Environmental protection based red mud combination modification synergism fire-retardant polyethylene

A technology of synergistic flame retardant and polyethylene, applied in the field of environmental protection and the comprehensive utilization of flame retardant plastics and red mud, can solve the problems of poor processing performance and mechanical properties, large addition amount, etc., achieve good flame retardant efficiency, promote The effect of forming carbon and expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

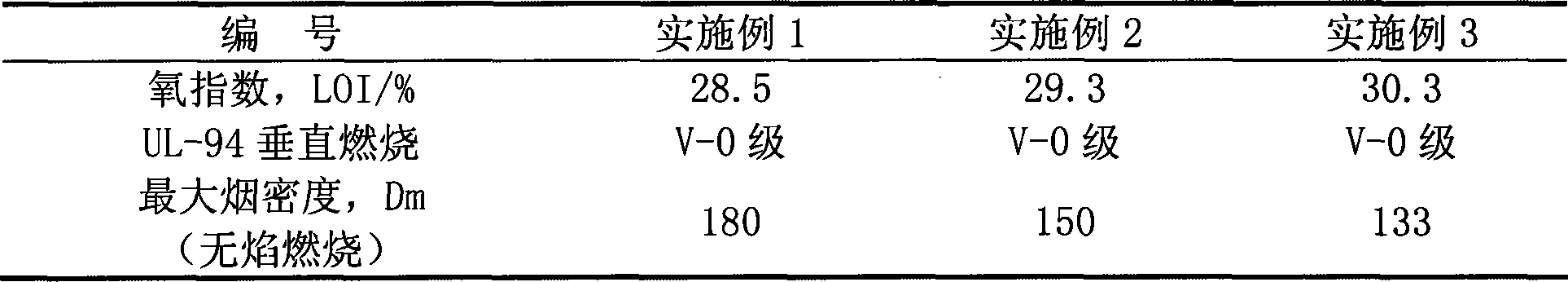

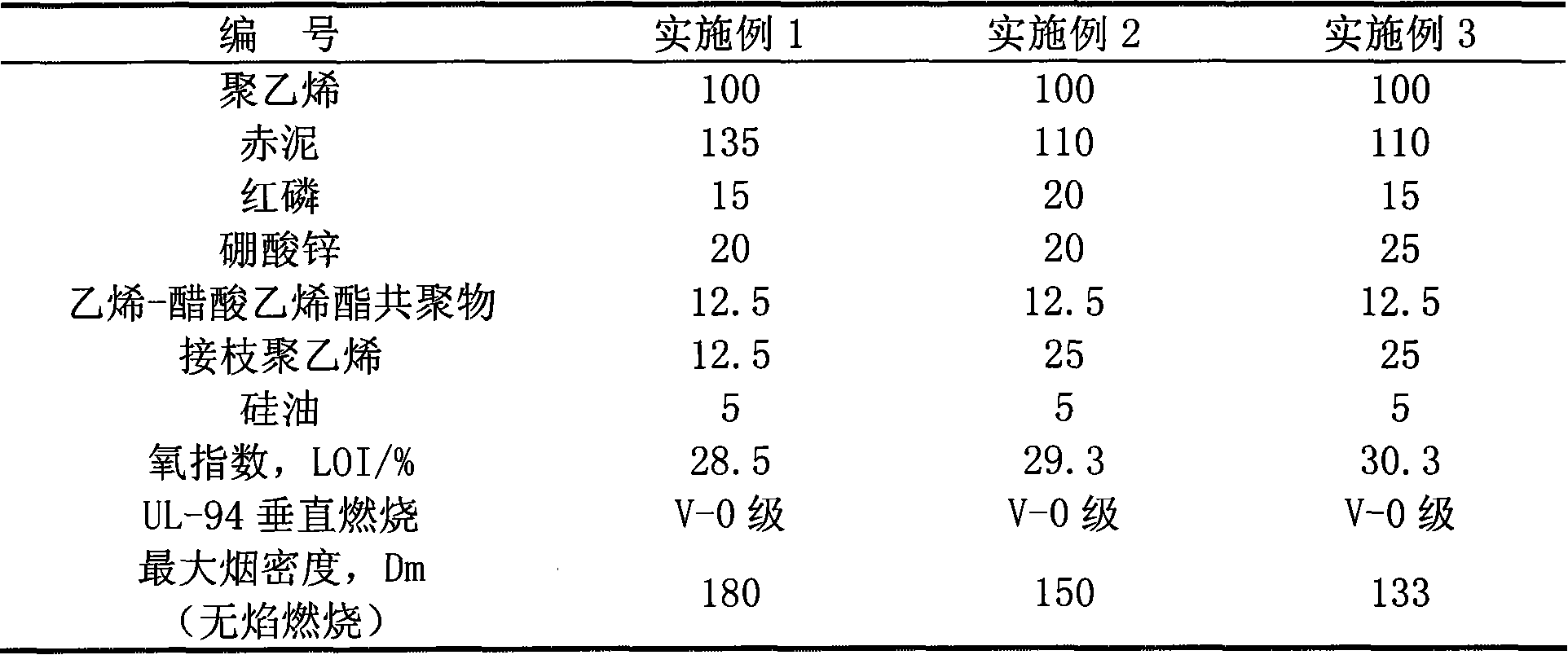

[0032] The red mud compound modified synergistic flame retardant polyethylene of the present invention is measured by the mass of polyethylene matrix resin as 100 parts, and the remaining components are calculated relative to 100 parts of resin (phr, the number of fillers added per 100 parts of resin). The formula component content and technical performance indicators are shown in Table 2.

[0033] Table 2 Components and performance indicators of the embodiments of the present invention

[0034]

[0035] The preparation method of each embodiment in Table 2 is the same, according to Table 2 formulation component ratio batching, melt blending process, preparation sample. Processing conditions: the roller temperature of the double-roller mixer is 140-150°C; the sample molding temperature of the flat vulcanizer is 120-130°C, the heating time is 4min, and the pressure is 10MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com