Patents

Literature

1069 results about "Melt mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Injection molding method for neutral and acidic-group containing (meth)acrylate copolymers

InactiveUS20020160042A1Reduce contentOrganic dyesPharmaceutical non-active ingredientsMeth-Additive ingredient

The invention relates to a process for producing mouldings by injection moulding, the steps in the process being A) Melting a mixture made from a) a (meth)acrylate copolymer composed of from 40 to 100% by weight of free-radical-polymerized C1-C4-alkyl esters of acrylic or methacrylic acid and from 0 to 60% by weight of (meth)acrylate monomers having an anionic group in the alkyl radical, where the copolymer comprises b) from 0.1 to 3% by weight of a release agent, and, where appropriate, the mixture may comprise c) from 0 to 50% by weight of a drier, d) from 0 to 30% by weight of a plasticizer, e) from 0 to 100% by weight of additives or auxiliaries, f) from 0 to 100% by weight of an active pharmaceutical ingredient, g) from 0 to 20% by weight of another polymer or copolymer, where the amounts given for components b) to g) are based on the (meth)acrylate copolymer a) and the mixture prior to melting has a content of more than 0.5% by weight of low-boiling constituents with vapour pressure of at least 1.9 bar at 120° C., B) Devolatilizing the mixture in the thermoplastic state at temperatures of at least 120° C., thereby lowering to not more than 0.5% by weight the content of the low-boiling constituents with vapour pressure of at least 1.9 bar at 120° C., C) Injecting the molten and devolatilized mixture into the mould cavity of an injection mould, the temperature of the mould cavity being below the glass transition temperature of the (meth)acrylate copolymer by at least 10° C., cooling the molten mixture, and removing the resultant moulding from the mould.

Owner:PFIZER INC +1

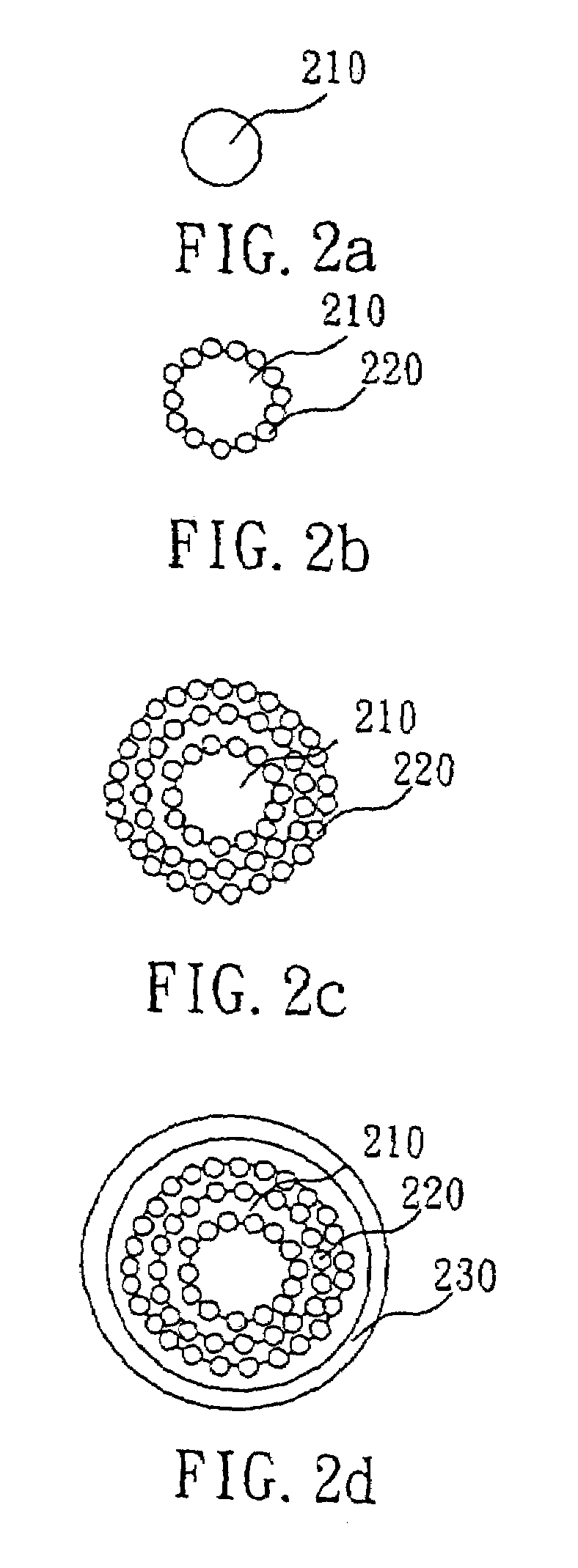

Encapsulation compositions and process for preparing the same

InactiveUS20100289164A1Improve physical stabilityReduce lossesBiocidePowder deliveryPolymer sciencePlasticizer

Encapsulation compositions in which an encapsulate (A) is encapsulated in a matrix (B) may be prepared by:(i) mixing matrix (B) with a liquid plasticizer and encapsulate (A) in an extruder, to obtain a melted mixture of encapsulate (A) and matrix (B); and(ii) extruding the melted mixture, to obtain an extruded mixture.

Owner:MCCORMICK & CO INC

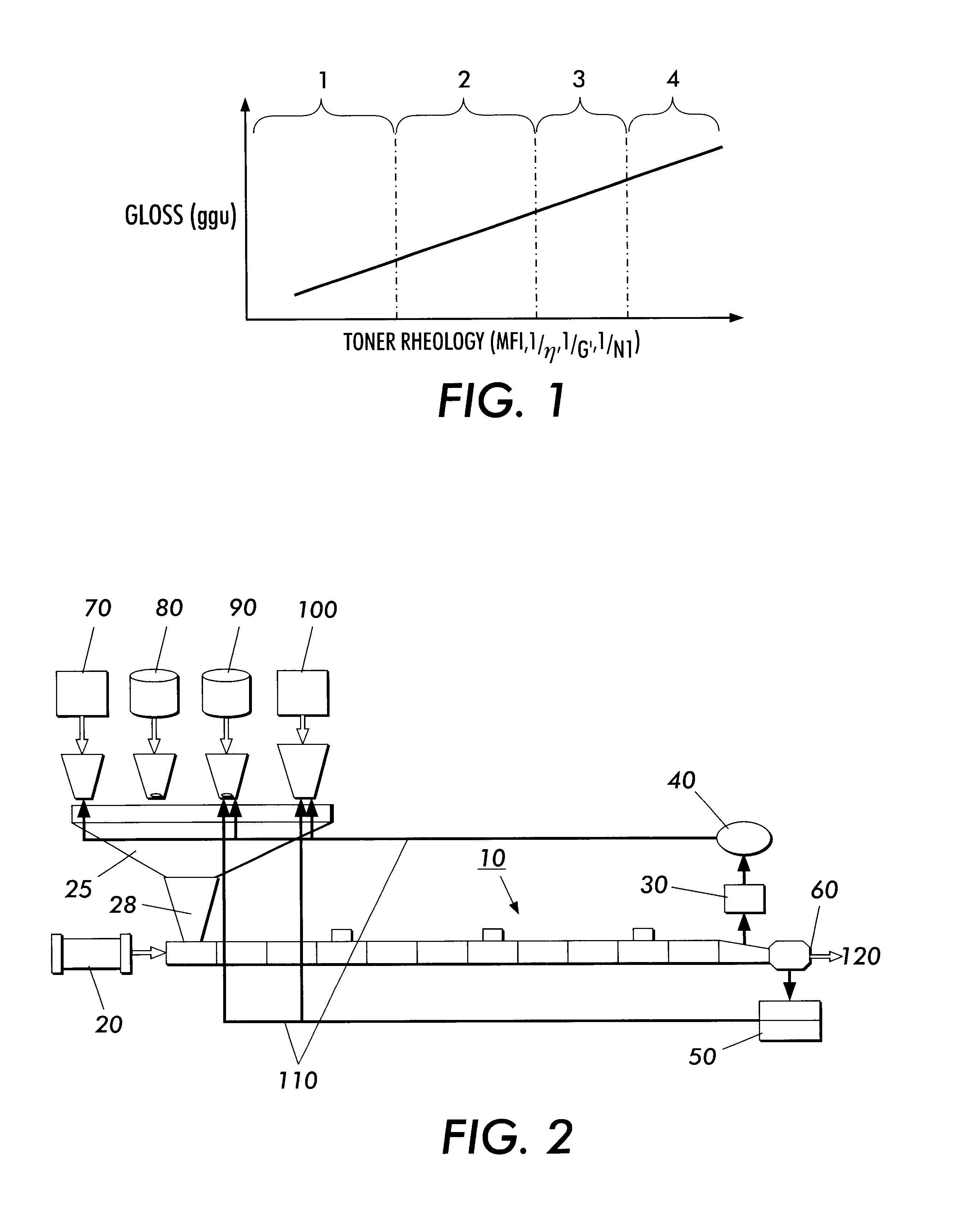

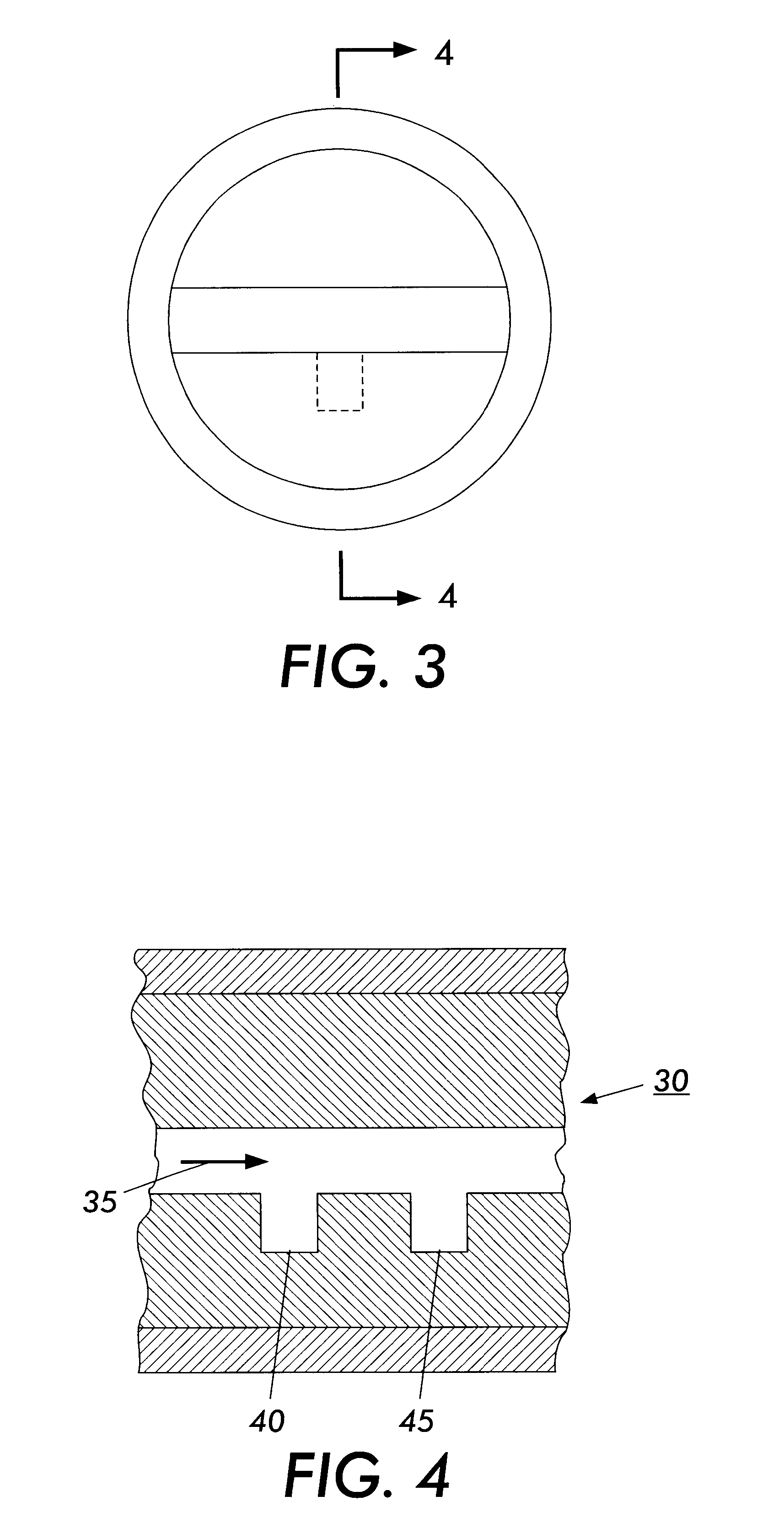

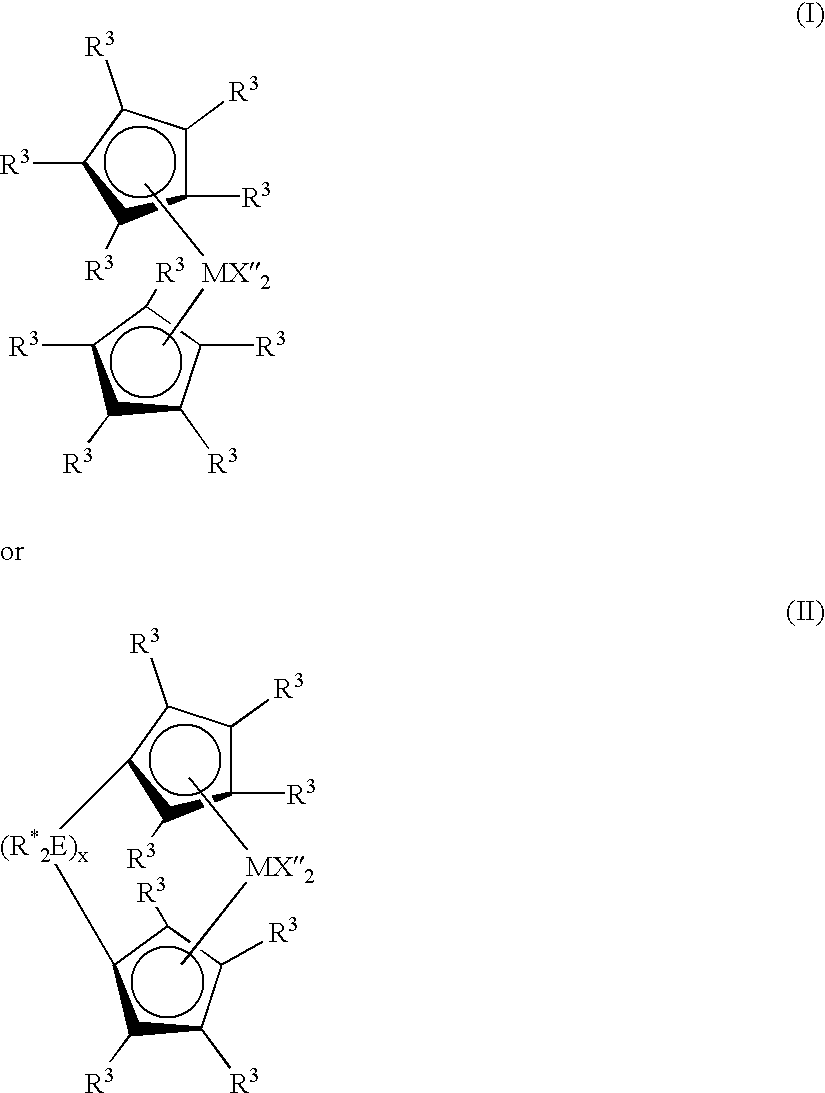

Method for controlling melt rheology of resin mixtures

InactiveUS6593053B1DevelopersFluid pressure measurement using capacitance variationMelt mixingChemistry

A process including: introducing and continuously melt mixing in an extruder a mixture of a first resin feed and a second resin feed; measuring within the extruder the melt rheology of the resulting melt mixture of the first and second resins; determining the relative ratio of the first resin and a second resin from the melt rheology in the resulting melt mixture; and adjusting the relative feed ratio of the first resin and second resin feeds introduced to the extruder.

Owner:XEROX CORP

Crosslinked, heat shrinkable polypropylene compositions

InactiveUS6569915B1Reduced effectivenessReduce the degree of crosslinkingElastomerEthylene Homopolymers

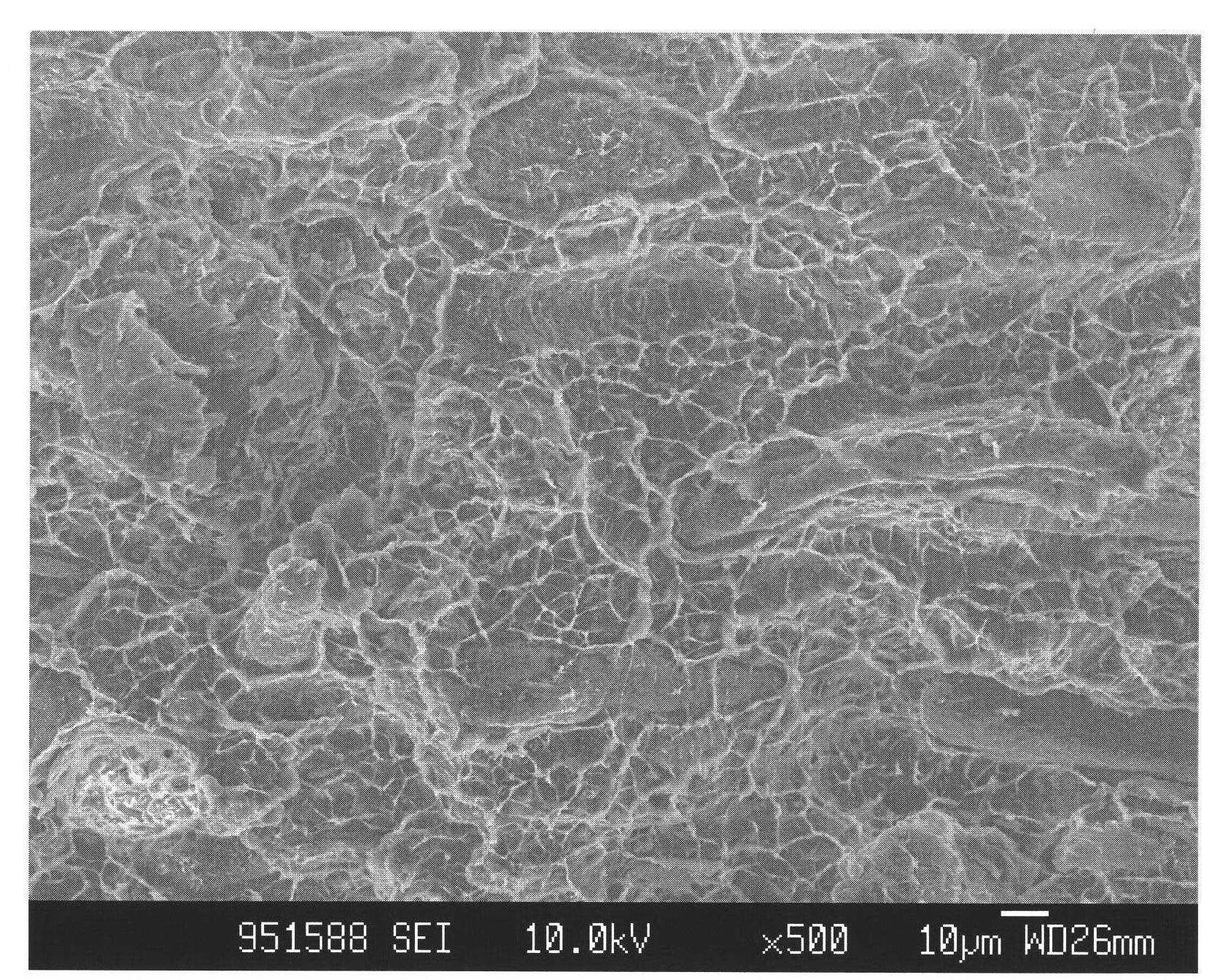

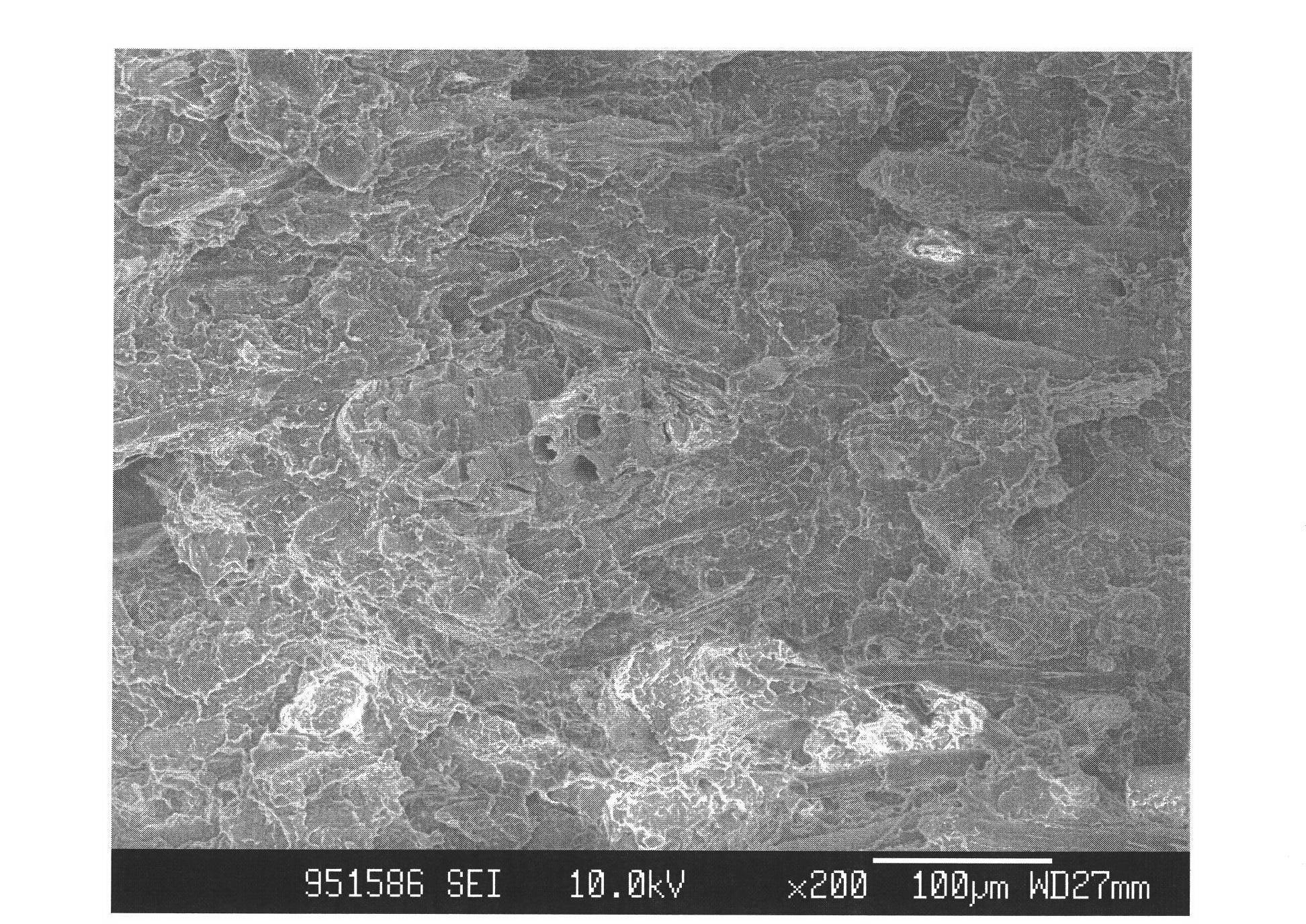

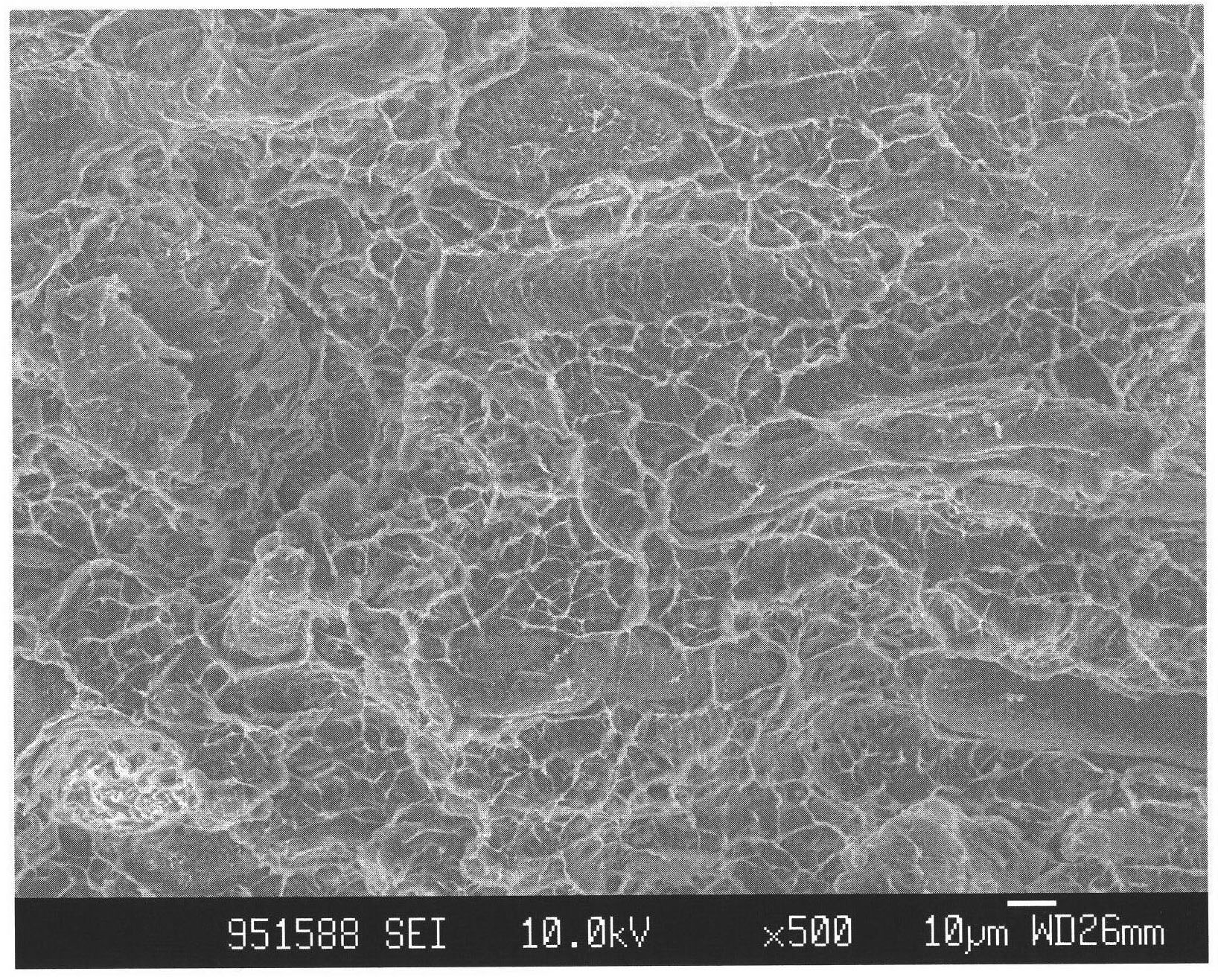

A heat-shrinkable article suitable for use as an insulating or coating material comprises a crosslinked composition of a polypropylene homopolymer or copolymer and an ethylene-propylene elastomer. The article is formed by a process comprising: i) creating a blend of the polypropylene homopolymer or copolymer and the ethylene-propylene elastomer by melt mixing; ii) melt processing the blend produced in i) to produce a melt processed material; iii) crosslinking the melt processed material produced in ii) by exposing it to radiation to produce a crosslinked material; iv) stretching the crosslinked material at a first temperature close to or above its softening or melting point and subsequently cooling it to a second temperature below its softening or melting point, to thereby freeze the crosslinked material in its stretched form. Subsequent heating of the article close to or above its softening point or crystalline melting point results in recovery of the pre-stretched dimensions of the article. Due to its relatively high content of polypropylene, the heat-shrinkable article thus produced has greater toughness and rigidity than polyethylene-based systems, making it suitable for use as insulation for wires and cables a heat-shrinkable corrosion resistant sleeves for high-temperature transmission pipeline joints, and for heat-shrinkable tubing or shapes for electrical insulation and mechanical protection.

Owner:SHAWCOR LTD

High density ethylene homopolymers and blend compositions

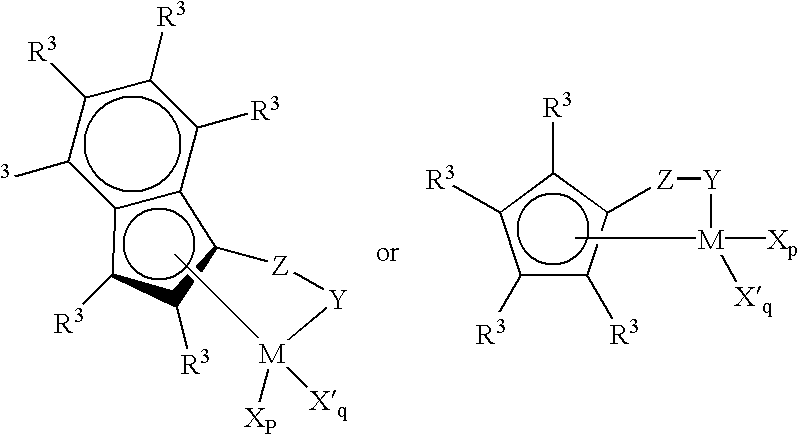

InactiveUS7153909B2High densityIncreased formationMetallocenesEthylene HomopolymersMechanical property

Blend compositions containing a novel homopolymer, the use of which allows the incorporation of more comonomer in the additional components of the blend (for the same overall density) resulting in increased tie molecule formation and improvement in properties such as ESCR, toughness and impact strength are disclosed. The homopolymers are important for applications where a high density is needed to ensure certain mechanical properties like abrasion resistance, indentation resistance, pressure resistance, topload resistance, modulus of elasticity, or morphology (for the chlorination of PE to CPE) and additional advantages such as melt processability. The blend can be obtained by dry or melt mixing the already produced components, or through in-situ production by in parallel and / or in series arranged reactors. These resins can be used in applications such as films, blow molded, injection molded, and rotomolded articles, fibres, and cable and wire coatings and jacketings and, various forms of pipe.

Owner:DOW GLOBAL TECH LLC

High wear-resistant wood-plastic composite and preparation method thereof

The invention provides a high wear-resistant wood-plastic composite and a preparation method thereof, and relates to a composite obtained by mixing modified plant fiber powder, modified nano ceramics particles and plastic powder. The high wear-resistant wood-plastic composite comprises the modified plant fiber powder, the modified nano ceramics particles, the recycled plastic powder and the like, wherein the modified nano ceramics particles comprises modified nano Al2O3, modified nano Si3N4, modified nano SiC or the mixture thereof, which can obviously improve the microhardness of the wood-plastic composite, reduce the wear rate and improve the mechanical property. The high wear-resistant wood-plastic composite is prepared from the components by the common melt-mixing method in the plastic processing. The surface hardness and the wearability of the wood-plastic composite are greatly increased, and the strength and the toughness are also greatly improved, so that the overall performance of the wood-plastic composite is greatly enhanced. The wood-plastic composite can be used in the fields of construction material, furniture, package and the like.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

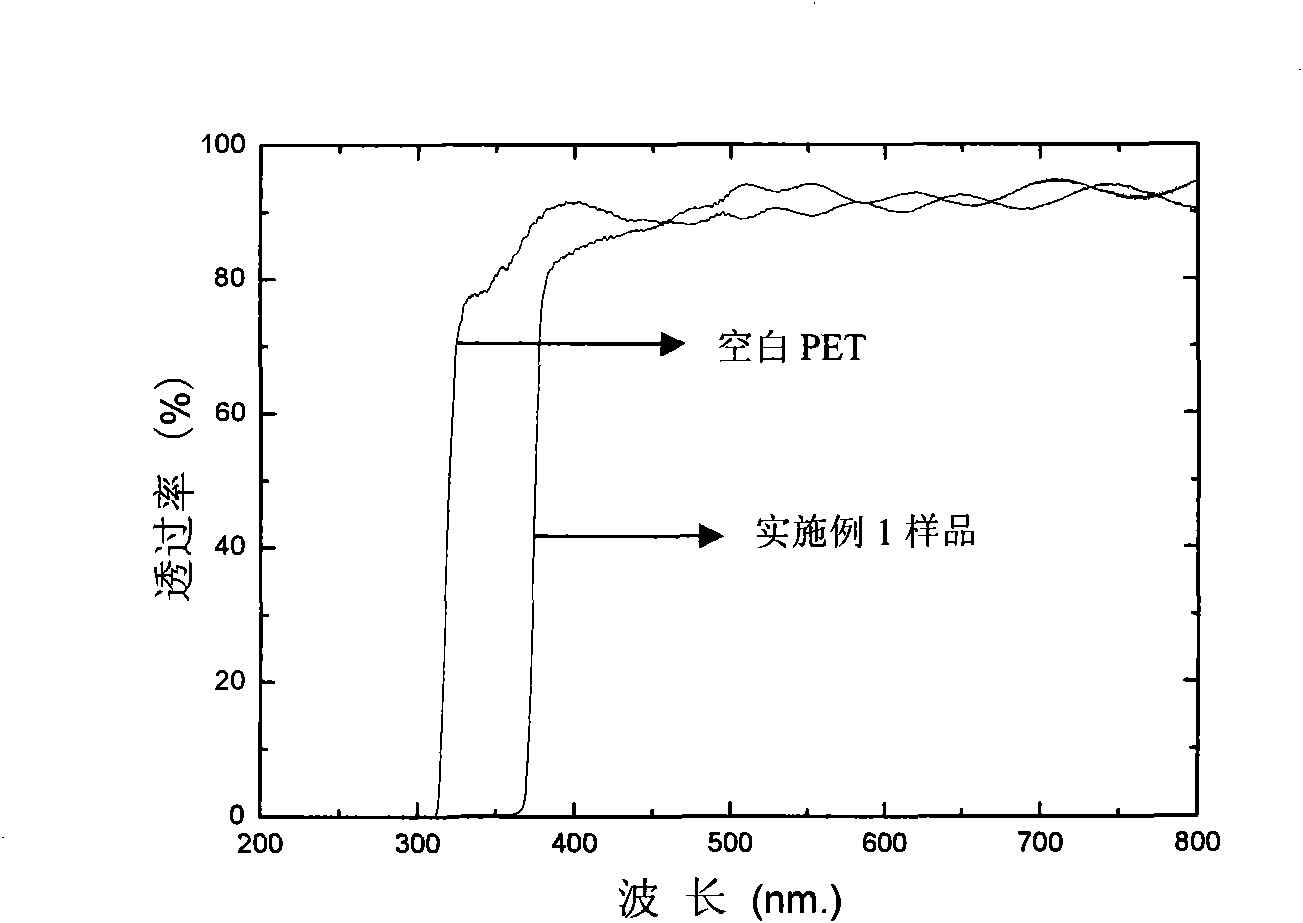

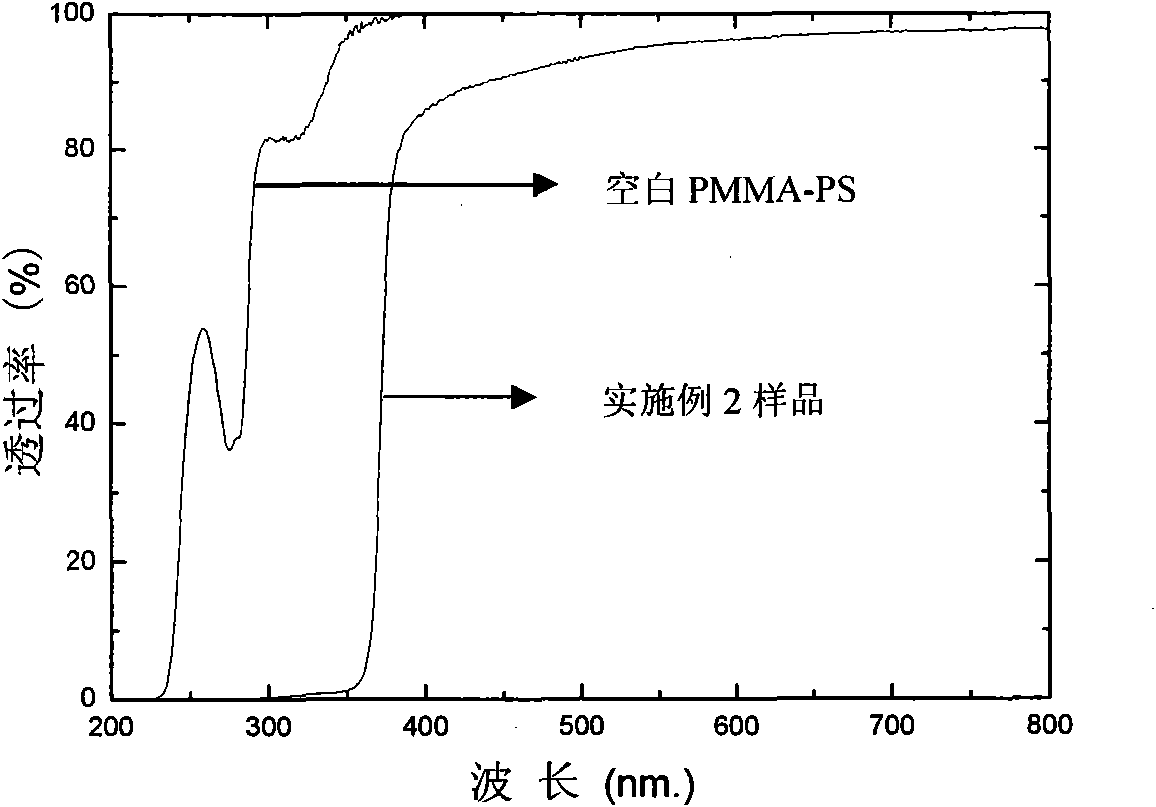

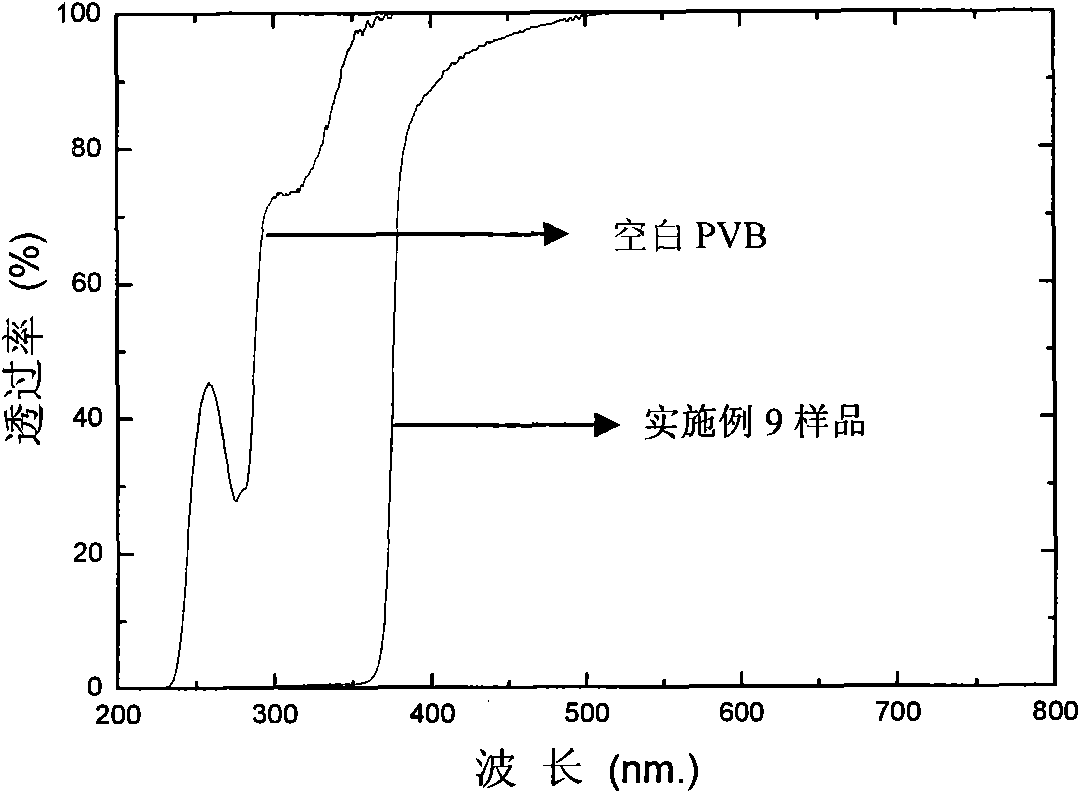

Highly-transparent ultraviolet-resistant energy-saving film and preparation method thereof

The invention relates to a highly-transparent ultraviolet-resistant energy-saving film and a preparation method thereof, belonging to the field of composite films synthesized by compounding polymer and inorganic nano-particles and aiming at overcoming the defects that the prior film has low visible light transmission and high production cost. The highly-transparent ultraviolet-resistant energy-saving film comprises the following components by the weight percent: 50-99.8 of organic polymer, 0.2-50 of metal-oxide nano-particles and 0-39.9 of polymer auxiliary agent. The highly-transparent ultraviolet-resistant energy-saving film is prepared by a solution mixing method or a solution-melting mixing method; with the solution mixing method, the organic polymer and the metal-oxide nano-particles are dispersed in dispersing medium to prepare film preparing stock solution, and the film preparing stock solution is used for preparing the energy-saving film on a substrate; with the solution-melting mixing method, the mixture of the organic polymer and the metal-oxide nano-particles is dried to prepare master batch, and the master bath is mixed with the organic polymer and the polymer auxiliary agent to prepare the energy-saving film. The highly-transparent ultraviolet-resistant energy-saving film has high visible light transmission, good ultraviolet resistance and energy-saving effect, simple preparation process and low cost, thereby being suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH +1

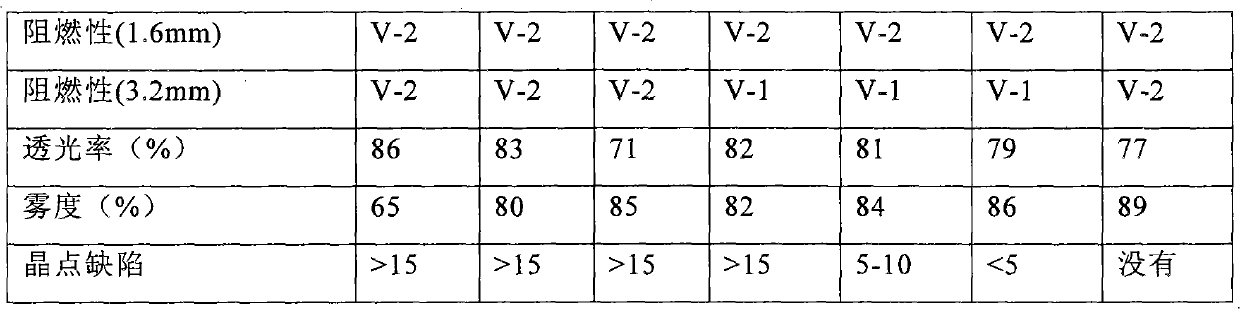

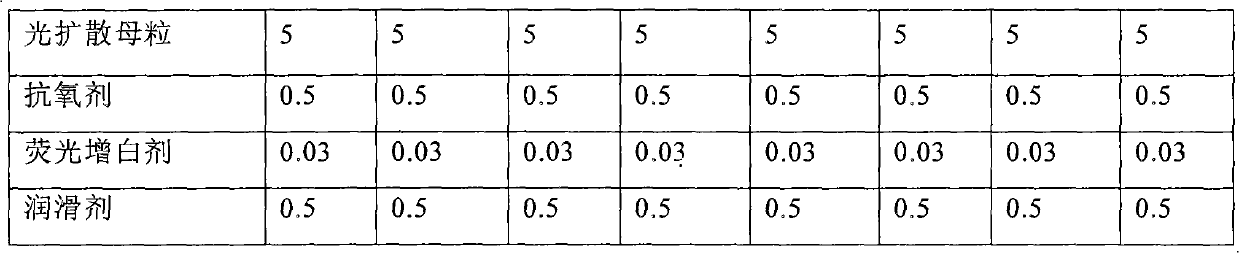

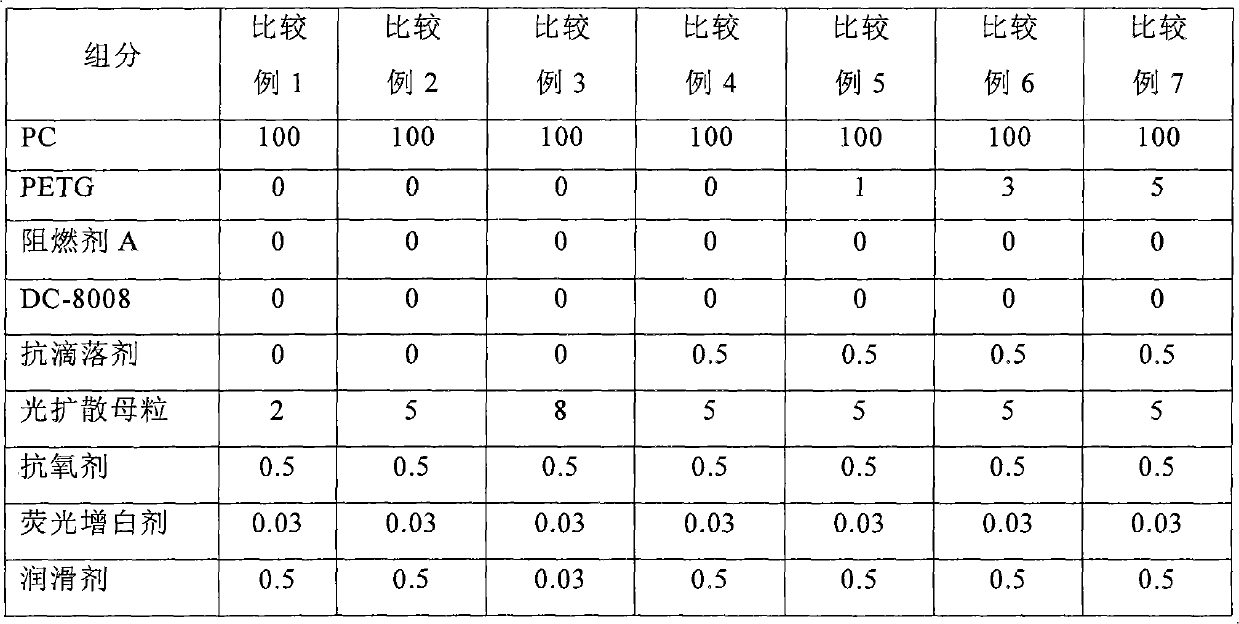

Polycarbonate combination and preparation method thereof

The invention provides a polycarbonate combination and a preparation method thereof. In terms of 100 parts of polycarbonate materials by weight, the polycarbonate combination comprises the following components in parts by weight: 100 parts of polycarbonate, 1-10 parts of copolyester, 0.01-0.5 part of aromatic sulphosalts fire retardant, 0.05-0.35 part of organic silicon fire retardant, 0.05-5 parts of anti-dripping agent, 1-15 parts of photodiffusion agent master batches and 0.05-5 parts of antioxidant. The preparation method of the polycarbonate combination comprises the following steps: adding the components of the polycarbonate combination as required into a blender mixer, and evenly stirring and mixing; and carrying out melt mixing, extrusion and granulation on the evenly mixed raw materials in eight temperature areas of a double-screw extruder. The polycarbonate combination provided by the invention has excellent photodiffusion performance, high light transmittance, excellent flame retardant property, safety, environmental protection, favorable heat resistance, easy molding and reduced crystal point defect.

Owner:SINOPLAST NEW MATERIAL

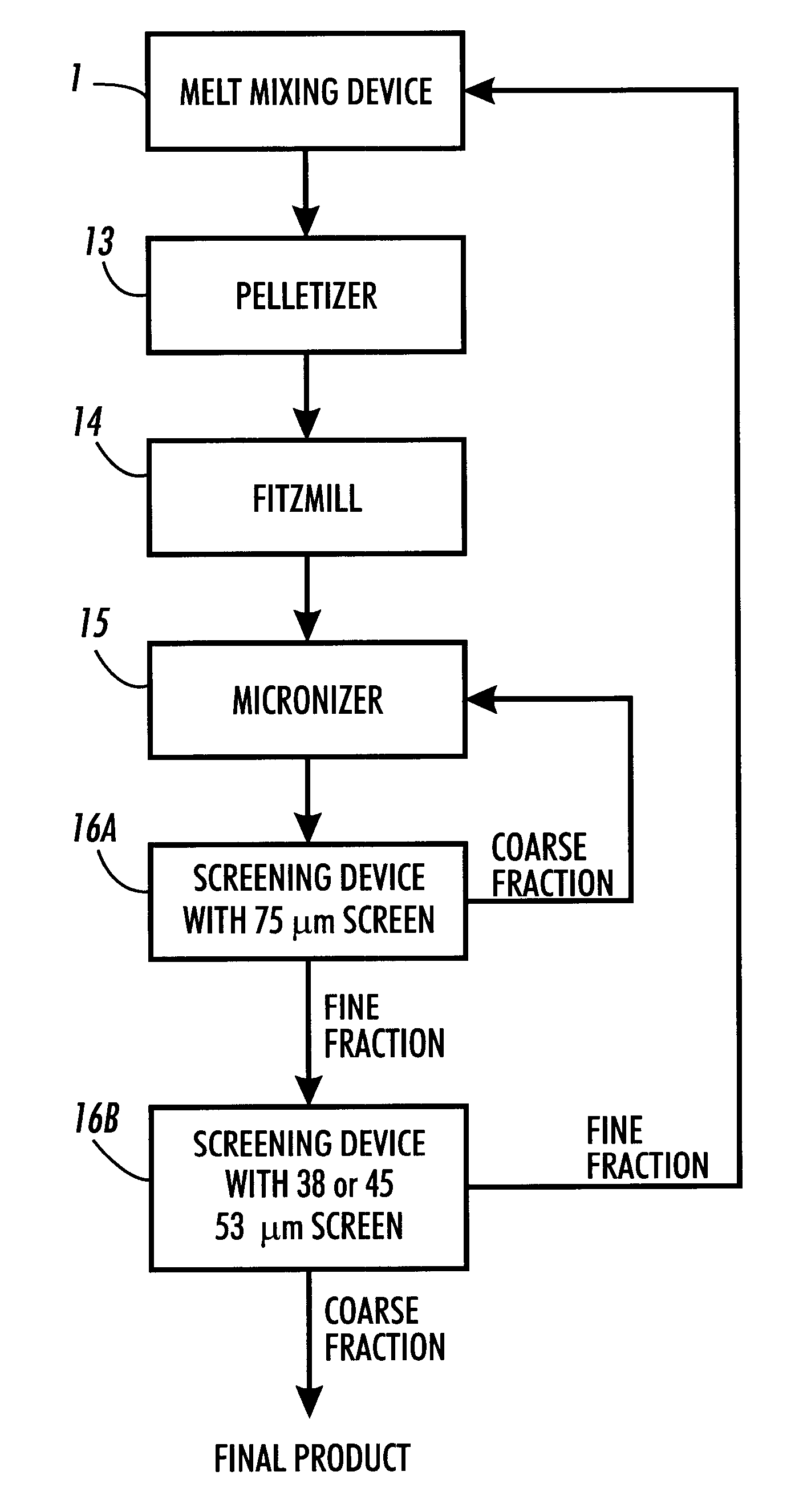

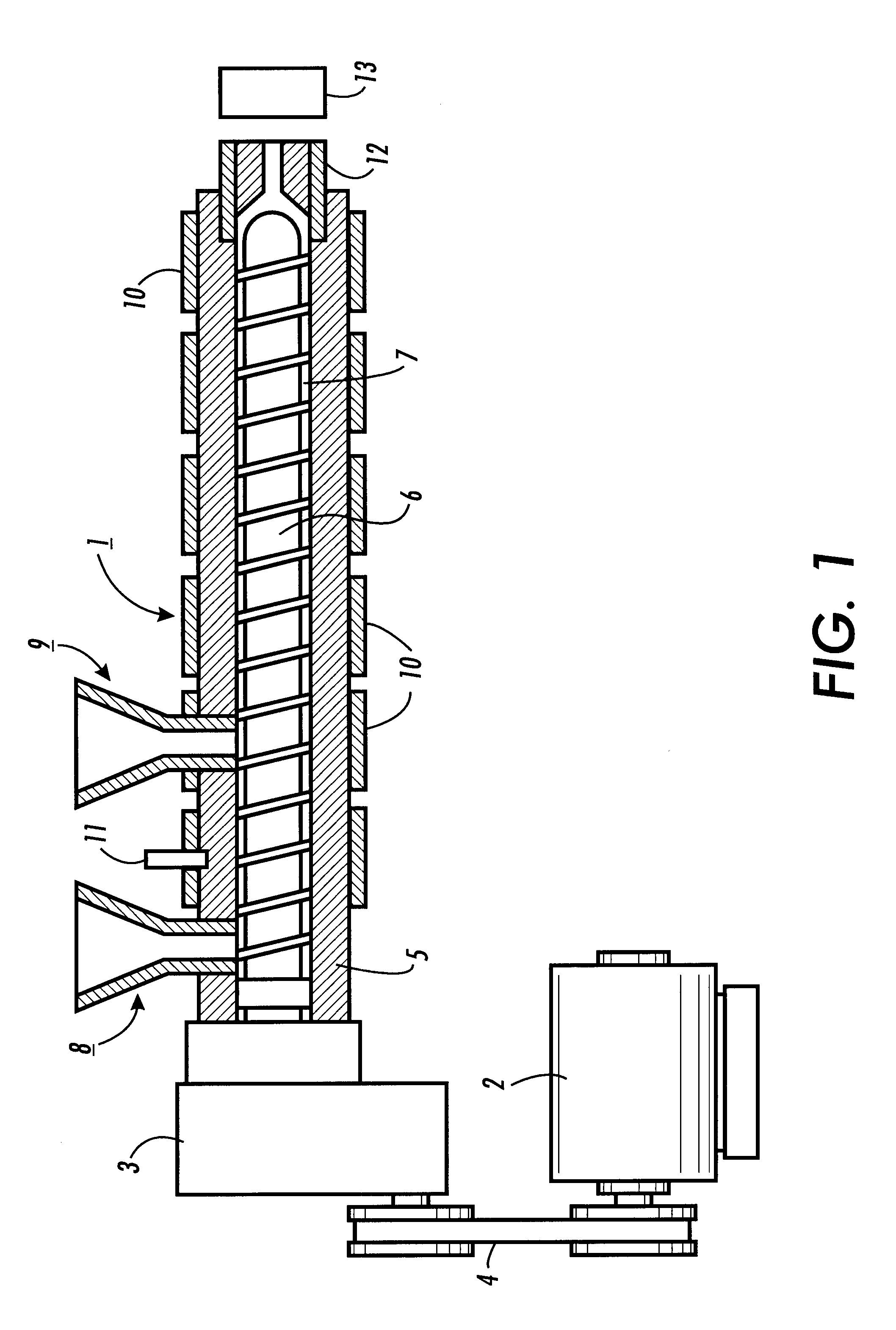

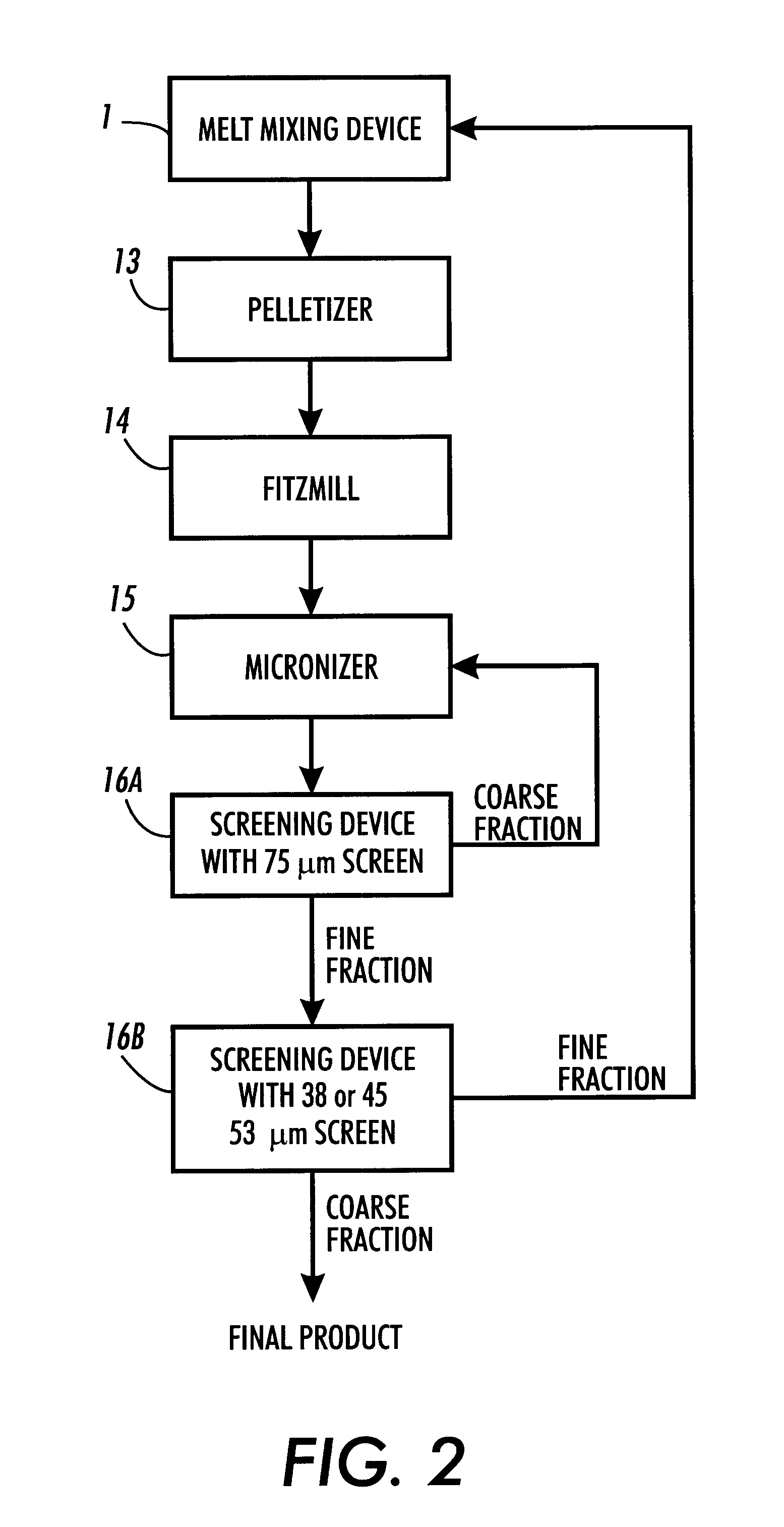

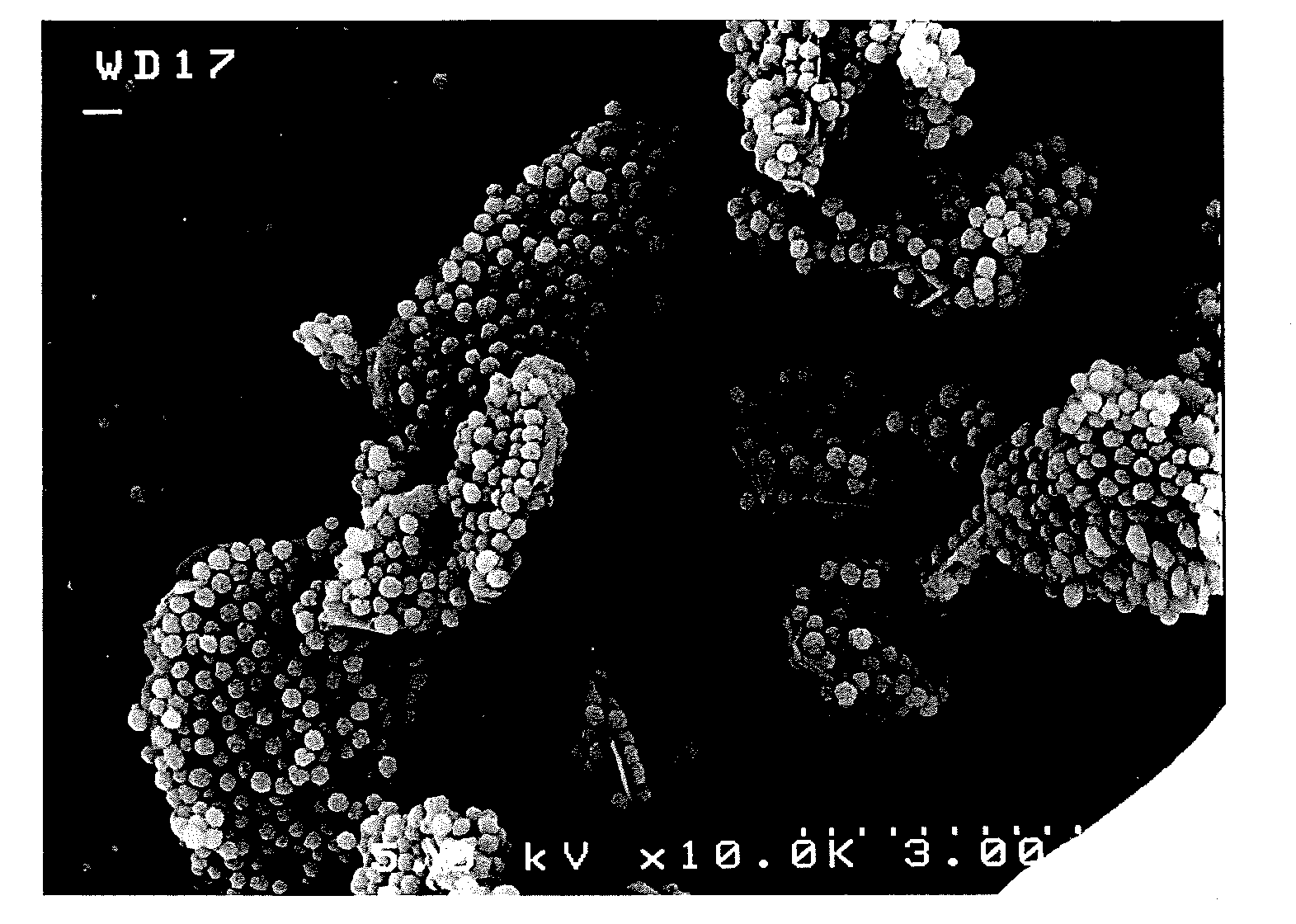

Carrier pelletizing processes

A process for the preparation of microsynthetic carrier comprising the melting of a mixture of binder resin, magnetic component, colorant and optionally charge control additive, thereby forming a polymer melt, and mixing said mixture in a melt mixing device, cooling and pelletizing said mixture, and thereafter grinding and classifying said pellets.

Owner:XEROX CORP

Zinc-based double antiseptic powder coating and preparing method thereof

InactiveCN101033364AReduce dosageEnsure zinc contentAnti-corrosive paintsPowdery paintsHeavy dutyZinc

The invention discloses a kind of heavy-duty zinc-based powder coating and its preparation. The coating is prepared by the following share weight of raw materials through the melt extruderion-mixing or melt-mixing, and the raw materials are as follow: 50-75% of resin and its flow-curing system, 10-40% of zinc flake, 0.1-10% of nanomaterial, 0.1-20% of rust paint, 0-30% of filler, and 0.1-5% of other functional additives.

Owner:XUZHOU ZENITH COATING

Poly(arylene ether) compositions and methods of making the same

A method of making a resin composition comprises melt mixing a first polymer comprising a polyamide powder or a polyester powder with a fluoropolymer at a temperature below a softening temperature of the fluoropolymer to form a first melt blend; fibrillating the fluoropolymer in the first melt blend to form a fibrillar network in the first melt blend; and melt mixing the first melt blend having the fibrillar network with i) a poly(arylene ether) and a compatibilizing agent or ii) a poly(arylene ether) and a reaction product of the poly(arylene) and a compatibilizing agent.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Method of making a flame retardant poly(arylene ether)/polyamide composition and the composition thereof

A composition comprises a poly(arylene ether), a polyamide, a reinforcing filler, a phosphinate, and an optional impact modifier. The composition is made by melt mixing a poly(arylene ether), a compatibilizing agent, a polyamide, a reinforcing filler, an optional impact modifier, and a flame retardant masterbatch wherein the flame retardant masterbatch comprises a phosphinate and a thermoplastic resin.

Owner:SABIC INNOVATIVE PLASTICS IP BV

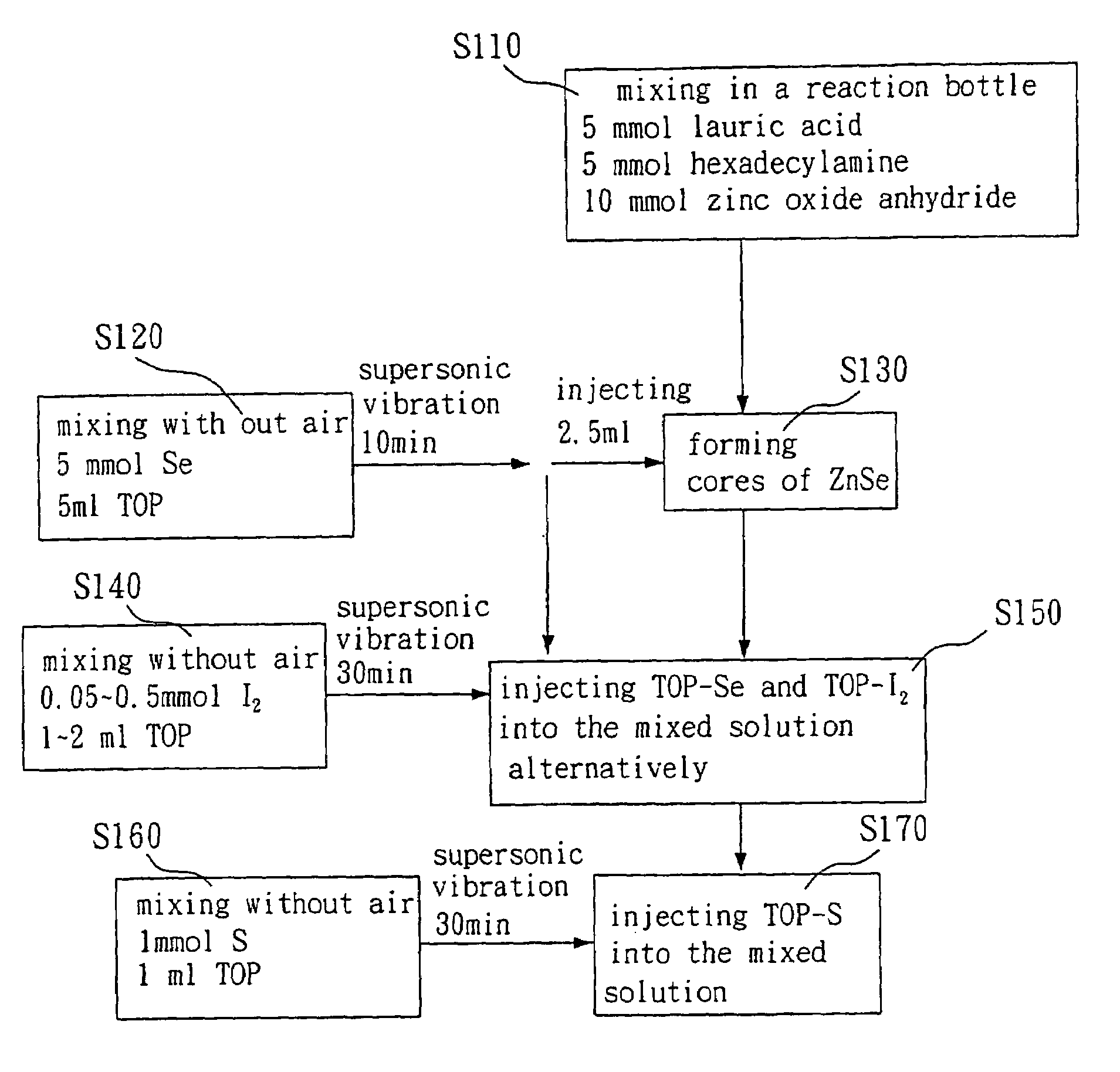

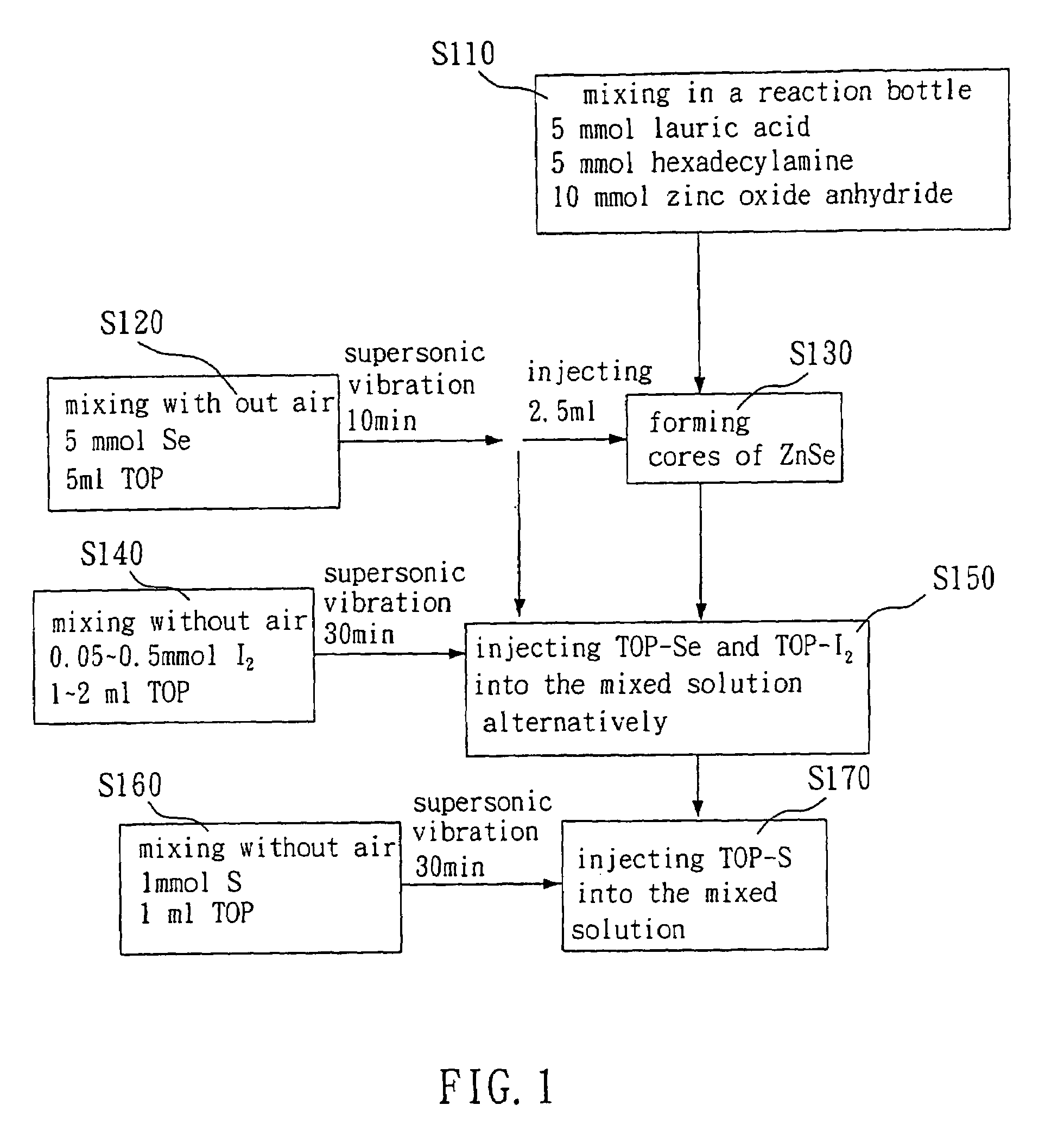

Method for doping quantum dots

ActiveUS7192850B2Improve radiation efficiencyAdjustable wavelengthMaterial nanotechnologyNanoinformaticsDopantHalogen

A doping method for forming quantum dots is disclosed, which includes following steps: providing a first precursor solution for a group II element and a second precursor solution for a group VI element; heating and mixing the first precursor solution and the second precursor solution for forming a plurality of II–VI compound cores of the quantum dots dispersing in a melting mixed solution; and injecting a third precursor solution for a group VI element and a forth precursor solution with at least one dopant to the mixed solution in turn at a fixed time interval in order to form quantum dots with multi-shell dopant; wherein the dopant described here is selected from a group consisting of transitional metal and halogen elements. This method of the invention can dope the dopants in the inner quantum dot and enhance the emission intensity efficiently.

Owner:IND TECH RES INST

Surface precipitation-free flame-retardant polypropylene compound and preparation method thereof

ActiveCN101880420AMeet the use requirementsHigh flame retardant efficiencyHydrobromideProcedure Agents

The invention relates to a surface precipitation-free flame-retardant polypropylene compound and a preparation method thereof. The surface precipitation-free flame-retardant polypropylene compound comprises the following components by weight percent: 70-98.5% of polypropylene resin, 1-15% of melamine hydrobromide, 0.3-7% of phosphinates, 0.2-4% of flame retardant synergist, 0-2% of synergetic flame retardant, 0-1% of antioxidant and 0-1% of processing acid. The preparation method thereof is implemented as follows: weighting the above components based on proportion, evenly mixing, melt-mixing the above mixture, pelletizing and drying to obtain the product in the invention. The surface precipitation-free flame-retardant polypropylene compound has high flame retardant efficiency, good flowability, no precipitation, and high flame retardant rating up to UL94 V-0, and can satisfy the use requirements of flame retardant materials in building materials, electrical appliance casings, sockets, bellows, lighting lamps and the like.

Owner:湖南美莱珀科技发展有限公司

Oxygen tailoring of polyethylene resins

InactiveUS20050012235A1Improve stabilityImprove uniformityWood working apparatusFlat articlesMolten stateEthylene Homopolymers

A process is provided for extruding a bimodal polyethylene resin. The process includes providing a polyethylene homopolymer or copolymer resin having a bimodal molecular weight distribution; conveying the resin through an extruder having a feed zone in which the resin is not melted, a melt-mixing zone in which at least a portion of the resin is melted, and a melt zone in which the resin is in a molten state, each zone being partially filled with the resin; and contacting the molten resin in the melt zone with a gas mixture of 8 to 40% by volume O2. The resin can be further pelletized. The oxygen-tailored resin can be used to make polyethylene films having improved bubble stability.

Owner:EXXONMOBIL CHEM PAT INC +1

Functionalized polypropylene fibre and its preparation method

InactiveCN1766184AWith deodorizing functionSolve reunionMonocomponent polyolefin artificial filamentArtifical filament manufactureNatural substanceSilicon dioxide

The invention discloses a functional polypropylene fibre contained and fused a plurality of natural inorganic materials and polypropylene, which comprises: tourmaline, alumina, zirconium phosphate carried-Ag antibacterial agent, silicon dioxde, and titania. The preparation method comprises: breaking and mixing the materials, fusing and mixing said materials with polypropylene slice to obtain mother grain; then, using common fusion spinning method to treat said grain and slice. This product has well spinnability, high strength, and deodorization function.

Owner:上海依福瑞实业有限公司

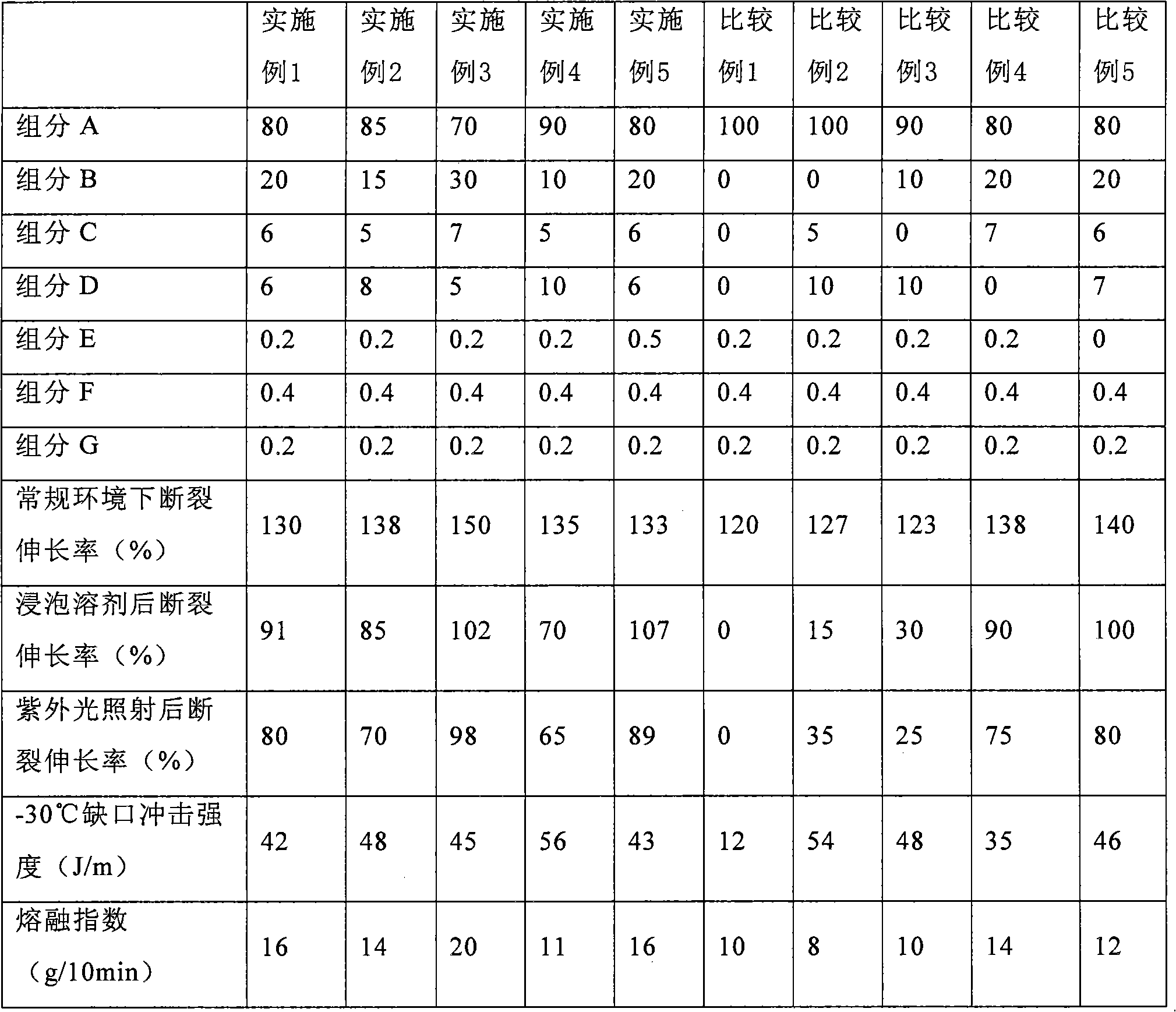

Polycarbonate composition and preparation method thereof

The invention provides a polycarbonate composition and a preparation method thereof. The polycarbonate composition comprises 30-90% of polycarbonate, 5-50% of polyester, 1-10% of compatible toughening agents, 1-10% of low-temperature impact modifiers, 0.1-1% of anti-ultraviolet assistant, 0.1-2% of antioxidants and 0.1-1% of lubricant by mass. The preparation method comprises the following steps: weighing the components in the composition according to the mass proportion; throwing the polycarbonate, the polyester, the compatible toughening agents, the low-temperature impact modifiers, the anti-ultraviolet assistant, the antioxidants and the lubricant into a mixer to be uniformly mixed; and melting, mixing, extruding and pelleting the uniformly mixed raw materials by an eight-temperature zone double-screw extruder. The polycarbonate composition has high molding processing mobility and excellent chemical reagent resistance, anti-ultraviolet property and low-temperature anti-impact property and can be widely applied to thin-wall workpieces.

Owner:SINOPLAST NEW MATERIAL

Preparation and application of open-cell foamed polyolefin

ActiveCN101531770AOther chemical processesWater/sewage treatment by sorptionPolymer sciencePolyolefin

The invention relates to a preparation method of open-cell foamed polyolefin. The preparation method comprises the following steps of: mixing the polyolefin with nucleating agent master batch prepared by same olefin type polyolefin granules, a nucleating agent, a foaming-assisting anti-shrinking agent and an antioxidant, putting the obtained mixture into a single-screw or double-screw extruder with the length-diameter ratio of 20-50 for heating, plasticizing and melting, injecting high-pressure gas, fully melting, mixing and extruding out the high-pressure gas and the polyolefin, releasing, expanding, foaming when extruding the obtained mixture out of a mold at an outlet mold of the extruder so as to prepare open-cell foaming products with various shapes. The open-cell foamed products are used as adsorption substrates and adsorption carriers, and can also be used as sound-insulating, sound-absorbing, and heat-insulating materials. According to the strength and visco-elasticity of the polyolefin melt, the invention selects an appropriate position to inject the high-pressure gas, and adjusts the structure of the screw, gas pressure and gas quantity, and the heating temperature so as to lead the polyolefin to be fully foamed and cells to be opened thereon when the materials are extruded out of the outlet mold of the extruder, therefore, the gas among the cells is mutually communicated, thus having relatively high adsorption capacity, overcoming the shortage of difficult cell-opening in the existing polyolefin foaming technology and causing the polyolefin application to be more diversified and practical.

Owner:上海高分子功能材料研究所 +1

Fabric softener composition and methods for manufacturing and using

ActiveUS7381697B2Cationic surface-active compoundsOrganic detergent compounding agentsEngineeringLaundry

A fabric softener composition is provided by melt mixing a fabric softener component and a carrier component to provide a fabric softener composition exhibiting a melting point greater than 90° C. The weight ratio of the fabric softener component to the carrier component can be between about 1:19 and about 19:1. Methods for manufacturing the fabric softener composition and using the fabric softener composition to soften fabric while drying laundry in a dryer are provided.

Owner:ECOLAB USA INC

Polymeric pipes and liners suitable for transporting oil and gas materials and made from blends of polyolefins and polyamides

InactiveUS20060185750A1Improve the immunityImprove barrier propertiesLayered productsPipe elementsPolyolefinPolyamide

A pipe or liner for use in the oil and gas industry that comprises a melt-mixed bend of polyamide and incompatible polyolefin and a compatibilizing agent where the polyamide exists as a discontinuous phase that is dispersed in a polyolefin matrix. The pipe or liner has enhanced resistance to the permeation of hydrocarbons relative to polyethylene.

Owner:MESTEMACHER STEVEN A

Biological-degradable starch/polyester plastic completely and production thereof

A complete biological degradable starch / polyester plastics and its production are disclosed. It consists of thermoplastic starch, fatty-aromatic block co-mixed polyester, long-chain unsaturated carboxylic acid or acid anhydride graft modified ingredient, organic peroxidate initiator, polyhydric alcohol ester compound plasticizer, organic compound or polyhydric alcohol stabilizer or lubricant. The process is carried out by mechanical-chemical modification and thermoplastic treating, melt mixing fatty-aromatic block co-mixed polyester material with initiator, modifier and stabilizer in high-speed mixer, graft reacting, milling, cooling, breaking, reaction extruding by second bi-screw reaction extruder and granulating. Its advantages include excellent physical and mechanical properties, complete degradation. It can be used for agriculture, medicine, sanitation, engineering materials, refuse bag and packing materials.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Fluoropolymer composite composition

InactiveUS20100036021A1Improve conductivityMaintain good propertiesMixing methodsFibre treatmentShear stressPolymer science

The present invention relates to a heat-meltable fluoropolymer composite composition having excellent thermal conductivity, gas and chemical liquid barrier properties and dynamic properties such as storage modulus which comprises a heat-meltable fluoropolymer fine powder and a layered-compound organized by treatment with tetraphenyl phosphonium ions. The present invention also relates to a heat-meltable fluoropolymer composite composition having similar properties to those mentioned above which is obtained by a process (I) in which a heat-meltable fluoropolymer composite composition is obtained by grinding and mixing a heat-meltable fluoropolymer fine powder and a layered-compound and a process (II) in which such heat-meltable fluoropolymer composite composition thus obtained is melted and mixed under shear stress by means of a melt-mixing extruder.

Owner:DUPONT MITSUI FLUOROCHEMICALS CO LTD +1

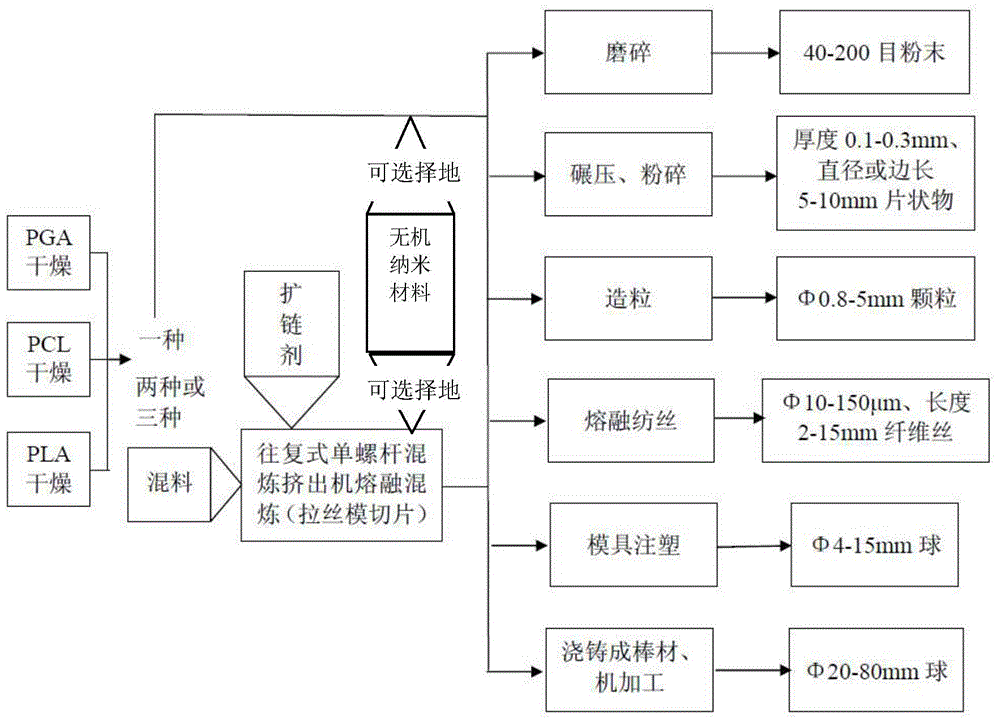

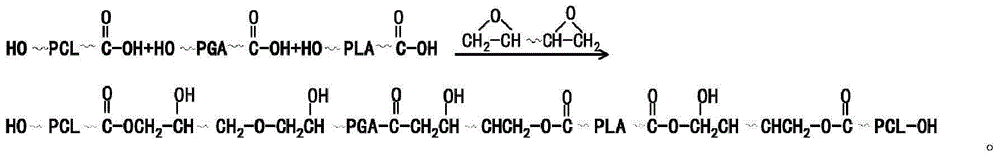

Biodegradable resin material applied to oil and gas fields and preparation method for biodegradable resin material

InactiveCN104987682ANew mechanical propertiesChange mechanical propertiesDrilling compositionWell drillingAlloy

The invention provides a biodegradable resin material applied to oil and gas fields and a preparation method for the biodegradable resin material. According to the preparation method for the biodegradable resin material applied to the oil and gas fields, two or three polymers of polyglycolic-colactic acid, polycaprolactone and polylactic acid and a chain extender are subject to melt mixing reaction to obtain a resin alloy, namely the biodegradable resin material applied to the oil and gas fields. The biodegradable resin material applied to the oil and gas fields is prepared from the method, can be prepared into the shapes of sheets, powder, granules, spheres and the like, or can be prepared into the shapes of the sheets, the powder, the granules, the spheres and the like by one of the polyglycolic-colactic acid, the polycaprolactone and the polylactic acid, is used for temporarily blocking filtrate to protect a reservoir, temporarily blocking a blast hole, a constructed layer section and the like in various construction (well drilling, well completing, well repairing, and acidizing and fracturing) operations of the oil and gas fields, and has the advantages of complete degradation and zero damage to stratum.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

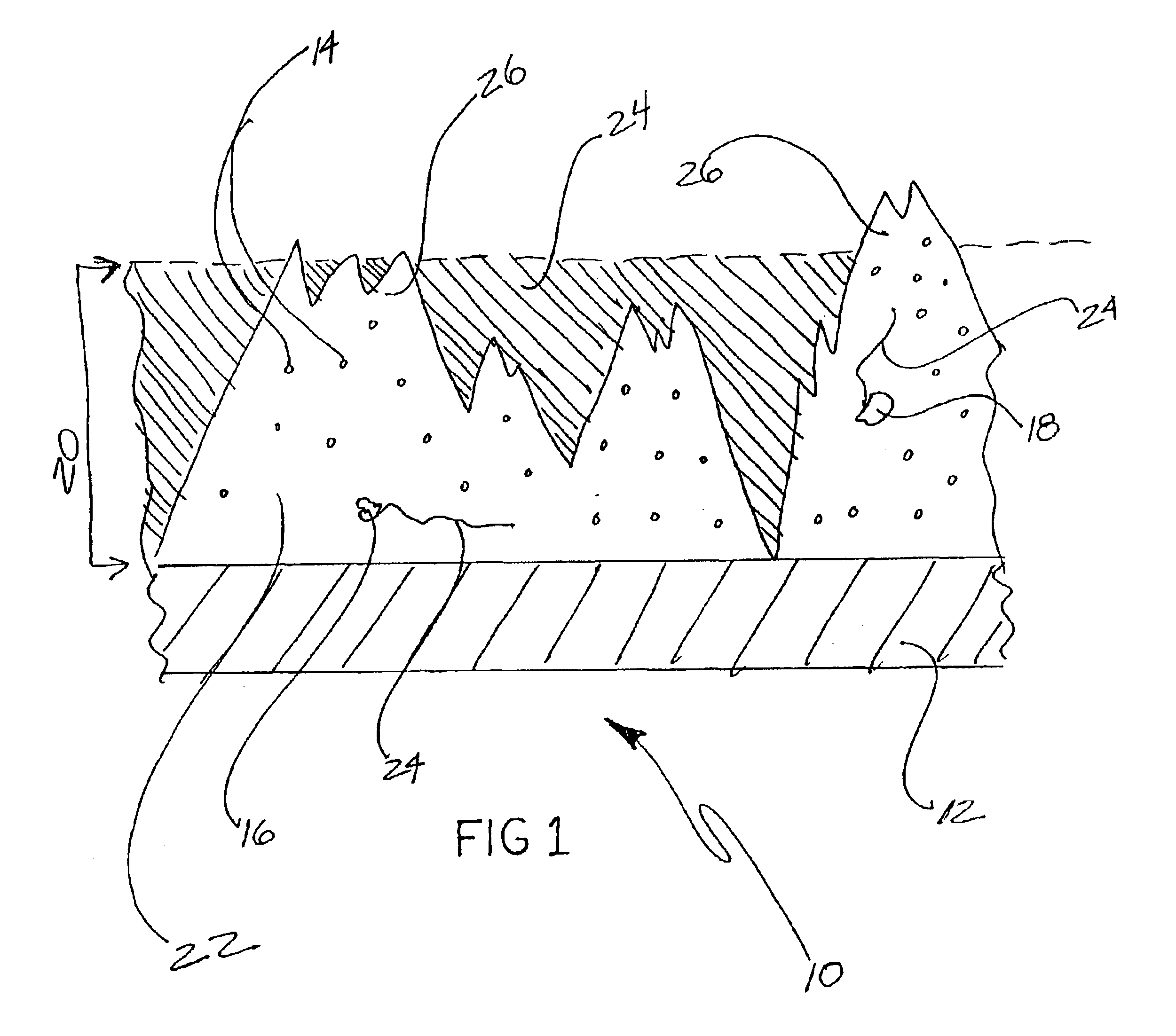

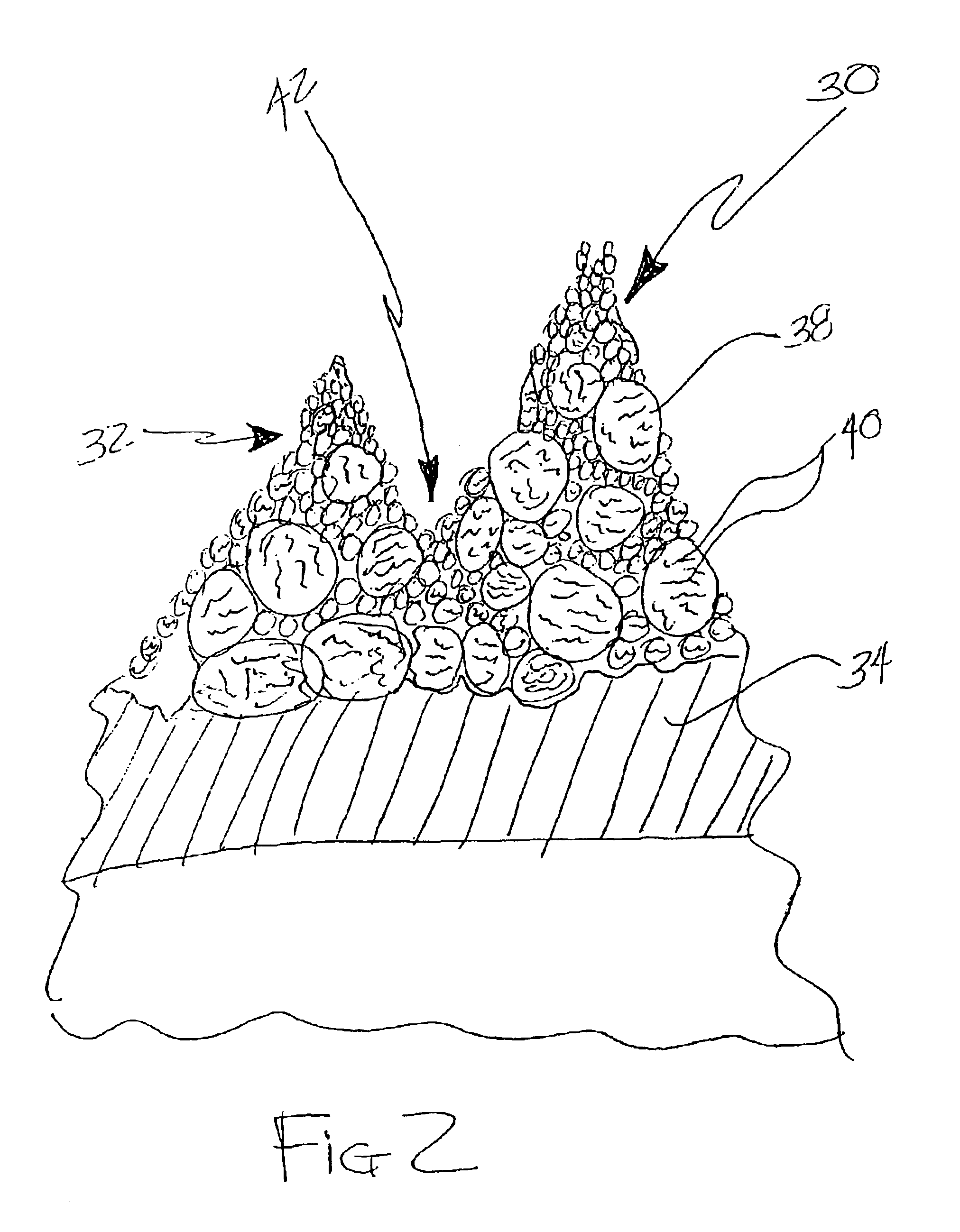

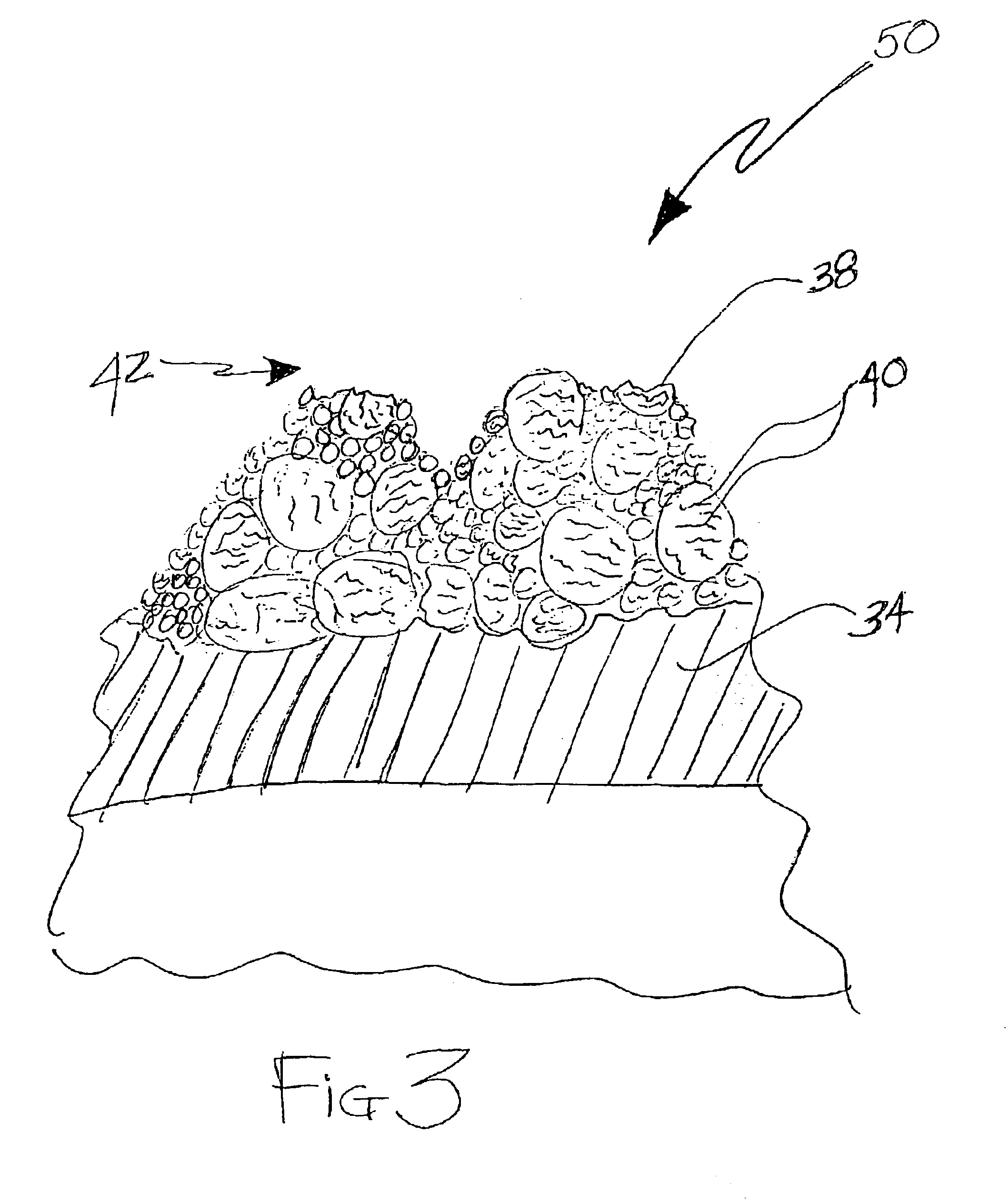

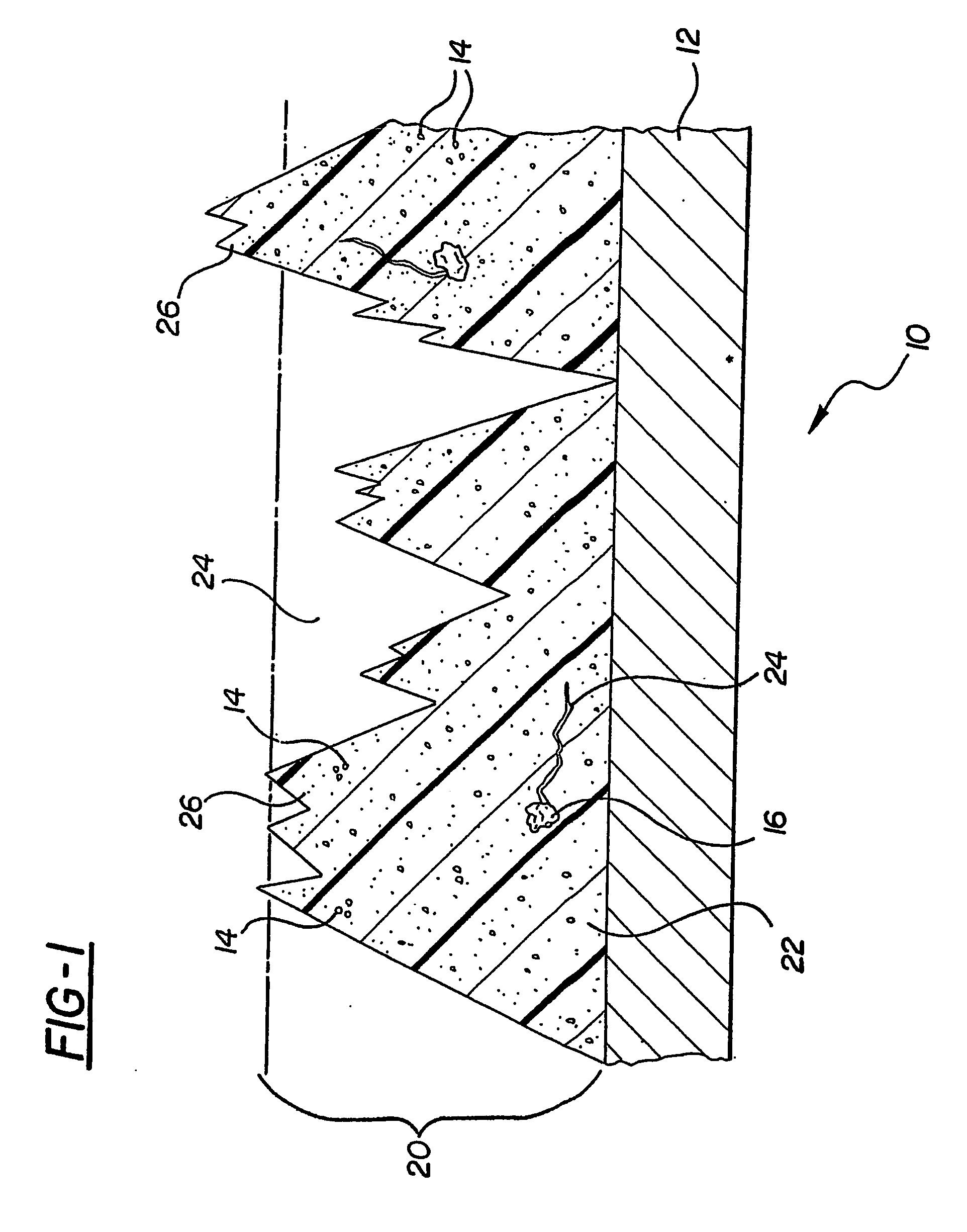

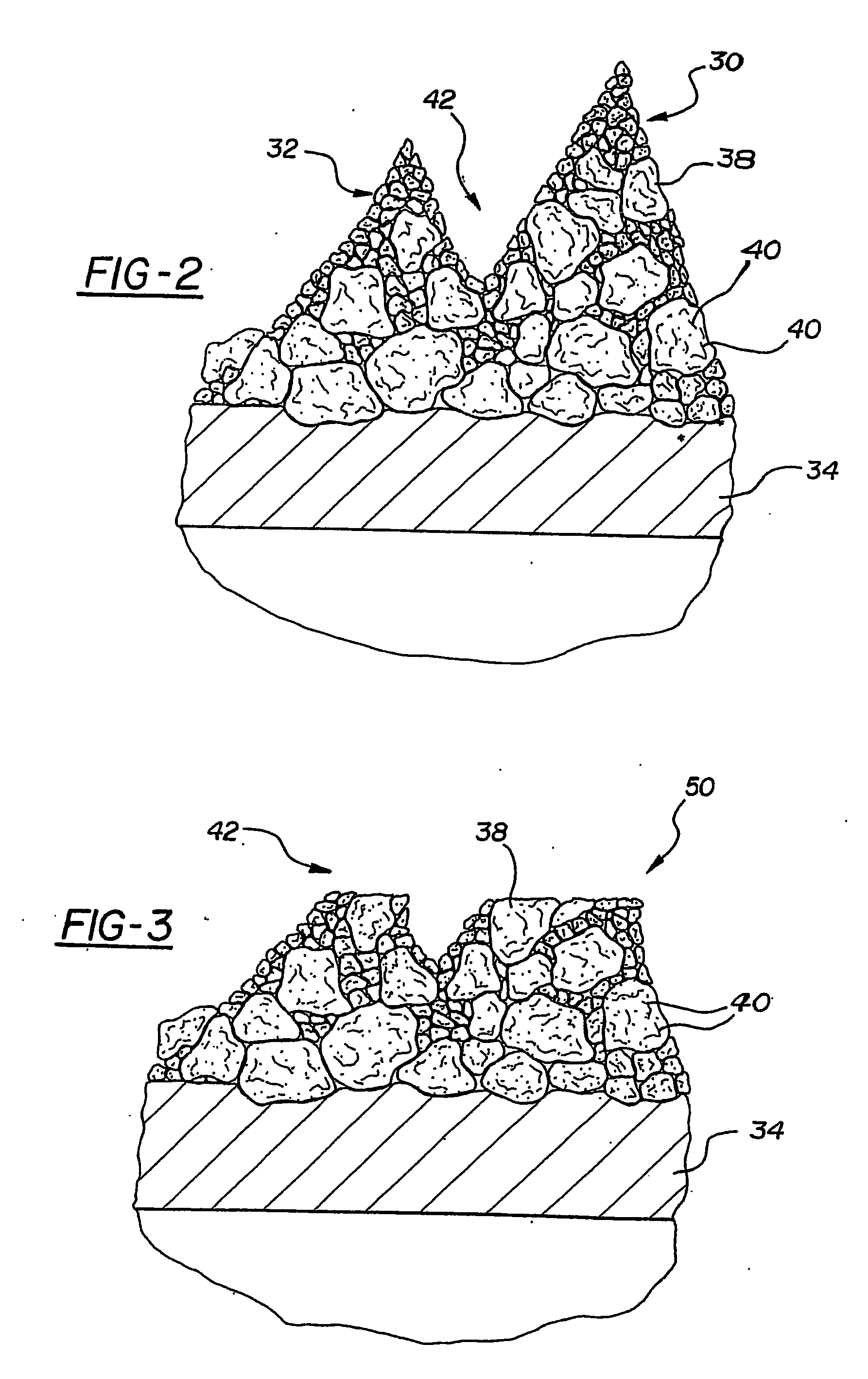

Abradable dry powder coatings, methods for making and coating, and coated articles therefrom

InactiveUS6844392B2Easy to appreciateNon-fibrous pulp additionEngine sealsElectrostatic coatingPolyresin

An abradable dry powder coating (22) composition for coating onto a surface (12) for subsequent curing to form into an abradable coating, including a powder (16) formed of uncured thermoset resin with at least 15 volume percent filler, wherein the filler does not substantially melt below the cure temperature of the resin. Method for making the coating composition includes melt-mixing the thermoset resin with at least 15 volume percent of filler, cooling the resulting mass composite, and then breaking the cooled mass composite into powder particles (16). Method of coating an article with an abradable coating includes applying the dry composite powder with the filler therein onto a substrate and curing the dry powder composition, preferably by electrostatic coating. An article is also disclosed which is coated with the abradable coating.

Owner:LINE 2 LINE INC

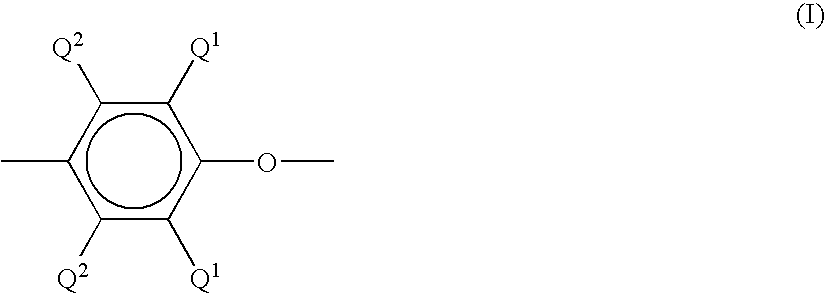

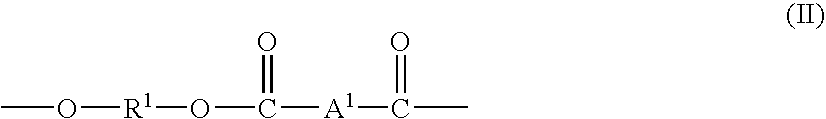

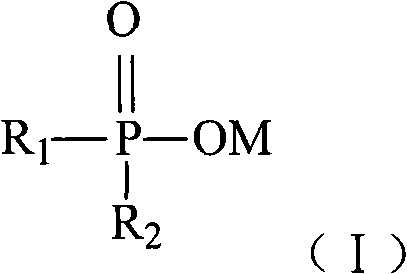

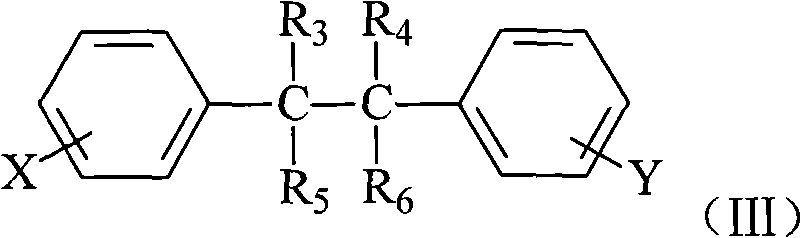

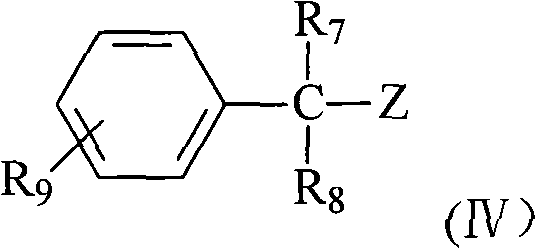

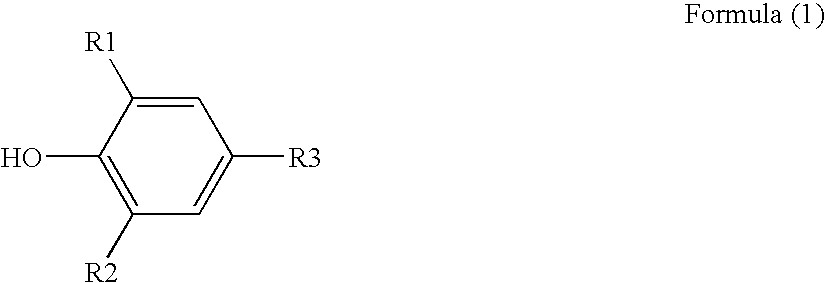

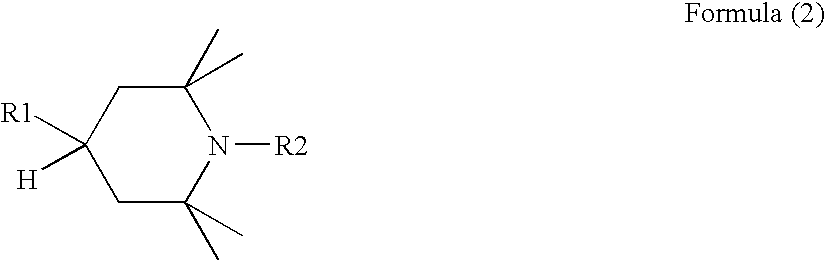

Method for manufacturing cellulose ester film, and cellulose ester film, optical film, polarizing plate and liquid crystal display device using the same

InactiveUS20060069192A1Excellent optical propertiesGood dimensional stabilityAbsorbent padsThin material handlingCellulose ester membranePolymer science

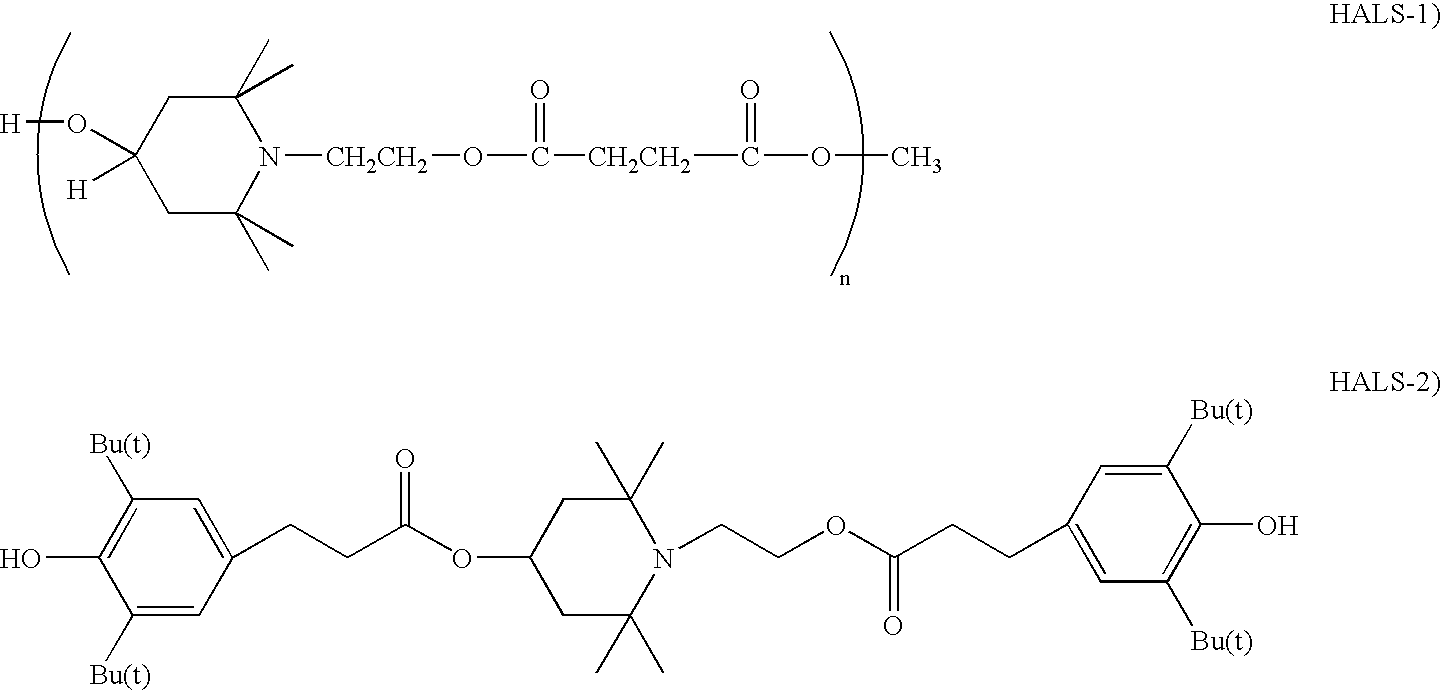

A method for manufacturing a cellulose ester film comprising the steps of 1) mixing a cellulose ester exhibiting a water content of not greater than 3.0 weight %, at least one plasticizer selected from the groups A and B in an amount of one to thirty weight % of the cellulose ester, and at least one additive selected from the groups of C and D in an amount of 0.01 to 5 weight % of the cellulose ester to obtain a mixture, group A: ester plasticizers formed from a polyhydric alcohol and a monohydric carboxylic acid; group B: ester plasicizers formed from a polyhydlic carboxylic acid and a monohydric alcohol; group C: hindered phenol anti-oxidants; group D: hindered amine light stabilizers, 2) heating to melt the mixture at a temperature (Tm) of between 150 and 300° C., and 3) forming a cellulose ester film with a melt casting method employing the melted mixture.

Owner:KONICA MINOLTA OPTO

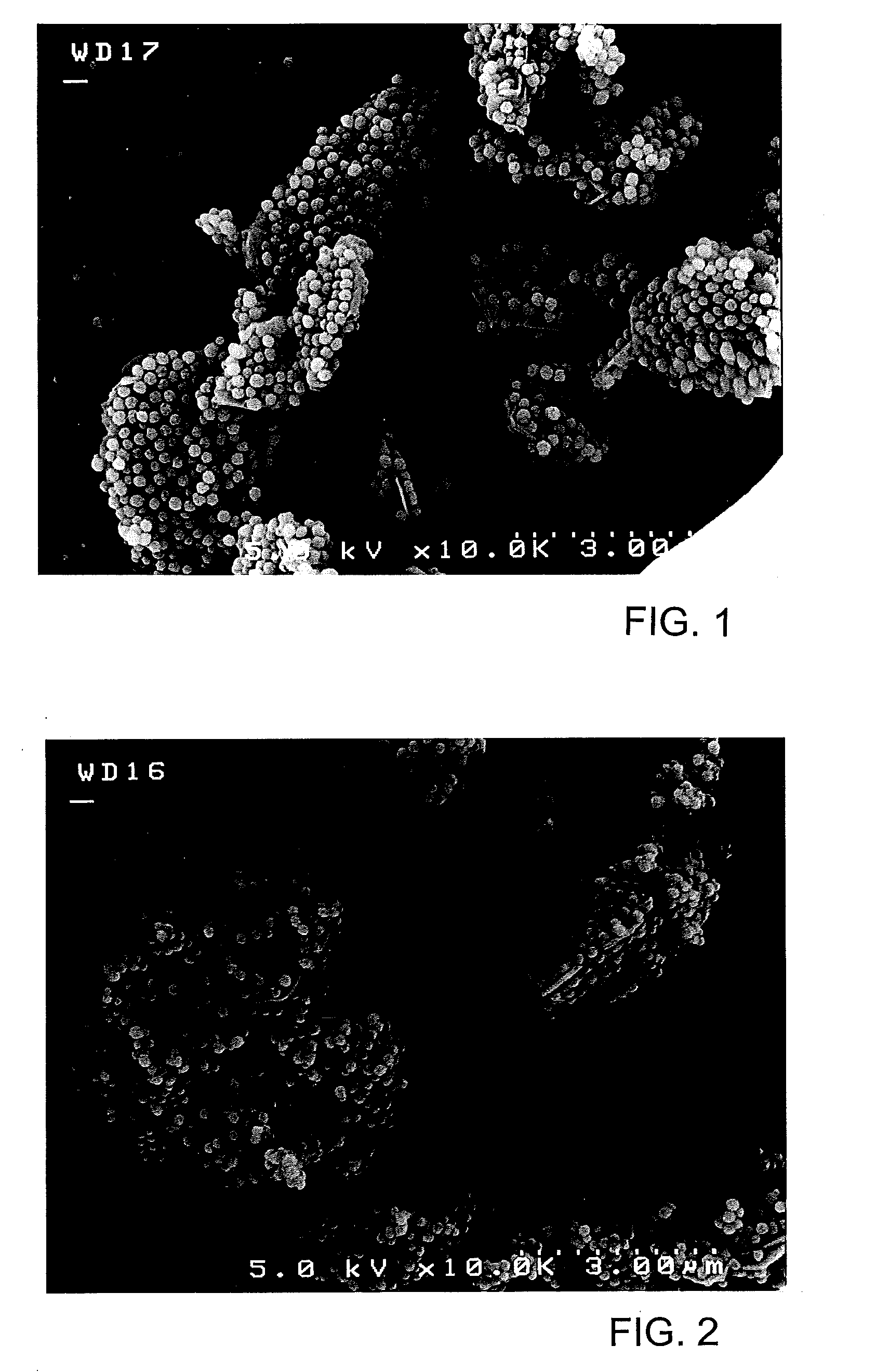

Radiation shielding members including nano-particles as a radiation shielding material and method for preparing the same

ActiveUS20100102279A1Increase the probability of collisionImproved Radiation Shielding PerformanceOther chemical processesBlast furnace componentsPorosityMaterials science

Disclosed is a radiation shielding member having improved radiation absorption performance, including 80.0˜99.0 wt % of a polymer matrix or metal matrix and 1.0˜20.0 wt % of a radiation shielding material in the form of nano-particles having a size of 10˜900 nm as a result of pulverization, wherein the radiation shielding material is homogeneously dispersed in the matrix through powder mixing or melt mixing after treatment with a surfactant which is the same material as the matrix or which has high affinity for the matrix. A preparation method thereof is also provided. This radiation shielding member including the nano-particles as the shielding material further increases the collision probability of the shielding material with radiation, compared to conventional shielding members including micro-particles, thus reducing the mean free path of radiation in the shielding member, thereby exhibiting superior radiation shielding effects. At the same density, the shielding member has reduced thickness and volume and is thus lightweight. The porosity of the shielding member is minimized, thereby preventing the deterioration of shielding effects and properties of the shielding member and realizing applicability in spent fuel managing transport / storage environments and the like.

Owner:GIPS CO LTD

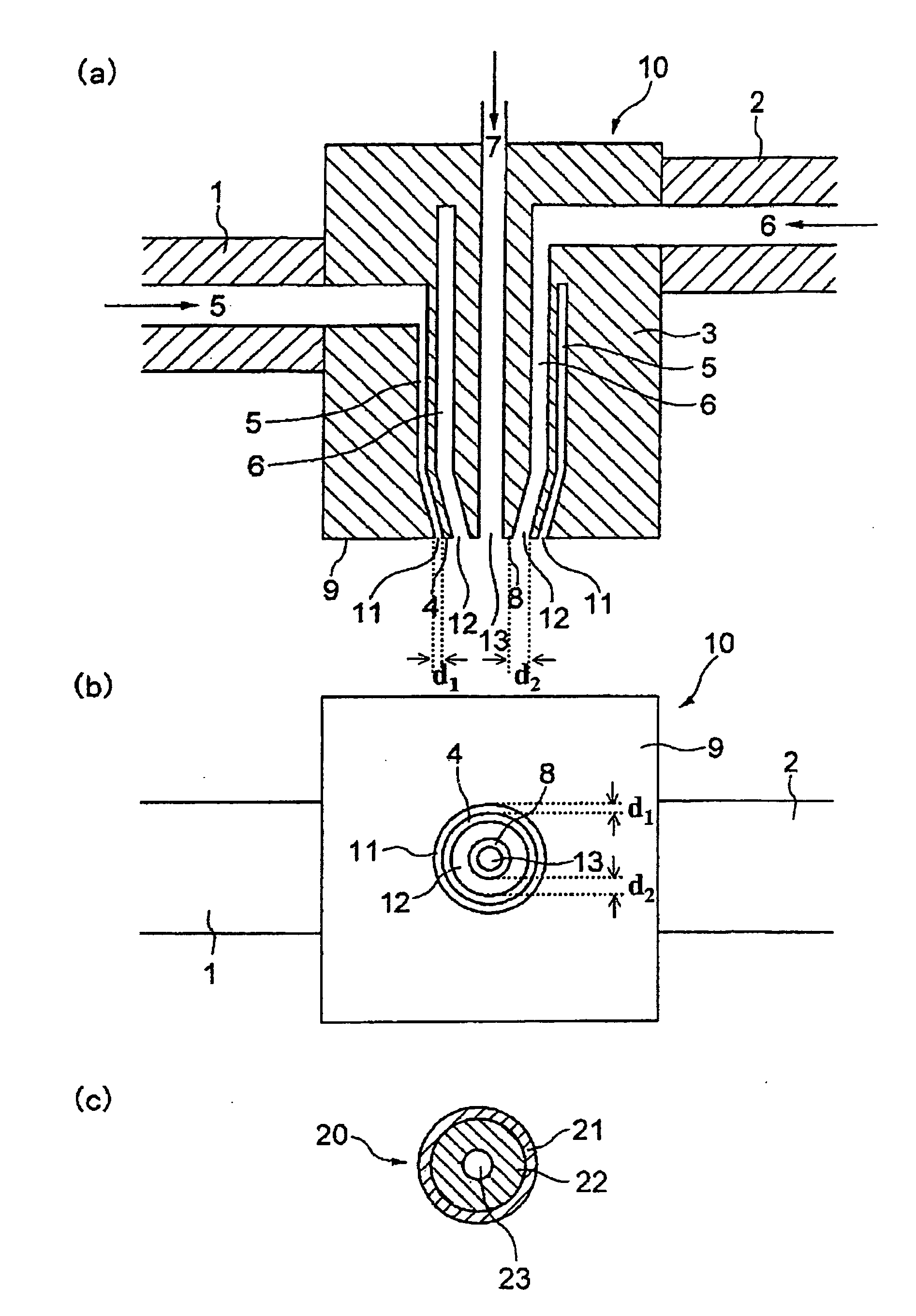

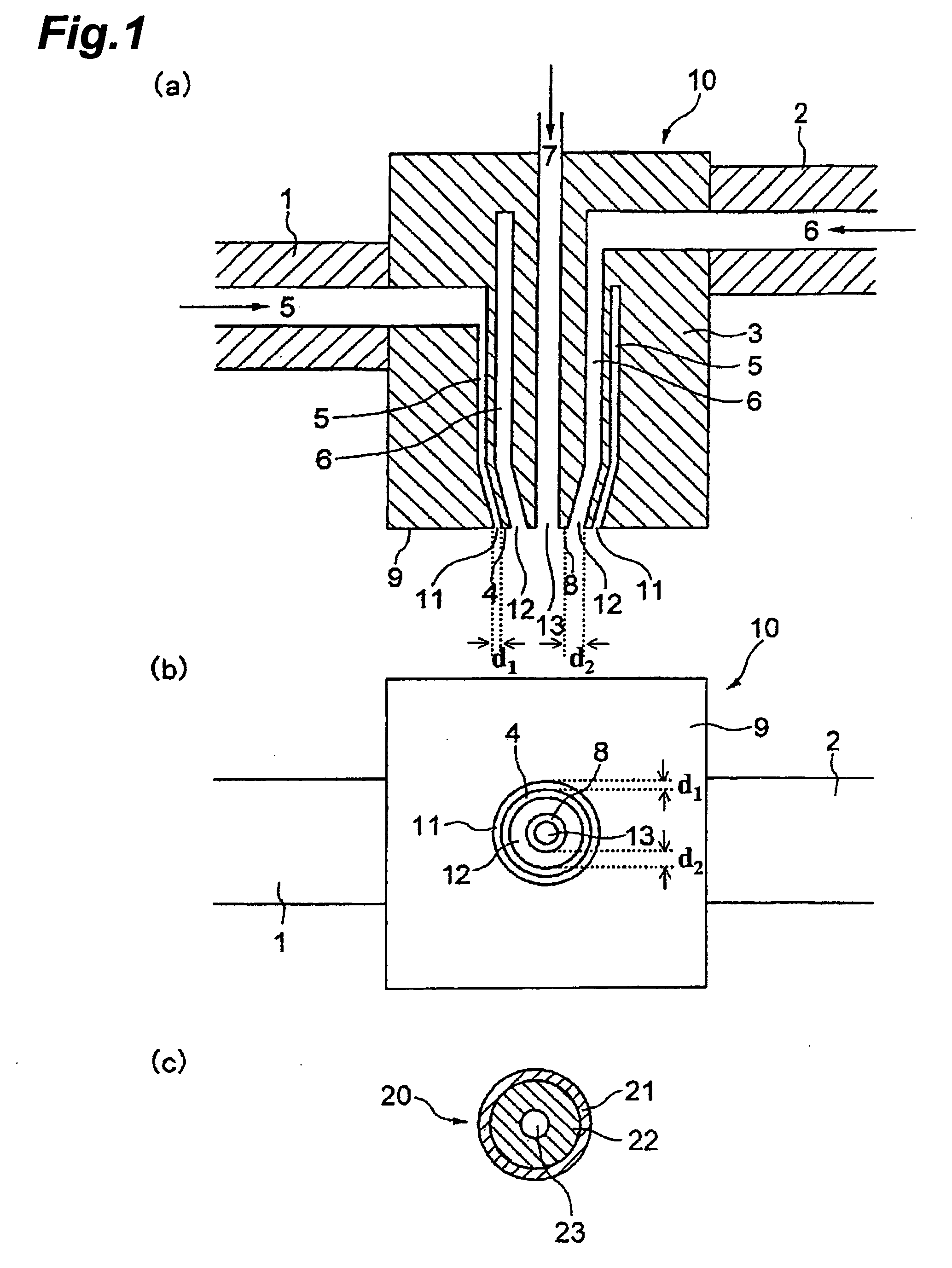

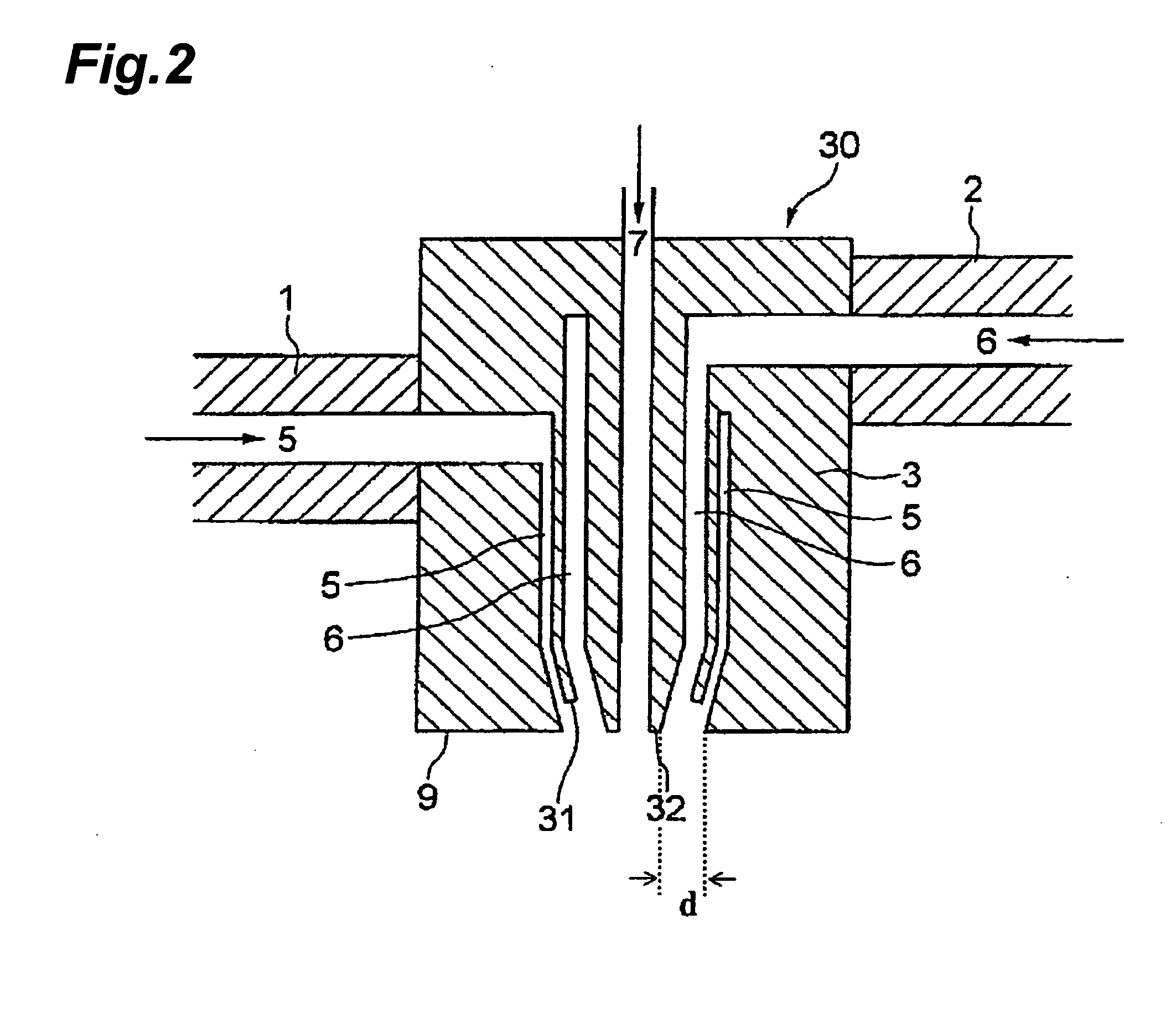

Porous multilayered hollow-fiber membrane and process for producing the same

ActiveUS20090297822A1Excellent strengthHigh water permeabilityMembranesSemi-permeable membranesHollow fibre membraneOrganic fluid

A porous hollow fiber membrane which has high blocking performance and high water permeability suitable for filtration and the like and exhibits excellent strength, and a process for stably producing the porous hollow fiber membrane are disclosed. The process utilizes a hollow fiber molding nozzle having two or more circular discharge ports which are disposed concentrically. Multilayer melt-extrusion is performed by discharging molten mixtures which include a thermoplastic resin and an organic liquid and differ in composition from the adjacent discharge ports. The resulting product is cooled to solidify to obtain a hollow fiber. The organic liquid is then removed from the hollow fiber by extraction to produce a porous hollow fiber membrane. The molten mixture discharged from at least one circular discharge port includes an inorganic fine powder in addition to the thermoplastic resin and the organic liquid. The inorganic fine powder is removed by extraction after cooling in addition to the organic liquid.

Owner:ASAHI KASEI CHEM CORP

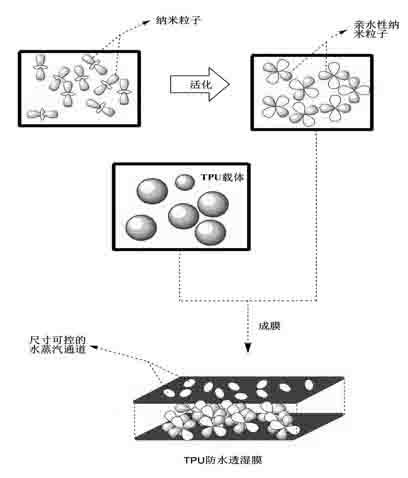

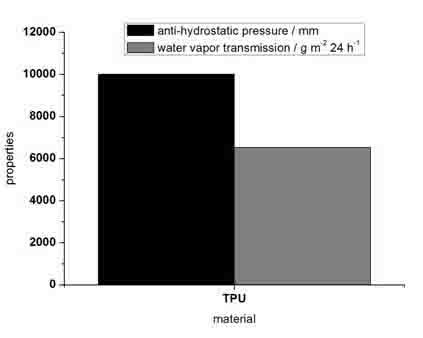

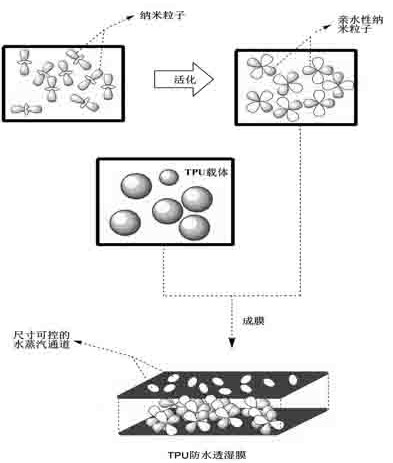

Intelligent waterproof moisture-permeable film and preparation method thereof

InactiveCN102604370AImprove performanceExcellent waterproof and moisture-permeable functionMoistureMaterials science

The invention discloses an intelligent waterproof moisture-permeable film. A matrix material and a waterproof moisture-permeable functional material are prepared into the waterproof moisture-permeable film by using a screw extruder in a film blowing method or a flow casting method. The preparation method comprises the following steps of: firstly cleaning and drying the matrix material for standby application; secondly, squeezing out a thermoplastic carrier material, inorganic nanometer particles and a processing agent at a certain extrusion temperature by using the extruder in a melt mixing method according to a certain mass ratio to prepare the waterproof moisture-permeable functional material; and finally, preparing the product by adopting the film blowing method or the flow casting method at the extrusion temperature condition of 120 DEG C-250 DEG C after mixing the matrix material and the prepared waterproof moisture-permeable functional material according to a mass ratio of 100:5-200. The intelligent waterproof moisture-permeable film has excellent waterproof moisture-permeable function in all weathers, i.e. a preferential temperature and a humidity range and has the characteristics of simple production technology, low cost of raw materials and high production efficiency.

Owner:宁波市江北成达色母粒有限公司

Telecommunications cable composition process

A process for the preparation of a composition useful in telecommunications jacketing comprising:(i) introducing a polyolefin into the first mixing zone of a melt / mixer having first and second mixing zones;(ii) introducing particulate carbon black per se or a premix of said carbon black and polyolefin into the first mixing zone, said carbon black being in an amount of about 2 to about 50 percent based on the weight of the polyolefin introduced into the first mixing zone;(iii) melting the polyolefin in the presence of the carbon black in the first mixing zone;(iv) mixing the carbon black and the molten polyolefin in the first mixing zone to provide a molten mixture;(v) passing the molten mixture from step (iv) into the second mixing zone;(vi) adding sufficient polyolefin to the molten mixture from step (v) to dilute the carbon black to a level of about 2 to about 3 percent by weight based on the weight of the total polyolefin in the melt / mixer;(vii) mixing the added polyolefin with the molten mixture in the second mixing zone to provide a molten mixture;(viii) about simultaneously with step (vii), venting the second mixing zone;(ix) recovering the mixture from step (vii); and(x) optionally, pelletizing the mixture from step (ix).

Owner:UNION CARBIDE CORP

Abradable dry powder coatings on piston assembly components

InactiveUS20070071990A1Increase volumeLow costLiquid surface applicatorsLayered productsVolume percentPowder coating

An abradable dry powder coating composition (20) for coating onto a piston assembly component (12) for subsequent curing to form into an abradable coating, including a powder (16) formed of uncured thermoset resin with at least 5 volume percent filler, wherein the filler does not substantially melt below the cure temperature of the resin. Method for making and coating the coating composition includes melt-mixing the thermoset resin with at least 5 volume percent of filler, cooling the resulting mass composite, and then breaking the cooled mass composite into powder particles (16). Method of coating an article with an abradable coating includes applying the dry composite powder with the filler therein onto the piston assembly component and curing the dry powder composition, preferably by electrostatic powder coating.

Owner:SUMAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com