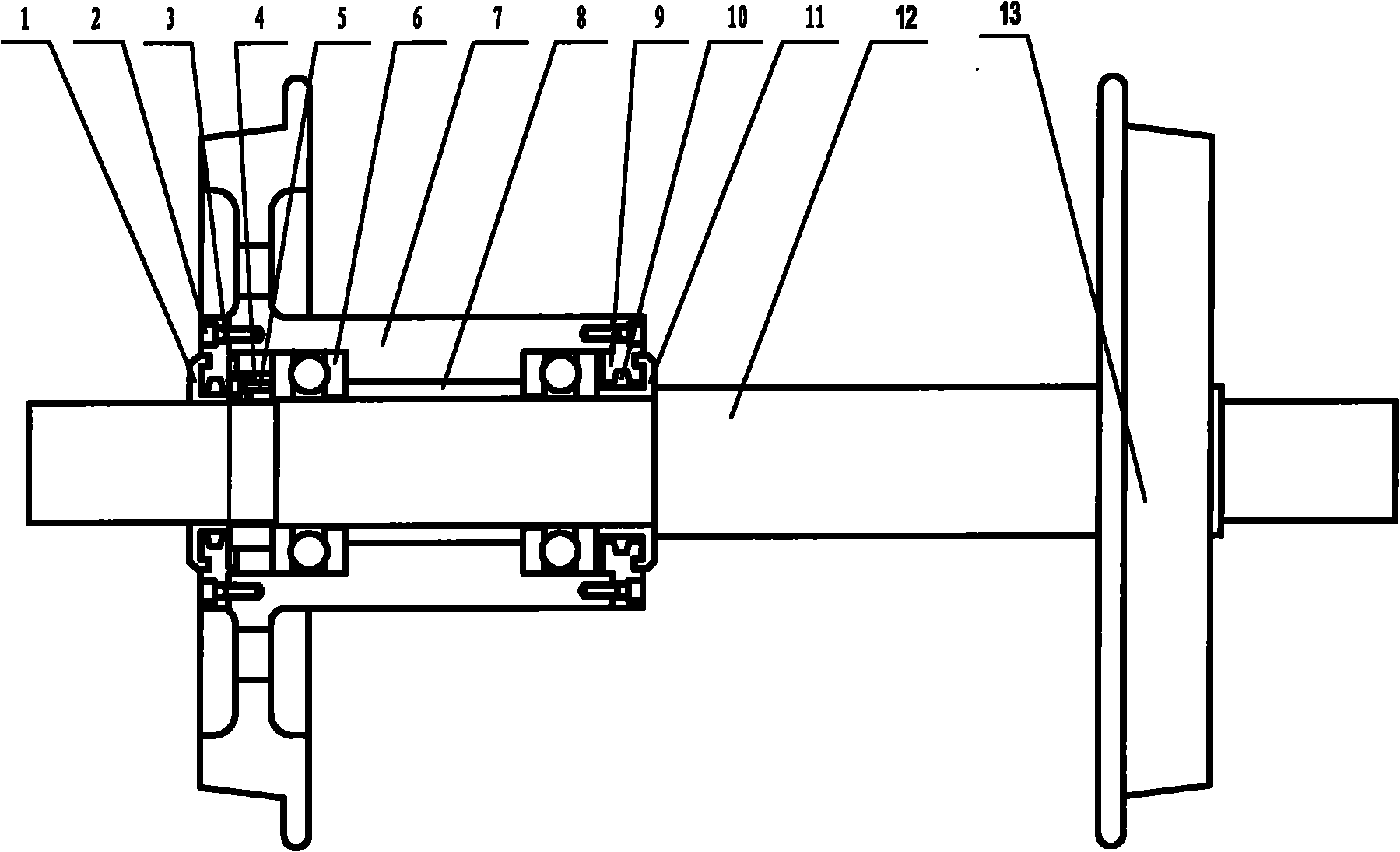

A Double Row Radial Piston Hydraulic Retarder with Two End Face Discs

A double-row radial plunger hydraulic retarder with two end face distribution plates, including a transmission shaft, the front end of the transmission shaft is connected with the gearbox, the rear end is connected with the drive axle, and two cylinders are installed side by side in the middle of the transmission shaft One cylinder has an annular groove and is equipped with an intermediate ring of the cylinder. A row of radial plunger holes are respectively opened in parallel on the outer circumference of the two cylinders. Between each plunger hole and the plunger Equipped with a return spring, the top of the sliding shoe installed on the plunger is pressed against the inner ring of the needle roller bearing fixed on the stator. The upper and lower sides of the stator are pressed by two variable pistons, and the left and right sides are pressed by friction blocks. Compression and positioning are carried out through the left end cover of the retarder and the right end cover of the retarder, the variable piston is installed in the middle housing, and the two cylinders are respectively pressed against the flow plate installed on the left and right end covers of the retarder. Recycling of kinetic energy during braking, compact overall structure, stable operation, no axial force, and automatic hydraulic compensation.

Owner:XI AN JIAOTONG UNIV

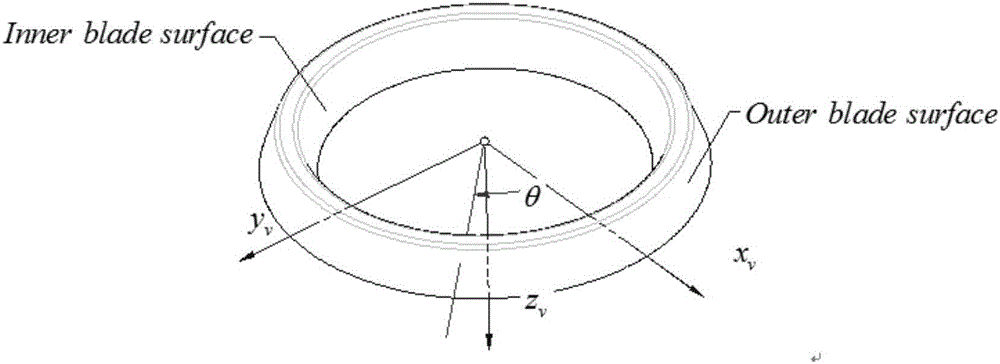

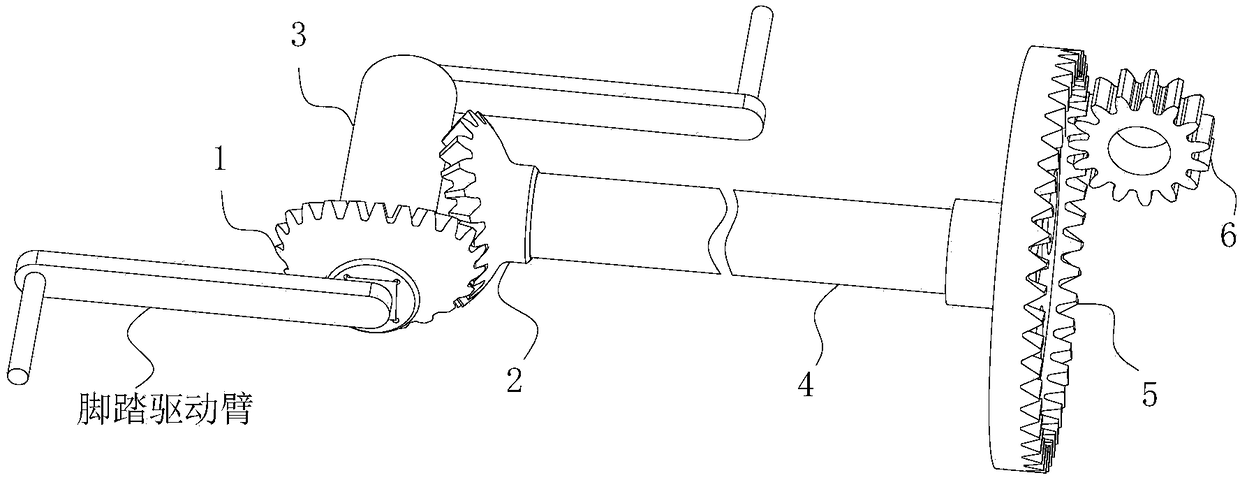

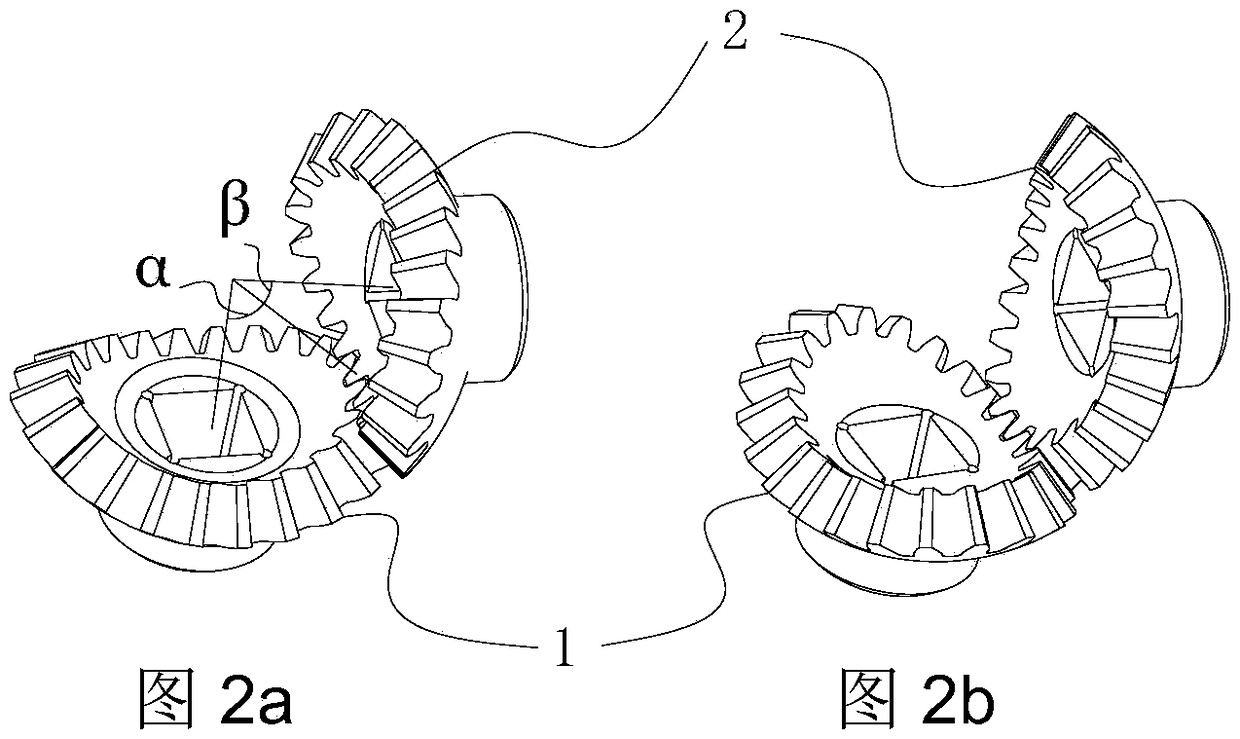

Pedal-type shaft transmission mechanism which adopts a non-circular bevel gear

InactiveCN109110043ALess discomfortImprove ergonomicsWheel based transmissionRotary transmissionsLongest DiameterDrive wheel

The invention relates to a pedal-type shaft transmission mechanism which adopts a non-circular bevel gear. The pedal-type shaft transmission mechanism includes a non-bevel gear pair, a pedal shaft, apower shaft and a face gear pair; a non-circular bevel gear pair is an oval bevel gear pair having a long diameter portion and a short diameter portion. During working, the non-bevel gear pair transmits the power to the face gear pair through the power transmission shaft to realize the pedal drive. When the foot pedal is in a state nearly perpendicular to the ground, the short diameter portion ofthe non-conical driving wheel engages with the long diameter portion of the non-conical driven wheel; when the foot pedal is in a state nearly parallel to the ground, the long diameter portion of thenon-conical driving wheel meshes with the short diameter portion of the non-conical driven wheel. When the foot pedal is in the vicinity of the dead point, the invention can make the power transmission part have a smaller speed increase ratio, and when the foot pedal is in the power generating area, the power transmission part has a larger speed increase ratio, so as to improve the cycling experience of the rider and reduce the discomfort feeling in the cycling process for a long time.

Owner:HEFEI UNIV OF TECH

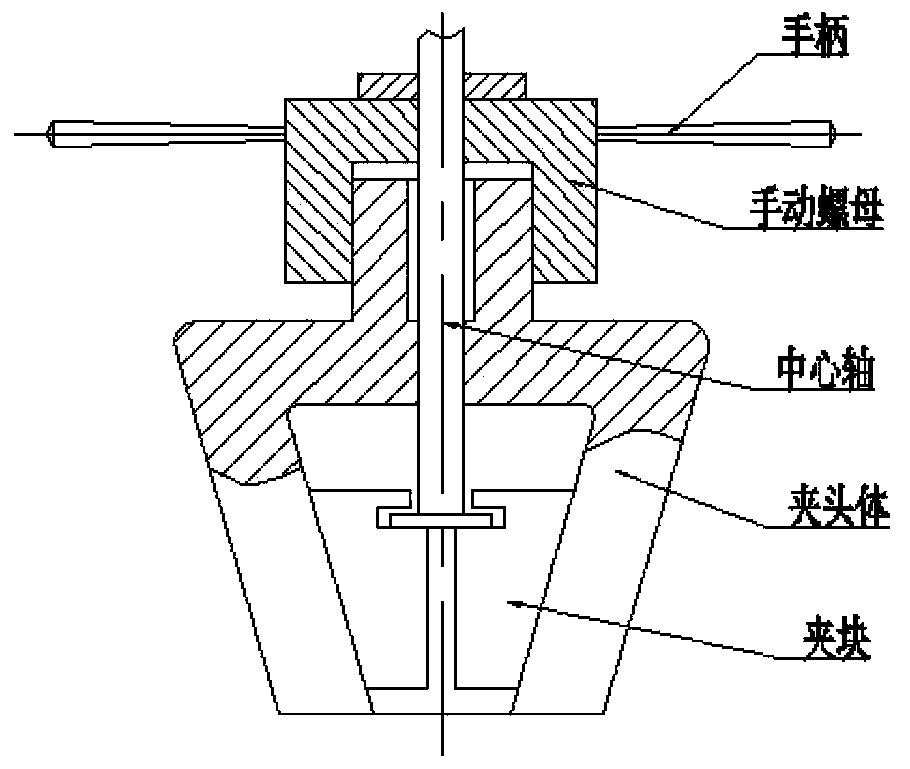

A flat-push wedge-shaped clamping device

The invention discloses a horizontal pushing wedged clamping device, and belongs to the field of tester clamps. An execution mechanism of the horizontal pushing wedged clamping device is composed of wedge block bodies and wedge blocks; during testing, the wedge block bodies and a clamp body are stressed; the front end of each wedge block body is a wedged mechanism, so that clamping force can be strengthened as drawing force applied to a sample is strengthened, the sample is not liable to slip, and clamping implemented to the sample is reliable; and meanwhile, operation is simple and convenient, a clamping range is larger than that of a wedged clamp, and in addition, the wedged blocks clamp the sample in a translation manner without any axial additional force. According to the technical scheme, the horizontal pushing wedged clamping device has the advantages that by taking compressed air as a power source, a medium is clean, energy supply is convenient, clamping and loosening are rapid, the test time is short, the working efficiency is high, the labor intensity is low, and the like, and also has various advantages that the initial clamping force is small, the sample can be asymmetrically clamped, and the like. By adopting the device, the tester industry goes up to a new stage, automation of a clamping process can be further realized at the same time, the controllability is strengthened, and a solid foundation is laid for further realizing full automation of material tests.

Owner:中机检测有限公司

Partial emission pump with low specific speed

ActiveCN101865160BEasy to controlMake up for the shortcomings of unstable working conditionsPump componentsPumpsDrive shaftEngineering

The invention relates to a partial emission pump with a low specific speed, which comprises an inlet component and a shell component. The shell component comprises a shell, an impeller, an inducer, a transmission shaft, a diversion sleeve and a diffusion pipe; the impeller, the inducer, the transmission shaft and the diversion sleeve are arranged in the shell; the diffusion pipe is arranged on the shell and is communicated with the shell; the inlet component comprises an inlet shell and an inlet pipe; the inlet pipe is connected with the inlet shell; the partial emission pump also comprises athroat part arranged on the shell; the shell is communicated with the diffusion pipe through the throat part; and the central line of the diffusion pipe is parallel to the external tangent line of anannular channel on the shell. The invention solves the technical problems of narrow blade outlet, difficult manufacture and processing of the impeller and low efficiency of the centrifugal pump, facilitates the large-scale adjustment of operating conditions, and improves the hydraulic efficiency of the pump.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

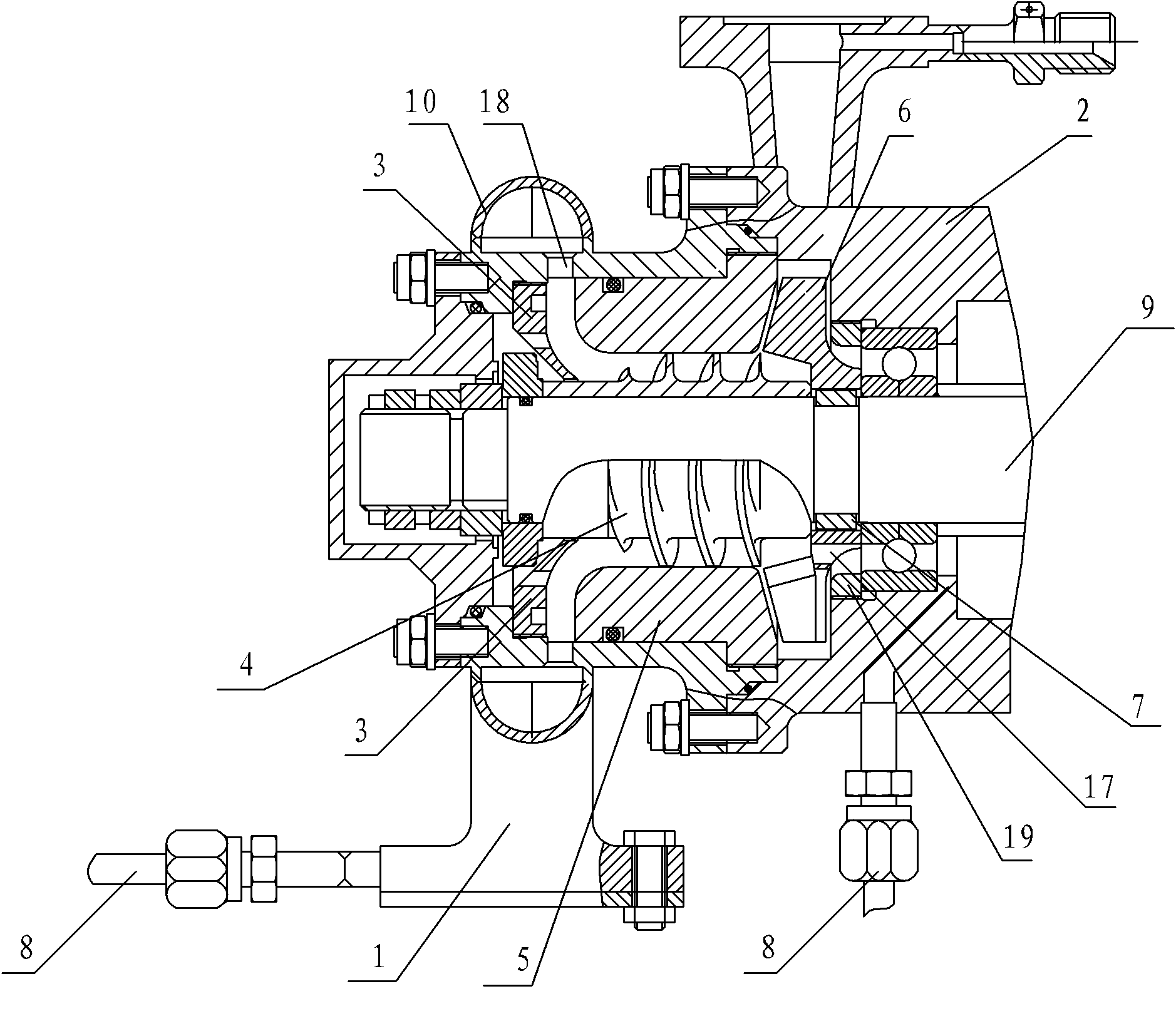

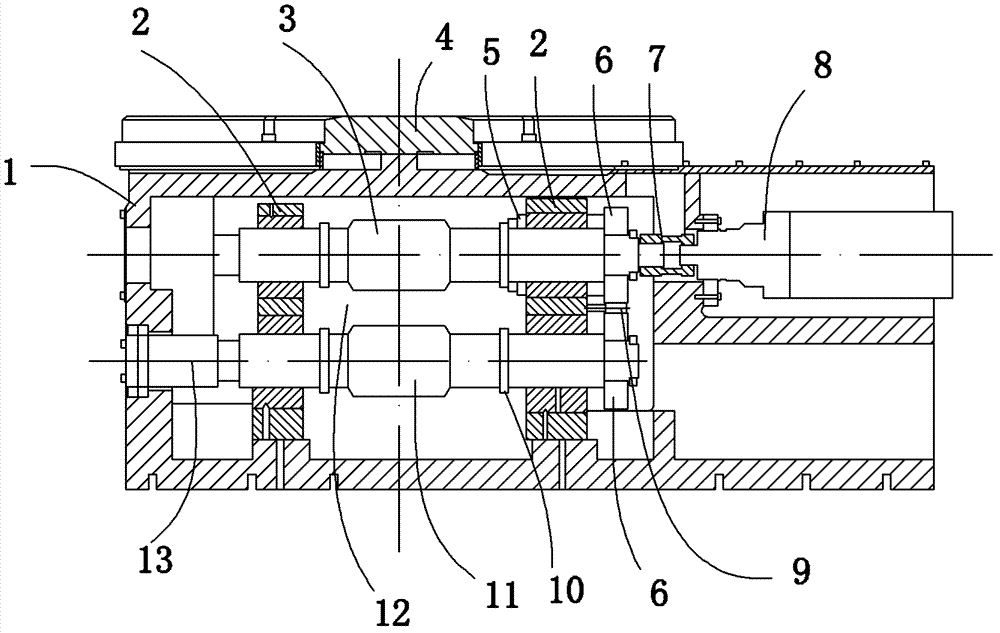

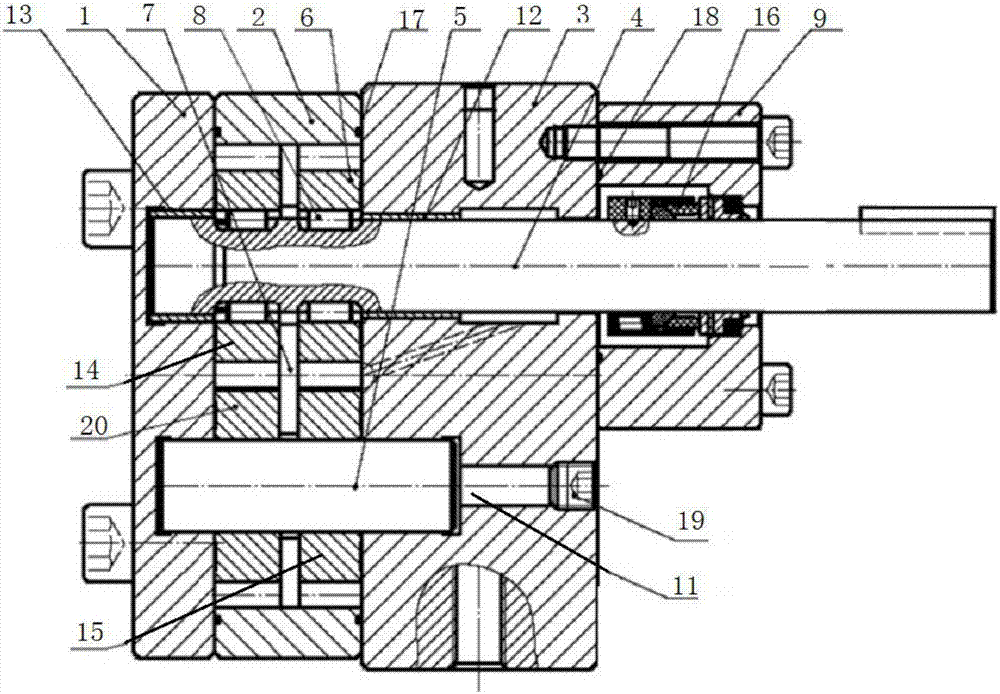

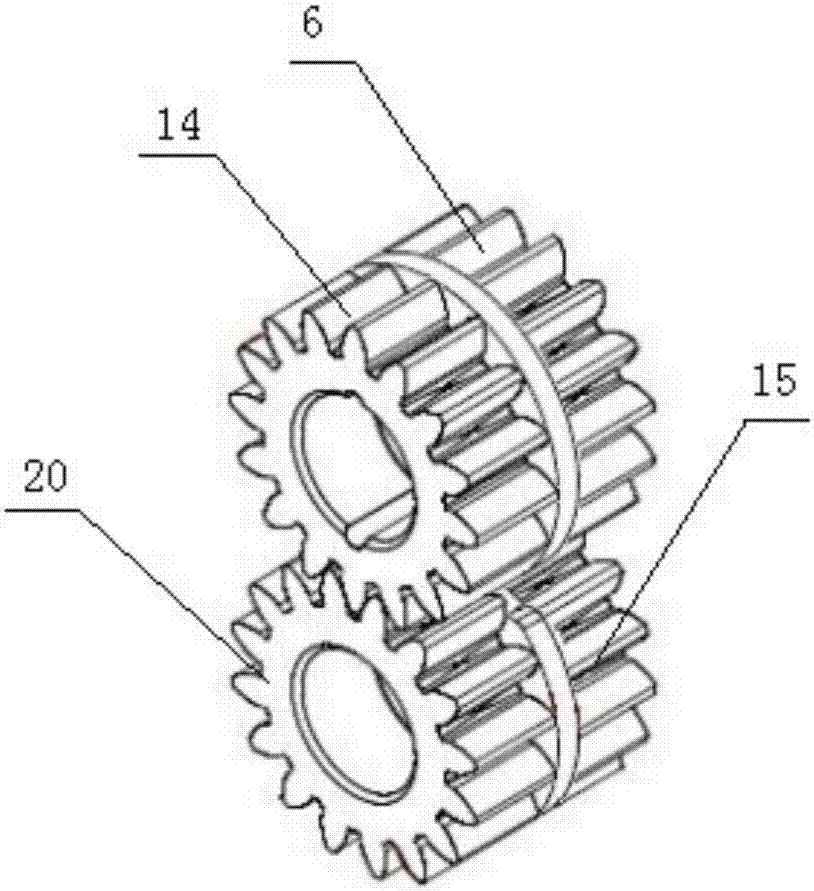

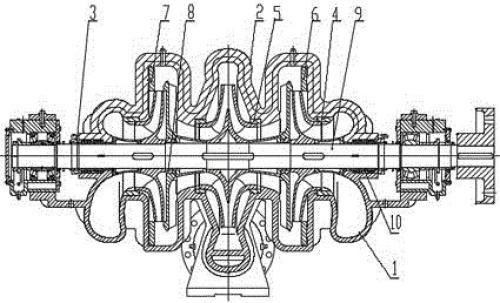

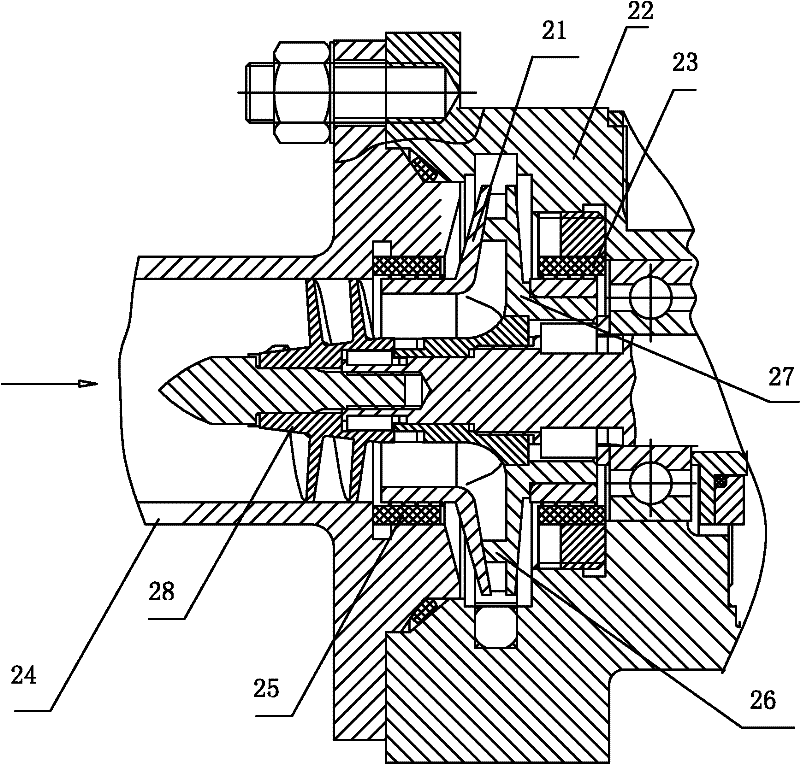

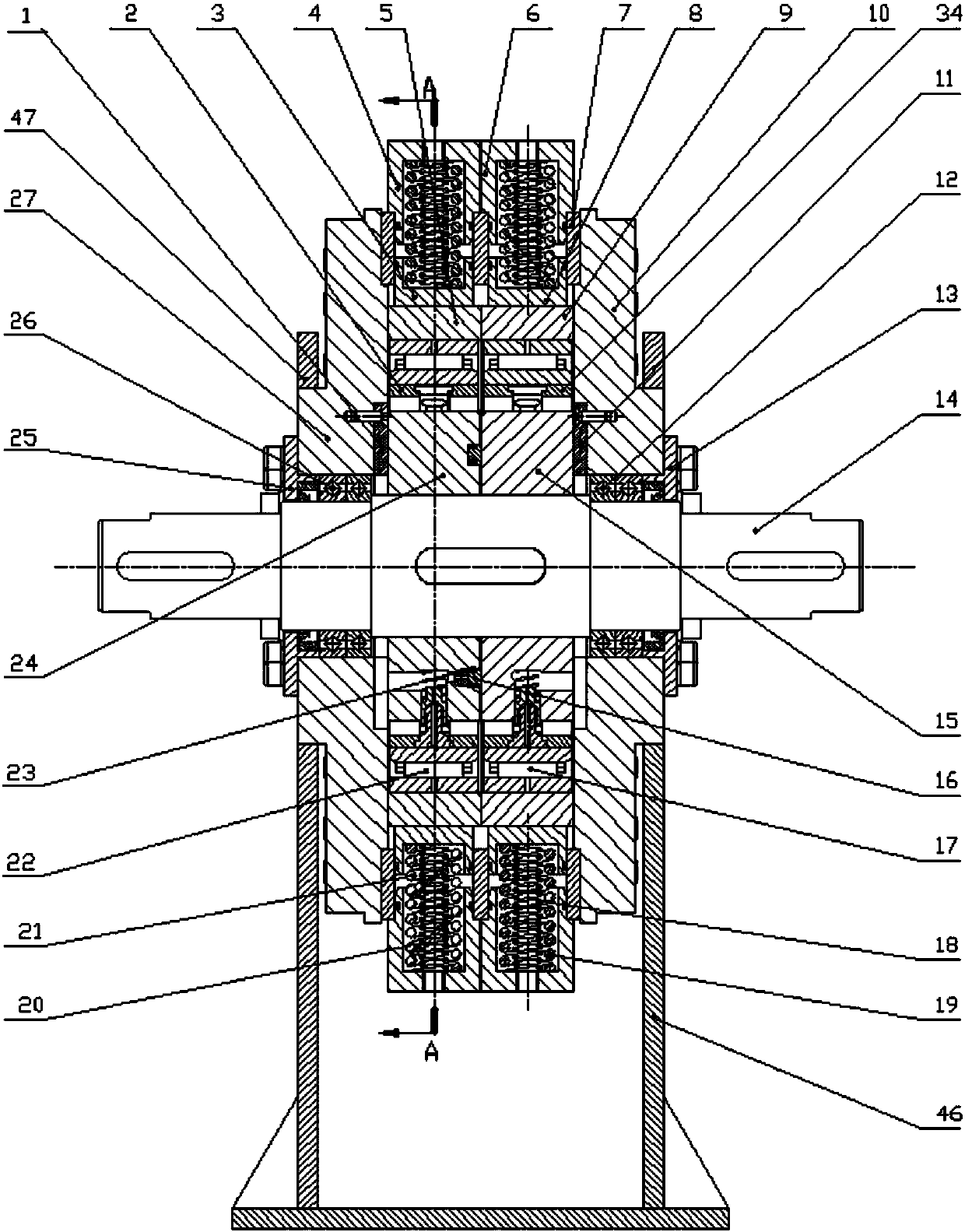

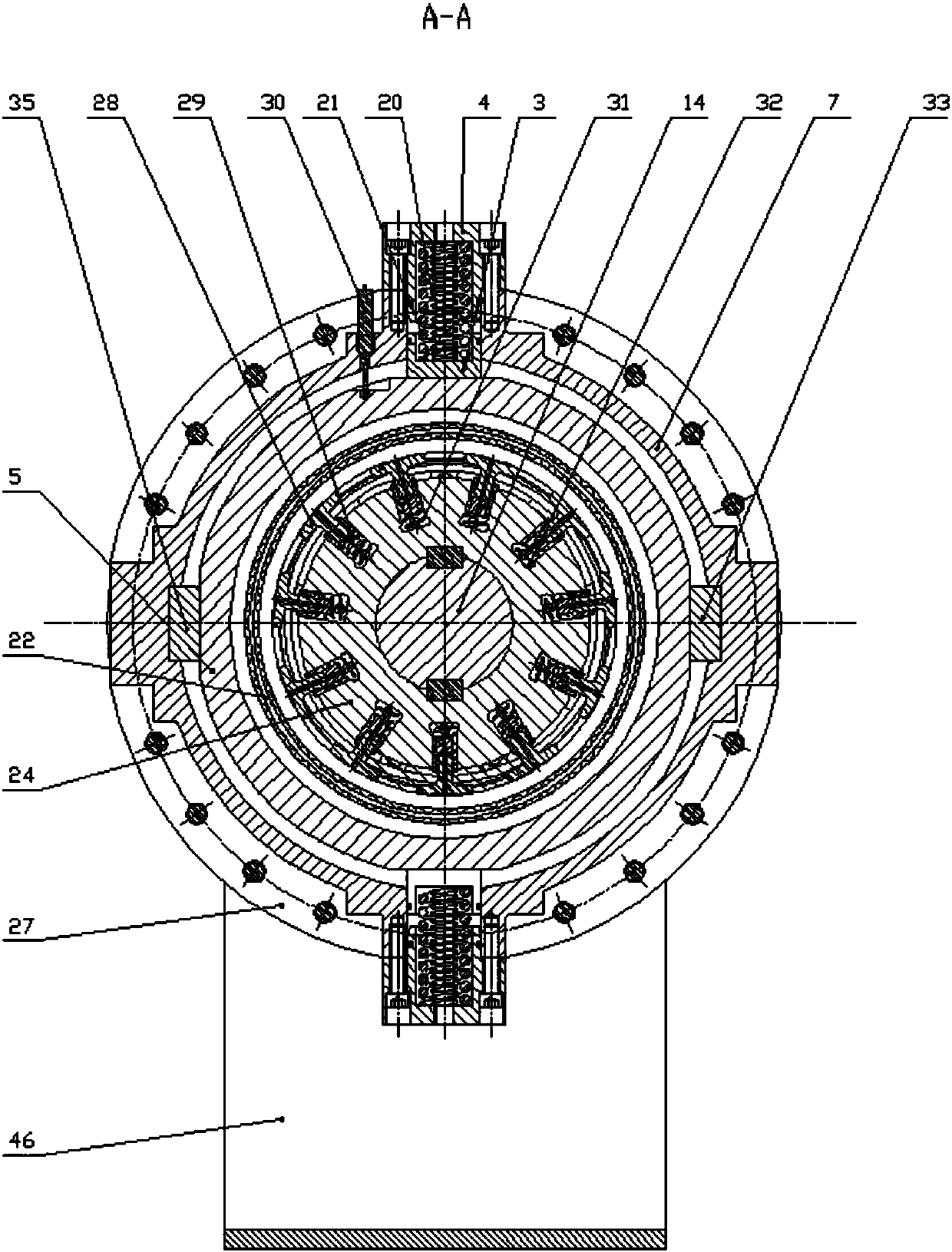

A pressure-compensated end-face oil-distribution double-row radial piston variable pump with annular piston

ActiveCN106014901BCompact structureHigh strengthPositive displacement pump componentsPositive-displacement liquid enginesRadial piston pumpEngineering

A pressure-compensated end-face oil-distribution double-row radial piston variable pump with annular pistons, including a transmission shaft on which two cylinders are installed side by side, one cylinder has an annular groove and is equipped with a pressure-compensated annular piston , a row of radial plunger holes are opened in parallel on the outer surface of the cylinder body, and a plunger is installed on each plunger hole, and a return spring is installed between the plunger hole and the bottom of the plunger, and the plunger Sliding shoes are installed on the top, and the top of the sliding shoe is pressed against the inner ring of the needle roller bearing fixed on the inner ring of the stator. The upper and lower sides of the stator are pressed by variable pistons, and the left and right sides are pressed by friction blocks, which pass through the pump. The end cover is pressed and positioned, and the variable piston is symmetrically installed in the round hole of the intermediate housing, and the boss outside the round hole of the intermediate housing is equipped with a variable end cover, and the variable end cover and the variable piston are respectively compressed. With a variable spring, the invention works stably and has strong continuous working ability, and has the advantages of no axial force and automatic hydraulic compensation.

Owner:XI AN JIAOTONG UNIV

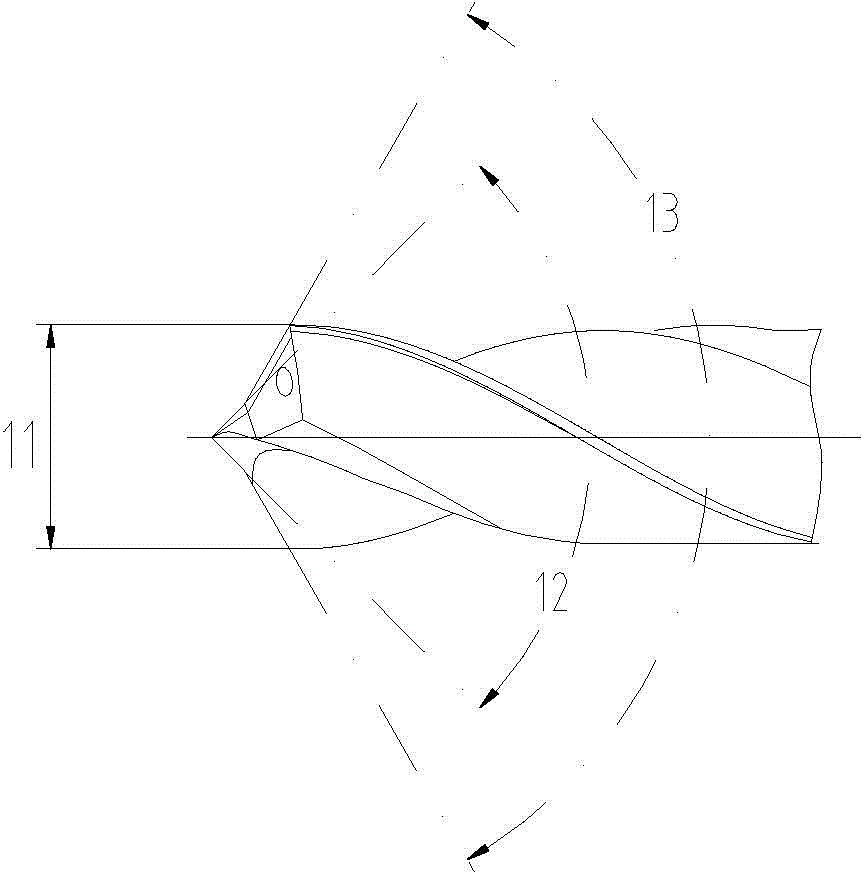

A kind of diamond grinding roller and its manufacturing method

ActiveCN104308756BEasy chip removalNo axial forceBonded abrasive wheelsGrinding devicesPulp and paper industryRadial surface

The invention provides a diamond grinding roller and a manufacturing method of the diamond grinding roller. The diamond grinding roller comprises a basic roller, a grinding bucket and a column type fixed part, wherein the basic roller comprises a connecting part used for being connected with using equipment, the column type fixed part is used for connecting a grinding ring in a sleeved mode, the surface of the fixed part is axially provided with at least one constant hump or one depression, and the grinding bucket is provided with a plurality of superimposed grinding rings. Two ends of the diamond grinding roller are designed into an integrated cutting head, the middle part of the diamond grinding roller is a discontinuous cutting head, so that the relative positions of middle pieces can be arbitrarily placed, and the integrated gap groove is a large helical angle. The radial surface of the cutting head is an arc-shaped surface or a surface with an angle is formed with the radius, the structure is better for chip removal, the cutting blade is broken line shaped of parallel axes, an axial component force cannot occur during working, and the grinding is more stable. The integrated cutting head end pieces are arranged on the two ends, so that the outer working surface of the whole grinding roller has the cutting head contact grinding at any time, and the impact due to the intermittent grinding is prevented.

Owner:石家庄泰威科技有限公司

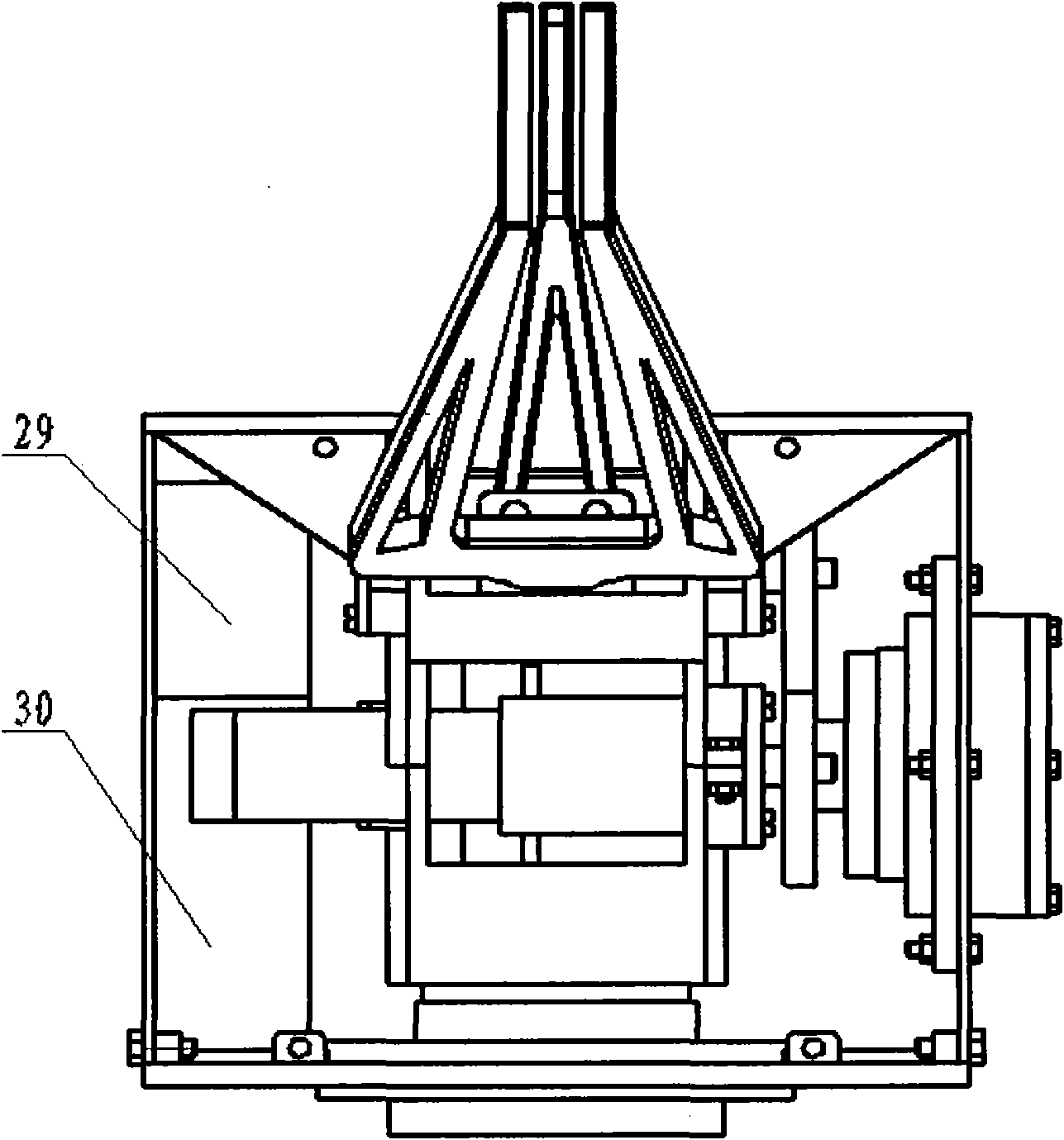

A type of elliptical double-suction four-channel pump impeller

The invention belongs to the field of fluid machinery, and particularly relates to a similarly oval double-suction four-flow-channel pump impeller. The whole impeller is similarly oval, and is provided with a front cover plate, a rear cover plate, a middle partition, four screw type thin-walled flow channel blades and an axle center, wherein two inlets are respectively formed in two sides of the axle center; the two cover plates, the middle partition and the four screw type thin-walled flow channel blades jointly form four flow channels, the four flow channels are separated into front double flow channels and rear double flow channels by the middle partition, outlets of the flow channels of the impeller are double-side wide outlets, outlet sides are large-V-shaped, and a V-shaped vertex of each outlet is positioned on a center line of the corresponding flow channel. Blades of the impeller are thin, the weight of the impeller is light, the outlets are folded-V-shaped and are wide, the structure is simple, and the similarly oval double-suction four-flow-channel pump impeller has good passing ability to impurities such as various large particles, long fibers and household garbage, and is high in efficiency, low in noise and stable and reliable in running. The similarly oval double-suction four-flow-channel pump impeller which is mounted in a sewage pump can be used for treating domestic sewage, municipal sewage, industrial sewage and the like in a centralized manner, so that the sewage can reach the standard when drained.

Owner:山西天海给排水设备有限公司 +1

Single-rack drive bicycle with reciprocating variable circular motion

ActiveCN113581354BImprove interchangeabilityHigh coincidenceWheel based transmissionRider propulsionLow noiseLow speed

The invention discloses a single-rack drive bicycle with reciprocating and variable circular motion. device, single rack, reciprocating and changing circumference device, speed change device and reversing device, the reciprocating and changing circumference device converts the reciprocating motion of the rack into a circular motion, the speed change device can realize the high and low speed switching of the circular motion, and the reverse device can realize the A coordinated action like raising the rack can reverse the car. Its characteristics are that the up and down motion of the pedal is converted into the reciprocating motion of the rack, and then converted into a circular motion with high efficiency and low noise through the reciprocating circular device; the gear and the rack can be sealed, which not only reduces oil pollution but also achieves full lubrication; There will be no problem of "dropping the chain"; a single rack is equivalent to the large chainring of a traditional bicycle, which can realize the function of continuously shifting.

Owner:董建国

Coaxial and variable-speed energy-saving wheel of train

The invention relates to a coaxial and variable-speed energy-saving wheel of a train. One wheel at one side of a train shaft is a static wheel (relative to the train shaft), and the other side of the train shaft is provided with a movable wheel which can rotate around the shaft of the static wheel; and when the train runs, the relative rotating speed of two wheels is extremely low, thus the movable wheel is basically in a static load state. The running friction of the wheel is less, therefore, a sliding bearing is selected to serve as the bearing for bearing main load. Thrust bearings are selected in the axis direction of the two sides of the sliding bearing so as to be used for balancing axial forces generated due to leftward and rightward swinging when the train runs. When the train with the coaxial and variable-speed energy-saving wheel passes through a bend, no strict requirement is needed for turning radius, rolling friction instead of sliding friction is realized between the two wheels and iron rails, the wheels are avoided from generating sliding friction to consume energy and generate harsh noise, and no axial force is generated when in braking.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

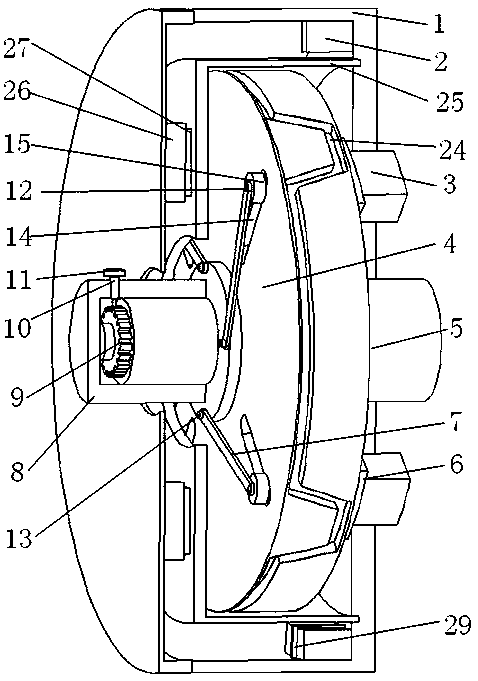

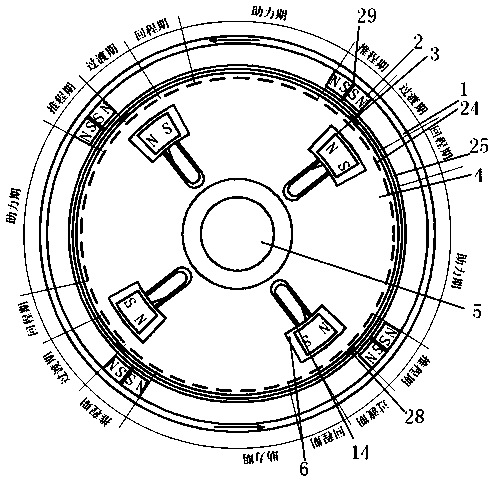

A Rehabilitation Robot Revolving Joint Permanent Magnet Assisting Mechanism

ActiveCN107349080BCompact structureMeeting rehabilitation needsChiropractic devicesMagnetic polesTangential force

The invention discloses a rehabilitation robot rotary joint permanent magnet assisting mechanism, and relates to the field of medical care. The rehabilitation robot rotary joint permanent magnet assisting mechanism comprises a stator unit, a rotor unit, an adjusting unit, a locking unit, a magnetic shielding ring and a central shaft. The stator unit comprises and stator permanent magnets; the rotor unit comprises a rotating substrate, a permanent magnet holding grooves and rotor permanent magnets; the adjusting unit comprises turn button binding posts, slide block units, pull bars and an adjusting turn button; and the locking unit comprises a locking pin unit and a locking pin mounting base. Four groups of permanent magnets are uniformly arranged on the stator mechanism, each group includes two permanent magnets, and like poles of the two permanent magnets are opposite to each other; the permanent magnets are uniformly arranged on the rotor mechanism, the group number of the permanent magnets is the same as that of the stator permanent magnets, and the N poles and the S poles are alternately arranged; when the stator mechanism rotates at an angle, because like magnetic poles mutually repel, opposite magnetic poles attract each other, a generated tangential force drives the rotor to rotate. By changing the size of the air gap between the stator permanent magnets and the rotor permanent magnets, furthermore the magnitude of the output assisting force is changed, and the rehabilitation robot rotary joint permanent magnet assisting mechanism can meet demands of patients of different phases on the rehabilitation assisting power.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com