Patents

Literature

607results about How to "Increase water flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washing machines

ActiveUS20070113595A1Increase water flowReduce stressOther washing machinesControl devices for washing apparatusWastewaterEngineering

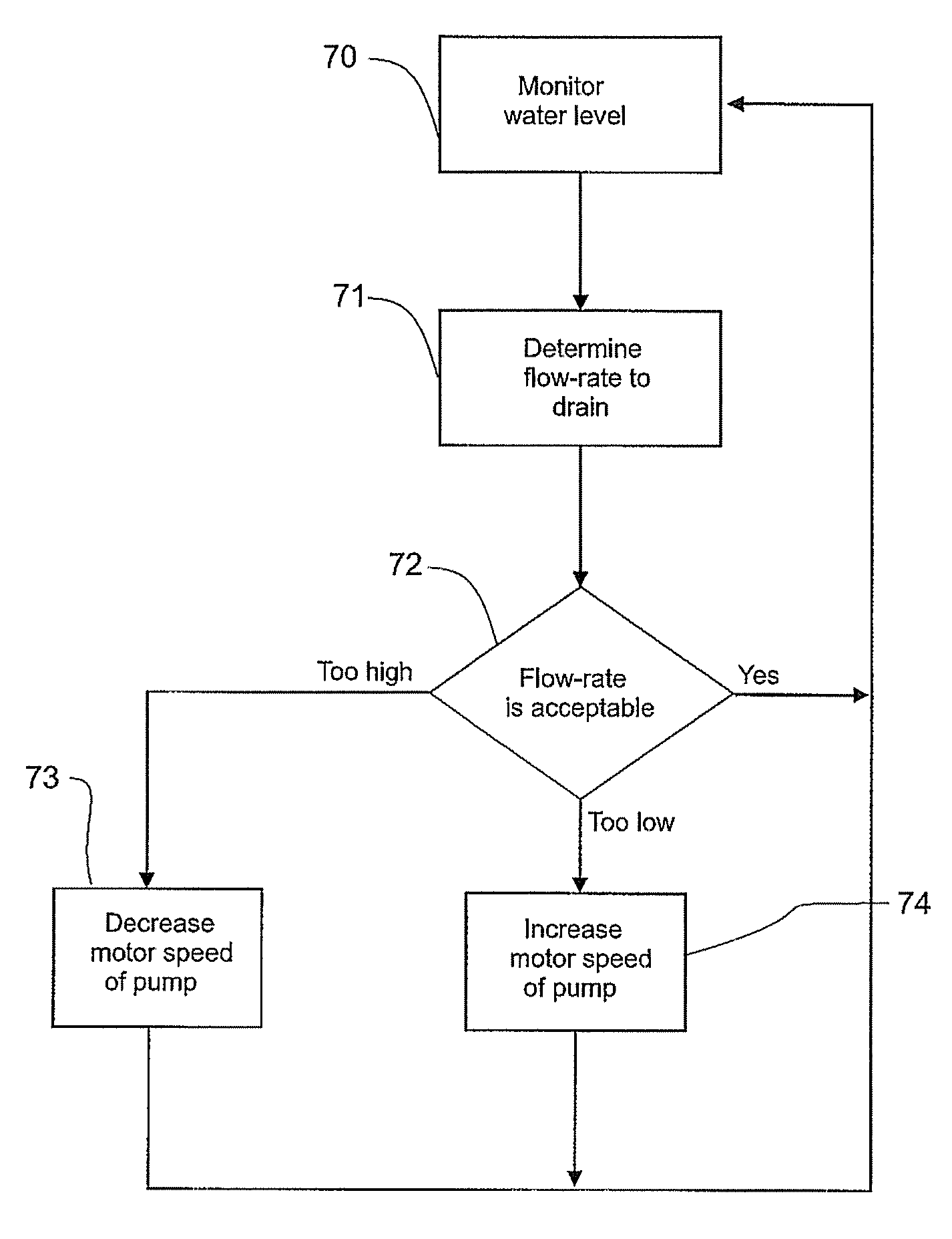

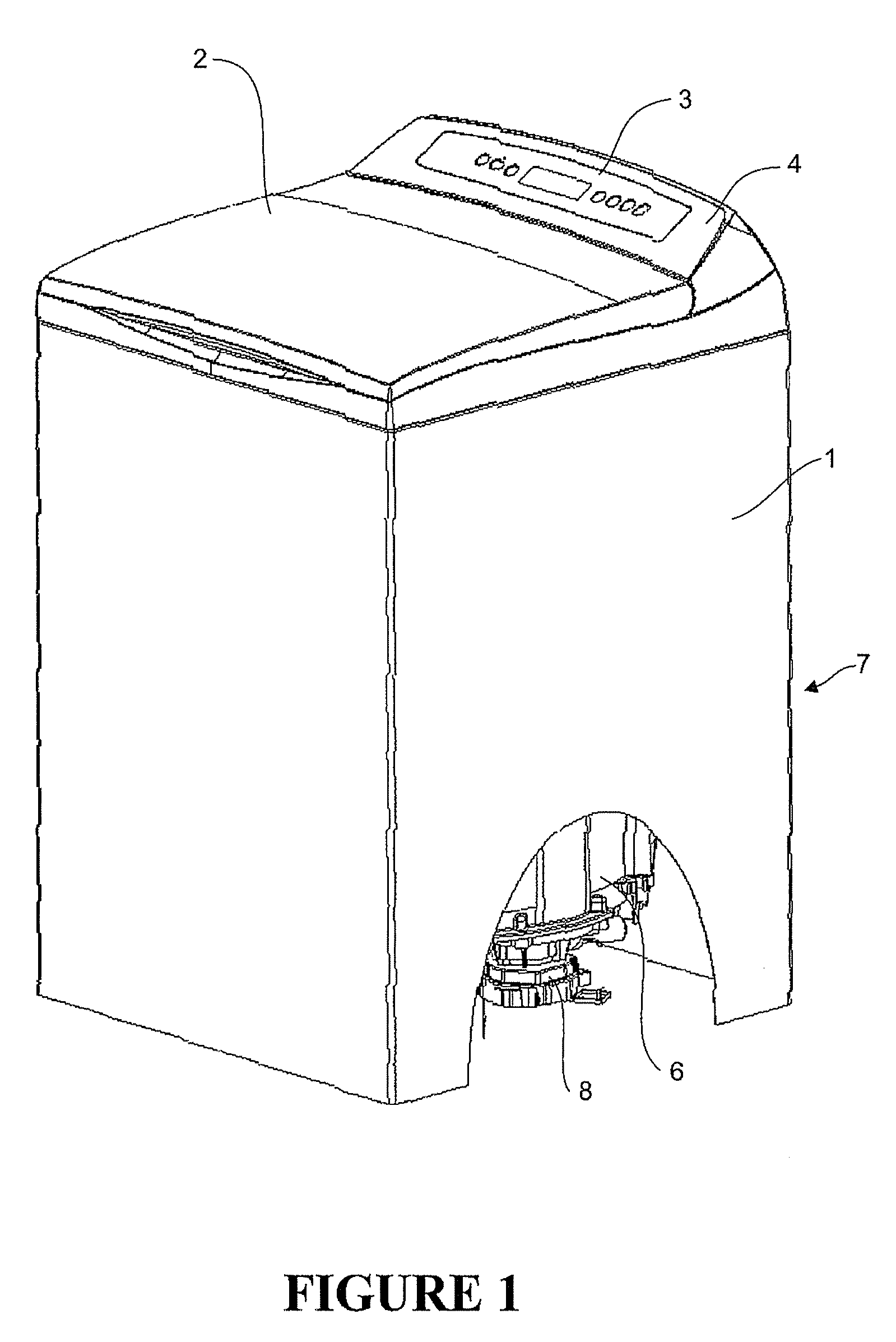

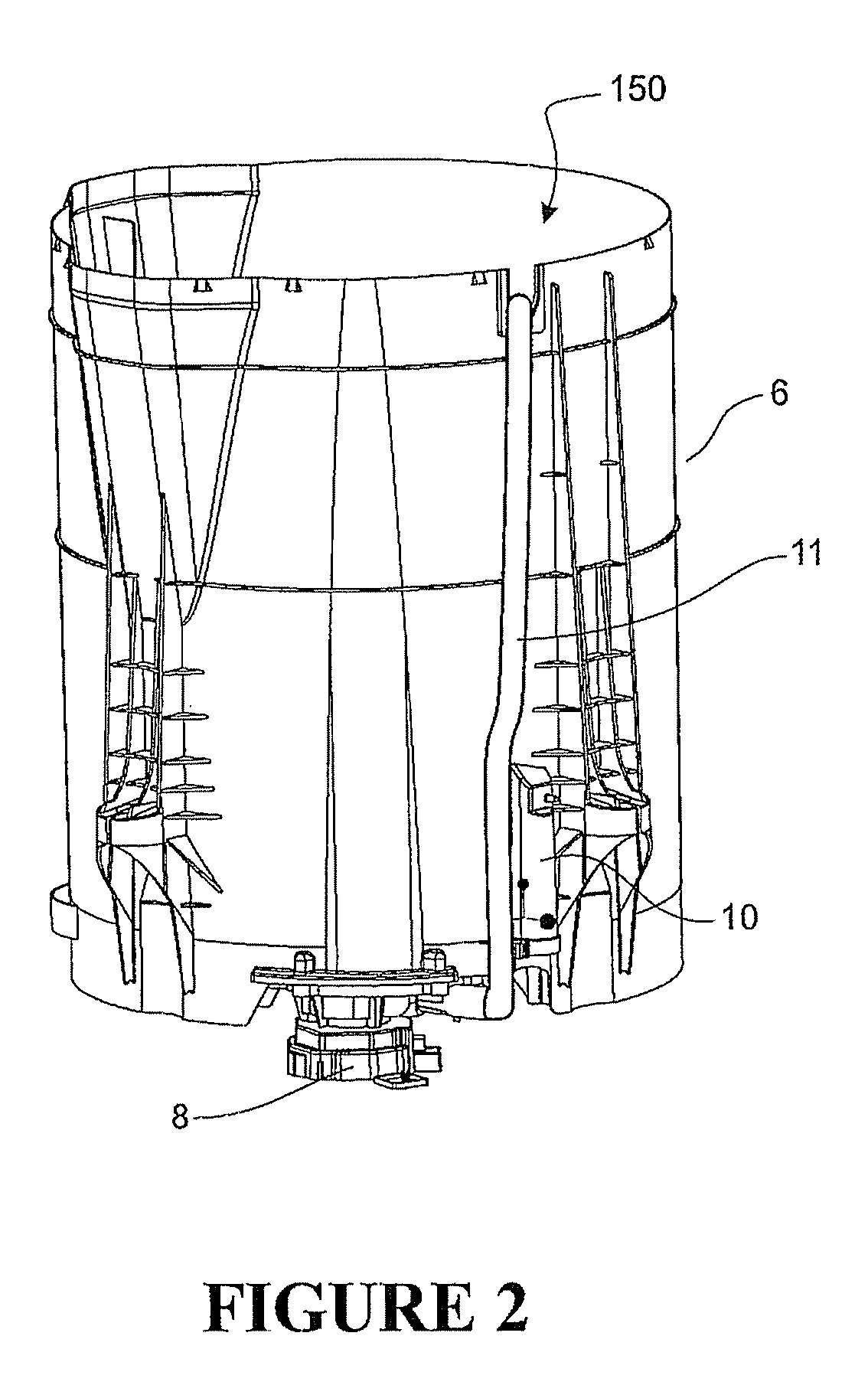

The present invention relates to a washing machine (7) and pump (8) for a washing machine (7). The pump is driven by a brushless DC motor (38). The pump can be controlled to improve the operation of the washing machine. In one aspect the invention comprises a washing machine (7) with a variable speed pump (8) for pumping out wastewater, a controller (50) for controlling the speed of the pump and a sensor (10) for determining the flow-rate of water being pumped from the washing machine, wherein the controller (50) controls the speed of the pump to maintain the flow-rate at a desirable level.

Owner:FISHER & PAYKEL APPLIANCES LTD

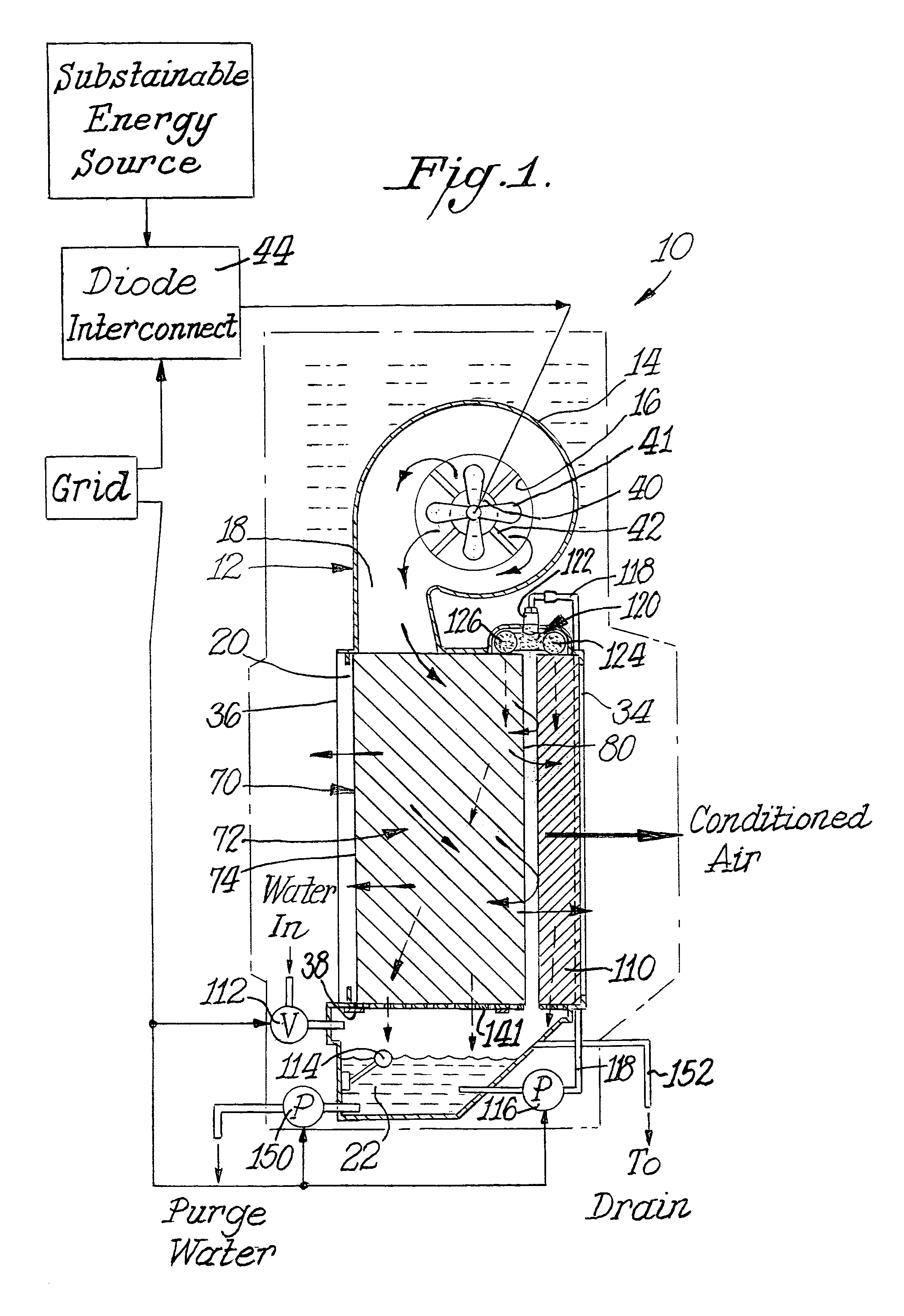

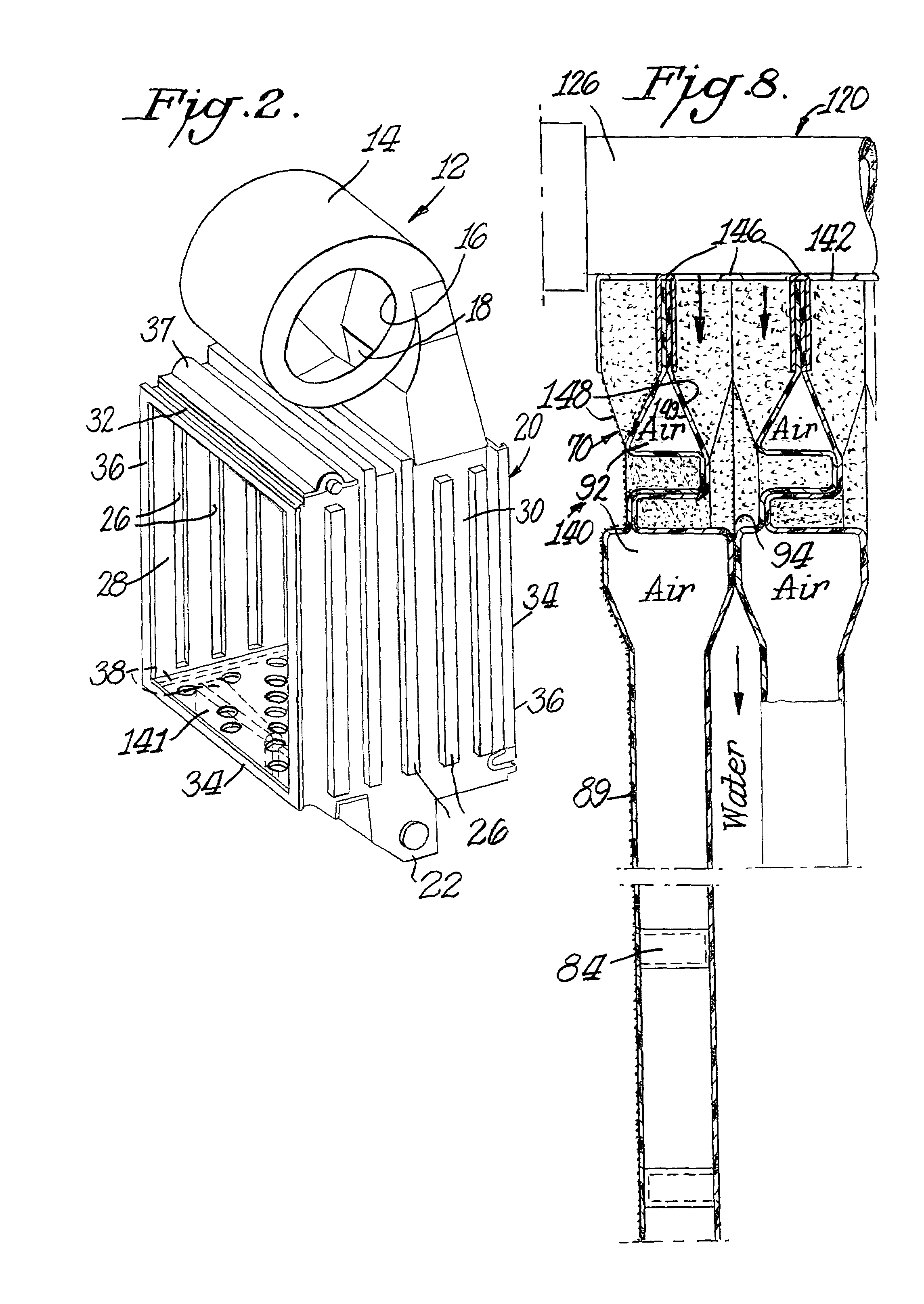

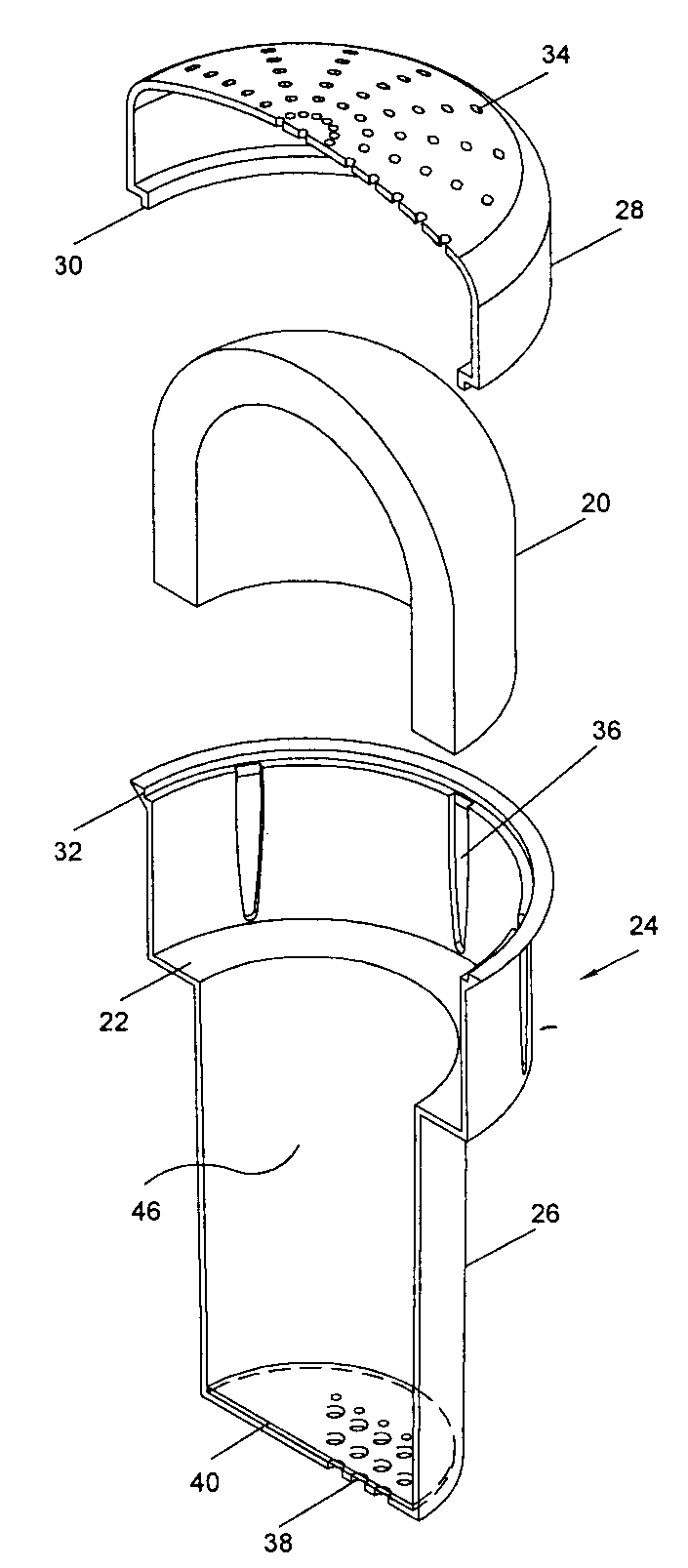

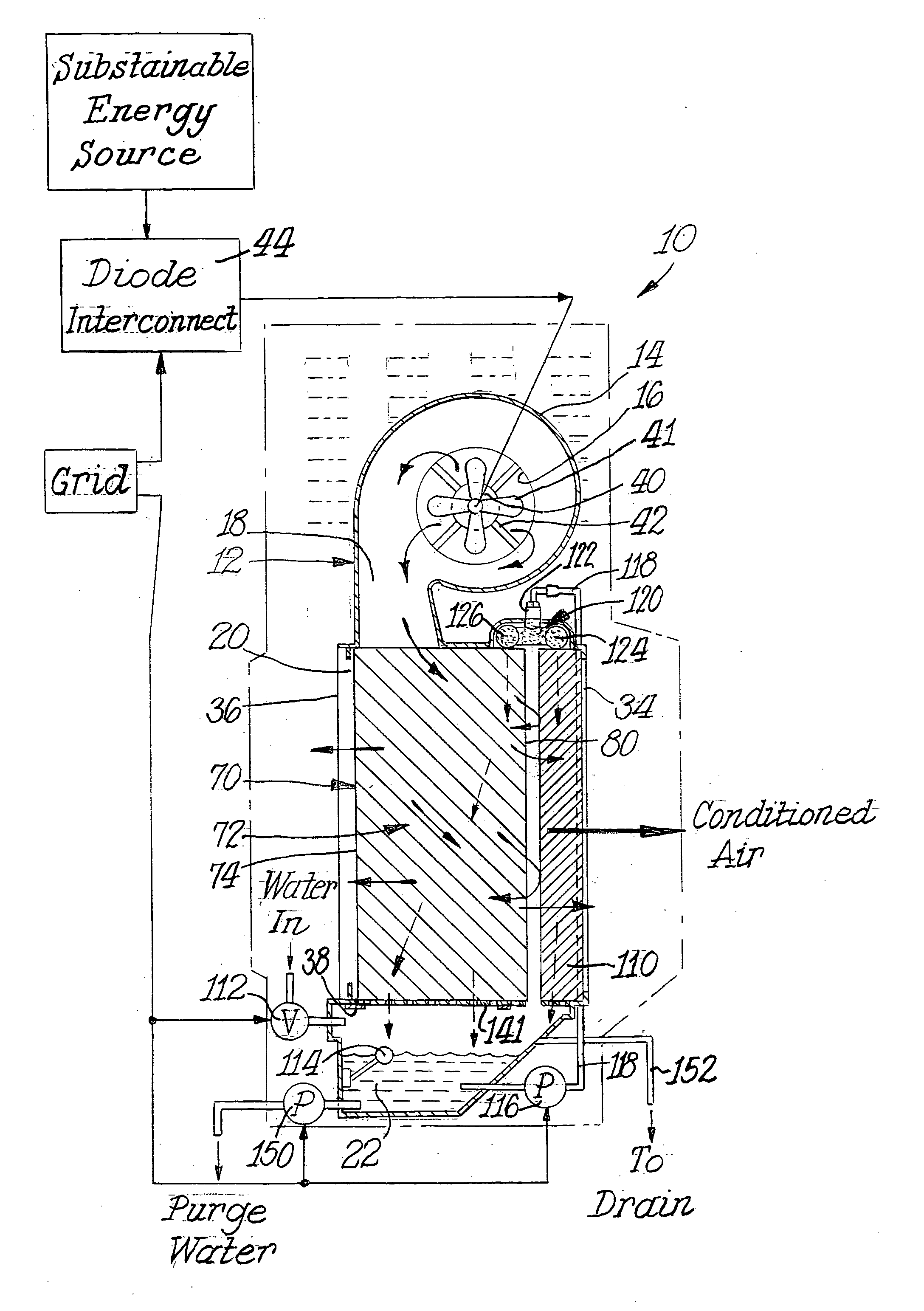

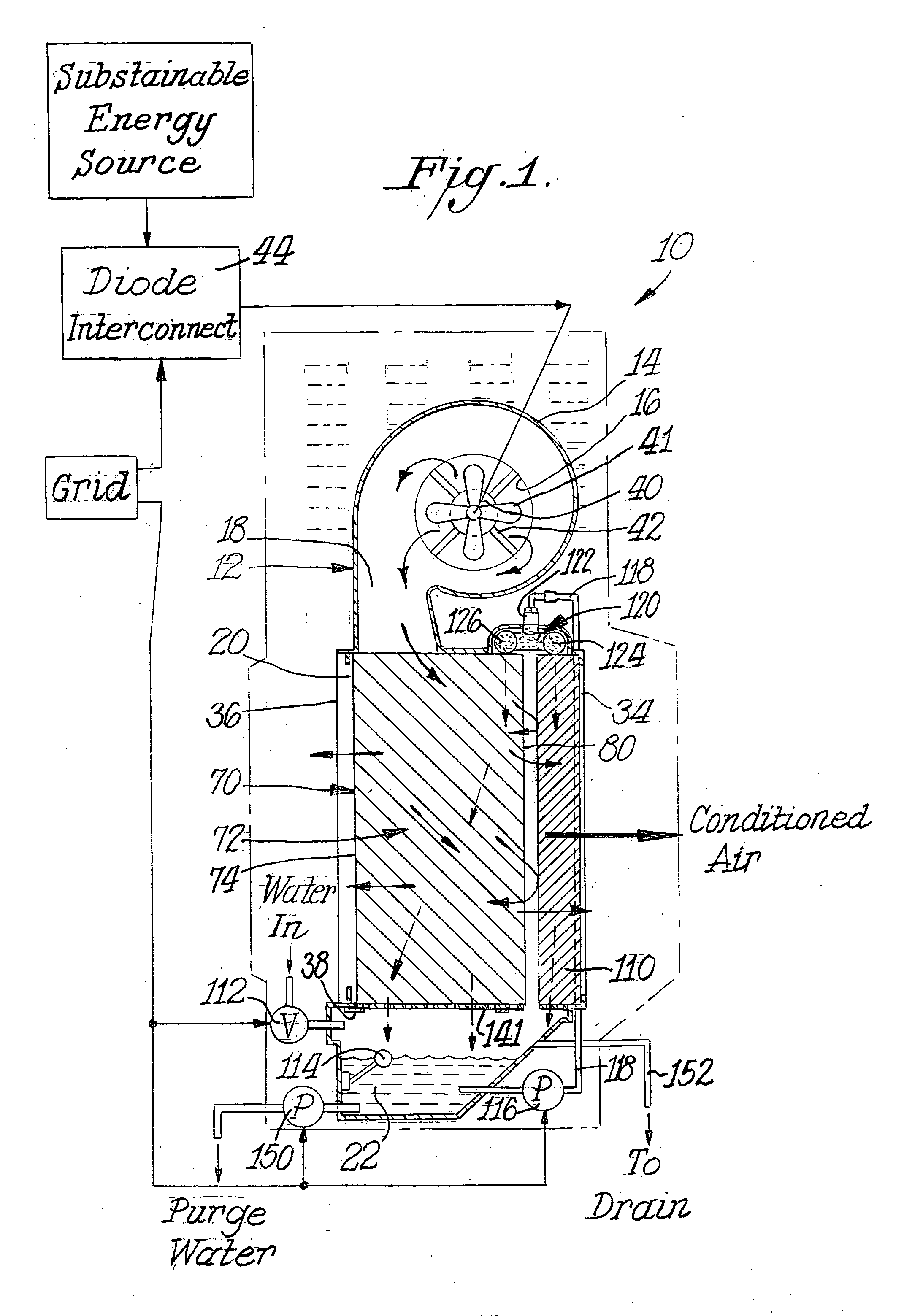

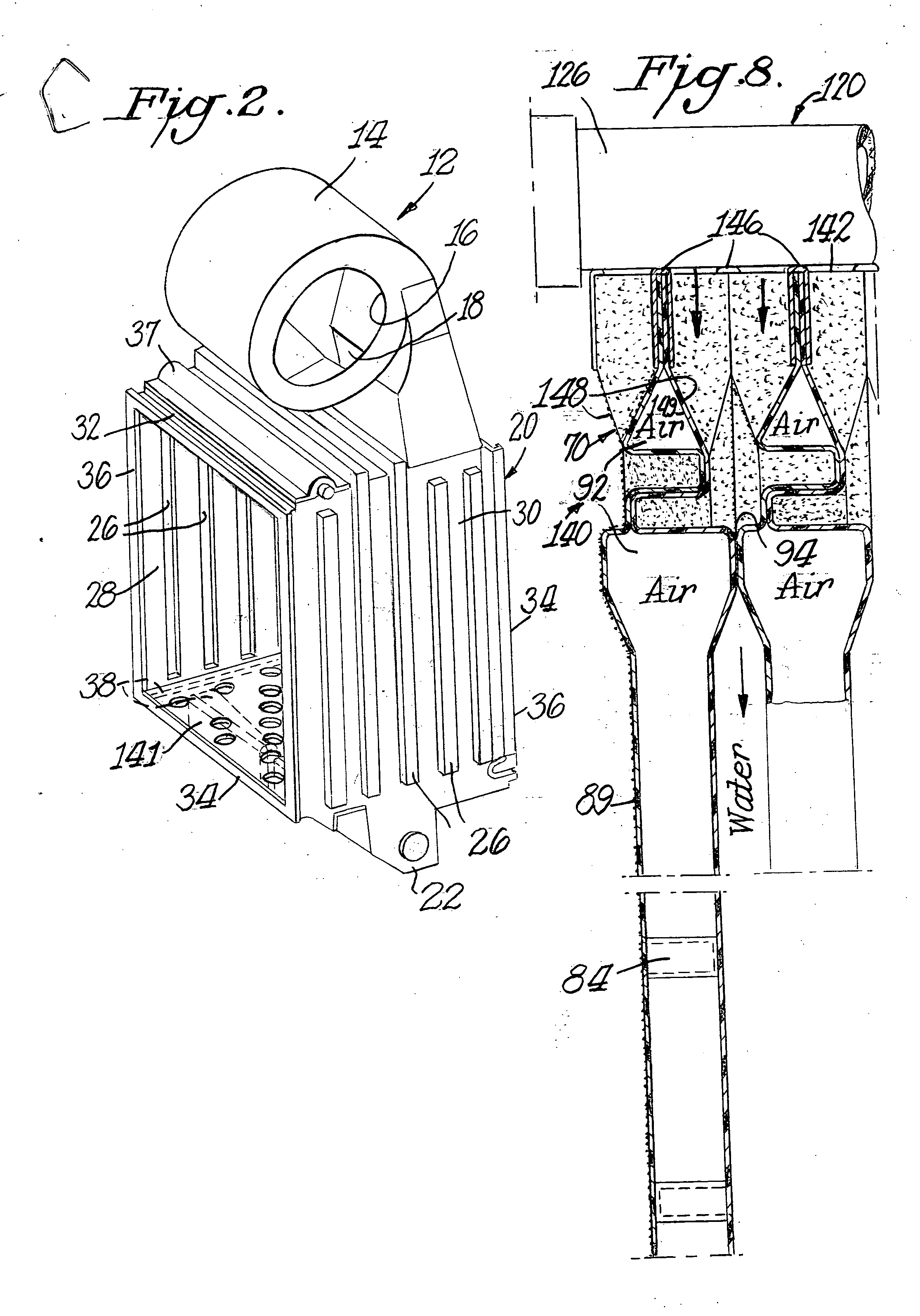

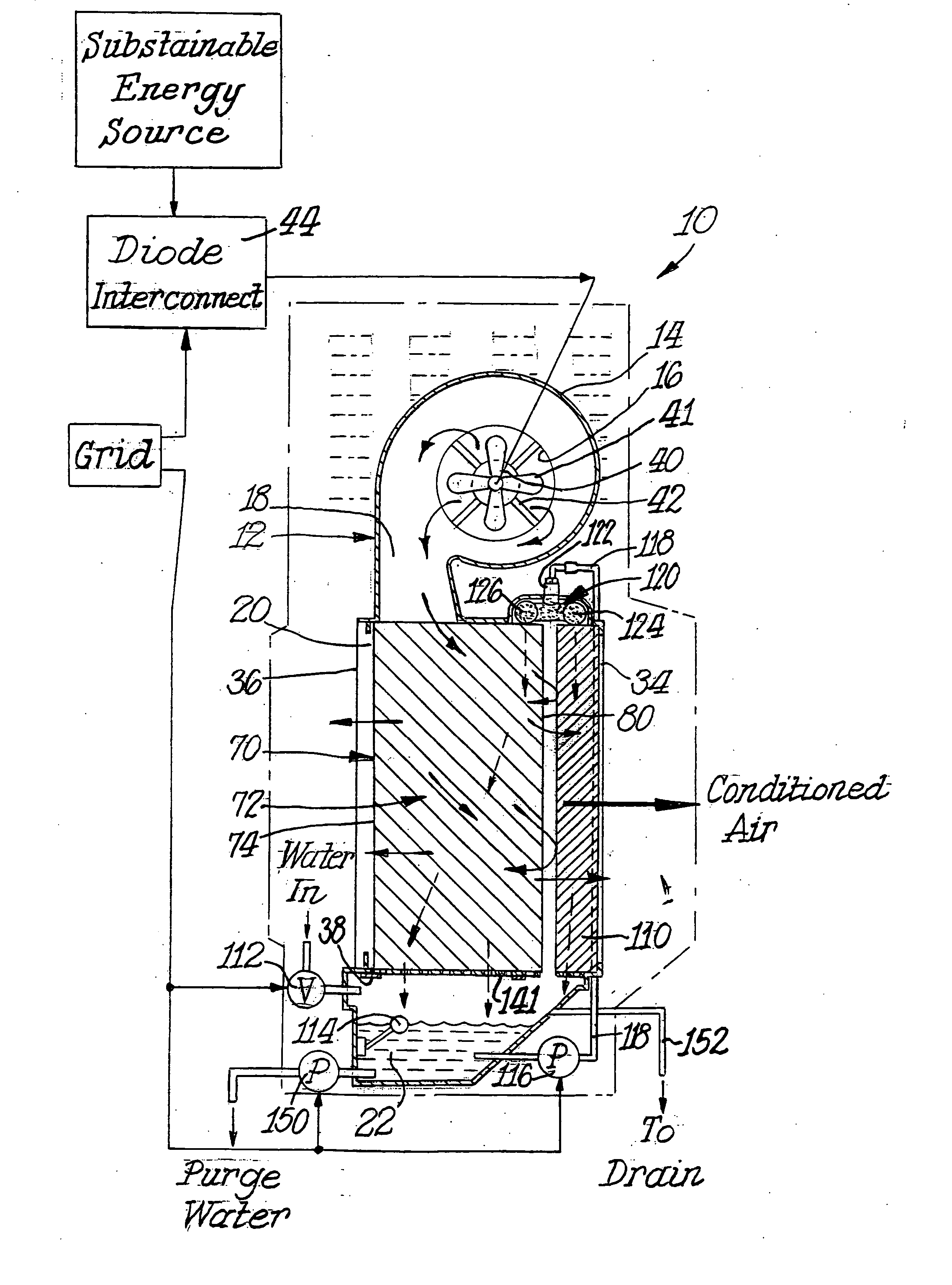

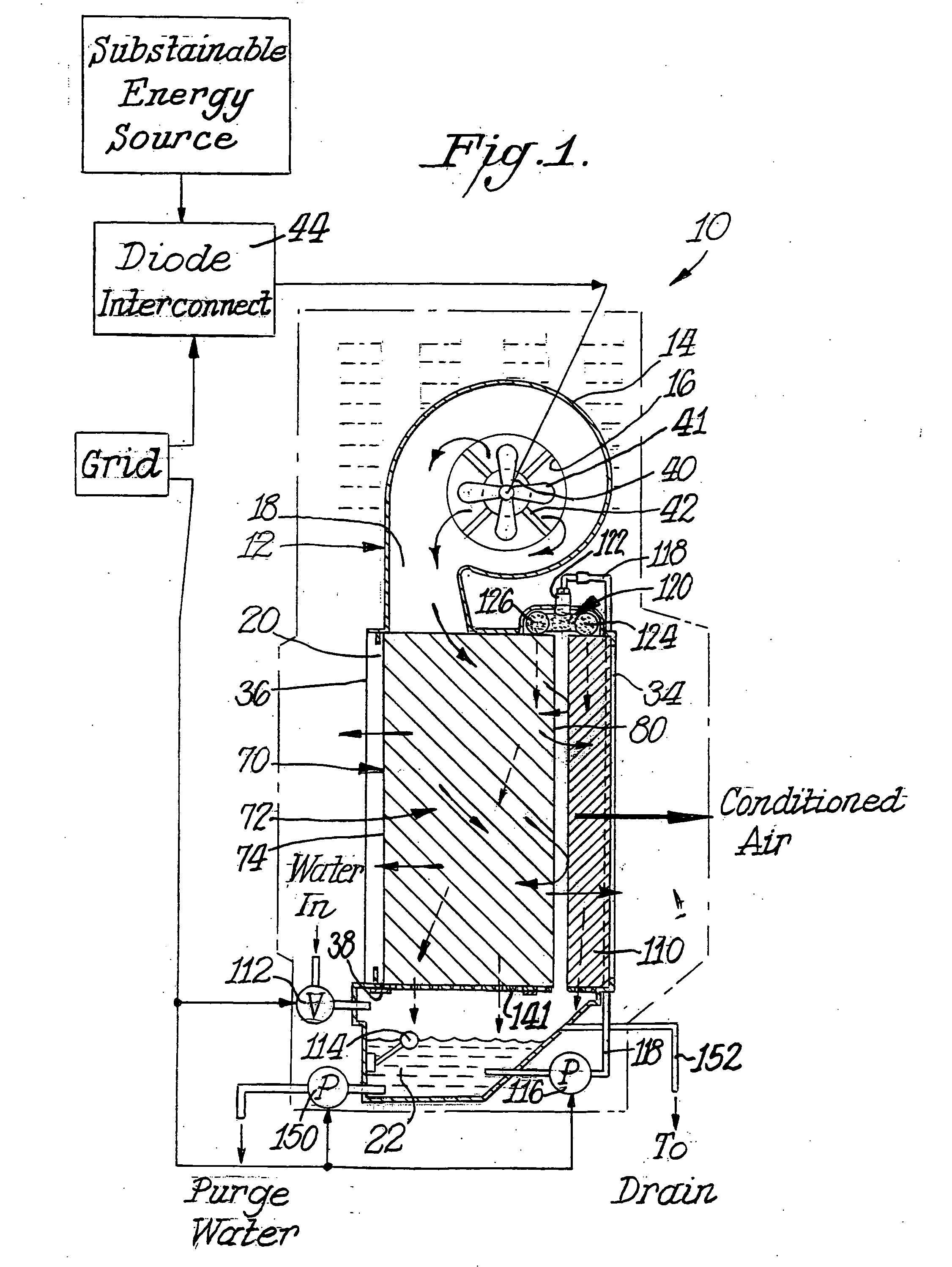

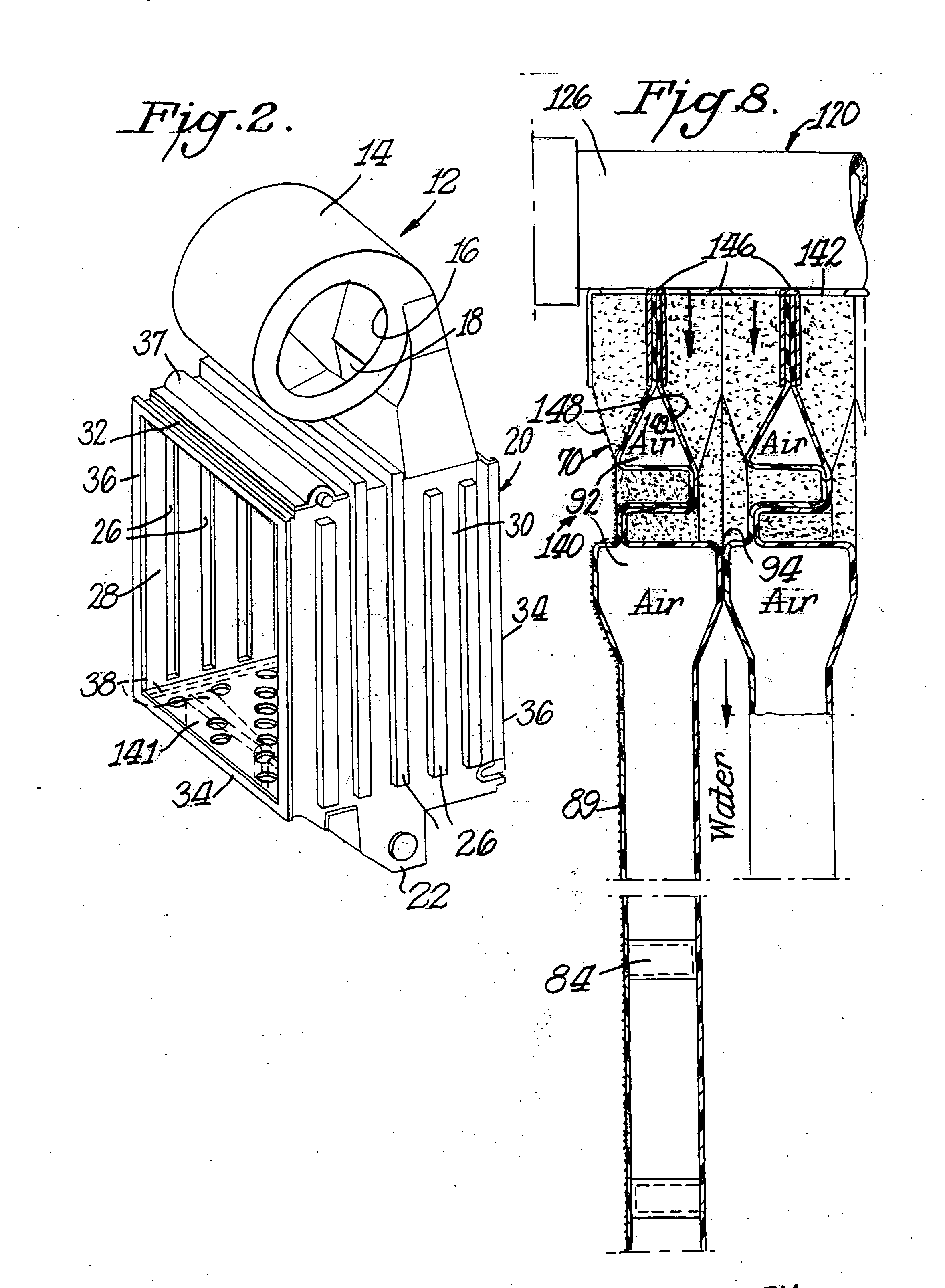

Indirect-direct evaporative cooling system operable from sustainable energy source

InactiveUS7143597B2Reduce the amount requiredImprove cooling effectFree-cooling systemsStationary conduit assembliesPower gridProcess engineering

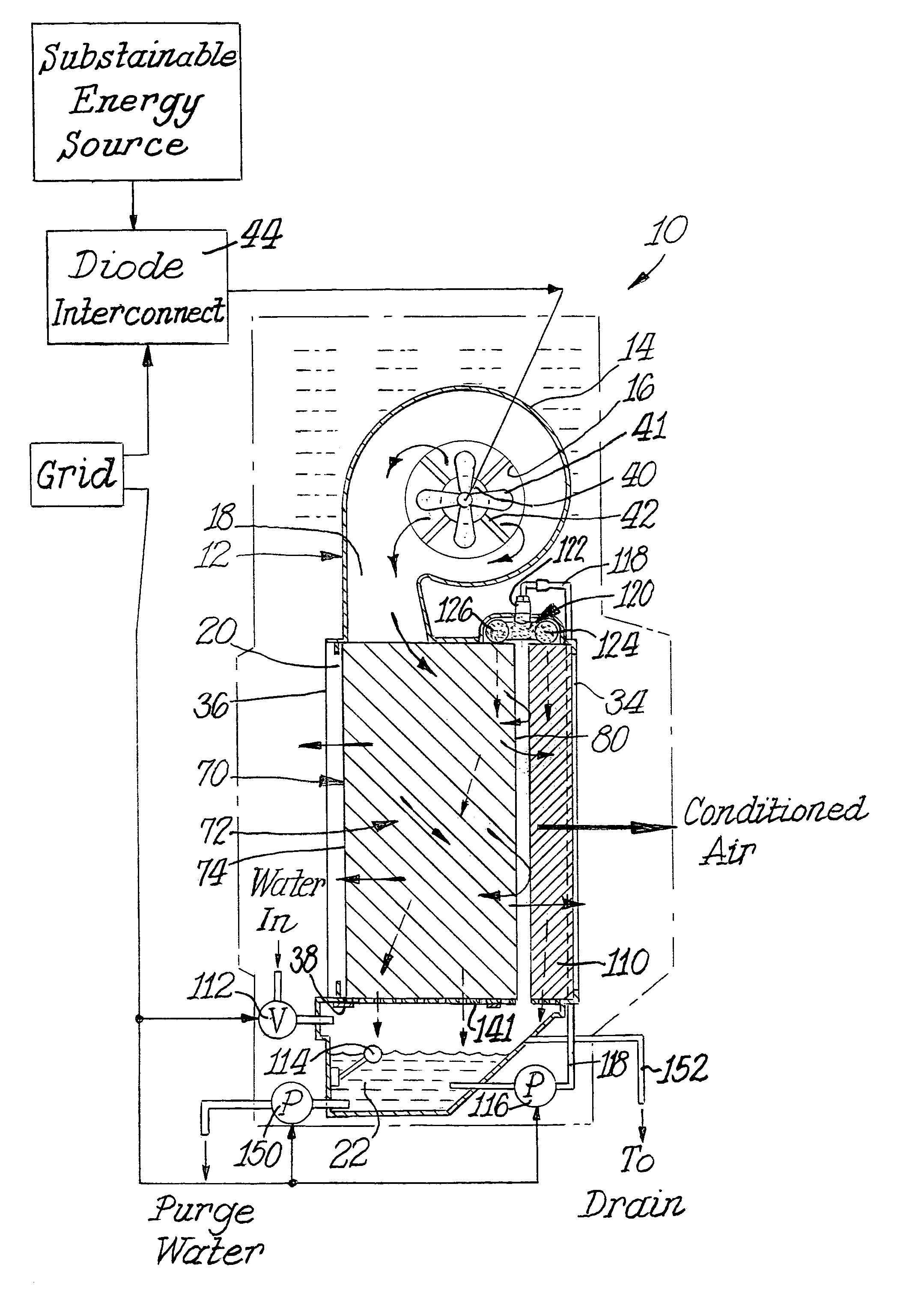

Improved means for powering and increasing evaporative cooling in an indirect-direct evaporative cooling (IDEC) apparatus are disclosed. Sustainable energy from solar energy mixed with grid power, when needed, power the IDEC device. These DC and AC power sources are seamlessly merged in a unique diode interconnect unit. Improved means for evaporative cooling include a rayon-based flocking on the wet side of molded plastic indirect evaporative cooling plates. Separate wet and dry passages through those plates are facilitated by a unique means for clamping the upper ends of the plates. These clamping means also add to the structural integrity of an array of plates so that the array can be inserted in and removed from a housing containing other operational components of the IDEC such as fan, direct cooling plates and water distribution means. Applicants IDEC utilizes improved porous piping that allows uniform and continuous distribution of water to all wet passages within both the indirect and direct stages of the IDEC. Operational controls for the system limit the potential water damage caused by overflow of water from the IDEC housing.

Owner:SPEAKMAN

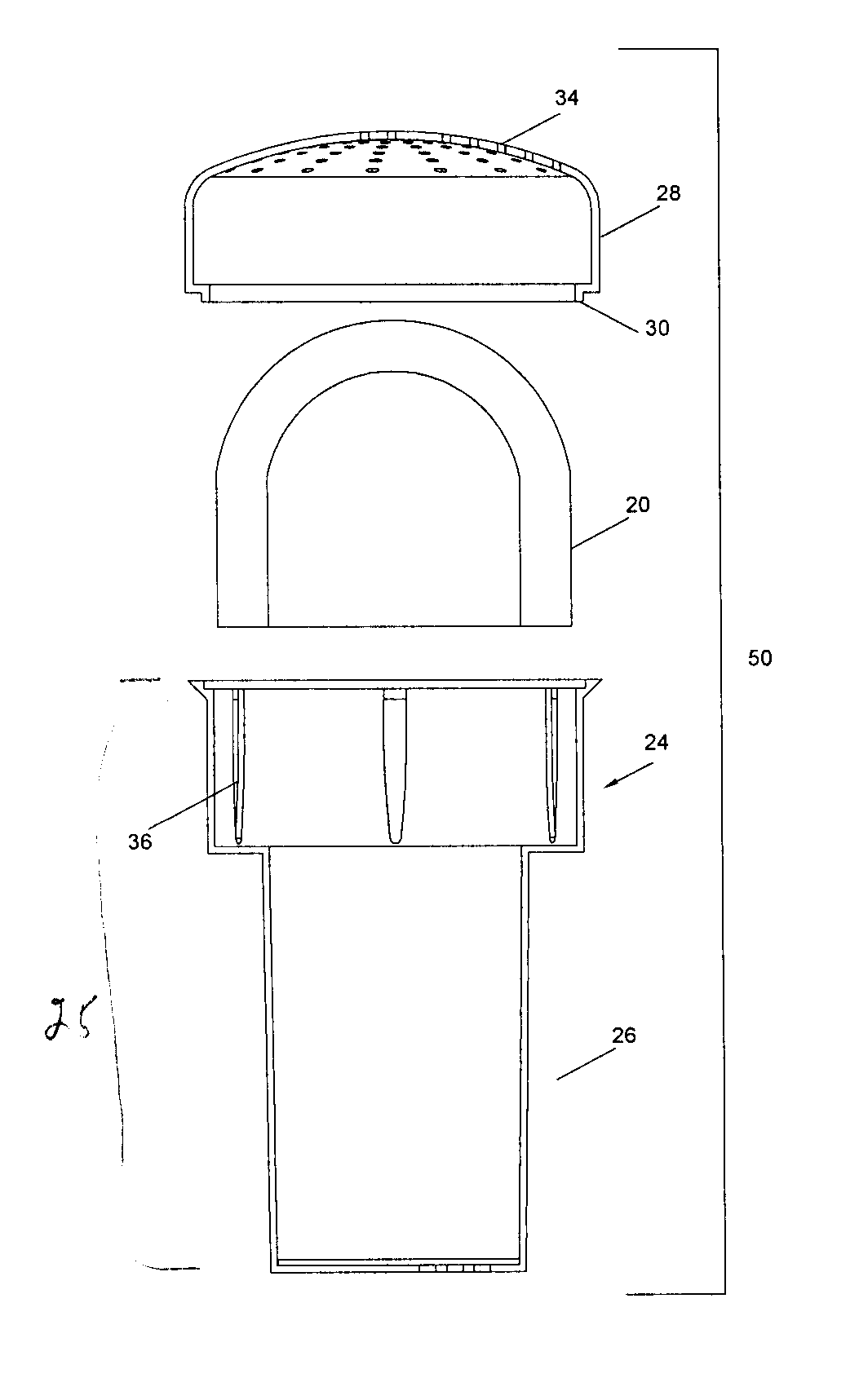

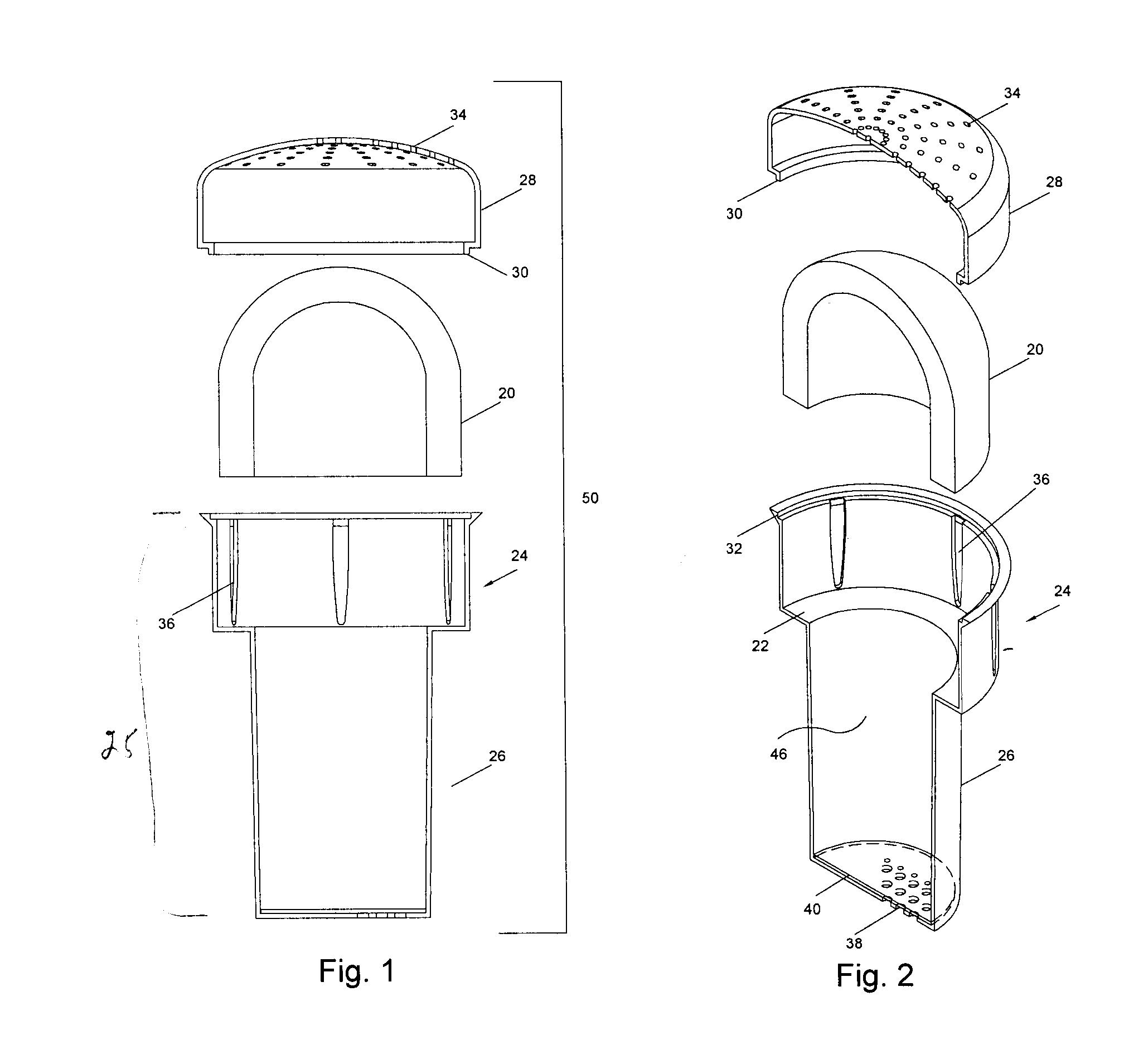

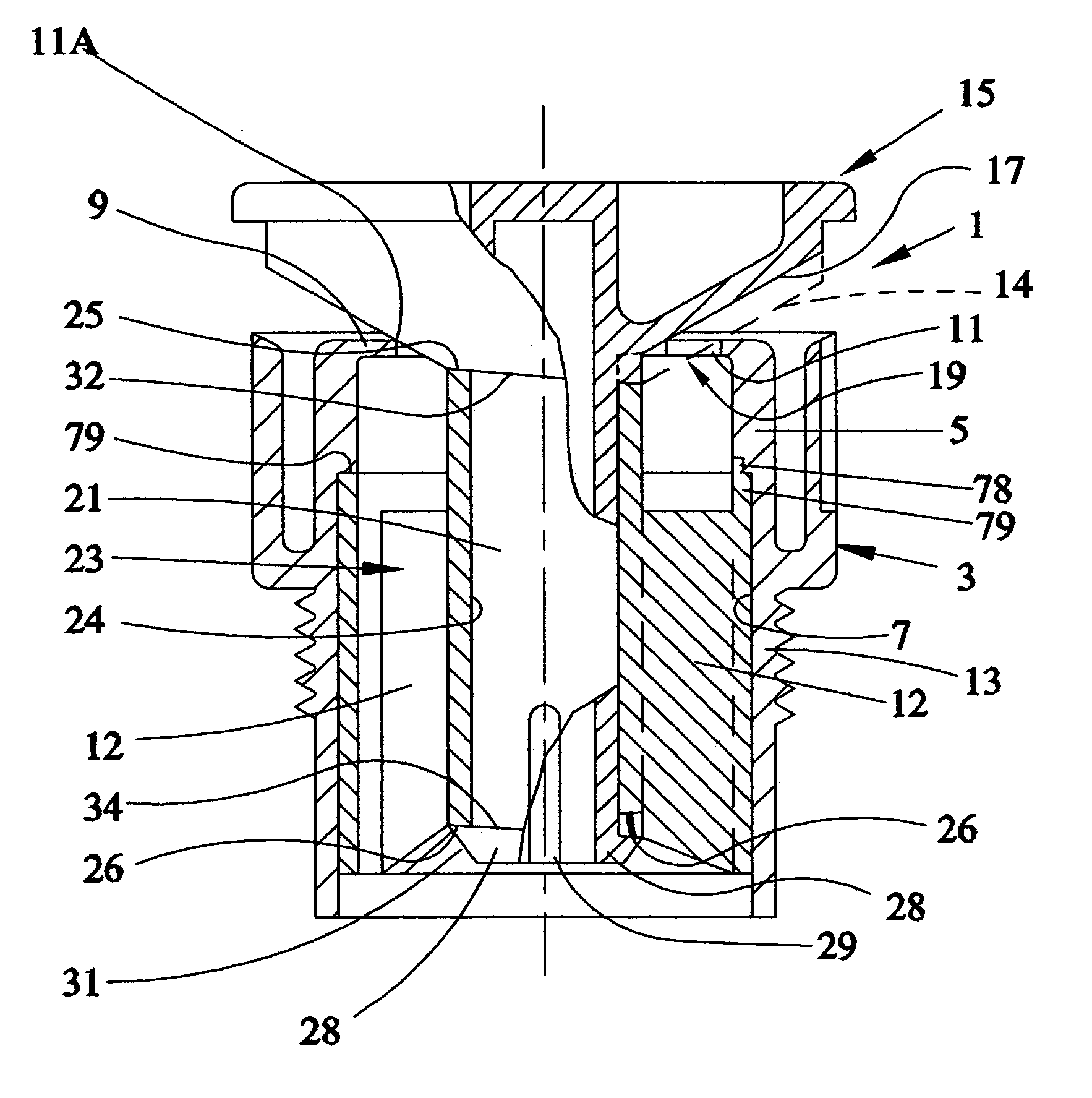

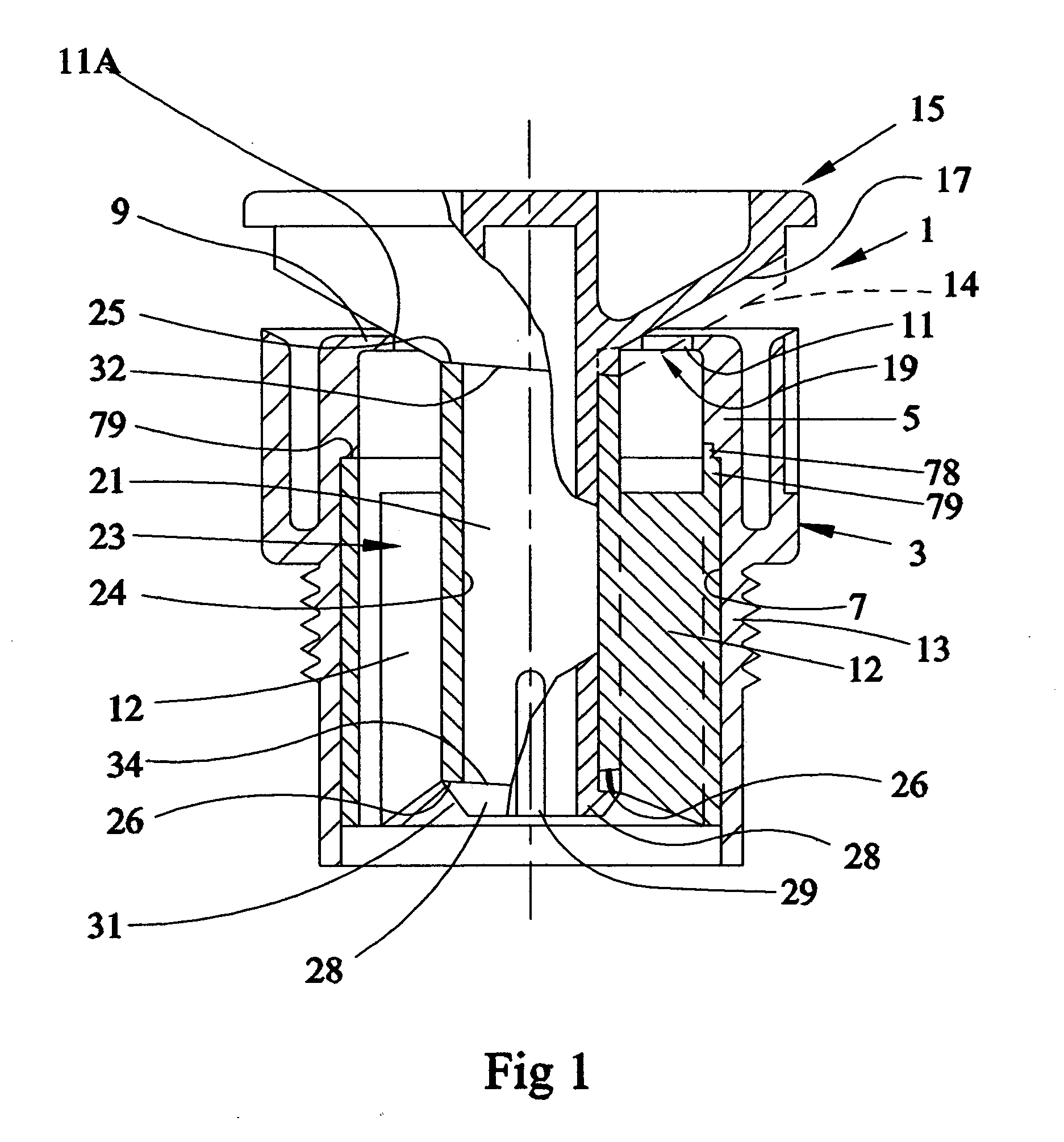

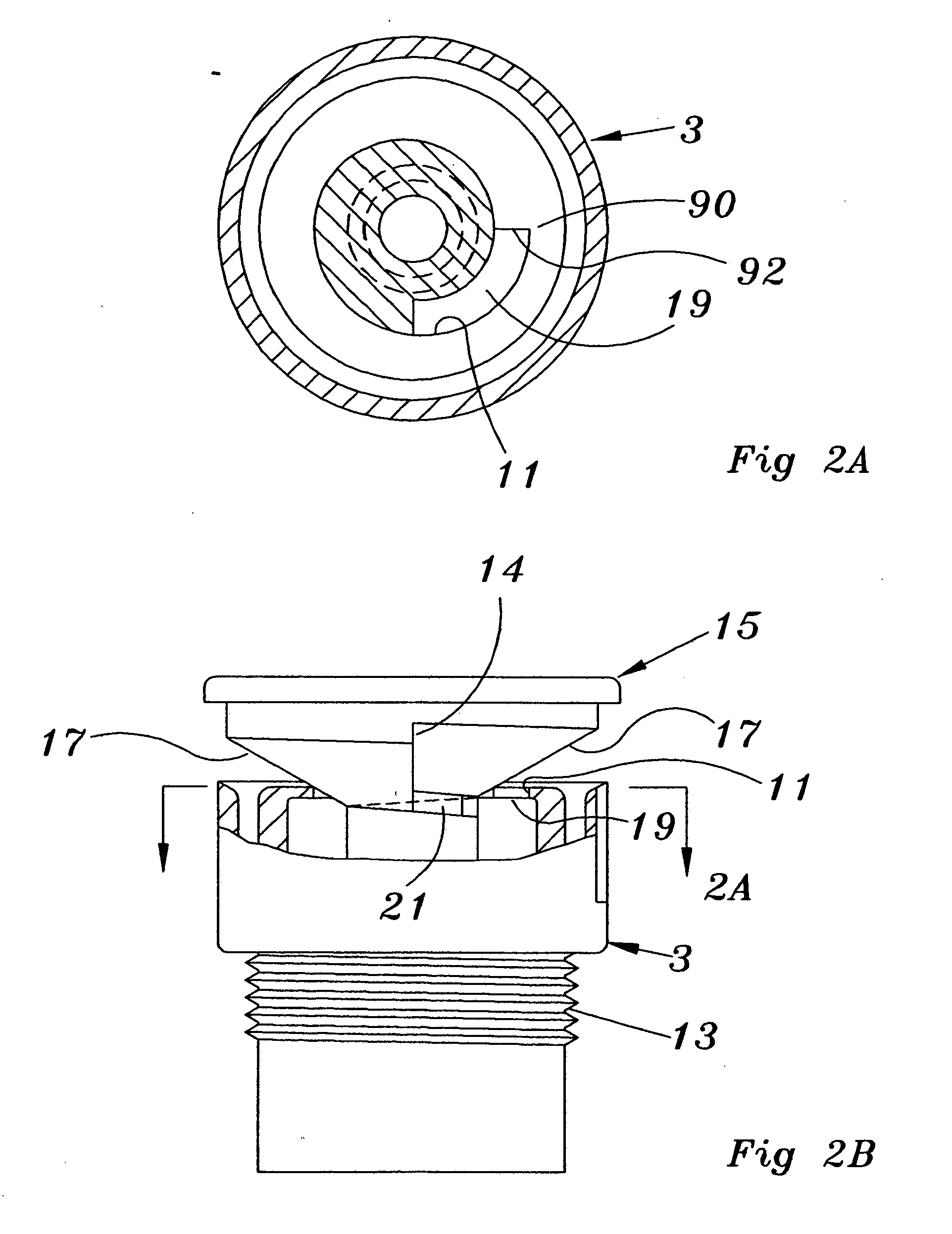

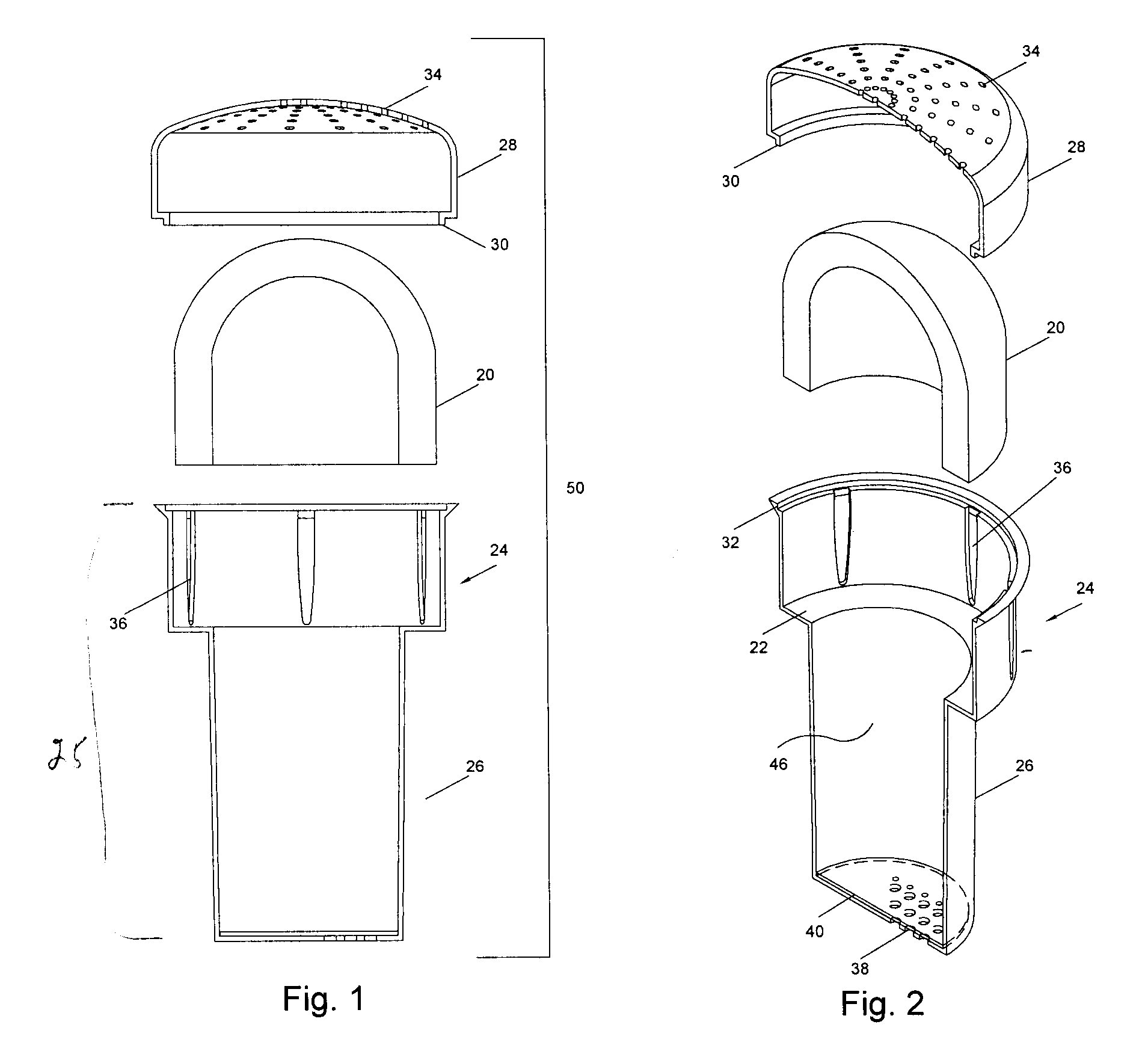

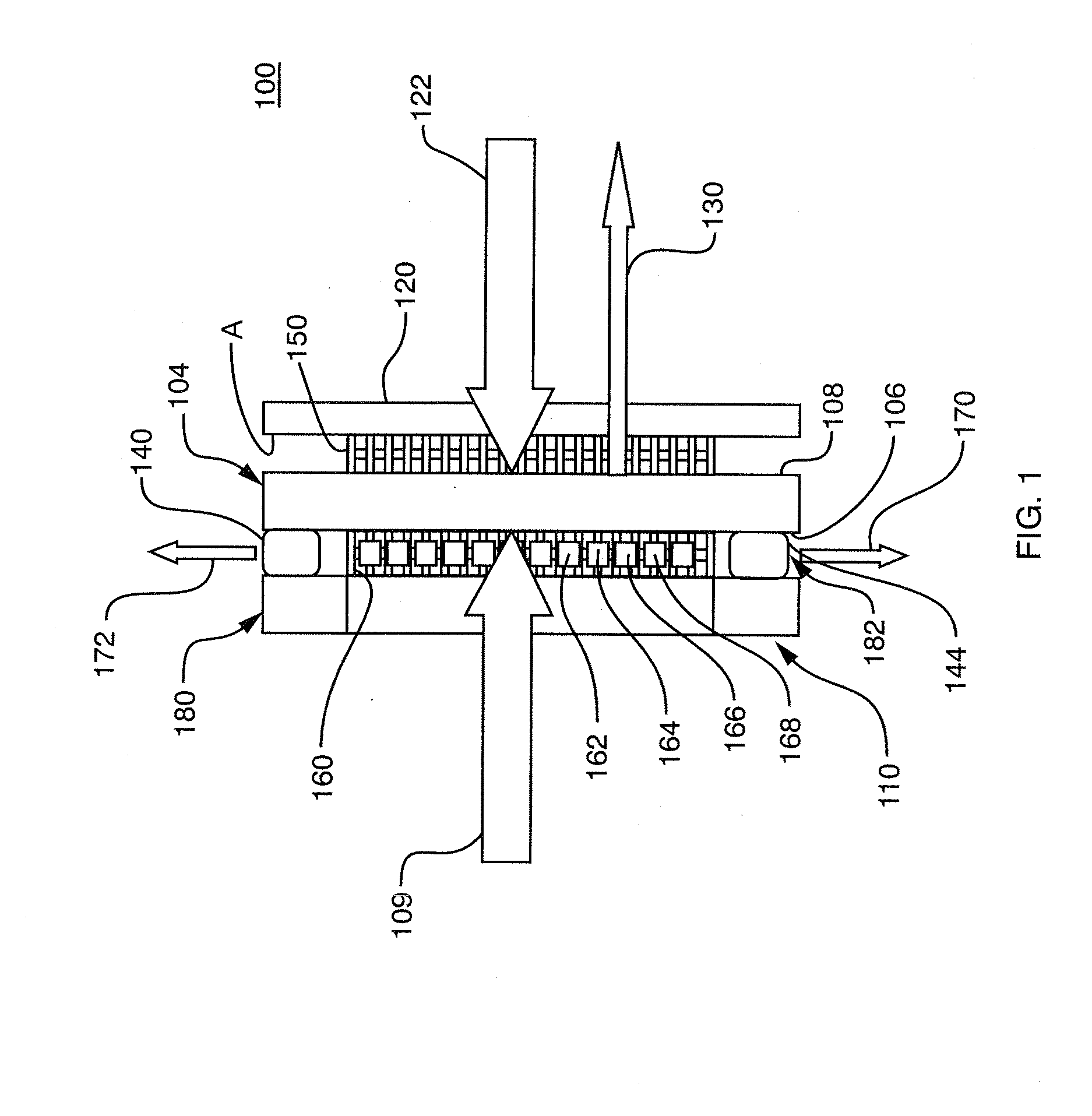

Filter cartridge for gravity-fed water treatment device

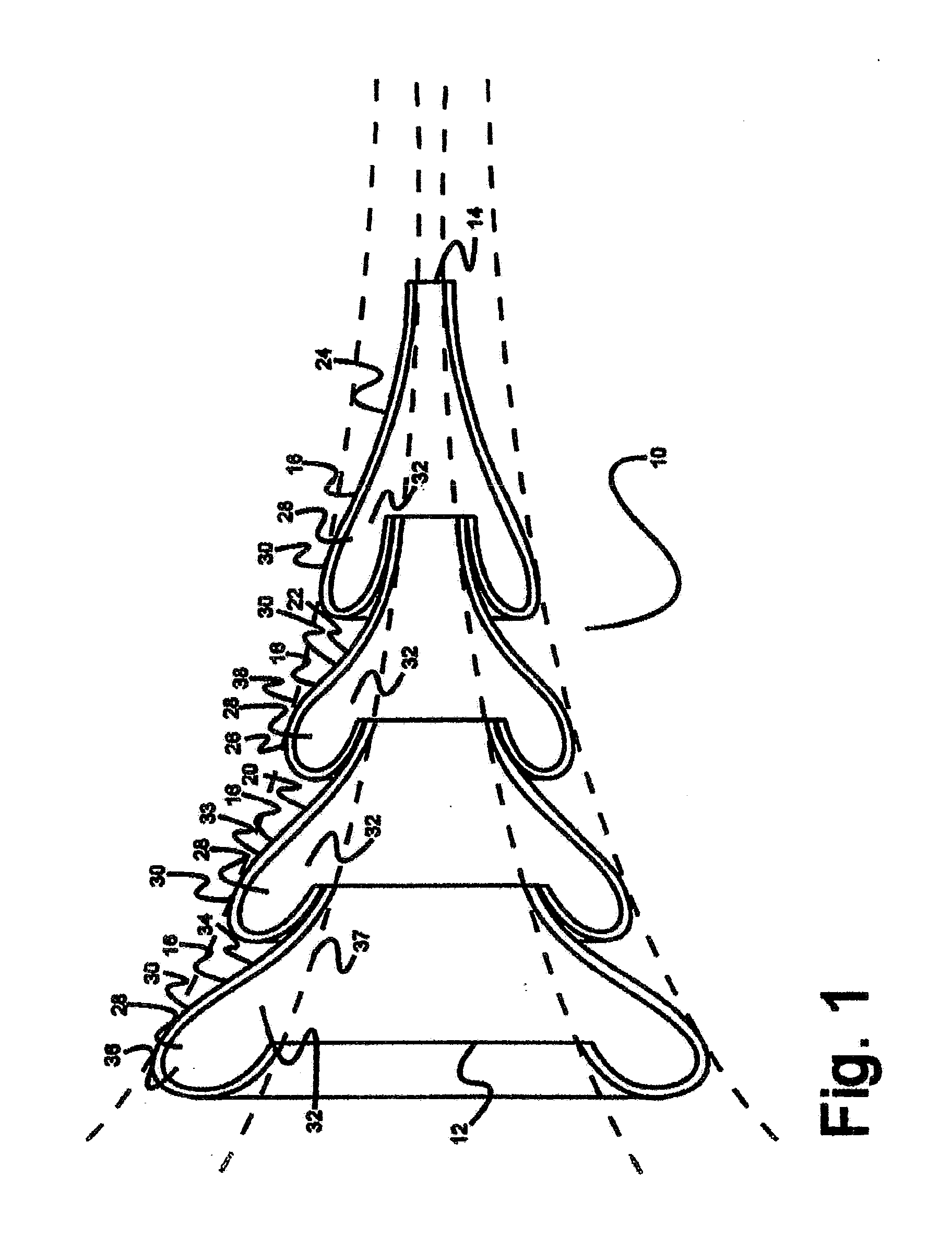

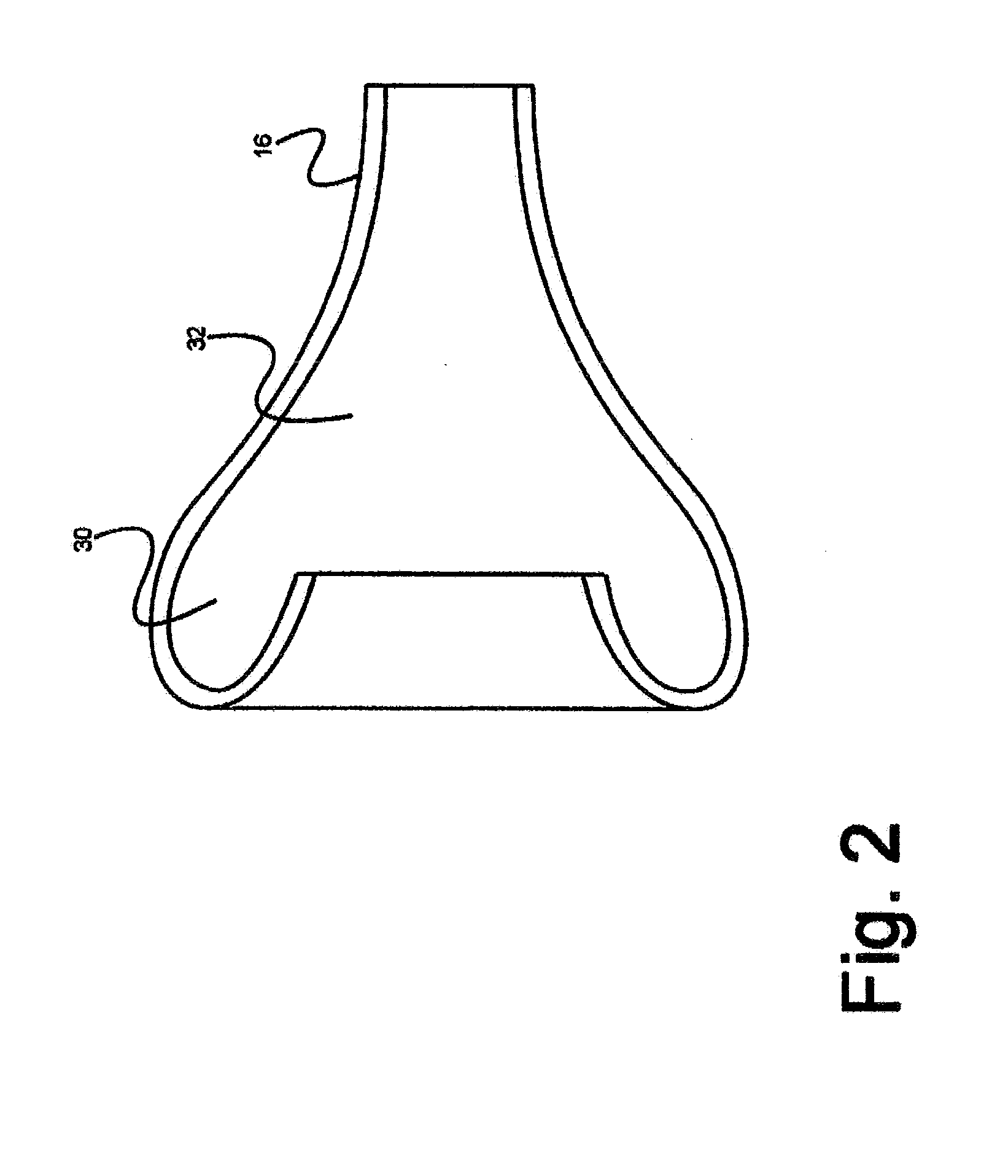

InactiveUS20070215536A1Increase water flowTreatment involving filtrationWater treatment locationParticulatesWater treatment system

A filter cartridge for use in gravity-fed water treatment systems wherein filter elements include a dome-shaped hydrophilic porous particulate carbon powder block filter in a polymeric binder. The filter has a closed upper end and an open lower end with sidewalls extending there between, additional filter media and includes ion exchange resins and a fine mesh hydrophilic filter sheet to reduce contaminant content of water for drinking purposes.

Owner:MARMON WATER SINGAPORE

Method and apparatus for making crystalline PET pellets

InactiveUS20050110184A1Reduce dwell timeImprove heating conditionsMouldsDrying solid materials without heatPolyethylene terephthalateSlurry

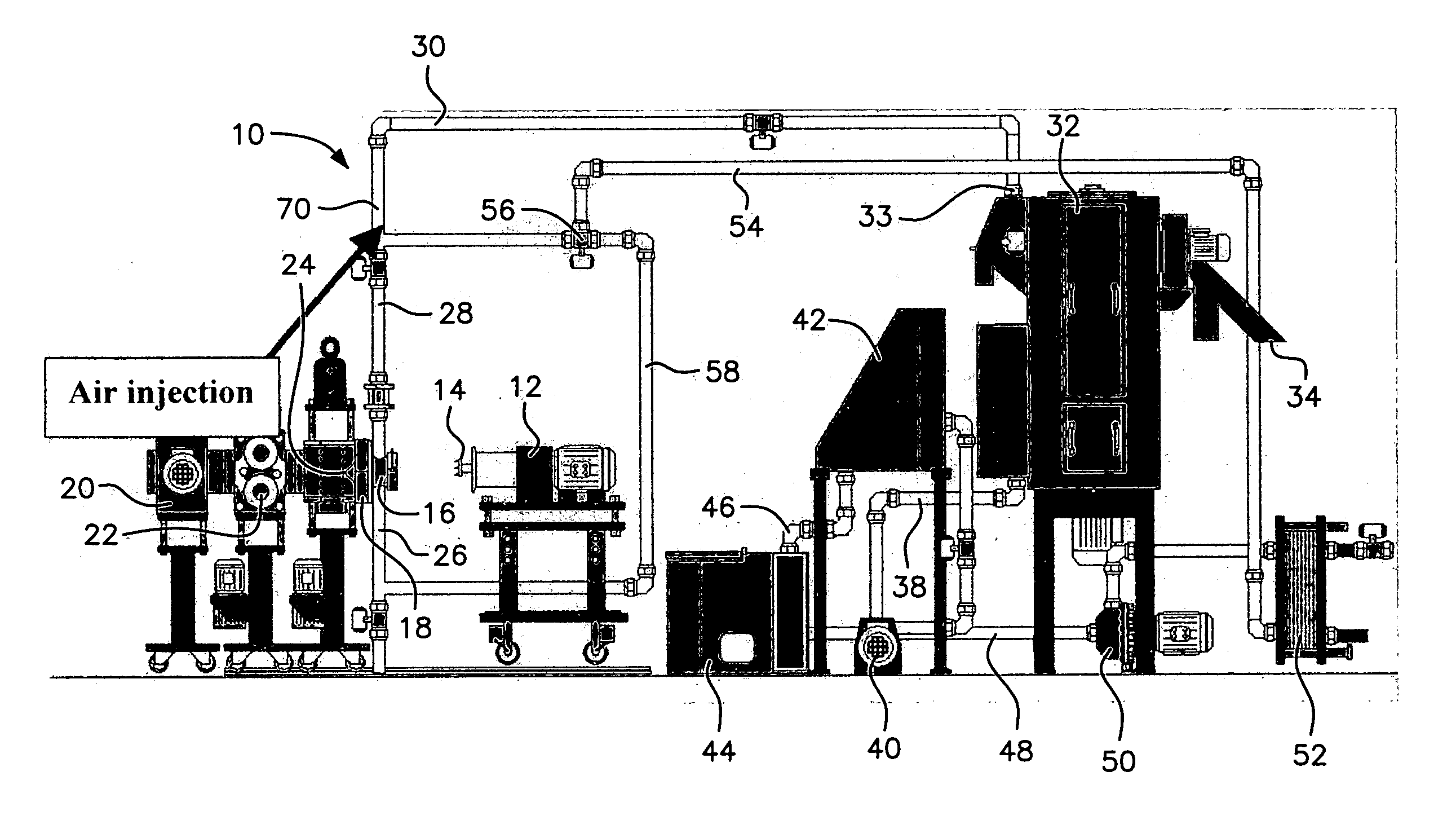

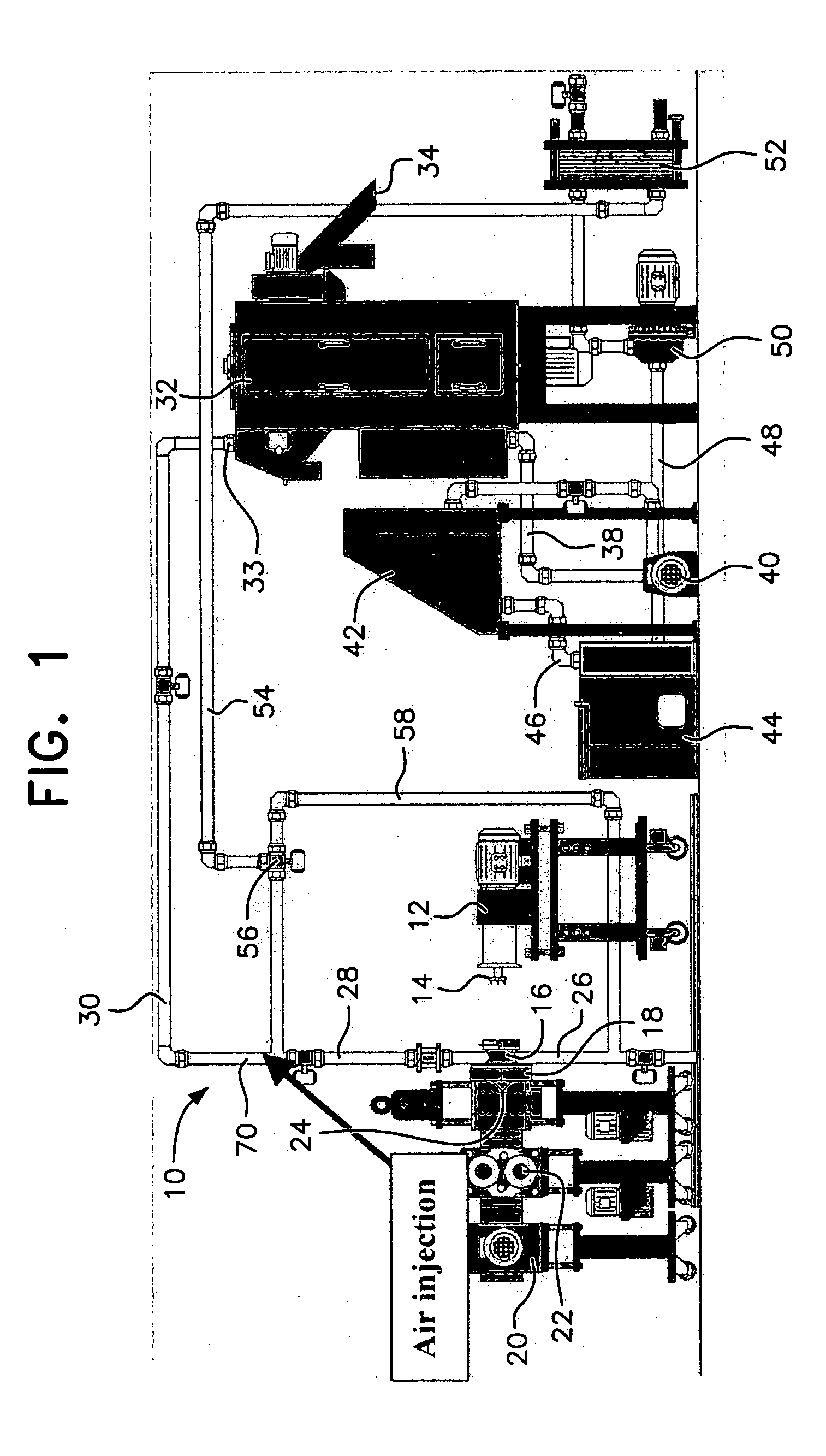

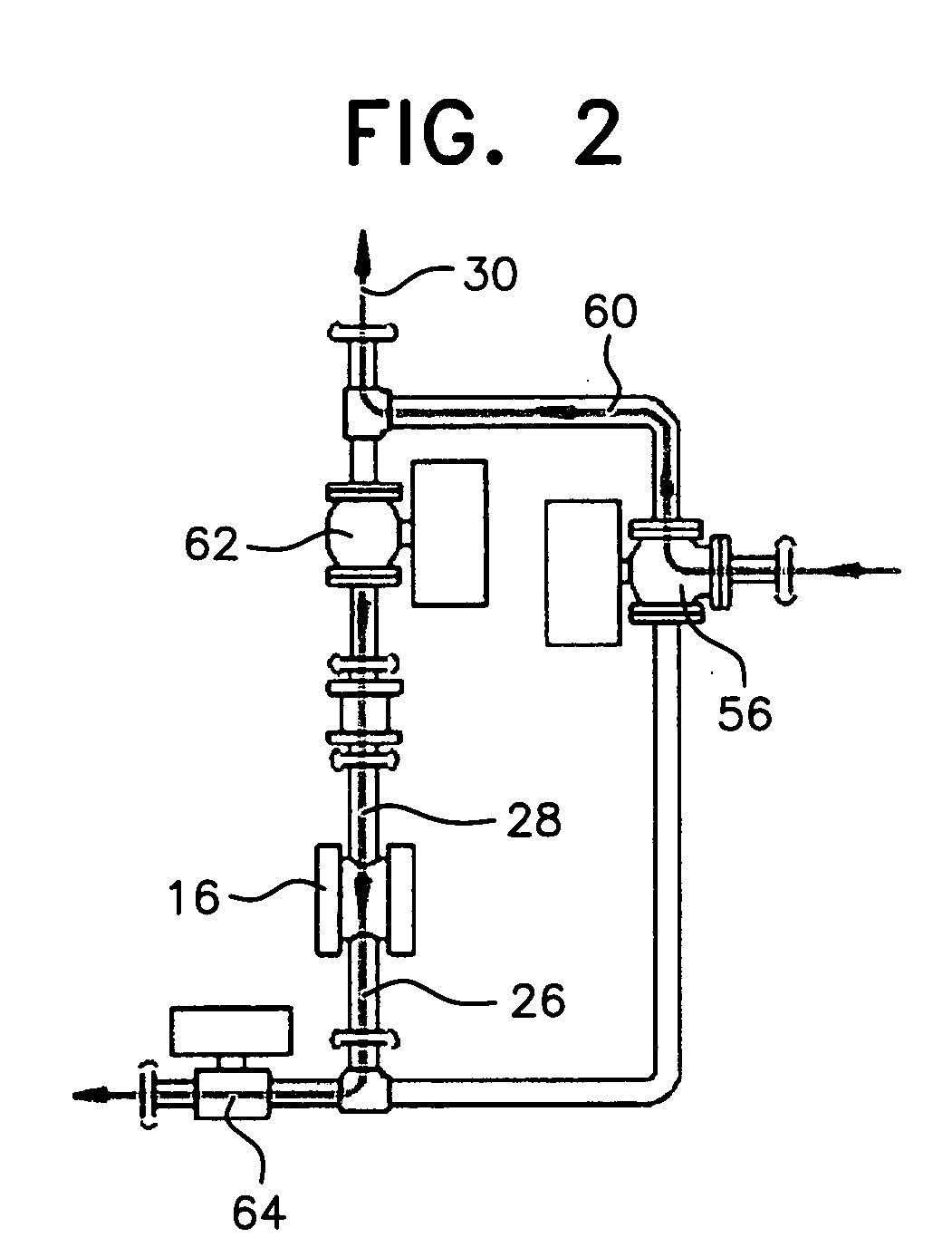

A method and apparatus for underwater pelletizing and subsequent drying of polyethylene terephthalate (PET) polymers and other high temperature crystallizing polymeric materials to crystallize the polymer pellets without subsequent heating. High velocity air or other inert gas is injected into the water and pellet slurry line to the dryer near the pelletizer exit. The slurry line has a substantially straight component, and air is preferably injected at the end of the straight component nearest the pelletizer exit and in a direction substantially coincident with the axis of the straight component. The air injection significantly increases the speed of the pellets into and out of the dryer such that the PET polymer pellets leave the dryer above at least 135° C., and preferably above 145° C., to self-initiate crystallization.

Owner:GALA INDUSTRIES INC

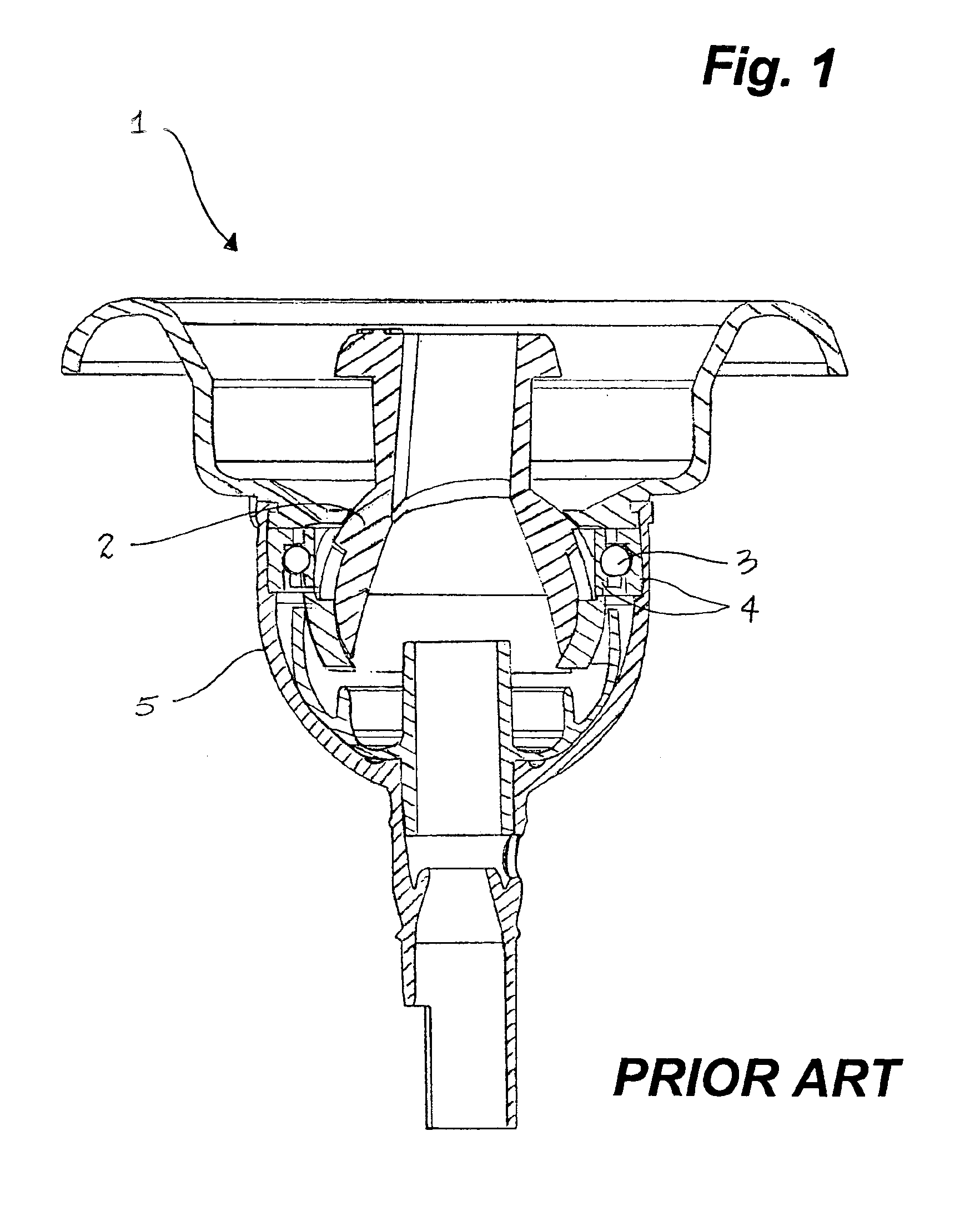

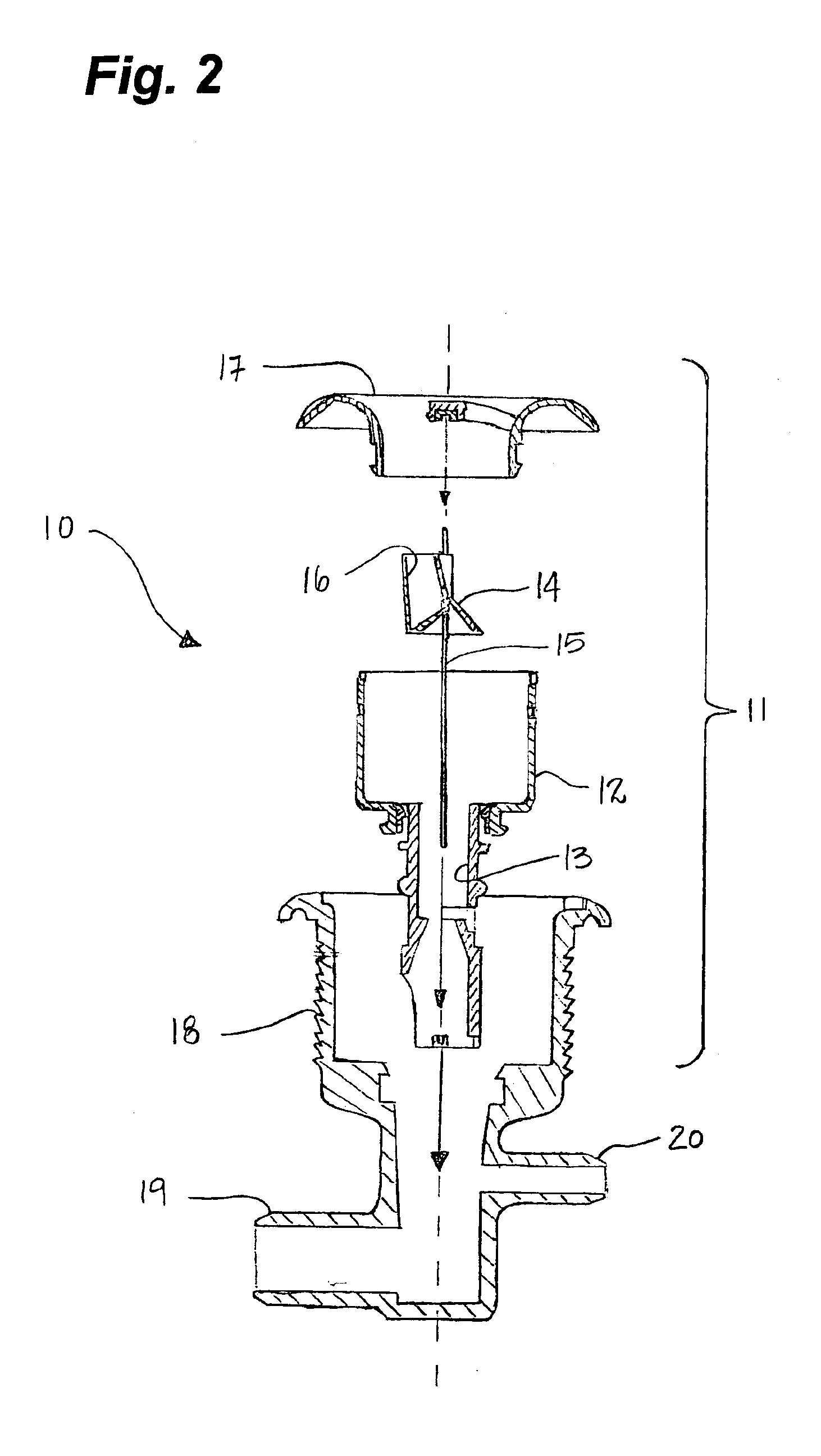

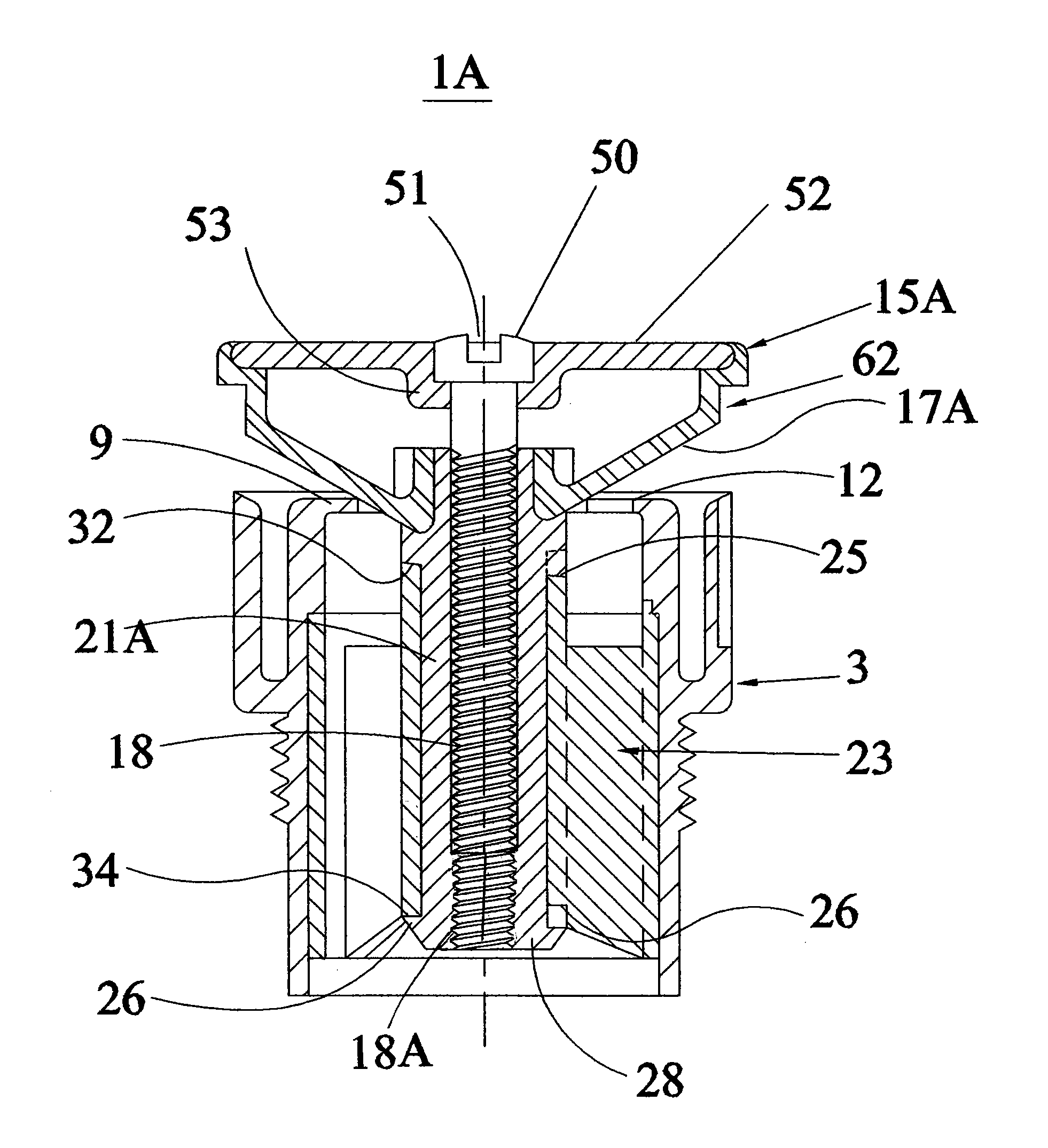

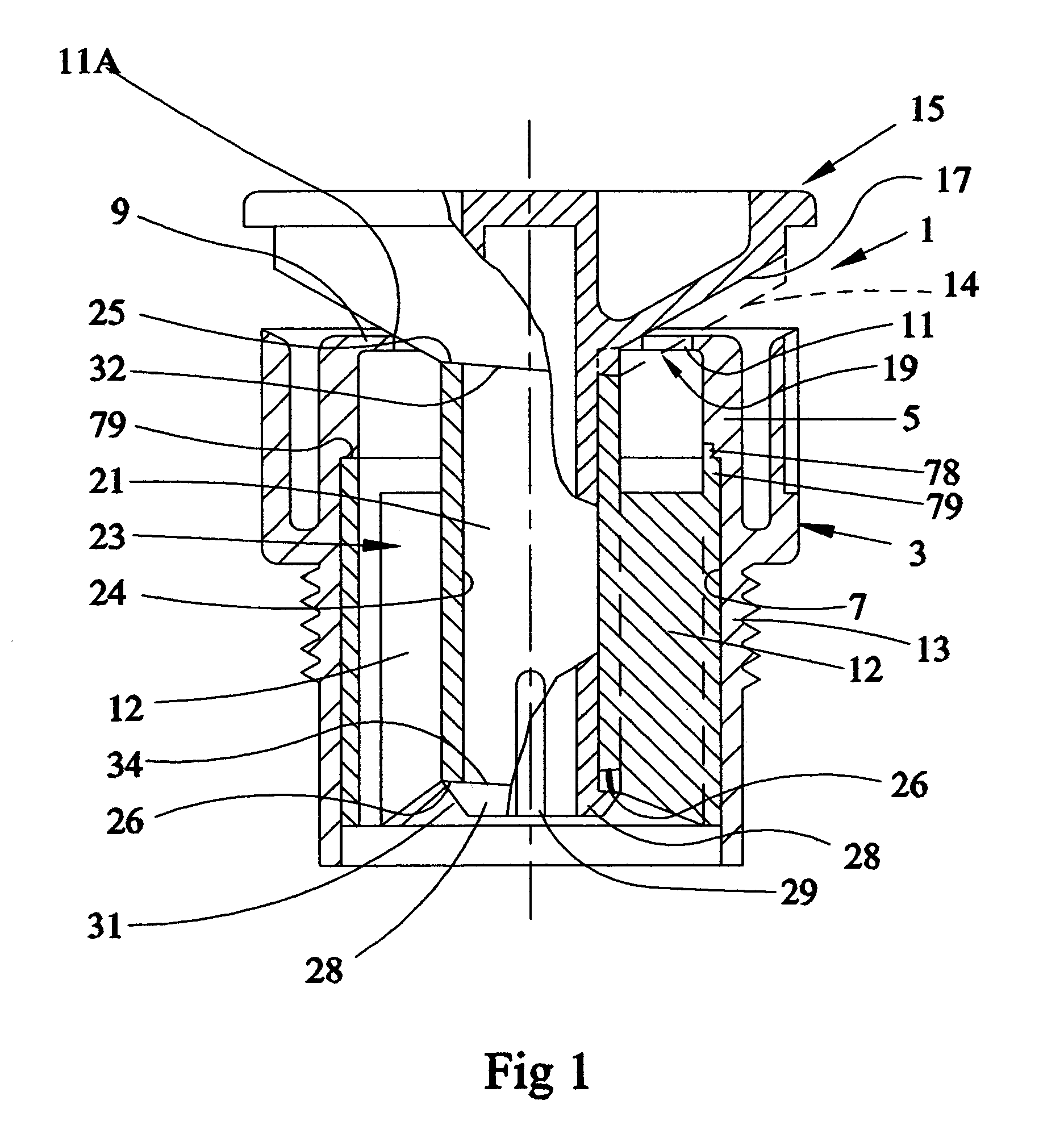

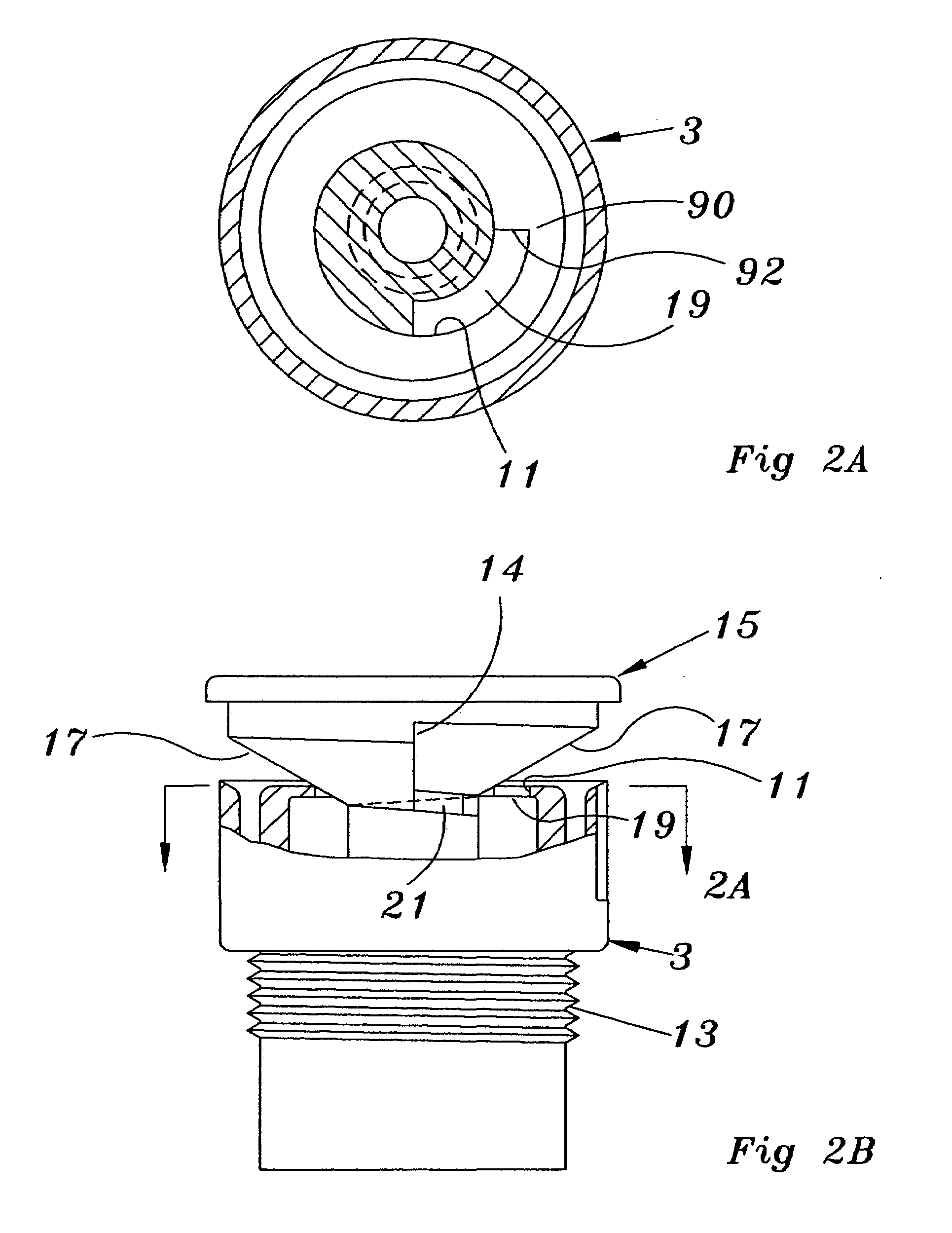

Jet barrel for a spa jet

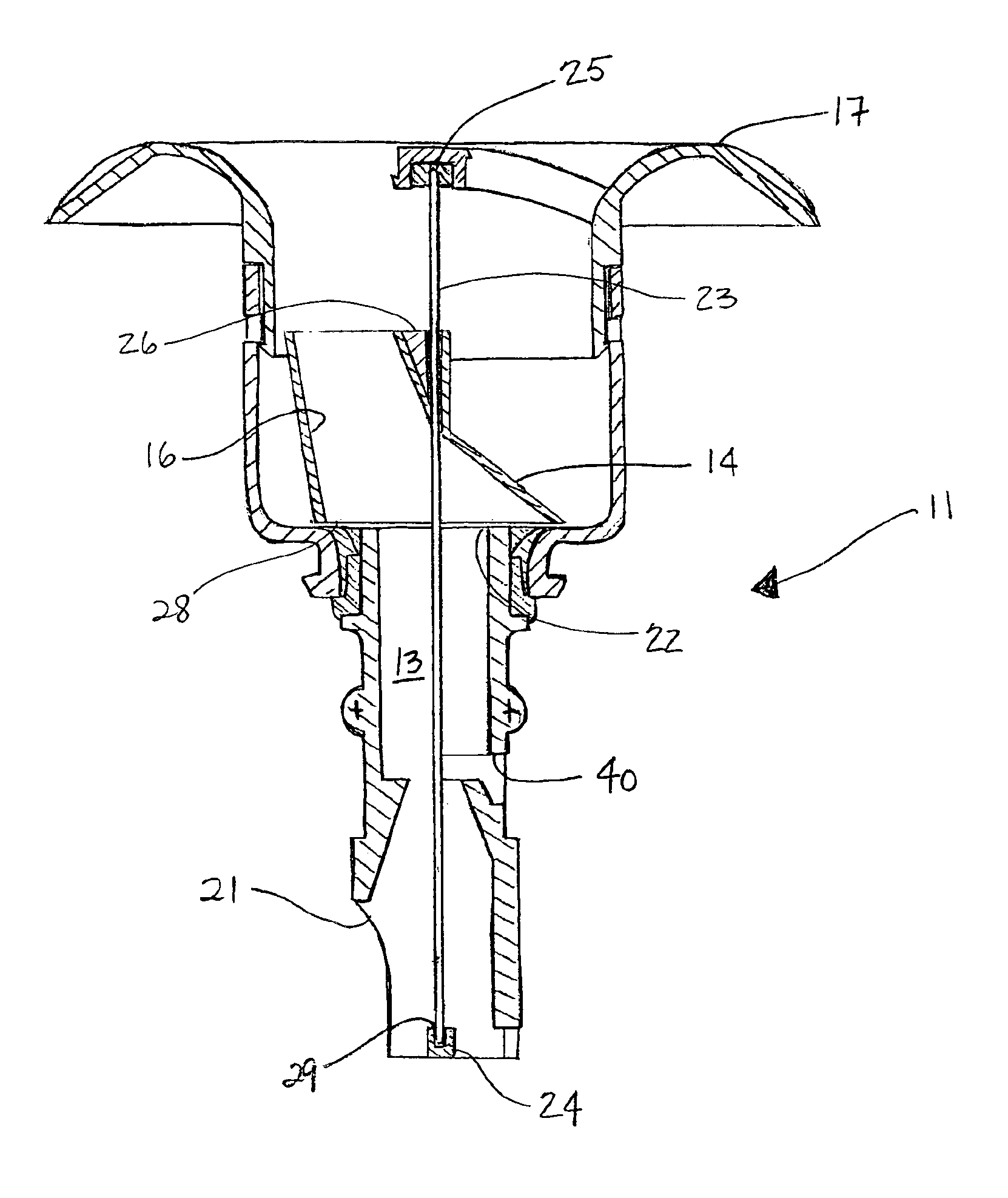

A jet barrel adapted for use in a spa jet housing having a rotor rotatably supported on a spindle pin aligned along a longitudinal axis in the bore of the jet barrel. The spindle pin is supported at upstream and downstream pivot points. An offset nozzle extends from a conical base of the rotor, an inlet to the rotor being aligned with an outlet from the jet barrel's bore. As water exits the jet barrel bore into the rotor, the rotor and spindle pin are caused to co-rotate. Hard water deposits, sufficient to prevent rotation do not readily build around the pivot points.

Owner:GUANGZHOU RISING DRAGON RECREATION IND CO LTD

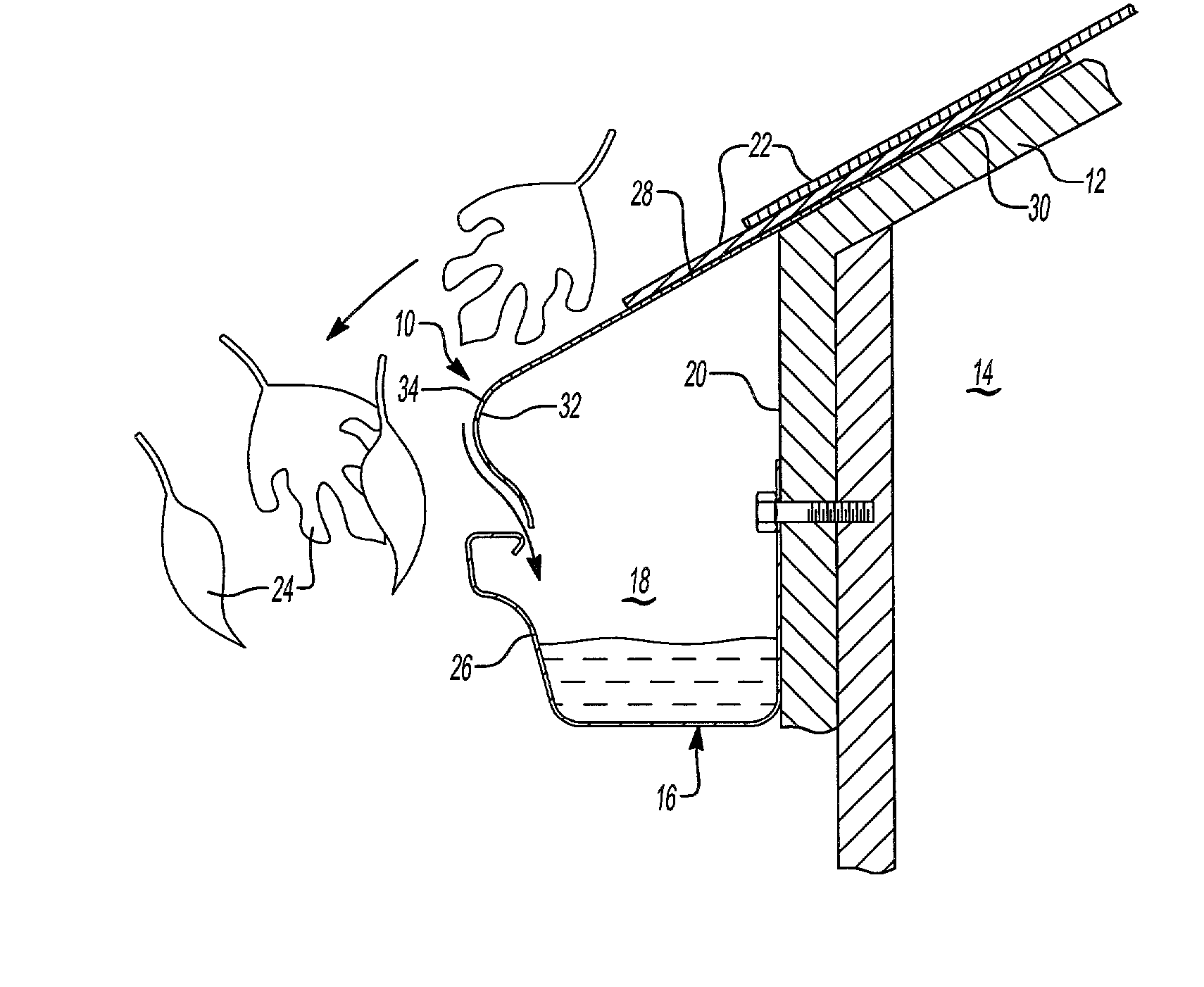

Gutter cover device

InactiveUS6672012B2High trafficOvercome disadvantagesRecord information storageLiquid displacementCoatingCivil engineering

Owner:SOUTHEASTERN METALS MFG

Spray nozzle with adjustable ARC spray elevation angle and flow

An adjustable spray nozzle with adjustable arc of coverage as well as spray elevation angle and flow rate. A very simple adjustable arc of coverage spray nozzle configuration is also disclosed which may be easily assembled for a particular precipitation rate and / or range of coverage at a selected nominal pressure. Also disclosed is a simple fixed arc of coverage spray nozzle with selectable ranges for a particular precipitation rate.

Owner:KAH JR CARL L +1

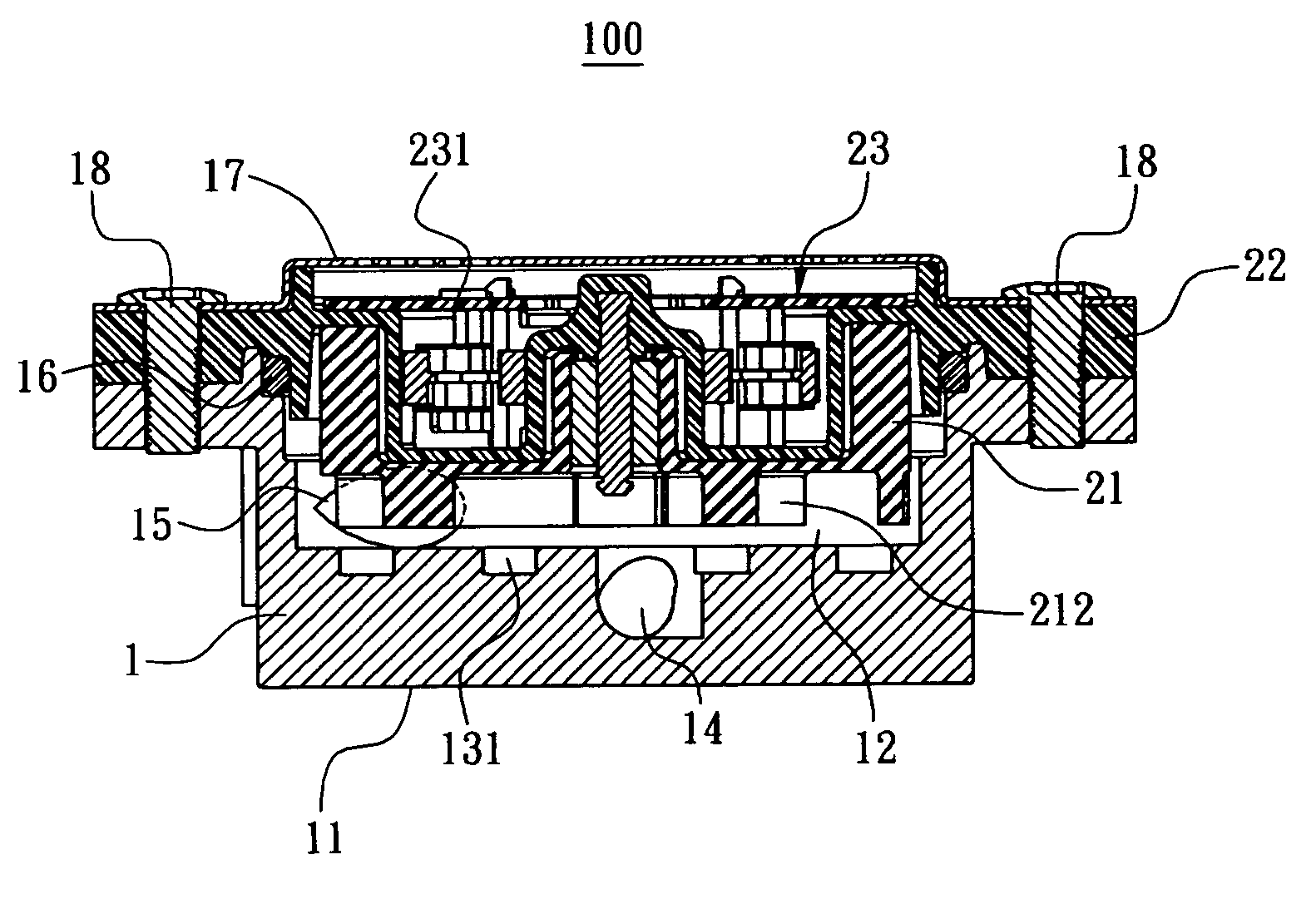

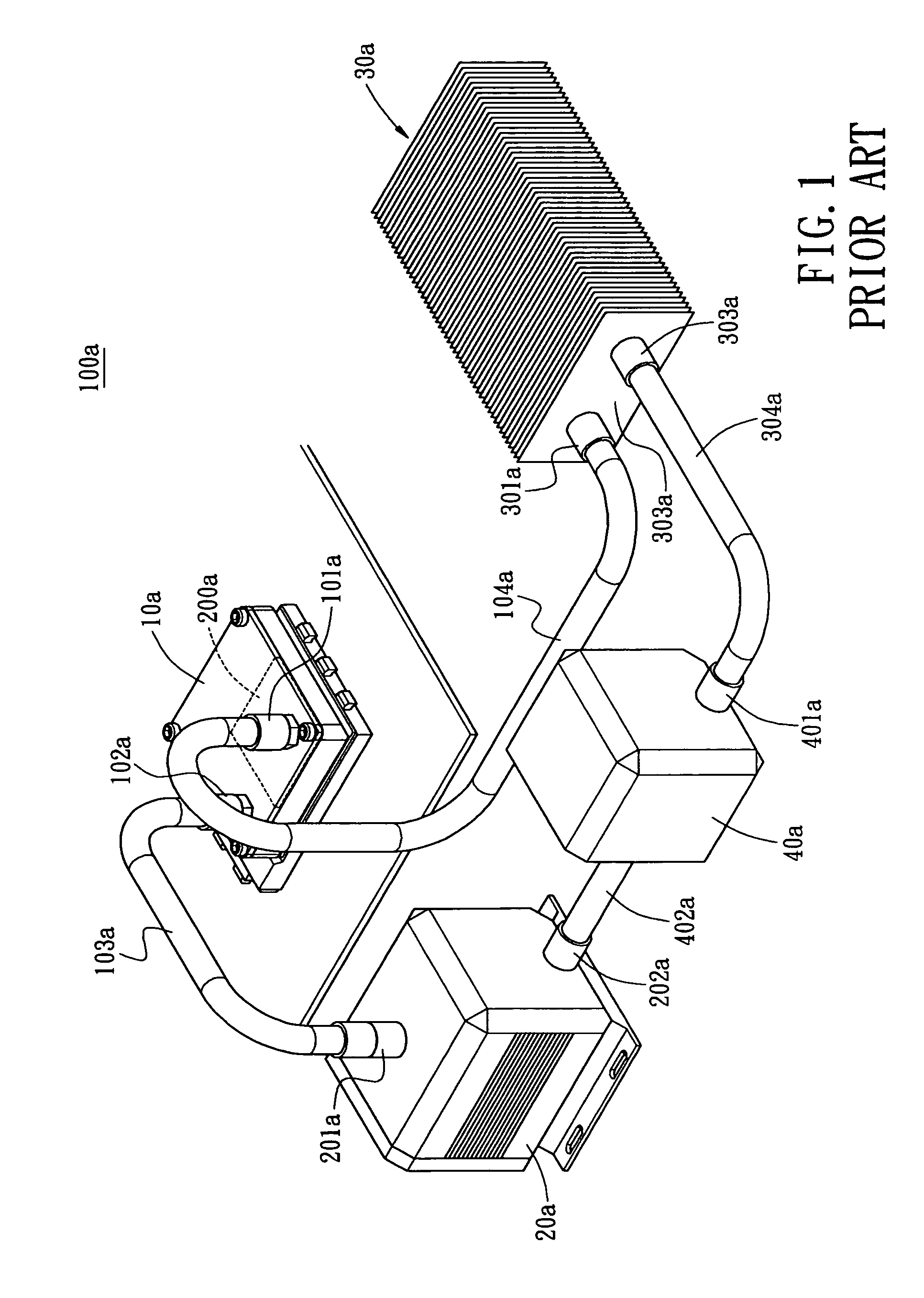

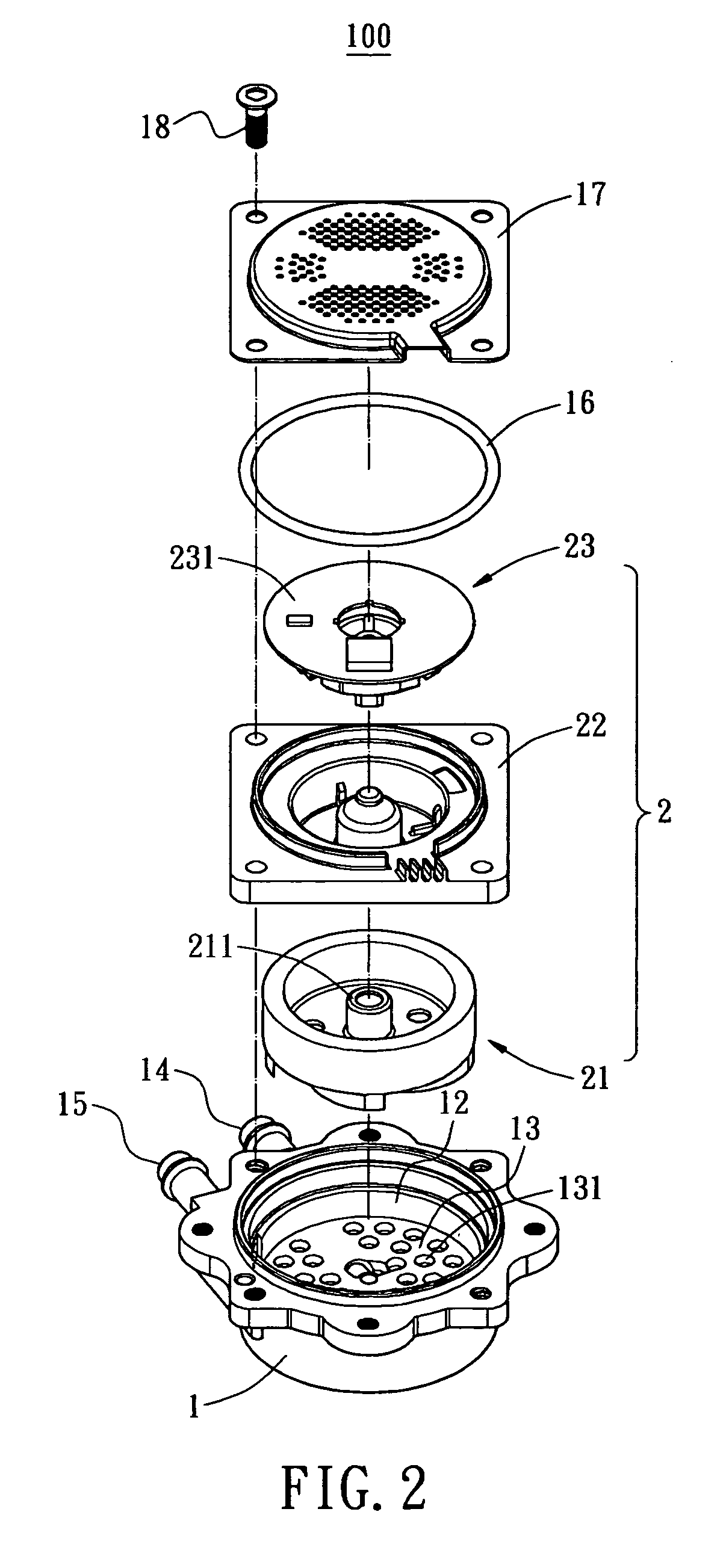

Water-cooling heat dissipation device

ActiveUS7249625B2Compact structureLow costDigital data processing detailsSemiconductor/solid-state device detailsNuclear engineeringCooling fluid

Owner:CHEMTRON RES

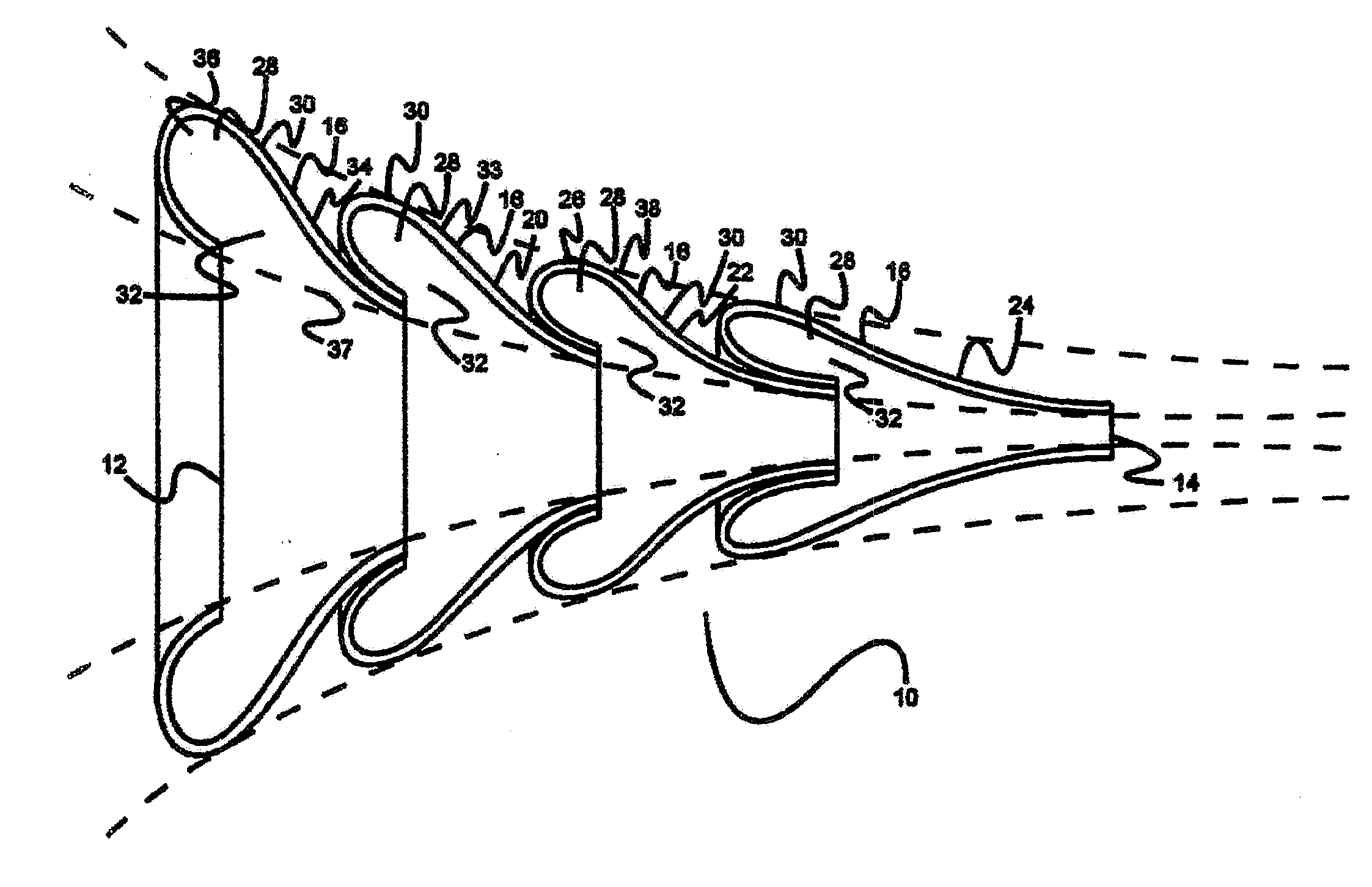

Channeling fluidic waveguide surfaces and tubes

InactiveUS20150337878A1Reduce fluid frictionReduce surfaceVehicle seatsVehicle body stabilisationJet engineEngineering

Waveguide or flow guide surfaces can improve the efficiency of fluid flow through tubes or over surfaces. When incorporated in a tube, the waveguides improve flow and function as sound absorbers making them useful in engine mufflers, firearm silencer / suppressors and jet engine exhaust attenuators. On surfaces, the waveguides can reduce fluid drag and find use on projectiles (e.g., bullets), airfoils for aircraft, and land borne vehicles. The waveguide array in either a tubular chamber or on a surface comprises a plurality of successive wave-like undulations inclined generally in the direction of flow and when employed in tubes extending inwardly to permit an unobstructed path for the fluid gas from entry to exit. The waves define annular wave cavities between their successive inwardly extending edges and the wall of the chamber with each cavity having a cavity mouth open to the unobstructed path. The waveguides are sized and spaced so that gas vortices are created within the cavities when gas flow occurs which vortices create a fluid boundary layer that assists the gas flow.

Owner:PARAFLUIDICS

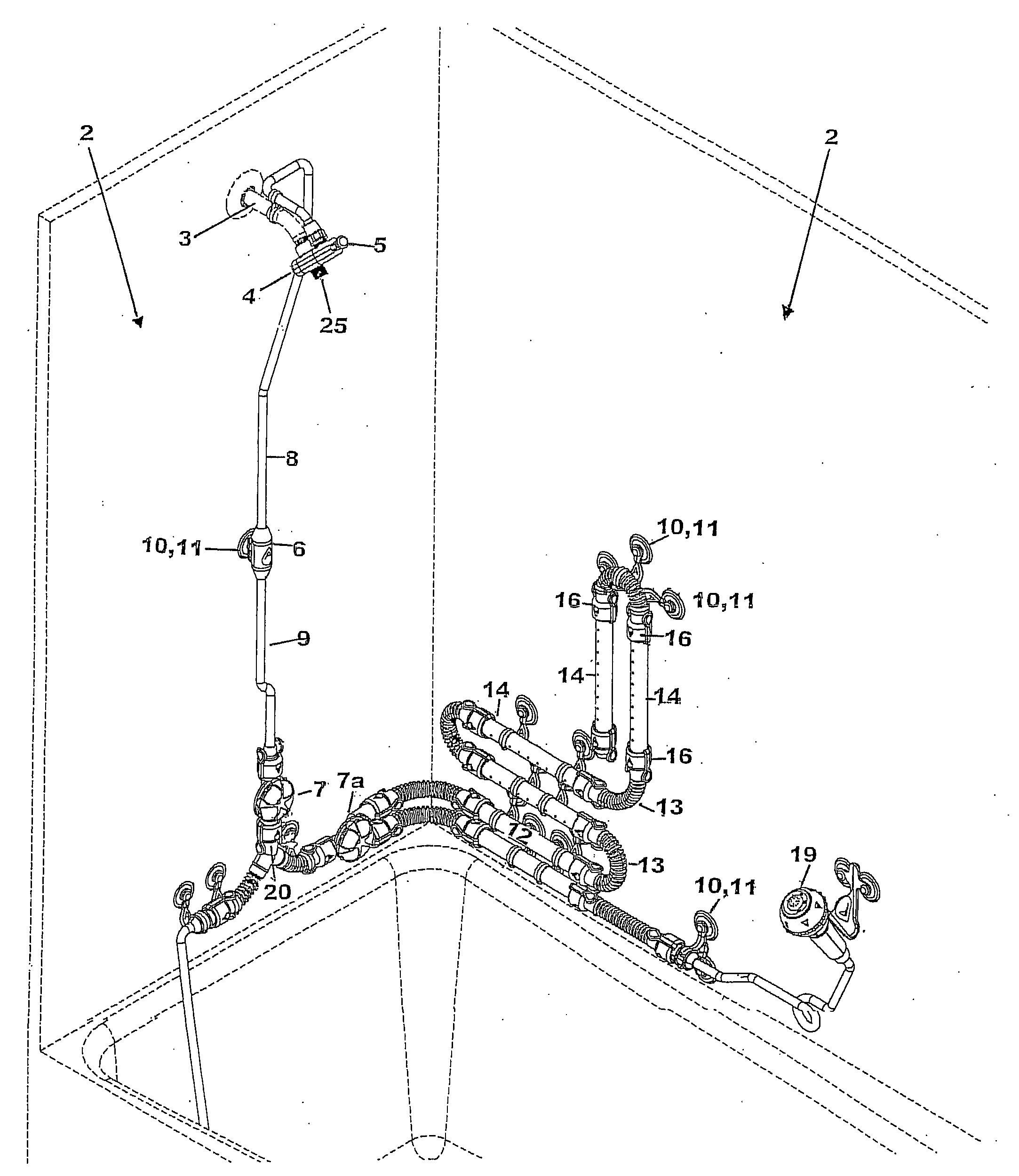

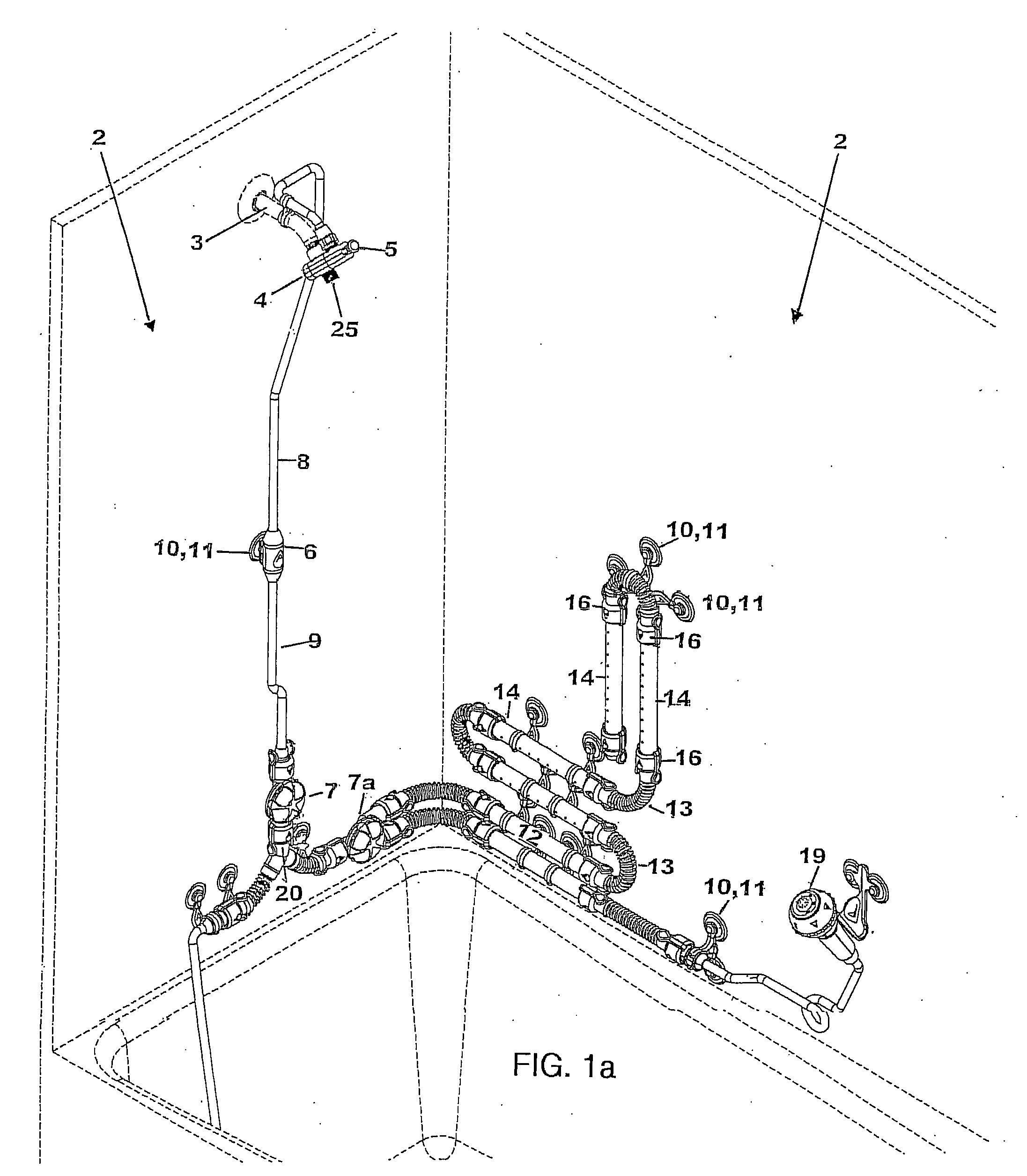

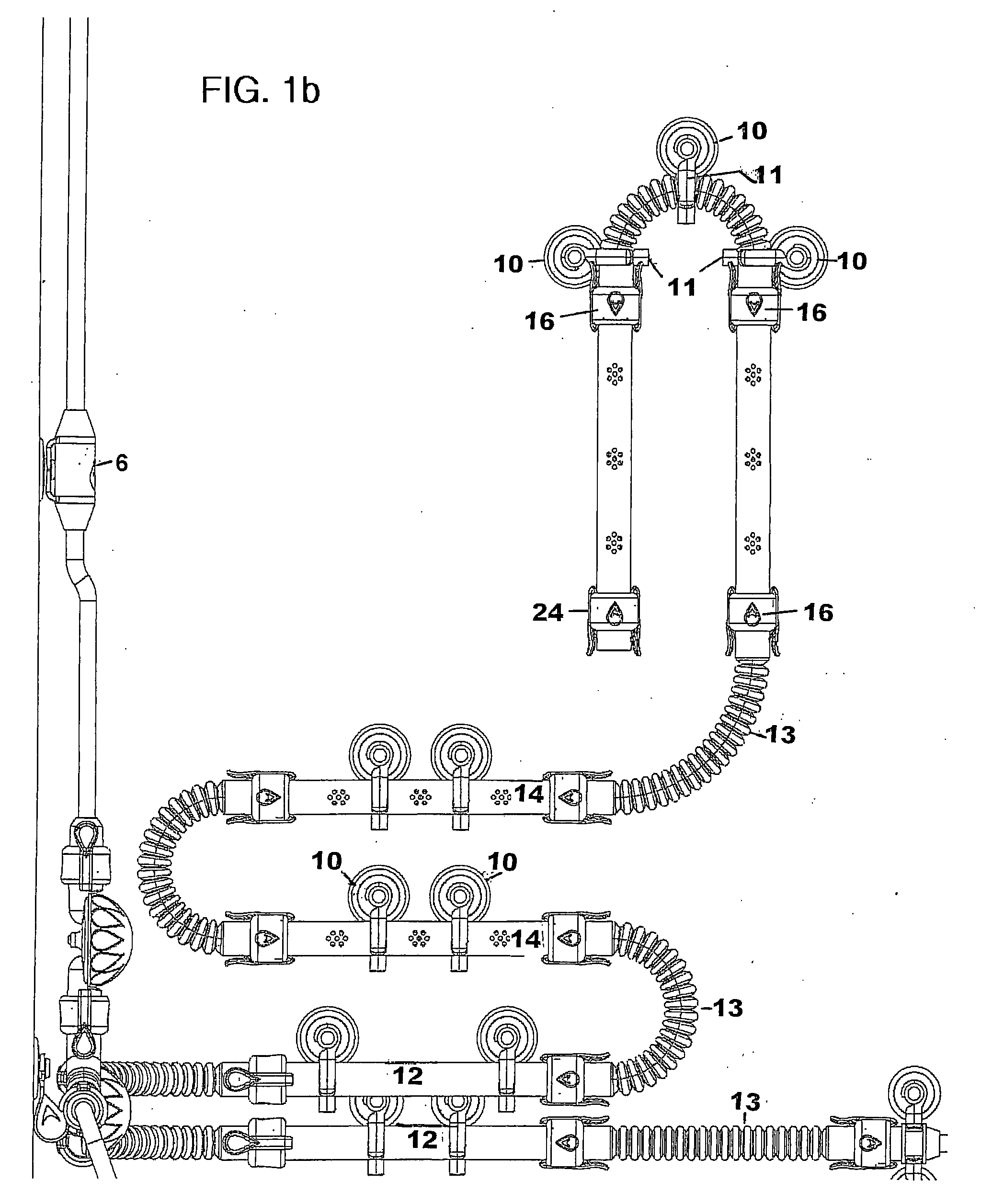

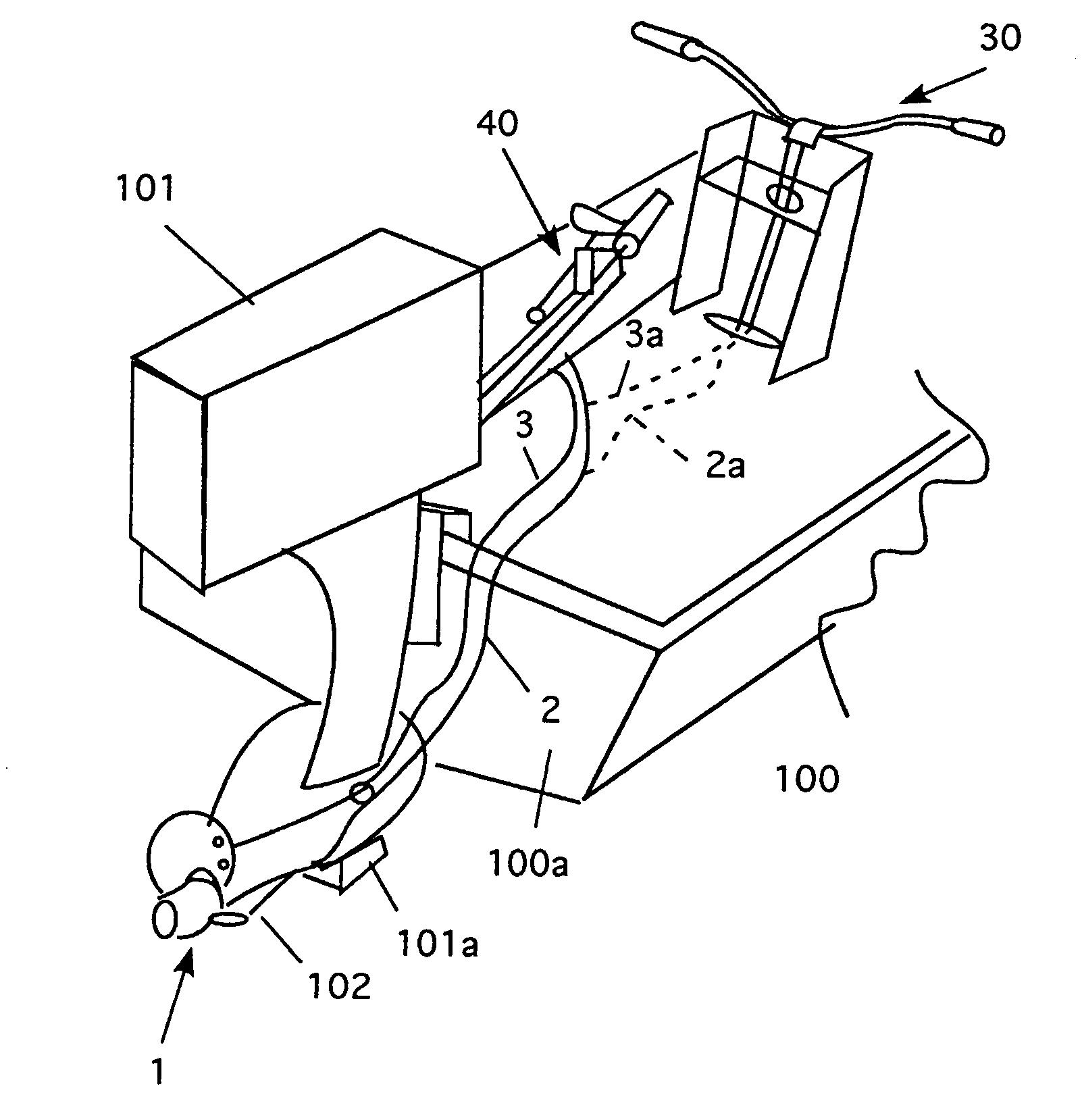

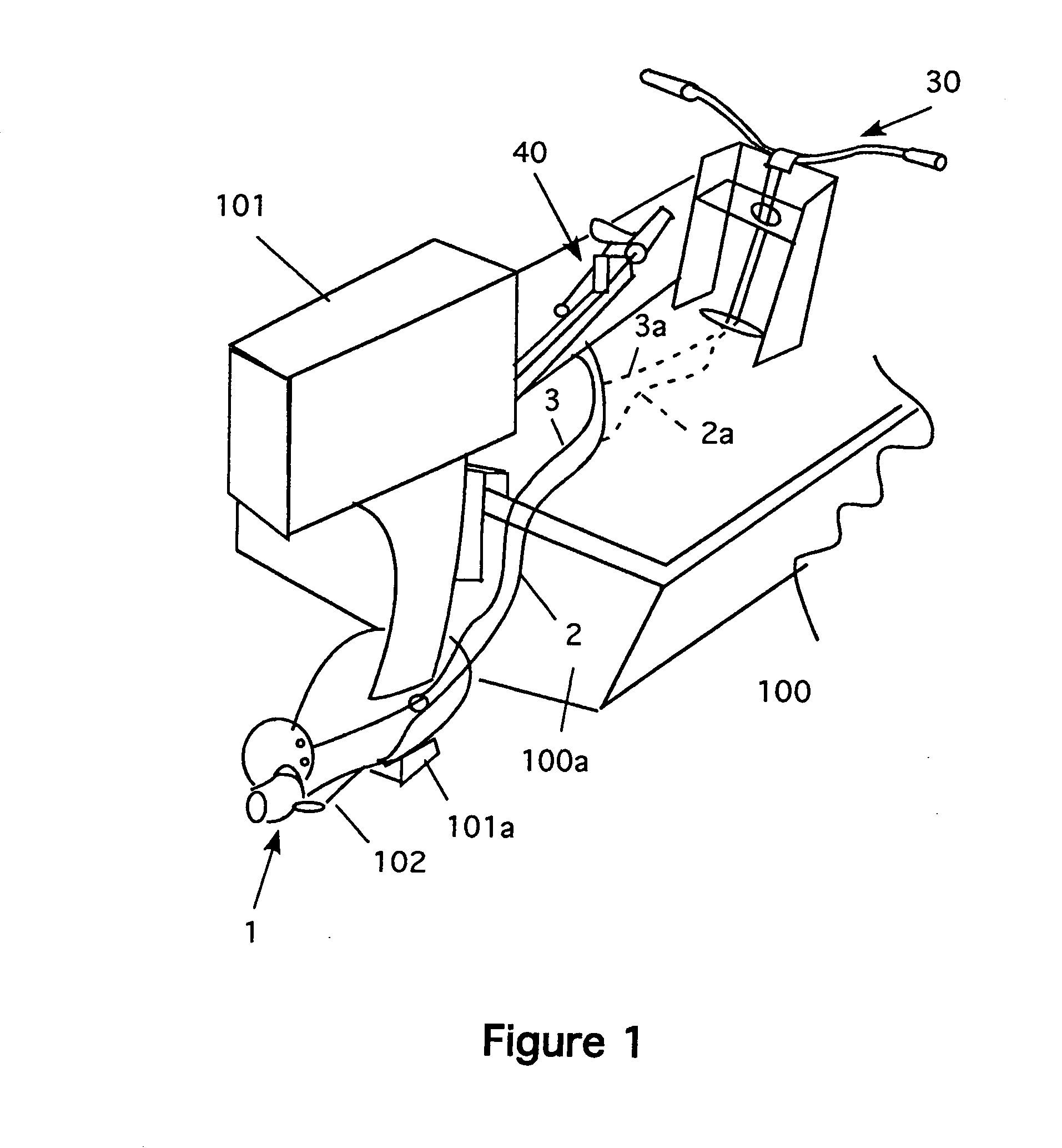

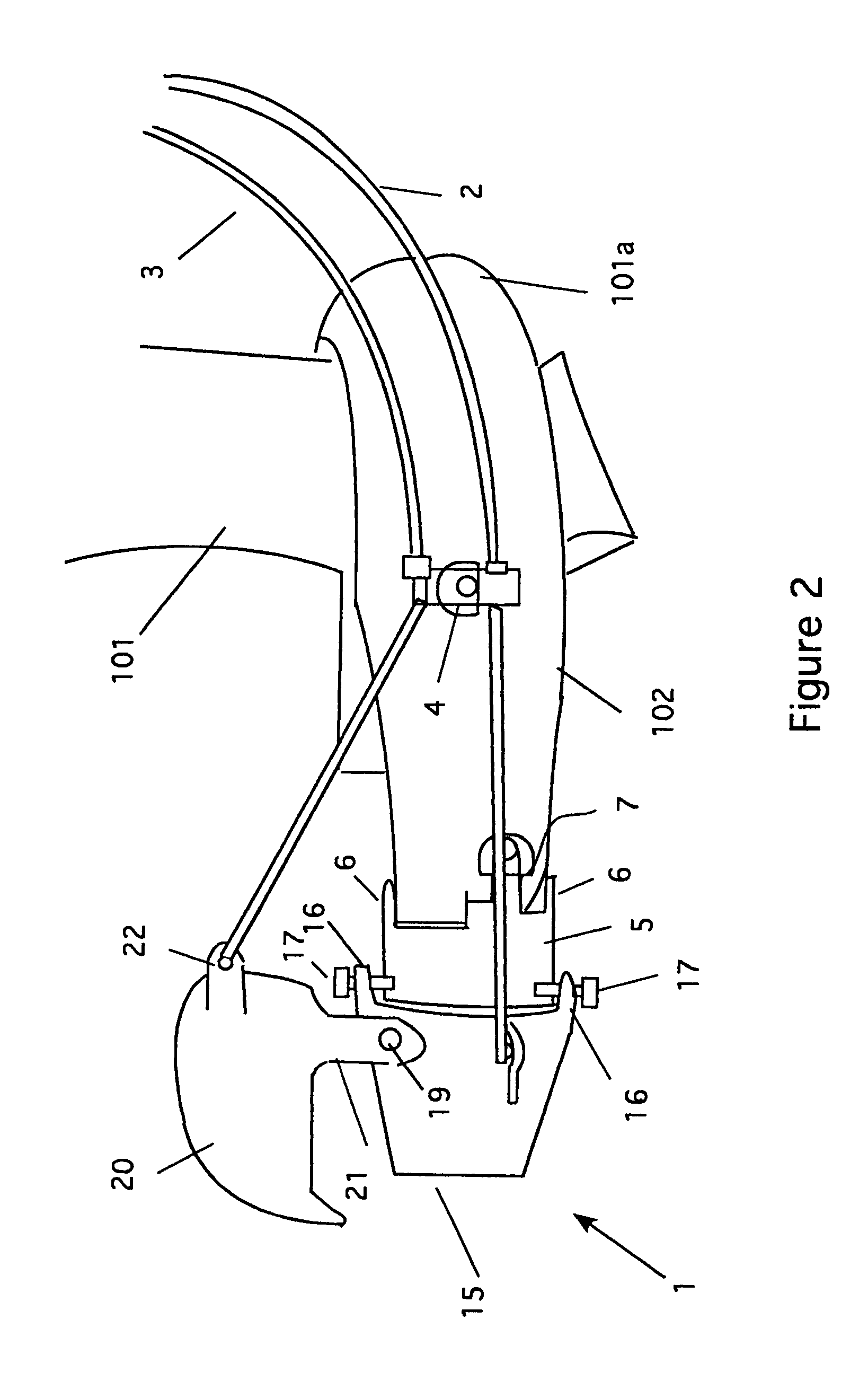

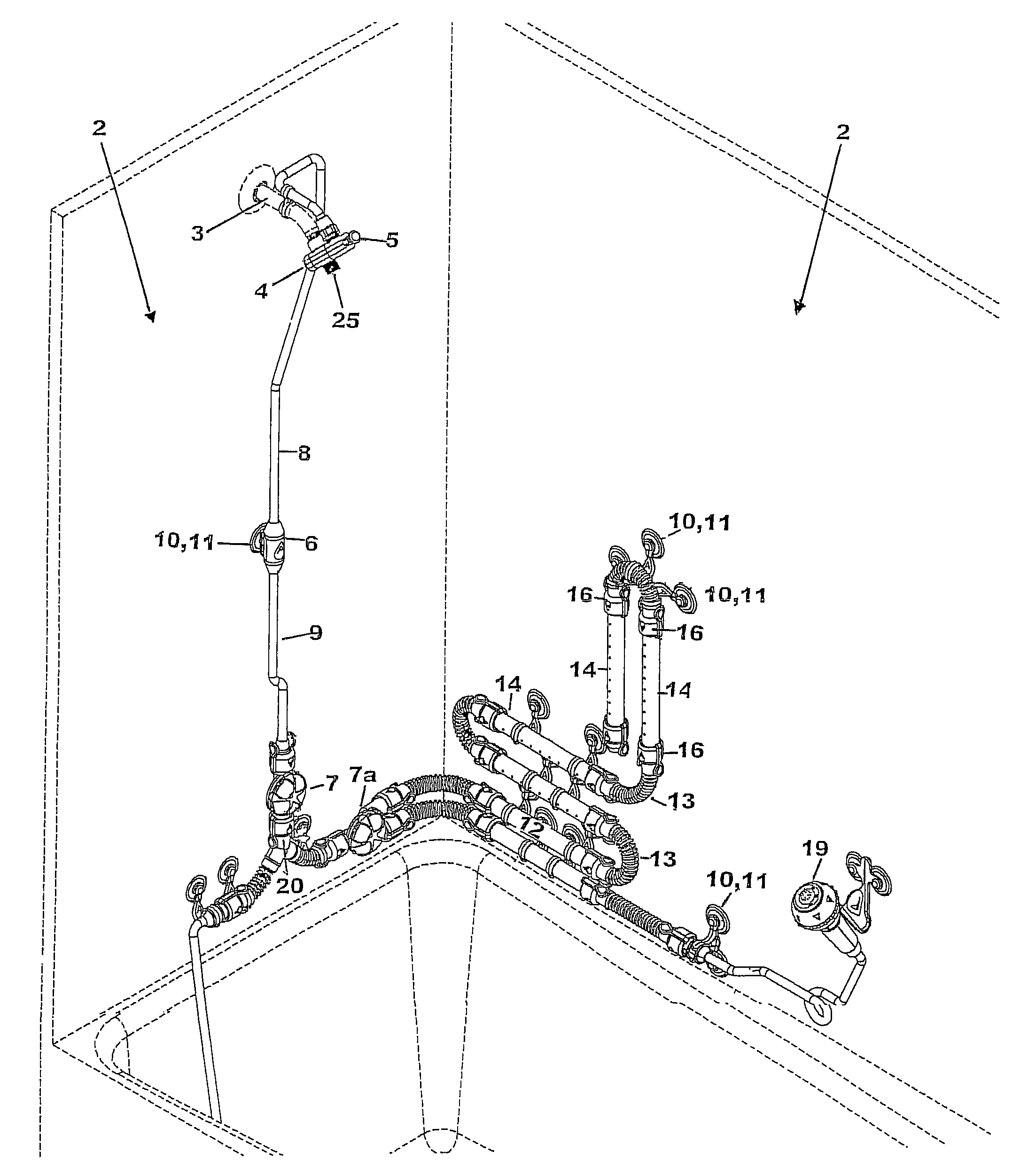

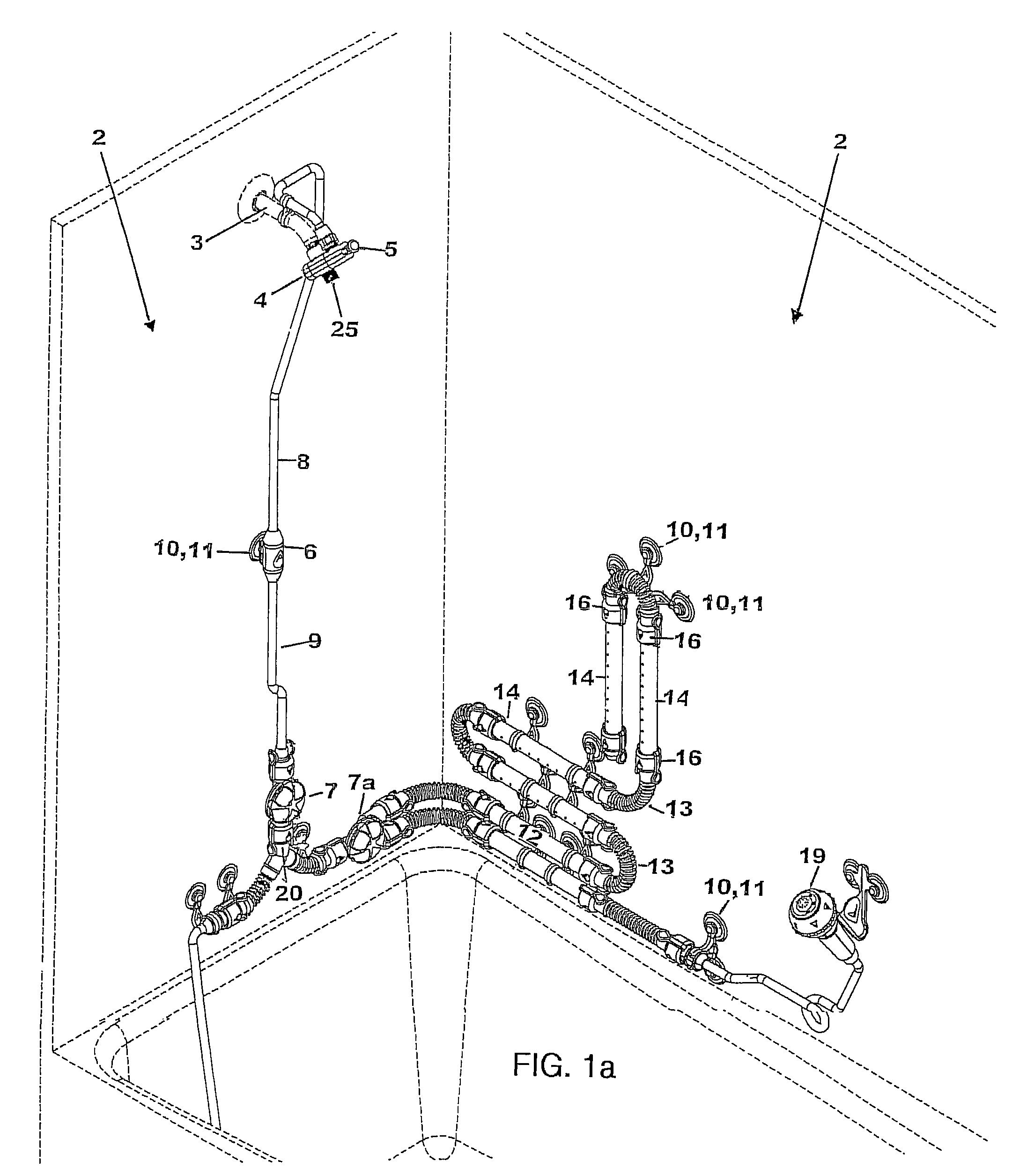

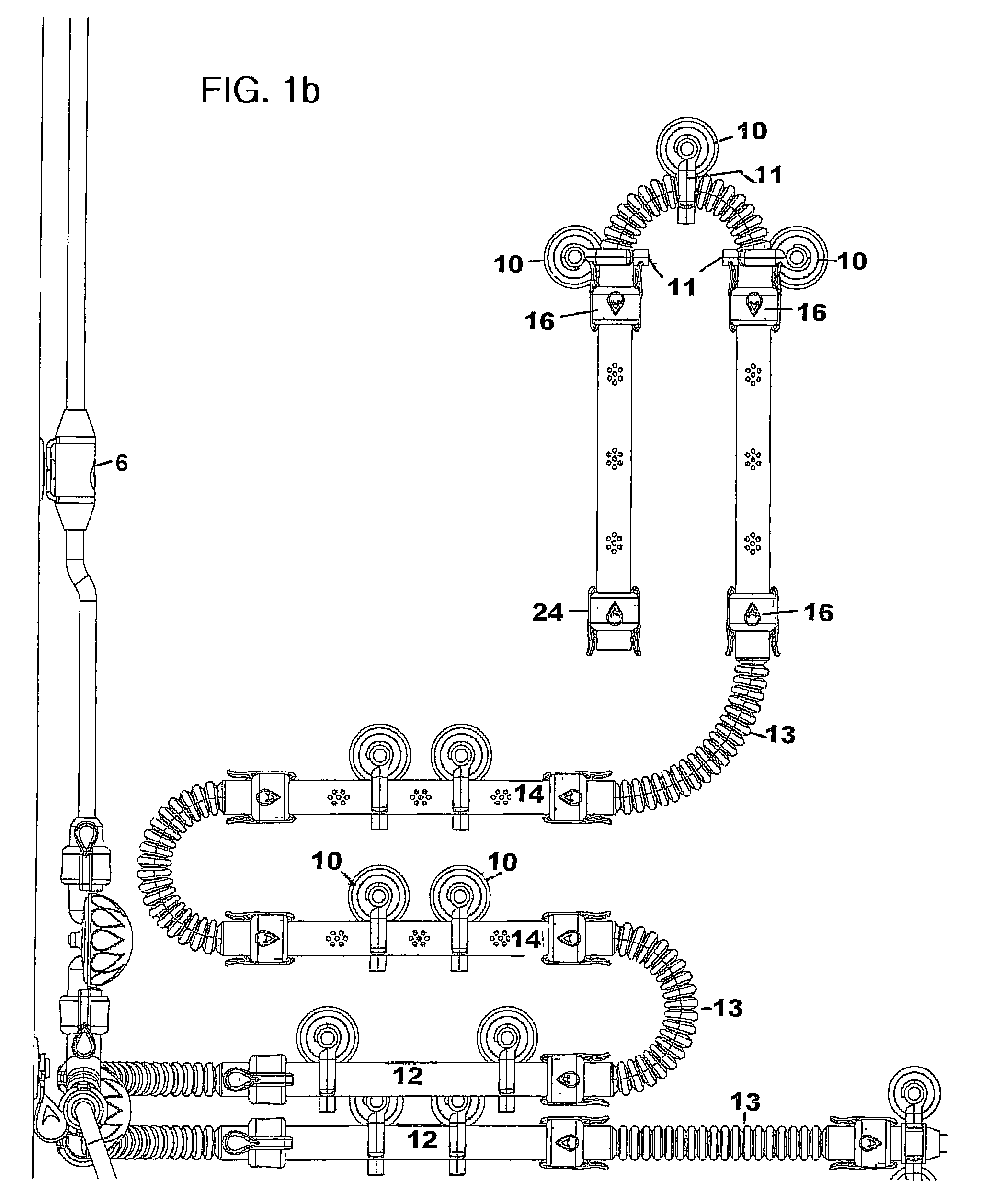

Shower water toy construction system

A shower water construction system for a child / user, which also functions as a showering system and utilizes a pre-existing bath / shower unit as a supporting structure. The construction system comprises a main control valve to divert water from a pre-existing shower water pipe stem, a pressure regulator to limit water pressure to downstream components, child / user control and diverter valves to allow for turning the system off and on and allocating water flow between components, semi-rigid and flexible pipe, “Y” connectors and suction cups and brackets. Other components, such as a hand-held sprayer, spraying bathtub mat and spraying shower curtain may also be integrated / connected into the system.

Owner:AQUASTRUCT

Spray nozzle with adjustable ARC spray elevation angle and flow

Owner:KAH JR CARL L +1

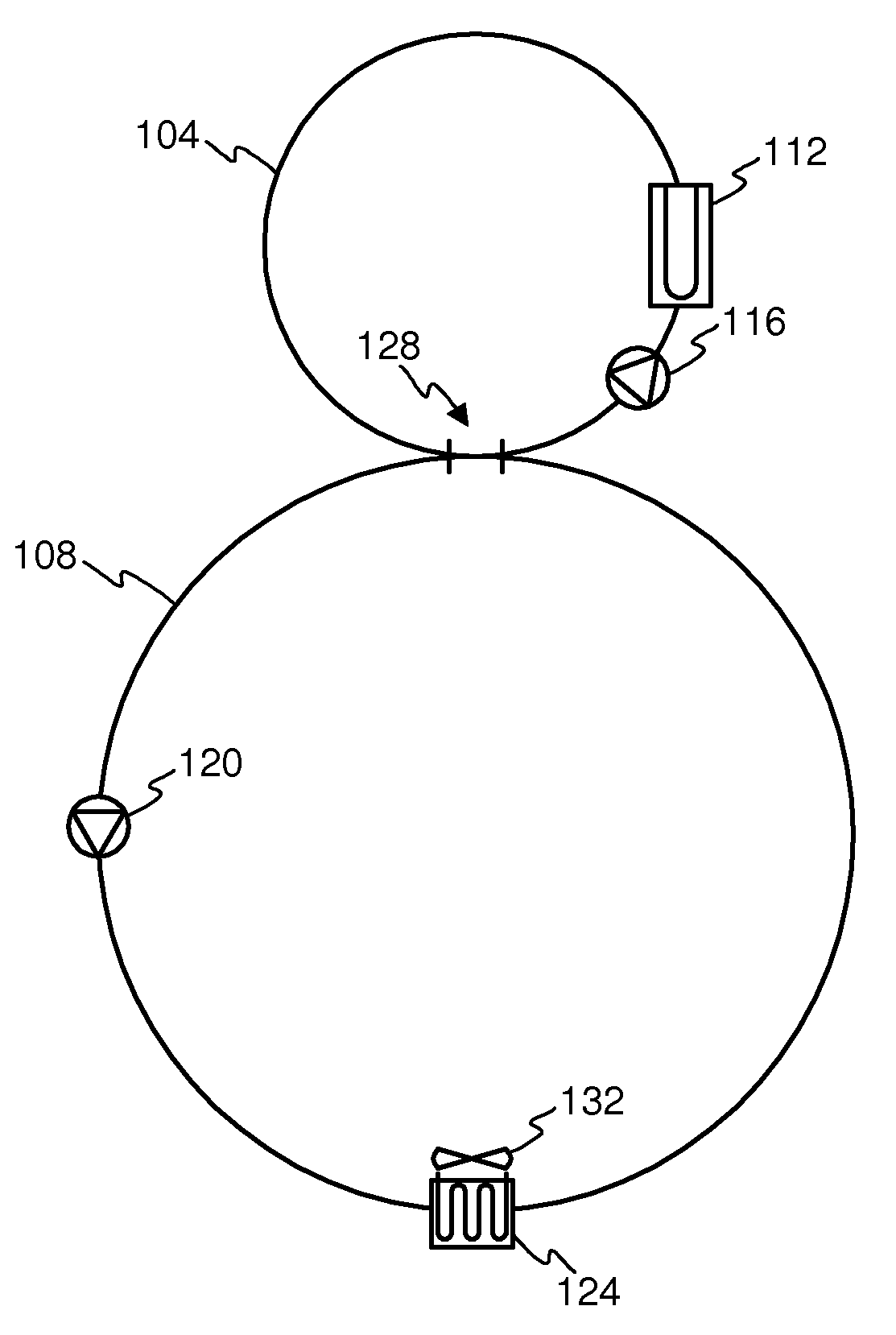

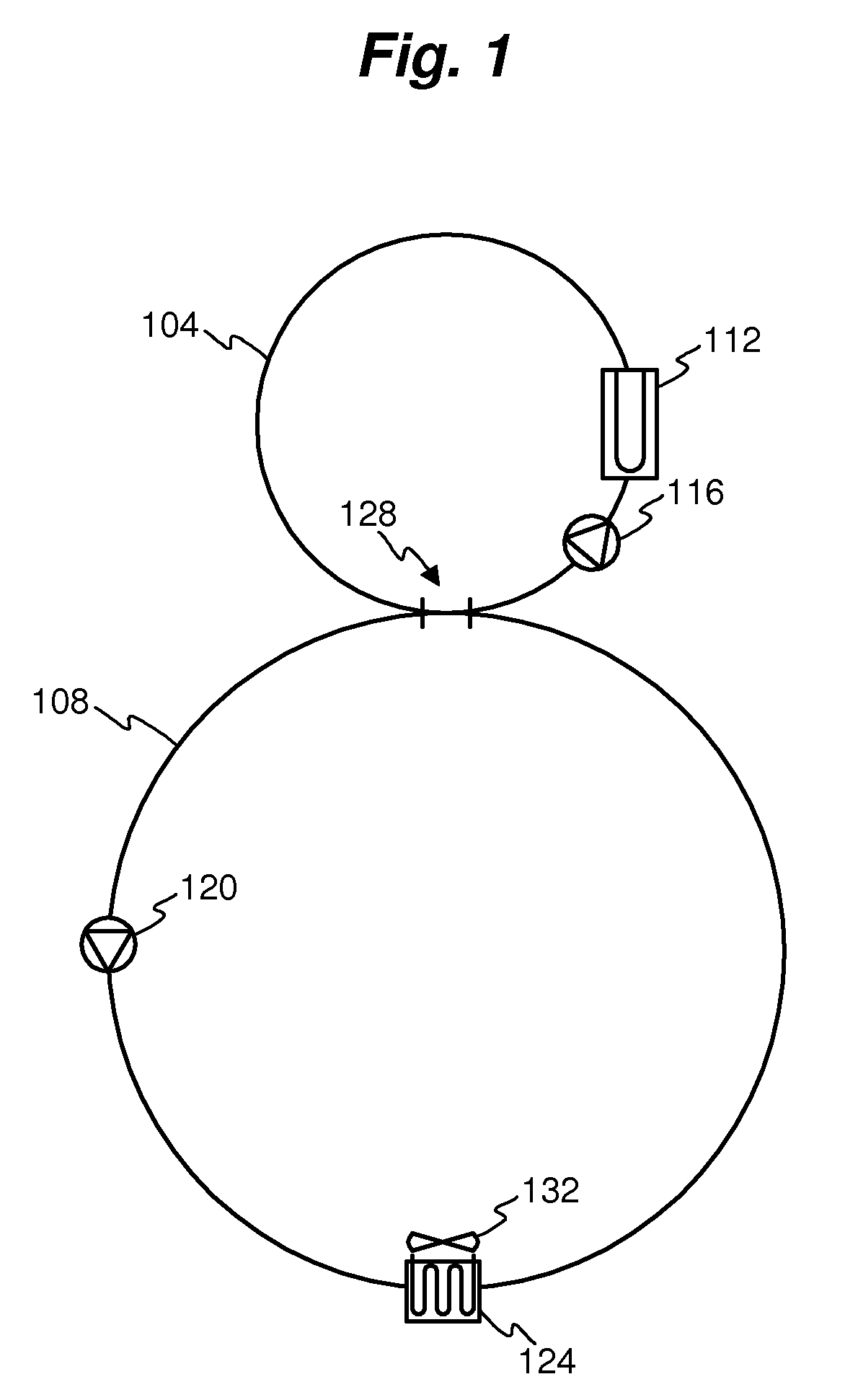

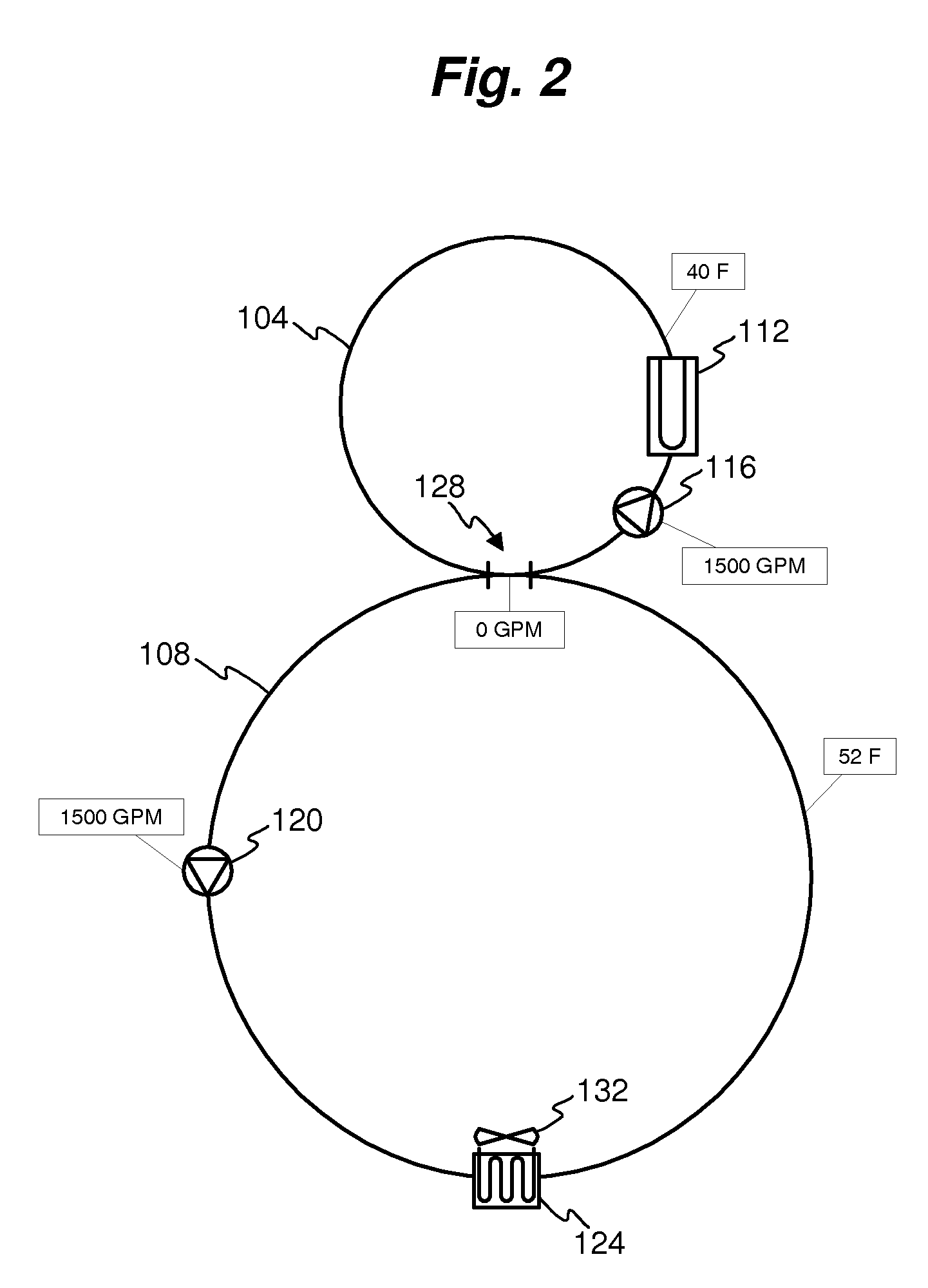

Demand flow pumping

ActiveUS20110022236A1Easy to operateSignificant energy savingMechanical apparatusTemperatue controlAir handlerEngineering

Demand Flow operates chilled water plants at substantially improved efficiency, regardless of plant load conditions. In general, Demand Flow utilizes an operating strategy which controls chilled and condenser water pumping according to a constant Delta T line, which is typically near or at design Delta T. This reduces or eliminates Low Delta T Syndrome and reduces energy usage by chilled and condenser water pumps for given load conditions. Operation of chilled water pumps in this manner creates a synergy which generally balances flow rates throughout the plant, reducing undesirable bypass mixing and energy usage at air handler fans and other components of the chilled water plant. At plant chillers, application of Demand Flow increases the refrigeration effect through refrigerant sub-cooling and superheating, while preventing stacking. Demand Flow includes a critical zone reset feature which allows the constant Delta T line to be reset to adjust to changing load conditions.

Owner:SIEMENS IND INC

Filter cartridge for gravity-fed water treatment device

InactiveUS7396461B2Increase water flowTreatment involving filtrationWater/sewage treatment by ion-exchangeParticulatesWater treatment system

A filter cartridge for use in gravity-fed water treatment systems wherein filter elements include a dome-shaped hydrophilic porous particulate carbon powder block filter in a polymeric binder. The filter has a closed upper end and an open lower end with sidewalls extending there between, additional filter media and includes ion exchange resins and a fine mesh hydrophilic filter sheet to reduce contaminant content of water for drinking purposes.

Owner:MARMON WATER SINGAPORE

Water supply and drainage pipeline repair technique adopting size film lining method

A water supply and drainage pipeline repair technique adopting a size film lining method comprises the steps of: (1) dredging and cleaning a pipeline; (2) inspecting a pipeline internal observing video; (3) producing a working pit; (4) welding a lining pipe; (5) plugging, deflecting and transferring water to the pipeline; (6) internally pretreating and repairing the pipeline to be repaired; (7) drawing the lining pipe into the pipeline to be repaired; (8) sealing the two ends of the lining pipe and embedding a pipe fitting; (9) filling water into the lining pipe and pressurizing; (10) preparing size and auxiliary vacuum casting; (11) keeping the internal water pressure of the lining pipe, and supplying water again after the size is solidified; (12) videoing the inner side of the pipeline and recording the videos after the repair; and (13) the step 1 to step 12 belong to repair construction, taking every two continuous inspection wells as a construction working segment, constructing towards the upstream and downstream sequentially from the inspection well which is next to the working pit, after completing all the working pipeline segments, laying a new pipeline in the working pit, refilling the soil and compacting to restore the pavement; and the pipeline has long service life, high water flow, fast construction speed, less pollution and small influence to roads.

Owner:杨兵

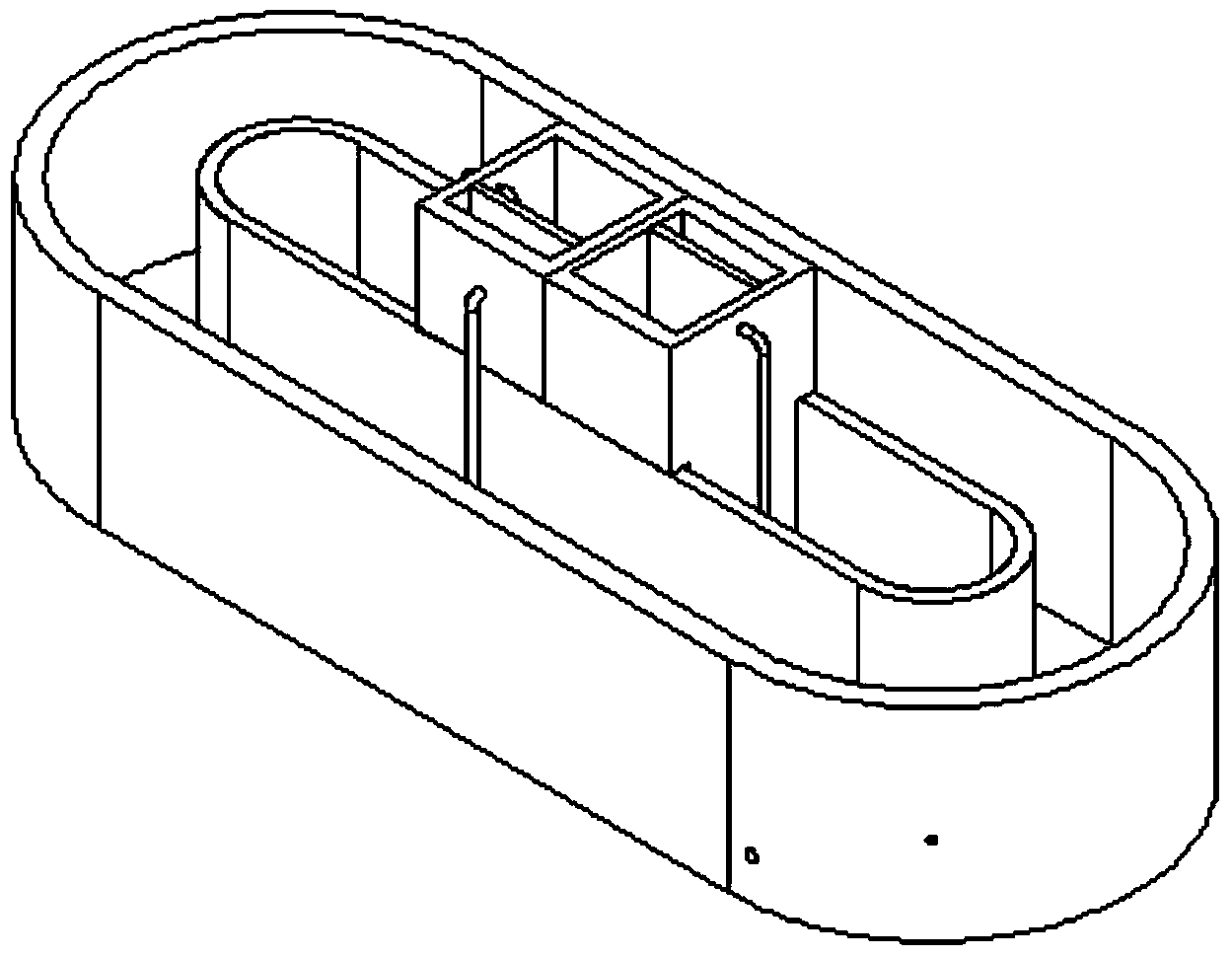

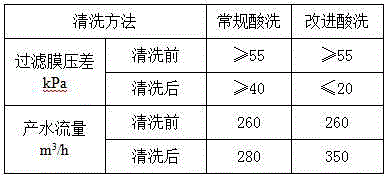

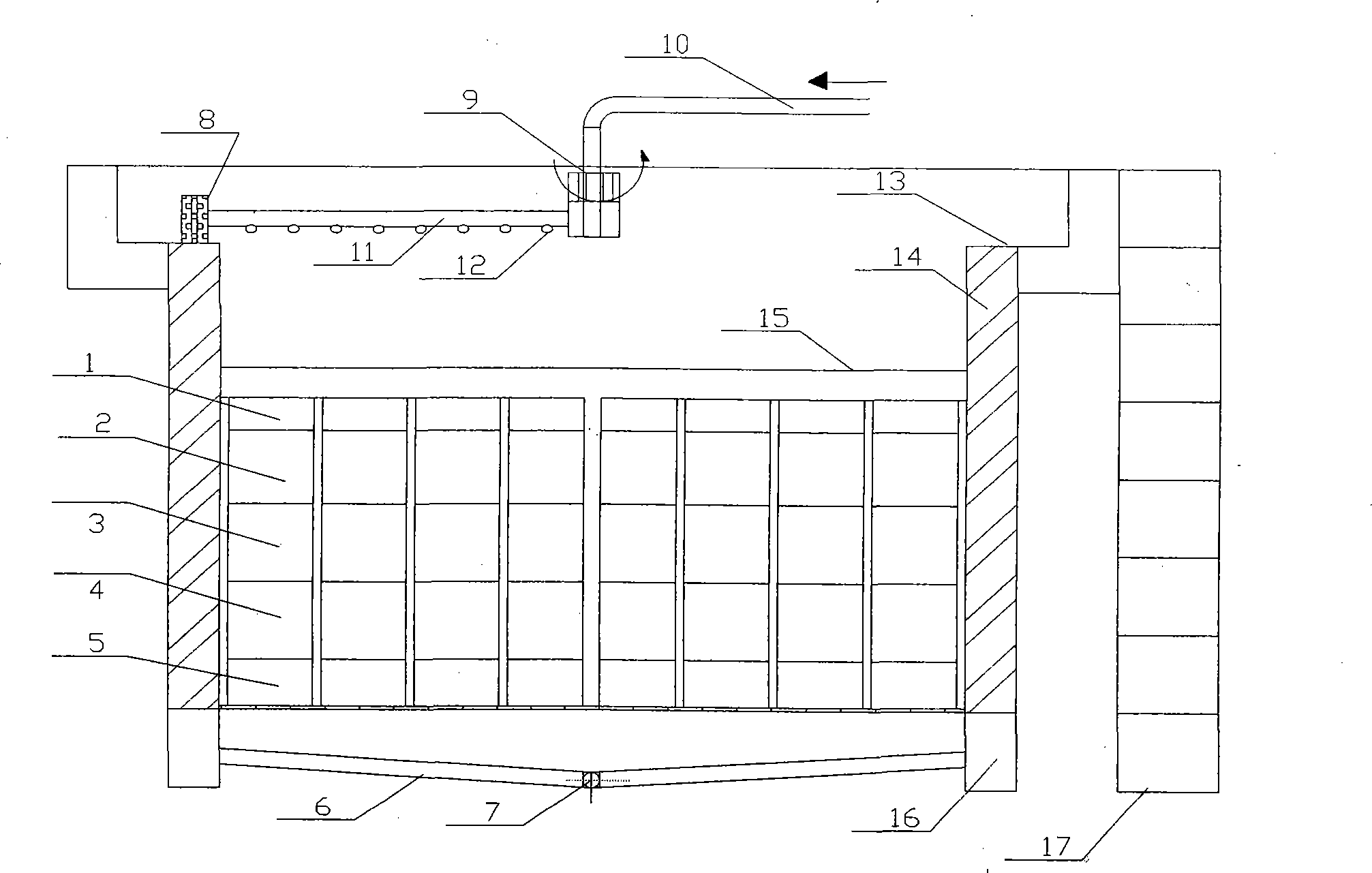

Circuit-type fishpond breeding system integrating circulating water treatment process

The invention relates to a circuit-type fishpond breeding system integrating a circulating water treatment process. The circuit-type fishpond breeding system integrating the circulating water treatment process comprises a fishpond shaped like an annular runway, and sewage treatment systems arranged in an inner ring of the fishpond. Each sewage treatment system comprises a vertical flow type solid-liquid separator (1), wherein a sewage discharging groove (5) perpendicular to the water flow direction is formed in the bottom of the fishpond and communicated with an inlet of the vertical flow type solid-liquid separator (1), an outlet of the vertical flow type solid-liquid separator (1) is communicated with a micro-filtration machine (2), outlet water of the micro-filtration machine (2) adopts a water pump (3) and a water lifting pipe (4) for water lifting and is injected into a biological filter (6), the biological filter (6) is separated from an aeration oxygenation pond (8) through a separation plate and is communicated with the aeration oxygenation pond (8) through a through hole in the lower portion of the separation plate, a water falling pipe (7) is arranged on the lateral wall of the aeration oxygenation pond (8) and communicated with the fishpond, and the water outlet direction at the bottom of the water falling pipe (7) is the same as the water flow direction of the fishpond. The number of the sewage treatment systems is two, and the sewage treatment systems are evenly distributed in the inner ring of the annular fishpond in a central symmetry mode.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

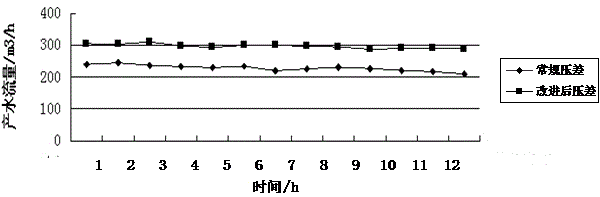

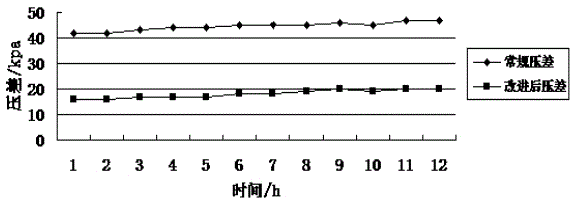

Method for cleaning immersed ultrafiltration membrane in wastewater reuse

ActiveCN103949163AGood water flowGood operating differential pressureSemi-permeable membranesOXALIC ACID DIHYDRATEUltrafiltration

The invention discloses a method for cleaning an immersed ultrafiltration membrane in wastewater reuse. The method comprises the following step of chemical cleaning. The method is characterized in that the step of chemical cleaning comprises the following substeps of alkali cleaning, acid cleaning or combined alkali cleaning and acid cleaning, wherein each of the alkali cleaning method and the acid cleaning method is of a method combining the circulatory cleaning with the immersed cleaning, and an alkali cleaning agent comprises sodium hypochlorite, sodium dodecyl benzene sulfonate and sodium tripolyphosphate; an acid cleaning agent comprises citric acid, hydrochloric acid and oxalic acid. The method has the advantages that sodium dodecyl benzene sulfonate and sodium tripolyphosphate are added in the process of alkali cleaning by sodium hypochlorite, so that the cleaning effect of the method on ultrafiltration organic matters and oil pollutants is obviously better than that of a normal alkali cleaning method, the polluting and plugging degree of the cleaned ultrafiltration membrane can be reduced, and stability in operation can be realized; the acid cleaning is adopted as required after alkali cleaning, and the oxalic acid agent is added in the process of acid cleaning, so that the ultrafiltration membrane can be thoroughly cleaned, and the produced water flow and the running differential pressure of the ultrafiltration membrane can be recovered to be the optimal effect.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

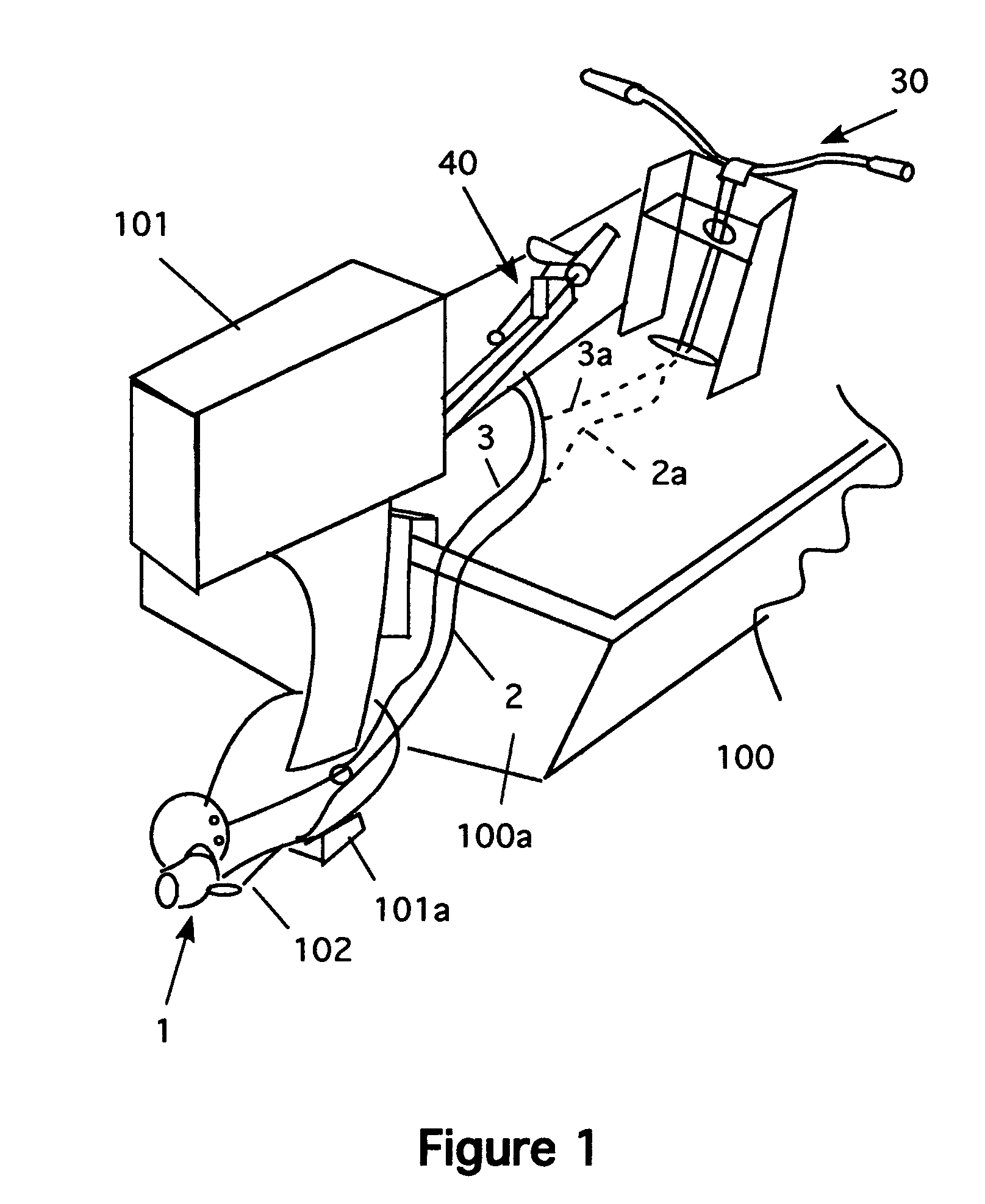

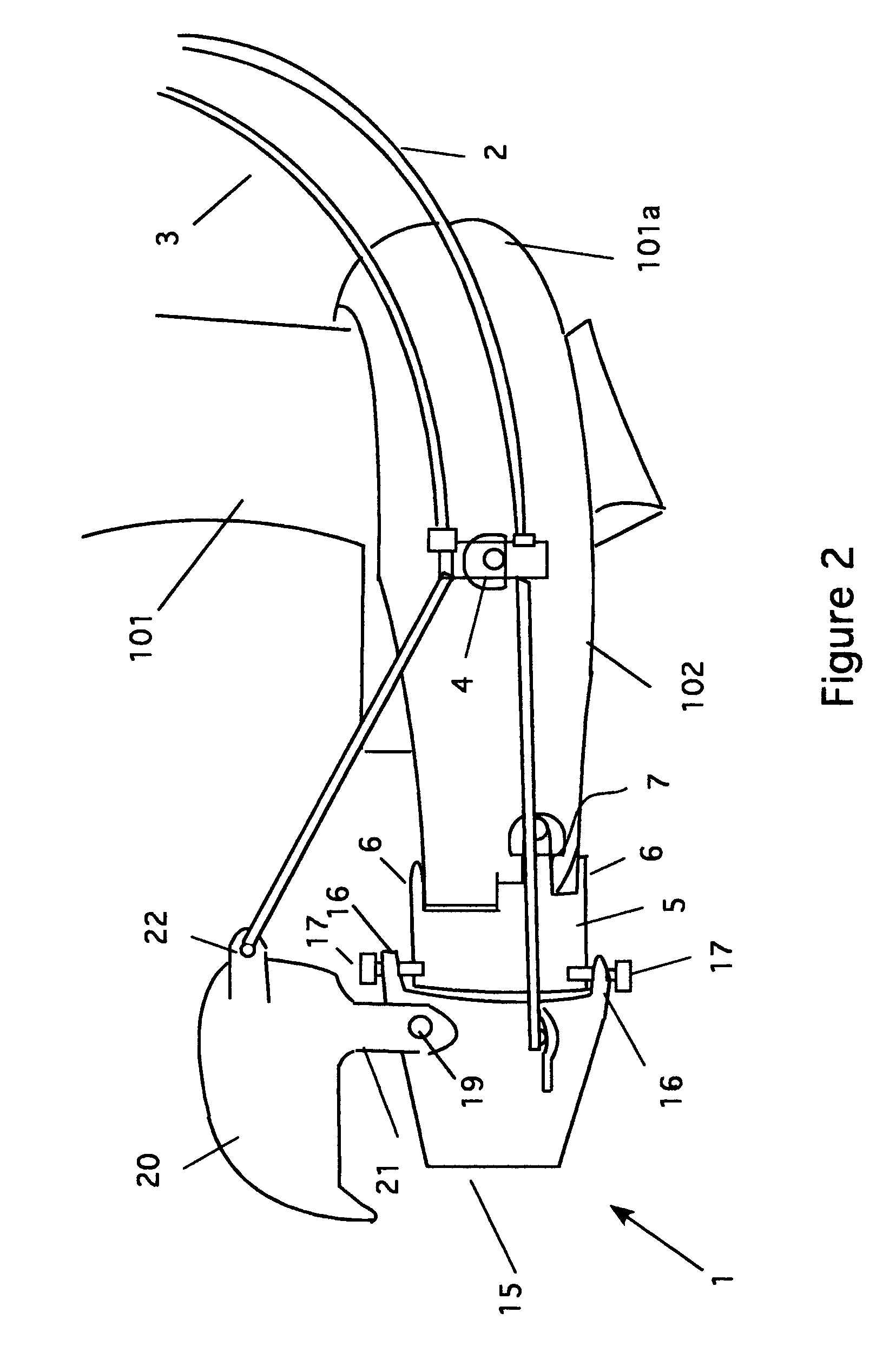

Jet powered steering system for small boat outboard motors

InactiveUS7476134B1Steering response is fastSteering control is minimizedPropulsion power plantsOutboard propulsion unitsCombined useElectric cables

A directional nozzle for the jet output that is attached to a control cable system. This cable turns the directional nozzle, which causes the trust of the jet output to turn the boat. Thus, the boat can be steered without having to turn the entire motor. Two different mechanisms are disclosed that enable the steering. The first is a tiller system that operates much like the traditional tiller on an outboard motor. However, unlike those tillers, this tiller operates the directional nozzle and does not turn the entire motor. The second mechanism is a bicycle handlebar system that is placed forward of the motor, much like a traditional wheel. The handlebar system, when combined with the directional nozzle system, produces faster steering response without the effort required to turn the wheel to make large sweeping turns.

Owner:FELL WILLIAM P +1

Indirect-direct evaporative cooling system operable from sustainable energy source

InactiveUS20060000227A1Reduce power consumptionReduce the amount requiredFree-cooling systemsStationary conduit assembliesPower gridImproved method

Improved means for powering and increasing evaporative cooling in an indirect-direct evaporative cooling (IDEC) apparatus are disclosed. Sustainable energy from solar energy mixed with grid power, when needed, power the IDEC device. These DC and AC power sources are seamlessly merged in a unique diode interconnect unit. Improved means for evaporative cooling include a rayon-based flocking on the wet side of molded plastic indirect evaporative cooling plates. Separate wet and dry passages through those plates are facilitated by a unique means for clamping the upper ends of the plates. These clamping means also add to the structural integrity of an array of plates so that the array can be inserted in and removed from a housing containing other operational components of the IDEC such as fan, direct cooling plates and water distribution means. Applicants IDEC utilizes improved porous piping that allows uniform and continuous distribution of water to all wet passages within both the indirect and direct stages of the IDEC. Operational controls for the system limit the potential water damage caused by overflow of water from the IDEC housing.

Owner:SPEAKMAN

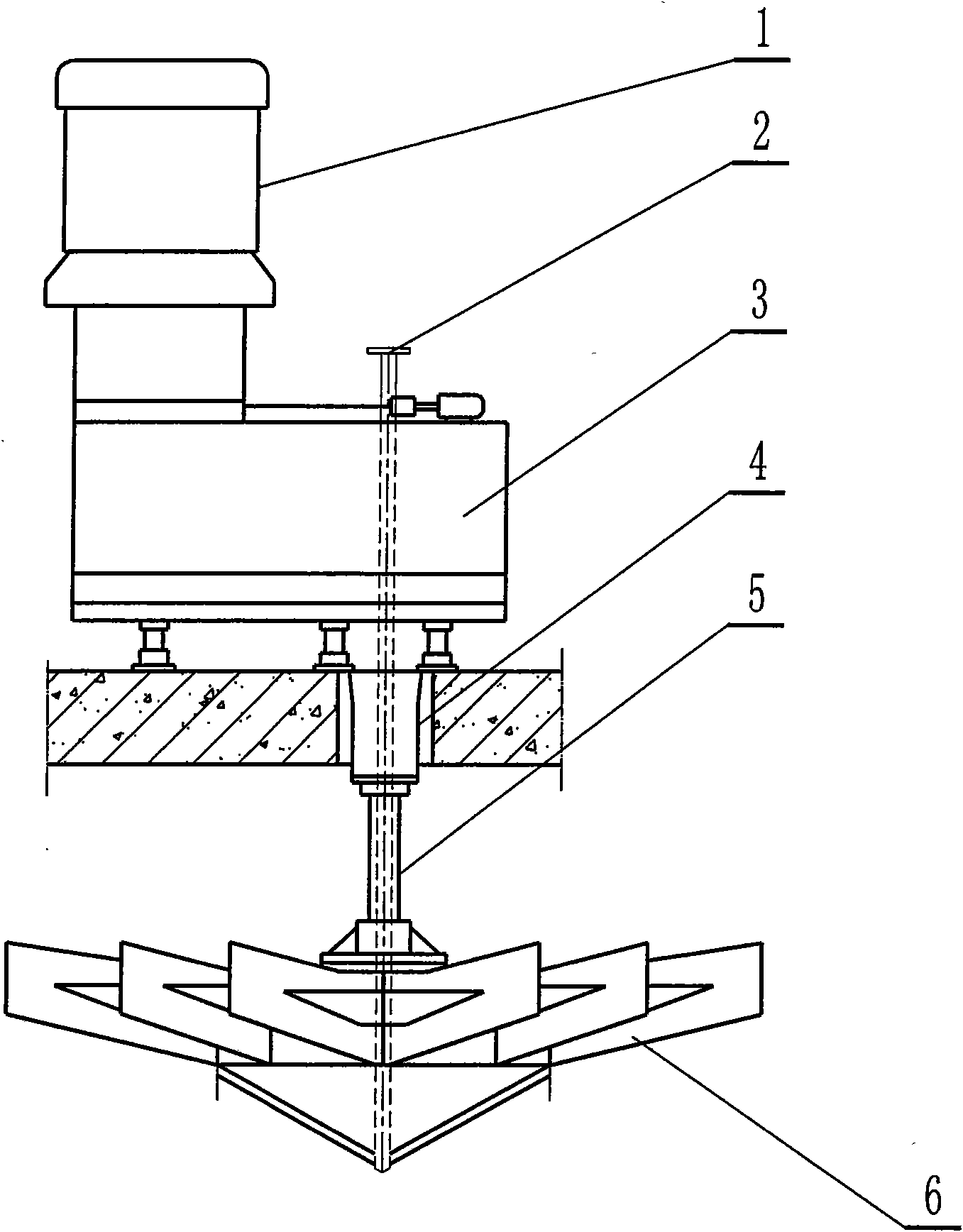

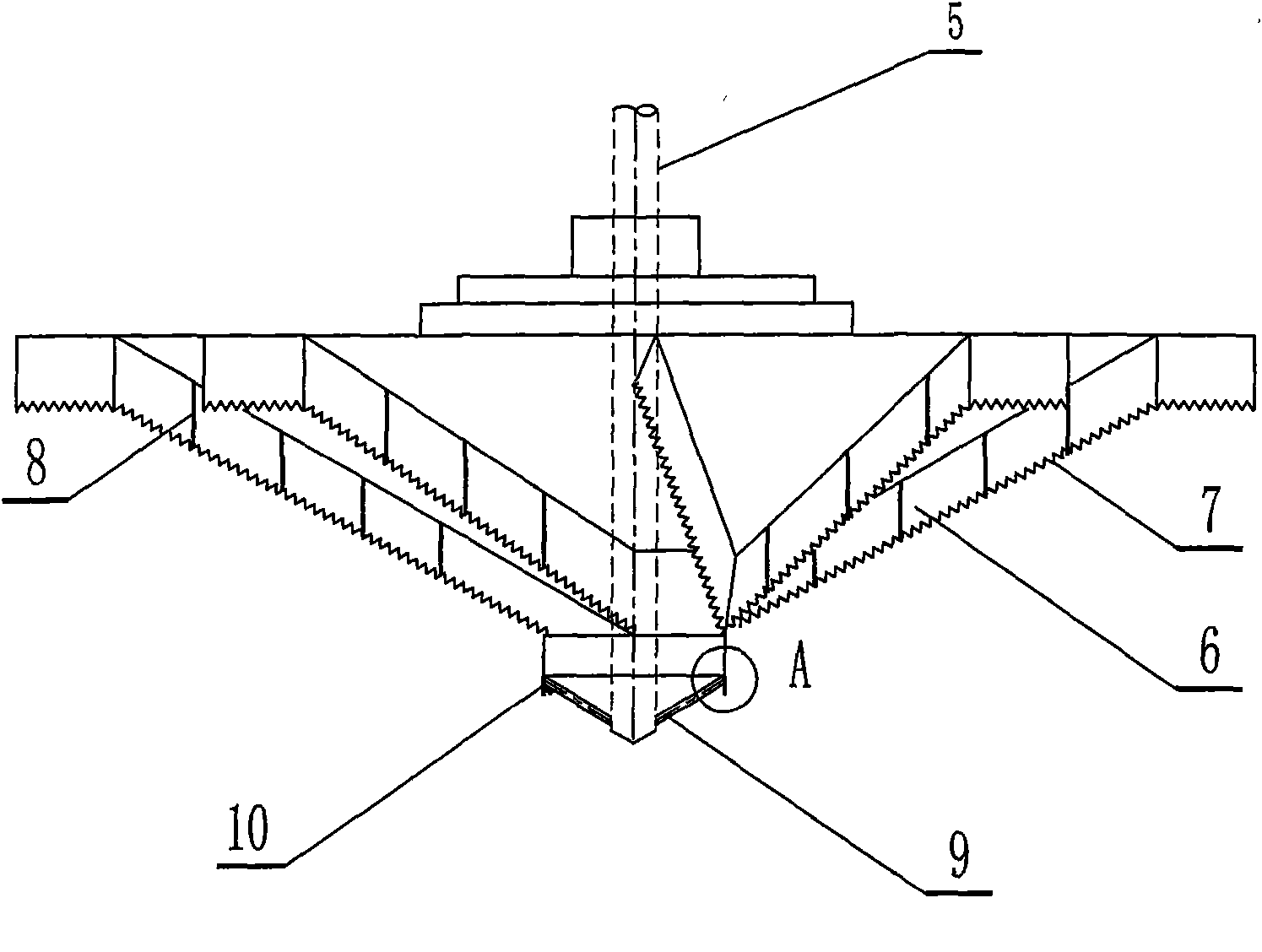

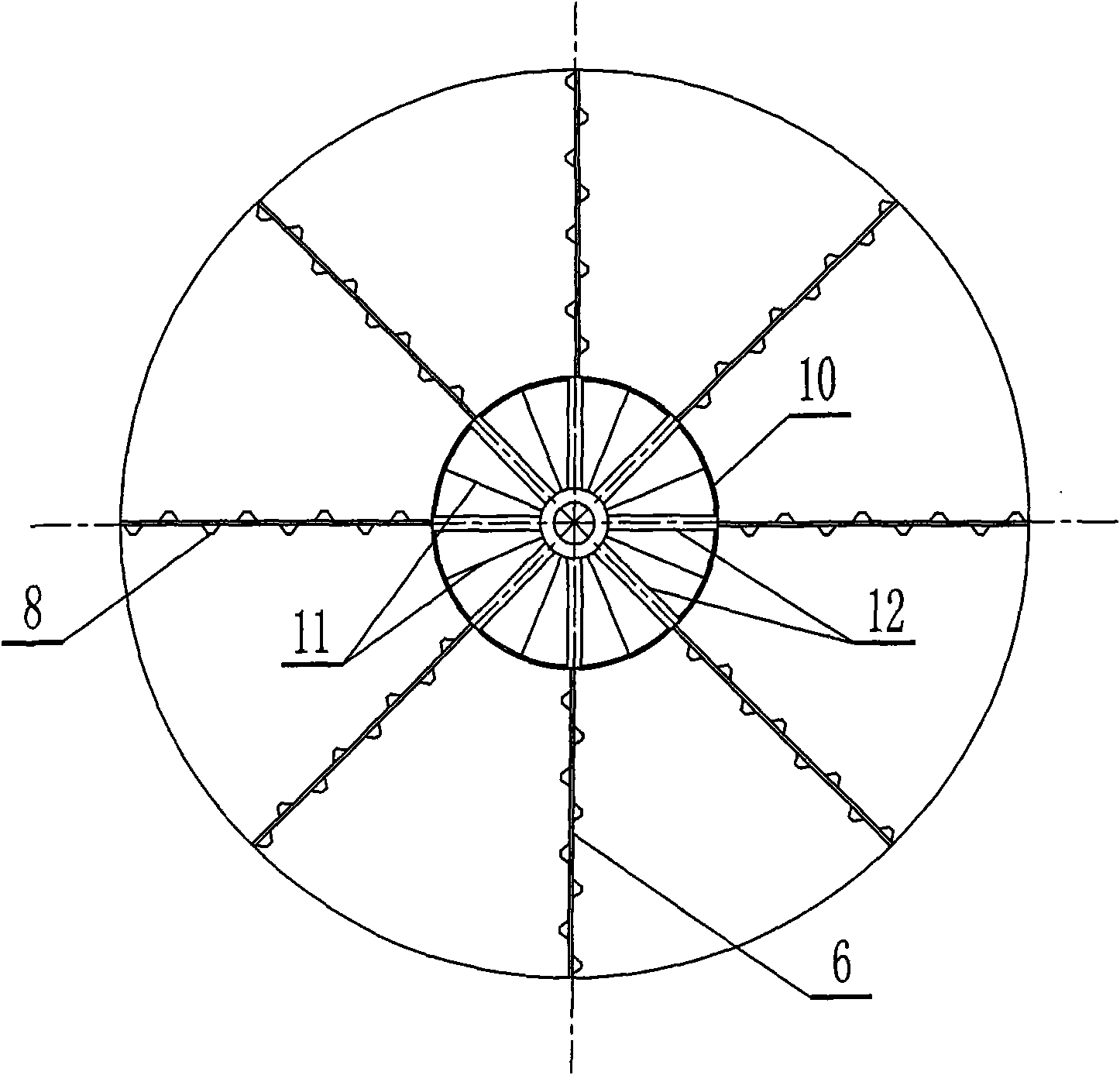

Inverted umbrella-shaped aeration machine

InactiveCN101624232ALow powerHigh oxygenationSustainable biological treatmentBiological water/sewage treatmentImpellerMicro bubble

The invention relates to improvement on an inverted umbrella-shaped aeration machine of a surface aeration apparatus for sewage treatment. The inverted umbrella-shaped aeration machine is characterized in that a rotary shaft is in a hollow structure, and at least the aeration is carried out in the water through an air distributing tube or a micropore aeration device in a terminal area, so that the inverted umbrella-shaped aeration machine is oxygenated by the swathed air generating whirl through rotation and oxygenates water by more air forcibly injected air, and the injected air is rotated through an impeller to stir and cut bubbles aerated into the water, particularly, the bubbles are cut through a sawtooth to ensure that the bubbles are finer to form micro-bubbles, thereby greatly improving the oxygenate capacity and the dissolved oxygen concentration of the inverted umbrella-shaped aeration machine and the deep oxygenation of the water body.

Owner:LINGZHI ENVIRONMENTAL PROTECTION CO LTD +2

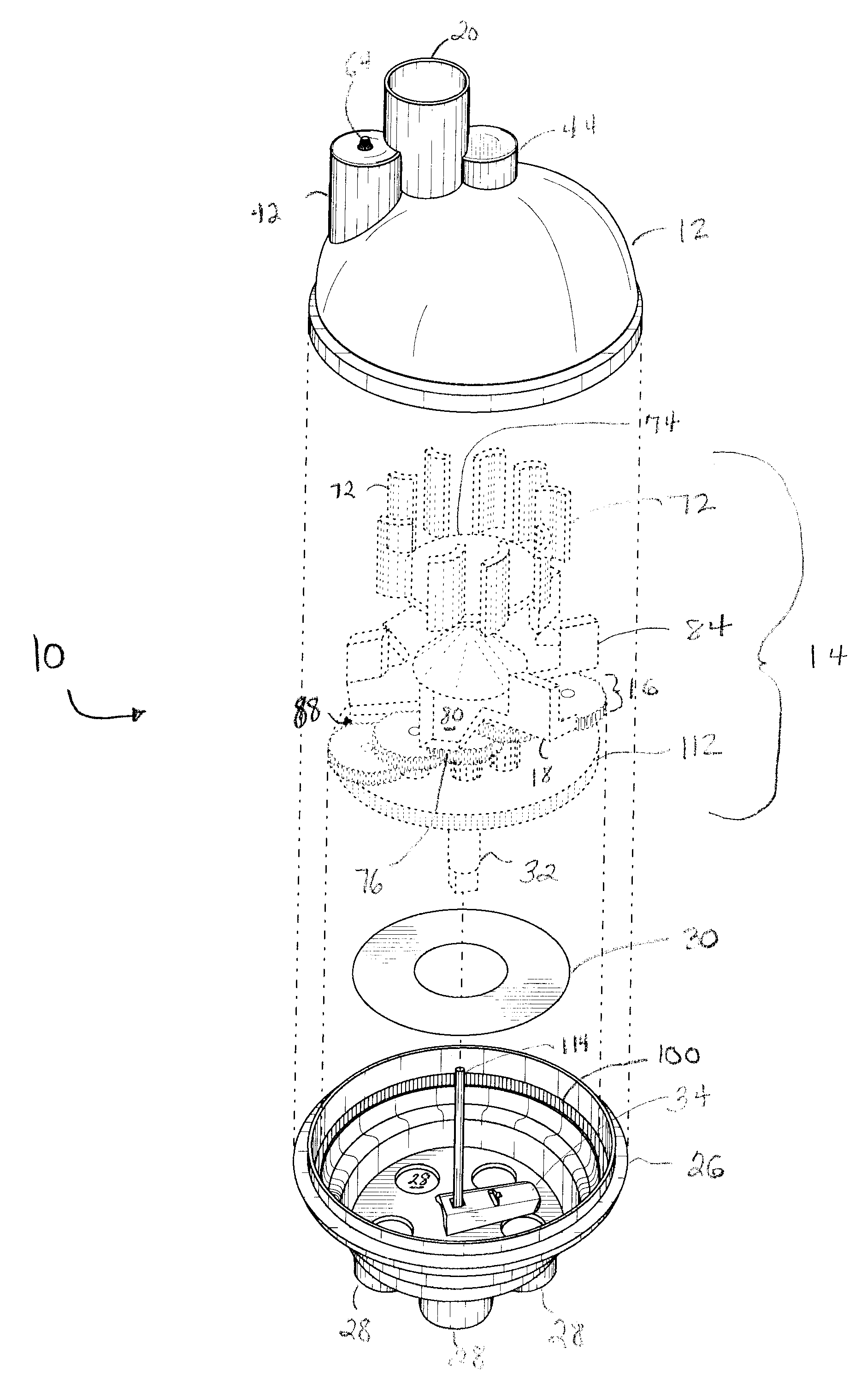

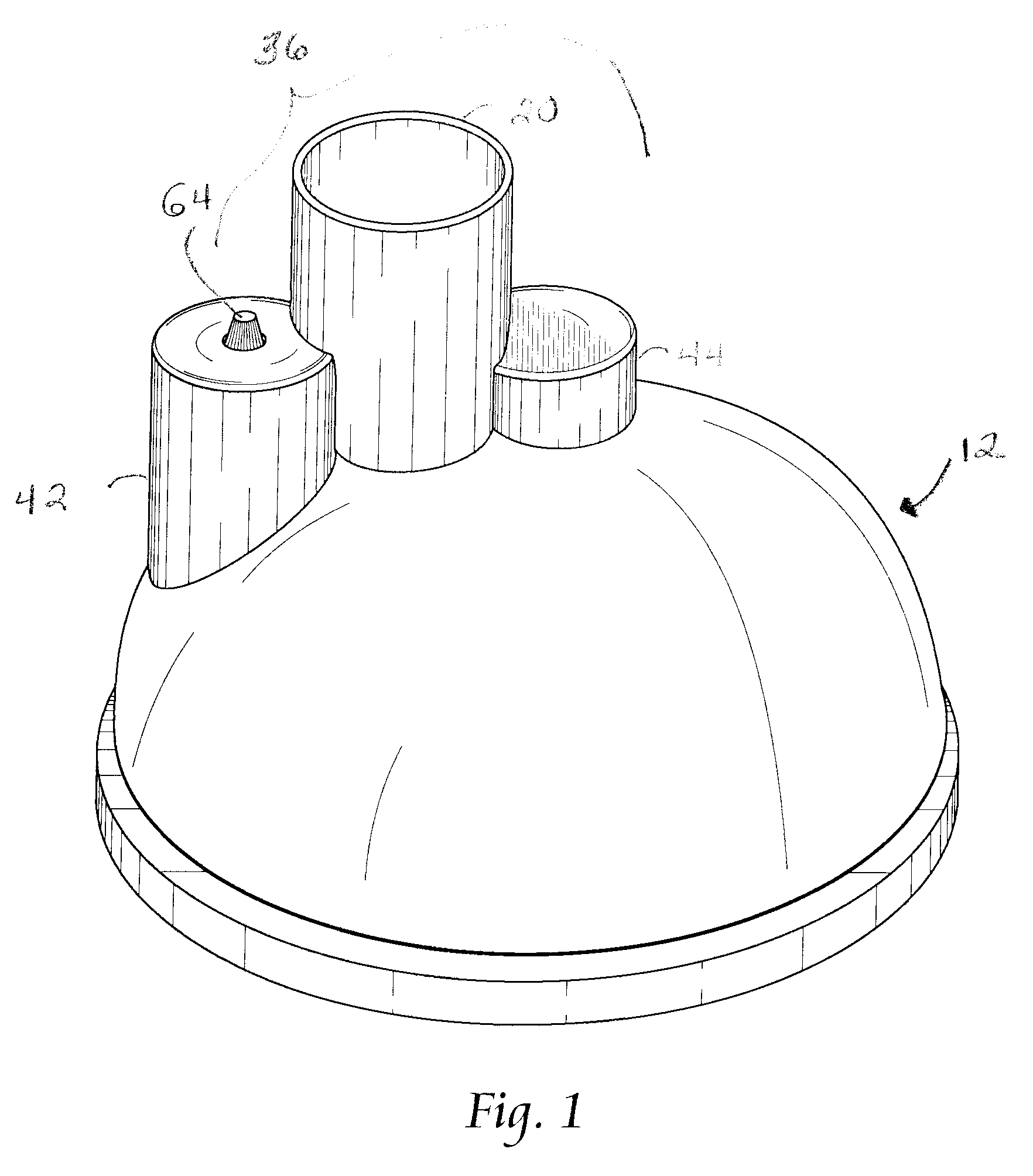

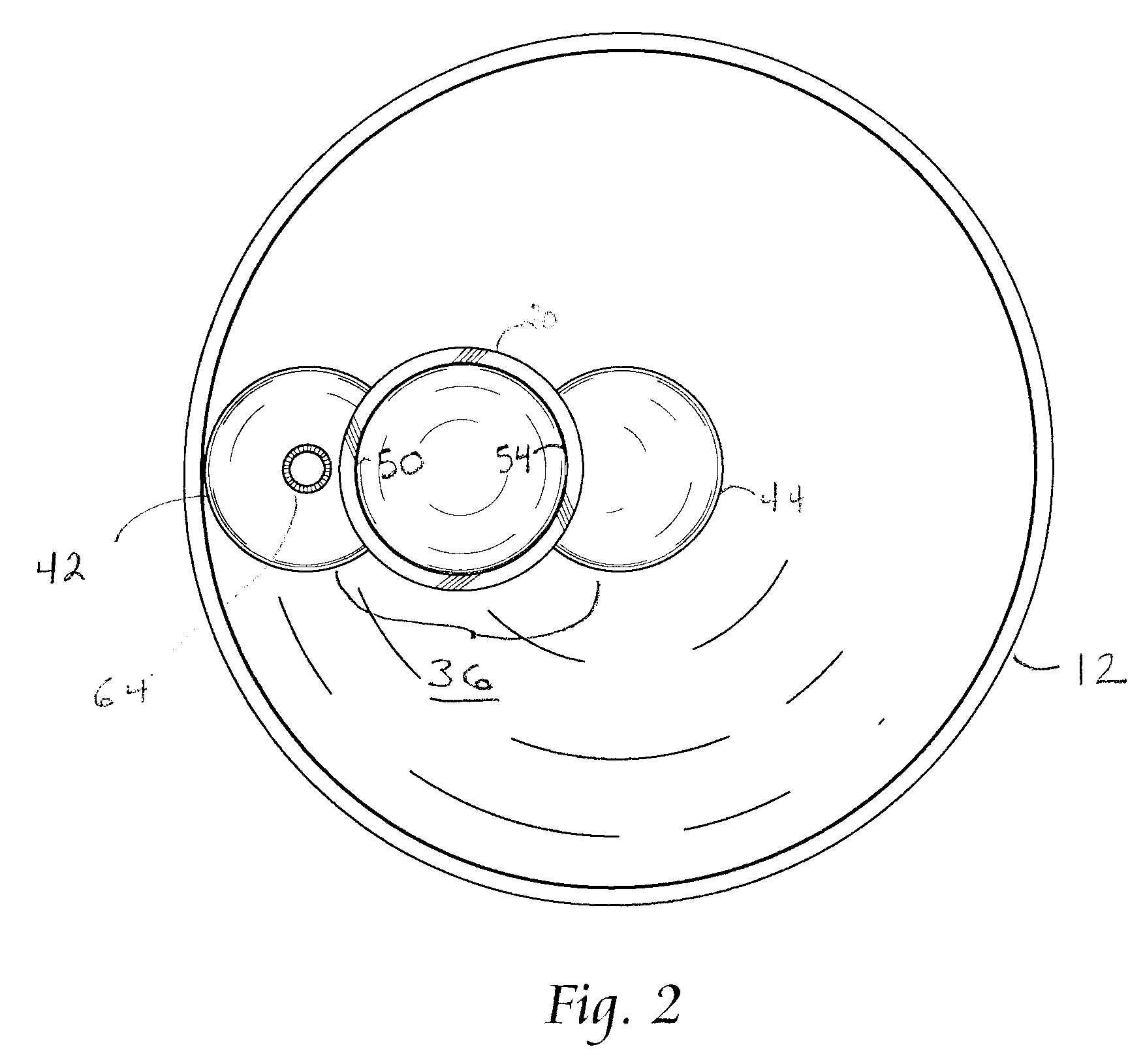

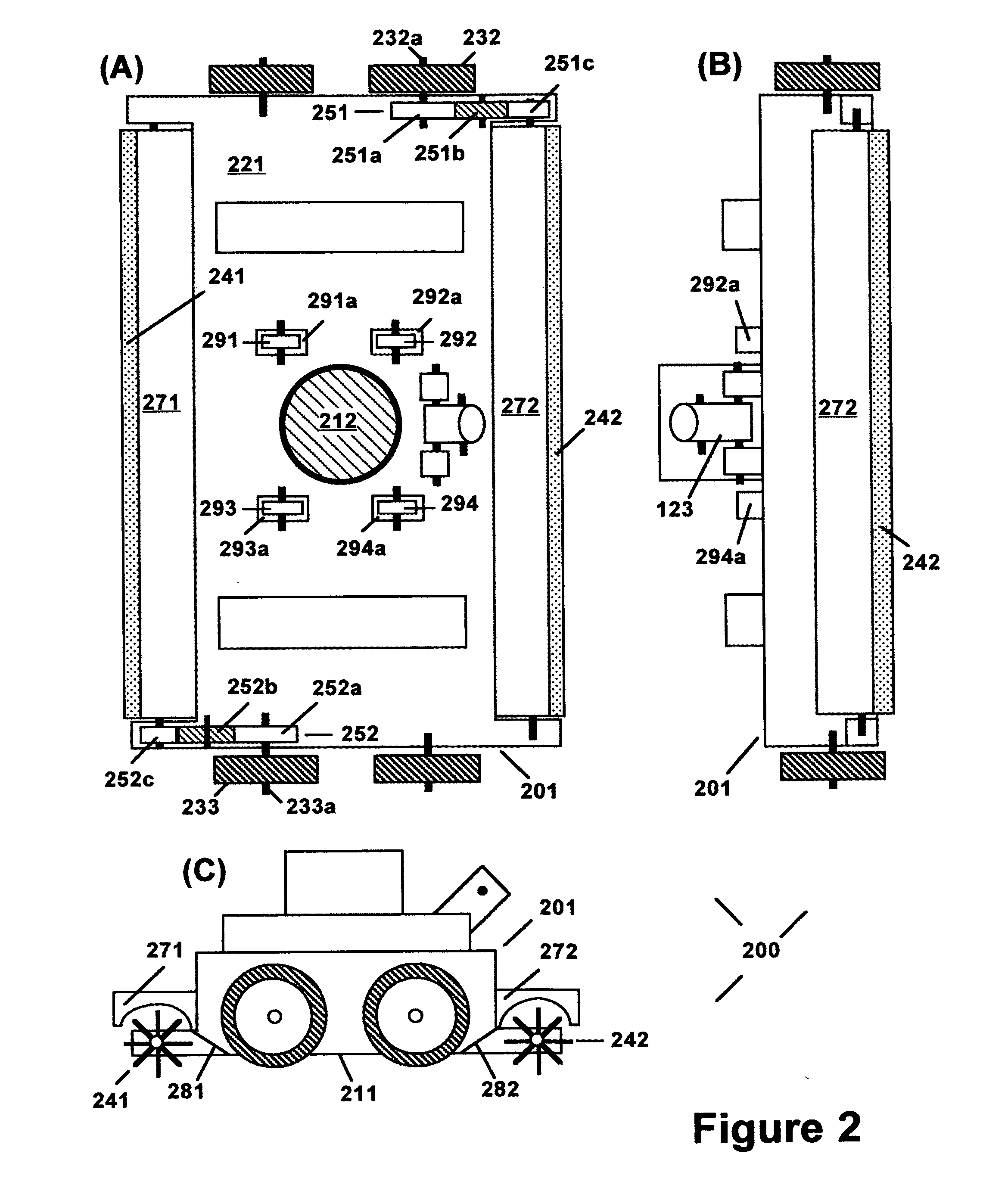

Distribution valve and method

InactiveUS20090211641A1Reduce maintenanceReduce repair costsOperating means/releasing devices for valvesMultiple way valvesImpellerWater flow

An improved distribution valve is provided that distributes water from a swimming pool pump to cleaning heads located along the inner surface of a swimming pool. The distribution valve includes a housing having a fluid inlet and a plurality of fluid outlet ports. The housing includes a lower section and a removable upper section. A gear reduction assembly located in the housing includes a gear reduction mechanism and impeller located near the inlet port and connected to a rotary input shaft of the gear reduction mechanism. A cam device engages a rotary output shaft of the gear reduction mechanism so as to rotate the cam device in response to rotation of the impeller. The cam device rotates under a pliable annular disc on the rotary output shaft and lifts and lowers portions of the annular disc to sequentially open and close fluid paths through the fluid outlet ports.The improved distribution valve may include a bypass chamber with a rotatable drum therein and a diffusion chamber in fluid communication with the fluid inlet. The drum wall includes a cutout. The drum is rotatable to fully or partially align the cutout with a bypass chamber inlet to permit water flow through the bypass chamber to help rotate the impeller. The impeller speed may be controlled by adjusting the water flow through the bypass chamber. The more water flow, the faster the impeller rotates. The drum is also rotatable to block the bypass chamber inlet to prevent water flow through the bypass chamber, in which case water from the diffusion chamber rotates the impeller. Impeller rotation will be at a slower speed due to the decreased water flow.

Owner:TIPOTSCH DONALD

Indirect-direct evaporative cooling system operable from sustainable energy source

InactiveUS20070017241A1Reduce the amount requiredImprove cooling effectFree-cooling systemsStationary conduit assembliesPower gridProcess engineering

Improved means for powering and increasing evaporative cooling in an indirect-direct evaporative cooling (IDEC) apparatus are disclosed. Sustainable energy from solar energy mixed with grid power, when needed, power the IDEC device. These DC and AC power sources are seamlessly merged in a unique diode interconnect unit. Improved means for evaporative cooling include a rayon-based flocking on the wet side of molded plastic indirect evaporative cooling plates. Separate wet and dry passages through those plates are facilitated by a unique means for clamping the upper ends of the plates. These clamping means also add to the structural integrity of an array of plates so that the array can be inserted in and removed from a housing containing other operational components of the IDEC such as fan, direct cooling plates and water distribution means. Applicants IDEC utilizes improved porous piping that allows uniform and continuous distribution of water to all wet passages within both the indirect and direct stages of the IDEC. Operational controls for the system limit the potential water damage caused by overflow of water from the IDEC housing.

Owner:SPEAKMAN

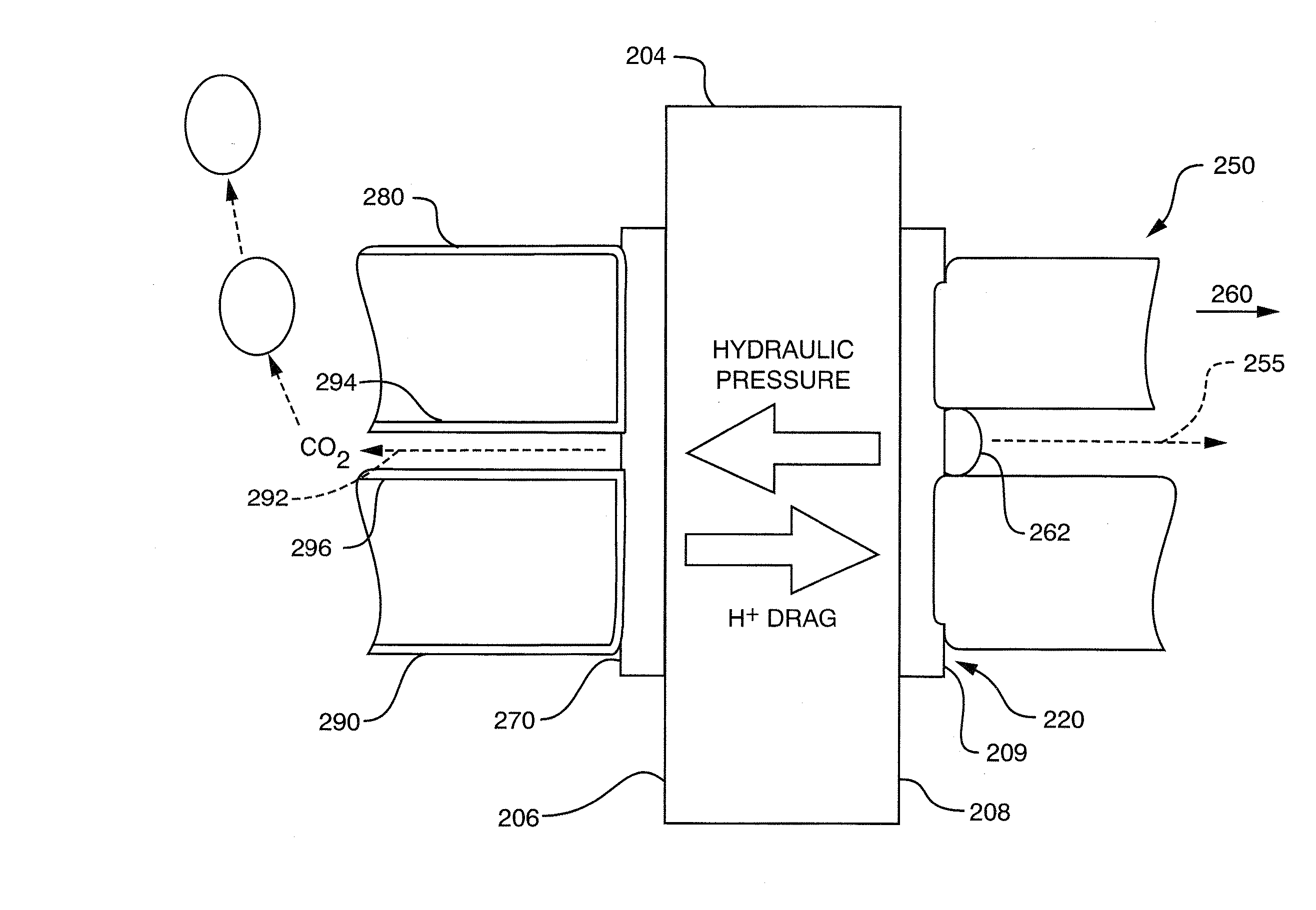

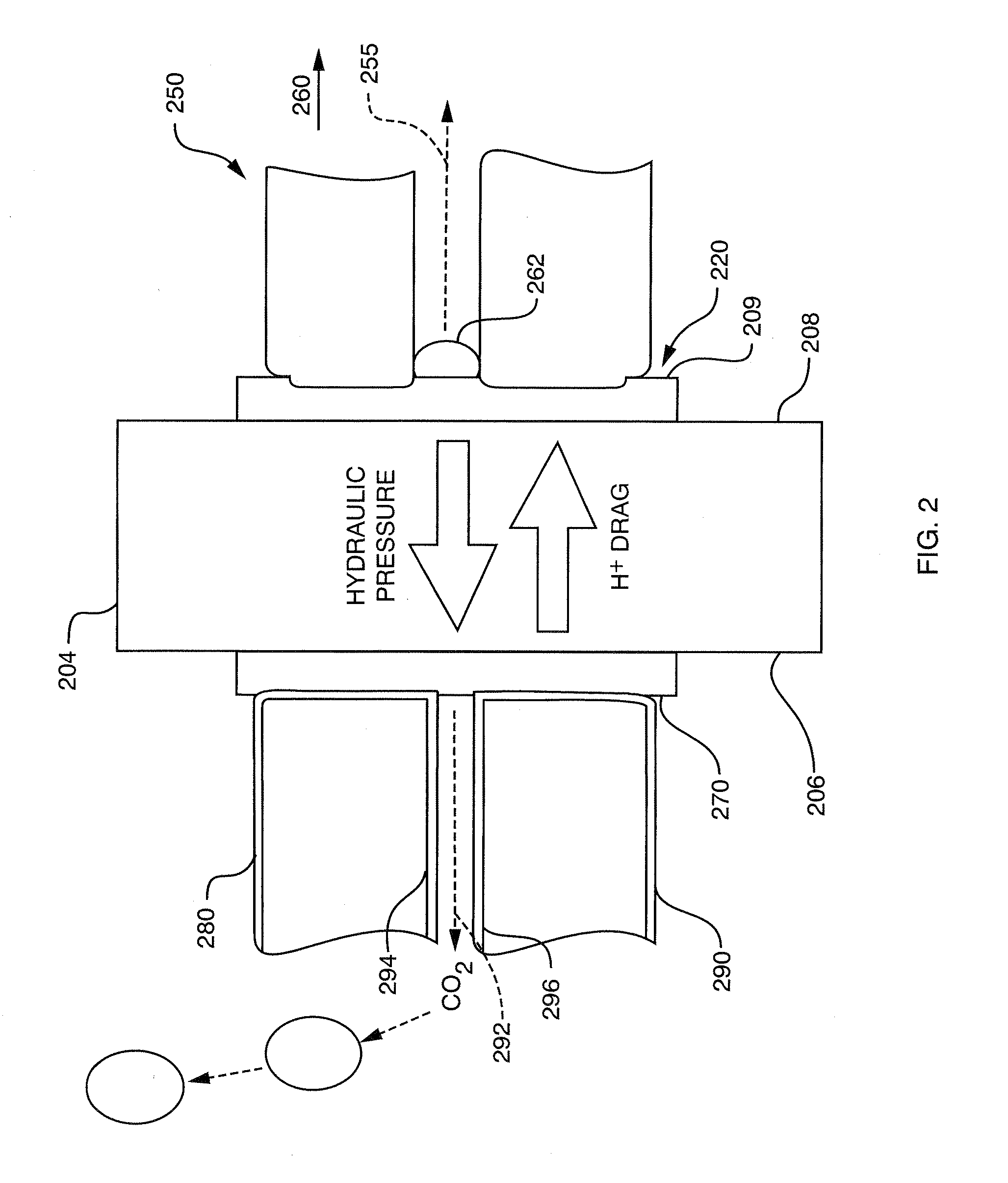

Passive water management techniques in direct methanol fuel cells

InactiveUS20080032182A1Neat, or highly concentrated methanol fuel supplyOvercome disadvantagesWater management in fuel cellsActive material electrodesWater vaporLiquid water

Passive water management techniques are provided in an air-breathing direct oxidation fuel cell system. A highly hydrophobic component with sub-micrometer wide pores is laminated to the catalyzed membrane electrolyte on the cathode side. This component blocks liquid water from traveling out of the cathode and instead causes the water to be driven through the polymer membrane electrolyte to the cell anode. The air-breathing direct oxidation fuel cell also includes a layer of cathode backing and additional cathode filter components on an exterior aspect of the cell cathode which lessen the water vapor escape rate from the cell cathode. The combination of the well laminated hydrophobic microporous layer, the thicker backing and the added filter layer, together defines a cathode structure of unique water management capacity, that enables to operate a DMFC with direct, controlled rate supply of neat (100%) methanol, without the need for any external supply or pumping of water. The cell anode is provided with a hydrophilic backing layer. When the water is driven through the polymer membrane electrolyte from the cell cathode to the cell anode chamber, it is available for the anodic reaction, and any excess water is carried out along CO2 ventilation channels to the outside environment.

Owner:MTI MICROFUEL CELLS

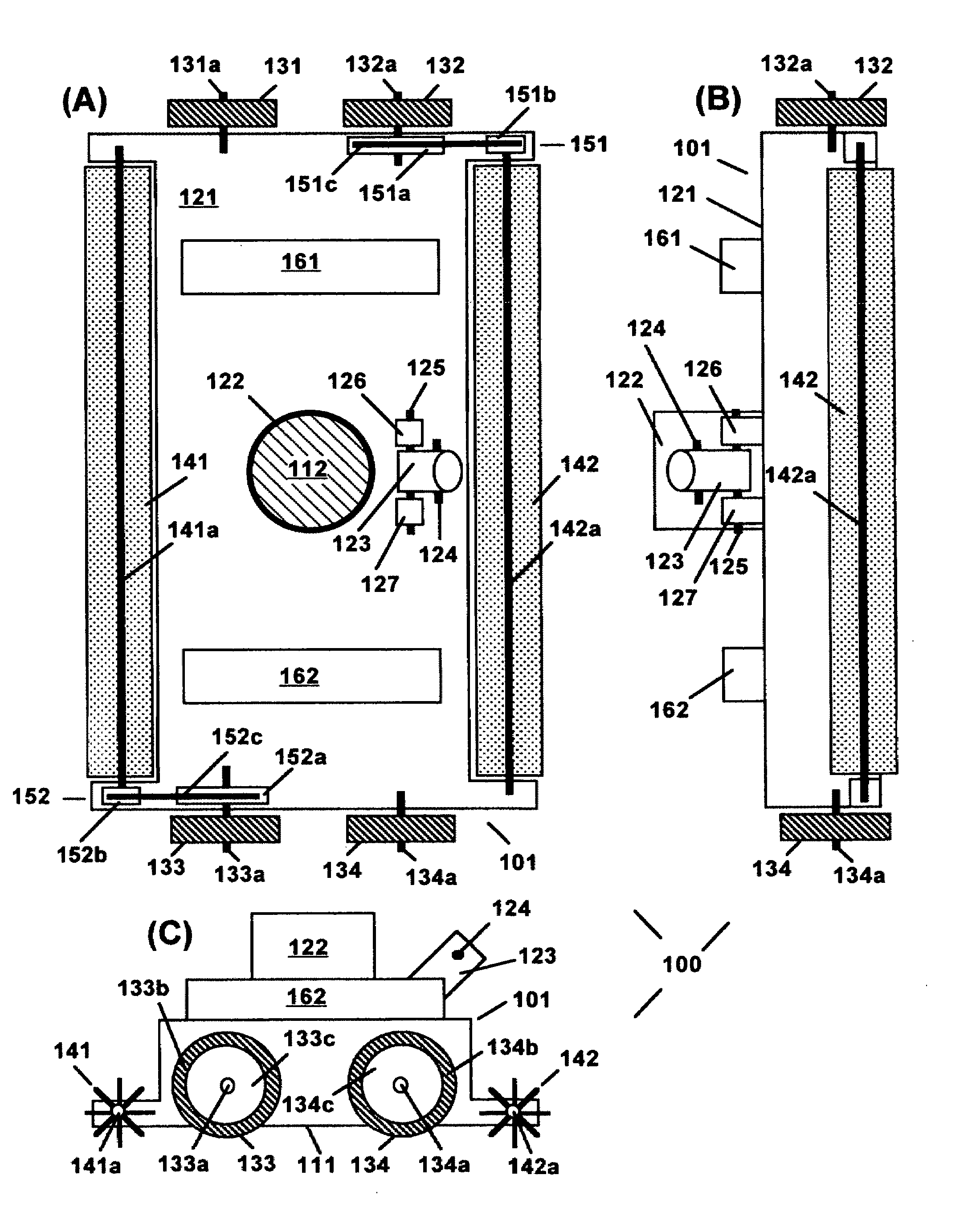

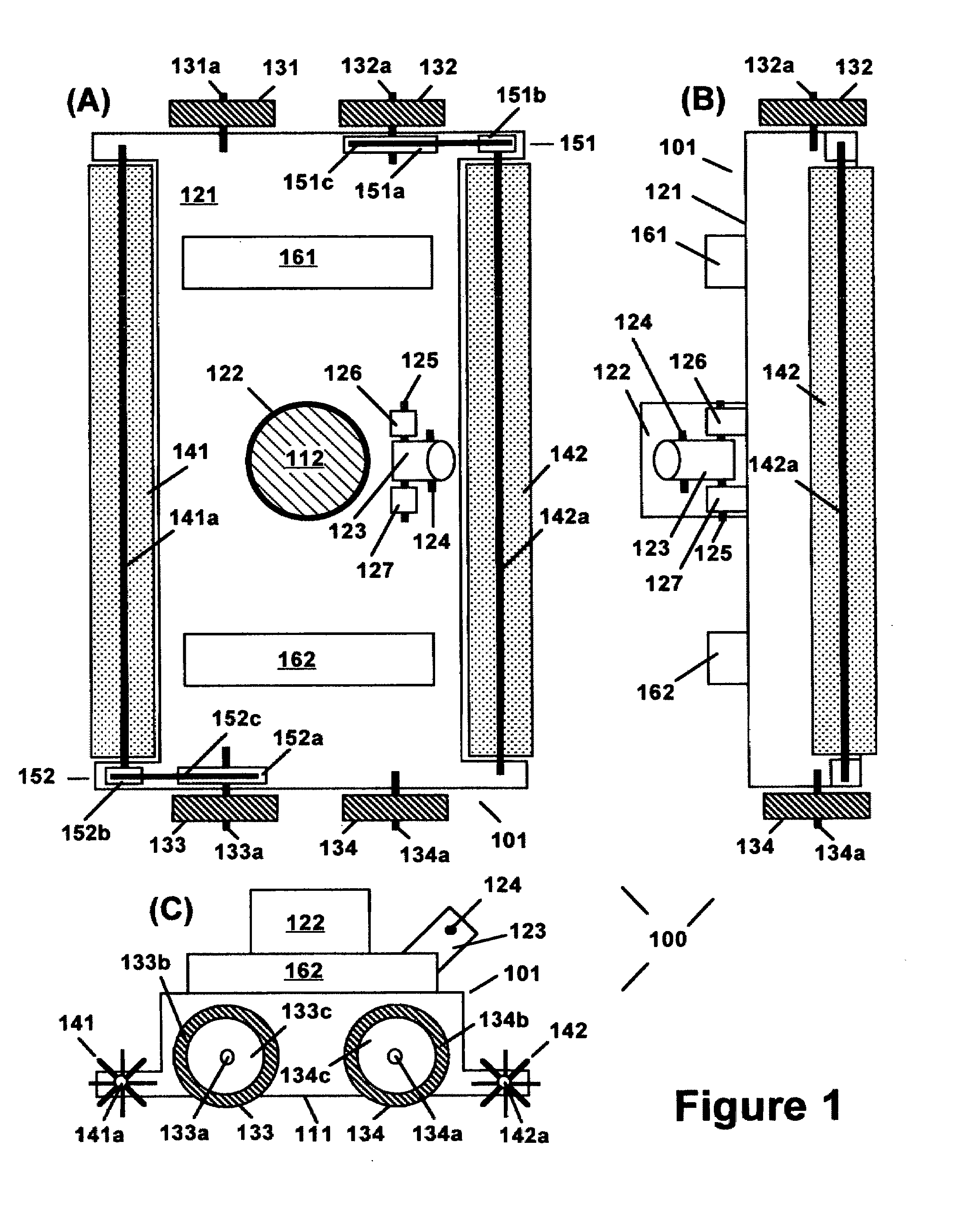

Swimming pool cleaning device

ActiveUS20100299863A1Easy to captureMinimize the possibilityCleaning filter meansSuction filtersLeading edgeMarine engineering

The swimming pool cleaner of the invention is a suction device comprising a rectangular housing, at least four wheels enabling the device to be manually rolled along the swimming pool bottom with the long sides perpendicular to the direction of motion, and two cylindrical rotary brushes adjacent and parallel to opposing long sides of the housing and driven by rotation of the device wheels. Tree leaves and other debris are effectively captured due to a downward sweeping action produced by rotation of the cylindrical rotary brush on the leading edge as the cleaning device, connected to a suction means, is rolled back and forth over the swimming pool bottom by an operator pulling and pushing on a pole attached to the top of the housing. The performance of the device is enhanced via fenders that wrap around the tops of the rotary brushes, and inclusion of various housing bottom features.

Owner:DEWING DAVID

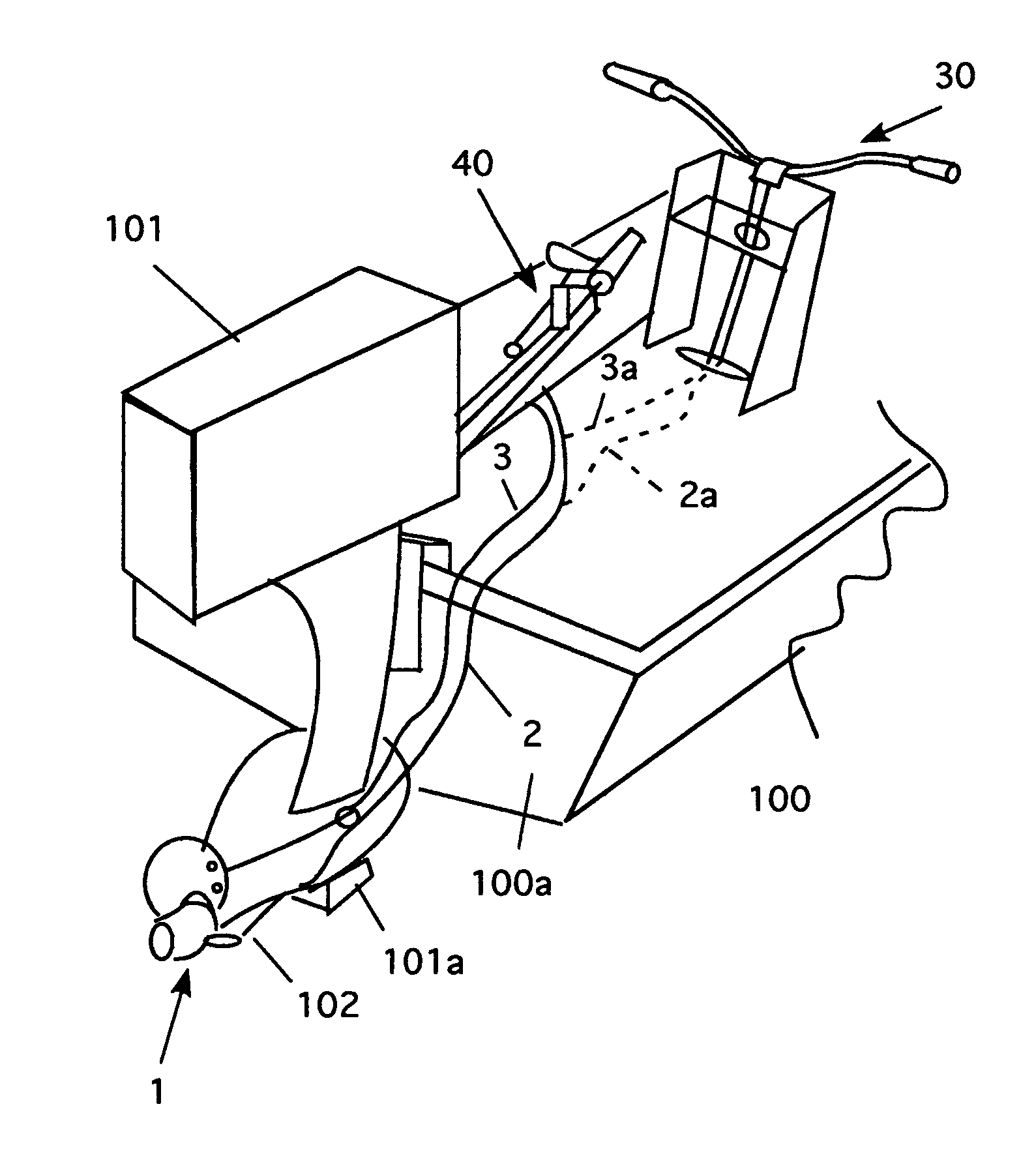

Joy stick control system for a modified steering system for small boat outboard motors

InactiveUS6942531B1Steering response is fastSteering control is minimizedPropulsion power plantsOutboard propulsion units

A joystick controller for modified steering system for boats with outboard motors. The system uses a directional nozzle for the jet output that is attached to a control cable system. This cable turns the directional nozzle, which causes the trust of the jet output to turn the boat. Thus, the boat can be steered without having to turn the entire motor. The system also has a reversing cup to change direction. The system uses a joystick that connects to a set of actuators, which in turn, connect to the directional nozzle, reverse cup and throttle. In this way, the joystick can control the movement of the boat in any direction. The joystick can be used with a conventional motor as well.

Owner:FELL WILLIAM P +1

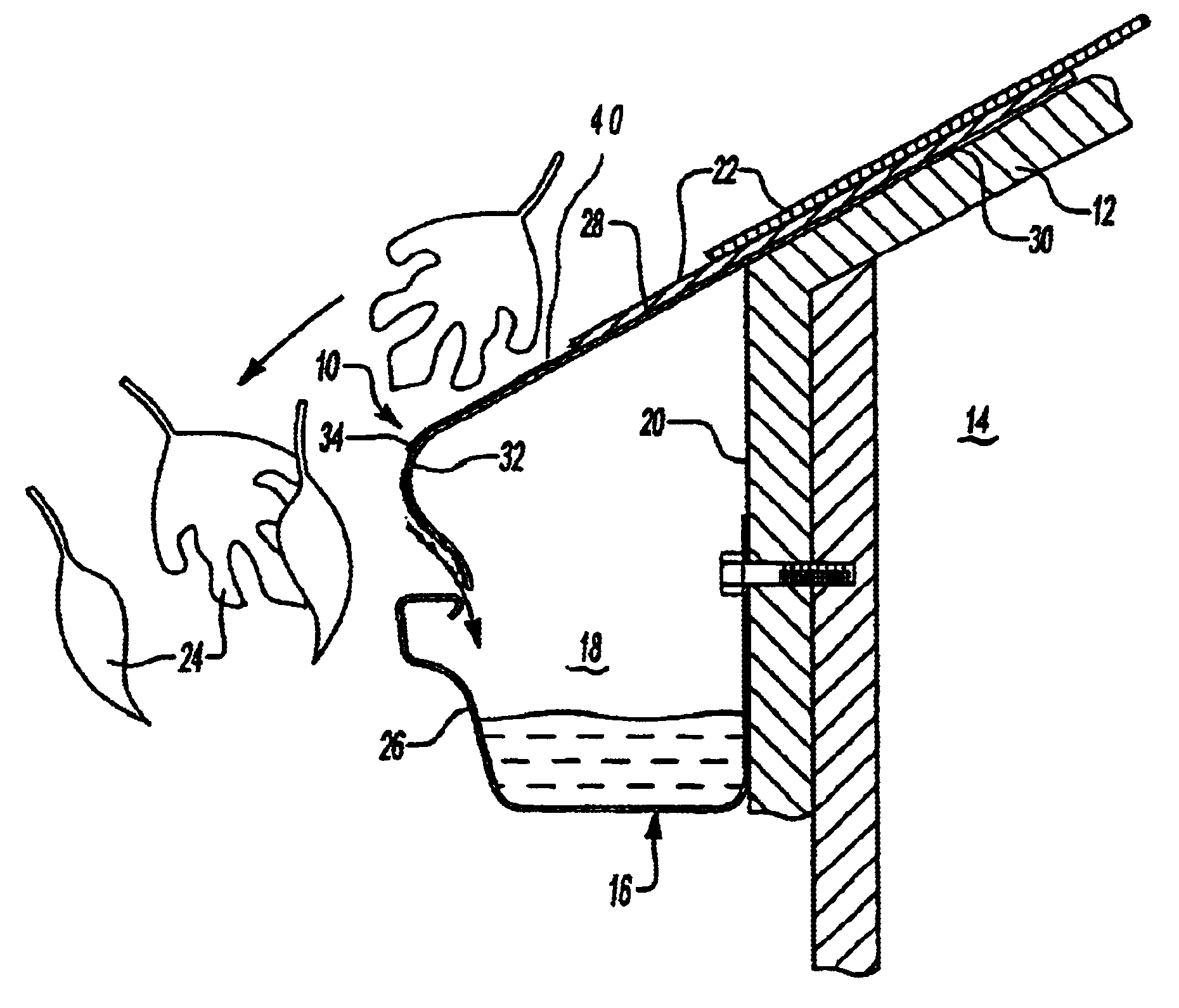

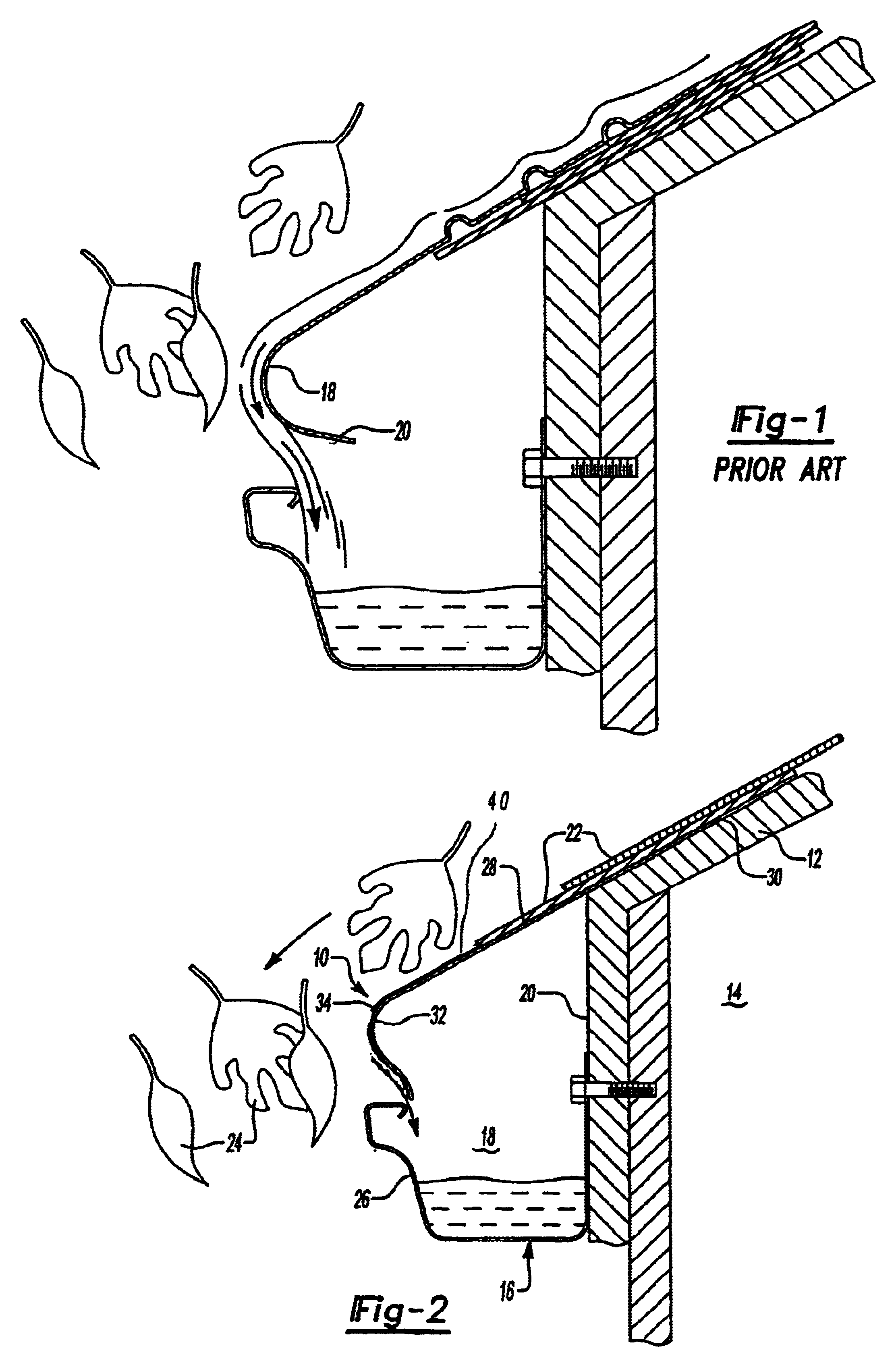

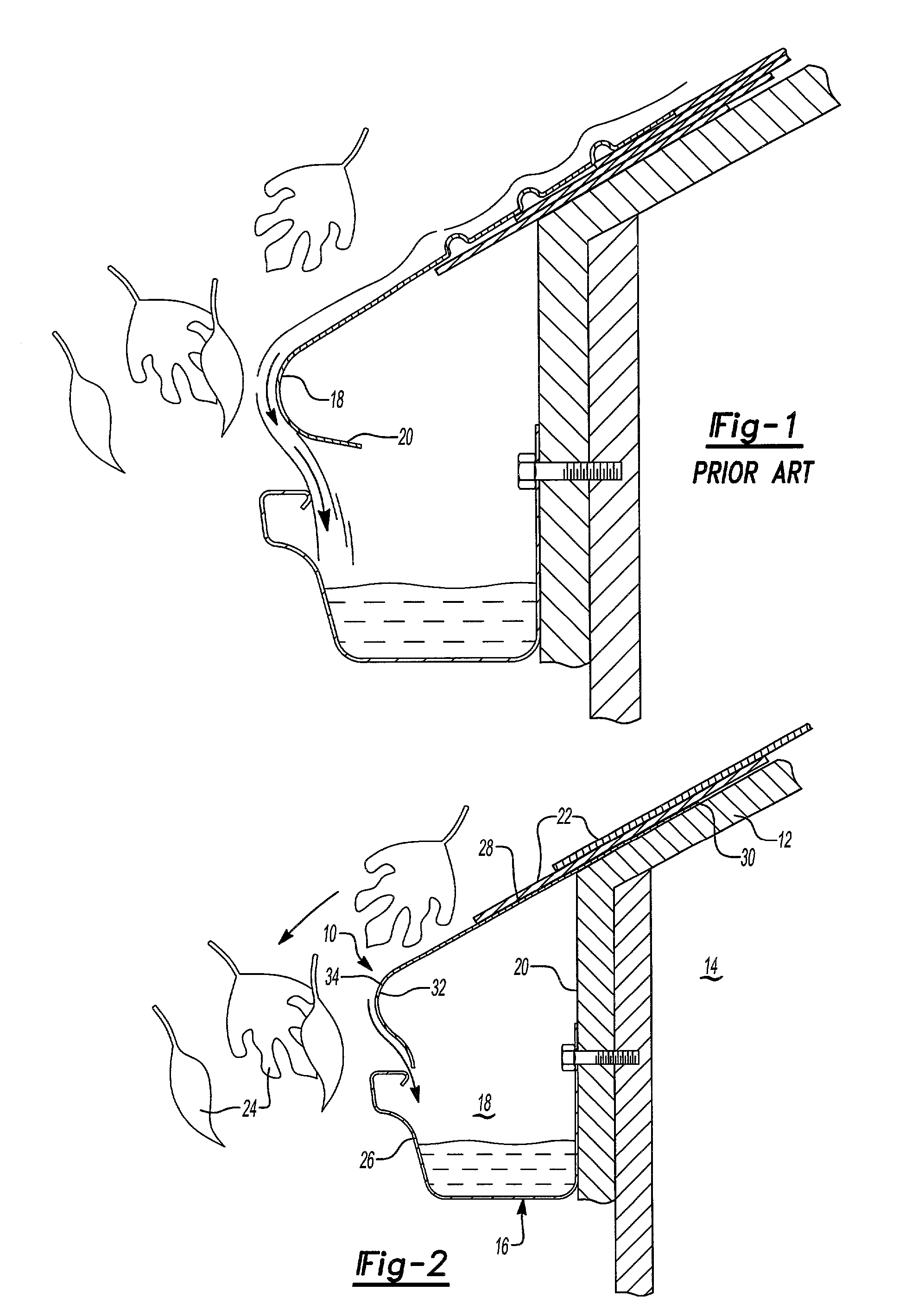

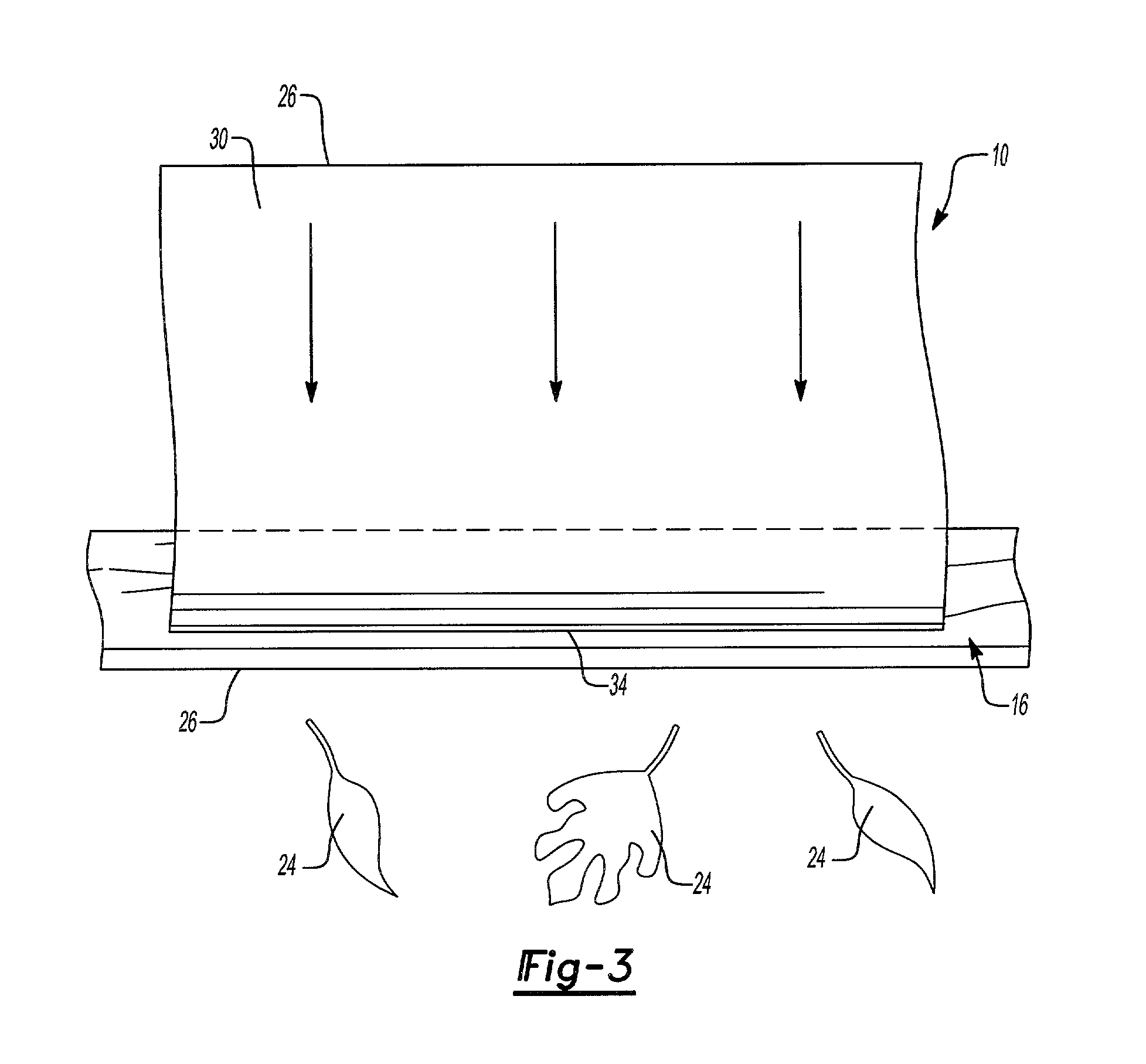

Gutter cover device

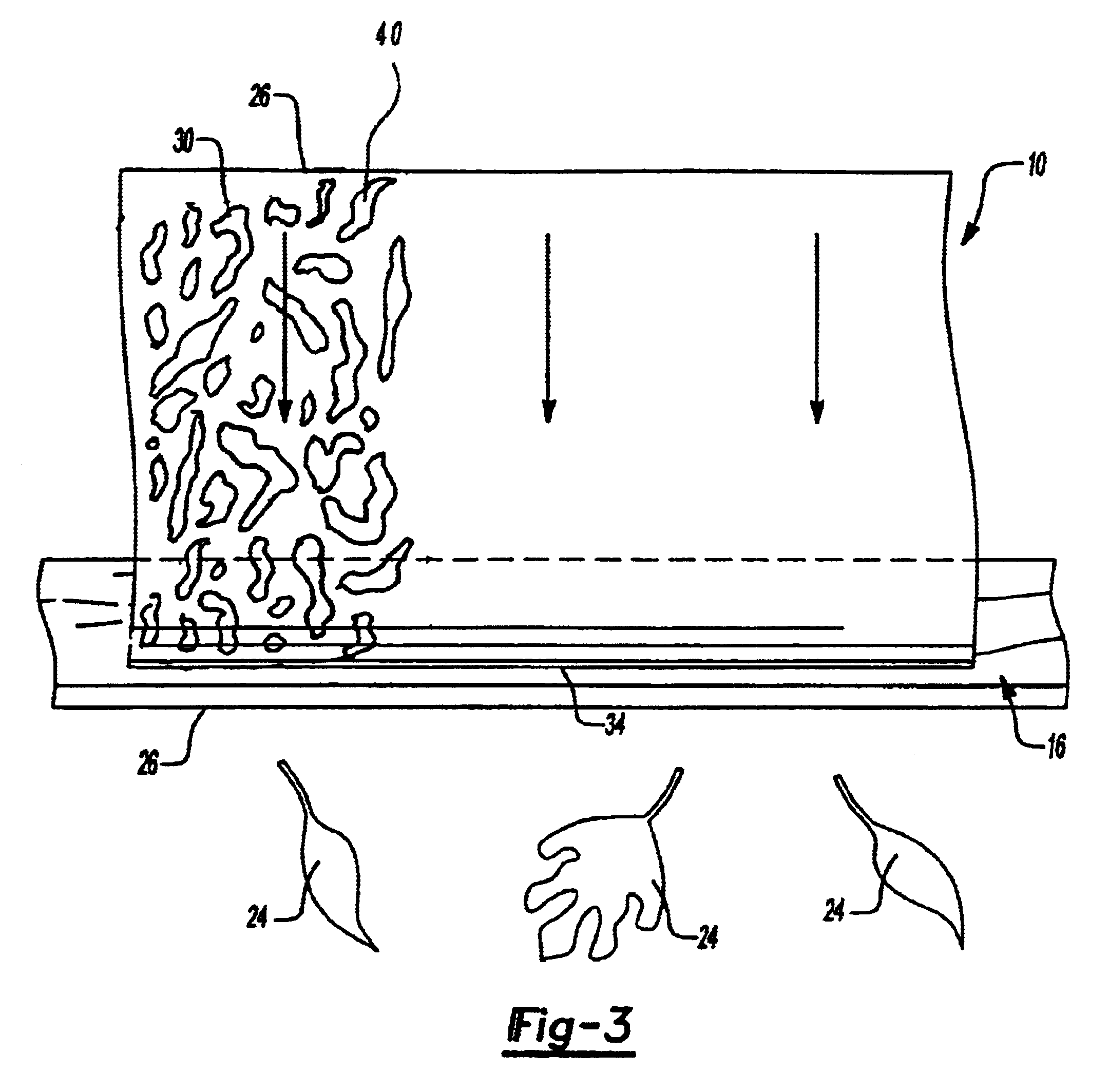

InactiveUS20020152692A1High trafficStable deliveryRecord information storageLiquid displacementCoatingCivil engineering

A gutter cover for directing the flow of rainwater from a building roof into a gutter mounted to the peripheral edge thereof while preventing debris such as leaves and twigs from entering and clogging the gutter The cover is secured to the roof of the building such that rainwater flowing down the shingles will flow across the cover at the bottom roof line. A lower end of the cover has an arcuate nose disposed substantially above the outer edge of the gutter The surface of the gutter is treated with one or more combinations of coatings and / or substrate textures to slow the flow of water while improving flow to the cover surface. Rainwater will flow around the arcuate nose into the gutter while debris carried by the rainwater is expelled outwardly over the edge of the gutter.

Owner:SOUTHEASTERN METALS MFG

Shower water toy construction system

InactiveUS7987533B2Increase water flowEasy to use connect/disconnectBathsDouchesSprayerPore water pressure

A shower water construction system for a child / user, which also functions as a showering system and utilizes a pre-existing bath / shower unit as a supporting structure. The construction system comprises a main control valve to divert water from a pre-existing shower water pipe stem, a pressure regulator to limit water pressure to downstream components, child / user control and diverter valves to allow for turning the system off and on and allocating water flow between components, semi-rigid and flexible pipe, “Y” connectors and suction cups and brackets. Other components, such as a hand-held sprayer, spraying bathtub mat and spraying shower curtain may also be integrated / connected into the system.

Owner:AQUASTRUCT

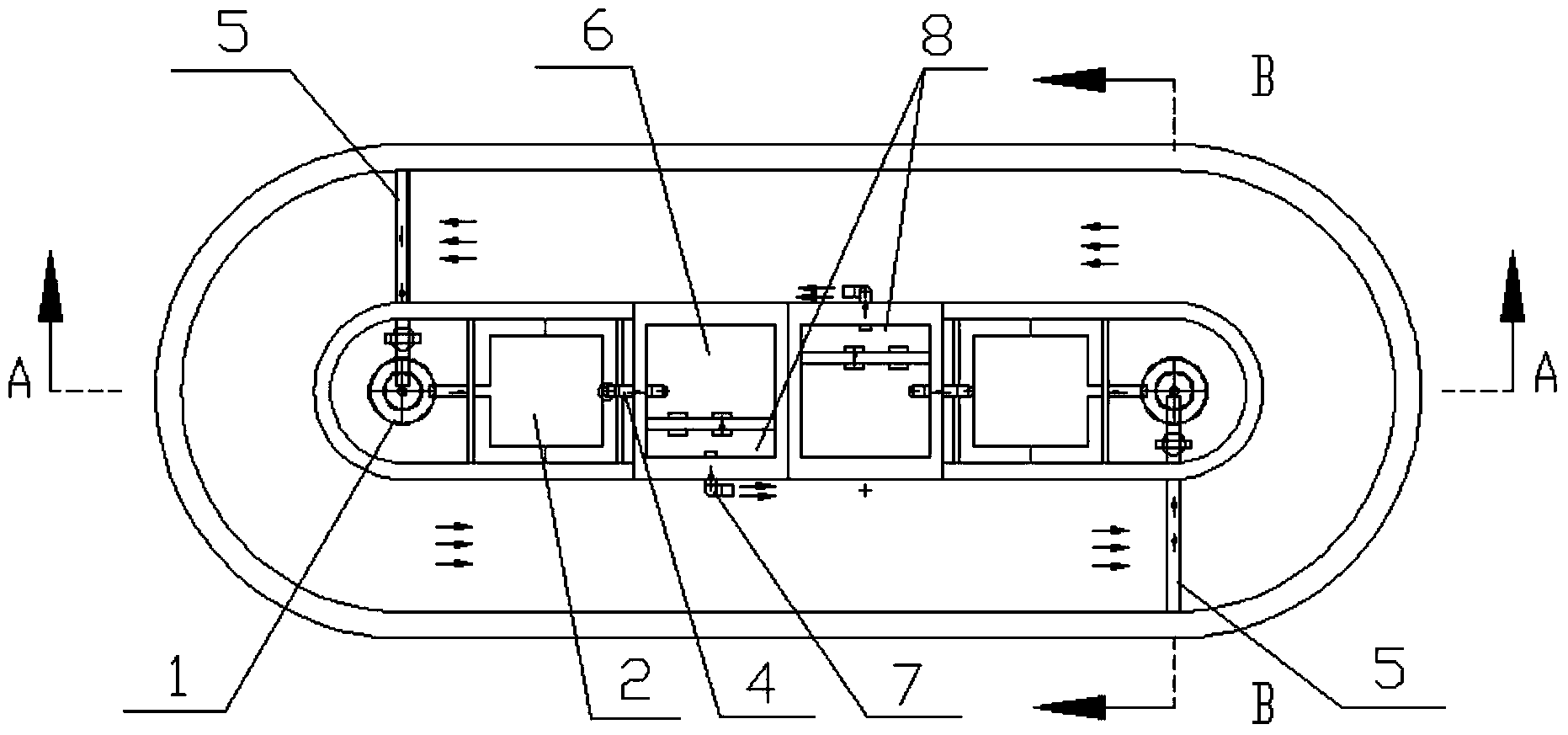

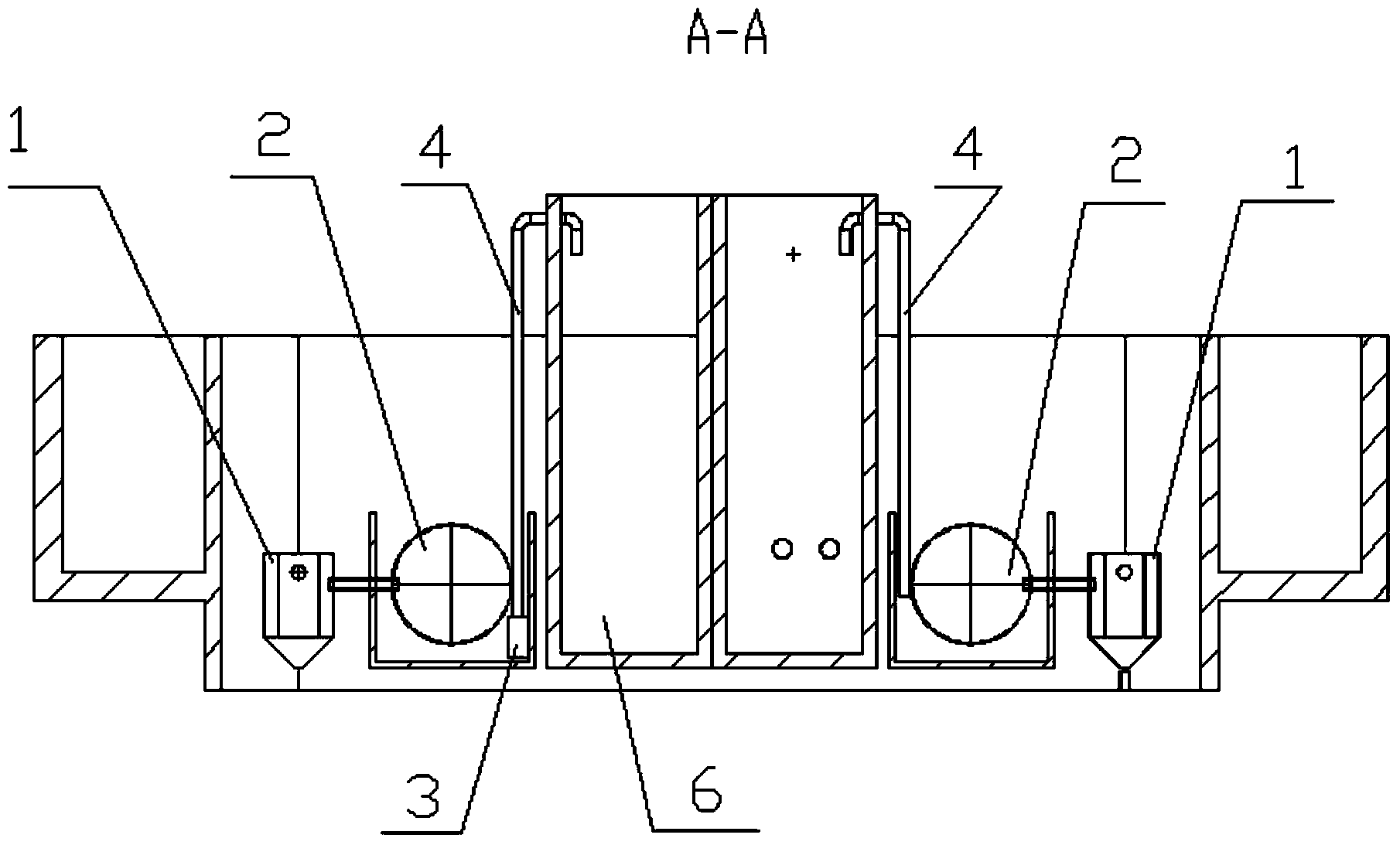

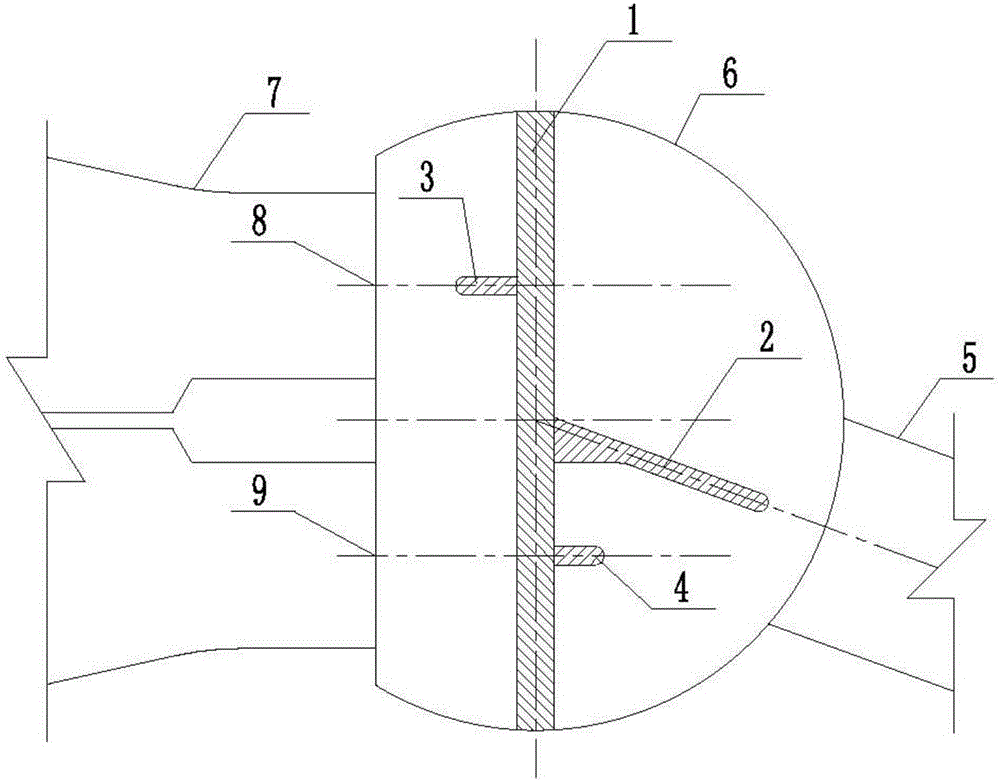

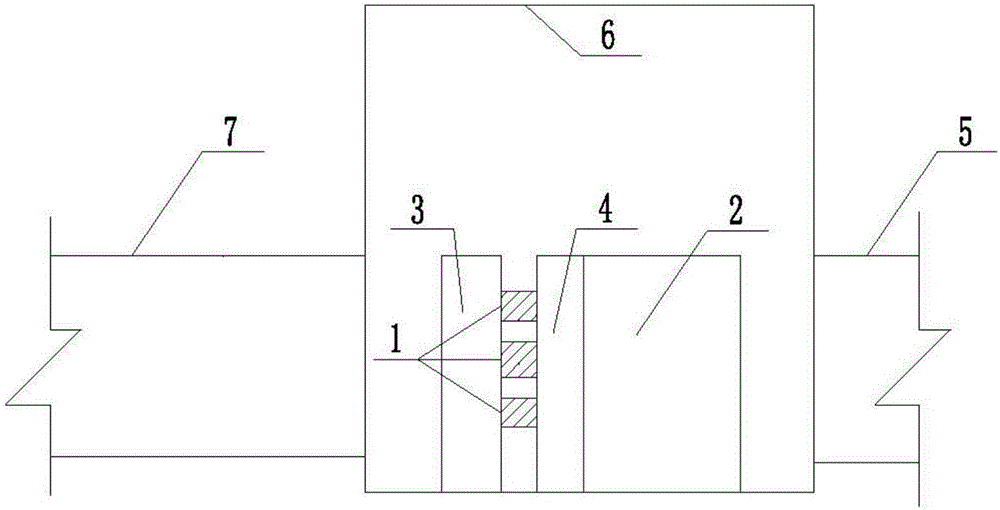

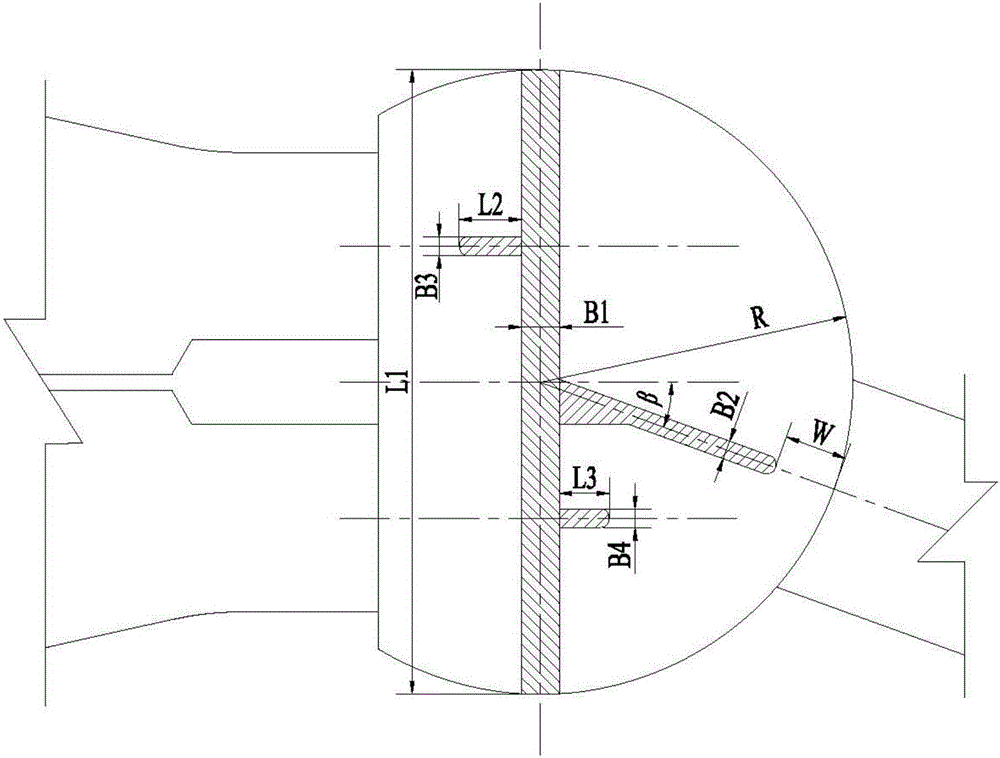

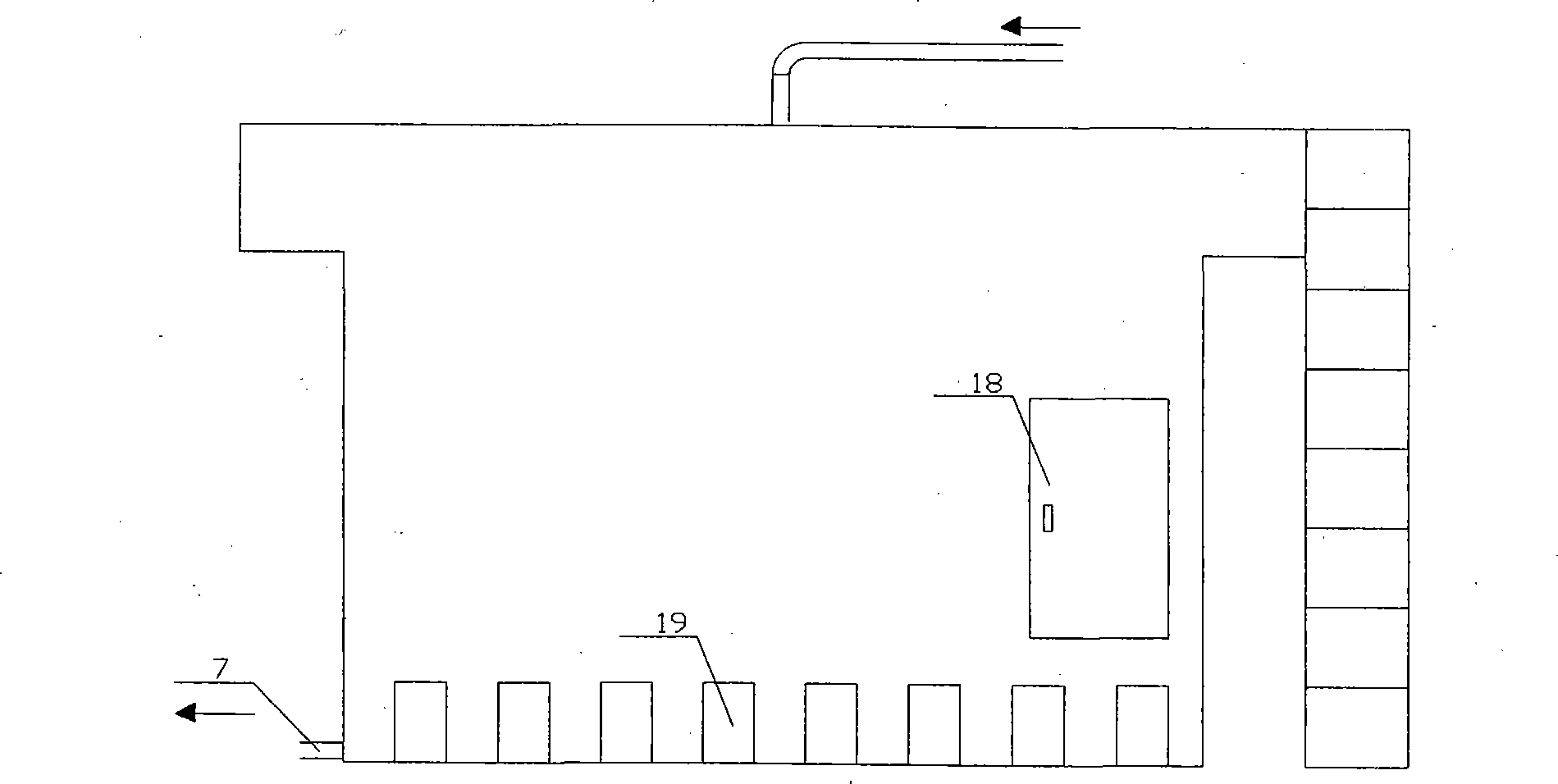

Combined rectifying device for improving inlet flow patterns of urban rainwater pump stations

ActiveCN106759833AEnsure safe, efficient and stable operationSimple structureSewerage structuresRADIUSStormwater

The invention discloses a combined rectifying device for improving inlet flow patterns of urban rainwater pump stations. The rectifying device is arranged inside a gate well. The gate well is arranged between a rainwater main pipe and an inlet water box culvert. The radius of the gate well is R. The rectifying device comprises a beam, a main flow dividing and guiding pier, an upper flow dividing and guiding pier and a lower flow dividing and guiding pier. The combined rectifying device can effectively homogenize the flow velocity distribution of the flow from the rainwater main pipe into the gate well on the horizontal and vertical faces, and homogenize the water flowing in the inlet water box culvert and the water collecting tank in the rainwater pump stations, which can solve a series of unhealthy hydraulic flow problems that mainstream inside the gate well is in the middle, the flow velocity distribution in the inlet water box culvert is uneven, inflow in the water collecting tank is bias and the like. It is guaranteed that the urban rainwater pump stations have good inlet flow conditions. The device has a great significance in ensuring the safe, efficient and stable operation of pump stations and pump units.

Owner:HOHAI UNIV

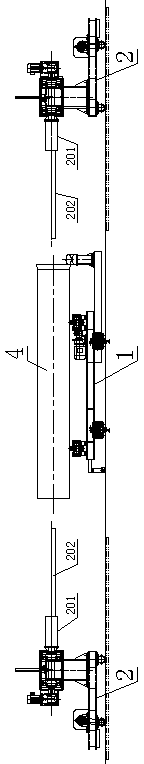

Lining coating technology for spheroidal graphite cast iron tube

ActiveCN103691625AWill not affect the formationNo shedding phenomenonLiquid surface applicatorsCoatingsPolyvinyl chlorideEngineering plastic

The invention discloses a lining coating technology for a spheroidal graphite cast iron tube. The lining coating technology is characterized by comprising the following steps of 1, polishing the inner wall of a blank tube, and performing shot blasting; 2, putting the treated tube on a riding wheel of lining coating equipment through a transferring tool, and switching on a variable-frequency motor connected with the riding wheel to drive the tube to rotate at the rotating speed of less than or equal to 50rpm; 3, switching on a heating fire gun arranged below the tube to preheat the outer wall of the tube, and controlling the temperature between 140 DEG C and 230 DEG C; 4, after preheating is finished, uniformly distributing polyvinyl chloride or polyethylene or ABS (acrylonitrile butadiene styrene) engineering plastic or polytetrafluoroethylene or polypropylene powdered substances on the inner wall of the tube through a material distribution trolley to form a lining layer, and then cooling the lining layer, wherein in the cooling process, the tube is continuously rotated until the tube is completely cooled. The problem of the influence, which is caused by a fact that the lining layer prepared by an existing lining coating technology for the spheroidal graphite cast iron tube is easy to fall off, on normal mounting, the use of metering equipment, the sanitation of water quality and the like is solved; the manufacturing cost of the lining layer is reduced.

Owner:广西安钢永通铸管管业有限公司

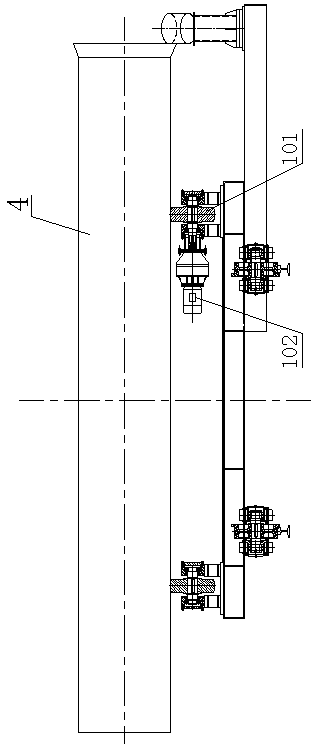

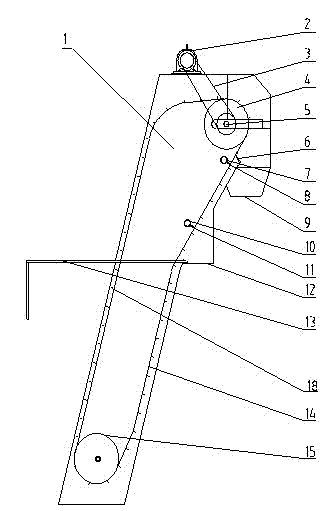

Combined biological trickling filter of denitrification and dephosphorization

InactiveCN101244865AEfficient removalEasy to controlTreatment using aerobic processesSustainable biological treatmentSlagSprayer

The invention relates to a composite biological trickling filter for denitrification and dephosphorization, belonging to the technical field of sewage treatment. The biological trickling filter is cylinder-shaped and comprises a water distributing area, a stuffing layer and a water catch area from top to down; wherein, the water distributing area comprises a plurality of rollers, a rotary water distributor, a water inlet pipe, a water pipe, a water sprayer and tracks; the water inlet pipe is connected with the rotary water distributor, the rotary water distributor is connected with the water pipe which is provided with a water outlet, the water sprayer is positioned below the water pipe and is connected with the rollers; five layers of grid frames are arranged vertically in the stuffing layer, and the grid frames separate the stuffing layer into a grid structure, so that the stuffing layer is successively separated from bottom to top into a stone and sand layer, a composite steel slag stuffing layer, a plaster stuffing layer, a sawdust stuffing layer and a coke layer; the water catch area comprises a header tank, a water outlet pipe and a water catch plate, wherein, the header tank is positioned at the bottom of the trickling filer, and the water outlet pipe is connected with the header tank. By introducing the grid frames, the composite biological trickling filter has the advantages of eliminating the problems of the filter blockage, water accumulation and other defects, effectively improving the aerobic bacteria processing performance of the composite biological trickling filter, efficiently removing COD and simultaneously achieving the effects of denitrification and dephosphorization.

Owner:TONGJI UNIV

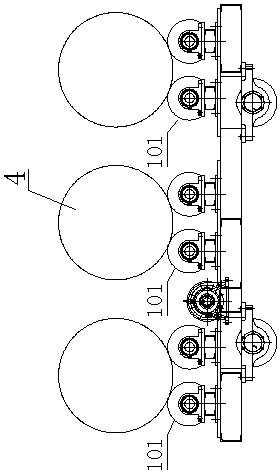

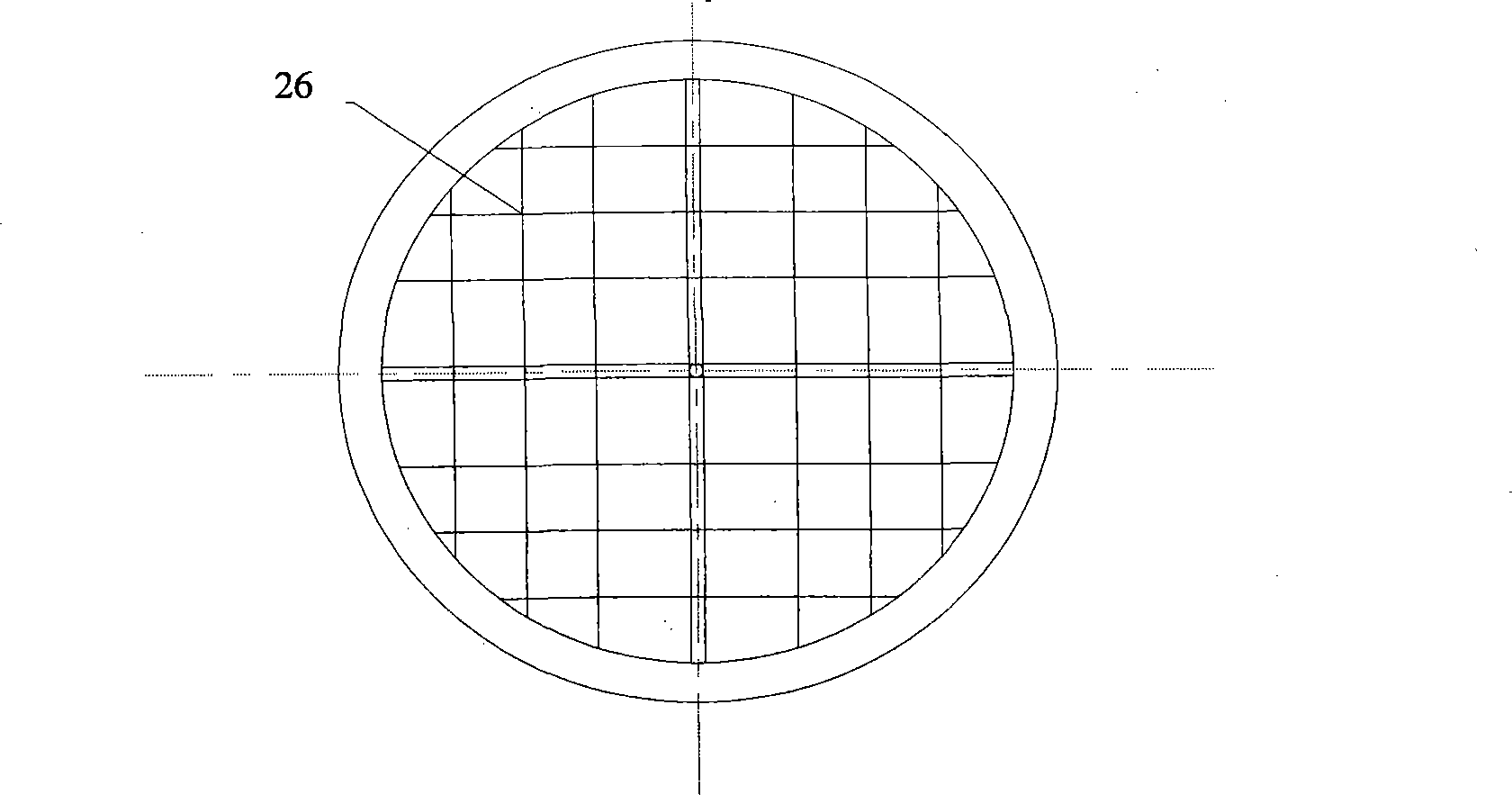

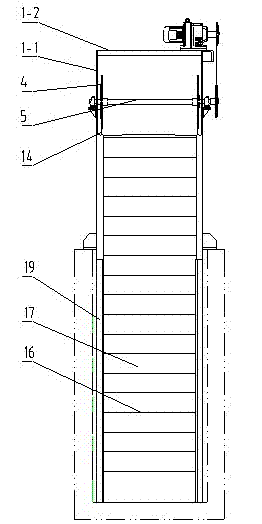

Rotary filter screen type bar screen cleaner

The invention discloses a rotary filter screen type bar screen cleaner. The rotary filter screen type bar screen cleaner comprises a frame, a driving device, a transmission chain, two main chain wheels, a main shaft, a cleaning brush, an air inlet pipe, an air nozzle, two traction chains, two secondary chain wheels, a filter frame, a filter screen, a mesh plate, a water stopping plate, and an air compressor; the driving device is fixedly connected to a top plate of the frame, the main shaft is fixed on a side plate of the frame; one end of the transmission chain is sleeved on a power output shaft of the driving device, and the other end is sleeved on a power input end of the main shaft; the main chain wheels are fixedly connected to the main shaft, and the secondary chain wheels are fixed to the lower part of the frame; two traction chains are respectively sleeved to one main chain wheel and one secondary chain wheel; the end part of the filter frame is fixedly connected to the traction chains, the filter screen and the mesh plate are arranged on the filter frame; the cleaning brush is fixed inside the side plate of the frame, brush bristle of the cleaning brush is contacted with the filter screen. By adopting the rotary filter screen type bar screen cleaner, fine floater and suspending solid matters in sewage can be intercepted; and furthermore, cleaning efficiency is high.

Owner:LANSHEN GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com