Transparent polylactic acid alloy material

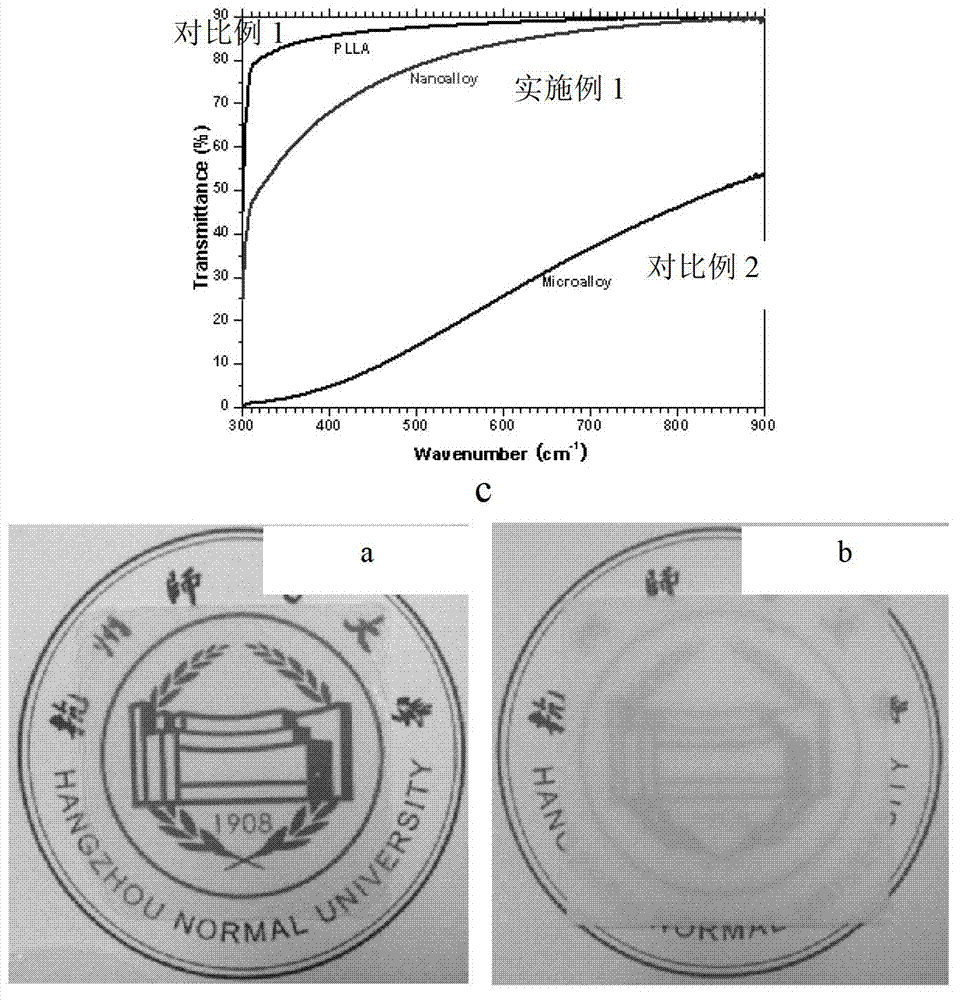

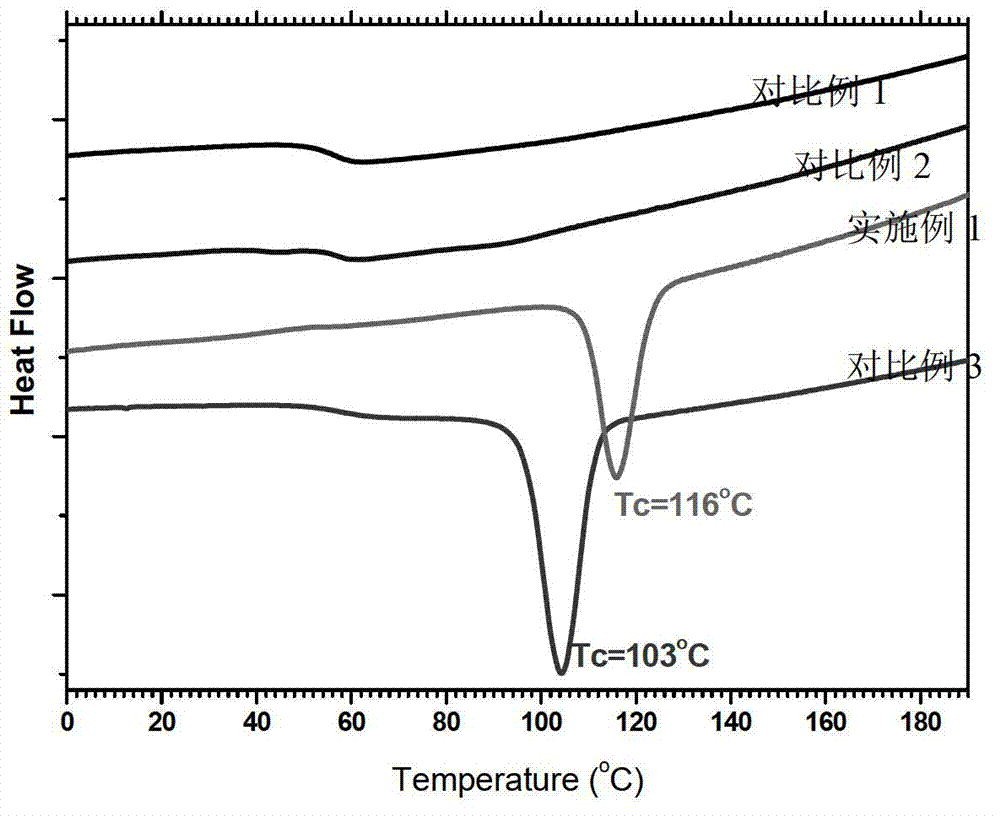

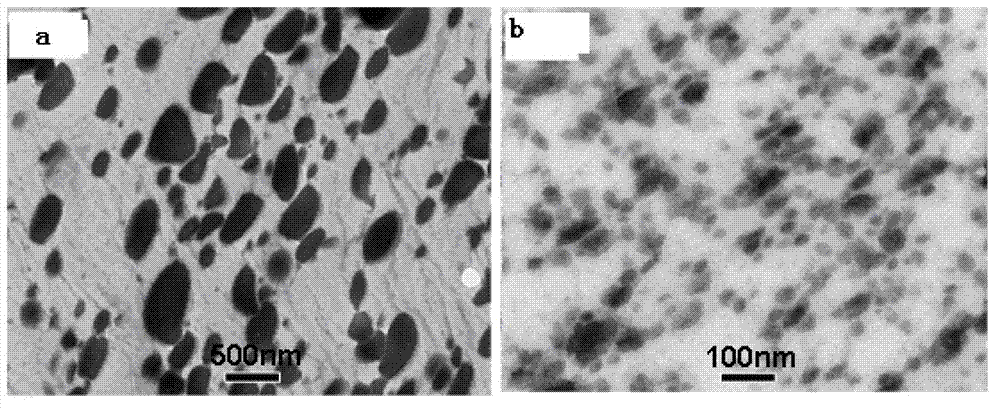

An alloy material and polylactic acid technology, applied in the field of transparent polylactic acid alloy material and its preparation, can solve the problems of damage to the transparent performance of polylactic acid, failure to achieve, etc., and achieve the effects of excellent light transmission performance, short molding cycle, and simple industrial preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The elastomer used is ethylene-acrylate-glycidyl methacrylate copolymer, the weight fractions of ethylene, acrylate, and glycidyl methacrylate are 68%, 22% and 10%, and the epoxy value is 0.07 equivalent / 100g , The melt index is 6g / 10min. The sample was purchased from the French company Arkema, the brand name is AX8900. After drying polylactic acid (PLA) and elastomer in a vacuum oven at 80°C for 24 hours, according to the mass ratio of PLA and elastomer at a ratio of 80:20, mix and stir at room temperature, add to the internal mixer, and banbury The machine temperature is 200°C, the screw speed is set at 100rpm, and the mixing time is 15min.

[0034] The above mixed samples were hot-pressed into sheets in a hot press at 210°C, and standard test specimens were prepared with standard dumbbell-shaped punching knives for performance testing. The results are shown in Table 1.

Embodiment 2

[0036] The elastomer is ethylene-glycidyl methacrylate copolymer, the mass fractions of ethylene and glycidyl methacrylate are 92% and 8%, and the epoxy value is 0.056 equivalent / 100g. The melt index was 5 g / min. The sample was purchased from the French company Arkema, the brand name is AX8840. After drying polylactic acid (PLA) and elastomer in a vacuum oven at 80°C for 24 hours, according to the mass ratio of PLA and elastomer at a ratio of 80:20, mix and stir at room temperature, add to the internal mixer, and banbury The machine temperature is 200°C, the screw speed is set at 100rpm, and the mixing time is 15min.

[0037] The above mixed samples were hot-pressed into sheets in a hot press at 210°C, and standard test specimens were prepared with standard dumbbell-shaped punching knives for performance testing. The results are shown in Table 1.

Embodiment 3- Embodiment 5

[0039] The elastomer is the same as in Example 1, and other operations are the same as in Example 1. The difference is that the mass ratios of polylactic acid and elastomer are respectively 85:15, 90:10, and 95:5, and are prepared by the same operation method as in Example 1. The mixed samples were obtained, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com