Patents

Literature

3476 results about "Zinc borate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc borate is an inorganic compound, a borate of zinc. It is a white crystalline or amorphous powder insoluble in water. Its toxicity is low. Its melting point is 980 °C.

Polyamide composition with flame retardance and thermoplasticity

The invention discloses a polyamide composition with flame retardance and thermoplasticity. The polyamide composition with flame retardance and thermoplasticity comprises the following components in percentage by weight: 30-90% of thermoplastic polyamide resin, 5-40% of a brominated flame retardant, 0.5-15% of a flame-retardant synergist and 0-50% of a reinforcing material. According to the polyamide composition, the brominated flame retardant, the high-efficiency flame-retardant synergist (namely zinc borate) and organic silicon are added in polyamide resin, on the one hand, the polyamide composition can replace antimony trioxide which is a rare material and is limited to be exploited by the nation at present, limited strategic resources of the nation can be saved, and the cost is lowered; and on the other hand, the flame retardance, a CTI (comparative tracking index) value and GWIT (glow wire ignition temperature) of the polyamide composition can be improved greatly, and the safety guarantee is provided for the use of the flame-retardant polyamide product on electronic appliances with high requirements.

Owner:KINGFA SCI & TECH CO LTD +1

Mixed solubility borate preservative

InactiveUS7449130B2Reduce solubilityImprove solubilityBiocideOther chemical processesCelluloseSolubility

Preservative composition for lignocellulosic-based composites providing rapid and long-lasting protection against insect and fungal attack, in both low and high moisture environments, through the use of a combination of higher solubility and lower solubility borates. Pesticidal amounts of a lower solubility borate and a higher solubility borate are combined before or during their incorporation into a lignocellulosic-based composite. Useful low solubility borates includes copper borate, zinc borate and barium metaborate. Useful high solubility borates includes boric acid, boric oxide, ammonium borate and alkali metal borates such as sodium borate. Some alkaline earth metal borates, including calcium borates, are of intermediate solubility and may be used effectively as either a low soluble or high soluble borate depending on the combination used.

Owner:U S BORAX INC

Silicone rubber compositions for producing cables or profiles with retention of function in the event of fire

InactiveUS6387518B1Improve the level ofPropertyFireproof paintsAntifouling/underwater paintsZinc boratePlatinum complex

A composition which is useful for producing profiles and cable insulation which retain their function in the event of fire, comprise peroxidically crosslinking or condensation-crosslinking silicone rubber, metal oxides selected from magnesium oxide, aluminum oxide, tin oxide, calcium oxide and barium oxide and metal compounds of this class which produce oxides on heating, boric acid, zinc borate, and a platinum complex having at least one unsaturated group.

Owner:WACKER CHEM GMBH

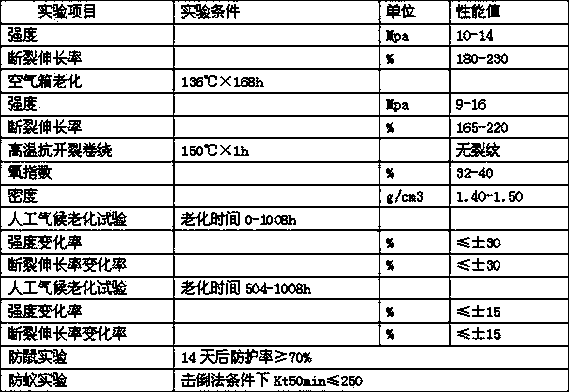

Sealing strip using epdm rubber as host material

ActiveCN101230248AReduce viscosityInhibitionEngine sealsOther chemical processesPolyethylene glycolEPDM rubber

The invention discloses a sealing strip which takes EPDM as the host material and the preparing method, which is characterized in that the composition contains the following constituents (expressed by wt percent): EPDM 26 percent, zinc oxide 1-1.5 percent, stearic acid 1-6 percent, polyethyleneglycol 0.5-1.6 percent, hydrafil 10-32 percent, zinc borate 5-16 percent, orthophosphoric lipid 3-16 percent, black carbon 7-20 percent, paraffin oil 7-21 percent, calcium oxide 2-5 percent, sulfur 0.25-0.5 percent and accelerant 0.65-1.5 percent. The invention ensures the mechanical performance and extrusion performance, is convenient for extrusion, adopts the hydrafil, the zinc borate, and a inflaming retarding system; is the most realistic non-halogen inflaming retarding; can produce a lot of crystal water on the surface of the burning substance; can separate the burning substance from contacting oxygen, and then can perform the inflaming retarding effect; can inhibit the gases produced by the burning substance, accordingly does not produce smog.

Owner:DANYANG WANBEN AUTOMOTIVE PARTS

Flame Retardant Poly(Arylene Ether)/Polyamide Composition

A composition comprises a compatibilized poly(arylene ether) / polyamide blend, an optional electrically conductive filler, a phosphinate, and flame retardant augment selected from the group consisting of melamine polyphosphate, zinc borate, low melting glass, talc, and combinations of two or more of the foregoing flame retardant augments.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Extinguishing agent

InactiveCN102058951AReduce pollutionRestricted free movementFire extinguisherSesquioxideAluminium hydroxide

The invention discloses an extinguishing agent. The extinguishing agent is formed by mixing and stirring strong hydrophobic solid particles and aqueous solution at high speed, wherein the strong hydrophobic solid particles are one type or more of magnesium hydroxide particles, silicon dioxide particles, calcium carbonate particles, talcum particles, aluminium oxide particles, aluminium hydroxide particles, zinc borate particles, zinc oxide particles, iron sesquioxide particles, titanium dioxide particles, montmorillonite particles, hydrotalcite particles, coal ash particles, diatomite particles, mica particle, attapulgite particles and zeolite particles after hydrophobic modification. The extinguishing agent disclosed by the invention is nontoxic, environmental pollution is less, and secondary loss caused by strong flowability of water can be avoided while playing the advantages of the water as the extinguishing agent and reducing the using amount.

Owner:XIAN UNIV OF SCI & TECH

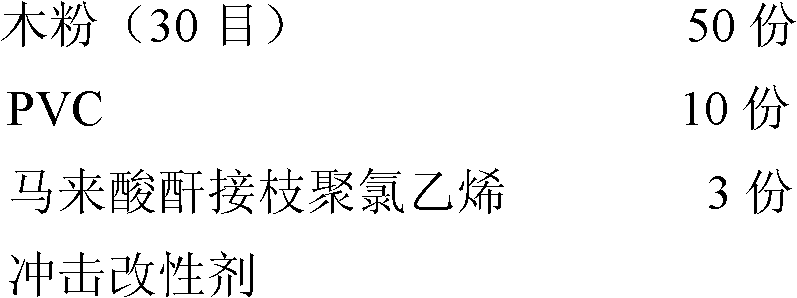

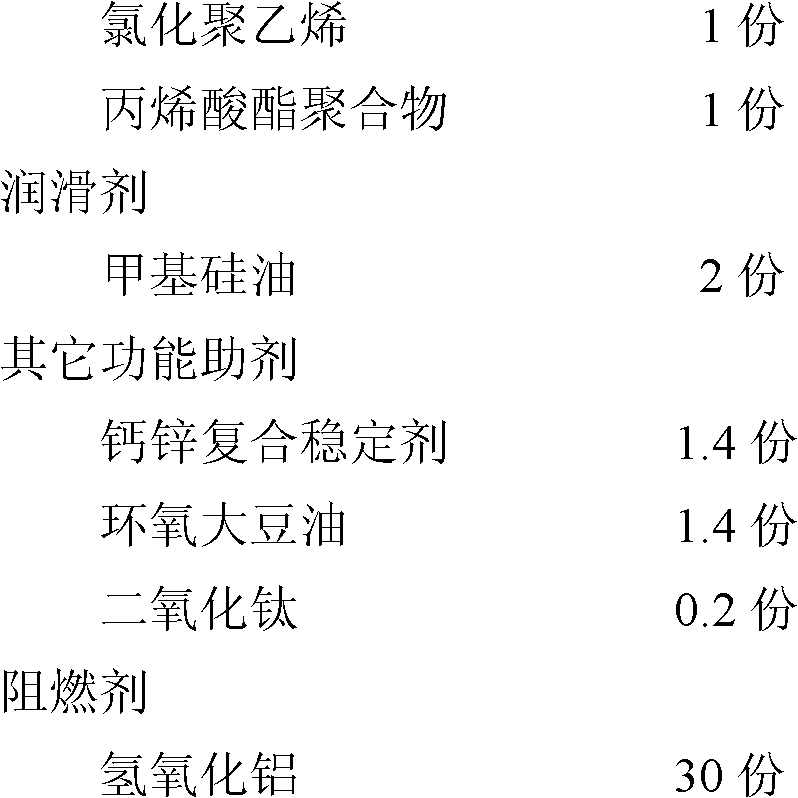

High-efficiency flame retardant wood plastics composite and preparation method thereof

The invention discloses a high-efficiency flame retardant wood plastics composite. The high-efficiency flame retardant wood plastics composite is prepared from 50 to 75 weight parts of wood powder, 10 to 30 weight parts of plastic resin, 1 to 5 weight parts of interfacial compatibilizer, 0.5 to 2 parts of impact modifier, 1 to 3 weight parts of lubricant, 1 to 5 weight parts of other functional aid, and 10 to 30 weight parts of flame retardant. The preparation method comprises the following steps of: degreasing and drying wood powder, organically modifying bentonite and zinc borate and mechanically grinding, mixing in a high-speed mixing machine to obtain premix, and mixing and plasticizing in a double-roll plasticator and performing compression molding. The bentonite and the zinc borate which are treated organically and aluminum hydroxide are compounded to form a novel fire retardant, the mechanical property of the material is kept, the flame retardant effect of the wood plastics composite is improved and the using amount of the aluminum hydroxide is greatly reduced; and the bentonite and the zinc borate are organically ultrafined, the problem that an inorganic additive is not easily compatible with other components so as to influence the mechanical property of the composite is solved and the flame retardant requirement of the wood plastics composite is met.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Low-smoke halogen-free inflaming-retarding cable material and preparation method thereof

InactiveCN101597395AHigh strengthHigh elongationRubber insulatorsPlastic/resin/waxes insulatorsLow-density polyethyleneLinear low-density polyethylene

The invention provides a low-smoke halogen-free inflaming-retarding cable material and preparation method thereof. The cable material comprises 5 to 15 parts (part by weight) of compatilizer that comprises maleic anhydride functional group grafted ethylene-vinyl acetate copolymer and maleic anhydride functional group grafted ethylene propylene terpolymer; 85 to 95 parts of base material formed by blending two or more than two of linear low-density polyethylene, ethylene-vinyl acetate copolymer and ethylene propylene terpolymer granular materials; 2 to 6 parts of composite antioxidant composed of the following antioxidants in terms of weight ratio: hindered phenol antioxidants : thiol ester antioxidants = 1 : (2 to 6); 20 to 40 parts of ammonium polyphosphate; 10 to 20 parts of pentaerythritol; 8 to 15 parts of melamine; 50 to 100 parts of composite inorganic fire retardant composed of the following fire retardants: magnesium hydroxide : zinc borate = (2 to 4) : 1; 2 to 6 parts of lubricant; 0 to 0.5 parts of metal passivator; 0 to 3 parts of crosslinking assistant agent; and 0 to 5 parts of halogen-free master batch. The invention has provided a harmless halogen-free inflaming-retarding cable material having high temperature tolerance, high tension, high elongation and high fire resistance.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI +2

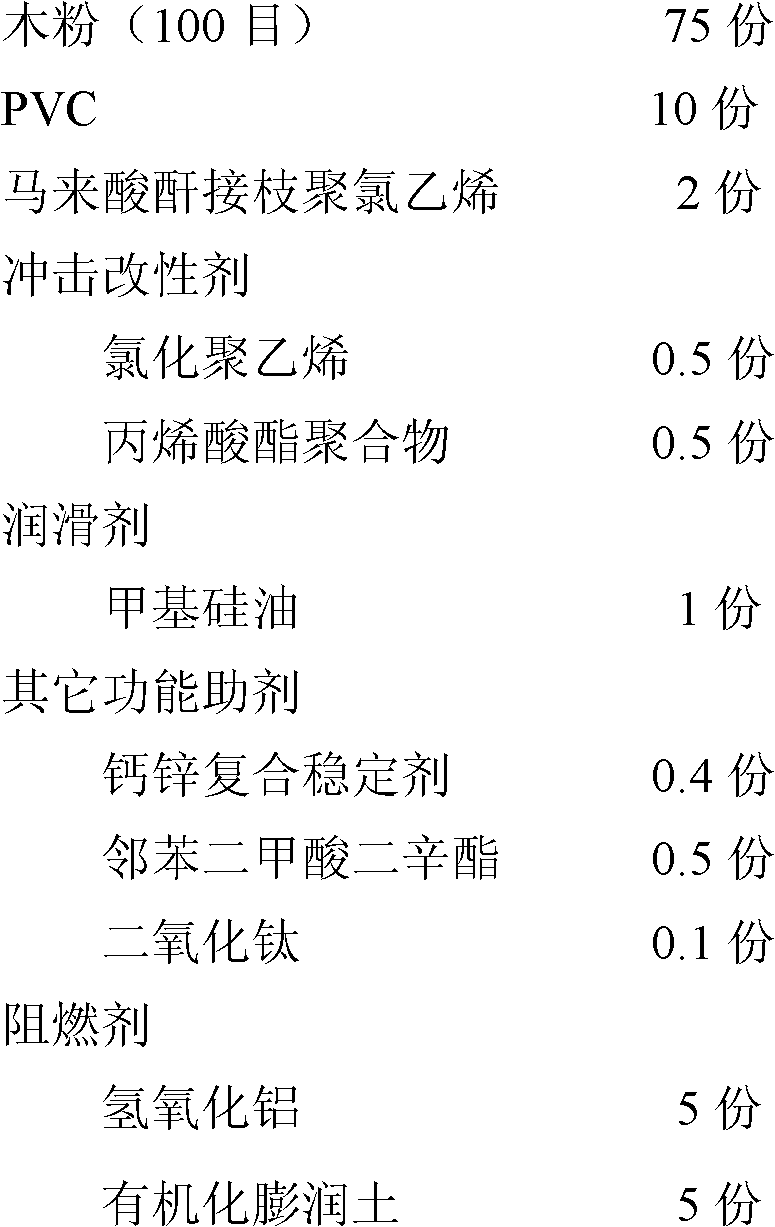

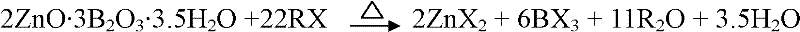

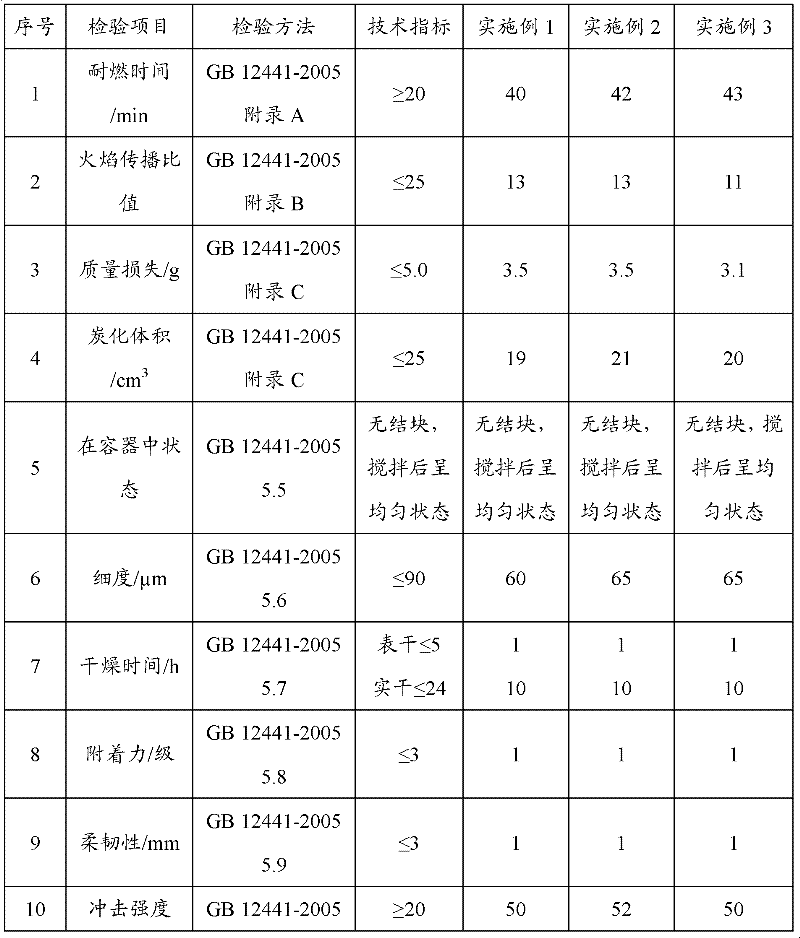

Expanded type aqueous facing fireproof coating and preparation method thereof

ActiveCN102675992AImprove fire resistanceImprove water resistanceFireproof paintsCelluloseChlorinated paraffins

The invention provides an expanded type aqueous facing fireproof coating, which comprises the following components by weight: 10% to 30% of styrene-acrylic emulsion, 20% to 30% of ammonium polyphosphate, 10% to 20% of pentaerythritol, 15% to 25% of melamine, 5% to 10% of titanium dioxide, 2% to 8% of aluminum hydroxide, 1% to 5% of zinc borate, 1% to 2% of chlorinated paraffin, 0.05% to 0.2% of antiseptic, 0.1% to 0.2% of dispersing agent, 0.3% to 1.0% of film-forming auxiliary, 0.1% to 0.5% of cellulose ether, 0.5% to 2.0% of hydroxy silicone oil and the balance of water. The expanded type aqueous facing fireproof coating, provided by the invention, has the advantages of excellent water resistance and salt mist resistance, excellent adhesion and flexibility, good storage stability, no layering, no fineness change and no packing phenomenon, excellent waterproof resistance, smooth and fine coating film, no toxicity and pollution, and environment-friendliness.

Owner:CARPOLY CHEM GRP

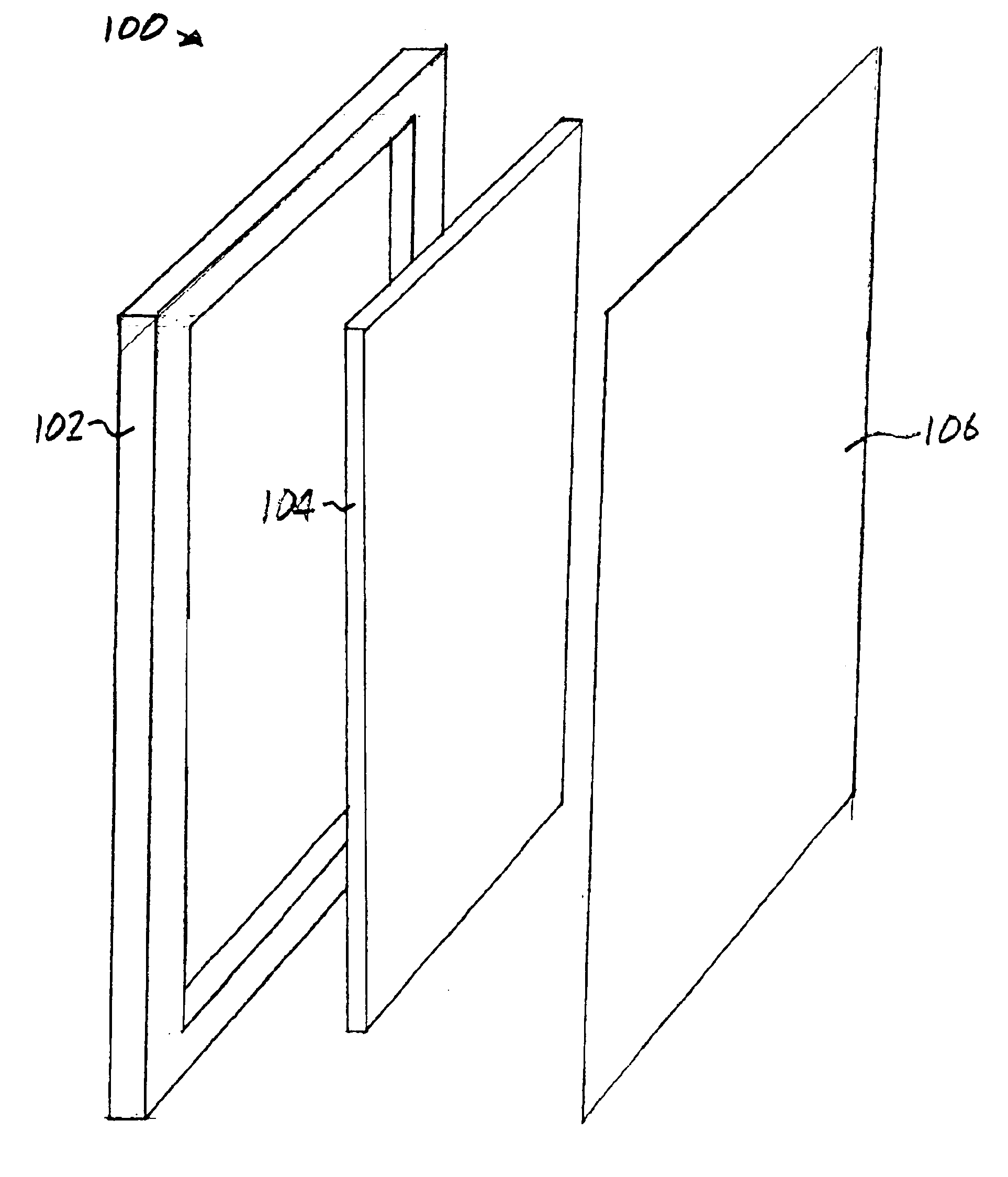

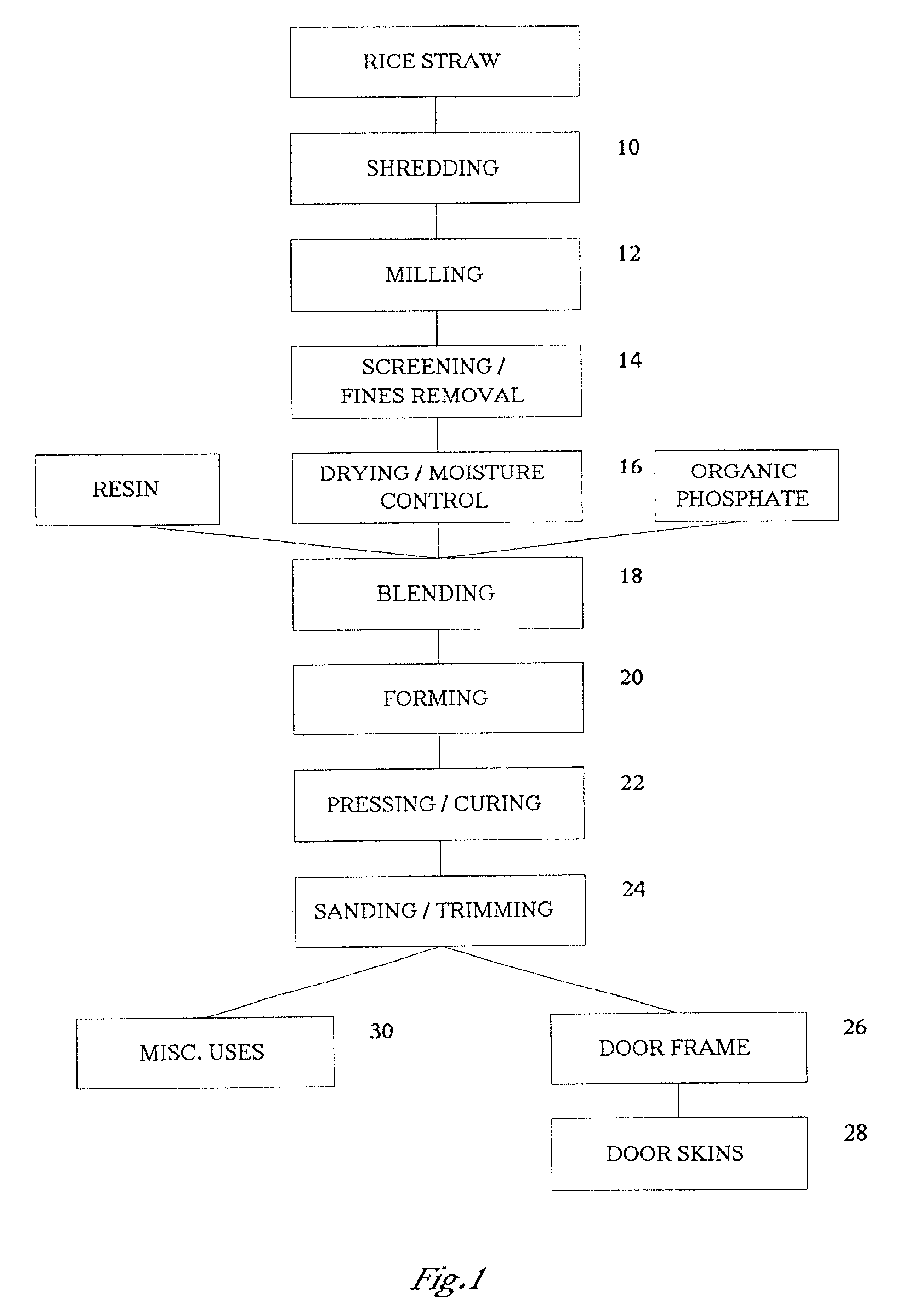

Fire-resistant material and method of manufacture

InactiveUS6886306B2Improve fire resistanceImprove the level ofConstruction materialClimate change adaptationCelluloseZinc borate

The present invention provides a building material derived from straw, such as rice straw, that has significantly improved fire-resistance properties over traditional cellulose-based materials. In one embodiment, the invention provides a method of fabricating a board from milled rice straw. The milled rice straw is blended with a binder to form a mixture. The mixture is then formed into a mat with sufficient size to achieve a predetermined board thickness and density. The mat is then pressed into the board. In another embodiment, the present invention provides a fire resistant board that includes milled rice straw, a resin binder, and a fire retardant material such as an organic phosphate, zinc borate, aluminum trihydrate, sodium silicate, or even rice hulls.

Owner:GREENCOR COMPOSITES

Fire-retardant paint with steel structure

ActiveCN101857756AExtend fire resistance timeImprove fire resistanceFireproof paintsPolyurea/polyurethane coatingsPhosphoric acidComposite substrate

The invention relates to fire-retardant paint with a steel structure, which is prepared from the following raw materials proportioning by weight: 45 to 60 of composite substrate resin, 6 to 8 of melamine, 6 to 8 of pentaerythritol, 16 to 20 of ammonium polyphosphate, 4 to 10 of expansible graphite, 2 to 5 of nano magnesium hydroxide, 1 to 3 of zinc phosphate, 1 to 3 of zinc borate, 2 to 5 of aluminum hydroxide, 3 to 5 of aluminum polyphosphate, 6 to 9 of titanium dioxide, 0.5 to 0.8 of flatting agent and 15 to 20 of acetone. The paint has excellent capabilities of fire prevention and corrosion prevention.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

Flame resistant semicaromatic polyamide resin composition and articles therefrom

Polyamide compositions containing semi-crystalline polyamide, amorphous polyamide, non-halogenated flame retardant, zinc borate and fillers that have a high stiffness and hardness, a low warpage, and external appearance, such as gloss and reduced corrosion effects on melt processing equipment.

Owner:EI DU PONT DE NEMOURS & CO

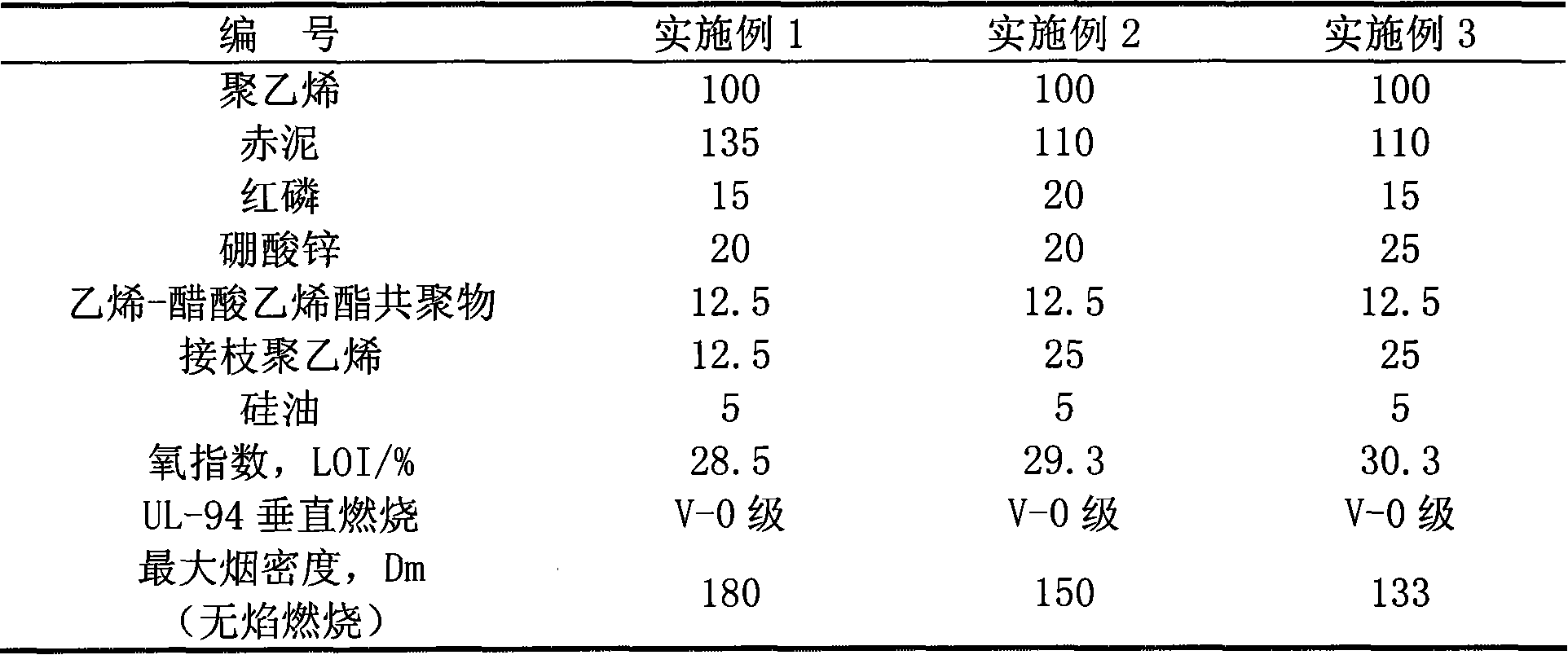

Environmental protection based red mud combination modification synergism fire-retardant polyethylene

InactiveCN101624457AIncrease added valueMeet environmental protection requirementsRed mudCarvacryl acetate

The invention relates to an environmental protection based red mud combination modification synergism fire-retardant polyethylene, and belongs to the technical field of compressive utilization and fire-retardant plastics. The fire-retardant polyethylene is suitable for fire safety protection in important public places in the fields of electric products, building materials and transportation. The fire-retardant polyethylene consists of the following components in percentage by weight: 30 to 35 percent of polyethylene, 34 to 39 percent of red mud, 6 to 13 percent of red phosphorus, 5 to 17 percent of zinc borate, 3 to 8 percent of ethylene-vinyl acetate copolymer, 2 to 7 percent of grafted polyethylene, and 2 to 8 percent of silicone oil. The preparation process comprises the following steps of: grinding and drying the red mud; blending the ground red mud with other raw materials according to the blending ratio; mixing the mixture with polyethylene resin by fully stirring at a high speed; fusing, co-mixing and processing the mixture; and preparing a sample. The processing conditions comprise that: the roll temperature of a double-roller mixing mill is between 140 and 150 DEG C; and the forming temperature of the flat vulcanizing machine sample is between 120 and 130 DEG C, the heating time is between 4 and 8 minutes, and the pressure is between 10 and 20MPa. The fire-retardant system meets the requirements of industrial application on mechanical property, and simultaneously has comprehensive properties such as good fire-retardant effect, low cost, environmental protection and the like; moreover, the application field of the red mud is widened, and the red mud product with high added value is prepared.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

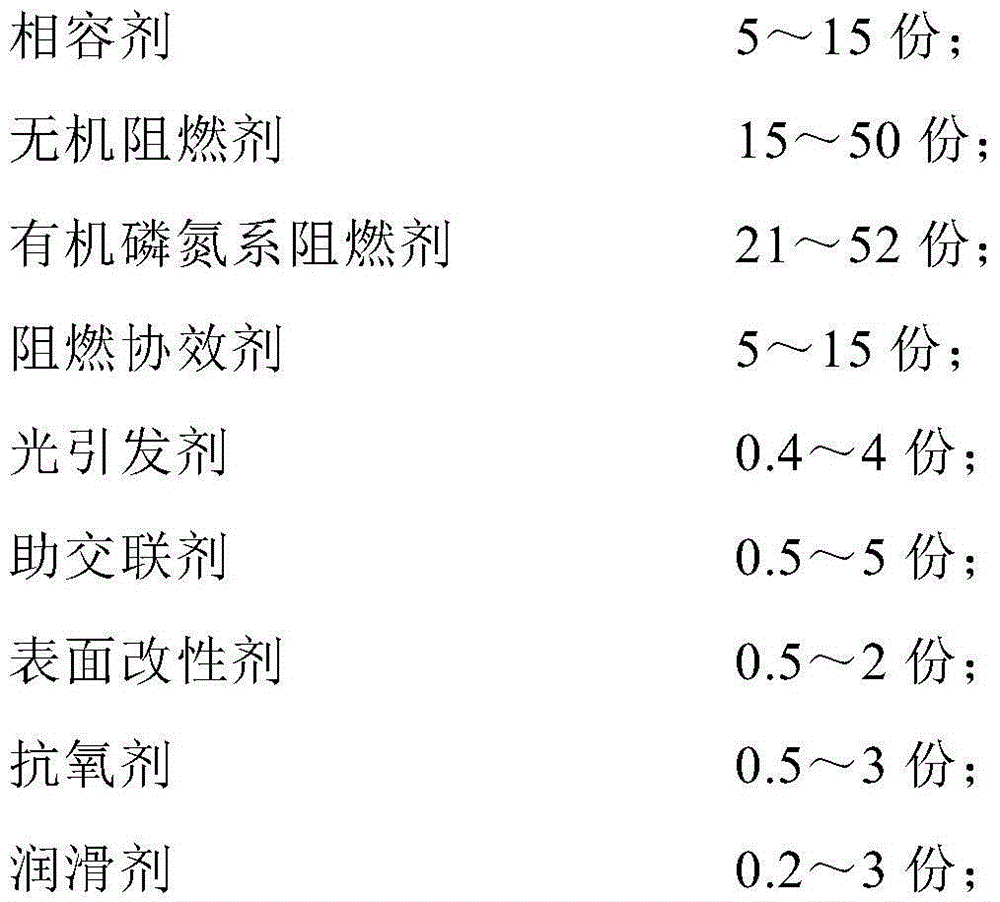

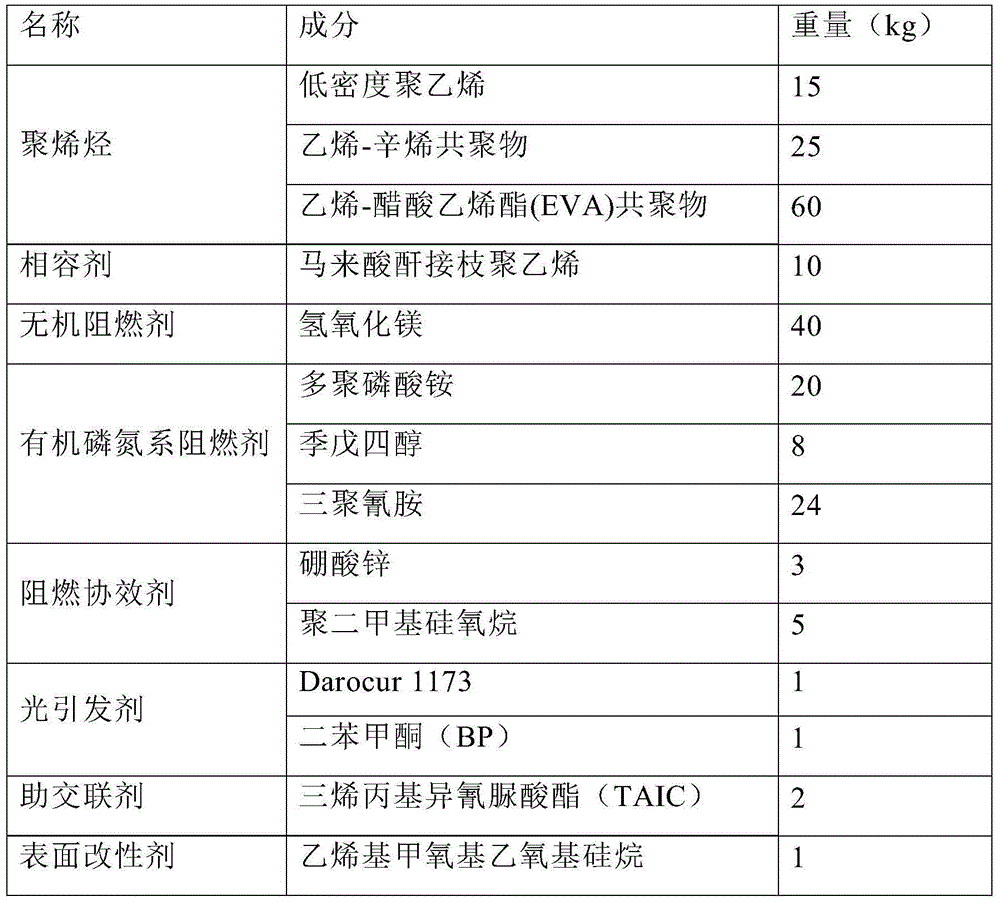

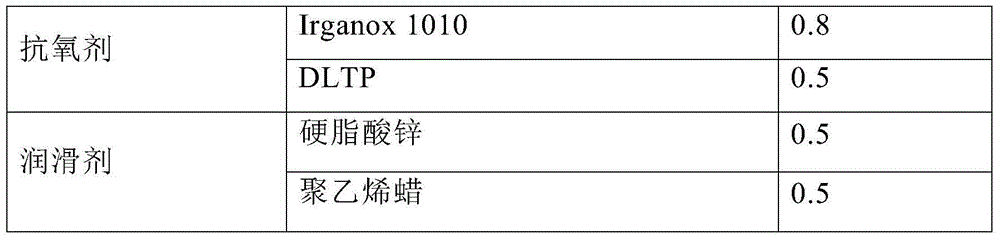

Ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material and preparation method thereof

ActiveCN104893088AImprove mechanical propertiesImprove flame retardant performancePlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention provides an ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material. The cable material comprises polyolefin, a compatilizer, an inorganic flame retardant, an organic phosphorus-nitrogen-containing flame retardant, a flame-retardant synergist, a photoinitiator, an assistant crosslinker, a surfactant, an antioxidant and a lubricant, wherein polyolefin contains low-density polyethylene, an ethylene-octylene copolymer and an ethylene-vinyl acetate copolymer in the weight proportion being (10-25):(20-35):(55-65); the compatilizer is polyethylene for grafting of maleic anhydride; the inorganic flame retardant is selected from magnesium hydroxide and aluminum hydroxide; the organic phosphorus-nitrogen-containing flame retardant contains polyphosphoric acid, pentaerythritol and melamine in the weight proportion being (10-20): (4-8): (15-30); the flame-retardant synergist contains zinc borate and / or polydimethylsiloxane. The cable material has good thermal resistance and anti-aging performance, can be used at the temperature of 125 DEG C for a long time and is excellent in comprehensive mechanical performance and better in flame retardance.

Owner:上海至正新材料有限公司

Fire-extinguishing agent and preparation method thereof

InactiveCN102500086AImprove fire extinguishing efficiencyLow costFire extinguisherSolubilitySolid particle

The invention discloses a fire-extinguishing agent. The fire-extinguishing agent is prepared by uniformly mixing hydrophilic solid powder and water or an aqueous solution, adding hydrophobic solid particles and then carrying out mixing and dispersing, wherein the hydrophilic solid powder is one or more of magnesium hydroxide powder, aluminum oxide powder, aluminum hydroxide powder, magnesium carbonate powder, calcium carbonate powder, calcium hydroxide powder, zinc borate powder, montmorillonoid powder, hydrotalcite powder, hydrotalcite like compound powder, fly ash powder, diatomite powder, mica powder and attapulgite powder. The fire-extinguishing agent disclosed by the invention can exert stifling, cooling, separating and chemically restraining functions at the same time, and has the advantages of no toxicity, small environment pollution, high fire extinguishing efficiency and the like. According to the fire-extinguishing agent disclosed by the invention, the hydrophilic solid powder with a certain fire extinguishing performance and smaller solubility in water is added into a water phase so as to reduce the using amount of water-soluble substances, thus the cost of the fire-extinguishing agent is reduced when higher fire-extinguishing efficiency is kept, and the fire-extinguishing agent is easier to clean after being used for extinguishing fire.

Owner:XIAN UNIV OF SCI & TECH

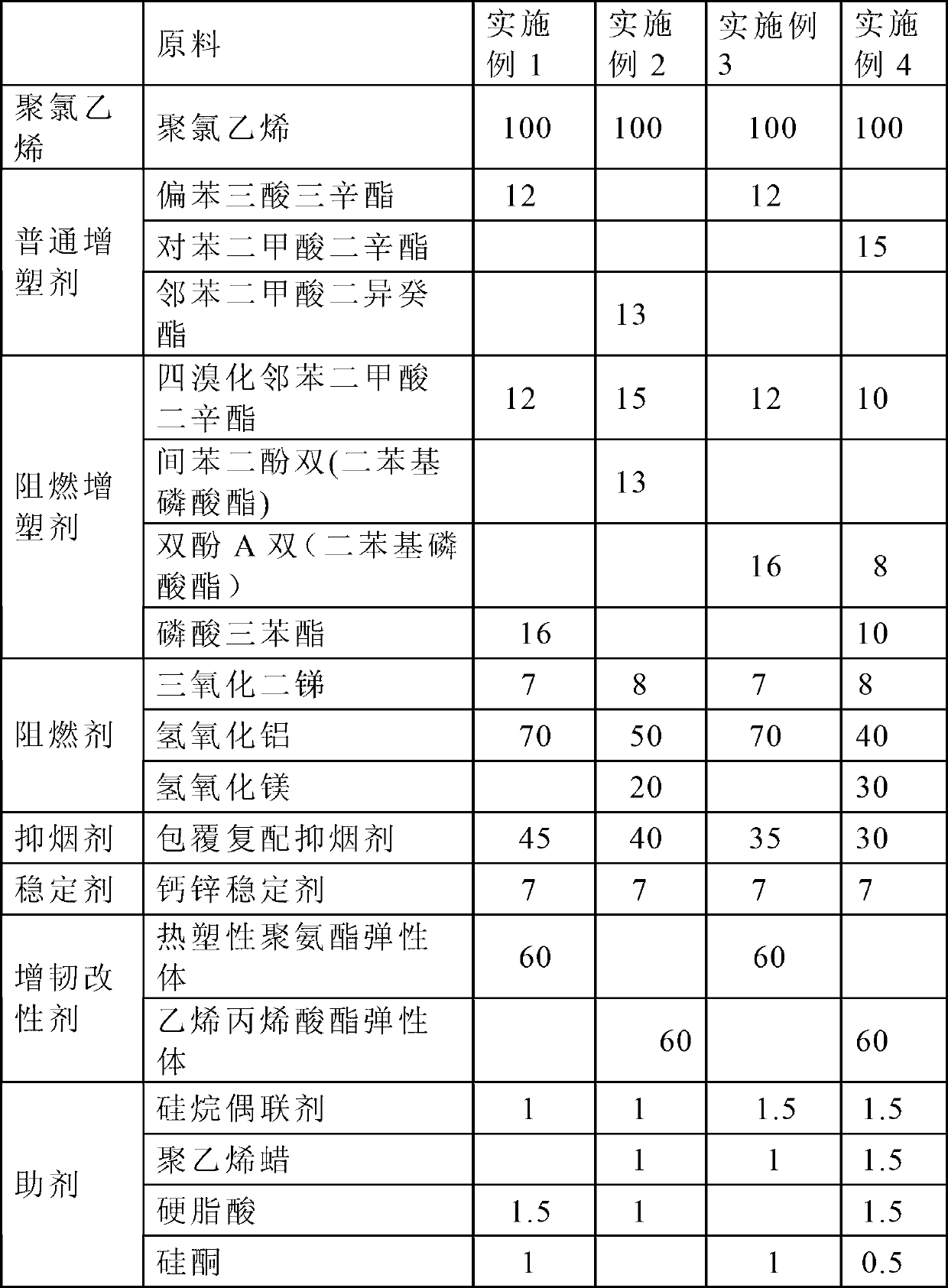

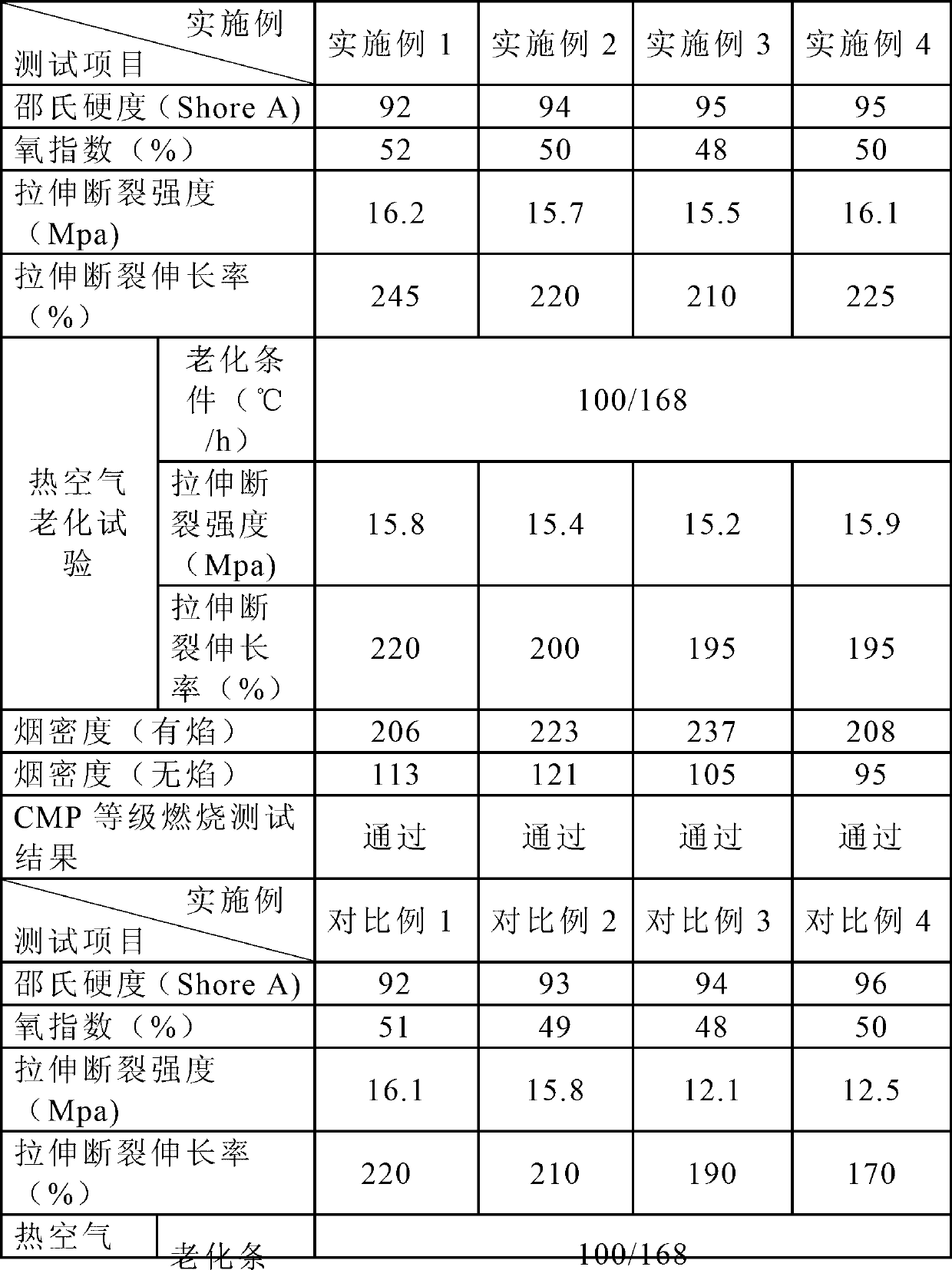

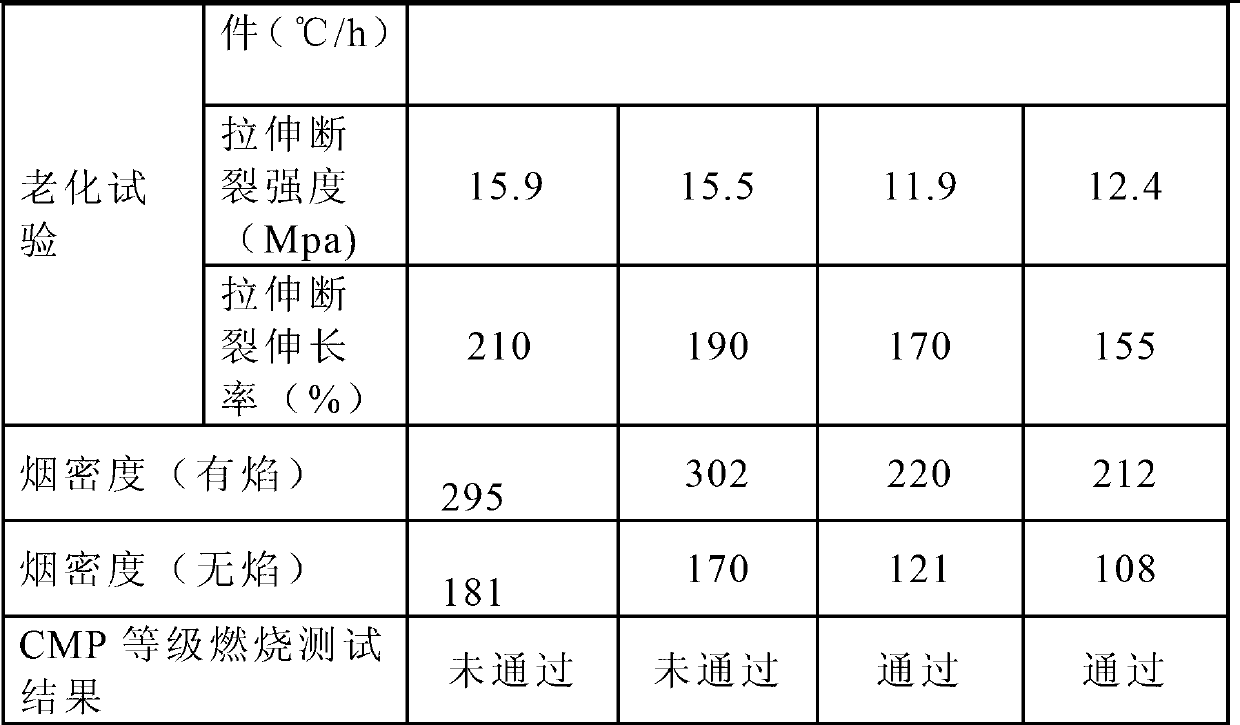

Corrugated metal pipe (CMP) grade flame-retardant smoke-suppressing polyvinyl chloride cable sheath material and preparation method thereof

ActiveCN102993602AReasonable cooperationImprove flame retardant and smoke suppression performanceInsulated cablesInsulated conductorsAluminium hydroxidePolyvinyl chloride

The invention provides a corrugated metal pipe (CMP) grade flame-retardant smoke-suppressing polyvinyl chloride cable sheath material and a preparation method thereof and belongs to the technical field of material. The invention solves the problem that in the prior art, the flame-retardant and smoke-suppressing effects and the mechanical property and the physical property of the cable sheath material are all good. The raw materials thereof comprise the following components in parts by weight: 100 parts of polyvinyl chloride, 5-15 parts of common plasticizer, 20-50 parts of flame-retardant plasticizer, 40-100 parts of fire retardant, 20-50 parts of smoke-suppressing agent, 5-10 parts of stabilizer, 40-80 parts of toughening modification agent and 1-5 parts of promoter; wherein the smoke-suppressing agent comprises ammonium octamolybdate, zinc molybdate and zinc borate which are compounded according to the proportion of 1:1 to 3:1 to 3 and coated by aluminium hydroxide the grain size of which is 1-5mu m according to the proportion of 1:1 to 3. The CMP grade flame-retardant smoke-suppressing polyvinyl chloride cable sheath material has the advantages of good flame-retardant and smoke-suppressing effect, mechanical property and physical property.

Owner:江西一舟数据技术有限公司

Flame-retardant and environmentally-friendly polyurethane cable material and its preparation method

ActiveCN102977585AImprove flame retardant performanceExcellent non-flammabilityElastomerDecabromodiphenyl ether

The invention provides an flame-retardant and environmentally-friendly polyurethane cable material. The cable material is prepared from the following raw materials, by weight, 20-30 parts of chloroprene rubber, 60-80 parts of a polyurethane thermoplastic elastomer, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of chlorinated paraffin, 0.5-1.0 part of stearic acid, 1-3 parts of barium stearate, 4-6 parts of iron oxide, 0.5-1.0 part of ammonium trimolybdate, 30-50 parts of precipitated silica, 10-13 parts of modified argil, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenyl oxide, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance, and the cables processed through using the cable material can prevent the harms of mice and termites and simultaneously have the efficacies of low smoke, environmental protection and flame retardation.

Owner:蚌埠尚维知识产权运营有限公司

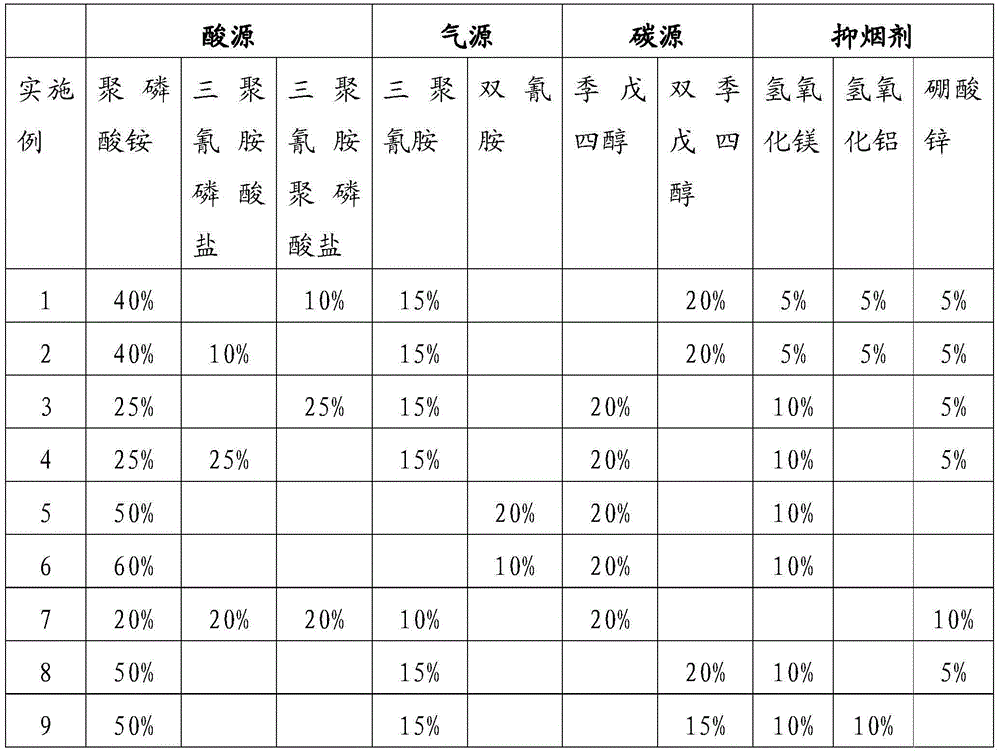

Composite intumescent flame retardant and preparation method thereof

InactiveCN104532588AReduce generationImprove flame retardant performanceFibre typesMelamine phosphateAluminium hydroxide

The invention discloses a composite intumescent flame retardant which is composed of the following components in percentage by weight: 50-65% of acid source, 10-20% of gas source, 15-20% of carbon source and 10-20% of smoke inhibitor. The acid source is composed of at least one of ammonium polyphosphate, melamine phosphate and melamine polyphosphate, wherein the ammonium polyphosphate is crystal II ammonium polyphosphate with the average degree of polymerization of greater than 1000; the gas source is composed of at least one of melamine and dicyandiamide; the carbon source is composed of at least one of pentaerythritol and bis pentaerythritol; and the smoke inhibitor is composed of at least one of magnesium hydroxide, aluminum hydroxide and zinc borate. The invention also discloses a preparation method of the composite intumescent flame retardant.

Owner:SHIFANG TAIFENG NEW FLAME RETARDANT

105 DEG C thermoplastic, halogen-free, low-smoke, fire-retardant and ultraviolet-resistant covering material capable of preventing mice and ants and resisting cracking and preparation method thereof

InactiveCN103965541AImprove mechanical propertiesGood electrical performancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolymer science

The invention provides a 105 DEG C thermoplastic, halogen-free, low-smoke, fire-retardant and ultraviolet-resistant covering material capable of preventing mice and ants and resisting cracking. The covering material comprises the following raw materials: an ethylene vinyl acetate copolymer, linear low density polyethylene, high density polyethylene, ethylene-octene copolymer elastomer, a maleic anhydride grafting material, silicone master batch, aluminium hydroxide, magnesium hydrate, zinc borate, a phosphorus-nitrogen type intumescent flame retardant, a silane coupling agent, a lubricating agent, a complex antioxidant, a light stabilizer, and an environment-friendly mice and ants preventing agent. The preparation method comprises the following steps: uniformly mixing the raw materials above through a high-speed mixer; and then extruding and granulating through a double-step single-screw reciprocating extruding unit to obtain the covering material. The covering material is scientific and reasonable in formula and matching, and advanced in process; the prepared 105 DEG C thermoplastic, halogen-free, low-smoke, fire-retardant and ultraviolet-resistant covering material capable of preventing mice and ants and resisting cracking is applicable to manufacture of cables, and the prepared cable is high in mechanical performance, flame retardant performance, electrical performance and low-temperature performance, outstanding in resistance to mice and ants, resistance to thermo-oxidative aging, and excellent in resistance to high-temperature cracking.

Owner:BAOSHENG SCI & TECH INNOVATION +1

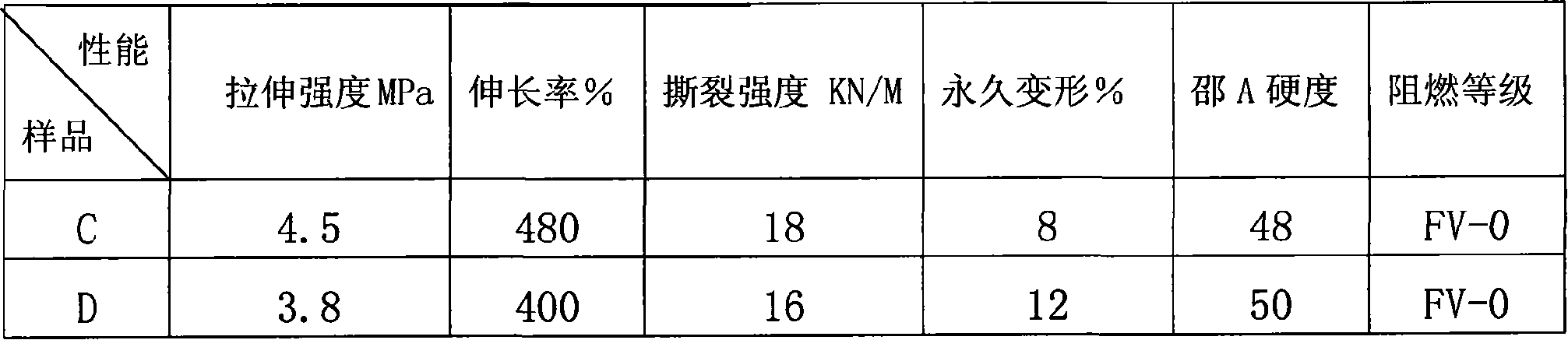

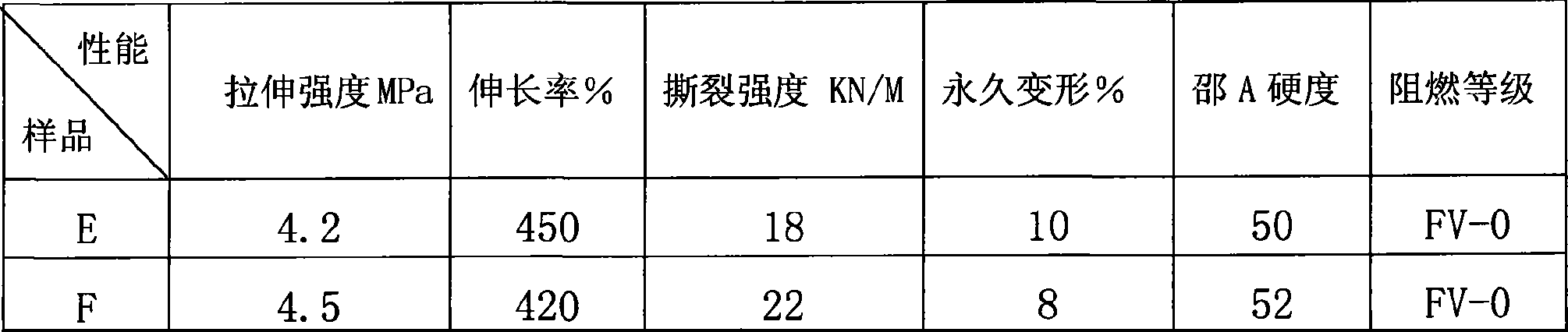

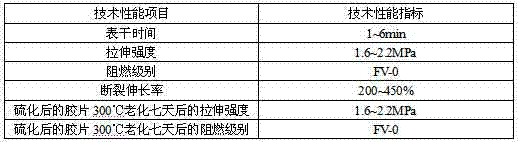

Halogen-free anti-flaming silicon rubber and its preparing method and use

A halogen-free flame retardant silicone rubber is made by the vulcanization of the compound with the methyl vinyl silicone rubber as the basic gel and the vulcanization agent; the compound consists of the two-component mixing gel; according to the weight shares, the compound includes: A component: 10 to 30 shares of methyl vinyl silicone rubber with the high content of vinyl, 20 to 40 shares of methyl vinyl silicone rubber with the low content of vinyl, 0.25 to 1 share of hydrogen silicone oil, 2 to 4 shares of hydroxy silicone oil, 20 to 40 shares of white carbon; B component: 90 to 110 shares of methyl vinyl silicone rubber with the low content of vinyl, 0.5 to 2 shares of methyl silicone oil, 0.25 to 1 share of hydrogen silicone oil, 50 to 70 shares of aluminum hydroxide and virgule or cyanuric melamine, and 2 to 5 shares of zinc borate. The preparation method is to mix and refine well the silicone rubber with the high and low content of vinyl; the hydrogen silicone oil, hydroxy silicone oil and white carbon are added to make the mixed and refined gel A; the silicone rubber with the low content of vinyl, the methyl silicone oil, hydrogen oil, aluminum hydroxide and virgule or cyanuric melamine, zinc borate are added to make the mixed and refined gel B; the mixed and refined gel A and B are mixed and vulcanized ; the fire-retardant performance can reach to the level of FV-0.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

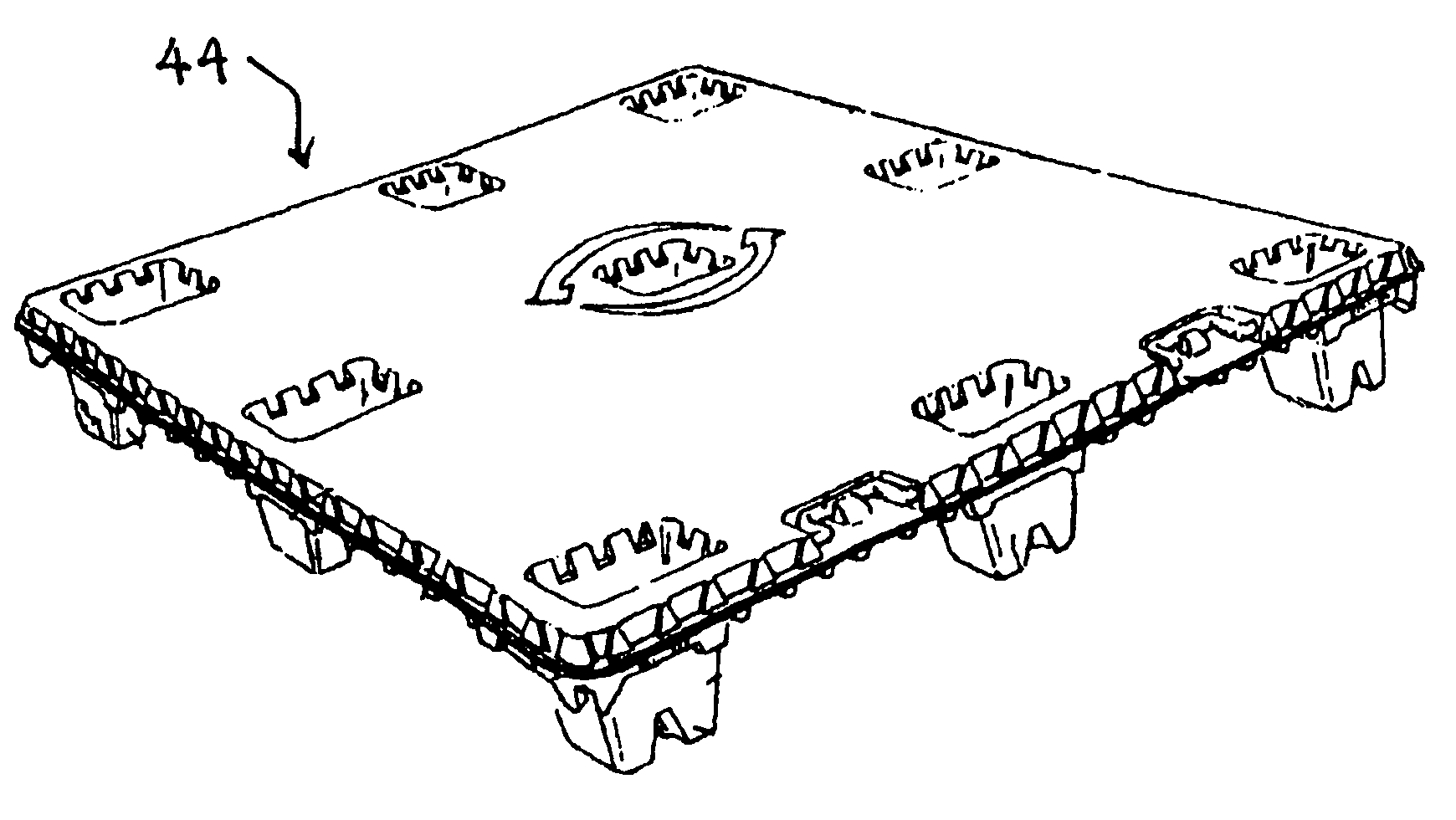

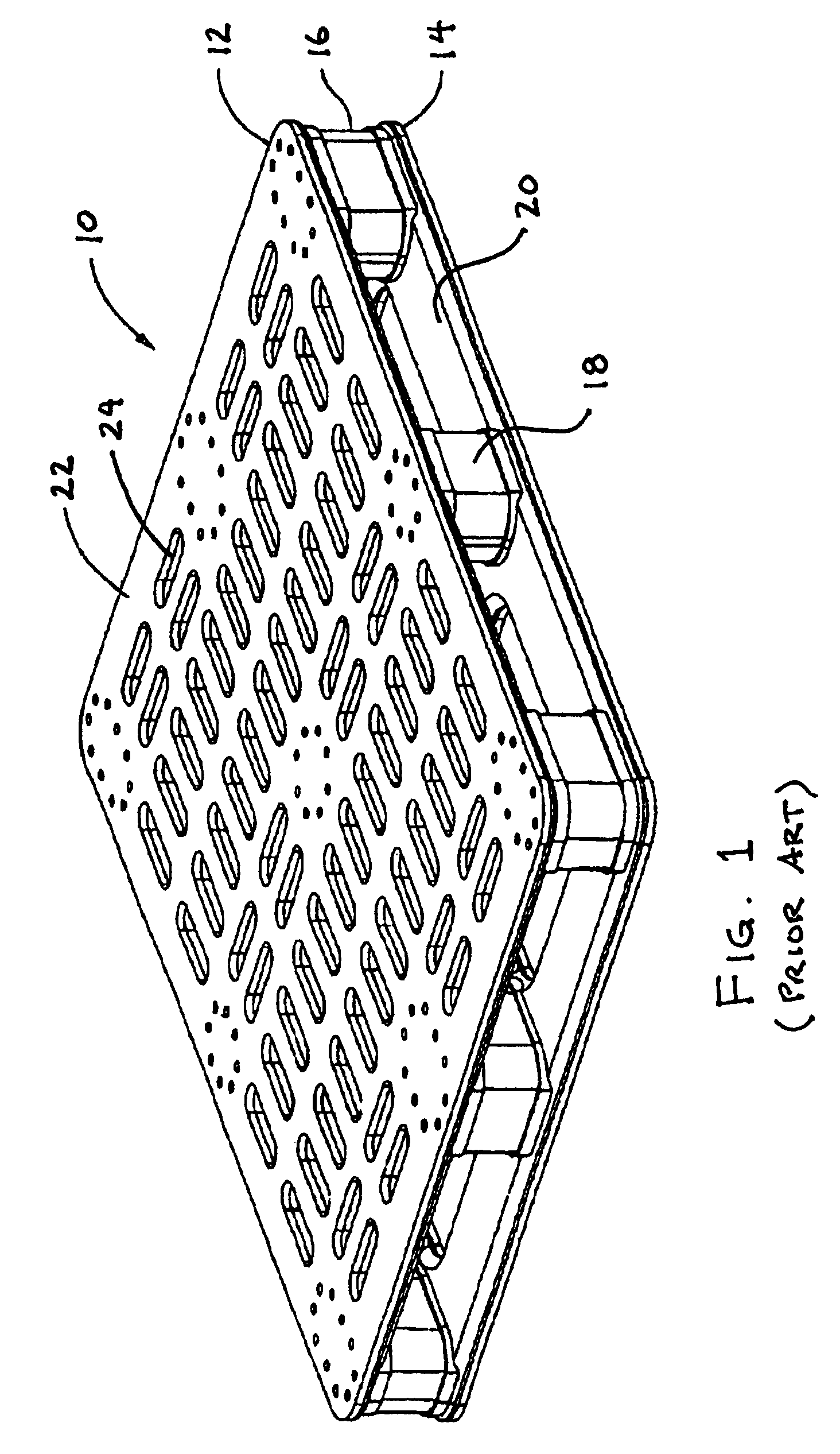

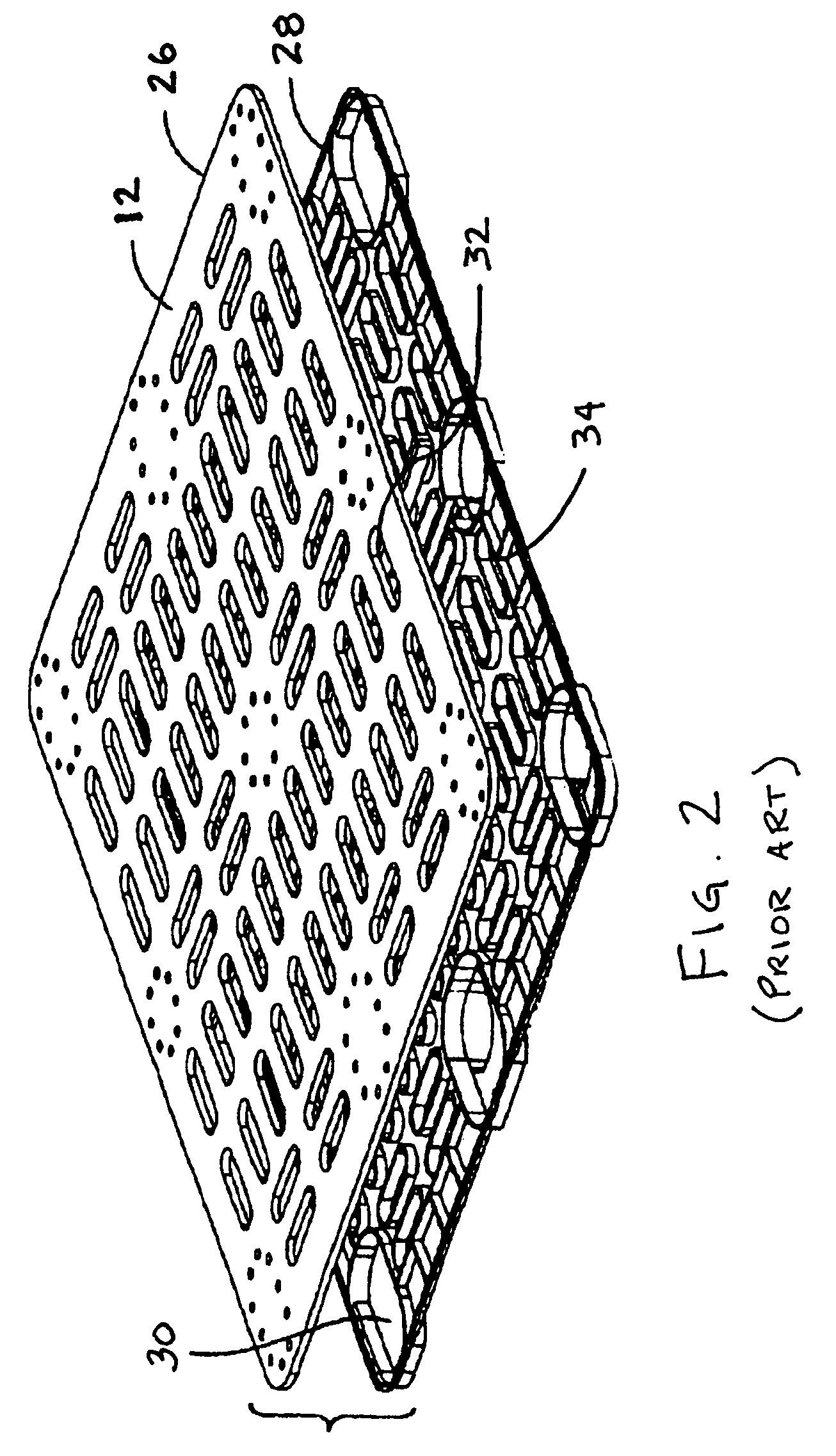

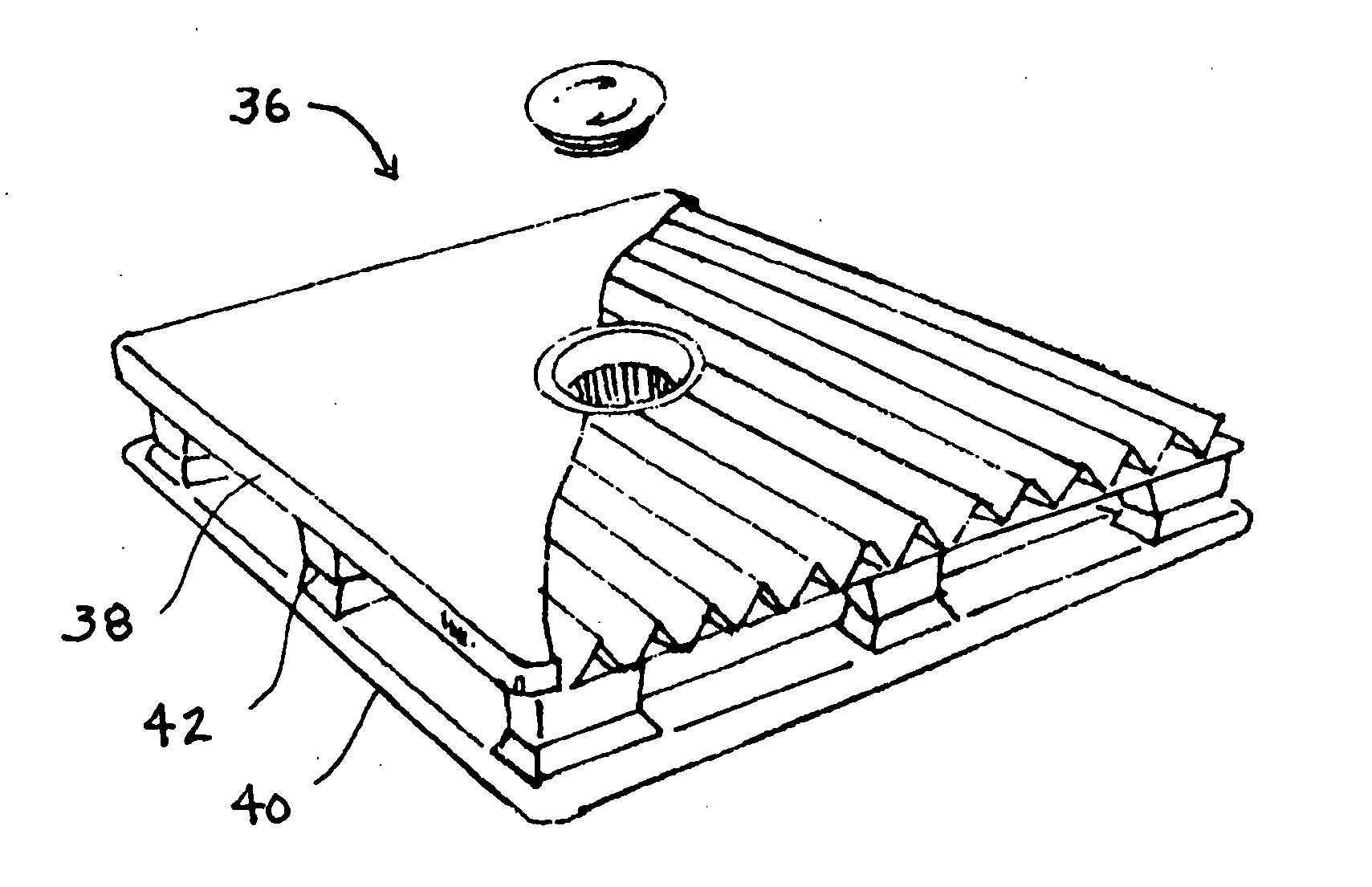

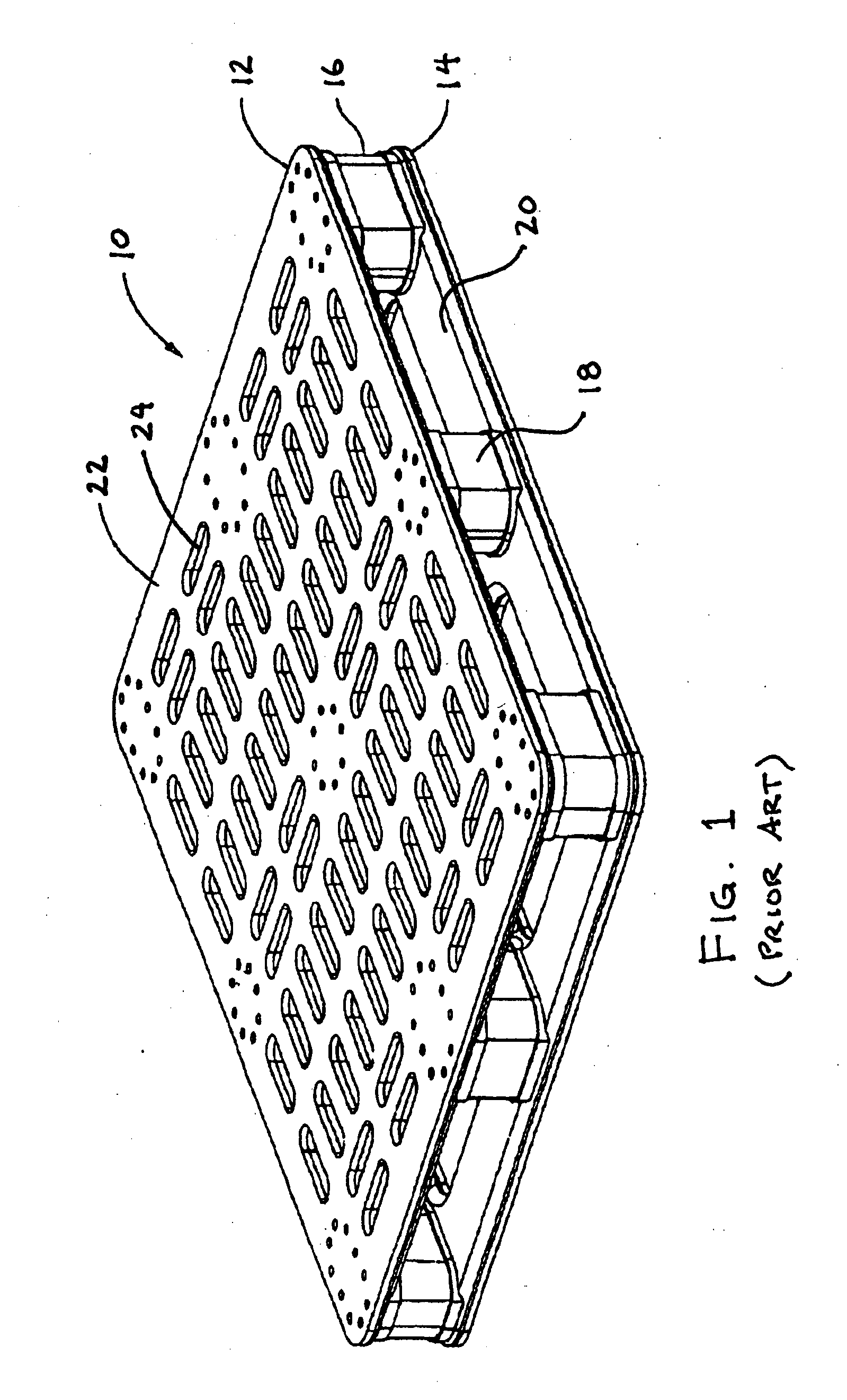

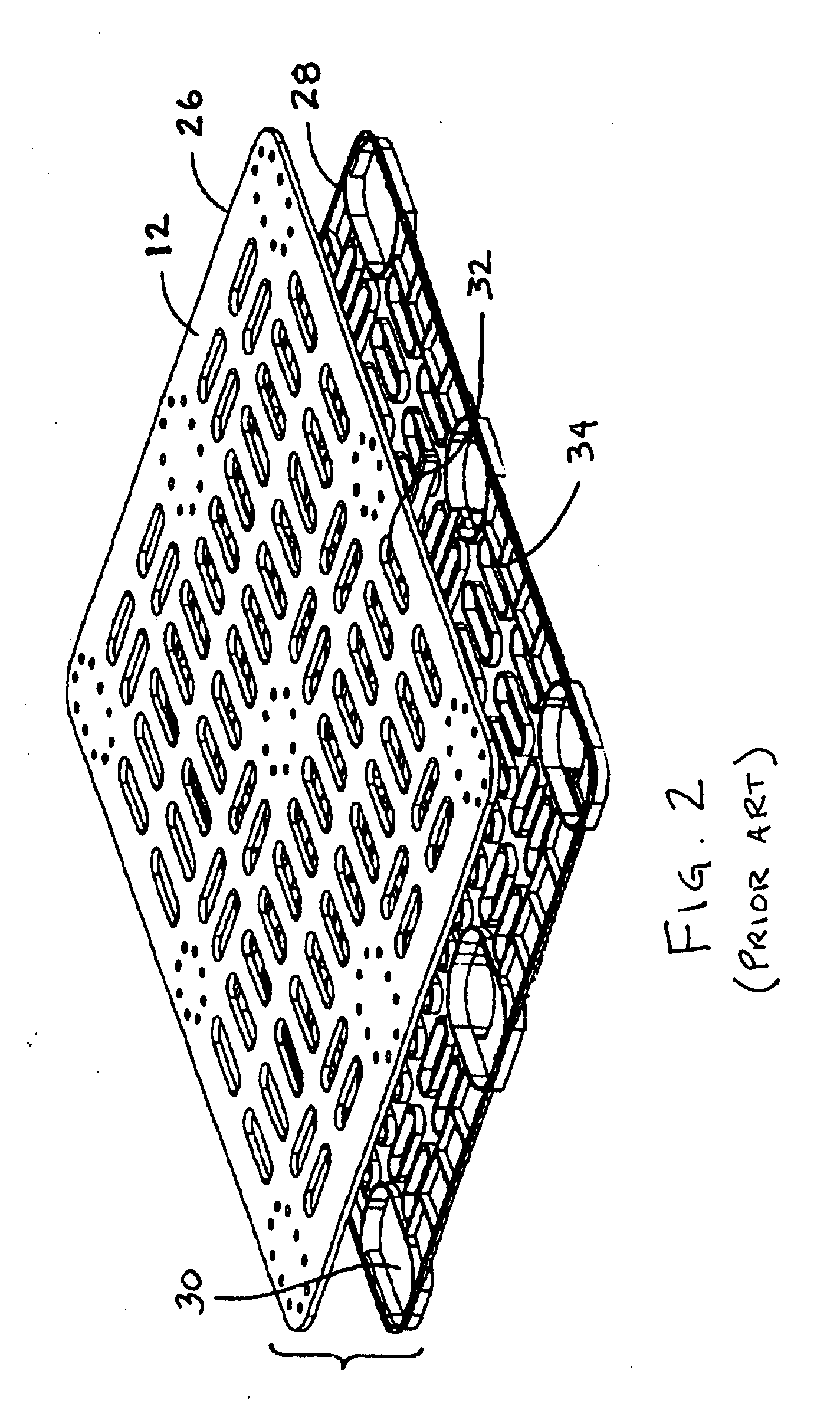

Fire resistant plastic pallet with low radio frequency resistivity

A halogen free fire resistant RF transparent polymer pallet has attenuated electrical resistance. A pallet body has a fire resistant layer and a substrate supporting the fire resistant layer. The fire resistant layer includes fire retardant materials, such as Al(OH)3, Mg(OH)2, intercalated graphite, zinc borate, and antimony oxide. The substrate is substantially free of the fire retardant materials to reduce the density and the electrical resistance of the pallet body. The fire resistant layer is substantially thinner than the substrate to lower RF distortion effects on RF transponder communications from additives and the conductive materials within an RF tracking system.

Owner:NEXTREME

Silicon rubber cross-linked flame-retardant cable material and its preparation method

ActiveCN102977605AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesCalcium silicateAntimony trioxide

The invention provides a silicon rubber cross-linked flame-retardant cable material. The cable material is prepared from the following raw materials, by weight, 100 parts of silicon rubber, 20-30 parts of ethylene propylene diene monomer, 8-10 parts of chlorinated polyethylene, 15-20 parts of acetylene black, 0.5-1.0 part of dimethyl silicone oil, 0.2-0.5 parts of dicumyl peroxide (DCP), 20-30 parts of high-density polyethylene, 15-25 parts of calcium silicate, 0.5-1.0 part of modified argil, 30-40 parts of precipitated silica, 1-3 parts of a silane coupling agent, 0.2-0.5 parts of an antioxidant 4040, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of a vulcanizing agent BP, 2-4 parts of tribasic lead sulfate, 12-15 parts of antimony (III) oxide, and 6-8 parts of zinc borate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good high and low temperature resistances, good corrosion resistance, good water resistance, good ozone resistance, and good ageing resistance.

Owner:佛山市石湾陶瓷工业研究所有限公司

Antimicrobial enamel glaze

InactiveUS20050196430A1Reduces and substantially eliminates growth and proliferationBiocideInorganic active ingredientsZinc borateNuclear chemistry

An antimicrobial enamel glazing composition comprising zinc borate for imparting antimicrobial characteristics to numerous enameled products. A method for producing the antimicrobial glazing composition and coating an article with the the antimicrobial enamel glazing composition.

Owner:MICROBAN PROD CO INC

Grease-proof low-smoke halogen-free flame-proof cable material

The invention discloses a cross-linking type environment-friendly cable insulation material, characterized in oil resistance, low content of smoke, zero halogen and flame resistance. The cable insulation material comprises the components with the following weight portions: 20 to 40 percent of ethylene-vinyl acetate copolymer, 0 to 20 percent of nitrile rubber, 40 to 60 percent of flame retardant, 0.5 to 3 percent of oxidizing agent, 1 to 3 percent of cross-linking sensitizer, 0 to 15 percent of coloring agent and 0.5 to 1 percent of processing agent. The flame retardant is made from one or two of aluminum hydroxide and magnesium hydroxide of which surfaces are treated and one or more of red phosphorus, antimony trioxide, zinc borate or phosphate flame-retardant agent of which surfaces are treated; the invention selects the appropriate macromolecule base stock ethylene-vinyl acetate copolymer to compound with the nitrile rubber and applies the surface treatment to inorganic powders for improving the oil resistance of the material. The cable insulation material characterized in low content of smoke and zero halogen has good oil resistance.

Owner:SHANGHAI ELECTRIC CABLE RES INST

Preparation method of cable fire-proof sealing filling

InactiveCN101037583AImprove fire resistanceImprove air tightnessOther chemical processesInsulated cablesAluminium hydroxideSlurry

The relates to a fireproof seal filler for ship cable transfixion channel and opening and preparing method thereof, which belongs to flame-proof sealing material technique field. Components and weight percent of raw materials employed by the invention are that: kaolin of 10-20%, talcum powder of 5-10 % and silicon micro-powder of 30-50% are used as base-material; aluminum hydroxide of 10-20%, hydrated zinc borate of 5-10% and magnesium hydroxide of 10-20% are used as flame retardant; wherein proportion of the base-material and the flame retardant is 1:1-2.3:1; in addition, coagulants of calcium sulfate, calcium chloride, magnesium chloride and sodium carbonate are added, weight percents of the four coagulants are separately 20-40% based on total weight of the base-material and the flame retardant as 100%. Firstly the coagulant is mixed with water to prepare serum, when actually using, the serum is added in mixed powder material of the base-material and the flame retardant, and the pasty fireproof seal filler is obtained by sufficiently stirring of highly effective stirring machine.

Owner:SHANGHAI UNIV

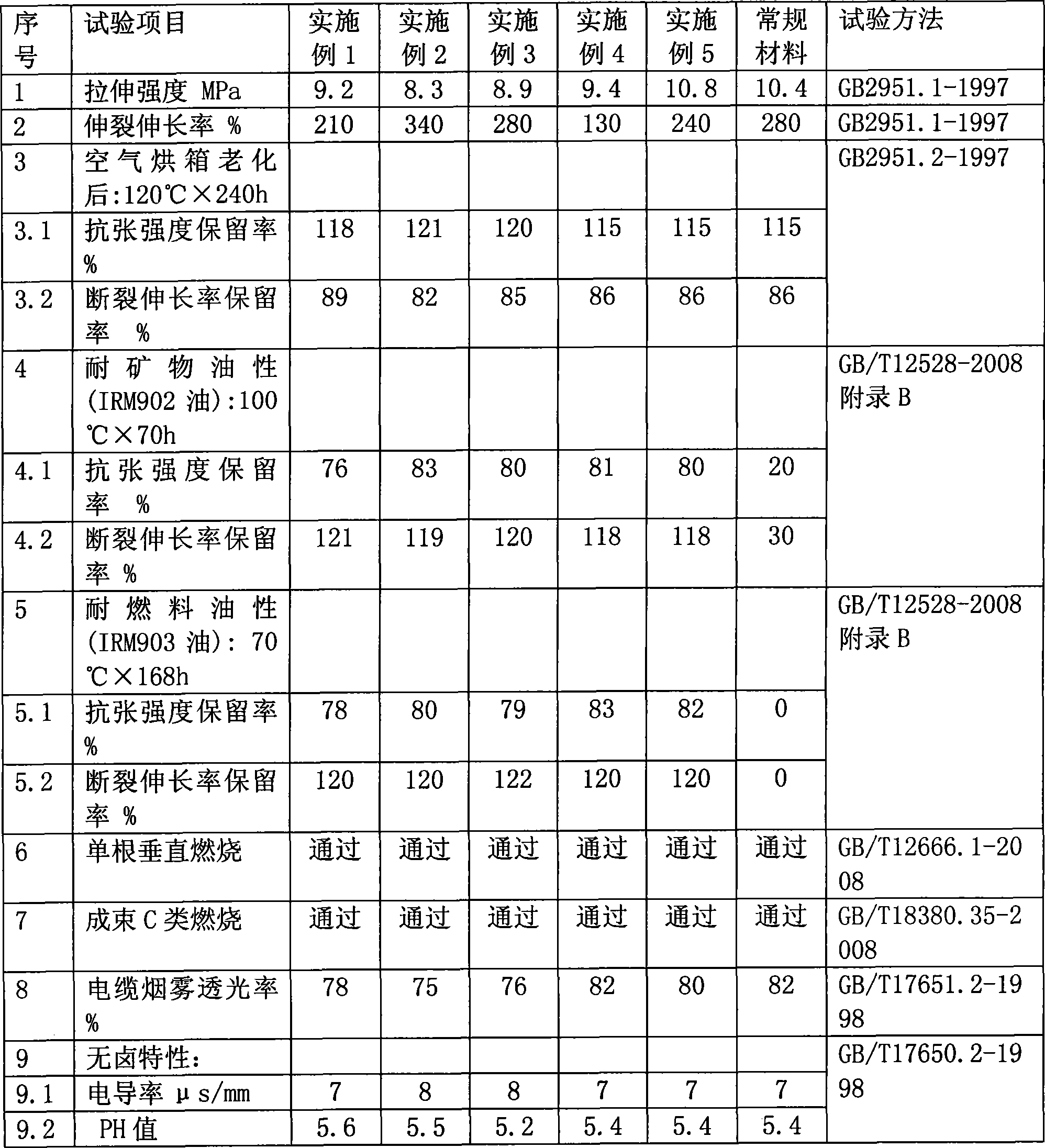

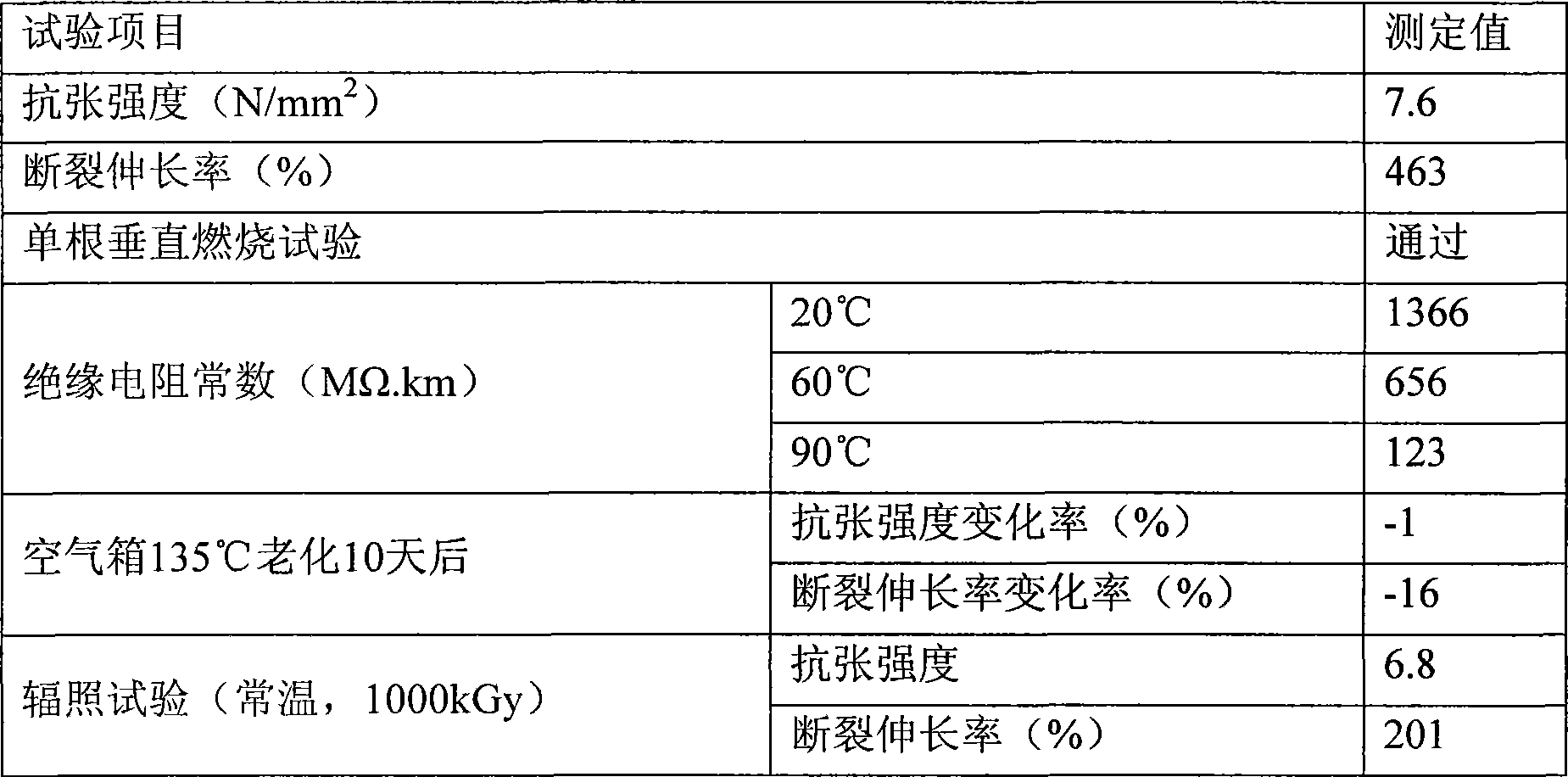

Radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and preparation method

ActiveCN101531789AImprove radiation resistanceThe ratio is scientific and reasonableRubber insulatorsSilanesNuclear power

The invention discloses a radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and a preparation method. The radiation-resistant halogen-free low smoke flame retardant insulating material is prepared from the following raw materials: ethylene propylene diene rubber, phenyl siloxane rubber, magnesium hydrate, aluminium hydroxide, zinc borate, white carbon black, cerium dioxide, zinc oxide, Bis(tert-butyldioxyisopropyl)benzene, tri allyl cyanurate, 2-mercaptobenzimidazole, 2,2,4-trimethyl-1,2-dihydroquinoline, Aflux A-25, stearic acid, vinyl tris(beta-methoxyethoxy) silane, and paraffin oil by heating and mixing. The formulation and the mixture ratio are scientific and reasonable, and the process is advanced. The prepared insulating material has good radiation resistance, excellent mechanical property, good electrical property and long service life, and is a good radiation-resistant halogen-free low smoke flame retardant insulating material for manufacturing the cables of the nuclear power plants.

Owner:BAOSHENG SCI & TECH INNOVATION

Fire resistant plastic pallet with low frequency resistivity

InactiveUS20080053342A1Low costReduce distortionContainer decorationsLevel indicationsEngineeringConductive materials

A halogen free fire resistant RF transparent polymer pallet has attenuated electrical resistance. A pallet body has a fire resistant layer and a substrate supporting the fire resistant layer. The fire resistant layer includes fire retardant materials, such as Al(OH)3, Mg(OH)2, intercalated graphite, zinc borate, and antimony oxide. The substrate is substantially free of the fire retardant materials to reduce the density and the electrical resistance of the pallet body. The fire resistant layer is substantially thinner than the substrate to lower RF distortion effects on RF transponder communications from additives and the conductive materials within an RF tracking system.

Owner:NEXTREME

Antimicrobial ceramic glaze

ActiveUS20050158400A1Commercially acceptable level of antimicrobial efficacyBiocidePigmenting treatmentZinc borateMaterials science

An antimicrobial ceramic glazing composition comprising zinc borate for imparting antimicrobial characteristics to numerous ceramic products. A method for producing the antimicrobial glazing composition and ceramic products incorporating the antimicrobial glazing composition.

Owner:MICROBAN PROD CO INC

Fire-resisting paint and preparation method thereof

ActiveCN101397469AIncrease elasticityImprove adhesionFireproof paintsInsulated cablesGas releaseChemistry

The invention discloses a fire retardant coating and a preparation method thereof, wherein, the fire retardant coating comprises base materials and auxiliary materials. The preparation method comprises the following steps of: selecting water-soluble polyacrylic resin elastic emulsion and a variety of assistants; taking water as diluent, adding flame retardants such as ammonium polyphosphate, melamine, aluminum hydroxide, zinc borate, dipentaerythritol and the like, as well as auxiliary fillers and colorants; then blending, grinding and filtering, and acquiring the fire retardant coating. The fire retardant coating has good performance of flame retarding, is free of organic solvent volatilization in the curing process; with non-toxic and environmental protecting formula, the formed film has better elasticity and adhesion and releases no toxic and harmful gases such as halogens when on fire, thus meeting the environmental protecting requirements.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Halogen-free flame retardant, high-temperature resisting and rapidly solidified deacetone silicon rubber and preparation method thereof

InactiveCN103044922AFast curingExtensive adhesionNon-macromolecular adhesive additivesPolymer sciencePhosphate

The invention discloses a halogen-free flame retardant, high-temperature resisting and rapidly solidified deacetone silicon rubber and a preparation method thereof. Hydroxy-end-capped polydimethylsiloxane is used as the main body and is compounded with a thermal-resisting additive and a flame retardant additive, wherein the halogen-free flame retardant, high-temperature resisting and rapidly solidified deacetone silicon rubber comprises the following ingredients by weight: 100 parts of the hydroxy-end-capped polydimethylsiloxane serving as a main body, 1-50 parts of polydimethylsiloxane, 5-18 parts of silicon oxide, 5-15 parts of thermal-resisting additive, 50-200 parts of flame retardant additive, 0.5-2.5 parts of tackifier, 0.5-1 part of organic guanidine catalyst and 5-8 parts of deacetone siloxane cross-linking agent; the thermal-resisting additive is one or a mixture of several of iron oxide red, cerium oxide of which the purity is not less than 90% and tin oxide of rutile structure; and the flame retardant additive is one or a mixture of several of aluminum hydroxide, magnesium hydrate, zinc borate, phosphate ester, phosphonate, phosphine oxide and organic phosphorus. The deacetone silicon rubber has good thermal resistance, flame retardant effect and mechanical properties at 250-300 DEG C, and is simple in preparation method and high in production efficiency.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com