Patents

Literature

373 results about "Saturated water vapor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

For example, air at sea level, and saturated with water vapor at 20 °C, has partial pressures of about 2.3 kPa of water, 78 kPa of nitrogen, 21 kPa of oxygen and 0.9 kPa of argon, totaling 102.2 kPa, making the basis for standard atmospheric pressure.

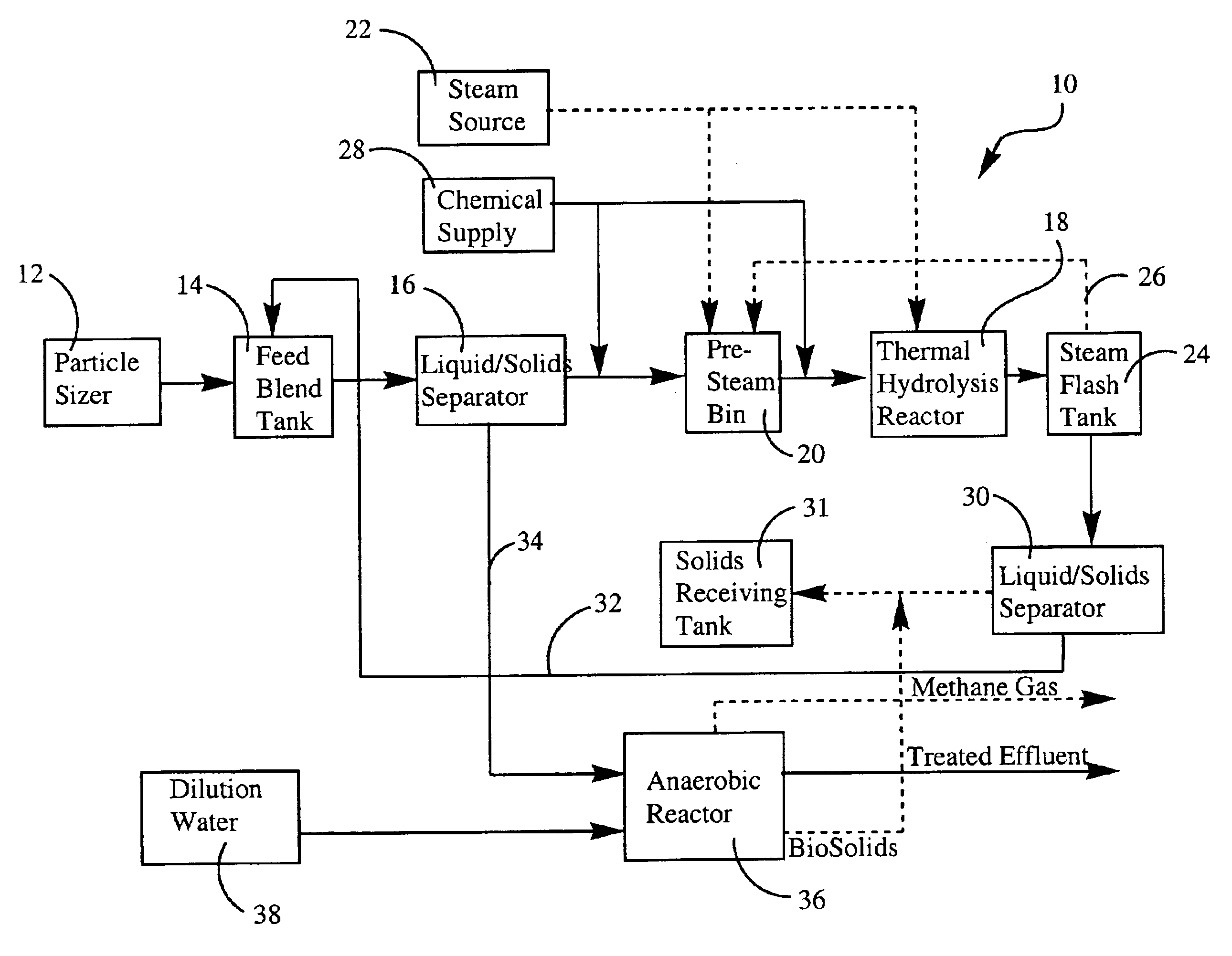

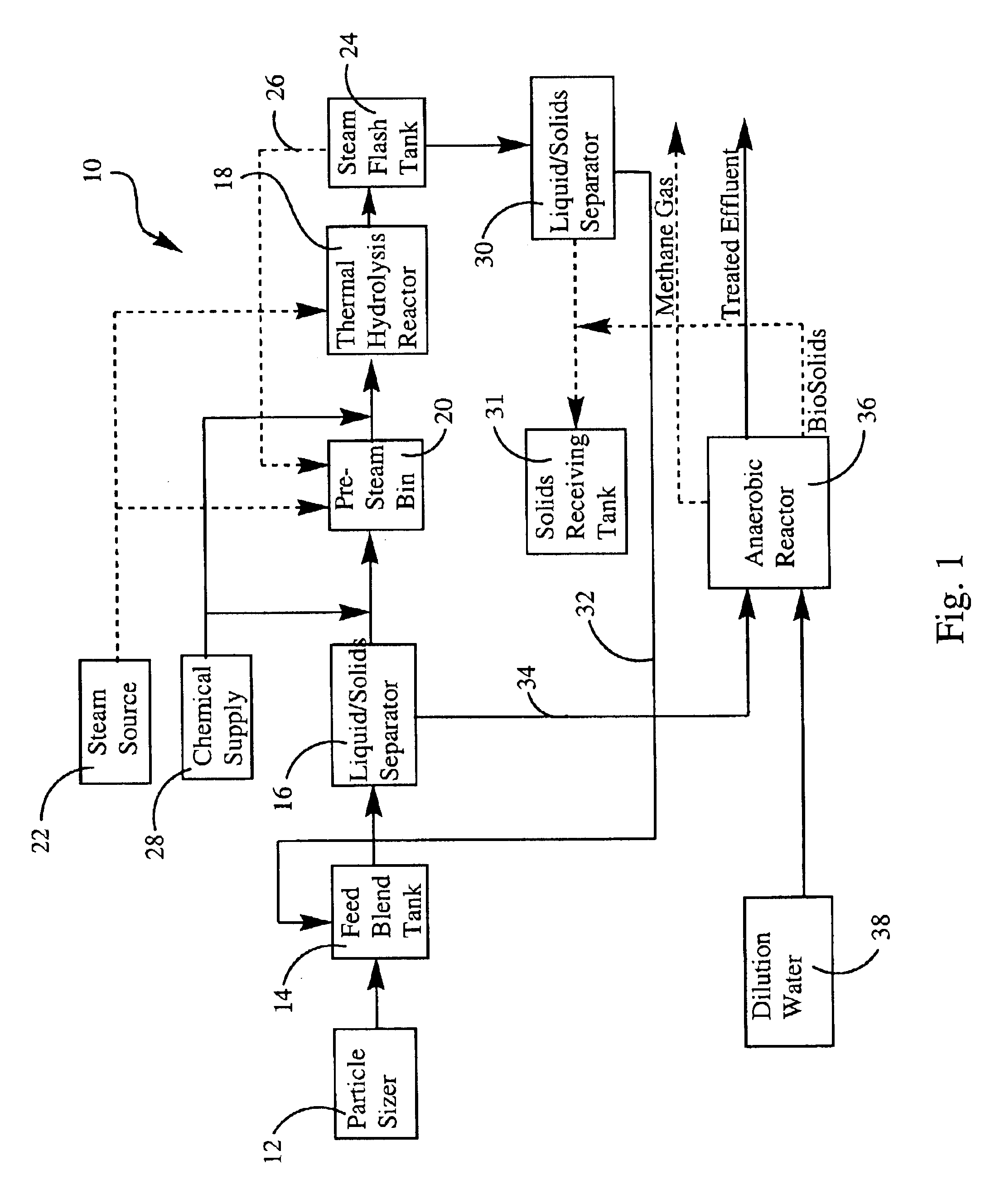

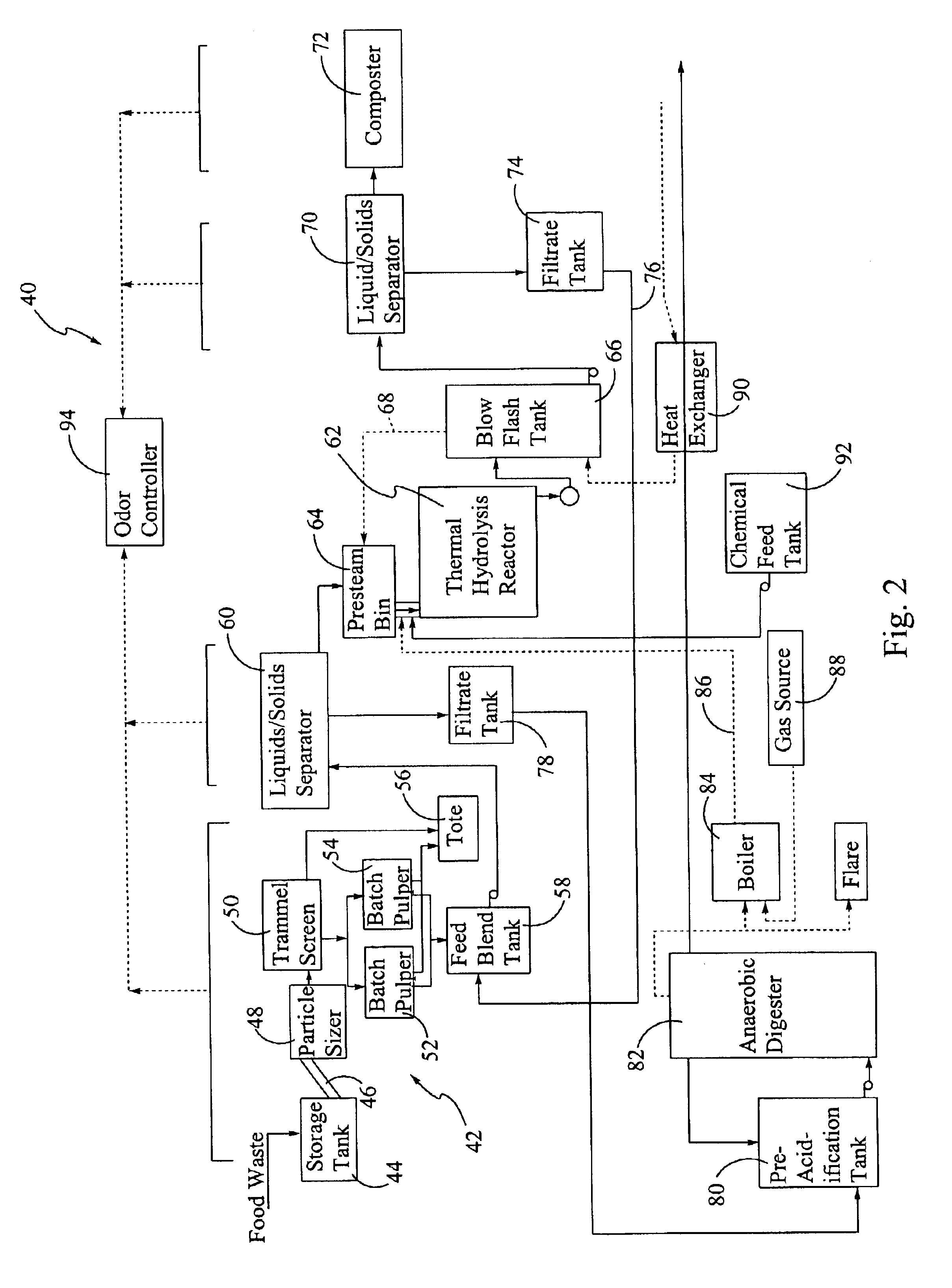

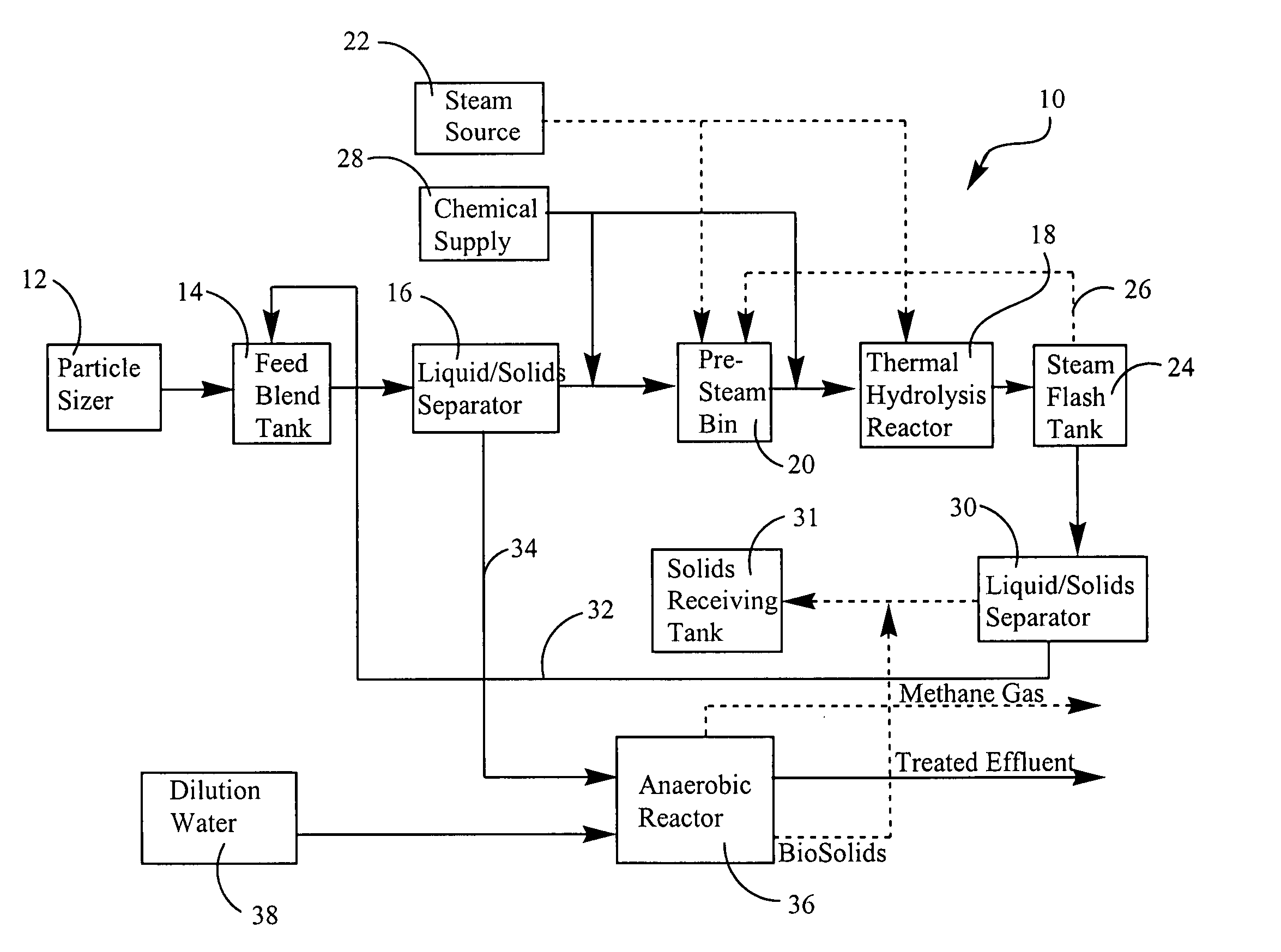

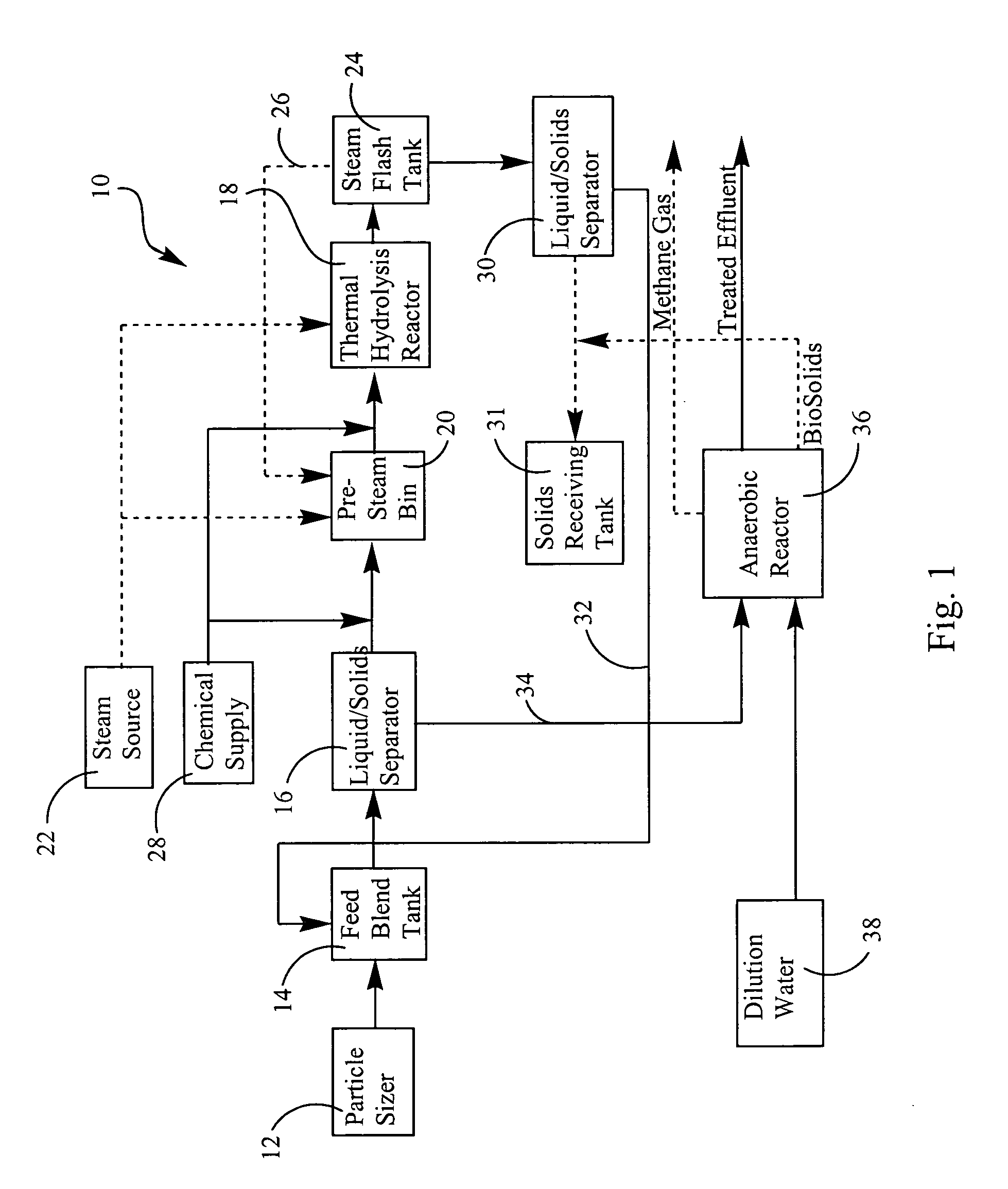

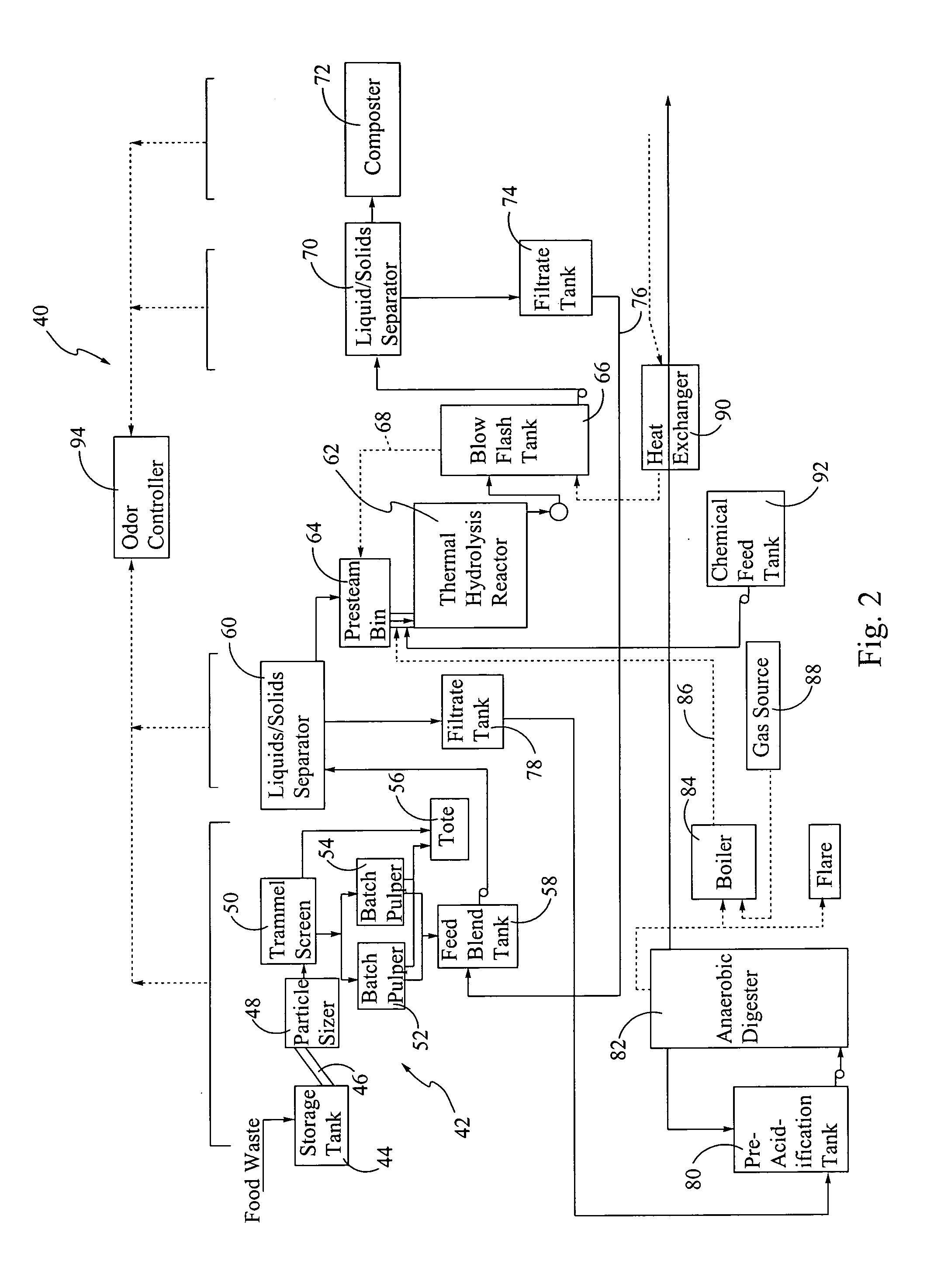

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS6905600B2Lower the volumeSaving in volume requirementBio-organic fraction processingBiological substance pretreatmentsPotassium hydroxideSaturated water vapor

A method for treating particulate biodegradable organic waste includes sizing the waste and adding a base prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The base is preferably potassium hydroxide (KOH) at a concentration of about 1%. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

Wood carbonization treatment method

ActiveCN1868704AAvoid defectsQuality improvementWood treatment detailsCarbonizationSaturated water vapor

A carbonization process for increasing the quality of wood by continuous gradient heating method includes such steps as heating to 120-140 deg.C, eating to 160-240 deg.C, spraying atomized water for slowly cooling to 100 deg.C, filling the saturated steam at 100 deg.C to return the water content back to 4-6%, and cooling to 15-30 deg.C.

Owner:ZHEJIANG SHIYOU TIMBER

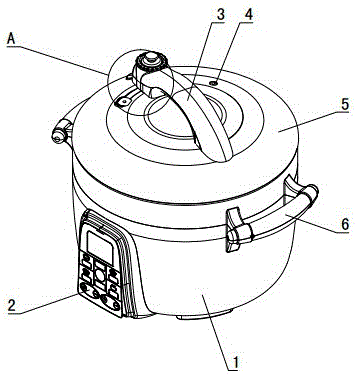

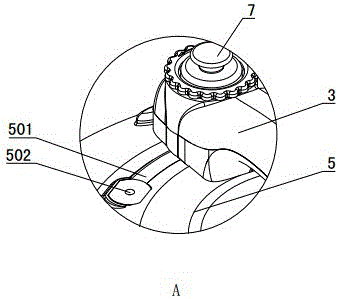

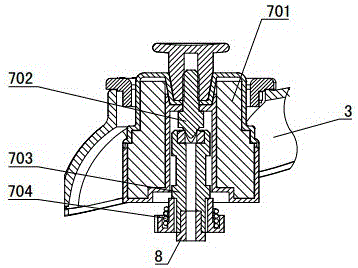

Sealed electric cooker

ActiveCN105919411AEasy to useHeating evenlyCooking-vessel lids/coversWarming devicesLocking mechanismSaturated water vapor

Provided is a sealed electric cooker, pertaining to the field of household cookers.The sealed electric cooker is characterized in that the position between a pot cover (5) and a pot body (1) is sealed; a retractable locking mechanism used for locking the pot cover (5) and the pot body (1) is arranged between the pot cover (5) and the pot body (1); the pot cover (5) is provided with an exhaust seal valve (4) communicating the pot body (1) with the air; the exhaust seal valve (4) is controlled by temperature so that exhaust is achieved; pressure can make the pot body (1) sealed when the pot body (1) reaches at certain temperature; ventilation is achieved when pressure of the pot body (1) is lower than the above pressure; and a safety valve (7) is arranged on the pot cover (5).The sealed electric cooker has following beneficial effects: air can be exhausted when water temperature increases to the boiling state; when saturated steam reaches certain pressure, the exhaust seal valve is sealed; when the saturated steam is condensed to water, the exhaust seal valve is opened; and by absorbing air in the pot, temperature for water, rice and saturated steam in the pot body can be up to 105-120 DEG C so that rice can be heated in an all-round way.

Owner:山东多星电器有限公司

Method of modifying biomass, modified biomass aqueous biomass sluryy and method of producing the same, modified biomass gas and method of gasifying biomass

InactiveUS20060112638A1Reduce the amount of oxygenImprove efficiencyPressurized chemical processSolid waste disposalCelluloseSolid component

This method of upgrading a biomass comprises: an upgrading step for performing upgrading treatment of a cellulose based biomass with an oxygen / carbon atomic ratio of at least 0.5, in presence of water and under a pressure of at least saturated water vapor pressure, and reducing said oxygen / carbon atomic ratio of said biomass to no more than 0.38, and a separation step for separating an upgraded reactant obtained from said upgrading step into a solid component and a liquid component.

Owner:JGC CORP +1

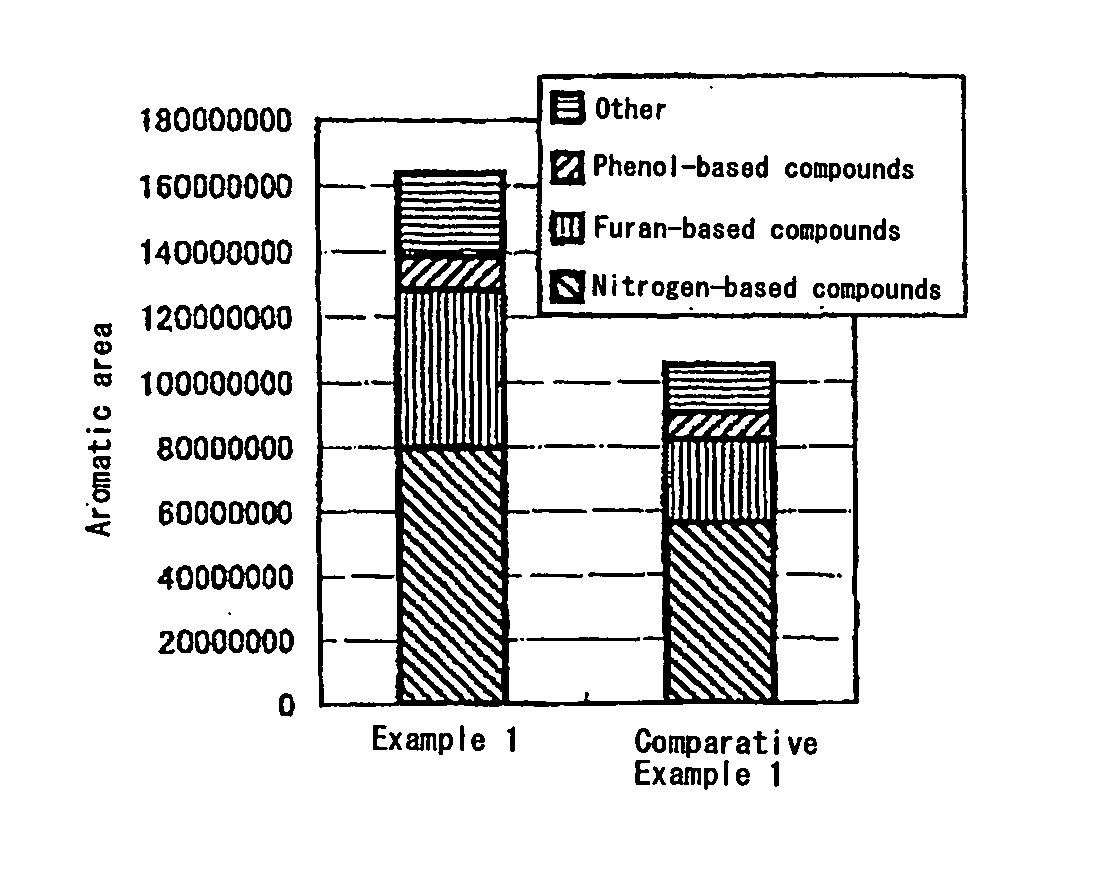

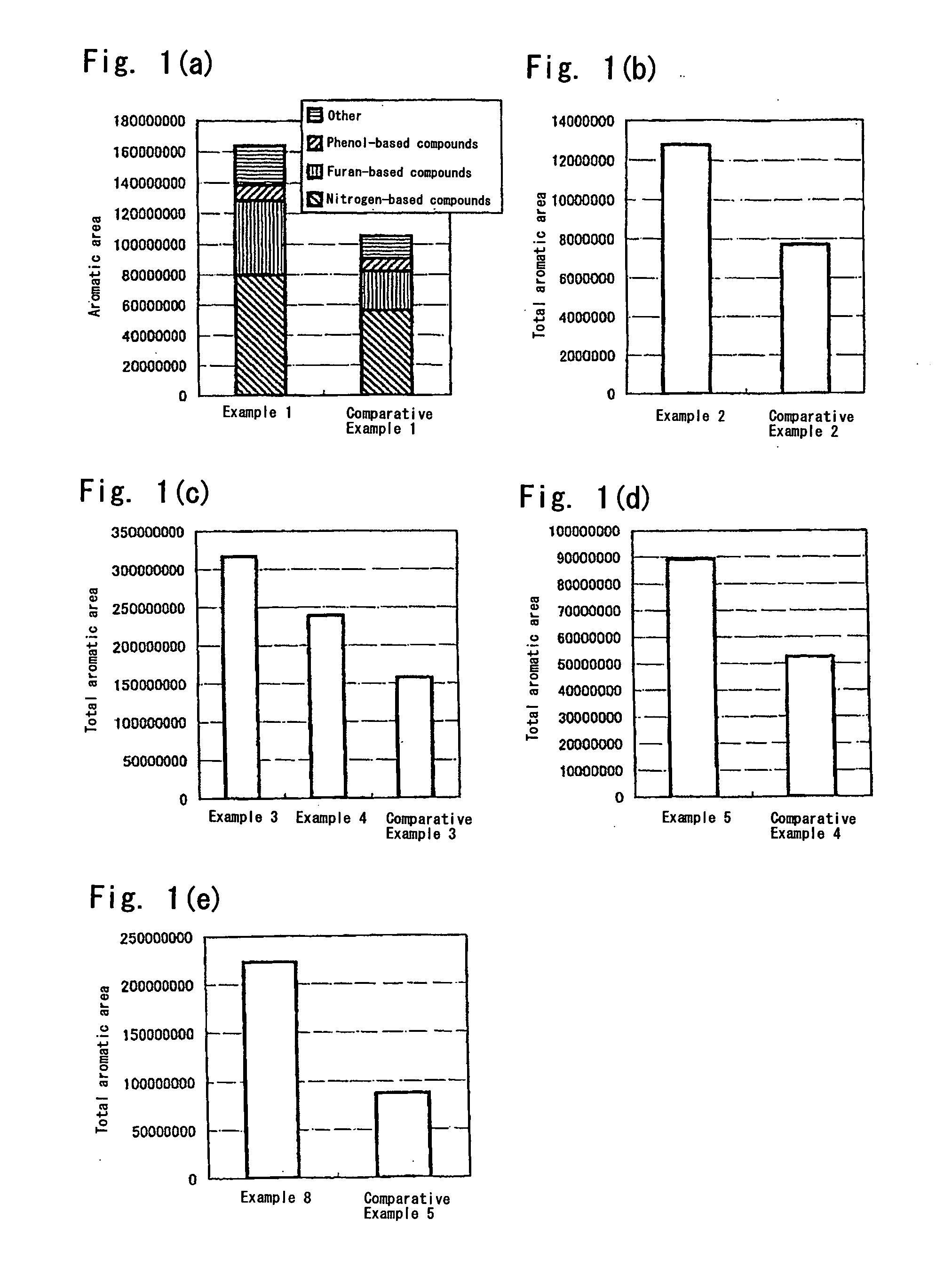

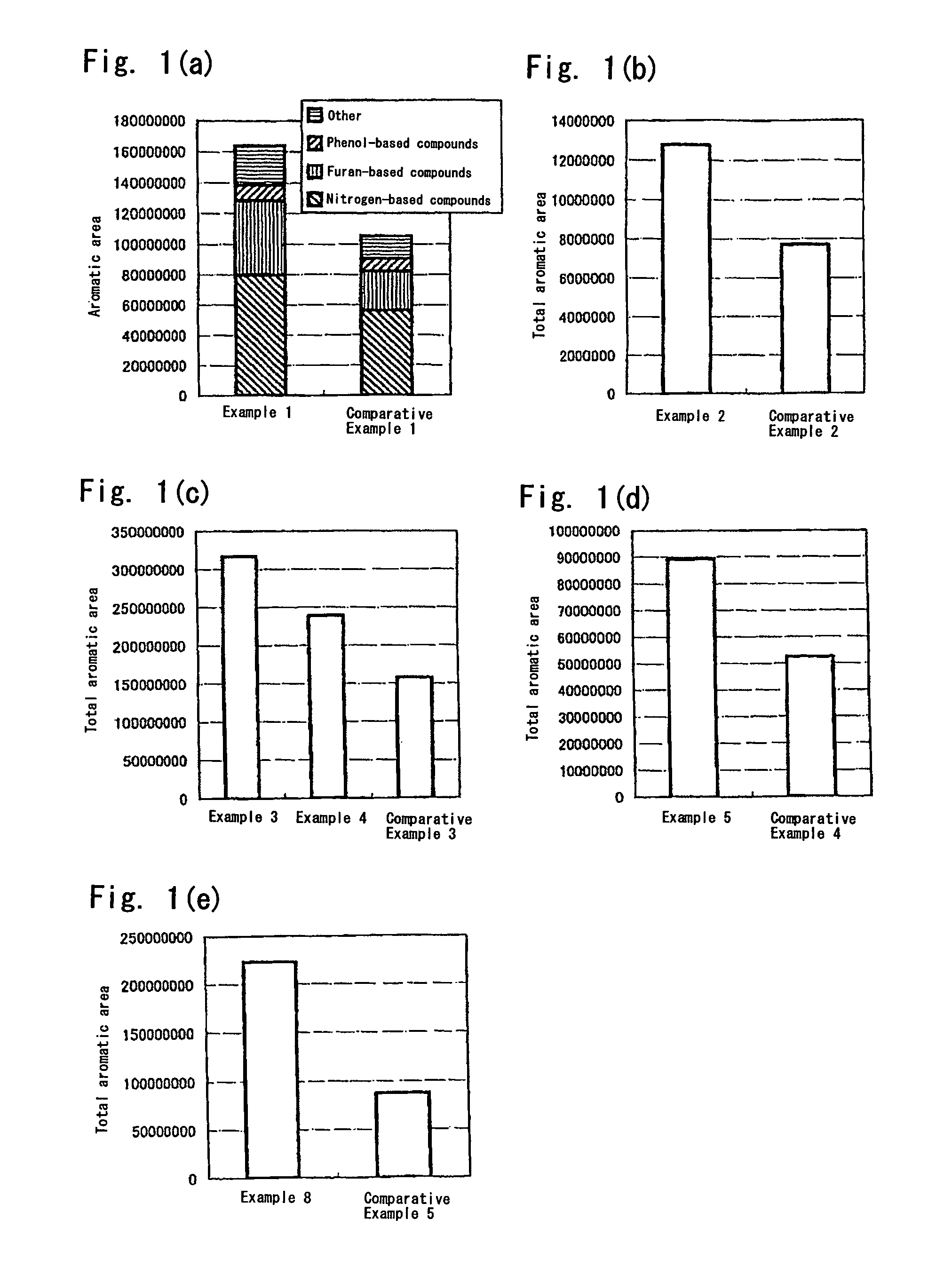

Method of extracting volatile component from tasty material, the volatile component and foods and drinks containing the volatile component

InactiveUS20070003683A1Meat/fish preservation by heatingTea extractionSaturated water vaporSuperheated steam

Volatile components are obtained by steam extraction of tasty materials. Coffee beans following roasting or tea leaves following tea manufacturing are used as tasty materials. Steam extraction includes of processing in which steam is contacted with a tasty material followed by recovery of the steam after that contact. Saturated water vapor or super heated steam is used for the steam, while super heated steam is used preferably. The coffee beans are preferably those that have been obtained by roasting raw coffee beans using super heated steam. The food or drink contains the aromatic components, and preferably contains the volatile components as well as an aqueous extract of the tasty material.

Owner:POKKA SAPPORO FOOD & BEVERAGE

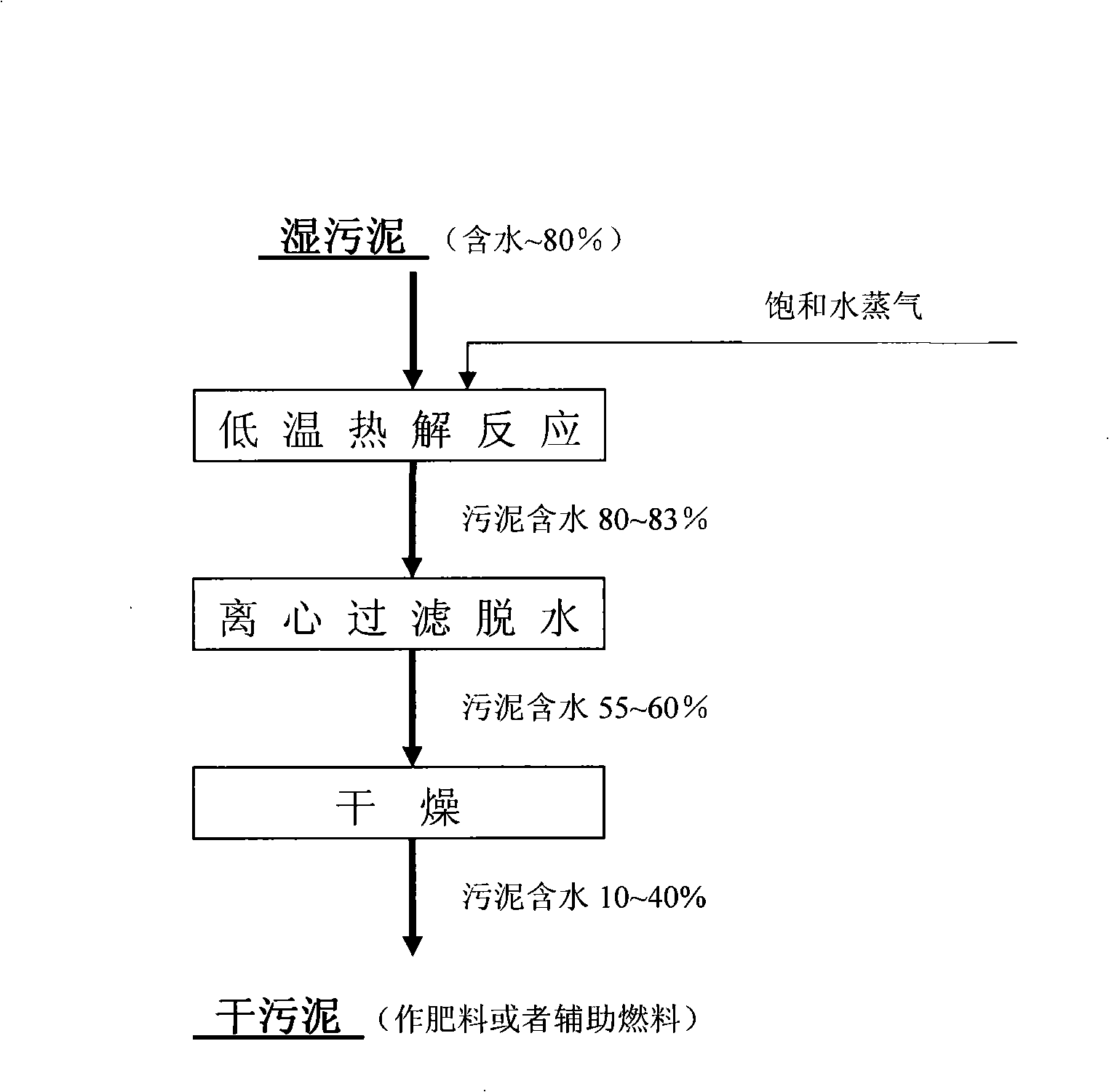

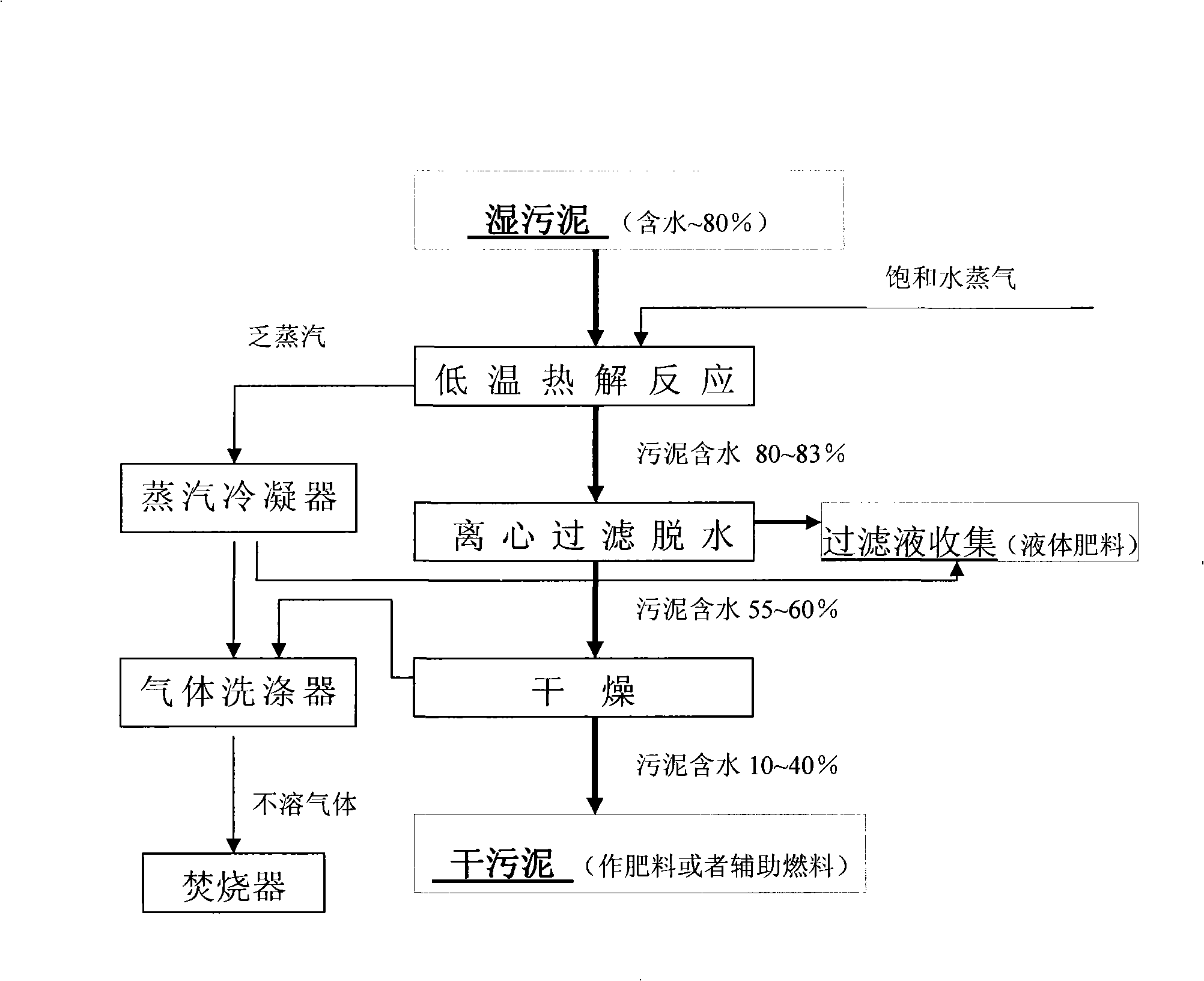

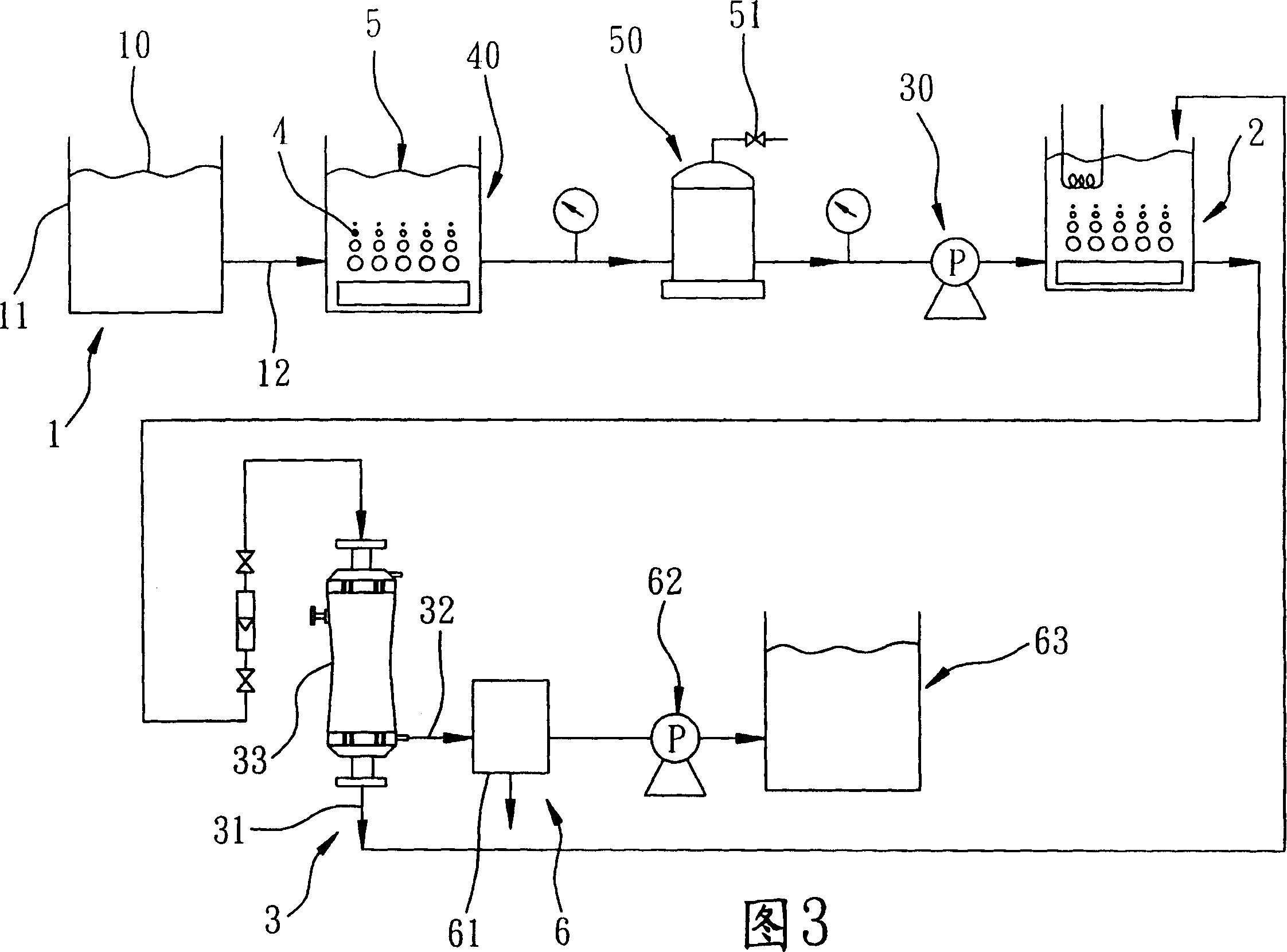

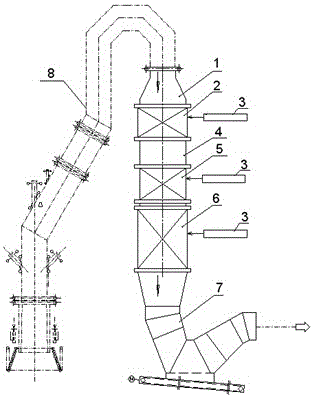

System and process for anhydration treatment of wet sludge

ActiveCN101289267AAvoid it happening againNo odorSludge treatment by de-watering/drying/thickeningWaste processingResource utilizationSludge

The invention relates to a wet sludge anhydration treatment system which comprises a low-temperature pyrolysis reaction device which is used for carrying out the low-temperature pyrolysis reaction of wet sludge and saturated water vapor to convert macromolecular organics in the wet sludge into low-molecular organics, a spiral centrifugal filtering device which is used for carrying out centrifugal filtering and dehydration to the wet sludge after the pyrolysis in a mechanical separation manner so as to obtain semi-dry sludge with the water content of 55 percent to 60 percent, and a drying device which is used for drying and removing the water in the semi-dry sludge after the filtering and hydration so as to obtain dried-sludge solid fuel with the water content of 10 percent to 40 percent. Meanwhile, the invention also relates to a wet sludge anhydration treatment technology by adopting the treatment system. The system and the technology of the invention can solve the problem of renewable resource of sludge in a method of environment protection, energy saving, high resource utilization and low operating cost.

Owner:SHENZHEN ECO SOLUTION TECH CORP

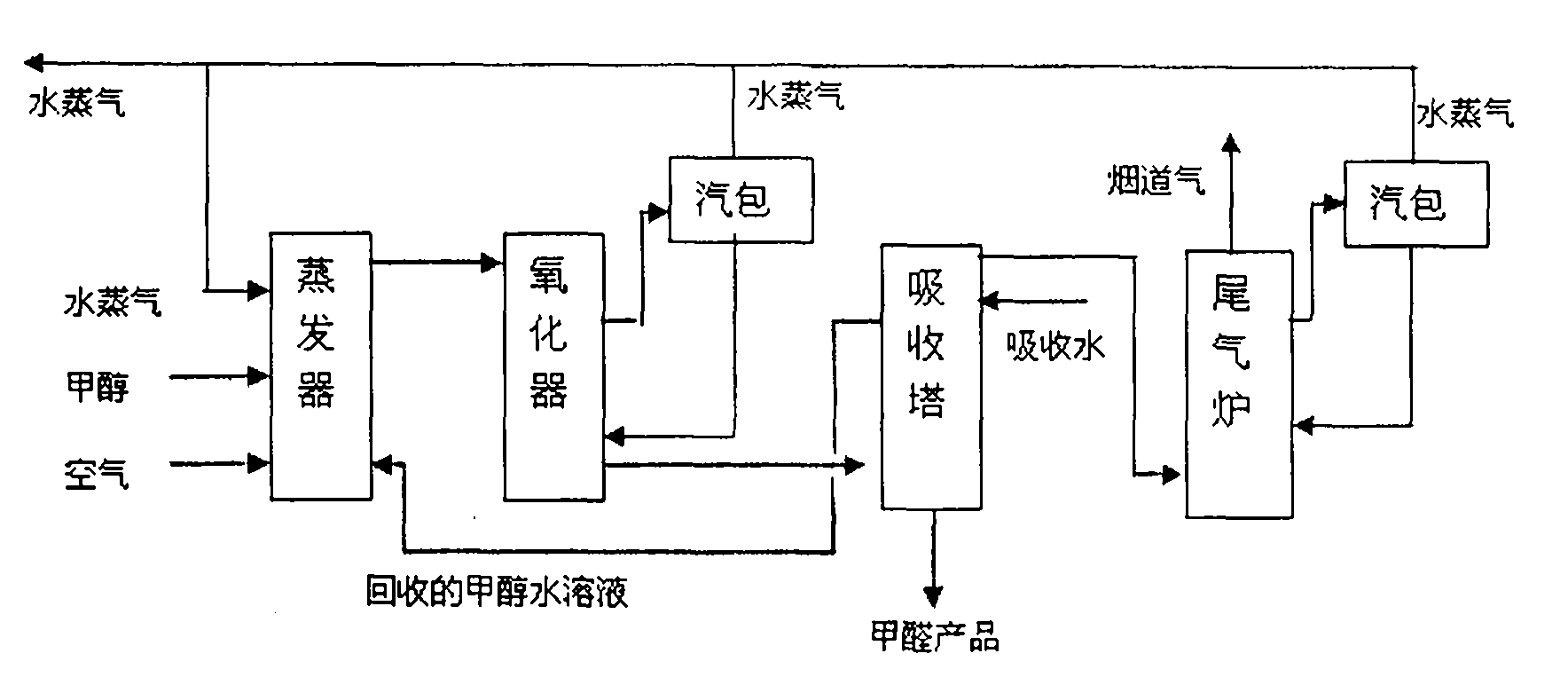

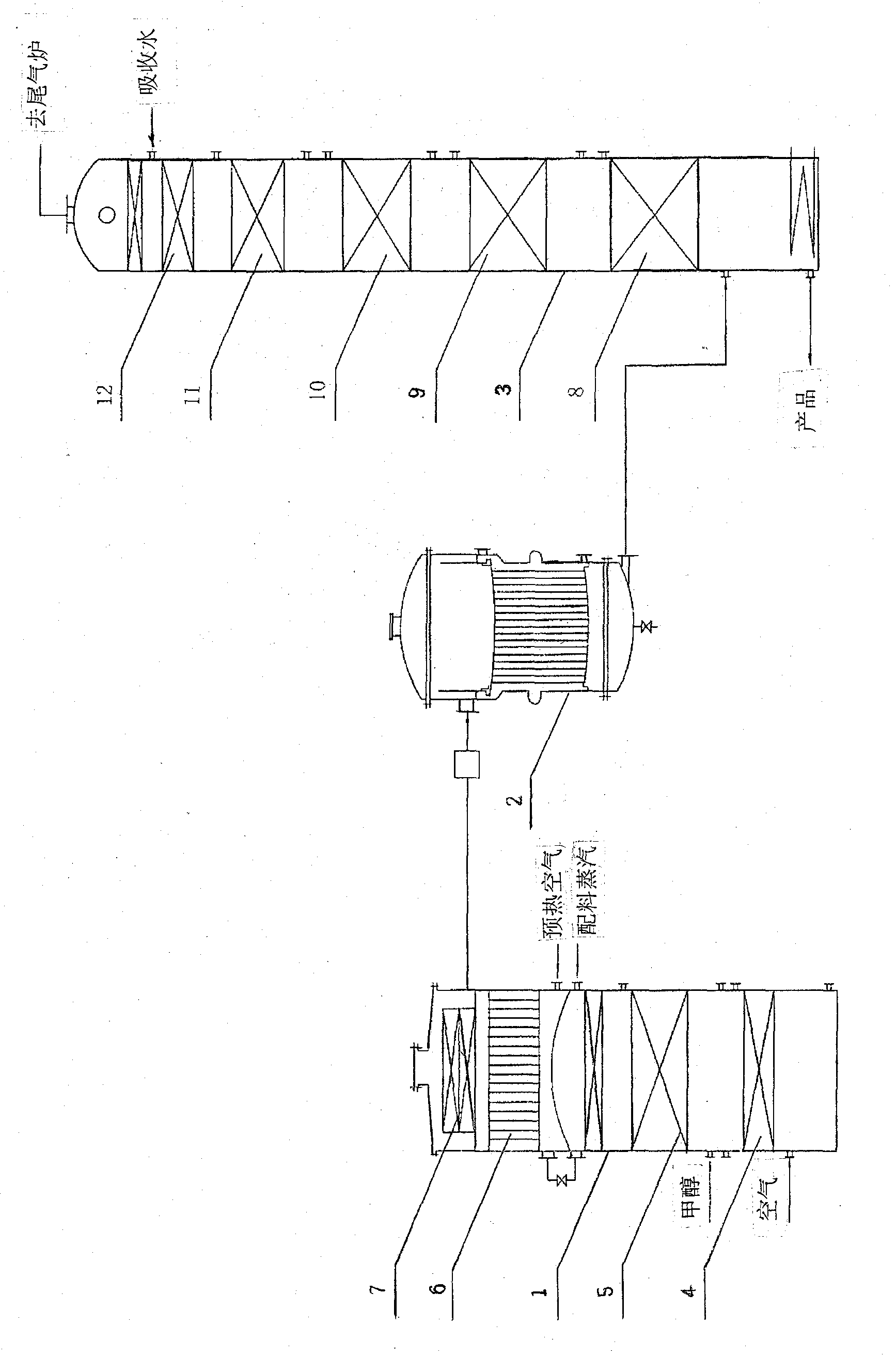

Production process and device of formaldehyde

InactiveCN102320942AExtend your lifeShort processOrganic compound preparationCarbonyl compound separation/purificationMaterial consumptionSaturated water vapor

The invention relates to a production process and device of formaldehyde, in particular to a production process and device of the formaldehyde, which can realize circulated recycling of unreacted methanol. The process comprises the following steps of: defogging after heated methanol and recycled diluting methanol form a mixed gas with air in an evaporator; then adding a small amount of saturated steam or not adding the saturated steam; and heating and filtering; introducing the mixed gas to a reactor filled with a silver catalyst for reacting to generate a formaldehyde gas; recycling the waste heat of the generated gas to produce steam; then introducing the steam to an absorbing tower for absorbing; carrying out dealcholization on the extracted finished product by utilizing a high-temperature generated gas; and extracting diluting methanol from the upper part of the absorbing tower back to the evaporator for recycling. The device comprises three kinds of main equipment, such as the evaporator, the reactor and the absorbing tower as well as auxiliary equipment, such as a fan, a pump, a heat exchanger, and the like. The invention has the advantages of simple process, low unit product energy consumption and material consumption, high product concentration methanol content close to zero.

Owner:田宝峰

Vapour explosion cracking method for cell wall of marine algae

InactiveCN1502273APromote digestion and absorptionHigh nutritional valueFood preparationNutritive valuesEngineering

The present invention relates to a steam explosion wall-breaking method of seaweed cell wall, and said method includes the following steps: (1). placing wet seaweed in steam explosion tank, introducing saturated steam until the tank interior temp is up to 80-100 deg.C, and retaining for 1-8 min.; (2). stopping steam supply, introducing high-pressure air into the steam explosion tank until tank interior pressure is up to 0.8-1.5 MPa; and (3). instantaneously reducing pressure and releasing so as to obtain seaweed product whose wall-broken rate is up to 100%. Said seaweed product can be used for preparing seaweed functional food with high nutritive value and good taste, agar and carrageen gum, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for manufacturing flash evaporation defibricating glue-free light corps stalk fibrous composite material

InactiveCN101234504AAchieving self-gluingKeep shapeDomestic articlesFlat articlesEmulsionSaturated water vapor

The invention discloses a method for manufacturing a flashing defibrillator non-gel light crop straw fiber composite material, the technique of which is that: the straw material is crashed into units with a length of 20-30mm and a water ratio of 50-60 percent; the straw units are placed in a steam explosion processor, then are stewed by high-temperature high-pressure saturated steam led into the processor, and a valve is instantaneously opened to release the pressure and discharge material; two-part form steam exploded processing technique is adopted, namely, the straw units are pretreated under a relatively low steam tension for 5-8 minutes, then are treated under a relatively high steam tension for 2-5 minutes, and the valve is opened abruptly to release the pressure and discharge material, in order to obtain a dissociative fiber; slabs are molded; an enclosed steam injection pressing technique is adopted, with a vapor pressure of 0.6-1.0MPa, and steam-injection time of 10-30 seconds; after the steam injection, the periphery of the slab is enclosed, with a hot-pressing temperature of 180-190 DEG C and hot-pressing time of 4-15 minutes. The method for manufacturing flashing defibrillator non-gel light crop straw fiber composite material has the advantages that in the whole processes of product manufacturing and employment, no environmental pollution is caused; an emulsion sizing procedure is saved; the production cost is lowered; different width of light sheet are manufactured.

Owner:NANJING FORESTRY UNIV

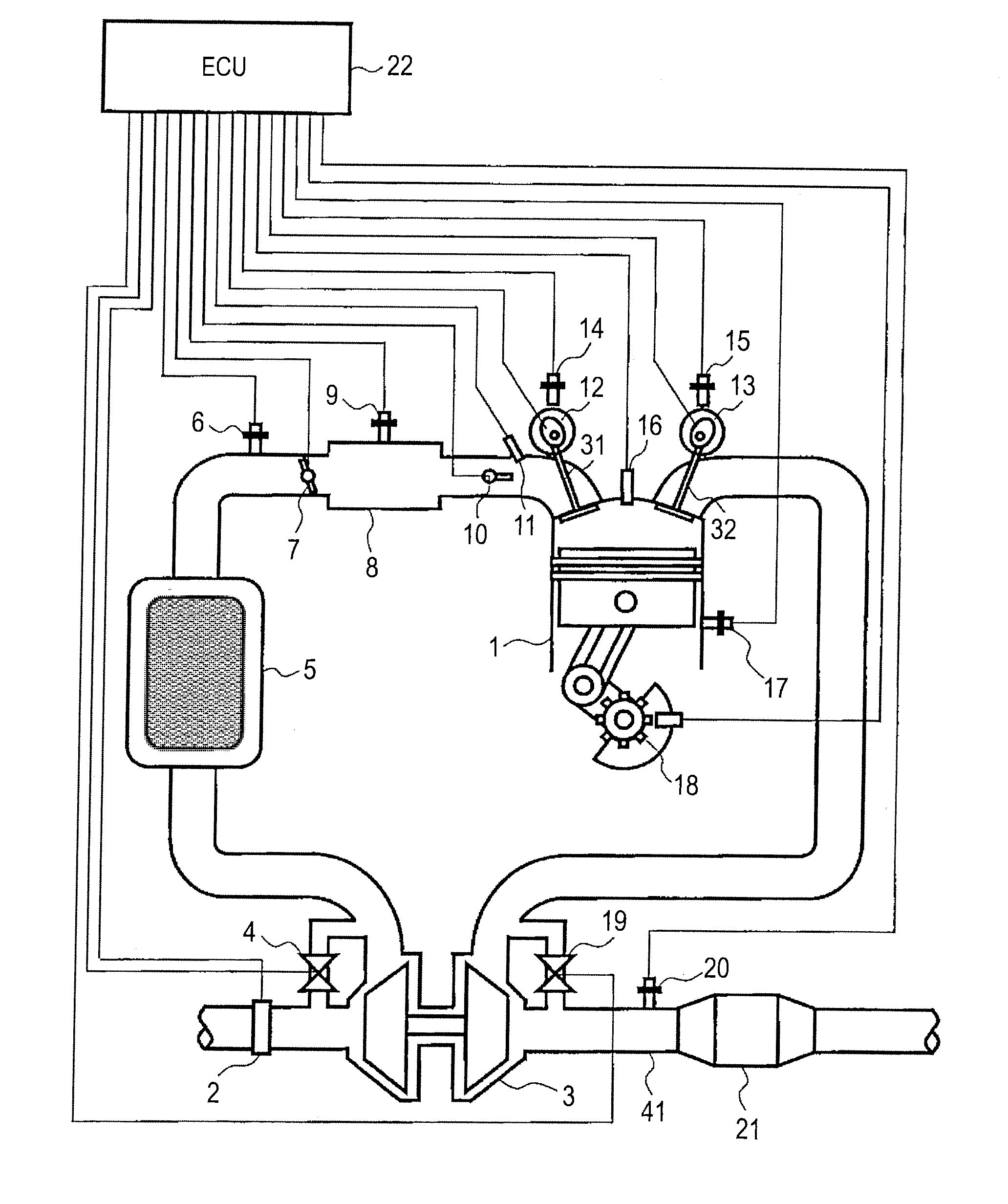

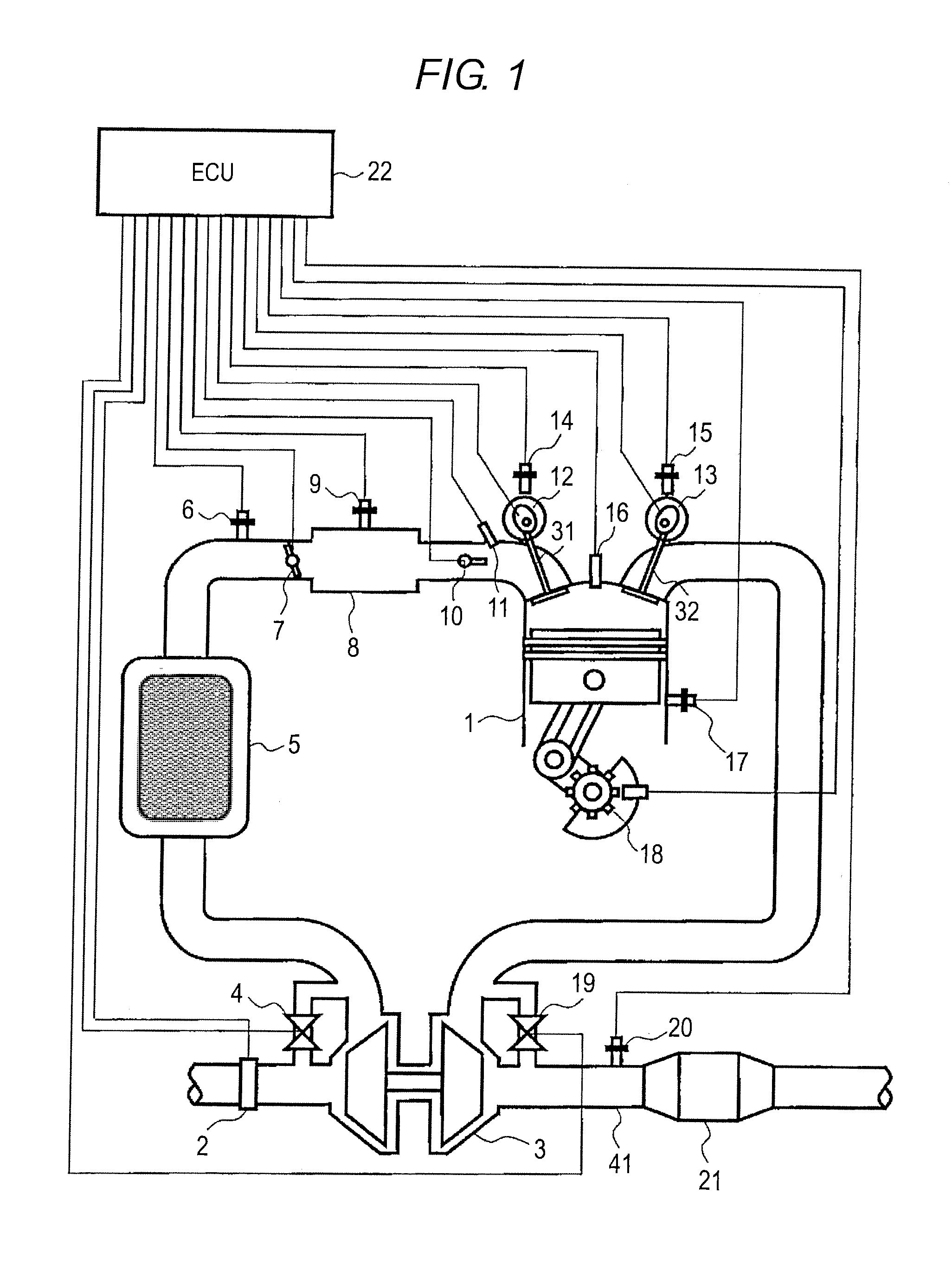

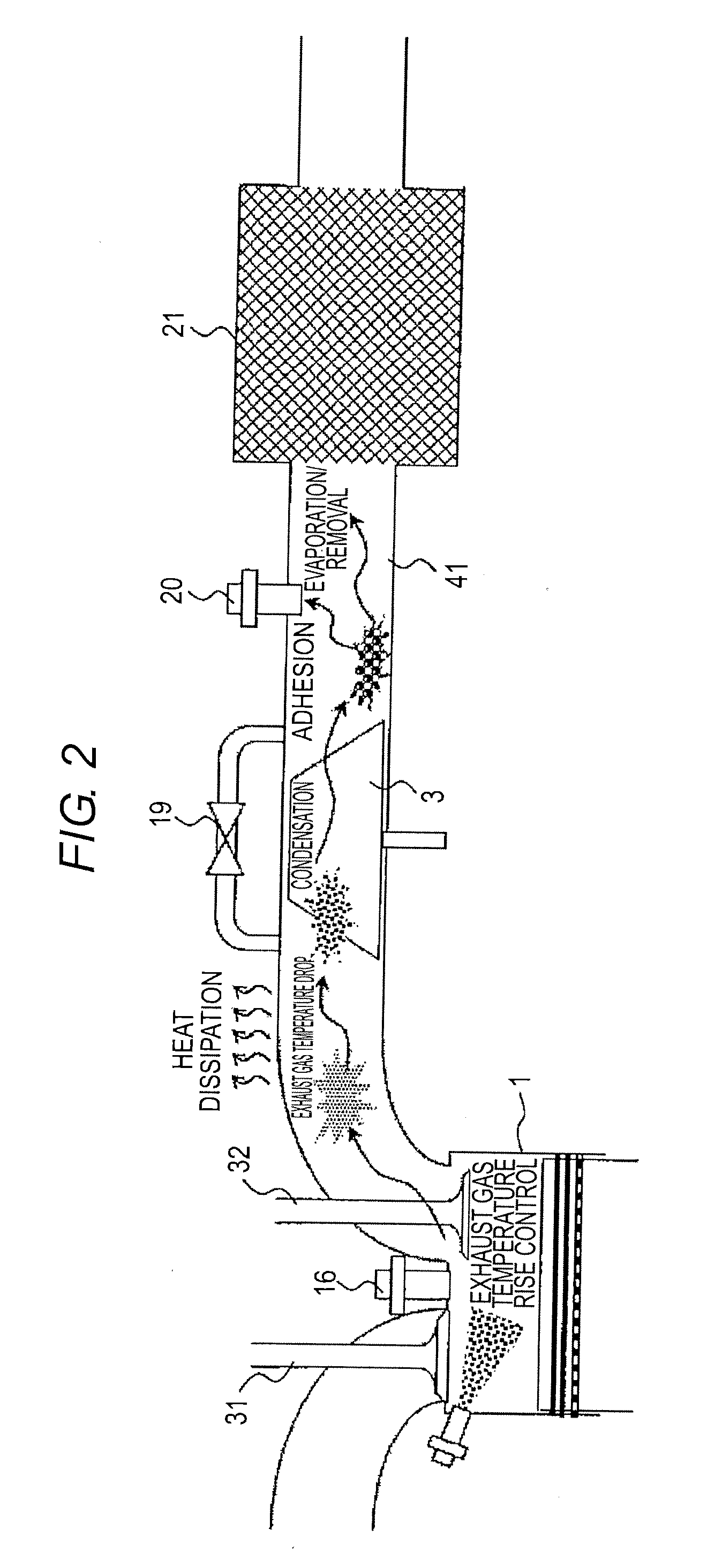

Control device of internal combustion engine

ActiveUS20130024088A1Improve exhaust performanceDecrease in fuel efficiency performanceAnalogue computers for vehiclesElectrical controlExternal combustion engineEvaporation

Control device of an internal combustion engine that determines whether or not to perform sensor element heating control of an air-fuel ratio sensor with high accuracy based on the mass of condensed water in an exhaust pipe. The control device computes the rate of change of condensed water mass in an exhaust pipe based on the saturated water vapor pressure and the water vapor partial pressure of exhaust gas, and computes the rate of change of evaporation mass in the exhaust pipe based on the amount of heat which the condensed water receives in the exhaust pipe. The control device updates the mass of condensed water based on the rate of change of condensed water mass and the rate of change of evaporation mass, and determines whether or not to perform heating control by a heating controlling unit based on the updated mass of condensed water.

Owner:HITACHI ASTEMO LTD

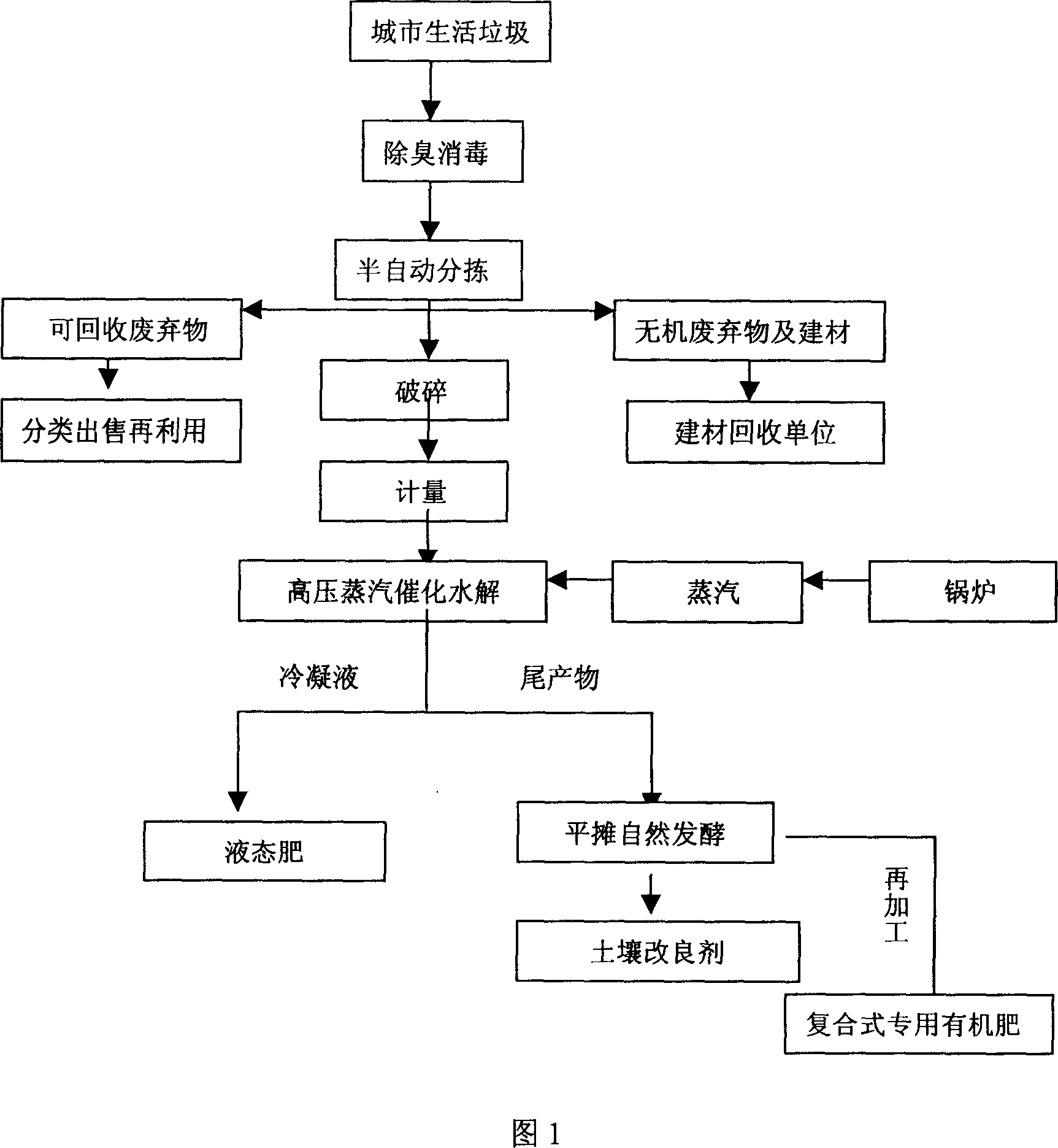

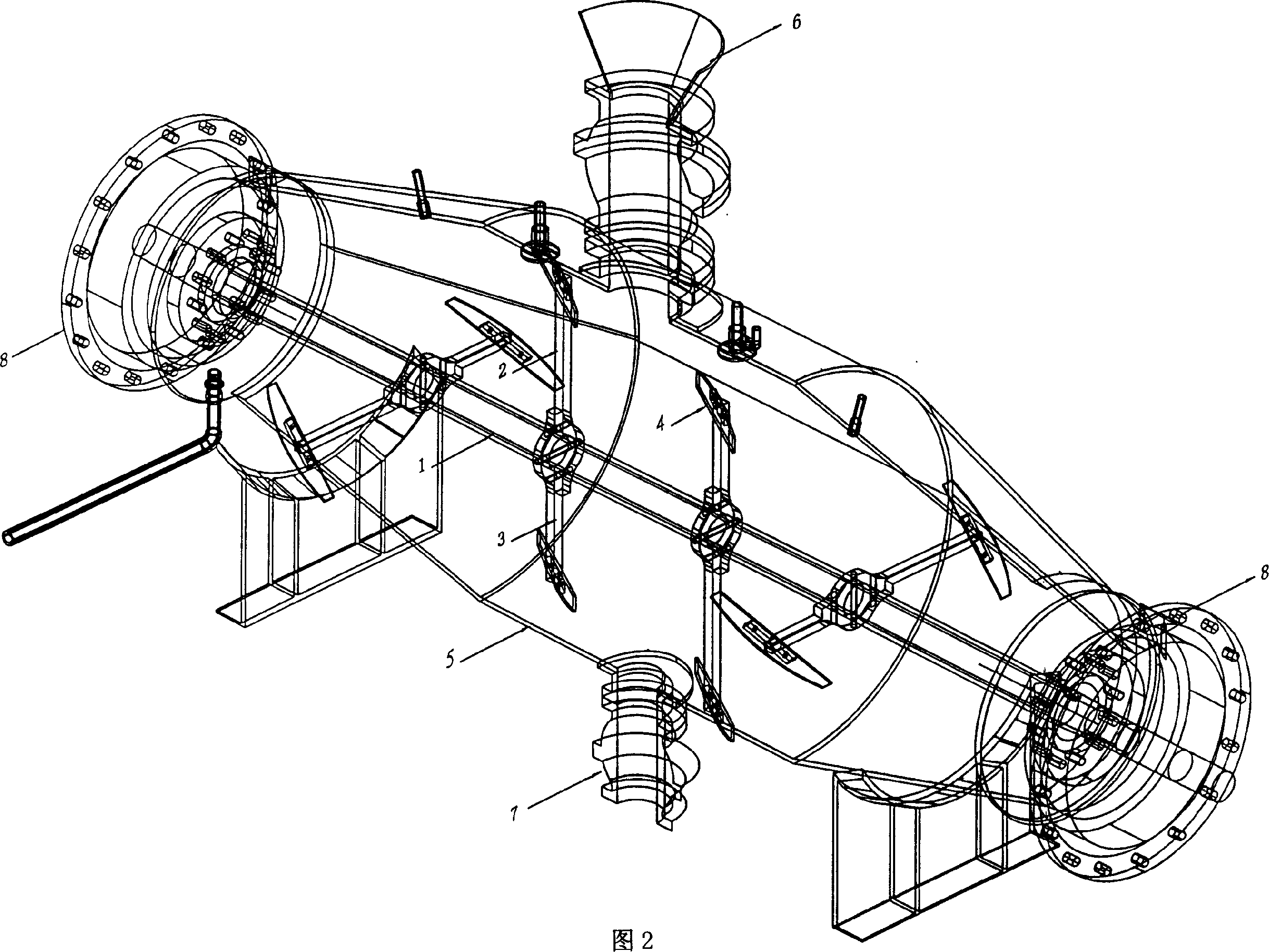

High pressure steam catalysis hydrolysis process for treating domestic refuse

InactiveCN1923383AReach the goal of reducingAchieve the goal of harmlessSolid waste disposalClimate change adaptationChemical reactionSaturated water vapor

The invention relates to a method for treating life waste. Wherein, it uses high-pressure steam catalyst hydrolysis processor; and the treatment comprises that: first using high-pressure steam treated chip condensed liquid to disinfect the waste; then classifying and selecting to picking the un-treated waste as glass, metal and rubber, and the ones which can be recycled; breaking left organic waste and feeding into high-pressure steam catalyst hydrolysis processor; chemically reacting at certain pressure, temperature and saturated steam, the energy generated in water molecule structure change will break off the molecule chain of macromolecule polymer, to reduce it into micromolecule polymer which can be absorbed by plant.

Owner:周钜洸

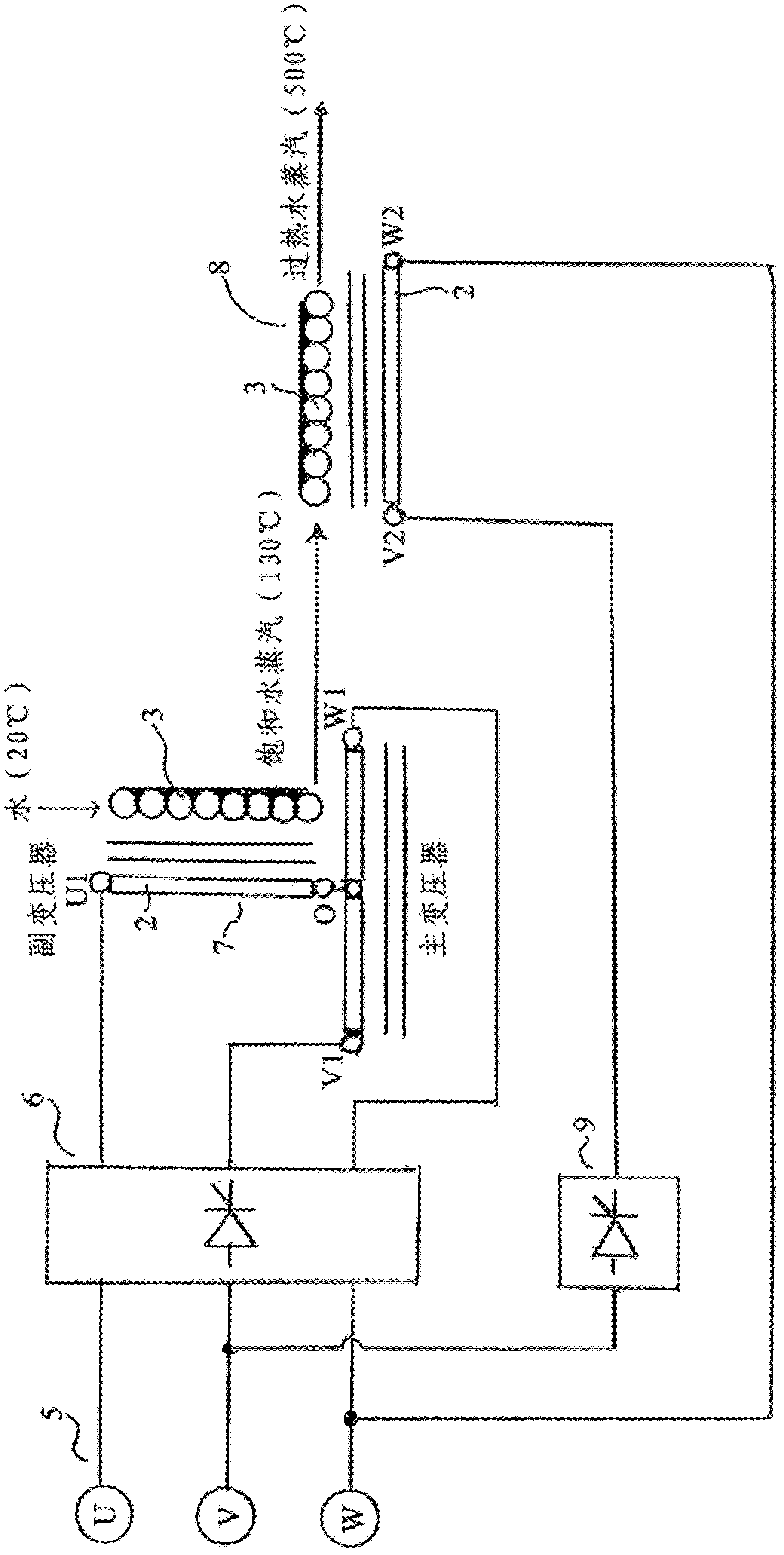

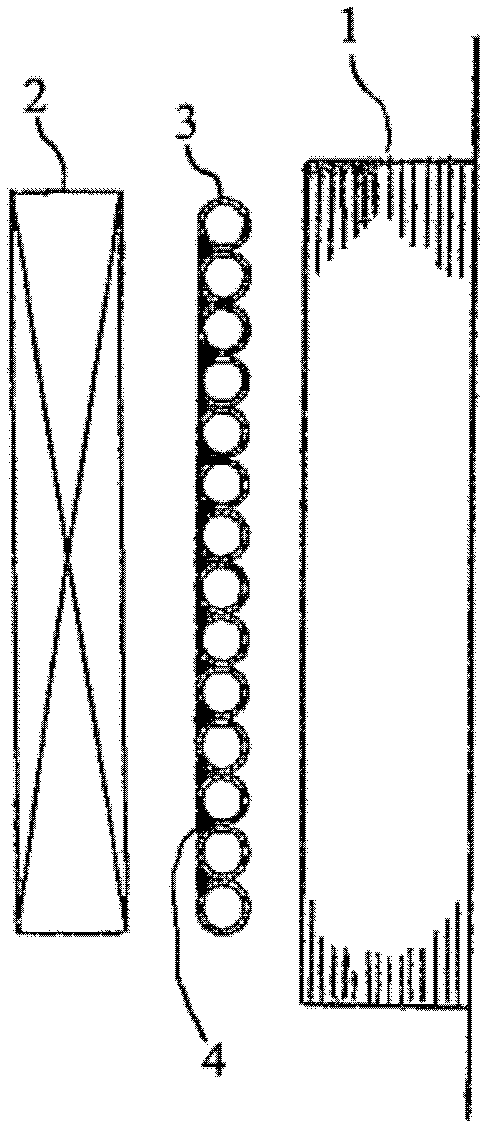

Superheated steam generator

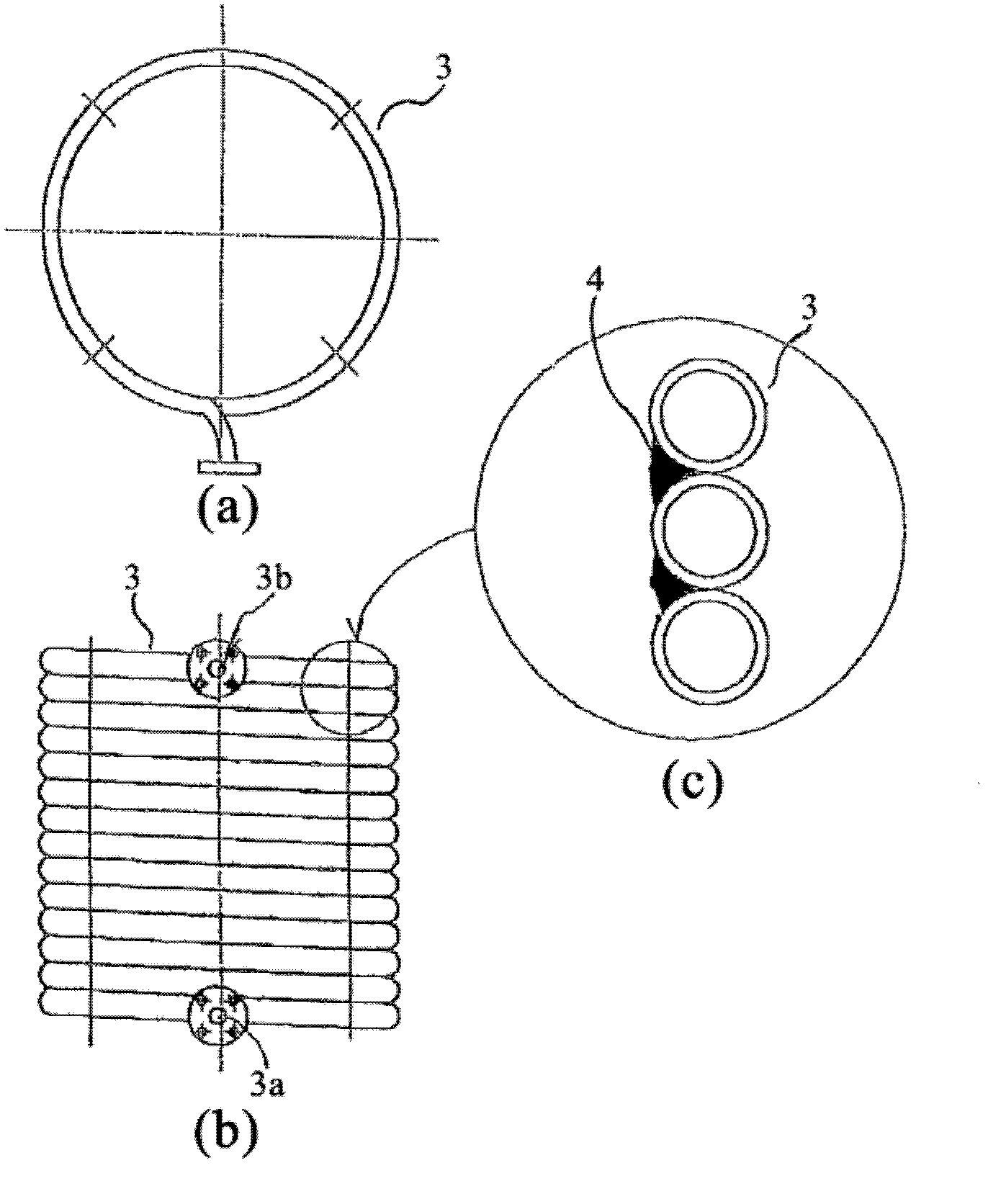

InactiveCN102628588AImprove temperature control effectIncrease the lengthSteam generation heating methodsCoil arrangementsPower flowElectrical conductor

The invention provides a superheated steam generator including: a first sensing heater formed by winding a conductor pipe on an iron core of a closed magnetic circuit coiled with a primary coil, wherein the conductor pipe heats through alternating current flowing through the primary coil; and a second sensing heater formed by winding a conductor pipe on an iron core coiled with a primary coil, wherein the conductor pipe heats through the alternating current flowing through the primary coil. One end of the first sensing heater connects with a water supply pipe while the other end of the conductor pipe of the first sensing heater connects with an end of the conductor pipe of the second sensing heater. Water is filled into the conductor pipe of the first sensing heater, thereby generating saturated steam. And the generated saturated steam is made to flow through the conductor pipe of the second sensing heater, and the generated saturated steam is heated, thereby generating superheated steam generator.

Owner:TOKUDEN CO LTD

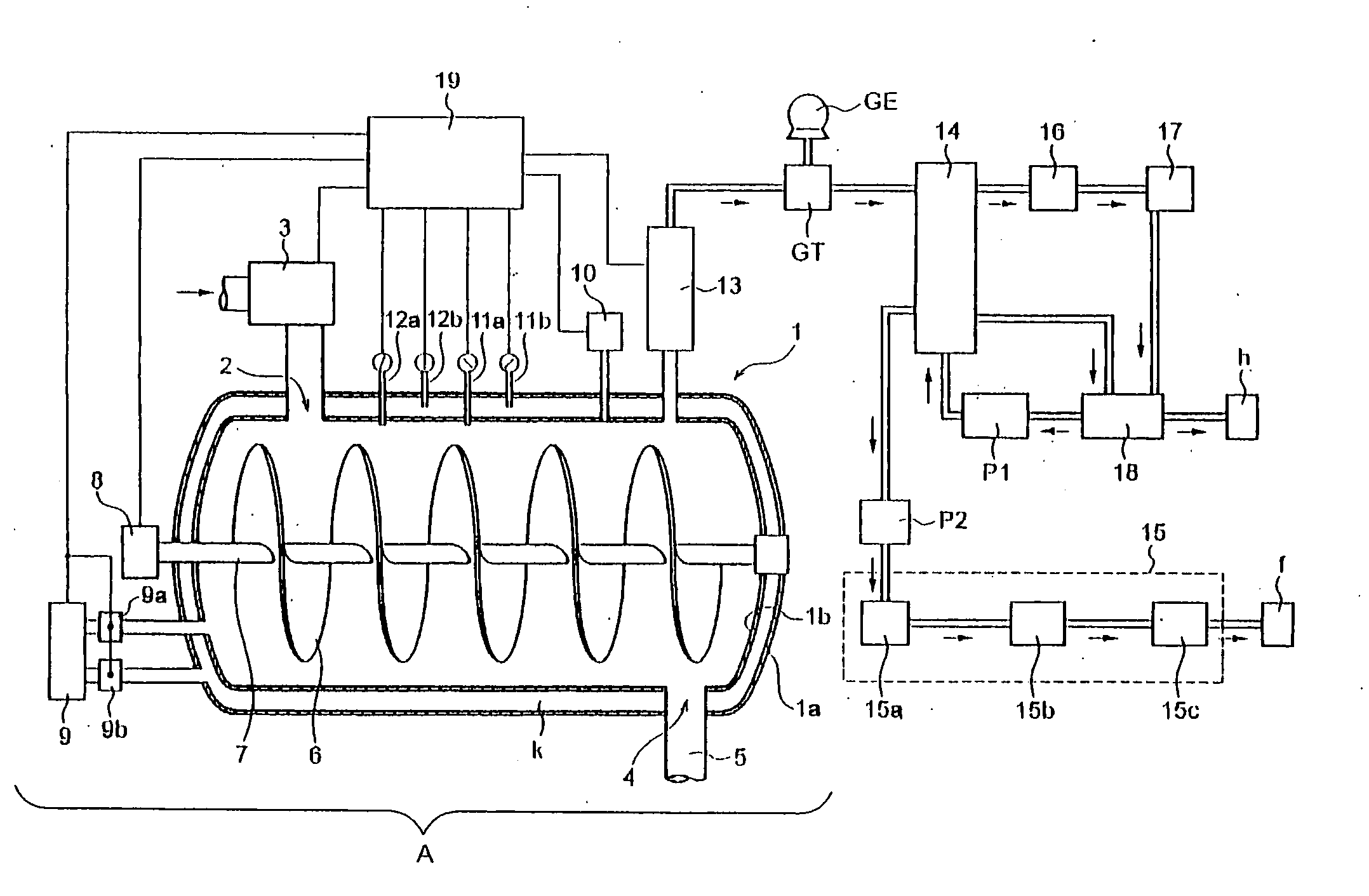

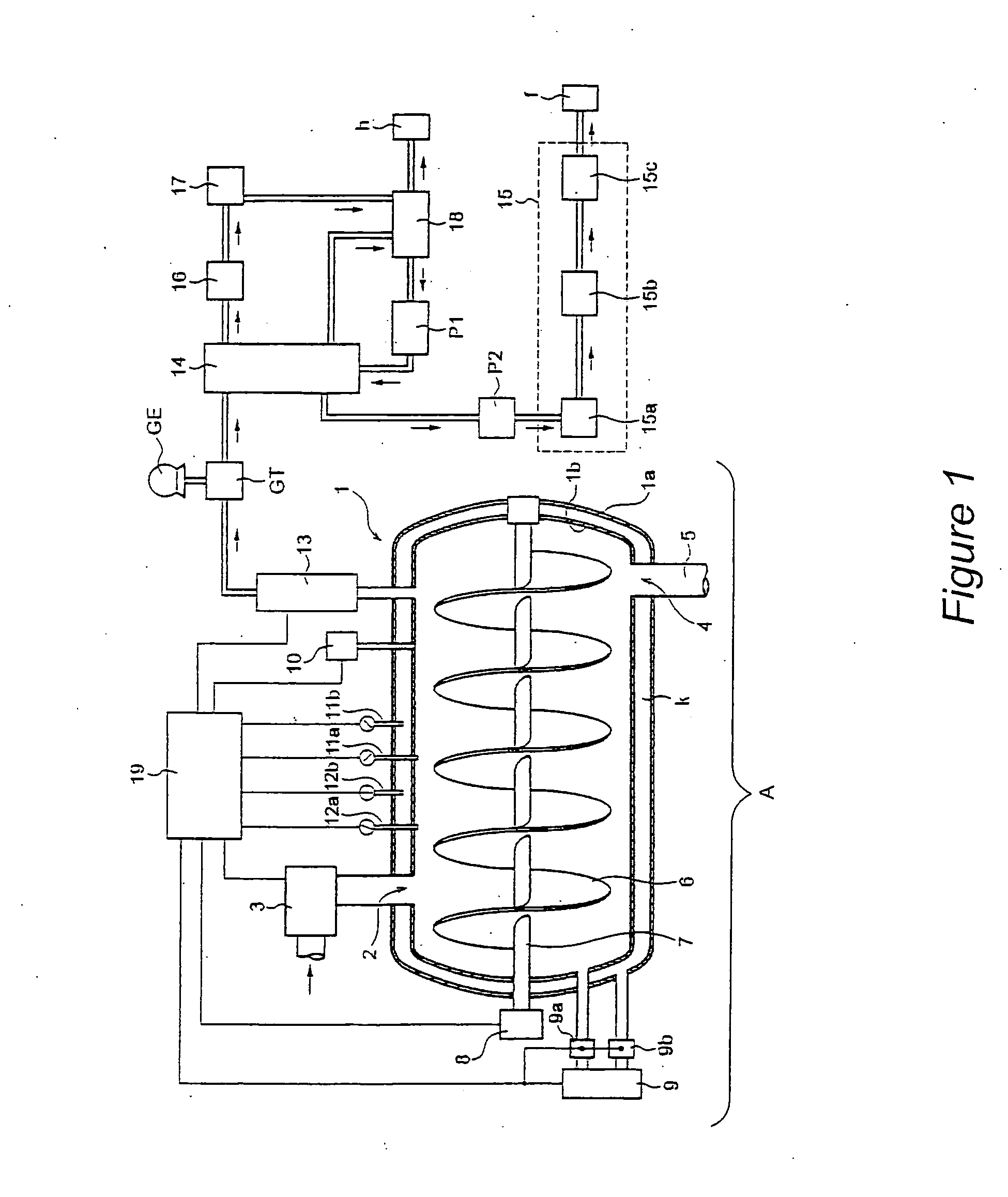

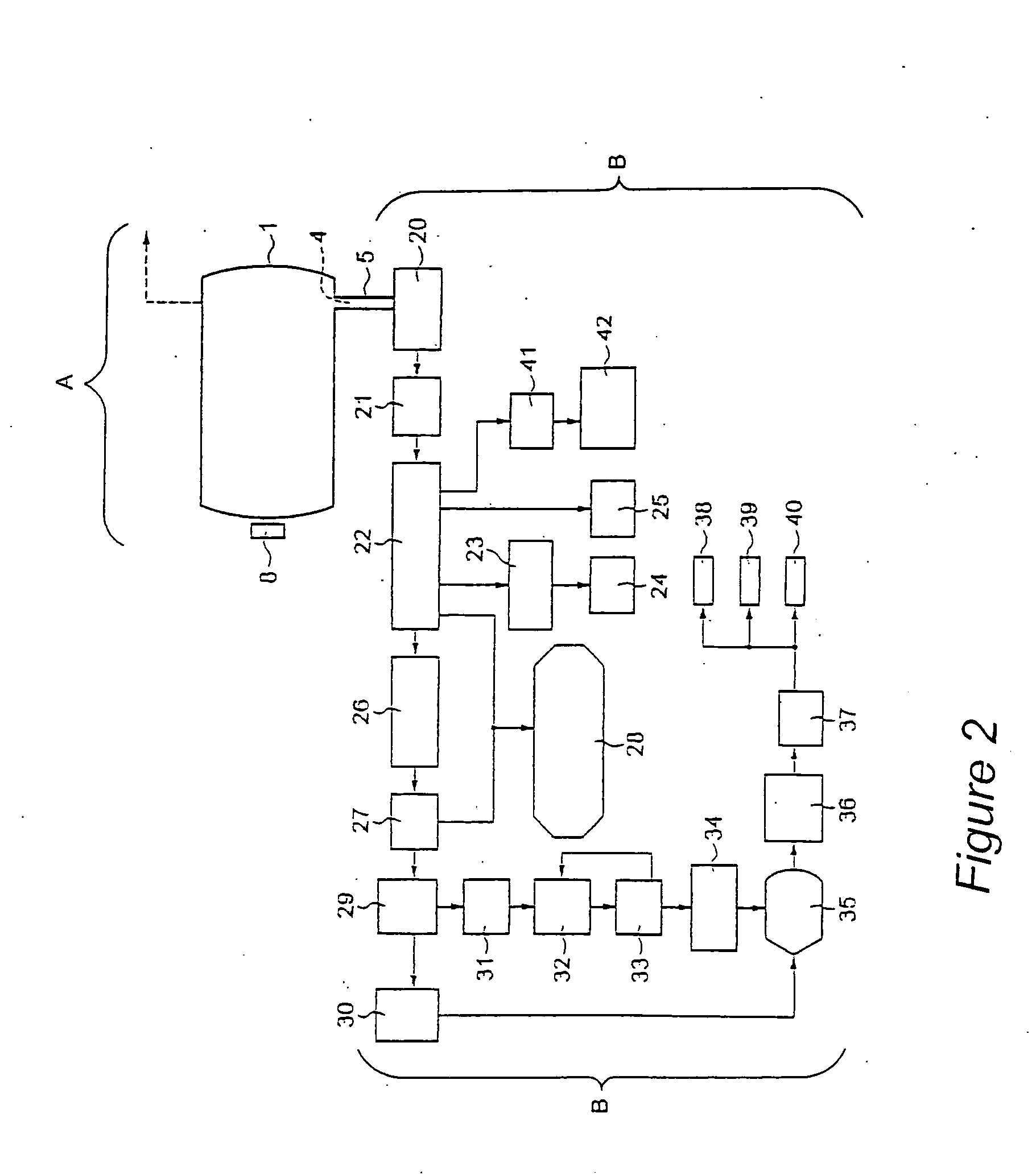

Organic waste treatment system

InactiveUS20090283397A1Low costEasy to wasteBio-organic fraction processingCombustible gas coke oven heatingDecompositionSludge

[Object] To provide an organic waste treatment system in which general wastes from home, ordinary offices, and the like as well as industrial wastes including sludge, waste plastics, and the like can be subjected to treatment such as decomposition by a hydrothermal reaction under a subcritical water condition and in which treated wastes can be taken out in a dried state, sorted, and recycled.[Approach] In a waste treatment system for hydrolyzing organic wastes while stirring the wastes under a high-temperature and high-pressure environment and thermally decomposing or carbonizing the wastes in a double-walled pressure-resistant container 1, the system includes at least: water vapor supply means 9a for supplying high-heat saturated water vapor into the container 1; pressure regulating means 10 for regulating pressure in the container 1 by using an on-off valve; and stirring means 6 having a shaft 7 for stirring the charged wastes in the container 1 and provided to penetrate the container 1 and the system includes the steps of: hydrolyzing the wastes while adjusting temperature to 230° C. or higher and pressure to 3 MPa in the container 1 and stirring the wastes and thermally decomposing or carbonizing the wastes; adjusting the pressure in the container 1 to atmospheric pressure or lower and discharging the treated wastes out of the container while maintaining a dried state of the wastes; and sorting the discharged treated wastes and forming at least one of fertilizer, feed, and auxiliary fuel depending on types of the wastes.

Owner:ECO MATERIAL

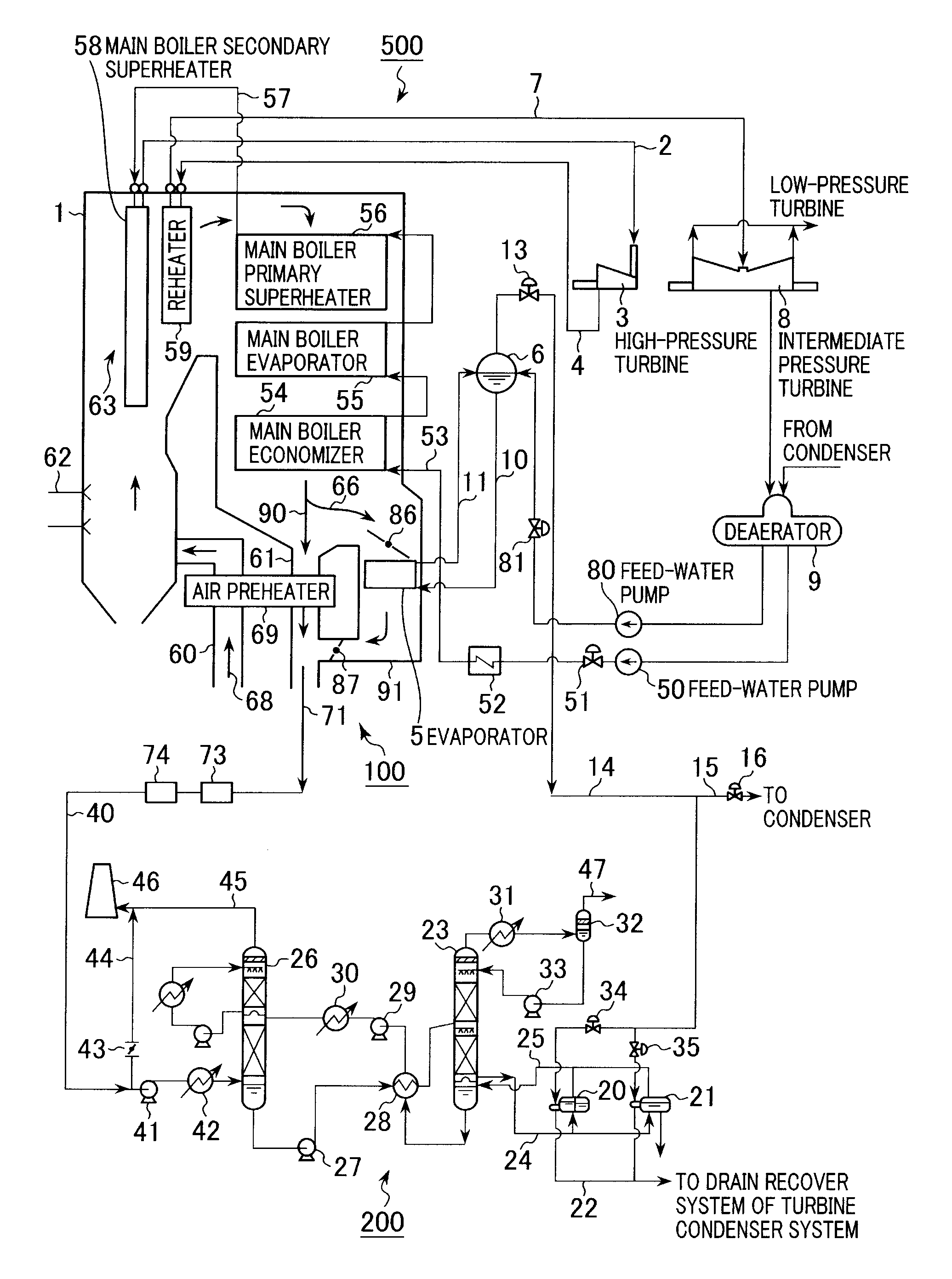

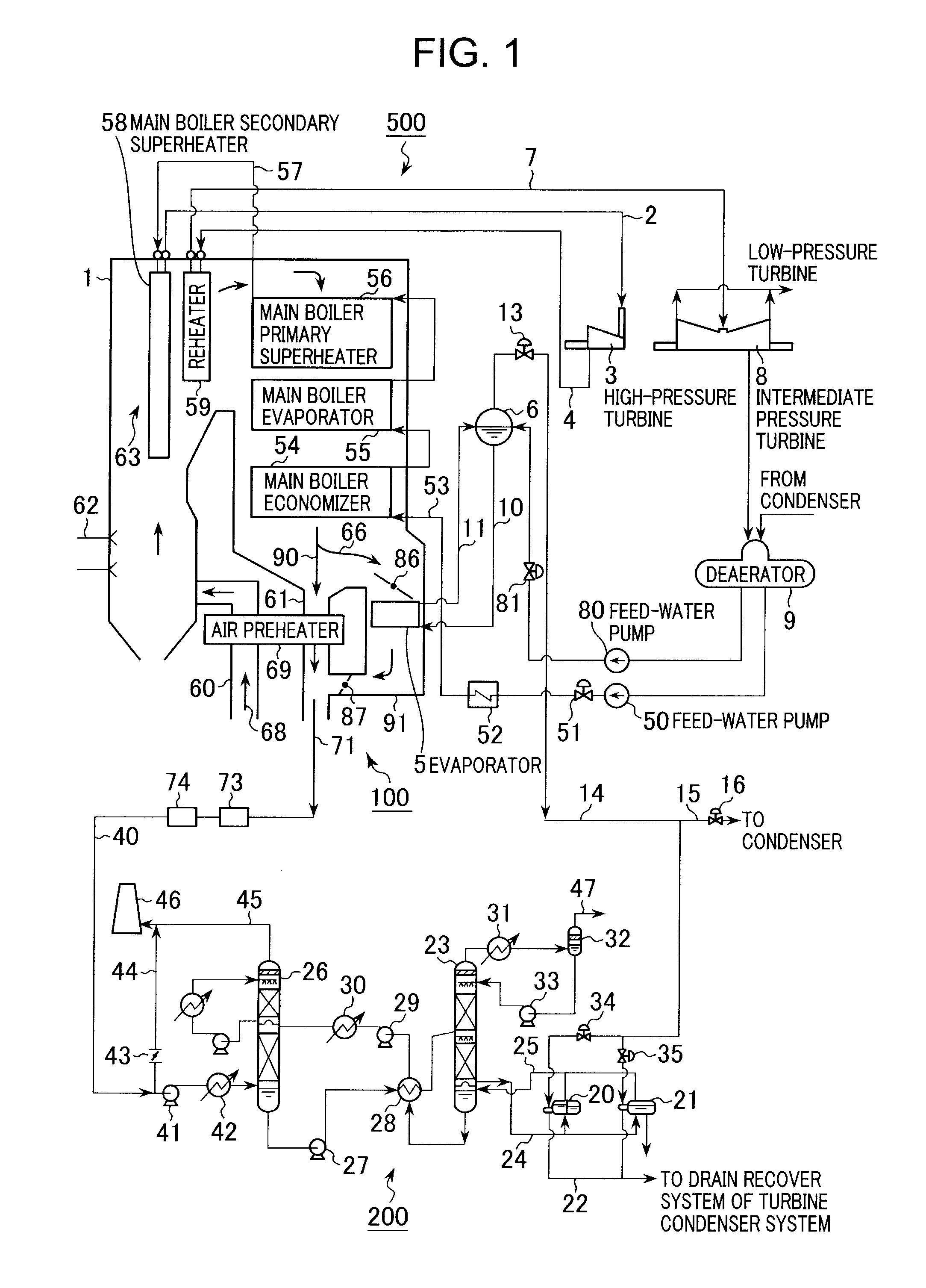

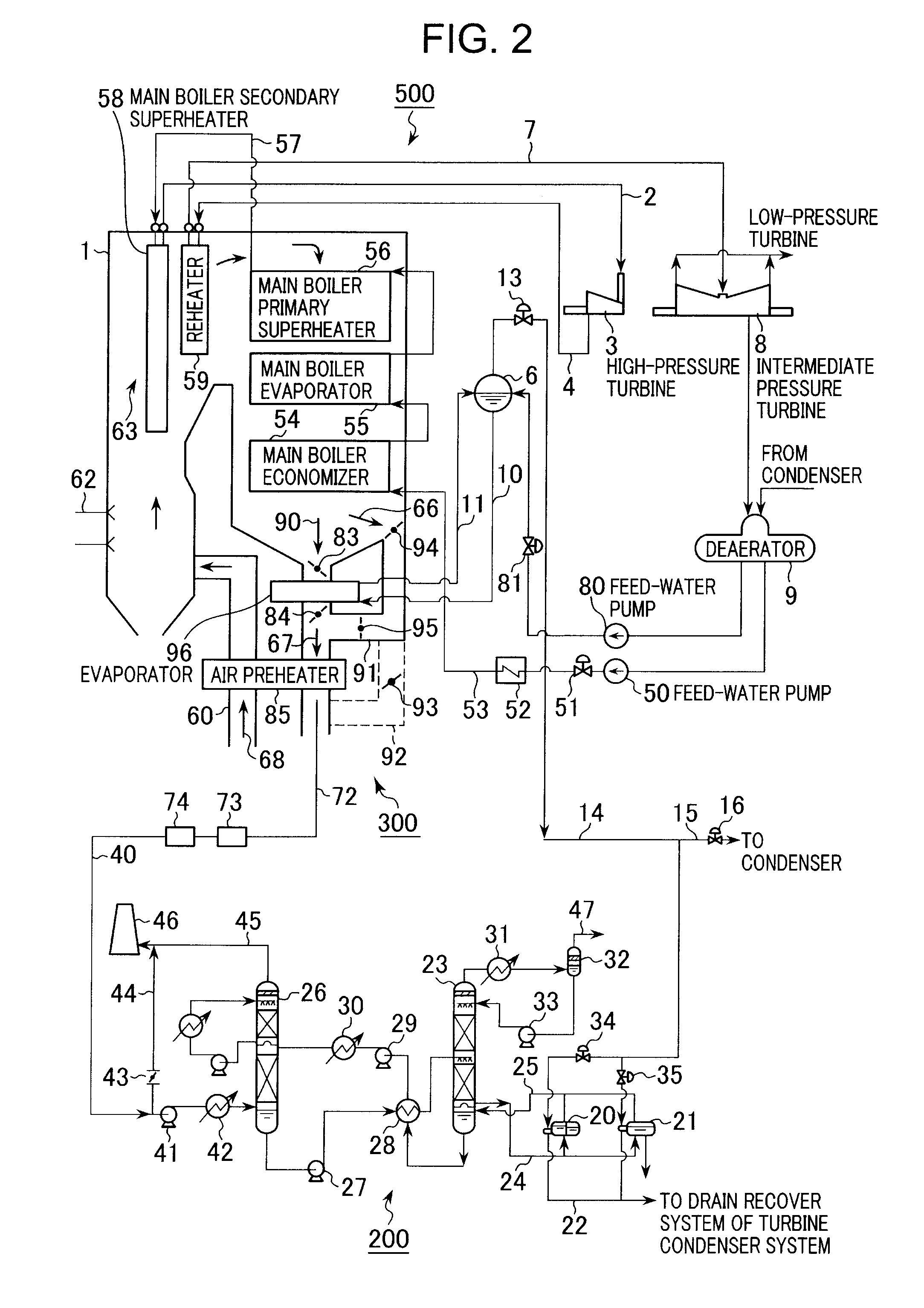

Boiler Apparatus

ActiveUS20110232286A1Efficient regenerationWithout lowering steam turbine efficiencyGas treatmentBoiler water tubesAir preheaterWorking fluid

A boiler apparatus is provided that generates a heat source capable of efficiently regenerating absorbing liquid while maintaining steam turbine efficiency to a maximum extent.The boiler apparatus includes: an economizer 54 preheating water serving as working fluid of a steam turbine system 500; an air preheater 69 installed downstream of the economizer 54; an evaporator 5 installed downstream of the economizer 54; an evaporator drum 6 using the water vapor from the evaporator 5 to generate saturated water vapor; a reboiler 20 using the saturated water vapor from the evaporator drum 6 to evaporate the absorbing liquid from a regeneration tower 23; a steam bypass pipe 15 connected to a steam pipe 14 through which the saturated water vapor from the evaporator drum 6 passes; a steam escape valve 16 installed in the steam bypass pipe 15; an exhaust gas bypass pipe 44 connected to an exhaust gas pipe 40 connecting the air preheater 69 with an absorption tower 26; and a butterfly valve 43 installed in the exhaust gas bypass pipe 44.

Owner:MITSUBISHI POWER LTD

Method for preparing sulfuric acid by pyrolyzing alkylated waste sulfuric acid at high temperature

InactiveCN106744716ASimple processReasonable layoutSulfur compoundsCatalytic oxidationEconomic benefits

The invention relates to a method for preparing sulfuric acid from waste sulfuric acid, in particular to a method for preparing sulfuric acid by pyrolyzing alkylated waste sulfuric acid at high temperature. The method comprises the following steps: (1) pumping waste sulfuric acid into a high-temperature pyrolysis furnace to form mist waste sulfuric acid drops; (2) introducing natural gas and air into the furnace and controlling the temperature in the furnace to be 1,000-1,100 DEG C; (3) cooling SO2 and H2O to be at 330-400 DEG C; (4) humidifying by spraying dilute acid; (5) performing a catalytic oxidation reaction, so that SO2 is converted into SO3; (6) cooling SO3 gas to be at 260-320 DEG C, so as to form saturated steam; and (7) performing heat exchange between SO3 gas and air for further cooling, wherein the final temperature of cooling is 60-120 DEG C; and spraying 98% sulfuric acid with the temperature of 70 DEG C to absorb the generated SO3, so as to form the sulfuric acid. The invention provides a brand-new regeneration method of waste sulfuric acid, so that the technological processes are greatly simplified, equipment layout is reasonable, the operation is simple and convenient, the economic benefits are obvious, and the comprehensive energy utilization is high.

Owner:广西防城港五星环保科技股份有限公司

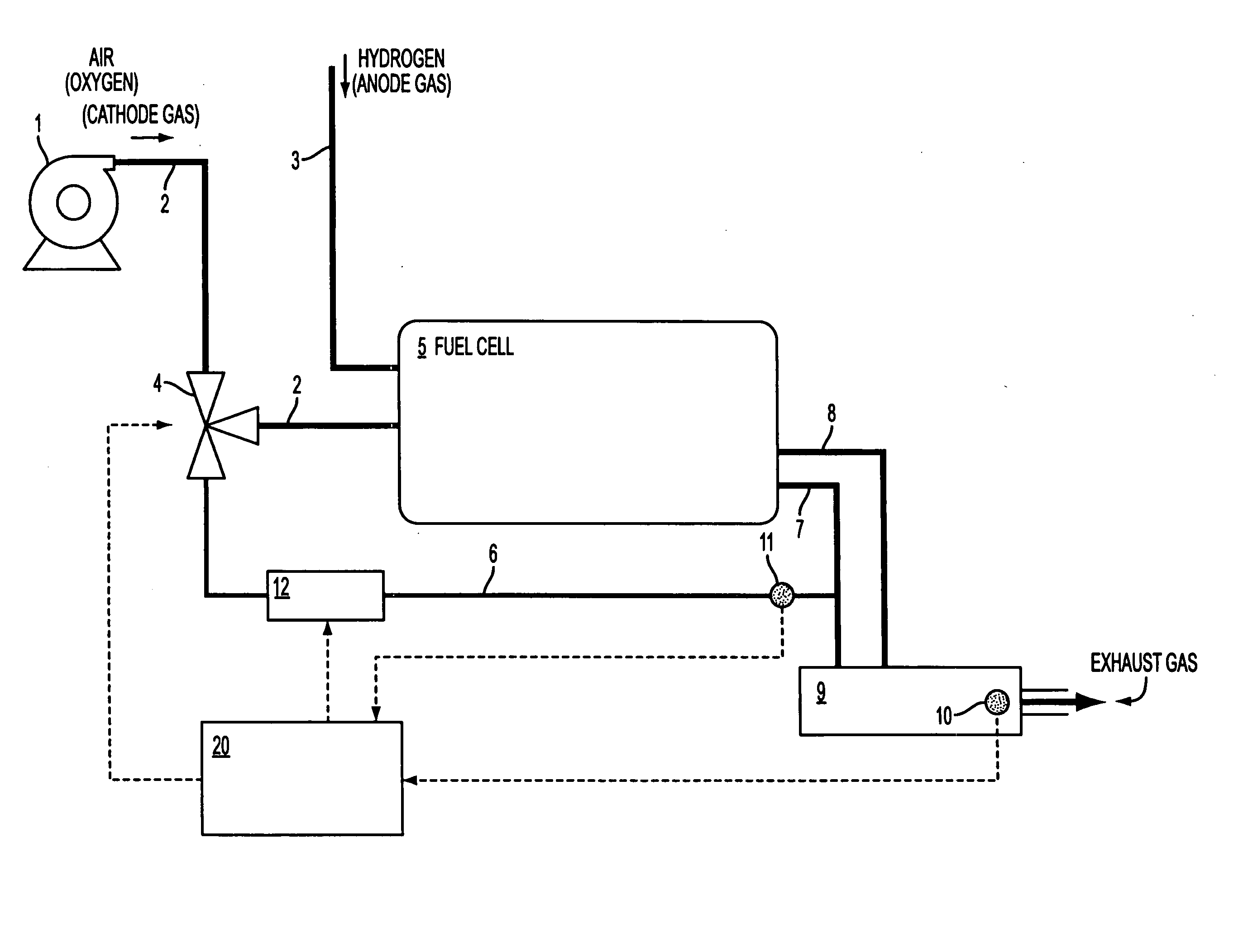

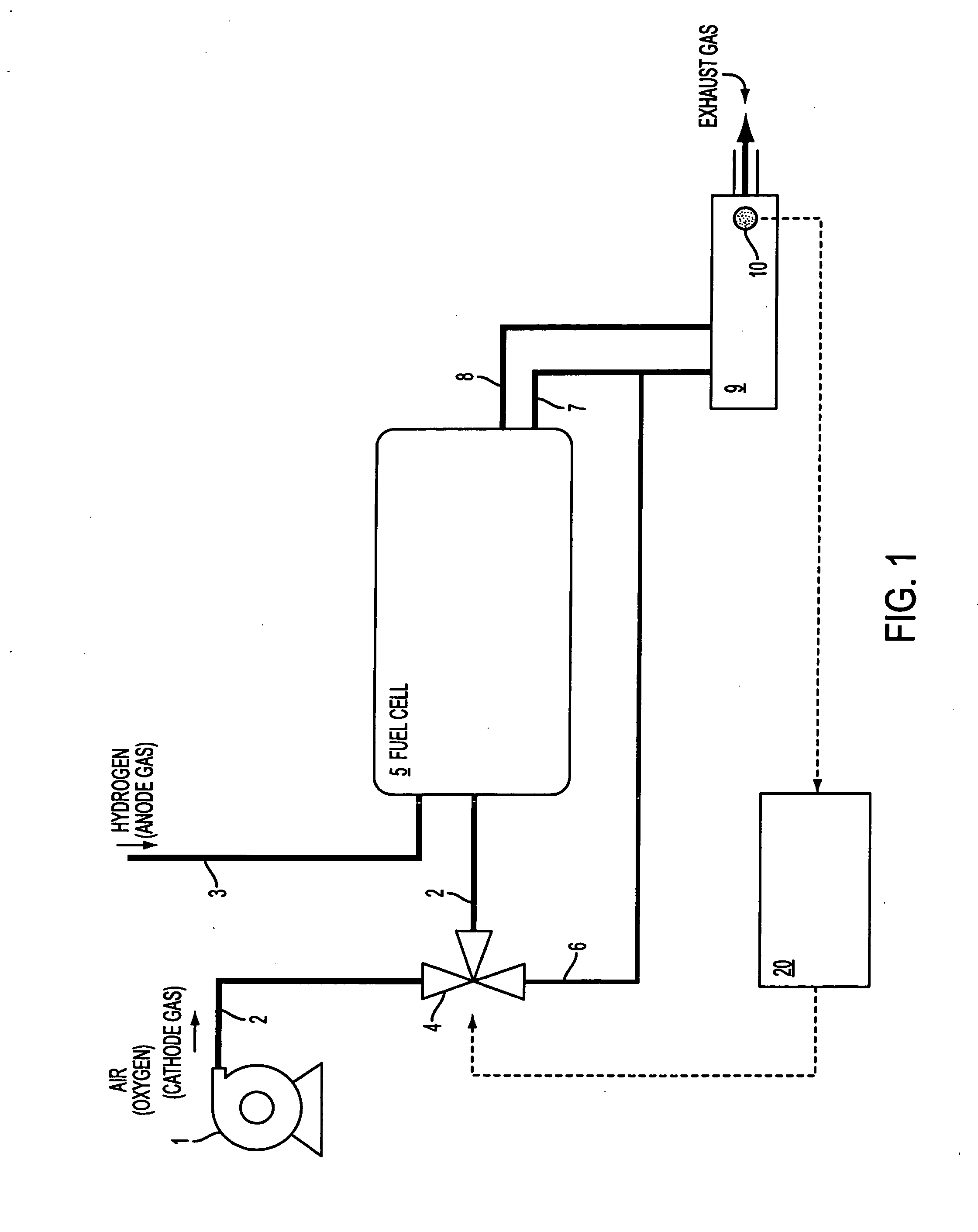

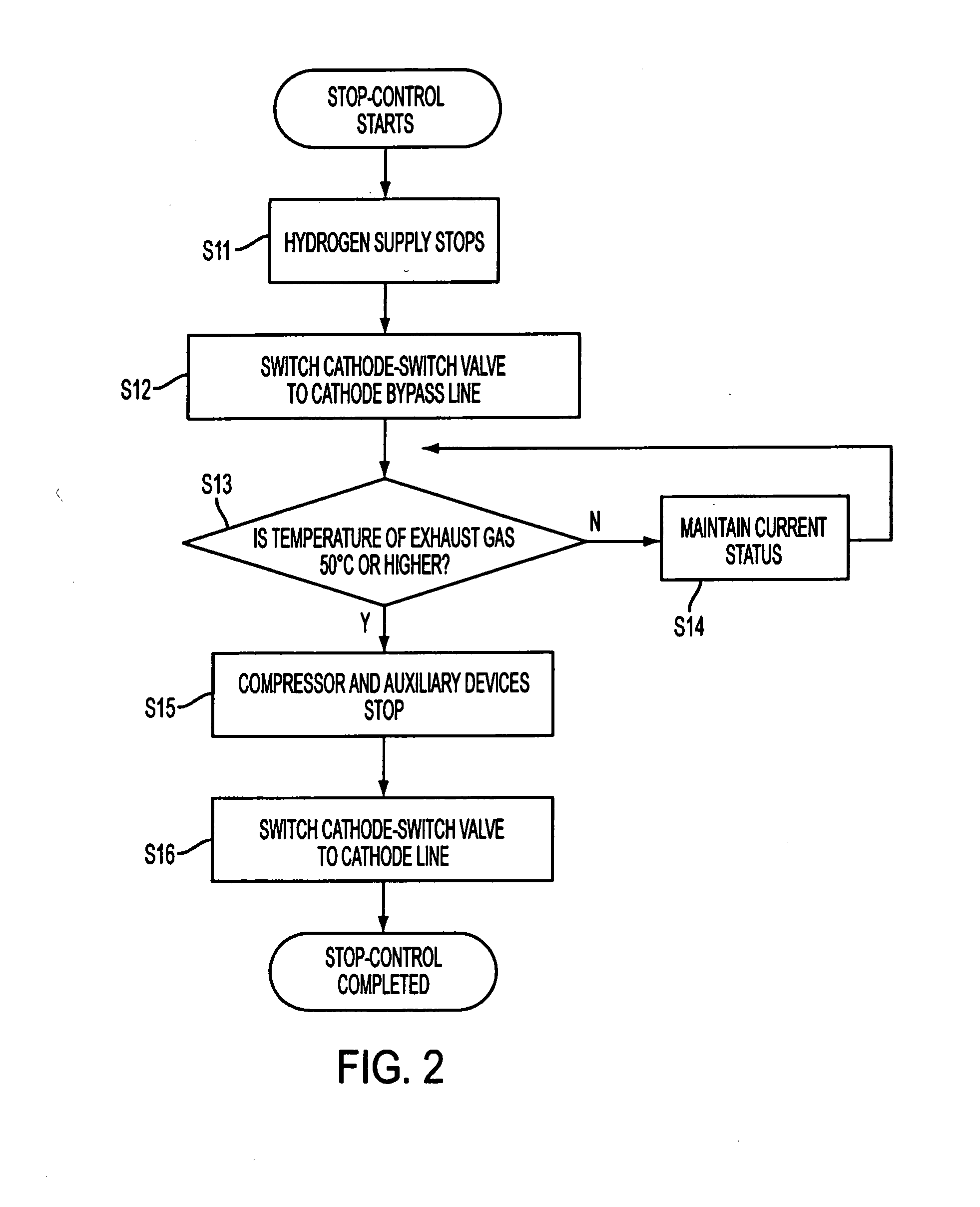

Fuel cell system

InactiveUS20050136302A1Simple compositionFuel cell auxillariesSolid electrolyte fuel cellsElectrochemical responseFuel cells

A fuel cell generates electric power by the electrochemical reaction of hydrogen and the oxygen in air. After the hydrogen discharged without being consumed by an anode is burned in a burner, it is discharged out of a fuel cell system. Therefore, the fuel cell system has a cathode switch valve in the middle of the cathode line, and when the fuel cell system stops, non-saturated air of a compressor bypasses the fuel cell, and supplies the air to the catalytic burner. Although the cathode exhaust gas of saturated water vapor is circulating to the catalytic burner at the time of regular operation of the fuel cell, the non-saturated air which bypasses the fuel cell and is supplied can replace the inside of the catalytic burner with dry air. Therefore, the amount of water vapor in the catalytic burner is decreased at the time of a stop, and the catalyst is quickly activated at the time of re-starting.

Owner:NISSAN MOTOR CO LTD

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS20050274668A1Lower the volumeSave volumeBio-organic fraction processingBiological substance pretreatmentsParticulatesSaturated water vapor

A method for treating particulate biodegradable organic waste includes adjusting the pH as necessary to provide an acidic pH prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

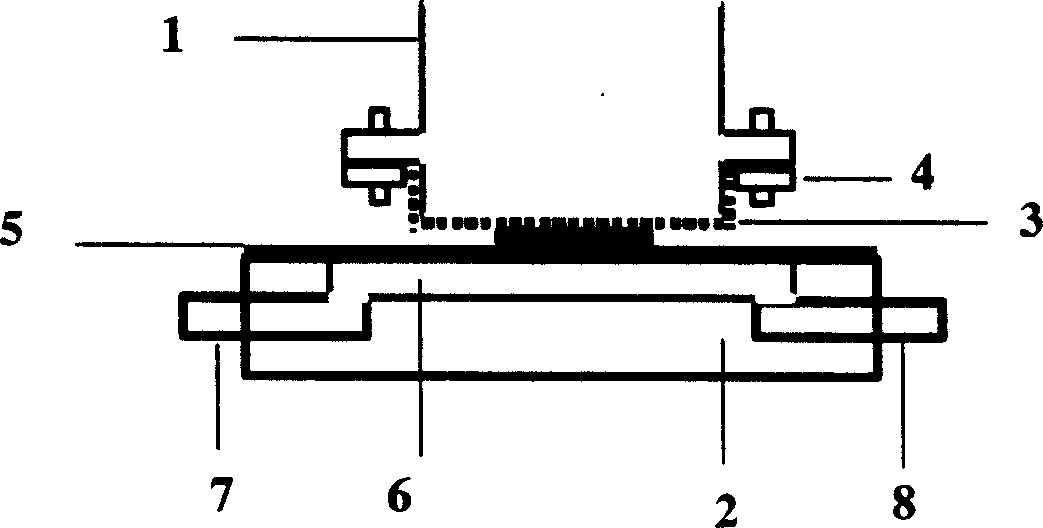

Fabric moisture-penetrability testing device and testing method

InactiveCN1975416AReduce precisionReduce sensitivityInspecting textilesSurface/boundary effectTextile millSaturated water vapor

The invention relates to a testing device and the method for the fabric moisture-penetrability. The device is made up of the column canister, the base, the waterproof moisture film, the pressure ring and the testing board. The shallow groove is set on the base which the two ends are connected with the air inlet and the air outlet carved on the base two sides. The waterproof moisture film is the bottom of the column canister to form the saturate water vapor resource; the dry quick flowing N2 is the carrier to carry the water vapor through the fabric away. So it can measure the relative humidity of the N2 flow to get the moisture content of the fabric. The invention has the high precision and good repetition, the testing time is short and the cost is low; so the device can be used in the textile mill to control the product moisture-penetrability quality.

Owner:WUHAN TEXTILE UNIV

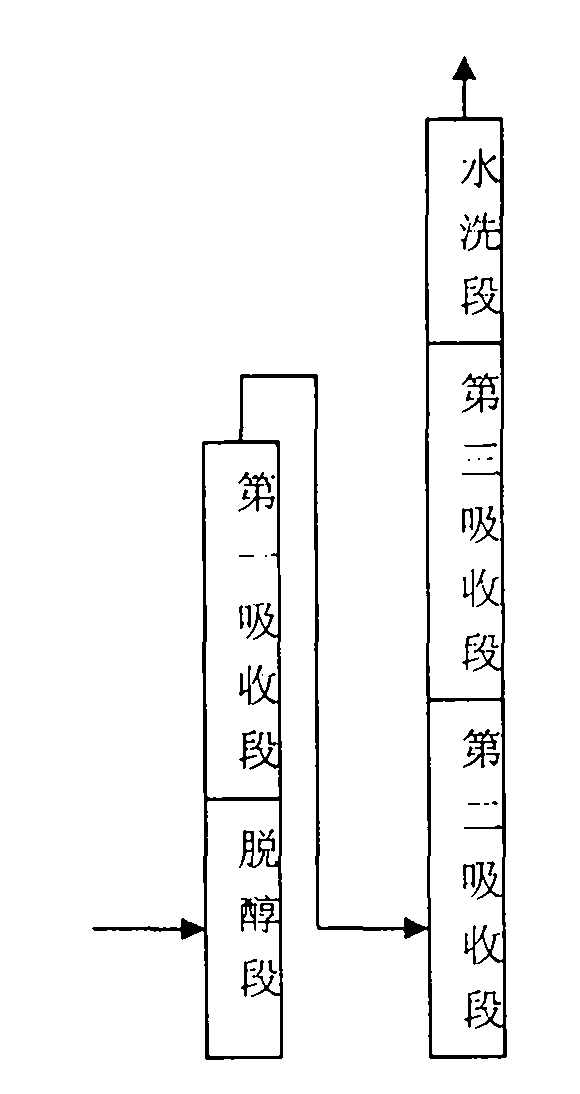

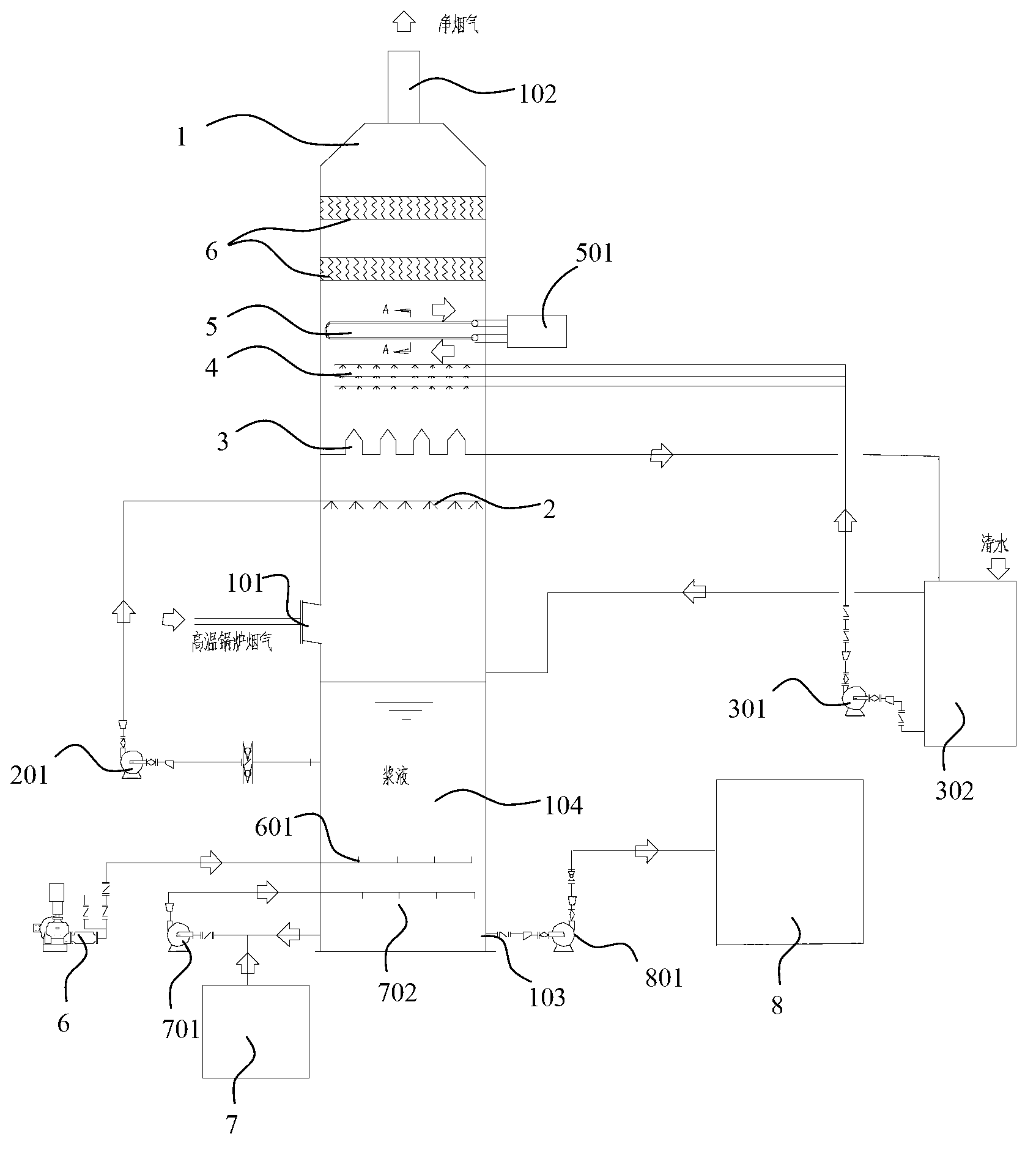

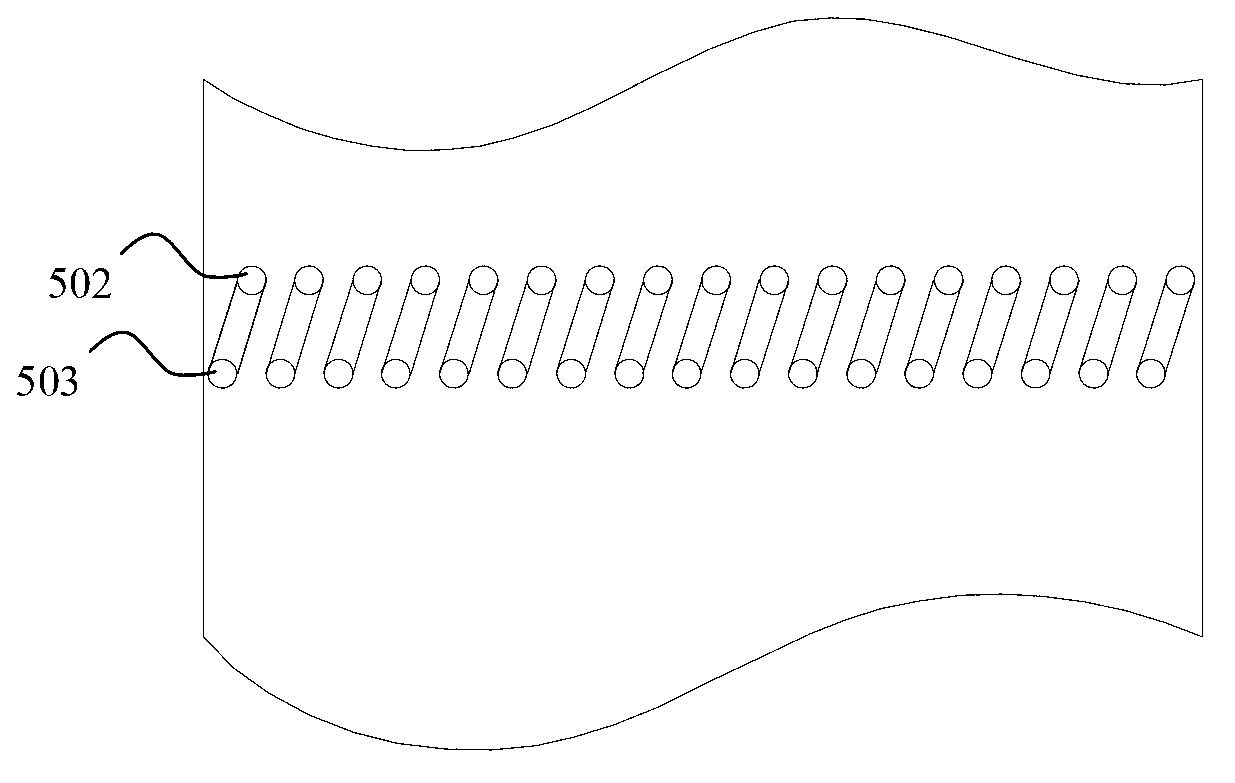

Desulfurization system and desulfurization process thereof

InactiveCN103252158AReduce consumptionUniform flow rateDispersed particle separationEscape rateSaturated water vapor

The invention discloses a desulfurization system comprising a tower body, wherein a smoke inlet is arranged in the middle of the tower body; a pure smoke outlet is arranged at the top of the tower body; a slurry pool for containing slurry is formed on the lower part of the tower body; the slurry pool is provided with a mixed liquid outlet; a slurry spraying layer, a rising air gap and a clean water spraying layer are sequentially arranged from the smoke inlet to the pure smoke outlet from bottom to top; the bottom of the slurry pool is respectively connected with an oxidization mechanism and an ammonia supplying mechanism; and the desulfurization system further comprises a slurry circulating mechanism and a clean water circulating mechanism. The invention further provides a desulfurization process; and the process is low in water consumption amount so that the amount of saturated steam in pure smoke is reduced by 30-40% and consumption of external clean water is reduced. According to the desulfurization system and the desulfurization process disclosed by the invention, the operation cost is low; and the consumption of the steam is 20% of that of an ammonia-fertilizer method process and the consumption of power is 40% of that of the ammonia-fertilizer method process. The escaping rate of ammonia is low; the content of the ammonia in the pure smoke is less than 8mg / Nm<3>; no three wastes are discharged; and secondary pollution to an environment is not caused.

Owner:九美科技有限公司

Method for generating palladium catalyst for producing hydrogen peroxide by using anthraquinone process

InactiveCN104475175AActive recovery is goodExtend the life cycleCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsPalladium catalystNitrogen

The invention discloses a method for generating a palladium catalyst for producing hydrogen peroxide by using an anthraquinone process. The method comprises the following comprehensive regeneration steps: soaking or circularly washing a catalyst to be regenerated by using aromatic hydrocarbon with temperature of 30-70 DEG C, treating by using saturated steam with temperature of 100-120 DEG C, soaking or circularly washing by using hot water with temperature of 30-95 DEG C, displacing with nitrogen, activating with nitrogen, and the like. The regenerated catalyst is thorough in regeneration degree, good in activity recovery, and long in regeneration period and service life.

Owner:YANTAI BAICHUAN HUITONG TECH CO LTD

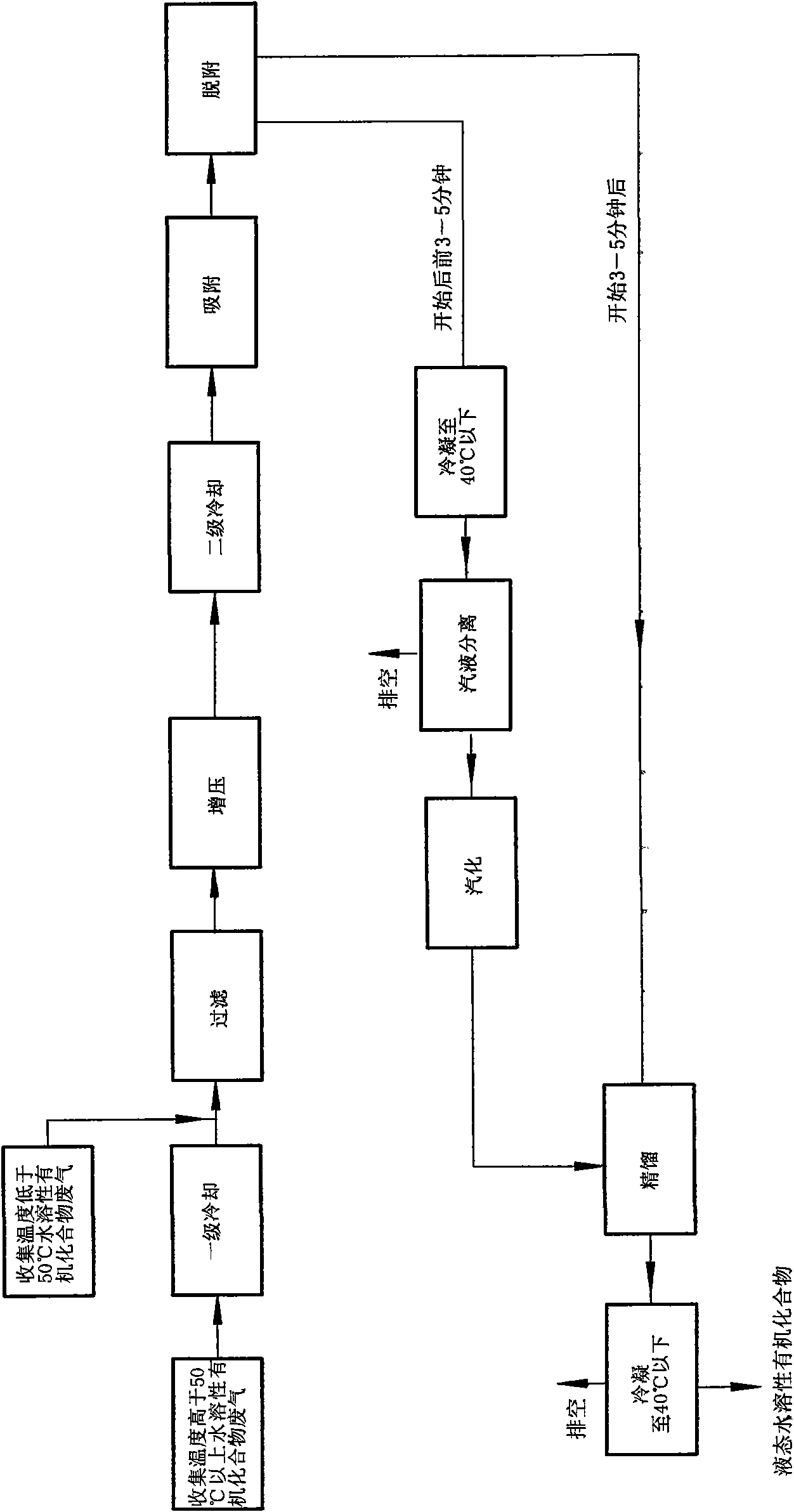

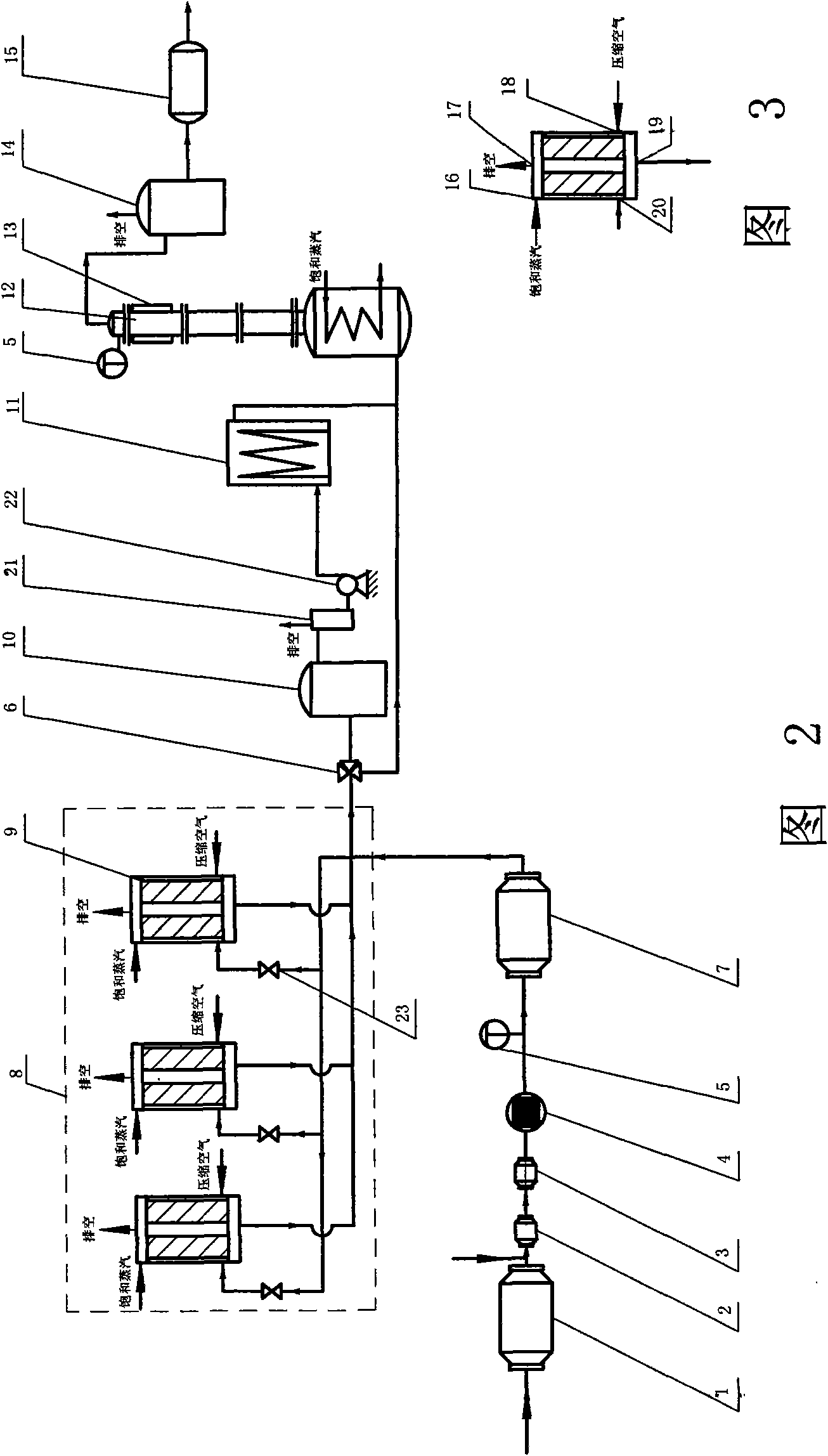

Method and device for recovering gas containing water-soluble organic compounds

ActiveCN101564635AContinuous operationReduce consumptionCombination devicesTemperature controlDesorption

The invention relates to a method and a device for recovering gas containing water-soluble organic compounds. The method includes steps of using saturated water vapor to carry out desorption for waste gas adsorbed by a absorber, conveying desorbed gas containing mixture of air and liquid from the third minute to the fifth minute after the desorption begins to a desorption gas condenser to condense under 40 DEG C, conveying the condensed gas into a gas-liquid phase-splitter to carry out gas liquid separation, pumping water solution containing the solvent into a reboiler to vaporize by heating, conveying the gas into a distillation tower for rectifying after vaporizing; directly conveying desorbed gas not containing the mixture of air and liquid 5 minutes after the desorption begins into the distillation tower for rectifying, controlling tower top temperature of the distillation tower in a range of + / - 1 DEG C of boiling point of the water-soluble organic compounds, and obtaining the water-soluble organic compounds capable of being circularly used after conveying tower top fraction into a fraction condenser to condense to temperature lower than 40 DEG C. The invention not only can excellently recovers waste gas, but also reduces heat energy consumption by more than 40% in device operation process.

Owner:何金星 +1

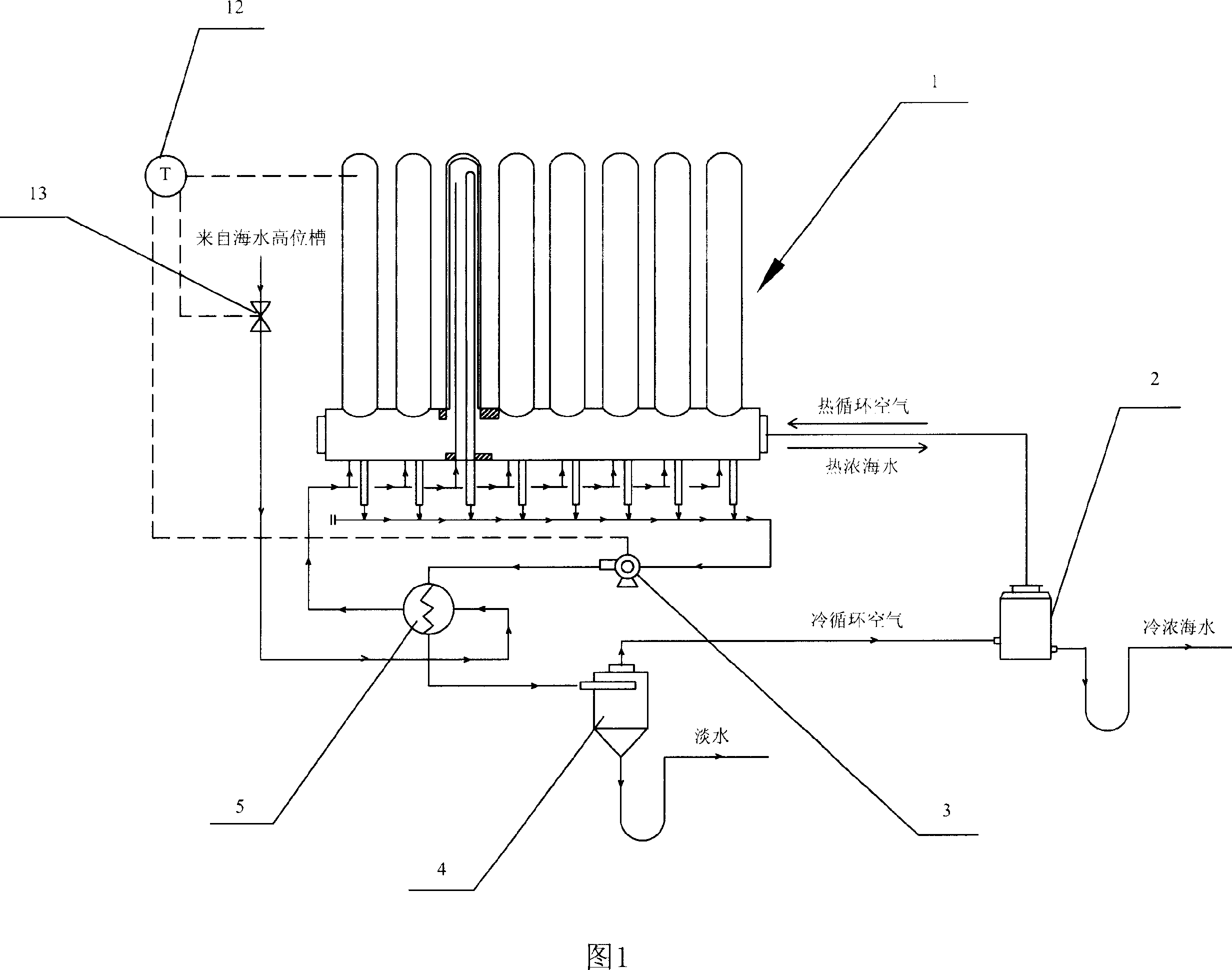

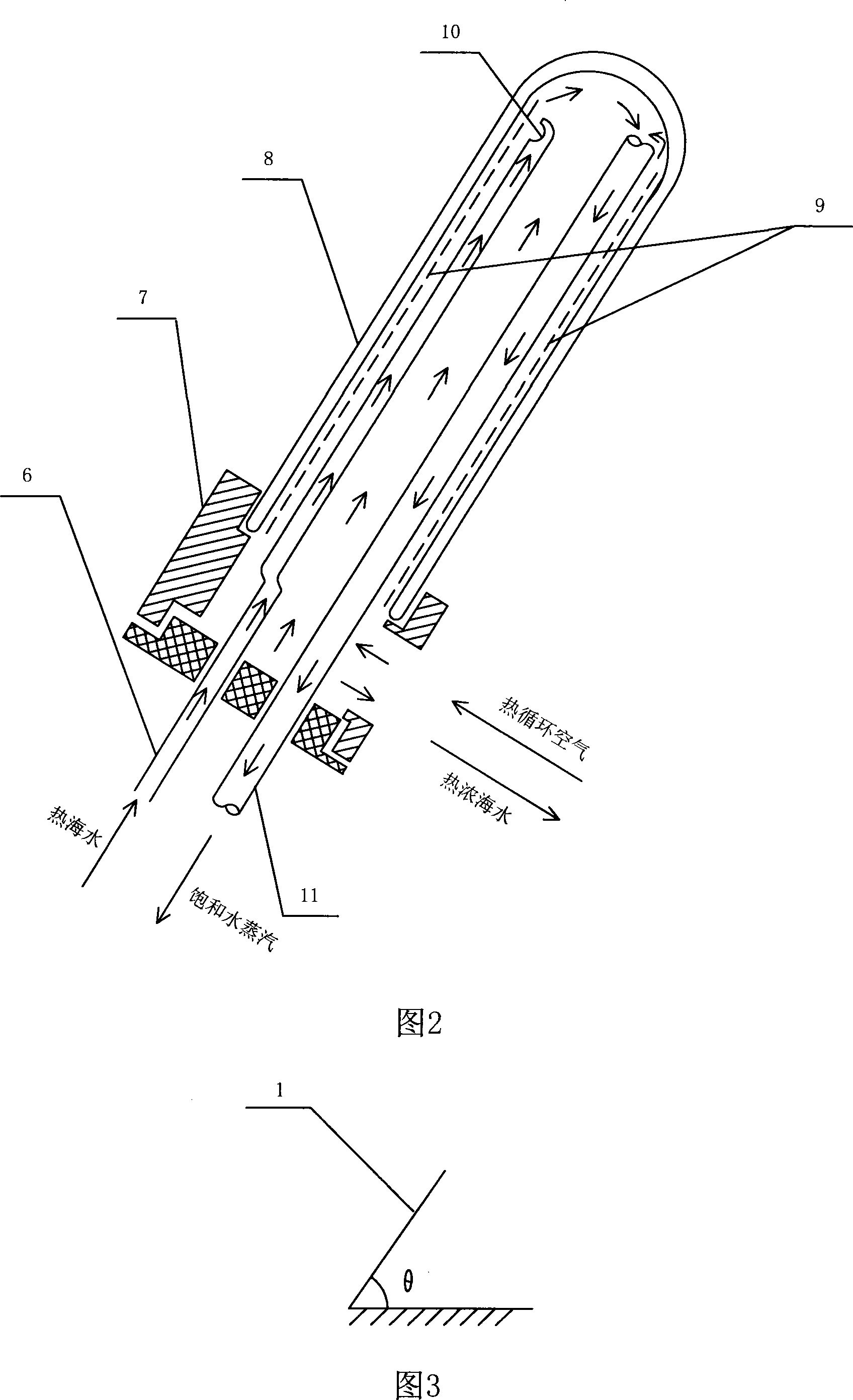

Integral solar energy sea water desalination production apparatus

InactiveCN101117246AIncrease profitIncrease productivitySolar heating energyGeneral water supply conservationTemperature controlWater desalination

The invention discloses an integrated solar energy overall production device for seawater desalting, comprising a heat collecting and diaphragm transferring distiller, a heat exchanger, a blower, a cyclone separator, a temperature sensor and so forth, the distiller consists of a connecting box, a vacuum tube plugged on the connecting box, a seawater input tube inside the vacuum tube and a saturate vapor output tube, the internal side wall of the vacuum is provided with a wet diaphragm; with using the utility model, the heat collecting temperature of solar energy can be controlled within a low heat range from 40 to 60 DEG C, the light-heat exchanging rate can be increased; the side wall at the upper end of the seawater input tube is provided with a water distribution hole, the seawater is sprayed to the wet diaphragm through the water distribution hole, so the processes of heat collecting, diaphragm transferring distillation and micro negative pressure distillation can be conducted simultaneously, a diaphragm distilling area of seawater can be increased, the invention solves the problems where the utilization rate of solar energy light-heat is lower, the production efficiency is low, the clear water is easy to be polluted., etc, the efficiency can be largely increased, the cost is decreased.

Owner:贾海滨 +1

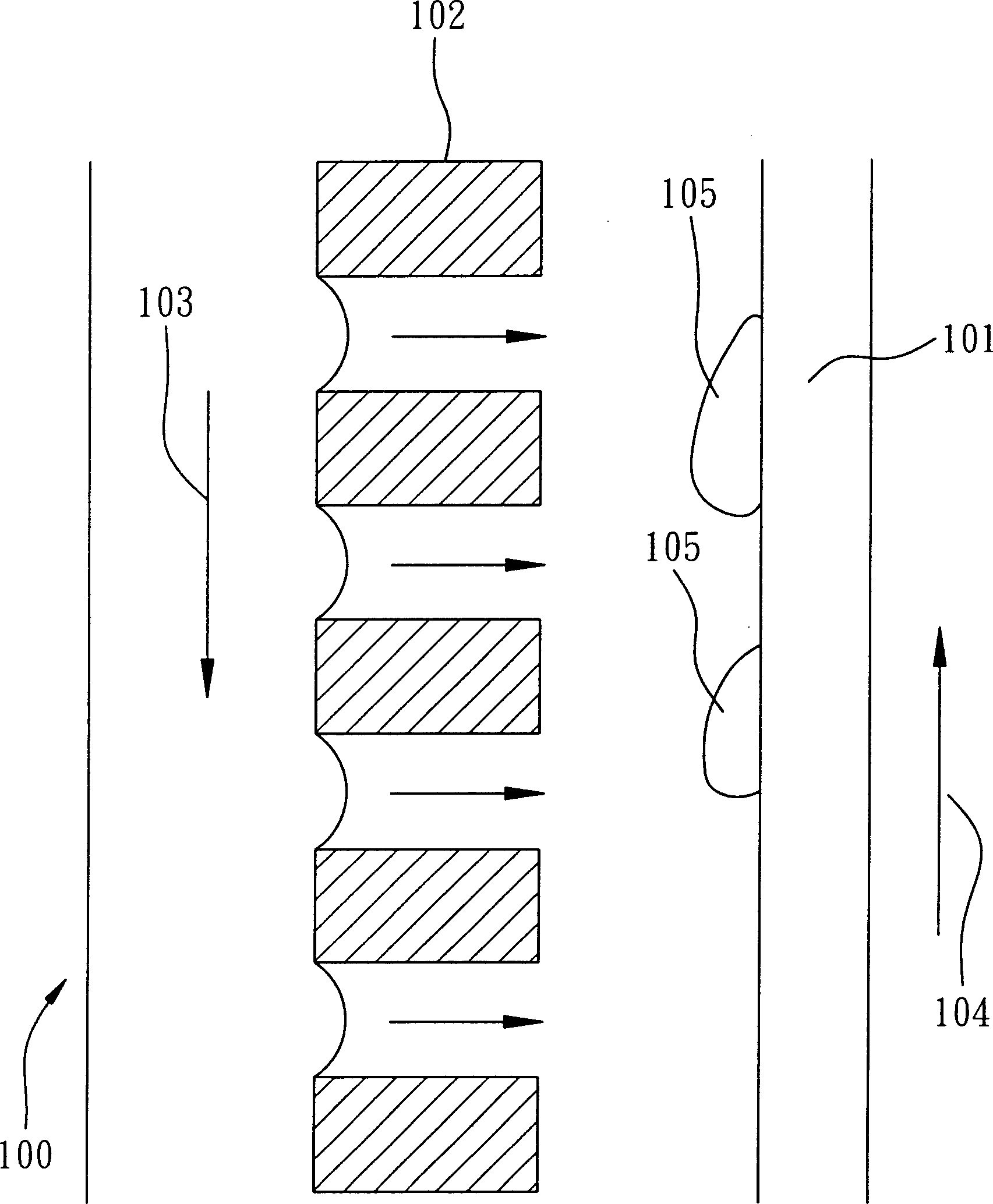

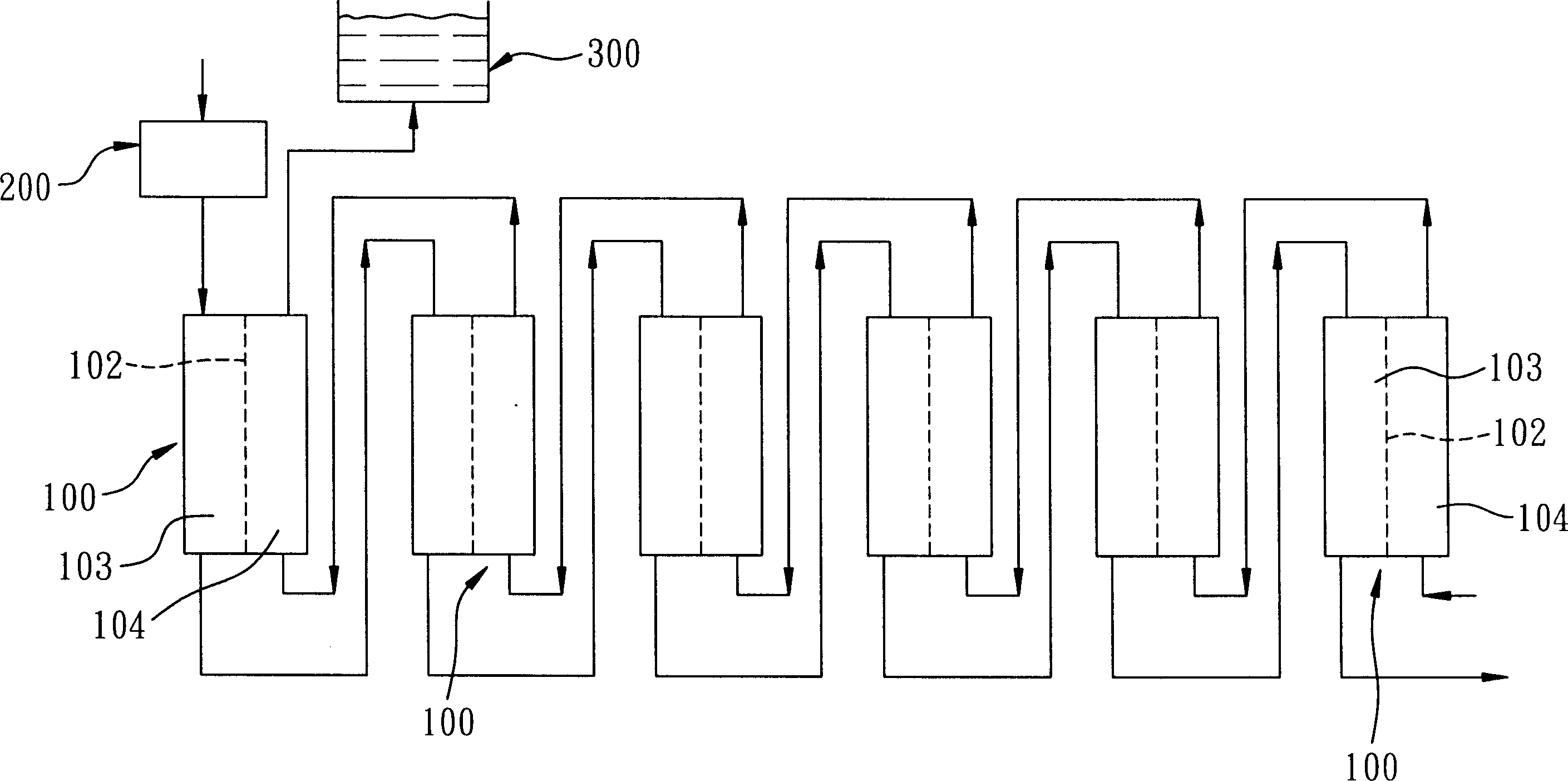

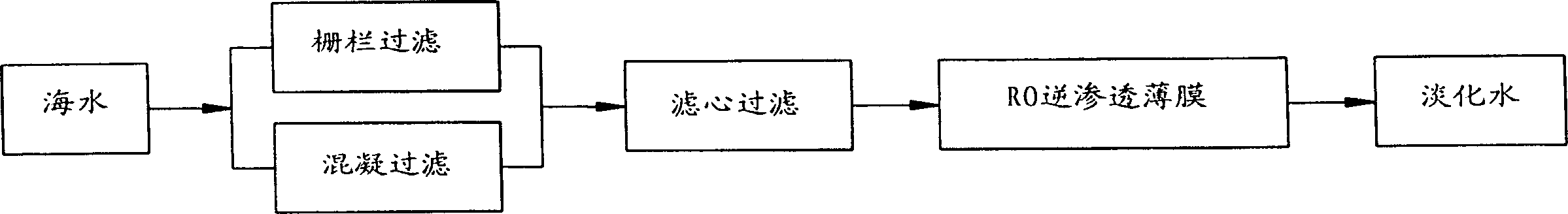

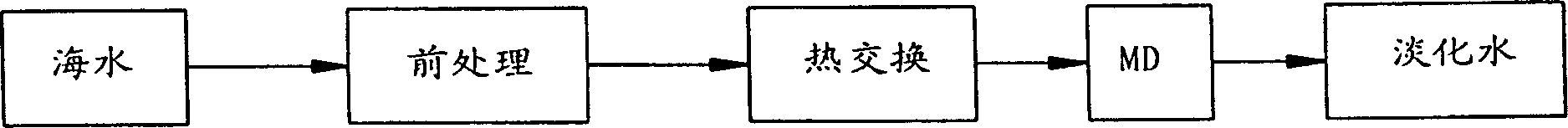

Sea water desalting membrane distillation system with high efficiency and low cost

InactiveCN1526650AGeneral water supply conservationEnergy based wastewater treatmentMicro bubbleSaturated water vapor

The efficient and cheap sea water desalting membrane distillation system includes one sea water feeding loop; one micro bubble forming unit to pump sea water, pressurize and emulsify sea water into work liquid containing saturated water vapor; one desalting unit with at least one ventilation room, porous hydrophobic membranes inside the ventilation room, separate high temperature sea water regions, into which work liquid containing saturated water vapor is pumped into, and low temperature condensated fresh water regions; and one condensating desalting unit to condensate fresh water connected successively.

Owner:郭兴中 +1

Rosin-based fruit and vegetable fresh-keeping coating agent and preparation method thereof

The invention provides a rosin-based fruit and vegetable fresh-keeping coating agent and a preparation method of the rosin-based fruit and vegetable fresh-keeping coating agent. The preparation method comprises the following steps: 1, performing D-A addition reaction on rosin, namely, heating 100 parts of rosin to about 160 DEG C to melt, adding 5-30 parts of unsaturated acid or anhydride under stirring, keeping the temperature to 180-220 DEG C, reacting for 1-4 hours to obtain a rosin addition product; 2, performing moderate esterification reaction, namely, slowly adding 5-20 parts of polyol and 0.2 part of nano ZnO catalyst in 100 parts of prepared rosin addition product, keeping the temperature to 200-230 DEG C, reacting for 1-6 hours to obtain a rosin esterification product; and 3, post-treating, namely, introducing saturated water vapor in a reaction kettle filled with the rosin esterification product, continuously blowing and steaming for 1-3 hours, then removing water and low-boiling point neutral products in the esterification product through vacuum decompression to obtain a coating agent product. The rosin-based fruit and vegetable fresh-keeping coating agent can be well soluble with alcohol, and is good in gloss durability and weather resistance.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for treating titanium-silicon molecular sieve

ActiveCN102311128AReduce consumptionNo emissionsCrystalline aluminosilicate zeolitesEnvironmental resistanceMolecular sieve

The invention relates to a method for treating a titanium-silicon molecular sieve. The method is characterized by modifying the titanium-silicon molecular sieve by a modifying solution in the presence of saturated steam, wherein the modifying solution is obtained by hydrolyzing a silicon source and a titanium source in a base solution. According to the method, mother liquor separation is not required, the filtration and washing procedures are omitted, pollution to environment is reduced greatly, the volume utilization efficiency of a high-pressure device is improved, the preparation cost is lowered, and the environmental protection and economic benefits of synthesis are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Membrane distillation sea water desalination method

InactiveCN1513770AEasy to see throughGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisWater desalinationEmulsion

A membrane distilling process for desalinating seawater includes filtering seawater, bubbling while pressure floating to rmeove seaweeds and solid impurities, bubbling again to mix air with water to become emulsion and making the bubbles contain saturated water vapour, delivering it into a desalinating equipment containing one or more porous hydrophobic membranes to penetrate the emulsion containing a lot of saturated water vapour through the membrane, and condensing the water vapour to obtain fresh water.

Owner:郭兴中 +1

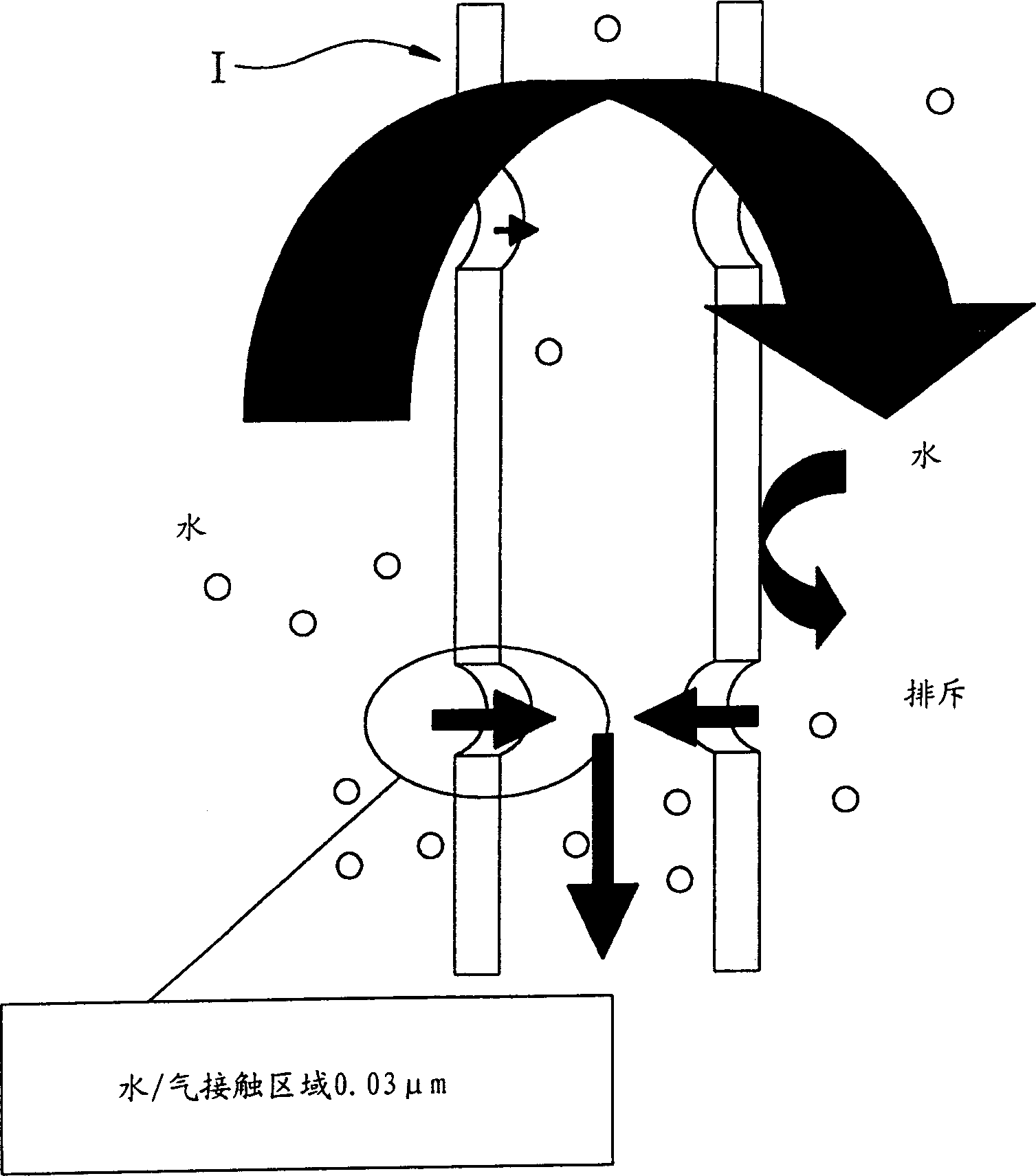

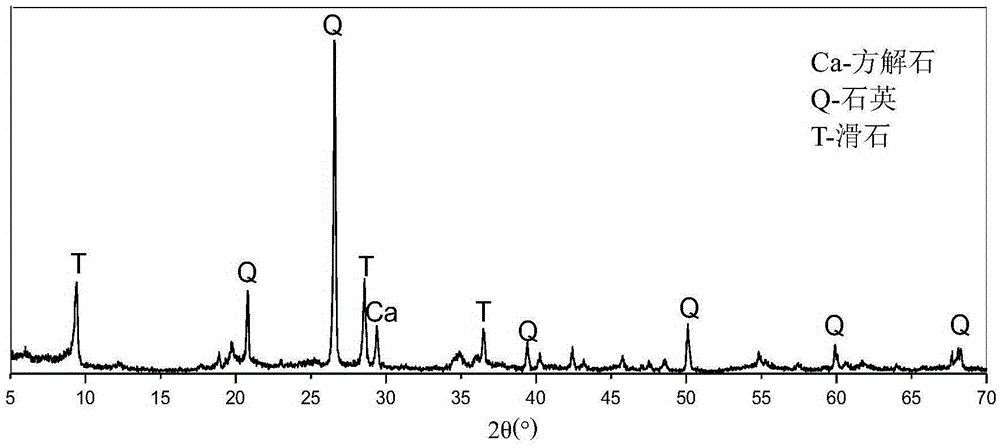

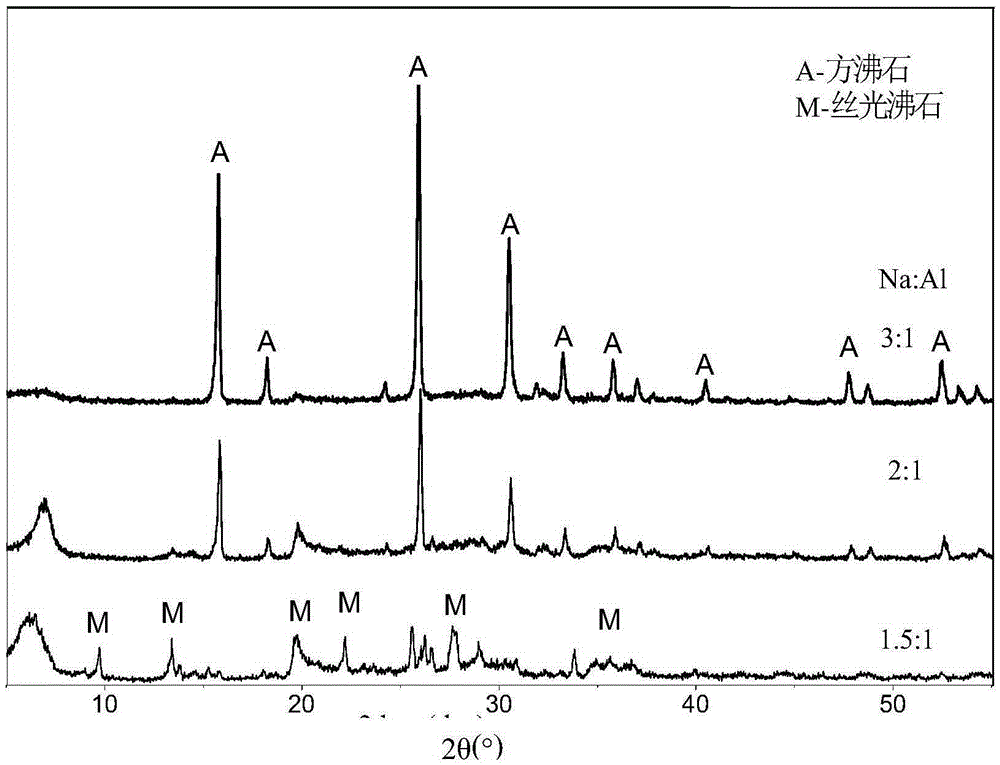

Method for producing zeolite by using soil clay minerals as raw materials

ActiveCN105417554ARich sourcesLow priceMolecular-sieve and base-exchange compoundsClay mineralsEconomic benefits

The invention relates to a method for producing zeolite by using soil clay minerals as a raw material, and belongs to the technical field of mineral synthesis. The method is characterized by using the soil clay minerals as the raw material, drying the raw material and detecting the content of elements in the soil clay mineral; using NaOH and NaCl as sodium sources, wherein an alkaline environment is provided by NaOH; weighing the soil clay minerals and the sodium sources according to a molar ratio, which is (0.7 to 3):1, of Na and Al, weighing water according to a mass ratio, which is (0.15 to 0.75):1, of the water and the soil clay minerals, and adding NaOH or NaOH and NaCl in the soil clay minerals after dissolving NaOH or NaOH and NaCl in the water; then putting the mixture in a reaction kettle, treating the mixture for 4 to 12 hours under saturated water vapor of which the temperature is 120 to 240 DEG C, and obtaining a reaction product-the zeolite after drying, wherein the soil clay minerals are commercially available montmorillonite raw materials or illite raw materials, and NaCl and NaOH of the sodium sources are weighed according to a molar ratio which is (0 to 2):1. According to the method for producing the zeolite by using the soil clay minerals as the raw material, disclosed by the invention, the process is simple and convenient, the economic benefit is high, and the obtained product-analcime is purer.

Owner:TONGJI UNIV

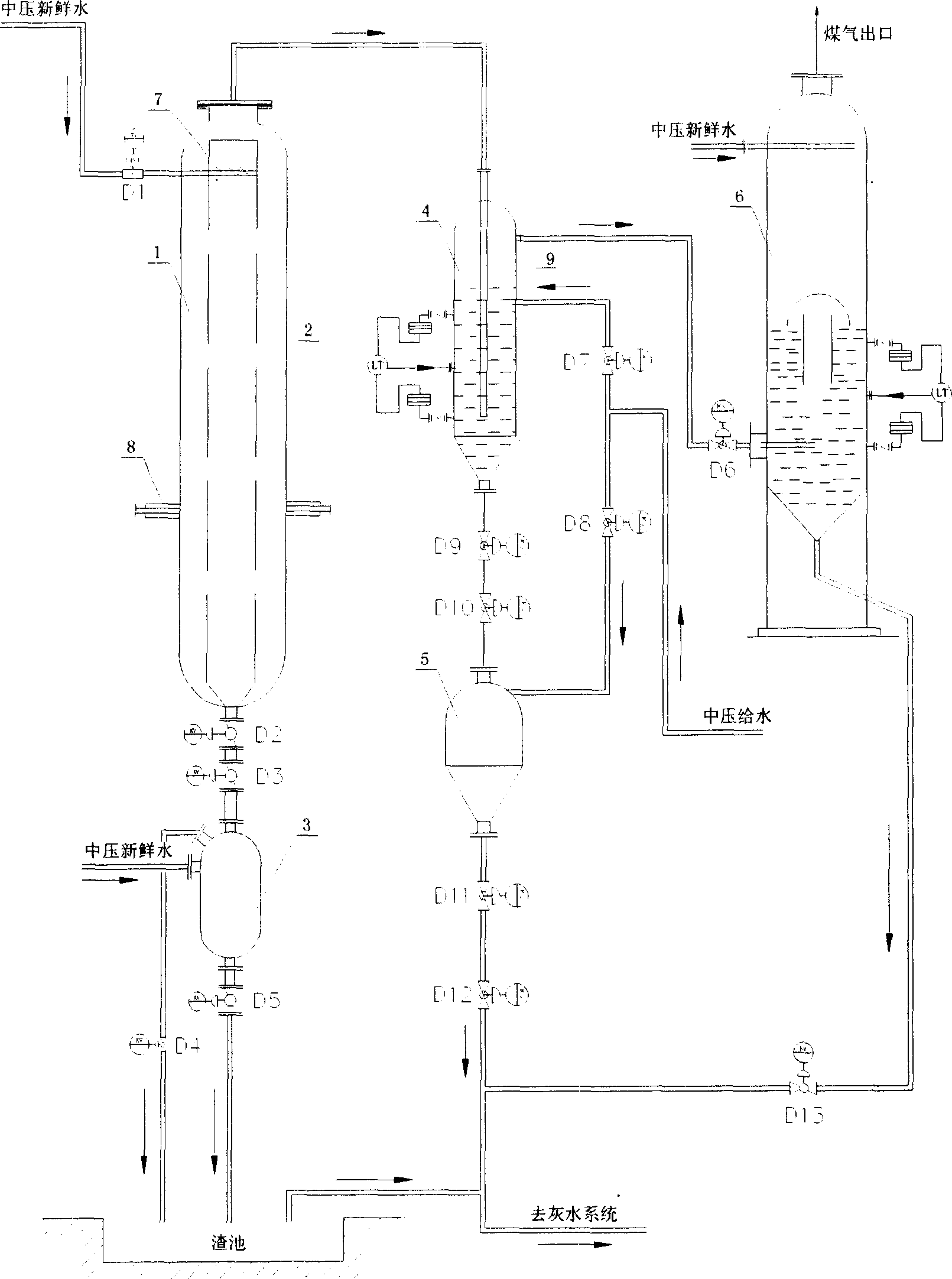

Chilling device and process for dry coal powder pressure gasifying

InactiveCN1900234ALow costImprove efficiencyCombined combustion mitigationGranular/pulverulent flues gasificationHydrogenSaturated water vapor

The coal powder pressurized gasifying and chilling apparatus includes five parts for coal powder pressurizing gasification, water spraying chilling, chilling in a chilling chamber, clinker exhaustion and grey water treatment separately. The coal powder pressurized gasifying and chilling process includes the pressurized gasifying of coal powder n the pressurized gasifying furnace through reaction with O2 and water vapor to produce crude gas with CO and H2 as main components, chilling of the crude gas in the sparger, further chilling in the chilling chamber, and final washing in the washing tower. The produced synthesized gas may be used in producing methanol, synthetic ammonia, hydrogen, synthetic oil and other chemical product and energy source product.

Owner:XIAN THERMAL POWER RES INST CO LTD

Method of extracting volatile component from tasty material, the volatile component and foods and drinks containing the volatile component

InactiveUS7976887B2Meat/fish preservation by heatingTea extractionSaturated water vaporSuperheated steam

Volatile components are obtained by steam extraction of tasty materials. Coffee beans following roasting or tea leaves following tea manufacturing are used as tasty materials. Steam extraction includes of processing in which steam is contacted with a tasty material followed by recovery of the steam after that contact. Saturated water vapor or super heated steam is used for the steam, while super heated steam is used preferably. The coffee beans are preferably those that have been obtained by roasting raw coffee beans using super heated steam. The food or drink contains the aromatic components, and preferably contains the volatile components as well as an aqueous extract of the tasty material.

Owner:POKKA SAPPORO FOOD & BEVERAGE

Waste heat recovery equipment and waste heat recovery method in the low temperature section of converter primary flue gas

ActiveCN104004879BFully recycleCurb local gatheringManufacturing convertersSolid removalRecovery methodThermal insulation

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com