Patents

Literature

313 results about "Splice joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A splice joint is a method of joining two members end to end in woodworking. The splice joint is used when the material being joined is not available in the length required. It is an alternative to other joints such as the butt joint and the scarf joint. Splice joints are stronger than unenforced butt joints and have the potential to be stronger than a scarf joint.

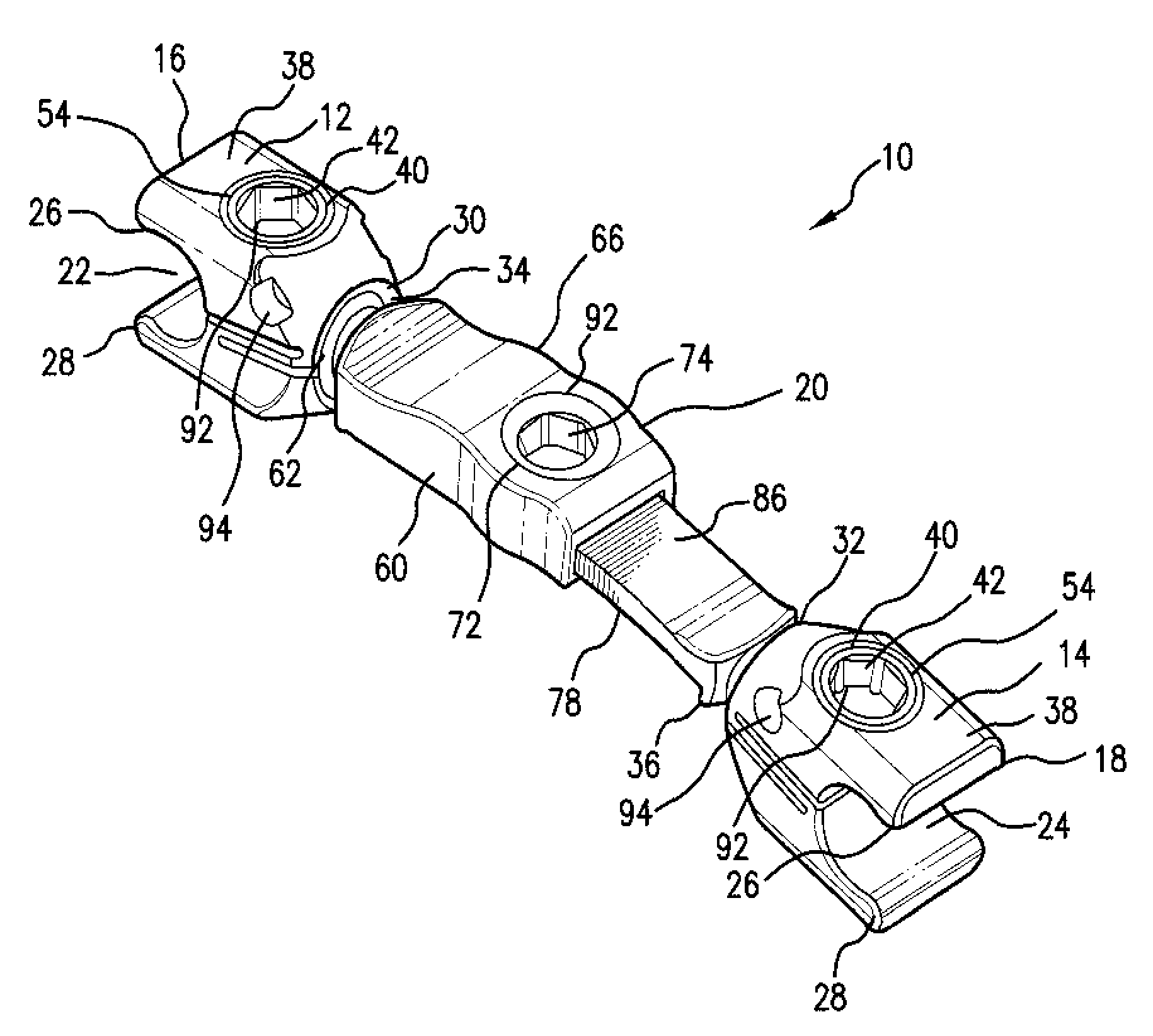

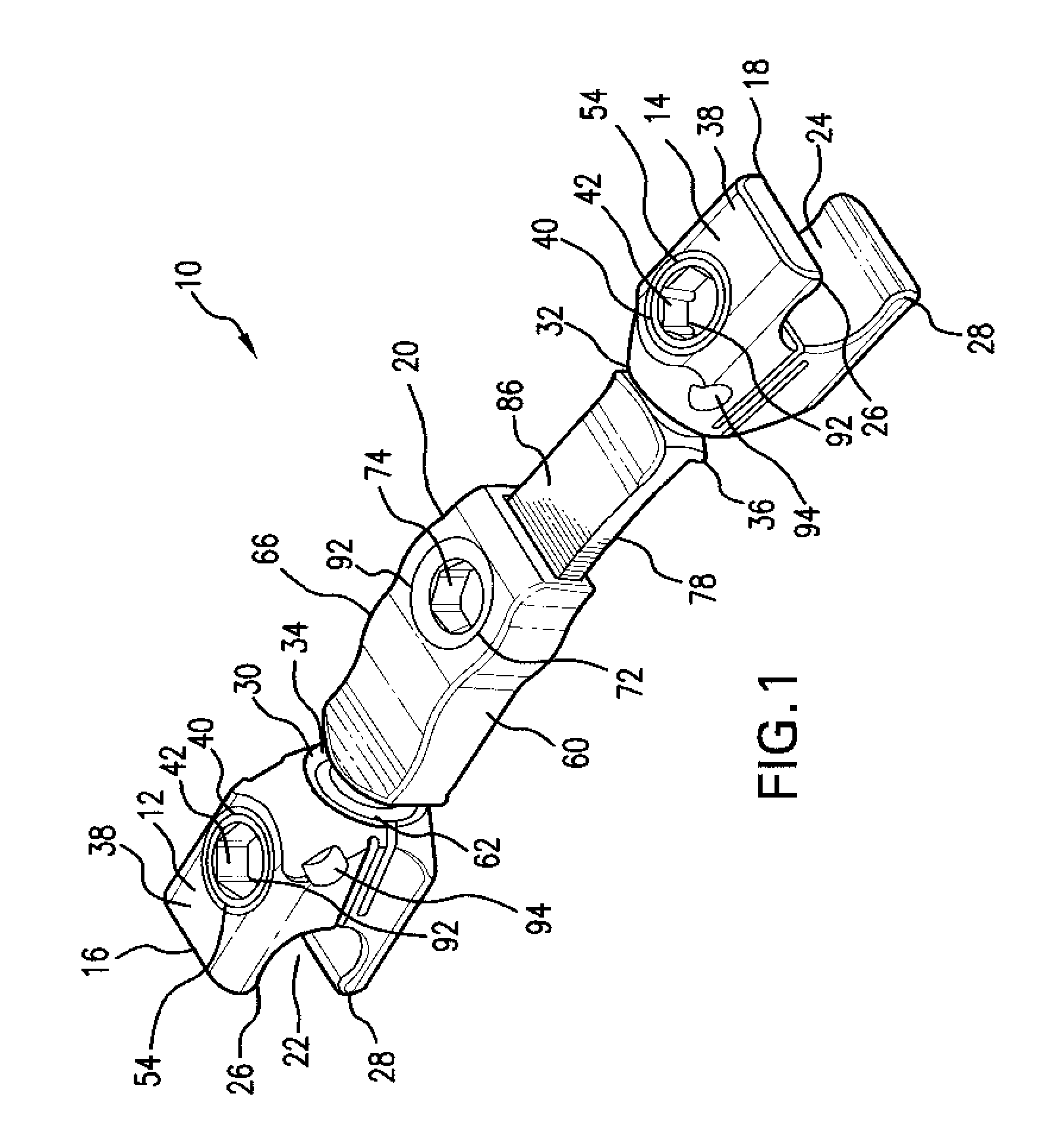

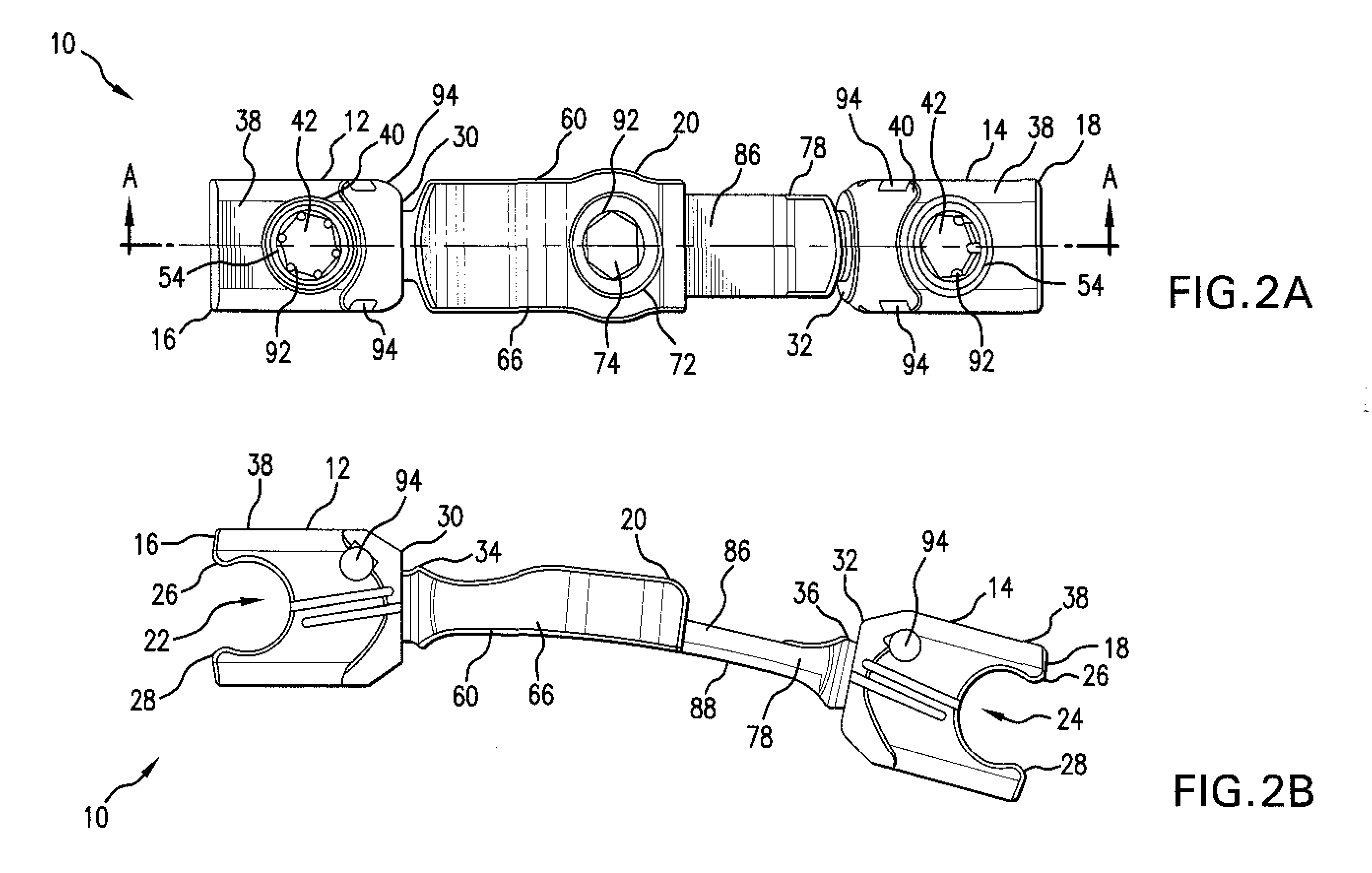

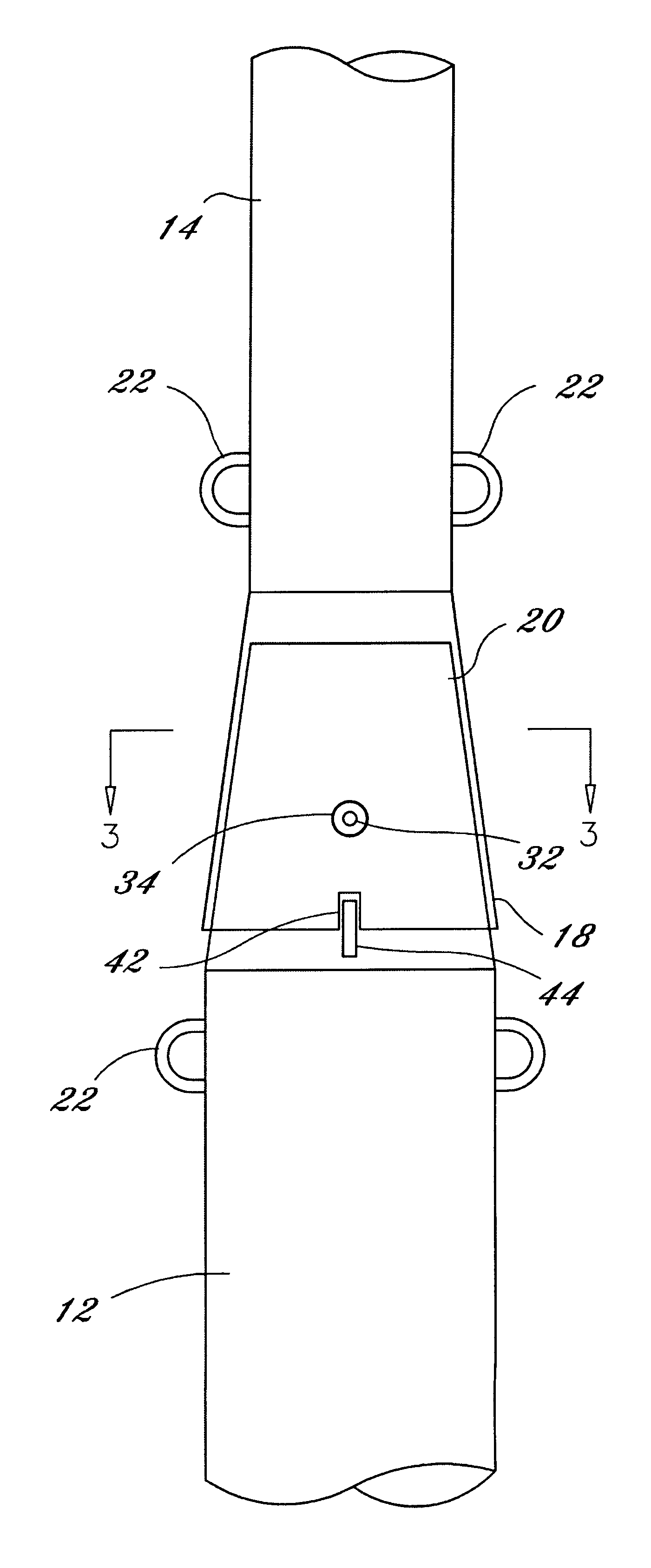

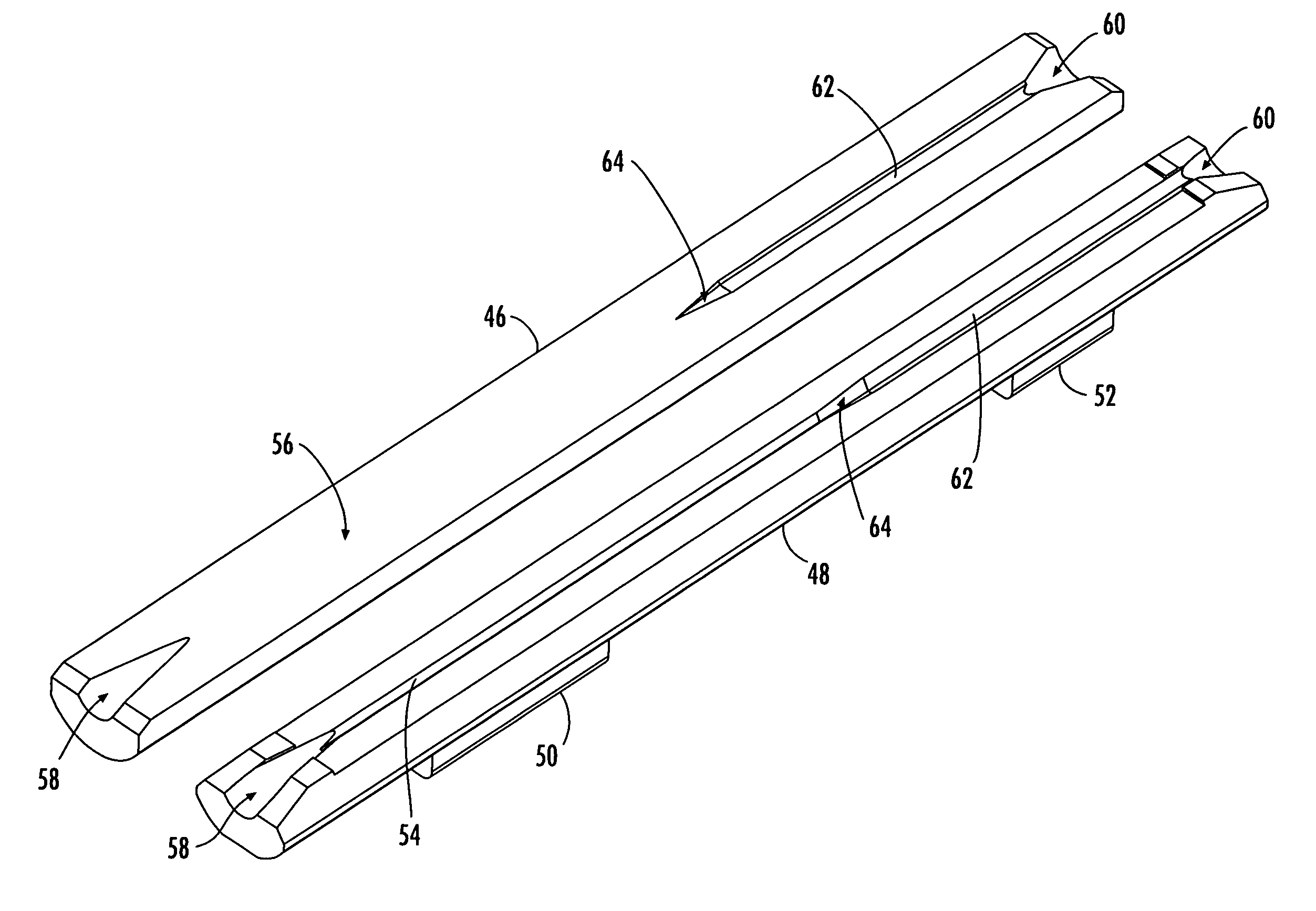

Low profile transverse connector

ActiveUS20080306538A1Firmly connectedInternal osteosythesisJoint implantsCross connectionEngineering

Provided is a novel low profile transverse connector system having a first and second spinal rod connection member disposed at opposing ends of an elongated cross connection device, each connection member having a distal end configured to be capable of connecting to a spinal rod and a proximal end having a multidirectional articulation joint at which a centrally disposed cross connecting assembly is provided to attach the first and second connection members to each other, the first and second spinal rod connection members each defining two opposing compression slots that serve to facilitate a secure connection to spinal rods and to the cross connecting assembly by the tightening of only one locking screw. Also provided is a method of stabilizing vertebrae using the disclosed system.

Owner:K2M

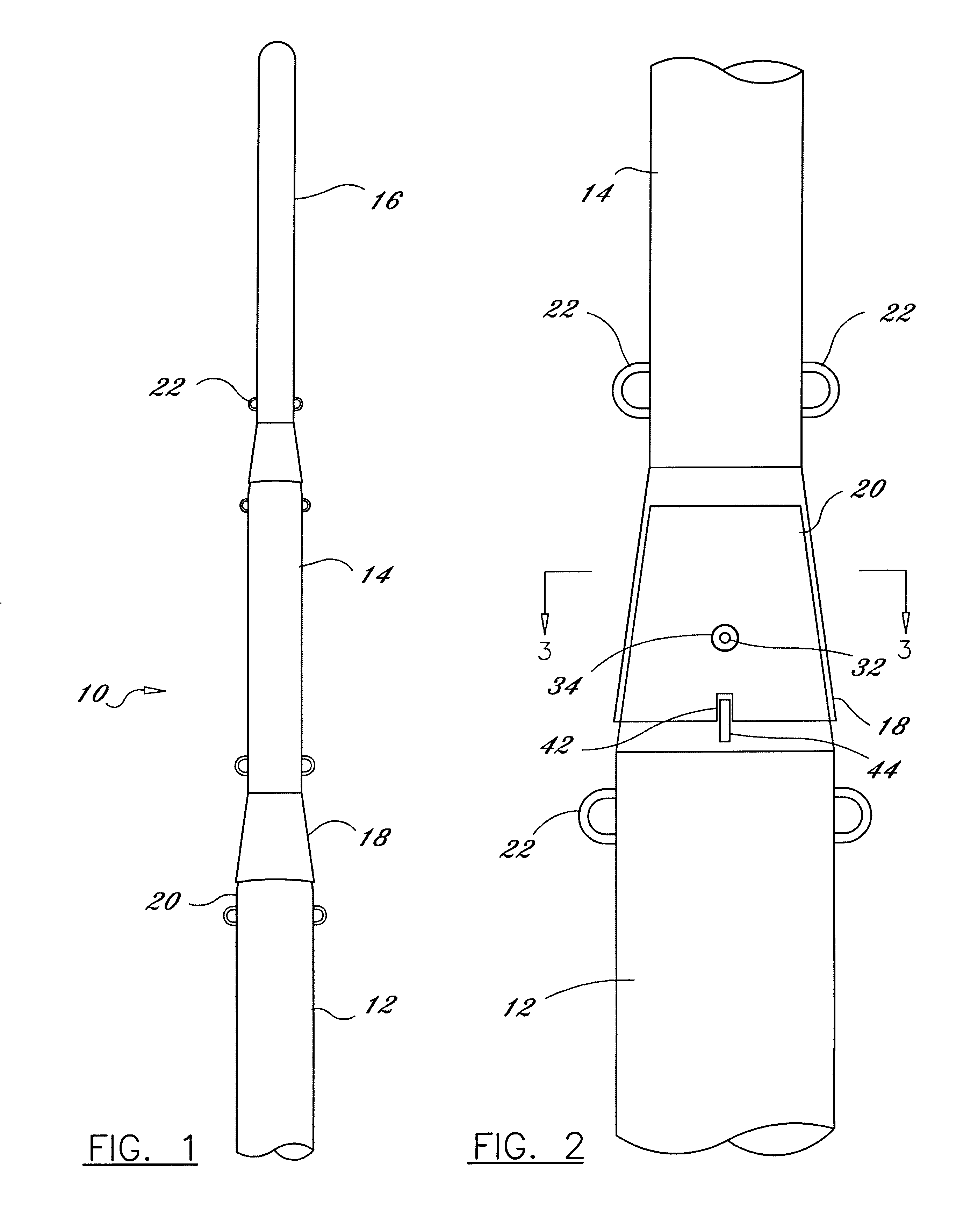

Multi-sectional utility pole having slip-joint conical connections

InactiveUS6191355B1Reducing circumferenceImprove the circumferenceLoad-supporting elementsTowersStraight tubeSlip joint

A multi-sectional utility pole includes at least two sections of straight pipe, which are joined and connected by a slip joint connection. The slip joint preferably consists of two mating conical sections, with one attached to each section of the pole. The slip joint is compressed with the aid of rings, which are attached to the pipe, and a key and slot. The two conical sections are fastened together with bolts that pass through the female conical section and thread into the male conical section of the slip joint. The pole is easily assembled on the ground and the pole sections are fungible with other sections of the same diameter. The sections are also inexpensively manufactured. The conical sections can be swaged from the ends of the pipe, or can be fabricated separately and welded on to the ends of the pipe.

Owner:EDELSTEIN HANS P

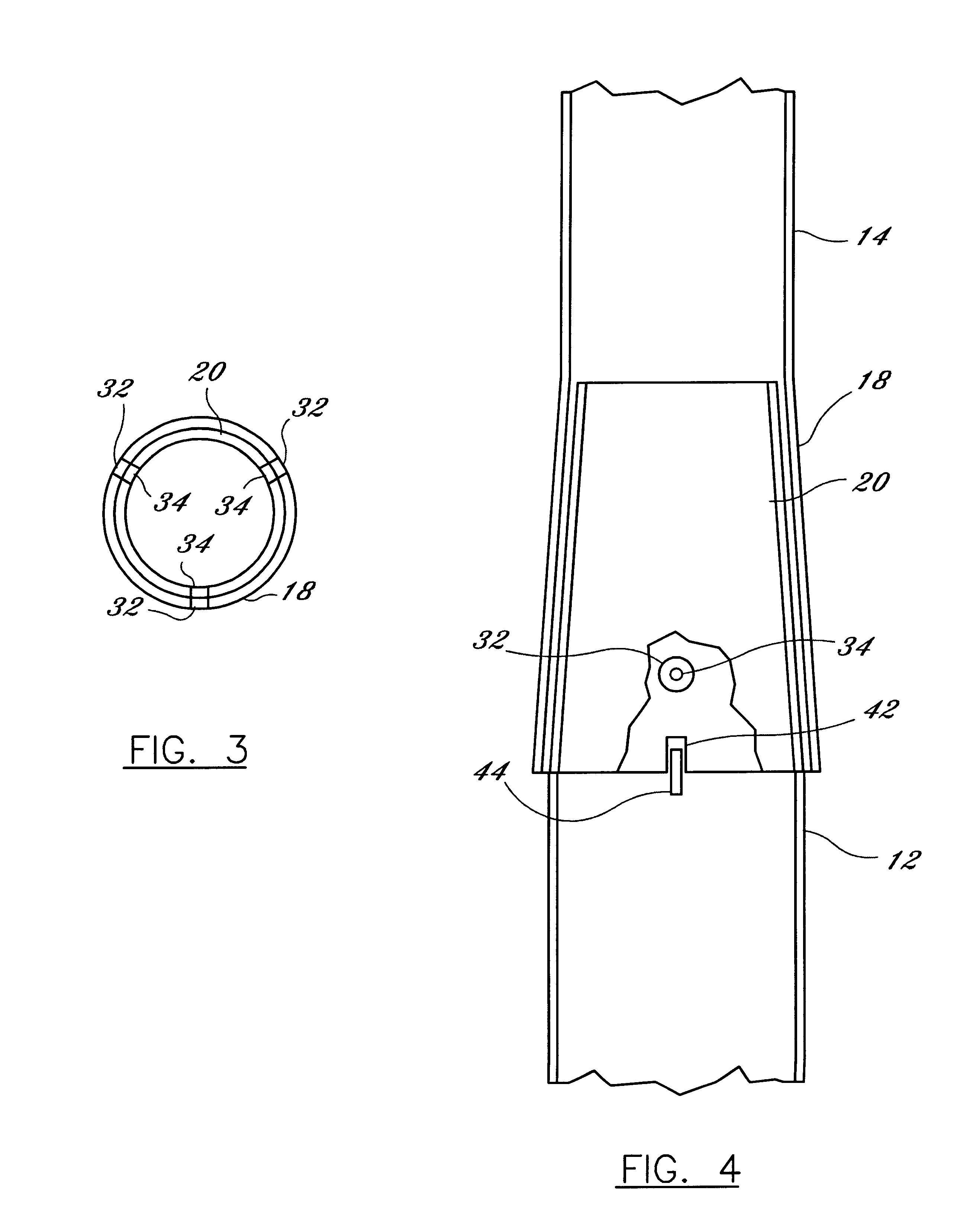

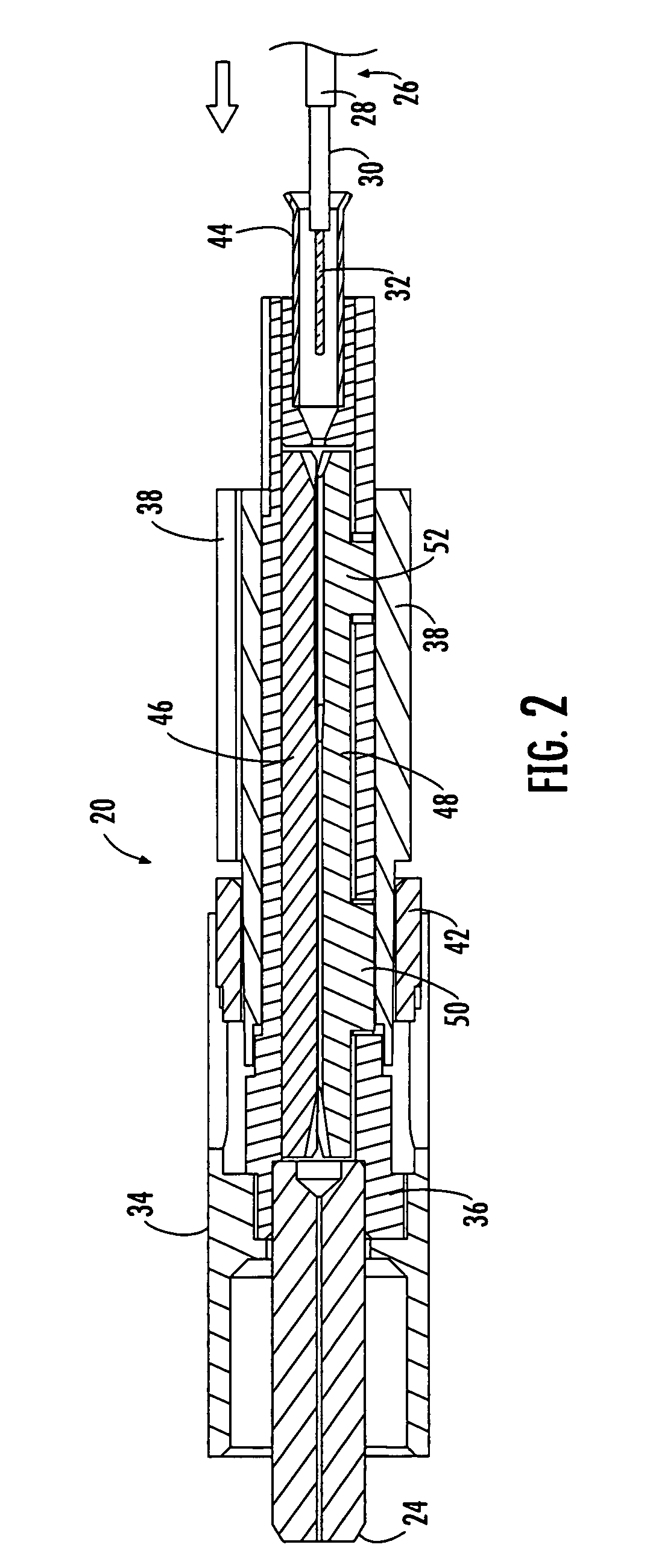

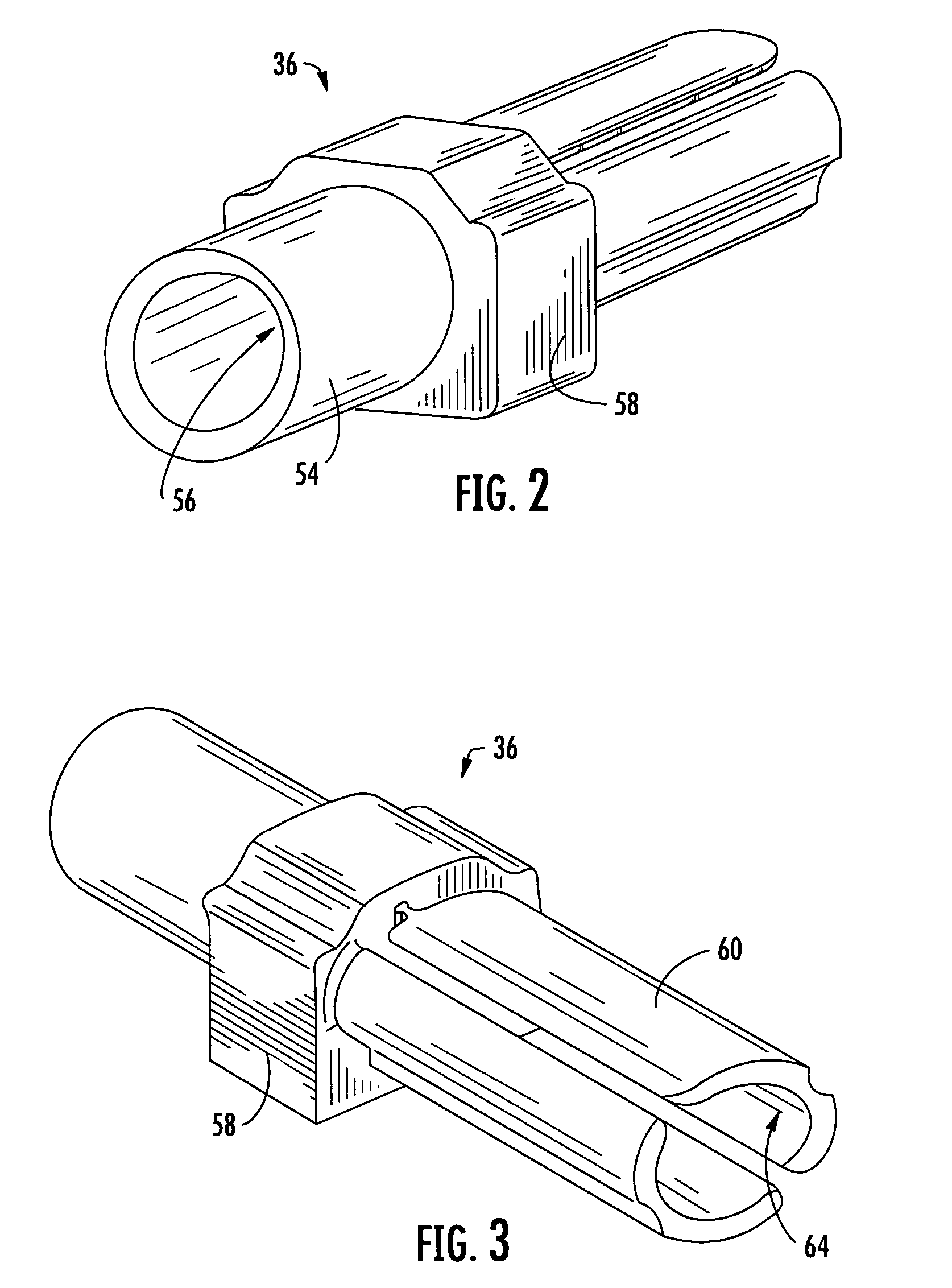

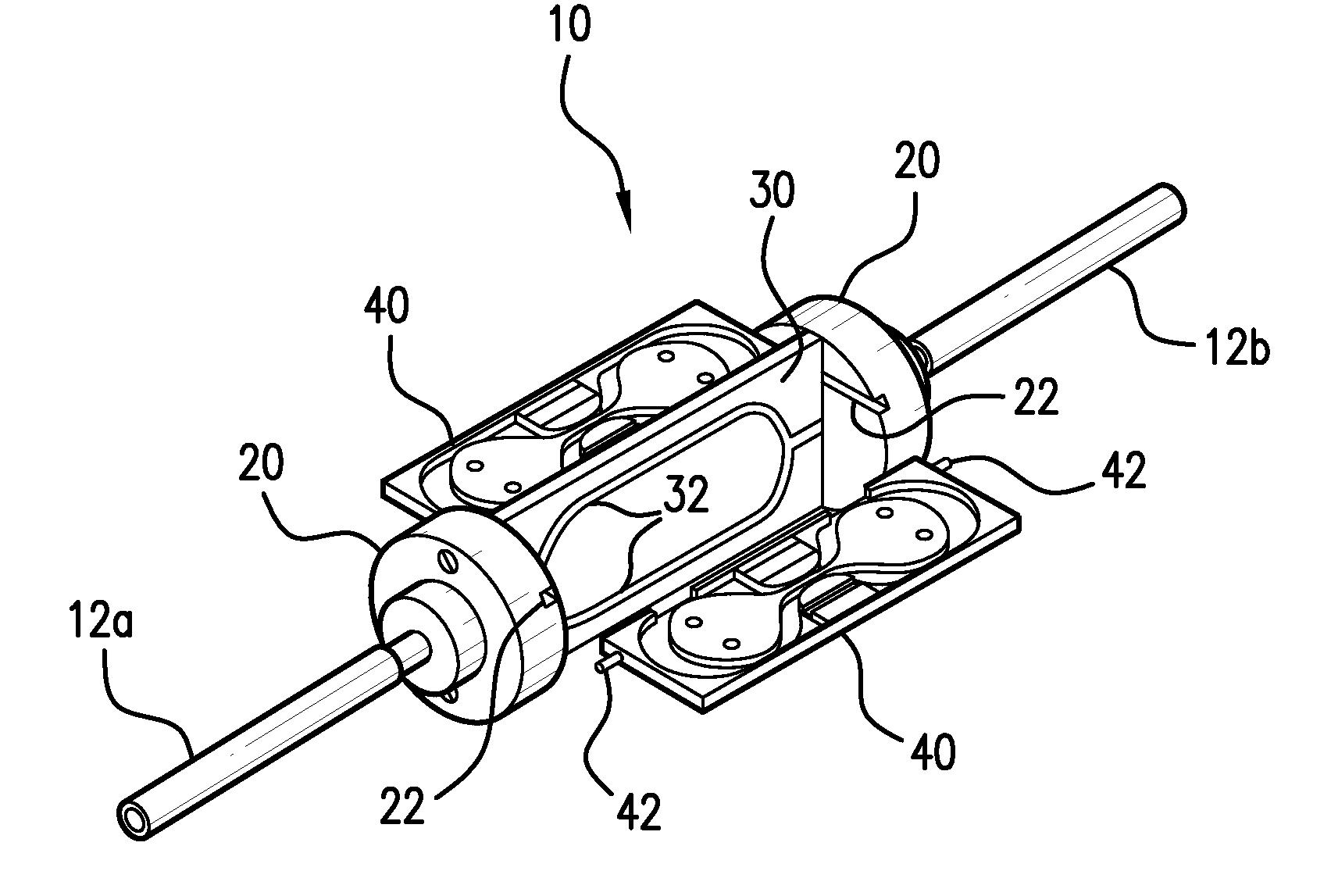

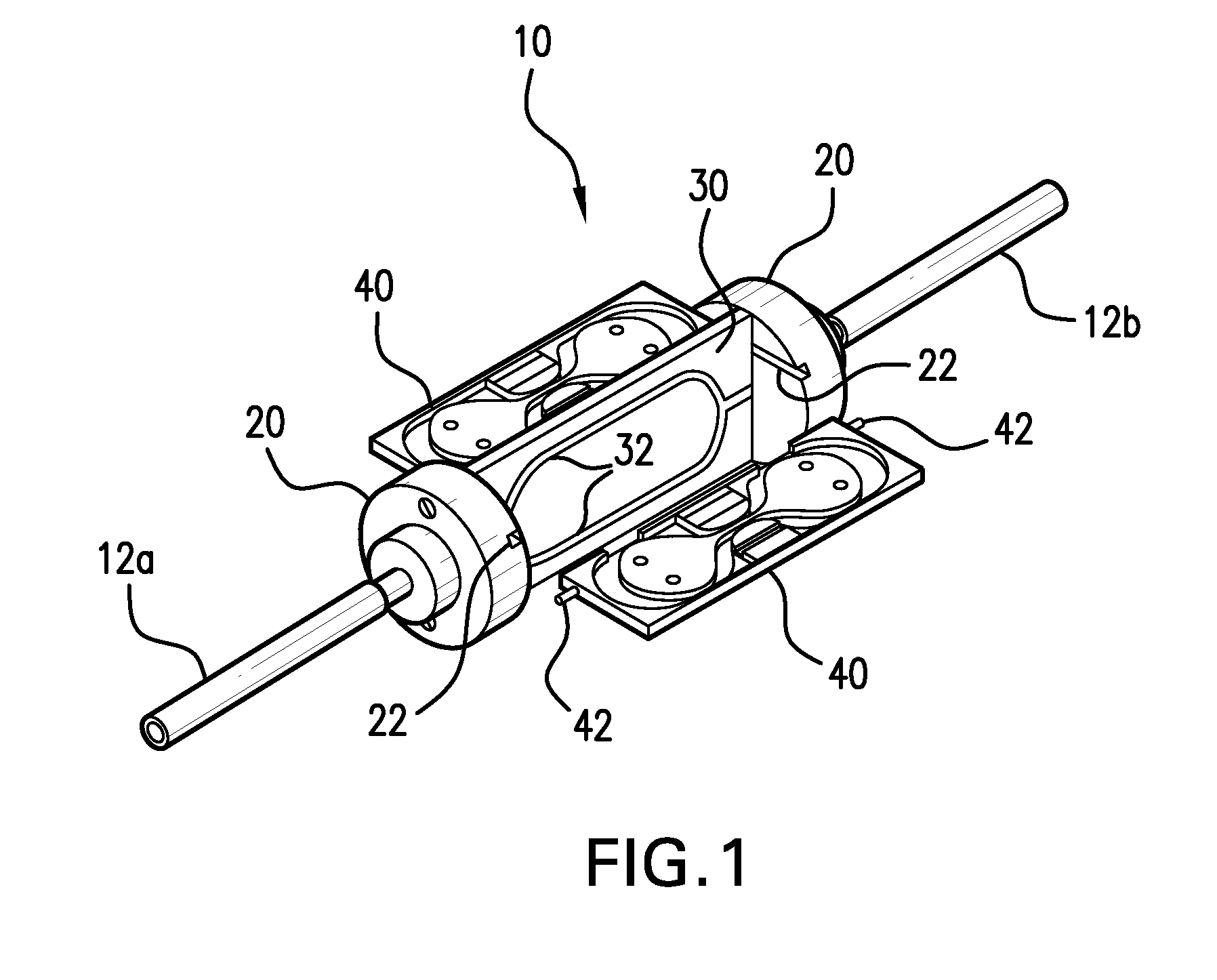

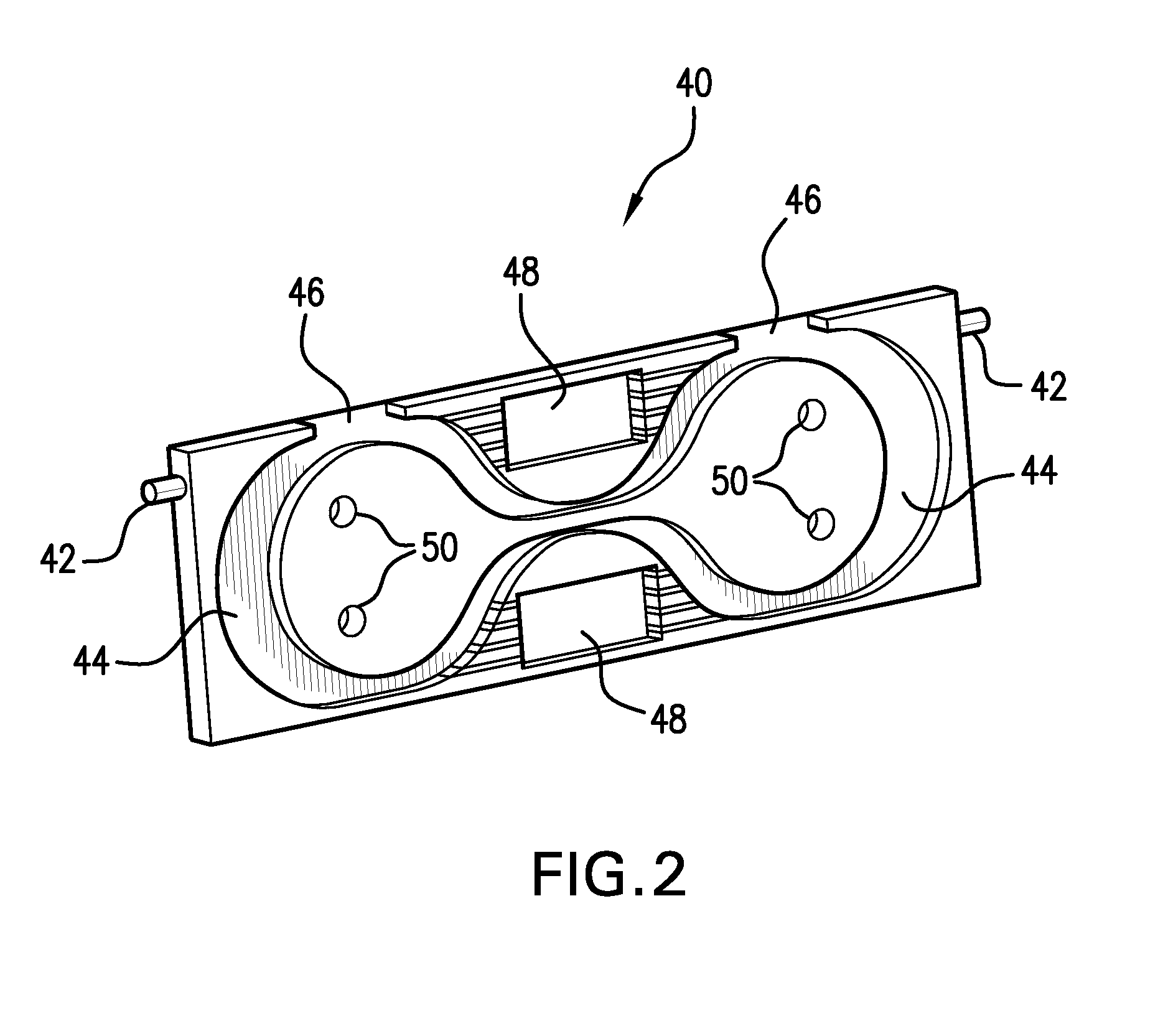

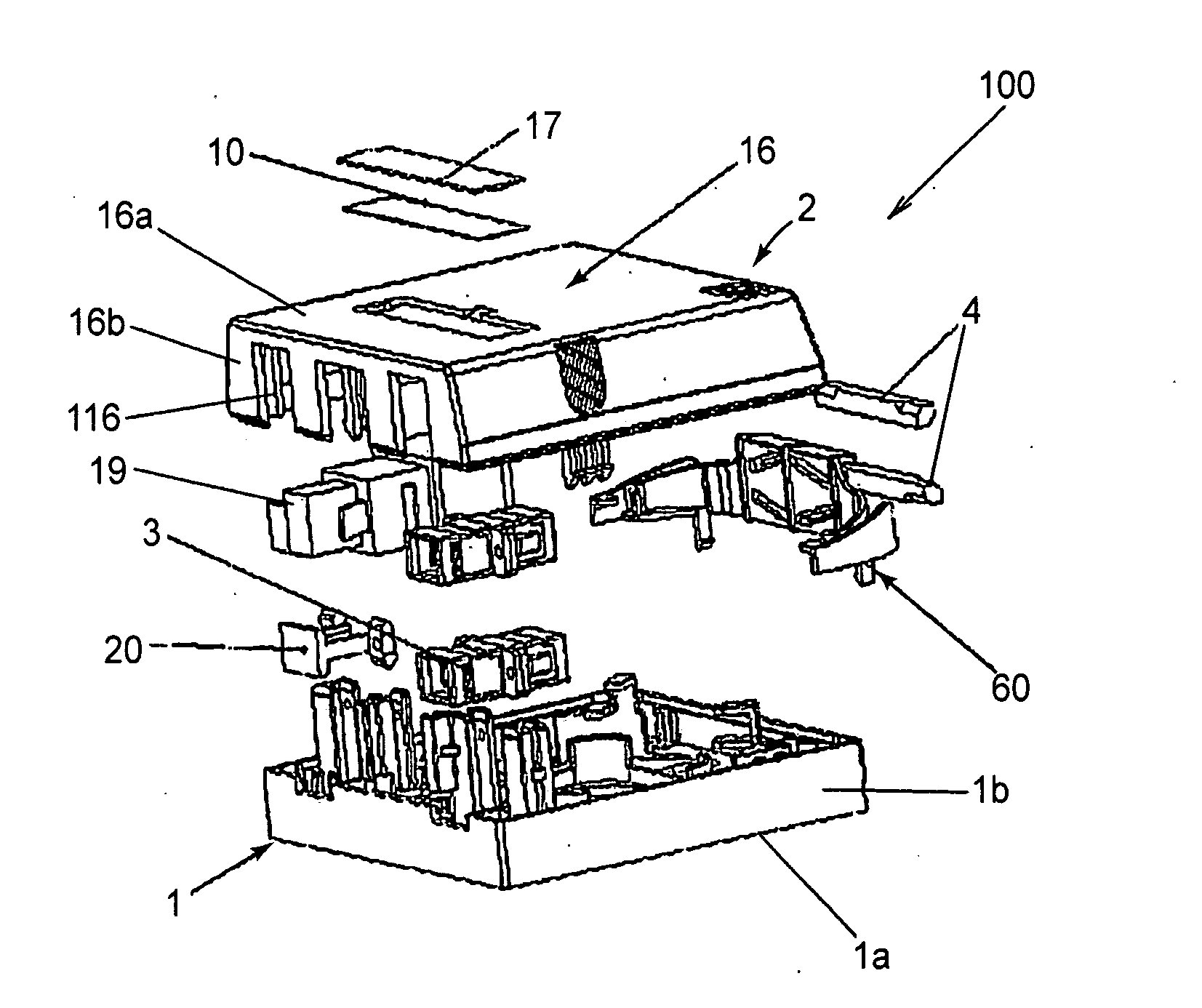

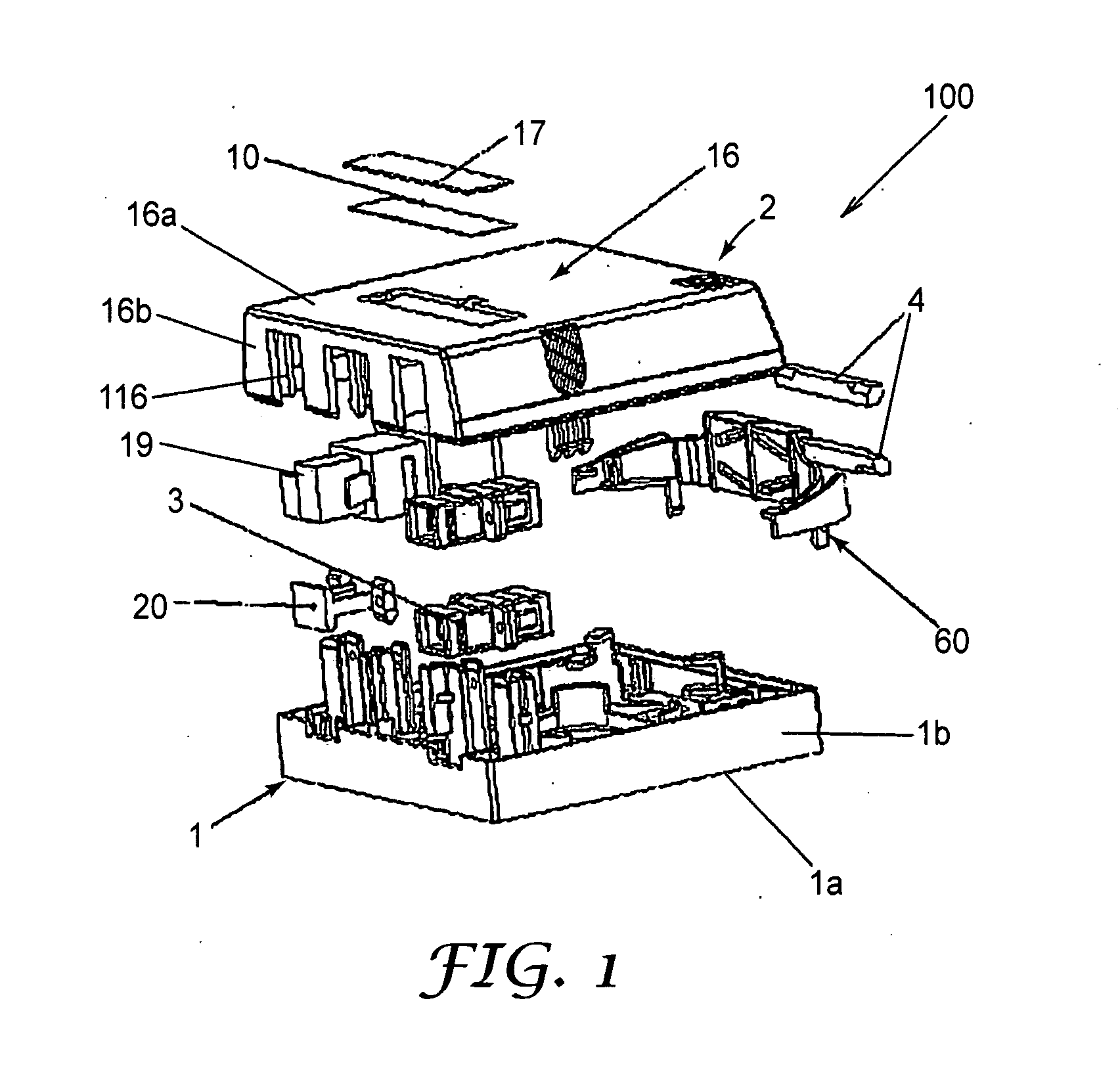

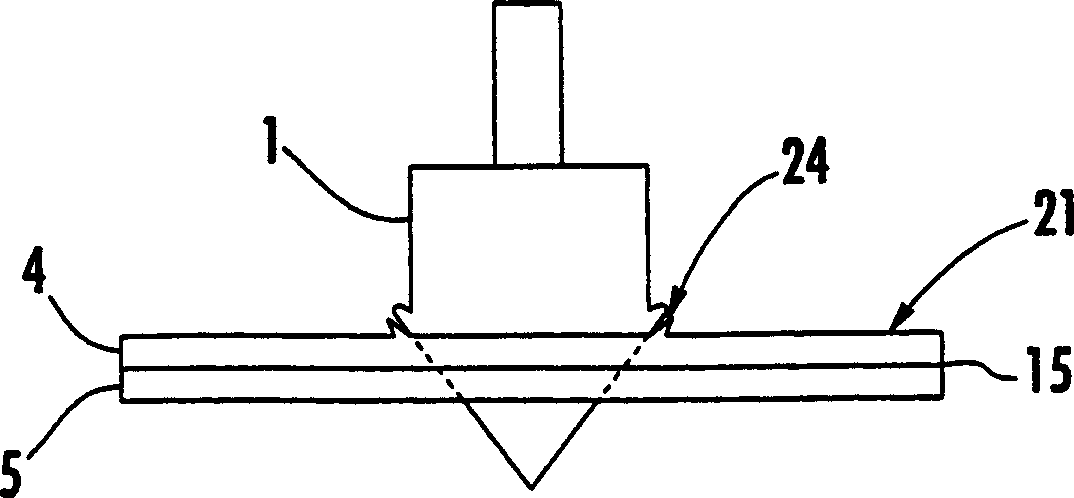

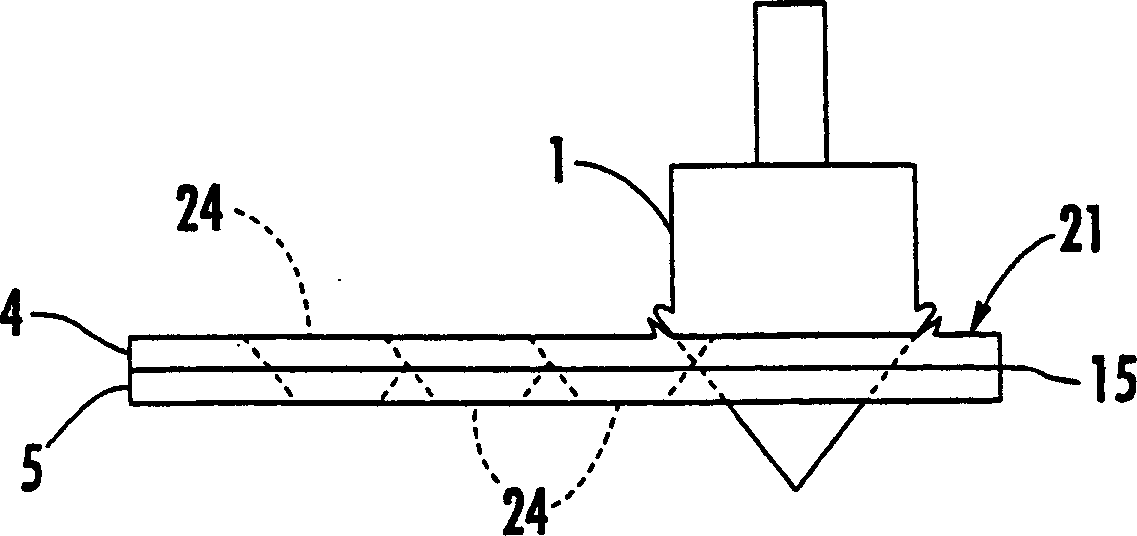

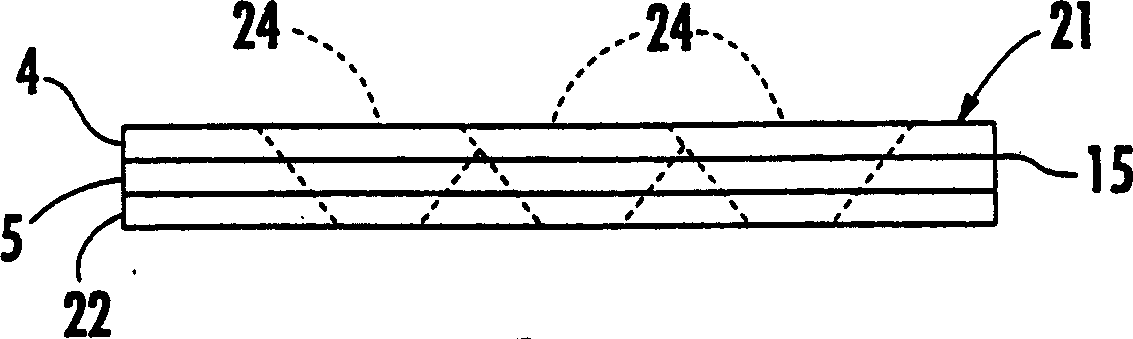

Dual function splice component for mechanical splice connector

ActiveUS7264410B1Eliminate positioning effectsOptical strainCoupling light guidesFiberMechanical splice

A fiber optic mechanical splice connector including a single connector element operable for providing optical fiber alignment and strain relief includes opposed splice components that define first and second grooves for receiving the bare glass portions of mating optical fibers, as well as the coated or buffered portion of at least one of the optical fibers when the splice components are biased together by an actuator. The mating optical fibers are aligned while the coated or buffered portion of one of the optical fibers is retained within the same connector element, thus eliminating positioning problems that occur when separate connector elements are utilized for fiber alignment and strain relief. The splice components may be unbiased to allow removal of at least one of the mating optical fibers without destroying the connector assembly or potentially damaging the optical fibers.

Owner:CORNING OPTICAL COMM LLC

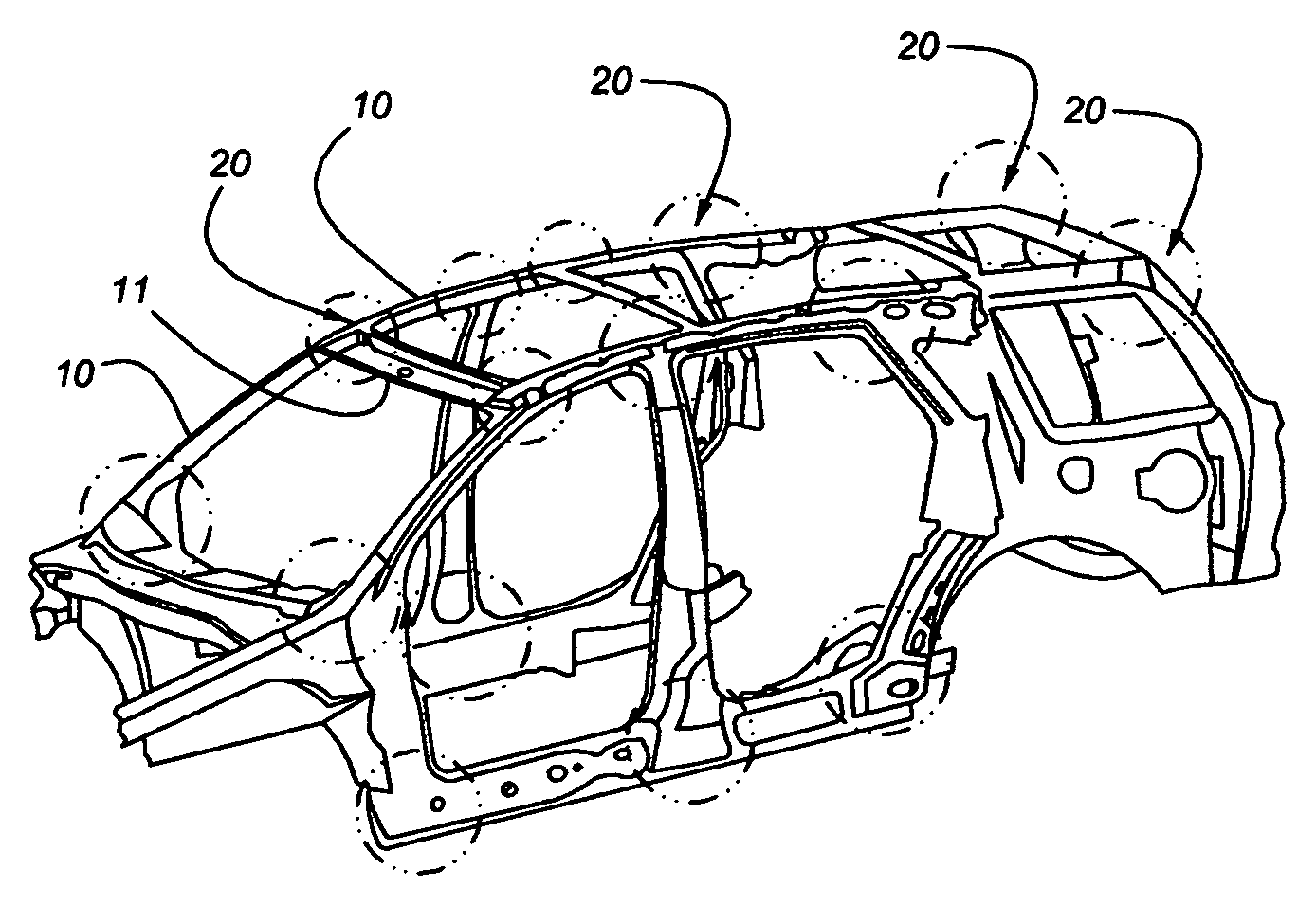

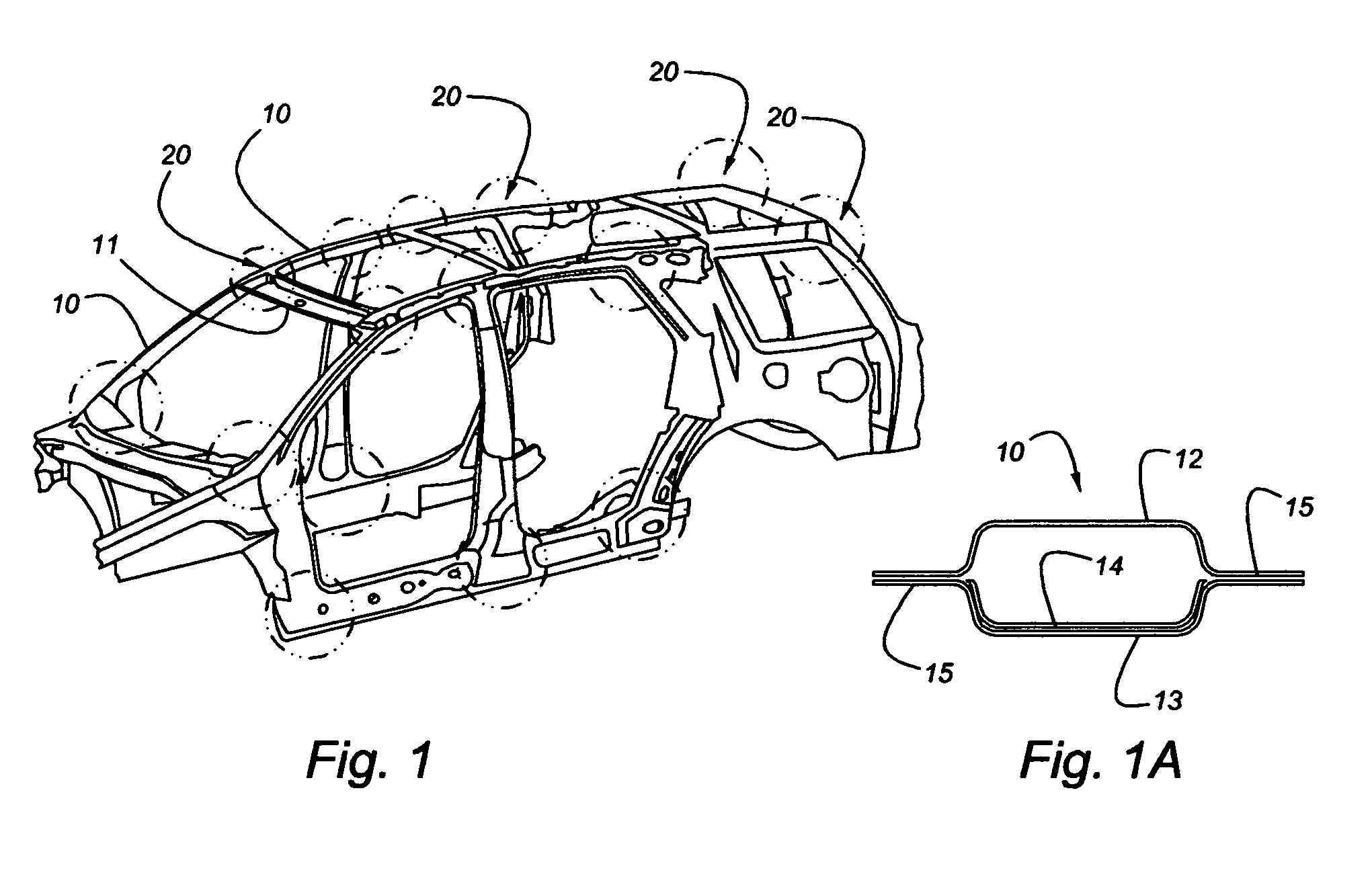

Universal structural joint for automotive frames

ActiveUS7488022B2Improve carrying capacityVehicle seatsSuperstructure subunitsUniversal structureAdhesive

A structural joint configuration is formed in an automotive frame in which the frame members are bent into an angular orientation and joined together to form a structural joint in the automotive frame in which loads imposed on any of the frame members forming the joint will be transferred to and shared with the other frame members in the joint. The structural joint can be configured with as many legs as needed to conform to the number of frame members entering the joint. The frame members can be formed with any cross-sectional shape and from any conventional material or combination of materials. Joining the frame members at the structural joint can be accomplished by welding or by applying adhesives. Load distribution through the frame members forming the structural joint enables the joint to withstand an application of high loads without major cracks or bending at the structural joint.

Owner:FORD GLOBAL TECH LLC

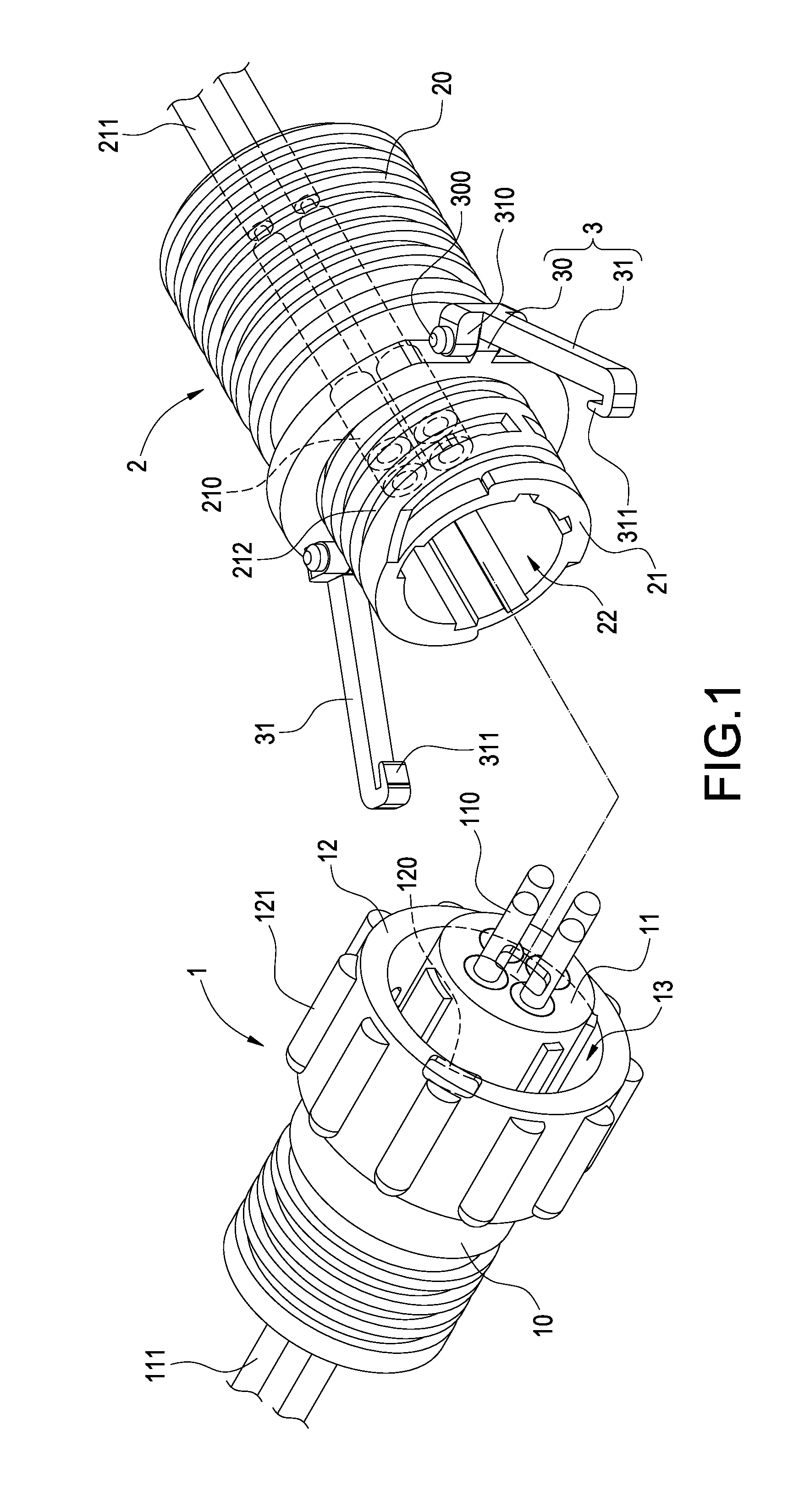

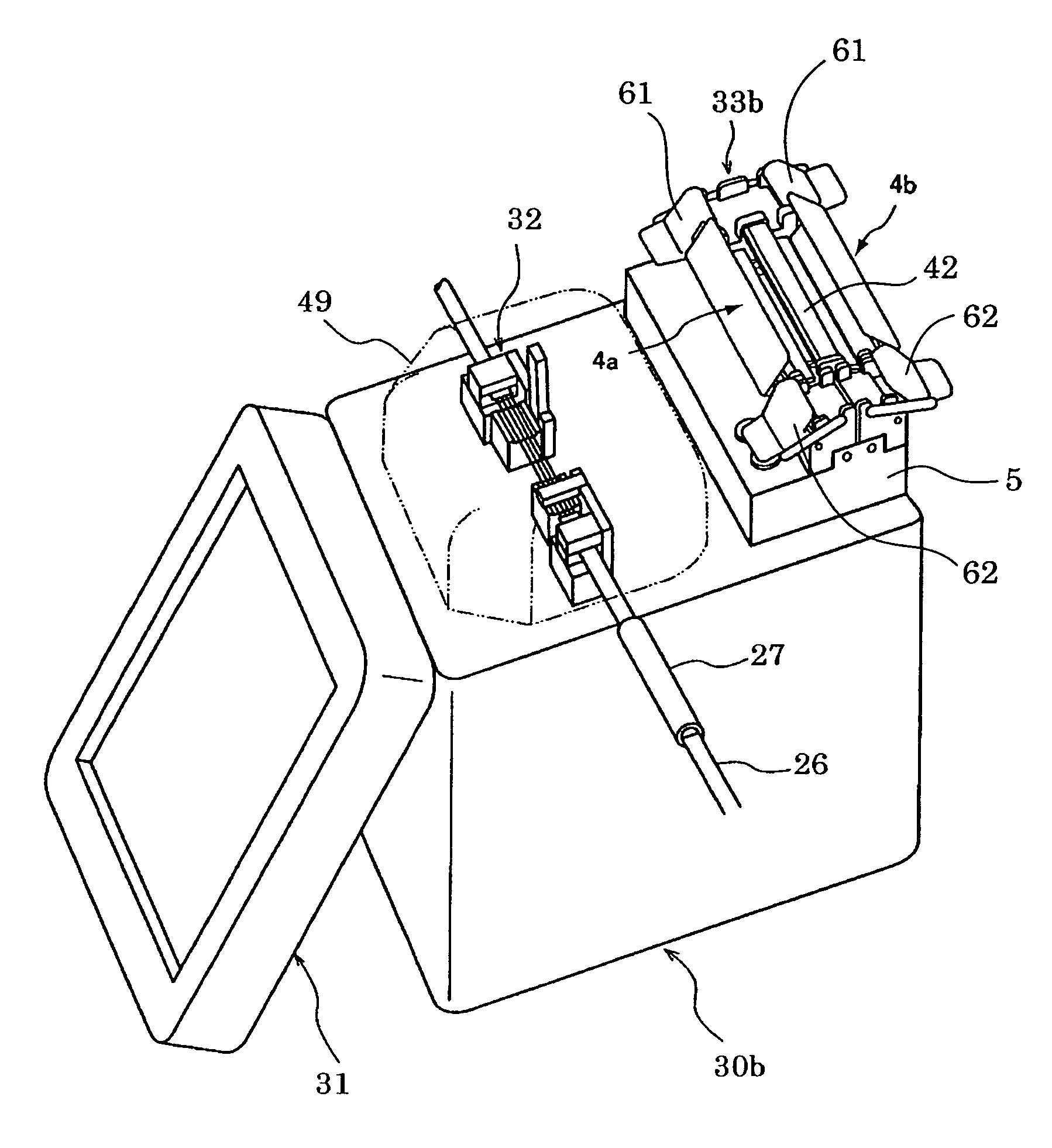

System for Connecting Motor Drives

ActiveUS20120264317A1Quick coverQuickly to uncoupledSwitchgear arrangementsIncorrect coupling preventionMotor driveConductive materials

A system for connecting motor drives to each other is disclosed that does not require the use of wire or tools. The system includes an adapter plug and bus bar modules that connect to each other at a conductive receptacle of the adapter plug to define a splice joint at the point of connect of the bus bar modules. The bus bar modules may include insulating covers and insulating clips may overlie the splice joints so that the system is substantially devoid of exposed surfaces of its conductive materials.

Owner:ROCKWELL AUTOMATION TECH

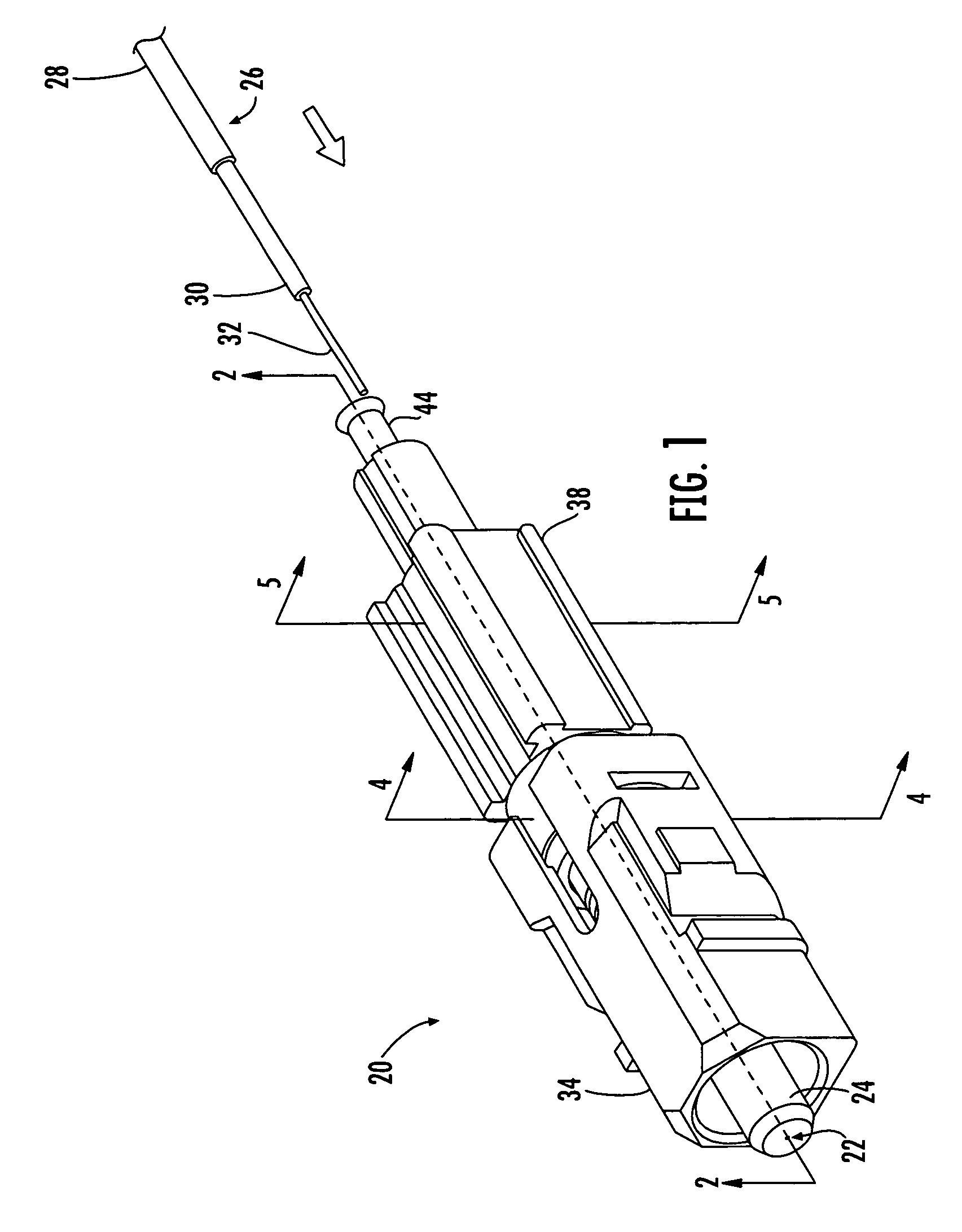

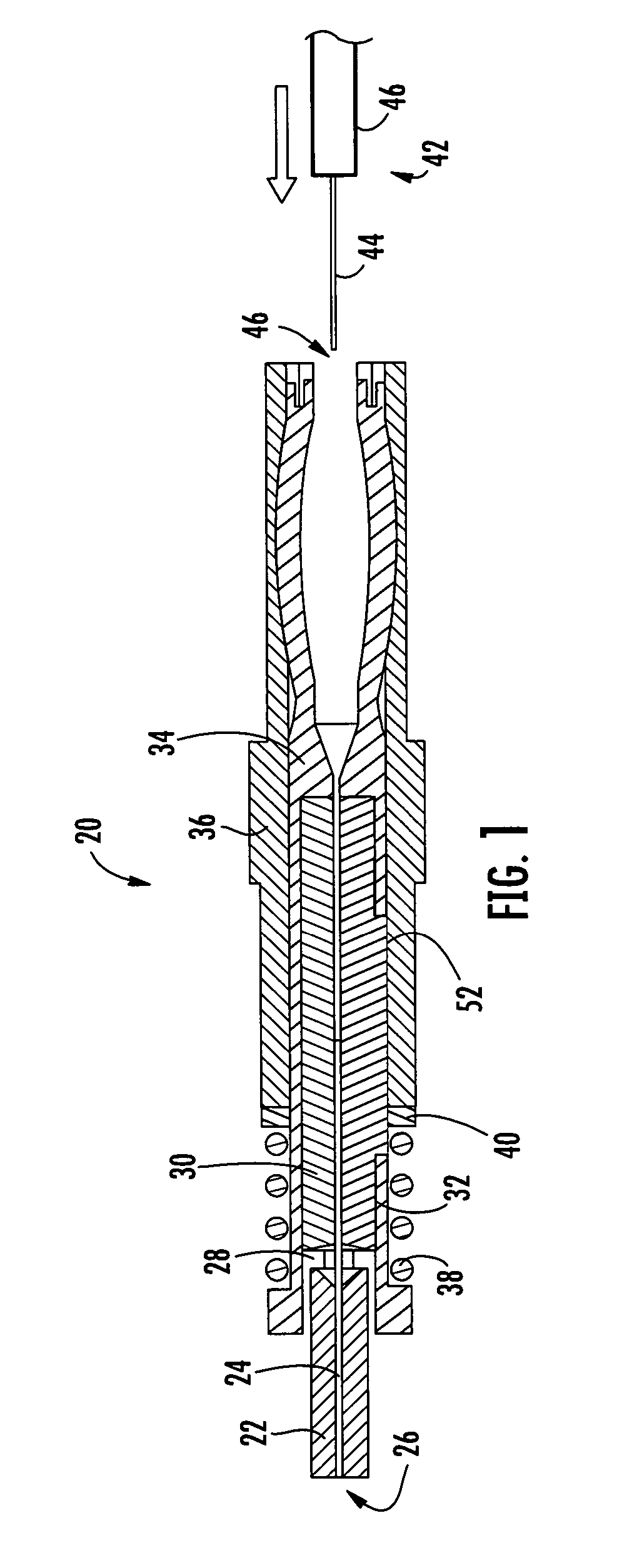

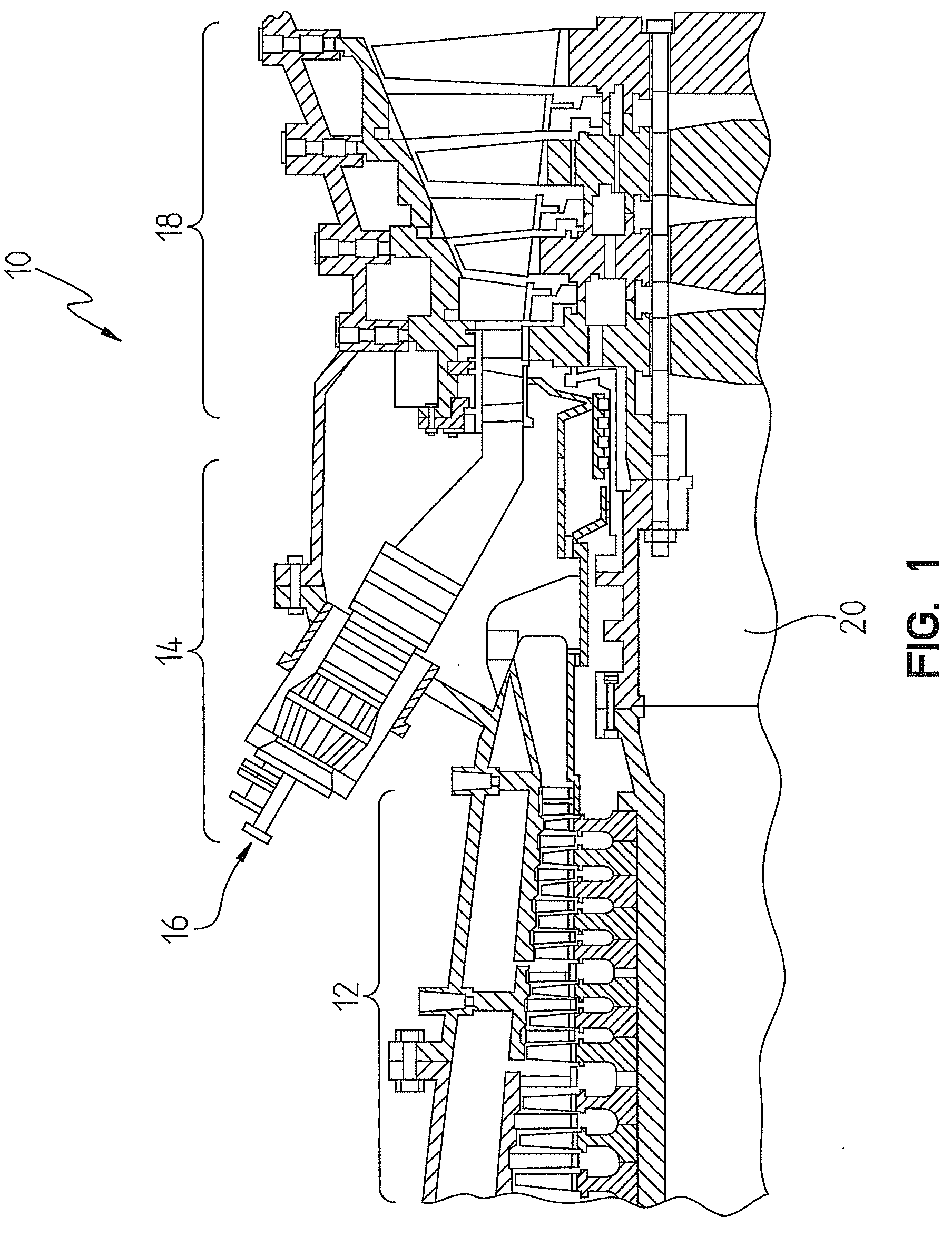

Mechanical splice connector with sequential splice and strain relief

A mechanical splice connector is shown and described for sequentially performing a splice actuation followed by a strain relief actuation by rotating a single, multiple-position cam member or multiple cam members from an unactuated position to a first actuated position and a second actuated position. The mechanical splice connector aligns and retains at least one stub optical fiber and the bare glass portion of at least one adjoining field optical fiber, as well as strain relieving a coated portion of the field optical fiber, or alternatively, a buffered portion of the field optical fiber. A method is also described for sequentially performing a splice actuation followed by a strain relief actuation, wherein the splice actuation is reversible prior to performing the strain relief actuation in the event that the optical continuity of the splice coupling is unacceptable, thereby avoiding potential damage to the field optical fiber or the connector.

Owner:CORNING OPTICAL COMM LLC

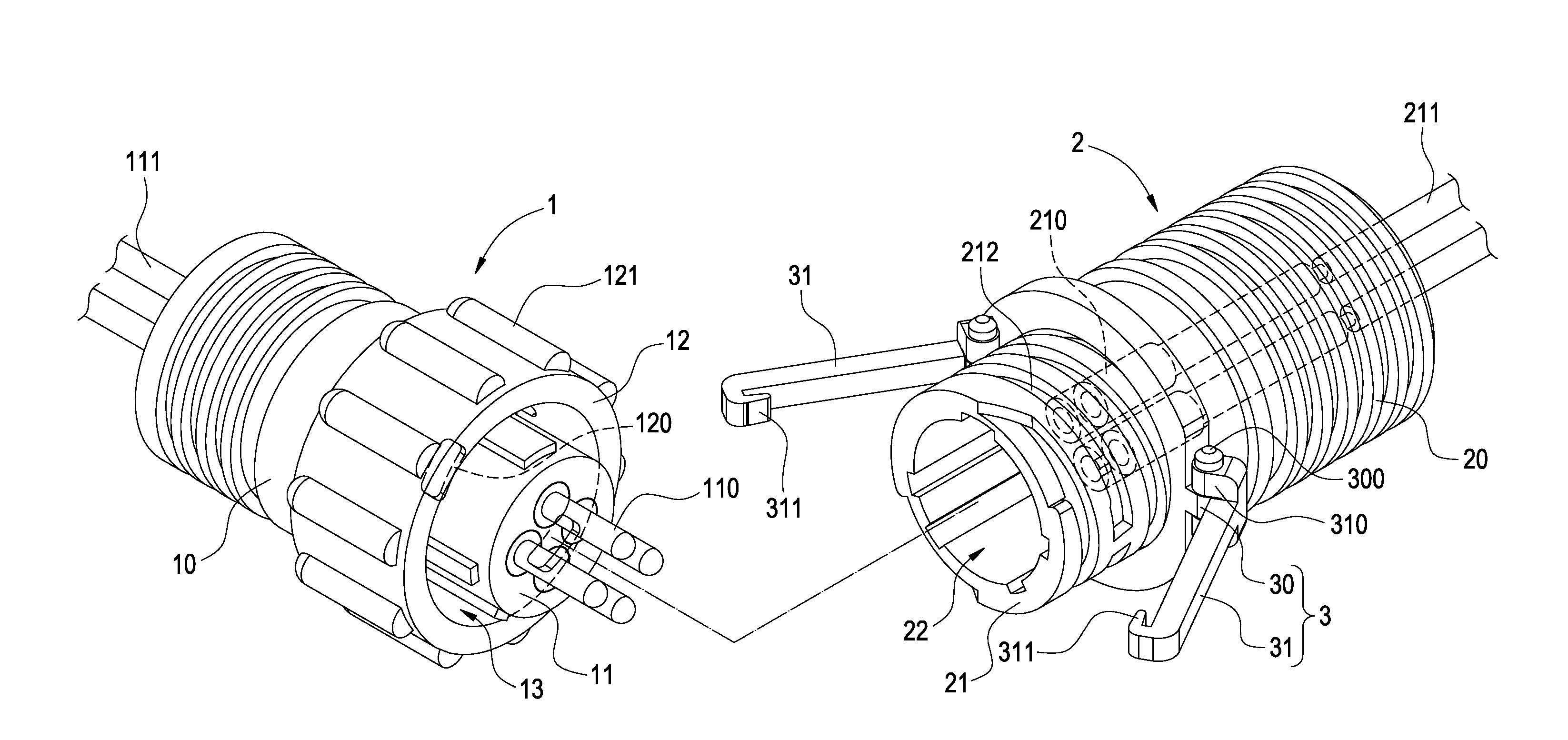

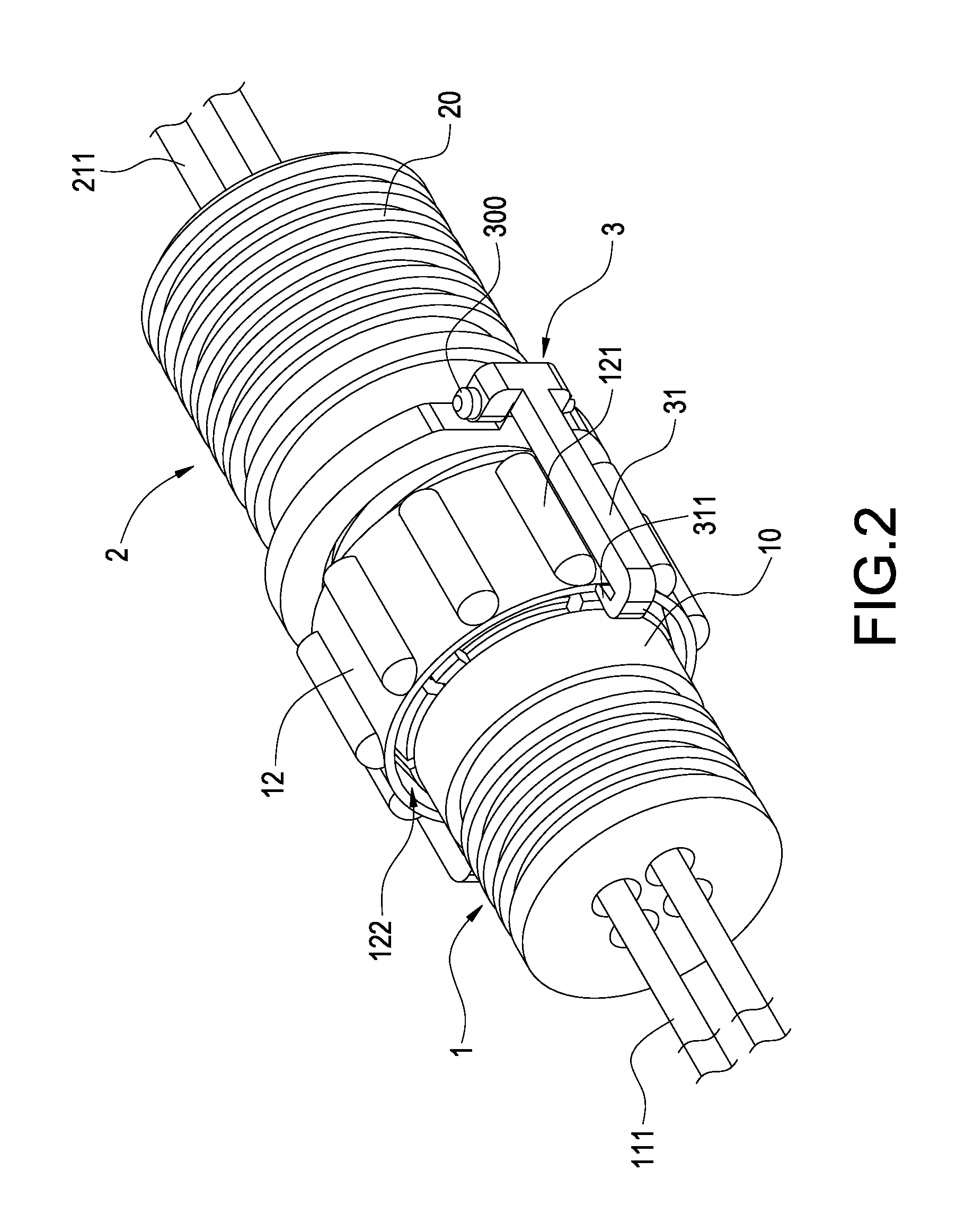

Cable connector joint fastening structure

InactiveUS8328574B1Prevent looseningEngagement/disengagement of coupling partsIncorrect coupling preventionEngineeringSplice joint

A cable connector joint fastening structure includes a male connector, a female connector, and a fastener. The male connector includes a male terminal body with a male terminal joint, a freely rotating screw sleeve locked around the external periphery of the male terminal joint. The female connector includes a female terminal body with a female terminal joint, and an insert space formed in the female terminal joint for inserting the male terminal joint, and the screw sleeve is screwed and coupled to the female terminal joint. The fastener includes a pivot portion formed at an external side of the female connector, and a locking arm pivotally installed onto the pivot portion, extended towards the male terminal body, disposed across the screw sleeve, and locked to the male connector.

Owner:QUANTUM PRECISION TECH

Multiple hinged tray cable connecting joint and method of using same

A multiple hinged tray cable connecting joint includes a plurality of fiber trays pivotably coupled between sockets connected to fiber optic cables. The fiber trays can be positioned in a fiber loading position in which the fiber is spliced and coiled into the tray. The fiber trays can then be pivoted to a fiber storage position.

Owner:SUBCOM LLC

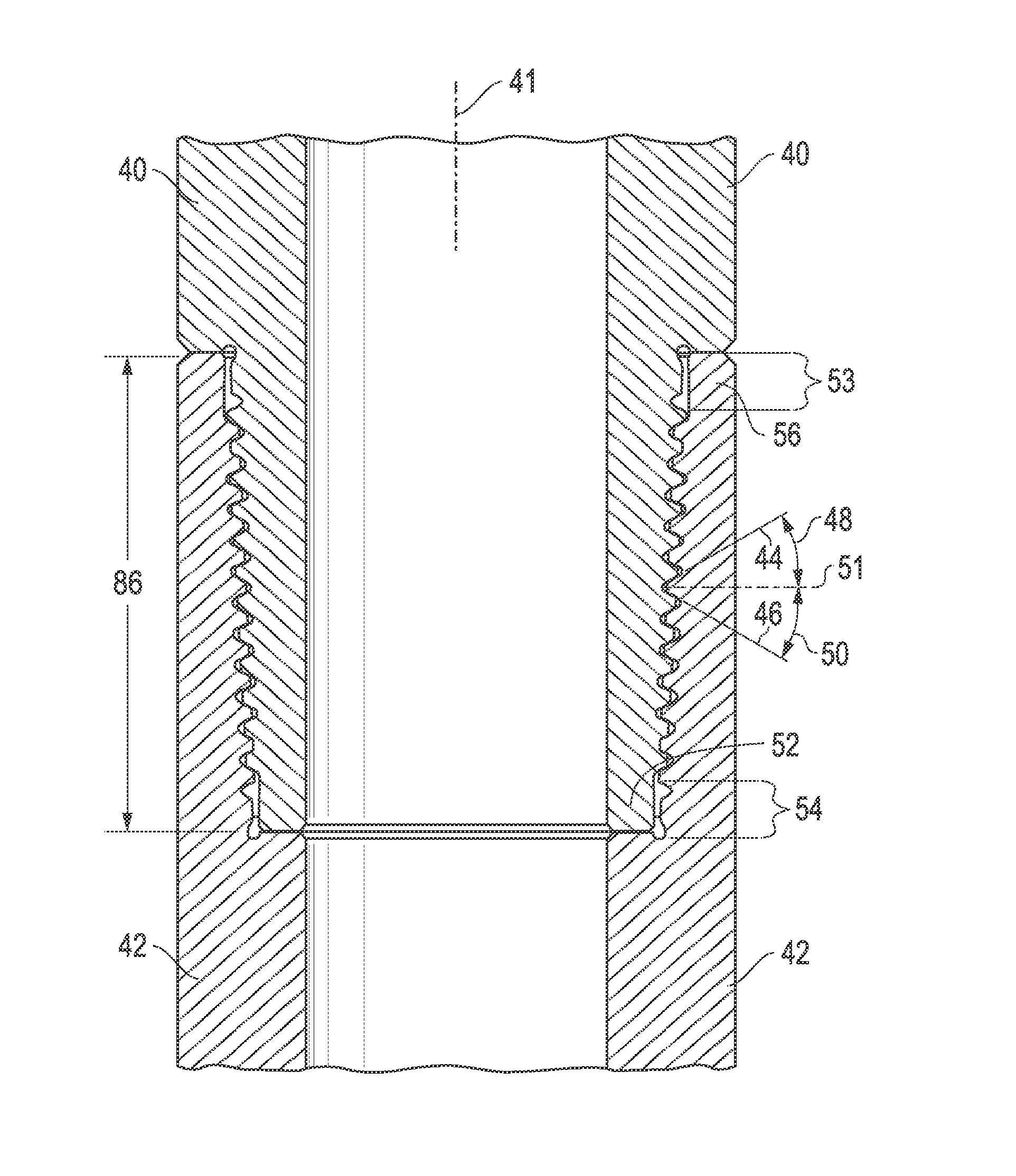

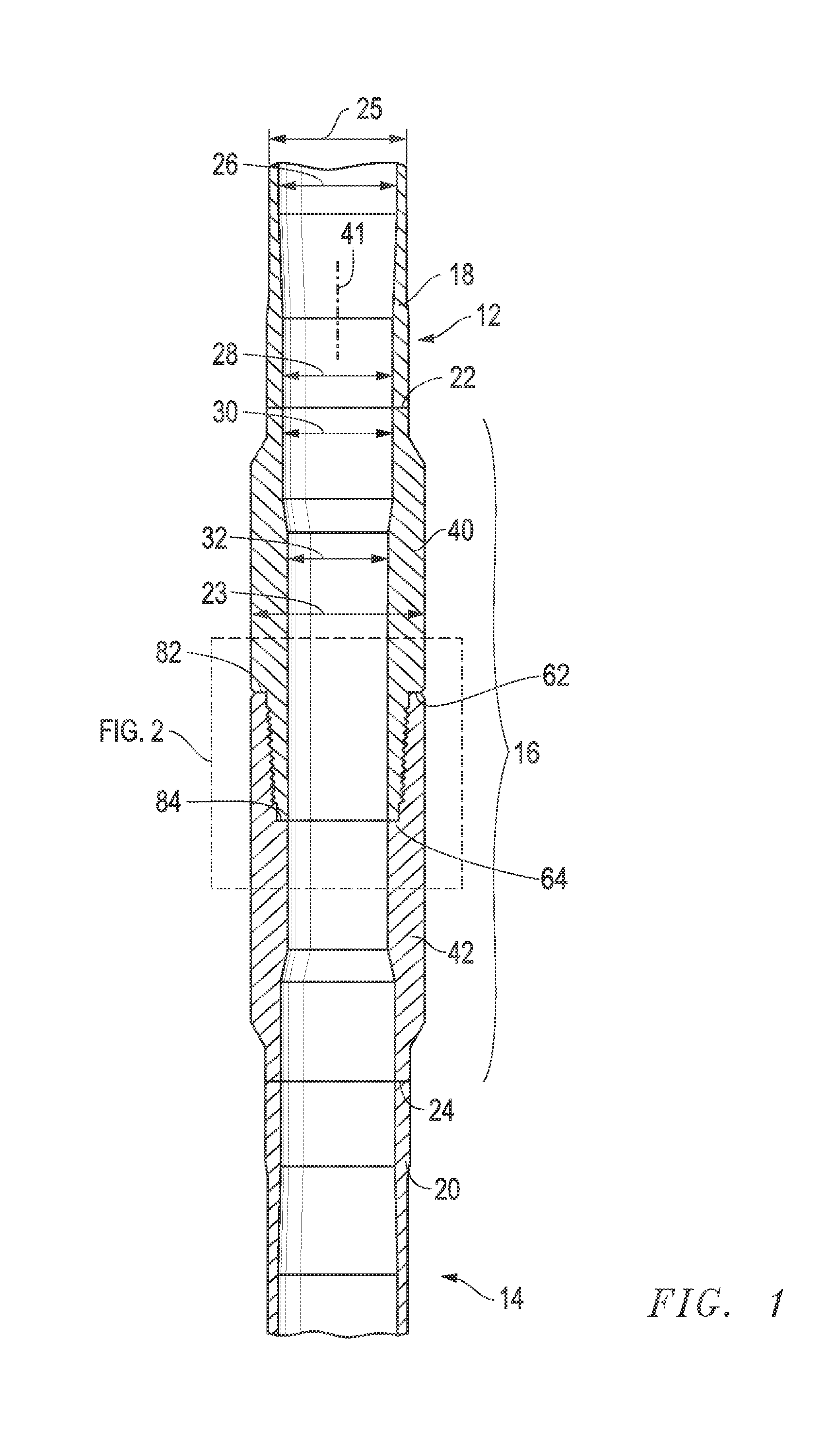

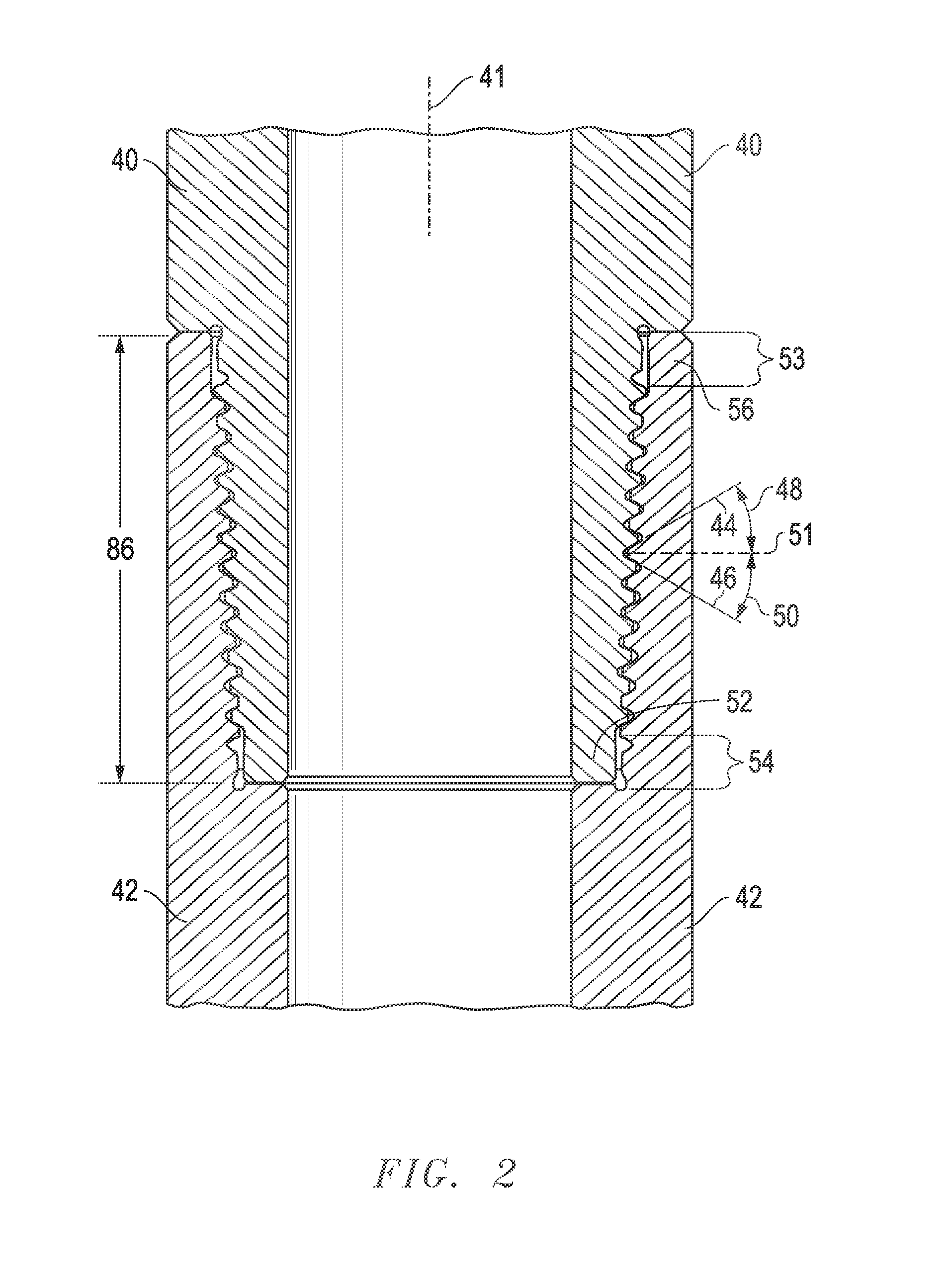

Threaded Tool Joint Connection

In a double-shoulder threaded tool joint connection, the pin external threads and the box internal threads have a thread taper between 0.75 inch per foot and 1.0 inch per foot. The pin external threads and the box internal threads have equal stab flank and load flank angles, and are in a range from thirty-three to thirty-nine degrees. Both the pin external threads and the box internal threads have roots formed in a shape of a portion of a circle tangent to both thread flanks with a minimum radius of 0.063 inch. The pin external threads and the box internal threads are in the range of two to three per inch. The box counterbore has a length of 0.750 or less. The pin nose has a length in a range of 30% to 90% of the length of the box counterbore.

Owner:TEXAS STEEL CONVERSION INC

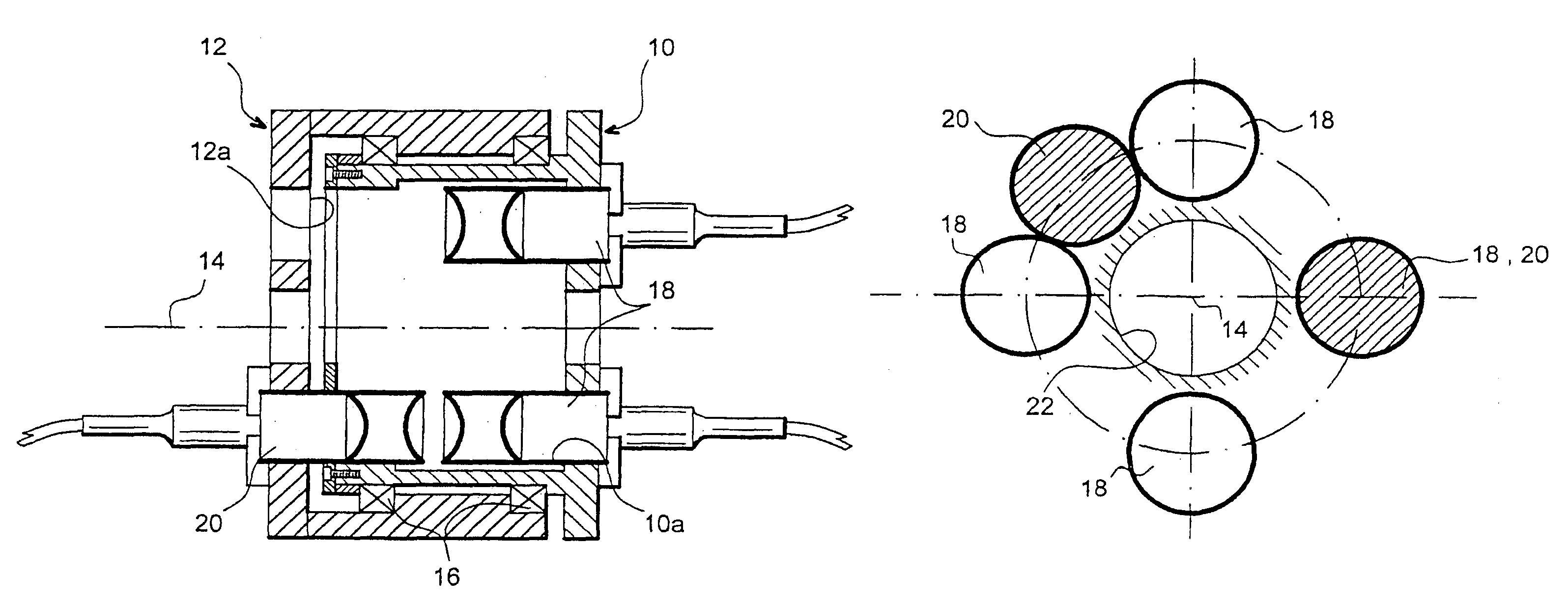

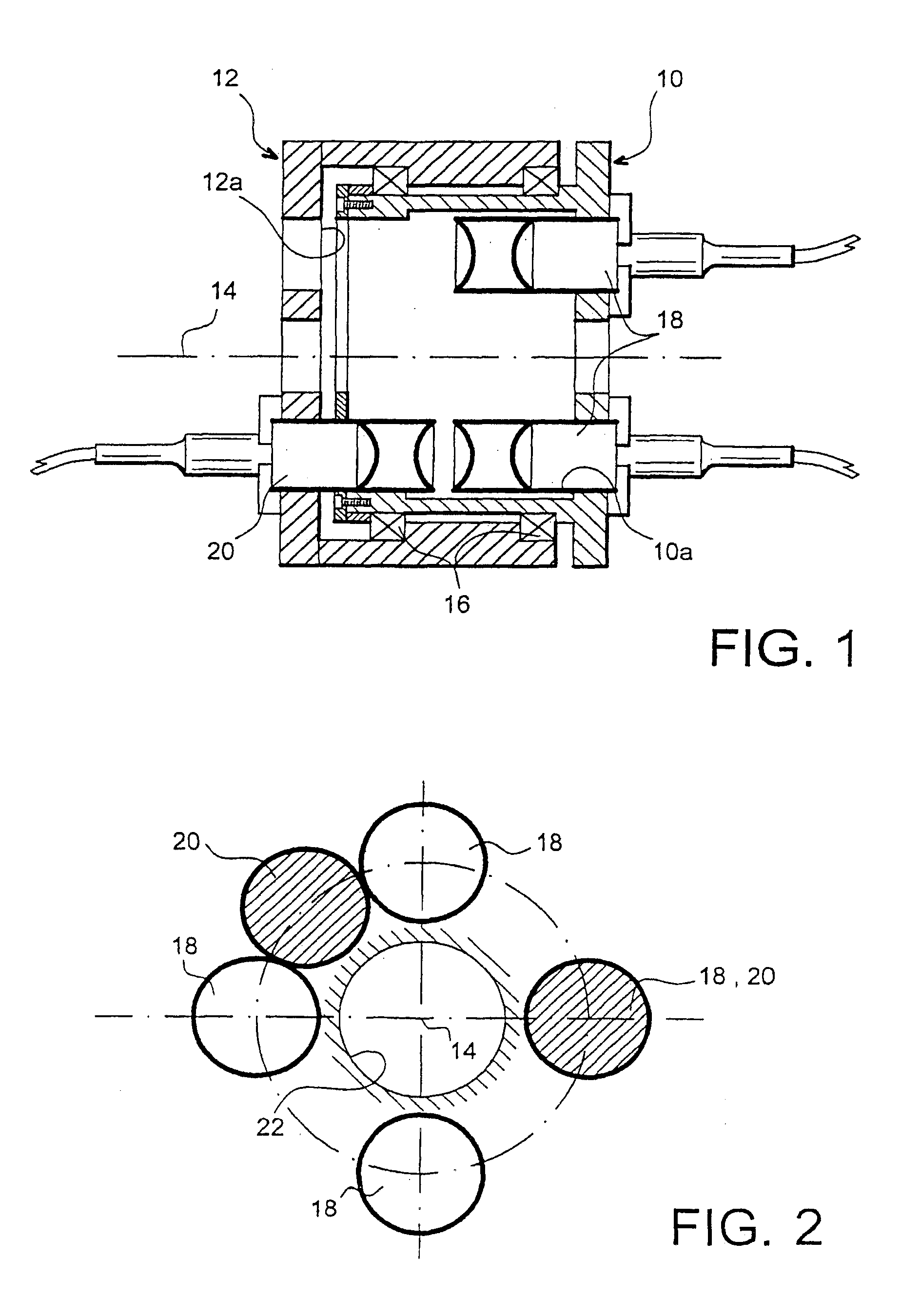

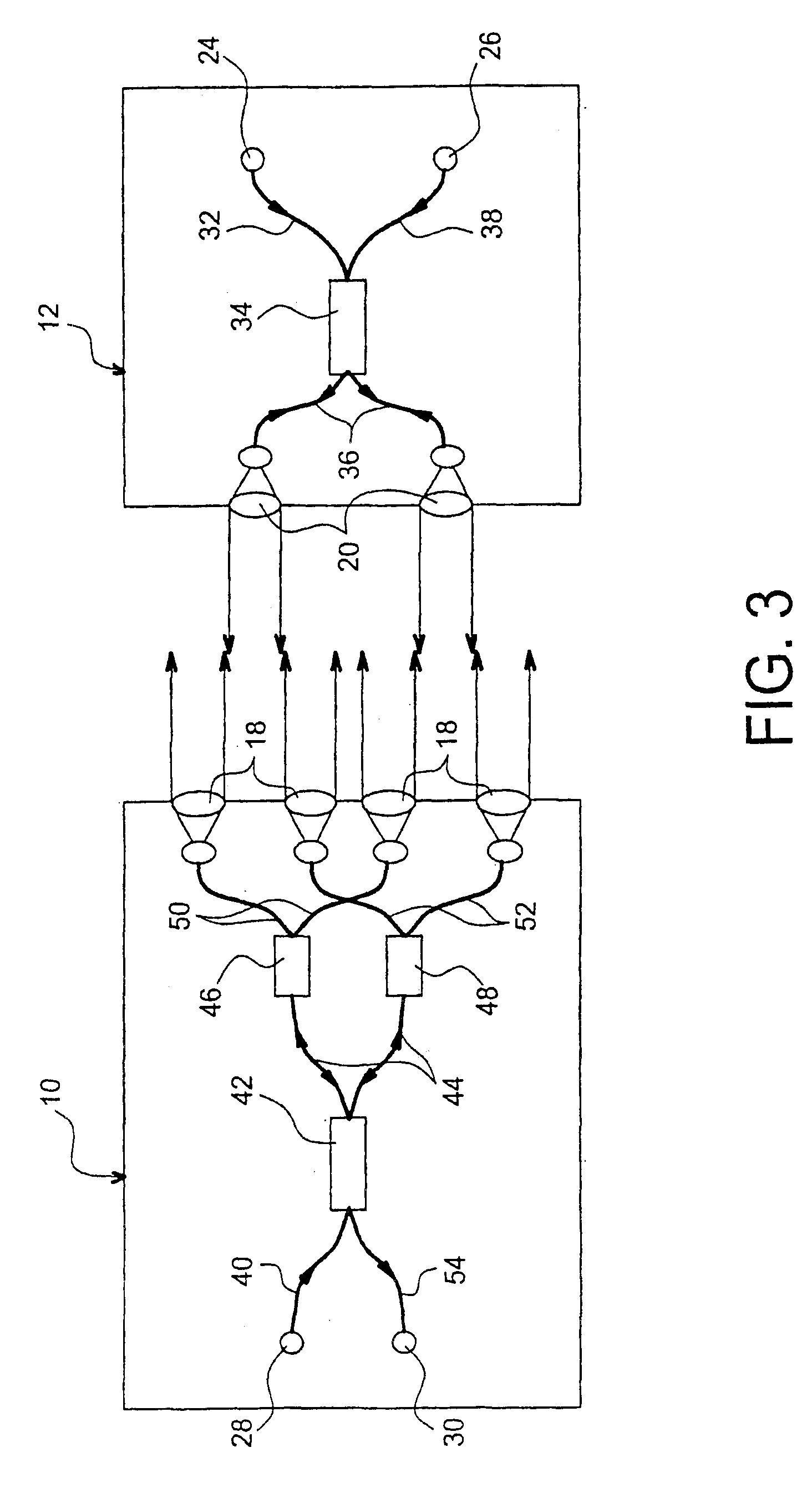

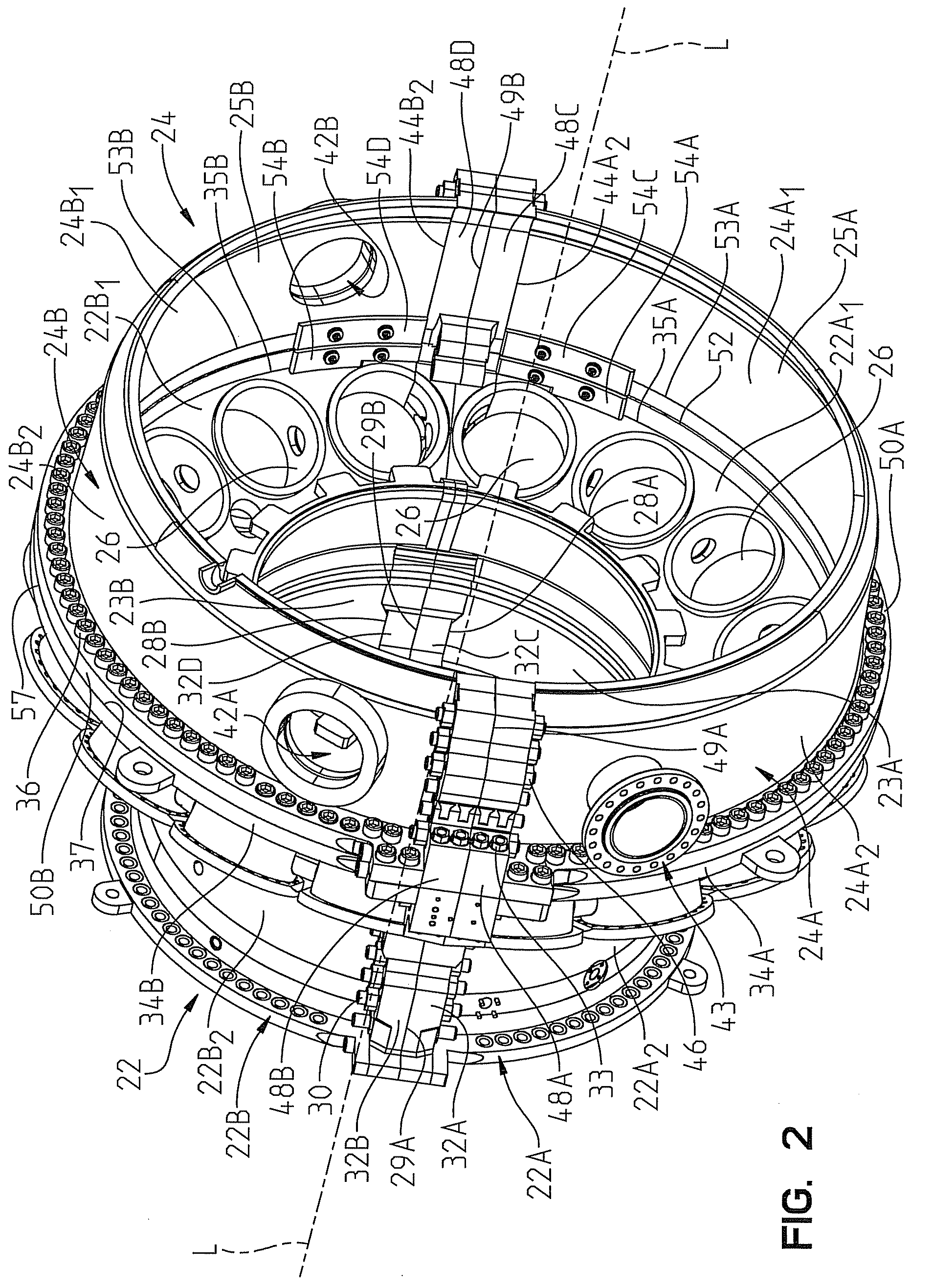

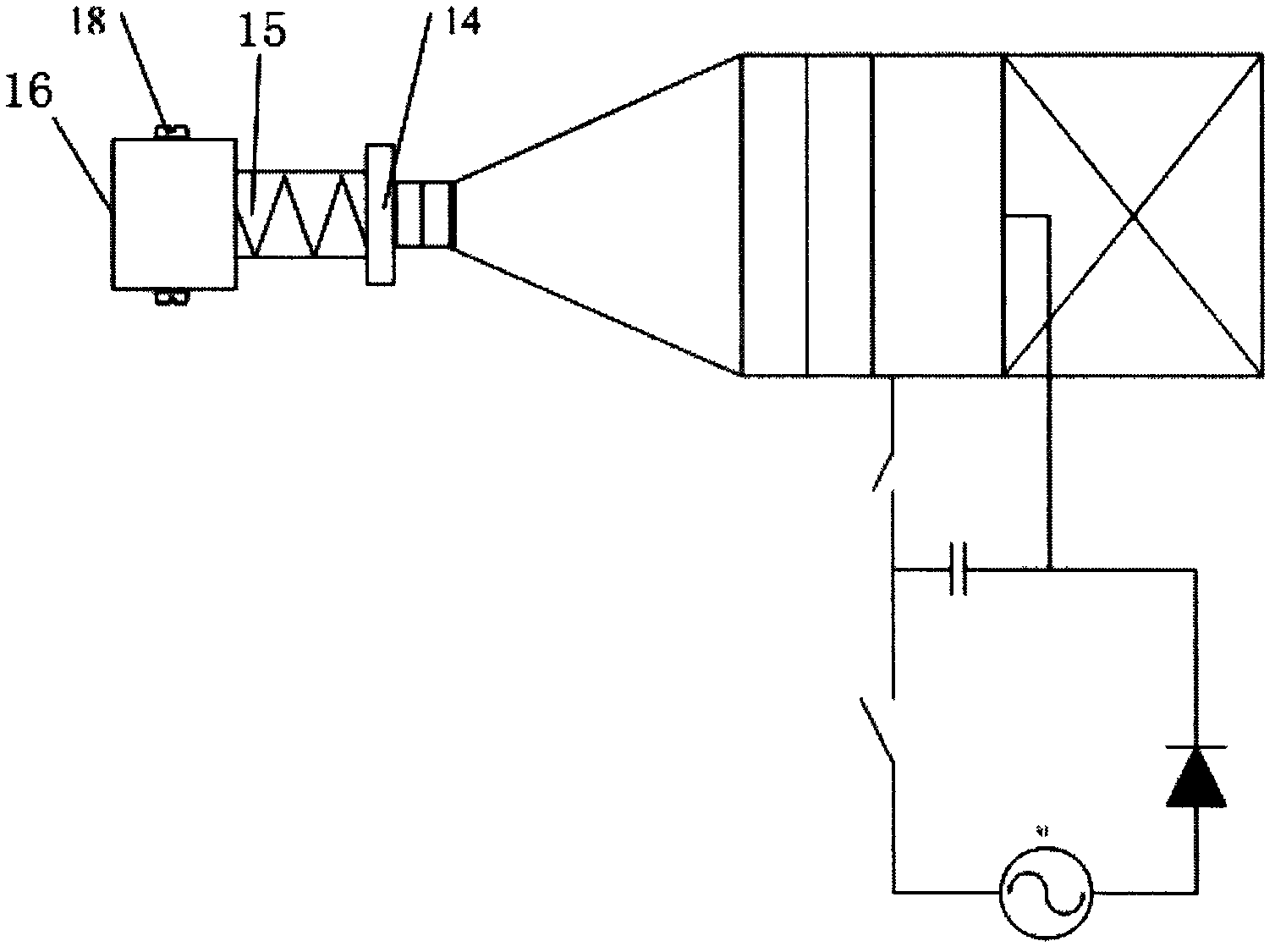

Rotating optical joint

A rotating optical joint has two organs which are able to rotate independently of one other on a common axis (14). Collimators (18, 20) are mounted directly opposite one another on the organs, in an arrangement such that they permanently provide a variation of the power of the transmitted signal of less than 25%, during relative rotation of the said organs. The total number of collimators (18, 20) is preferably less than or equal to eight. Advantageously, three collimators (20) are mounted on one of the organs and four collimators (18) are mounted on the other organ.

Owner:AIR PRECISION

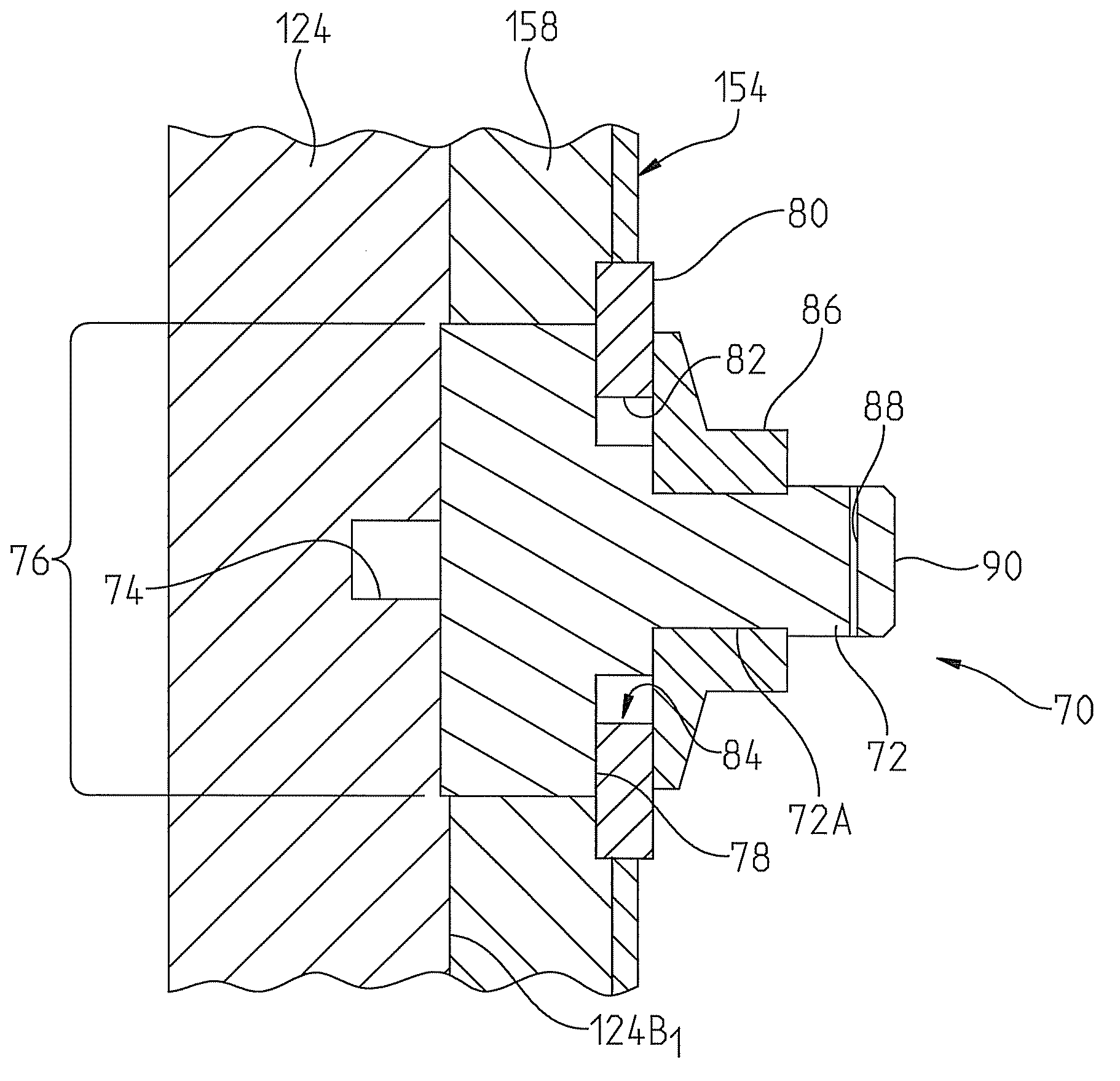

Thermal shield at casing joint

InactiveUS8092161B2Reduce thermal stressReduce heat transferPump componentsReaction enginesProduct gasEngineering

A thermal shield for reducing thermal stress induced proximate to a first joint formed between adjacent engine casing components in a gas turbine engine. The thermal shield includes a cover structure for covering a radially inner portion of at least one of the engine casing components. The cover structure is disposed proximate to the first joint and attached to the respective engine casing component so as to limit exposure of a covered inner portion of the engine casing component to hot gases in an interior volume defined by the engine casing components. A thermally insulating layer is disposed between the cover structure and the engine casing component for effecting a reduced amount of heat transfer to the covered inner portion of the engine casing component from the hot gases in the interior volume defined by the engine casing components.

Owner:SIEMENS ENERGY INC

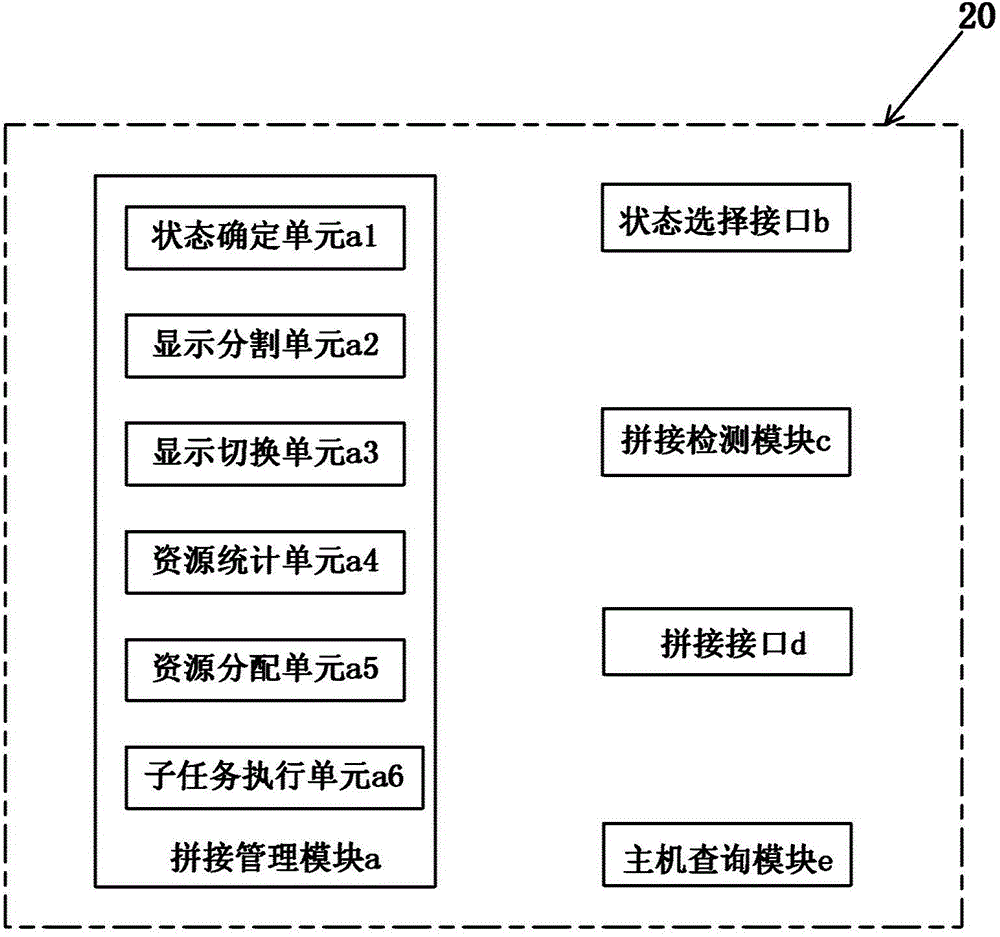

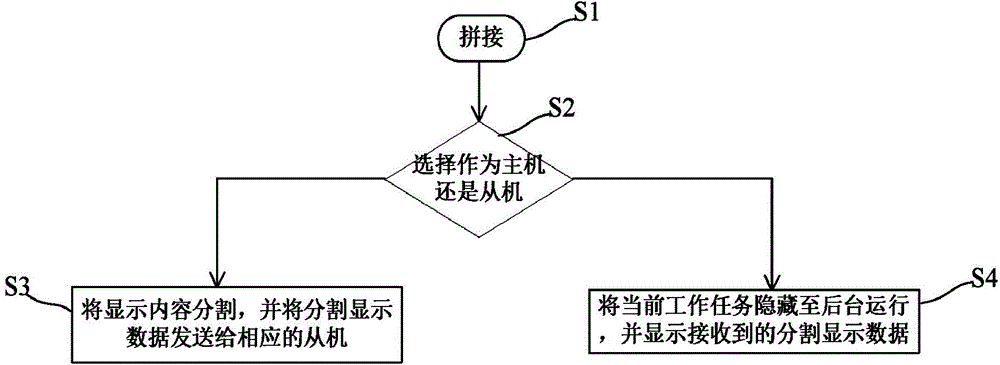

Mobile terminal, combined terminal equipment and splicing joint control method

ActiveCN104679470AMeet the needs of large display areaAvoid secondary pollutionSpecific program execution arrangementsDigital output to display deviceTerminal equipmentLarge screen

The invention relates to a mobile terminal, in particular to a mobile terminal, combined terminal equipment and a splicing joint control method of the mobile terminal. The mobile terminal capable of realizing splicing joint is characterized in that according to a state determination instruction, the mobile terminal selectively enters a host work state or a slave work state; a display division unit divides the display contents of a host according to display screen resources of each mobile terminal in the combined terminal equipment when the mobile terminal is used as the host to work, so that a plurality of division display data corresponding to a plurality of mobile terminals in the combined terminal equipment is obtained, and the corresponding division display data is sent to slaves; a display switching unit displays the received division display data when receiving the division display data from the host under the condition that the mobile terminals are used as the slaves. The contents displayed by the host can be displayed by the slaves, when the number of the slaves is great, the contents can be displayed to a user by a larger screen consisting of a plurality of slaves, and the requirement of people on the large display area can be met.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

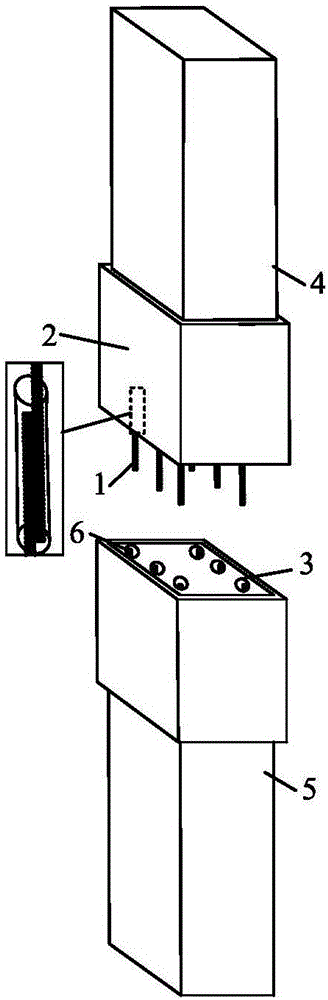

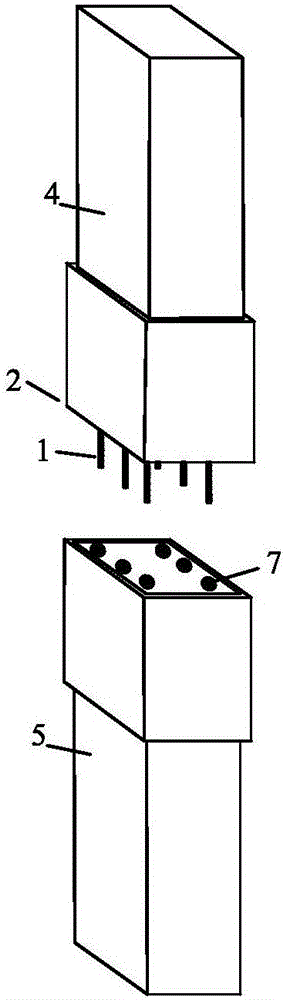

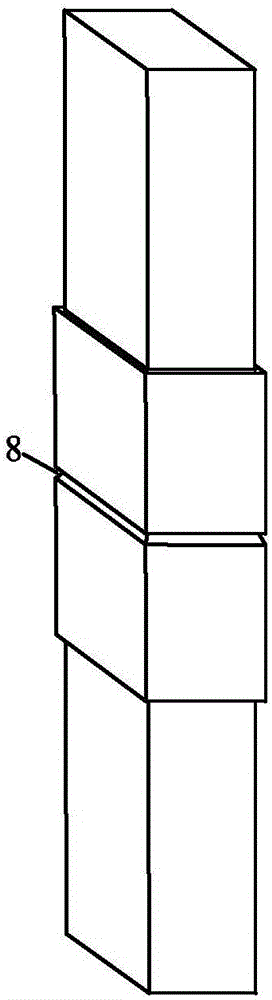

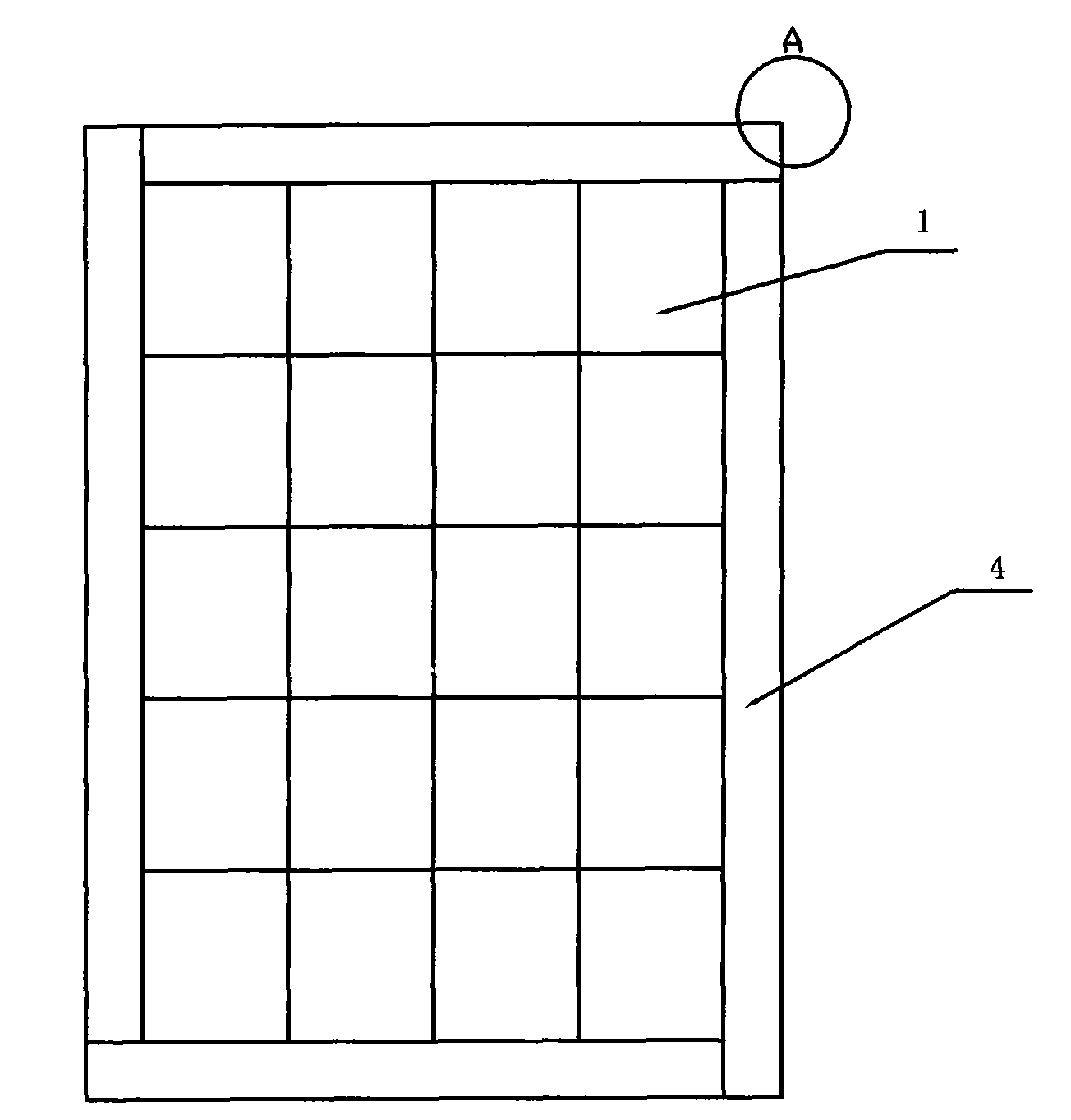

Prefabricated reinforced concrete column and column splice joint with sleeves

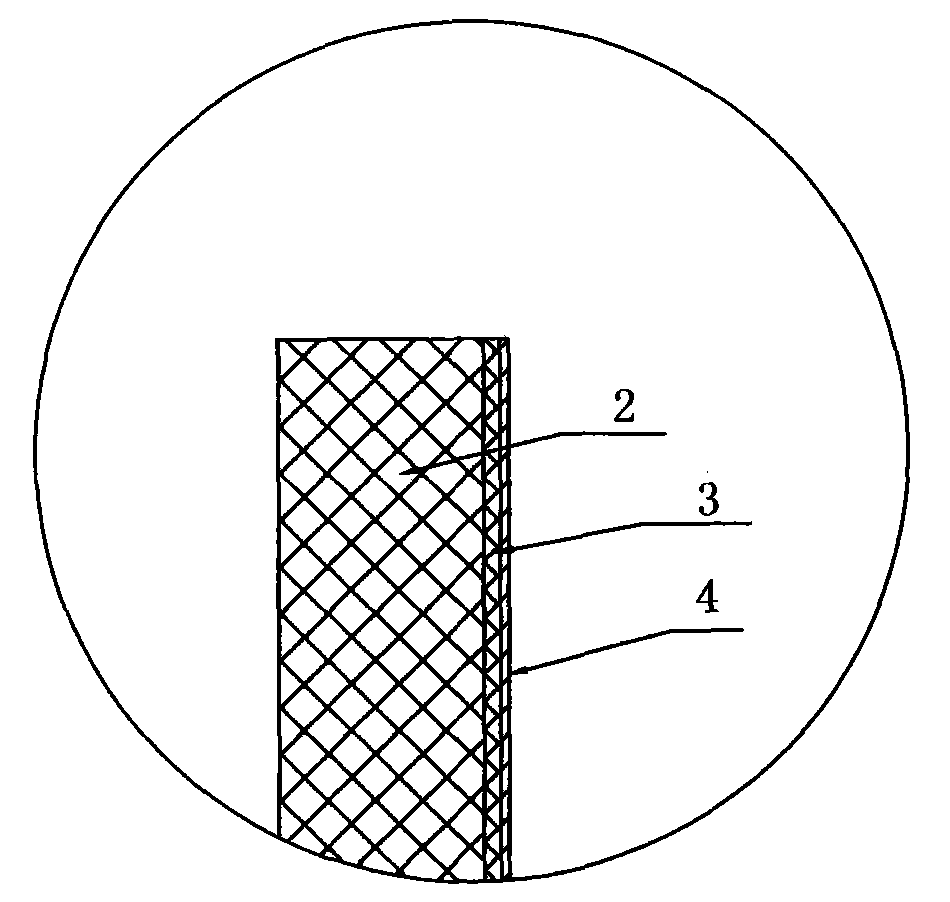

InactiveCN106381925AImprove bending abilityAchieve connectionBuilding reinforcementsHigh strength concreteReinforced concrete column

The invention discloses a prefabricated reinforced concrete column and column splice joint adopting connection of embedded corrugated sleeves and high-strength reinforcement. The splice joint mainly comprises a prefabricated reinforced concrete upper column, a prefabricated reinforced concrete lower column, steel sleeves, the embedded corrugated sleeves and the high-strength reinforcement. An installation method of the splice joint comprises the following steps: in a factory, realizing the embedded high-strength reinforcement by a method of firstly pouring non-shrinkage self-compacting high-strength concrete into the embedded corrugated sleeves of the prefabricated reinforced concrete upper column and then inserting the high-strength reinforcement; and at the construction site, grouting the corrugated sleeves of the reinforced concrete lower column, inserting the embedded high-strength reinforcement of the upper column in the corrugated sleeves of the lower column and simultaneously welding the steel sleeve joint parts on the outer surfaces of the columns, thus realizing prefabricated reinforced concrete column and column splicing. The splice joint has the beneficial effects that all the used components are assembled and connected on the site, thus reducing reinforcement assembling and formwork supporting on the site, improving the building industrial assembly efficiency and reflecting the novel building concepts of environment friendliness and energy saving of building components.

Owner:HUNAN UNIV

Method for manufacturing holographic mother board by using electroforming imposition

InactiveCN101618628AStitching fitSplicing speed is fastInstrumentsPrinting formes reproductionUnit sizeGraphics

The invention relates to a method for manufacturing a holographic mother board by using an electroforming imposition, which is used for big-size unit holographs. The method comprises the following steps: firstly, fixing a plurality of nickel boards of unit holographs on a flat plastic bottom board by using double-faced adhesive tapes, and then, eliminating spliced joints between every two nickel boards of the unit holographs to manufacture a big-size holographic mother board. The invention has the advantages that the method can be used for splicing a large holographic mother board containing unit holographs in different unit sizes, the splicing speed is quick, the splicing precision is high, and the subsequent electroforming process can level up and eliminate the joints, thus the nickel boards can be combined together to form an ideal large holographic mother board.

Owner:HUBEI XINGLONG PACKAGING MATERIAL

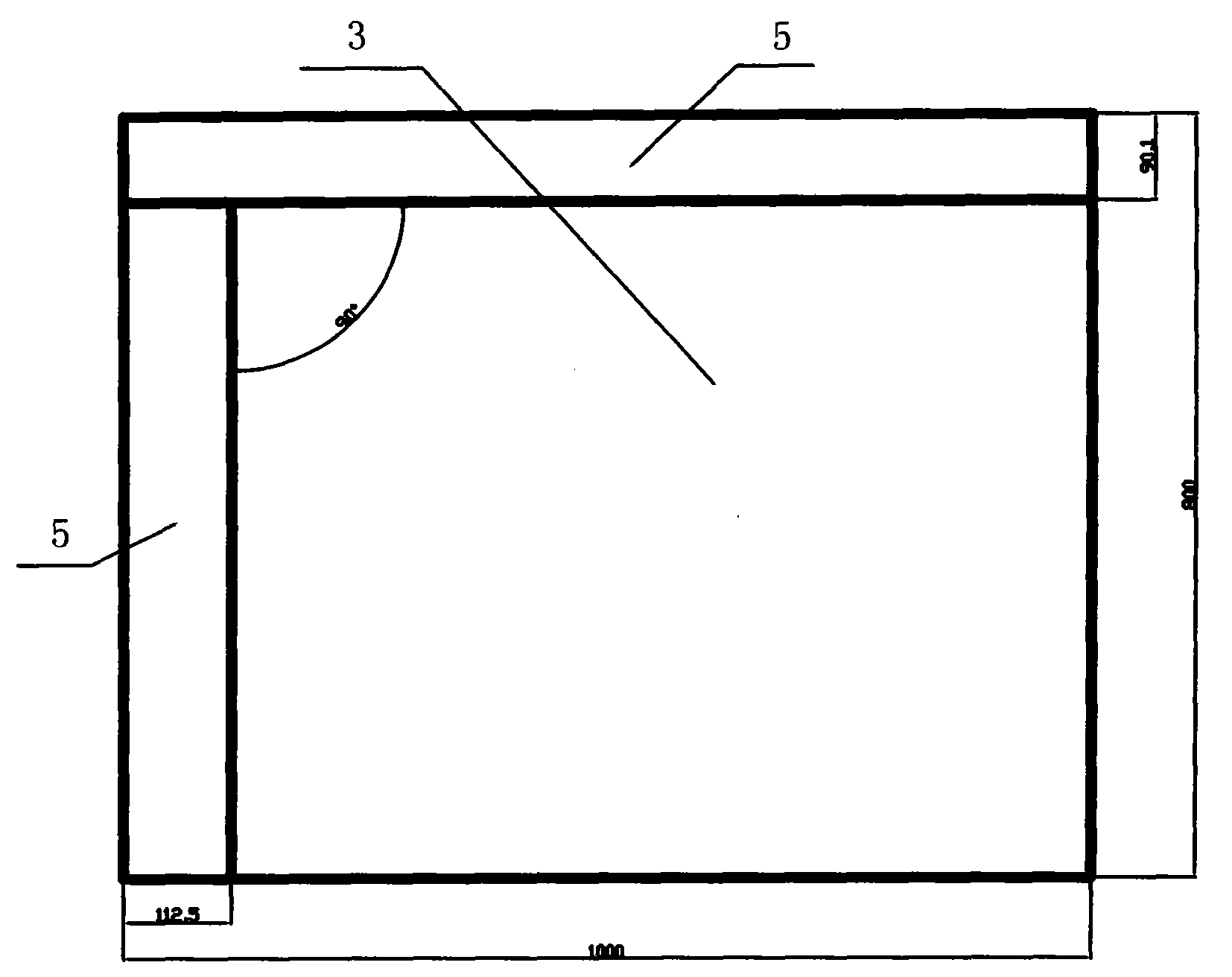

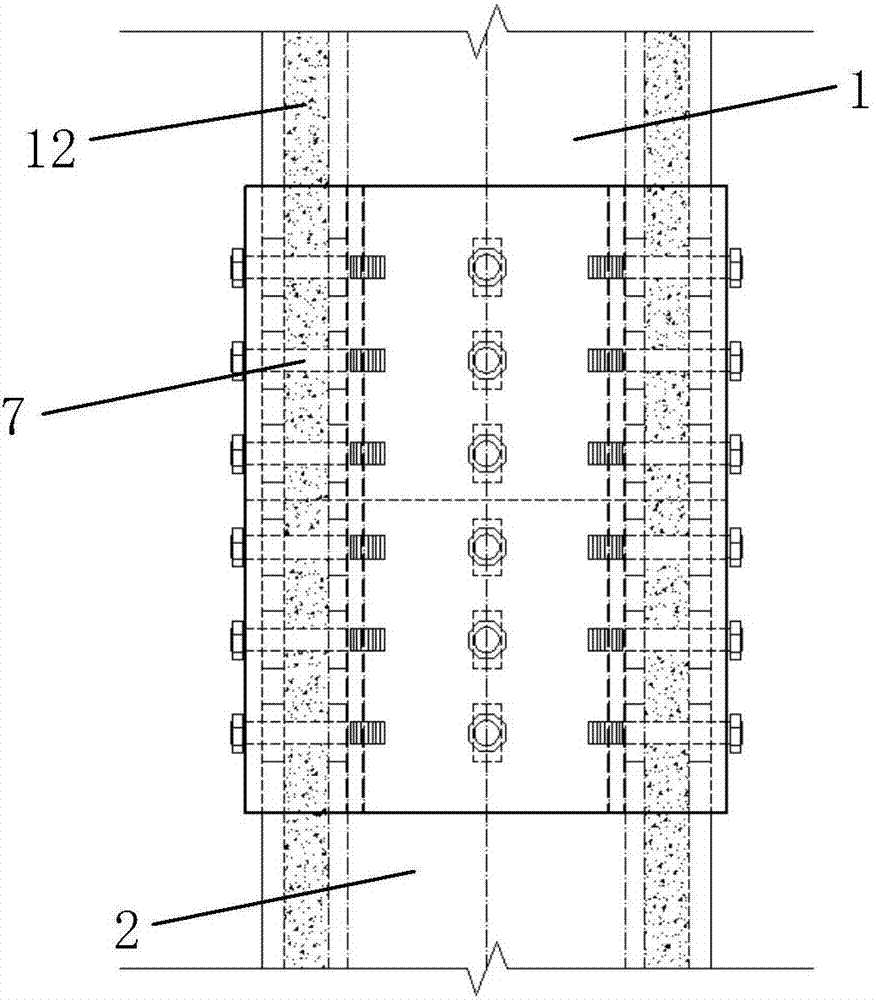

Square steel core filling inner sleeve and opposing screw bolt splicing joint and construction method of splicing joint

InactiveCN102733490AHigh node stiffnessSimple and fast operationBuilding material handlingProject sizeScrew cap

The invention relates to a square steel core filling inner sleeve and opposing screw bolt splicing joint and a construction method of the splicing joint. The joint comprises an upper section square steel pipe, a lower section square steel pipe, a core filling inner sleeve and opposing screw bolts, wherein the core filling inner sleeve and the opposing screw bolts are connected between the upper section square steel pipe and the lower section square steel pipe, the core filling inner sleeve is in a rectangular cylinder shape, concrete is filled inside a tube body, the upper half part of the core filling inner sleeve penetrates through a longitudinal supper section screw bolt and a transverse upper section screw bolt in mutual staggered arranged at top and bottom, and the number of the opposing screw bolts is identical to the number of screw bolt holes arranged on the core filling inner sleeve. The joint rigidity is high, the operation is simple and convenient, the construction speed is high, and compared with the traditional lug plate and flange connection, the joint and the construction method have the advantages that the projected size is greatly reduced, and the design and the installation of adjacent components are convenient. The concrete is also filled in the inner sleeve, the huge pressure transferred by the steel pipe wall can be born, and the inner wall deformation caused by screw cap and screw bolt extrusion is prevented.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

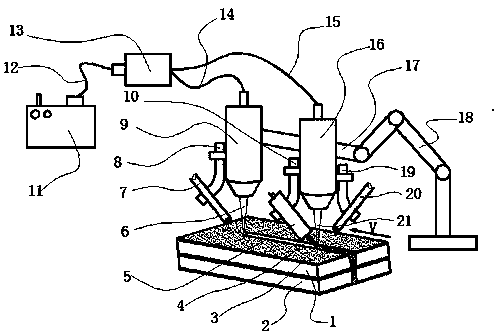

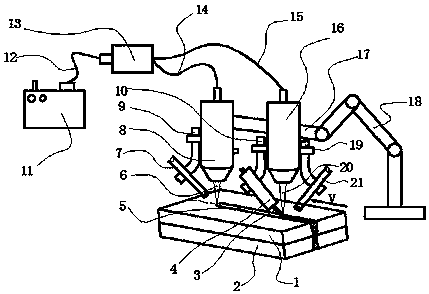

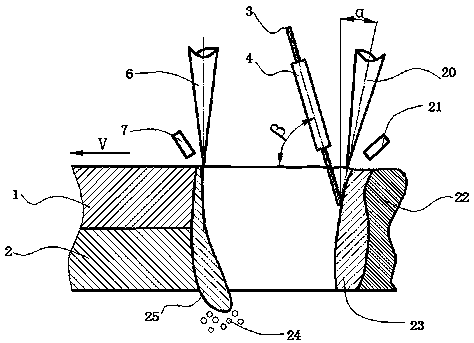

Zero-gap galvanized steel sheet spliced joint laser welding method and system

InactiveCN107953032AImprove stabilitySuppresses surface splashWelding/soldering/cutting articlesMetal working apparatusSheet steelHigh energy laser beam

The invention relates to a zero-gap galvanized steel sheet spliced joint laser welding method which is characterized by including the steps: firstly, providing a first workpiece and a second workpiecewhich need to be welded in a spliced manner; secondly, vertically splicing and clamping the first workpiece and the second workpiece; thirdly, providing a laser self-fusion welding system; fourthly,providing a laser filler wire welding system; fifthly, starting the laser self-fusion welding system; sixthly, starting the laser filler wire welding system, performing filler wire welding by a secondlaser welding head and a wire feeding head along a track of a first laser welding head to finish a welding process. The second laser welding head, the wire feeding head and the first laser welding head are serially arranged to form a column in a welding direction, the first laser welding head focalizes to form high-energy laser beams, and the laser beams vertically irradiate the surface of the first workpiece. The invention further discloses a zero-gap galvanized steel sheet spliced joint laser welding system. Compared with the prior art, the method has good welding effect and is simple in process.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

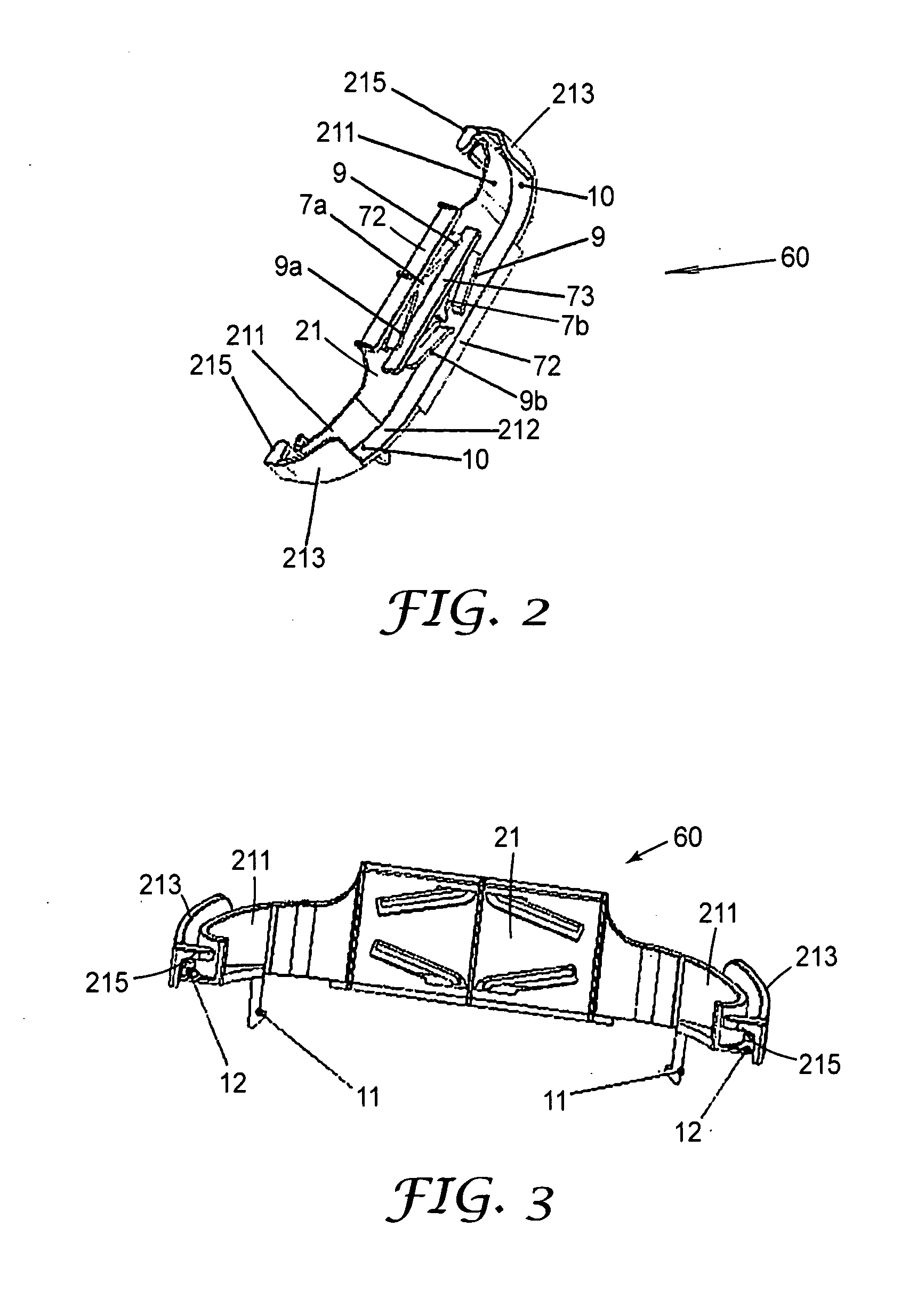

Splice holder for communication socket

InactiveUS20100310222A1Easy to operateMinimum bending radius of an optical fiberOptical light guidesBend radiusElectric cables

The present invention discloses a splice holder, which is used for holding at least one splicing sleeve (4), each of the splicing sleeves (4) is used for coupling two optical fibers. The splice holder comprises: a body; a splice channel (7) provided on the body; and an elastic device (9) in each splice channel, wherein the elastic device holds the splicing sleeve (4) elastically in the splice channel. The present invention also includes a communication socket having a splice holder mounted therein. By the splice holder of present invention, optical fiber connection points can be accommodated in a communication socket, so that electrical cables and optical fibers in the communication socket may be managed in an orderly way. Furthermore, inclusion of the inventive splice holder ensures than a minimum bending radius of optical fiber can be maintained when the optical fiber is stored in the communication socket.

Owner:CORNING RES & DEV CORP

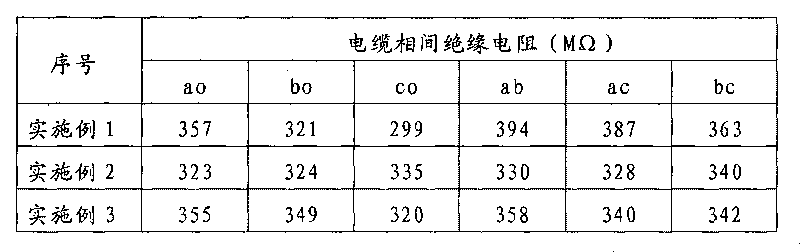

Insulation material for cable joint

The invention provides an insulation material for a cable joint, which comprises the following components in weight percent: 55-70% of epoxy resin, 15-23% of curing agent, 6-11% of glass fiber, 5-10% of polyethylene reagent and 1-7% of additive. The insulation material of the invention has excellent forming ability, and the material quality is uniform after the insulation material is formed. By detection, the insulation resistance between cables of a cable joint device adopting the insulation material fully meets the requirement of the insulation strength required for the power engineering, the flame resistance of the insulation material reaches V0 level, and simultaneously, the manufacturing cost is very low.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

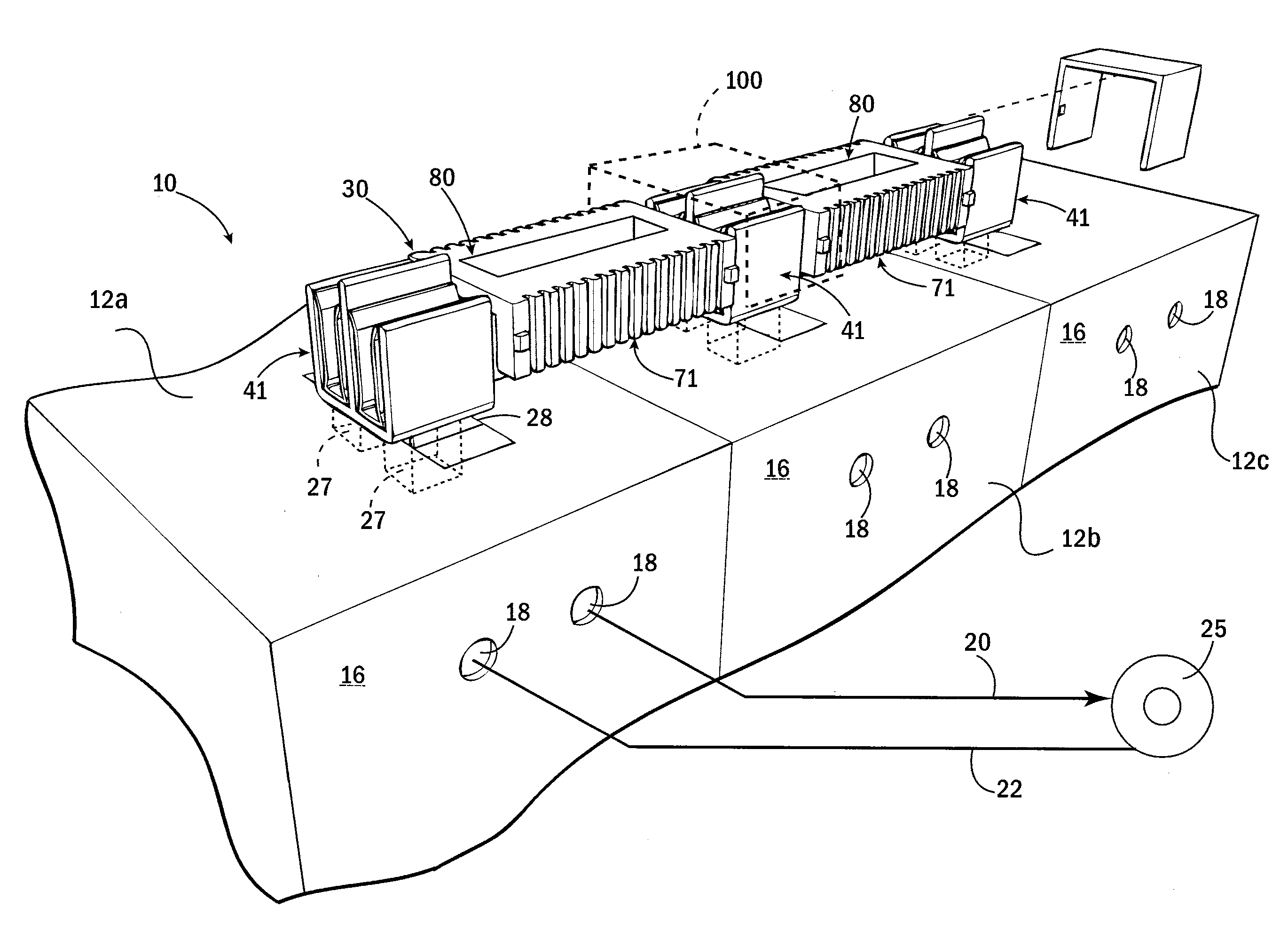

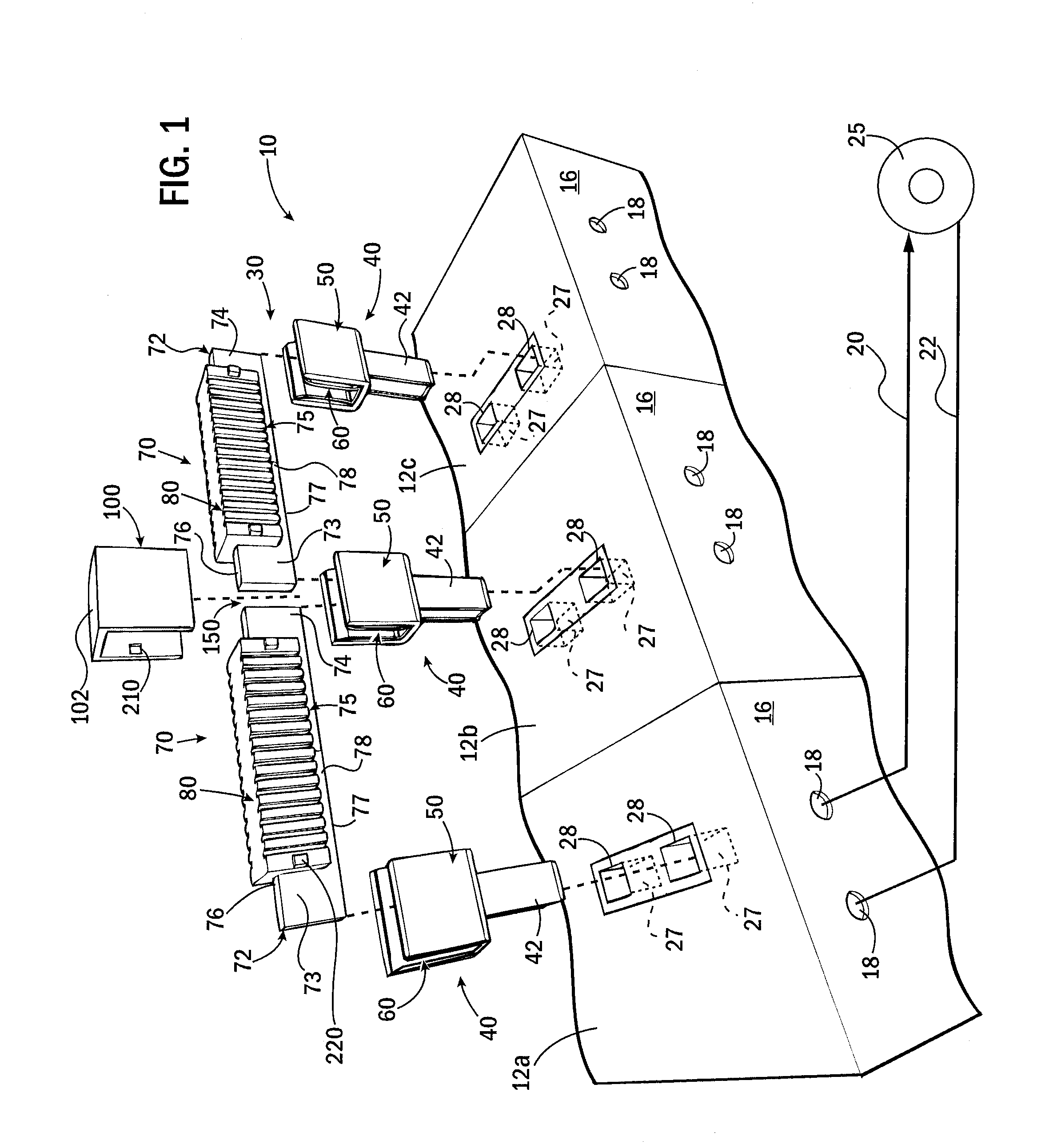

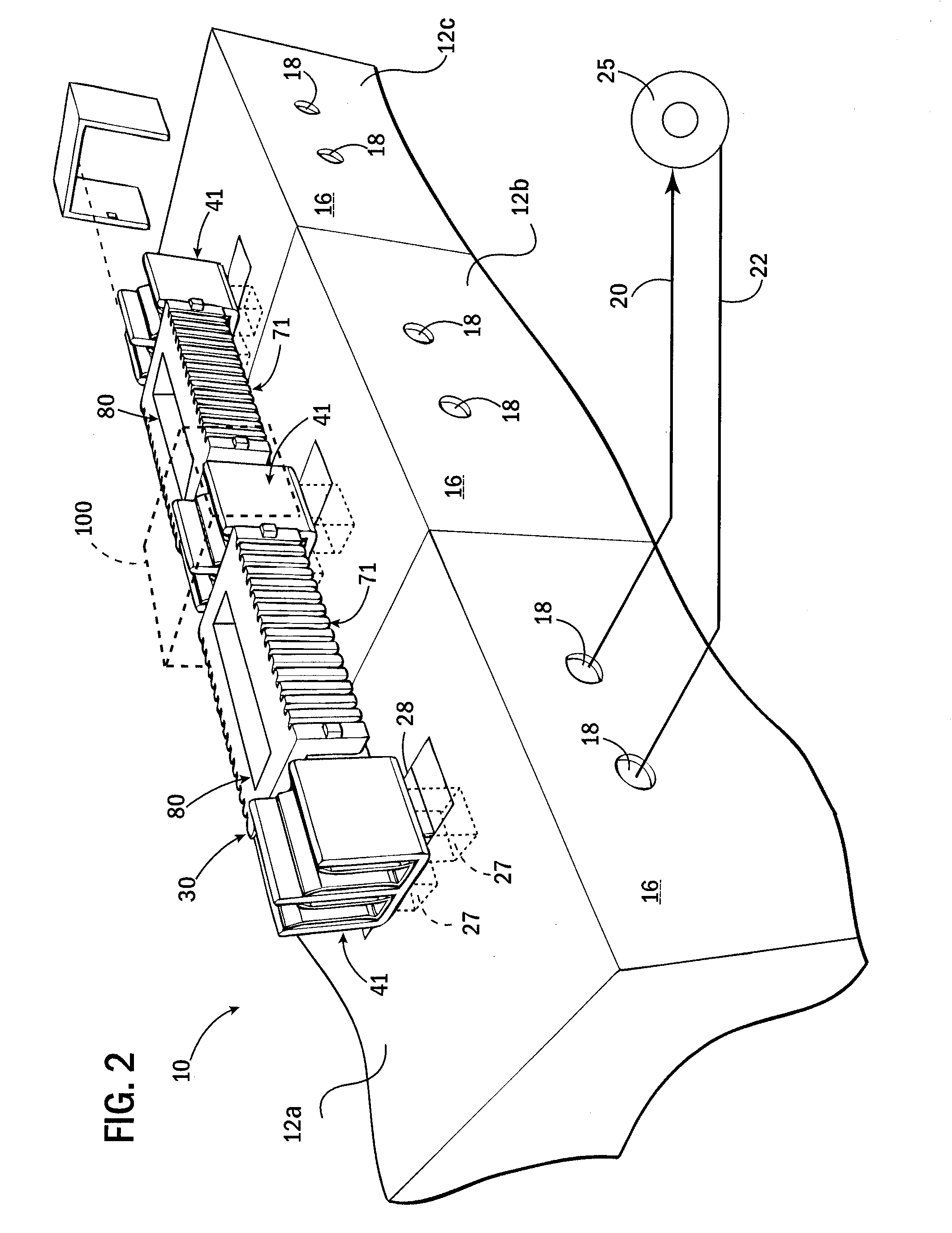

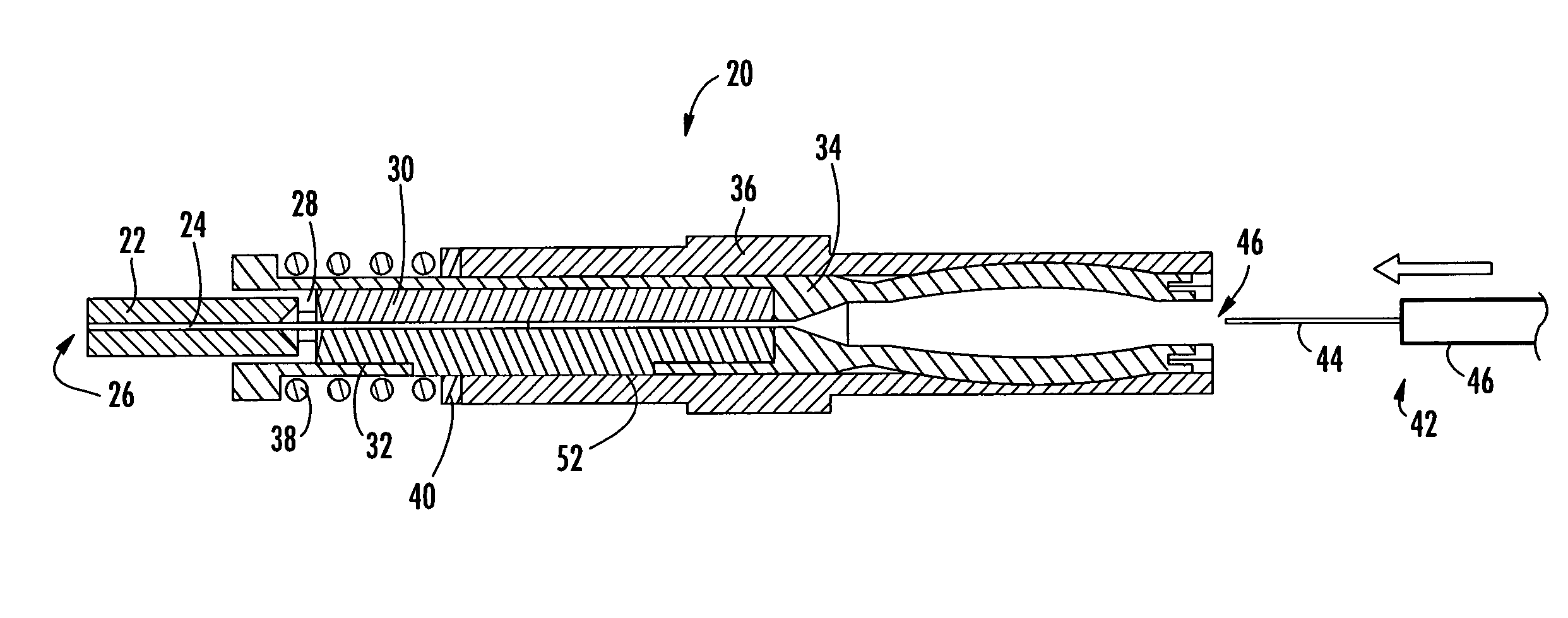

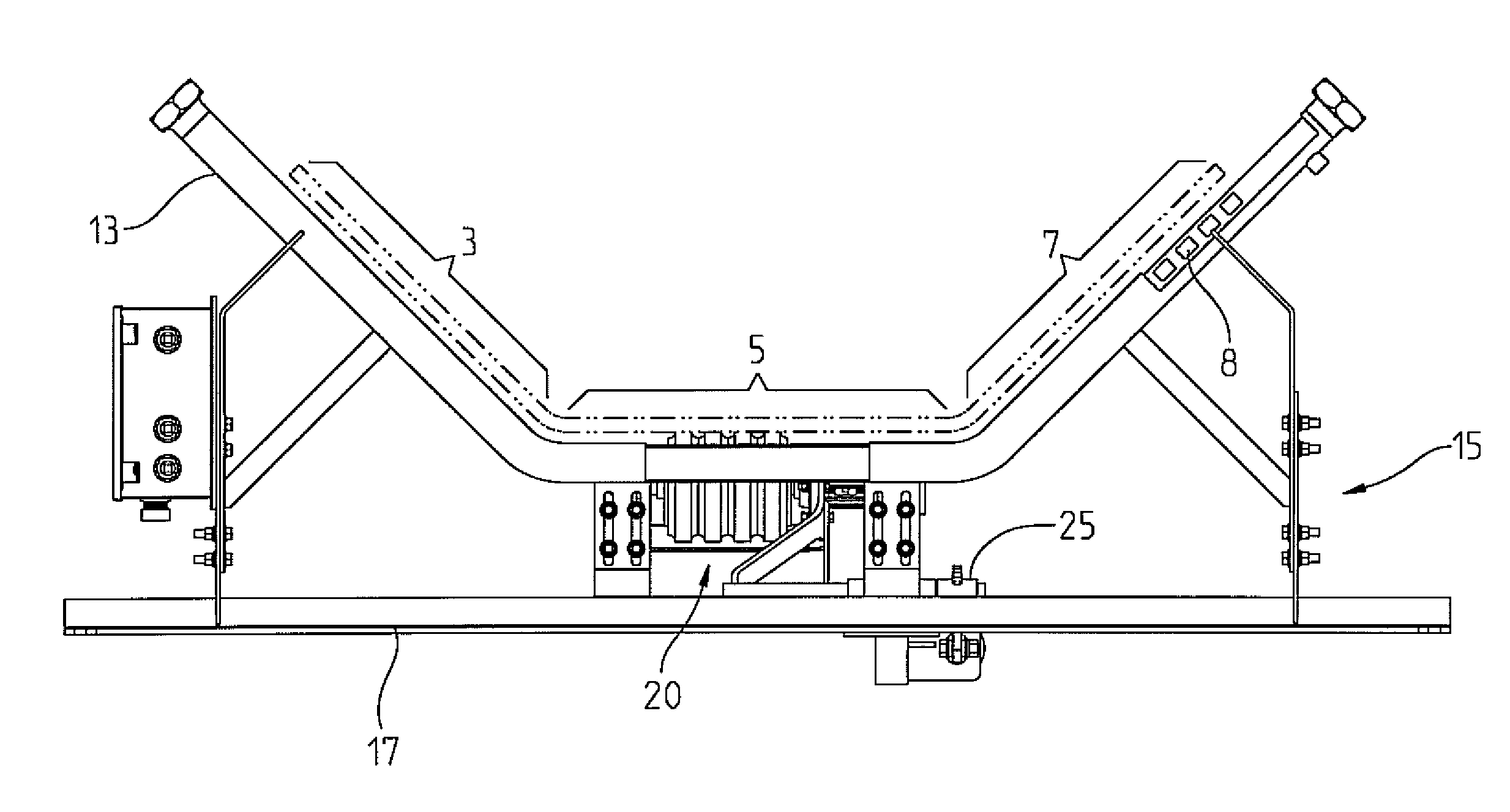

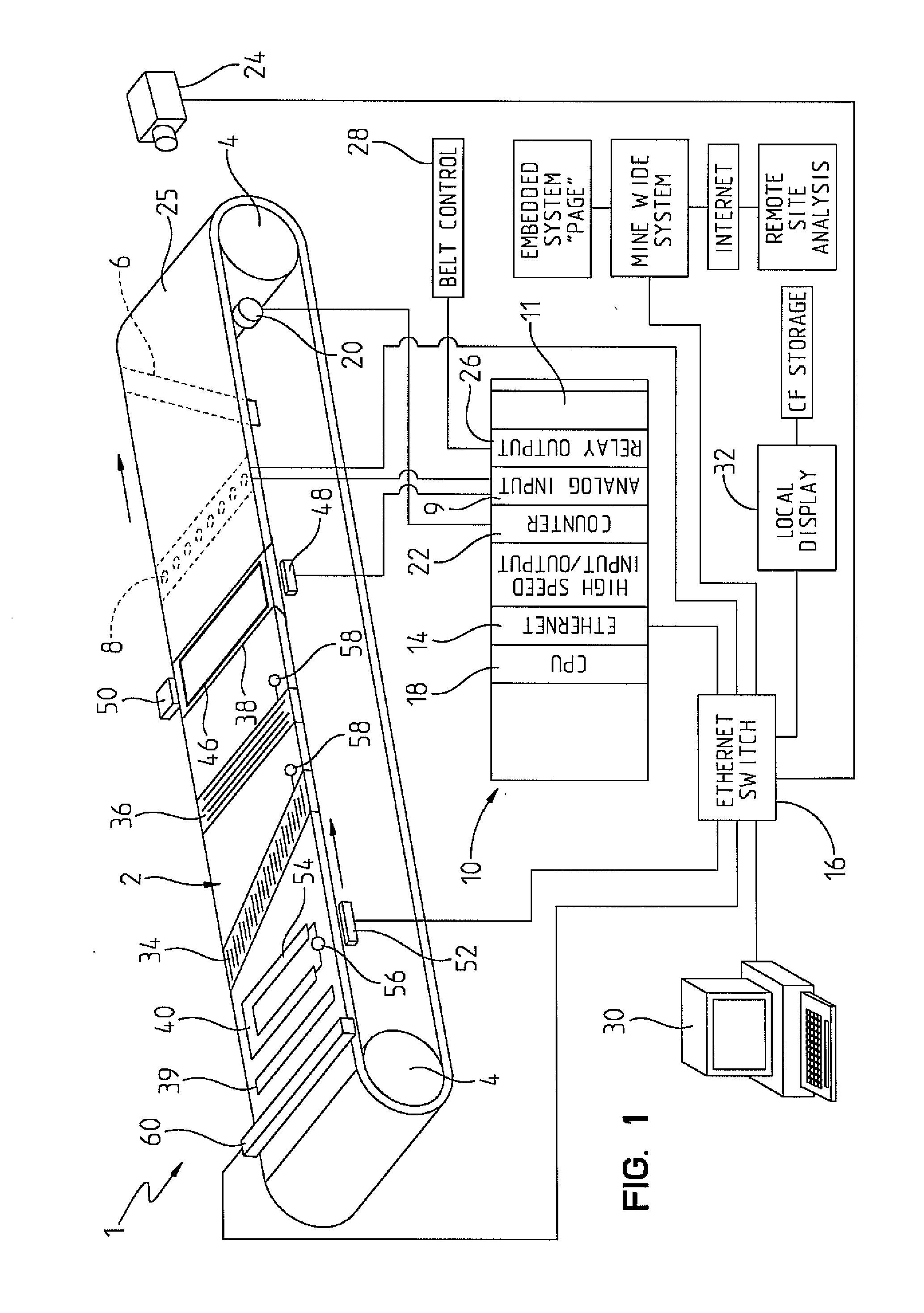

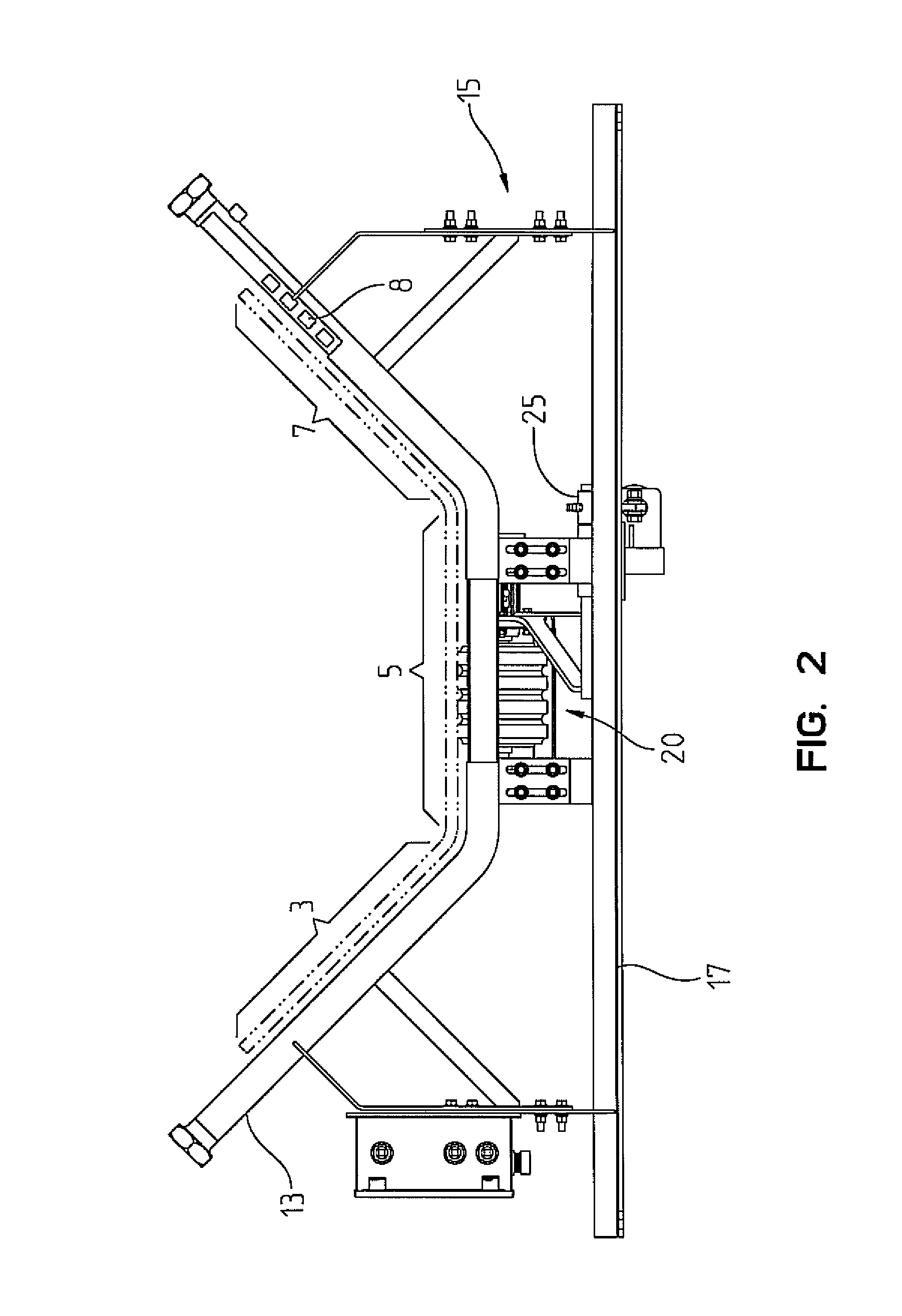

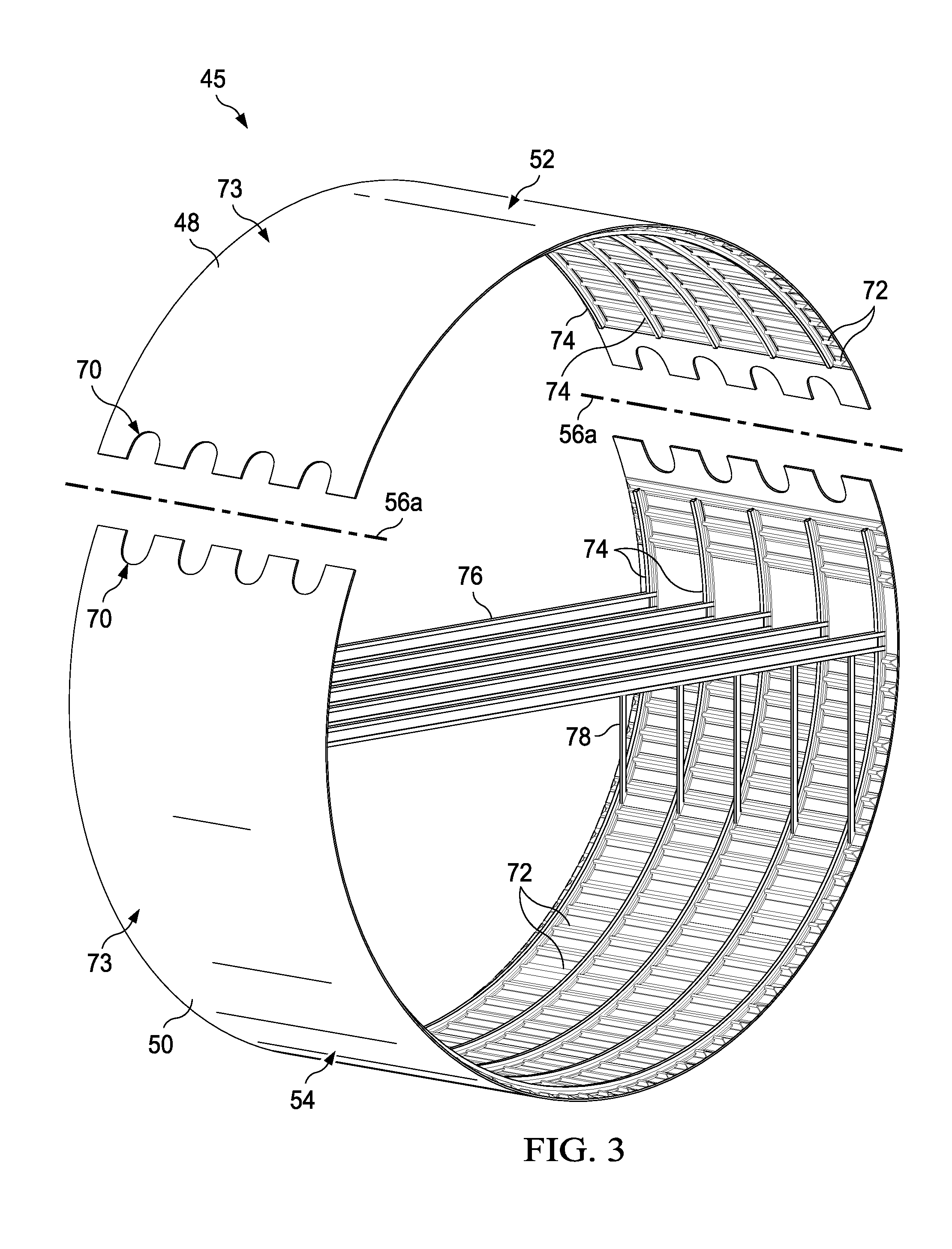

Conveyor belt condition monitoring system

A conveyor belt monitoring system is disclosed that uses sensors to measure magnetic disruptions (“events”) in a conveyor belt which are indicative of one or more splice joints, rip panels and reinforcing cord damage. The system may comprise a plurality of sensing components, including coils or Hall Effect sensors for sensing rip panels, splices and generalized reinforcing cord damage. The system may also have RFID-based rip panels and may use RFID chips to identify various belt components. A PLC-based control system may communicate with the aforementioned components via an Ethernet link Data received by the control system is used to chart belt wear and damage trends and to provide user alarms when signal levels exceed predetermined norms. The system may stop the belt when imminent belt failure is predicted. The PLC-based control system is highly scalable and will integrate easily into existing conveyor control systems and facility-wide monitoring systems.

Owner:FENNER DUNLOP AMERICAS

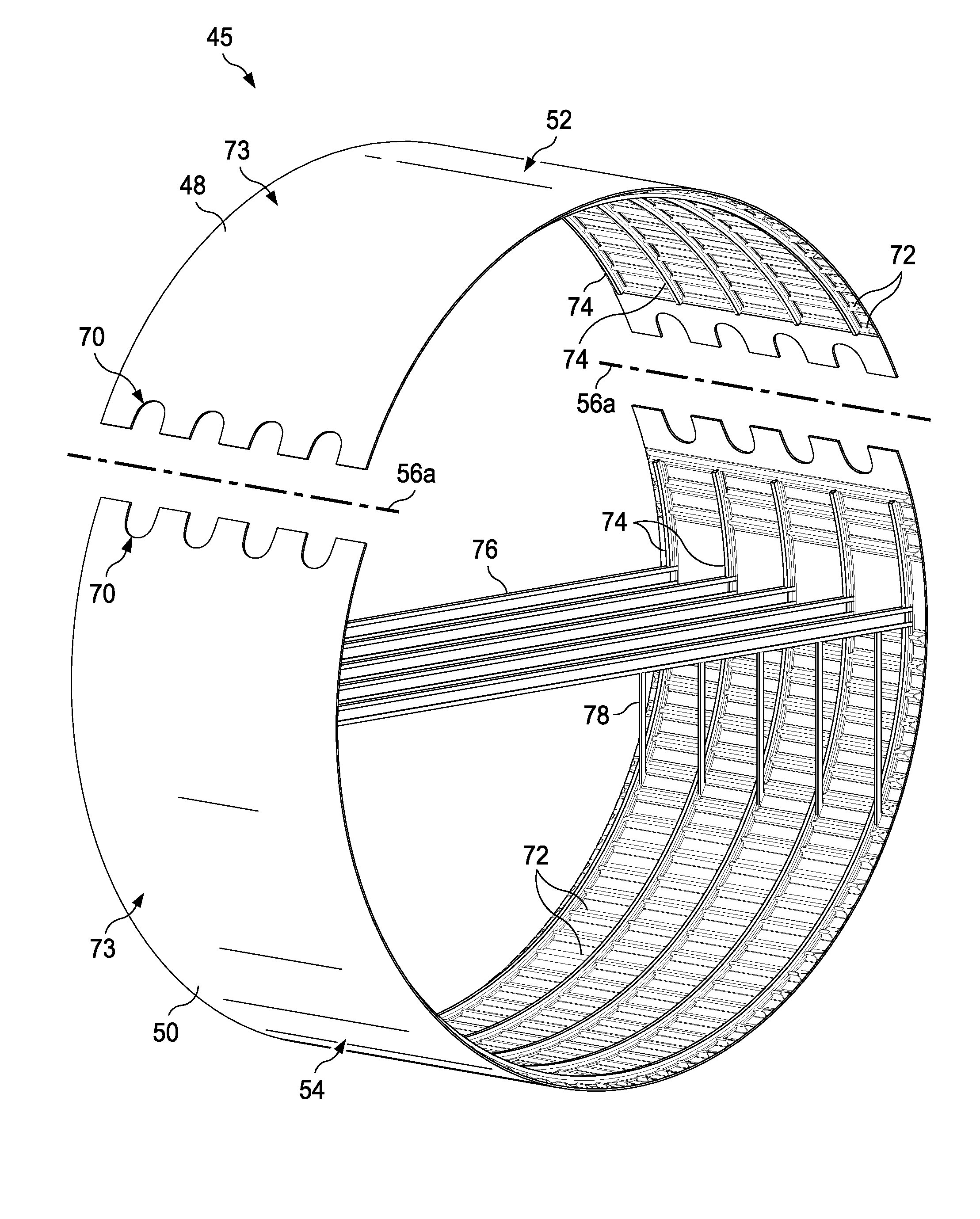

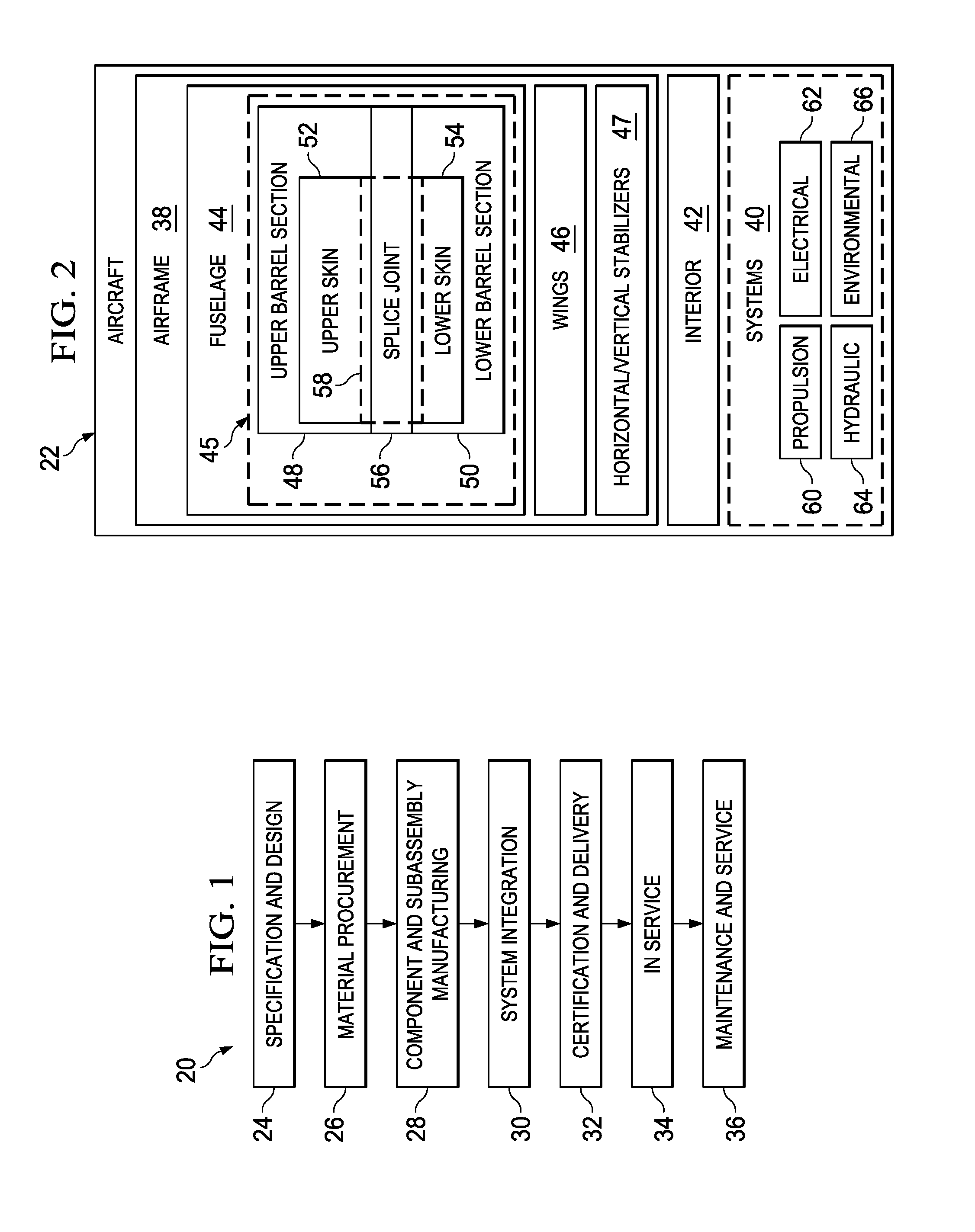

Joining Composite Fuselage Sections Along Window Belts

ActiveUS20140001311A1Improves production flow timeShorten assembly timeLamination ancillary operationsLaminationWindow openingEngineering

A fuselage having a longitudinal window belt has a composite outer skin including upper and lower composite skin sections. The skin includes at least one window opening located at the window belt. The upper and lower skin sections are joined together by a longitudinal splice joint located at the window belt.

Owner:THE BOEING CO

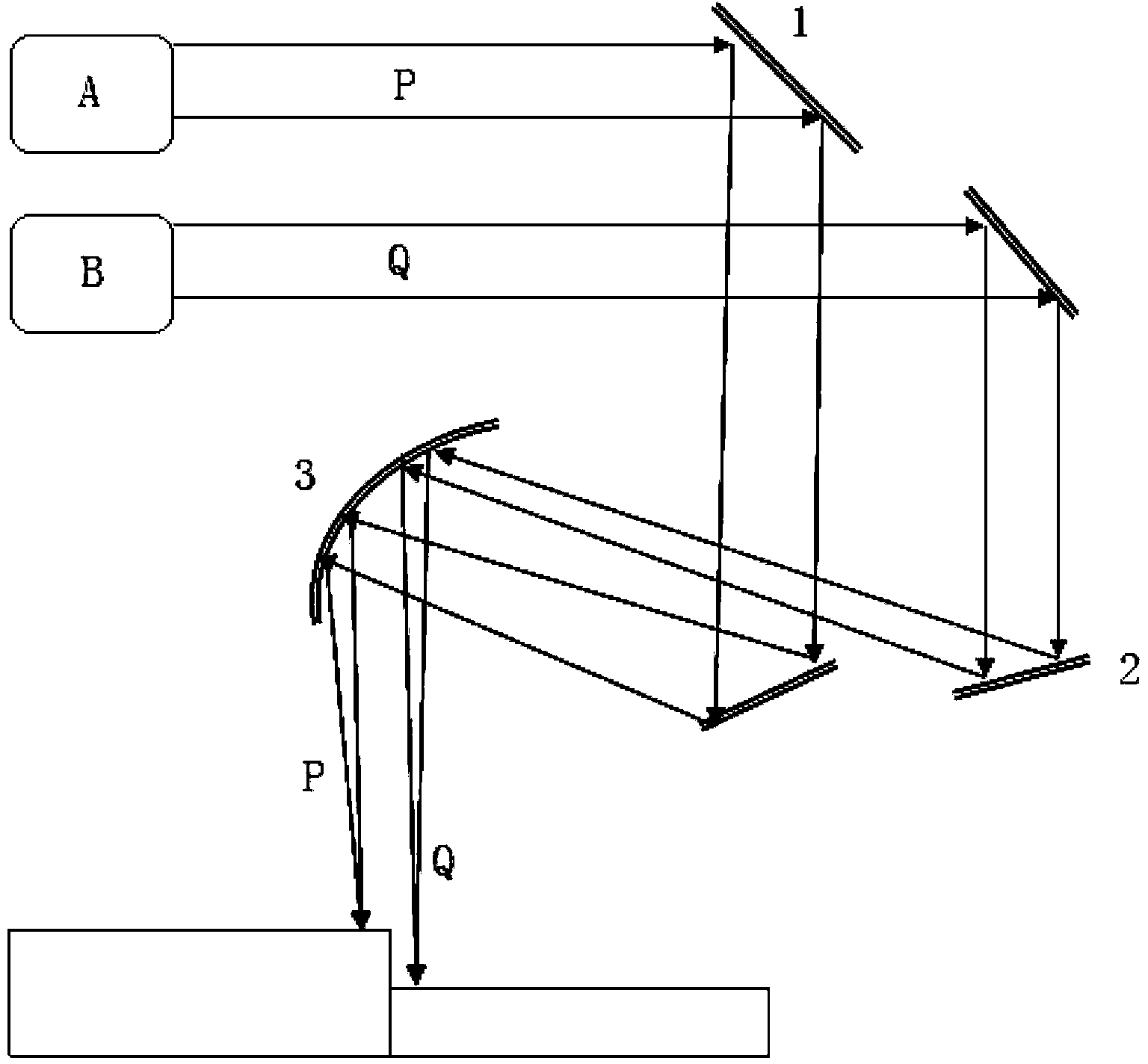

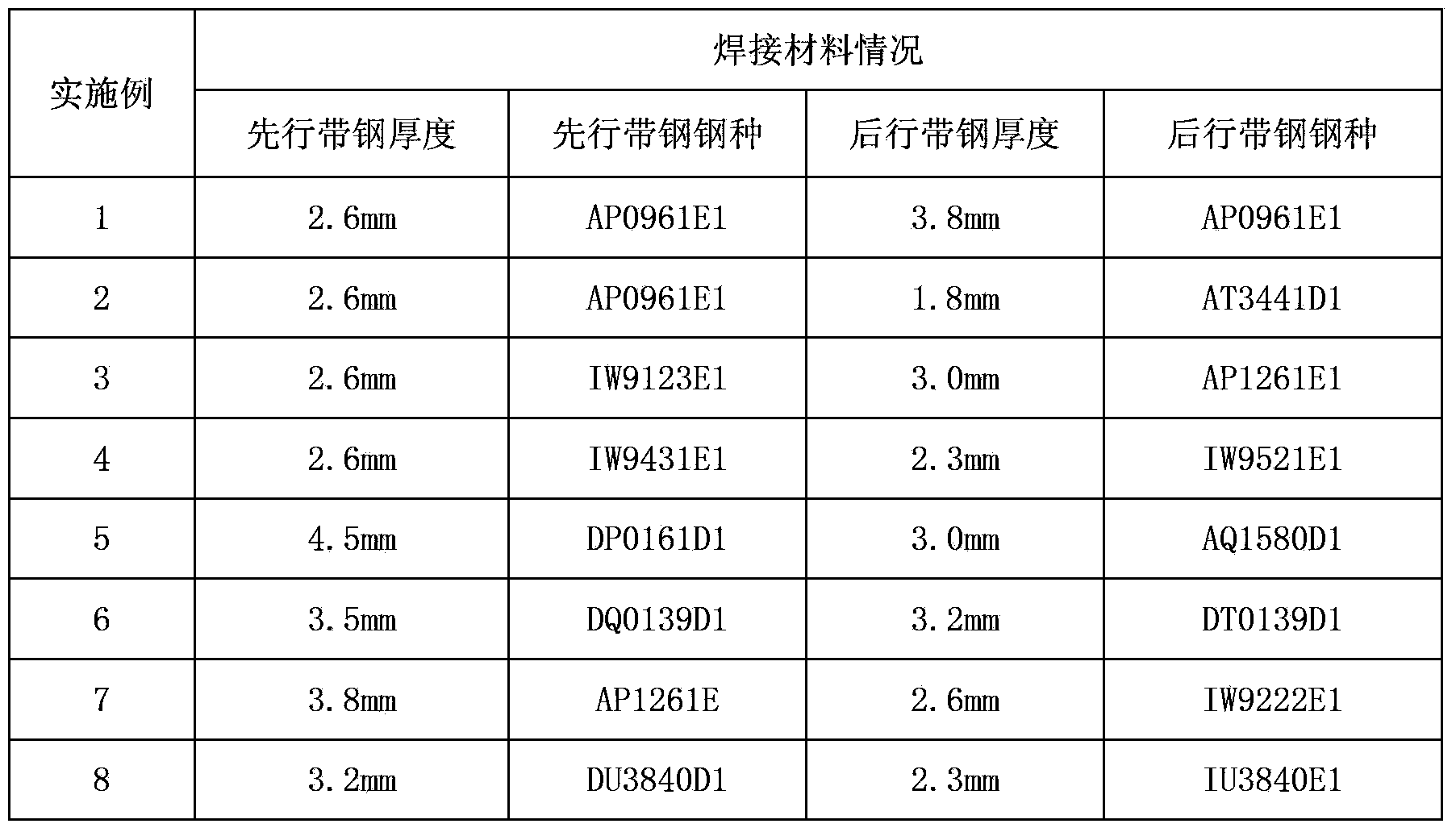

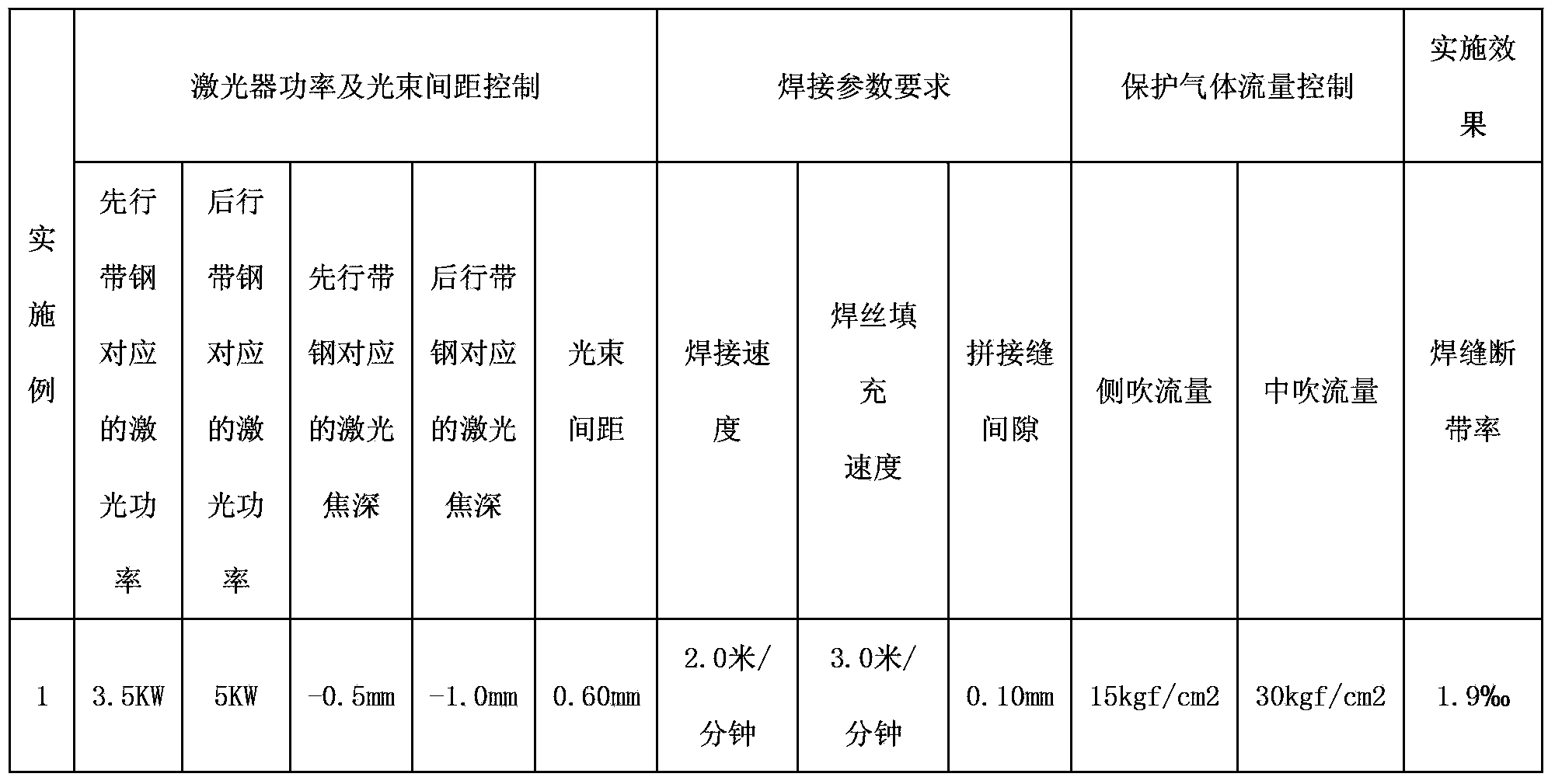

Laser welding method for tailored band steel

ActiveCN104227239AGuaranteed transmission effectEliminate formationWelding/soldering/cutting articlesMetal working apparatusStrip steelEngineering

The invention discloses a laser welding method for tailored band steel. The laser welding method is characterized by comprising steps of (1), shearing the tail of front band steel and the head of rear band steel and then aligning and splicing the front band steel and the rear band steel to form a spliced joint; (2), projecting two laser beams with adjustable distance and adjustable focal depths to positions near the spliced joint, enabling one laser beam to illuminate the front band steel and enabling the other laser beam to illuminate the rear band steel; filling the spliced joint with welding wires to weld the front band steel and the rear band steel. The laser welding method has the advantages that the welding joint is high in quality, and accordingly breakage of the cold-rolled band steel in continuous production procedures can be prevented.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for joining of structural members by friction plug welding

InactiveCN1564724AEfficient connectionCost-effectiveWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingEngineering

Owner:THE BOEING CO

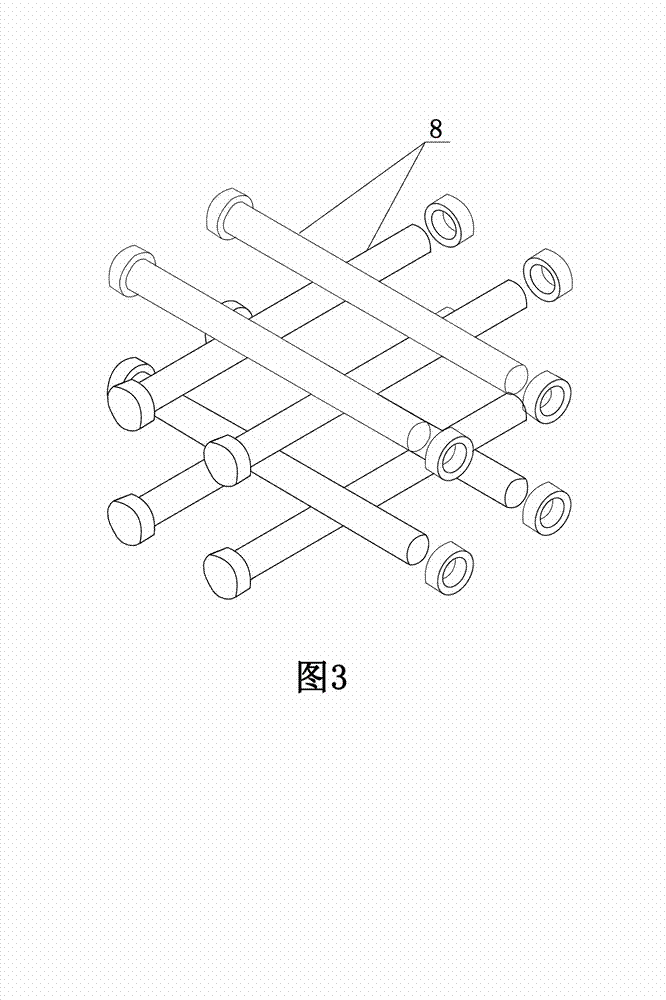

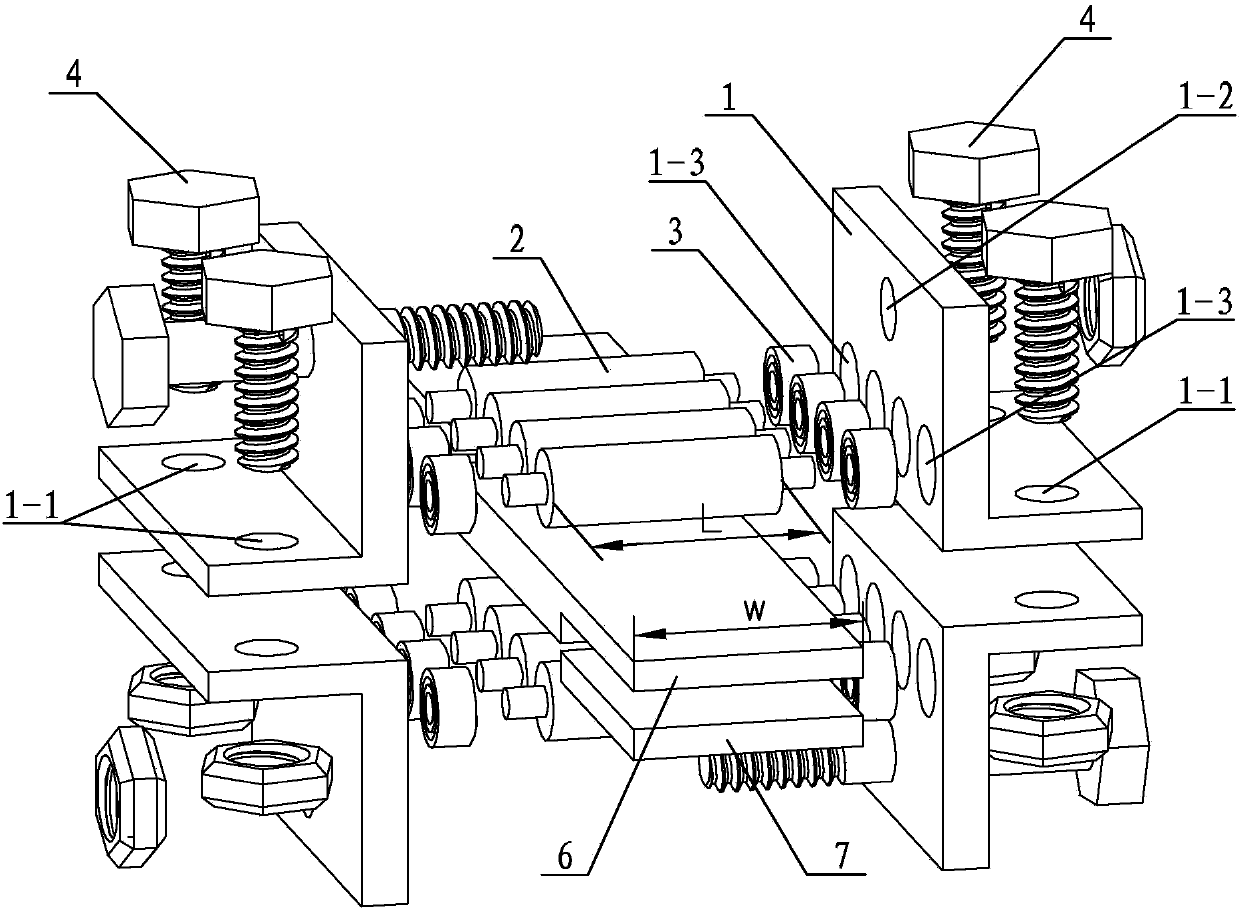

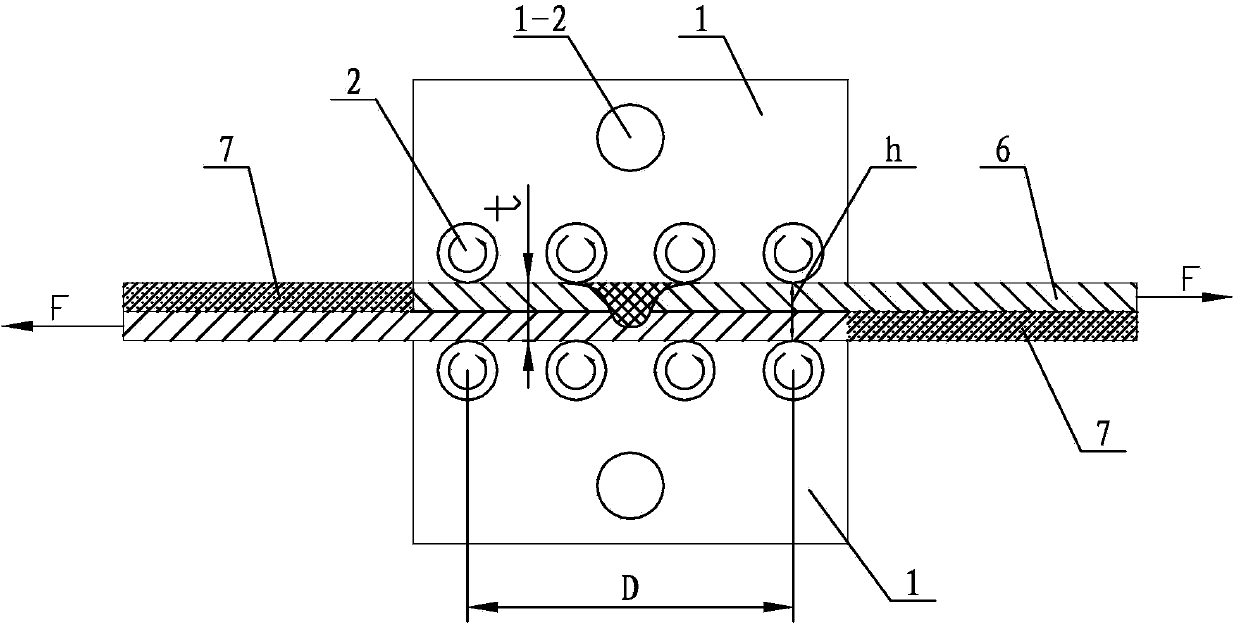

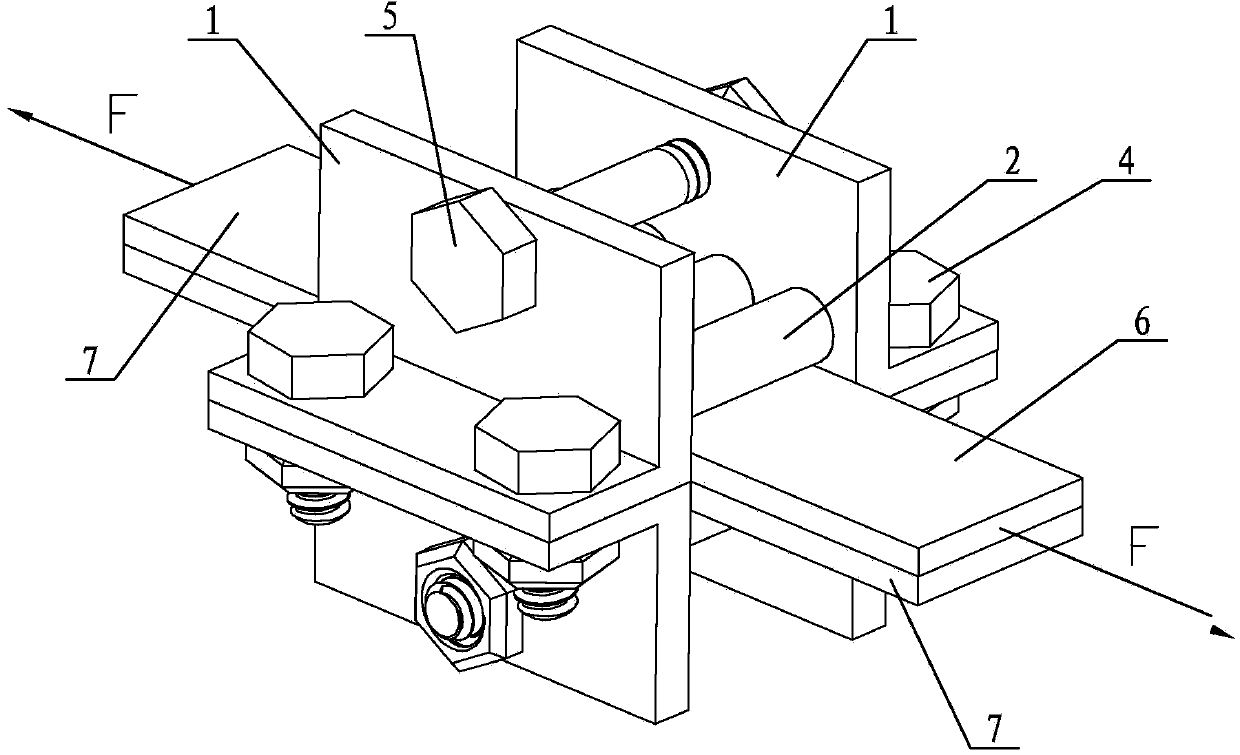

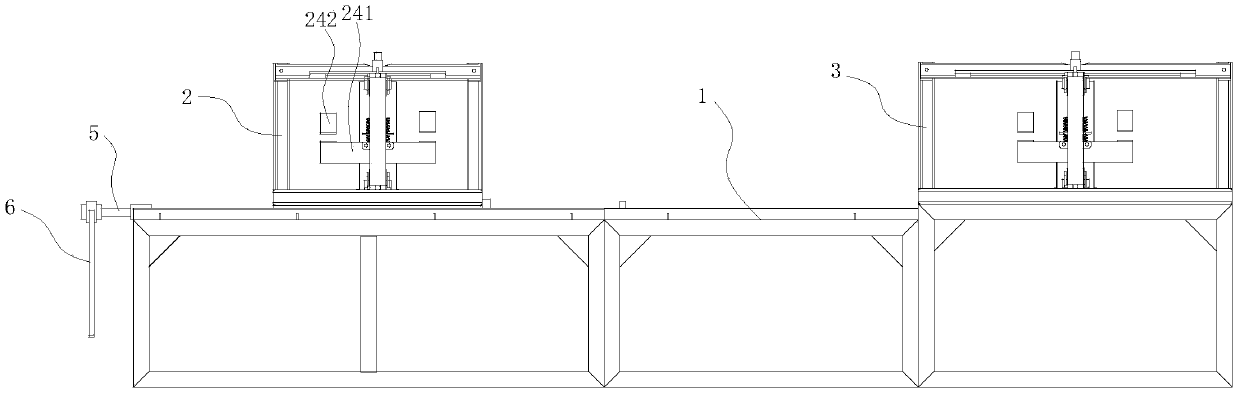

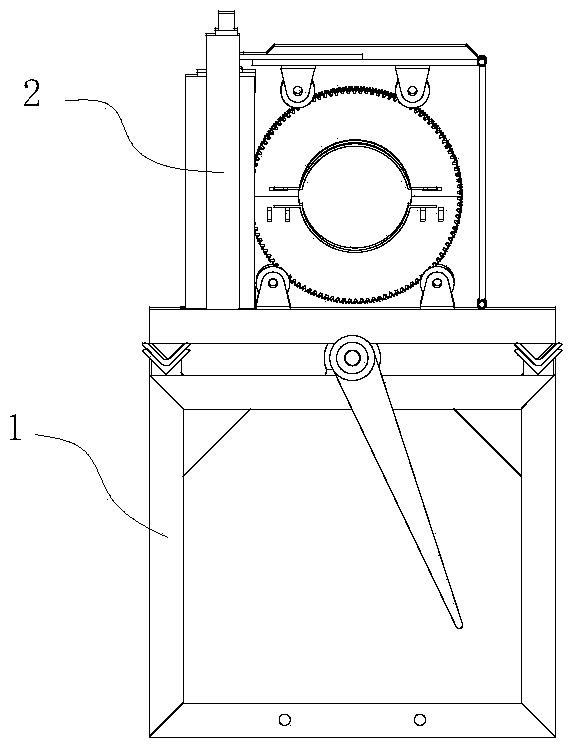

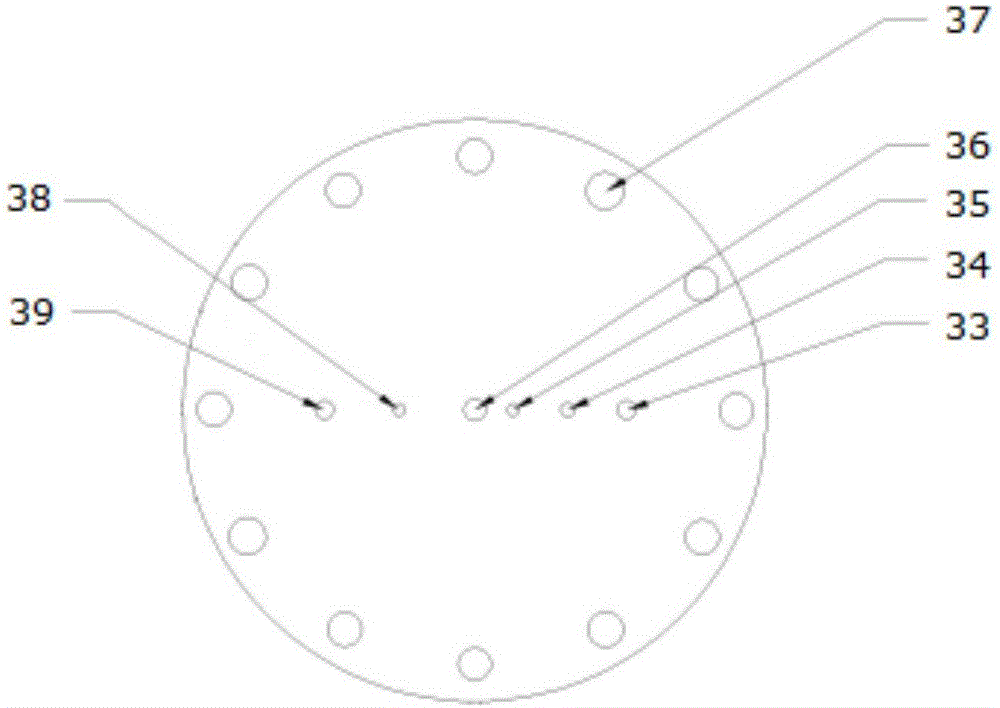

Fixture and method for measuring maximum tensile and shearing force of lap joint of friction stir welding

ActiveCN103592181AGuaranteed pure tensile shear failureEliminate additional bending momentsMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesFriction weldingLap joint

The invention provides a fixture and a method for measuring the maximum tensile and shearing force of a lap joint of friction stir welding to overcome the problem that additional bending moment influences measurement results of the maximum tensile and shearing force of a lap joint of friction stir welding in a traditional tensile and shearing test. According to the fixture, four bearing installing holes are arranged along a same horizontal line; eight rollers are arranged in two layers, each layer consisting of four parallely arranged rollers; the end parts of each roller is mounted in a corresponding bearing installing hole through a positioning bearing. The method comprises the following steps: 1, allowing the distance between axle centers of two rollers located at two outermost sides of each layer of rollers to be 10 to 20 times thickness of the lap part of a test piece for tensile and shearing testing; 2, placing the test piece for tensile and shearing testing between the upper layer of rollers and the lower layer of rollers; and 3, clamping the assembled test piece for tensile and shearing testing, the fixture and cushion blocks on a tensile and shearing testing machine, carrying out tensile and shearing testing on the test piece for tensile and shearing testing at a loading speed of 0.5 to 1.5 mm / min and recording a maximum tensile and shearing test load F. The fixture and the method provided by the invention are used for measuring the maximum tensile and shearing force of the lap joint of friction stir welding.

Owner:HARBIN INST OF TECH

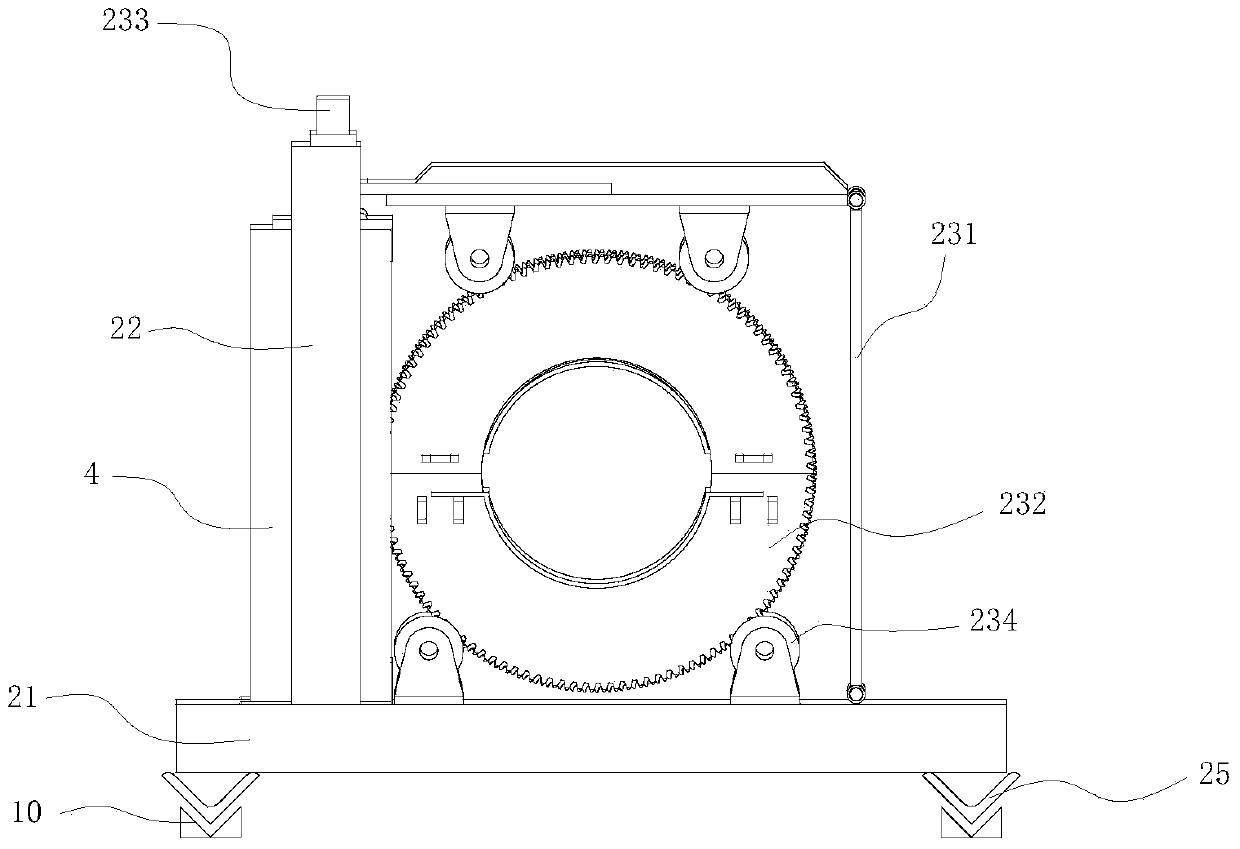

Cable butt joint device

ActiveCN103762531AControl rotational stressGuaranteed normal consumptionApparatus for joining/termination cablesButt jointMaterial consumption

Provided is a cable butt joint device. The cable butt joint device is simple in structure and convenient and fast to operate, and can control the rotation stress of cables effectively and improve the work efficiency. The cable butt joint device comprises a first cable connector, a second cable connector and a machine frame. The first cable connector comprises a base, a support, a cable rotation mechanism and a cable fixing mechanism. The cable rotation mechanism comprises a base frame, a worm gear, a worm and a plurality of idler wheels, and the worm gear is composed of a first gear and a second gear, wherein the first gear and the second gear are paired. The cable fixing mechanism comprises a first hoop and a second hoop, wherein the first hoop and the second hoop are paired. The second cable connector comprises a cable fixing base. According to the cable butt joint device, manpower consumption is greatly reduced, when cable cores are inserted into a connection pipe, the cable cores at the two ends can fully make contact in the connection pipe, and therefore the connection quality of the cable cores is improved. The cable butt joint device can guarantee that the phase sequence after cable butt joint is identical with an original phase sequence, achieve identification of the phase of the cable cores and the phase of a line, standardize the construction process of the cable line, reduce material consumption and guarantee the quality of a middle connector of the cable.

Owner:YANGZHOU JIANGDU POWER SUPPLY COMPANY OF JIANGSU ELECTRIC POWER +3

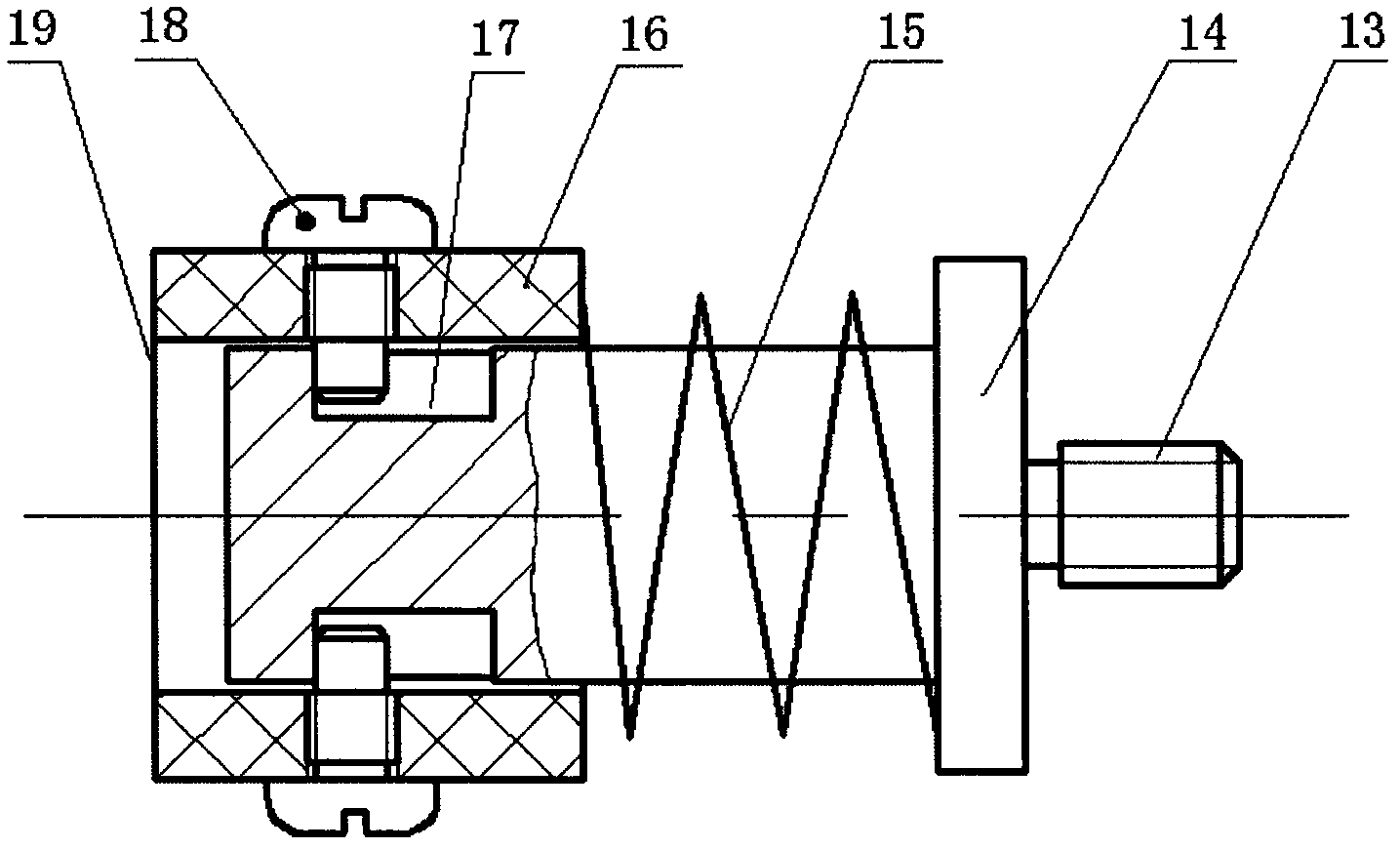

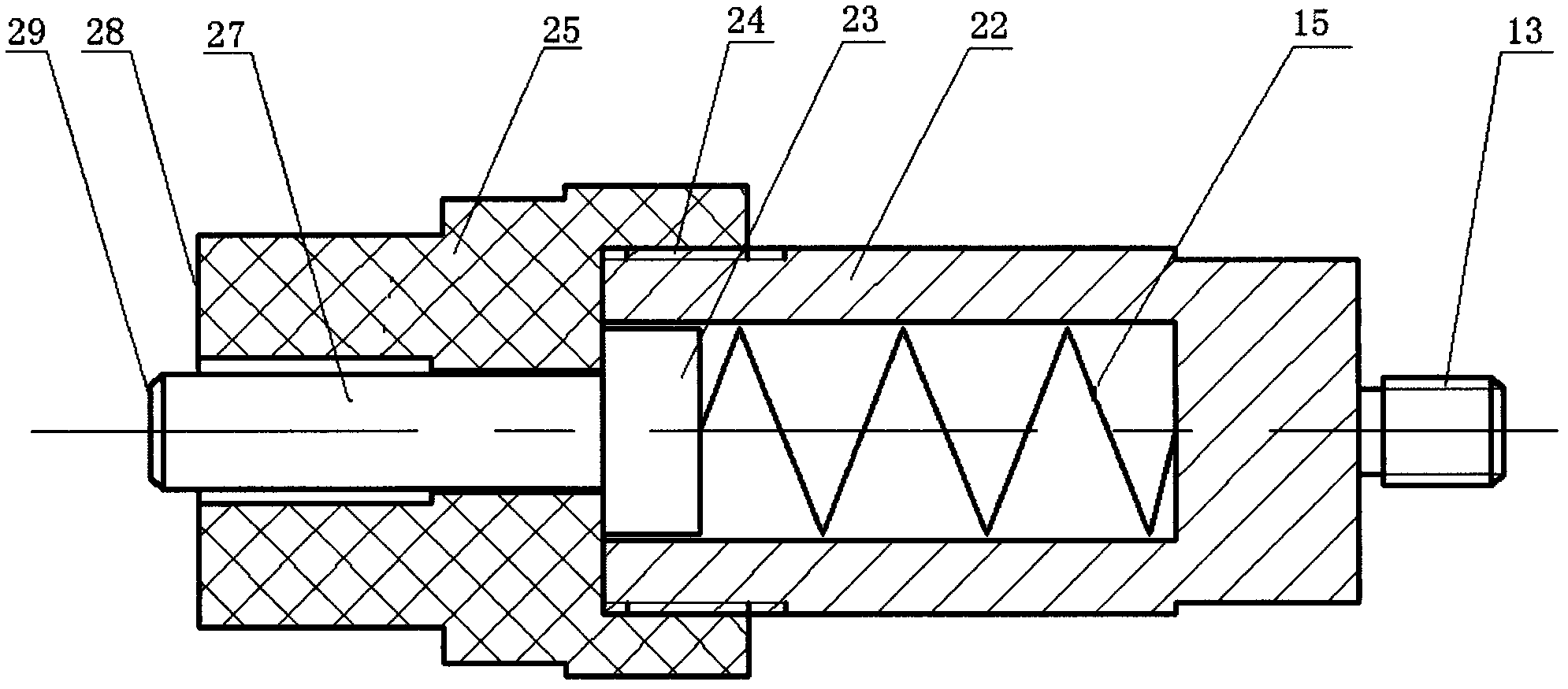

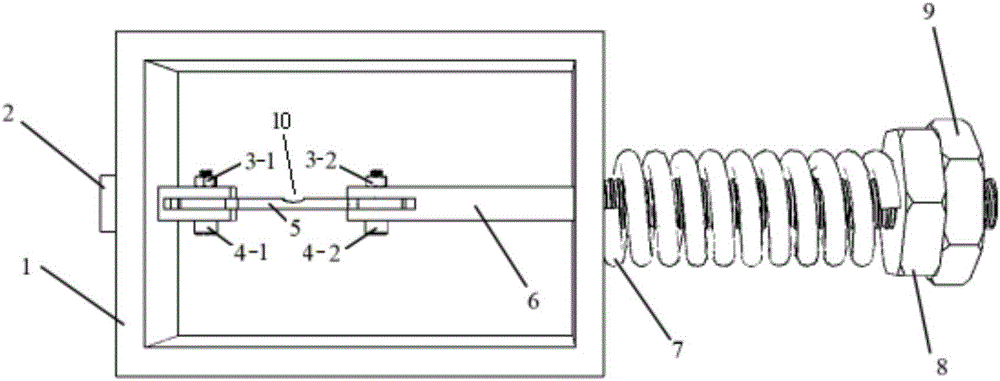

Rivet joint, auxiliary rivet joint and method for stress wave mounting of interference fit fastener

The invention discloses a rivet joint, an auxiliary rivet joint and a method for stress wave mounting of an interference fit fastener, which are used for solving the technical problem that the structure of a riveted piece is prone to deformation when an existing stress wave mounting device is used for stress wave mounting of the interference fit fastener. The technical scheme is as follows: the rivet joint and the auxiliary rivet joint are respectively mounted on two electromagnetic riveting guns through connectors 13, and position-limiting and guide structures are respectively arranged on the rivet joint and the auxiliary rivet joint, thereby ensuring the alignment between the electromagnetic rivet guns and the fastener. The rivet joint and the auxiliary rivet joint can apply force on the two surfaces of the riveted piece, thereby avoiding the deformation of the riveted piece when the single electromagnetic rivet gun is used for applying the force on the single surface of the riveted piece.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

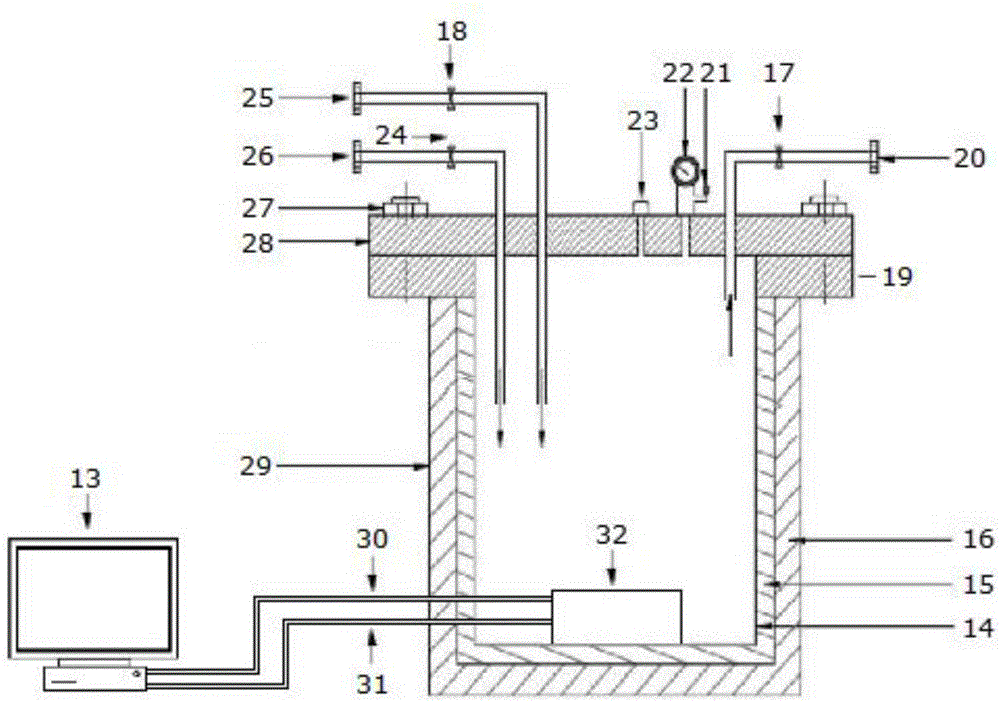

Welded joint force-corrosion coupling testing experimental method and welded joint force-corrosion coupling testing experimental device

ActiveCN105891099AWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesInsulation layerHigh pressure

The invention discloses a welded joint force-corrosion coupling testing experimental method and a welded joint force-corrosion coupling testing experimental device. The welded joint force-corrosion coupling testing experimental device is characterized in that a heating device is arranged on the outer side of an autoclave body, a heat insulation layer is arranged on the outer side of the heating device, an autoclave cover is arranged on the upper surface of the autoclave body, a first gas inlet pipe, a second gas inlet pipe, a gas outlet pipe, an auxiliary feeding device, a pressure sensor and a pressure gauge are arranged on the round surface of the autoclave cover sequentially along the diameter direction, a testing device is arranged at the inner bottom of the autoclave body, a tensile test specimen is arranged between a left chuck and a right chuck, an extensometer is arranged above the tensile test specimen, and a strain gauge is arranged below the tensile test specimen. The welded joint force-corrosion coupling testing experimental method and the welded joint force-corrosion coupling testing experimental device have the advantages that required strain is applied to a welded joint successfully and strain in the welded joint and parent metal positions are obtained to study effect of deformation on corrosion of different portions of the welded joint so as to evaluate the service environment of the welded joint.

Owner:TIANJIN UNIV

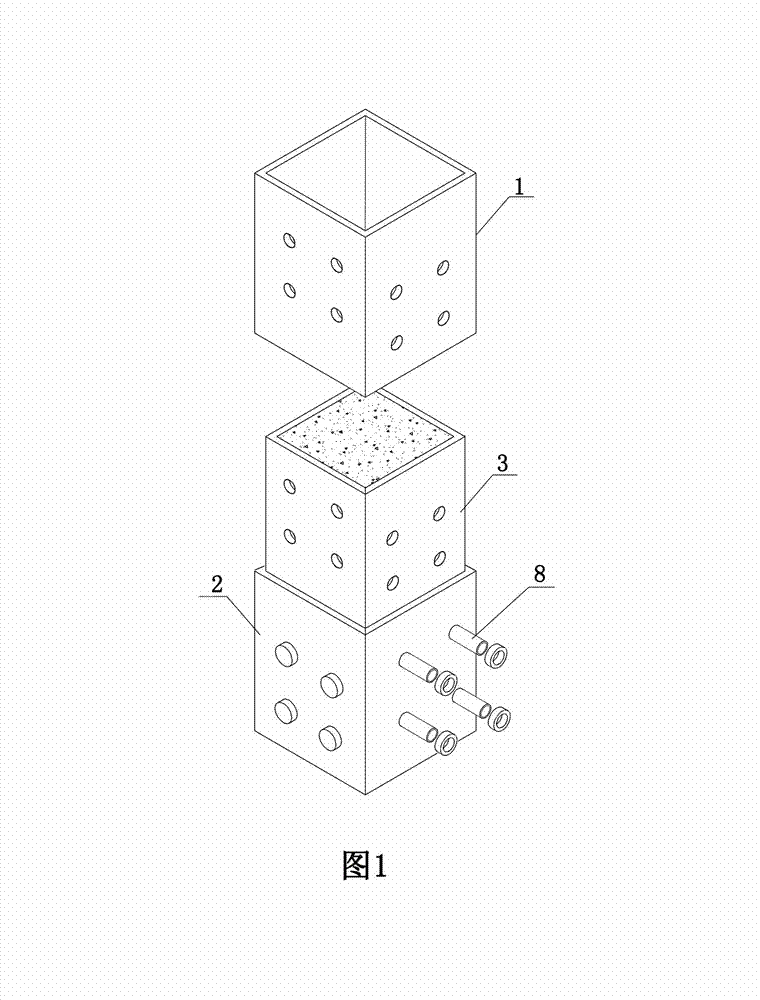

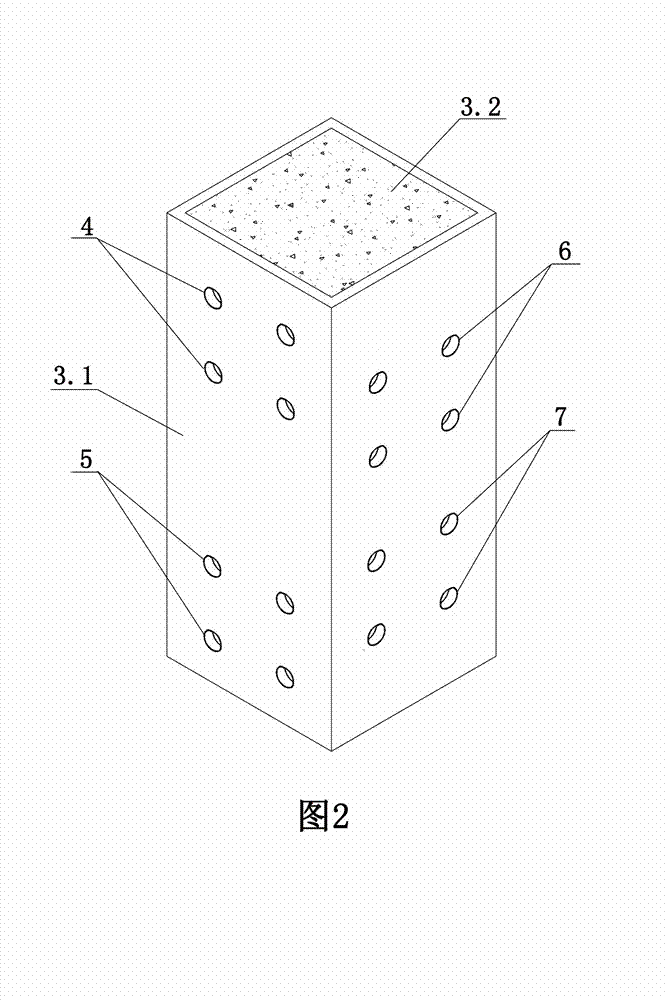

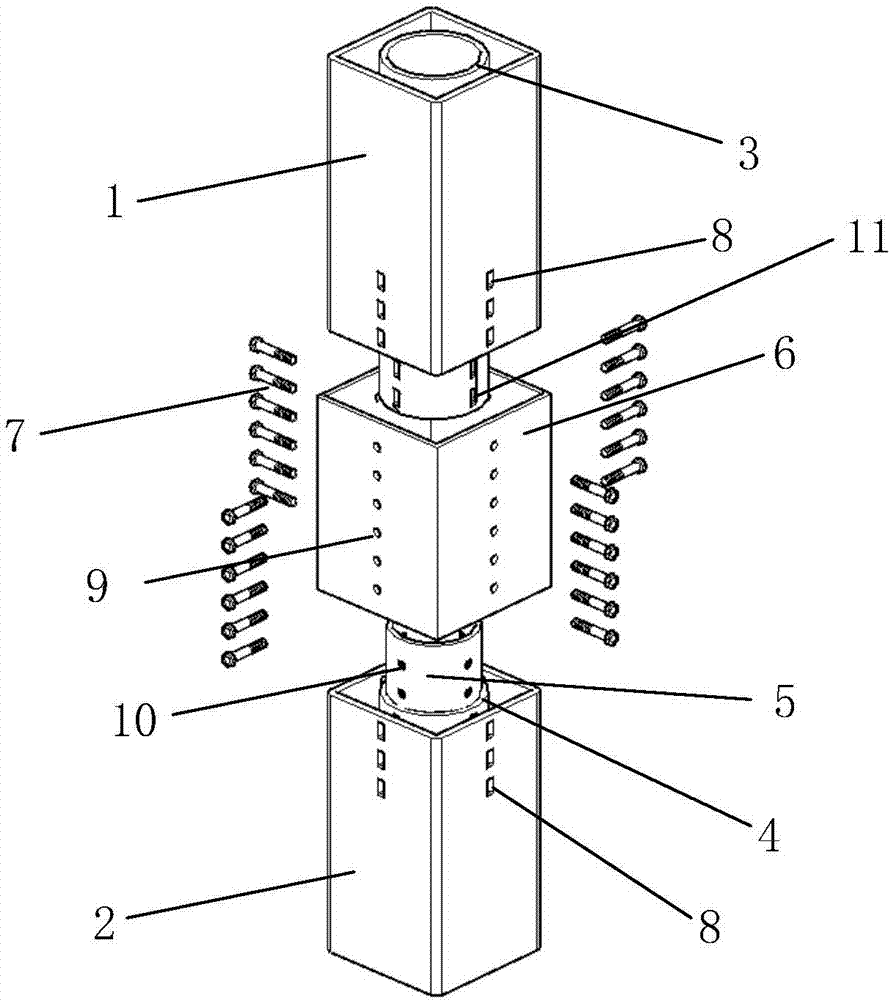

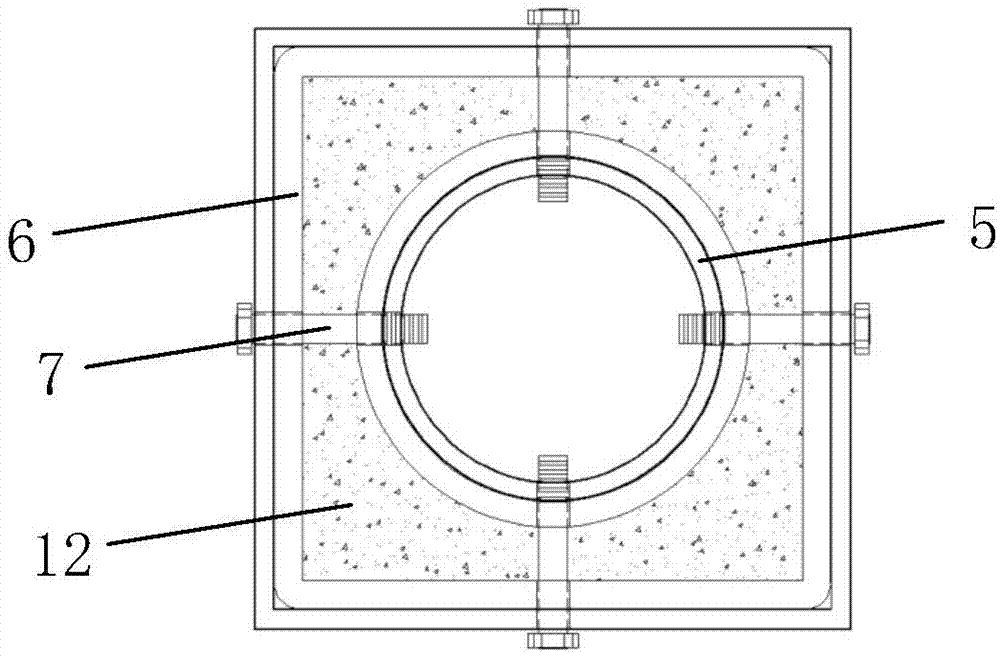

Outer-square and inner-circular steel pipe double-sleeve splicing joint and construction method thereof

InactiveCN107514061ATroubleshoot technical issues with structural collapseImprove vertical load carrying capacityBuilding constructionsStructure CollapseVertical load

The invention relates to the technical field of building steel structure construction, in particular to an outer-square and inner-circular steel pipe double-sleeve splicing joint and a construction method thereof. The outer-square and inner-circular steel pipe double-sleeve splicing joint comprises an upper-section square steel pipe column, a lower-section square steel pipe column, an upper-section circular steel pipe column and a lower-section circular steel pipe column. The square steel pipe columns comprise the upper-section square steel pipe column and the lower-section square steel pipe column, and the circular steel pipe columns comprise the upper-section circular steel pipe column and the lower-section circular steel pipe column. The joint further comprises a square outer sleeve connected between the upper-section square steel pipe column and the lower-section square steel pipe column, a circular inner sleeve connected between the upper-section circular steel pipe column and the lower-section circular steel pipe column and a long bolt. According to the outer-square and inner-circular steel pipe double-sleeve splicing joint and the construction method thereof, the problems that as for an existing outer-square and inner-circular steel pipe core cylinder joint connecting mode, on-site construction operation is inconvenient, connecting components are complex in design and construction, the rigidity of a joint is insufficient, and how a current core cylinder joint is spliced through sleeves is not determined are solved; and the technical problem that when the vertical load of a column is over large, a bolt fractures, and thus a structure collapses is solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

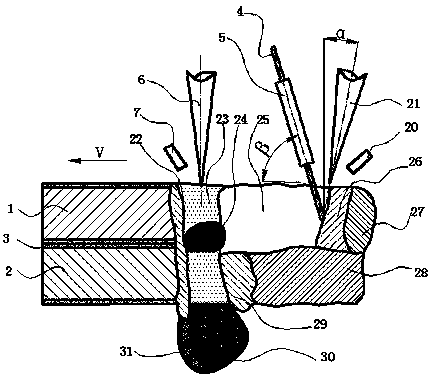

Car steel-aluminum splicing joint welding method and system

InactiveCN107971650AImprove connection strengthIncrease binding areaWelding/soldering/cutting articlesWelding apparatusLaser cuttingEngineering

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

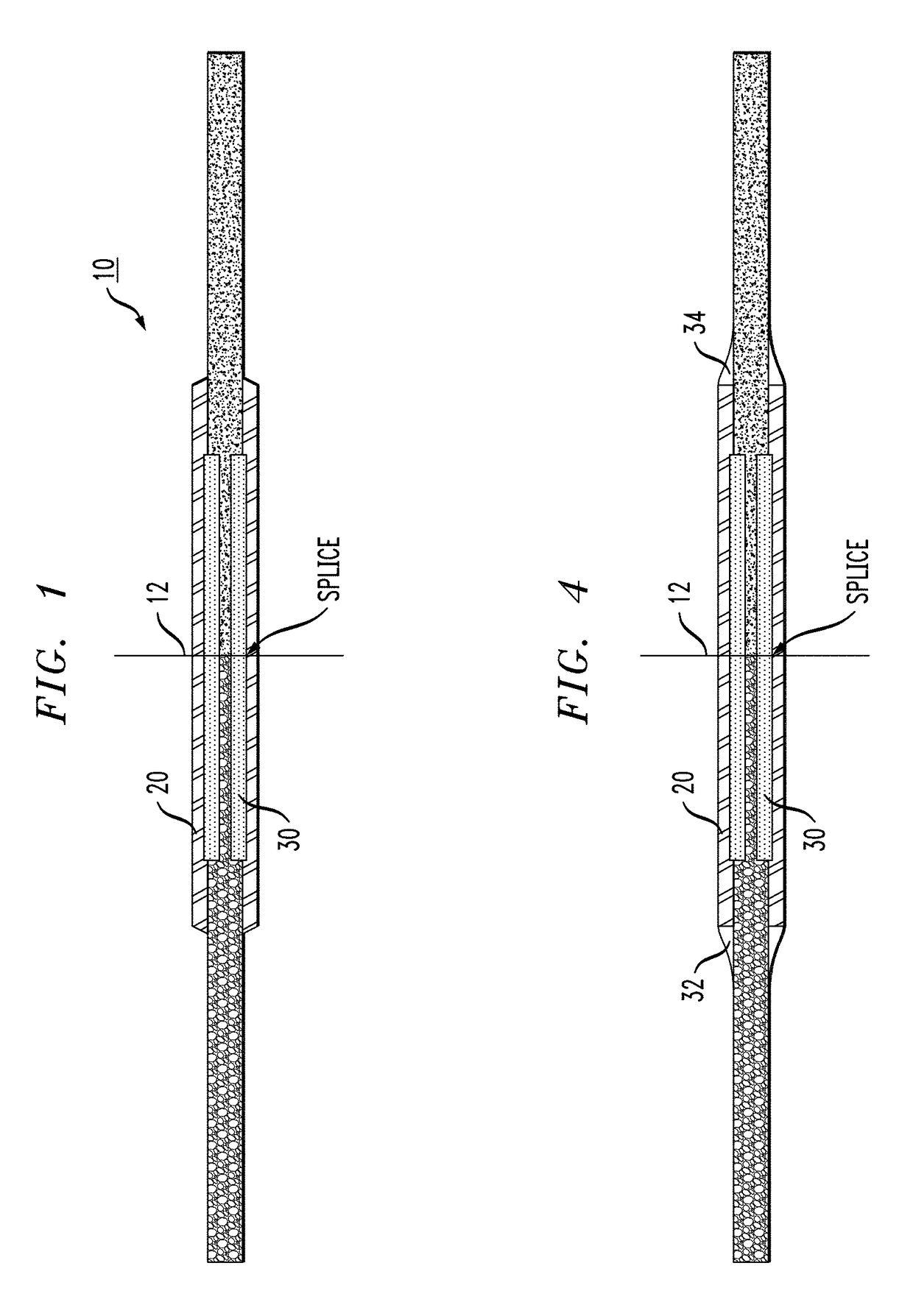

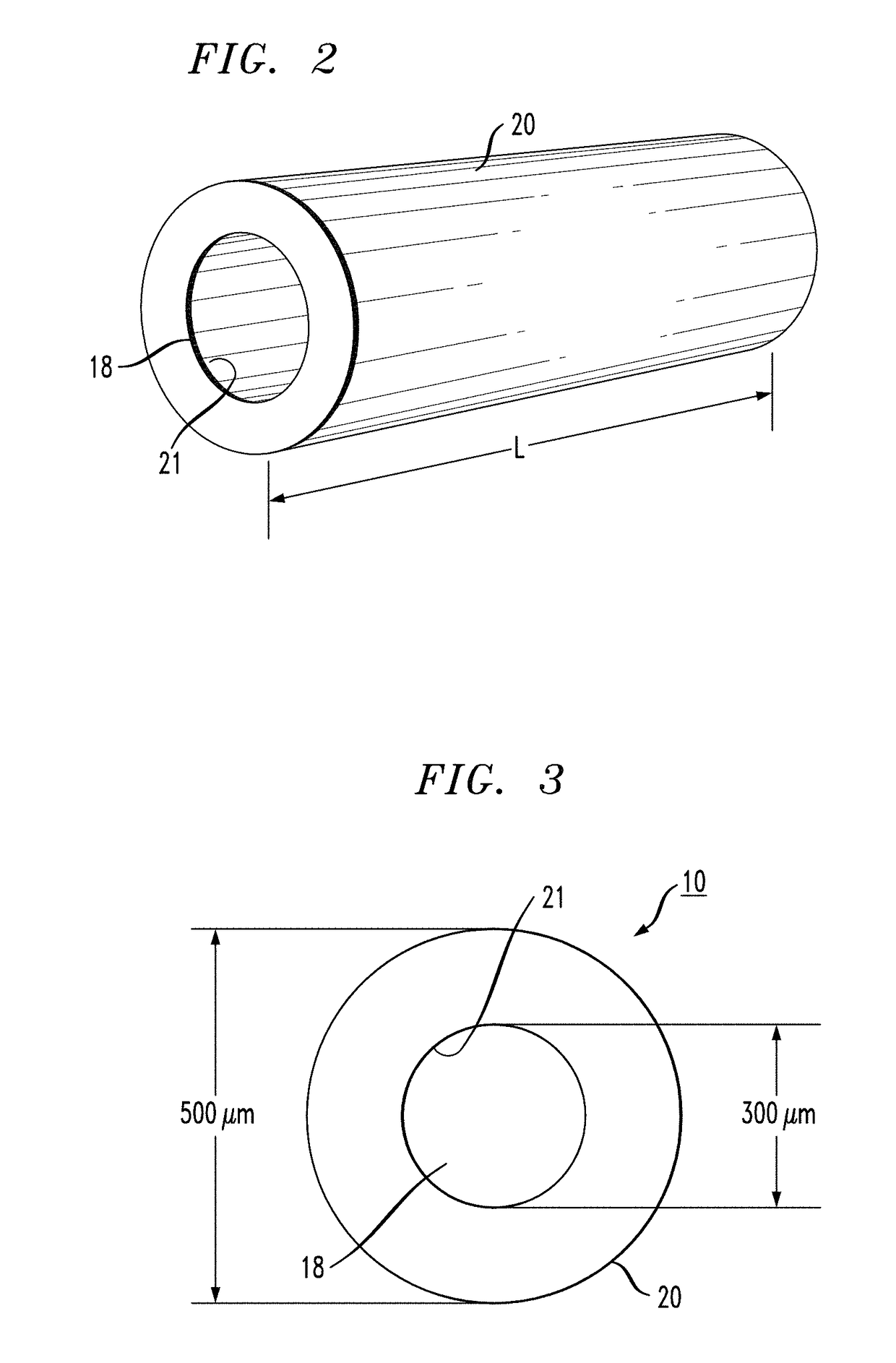

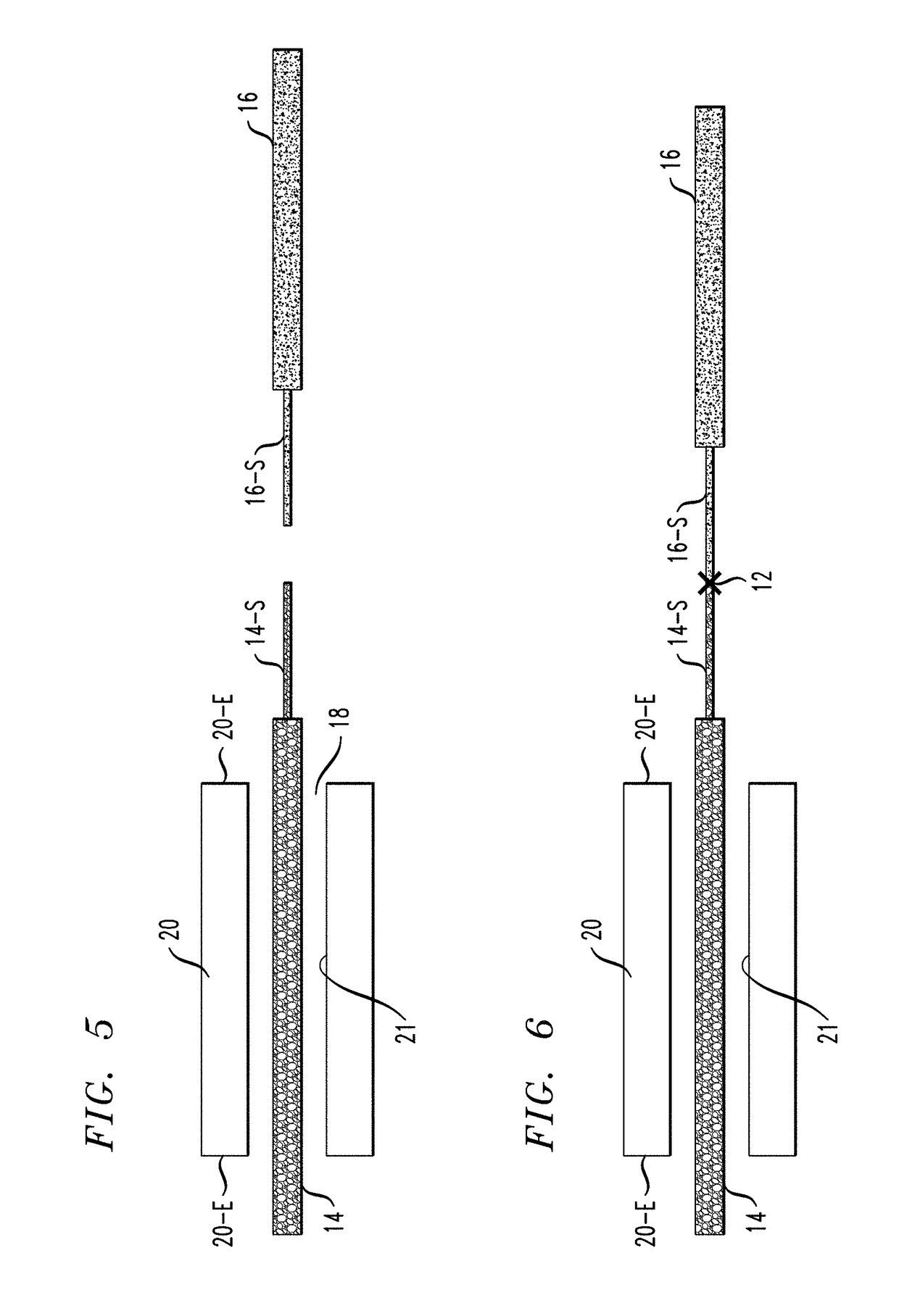

Micro splice protector

A micro splice protector for a fusion connection between a pair of optical fibers takes the form of a cylindrical sleeve of dimensions similar to that of the fusion splice itself, with an epoxy material used to encase the fusion splice within the sleeve. The sleeve is formed to exhibit an inner diameter only slightly greater than the outer diameter of the optical fibers, with the length of the sleeve typically formed to be only slightly longer than the stripped end terminations of the pair of fibers being spliced together. The cylindrical sleeve is formed of a rigid, but lightweight, material (e.g., stainless steel, fused silica) and an epoxy material is injected into the configuration to fill any gaps between the fusion connection and the inner surface of the sleeve. The result is relatively stiff fusion splice protector that is extremely small in size and well-suited for use in optical component packages where space is at a minimum.

Owner:II VI DELAWARE INC

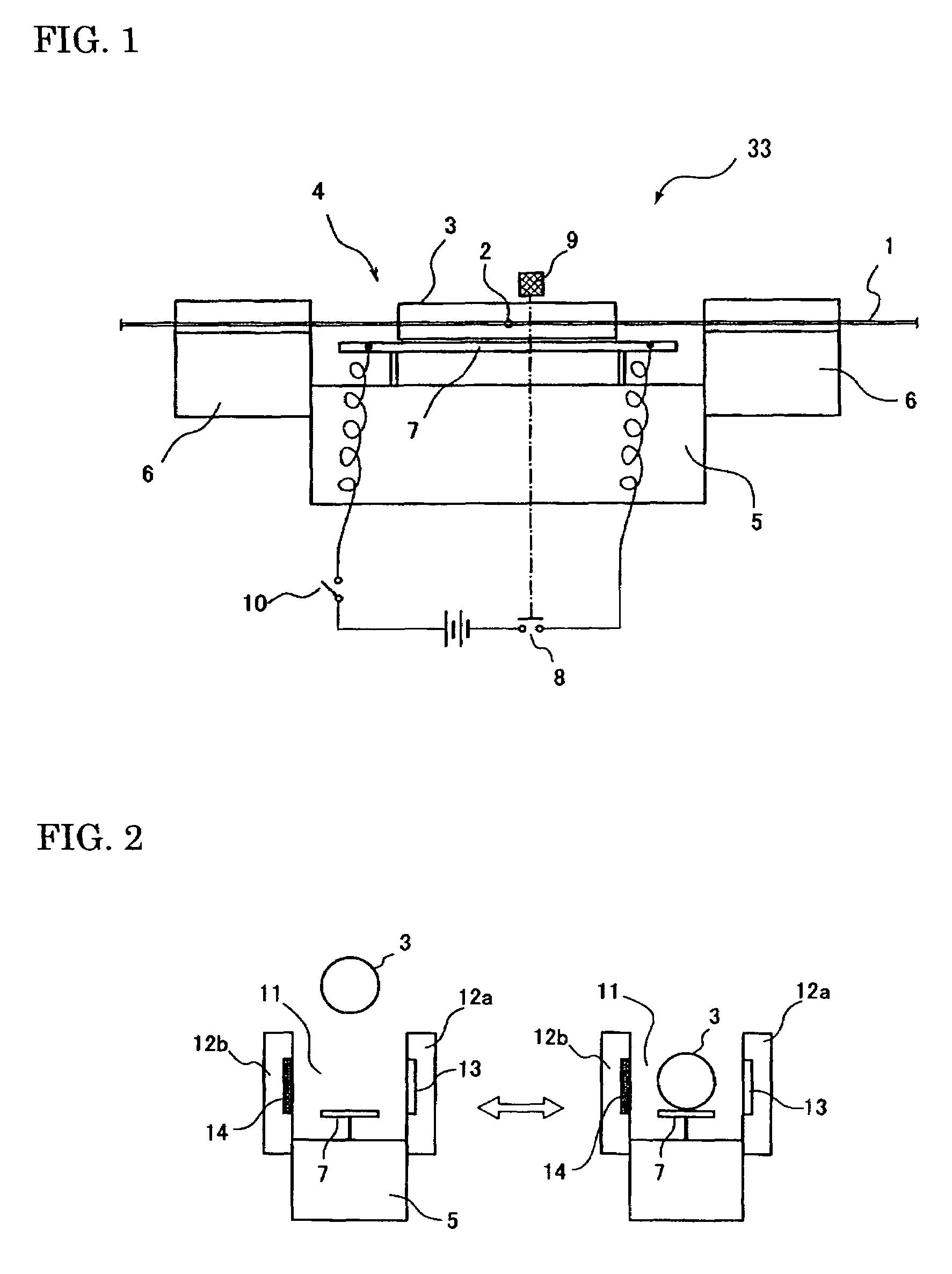

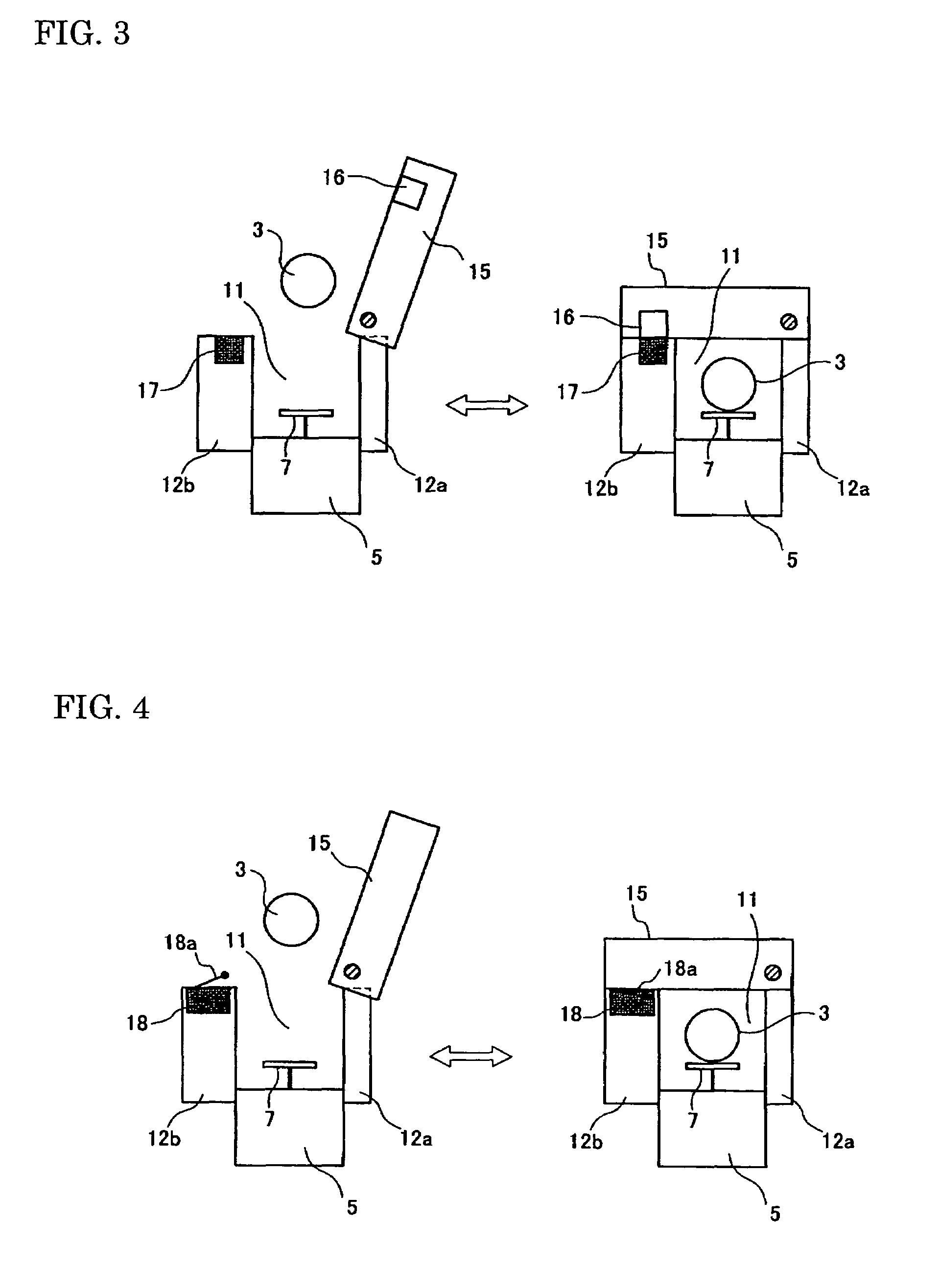

Splice protection heater, fusion splicer including the splice protection heater, and fusion splicing method

ActiveUS7412146B2Efficient executionPerformed quickly and efficientlyCoupling light guidesHeating timeEngineering

A splice protection heater capable of quickly and efficiently performing a fusion process without an excessive heating time, a fusion splicer including the splice protection heater, and a fusion splicing method are provided. The apparatus has a heating part for heat shrinking a protection sleeve that covers a fusion spliced portion of an optical fiber, a plurality of heating elements that can individually heat a plurality of protection sleeves with different timings by being individually turned ON / OFF by switches, or a heating element turned ON / OFF by a switch. This apparatus may also be provided with detecting section that detects whether or not the protection sleeve is set on the heating element, and turns the switch ON / OFF.

Owner:SUMITOMO ELECTRIC IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com