Light source framework and backlight module

A light source and frame technology, applied in the field of light source frame and backlight module, can solve the problems of long molding cycle, high equipment cost, complex molding process, etc., and achieve the effect of short molding cycle, simple mold and process, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

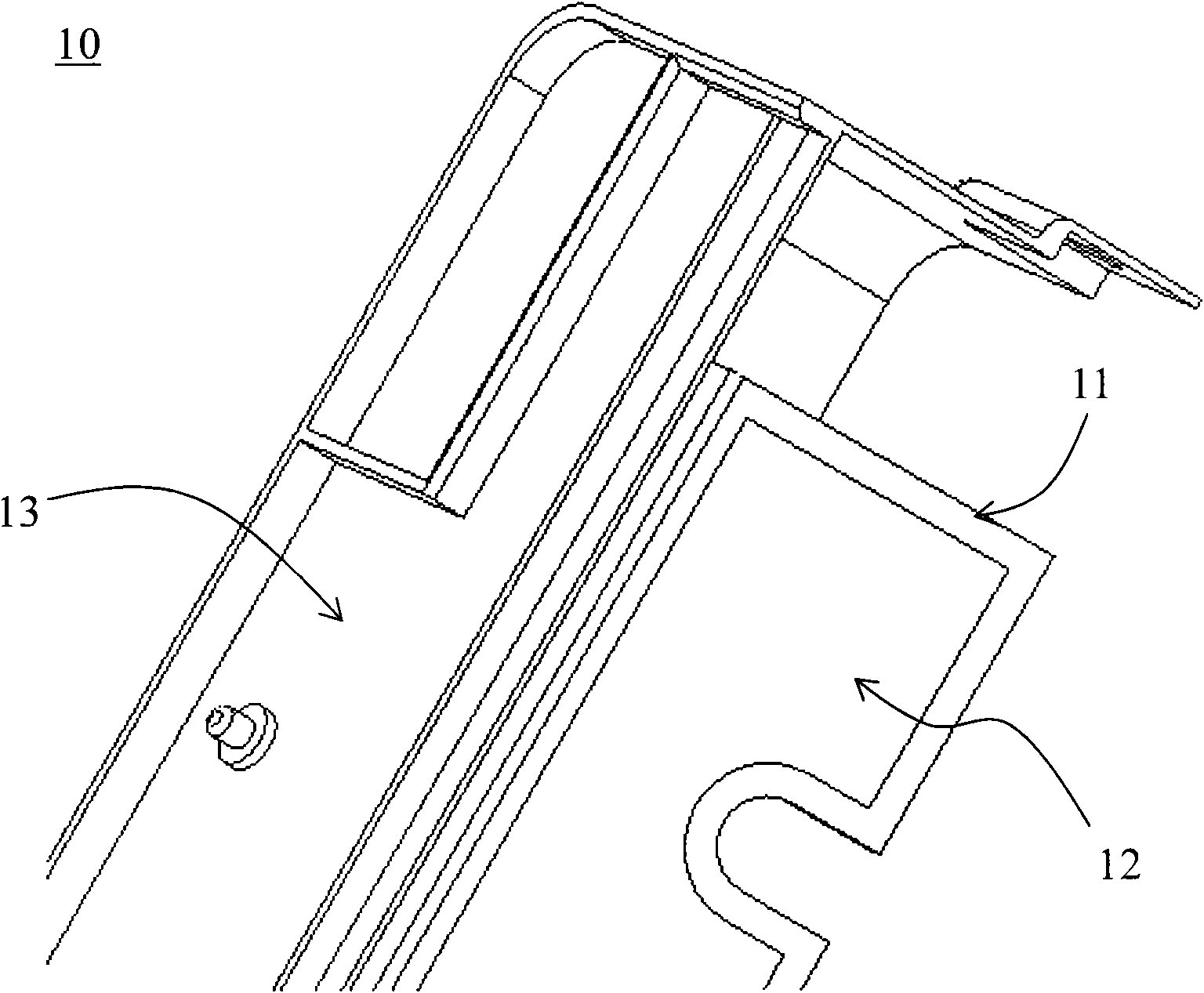

[0022] The light source frame provided by the present invention can be applied to a backlight module in a liquid crystal display device. The backlight module also includes a light source, such as a lamp tube or an LED light source, which is arranged in the light source frame.

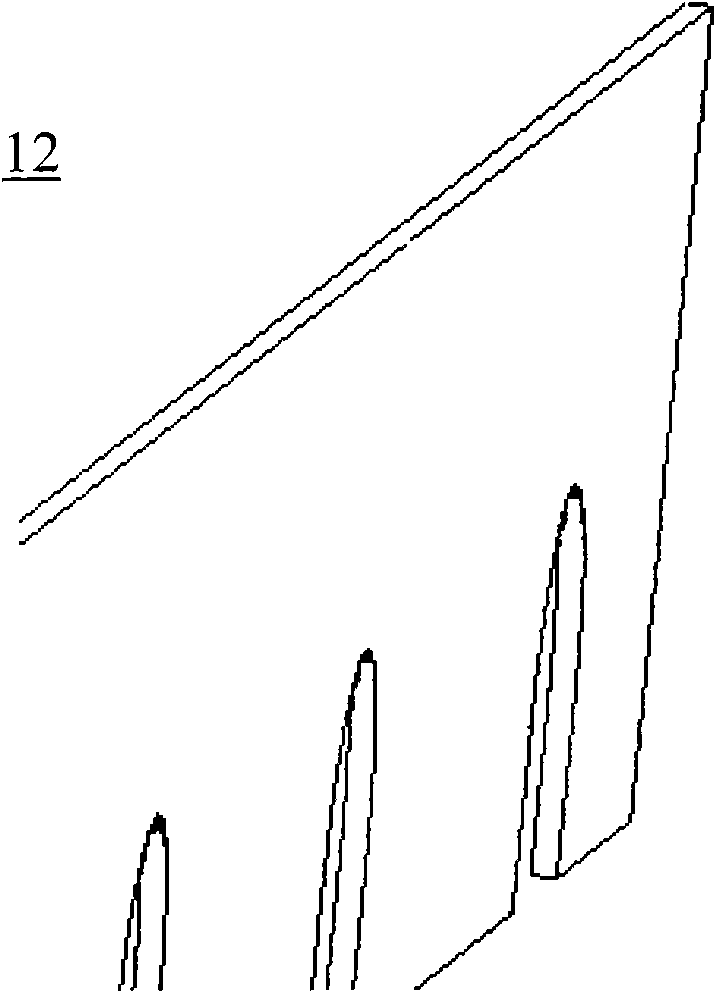

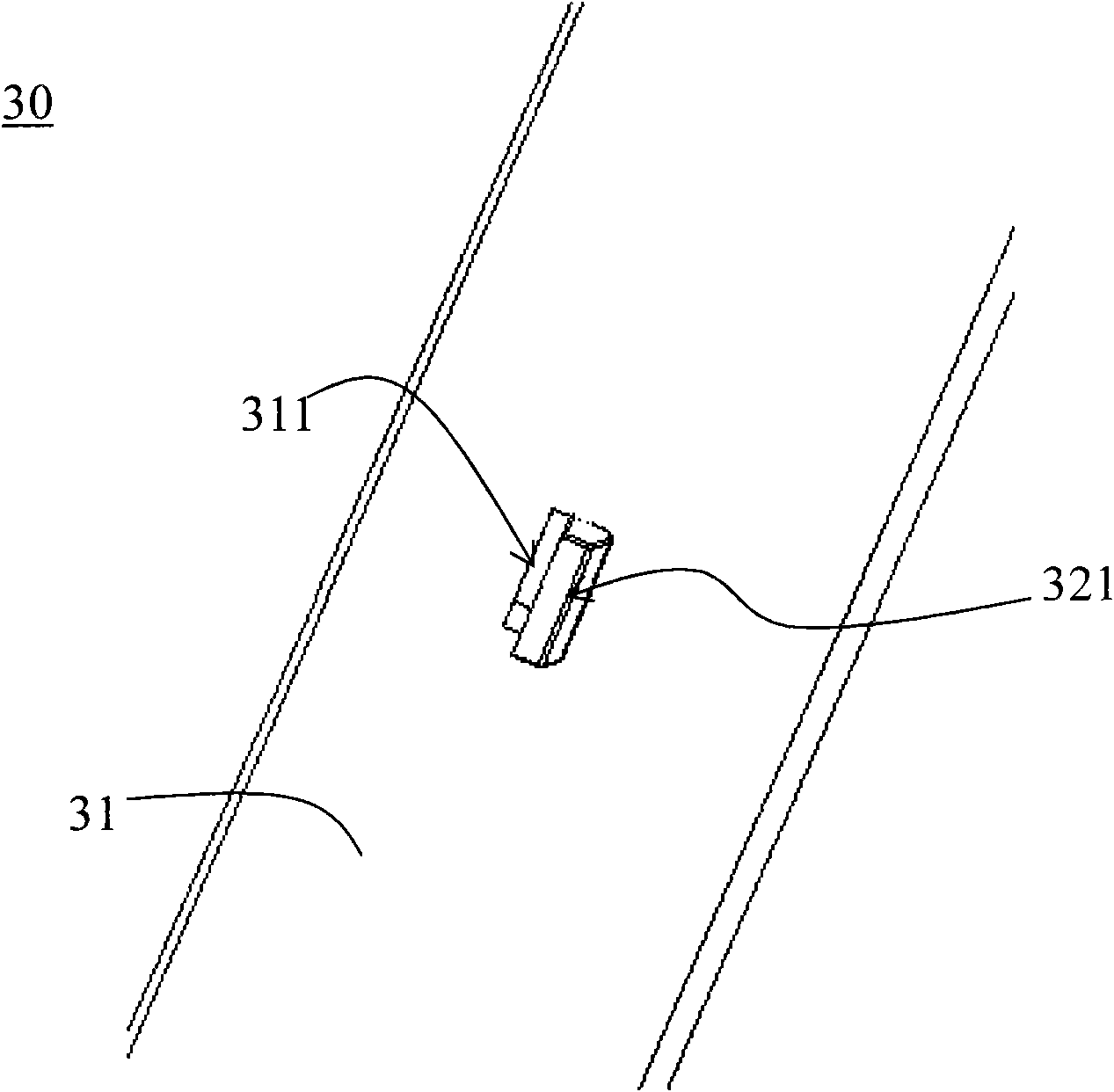

[0023] See image 3 and Figure 4 , image 3 is a schematic diagram of the light source frame 30 of the present invention, Figure 4 for image 3 A schematic diagram of the reflective sheet 32 in . The light source frame 30 includes a frame (not shown), side strips 31 and reflectors 32 (please refer to Figure 4 ,exist image 3 is blocked by the edge strip 31). The side bar 31 is disposed on the frame, and the side bar 31 has at least one positioning hole 311 . The reflective sheet 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com