Patents

Literature

52results about How to "Eliminate radial play" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

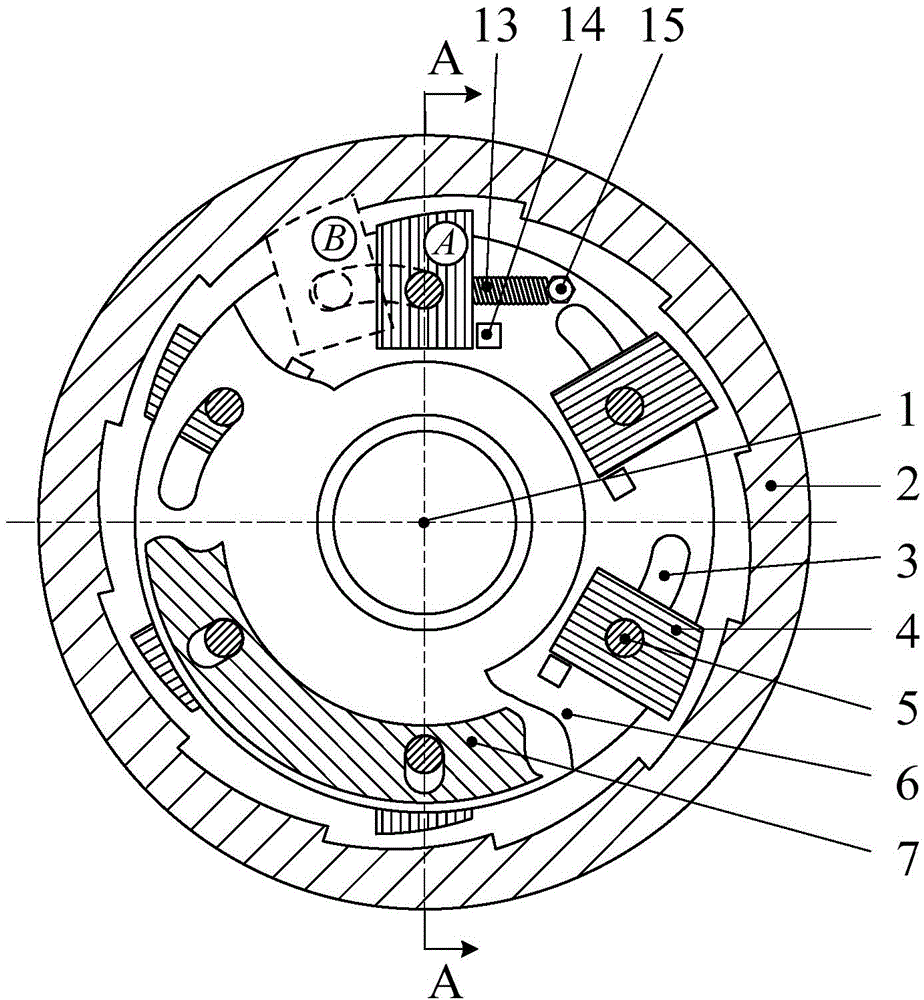

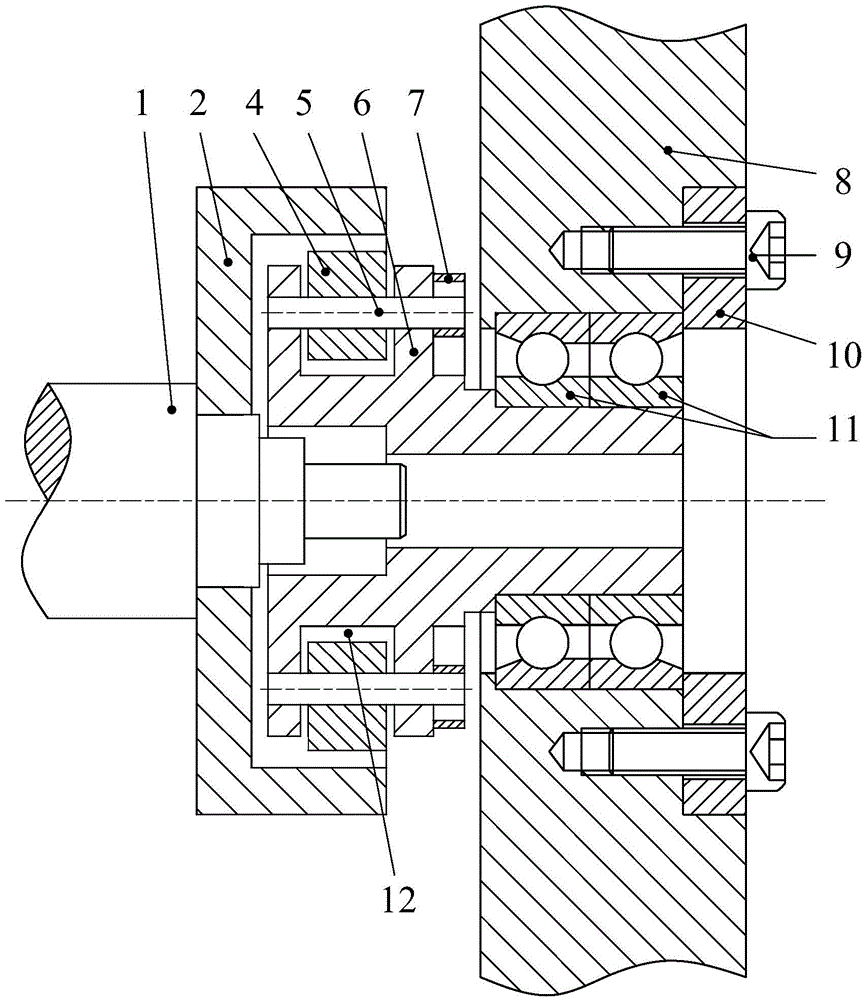

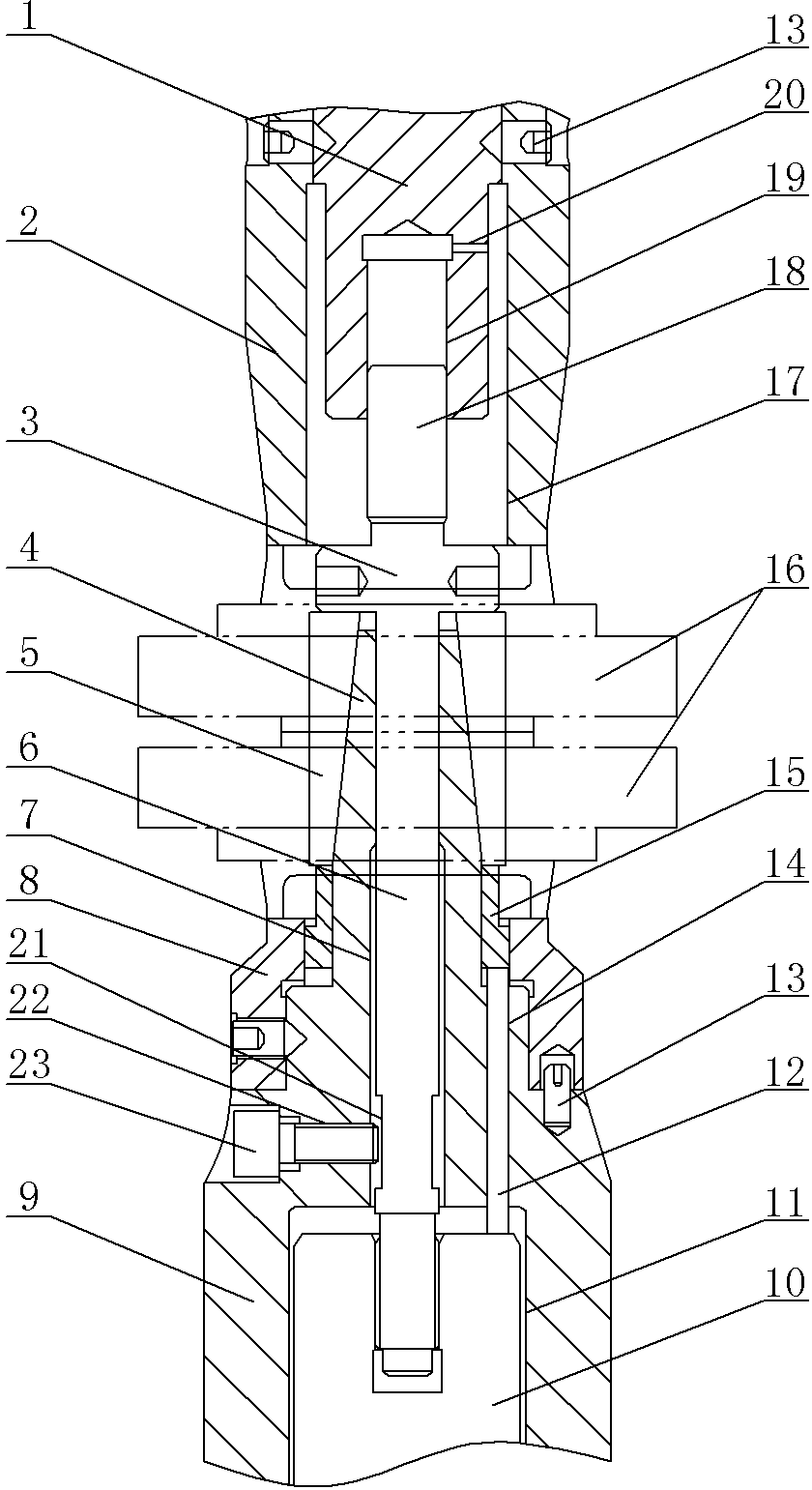

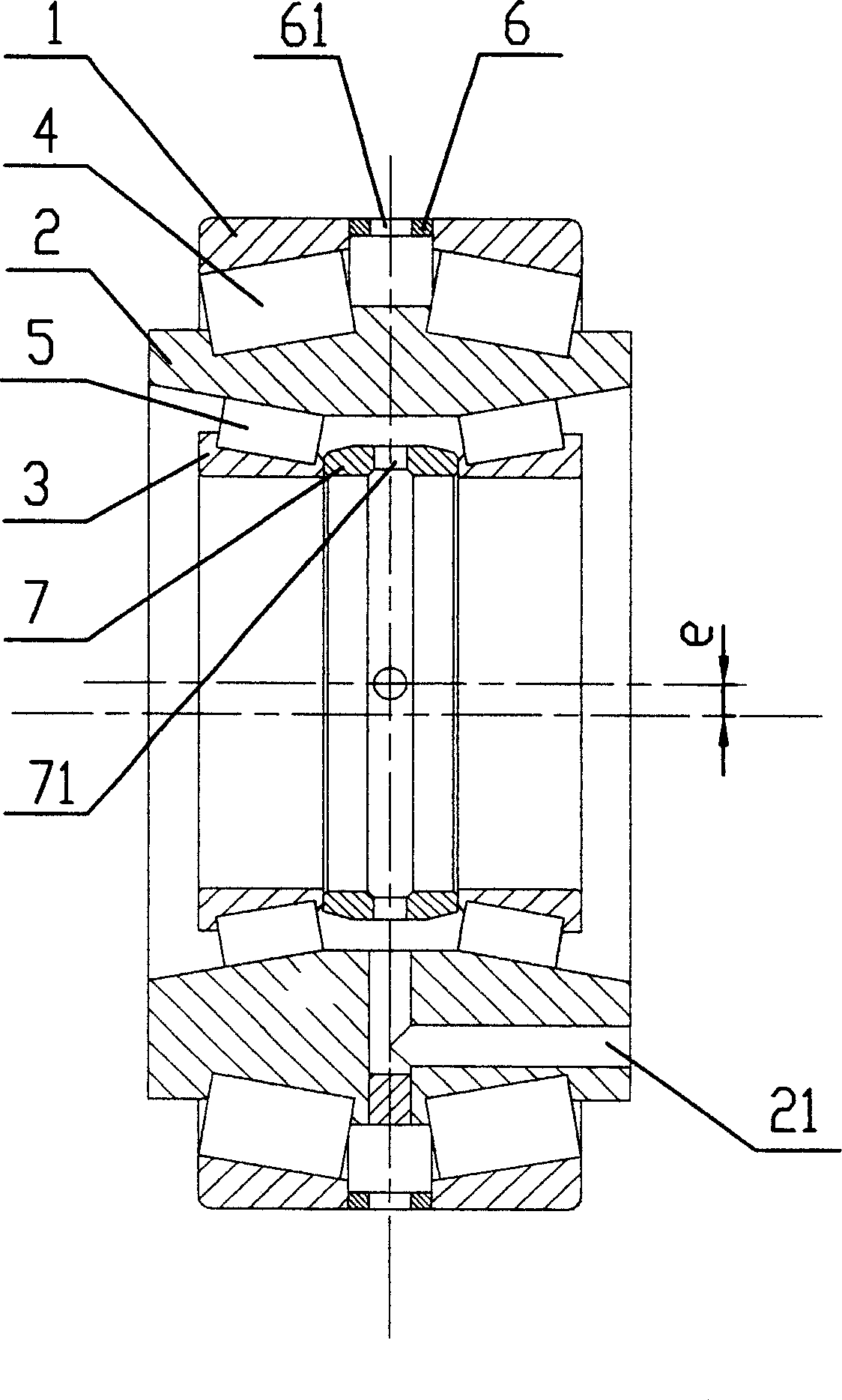

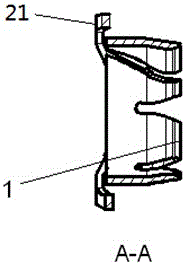

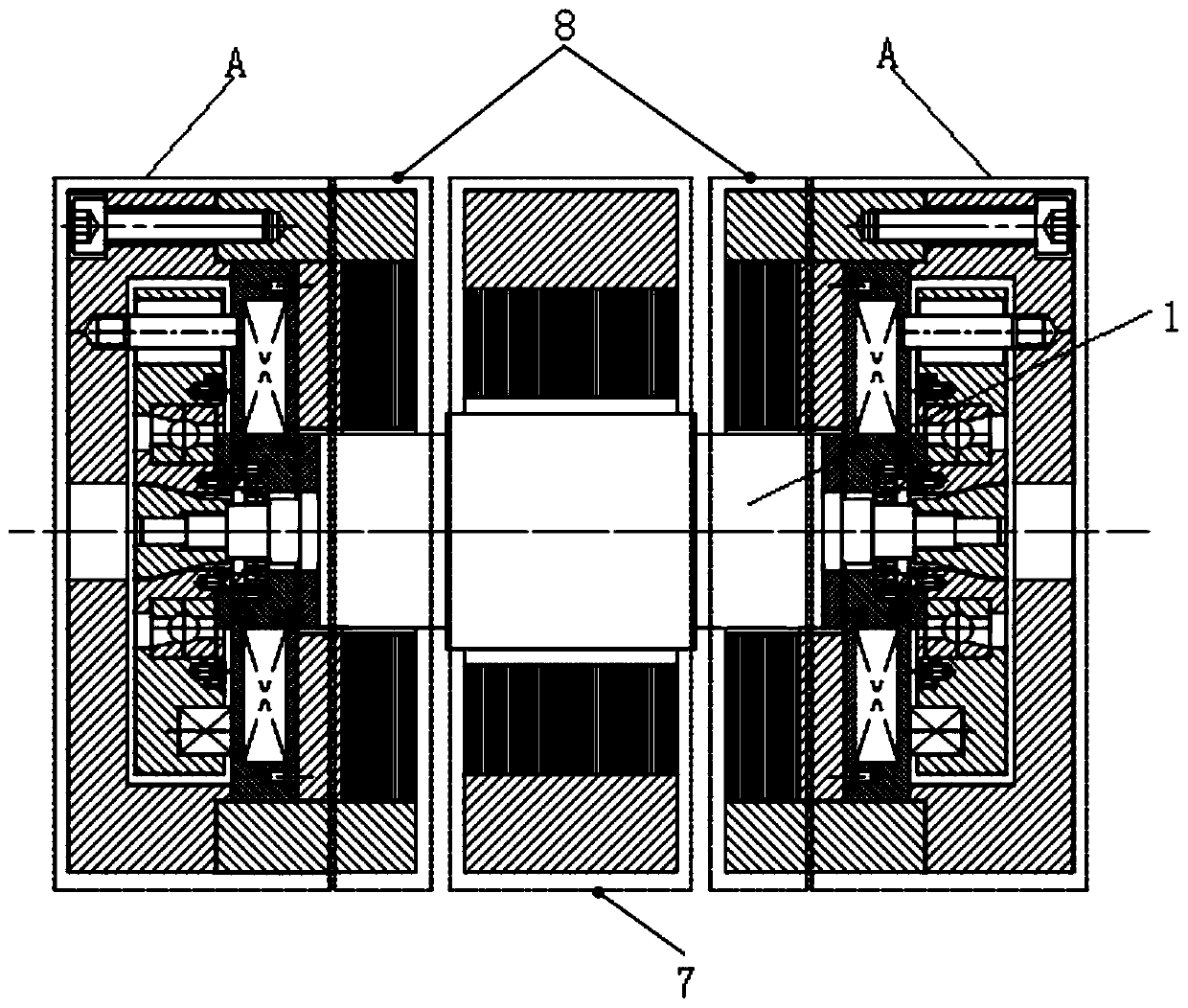

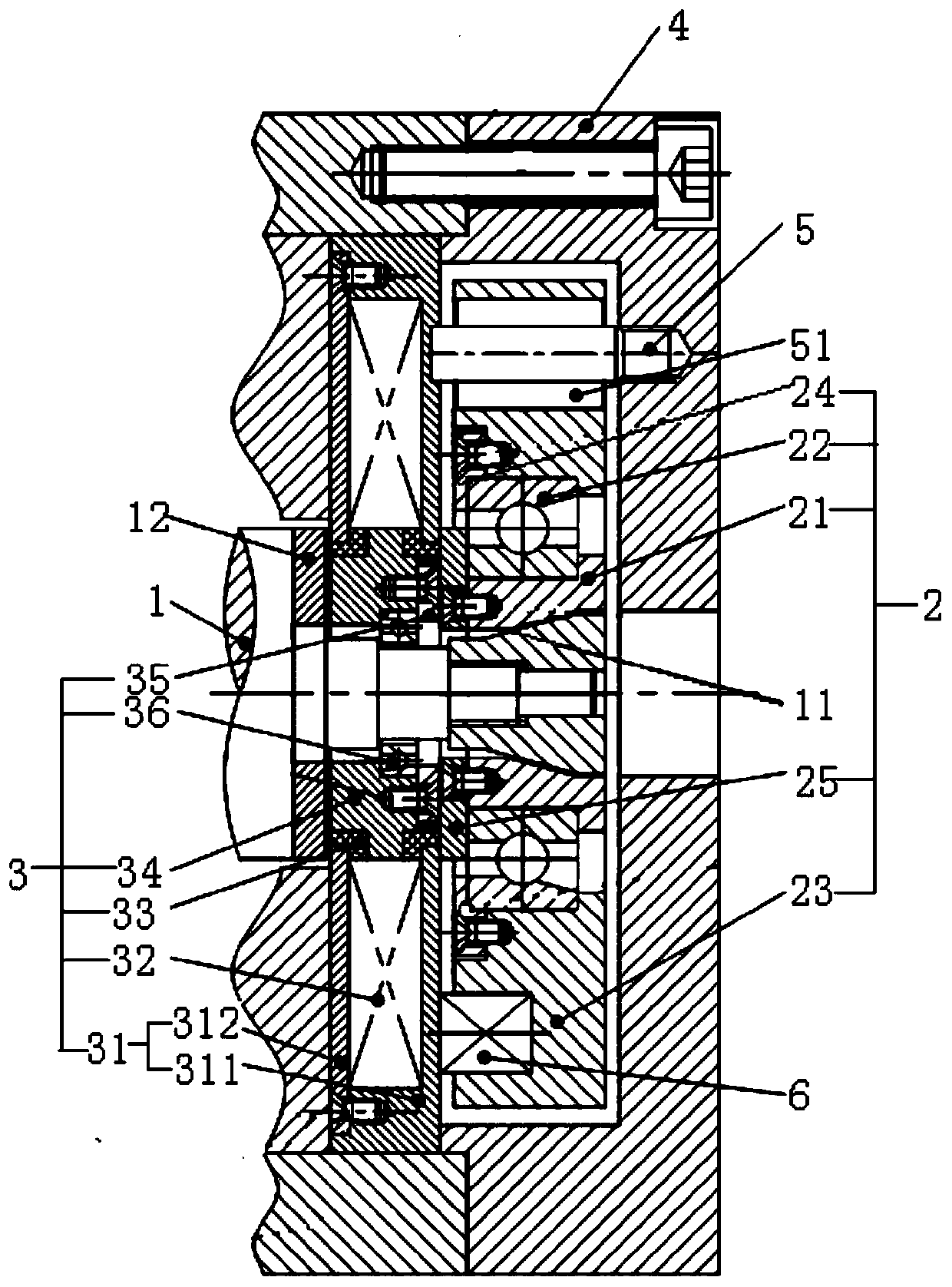

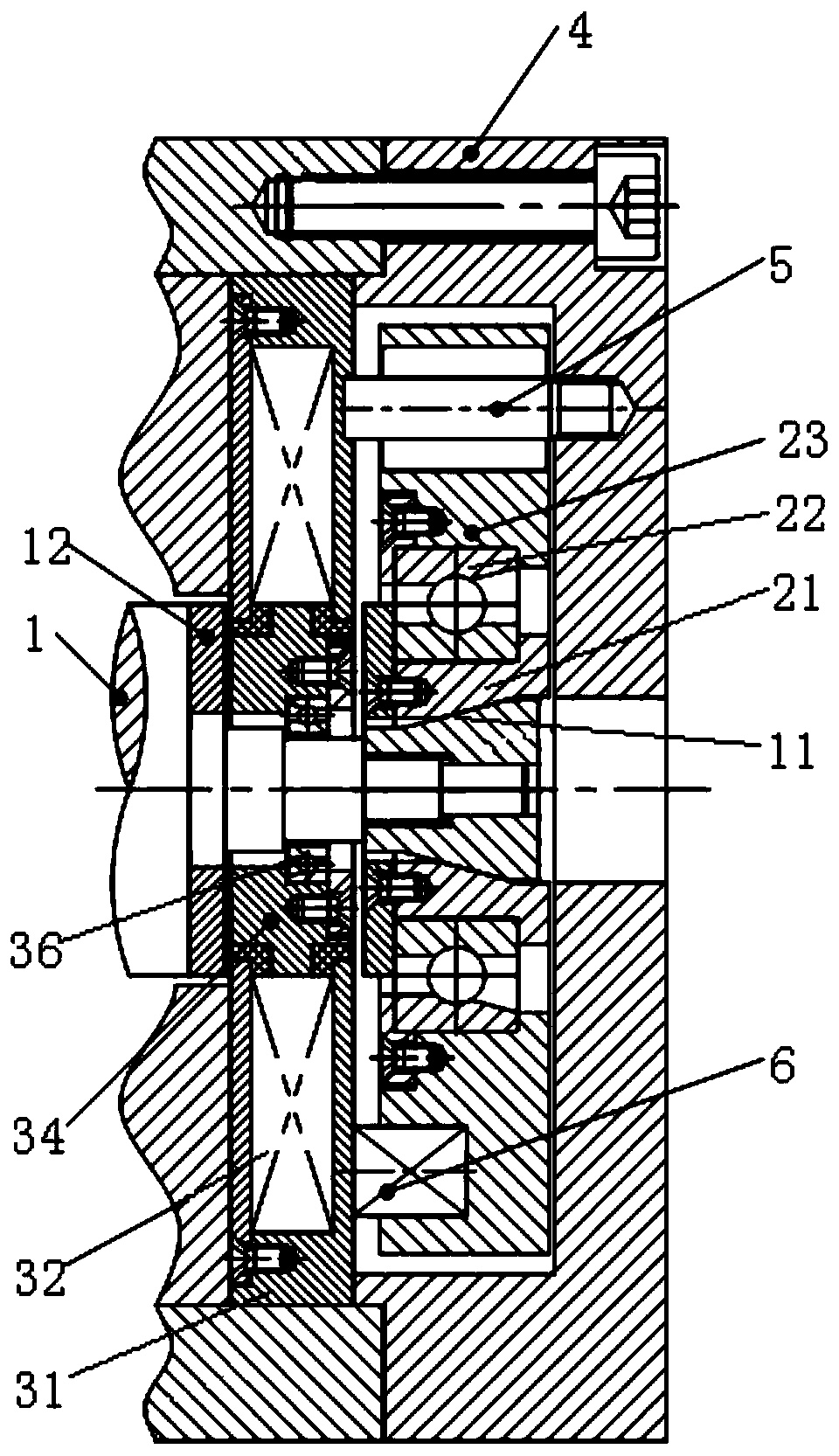

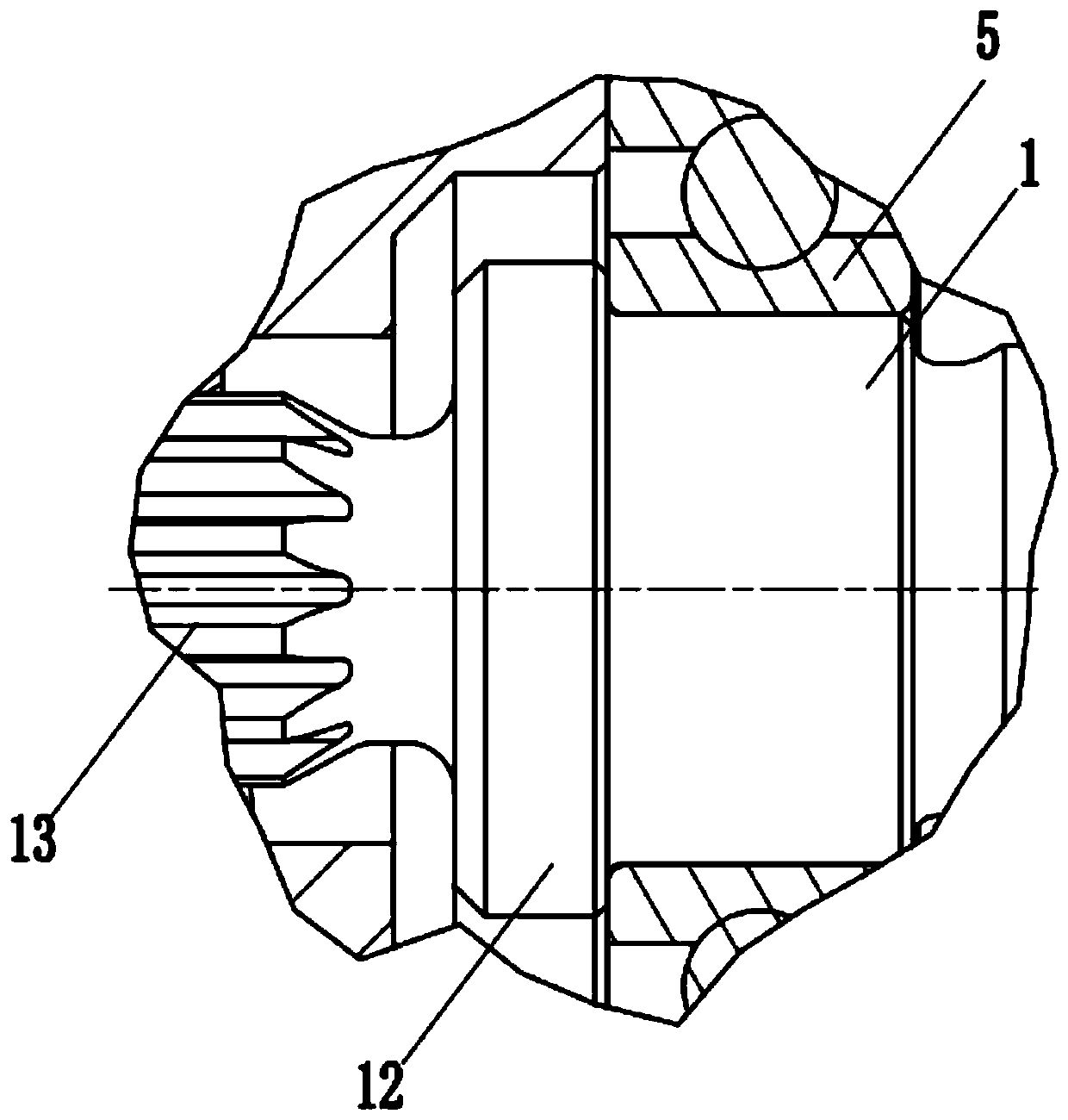

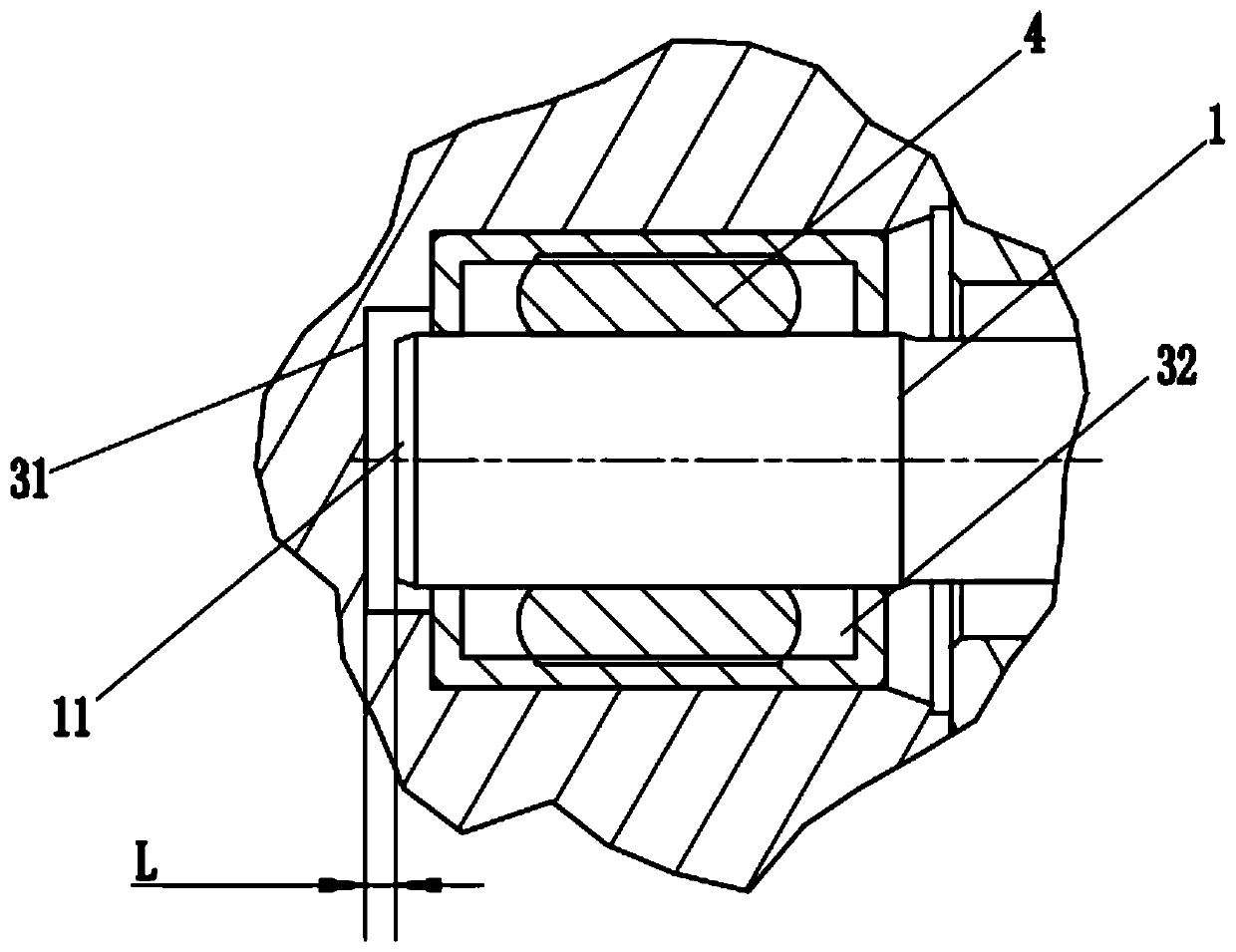

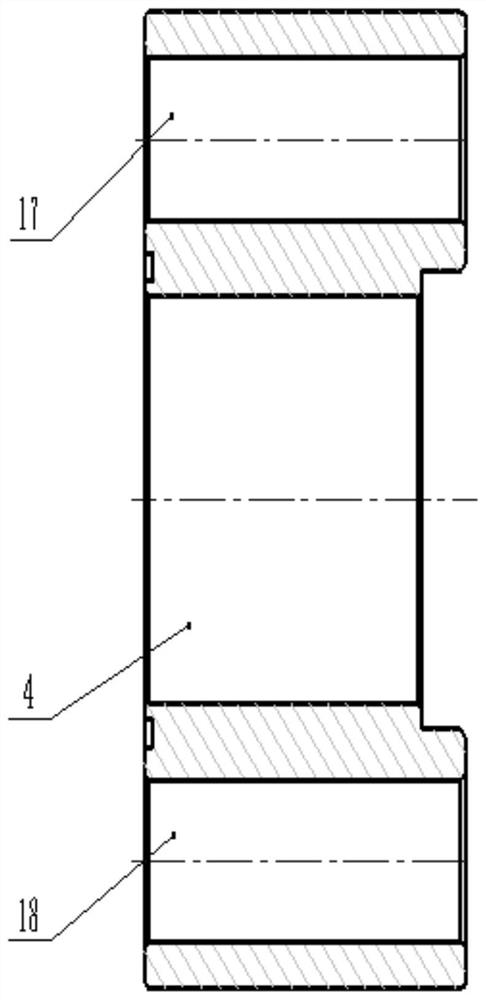

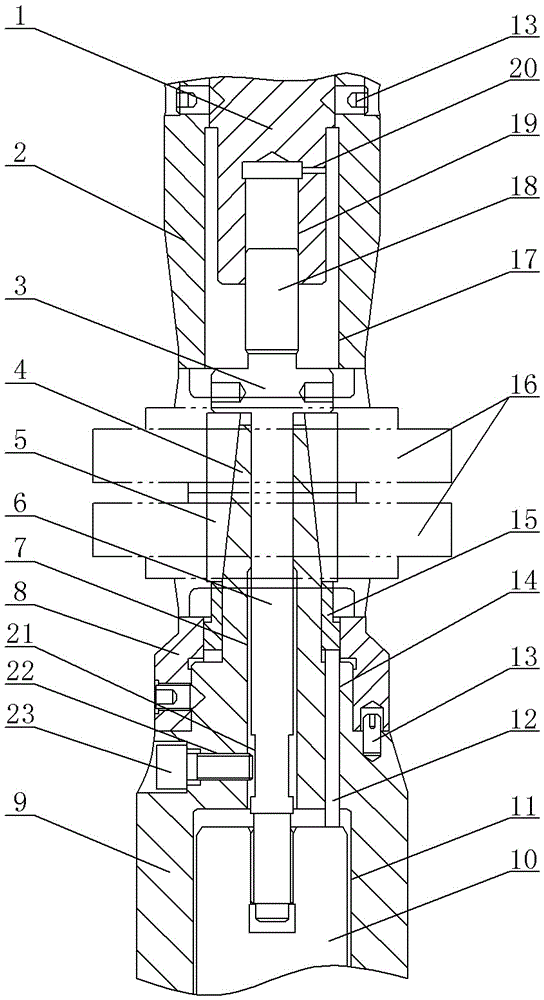

Centripetal thrust protection bearing device for automatically eliminating clearance

InactiveCN103912589AAchieve axial protectionReduce gapRolling contact bearingsBearing unit rigid supportBall bearingRolling-element bearing

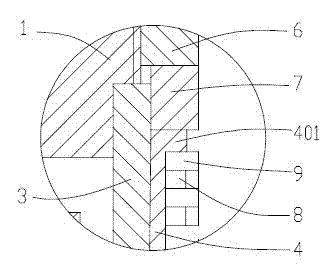

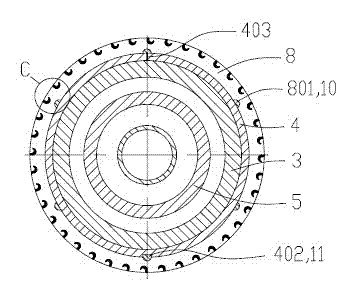

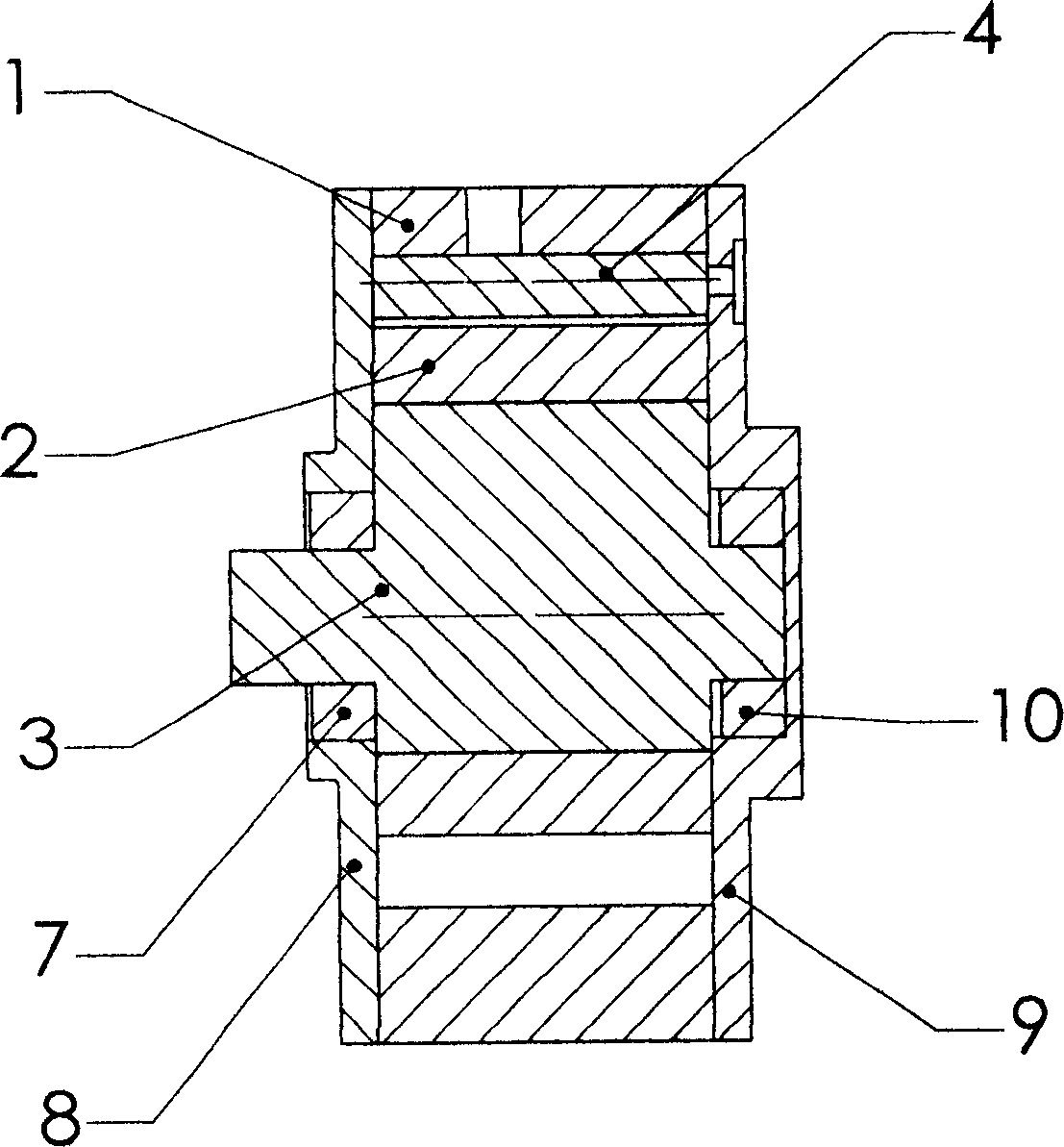

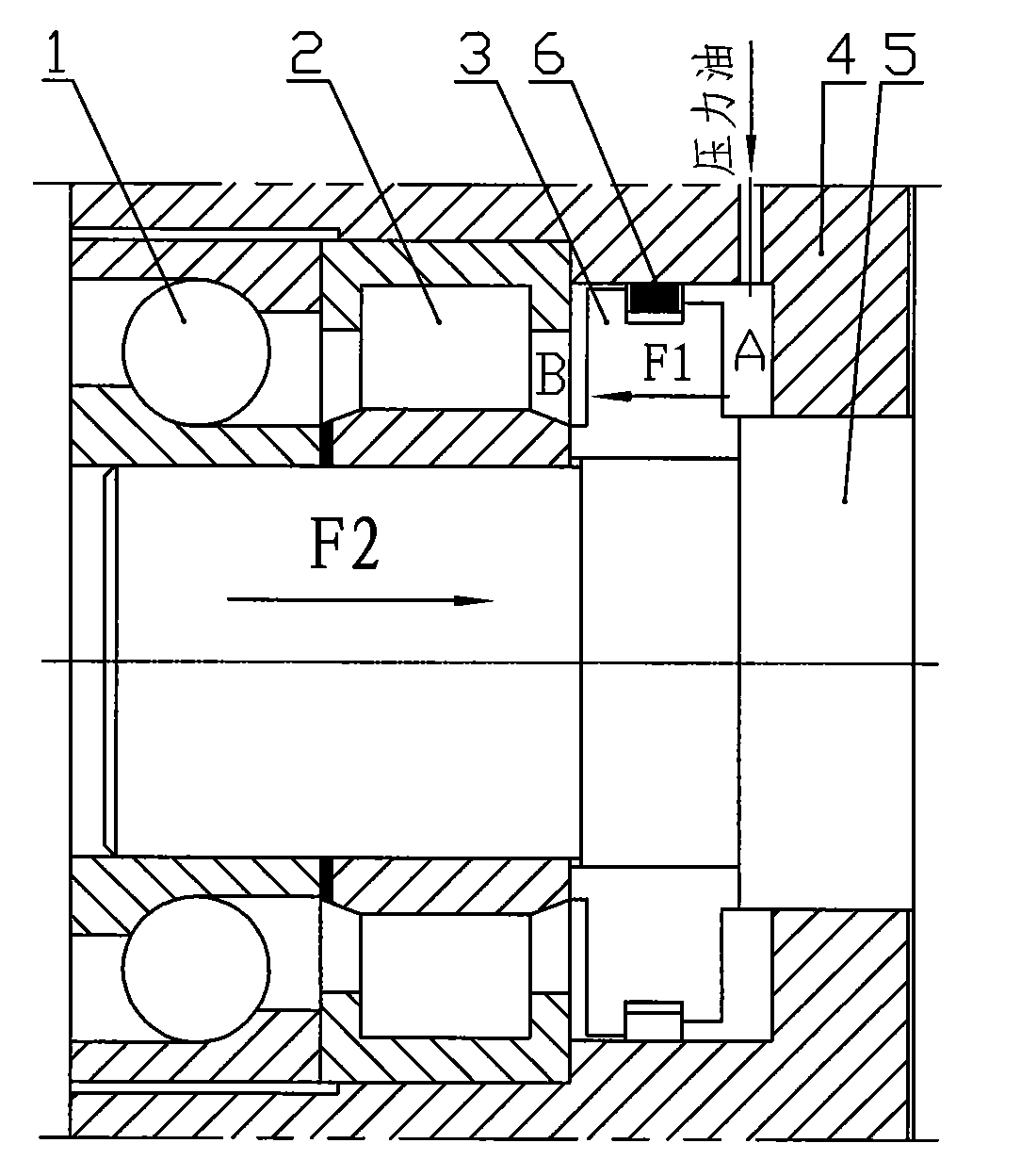

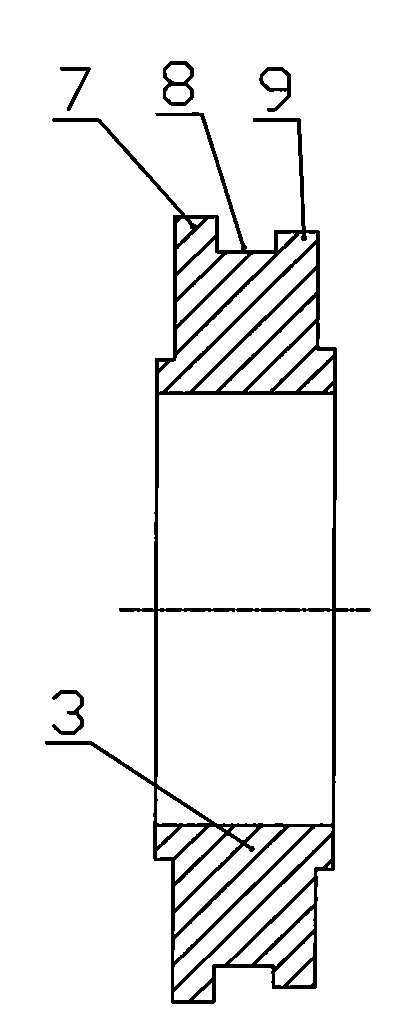

The invention discloses a centripetal thrust protection bearing device for automatically eliminating a protection clearance in a magnetic suspension bearing system. The centripetal thrust protection bearing device comprises a rotary shaft, a rotor assembly, a sliding block, an installation seat and a bearing seat, wherein two angular contact ball bearings are arranged between inner cavities of the installation seat and the bearing seat; the sliding block comprises more than two sliding block sub-bodies; each sliding block sub-body is arranged in a sliding block guide groove through a sliding rod; all the sliding rods are connected into a whole through an annular connecting piece; waist-shaped holes are formed in positions, corresponding to the sliding rods, on the annular connecting piece; at least one sliding block sub-body is provided with a sliding block retaining device; a proper axial clearance is formed between the rotary shaft and the installation seat. Therefore, the device can protect a rotor in the radial and axial directions when the magnetic suspension bearing system fails and the rotor drops, and a radial clearance between the rotary assembly and a rolling bearing can be eliminated, so that vibration and impact on the rolling bearing after the high-speed rotor drops are eliminated, and the reliability and the safety of a centripetal thrust protection bearing are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

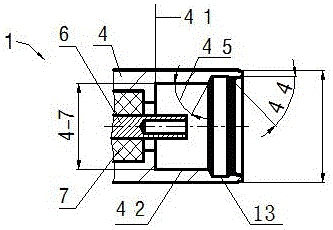

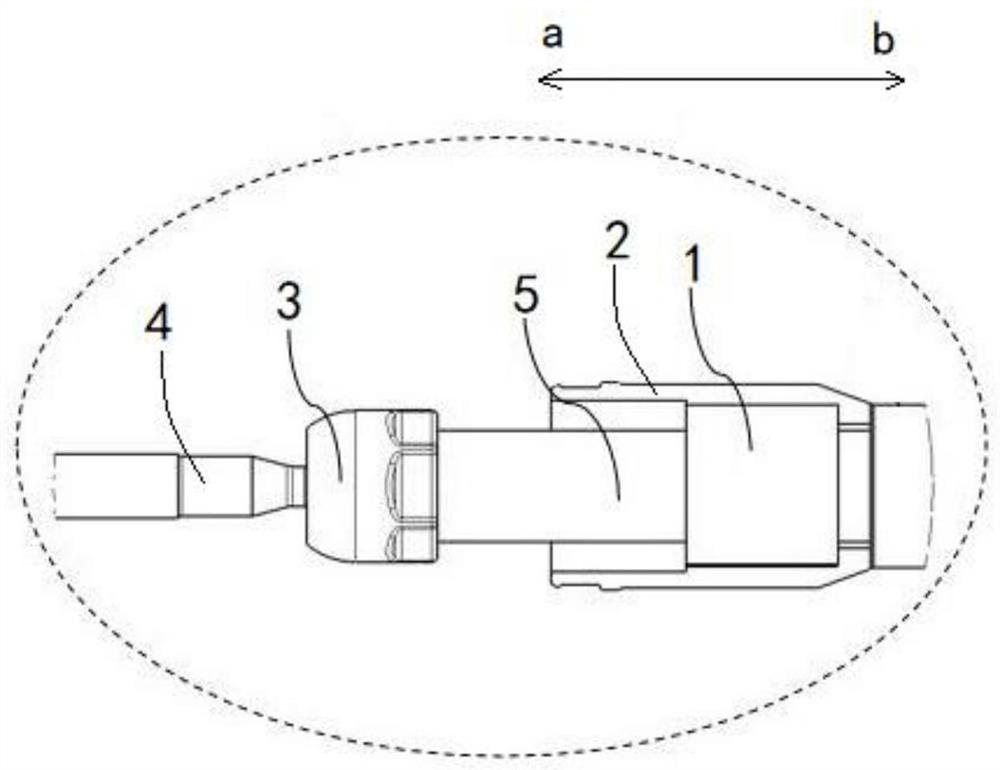

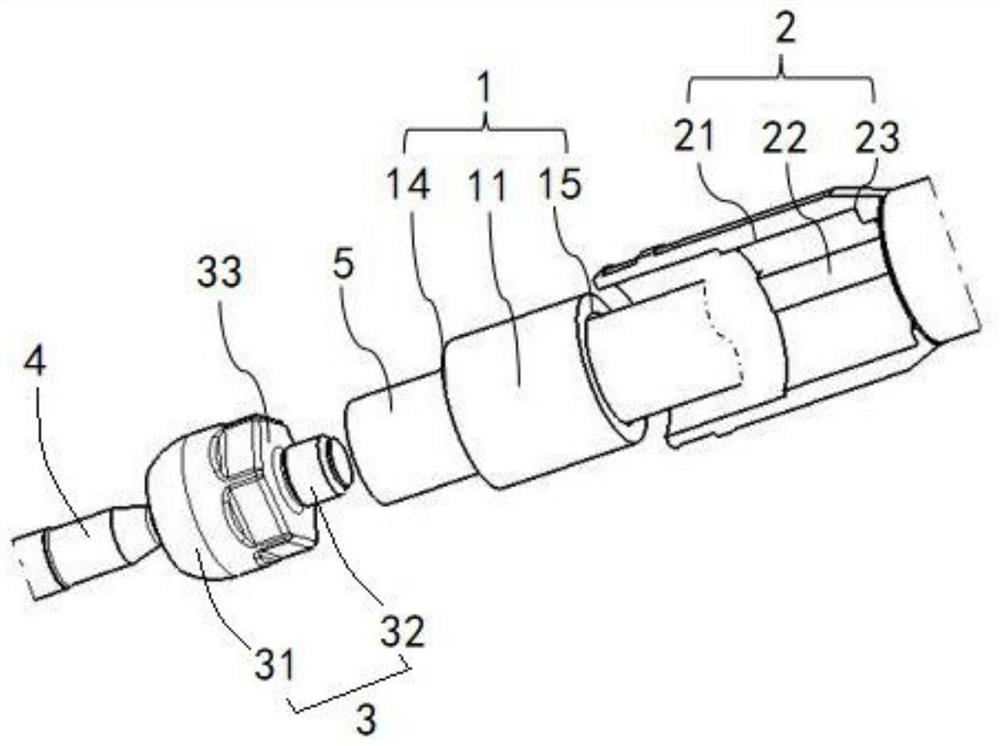

Quick-blind-mating floating-type-mounted RF coaxial connector and connecting method thereof

InactiveCN106229775AEliminate blind matingGuaranteed continuityCoupling device detailsTwo-part coupling devicesCapacitanceElectrical conductor

The invention discloses a quick-blind-mating floating-type-mounted RF coaxial connector and a connecting method thereof. The RF coaxial connector comprises a socket and a plug. The socket comprises an inner conductor jack, an insulator, a socket outer conductor, a floating sleeve, a spring and a mounting panel. The plug comprises a plug outer conductor, an inner conductor inserting pin, an elastic collar and a mounting board. The elastic collar is connected with an engaging trough in an adapted engaging manner. The inner hole linear section of the socket is in insertion fit with the outer cycle linear segment of the plug. According to the RF coaxial connector, on the condition that the plug is inserted into the socket, two reference surfaces are superposed, thereby forming a theoretical zero clearance and ensuring continuity of capacitance. Furthermore a specific engagement structure is utilized, thereby eliminating radial clearance and preventing axial endplay clearance in a stationary state in insertion. Furthermore the quick-blind-mating floating-type-mounted RF coaxial connector and the connecting method have advantages of small size, compact structure, low reflection coefficient, low voltage standing wave, full-band linear voltage standing-wave ratio, excellent shielding efficiency, etc.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD

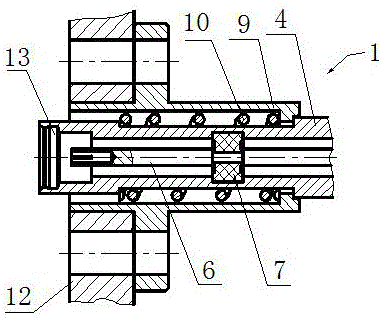

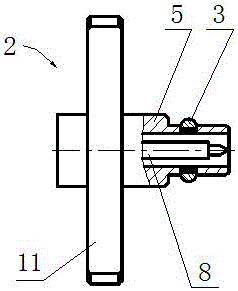

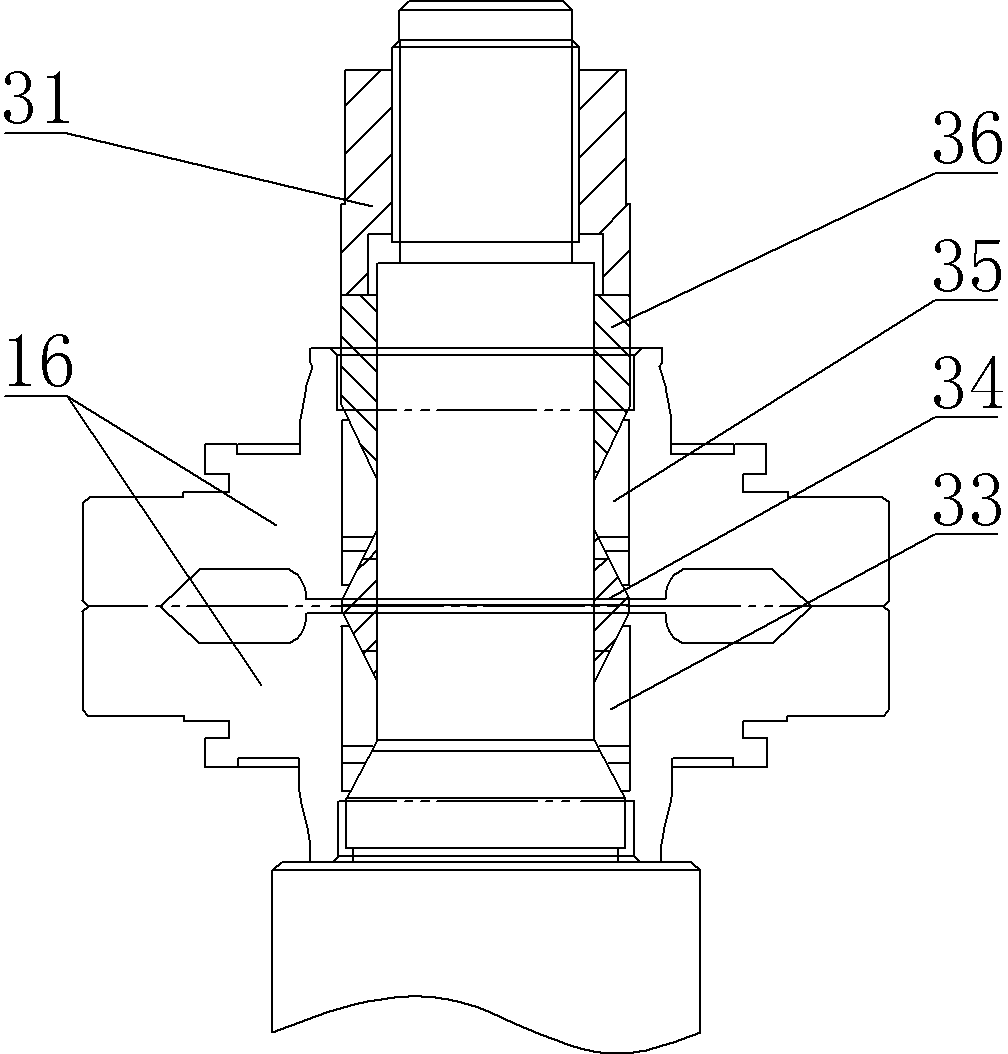

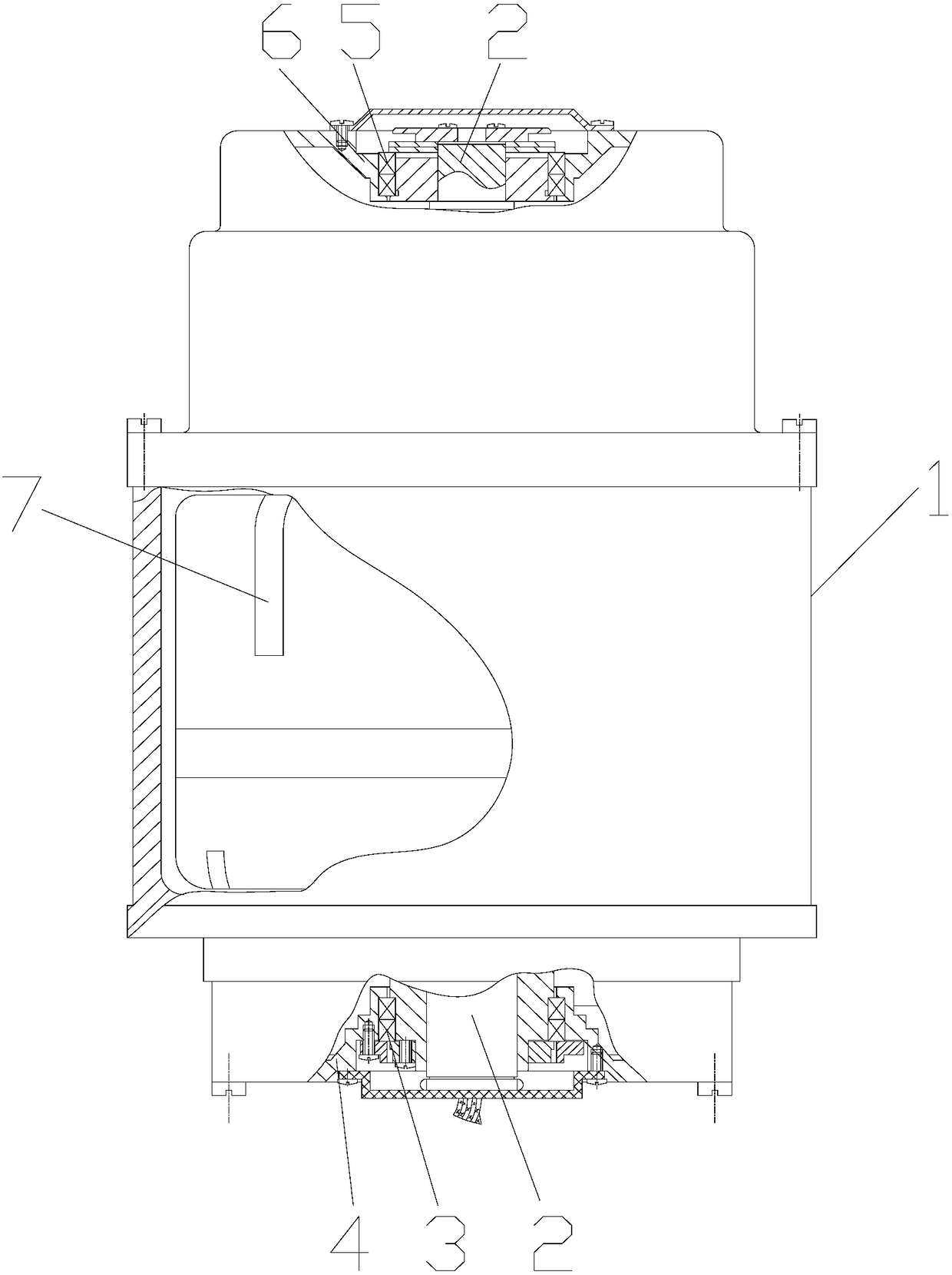

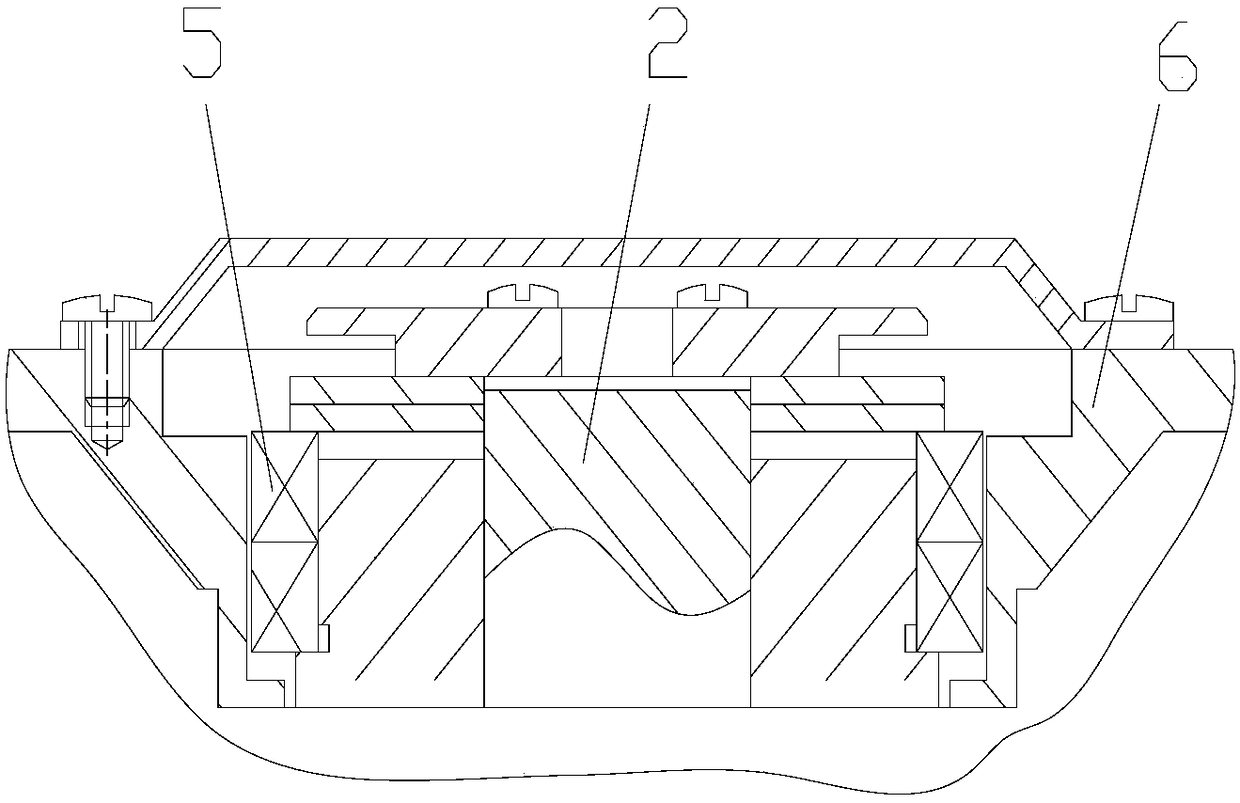

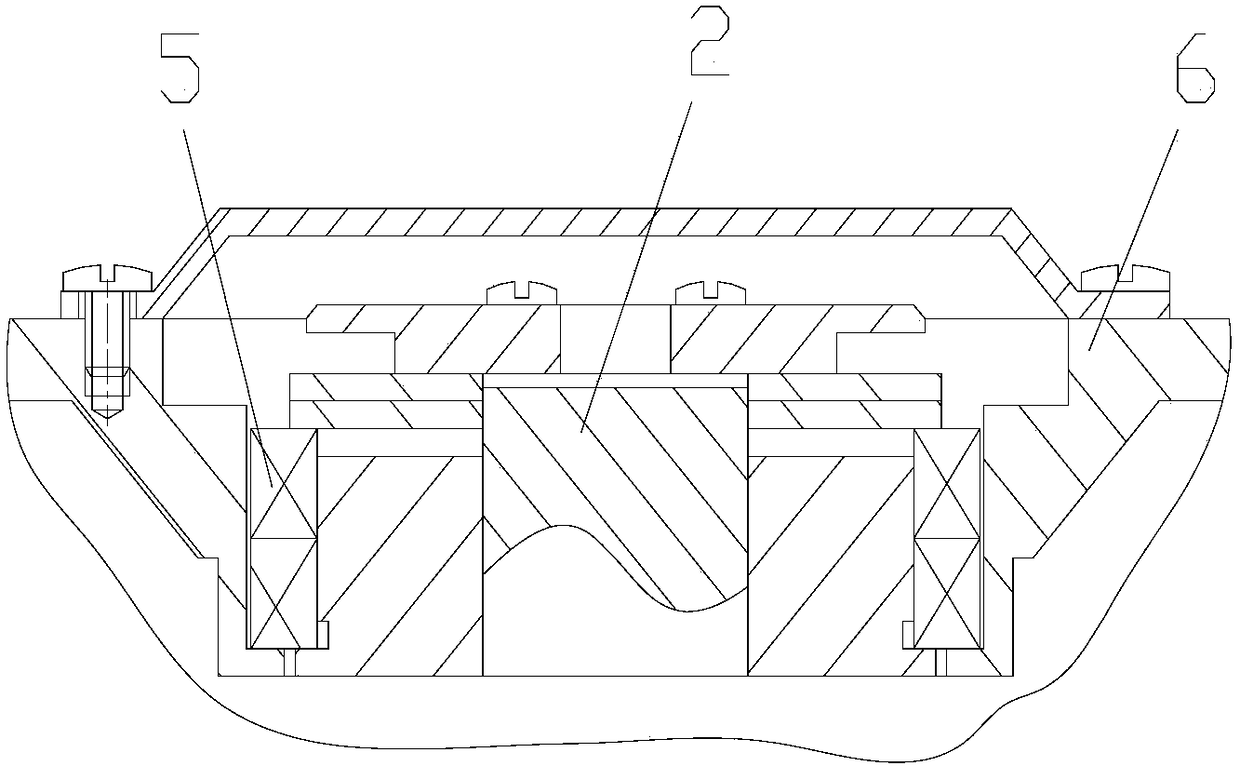

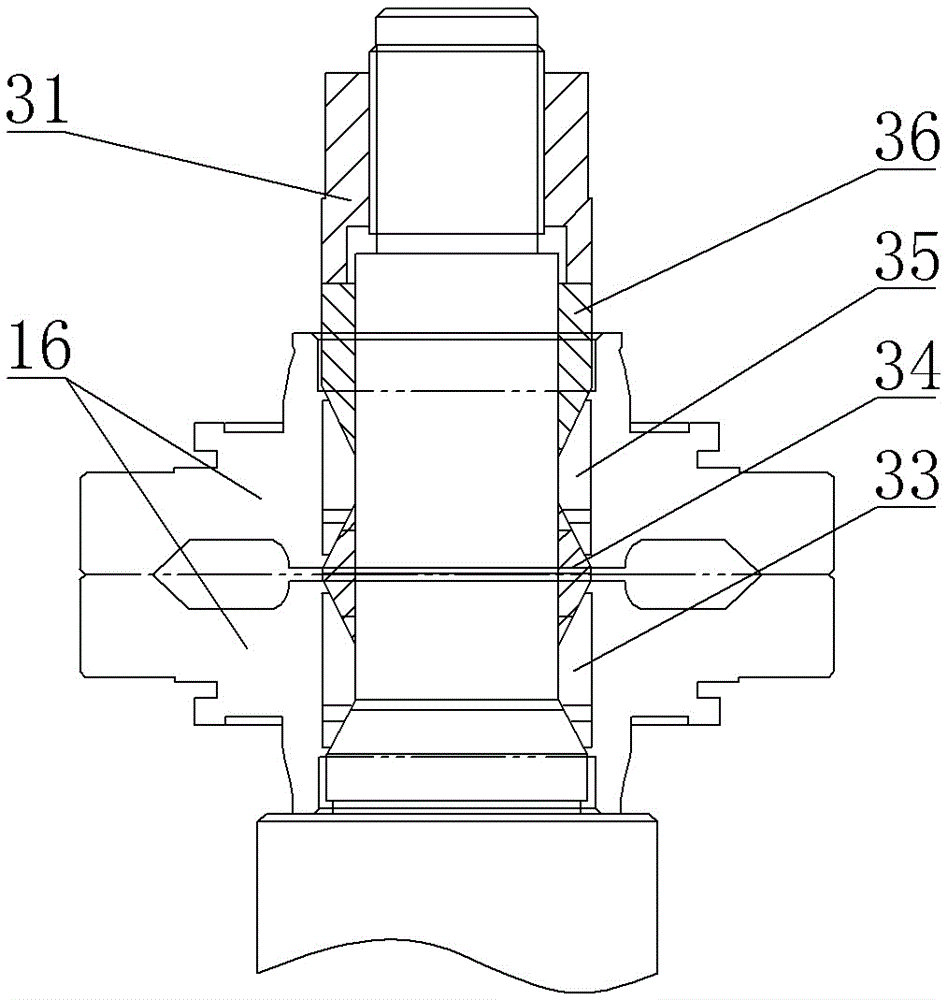

Manual type bearing protection device

The invention relates to a magnetic levitation bearing system, in particular to a manual type bearing protection device. The manual type bearing protection device comprises a rotor, two bearing seats,two groups of bearing protection assemblies and a manual driving assembly; two ends of the rotor are in a circular truncated cone shape; the two bearing seats are arranged at the two ends of the rotor, and the two ends of the rotor extend into the bearing seats; the two groups of the bearing protection assemblies are symmetrically and slidably arranged in the bearing seats, cone-shaped holes which are matched with the ends of the rotor are formed in the bearing protection assemblies; and the manual driving assembly drives the bearing protection assemblies to axially move close to each other until the bearing protection assemblies are in contact with the rotor. The manual type bearing protection device can temporarily support the rotor when a magnetic bearing system fails, can manually protect the rotor, prevents damage caused by falling of the high-speed rotor, and improves the security of the system.

Owner:JIANGSU UNIV OF TECH

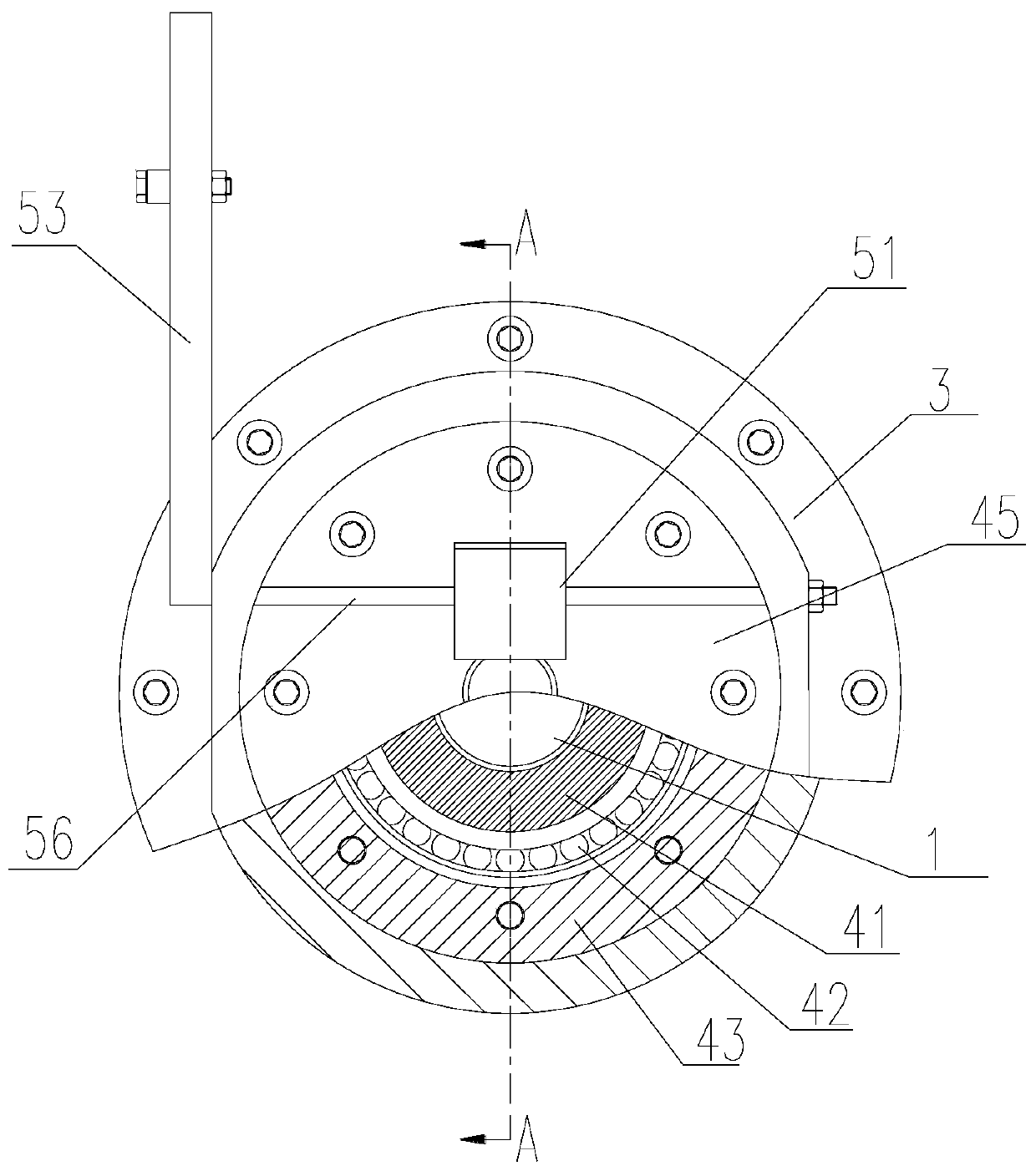

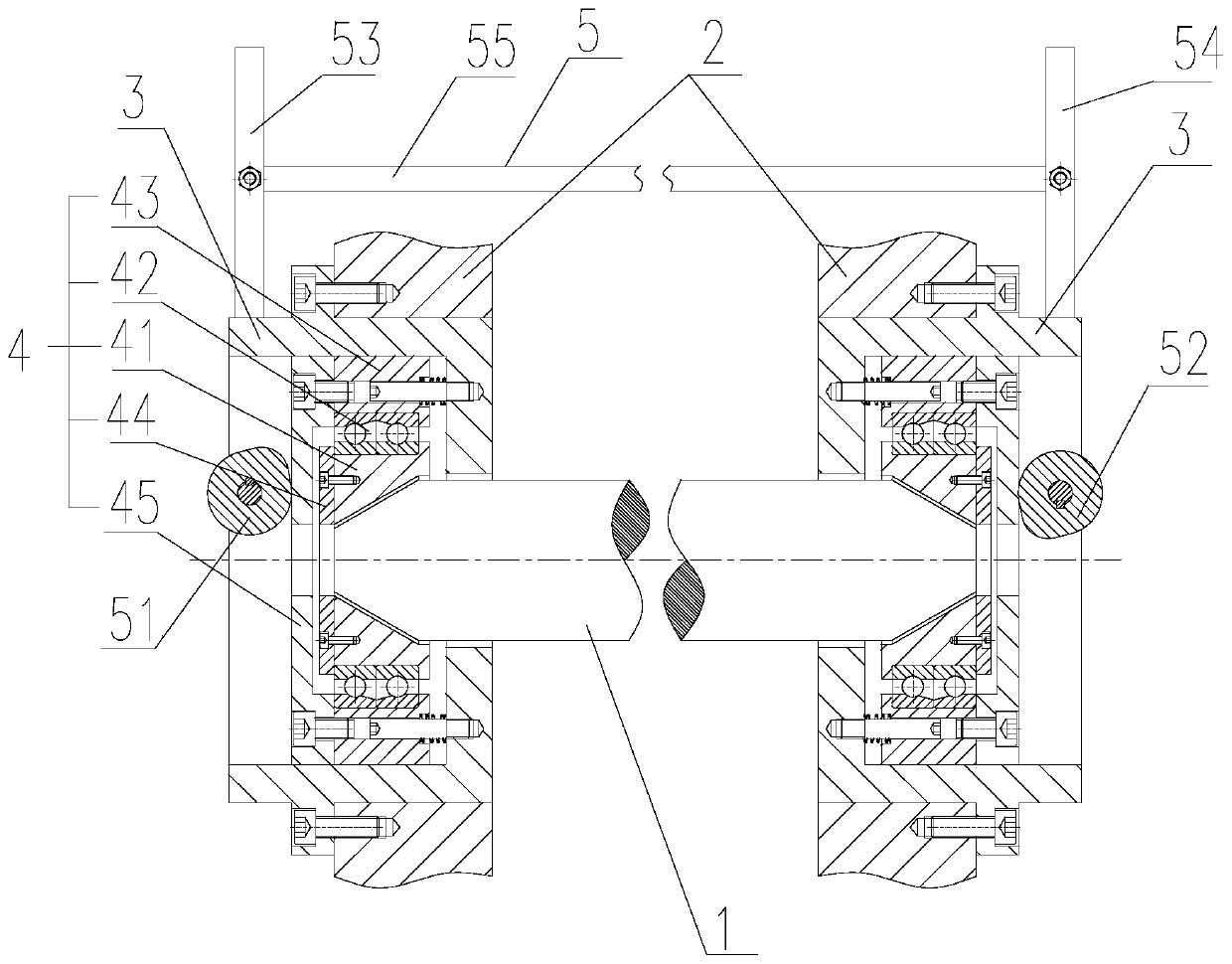

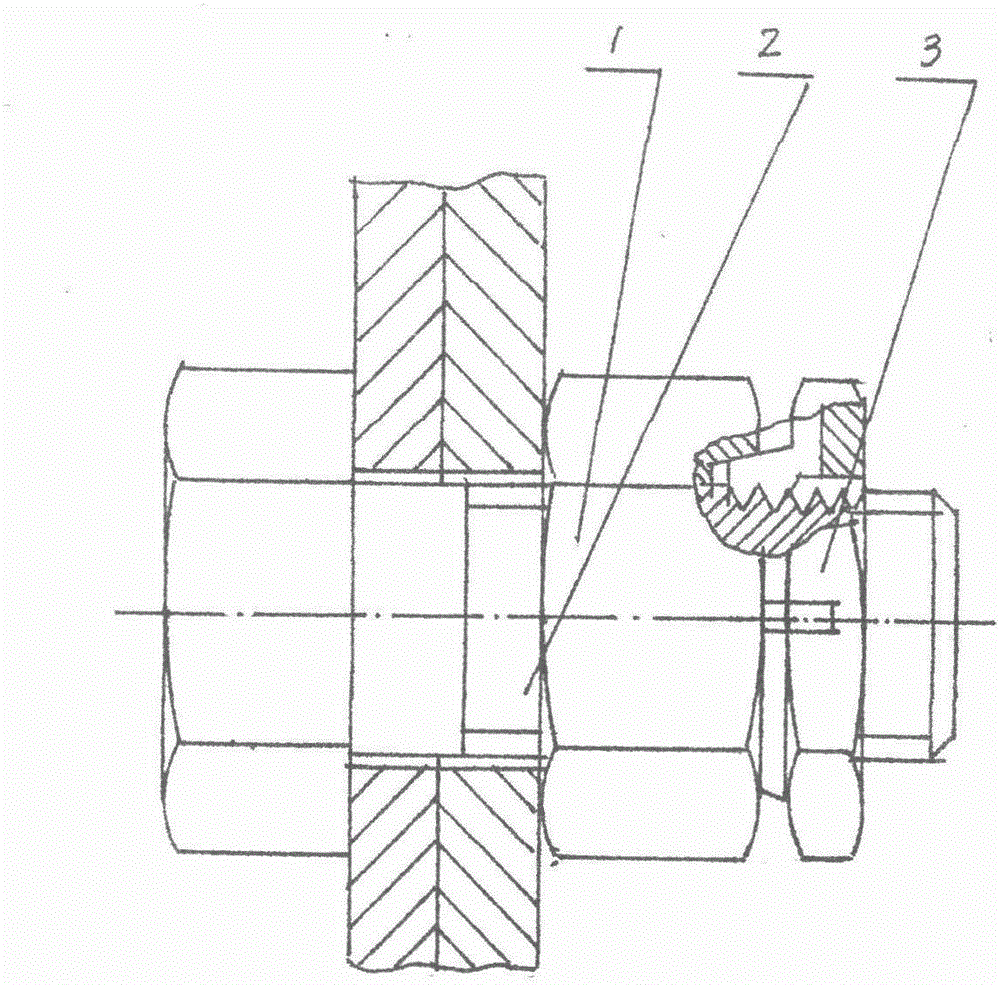

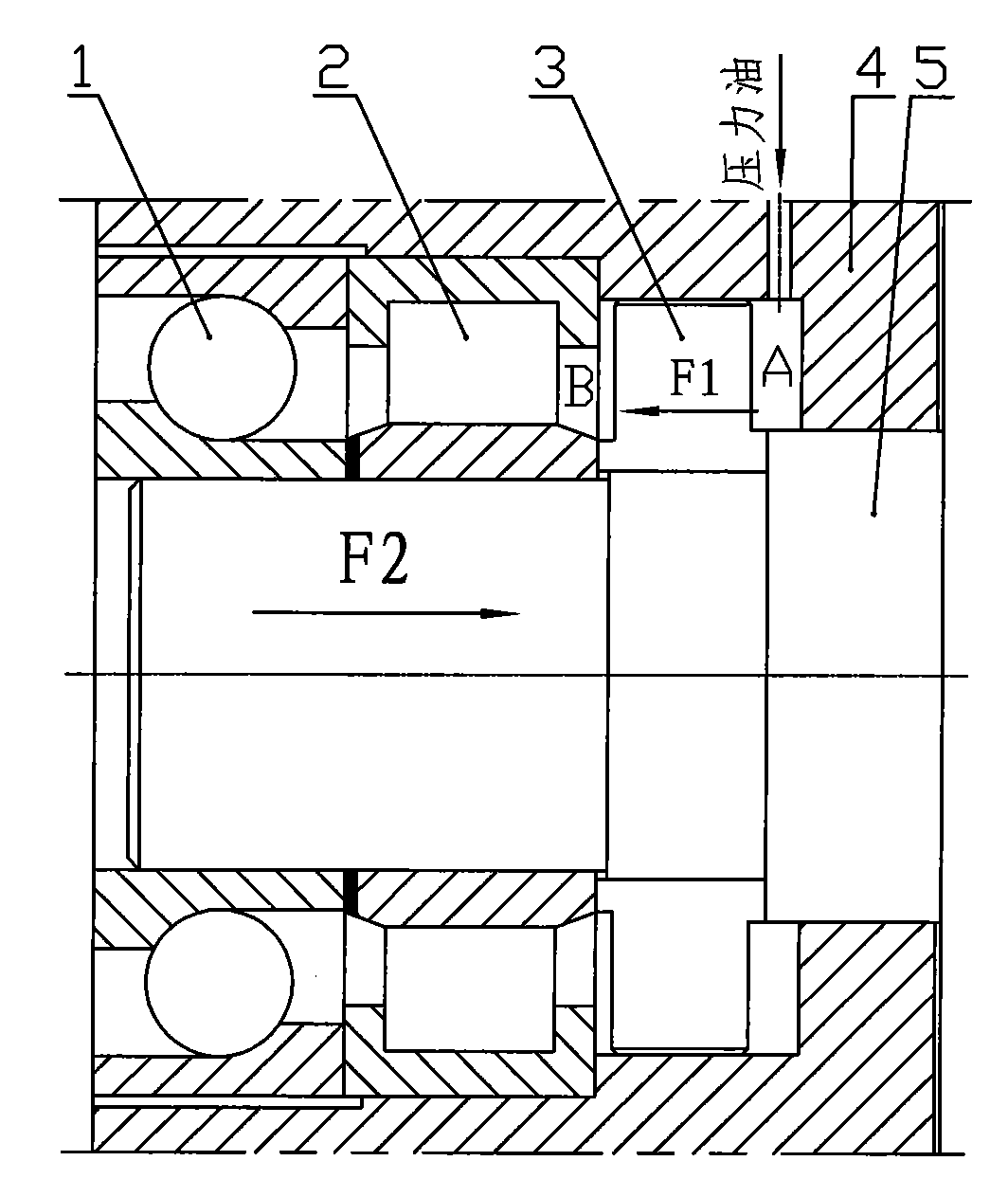

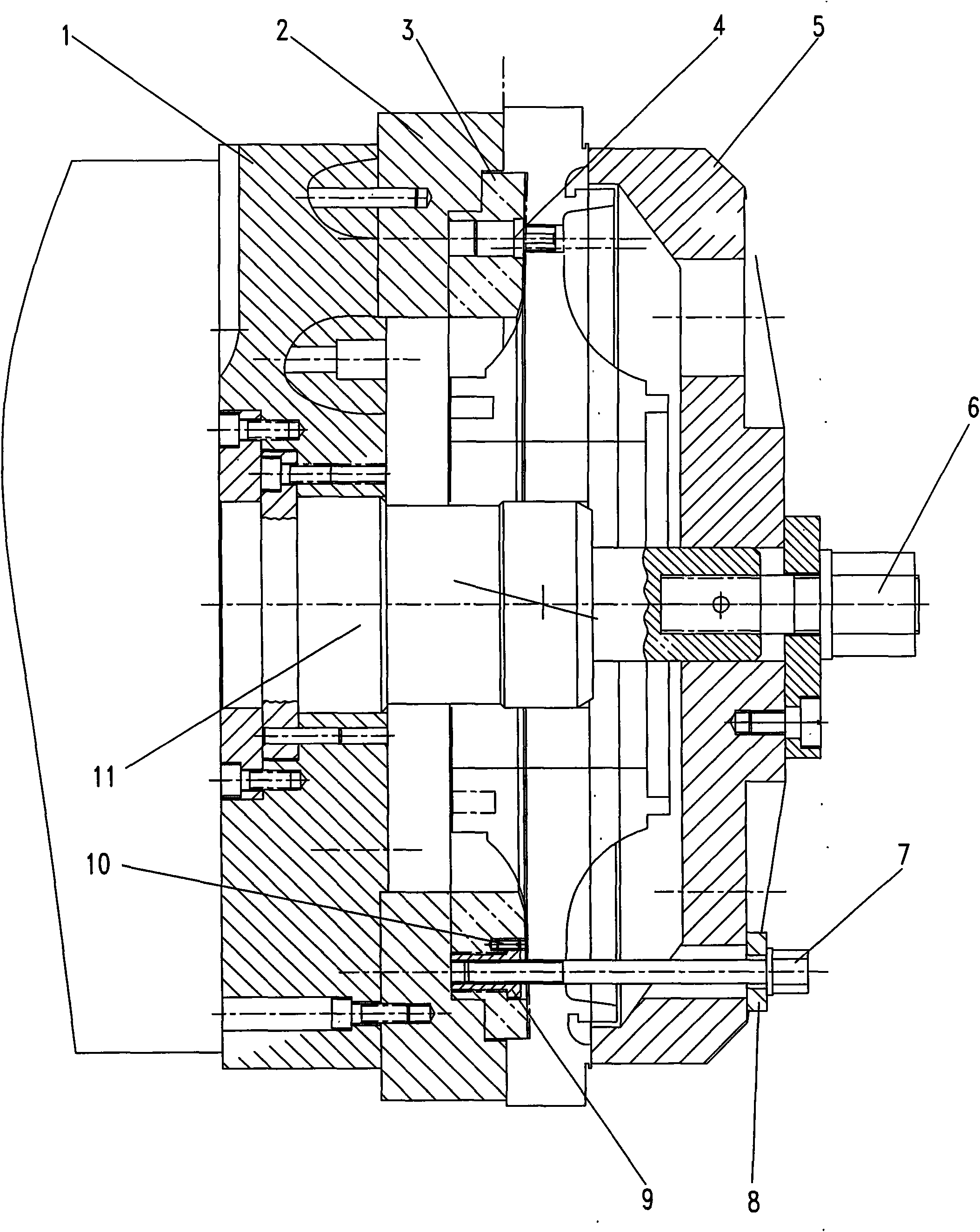

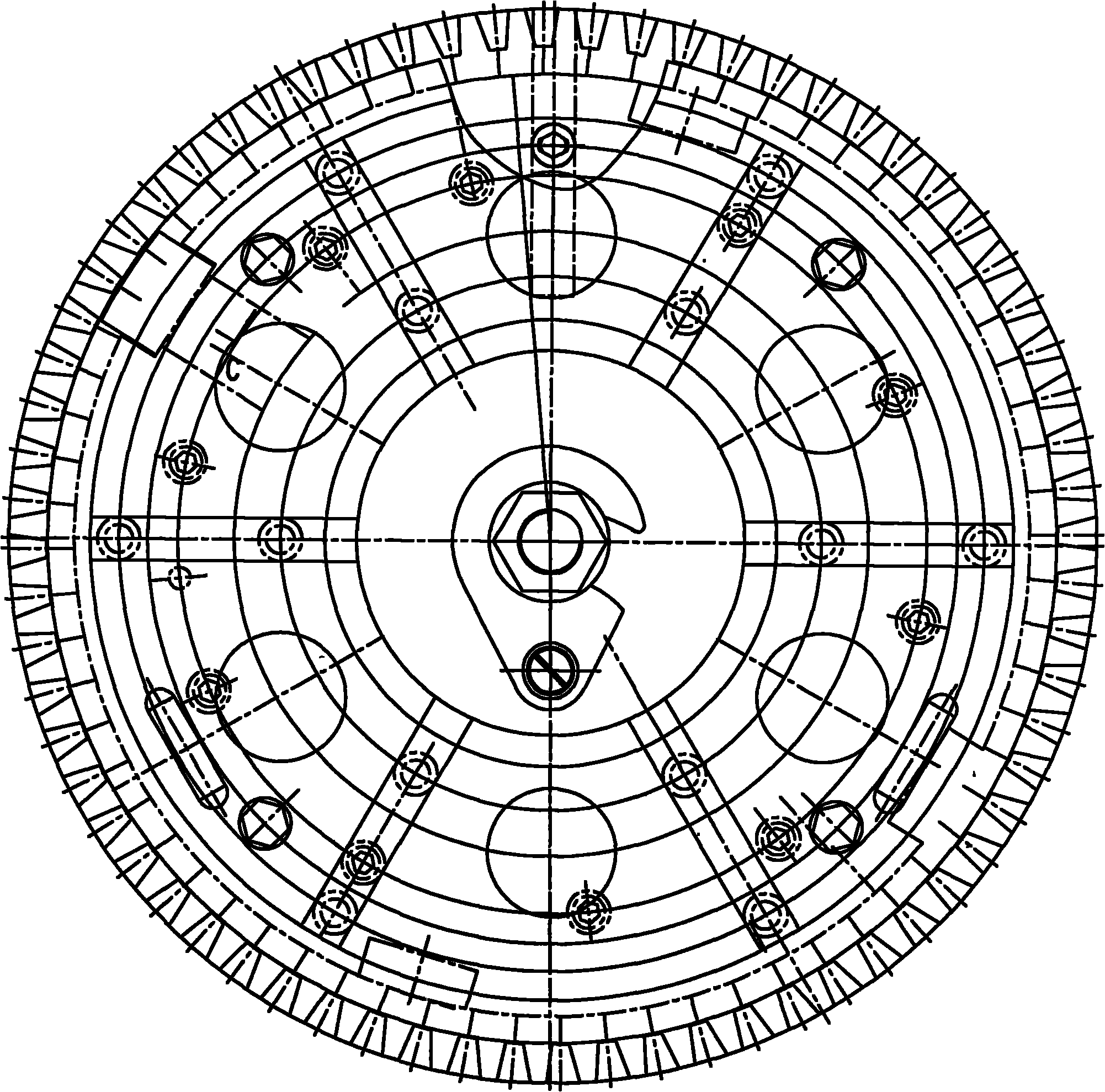

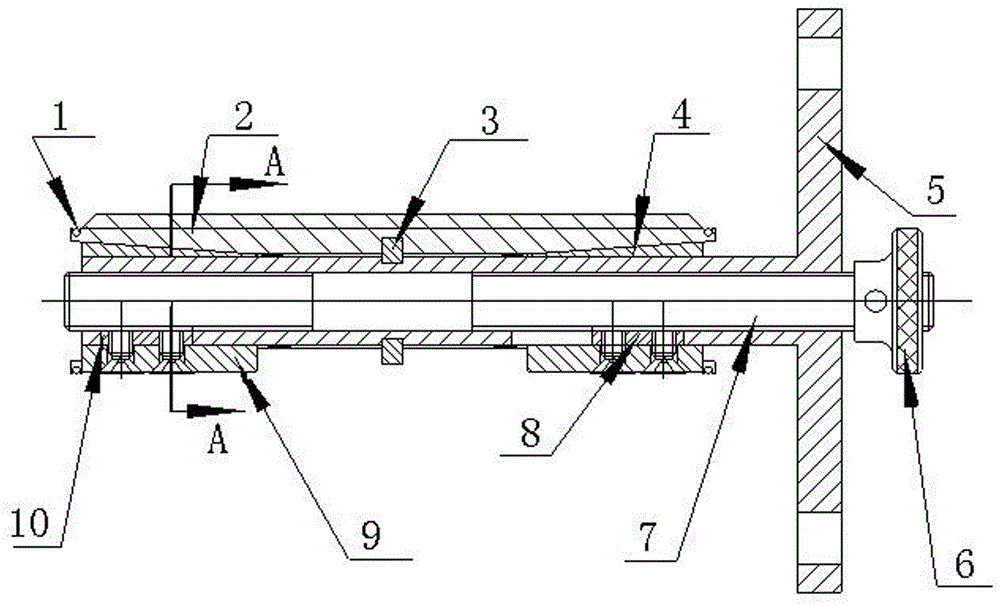

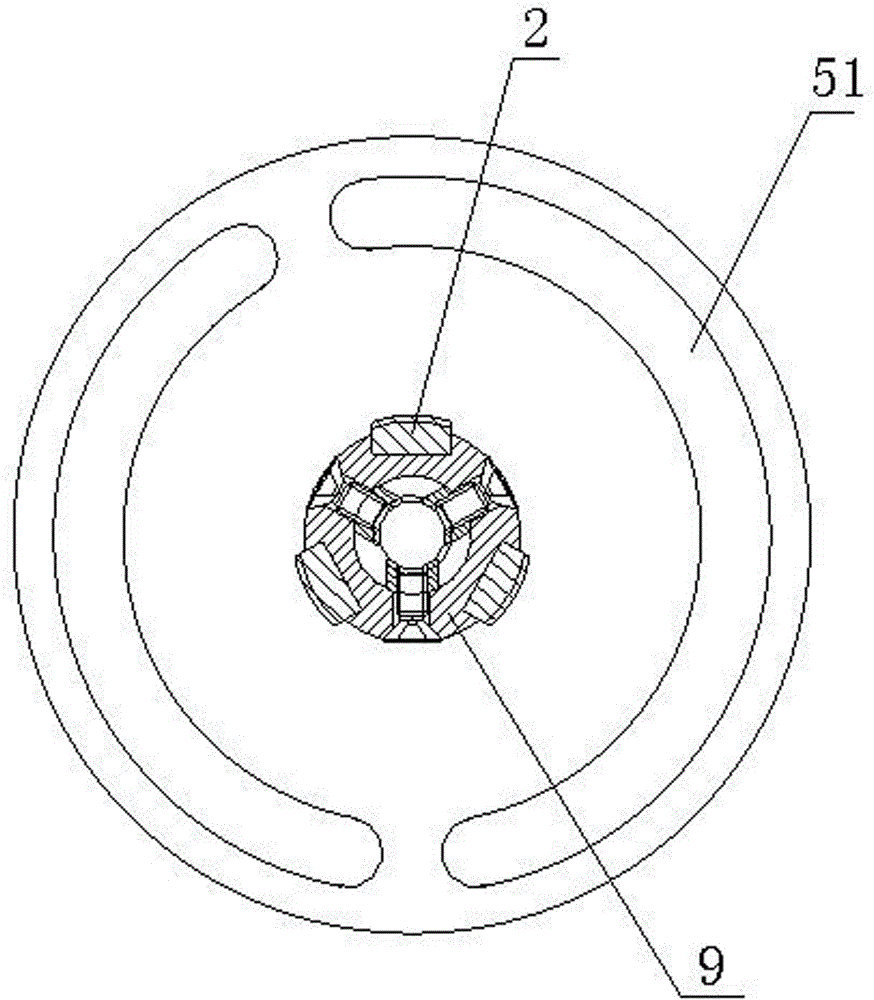

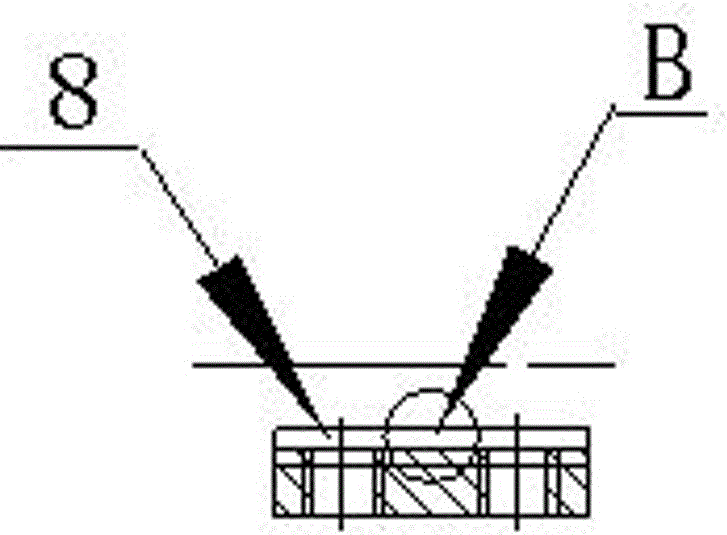

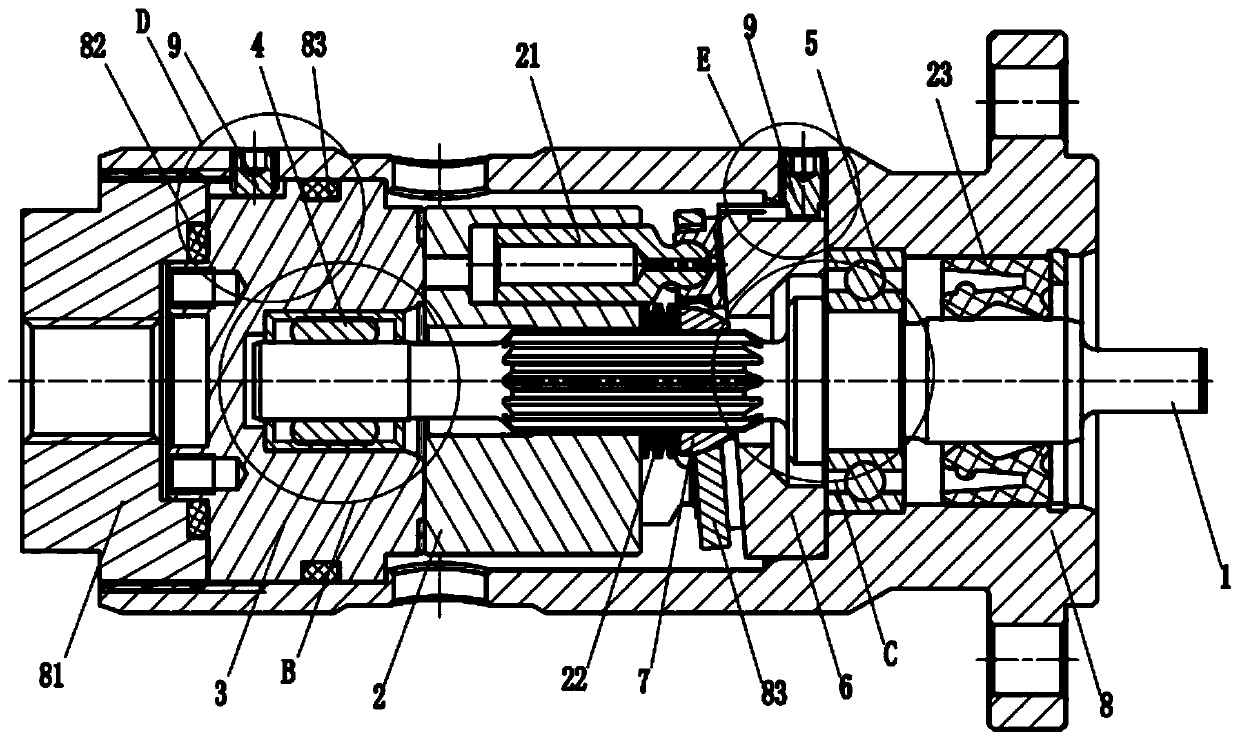

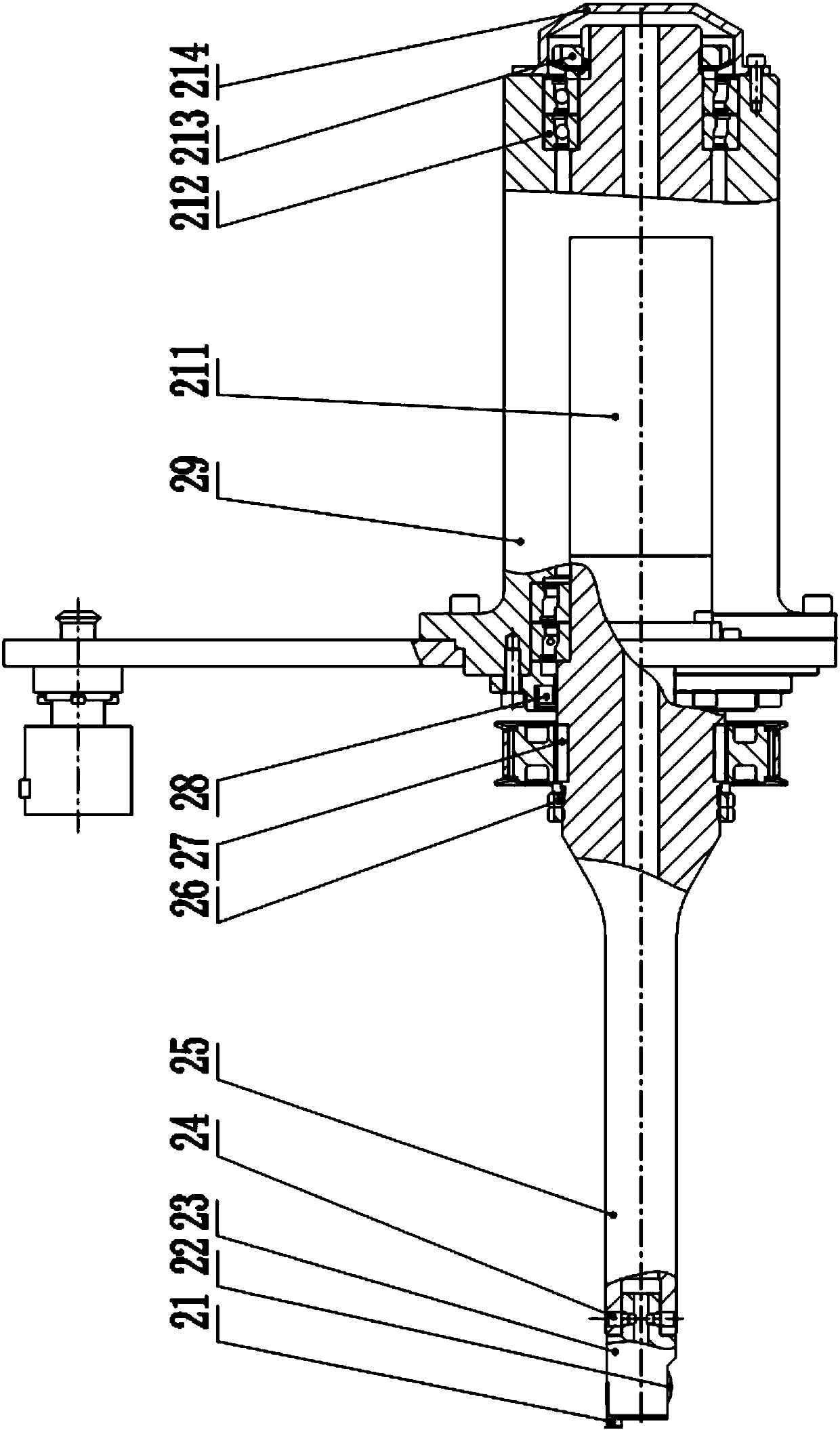

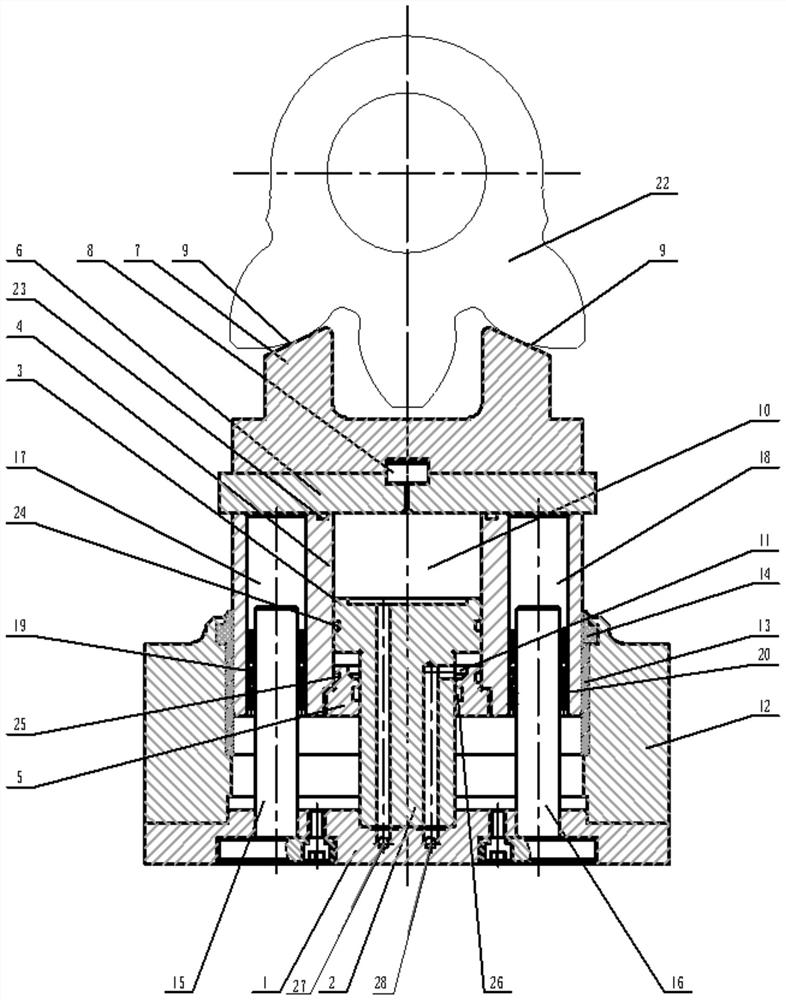

Hydraulic gear grinding clamp capable of rapidly replacing large-size workpieces and clamping method of hydraulic gear grinding clamp

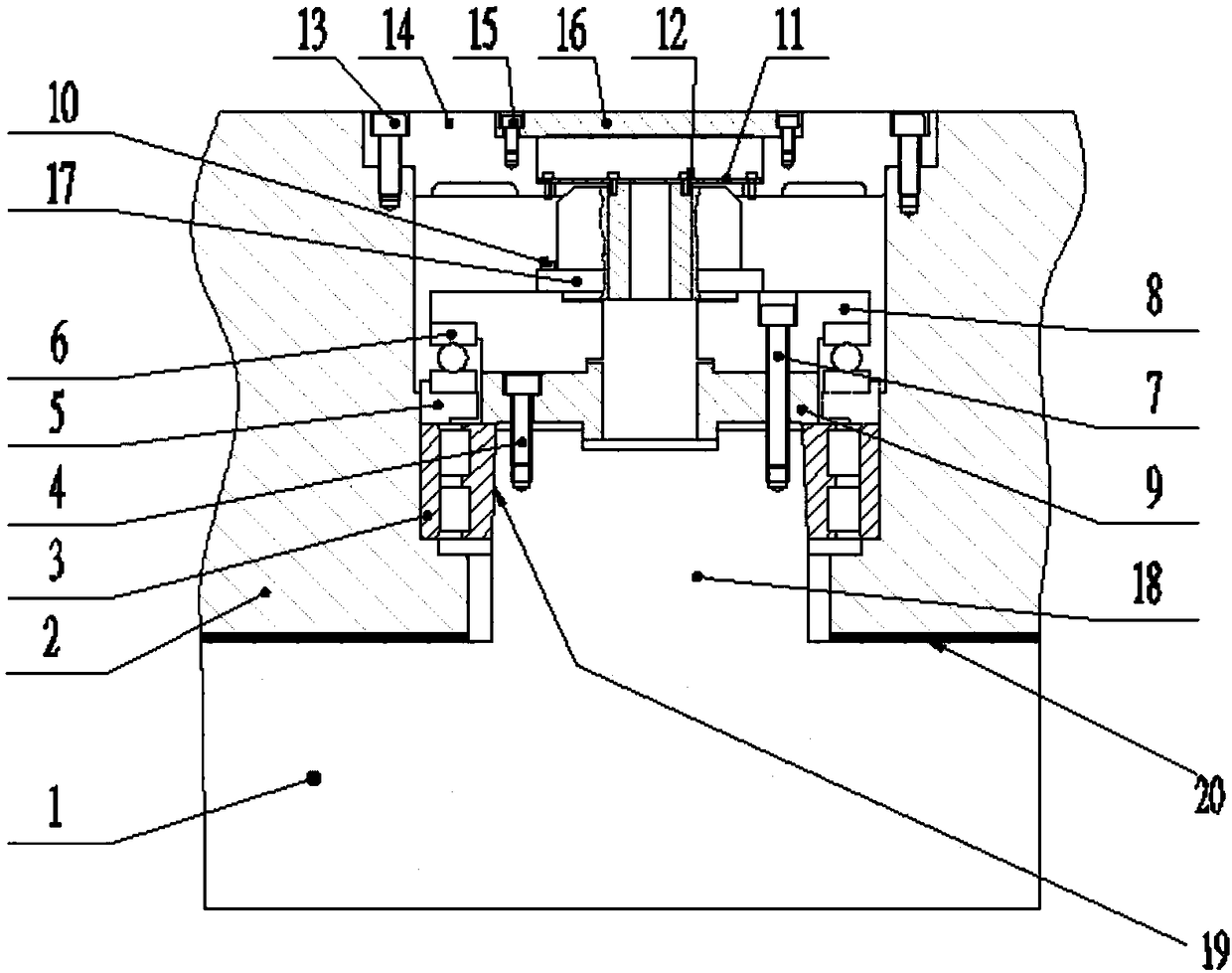

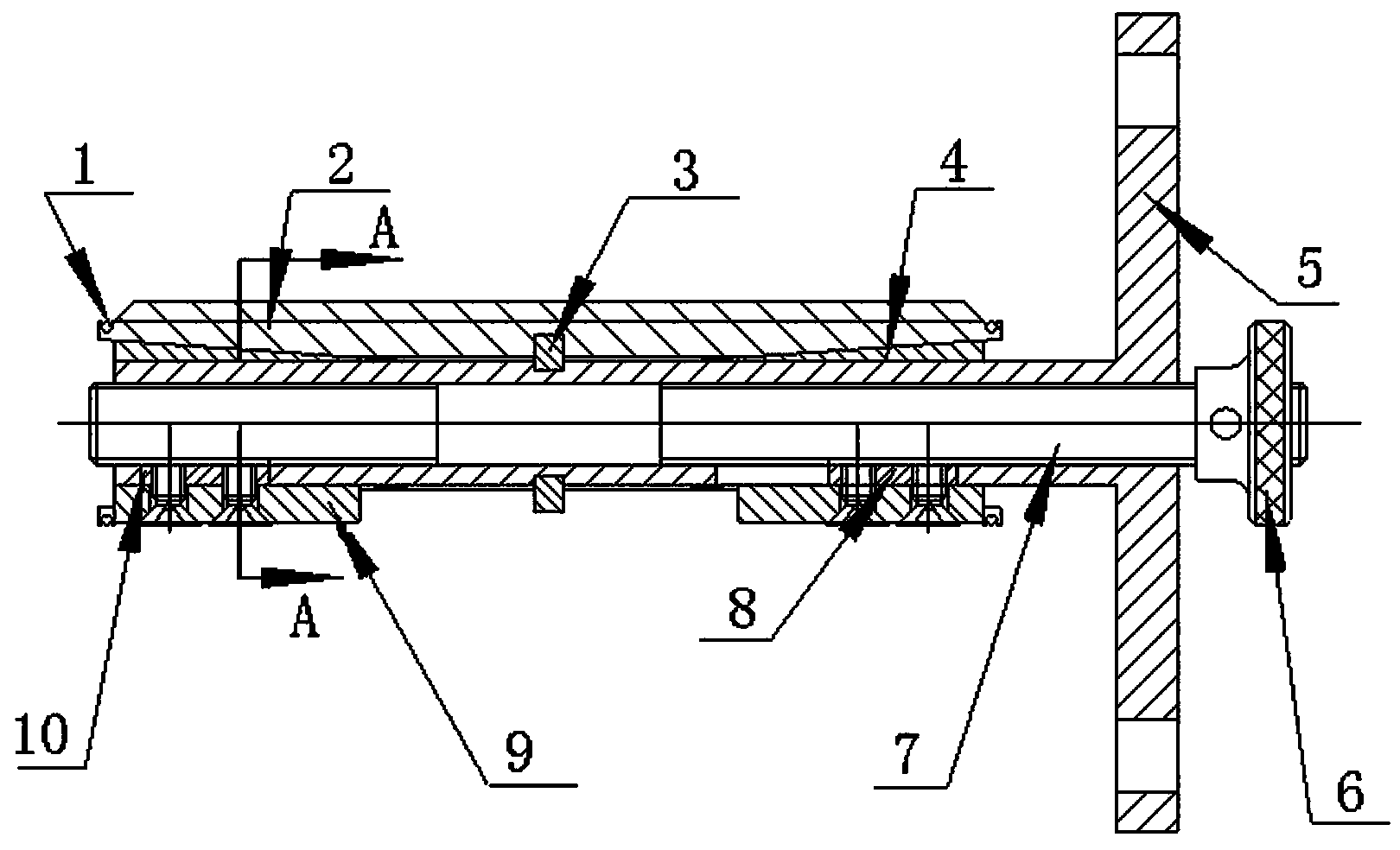

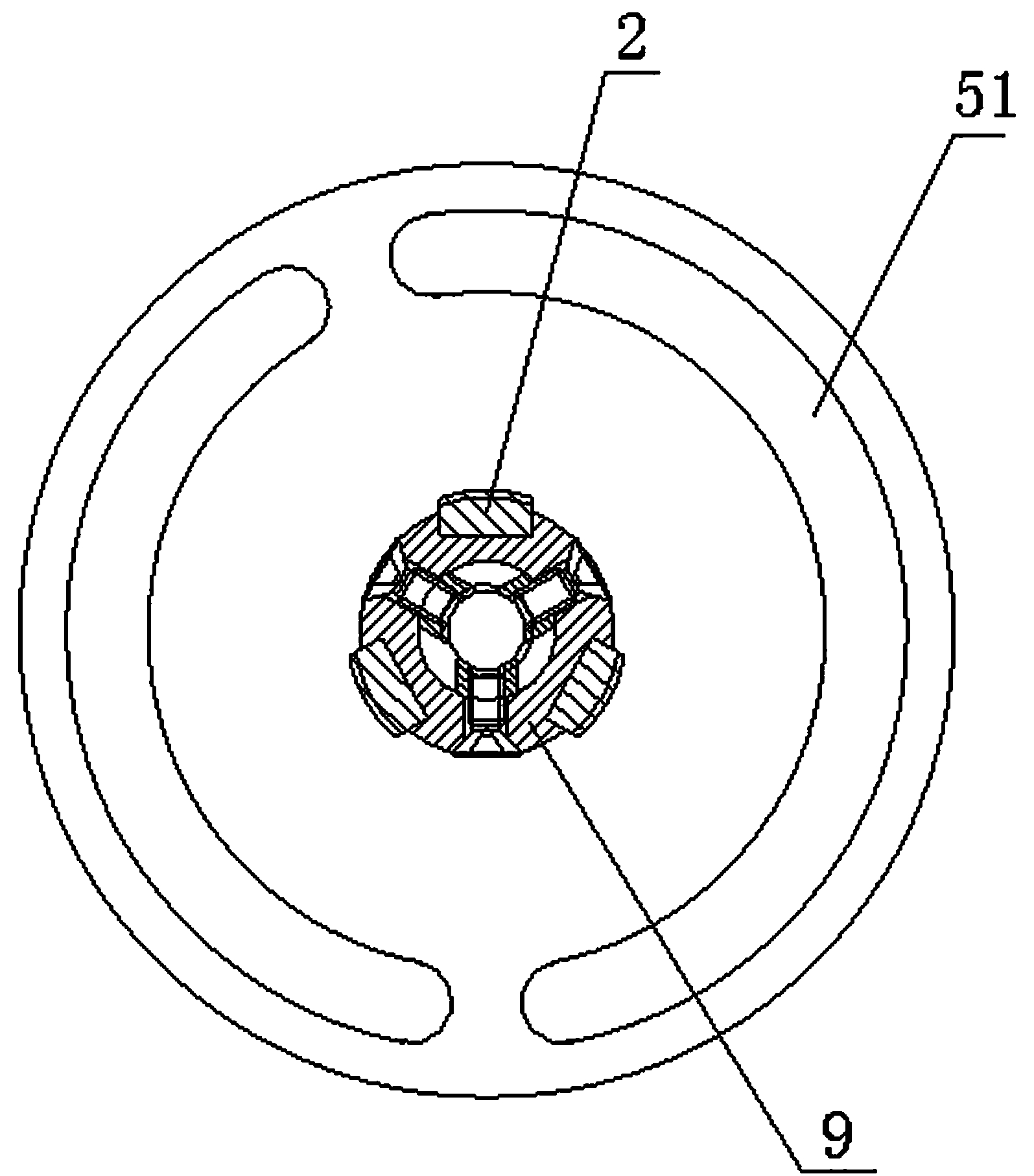

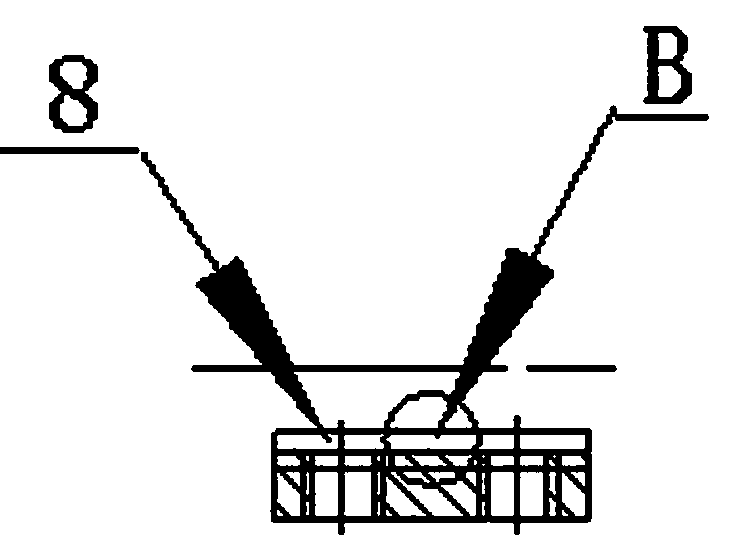

ActiveCN105562838AFast automatic clampingIncrease the level of automationGear-cutting machinesGear teethGear grindingEngineering

The invention provides a hydraulic gear grinding clamp capable of rapidly replacing large-size workpieces and a clamping method of the hydraulic gear grinding clamp. The hydraulic gear grinding clamp comprises an oil cylinder base, a sliding ring, a supporting ring, an elastic expanding sleeve, a conical central spindle, a connecting plate, a connecting shaft, a dense ball guiding sleeve, a centering seat and a piston. The oil cylinder base is mounted on a rotary table surface. The sliding ring and the oil cylinder base form two independently sealed annular oil cavities by being matched in the radial direction, and the oil cavities correspond to oil inlets A and B respectively. Oil channels are formed in the oil cylinder base, correspond to the oil inlets A and B respectively and lead to an upper oil cavity and a lower oil cavity of the piston respectively. The conical central spindle is connected with the piston into a whole through the connecting plate and the connecting shaft. The dense ball guiding sleeve is mounted between the centering seat and the conical central spindle. The elastic expanding sleeve is mounted by being coaxial with the conical central spindle and fixed to the upper end of the oil cylinder base. According to the hydraulic gear grinding clamp capable of rapidly replacing the large-size workpieces and the clamping method of the hydraulic gear grinding clamp, hydraulic oil drives the piston to drive the conical central spindle to squeeze and loosen the elastic expanding sleeve so as to achieve clamping and loosening actions of the workpieces, large-size gears can be rapidly and automatically clamped, the machining efficiency is improved, and the automation level of a machine tool is raised.

Owner:秦川机床工具集团股份公司

Automatic anti-backlash worm wheel dividing mechanism

InactiveCN101537583AEliminate radial playImprove uniquenessPrecision positioning equipmentCouplingBearing surface

The invention provides an automatic anti-backlash worm wheel dividing mechanism. A worm wheel and a worm mutually meshed are arranged in a case. A servo motor is connected with the worm through a coupling. The mechanism is characterized in that an anti-backlash mechanism is arranged in the case; the movable part of the anti-backlash mechanism has a pressurizing contact capable of extending out to contact a pressure bearing surface of the worm and exerting pressure on the worm; and the direction of pressure is perpendicular to or inclined to the axis of the worm, points at the worm and passes through the central plane of the worm wheel. The dividing mechanism can effectively eliminate the non-uniqueness of the output angle of existing worm wheel dividing mechanisms, greatly increase the non-uniqueness and is beneficial to decreasing the manufacturing difficulty of a precision worm wheel dividing mechanism.

Owner:邵文远

Dual-piece hobbing fixture

InactiveCN103418856AHigh positioning accuracyGuaranteed machining accuracyGear-cutting machinesGear teethHydraulic cylinderHobbing

The invention discloses a machine tool part and particularly relates to a dual-piece hobbing fixture which comprises a conical core shaft, an upper vertical column and a first draw rod, wherein the conical core shaft comprises a stepped shaft and a conical body; the upper end of the stepped shaft and one end, which has larger diameter, of the conical body are connected and are equal to each other; the lower end face of the conical core shaft is provided with a first through hole along the axial direction; the stepped shaft is provided with a locating sleeve; the conical body is provided with a spring tensioning sleeve; one end of the first draw rod is coaxially provided with a truncated cone with the diameter not greater than the outer diameter of the spring tensioning sleeve, and the other end of the first draw rod passes through the first through hole; the upper vertical column coaxial with the first draw rod is arranged above the first draw rod, and is fixedly connected with a pressing sleeve. After such a structure is adopted, the machine tool hydraulic cylinder and the upper vertical column are fully utilized, so that workpiece loading and unloading time is shortened, and the labor efficiency is improved; meanwhile the rigidity of the fixture is enhanced; since a sliding bush capable of performing relative movement is not adopted, the workpiece locating precision is high, and the gear processing accuracy is stably ensured.

Owner:CHONGQING YUQING MACHINERY MFR

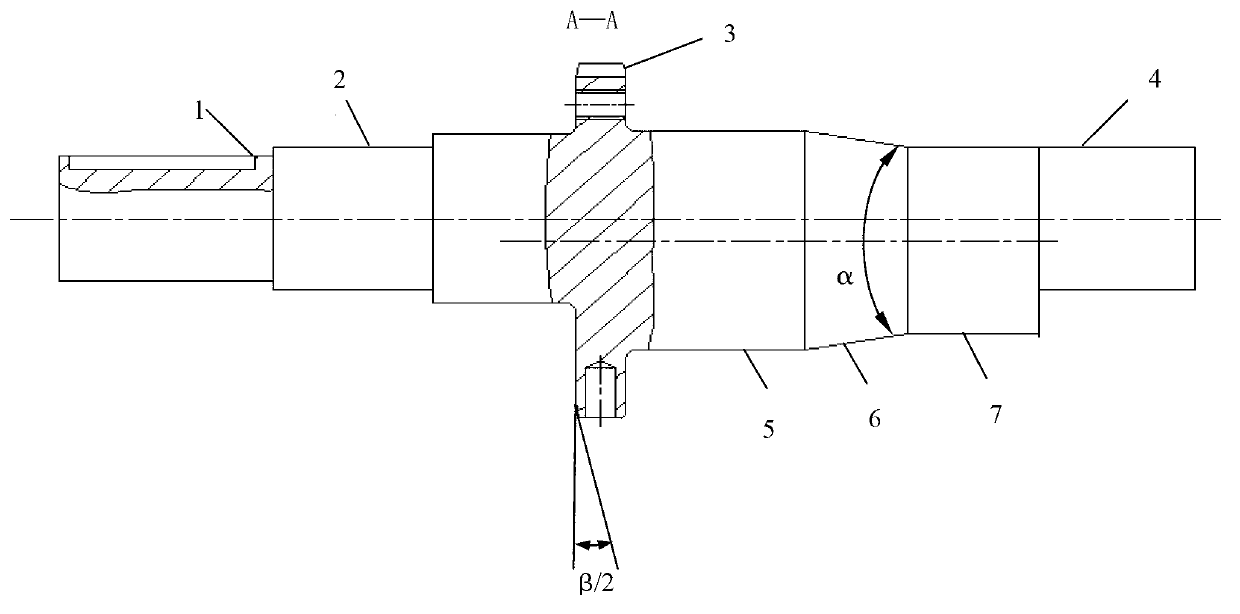

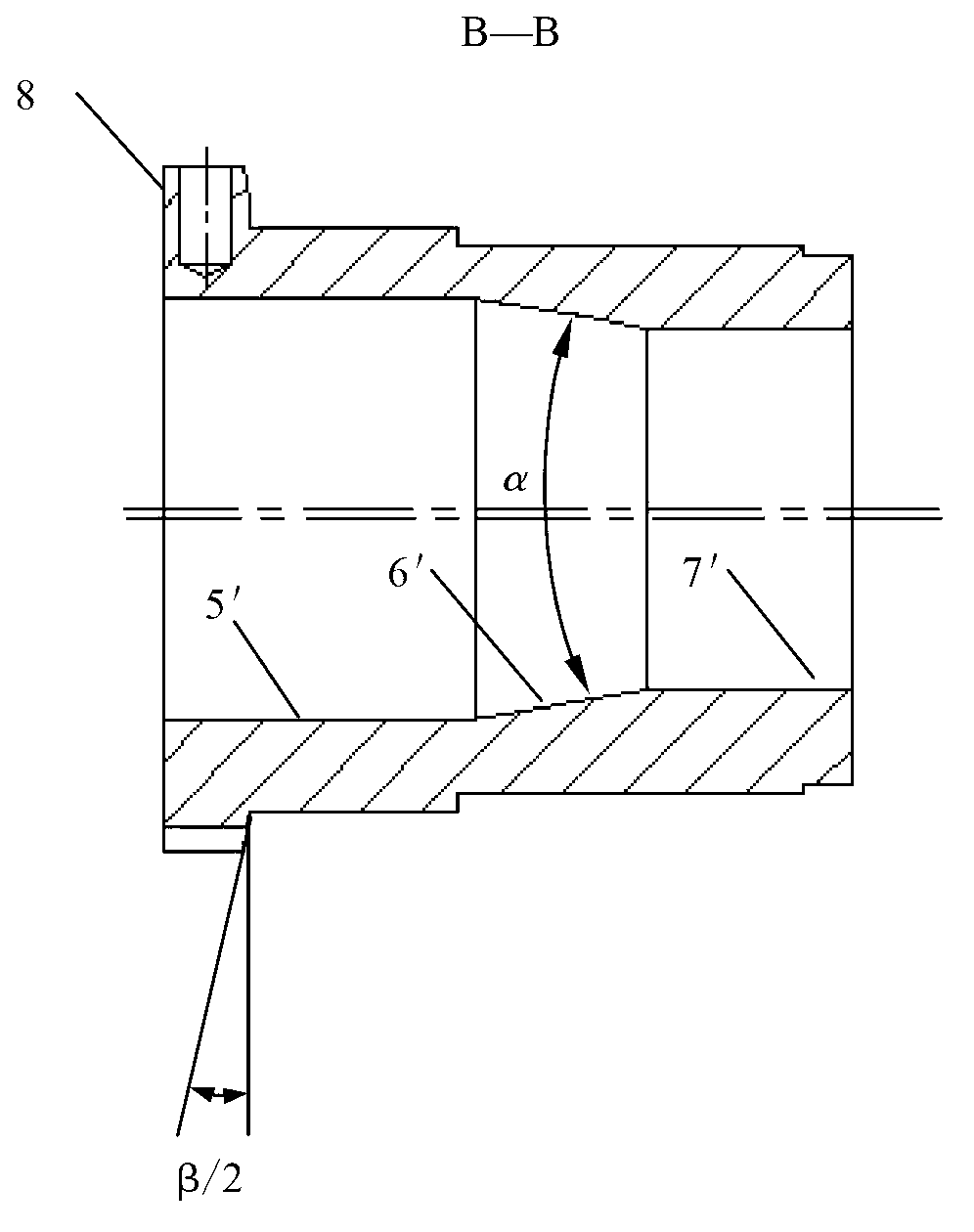

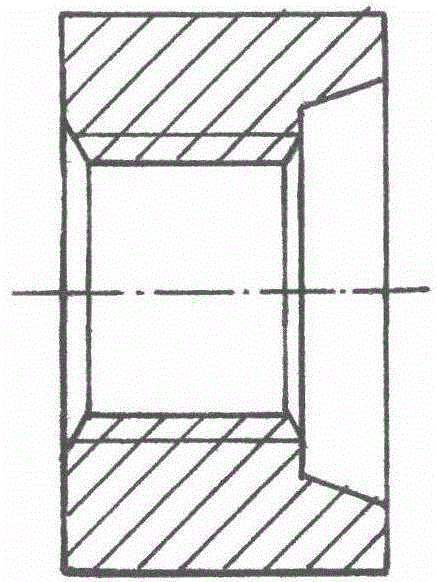

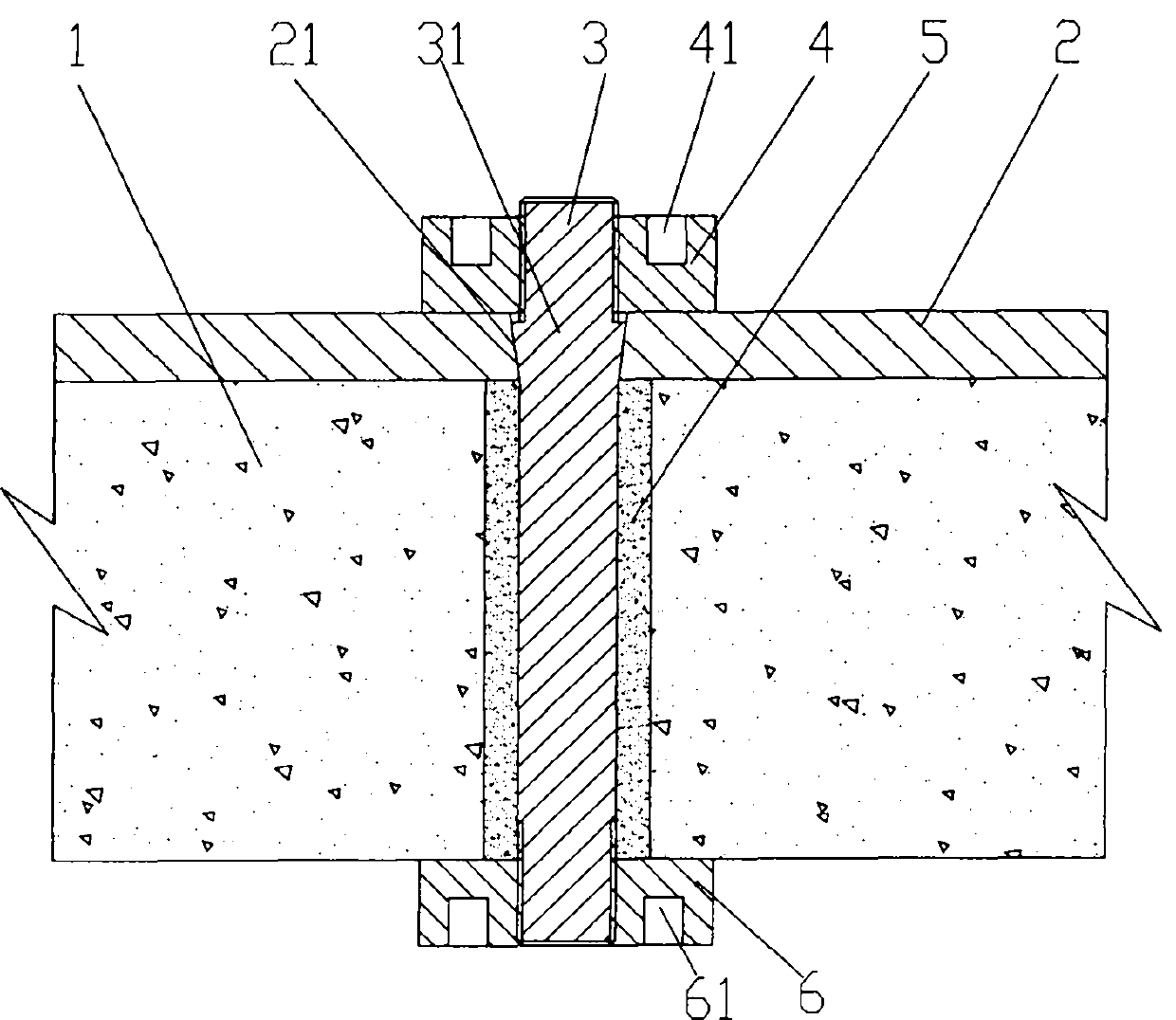

Crystallizer-oscillated eccentric mechanism without radial clearance

InactiveCN102990019AEasy to disassembleEliminates radial vibration backlash and wearMechanical engineeringRadial clearance

The invention discloses a crystallizer-oscillated eccentric mechanism without a radial clearance, and relates to continuous casting equipment. The eccentric mechanism is characterized in that a matching part of an eccentric shaft and an eccentric sleeve is formed by connecting large cylindrical surfaces, circular table surfaces and small cylindrical surfaces; two disc bodies with the equal external diameter are arranged on the eccentric shaft and the eccentric sleeve respectively and are connected with the large cylindrical surfaces of the eccentric shaft and the eccentric sleeve respectively; a key groove is formed in the circumference of each disc body respectively; keys are mounted in the aligned key grooves; and the two disc bodies are fastened together through a clamping ring. According to the invention, the circular table surfaces are matched without a clearance, so that the radial displacement of the eccentric shaft and the eccentric sleeve is avoided; and therefore the defects of radial oscillation and radial abrasion generated between the eccentric shaft and the eccentric sleeve due to the fact that a mounting clearance is preformed on the existing eccentric mechanism is overcome. In addition, the clearance matching is adopted by the cylindrical surfaces of the eccentric shaft and the eccentric sleeve, so that the eccentric mechanism is mounted and disassembled simply and easily, and the eccentric distance of the eccentric mechanism is also regulated simply and easily. The eccentric mechanism provided by the invention has the advantages of simple structure, long service life, stability in running and high oscillation precision.

Owner:YANSHAN UNIV

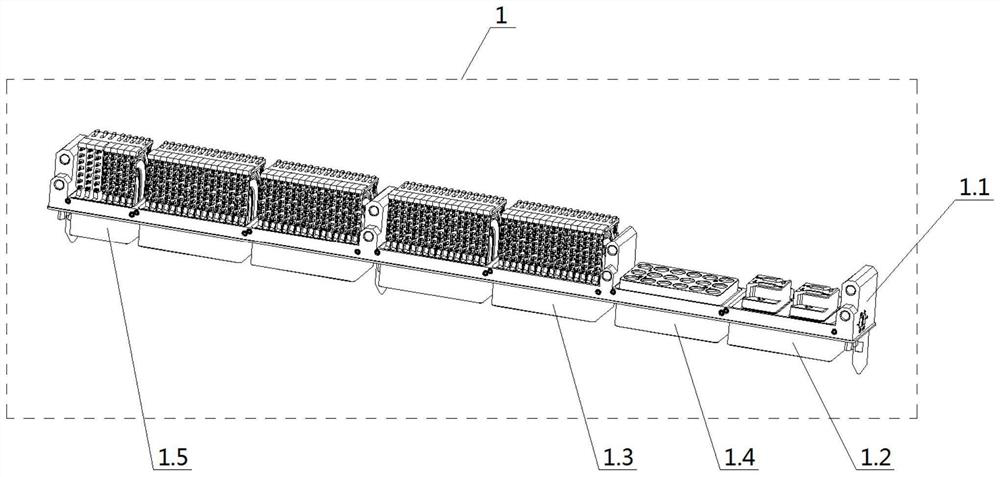

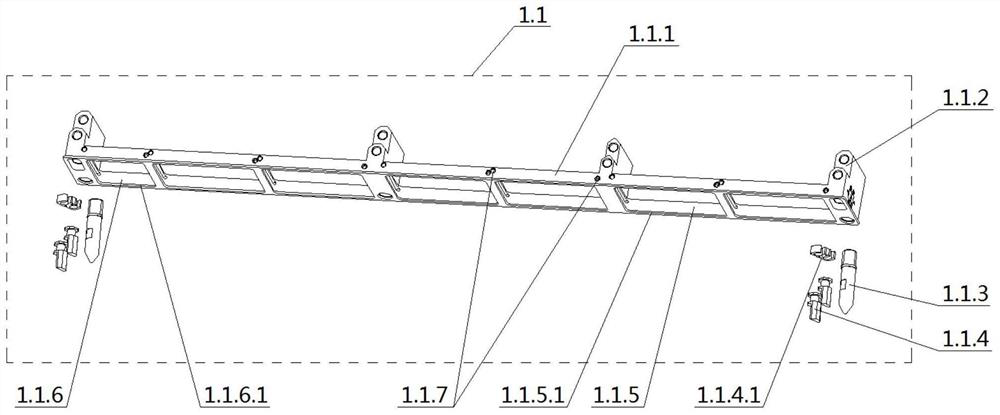

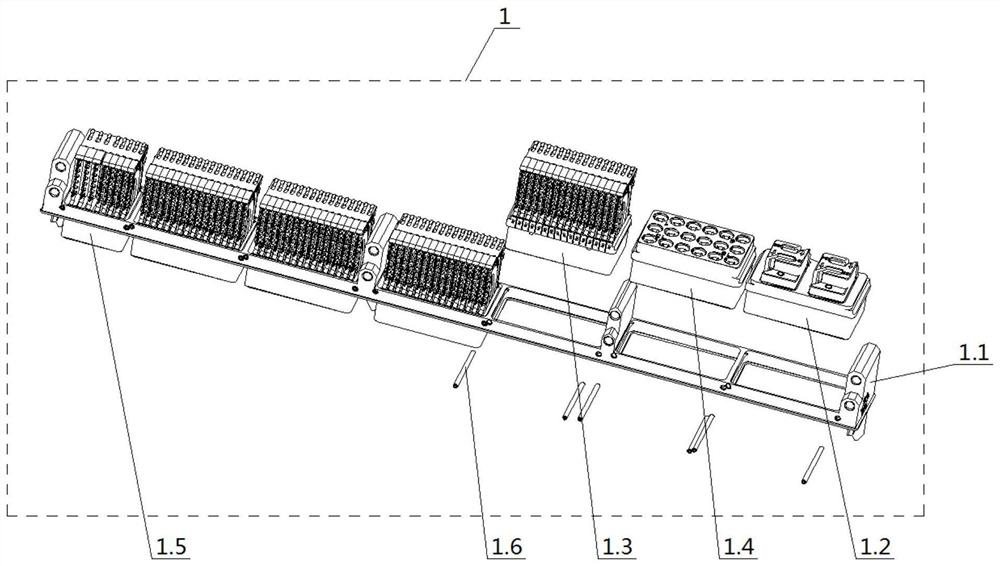

LRM photoelectric radio frequency integrated connector compatible with VPX standard

ActiveCN111969376AEliminate radial playEliminate axial playIncorrect coupling preventionTwo-part coupling devicesRadio frequencyMechanical engineering

The invention provides an LRM photoelectric radio frequency integrated connector compatible with VPX standard. The LRM photoelectric radio frequency integrated connector comprises a plug and a socket,wherein the plug comprises a plug shell provided with an optical fiber plug module, a plurality of high-speed plug modules, a radio frequency plug module and a mixed plug module, the socket comprisesa socket shell fixedly provided with an optical fiber socket module, a plurality of high-speed socket modules, a radio frequency socket module and a mixed socket module, and the plug and the socket are matched and inserted to form the LRM photoelectric radio frequency integrated connector compatible with the VPX standard. According to the invention, different types of connectors meeting the VPX standard requirements are integrated on the same connector shell, and through structural optimization design, the connector has the advantages of being small in occupied total space, light in weight, highly uniform in connector installation height and accurate in connector relative position, the reliability of signal transmission between components or systems meeting the VPX standard is guaranteed,and the increasingly complex and precise signal connection requirements between hardware components and systems compatible with the VPX standard are met.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

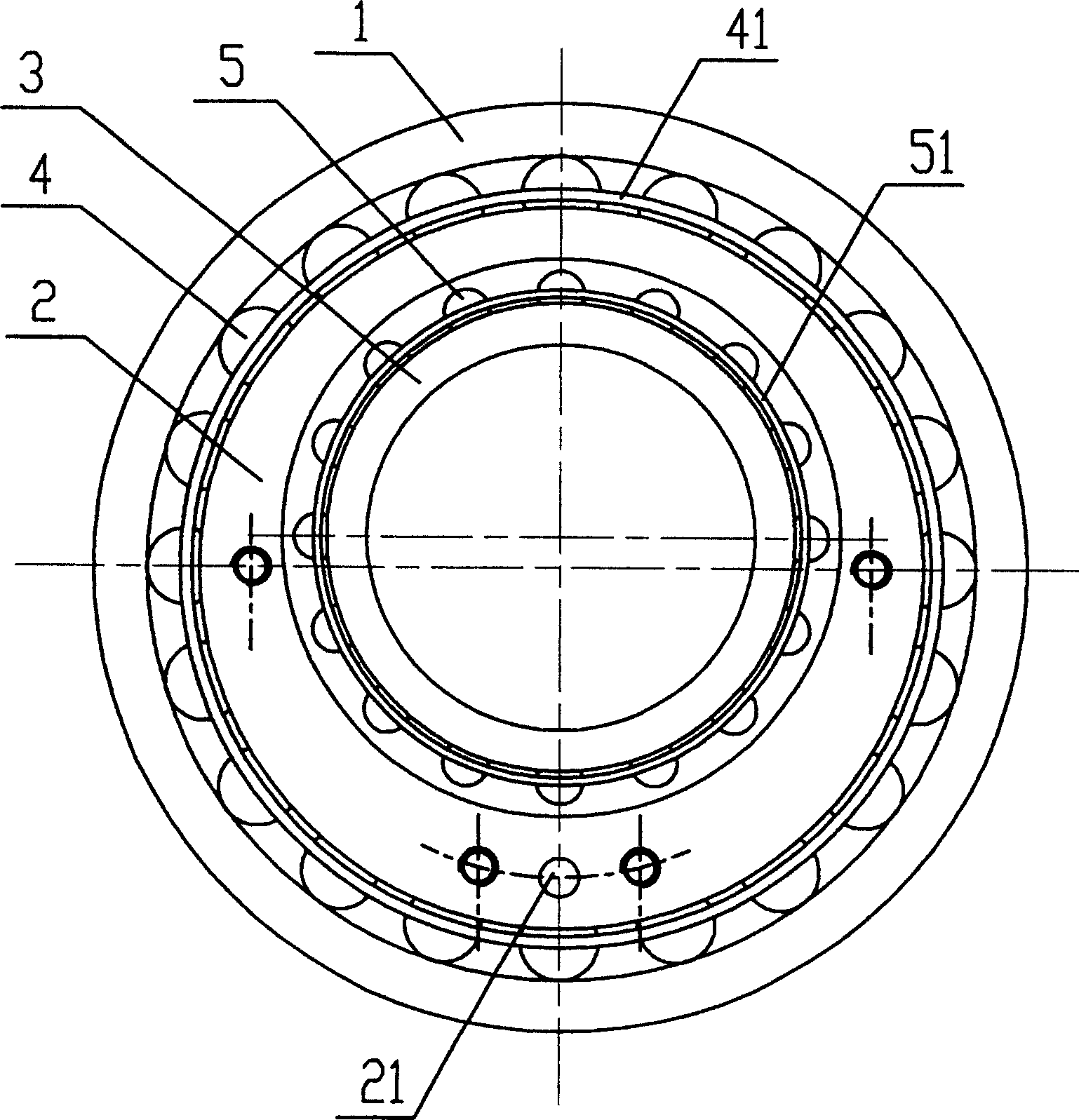

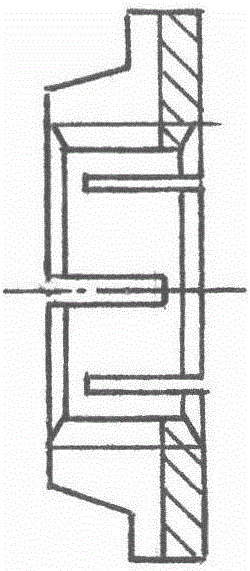

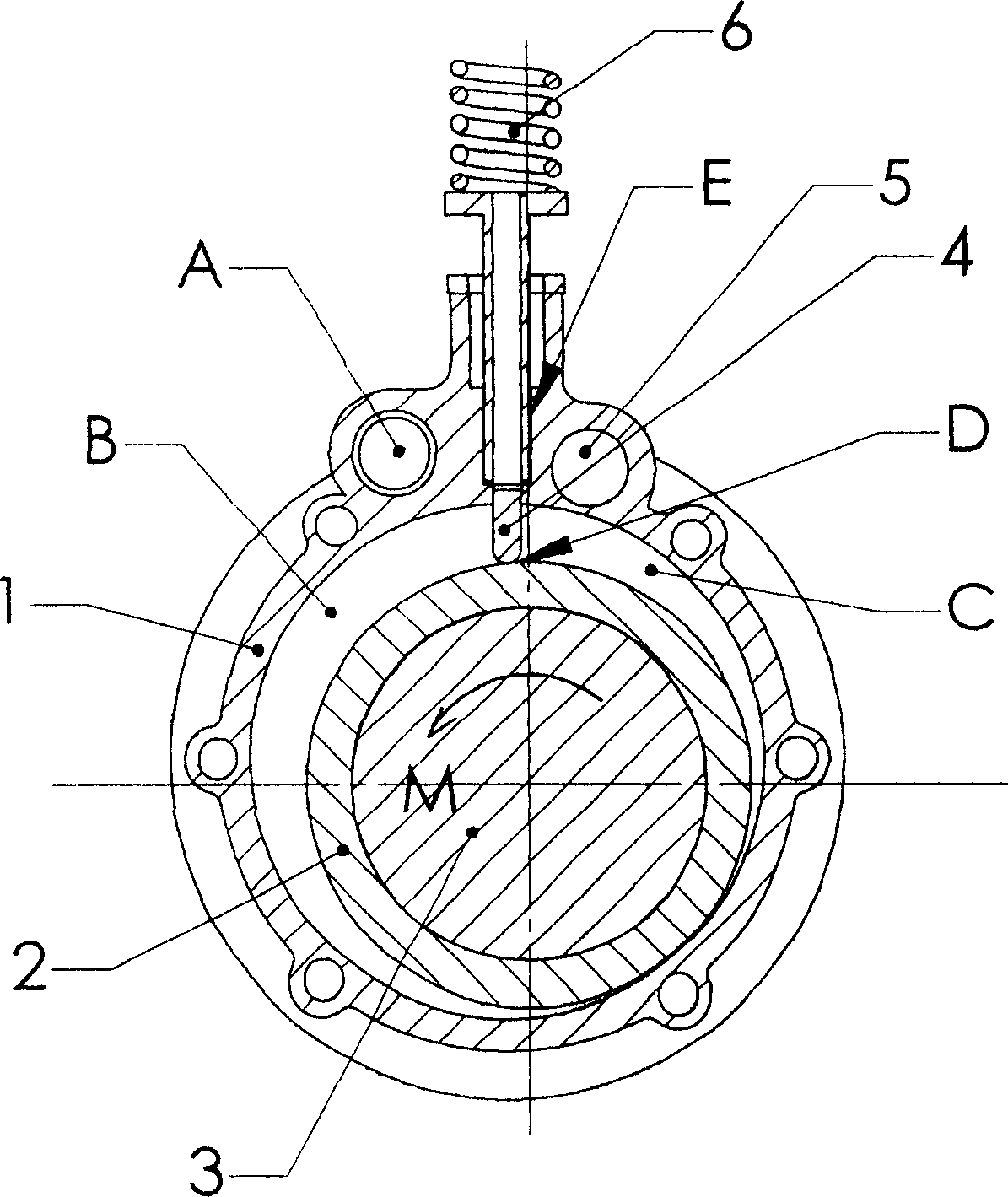

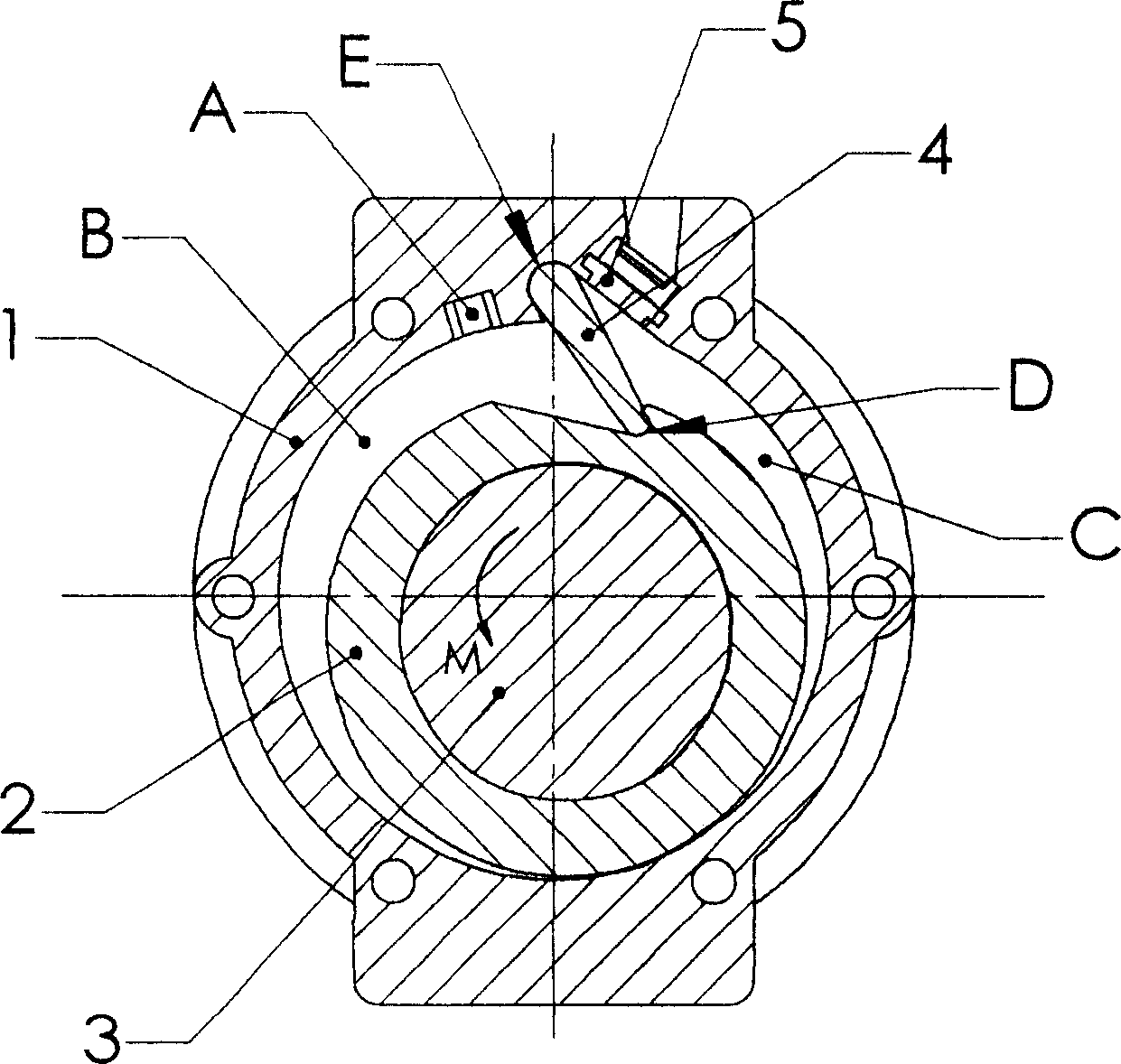

Combined bearing for offset press

InactiveCN1831348AHigh precision rotaryImprove printing qualityRolling contact bearingsRotary pressesClutchWindage

The invention discloses a combination bearing for an offset press, comprising a double-outer ring double-column center cone roller bearing, where there is a double-inner ring double-column center cone roller bearing arranged in a space inside inner ring of the former roller bearing, rotation centers of the two roller bearings are displaced, and the preloads applied onto the two roller bearings to eliminate radial windage of bearings are opposite and offset each other and therefore can not be transferred to wall panels so as to be able to realize high-rigidity, high-speed and high-accuracy rotation and improve printing quality, and it can realize clutch operation and pressurization between rollers by rotation of the inner ring of the double-outer ring double-column center cone roller bearing, simple in structure and reliable to operate and able to be continuously adjusted.

Owner:潍坊东航印刷科技股份有限公司

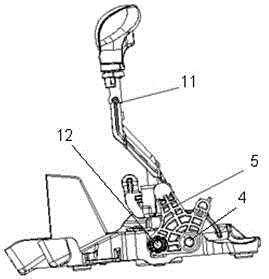

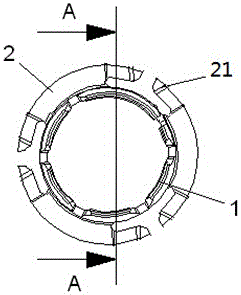

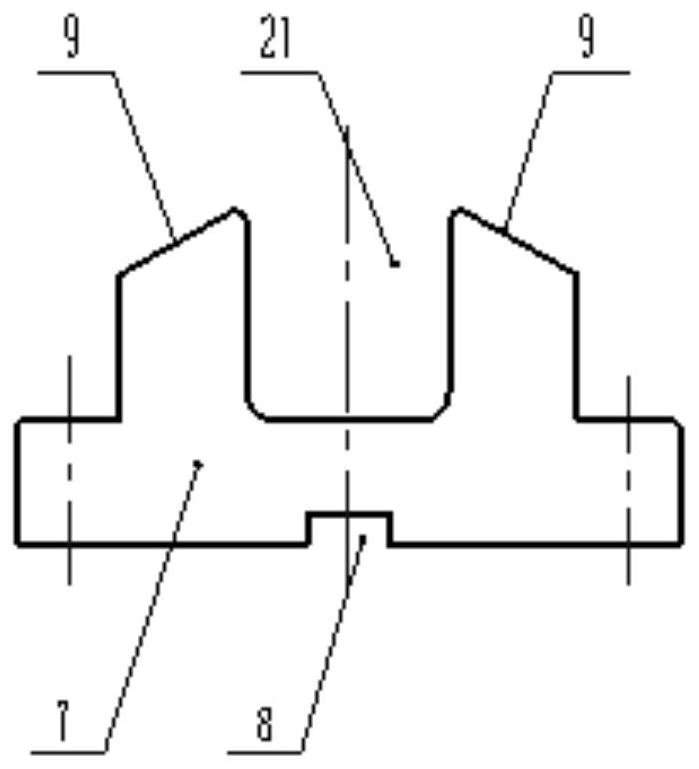

Selection arm neck bush of gear-shifting control assembly and installation structure thereof

InactiveCN105840803AEliminate axial playEliminate radial playGearing controlBearing componentsRetainerEngineering

The invention discloses an installation structure of a selection arm neck bush of a gear-shifting control assembly. The installation structure comprises a base body, a selection arm, a shaft pin, the selection arm neck bush and a fixing retainer ring. The base body is rotatably arranged on the shaft pin in a sleeving mode. The selection arm is fixedly arranged on the shaft pin in a sleeving mode. A bush main body of the selection arm neck bush is an elastic neck bush with an axial opening. The shaft pin is sleeved with the bush main body. The bush head of the selection arm neck bush radially extends to form flangings. Splay convex corners are arranged on the flangings circumferentially. The bush main body is pressed between the selection arm and the shaft pin, and the splay convex corners are pressed and padded between the sidewall of the selection arm and the fixing retainer ring. Certain elasticity is produced in the radial direction and the axial direction of the selection arm neck bush, and backlashes of the selection arm after installation are eliminated.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Elastic cone wedge-caulking type anti-disengagement nut

The invention provides an elastic cone wedge-caulking type anti-disengagement nut mainly formed by combining a thick nut body with a conical hole in the right end and a thin nut body with an outer cone boss at the left end. At least two blind grooves with one ends closed and the other ends closed are evenly distributed in each of the two ends of the thin nut body. During use, because of the wedge-caulking of a cone and the tightening effect of the blind grooves, the axial clearance and the radial clearance between the elastic cone wedge-caulking type anti-disengagement nut and a thread of a bolt can be effectively eliminated, and the anti-disengagement and retreating stopping effects of the elastic cone wedge-caulking type anti-disengagement nut are achieved. According to the elastic cone wedge-caulking type anti-disengagement nut, the plane wedge-caulking principle is ingeniously applied in the three-dimensional cone and is combined with the blind groove elastic shrinkage principle, the structure is simple, the anti-disengagement and retreating stopping effects are stable and reliable, installation and detachment are convenient, and the elastic cone wedge-caulking type anti-disengagement nut can be widely applied to various occasions, having strict anti-disengagement requirements for thread tightening pieces, especially occasions where air planes, automobiles and high-speed trains have special requirements for disengagement prevention of the tightening pieces.

Owner:华和平

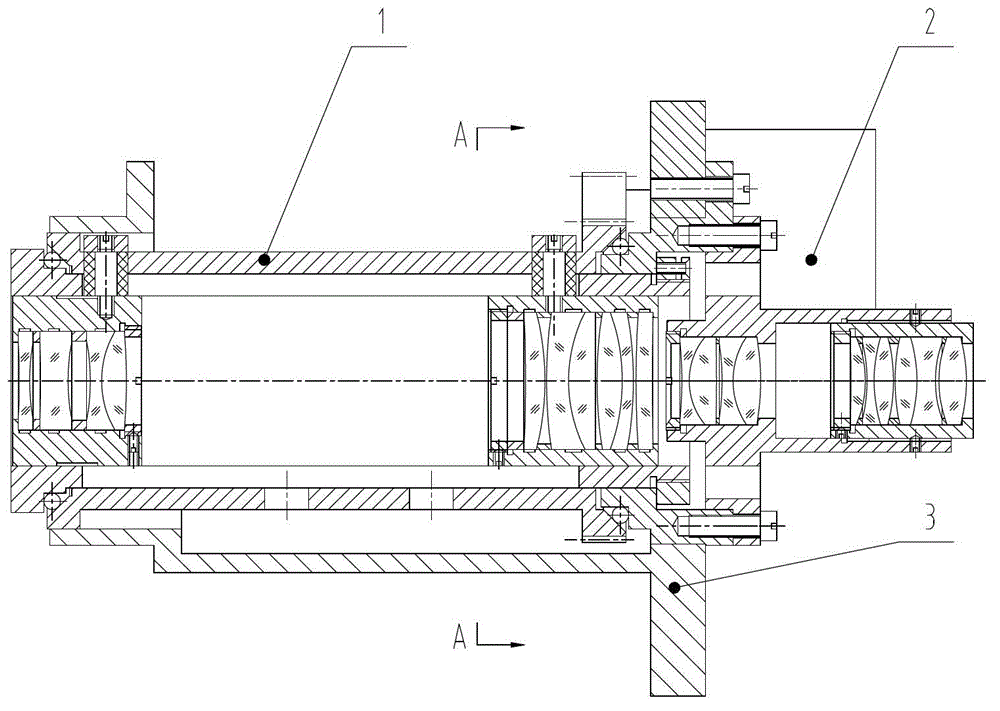

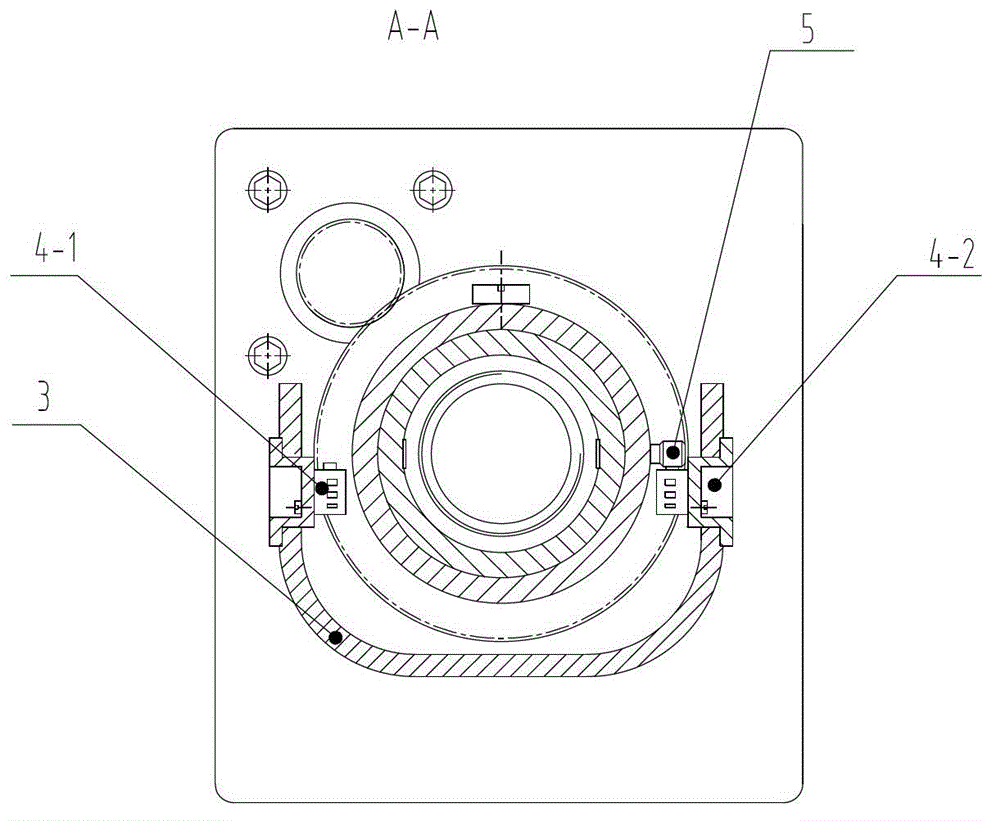

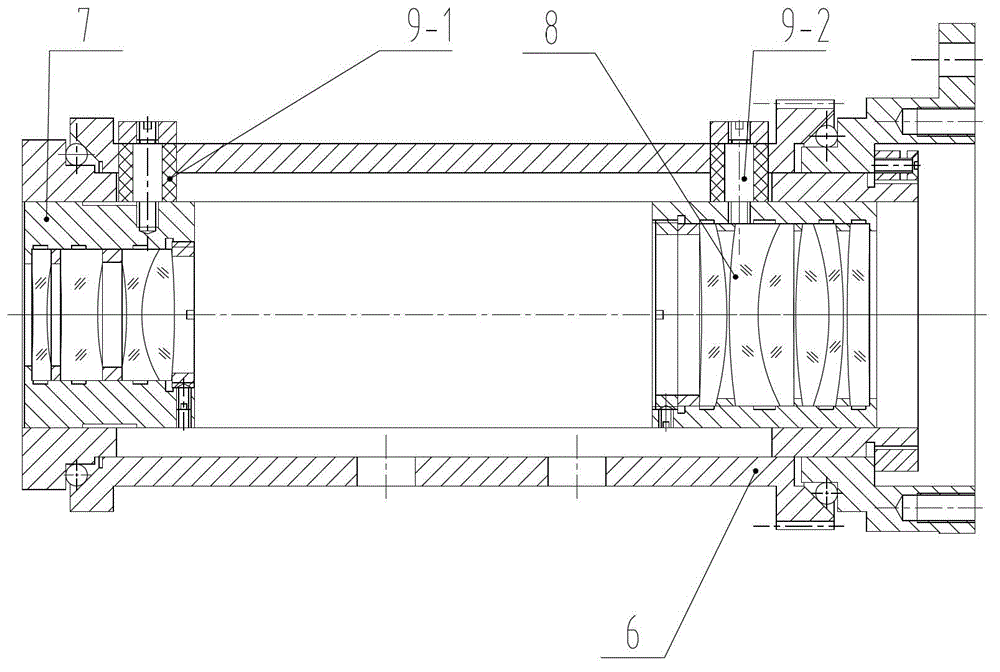

Electric continuous zooming mechanism with high-stability image surface

The invention discloses an electric continuous zooming mechanism with a high-stability image surface. The electric continuous zooming mechanism comprises a zoom lens group, a motor group, a shell, a first limit switch, a second limit switch and a contact, wherein the zoom lens group, the motor group, the first limit switch and the second limit switch are respectively fixed on the shell, the zoom lens group comprises a zoom guide rail group, a zoom light group, a compensating light group, a first cam group and a second cam group, the zoom guide rail group is a gapless rolling guide rail, and comprises an inner zoom barrel, an outer zoom barrel, a bearing seat, an opened pressing ring, a key, a first ball and a second ball. According to the invention, stability of the image surface during continuous zoom in specific environment such as temperature, impact and vibration can be realized, and imaging quality of a zoom system is improved.

Owner:NANJING NORTH OPTICAL ELECTRONICS

Plastic hook piece rolling mold

The invention discloses a plastic hook piece rolling mold which comprises a hollow shaft, a plurality of working circular thin pieces, adjusting circular thin pieces and compression nuts, wherein the hollow shaft is composed of an upper shaft head, a lower shaft head, an outer conical cylinder between the upper shaft head and the lower shaft head and an inner conical expansion sleeve sheathed on the outer conical cylinder; the plurality of working circular thin pieces and the adjusting circular thin pieces are sequentially sheathed on the hollow shaft; the compression nuts are arranged at thetwo ends of the hollow shaft and compress the working circular thin pieces and the adjusting circular thin pieces; the compression nuts correspond to the diameters of the outer conical cylinder and the inner conical expansion sleeve; an annular shoulder is arranged at one end of the inner conical expansion sleeve; an axial opening is arranged on the peripheral wall of the inner conical expansion sleeve; and a cooling liner is arranged in the hollow shaft. The inner conical expansion sleeve with the axial opening expands under the extrusion of the compression nuts, thereby eliminating the radial clearances between the inner holes of the working circular thin pieces and the adjusting circular thin pieces and the central shaft, improving the coaxiality and roundness of the rolling mold and enabling the thickness of a plastic hook piece to be more uniform. In addition, through cooling of the cooling liner, the mold stripping effect of the rolling mold is improved.

Owner:宁波科光机电有限公司

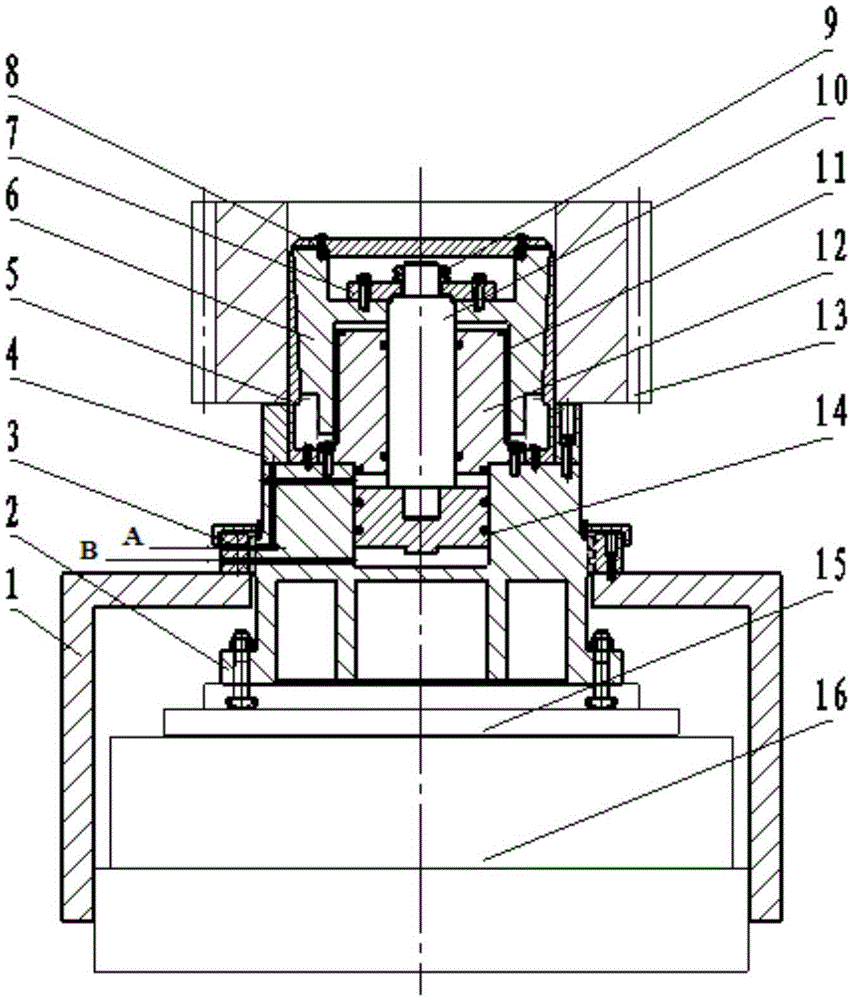

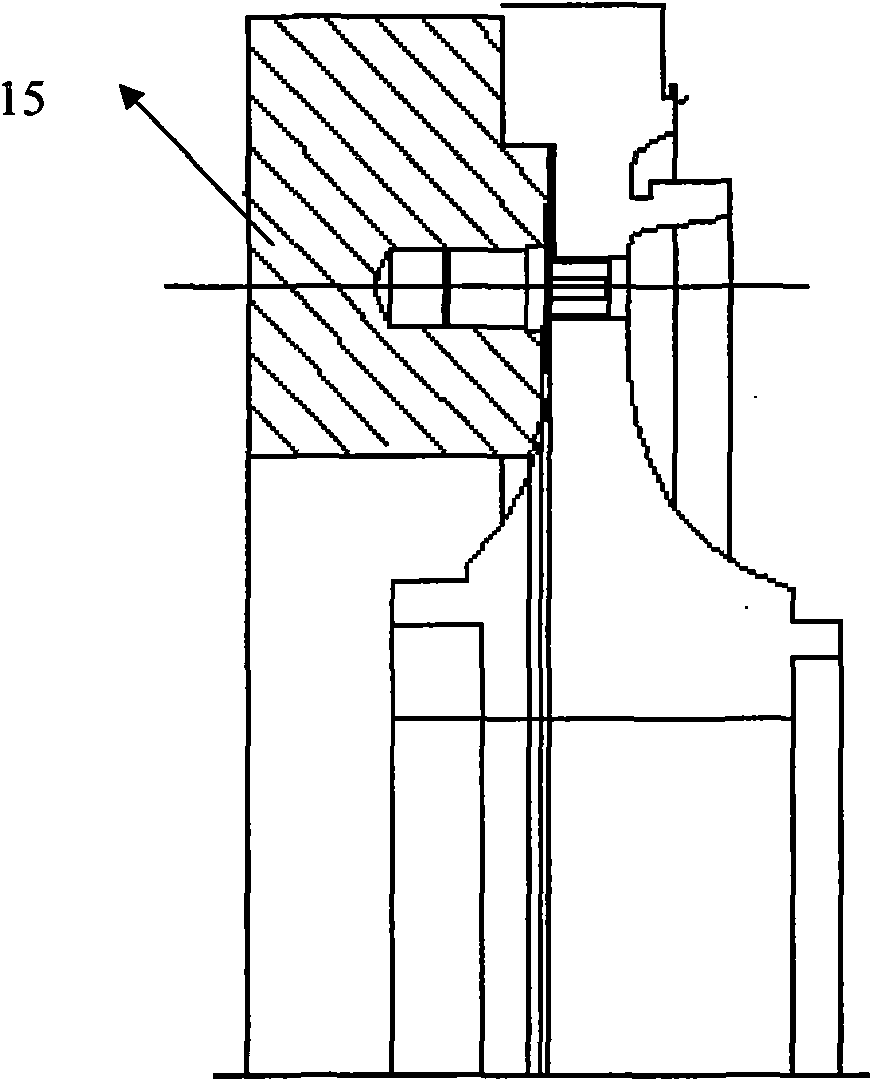

Precision centering anti-tilting device with static pressure rotary workbench

PendingCN108453519AHigh rotation accuracyAvoid Positioning ErrorsLarge fixed membersDouble rowEngineering

The invention discloses a precision centering anti-tilting device with a static pressure rotary workbench. The precision centering anti-tilting device with the static pressure rotary workbench structurally comprises a static pressure rotary workbench mounting base, the static pressure rotary workbench, double-row cylindrical roller bearings, a thrust ball bearing, an annular base plate, a bearinggland, a shrink ring, a connection board, a gland, an angle encoder and a center shaft, wherein the center shaft is fixedly arranged on the static pressure rotary workbench mounting base; the center shaft is sleeved with the double-row cylindrical roller bearings; an inner hole of the double-row cylindrical roller bearings and the center shaft matched with the inner hole both have tapers; the shrink ring is installed on the center shaft; the circumference of the shrink ring is sleeved with the annular base plate; the thrust ball bearing is arranged on the annular base plate; the bearing glandis installed on the shrink ring and the thrust ball bearing; the angle encoder is installed on the bearing gland; the gland is installed on the upper end face of the workbench; and the connection board is connected with an output shaft of the angle encoder and the gland. The precision centering anti-tilting device with the static pressure rotary workbench is compact in structure, simple and reasonable in design, remarkable in anti-tilting effect, and capable of reducing the positioning errors and improving the positioning precision and rotation accuracy.

Owner:WORLDWIDE INDAL MACHINERY DONGGUAN

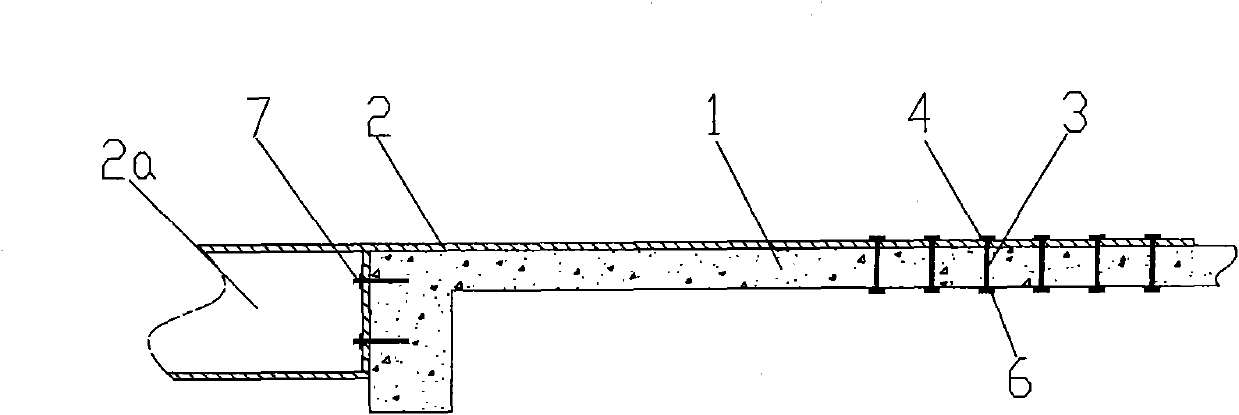

Special shearing-resistance anchor bolt pair for anchor group

InactiveCN101906850AReduce adverse effectsImprove mechanical performanceBuilding reinforcementsEngineeringStress effects

The invention discloses a special shearing-resistance anchor bolt pair for an anchor group, comprising a basic part, an anchored part overlapped on the basic part and an anchor part for fixing the anchored part on the basic part, wherein the anchor part comprises an anchor bolt and an anchor nut; the anchor bolt successively passes through the anchored part and the basic part, and is fastened by the anchor nut; and the anchor bolt and the anchored part are closely matched through a cone pair. The shearing-resistance anchor bolt pair ensures that the anchor bolt and the anchored part are closely matched through the cone pair, avoids adverse impact on the anchor structure due to the thickness of the basic part, and can be applied to an outward overhung additional structure of a lamina basic part, and the matching structure of the cone can eliminate the radial clearance between the anchor bolt and the anchored part to increase the stress effect of the anchor bolt; and the anchor bolt pair has stronger adaptability to shearing force, so after the anchor bolt pair is anchored, the anchor part in the shearing-resistance anchor group can be synergically stressed to improve the anchor capability, reinforce the stability of the structure, and eliminate potential safety hazard.

Owner:CHONGQING UNIV

Swing plate and rolling loop type compressor

InactiveCN1670373AExtended service lifeIncrease speedRotary piston pumpsRotary piston liquid enginesExhaust valveGas compressor

This invention relates to a toggle plate rolling hoop type compressor, it belongs to positive displacement compressor. It mainly includes cylinder block and end cap fixed connected to its two ends. Eccentric pivot is coaxial core to its inner hole, air intake and vent valve are on cylinder block. Rolling hoop is muffcoupled eccentric wheel exterior of eccentric pivot, one end of toggle plate is splice jointed to the groove on rolling hoop, the other end is splice jointed to the groove on cylinder, cylinder is separated into inspiration cavity and compression cavity by the toggle plate and rolling hoop. The advantage is that components are few, weight is light, easy to processing, manufacturing cost and using cost is low, maintenance period and useful life are long and can compensate radial clearance automatically, so its application scope is wide, it can be not only applied to small air displacement low rotary speed, but also be applied to big air displacement and high rotary speed occasion. This invention can be applied to all kinds of refrigerating plant, air compressor, vacuum pump and oil transfer pump field.

Owner:白葆山

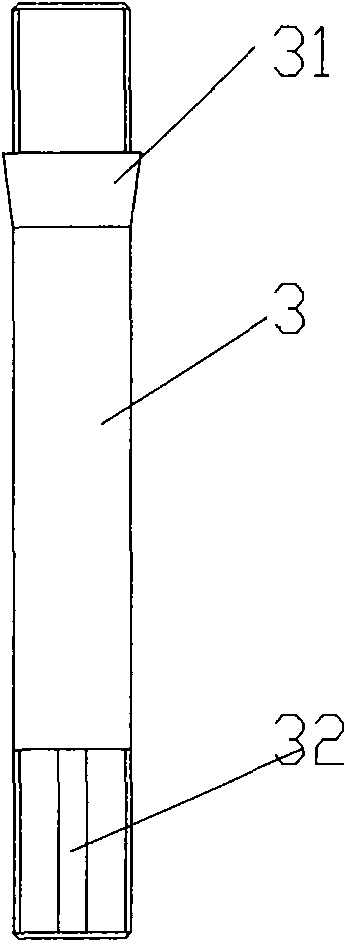

Screw rod and threaded hole perpendicularity test tool with same

ActiveCN104142111AEliminate radial playHigh precisionMechanical measuring arrangementsEngineeringScrew thread

The invention relates to a screw rod and a threaded hole perpendicularity test tool with the same. The screw rod comprises a central screw rod body, a taper sleeve, at least two external threaded blocks evenly distributed on the periphery of the taper sleeve in the circumference direction, and an elastic maintaining structure used for hooping the external threaded blocks on the peripheral face of the taper sleeve. A threaded part used for being connected with the central screw rod body in a threaded mode is arranged in the taper sleeve, the peripheral face of the taper sleeve is an external taper face with the small end and the large end distributed in the axial direction of the central screw rod body, the external threaded blocks are provided with external threads coaxial with the central screw rod body, the external threaded blocks and the taper sleeve are matched in the axial direction of the central screw rod body in a rotation-stopping movement mode, and the external threaded blocks are further provided with inner taper faces which are matched with the external taper face of the taper sleeve and are subjected to radial opening acting force under the axial moving effect of the taper sleeve. The central screw rod body is rotated to enable the external threaded blocks to be expanded and retracted, so that the diameter of the circumferential face where the external threaded blocks are located is changed, and when the screw rod is used for carrying out threaded hole perpendicularity testing, the radial gap generated when the screw rod is connected with a tested threaded hole can be eliminated, and precision of a testing result is improved.

Owner:STATE GRID CORP OF CHINA +1

Integrated electromagnetic protective bearing device

ActiveCN111503149AAchieve axial balanceAxial position adjustmentShaftsMagnetic bearingsAxial thrustMechanical engineering

The invention relates to the field of magnetic suspension bearing systems, in particular to an integrated electromagnetic protective bearing device. The integrated electromagnetic protective bearing device includes conical outer surfaces, two sets of supporting assemblies, two axial thrust discs and two sets of electromagnetic adsorption assemblies. The two conical outer surfaces are symmetricallyarranged at the two ends of a rotor; the two sets of supporting assemblies correspond to the two conical outer surfaces respectively, the inner peripheral surfaces of the supporting assemblies are inner conical surfaces matched with the conical outer surfaces, and the supporting assemblies can axially approach and rotationally support the conical outer surfaces; the two axial thrust discs are symmetrically arranged at the two ends of the rotor; and each electromagnetic adsorption assembly provides adsorption force for the corresponding supporting assembly and the corresponding axial thrust disc located at the same end, the rotor can normally rotate in a normal working state, the two axial thrust discs can ensure the axial balance of the rotor under the effect of the adsorption force, andin an emergency, the supporting assemblies axially approach and support the conical outer surfaces under the action of a reset element. The technical problems that a protective bearing device in the prior art has slow respond speed and a complex structure are solved.

Owner:JIANGSU UNIV OF TECH

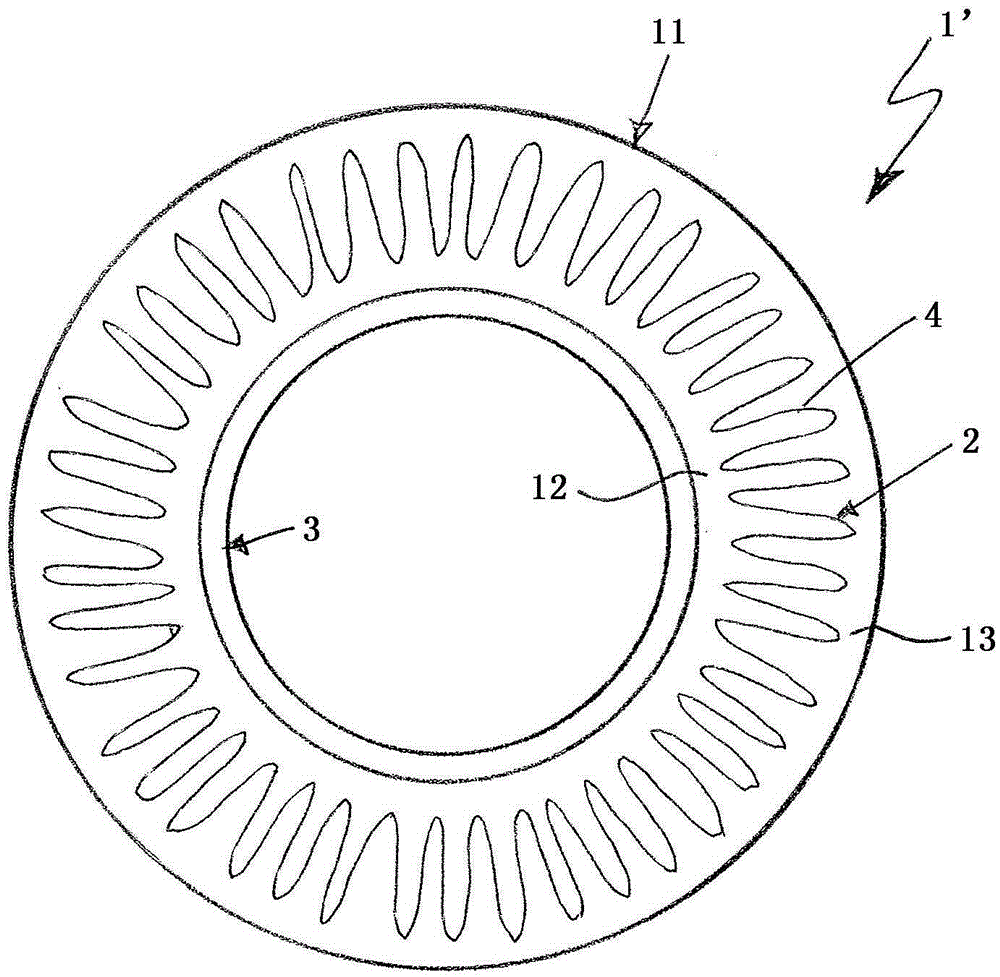

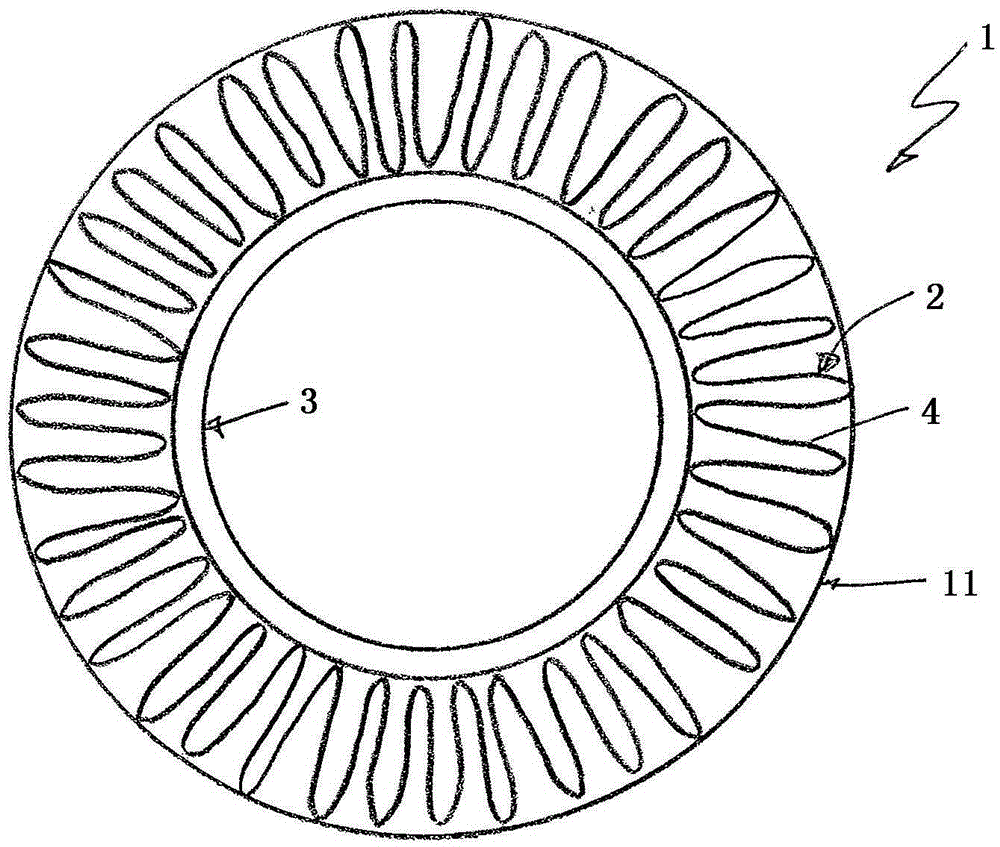

Annular balancing piston

ActiveCN101560982AEliminate radial playPressure Easy GuaranteedRotary/oscillating piston pump componentsLiquid fuel engine componentsPiston ringEngineering

The invention relates to an annular balancing piston used in a bearing base at an exhaust end of an oil-jet screw compressor, an annular groove is formed on the outer circumference of the piston, a movable device in the annular groove is provided with a piston ring, and the outer diameter of the piston ring is larger than the outer diameter of the piston. As the annular groove is formed on the outer circumference of the piston and the movable device in the annular groove is provided with the piston ring, gap is existed between the annular groove and the piston ring; when in use, the piston ring and an inner cavity of the bearing base of a rotor are in close fit, the radial gap between the piston and the bearing base can be eliminated, pressure oil flows out through the gap between the annular groove and the piston ring, and the pressure in a pressure cavity of the bearing base is easy to ensure.

Owner:WUXI COMPRESSOR CO LTD

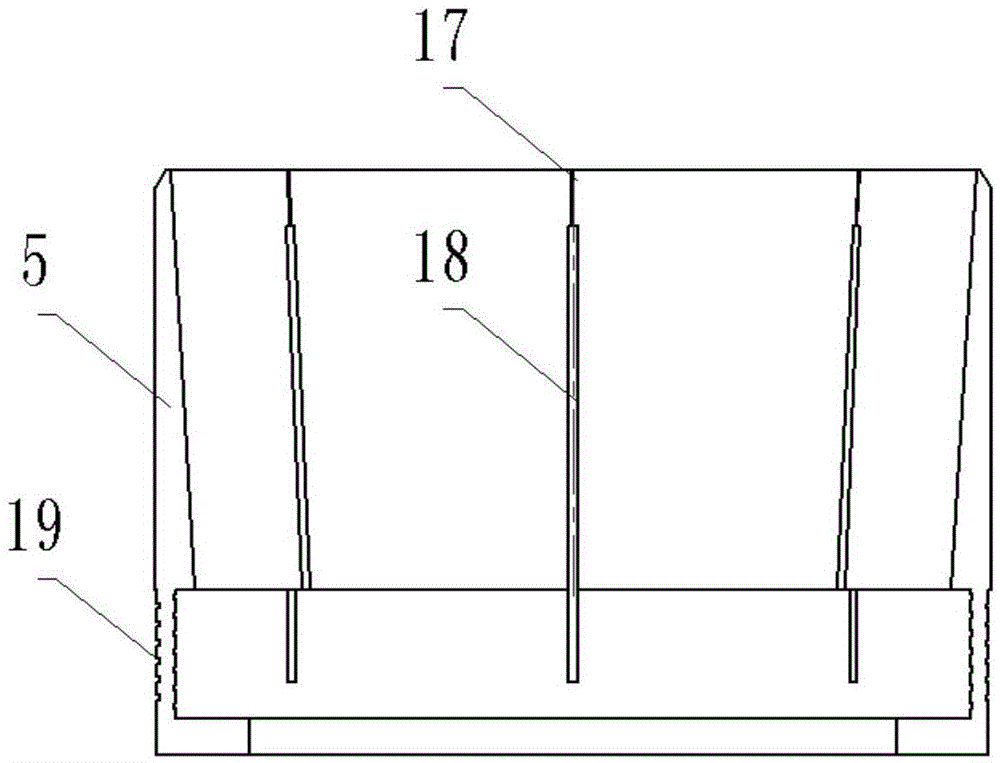

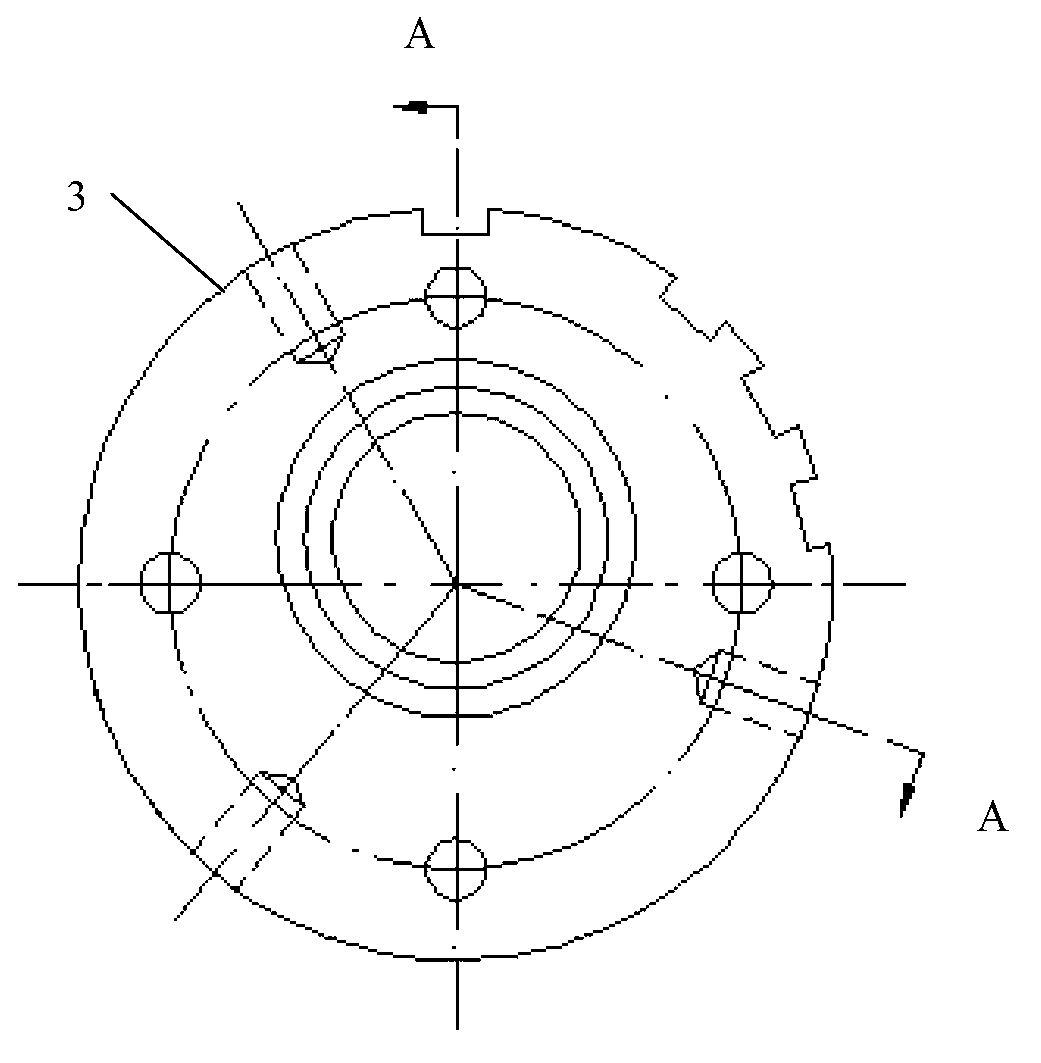

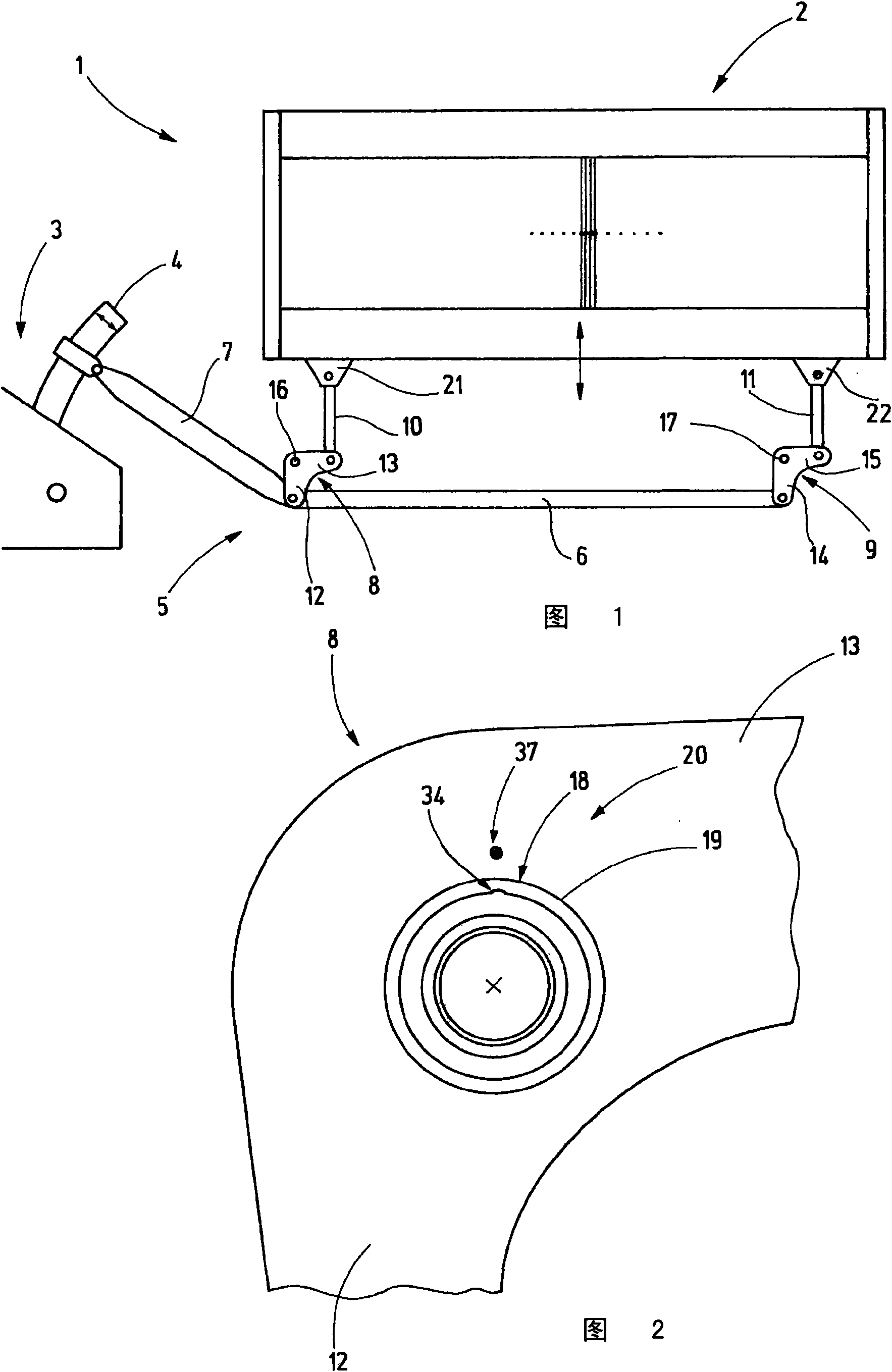

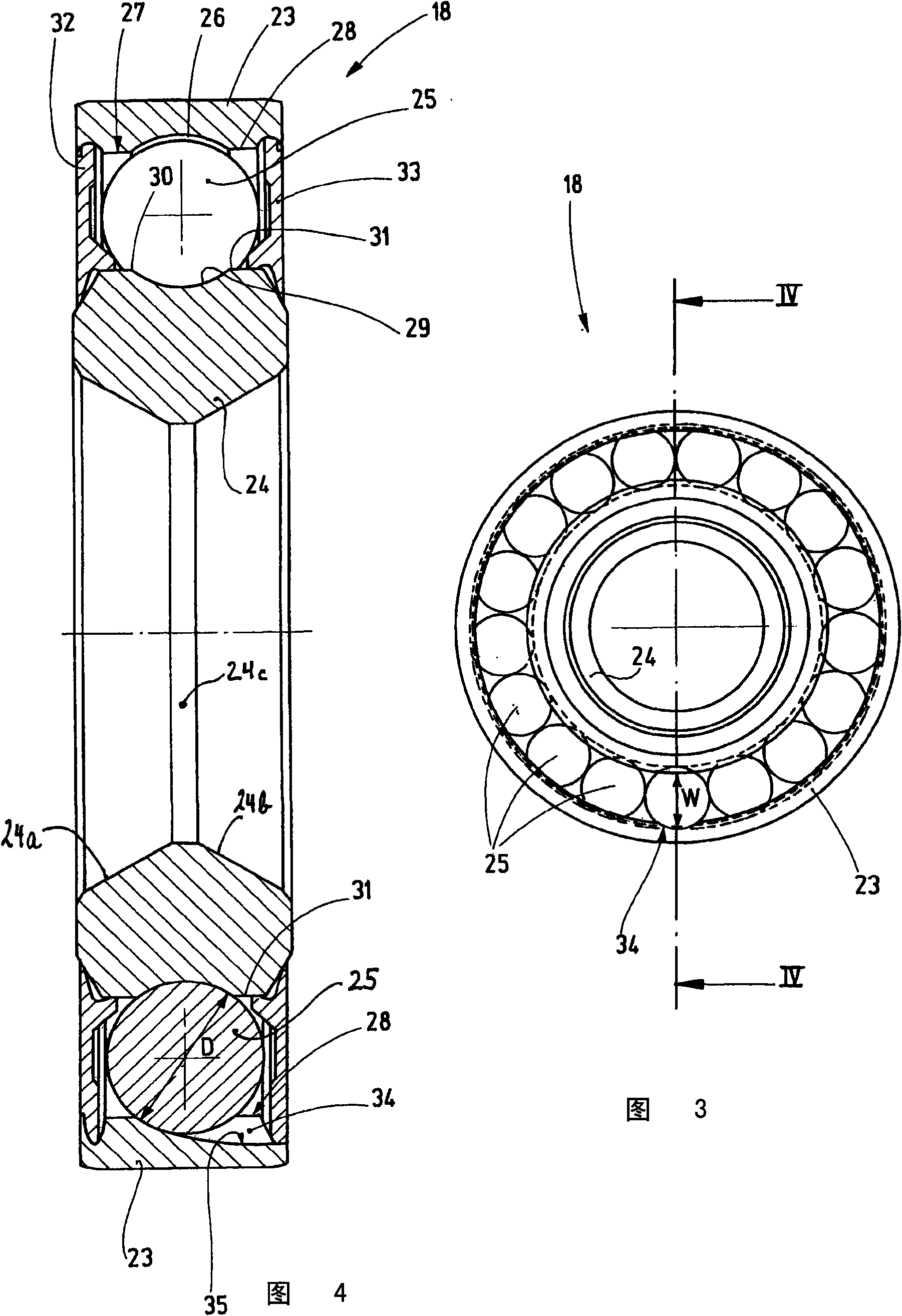

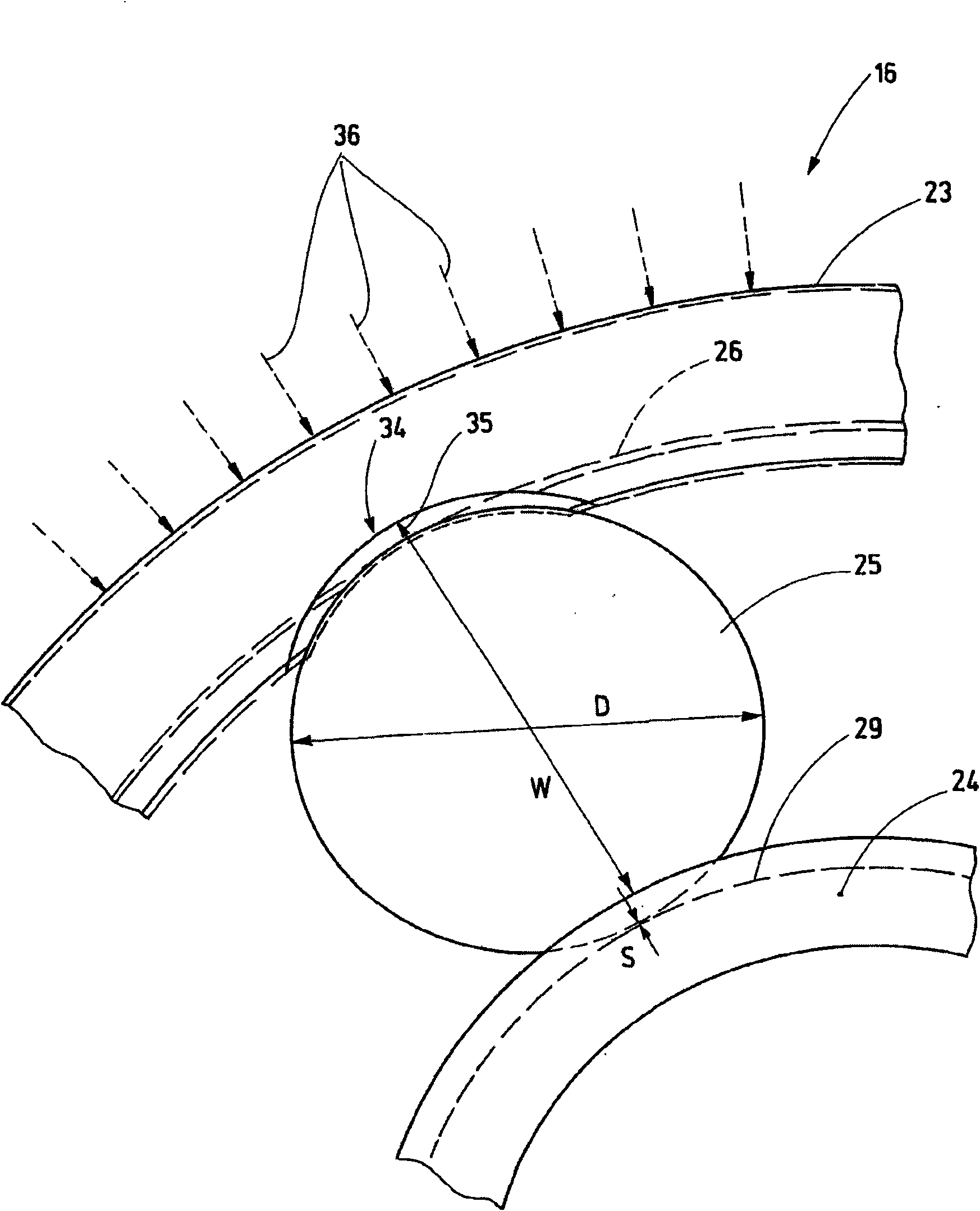

Storage device and beam for loom

According to the invention, the antifriction bearing (18) needs not to open the outside lane (23). However, the outside lane (23) has a filling groove (34) for keeping unblock when being used. However, the diameter of the filling groove (34) is smaller than the diameter (D) of the ball, thereby the ball (25) does not fall off. In addition, the outside lane (23) of the bearing (18) displays a definite radial elastic. And the antifriction bearing (18) is radially and constrainedly installed through a pressing cooperation, thereby the ball (25) no longer jump out of the bearing (18). In order to assembly antifriction bearing (18) in an accurate angle, the filling groove (34) is out of the range of maximum stress. For this purpose, the filling groove (34) is preferably structured to cause the sealed ring (33) to keep existed and visible.

Owner:GROZ BECKERT KG

Fixture special for mortise of broaching disc type part

InactiveCN101664883BEliminate radial playIncrease productivityPositioning apparatusBroaching machinesScrew threadCompression screw

The invention relates to a fixture special for a mortise of a broaching disc type part, belonging to the technical field of fixture machinery. The fixture comprises a base, an angular positioning pin, a press cover, a compression nut, a compression screw, a gasket, a screw-thread bush, a lock screw, a positioning mandrel and radial gap elimination mechanisms, wherein each radial gap elimination mechanism comprises a positioning end surface ring, a positioning stop opening ring, a radial positioning gap regulation top block, a tightening screw and a spring. By uniformly distributing the radialgap elimination mechanisms on the circumferences of two layers of positioning rings, the fixture can eliminate the positioning radial gap of the part also enable the part to be coaxial with a positioning stop opening of a puller and enhance the production efficiency and the product qualification rate of the part and the qualification rate from original 10 percent to 95 percent and directly enhance the economic efficiency by 50 percent.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Screw rod and threaded hole verticality inspection tool using the screw rod

ActiveCN104142111BEliminate radial playHigh precisionMechanical measuring arrangementsEngineeringScrew thread

The invention relates to a screw rod and a threaded hole verticality inspection tool using the screw rod, comprising a central screw rod, a taper sleeve, at least two external thread blocks uniformly distributed on the periphery of the taper sleeve along the circumference, and tightening each external thread block inside The elastic retaining structure on the outer peripheral surface of the tapered sleeve has a threaded part connected with the central screw thread inside the tapered sleeve. The outer peripheral surface of the tapered sleeve is an outer tapered surface with a large end and a small end distributed along the axial direction of the central screw. Each external thread block has a The external thread provided on the central screw axis, the external thread block and the tapered sleeve move along the axial direction of the central screw to prevent rotation. Under the action, the inner cone surface is subjected to radial opening force. In the present invention, the expansion and contraction of the external thread block is changed by rotating the central screw to change the diameter of the circumferential surface of the external thread block. When the screw is used to detect the verticality of the threaded hole, the radial gap when the screw is connected to the measured threaded hole can be eliminated. Therefore, the accuracy of the detection result can be improved.

Owner:STATE GRID CORP OF CHINA +1

Floating type transmission mechanism and micro pump

InactiveCN111120238AEliminate radial playSmooth connection movementPositive-displacement liquid enginesMulti-cylinder pumpsDrive shaftEngineering

The invention relates to a floating type transmission mechanism and a micro pump. The floating type transmission mechanism comprises a transmission shaft. The transmission shaft is connected with a cylinder body through a spline. The tail end of the transmission shaft is located in a flow distributing plate. A floating gap is formed between the tail end of the transmission shaft and the inner endface of the flow distributing plate. During transmission of the transmission shaft, floating can be performed within the axial range permitted by the floating gap. The transmission stress caused by the transmission of the spline and the radial gap of the transmission of the spline can be eliminated, the transmission shaft of the micro pump can float at the small amplitude in the axial direction, the transmission cumulative stress within a certain range can be eliminated, and the connection movement of the transmission shaft and other components is more stable and efficient.

Owner:中船重庆液压机电有限公司

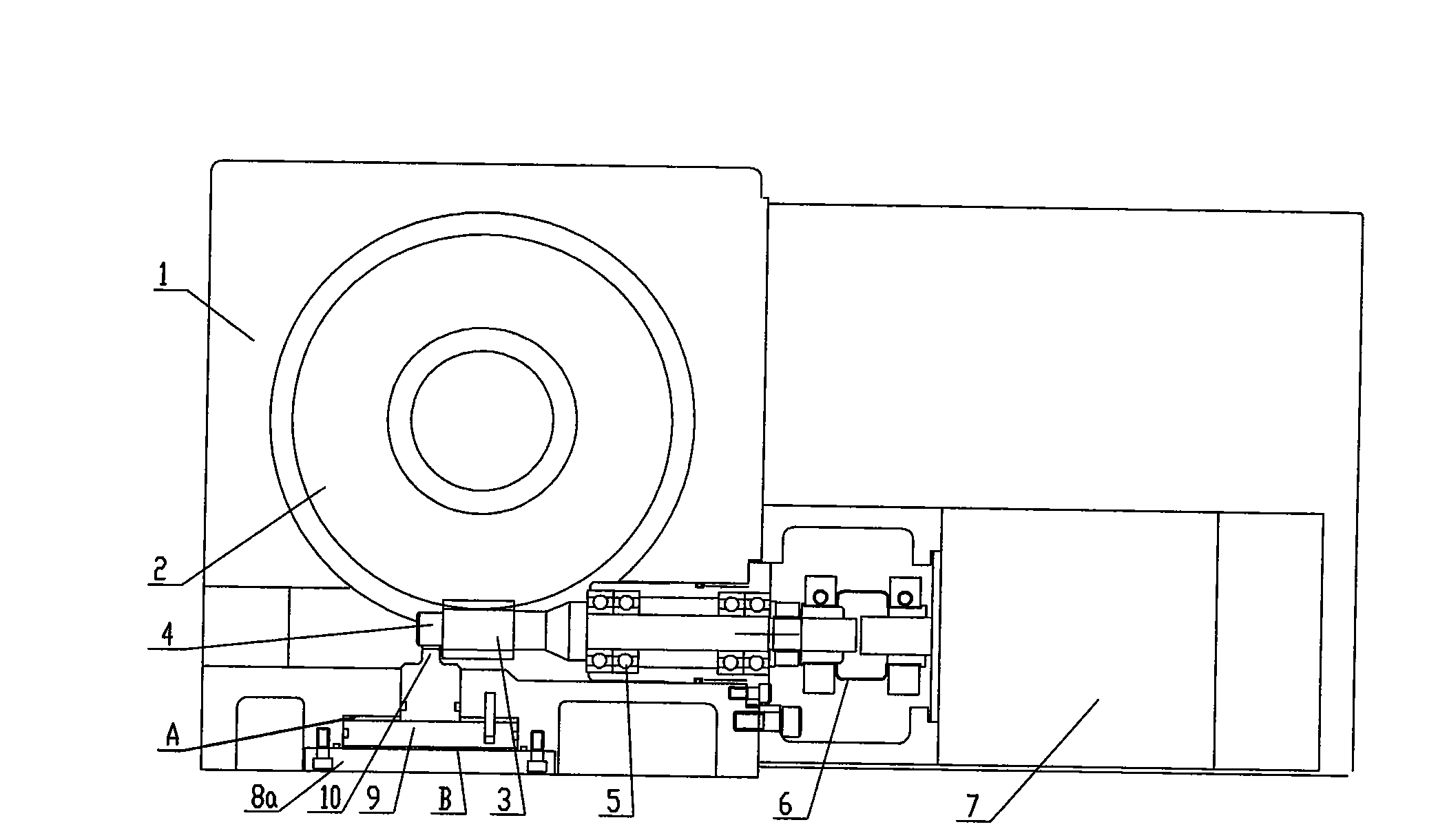

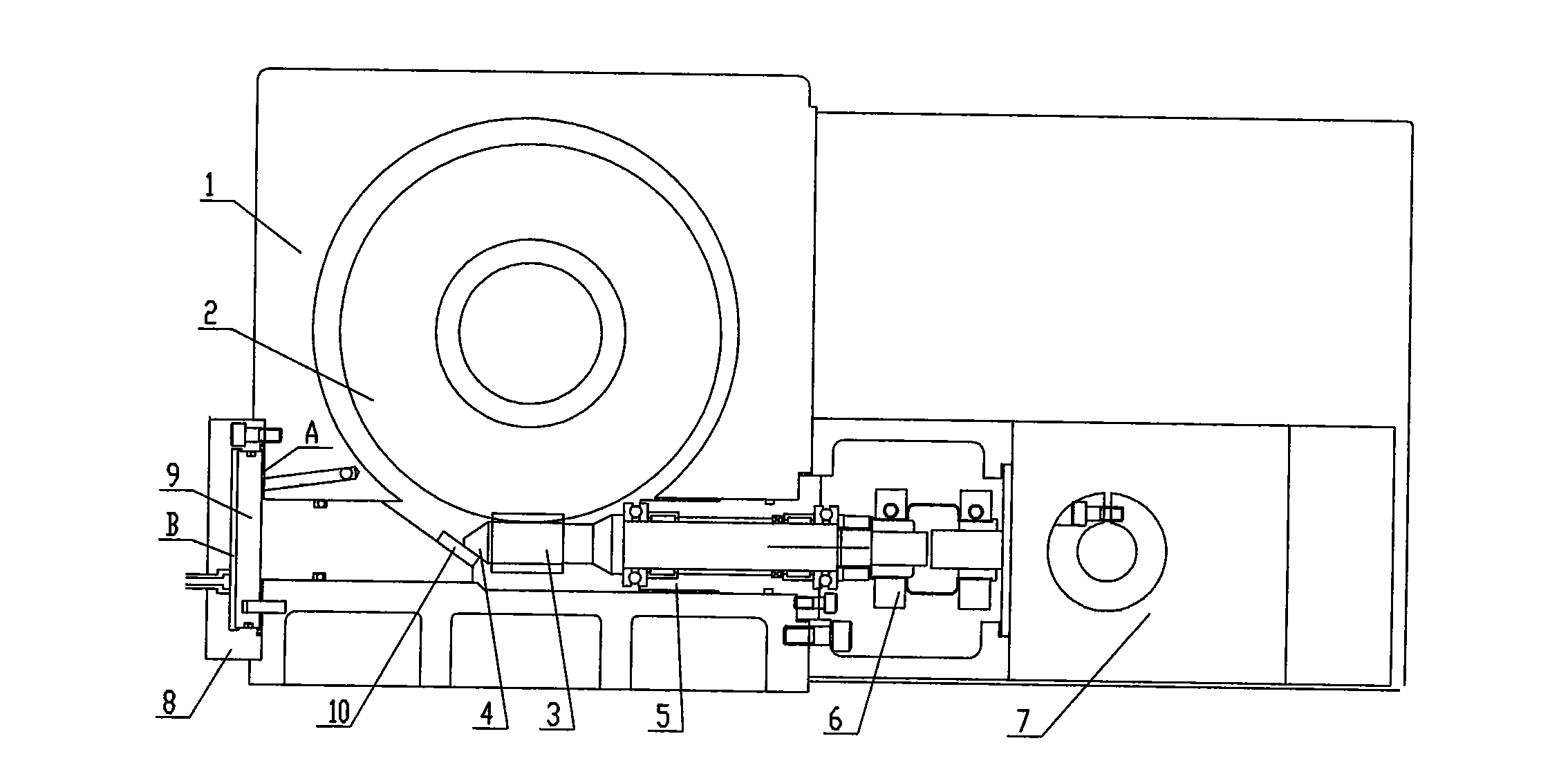

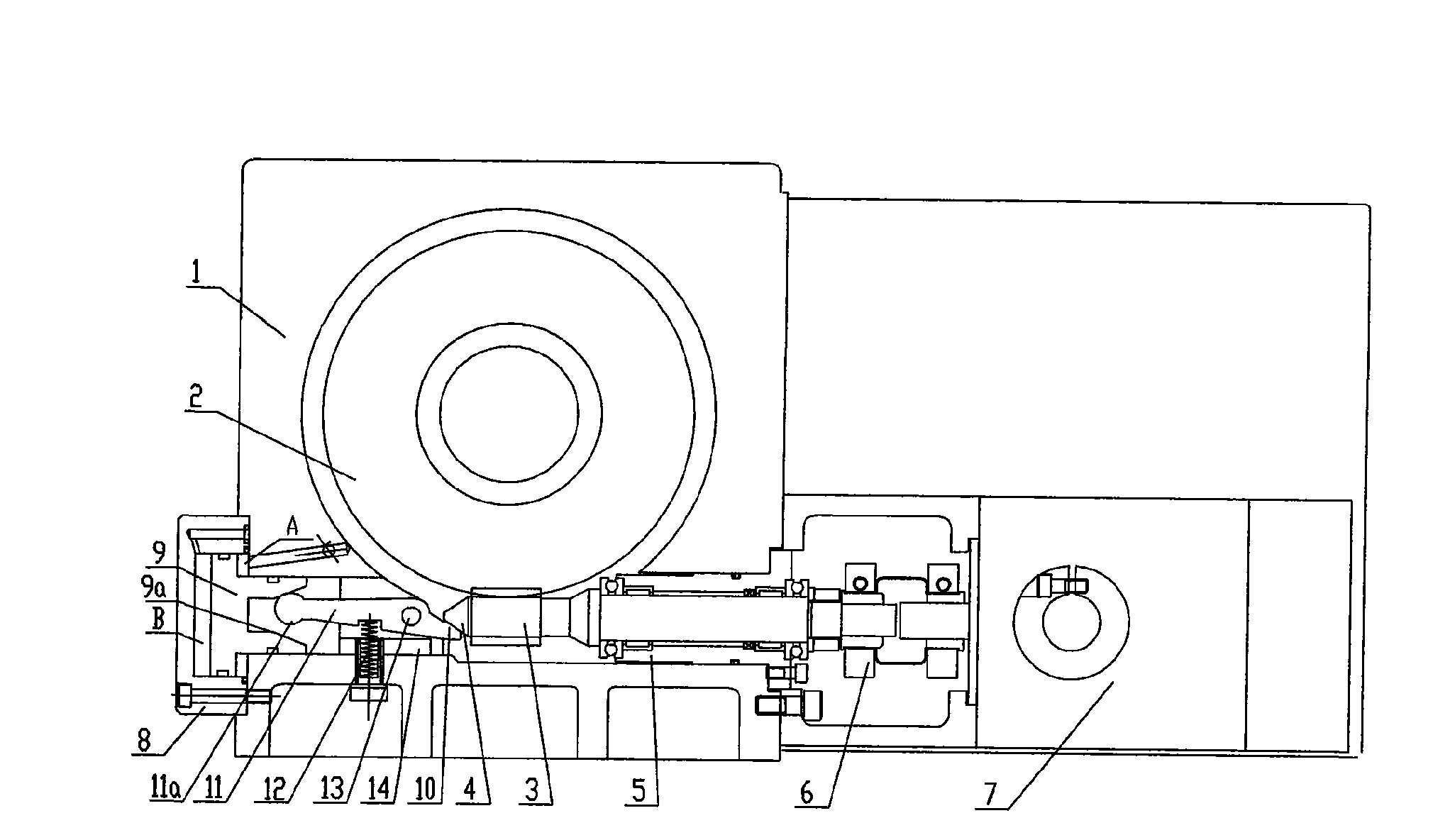

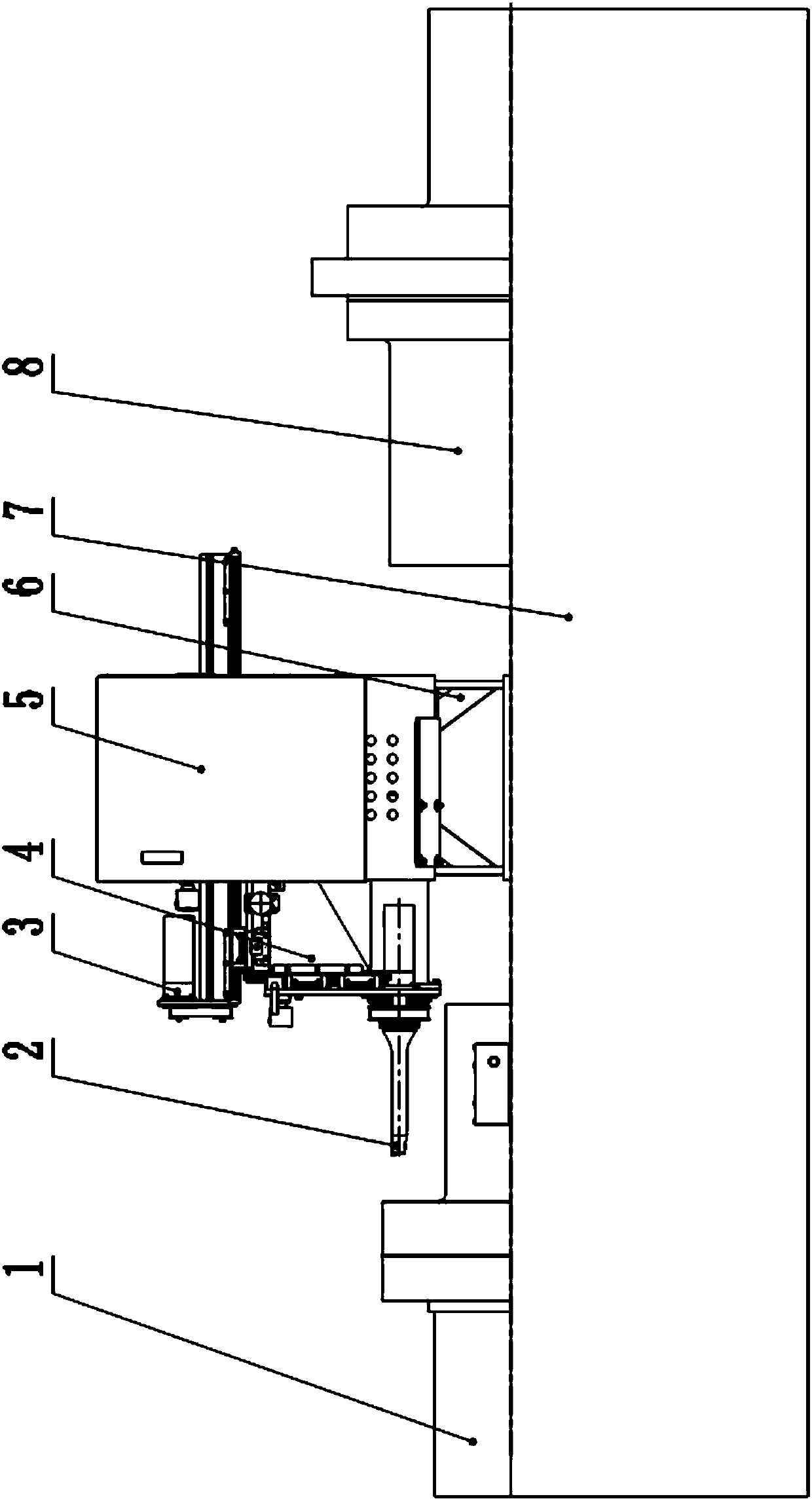

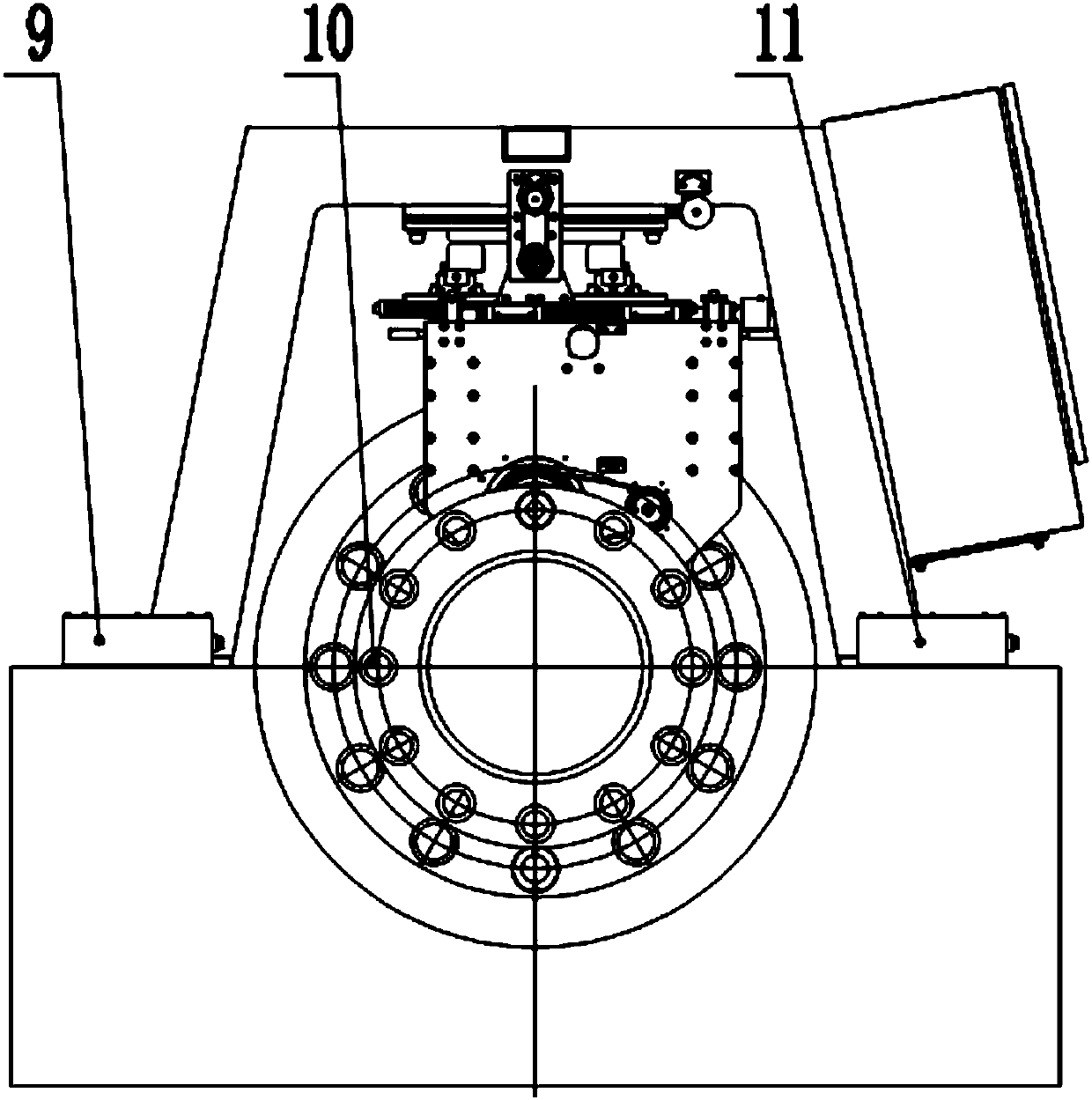

Numerical-control automatic boring machine tool for shaft coupler hole

ActiveCN107838470ARealize automatic alignmentQuick alignmentAutomatic control devicesDrilling/boring measurement devicesEngineeringTouchscreen

The invention discloses a numerical-control automatic boring machine tool for a shaft coupler hole. The numerical-control automatic boring machine tool comprises a rack which is fixedly arranged on asteam turbine cylinder body, wherein a rotary assembly, a feeding assembly, a regulating control part, an electric control box, a laser centering apparatus and a control touch screen are arranged on the rack; the rotary assembly, the feeding assembly, the regulating control part, the laser centering apparatus and the touch control screen are connected with the electric control box; the rotary assembly is used for realizing positive rotation or negative rotation of a boring head for boring a shaft coupler bolt hole; the feeding assembly realizes enabling the rotary assembly including the boringhead to advance and retreat towards a shaft coupler; the laser centering apparatus is used for measuring a coaxiality value of the shaft coupler bolt hole and the boring head, feeding back the valueto the electric control box, controlling a corresponding button of the control touch screen according to the fed-back value, and realizing horizontal front-rear movement, vertical up-down movement andhorizontal swing-angle movement of the boring head by automatic linkage of the regulating control part. The numerical-control automatic boring machine tool is used for automatic boring for holes in ashaft coupler of a steam turbine, and can realize functions of automatically centering, automatically feeding and boring, and controlling the action of the touch control screen.

Owner:河北国源电气股份有限公司

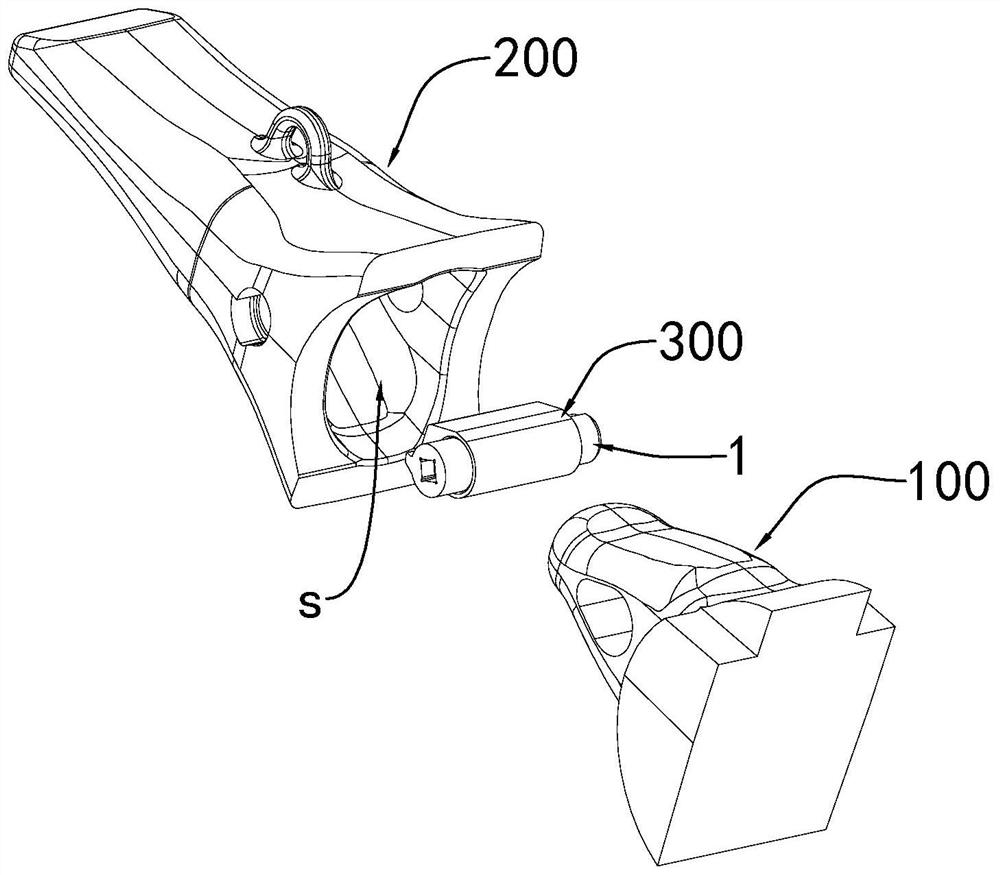

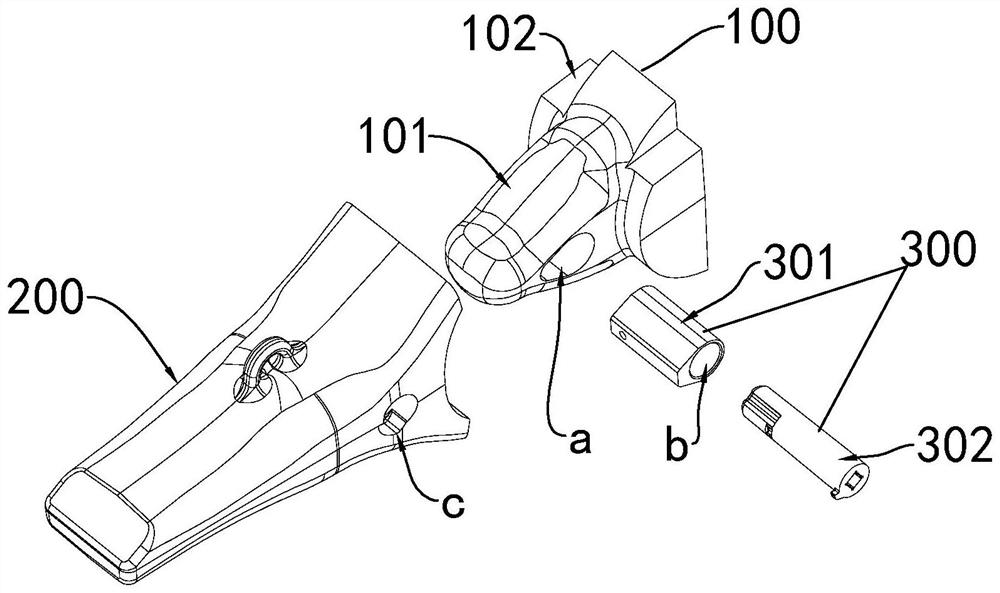

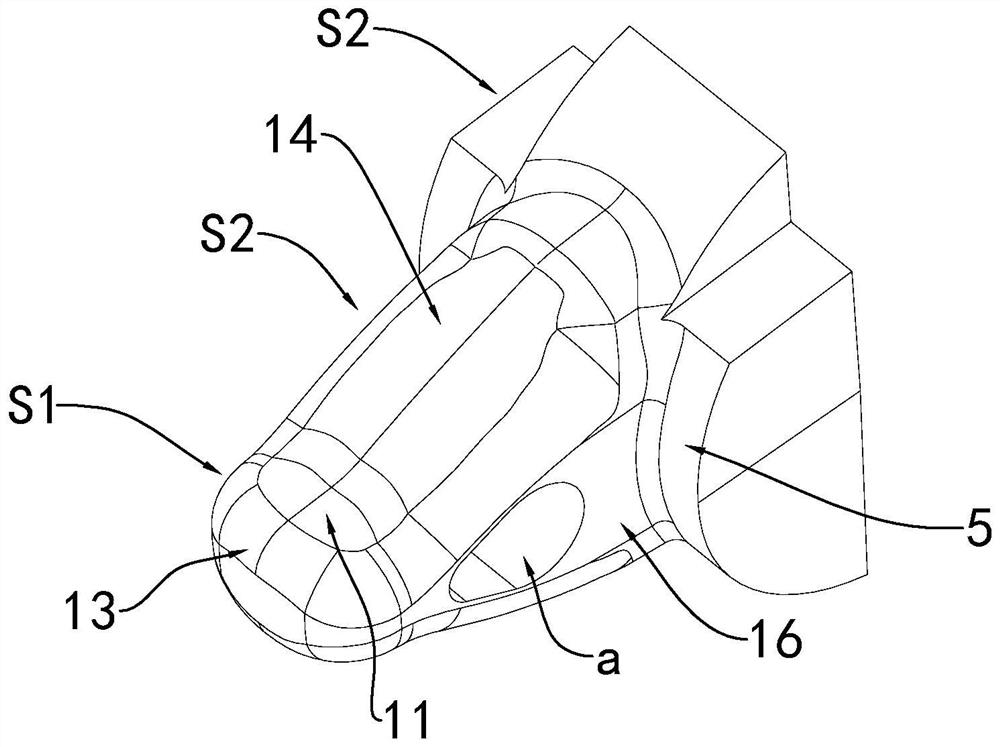

Excavating tooth fixing method and system

PendingCN114607006AEasy to assembleImprove connection strengthSoil-shifting machines/dredgersEngineeringStructural engineering

The invention discloses an excavation tooth fixing method and system, and the method at least comprises the steps: installing a lock body in a lock body accommodation hole, and enabling the lock body to be installed on a tooth holder in a non-rotating manner; moving the bucket tooth, and inserting the nose part of the tooth holder into the inner cavity of the bucket tooth; the lock pin is inserted into a lock pin through hole in one side of the bucket tooth and is initially positioned to ensure that the concave slide way is located at the corresponding position of the elastic lock head; the lock pin penetrates into the pin hole and reaches the lock pin through hole in the other side, the elastic lock head moves to the position beside the concave lock position along the concave sliding way, the middle section of the lock pin is wrapped by the lock body, and the pin ends at the two ends of the lock pin are placed in the lock pin through holes. Rotating force is applied to the end of the lock pin to enable the lock pin to rotate by a certain angle relative to the lock body, the elastic lock head is clamped into the concave lock position from the concave slide way, the lock pin and the lock body are limited, and then the bucket tooth and the tooth holder are fixed; the invention has the advantages of simple and convenient assembly, more reliable and stable connection strength, influence on the bucket tooth strength, and capability of resisting vibration and impact in the excavation tooth operation process.

Owner:NINGBO HOPESUN NEW MATERIAL

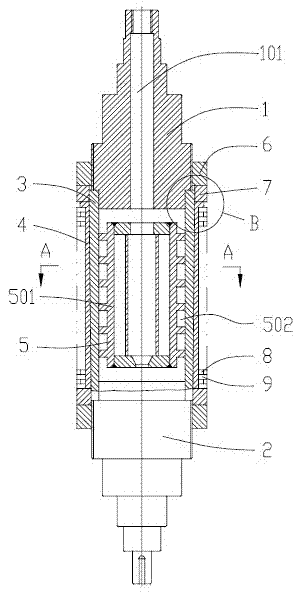

A rotating device for axially floating and radially preloading and fixing a rotating body where an inertial element is located

ActiveCN105697561BAdjust axial playMeet the requirements of normal workBearing unit rigid supportEngineeringMechanical engineering

Owner:SHAANXI BAOCHENG AVIATION INSTR

Gear angle quick aligning and positioning device for gear grinding and positioning method

InactiveCN111673204AImprove efficiency and machine automation levelEliminate radial playGear-cutting machinesGear teethEngineeringMachine tool

The invention discloses a gear angle quick aligning and positioning device for gear grinding and a positioning method. The gear angle quick aligning and positioning device for gear grinding comprisesa bottom plate mounted on a working table of a machine tool, a piston is fixedly arranged in the center of the bottom plate, an oil cylinder is arranged on the piston in a sleeving mode, and the outerwall of the piston is in close contact with the inner wall of the oil cylinder; an oil cylinder end cover is mounted at one end of the oil cylinder, an aligning and tool-setting mechanism matched with a workpiece gear is mounted at the other end of the oil cylinder, and the oil cylinder end cover is arranged on a piston rod of the piston in a sleeving mode and is in sealed connected with the piston rod; a first oil circuit and a second oil circuit are formed in the piston to communicate with a first working oil cavity and a second working oil cavity correspondingly; and when the first oil circuit works, the aligning and tool-setting mechanism is driven to move upwards to complete tool-setting positioning, and when the second oil circuit works, the aligning and tool-setting mechanism is driven to move downwards to complete tool retracting. Quick aligning and precise positioning of the workpiece angle can be realized, positioning stability is good, and the quality and efficiency of batch machining and the automation level of the machine tool are improved.

Owner:秦川机床工具集团股份公司

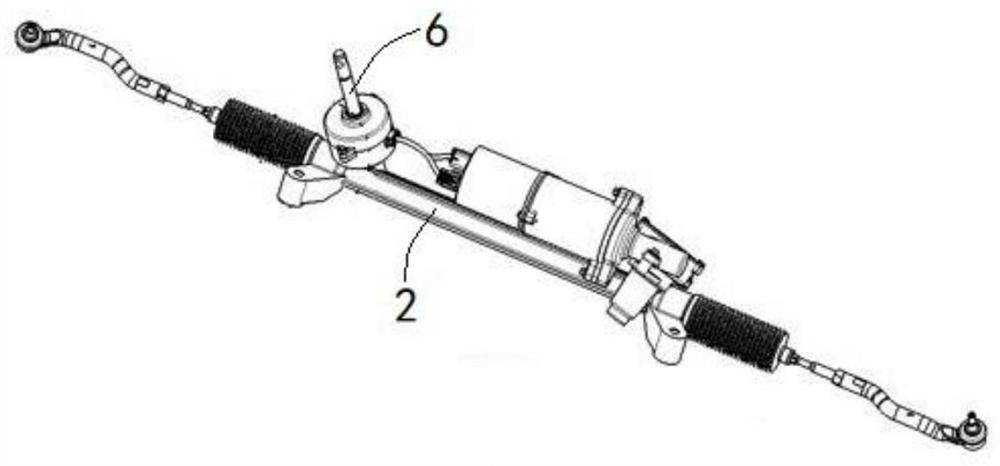

Gap adjusting device and gear rack steering gear

PendingCN114060485ASimple structureLow costGear vibration/noise dampingMechanical steering gearsGear wheelEngineering

The invention relates to the technical field of steering, and discloses a gap adjusting device and a gear rack steering gear. When the gear rack steering gear is assembled, a friction plate of at least one gap adjusting device is located on the side, back to a gear of a gear rack mechanism, of a rack; and the clearance adjusting piece is used for providing pressure for the friction plate to enable the friction plate to abut against the acting force of the rack so that the radial clearance during rack assembling is eliminated. When the gear rack steering gear works, the radial clearance of the rack is eliminated through elastic deformation of the clearance adjusting piece so as to guarantee stable movement of the gear, the radial clearance generated by abrasion of the tooth profile of the rack can be dynamically compensated, and the buffering effect can be achieved when the gear rack steering gear is subjected to impact loads so as to absorb shock and reduce noises. The friction force between the rack and the gap adjusting device in the moving process of the rack is reduced through the friction plate, and the abrasion and noise are reduced; and the friction plate is supported through the base body so as to avoid plastic deformation of the friction plate, and the service life of the gap adjusting device is prolonged.

Owner:CHINA AUTOMOTIVE INNOVATION CORP

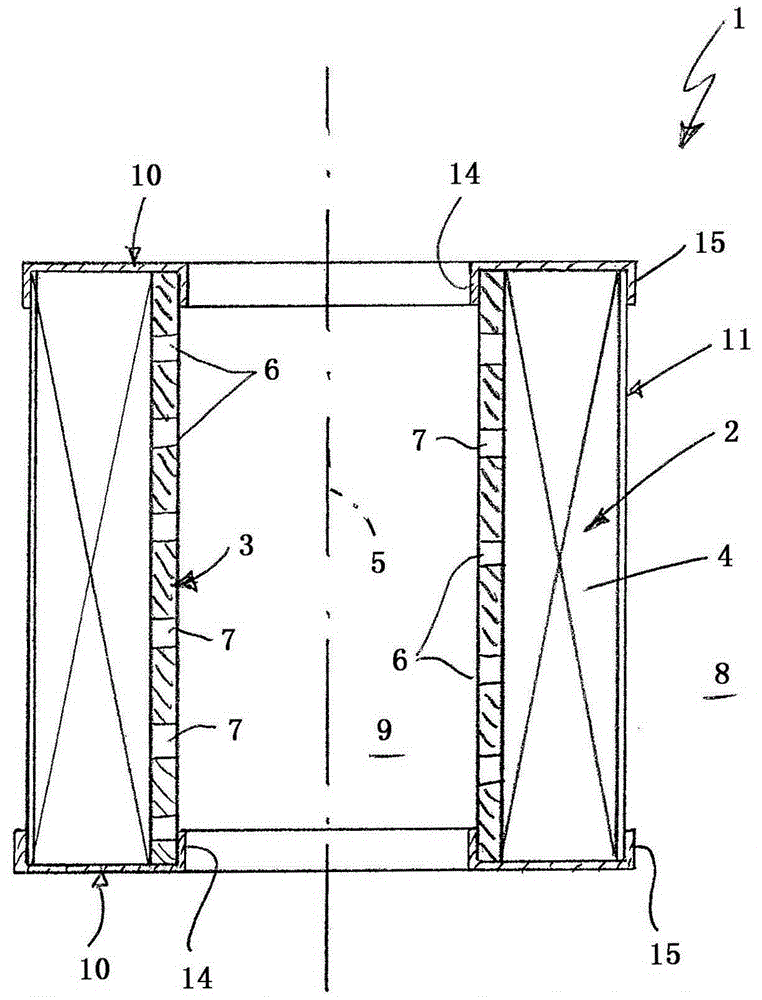

Hydraulic filter element and related method of manufacture

ActiveCN103079669BEasy to useEasy to manufactureMembrane filtersStationary filtering element filtersFilter materialMechanical engineering

The invention relates to a hydraulic filter element (1), in particular an oil filter element, with a cylindrical filter body (2) made of star-shaped folded filter material (4) and a cylindrical Shaped inner frame (3), on which the filter body (2) is supported radially inwardly. A simplified production of the hydraulic filter element results in that a cylindrical sleeve ( 11 ) permeable to the respective hydraulic medium is provided, which rests radially outward on the filter body ( 2 ).

Owner:上海弗杰过滤器材有限公司

Double Piece Hobbing Fixture

InactiveCN103418856BHigh positioning accuracyGuaranteed machining accuracyGear-cutting machinesGear teethHydraulic cylinderHobbing

The invention discloses a machine tool part and particularly relates to a dual-piece hobbing fixture which comprises a conical core shaft, an upper vertical column and a first draw rod, wherein the conical core shaft comprises a stepped shaft and a conical body; the upper end of the stepped shaft and one end, which has larger diameter, of the conical body are connected and are equal to each other; the lower end face of the conical core shaft is provided with a first through hole along the axial direction; the stepped shaft is provided with a locating sleeve; the conical body is provided with a spring tensioning sleeve; one end of the first draw rod is coaxially provided with a truncated cone with the diameter not greater than the outer diameter of the spring tensioning sleeve, and the other end of the first draw rod passes through the first through hole; the upper vertical column coaxial with the first draw rod is arranged above the first draw rod, and is fixedly connected with a pressing sleeve. After such a structure is adopted, the machine tool hydraulic cylinder and the upper vertical column are fully utilized, so that workpiece loading and unloading time is shortened, and the labor efficiency is improved; meanwhile the rigidity of the fixture is enhanced; since a sliding bush capable of performing relative movement is not adopted, the workpiece locating precision is high, and the gear processing accuracy is stably ensured.

Owner:CHONGQING YUQING MACHINERY MFR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com