Equipment specially used for diamond drying

A special equipment, diamond technology, applied in the direction of drying solid materials, lighting and heating equipment, drying, etc., can solve the problems of slow drying efficiency, long drying cycle, low output, etc., to improve efficiency, reduce energy consumption, broad The effect of market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

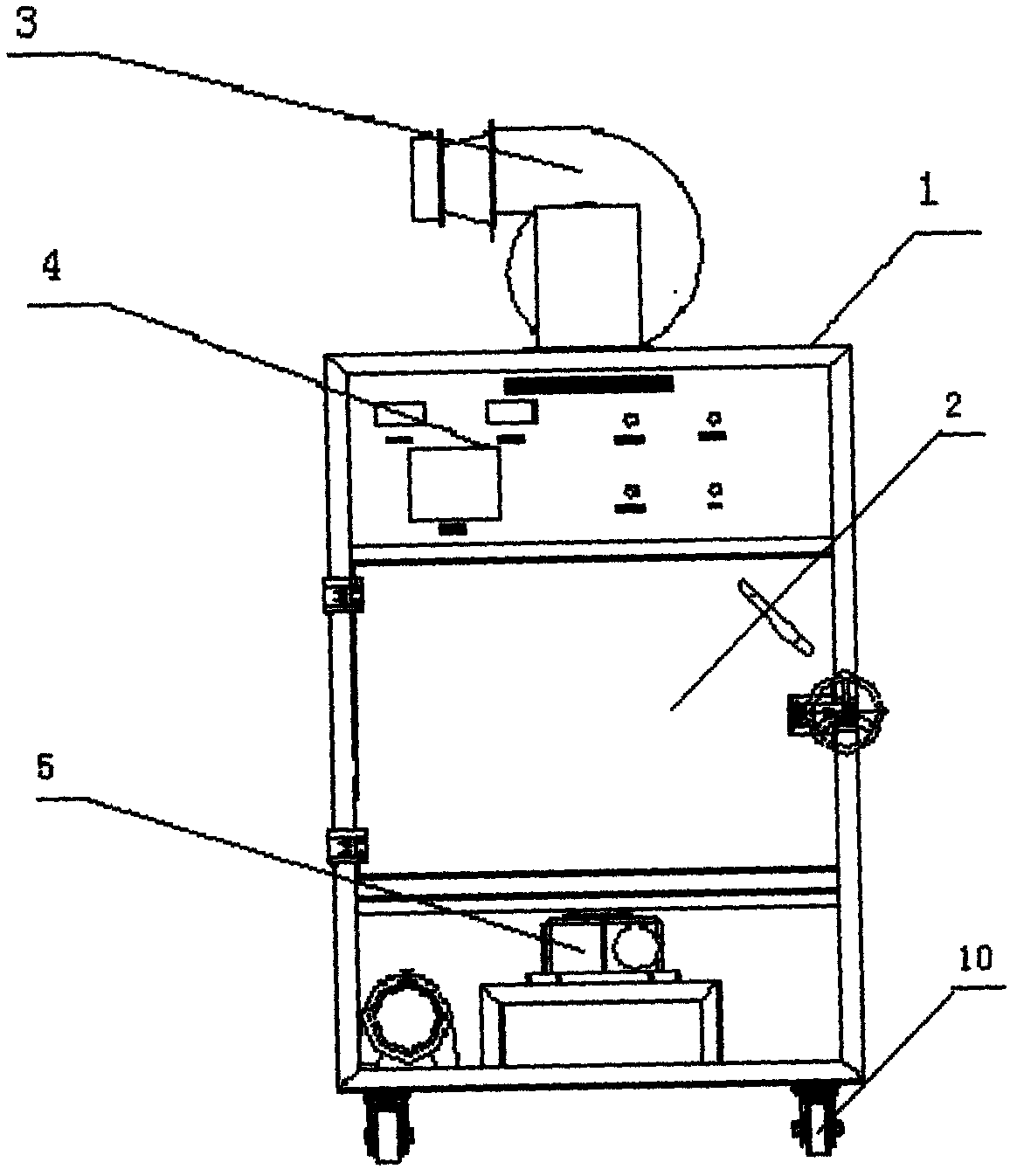

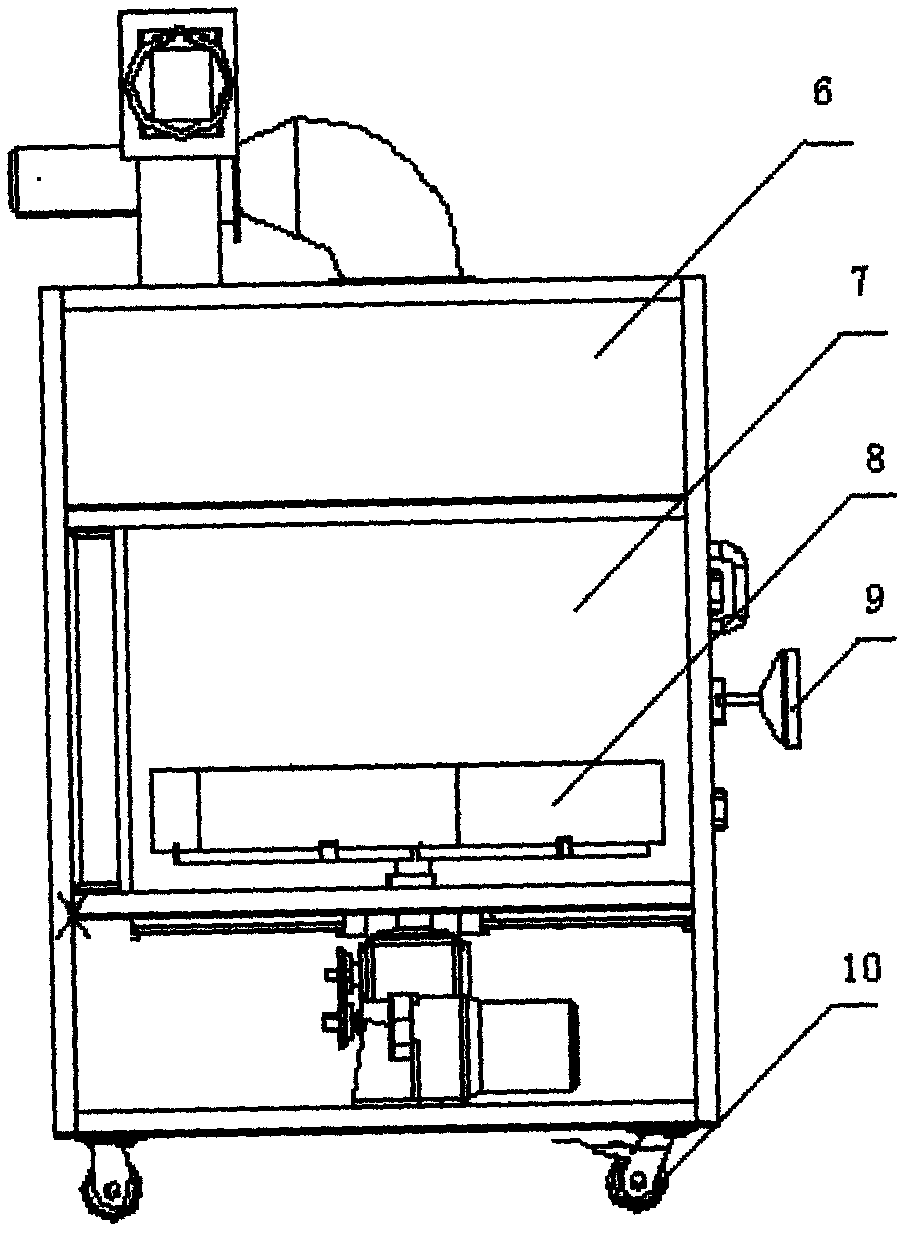

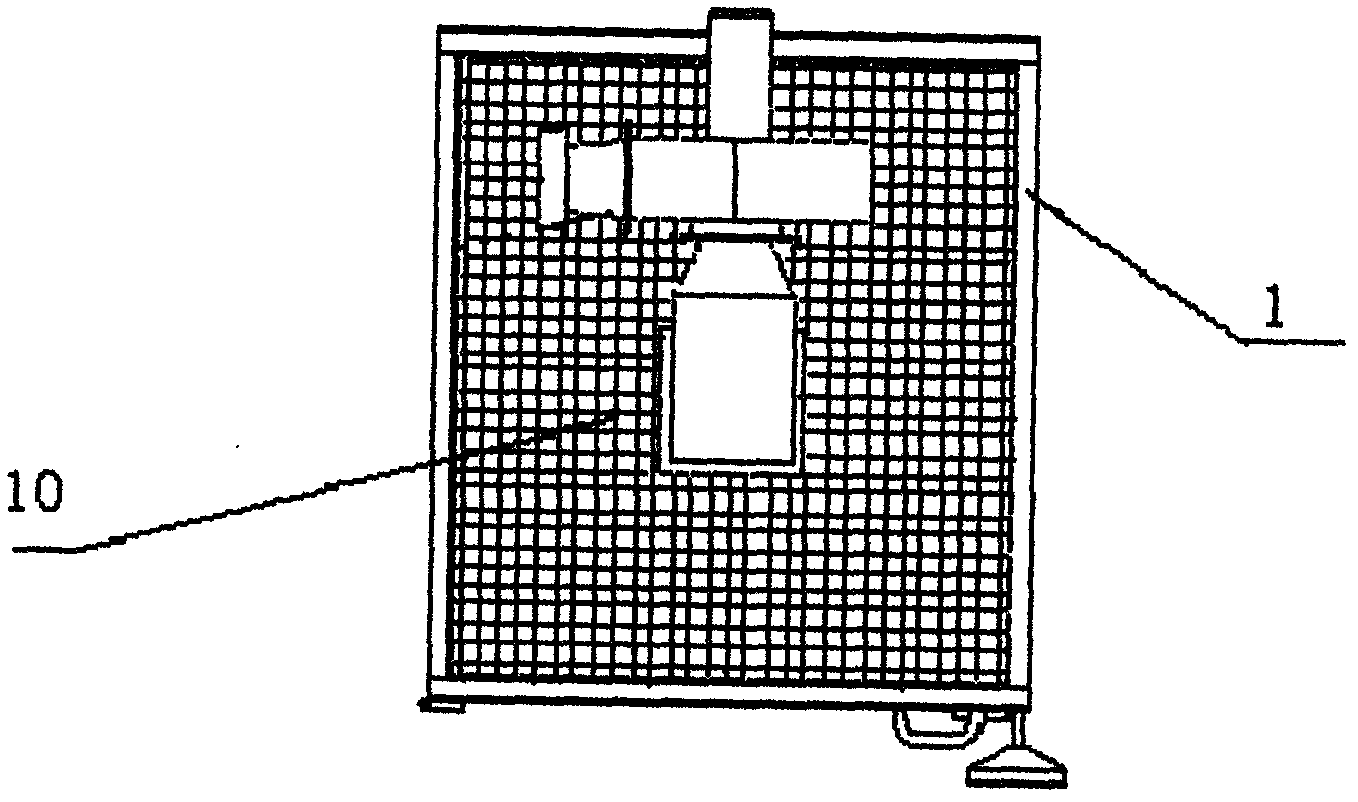

[0040] Such as Figure 1-3As shown, a special equipment for diamond drying includes a box body 1, a door body 2, a dehumidification system 3, an electric control system 4, a rotating part 5, a microwave generating source 6 and a microwave action chamber 7. The microwave generating source 6 is connected with the microwave action cavity 7 by riveting. The rotating part 5 includes a motor, a rotating shaft and a material tray 8, the motor drives the rotating shaft to rotate, and the rotating shaft drives the material tray 8 to rotate. The material tray 8 is placed in the microwave action cavity 7, the motor is placed in the lower part of the microwave action cavity 7, and the motor is connected to the material tray 8 through a rotating shaft. The dehumidification system 3 is placed on the top of the box body 1 . The dehumidification pipeline of the equipment is connected to the microwave action chamber 7 by welding, and the fan is connected to the dehumidification pipeline by b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com