Patents

Literature

3313 results about "Cobalt oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt oxide may refer to Cobalt oxide - CoO Cobalt oxide - Co₂O₃ Cobalt oxide - Co₃O₄

Process for activating cobalt catalysts

InactiveUS20050227866A1Improve reducibilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsParticulatesHydrogen

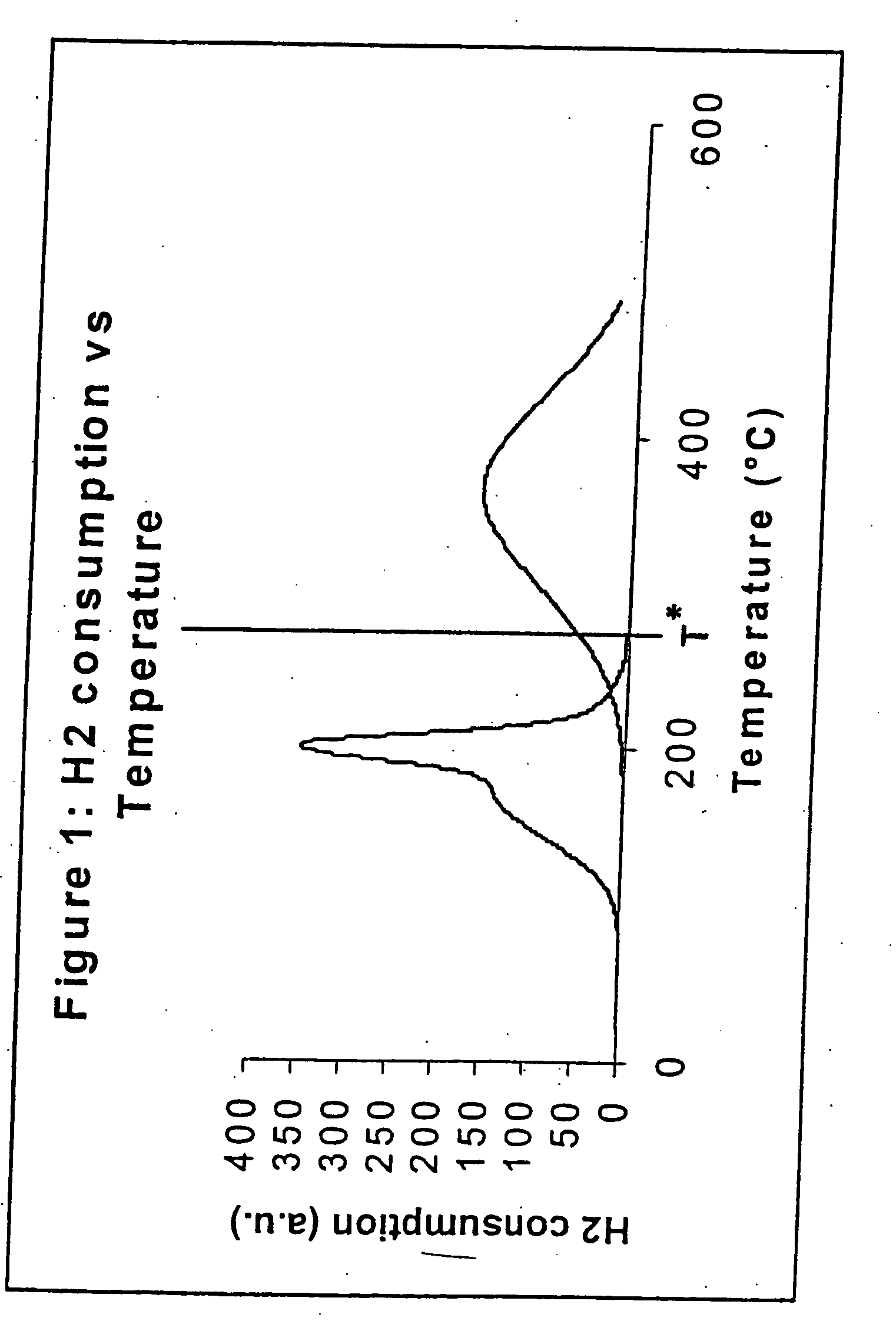

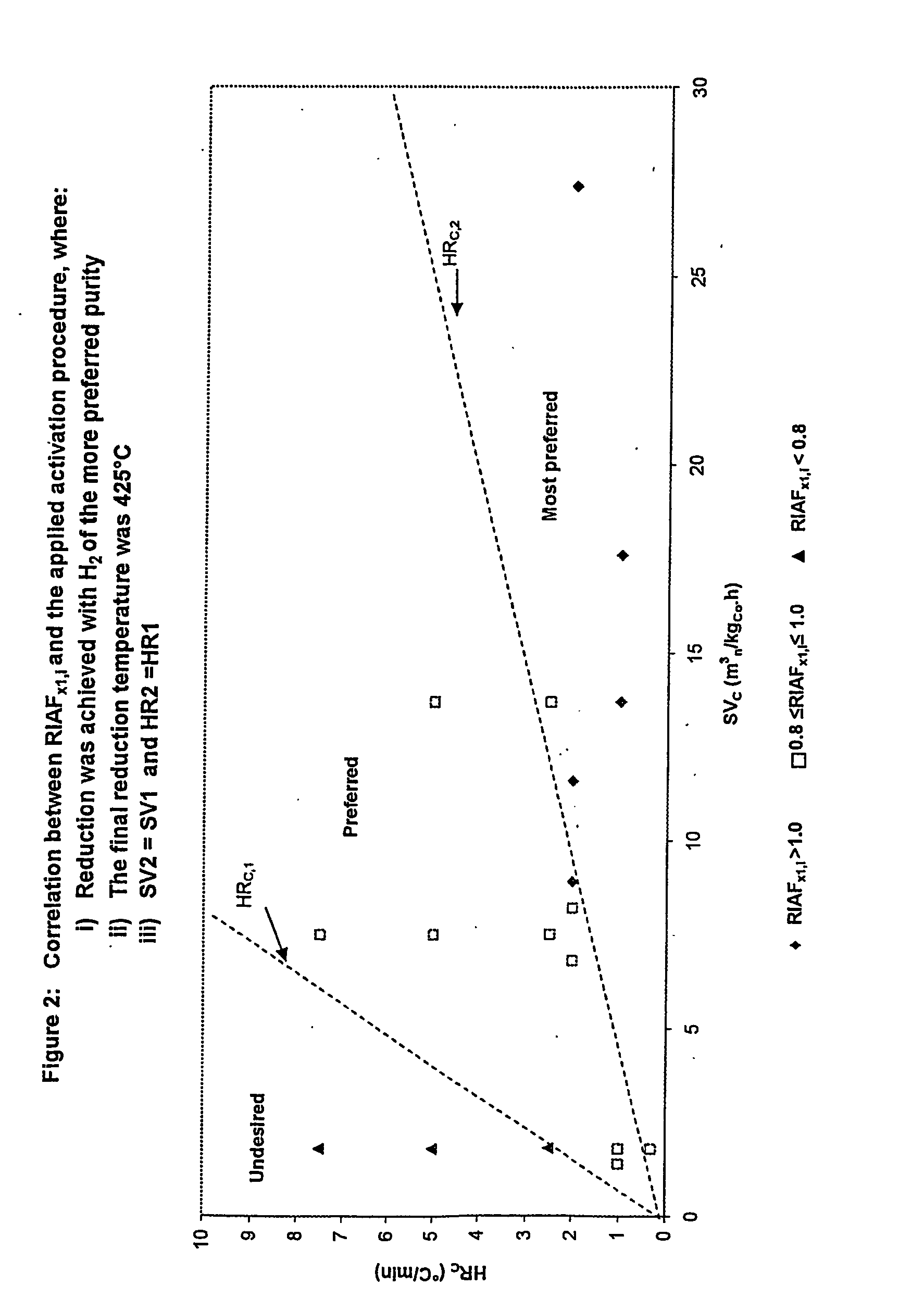

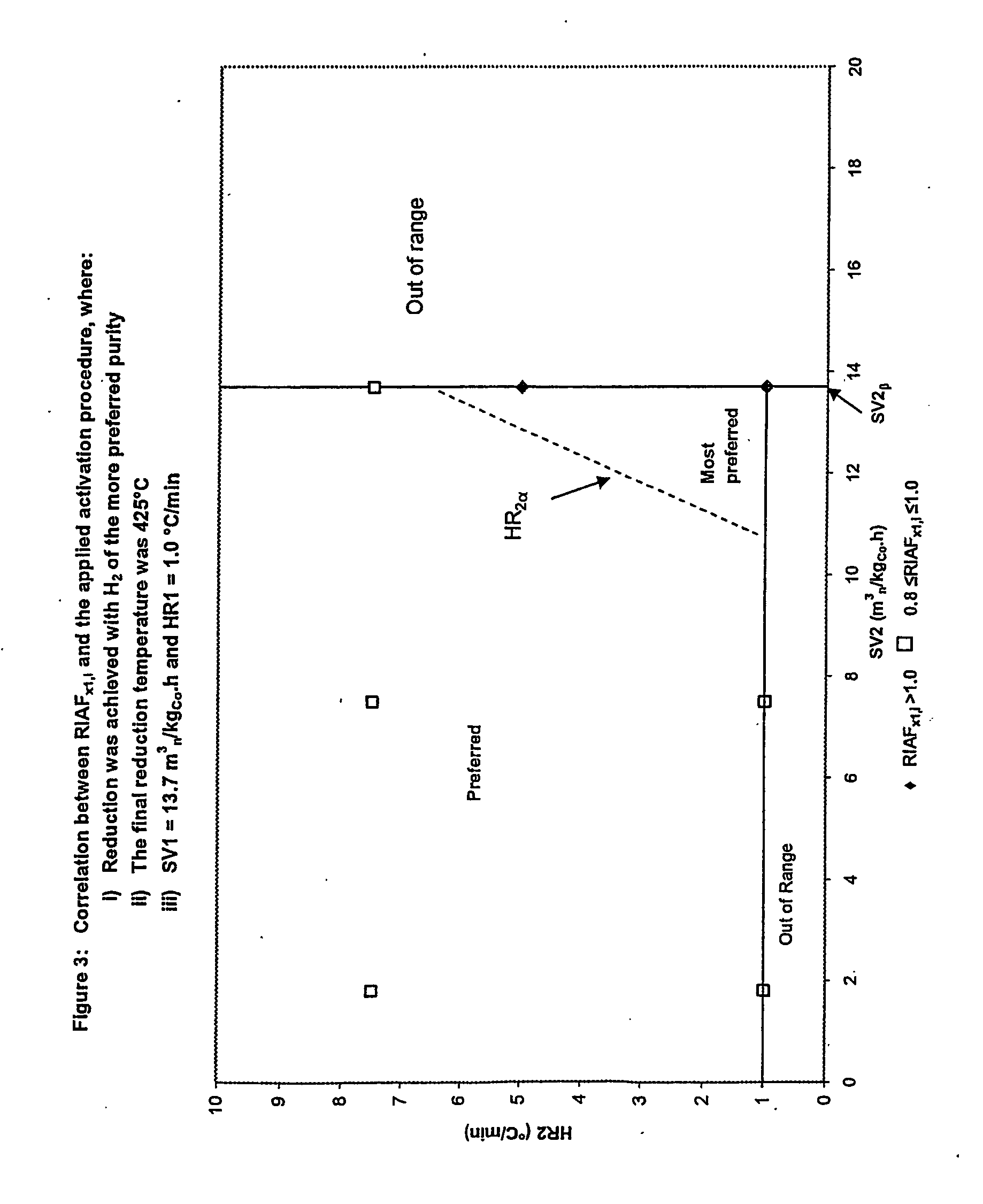

A particulate pre-reduction cobalt supported Fischer-Tropsch synthesis catalyst precursor which comprises a catalyst support impregnated with cobalt, is treated with a pure hydrogen reducing gas, at a first specific feed gas space velocity, SV1, and at a first heating rate, HR1, to obtain a partially reduced precursor. The support contains reducible cobalt oxide in a calcined state and having a formula-unit in which each mole of cobalt atoms is associated with more than 4 / 3 moles of oxygen atoms and displaying a reducible cobalt oxide specific surface area at least equal to that of Co3O4 spinel. The partially reduced precursor is then treated with a pure hydrogen reducing gas, at a second specific feed gas space velocity, SV2, and at a second heating rate, HR2, to obtain an activated supported Fischer-Tropsch catalyst, with SV2≦SV1 and / or HR2≧HR1; however, when SV2=SV1, HR2≠HR1 and when HR2=HR1, SV2≠SV1.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

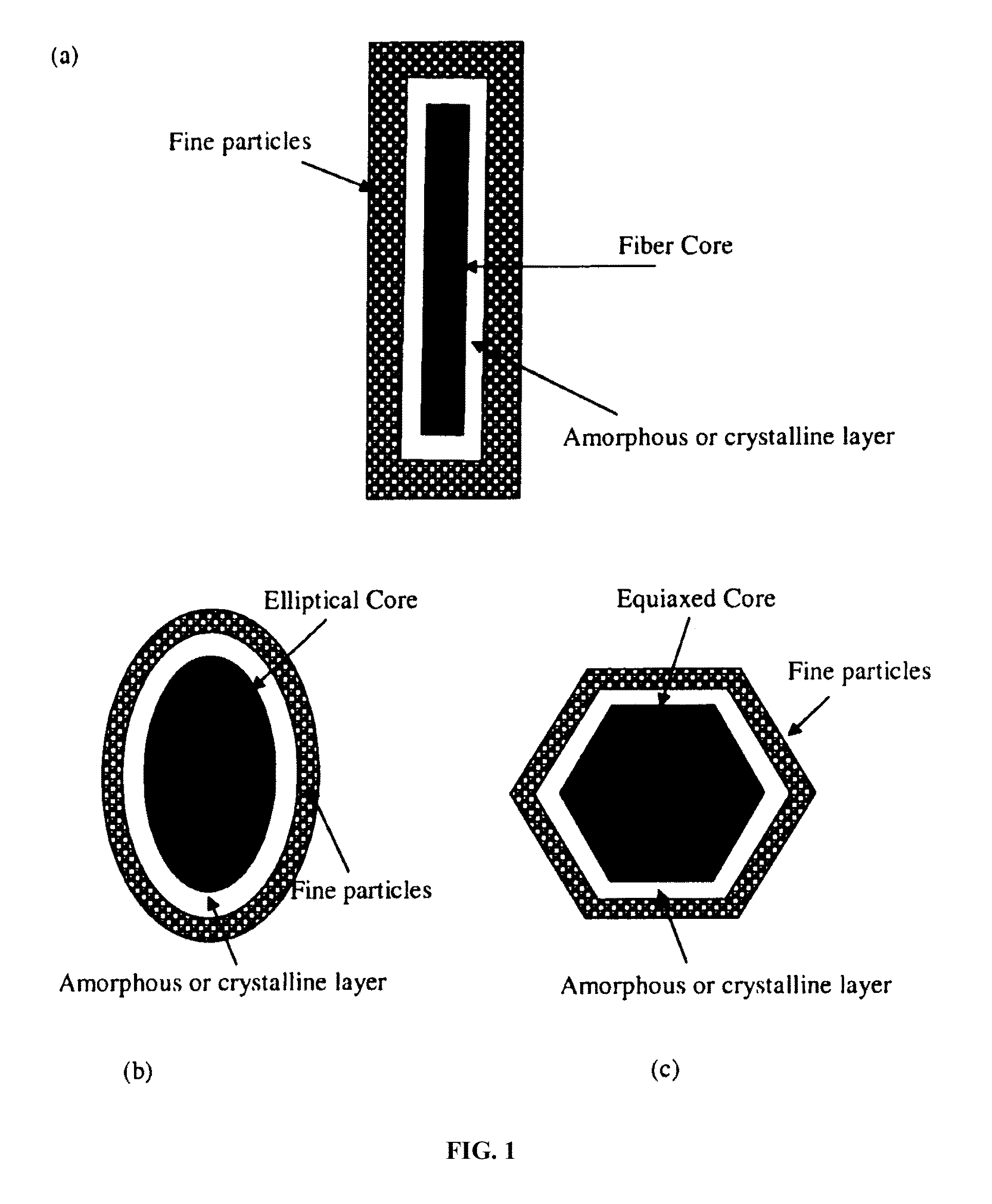

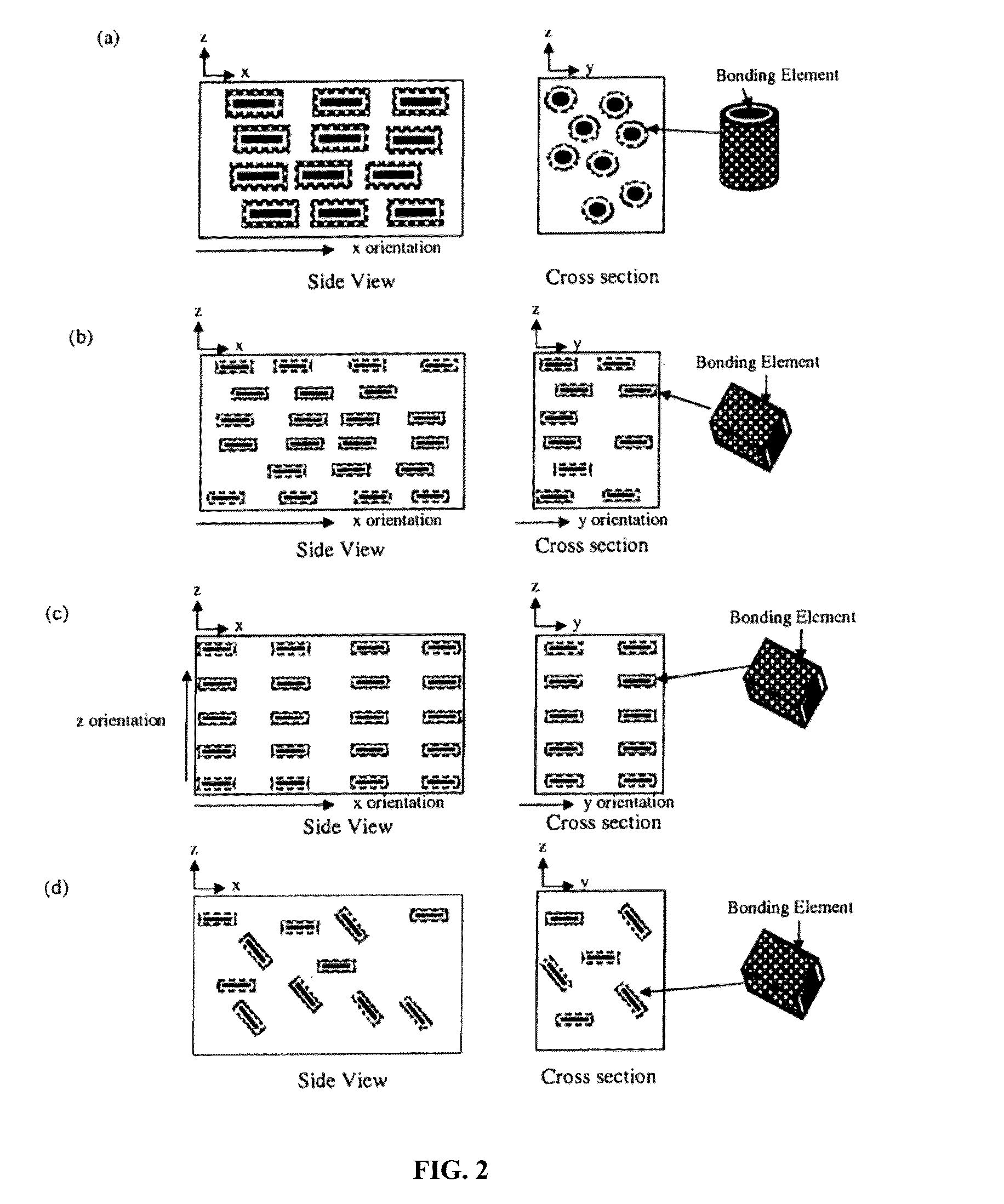

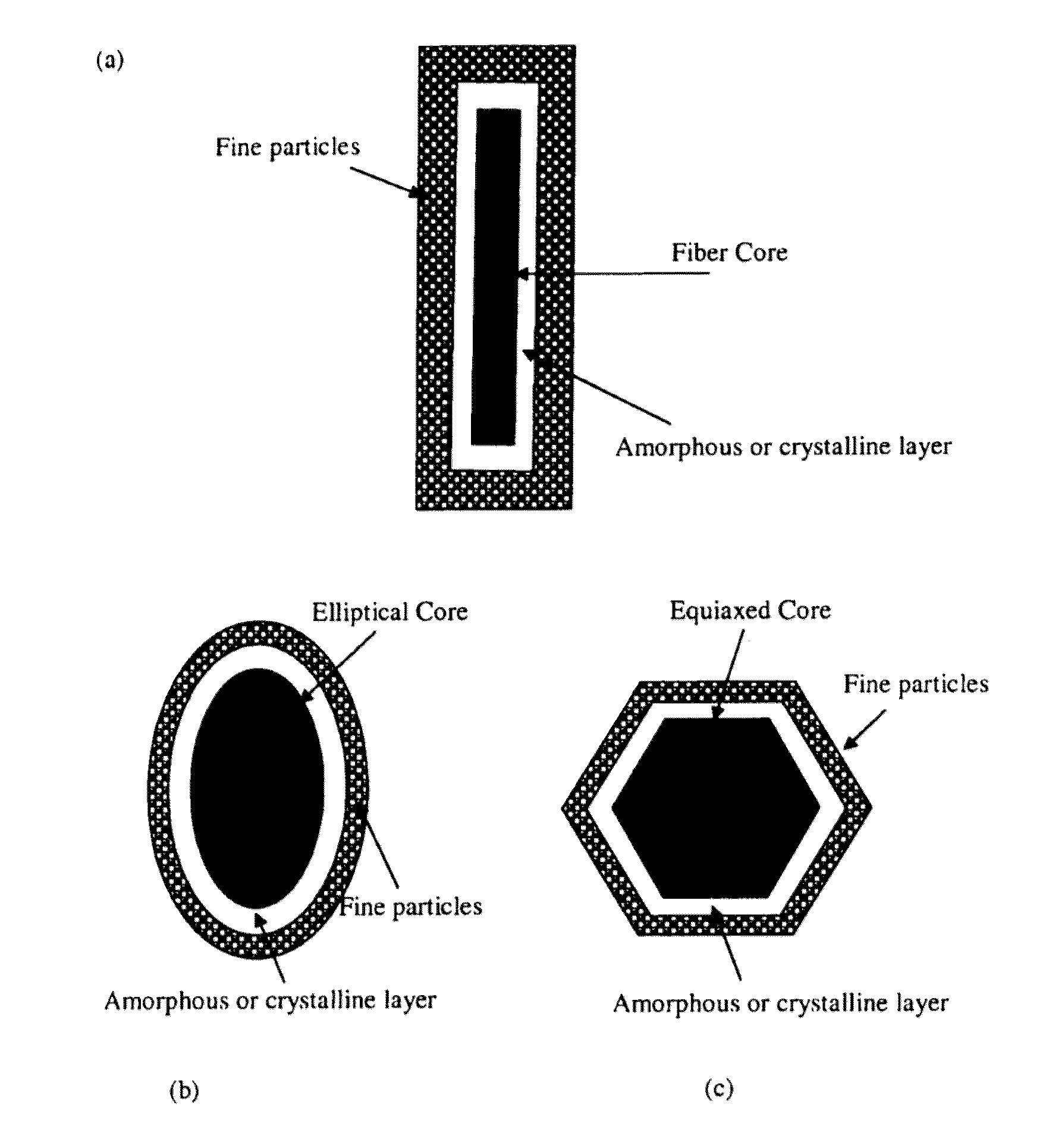

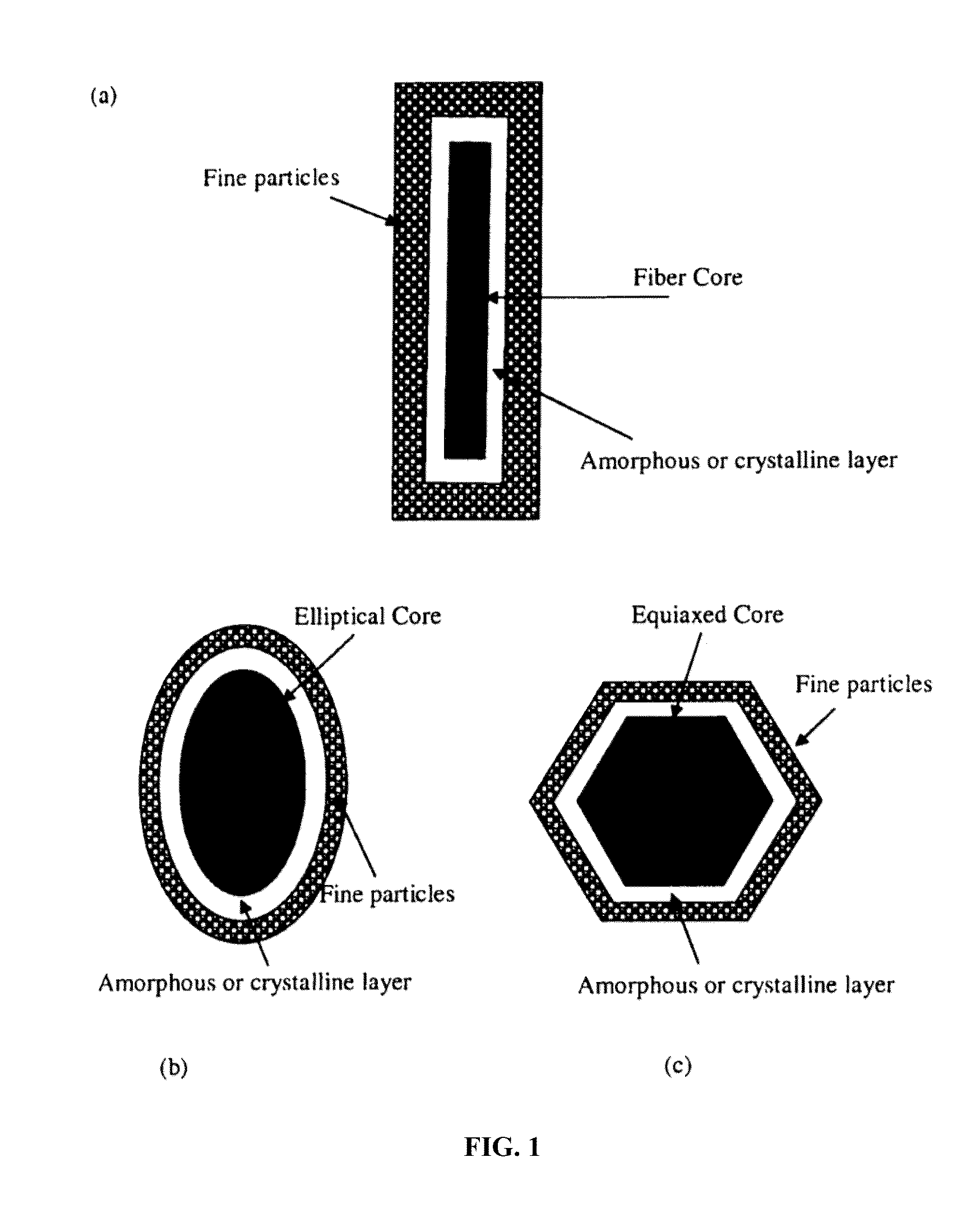

Marble-like composite materials and methods of preparation thereof

InactiveUS20140127450A1Low costIncrease consumptionLayered productsCoatingsCalcium silicateFlexural strength

The invention provides novel marble-like composite materials and methods for preparation thereof. The marble-like composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production. The precursor materials include calcium silicate and calcium carbonate rich materials, for example, wollastonite and limestone. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as pigments (e.g., black iron oxide, cobalt oxide and chromium oxide) and minerals (e.g., quartz, mica and feldspar). These marble-like composite materials exhibit veins, swirls and / or waves unique to marble as well as display compressive strength, flexural strength and water absorption similar to that of marble.

Owner:RIMAN RICHARD E +1

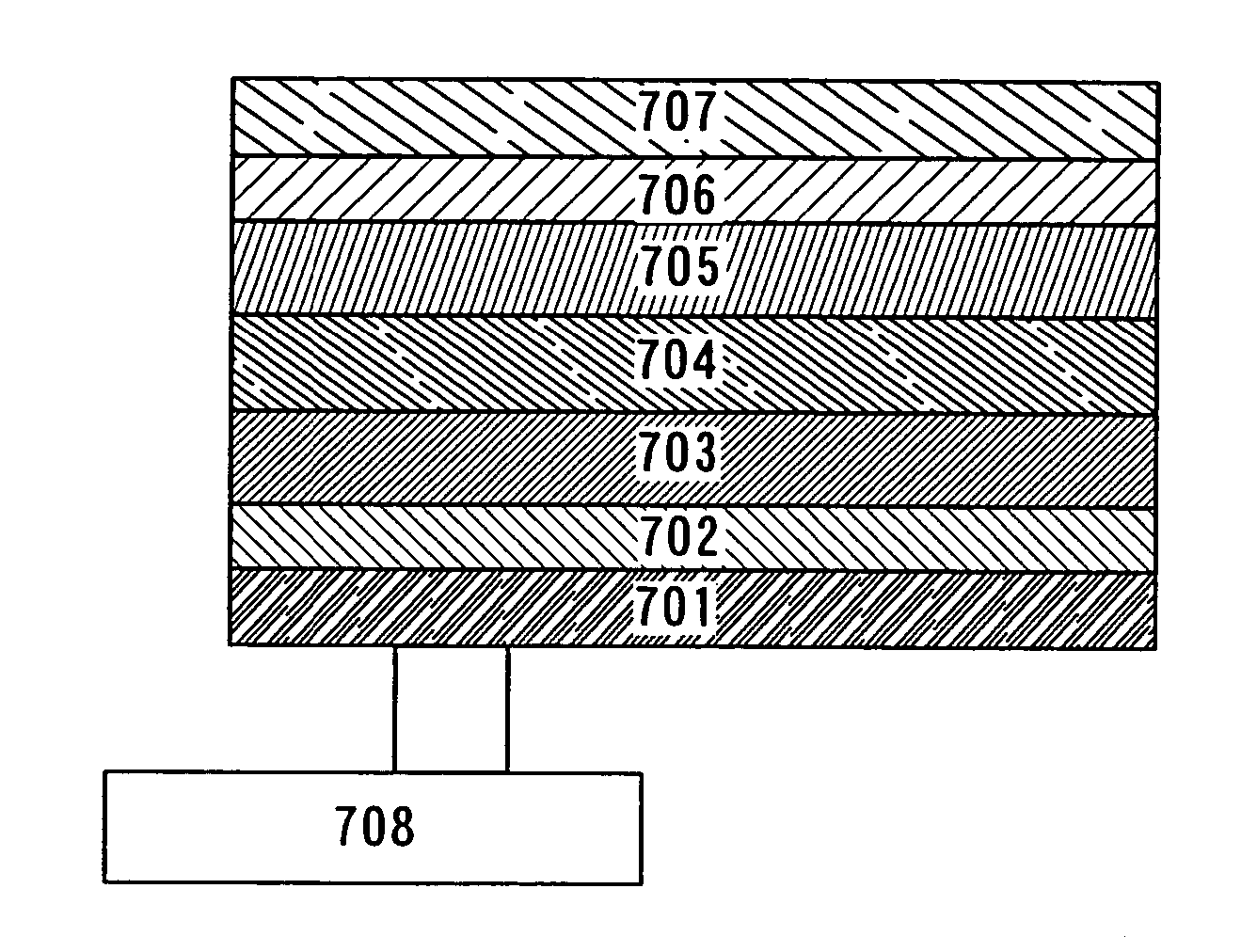

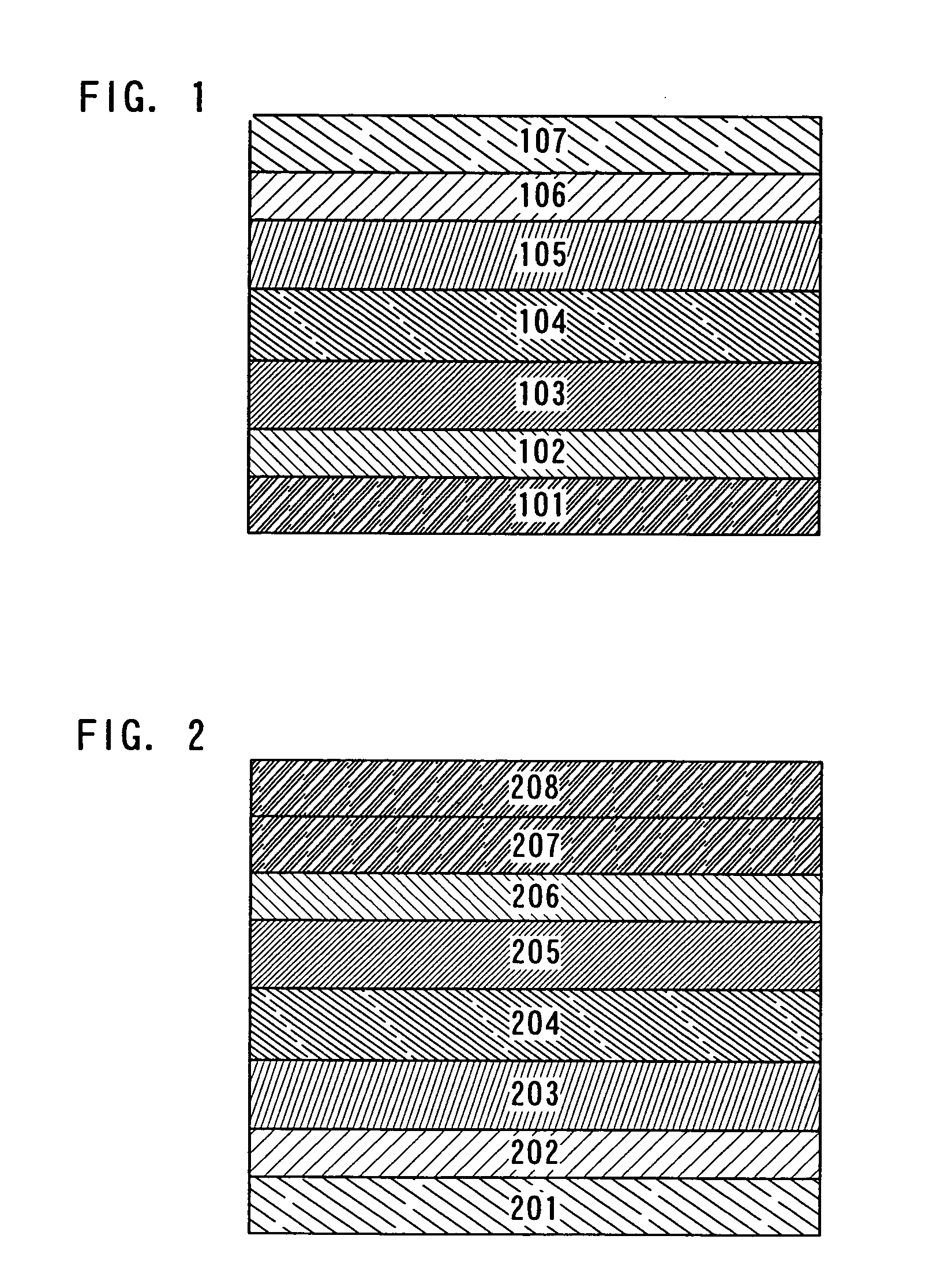

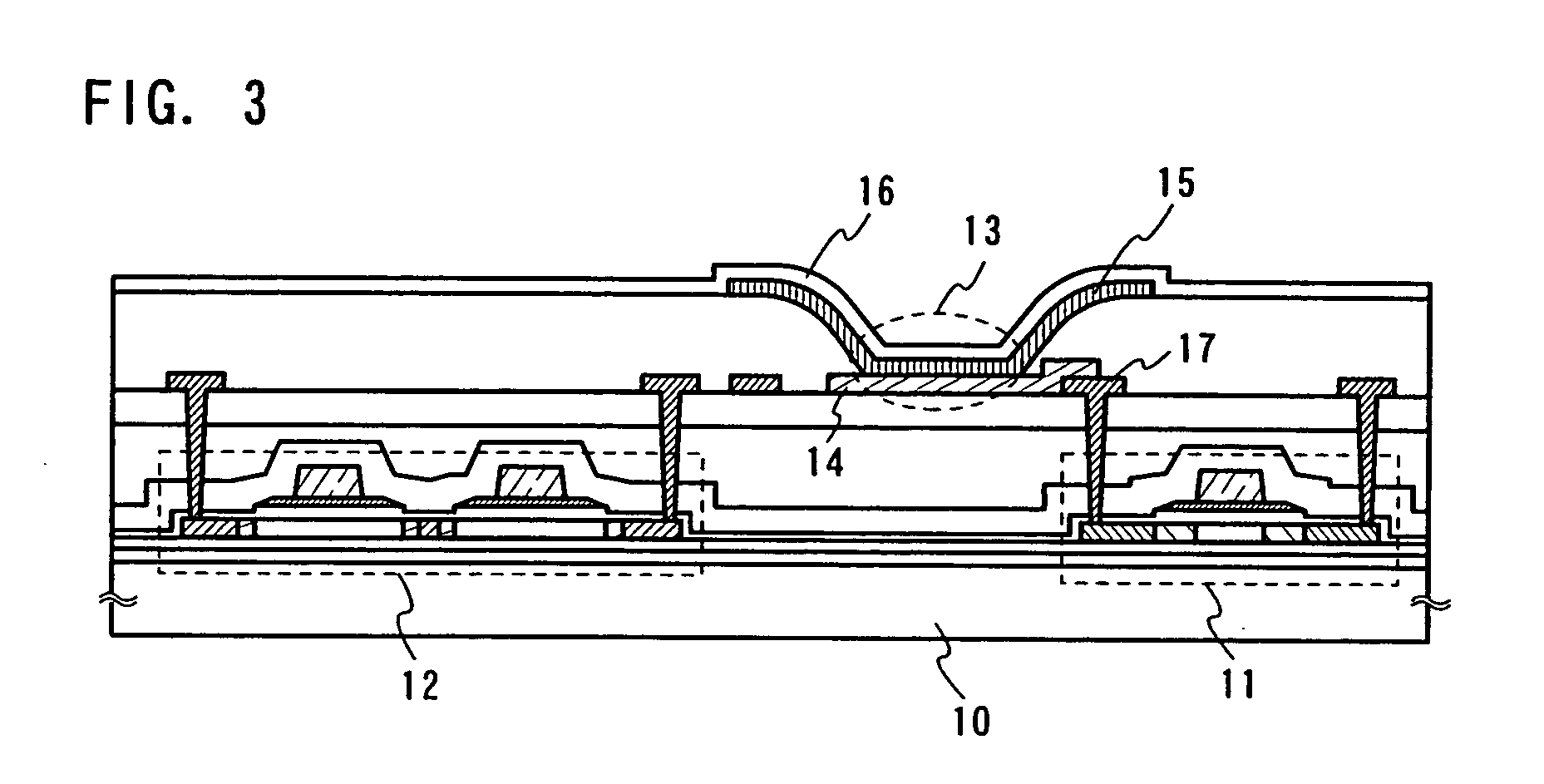

Light-emitting element and light-emitting device using the same

InactiveUS20050116633A1Luminous stabilityEfficient emissionsDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringCopper oxide

It is an object of the invention is to provide a light-emitting element in which failure of the light-emitting element due to separation can be controlled and stable luminescence can be obtained with high-efficiency and for a long stretch of time by controlling separation of layers constituting the light-emitting element. According to one aspect of a light-emitting element of the invention, the light-emitting element sandwiches a plurality of layers between a pair of electrodes, wherein at least one layer of the plurality of layers is a layer containing a substance selected from bismuth oxide, cobalt oxide, chromium oxide, copper oxide, nickel oxide, and titanium oxide, or at least one layer of layers different from a light-emitting layer among the plurality of layers is a mixed region of one substance selected from bismuth oxide, cobalt oxide, copper oxide, magnesium oxide, nickel oxide, zinc oxide, and titanium oxide and an organic compound.

Owner:SEMICON ENERGY LAB CO LTD

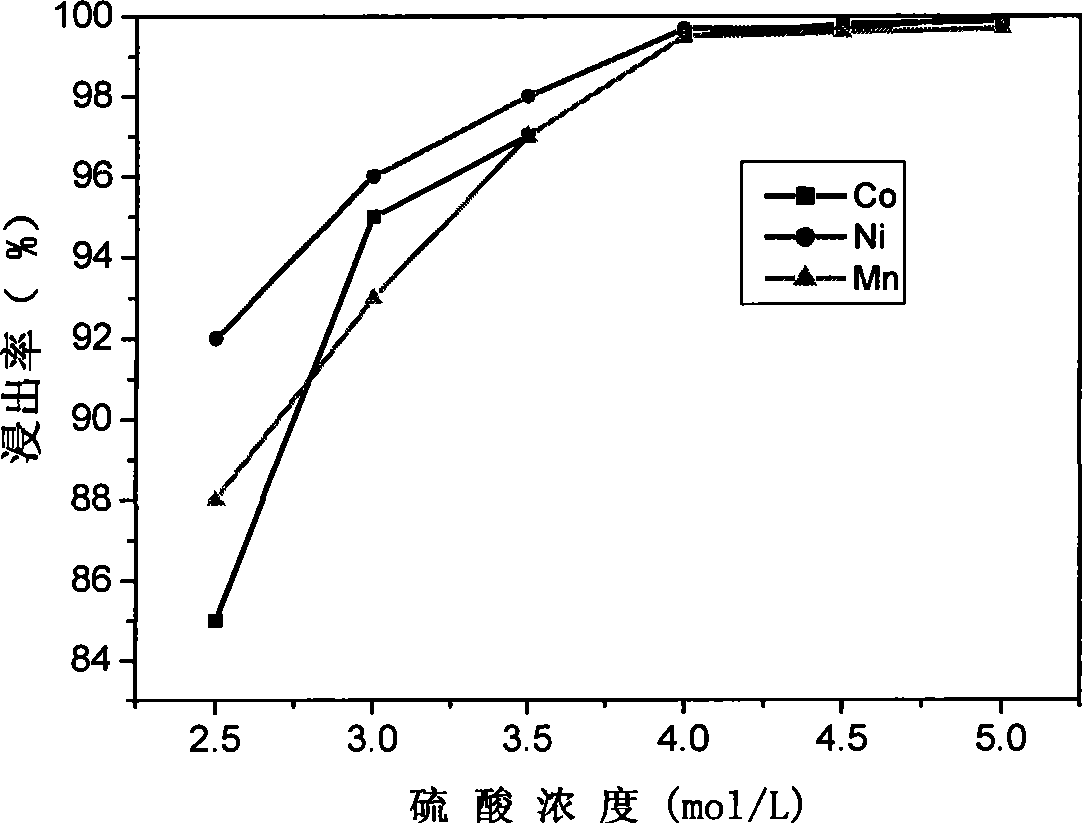

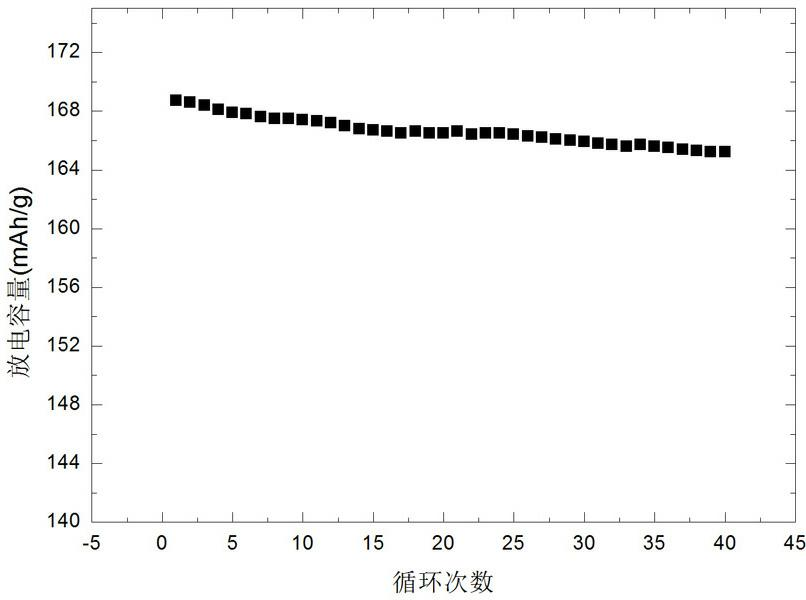

Method for preparing nickel and cobalt doped lithium manganate by using waste and old lithium ionic cell as raw material

InactiveCN101450815ASimultaneous recyclingShort processManganates/permanganatesManganateManganese oxide

The invention discloses a method for preparing lithium nickel cobalt manganese oxide by taking a waste lithium ion battery as a raw material. The method is mainly characterized in that a waste lithium ion battery taking the lithium nickel cobalt manganese oxide, lithium nickel cobalt oxide and so on as a battery positive material is selected as the raw material and is pretreated through disassembly, separation, crushing, screening and so on, and then processes such as adhesive removal at high temperature and aluminum removal by sodium hydroxide are adopted to obtain an inactivated positive material containing nickel, cobalt and manganese; then a sulfuric acid and hydrogen peroxide system is adopted to leach, and P204 is adopted to remove impurities by extraction to obtain pure nickel, cobalt and manganese solution, and proper manganese sulfate, nickel sulfate or cobalt sulfate is blended to ensure that the mol ratio of nickel, cobalt and manganese elements in the solution is 1: 1: 1; and then ammonium carbonate is adopted to adjust the pH value to form a nickel cobalt manganese carbonate precursor, and then a proper amount of lithium carbonate is blended for high temperature sintering to synthesize a lithium nickel cobalt manganese oxide battery material. The first discharge capacity of the material is 150 mAh / g, the discharge capacity is still kept more than 130mAh / g after the circulation for 30 times, and the material has good electrochemical performance.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Unsaturated hydrocarbon hydrogenation catalyst, preparation method and applications thereof

ActiveCN102218323ASolve the problem of hydrogenationExpansion of comprehensive utilization channelsHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsCoalCerium oxide

The invention discloses an unsaturated hydrocarbon hydrogenation catalyst which comprises a carrier, an active component and an additive; the active component is a mixture of nickel oxides and other metal oxides; the additive is at least two out of magnesia oxide, lanthanum oxide and ceria; counted by weight percentage, the unsaturated hydrocarbon hydrogenation catalyst comprises 5-15% of nickel oxides, 1-10% of other metal oxides, 1-10% of additive and remaining quantity of carrier; and the metal oxide is one or more oxides out of molybdenum oxide, cobalt oxide and ferric oxide. The invention also discloses a preparation method and applications of the unsaturated hydrocarbon hydrogenation catalyst. The unsaturated hydrocarbon hydrogenation catalyst has the advantages of high hydrogenation precision, strong side effect resistance, good thermal stability, long service life and the like, can be used for processing tail gas in indirect coal oil production industrial and can be also used for processing unsaturated hydrocarbon in synthesis gas.

Owner:THE NORTHWEST RES INST OF CHEM IND

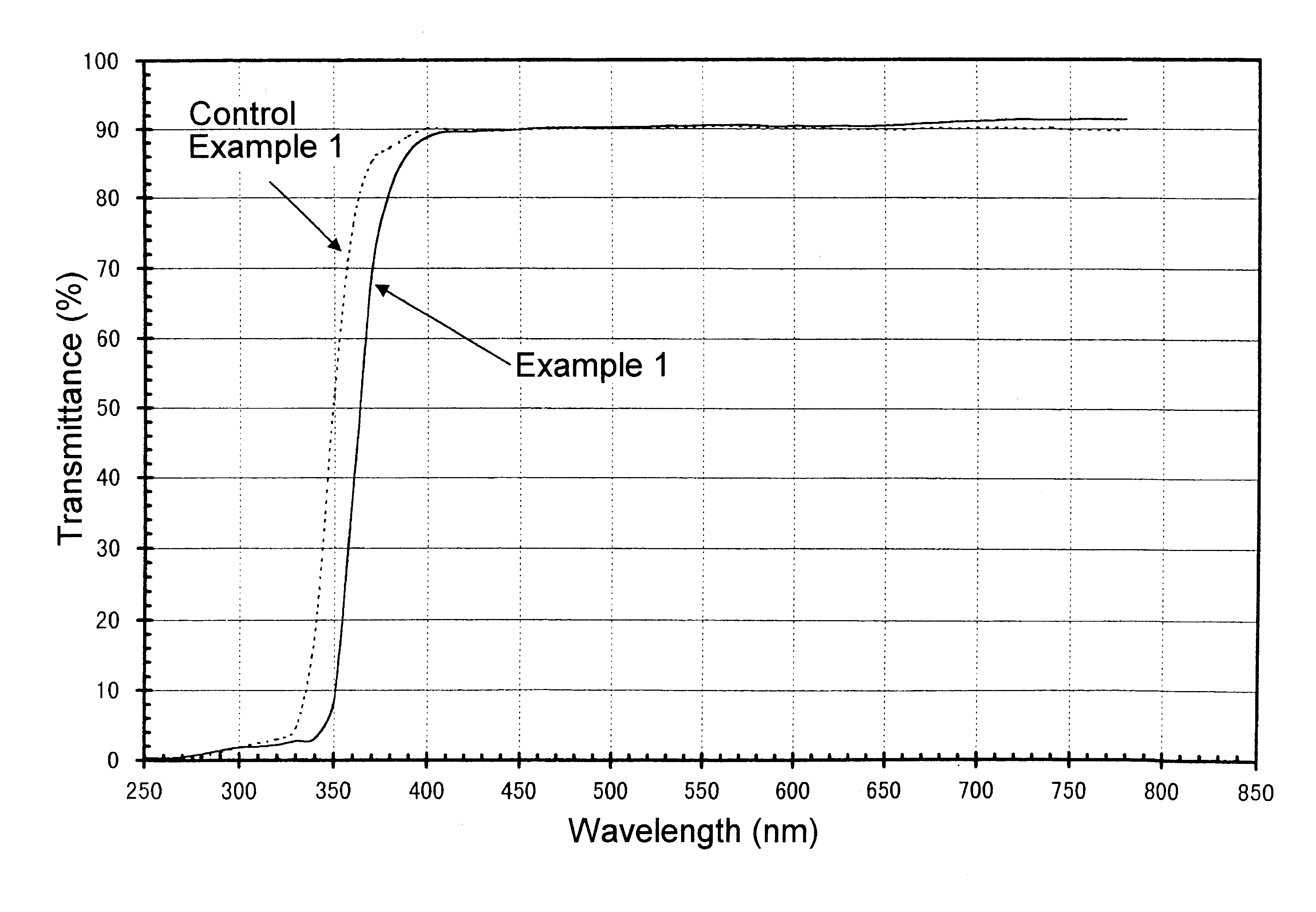

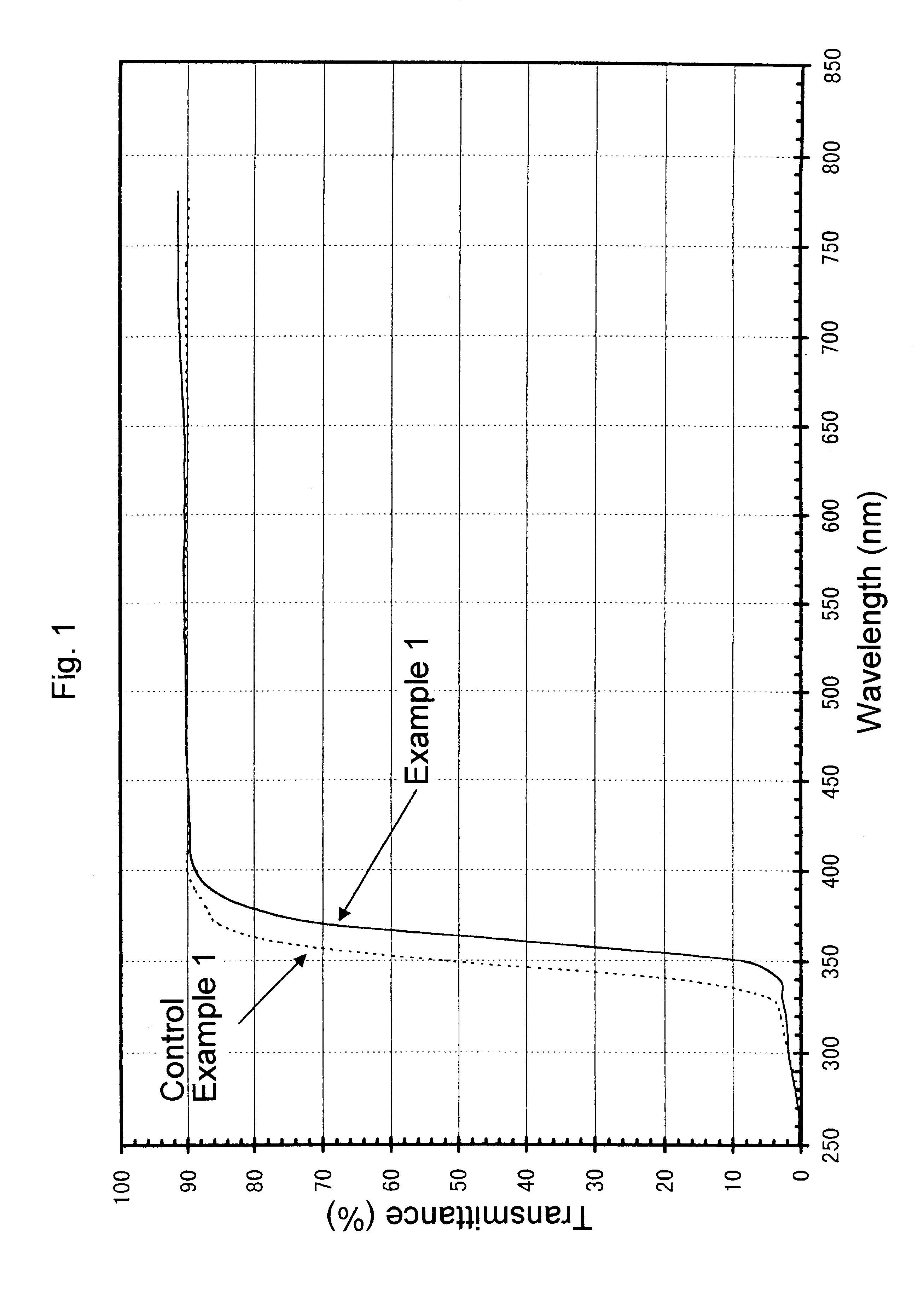

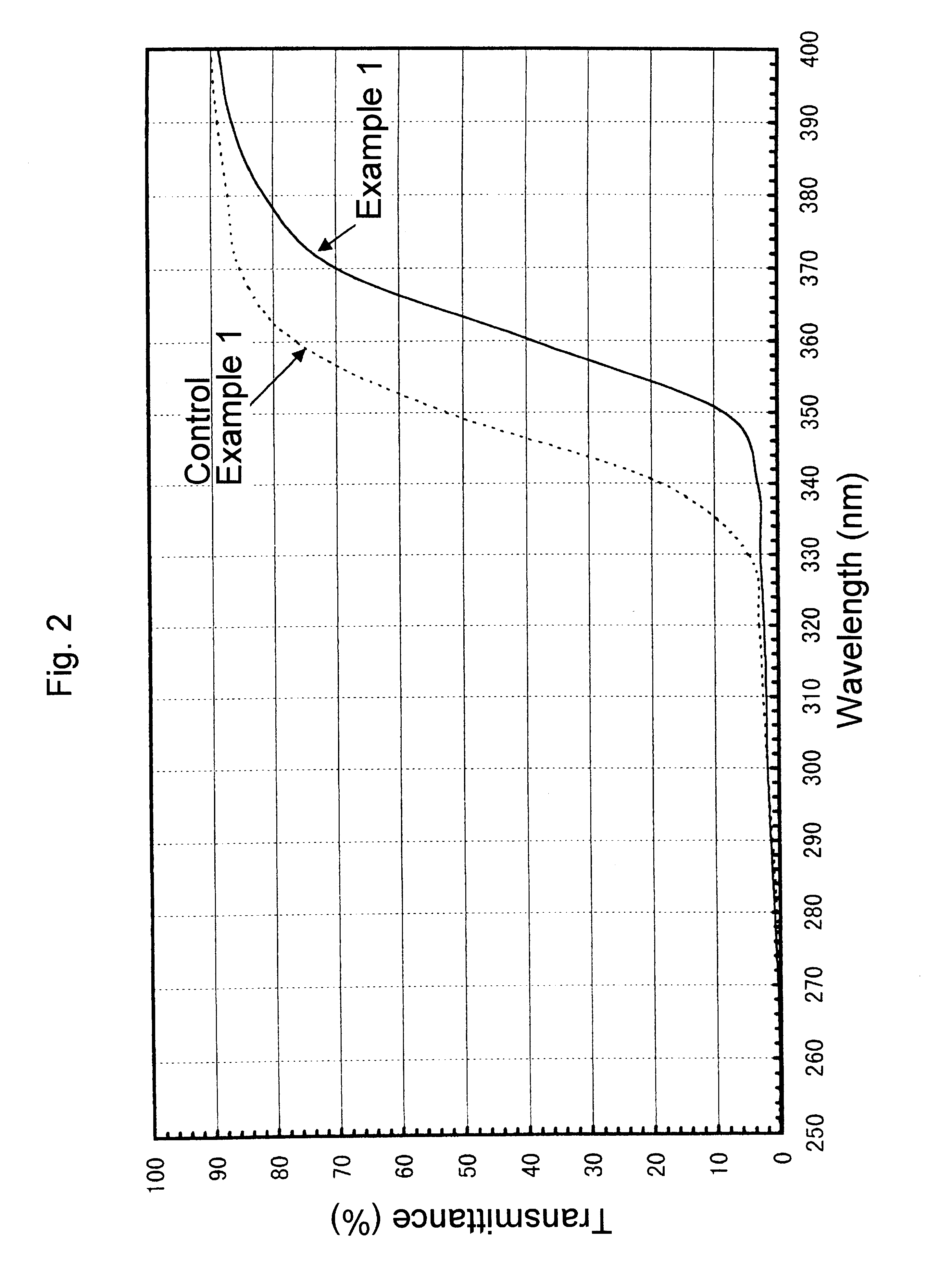

Ultraviolet radiation-absorbing, colorless, transparent soda-lime silica glass

An ultraviolet radiation-absorbing, colorless, transparent soda-lime-silica glass as well as glass bottles formed out of the glass are disclosed which, while maintaining high transmittance to light in the visible region and thereby allowing the contents to be seen clearly, absorbs ultraviolet radiation and thus prevents coloration, discoloration, fading in color or deterioration of the flavor of the contents caused by ultraviolet radiation. The glass is characterized in that its composition includes, in % by weight, SO3 . . . 0.15-0.4%; Cerium oxide . . . 0.2-1% (calculated as CeO2); Fe2O3 . . . 0.01-0.08%; FeO . . . 0-0.008%; Manganese oxide . . . 0.01-0.08% (calculated as MnO); and Cobalt oxide . . . 0-0.0005% (calculated as CoO).

Owner:NIHON YAMAMURA GLASS CO LTD

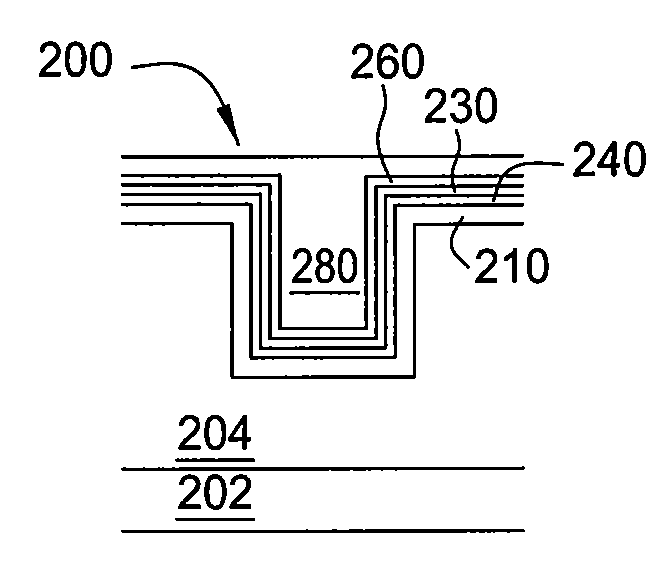

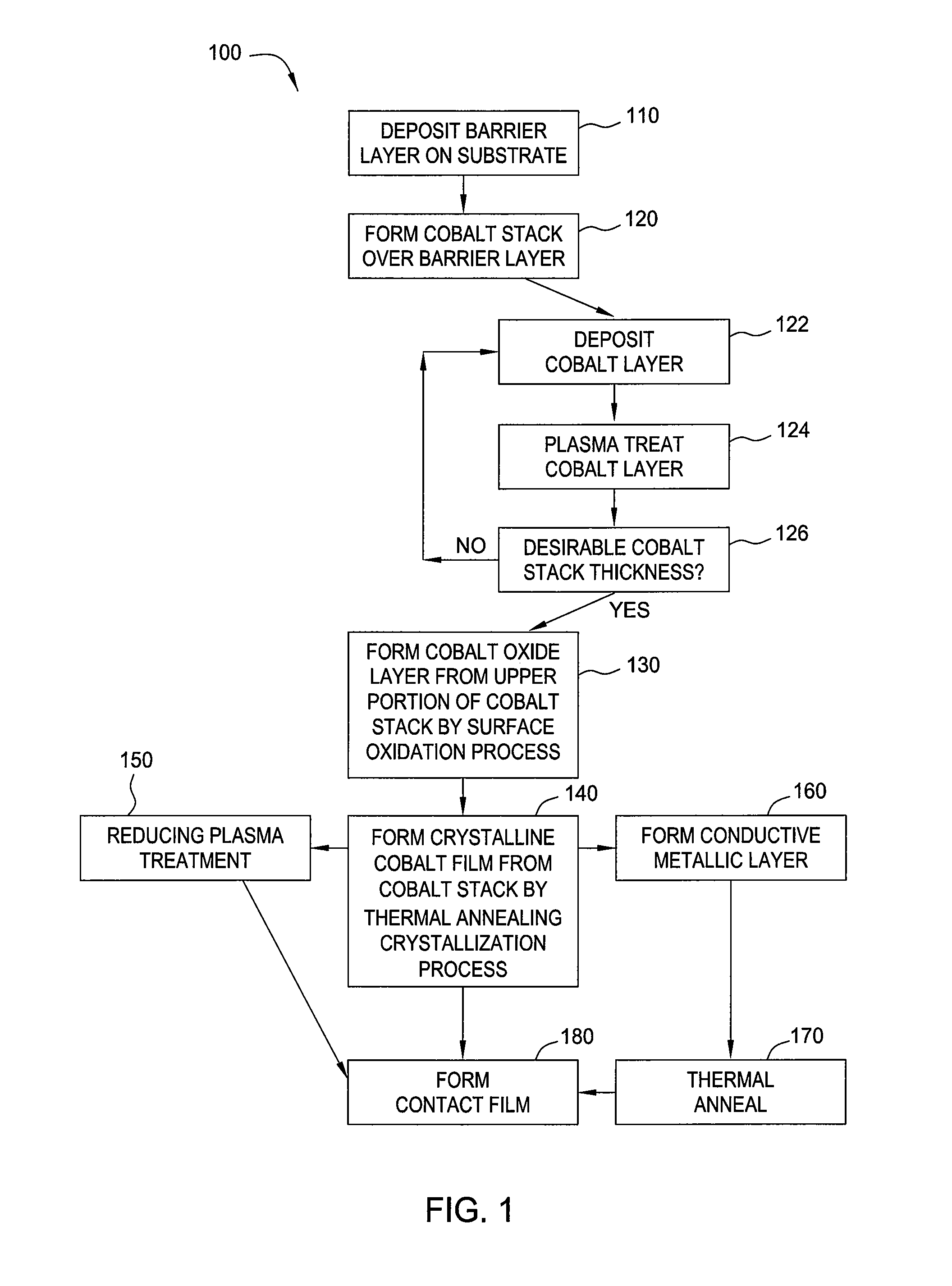

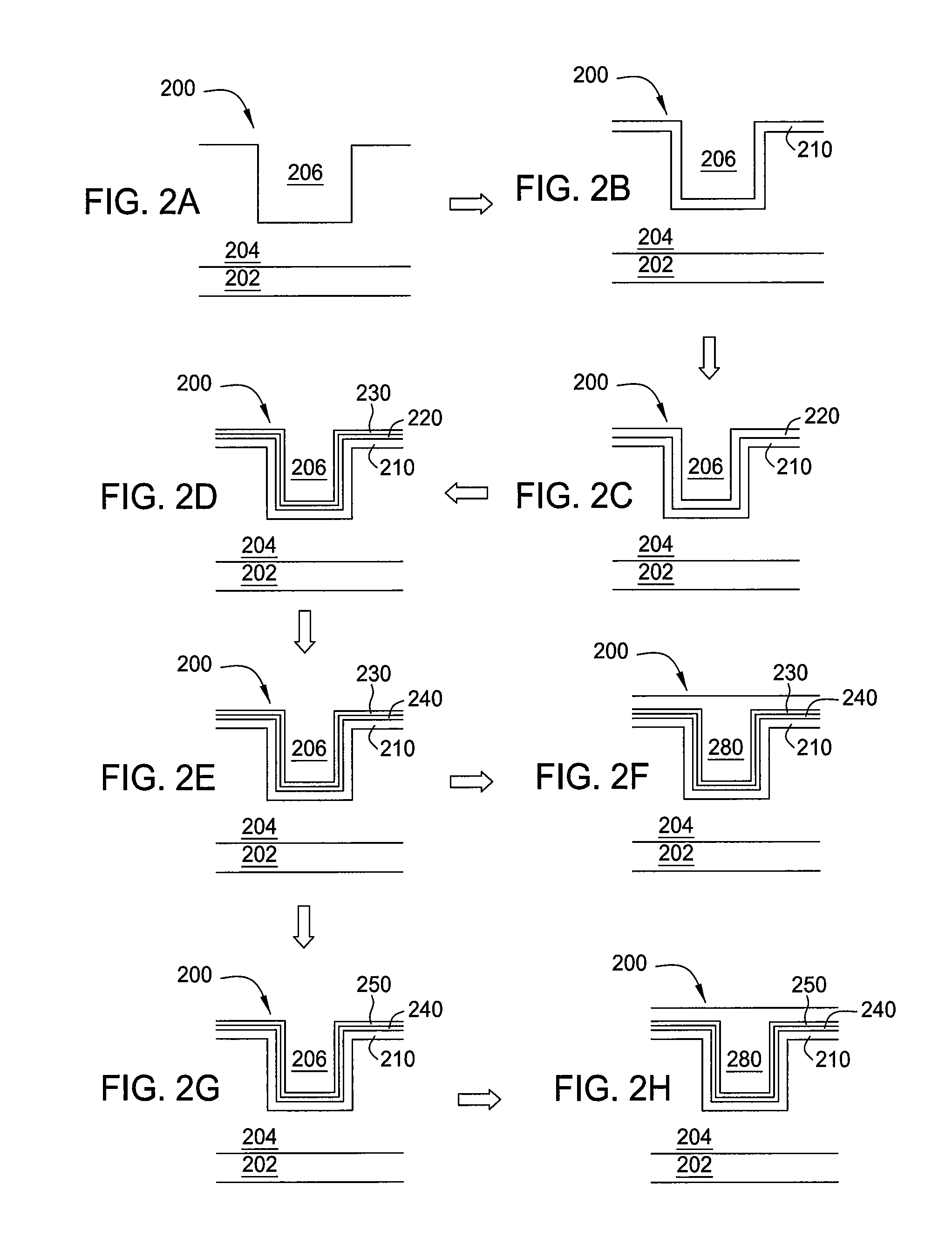

Post deposition treatments for CVD cobalt films

InactiveUS20120252207A1Reduce resistanceSemiconductor/solid-state device detailsSolid-state devicesSurface oxidationDeposition process

Embodiments of the invention provide methods for forming materials on a substrate used for metal gate and other applications. In one embodiment, a method includes forming a cobalt stack over a barrier layer disposed on a substrate by depositing a cobalt layer during a deposition process, exposing the cobalt layer to a plasma to form a plasma-treated cobalt layer during a plasma process, and repeating the cobalt deposition process and the plasma process to form the cobalt stack containing a plurality of plasma-treated cobalt layers. The method further includes exposing the cobalt stack to an oxygen source gas to form a cobalt oxide layer from an upper portion of the cobalt stack during a surface oxidation process and heating the remaining portion of the cobalt stack to a temperature within a range from about 300° C. to about 500° C. to form a crystalline cobalt film during a thermal annealing crystallization process.

Owner:APPLIED MATERIALS INC

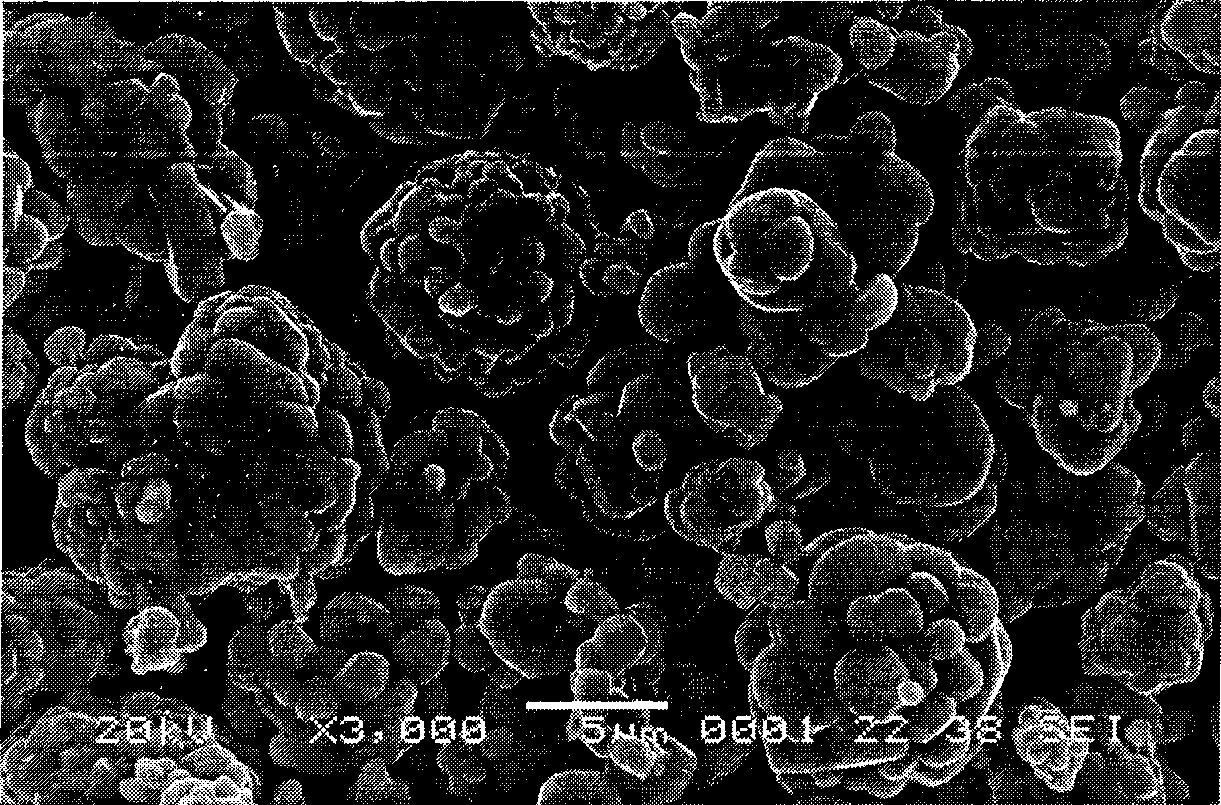

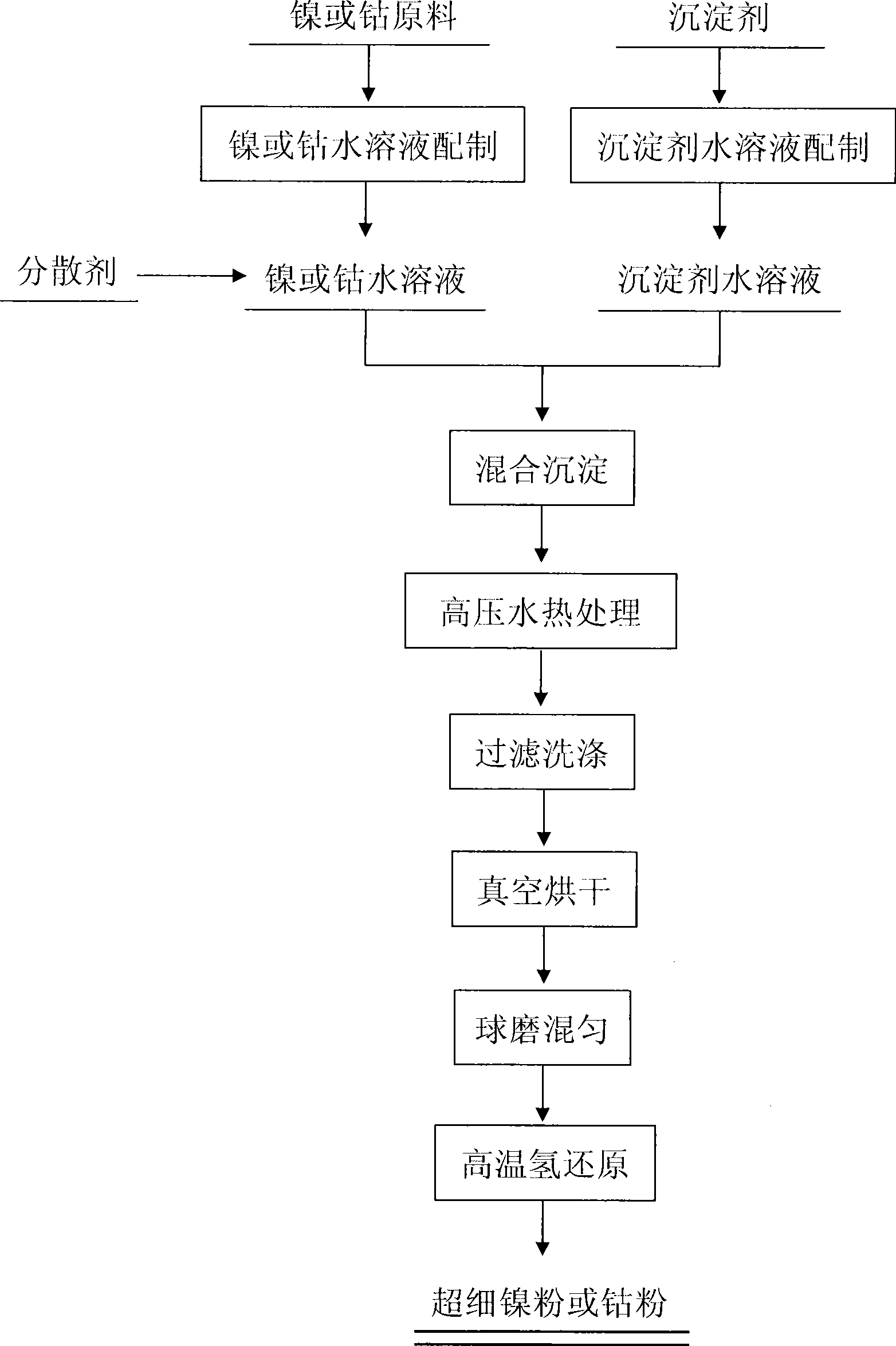

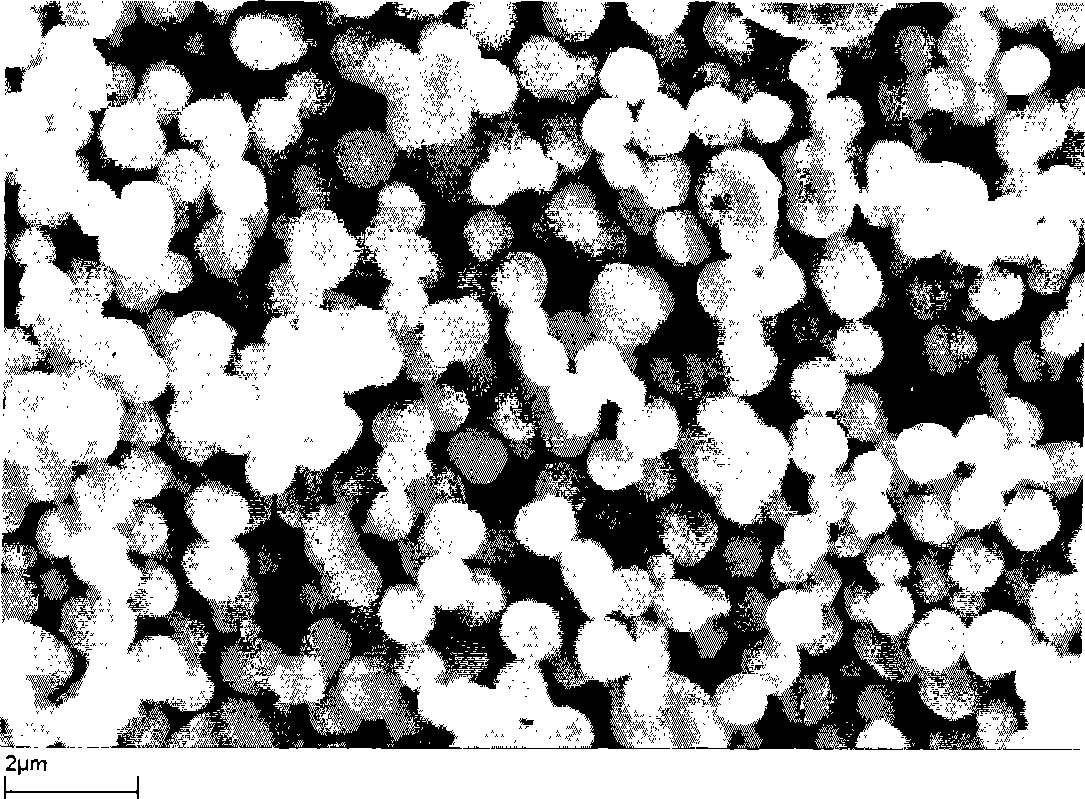

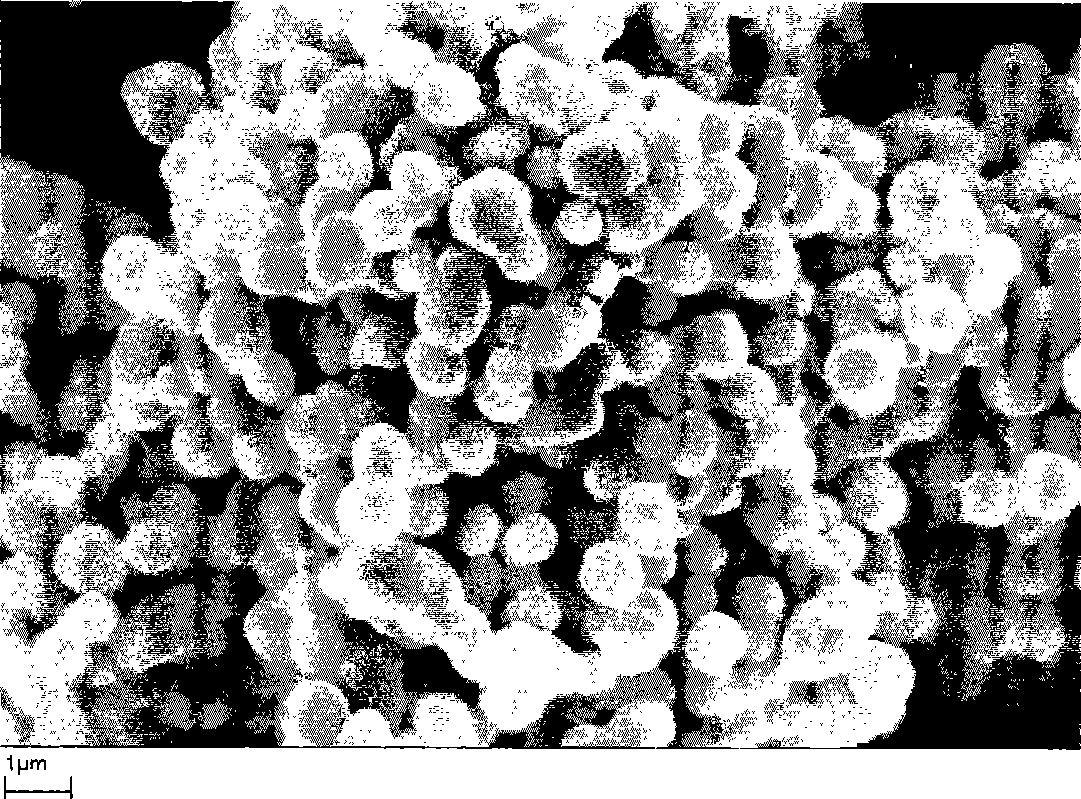

Process for producing spherical submicron metal with hydro-thermal treatment

The invention discloses a technological method for preparation of sphere-shaped ultrafine metallic powders through hydro-thermal treatment, which relates to a technological method for preparation of sphere-shaped ultrafine nickel powders or ultrafine cobalt powders through the procedures such as precipitation, dispersing agent surface finish, high-pressure hydro-thermal treatment, washing, drying and high-temperature hydrogen reduction and the like, and which belongs to the technical field for preparation of metal powder materials. The technological method adopts water soluble salts with nickel and cobalt, cobalt oxide, sub-carbonate, carbonate or hydroxide as raw materials, which are prepared into water solution after processing, the dispersing agent is added, then nickel ion and cobalt ion in the water solution are precipitated through alkali, carbonate, oxalic acid or ammonium oxalate and the like, the hydro-thermal treatment of water pulp of the precipitate is performed in an autoclave, and products of sphere-shaped ultrafine nickel powders or ultrafine cobalt powders with even graininess and good dispersibility can be obtained through washing, drying and high-temperature hydrogen reduction. The technological method is not only suitable for medium- and small-scale discontinuous-type manufacture, but also used for large-scale continuous manufacture, and the manufacturing cost is low.

Owner:张建玲

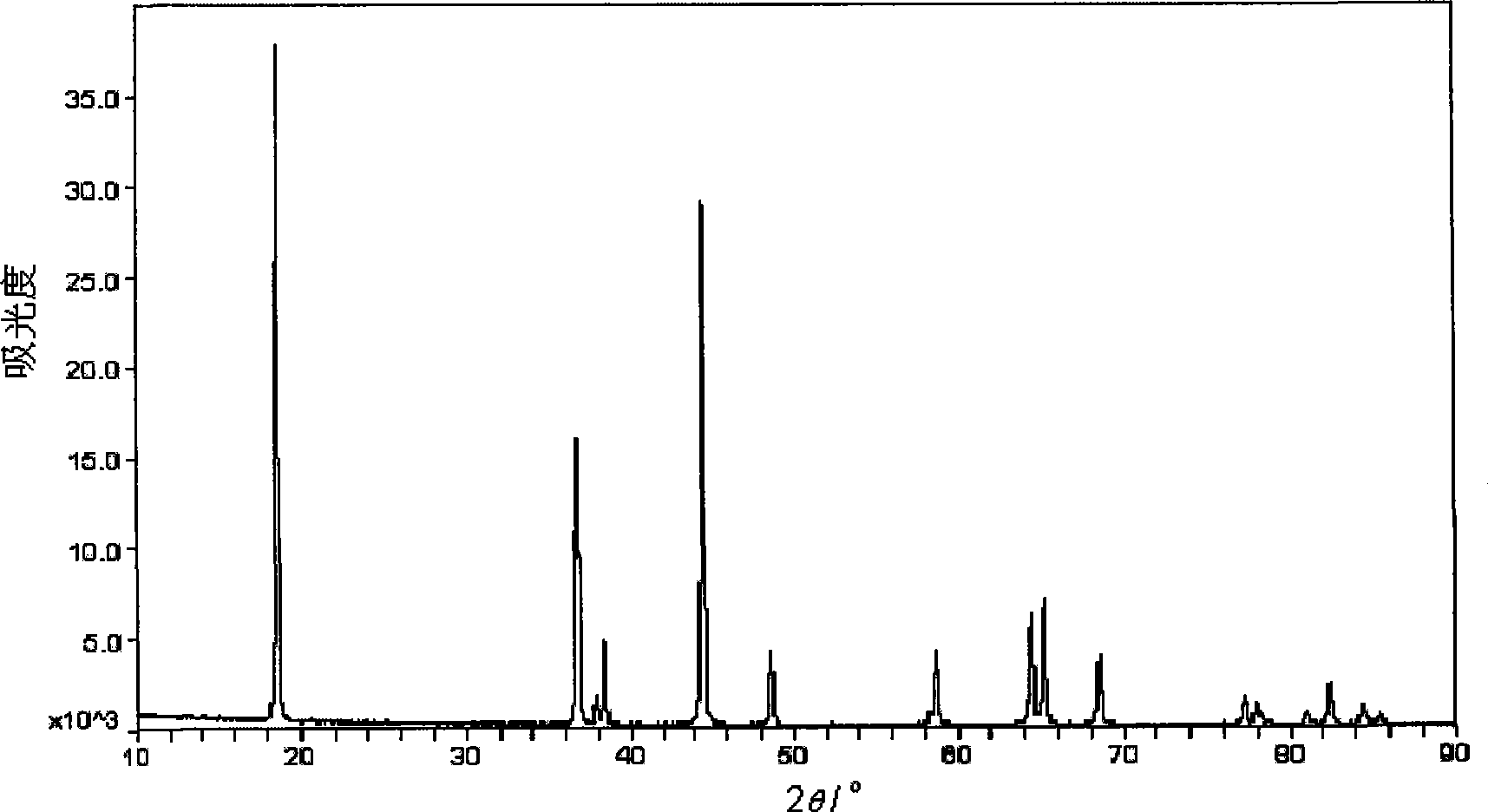

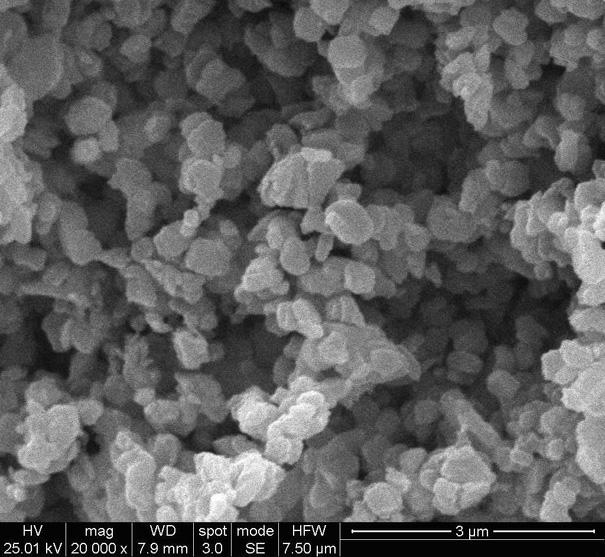

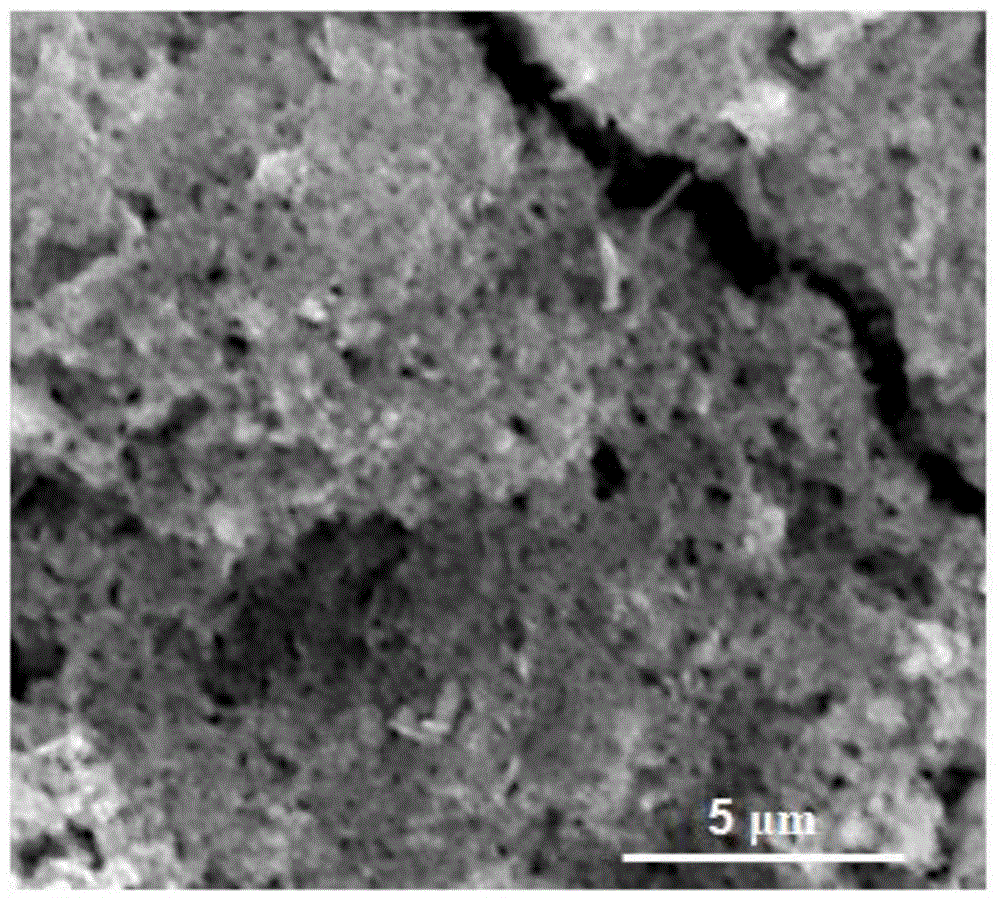

Preparation method of nano positive material for lithium ion battery

InactiveCN102386381AShort heat treatment timeReduce energy consumptionNanostructure manufactureCell electrodesNickel saltElectrical battery

The invention belongs to the field of preparation techniques of nanophase materials and green energy resources, and relates to a preparation method of a nano positive material LiNi1 / 3Mn1 / 3Co1 / 3O2 applied to a lithium ion battery. By using the method, the defects that the calcining temperature needed by a current synthetic material is high, the calcining time is long, the particle sizes of a product are not uniform, and the like, are mainly solved. The preparation method comprises the following steps: adding a certain amount of template agent in a mixed aqueous solution of a nickel salt, a manganese salt and a cobalt salt, and then, dripping a precipitant and a complexing agent into the obtained mixture to form a precipitate; subjecting the precipitate and the mixed aqueous solution to a high-pressure thermal reaction in a hydrothermal kettle, cleaning and baking the obtained product to be dry, so as to obtain a nickel manganese cobalt oxide; and finally, uniformly mixing the nickel manganese cobalt oxide with the lithium salt to prepare a final product by calcining and cooling. By using the preparation method, the product with favorable electrochemical performance can be obtained within a shorter calcining time; the energy consumption is decreased; and the preparation method has obvious economic benefit in the large-scale application of industrial synthesis.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

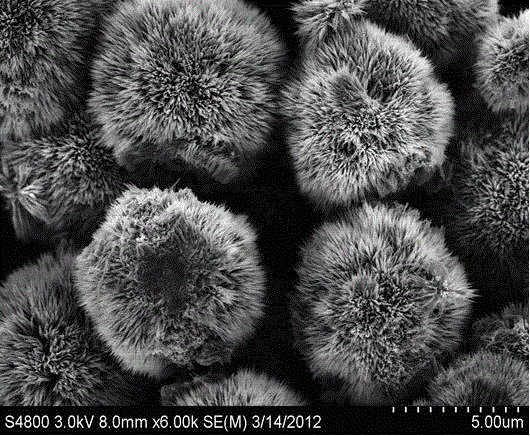

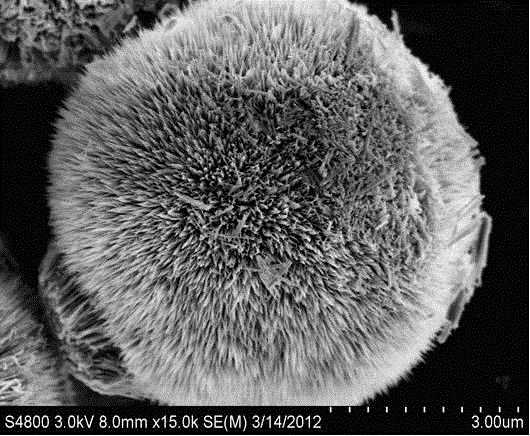

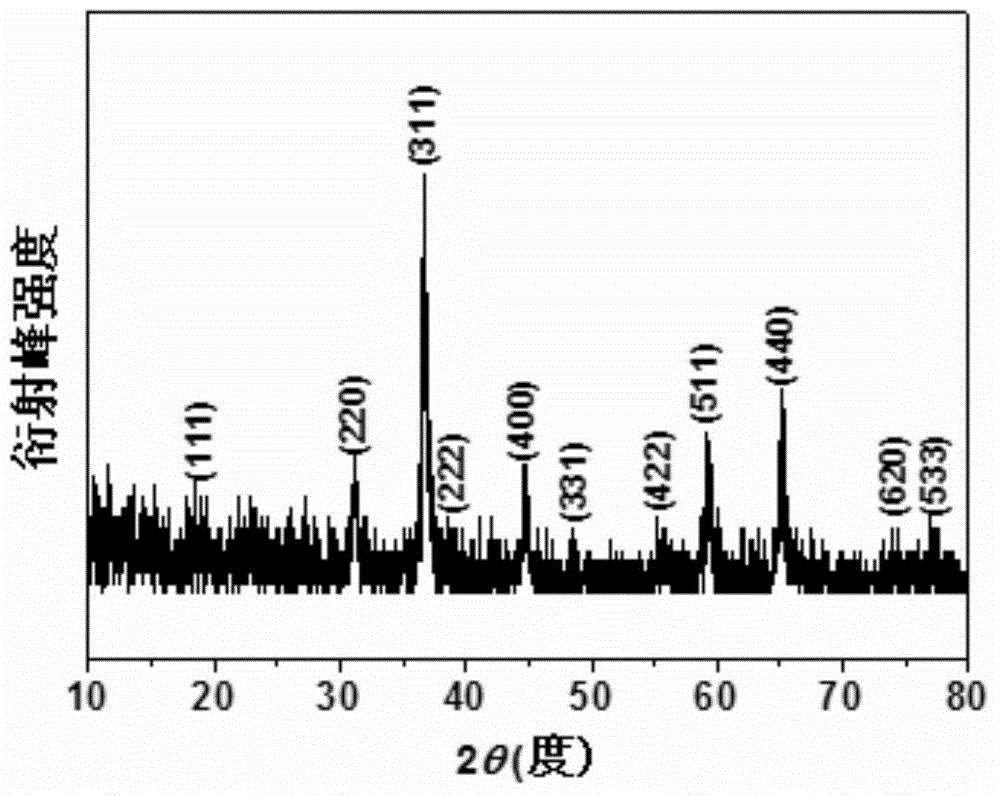

Method of synthesizing mesoporous nickel cobalt oxide nanowire using hydrothermal method and application thereof

InactiveCN102745752AHigh purityLarge specific surface areaMaterial nanotechnologyElectrolytic capacitorsCapacitanceAir atmosphere

The invention relates to a method of synthesizing nickel cobalt oxide electrode material using a hydrothermal method and an application thereof. The method comprises dissolving CoCl2.6H2O, NiCl2.6H2O and CO(NH2)2 into an appropriate amount of deionized water, wherein the mole ratio of CoCl2.6H2O to NiCl2.6H2O is 1 : 2; uniformly stirring the mixed solution by using a magnetic stirrer, transferring the solution into an autoclave, heating the solution to 100 DEG C and keeping the temperature constant for 10 hours; cooling the solution to room temperature, filtering, washing and drying reactants, and then annealing the reactants for 2 hours in an air atmosphere of 250 DEG C. The method is simple to operate and environmental-friendly. The prepared nickel cobalt oxide nanowire is a spinel-type cubic phase and porous, has high purity and relatively high specific surface area, and can be used as electrode materials for super capacitors, with specific capacitance thereof being 722 F / g.

Owner:TONGJI UNIV

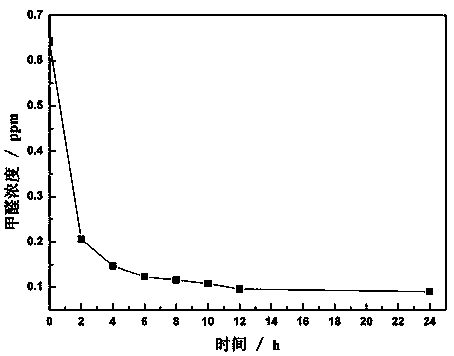

Preparation of room temperature formaldehyde catalyst

Belonging to the technical field of adsorption catalysis and air pollution control, the invention relates to preparation of a room temperature formaldehyde catalyst. The invention is characterized in that: zeolite, sepiolite, a porous activated carbon material, cordierite or a self-made carrier is adopted as the catalyst carrier, one or more non-noble metal oxides, like magnesium oxide, aluminum oxide, silicon oxide, manganese oxide, iron oxide, cobalt oxide, nickel oxide, copper oxide, zinc oxide, zirconium oxide, lanthanum oxide or cerium oxide are taken as active components, and an impregnation technique is employed to prepare the catalyst, which can be powdery, strip, blocky, spherical or honeycomb. The loading amount of the non-noble metal oxides is 2-15wt%, and the content of the catalyst carrier is 85-98%. Under normal temperature and ambient humidity conditions, the catalyst has the capacity of catalytic oxidation of formaldehyde into non-toxic and harmless CO2 and H2O up to over 95%, no intermediate product is generated, and the catalyst has the characteristics of high catalytic oxidation activity, strong moisture resistant ability, stable operation, long service life and the like, thus being suitable for formaldehyde purification treatment in offices, office buildings, living rooms, shopping malls, hospitals, hotels and other places.

Owner:江苏瑞丰科技实业有限公司

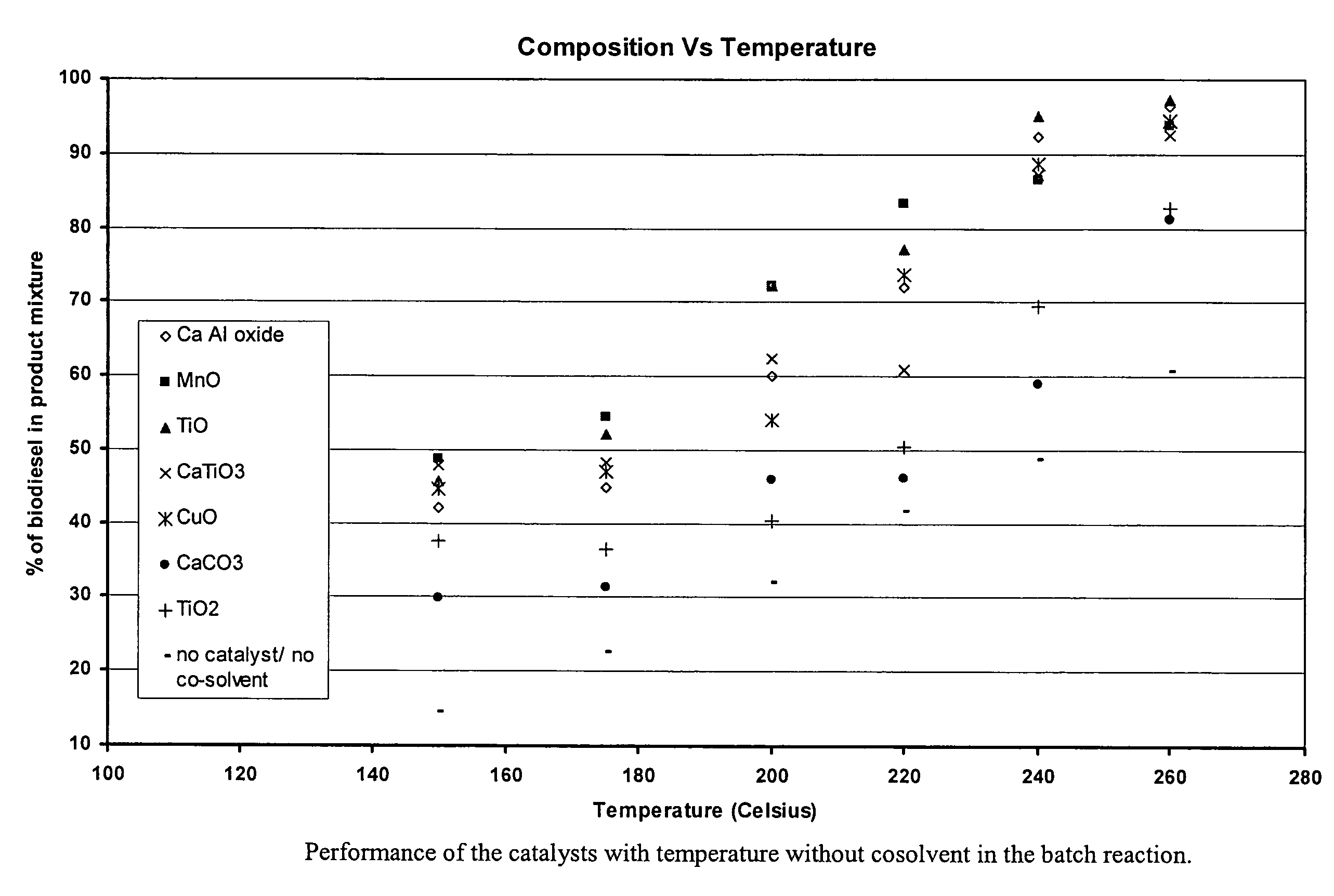

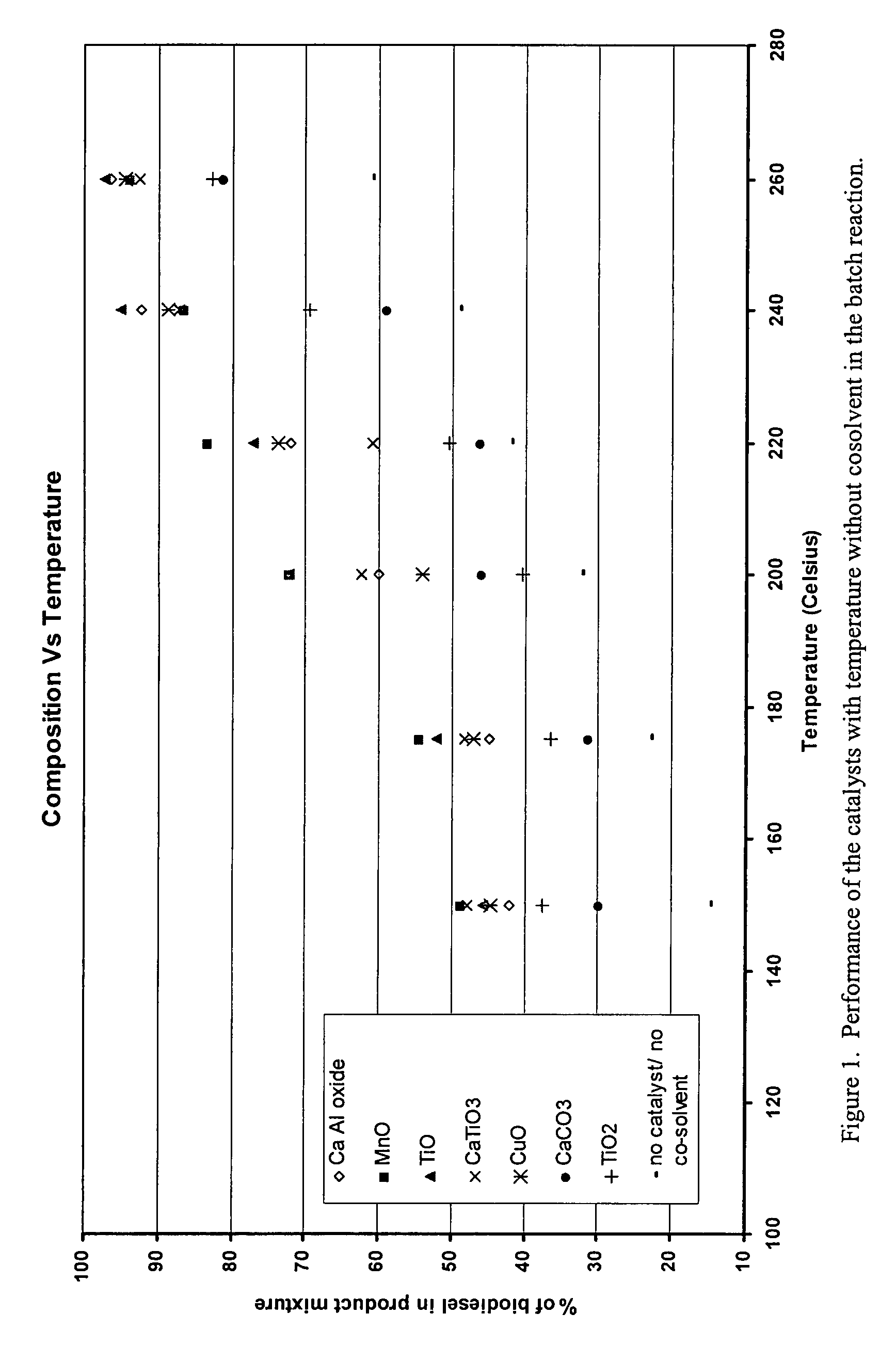

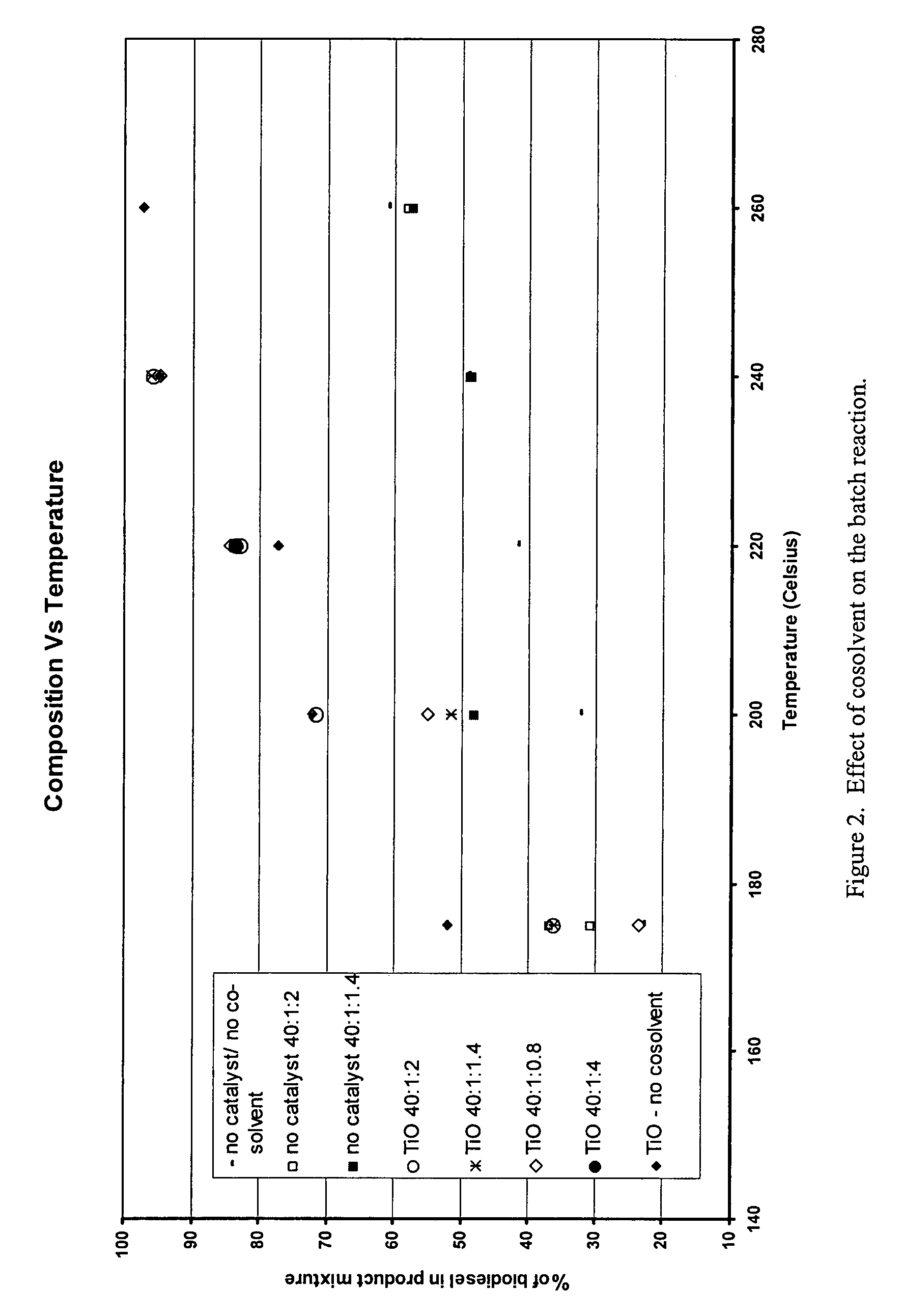

Green biodiesel

InactiveUS7563915B2Reduce wasteSignificant energyFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

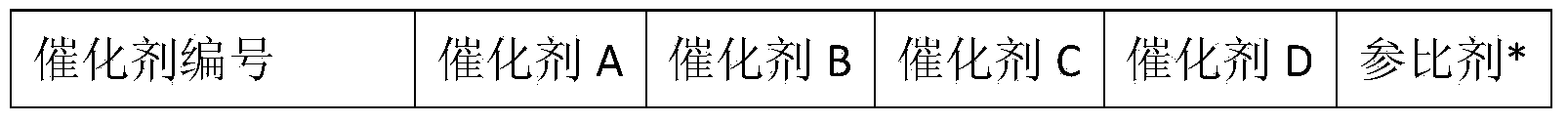

Diesel hydrodesulfurization and denitrification catalyst and preparation method thereof

InactiveCN103551162AGood dispersionIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationOxide composite

The invention discloses a diesel hydrodesulfurization and denitrification catalyst. The catalyst comprises the following compositions: a carrier, an additive, and an active metal, wherein the carrier is an Al2O3-ZrO2-TiO2-SiO2 multibasic oxide composite carrier; the additive is phosphorus; nickel, cobalt, molybdenum and tungsten are taken as active components; through taking the catalyst as a benchmark, in terms of oxides, the catalyst comprises the following components in percentage by weight, 1-6wt% of cobalt oxide, 1-15wt% of nickel oxide, 2-12wt% of molybdenum oxide, 12-35wt% of tungsten oxide and 1.5-5wt% of an additive phosphorus pentoxide; and the pore volume of the catalyst is not less than 0.2 mL / g, the specific surface area of the catalyst is not less than 140 m<2> / g, and the mechanical strength of the catalyst is not less than 15N / mm; and the composite carrier comprises the following components in percentage by weight: 2-15wt% of titanium oxide, 2-20wt% of silicon oxide, 5-15wt% of zirconium oxide, and the balance of aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Supported noble metal catalyst for low-temperature catalytic oxidation benzene series and preparation method thereof

The invention discloses a supported noble metal catalyst for low-temperature catalytically oxidizing benzene series (benzene, methylbenzene and dimethylbenzene) gas to CO2 and H2O. Active components of the noble metal catalyst are: at least one of Pd, Pt, Ag, Au and Rh; carrier is at least one of active carbon, red mud, molecular sieve, aluminum sesquioxide, titanium dioxide, manganese dioxide, zirconium dioxide, silicon dioxide, cerium dioxide, lanthanum sesquioxide, cobalt oxide, magnesium oxide, zinc oxide, calcium oxide and cupric oxide. Under general pressure, in atmosphere ambient, in fixed bed reactor, with a space velocity range from 10,000 to 100,000h<-1> and at a temperature range from 110 to 210 DEG C, the catalyst can be used for directly oxidizing 100 to 800ppm benzene series gas to CO2 and H2O without byproduct, which shows good low-temperature catalytic activity. The catalyst of the invention has the advantages of simple preparation, lower complete oxidation temperature, immunity to H2O, good stability and high practical value.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

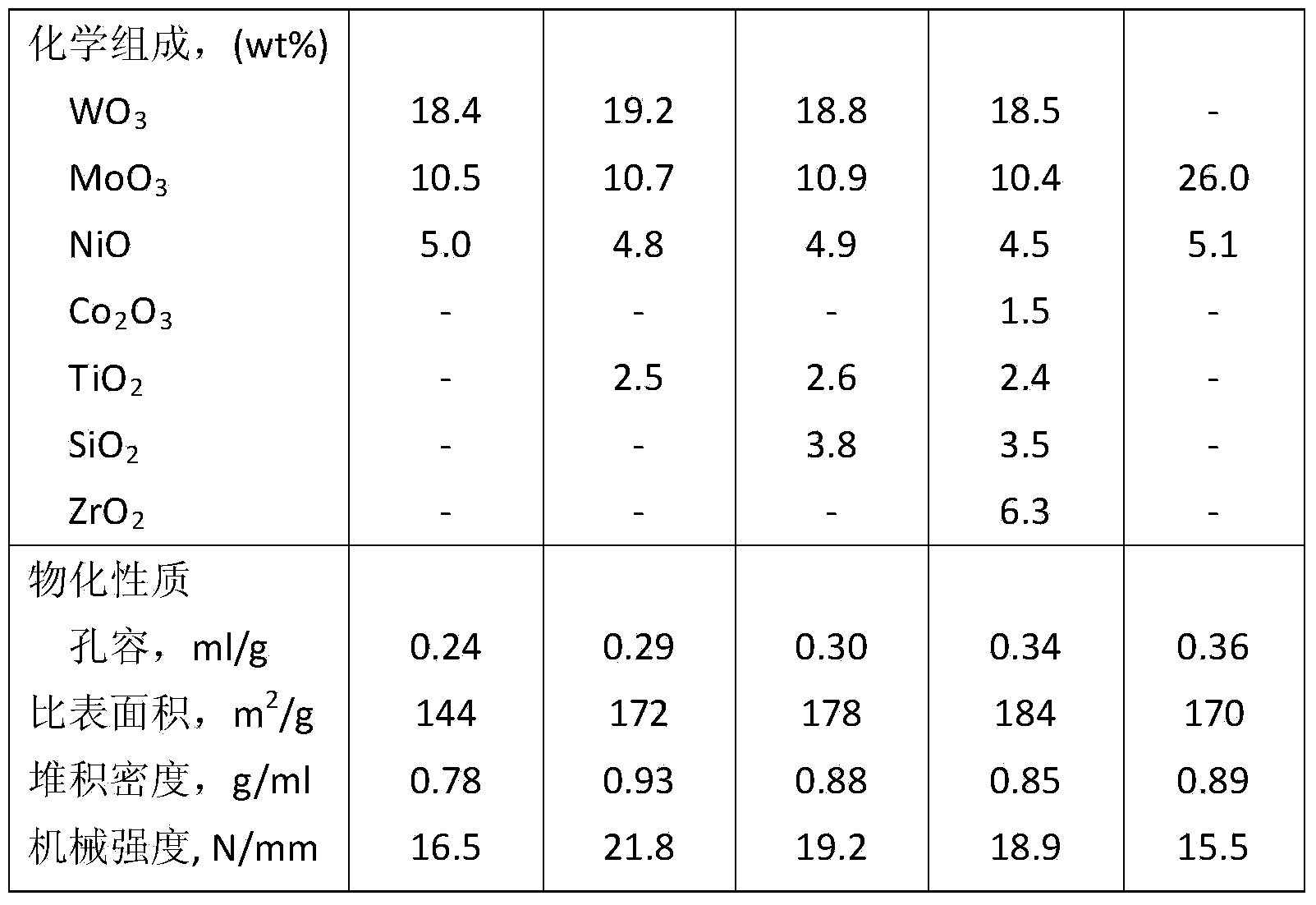

Slate-like composite materials and methods of preparation thereof

InactiveUS20140127458A1Low costIncrease consumptionRoof covering using tiles/slatesRecord information storageCalcium silicateFlexural strength

The invention provides novel slate-like composite materials and methods for preparation thereof. The slate-like composite materials can be readily produced from widely available, low cost precursor materials by a process suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as colored glass, colored sand, and colored quartz particles, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These slate-like composite materials exhibit visual patterns unique to slate as well as display compressive strength, flexural strength and water absorption similar to that of slate.

Owner:ZAMBRZYCKI DAWID +6

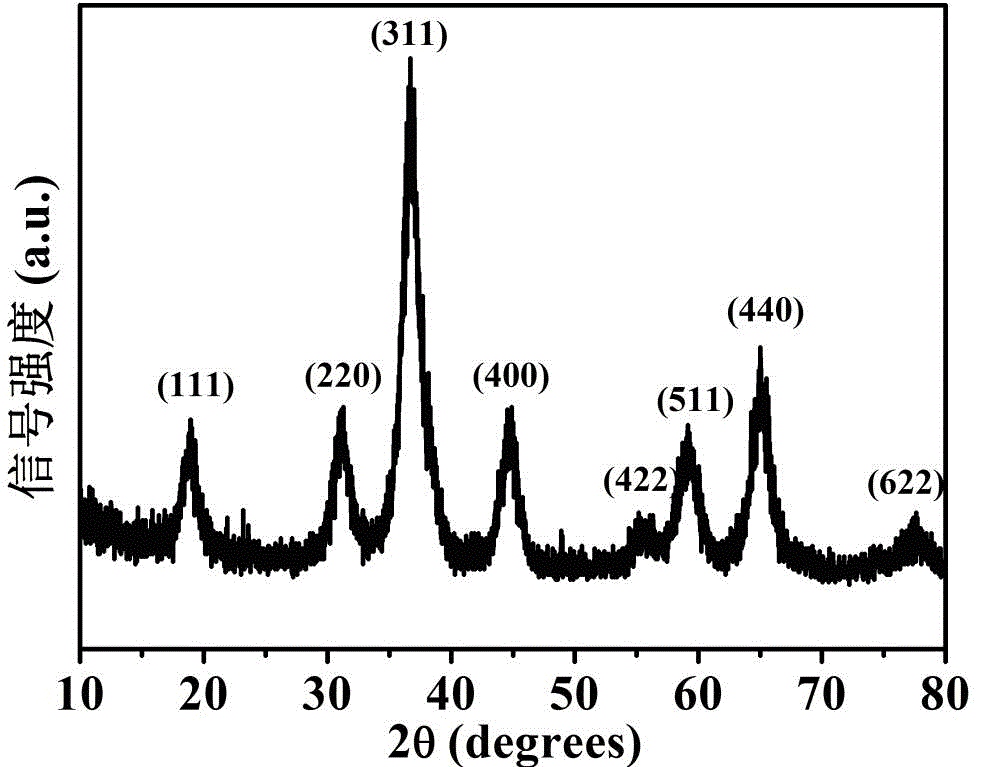

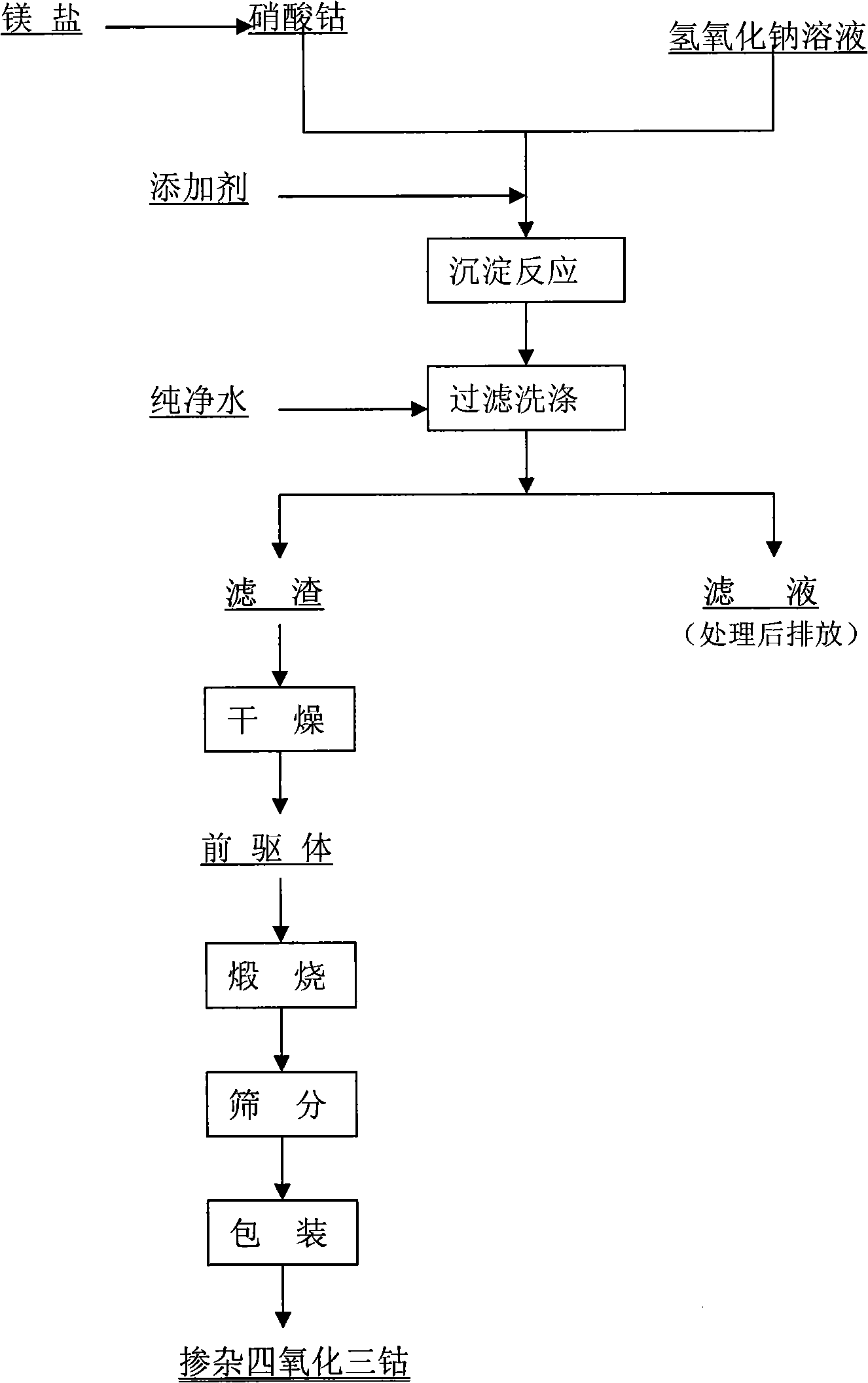

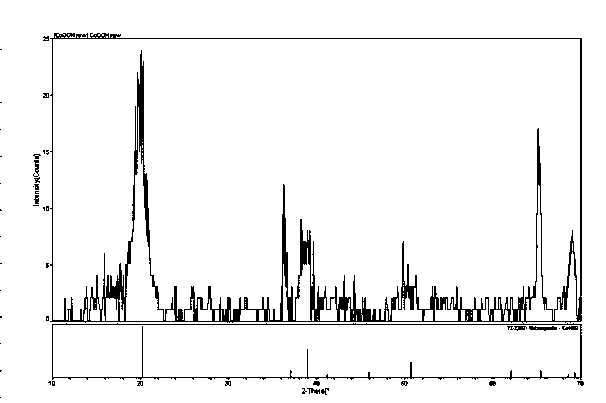

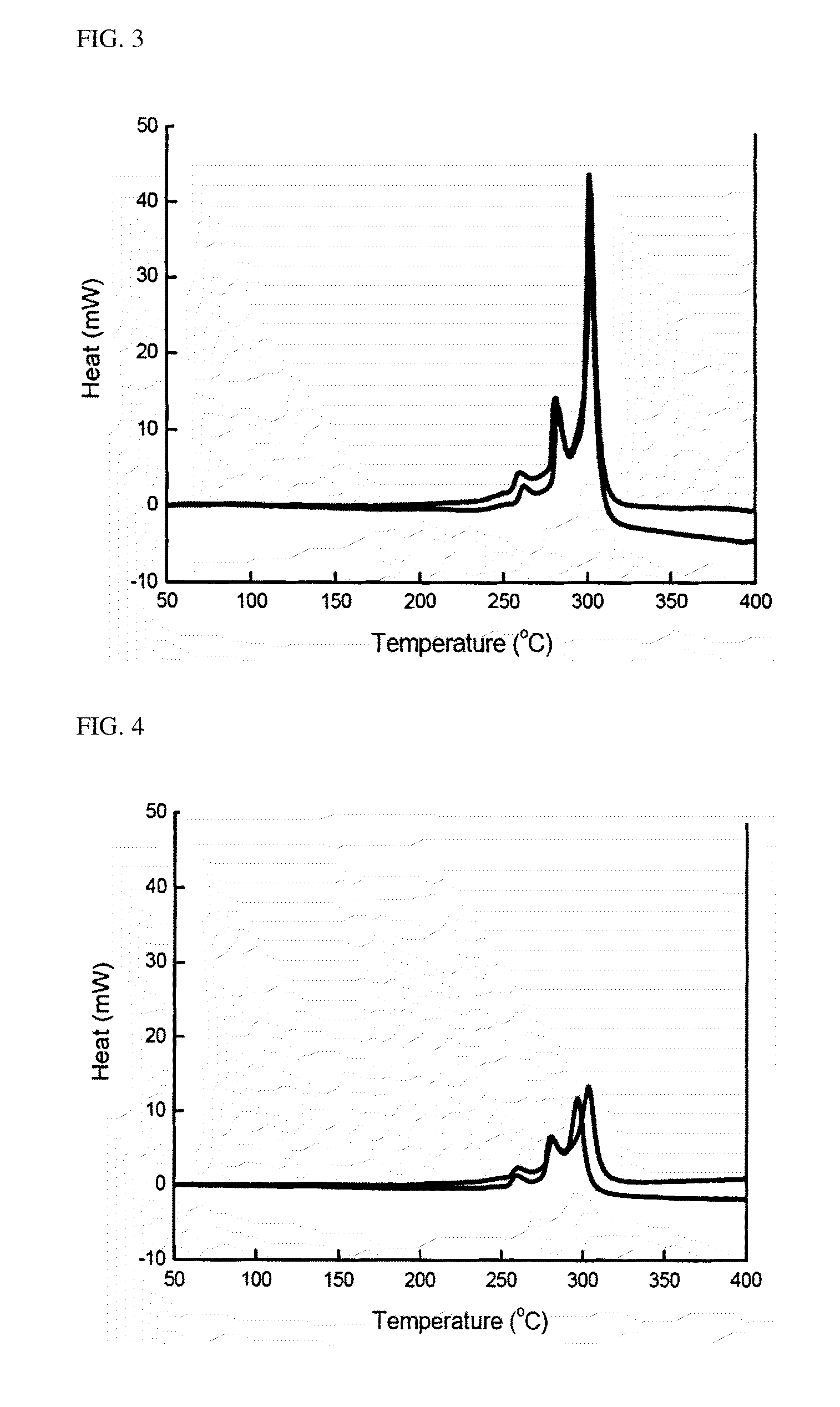

Preparation of doped cobaltic-cobaltous oxide

InactiveCN101279771AImprove stabilityImprove electrochemical performanceCobalt oxides/hydroxidesSal ammoniacNitrate

Disclosed is a process for preparing a doping cobaltosic oxide, which relates to a method for the production of a modified cobaltosic oxide used for a Lithium-ion battery anode material. The method is characterized in that the preparation process comprises: 1) mixing a cobalt nitrate solution containing doped chemical ions with a mixed precipitator solution containing ammonia and sodium hydroxide and making the mixture react for eight to twenty hours at a pH value of between 8.4 to 10 and a temperature of between 40 and 80 DEG C so as to prepare a cobalt hydroxide precipitation containing doped chemical; and 2) washing and drying the cobalt hydroxide precipitation containing the doped chemical and then burning the precipitation for two to six hours at a temperature of between 500 and 800 DEG C so as to obtain the doping cobaltosic oxide. The method of the invention can get even particles with regular shapes after the reaction, the particle sizes of the doping cobalt hydroxide are controllable in a certain range, and the doping cobaltosic oxide can be obtained by calcinations. The method of preparation is characterized in that a magnesium source, an aluminum source, a titanium source, etc. are induced to the cobalt nitrate solution directly, and the process and operation are simple and easy.

Owner:JINCHUAN GROUP LIMITED

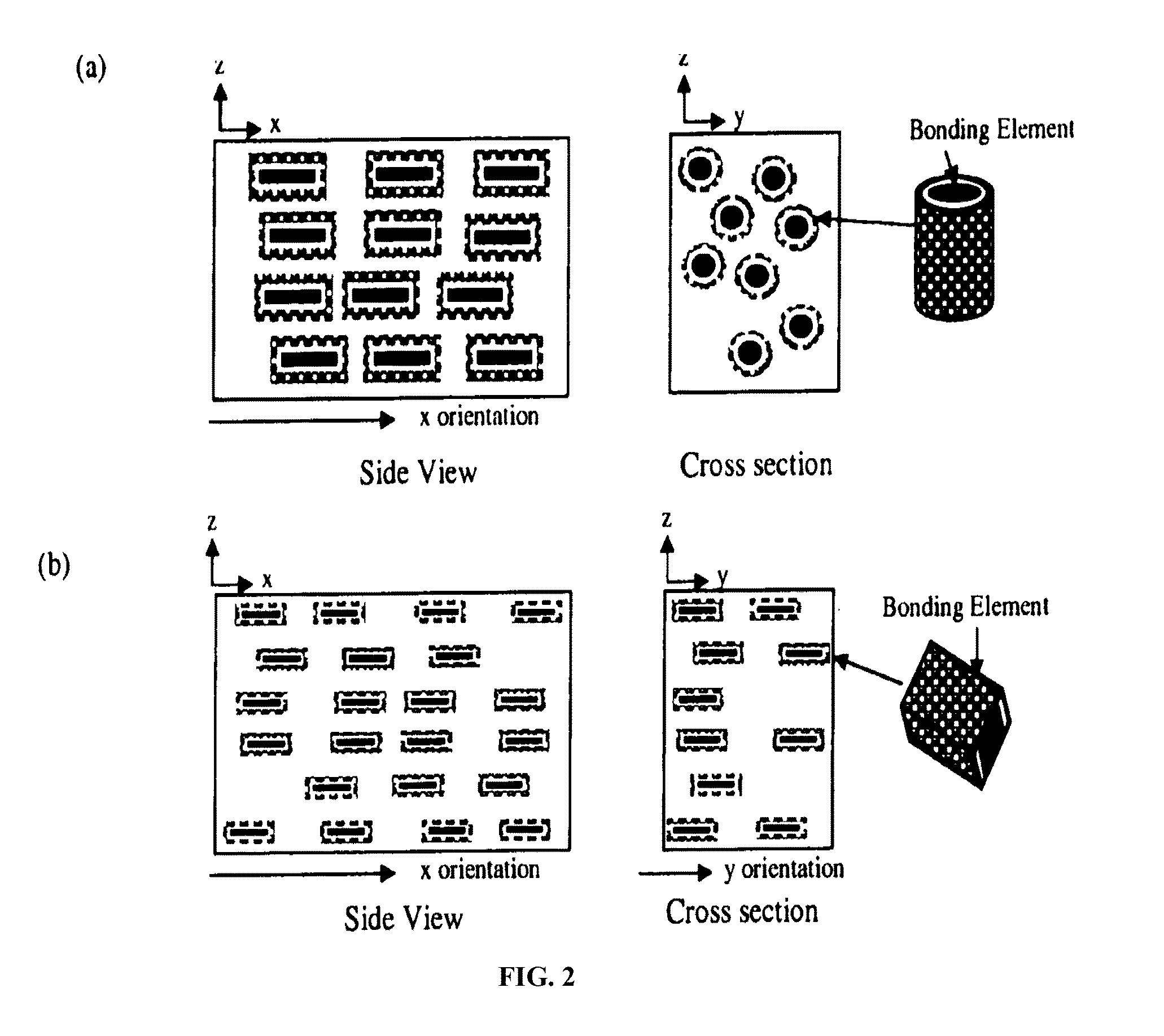

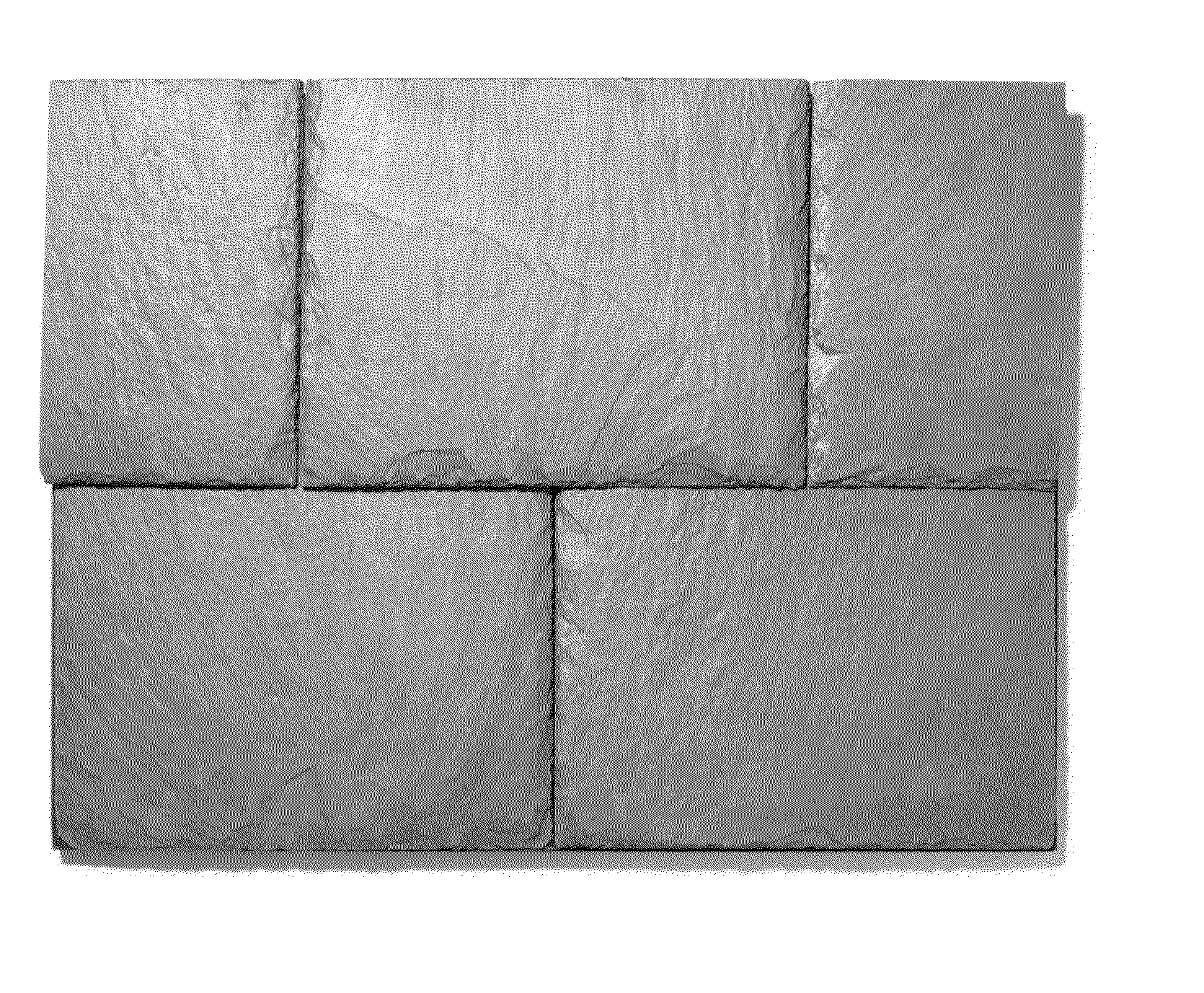

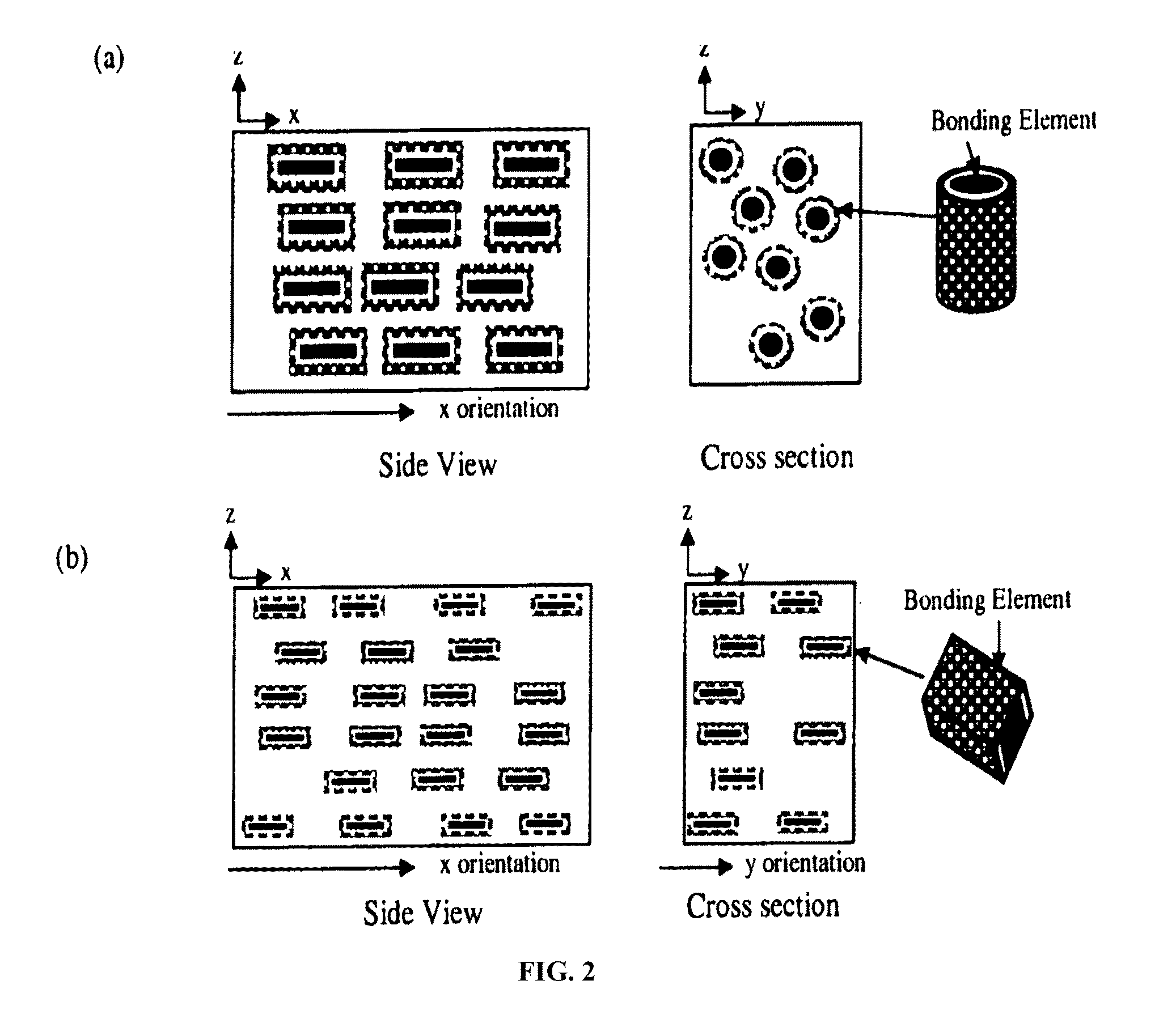

Metal oxide nanorod arrays on monolithic substrates

ActiveUS20140256534A1Improve thermal stabilitySulfur poisoningMolecular sieve catalystsLayered productsCerium(IV) oxideMetal particle

A metal oxide nanorod array structure according to embodiments disclosed herein includes a monolithic substrate having a surface and multiple channels, an interface layer bonded to the surface of the substrate, and a metal oxide nanorod array coupled to the substrate surface via the interface layer. The metal oxide can include ceria, zinc oxide, tin oxide, alumina, zirconia, cobalt oxide, and gallium oxide. The substrate can include a glass substrate, a plastic substrate, a silicon substrate, a ceramic monolith, and a stainless steel monolith. The ceramic can include cordierite, alumina, tin oxide, and titania. The nanorod array structure can include a perovskite shell, such as a lanthanum-based transition metal oxide, or a metal oxide shell, such as ceria, zinc oxide, tin oxide, alumina, zirconia, cobalt oxide, and gallium oxide, or a coating of metal particles, such as platinum, gold, palladium, rhodium, and ruthenium, over each metal oxide nanorod. Structures can be bonded to the surface of a substrate and resist erosion if exposed to high velocity flow rates.

Owner:UNIV OF CONNECTICUT

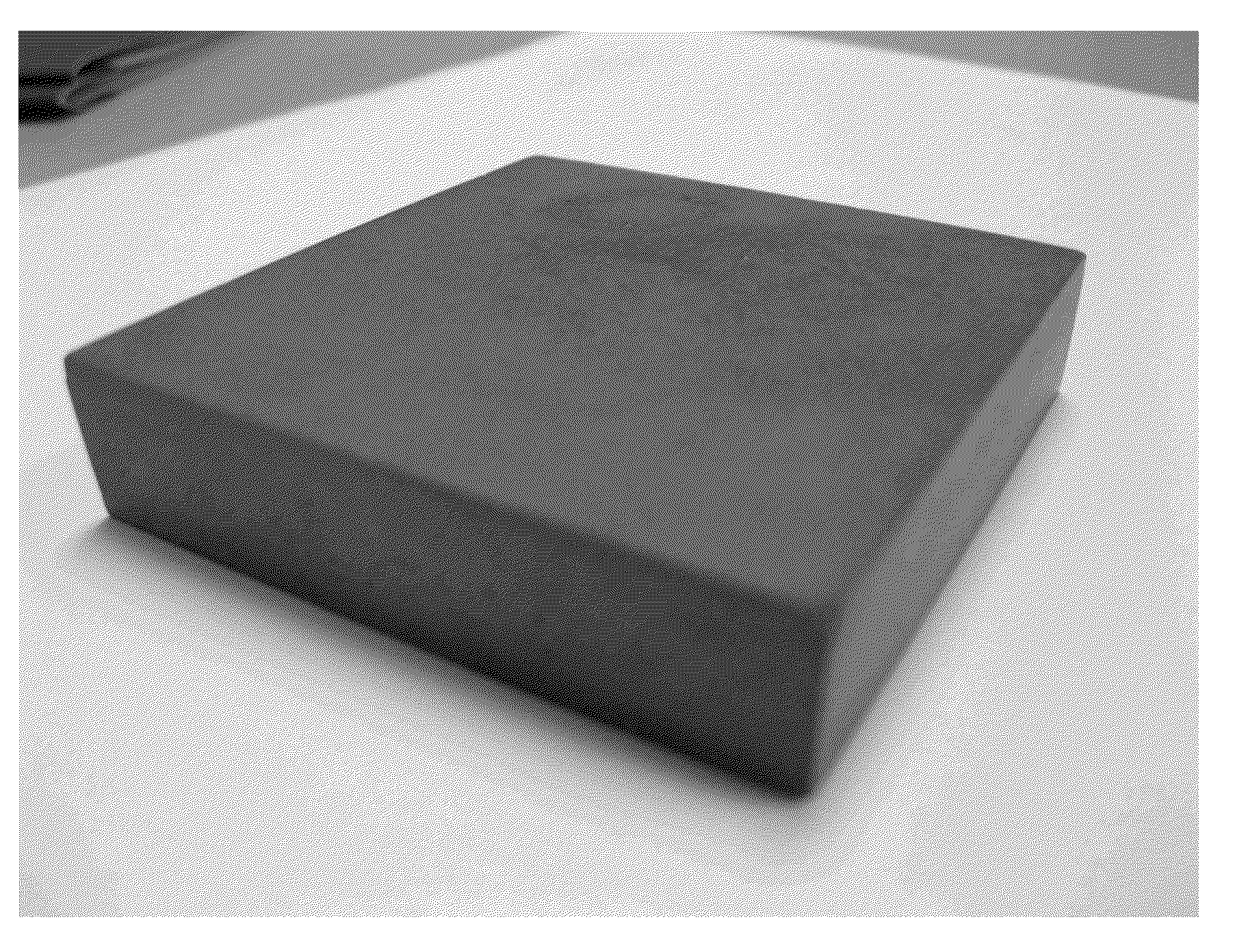

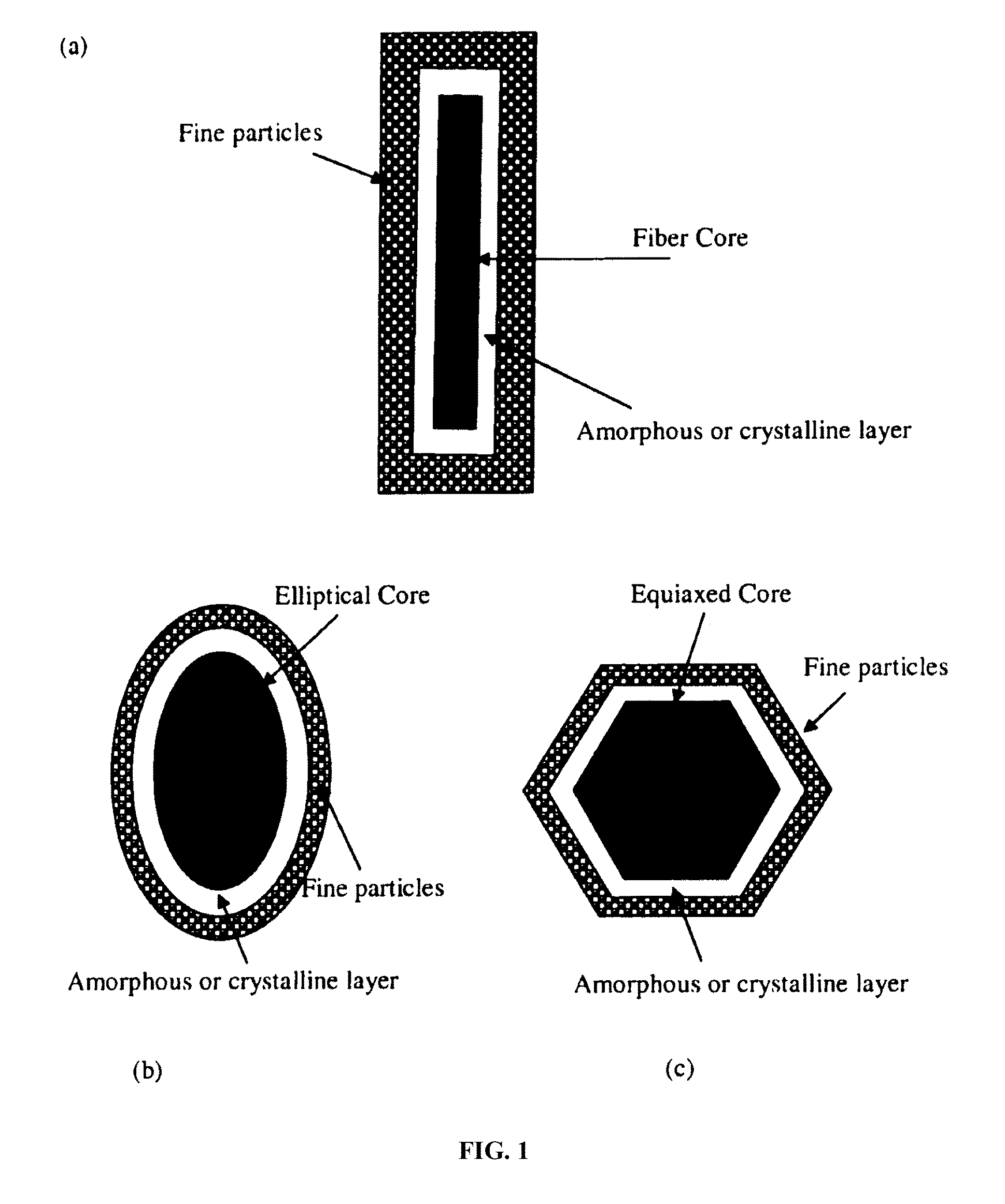

Pavers and block composite materials and methods of preparation thereof

ActiveUS20140314990A1Acceptable compressive strengthLow costRecord information storageCeramic shaping apparatusCalcium silicateCOLORED MATERIAL

The invention provides novel paving stones and construction block composite materials and methods for preparation thereof. The paving stones and construction block composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves compacting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which can comprise silicon dioxide-rich materials. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These paving stones and construction block composite materials exhibit visual patterns similar to stone as well as display compressive strength and water absorption equal to or better than that of stone.

Owner:SOLIDIA TECH

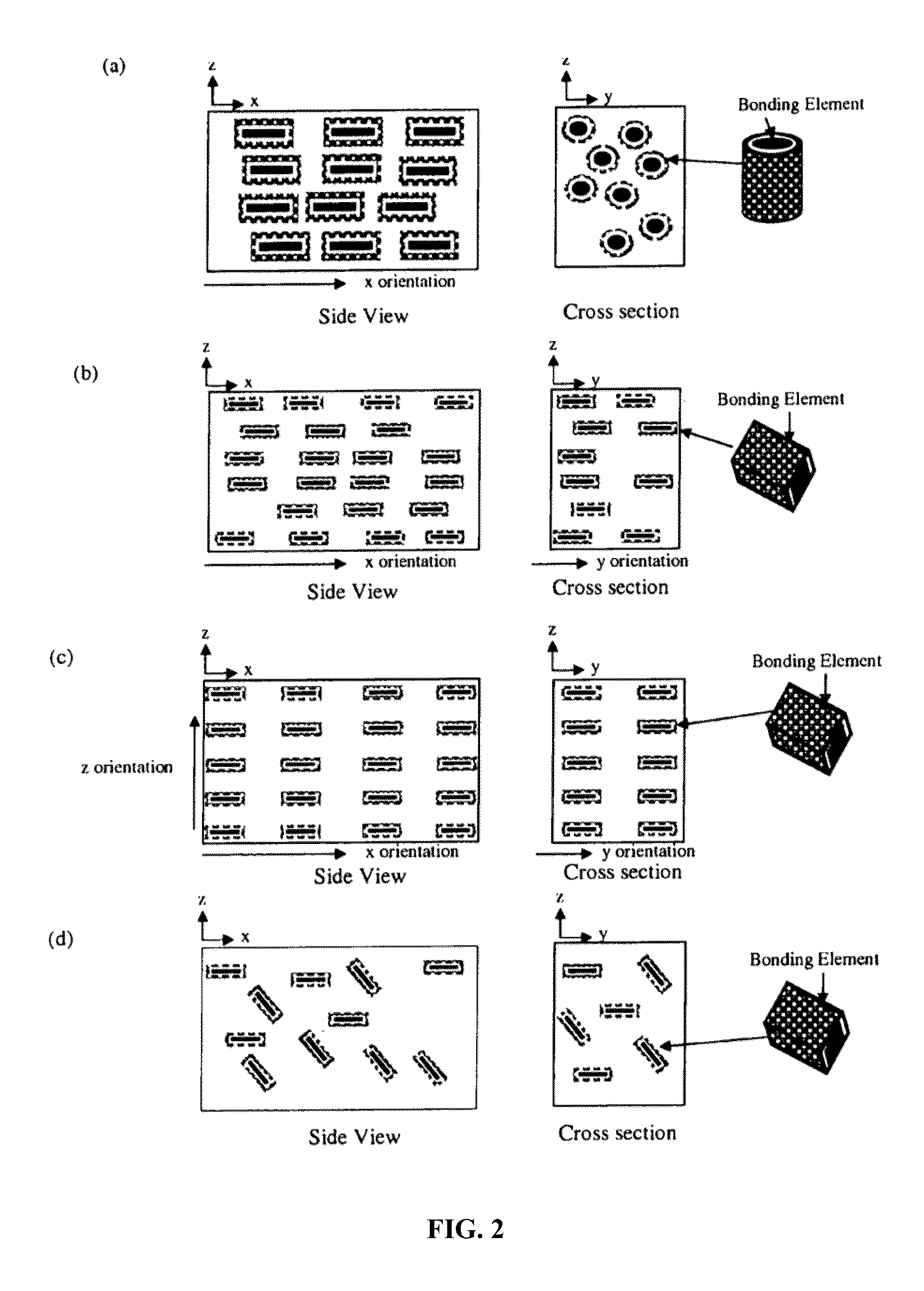

Granite-like composite materials and methods of preparation thereof

InactiveUS20150266778A1Low costImproved carbon footprintAuxillary shaping apparatusCoatingsCobalt oxideMagnesium

The invention provides novel granite-like composite materials and methods for preparation thereof. The granite-like composite materials can be readily produced from widely available, low cost precursor materials by a process suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as colored glass, colored sand, and colored quartz particles, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These granite-like composite materials exhibit visual patterns unique to granite as well as display compressive strength, flexural strength and water absorption similar to that of granite.

Owner:RUTGERS THE STATE UNIV

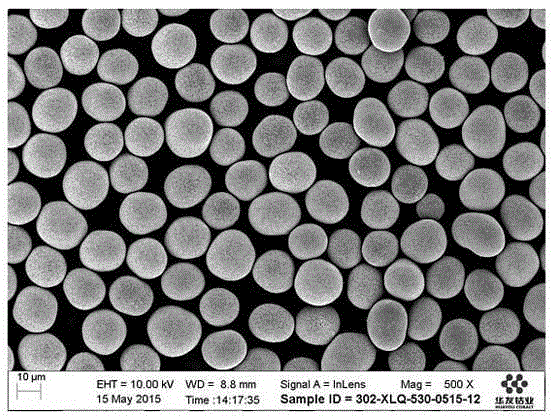

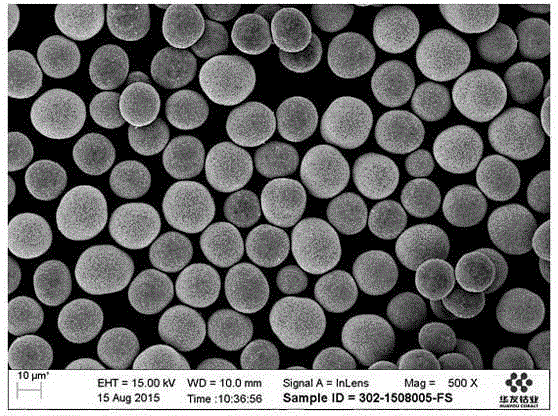

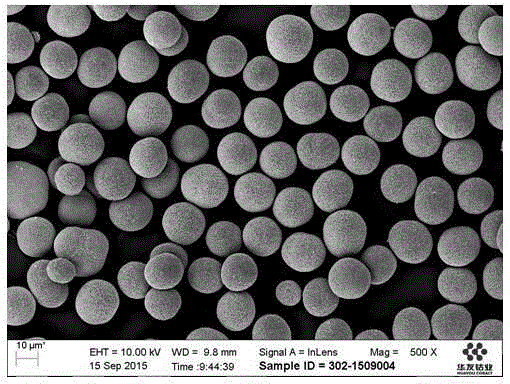

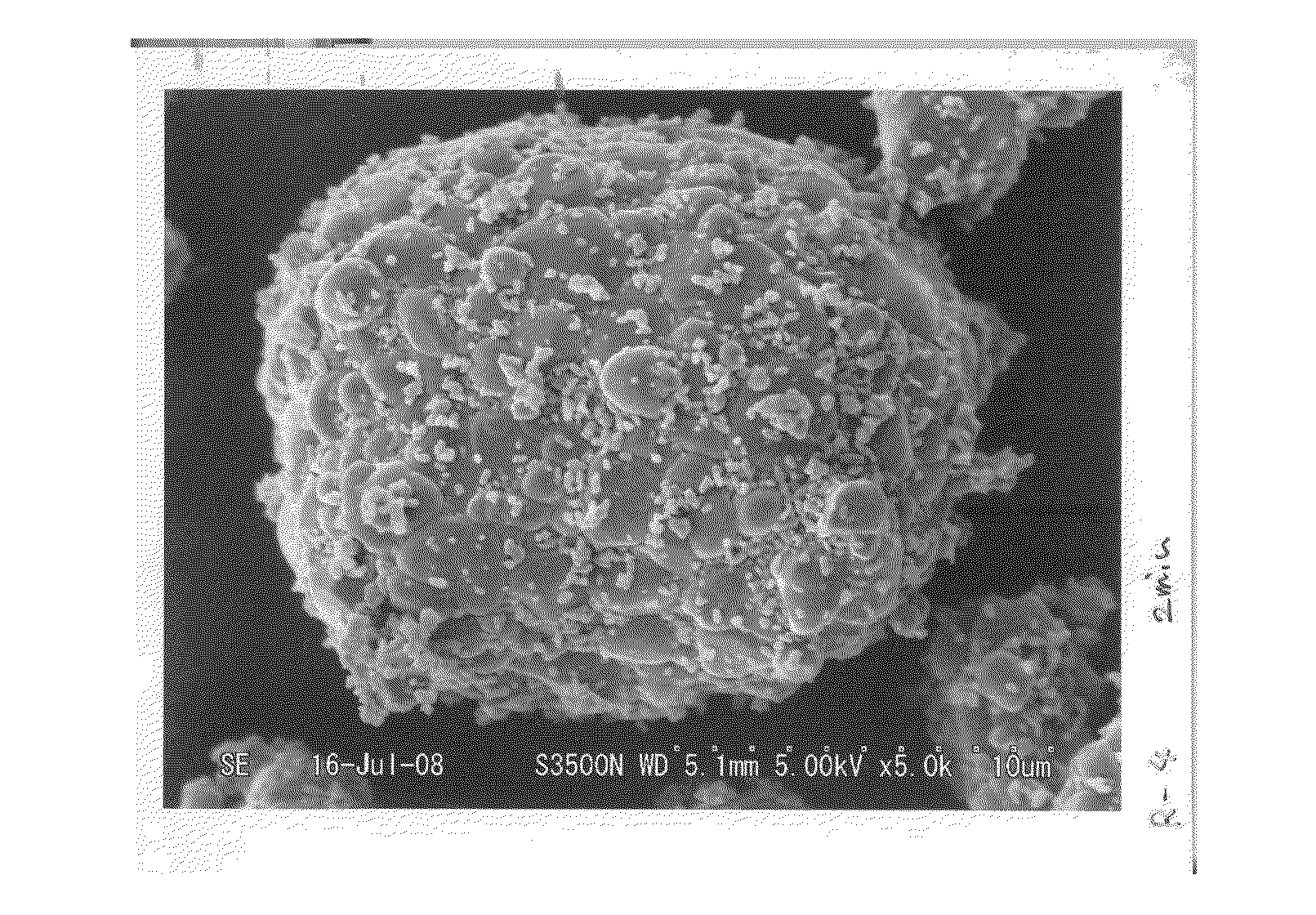

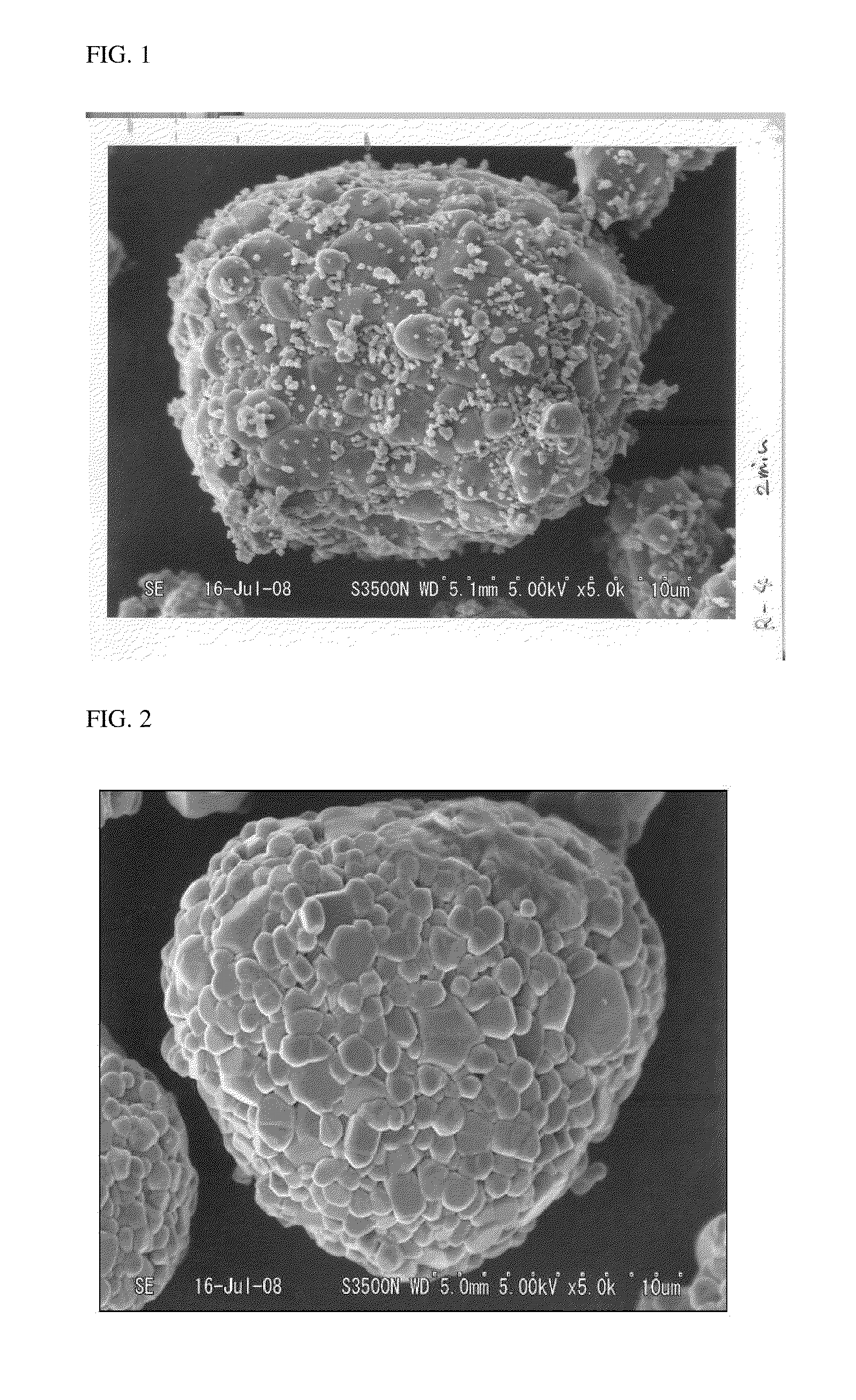

Preparation method for spherical cobalt oxyhydroxide

ActiveCN103904323AHigh densityGood sphericityCell electrodesSecondary cellsHigh densityPhysical chemistry

The invention discloses a preparation method for spherical cobalt oxyhydroxide. Prepared spherical cobalt oxyhydroxide can be directly used as a raw material for preparation of lithium cobalt oxide. According to the invention, wet processing and doping of trace metal elements are adopted to improve related performance like cycle and voltage of the product; the method is simple and produces no pollution; and the product has the advantages of uniform distribution of doped elements, high density and a good sphericity degree.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Wood-like composite materials and methods of preparation thereof

InactiveUS20140342124A1High compressive strengthLow water absorptionConstruction materialNatural patternsCalcium silicateFlexural strength

The invention provides novel wood-like composite materials and methods for preparation thereof. The wood-like composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves casting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These wood-like composite materials exhibit visual patterns unique to wood as well as display compressive strength, flexural strength and water absorption superior to that of wood.

Owner:ZAMBRZYCKI DAWID +4

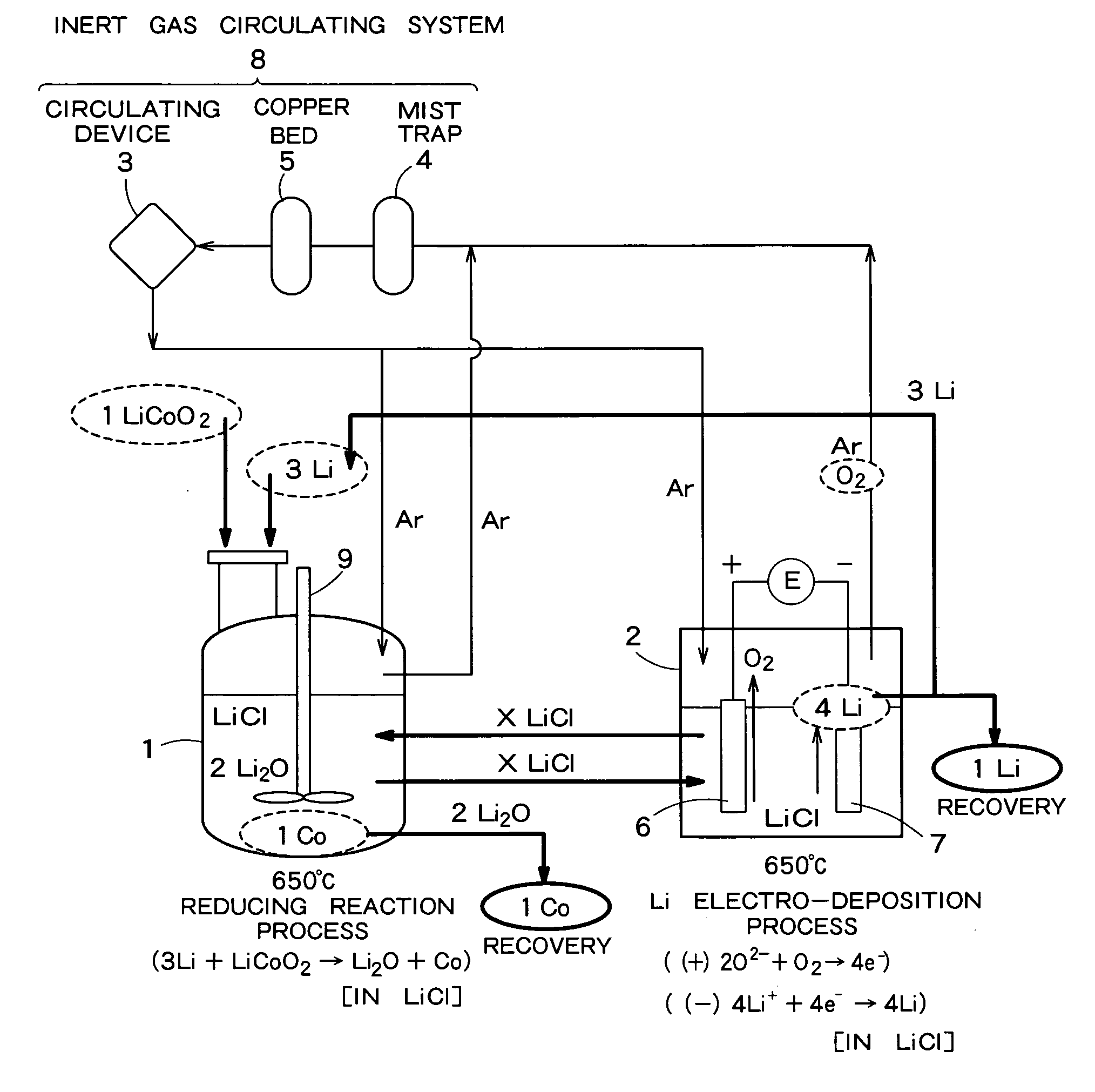

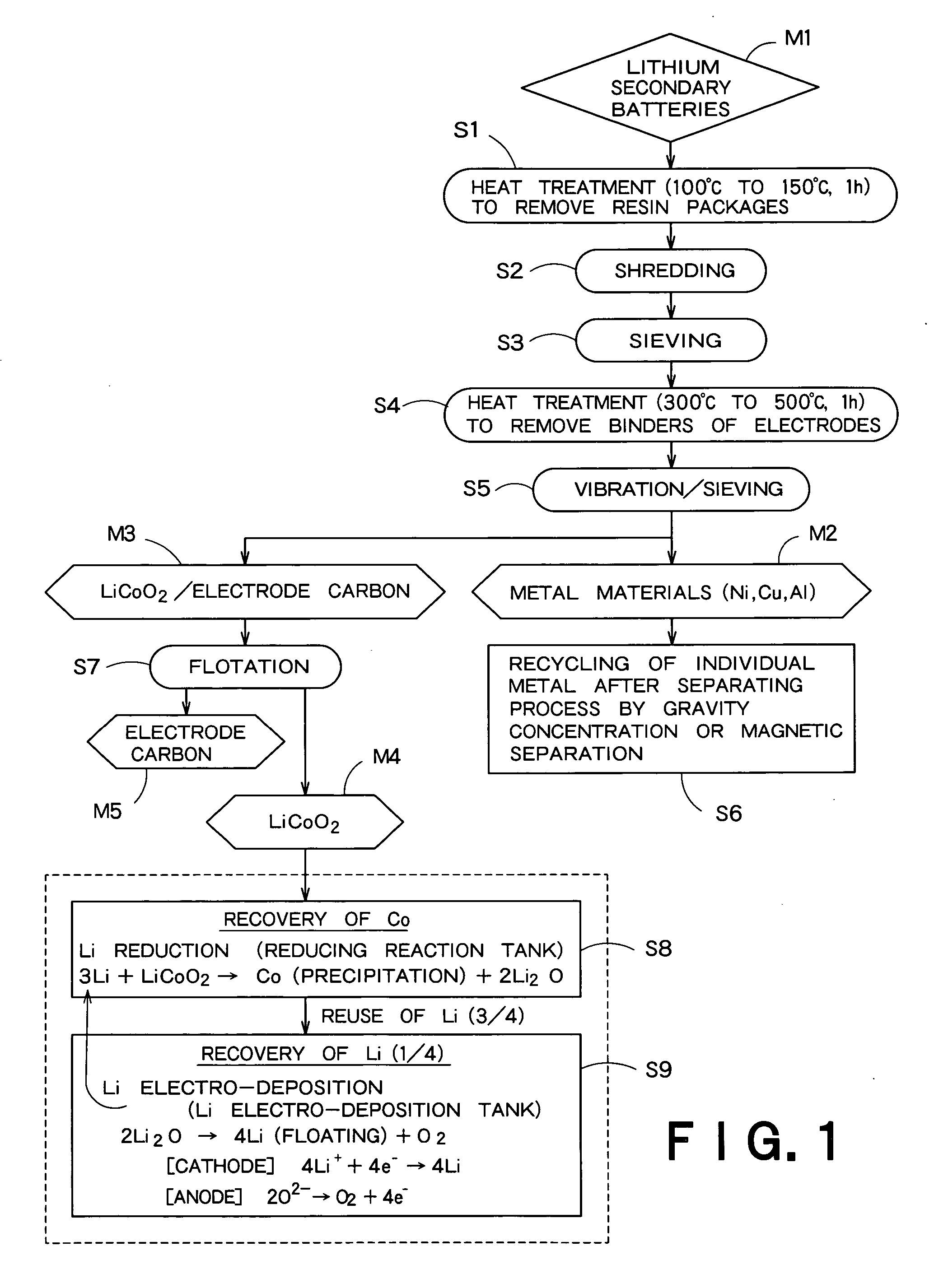

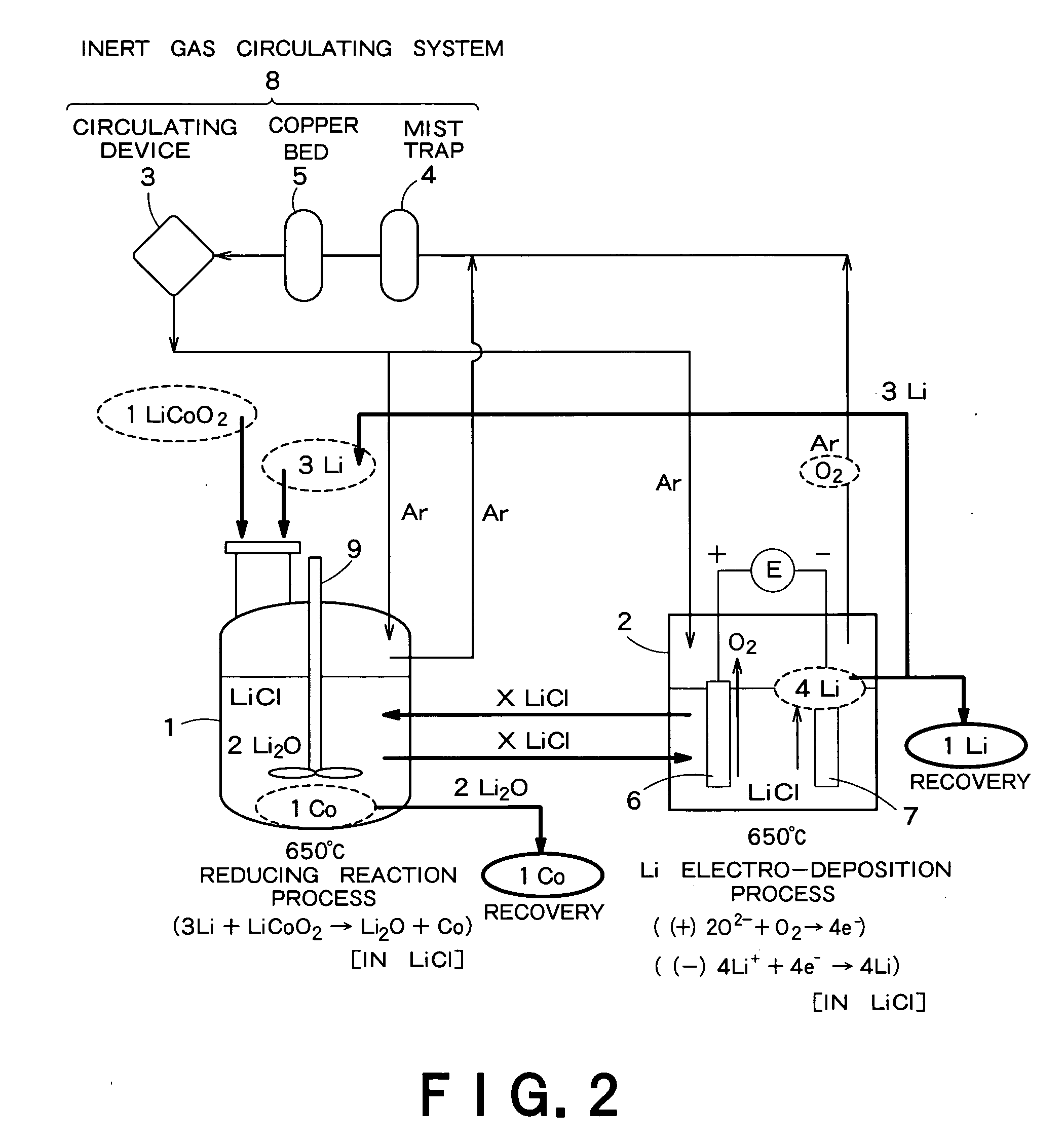

Method and apparatus for recycling electrode material of lithium secondary battery

ActiveUS20050241943A1Reduce equipment costsReduce operating costsCellsPhotography auxillary processesLithium oxideLithium chloride

Lithium cobaltate forming the positive electrode of a lithium secondary battery is subjected together with lithium metal to reducing reaction in molten lithium chloride to produce lithium oxide and to precipitate and separate cobalt or cobalt oxide. The lithium oxide is subjected to electro-deposition in molten lithium chloride contained in a lithium electro-deposition tank provided with an anode and a cathode to recover lithium metal deposited on the cathode.

Owner:KAWASAKI HEAVY IND LTD +1

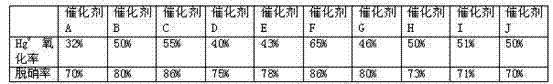

Denitrification catalyst capable of oxidizing simple substance mercury

InactiveCN102335603ADispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCobalt oxideCopper oxide

The invention belongs to the field of denitrification, and particularly relates to a denitrification catalyst capable of oxidizing simple substance mercury, which is prepared from the following components in percentage by mass: 0.3-1.5% of vanadium pentoxide, 3-10% of tungsten trioxide, 0.3-5% of metal oxide and the balance of titanium dioxide, wherein the metal oxide is one or mixture of manganese oxide, chromic oxide, copper oxide, cerium oxide, ferric oxide, cobalt oxide, nickel oxide, zinc oxide and molybdenum oxide. The oxidation rate for simple substance mercury of the denitrification catalyst capable of oxidizing simple substance mercury is up to 65%, and the maximum denitrification rate is up to 86%.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

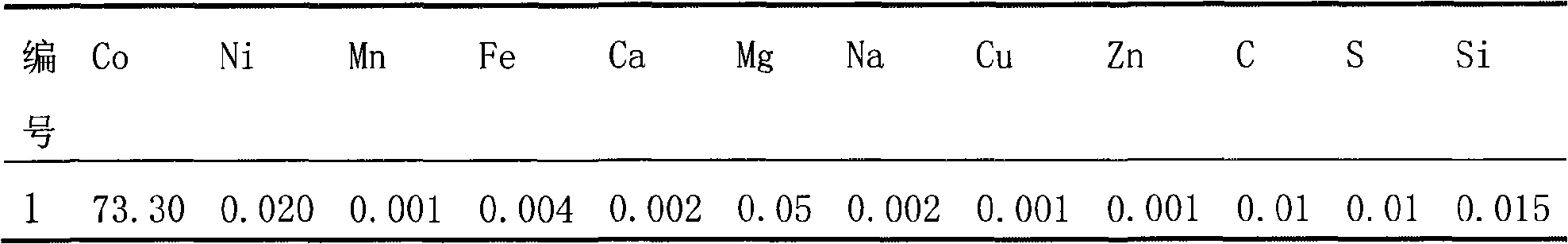

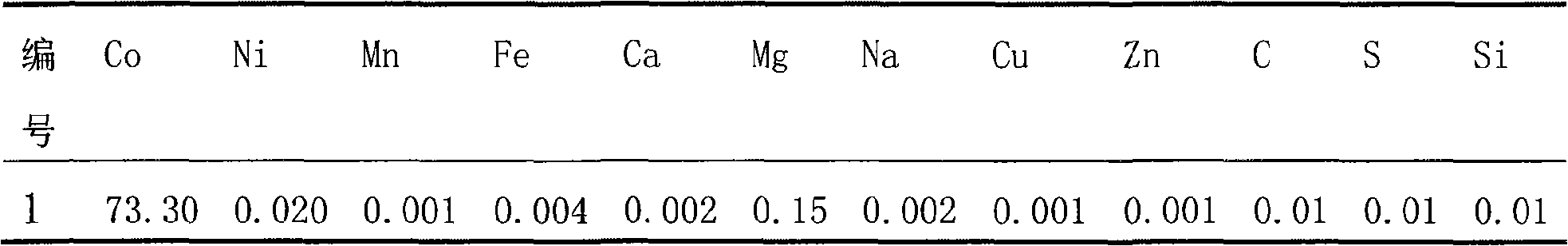

Preparation method of large-particle-size and high-density spherical cobalt oxide

The invention discloses a preparation method of large-particle-size and high-density spherical cobalt oxide. The preparation method aims at achieving the purposes that the median particle size D50 of the cobalt oxide is larger than or equal to 15 microns, particle size distribution is uniform, compacting density (TD) is larger than or equal to 2.2 g / cm<3>, and the large-particle-size and high-density spherical cobalt oxide can meet the development requirement of high-voltage lithium cobaltate. The preparation method of the cobalt oxide includes the cobalt carbonate synthesis stage and the spherical cobalt carbonate thermal decomposition stage. In the cobalt carbonate synthesis stage, a cobalt carbonate precursor prepared through many times of cyclic crystallization is compact and uniform in particle size distribution; due to the segmented thermal decomposition, cobalt carbonate is locally decomposed in the low-temperature pre-decomposing stage, a micro hole channel is formed, release of CO2 gas during subsequent decomposition is facilitated, and particles are prevented from crazing or being broken; in the high-temperature thermal decomposition stage, the particle surface is compact, and therefore the large-particle-size and high-density spherical cobalt oxide is prepared.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

Cathode active material for lithium secondary battery

ActiveUS20110086274A1Properties can be deteriorationStability can be deteriorationNon-aqueous electrolyte accumulator electrodesLi-accumulatorsManganeseLithium-ion battery

Disclosed herein is a cathode active material based on lithium nickel-manganese-cobalt oxide represented by Formula 1, wherein an ion-conductive solid compound and conductive carbon are applied to a surface of the lithium nickel-manganese-cobalt oxide. A lithium secondary battery having the disclosed cathode active material has improved rate properties and high temperature stability, in turn embodying excellent cell performance.

Owner:LG ENERGY SOLUTION LTD

Induction cured power coatings for temperature sensitive substrates

According to the present invention, powder coating compositions comprise one or more than one thermoplastic or thermosetting polymer or resin and one or more than one finely divided magnetic material, such as a ferromagnetic material. Preferred magnetic materials include Ni1−xZnxFe2O4 compounds, wherein 0.4≦X≦0.75, piezoelectric compounds, ferrimagnetic δFeOOH, Fe—Ni—B, Cu2MnIn, transparent polymer-Cobalt oxide nanocomposites and soft ferrites. In addition, the present invention provides methods of making powder coatings on a substrate comprising applying to a substrate a resinous powder coating composition comprising one or more than one magnetic material to form a powder coating layer, followed by induction heating to melt the applied powder coating to form a coating film and, optionally, to cure the powder coating. The powder coatings remain at a pre-selected temperature equal to or less than the Curie temperature (TC) of the one or more than one finely divided magnetic material during induction heating of the powder coating without directly heating the substrate. Powder coatings on metal parts may also be induction heat cured.

Owner:ROHM & HAAS CO

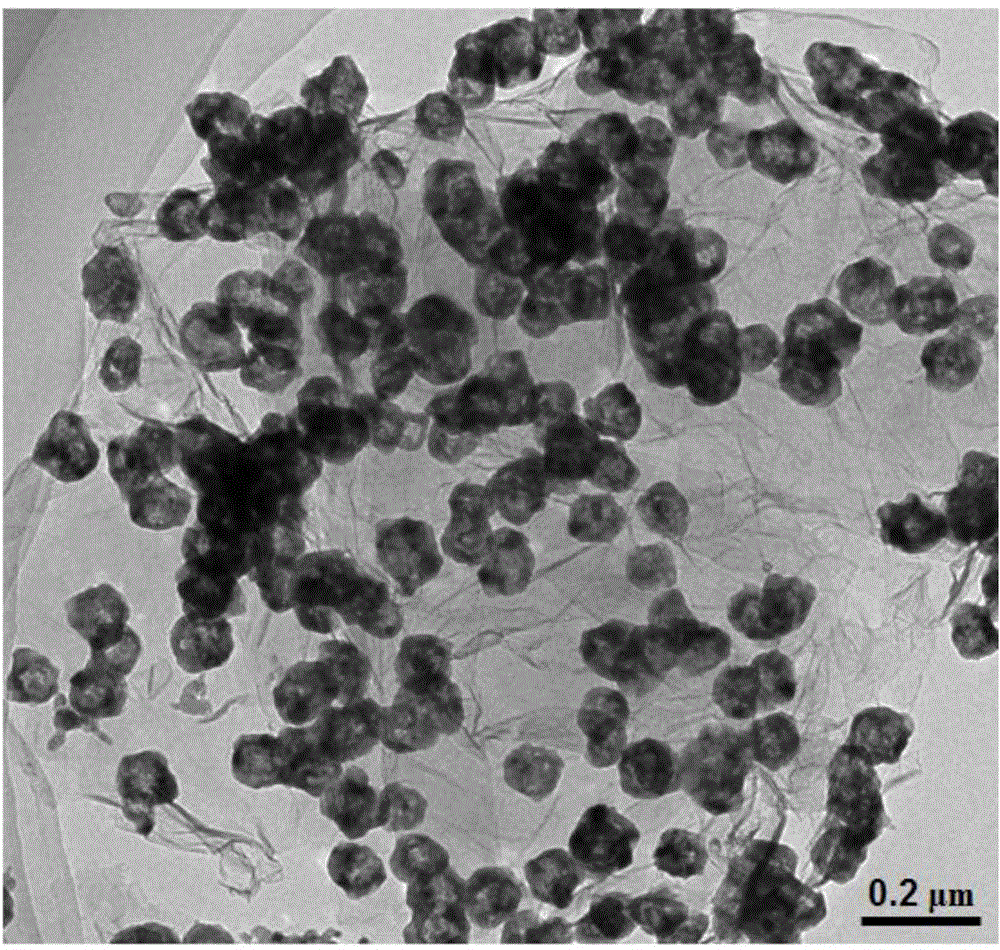

Nitrogen-doped graphene and Co3O4 hollow nanosphere composite material as well as preparation method and application of composite material

ActiveCN104681823AImprove conductivityLarge specific surface areaMaterial nanotechnologyPhysical/chemical process catalystsDoped grapheneNitrogen doped graphene

The invention relates to a novel composite material, and particularly relates to a preparation method and application of a nitrogen-doped graphene and cobaltosic oxide hollow nanosphere composite material. The novel composite material comprises a doped graphene substrate and cobaltosic oxide hollow nanospheres which is attached to the surface of the doped graphene substrate. Melamine resin is taken as a cross-linking reagent for integrating graphite oxide with Co<2+> into a single coordination precursor. The preparation method comprises the following steps: in a pyrolysis process of the precursor, taking the melamine resin as a new nitrogen source to uniformly dope the graphene with nitrogen, fixing cobalt oxide which is generated in situ, and finally preparing the nitrogen-doped graphene / Co3O4 hollow nanosphere composite material with a sandwich structure. The composite material has a graded porous structure, is high in specific surface area, more in active sties, good in electron conductivity and ion conductivity, and good in application prospect in the field of new energy resources and catalysis.

Owner:CHINA WEST NORMAL UNIVERSITY

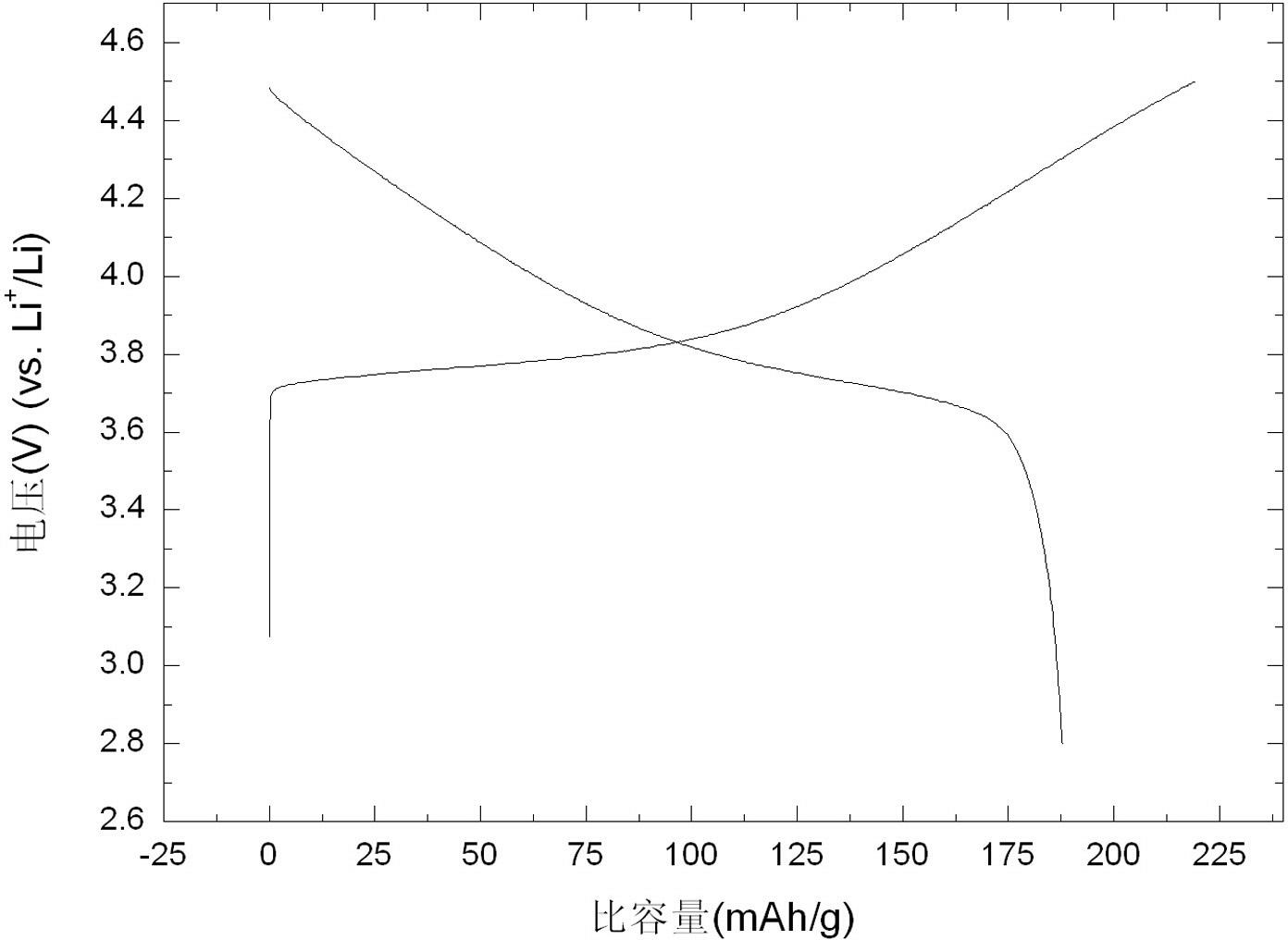

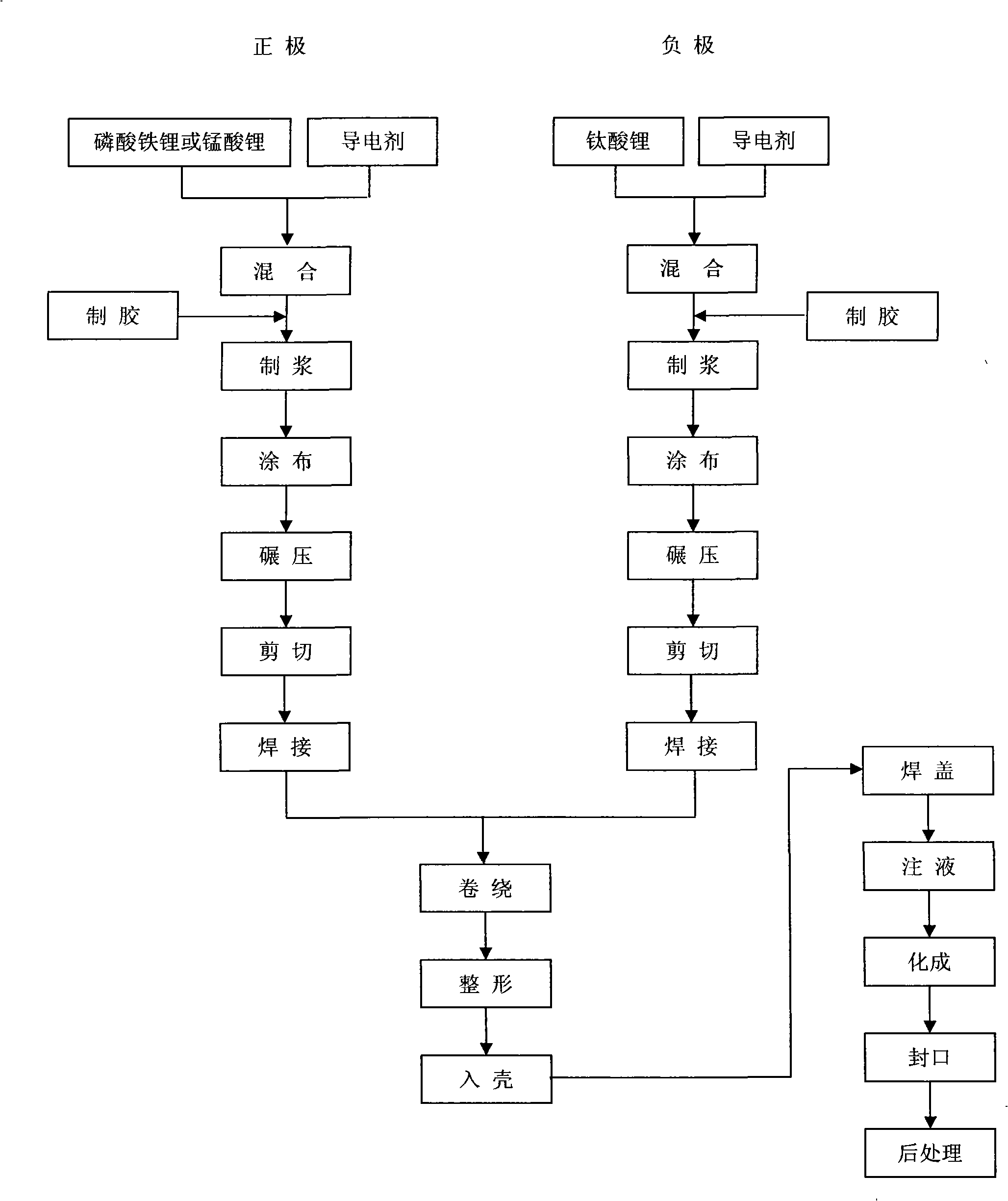

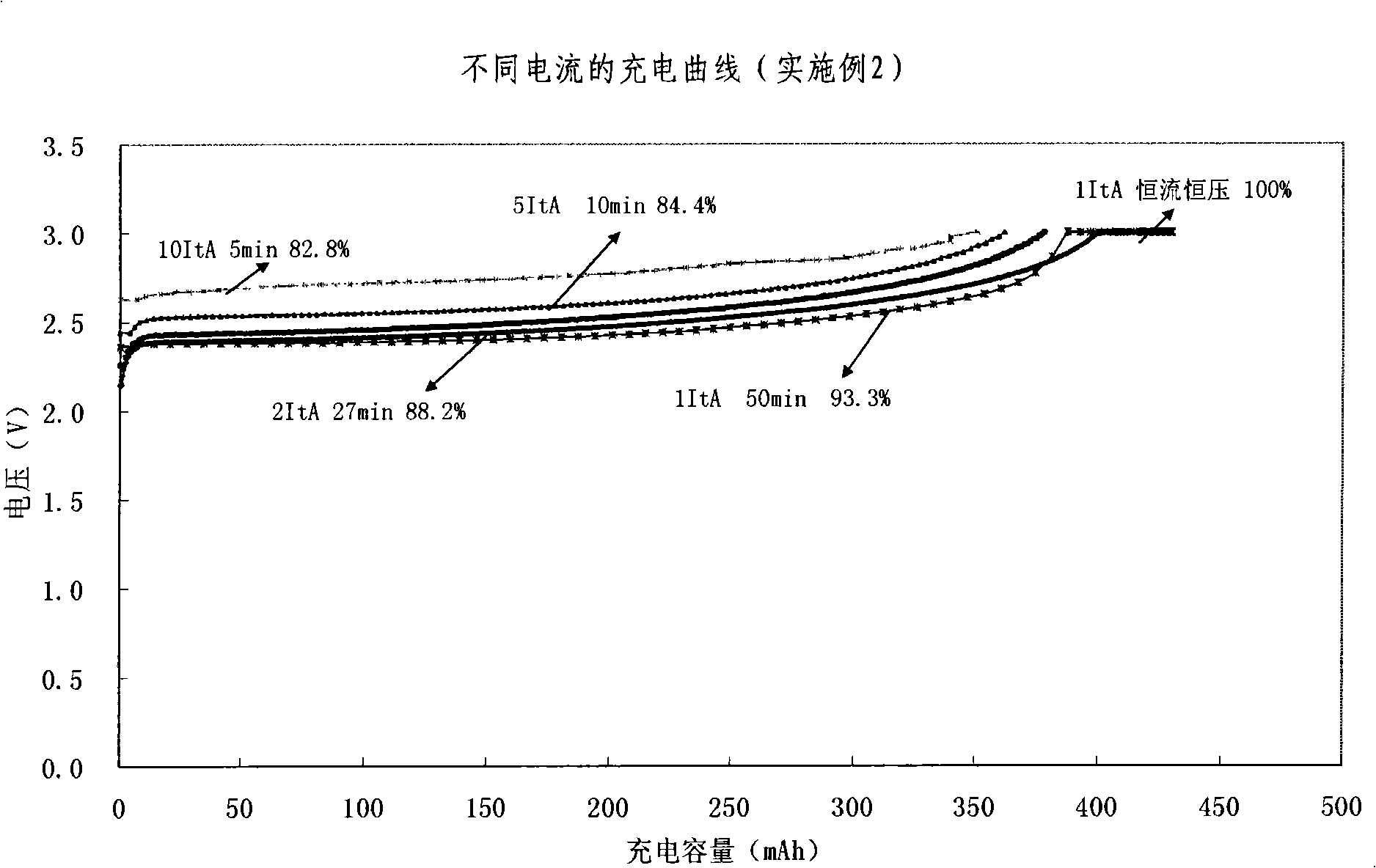

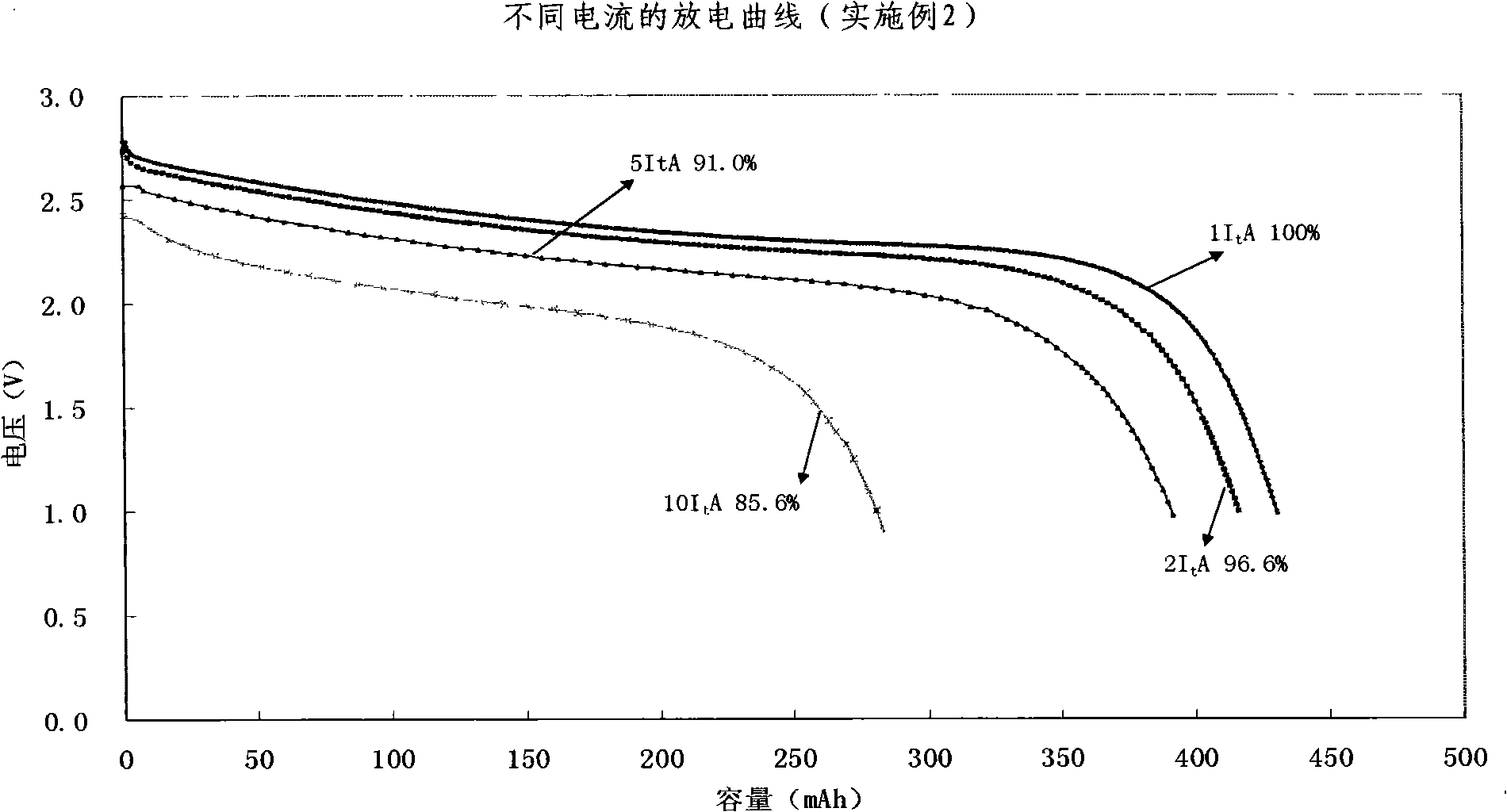

Quickly chargeable lithium ion battery and its making method

InactiveCN101262078AExcellent fast charge and discharge performanceCell electrodesFinal product manufactureMethyl carbonateManganate

The invention discloses a lithium-ion battery with fast charge property, which comprises an anode, a cathode, a diaphragm sandwiched between the anode and the cathode and an organic electrolyte, wherein, sub micrometer lithium titanate is used as the active substance of the cathode; one or several materials of lithium manganate (LiMn2O4), lithium iron phosphate (LiFePO4), lithium nickel cobalt oxide (LiNixCoyMzO2), ternary substance(LiNixMnxCo1-2xO2) are used as active materials of the anode, or a mixture of lithium cobalt (LiCoO2) and one of lithium manganate (LiMn2O4), lithium iron phosphate (LiFePO4), lithium nickel cobalt oxide (LiNixCoyMzO2), ternary substance(LiNixMnxCo1-2xO2) is adopted as the active materials of the anode; lithium hexafluorophosphate (LiPF6) is adopted as the electrolyte, and a multicomponent mixture of ethylene carbonate (EC), dimethylcarbonate(DMC), Ethyl Methyl Carbonate (EMC) is used as a solution. The invention also discloses a preparation method of the lithium-ion battery with fast charged property. The lithium-ion battery of the invention has excellent fast charging and discharging performance.

Owner:TIANJIN B&M SCI & TECH

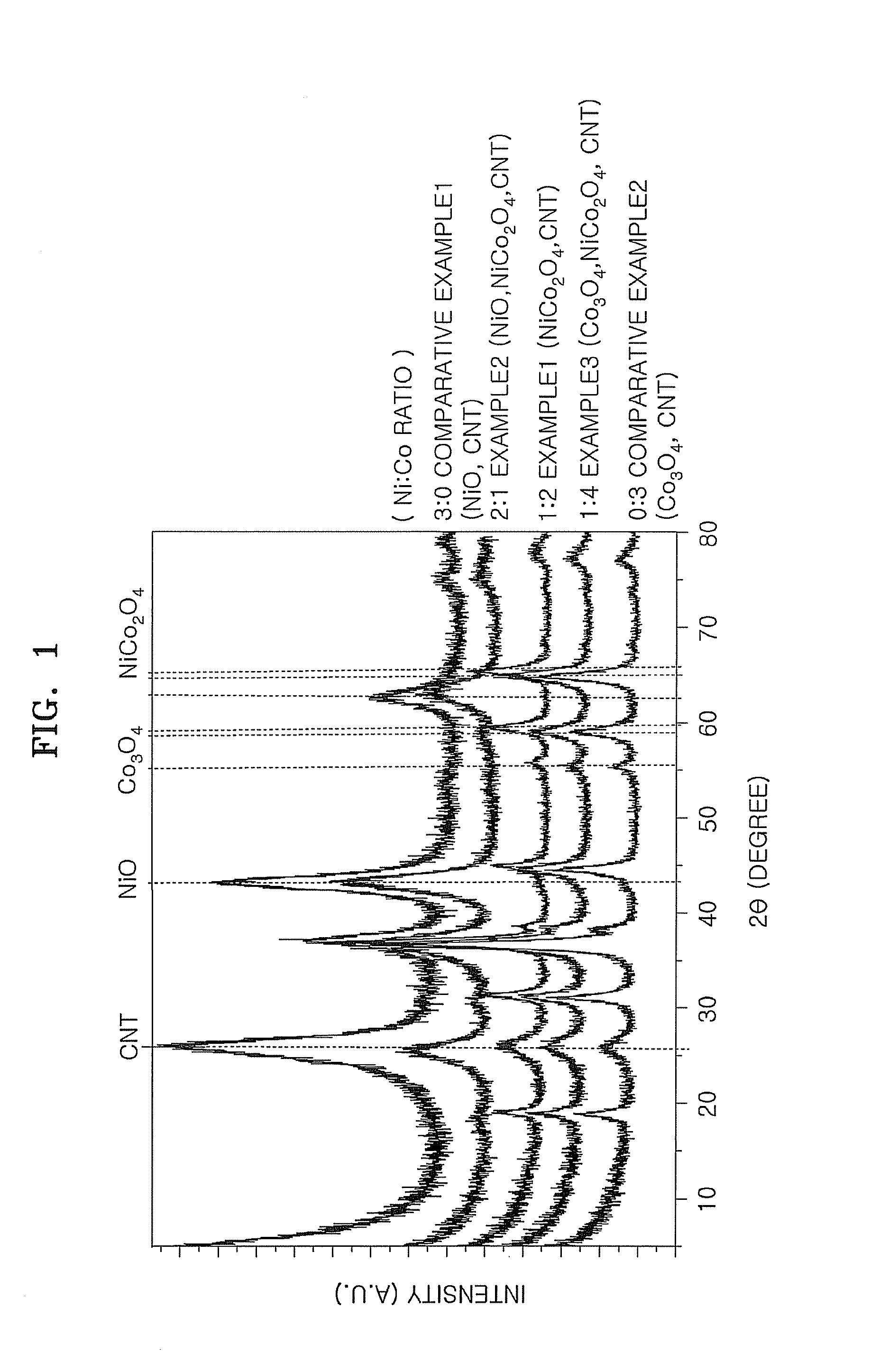

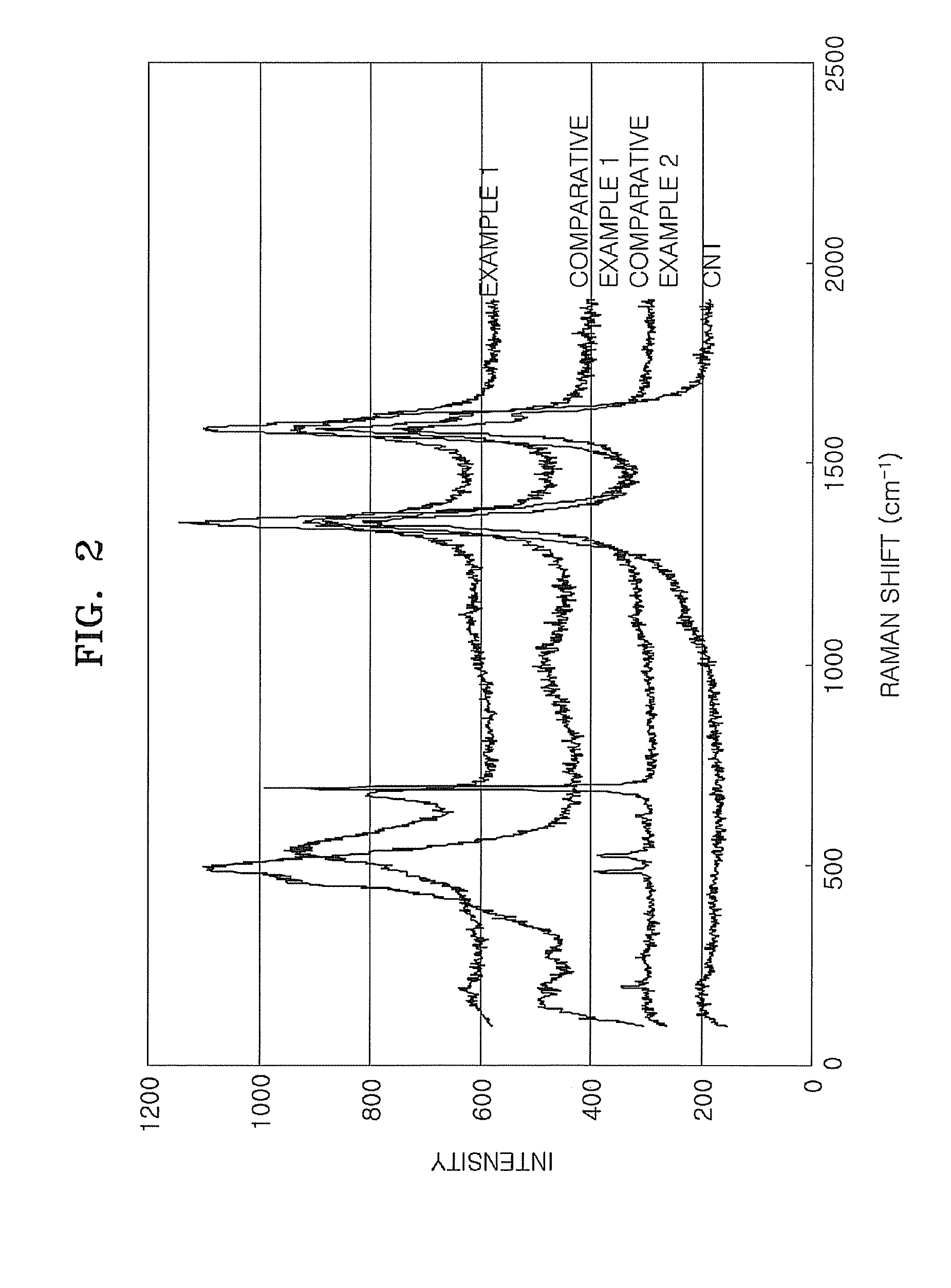

Transition metal/carbon nanotube composite and method of preparing the same

ActiveUS20100181200A1Good capacitance characteristicsImprove material removal rateElectrostatic separatorsMolten spray coatingCarbon nanotubeOxide coating

A transition metal / carbon nanotube composite includes a carbon nanotube and a transition metal oxide coating layer disposed on the carbon nanotube. The transition metal oxide coating layer includes a nickel-cobalt oxide

Owner:SAMSUNG ELECTRONICS CO LTD +1

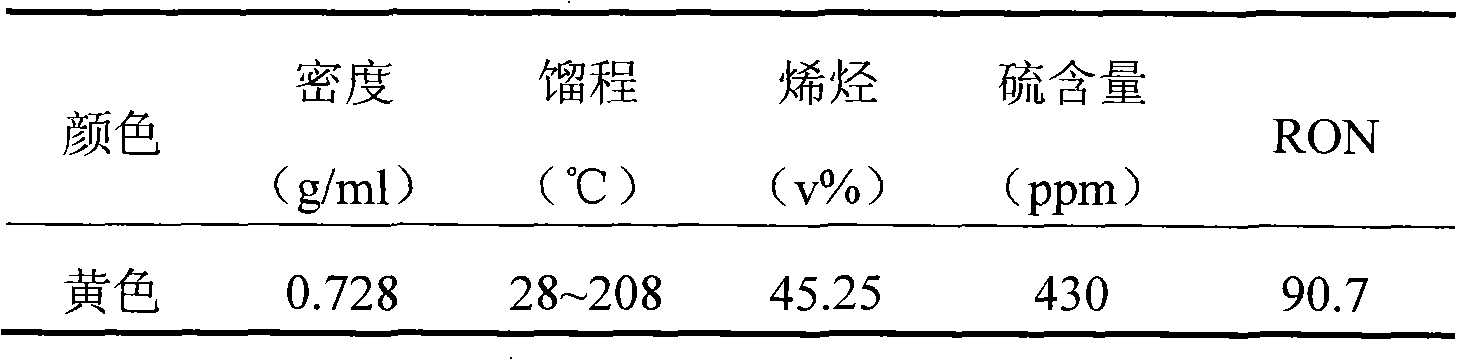

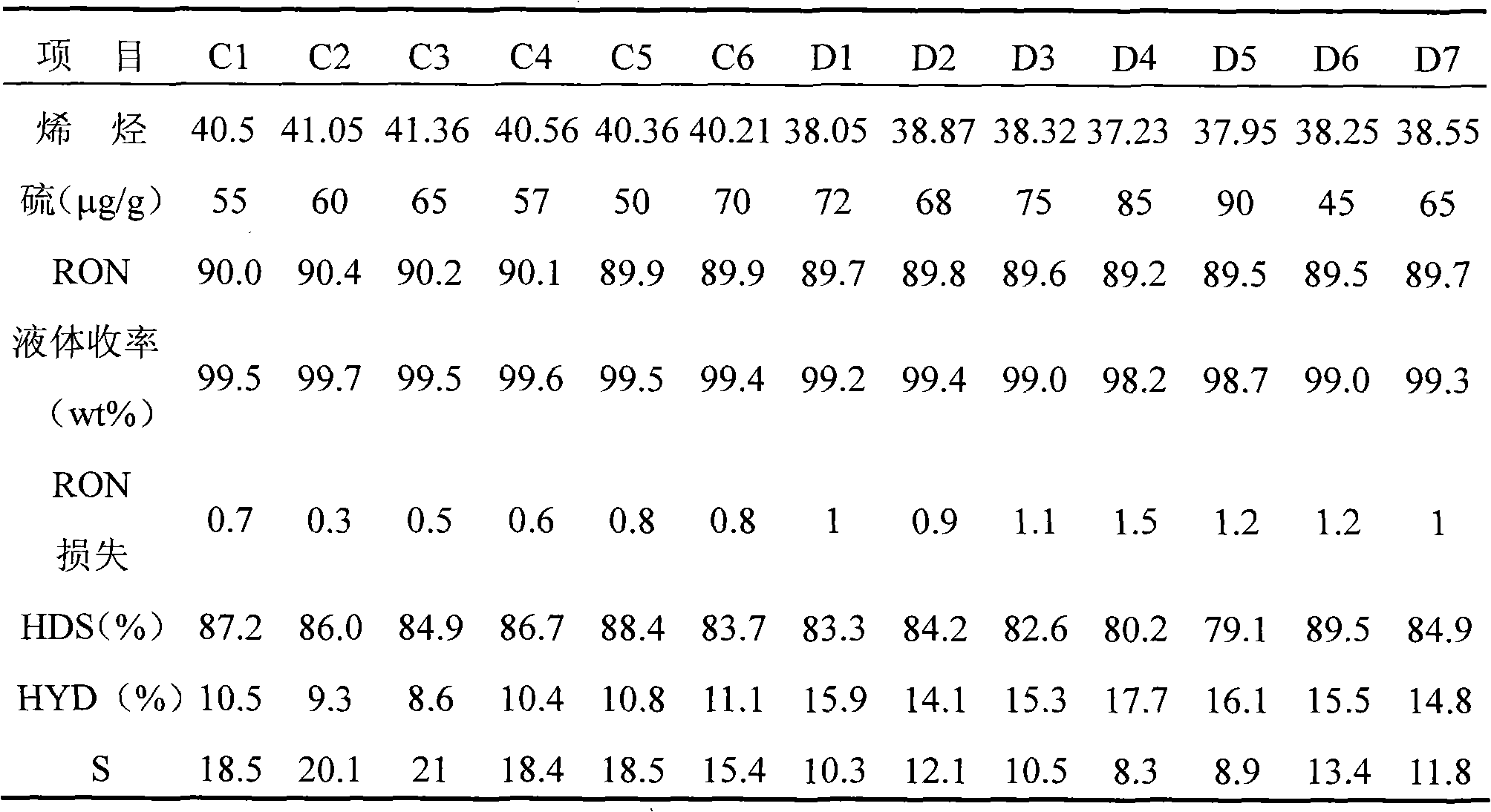

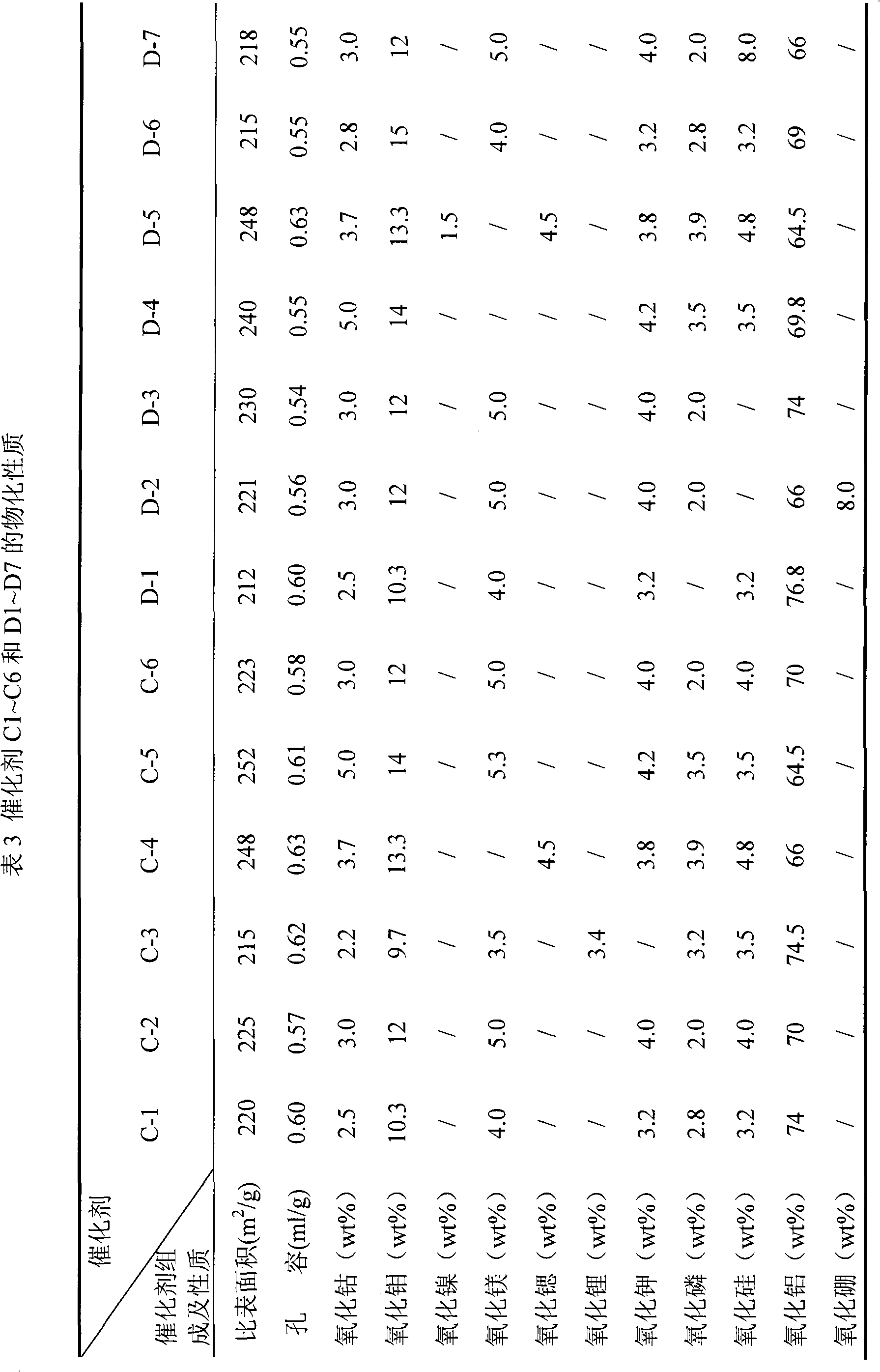

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN102335612AReduce acid strengthEnhance the interaction strengthMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

The invention relates to a selective hydrodesulfurization catalyst contains cobalt and molybdenum as active components. The selective hydrodesulfurization catalyst is characterized in that silicon oxide and aluminum oxide are used as carriers of the catalyst; based on the total weight of 100%, the catalyst comprises 2-6wt% of cobalt oxide, 9-15 wt% of molybdenum oxide, 2-8wt% of alkaline earth metal oxide, 2-6wt% of phosphorus oxide, 3-5wt% of alkali metal oxide, 2-6wt% of silicon oxide and 54-80 wt% of aluminum oxide; and the catalyst has the specific surface area of 200-300m<2> / g and the pore volume of 0.5-0.7mL / g. The catalyst has high hydrogenation activity and selectivity, good stability, low research octane number loss and high liquid yield. The catalyst is suitable for selective hydrodesulfrization of low-quality gasoline and is particularly suitable for selective hydrodesulfrization of low-quality FCC (Family Car China) gasoline.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com