Swing plate and rolling loop type compressor

A rolling ring type and compressor technology, applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve the problems of low service life of the whole machine, increased use cost, low compressor efficiency, etc., to increase manufacturing costs , reduce processing costs, increase the effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

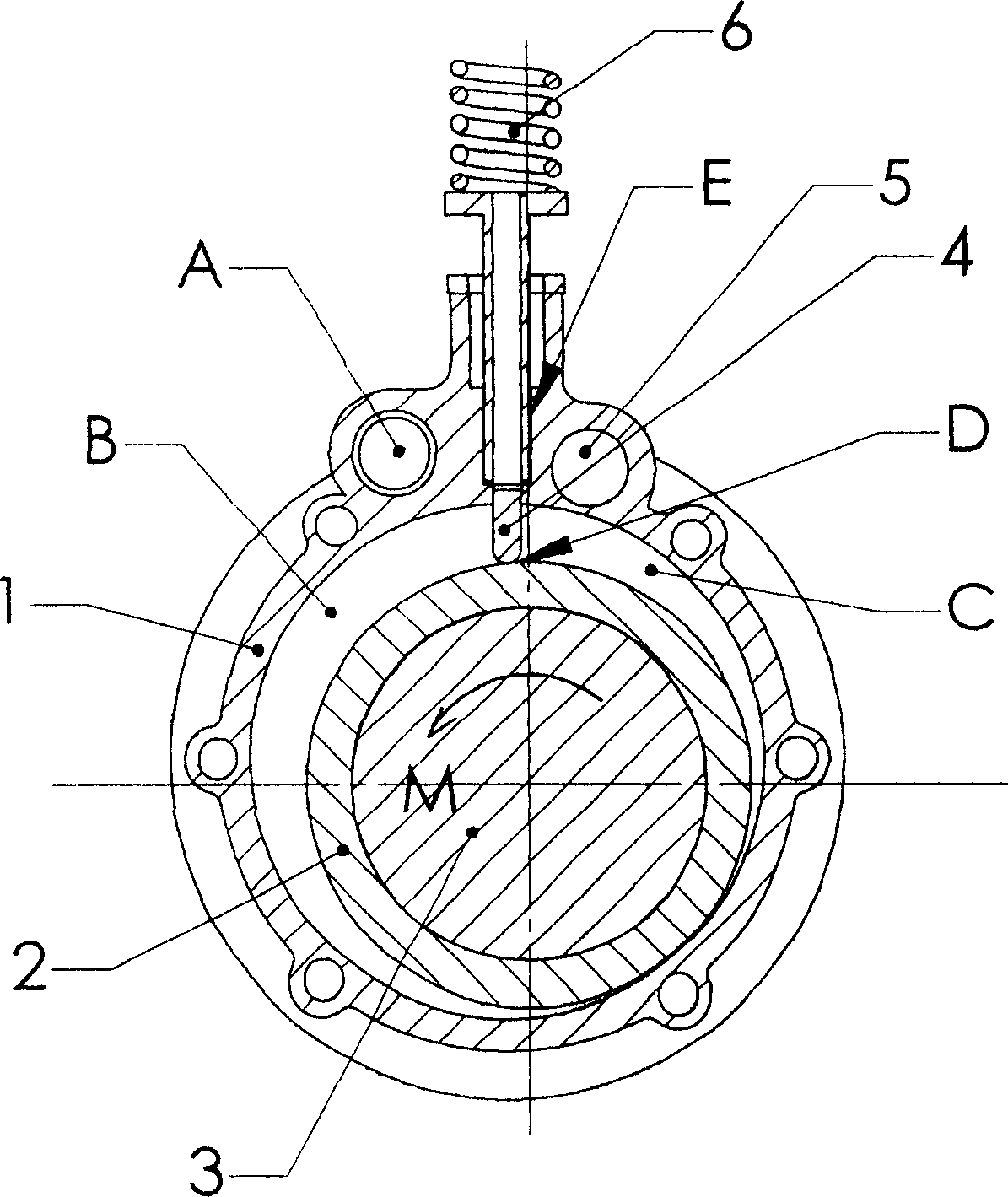

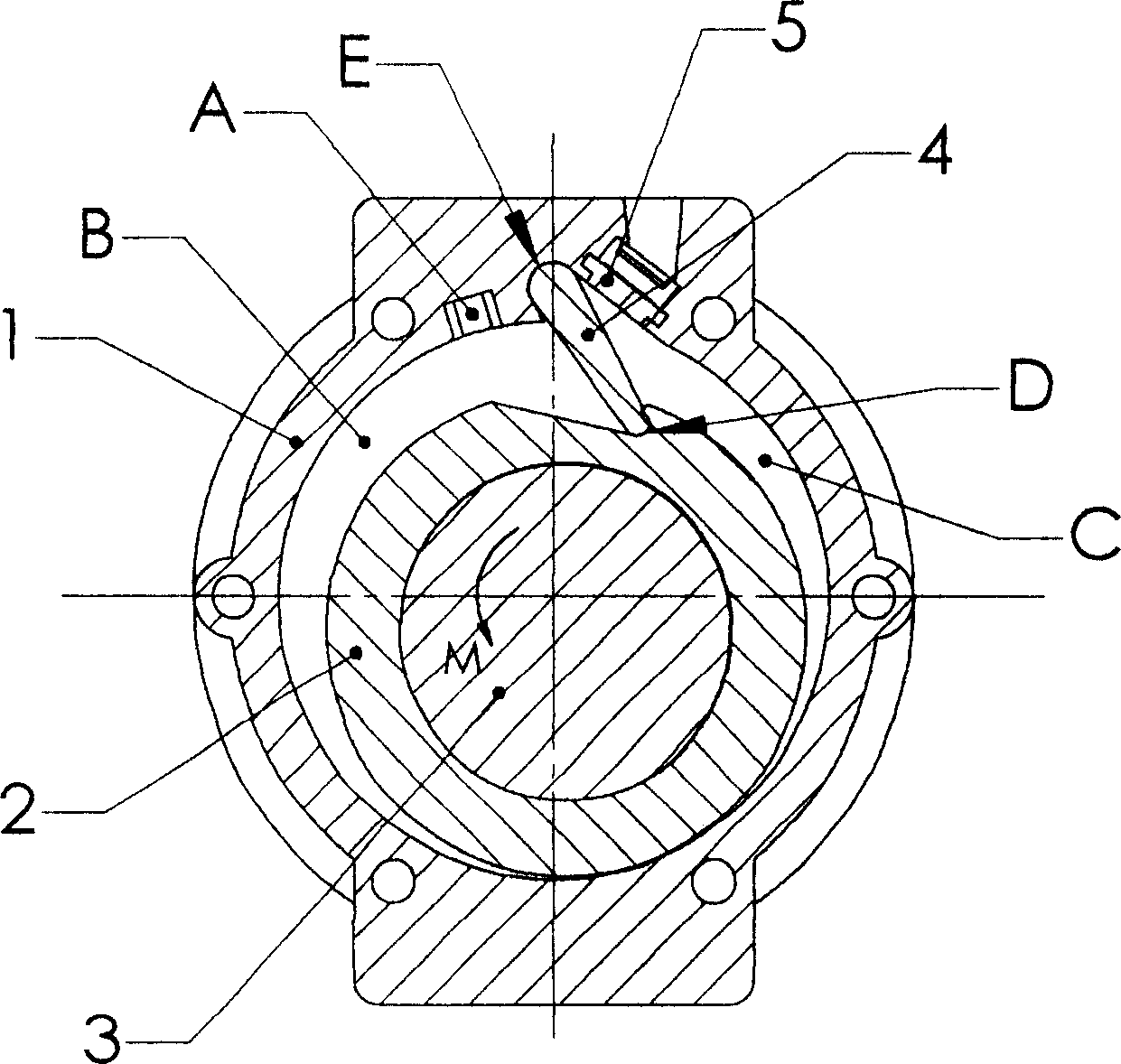

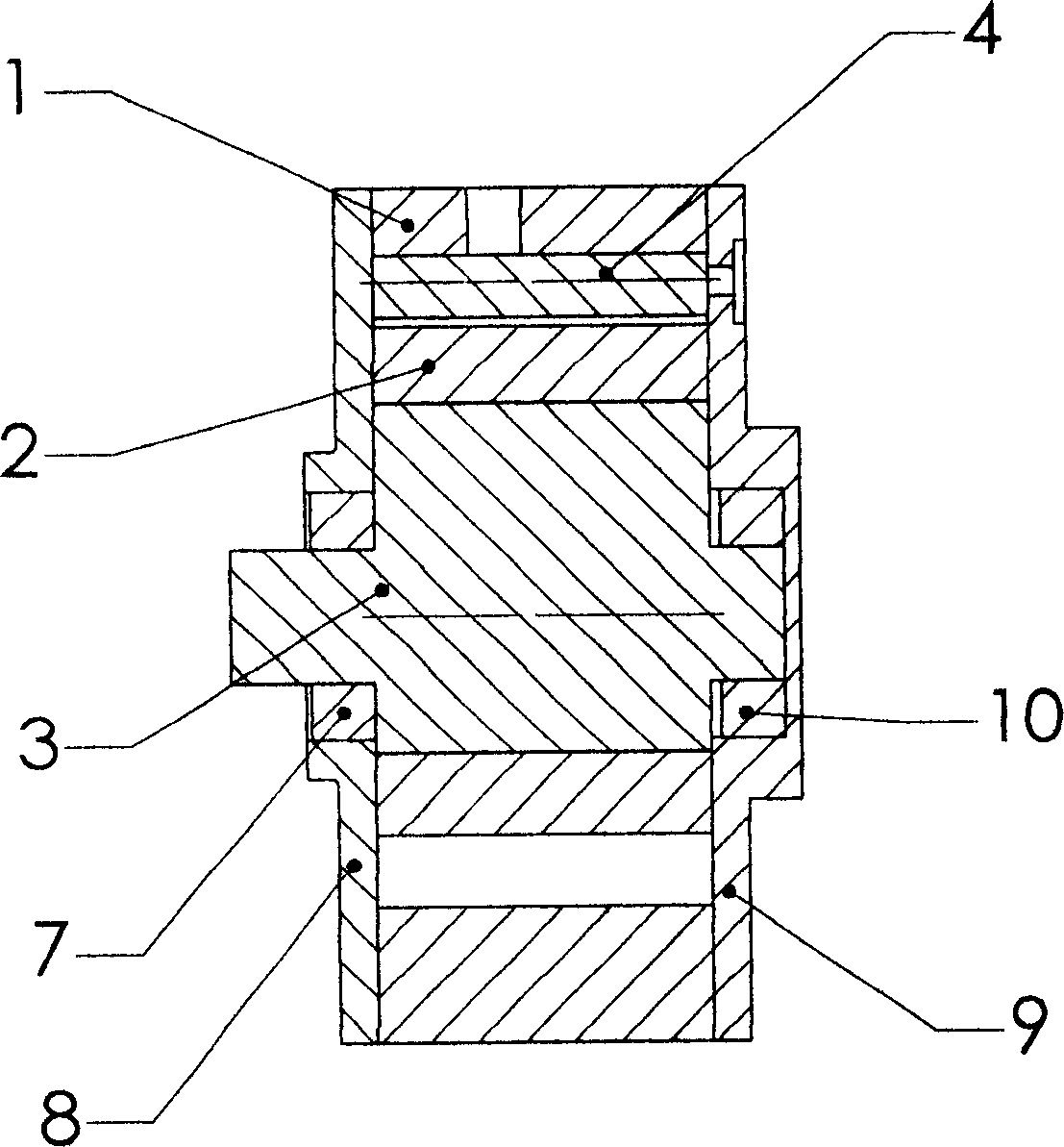

[0030] Such as figure 2 and image 3 As shown, the wobble plate rolling ring compressor of the present invention is mainly composed of a cylinder block 1, a rolling ring 2, an eccentric shaft 3, a wobble plate 4, an exhaust valve 5, end covers 8 and 9 on both sides, and two ends of the eccentric shaft 3. Parts such as bearing 7 and 10 are formed.

[0031] The eccentric shaft 3 is installed coaxially with the inner hole of the cylinder block 1, and the rolling ring 2 is installed outside the eccentric wheel on the eccentric shaft 3, and one end of the pendulum plate 4 is hingedly lying in the groove D of the rolling ring 2, and its other One end is hingedly supported in the groove E of the cylinder block 1; an air inlet A is set on the cylinder block 1, and an exhaust valve 5 is installed.

[0032] The wobble plate 4 and the rolling ring 2 divide the cylinder 1 into two parts, the suction chamber B and the compression chamber C.

[0033] The working process of the wobble pl...

Embodiment 2

[0035] Such as Figure 7 As shown, a needle roller bearing 11 is installed between the roller ring 2 and the eccentric wheel on the eccentric wheel shaft 3 .

Embodiment 3

[0037] A wear-resistant bushing is installed between the roller ring 2 and the eccentric wheel on the eccentric wheel shaft 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com