Patents

Literature

548 results about "Manipulator system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manipulator system

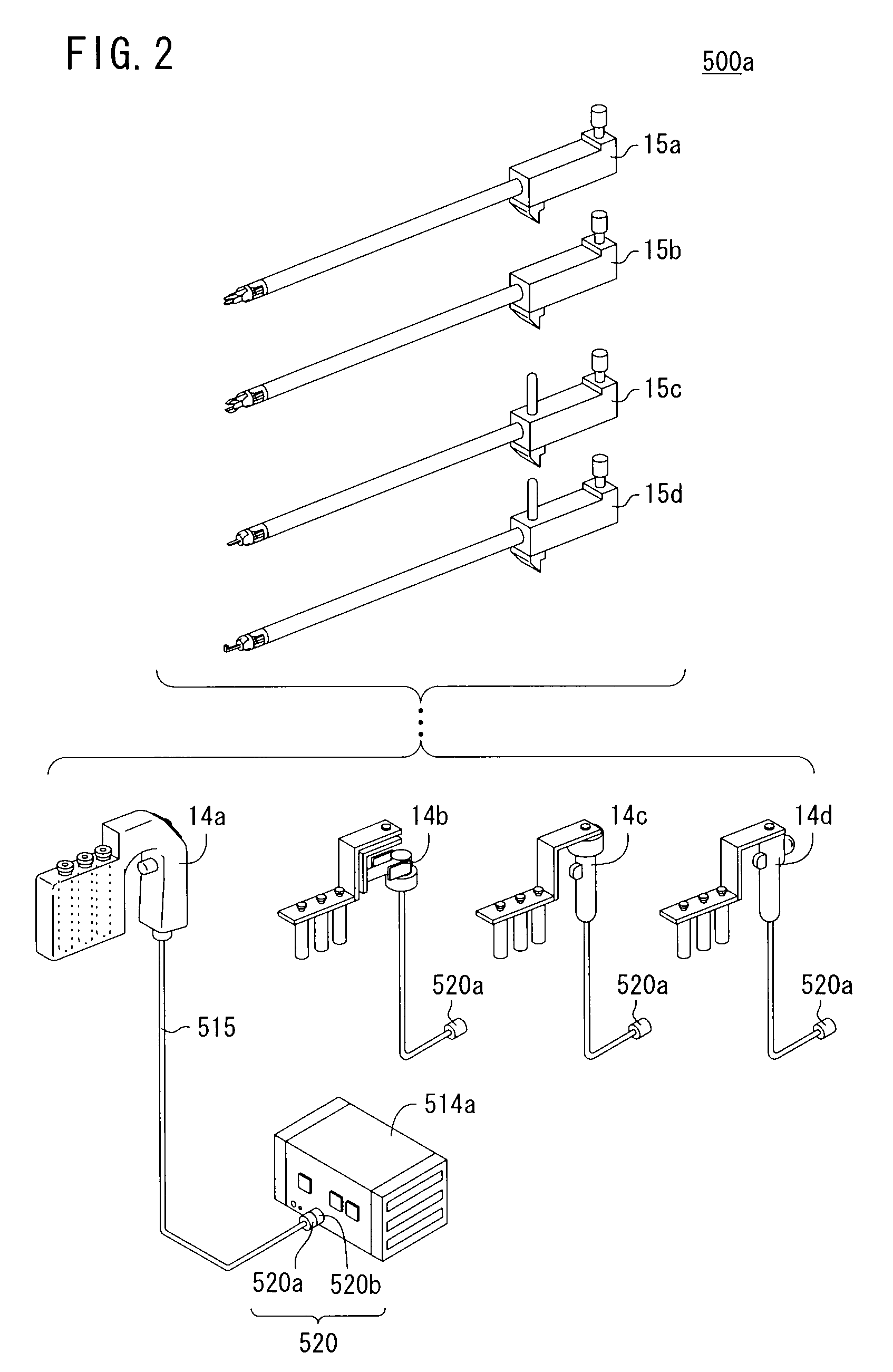

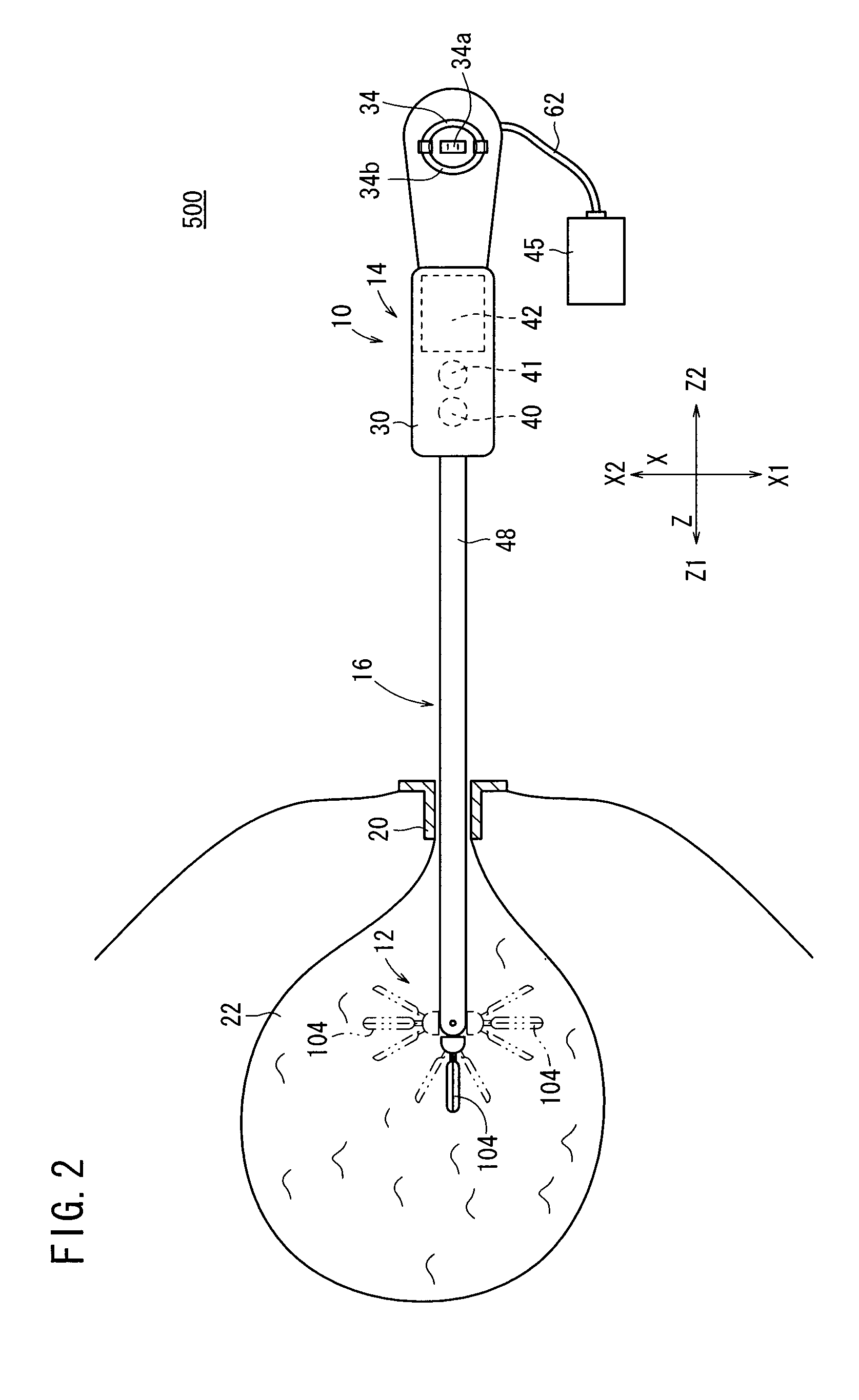

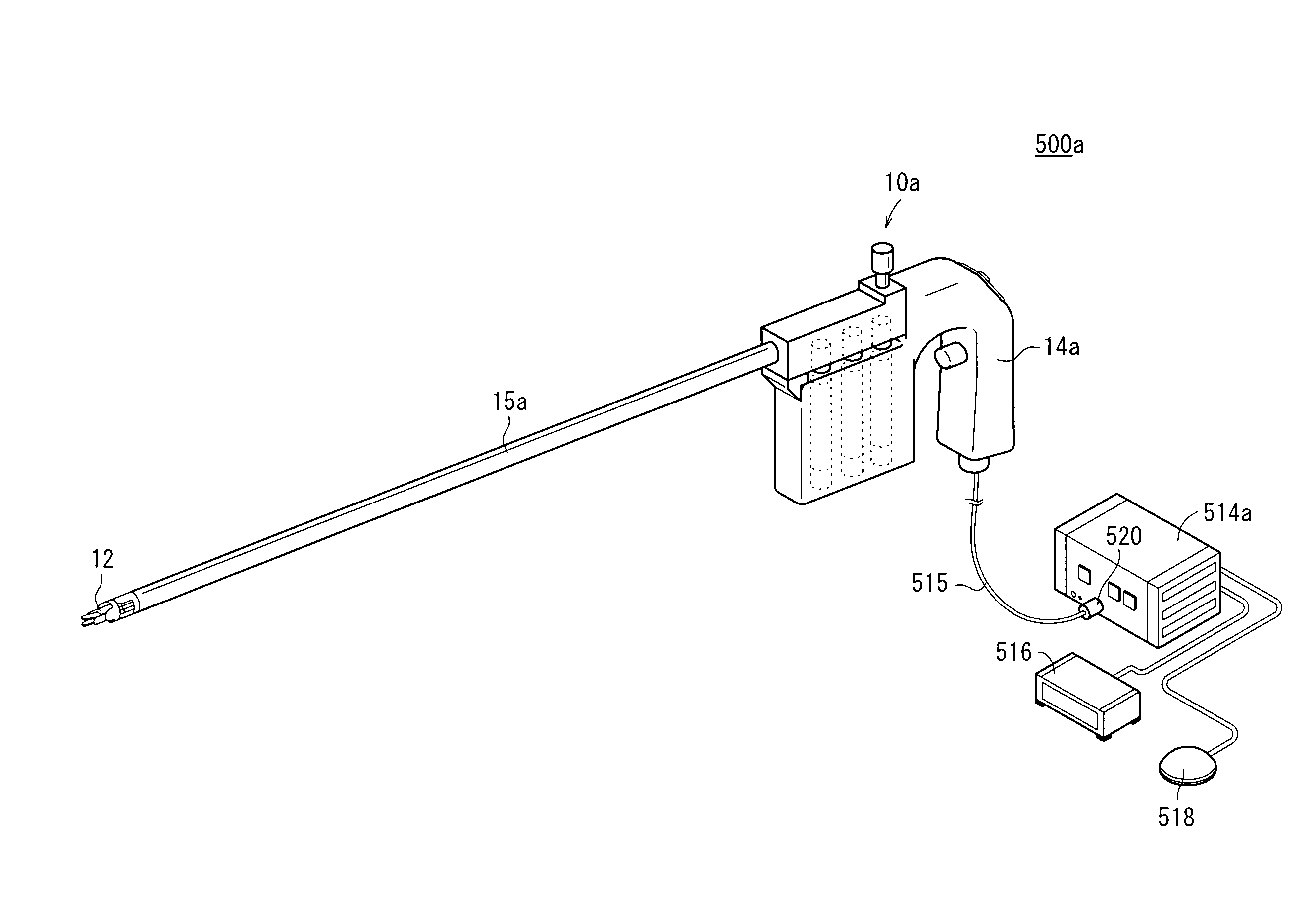

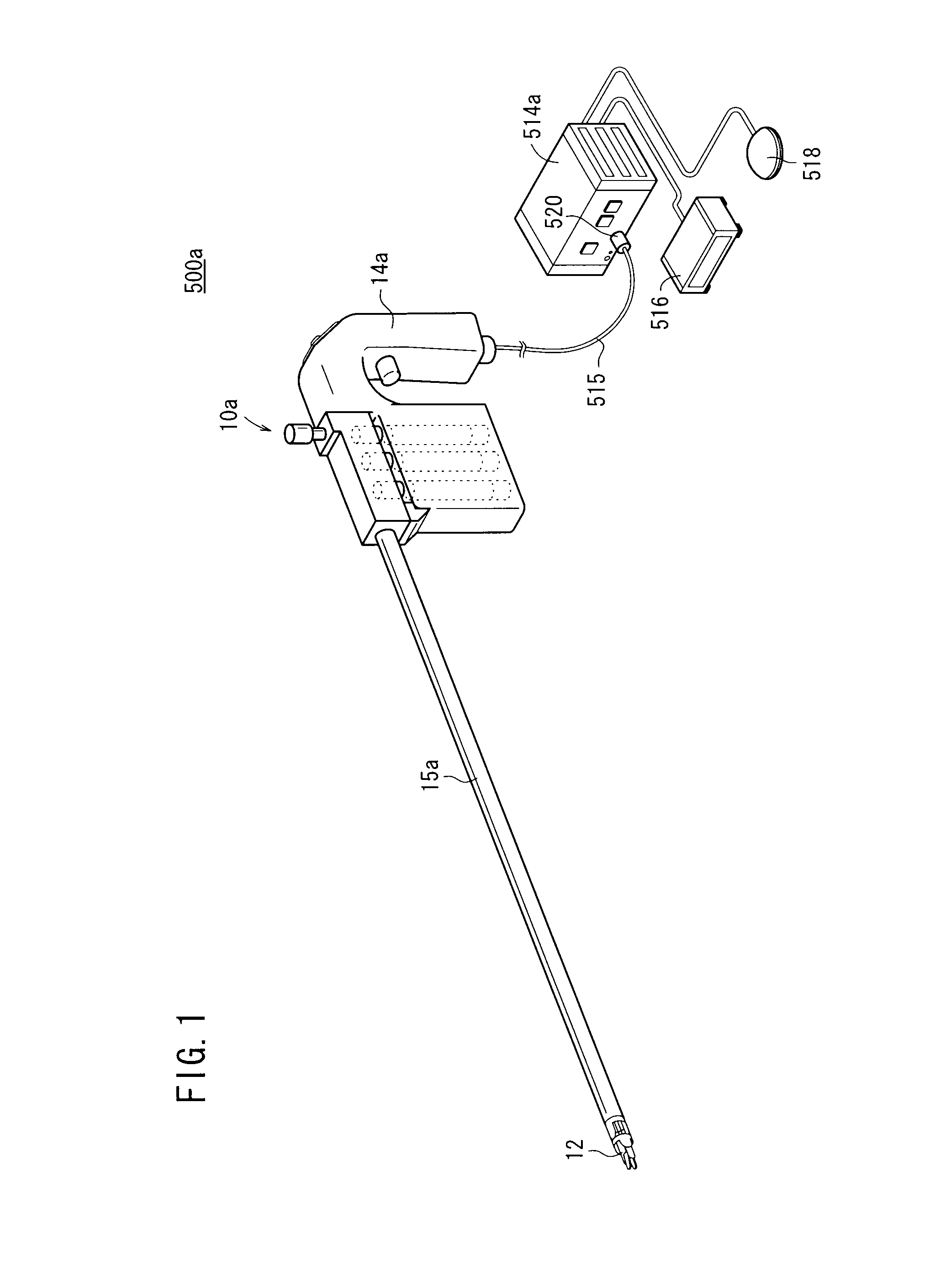

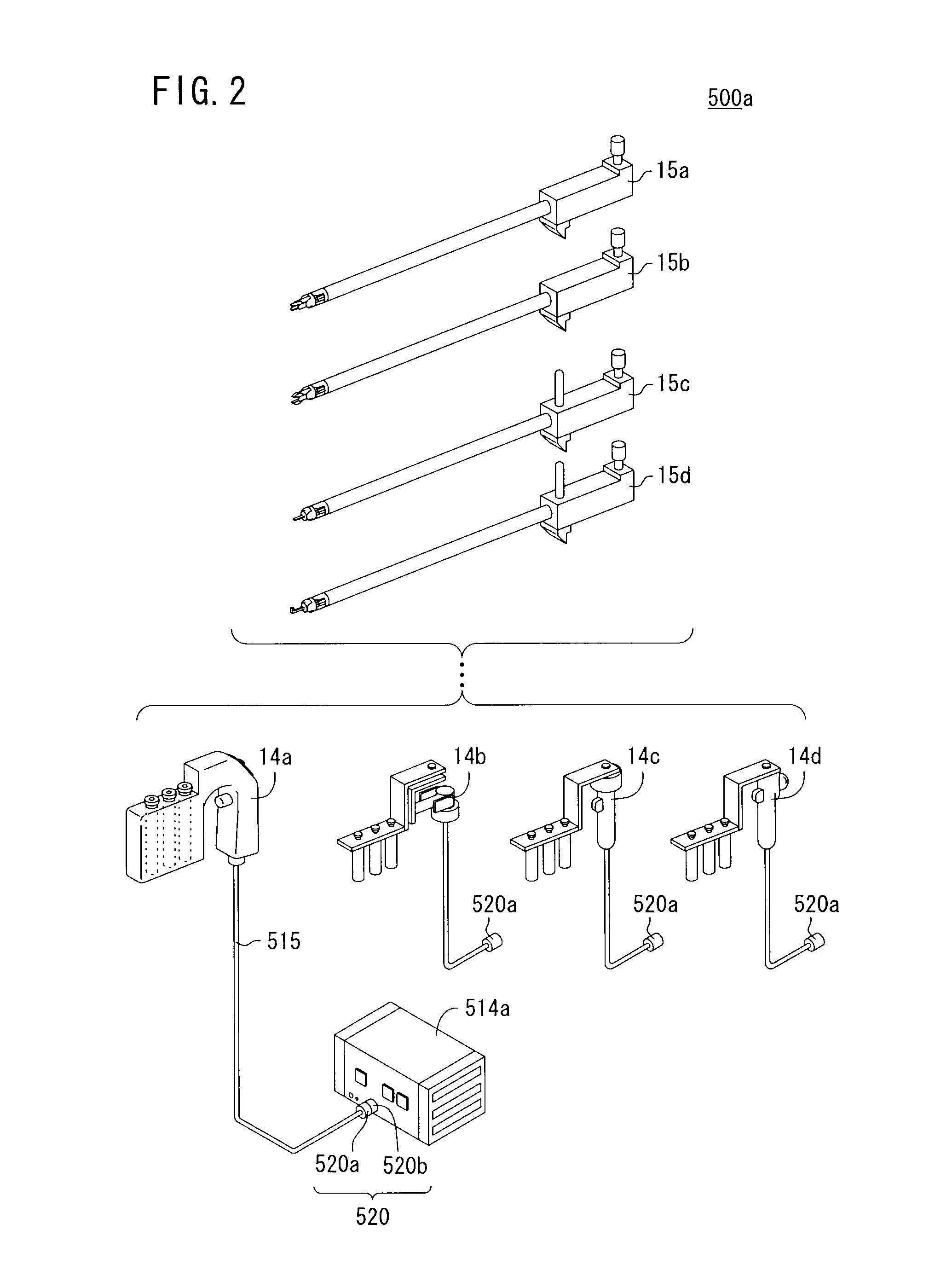

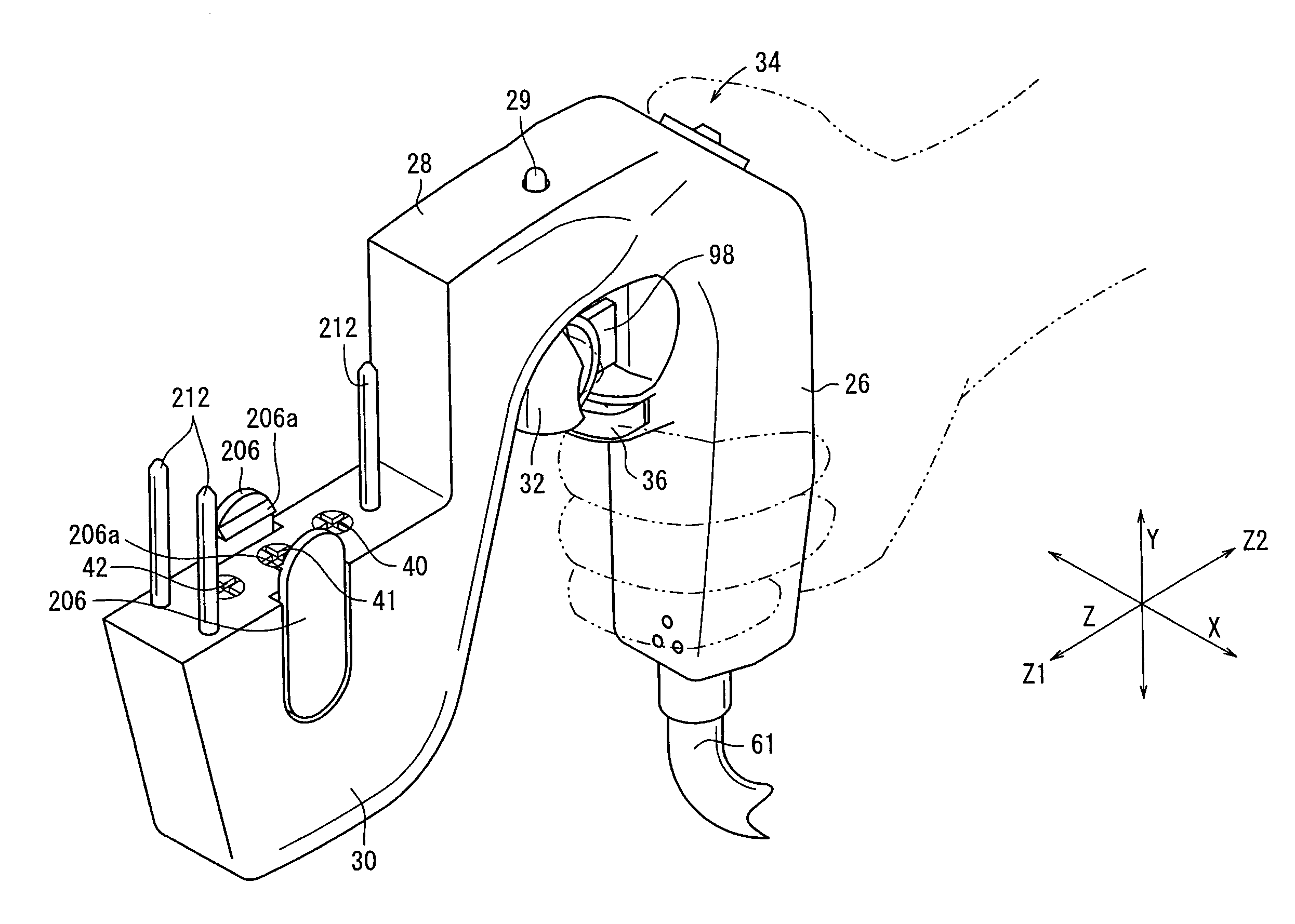

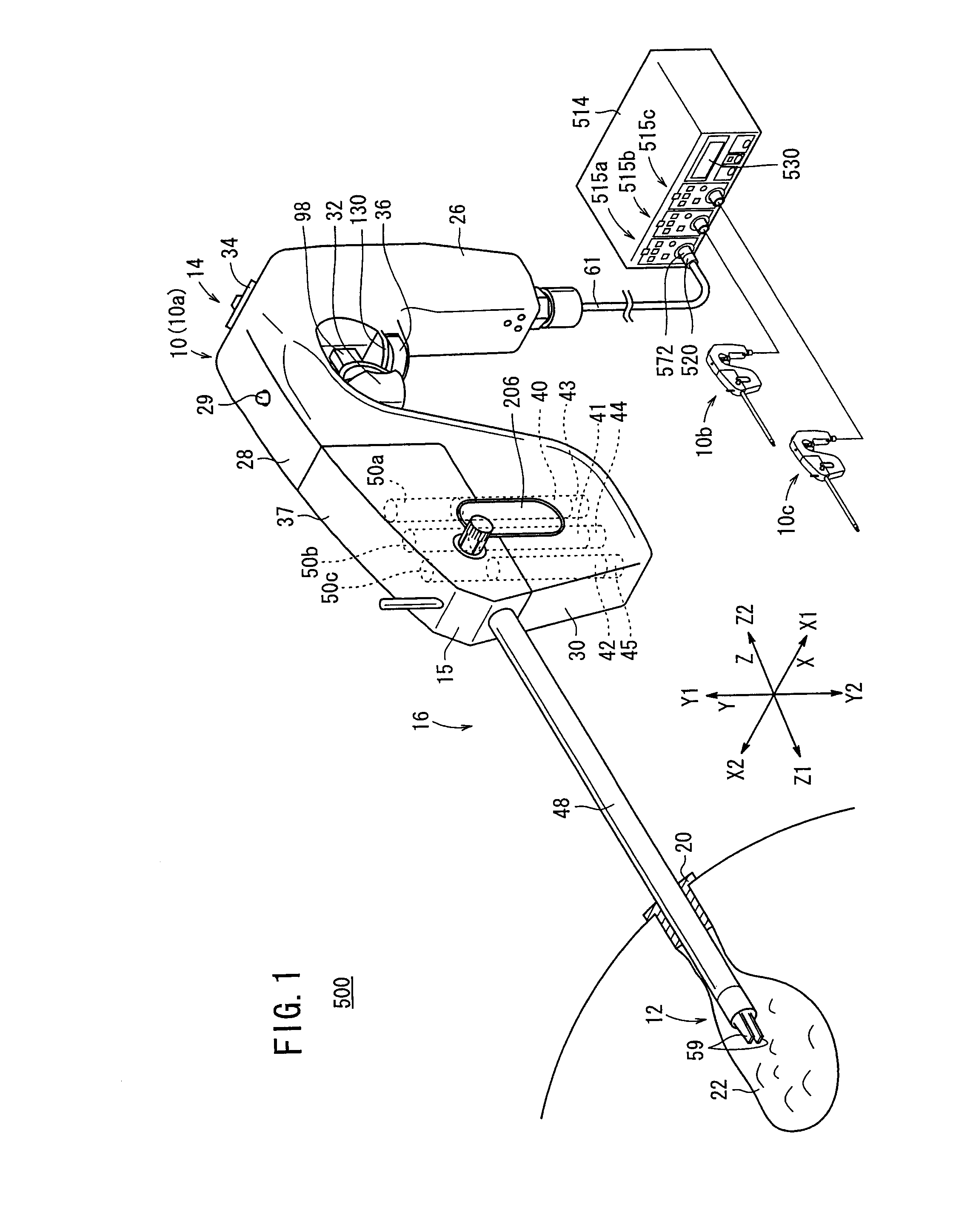

InactiveUS20080262654A1Improve the bactericidal effectEasy to washDiagnosticsSurgical manipulatorsWork unitActuator

A manipulator comprises an actuator block and a working unit attachable to and detachable from the actuator block. The actuator block has a motor, the working unit has a connecting shaft and an end working portion disposed at the distal end thereof, and the end working portion is rotated in conjunction with the motor. The working unit further has a two-dimensional code holding an identification signal, and the actuator block further has an infrared camera for recognizing the identification signal in the code and supplying it to a controller, is the camera being not in contact with the code. The controller controls the working unit based on the supplied identification signal.

Owner:TERUMO KK +1

Medical manipulator system

ActiveUS8409174B2Efficient executionEasy to confirmDiagnosticsSurgical manipulatorsWork unitOperation mode

Owner:KARL STORZ GMBH & CO KG

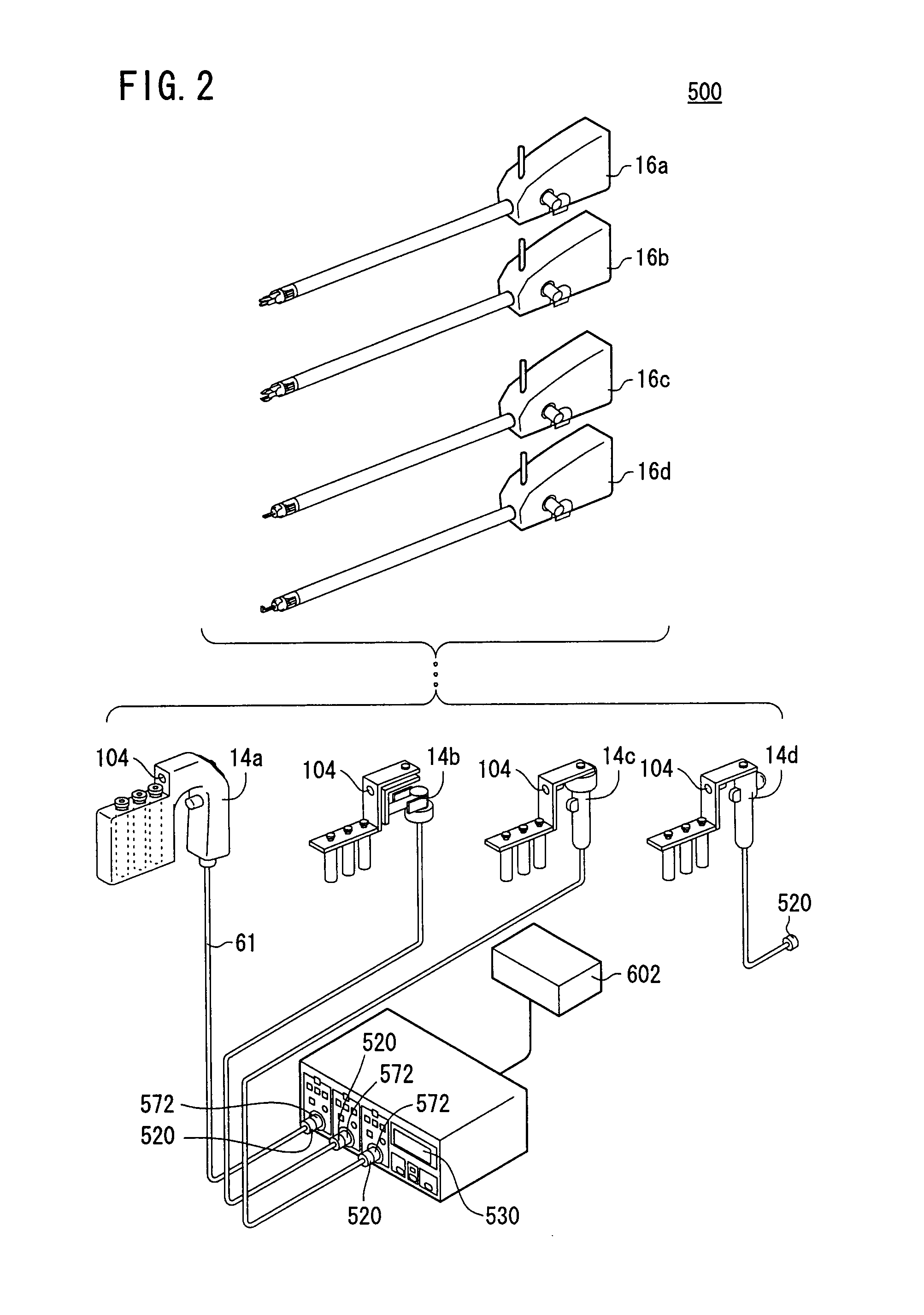

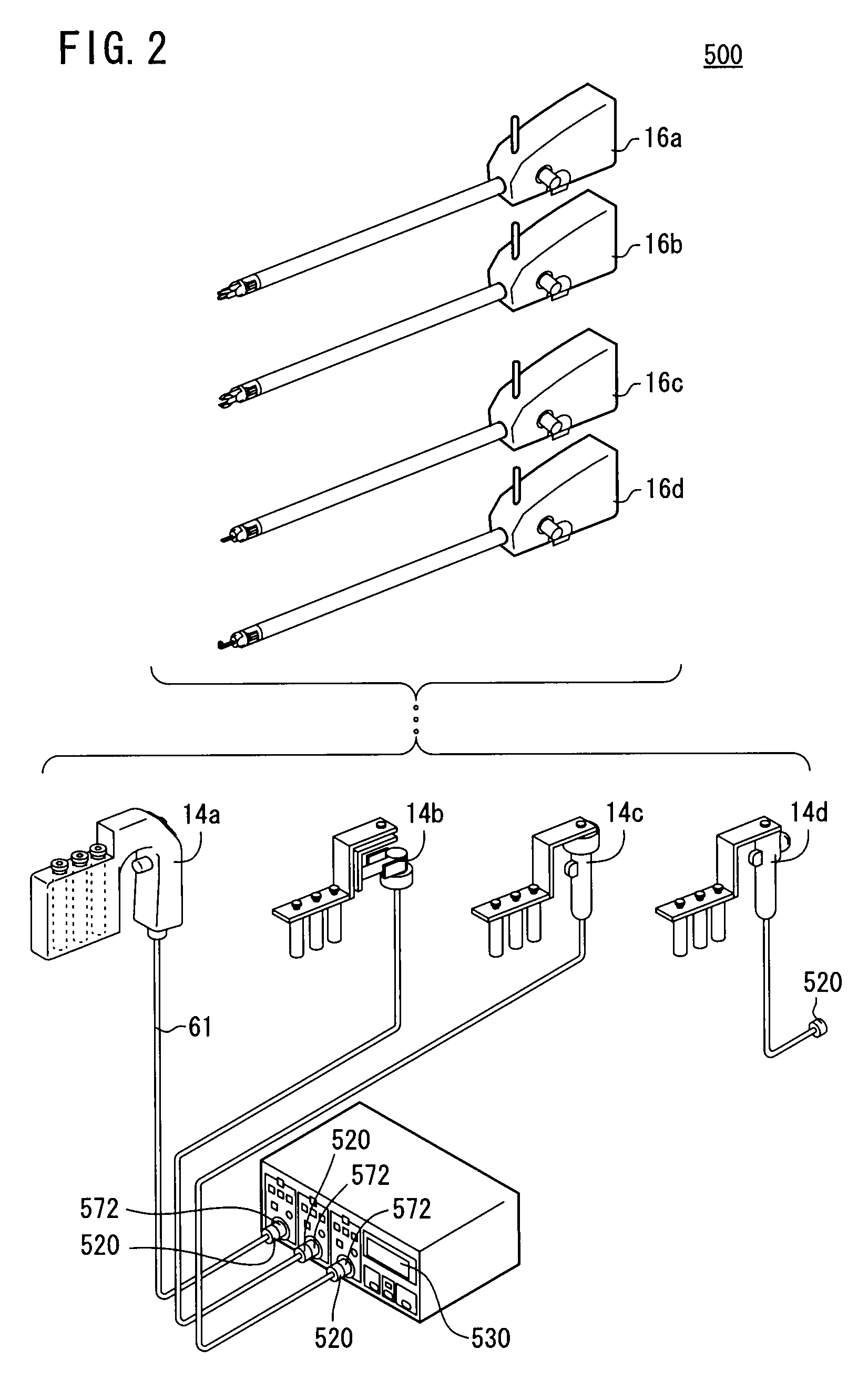

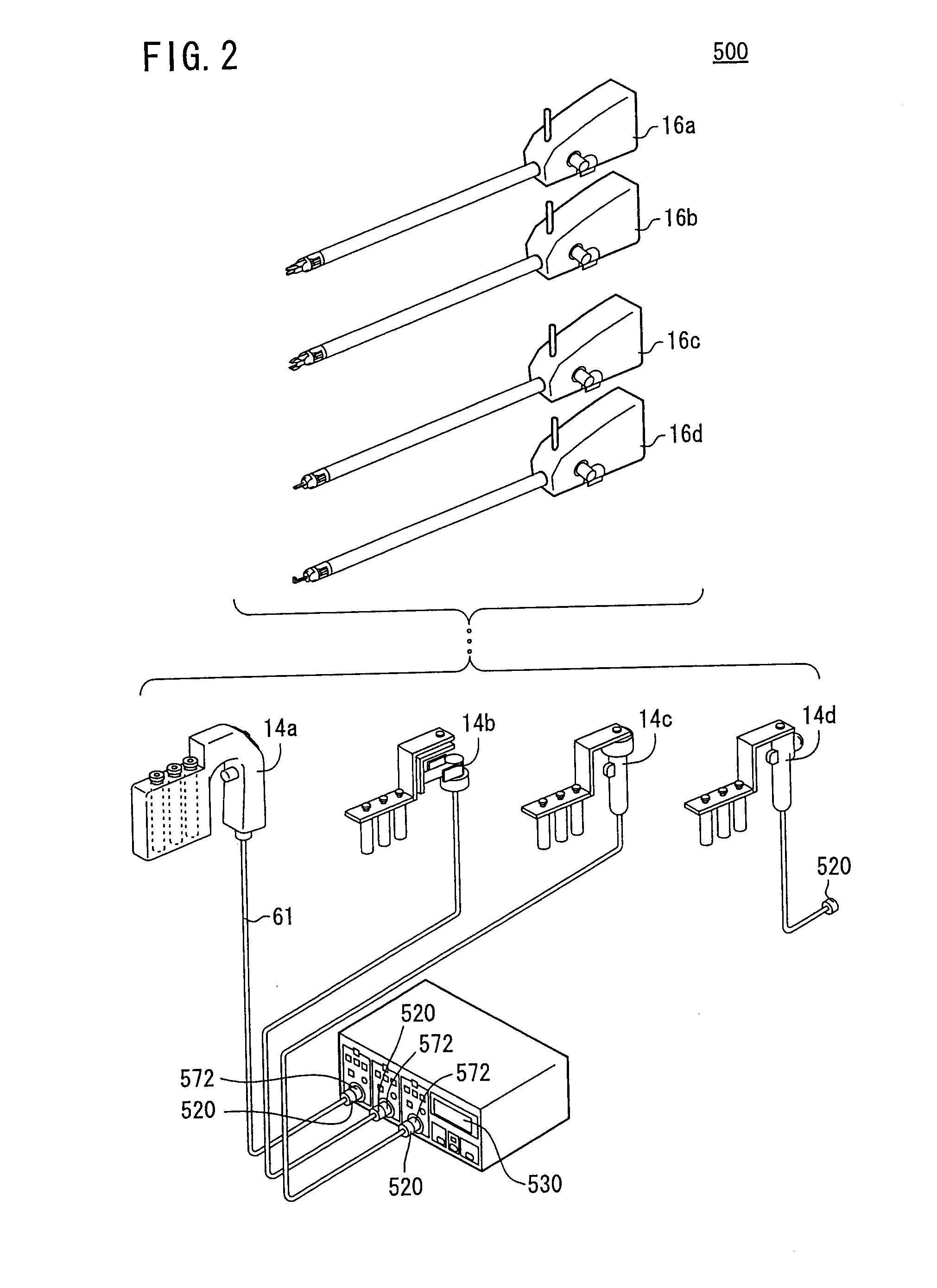

Manipulator system and control apparatus

A manipulator has an operation command unit and an exchangeable working unit. The working unit comprises an end effector operable under actions of a control apparatus, and an ID retaining section holding an ID for individualized discrimination of the working unit. The control apparatus includes an ID identification section for identifying the ID and for determining whether the working unit is connected to the operation command unit, an origin point recognition section for recognizing whether the end effector is in a prescribed origin point position or in a non-origin point position, and a warning section which generates a detachment warning when it is determined that the end effector has been detached from the operation command unit, in the event it is determined that the end effector is in a non-origin point position.

Owner:KARL STORZ GMBH & CO KG

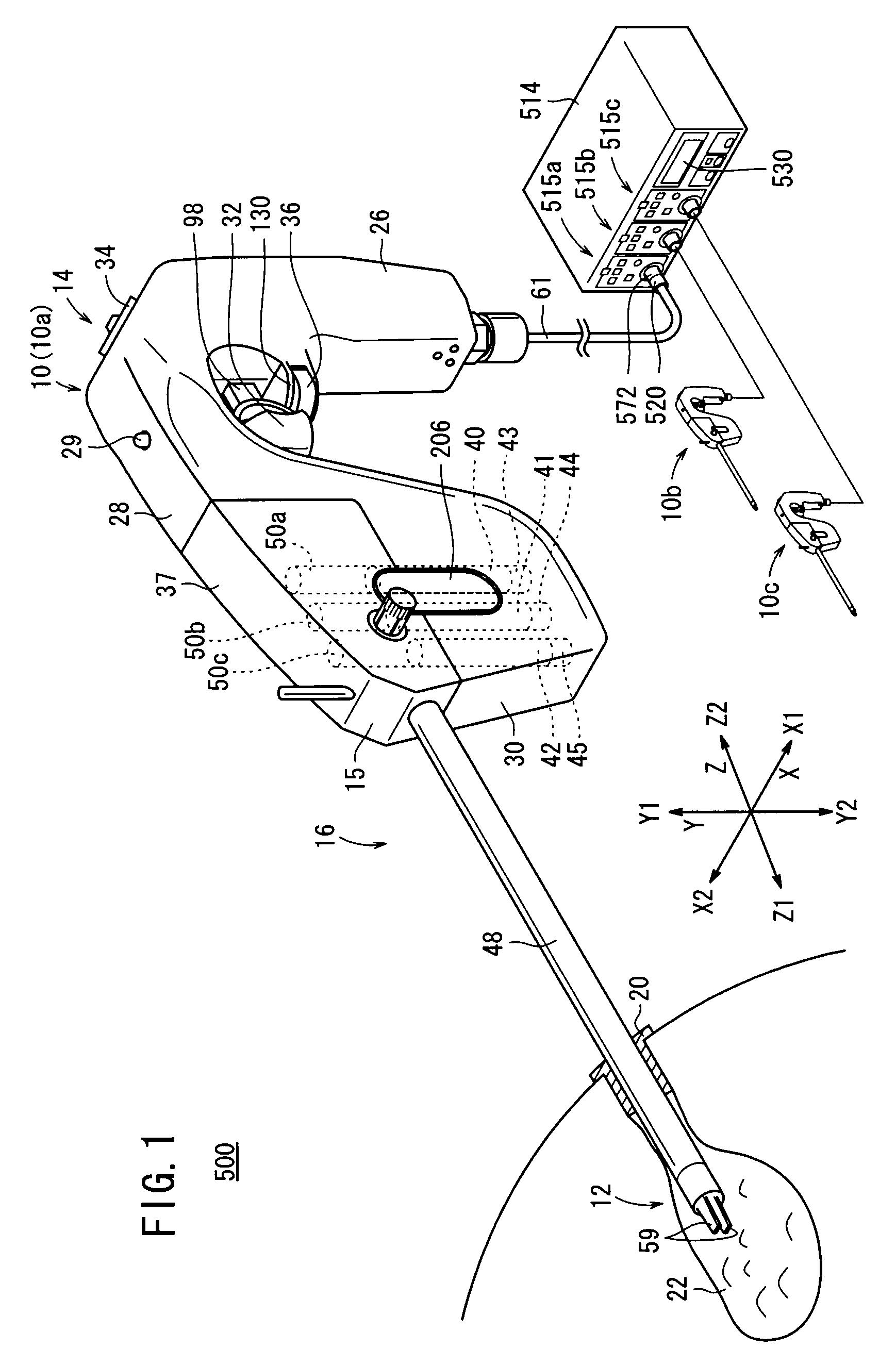

Medical manipulator system

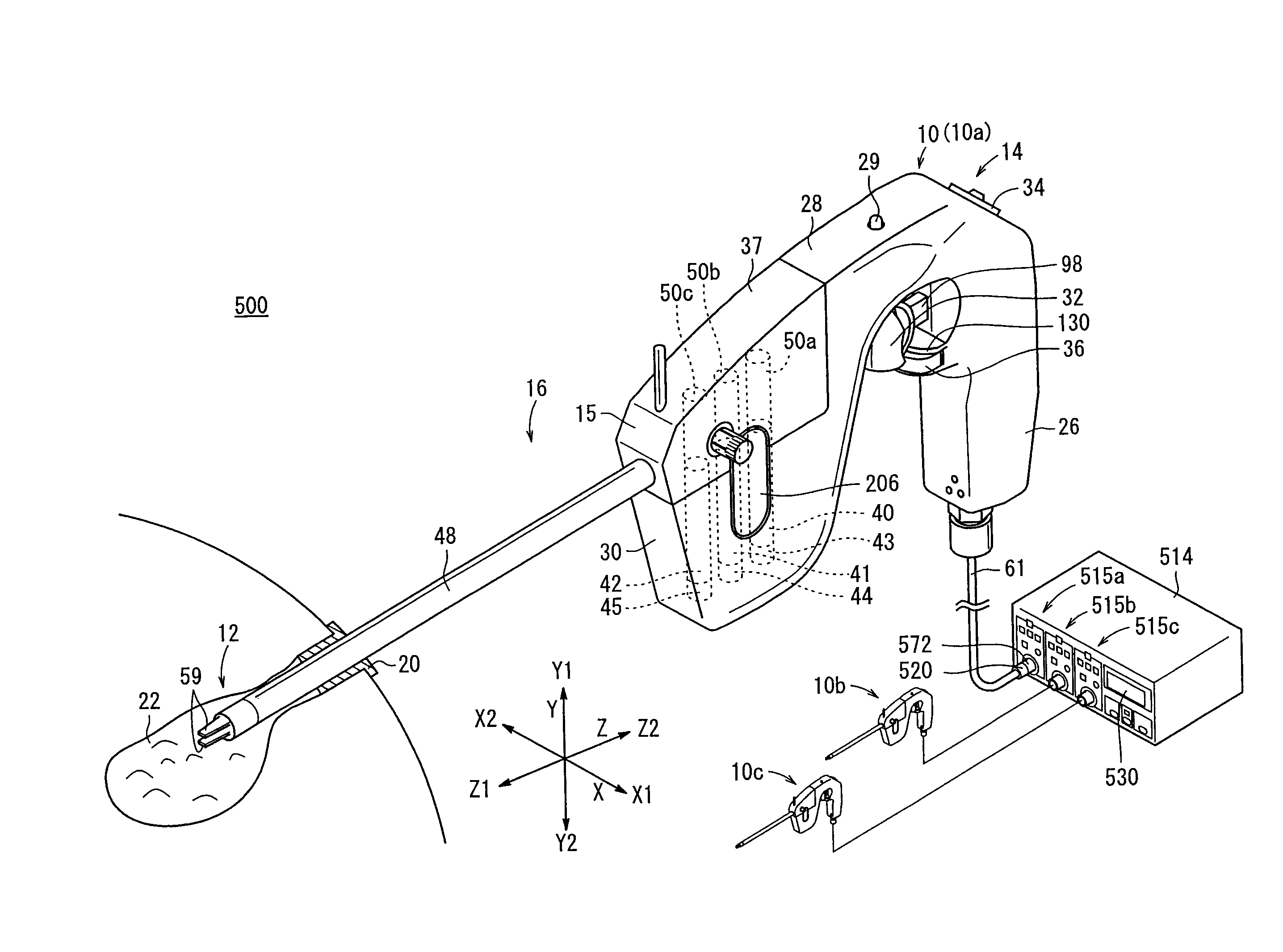

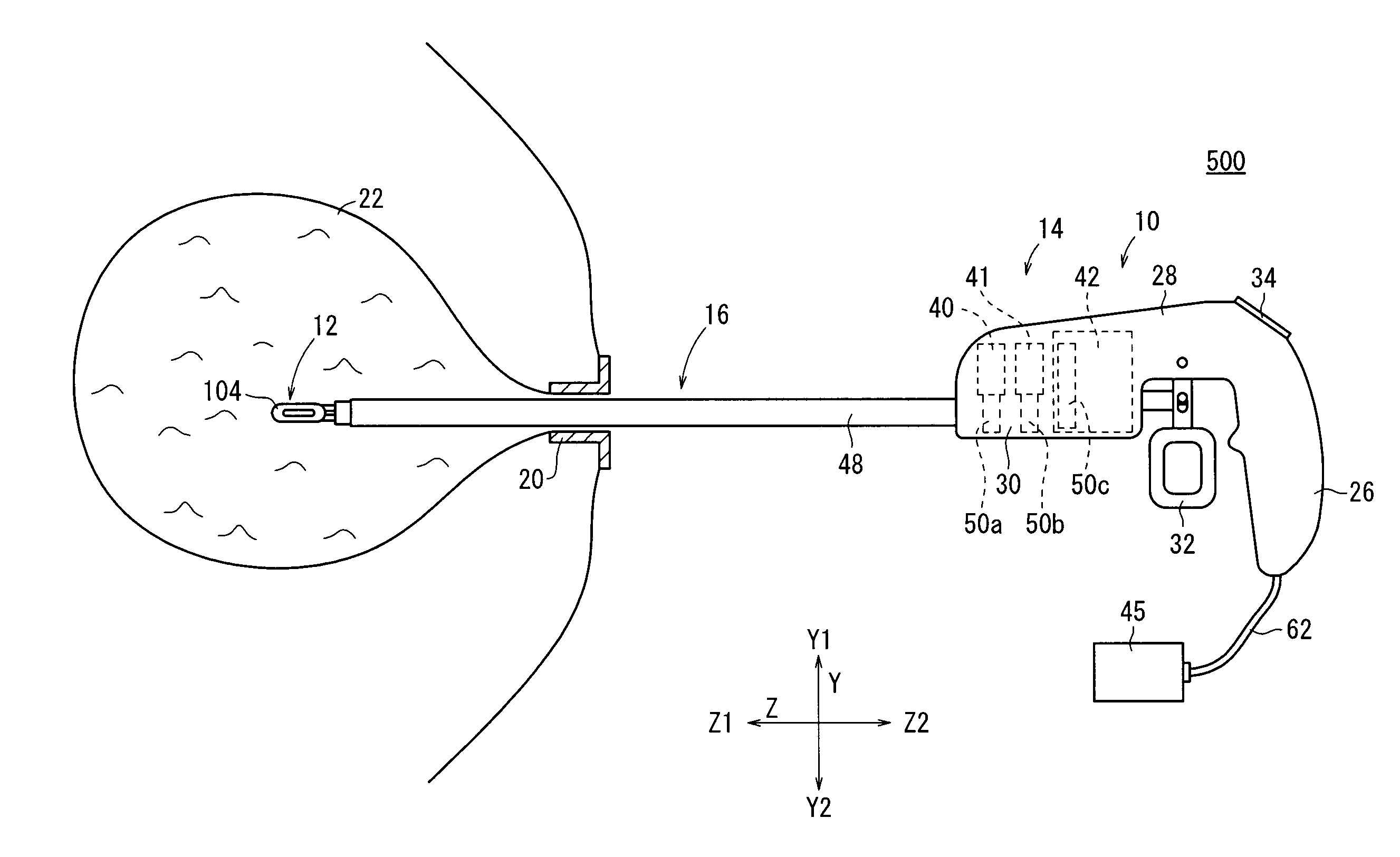

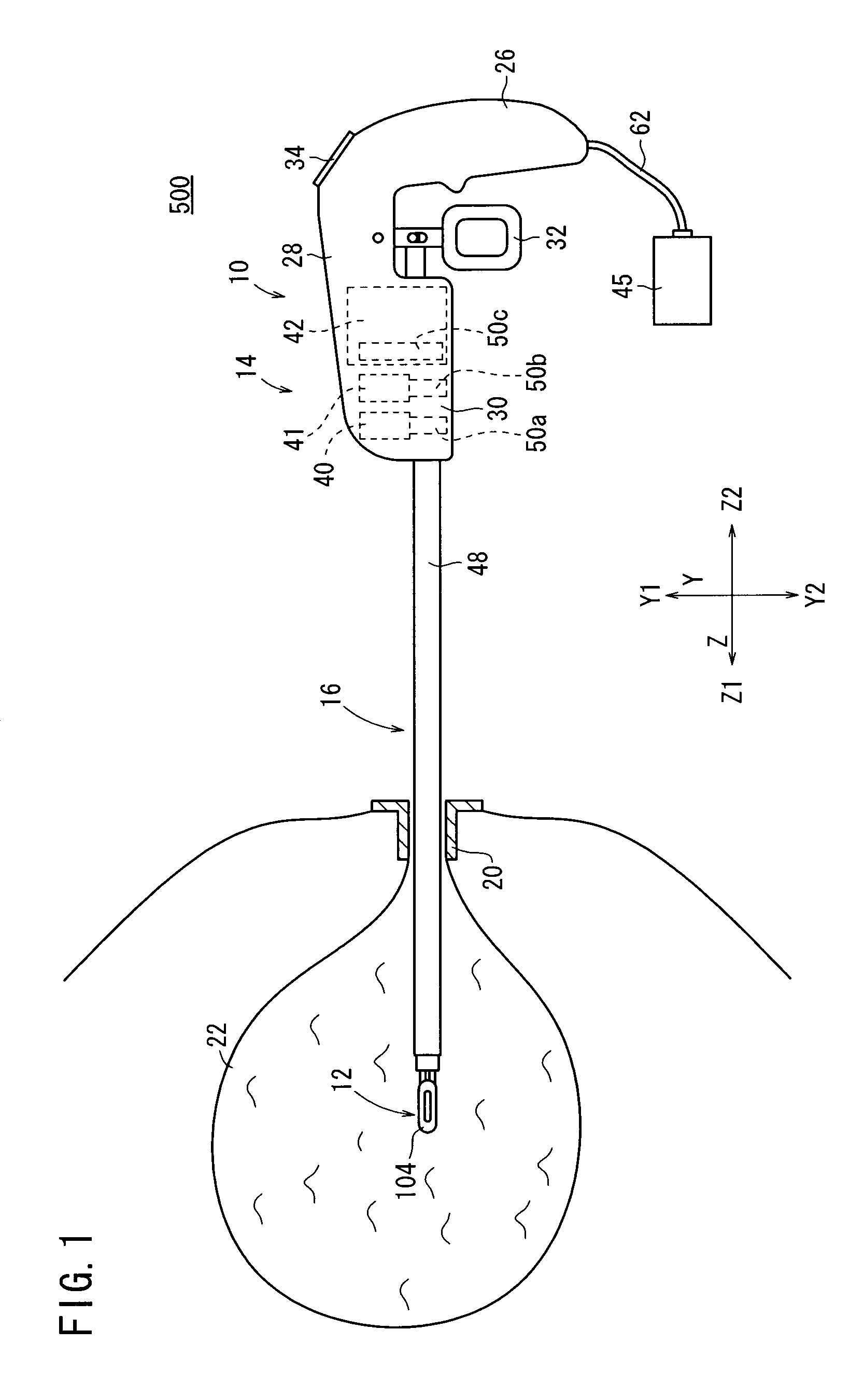

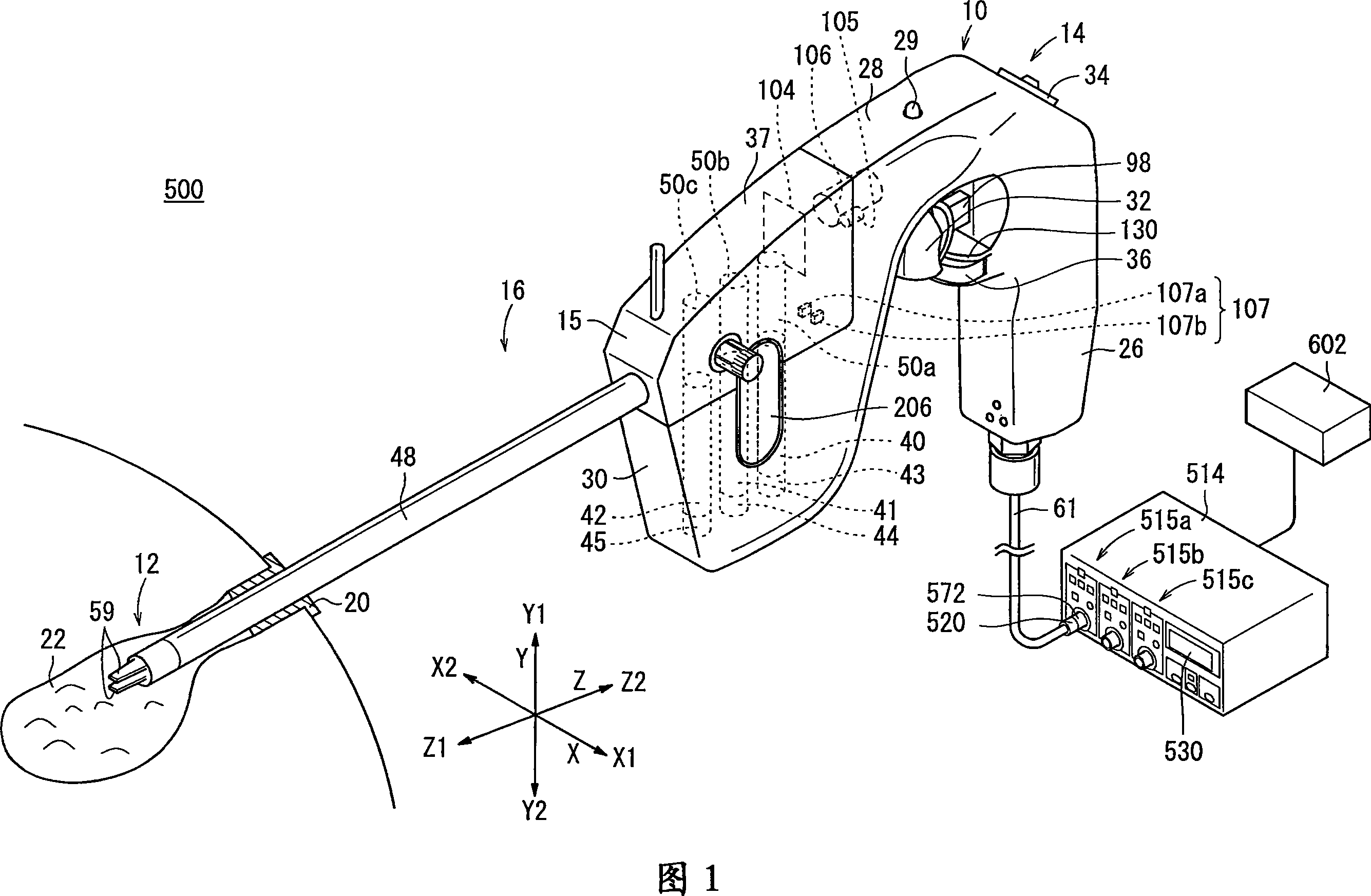

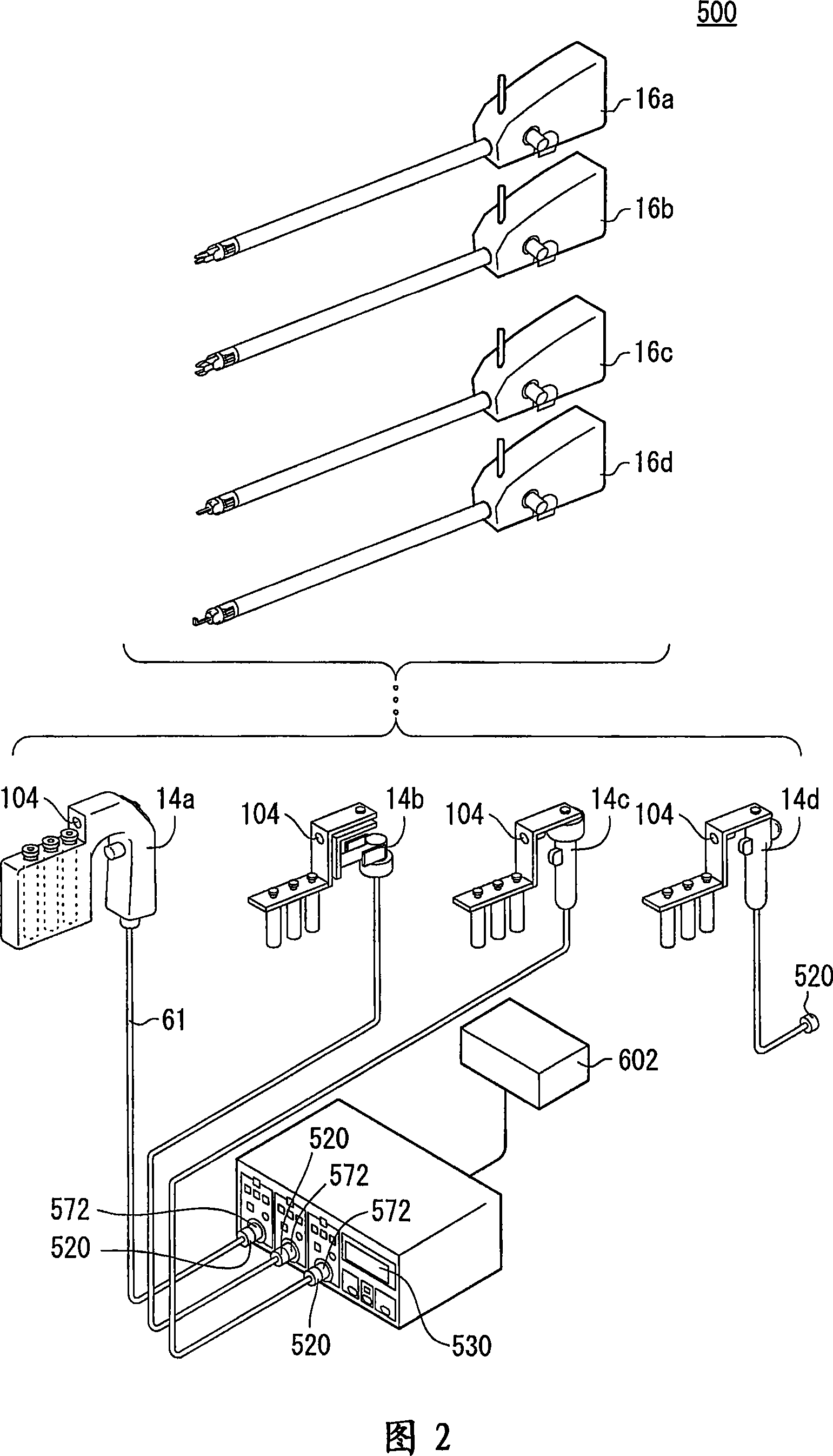

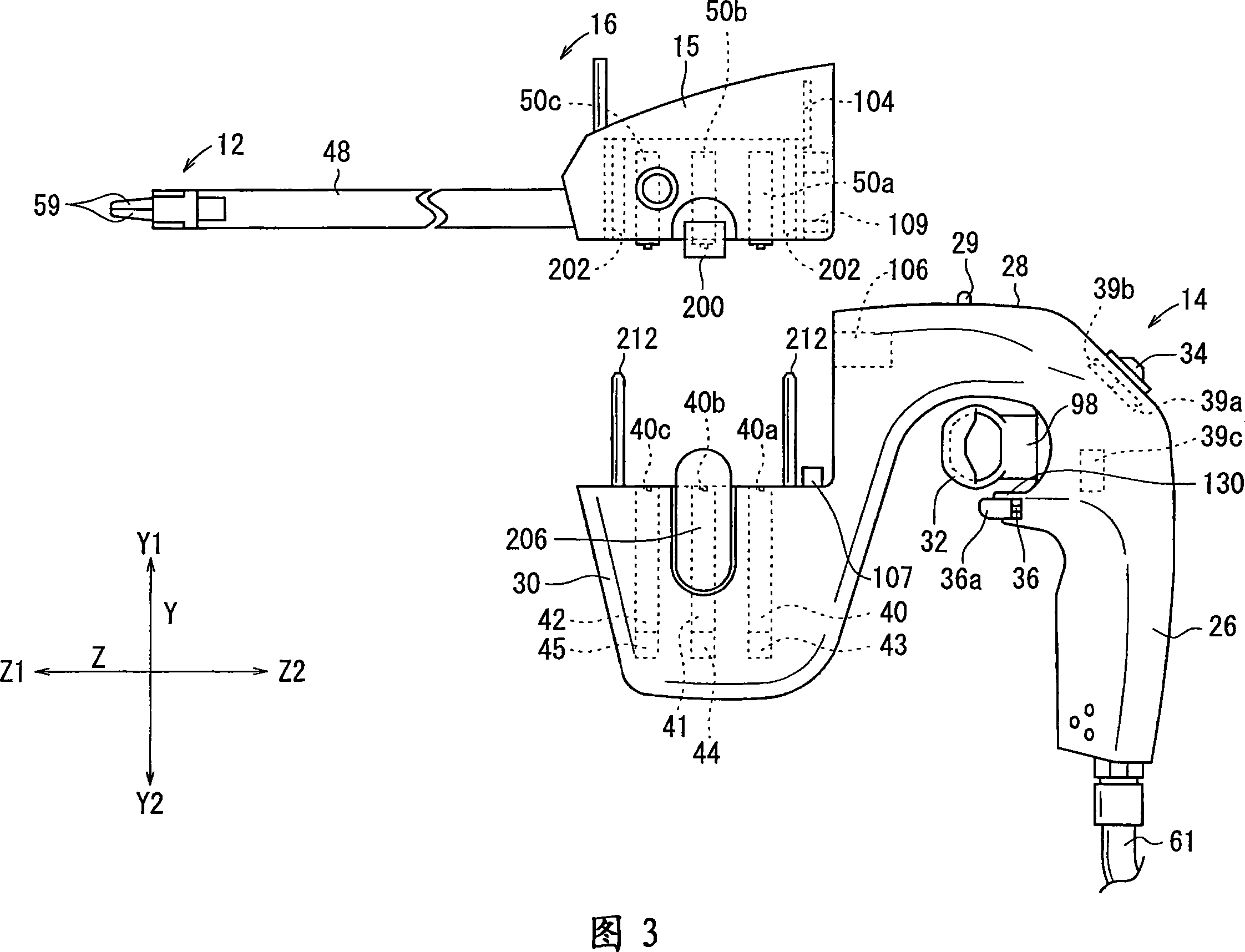

ActiveUS8246608B2Easy to controlSuture equipmentsInternal osteosythesisWork unitBiological activation

A medical manipulator system includes a manipulator, an operating unit for entering operation commands, motors for actuating a working unit, and a controller for energizing the motors based on operation commands supplied from the operating unit. When an activation resetting switch and a resetting switch are operated according to a predetermined procedure, the controller performs a resetting process to return the motors to an origin. The controller is capable of controlling three manipulators. The activation resetting switch is shared by the three manipulators, and there are three resetting switches corresponding to the three manipulators.

Owner:KARL STORZ GMBH & CO KG

Medical manipulator system

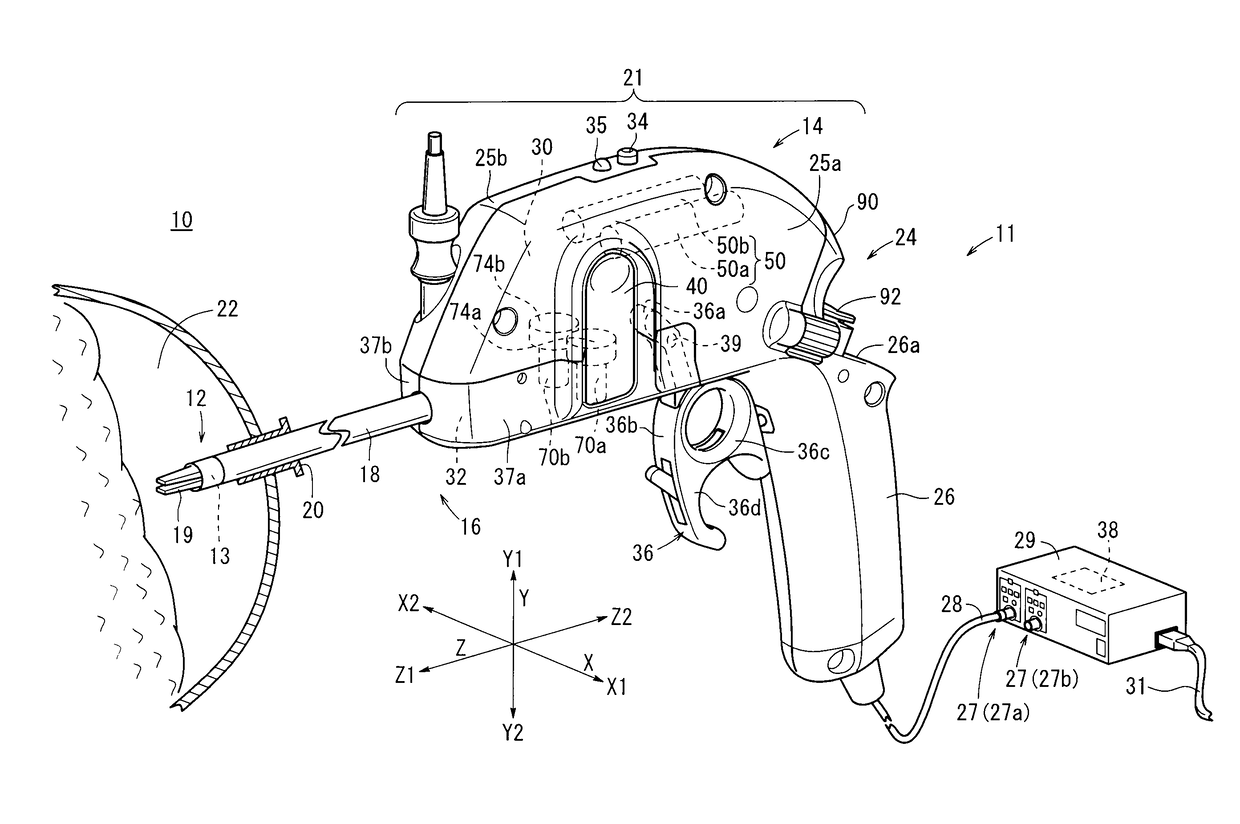

ActiveUS9730717B2Suffers from problemGuaranteed uptimeDiagnosticsSurgical manipulatorsOperating pointWork unit

A medical manipulator system has an operating unit including a grip handle and a composite input unit, a working unit detachably mounted on the operating unit and including an end effector, and a controller for controlling the operating unit. The controller judges starting and ending of a surgical case and increments the usage count of the working unit based on a manner in which the working unit is mounted and dismounted, and the times at which the working unit is mounted and dismounted, and disables the working unit if the usage count of the working unit exceeds a preset count.

Owner:KARL STORZ GMBH & CO KG

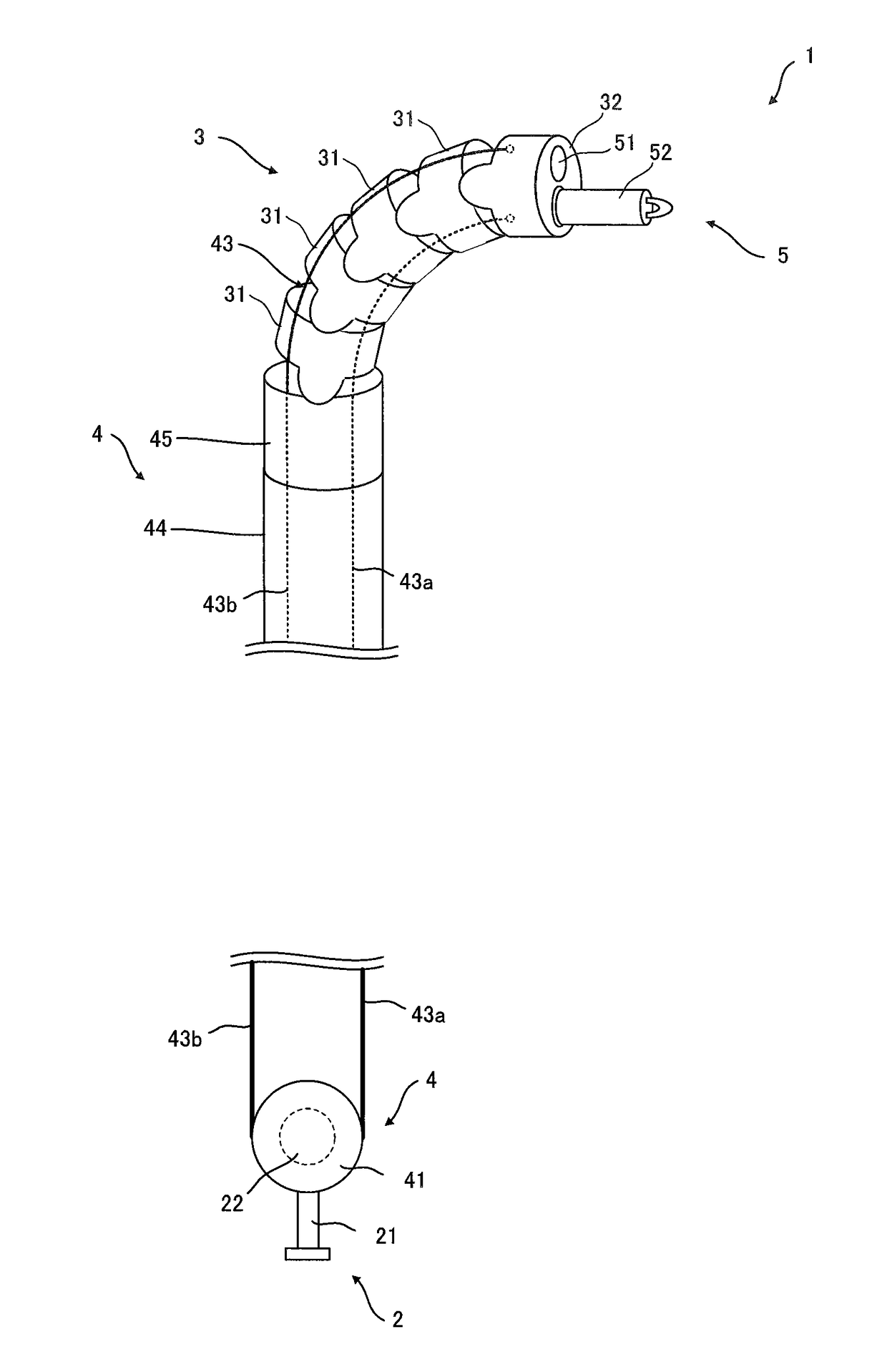

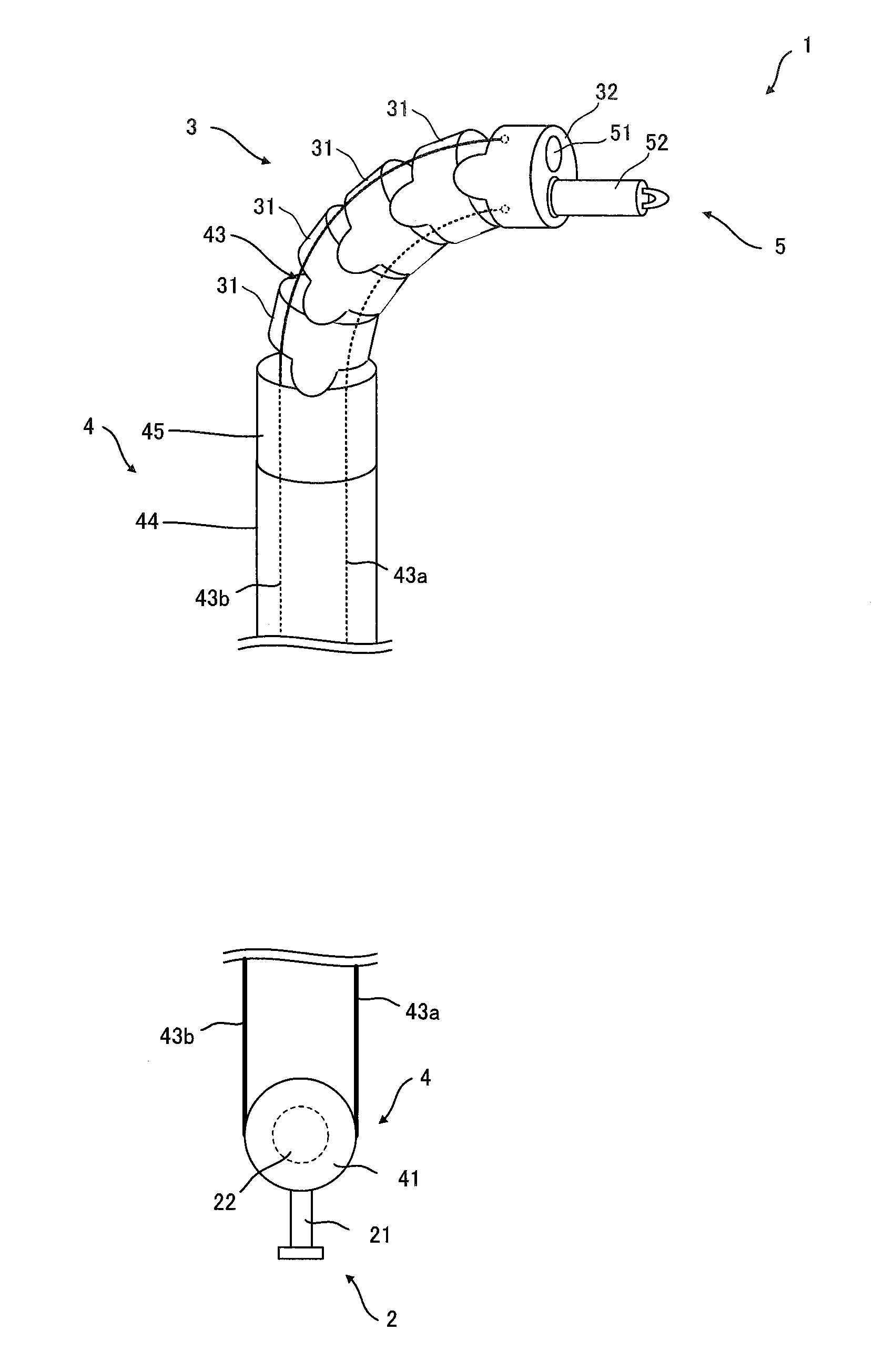

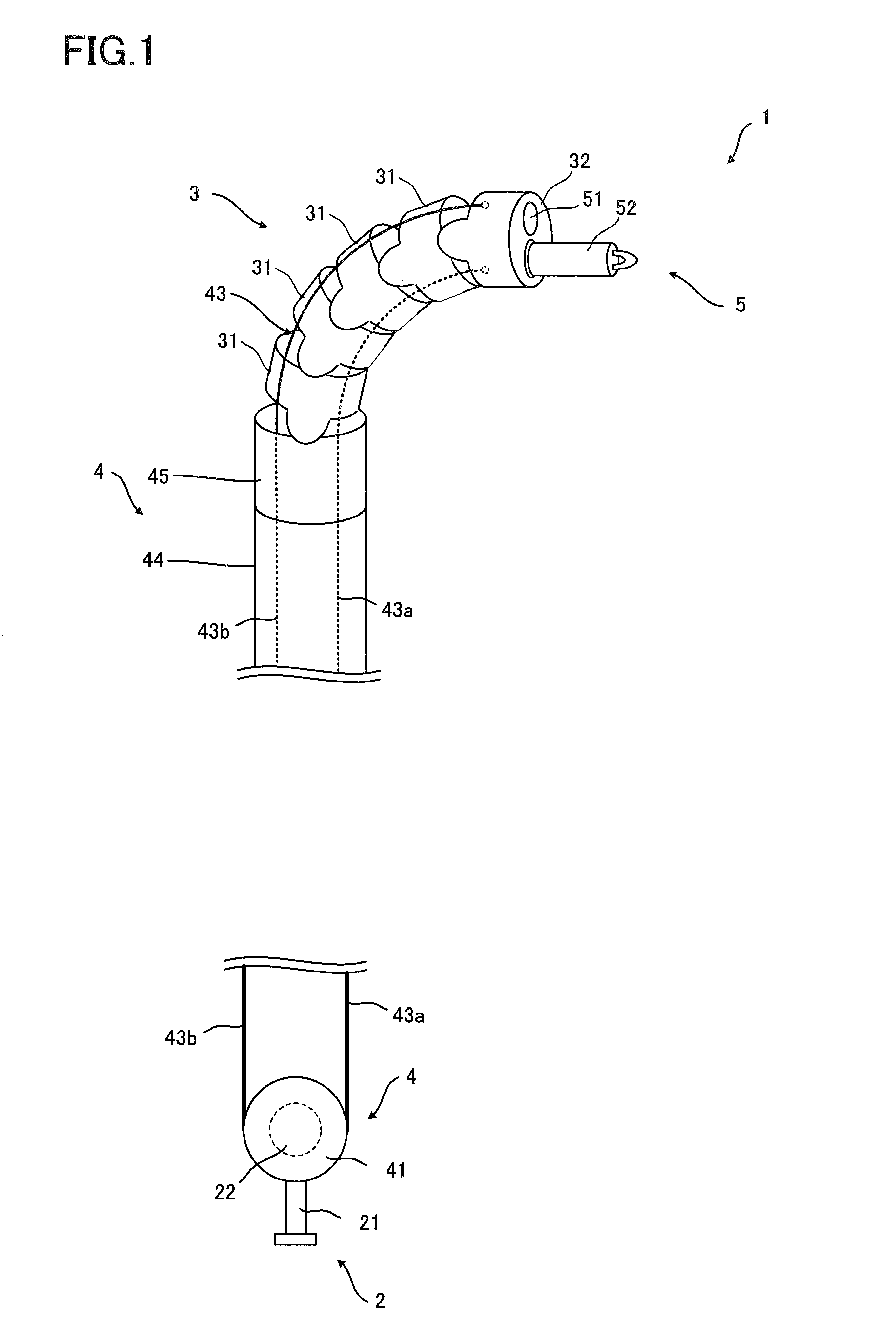

Manipulator and manipulator system

ActiveUS10085624B2Programme controlProgramme-controlled manipulatorManipulator systemWaste management

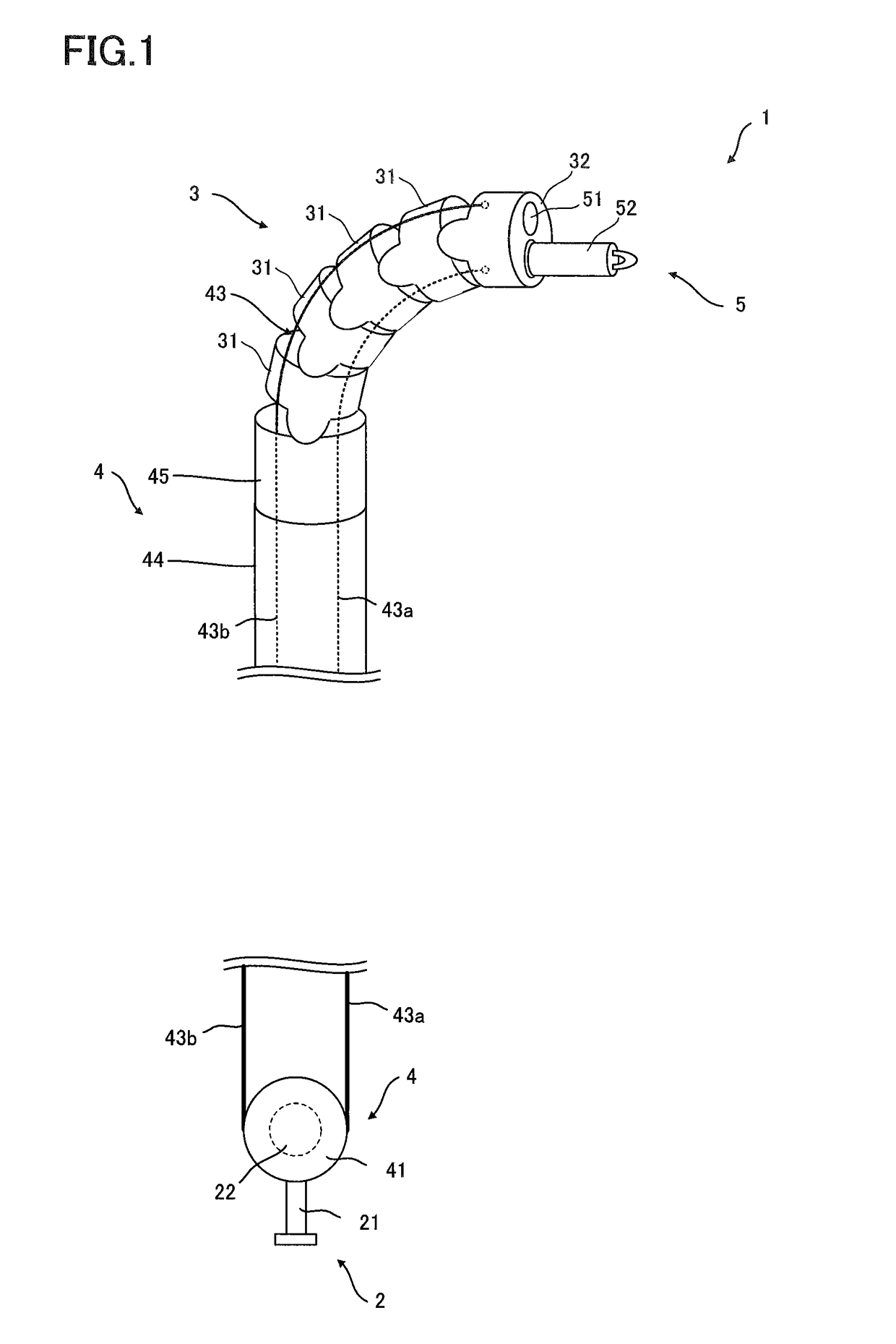

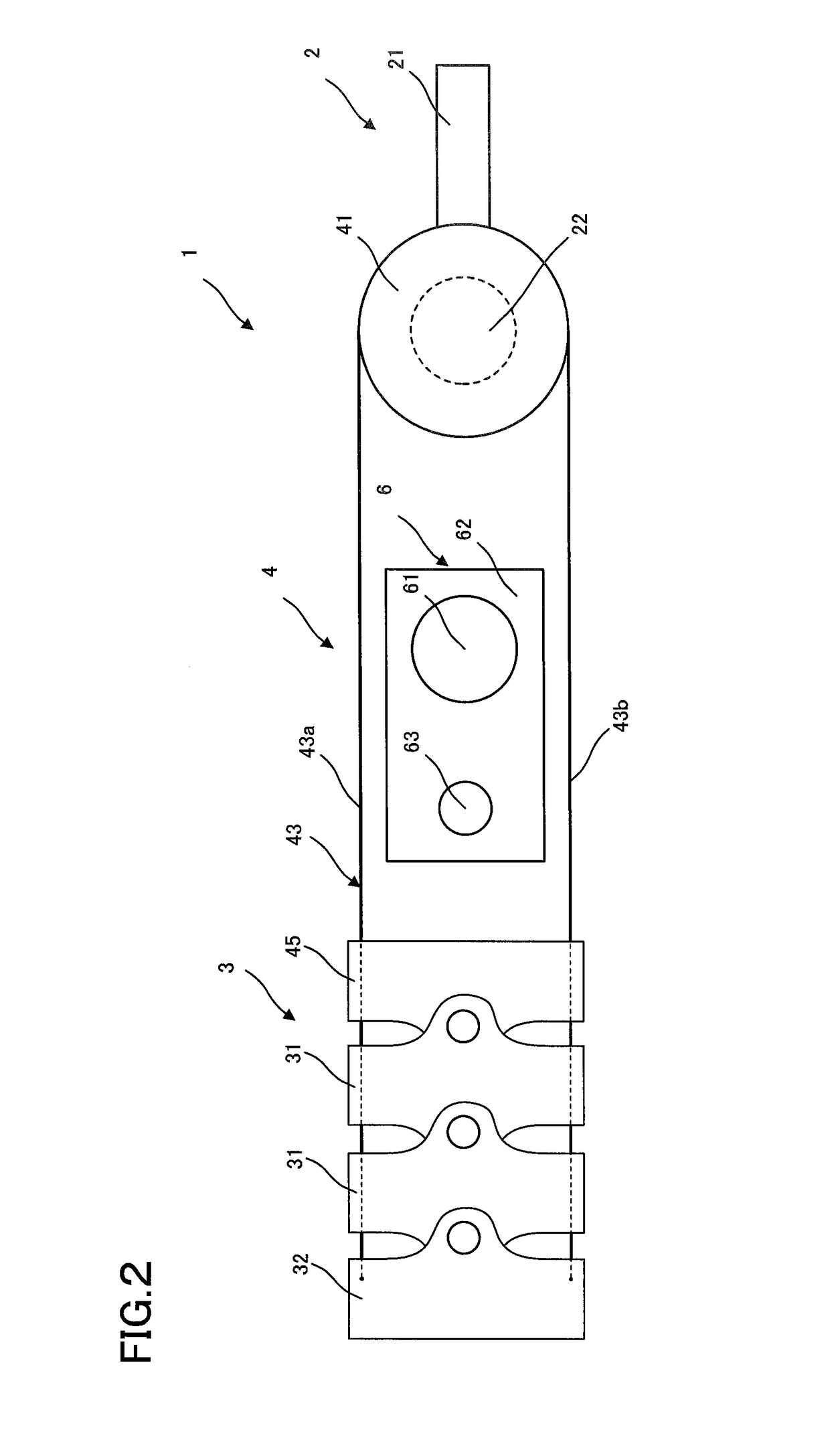

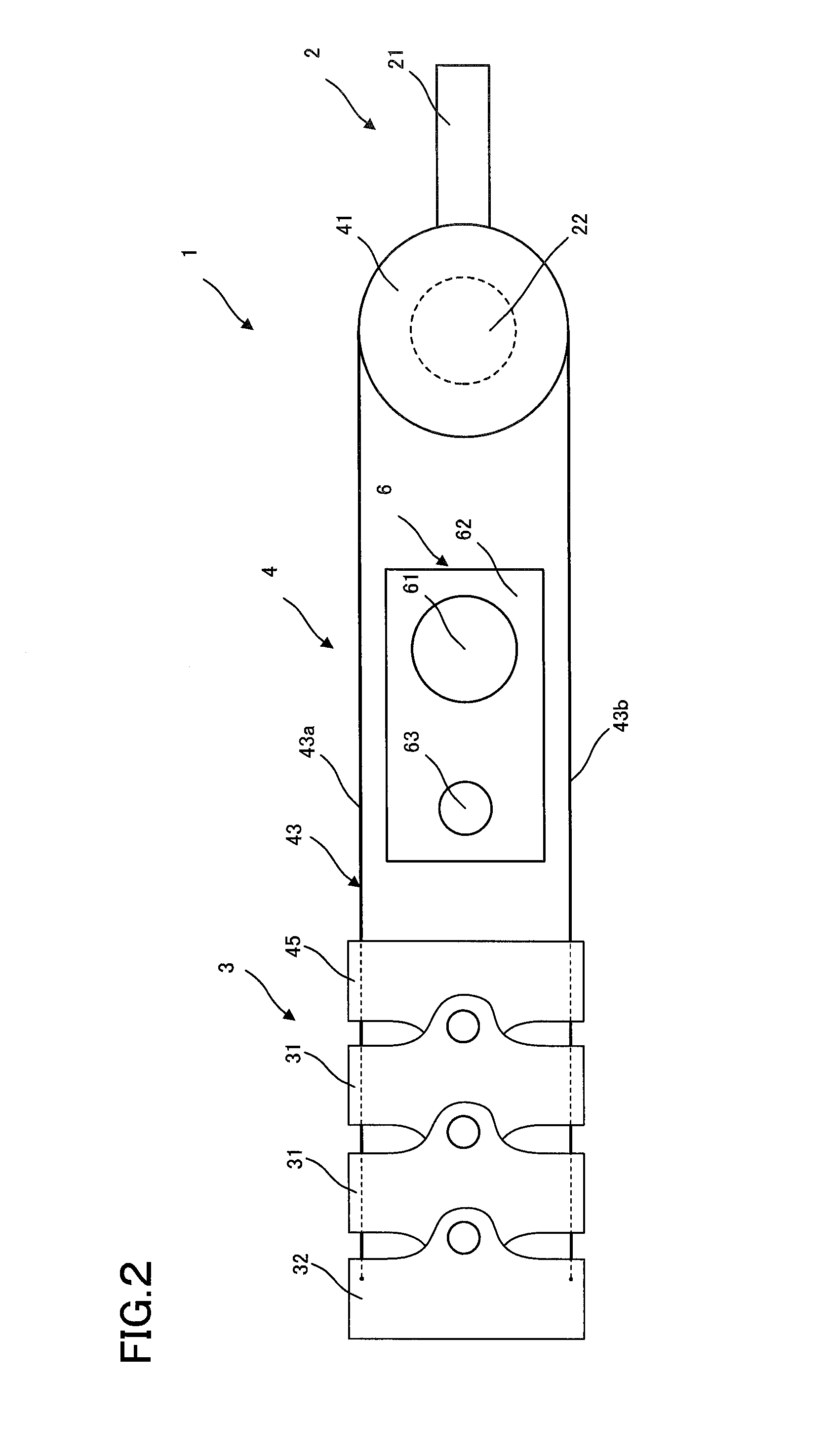

The invention has for its object to provide a manipulator and manipulator system in which a dynamic surplus is rapidly removed and a moving assembly actuates rapidly in association with the operation of an operating assembly.The manipulator 1 includes an operating assembly 2 operated by an operator, a moving assembly 3 operated by the operating assembly 2, a transmitting assembly 4 for coupling the operating assembly 2 to the moving assembly 3 to transmit driving force of the operating assembly 2 to the moving assembly 3, and a transmission compensating assembly 6 for making up for a dynamic surplus occurring in the transmitting assembly 4 in association with the operation of the operating assembly 2.

Owner:OLYMPUS CORP

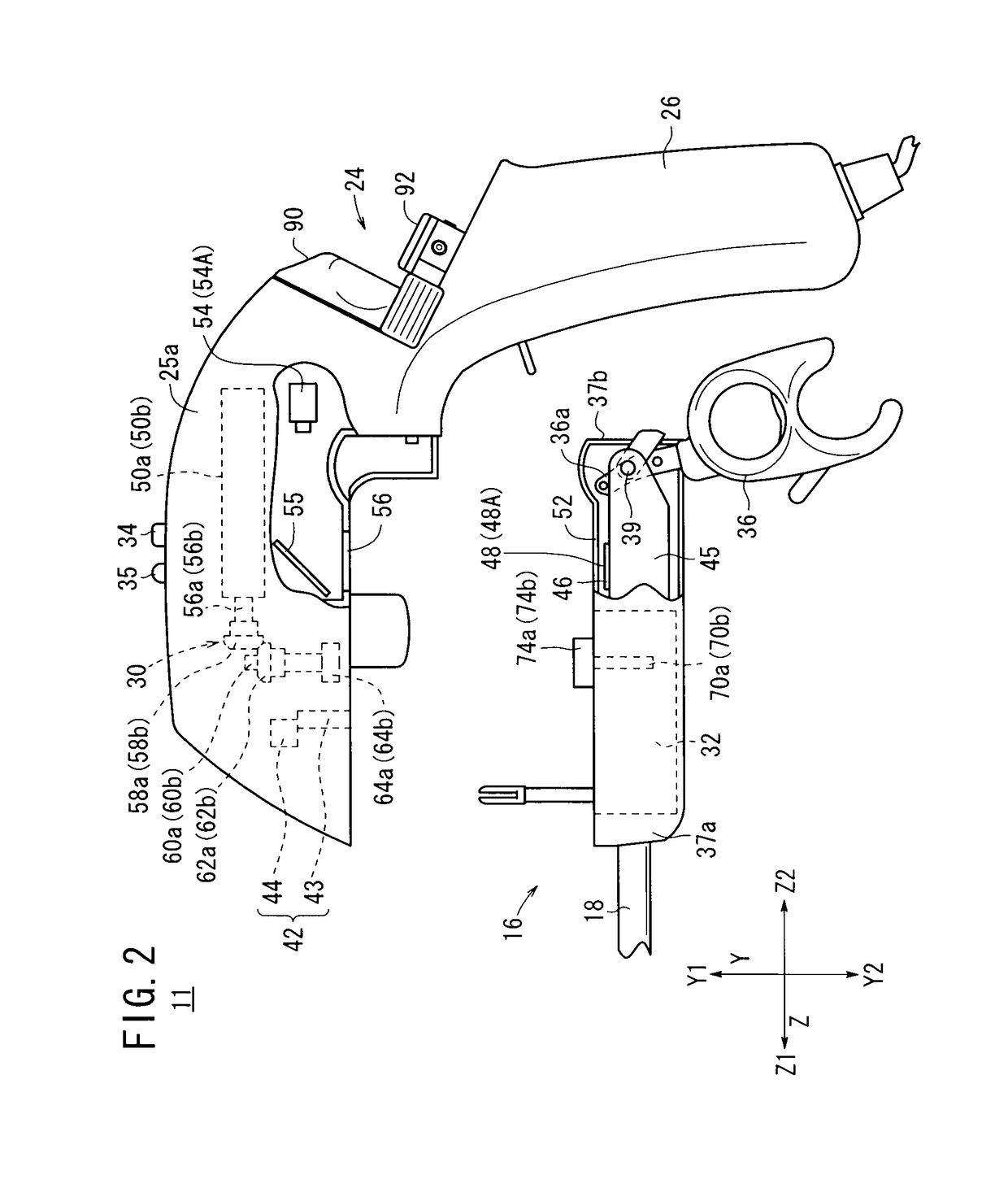

Manipulator system and manipulator control method

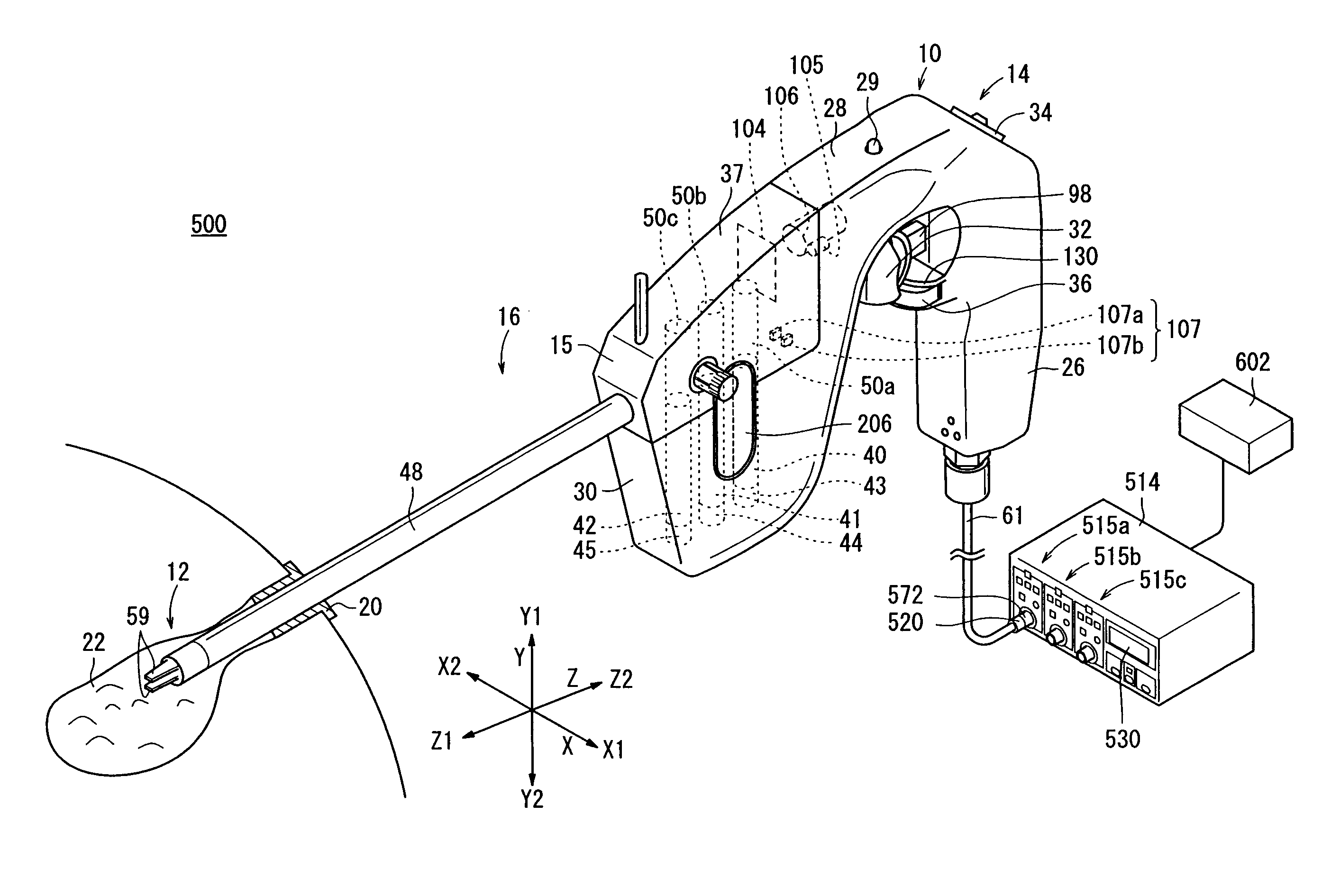

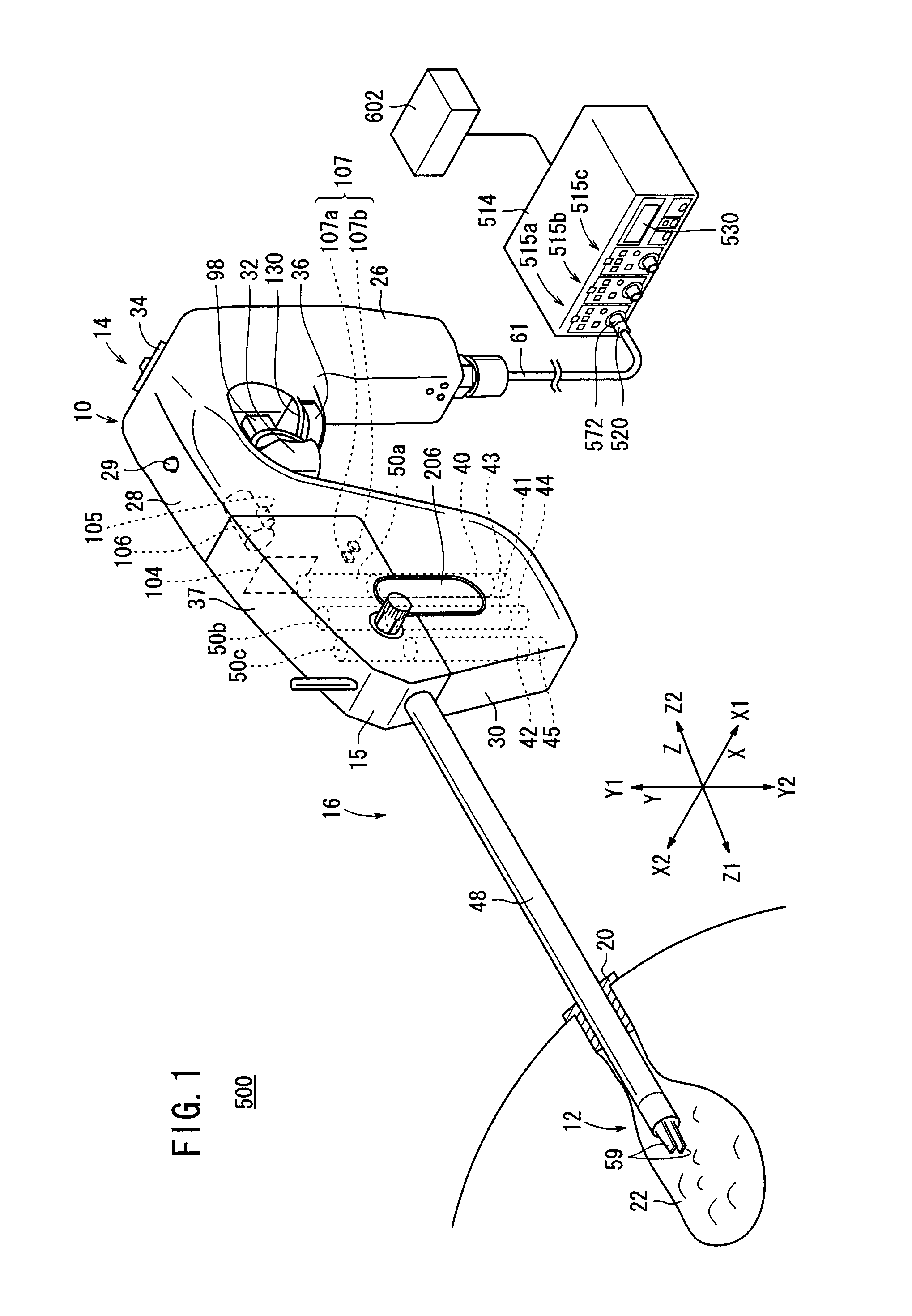

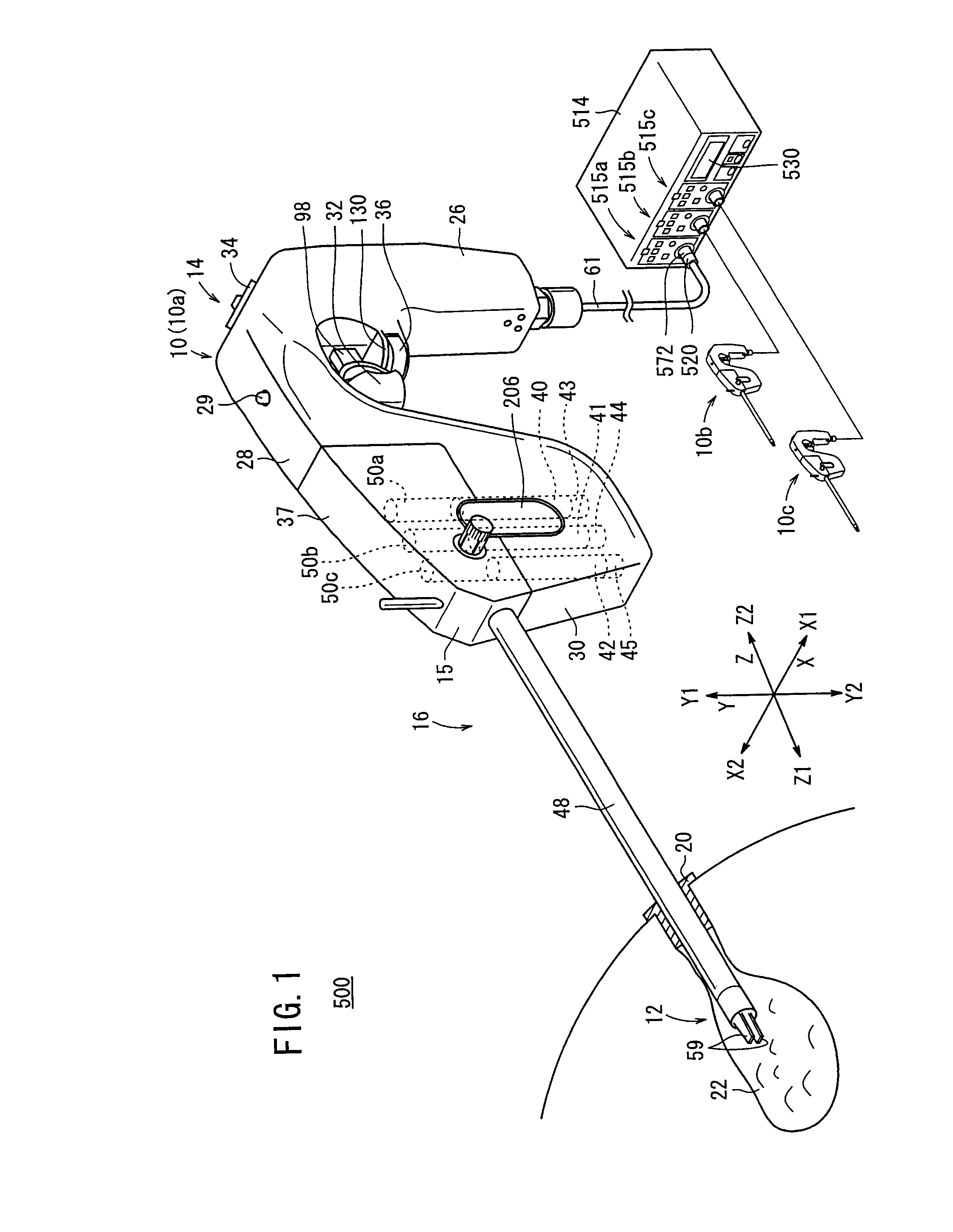

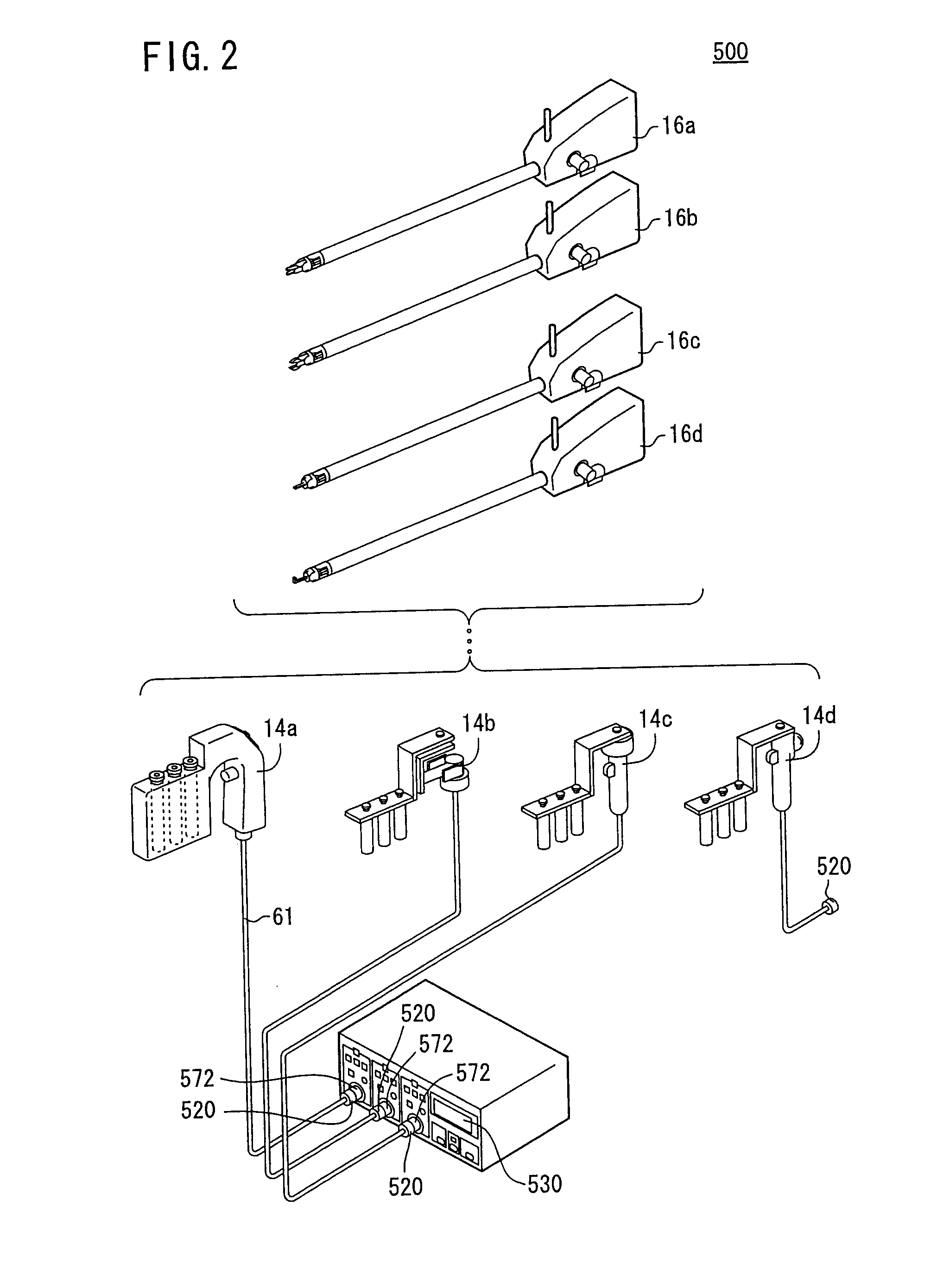

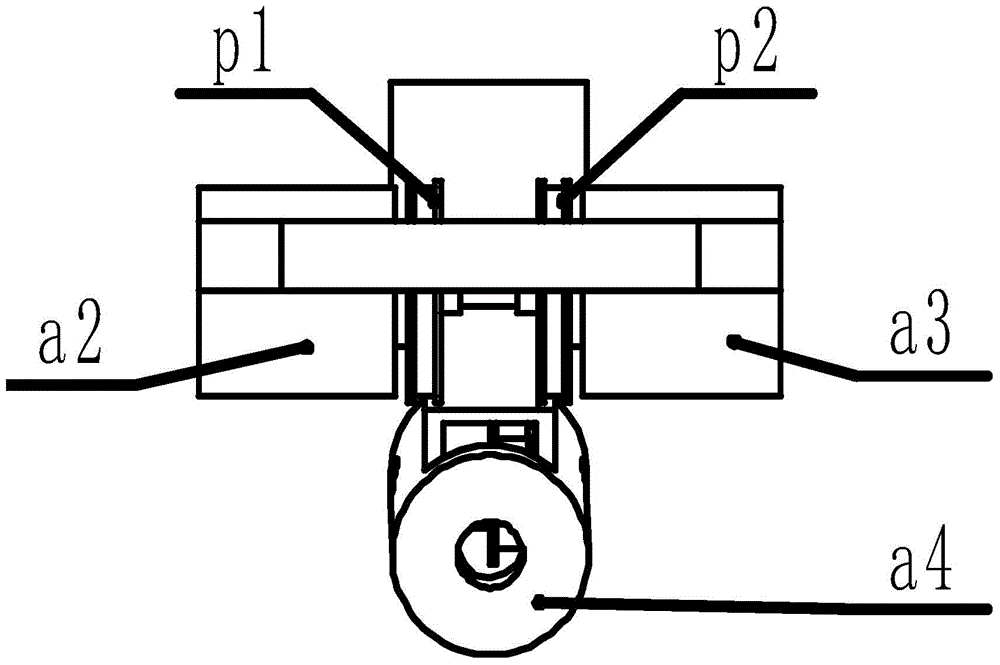

InactiveUS20090110533A1Increase freedomAdjustable effectDiagnosticsSemiconductor/solid-state device manufacturingWork unitActuator

A manipulator has an operating unit including a trigger lever, a distal end working unit including an end effector and a yaw axis and a roll axis for changing the direction of the end effector, and a connector shaft interconnecting the operating unit and the distal end working unit. The operating unit includes an actuator block housing therein motors for actuating the yaw axis and the roll axis and a gripper operational quantity corrector for mechanically transmitting an operational action of the trigger lever to actuate the end effector. A controller calculates an interference amount caused on the end effector by the attitude angles of the yaw axis and the roll axis. The gripper operational quantity corrector is controlled by the controller to extend or retract a push rod, for correcting the operational quantity of the operational action of the trigger lever to compensate for the interference amount.

Owner:KK TOSHIBA

Master-slave manipulator system

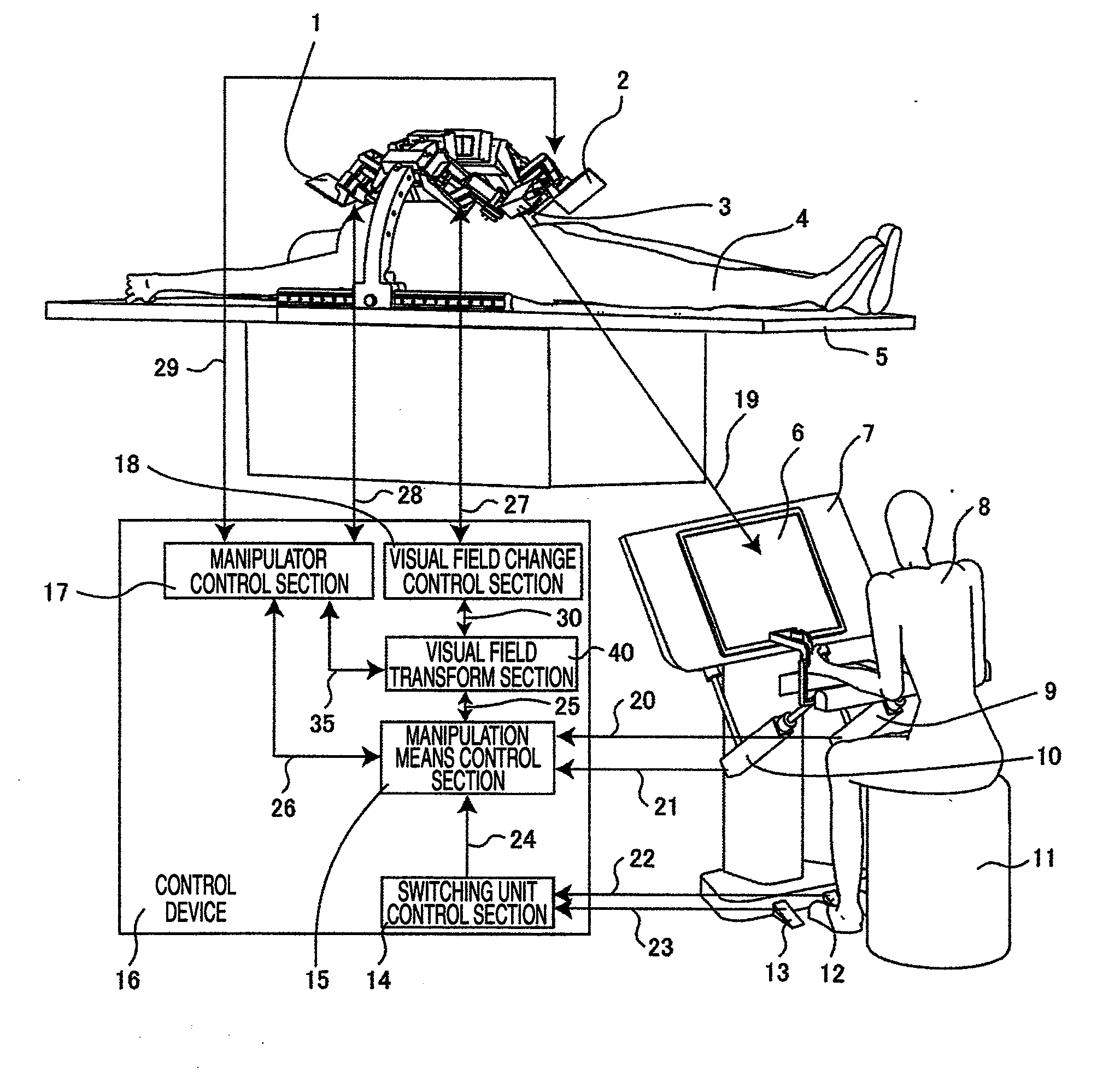

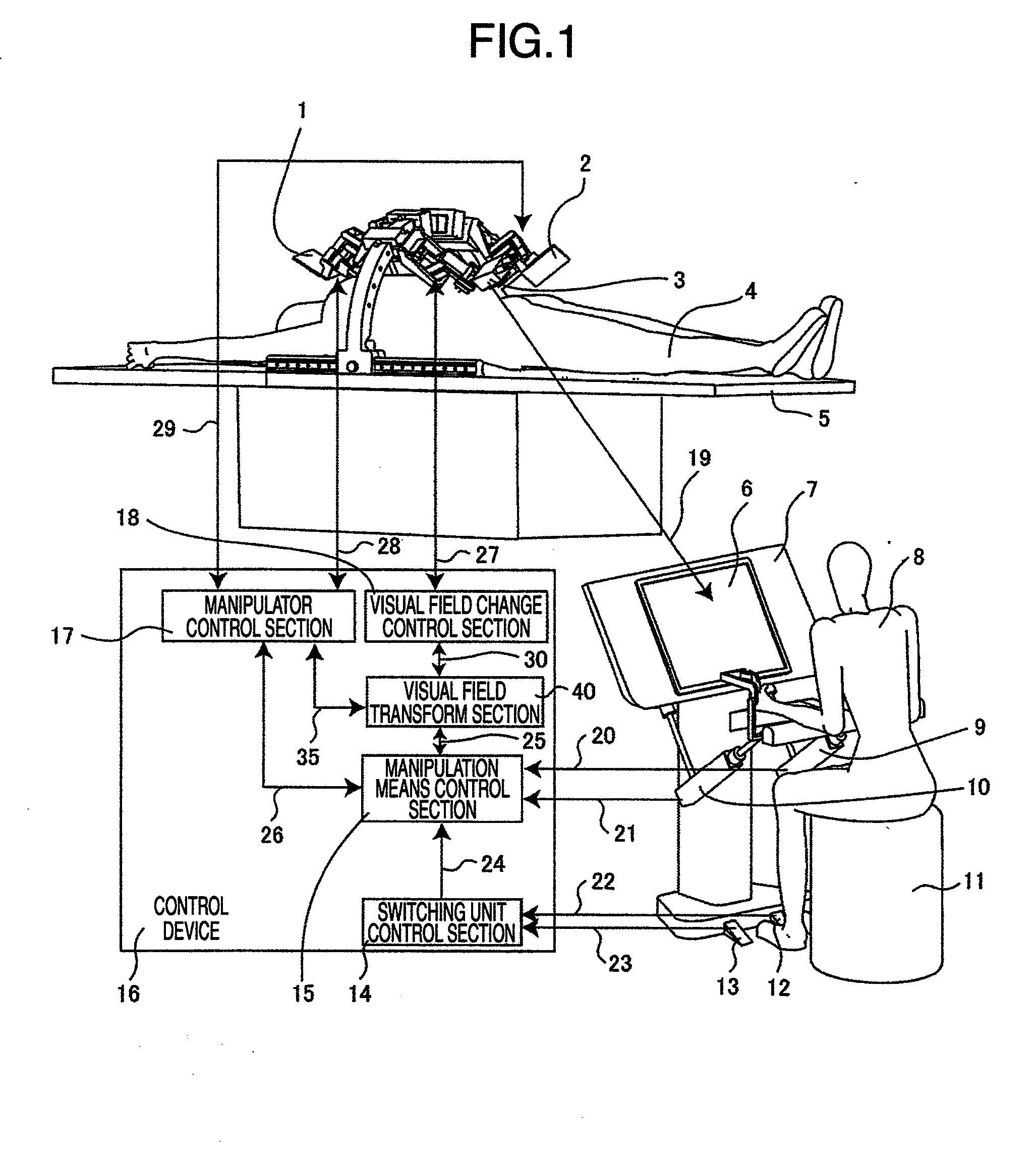

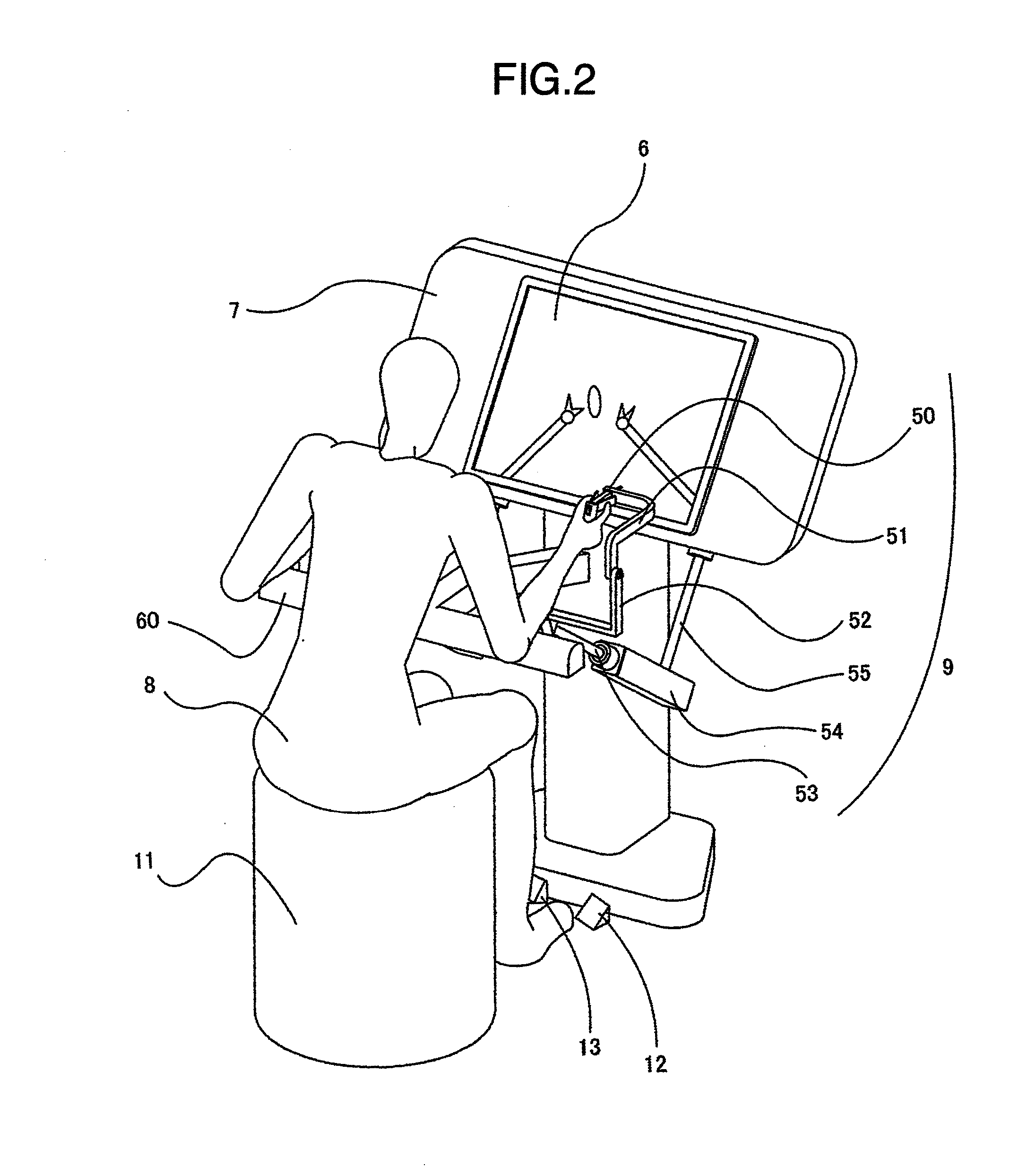

ActiveUS20080234866A1Maintain positionEasy to operateProgramme controlProgramme-controlled manipulatorVisual field lossDisplay device

In a master-slave manipulator system, manipulation device can be manipulated intuitively even when clutch manipulation is performed. A master-slave manipulator system includes: mode switching device for switching between a master-slave mode, in which the slave manipulator is controlled, and an observation device visual field tracking clutch mode, in which transmission of an operation command to the slave manipulator from the manipulation device is cut off to move the manipulation device to an optional position and orientation; a switching unit control section that reads a signal of the mode switching device to forward a mode signal to the manipulation device control section; and a visual field transform section that forwards a third control command to the manipulator control section and forwards a fourth control command to the visual field change control section on the basis of an operation command read by the manipulation device control section at the time of the observation device visual field tracking clutch mode so as to make an agreement between a direction of motion of an image of the slave manipulator displayed on the display device and a direction of manipulation of the manipulation device.

Owner:HITACHI LTD +1

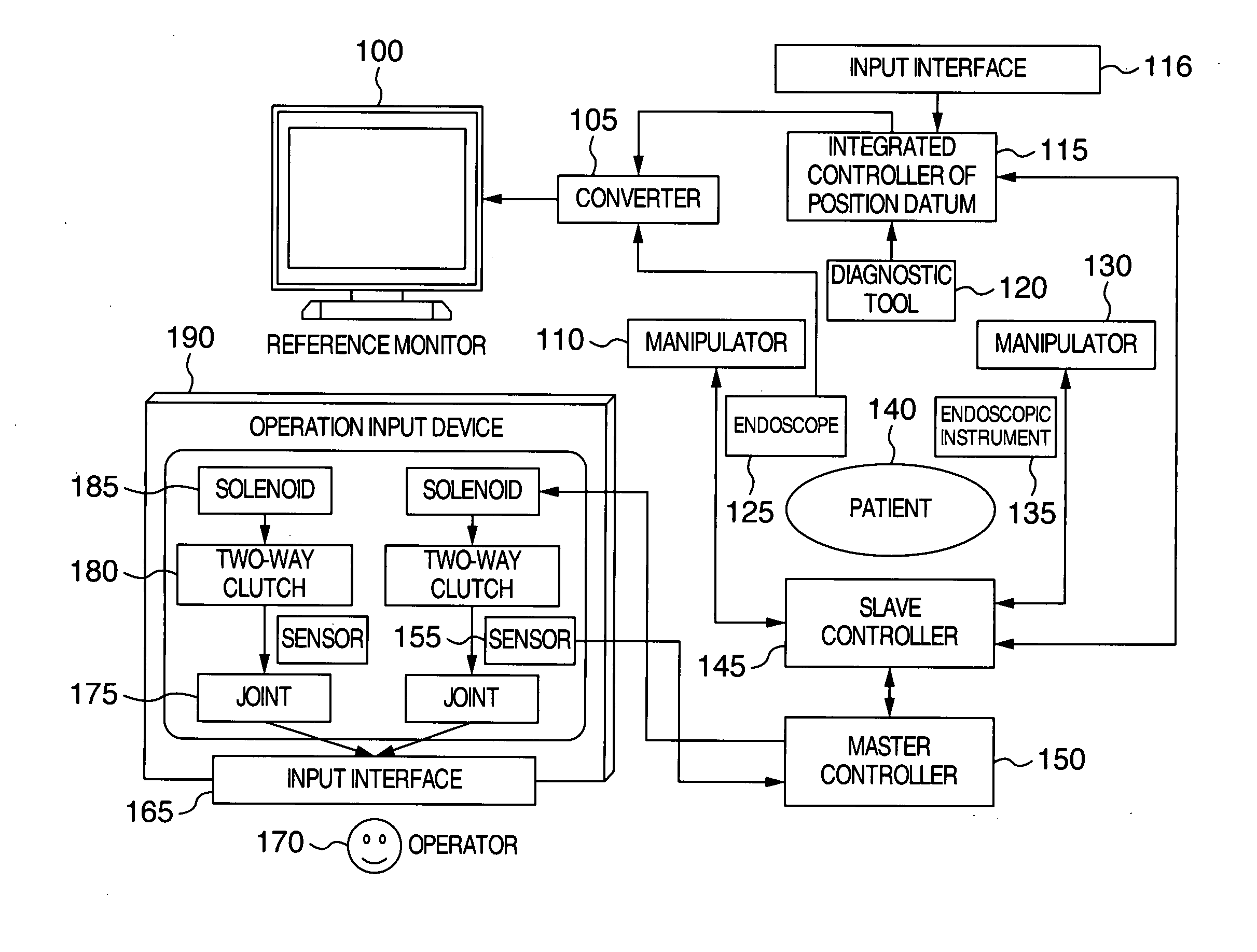

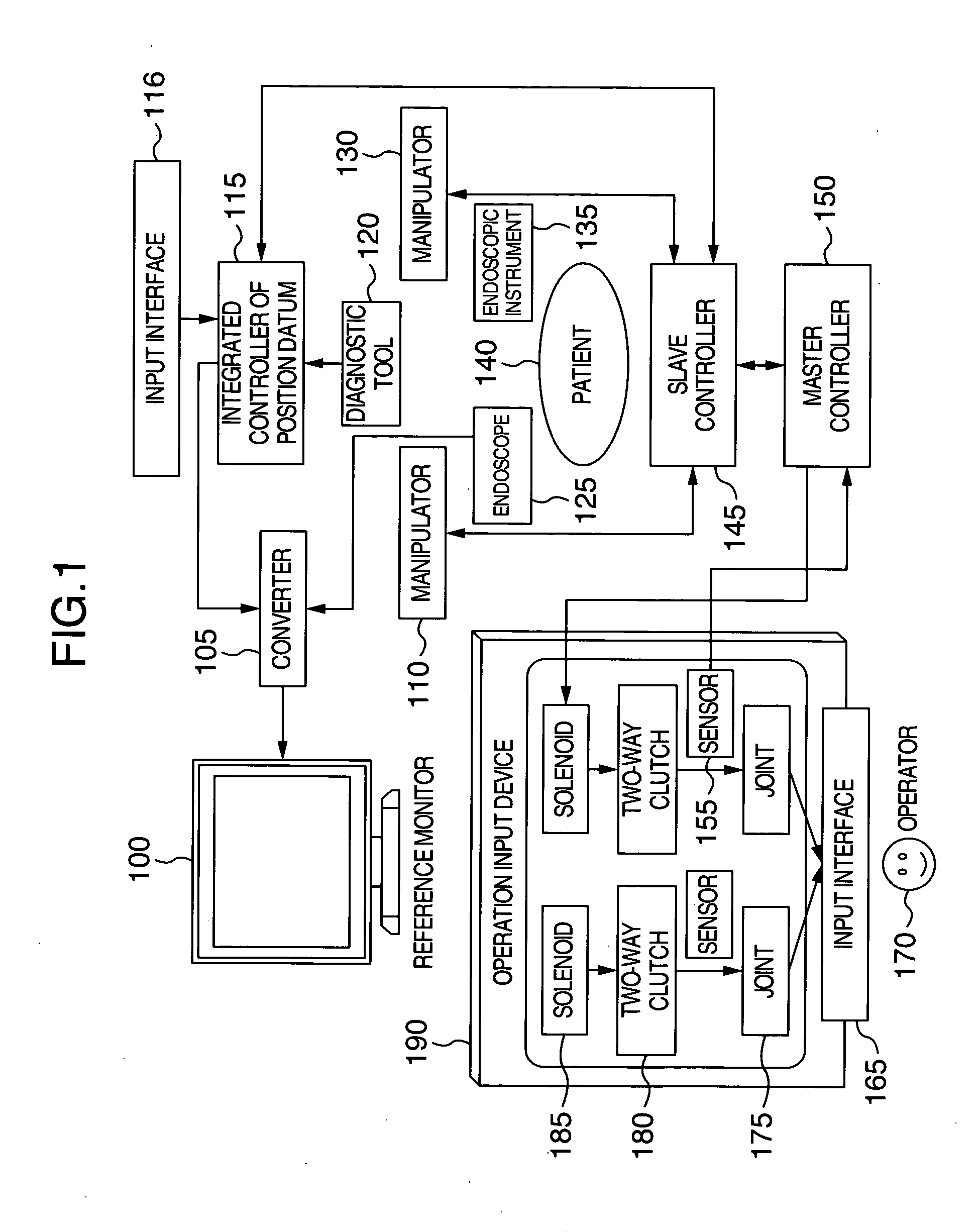

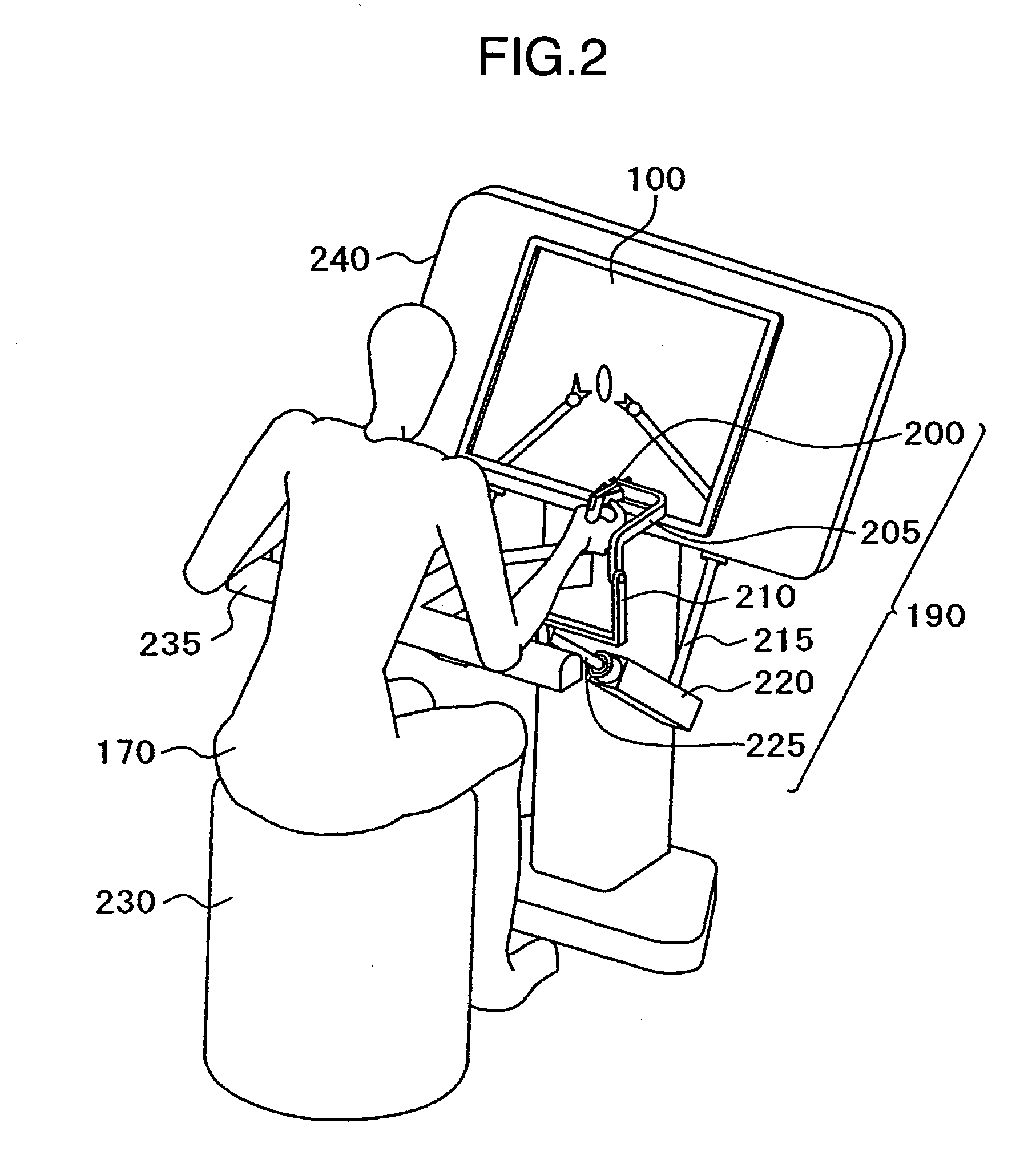

Master-slave manipulator system and this operation input devcies

ActiveUS20060261770A1Improve reliabilityEasy to operateProgramme-controlled manipulatorComputer controlMiniaturizationOperability

In a master-slave manipulator system capable of presenting an obstacle and a limit to an operating range as a force feed-back with no use of a motor in an operation input device and having high reliability, a small size and good operability, the system comprises a manipulator having an arm, an operation input device for moving the arm of the manipulator, and a controller for controlling the manipulator and the operation input device, and the operation input device is provided on joints with a mode change-over mechanism having three modes: of which, in a first mode, power is not transmitted; in a second mode, power is transmitted in one direction and is not transmitted in a reverse direction thereof; and in a third mode, power is transmitted in the reverse direction and is not transmitted in the one direction, selecting one of the above modes and changing over from one mode to the selected mode.

Owner:HITACHI LTD

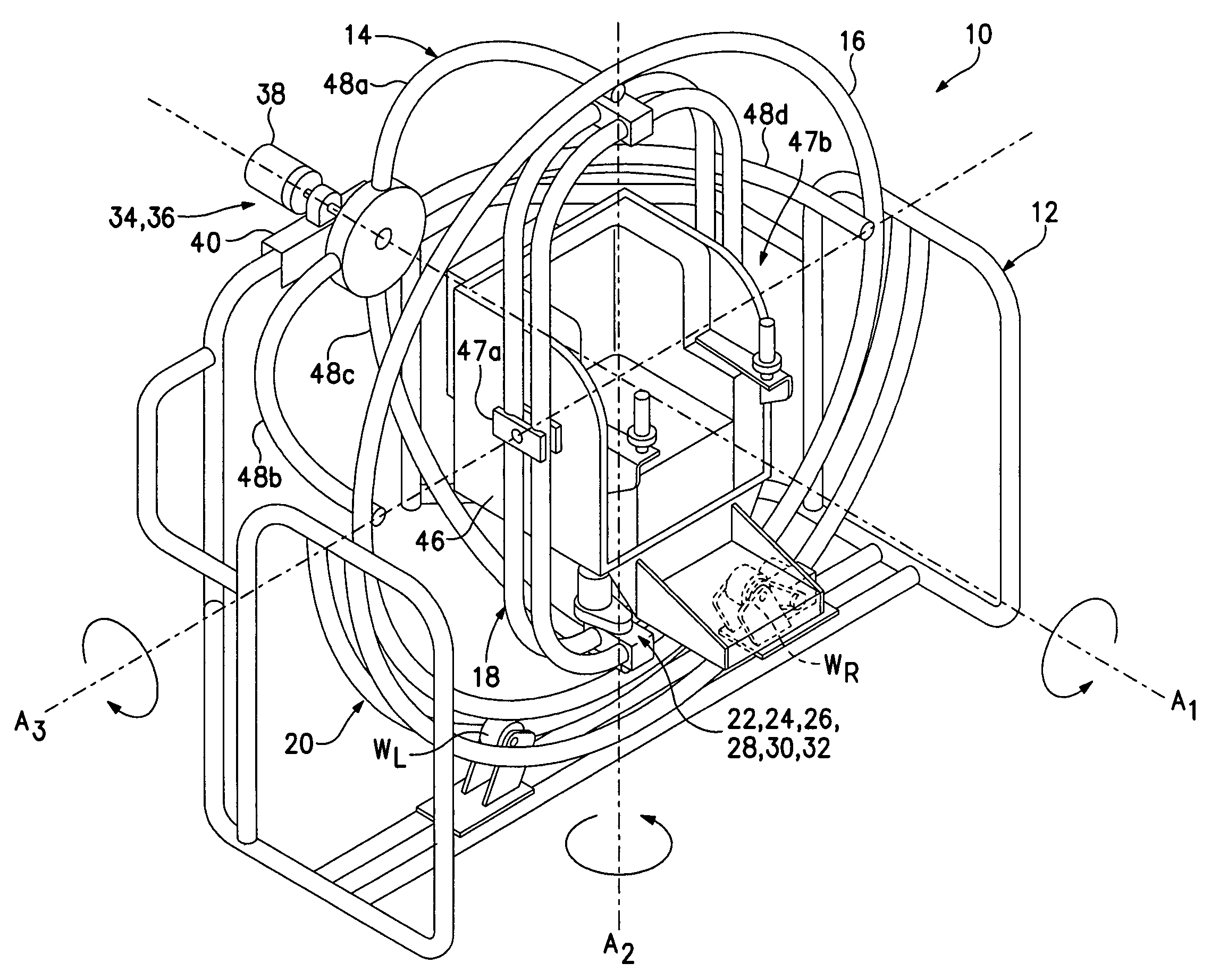

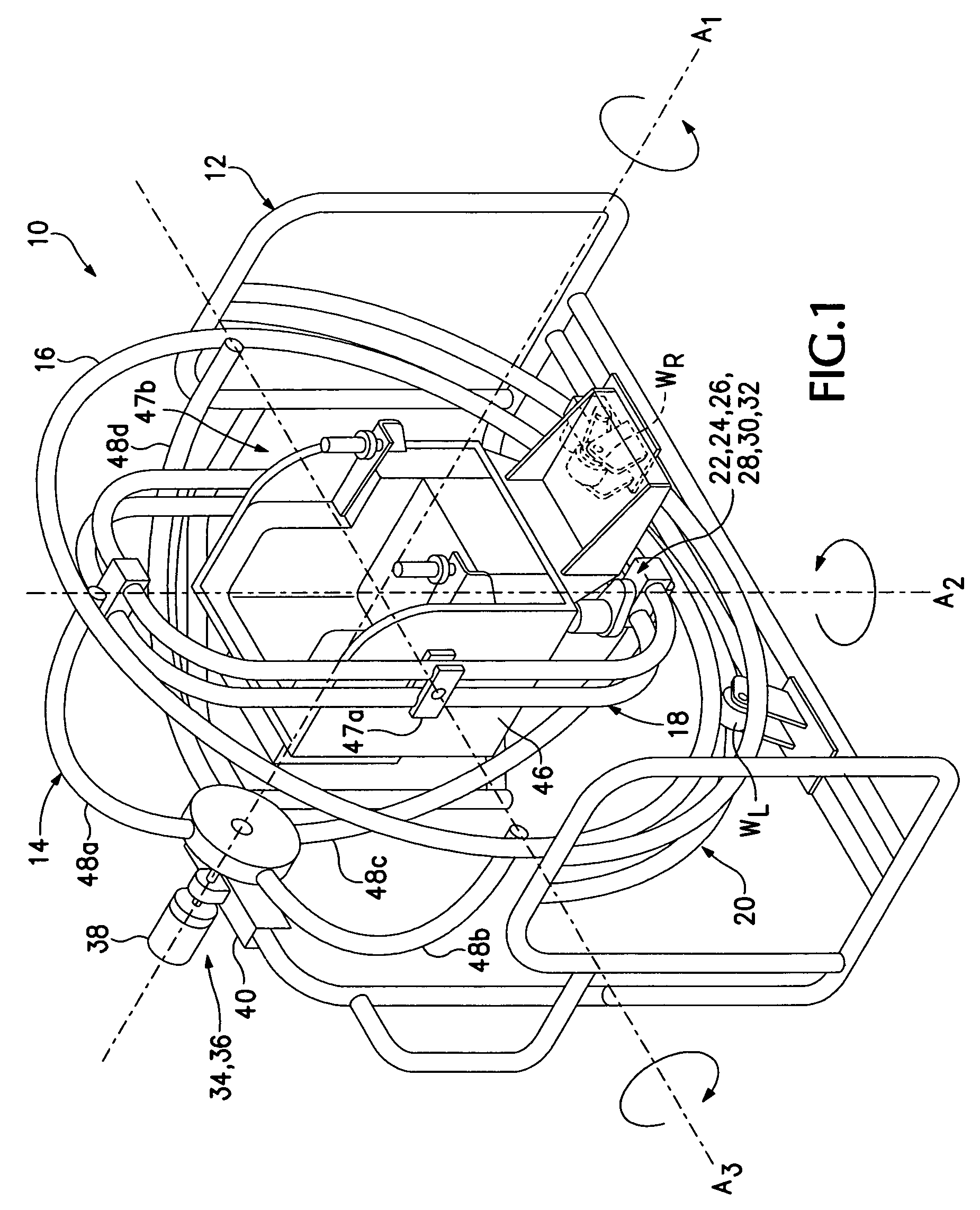

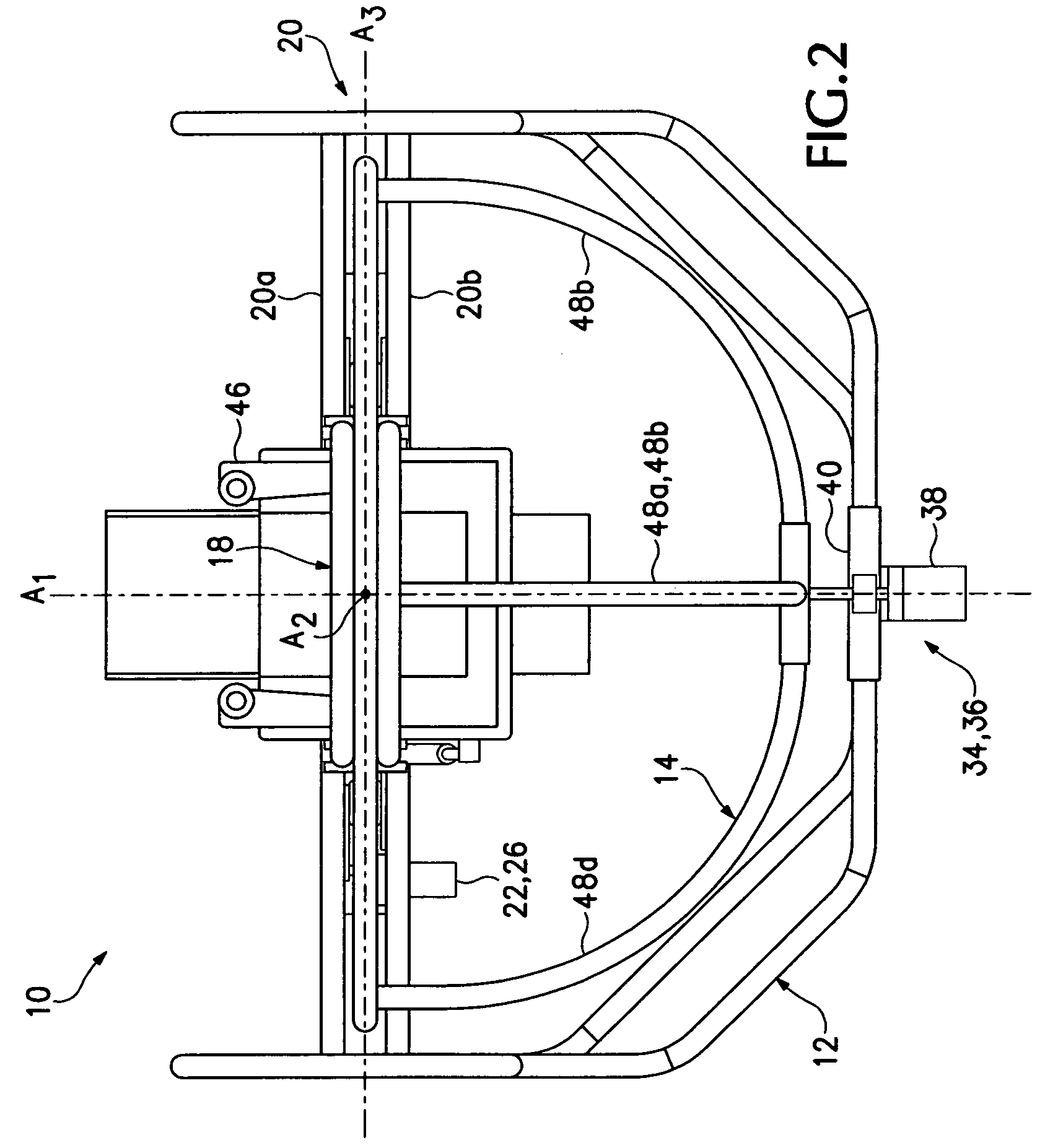

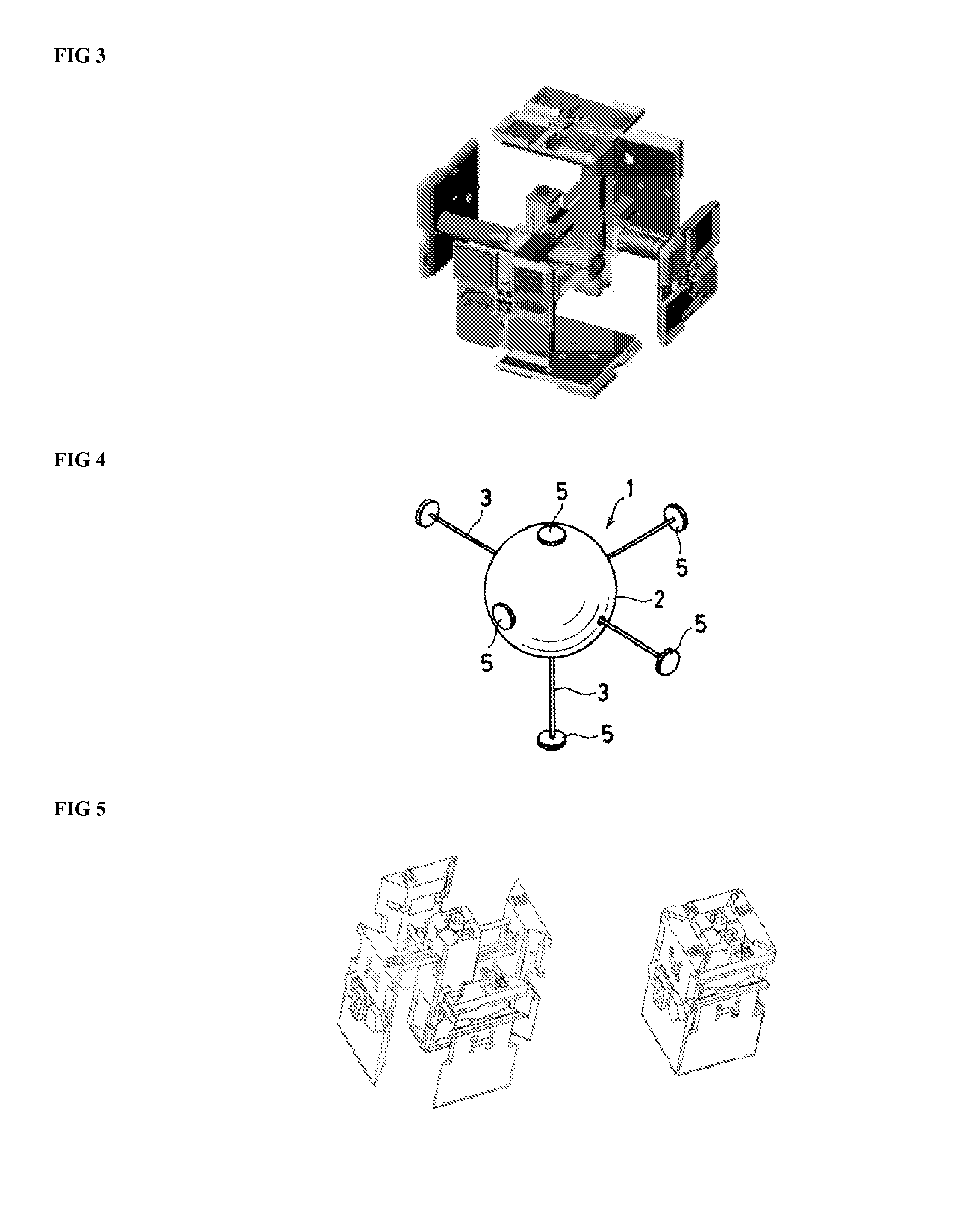

Hemispheroidal-truss spatial manipulator system and apparatus

ActiveUS7559766B2Cosmonautic condition simulationsHoop exercising devicesSpatial OrientationsRotational axis

Spatial manipulator apparatus for a mammalian subject includes a stabilizing base; a hemispheroidal truss frame mounted for rotation on the stabilizing base, the truss frame supporting and stabilizing an outer generally circular rim in relation to a non-concentric hub located at its rotational axis; and a second frame mounted orthogonally within the outer rim on a second rotational axis, the second frame being configured to support a mammalian subject during spatial manipulation thereof by rotation about one or more of the orthogonal rotational axes. Preferably, the truss frame and the second frame are driven for rotation about the orthogonal rotational axes to achieve a desired mammalian-subject spatial orientation within a chair-like structure pivotally adjustably mounted within the second frame. Preferably, the truss frame includes a substantially circular rim member mounting the second frame for rotation therein; three or more struts connecting from circumferential substantially evenly spaced locations along the circular rim member to a point of convergence on the truss frame through which the first axis extends; and a hub at the point of convergence mounting the three or more struts.

Owner:WEST TEXAS PCS LLC

Manipulator and manipulator system

ActiveUS20160135663A1Programme controlProgramme-controlled manipulatorControl engineeringManipulator system

The invention has for its object to provide a manipulator and manipulator system in which a dynamic surplus is rapidly removed and a moving assembly actuates rapidly in association with the operation of an operating assembly.The manipulator 1 includes an operating assembly 2 operated by an operator, a moving assembly 3 operated by the operating assembly 2, a transmitting assembly 4 for coupling the operating assembly 2 to the moving assembly 3 to transmit driving force of the operating assembly 2 to the moving assembly 3, and a transmission compensating assembly 6 for making up for a dynamic surplus occurring in the transmitting assembly 4 in association with the operation of the operating assembly 2.

Owner:OLYMPUS CORP

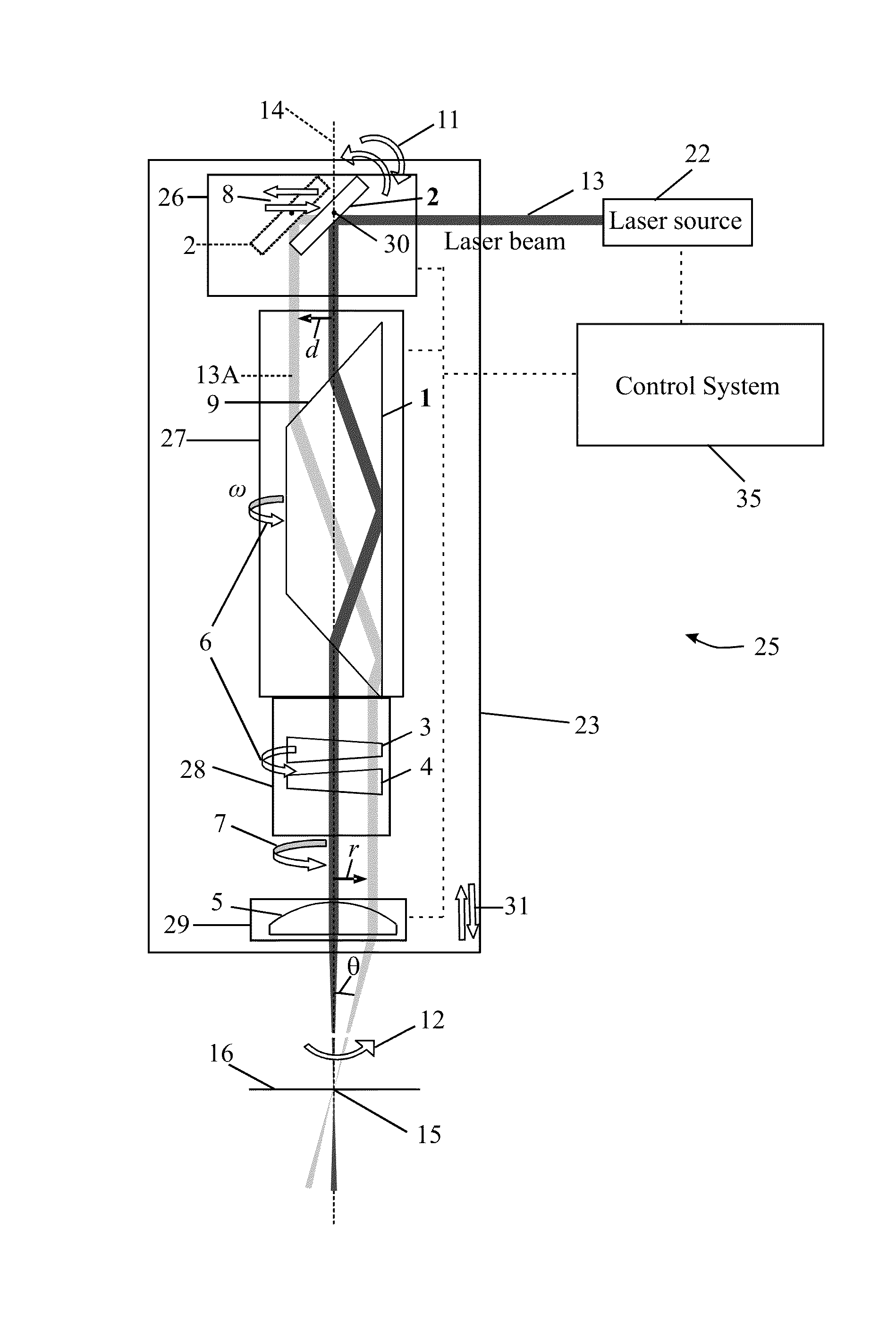

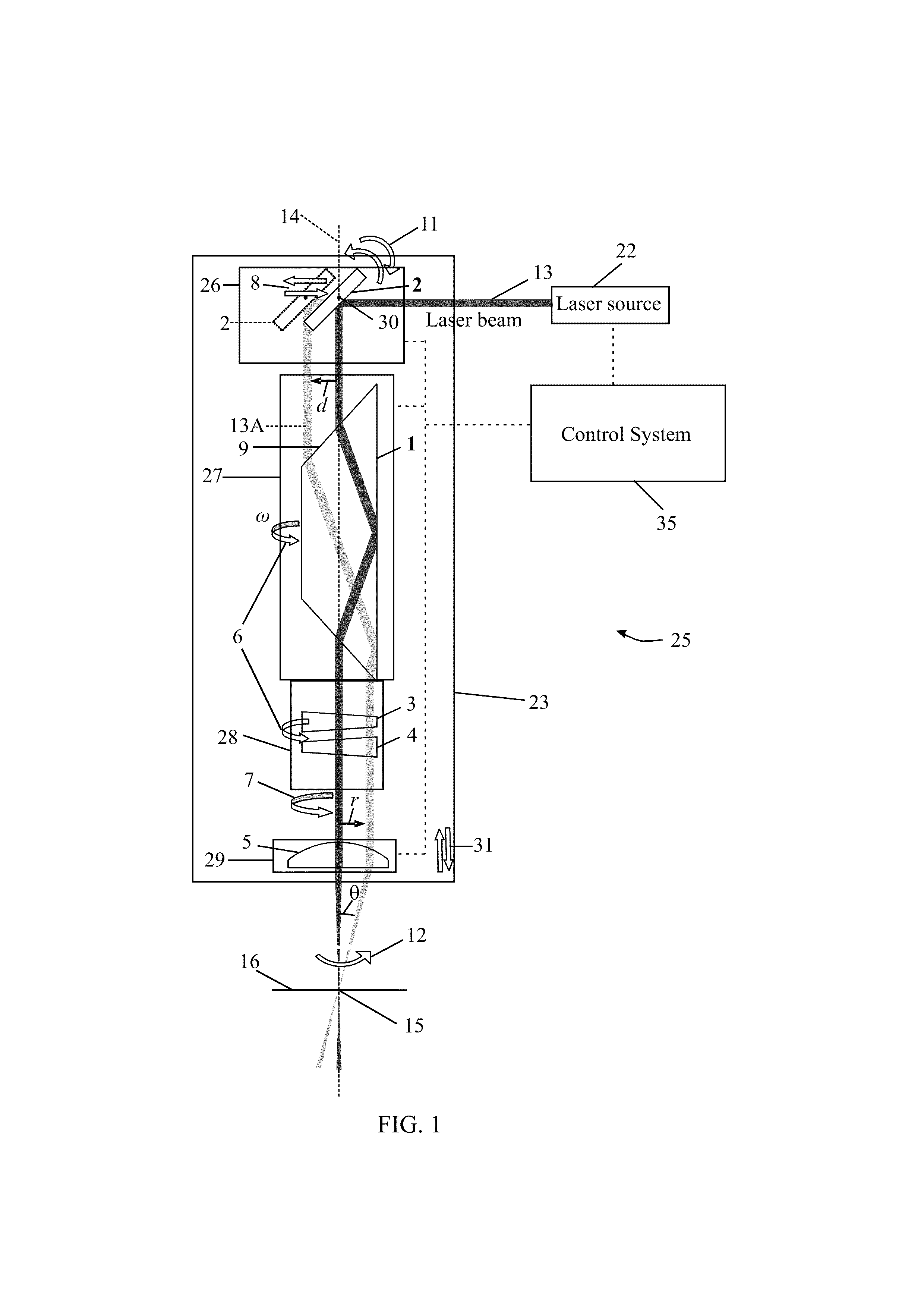

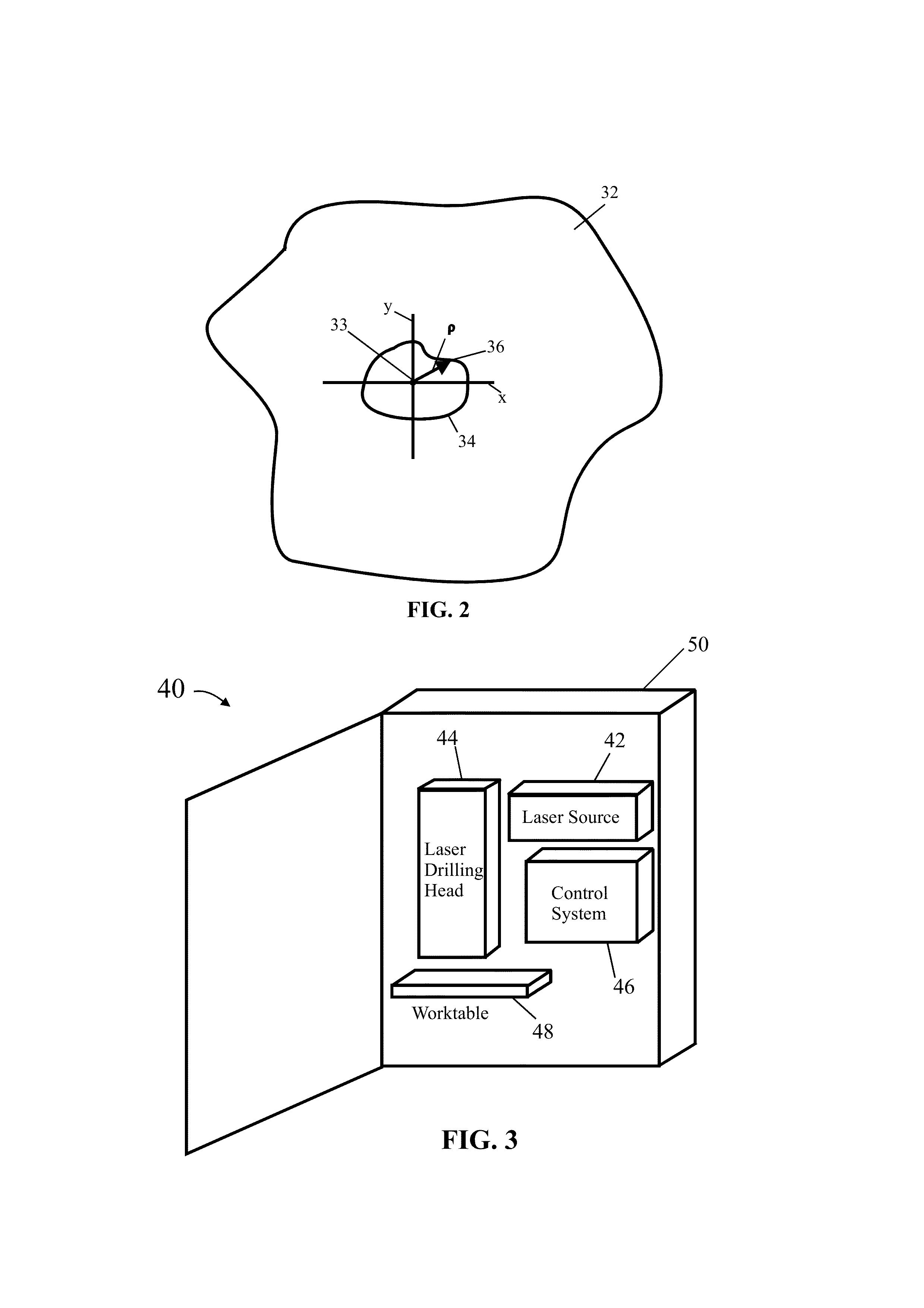

Laser Drilling and Trepanning Device

Laser drilling devices are disclosed which include a laser beam source and a laser drilling head. The laser drilling head includes a beam manipulator system in which the only dynamically moving optical element is a mirror. The mirror is dynamically and reciprocally translatable along the direction of the incoming laser beam and is also dynamically and reciprocally tiltable about an axis that is perpendicular to the nominal optical axis of the drilling head. The drilling head also includes a spinnable laser beam rotating system, a simplified compensation system, and a focusing system. The compensation system includes as its only laser beam path shifting optical elements on or two wedge plates which, if two, are fixably rotatable relative to one another in planes which are perpendicular to the nominal optical axis of the laser drilling device.

Owner:LUXCELIS TECH LLC

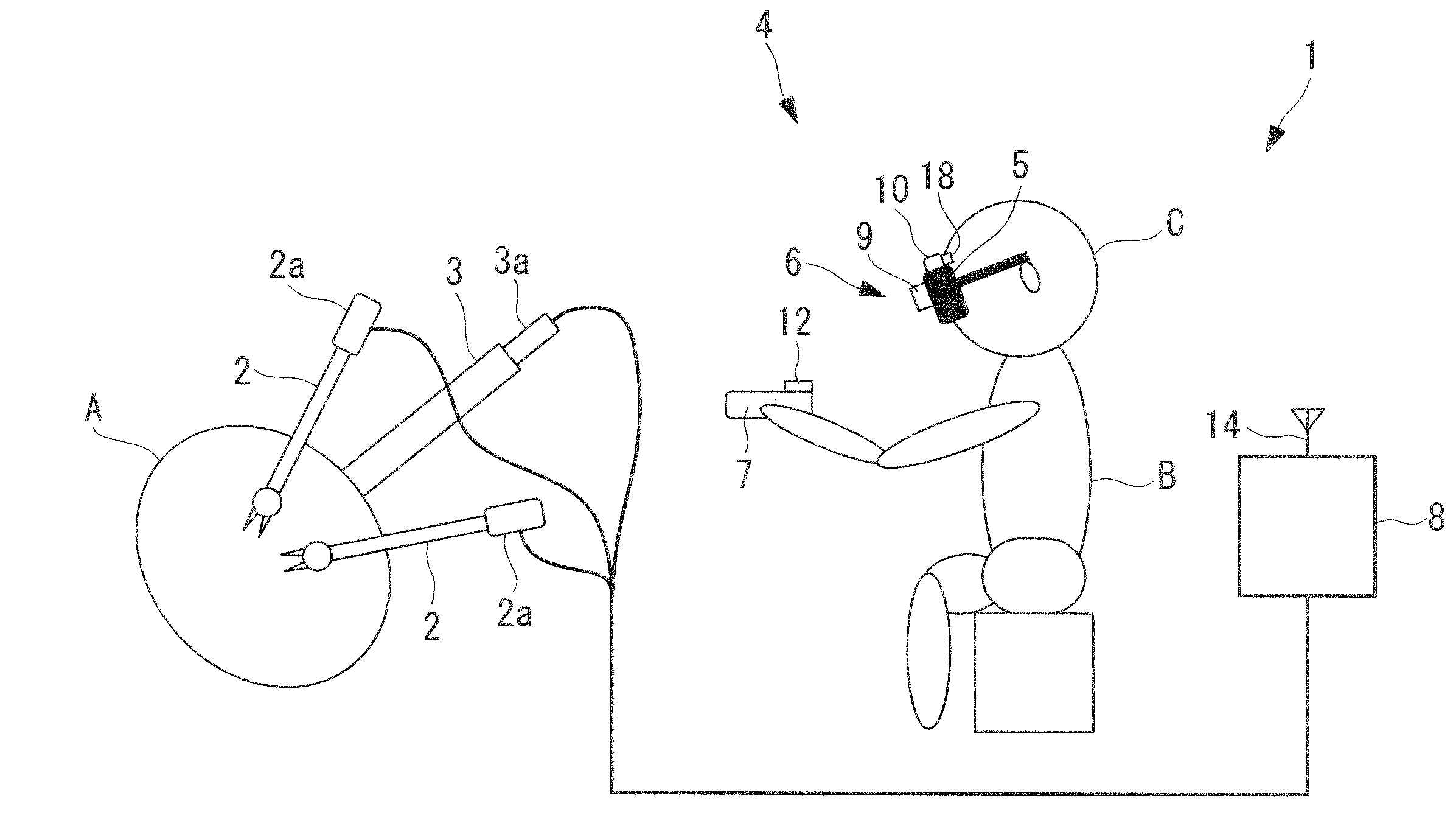

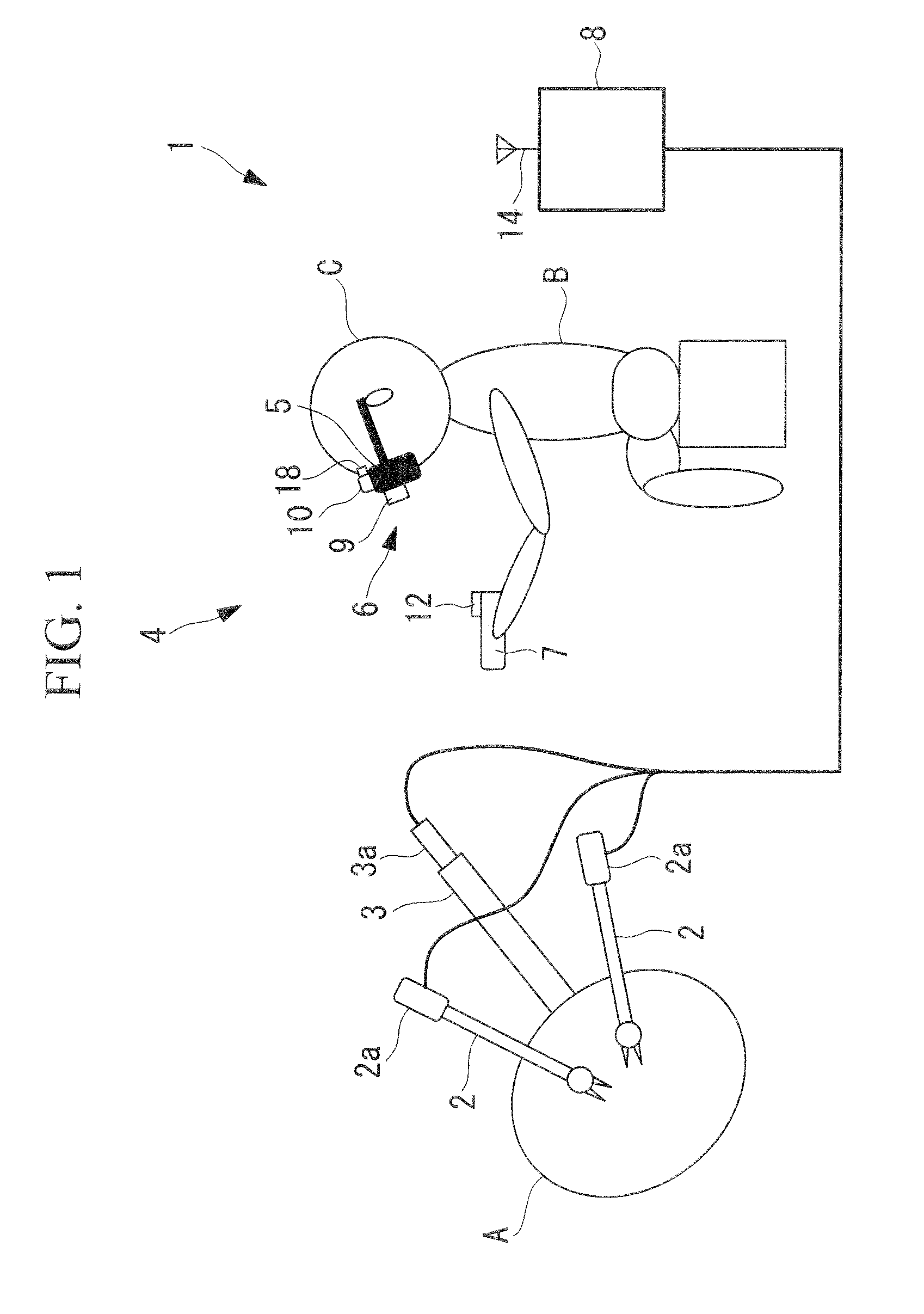

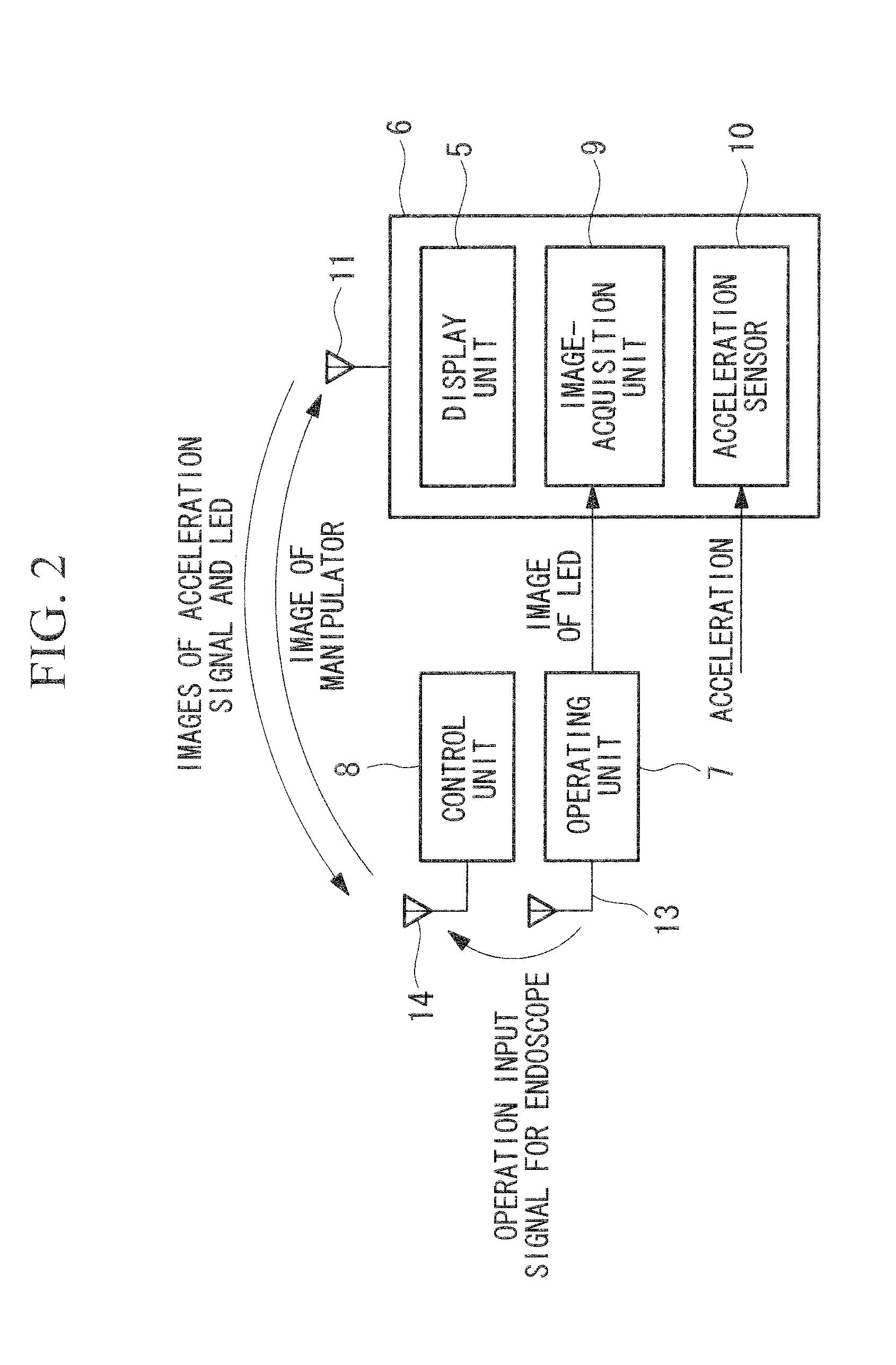

Operation input device and manipulator system

ActiveUS20130063580A1Simple configurationAvoid areaProgramme controlProgramme-controlled manipulatorControl engineeringDisplay device

With a simple configuration, a area in which an operating unit can move is prevented from being limited. Provided is an operation input device including a display; an operating unit that operates a display object displayed on the display; a head-mounted unit that is mounted on the head of an operator; relative position sensors that detect a relative position and a relative orientation of one of the head-mounted unit and the operating unit with respect to the other; and a control unit that actuates the display object displayed on the display on the basis of changes in the relative position and the relative orientation detected by the relative position sensors.

Owner:OLYMPUS CORP

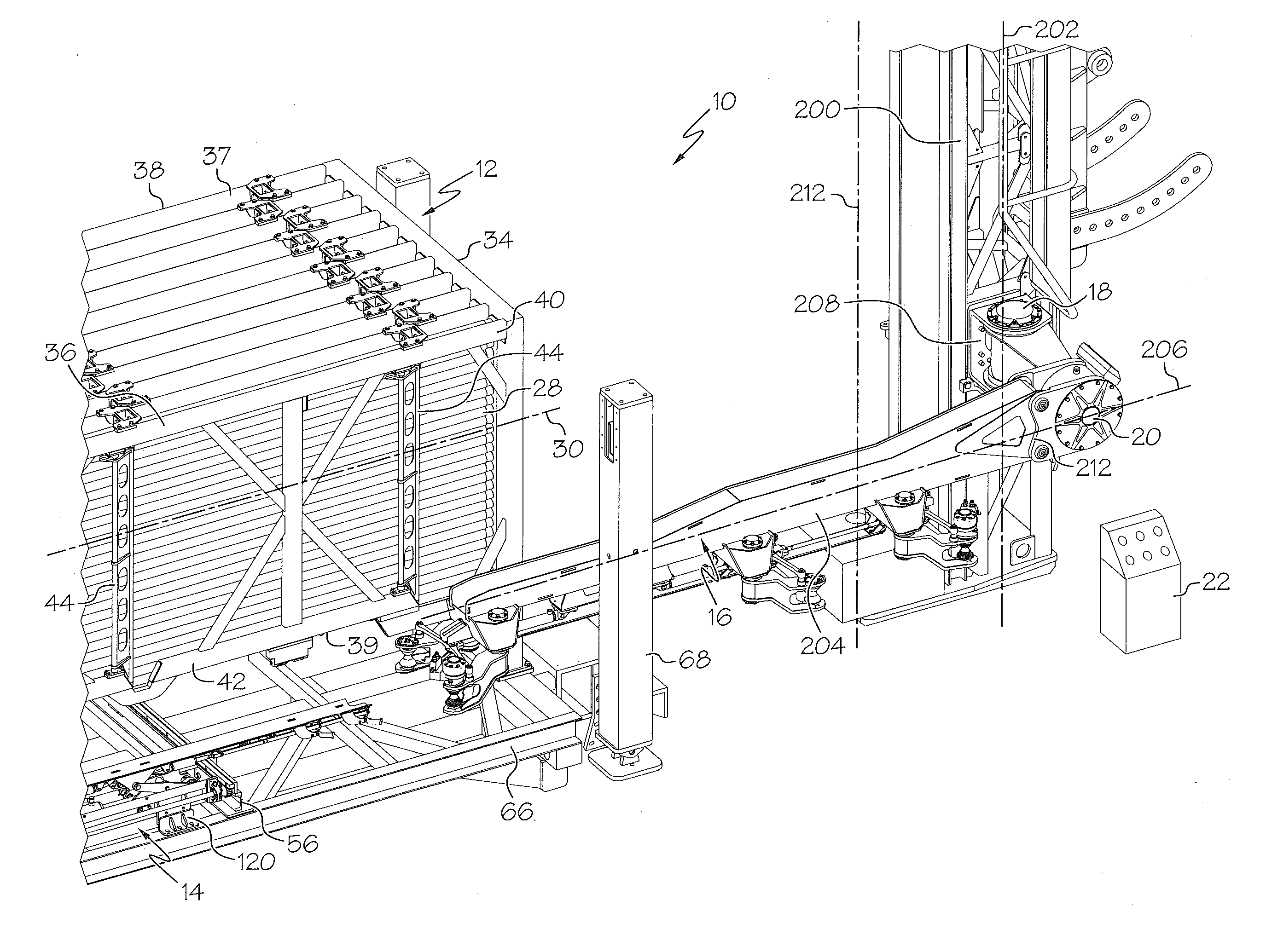

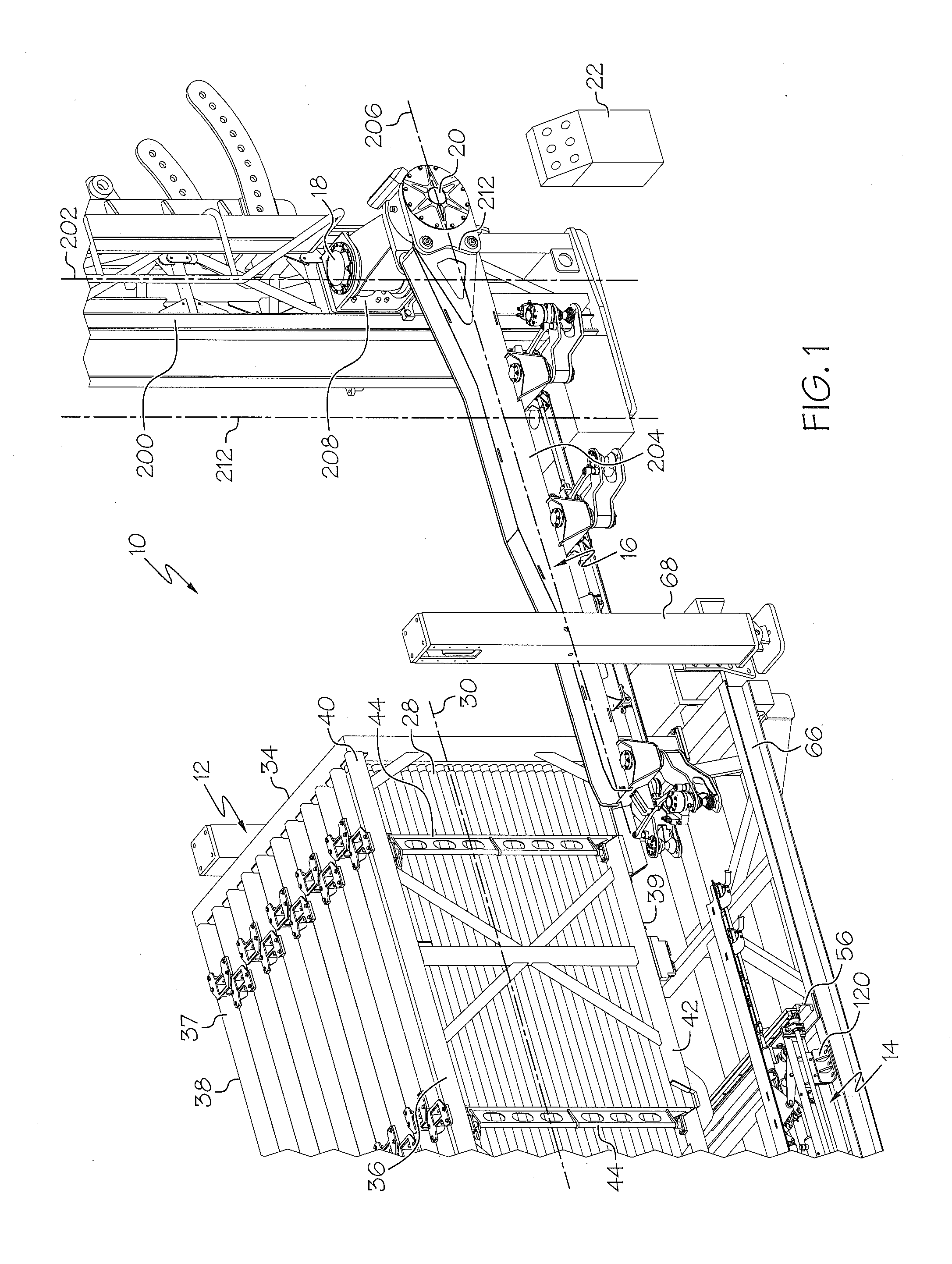

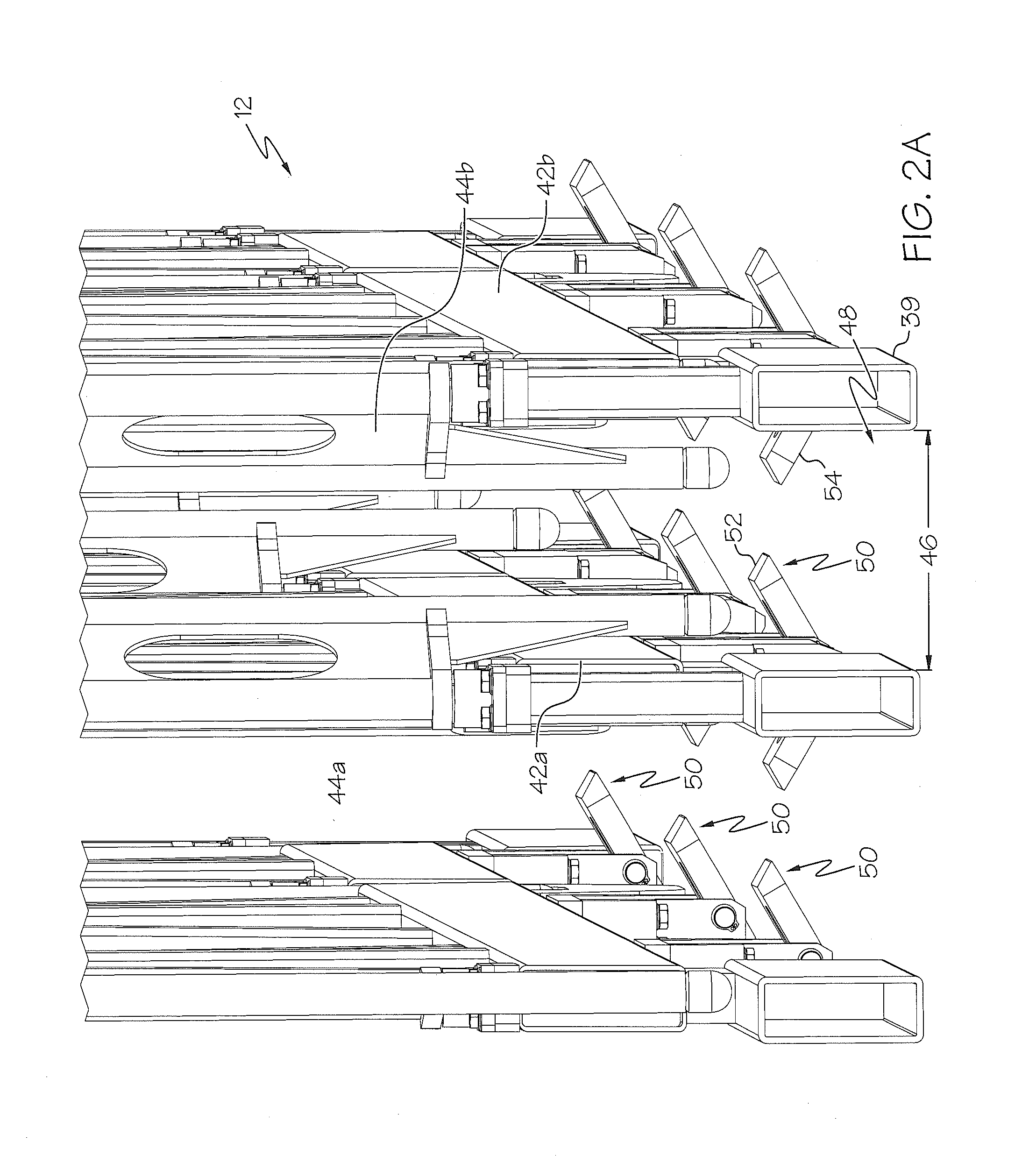

Automated rod manipulator

An automated rod manipulator system for moving a drill rod section from a storage magazine to a drill rig and connecting the drill rod to a drill string of the drill rig without manual manipulation of any parts. The automated rod manipulator system may comprise a magazine to store and dispense a plurality of drill rod sections, a carriage to convey one of the plurality of drill rod sections from the magazine to a transfer position; and a gripping arm coupled to a drill rig mast of a drilling rig, the gripping arm operable to convey one of the plurality of drill rod sections from a transfer position to a position aligned with a spindle center line of the drilling rig. The automated rod manipulator may also include a control system and an alignment assembly for aligning the drill rod section on a spindle centerline of the drill rig.

Owner:LAYNE MINERALS LLC

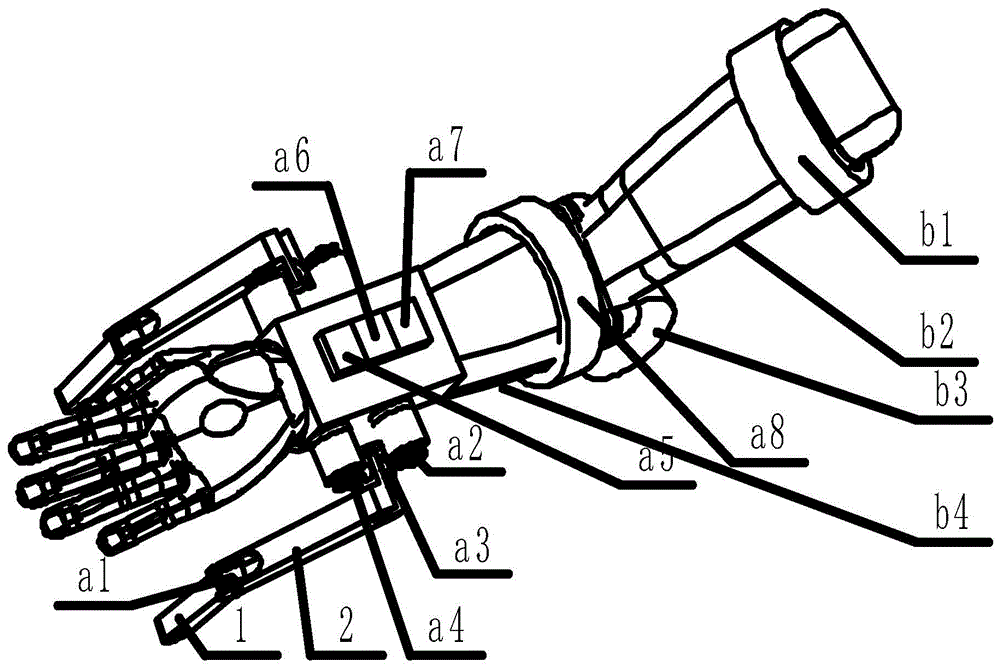

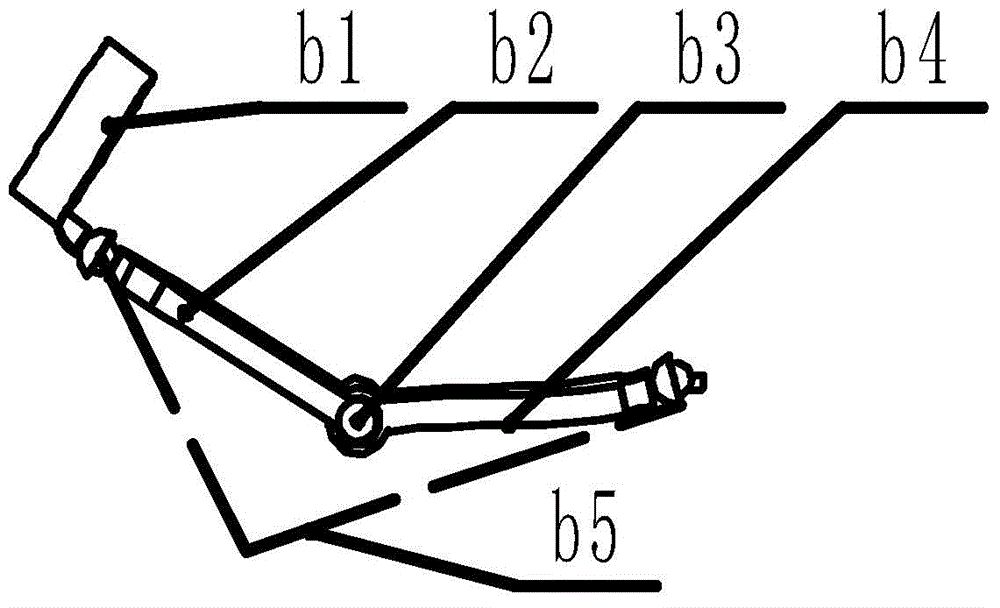

Wearable function-enhanced manipulator system as well as assisting fingers and control method thereof

InactiveCN104665962AReduce weightReduce volumeChiropractic devicesArtificial handsEngineeringManipulator system

The invention provides a wearable function-enhanced manipulator system and assisting fingers thereof. Assisting fingers adopt rope drive; force sensing is formed by using a spring connected with a driving rope; an annular electromyography acquiring array is worn on a forearm of a user and is used for estimating motion and force information of the wrist and fingers of the user, and estimating the behavior intention of the user according to the extracted position and the force information, so that a corresponding decision is made for assisting or enhancing the activity function of the fingers; a passive arm mechanism shares forces borne by the wrist and the fingers of a human body and can realize the actions of assisting and enhancing the function of the fingers under the condition that normal activities of the human body are not influenced. Meanwhile, the invention provides a control method for the manipulator system. The wearable function-enhanced manipulator system has the advantages of compact structure, light weight, good flexibility and good safety; the functions of the fingers can be enhanced to the maximum extent, and natural hands of the user are enabled to engage other tasks; the wearable function-enhanced manipulator system has better use potential in the industry, agriculture, household demand, entertainment and other aspects.

Owner:SOUTH CHINA UNIV OF TECH +2

System, method and computer program for autonomously emulating robot manipulators of continuously-varying configurations

ActiveUS20140222198A1Continuous reconfigurabilityRecovery functionProgramme-controlled manipulatorComputer controlKinematicsSimulation

The invention is a modular and autonomously reconfigurable manipulator system which introduces a new dimension to the versatility of robot manipulation for diverse tasks. The hardware component is a redundant mechanism which can lock any number of its joints at any relative position to form a particular configuration with a certain number of degrees of freedom and specific values for kinematic, dynamic and control parameters, optimum for a given task to be performed. The process of identifying the optimum configuration for a given task and implementing it on the manipulator is done autonomously through the system software. Therefore, no manual interaction is required to form a new configuration most suitable for a given task. The kinematic, dynamic and control parameters of the system can vary continuously enabling the manipulator to form virtually an infinite number of configurations.

Owner:EMAMI MOHAMMAD REZA +1

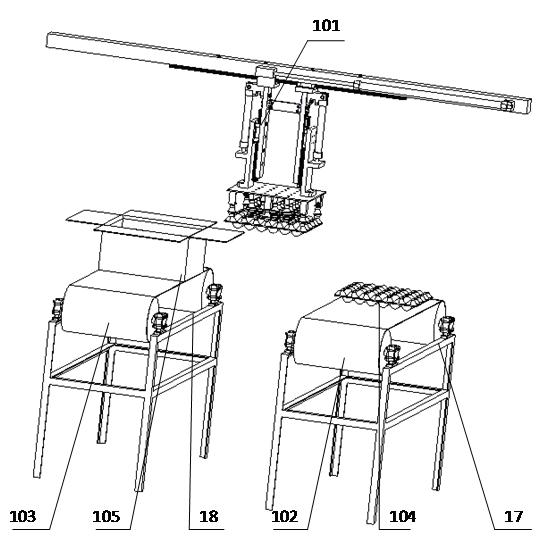

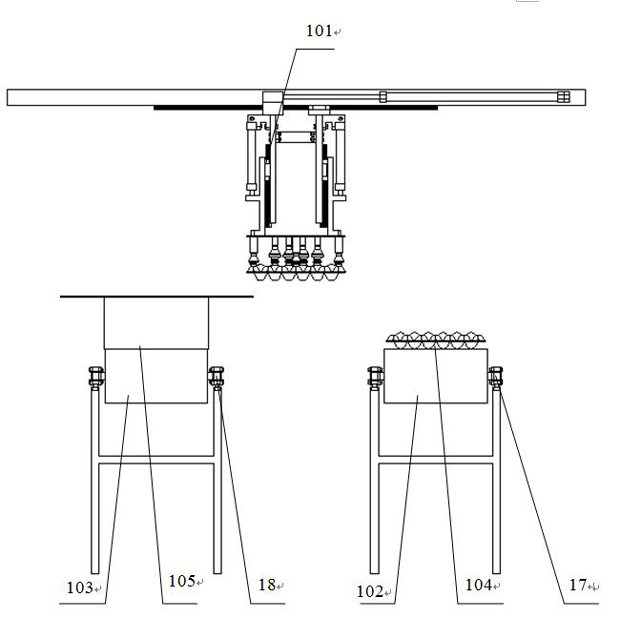

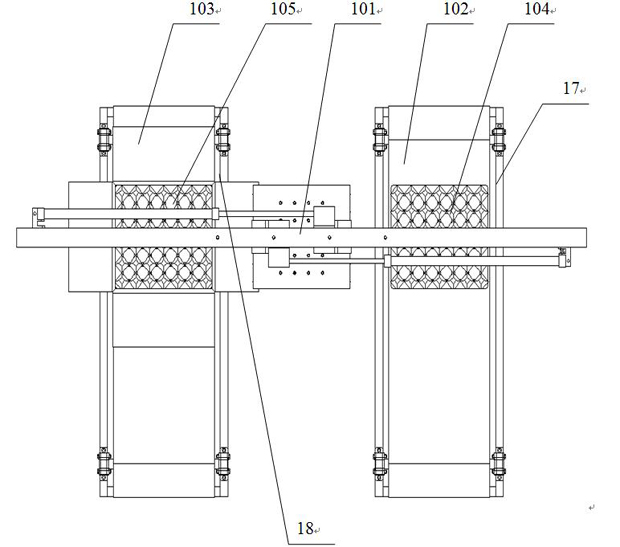

Automatic egg boxing mechanical arm as well as boxing method and control method thereof

InactiveCN101982375AGuaranteed accuracyReduce maintenance costsProgramme-controlled manipulatorPackaging eggsProduction lineProgrammable logic controller

The invention discloses a novel automatic egg boxing mechanical arm as well as a boxing method and a control method thereof. The boxing mechanical arm consists of a mechanical arm system and a control system, and is arranged on the tail end of the existing egg classification production line by a bracket; a horizontal cylinder of the mechanical arm and a guide rail slider are synergized to realize horizontal motion of the mechanical arm; a cylinder and a guide rail slider which are arranged vertically in the vertical direction drive the lower arm of the mechanical arm to do vertical motion; an egg suction cup and an egg support suction cup are arranged on a lower arm bracket, and are matched with open and close of an electromagnetic valve to realize grasp and release actions to the eggs and the egg support; eggs and cartons are conveyed by a stepping motor and a conveying belt; and the mechanical arm and the conveying belt are controlled by a (programmable logic controller (PLC) control module.

Owner:JIANGSU UNIV

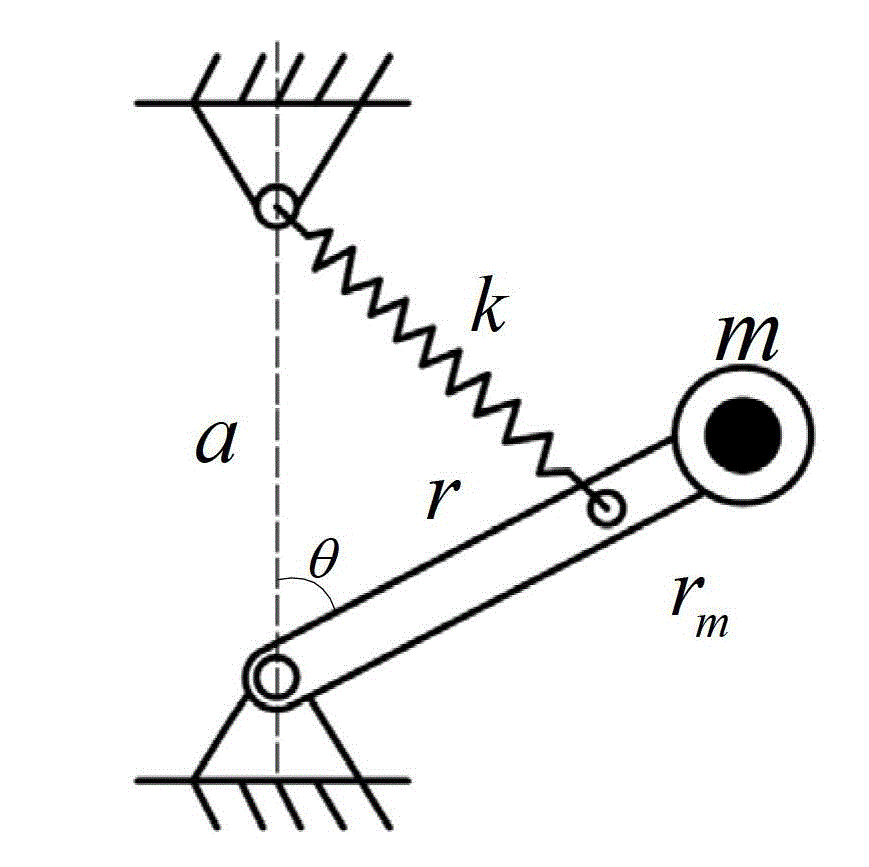

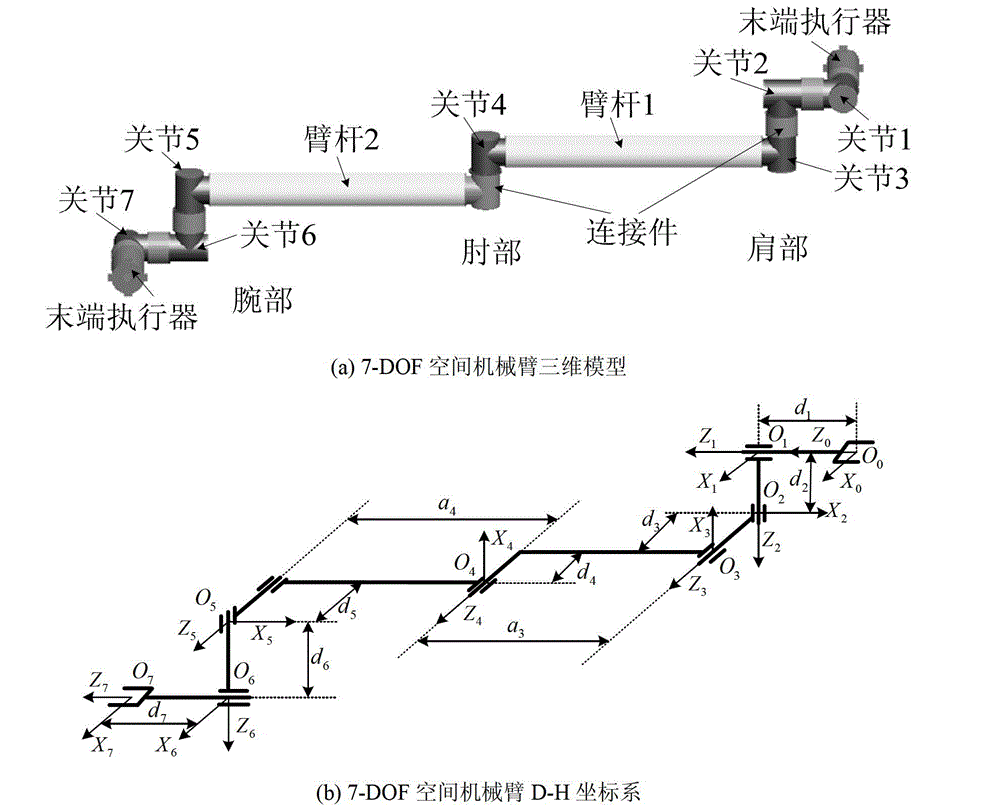

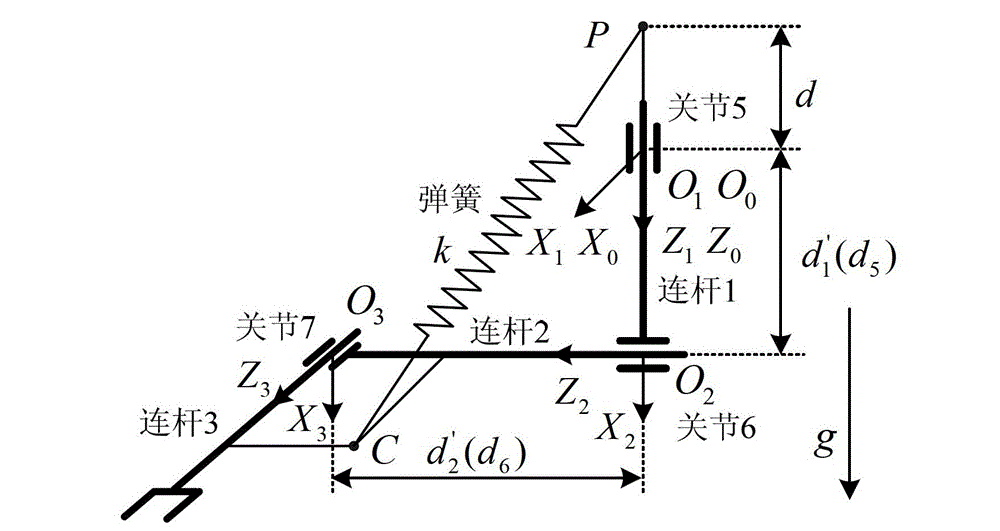

7-DOF (degree of freedom) space manipulator ground microgravity hybrid simulation method

InactiveCN103144104ASmall footprintRealize three-dimensional space movementProgramme-controlled manipulatorEngineeringDegrees of freedom

The invention discloses a space manipulator ground microgravity hybrid simulation method, and particularly relates to a realization method for ground-based simulation of a space microgravity environment by a 7-DOF space manipulator. Gravity compensation is realized at the middle part of the 7-DOF space manipulator by adopting the gas flotation method; the middle part of the 7-DOF space manipulator is supported on two gas flotation feet; shoulder parts and wrist parts at two ends as well as an end effector adopt static balance mechanisms to realize gravity compensation; two static balance mechanisms are designed, respectively named as a shoulder part static balance mechanism and a wrist part static balance mechanism, and used for realizing gravity compensation for a 2-DOF manipulator formed by a shoulder joints 1 and 2 and the end effector as well as gravity compensation for a 3-DOF manipulator formed by wrist joints 5, 6 and 7 and the end effector, as a result, gravity compensation for the whole space manipulator system is realized.

Owner:BEIJING UNIV OF POSTS & TELECOMM

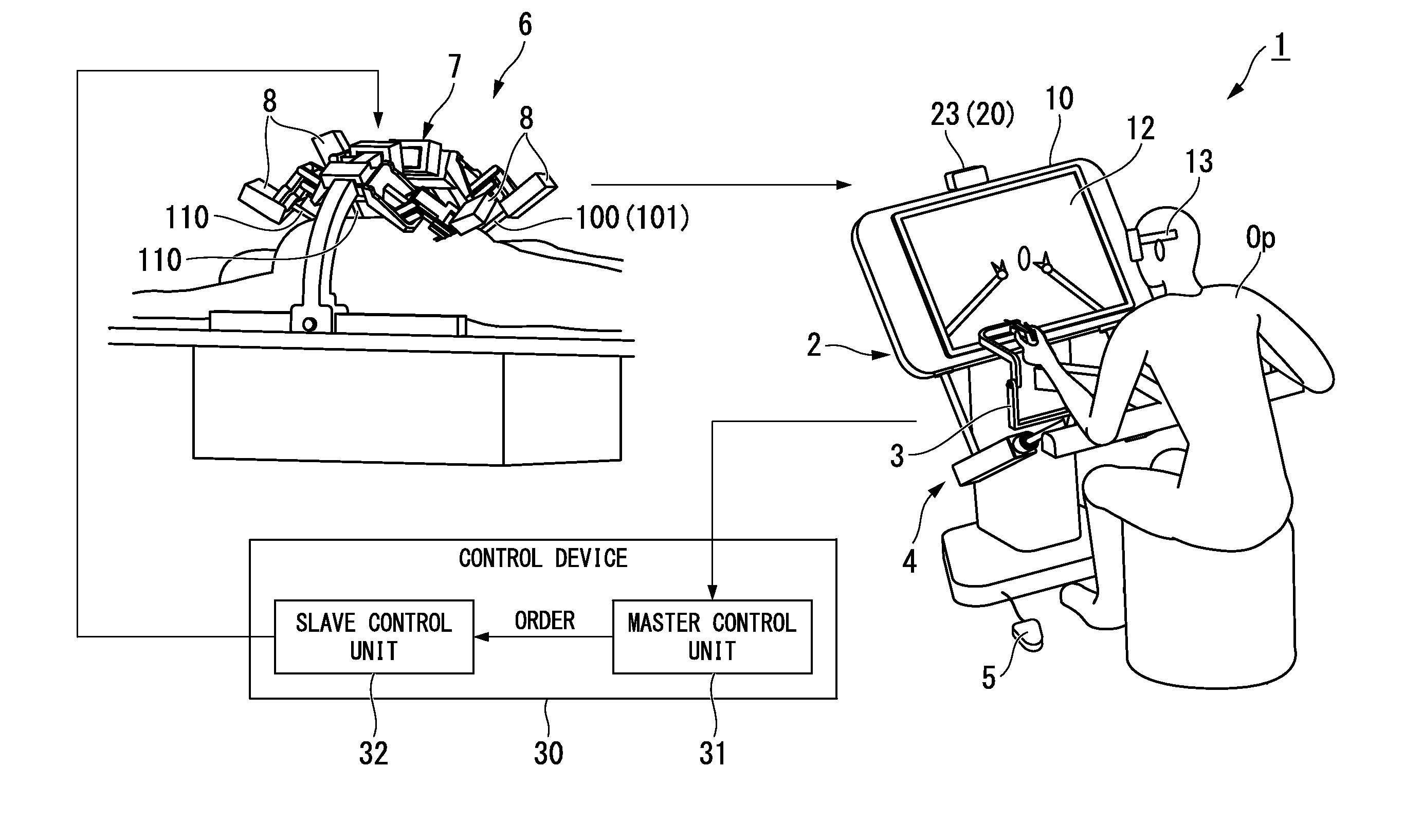

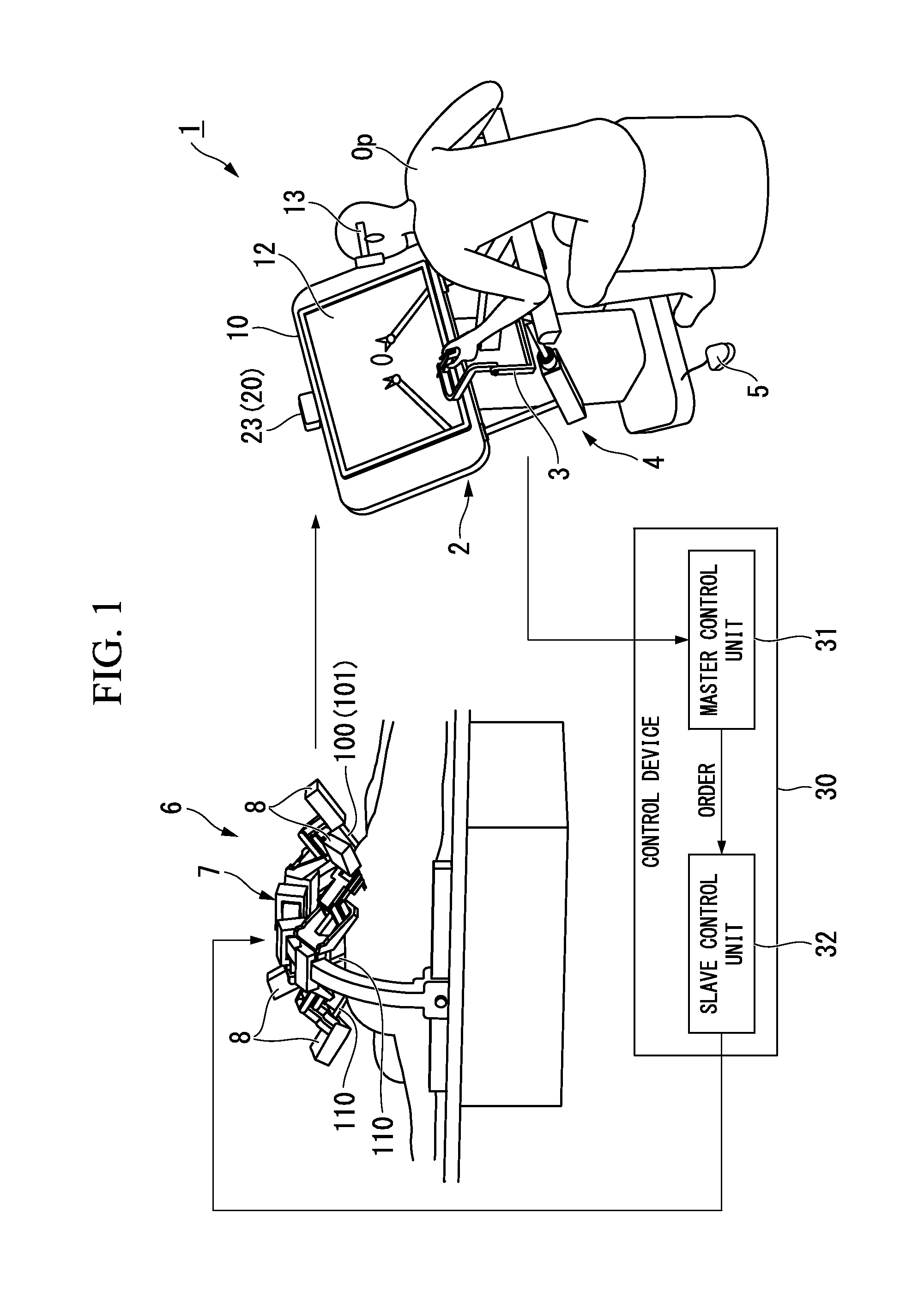

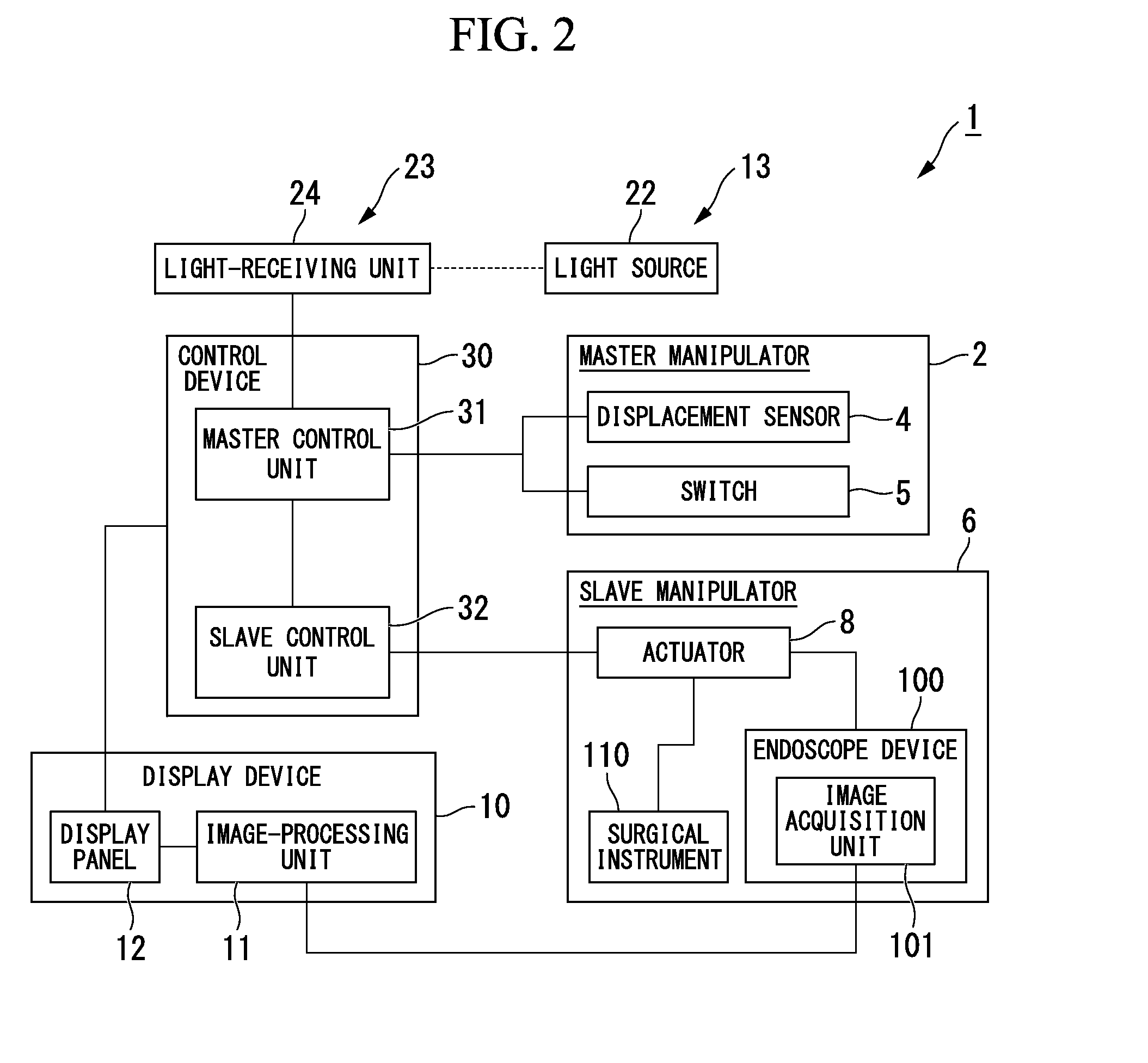

Manipulator system

A manipulator system includes a master manipulator configured to send an input command, a slave manipulator configured to operate according to the input command, an image capturing unit configured to acquire an image of an object, a display device placed in front of the operator and configured to display the image acquired by the image capturing unit, a detection device configured to detect the direction of an operator's face of the operator with respect to the display device, and a control unit configured to determine whether the direction of the operator's face is within a predetermined angle with respect to the display device based on the detection result in the detection device, and to shift an operation mode of the slave manipulator between a first control mode and a second control mode in which an operation is limited more than in the first control mode based on a determination result.

Owner:OLYMPUS CORP

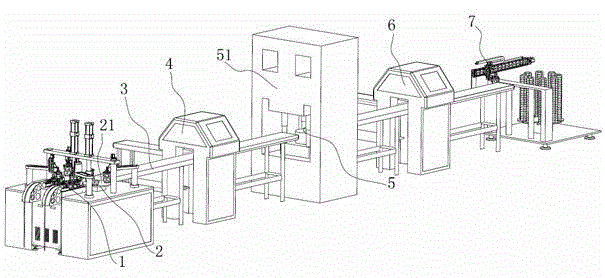

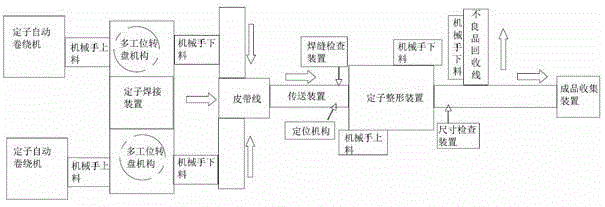

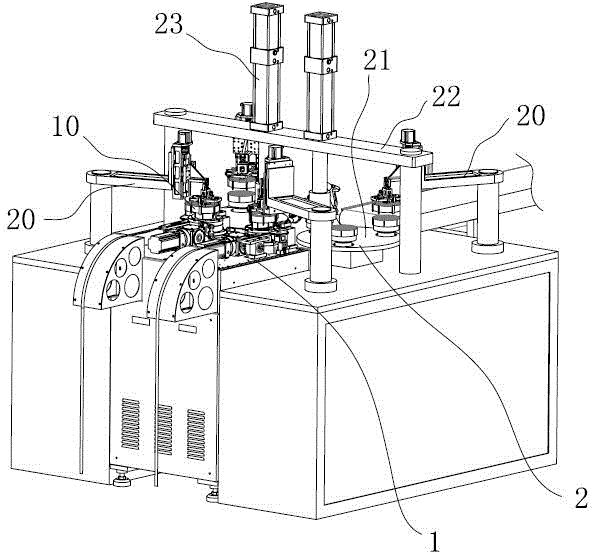

Automatic stator core production line

ActiveCN104810992ARealize intelligent productionIncrease productivityOther manufacturing equipments/toolsManufacturing stator/rotor bodiesWinding machineProduction line

The invention discloses an automatic stator core production line. The automatic stator core production line comprises an automatic stator winding machine, a stator welding device, a conveying device, a weld joint detecting device, a stator reshaping device, a size detecting device and a finished product collecting device, mechanical arm systems are arranged among the devices, and working instructions among the devices are achieved via an instruction system. The automatic stator core production line has the advantages that in the full process, mechanical arms are adopted, automatic pipeline operation is achieved, unqualified stator cores generated in working procedures during production can be removed automatically, intelligent production is achieved, production efficiency is improved, and production cost is reduced.

Owner:CHANGYING XINZHI TECH CO LTD

Automatic laminator and an automatic laminating method

ActiveCN104670937AQuality improvementShorten the effective strokeTransformers/inductances detailsInductances/transformers/magnets manufactureRobot handControl engineering

The invention discloses an automatic laminator and an automatic laminating method. The automatic laminator comprises an electric control cabinet, feed devices, lamination platforms, laminate output devices, a lamination robot, throwing devices, positioning devices and a manipulator system. The laminate output devices are mounted around the lamination robot, the lamination platforms are arranged on the left of the lamination robot, the throwing devices are mounted on the left of the lamination platforms, the positioning devices are mounted on the left of the throwing devices, the feed devices are mounted near the positioning devices, and the manipulator system is mounted between the feed devices and the positioning devices. Automatic lamination is performed by taking laminates via feeding and twin-axis manipulators, positioning via the positioning devices, throwing and laminating of the lamination robots and outputting via the laminate output devices. Silicon steel sheets can be laminated into a reliable-precision transformer iron core according to needs, labor intensity of operators is reduced and production efficiency is improved.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

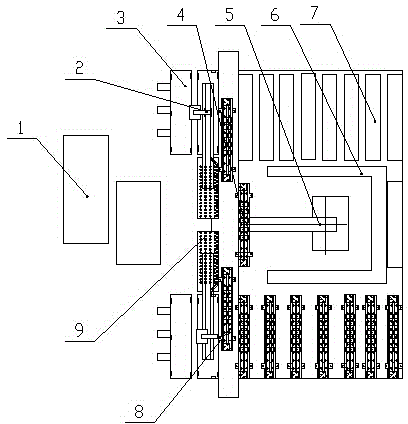

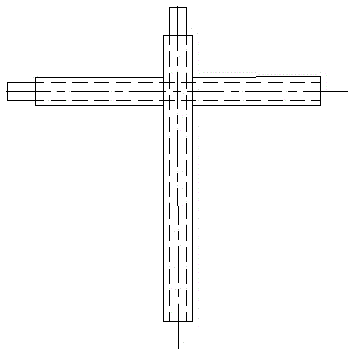

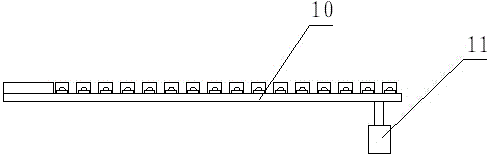

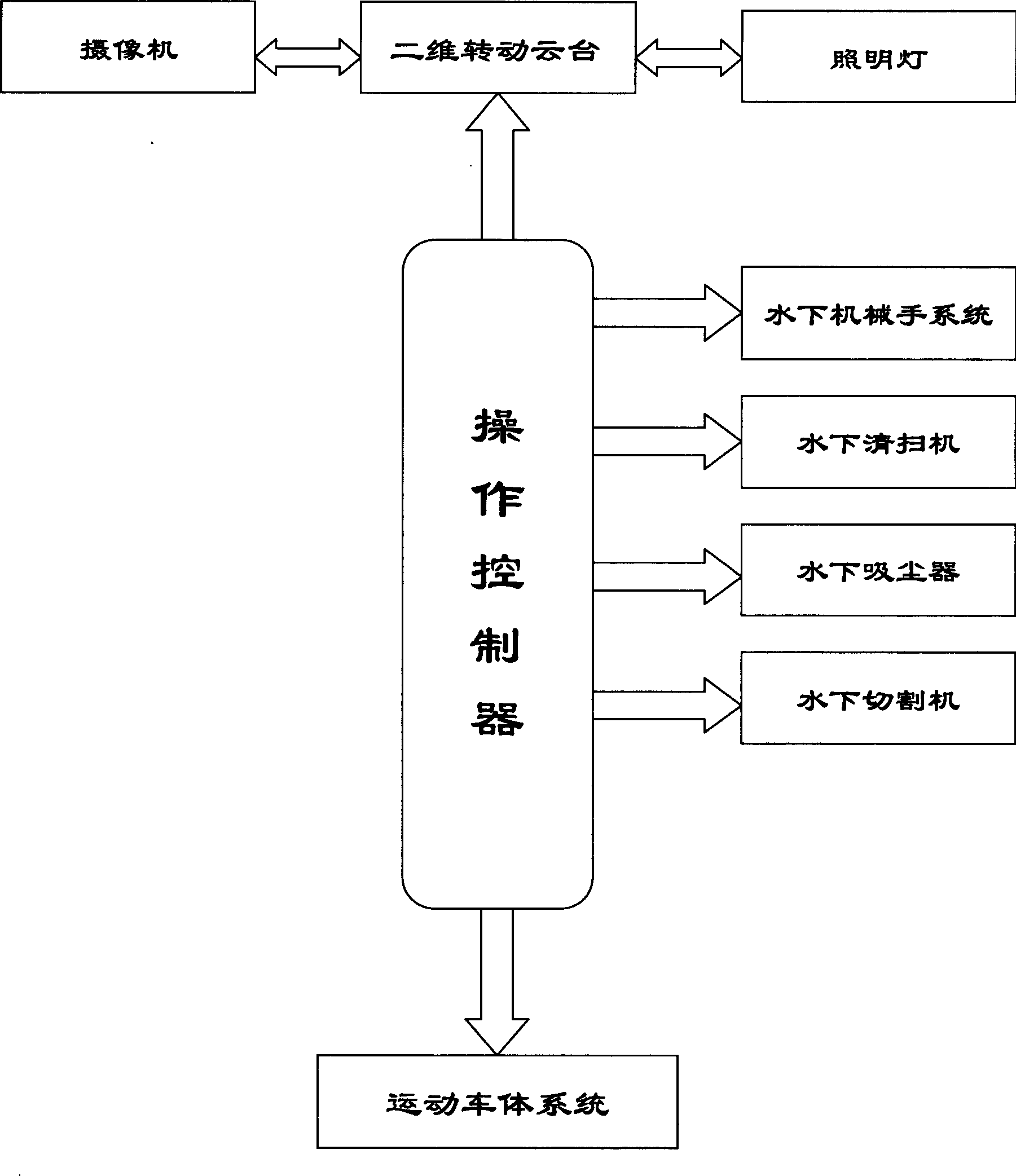

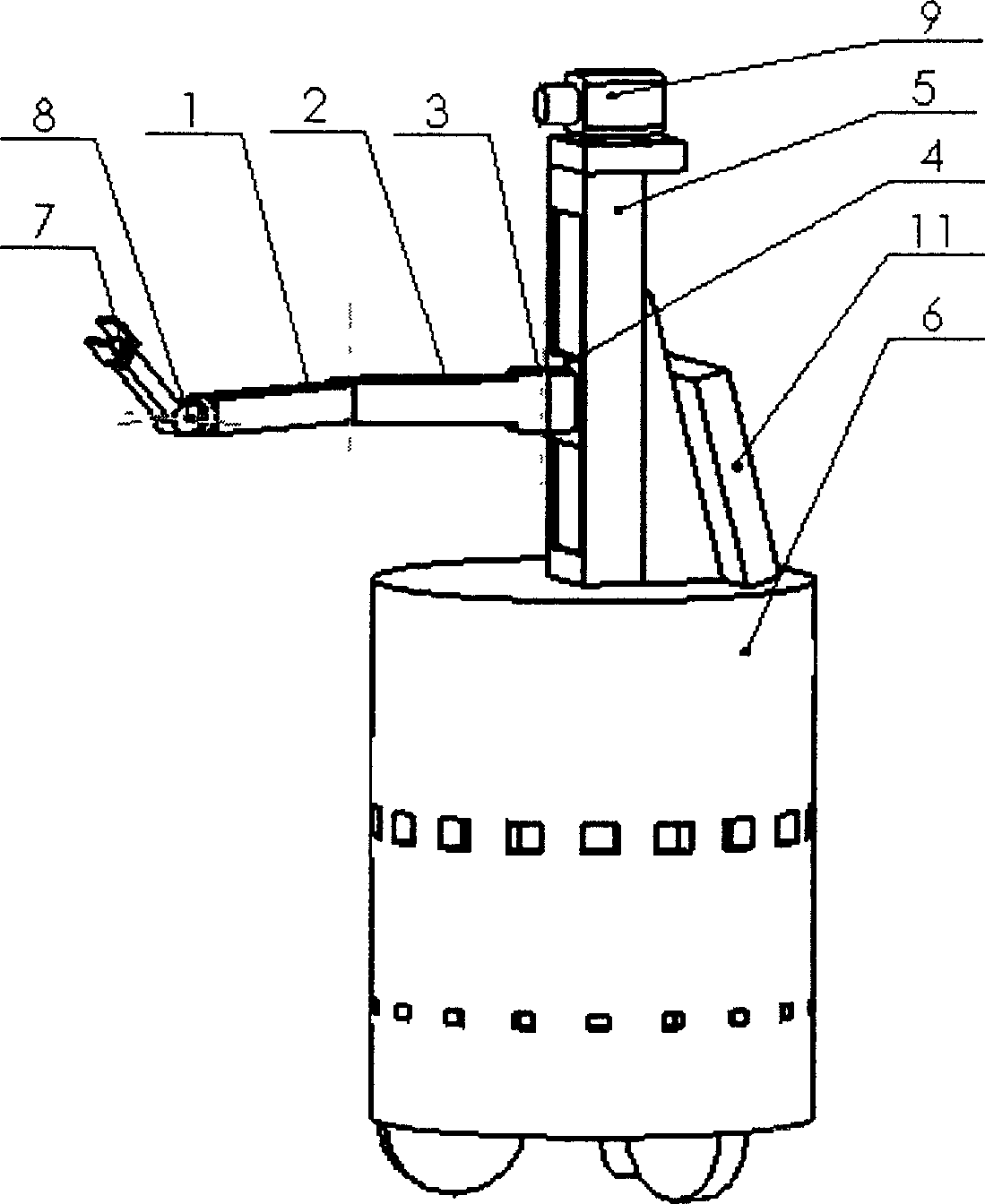

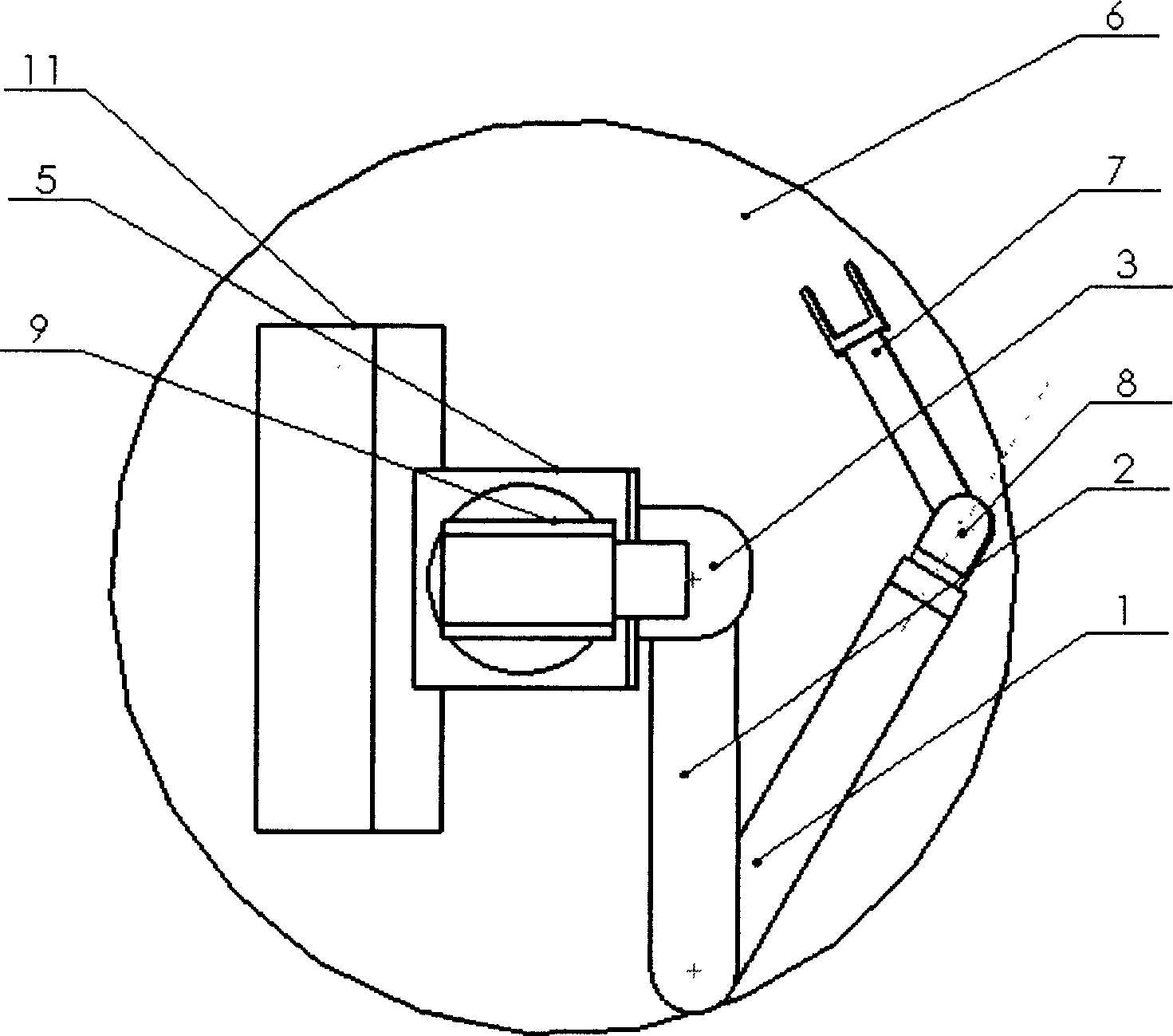

Multifunctional underwater robot

InactiveCN1876486AReduce volumeFunction increaseManipulatorUnderwater equipmentMarine engineeringControl line

The invention relates to an underwater multifunctional robot, which is characterized in that: it comprises a motion vehicle system, a underwater camera system carried on the motion vehicle system, a mechanical hand system, function elements, and operation controller, wherein said function elements comprises one or the combination of underwater cleaner, underwater adsorption pump, underwater cutter, or underwater bonding machine; the operation controller via control line is connected to the motion vehicle system, mechanical hand system, function elements and underwater camera system to drive or control them. The invention has small volume, complete function, high automatic degree, wide application, high reliability, and simple operation, which it can be used in worse condition.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Manipulator system and control apparatus

A manipulator has an operation command unit and an exchangeable working unit. The working unit comprises an end effector operable under actions of a control apparatus, and an ID retaining section holding an ID for individualized discrimination of the working unit. The control apparatus includes an ID identification section for identifying the ID and for determining whether the working unit is connected to the operation command unit, an origin point recognition section for recognizing whether the end effector is in a prescribed origin point position or in a non-origin point position, and a warning section which generates a detachment warning when it is determined that the end effector has been detached from the operation command unit, in the event it is determined that the end effector is in a non-origin point position.

Owner:KARL STORZ GMBH & CO KG

Manipulator system

Owner:KARL STORZ GMBH & CO KG

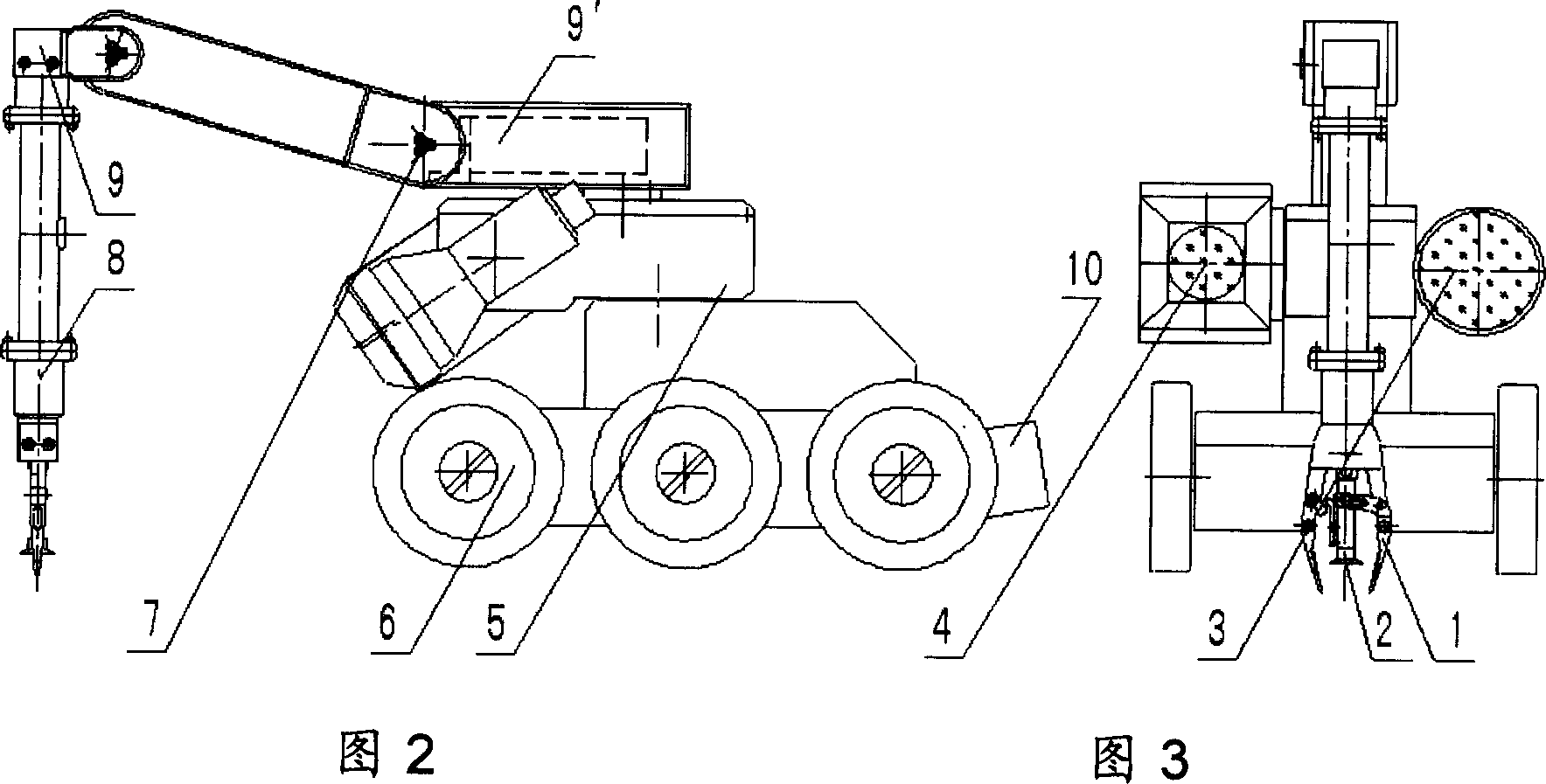

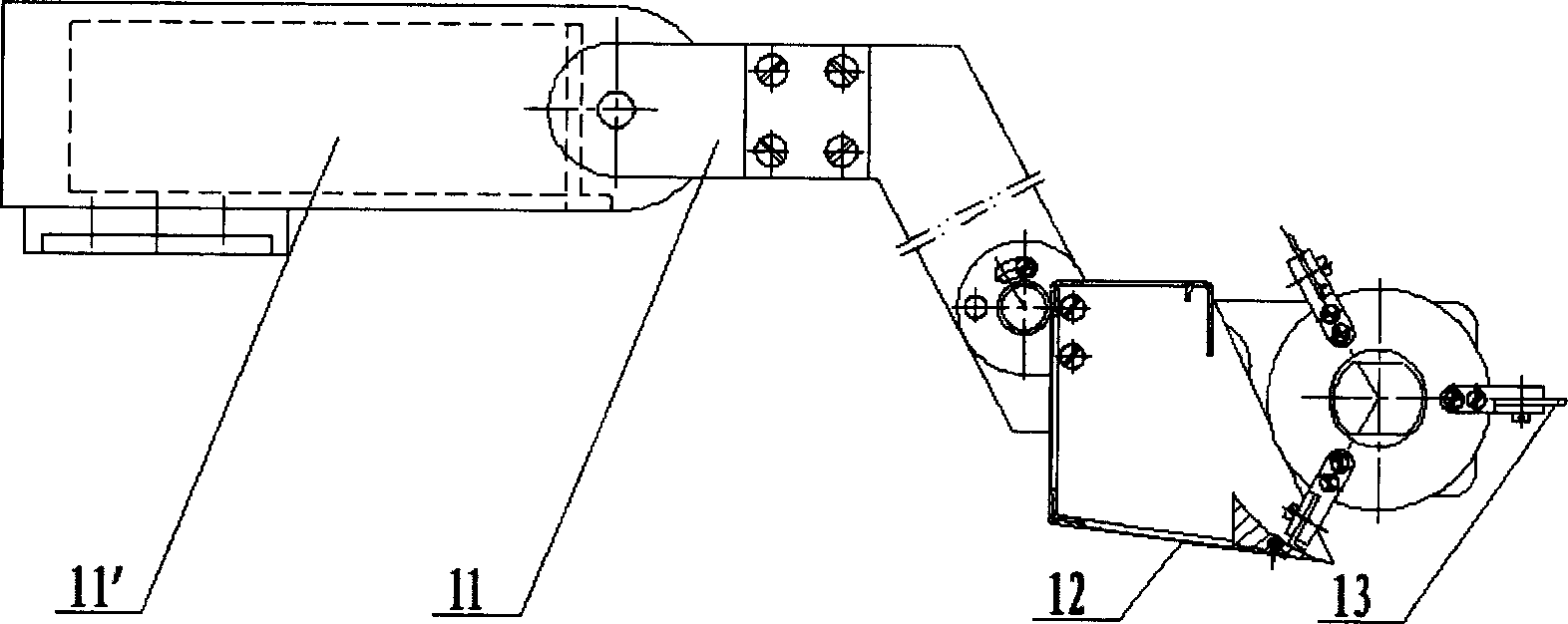

Movable manipulator system

The present invention relates to a mobile robot system, include a 3-freedom mobile platform, a 5-freedom robot, vision system and comptuer control system. Its camera with rotation and pitching function is mounted in the top end of straight-line guideway of robot, the mobile platform can implement forward, backward, leftward, rightward and automatic revolving 3-freedom omnibearing movement, and its 5-freedom robot is consisted of 1 moving joint and 4 turning joints, and its operation is flexible. The movement of said robot can implement large range movement operation function. Besides, said invention also provides the application range and method of said mobile robot system.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

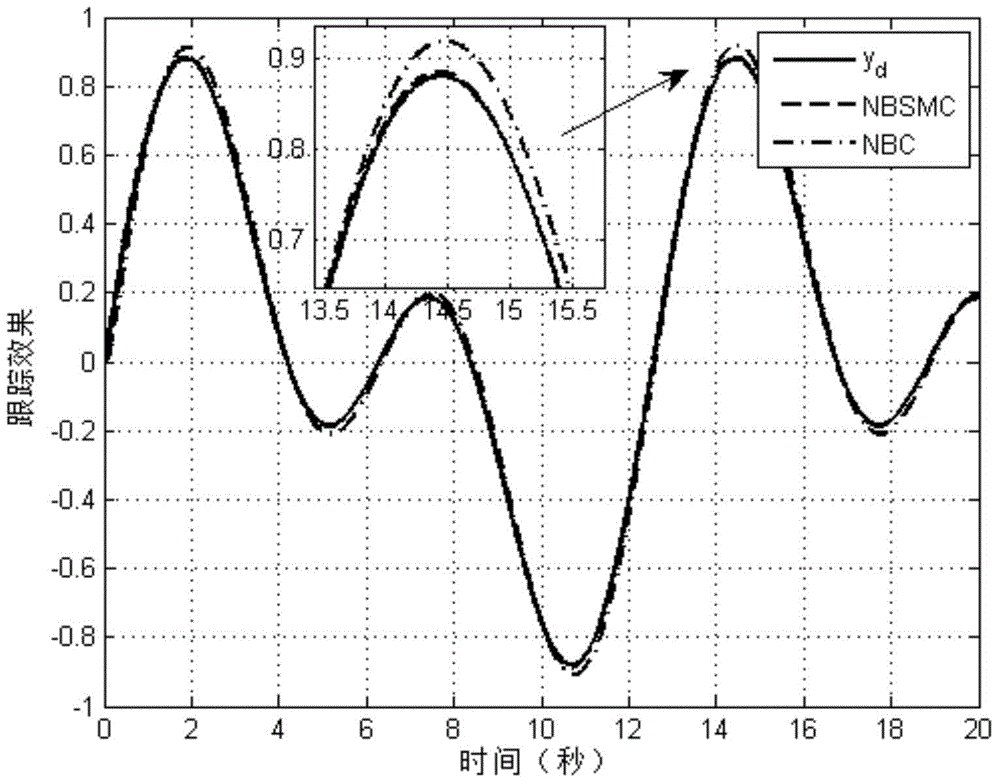

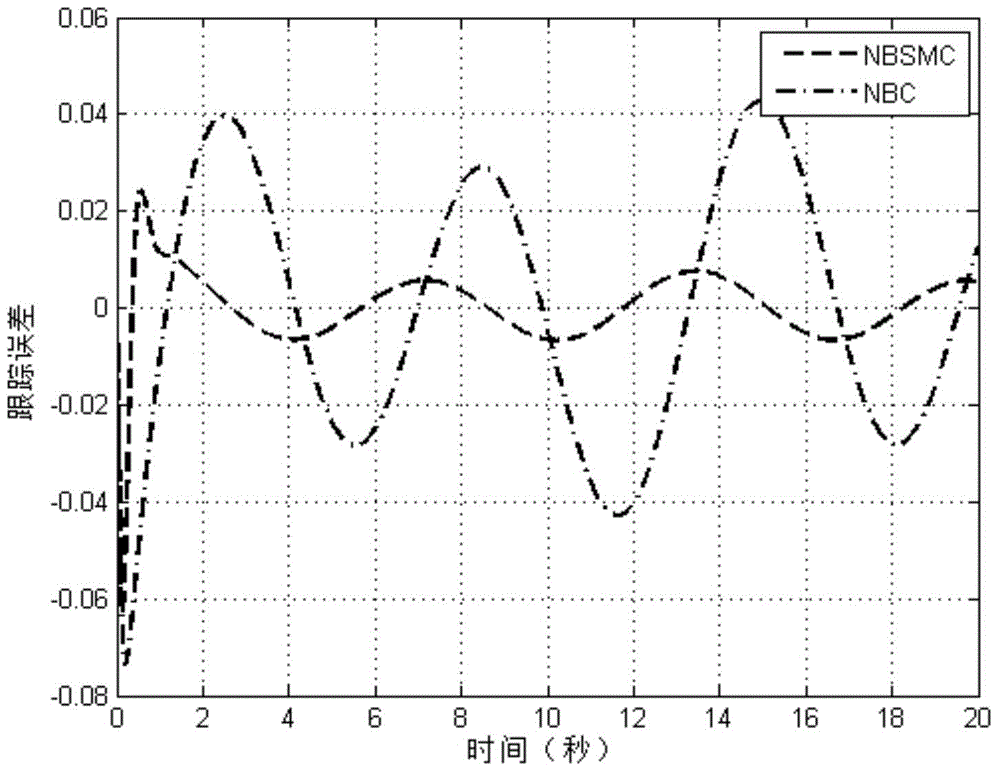

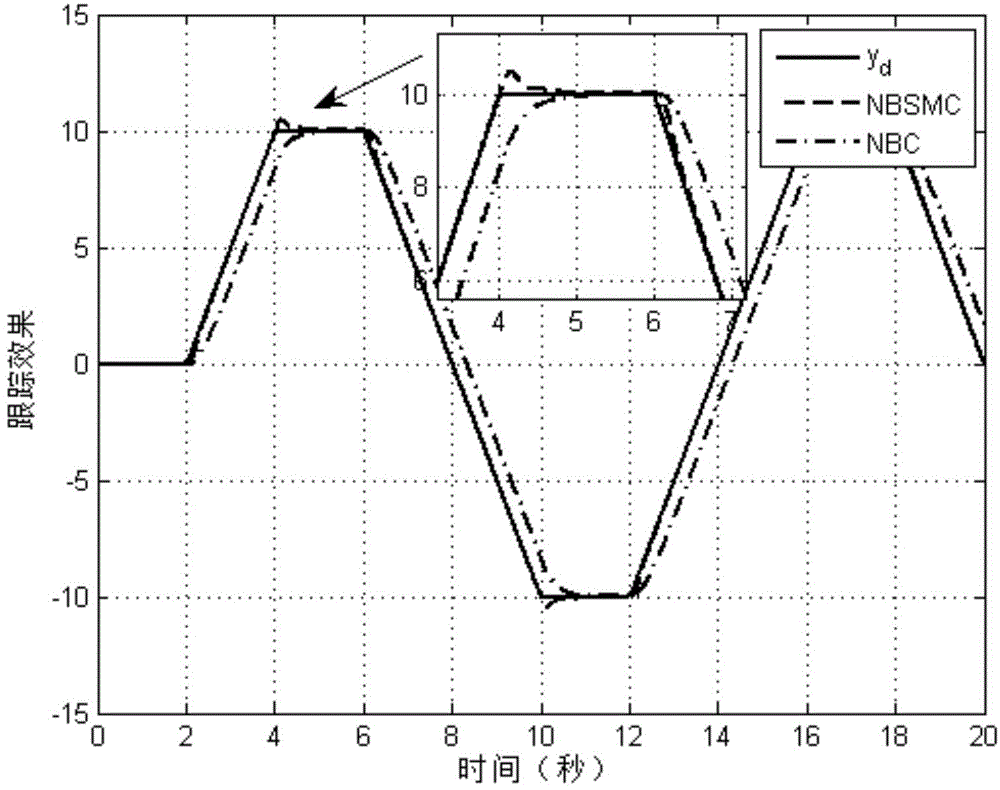

Neural network inversion control method for flexible manipulator system

ActiveCN104950678AAvoid Control Chattering ProblemsRealize position tracking controlAdaptive controlDynamic modelsModel parameters

The invention discloses a neural network inversion control method for a flexible manipulator system. The neural network inversion control method comprises the following steps of establishing a dynamic model of a flexible manipulator servo system and performing equivalent transformation on the dynamic model, and initializing a system state, sampling time and a control parameter; introducing a virtual control variable into the design of each step by combining sliding-mode control and an inversion method, and finally deducing self-adapting controller input; calculating the tracking error, the integral sliding mode surface, the error variable and the differential of a control system. Meanwhile, by utilizing the approximation characteristic of a neural network, the complexity explosion problem brought by the inversion method and the approximation of model parameter uncertainty are avoided; the invention provides the neural network inversion control method capable of effectively improving the location tracking control performance of the flexible manipulator servo system, therefore the stable and rapid tracking of the system is realized.

Owner:GUANGZHOU ETON ELECTROMECHANICAL

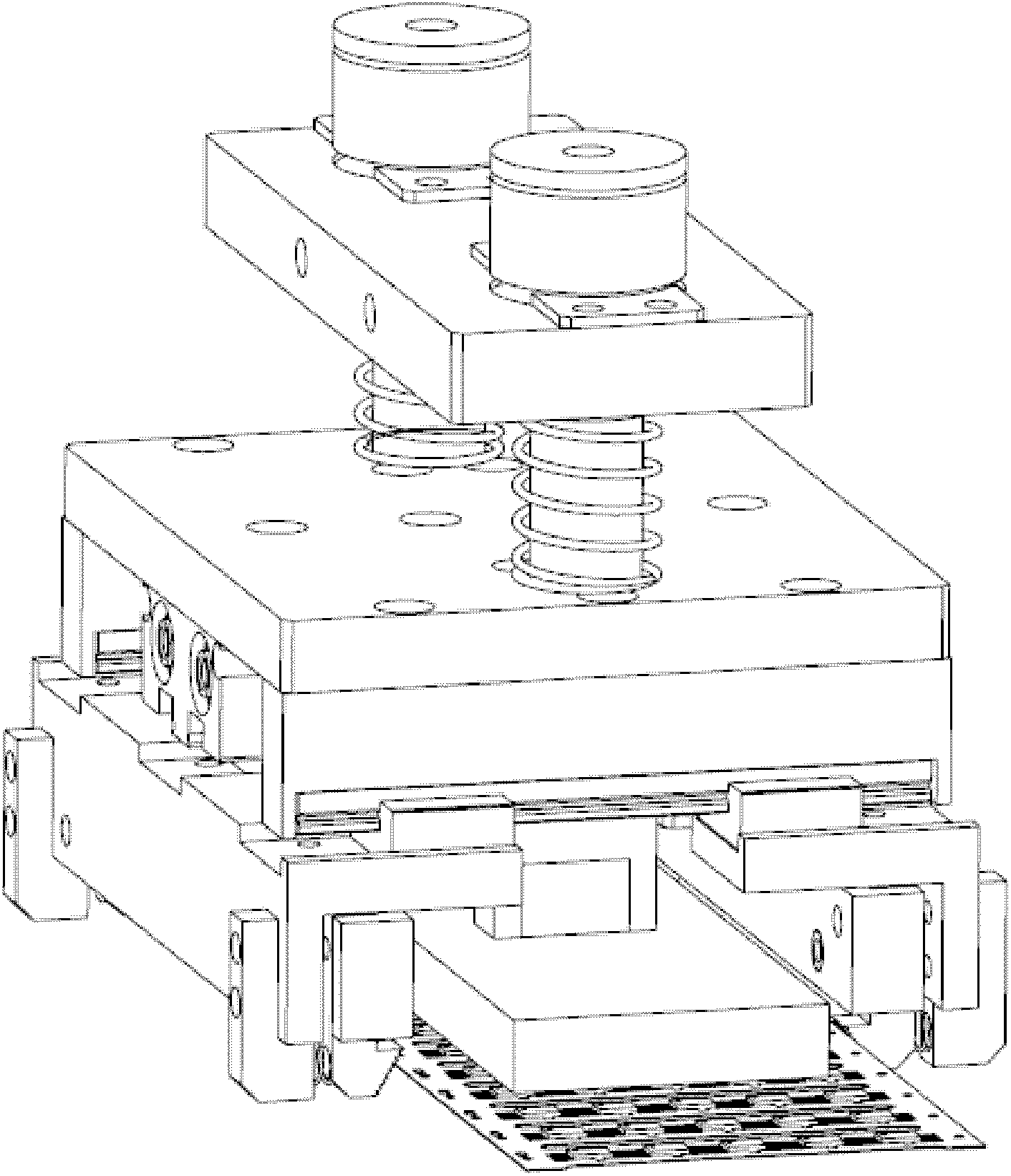

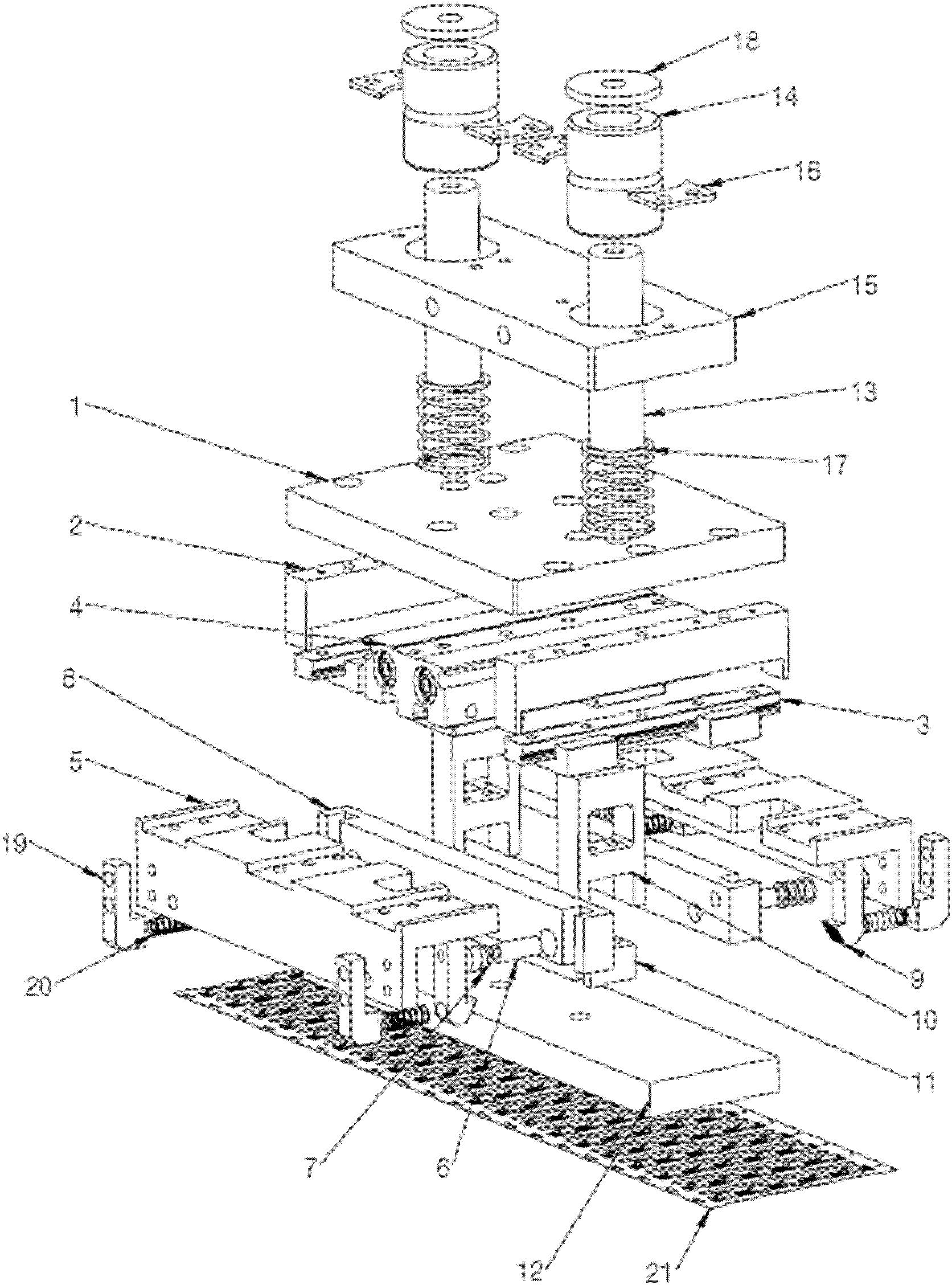

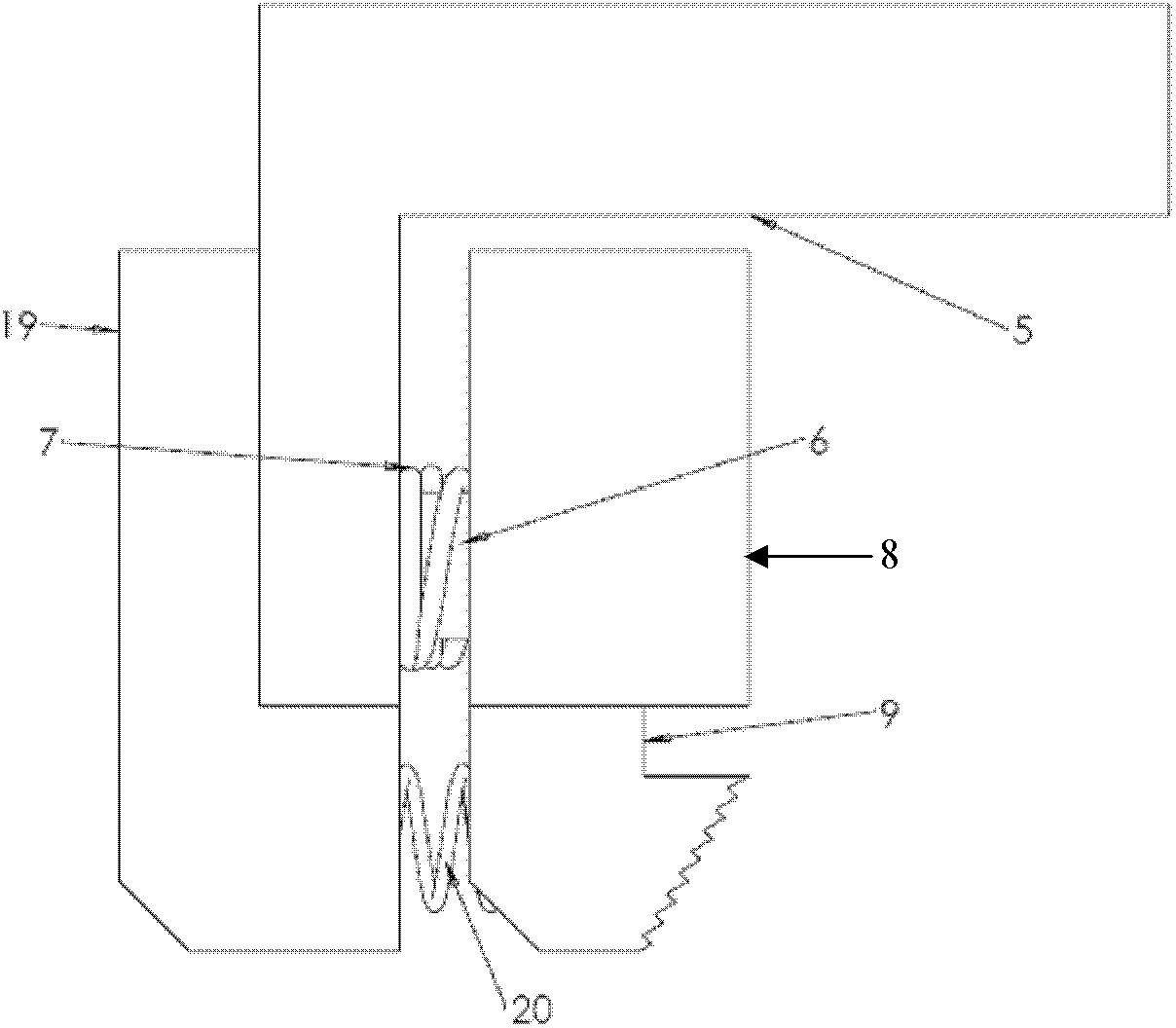

Grabbing manipulator system for semiconductor packaging equipment

ActiveCN102569148ASimple structureDoes not take up spaceGripping headsSemiconductor/solid-state device manufacturingSemiconductor packageEngineering

The invention relates to a grabbing manipulator system for semiconductor packaging equipment. The system comprises a mechanical grabbing device, an air cylinder grabbing device and a pressing plate buffering device, wherein the mechanical grabbing device comprises a guide rod fixing block, a claw, a guide rod, a first spring and a grabbing fixing block; the air cylinder grabbing device comprises an air claw, a slide rail fixing block and a slide rail; and the pressing plate buffering device comprises a substrate, a guide shaft, a third spring, a guide shaft fixing plate, a stop sheet, a linear bearing, a pressing plate and a pressing plate fixing block. Compared with the prior art, the manipulator system for grabbing the semiconductor packaging equipment is simple in structure, does not occupy space, and can adapt to a semiconductor product of which width and thickness are in certain range; when different types of products are machined, replacement and adjustment are not required; the equipment is stable in running and low in cost; and the production efficiency and the utilization efficiency of the equipment are greatly improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

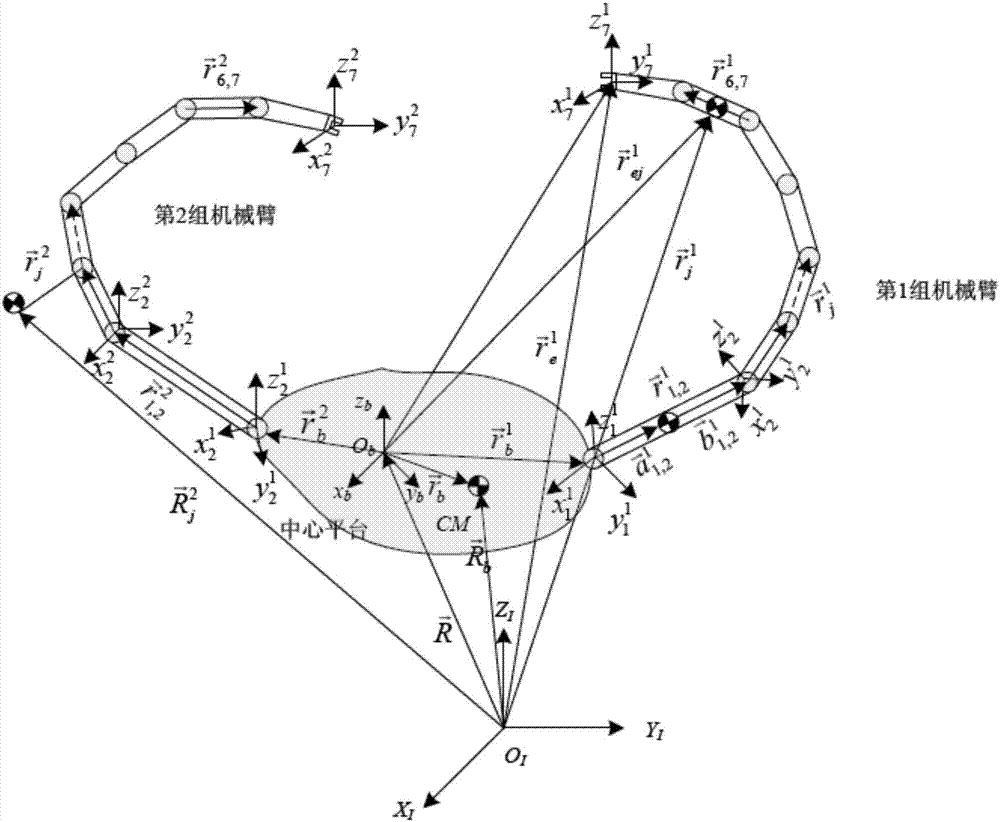

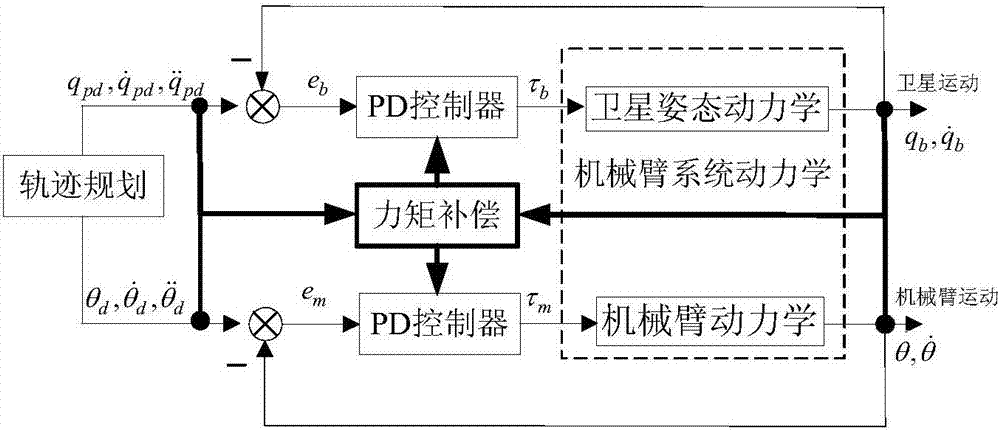

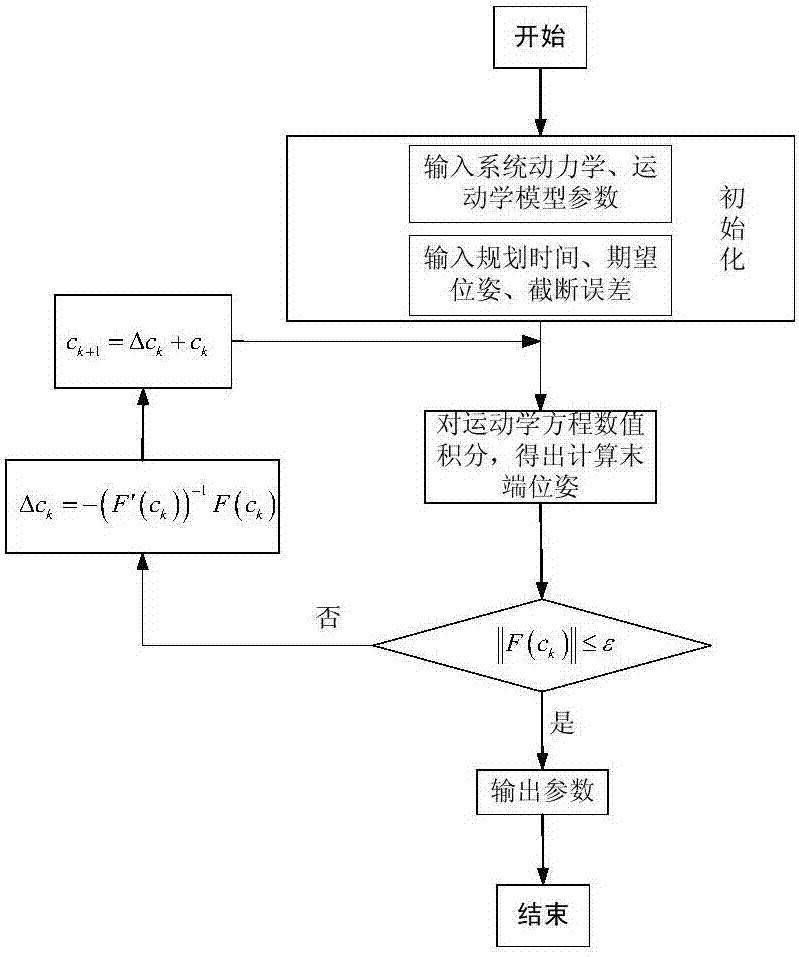

Motion coordination control method for space dual-manipulator system

ActiveCN106945020AFast trackImprove operating precisionProgramme-controlled manipulatorKinematics equationsControl system

The invention relates to a motion coordination control method for a space dual-manipulator system, and belongs to the technical field of space manipulators. In order to overcome the defects that no space manipulator system specific to dual manipulators exists at present, the coordinated relation between a manipulator and a satellite body is not considered in an existing space manipulator system and tracking errors are high, the motion coordination control method for the space dual-manipulator system is provided. The motion coordination control method for the space dual-manipulator system includes the steps that a kinematical equation and kinetic equation of the space dual-manipulator system are established; the space dual-manipulator system is subjected to trajectory planning according to the initial postures and tail-end postures of the manipulators; and trajectories of the space dual-manipulator system are subjected to tracking control through a PD controller. The motion coordination control method for the space dual-manipulator system is suitable for a space manipulator control system.

Owner:黑龙江省工研院资产经营管理有限公司

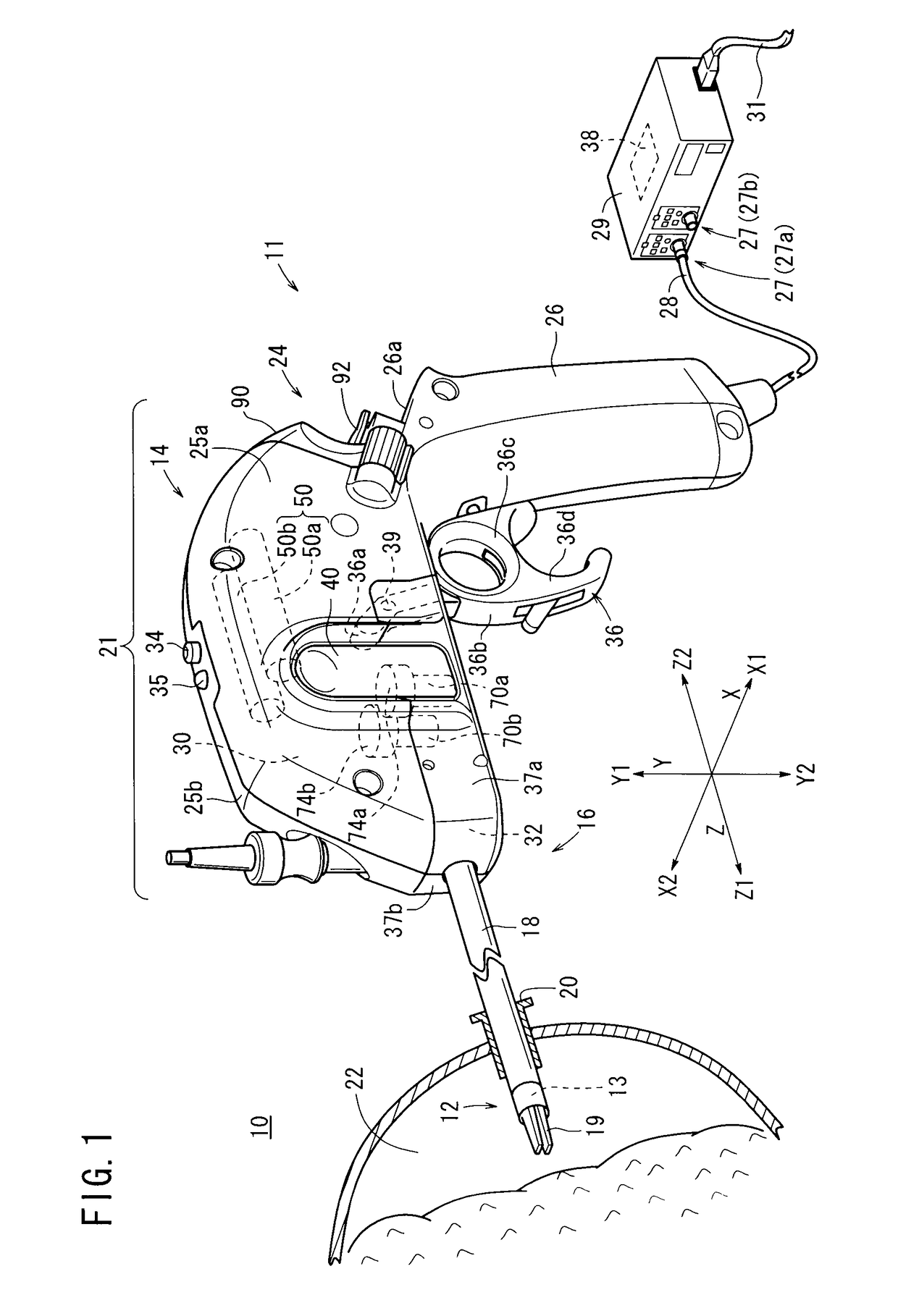

Medical manipulator system

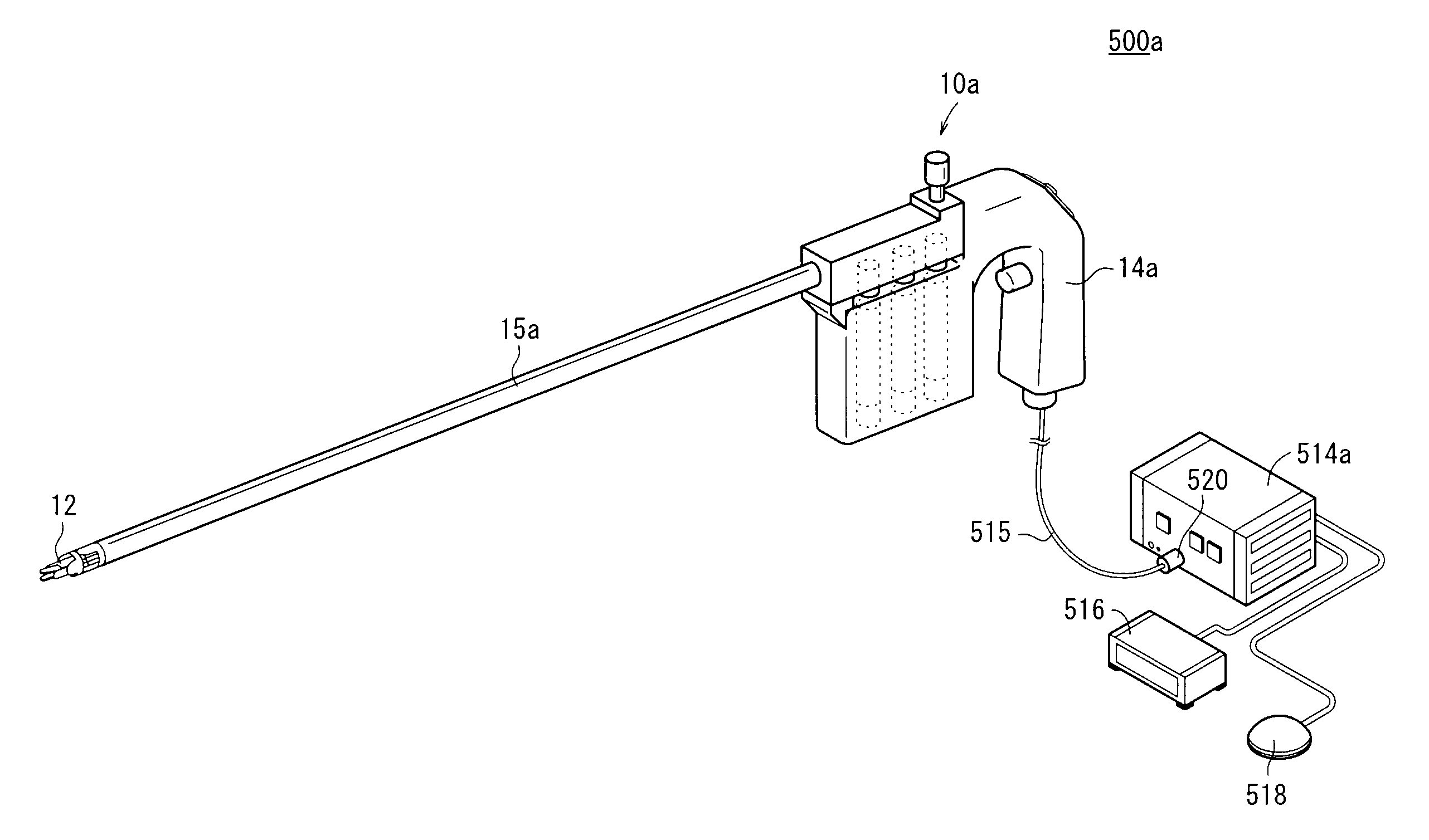

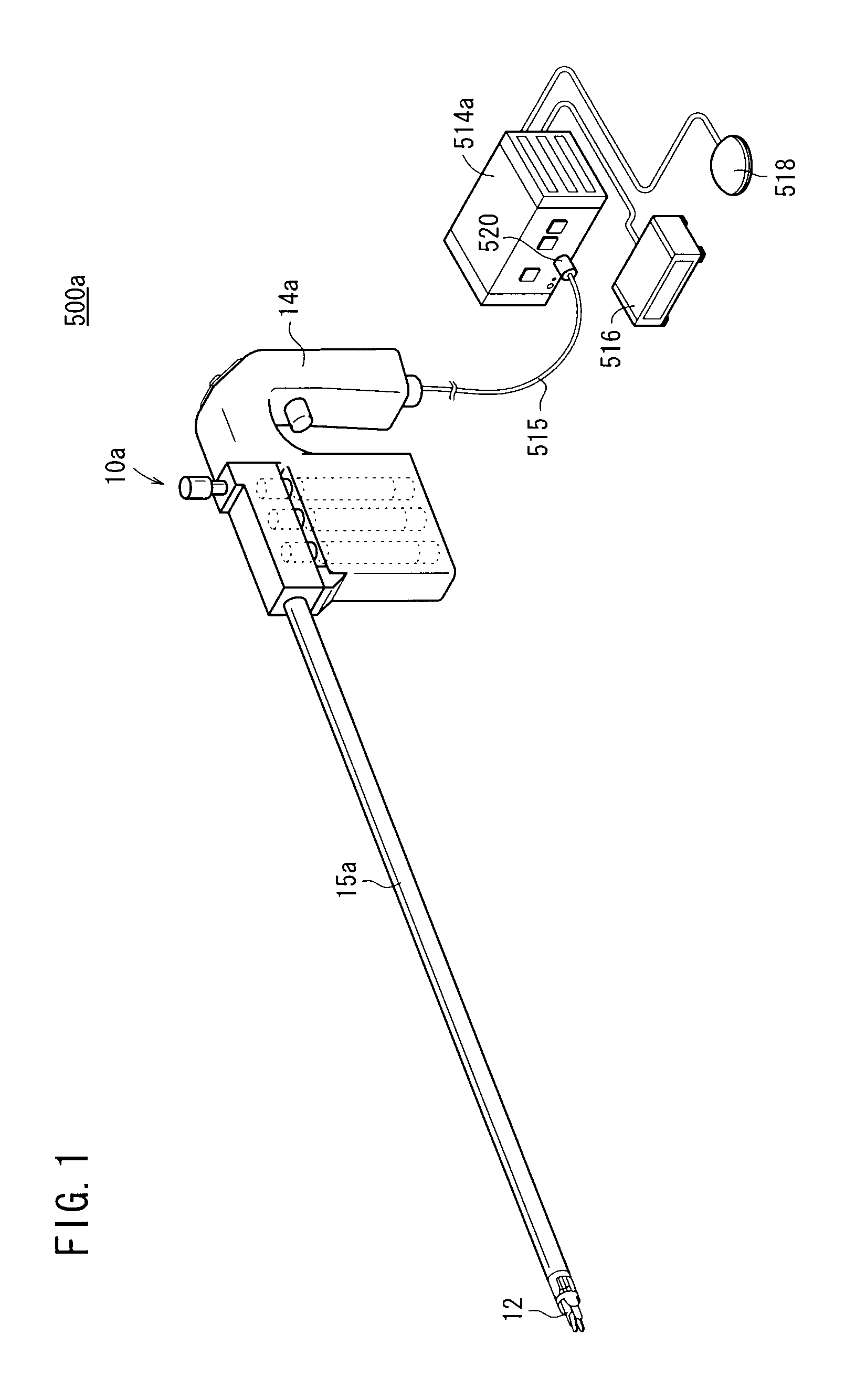

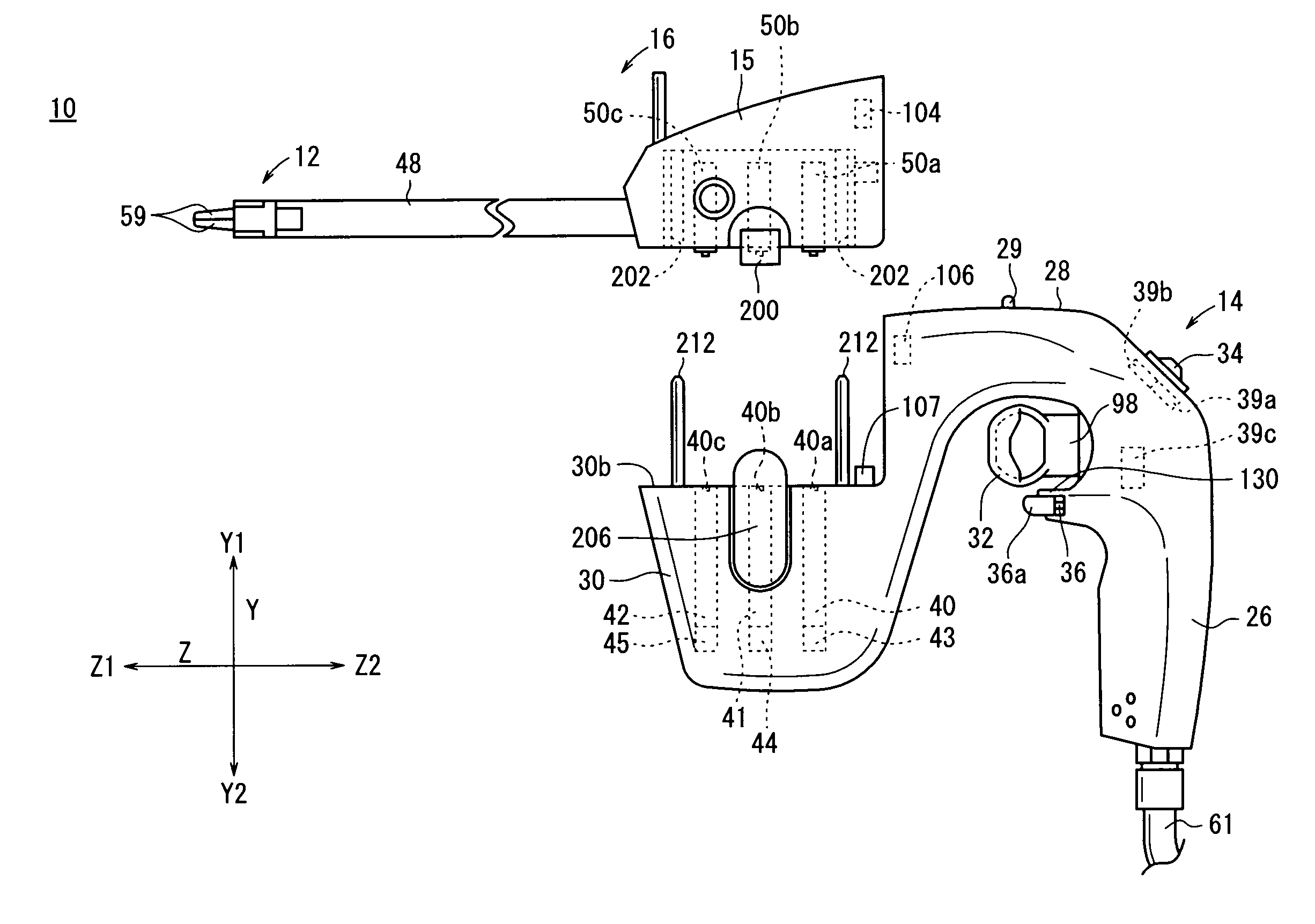

ActiveUS20090036901A1Efficient executionEasy to confirmDiagnosticsSurgical manipulatorsWork unitDrive motor

A medical manipulator system includes a medical manipulator, an operating unit for inputting operation commands, motors for driving a working unit, a controller for driving the motors based on operation commands supplied from the operating unit, and an LED that displays an operational state. The controller carries out controls for distinguishing between an operational mode in which the operation command is validated and the motors are driven, and a stopped mode in which the motors are halted regardless of whether the operation command is present or not. An illumination state of the LED is switched dependent on whether the system is in the operational mode or the stopped mode. The LED is disposed in the center of an upper surface of a bridge, which interconnects a grip handle and an actuator block.

Owner:KARL STORZ GMBH & CO KG

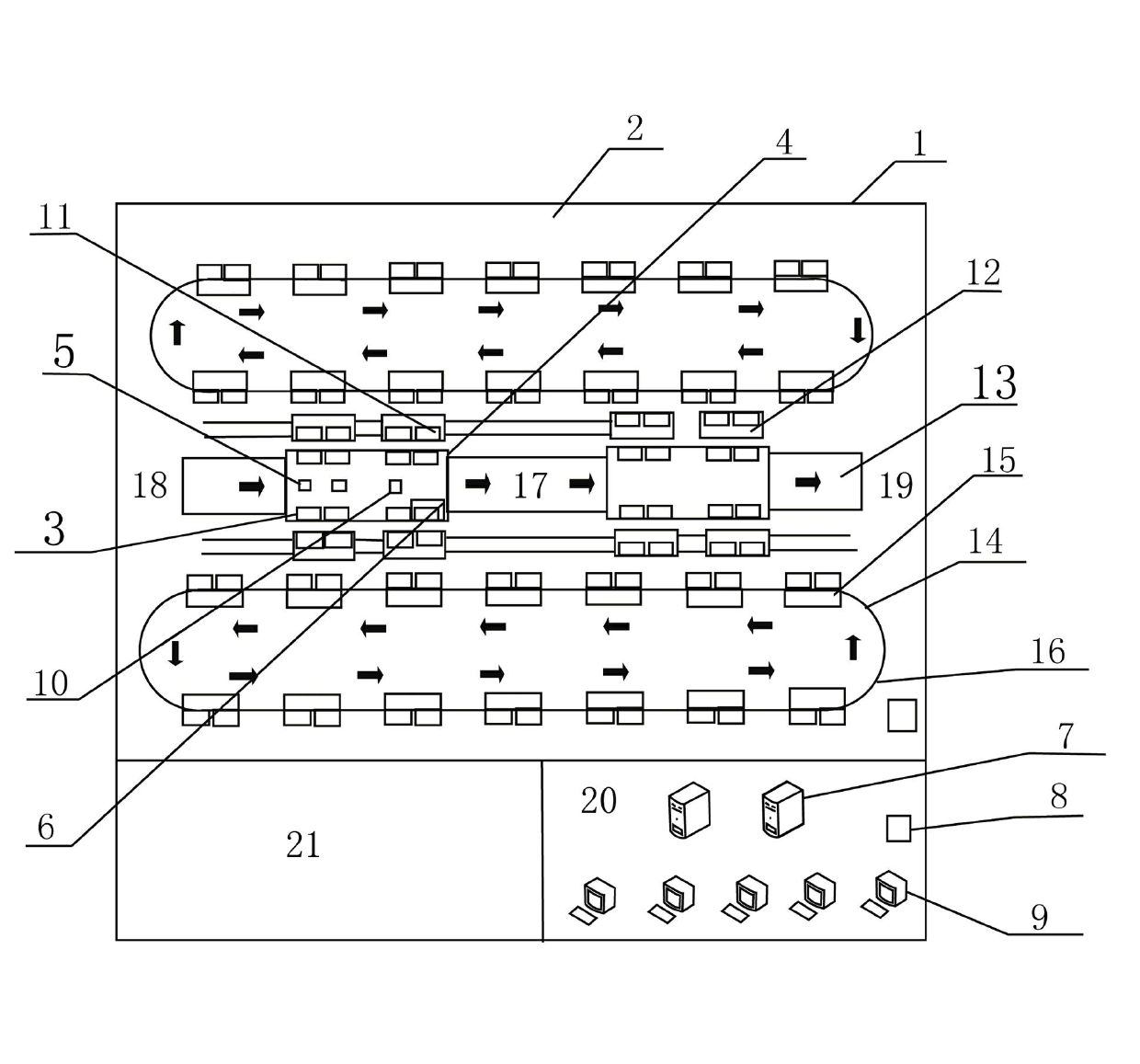

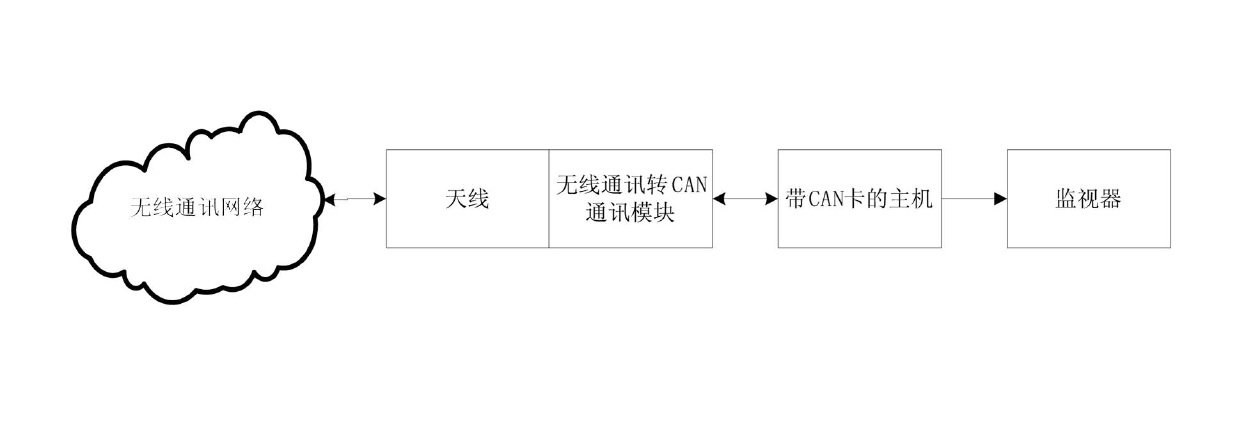

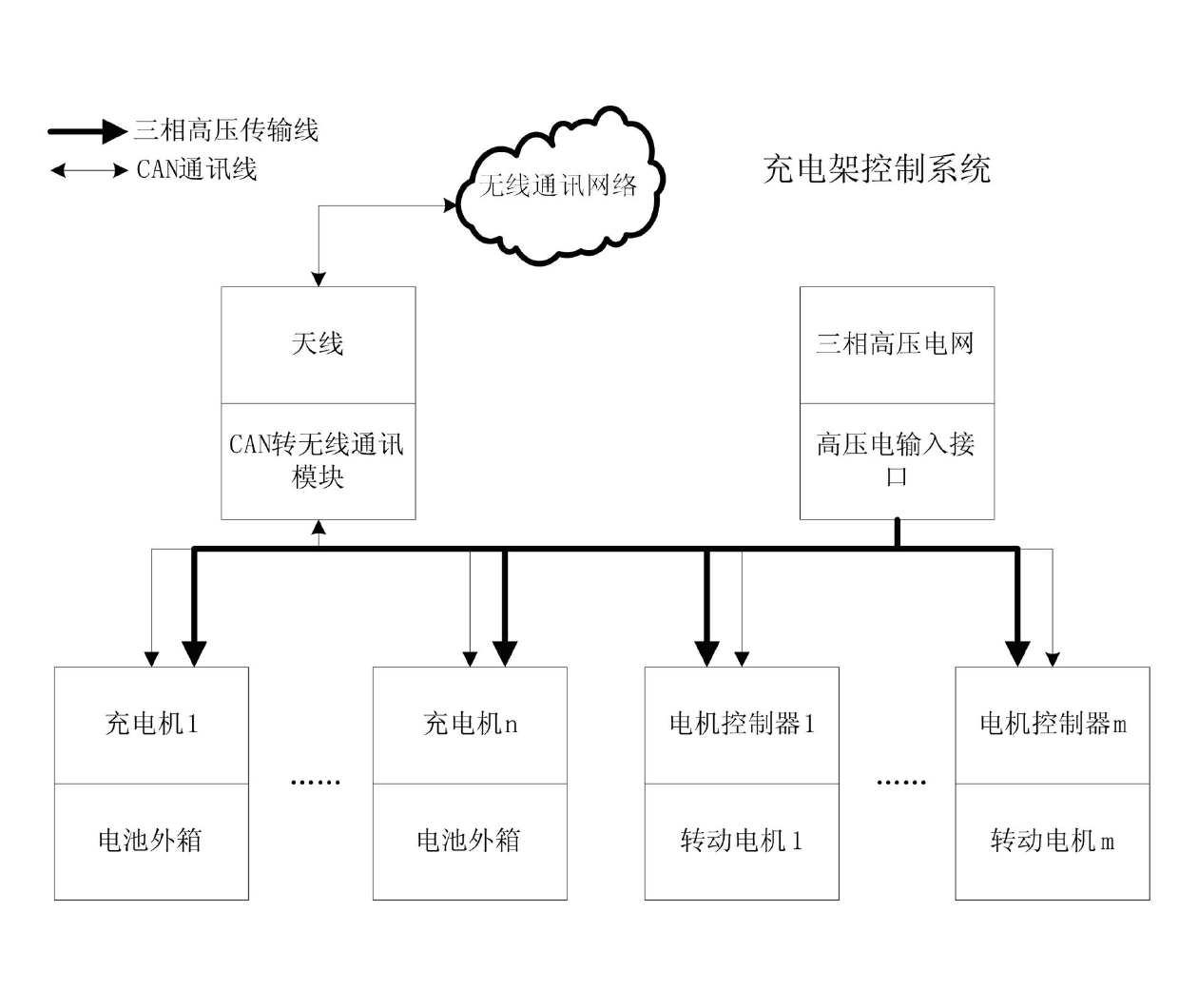

Fast-replacement station for power battery of pure electrically-driven vehicle

The invention relates to a fast-replacement station for a power battery of a pure electrically-driven vehicle. A pure electrically-driven vehicle integrated control system, a fast-replacement manipulator system, a vehicle transferring control system, a charging rack operation control system, a charging machine control system and a monitoring scheduling system are connected together in a wireless communication manner to form an intelligent fast-replacement system for the power battery of the pure electrically-driven vehicle. Automatic vehicle inbound, parking, battery pack cabin door opening, battery pack unlocking, battery replacing, battery pack locking, battery pack cabin door closing and vehicle outbound can be realized through the intelligent fast-replacement system, thus the power battery in the vehicle can be automatically replaced rapidly and conveniently.

Owner:BIT HUACHUANG ELECTRIC VEHICLE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com