Sea water desalting membrane distillation system with high efficiency and low cost

A low-cost, membrane distillation technology, applied in the field of membrane distillation and the applied equipment, can solve the problems of poor energy consumption efficiency, reduced service life of membrane tubes, and the operating temperature of membrane materials cannot be too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

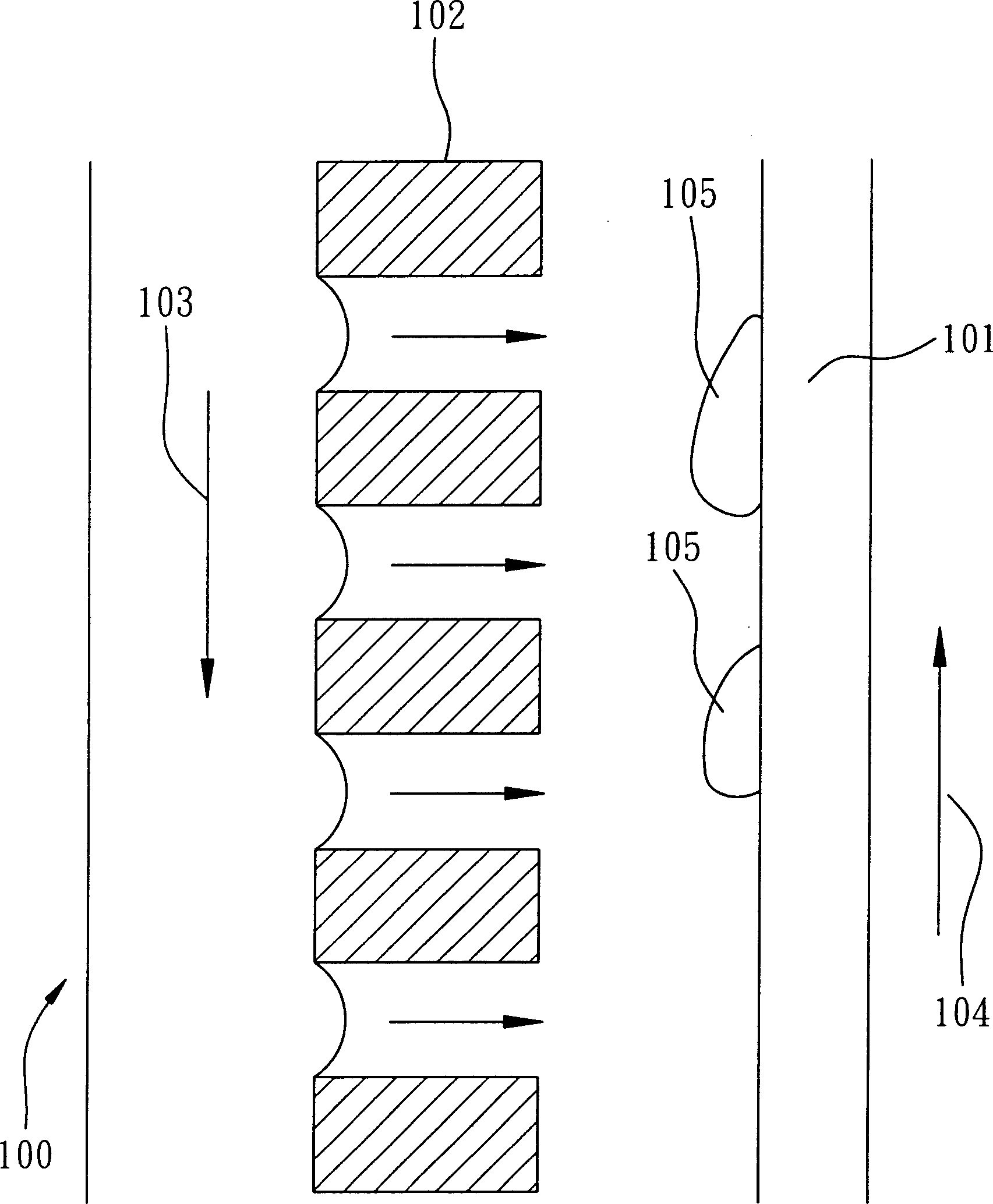

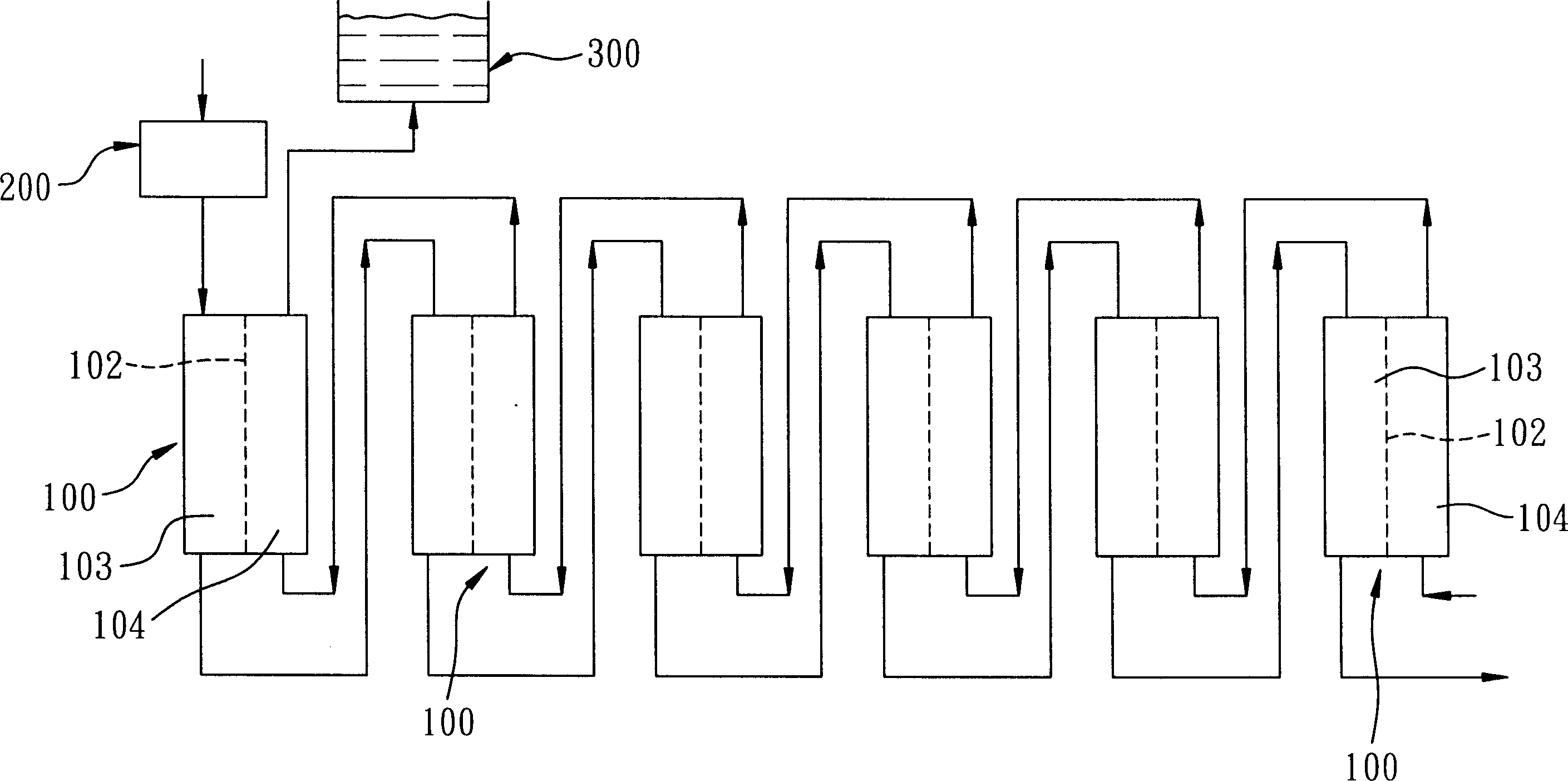

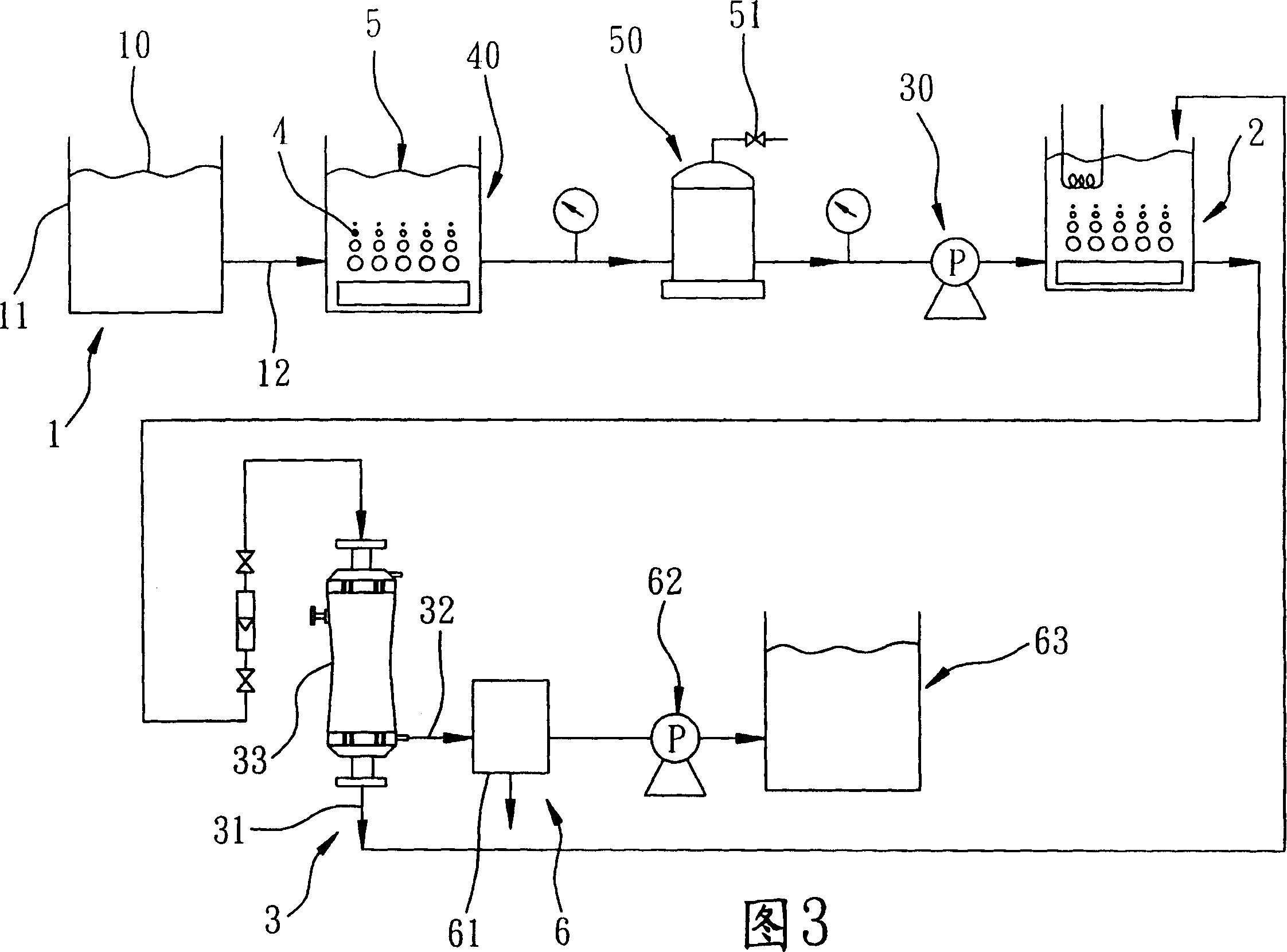

[0025] 3 and 4, a preferred embodiment of the high-efficiency and low-cost membrane distillation seawater desalination system of the present invention includes a feeding water circuit 1, a micro-bubbling device 2, a desalination device 3 and a condensed fresh water device 6.

[0026] The feeding water circuit 1 has a container 11 capable of containing seawater 10 with a predetermined capacity, and several sections of pipelines 12 for transporting liquid.

[0027] The micro-bubbling device 2 is connected to one side of the feeding water circuit 1, and includes a pumping motor 30 arranged on the pipeline 12 to pump seawater 10 from the container 11, and a pressurized gas supplier located on the front side 40. Pump the seawater 10 in the pipeline 12 into a preheated and pressurized gas 4, so that the seawater 10 can be mixed into a high-temperature working fluid 5, and the purpose of heating is mainly to make the mixed working fluid 5 has a certain high temperature, which can acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com