Halogen-free flame-retardant reinforced polyamide composite material and preparation method thereof

A composite material, polyamide technology, applied in the field of materials, can solve the problems of production, application and environmental secondary disasters, failure to achieve high temperature resistance, toxic smoke and dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

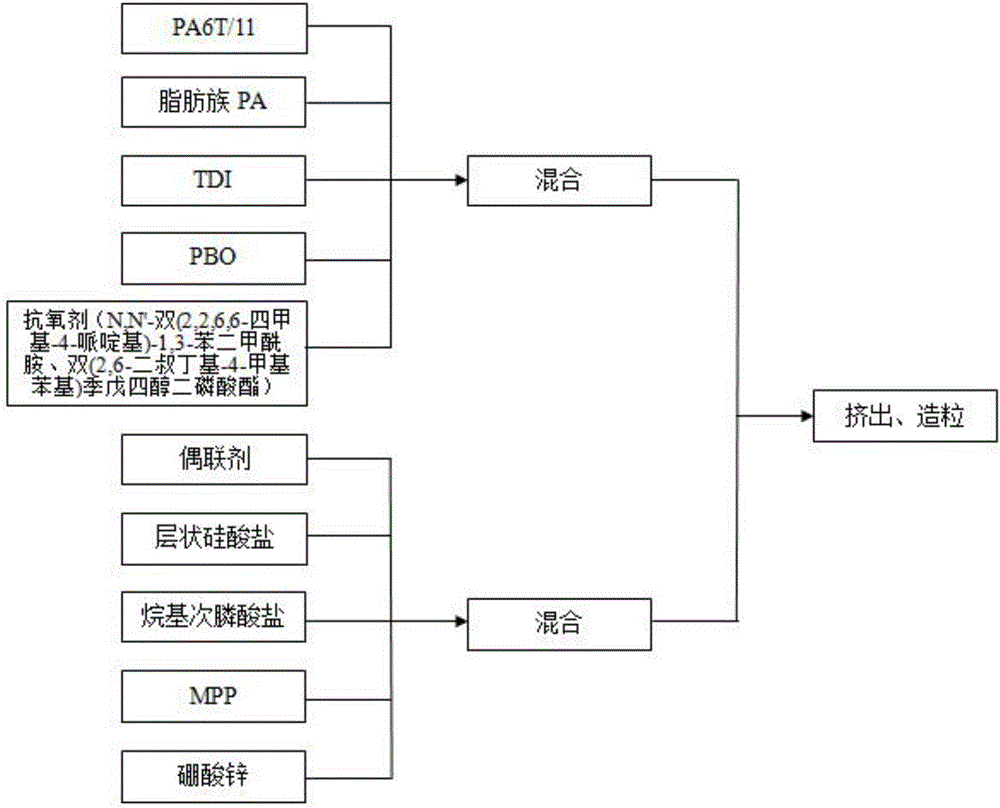

Method used

Image

Examples

Embodiment 1

[0078]The raw material composition and synthesis steps of the polyamide 6T / 11 resin used in the present embodiment are as follows:

[0079] (1) Add monomer 1 after vacuum drying: 1mol hexamethylenediamine, 1mol terephthalic acid, 0.5mol 11-aminoundecanoic acid into the stirred polymerization reactor, and add 4% of the total weight of monomer 1 at the same time Polyesteramide, 1.5% benzoic acid, 0.2% N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,3-phthalamide, add 100mL Water is used as the medium for mass transfer and heat transfer; then vacuumize for 5 minutes, and pass nitrogen for 5 minutes, and circulate like this 6 times, so that the reactant exists in the environment under nitrogen protection, and the system pressure in the stirred polymerization reactor is controlled to be 0.3MPa;

[0080] (2) within 3 hours, heat the stirred polymerization reactor airtight to 275°C at a uniform speed, adjust the stirring speed of the stirred polymerization reactor to 40r / min, wherein, ...

Embodiment 2

[0090] The raw material composition and synthesis steps of the polyamide 6T / 11 resin used in this example are the same as those in Example 1.

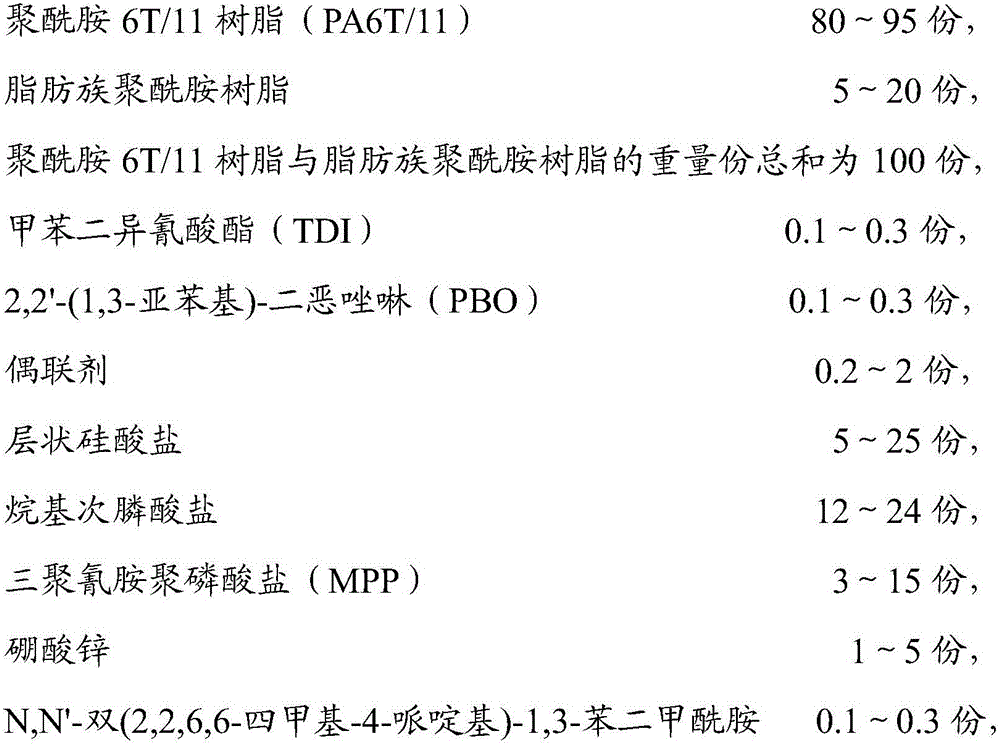

[0091] In this embodiment, a halogen-free flame-retardant reinforced polyamide composite material is prepared from the following raw materials:

[0092]

[0093] The preparation method of the above-mentioned halogen-free flame-retardant reinforced polyamide composite material comprises the following steps:

[0094] (1) Put the polyamide 6T / 11 resin and polyhexamethylene adipamide resin at 90°C, dry for 5 hours, and cool, and put the cooled polyamide 6T / 11 resin, polyhexamethylene adipamide resin , and toluene diisocyanate, 2,2'-(1,3-phenylene)-bisoxazoline, N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl )-1,3-phthalamide and bis(2,6-di-tert-butyl-4-methylphenyl)pentaerythritol diphosphate are added to a high-speed mixer for mixing;

[0095] (2) coupling agent (γ-aminopropyltriethoxysilane), montmorillonite, aluminum diethylphosphinate...

Embodiment 3

[0099] The raw material composition and synthesis steps of the polyamide 6T / 11 resin used in this example are the same as those in Example 1.

[0100] In this embodiment, a halogen-free flame-retardant reinforced polyamide composite material is prepared from the following raw materials:

[0101]

[0102] The preparation method of the above-mentioned halogen-free flame-retardant reinforced polyamide composite material comprises the following steps:

[0103] (1) Put the polyamide 6T / 11 resin and polyhexamethylene adipamide resin at 90°C, dry for 5 hours, and cool, and put the cooled polyamide 6T / 11 resin, polyhexamethylene adipamide resin , and toluene diisocyanate, 2,2'-(1,3-phenylene)-bisoxazoline, N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl )-1,3-phthalamide and bis(2,6-di-tert-butyl-4-methylphenyl)pentaerythritol diphosphate are added to a high-speed mixer for mixing;

[0104] (2) coupling agent (γ-aminopropyltriethoxysilane), montmorillonite, aluminum diethylphosphinate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com