Patents

Literature

59results about How to "Good leveling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

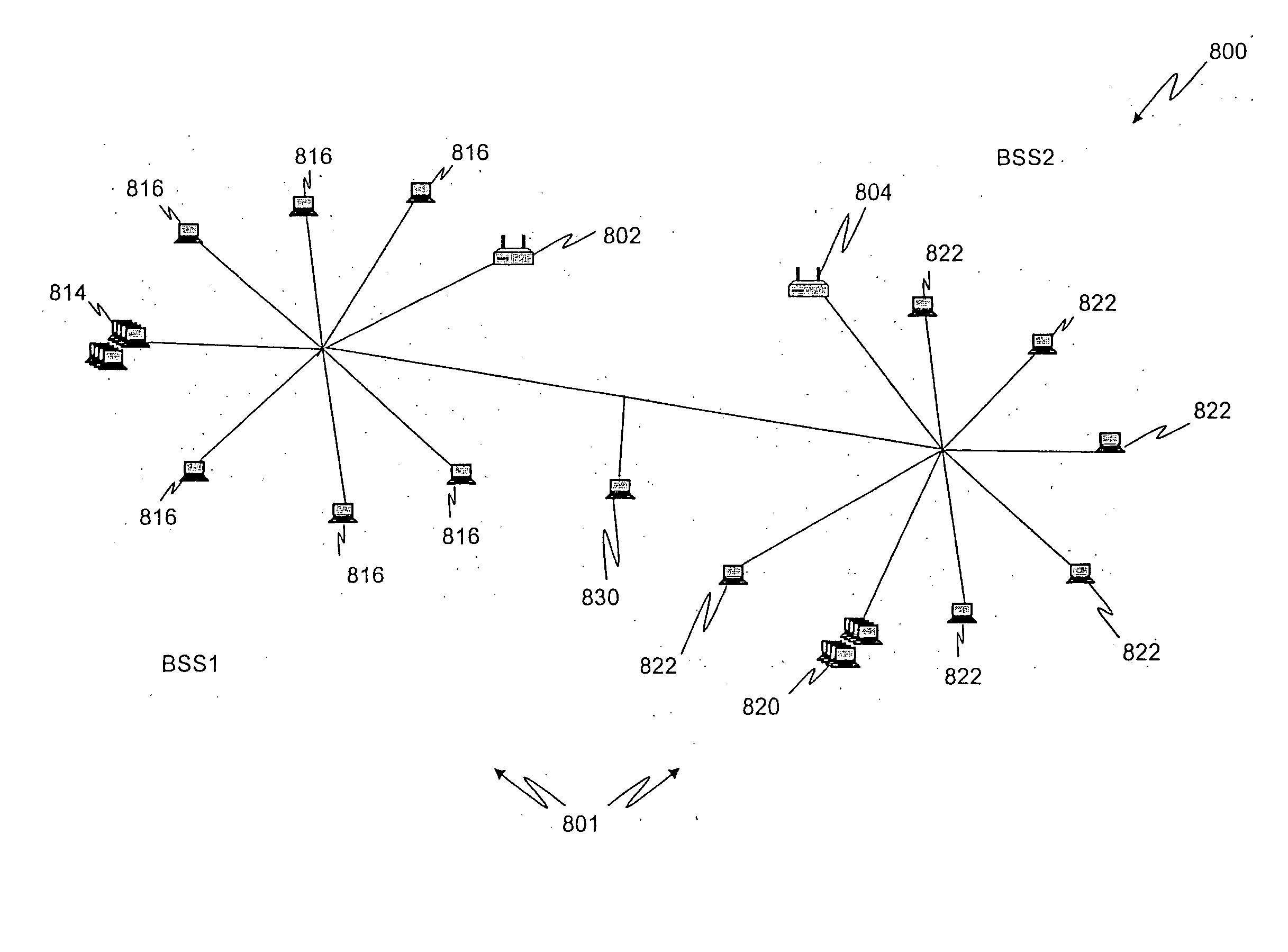

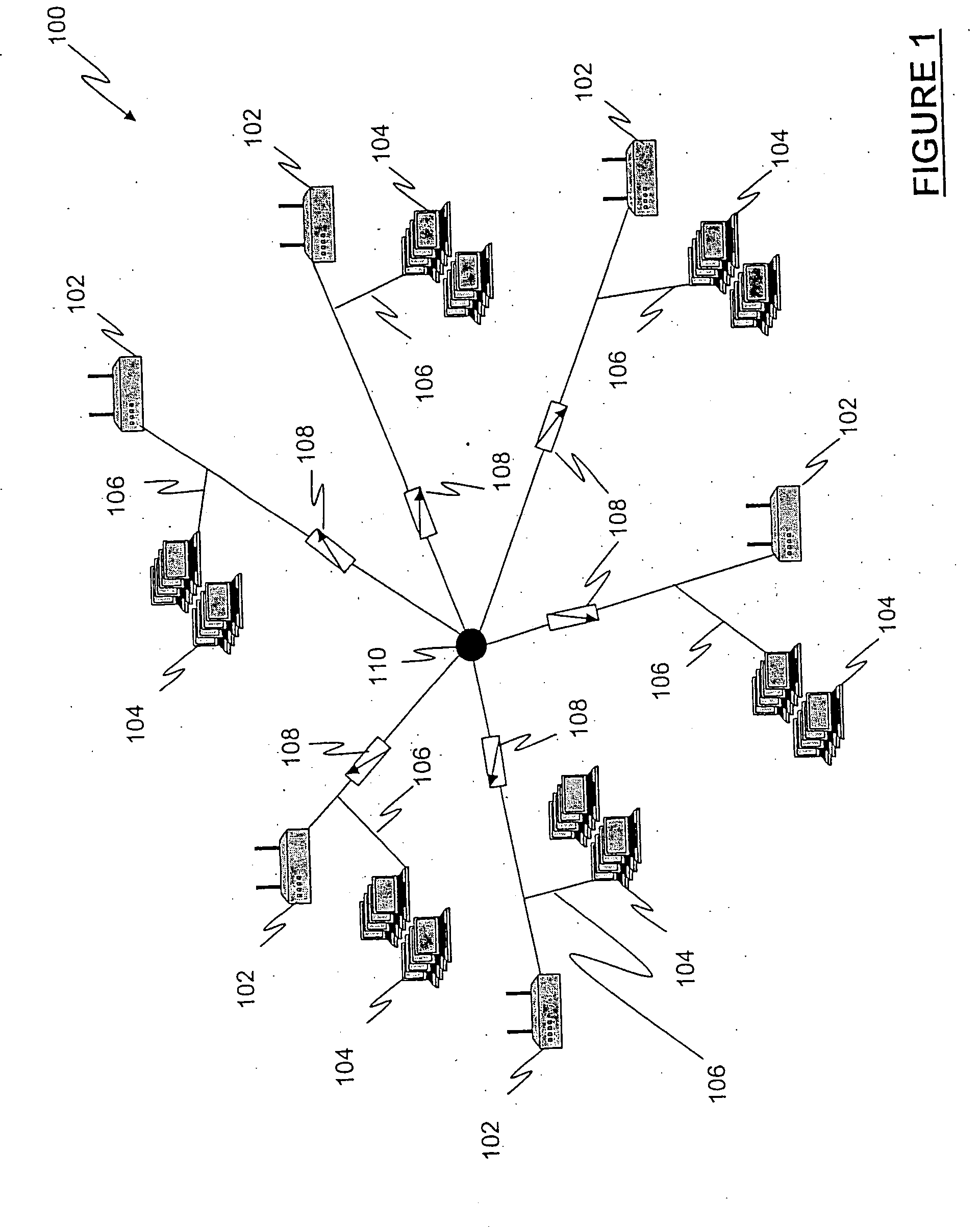

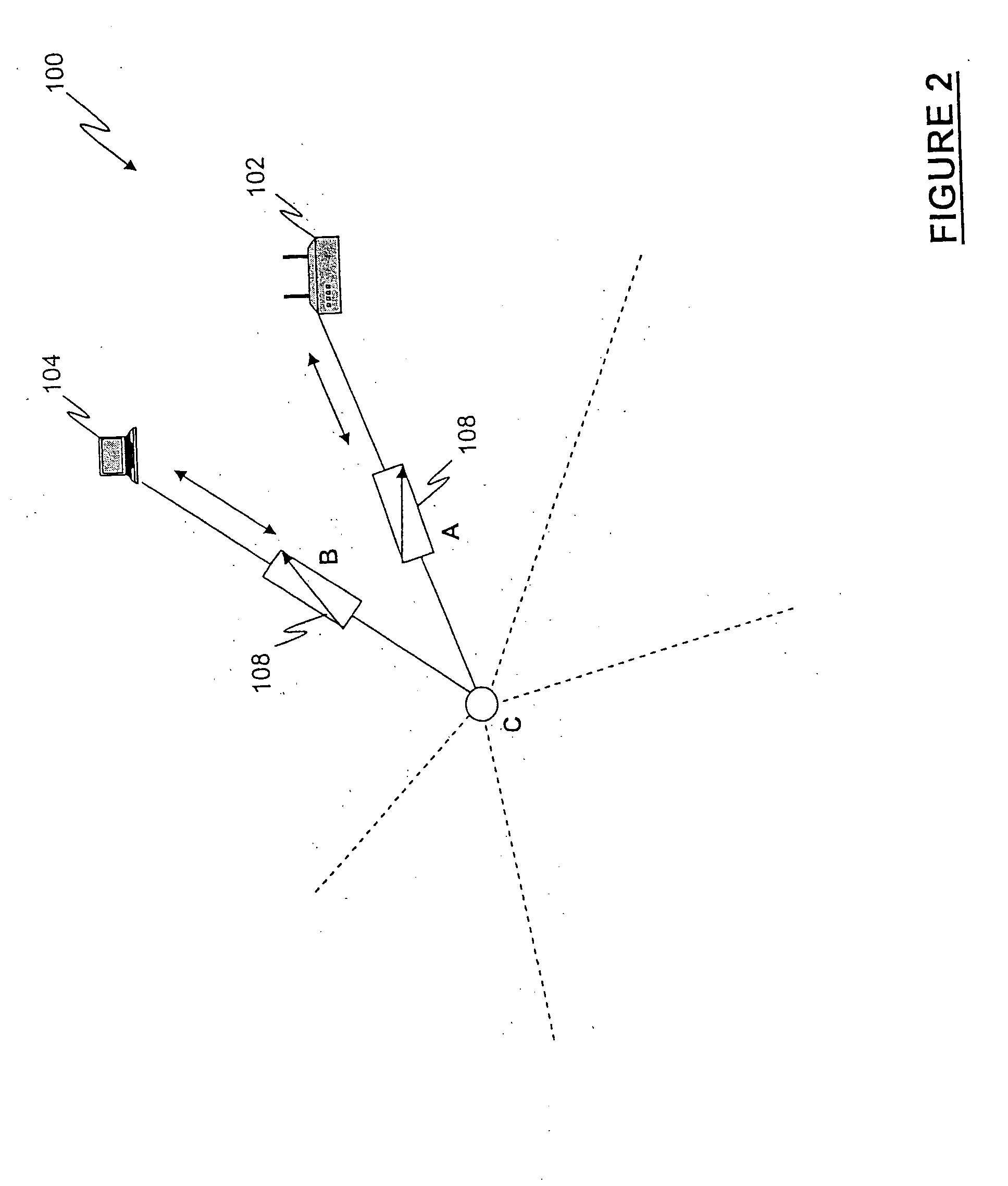

Wireless device isolation in a controlled RF test environment

InactiveUS20050053008A1Good levelingReduce decreaseSpatial transmit diversityError preventionSignal onRF module

A system and method for testing wireless devices in a simulated a wireless environment is provided. RF modules for creating and receiving RF signals in a test environment are also provided. Features include RF isolation of a wireless device, including filtering signals on electrical paths to and from the device, and circuits to reduce undesired RF signals on such electrical paths, for example PCI bus paths. The system and method also include a test enclosure with isolation chambers with filtered electrical signal paths to allow testing of wireless devices inserted into the isolation chambers. This system and method also allows controlled testing of antennae diversity features of the wireless device.

Owner:AZIMUTH NETWORKS

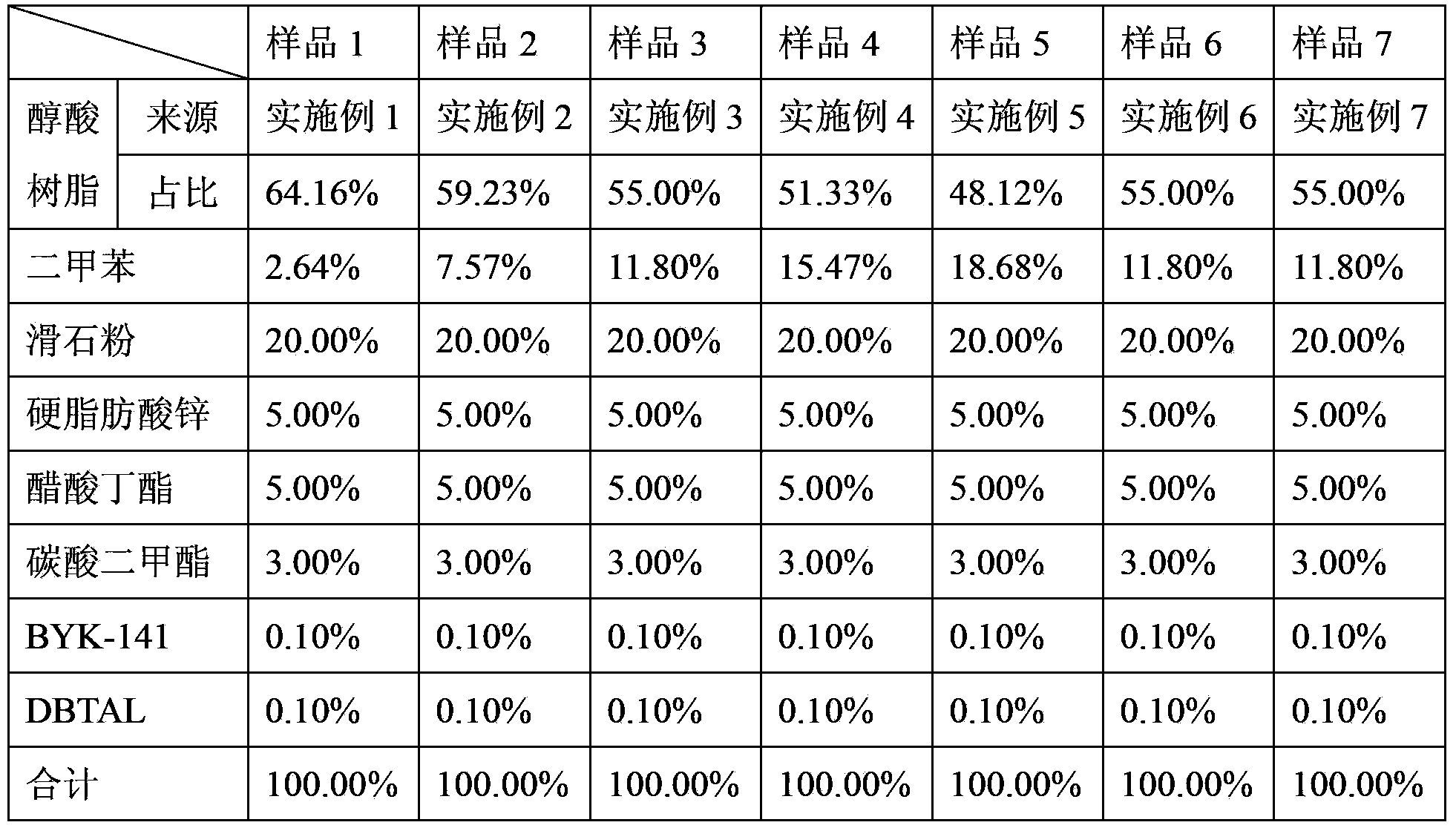

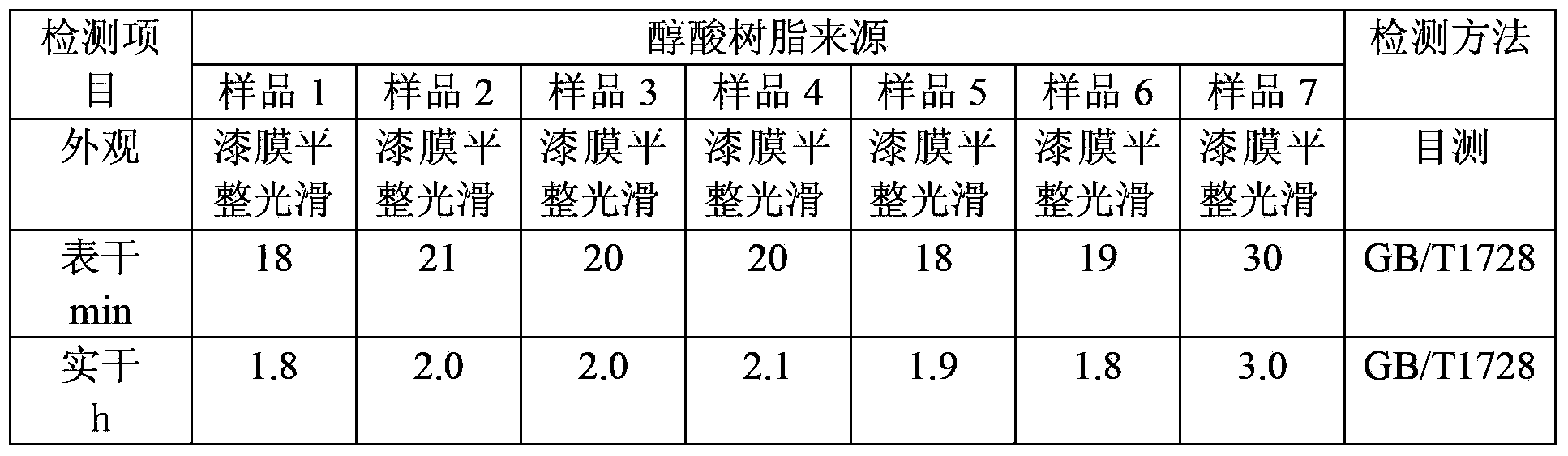

Acid alcohol resin for light-smell dope and preparation method of acid alcohol resin

ActiveCN103435791AGood adhesionGood levelingPolyurea/polyurethane coatingsPolyester coatingsSolventDiol

The invention provides acid alcohol resin for light-smell dope, which comprises the following components in parts by weight: 13.4-26.5 parts of vegetable oil, 9.6-23.4 parts of polyhydric alcohol, 0-16 parts of dihydric alcohol, 16.6-40 parts of diacid, 0.01-0.02 parts of catalyst and 18.4-38 parts of solvent. The alkyd resin is synthesized by the pure natural vegetable oil, and the used vegetable oil is basically free from free fatty acid, so that unpleasant smells such as an acid smell cannot be generated; after two-component polyurethane paint or nitrolacquer prepared by the alkyd resin is applied on the surface of wood for 24h, a light-smell effect or an odorless effect can be achieved; and the two-component polyurethane paint or the nitrolacquer prepared by the alkyd resin is good in paint film ply adhesion and levelling property, high in rigidity, and stable in luster.

Owner:山东奔腾漆业股份有限公司

Neutral ball-pen ink and its preparation method

The composition of the invented neutral ball-pen ink contains pigment 2-10g, solvent 2-10g, pigment dispersing agent 1-20g, thickening agent 0.2-10g, water soluble rsin 1-10G, levelling agent modified polysiloxane ether 0.1-0.4g, neutralizer 2-10g, preservative carson-88 0.1-0.4g, defoaming agent SPA-102 and rust-preventing agent benzotriazole each 0.1-0.4g, and deionized water 30-70g. This invention possesses bright colour, does not dry or does not settle, can be stored for a long period, and its stability is good.

Owner:宋哲 +1

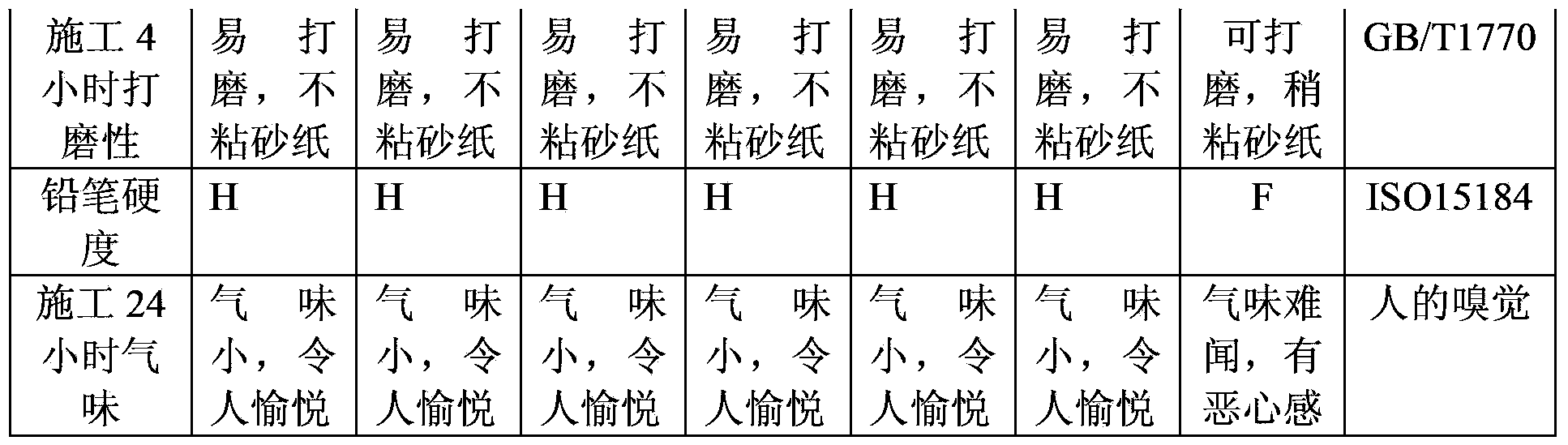

Organosilicone packaging glue for packaging LED lamp filament

InactiveCN104531056AGood thixotropyGood levelingNon-macromolecular adhesive additivesSemiconductor devicesChemistryTransmittance

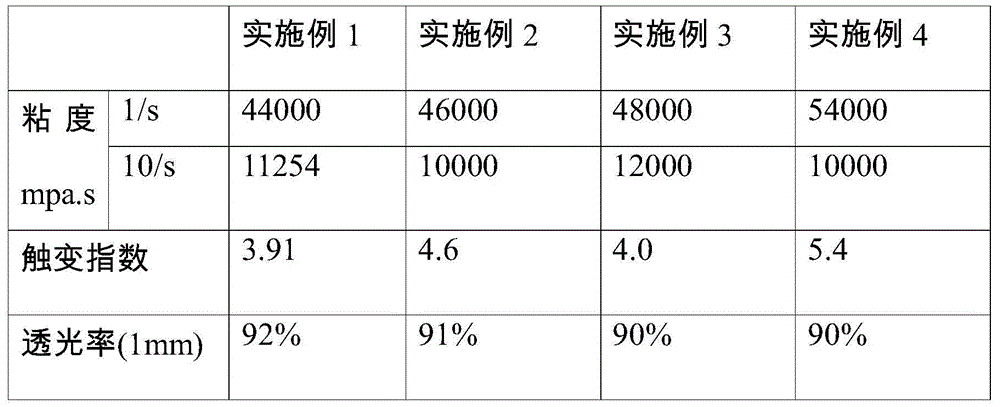

The invention provides organosilicone packaging glue for packaging an LED lamp filament. The glue is prepared from a component A and a component B in a weight ratio of 1: 1, wherein the component A is prepared from the following raw materials in parts by weight: 80-90 parts of vinyl silicone oil, 10-20 parts of a thixotropic agent white carbon black and 0.1-0.3 part of a catalyst; the component B is prepared from the following raw materials in parts by weight: 75-95 parts of vinyl silicone oil, 5-15 parts of a catalyst, 2-5 parts of an adhesive and 0.1-0.3 part of an inhibitor. The LED lamp filament packaging silica gel provided by the invention is prepared from the components A and B. The component A provides the special thixotropic agent in the system, so that the glue has a good leveling property and strong operability while having good thixotropy. The light transmittance of cured glue is not decreased.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

Black top paint with high blackness and blue phase, and preparation method thereof

InactiveCN104312399AGood matchingGood levelingPolyurea/polyurethane coatingsSolventWeather resistance

The invention discloses a black top paint with high blackness and blue phase, and a preparation method thereof. The top paint is composed of the following components by weight: 55-75 parts of a hydroxyl acrylic resin, 10-15 parts of a hydroxyl polyester resin, 0.25-0.55 parts of a leveling agent, 1.5-4.0 parts of a light stabilizer, 2.0-3.0 parts of high coloring carbon black, 2.0-3.0 parts of a wetting dispersant, 0.2-0.4 part of a synergistic dispersant, 0.03-0.05 part of a catalyst and 12-16 parts of a solvent. The black top paint with high blackness and blue phase is compounded by the hydroxyl acrylic resin, the hydroxyl polyester resin and a plurality of auxiliary agents, and has the advantages of excellent overcoatability, good leveling property, good weather resistance, good hardness and good scratch resistance. Compared with conventional black top paint, the black top paint provided by the invention has high blackness, high blue phase, high glossiness, high distinctness and high fullness, and can meet requirements for high-grade black top paint by coating and repairing in car and automobile industries.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Water-borne UV paint and preparation method thereof

ActiveCN105331279AHigh water and alcohol resistanceGood levelingAnti-corrosive paintsPolyurea/polyurethane coatingsPhotoinitiatorFluorocarbon

The invention provides water-borne UV paint and a preparation method thereof. The water-borne UV paint is prepared from, by mass, 25%-35% of urethane acrylate, 20%-30% of epoxy acrylate, 5%-10% of water-borne hyperbranched polyurethane, 5%-10% of fluorocarbon resin, 5%-15% of photoinitiator, 2%-5% of dispersing agent and 2%-10% of assistant. Urethane acrylate is fluorinated fluorinate containing urethane acrylate, epoxy acrylate is a mixture of bisphenol A epoxy acrylate and epoxy acrylate epoxy tetrapropylene acid ester, and the auxiliary is a mixture of an organic silicone flatting agent and a fluorocarbon modified flatting agent. The preparation method of the water-borne UV paint is simple in process, the prepared paint has good attachment performance and water-repellent and water-resistant performance, compared with traditional UV paint, the water-borne UV paint is higher in curing speed, and bubbles generated in the curing process are avoided. Meanwhile, the corrosion resistance, aging resistance and acid-alkali resistance of the paint are remarkably improved, and the water-borne UV paint is ideal metal and woodware surface paint.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

Waterborne polyurethane spray paint for fabric and shoe materials and preparation method of waterborne polyurethane spray paint

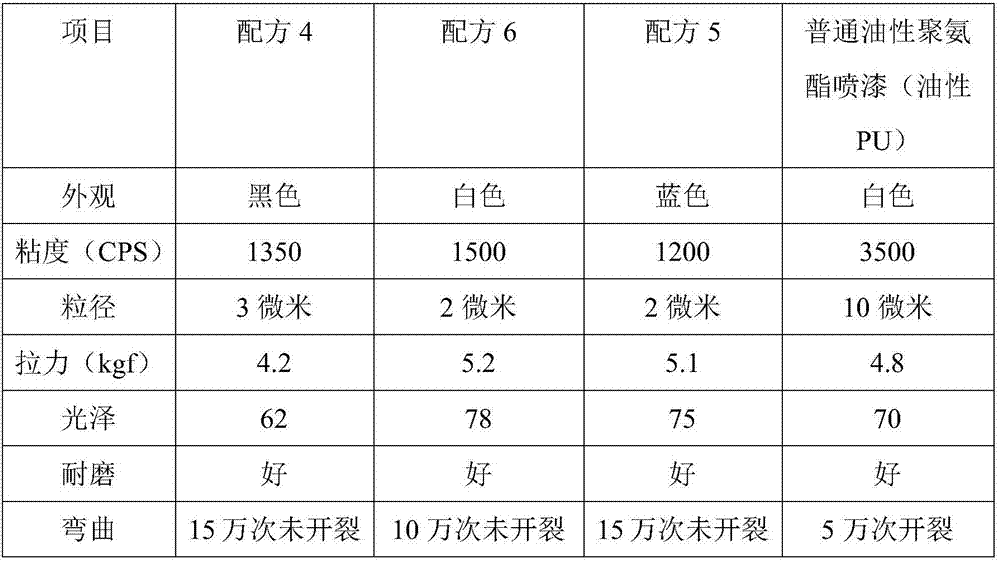

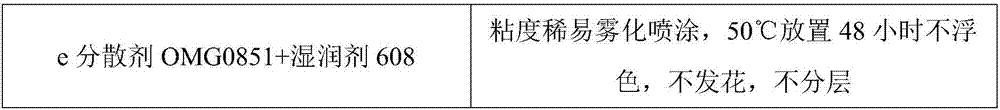

InactiveCN107418418AGood dispersionLow viscosityPolyurea/polyurethane coatingsEmulsion paintsDispersion stabilityBiological activation

The invention discloses waterborne polyurethane spray paint for fabric and shoe materials and a preparation method of the waterborne polyurethane spray paint. The waterborne polyurethane spray paint is prepared from components such as waterborne polyurethane, water, toner and auxiliaries. The spray paint is good in dispersion stability, high in dyeing degree, good in brilliance, easy to process, free of sagging, free of bubbles, good in levelling, physical property and activation property, easy for secondary processing and free of polishing, can be bent for 130 thousand times or more, and is especially suitable for materials such as the fabric and the shoe materials.

Owner:HUNAN XINLIHUA NANO TECH

Antivibration wear resistant paint or shock absorption sound deadening sheet

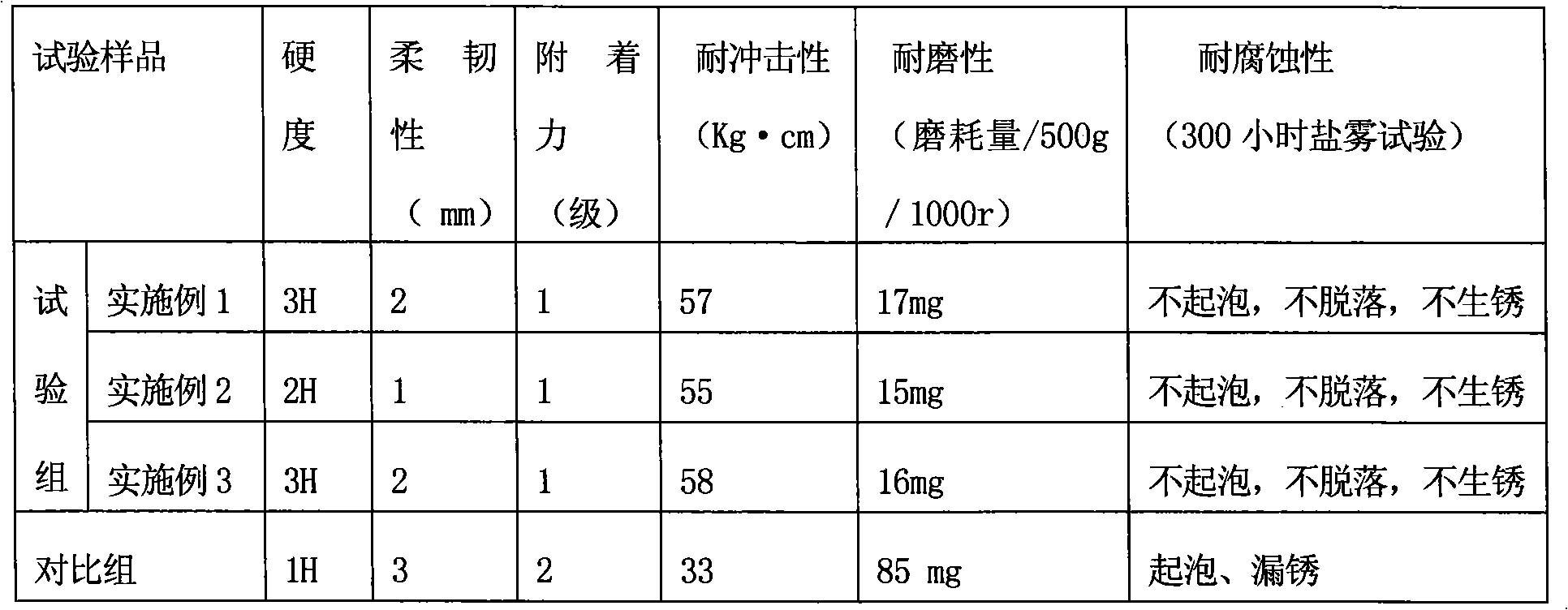

The invention relates to a shakeproof and wearproof paint for a damping silencing plate, which is mixed with amino resin according to the proportion of between 1 to between 0.25 and 0.3 in use; the shakeproof and wearproof paint mainly consists of the following compositions in portion by weight: 82 to 100 portions of thermosetting hydroxy acrylic resin, 15 to 20 portions of alicyclic epoxy resin, 8 to 10 portions of hydrocarbon black, 5 to 7 portions of nanometer silicon dioxide, 2 to 3 portions of nanometer permanent white, 1 to 2 portions of amino silane coupling agent, 1 to 1.5 portions of p-toluene sulfonic acid, 1.5 to 2 portions of cellulose acetate butyrate, 1.5 to 2.5 portions of octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate, 15 to 24 portions of butyl acetate and 20 to 30 portions of xylene. The shakeproof and wearproof paint has the characteristics of good constructing, levelling and decorating performances; and a paint film of the damping plate using the shakeproof and wearproof paint has good anticorrosive performance and prominent manifestations in wearing resistance, flexility, adhesive force and other mechanical performances.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

Solid polyaddition compounds containing uretdione groups

InactiveUS20050085615A1Good levelingHigh glossPolyurea/polyurethane coatingsPowdery paintsPowder coatingPolyurethane

Solid polyaddition compounds containing uretdione groups for polyurethane powder coating compositions which can be cured at a low temperature.

Owner:DEGUSSA AG

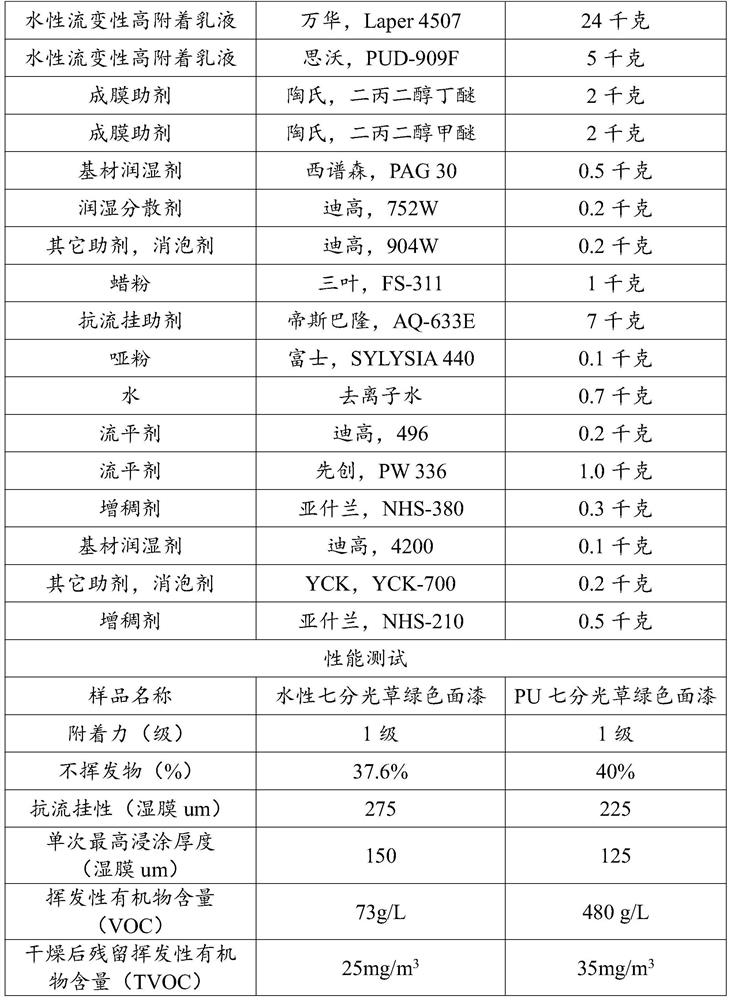

Photodiffusion agent, photodiffusion film and preparation method of photodiffusion film

ActiveCN102101971AGood levelingGood scratch resistanceDiffusing elementsPolyurea/polyurethane coatingsTransmittanceMicrometer

The invention provides a photodiffusion agent which contains polyurethane-acrylate, polymerizable monomers and organic particles, wherein the number-average molecular weight of the polyurethane-acrylate is 1000-10000, the polymerizable monomers are acrylate monomers of at least two multifunctional groups, and the average particle diameter of the organic particles is 1.8-30 micrometers. The invention also provides a photodiffusion film and a preparation method thereof. The photodiffusion film comprises a substrate and a photodiffusion layer attached to one surface of the substrate, wherein thephotodiffusion agent provided by the invention cures under the action of UV (ultraviolet) to form the photodiffusion layer. The photodiffusion layer in the photodiffusion film, which is prepared fromthe photodiffusion agent provided by the invention, has favorable mar resistance, and the photodiffusion film has favorable light transmittance and photodiffusion performance.

Owner:BYD CO LTD

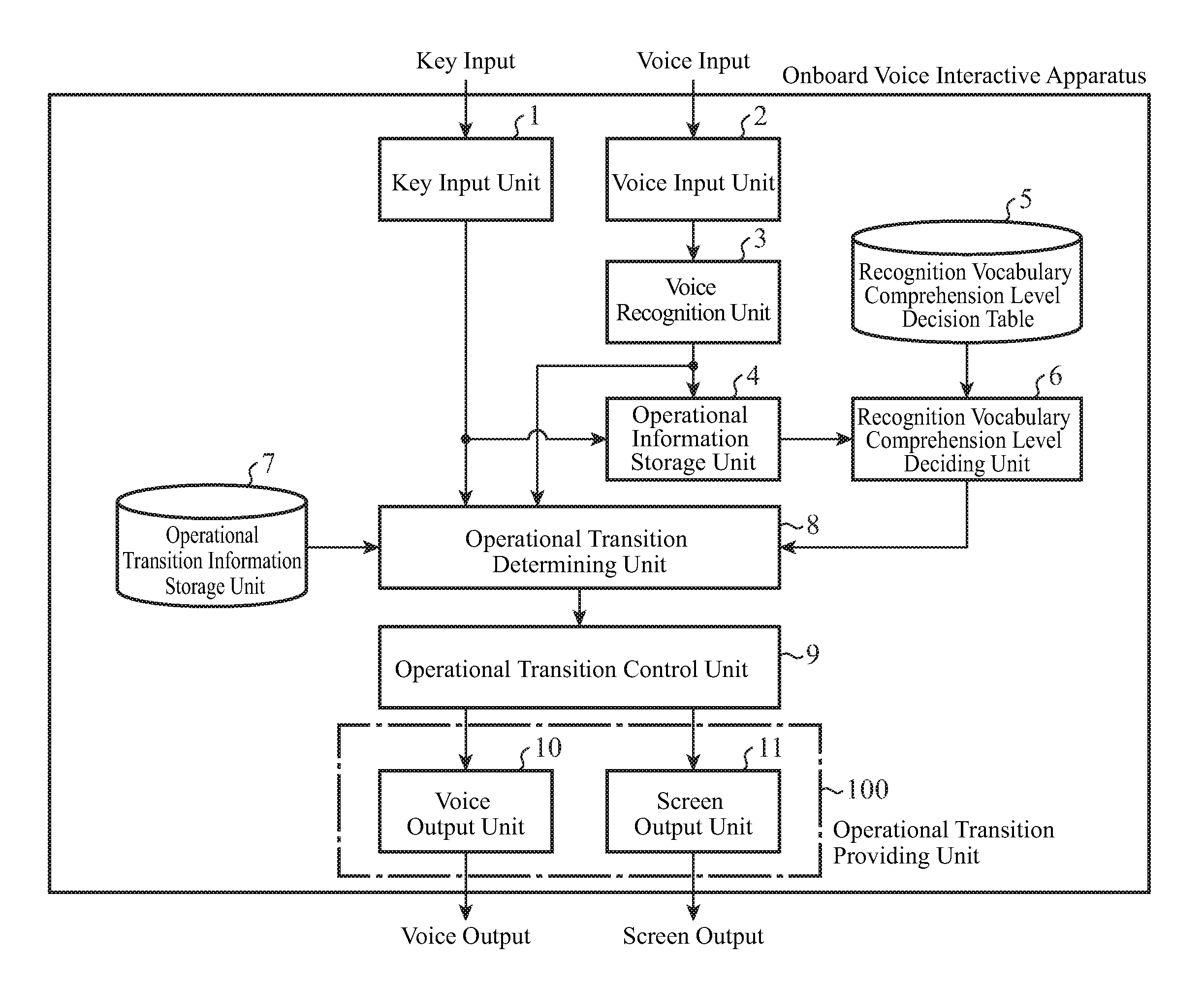

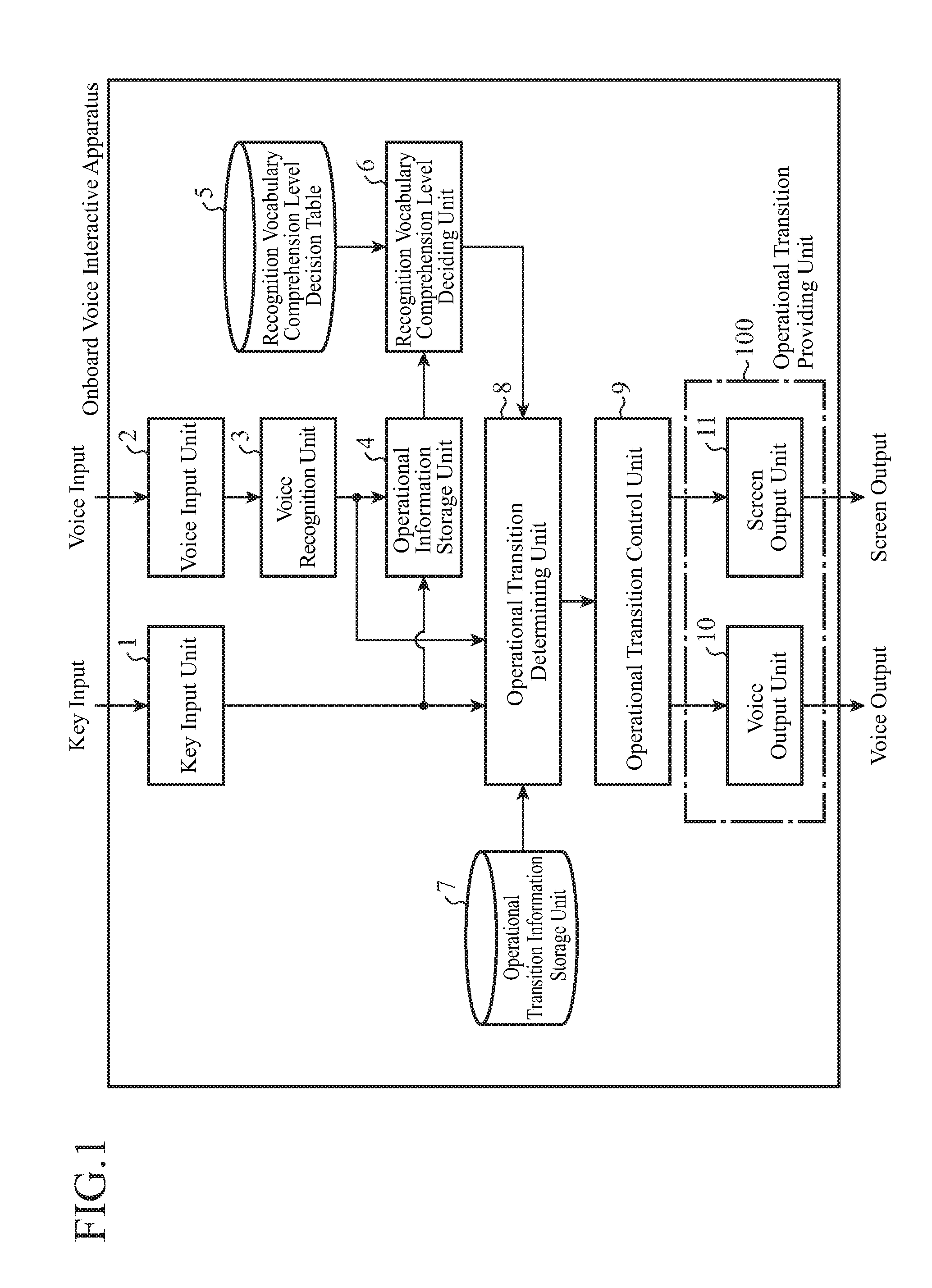

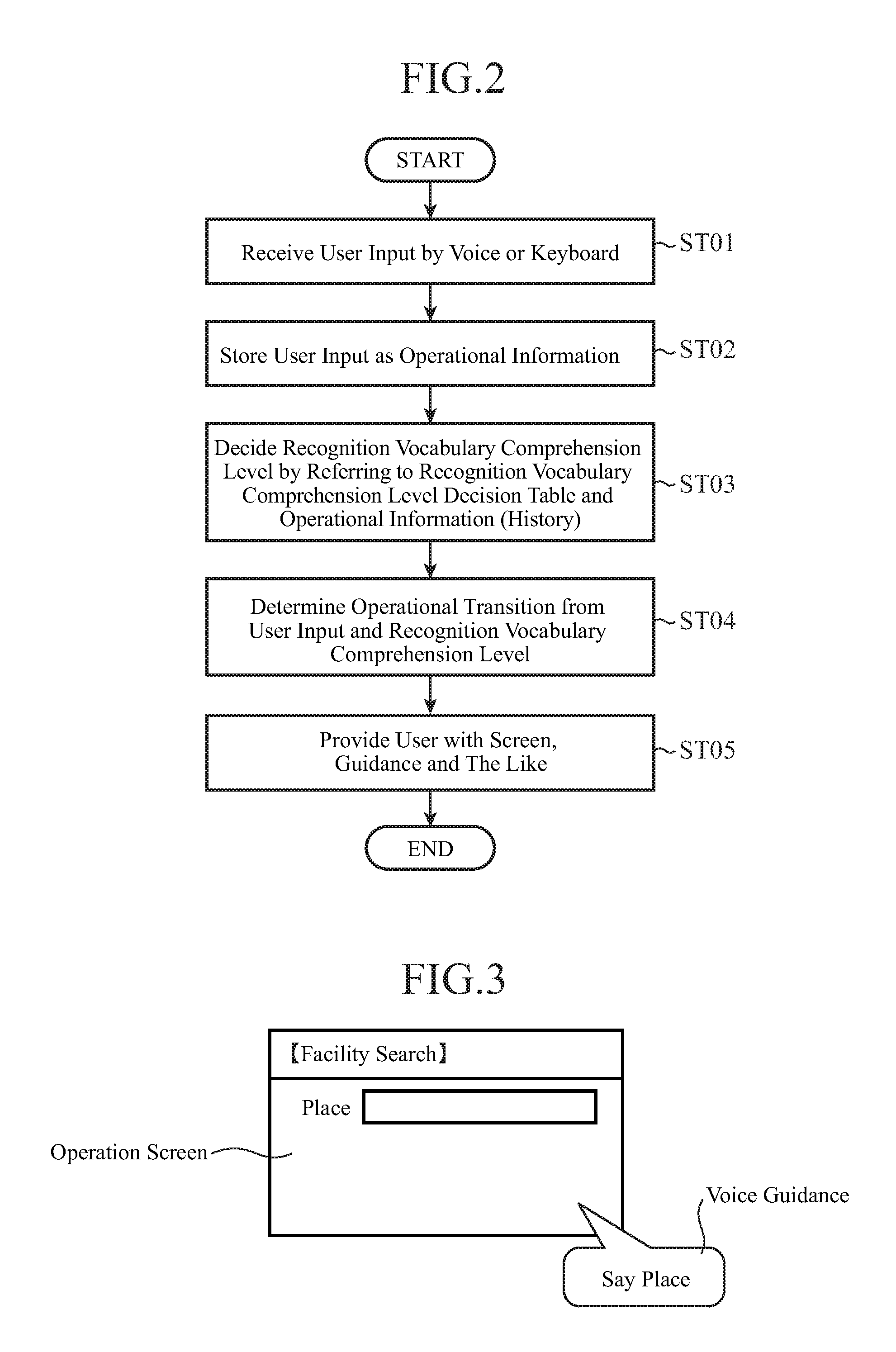

Navigation apparatus

ActiveUS20140074473A1Good levelingIncrease possibilityNavigation instrumentsSpeech recognitionSpeech recognitionMarine navigation

Owner:MITSUBISHI ELECTRIC CORP

Flowability Improver for Engineering Plastics Thermoplastic Resin Compositions Containing the Same and Molded Articles of the Compositions

ActiveUS20070213451A1Good levelingGood chemical resistanceOrganic dyesThermoplasticPolymer chemistry

A flowability improver for engineering plastics which consists of a polymer (A) composed of 0.5 to 99.5% by mass of aromatic vinyl monomer units (a1), 0.5 to 99.5% by mass of (substituted) phenyl (meth)acrylate monomer units (a2), and 0 to 40% by mass of other monomer units (a3) (with the proviso that the total of the units (a1) to (a3) is 100% by mass) and having a weight-average molecular weight of 5000 to 15000. The flowability improver can improve engineering plastics in melt-flow characteristics (processability in molding) and chemical resistance without impairing the plastics in heat resistance, exfoliation resistance, transparency, and so on.

Owner:MITSUBISHI CHEM CORP

Anti-yellowing photocuring liquid acrylic glue and preparation method thereof

InactiveCN107011811ALow viscosityGood levelingOrganic non-macromolecular adhesiveSolventButyl methacrylate

The invention relates to the technical field of advertisement word manufacturing, in particular to anti-yellowing photocuring liquid acrylic glue and a preparation method of the acrylic glue. The acrylic glue comprises the following raw materials in parts by weight: 15-25 parts of PMMA (polymethyl methacrylate) resin, 40-60 parts of methyl methacrylate, 25-35 parts of butyl methacrylate, 0.3-0.7 part of light homogenizer and 0.5-1.5 parts of photoinitiator. The acrylic glue resists yellowing and ageing, is low in viscosity and good in leveling property and defoaming performance, can be cured at room temperature or moderate temperature and is moderate in curing velocity; a cured product is better in toughness and flexibility, good in transparency, smooth and bright in surface strong in adhesion and free from bubbles; and the cured product further has good solvent resistance and excellent moisture resistance and water resistance.

Owner:东莞市卓翼新材料科技有限公司

High-temperature resistant environment-friendly glue powder

The invention discloses high-temperature resistant environment-friendly glue powder which consists of the following components in parts by weight: 40-60 parts of hydroxymethyl cellulose, 5-10 parts of corn starch, 1-5 parts of nano calcium carbonate, 5-10 parts of latex powder, 10-20 parts of shell powder, 15-20 parts of fly ash, 5-10 parts of viscose reinforcing agent and 3-5 parts of sodium benzoate. After the glue powder disclosed by the invention is dissolved in water, the high-molecular material and auxiliary thereof are adhered to the light calcium carbonate to form a high-performance glue binder; and the coating prepared from the glue powder has the advantages of convenience in construction, no urinary stream, good leveling property, no rolling and fast film formation and avoids the phenomena of rolling and falling in a high-temperature state.

Owner:QINGDAO SANLI XINYUAN ELECTRICAL APPLIANCES

Waterproof caulking mortar and preparation method thereof

The invention discloses waterproof caulking mortar prepared from the following raw materials in parts by weight: 30-40 parts of talc powder, 30-40 parts of tremolite, 5-6 parts of liquid wax, 50-60 parts of fly ash, 30-40 parts of waste diatomite, 3-5 parts of borax, 3-4 parts of ferrous sulfate, 4-6 parts of calcium ammonium nitrate, 2-4 parts of sodium tetraborate, 4-7 parts of used oil, an appropriate amount of water, 20-30 parts of an auxiliary agent, 130-150 parts of cement, 20-25 parts of beta-semi-hydrated gypsum and 170-190 parts of quartz sand. The mortar disclosed by the invention is good in thixotropy, good in leveling property, easy in crack pouring, high in condensation rate, high in bonding strength, non-cracking and good in waterproof property; and by using the auxiliary agent provided by the invention, the compression resistance and breaking strength of the mortar are improved, and the workability, sagging resistance, thixotropy and sedimentation resistance of the mortar are also improved.

Owner:魏超产

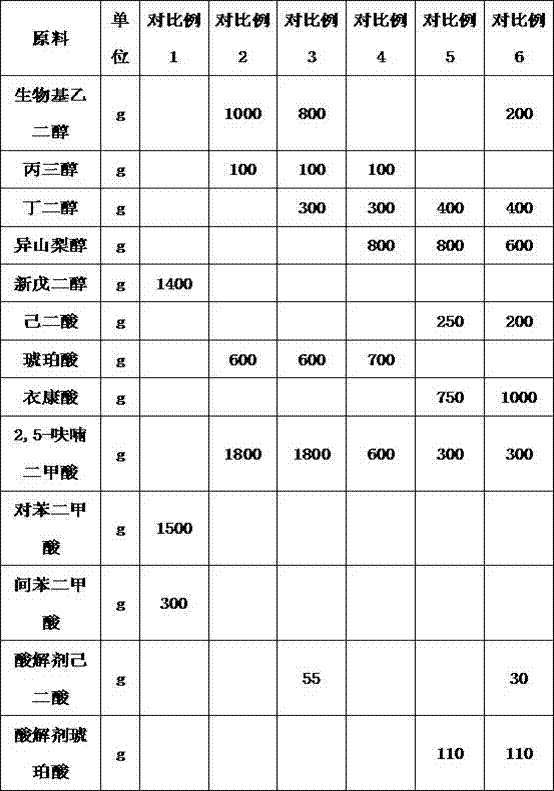

Bio-based polyester resin for powder coating and preparation method of bio-based polyester resin

InactiveCN107163234AGood levelingGood mechanical propertiesPowdery paintsPolyester coatingsChemistryNatural material

The invention discloses a bio-based polyester resin for powder coatings, which is characterized in that it comprises the following components and their mass percentages: bio-based polyol: 30-50%; bio-based polyacid 40-60%; bio-based acid Debonding agent 5-20%; Catalyst 0.03-0.15%; Said components are formed by melt polymerization, the acid value is 45-75mgKOH / g, the viscosity is 1500-3500mPa.s, and the number-average molecular weight is 1500-3000. A bio-based polyester resin with a glass transition temperature of 48-60°C; the invention also discloses a preparation method of the polyester resin: since the main raw materials used to synthesize the polyester resin are completely extracted from natural materials, the polyester The resin can be buried in the soil to degrade naturally without any impact on the ecology, and has obvious economic and social benefits; at the same time, the powder coating prepared with it has excellent leveling, excellent mechanical properties, and good storage performance, which can fully meet the indoor use of powder coatings.

Owner:广东猛特新材料有限公司

Functional self-flame-retardant coating material

The invention relates to a functional self-flame-retardant coating material, which comprises an aqueous alkyd self-flame-retardant resin, a pigment filler, an auxiliary agent and deionized water, wherein the aqueous alkyd self-flame-retardant resin is prepared by a reaction of dry oil, an organic acid anhydride, a polybasic acid, a polyol, an octadecyl alcohol, benzoic acid, a melamine derivative,an acrylic monomer, bis(hydroxymethyl)propionic acid and a neutralizing agent. According to the present invention, the prepared functional self-flame-retardant coating material does not precipitate during storage, has advantages of good film leveling property, no sagging and no requirement of additional flame retardants during the film forming, and can be widely used in the surface protection anddecoration of furniture, musical instruments, metals, concrete and the like, wherein the formed film has advantages of good adhesion, good fullness, good durability, chemical resistance, flame retardant performance and low price.

Owner:SHAOGUAN HEZHONG CHEM CO LTD +1

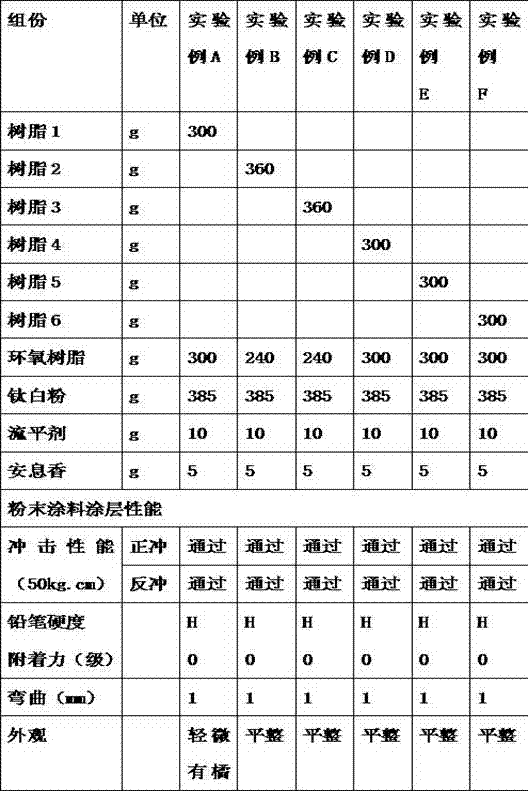

High-strength powder paint

ActiveCN104119772AGood levelingHigh strengthPowdery paintsEpoxy resin coatingsTitaniumHome appliance

The invention discloses a high-strength powder paint which is composed of the following components in percentage by weight: 33-41% of epoxy resin, 8-10% of acrylic resin, 3-6% of EVA (ethylene-vinyl acetate) resin, 15-22% of titanium white, 20-24% of barium sulfate, 3-6% of curing agent, 0.5-1.5% of leveling agent, 0.5-1.5% of brightening agent and 1% of pigment and filler. On the premise of ensuring favorable leveling property of the paint, the coating strength of the paint is enhanced, and the cost is lowered. The product adopts the existing production equipment, is simple in operational procedure, and is widely suitable for anticorrosion coatings of household appliances, home appliances, vehicles and hardware machines.

Owner:佛山市涂亿装饰材料科技有限公司

Finishing method for improving lamination degree of coating and crust leather

The invention relates to the technical field of leather making chemistry and engineering and provides a finishing method for improving the lamination degree of a coating and crust leather. According to the finishing method, non-ionic polyurethane resin without charges and a non-ionic oil wax auxiliary agent are selected as main body materials of a finishing agent; the surface tension of a finishing agent is reduced so that the leveling property and the permeability are improved; a technology is balanced and primary and secondary aspects in each phase and each operation are grasped; the lamination degree of the coating and the crust leather is improved; an ideal thin film is formed on the surface of the crust leather through the finishing agent and a shell is not easy to form after the coating is repeatedly bent or stretched; the non-ionic oil wax auxiliary agent has good filling and covering effects and can be used for improving the flatness and fineness of a particle surface of the crust leather; injuries on the particle surface of the crust leather are covered; the grading rate and utilization rate of the crust leather are improved.

Owner:XINGYE LEATHER TECH CO LTD

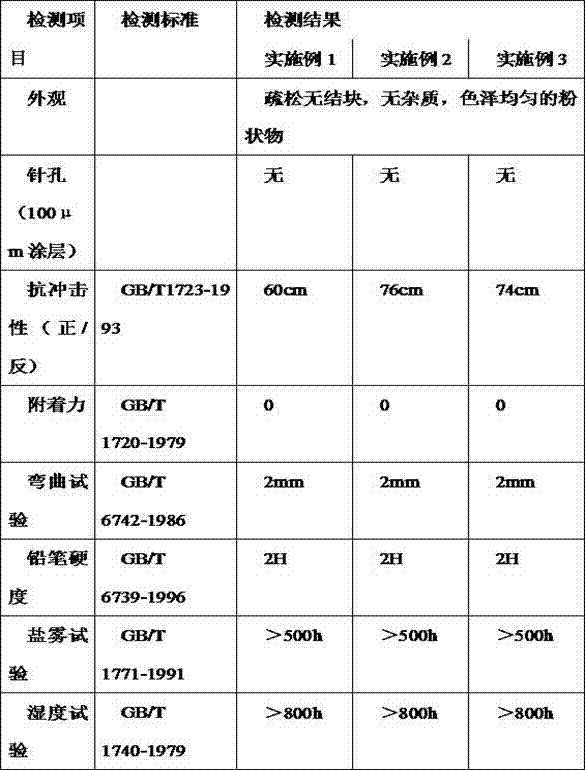

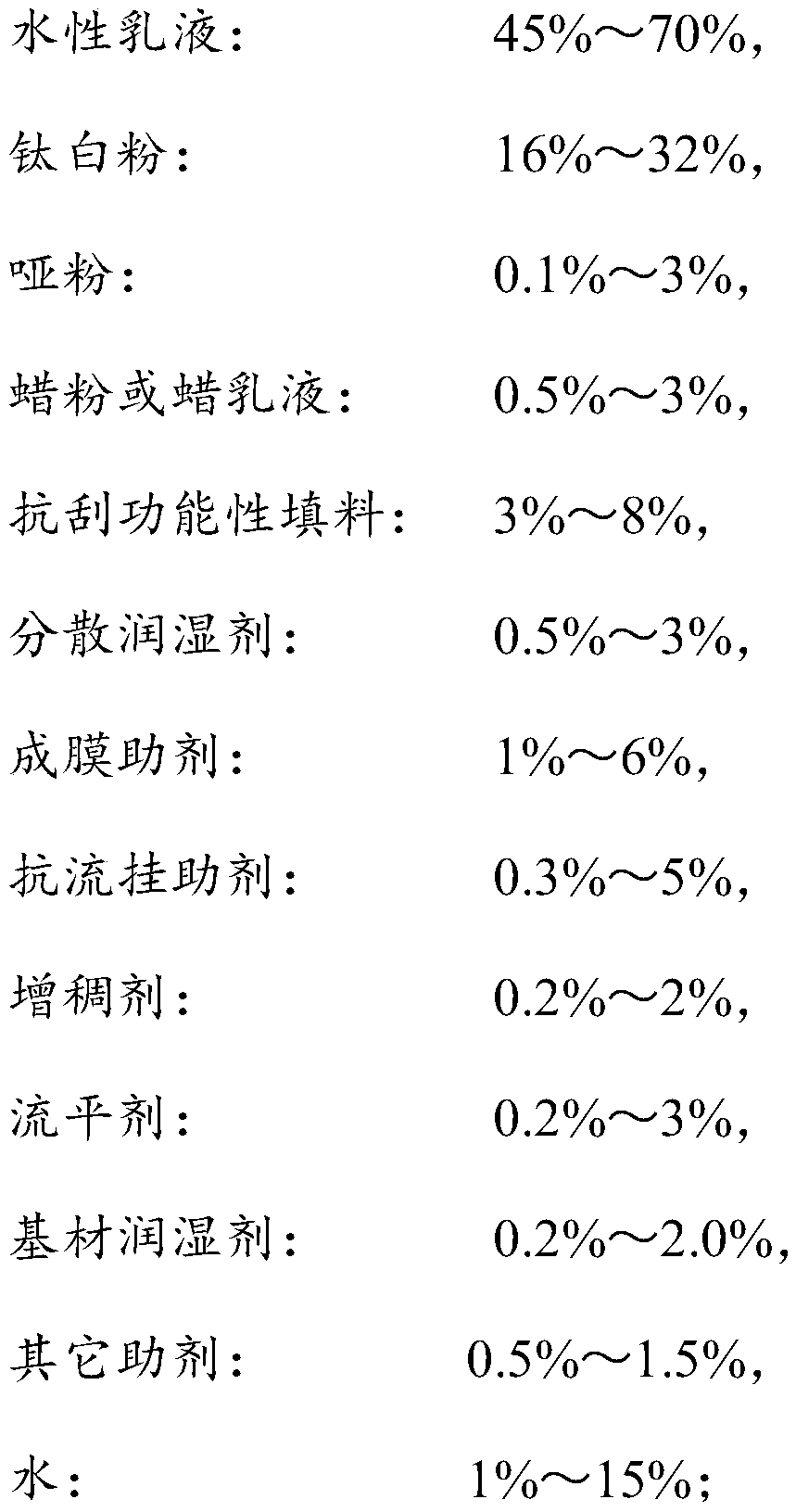

High-adhesion water-based electrostatic white finish paint and preparation method thereof

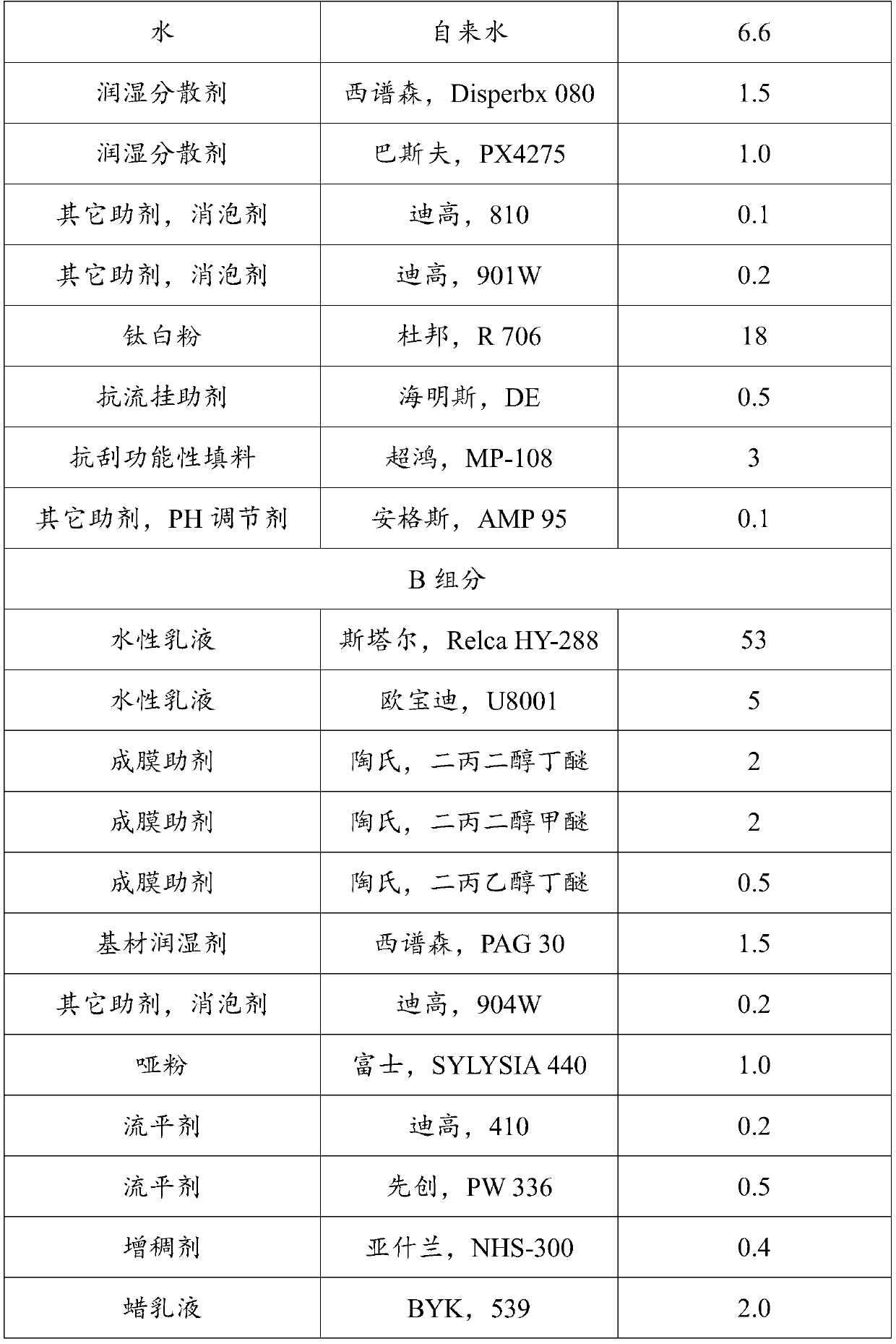

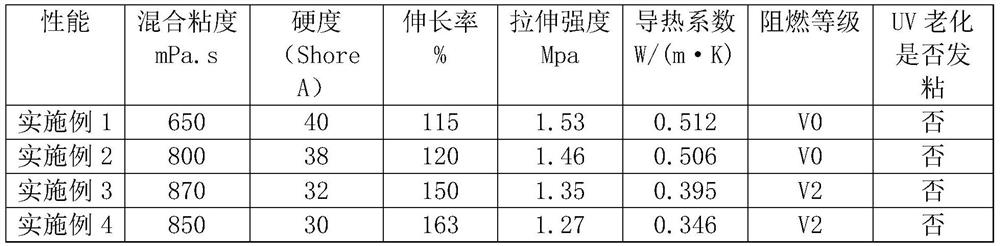

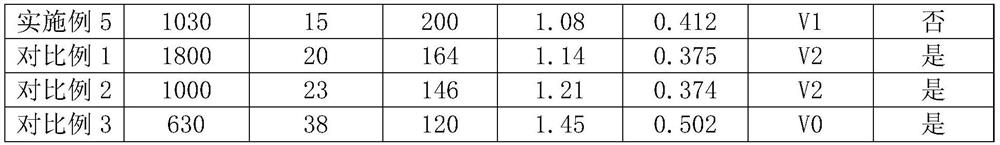

InactiveCN110951346AGood levelingDecorativePolyurea/polyurethane coatingsPolyether coatingsElectrostatic adsorptionWax

The invention relates to a high-adhesion water-based electrostatic white finish paint. The white finish paint comprises, by mass, 45-70% of an aqueous emulsion, 16-32% of titanium dioxide, 0.1-3% of matt powder, 0.5-3% of a wax powder or wax emulsion, 3-8% of an anti-scratch functional filler, 0.5-3% of a dispersion wetting agent, 1-6% of a film forming aid, 0.3-5% of an anti-sagging aid, 0.2-2% of a thickener, 0.2-3% of a leveling agent, 0.2-2.0% of a base material wetting agent, 0.5-1.5% of other aids and 1-15% of water. The product disclosed in the invention meets the requirements of GB / T 23999-2008, and is safe and environmentally friendly, has the advantages of good leveling property, high electrostatic adsorbability, good wettability for a base material, good wear resistance, good scratch resistance, good chemical resistance, fine and smooth paint film, easiness in production and manufacturing, and improved construction safety in the coating process.

Owner:上海展辰涂料有限公司 +1

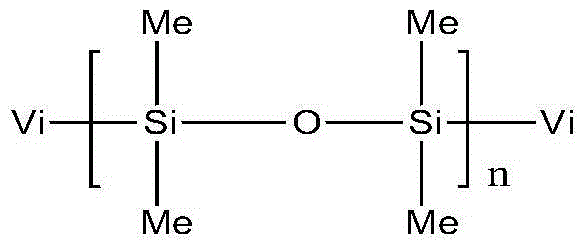

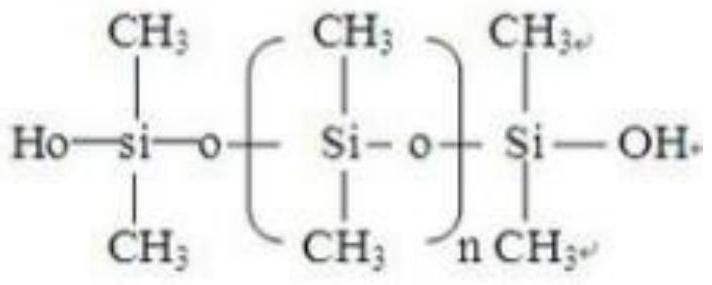

Organic silicon pouring sealant and preparation method thereof

ActiveCN112080246AGood levelingHigh UV resistanceNon-macromolecular adhesive additivesPhotovoltaic energy generationDisiloxaneOrganosilicon

The invention relates to the technical field of high polymer materials, in particular to an organic silicon pouring sealant and a preparation method thereof. The organic silicon pouring sealant is prepared from a component A and a component B. The component A is prepared from the following raw materials in parts by mass: 100 parts of base glue, 20-100 parts of double hydroxyl-terminated polydisiloxane A, 6-12.8 parts of liquid MQ resin, 0-9.6 parts of a plasticizer A, 1.3 parts of pigment and 1.2 parts of a deep curing agent. The component B is prepared from the following raw materials in parts by mass: 100 parts of a plasticizer B, 10-40 parts of a cross-linking agent, 5-25 parts of a coupling agent and 0.5-2 parts of an organic tin catalyst; wherein the viscosity of the double hydroxyl-terminated polydimethylsiloxane is 200 to 750 mPa.s, and the base rubber is prepared from the following raw materials: double hydroxyl-terminated polydisiloxane B and a semi-reinforcing filler. The organic silicon pouring sealant provided by the invention is an organic silicon pouring sealant with good leveling property and high UV resistance, and can be well used as a pouring sealant for LED small-spacing display screen modules.

Owner:广州硅芯材料科技有限公司

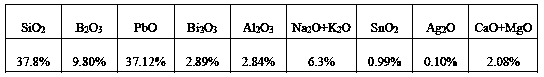

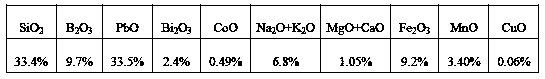

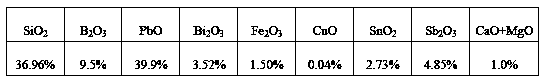

Enamel color material, preparation method thereof, and application in porcelain body painting enamel cultural relic repair

The invention discloses an enamel color material, a preparation method thereof, and an application of the enamel color material in porcelain body painting enamel cultural relic repair. The enamel color material is prepared from the following chemical components in percentage by mass: 33%-51% of silicon dioxide, 0%-3.8% of aluminum oxide, 8%-19% of boron oxide, 31%-53% of lead oxide, 0%-6% of calcium oxide and magnesium oxide, 0%-6.9% of sodium oxide and potassium oxide, 0.5%-6% of bismuth trioxide, 0%-7.2% of tin oxide, 0%-6.5% of antimonous oxide, 0%-13% of ferric oxide, 0%-4.2% of copper oxide, 0%-4% of cobalt oxide, 0%-9% of manganese oxide, 0%-2% of silver oxide and 0%-0.15% of gold oxide. Compared with the traditional enamel painted porcelain, the enamel painted porcelain provided bythe invention has the advantages that the melting point is lower; the colored glaze and an ancient enamel colored pigment layer show a "like-fusion-like" phenomenon at high temperature, can be matchedwith the thermal expansion coefficients of the surface glaze and the pigment layer of the traditional enamel color, has good adhesiveness and good adhesiveness before firing, is easy to disperse, hasmoderate material surface tension in the firing and fusing process, not only meets the fusing property, but also can keep a certain colored drawing three-dimensional shape.

Owner:佛山市天工嘉荟文化科技有限公司 +1

Polyester resin for indoor powder coating and preparation method of polyester resin

InactiveCN109679467AReduce melt viscosityGood levelingPowdery paintsPolyester coatingsMelt viscosityChemistry

The invention relates to the technical field of powder coatings, in particular to polyester resin for an indoor powder coating and a preparation method of the polyester resin. The powder coating prepared from the polyester resin for the indoor powder coating with high levelling property and high gloss has the following characteristics: 1, the melt viscosity is low during melt leveling, so that thepowder coating has sufficient leveling time, good film leveling property and high gloss; 2, adhesion to a coated object is good, and base coat is not needed; 3, the preparation range of the coating is wide, and coatings with different performance requirements and curing speeds can be prepared; 4, a film has good physical mechanical properties and chemical resistance.

Owner:YANGZHOU XINBAO RESIN

High temperature-resistant environment-friendly glue powder

The invention discloses high temperature-resistant environment-friendly glue powder. The glue powder comprises the following components in parts by weight: 40-60 parts of resin, 5-10 parts of corn starch, 1-5 parts of nano calcium carbonate, 5-10 parts of borax, 10-20 parts of silicon dioxide, 15-20 parts of salicylic acid, 5-10 parts of viscous reinforcing agent and 1-5 parts of titanium dioxide. After the glue powder is dissolved in water, high polymer materials and auxiliaries of the glue powder form a high-performance glue connection body through depending on light calcium carbonate, coating which is prepared from the high-performance glue connection body is convenient to construct, does not wet lines, has good levelling property, does not reel, quickly forms films and does not have the rolled falling phenomenon under high temperature conditions.

Owner:JIAOZHOU FUTIAN CHEM ENG

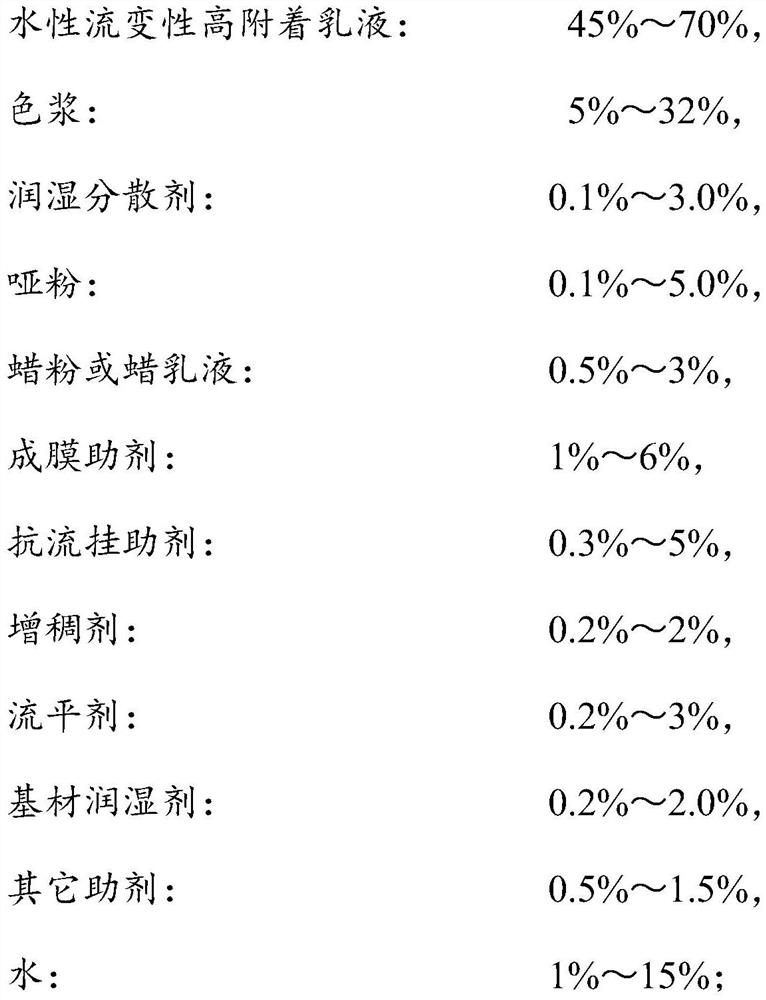

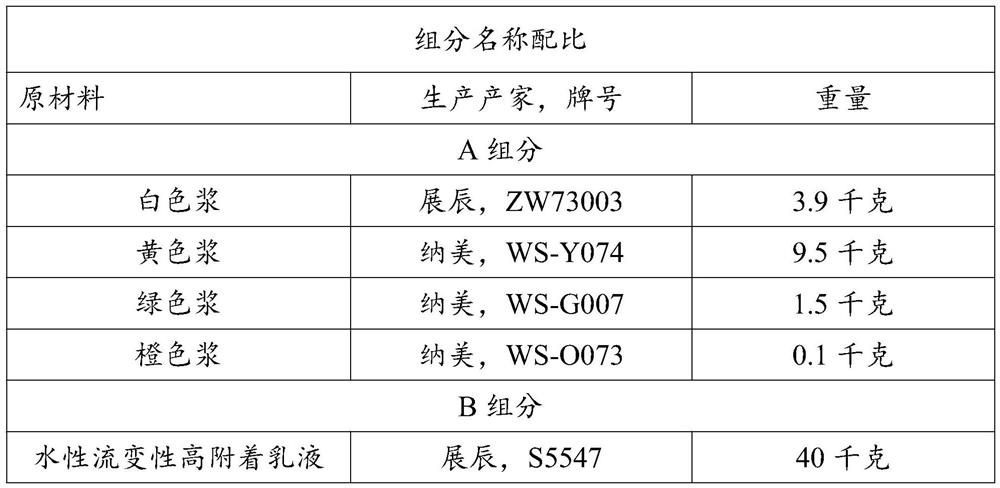

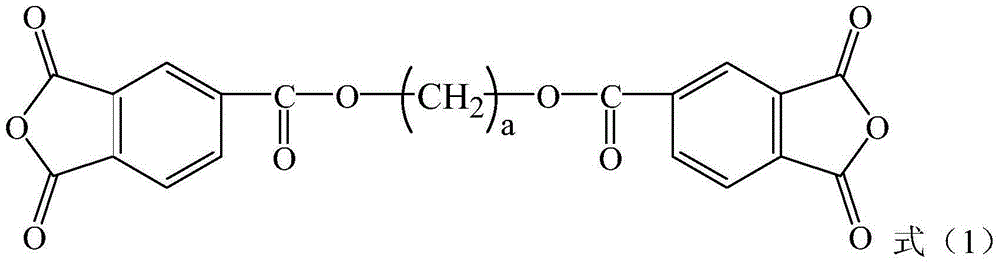

High-adhesion dip-coating water-based color matching finish paint and preparation method thereof

The invention provides a high-adhesion dip-coating water-based color matching finish paint and a preparation method thereof. The water-based color matching finish paint comprises the following components in percentage by mass: 45-70% of water-based rheological high-adhesion emulsion, 5-32% of color paste, 0.1-3.0% of a wetting dispersant, 0.1-5.0% of matt powder, 0.5-3% of wax powder or wax emulsion, 1-6% of a coalescing agent, 0.3-5% of an anti-sagging agent, 0.2-2% of a thickener, 0.2-3% of a leveling agent, 0.2-2.0% of a basic material wetting agent, 0.5-1.5% of other auxiliaries, and 1-15%of water. The product disclosed by the invention meets the related requirements of GB / T 23999-2008, and is safe and environment-friendly; the color mixing requirements of different colors are met, the leveling property is good, and wear resistance and scratch resistance are achieved; VOC emission is reduced, production and manufacturing are easy, construction safety is improved, and harm to terminal consumers is reduced.

Owner:上海展辰涂料有限公司

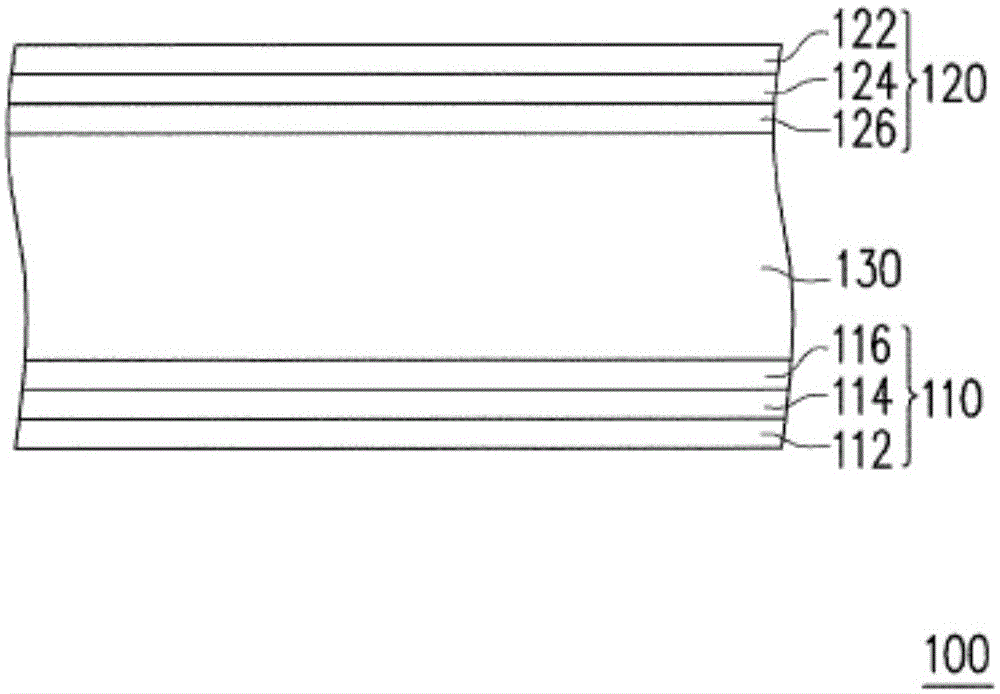

Liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element

InactiveCN105482830AGood levelingImprove yieldLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

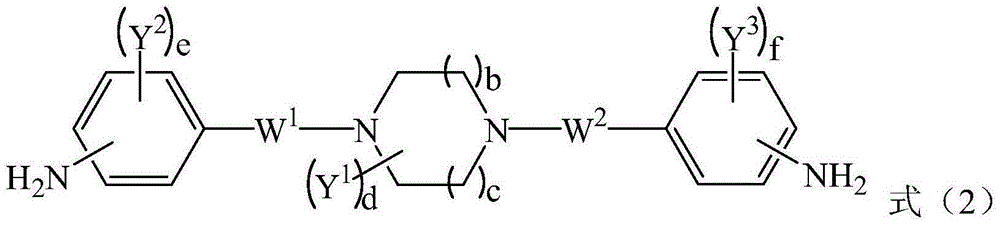

The invention provides a liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element, wherein the liquid crystal alignment agent can form the liquid crystal alignment film with good frame glue flattening performance. The liquid crystal alignment agent includes a polymer (A) and a solvent (B), wherein the polymer (A) is obtained by reaction of a mixture including a tetracarboxylic dianhydride component (a) and a diamine component (b). The tetracarboxylic dianhydride component (a) includes at least one tetracarboxylic dianhydride compound (a-1) represented by Formula (1). The diamine component (b) includes at least one diamine compound (b-1) represented by Formula (2).

Owner:CHI MEI CORP

UV (Ultraviolet) cured primer having flame-retarding effect and preparation method thereof

InactiveCN103834205AGood flame retardant effectGood levelingFireproof paintsBond propertiesUltraviolet

The invention discloses a UV (Ultraviolet) cured primer having a flame-retarding effect. The UV cured primer is characterized by being prepared from the following raw materials in parts by weight: 50-55 parts of acrylic resin, 8-11 parts of N-acryloylmorpholine, 7-10 parts of 2-hydroxyethyl acrylate, 4-6 parts of 1-hydroxycyclohexyl phenyl ketone, 11-13 parts of glycol ether, 9-10 parts of allyl glycidyl ether, 3-5 parts of butanone, 1-2 parts of benzyltrimethylammonium tribromide, 1-2 parts of polydimethylsiloxane, 5-7 parts of brown fused alumina powder, 3-4 parts of aluminum hydroxide and 4-5 parts of aid. The coating is added with the aluminum hydroxide, so that a good flame-retarding effect is achieved; the aid is added, so that high levelling property, uniform coating, good coating of devices, excellent airtightness and high rubbing property are realized. The prepared coating has excellent water resistance, hot water resistance, drug resistance, bonding property and toughness, and is suitable to be taken as a primer.

Owner:WUHU EDISON AUTOMATION EQUIP

Anion environment-friendly latex paint containing sweet marjoram natural extract

ActiveCN104177949AStrong weather resistanceGood levelingAntifouling/underwater paintsPaints with biocidesWeather resistanceChemistry

The invention relates to an anion environment-friendly latex paint containing sweet marjoram natural extract. The latex paint has the characteristics of aging resistance, no scaling, no discoloration, high weather resistance, no toxicity, no smell, favorable leveling property, high constructability, scrub resistance, no toxicity or harm and fresh smell, has health-care effect, is beneficial to human health, can still keep the original strength and quality after adding proper amounts of other functional components, and can release air anions to purify air for a long time. The latex paint can resist and kill bacteria, has aromatic smell and mild properties, and has the effects of helping hormone secretion, relieving anxiety, improving insomnia and the like, thereby achieving the effects of relieving mental pressure and enhancing work efficiency. More importantly, the latex paint can not generate adverse effect on the human body, and is suitable for people at all ages.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD +1

Polyesteramide imide wire enamel and preparation method thereof

The invention relates to polyesteramide imde wire enamel and a preparation method thereof. The wire enamel is prepared from the following components in the following proportions: 4,4'-diphenyl-methane-diisocyanate and trimellitic anhydride in a molar ratio of 1:1, trimellitic anhydride and terephthalic acid in a molar ratio of (1:1)-(1:4), the terephthalic acid and ethylene glycol in a molar ratio of (1:1)-(1:2), and the terephthalic acid and glycerol in a molar ratio of (1:0.5)-(1:0.6). According to the preparation method, amide imide is modified based on polyester wire enamel, and amide and imide groups are introduced, so that the levelling property and coating property during high-speed wire coating can be improved, and the surface, performance and production efficiency of the wire enamel can be greatly improved.

Owner:DANYANG STAR CHEM

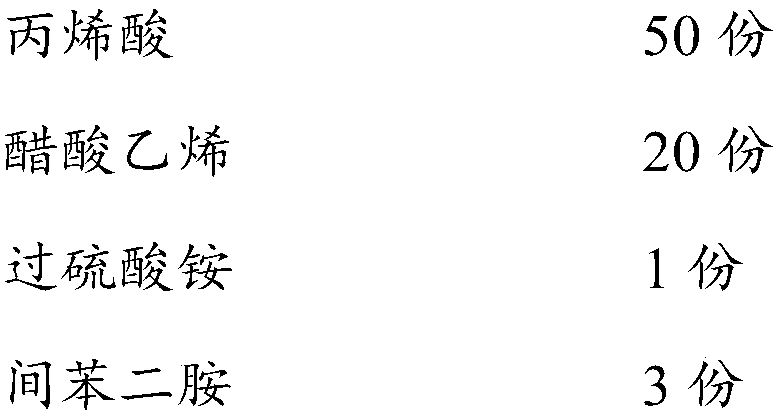

Acrylic acid modified epoxy resin paint and use method thereof

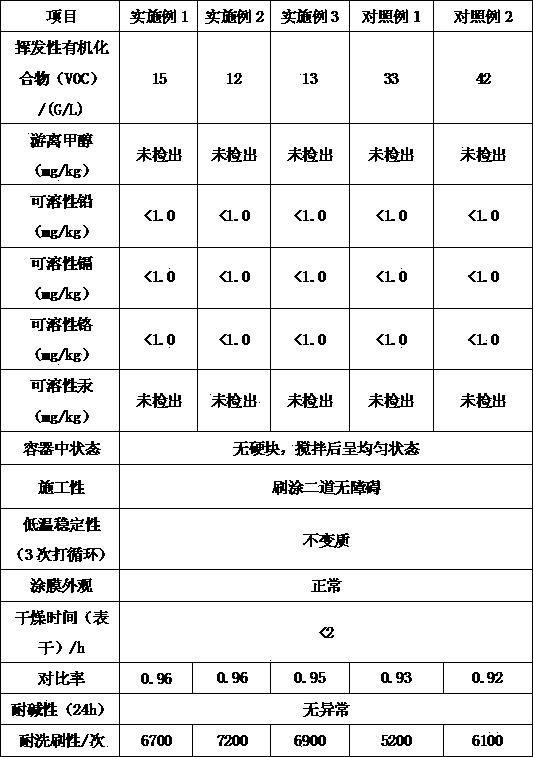

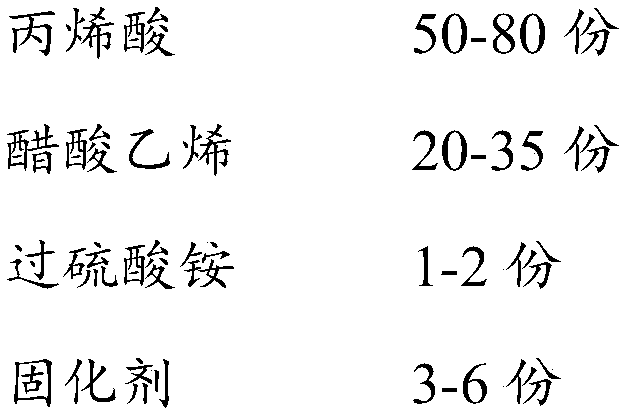

ActiveCN107603383ASimple preparation processGood levelingPowdery paintsEpoxy resin coatingsAmmonium sulfateSlag

The invention discloses acrylic acid modified epoxy resin paint, which is prepared from 50 to 80 parts of acrylic acid, 20 to 35 parts of vinyl acetate, 1 to 2 parts of ammonium persulfate, 3 to 6 parts of curing agents, 60 to 90 parts of epoxy resin and 10 to 15 parts of butyl amine. The invention also discloses a use method of the acrylic acid modified epoxy resin paint. The method comprises thesteps of low-temperature preparation of ingredient A and B particles, primary hot roller rolling at 50 to 60 DEG C and secondary hot roller rolling at 150 to 160 DEG C. The acrylic acid modified epoxy resin paint has the beneficial effects that all ingredients of the acrylic acid modified epoxy resin paint do not contain organic solvents; no VOC harmful gas is volatilized in the construction anduse process; waste water, waste gas and waste slag cannot be generated; the safe, environment-friendly and nontoxic effects are achieved; in the use process, the formation is controlled by using different polymerization degrees of all ingredients; after coating, heating is performed for secondary melting; secondary reaction is performed at high temperature into a coated surface; the levelling property of the two-ingredient particle paint is good; the adhesive force is strong; the impact resistance is realized; the shrinking rate is small; the coating thickness is controlled; the production process is simple; the use is convenient; the cost is low.

Owner:上海瑞泽丰标准技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com