Car steel-aluminum splicing joint welding method and system

A welding system and vehicle-used technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of easy occurrence of brittle intermetallic compounds, low joint strength, small bonding interface, etc., to improve steel- Aluminum dissimilar metal connection strength, improved connection strength, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

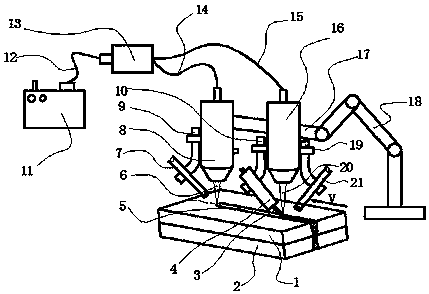

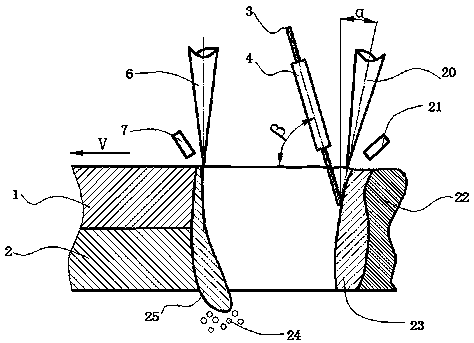

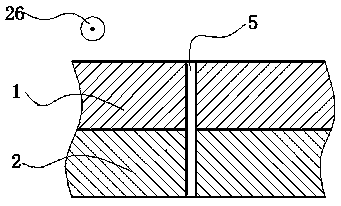

[0040] The following will be combined with Figure 1-5 The technical solution of the present invention will be described in detail along with specific embodiments.

[0041] This embodiment provides a laser welding method for a steel-aluminum lapped joint for vehicles, the steps of which include:

[0042] Step 1. Provide a first workpiece 1 and a second workpiece 2 that require lap welding. The first workpiece 1 and the second workpiece 2 are steel plates for vehicles and aluminum alloy plates respectively, and can be prepared and formed by mechanical processing. In this embodiment, the thickness of the first workpiece 1 and the second workpiece 2 is 0.8-3 mm.

[0043] Step 2. Remove impurities on the upper and lower surfaces of the first workpiece 1 and the second workpiece 2, and use a welding fixture to accurately stack and clamp the first workpiece 1 and the second workpiece 2 vertically up and down, so that the first workpiece 1 and the second workpiece 2 Closely fit under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com