Agricultural machinery engine electromagnetic clutch

An electromagnetic clutch, agricultural machinery technology, applied in non-mechanical drive clutches, magnetic drive clutches, clutches, etc., can solve the problems of complex structure, large structure size, easy damage, etc., to achieve simple operation control, compact design structure, easy to use Effort-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

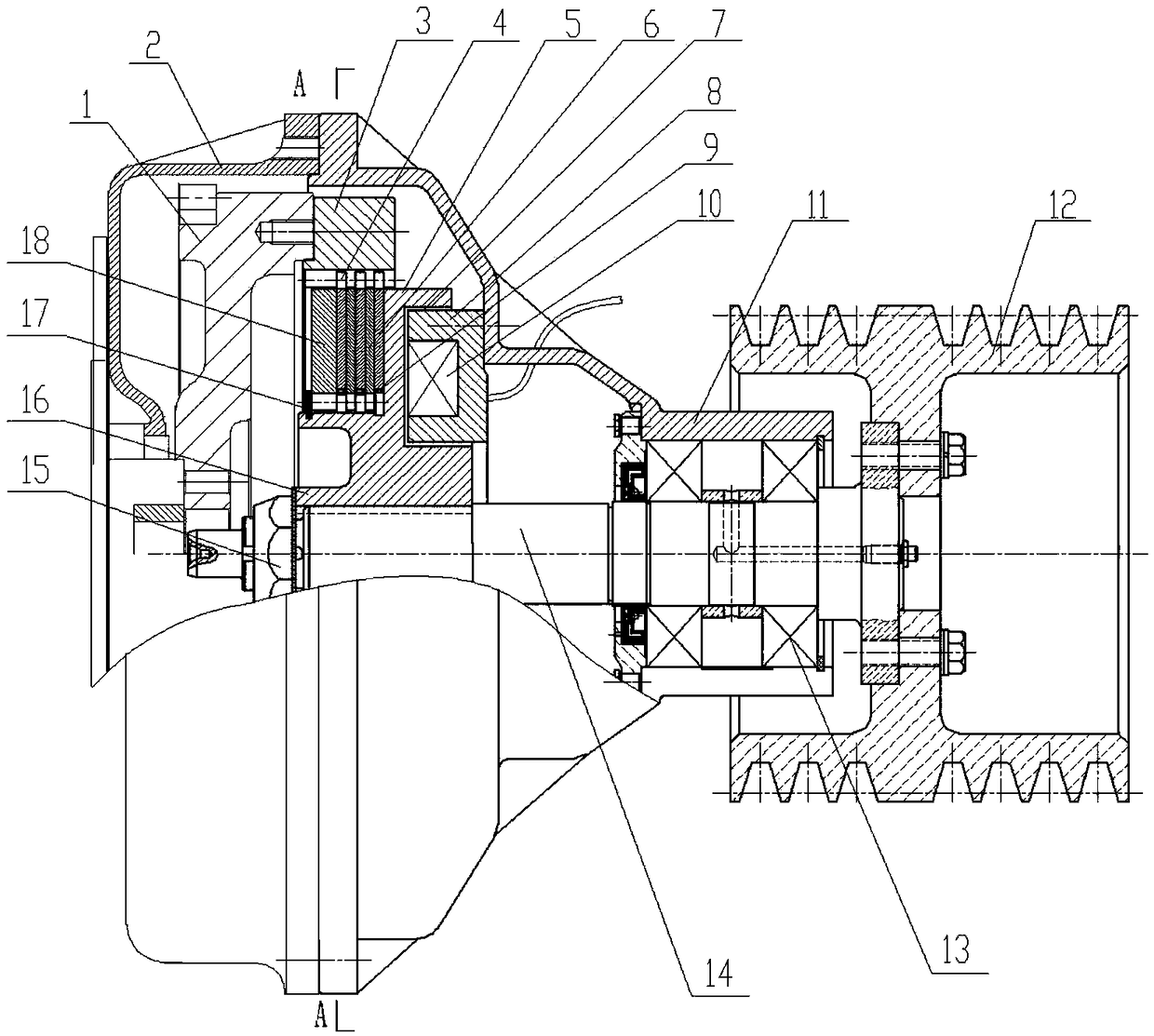

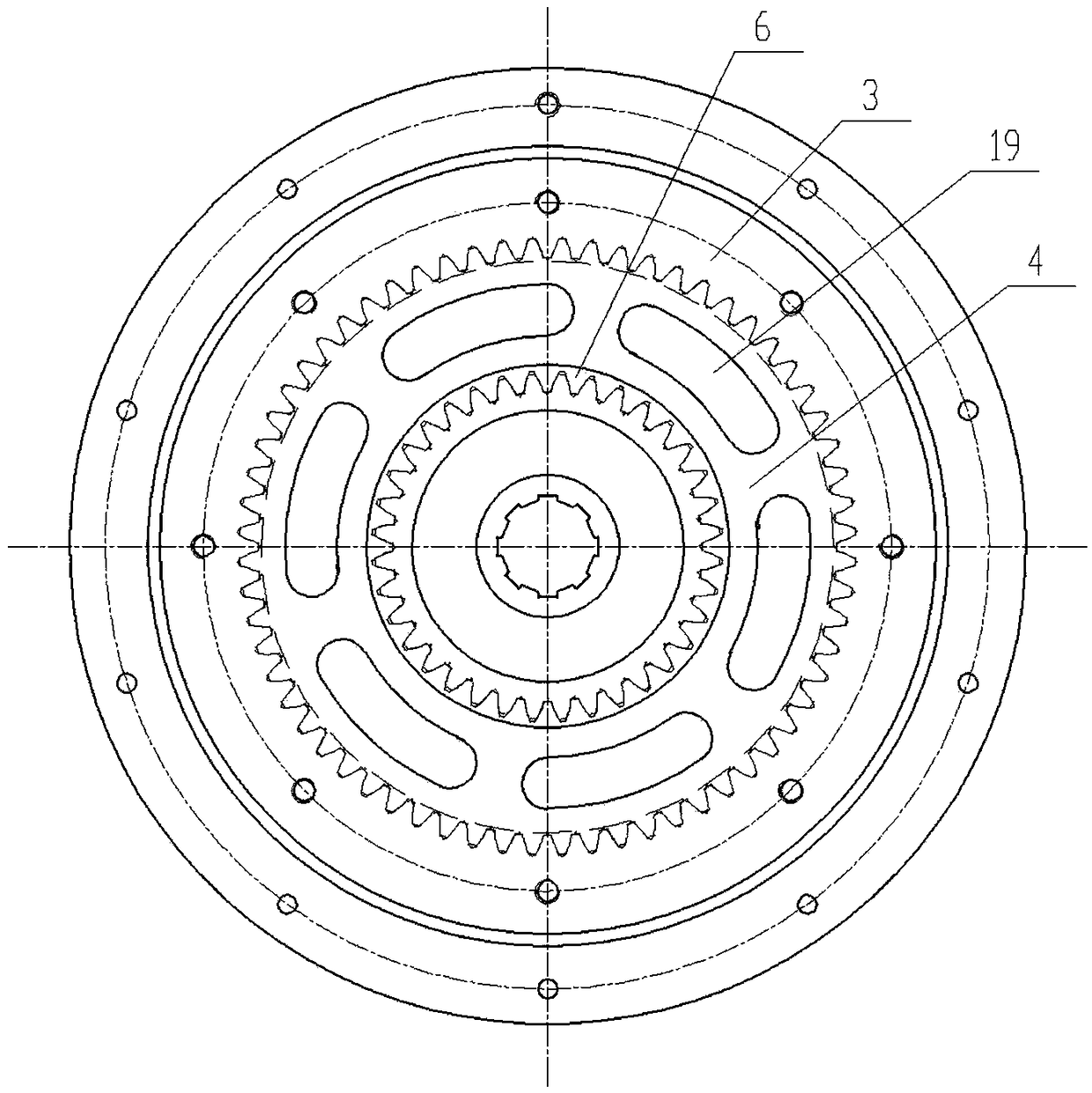

[0023] like figure 1 and figure 2 As shown, an agricultural machinery engine electromagnetic clutch related to the present invention includes a clutch housing 11 for connecting the engine flywheel housing 2, and a coil is fixed in the large-diameter port of the clutch housing 11 by screws uniformly distributed around the circumference. The sleeve 8 is provided with an annular groove on the outer end surface of the coil installation sleeve 8 and a coil 10 is packaged in the annular groove, and the two terminals of the coil 10 are drawn out from the clutch housing 11 . In the clutch housing 11, a rotatable main shaft 14 is installed through two sets of bearings 13, and a spacer sleeve is arranged between the two sets of bearings on the main shaft 14, and the large diameter end of the main shaft 14 is located in the clutch housing 11 through a spline An external gear sleeve 16 is connected, and a positioning nut 15 is connected to the outside of the external gear sleeve 16 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com