Patents

Literature

234results about How to "Improve performance reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

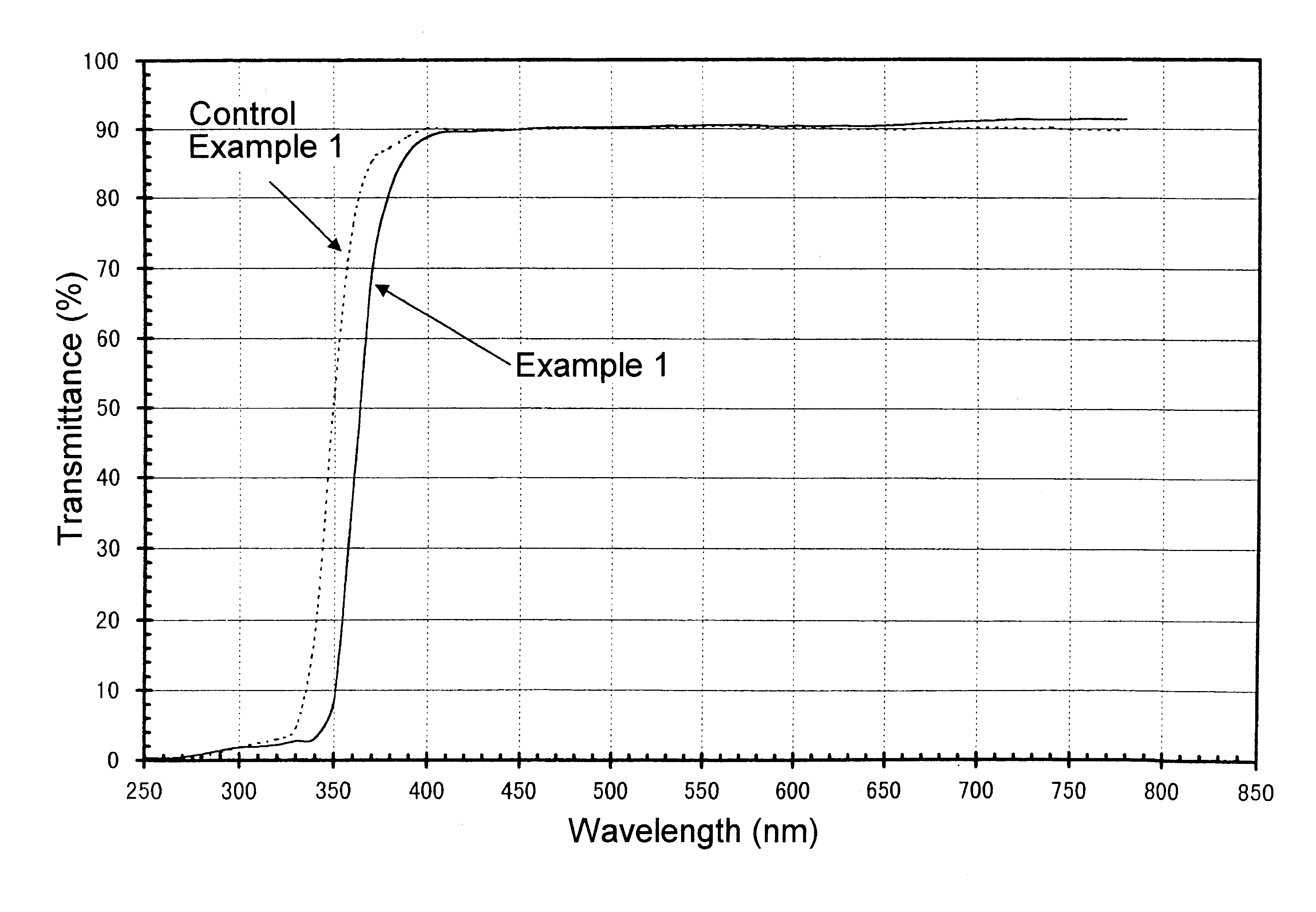

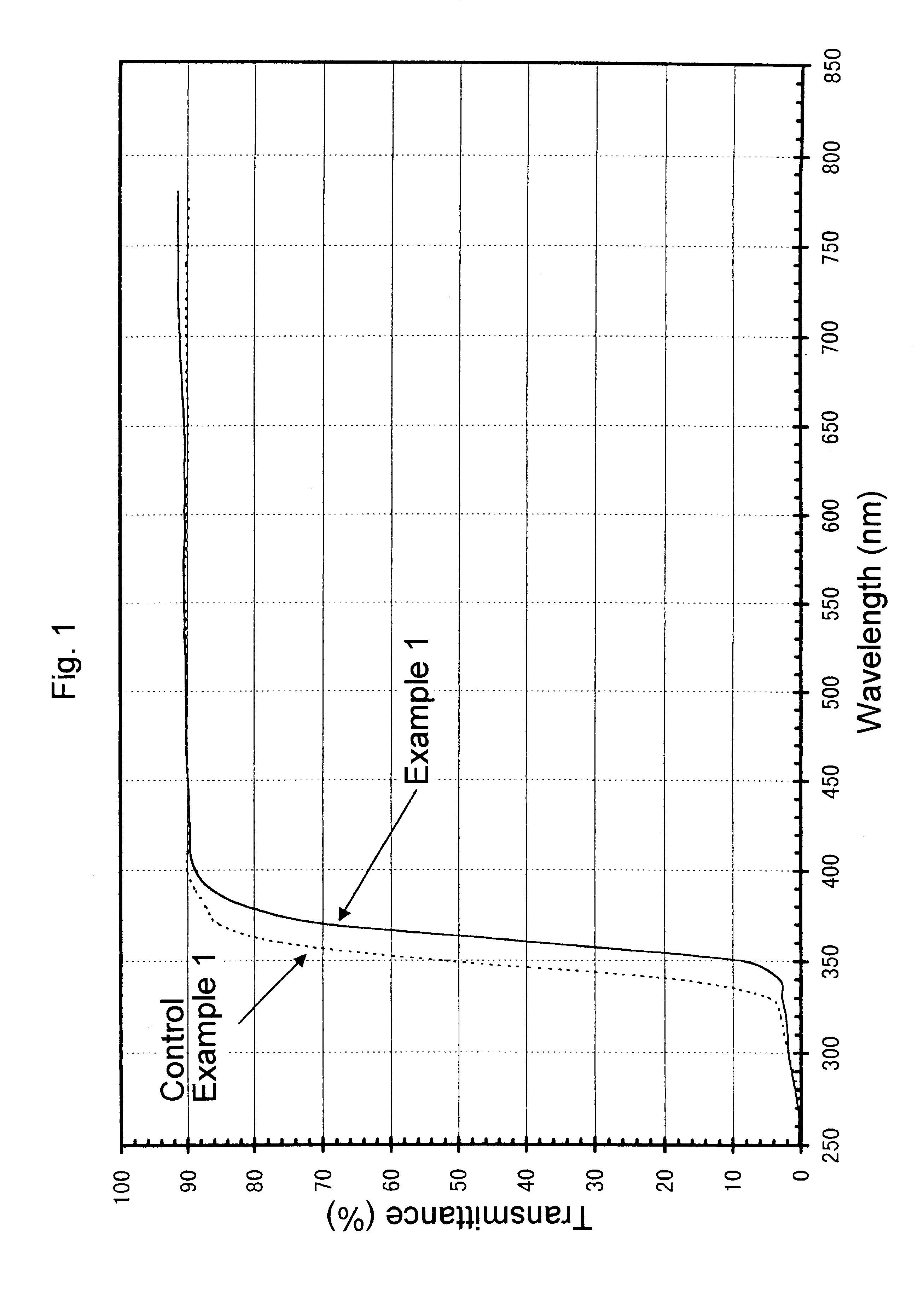

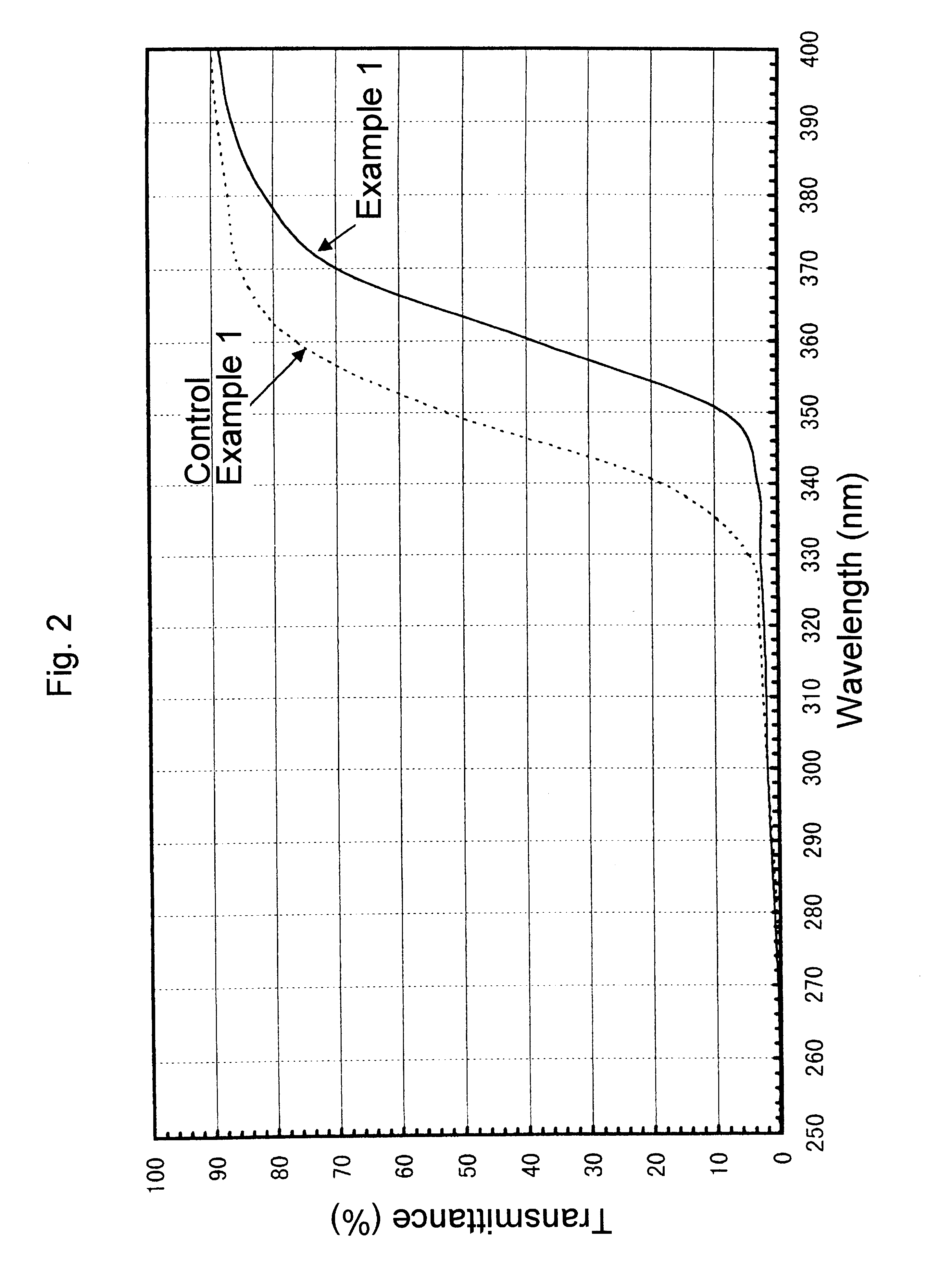

Ultraviolet radiation-absorbing, colorless, transparent soda-lime silica glass

An ultraviolet radiation-absorbing, colorless, transparent soda-lime-silica glass as well as glass bottles formed out of the glass are disclosed which, while maintaining high transmittance to light in the visible region and thereby allowing the contents to be seen clearly, absorbs ultraviolet radiation and thus prevents coloration, discoloration, fading in color or deterioration of the flavor of the contents caused by ultraviolet radiation. The glass is characterized in that its composition includes, in % by weight, SO3 . . . 0.15-0.4%; Cerium oxide . . . 0.2-1% (calculated as CeO2); Fe2O3 . . . 0.01-0.08%; FeO . . . 0-0.008%; Manganese oxide . . . 0.01-0.08% (calculated as MnO); and Cobalt oxide . . . 0-0.0005% (calculated as CoO).

Owner:NIHON YAMAMURA GLASS CO LTD

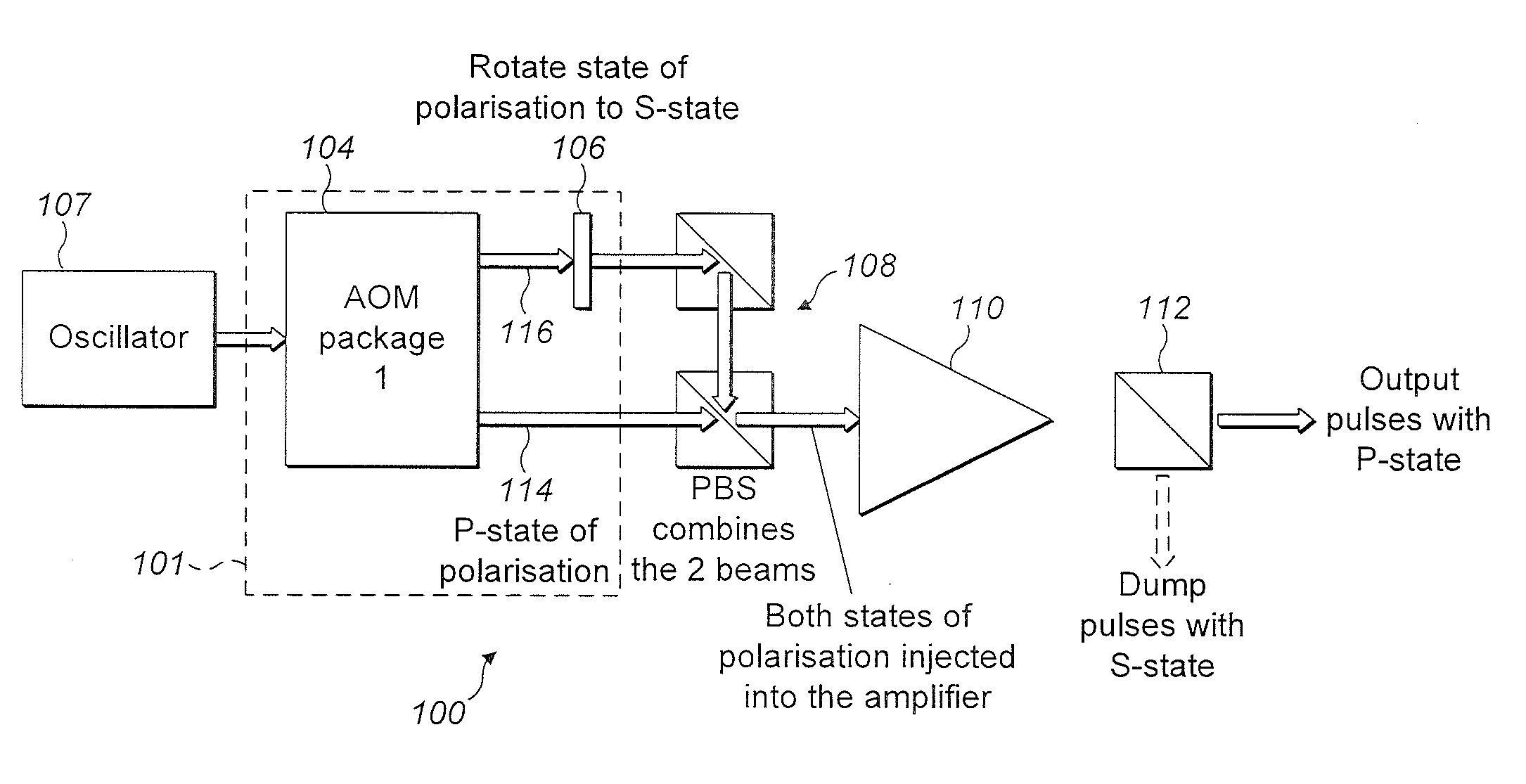

Optical Systems

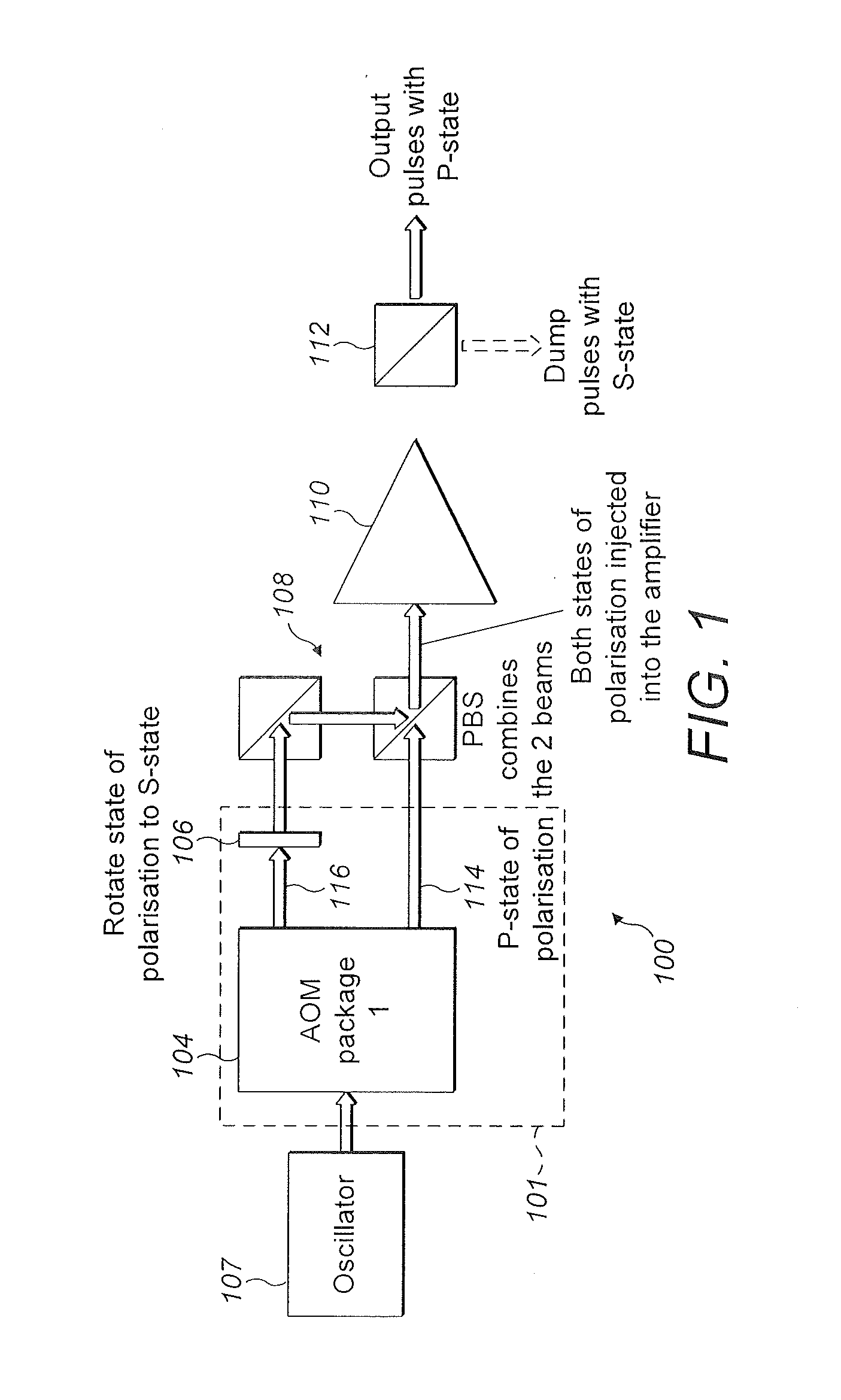

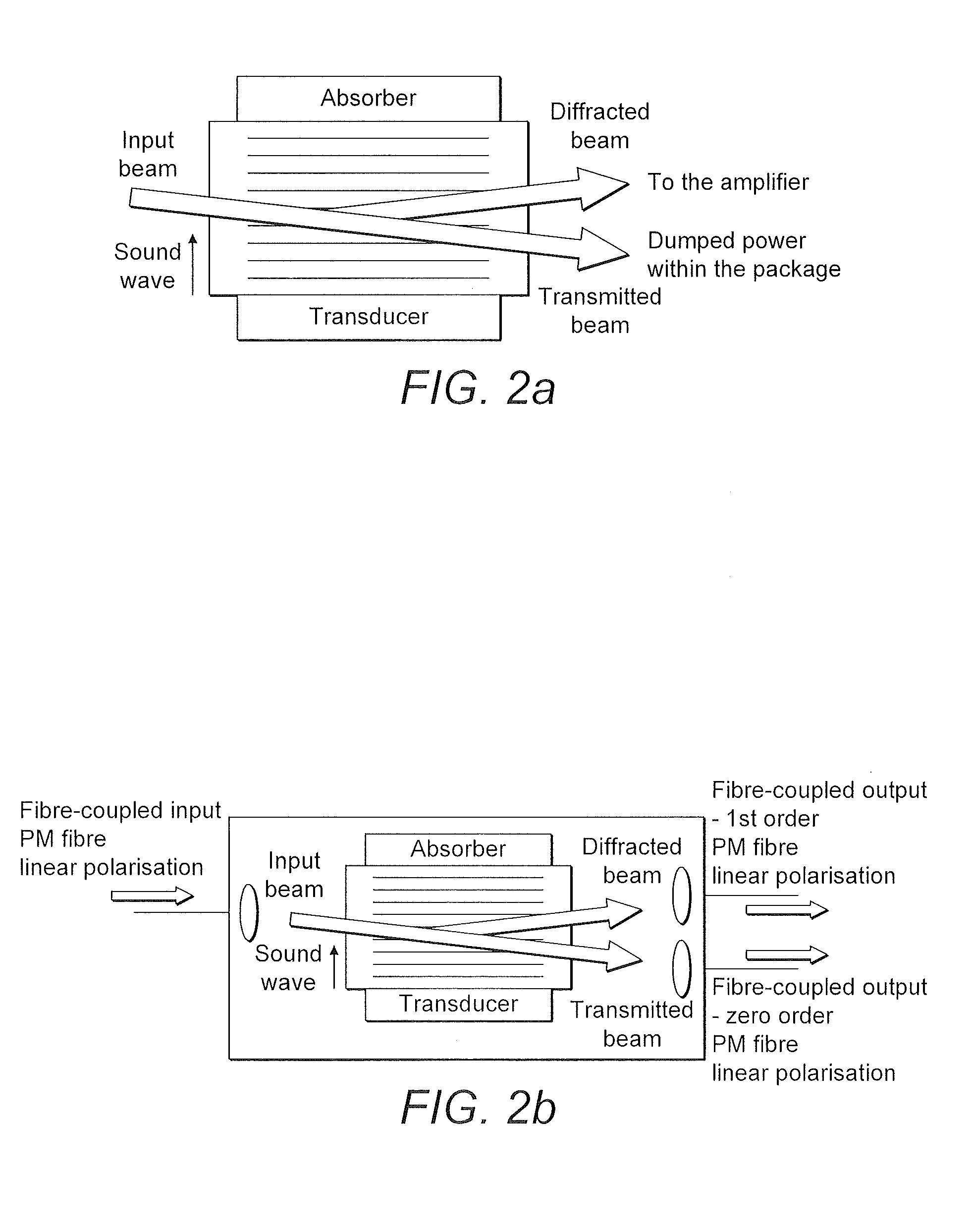

ActiveUS20140050235A1Wide rangeWithout high level of amplified noiseLaser using scattering effectsOptical devices for laserAudio power amplifierOptical communication

An optical system comprises an optical apparatus arranged to direct received light to different paths and to provide a first signal and a second signal, said first and second signals having an optical difference therebetween sufficient for distinguishing optical signals, an amplifier in optical communication with the optical apparatus for amplifying the first and second signals, and a discrimination device to receive amplified light and to provide output light responsive to the optical difference.

Owner:NKT PHOTONICS

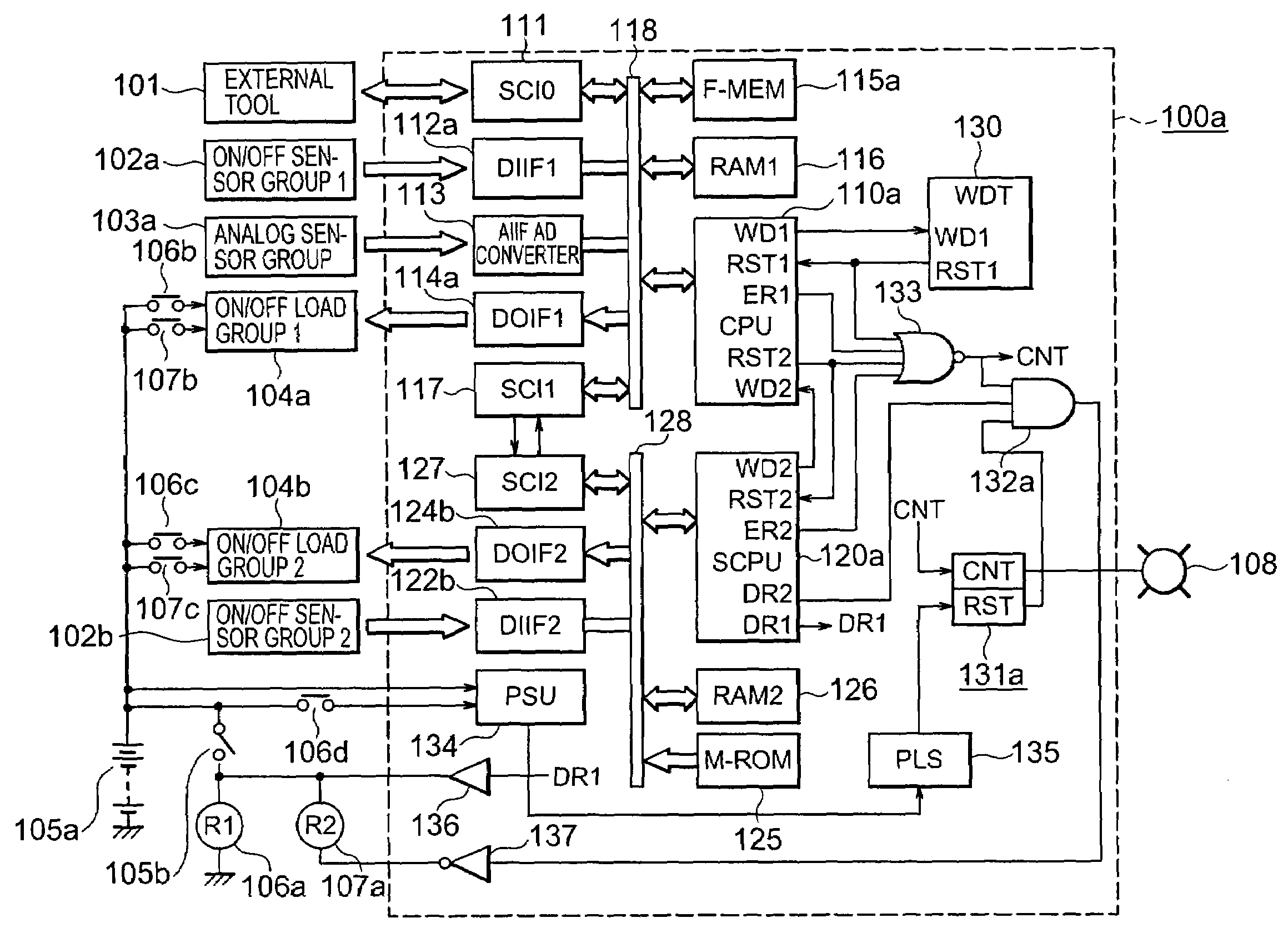

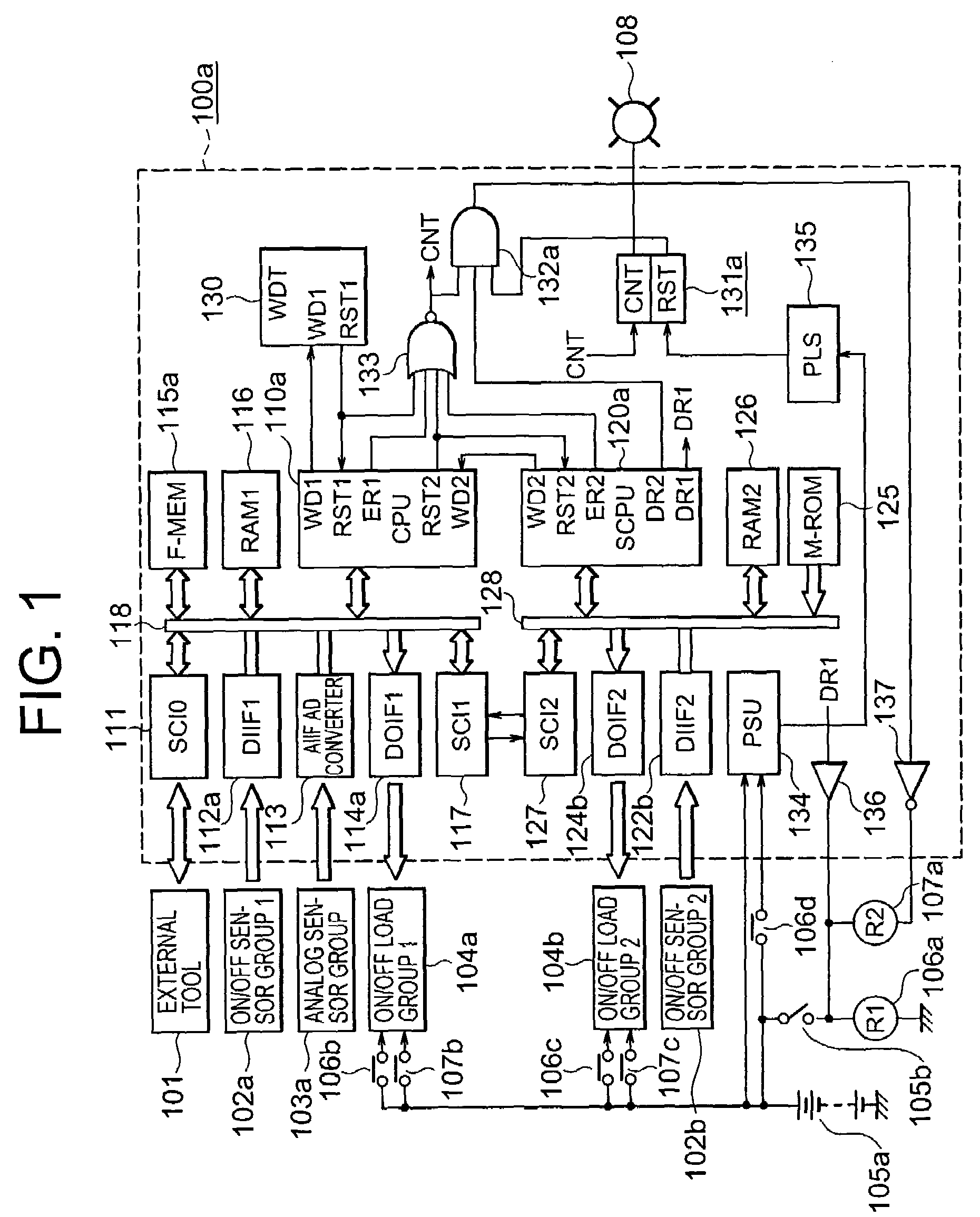

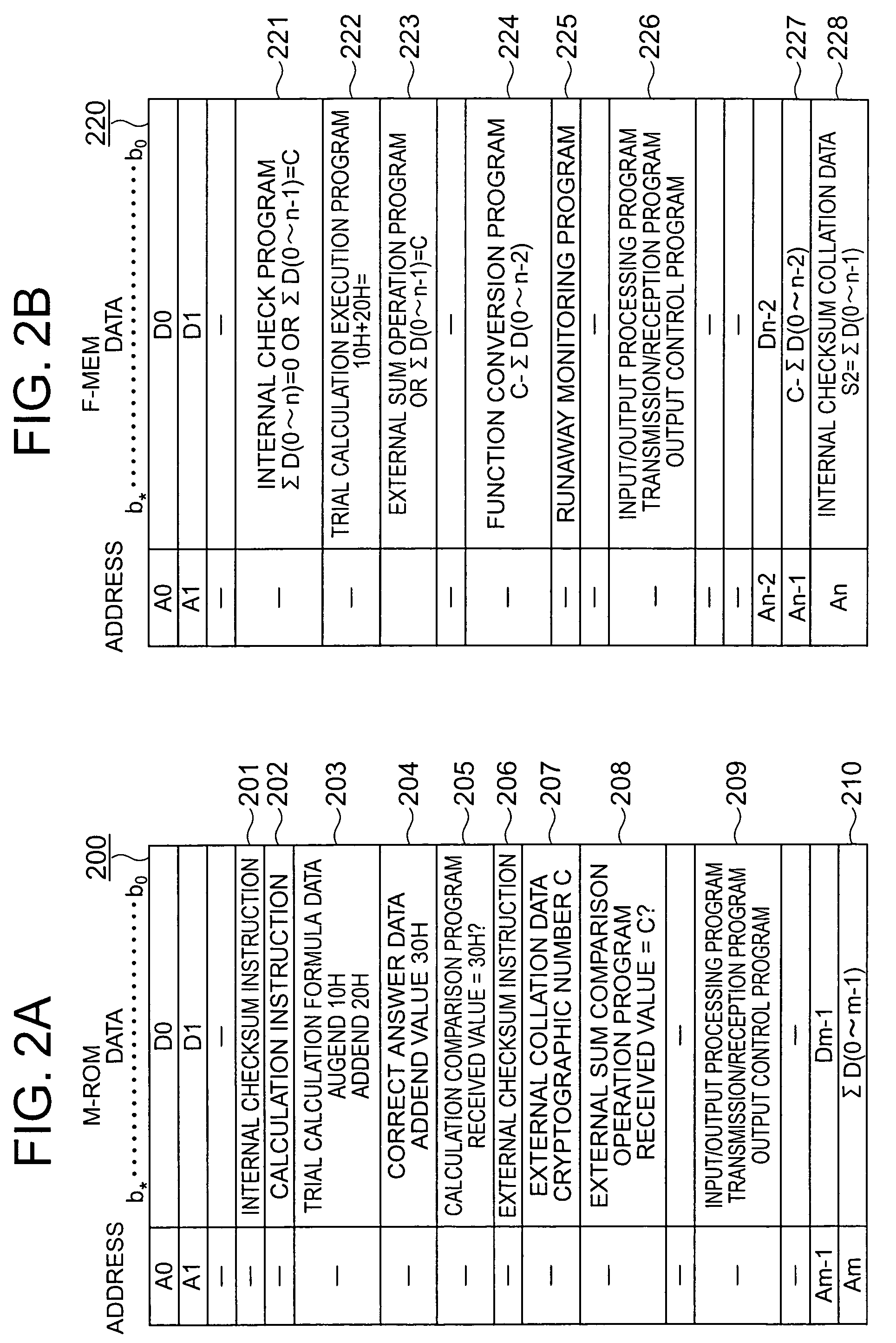

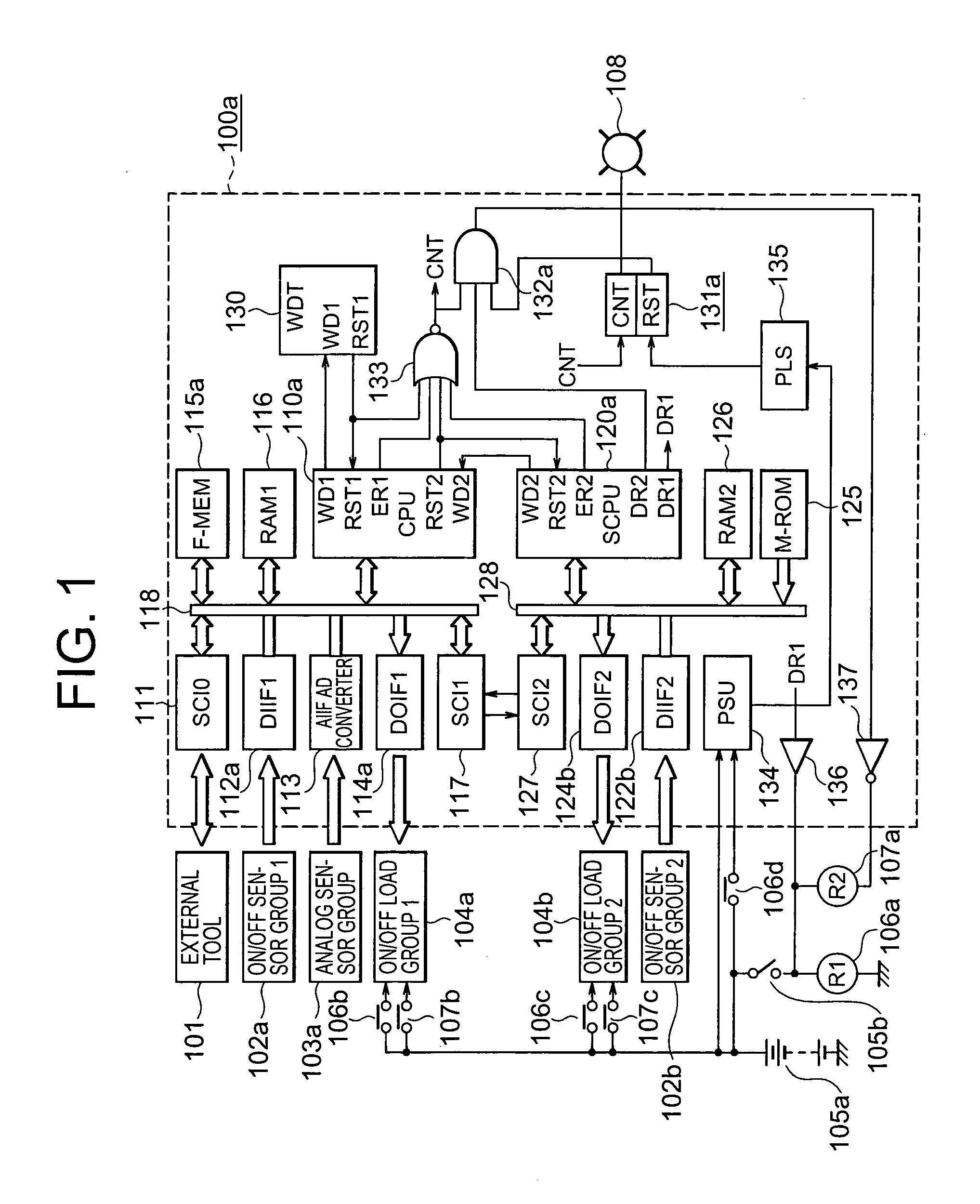

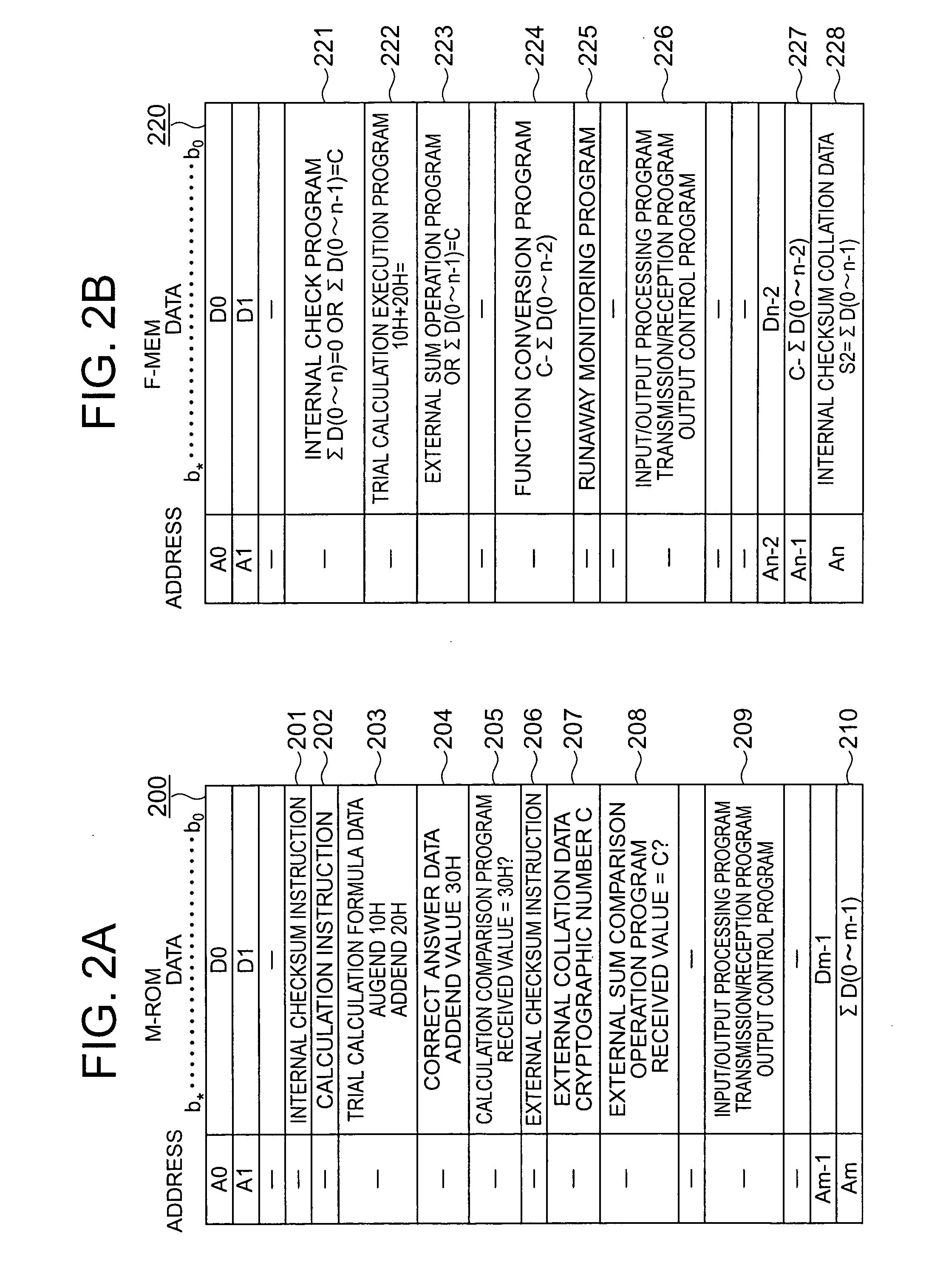

On-vehicle electronic control device

ActiveUS7251551B2Improve performance reliabilityVehicle testingElectrical controlElectricityChecksum

An on-vehicle electronic control device includes an auxiliary microprocessor and subjects a microprocessor allocated to a main part of control to an external diagnosis, thereby improving reliability of performance. A microprocessor including a nonvolatile program memory into which a control program is written is serially connected to an auxiliary microprocessor including an auxiliary nonvolatile program memory. The microprocessor and the auxiliary microprocessor function in cooperation to control on-vehicle electric load groups in response to input signals from on-vehicle sensor groups and on-vehicle analog sensor group. The nonvolatile program memory and the microprocessor are subjected to runaway monitoring performed by a watchdog timer and to an external checksum diagnosis performed periodically by the auxiliary microprocessor. If an anomaly occurs in the runaway monitoring, the external checksum diagnosis, and a checksum interval, parts of electric loads are cut off of power supply by load power relay.

Owner:MITSUBISHI ELECTRIC CORP

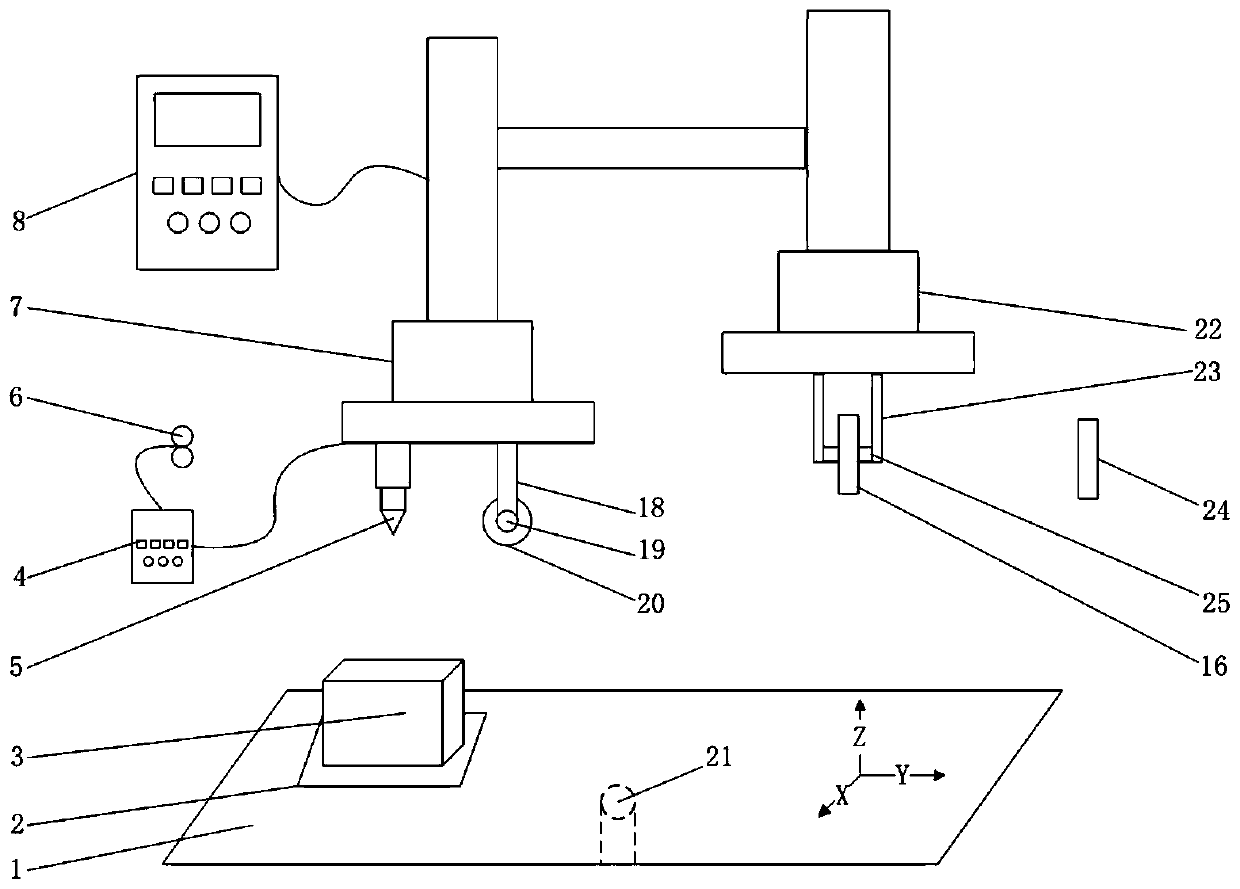

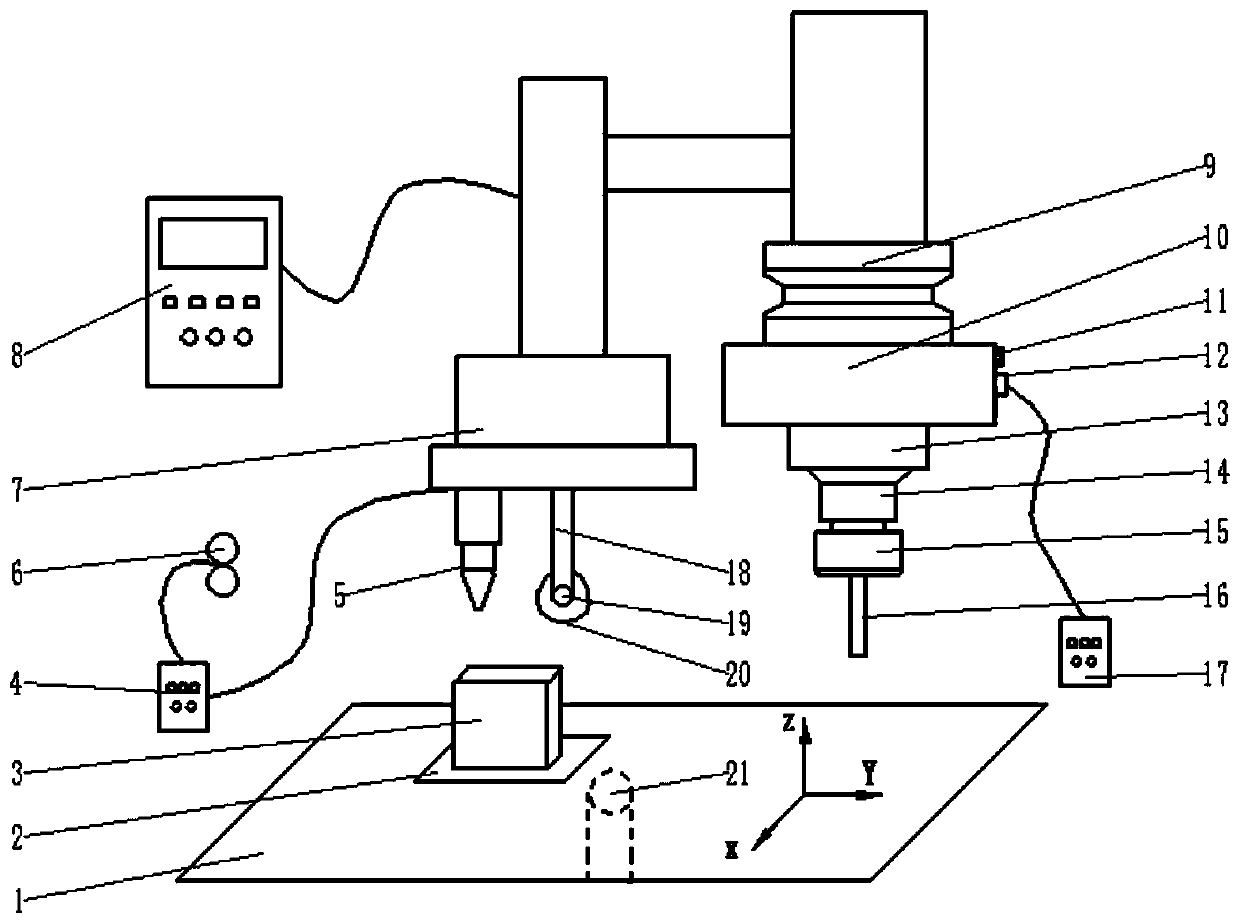

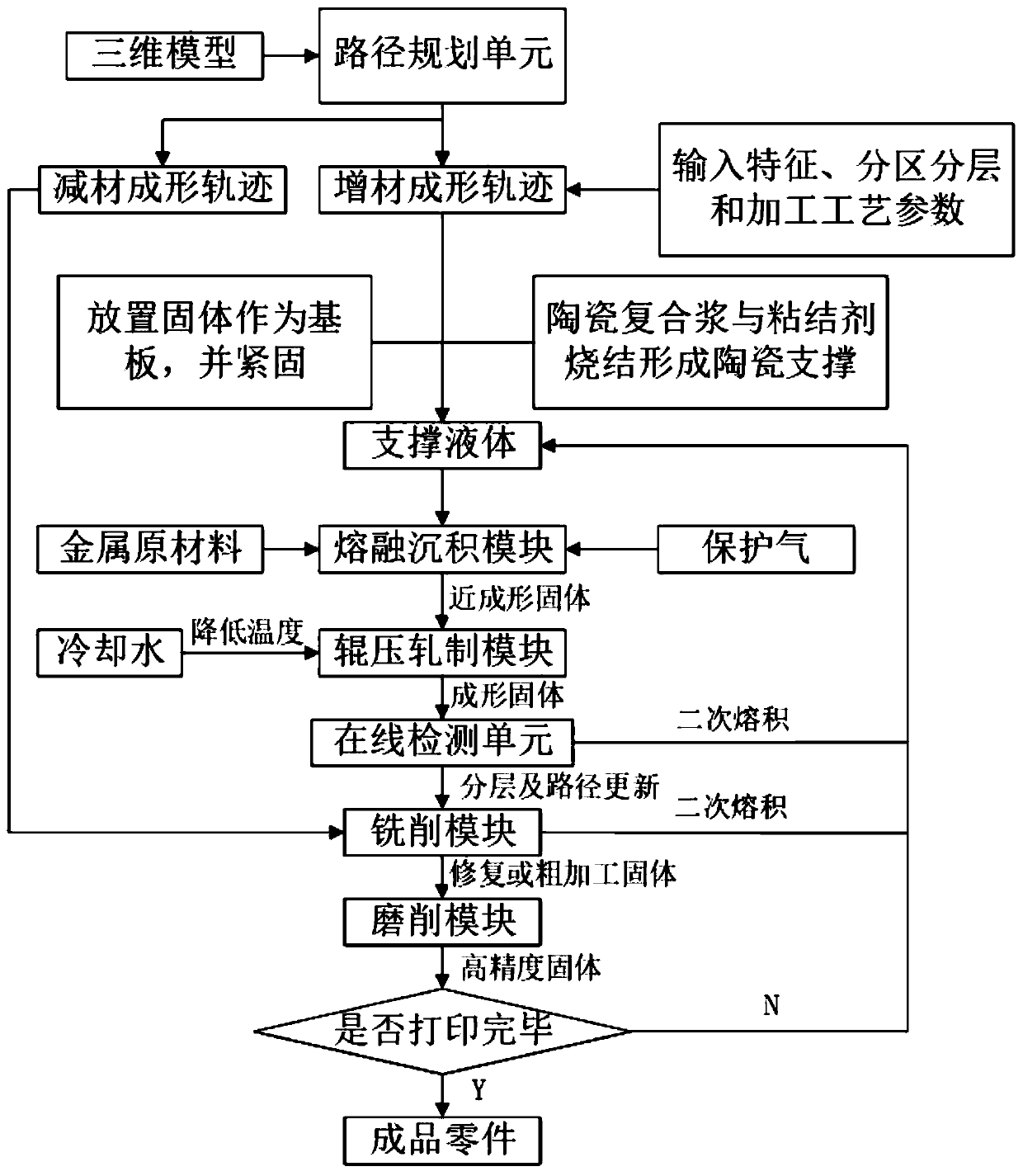

Metal part manufacturing system and method adopting micro-casting-forging and milling-grinding in-situ composite

InactiveCN110076566AImprove tissue mechanical propertiesImprove processing efficiencyAdditive manufacturing apparatusOther manufacturing equipments/toolsEngineeringManufacturing systems

The invention belongs to the field of metal part manufacturing, and particularly discloses a metal part manufacturing system and method adopting the micro-casting-forging and milling-grinding in-situcomposite. The system involves a micro-casting-forging module, a milling module, a five-axis linkage workbench and a control device, wherein the micro-casting-forging module is connected with the milling module and comprises a fusion deposition sub-module and a roller-pressing rolling sub-module, the five-axis linkage workbench is positioned below the micro-casting-forging module and the milling module, and is used for containing metal parts to be formed, and the control device is connected with the fusion deposition sub-module, the roller-pressing rolling sub-module, the milling module and the five-axis linkage workbench. According to the system and method, micro-casting-forging and a milling process are composited to process and manufacture the metal parts, so that the problems that whenthe metal parts are made through the additive manufacturing, the structure is not uniform, the deformation is serious, the residual stress is large, the structure performance is poor, and the surfacequality is poor are solved, and the system and method is especially suitable for processing a high-performance complicated special-shaped element.

Owner:HUAZHONG UNIV OF SCI & TECH

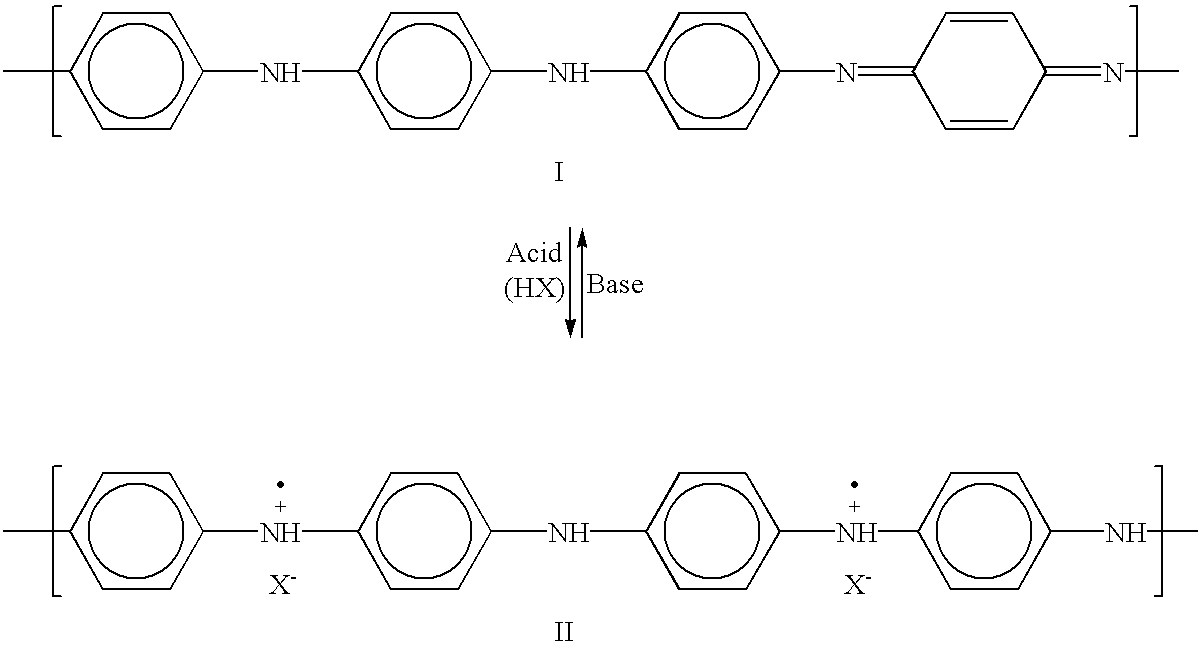

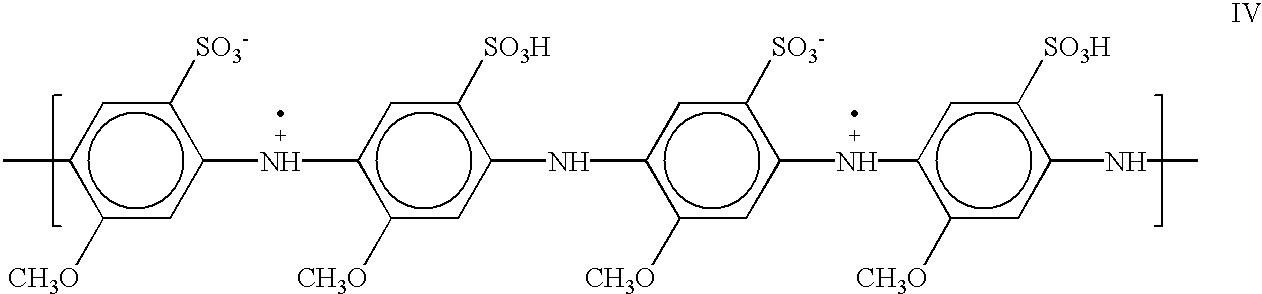

Organic electronic devices having conducting self-doped polymer buffer layers

InactiveUS6611096B1Improve performance reliabilityImprove performanceDischarge tube luminescnet screensElectroluminescent light sourcesCounterionConductive polymer

Organic electronic devices having a conducting self-doped polymer buffer layer, particularly a self-doped polyaniline buffer layer, are described. Also described are organic light emitting diodes with buffer layers comprised of an intrinsically conducting polymer having no mobile counterions.

Owner:3M INNOVATIVE PROPERTIES CO

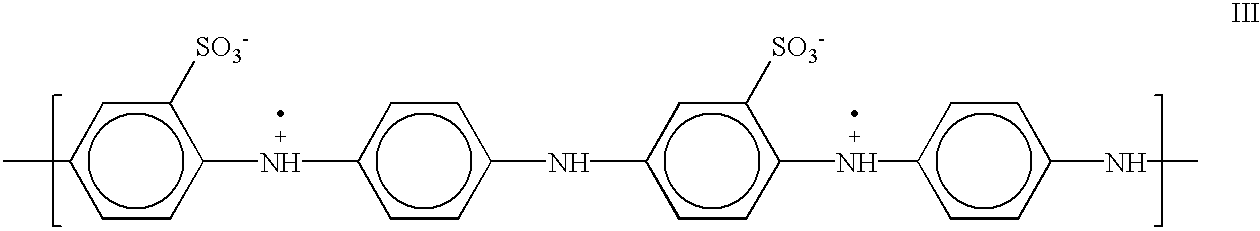

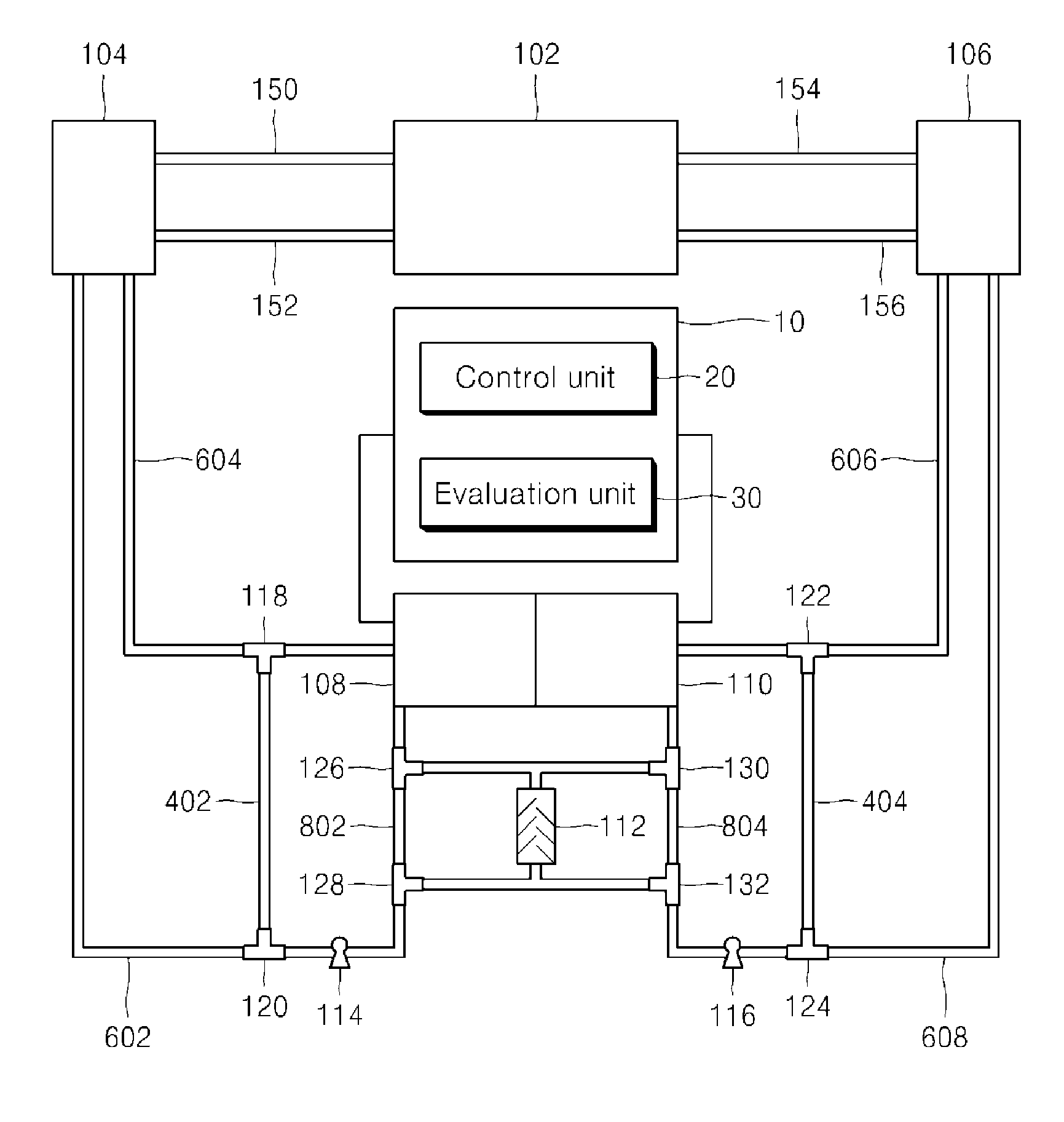

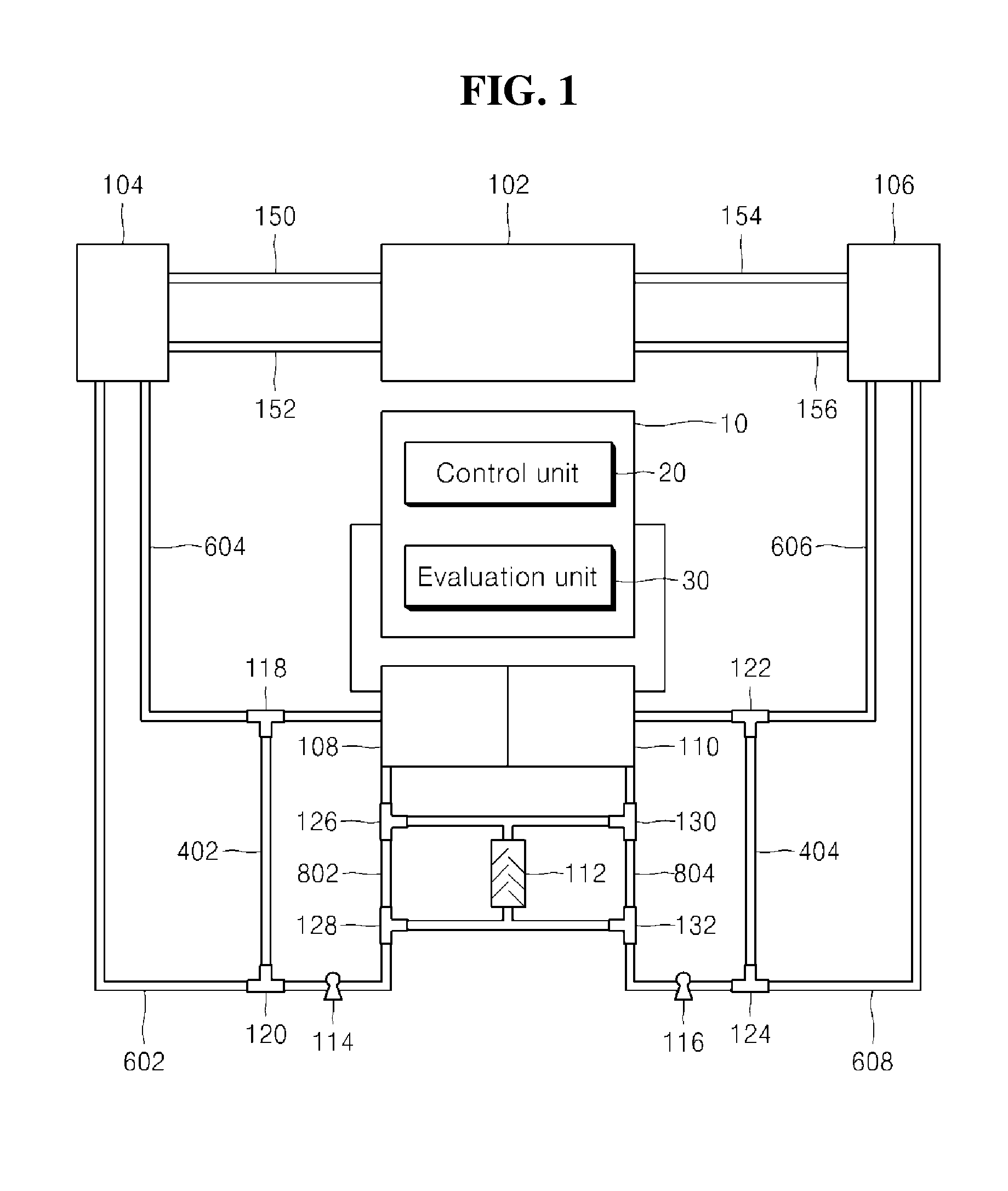

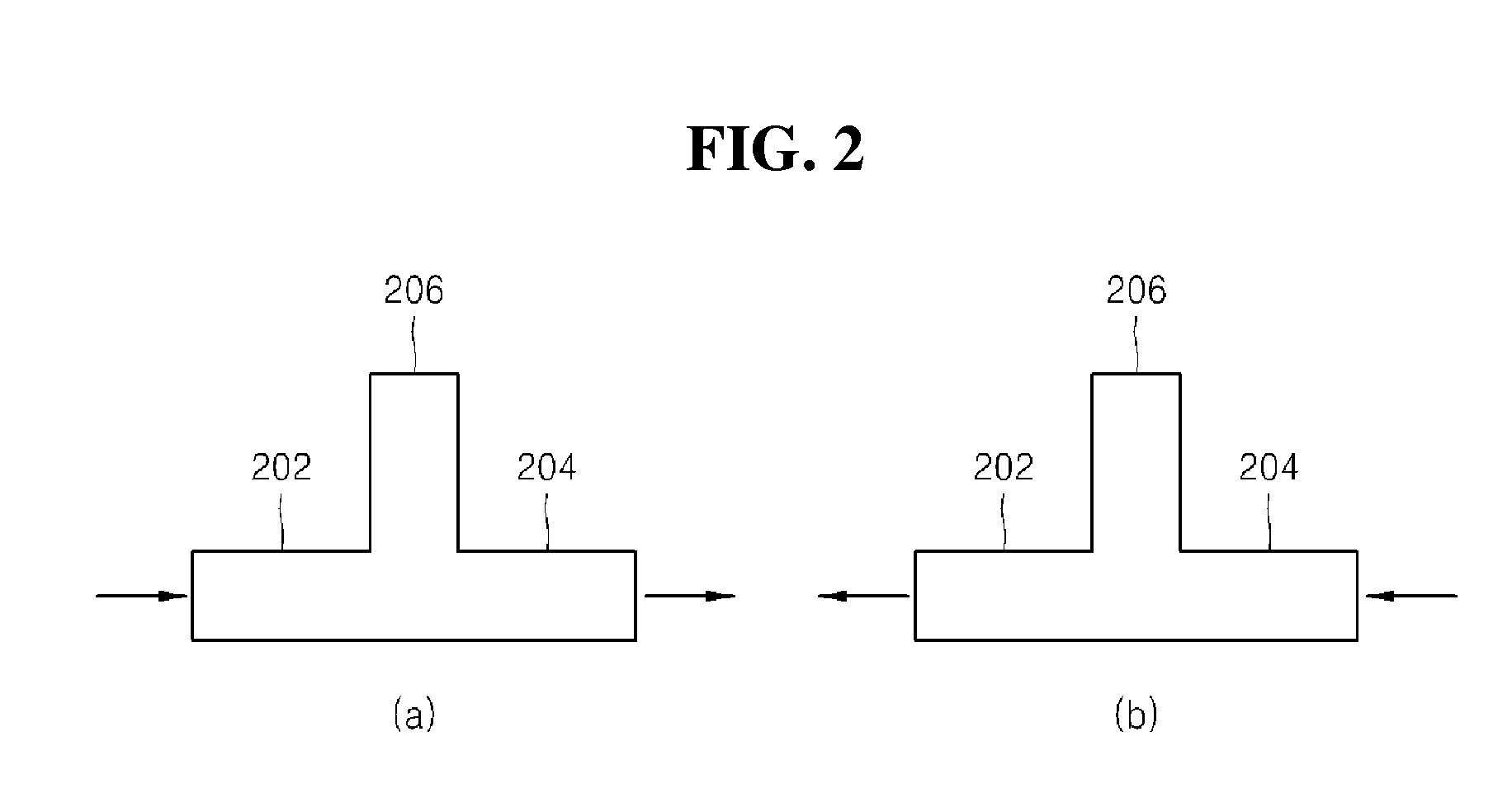

Method and system for evaluating redox flow battery

InactiveUS20150226806A1Effective controlImprove performance reliabilityElectrolyte stream managementRegenerative fuel cellsElectrical batteryRedox

A system for evaluating a redox flow battery according to an embodiment of the present disclosure includes: a control unit configured to control the path of a flow channel connected between a detection cell and the redox flow battery or a flow channel connected between the detection cell and an agitator; and an evaluation unit configured to evaluate any one of the state of charge, capacity fade and oxidation number balance of an electrolyte, which is used in the redox flow battery, by measuring a current or voltage of the detection cell based on the controlling of the path by the control unit. According to the present disclosure, the capacity fade problem of a redox flow battery can be quickly coped with by evaluating the information of the positive and negative electrode electrolytes on battery capacity fade and information about the valence balance of the electrolytes in situ.

Owner:OCI

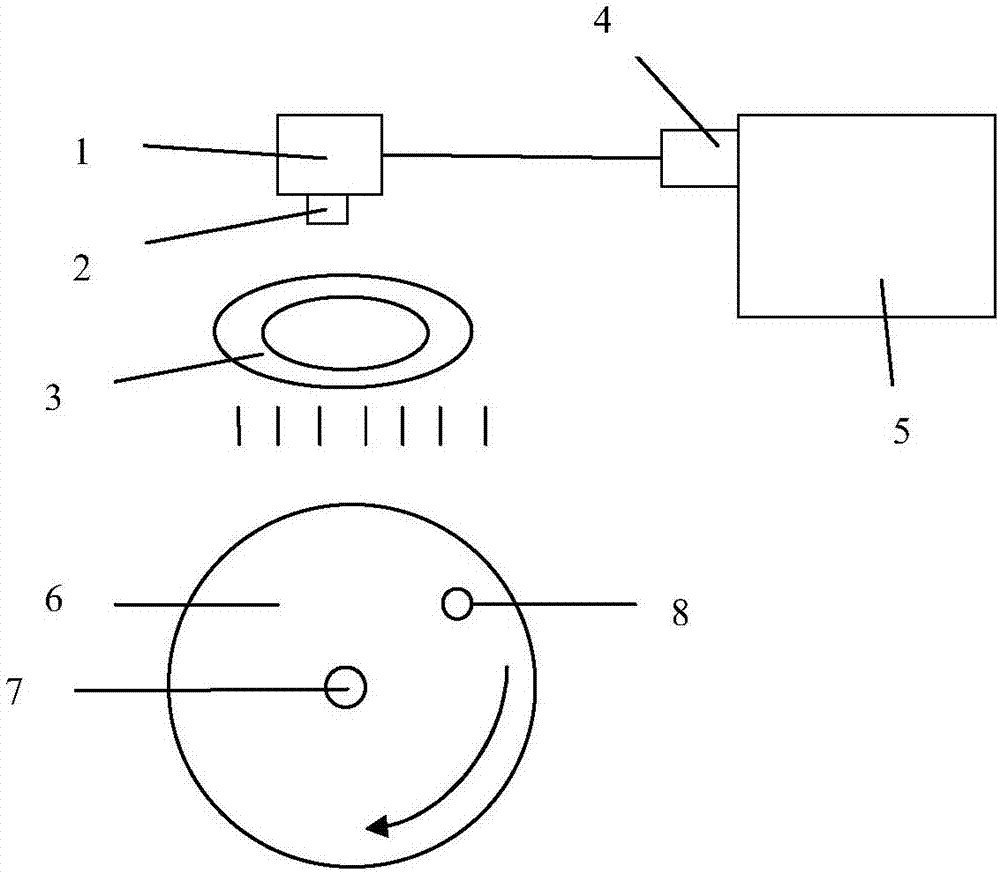

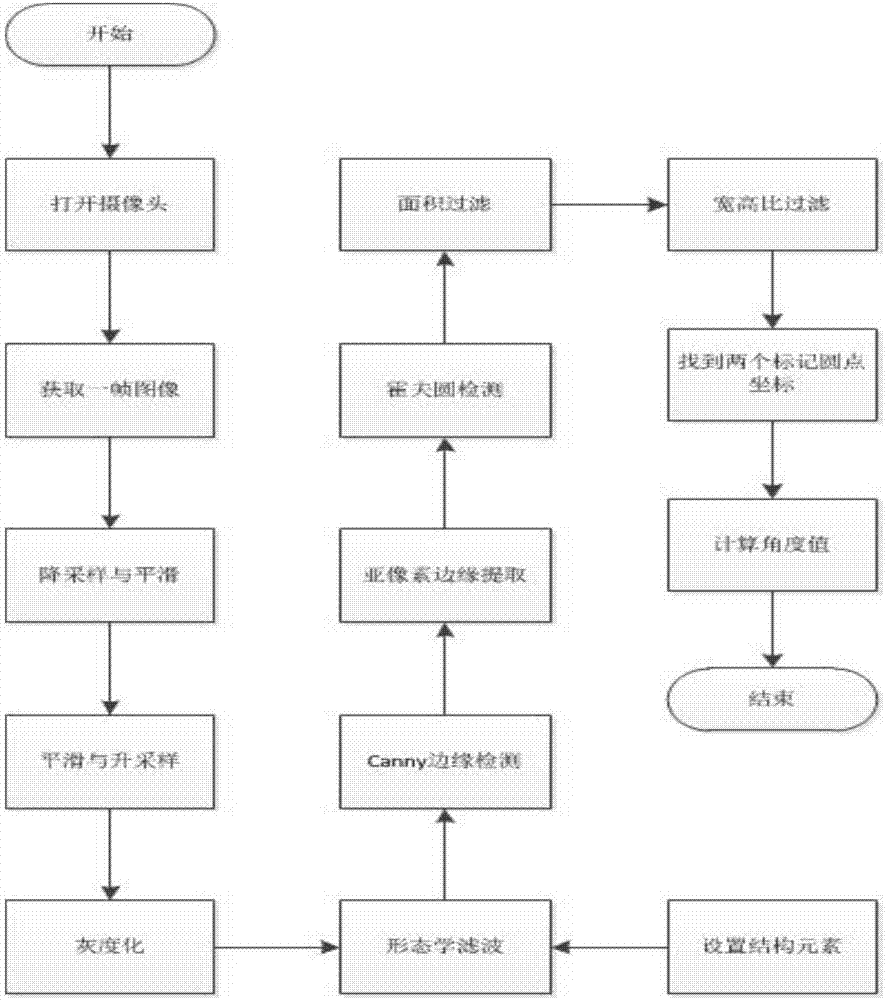

Machine vision based turn plate angle high-precision online measurement method

The invention discloses a machine vision based turn plate angle high-precision online measurement method. Real time image collection is performed on mark round hole points in a turn plate by utilizinga monocular industrial camera. Through vision and image metrology analysis on acquired images, position information of the mark round hole points in the turn plate can be obtained. Then rotation angle information can be calculated through a geometric method. The advantages of the invention achieved in angle measurement include high measurement speed and realization of real time online measurement; avoidance of influence and damage to working piece surface through implementation of a measurement function by adoption of a non-contact technology; and elimination of interference on measurement results due to lighting environment complexity, spray liquid, water spots and the like in a production field through adoption of an improvement algorithm in the highest level.

Owner:CHANGSHA XIANGJI HAIDUN TECH CO LTD

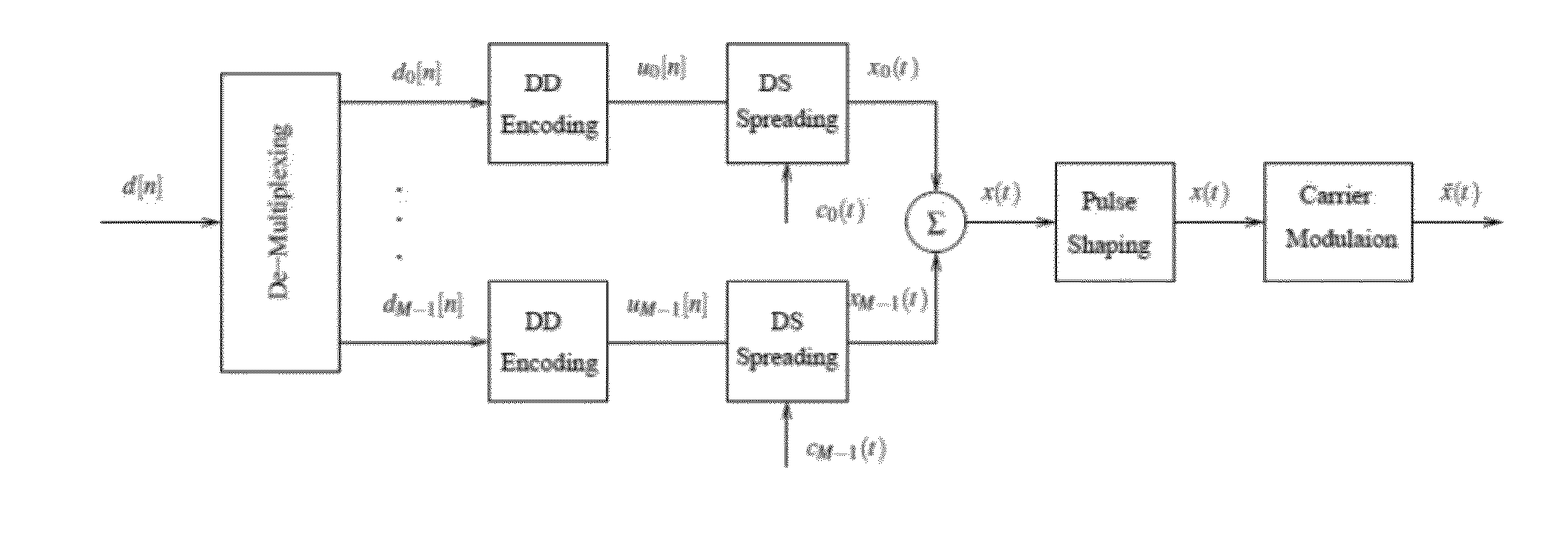

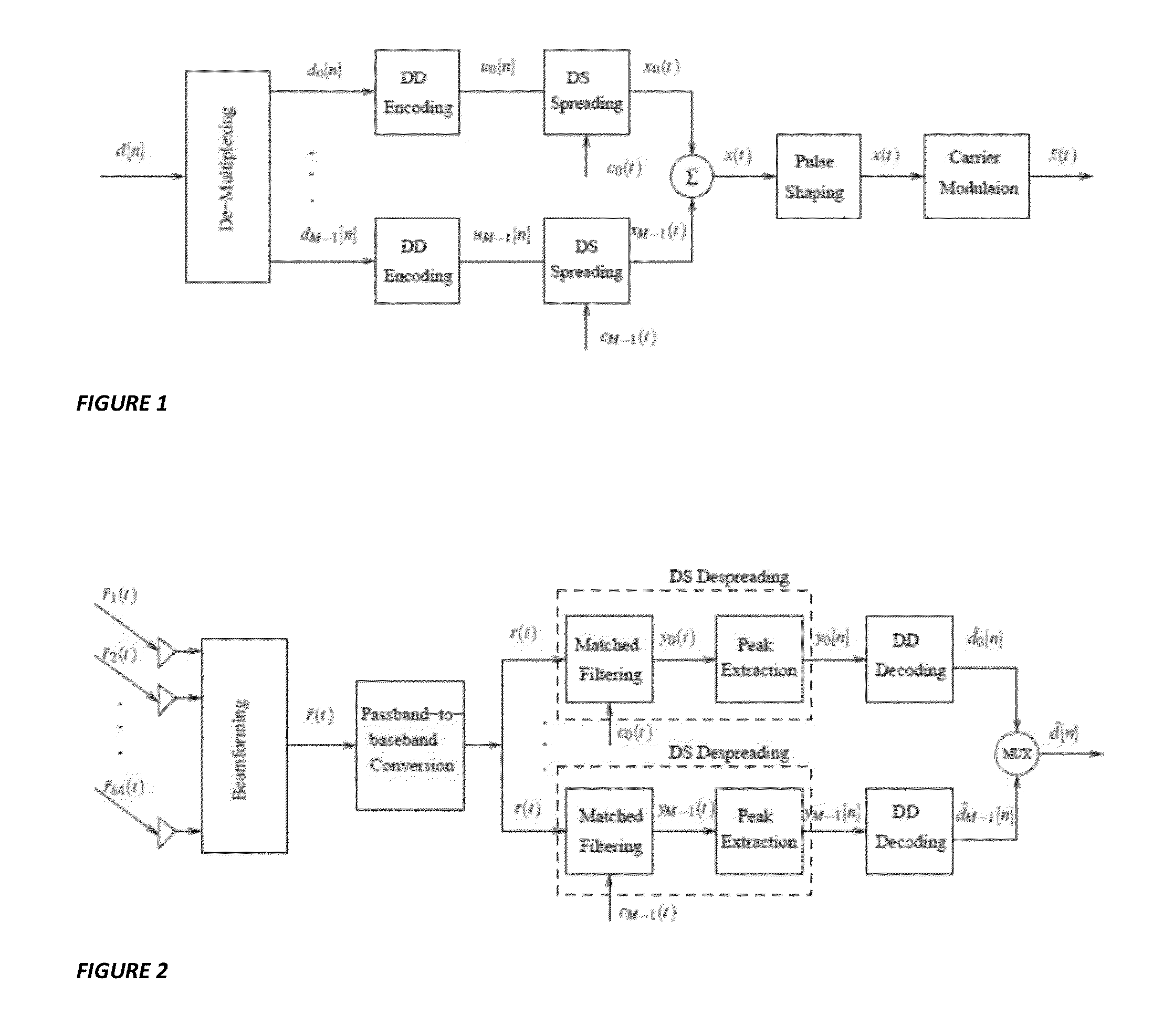

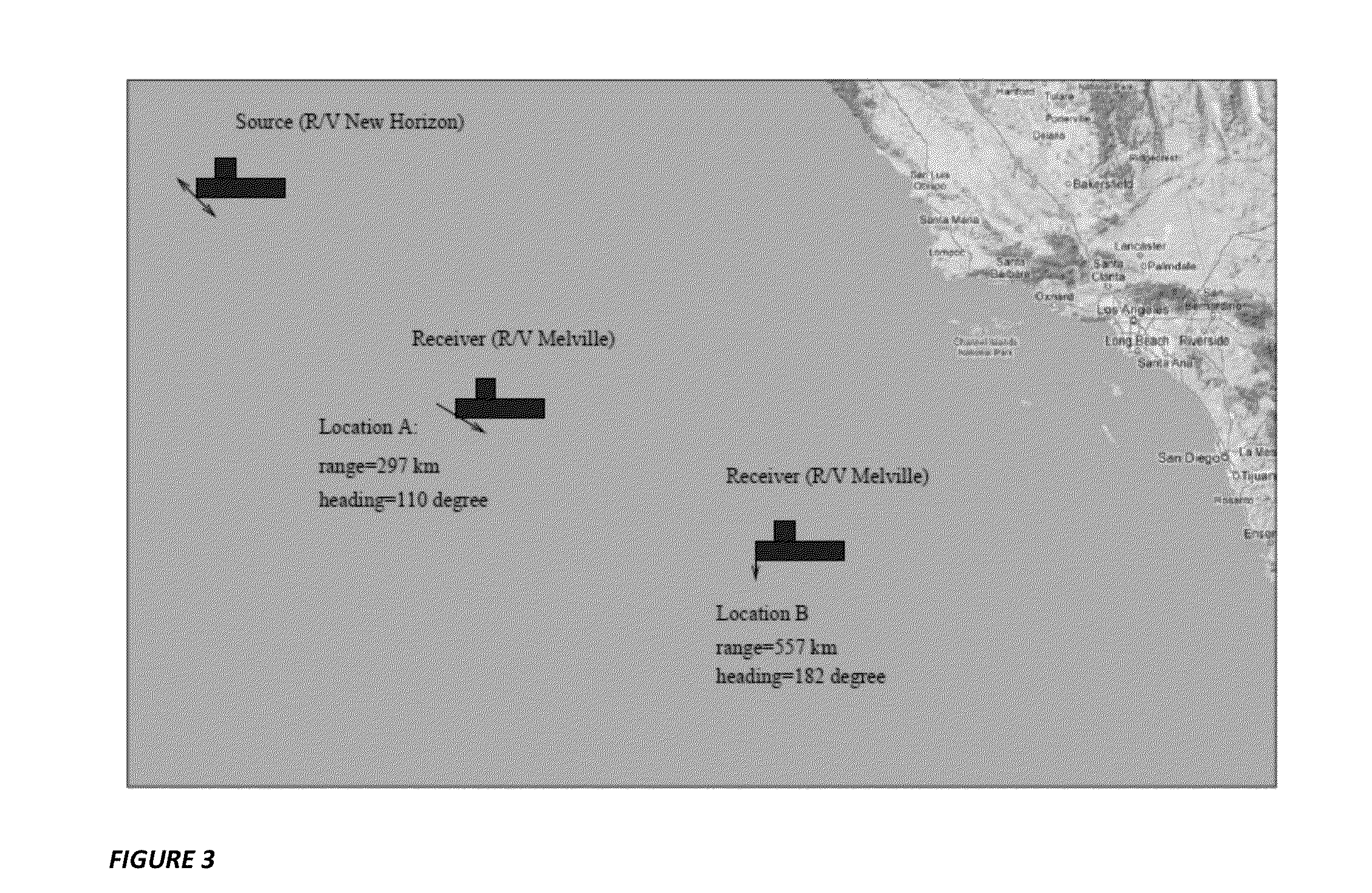

Method for mobile underwater acoustic communications

ActiveUS20140269201A1Invention is simpleImprove signal-to-noise ratioSonic/ultrasonic/infrasonic transmissionMultiplexingDirect-sequence spread spectrum

A method for mobile underwater acoustic communications includes double differentially (DD) encoding a communication signal to produce a DD-encoded communication signal, applying direct sequence spread spectrum (SS) to the DD-encoded signal to produce a DD-SS communication output signal, and transmitting the DD-SS communication output signal. The method i) increases the SNR via processing gain, ii) eliminates the ISI through multipath suppression, and iii) enables bandwidth efficiency improvement via data multiplexing. The method is shown capable of facilitating simple receiver processing and offering performance robustness against unpredictable channel fluctuations.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

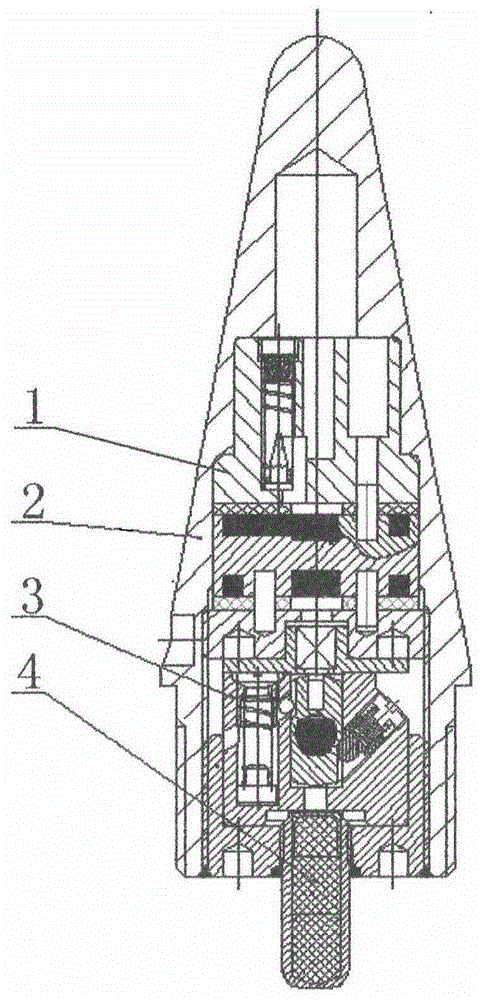

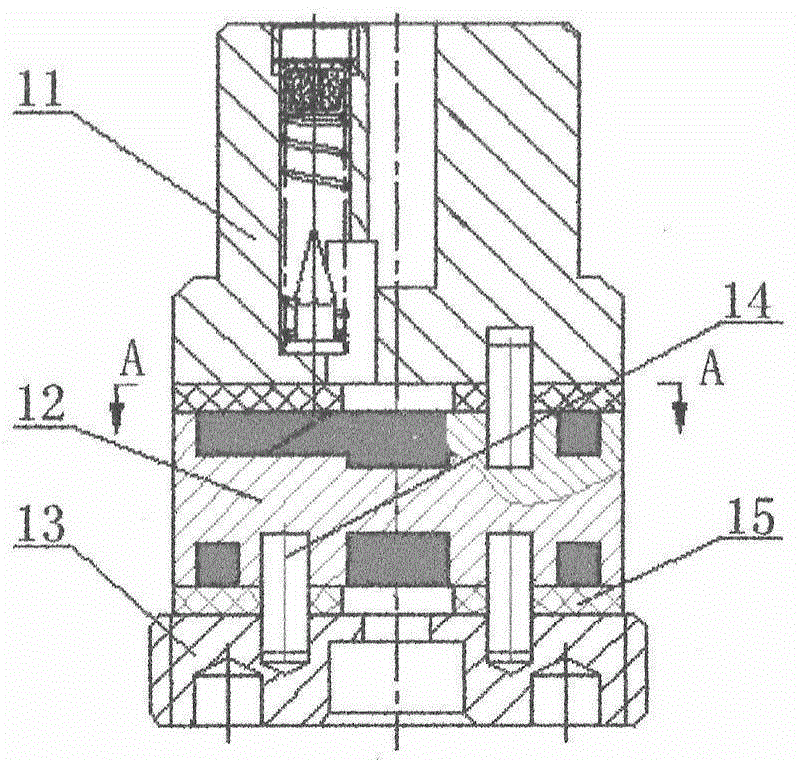

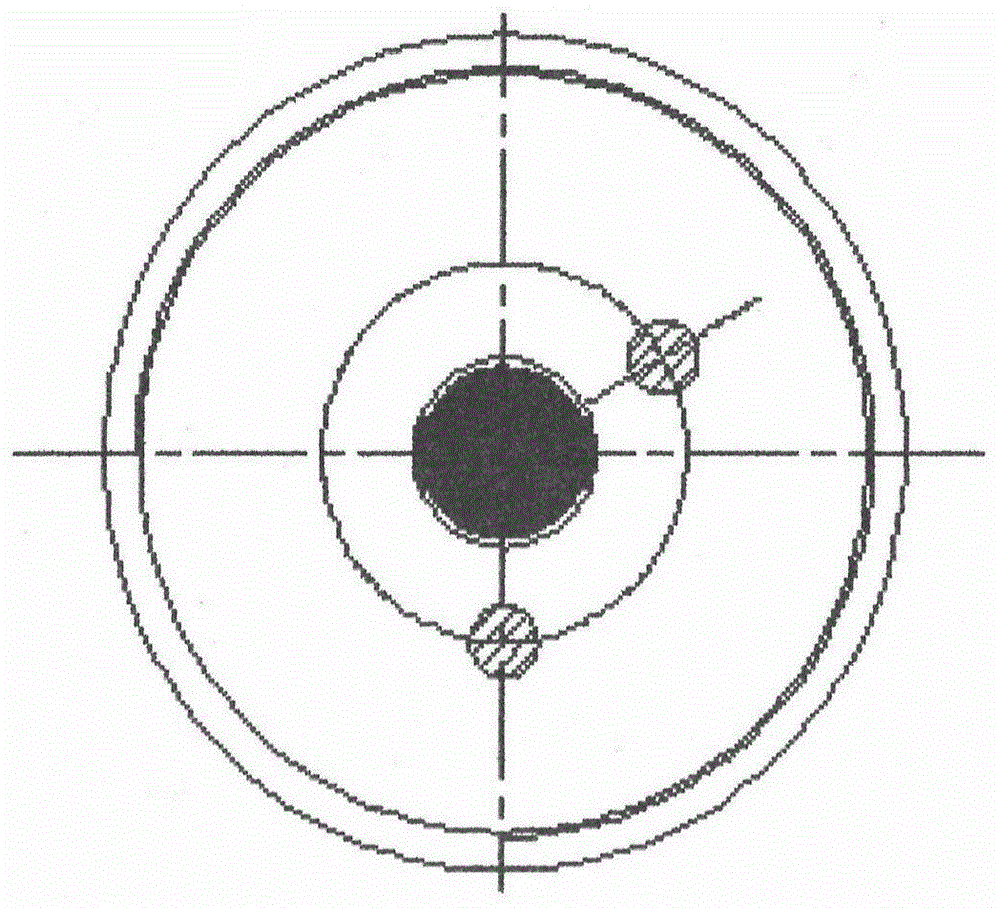

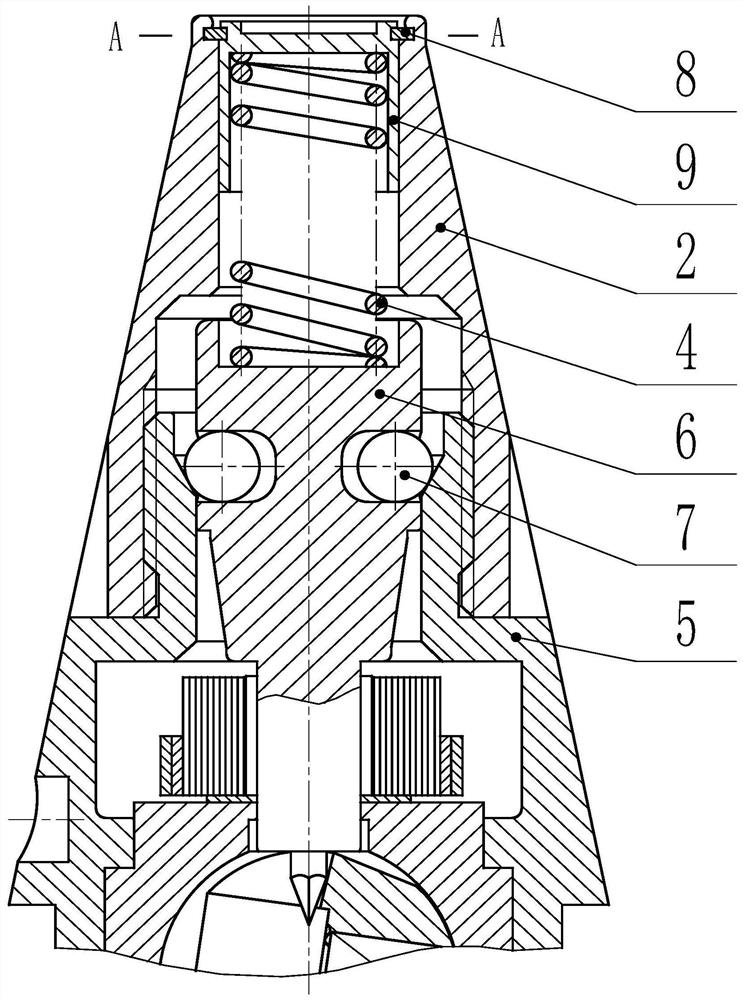

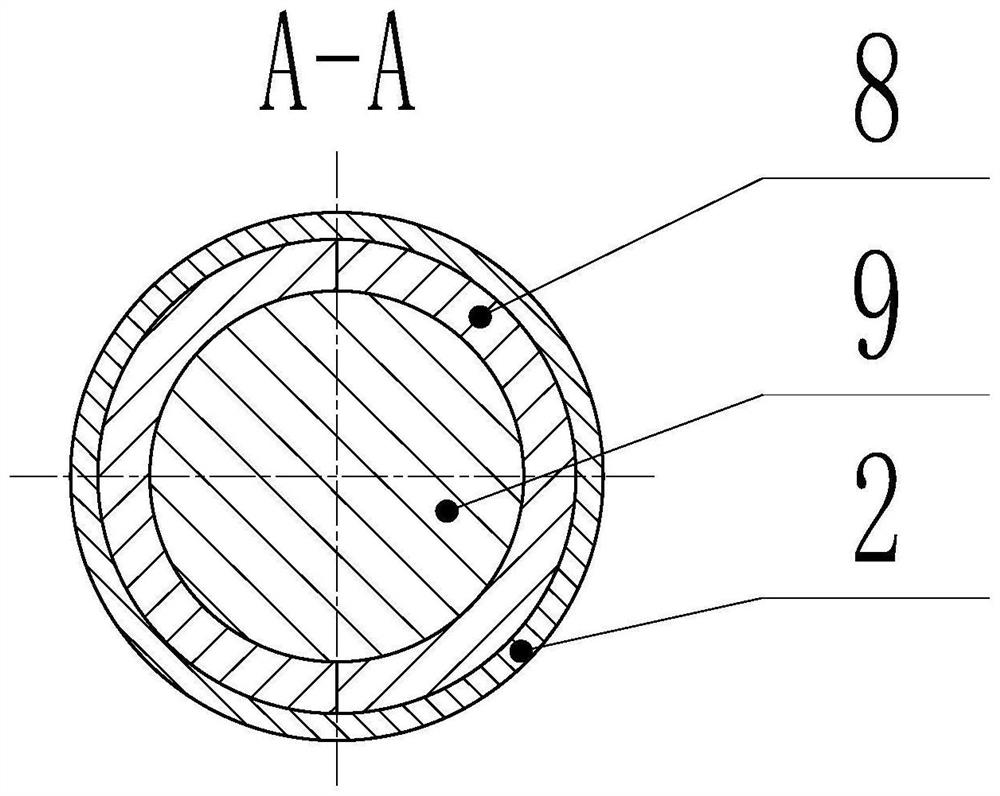

Fuze device for artificial precipitation projectile

InactiveCN105890473AImprove the reliability of fire transmissionImprove intrinsic safetyAmmunition fuzesDetonatorEngineering

The invention discloses a fuze device for an artificial precipitation projectile. The fuze device comprises a fuze body, an ignition self-destructive mechanism, a safety mechanism and a detonator, wherein the middle of the fuze body is a cavity structure; and in the cavity structure, the ignition self-destructive mechanism is arranged at the upper part of the cavity structure, the safety mechanism is arranged at the lower part of the ignition self-destructive mechanism, and the detonator is inserted into the lower part of the safety mechanism. The ignition self-destructive mechanism produces flames after being ignited, the flames are transmitted into the detonator under the control of the safety mechanism, a gunpowder charging projectile body of the artificial precipitation projectile is arranged at the lower part of the detonator, the flames enter the gunpowder charging projectile body via the detonator, and gunpowder in the gunpowder charging projectile body is detonated so as to produce thrust to launch the artificial precipitation projectile. The fuze device eliminates the potential safety risk that the chamber of the existing artificial hail preventing and precipitation increasing projectile explodes, solves the potential safety problems of the existing artificial precipitation increasing and hail preventing projectile, such as dud, half explosion and large explosion remnant fragments, and has high safety and high reliability.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

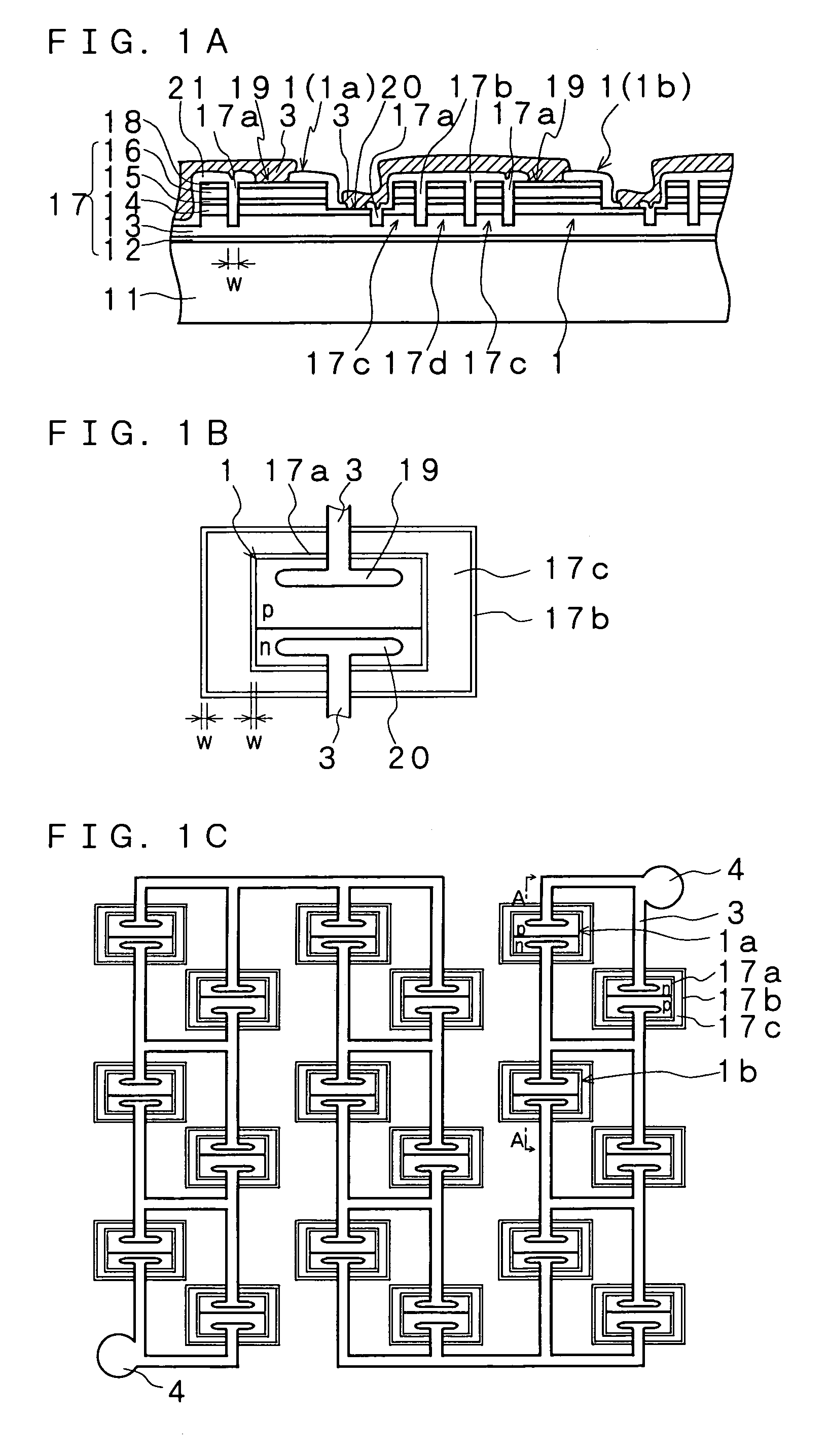

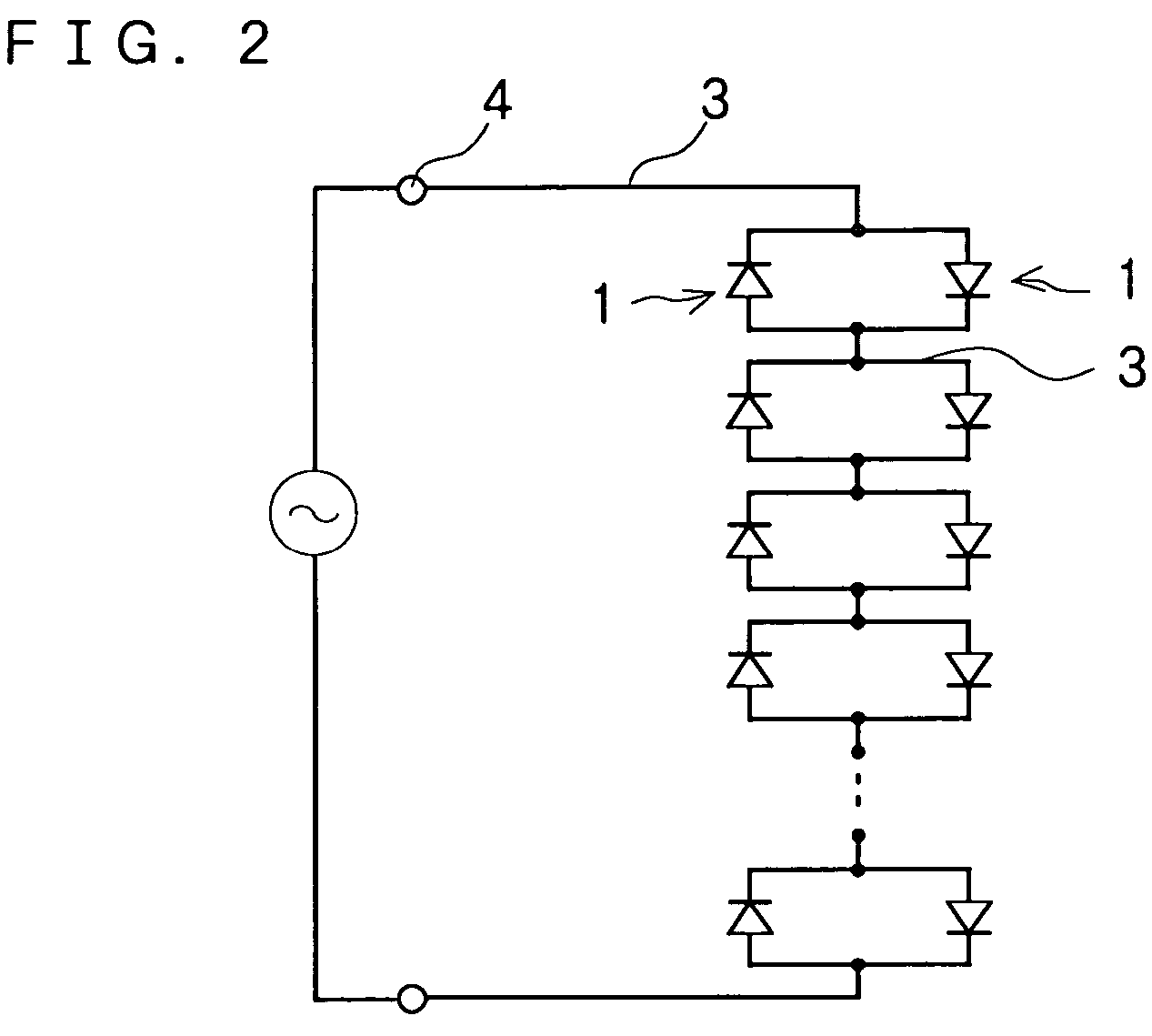

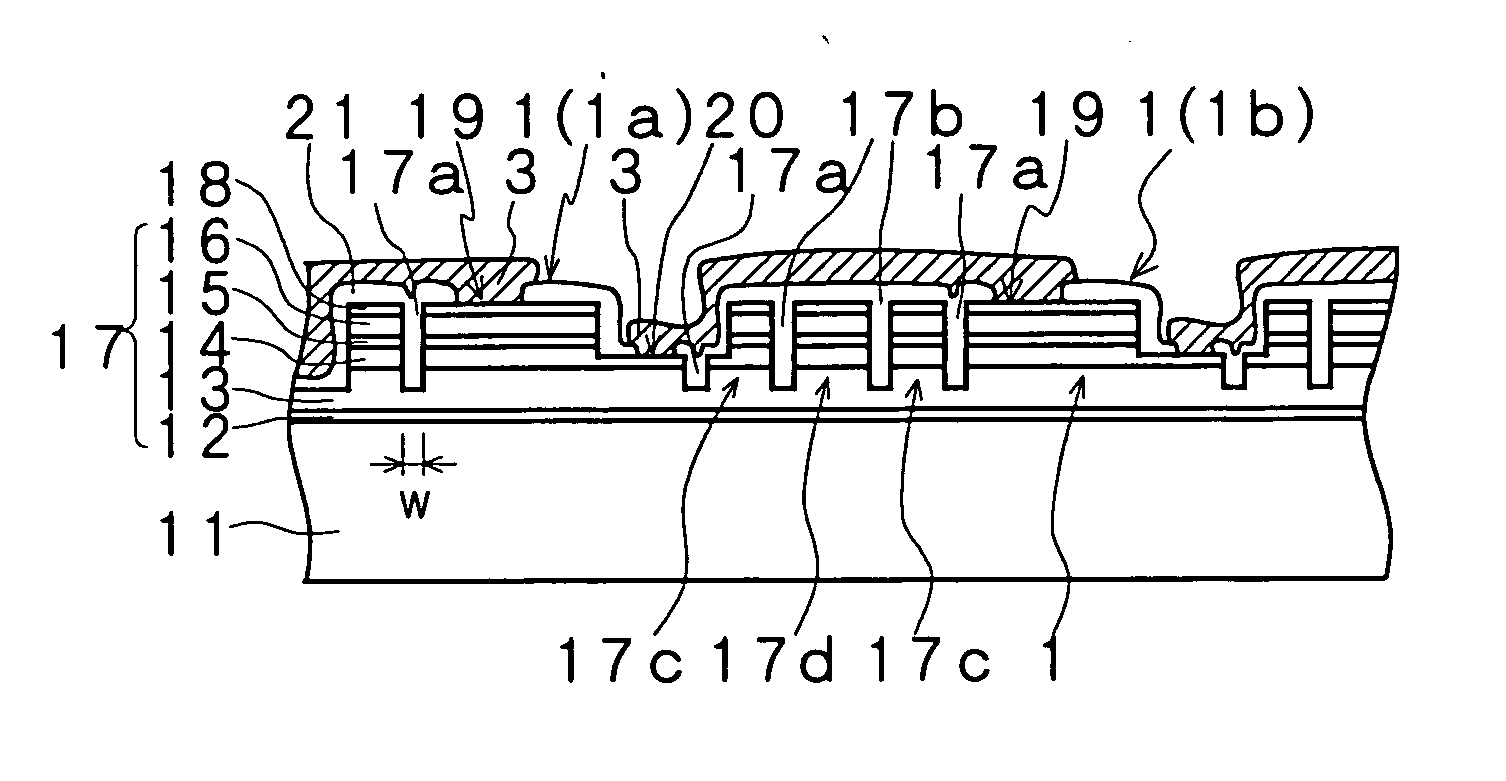

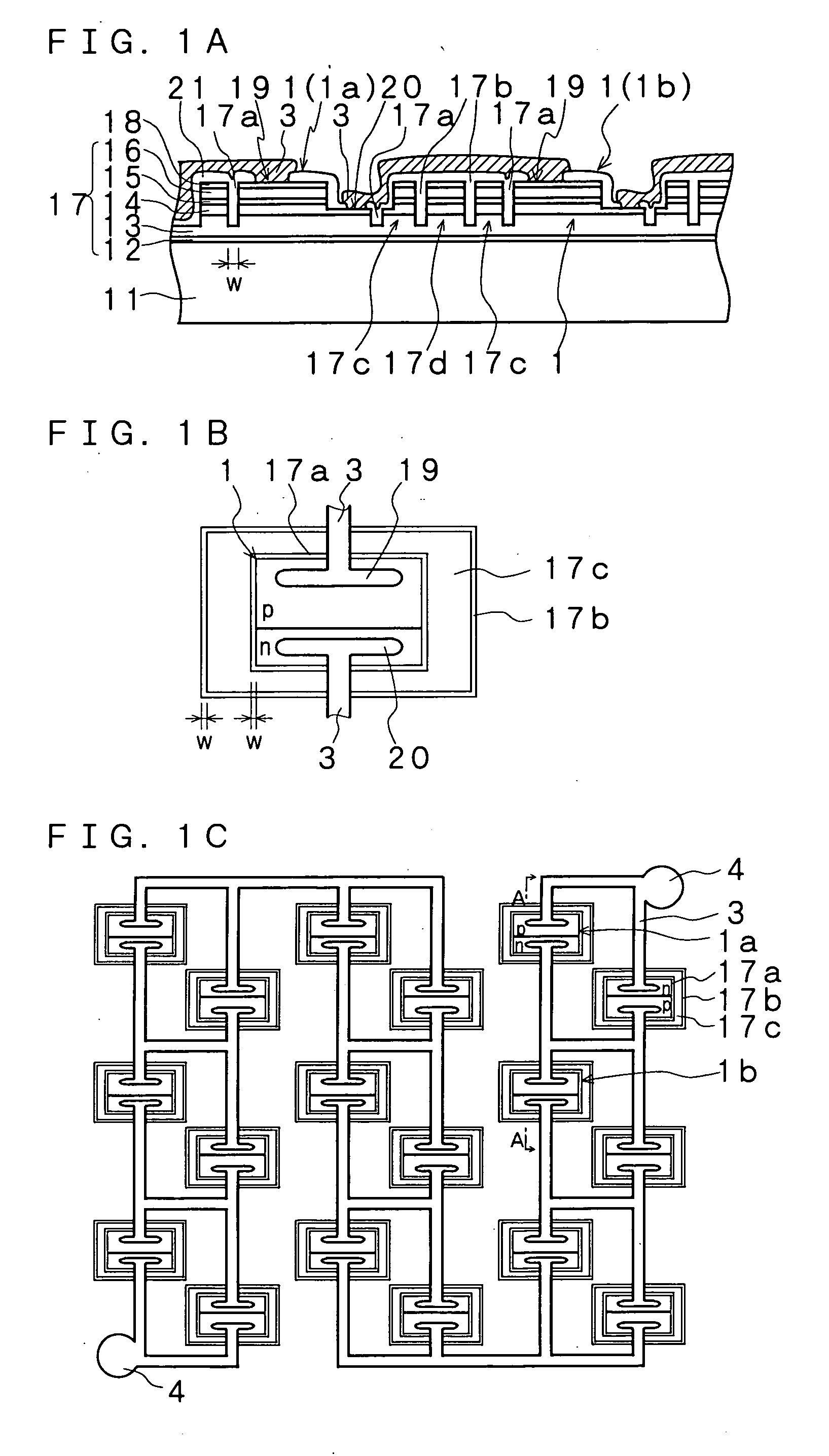

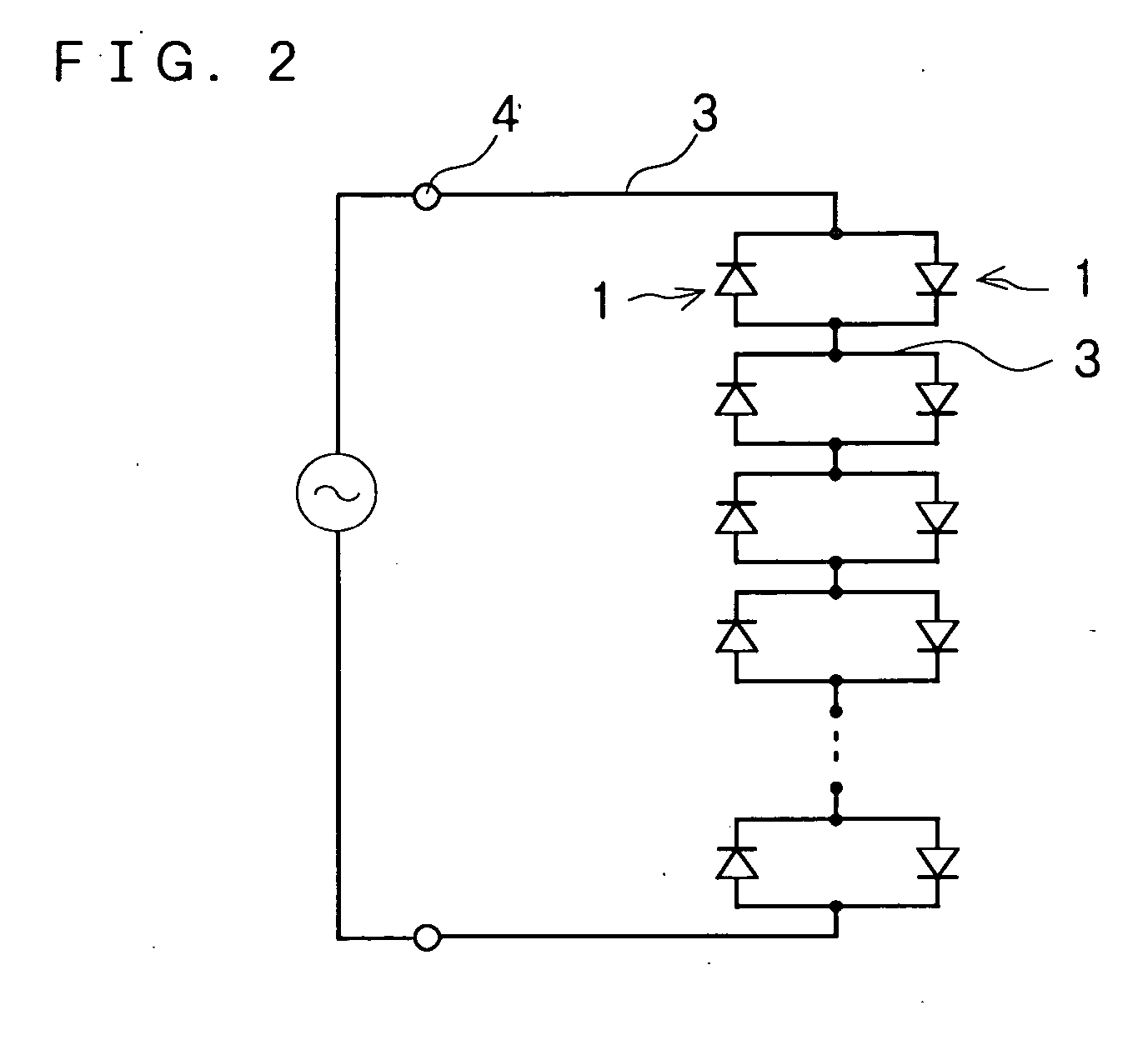

Semiconductor light emitting device

InactiveUS7592633B2Improve performance reliabilityIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingHigh luminanceLight emitting device

Owner:ROHM CO LTD

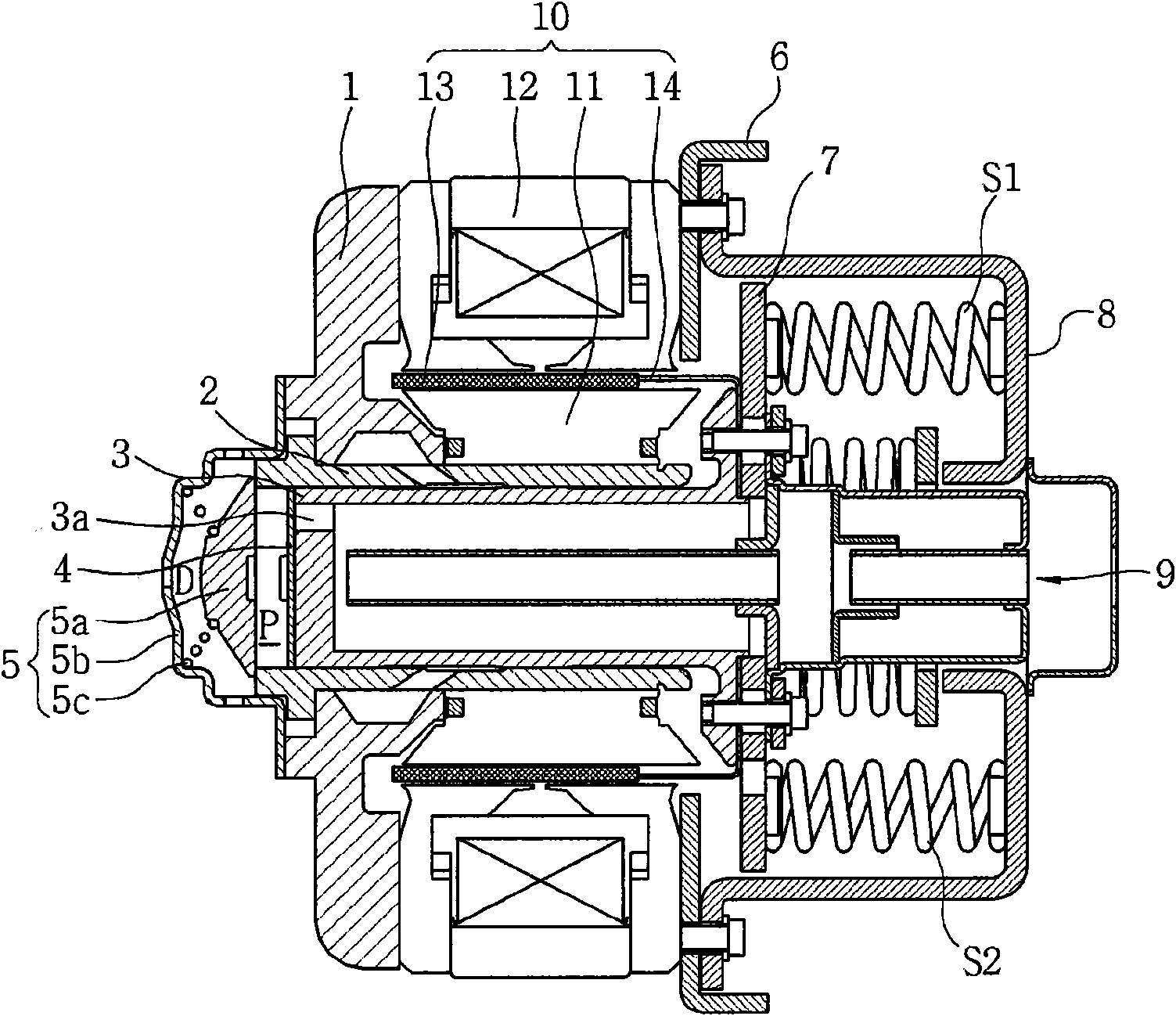

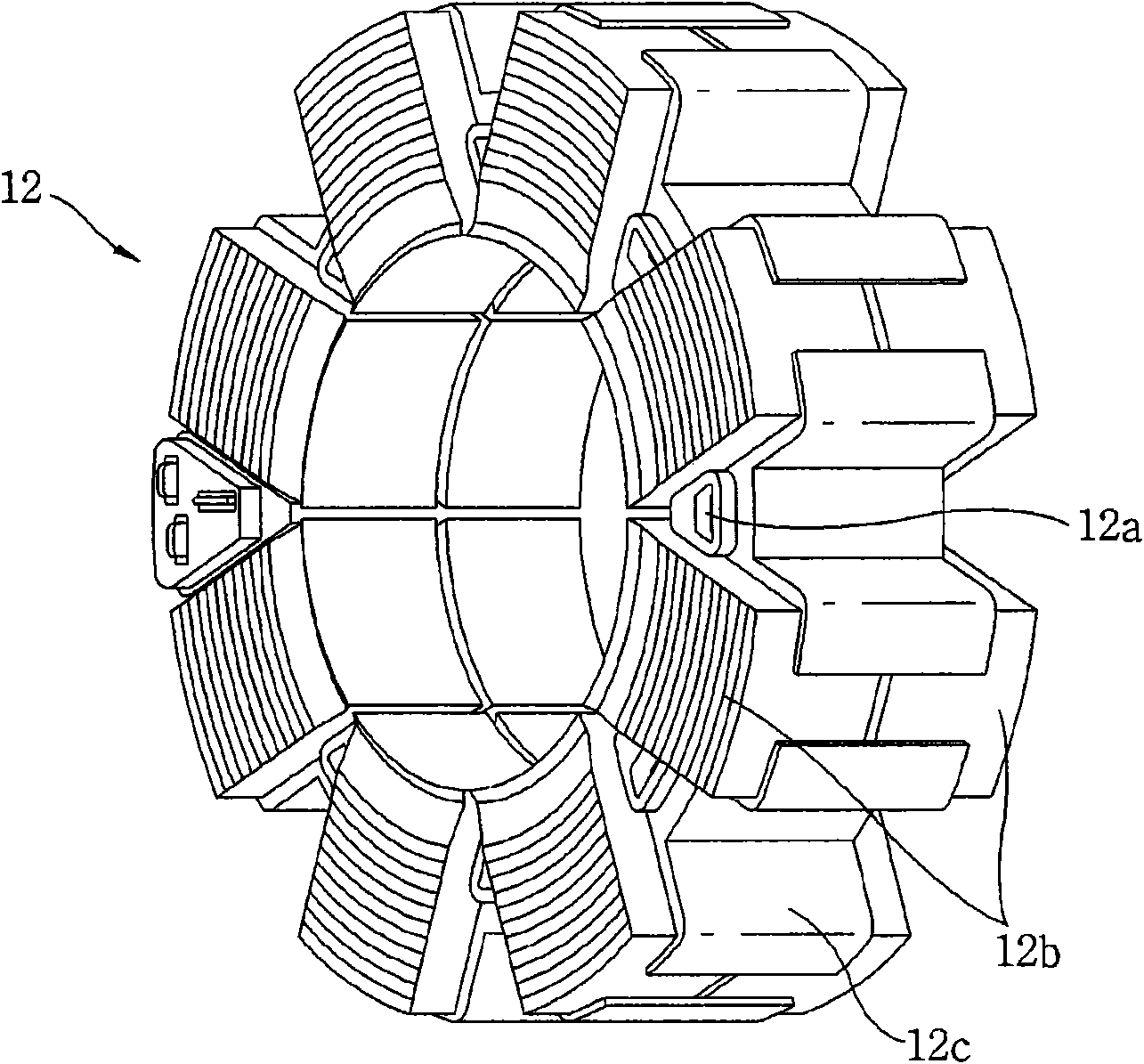

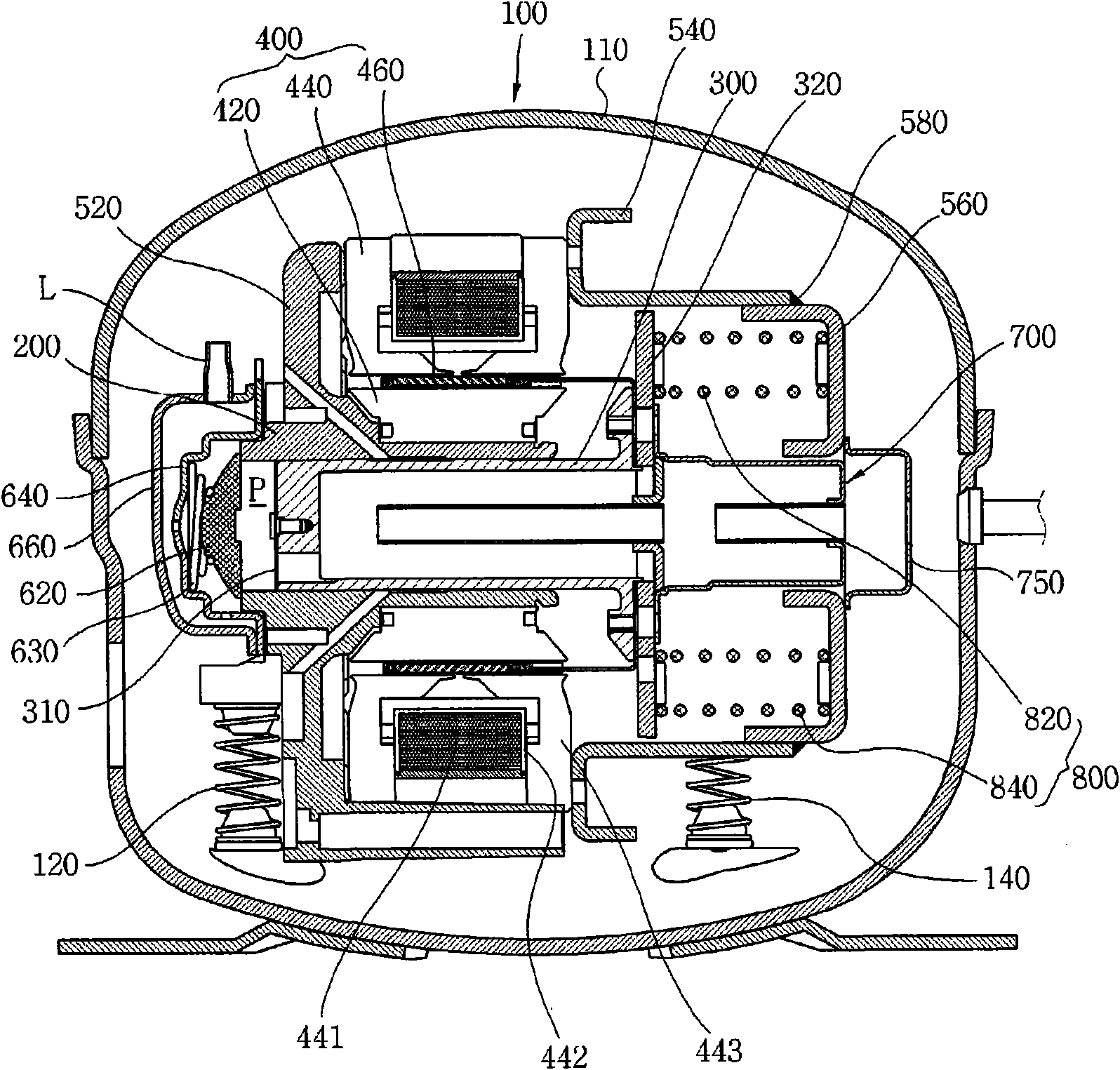

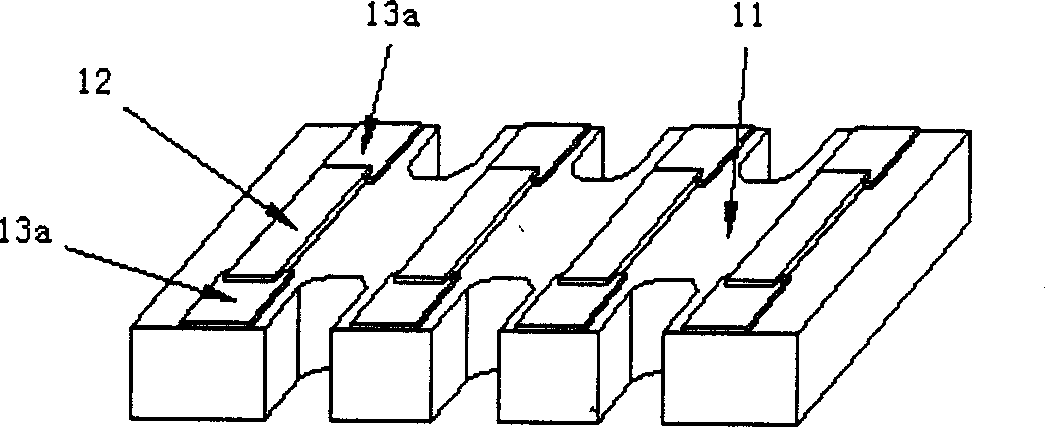

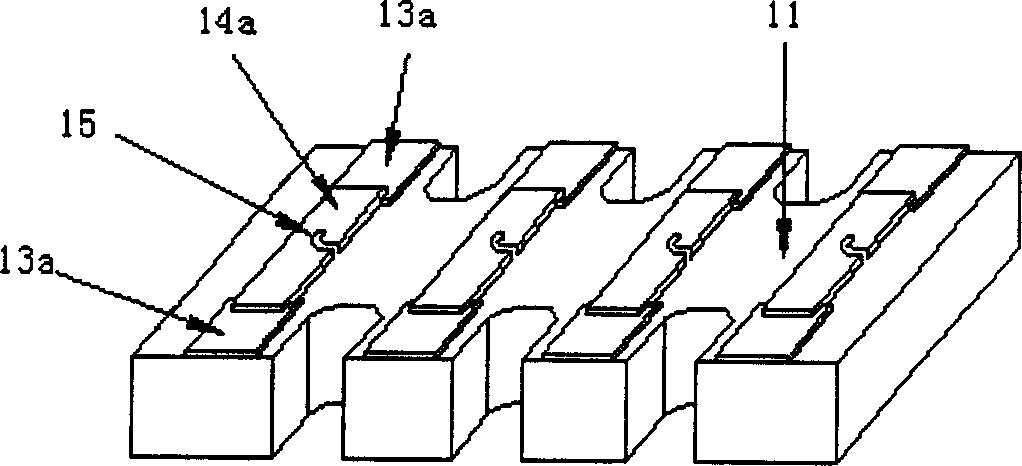

Stator for linear compressor

ActiveCN101971468AAvoid Assembly DistortionImprove performance reliabilityCompressorPositive displacement pump componentsBobbinLinear compressor

A stator for a linear compressor comprises a coil winding, in which a coil winds in a circumference direction and current flows; a bobbin set, which is wound with the coil winding and which insulates the coil winding; and a plurality of core blocks, which are arranged in a circumference direction of the bobbin set at predetermined intervals from an axial direction of the bobbin set, which is advantageously used for simplifying the manufacturing process, enhancing the clamping force, cutting an overall production cost, and reducing the size of a product incorporating the same.

Owner:LG ELECTRONICS INC

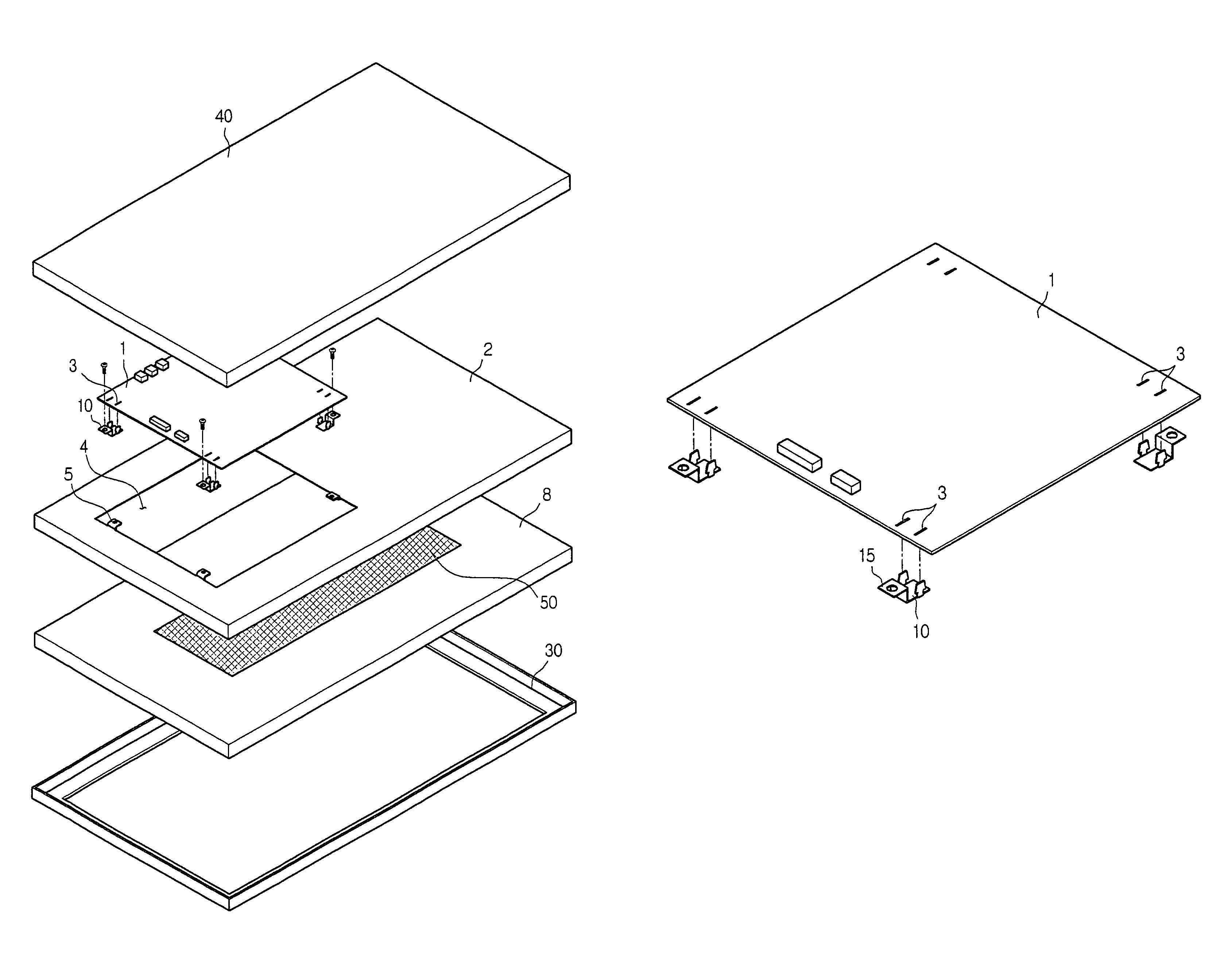

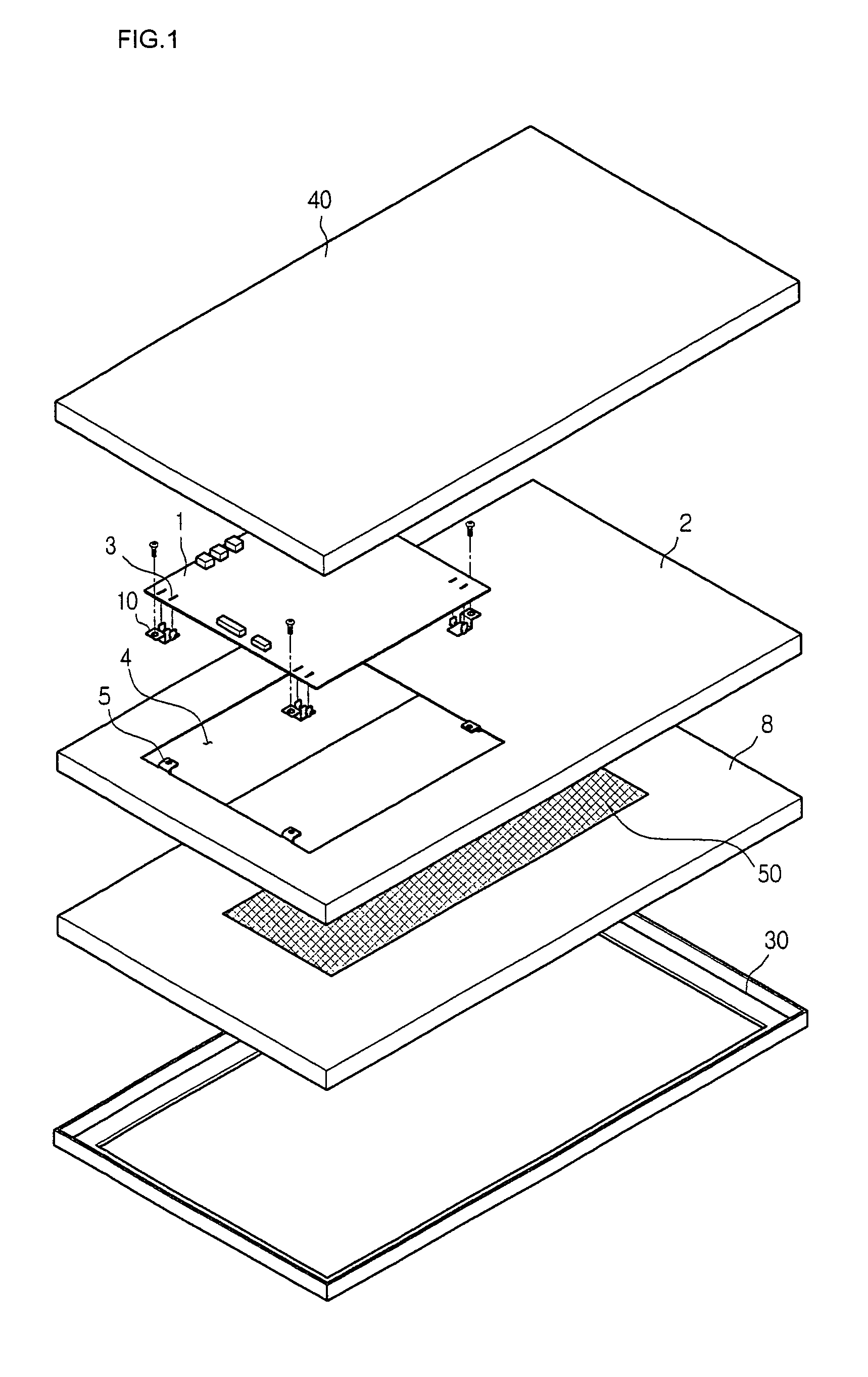

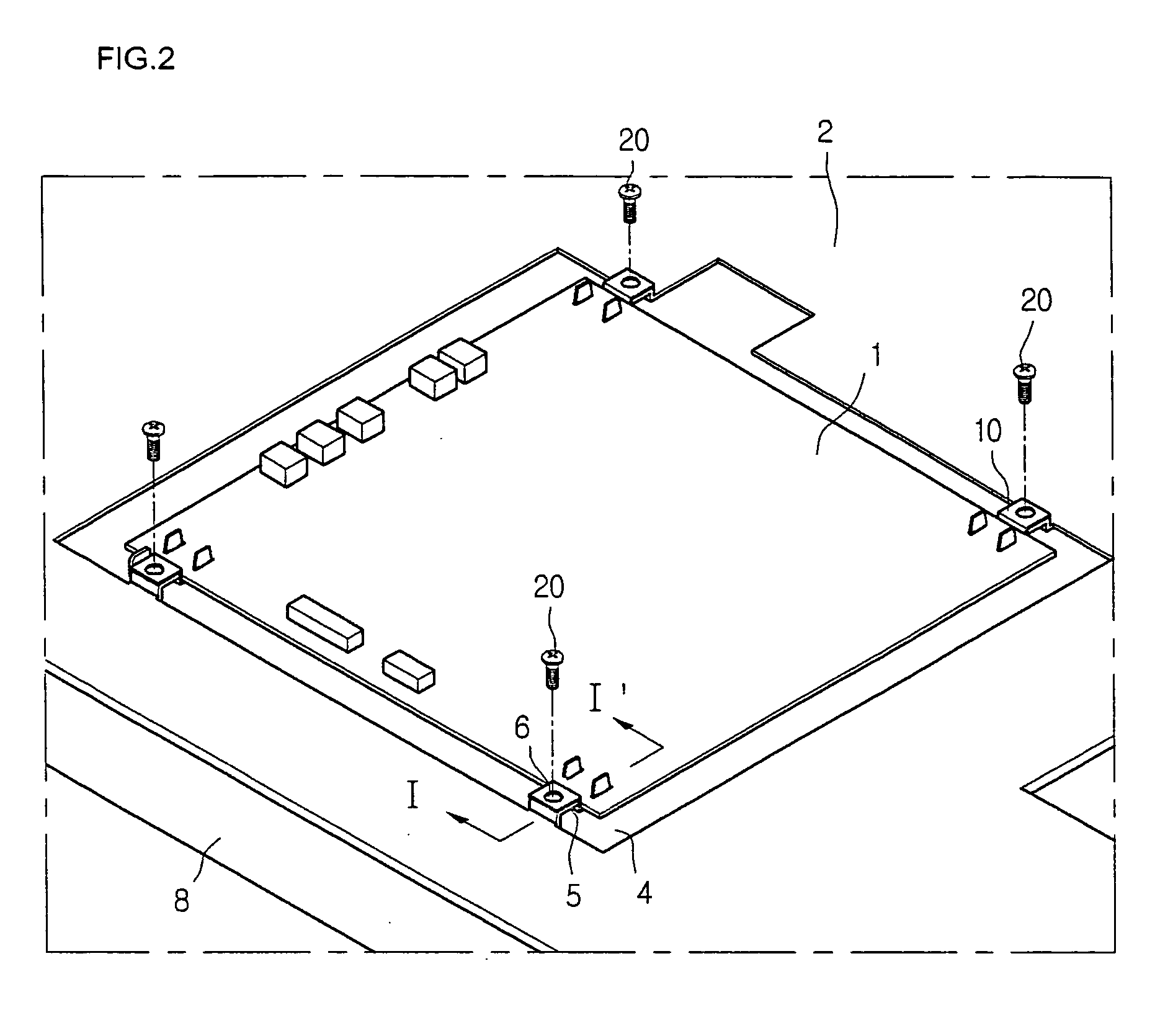

Display device and board supporting structure

ActiveUS7839658B2Direct contact guaranteeEasy to fixStatic indicating devicesSupport structure mountingEngineering management

Provided are a display device and a board supporting structure. The board supporting structure includes: a board; a main frame to which the board is fixed; a receiving portion formed at the main frame and on which the board is placed; and a connection member being a separate component fixing the board to the main frame and including a first portion coupled to the main frame and a second portion coupled to the board. Accordingly, an increase in thickness of the display device due to installation of the board is reduced, the performance reliability of the board is improved, the installation of the board is facilitated, and damage to the board is prevented.

Owner:LG ELECTRONICS INC

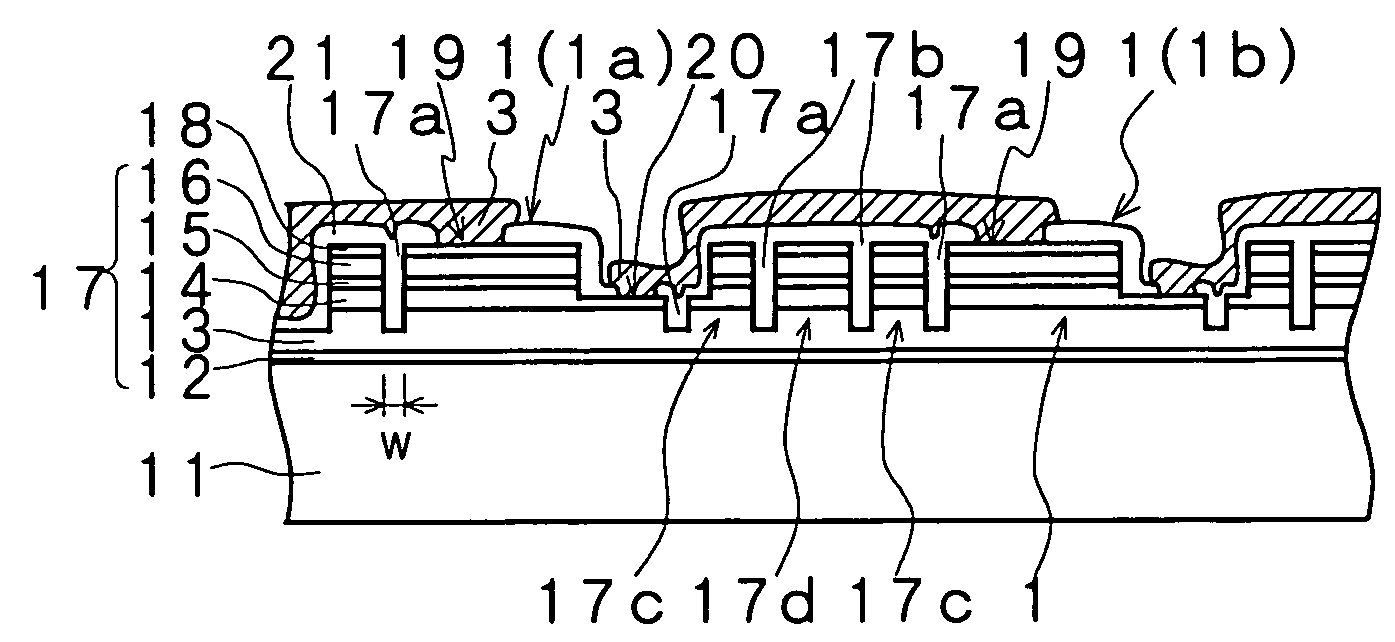

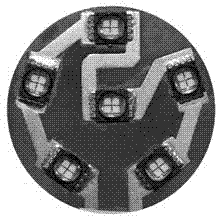

Semiconductor light emitting device

InactiveUS20060261361A1Improve reliabilityGuaranteed uptimeSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceHigh luminance

A semiconductor lamination portion is formed on a substrate by laminating semiconductor layers so as to form a light emitting layer, and a plurality of light emitting units are formed by separating the semiconductor lamination portion electrically into a plurality of units. Each of the units has a pair of electric connecting portions which are connected to a pair of conductivity type layers and they are connected to each other with a wiring film. Each of the plurality of the light emitting units is separated electrically by dividing the conductivity type layers of the semiconductor lamination portion with at least twofold separating grooves (a first separating groove and a second separating groove). As a consequence, a semiconductor light emitting device with a high luminance and being formed in a monolithic type having a plurality of light emitting units can be obtained to solve a problem of a short-circuit occurrence between the light emitting units while keeping high reliability of wiring or the like.

Owner:ROHM CO LTD

Method for preparing slice type network resistor and slice type network resistor prepared by the same method

InactiveCN1525498AReduce the number of sinteringReduce manufacturing costImpedence networksResistive material coatingAgricultural engineeringProtection layer

The invention discloses a manufacturing method for a kind of piece network resistance and the product. The method includes following steps: (1) it forms two pairs or more separated front poles on the upper surface of the insulating base piece; (2) forms two or more resistance layers connected to each pair of front surface poles on the insulating base piece; (3) forms a protection layer on the resistance layer; (4) forms the side poles on the convex part on the side surface of the base piece. It uses subjacent coating mode to add pole pulp on the convex part of the side surface in step (4). The invention can avoid the short pass between the side poles; the piece network resistance has excellent performance.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

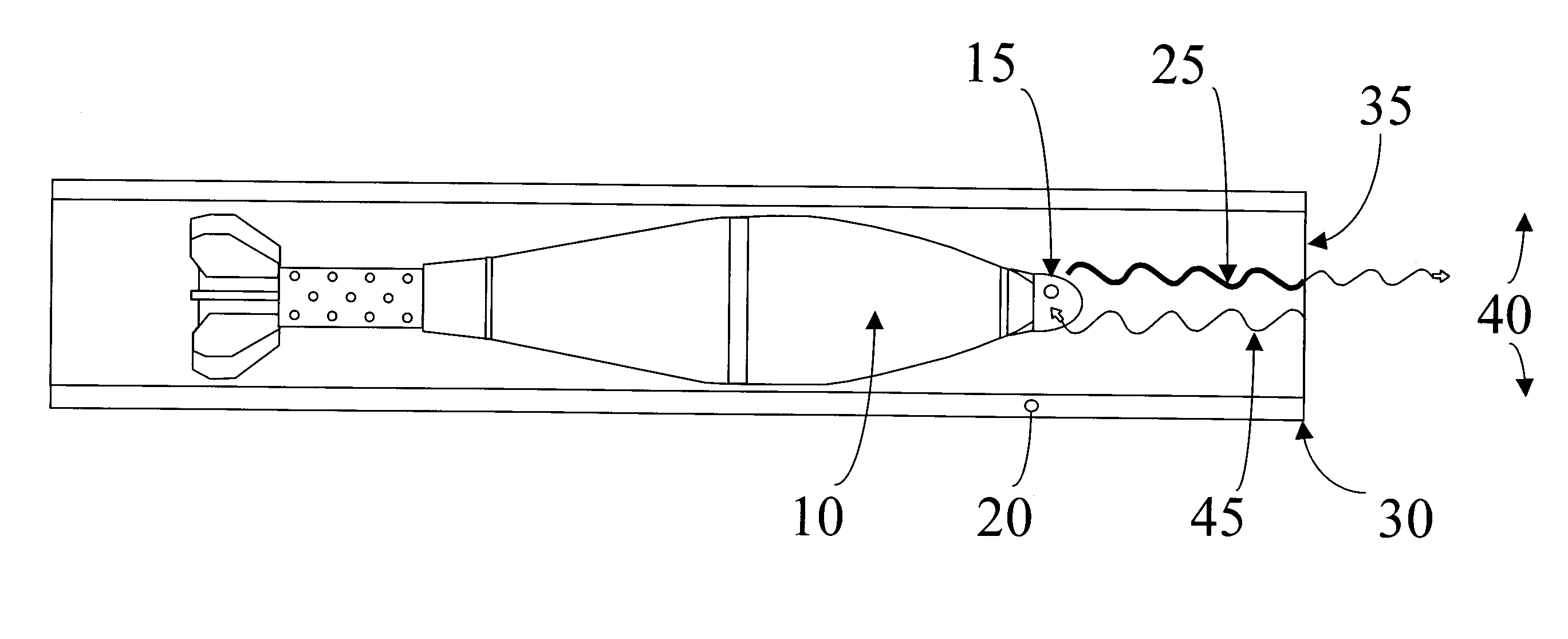

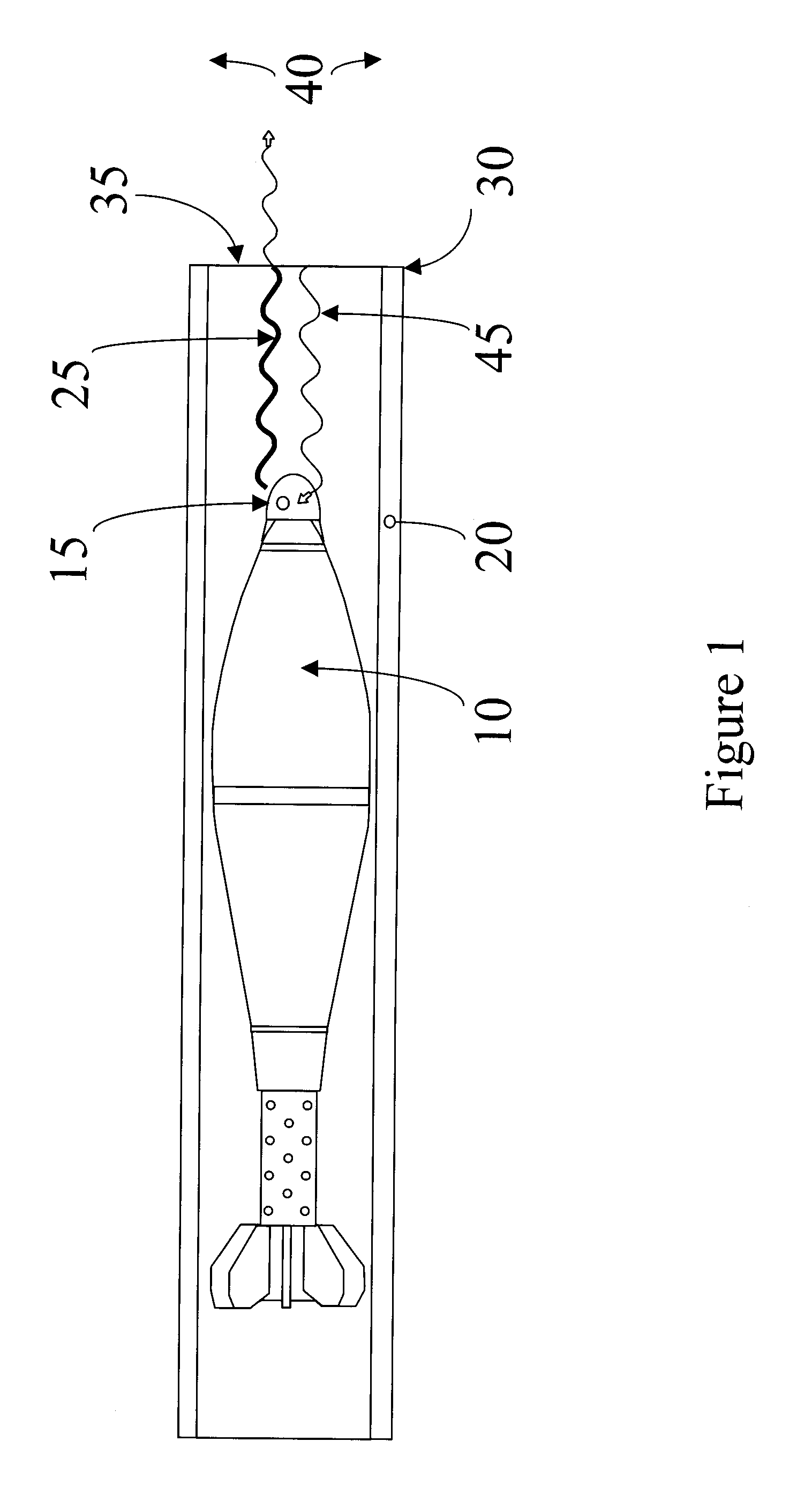

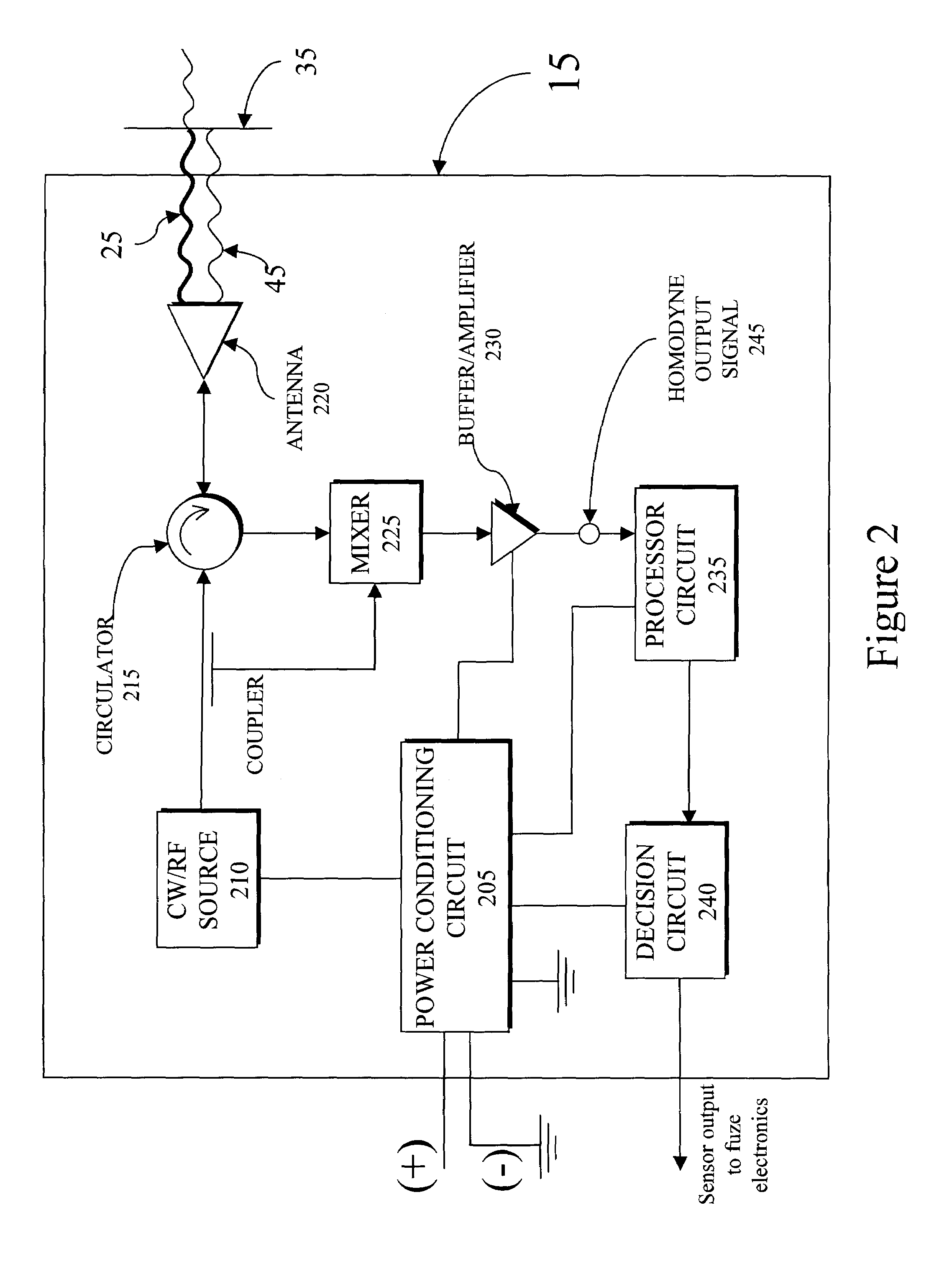

Projectile launch detection system utilizing a continuous wave radio frequency signal to confirm muzzle exit

InactiveUS6967614B1Improve performance reliabilityProtect environmentCommunication jammingAmmunition fuzesRadio frequency signalContinuous wave

A projectile launch detection system utilizes a continuous wave radio frequency signal (CW / RF) to confirm muzzle exit. The projectile launch detection system can be used in smoothbore, fin-stabilized, non-air breathing projectiles. The gun tube appears as a waveguide to the projectile launch detection system during projectile launch. The projectile launch detection system transmits a CW / RF signal down the gun tube during launch of the projectile. A portion of the CW / RF signal is reflected back by an impedance mismatch at the boundary between the muzzle of the gun tube and free space. Upon exit by the projectile from the gun tube, an exit signature is detected that is defined by the impedance of the gun tube and by a ratio of the diameter of the gun tube to the frequency of the CW / RF signal. The projectile launch detection system processes the exit signature to detect a muzzle launch of the projectile from a specific gun tube.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

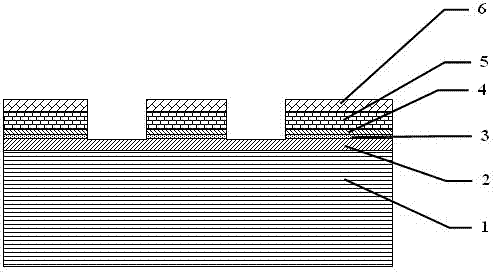

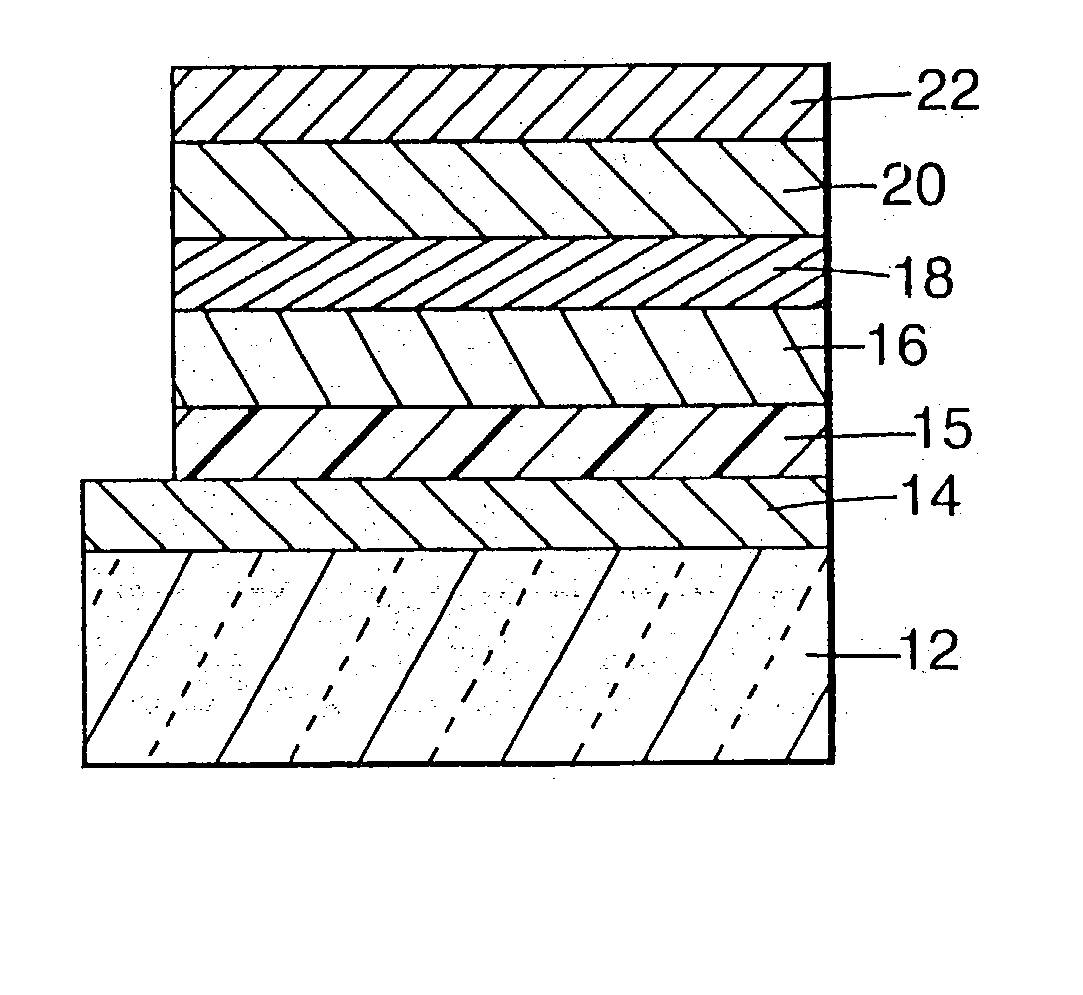

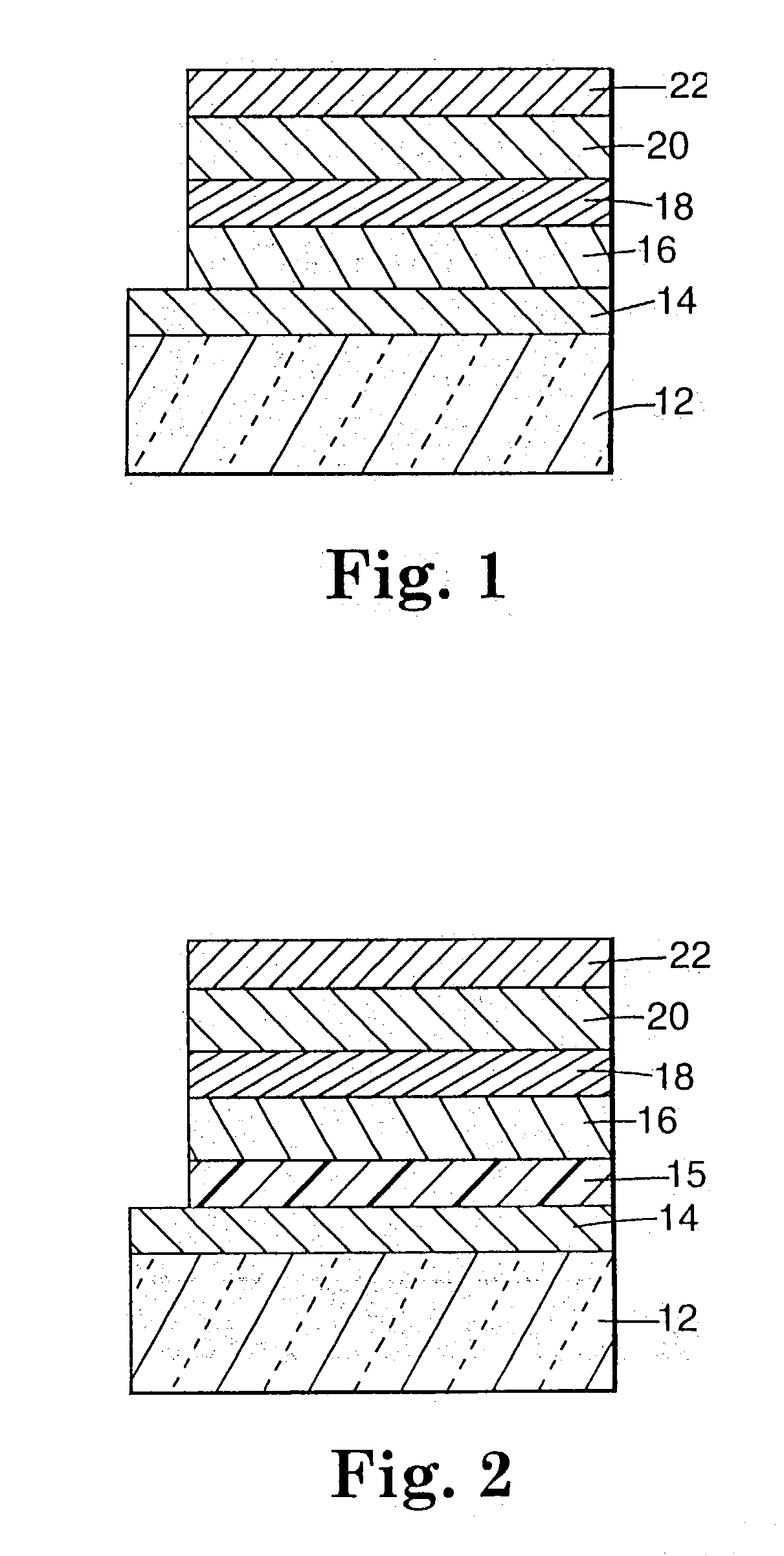

Metal substrate of heat conducting aluminium-based core and preparation method thereof

InactiveCN102256441ARaw materials are easy to obtainStable production processCircuit susbtrate materialsMetal core circuit manufactureMetallic aluminumHeat conducting

The invention discloses a metal substrate of a heat conducting aluminium-based core and a preparation method thereof. The metal substrate is composed of a metal aluminium substrate, an alumina insulating layer, a buffer layer, a first conducting layer, a second conducting layer and a weldable layer, wherein the metal aluminium substrate, the alumina insulating layer, the buffer layer, the first conducting layer, the second conducting layer and the weldable layer are superposed successively. According to the preparation method, a surface of the aluminium substrate is processed by using an anodization solution to generate the alumina insulating layer; the buffer layer and the first conducting layer are coated on the alumina insulating layer by a physical deposition method and then the second conducting layer is coated by an electrochemical deposition method; pad pasting and etching processes are carried out on the surface of the second conducting layer to obtain a needed circuit; at last, the weldable layer metal is coated on the second conducting layer by the electrochemical deposition method. According to the invention, the metal substrate has advantages of light weight, high heat radiation efficiency, long service life, and high reliability of performance; moreover, the metal substrate completely meets packaging requirements of various components and has low production cost; therefore, the metal substrate provided in the invention satisfies a condition of large-scale industrial application.

Owner:SUN YAT SEN UNIV

Method of forming a liquid crystal display

InactiveUS6924874B2Precise alignmentImprove reliabilityTransistorSolid-state devicesDielectricDopant

The present invention provides a method of forming a liquid crystal display (LCD). Active layers of N-type and P-type low temperature polysilicon thin film transistors and a bottom electrode of a storage capacitor are formed first. Then a N-type source / drain is formed and the bottom electrode is doped with dopants. A gate insulator, a gate electrode, a capacitor dielectric, and a top electrode are thereafter formed. After that, a P-type source / drain is formed. Finally, a source interconnect, a drain interconnect, and a pixel electrode of the liquid crystal display are formed.

Owner:INNOLUX CORP

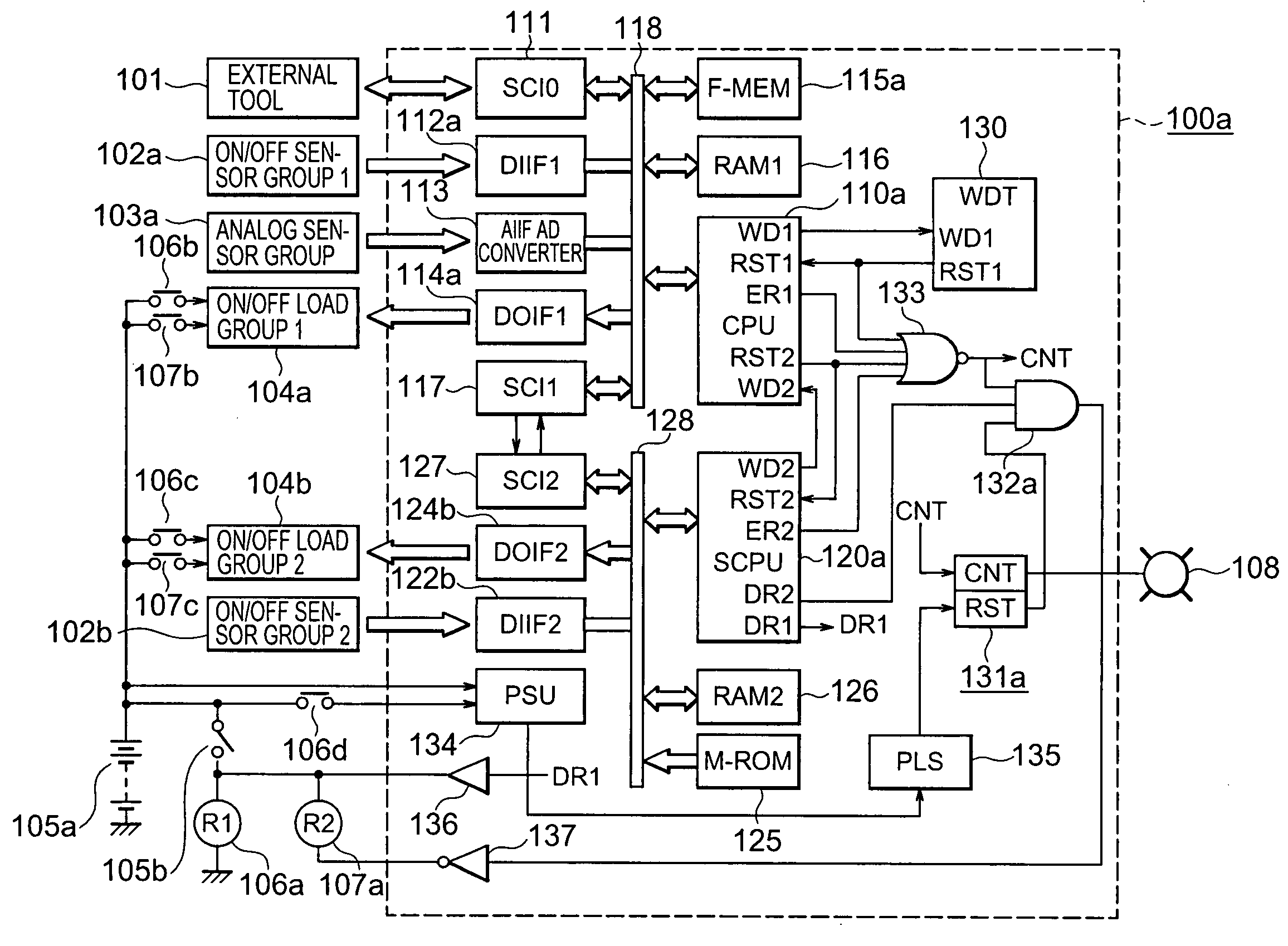

On-vehicle electronic control device

ActiveUS20050085967A1Improve reliabilityImprove performance reliabilityVehicle testingElectrical controlElectric forceChecksum

An on-vehicle electronic control device is provided, which includes an auxiliary microprocessor and subjects a microprocessor allocated to a main part of control to an external diagnosis, thereby improving reliability of performance. A microprocessor (110a) including a nonvolatile program memory (115a) into which a control program is written is serially connected to an auxiliary microprocessor (120a) including an auxiliary nonvolatile program memory (125). The microprocessor (110a) and the auxiliary microprocessor (120a) functions in cooperation to control on-vehicle electric load groups (104a and 104b) in response to input signals from on-vehicle sensor groups (102a and 102b) and an on-vehicle analog sensor group 103a. The nonvolatile program memory (115a) and the microprocessor (110a) are subjected to runaway monitoring performed by a watchdog timer (130) and to an external checksum diagnosis performed periodically by the auxiliary microprocessor (120a). If an anomaly occurs in the run away monitoring, the external checksum diagnosis, and a checksum interval, parts of electric loads are cut off of power supply by load power relay (107a).

Owner:MITSUBISHI ELECTRIC CORP

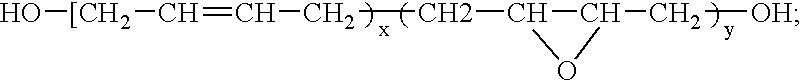

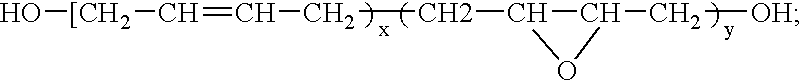

UV-curable solvent free compositions and use thereof in ceramic chip defect repair

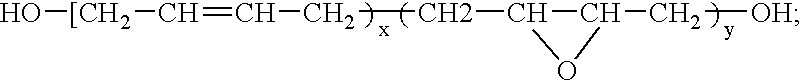

InactiveUS7329439B2Improve performance reliabilityAvoid YieldImpression capsSemiconductor/solid-state device detailsThermoplasticElastomer

Solvent-free UV-curable polymer materials derived from miscible blends of reactive organic monomeric, oligomeric and low molecular polymeric systems and organic and inorganic fillers such as polytetrafluoroethylene and talc are provided to form polymer-filler composite compositions for use in the fabrication and repair of electronic components and microelectronic assembly processes. The composition contains a preformed thermoplastic or elastomeric polymer / oligomer with reactive end groups, a monofunctional and / or bifunctional acrylate monomer, a multifunctional (more than two reactive groups) acrylated / methacrylated monomer, a photoinitiator and a fluorocarbon polymer powder as an organic filler which is preferably PTFE and an inorganic filler such as talc. A nano-filler may also be used as the inorganic filler alone or in combination with another inorganic filler such as talc. A method is also provided for repairing defects on ceramic substrates using the composition of the invention or other curable polymeric compositions.

Owner:TAIWAN SEMICON MFG CO LTD

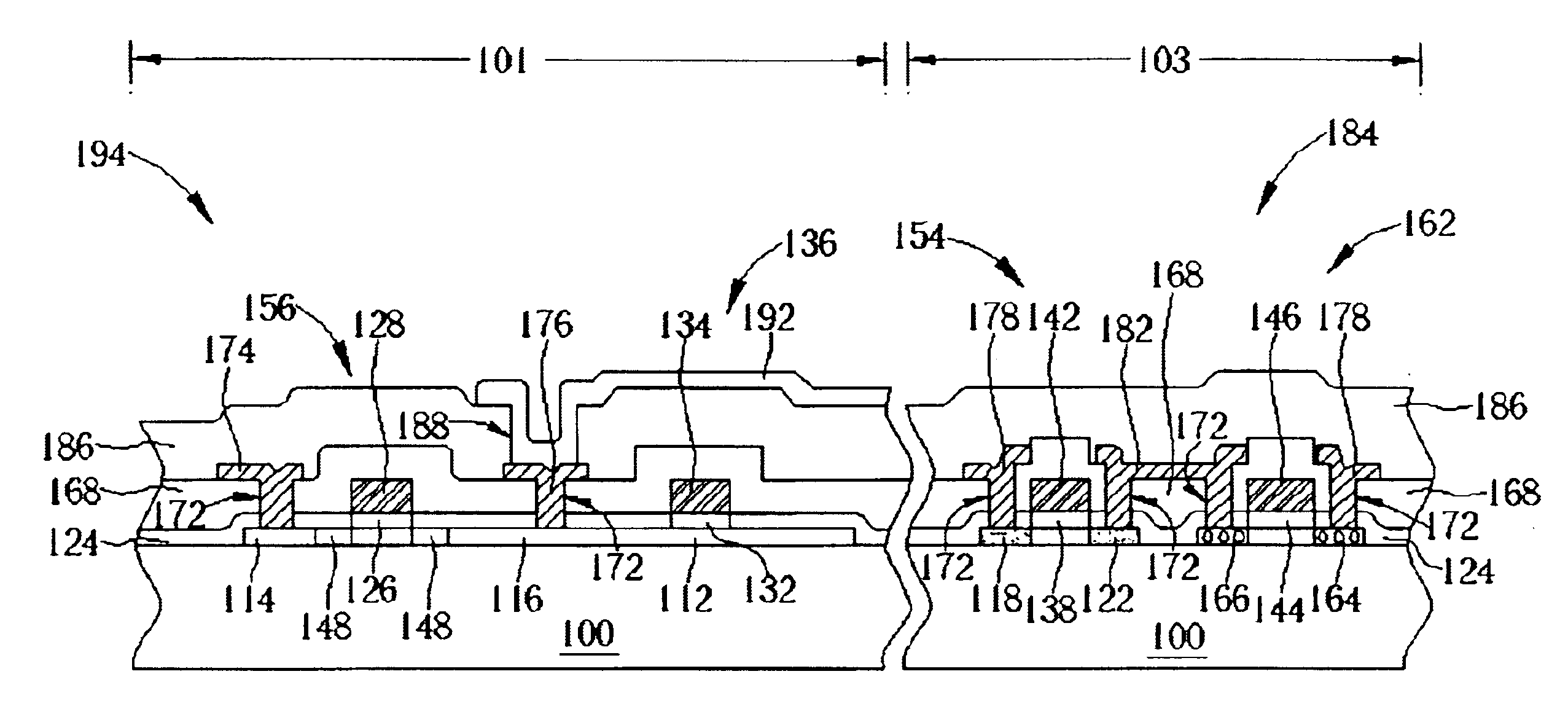

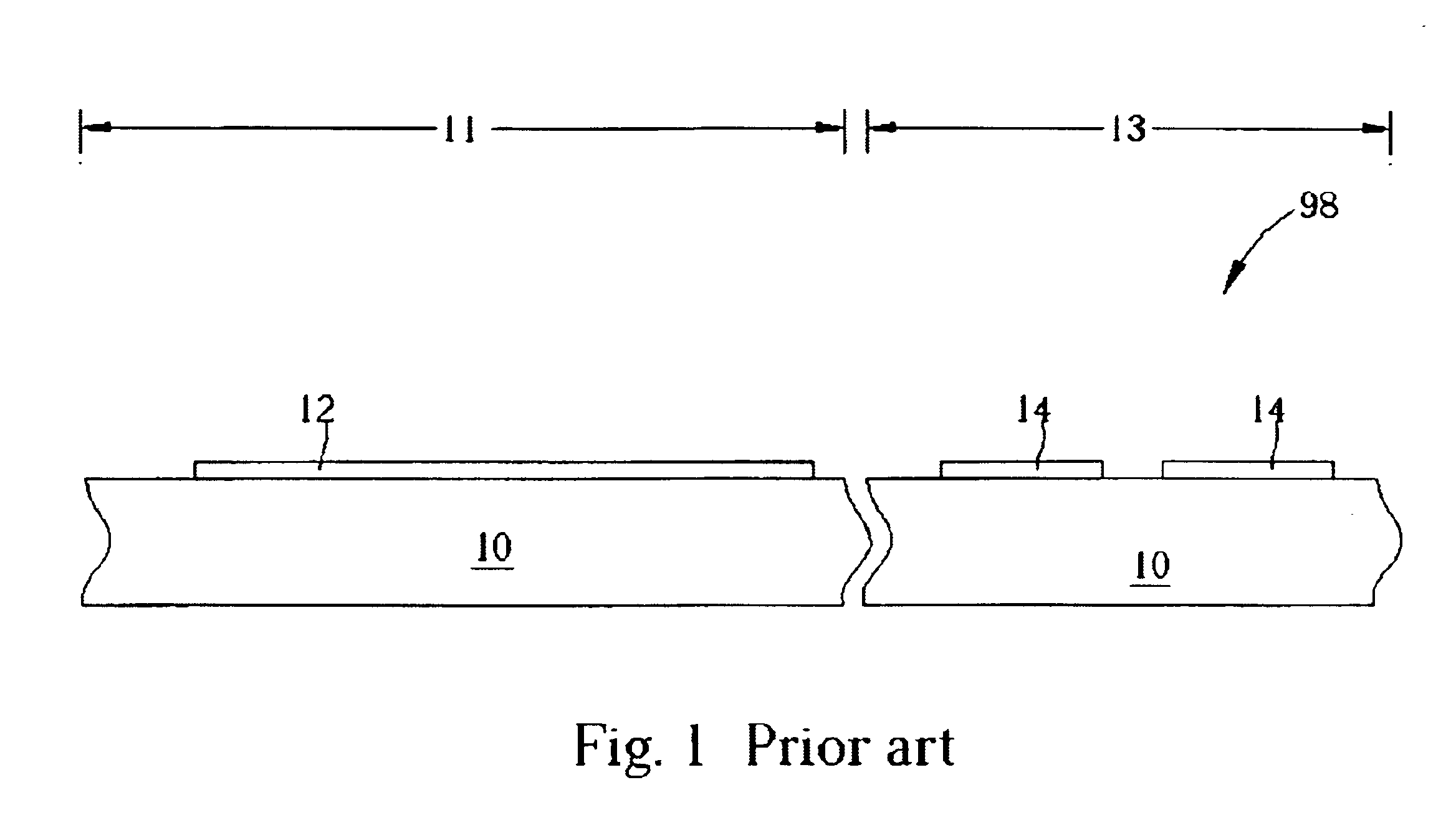

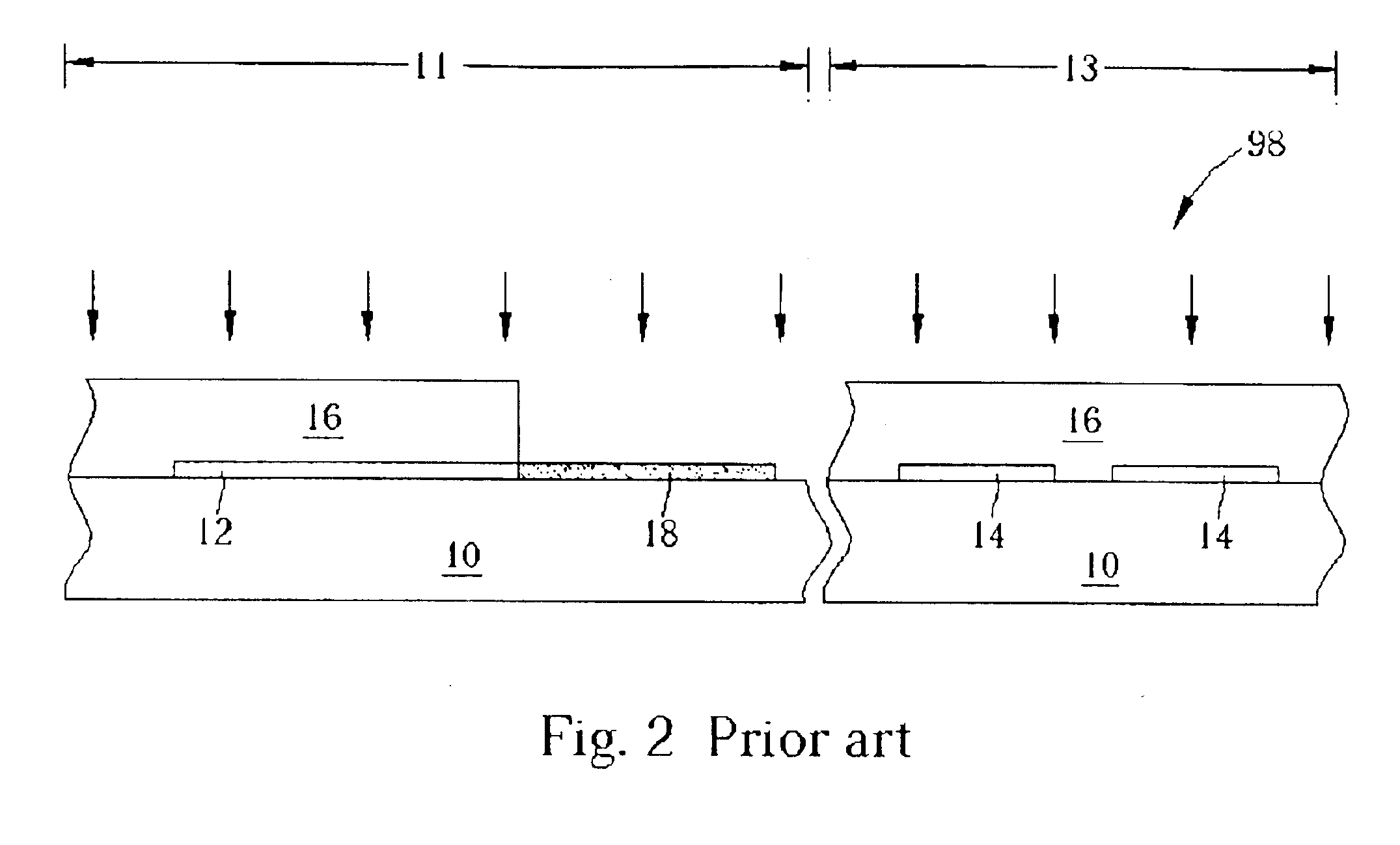

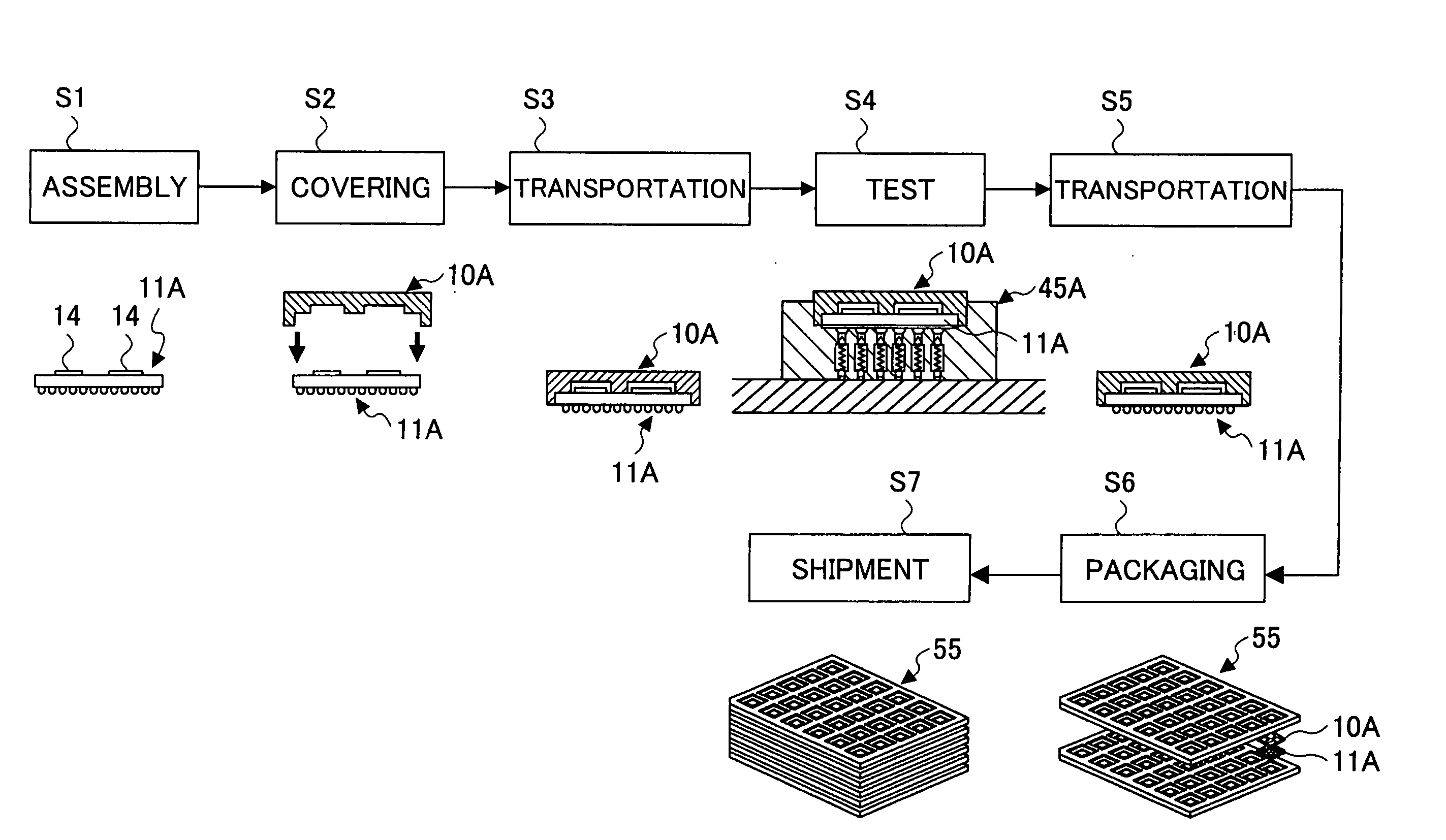

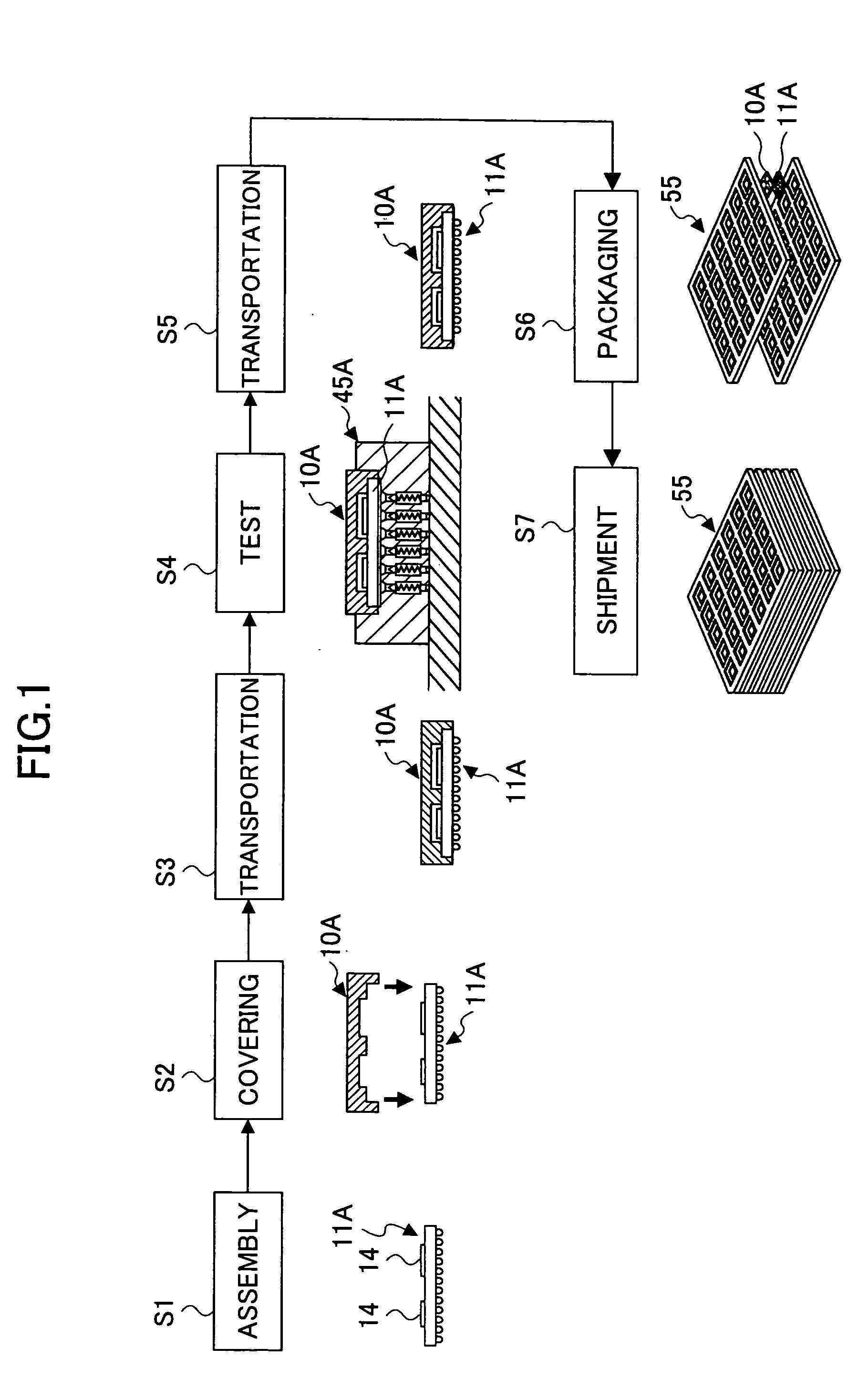

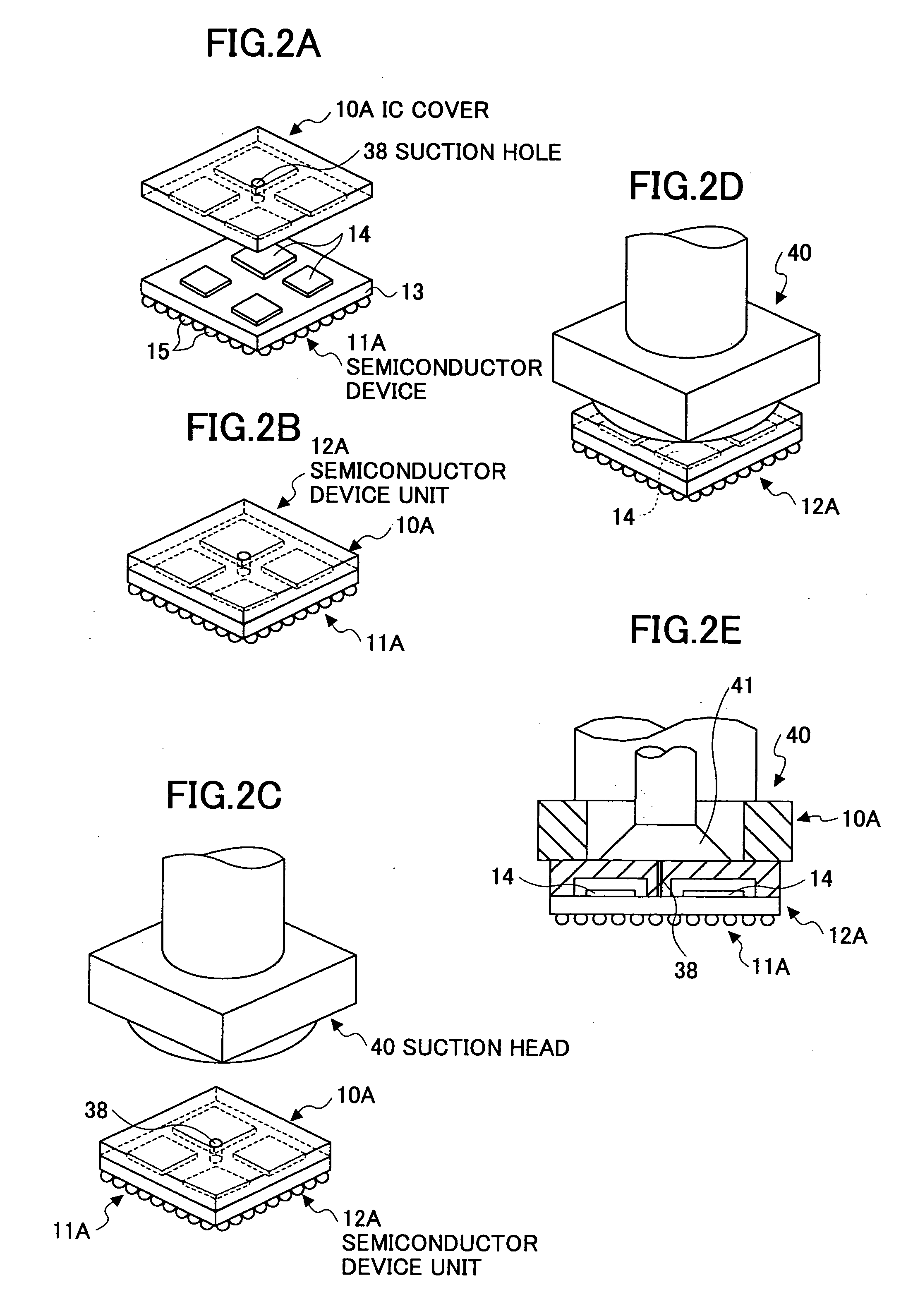

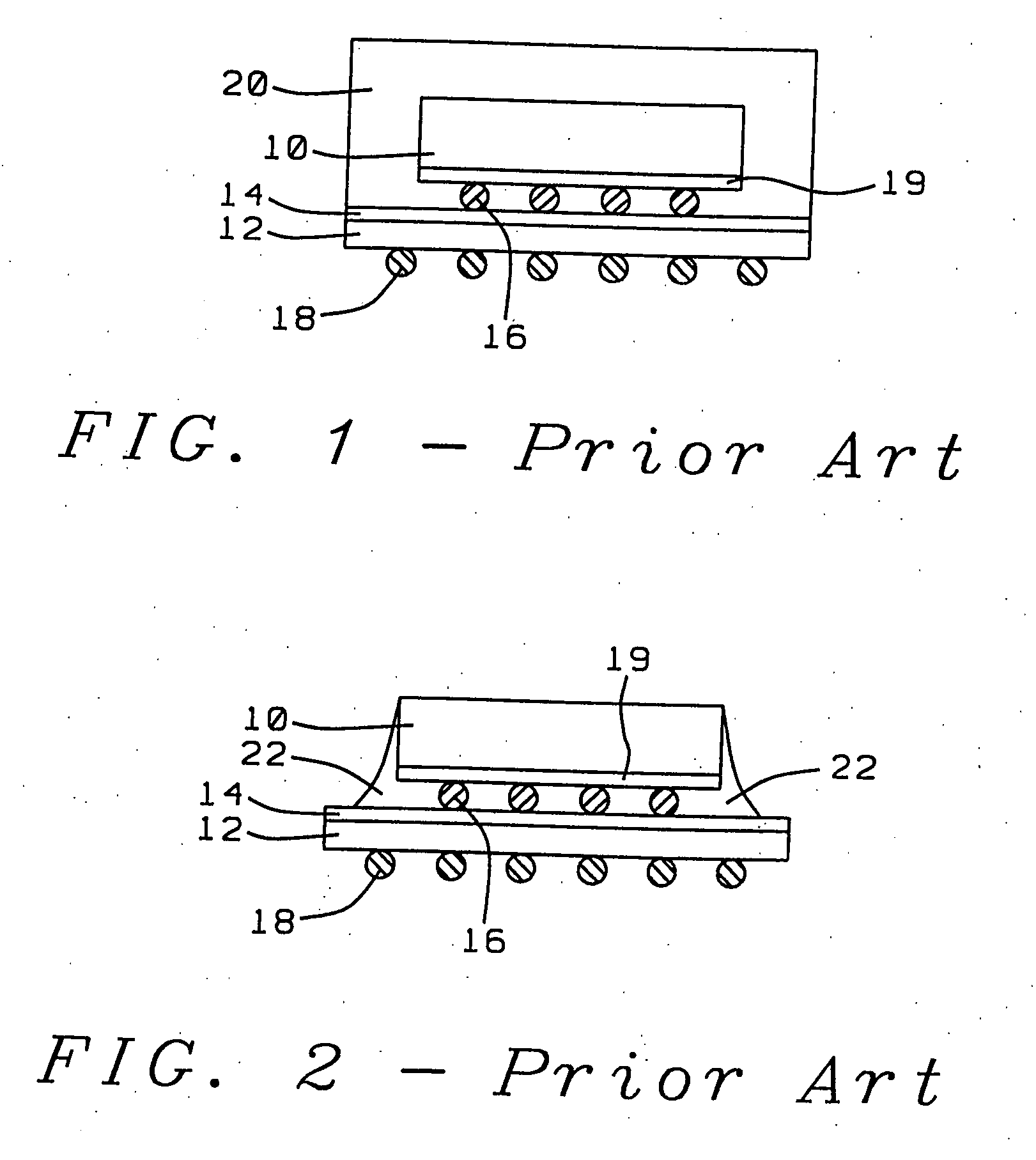

Method of semiconductor device protection, package of semiconductor device

InactiveUS20050072972A1Avoid damageImprove performance reliabilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice materialSemiconductor chip

A method for protecting a semiconductor device is disclosed that can improve reliability of a performance test for the semiconductor device and prevent damage to the semiconductor device during transportation or packaging for shipment. An IC cover is attached to the semiconductor device, which has height unevenness because it includes semiconductor chips and electric parts having different heights. The IC cover includes projecting portions and a base portion. After being attached to the semiconductor device, the projecting portions stand in a free area in the semiconductor device, and the base portion is supported by the projections to be separated from the semiconductor chips and electric parts in the semiconductor device. The IC cover is detachably attached to the semiconductor device.

Owner:SOCIONEXT INC

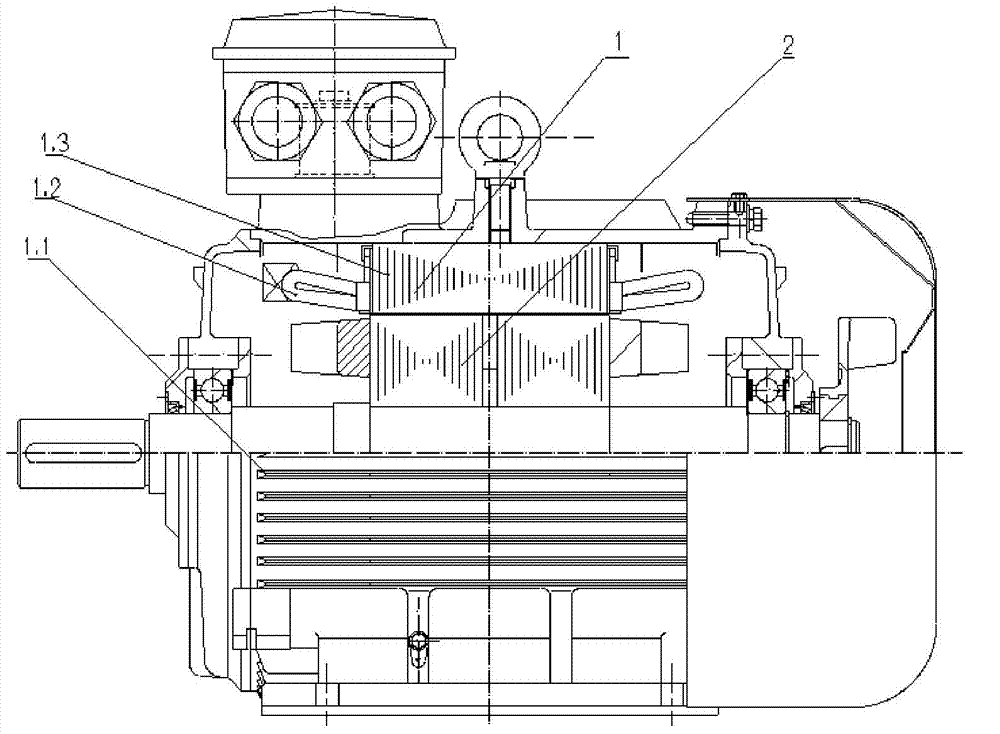

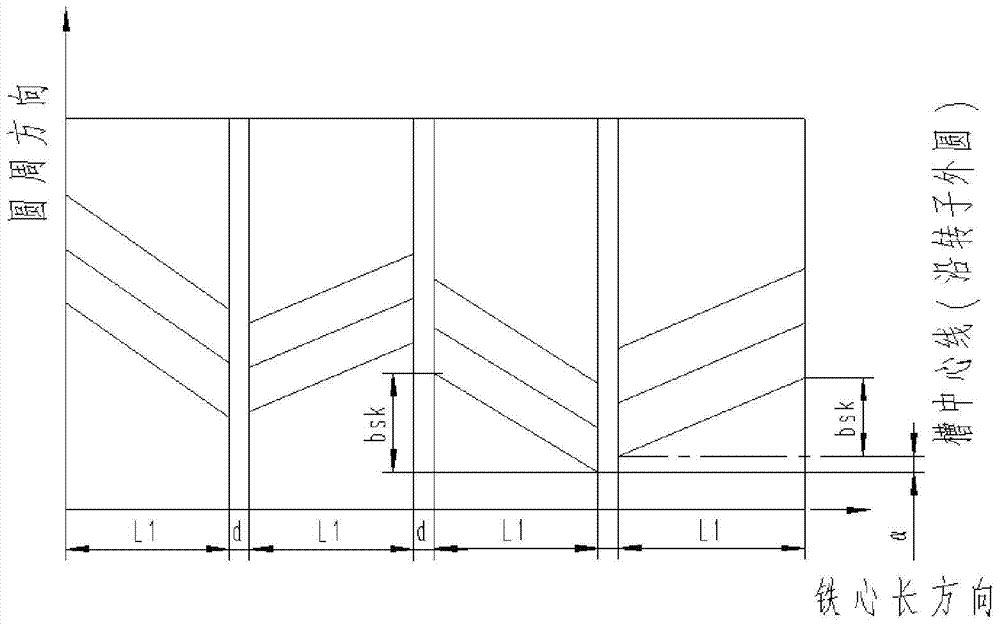

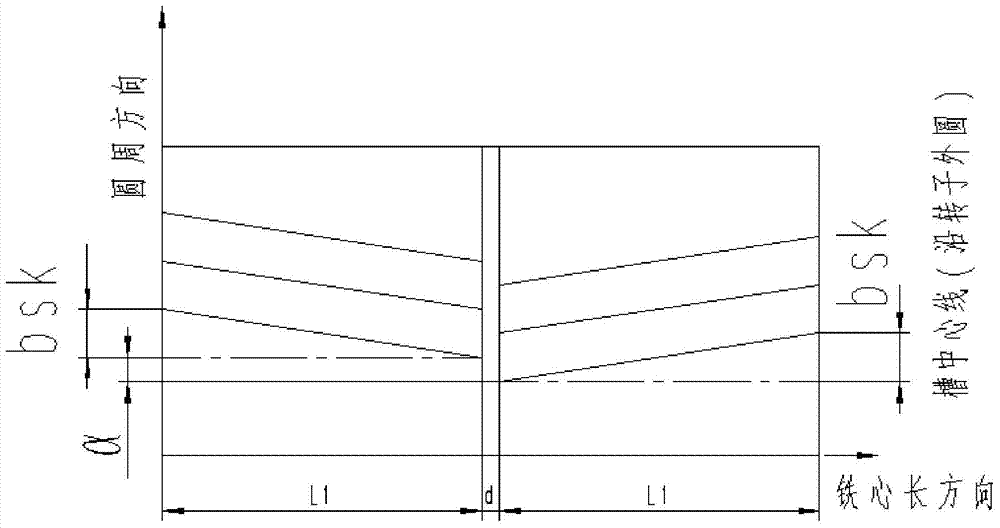

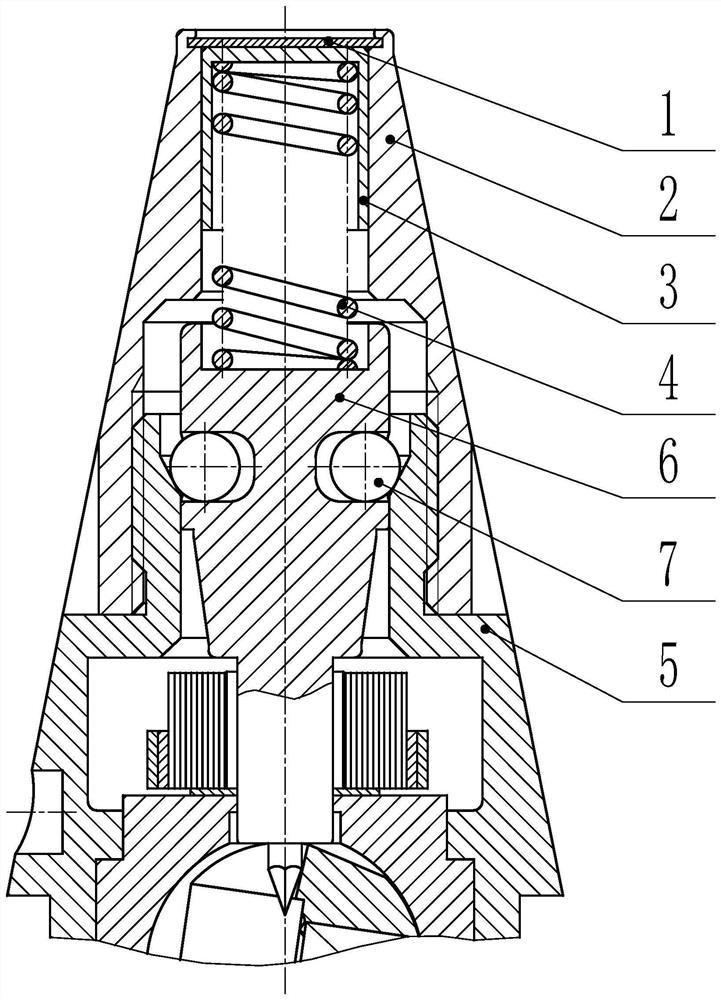

Chute low-noise motor

ActiveCN103501065AEliminate axialEliminate torsional vibrationMagnetic circuit rotating partsLow noiseElectric machine

The invention relates to a motor, in particular to a chute low-noise motor, which comprises a machine seat, a stator, a rotor and a rotating shaft, wherein the stator, the rotor and the rotating shaft are arranged on the machine seat, the rotor comprises at least two sections of rotor iron cores, the rotor iron cores are punched and laminated by a false axis inclination angle taper key method to form chute iron cores; chutes of the adjacent chute iron cores are in opposite directions and are in arrangement in a way of staggering for an angle alpha. Therefore, the chute low-noise motor has the following advantages that 1, great-degree optimization is respectively realized in aspects of vibration, noise, iron core laminating quality, cast aluminum quality and chute cast aluminum rotor structure adopted by a high-power motor, and the chute low-noise motor is suitable for small and medium-sized cast aluminum rotor structure alternating current motors with higher vibration and noise requirements; 2, the stress uniformity and the rigidity of iron core laminating punching are fundamentally ensured, the iron core laminating quality is improved, the influence of deformation on vibration noise is reduced, the aluminum overflowing and bubble problems are solved, and the quality of the cast aluminum rotor and the motor performance reliability are improved.

Owner:中国船舶重工集团公司第七一二研究所

Fuse capable of improving grazing impact and self-destruction reliability

ActiveCN111928742AImprove reliabilityReasonable use of internal spaceImpact fuzesMechanical fuzesExplosive trainForeign matter

The invention discloses a fuse capable of improving grazing impact and self-destruction reliability. On the basis of the original standard product design, a piston type part (such as a support barrelor a shearing barrel) capable of sliding axially is additionally arranged at the head of the fuse, the piston type part is pushed to move axially by the aid of target fragments produced when the fusecollides with a target or ground sediments during landing, a self-destruction spring is compressed, then a firing pin is pushed to trigger a detonator, the explosive sequence is detonated, and projectile detonation is realized. Meanwhile, the piston type part capable of sliding axially can stop foreign matters such as the ground sediments and the like from entering an inner cavity of the fuse to hinder movement of the firing pin when the fuse lands (particularly grazes), the firing pin stabs the detonator reliably, and the reliable grazing impact effect of the fuse is guaranteed. The fuse is simple in structure, and few changes are made on the original structure.

Owner:NANJING UNIV OF SCI & TECH

Large area organic electronic devices having conducting polymer buffer layers and methods of making same

InactiveUS20030209973A1Improve performanceImprove performance reliabilityDischarge tube luminescnet screensElectroluminescent light sourcesConductive polymerElectron

Owner:3M INNOVATIVE PROPERTIES CO

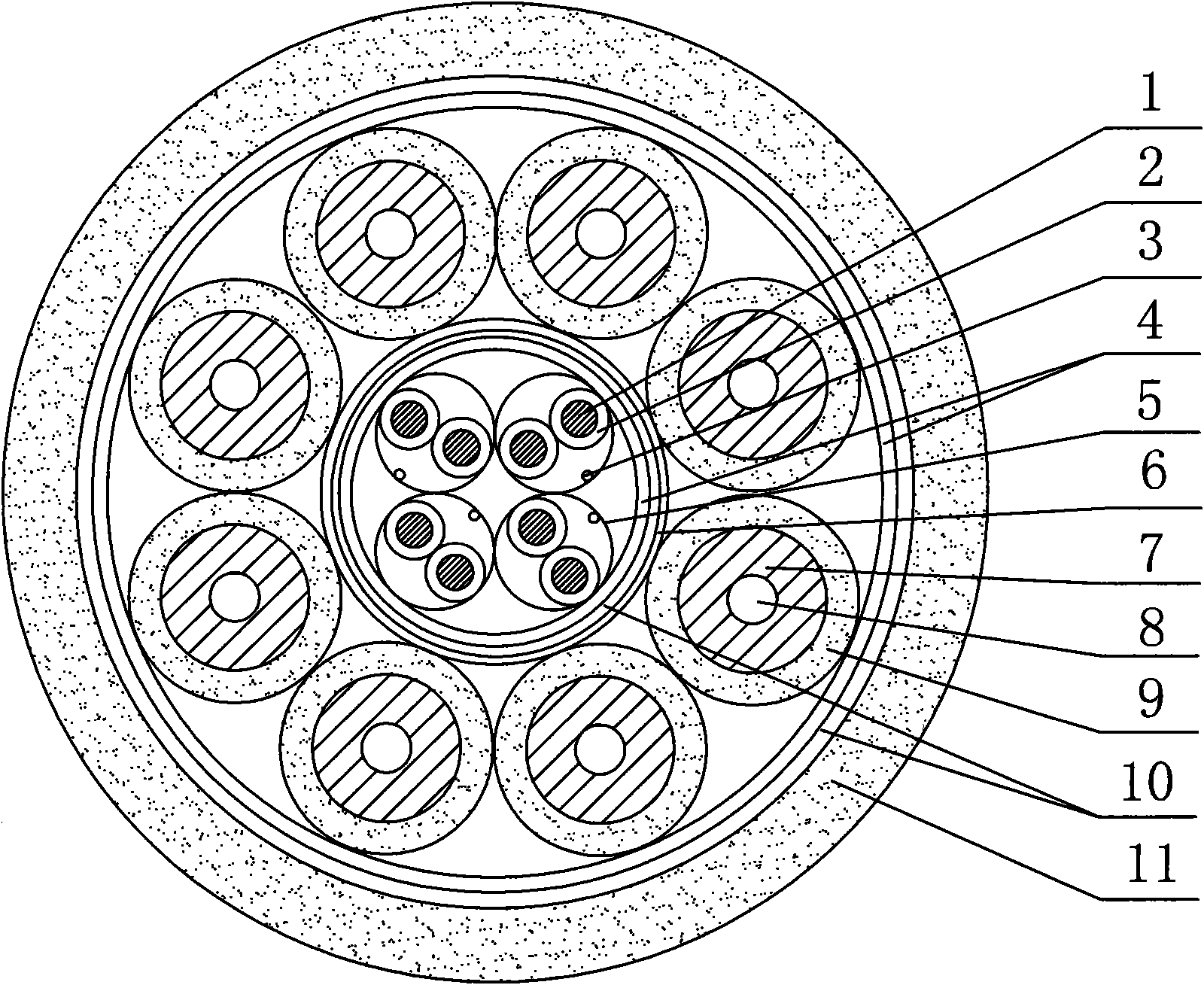

Anti-torsion data power composite cable and manufacturing method thereof

ActiveCN101562062ASimple structureAdvanced technologyPlastic/resin/waxes insulatorsInsulated cablesCapacitanceEngineering

The invention discloses an anti-torsion data power composite cable and a manufacturing method thereof. The composite cable comprises a cable core, an outer jacket, and is provided with a data line core and a power control line core; wherein, the data line core is formed by stranding of quad and positioned in the center of cable, the quad is provided with two insulated cores and drainage lines, and wounded and wrapped with a plastic-aluminum composite strip sub-shielding layer, the data line core is provided with a main shielding layer, the power control line core is formed in a manner that multi-assemble reinforced cores are mounted on the periphery of the data line core, the data line core and the cable core are provided with a composite cushion layer respectively. The invention has the advantages of simple and reasonable structure, advanced technique, high mechanical strength of products, low capacity and low attenuation. The invention is also characterized by strong anti electromagnetic interfere property, shock resistance, fine torsion bending resistance property, oil proofness, chemical solvent resistance, hard wearing, high / low temperature resistance, water erosion resistance, environmental leaching and loss resistance, ensuring stable property of cables in various severe environments so that cable property is reliable and safe.

Owner:BAOSHENG SCI & TECH INNOVATION

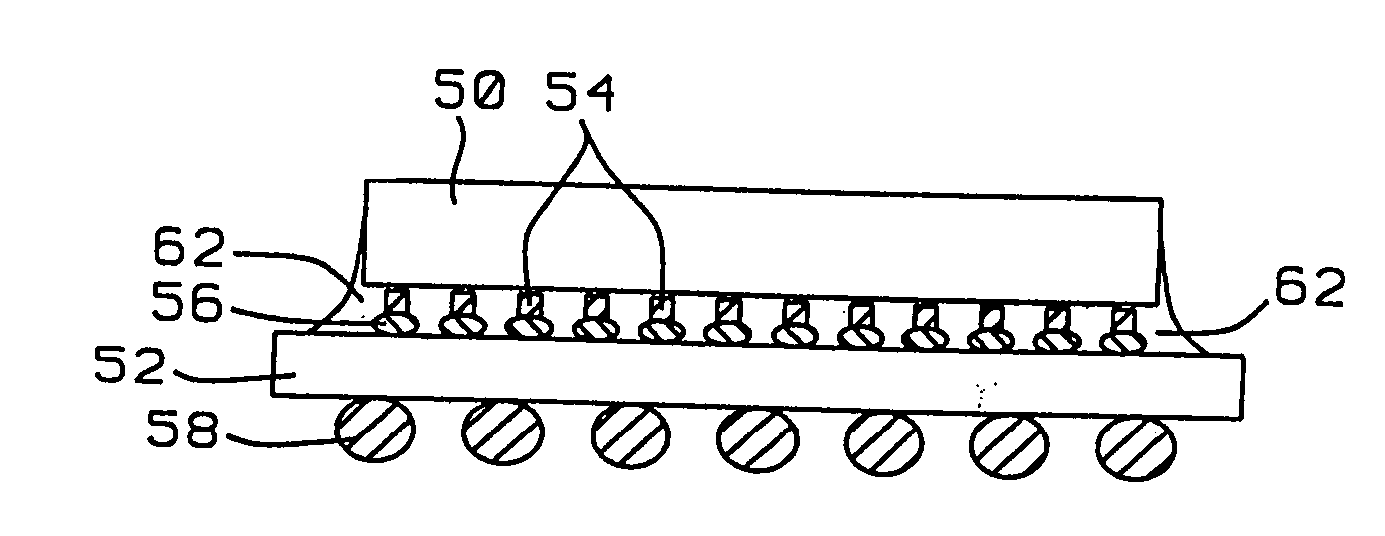

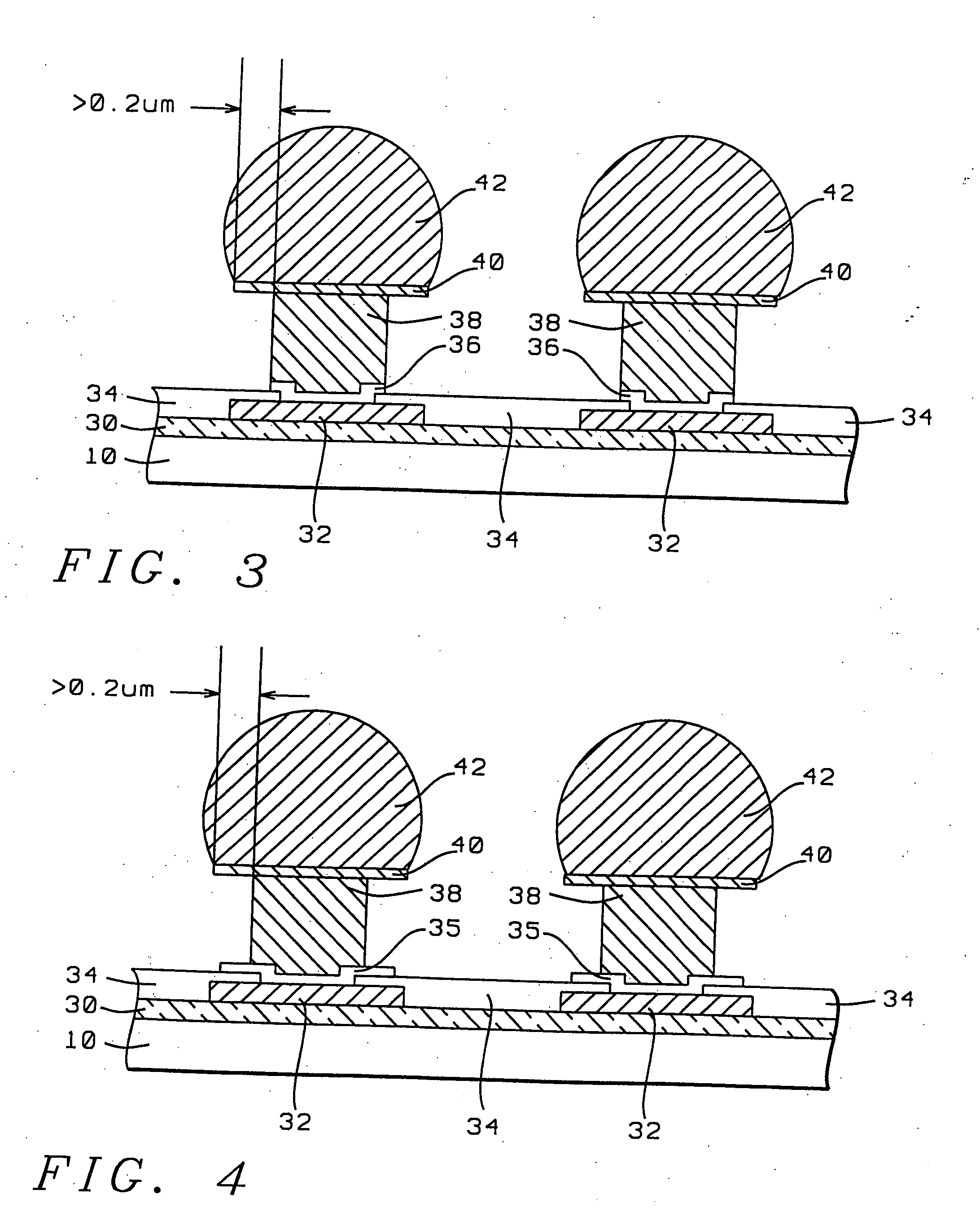

Structure and manufacturing method of a chip scale package

InactiveUS20080067677A1Reduce interconnectionImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor

A new method and package is provided for the mounting of semiconductor devices that have been provided with small-pitch Input / Output interconnect bumps. Fine pitch solder bumps, consisting of pillar metal and a solder bump, are applied directly to the I / O pads of the semiconductor device, the device is then flip-chip bonded to a substrate. Dummy bumps may be provided for cases where the I / O pads of the device are arranged such that additional mechanical support for the device is required.

Owner:QUALCOMM INC

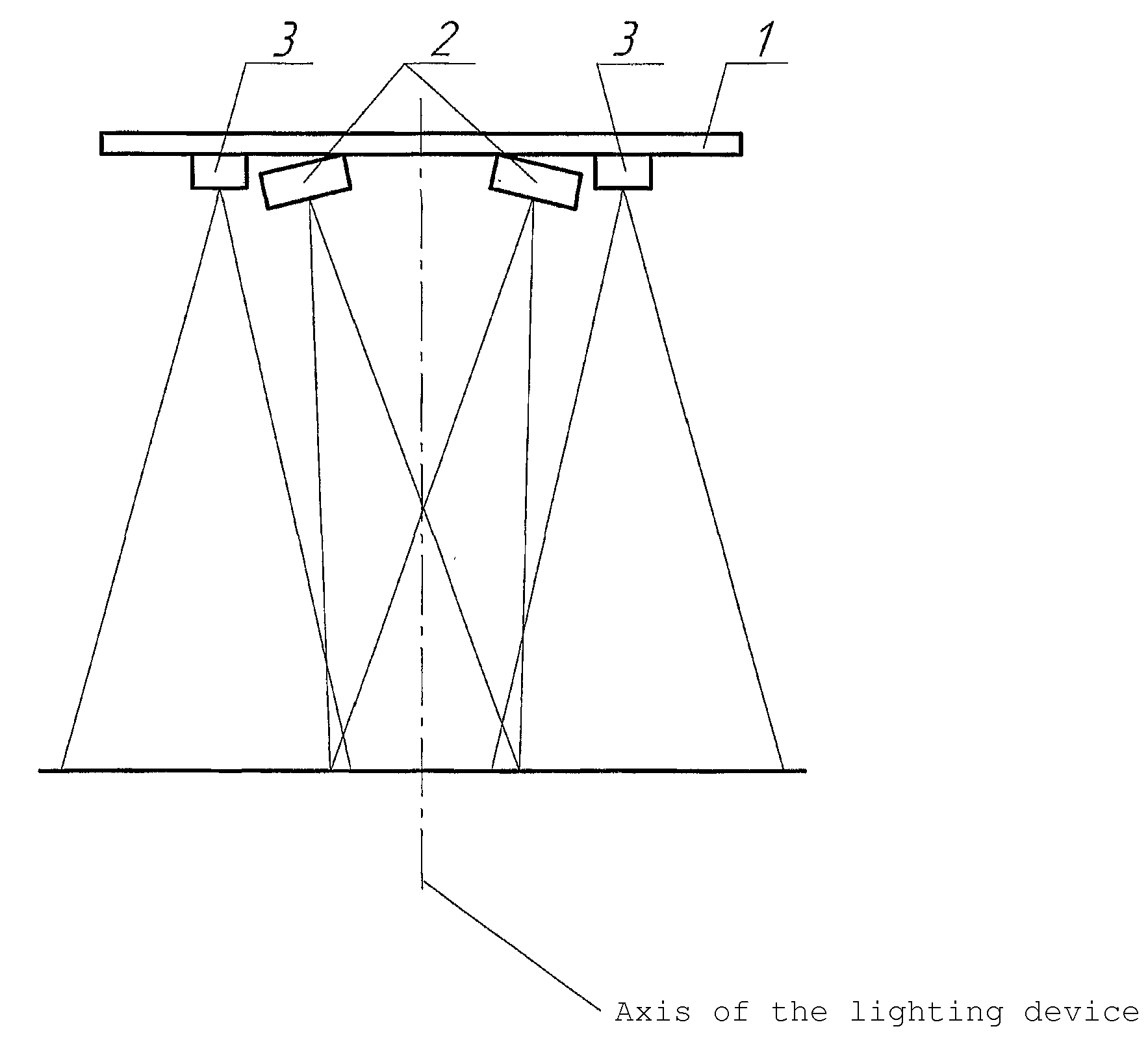

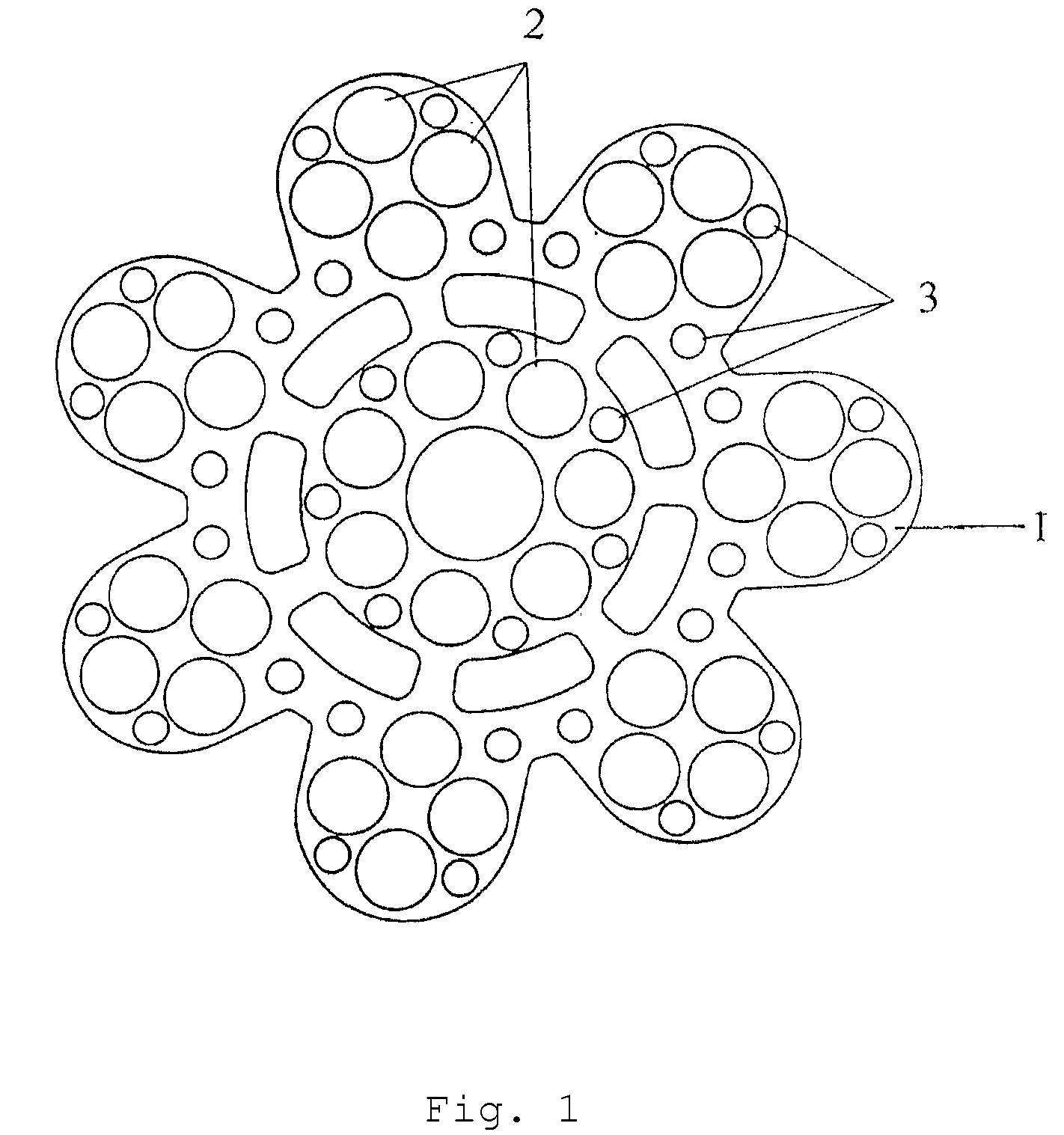

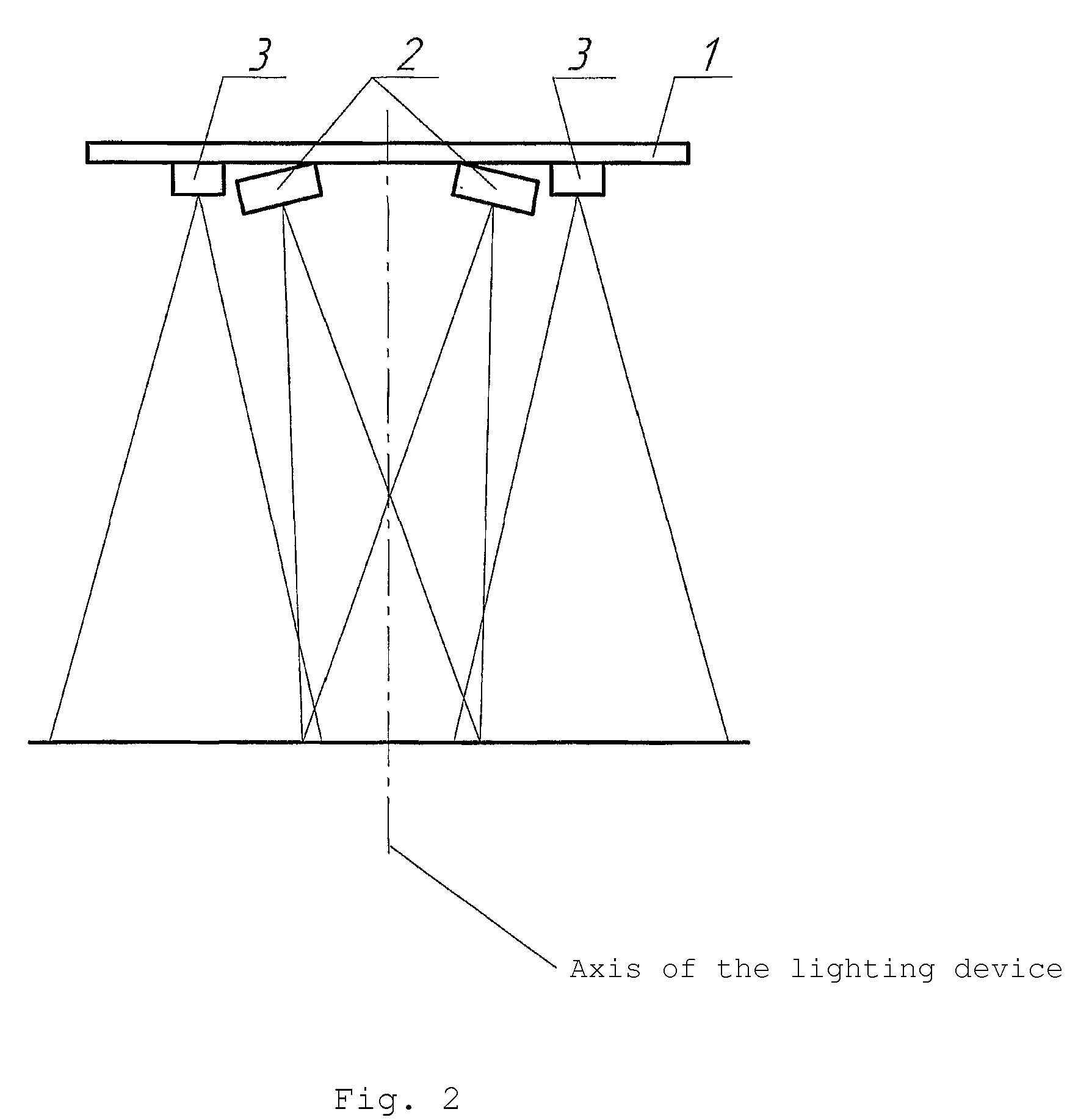

Surgical light provided with a light emission control

InactiveUS20080273317A1Improve reliabilityImprove performance reliabilityMechanical apparatusPoint-like light sourceSpatial OrientationsOptical axis

The inventive surgical light comprises a body provided with main light-emitting diodes and additional light-emitting diodes arranged therebetween, which are spaced on said body and fixed thereto, wherein said additional light-emitting diodes are grouped and are characterised in that the spatial orientation thereof differs from the spatial orientation of the main light-emitting diodes. A light field control device comprises a control unit to which the groups of light-emitting diodes are connected by means of adjusters each of which is connected to a power supply unit. The main light-emitting diodes are fixed to the light body in such a way that the optical axes thereof cross the light axis in the center of a light spot. The additional light-emitting diodes are fixed to the light body in such a way that the optical axes thereof form a concentric light spot in the form of a ring around the main light spot.

Owner:ZAO ZAVOD EMA

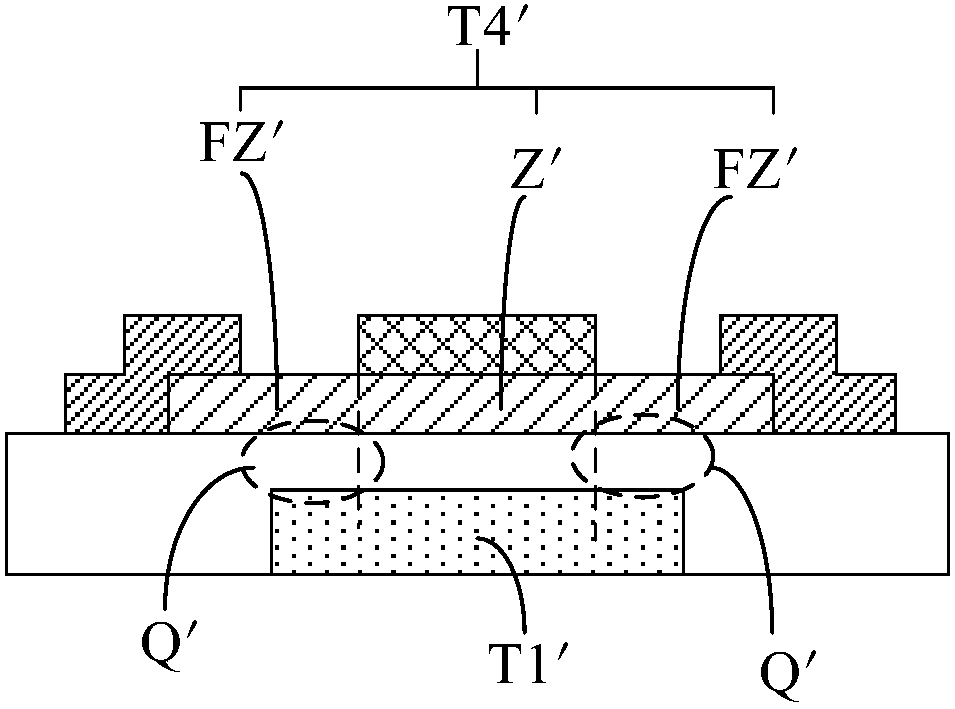

Array substrate, manufacturing method therefore, and display panel

ActiveCN108417580AAchieve conductionReduce overlap areaSolid-state devicesSemiconductor/solid-state device manufacturingParasitic capacitanceSemiconductor

The invention discloses an array substrate, a manufacturing method therefore, and a display panel. The array substrate includes a plurality of thin film transistor, and each thin film transistor comprises a gate electrode, an oxide semiconductor layer, and an etching barrier layer, wherein the etching barrier layer is located on the oxide semiconductor layer which includes a channel region and a non-channel region, the non-channel region includes an electrode region and a connection region, and the electrode region includes a first electrode region and a second electrode region. Each connection region includes a first connection region and a second connection region, and the first electrode region, the first connection region, the channel region, the second connection region and the secondelectrode region are sequentially arranged in a first direction, and the first direction is parallel to the array substrate. A region, covered by the corresponding etching barrier layer, of each oxide semiconductor layer is a channel region. Each gate electrode is located at one side, far from the corresponding etching barrier layer, of the corresponding oxide semiconductor layer. The width of atleast one connection region is less than the width of the channel region in a second direction. The overlapping area of the gate electrodes with the non-channel regions is reduced, and the parasiticcapacitance is also reduced.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

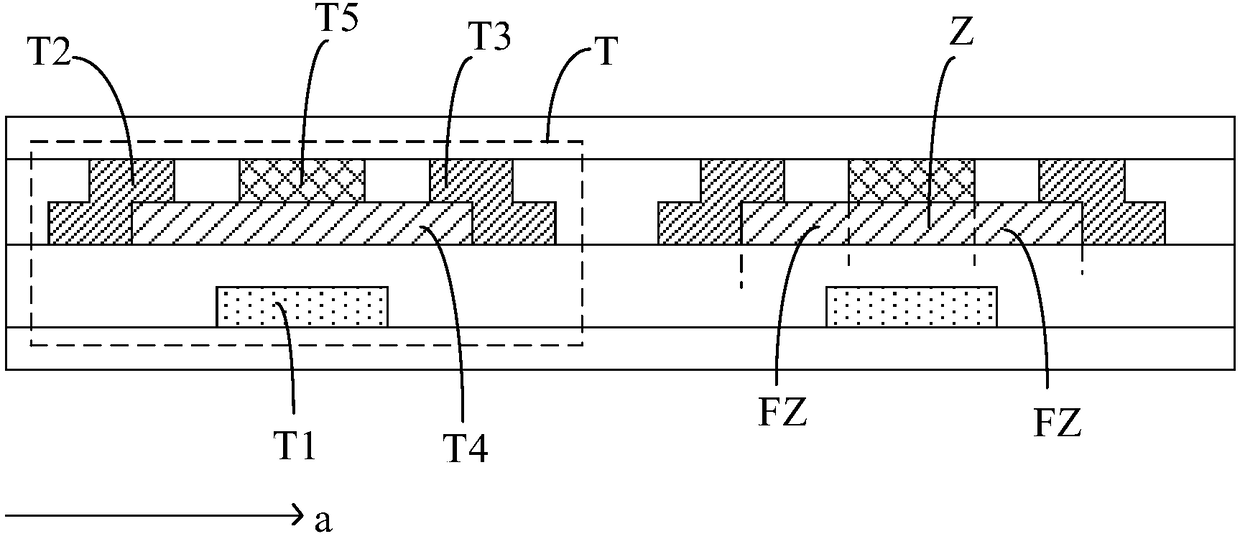

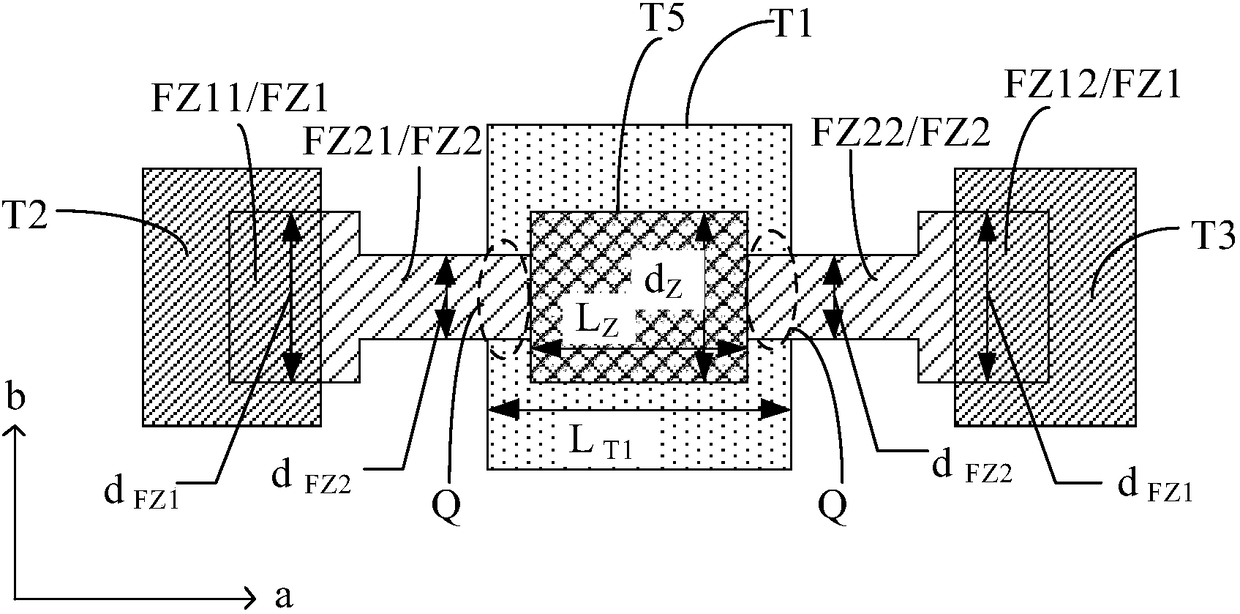

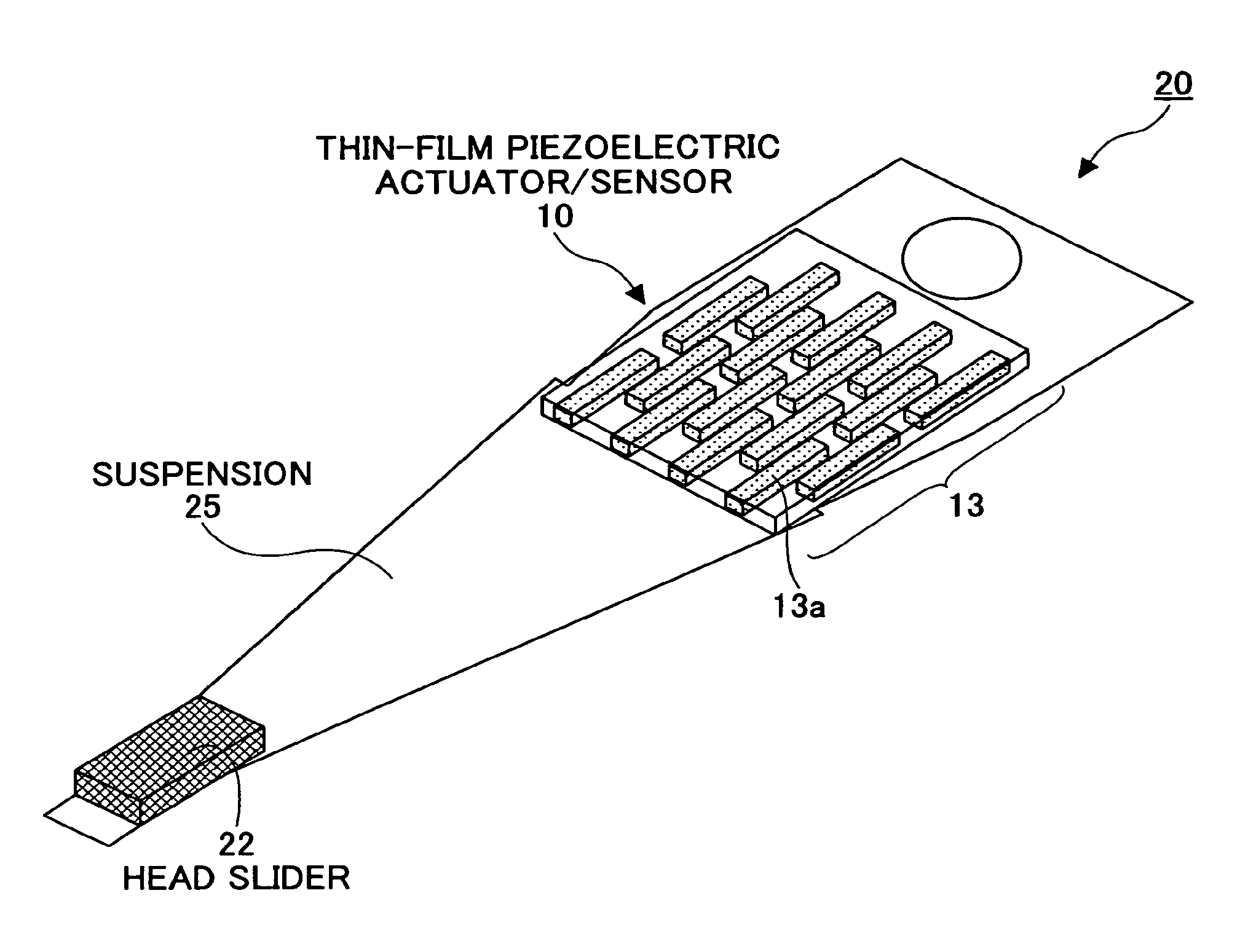

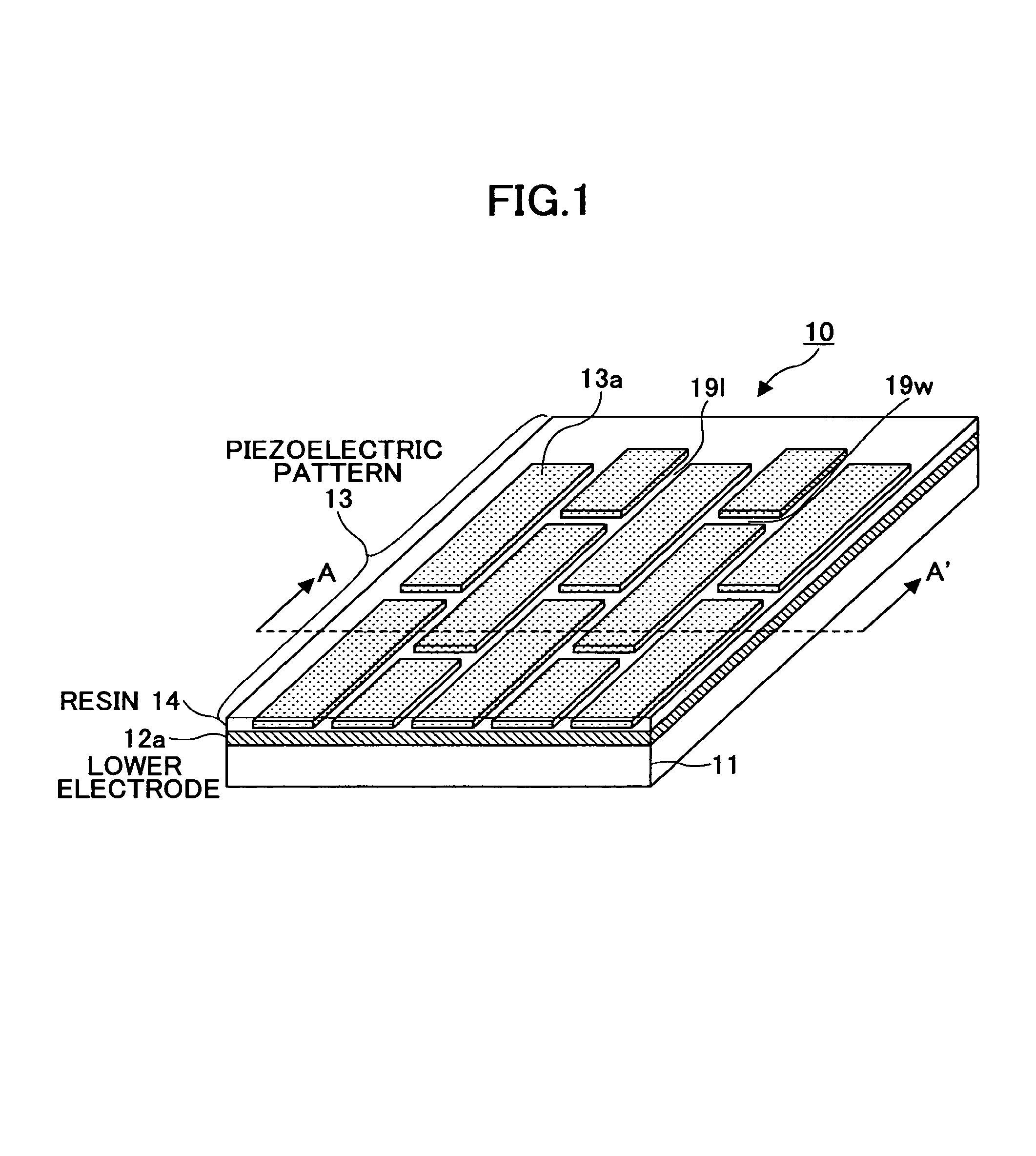

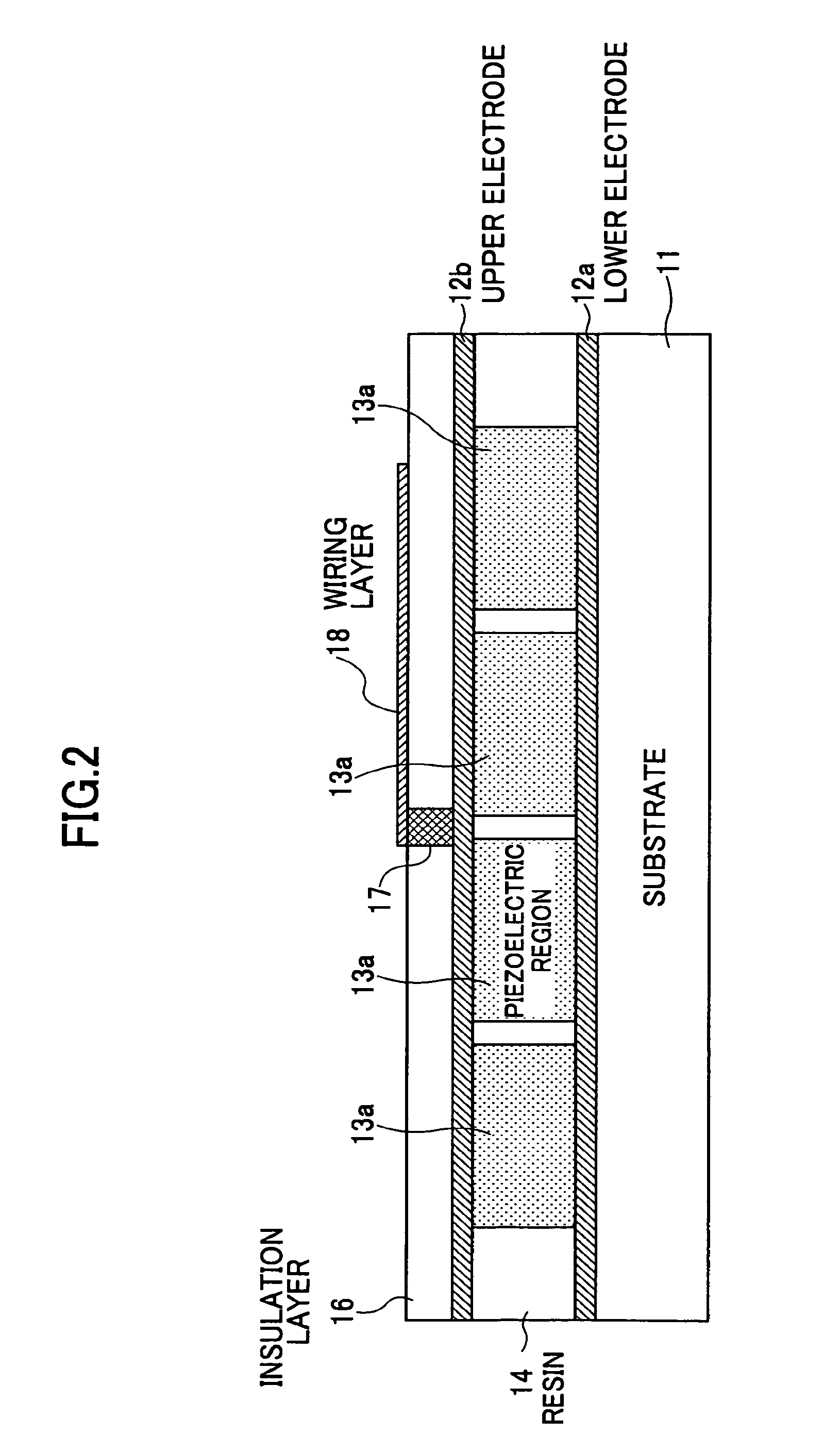

Thin-film piezoelectric device and method of manufacturing the same

InactiveUS7595581B2Improve performance reliabilityTrack finding/aligningPiezoelectric/electrostrictive device manufacture/assemblyAcousticsElectric field

A thin-film piezoelectric device is disclosed that includes a substrate, a piezoelectric pattern disposed on the substrate, the piezoelectric pattern including plural spaced-apart piezoelectric regions, and a pair of electrodes that apply an electric field to the piezoelectric pattern.

Owner:TOSHIBA STORAGE DEVICE CORP

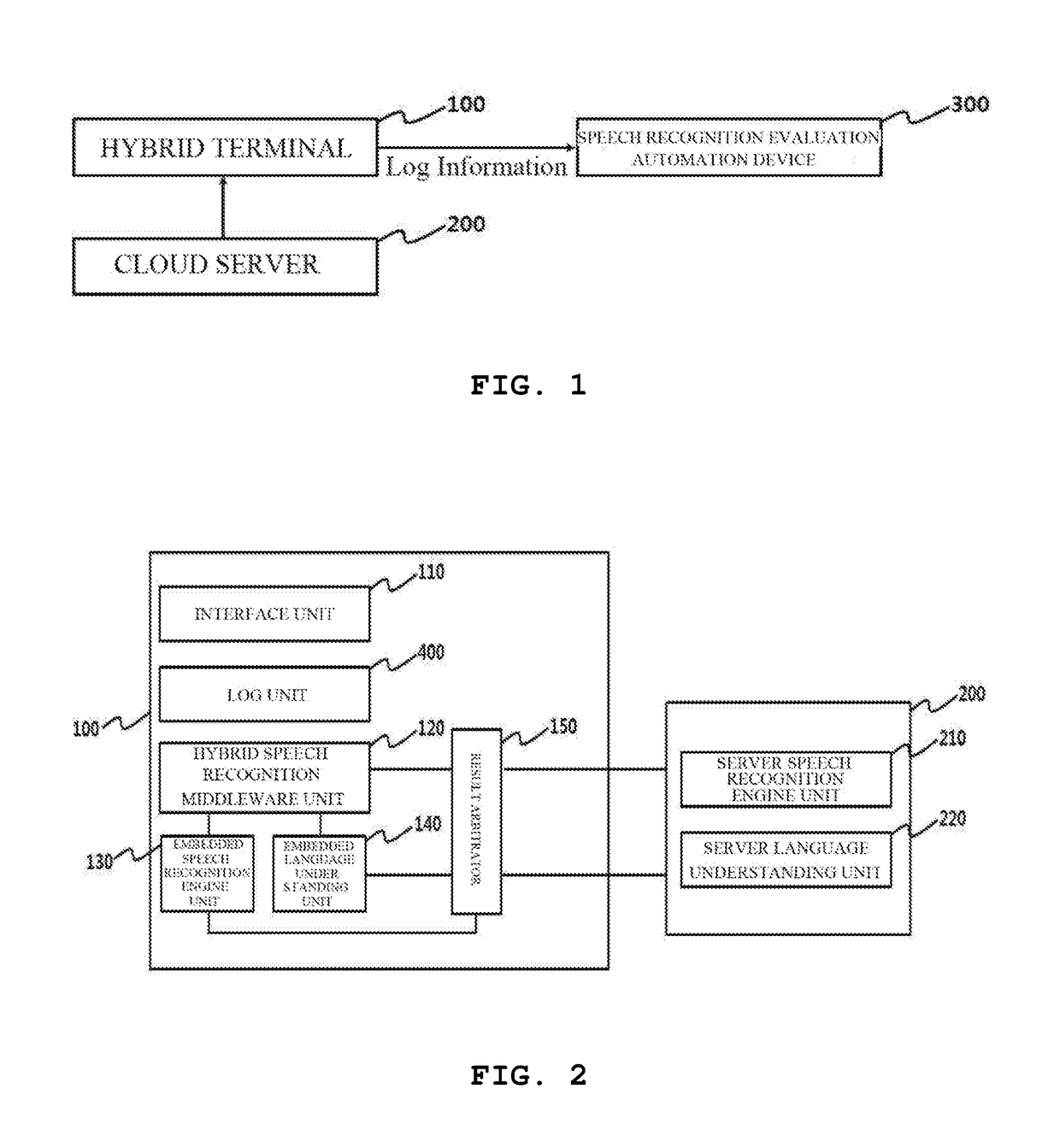

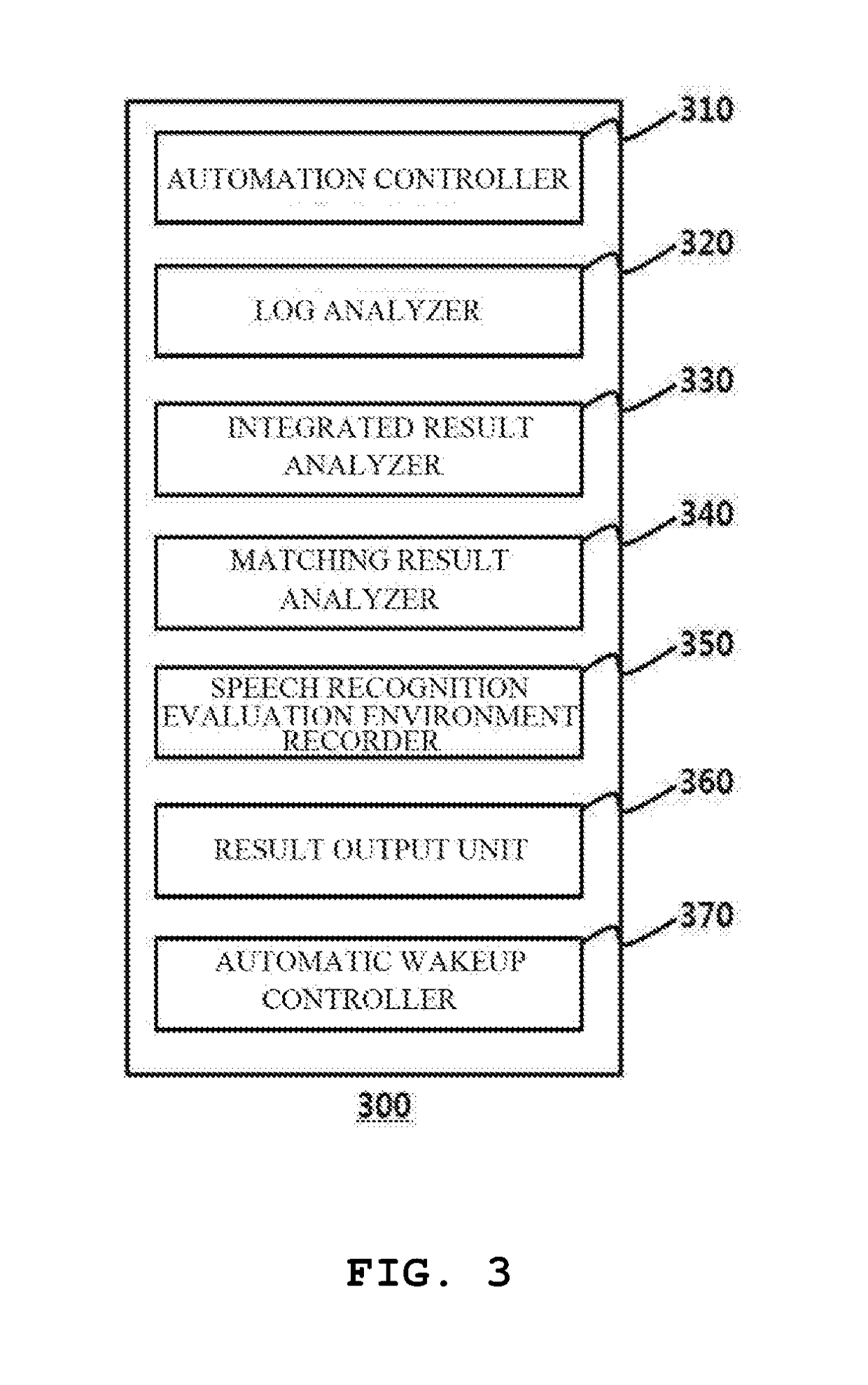

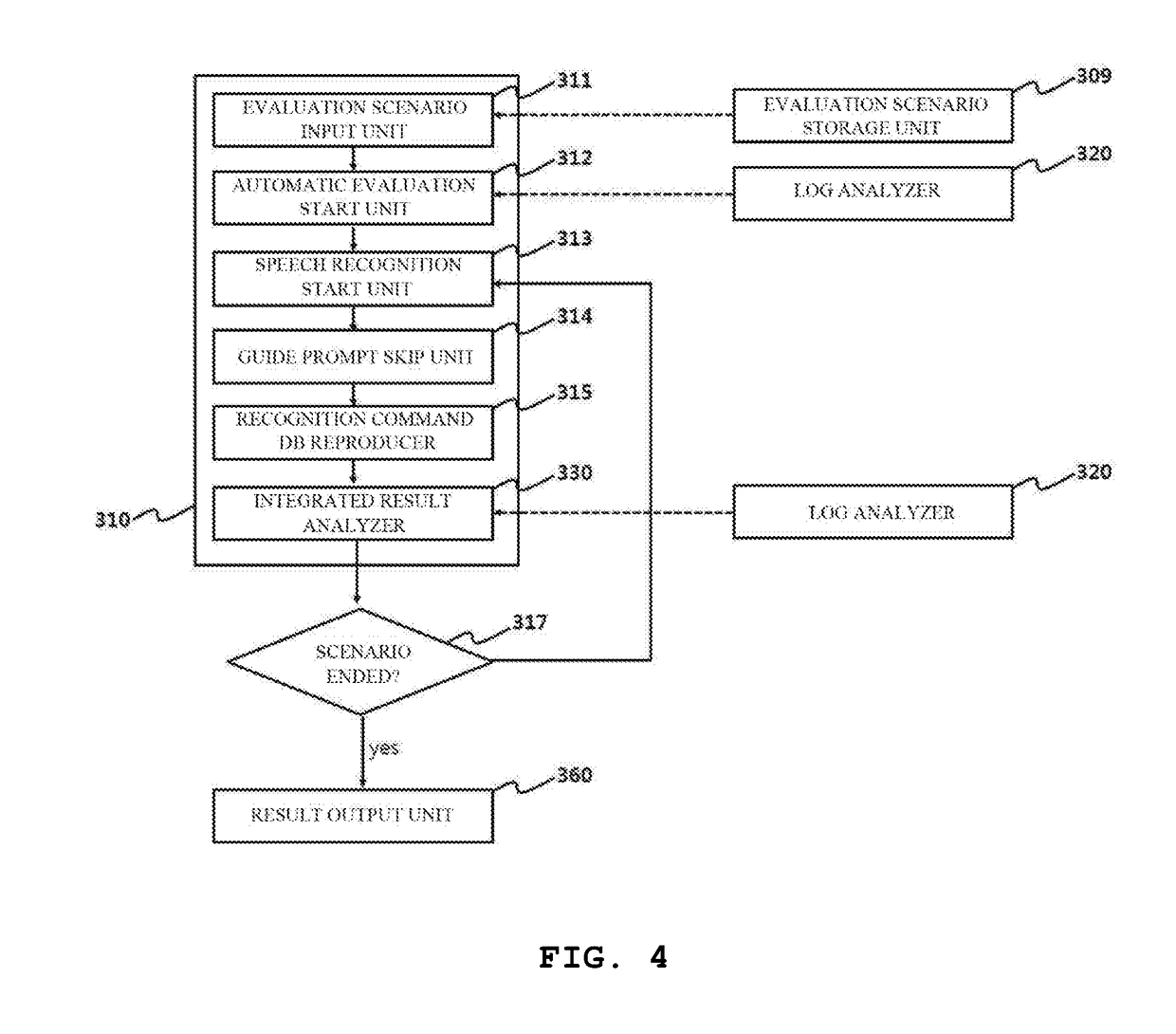

Automatic multi-performance evaluation system for hybrid speech recognition

ActiveUS20180342236A1Improve performance reliabilityImprove reliabilitySpeech recognitionLanguage understandingSpeech identification

The present invention relates to an automatic multi-performance evaluation system for hybrid speech recognition and, more particularly, to an automatic multi-performance evaluation system for hybrid speech recognition capable of automatically evaluating a processing result of speech recognition and language understanding through a hybrid terminal and a processing result of server speech recognition and language understanding through a cloud server by simultaneously using the hybrid terminal and the cloud server, to thereby output an accurate and fast performance and function verification result.

Owner:MEDIAZEN

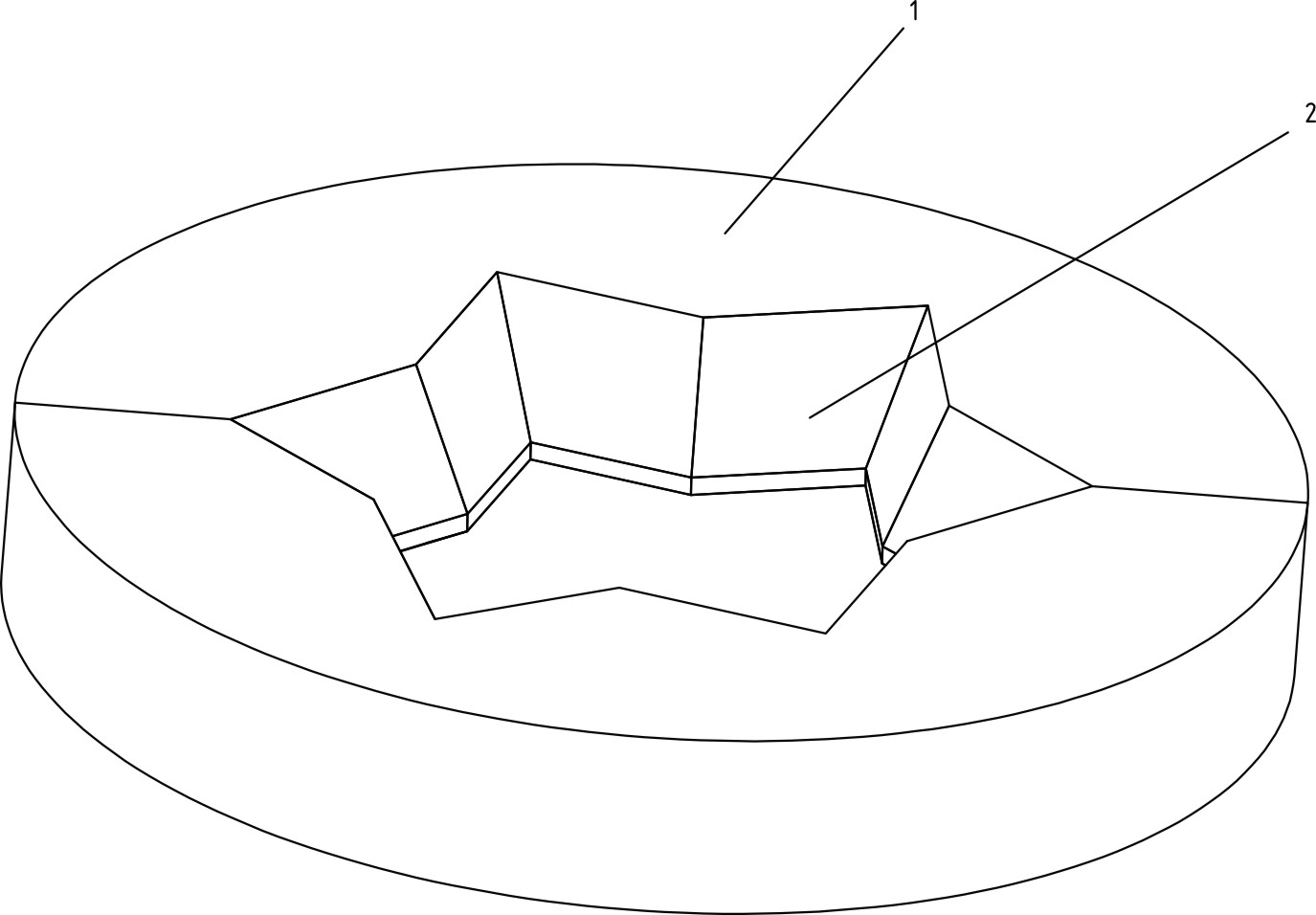

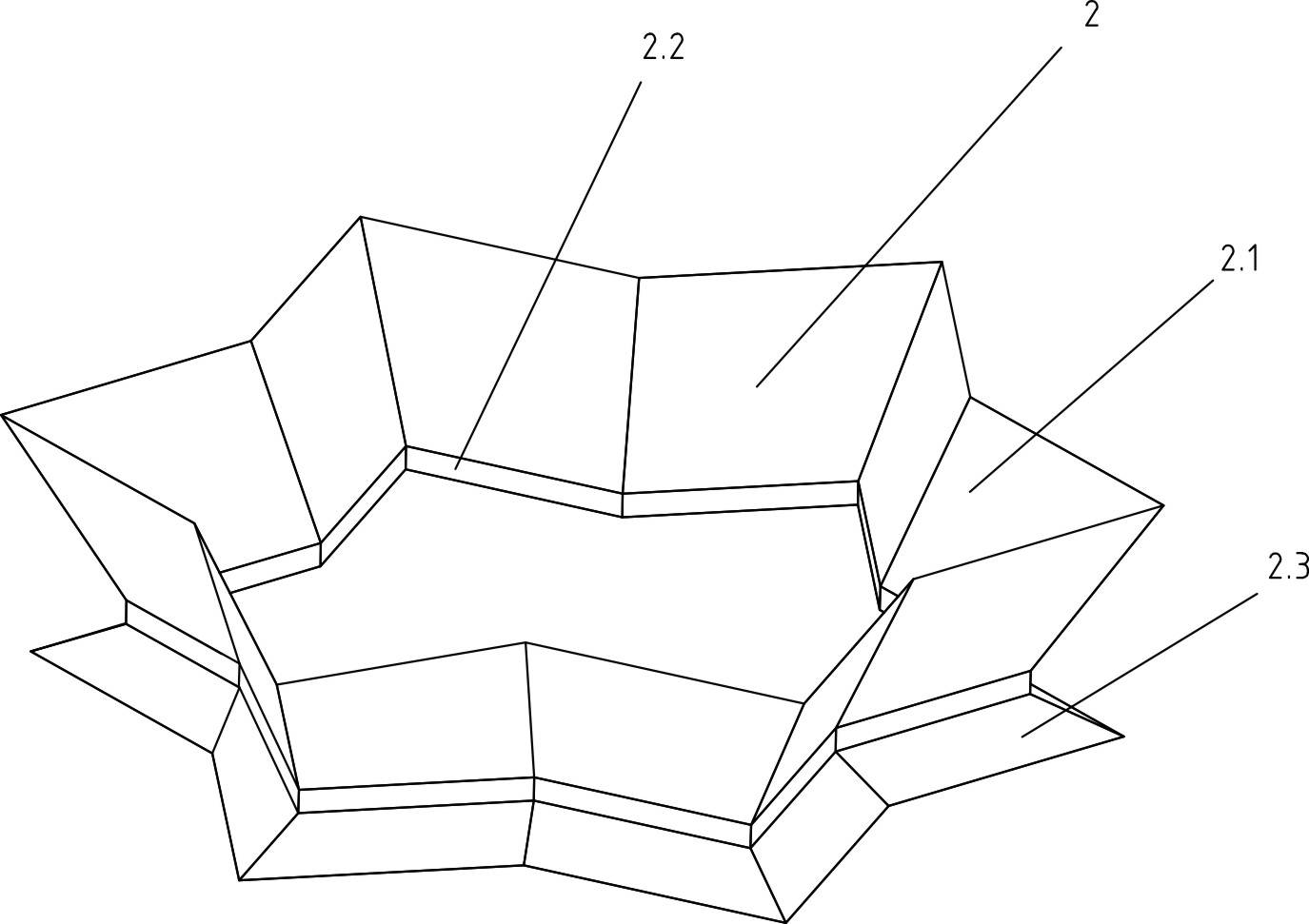

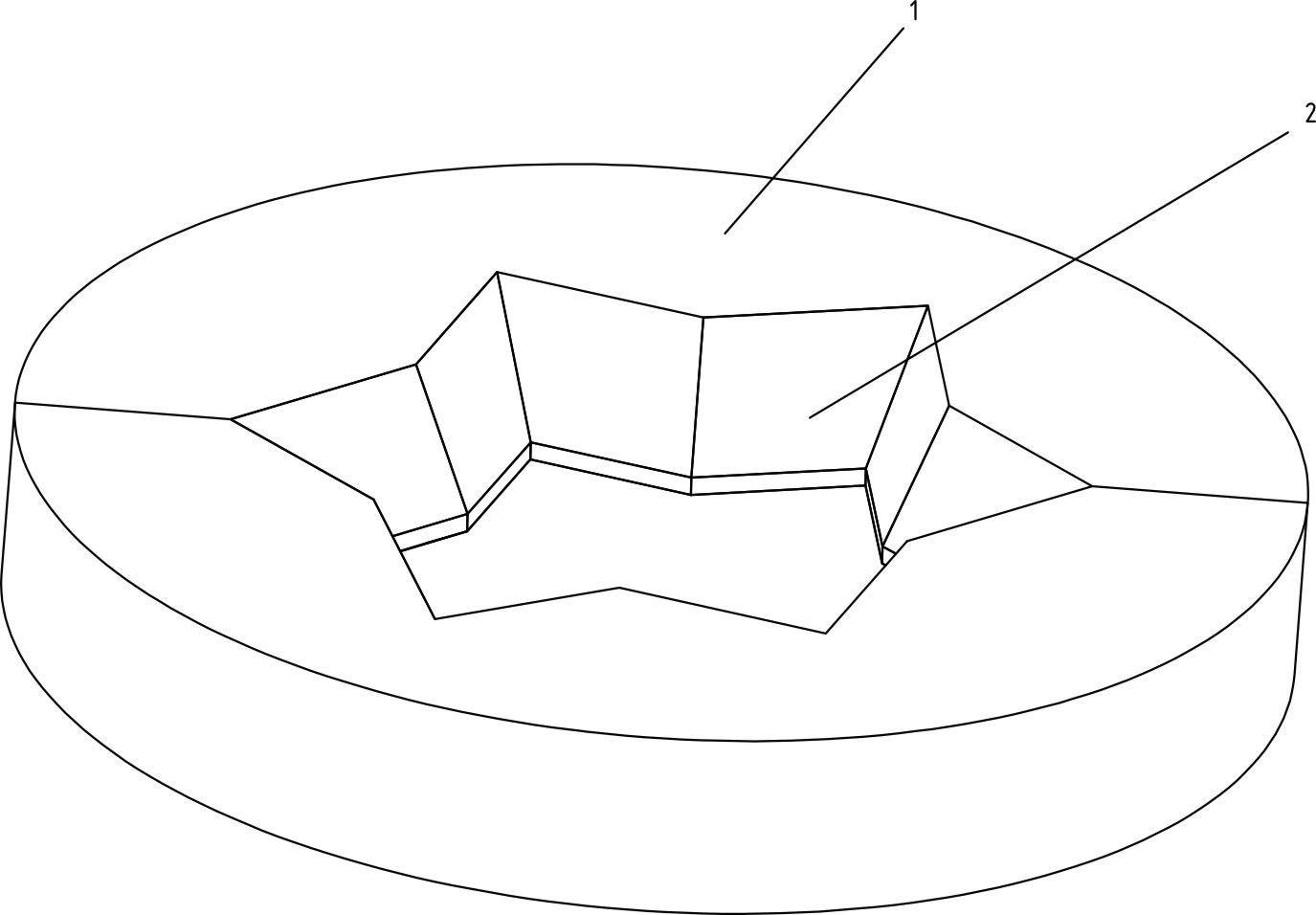

Feeder head knock-off core

ActiveCN102328030AResolve separation difficultiesReduce connection strengthFoundry mouldsFoundry coresUltimate tensile strengthMaterials science

The invention relates to the cast field, in particular relates to a knock-off core between a cast cavity and a feeder head. The feeder head knock-off core solves the technical problems that a cast feeder head and a cast main body in the existing feeder head knock-off core have high connection strength, the cast feeder head is hard to separate from the cast main body, and the separation work of the cast feeder head and the cast main body has high strength in the prior art. The invention provides a feeder head knock-off core, wherein the cast feeder head and the cast main body have low connection strength, the cast feeder head is easy to separate from the cast main body, the separation work strength of the cast feeder head and the cast main body is low, and the processing work load after the casting of the cast main body is low. The feeder head knock-off core provided by the invention comprises a knock-off core main body on which a liquid communicating hole for communicating upper and lower surfaces of the knock-off core is arranged; the liquid communicating hole comprises an upper liquid communicating hole and a lower communicating hole; and cross section outlines of the upper and lower communicating holes are in four-pointed star shape or five-pointed star shape or six-pointed star shape, and a lower opening of the upper liquid communicating hole is congruent to a small opening of the lower communicating hole.

Owner:ZHEJIANG WUJING MACHINE MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com