Automatic stator core production line

A technology for automated production lines and stator cores, which is used in the manufacture of stator/rotor bodies, metal processing, and manufacturing tools, etc., and can solve problems such as defective products and lack of dimensional inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

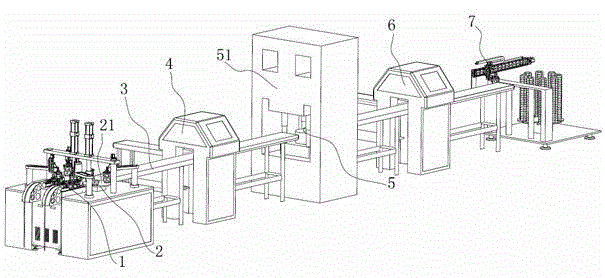

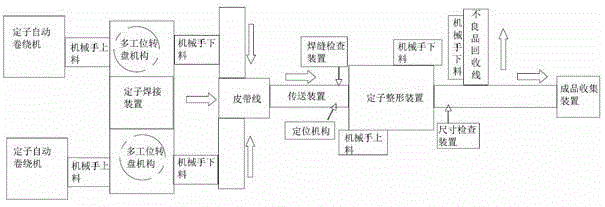

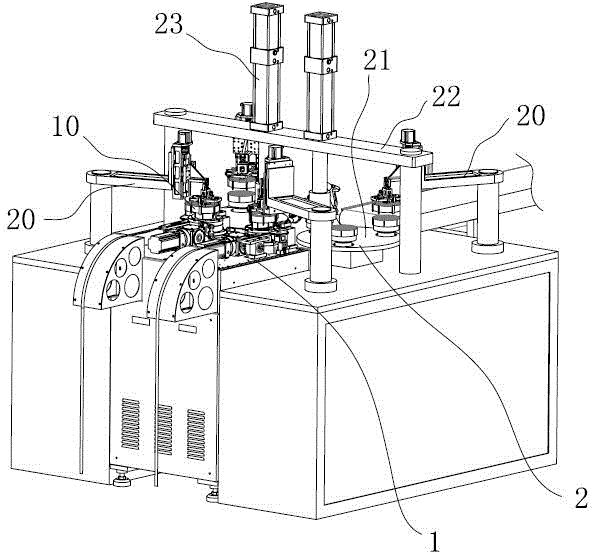

[0020] Such as figure 1 , 2 As shown, the stator core automatic production line includes a stator automatic winding machine 1, a stator welding device 2, a transmission device 3, a weld inspection device 4, a stator shaping device 5, a size inspection device 6 and a finished product collection device 7, among which There is a manipulator system between the devices, and the work instructions between the devices are realized through the instruction system. The stator automatic winding machine 1 sends the coiled and formed spiral stator laminations 10 into the multi-station turntable mechanism 21 of the stator welding device 2 through the automatic stator feeding manipulator; the welding of the stator welding device 2 The gun receives the instruction to carry out the compression welding operation on the stator laminations 10 corresponding to the station on the turntable mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com