Method and device for preparing high-strength alpha hemihydrate gypsum by using phosphogypsum

A technology of hemihydrate gypsum and phosphogypsum, which is applied in the field of comprehensive utilization of solid waste, can solve the problems of difficult application of phosphogypsum and high cost of production technology, and achieve the effects of improving steam curing and drying efficiency, low cost, and sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

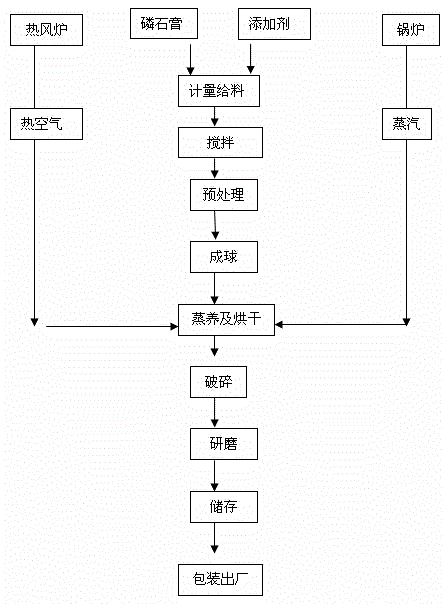

[0043] Embodiment 1: The specific steps of the method for preparing high-strength α hemihydrate gypsum from this phosphogypsum are as follows:

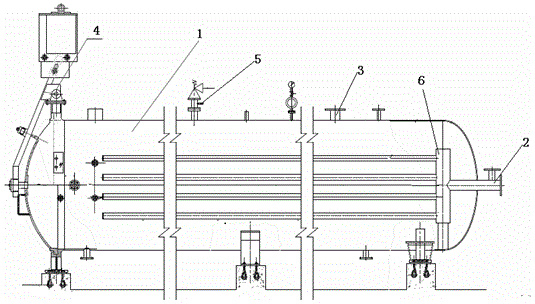

[0044] (1) Mix phosphogypsum, pretreatment additives, water, and crystal modifier, and stir evenly. After aging for 1 day, press the mixture into balls at a pressure of 15Mpa. The amount of pretreatment additive CaO is the mass of phosphogypsum 2% of phosphogypsum, the amount of water added is 12% of the mass of phosphogypsum, and the amount of sodium citrate and aluminum sulfate added in the crystal transformation agent is 0.04% of the mass of phosphogypsum respectively;

[0045] (2) Put the pelletized material in a closed autoclave, use high-temperature saturated water vapor at 117°C for 4 hours at a pressure of 0.17Mpa, then reduce the pressure and use hot air to heat and dry the reaction product, collect the product after cooling down, and grind it Afterwards, high-strength α-hemihydrate gypsum was obtained, and its performance wa...

Embodiment 2

[0048] Embodiment 2: The specific steps of the method for preparing high-strength α hemihydrate gypsum from this phosphogypsum are as follows:

[0049] (1) Mix phosphogypsum, pretreatment additives, water, and crystal modifier, and stir evenly. After aging for 2 days, press the mixture into balls at a pressure of 5Mpa. The amount of pretreatment additive CaO is the mass of phosphogypsum 4% of phosphogypsum, the addition of water is 8% of the mass of phosphogypsum, and the addition of sodium citrate and aluminum sulfate in the crystal transformation agent is 0.02% of the mass of phosphogypsum respectively;

[0050] (2) Put the pelletized material in a closed autoclave, and use high-temperature saturated water vapor at 134°C to treat it at a pressure of 0.3Mpa for 5 hours, then use hot air to heat and dry the reaction product, collect the product after lowering the temperature and pressure, and grind it After that, high-strength α-hemihydrate gypsum was obtained, and its perfor...

Embodiment 3

[0052] Embodiment 3: The specific steps of the method for preparing high-strength α hemihydrate gypsum from this phosphogypsum are as follows:

[0053] (1) Mix phosphogypsum, pretreatment additives, water, and crystal modifier, and stir evenly. After aging for 1.5 days, press the mixture into balls at a pressure of 20Mpa. The amount of pretreatment additive CaO is the mass of phosphogypsum 3%, the addition of water is 6% of the mass of phosphogypsum, and the addition of sodium citrate and aluminum sulfate in the crystal transformation agent is 0.08% of the mass of phosphogypsum respectively;

[0054] (2) Put the pelletized material in a closed autoclave, use high-temperature saturated water vapor at 160°C for 2 hours at a pressure of 0.6Mpa, then use hot air to heat and dry the reaction product, collect the product after cooling down, and grind it After that, high-strength α-hemihydrate gypsum was obtained, and its performance was tested by conventional methods. The flexural ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com