Patents

Literature

278results about How to "Short molding cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing upsized frp member

InactiveUS20040130072A1Improve mass productionReduce manufacturing costLamination ancillary operationsLaminationAir cycleFiber

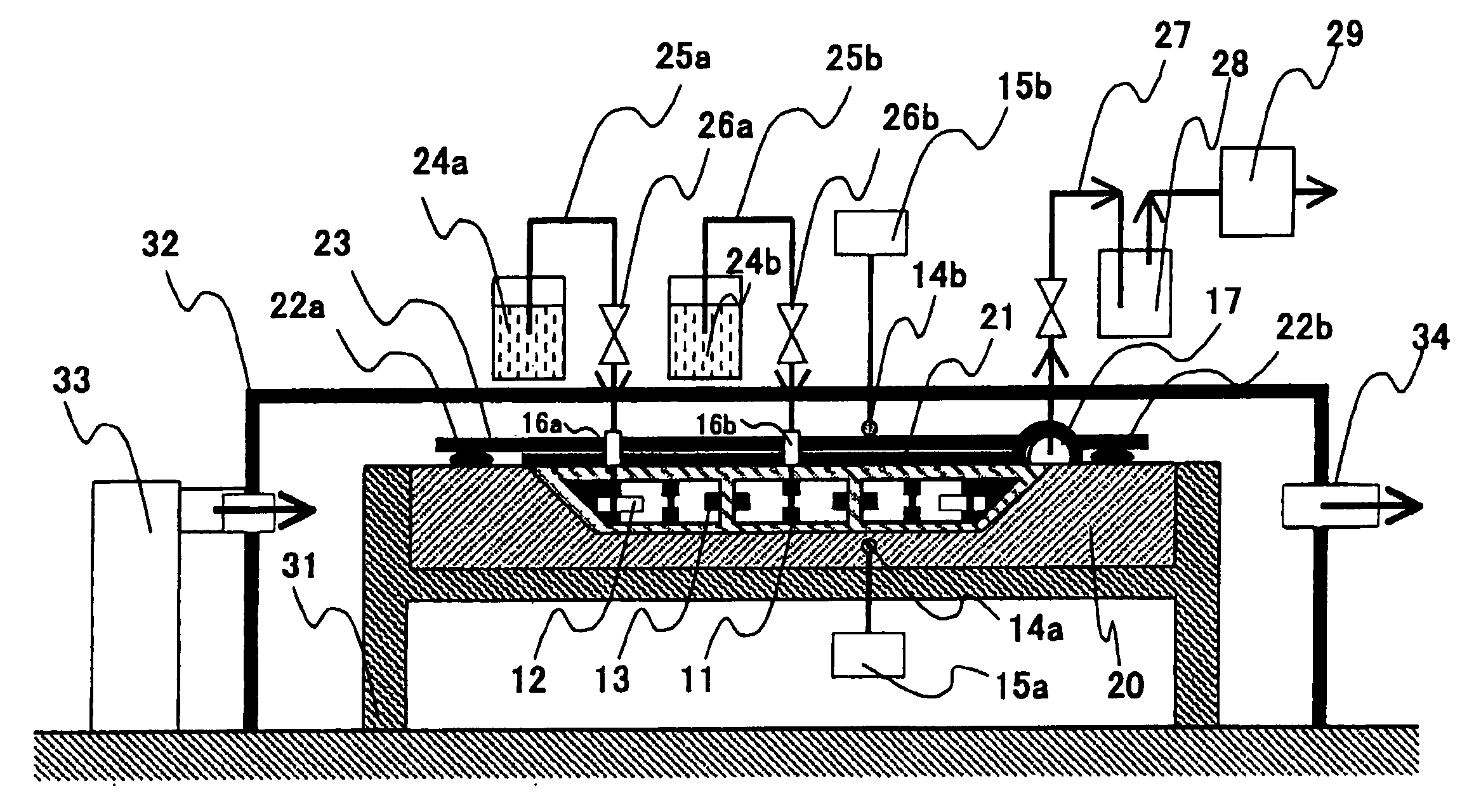

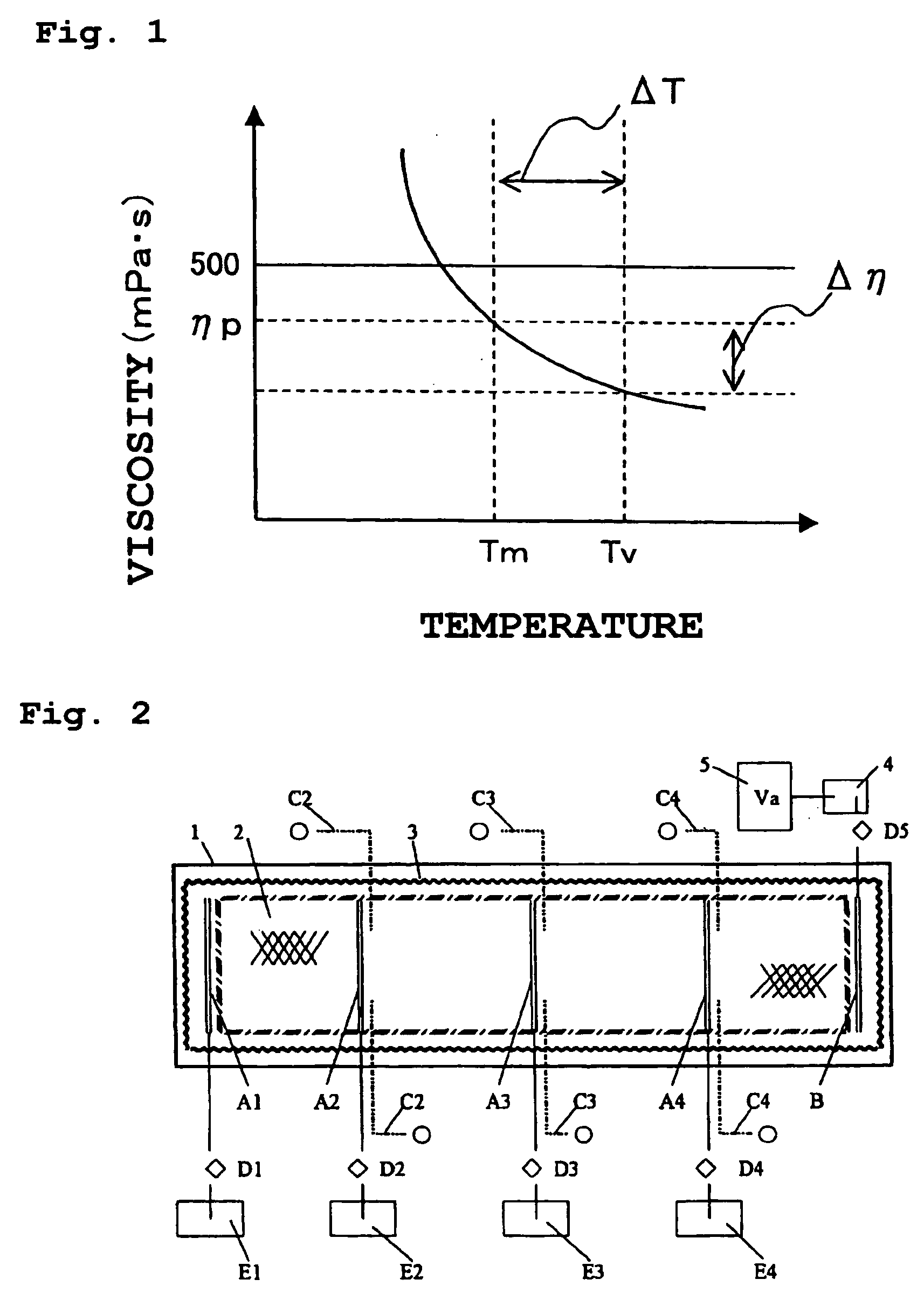

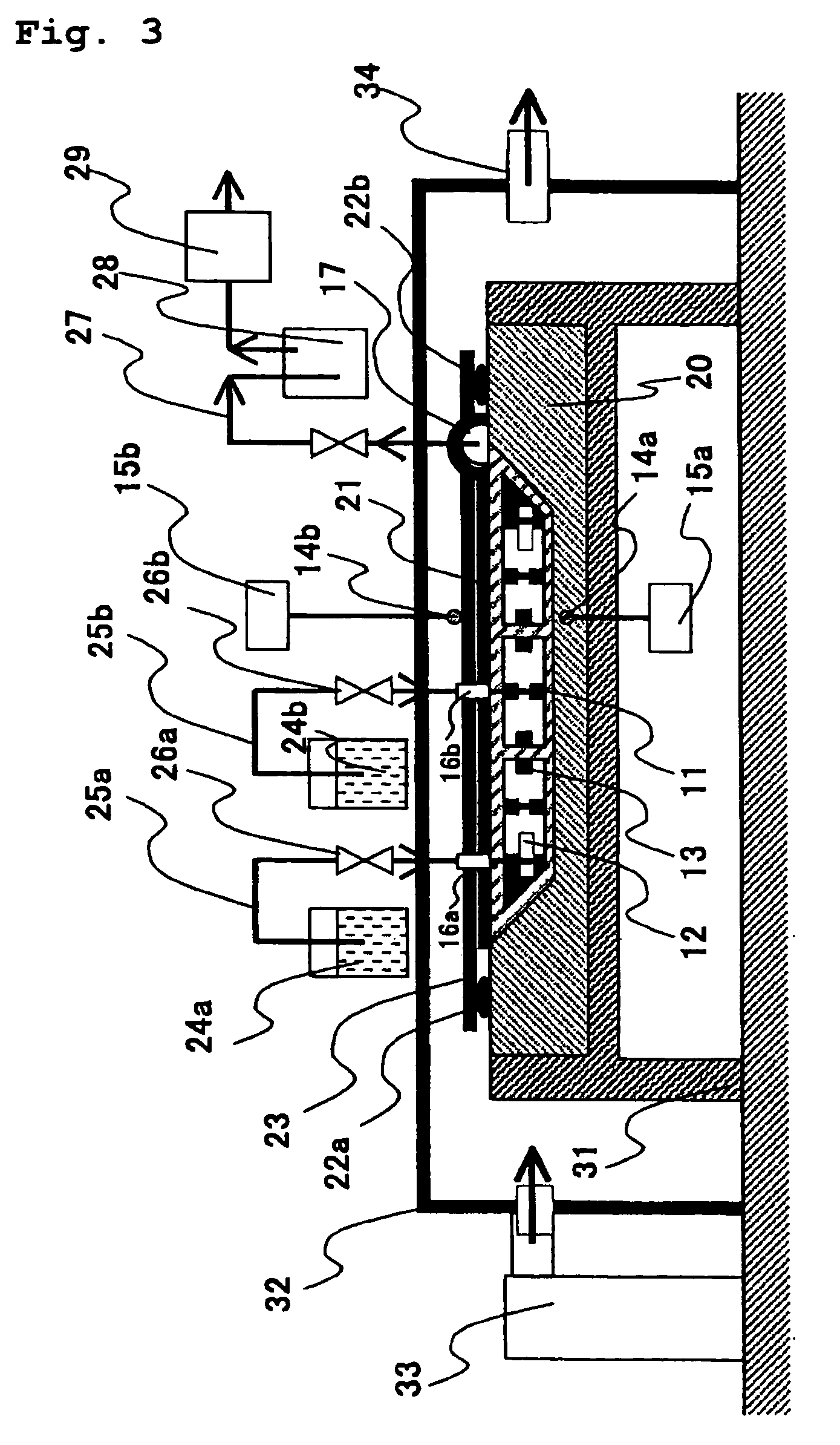

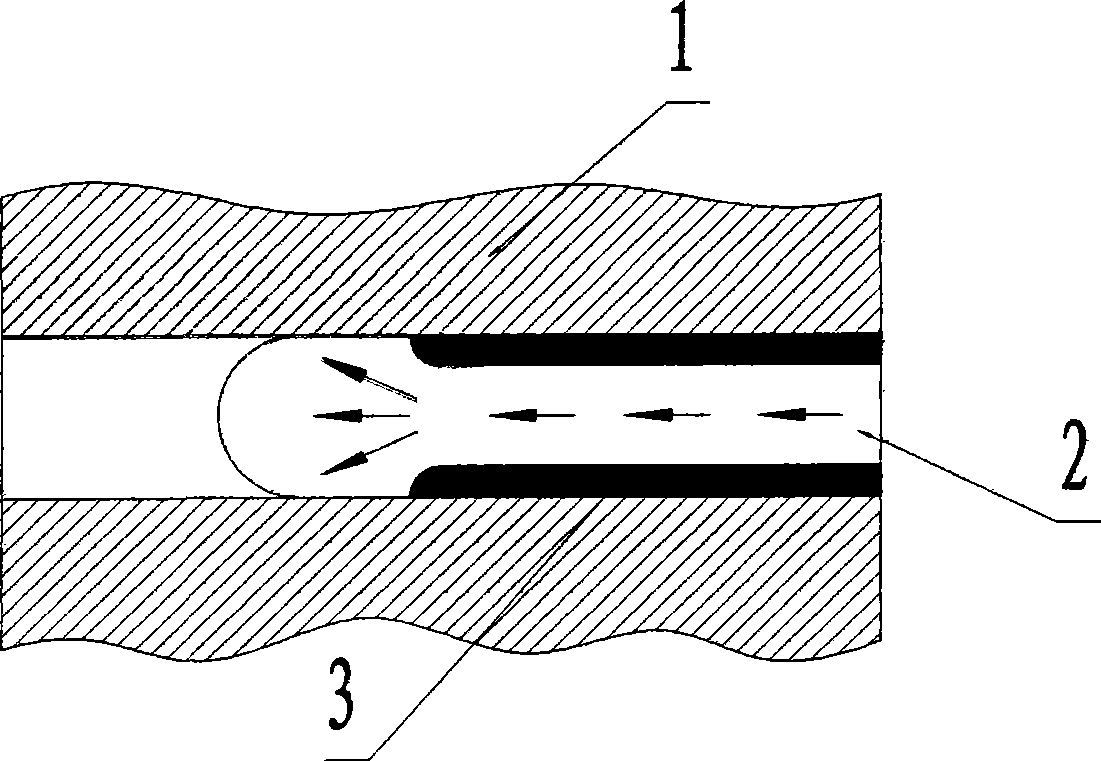

The present invention relates to a method for manufacturing a large FRP member and has the following structure. The method for manufacturing a large FRP member, comprising the following steps (A) to (F). They are: setting step (A) of disposing a preform containing a reinforcing fiber base material on a surface of a molding die; sealing step (B) of covering a molding portion with a bagging material or a mold and providing at least one suction port and at least one resin injection port for sealing; evacuating step (C) of evacuating the molding portion through the suction port; hot-air heating step (D) of heating the molding portion by hot air; resin injection step (E) of injecting a thermosetting resin from the resin injection port for impregnating the reinforcing fiber base material with the resin while a temperature Tm of the molding die and a temperature Tv of the bagging material or the mold are both set to room temperature or more, and a difference DeltaT in temperature between the Tm and the Tv is set to 10° C. or less; and curing step (F) of curing the resin by maintaining the molding portion at a predetermined temperature Tpc which is equal to or more than room temperature. Preferably, the preform described above includes the reinforcing fiber base material and a resin distribution medium. In addition, it is preferable that in the hot-air heating step (D), the molding die be placed in a sealed chamber which is heat insulated with a heat insulating material, the hot air be circulated and supplied, and timing of starting the injection of the resin from a plurality of the resin injection ports be controlled in accordance with signals supplied from resin detection sensors provided in the molding die. The present invention provides a method for manufacturing a large FRP member having superior quality at an inexpensive cost and with high production yield, in which non-impregnated portions and voids are unlikely to be formed.

Owner:TORAY IND INC

Surface treated inorganic particle additive for increasing the toughness of polymers

InactiveCN101918485AImproved crystallization kineticsFast crystallizationRefuse receptaclesPolyolefinBiopolymer

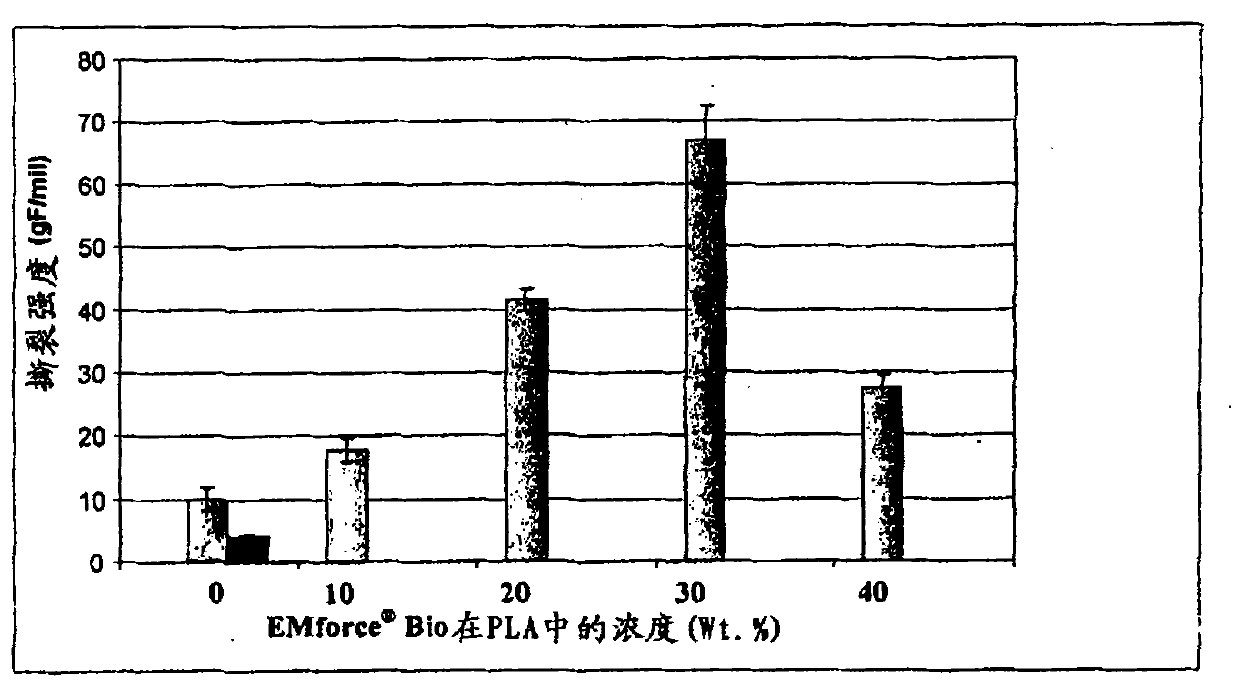

A bioplastic composition comprising a biopolymer containing from 10 - 40 wt% of coated inorganic particles; the particles being coated with one or more of fatty acids, fatty acid derivatives, rosins, rosinates, polyolefin based waxes, oligomers and mineral oils, and combinations thereof has improved stiffness and toughness and also has improved crystallisation kinetics rendering it useful for extrusion, injection moulding and thermoforming.

Owner:SPECIALITY MINERALS (MICHIGAN) INC

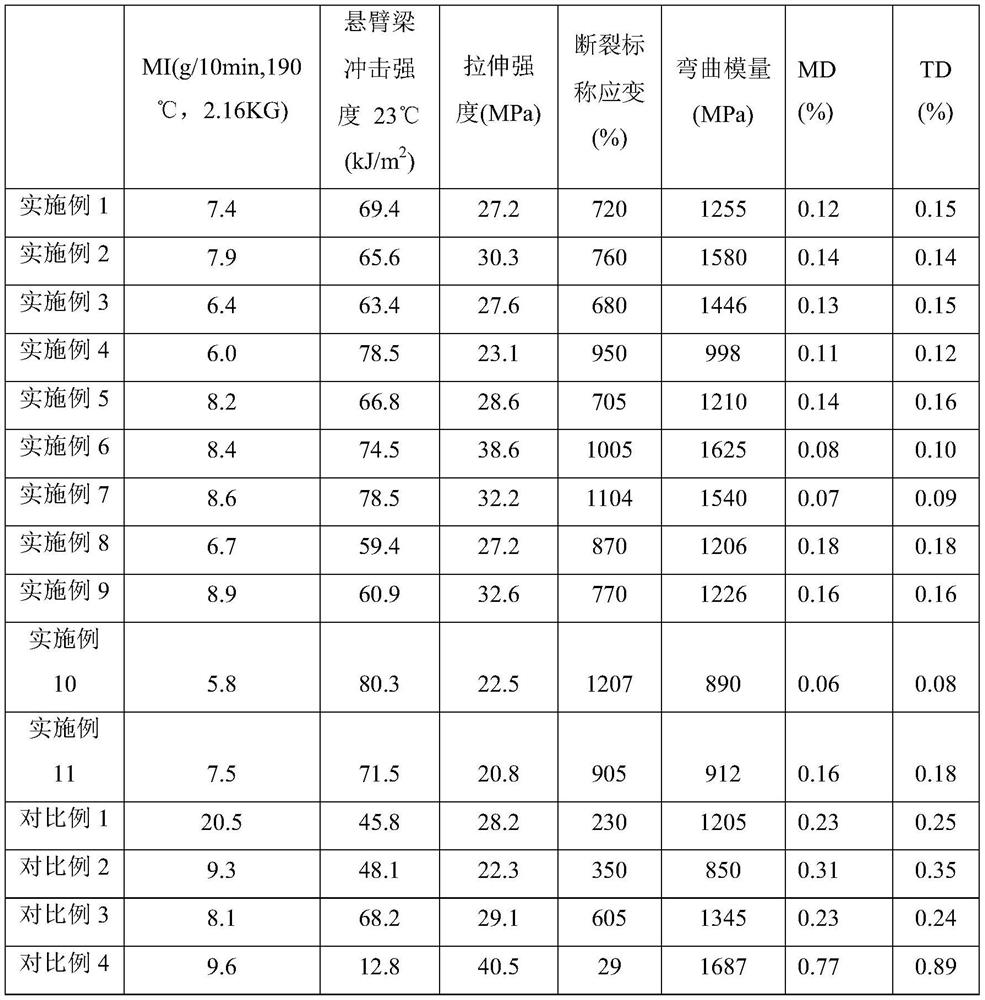

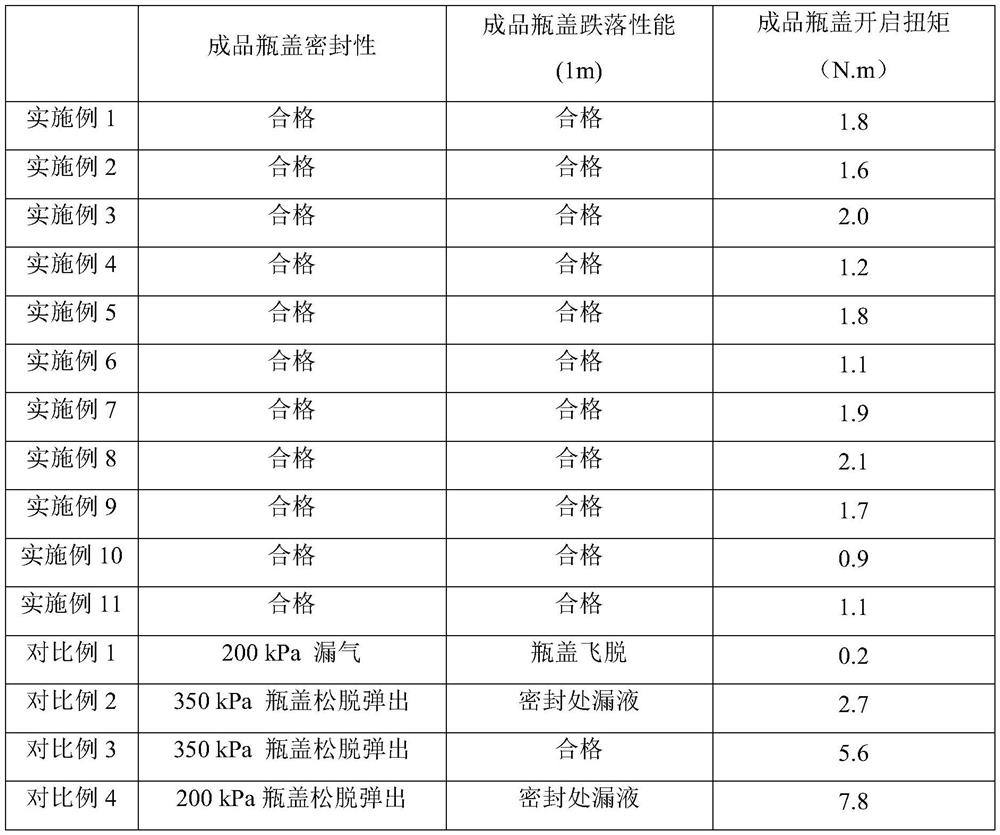

Degradable plastic composition as well as preparation method and application thereof

ActiveCN111995848ASolve rigid problemsImprove mechanical propertiesBio-packagingPolymer scienceUltimate tensile strength

The invention discloses a degradable plastic composition as well as a preparation method and application thereof. The degradable plastic composition comprises the following components in parts by weight: 70-99 parts of at least two degradable resins, 0-6 parts of a toughening agent, 0.5-5 parts of a compatilizer, 0.05-3 parts of a chain extender, 0.05-5 parts of an anti-hydrolysis agent, 0.05-5 parts of a nucleating agent and 0.05-3 parts of a slipping agent. By matching two or more degradable resins, the problem of poor toughness or rigidity of the existing single degradable resin is solved,so that the product has excellent comprehensive mechanical properties, excellent rigidity and toughness, high impact property, high nominal strain at break and higher flexural modulus and tensile strength.

Owner:联泓(江苏)新材料研究院有限公司

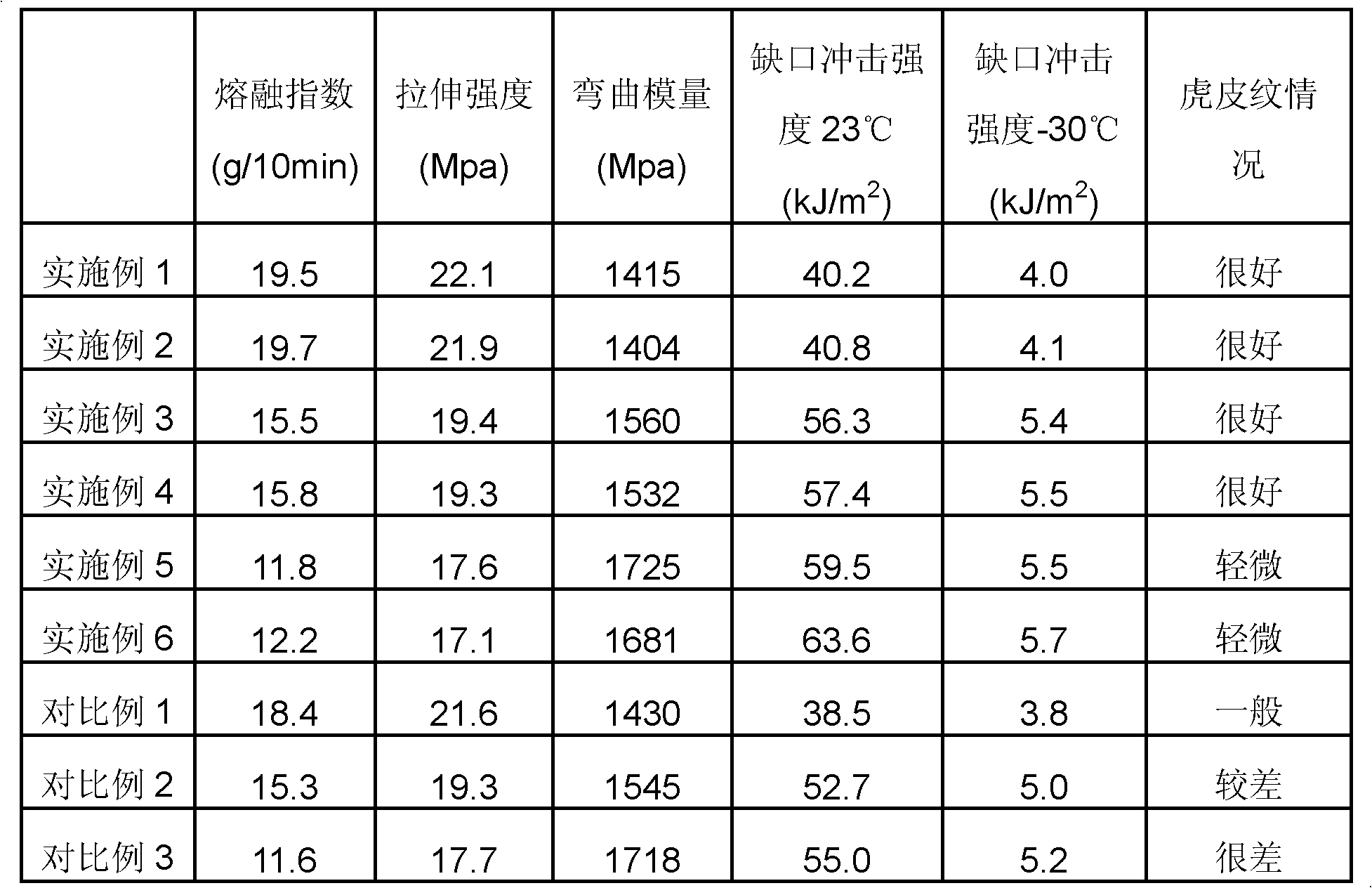

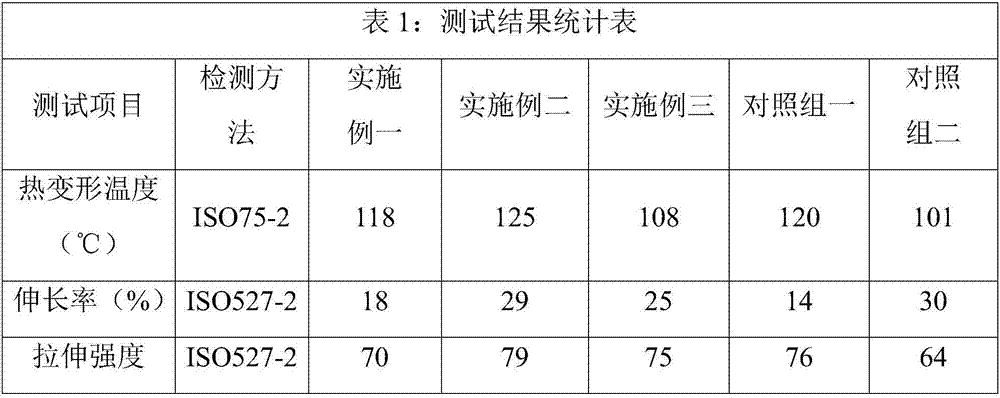

Polypropylene composite material for automotive instrument panel and preparation method for polypropylene composite material

The invention discloses a polypropylene composite material for an automotive instrument panel and a preparation method for the polypropylene composite material. The polypropylene composite material comprises the following components in percentage by weight: 45 to 80 percent of polypropylene, 10 to 30 percent of inorganic filler, 5 to 20 percent of toughening agent polyolefin elastomer (POE), 2 to 10 percent of polybutylene-1, 0.1 to 2 percent of antioxidant, 0.1 to 1 percent of light stabilizer, 0 to 3 percent of anti-scratch aid and 0 to 3 percent of the balance. The polypropylene composite material has excellent rigid-tough balance; the low-temperature notch strength is far higher than that of general polypropylene composite materials; the injection molding cycle is short; apparent defects such as tiger skin and the like are avoided on the surfaces of injection-molded sample pieces; and the characteristics efficiently meet the requirements of automotive instrument panels.

Owner:SHANGHAI PRET COMPOSITES

Long glass fiber reinforced polypropylene composite material and preparation method thereof

The invention discloses a long glass fiber reinforced polypropylene composite material, which comprises the following ingredients by weight percentage: 55-70% of polypropylene, 45-30% of long glass fiber, 0.3-1% of coupling agent,0-10% of MPP compatilizer, 0-15% of propylene copolymer, 0-5% of flexibilizer, 0.3-0.6% of anti-oxidant and 0-20% of filling materials. Simultaneously, the invention discloses a method for preparing the composite material. The invention uses a direct method for preparing the long glass fiber reinforced polypropylene composite material, which simplifies the technical links of cooling, solidifying heating and melting of prepreg, so that the long glass fiber reinforced polypropylene composite material saves the energy consumption, reduces the cost, and the production process is flexible.

Owner:无锡利保科技发展有限公司

Production process for preparing silica ceramic crucible by use of pressure grouting method

InactiveCN102528899AAccelerate the injection molding speedImprove work efficiencyCeramic shaping apparatusSmall footprintPolycrystalline silicon

The invention relates to a production process for preparing a silica ceramic crucible by use of a pressure grouting method and belongs to the technical field of high-grade refractory materials in a polycrystalline silicon industry. The pressure grouting comprises steps of preparation of pouring slurry, die assembling, molding by pouring slurry and demolding for fetching a green body, i.e., (1) ball-milling fused silica grain composition into slurry; and (2) fixing a resin die and assembling the die, grouting, pressurizing quartz slurry with the initial pressure being 0.1-0.2Mpa, enhancing the pressure to 0.3-1.5Mpa after a die cavity is filled with quartz slurry, keeping the pressure for about 5 minutes to filter water in the silica slurry by virtue of a micro-reticular resin mold to form a square crucible green body, and during demolding of the green body, and applying pressure of 0.2-0.3Mpa to the surface of the green body through the back layer of the micro-reticular resin mold by utilizing compression air. The green body of the silica ceramic crucible, prepared by the process, has high intensity, does not have residual air holes and is easy to demold, the product is good in thermal shock resistance and high in temperature resistance, and can meet the process requirements of polycrystalline silicon production; and the process has the advantages of high biscuit drying speed, small occupied area for production, shortened manufacturing period, low cost, and suitability for scale production.

Owner:咸阳陶瓷研究设计院有限公司

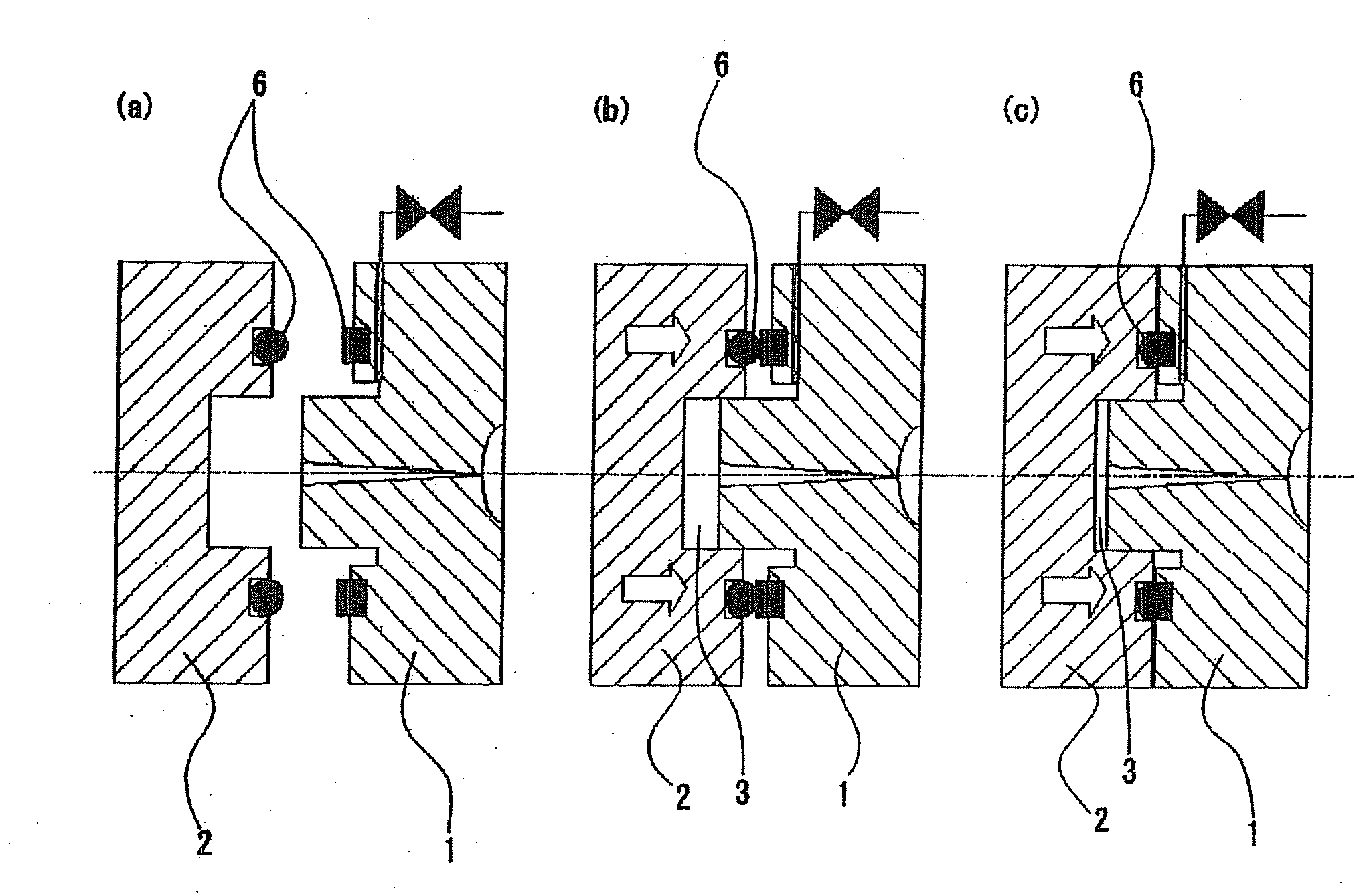

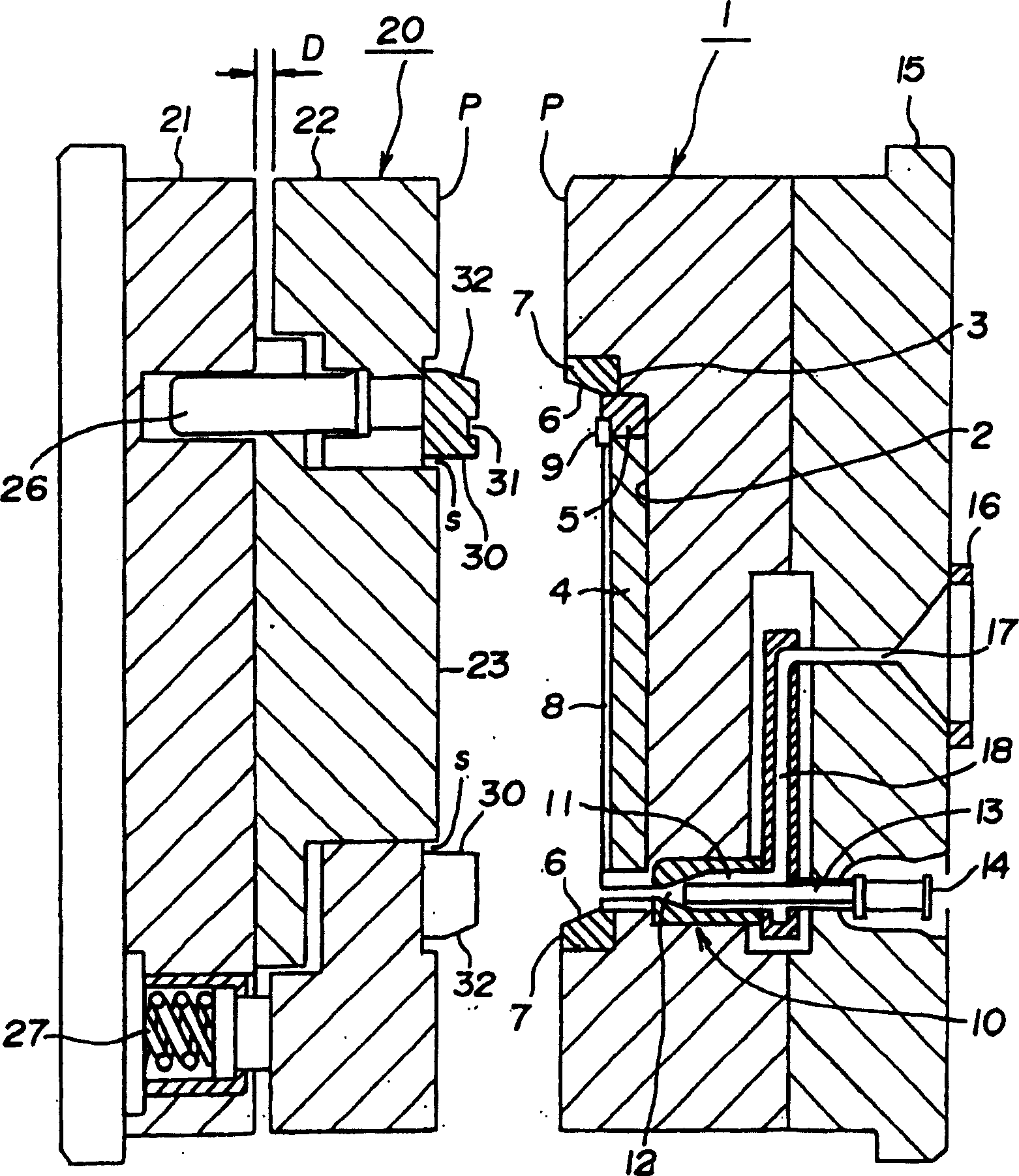

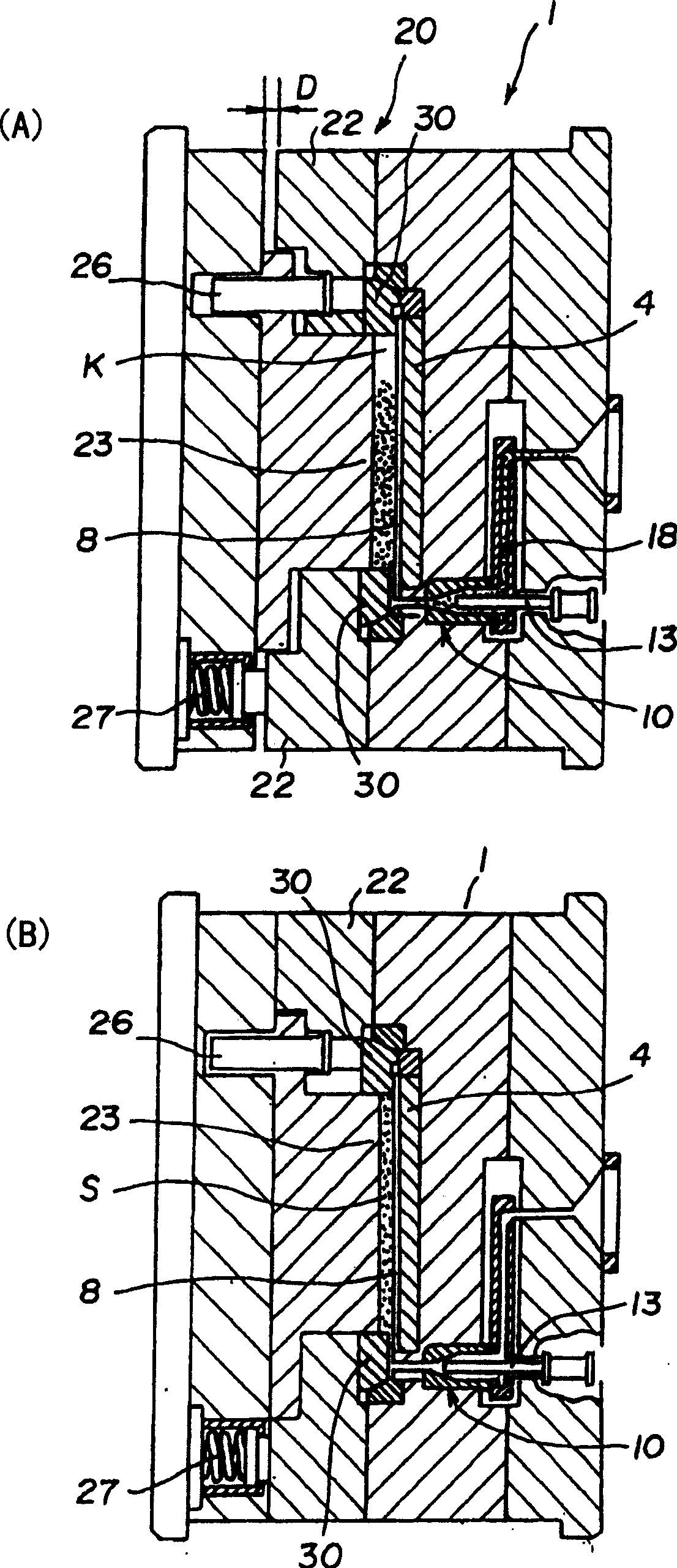

Expansion Injection Molding Process And Mold For Expansion Injection Molding

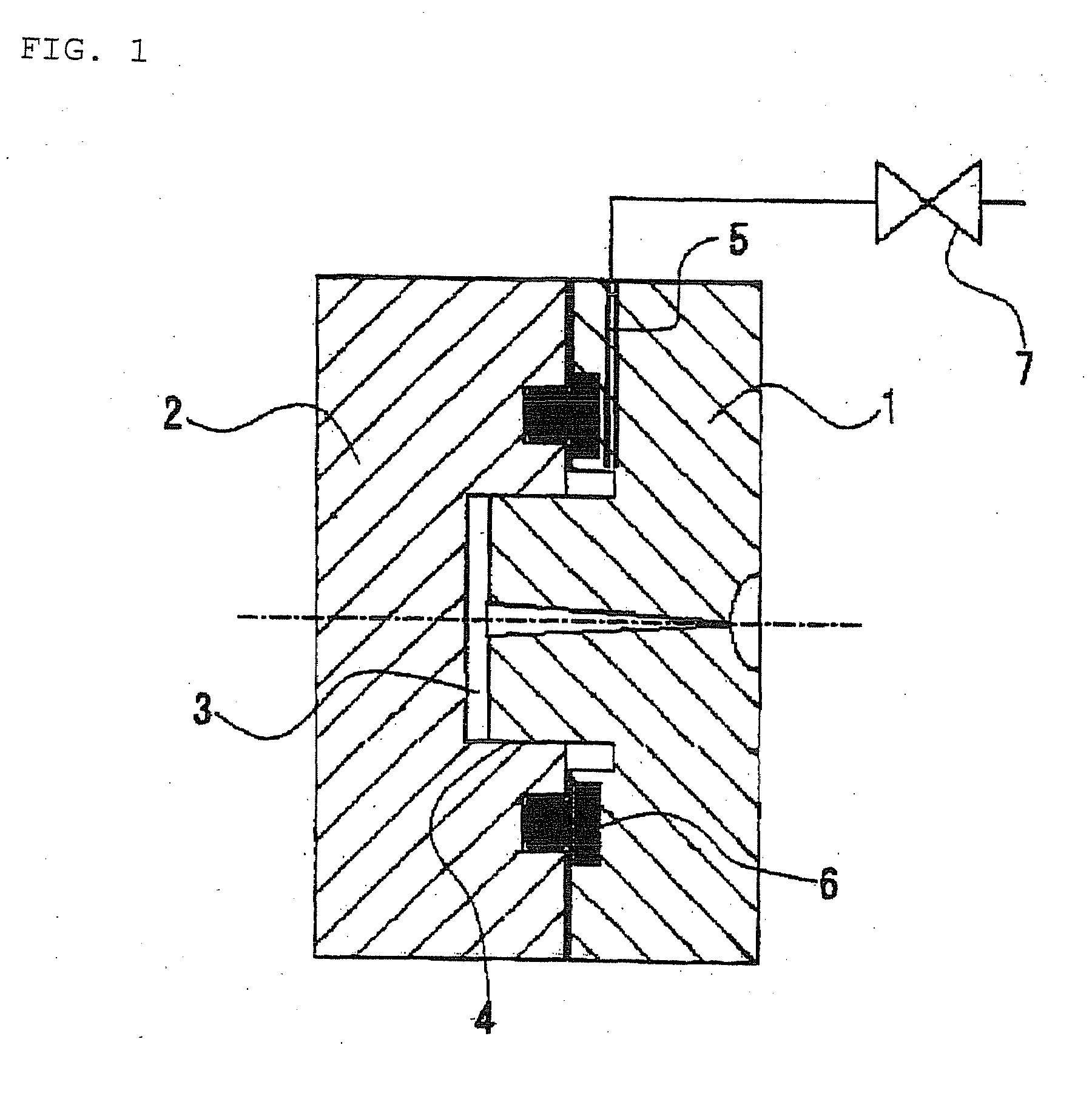

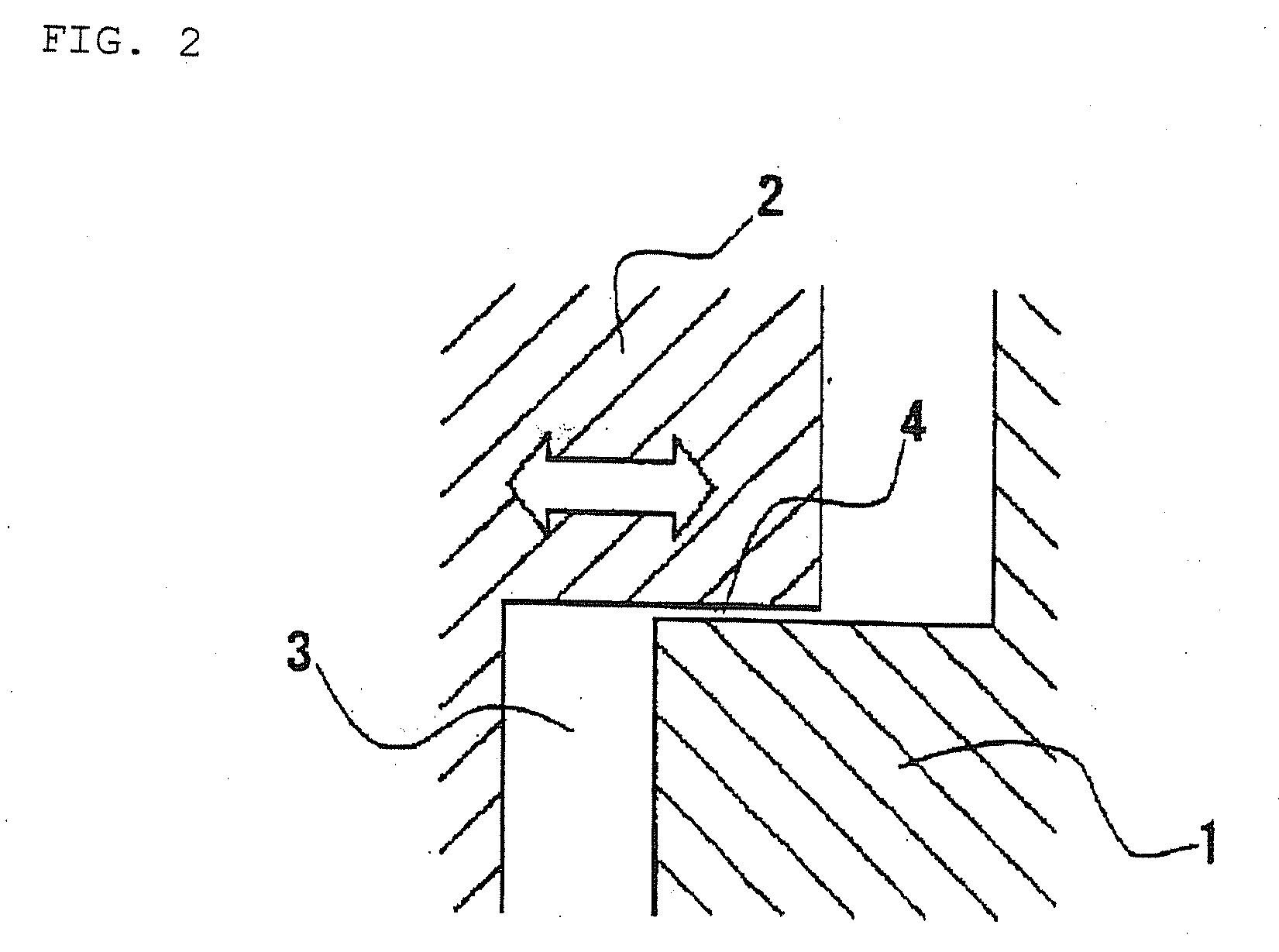

To provide an expansion injection molding process, which is freed from the occurrence of swirl marks on the surface of a molded article and by which foamed injection moldings having good appearance can be produced in a short molding cycle and at a low cost; and a mold for expansion injection molding.A movable mold 2 is moved toward a fixed mold 1, whereby a sealing member 6 set on at least one of a pair of facing surfaces of the mold 1 and mold 2 in the outside of a cavity is brought into contact with the other of the facing surfaces or a sealing member 6 set thereon to make the cavity 3 gas-sealed state. While keeping the gas-sealed state, the movable mold 2 is further moved toward the fixed mold 1 with the sealing member 6 compressed, whereby the volume of the cavity 3 is decreased to enhance the pressure in the cavity 3 to a level exceeding the atmospheric pressure. Then, a thermoplastic resin is injected into the cavity 3 of an enhanced pressure.

Owner:PRIME POLYMER CO LTD

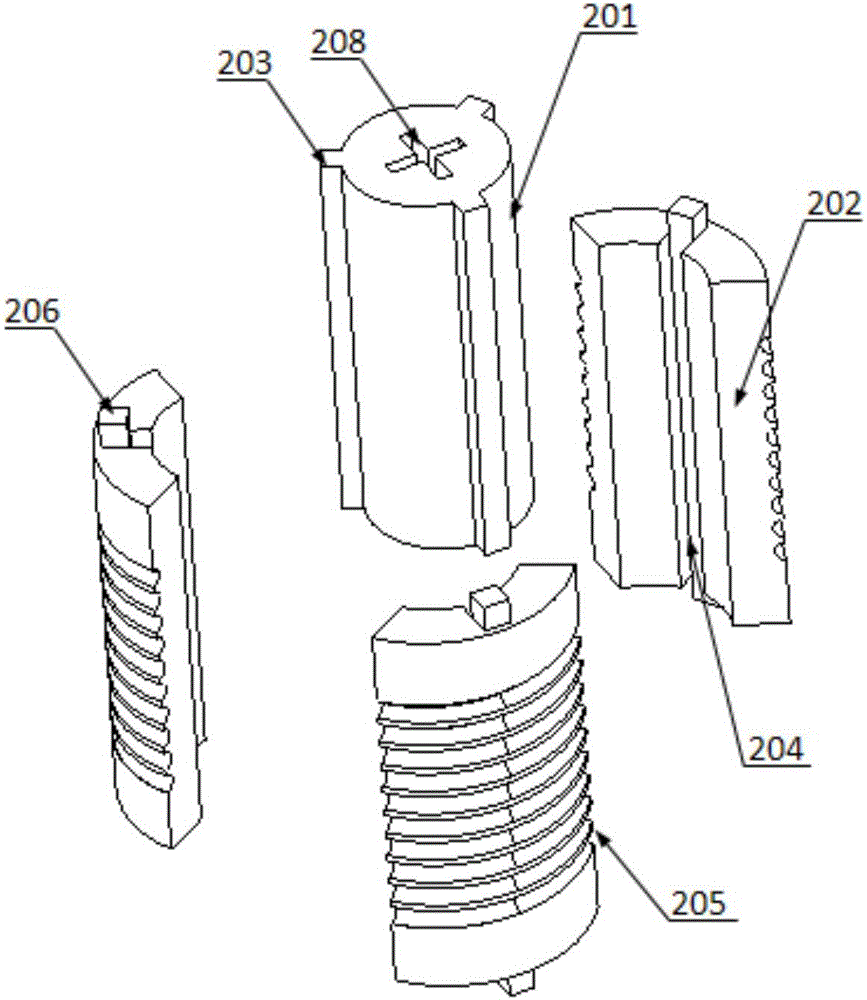

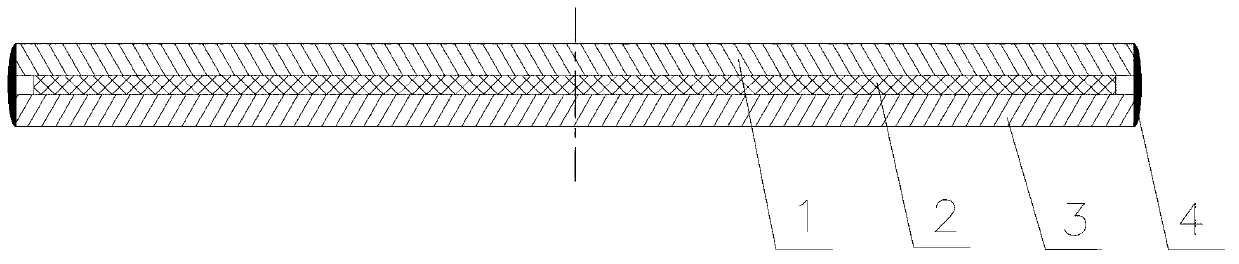

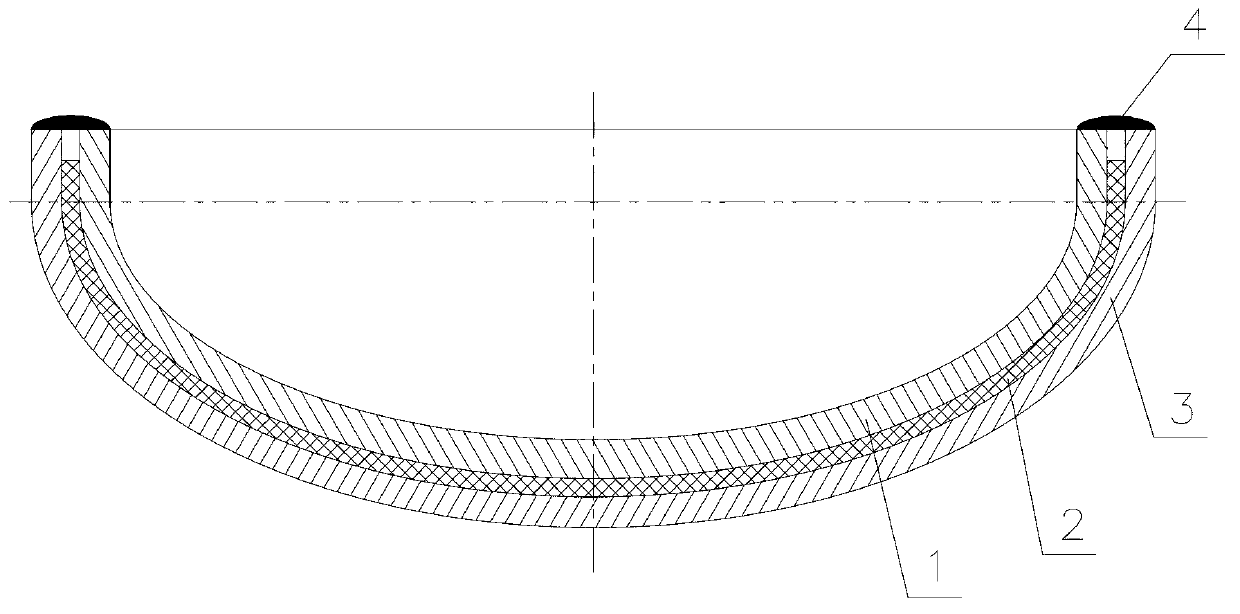

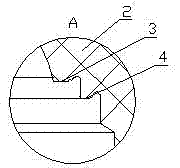

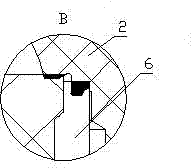

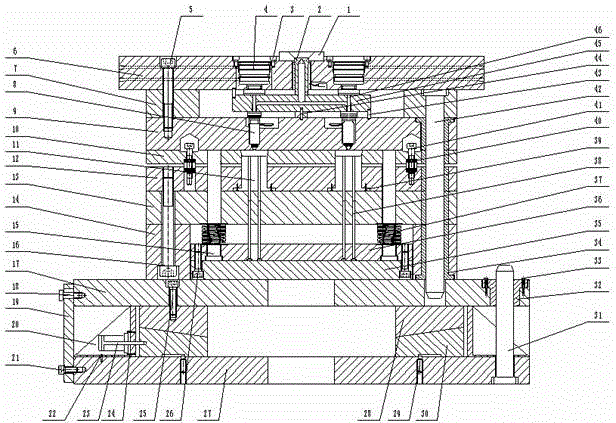

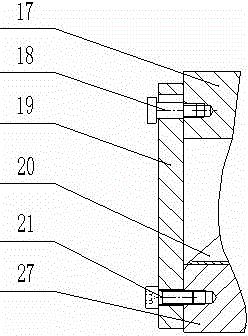

Carbon fiber composite material spring forming mold and method

PendingCN106671447ASimple and reasonable structure settingHigh strengthDomestic articlesCircular discChemical products

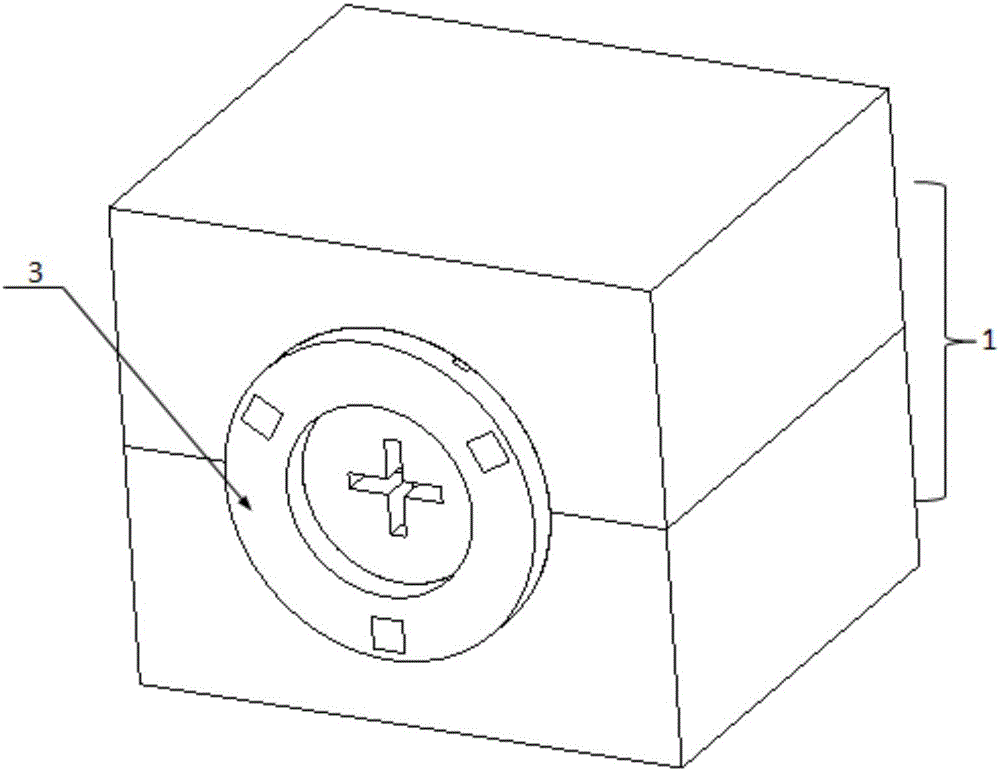

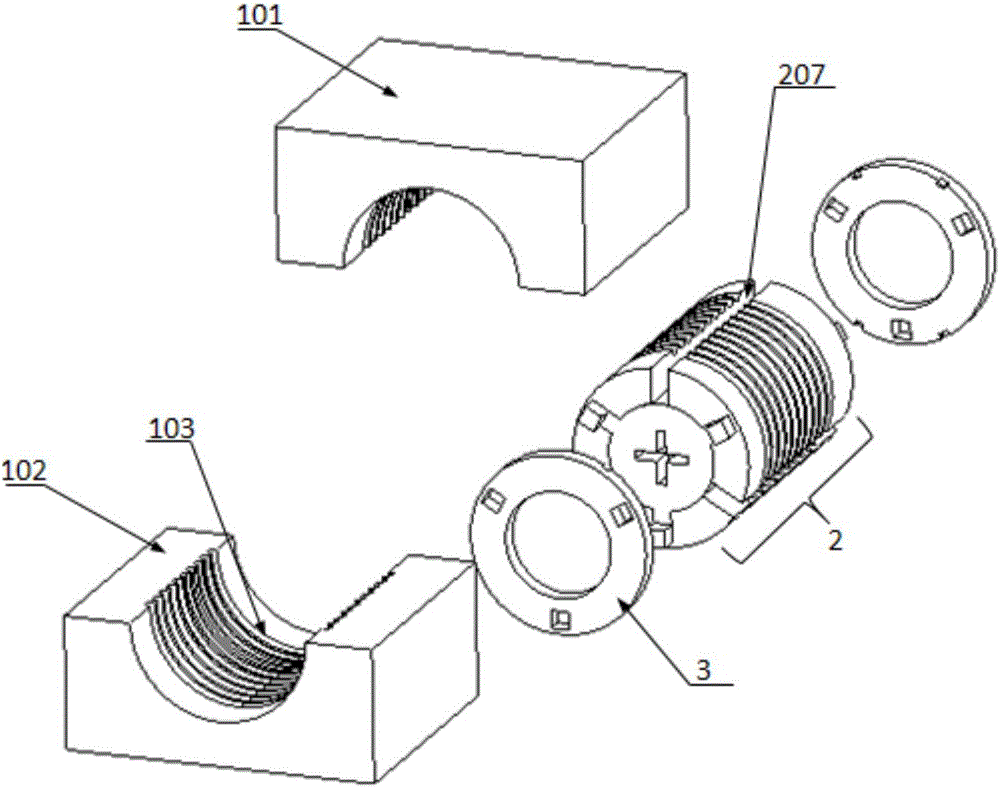

The invention discloses a carbon fiber composite material spring forming mold. The forming mold comprises an outer mold set and a core mold set arranged in the outer mold set. The core mold set comprises an inner mold core rod and a plurality of sector-shaped sliding blocks. Core rod protruding blocks with the number equal to that of the sector-shaped sliding blocks are uniformly arranged on the outer wall of the inner mold core rod; sliding block grooves are formed in the inner walls of the sector-shaped sliding blocks; sliding block spring lines are designed on the outer walls of the sector-shaped sliding blocks; sliding block protruding blocks are symmetrically arranged at the top edges of the two ends of the corresponding sector-shaped sliding blocks; and rotary disks are arranged at the two ends of the sector-shaped sliding blocks. The continuous carbon fiber composite material spring forming mold is reasonable and simple in structure; a carbon fiber composite material spring can be formed through the core mold set composed of the inner mold core rod which can be designed in different specifications and the multiple sector-shaped sliding blocks, and the diameter of the spring can be adjusted as required; and in addition, the forming process is convenient, the forming period is short, and an adopted material is good in strength, corrosion resistance, resistance to chemical product corrosion and the like.

Owner:GUANGDONG YATAI NEW MATERIAL TECH CO LTD

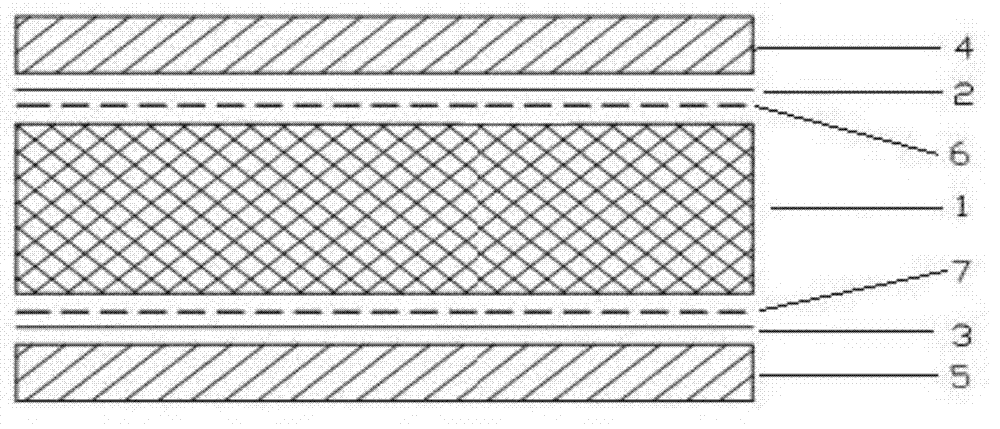

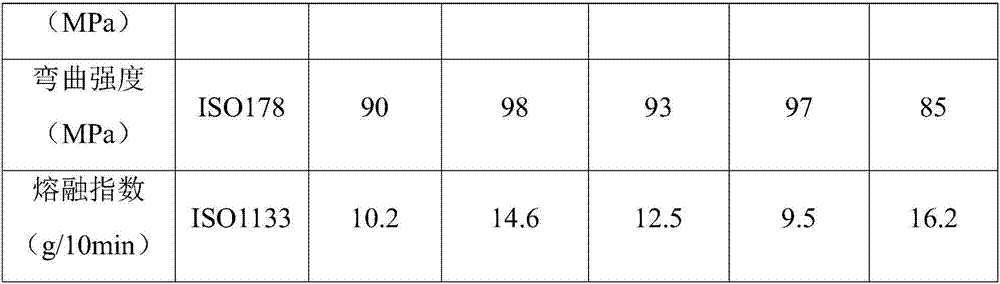

Continuous fiber reinforced polypropylene sandwich plate and preparation method thereof

InactiveCN103921511ALow priceReduce processing requirementsSynthetic resin layered productsLaminationPolymer scienceNonwoven fabric

The invention belongs to the technical field of polymer materials, and relates to a continuous fiber reinforced polypropylene sandwich plate and a preparation method thereof. The sandwich plate sequentially comprises an upper prepreg layer, an upper nonwoven fabric layer, an upper glue film material, a honeycomb core material layer, a lower glue film material, a lower nonwoven fabric layer and a prepreg layer from top to bottom, wherein the adjacent layers are connected through hot pressing. According to the present invention, the prepared continuous fiber reinforced polypropylene sandwich plate has advantages of high strength, high modulus, corrosion resistance, good water resistance, no electric conduction, high dielectric strength, easy processing, easy cleaning, no requirement of special storage conditions and long storage life, provides inertia for a variety of acids and alkalis, has low molding pressure and low molding temperature so as to reduce the mold cost, has a short molding period so as to be repeatedly molded, and has good design flexibility so as to adopt the appropriate fiber type, the appropriate fiber content and the appropriate fiber orientation to meet requirements of specific uses; and 100% of the waste material during production and the final product can be recycled, and the technology belongs to the green product technology.

Owner:LIAONING LIAOJIE SCI & TECH

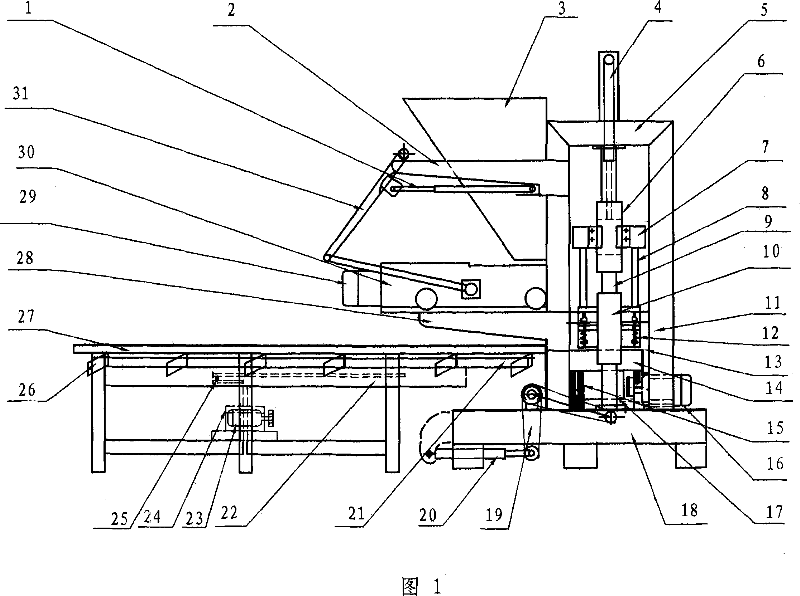

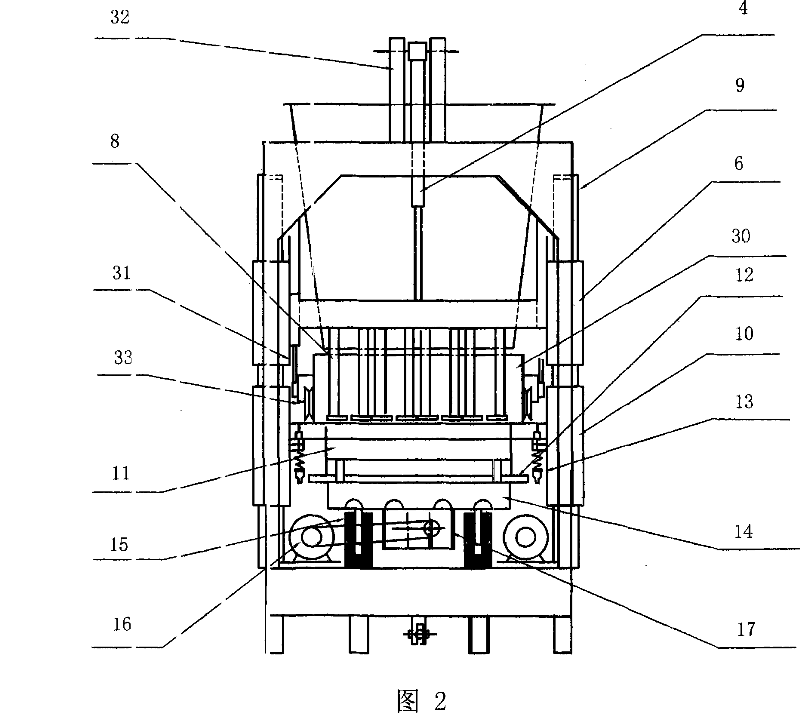

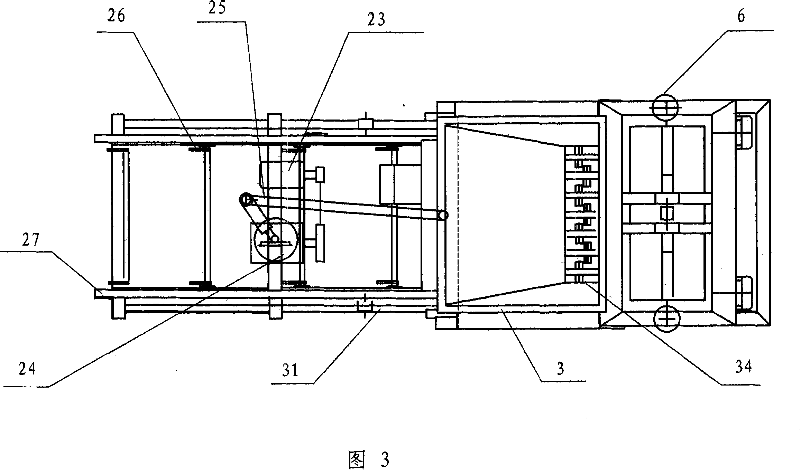

Full-automatic small type block machinery having environment-protecting and energy-saving functions

InactiveCN101037009ALow costReduce power consumptionDischarging arrangementCeramic shaping plantsElectricityManufacturing technology

A full automation minitype building block forming machine with environmental protection and conservation of energy, belongs to machine manufacturing technology field, while relates to machine, electricity, fluid, magnetism technology. The invention includes a storing module system, a distributing module system, a building block forming module system, a hydraulic pressure demouding module system and a feeding plate module system; the storing module system is provided on the topest part of the rectangle machine frame, the distributing module system is provided on the lower part of the storing module system, both are connected by automatic discharge tube of the storing box, the forming module system is provided on the lower part of the distributing module system, and is connected to the distributing module system by the discharge port of the distributing box, the hydraulic pressure demouding module system is provided on the lower part of the forming module system, and is connected to the forming module system by the crank connecting rod and, the feeding plate module system is provided on the side lower part of the forming module system, and is connected to the forming module system by the bearing plate conveying car. The invention has advantages of small investment, low energy consume, high automation degree, low cost of produced building block and so on.

Owner:HEBEI AGRICULTURAL UNIV.

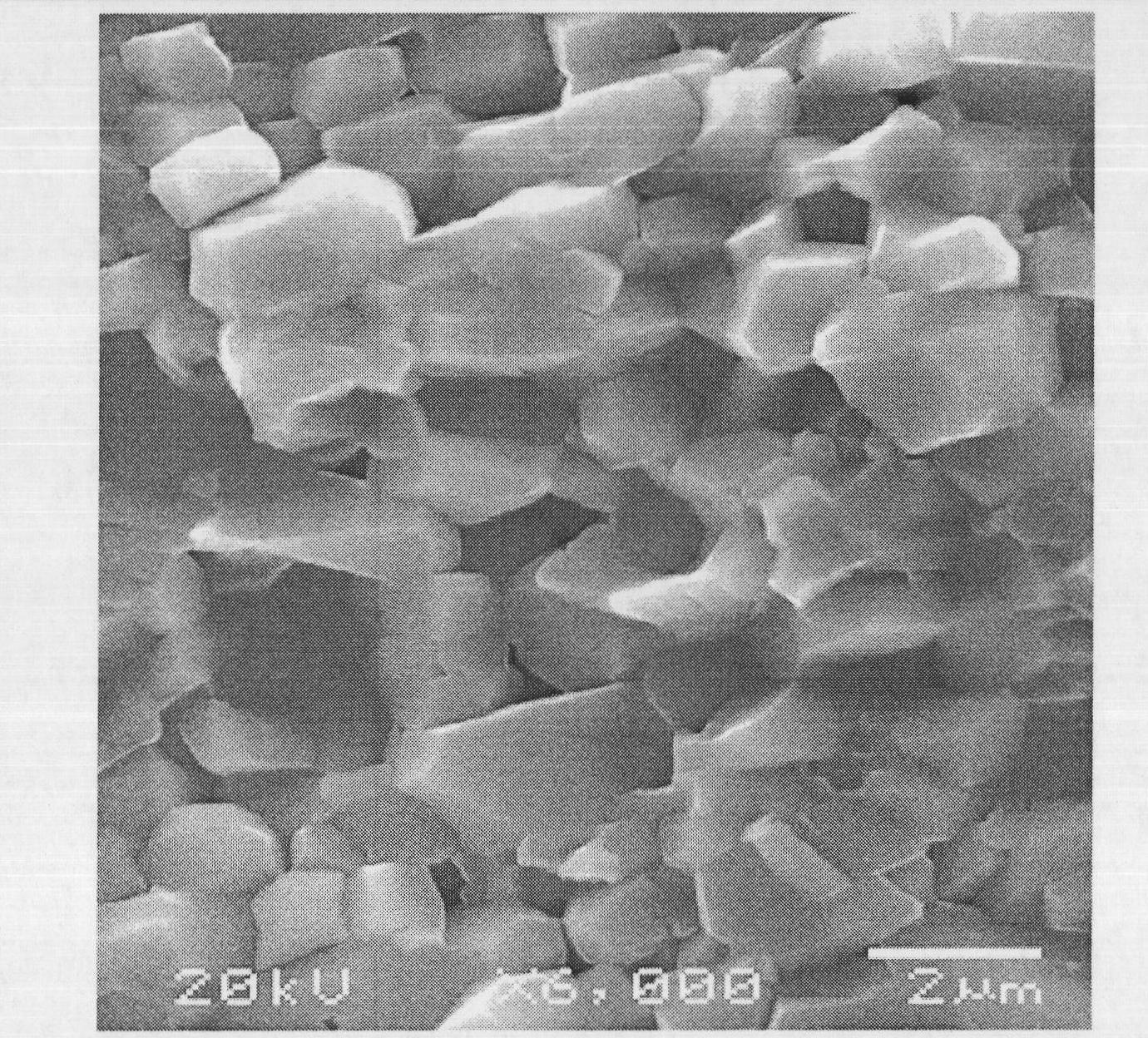

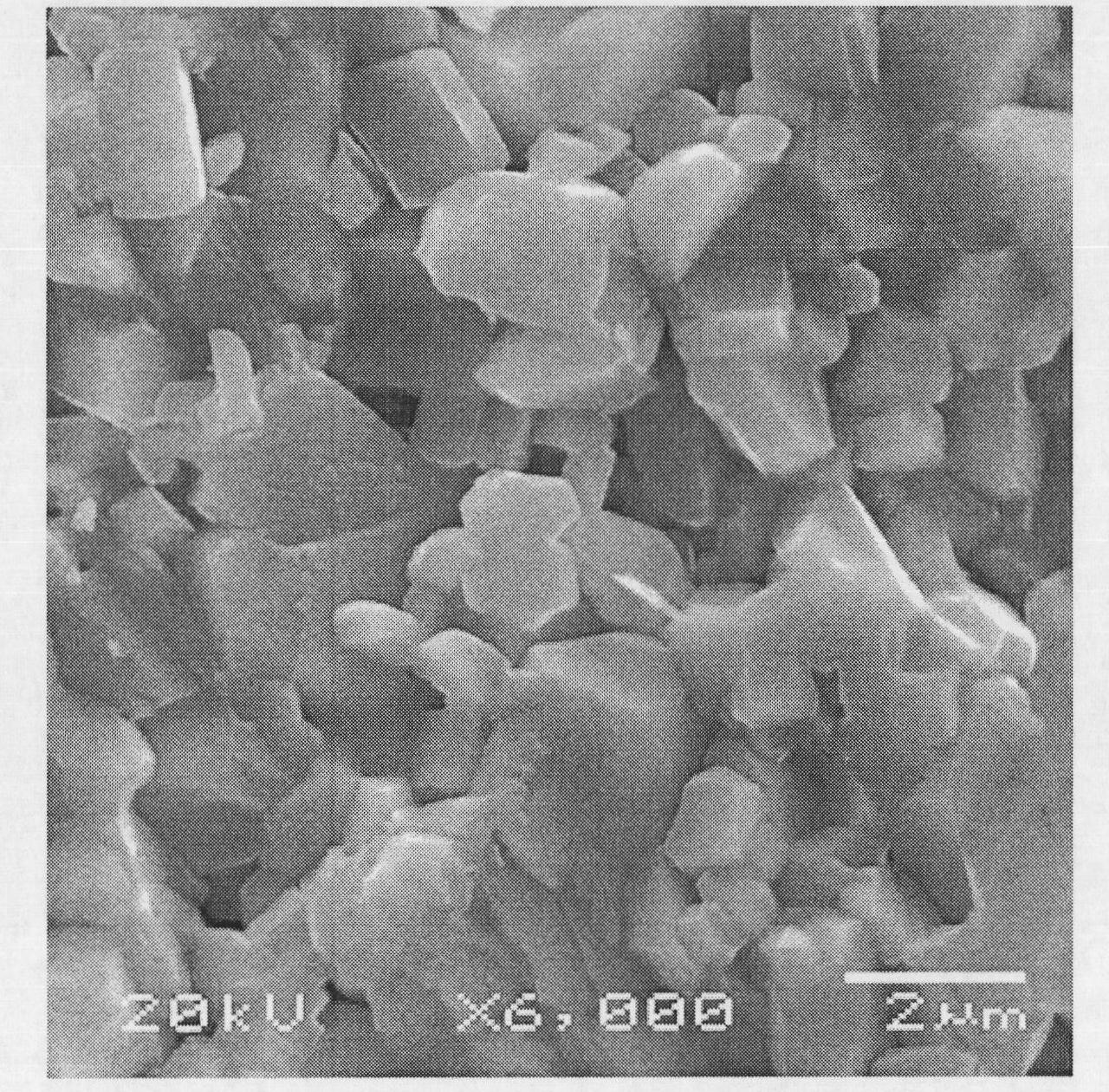

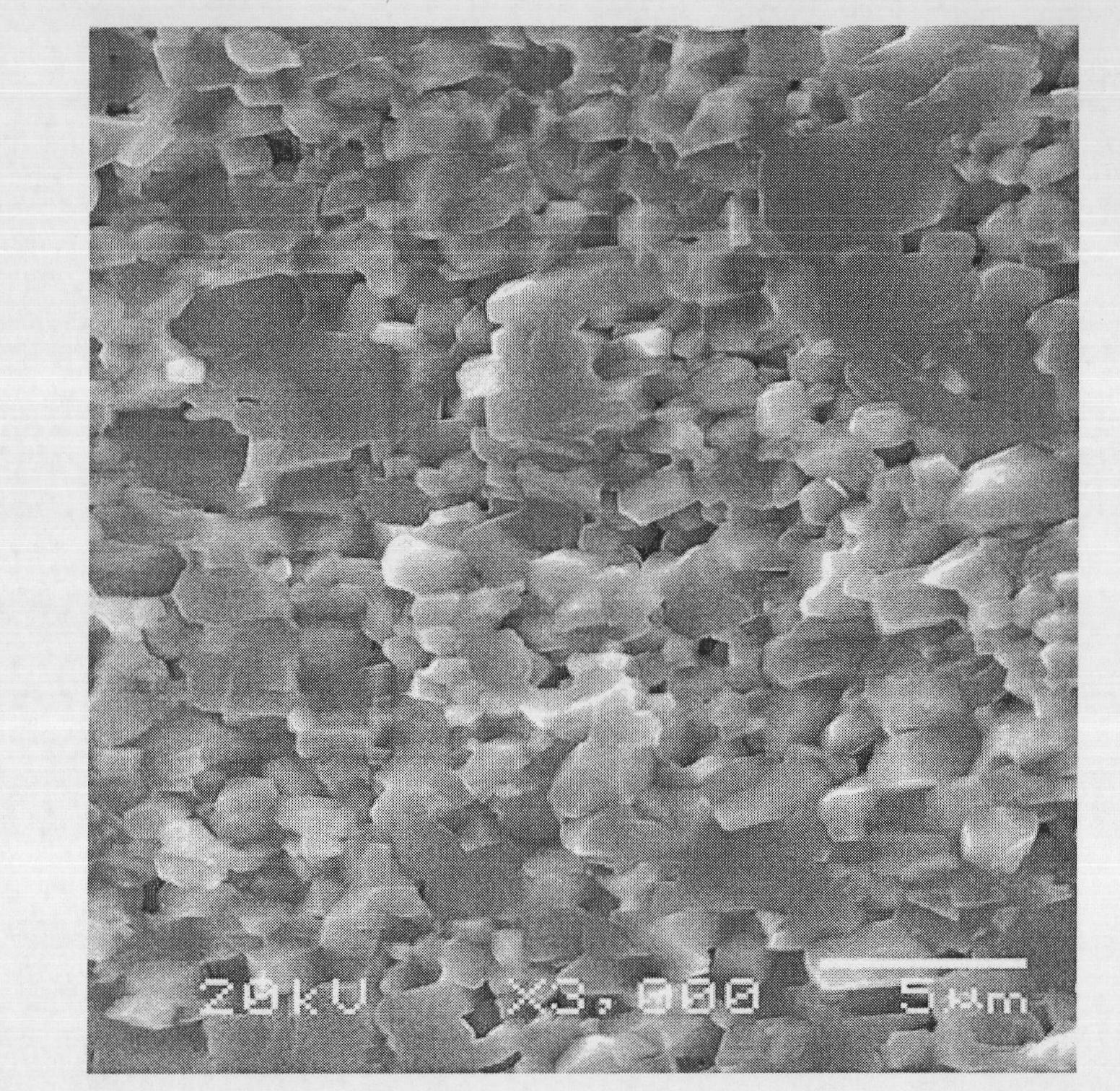

Magnetoplumbate-type permanent magnetic ferrite and manufacturing method thereof

InactiveCN101844914AImprove powder propertiesUniform powder propertiesCrystal structureProcess design

The invention relates to a magnetoplumbate-type permanent magnetic ferrite and a manufacturing method thereof, which relate to the field of the permanent magnet. Main component of the magnetoplumbate-type permanent magnetic ferrite is expressed by the following formula: (1-x-y)Ca0.xSrO.(y / 2)R2O3.(n-z / 2-m / 2)Fe2O3.zMO.MzrO2, wherein R is of at least one element of La, Nd and Pr and contains La, M is selected from at least one element of Co, Zn, Ni, Mn and Cu and contains Co, and x, y, z, m and n respectively indicating the addition ratio of each main metal element calculated at mol. By adopting optimized formula and process design and adding less Zr element, the Zr element is introduced into ferrite lattice during the pre-burning process so as to inhibit the growth of abnormal crystal particle and to reduce the pores; moreover, N(CH2CH2OH)3 dispersing agent is particularly added, the appearance of the powder particles is effectively controlled, so the obtained crystal particles are moreuniform, the arrangement of the crystal structure is more compact, and the permanent magnetic ferrite material is obtained under the condition that substitute of the Co element is not high.

Owner:杨宗维

Injection molding process of thin wall plastic products

ActiveCN101439575AGuaranteed accuracyGuaranteed stabilityDomestic articlesInjection pressureManufactured material

The invention relates to an injection molding process of thin-wall plastic products, the wall thickness of the formed plastic products is within 0.5mm; the process mainly includes an injection stage, a pressure maintaining stage and a cooling stage, the temperature of fused mass adopts the recommended temperature and does not need to be raised; according to the properties of different plastic raw materials and different mould structures, the temperature of the moulds is adjusted within the range of 20-150 DEG C, according to different molding areas, the injection pressure is controlled within the range of 1500-3000kg / cm<2>, the injection speed is controlled within the range of 400-2000mm / s, the fused mass is injected into the mould and fast switched to the process of pressure maintaining, the pressure maintaining is carried out by adopting 2 or 3 or 4 stages, the pressure and time of each pressure maintaining stage is adjusted, and the molding process is completed after cooling.

Owner:DONGMING XINGYE SCI TECH CO LTD

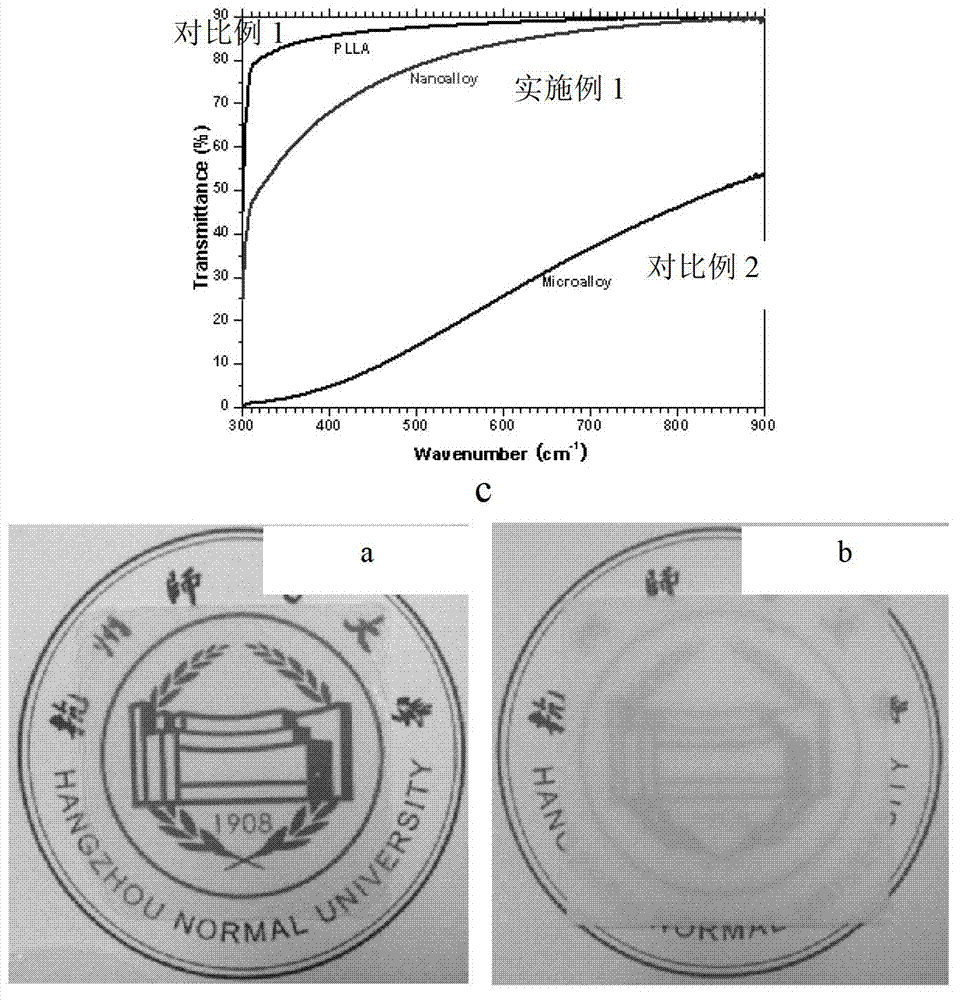

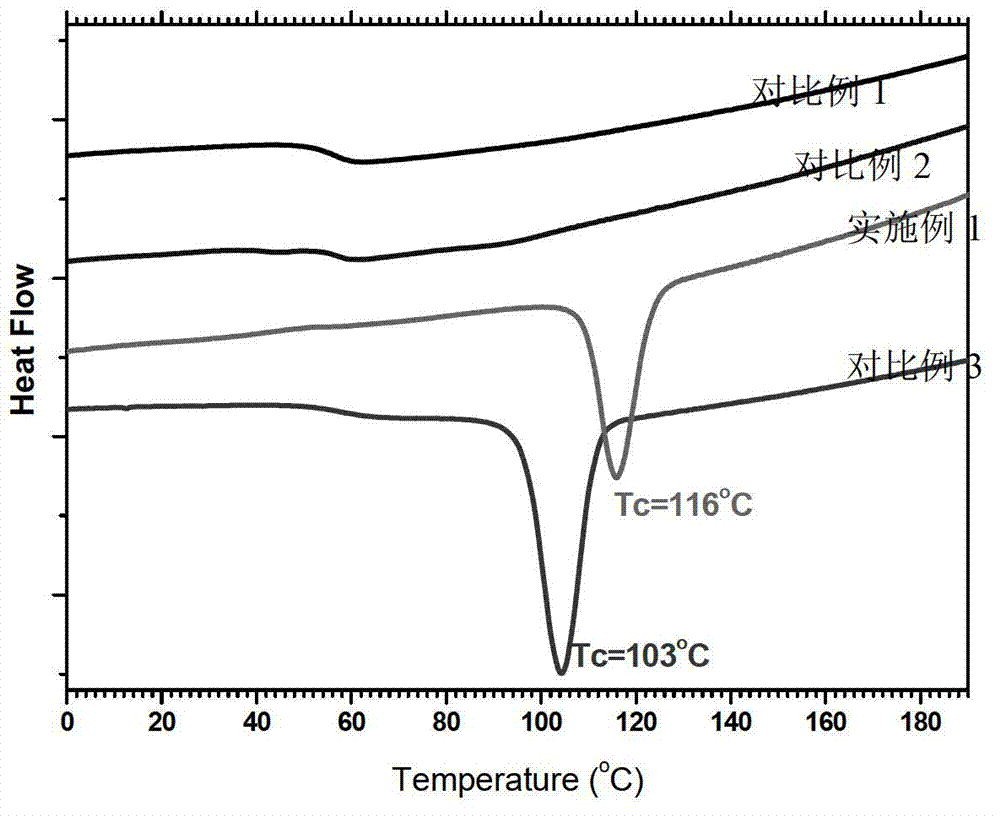

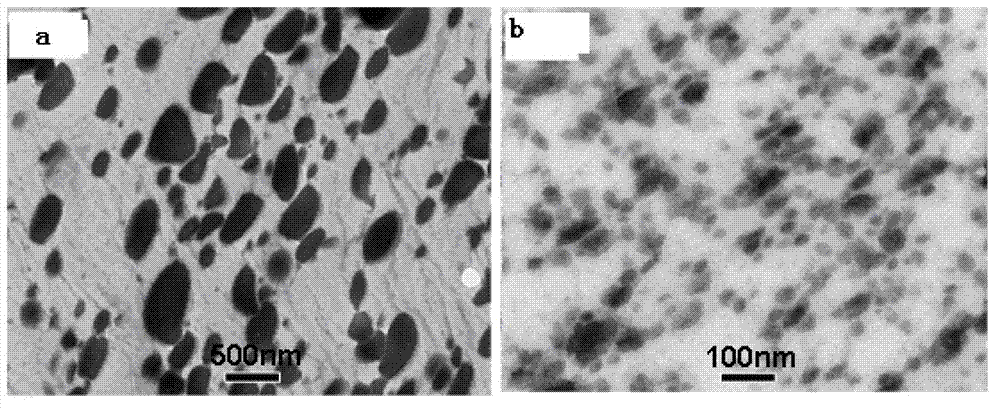

Transparent polylactic acid alloy material

The invention discloses a transparent polylactic acid alloy material, which is prepared by polylactic acid and an elastomer by a melt mixing device through melt blending, based on the polylactic acid and the elastomer, the mass fraction of the polylactic acid accounts for 75-98% and the mass fraction of the elastomer accounts for 2-25%, and the elastomer is the elastomer containing maleic anhydride or an epoxy group. According to the invention, a certain amount of elastomer capable of being reacted with polylactic acid is added in the polylactic acid, the melt blending condition of the material is adjusted in a reasonable mode, all elastomer micro-areas are uniformly dispersed in the polylactic acid, and the disperse size is less than 100nm, thereby the transparent polylactic acid alloy material with substantially enhanced material shock resistance and fast crystallization speed of matrix polylactic acid can be obtained. A purpose that primary modification overcomes a plurality of polylactic acid application barriers can be realized. The transparent polylactic acid alloy material can be used in the industries of package, electron, building material, automobile and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

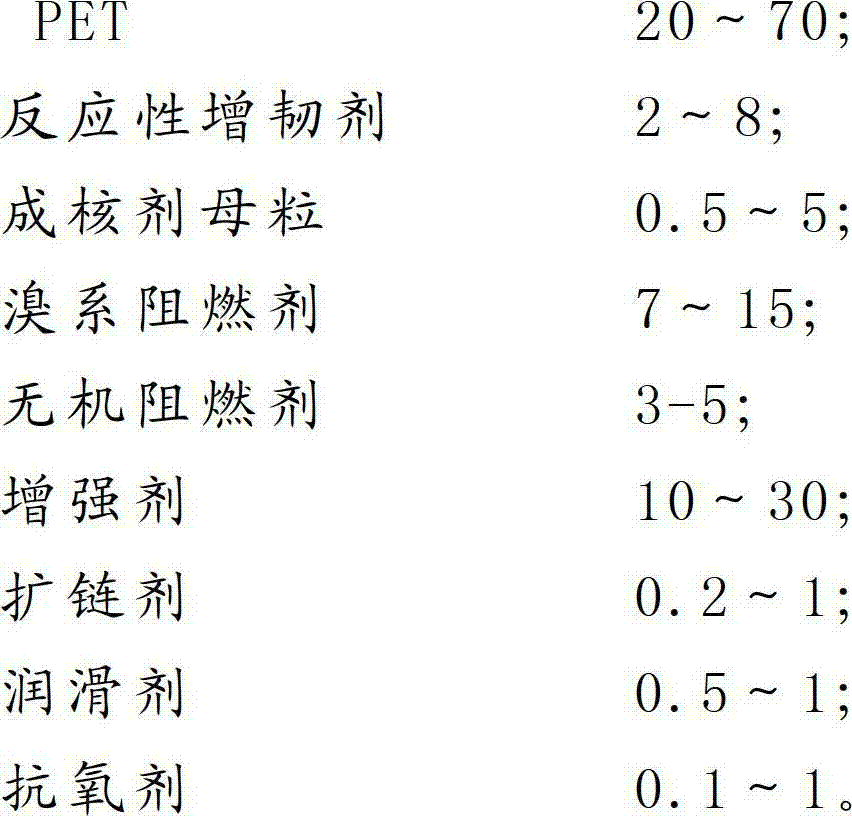

High heat-resistant fire-retardant reinforced polyethylene terephthalate (PET) composition and preparation method thereof

ActiveCN102816414AImprove utilization efficiencyImprove dispersion uniformityPolyethylene terephthalate glycolPolymer science

The invention provides a high heat-resistant fire-retardant reinforced polyethylene terephthalate (PET) composition and a preparation method thereof. The preparation method solves the problem that the existing preparation technology produces poor effective availability and poor heat resistance of a material because of non-associated nucleating agents. The high heat-resistant fire-retardant reinforced PET composition comprises: by weight, 20 to 70 parts of PET, 2 to 8 parts of a reactive flexibilizer, 0.5 to 5 parts of nucleating agent master batches, 7 to 15 parts of a brominated flame retardant, 3 to 5 parts of an inorganic flame retardant, 10 to 30 parts of an enhancer, 0.2 to 1 part of a chain extender, 0.5 to 1 part of a lubricant and 0.1 to 1 part of one or more antioxidants. The preparation method comprises that through a unique nucleating technology and a compounding flame retardation technology, PET as a raw material is subjected to double-screw extruder-based plastification granulation so that the high heat-resistant fire-retardant reinforced PET composition is obtained. The high heat-resistant fire-retardant reinforced PET composition has excellent integrated performances, a fast crystallization rate, a short shaping period, a high thermal deformation temperature, good flame resistance reaching to the UL94V-0 standard, and excellent mechanical properties.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

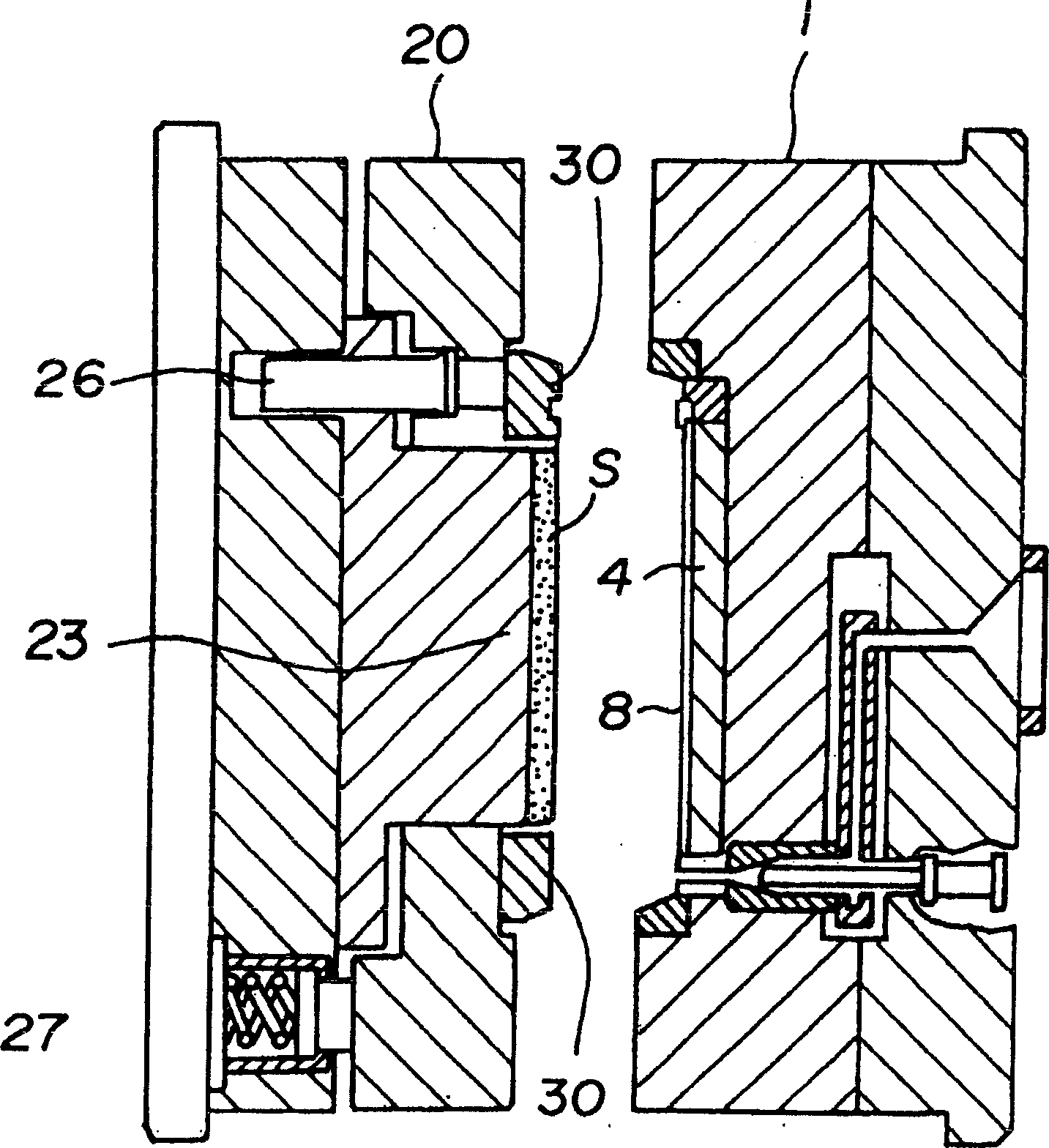

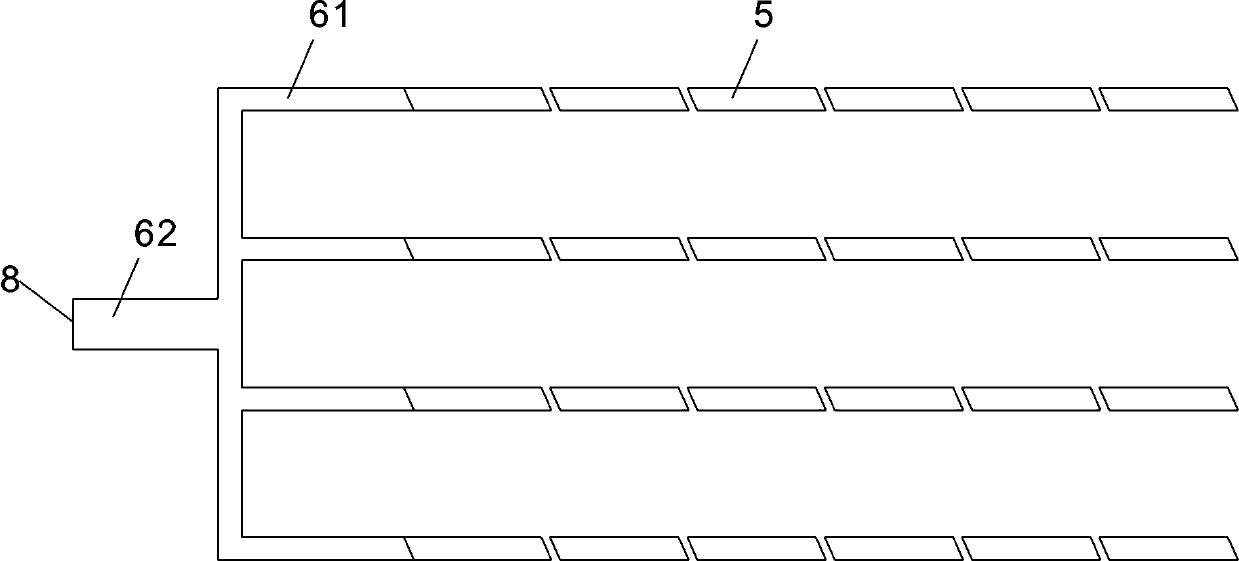

Shaping method of thick light guiding plate and its mould

InactiveCN1727169AShorten filling timeShorten molding cycleOptical articlesOptical light guidesLight guideCooling speed

The present invention provides a molding method capable of molding a thick-walled light guide plate of high quality by a short molding cycle. A predetermined amount of a molten resin is charged in the shaping space K constituted of the stamper (8) provided to the core (4) on the cavity side of a fixed mold, the core 23 on the core side of a movable mold and cores 30 and 30 on the peripheral wall side of the movable mold. Then, a valve gate is closed to compress the molten resin by the core 23 on the core side. Transfer properties are enhanced by compression and the molding cycle is shortened. At the time of compression, the temperature of the cores (30 and 30) on the peripheral wall side is made higher than the temperature of the core (4) on the cavity side and the core (23) on the core side. By this constitution, the cooling speed of the cores (30 and 30) on the peripheral wall side becomes slow to enhance a compression effect and the occurrence of a sink is suppressed.

Owner:JAPAN STEEL WORKS LTD +2

Punch forming method of thin-wall end socket

InactiveCN102989922ASolve sizeSolve the thickness of the wallHollow articlesMetallurgyEconomic benefits

The invention provides a punch forming method of a thin-wall end socket. The method comprises the following steps of 1, cutting a non-ferrous metal plate to obtain an end socket plate, and cutting a steel plate to obtain an upper steel plate and a lower steel plate; 2, putting the end socket plate between the upper steel plate and the lower steel plate, and welding the upper steel plate and the lower steel plate into a whole plate along a circular arc; 3, heating the whole plate; 4, carrying out punch forming on the heated whole plate to obtain an entire end socket; and 5, removing the upper steel plate and the lower plate to obtain the thin-wall end socket of which the wall thickness is 0.5-3.0mm. The punch forming method is novel in technique, reliable and practical, and advanced in process. Two steel plates are adopted to clamp the end socket plate in the middle; the thin-wall end socket is punched and formed by a common die; the problems of large size, thin wall and large molding difficulty of lined end socket of chemical equipment can be effectively solved; the quality and the yield of the thin-wall end socket are improved; and the production cost is greatly reduced, and the economic benefit is obviously improved.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

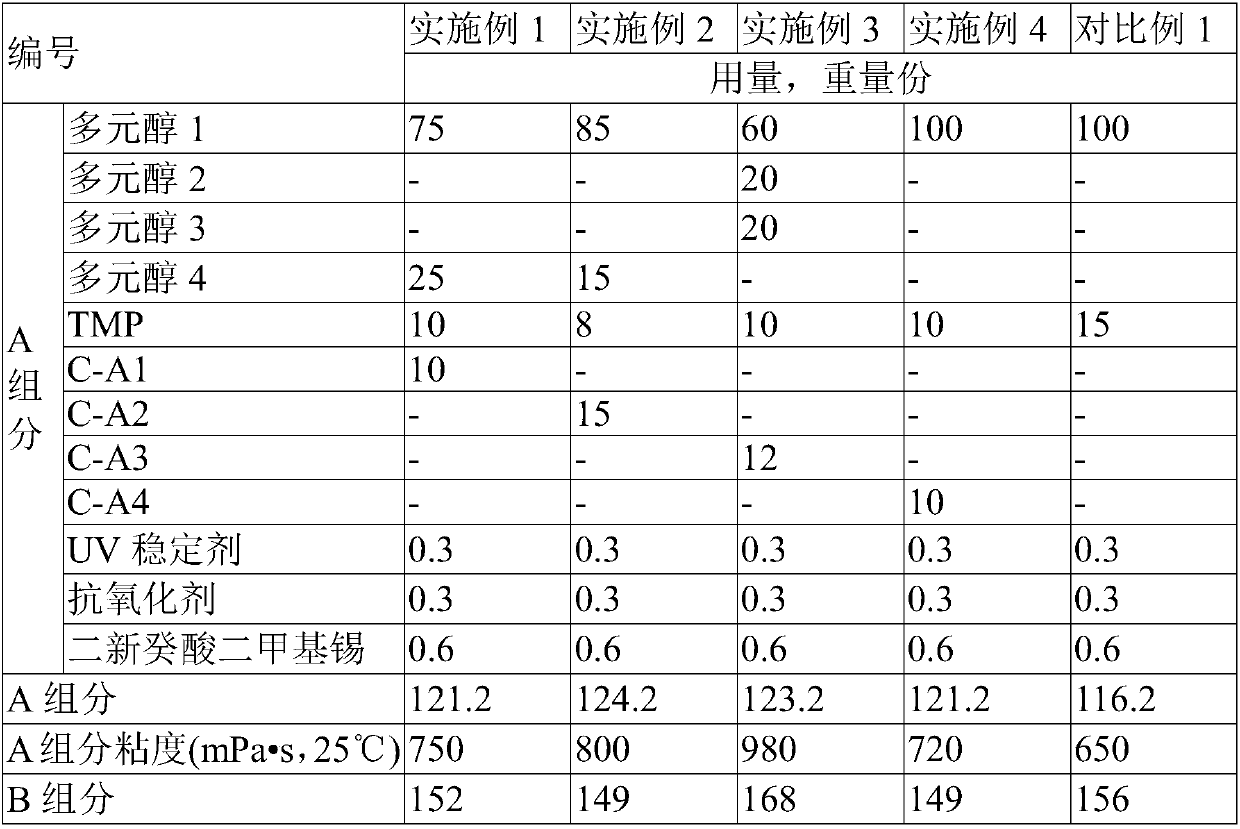

Composition for preparing transparent polyurethane, workpiece and forming method thereof, automobile appearance part and forming method

ActiveCN109796749AHigh transparencyImprove heat resistanceSynthetic resin layered productsDomestic articlesCross-linkPolyester

The invention relates to the field of matrix resin used for a resin transfer molding technology, and discloses a composition for preparing transparent polyurethane, a workpiece and a forming method thereof, an automobile appearance part and a forming method. The composition comprises a component A and a component B; the component A comprises polyether glycol, polyester polyol and a micromolecule cross-linking agent; the component B is isocyanate, wherein the micromolecule cross-linking agent comprises an isocyanate active compound with tri-functionality and a compound C-A prepared from organicamines and bifunctionality epoxy resin through a reaction; the isocyanate active compound with tri-functionality is selected from one or more of trimethylolpropane, glycerin, triethanolamine and diethanolamine; in the component A, by weight, 50-90 parts of polyester glycol, 0-25 parts of polyester polyol, 0-10 parts of isocyanate active compound with tri-functionality and 10-25 parts of the compound C-A are contained; the weight ratio of the component A to the component B is 1:3-3:1. When the composition is used for RTM forming processing, curing speed is high, the forming period is short, and heat resistance is improved.

Owner:BYD CO LTD

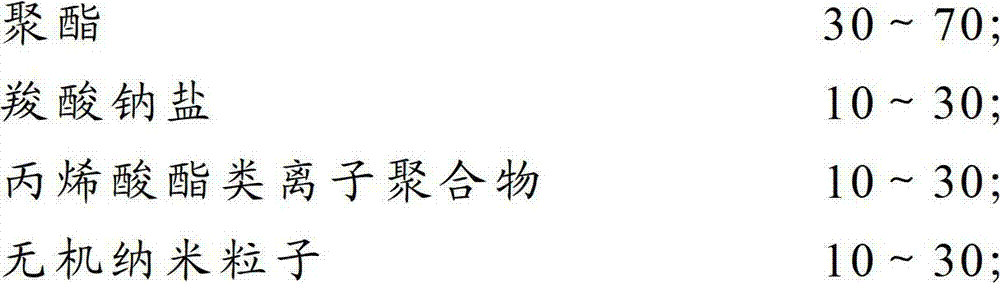

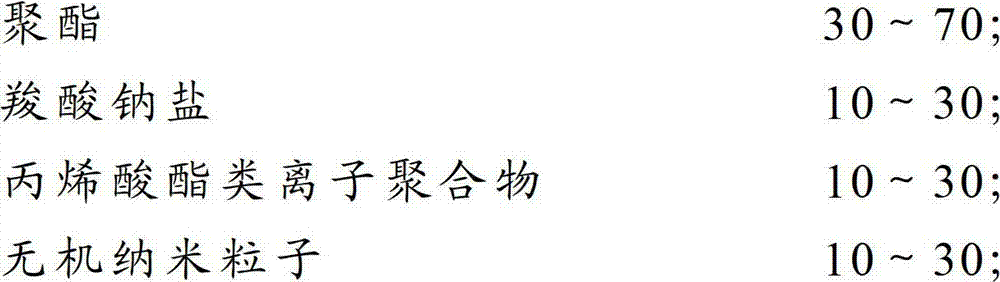

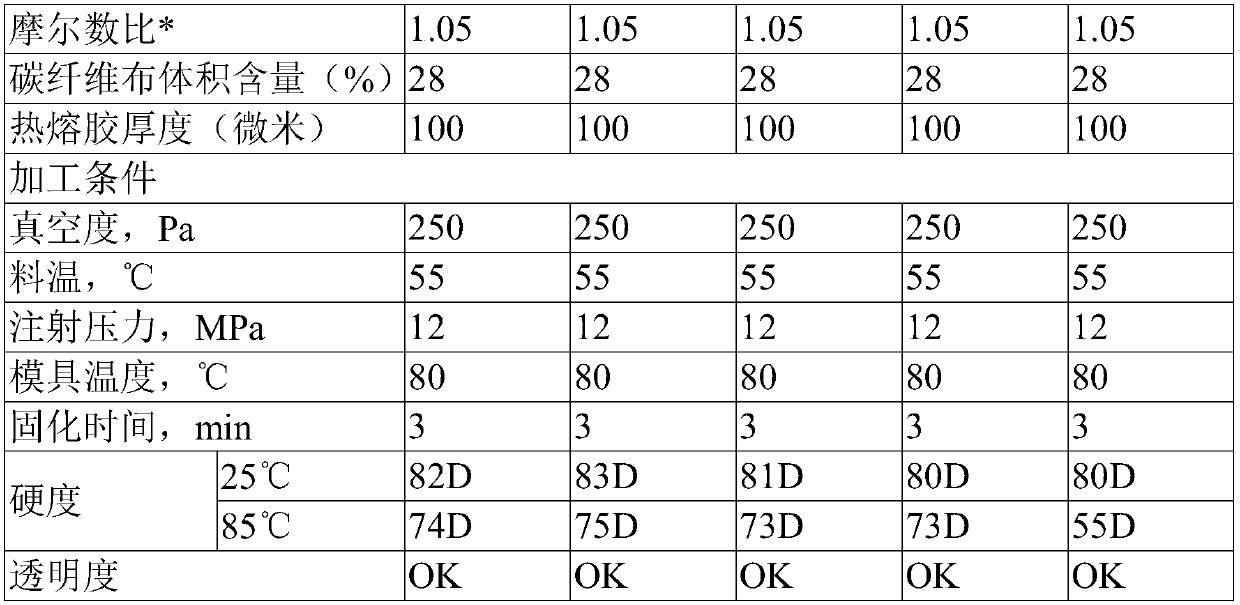

Resin additive composition and antistatic thermoplastic resin composition

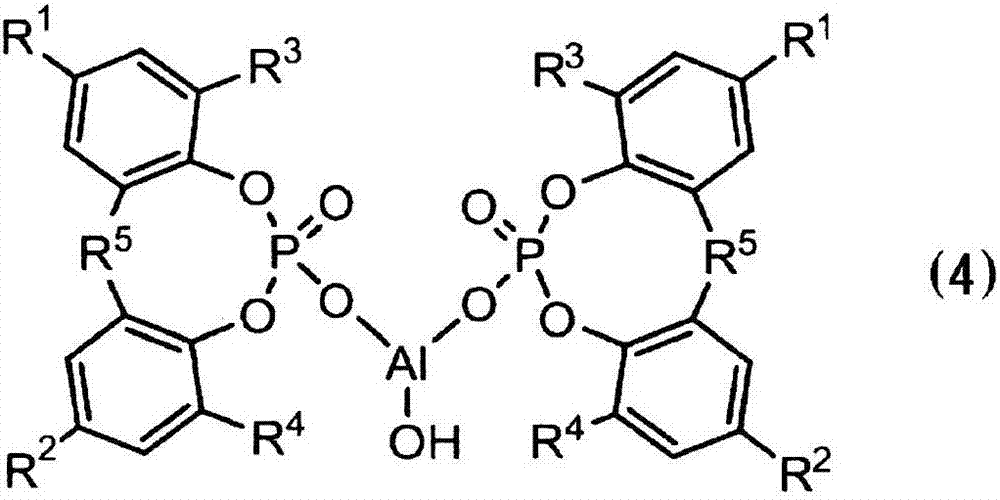

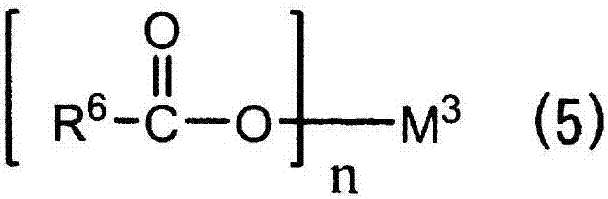

ActiveCN107429048AImprove antistatic performanceShort molding cycleOther chemical processesGroup 3/13 element organic compoundsPolymer sciencePhosphate

Provided are a resin additive composition whereby excellent antistatic effects can be imparted using a small added amount thereof, and an antistatic thermoplastic resin composition. A resin additive composition containing 0.001-50 parts by mass of two or more species selected from metal salts of aromatic phosphate esters represented by general formula (3) or (4) with respect to 100 parts by mass of a polymer compound (E). The polymer compound (E) has a structure obtained by bonding, via ester bonds, of a diol, an aliphatic dicarboxylic acid, an aromatic dicarboxylic acid, a compound (B) having one or more groups represented by general formula (1) and having hydroxyl groups at both terminal ends thereof, and an epoxy compound (D) having two or more epoxy groups.

Owner:ADEKA CORP

Efficient compound thermoplastic elastomer

The invention belongs to an efficient compound thermoplastic elastomer and provides a full curing thermoplastic elastomer which is more oil-resisting than a common full curing polyolefine thermoplastic vulcanized rubber. The elastomer adopts a compound system of an ethylene propylene diene rubber, a nitrile rubber and a polyolefine resin and a compound system of a maleic anhydride graft, a carboxylic acrylonitrile butadiene rubber and organic aminated compounds. The compound thermoplastic elastomer has excellent oil-resisting property and mechanical property.

Owner:DALIAN COMPOUNDING NEW MATERIALS

Gel cast fused quartz crucible and manufacturing method thereof

The invention discloses a gel cast fused quartz crucible which contains the following components by mass percentage: more than 99.74% of silica, less than 40ppm of ferric oxide, less than 1000ppm of alumina, and the balance inevitable impurities such as potassium, sodium, magnesium or calcium oxides. A green body of the gel cast fused quartz crucible is high in strength and density, and even in structure, and can be used for producing large-sized crucibles. The invention also discloses a manufacturing method of the gel cast fused quartz crucible.

Owner:龙立华

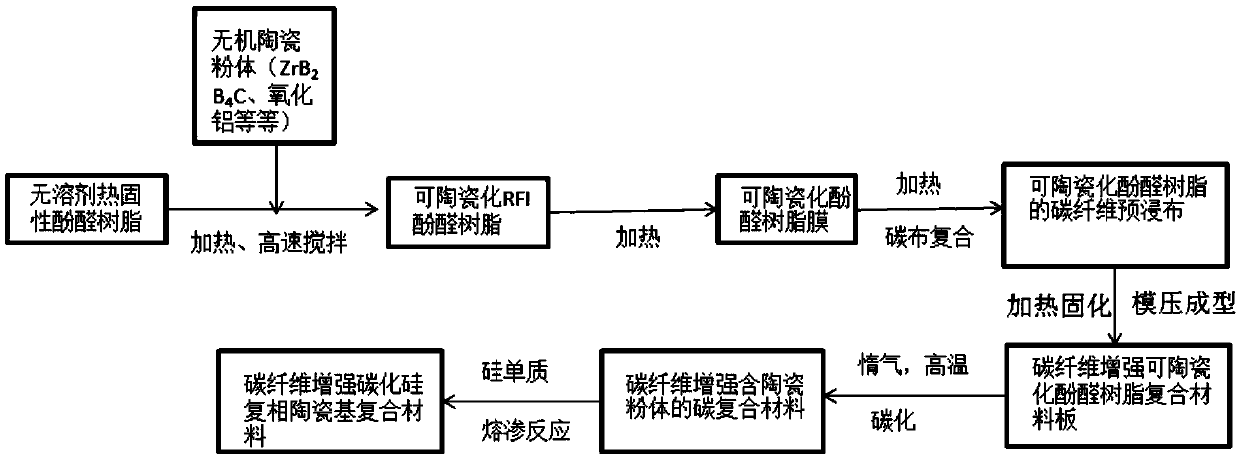

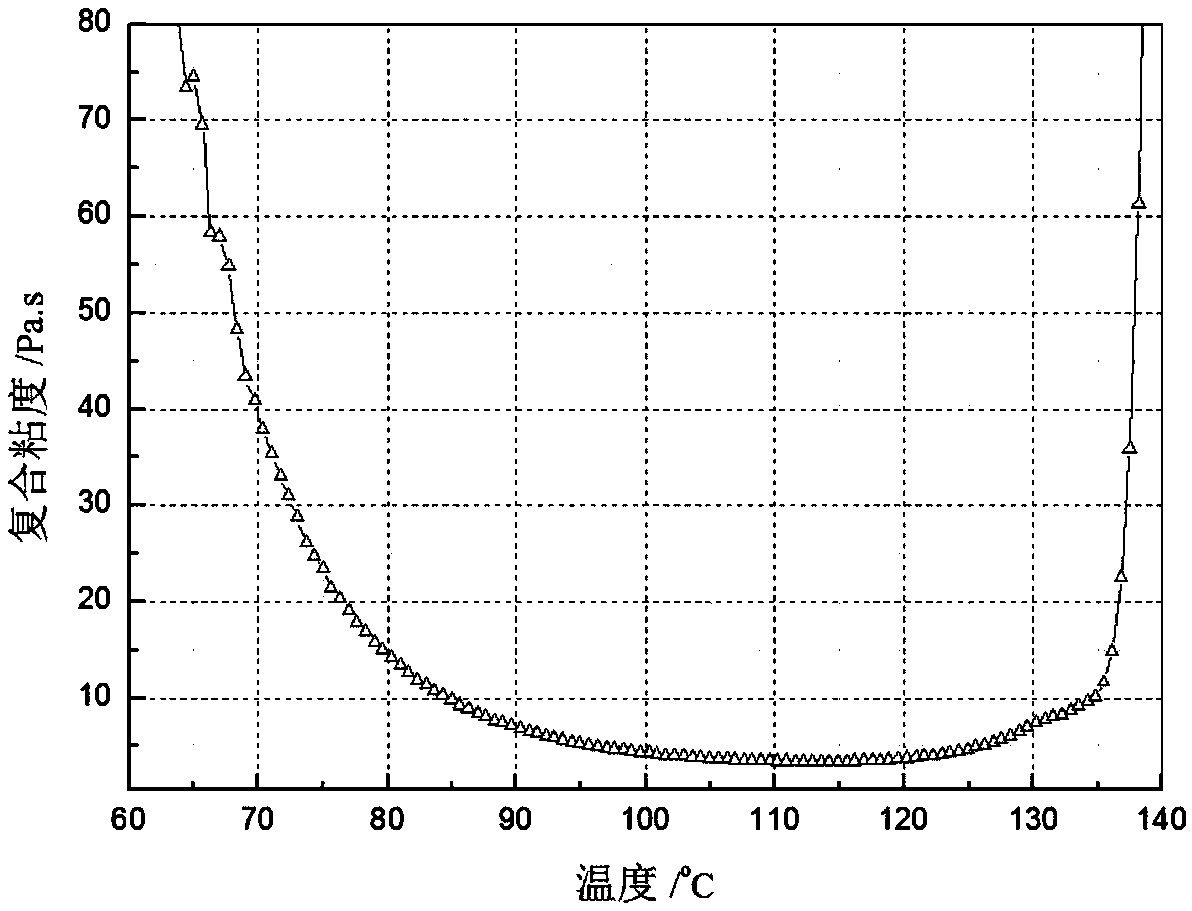

Ceramic-able phenolic resin, and preparation method and application thereof

The invention provides a ceramic-able phenolic resin, and a preparation method and an application thereof; the ceramic-able phenolic resin has effects of high temperature resistance, high carbon residue and anti-oxidization, is excellent in processability, can satisfy technical requirement of RFI, and can be used for preparing a fiber-reinforced silicon carbide ceramic-based composite material athigh efficiency and quality. The ceramic-able phenolic resin is good in designability on formula, wherein according to practical work temperatures, different ultrahigh temperature ceramic powders, such as boron carbide, silicon carbide, zirconium boride, hafnium carbide, tantalum carbide, SiO2, Al2O3, zirconia and the like, can be selected. In the invention, the fiber-reinforced silicon carbide ceramic-based composite material is produced through a reactive infiltration process of silicon simple substance; compared with a conventional precursor impregnation cracking method, the preparation method is low in raw material cost, short in shaping period, simple in processes, strong in operability, low in manufacturing cost and high in shaping quality. The phenolic resin is convenient in industrial large-scale preparation and is easy to promote and apply.

Owner:INST OF CHEM CHINESE ACAD OF SCI

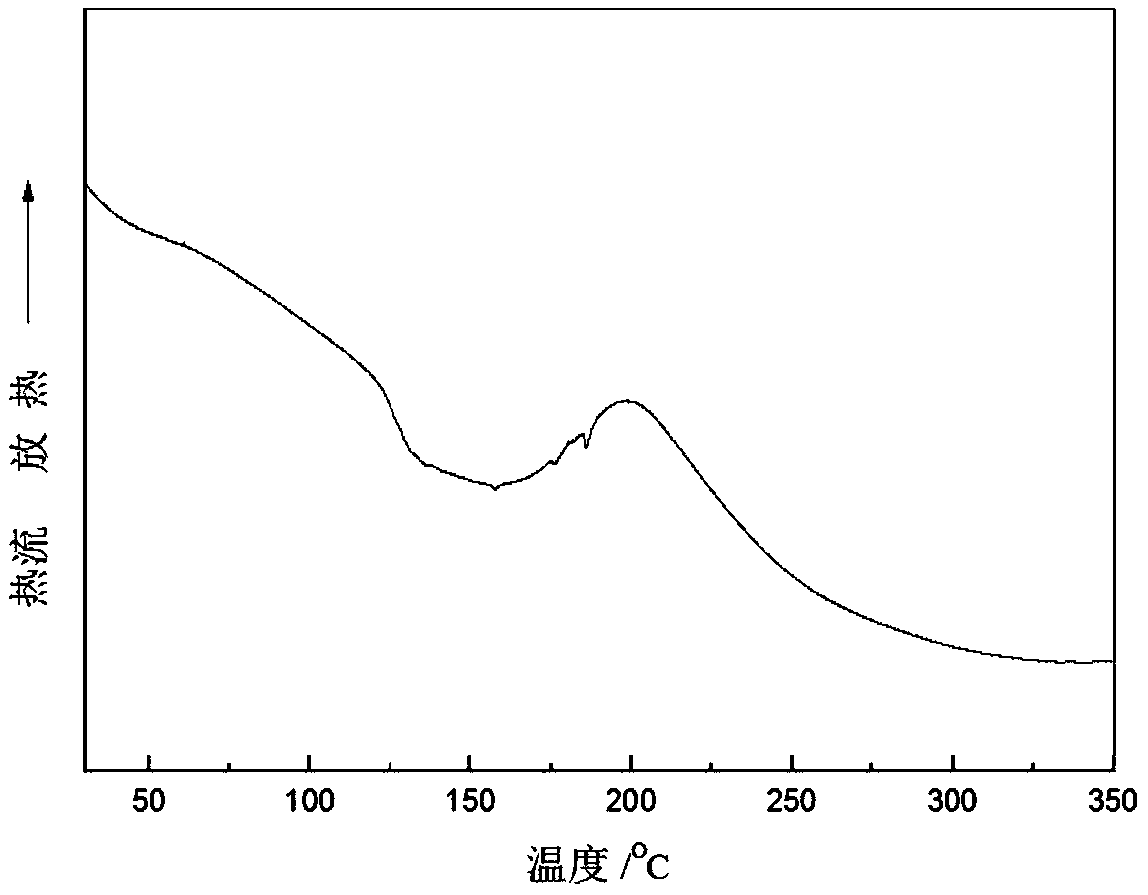

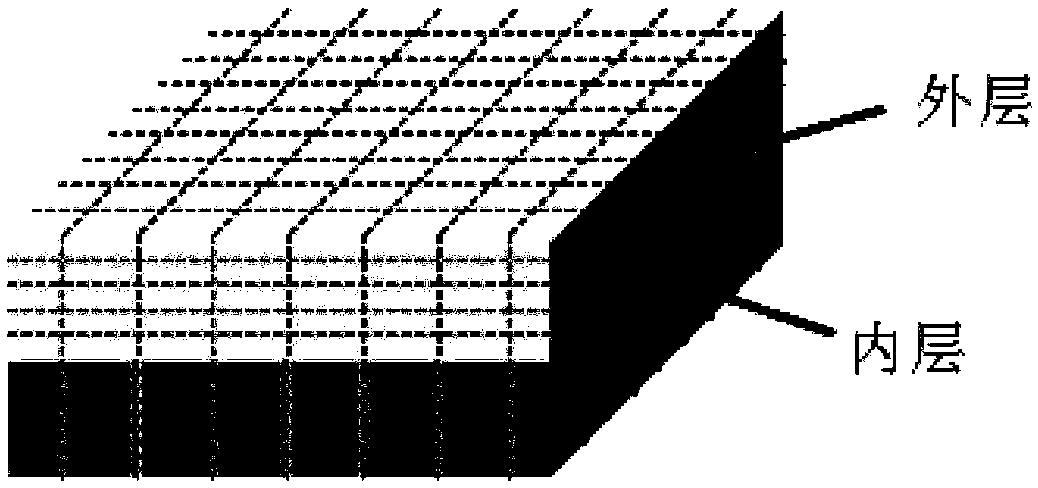

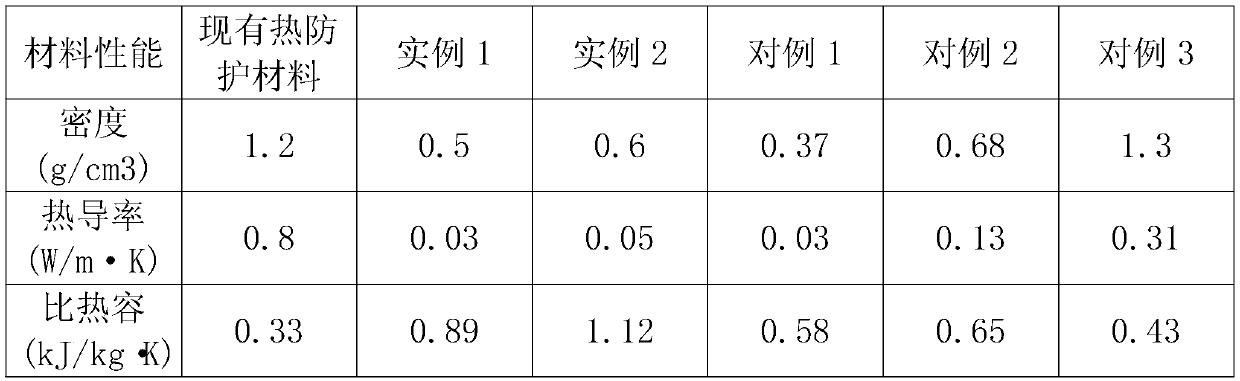

Integrated density gradient thermal protection material and preparation method thereof

ActiveCN111331941AGuaranteed insulation effectLow costSynthetic resin layered productsThermal protectionFiber reinforcement

The invention provides an integrated density gradient thermal protection material and a preparation method thereof. The thermal protection material comprises a matrix and a reinforcement body, whereinthe matrix is of a network-shaped porous resin structure; the reinforcement body comprises a fiber reinforcement body inner layer with a second volume density and a fiber reinforcement body outer layer with a first volume density arranged on the inner layer; a network-shaped porous structure is further dispersed and cured in the fiber reinforcement body outer layer and the fiber reinforcement body inner layer, and the first volume density is 0.5-2.0 g / cm<3>; and the second volume density is 0.05-0.4 g / cm<3>. The method comprises the following steps: preparing the reinforcement body; preparinga solution of a matrix raw material; injecting the solution into the reinforcement body to enable the reinforcement body to fully infiltrate the solution; and curing at a resin curing temperature. The technical problems that an outer heat-proof layer of an existing heat-proof material is prone to oxidation and cannot be used for a long time, an inner heat-insulating layer is long in forming process period and high in cost, and the overall heat-proof effect is poor due to a preparation method can be solved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Hemodialyzer with polypropylene material outer shell and manufacturing method thereof

The invention discloses a hemodialyzer with a polypropylene material outer shell and a manufacturing method thereof, and relates to the field of hemodialysis. The hemodialyzer comprises an outer shell body and membrane fibers. The outer shell body comprises an end cover and a tubular body, and the outer shell body is made of polypropylene. A welding bulge loop which is matched with the end face of the body is arranged at the position, opposite to the end face of the tubular body, of the end cover. The welding bulge loop of the end cover and the tubular body are welded together through ultrasonic waves. The manufacturing method of the hemodialyzer with the polypropylene material outer shell includes the steps that injection molding, pre-assembling, sintering, centrifugal can sealing and cropping of the end cover and the tubular body are conducted, the end cover is fixedly mounted on the tubular body, and leak hunting, drying and assembling are carried out on a dust cap. Plasma activating treatment is conducted on the end cover and the tubular body. The outer shell body is not poisonous, using is safe, the cost of raw materials is low, the molding cycle is short, and the preparation efficiency is high. The manufacturing method saves time and labor, improves efficiency, lowers manufacturing cost, and prevents a sealing ring from releasing substances harmful to the health of people when the end cover and the tubular body are in ultrasonic welding.

Owner:WEIHAI WEIGAO BLOOD PURIFICATION PROD

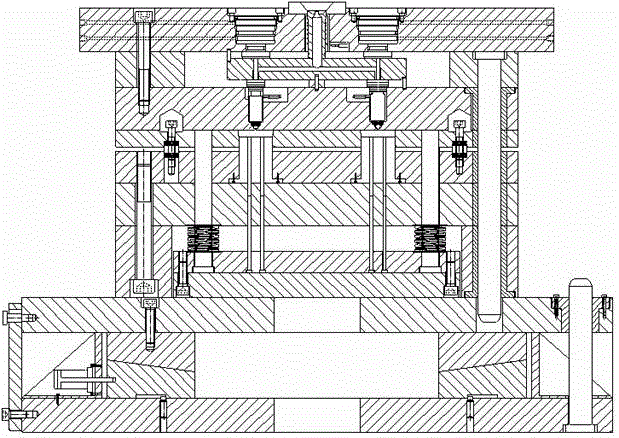

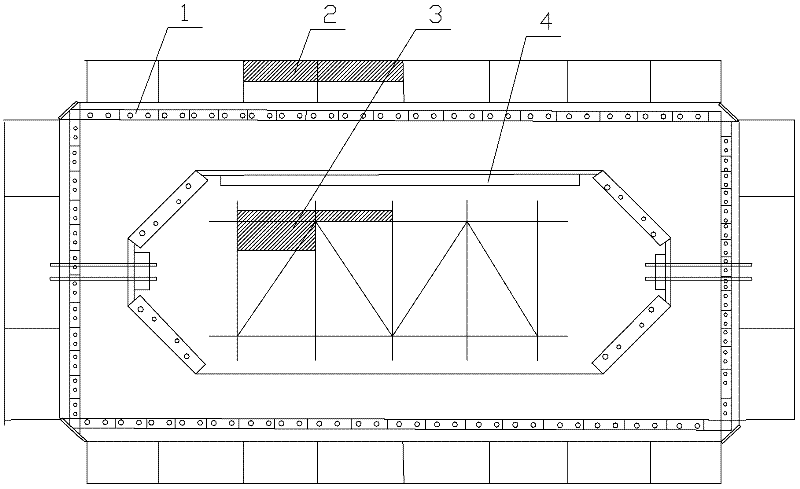

Injection compression molding composite mould

The invention provides an injection compression molding composite mould. On the basis of a common valve type hot runner injection mould, a compression gap is reserved between a cavity plate and a core insert fixing plate; a slide block is pushed by a compression hydraulic cylinder mounted on a movable mould seat plate to slide horizontally on the movable mould seat plate; the horizontal movement is converted into movement vertical to mould splitting surfaces of other parts except the cavity plate, namely a fixed slide block, a pressure plate and a movable mould side through a contacted surface of a movable slide block and the fixed slide block; and finally, movement relative to the reserved compression gap is formed between a core insert and the cavity plate. A common injection molding machine does not have a secondary mould closing function and the composite mould can realize an injection compression molding process on the common injection molding machine, so that the precision of a product is improved on the basis of existing equipment and control system, and the application range of the common injection molding machine is enlarged.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Double-component ceramic 3D printing extrusion molding material and use method thereof

InactiveCN106810200AFew stepsShort molding cycleAdditive manufacturing apparatusClaywaresAdhesiveSlurry

The invention discloses a double-component ceramic 3D printing extrusion molding material which comprises a material A and a material B, wherein the material A is a mixture of pottery clay and an adhesive; the material B is a mixture of pottery clay and a curing agent; the materials are slurry; the mass ratio of the pottery clay to the adhesive in the material A is (60-80):(40-20); the mass ratio of the pottery clay to the curing agent in the material B is (60-80):(40-20). The use method comprises the following steps: in printing, respectively putting the material A and the material B of the ceramic slurry into a storage tank A and a storage tank B, connecting the storage tank A and the storage tank B respectively with a mixing tube by using a conveying pipeline, printing a ceramic blank, naturally drying the blank, baking, performing aftertreatment, sintering the blank, and cooling, so as to obtain an expected ceramic product. As the material is divided into two components which are respectively prepared and preserved, the preservation time of the material is prolonged, product curing can be accelerated in printing, and the printing speed can be increased.

Owner:醴陵市陶瓷3D打印研究所

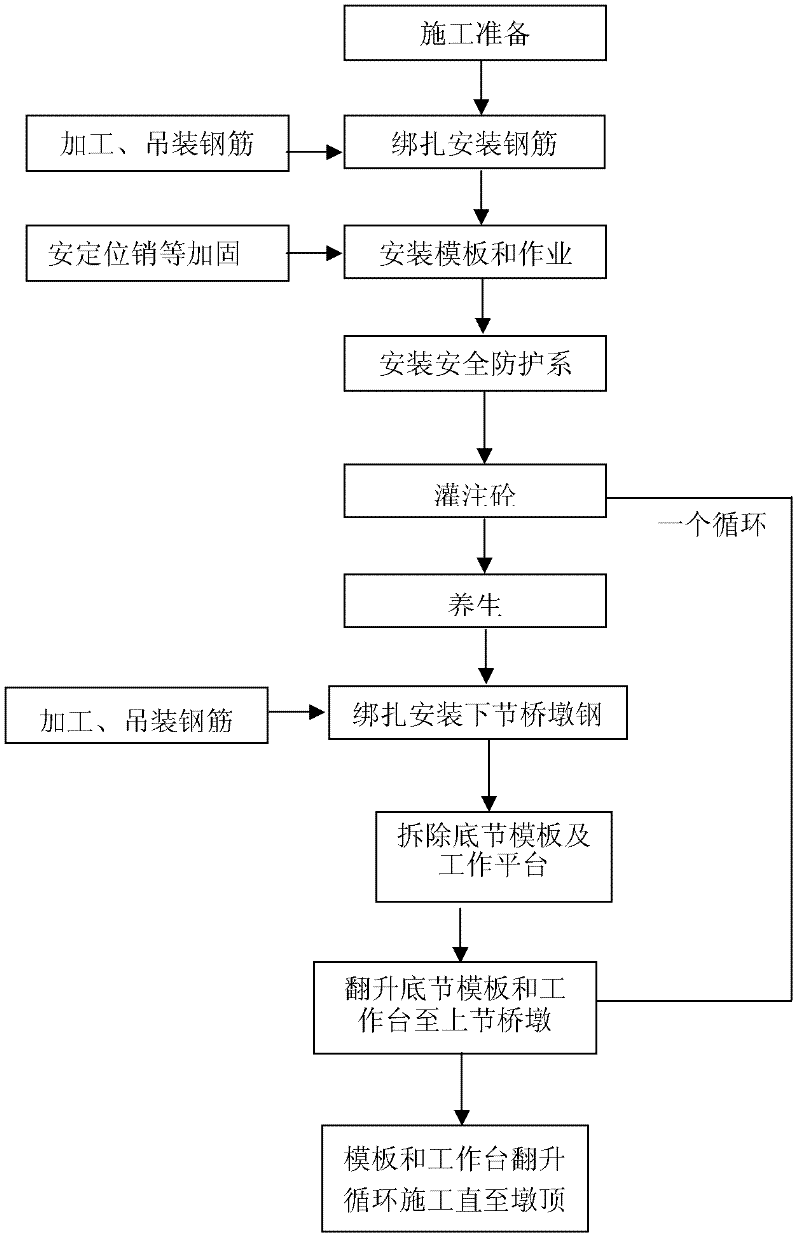

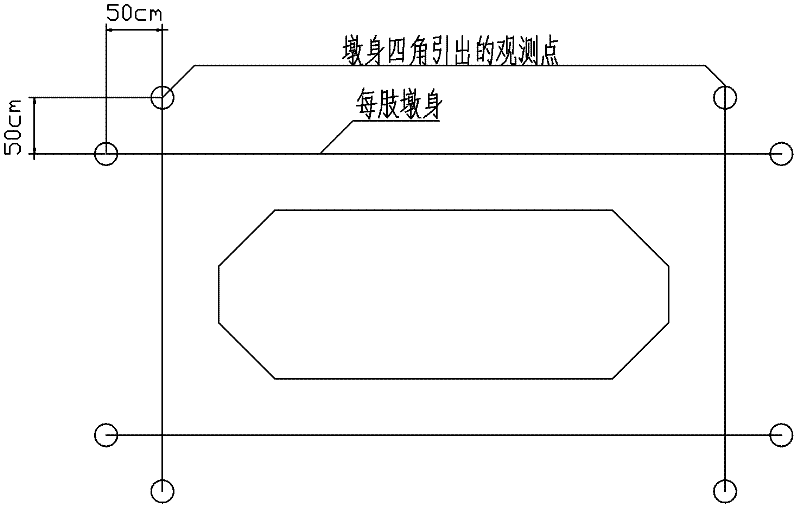

Method for constructing high pier

InactiveCN102409617AShort molding cycleShort turnaround timeBridge structural detailsBridge erection/assemblyEngineeringUltimate tensile strength

The invention discloses a method for constructing a high pier, which comprises the following steps of: 1) constructing a first section of pier through at least two upper and lower templates; 2) after concrete strength in a bottom template is more than or equal to 75 percent of design strength and concrete strength in the uppermost template is more than or equal to 2.5Mpa, detaching the bottom template and turning the bottom template above the uppermost template to serve as a second section of pier for installation, and finishing construction of the second section of pier; and 3) repeating the step 2) until construction of the whole pier is finished. Compared with a sliding formwork method, the method has the advantages that: the molding period is short, the pier is convenient to construct, and the method is convenient to operate; and compared with a creeping formwork method, the method has the advantages that: the molding period is short, a high scaffold is not needed to be erected, a few materials are occupied, and construction cost is low. The method has the advantages of sliding formwork and creeping formwork construction methods, the turnover period of the template is short, the construction period of each section of pier is short and is generally about five days, and the concrete joint of the pier has high quality.

Owner:TIANJIN 20 CONSTR

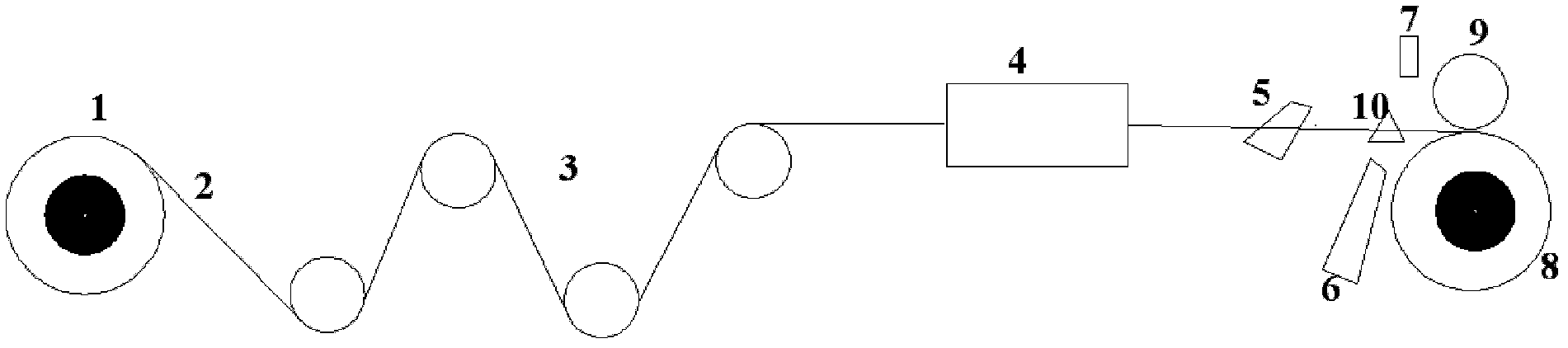

Preparation method of continuous fiber-reinforced thermoplastic compound prepreg tape pipe

The invention belongs to the technical field of high polymer materials and relates to a preparation method of a pipe. The preparation method comprises the following steps of: (1) placing a compound prepreg tape in a winding device, and then enabling the compound prepreg tape to pass through each tension roller in the tension roller group sequentially; (2) pre-heating the compound prepreg tape which is treated in the step (1); (3) heating the compound prepreg tape preheated in the step (2) at a winding point; (4) winding the compound prepreg tape heated in the step (3); and (5) finally, solidifying and shaping in situ to obtain the pipe. Compared with the prior art, the preparation method of the continuous fiber-reinforced thermoplastic compound prepreg tape pipe, disclosed by the invention, has the advantages of low cost, simple equipment, short shaping period and the like; and the produced thermoplastic compound pipe has a light weight, is high-pressure resistant and anticorrosive, and can be applied to the high-end field such as petrochemical engineering.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

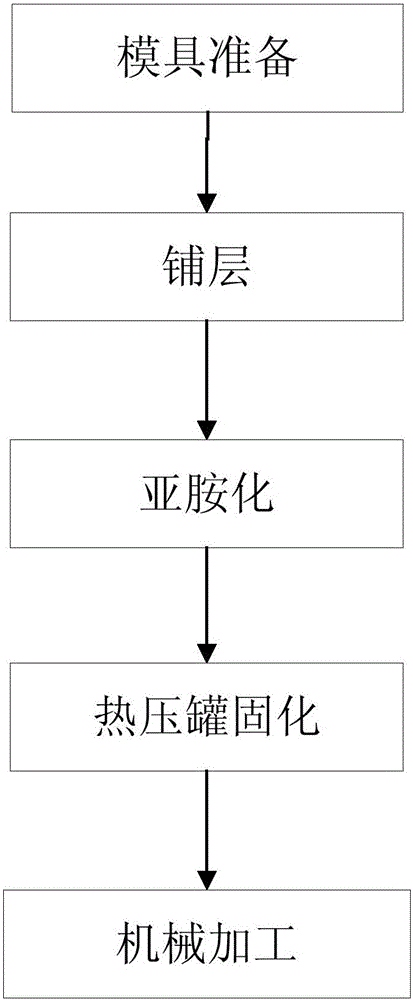

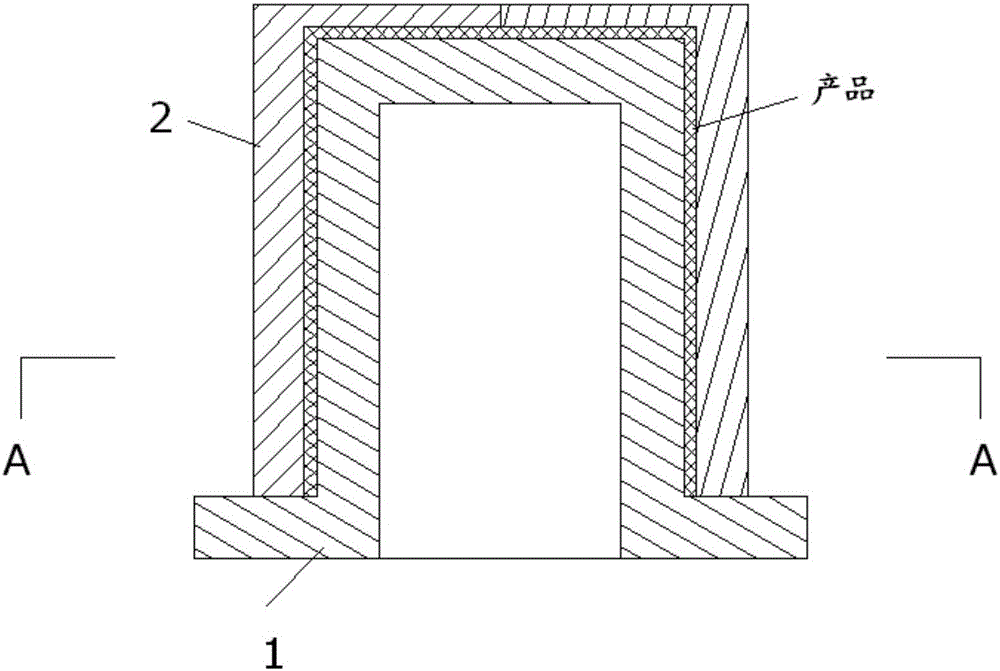

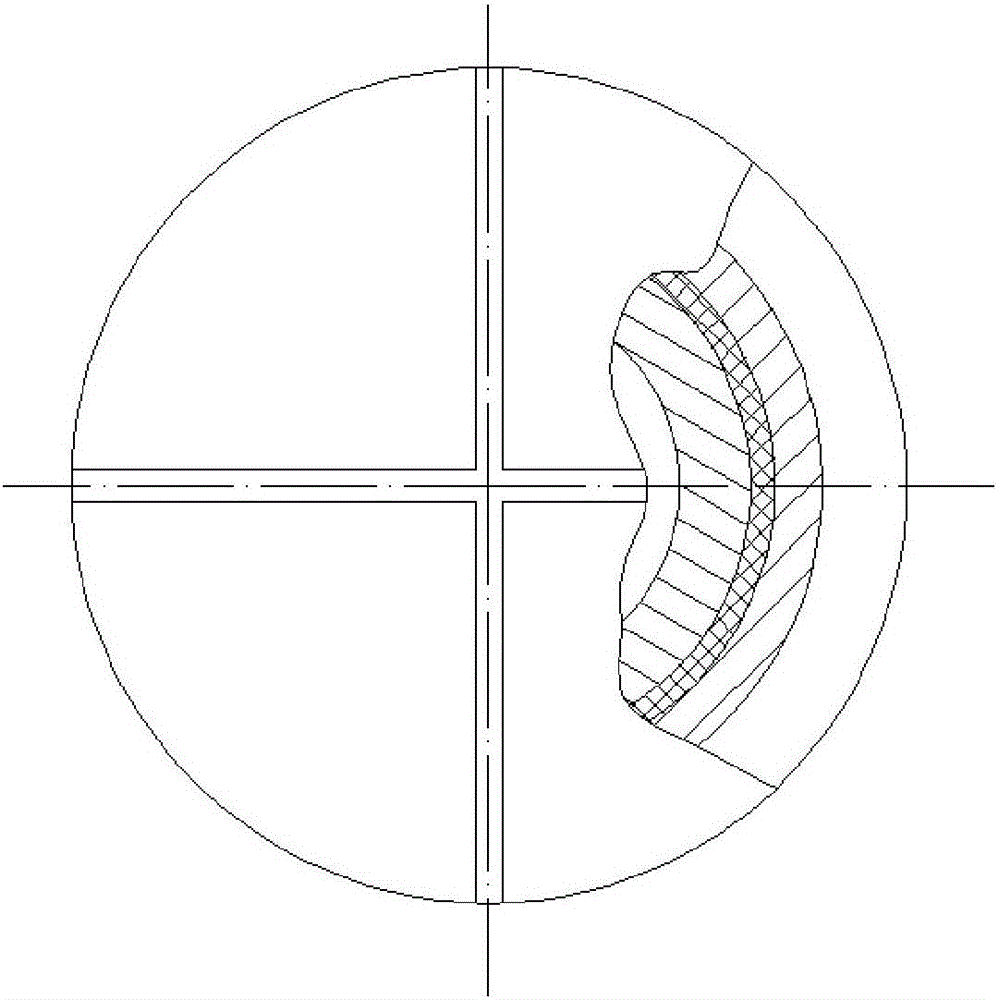

Forming method of thin-walled helical antenna supporting medium tube made of high-temperature-resistant polyimide composite

The invention relates to a forming method of a thin-walled helical antenna supporting medium tube made of a high-temperature-resistant polyimide composite, belongs to the technical field of high-temperature-resistant wave-transparent resin matrix composite forming, and particularly relates to a forming method applied in space returner GPSs and S-frequency-band antenna spiral supporting medium tubes. A thin wall refers to the wall, with the wall thickness ranging from 1.5 mm to 3 mm, of the spiral antenna supporting medium tube. According to the mechanics, wave transmissivity, heat resistance and weight reduction requirements of the high-temperature-resistant thin-walled helical antenna supporting medium tube used for air returners, a special mold is designed, materials are preferentially selected, and the prepared spiral antenna supporting medium tube has the following excellent comprehensive performance.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

High-temperature-resistant easy-to-form PC/PCTG material and preparation method thereof

The invention relates to the field of rubber materials, in particular to a high-temperature-resistant easy-to-form PC / PCTG material and a preparation method thereof. The high-temperature-resistant easy-to-form PC / PCTG material is prepared from the following components in percentage by mass: 50-70% of PC, 20-60% of PCTG, 0.05-0.3% of a lubricating agent, and 0.2-0.4% of an anti-oxidant. The high-temperature-resistant easy-to-form PC / PCTG material is high in flowing property, is good in processing and forming property, is good in heat resistance and is high in mechanical strength.

Owner:东莞市优特美工程塑料有限公司

Thermal insulation board and preparation method thereof

ActiveCN111516346AImprove mechanical propertiesSolve the problem of falling powderSynthetic resin layered productsDomestic articlesThermal insulationMold removal

The invention belongs to the technical field of thermal insulation materials, and discloses a thermal insulation board and a preparation method thereof. The thermal insulation board comprises a firstpanel layer, a second panel layer, a sandwich layer and framework supporting layers. The sandwich layer is arranged between the first panel layer and the second panel layer; the sandwich layer is formed by splicing a plurality of fiber reinforced aerogel composite felts; the framework supporting layers are integrally formed and fill between the sandwich layer and the first panel layer and betweenthe sandwich layer and the second panel layer, the peripheral edges of the sandwich layer and splicing seams of any two adjacent fiber reinforced aerogel composite felts in the sandwich layer, and theframework supporting layers, the first panel layer and the second panel layer are integrally formed. The preparation method comprises the following steps: laying, sealing, preparing a glue solution,injecting glue, curing and demolding to obtain the thermal insulation board. An integral curing molding method is adopted, the fiber reinforced resin composite panel is obtained, and meanwhile, the framework supporting layers are formed between the fiber reinforced aerogel composite felts so that the prepared thermal insulation board is light in weight, thermal-insulating and greatly improved in mechanical property.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com