Chute low-noise motor

A low-noise, chute technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problem of weakening the harmonics of the weak teeth of the motor and the size of the harmonic magnetomotive force, and the axial force that is easy to cause the shaft Problems such as serial motion and torsional vibration, uneven pressure of punching sheets, etc., achieve the effect of reducing motor vibration and electromagnetic noise, solving overflow and air bubbles, and expanding the application field and scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

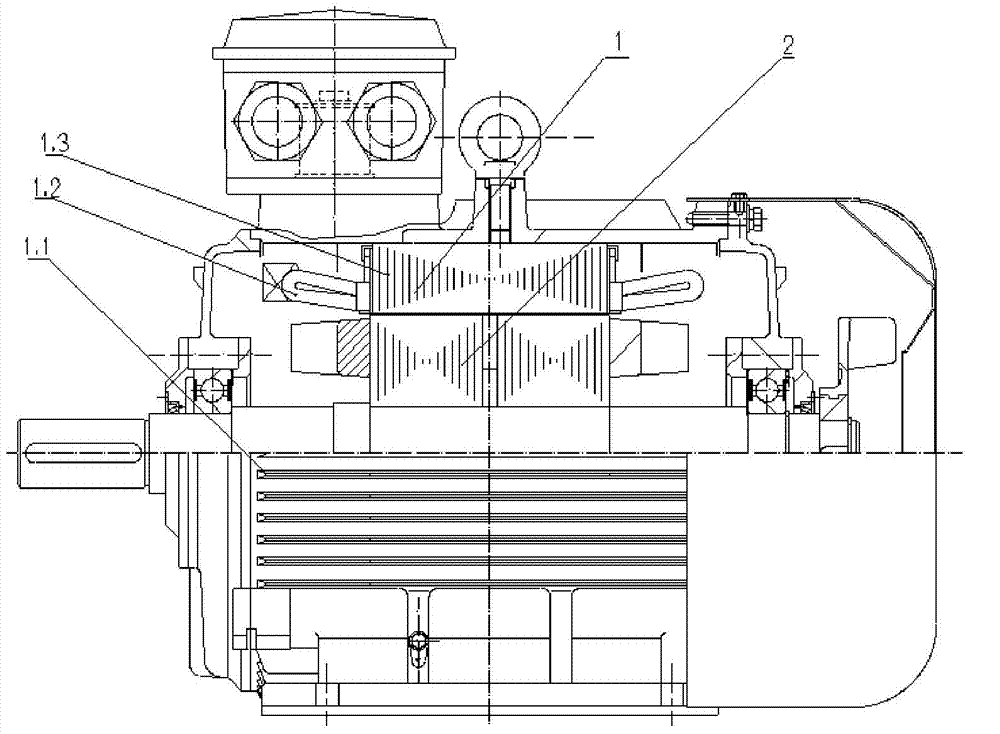

[0021] Introduce the specific embodiment of the present invention and relevant part size requirement below:

[0022] Such as Figure 1~5 As shown, a special inclined slot low-noise motor is composed of a stator 1 and a rotor 2; the stator 1 is composed of a machine base 1.1, a stator winding 1.2 and a stator core 1.3; the rotor 2 is composed of a rotor core 2.1 and a new damping ring 2.2 , composed of aluminum 2.3 and shaft 2.4;

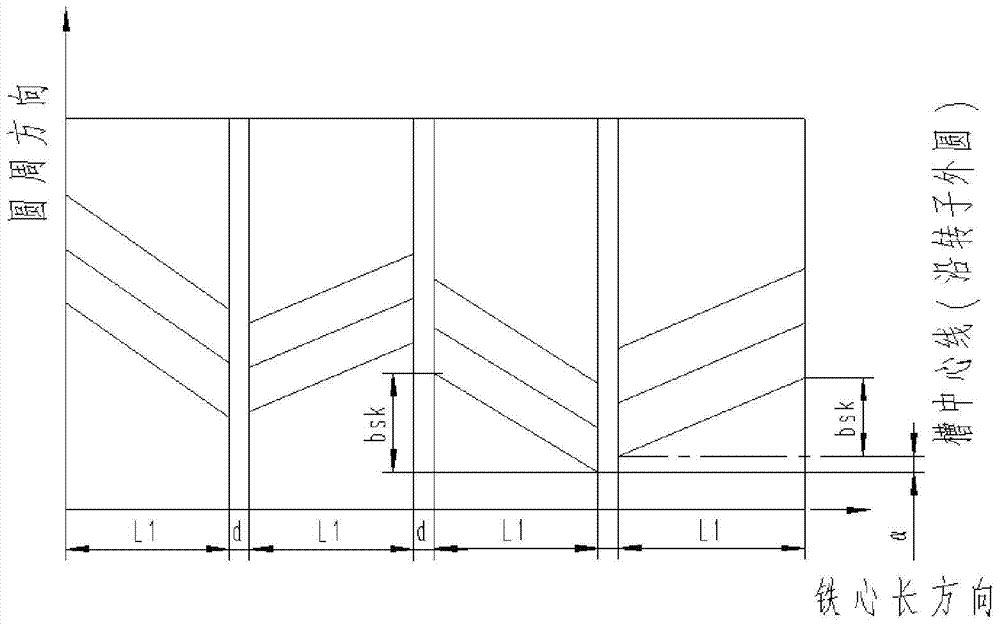

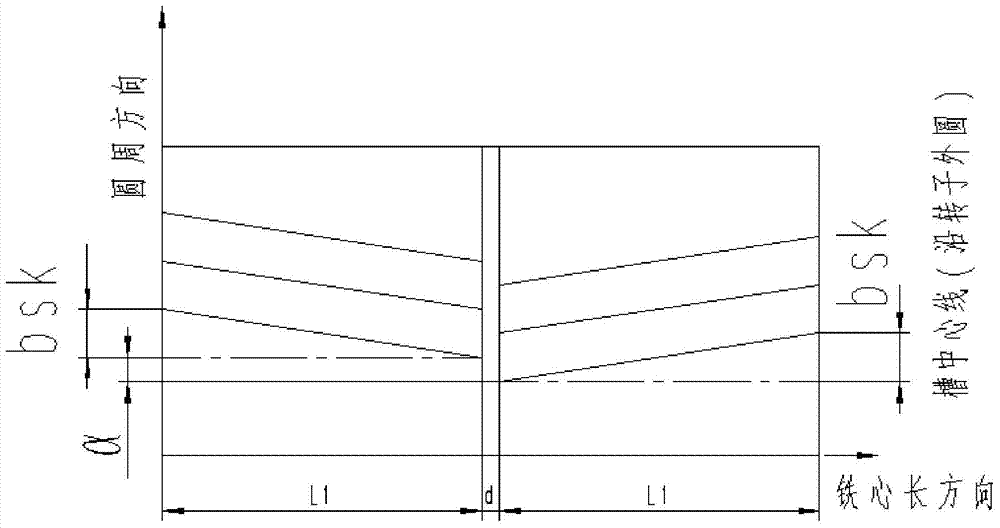

[0023] figure 2 with image 3 The special chute low-noise motor core chute pitch bsk does not use the conventional 1 times the stator pitch, but this embodiment uses 1.2 times the stator pitch, and is formed by laminating the plates with a false shaft inclination angle oblique key method. , the calculation of the inclination angle of the false axis is carried out according to the above method. The two-stage chute core is divided into two sections of reverse chute, and an angle is staggered. The misalignment angle of the rotor core is along the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com