Inverted umbrella-shaped aeration machine

An aerator and inverted umbrella technology, which is applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of limited air intake, limited oxygenation capacity, and power oxygenation efficiency. Low-level problems, to achieve the effect of improving oxygenation efficiency, improving oxygenation capacity, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

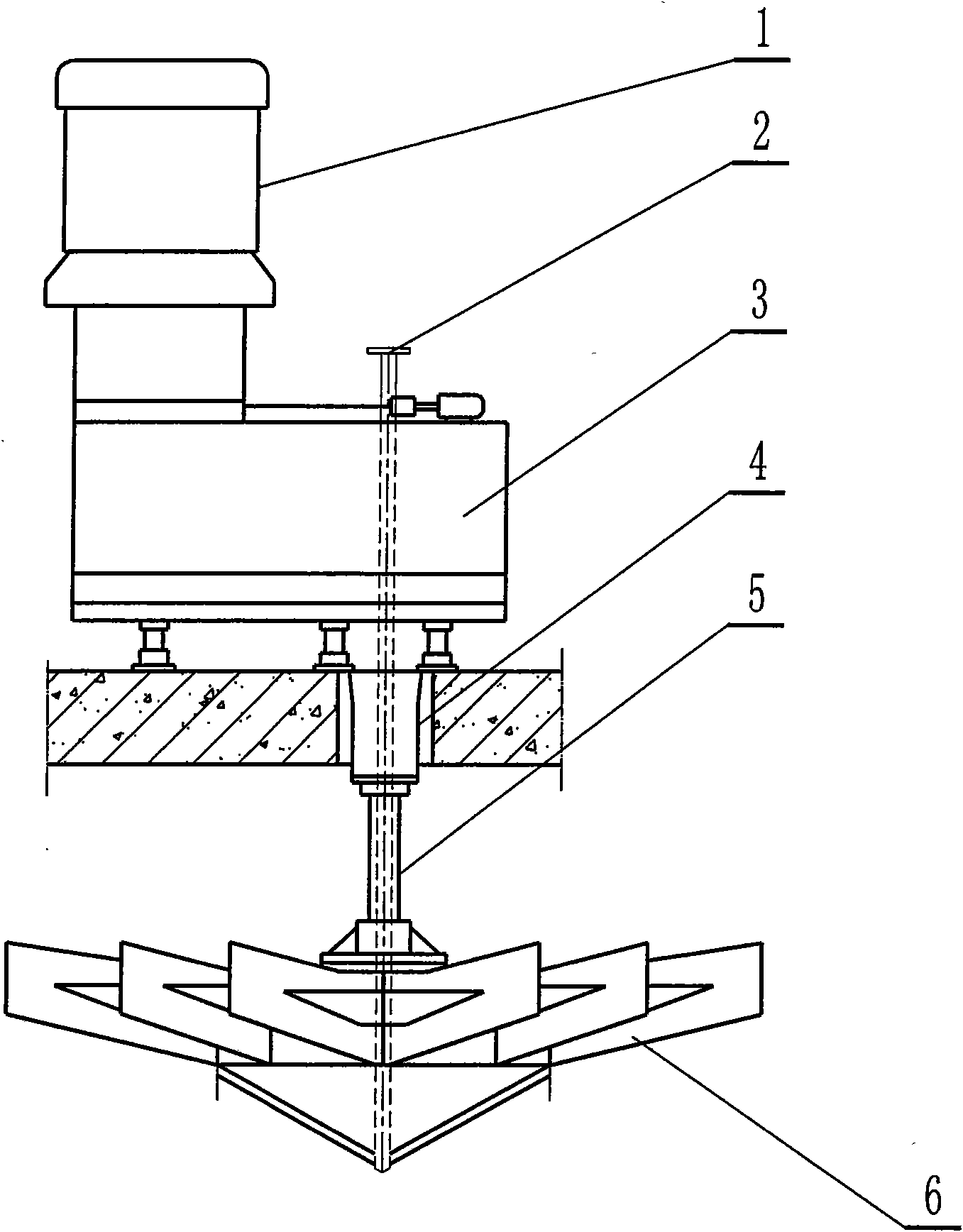

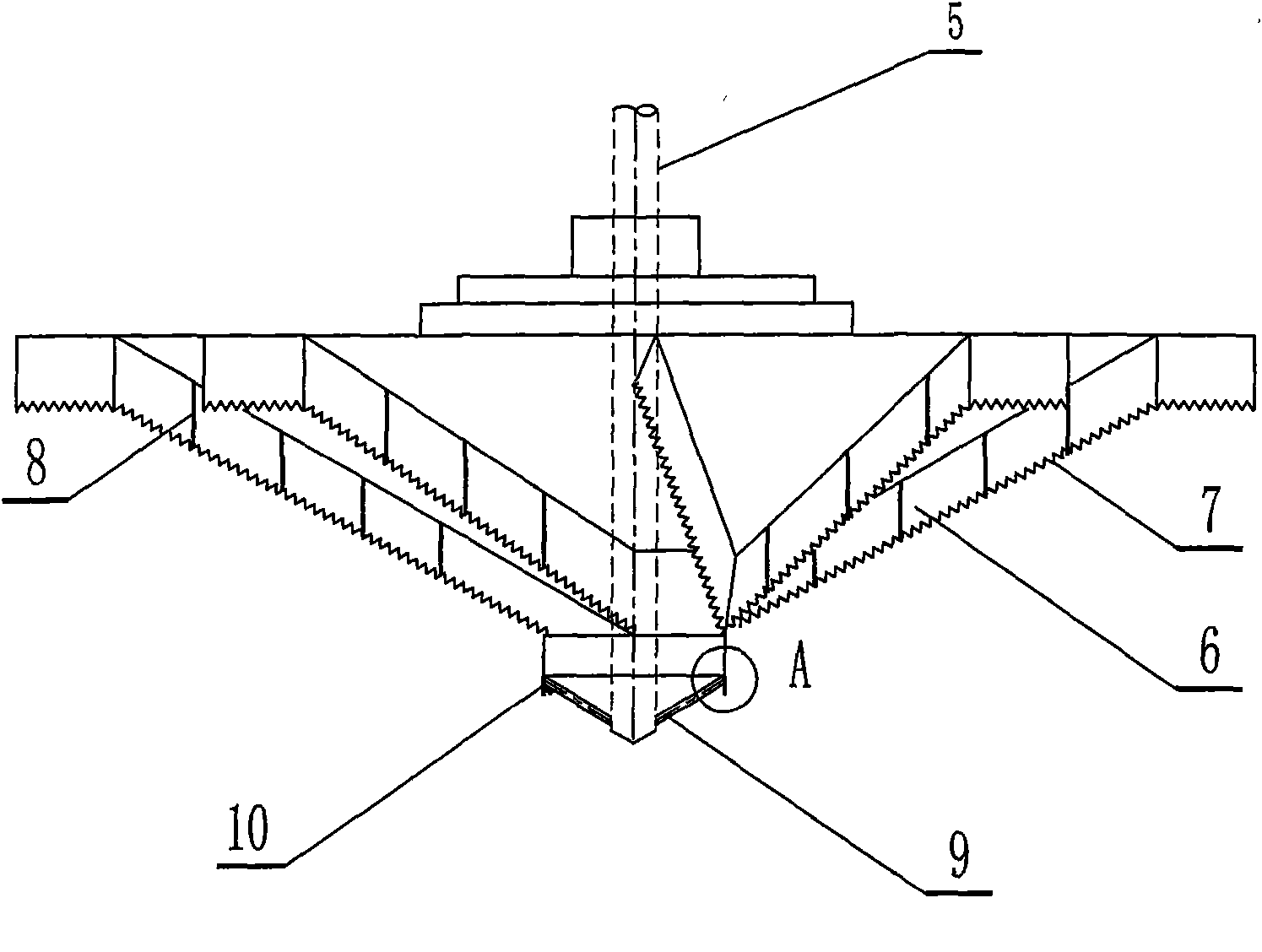

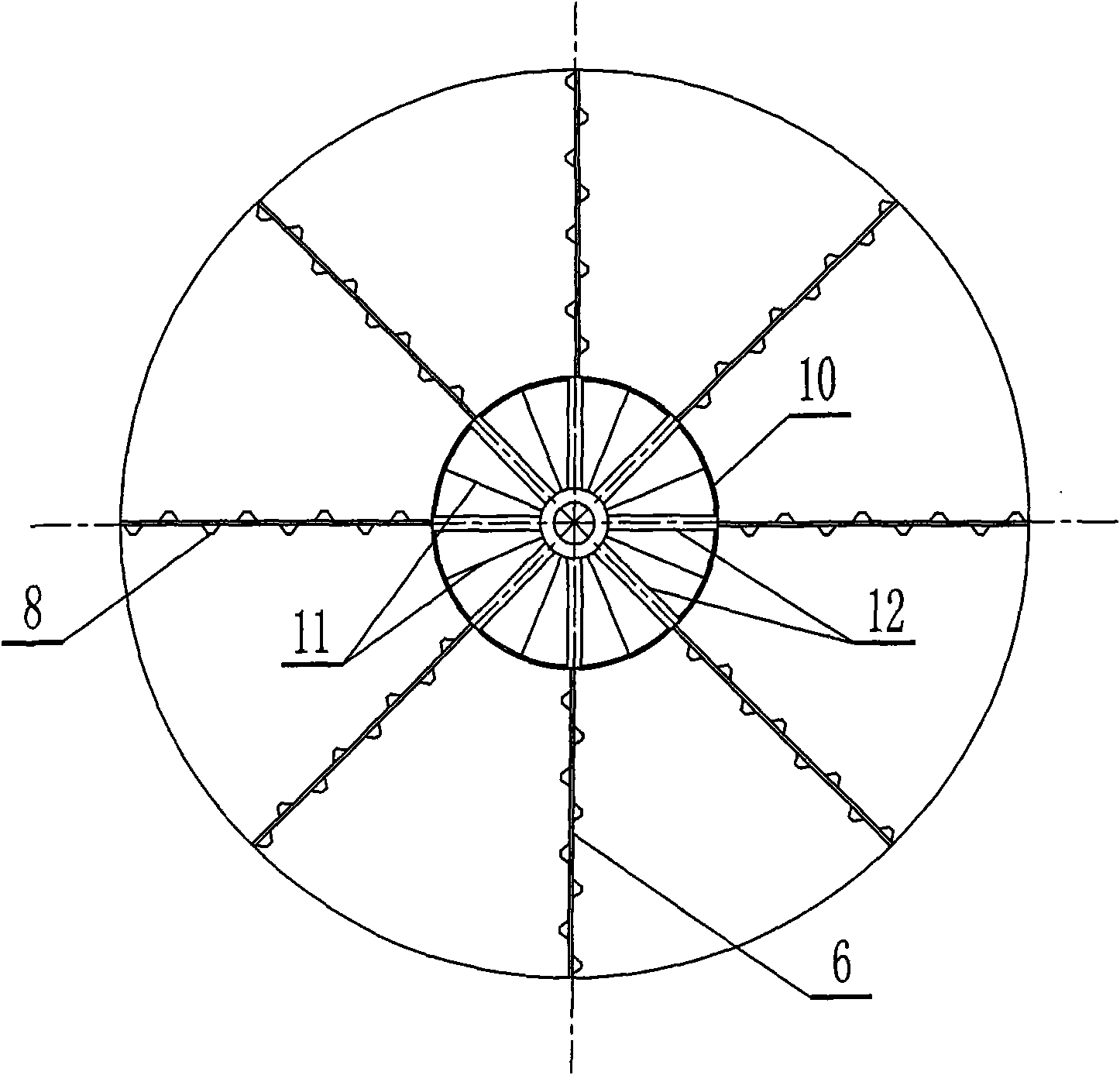

[0020] Embodiment 1: see Figure 1-4 , the inverted umbrella aerator of the present invention comprises a drive motor 1 and a deceleration device 3, the output shaft of the deceleration device and the rotating shaft 5 of the inverted umbrella impeller 6 are hollow inertial shafts, and the upper port 2 inputs compressed air through a joint, and the entire aerator Stand vertically on the mounting base 4. The lower end of each blade radially distributed alternately on the cone surface of the inverted umbrella impeller 6 is a sawtooth edge 7, and there are alternate sawtooth strips 8 on both sides of each blade. The aeration pipe 12 communicated with the hollow shaft has aeration micropores on it, and sawtooth rings 10 are arranged on the outer ring, and several radial sawtooth bars 11 are distributed alternately between the air distribution pipes.

[0021] When the aerator rotates, the low-pressure blower injects air through the hollow shaft of the inverted umbrella aerator thro...

Embodiment 2

[0022] Example 2: see Figure 5 , as in embodiment 1, the hollow rotating shaft 5 of the inverted umbrella impeller 6 extends downwards, such as lengthening 1m, and another inverted umbrella-shaped air distribution cone 13 is arranged at the end, and aeration tubes, sawtooth rings, and sawtooth are distributed on the umbrella surface as in Example 1. Bar, can further improve the depth of oxygenation, this structure is especially suitable for deep ditch-shaped oxidation ditch or aeration tank.

Embodiment 3

[0023] Embodiment 3: see Figure 6 , as mentioned above, the aeration tubes 14 distributed radially alternately on the inverted umbrella-shaped air distribution cone are in the shape of a curved arc.

[0024]For those skilled in the art, under the inspiration of the patent concept and specific embodiments, some deformations that can be directly derived or associated from the patent disclosure and common sense, those of ordinary skill in the art will realize that other methods can also be used, Or the replacement of commonly used known technologies in the prior art, and the different combinations of features, for example, the upper and lower sides of each blade on the inverted umbrella have serrations, only the shaft of the inverted umbrella impeller is hollow (the shaft of the reducer is not hollow), and the air passes through the side by rotating Flexible access, changes in the form of the bottom aeration tube, such as using the aerator head, omitting the serrations on the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com