Patents

Literature

589 results about "Phosphinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphinates or hypophosphites are a class of phosphorus compounds conceptually based on the structure of hypophosphorous acid. IUPAC prefers the term phosphinate in all cases, however in practice hypophosphite is usually used to describe inorganic species (e.g. sodium hypophosphite), while phosphinate typically refers to organophosphorus species.

Halogen-free flame retardant polyamide composition with improved electrical properties

Owner:SABIC GLOBAL TECH BV

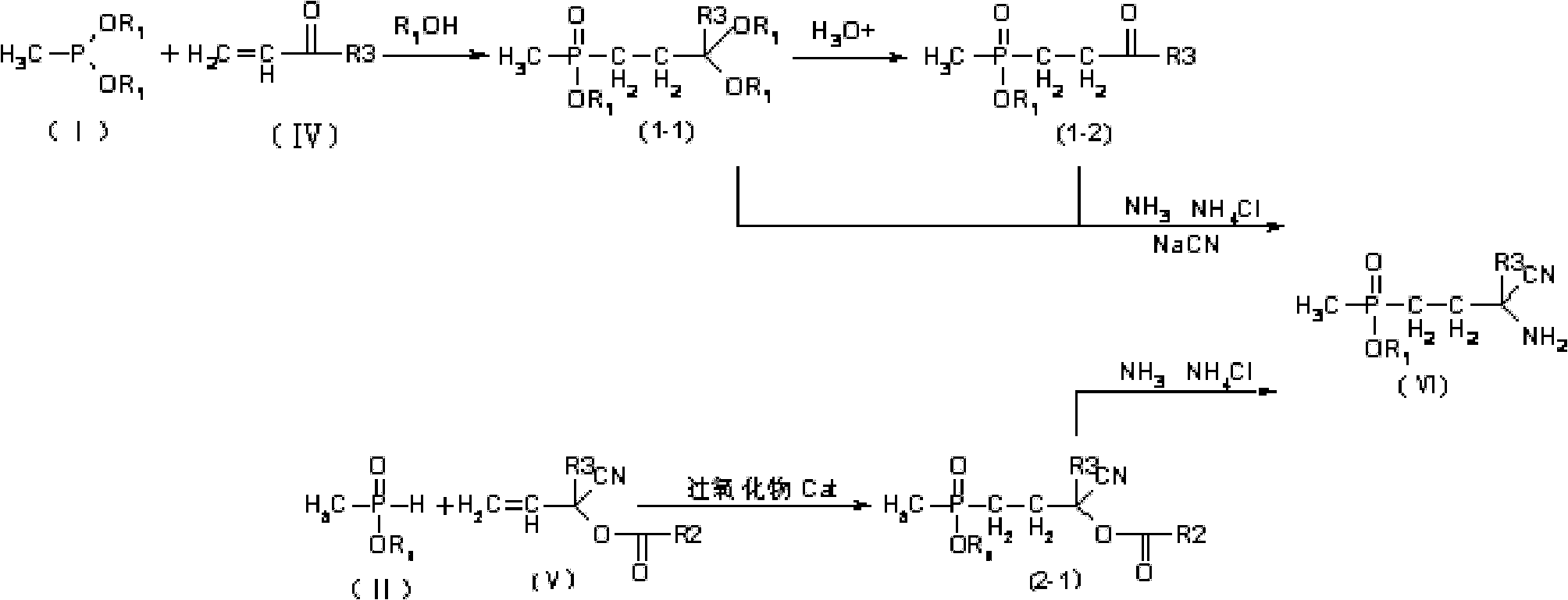

Dialkyl metal phosphinate and synthesis process of fire retardant thereof

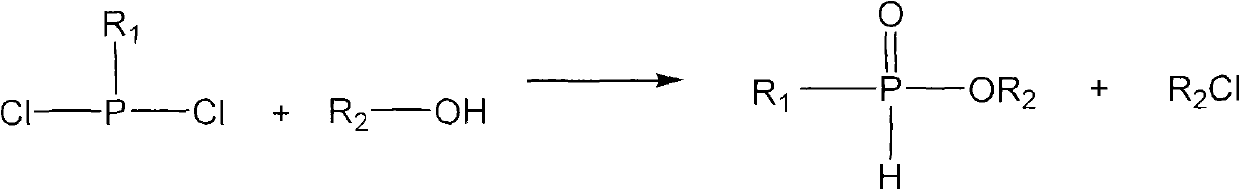

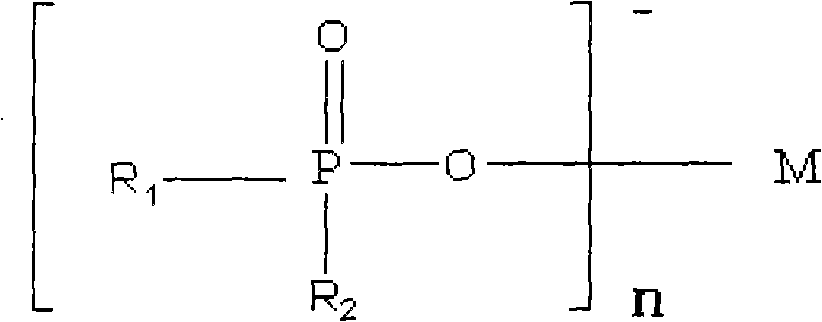

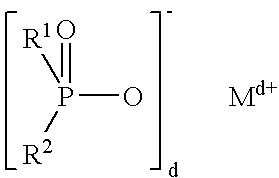

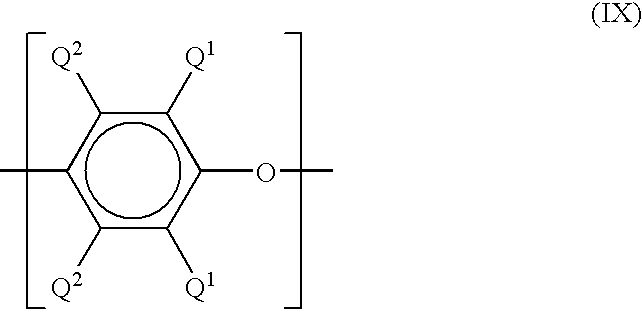

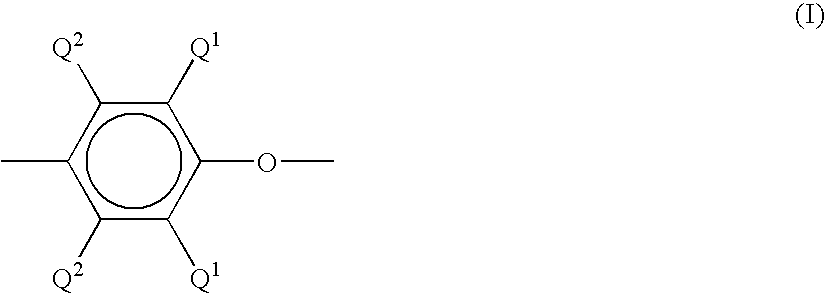

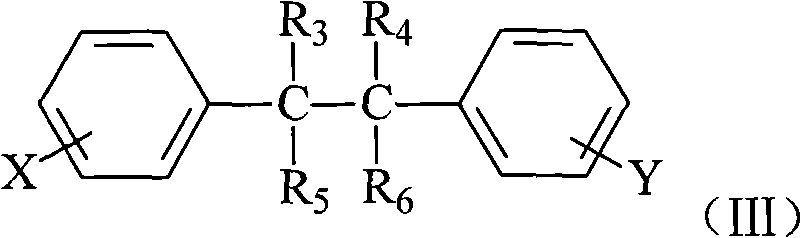

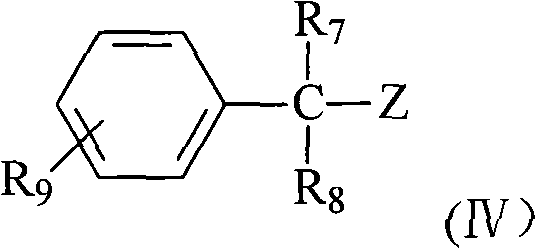

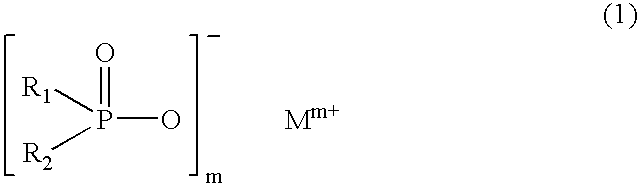

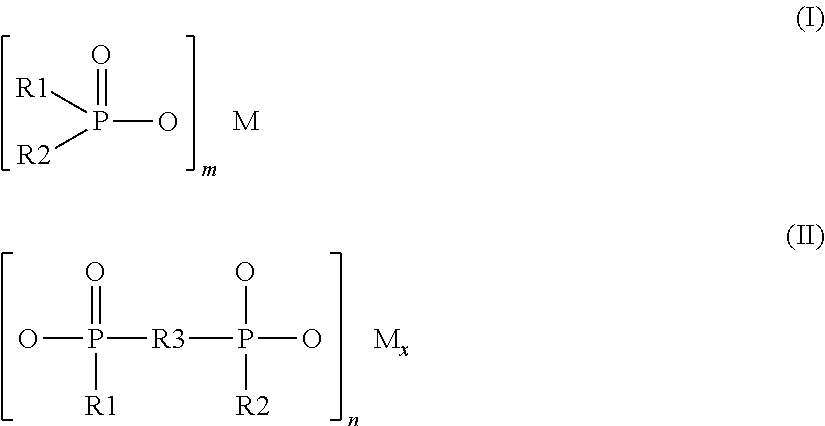

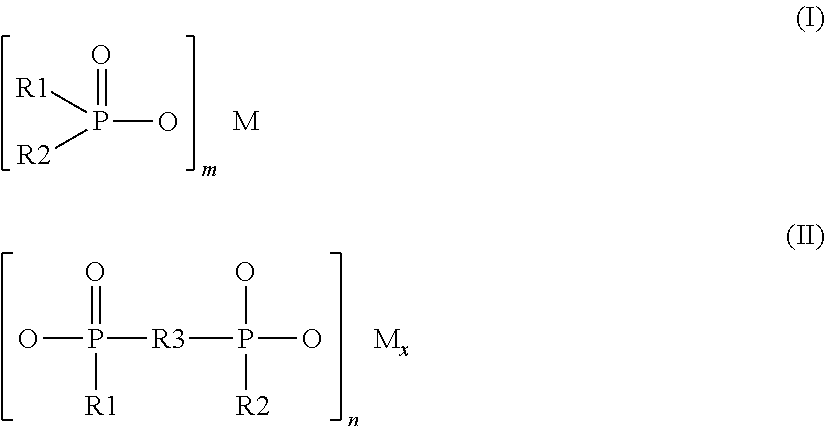

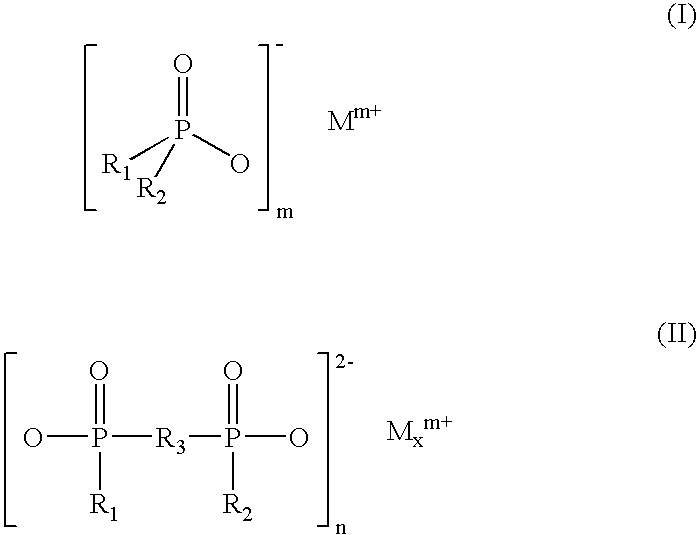

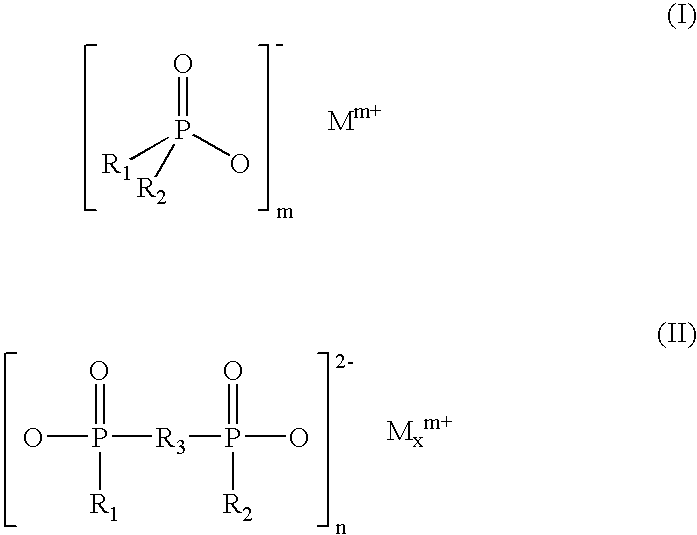

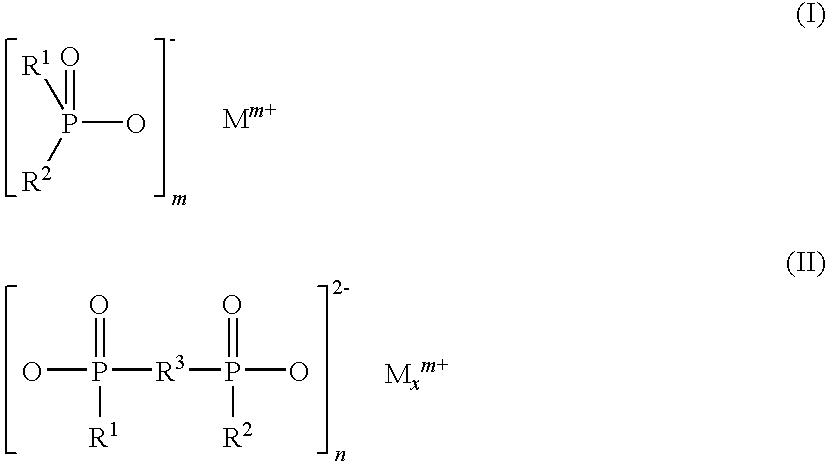

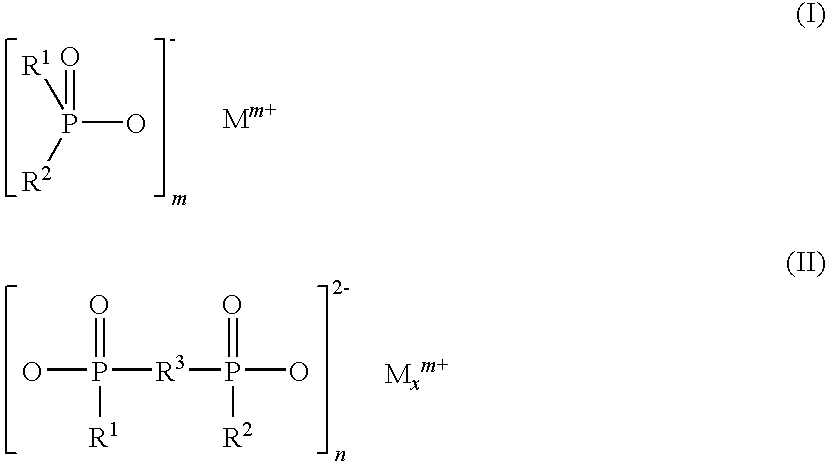

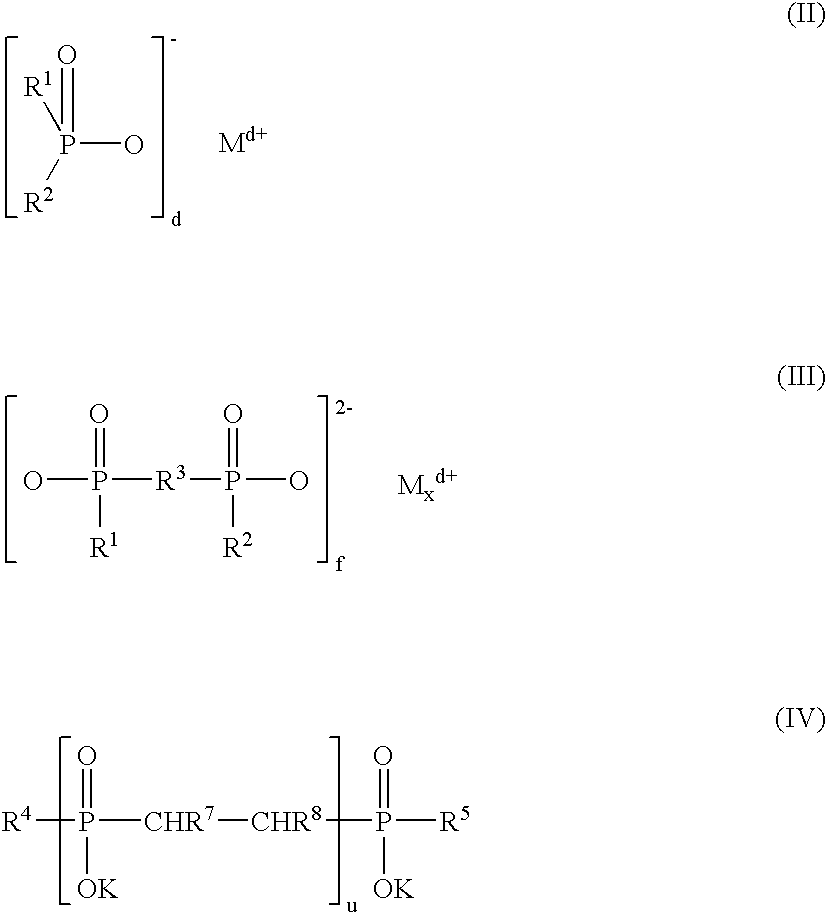

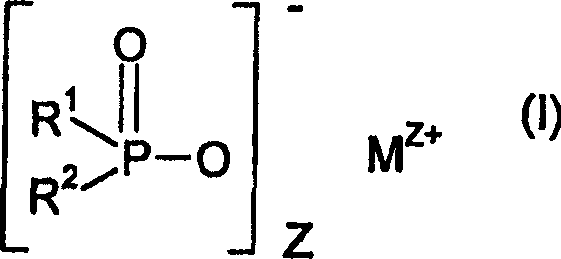

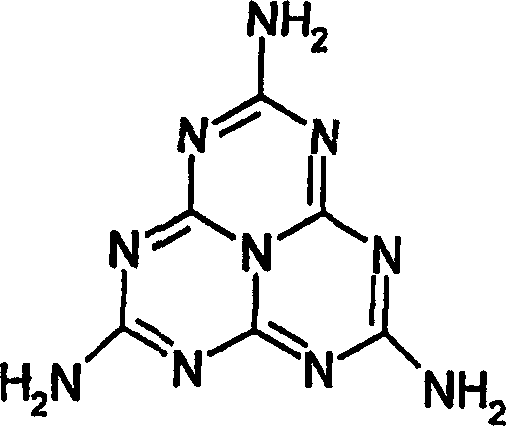

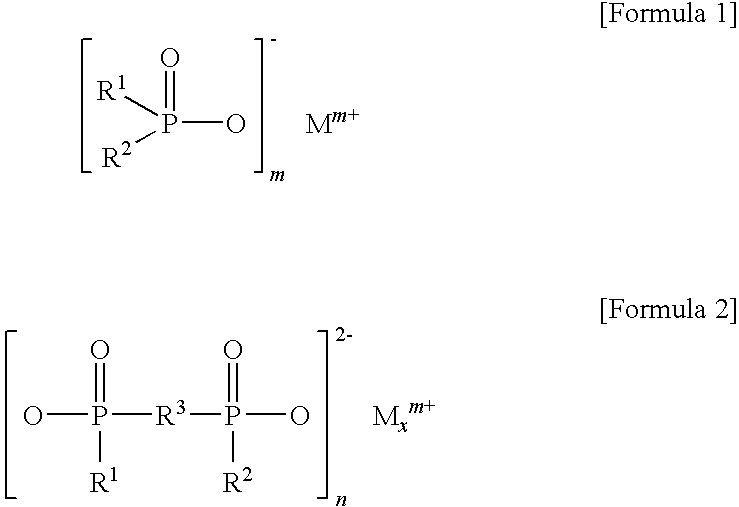

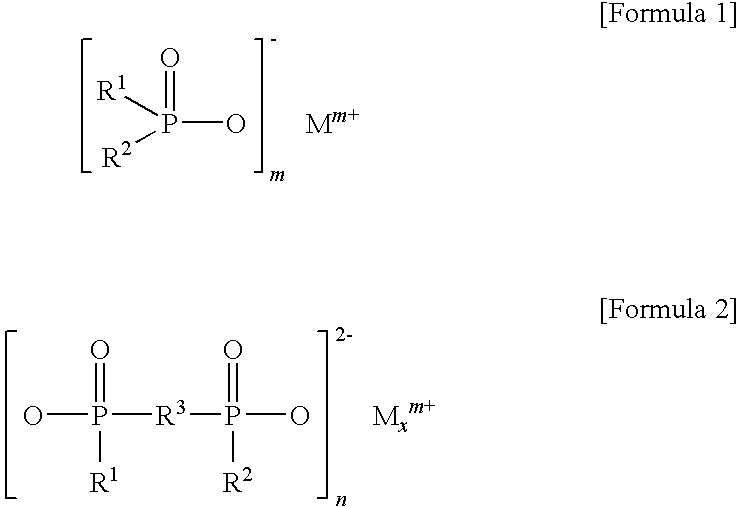

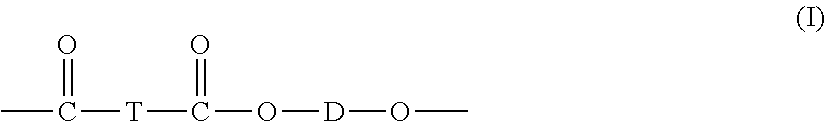

ActiveCN101830926AEasy to prepareMild reaction conditionsGroup 5/15 element organic compoundsPhosphateStructural formula

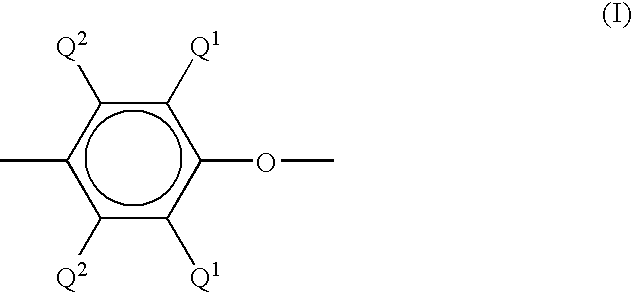

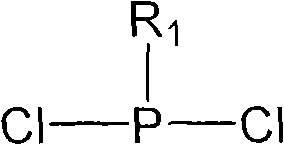

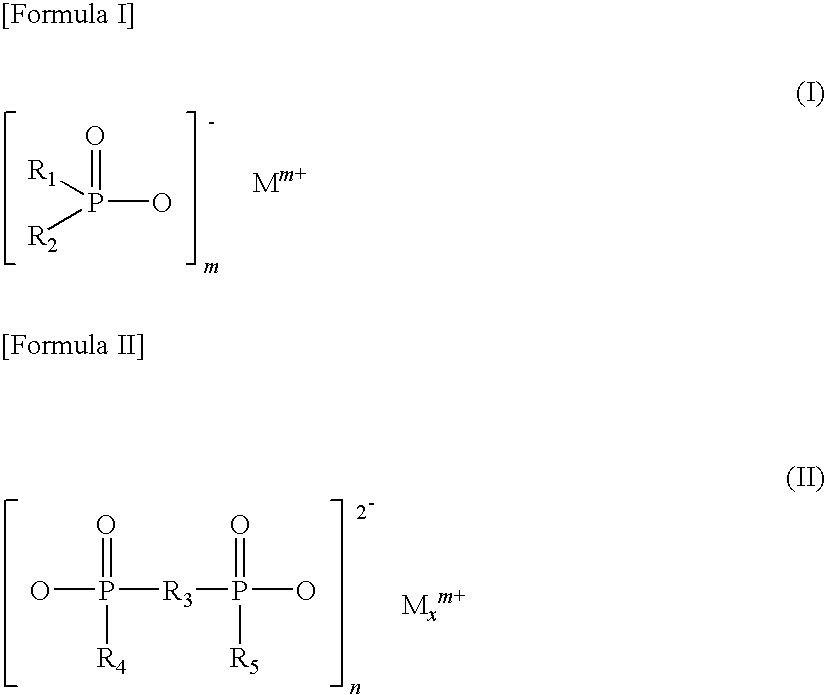

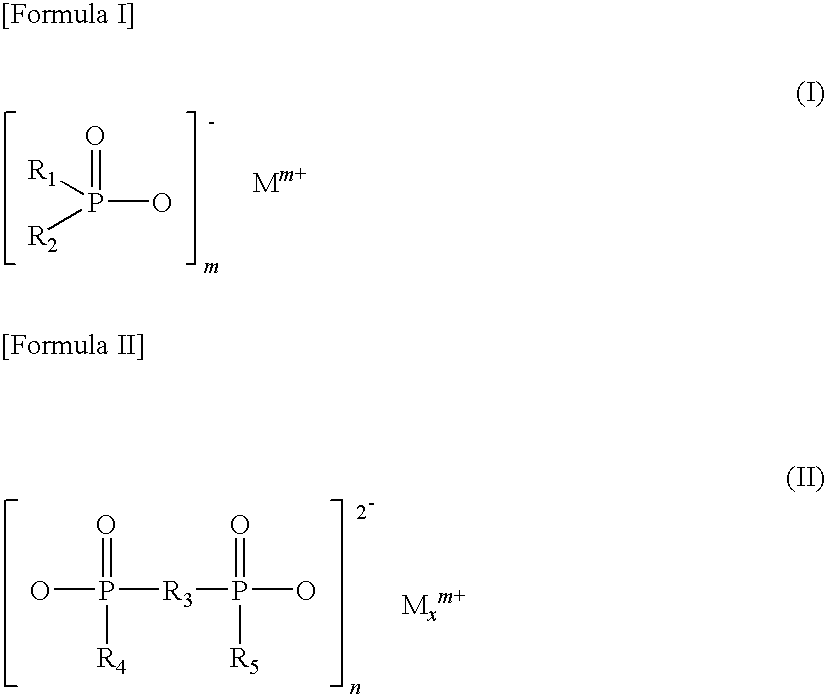

The invention relates to a preparation method of a fire retardant, in particular to a dialkyl metal phosphinate and a synthesis process of a fire retardant thereof. The dialkyl metal phosphinate has a structural formula described in the specification, wherein R1 represents alkyl, M represents metal ions, n represents an integer from 1 to 3, and R2 represents olefin of aliphatic series. The preparation method comprises the steps of: reacting alkylphosphonous dichloride with alcohol to obtain monoalkyl phosphate; carrying out radical reaction on the monoalkyl phosphate with olefin to obtain dialkyl ester phosphinate; and reacting the dialkyl ester phosphinate with lewis acid to obtain the dialkyl metal phosphinate fire retardant. The invention has mild reaction condition; the prepared product has good thermal stability and high yield, wherein the yield can reach 87.6 percent by the count of methyl butyl ester phosphate; and the preparation method is suitable for industrialized production.

Owner:HONGHU YITAI TECH CO LTD

Flame Retardant Poly(Arylene Ether)/Polyamide Composition

A composition comprises a compatibilized poly(arylene ether) / polyamide blend, an optional electrically conductive filler, a phosphinate, and flame retardant augment selected from the group consisting of melamine polyphosphate, zinc borate, low melting glass, talc, and combinations of two or more of the foregoing flame retardant augments.

Owner:SABIC INNOVATIVE PLASTICS IP BV

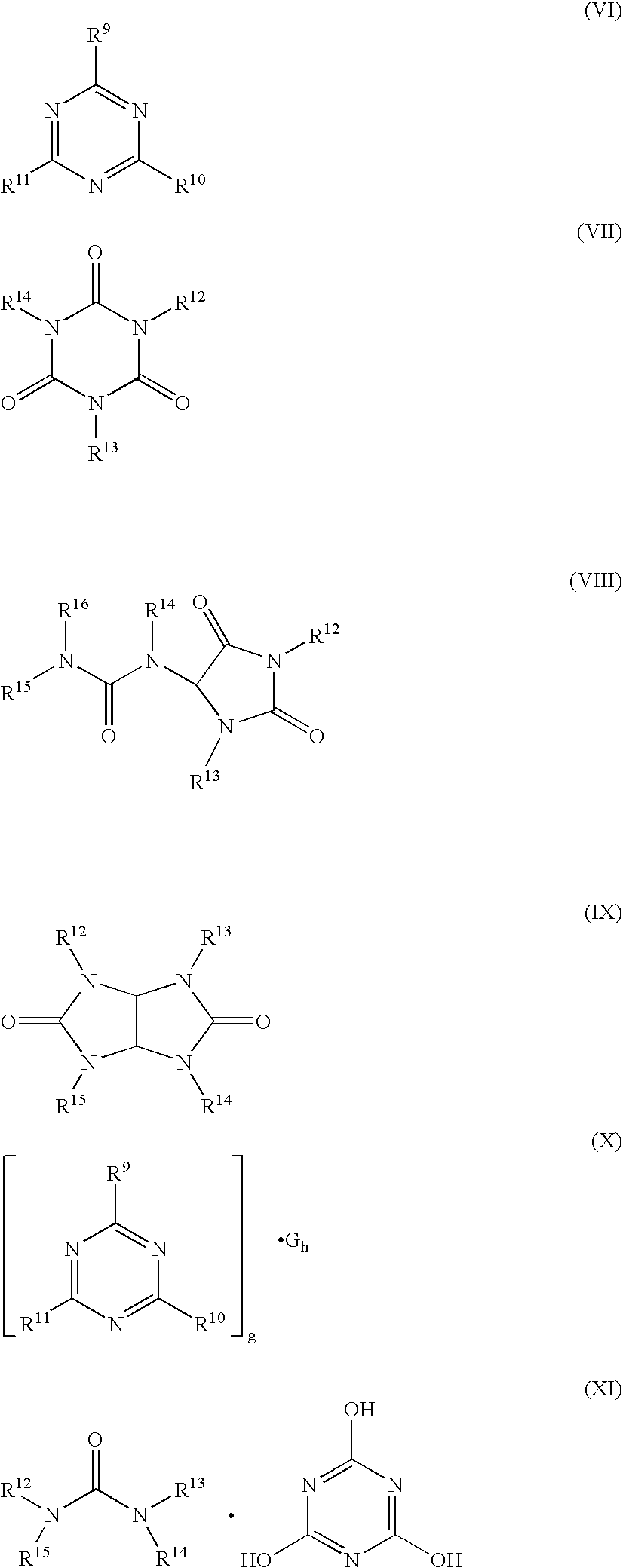

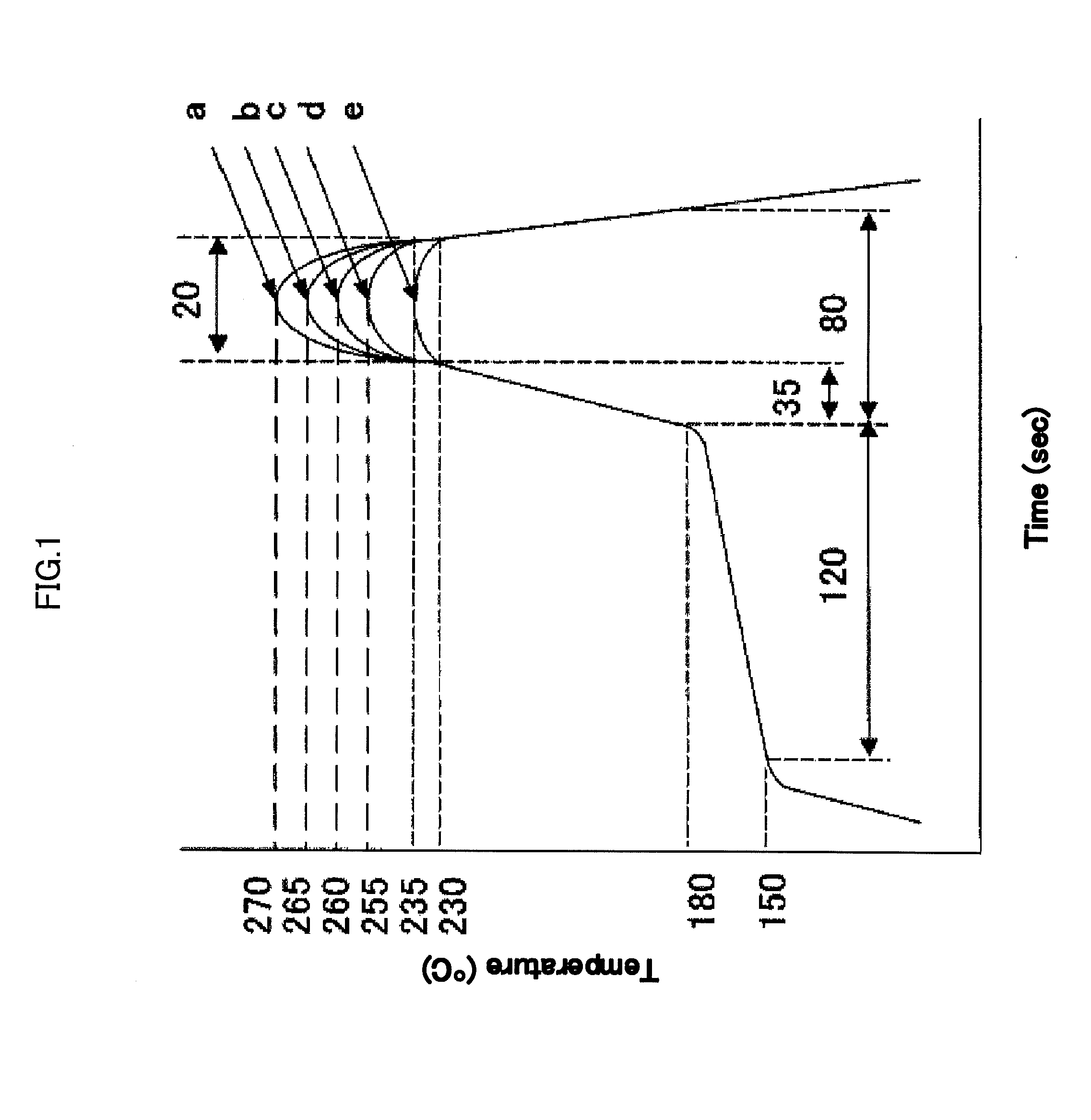

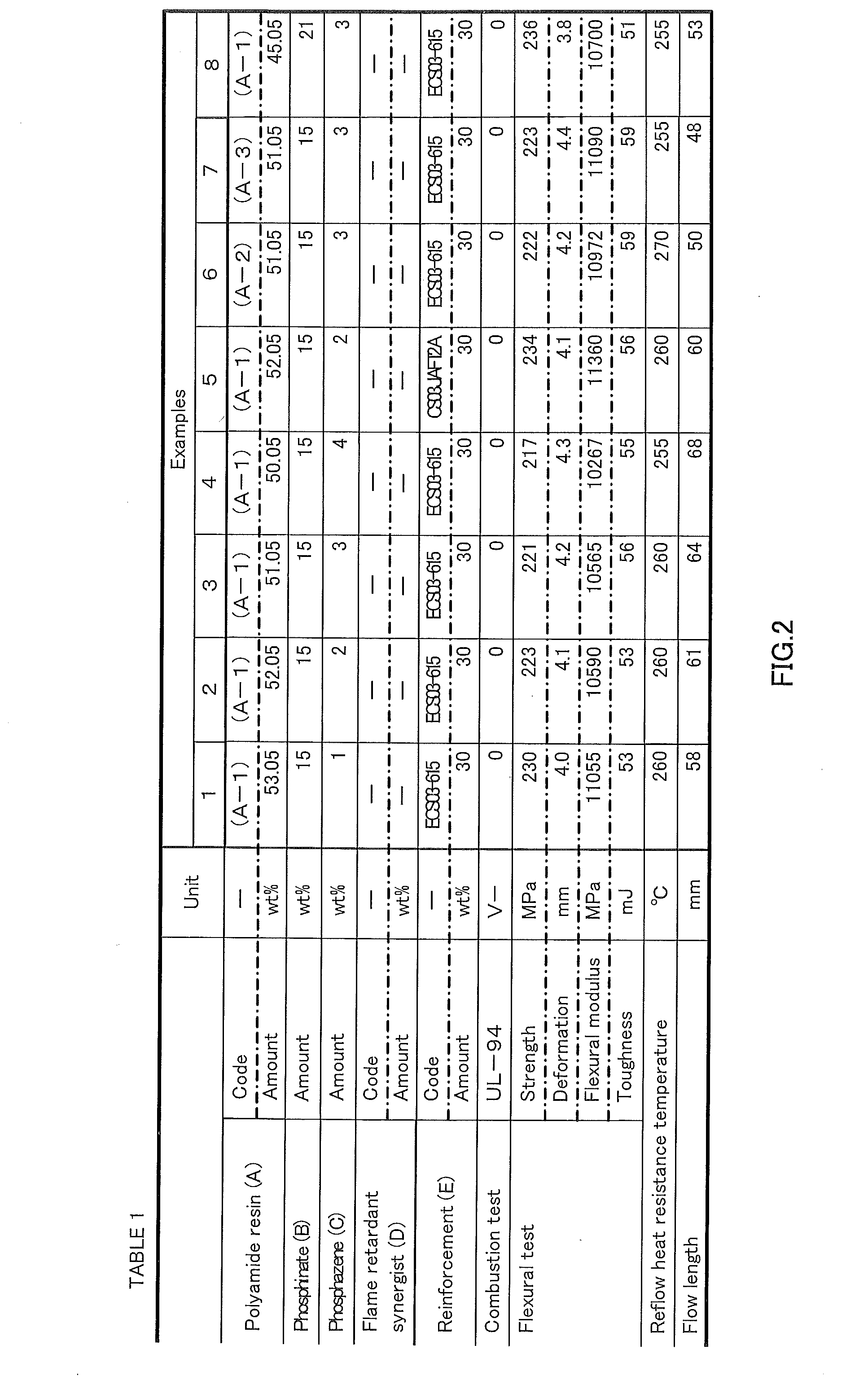

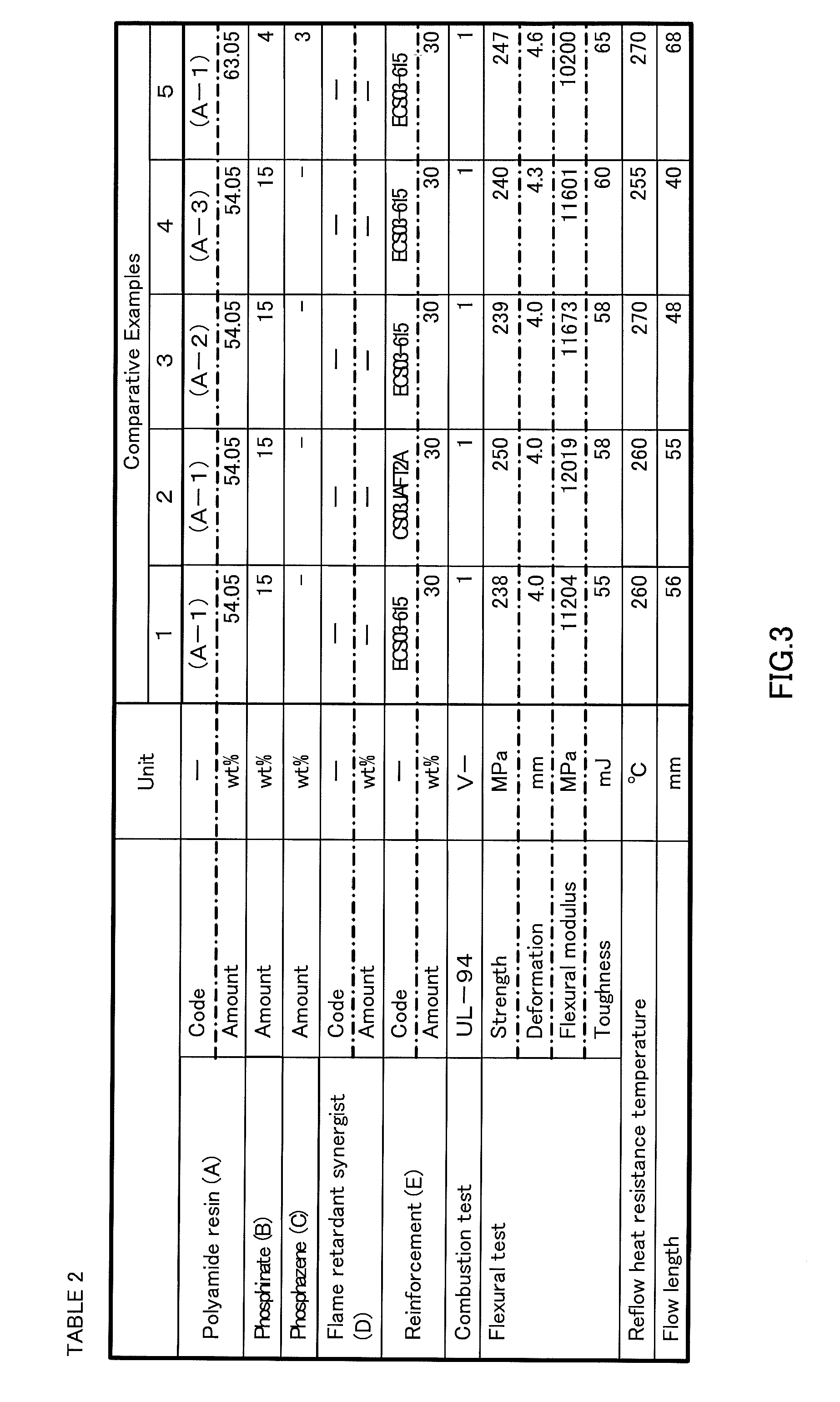

Flame-retardant polyamide composition

Disclosed is a flame-retardant polyamide composition which has excellent mechanical properties such as toughness, excellent heat resistance and flow ability during reflow soldering, and good thermal stability during molding, without using a halogen flame-retardant. This flame-retardant polyamide composition exhibits stable flame retardance particularly when a thin article is molded. Specifically disclosed is a flame-retardant polyamide composition containing 20-80% by mass of a specific polyamide resin (A), 5-30% by mass of a phosphinate compound (B), and 0.01-10% by mass of a phosphazene compound (C).

Owner:MITSUI CHEM INC

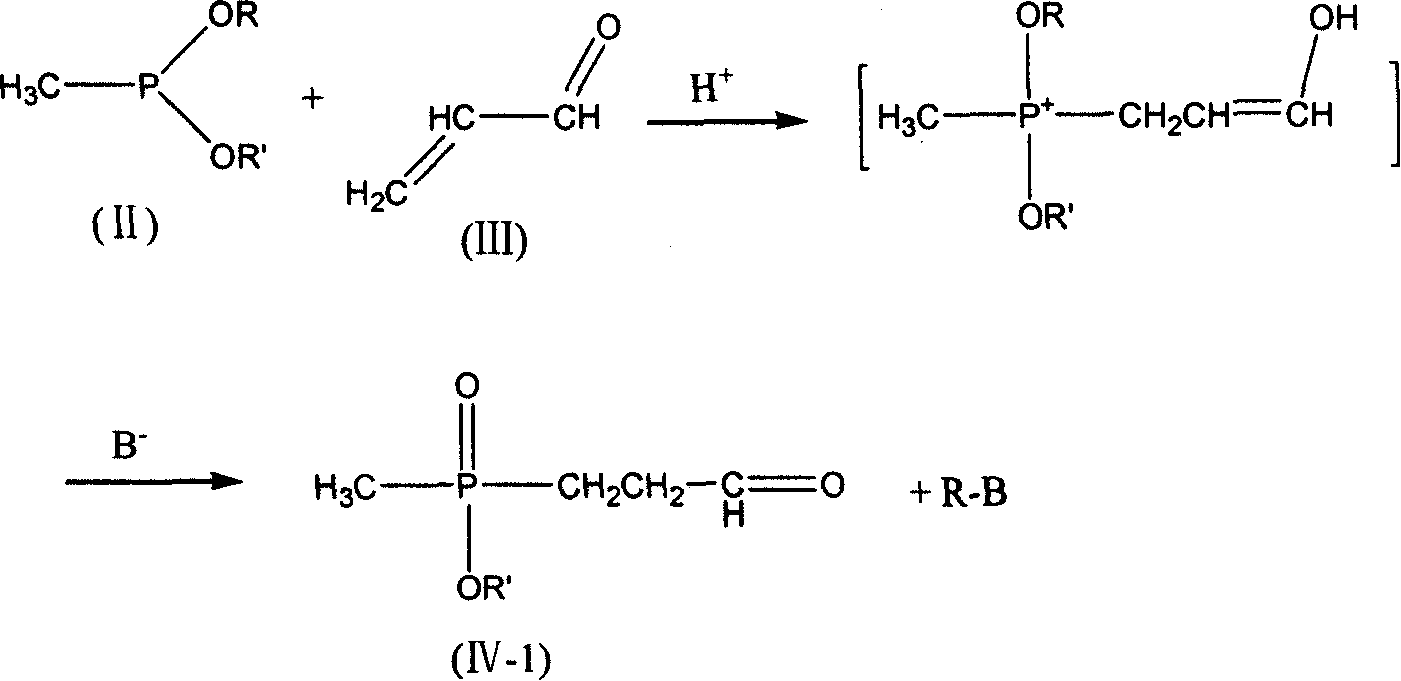

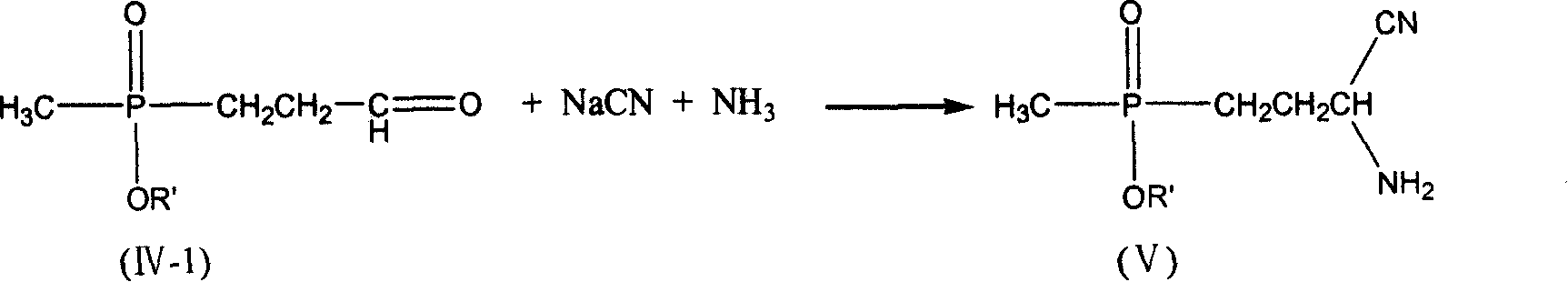

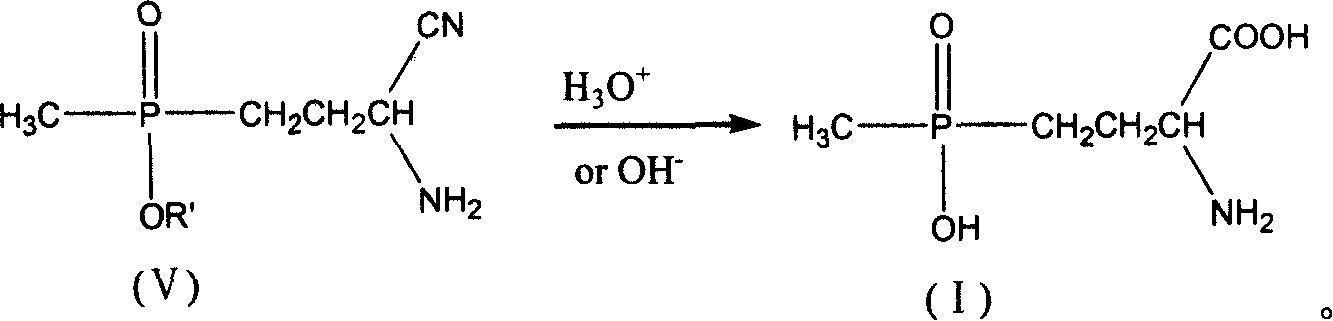

Improved synthesis method for glufosinate and analogue thereof

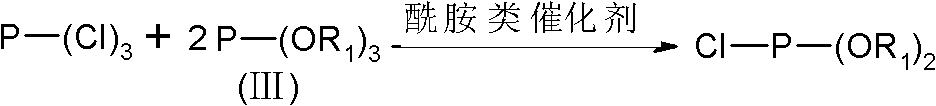

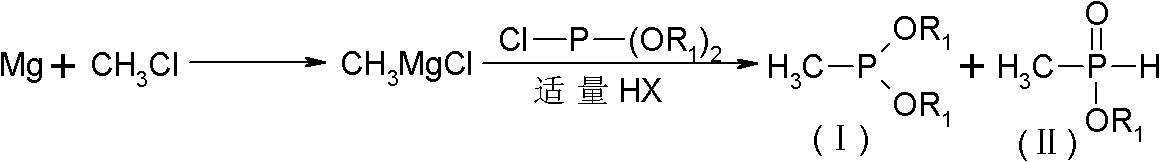

InactiveCN102399240AReduce generationReduce processing costsGroup 5/15 element organic compoundsDiethyl phosphateHydrogen halide

The invention discloses a comprehensive method for synthesizing glufosinate and analogue thereof by using phosphorus trichloride, triethyl phosphate and chloromethane as initiative raw materials. The method comprises the following steps of: performing Grignard, disproportionation and coupling; introducing a proper amount of hydrogen halide; and synthesizing to obtain two intermediates, namely methyl diethyl phosphate (intermediate I) and methyl phosphinate (intermediate II), wherein the two intermediates can synthesize the glufosinate and the analogue thereof. By the method, the glufosinate and the analogue thereof are synthesized by completely utilizing the methyl diethyl phosphate and the methyl phosphinate synthesized by a Grignard route; yield is increased; production cost is reduced; and three wastes are reduced.

Owner:JIANGSU YOUTH CHEM +1

Flame retardant poly(arylene ether)/polyamide compositions, methods, and articles

A flame retardant poly(arylene ether) / polyamide composition includes a poly(arylene ether), a polyamide, about 5 to about 15 weight percent glass fiber, and a flame retardant consisting of a metal dialkyl phosphinate. Methods of preparing the composition are described, as are articles that include it.

Owner:SHPP GLOBAL TECH BV

Halogen-free flame retardant polyamide composition with improved electrical and flammability properties

Flame retardant polyamide compositions are provided containing a polyamide; a flame retardant system including a metal phosphinate or diphosphinate salt and a nitrogen compound; an aromatic polymer, and optionallly untreated nanoclay having an aspect ratio of about 100 to about 1000.

Owner:SHPP GLOBAL TECH BV

Poly(arylene ether)/polyamide composition and method of making

An composition comprises a poly(arylene ether), a polyamide, electrically conductive filler, an impact modifier, and a phosphinate. The composition may be used in a variety of articles such as furniture, partitions, containers, and vehicle interiors.

Owner:SABIC GLOBAL TECH BV

Method of making a flame retardant poly(arylene ether)/polyamide composition and the composition thereof

A composition comprises a poly(arylene ether), a polyamide, a reinforcing filler, a phosphinate, and an optional impact modifier. The composition is made by melt mixing a poly(arylene ether), a compatibilizing agent, a polyamide, a reinforcing filler, an optional impact modifier, and a flame retardant masterbatch wherein the flame retardant masterbatch comprises a phosphinate and a thermoplastic resin.

Owner:SABIC INNOVATIVE PLASTICS IP BV

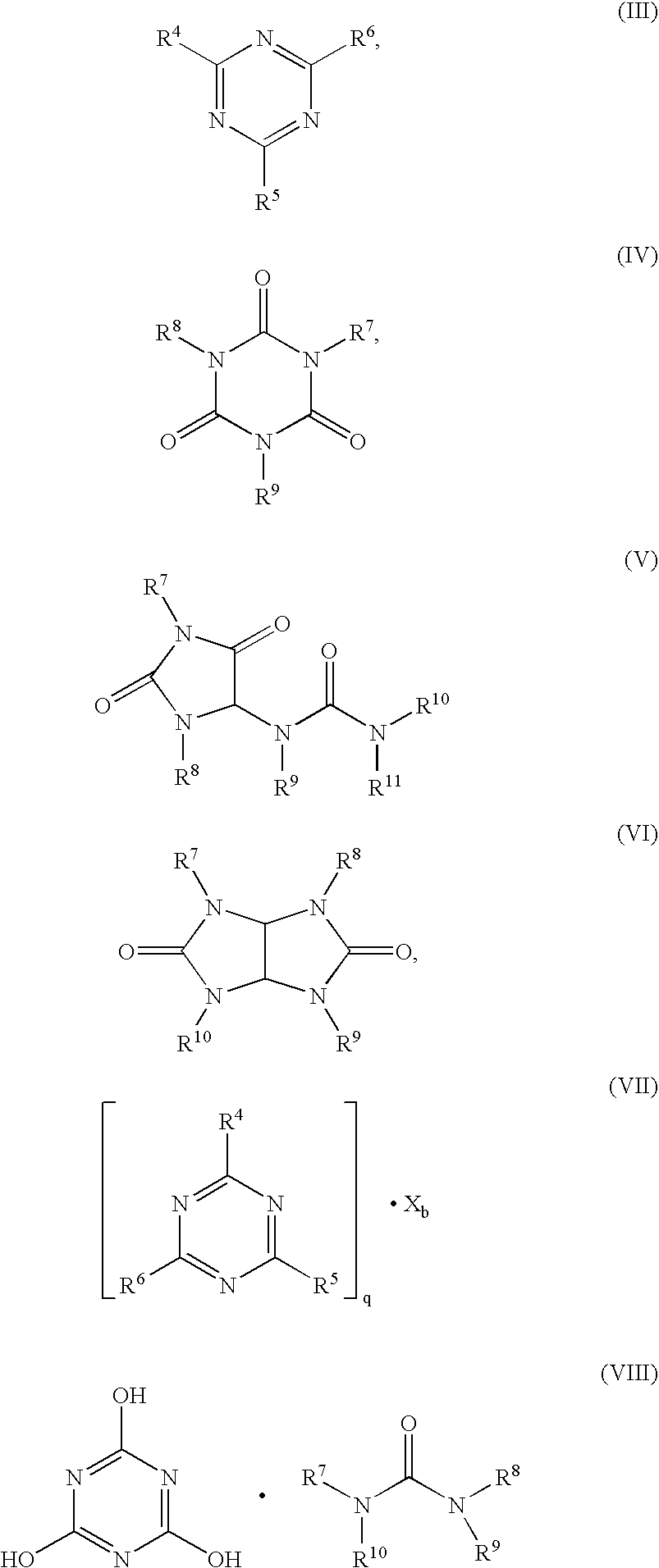

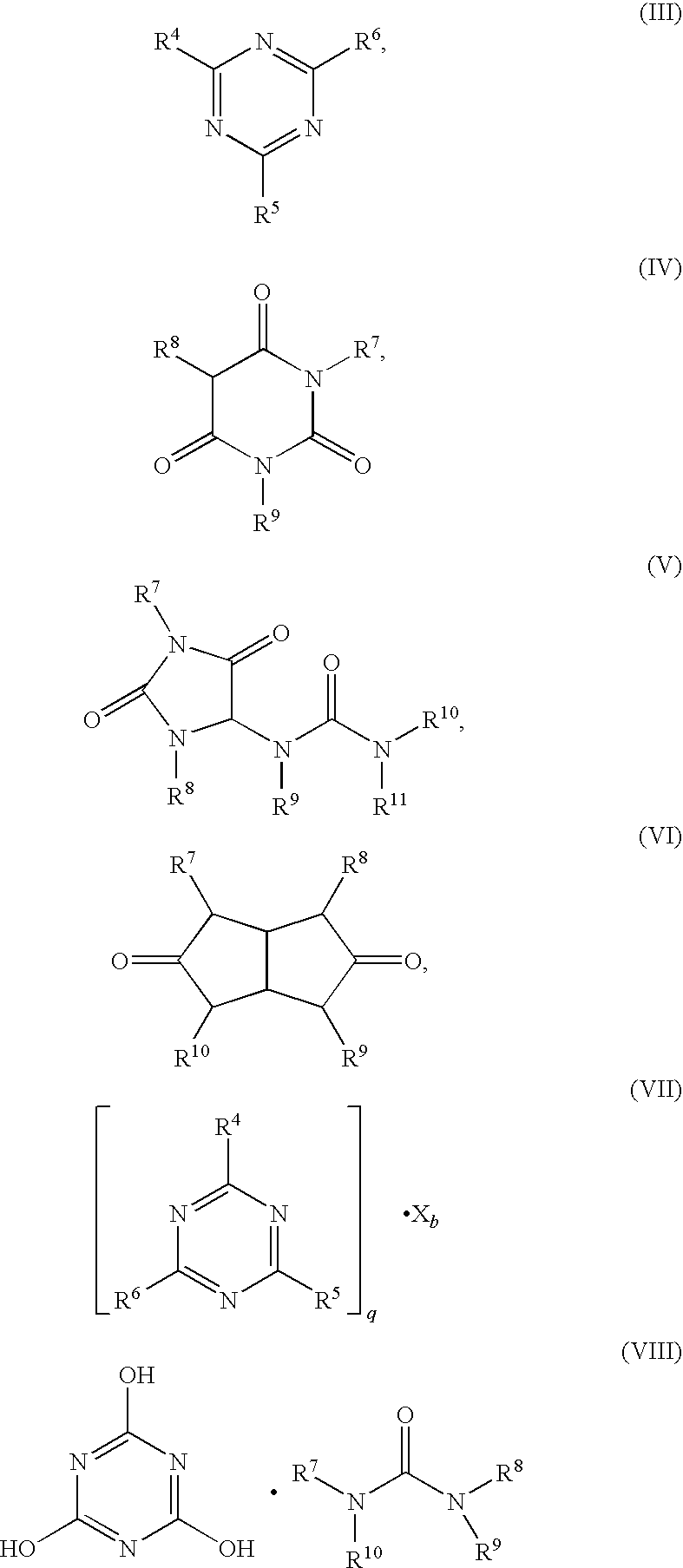

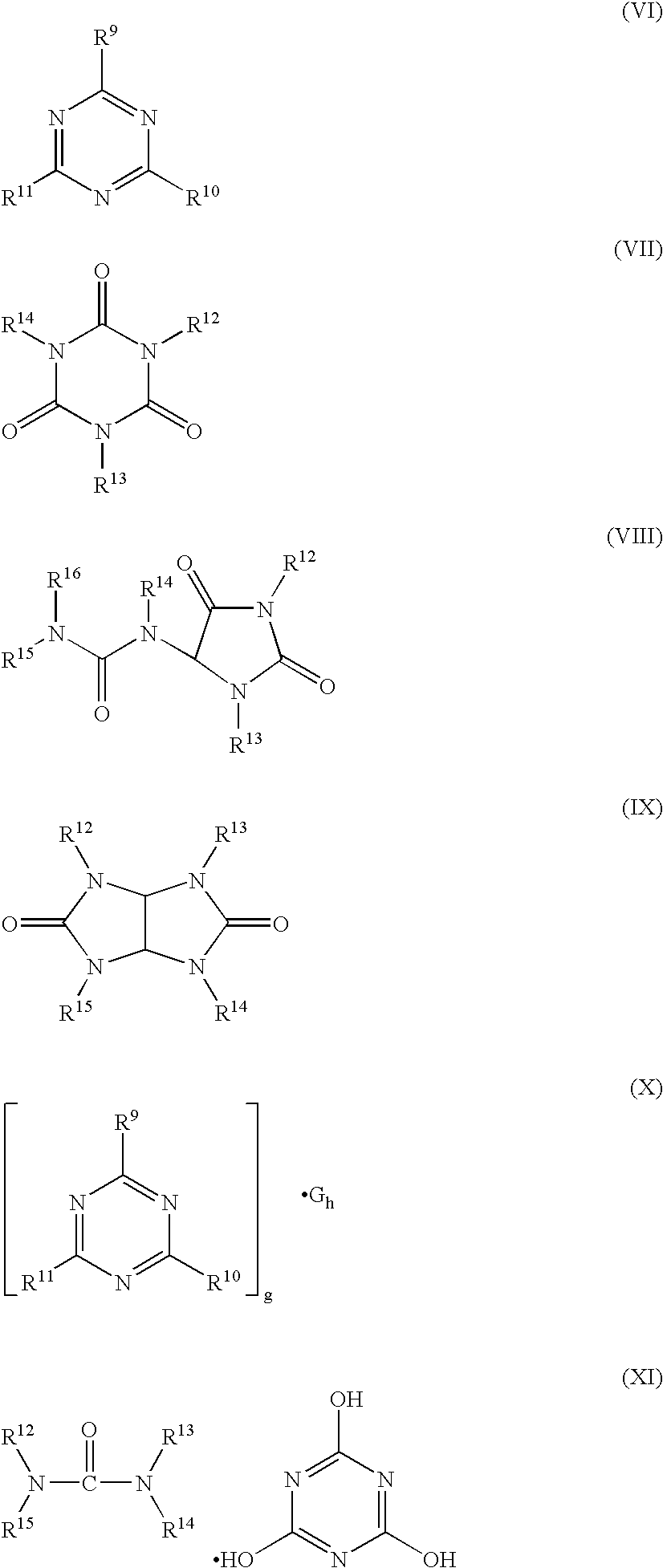

Flame retardant resin composition

Disclosed is a flame retardant resin composition which is excellent in flame retardance and greatly improved in electrical characteristics. Specifically disclosed is a resin composition composed of (A) a base resin (specifically, a polyester resin, a polyamide resin or the like), (B) a halogen flame retardant (specifically, a bromine-containing flame retardant such as a brominated polybenzyl(meth)acrylate resin or a brominated styrene resin), (C) an organic / inorganic acid salt, specifically an organic phosphinate (such as a metal salt or an aminotriazine compound salt) or an oxo acid salt (such as a polyphosphate or (pyro)sulfate) of a basic nitrogen-containing compound (such as an aminotriazine compound), and (D) an electrical characteristics improver, specifically an olefin resin (such as a-C2-3olefin-(meth)acrylate copolymer), a fluorine resin or a group IV metal compound (such as titanium oxide).

Owner:POLYPLASTICS CO LTD

Surface precipitation-free flame-retardant polypropylene compound and preparation method thereof

ActiveCN101880420AMeet the use requirementsHigh flame retardant efficiencyHydrobromideProcedure Agents

The invention relates to a surface precipitation-free flame-retardant polypropylene compound and a preparation method thereof. The surface precipitation-free flame-retardant polypropylene compound comprises the following components by weight percent: 70-98.5% of polypropylene resin, 1-15% of melamine hydrobromide, 0.3-7% of phosphinates, 0.2-4% of flame retardant synergist, 0-2% of synergetic flame retardant, 0-1% of antioxidant and 0-1% of processing acid. The preparation method thereof is implemented as follows: weighting the above components based on proportion, evenly mixing, melt-mixing the above mixture, pelletizing and drying to obtain the product in the invention. The surface precipitation-free flame-retardant polypropylene compound has high flame retardant efficiency, good flowability, no precipitation, and high flame retardant rating up to UL94 V-0, and can satisfy the use requirements of flame retardant materials in building materials, electrical appliance casings, sockets, bellows, lighting lamps and the like.

Owner:湖南美莱珀科技发展有限公司

Preparation method and application of diethyl phosphinates

InactiveCN101891762AShort reaction timeTrigger fastGroup 5/15 element organic compoundsReaction rateUltraviolet lights

The invention discloses a preparation method and application of diethyl phosphinates, belonging to the field of green flame retardants. The preparation method of the diethyl phosphinates comprises the following steps of: making hypophosphorous acid and / or an alkali metal salt thereof react with ethylene under the irradiation of ultraviolet light in the presence of a photoinitiator in a solvent system to obtain diethyl phosphinic acid and / or an alkali metal salt thereof; and making the obtained diethyl phosphinic acid and / or the alkali metal salt thereof react with metallic compounds of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Ce, Sn and / or Fe to obtain corresponding diethyl phosphinates. In the invention, the photoinitiator is decomposed into free radicals under the irradiation of the ultraviolet light to initiate an additive reaction so that the reaction rate can be improved, the energy consumption required in the reaction can be reduced and the production cost of products can be lowered.

Owner:NANKAI UNIV

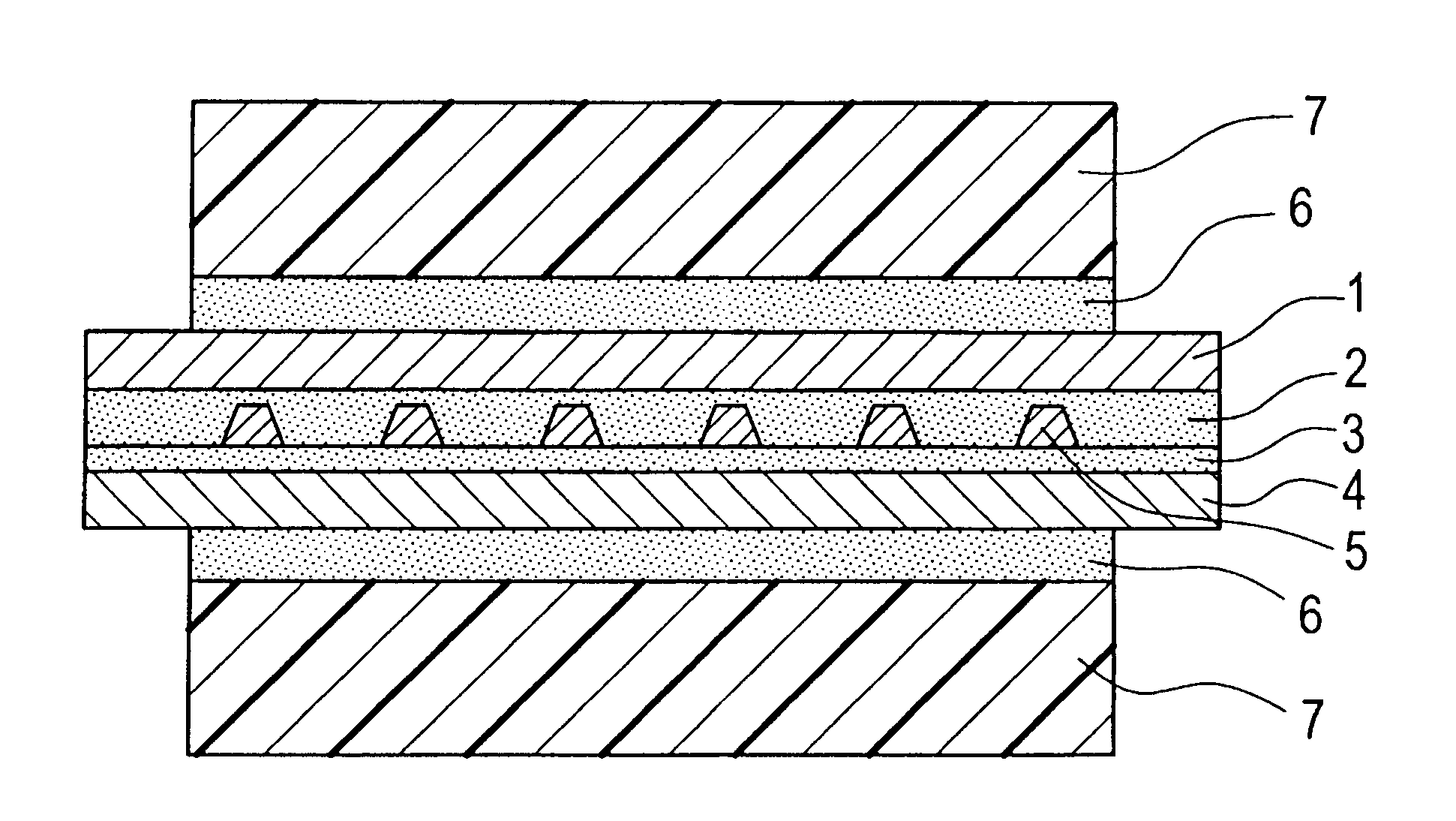

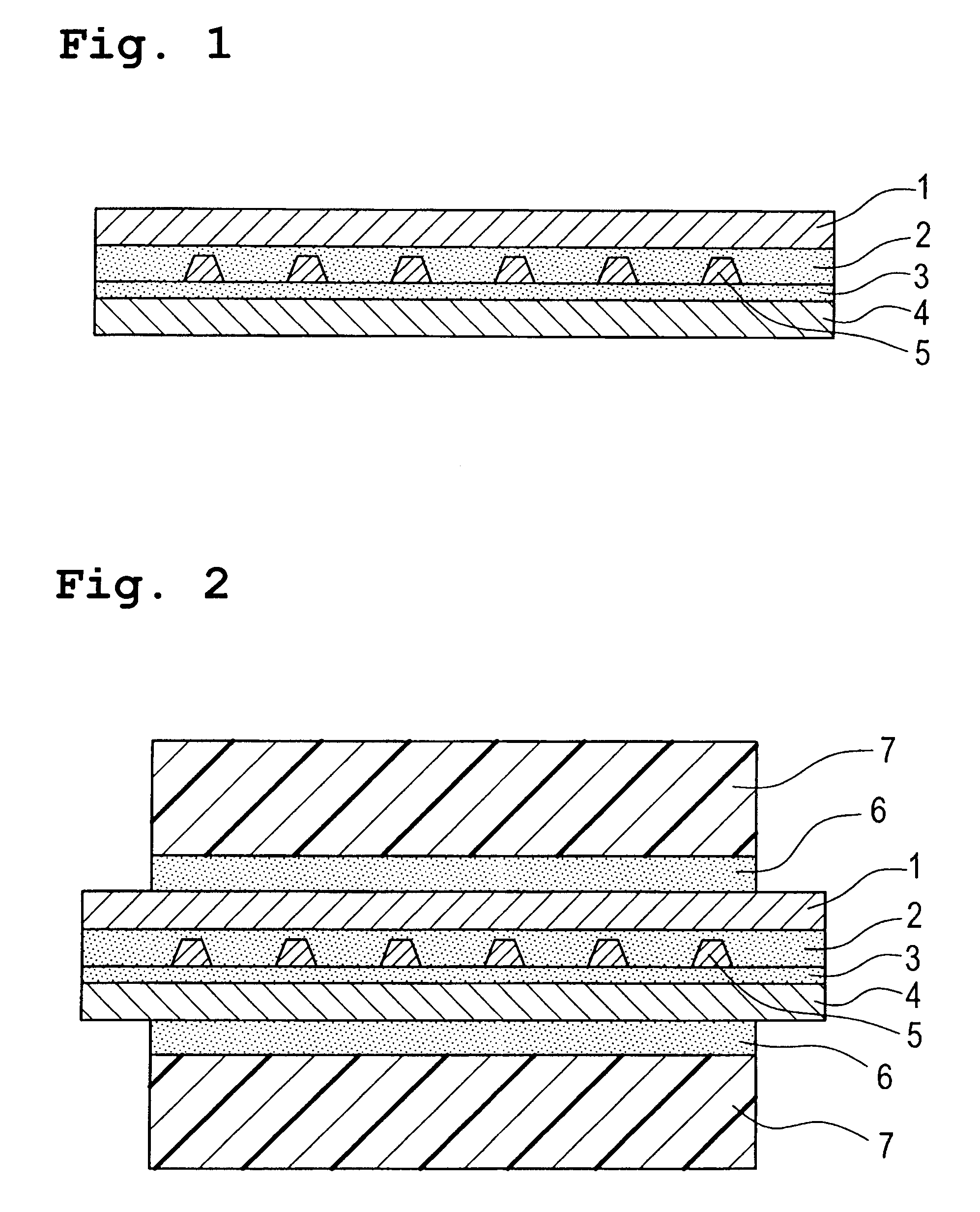

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveUS20080241452A1Improve flame retardant performanceGood adhesivenessNon-macromolecular adhesive additivesGroup 5/15 element organic compoundsEpoxyScavenger

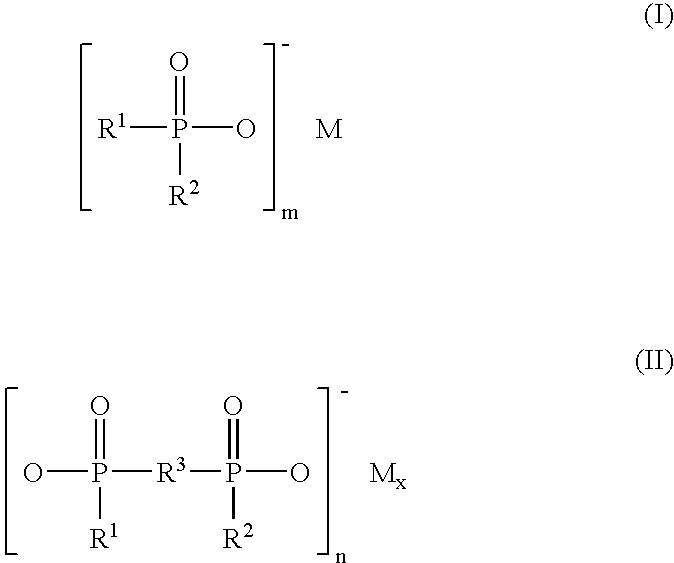

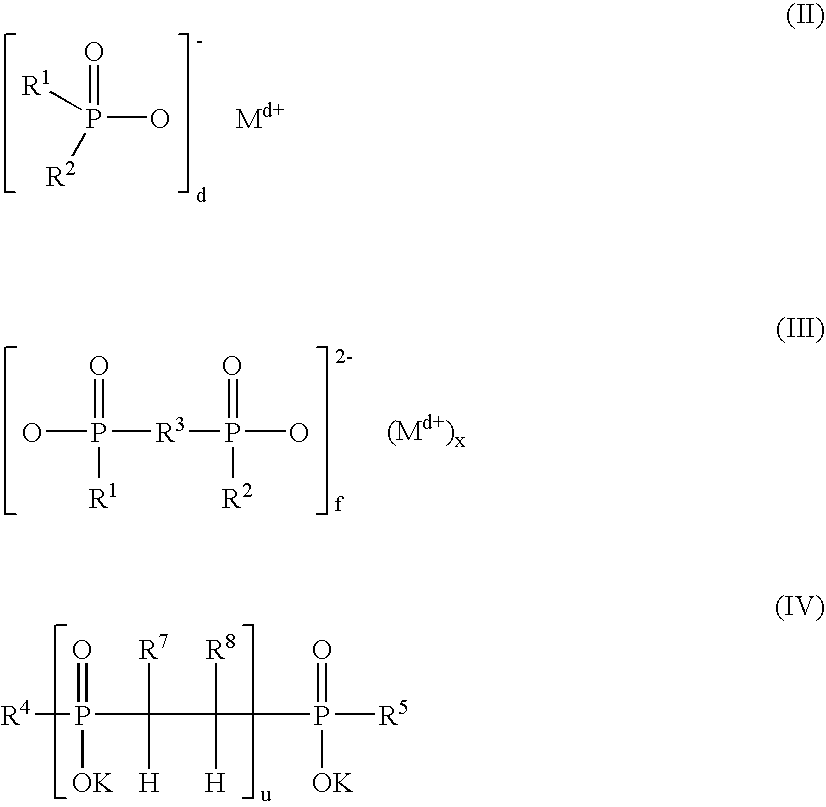

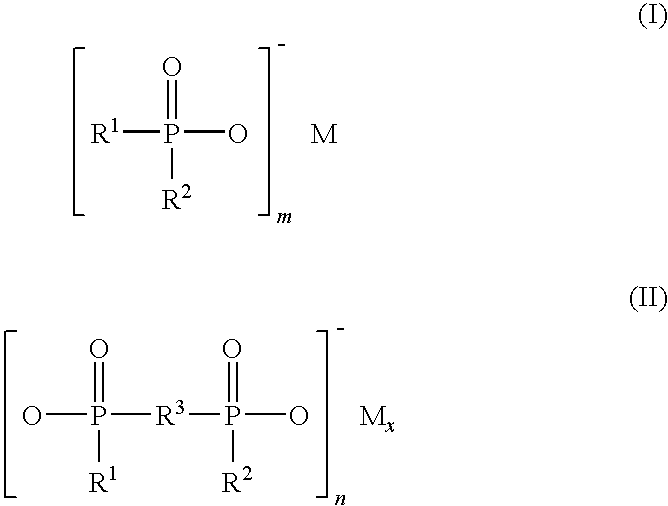

The present invention provides a halogen-free, flame retardant adhesive composition that exhibits excellent anti-migration properties, not only within single layer structures, but also within multilayer structures of much higher density such as copper-clad laminates.The flame retardant adhesive composition according to the present invention comprises: (A) a halogen-free epoxy resin, (B) a carboxyl group-containing acrylic resin and / or a carboxyl group-containing acrylonitrile-butadiene rubber, (C) a curing agent, (E) specific phosphinate and / or diphosphonate compounds, and (F) an ion scavenger and / or a heavy metal deactivator.

Owner:SHIN ETSU CHEM IND CO LTD

Fireproofing polyamide powders and their use in a sintering process

A subject-matter of the invention is the use of a polyamide powder possessing a fireproofing property in a process for the manufacture of an object made of polyamide by sintering this powder using radiation, the said powder comprising, by weight, 2 to 40% of at least one flame retardant for respectively 98 to 60% of at least one polyamide, the flame retardant being a blend of at least one organic phosphinate of a metal and of at least ammonium polyphosphate.

Owner:ARKEMA FRANCE SA

Flame-protected, partially aromatic polyamide molding compounds

ActiveUS20120083558A1Reduce the amount requiredGroup 5/15 element organic compoundsSynthetic resin layered productsThermoplasticPolyamide

The invention relates to a flame-retardant polyamide molding composition based on semicrystalline polyamides. This polyamide molding composition is based on(A) from 30 to 92% by weight of at least one aliphatic or semiaromatic, semicrystalline polyamide with melting point (Tm) in the range from 240° C. to 340° C.;(B) from 0 to 50% by weight of at least one filler and reinforcing agent;(C) from 8 to 18% by weight of at least one halogen-free flame retardant;(D) from 0 to 2.0% by weight of at least one barium carboxylate;(E) from 0 to 5% by weight of at least one additive;wherein the percentages by weight of components (A) to (E) give a total of 100%, and with the proviso that if the proportion of component (D) is in the range from 0 to 0.1% by weight the halogen-free flame retardant of component (C) is based on a barium phosphinate. The invention further relates to the use of barium carboxylate in a polyamide molding composition using a halogen-free flame retardant for inhibiting corrosive action during processing. The molding compositions comply with fire-protection class UL 94 V-0, and have no, or only slight, corrosive action with respect to the machine components used in thermoplastic processing, and exhibit good mechanical properties. They are suitable for producing, in particular, thin-walled moldings for the electrical and electronics industry, examples being housings, housing components, and connectors.

Owner:EMS PATENT AG

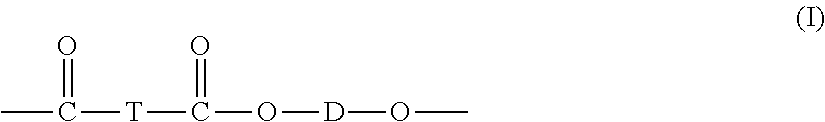

Flame resistant polyester compositions, method of manufacture, and articles thereof

A thermoplastic polyester composition comprising, based on the total weight of the composition, a chlorine- and bromine-free combination of: from 40 to 60 wt % of a polyester; from 25 to 35 wt % of a reinforcing filler; from 2 to 8 wt % of a flame retardant synergist selected from the group consisting of melamine polyphosphate, melamine cyanurate, melamine pyrophosphate, melamine phosphate, and combinations thereof; from 5 to 15 wt % of a phosphinate salt flame retardant; from more than 0 to less than 5 wt % of an impact modifier component comprising a poly(ether-ester) elastomer and a (meth)acrylate impact modifier; from more than 0 to 5 wt % poly(tetrafluoroethylene) encapsulated by a styrene-acrylonitrile copolymer; from more than 0 to 2 wt % of a stabilizer; wherein the thermoplastic polyester composition contains less than 5 wt % of a polyetherimide.

Owner:SHPP GLOBAL TECH BV

Preparation of organic additive-treated, pyrogenic silica-encapsulated titanium dioxide particles

One aspect of the invention is to provide a composition comprising a titanium dioxide particle having on the surface of said particle a substantially encapsulating layer comprising a pyrogenically-deposited metal oxide; said substantially encapsulating layer having on its surface at least one organic surface treatment material selected from an organo-silane, an organo-siloxane, a fluoro-silane, an organo-phosphonate, an organo-acid phosphate, an organo-pyrophosphate, an organo-polyphosphate, an organo-metaphosphate, an organo-phosphinate, an organo-sulfonic compound, a hydrocarbon-based carboxylic acid, an associated ester of a hydrocarbon-based carboxylic acid, a derivative of a hydrocarbon-based carboxylic acid, a hydrocarbon-based amide, a low molecular weight hydrocarbon wax, a low molecular weight polyolefin, a co-polymer of a low molecular weight polyolefin, a hydrocarbon-based polyol, a derivative of a hydrocarbon-based polyol, an alkanolamine, a derivative of an alkanolamine, an organic dispersing agent, or a mixture thereof. Another aspect of the invention is to provide processes for producing said composition.

Owner:EI DU PONT DE NEMOURS & CO

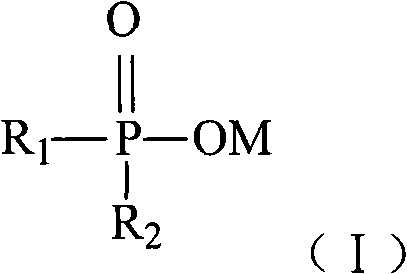

Grinding fluid composition

InactiveCN1384170AImprove surface qualityImprove surface propertiesOther chemical processesSemiconductor/solid-state device manufacturingHard disc driveMetallurgy

A polishing liquid composition containing an abrasive, an oxidizing agent, an organic phosphonic acid as a polishing accelerator, and water, a method for manufacturing a substrate including the step of using the polishing liquid composition to polish a substrate to be ground, and using the above polishing liquid composition to polish the ground substrate The method includes a method of reducing micro-scratches on a substrate to be polished, including the step of polishing the substrate to be polished with the above-mentioned polishing liquid composition, and a method of promoting polishing of a substrate for a magnetic disk by using the above-mentioned polishing liquid composition. The above-mentioned polishing liquid composition is suitable for polishing the substrates for magnetic disks required for high surface quality used in memory hard disk drives.

Owner:KAO CORP

Flame resistant aromatic polyamide resin composition and articles therefrom

Owner:DUPONT POLYMERS INC

Antistatic, halogen-free, and fire-retardant enhanced master batch dedicated for polyamide and preparation method thereof

InactiveCN103351618AGood modification effectImprove antistatic performanceZinc borateAntistatic agent

The invention relates to an antistatic, halogen-free, and fire-retardant enhanced master batch dedicated for polyamide and a preparation method thereof. The fire-retardant master batch is composed of following components in parts by weight: 25 to 50 parts of PA, 15 to 30 parts of alkyl phosphinate fire-retardant, 15 to 30 parts of melamine polyphosphate fire retardant, 8 to 15 parts of zinc borate fire retardant, 4 to 6 parts of CTI improver, 1 to 1.5 parts of antistatic agent, 3 to 8 parts of flexibilizer, 0.5 to 1 part of coupling agent, 0.7 to 1.5 parts of lubricant, and 0.3 to 1 part of anti-oxidant. The sum of the weight ratio of components mentioned above is 100 wt%. The fire-retardant master batch is used to produce fire-retardant enhanced and modified nylon, meets standards of the United States underwriters laboratories (UL)-941.6mm and a higher V-0 grade, simultaneously achieves that glowing wire temperature (GWIT) is equal to or larger than 750 DEG C and the CTI value is equal to or larger than 600 V, also has a antistatic performance, meets European Union RoHS, International Electrotechnical Commission (IEC) halogen-free and Reach rule requirements, is easy to use and excellent in comprehensive performance, and does not affect color matching.

Owner:GUANGDONG WAYLAM ENG PLASTICS

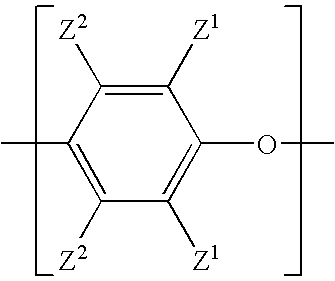

Resin Composition Excellent in Flame Retardance

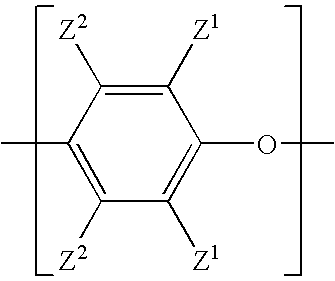

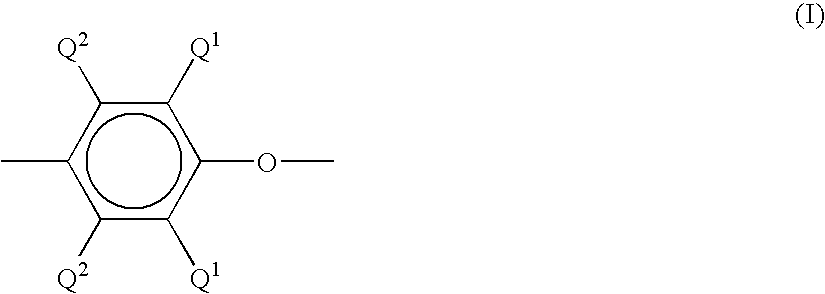

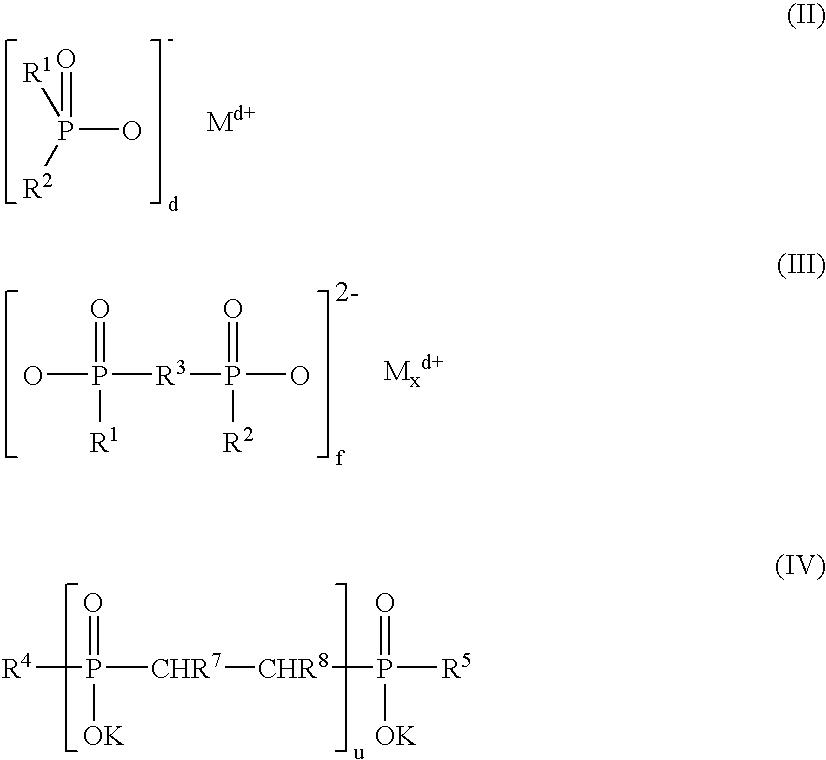

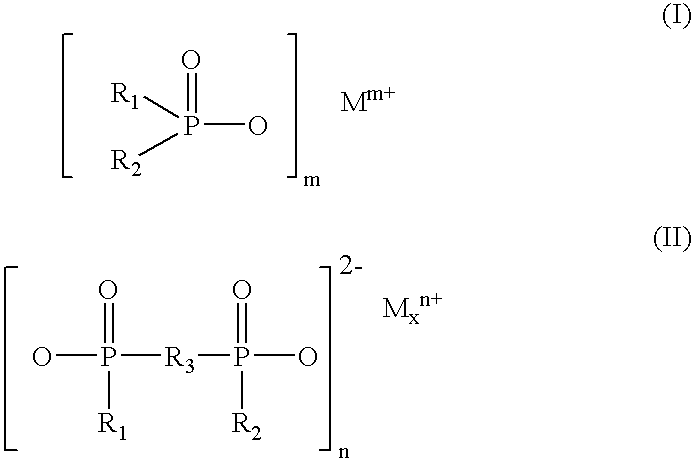

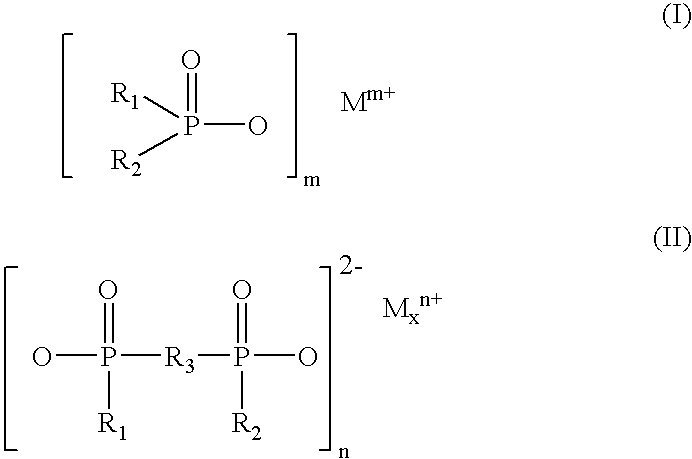

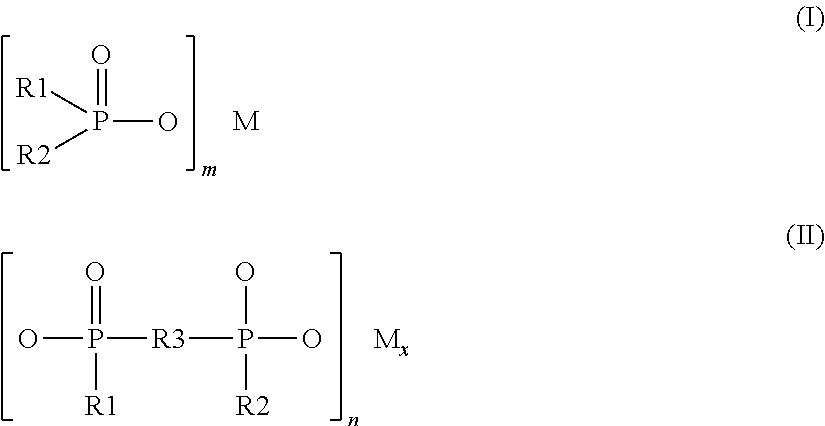

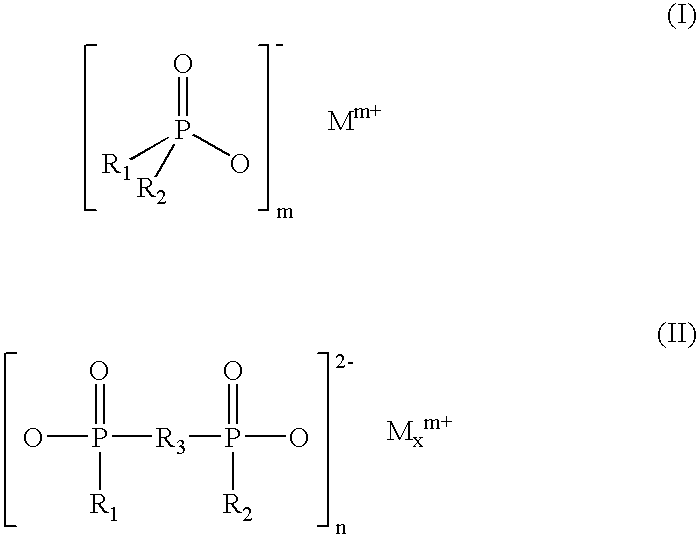

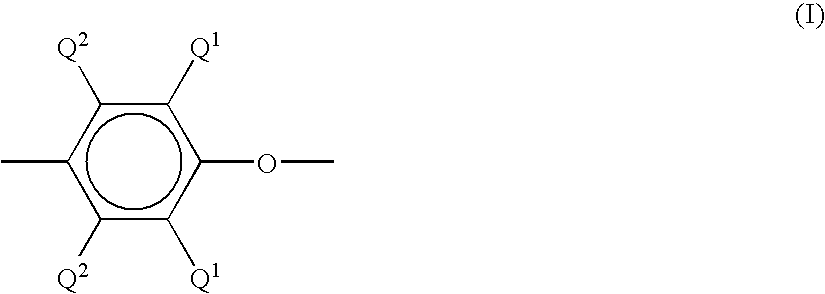

InactiveUS20090275682A1Improve flame retardant performanceImprove impact resistanceGroup 5/15 element organic compoundsEtherPolyamide

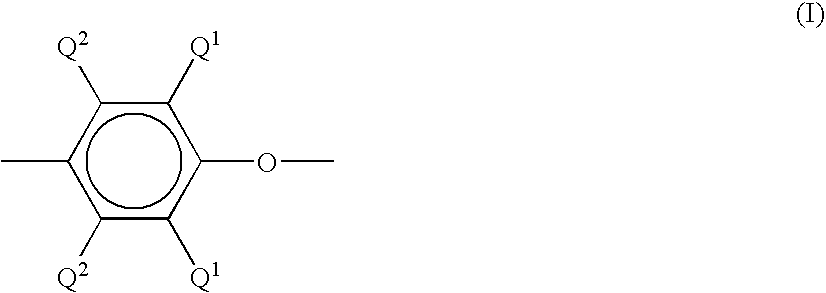

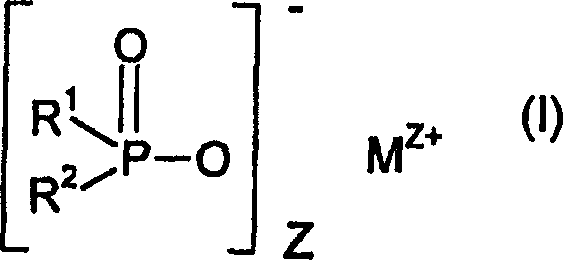

The present invention relates to a resin composition containing (A) a polyamide having a viscosity number (as measured in the 96% sulfuric acid according to ISO 307 (1997)) of from 50 ml / g to 250 ml / g; (B) a polyphenylene ether; and (C) a phosphinate represented by a particular formula. The resin composition according to the present invention is excellent in flame retardancy, impact resistance and thin-wall moldability and can significantly suppress gas generation during the molding process and substantially inhibit the generation of deposits on a mold during injection molding. As a result, a molded product thereof excellent in surface appearance can be provided.

Owner:ASAHI KASEI CHEM CORP

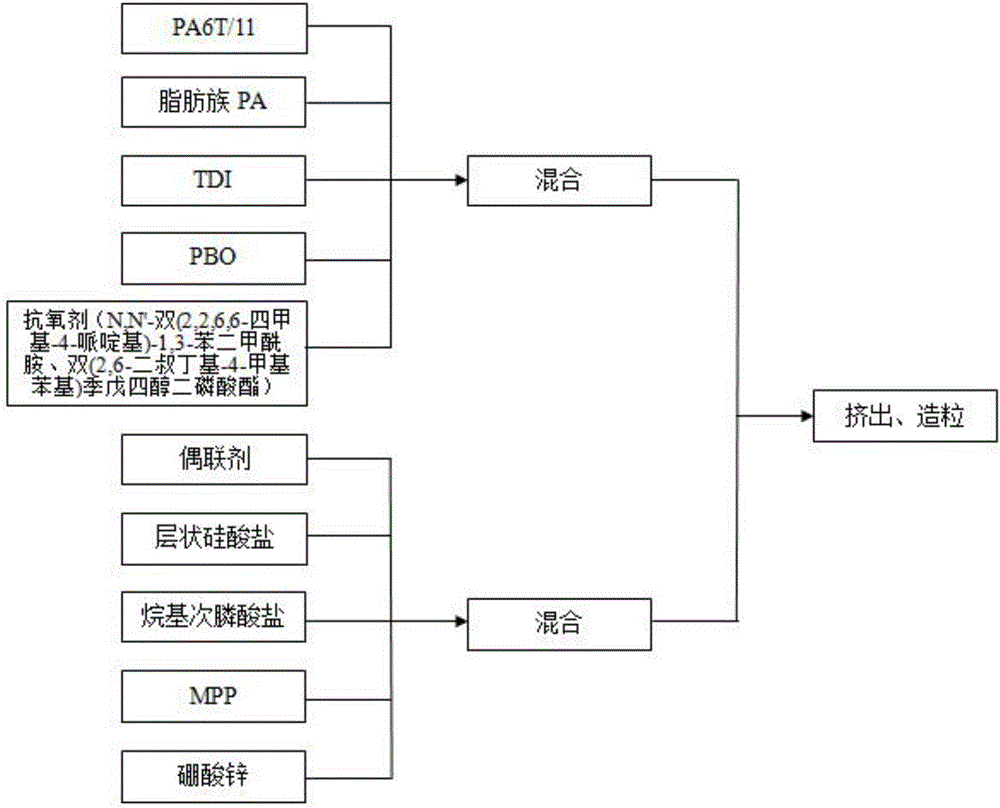

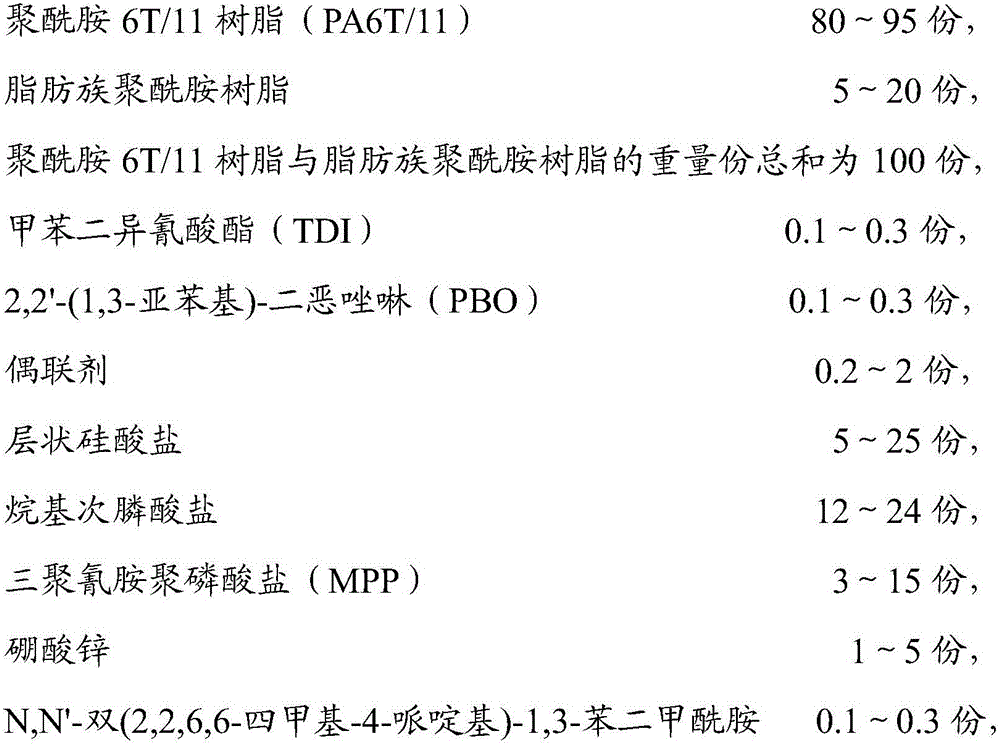

Halogen-free flame-retardant reinforced polyamide composite material and preparation method thereof

The invention relates to a halogen-free flame-retardant reinforced polyamide composite material and a preparation method thereof. The halogen-free flame-retardant reinforced polyamide composite material is prepared by polyamide 6T / 11 resin, aliphatic polyamide resin, toluene diisocynate, 2,2'-(1,3-phenylene)-bisoxazoline, a coupling agent, layered silicate, alkyl phosphinate, melamine polyphosphate, zinc borate, N,N'-bis(2,2,6,6-tetramethyl-4-piperidyl)-1,3-phthalic diamide and bis(2,6-ditert-butyl-4-methyl phenyl) pentaerythritol diphosphate. The halogen-free flame-retardant reinforced polyamide composite material is high in flame retardance, high in tensile strength, high in flowability, low in water absorption rate, and applicable to fields such as electronic products, LEDs, cars, aerospace and military industry.

Owner:SINOPLAST NEW MATERIAL

Method of making a flame retardant poly(arylene ether)/polyamide composition

A method of making a composition comprises melt mixing a first mixture comprising a poly(arylene ether) and a compatibilizing agent to form a first melt mixture; and melt mixing a second mixture comprising the first melt mixture and a polyamide, an electrically conductive additive and a flame retardant masterbatch wherein the flame retardant masterbatch comprises a phosphinate and a thermoplastic resin.

Owner:SABIC GLOBAL TECH BV

Flame-retardant glass fiber-reinforced polyamide resin composition

InactiveUS20100227957A1Improve rigidityNice appearanceGroup 5/15 element organic compoundsGlass fiberPolymer science

A flame-retardant glass fiber-reinforced polyamide resin composition, containing:100 parts by mass of a flame-retardant resin composition consisting of(A) 60 to 90 percent by mass of a polyamide resin, and(B) 40 to 10 percent by mass of a flame retardant containing no halogen atom,(A)+(B) being 100 percent by mass; and60 to 210 parts by mass of a flattened glass fiber (C) having a flat section of 1.5-10 in a ratio of major axis / minor axis,wherein the polyamide resin (A) contains a crystalline polyamide resin (a1) and an amorphous polyamide resin (a2),the flame retardant containing no halogen atom (B) contains a phosphinate (b1) and / or a diphosphinate (b2), anda blending ratio of the amorphous polyamide resin (a2) in the polyamide resin (A) is 0.1≦(a2) / (A)≦0.5.

Owner:UNITIKA LTD

Process for preparing phosphine oxamate and its derivatives

The present invention relates to preparation process of phosphine oxamate and its derivatives, and is especially preparation process through Michael addition reaction of methyl phosphinate and acrylaldehyde. The present invention features the condensing agent for the reaction of proper weak acid and the three step reaction for preparing phosphine oxamate product. Adopting weak acid as the condensing agent can obtain high yield and high purity of phosphine oxamate product. Adopting weak acid as the condensing agent to replace anhydride and using no alcohol can lower the production cost.

Owner:ZHEJIANG UNIV +1

Flexible high thermomechanical stress-resistant and fireproof halogen-free thermoplastic compositions

ActiveUS7897673B2No excessive viscosity increaseImprove performanceFireproof paintsPlastic/resin/waxes insulatorsThermoplasticPhosphate

The invention concerns flexible high thermomechanical stress-resistant and fire retardant halogen-free thermoplastic compositions, comprising a polyamide block-graft copolymer consisting of a trunk and on average at least one polyamide graft, wherein the grafts are bound to the trunk by the residues of an unsaturated monomer (X) having a function capable of reacting with a polyamide at the amine-terminal, the unsaturated monomer residues (X) being bound on the trunk by grafting or copolymerization from the double bond thereof. The invention is characterized in that the compositions comprise a mixture: 50 to 70 wt. % of polyamide block copolymer, 25 to 35 wt. % of a flame-retardant agent selected among ammonium phosphates, phosphinates, pyrophosphates, and polyphosphates, about 2 wt. % of zeolite, or hydrotalcitemolecular sieves. Said compositions are particularly useful for making electric cables, electric components, for molding electrotechnical housings, or for making coating layers or thermal protection sleeves for fluid transfer lines in the automotive industry.

Owner:ARKEMA FRANCE SA

Fireproof composition based on thermoplastic matrix

The present invention relates to a thermoplastic flame retardant composition comprising a specific flame retardant system based on phosphinates and melamine derivatives. Such compositions are especially useful in the preparation of articles for use in the field of electrical or electronic connectors.

Owner:POLYAMIDE HIGH PERFORMANCE

Halogen-Free Flame Retardant Thermoplastic Polyurethanes

InactiveUS20090326108A1Flame retardancyImproved flaming-dripFireproof paintsGroup 5/15 element organic compoundsHalogenPentaerythritol

Disclosed is a halogen-free flame retardant thermoplastic polyurethane composite resin composition. The disclosed flame retardant thermoplastic polyurethane composite resin composition is capable of improving flame retardancy and flaming-drip of a thermoplastic polyurethane resin through desirable formation of char during combustion, which uses a phosphinate, a diphosphinate and / or a polymer thereof, dipentaerythritol, talc, a melamine derivative, etc., instead of a halogen-based flame retardant, as a flame retardant.

Owner:LUBRIZOL ADVANCED MATERIALS INC

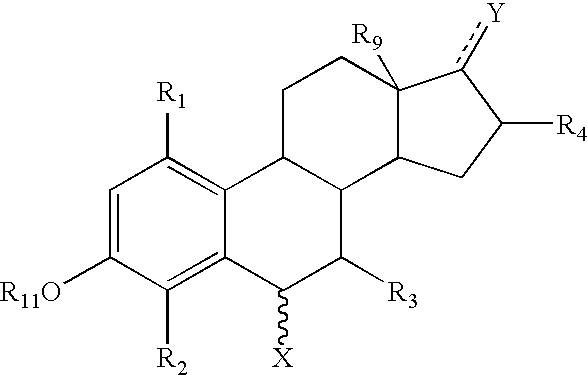

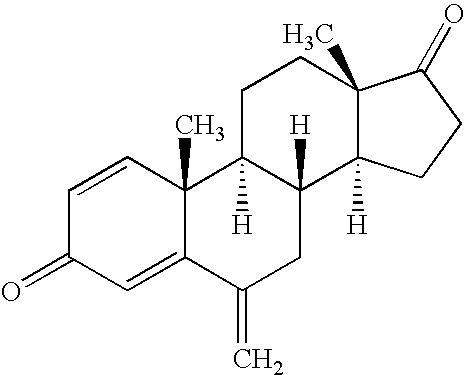

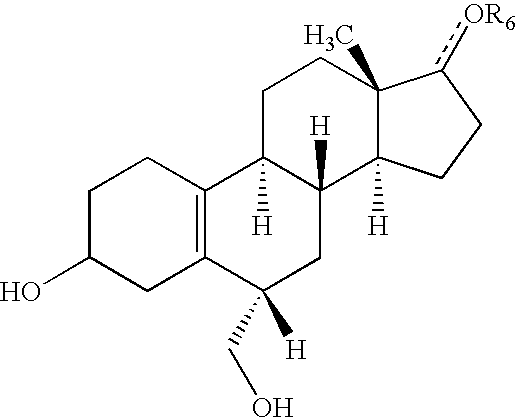

6-substituted estradiol derivatives and methods of use

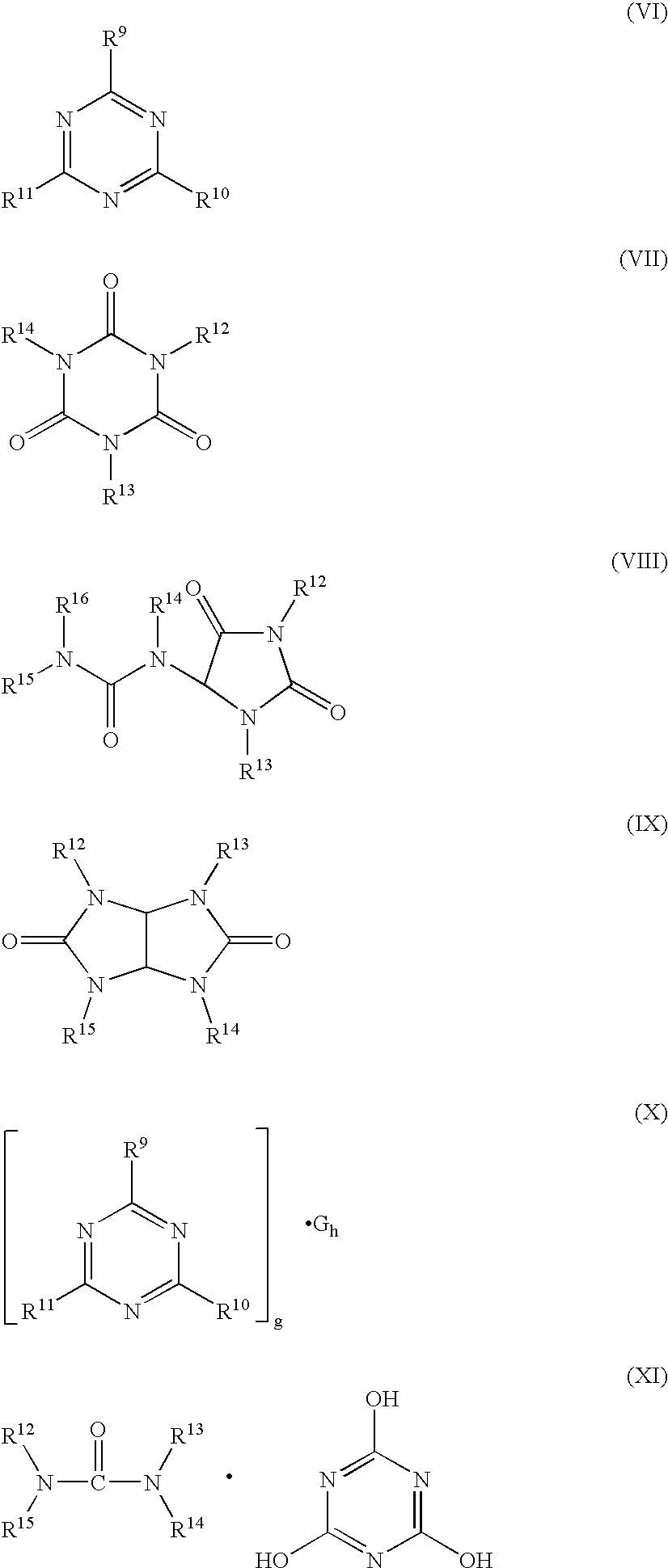

InactiveUS20100130463A1Improved prognosisImprove complianceOrganic active ingredientsEstrane derivativesEnantiomerPhosphate

Disclosed are compounds of the formula:wherein R1, R2, R3 and R4 are independently hydrogen, C1-C6 alkyl, halo, a sulfate, a glucuronide, —OH, a bulky group, aryl, cycloalkyl, heteroaryl, heterocycloalkyl, —N(CH2)n; a phosphate group, and a phosphinate group; R9 is hydrogen, halogen or alkyl; R11 is selected from the group consisting of H, C1-C6 alkyl, halogen, a sulfate, a glucoronide, —SO2NH2, —COOH, —CN, —CH2CN—, —NHCN—, —CHO, ═CHOCH3, —COO salt, —OSO2alkyl, —NH2, and —NHCO(CH2)n; R12 is selected from the group consisting of H, a C1-C6 alkyl, a sulfate, a glucoronide, a bulky group, aryl, cycloalkyl, heteroaryl and heterocycloalkyl; X is selected from the group consisting of C1-C12 alkyl, C2-C12 alkenyl, C2-C12 alkynyl, halogen, a glucoronide, —NH2, —SO2NH2, —COOH, —CN, —CH2CN, —NHCN, —CHO, —COOsalt, —OSO2alkyl, —SH, —SCH3, —CH[(CH2)nCH2]COOCH2, —(CH2)mCOOCH3, —(CH2)m—O—CH3, —(CH2)m—O—(CH2)nCH3, (CH2)m—S—CH3, —(CH2)m—S—(CH2)nCH3, —(CH2)m—NH—(CH2)nCH3, —C2-C8 alkenyl-O—(CH2)nCH3, —C2-C8 alkenyl-S—(CH2)nCH3, —C2-C8 alkenyl-N—(CH2)nCH3, —C2-C8 alkynyl-O—(CH2)nCH3, —C2-C8 alkynyl-S—(CH2)nCH3, —C2-C8 alkynyl-N—(CH2)nCH3, —(CH2)m—OH, —(CH2)m—O—NH2, —(CH2)m—S—NH2, —NH(CH2)mCH3, —NH(CH2)mOCH3, —NH(CH2)mCHOH—COOH, —N(CH3)2, —(CH2)m(NH)CH2OH, —NHCOOH, —(CH2)mNHCOOH, —NO2, —SCN, —SO2alkyl, —B(OH)2, —(CH2)m N(CH3)—SO2—NH3, —(CH2)m—NH—SO2—NH2, —NHC(═S)CH3, and —NHNH2; and Y is selected from hydrogen, ═O, —OCO(R6) and —OH; wherein m is an integer between 0-20, n is an integer between 0-8, the symbol represents either a single or a double bond capable of forming a keto group at position 3 or 17; and the symbol represents any type of bond regardless of the stereochemistry; and the respective enantiomers, other stereochemical isomers, hydrates, solvates, tautomers and pharmaceutically acceptable salts of said compounds. The compounds are useful in the treatment of various types of cancer.

Owner:ENDECE LLC

Flame resistant polyester compositions, method of manufacture, and articles thereof

A thermoplastic polyester composition comprising, based on the total weight of the composition, a chlorine- and bromine-free combination of: from 40 to 60 wt % of a modified poly(1,4-butylene terephthalate); from 25 to 35 wt % of a reinforcing filler; from 2 to 8 wt % of a flame retardant synergist selected from the group consisting of melamine polyphosphate, melamine cyanurate, melamine pyrophosphate, melamine phosphate, and combinations thereof; from 5 to 15 wt % of a phosphinate salt flame retardant; from more than 0 to less than 5 wt % of an impact modifier component comprising a poly(ether-ester) elastomer and a (meth)acrylate impact modifier; from more than 0 to 5 wt % poly(tetrafluoroethylene) encapsulated by a styrene-acrylonitrile copolymer; from more than 0 to 2 wt % of a stabilizer; wherein the thermoplastic polyester composition contains less than 5 wt % of a polyetherimide.

Owner:SHPP GLOBAL TECH BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com