Patents

Literature

111results about How to "No shedding phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Outdoor waterborne woodenware penetration paint and preparation method thereof

InactiveCN107936742AReduced shear damageResist moisture intrusionPolyurea/polyurethane coatingsEmulsionLacquer

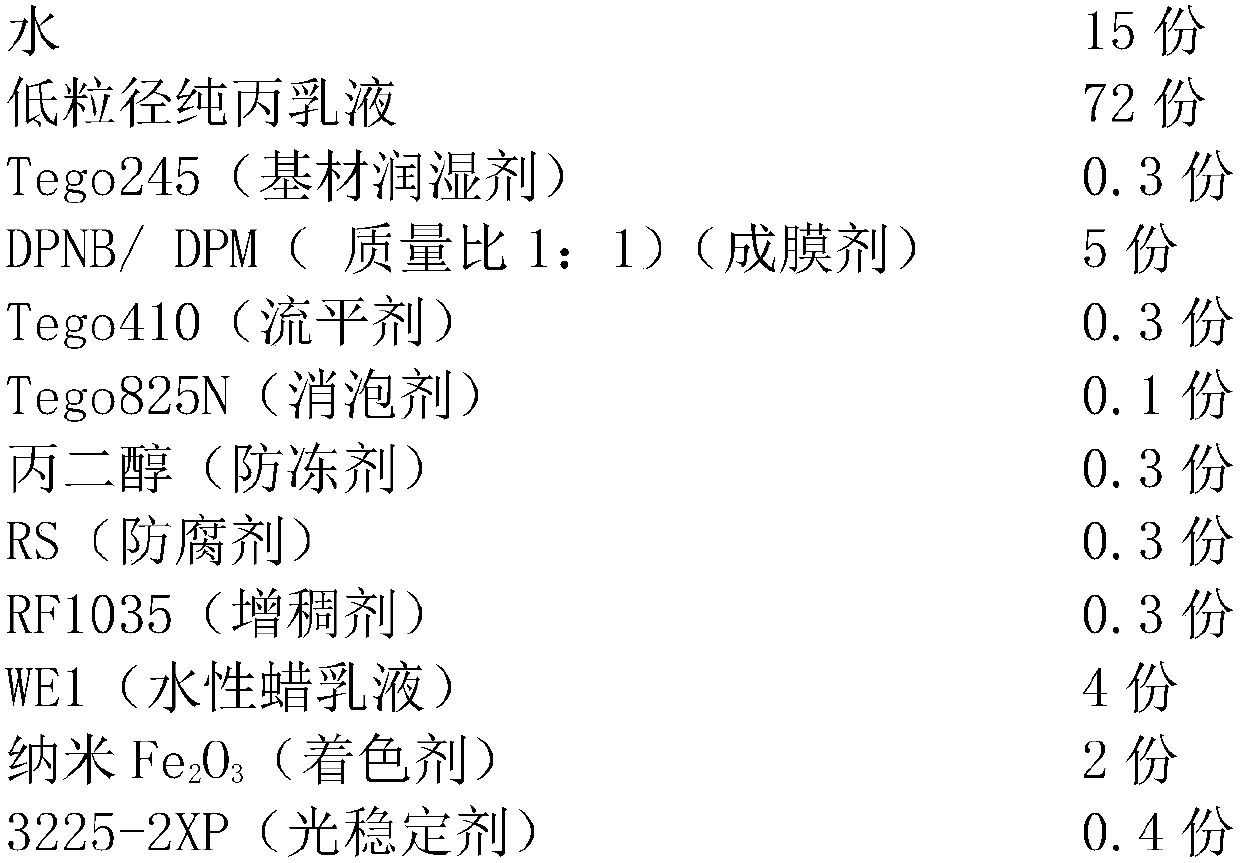

The invention belongs to the field of coatings for architectural ornament, and particularly relates to an outdoor waterborne woodenware penetration paint and a preparation method thereof. The penetration paint is prepared from the following components by weight: 10 to 15 parts of water, 65 to 80 parts of waterborne emulsion, 2 to 5 parts of coalescing agent, 2 to 25 parts of coloring agent and 4.5to 9 parts of other aids. The outdoor waterborne woodenware penetration paint prepared by the method has good base material closing property, excellent weather fastness and water resistance on the basis of a traditional woodenware paint; in addition, the cracking of a substrate can be reduced and the substrate can be protected from being corroded to a certain extent.

Owner:SHENYANG RES INST OF CHEM IND

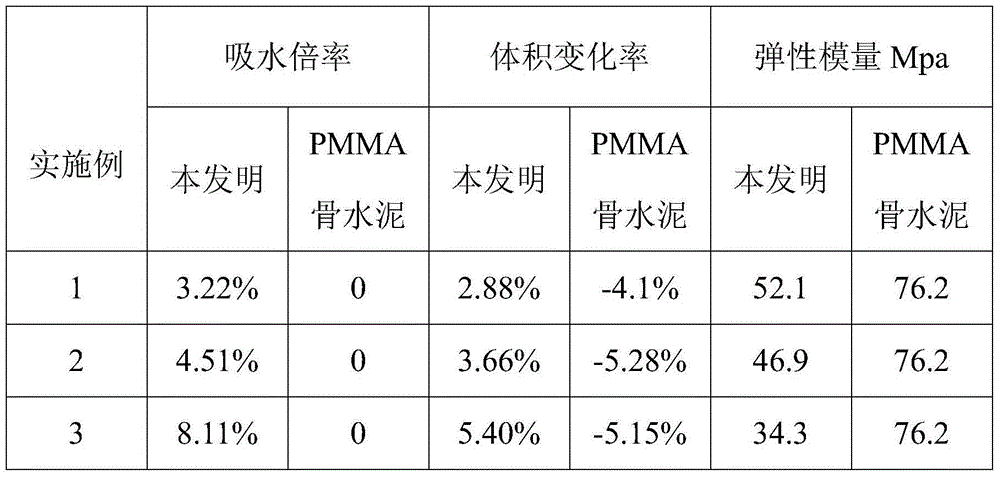

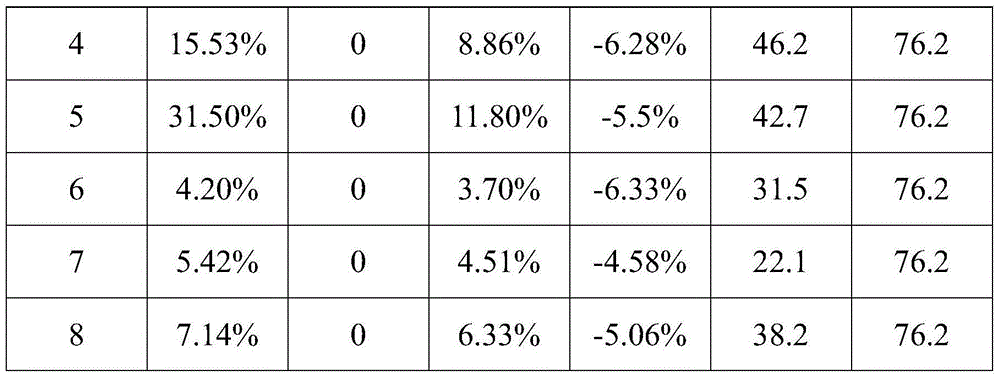

Injectable expansion type bone cement and preparation method thereof

ActiveCN104922733ANo shedding phenomenonThere will be no shedding phenomenonProsthesisCross-linkHydroquinone Compound

The invention discloses injectable expansion type bone cement. The injectable expansion type bone cement is made by mixing a solid phase composition and a liquid phase composition according to the mass ratio of 1.5:1-3:1, wherein the solid phase composition is a methyl methacrylate-acrylic acid copolymer while the liquid phase composition is a mixture of methyl methacrylate, N,N-dimethyl toluidine and hydroquinone. The preparation method includes: taking the methyl methacrylate and the crylic acid as reactive monomers generating polymerization reaction under the action of an initiator and a cross-linking agent to generate the methyl methacrylate-acrylic acid copolymer; evenly mixing the methyl methacrylate, the N,N-dimethyl toluidine and the hydroquinone to the liquid phase composition; mixing the solid phase composition with the liquid phase composition according to the mass ratio of 1.5:1-3:1 in proportion, stirring to obtain bone cement fluid, and obtaining the injectable expansion type bone cement after self-setting.

Owner:XIAN UNIV OF TECH

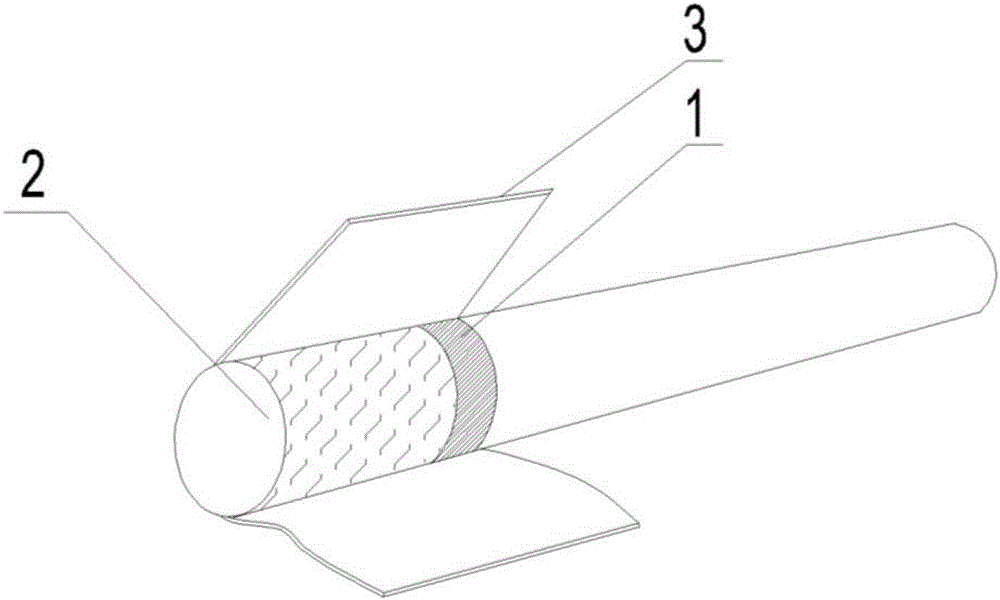

Compound cigarette filter tip

InactiveCN106036999AImprove performanceHigh filtration precisionCigar manufactureTobacco smoke filtersFiberFiltration

The invention relates to a compound cigarette filter tip which comprises a filter tip section close to the lip end, a filter tip section close to the tobacco shred end and wrapping paper. The filter tip section close to the lip end is provided with a fiber filtration layer, the filter tip section close to the tobacco shred end is provided with a metal sintered porous filtration layer, the metal sintered porous filtration layer is a micro-filtration element made from a metal powder sintered porous filtration material, the metal powder sintered porous filtration material is prepared by using metal particles as a raw material, one-time formation is achieved through a formation technology after pretreatment, and the metal powder sintered porous filtration material is formed after sintering. The filtration material is high in filtration precision, good in filtration effect, uniform in structure and good in reproducibility, so that the compound cigarette filter tip does not deform, has the very good filtration effect on nicotine, tar, nitrosamine and other non-gaseous-phase toxic and harmful substances, does not absorb beneficial aroma components in cigarettes, is high in melting point, does not cause overburning producing cancerogens, prevents scorch and toxic smoke (produced due to scorch of the filter tip), has a good cooling effect and makes cigarettes having a cool and refreshing taste.

Owner:普瑞特机械制造股份有限公司

Preparation method for super-hydrophobic metal surface

InactiveCN103981547AEliminate differencesImprove general performanceLiquid/solution decomposition chemical coatingChemical platingAlloy

The invention discloses a preparation method for a super-hydrophobic metal surface. The method comprises the following steps: constructing a micrometer structure on the surface of a frequently used engineering material (such as copper, iron, stainless steel, nickel, aluminum, an aluminum alloy and a high-molecular section covering the above-mentioned metal through chemical plating) by using an electrocoppering process; then constructing a nanometer structure by using a chemical silvering process; and carrying out modification with low-surface energy substances like octadecanethiol so as to obtain excellent and stable super-hydrophobicity. The method has a wide application scope and can be used on pure metal, alloys and metalized high-molecular sections; an obtained surface has stable and reliable surface performance, strong film-substrate bonding force and good corrosion resistance, especially good acid resistance, can be extensively applied in fields like self-cleaning, water prevention and dehumidification, corrosion prevention, fluid drag reduction, frost prevention and condensation and heat exchange, and has an industrialization value.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Lining coating technology for spheroidal graphite cast iron tube

ActiveCN103691625AWill not affect the formationNo shedding phenomenonLiquid surface applicatorsCoatingsPolyvinyl chlorideEngineering plastic

The invention discloses a lining coating technology for a spheroidal graphite cast iron tube. The lining coating technology is characterized by comprising the following steps of 1, polishing the inner wall of a blank tube, and performing shot blasting; 2, putting the treated tube on a riding wheel of lining coating equipment through a transferring tool, and switching on a variable-frequency motor connected with the riding wheel to drive the tube to rotate at the rotating speed of less than or equal to 50rpm; 3, switching on a heating fire gun arranged below the tube to preheat the outer wall of the tube, and controlling the temperature between 140 DEG C and 230 DEG C; 4, after preheating is finished, uniformly distributing polyvinyl chloride or polyethylene or ABS (acrylonitrile butadiene styrene) engineering plastic or polytetrafluoroethylene or polypropylene powdered substances on the inner wall of the tube through a material distribution trolley to form a lining layer, and then cooling the lining layer, wherein in the cooling process, the tube is continuously rotated until the tube is completely cooled. The problem of the influence, which is caused by a fact that the lining layer prepared by an existing lining coating technology for the spheroidal graphite cast iron tube is easy to fall off, on normal mounting, the use of metering equipment, the sanitation of water quality and the like is solved; the manufacturing cost of the lining layer is reduced.

Owner:广西安钢永通铸管管业有限公司

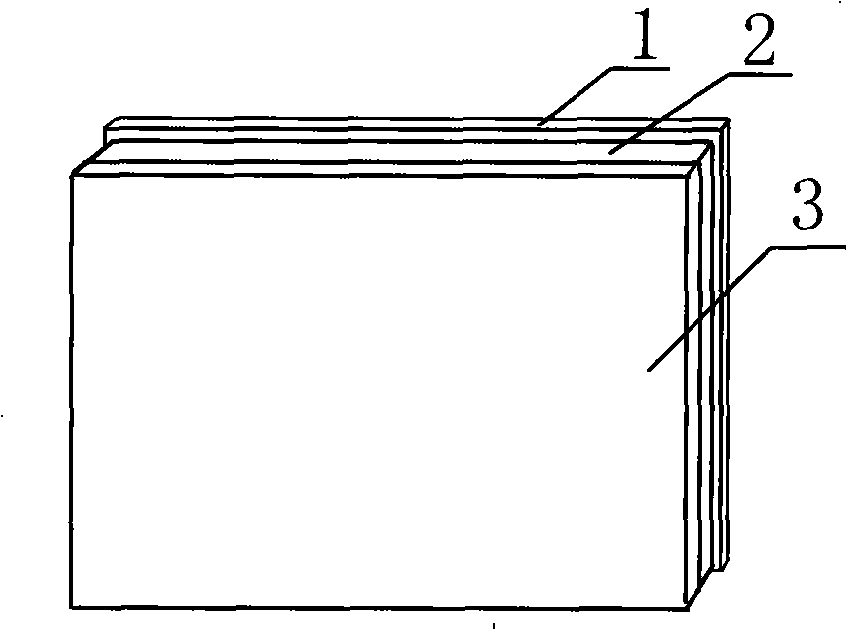

Exterior wall heat preservation decorative lamination integration system and its production and mounting method

InactiveCN101319522AEasy to installImprove ergonomicsCovering/liningsClimate change adaptationSurface layerArchitectural engineering

The invention relates to an external heat insulation board structure for a polyurethane external wall, which is mainly used for the modern building external wall external heat insulation technical field. The structure mainly comprises an inorganic fireproofing bottom layer, a flame-retardant hard polyurethane foam material, a decorative surface layer and so on. The structure has convenient and simple installation: firstly, the surface of a base course wall body is treated to remove floating ash on the surface of the base course wall body, then bonding mortar is used to level the surface of the base course wall body and then is used to directly and dryly paste one surface of the inorganic fireproofing bottom layer of a polyurethane heat insulation board on the surface of the external wall (whether an expanding screw is used to fix is determined according to the concrete requirement); a heat insulation wall body of the external wall can directly use materials such as marbles and so on as a finish layer, so only the waterproofing treatment at the seams needs to be well done, and the work for producing the finish layer on the surface of the wall body is saved. The quick and convenient installation mode improves the work efficiency of the construction and shortens construction period. At the same time, the energy-saving wall body also has the advantages of good heat insulation effect, excellent water resistance, long service life and so on.

Owner:董海光

Wood enclosing primer and application thereof

InactiveCN102504689AEasy to closeNo shedding phenomenonLiquid surface applicatorsPolyurea/polyurethane coatingsChemistryOrganic solvent

The invention discloses a wood enclosing primer and an application thereof. The wood enclosing primer is taken as an enclosing primer for grease-containing wood, and consists of a component A and a component B, wherein the component A consists of a first organic solvent and an isocyanate curing agent; the component B consists of a second organic solvent and a alkyd resin, or consists of a second organic solvent and hydroxyl-containing acrylic resin; and the components A and B are packaged separately. During use, the component A and the component B are mixed in the ratio of (0.5-2):(0.2-1), and is applied to the surface of wood. The wood enclosing primer has the advantages of good wood grease enclosing effect, continuous operability, short construction time and easiness for constructing, grease of wood can be enclosed within 3-5 hours, and the situations of poor adhesion and paint removal occurring during spraying of unsaturated polyester paint on grease-containing wood.

Owner:GUANGDONG LANYANG SCI & TECH

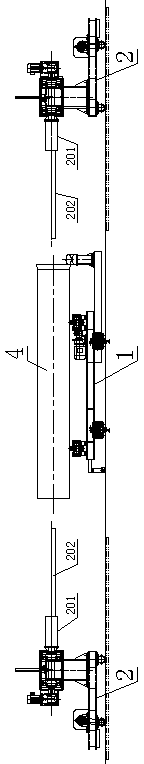

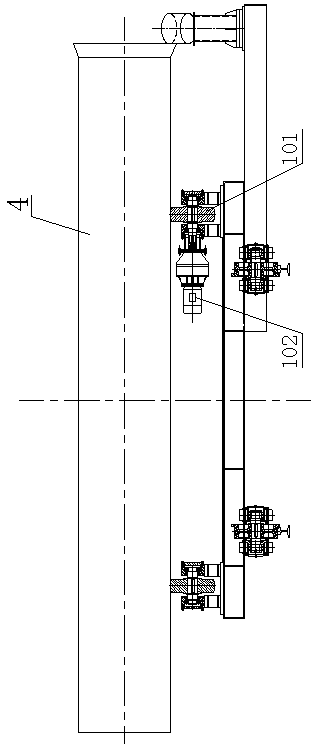

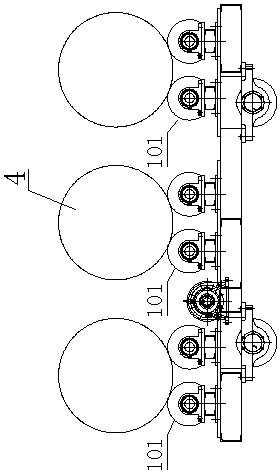

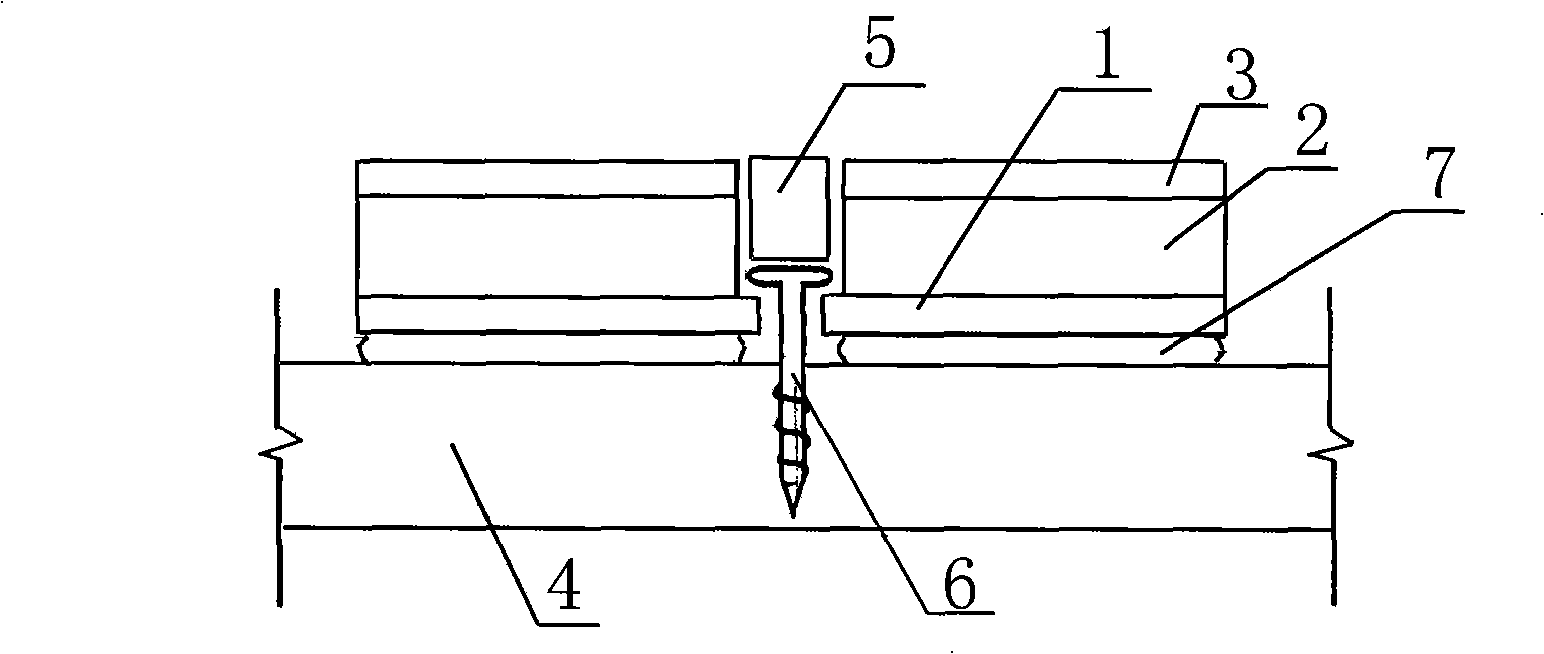

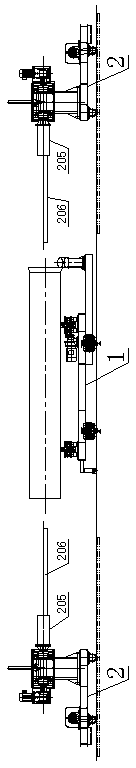

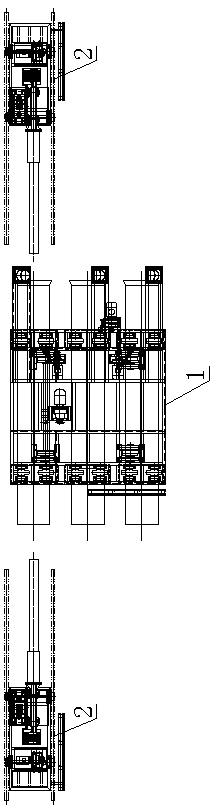

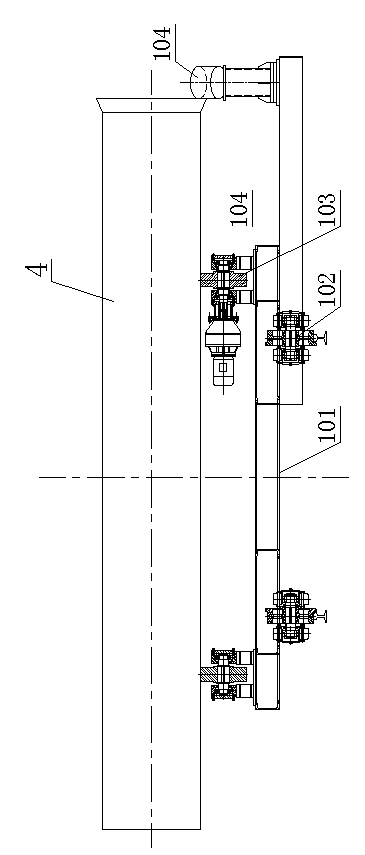

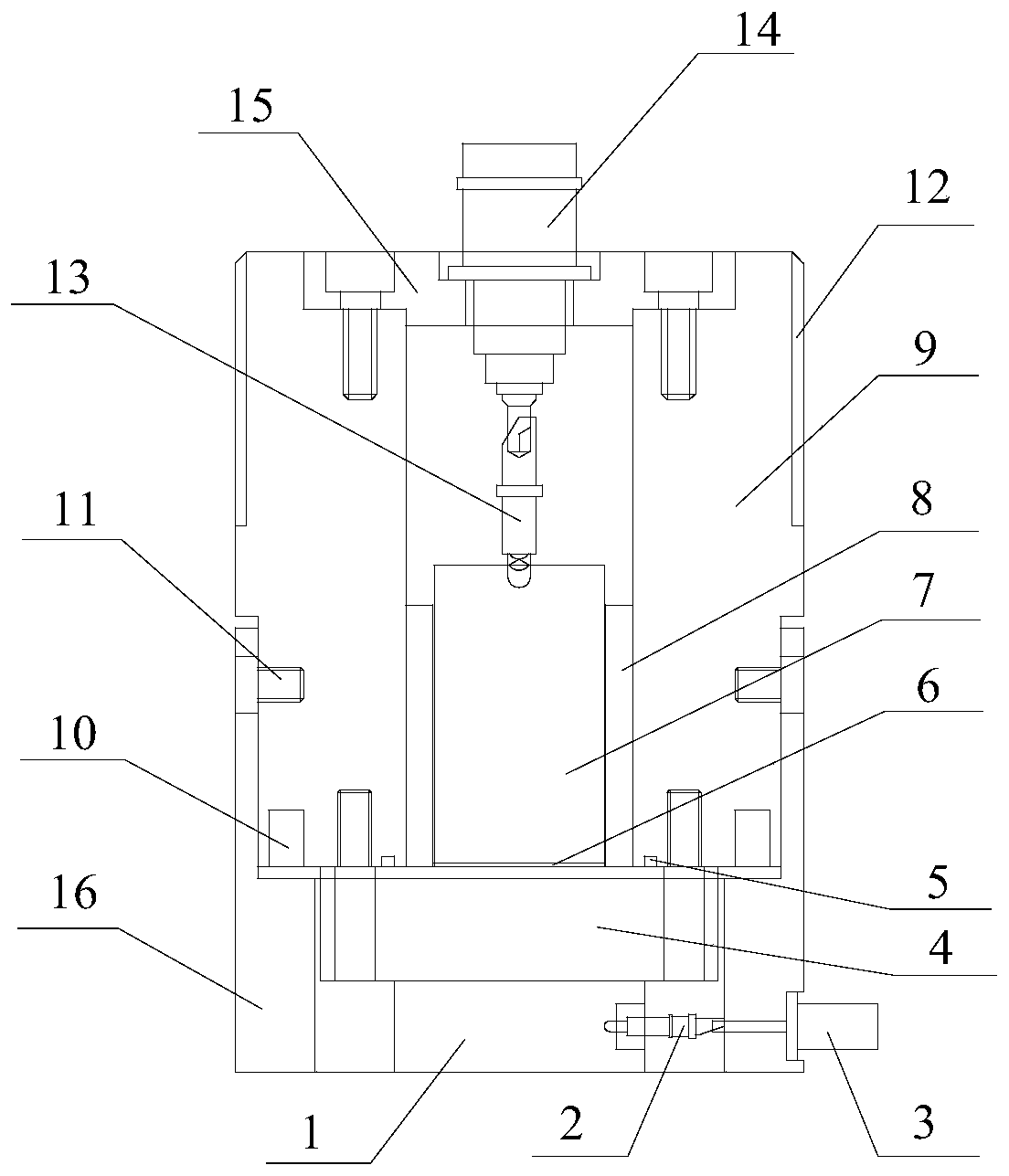

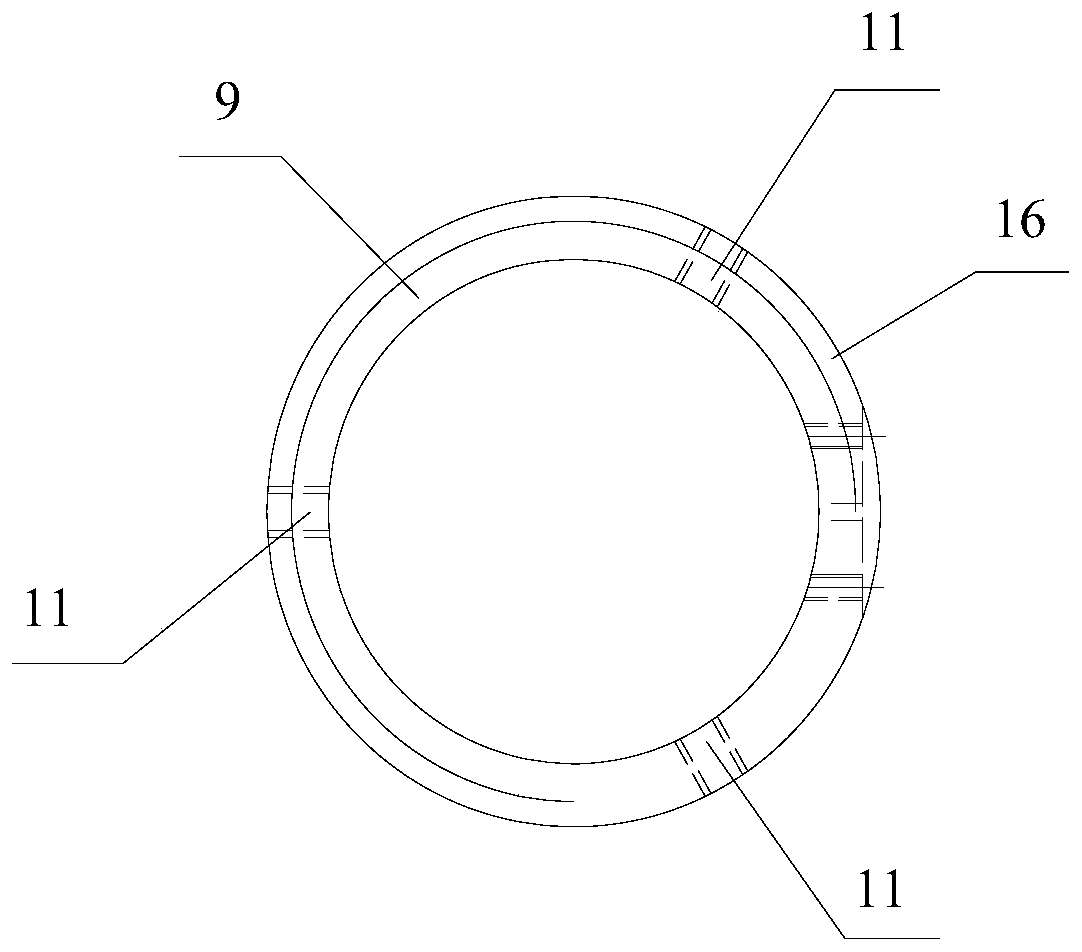

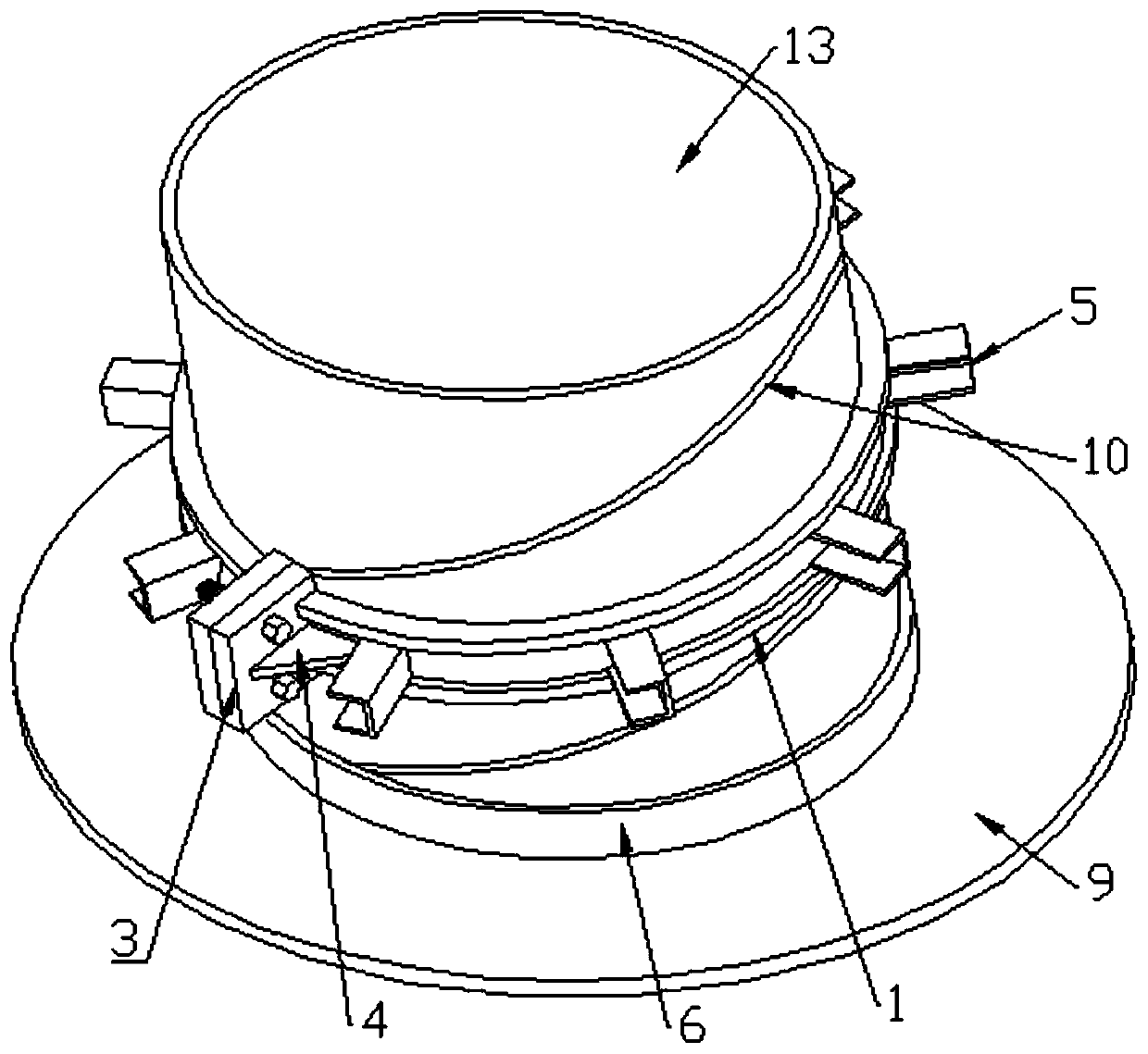

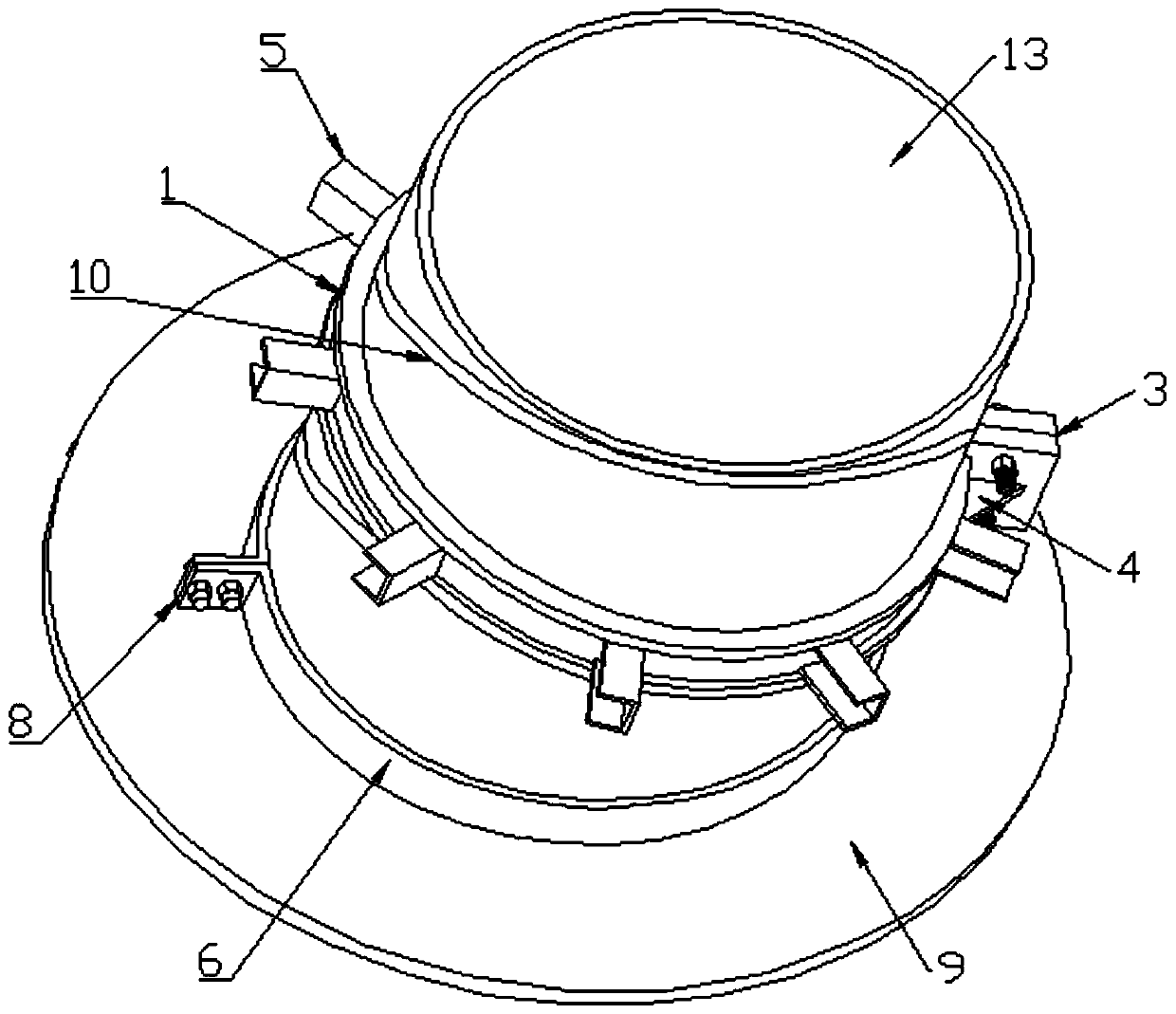

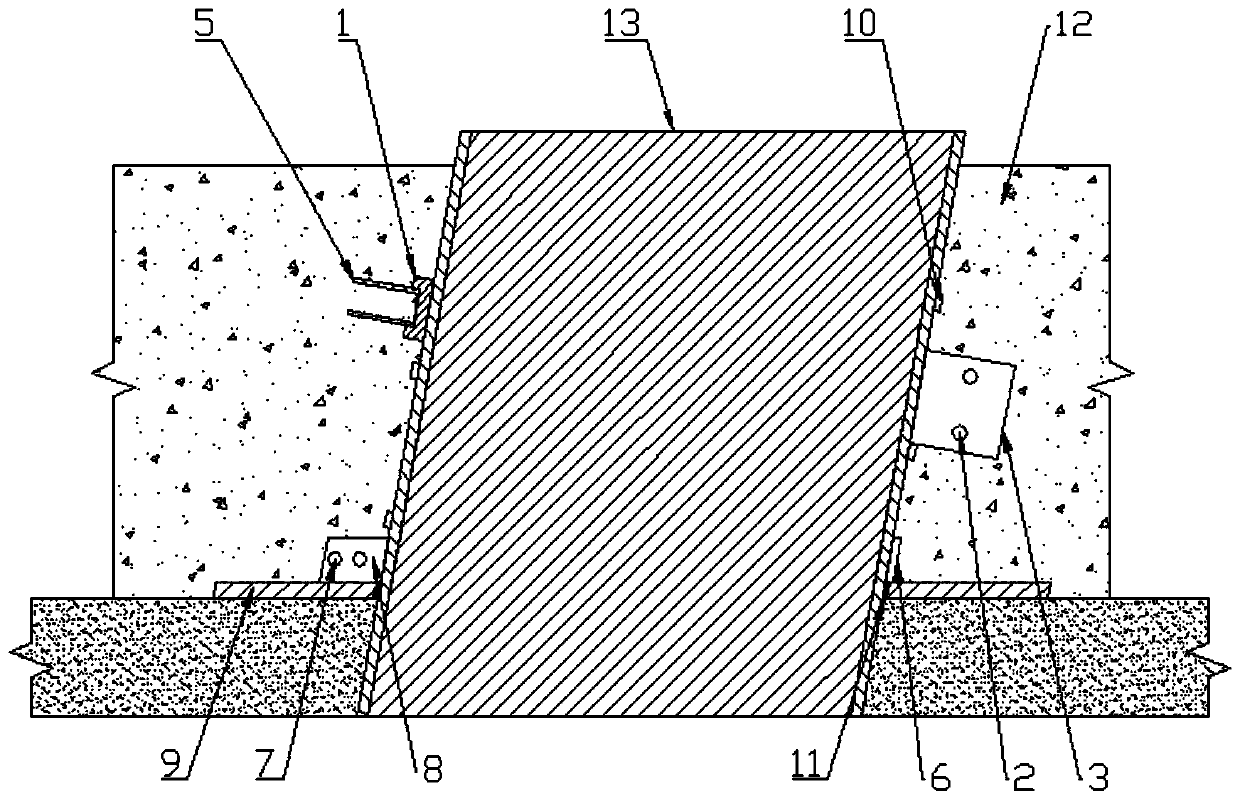

Lining coating equipment for ductile cast iron pipe

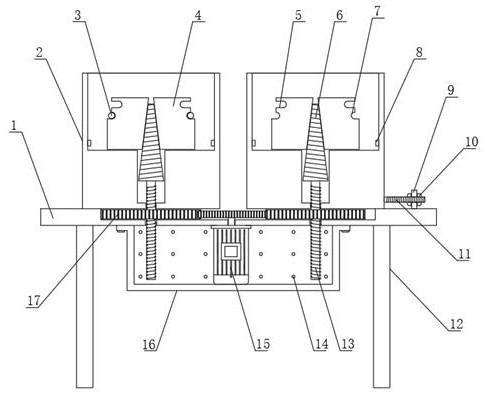

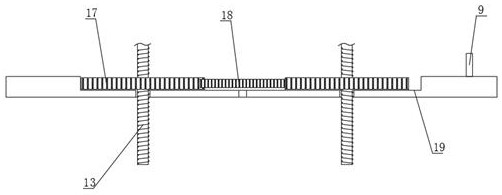

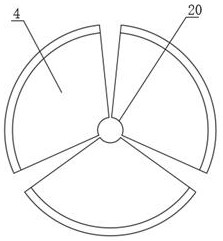

ActiveCN103707411AShorten processing timeIncrease productivityFeeding arrangmentsSurface layering apparatusVehicle frameCast iron pipe

The invention relates to lining coating equipment for a ductile cast iron pipe. The lining coating equipment comprises a rotary platform trolley and is characterized in that the rotary platform trolley is composed of a frame, a walking wheel set arranged below the frame and multiple riding wheel sets arranged above the frame, a heating fire gun used for preheating the ductile cast iron pipe is arranged at the position, corresponding to the riding wheel sets, below the frame, and material distributing trolleys are arranged on the two sides of the frame respectively. The lining coating equipment for the ductile cast iron pipe solves the problem that existing lining coating equipment has the defects that a lining is prone to disengagement, production efficiency is low, and the applicability is low; meanwhile, the machining forming time of the lining is shortened, and production efficiency is improved.

Owner:广西安钢永通铸管管业有限公司

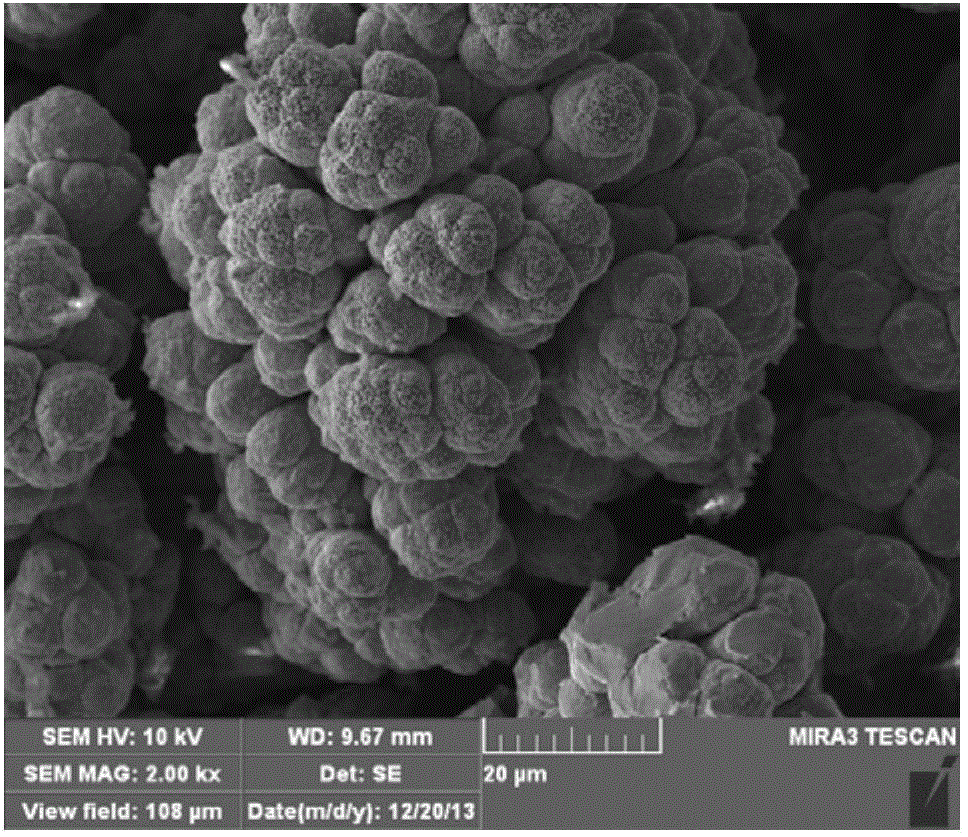

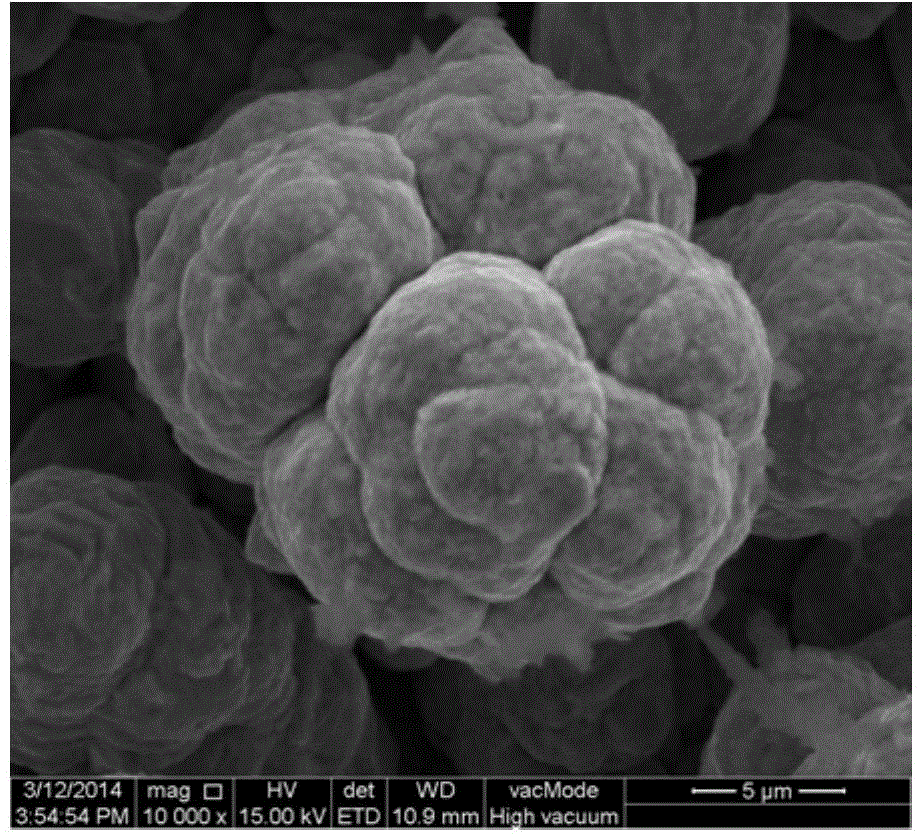

Oxidation type catalyst for diesel engine exhaust aftertreatment and manufacturing method of oxidation type catalyst

PendingCN114247448AFirmly attachedEasy to handleDispersed particle separationCatalyst activation/preparationPtru catalystCopper nitrate

The invention provides an oxidation catalyst for diesel engine exhaust aftertreatment and a manufacturing method of the oxidation catalyst. The oxidation catalyst can efficiently treat particulate matter, HC, CO and NOx, and a catalyst of the oxidation catalyst has firm binding power. The oxidation catalyst comprises a DOC carrier and a catalyst coating coated in the DOC carrier, and the catalyst coating takes a cerium-zirconium composite oxide as an inner coating and a lanthanum-manganese-copper composite oxide as an outer coating. The manufacturing method comprises the following steps: preparing the cerium-zirconium composite oxide powder, coating the cerium-zirconium composite oxide powder and the aluminum oxide sol with the inner coating, coating the lanthanum-manganese-copper nitrate solution with the outer coating, and sintering.

Owner:广东加南环保生物科技有限公司

Environment-friendly high-volume tailing unfired non-steamed brick and manufacturing method thereof

ActiveCN105016672ANo shedding phenomenonHigh compressive strengthSolid waste managementBrickMaterials science

The invention belongs to the technical field of building materials and particularly relates to an environment-friendly high-volume tailing unfired non-steamed brick and a manufacturing method thereof. Raw materials comprise a harmless treatment agent, cement, tailing sand and water. The raw material are screened, mixed, aged and mixed again and undergo dry pressing forming and natural curing to manufacture the environment-friendly high-volume tailing unfired non-steamed brick according to a process. The harmless treatment agent is a composite material made of magnesium chloride, quicklime, gypsum powder, calcium chloride, aluminum sulphate, silicate and silica fume and the like with the fineness of 400 meshes, and the cement is of a PO42.5 type. The environment-friendly high-volume tailing unfired non-steamed brick is characterized by comprising, by weight percentage, 2-6% of harmless treatment agent, 5-10% of cement, 80-85% of tailing sand and 5-8% of water. After long-term use, the environment-friendly high-volume tailing unfired non-steamed brick avoids wall bulging or dropping of a wall painting layer; the compressive strength of the environment-friendly high-volume tailing unfired non-steamed brick is also greatly improved; the problem that white crystal substances are separated out of the surface of a brick body is solved through the deep harmless treatment of tailings; and the consumption of the tailings through single brick bodies is improved, and the environment-friendly high-volume tailing unfired non-steamed brick is environmentally friendly.

Owner:安徽劲峰新材料科技有限公司

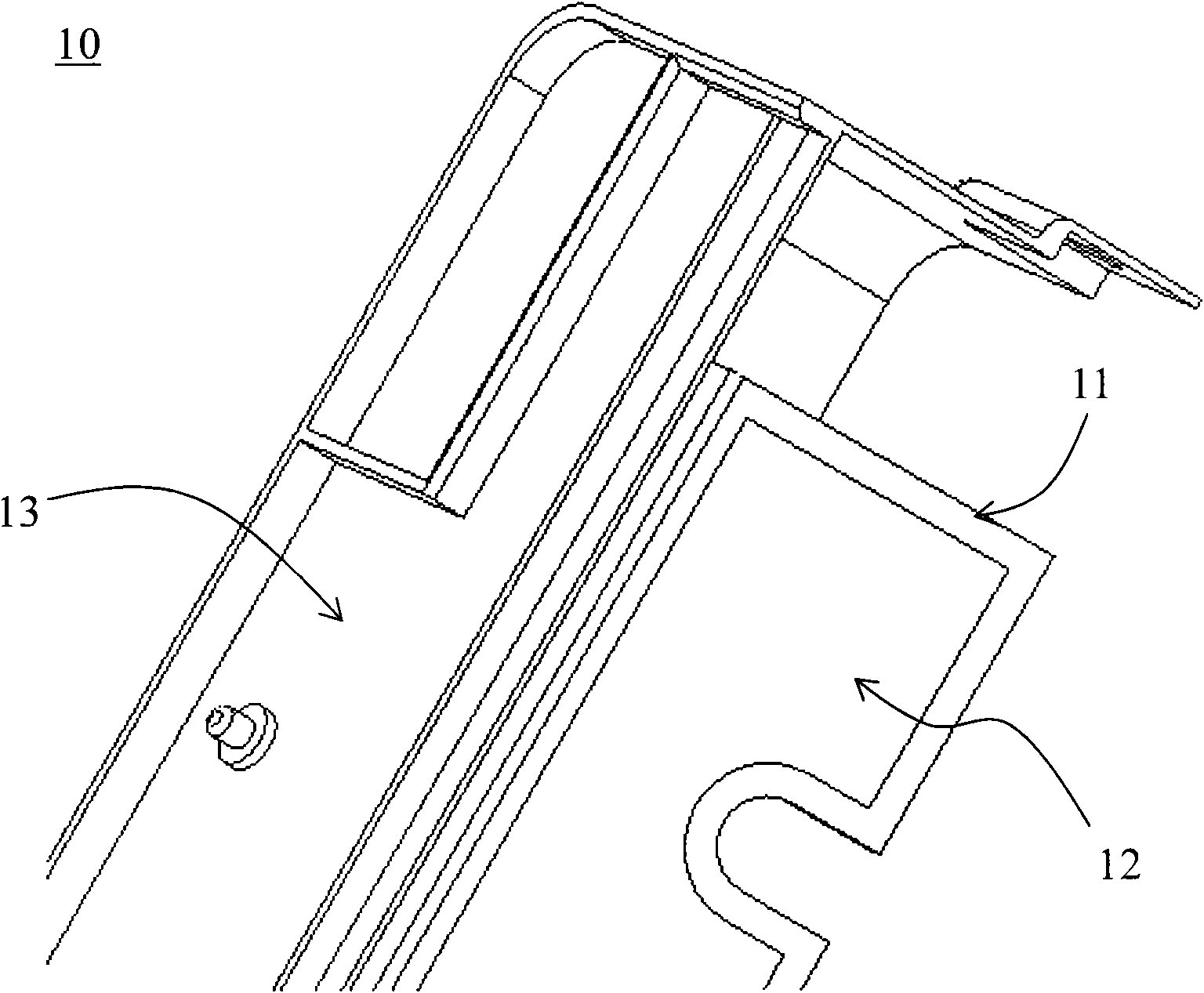

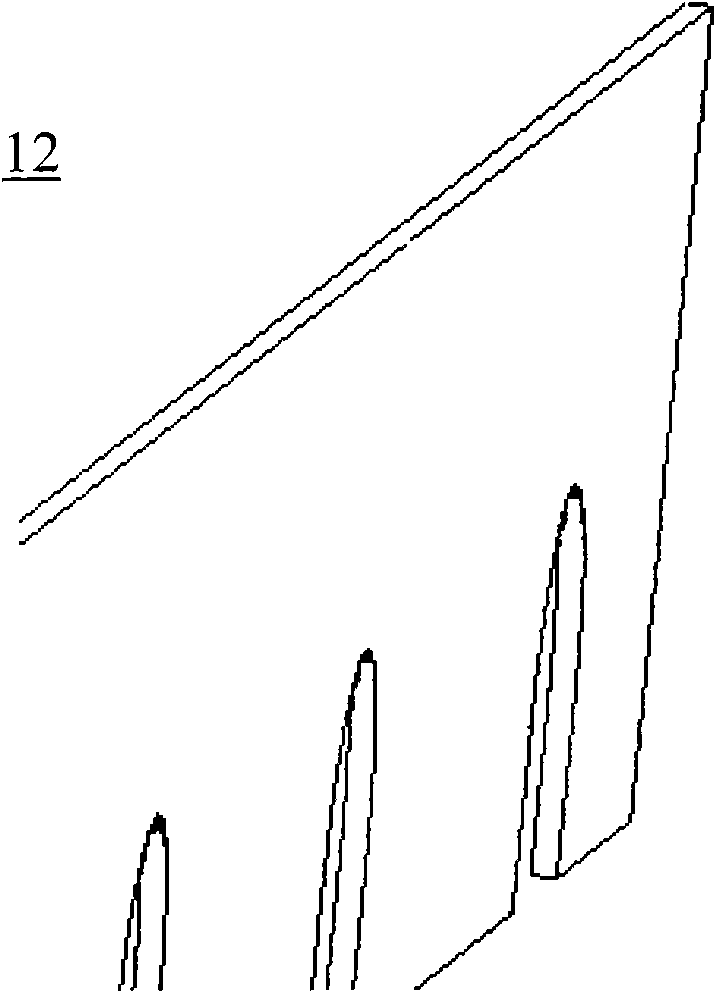

Light source framework and backlight module

InactiveCN101900308ASimple mold and processImprove efficiencyLighting support devicesLight fasteningsLight sourceOptoelectronics

The invention relates to a light source framework and a backlight module. The light source framework comprises a border, an edge strip and a reflector plate, wherein the edge strip is arranged on the border and provided with at least one positioning hole; the reflector plate comprises a first surface and a second surface; the first surface is an optical reflector surface, and the second surface is provided with at least one hook; and the hooks are matched with the positioning holes and used for fixing the reflector plate onto the edge strip. By adopting the invention, the production efficiency of the backlight module can be improved and the production cost is lowered.

Owner:AU OPTRONICS (XIAMEN) CORP +1

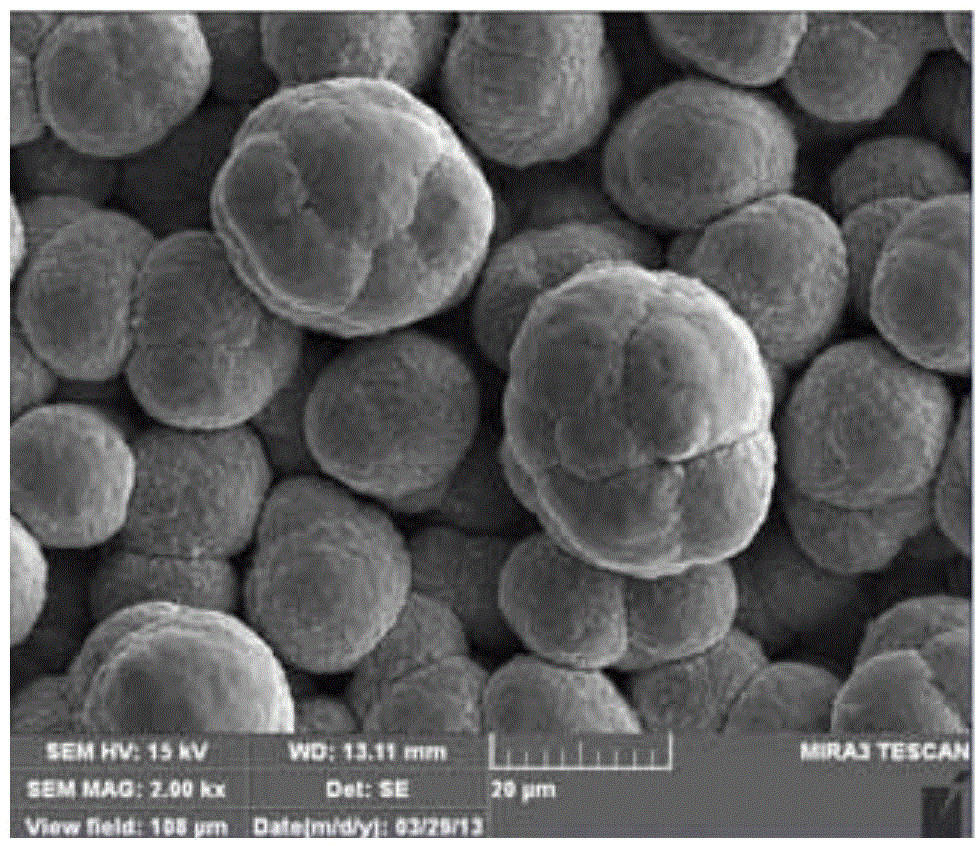

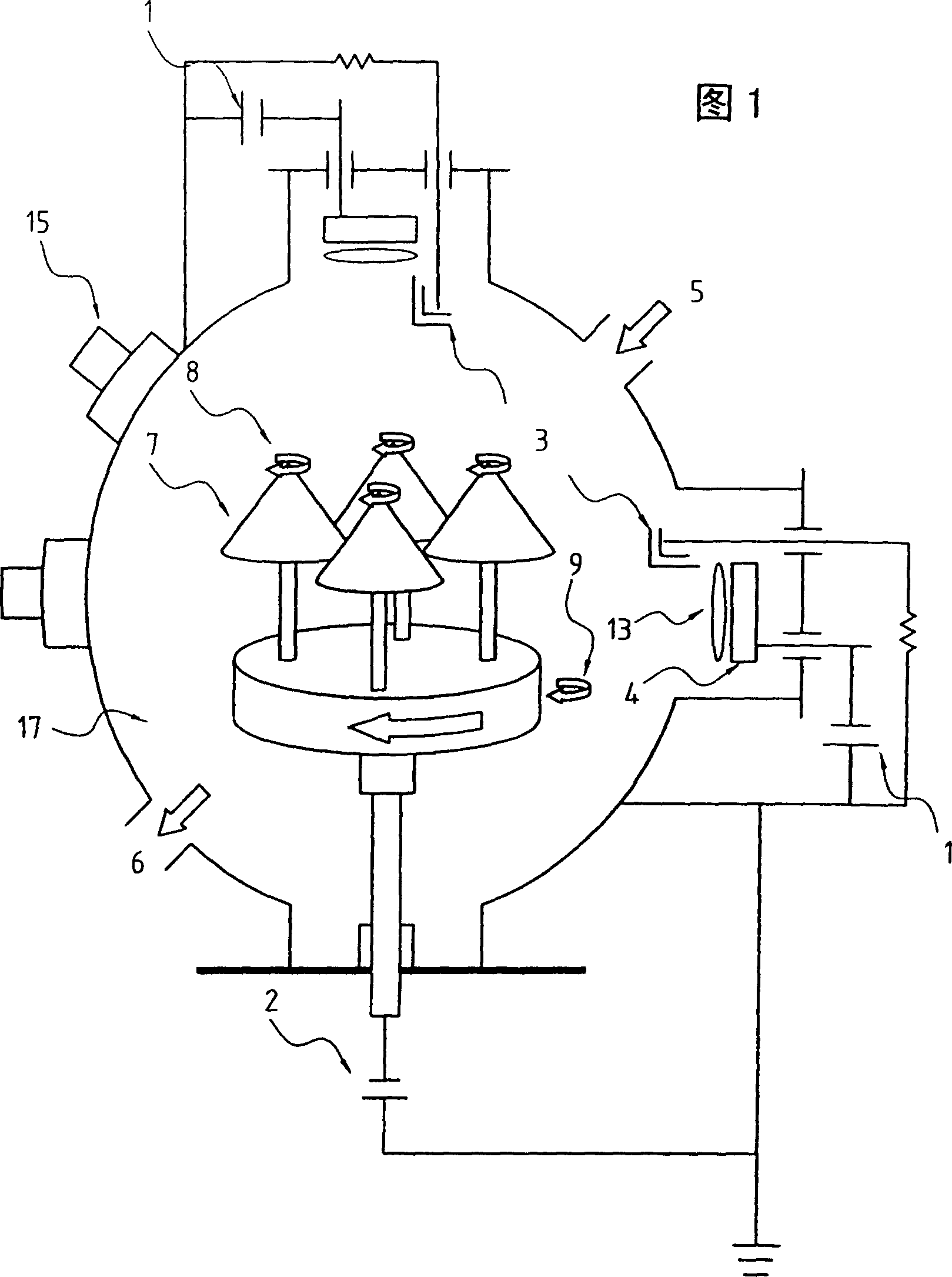

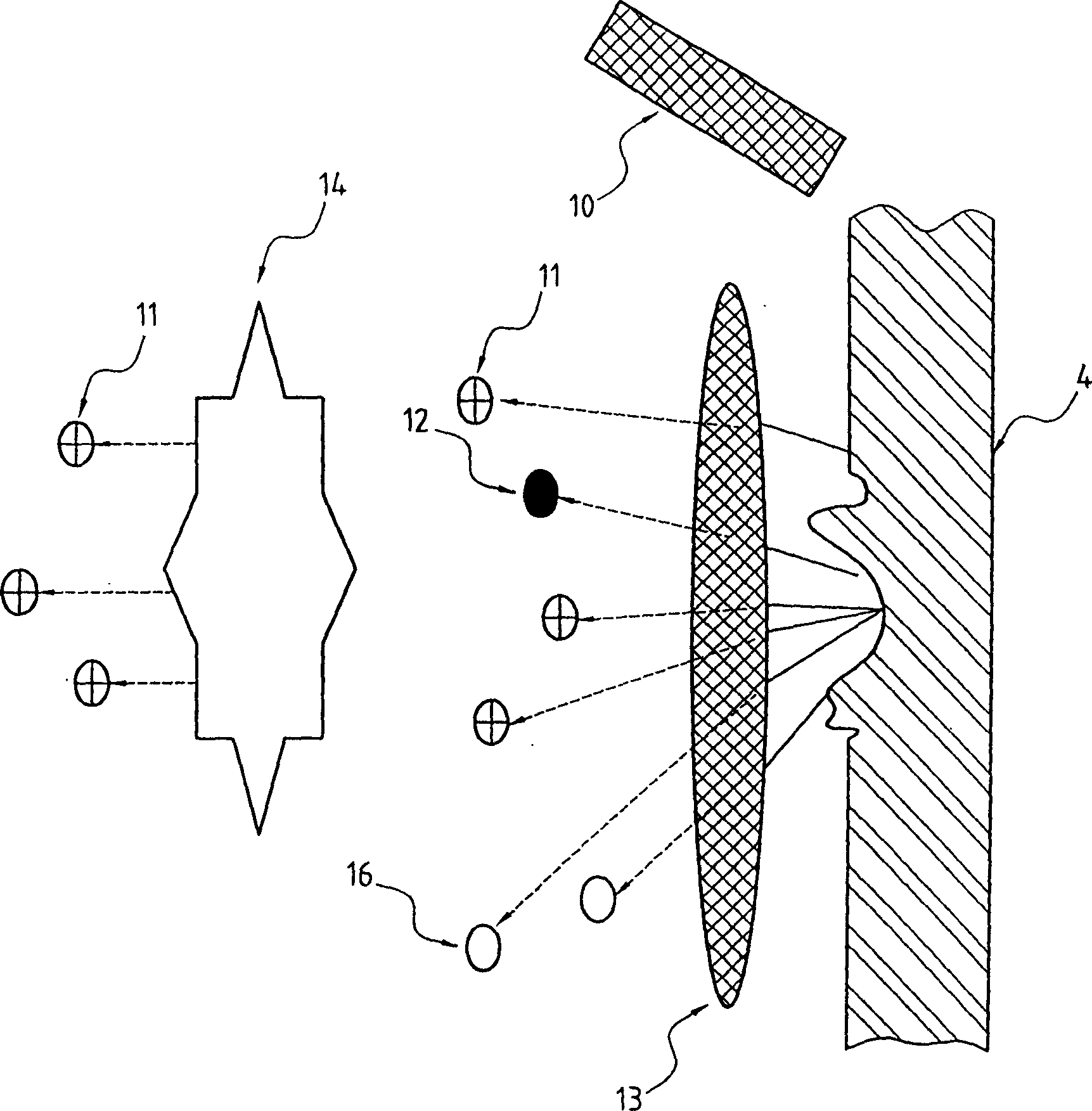

Process method for preparing electrodes of molten carbonate fuel cell by use of wet method

InactiveCN102244274AGuaranteed power generation performanceImprove compactnessCell electrodesPorosityFuel cells

The invention discloses a process method for preparing electrodes of a molten carbonate fuel cell by use of a wet method. The method comprises the following steps: stirring and mixing carbonyl nickel powder and an adhesion agent solution into slurry, so that nickle powder can be effectively adhered and filled on a supporting body, thus the compactness of the electrodes can increased; coating a nickle powder slurry on the supporting body at a certain thickness by virtue of a doctor blade; and then rolling by virtue of a roller shaft, thus the compactness and intensity of the electrodes are increased effectively, and the surfaces of the sintered electrodes are compact and flat, and have self-supporting capability. The supporting body also can play a role of a collector electrode in the cell, the power generation performance of the cell is ensured greatly, thus according to the method, ball milling for a long time is not required, an organic solvent is not required to be used, simultaneously holes on the surfaces of the prepared electrodes are distributed uniformly, and the porosity is high, the phenomenon of nickle power dropping does not exists, and the favorable performances of the electrodes are ensured; and in addition, the process and the method are simple and feasible, are low in manufacturing cost, and are very suitable for mass continuous production of the electrodes used for molten carbonate fuel cells.

Owner:HUANENG CLEAN ENERGY RES INST

Method for welding mother-daughter board connector long needle

ActiveCN103611996AEasy to controlAvoid errorsSoldering apparatusPrinted circuitsFree coolingEngineering

The invention discloses a method for welding a mother-daughter board connector long needle. The method includes the steps that a tin wire tightly winds a supporting bar, wherein the diameter of the supporting bar corresponds to that of the mother-daughter board connector long needle; then the tin wire on the supporting bar is cut, after one side of the tin wire to be welded is cut, a solder ring with openings in two sides is obtained, and then the solder ring is flattened; one or more flattened solder rings are arranged at the bottom of the mother-daughter board connector long needle in a sleeved mode, after the mother-daughter board connector long needle is horizontally arranged, hot air is blown into a mother-daughter board connector to heat the flattened solder rings, the hot air melts the flattened solder rings and enables the flattened solder rings to enter the position between a printing plate and the mother-daughter board connector long needle, after the solder rings are completely molten, the hot air stops being blown, the molten solder rings naturally cool, and the solidified solder rings connect the mother-daughter board connector long needle with the printing plate. The method avoids soldering of long needles distributed densely, avoids difficult operations and errors brought by the operations, and is simple and convenient to operate, and more importantly, control of the amount of tin is more accurate in the welding process.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

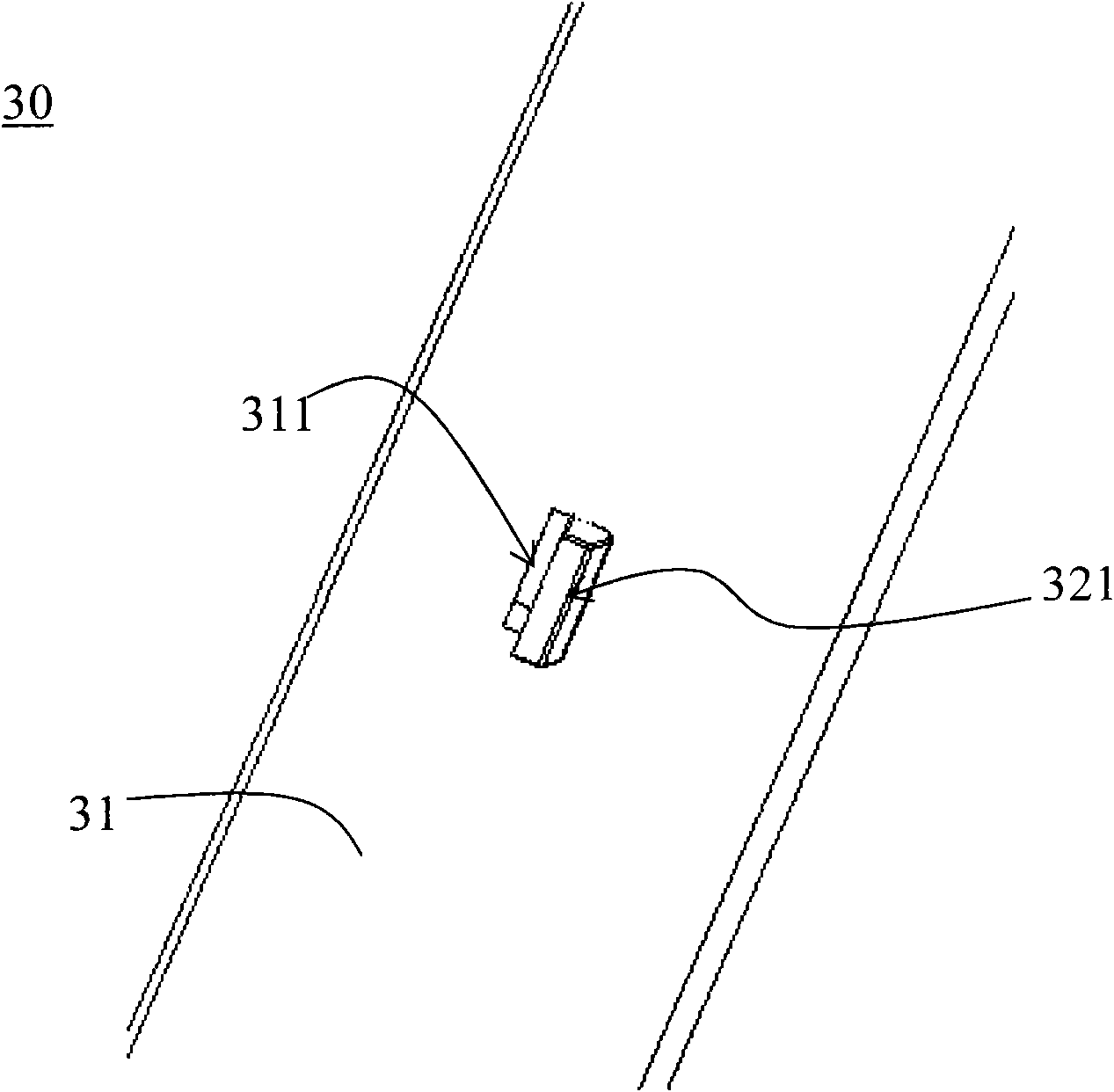

Composite probe for polymer space charge distribution measurement and measurement method thereof

ActiveCN111175549AImprove securityControllable inputElectrical measurement instrument detailsElectrical testingVoltage pulseConductive materials

Owner:TONGJI UNIV

Abrasion resistant coated process of miniature cutter

InactiveCN1552941AReduce toughnessAvoid the phenomenon of sheddingVacuum evaporation coatingSputtering coatingMilling cutterHardness

This invention relates to a process to coat a wear resistance film with thickness of 0.5 - 3um onto miniature machining tools, which can be sintered tungsten carbide or tungsten carbide cermet milling cutters or drill bits with shank diameters <4mm. Its constituent is ZrHfCN with Hf content of 0 - 10 wt%. It has good adhesion strength and can works at higher speed and with longer service life. Actually, it can make service life of tools 1.5 - 3 times long in machining printed circuit boards.

Owner:COSMOS VACUUM TECH CORP

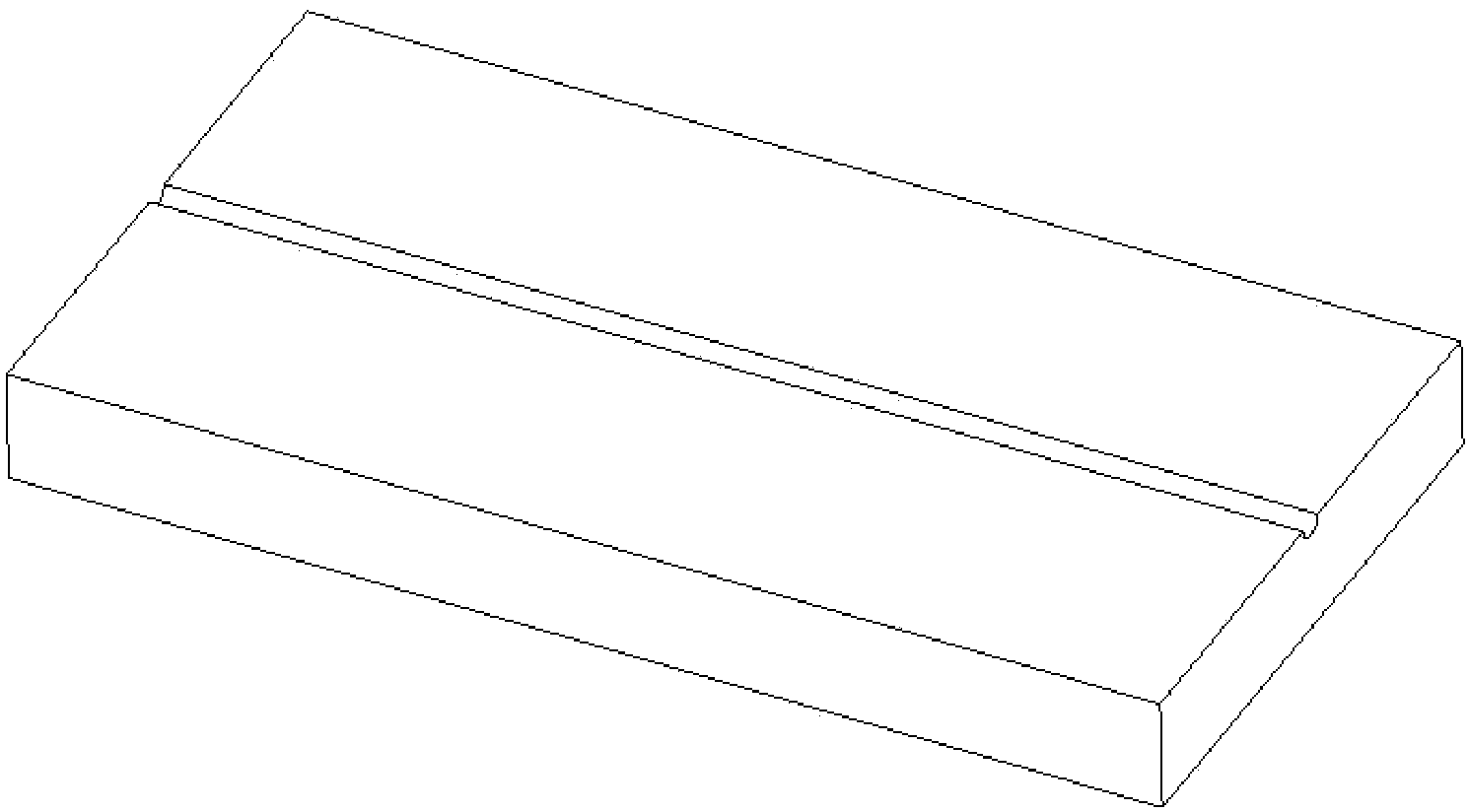

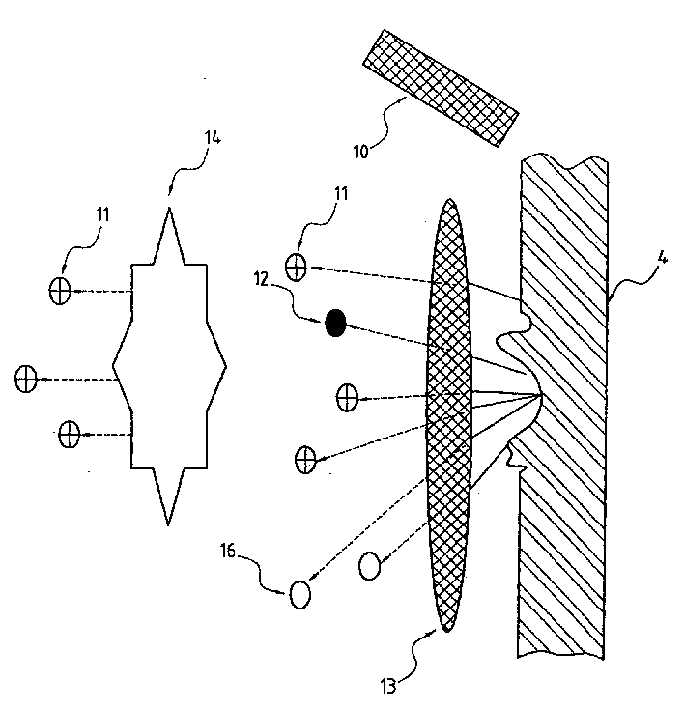

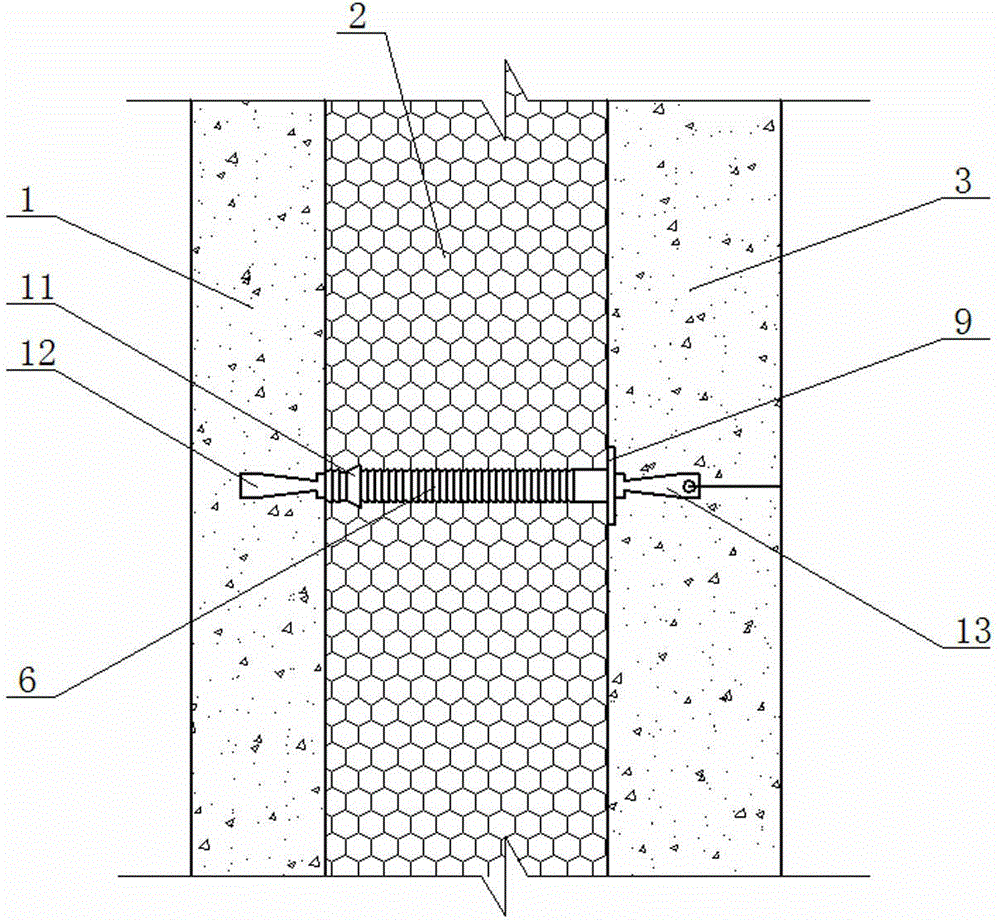

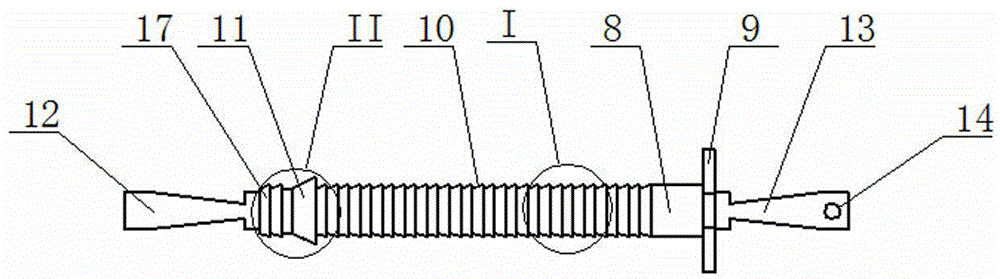

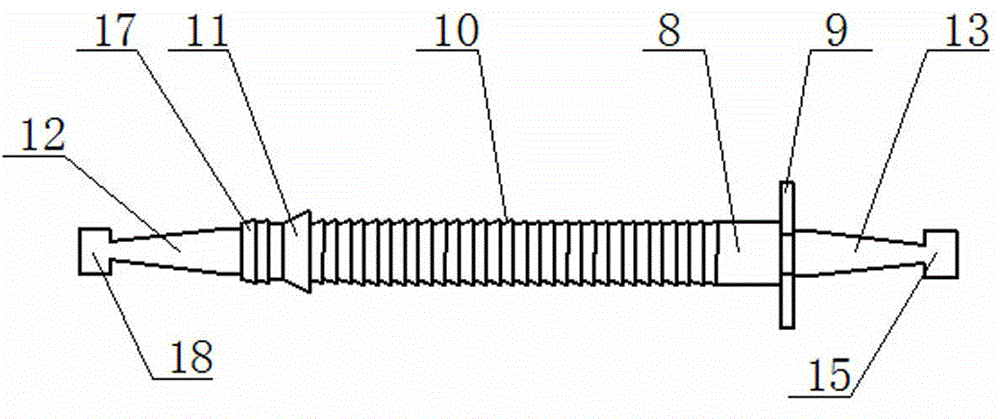

Building sandwich composite wallboard

The invention discloses a building sandwich composite wallboard, which comprises a concrete external wallboard and a concrete internal wallboard, a heat-insulation layer plate is arranged between the external wallboard and the internal wallboard, a nonmetal connecting bar is arranged in the external wallboard, the heat-insulation layer plate and the internal wallboard, a bar body is arranged at the central part of the nonmetal connecting bar, an annular tooth is arranged on the bar body, an annular baffle plate is arranged at one side of the bar body, an annular seal bench is arranged at opposite side of the bar body, a first anchoring body is connected to a seal bulge loop, a second anchoring body is connected to the annular baffle plate, the annular baffle plate is positioned at the connection part of the heat-insulation layer plate and the internal wallboard, the annular seal bench is positioned in the heat-insulation layer plate at the connection part of the heat-insulation layer plate and the external wallboard, the annular tooth can be positioned in the heat-insulation layer plate, the first anchoring body is positioned in the external wallboard, and the second anchoring body is positioned in the internal wallboard. According to the sandwich composite wallboard, the three layer structure enables mutually and firmly connection, wallboard strength is greatly increased, the connecting bar has good seal function while passing through the heat-insulation layer, so that heat insulation effect can be greatly increased.

Owner:山东万斯达建筑工业化研究院有限公司

Nickel plating method for stainless steel strips

InactiveCN106521587AUniform electrochemical etchingUniform chemical etchingFiller metalBinding force

The invention provides a nickel plating method for stainless steel strips. The method includes the steps of 1, degreasing; 2, pre-etching; 3, alkali washing; 4, etching; 5, nickel flash plating; and 6, nickel plating. In the step 1, the strips are placed into degreasing solutions for 2-5 minutes to remove greasy dirt on the surfaces of the strips; in the step 2, the degreased strips are pre-etched to remove Cr2O3 passivation films on the surfaces of the strips; in the step 3, alkali washing is carried out on the strips to neutralize pre-etching solutions; in the step 4, the strips are etched so that the surfaces of the strips can have certain microscopic roughness; in the step 5, nickel flash plating is carried out on the obtained strips for 1.5-2.5 minutes so that thin nickel layers can be deposited on the strips in a short time; and in the step 6, nickel plating is carried out on the strips so that the strips can have good wettability in the brazing process. According to the method, the nickel layers with the attractive appearances, the good binding force and the uniform thickness are deposited on the surfaces of the strips, and therefore the flowability of brazing filler metal is better in the subsequent brazing process of the strips and the brazing effect is improved.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND +1

Nickel silver platinum rhodium multilayer composite plating process

The composite multilayer Ni, Ag, Pt and Rh electroplating process includes successive Ag pre-electroplating step, Ni-electroplating step, Ag-electroplating step and Pt and Rh electroplating step, with special requirement in electrolyte composition and pH value, electroplating temperature and time, electrode current density and other technological parameters. The said electroplating process has no problem of color change in Ag plated surface, and the coating is bright, smooth, beautiful, fast and without color change.

Owner:刘广斯

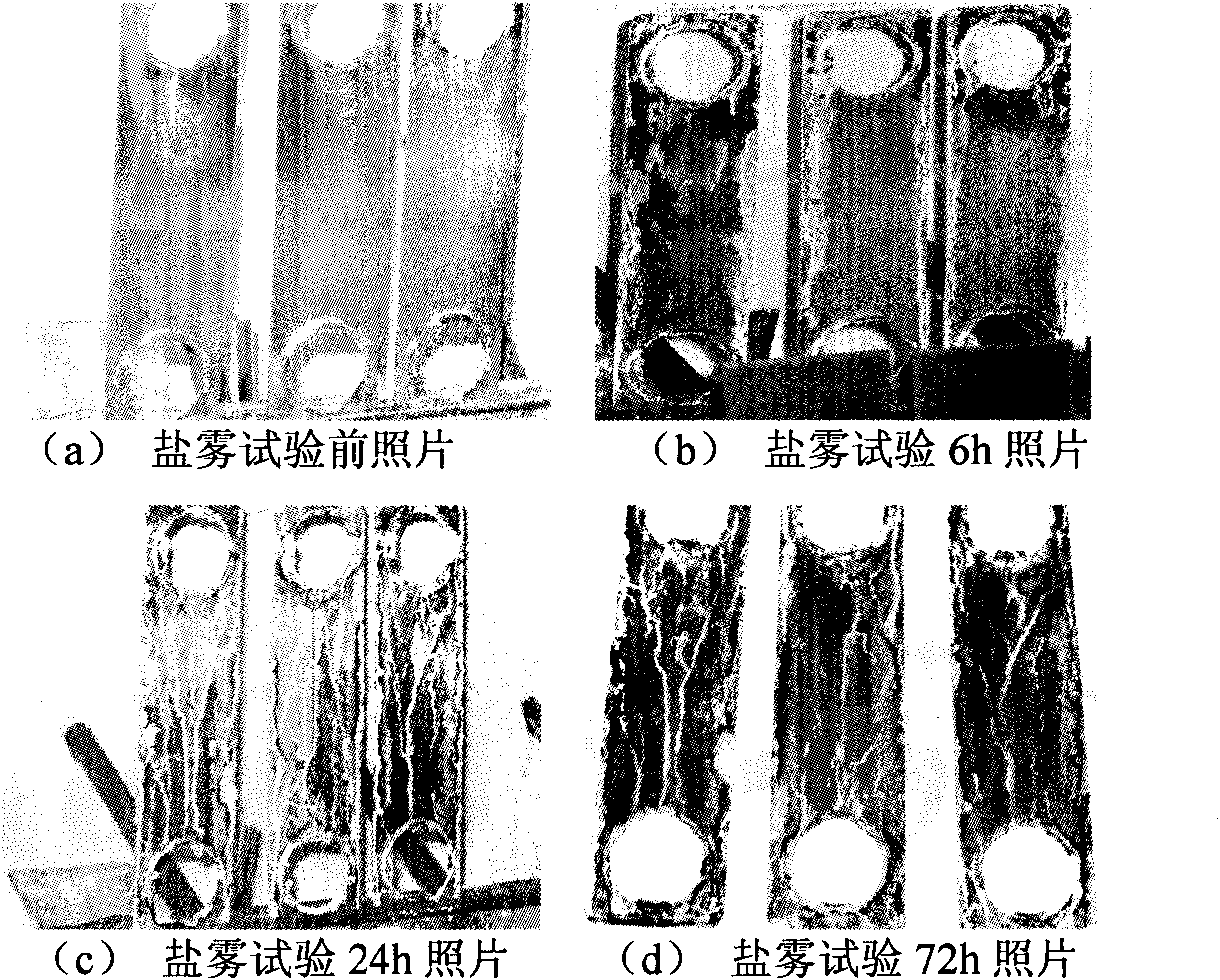

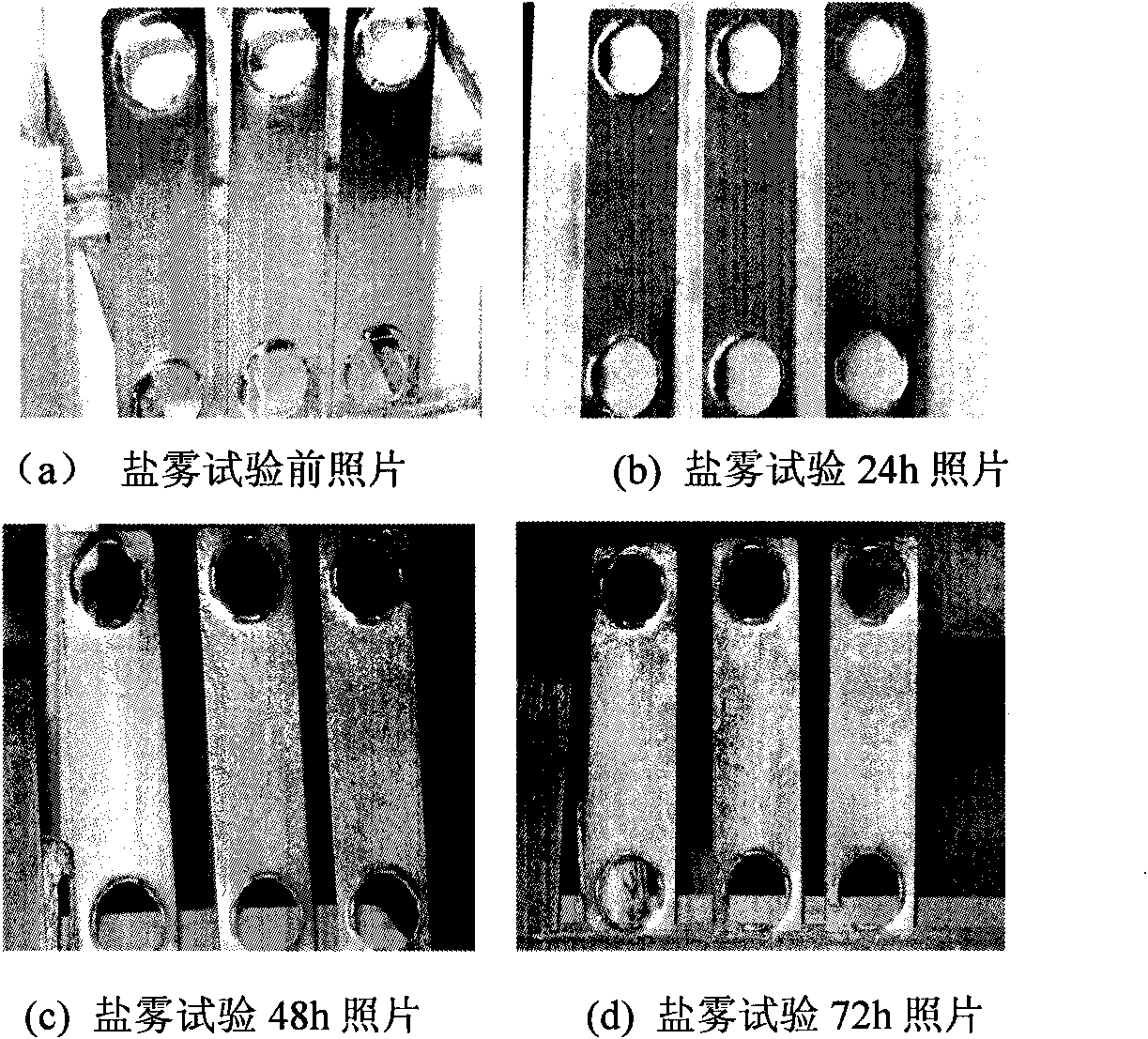

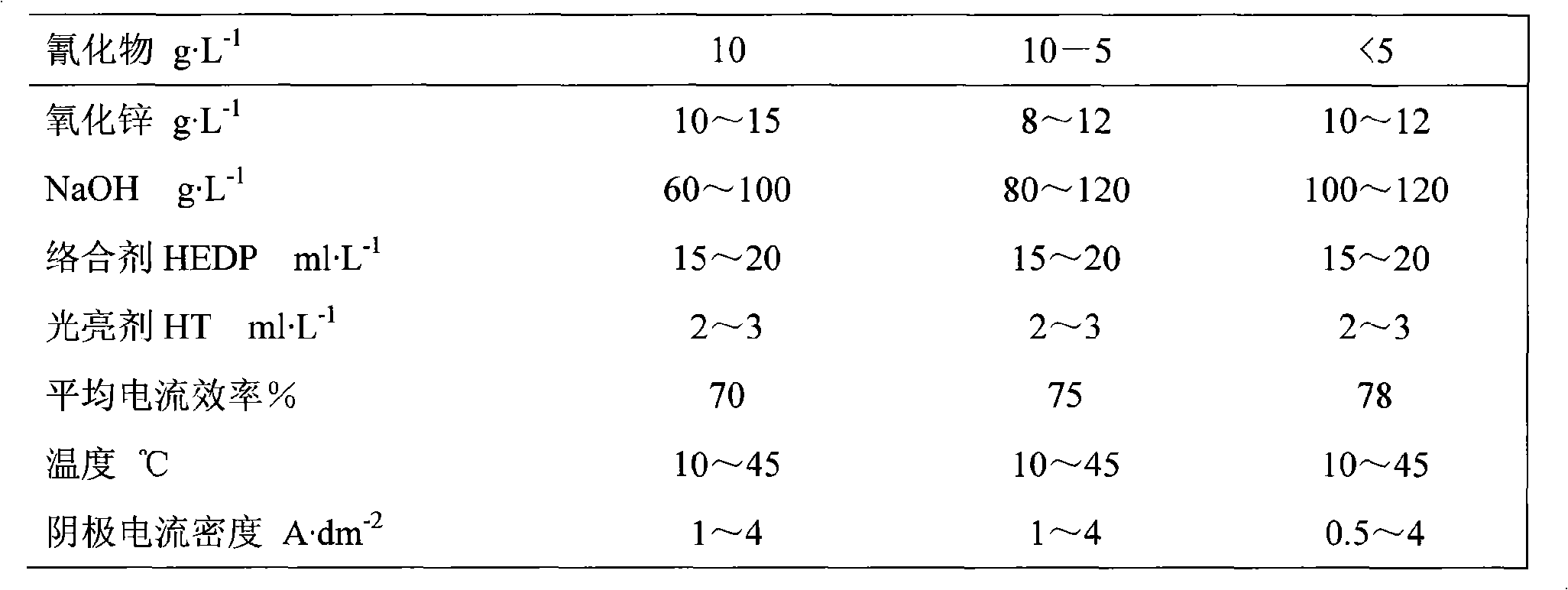

Non-cyanide converting method for cyanide plated zinc

The invention relates to a non-cyanide converting method for cyanide plated zinc. Non-cyanide conversion is as follows: a brightening agent (HT) and a complexing agent (HEDP) are added into plating liquid to carry out zinc plating by stopping adding NaCN and ZnO into the plating liquid. The plating liquid comprises the following components (g*L-1): 10-less than 5 of cyanide, 8-15 of zinc oxide, 60-120 of NaOH, 15-20 of HEDP and 2-3 of HT. The electroplating technical condition comprises the temperature of 10-45 DEG C, the cathode current density (A*dm<-2>) of 0.5-4 and the average current efficiency of 70-78 percent. The corrosion resistance, the bonding capability and the color change resistance of a plating layer completely meet the practical production requirement. The plating liquid has high impurity resistance and is still stable for continuously using for one month. The converted process does not use the cyanide, is easy to process electroplating wastewater and is a more clean production process, thereby replacing a cyanide zinc plating process in a peace way.

Owner:DALIAN MARITIME UNIVERSITY

Traceless hair extension device

InactiveCN106617623AGood hair extensionsNo hair lossPackaging toiletriesPackaging cosmeticsEngineeringHair loss

The invention belongs to the beauty hair industry in particular to a traceless hair extension device. The traceless hair extension device comprises a main body, a hair extension card slot, a heating dual concave and a stereotyped concave platform, resolving the problems in existing technologies such as hair piece sol flow which leads to negative effects of hair extension and uneven hair distribution. The lower end of the stereotyped concave platform is connected with the heating dual concave and the heating dual concave is arranged on the main body. The main board of the card slot is arranged on the one side of the heating dual concave which is away from the main body. The hair extension card slot is actively installed on the main board of the card slot. The hair slots for hair piece installment are evenly arranged on the hair extension card slot. Each hair slot is formed by the distance of the alveolar ridge. The upper side of the heating dual concave is arranged on the heating slot corresponding to the hair slot, which is characterized in that a jag is disposed on the top of each alveolar ridge. The heating dual concave and the traceless hair extension device improve the heating structure, so in the process of the hair extension, the traceless hair extension device has the advantages of avoiding the situation of sol flow, ensuring the even distribution of the hair extension sol, assuring the natural hair extension effects as well as preventing the occurrence of hair loss.

Owner:朴松锦

Nickel oxide high-temperature purple silk-gloss ceramic glaze and preparation method thereof

The invention provides nickel oxide high-temperature purple silk-gloss ceramic glaze and a preparation method thereof, and belongs to the field of ceramic. The nickel oxide high-temperature purple silk-gloss ceramic glaze is obtained by firstly preparing a nickel oxide high-temperature purple silk-gloss ceramic glaze material, and then glazing and sintering at high temperature, wherein the nickeloxide high-temperature purple silk-gloss ceramic glaze material is prepared from the following raw materials according to the mass percent of each raw material: 45 percent to 35 percent of potassium feldspar powder, 4.5 percent to 6 percent of silicon dioxide, 4.5 percent to 10 percent of kaolin, 10 percent to 20 percent of zinc oxide, 30 percent to 40 percent of a frit and 1 percent to 2 percentof nickel oxide. The frit is prepared from the following raw materials according to the mass percent of each raw material: 1 percent to 3 percent of potassium oxide, 12 percent to 20 percent of sodiumoxide, 2 percent to 8 percent of calcium oxide, 10 percent to 35 percent of barium carbonate and 40 percent to 60 percent of silicon dioxide. By adopting the method provided by the invention, a phenomenon in a firing process of a traditional glaze material that a lot of poisonous heavy metal is volatilized is overcome; meanwhile, phenomena that needle holes and cracks are formed in the surface ofa fired product are effectively prevented.

Owner:SHENYANG JIANZHU UNIVERSITY

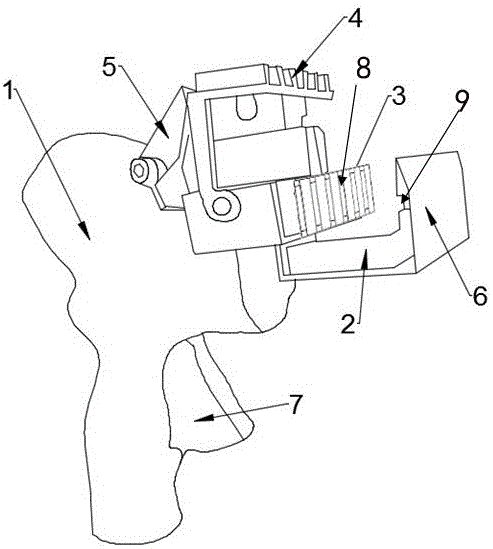

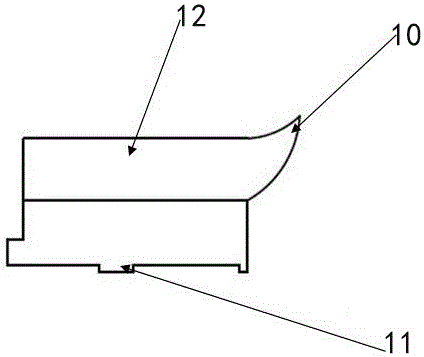

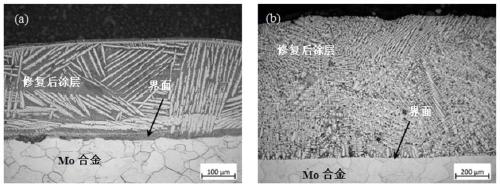

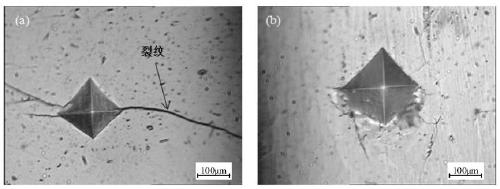

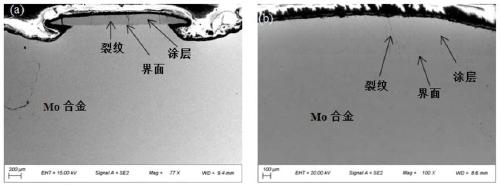

Method for repairing silicide coating on surface of Mo alloy sheet

InactiveCN111172530AImprove economyImprove the effect of practiceMetallic material coating processesAl powderOxidation resistant

The invention relates to a method for repairing a silicide coating on the surface of a Mo alloy sheet. The method comprises the following steps of first, polishing the surface of a peeling-off part ofthe silicide coating on the surface of the Mo alloy sheet, preparing from the following components in percentage by mass: 2%-5% of Nb powder, 3%-5% of Al powder, 1%-2% of Cr powder, 0.5%-1% of W powder, 0.2%-0.5% of B powder, 0.1%-0.2% of Ti powder, and the balance of MoSi2 powder, and performing ball milling to obtain mixed alloy powder mainly based on MoSi2, then using ethanol as a binder to bepre-arranged and attached to the coating peeling-off part, drying to obtain a pre-arranged coating, and finally performing TIG arc cladding on the pre-arranged coating by using TIG arc welding, thereby obtaining an arc cladding repair coating on the surface of the Mo alloy sheet. The method can improve the interface bonding strength and high temperature oxidation resistance of the repaired coating.

Owner:JIANGSU UNIV OF TECH

Environment-friendly putty powder and preparation method thereof

InactiveCN111849238ASimple manufacturing methodReduce manufacturing costFilling pastesEpoxyPolymer science

The invention discloses environment-friendly putty powder which is characterized in comprising the following components in parts by weight: 20-30 parts of palygorskite, 10-20 parts of montmorillonite,15-20 parts of white cement, 1-3 parts of lambda-carrageenan modified polyquaternium-10, 2-4 parts of rosin modified cationic guar gum, 1-3 parts of konjac gum, 0.5-1.5 parts of epoxy-terminated hyperbranched polyphosphate and 0.5-1.5 parts of amino-terminated hyperbranched polybenzimidazole. The invention further provides a preparation method of the environment-friendly putty powder. The environment-friendly putty powder disclosed by the invention is good in comprehensive performance, sufficient in strength and adhesive force, high in hardness, good in water resistance, free of phenomena ofhollowing, peeling, cracking and falling off after being wetted by water, and safe and environment-friendly to use.

Owner:刘超

Dry powder mortar

The invention provides a dry powder mortar used for making a waterproof paint, which can solve the problem of difficult long-term immersion and poor connection during usage of the current waterproof paint. The dry powder mortar comprises the following components by ratio: 30-40% of cement, heavy calcium, 40-45% of water-rich sand, 5-7% of glue powder, an antifoaming agent, an antiseptic, a water reducer, cellulose, 10-20% of water and 1-2% of PP fiber. The dry powder mortar can be used for gradually discharging moisture in building concrete, indoor wet and mildew can be avoided, and smooth breathing of the building can be realized; the dry powder mortar has same general character with concrete and a tile glue, strong affinity is generated among the dry powder mortar, the concrete and the tile glue, and phenomena of water leakage and tile shedding can not be generated due to long-term usage; comprehensive cost is low, construction is simple, the dry powder mortar has no strictness to base requirement, so that construction can be carried out when the flattening strength of base is enough and no water is generated.

Owner:王春义

Water-based paint which has high thermal dissipation and is applied to wooden door

InactiveCN108017975AStrong adhesionImprove protectionFireproof paintsEpoxy resin coatingsWater basedCocamidopropyl betaine

The invention discloses water-based paint which has high heat dissipation and is applied to a wooden door. The water-based paint is prepared from, in parts by weight, 50-70 parts of a main material, 1-2 parts of C9 petroleum resin, 0.1-0.2 part of a catalyst, 1-2 parts of a water-based curing agent, 0.2-0.8 part of cocamidopropyl betaine, 0.4-0.6 part of octylphenol polyoxyethylene ether, 1-4 parts of a composite flame retardant, 2-8 parts of illite, 3-5 parts of quartz sand, 1-4 parts of diatomaceous earth, 1-2 parts of heavy calcium carbonate, 2-8 parts of coal gangue powder, 1-4 parts of hollow glass microbeads, 1-3 parts of an anti-settling agent, 1-3 parts of a dispersant, 0.5-2 parts of a leveling agent and 1-2 parts of a defoamer. A coating of the water-based paint has strong adhesion, a full paint film, no yellowing and brittleness, no organic solvent, a good thermal dissipation effect, excellent flame-retardant performance, superior comprehensive performance and a good protection effect on the wooden door, no peeling emerges on the surface after long-term use of the wooden door, and fire can also be prevented effectively when a fire occurs.

Owner:合肥林邦门业有限公司

Method for enhancing back cover bond stress based on offshore steel inclined pile foundation

InactiveCN109778891AImprove stress resistanceGuaranteed firmnessFoundation engineeringReinforced concreteRebar

The invention discloses a method for enhancing back cover bond stress based on an offshore steel inclined pile foundation and relates to the technical field of civil engineering. The method comprisesthe steps of prefabricating shear connectors, prefabricating a hole sealing assembly, welding spiral ribs, assembling a prefabricated part, pouring concrete and sealing, and the like. The shear connectors are arranged on the periphery of the steel pipe pile, part of stress transmitted by the reinforced concrete layer can be transmitted in the direction perpendicular to the axis of the steel pipe pile, and therefore the compression resistance of the reinforced concrete layer is improved, and meanwhile the firmness of connection between concrete and the shear connectors can be guaranteed throughthe arranged extending pieces.

Owner:CCCC SHEC FOURTH ENG

Cyaniding silver immersion method adopted before copper ornament silvering

The invention discloses a cyaniding silver immersion method adopted before copper ornament silvering and relates to the technical field of electroplating. A copper ornament treated through acidic degreasing, chemical brightening and activating is placed in a basket for use. The cyaniding silver immersion method comprises the following steps that A, the copper ornament is immersed in silver immersion liquid for 5-15 seconds, wherein the silver immersion liquid comprises, by weight, 3-5 parts of silver nitrate, 75-85 parts of editpotassium cyanide and 75-85 parts of potassium carbonate; B, the copper ornament which is immersed in the silver immersion liquid in the step A is washed with water and aired. Compared with the prior art, the cyaniding silver immersion method adopted before copper ornament silvering can solve the problems that cracking and peeling phenomena are prone to happening due to existing pre-silvering treatment conducted on a copper ornament, and then the quality of the surface of the silvered copper ornament is influenced.

Owner:LIUZHOU XUPING JEWELRY

Modification method of anti-corrosion and anti-crack ulmus pumila board

InactiveCN107379176ANot easy to absorb waterImprove moisture resistanceWood treatment detailsThermal wood treatmentMoistureChemistry

The invention belongs to the technical field of wood treatment, in particular to a method for modifying anti-corrosion and anti-cracking white elm boards. The specific method is as follows: (1) immerse the cut white elm boards in superphosphate aqueous solution for heat preservation and soaking, take them out, and keep the temperature constant Refrigerate; (2) Immerse in boric acid aqueous solution and boil over medium heat, then continue to boil over low heat, take out the freezer and freeze at a constant temperature; (3) Hot press dry until the moisture content is 14%~16%, put it in a reaction kettle, add a treatment agent to The white elm board is submerged, steam-dried, vacuumized, and dried to a moisture content of 40% to 45%; (4) Freezing treatment, dried to a moisture content of 9% to 11%; the modified white elm board is sterilized and antiseptic Performance, not easy to absorb water, good moisture-proof performance, effectively reduce the loss rate of wood boards, and will not crack, warp, or fall off after 50 years of use, and has strong resistance to gravity, and is not easy to crack under high-strength pressure. It has high-efficiency anti-cracking ability.

Owner:FUNAN NATURE ARTS & CRAFTS

Testing device for processing sealing ring of anti-drop engine ignition coil cylinder body

PendingCN114216673AGuaranteed placementSimple mechanical structureMachine sealing rings testingIgnition coilStructural engineering

The invention discloses an anti-falling type engine ignition coil cylinder body sealing ring processing test device, which comprises a table plate, the top of the table plate is provided with a plurality of groups of test mechanisms, each group of test mechanism comprises a placing table, a plurality of carrying tables are arranged in the placing table, screw holes are formed among the carrying tables, and the screw holes are connected with the table plate. A conical stud is arranged in the screw hole, the conical stud is in threaded connection with the inner wall of the screw hole, a screw rod is fixed to the bottom end face of the conical stud, and a containing groove is formed in the top end face of the table plate; by means of the design, the mechanical structure is simplified, early-stage installation and later-stage disassembly and maintenance of the device are very convenient, the manufacturing cost is greatly reduced, meanwhile, detection can be conducted according to actual operation and installation of one or more sealing rings, the first clamping groove and the second clamping groove are designed, placement of the sealing rings can be guaranteed, and the sealing performance of the device is improved. And a falling phenomenon cannot occur in a test, and a plurality of defects in the existing device are overcome.

Owner:昆山合马密封技术有限公司

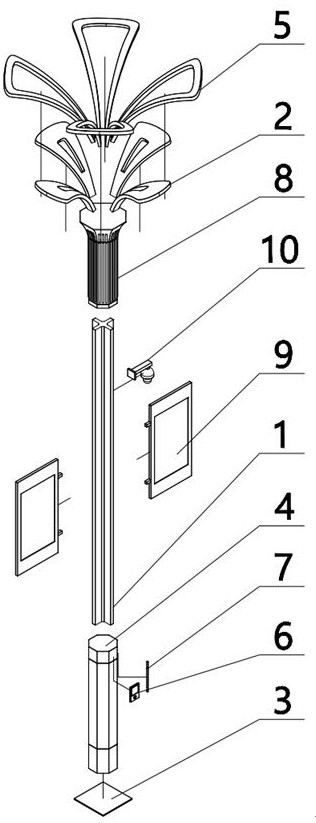

Intelligent petal high-pole street lamp

PendingCN112503454AEasy to chargeReduce the area of public facilitiesMechanical apparatusLighting support devicesEngineeringMechanical engineering

The invention discloses an intelligent petal high-pole street lamp which comprises a lamp pole, a charging pile is fixedly connected to the bottom of the lamp pole, an automobile charger is fixedly installed on the surface of the charging pile, a broadcaster is fixedly installed on the surface of the charging pile and located at the top of the automobile charger, and a flange plate is connected toa bottom flange of the charging pile; an advertising board is arranged in the middle of the surface of the lamp post, and a monitoring probe is installed at the position, located over the advertisingboard, of the upper end of the surface of the lamp post. The charging pile is arranged on the bottom of the lamp post, the lamp post is fixed to the ground through the flange plate, and the automobile charger and the broadcaster are arranged on the charging pile, so that people can charge a new energy automobile conveniently. The advertising board is arranged in the middle of the lamp post, and the advertising board does not need to be remanufactured for placement and installation, so that the area of public facilities is reduced, the manufacturing cost is reduced, and meanwhile, the environment-friendly and emission-reduction conditions are achieved; and the intelligent street lamp is attractive in appearance, complete in function and suitable for being used in intelligent cities.

Owner:詹慕华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com