Patents

Literature

178results about How to "Meet the mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

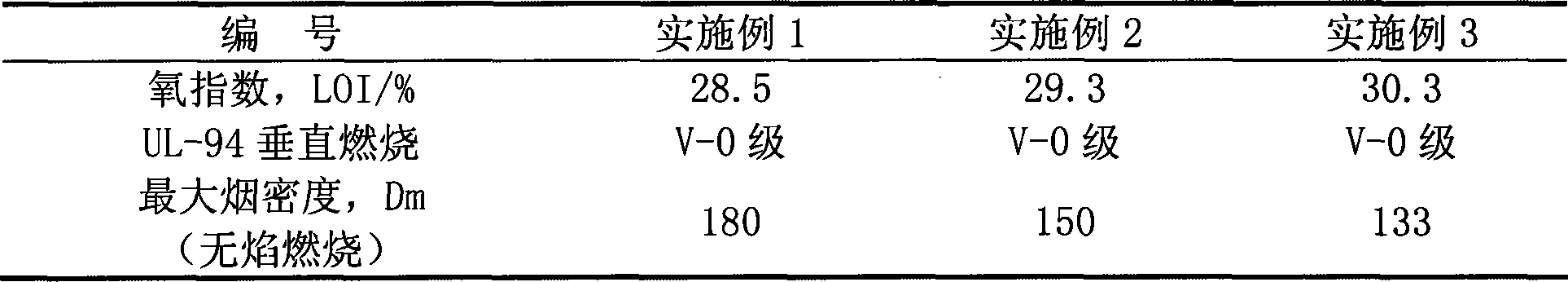

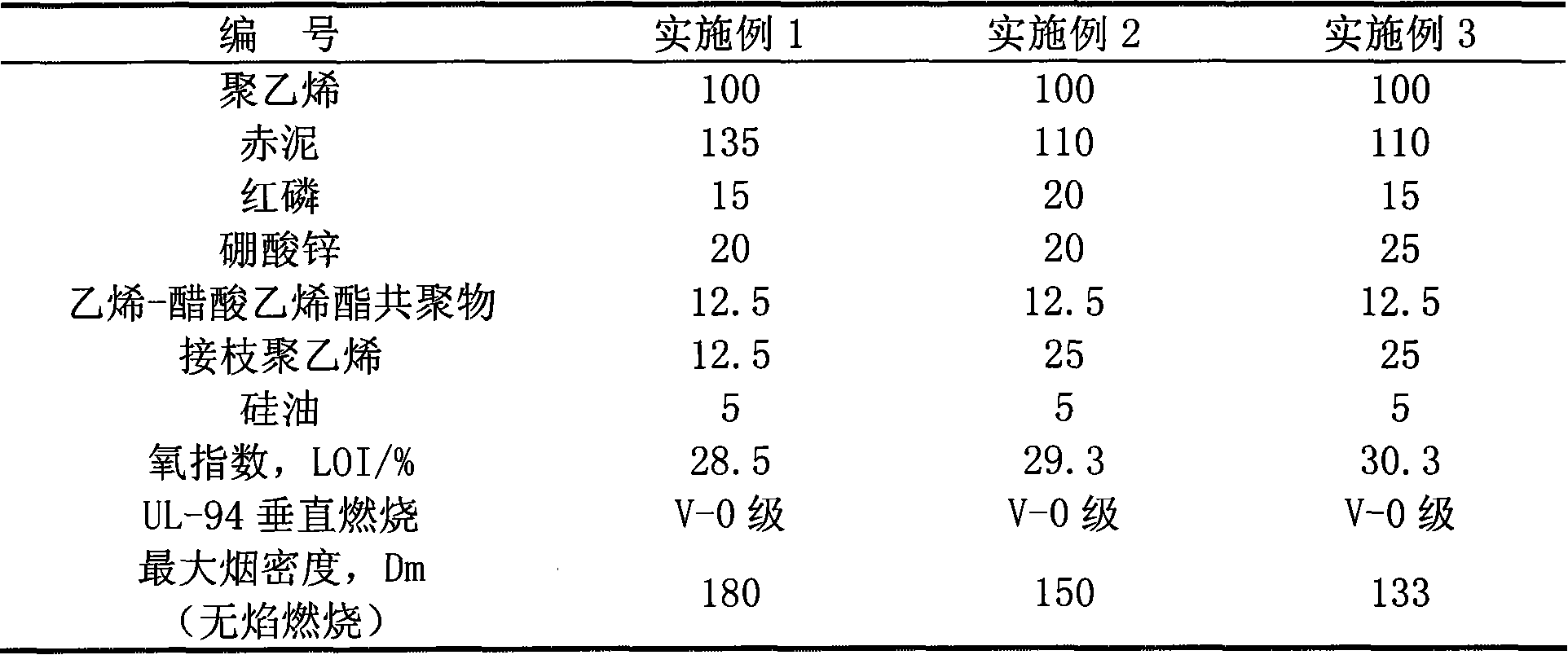

Environmental protection based red mud combination modification synergism fire-retardant polyethylene

InactiveCN101624457AIncrease added valueMeet environmental protection requirementsRed mudCarvacryl acetate

The invention relates to an environmental protection based red mud combination modification synergism fire-retardant polyethylene, and belongs to the technical field of compressive utilization and fire-retardant plastics. The fire-retardant polyethylene is suitable for fire safety protection in important public places in the fields of electric products, building materials and transportation. The fire-retardant polyethylene consists of the following components in percentage by weight: 30 to 35 percent of polyethylene, 34 to 39 percent of red mud, 6 to 13 percent of red phosphorus, 5 to 17 percent of zinc borate, 3 to 8 percent of ethylene-vinyl acetate copolymer, 2 to 7 percent of grafted polyethylene, and 2 to 8 percent of silicone oil. The preparation process comprises the following steps of: grinding and drying the red mud; blending the ground red mud with other raw materials according to the blending ratio; mixing the mixture with polyethylene resin by fully stirring at a high speed; fusing, co-mixing and processing the mixture; and preparing a sample. The processing conditions comprise that: the roll temperature of a double-roller mixing mill is between 140 and 150 DEG C; and the forming temperature of the flat vulcanizing machine sample is between 120 and 130 DEG C, the heating time is between 4 and 8 minutes, and the pressure is between 10 and 20MPa. The fire-retardant system meets the requirements of industrial application on mechanical property, and simultaneously has comprehensive properties such as good fire-retardant effect, low cost, environmental protection and the like; moreover, the application field of the red mud is widened, and the red mud product with high added value is prepared.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

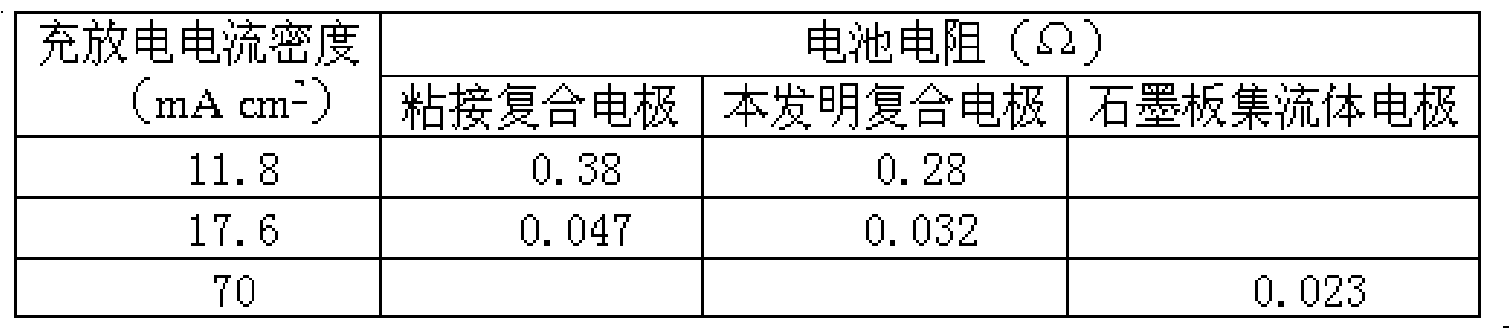

Combination electrode for all vanadium redox flow battery and preparation thereof

InactiveCN101335349AImprove mechanical propertiesImprove conductivityCell electrodesFiberVanadium redox battery

The invention relates to a composite electrode used in vanadium redox flow batteries and a preparation method thereof, pertaining to the vanadium battery manufacturing field. The composite electrode is prepared by adding three conductive fillers (conductive acetylene carbon black, conductive carbon fiber and graphite) into thermoplastic polymer to obtain a thermoplastic conductive plate which is compounded together with a graphite felt. Part of the conductive carbon fiber in the graphite felt is embedded into the surface of the conductive plate to form an interpenetrating conductive network and improve the conductivity of the whole product. Therefore, the composite electrode has excellent mechanical performance and conductivity (volume resistivity is less than or equal to 0.1omega question mark cm), integrates current collector and electrode into a whole, and effectively reduces surface resistance between the current collector and the electrode; meanwhile, during the process, no additional additive which can improve conductivity is used, thus ensuring relatively good conductivity and mechanical performance, and avoiding the falling of the additive which can improve conductivity into the electrolyte of a vanadium battery.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

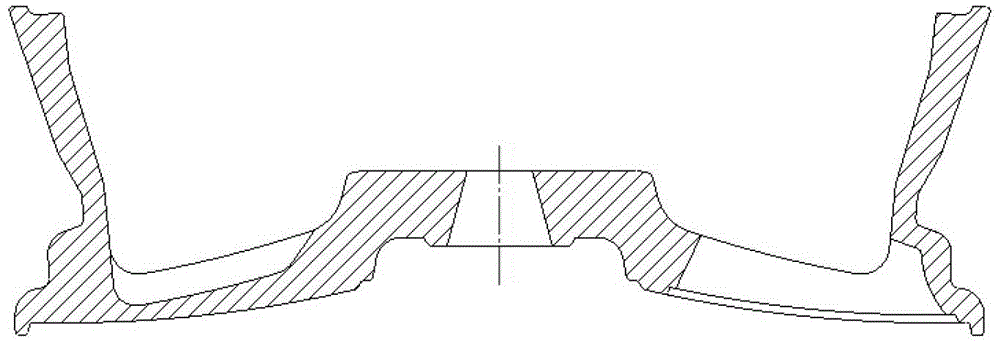

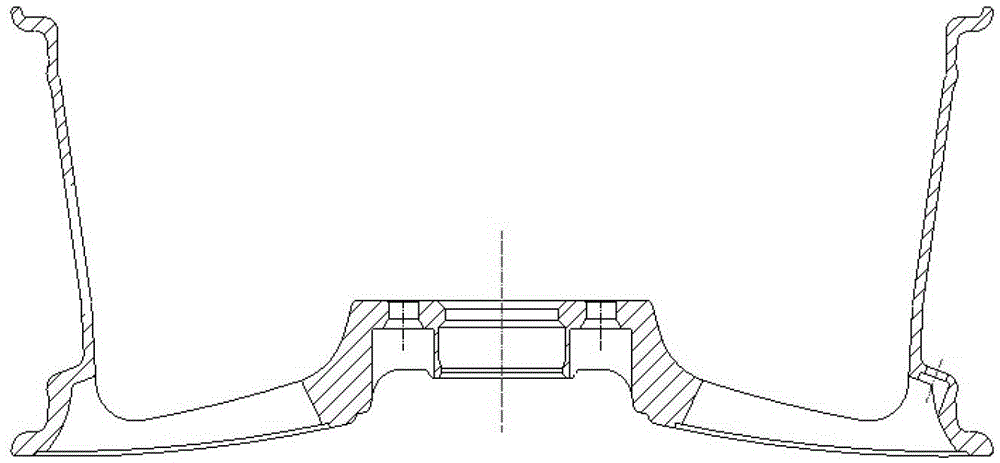

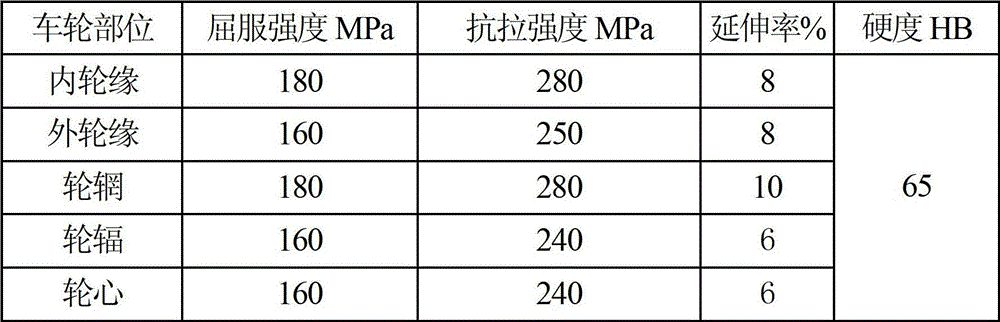

Magnesium alloy automobile hub casting spinning compound molding method

ActiveCN103056611AMeet performance indicatorsReduce manufacturing costPerformance indexUltimate tensile strength

The invention belongs to the field of magnesium alloy automobile hub manufacture and particularly relates to a magnesium alloy automobile hub casting spinning compound molding method. A magnesium alloy automobile hub spinning wheel blank is manufactured through gravity casting or low-pressure casting process, after a casting spinning blank undergoes surface machining and homogenization processing, an automobile hub blank is manufactured through hot spinning process, and the magnesium alloy automobile hub is manufactured through heat treatment, precise machining and surface coating. The magnesium alloy automobile hub casting spinning compound molding method is used for manufacturing the magnesium alloy automobile hub, the automobile hub with high mechanical performance and good surface quality is obtained, and requirements of the automobile field for automobile hub performance indexes can be fully met. By means of the magnesium alloy automobile hub casting spinning compound molding method, a problem that the strength and toughness of the magnesium alloy automobile hub are poor can be solved, and production cost of the magnesium alloy automobile hub can be obviously reduced.

Owner:NONFERROUS METALLIC OF HEBEI NEW LIZHONG GRP CO LTD +1

Nano-mesoporous molecular sieve synergistic intumescent flame-retardant rubber and preparation method thereof

ActiveCN102226016AHigh flame retardant efficiencyMeet the mechanical propertiesMolecular sieveRubber material

Nano-mesoporous molecular sieve synergistic intumescent flame-retardant rubber and a preparation method thereof relate to flame-retardant rubber and the preparation method thereof. The flame-retardant rubber provided by the invention comprises, by weight, 100 parts of a rubber matrix, 1.5-2.8 parts of a vulcanizing agent, 1-1.5 parts of a promoter CZ, 1-3 parts of stearic acid, 4.5-5 parts of zinc oxide, 1-2 parts of an antioxidant 4010, 1-3 parts of liquid paraffin, 30-40 parts of carbon black, 60-80 parts of an intumescent flame retardant, and 0-5 parts of nano-mesoporous molecular sieve. The preparation method provided by the invention comprises the following steps of: plasticating rubber in an open mill, successively adding eleaostearic acid, zinc oxide, the promoter CZ, the antioxidant 4010, the nano-mesoporous molecular sieve, carbon black, liquid paraffin, IFR and sulphur, mixing and discharging tablets, followed by sulfuration. By the adoption of the nano-mesoporous molecular sieve synergistic intumescent flame retardant, its excellent flame-retardant synergistic effect and interfacial compatibility effect greatly improve the flame-retardant performance and mechanical properties of the rubber material.

Owner:沈阳双骥橡塑科技有限公司

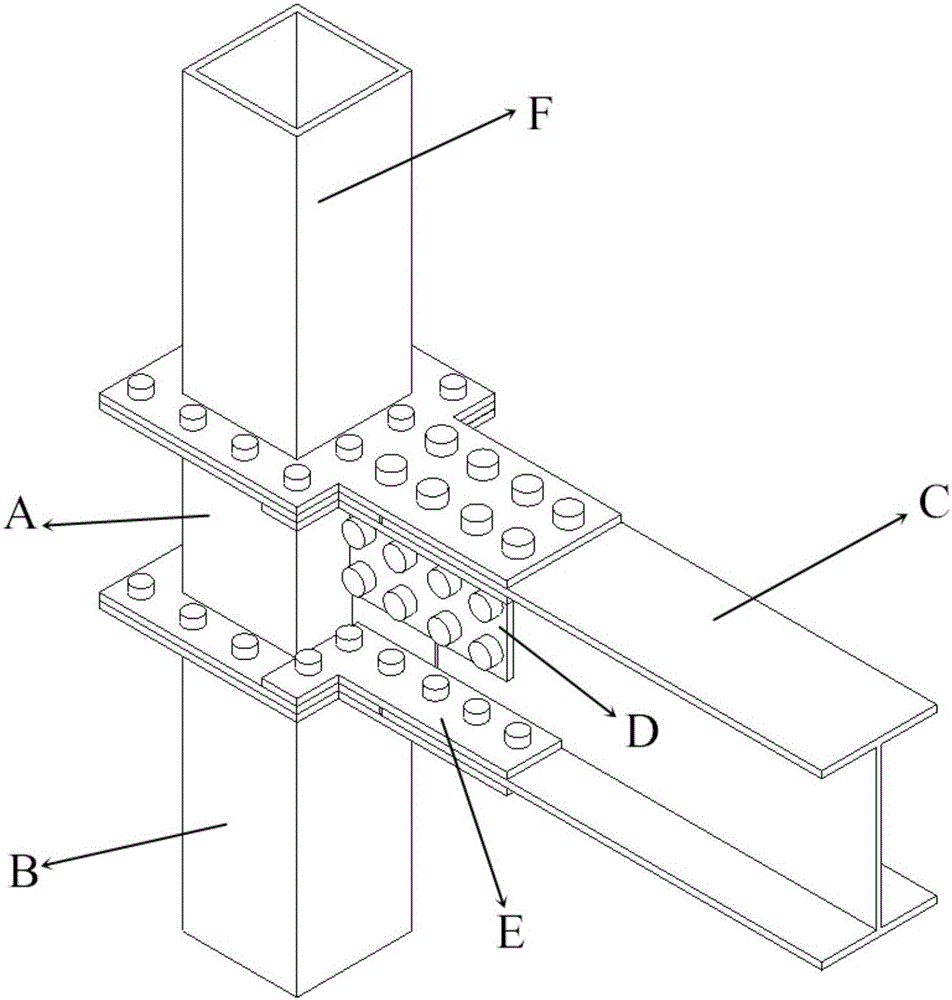

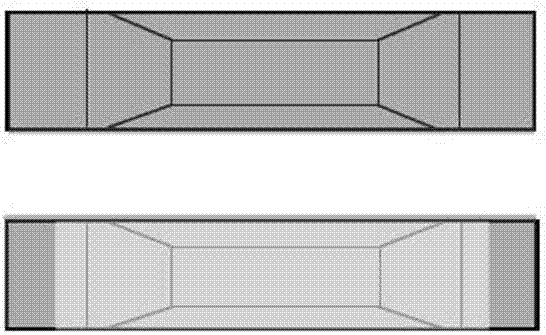

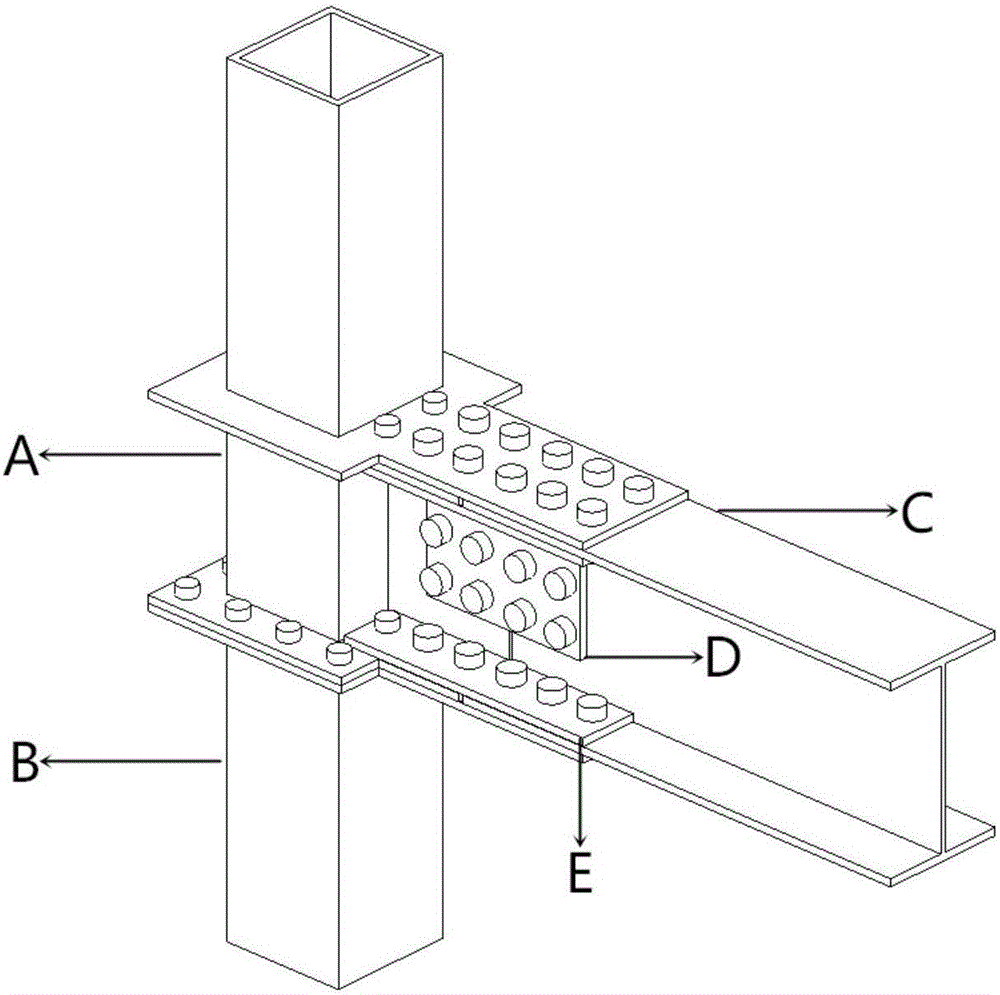

Fabricated beam-column bolt joint connection device with cover plate and double flanges

ActiveCN105888060AMeet the mechanical propertiesEasy to assembleProtective buildings/sheltersShock proofingEngineeringUltimate tensile strength

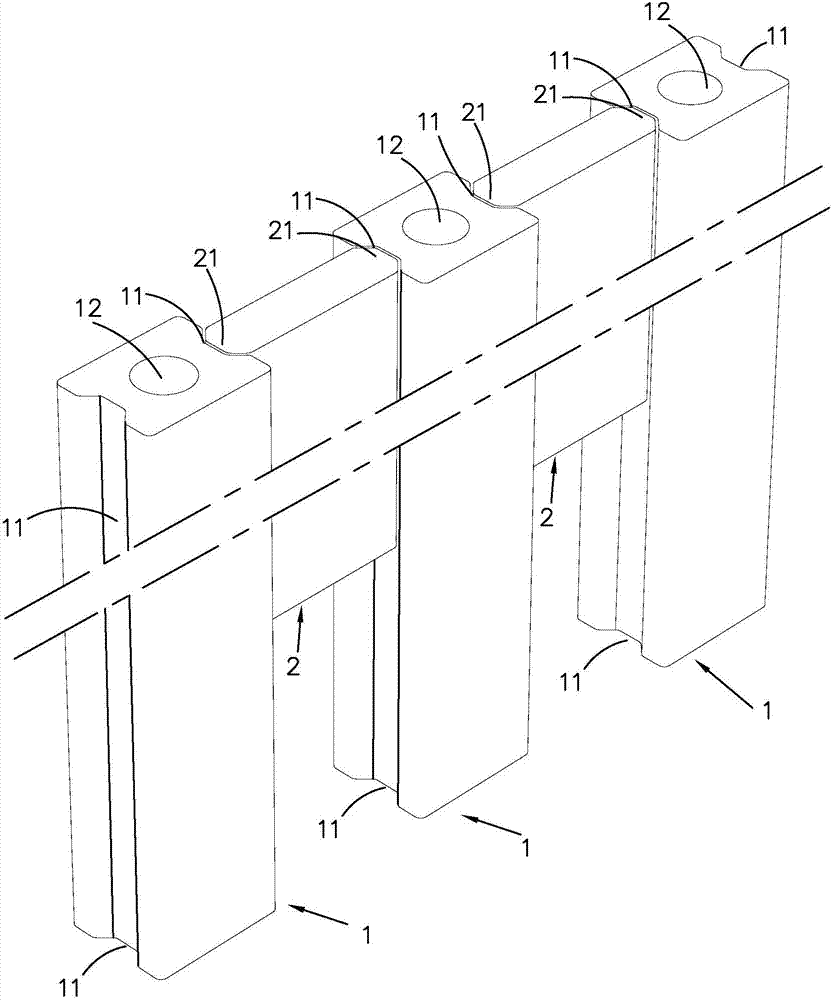

The invention discloses a fabricated beam-column bolt joint connection device with a cover plate and double flanges, and belongs to the technical field of structural engineering. The fabricated beam-column bolt joint connection device comprises an upper column flange plate (2), an upper column square-steel tubular column (1), column base flange plates (3) and (5), a column base square-steel tubular column (4), a shear plate (8), a lower column flange plate (6), a lower column square-steel tubular column (7), an H-shaped steel beam C, an attaching plate D and a clamping plate E. The upper square-steel tubular column and the lower square-steel tubular column are welded to the flange plates integrally in a factory. A column base in the middle is formed by integral welding of the upper flange plate, the lower flange plate, the middle square-steel tubular column and the shear plate in the factory. The welded portions can be completed in the factory, bolts are adopted for on-site assembly and are fastened conveniently and quickly, construction speed and quality are increased greatly, and the fabricated beam-column bolt joint connection device is suitable for the development of fabricated steel structures. According to the fabricated beam-column bolt joint connection device, joints are semi-rigid, with high ductility and bearing capability; clamping plates are made from steel material with low strength, so that earthquake energy can be dissipated fully and post-earthquake restoration is facilitated.

Owner:BEIJING UNIV OF TECH

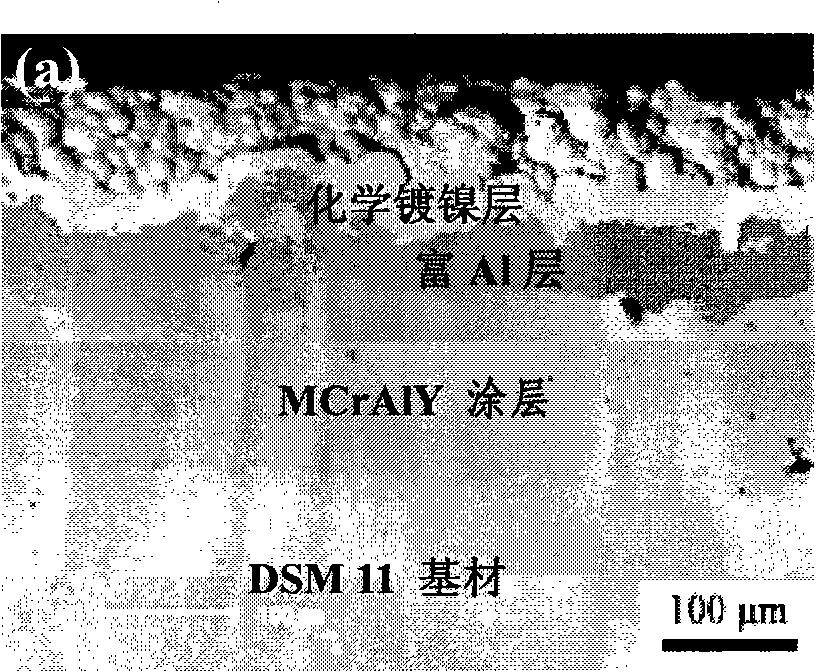

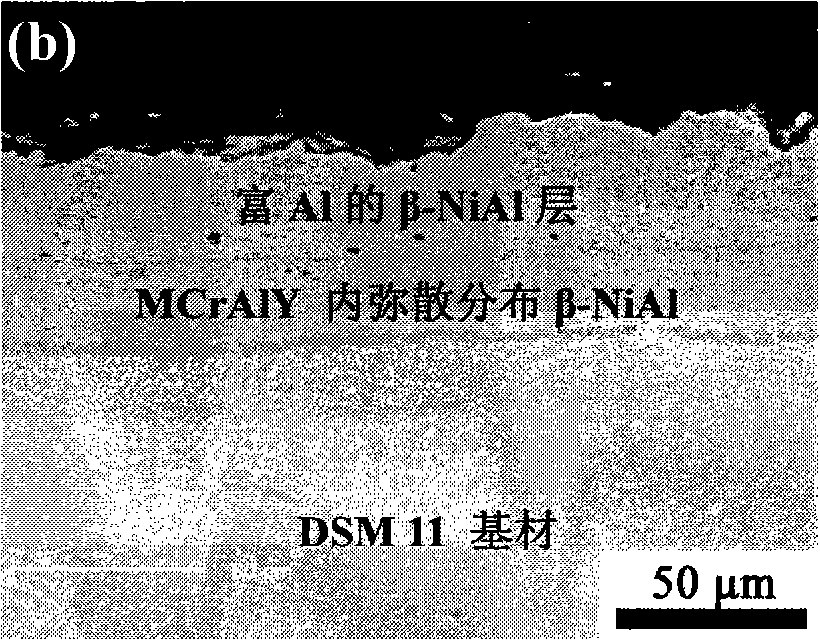

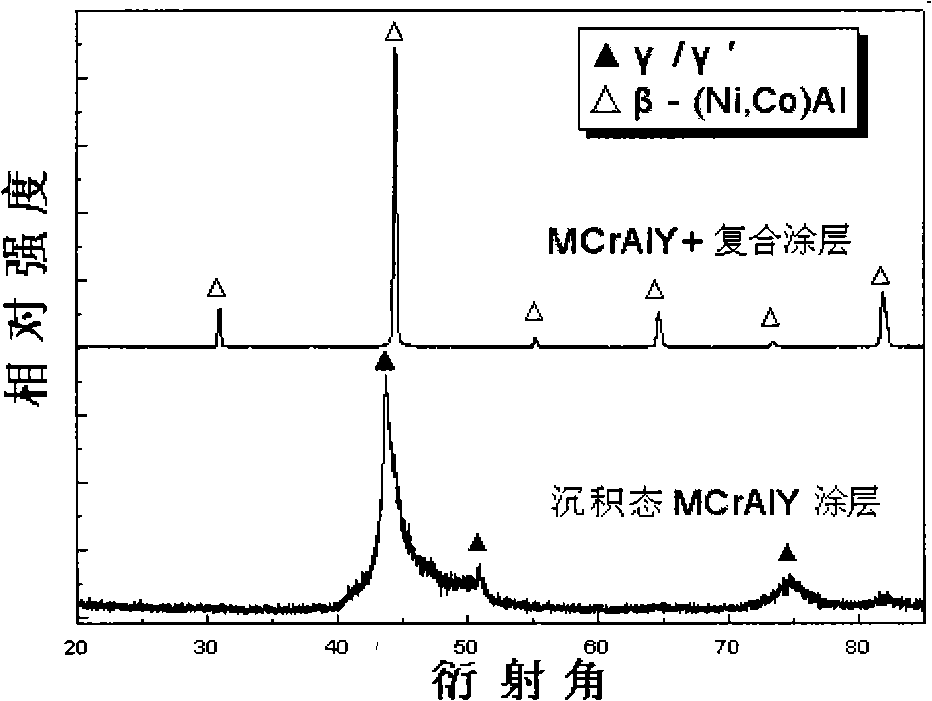

Ni-base superalloy complex gradient coating and preparation technique thereof

InactiveCN101310971ADoes not bring strippingImprove scoreLayered productsVacuum evaporation coatingSuperalloyDepth direction

The invention mainly relates to the coating technique, in particular to a gradient MCrAlY coating used for protecting high-temperature alloy and a preparation method thereof. The invention prepares an MCrAlY composite gradient coating by adopting the method combining the arc ion plating (AIP) and the diffusion aluminizing. The thickness of an aluminum-rich layer on the surface of the MCrAlY composite coating can be controlled by setting the aluminizing temperature and the period of heat preservation and the Al elements are distributed in a gradient way along the depth direction; in addition, the chemical vapor deposition method used for the aluminizing has the advantages of good uniformity on the aluminum-rich layer and being not affected by the size and shape of a sample. Since the method of direct diffusion is adopted without introducing a weak interface, the MCrAlY high-temperature protective coating can increase the content of Al memory phase to the utmost extent under the condition that the mechanical property of the coating is guaranteed, so as to improve the high-temperature oxidization resistance and the heat corrosion resistance of the coating, and can effectively prolong the service life of the coating. The MCrAlY composite gradient coating and the preparation method of the invention can be applied to the protection of Ni-based and Co-based high-temperature alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for producing 8014-H22 state aluminium alloy air-conditioner foil by cast-rolled blank

ActiveCN101805878AImprove use value and economic benefitsSolve process difficultiesRoll mill control devicesMetal rolling arrangementsCrystalliteHeat sink

The invention provides a method for producing 8014-H22 state aluminium alloy air-conditioner foil by a cast-rolled blank, belonging to the technical field of aluminium alloy plate belt foil processing. The method particularly comprises the steps of: adopting the production way of cast-rolling and cold-rolling, carrying out homogenizing annealing on the cast-rolled blank before cold rolling, and controlling the annealing temperature to be 520-530 DEG C and the annealing time to be 22-25h; after the homogenizing annealing, leading compound to be dispersed, thinning crystalline grains so as to be beneficial to the cold rolling and ensuring the final mechanical property of the product; reasonably distributing the cold rolling channels by the plasticity of metal and the capability of rolling equipment, and carrying out eight-channel cold rolling on the cast-rolled blank with the thickness of 6.4-7.4mm; and carrying out finished product annealing on aluminium foil which is rolled to be 0.17-0.24mm, and controlling annealing temperature to be 360-370 DEG C and the annealing time to be 14-17h. By adopting the method, the mechanical properties of the 8014-H22 state aluminium alloy air-conditioner foil with the thickness of 0.17-0.24mm can be controlled to be: tensile strength sigma b: 120-135MPa; percentage of elongtation delta: 25-30%; and the blank convex valve: more than or equal to 6.5. The method meets the requirement of the mouldability of a large air-conditioner radiating fin.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD +1

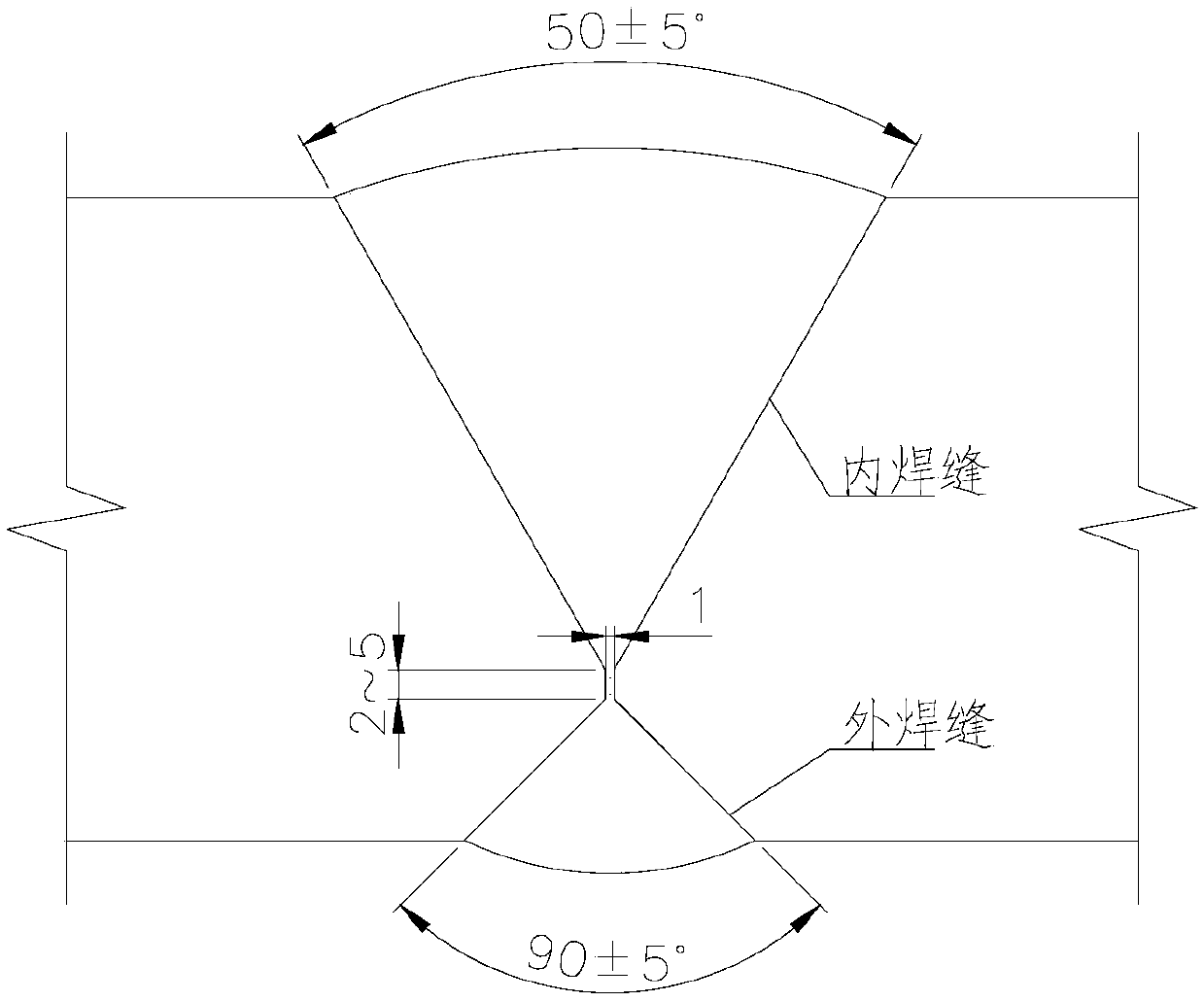

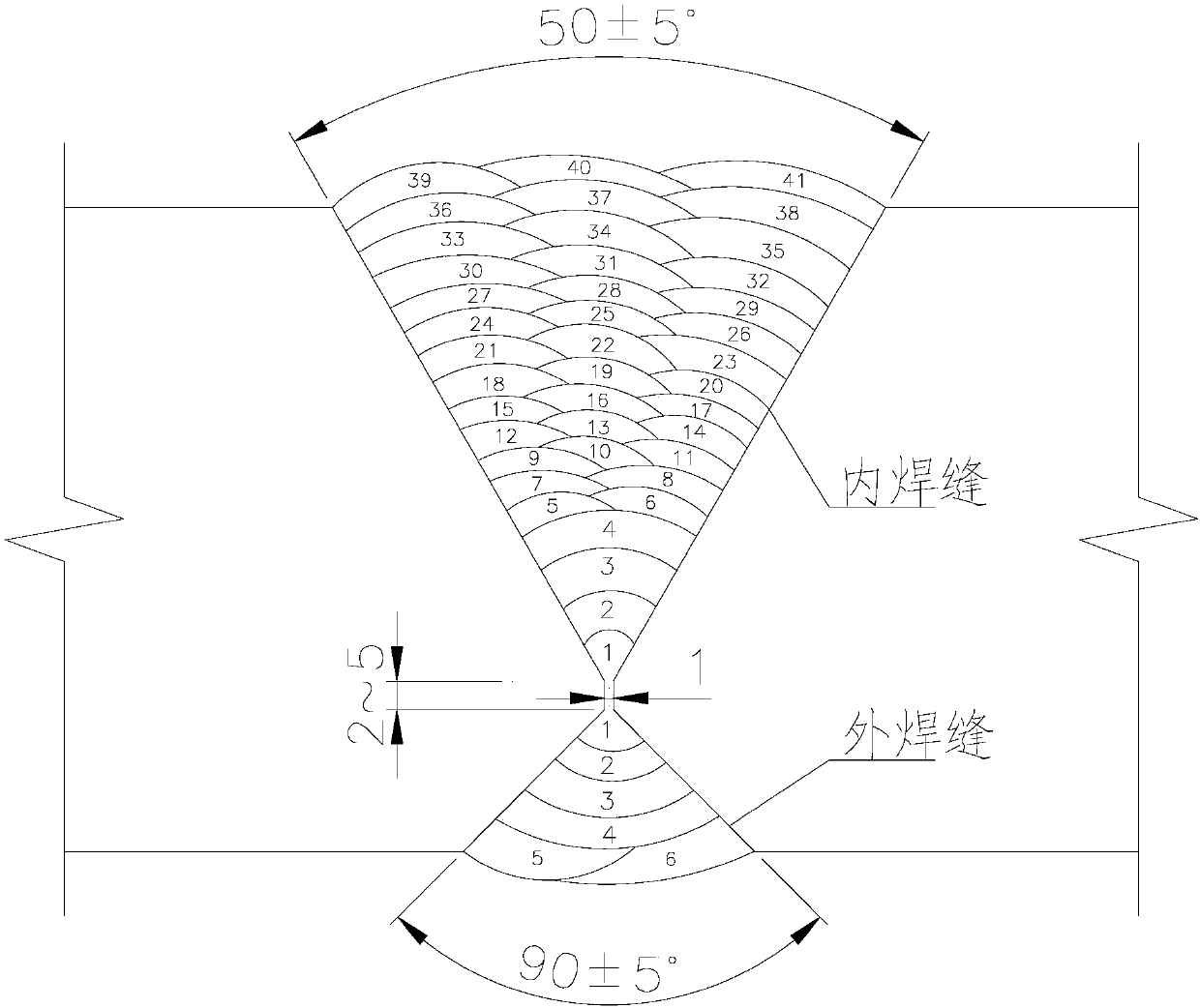

Welding process of offshore wind power foundation steel pipe pile

ActiveCN109590744AMeet the mechanical propertiesMeet bending resistanceArc welding apparatusOther manufacturing equipments/toolsEngineeringWeld seam

The invention discloses a welding process of an offshore wind power foundation steel pipe pile. The welding process comprises the following processes of weld groove forming, steel plate butt joint longitudinal seam welding, coiling and longitudinal seam welding, 1+1 single-pipe joint splicing circular seam welding, 2+2 section splicing circular seam welding, flange and single-pipe joint welding and whole-pile splicing circular seam welding. When a weld groove is formed, an X-shaped weld groove is formed in a butt joint edge of the steel plate, the angle of an inner weld groove is 50 + / -5 degrees, the depth of the inner weld groove is 2 / 3 of the thickness of the steel plate, a blunt edge is 2-5 mm, a root gap is 0-1 mm, and the angle of an outer weld groove is 90 + / -5 degrees. According tothe welding process, different welding methods such as automatic submerged arc welding and gas shielded welding are combined, so that a welding seam with excellent quality is obtained, requirements for the mechanical property, the bending resistance, the tension resistance and the impact resistance of the steel pipe pile are met, the welding defects such as longitudinal cracks and transverse cracks of the welding seam are greatly reduced, so that the impact resistance of the steel pipe pile can be effectively improved.

Owner:CCCC THIRD HARBOR ENG +2

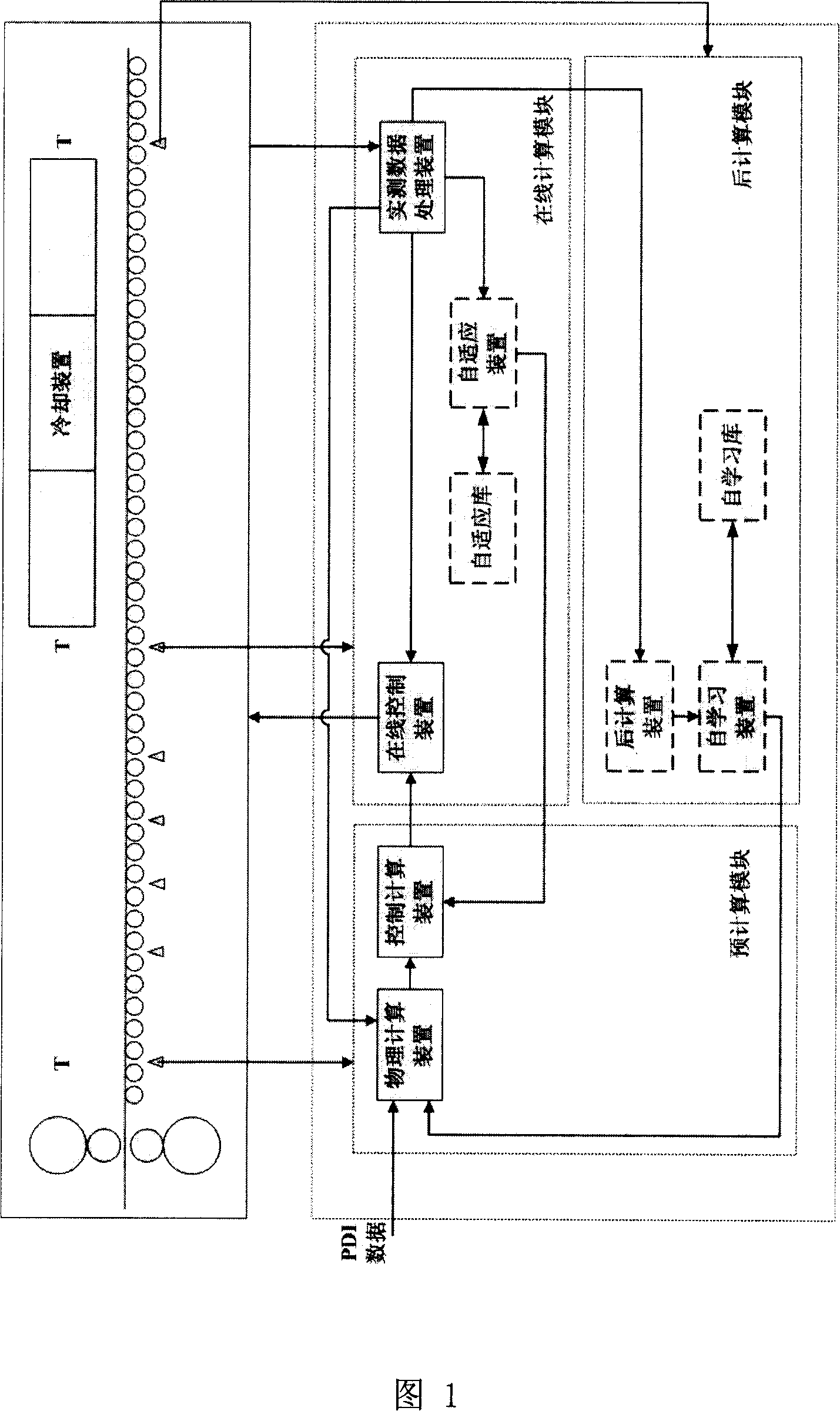

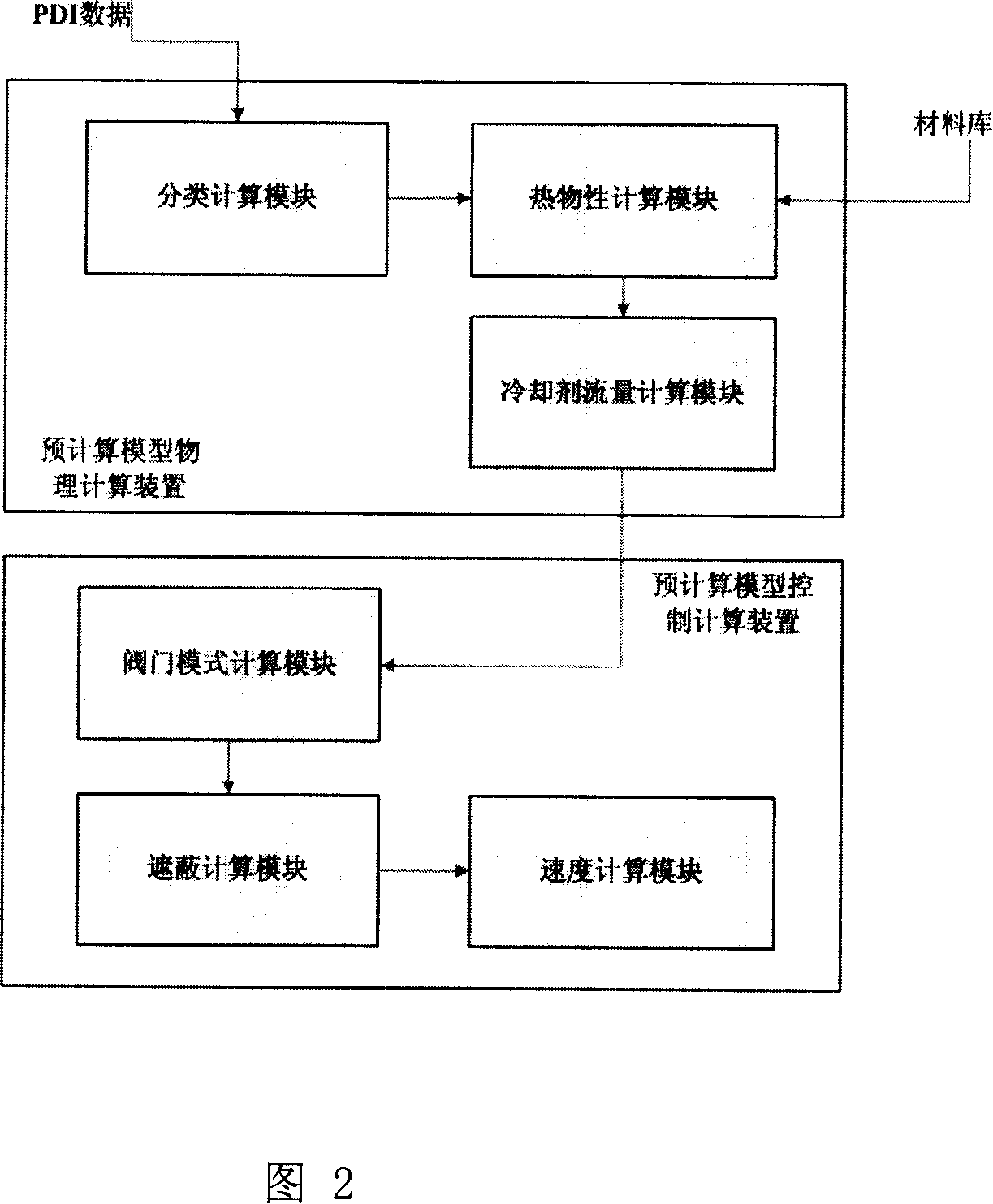

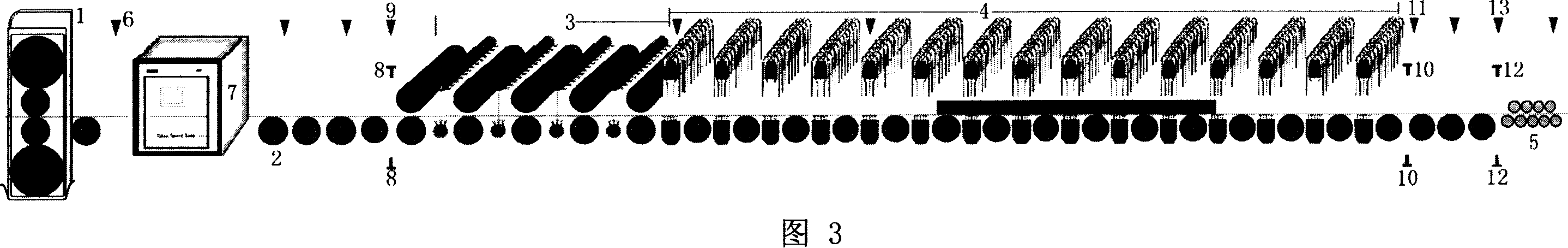

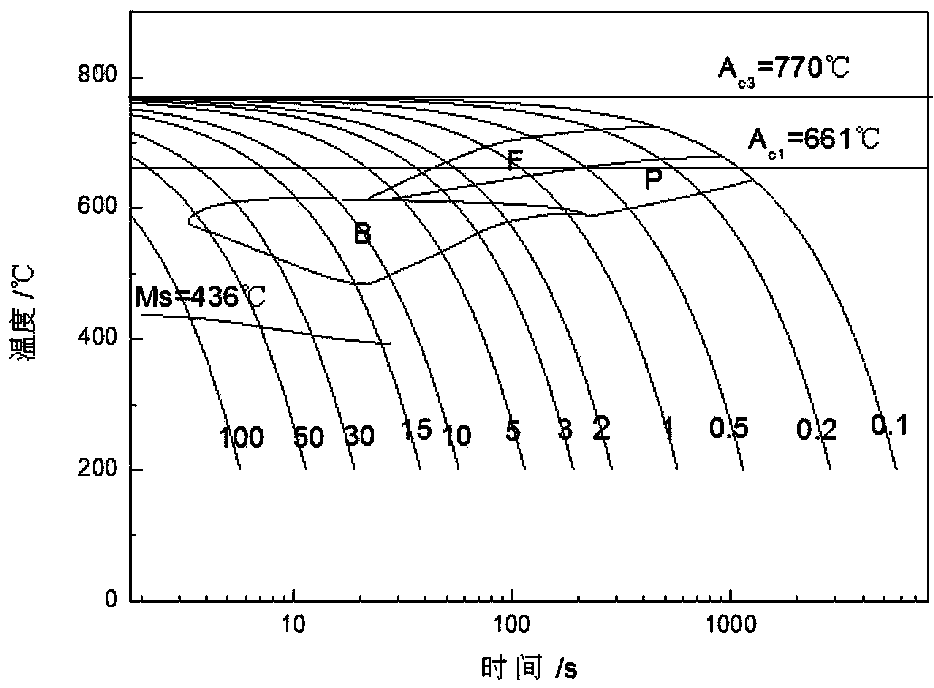

Control system and method for accelerating cooling process

InactiveCN101134998ATroubleshoot Cooling Control IssuesImprove the precision of cooling controlTemperature control deviceHeat treatment process controlThick plateAutomatic control

The control on the speeded cooling of steel plate is related to the profile and performance of the steel plate product. The present invention provides control system and method on accelerated cooling process. The control system includes one data acquiring device, one data pre-calculating module, one on-line calculation module and one post calculation module. The control method includes the decoupling presetting of controlling quantities, the on-line dynamic regulation on the set cooling values by means of considering the disturbance factors of the steel plate in the cooling system inlet and determining the real-time controlling quantities of different cooling sections accurately. The present invention is suitable for application in different thick plate cooling lines, and can reach the aim of reducing cost and raising economic benefit.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for manufacturing novel lining plate

InactiveCN101654873AReduce porosityIncrease surface areaSuperstructure subunitsTank wagonsFiberHigh intensity

The invention discloses a method for manufacturing a novel lining plate, comprising the following steps: (1) manufacturing surface blank felt; (2) manufacturing fabric felt; (3) spreading thermoplastic resin powder on the surface of the fabric felt and the blank felt to carry out the first presoaking; (4) carrying out fixed network, needling in advance and winding on the soaked blank felt and fabric felt; (5) carrying out unwinding and secondary dredge powdering in accordance with the sequence of blank felt, fabric felt and blank felt; (6) needling and reinforcing; (7) carrying out the seconddry method presoaking on the above formed continuous needling felt; and (8) utilizing an oven to plasticize and fuse the continuous needling felt at high temperature to produce finished products by rolling, cooling shape and cutting edge. The manufacturing method significantly improves the denseness and uniformity of fabric materials distributed in matrix, meets the mechanical property of matrix material constituents, thereby obtaining a structural board with high rigidity, high intensity, light weight and wide width, and accelerating the process of industrialization, which uses lining platesof fridge containers produced in China to substitute aluminium plates, stainless steel plates and coil products.

Owner:黄云清

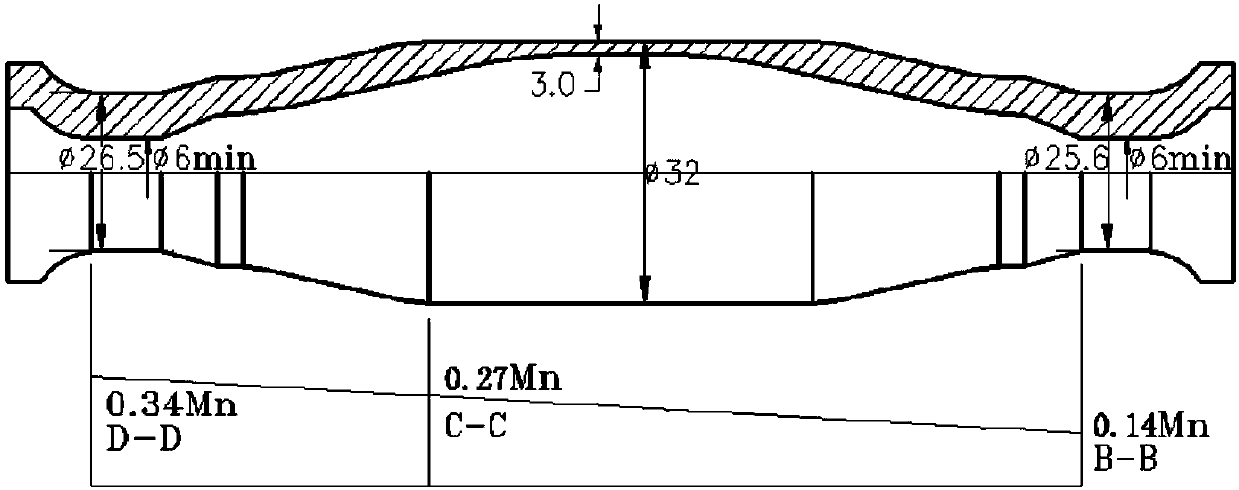

High-hardenability, medium-carbon, low-alloy round steel for fasteners and the manufacturing method thereof

InactiveUS20190284654A1Improve hardenabilityReduce manufacturing costFurnace typesHeat treatment furnacesChemical compositionMaximum diameter

The present invention relates to a high-hardenability, medium-carbon, low-alloy round steel for fasteners, the chemical constituents by mass percentage are as follows: C: 0.36˜0.44%, Si: 0.15˜0.40%, Mn: 0.80˜1.00%, Cr: 1.00˜1.15%, Mo: 0.05˜0.25%, Ni: 0.05˜0.25%, Cu: 0.05˜0.25%, Al: 0.015˜0.050%, B: 0.0010˜0.0050%, Ti: 0.020˜0.050%, the balance is Fe; the maximum diameter of the round steel is 65 mm. The manufacturing process are as follows: the raw materials are processed, in sequence, by converter smelting, LF refining, RH / VD degassing to obtain molten steel, feeding Ti wires and ferroboron, continuous casting, rolling into the bar, obtaining the quenched and tempered round steel after quenching and tempering treatment; the quenched and tempered round steel is able to be directly used in processing fasteners which meet ISO 898-1 standard for grade 10.9, such as bolts and the like.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

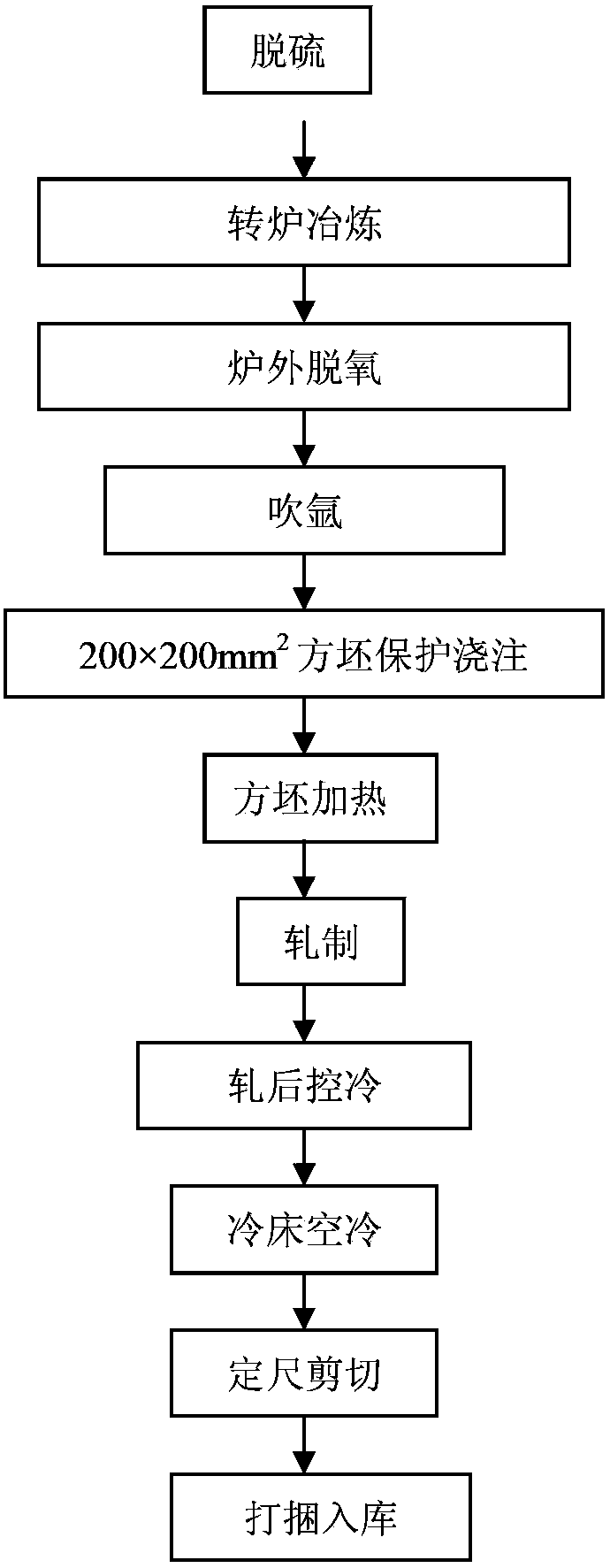

HRB500 reinforcing steel bar and preparation method thereof

The invention discloses an HRB500 reinforcing steel bar and a preparation method thereof. The reinforcing steel bar comprises the following chemical components in percentage by weight: 0.10-0.18% of C, 0.2-0.8% of Si, 1.2-1.6% of Mn, less than or equal to 0.04% of P, less than or equal to 0.04% of S, 0.001-0.005% of B and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: heating a billet to 1,150-1,250 DEG C in a furnace; performing heat preservation for 100-120 minutes; taking the billet out of the furnace; rolling when the temperature is within 1,050-1,150 DEG C; rolling, and cogging for two times, wherein the billet is rolled for 14-18 times in all roughly, moderately and finely, and the total compression ratio is 64-156; cooling to 600-680 DEG C at a speed of 8-12 DEG C / s after the fine rolling is finished; finally air-cooling to the room temperature. According to the HRB500 reinforcing steel bar and the preparation method, the strength of the reinforcing steel bar is improved through tissue phase change. Compared with the prior art, the HRB500 reinforcing steel bar is smelted by using a smelting method for ordinary steel, and is subsequently cast into the billet, and meanwhile the alloy content is reduced, so that the product cost is lowered.

Owner:武汉钢铁有限公司

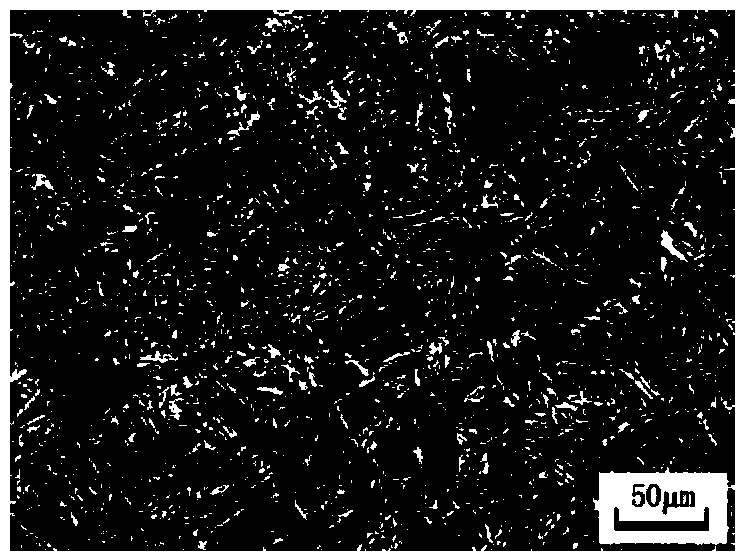

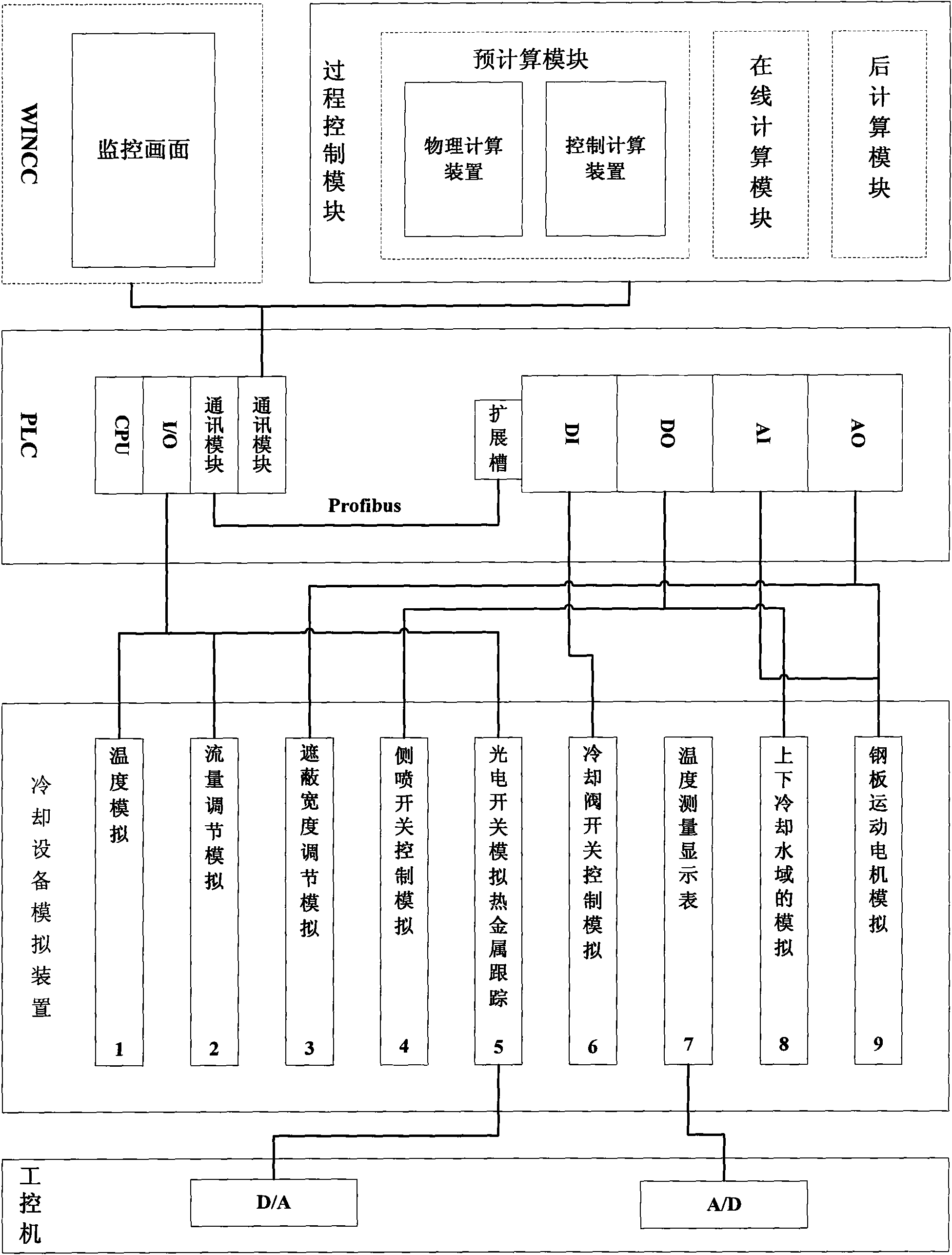

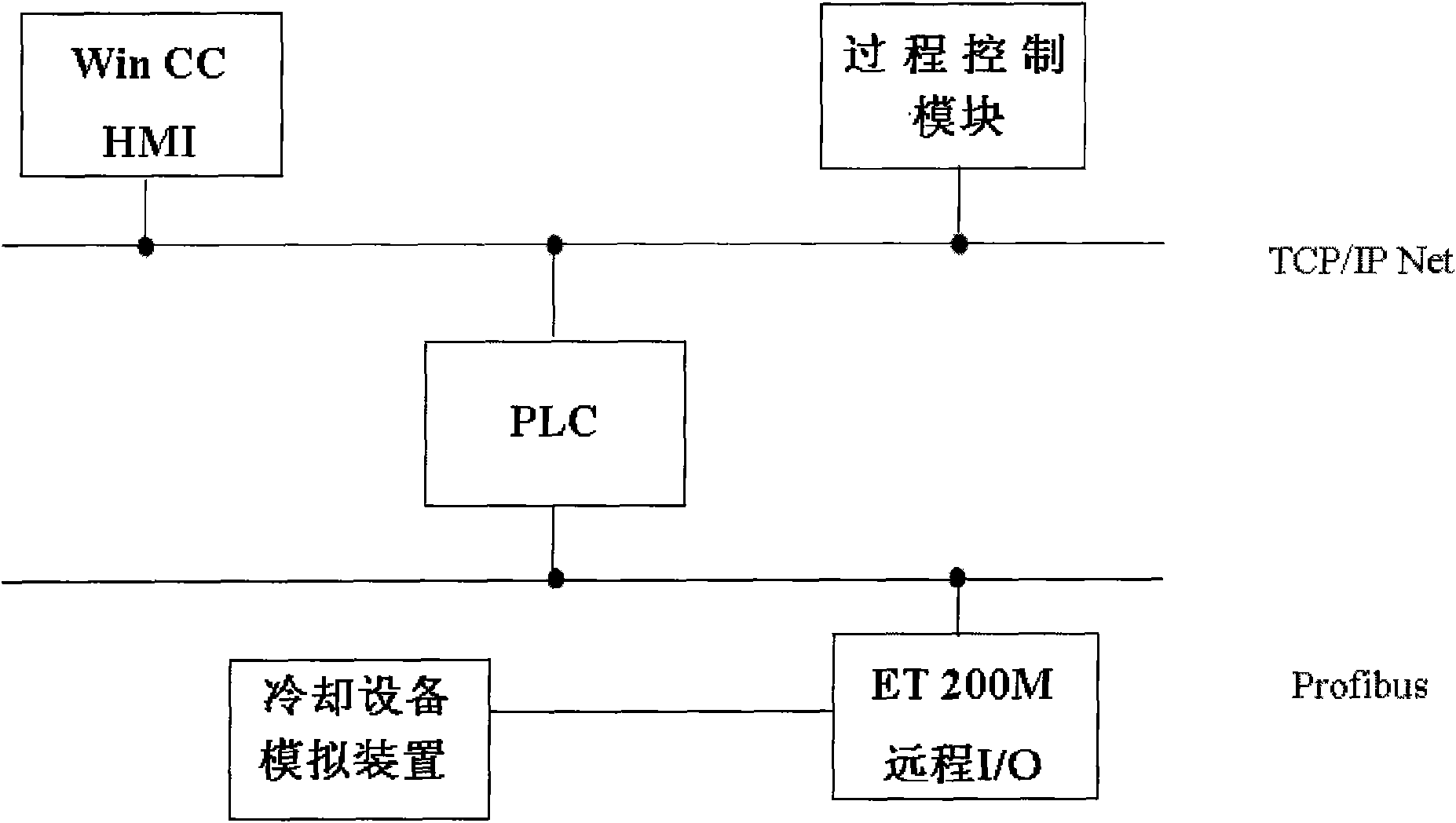

Method for simulating steel board cooling control

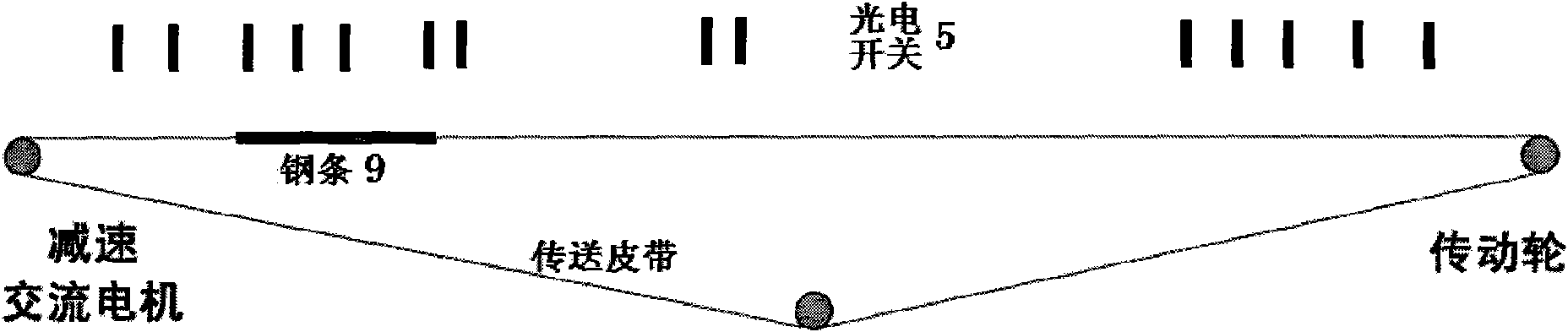

ActiveCN101639691ARealize closed-loop controlMeet the mechanical propertiesWork treatment devicesTotal factory controlProcess systemsControl system

The invention discloses a method for simulating steel board cooling control. A process control device is connected with a cooling apparatus simulating device by a PLC. The cooling apparatus simulatingdevice comprises a transmission device on which a steel bar is fixed, a cooling process temperature calculating device for simulating temperature measurement, a polling display instrument for displaying temperature, an electric potentiometer, a photoelectric switch and a position indicator. The photoelectric switch is arranged on a movement path of the steel bar. The process control device accomplishes the optimum setting of PLC control amount. The PLC accomplishes real-time control of a cooling simulating process. The cooling apparatus simulating device actually opens or closes and adjusts asimulating cooling line and realizes real-time data acquisition. Through the hardware mutual connection and software cooperation of the devices, the simulation on a cooling control process system isaccomplished. The invention provides a pilot plant test device of simulation evaluation for the improvement and completion of the control system.

Owner:BAOSHAN IRON & STEEL CO LTD

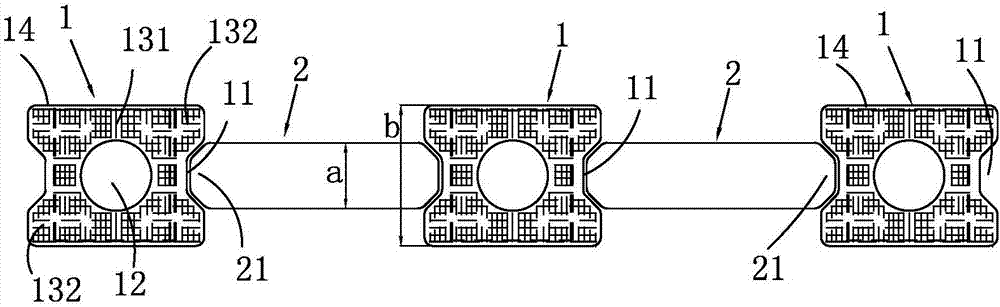

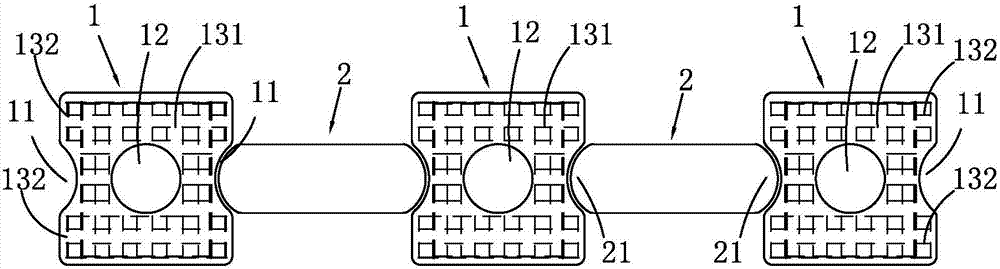

Ecological landscape combination revetment

An ecological landscape combination revetment comprises stress piles and inserting sheet piles, wherein, the inserting sheet piles are used for being in fit connection with the stress piles and used for blocking soil and stopping water, the left and right sides of one of the stress piles and the inserting sheet piles are correspondingly provided with inserting slots extending in the longitudinal direction, and the left and right sides of the other one of the stress piles and the inserting sheet piles are correspondingly provided with inserting parts which extend in the longitudinal direction and are matched with the corresponding inserting slots in a mutual abutting mode. A new technical scheme of the ecological landscape combination revetment is provided, the ecological landscape combination revetment is mainly composed of the stress piles and the inserting sheet piles, every two stress piles are connected through one inserting sheet pile for blocking soil and stopping water, the stress piles and the inserting sheet piles adopt two specifications, and the requirements for revetment and supporting stress can be met; and the skipped piling construction method is adopted during construction, thus the soil-squeezing effect is weakened, the positioning accuracy is high, and the effect of the formed surface is good.

Owner:建华建材科技(江苏)有限公司 +1

Low-pressure casting method of thin-wall aluminum alloy part

The invention discloses a low-pressure casting method of a thin-wall aluminum alloy part, and relates to the field of low-pressure metal casting. The method comprises the following steps: 1, coating a heat conducting lubricating paint on the inner walls of a mold cavity and a riser tube; 2, preheating the mold cavity and melting aluminum alloy; 3, performing gas replacement in a smelting furnace; 4, adding strontium salt; 5, deteriorating and removing impurities; 6, pouring under low pressure; 7, maintaining pressure and cooling after the pouring is finished; 8, performing bipolar homogenization treatment; 9, cooling, opening the mold and taking the part. A thin-wall aluminum alloy casting finished by the method can adapt to the complex and variable environments in aviation flight and meets the requirement on the mechanical property of the thin-wall casting in the aviation flight.

Owner:佛山市顺德区甲坚金属制品有限公司

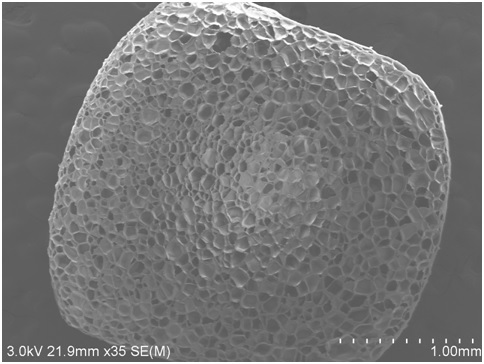

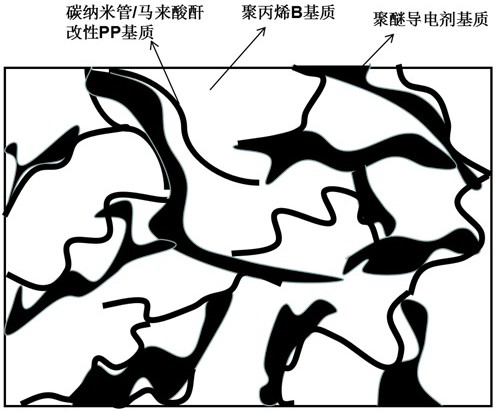

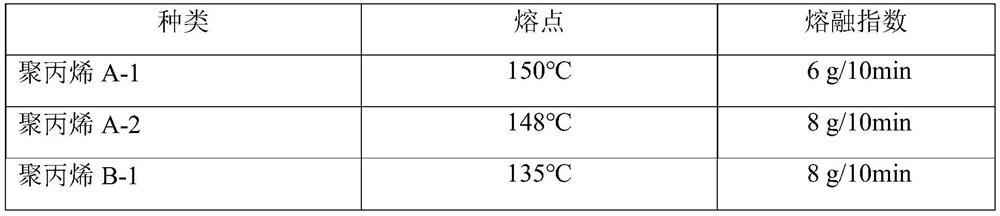

Gray antistatic polypropylene composite foamed beads with skin-core structure and molded product thereof

The invention discloses gray antistatic polypropylene composite foamed beads with a skin-core structure, which are composed of a foamed core layer and a non-foamed skin layer, and the foamed core layer is composed of polypropylene, a cell nucleating agent, an antioxidant, colored carbon black and a lubricant. The skin layer is prepared from polypropylene, a polyether block copolymer antistatic agent, maleic anhydride grafted modified polypropylene and multi-walled carbon nanotube; the composite foamed beads are obtained by extruding and granulating through a co-extrusion extruder and then foaming through a high-pressure foaming kettle. The skin layer contains the composite antistatic agent and the low-melting-point polypropylene, so that good fusion bonding, apparent quality and stable permanent antistatic property of the molded product are guaranteed; the foaming effect of the core layer is excellent, and the foaming ratio adjustability and the excellent mechanical property of a molded product are guaranteed. The molded product not only has permanent antistatic property, but also has good rigidity.

Owner:WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

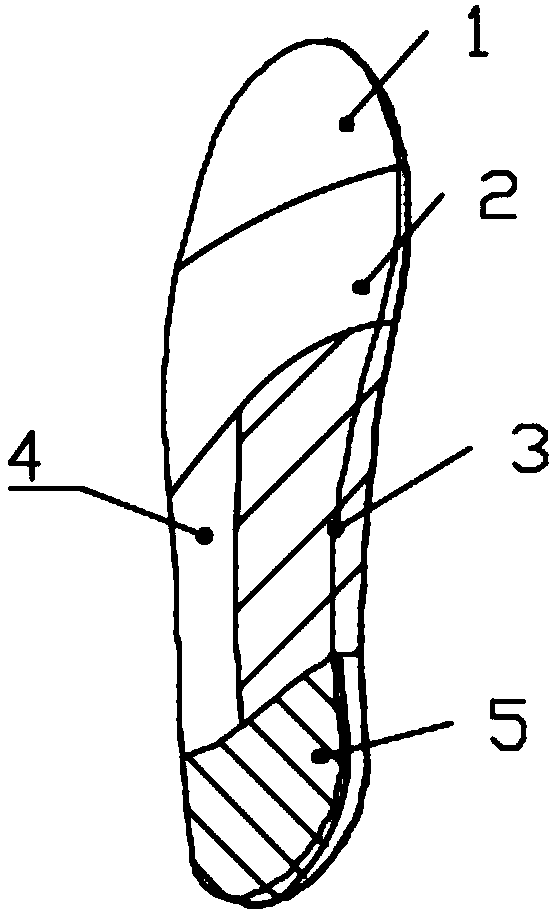

Flexible orthopedic shoe pad and preparation method thereof

ActiveCN109674144APrecise modulus designCorrectly designedFoot measurement devicesAdditive manufacturing apparatusStrength of materialsData acquisition

The invention discloses a flexible orthopedic shoe pad and a preparation method thereof. The method comprises the following steps: establishing a shoe pad model having foot bottom morphology accordingto foot data; by acquiring foot evaluation index data, foot bottom pressure distribution data and foot appearance scanning data, by using a corresponding optimization relation between key shoe-pad appearance parameters and the foot evaluation indexes and a corresponding relation between material performance distribution of the shoe pad and foot bottom pressure distribution, adjusting the outer contour model of the orthopedic shoe pad and the mechanical property of the material; and preparing the flexible orthopedic shoe pad by adopting a 3D printing process. The shoe pad is filled by virtue of a porous structure with adjustable mechanical property of the material, and finally the personalized porous shoe pad model is printed, so that the shoe pad can bring the optimal comfort level to a wearer and is convenient and rapid.

Owner:XI AN JIAOTONG UNIV

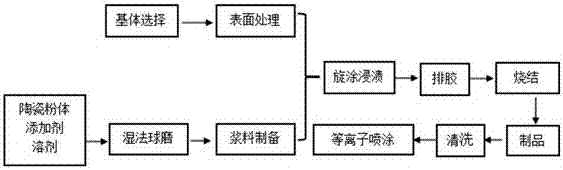

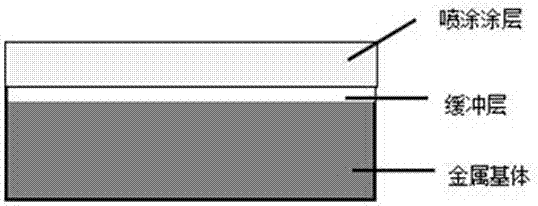

Internal-heated integrated evaporation boat with aluminum oxide porous structure buffering layer

InactiveCN107326330ASolve Oxidation ProblemsHigh bonding strengthVacuum evaporation coatingSputtering coatingPorosityStress relieving

The invention discloses an internal-heated integrated evaporation boat with an aluminum oxide porous structure buffering layer. Surface coatings of the evaporation boat totally comprise two layers. The inner layer is the Al2O3 buffering layer of a loose porous structure, and the outer layer is the compact low-porosity corrosion-resistantAl2O3 coating. Firstly, through a rotary-coating steeping technique, the Al2O3 buffering layer with the thickness being 0.1-0.3 mm is prepared on the surface of a matrix; and then through a plasma spraying technology, the Al2O3 corrosion-resistantlayer with the thickness being 0.5-1 mm is sprayed and prepared on the evaporation boat with the buffering layer. According to the composite technique, the evaporation boat with the Al2O3 coatings of different microstructures is prepared; in service, the buffering layer of the porous structure can achieve the stress relieving effect and can further prevent the problem of matrix oxidization caused by later spraying; and the compact low-porosity Al2O3 coating brings excellent corrosion resistance into play and can be widely applied to the technical field of vacuum evaporation metal thin films.

Owner:FUZHOU UNIV

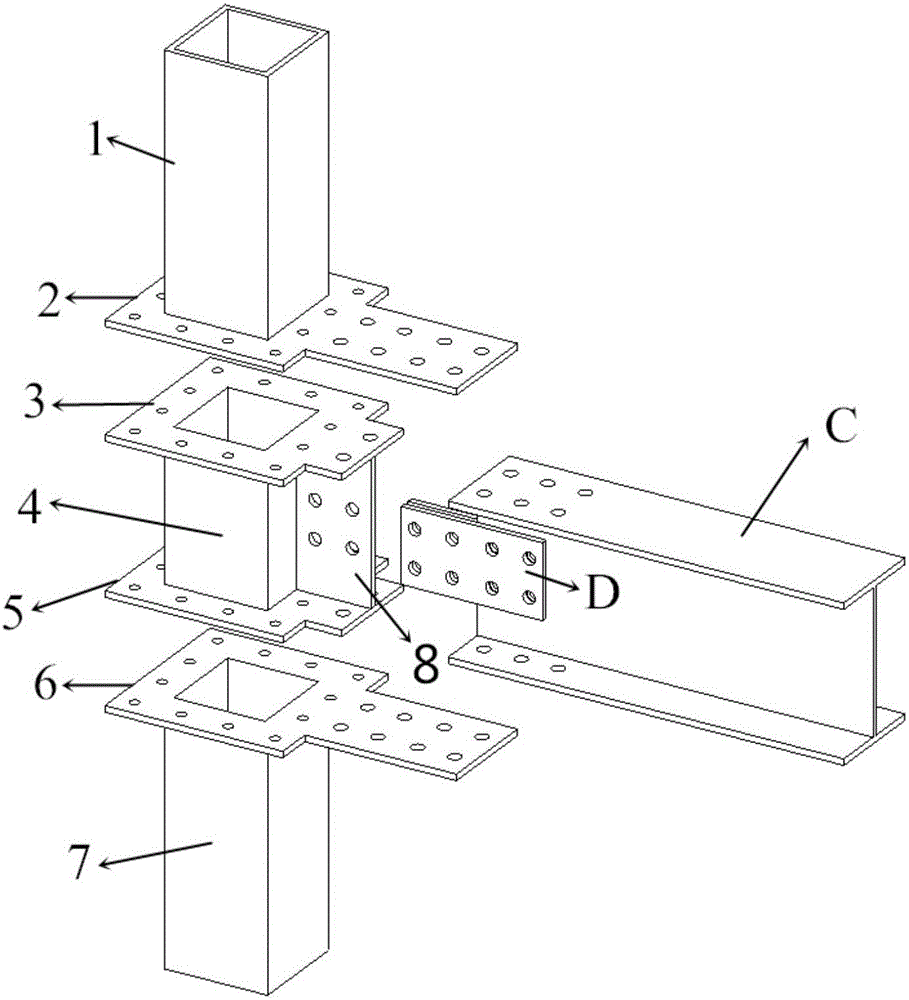

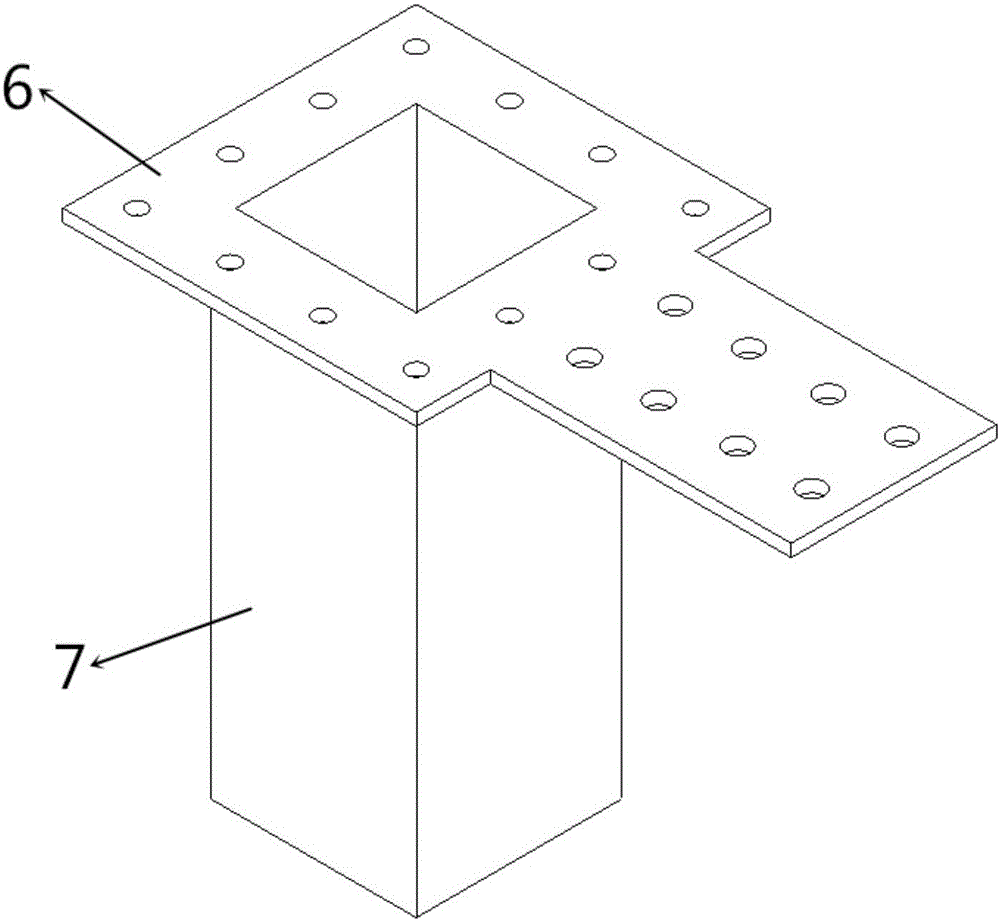

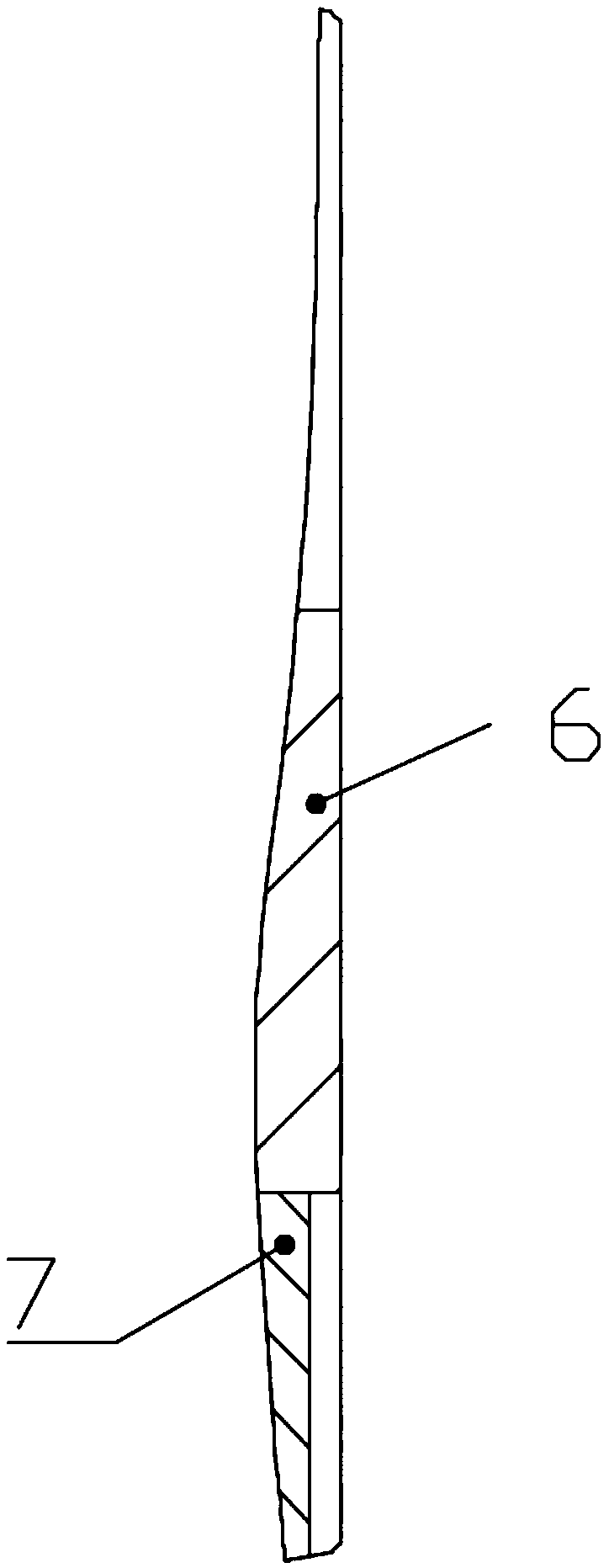

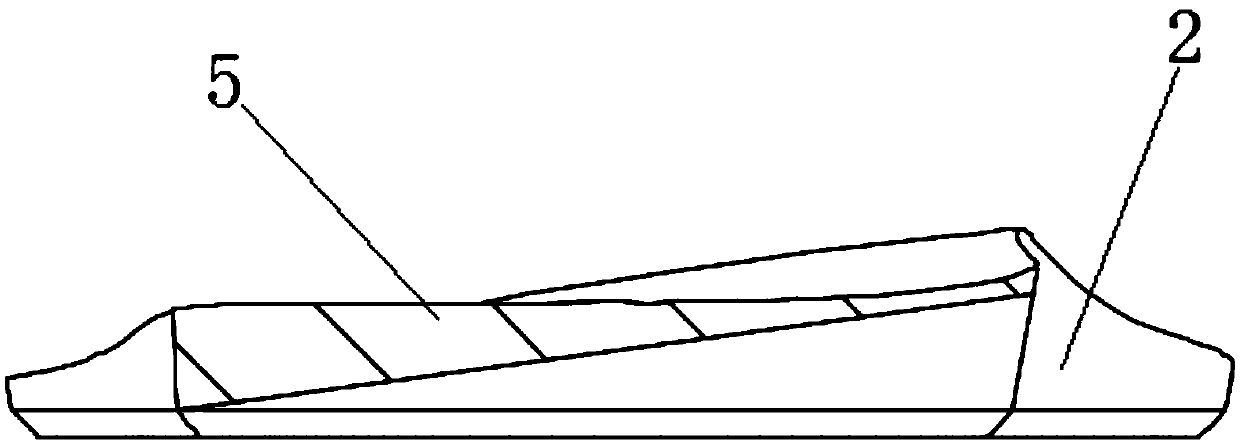

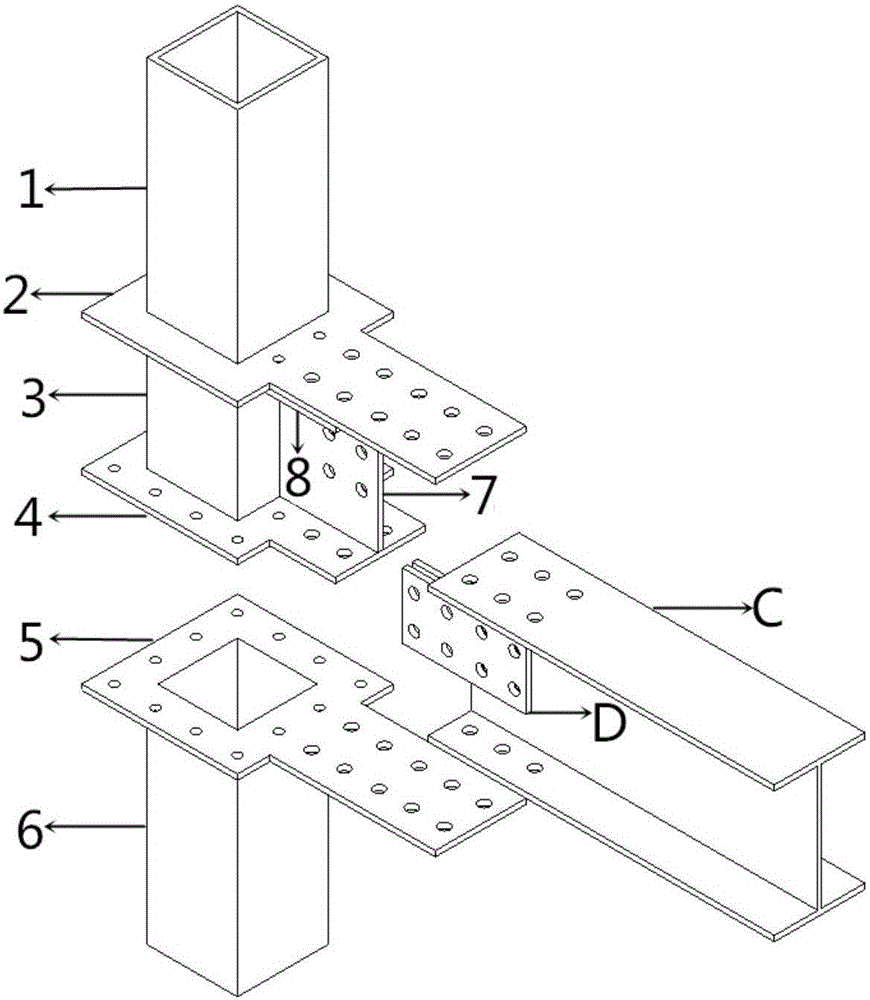

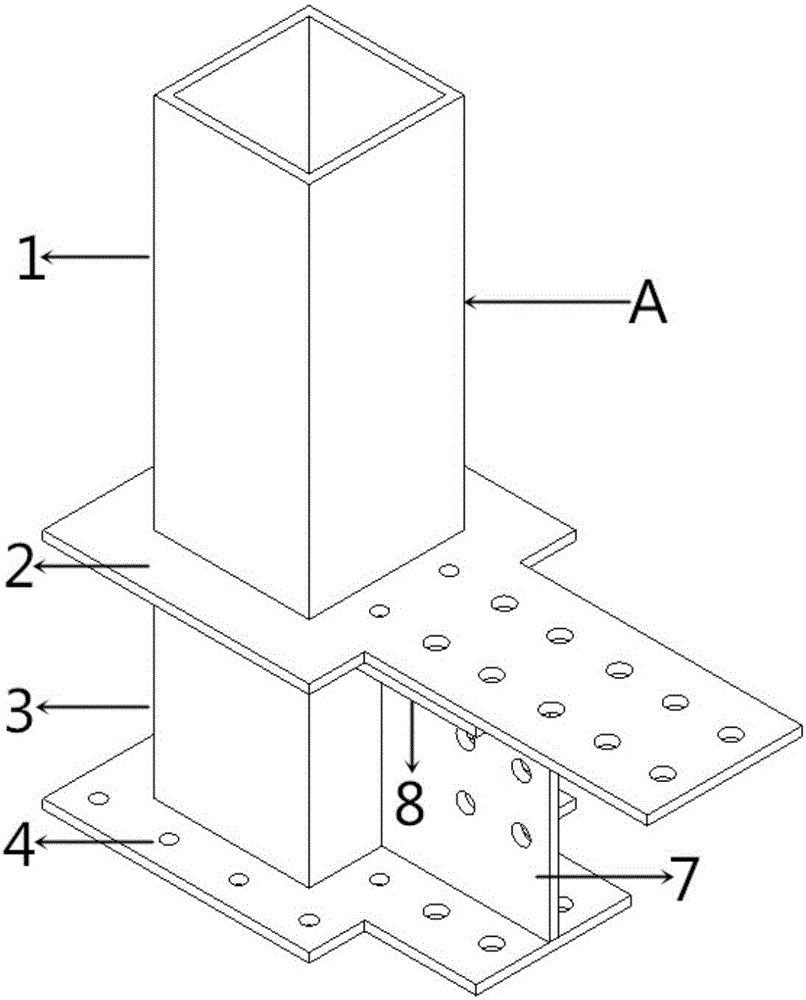

Assembly type single-flange beam column bolt joint connecting device provided with cover plates

ActiveCN105926773AMeet the mechanical propertiesEasy to assembleBuilding constructionsUltimate tensile strengthBeam column

The invention provides an assembly type single-flange beam column bolt joint connecting device provided with cover plates and belongs to the technical field of structural engineering. The assembly type single-flange beam column bolt joint connecting device comprises an upper column flange plate provided with the cover plate, a square steel pipe column, an outer rib provided with the cover plate, a lower column flange plate provided with the cover plate, a lower square steel pipe column, an H-shaped steel beam, a flitch plate and a clamping plate. The upper square steel pipe column, the corresponding flange plate provided with the cover plate, and the outer rig provided with the cover plate are welded into a whole in a factory. The lower square steel pipe column and the corresponding flange plate provided with the cover plate are welded into a whole in the factory. According to the assembly type single-flange beam column bolt joint connecting device, welding can be completed in the factory, bolts are used for filed assembly, fastening of the bolts is convenient and fast, the construction speed and quality are greatly improved, and the assembly type single-flange beam column bolt joint connecting device adapts to the development of an assembly type steel structure; and joints of the connecting device are semi-rigid joints and are good in ductility and high in bearing capacity. Meanwhile, the clamping plate is made of low-strength steel so that earthquake energy can be fully dissipated, and post-earthquake repairing is facilitated.

Owner:BEIJING UNIV OF TECH

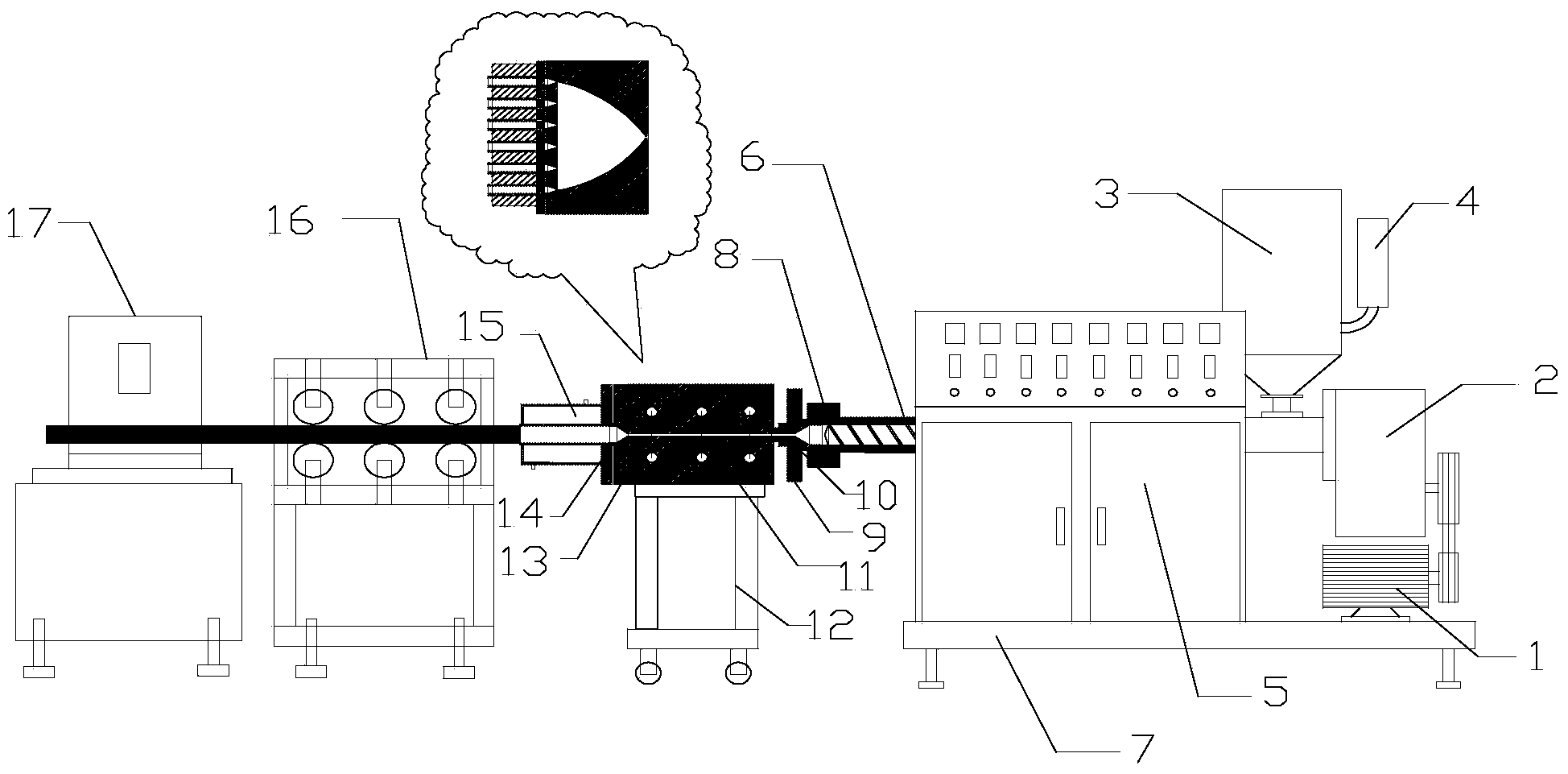

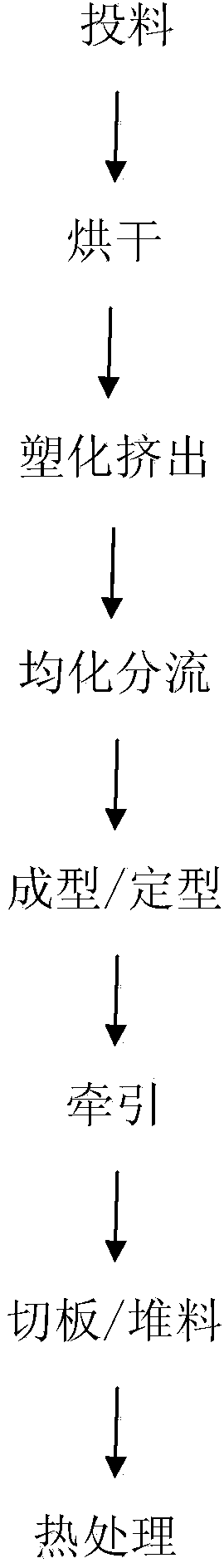

PEEK plastic rod production device and process

InactiveCN103722718AReduced flow marks and scratchesMeet the mechanical propertiesPolyether ether ketoneCompression device

The invention discloses a PEEK plastic rod production device and process. The PEEK plastic rod production device comprises a main machine and an auxiliary machine. The main machine is an extruder and comprises an extruding system, a rotating system and a control system, wherein the extruding system is a gun barrel screw; the rotating system comprises a motor and a reduction box; the control system comprises an electric appliance instrument and an actuating mechanism; the auxiliary machine comprises a mold, a traction machine, an oil temperature machine, a cutting machine and an oven; the mold comprises a main mold, a guide plate, a heat insulation ring, a forming shaping barrel and a cooling water tank; the oil temperature machine is installed on a shaping section of a forming pipe; the traction machine mainly comprises a transmission device, a roller compression device and a brake device, and is installed behind a heat preserving device; the cutting machine is installed behind an outlet of the mold; the oven is a closed box body. The process comprises the steps of charging, drying, plasticizing extruding, homogenizing distributing, forming / shaping, pulling, cutting / stacking and thermal processing.

Owner:深圳市恩欣龙特种材料股份有限公司

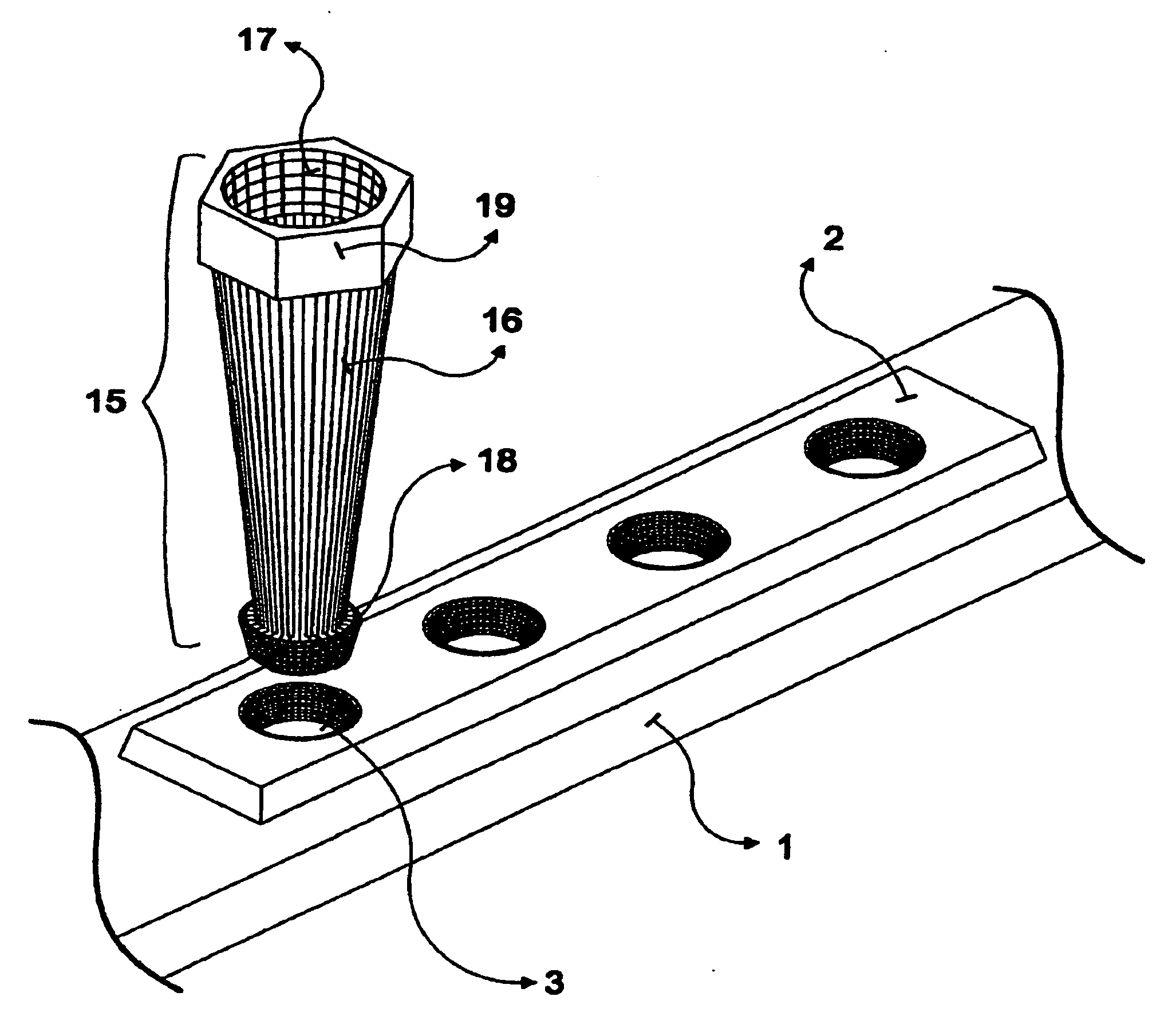

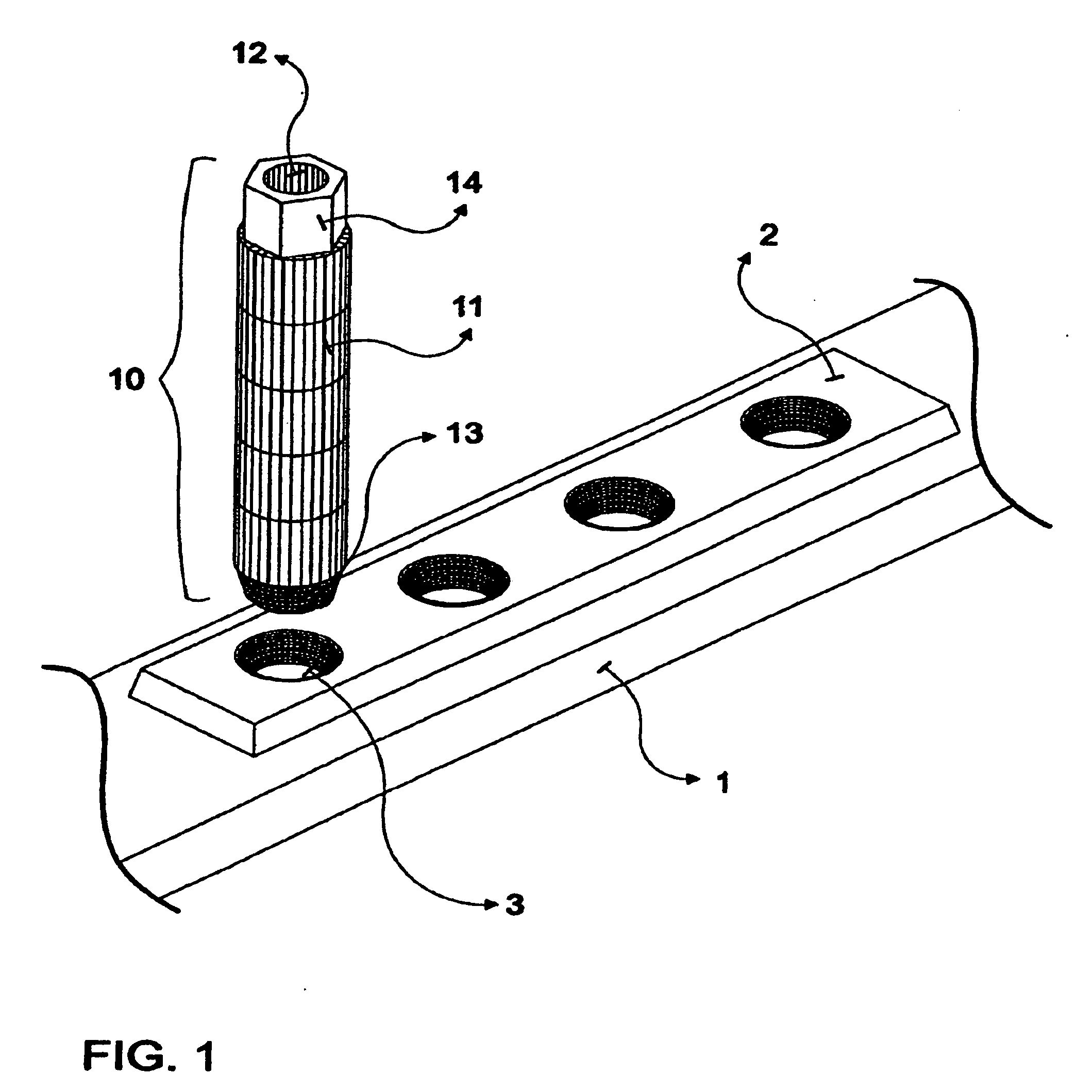

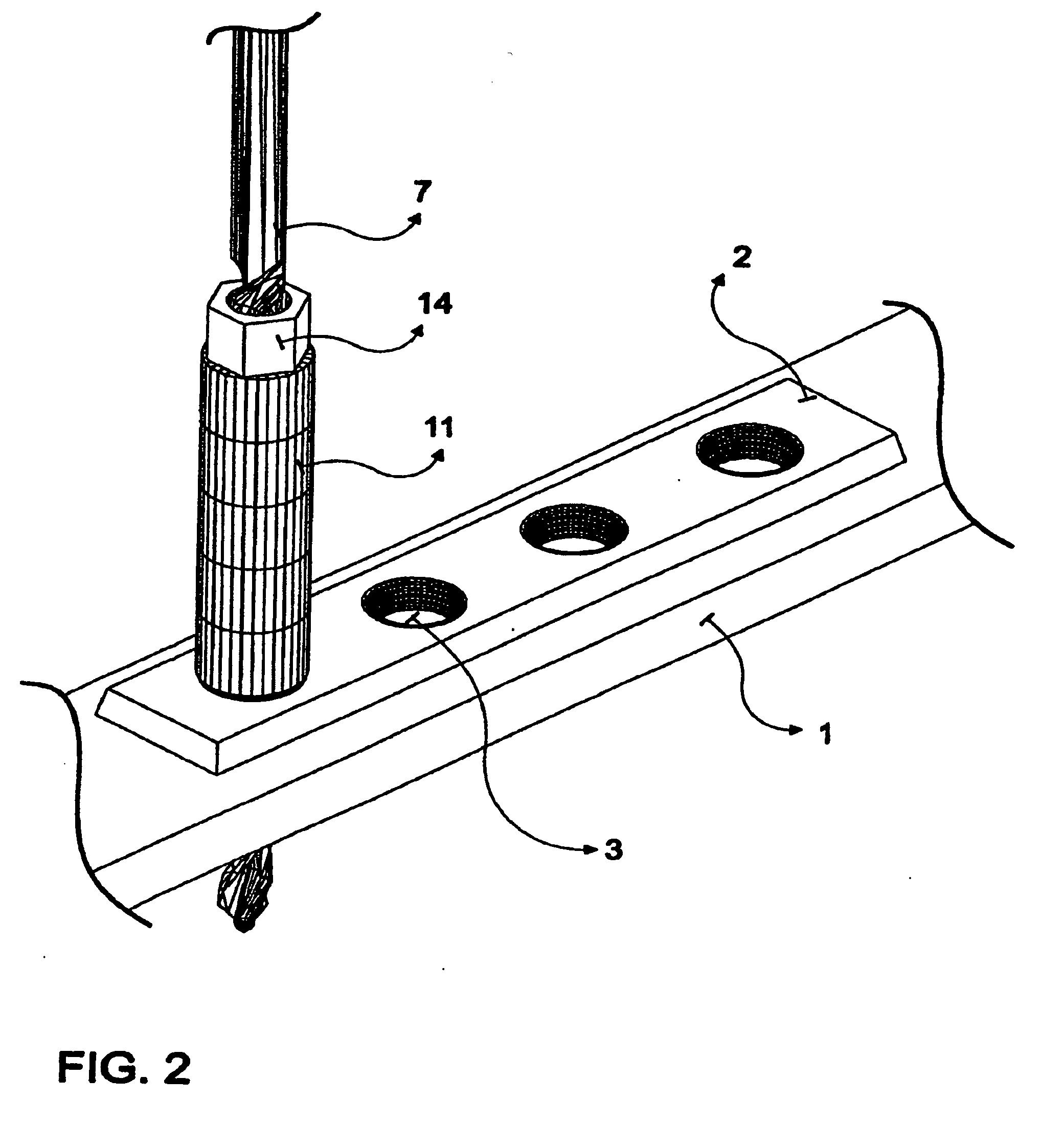

Locking Bone Plates with Controlled Locking Screw Misalignment

InactiveUS20090204157A1Safe and reliable removalLess vascular damageProsthesisFastenersEngineeringIliac screw

A bone plate system for fixing bone fractures includes a locking bone plate and a conically-shaped drilling sleeve. The bone plate has at least one threaded hole, and with the drilling sleeve screwed into the bone plate hole, a drill bit guided through the sleeve drills a hole into bone having a central axis angularly misaligned with the central axis of the bone plate hole. The angle between the drilled hole's central axis and the bone plate hole's central axis is equal to or less than the tolerance angle of the threads of the bone plate hole. This allows a bone plate screw to be imperfectly seated with respect to the bone plate hole and still screwed into the hole to lock the plate without jamming the screw head into the plate hole, while still allowing the screw to be screwed out if needed.

Owner:SYNTHES GMBH

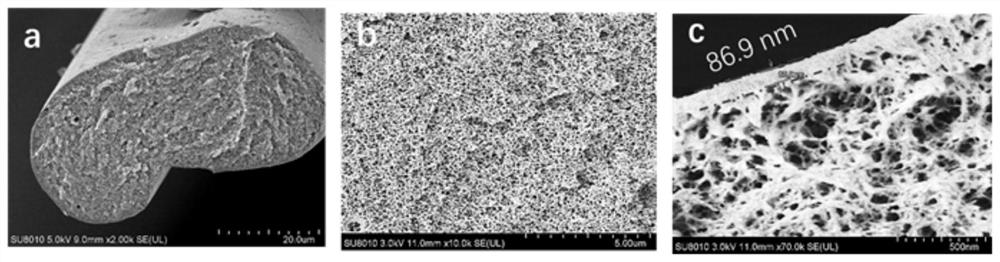

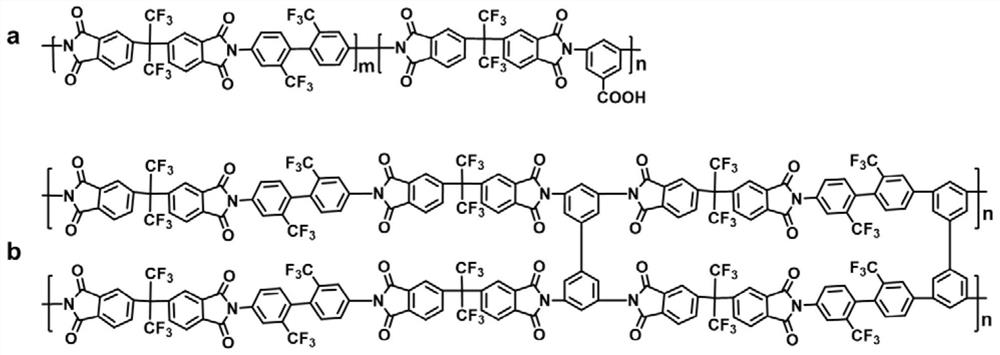

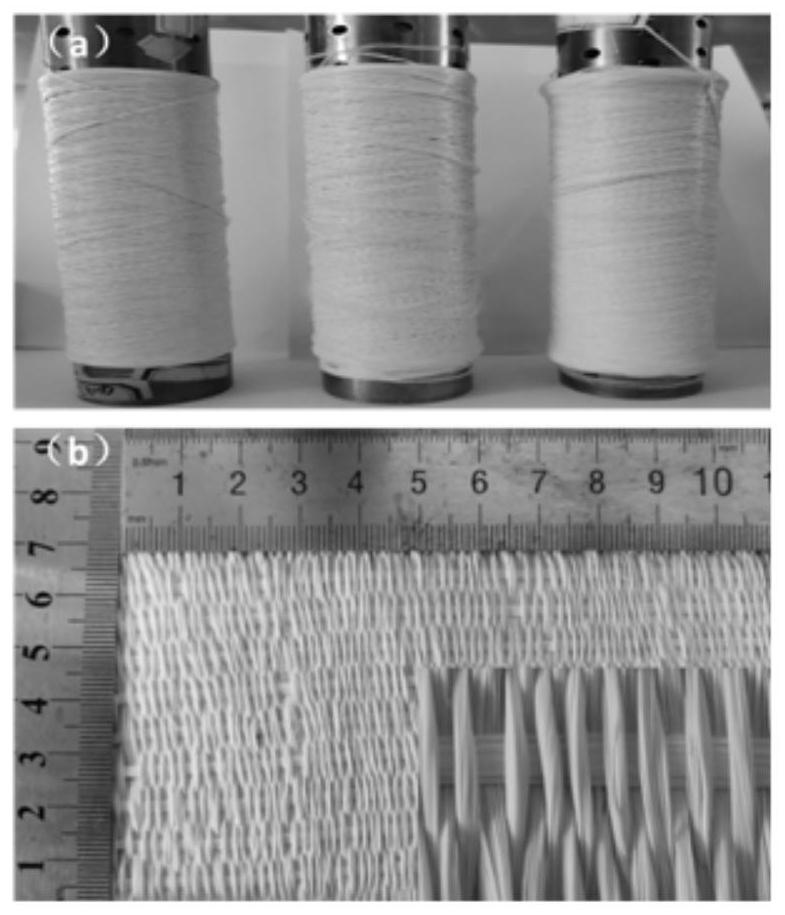

Polyimide aerogel fiber as well as preparation and application thereof

ActiveCN111808283ASimple processThe spinning process is green and environmentally friendlyArtificial filament washing/dryingArtificial filament heat treatmentDiaminePolyimide

The invention relates to a polyimide aerogel fiber as well as preparation and application thereof, and the polyimide aerogel fiber is obtained by taking a binary anhydride and a diamine as raw materials through wet spinning and freeze drying. The method is simple to operate, environment-friendly in process and beneficial to large-scale production. The polyimide aerogel fiber material prepared by the method is high in strength and good in heat resistance, has excellent heat insulation and preservation characteristics, and can be widely applied to the field of preparation of various heat insulation and preservation.

Owner:DONGHUA UNIV

Processing method of nickel and nickel alloy tubular products

The invention provides a processing method of nickel and nickel alloy tubular products, and belongs to the field of material processing. The processing method comprises following steps: a prepared raw material is subjected to melting in a vacuum melting furnace at a temperature of 2150 to 2750 DEG C; the melted raw material is injected into a graphite mould so as to obtain round rod-shaped ingot casting; the round rod-shaped ingot casting is cooled, is subjected to outer surface lathing so as to remove an outer rough layer, and is provided with a central hole along the central axis; the round rod-shaped ingot casting provided with the central hole is heated to a temperature of 800 to 1250 DEG C, and the temperature is maintained so as to realize complete roasting; the roasted round rod-shaped ingot casting is delivered into a large-tonnage extruding machine so as to obtain tube blank via extruding; the obtained tube blank is subjected to a plurality of times of oil removing and grease removing, vacuum annealing at a temperature of 550 to 950 DEG C, and rolling according to practically needed tubular product specification until the quality of an obtained product is close to demands on the finished tubular products; the obtained product is subjected to a last time of rolling or drawing so as to achieve practical dimensional precision, and then is subjected to straightening; the rolled head and the tail end of a straightened tubular product are cut off using a lathe; and then the tubular product is subjected to deburring and cleaning. The processing method is simple; yield is high; and quality of the prepared tubular products is stable and reliable.

Owner:高玉树

Method for machining shell liner of shell in semi-autogenous mill

ActiveCN103522016AGood toughness and work hardening abilityImprove hardenabilityFoundry mouldsFurnace typesHardnessEconomic benefits

The invention discloses a method for machining a shell liner of a shell in a semi-autogenous mill. A lifting strip is arranged in the center of the shell liner, the upper portion of the lifting strip is arranged to be a right angle, the lower portion of the lifting strip is arranged to be an obtuse angle, reinforcing ribs and lifting holes are symmetrically and evenly distributed in the two sides of the lifting strip, the shell liner is made of ultrahigh manganese steel alloy, according to the formula, the alloy comprises, by weight, 1.0-1.4% of carbon, 17-19% of manganese, less than 0.05% of phosphorus, 0.3-1.0% of silicon, less than 0.05% of sulphur, less than 0.2% of aluminum, less than 0.5% of vanadium, 1.5-2.5% of chrome, less than or equal to 1.5% of nickel, less than or equal to 0.5-1% of copper, 0.3-1.0% of molybdenum, a micro amount of bohemium, and the balance iron. According to the method, the material formula is changed, the structure of the shell liner is designed, the thermal treatment process is optimized, the whole intensity and hardness of the shell liner are improved, and the mechanical performance of the equipment is met. The labor intensity is reduced, the service life of the equipment is prolonged by at least more than six months, and the economic benefits are improved.

Owner:JIANGSU XINGYUAN POWER PLANT & METALLURGICAL EQUIP MFG

Production process of high-performance 6082 aluminum alloy cross beam product

ActiveCN106086540AStable mechanical propertiesMeet the mechanical properties6082 aluminium alloyMaterials science

The invention discloses a production process of a high-performance 6082 aluminum alloy cross beam product, and belongs to the technical field of processing of aluminum alloys. The production process comprises respective control of such procedures as raw material preparation, product production and aging. As the production process controls all parameters in the production process, the product mechanical performances are satisfied; meanwhile, the parking effect phenomenon is weakened; and after the product is parked by 30 days, through aging of 145+-3 DEG C*10 h, the mechanical performances are still qualified, the production demands are satisfied, and the guarantee is provided for later use of customers.

Owner:CHINA ZHONGWANG

High-temperature-resisting forge piece for turbine and forging method of high-temperature-resisting forge piece

InactiveCN107695266AMeet the mechanical propertiesReduce cracking phenomenonMetal-working apparatusTurbineForge

The invention provides a high-temperature-resisting forge piece for a turbine and a forging method of the high-temperature-resisting forge piece. The high-temperature-resisting forge piece for the turbine comprises, by weight percent, 0.20%-0.24% of C, 0.10%-0.50% of Si, 0.50%-0.80% of Mn, smaller than or equal to 0.025% of P, smaller than or equal to 0.020% of S, 11.8%-12.5% of Cr, 1.0%-1.20% ofMo, 0.60%-0.80% of Ni, 0.25%-0.35% of V, 0.02%-0.05% of Al, smaller than or equal to 0.60% of W, 0.02%-0.05% of Nb, and the balance Fe and inevitable impurities, wherein the concentration of N is 80 PPm-180 PPm.

Owner:JIANGYIN FANGYUAN RINGLIKE FORGING & FLANGE

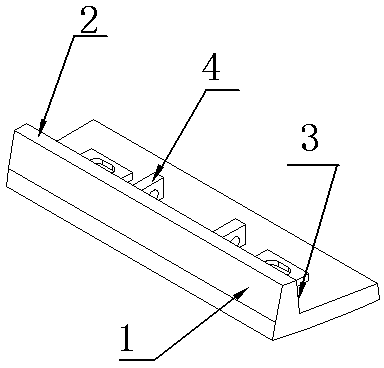

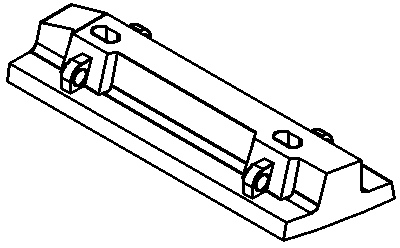

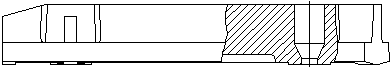

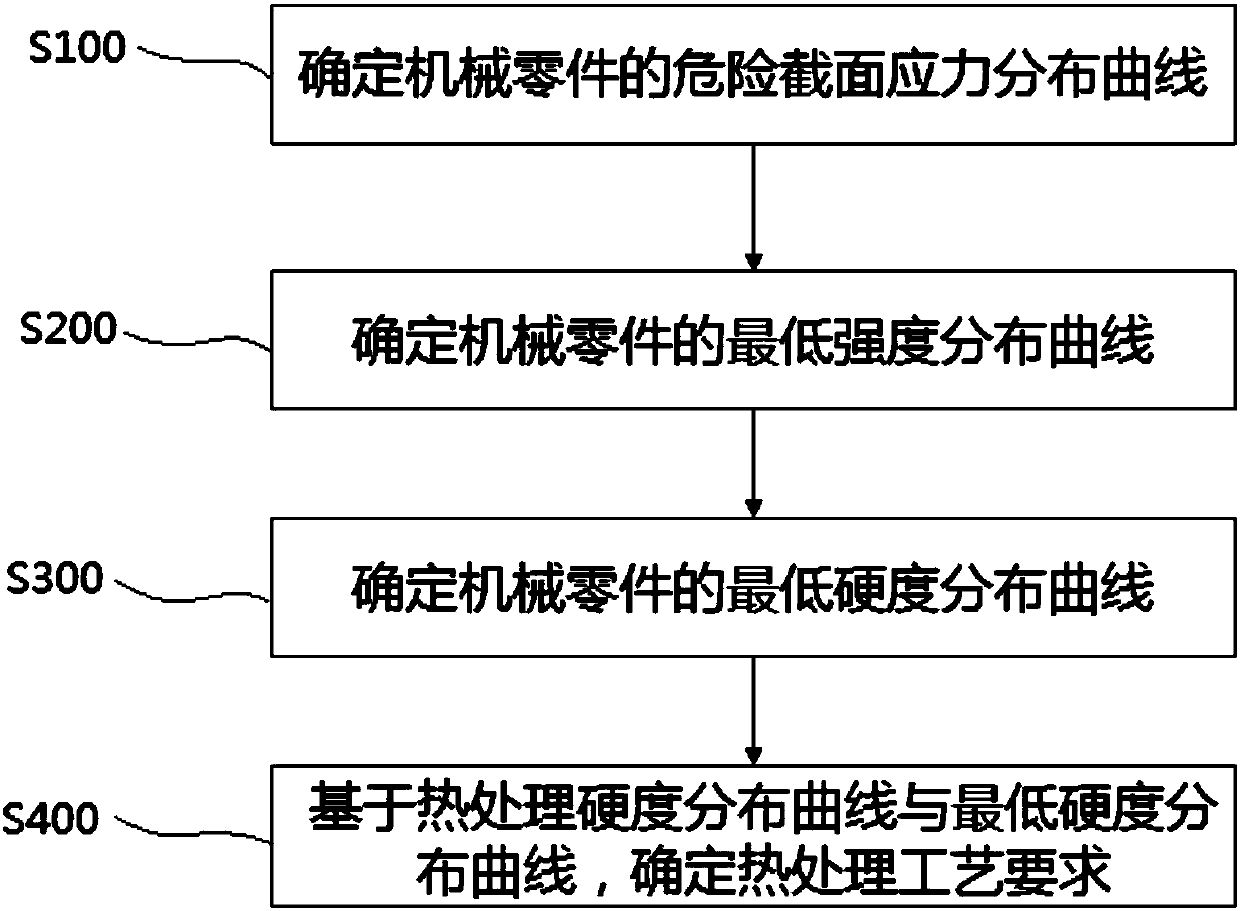

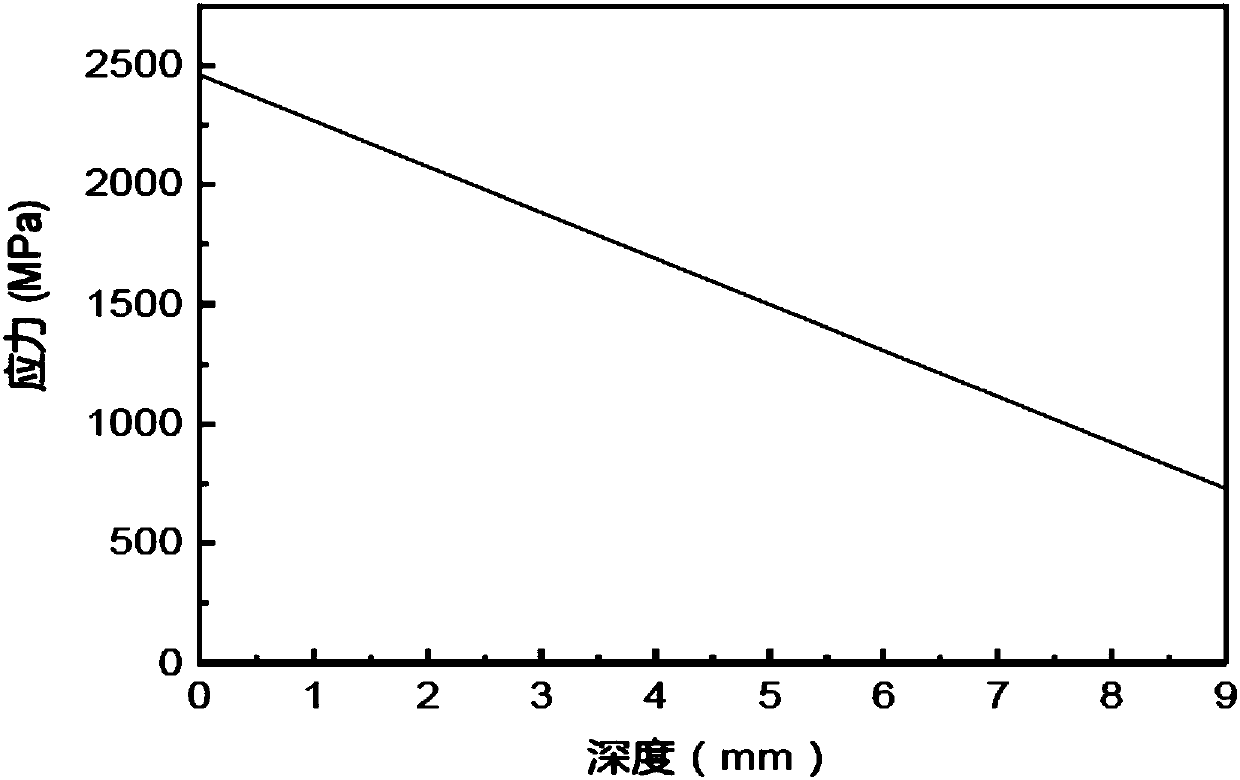

Determination method of mechanical part heat treatment strengthening process requirements

ActiveCN107904393AReduce the failure rateFully consider the hardness requirementsHeat treatment process controlHardnessUltimate tensile strength

The invention relates to the technical field of heat treatment, in particular to a determination method of mechanical part heat treatment strengthening process requirements. The method comprises the following steps: a mechanical part is provided; a lowest hardness distribution curve of the mechanical part is determined; and a heat treatment strengthening process of the mechanical part is determined based on the lowest hardness distribution curve of the mechanical part. The heat treatment strengthening process of the mechanical part is determined based on the lowest hardness distribution curveof the mechanical part, so that the requirements of the strength on the hardness can be considered more sufficiently, more reasonable and more reliable heat treatment process requirements are formulated, the mechanical part is heated to preferably satisfy the needed mechanical performances, physical performances and chemical performances, and the product reject ratio of the mechanical part after heat treatment is reduced.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Preparation method of through-hole dual-network polymeric hydrogel scaffold

ActiveCN107158476AControllable Pore SizeOptimal Control StructureTissue regenerationProsthesisDual networkMolecular materials

The invention relates to a preparation method of a through-hole dual-network polymeric hydrogel scaffold, and belongs to the field of biomedical high-molecular materials. The method is characterized in that a porous scaffold manufactured by three-dimensional printing is taken as a template, and two-step polymer pouring and subsequent removal of the porous scaffold template are performed obtain the through-hole dual-network polymeric hydrogel scaffold. By adopting a preparation technology disclosed by the invention, technical limits caused by overlapping layer by layer and limits on the application of a hydrogel material in a three-dimensional printing manufacturing process can be broken effectively, and a through-hole dual-network polymeric hydrogel scaffold which is consistent with the porous scaffold template in structure, is molded at one time and has high mechanical property can be obtained.

Owner:SICHUAN UNIV

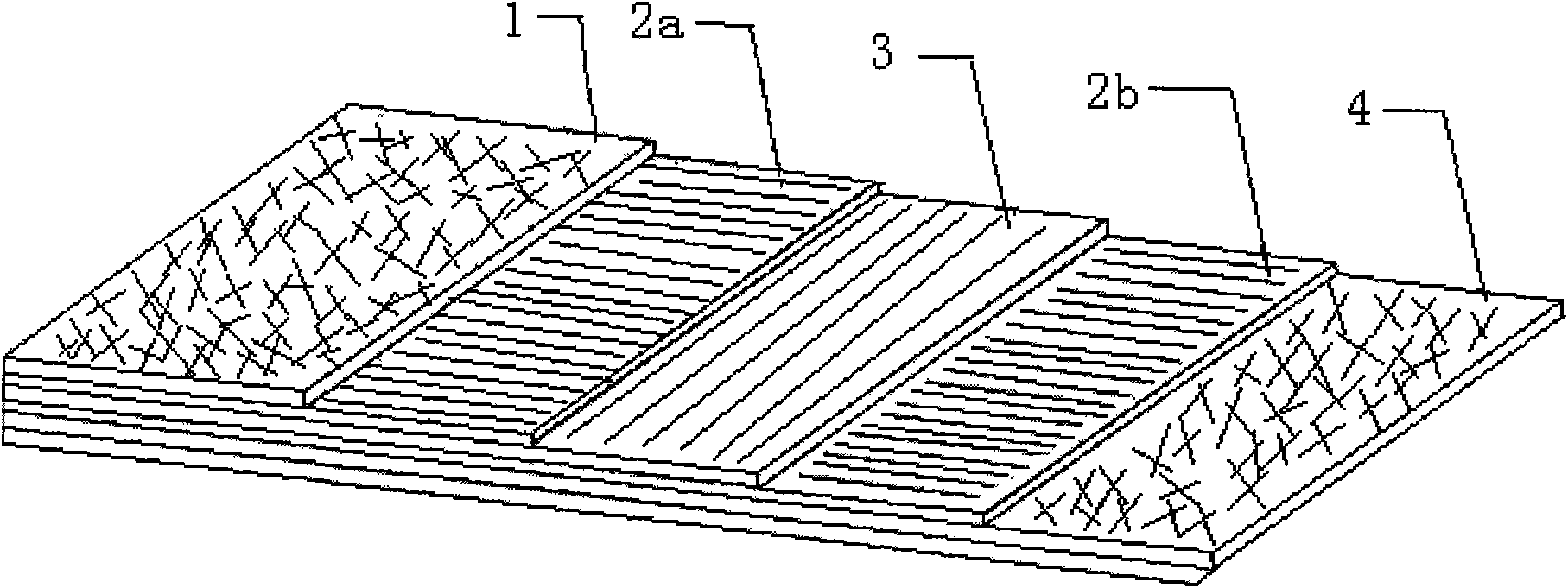

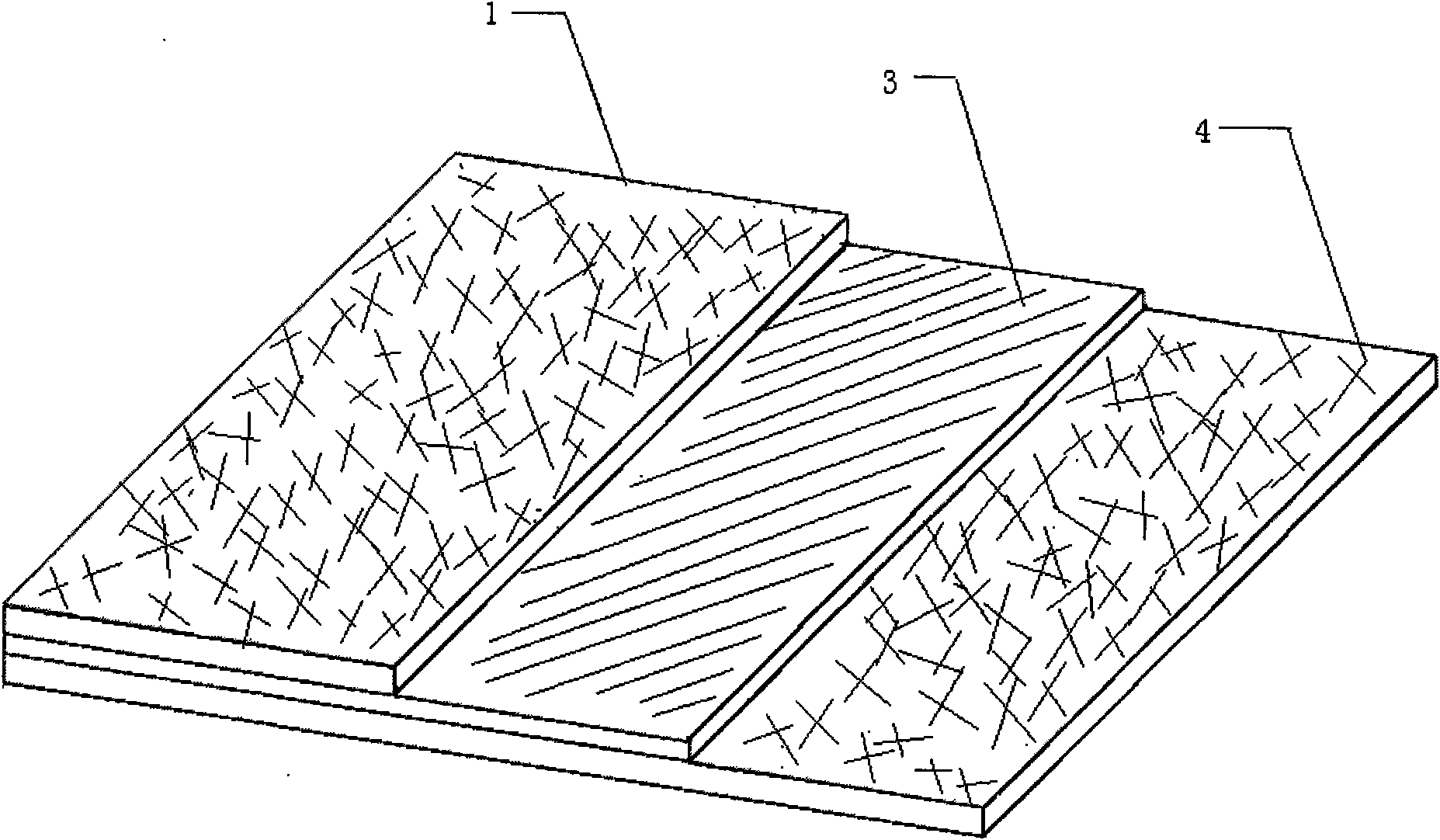

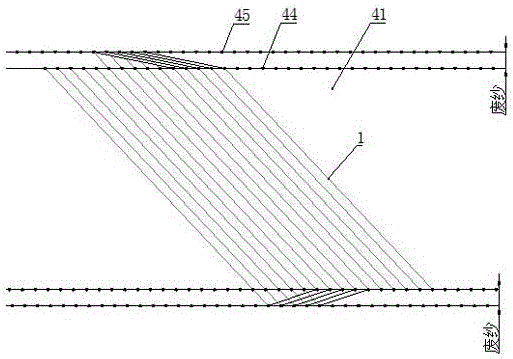

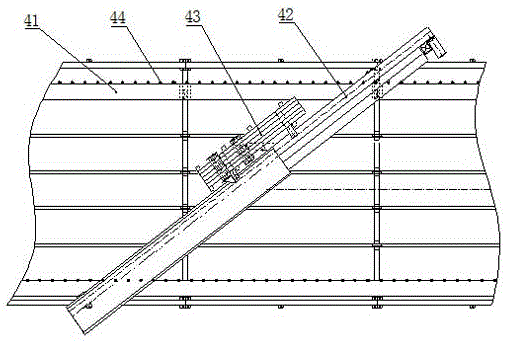

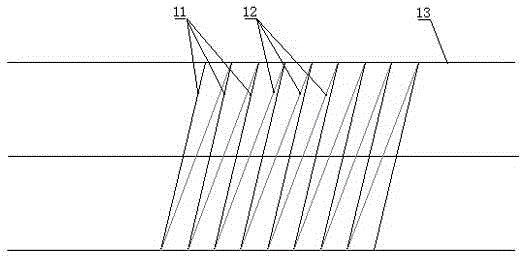

Manufacturing method of multi-axial composite base material

ActiveCN105015105AImprove structural strengthHigh surface finishLamination ancillary operationsLaminationGlass fiberWeft yarn

The invention relates to a manufacturing method of a multi-axial composite base material. The manufacturing method is characterized by comprising steps as follows: a multi-axial glass fiber yarn layer is laid, after a weft yarn laying trolley moves weft yarn layers of the glass fiber yarn layer from one side edge of a conveying belt to the outside of the other side edge of the conveying belt in a fixed direction, weft yarn is hooked on retaining pins of the conveying belt, then the weft yarn laying trolley returns to the starting point in the direction opposite to the original direction, and multiple pieces of continuous Z-shaped weft yarn with the same arrangement are formed on the conveying belt through combination of the weft yarn laying trolley with the direction of the conveying belt during forward and reverse movement; then glass fiber continuous felt is laid, sewn and wound. The manufacturing method has the advantages as follows: glass fiber weft yarn and glass fiber warp yarn are laid on the conveying belt respectively through a weft yarn laying device group and a let-off device, so that the multi-axial glass fiber yarn layer is formed, a layer of the glass fiber continuous felt is laid on the multi-axial glass fiber yarn layer after the multi-axial glass fiber yarn layer passes below a continuous felt unwinding device, then sewing is performed by a multi-needle quilting machine, and finally, the multi-axial composite base material is obtained through winding.

Owner:JIANGSU JIUDING UNIVERSAL WIND ENERGY

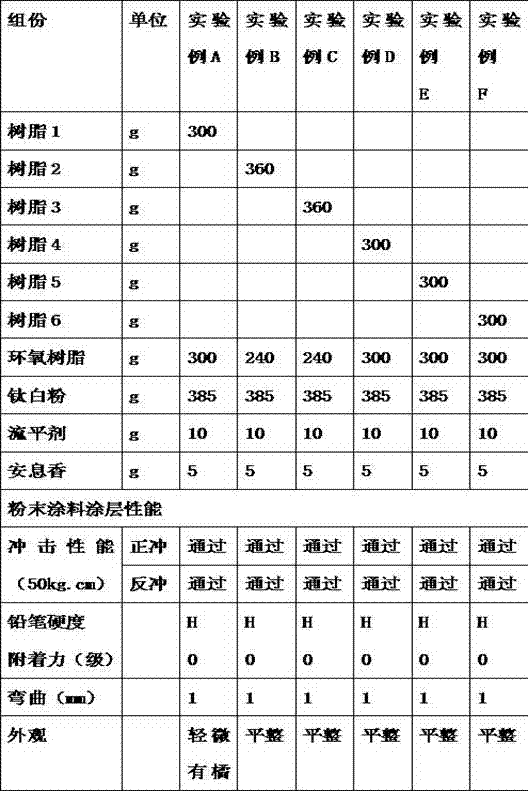

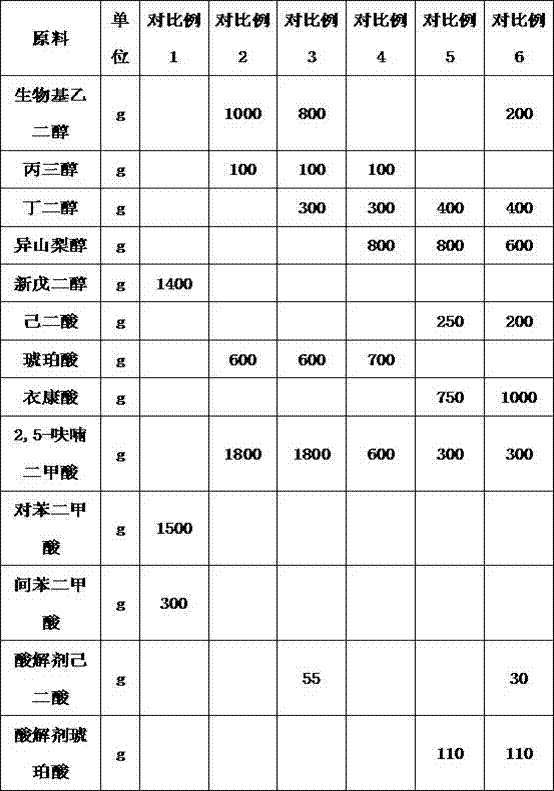

Bio-based polyester resin for powder coating and preparation method of bio-based polyester resin

InactiveCN107163234AGood levelingGood mechanical propertiesPowdery paintsPolyester coatingsChemistryNatural material

The invention discloses a bio-based polyester resin for powder coatings, which is characterized in that it comprises the following components and their mass percentages: bio-based polyol: 30-50%; bio-based polyacid 40-60%; bio-based acid Debonding agent 5-20%; Catalyst 0.03-0.15%; Said components are formed by melt polymerization, the acid value is 45-75mgKOH / g, the viscosity is 1500-3500mPa.s, and the number-average molecular weight is 1500-3000. A bio-based polyester resin with a glass transition temperature of 48-60°C; the invention also discloses a preparation method of the polyester resin: since the main raw materials used to synthesize the polyester resin are completely extracted from natural materials, the polyester The resin can be buried in the soil to degrade naturally without any impact on the ecology, and has obvious economic and social benefits; at the same time, the powder coating prepared with it has excellent leveling, excellent mechanical properties, and good storage performance, which can fully meet the indoor use of powder coatings.

Owner:广东猛特新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com