Bio-based polyester resin for powder coating and preparation method of bio-based polyester resin

A polyester resin and powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as different preparation methods, and achieve the effects of easy implementation, excellent mechanical properties, and suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

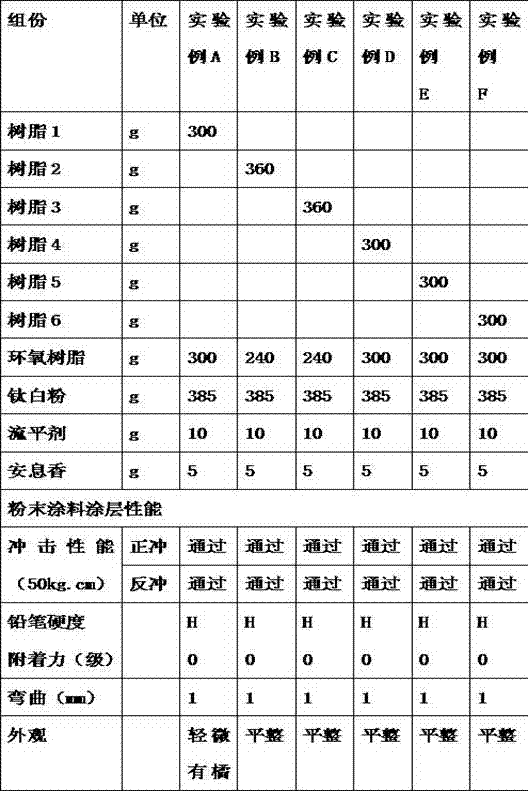

Examples

Embodiment Construction

[0019] The content of the present invention is described in more detail below through the examples, but in the following examples, it is only used to illustrate the content of the present invention, rather than limiting, so any changes within the meaning and scope equivalent to the claims of the present invention, should be considered to be included in the scope of the claims.

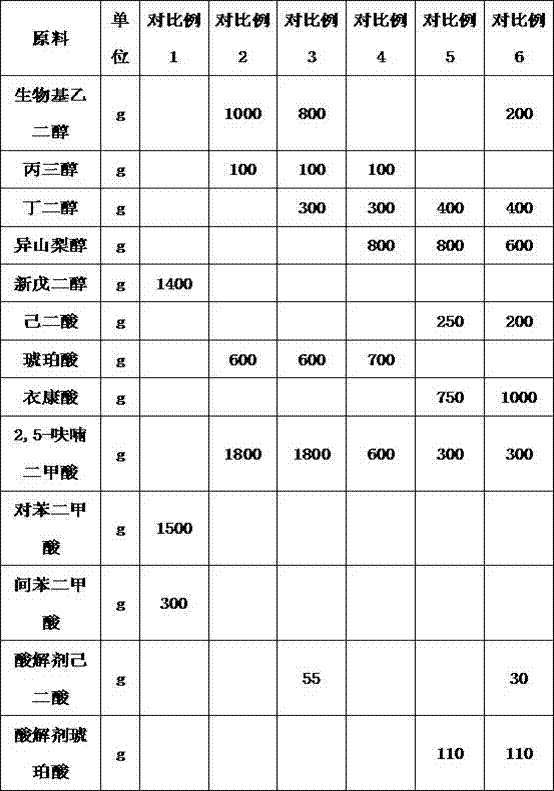

[0020] A bio-based polyester resin for powder coatings, characterized in that it includes the following components and their mass percentages: bio-based polyols: 30-50%; bio-based polyacids 40-60%; bio-based acidolytic agents 5- 20%; Catalyst 0.03-0.15%; The components are formed by melt polymerization, the acid value is 45-75mgKOH / g, the viscosity is 1500-3500mPa.s, the number-average molecular weight is 1500-3000, and the glass transition temperature Bio-based polyester resin for 48-60°C.

[0021] The polyhydric alcohol can be one or a mixture of bio-based ethylene glycol, glycerol, butanediol and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com