Patents

Literature

203 results about "High energy laser beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for repairing defect in tungsten copper-copper integral electric contact material

InactiveCN101635210AImprove mechanical propertiesLow costElectric switchesHigh energy laser beamVolumetric Mass Density

The invention provides a method for repairing a defect in a tungsten copper-copper integral electric contact material. The method comprises the following steps: firstly, eliminating impurities in the part of the defect; secondly, weighting metal powders containing the materials identical to that of the electric contact in the part of the defect, wherein the mass of the metal powders is 1.2 times the product of the volume of part of the defect and the density of the electric contact material in the part of the defect; thirdly, uniformly mixing the weighed metal powders with a glycerin solution to produce a filling material, and then coating the filling material in the part of the defect in the electric contact part; after the part of the defect is filled up with the filling material, in the circumstance of taking nitrogen as a protective atmosphere, scanning and remelting the filling material in the part of the defect with a high-energy laser beam; in the remelting process, complementing the filling material in the part of the defect blown away due to spraying nitrogen is replaced at the same time, and melting the refilled filling material with a parent material until the part of the defect is full and slightly convex; and finally, grinding and polishing the repaired electric contact part. The method is easy to operate, the product rate is high and the repaired product has stable performance and high quality.

Owner:NANTONG YONGDA PIPE IND

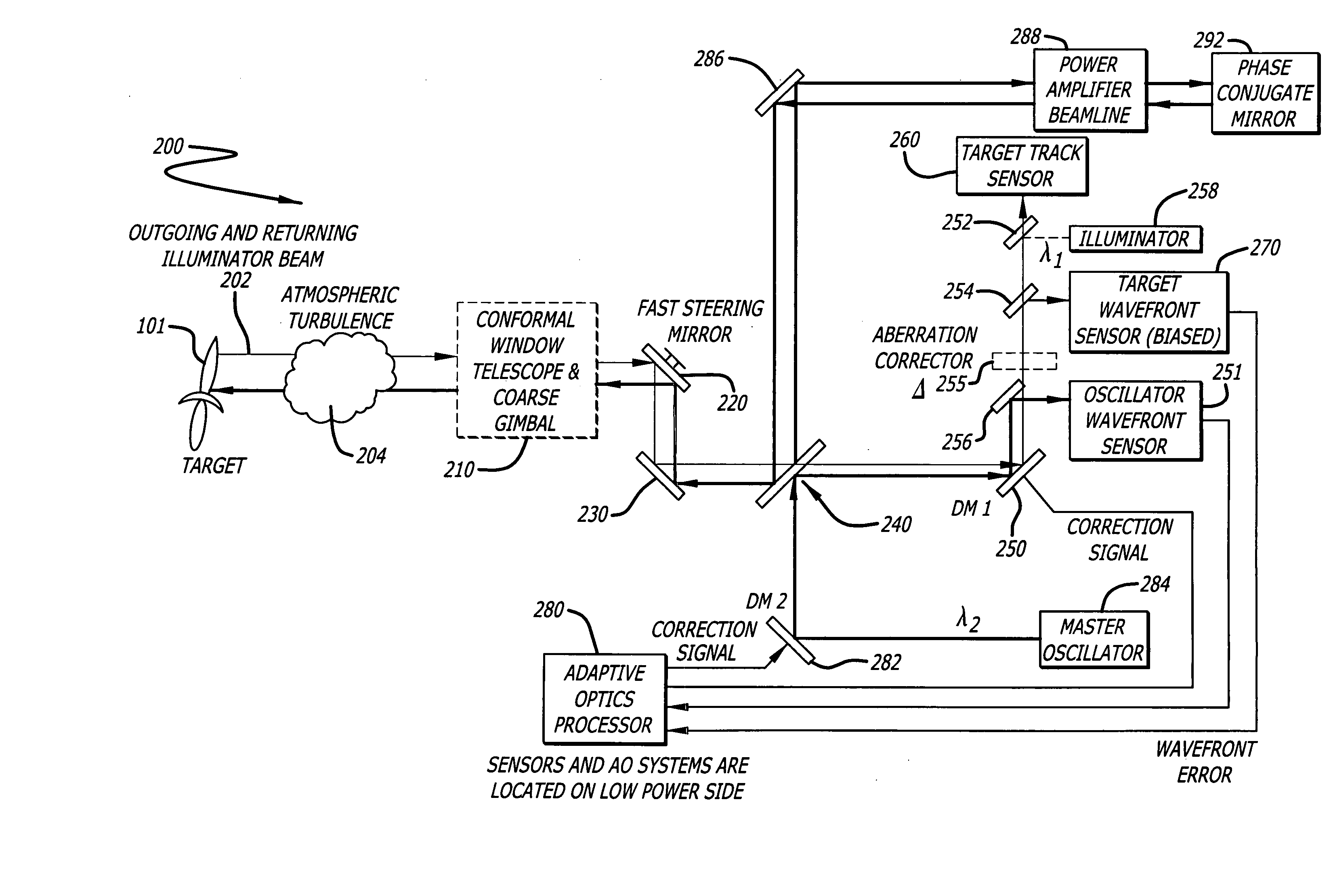

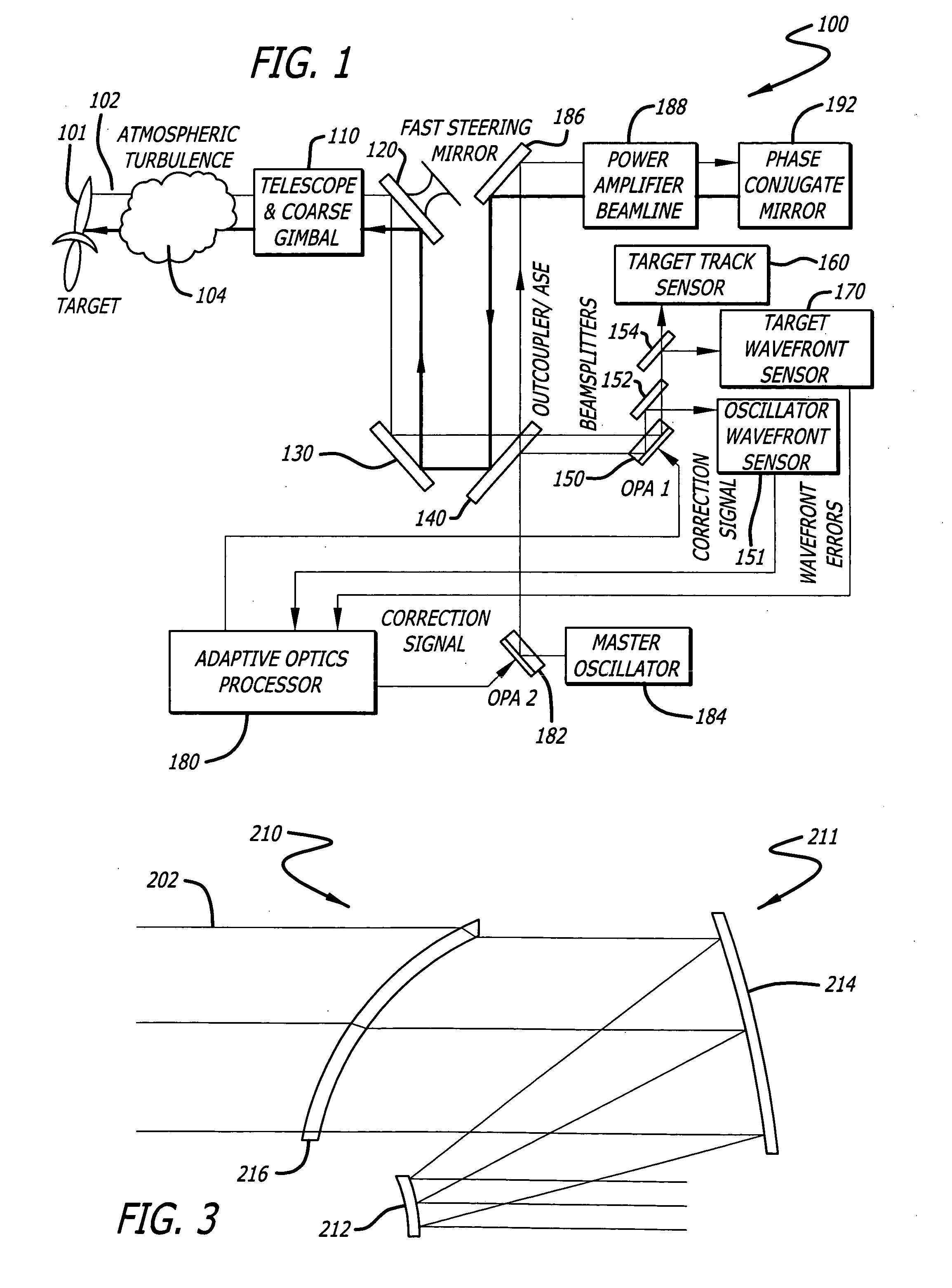

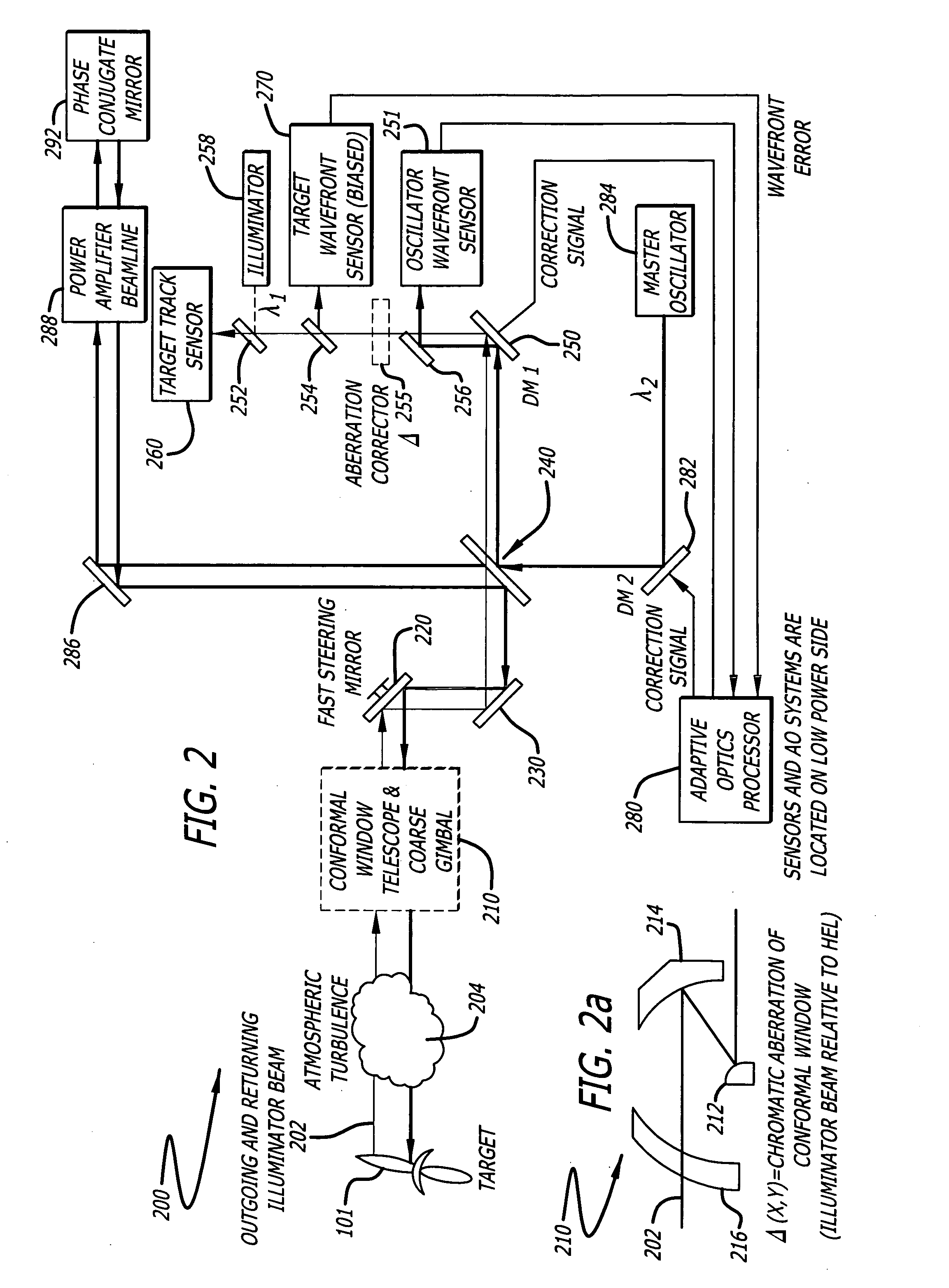

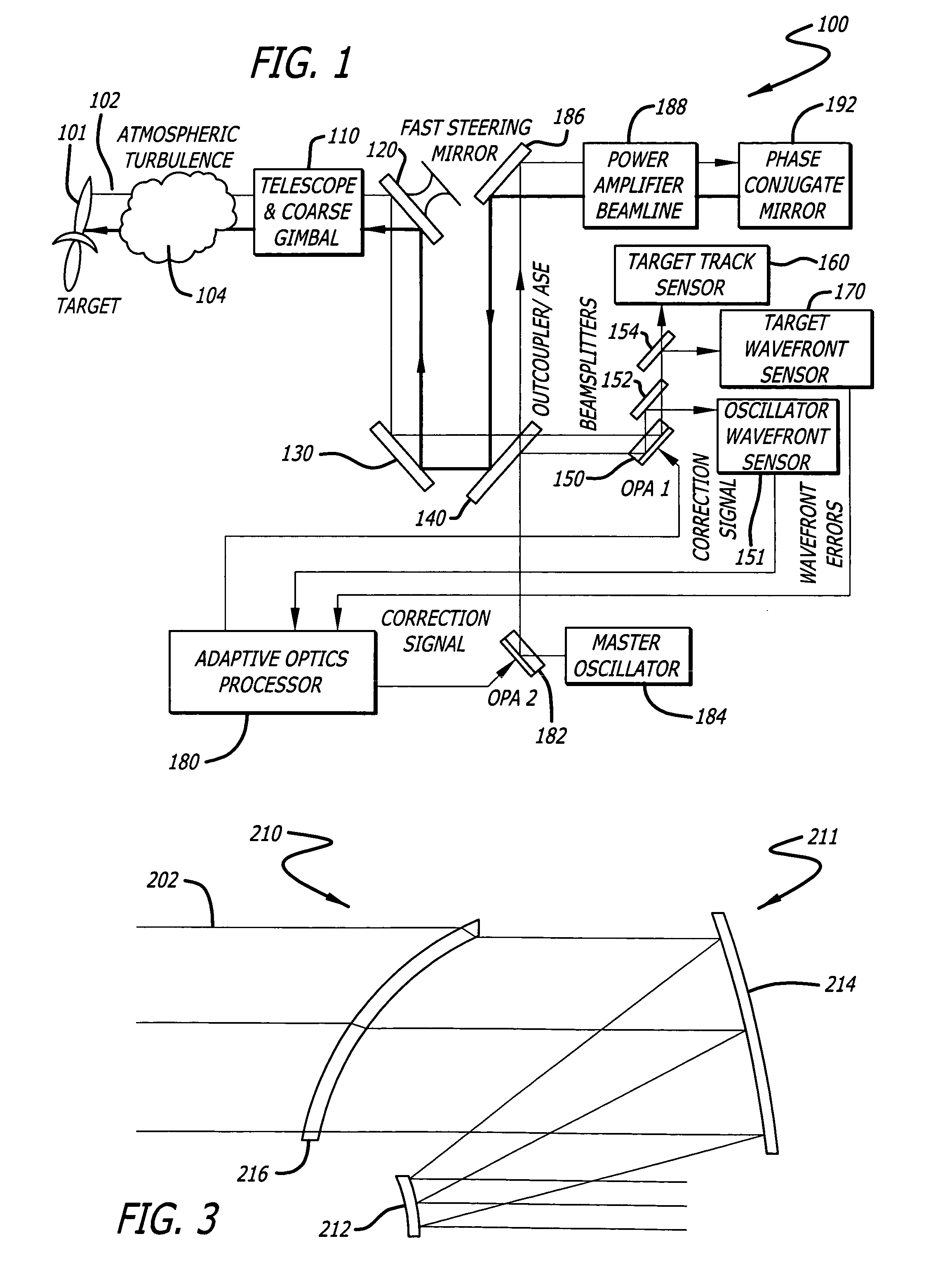

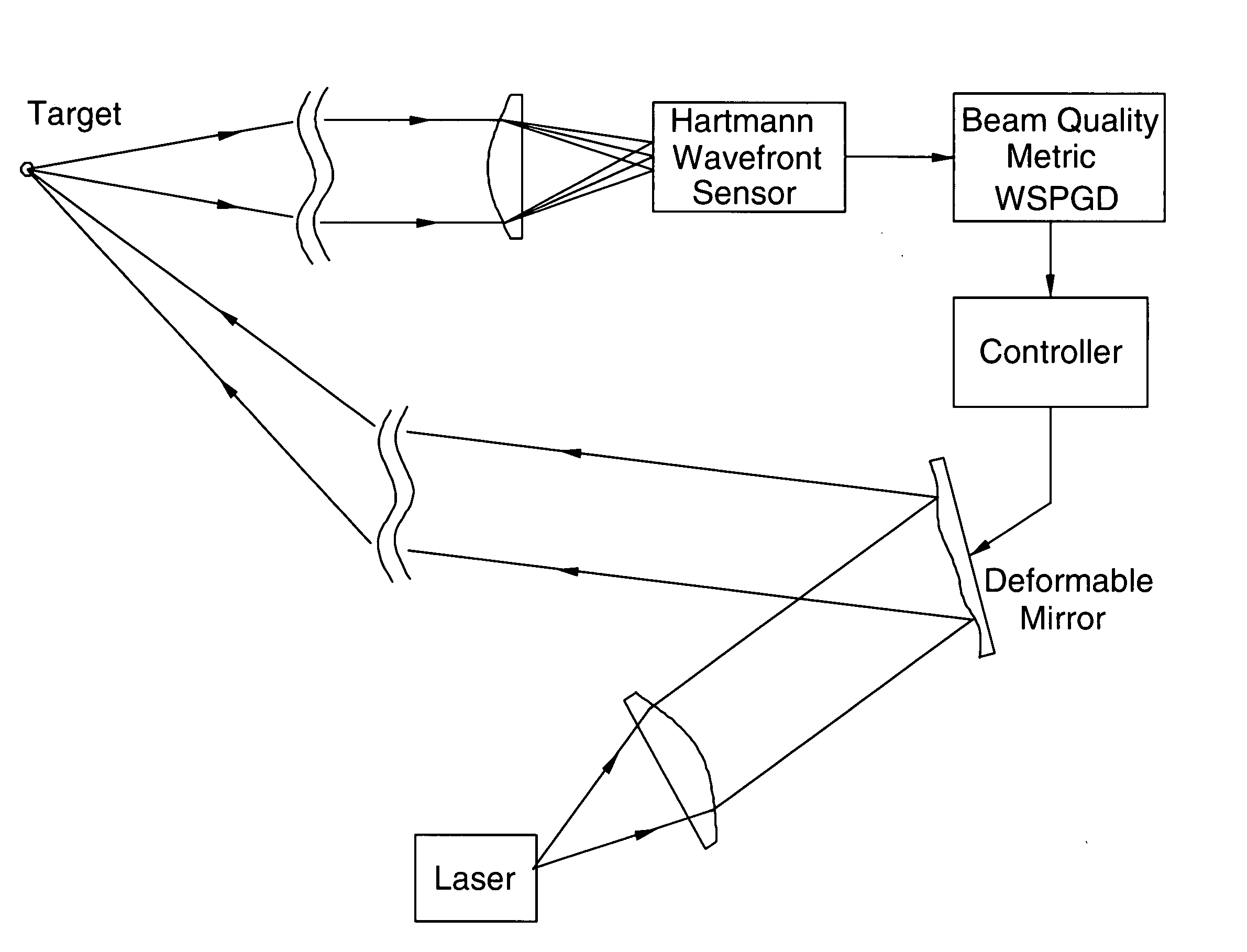

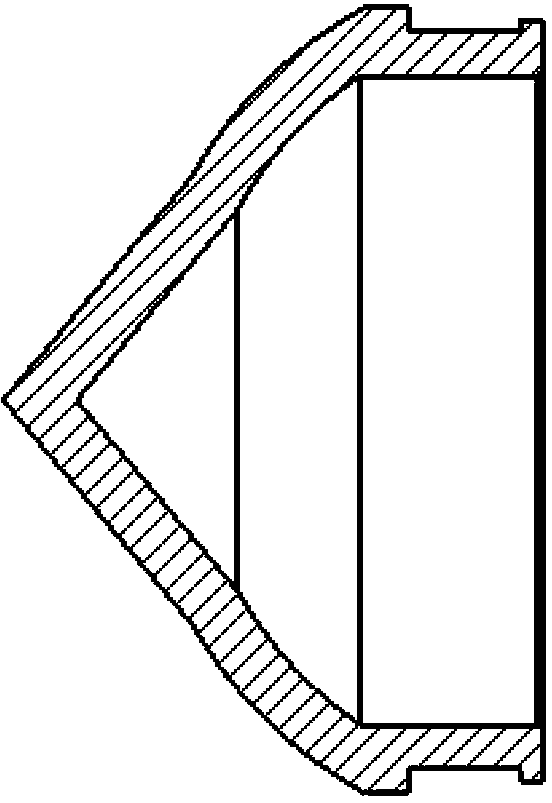

Beam director and control system for a high energy laser within a conformal window

ActiveUS20080042042A1Photometry using reference valueMaterial analysis by optical meansCorrection algorithmWavefront sensor

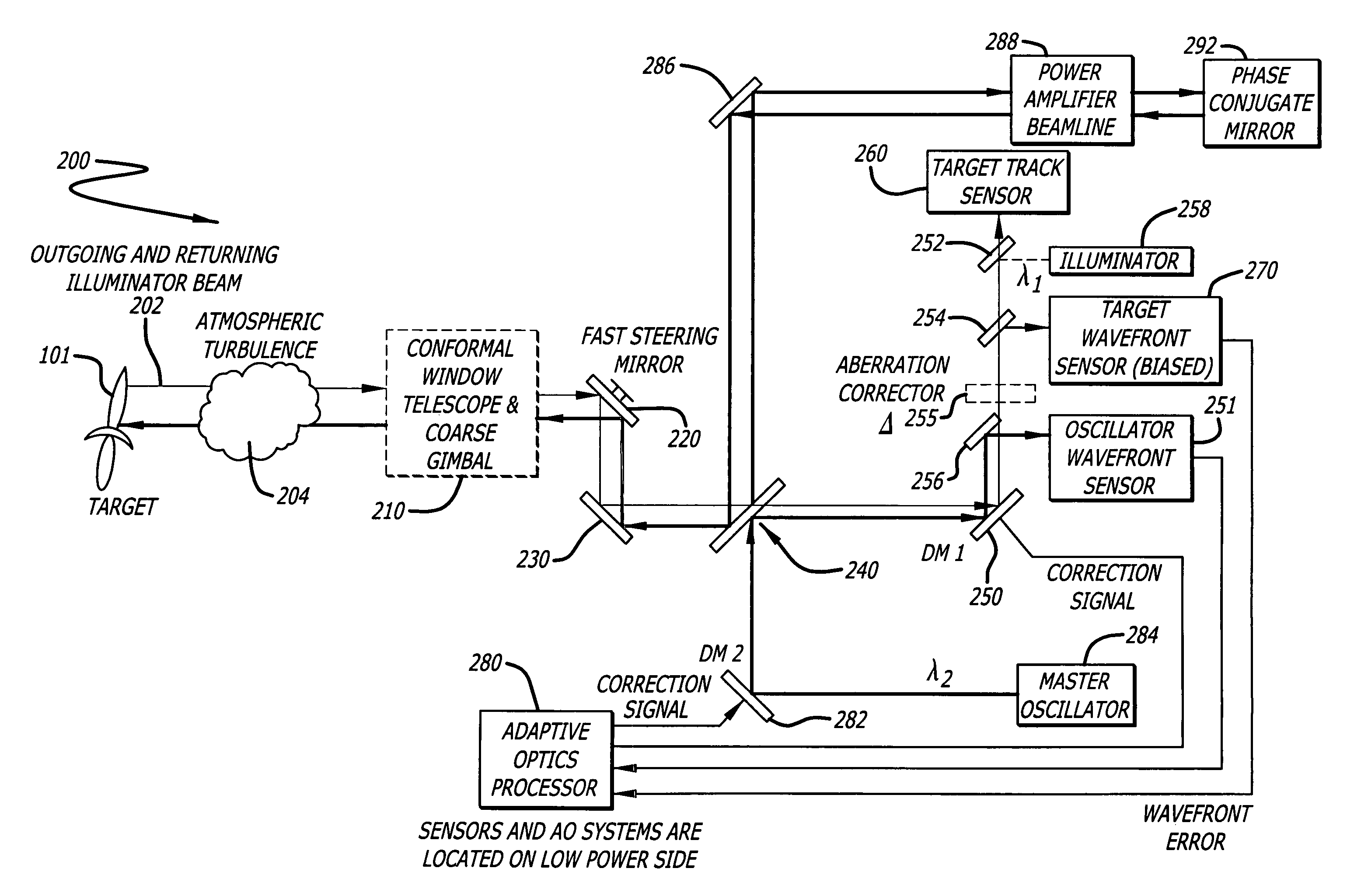

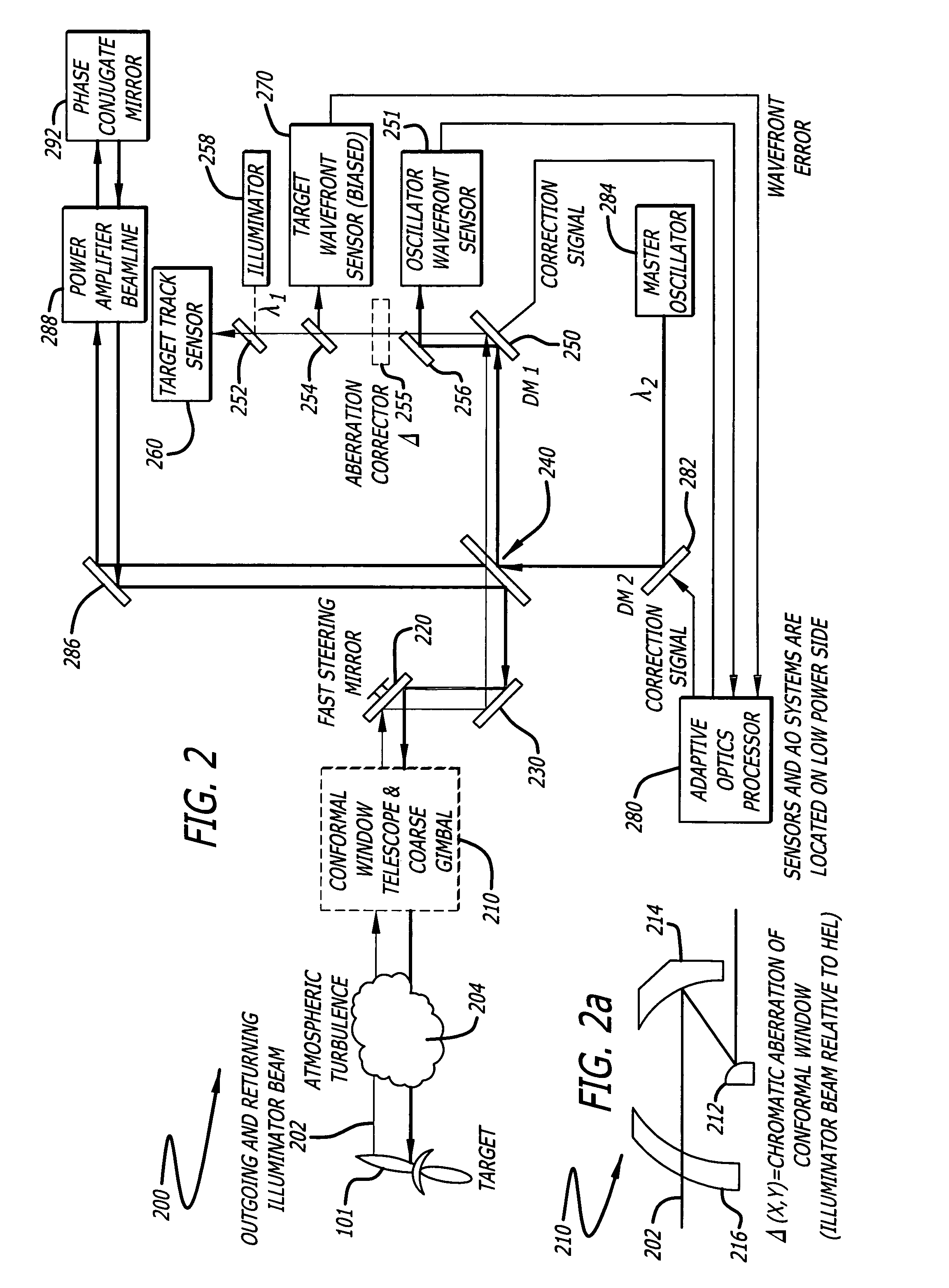

A beam control system and method. The system includes an illuminator for providing a first beam of electromagnetic energy at a first wavelength; a source for providing a second beam of electromagnetic energy at a second wavelength; and an arrangement for compensating wavefront errors in the second beam using a bias representative of a comparison between the first wavelength and the second wavelength. In the illustrative embodiment, the arrangement includes a processor which corrects wavefront errors using a bias representative of a difference between said first wavelength and said second wavelength. In the disclosed application, a target wavefront sensor is included and the laser is a high-energy laser beam. The wavefront errors include a chromatic aberration and the errors are compensated using a deformable mirror and a correction algorithm executed by an adaptive optics processor. In one alternative embodiment, the errors are compensated using an optical aberration corrector. The aberration corrector may be a holographic optical element or other suitable device. In another alternative embodiment, the errors are corrected with the above embodiment in combination with the use of “woofer” and “tweeter” correcting elements with the woofer being a long stroke low frequency element and the tweeter being a short stroke high frequency element.

Owner:RAYTHEON CO

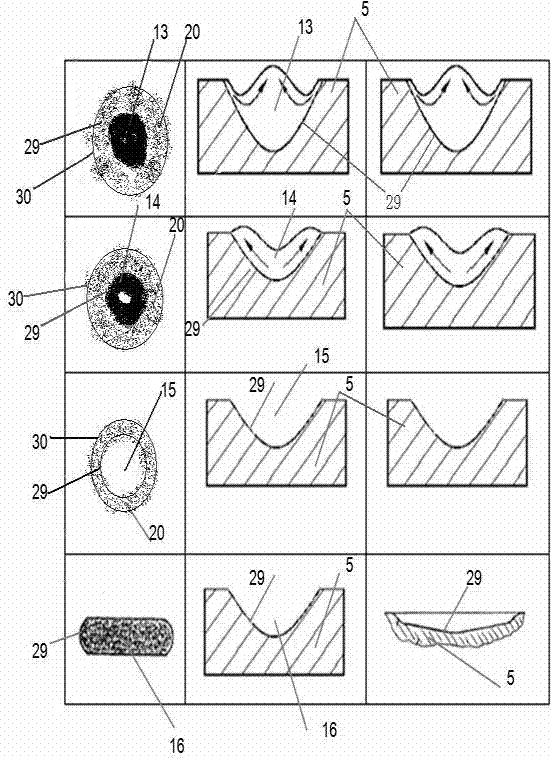

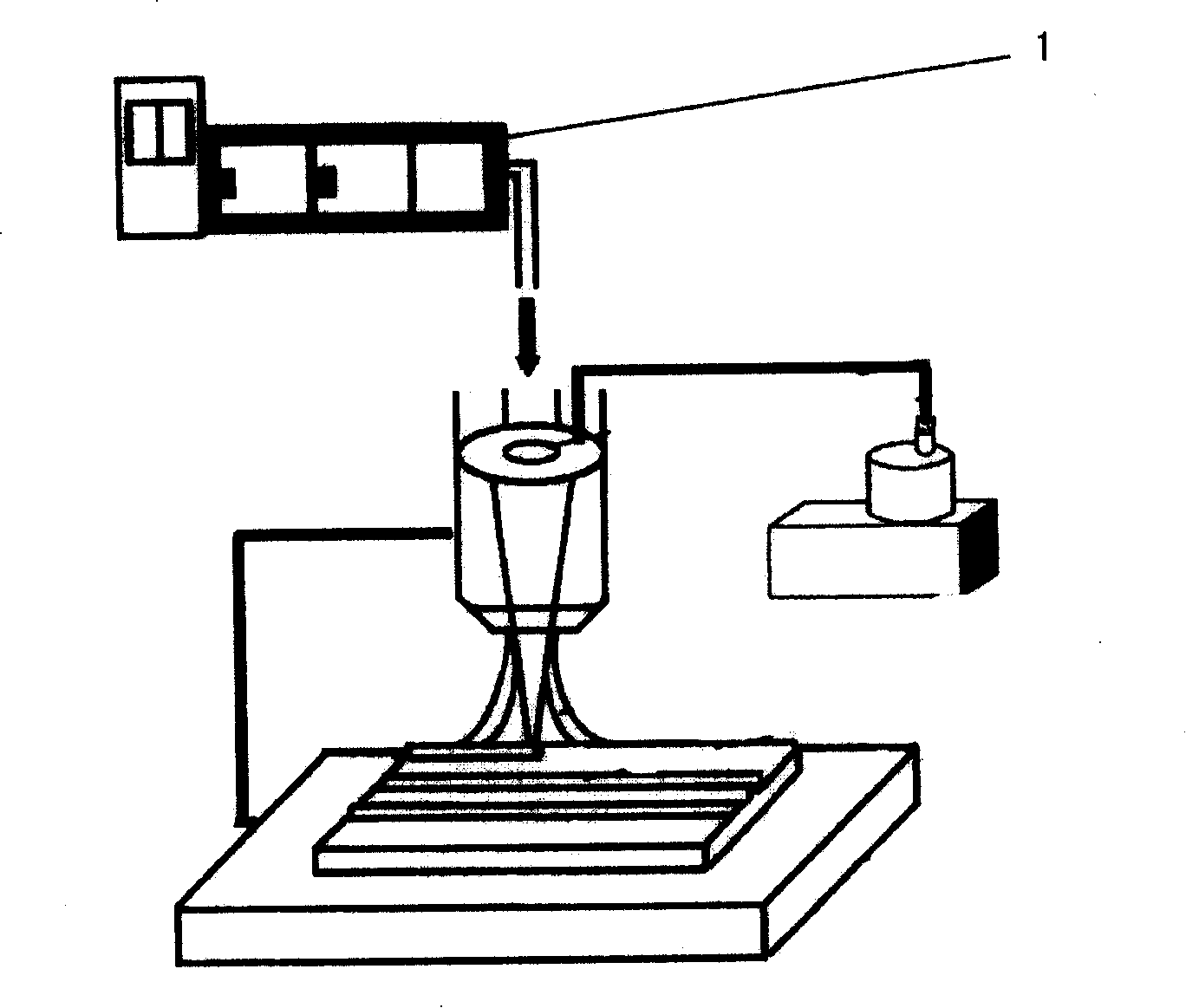

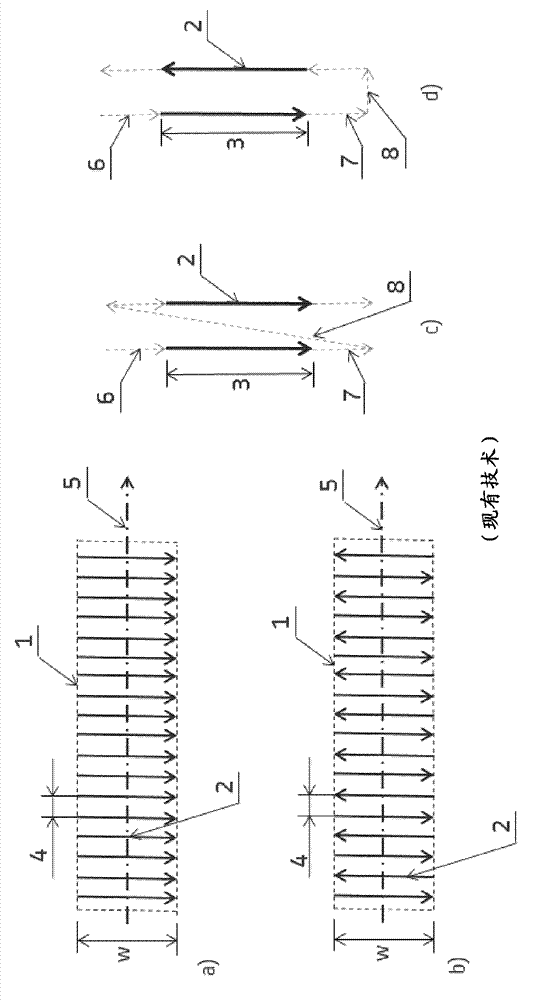

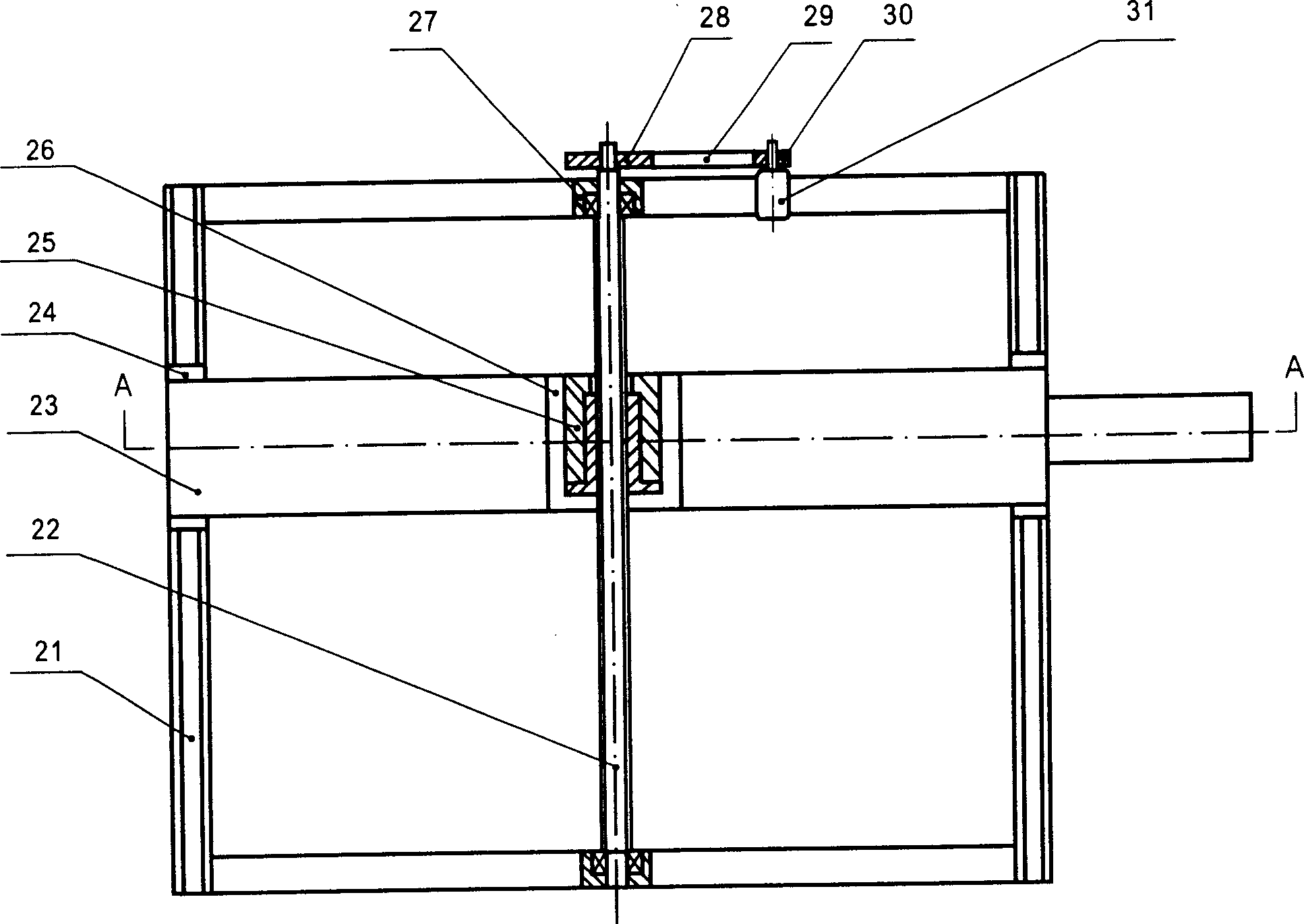

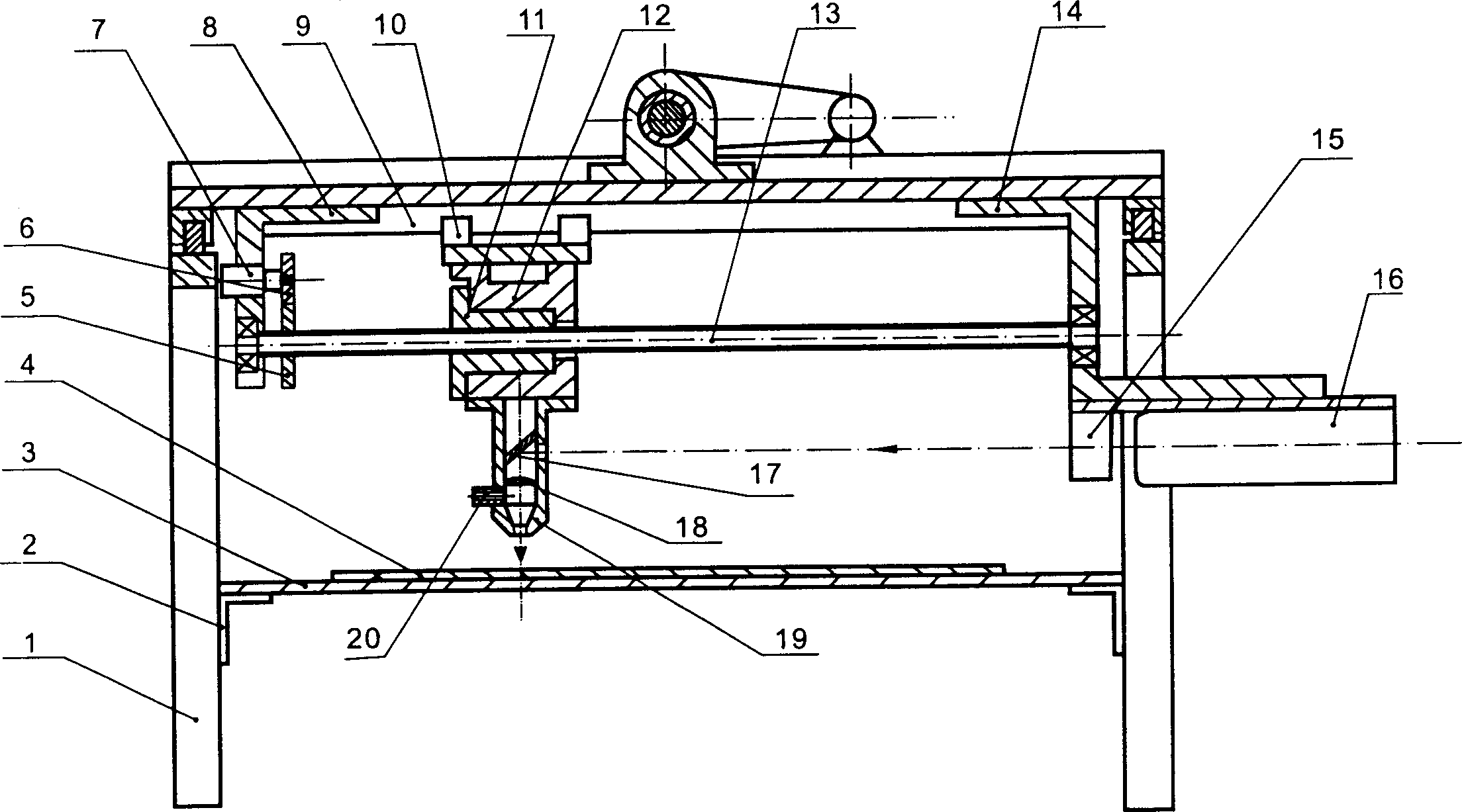

Compound model processing method and device for cutter

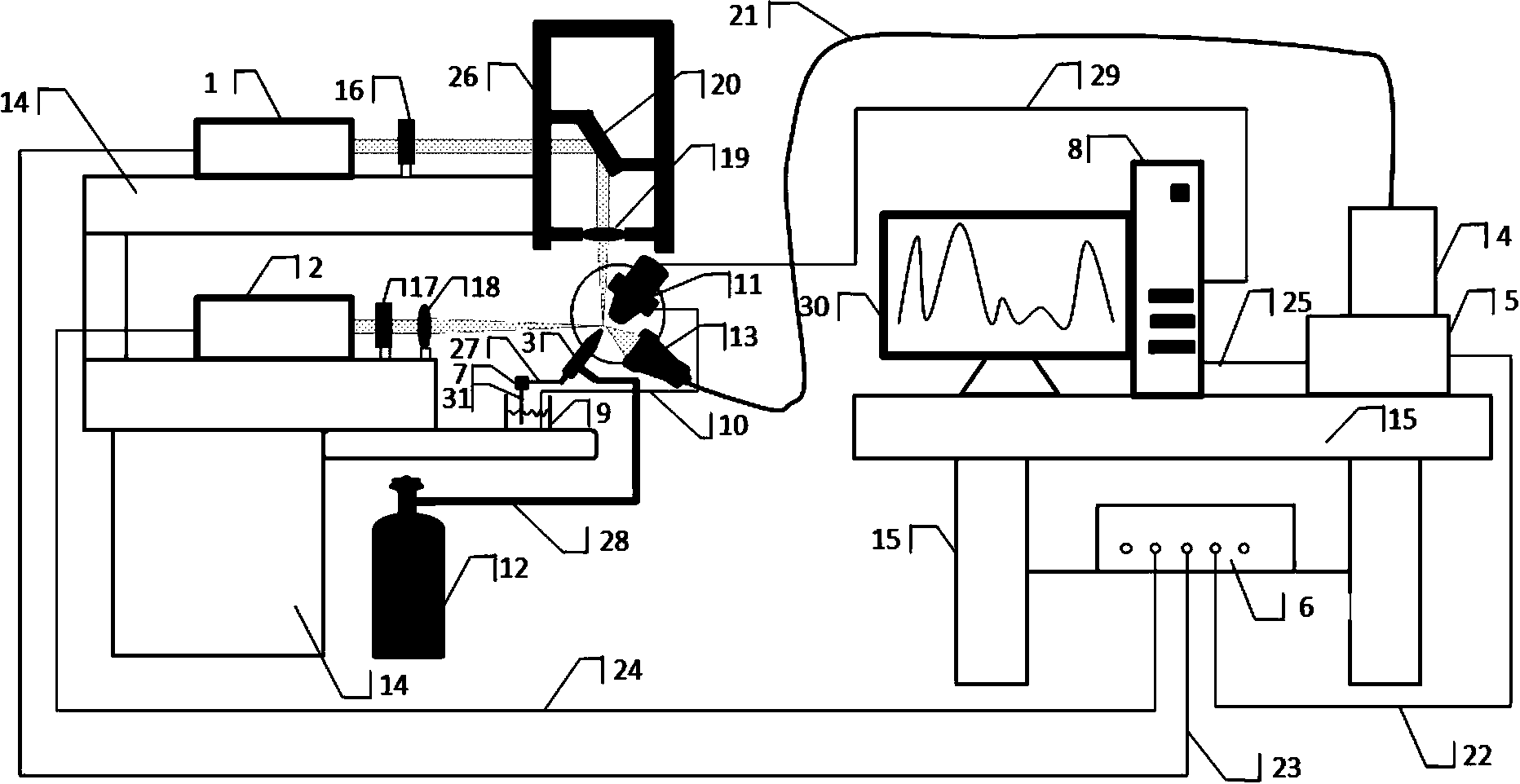

ActiveCN102962656AReduce wearImprove performanceMeasurement/indication equipmentsLaser beam welding apparatusNumerical controlHigh energy

The invention provides a compound model processing method and device for a cutter, relating to the active processing of microtexture compound morphologies on the main friction and abrasion surfaces of the cutter, and belonging to the field of machinery manufacture. Three microstructural models, namely micro concave cavities, fused bulges and micro grooves respectively, are processed at the main friction and abrasion parts of the cutter through high energy laser beams or high energy electron beams. With the adoption of the compound model processing method and device for the cutter, the continuous service life of the cutter is prolonged, the cutting quality of the cutter is improved, the surface quality and the cutting and cooling performances after the processing of a workpiece are improved, and the machining cost of metal cutting is lowered. The invention also discloses the processing device for applying the compound mould processing method; and the device is integrated with a high energy technique and a numerical control technique, so that predetermined compound microstructural morphologies and distributions thereof can be processed on the main cutting working face of the cutter efficiently and stably. Processing objects for the method and the device thereof provided by the invention are various cutters during the cutting processing.

Owner:JIANGSU UNIV

Beam director and control system for a high energy laser within a conformal window

ActiveUS7626152B2Photometry using reference valueMaterial analysis by optical meansCorrection algorithmWavefront sensor

Owner:RAYTHEON CO

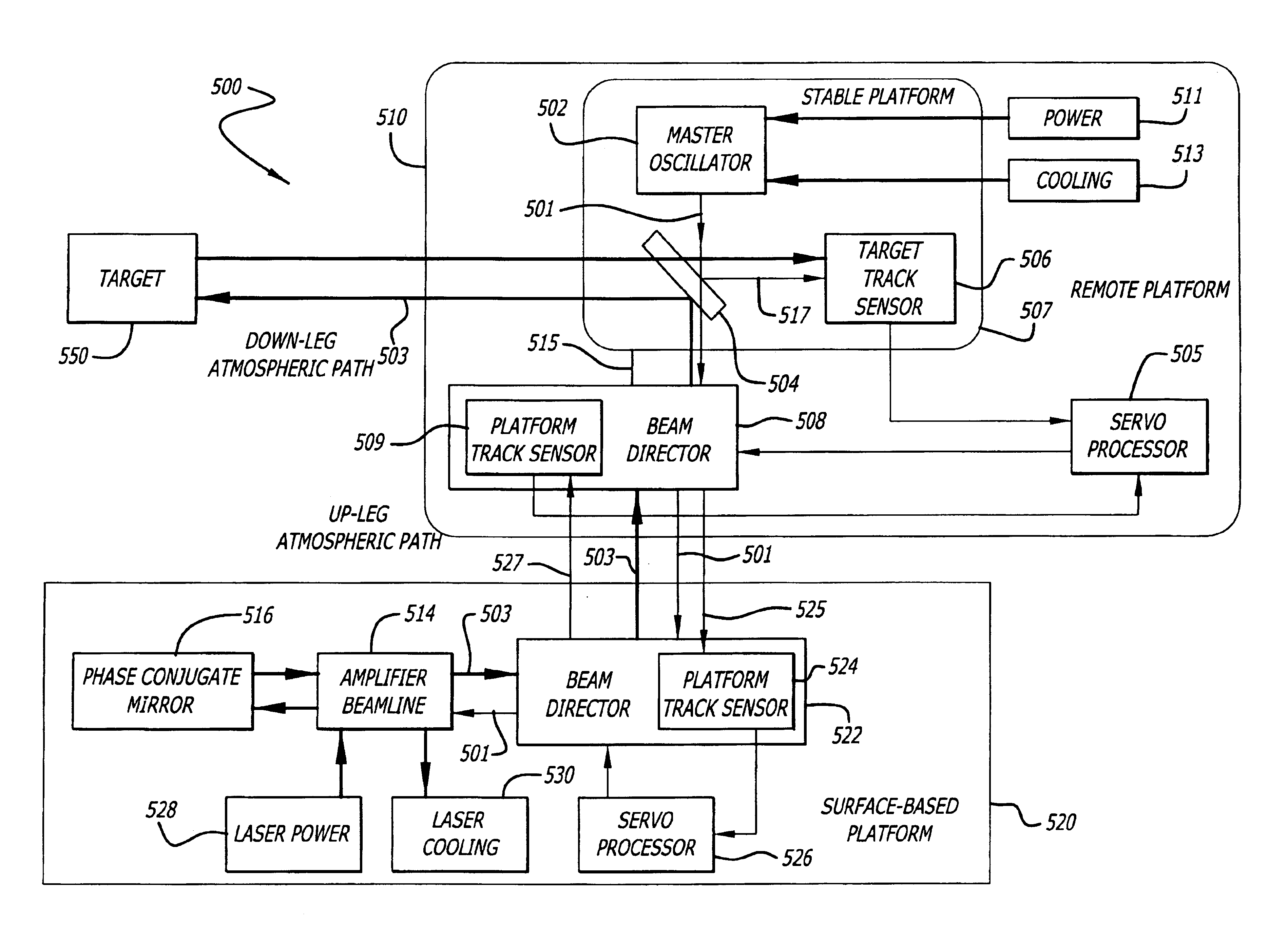

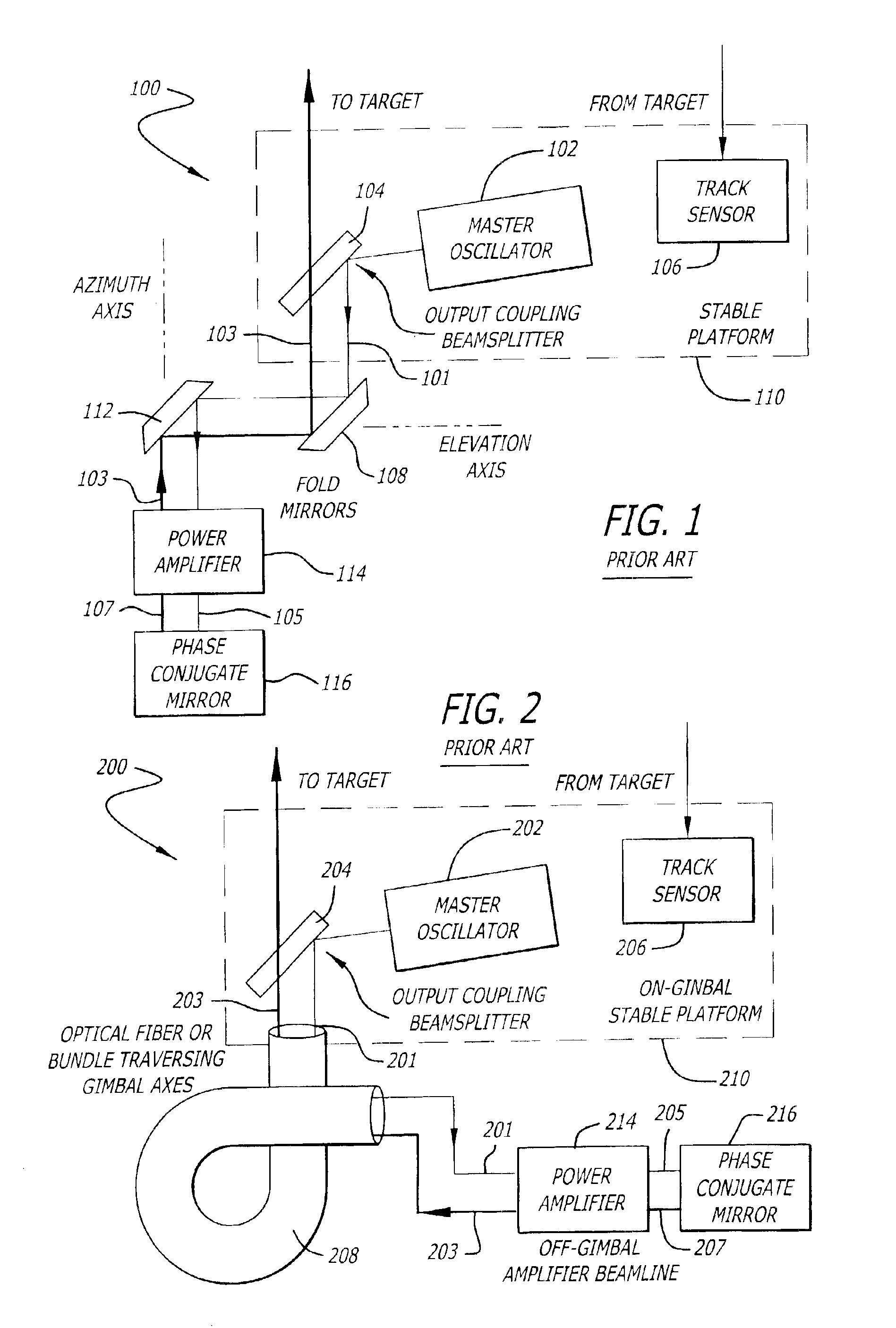

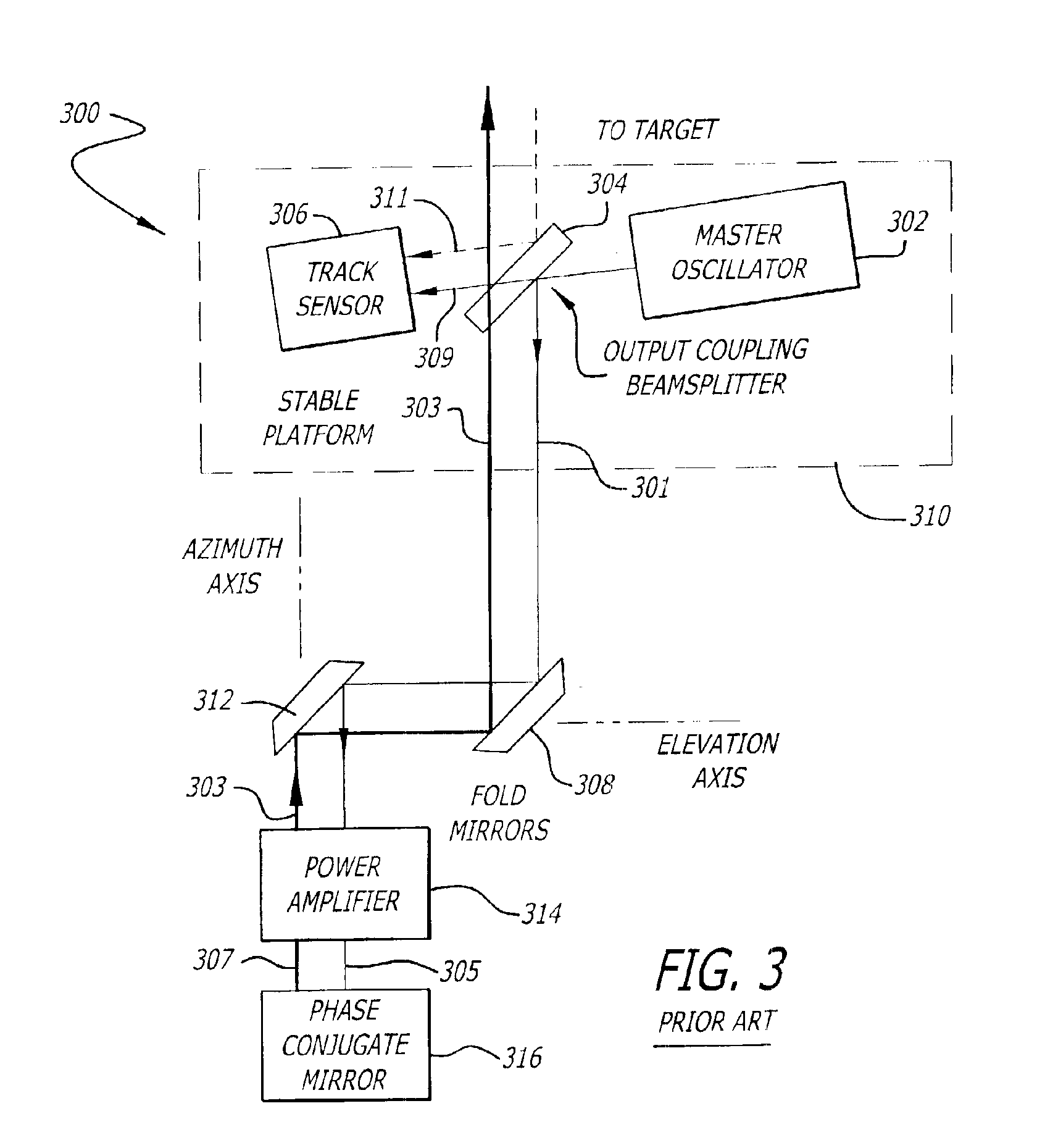

Phase conjugate relay mirror apparatus for high energy laser system and method

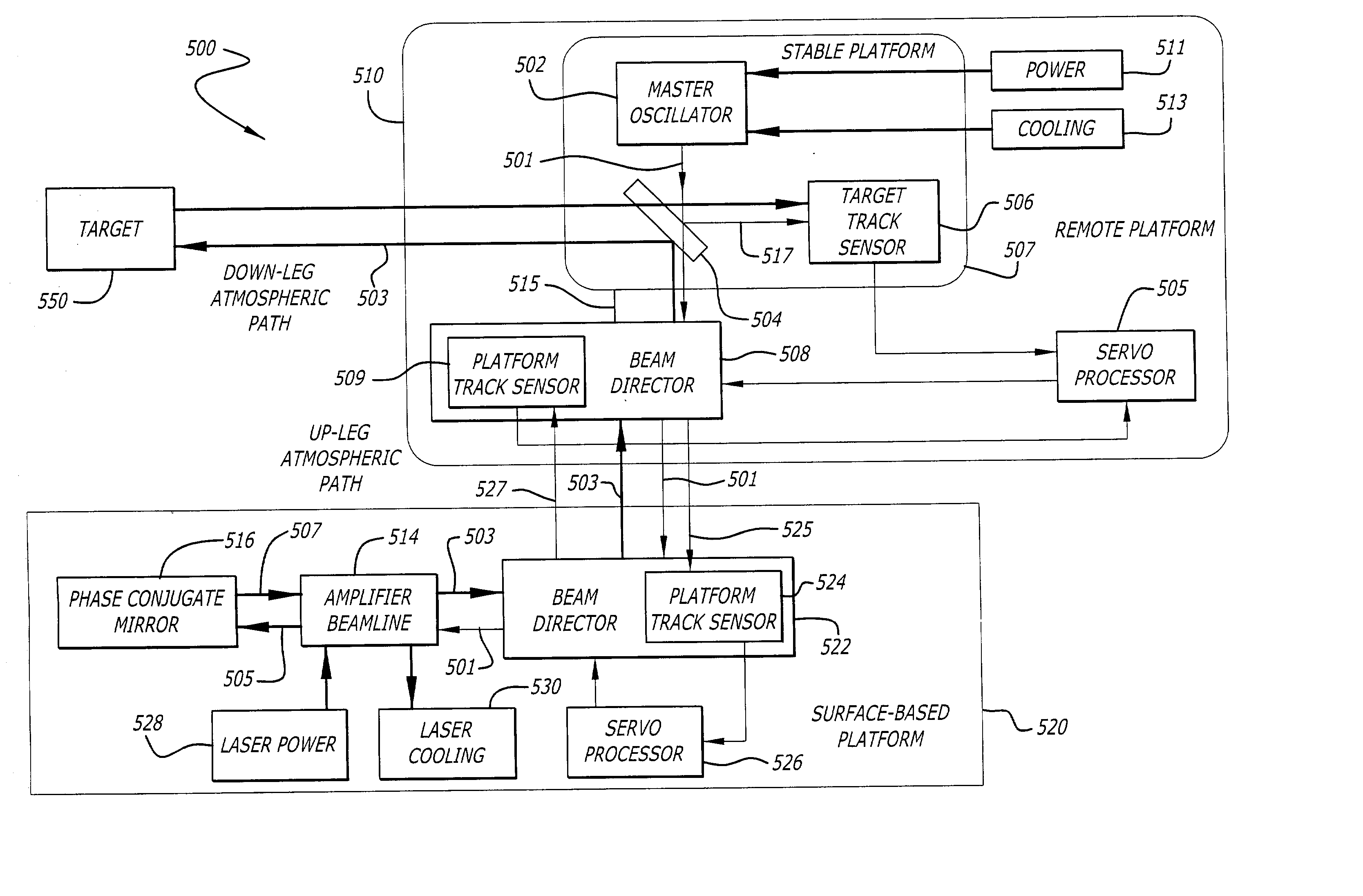

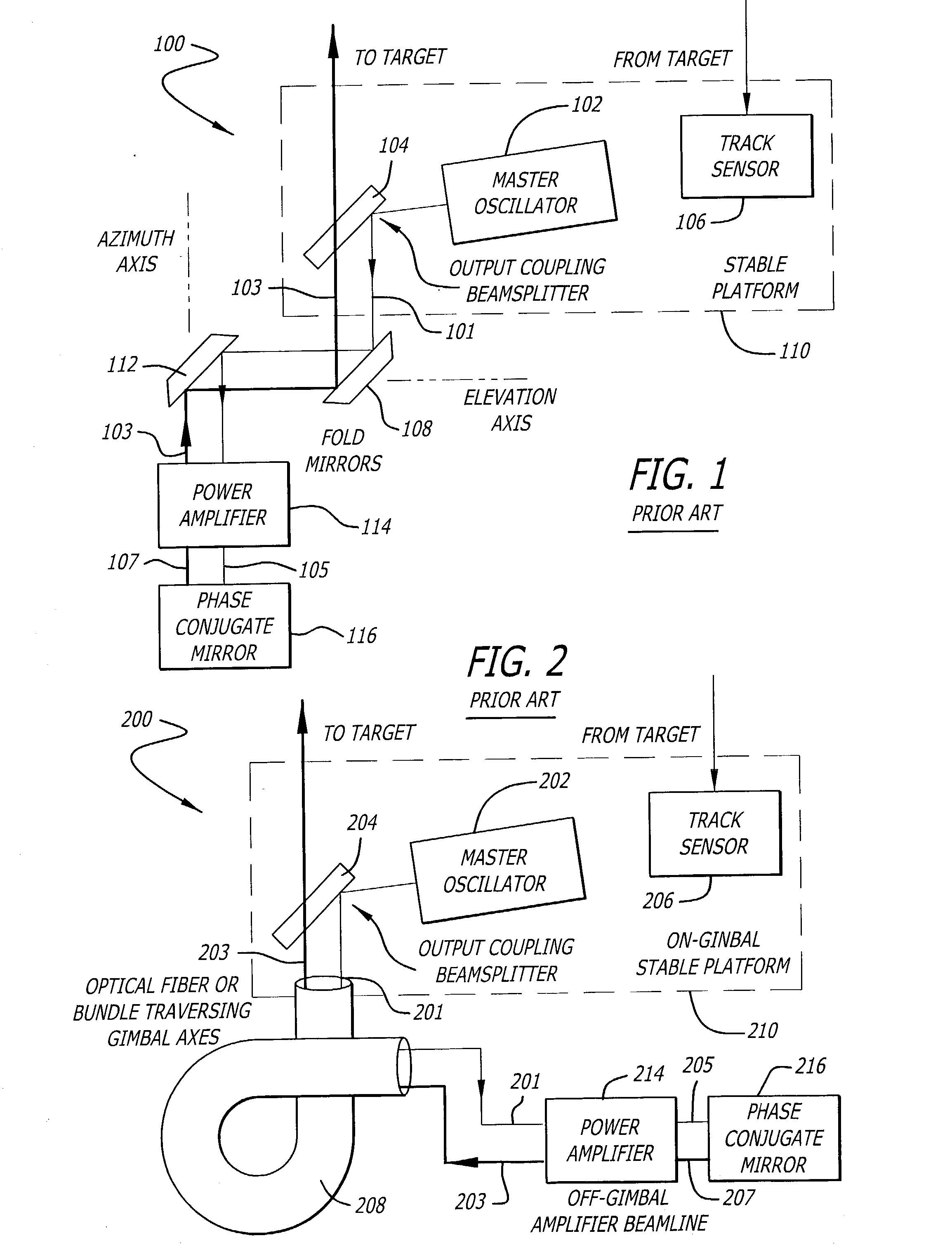

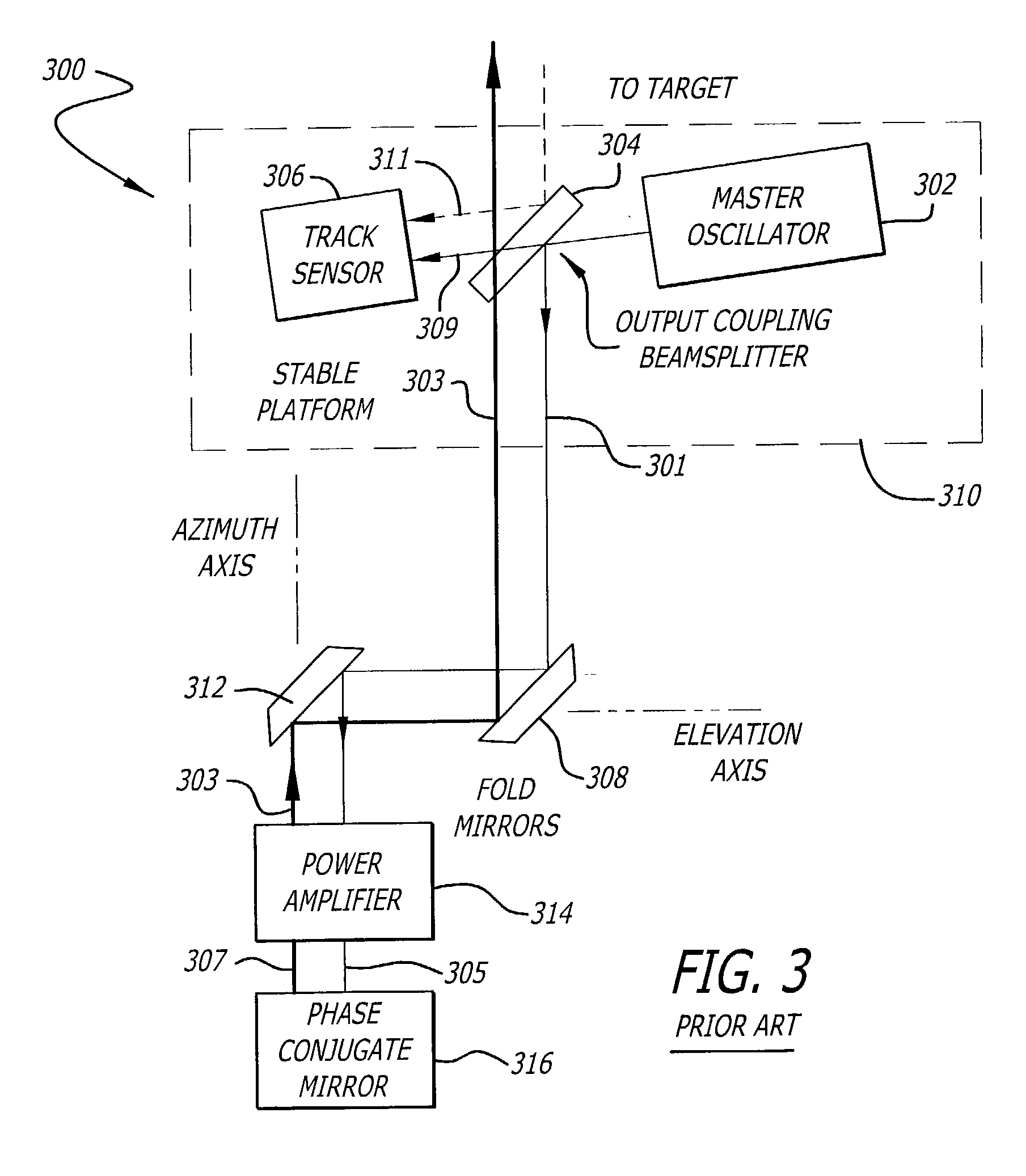

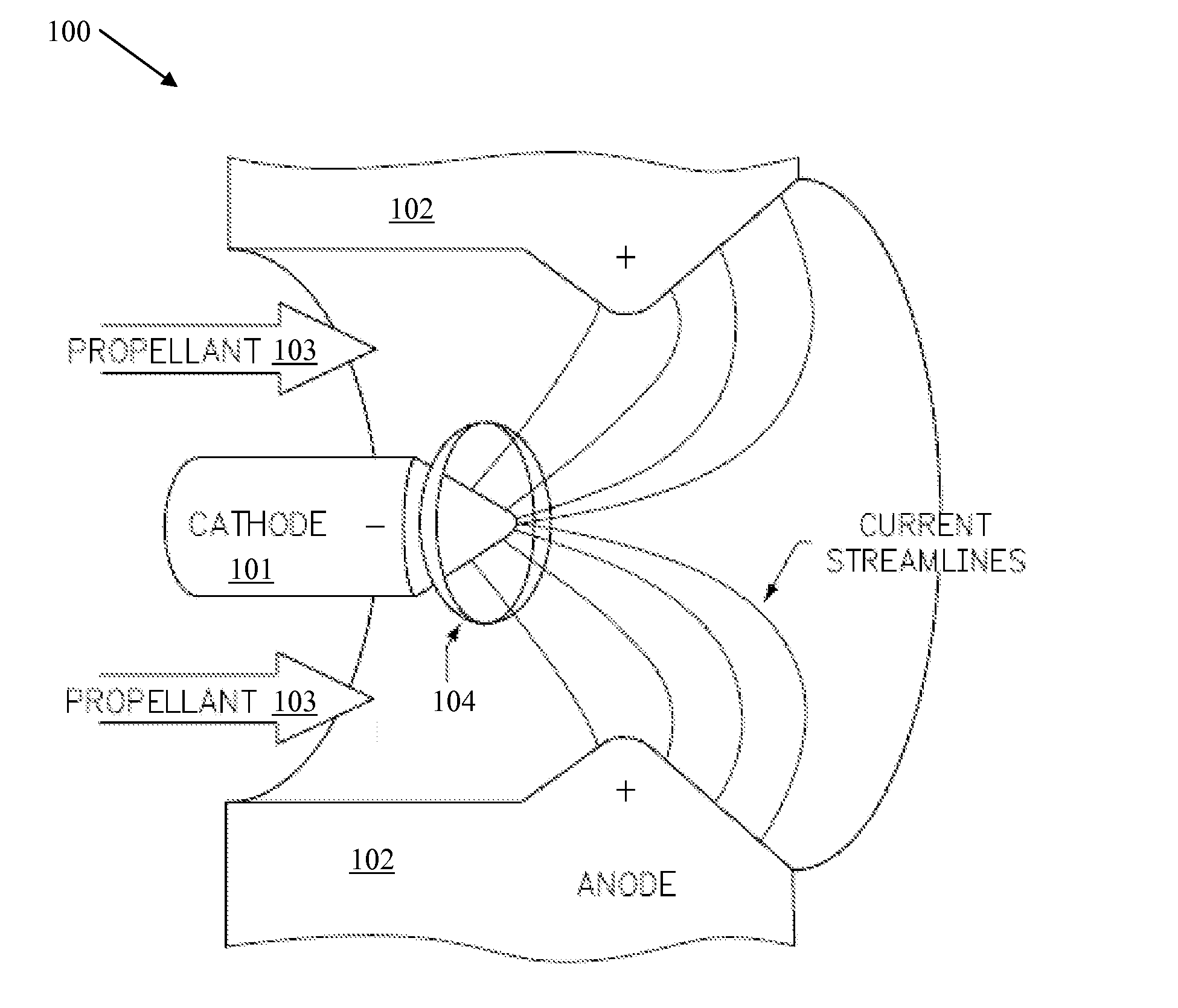

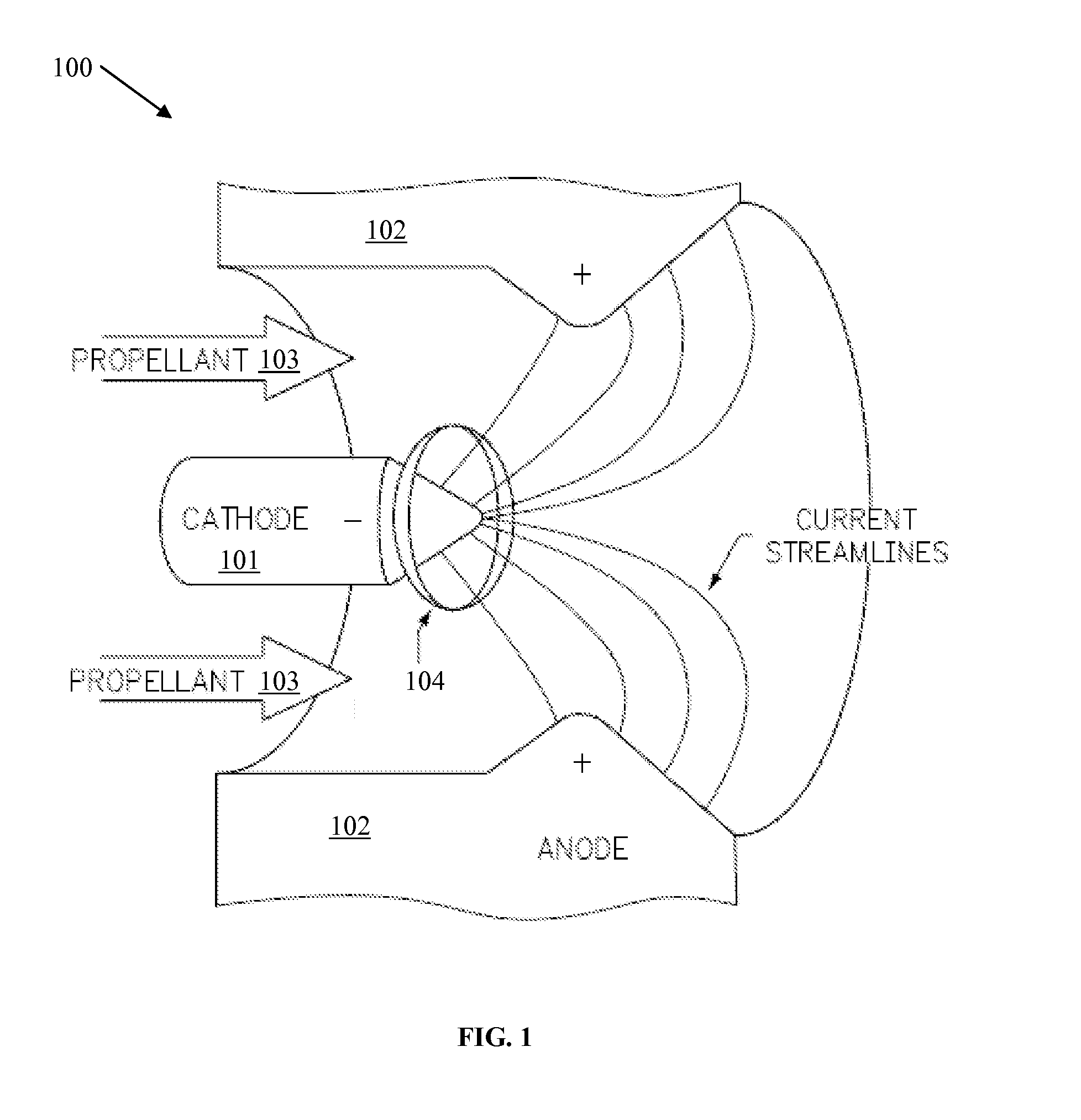

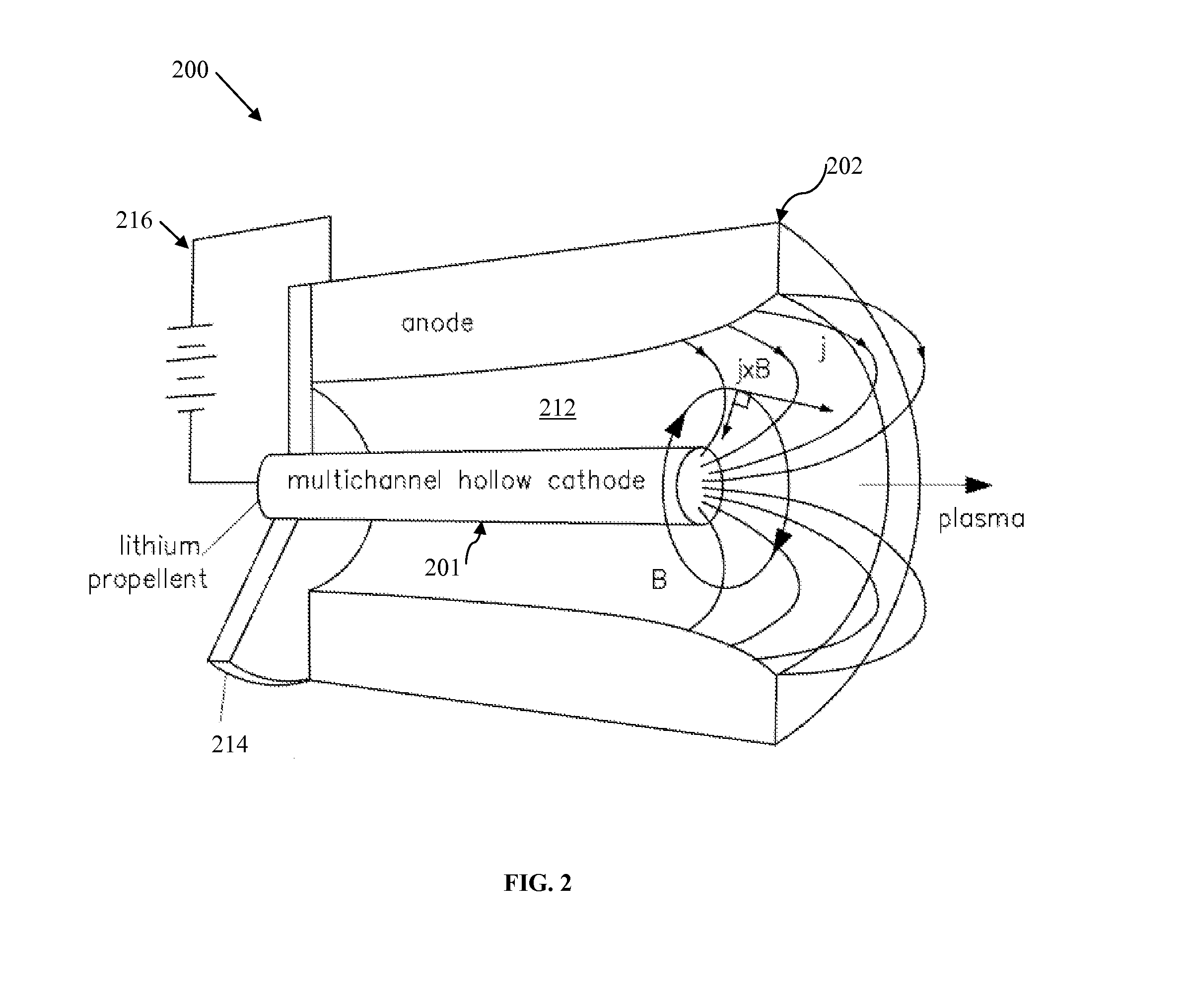

A system for directing electromagnetic energy. The inventive system includes a first subsystem mounted on a first platform for transmitting a beam of the electromagnetic energy through a medium and a second subsystem mounted on a second platform for redirecting the beam. In accordance with the invention, the second platform is mobile relative to the first platform. In the illustrative embodiment, the beam is a high-energy laser beam. The first subsystem includes a phase conjugate mirror in optical alignment with a laser amplifier. The first subsystem further includes a beam director in optical alignment with the amplifier and a platform track sensor coupled thereto. In the illustrative embodiment, the second subsystem includes a co-aligned master oscillator, outcoupler, and target track sensor which are fixedly mounted to a stabilized platform, a beam director, and a platform track sensor. In the best mode, the stable platform is mounted for independent articulation relative to the beam director. A first alternative embodiment of the second subsystem includes first and second beam directors. The first beam director is adapted to receive the transmitted beam and the second beam director is adapted to redirect the received beam. In accordance with a second alternative embodiment, an optical fiber is provided for coupling the beam between the first platform and the second platform.

Owner:RAYTHEON CO

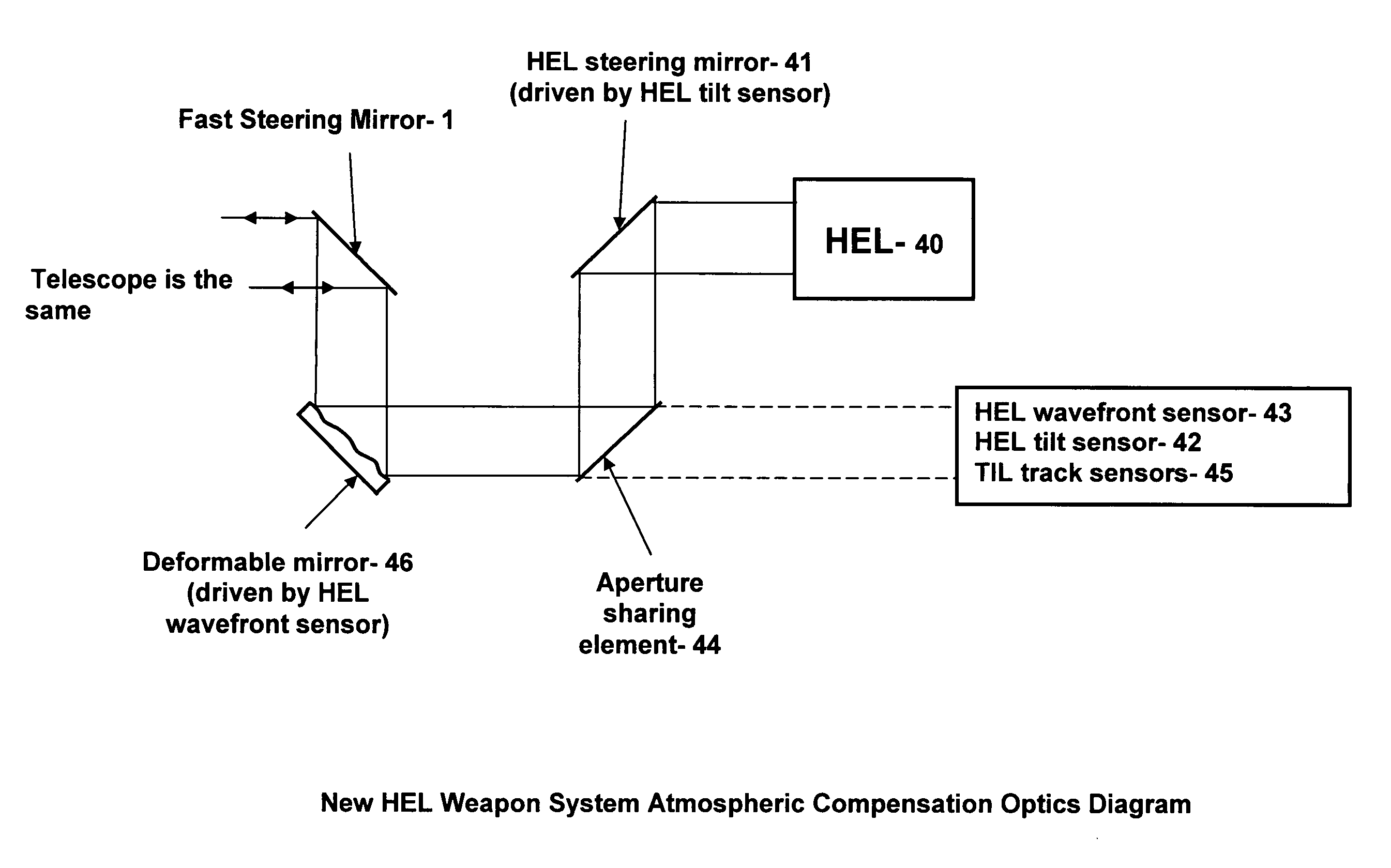

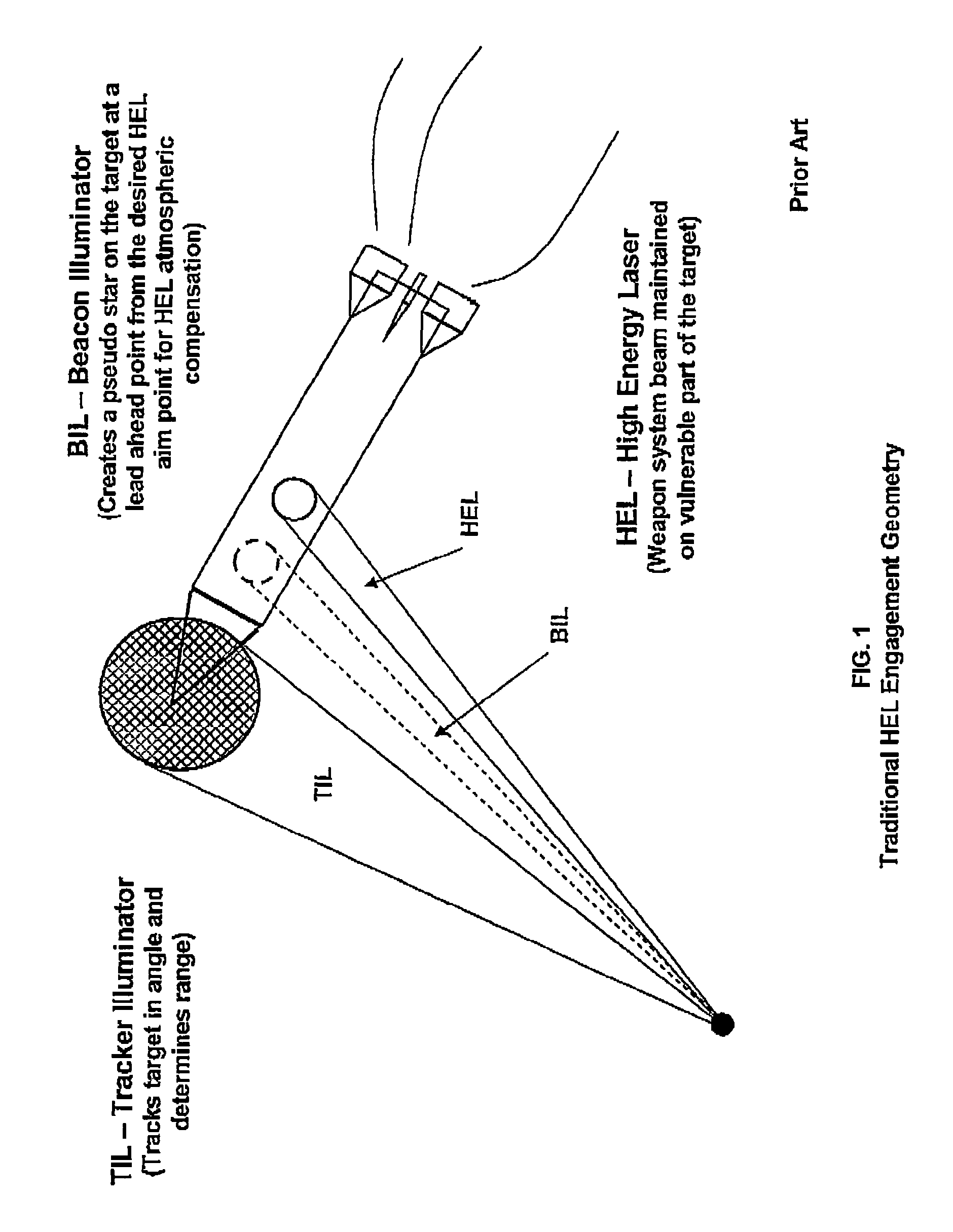

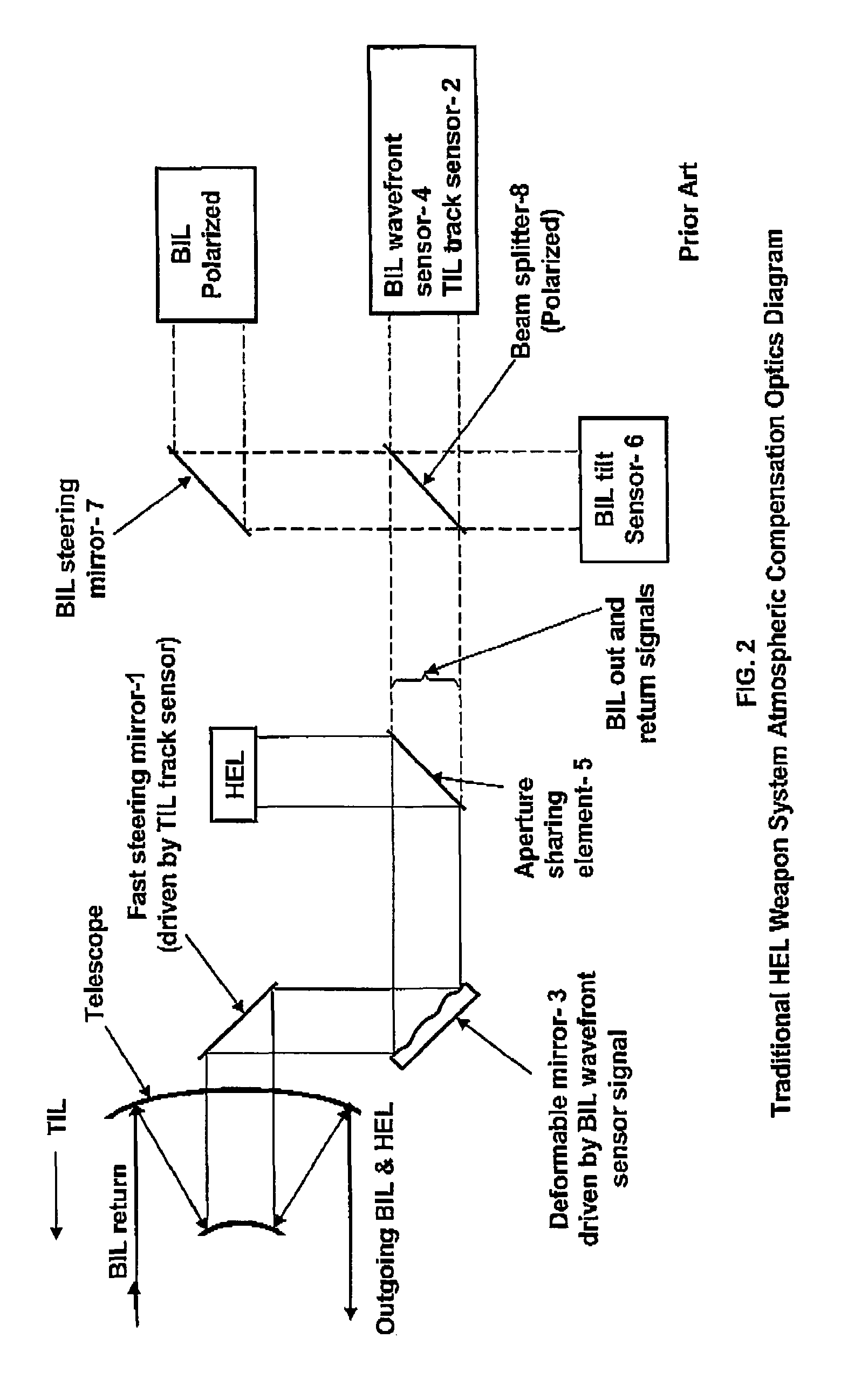

High-energy laser atmospheric compensation and aimpoint maintenance

A high-energy laser weapon system in which the high-energy laser beam itself is used to correct for atmospheric fluctuations thereby replacing a separate beacon illuminator system. The high-energy laser is turned off (negative pulse) periodically for a very short period giving a wavefront sensor an opportunity to measure the return of the high-energy laser beam from the target. A wavefront sensor drives a deformable mirror based on this return signal avoiding wavelength anisoplanatism. In addition, the high-energy laser weapon can be snapped ahead of the path of the target during the negative pulse to avoid tilt anisoplanitism.

Owner:THE GOVERNMENT OF THE UNITED STATES AS REPRESENTED BY THE UNITED STATES AIR FORCE

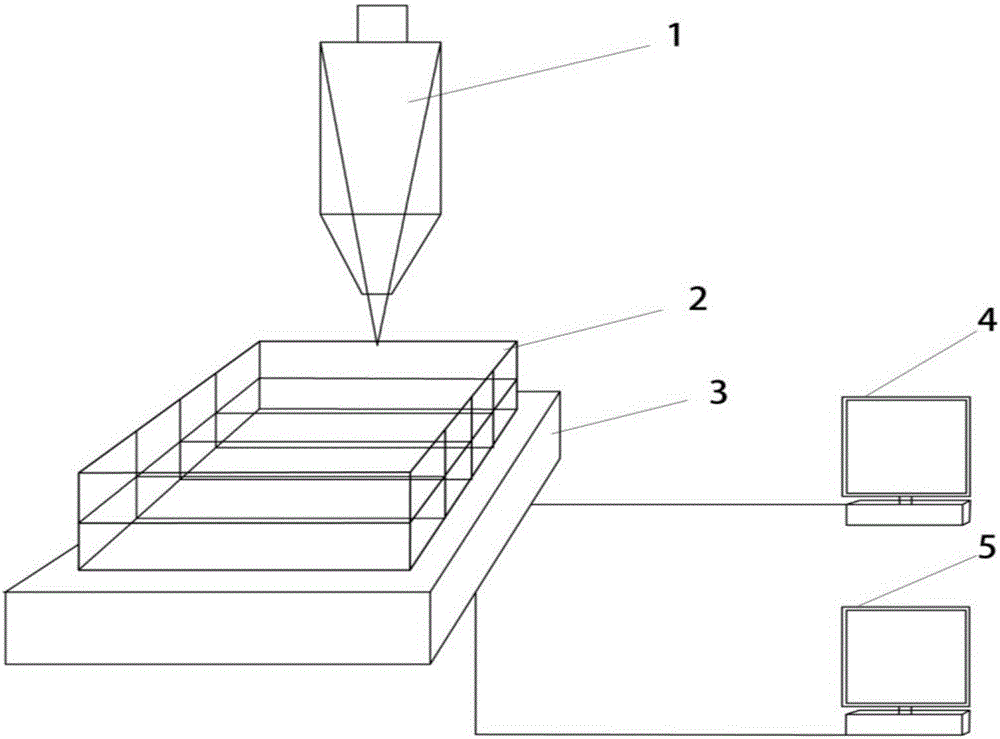

Material increasing manufacturing method of pure tungsten metal

ActiveCN104889392AHigh densityImprove performanceAdditive manufacturing apparatusSlice thicknessShielding gas

The invention relates to a material increasing manufacturing method of pure tungsten metal. The manufacturing method comprises steps of taking ball-shaped pure tungsten powder particles; screening out and mixing tungsten powder small particles and tungsten powder big particles to obtain mixed powder bodies; installing a metal substrate on an optical fiber laser work bench; filling a powder body stock bin with the mixed powder bodies and sealing a shaping cavity body; using a vacuum pump to pump the interior of the shaping cavity body to be in vacuum degree of -90Kpa; inputting protection gas into the shaping cavity body; repeating vacuumization and protection gas inputting so as to allow the oxygen content in the shaping cavity body to be reduced to less than 300ppm; scanning the sacrificing area of the metal substrate with laser until the oxygen content is reduced to less than 50ppm; sending the mixed powder bodies in the powder body stock bin to the metal substrate by a powder laying machine; using a powder laying scraper to lay the powder bodies so as to obtain a mixed powder body thin layer; fusing the mixed powder bodies in a shaping slicing area via high-energy laser beams; refusing the mixed powder bodies after each layer is shaped; after the refusing is finished, reducing the work bench by one slice thickness; and repeating the laser shaping and refusing until the whole part is finally shaped.

Owner:TSINGHUA UNIV

Laser quick repair process method for large rotary machine bearing bush

InactiveCN103451650ASmall dilutionDense tissueMetallic material coating processesSlagHigh energy laser beam

The invention relates to the technical field of laser cladding, in particular to a laser quick repair process method for a large rotary machine bearing bush. According to the laser quick repair process method, a layer of purpose-made powdered materials capable of meeting operating requirements is arranged on the surface of a part in advance; then, high-energy laser beams are used for quick scanning processing on the coating; the powdered materials arranged in advance melt instantaneously and solidify; base metal below the coating melts into a thin layer along with the coating, molecular or atomic interdiffusion quickly occurs in a quite narrow area in a boundary between the thin layer and the coating, and solid metallurgical bonding is formed at the same time; a substrate is extremely little affected by heat under a rapid heating condition and does not deform. The laser quick repair process method for the large rotary machine bearing bush achieves the effect that a local and whole-area Babbitt metal laser cladding layer is formed on the substrate made of cast steel and bronze alloy, a Babbitt metal layer which is 1.0-15 mm is formed as required, and metallurgical bonding between Babbitt metal and various substrates is realized; the laser cladding layer is low in dilution, compact in structure and free of delaminating, air holes, slag inclusion, cracks and other quality defects.

Owner:岳阳大陆激光技术有限公司

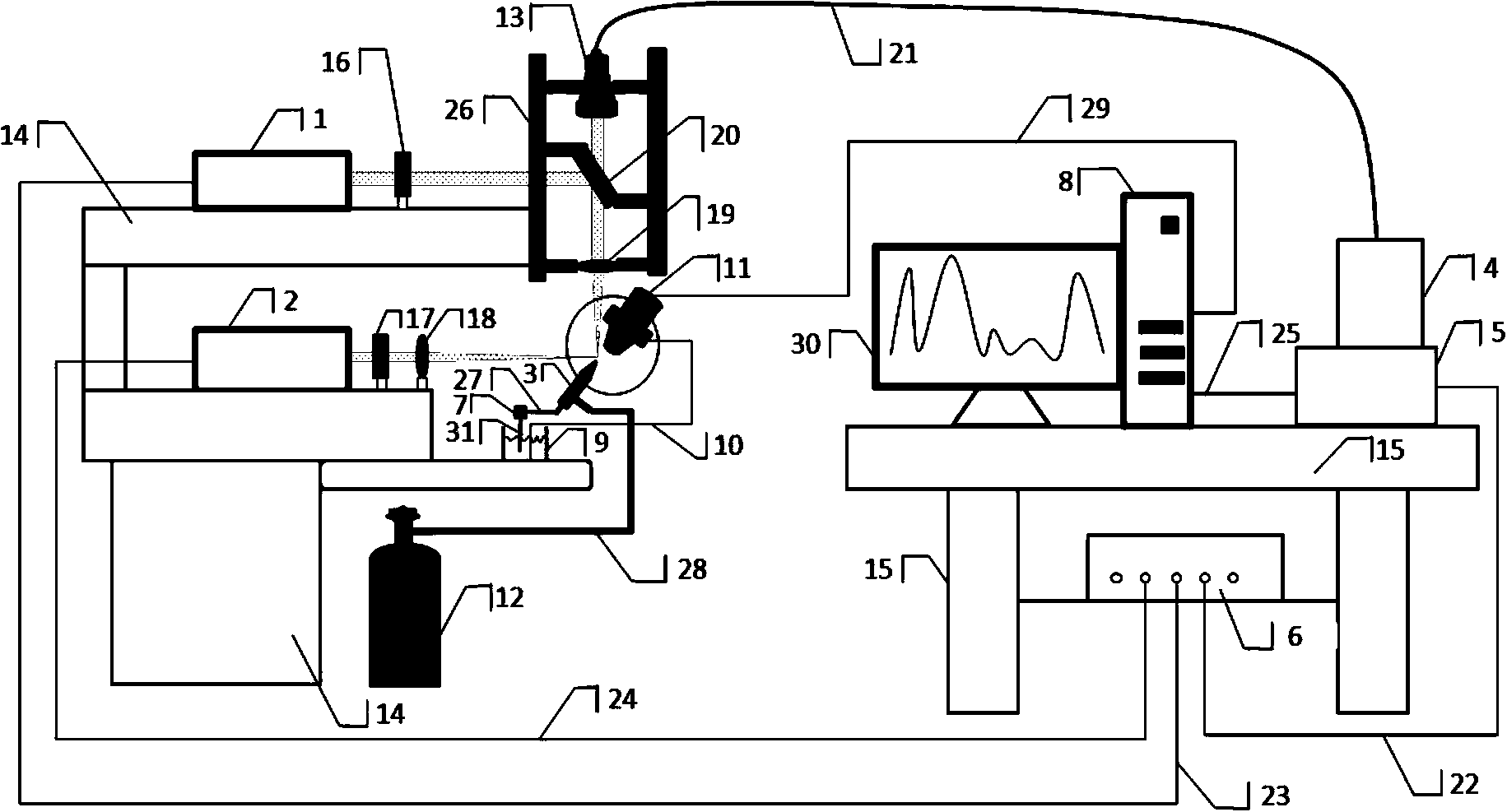

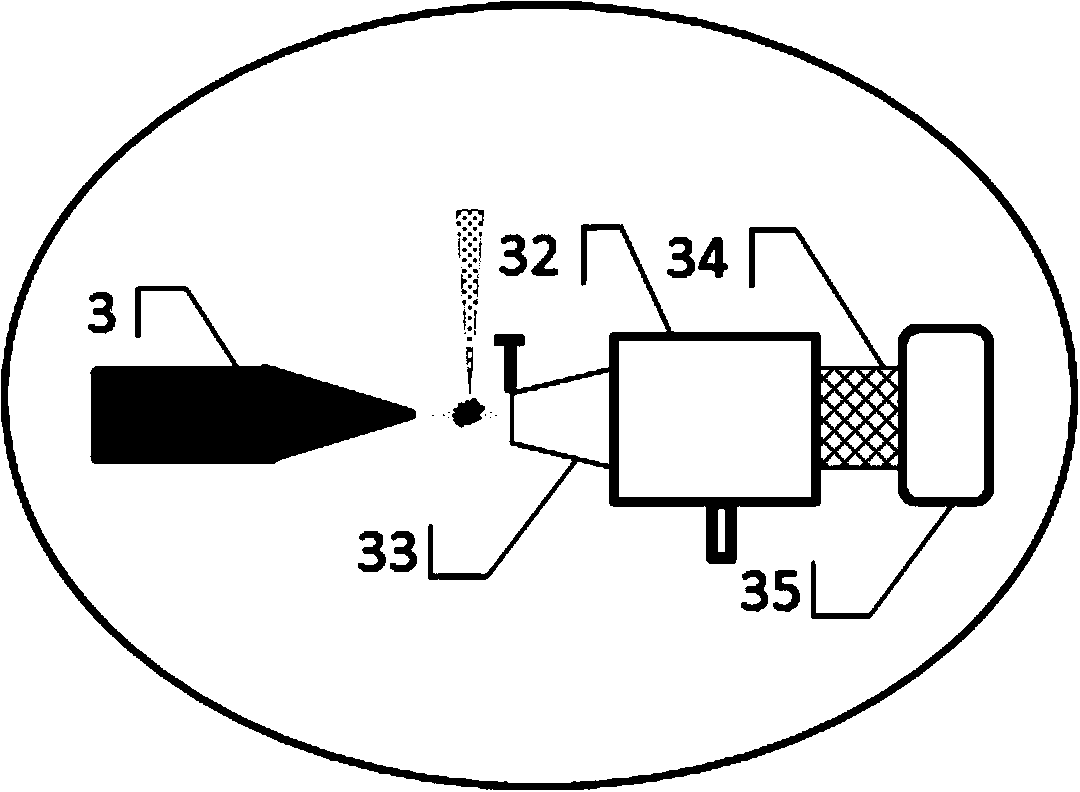

Laser probe analyzer based on aerosolization and resonance excitation

ActiveCN103712962AIncrease profitImprove compatibilityAnalysis by thermal excitationCollection systemLaser probe

The invention discloses a laser probe component analyzer. The laser probe component analyzer comprises a Nd. YAG (neodymium-doped yttrium aluminum garnet) laser system, a wavelength tunable laser system, an aerosolization system, a spectrum collection system and a computer, wherein the aerosolization system is used for producing an aerosol from a solution to be analyzed; the Nd. YAG laser is used for producing a high-energy laser beam and focusing the laser beam on the aerosol to excite plasma flame; the wavelength tunable laser system is used for producing a pumped laser beam with required resonance excitation wavelength and focusing the laser beam on the plasma flame to produce a resonance excitation effect; and the spectrum collection system is used for collecting characteristic spectral signals produced after resonance excitation, converting the spectral signals to electric signals and then transmitting the electric signals to the computer to analyze substance components in the solution. The system can overcome the shortcomings of the prior art, greatly improve the detection sensitivity of an LIBS (laser induced breakdown spectroscopy) technology in detection of trace elements in the solution, achieve the requirements of actual applications in the fields of environmental monitoring and the like and simultaneously perform online precise qualitative and quantitative analysis of substances in a liquid.

Owner:WUHAN XINRUIDA LASER ENG +1

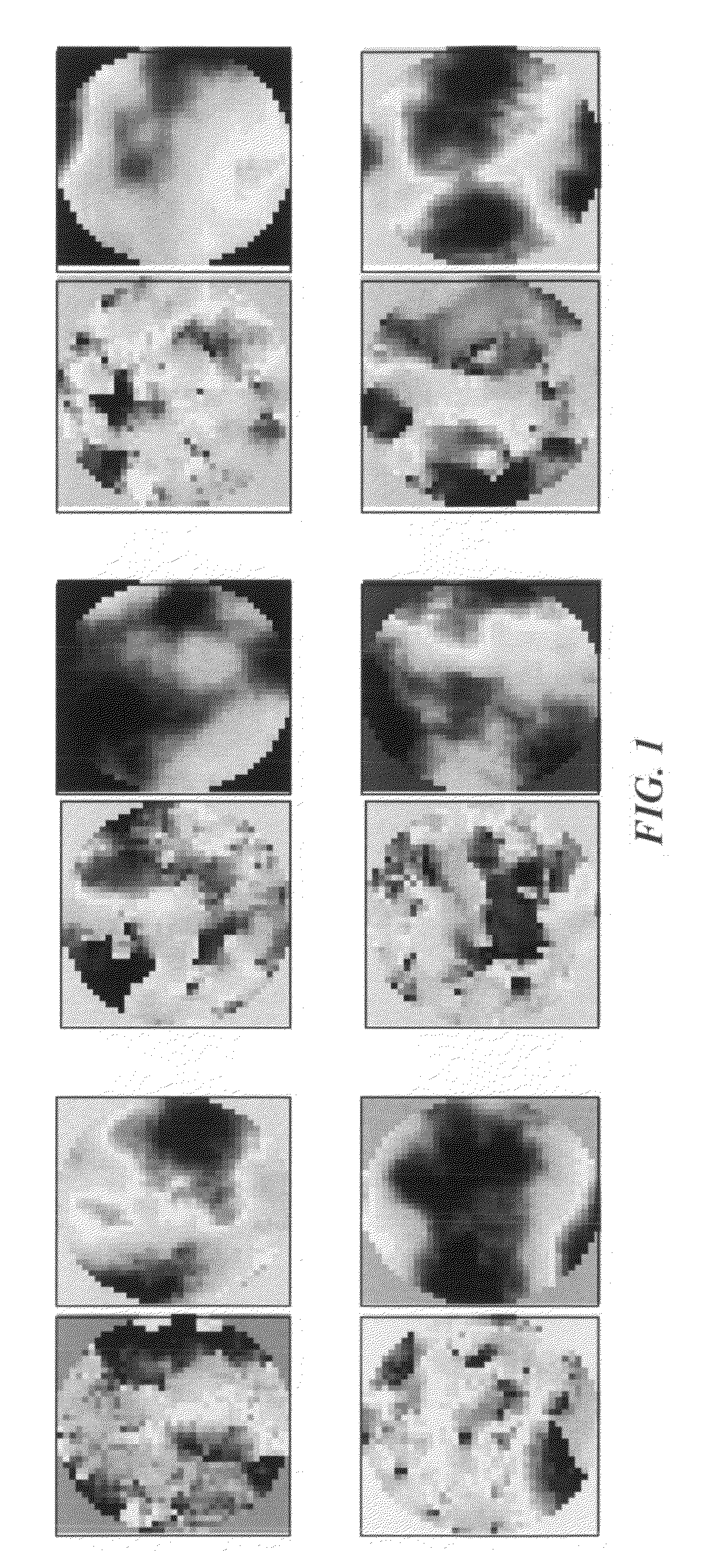

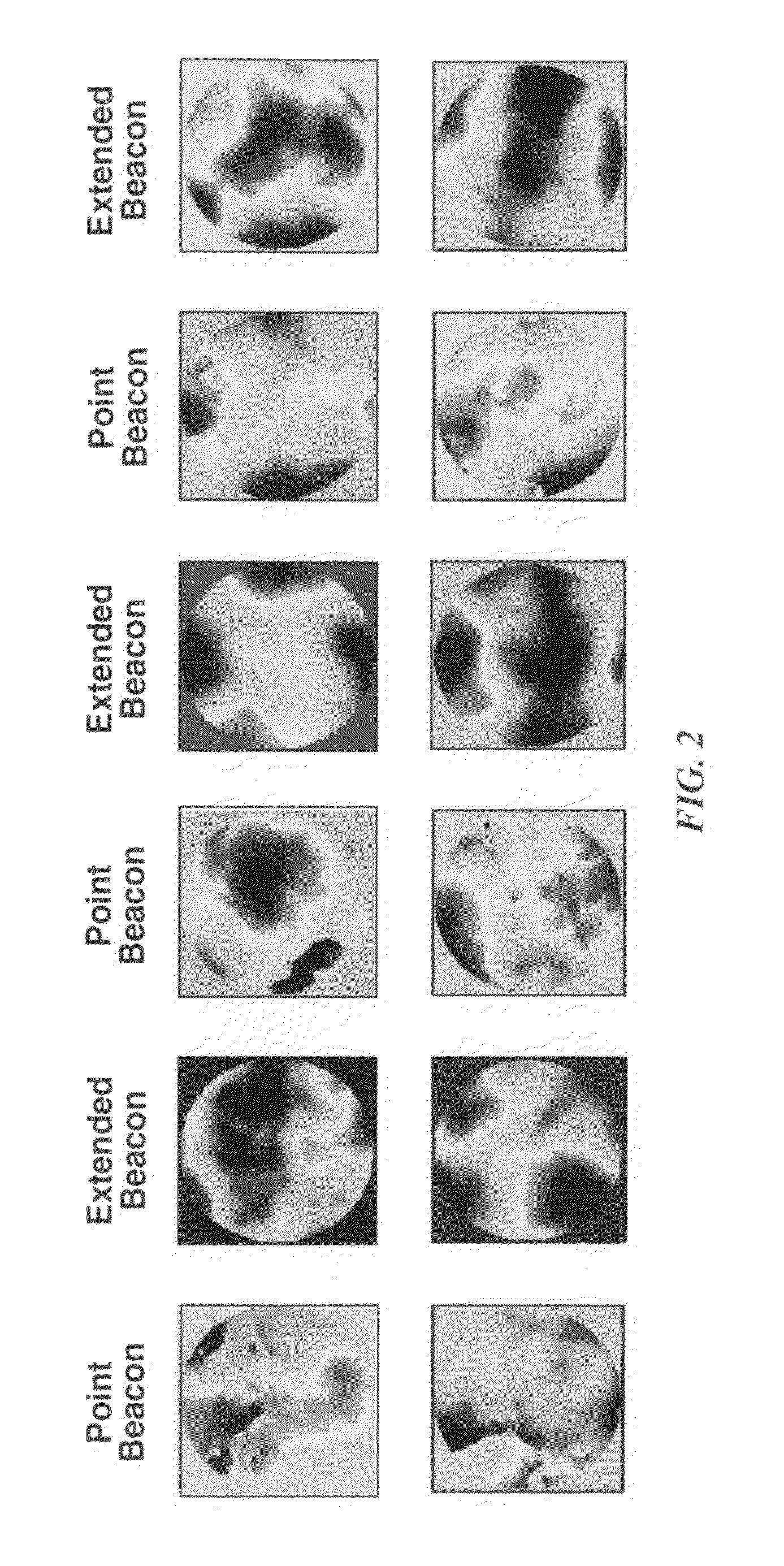

Beaconless adaptive optics system

InactiveUS20090028198A1High speed controlReduce in quantityPhotometry using reference valueLaser detailsHigh speed controlLight beam

An improved beaconless adaptive optics system and process. A target is illuminated with a high energy laser beam of a directed energy laser. Wave front measurements are made of high energy laser beam reflections from the target. These wave front measurements are analyzed by a high speed processor to determine both high frequency phase components and low frequency phase components in the wave front data. (Applicants' experiments have shown that there is a direct correlation between beam spot size on the target and the phase variance of the reflected laser beam. The correlation is: the greater the phase variance the smaller the beam spot size.) Applicants have developed a technique for providing special control algorithms that provide very high speed control of the elements of a deformable mirror using this phase variance as a feedback parameter. Applicants have also developed algorithms to correct a limited number of Zernike modes associated with the wave front control.

Owner:TREX ENTERPRISES CORP

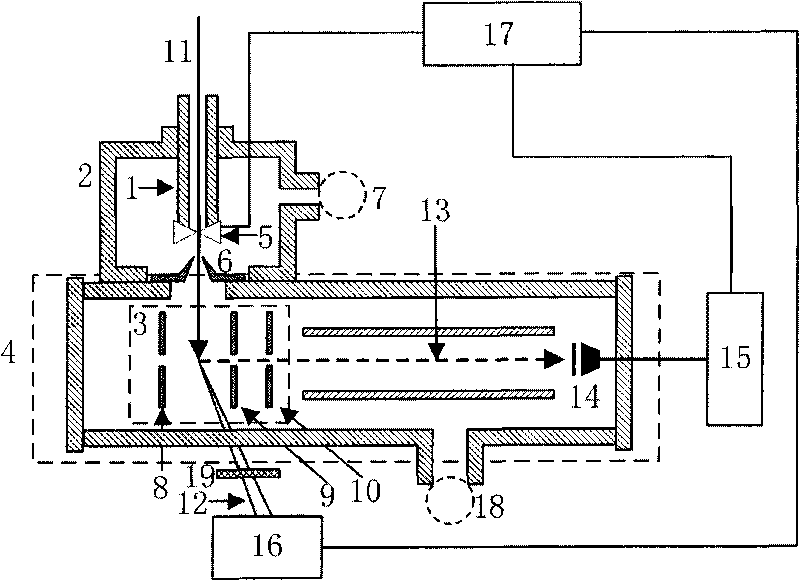

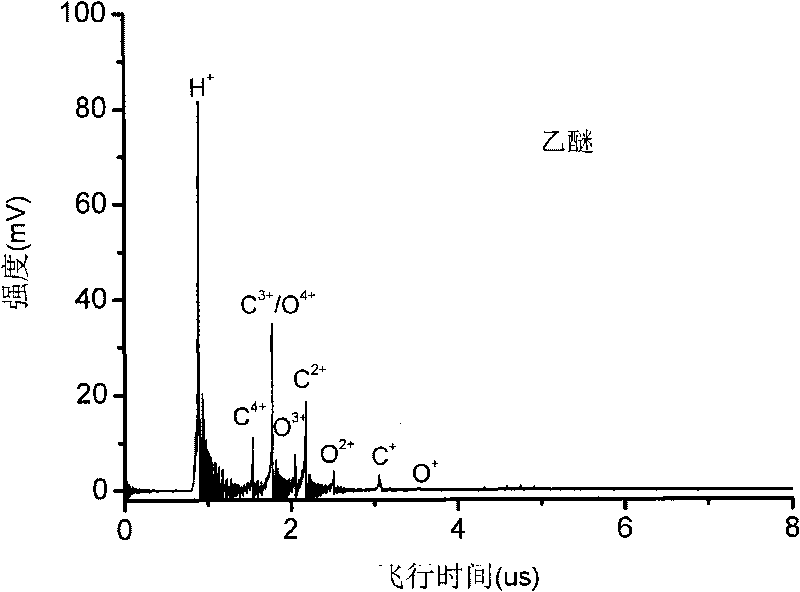

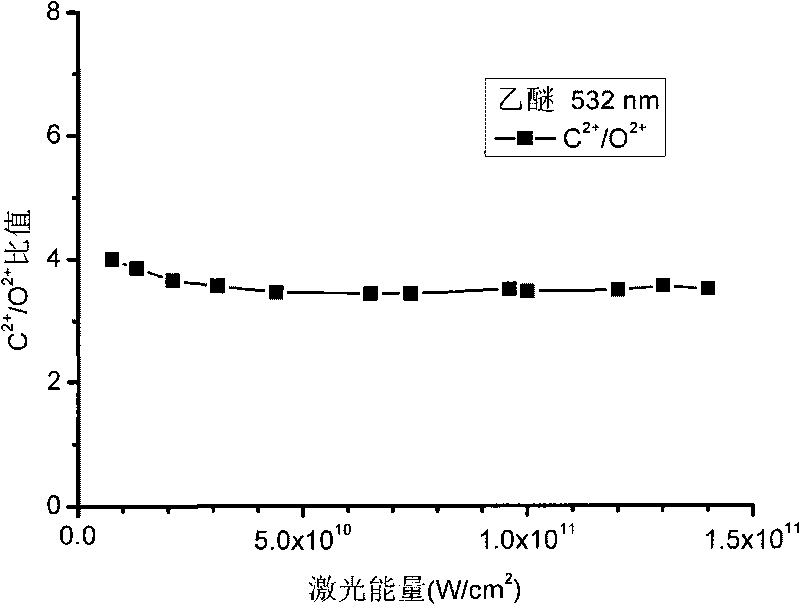

Time-of-flight mass spectrometer for measuring ratio of nano-particle component elements in real time

InactiveCN101750265AImprove hit efficiencyMaterial analysis by electric/magnetic meansBeam sourceSpectrograph

The invention relates to a time-of-flight mass spectrograph, in particular to a time-of-flight mass spectrometer for measuring ratio of nano-particle component elements in real time, comprising a pulse sampling device, a beam source chamber and a time-of-flight mass spectrum mass analyzer provided with an ionization chamber. The time-of-flight mass spectrometer is characterized in that the ionization chamber is positioned in the time-of-flight mass spectrum mass analyzer, the front end of the pulse sampling device is connected with a pulse valve, the pulse sampling device is inserted into the beam source chamber, the beam source chamber is positioned directly above the laser ionization chamber, the outlet of the beam source chamber is connected with the laser ionization chamber through a nozzle, a nanosecond long wavelength high-energy laser is installed at the outer side of the time-of-flight mass spectrum mass analyzer, the high-energy laser beams emitted by the laser pass through the ionization chamber vertically so as to ionize nano-particles completely into univalent and high valence ions, the ratio of the high valence ions can accurately reflect the ratio of nano-particle component elements, and the ions produced by ionization can be recorded by the time-of-flight mass spectrograph. The invention can measure the ratio of nano-particle component elements rapidly, and the measurement is not influenced by ionization laser energy.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

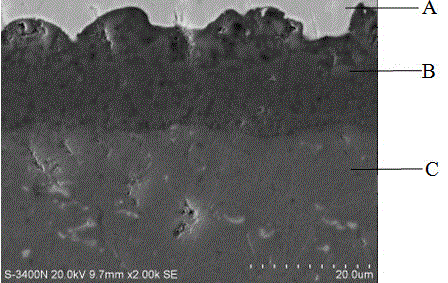

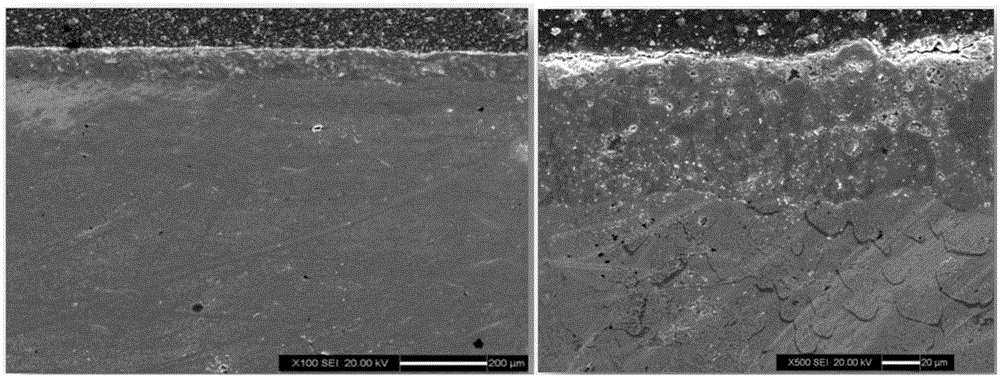

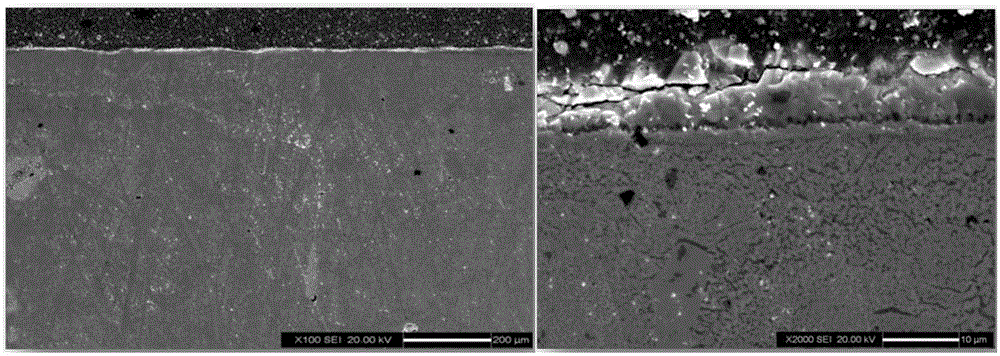

Method for improving compactness of aluminum alloy micro-arc oxide coating

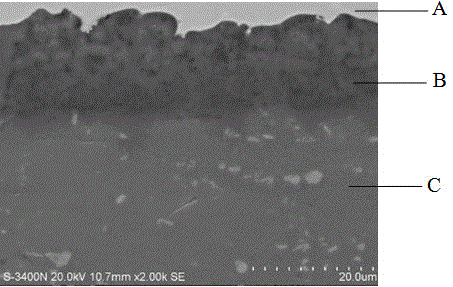

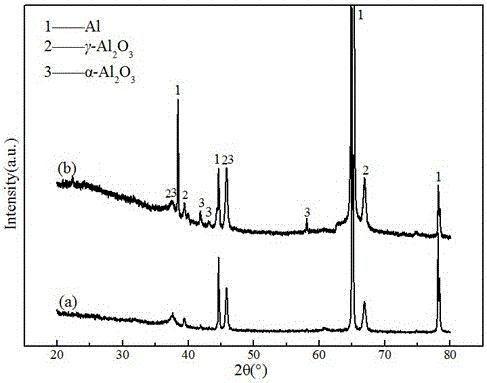

InactiveCN106637337AImprove densification performanceHigh hardnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a method for improving compactness of aluminum alloy micro-arc oxide coating, and belongs to the technical field of aluminum alloy surface modification. The method comprises the following steps of: grinding an aluminum alloy sample to be smooth, ultrasonically cleaning the aluminum alloy sample, putting the ultrasonically-cleaned aluminum alloy sample into electrolyte to perform micro-arc oxidization treatment, thereby preparing an aluminum-alloy micro-arc oxidation coating; and finally, performing laser scanning processing on the aluminum-alloy micro-arc oxidation coating by high-energy laser beams generated by laser unit equipment. The method disclosed by the invention can improve the structure of the aluminum-alloy micro-arc oxidation coating, so that a metastable phase in the coating is converted into a stable phase. The method effectively improves the problems that compaction of the coating is relatively poor as a result of porous characteristics, and the energy consumption for obtaining the micro-arc oxidation coating with good compactness is high, so that corrosion and wear resistance of the micro-arc oxidization coating is greatly improved; and moreover, the method is simple in process, is good in repeatability, and can be used for industrial large-area preparation.

Owner:GUANGXI UNIV +2

Method of preparing novel gradient functional material fine blanking die based on laser fusing-covering forming technique

InactiveCN101176950AImprove mechanical propertiesEliminate segregationMetallic material coating processesLaser beam welding apparatusMelting tankHigh energy laser beam

The invention relates to laser cladding molding technology; wherein, a common steel base is molded to high-performance material. The requirements for material performance are met during the manufacture process of fine blanking die. To prolong the service life of fine blanking die, the requirements for material are satisfied, which substitutes the costly metallurgical steel powders. Based on the laser cladding molding technology, the manufacture method of the new gradient functional material fine blanking die comprises the steps that: firstly, high-energy laser beam locally melt the metal surface of base to form a molten pool; secondly, metal materials are sent to the molten pool and forms a plurality of new metallic layers with low rate of dilution, combining with the base metal metallurgy. The invention has the advantages of enabling to achieve no-model rapid approximately-final molding of high-performance compact metal components, improving the prior rapid prototype technology to a new level of the directly molding of full-density high-intensity functional material component, and being an integration of rapid molding basic principle and laser process quintessence.

Owner:SHANGHAI MARITIME UNIVERSITY

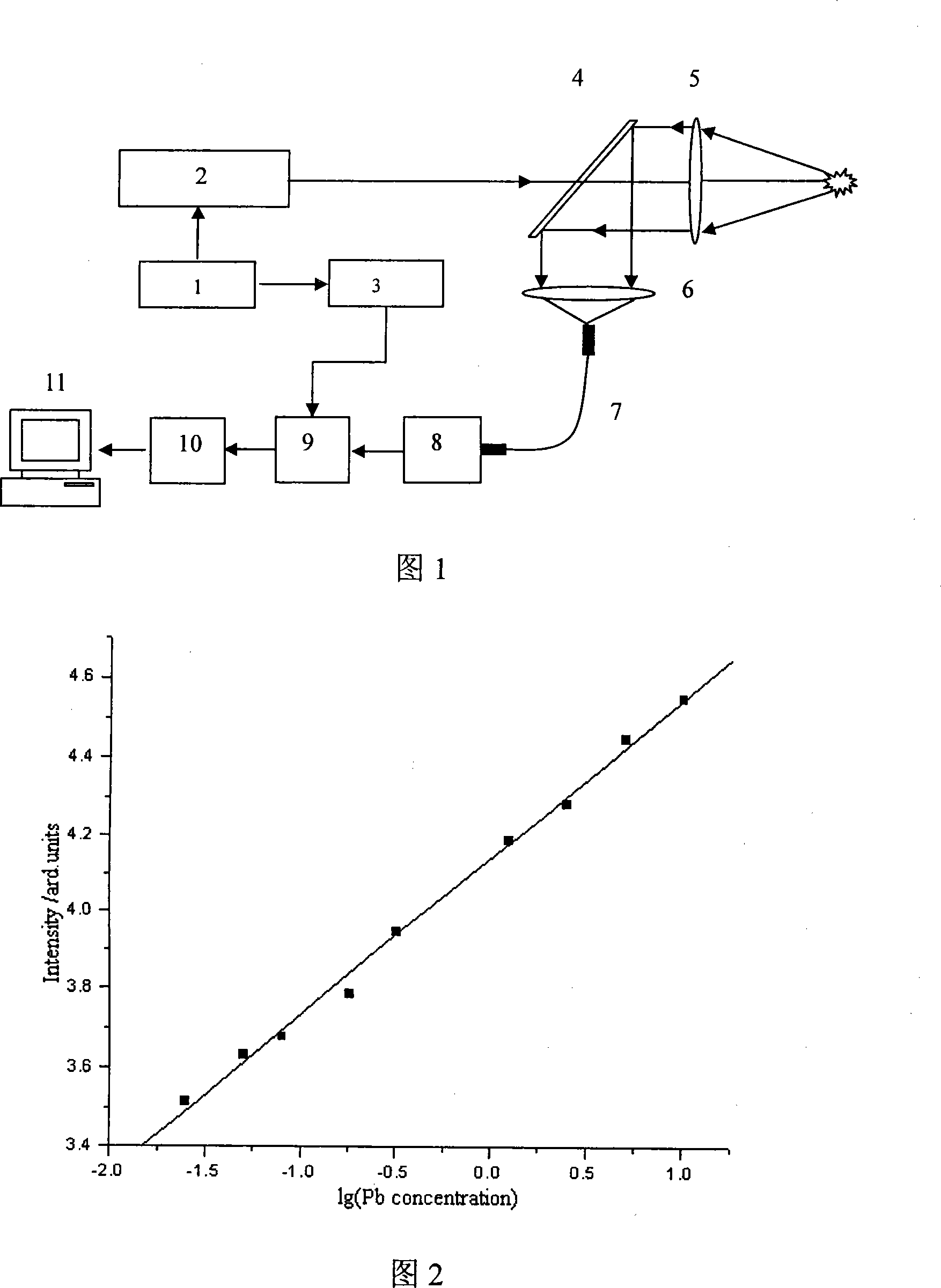

Device and method for real time on-line detecting flue gas pollutant

InactiveCN101231241AReal-time continuous detectionOnline continuous detectionAnalysis by material excitationParticle suspension analysisHigh energyHigh energy laser beam

The invention discloses a real-time on-line detecting apparatus of smoke pollutant and the test method thereof, and relates to the atmospheric environmental monitoring. The apparatus comprises a pulse generator (1), a pulse laser (2), a time delayer (3), a reflector (4), a long-focus focusing lens (5), a light receiving device (6), optical fibre (7), a spectrometer (8), an A / D converter (10), and a computer (11). The invention utilizes a focused high energy laser beam to motivate the substance in the smoke gas to be the high energy state, various substances radiate respective characteristic spectrums during the process of the high energy state returning the base state, the composition of the pollutant such as magnesium, iron, copper, aluminum, lead, chrome, hydrargyrum, arsenic, etc. in the tested smoke gas and the concentration thereof can be obtained by analyzing the characteristic spectrums. The invention has the advantages of simple structure, reliable method and convenient operation, and is suitable for performing the real-time and on-line continuous detection of the pipeline smoke gas during the combustion process of coal.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

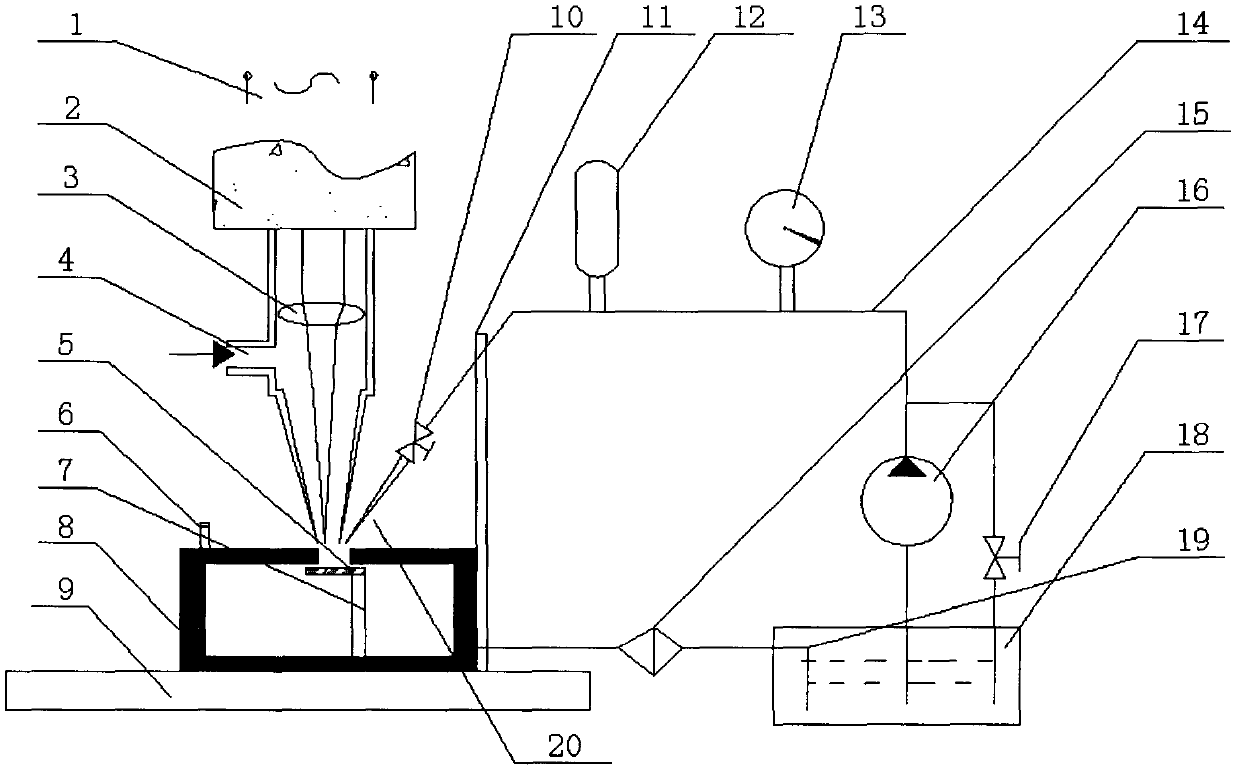

Laser induced low pressure jet flow combined etching processing method and device

InactiveCN103317234AEasy to cleanImprove surface finish qualityLaser beam welding apparatusHigh energy laser beamHigh pressure

The invention discloses laser induced low pressure jet flow combined etching processing method and device thereof. The method comprises the following steps: the operations of cutting, drilling and slotting are performed on a workpiece by utilizing high-energy laser beams generated by a laser processing system, and meanwhile erosion is performed on the material surface subjected to laser ablation through high-speed jet flow beams generated by a corrosive medium jet flow device, so that the purpose of removing the material is achieved; the device comprises a laser device and a power source, and further comprises a jet flow generation device and a corrosion liquid circulating reflux device, wherein the jet flow device comprises a corrosion liquid tank, a plunger piston high pressure pump, a pressure gauge, an accumulator, a one-way control valve, a corrosion-resistant spray nozzle and a jet flow device fixed fixture. The method disclosed by the invention has the advantages that the laser ablation is mainly performed, the cooling of high-speed corrosive medium jet flow beams, synchronous erosion and combined processing effect of the cooling and the erosion are added on the basis of the laser ablation, so that the laser induced low pressure jet flow combined etching processing of the material is realized; the invention provides an efficient, clean and combined etching processing process.

Owner:JIANGNAN UNIV

Phase conjugate relay mirror apparatus for high energy laser system and method

InactiveUS6961171B2Increase power consumptionIncrease heat loadDefence devicesLaser detailsAudio power amplifierLight beam

A system for directing electromagnetic energy. The inventive system includes a first subsystem mounted on a first platform for transmitting a beam of the electromagnetic energy through a medium and a second subsystem mounted on a second platform for redirecting the beam. In accordance with the invention, the second platform is mobile relative to the first platform. In the illustrative embodiment, the beam is a high-energy laser beam. The first subsystem includes a phase conjugate mirror in optical alignment with a laser amplifier. The first subsystem further includes a beam director in optical alignment with the amplifier and a platform track sensor coupled thereto. In the illustrative embodiment, the second subsystem includes a co-aligned master oscillator, outcoupler, and target track sensor which are fixedly mounted to a stabilized platform, a beam director, and a platform track sensor. In the best mode, the stable platform is mounted for independent articulation relative to the beam director. A first alternative embodiment of the second subsystem includes first and second beam directors. The first beam director is adapted to receive the transmitted beam and the second beam director is adapted to redirect the received beam. In accordance with a second alternative embodiment, an optical fiber is provided for coupling the beam between the first platform and the second platform.

Owner:RAYTHEON CO

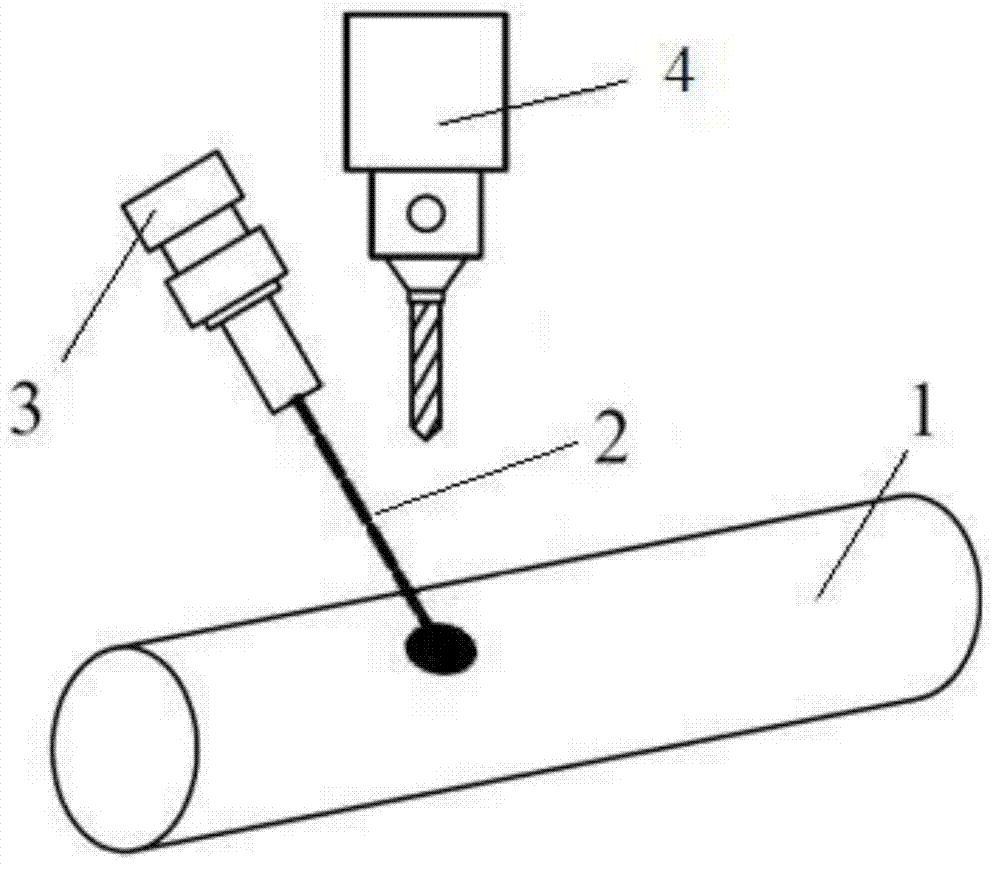

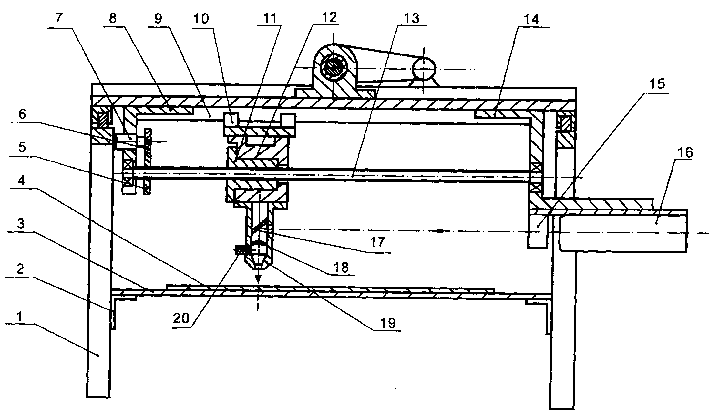

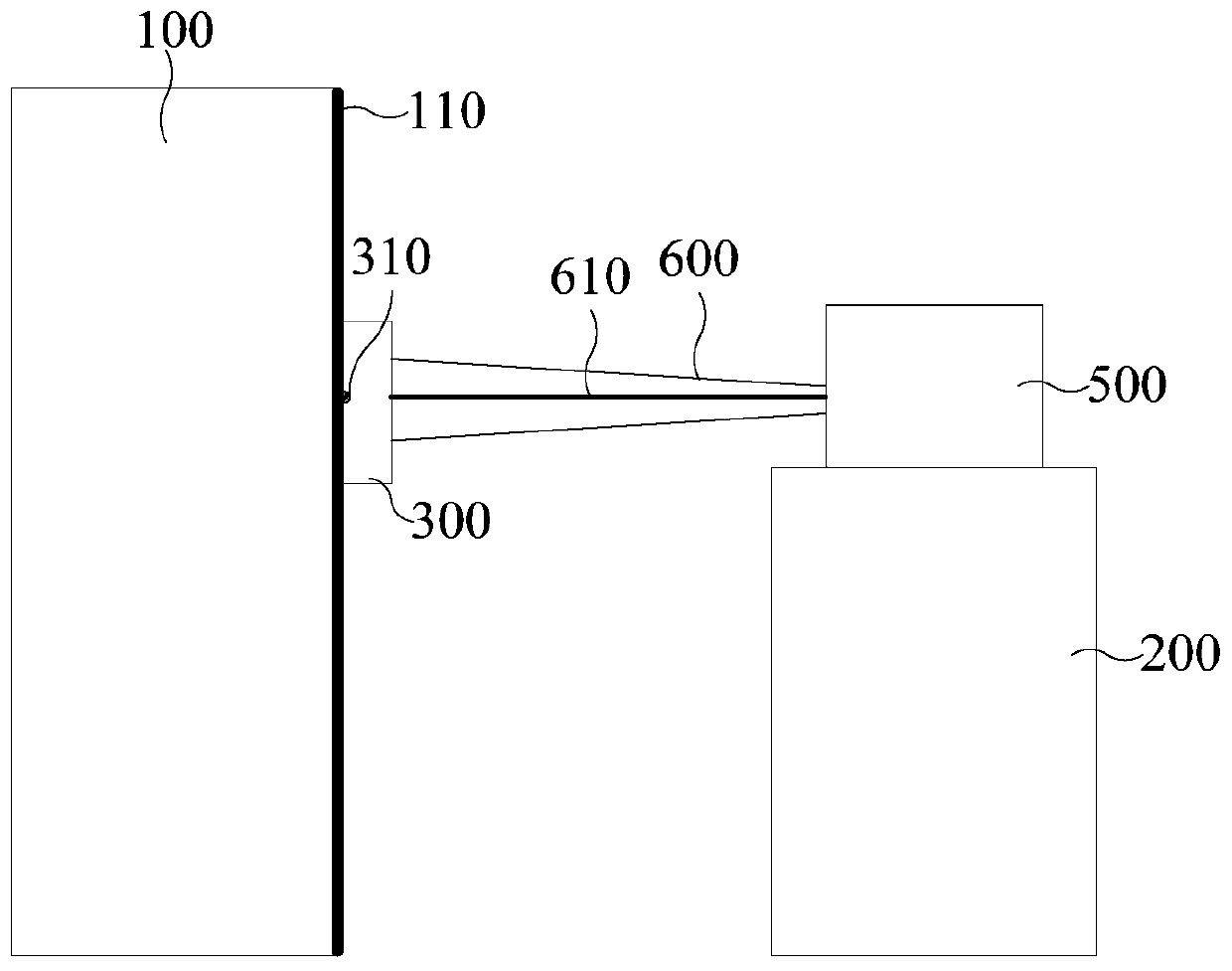

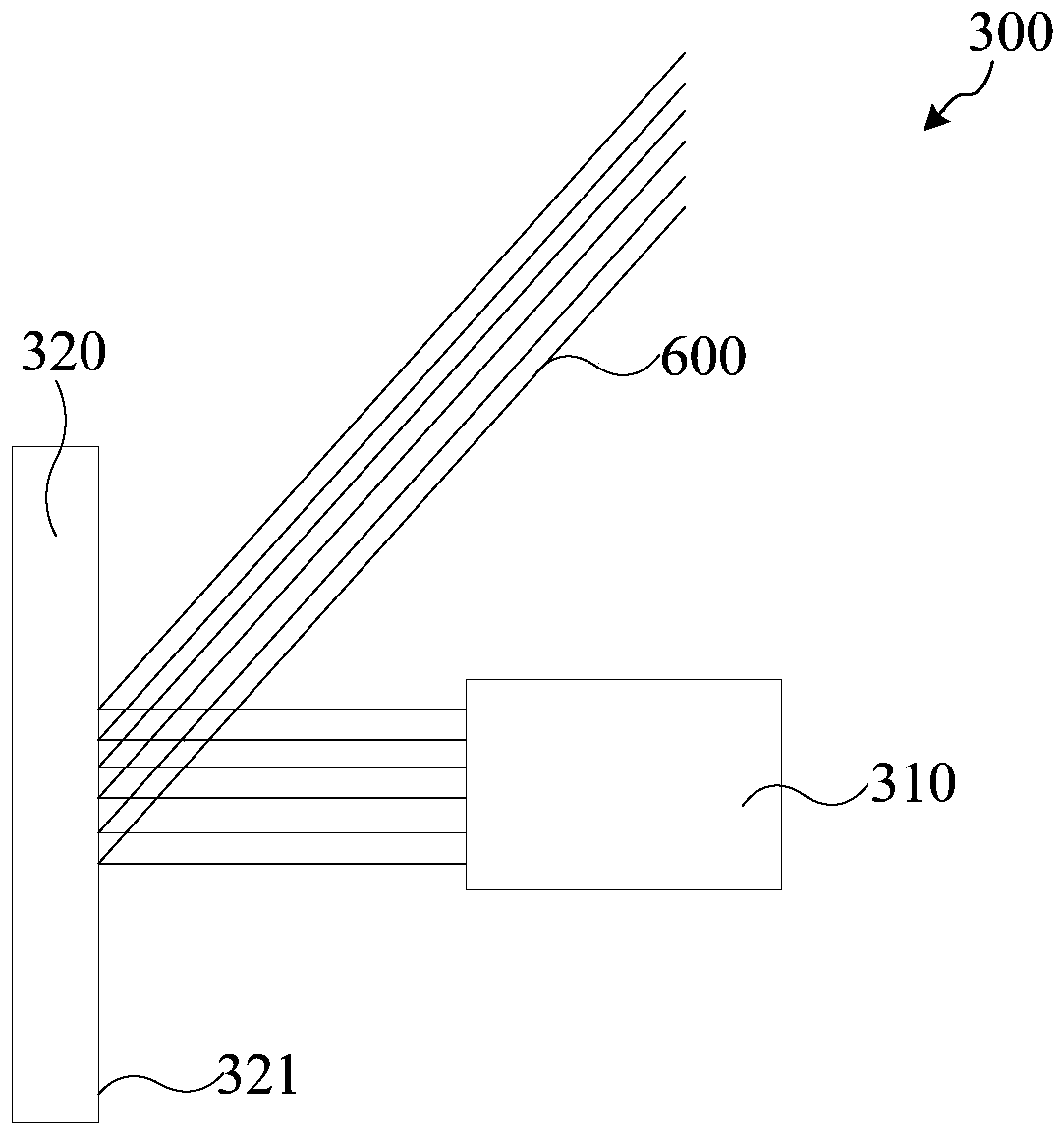

Laser-assisted drilling method and device

InactiveCN103753223AImprove machinabilityReduce wearOther manufacturing equipments/toolsMetal working apparatusLaser assistedHigh energy laser beam

The invention provides a laser-assisted drilling method and a laser-assisted drilling device. The laser-assisted drilling device comprises a workbench, a fixture mounted on the workbench, a drill bit and a laser device, wherein the drill bit and the laser device are respectively arranged on the workbench through a movable device and arranged above the fixture, and the laser device and the drill bit are arranged to be provided with an included angle therebetween. According to the laser-assisted drilling method, the to-be-drilled area of a workpiece is preheated by a high-energy laser beam, so that, in a very short time, part of the to-be-drilled area is heated to have a very high temperature, meanwhile, the physical performance of the material is changed under the high temperature, and the to-be-drilled area of the workpiece material is softened. Once the laser heating is completed, drilling starts rapidly. Thus the drilling resistance can be reduced, the machinability of the material can be improved, the tool wear can be reduced, the success of drilling can be ensured, and the machining precision and the machining efficiency can be improved.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

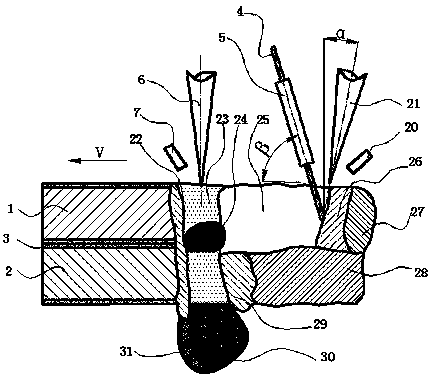

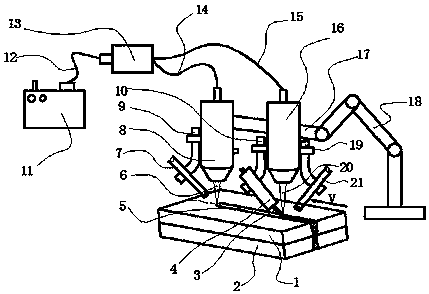

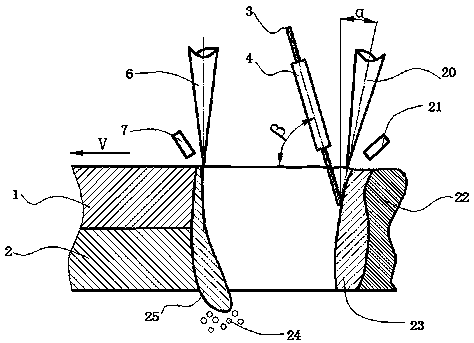

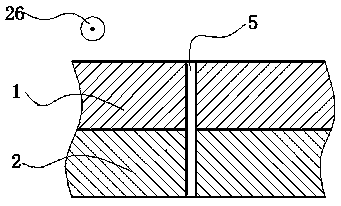

Zero-gap galvanized steel sheet spliced joint laser welding method and system

InactiveCN107953032AImprove stabilitySuppresses surface splashWelding/soldering/cutting articlesMetal working apparatusSheet steelHigh energy laser beam

The invention relates to a zero-gap galvanized steel sheet spliced joint laser welding method which is characterized by including the steps: firstly, providing a first workpiece and a second workpiecewhich need to be welded in a spliced manner; secondly, vertically splicing and clamping the first workpiece and the second workpiece; thirdly, providing a laser self-fusion welding system; fourthly,providing a laser filler wire welding system; fifthly, starting the laser self-fusion welding system; sixthly, starting the laser filler wire welding system, performing filler wire welding by a secondlaser welding head and a wire feeding head along a track of a first laser welding head to finish a welding process. The second laser welding head, the wire feeding head and the first laser welding head are serially arranged to form a column in a welding direction, the first laser welding head focalizes to form high-energy laser beams, and the laser beams vertically irradiate the surface of the first workpiece. The invention further discloses a zero-gap galvanized steel sheet spliced joint laser welding system. Compared with the prior art, the method has good welding effect and is simple in process.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

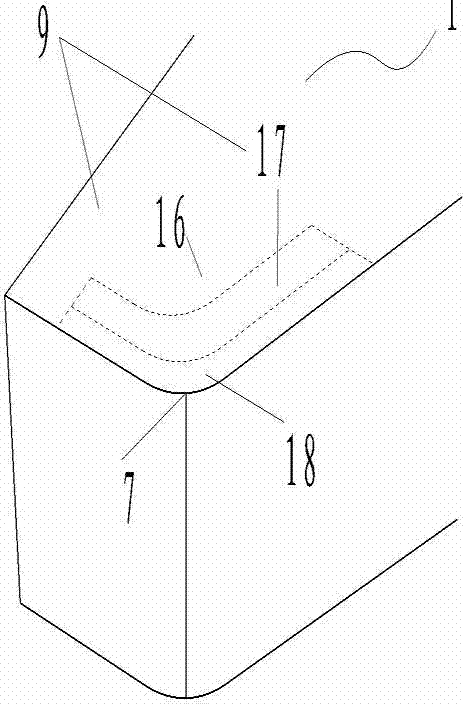

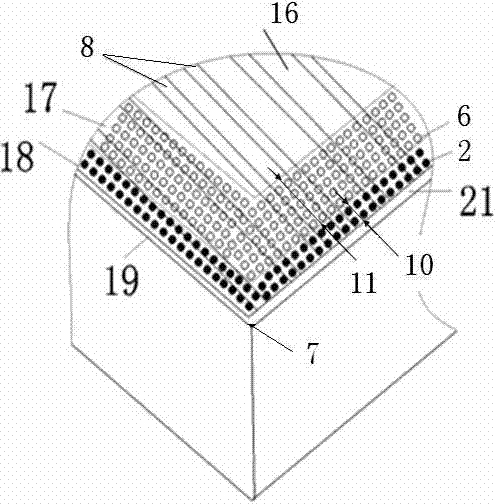

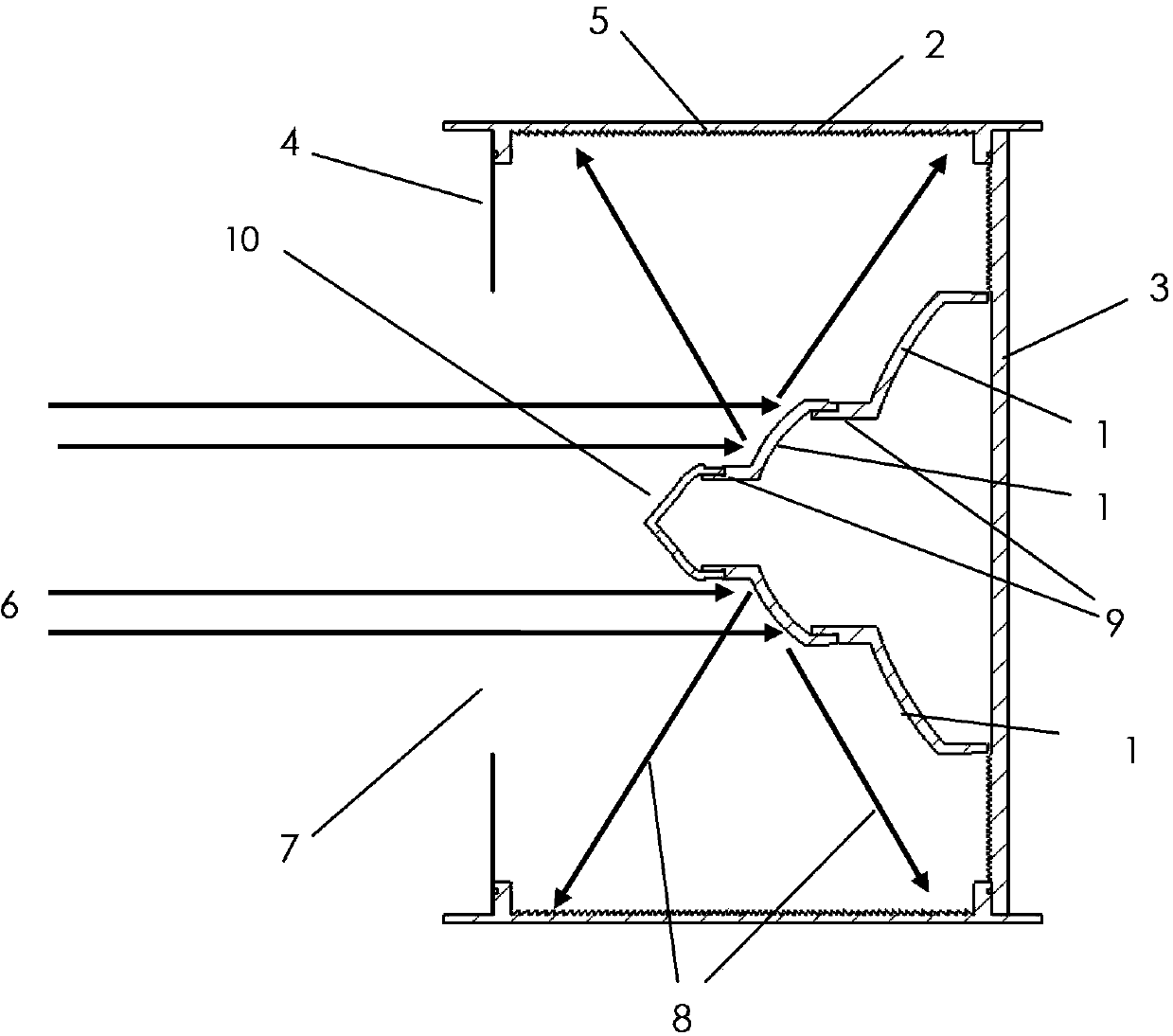

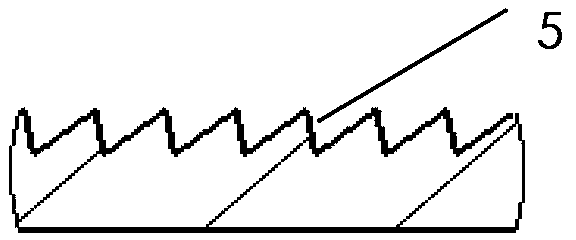

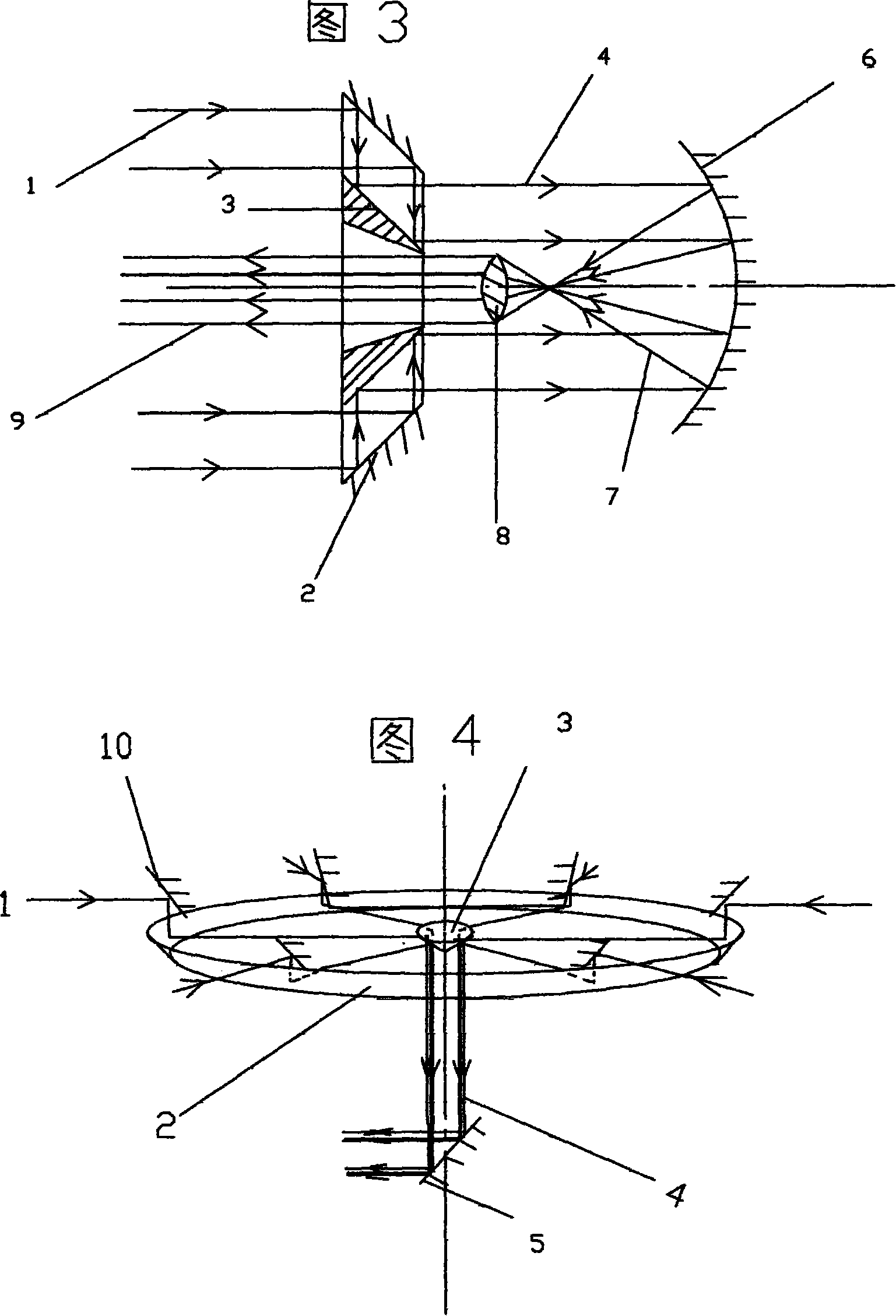

High-energy laser beam expanding and absorbing device

InactiveCN103389157AHigh measurement accuracyAchieve absorptionPhotometry using electric radiation detectorsHigh power lasersLaser power density

The invention discloses a high-energy laser beam expanding and absorbing device which comprises a laser beam expanding cone, an energy absorption cavity, a front panel and a fixing plate, wherein the energy absorption cavity adopts a hollow cylinder; the front panel is arranged at a laser incident end of the energy absorption cavity, and the fixing plate is arranged at the rear end of the energy absorption cavity and used for fixing the laser beam expanding cone; and the laser beam expanding cone comprises a pointed beam expanding cone, at least two spherical beam expanding cones and cylinder transition sections which are arranged in the laser incident direction sequentially, and radii of cylinders of the cylinder transition sections are increased gradually in the laser incident direction. The laser beam expanding cone simultaneously realizes beam expanding of incident laser beams in the length direction and the circumference direction of the absorption cavity, and effectively reduces the power density of laser shot to a heat absorption cylinder by the laser beam expanding cone; and by means of the high-energy laser beam expanding and absorbing device, absorption and conduction of hundred thousand joules to a megajoule of high-power laser energy of continuous waves are realized, the measuring accuracy of an energy meter is improved greatly, and the device has wide applicability.

Owner:NORTHWEST INST OF NUCLEAR TECH

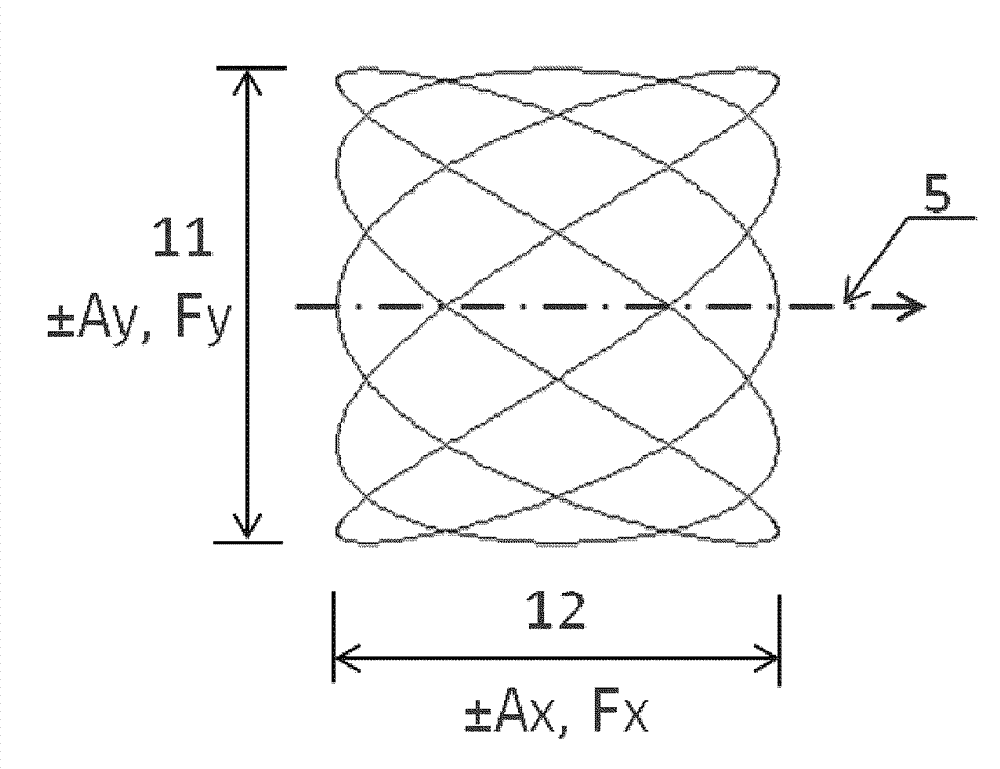

Method for manufacturing a metallic or ceramic component by selective laser melting additive manufacturing

InactiveCN104775116ALow costUniform irradiationTurbinesAdditive manufacturing apparatusSelective laser meltingMetallurgy

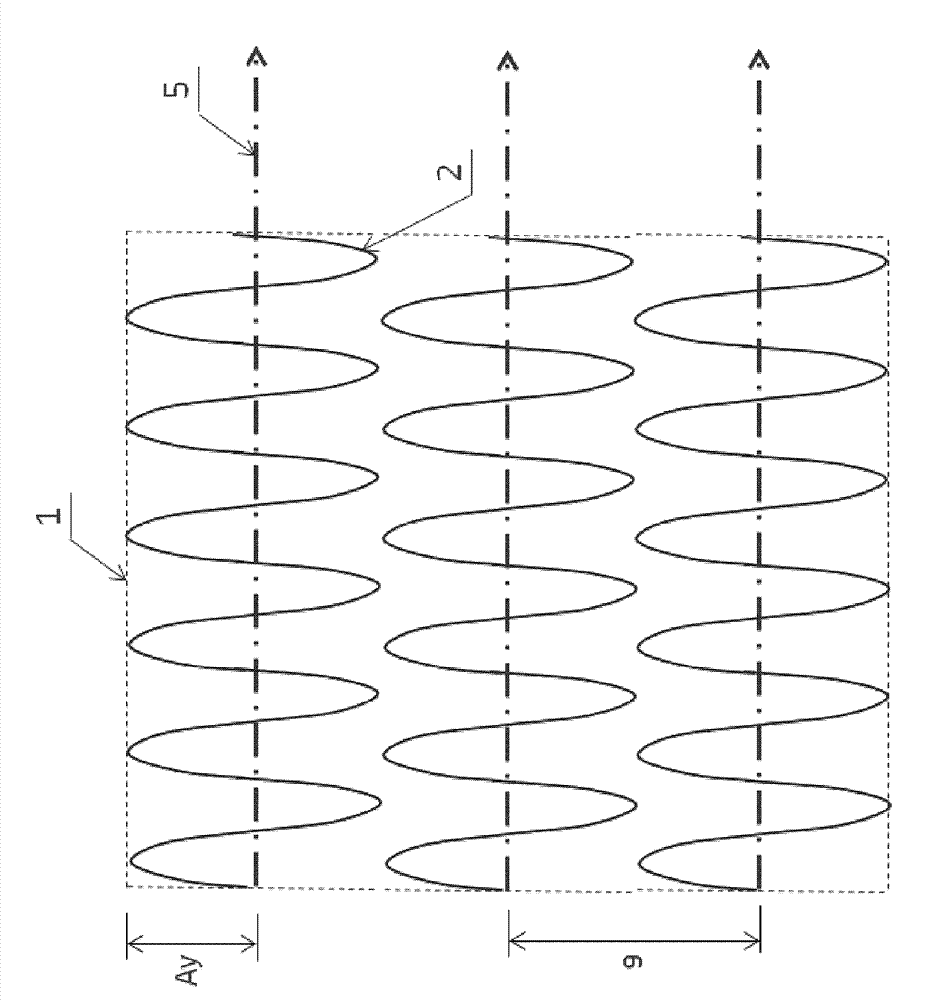

The invention refers to a method for selective laser melting additive manufacturing a three-dimensional metallic or ceramic article / component entirely or partly, comprising the steps of successively building up said article / component layer by layer directly from a powder bed of a metallic or ceramic base material by means of remelting the layers with a high energy laser beam, moving repetitively across the areas, which are to be solidified, wherein the movement of the laser beam is made of a superposition of a continuous linear movement and at least one superimposed oscillation with a determined frequency and amplitude and wherein the oscillation is created by a beam deflection device and the same beam deflection device is also used for linear positioning movement.

Owner:ANSALDO ENERGIA IP UK LTD

Novel process for making piston ring

InactiveCN1632297AHigh surface hardnessReduce coefficient of frictionPiston ringsMachines/enginesPiston ringHigh energy laser beam

The new processing technology of piston ring involves the processing technology of piston ring. It includes the following process steps: casting→grinding→heat treatment→grinding→gold processing→laser strengthening treatment→heat setting→gold processing. Since the surface layer of the piston ring is processed by laser alloying or laser cladding, and is rapidly melted by a high-energy laser beam, the matrix at a certain depth on the outer surface of the piston ring is rapidly melted and then solidified to form a specific ceramic particle reinforced composite coating. The coating and the piston ring body are metallurgical structures, which will not fall off or peel off under the action of external force. The invention is easy for industrial production, has excellent anti-adhesive wear and anti-abrasive wear capabilities, and has good product technical stability.

Owner:江苏仪征威龙活塞环有限公司 +1

Basic electromagnetic force field

An electromagnetic force field configured to protect designated assets against incoming objects, comprising a plurality of layers, wherein the layers are a member of a group consisting of a supercharged plasma window, a curtain of high-energy laser beams arranged in a lattice-like configuration, and a carbon nanotube (CNT) layer, wherein the laser beams are positioned at equal distance between each other and as such as to ensure that at least four laser beams are in the path of the smallest object, and wherein, the CNT layer comprises a plurality of CNT sheets.

Owner:MITRA MANU

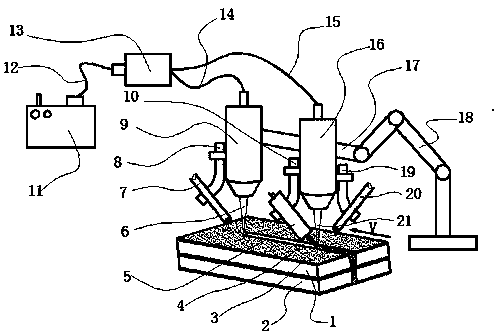

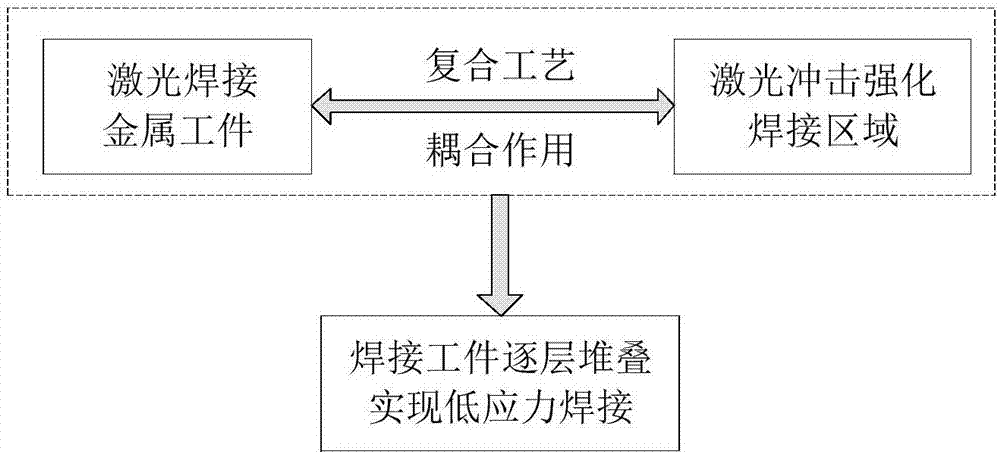

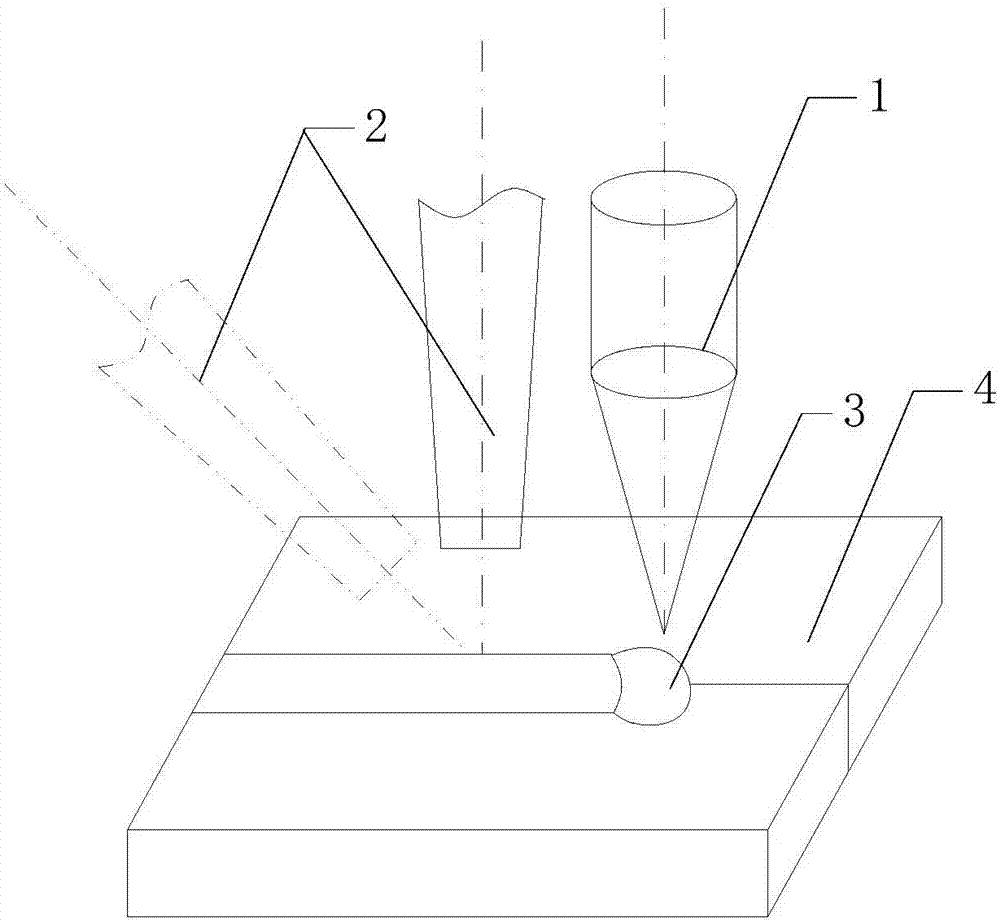

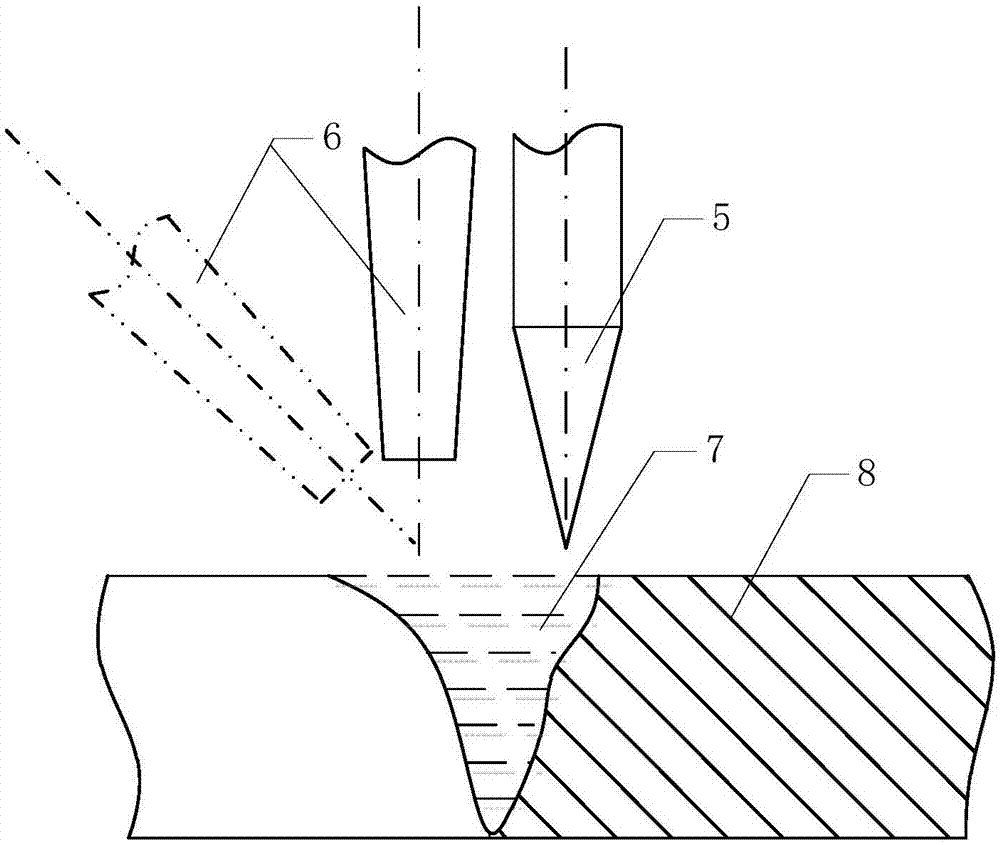

Metal double-laser-beam impact forging low-stress welding device and method

InactiveCN107322159AEliminate or reduce residual stressEliminate or reduce distortionLaser beam welding apparatusWelding residual stressHigh energy laser beam

The invention discloses a metal double-laser-beam impact forging low-stress welding device and method. The device comprises a laser welding system, a laser impact forging system and an intelligent detection control system. The method comprises the steps that 1, the laser welding system heats the surface of a metal workpiece via a high energy laser beam through heat effect radiation for welding, and at the same time, a second short pulsed laser beam conducts impact forging on a welding area within the forging temperature range through an impact wave mechanical effect; and 2, laser welding parameters like pulse width, energy, peak power and repetition frequency and the impact forging parameter are restricted and cooperate mutually, and the optimal temperature area and size range of laser impact forging and the impact strengthening parameter are determined. The heat effect and the impact wave mechanical effect are fully utilized through the two laser beams, time and labor are saved, special heating equipment is omitted, internal residual stress of weldments can be eliminated or relieved, damage of welding residual stress can be avoided or reduced, and great economic benefits and social benefits are brought.

Owner:GUANGDONG UNIV OF TECH

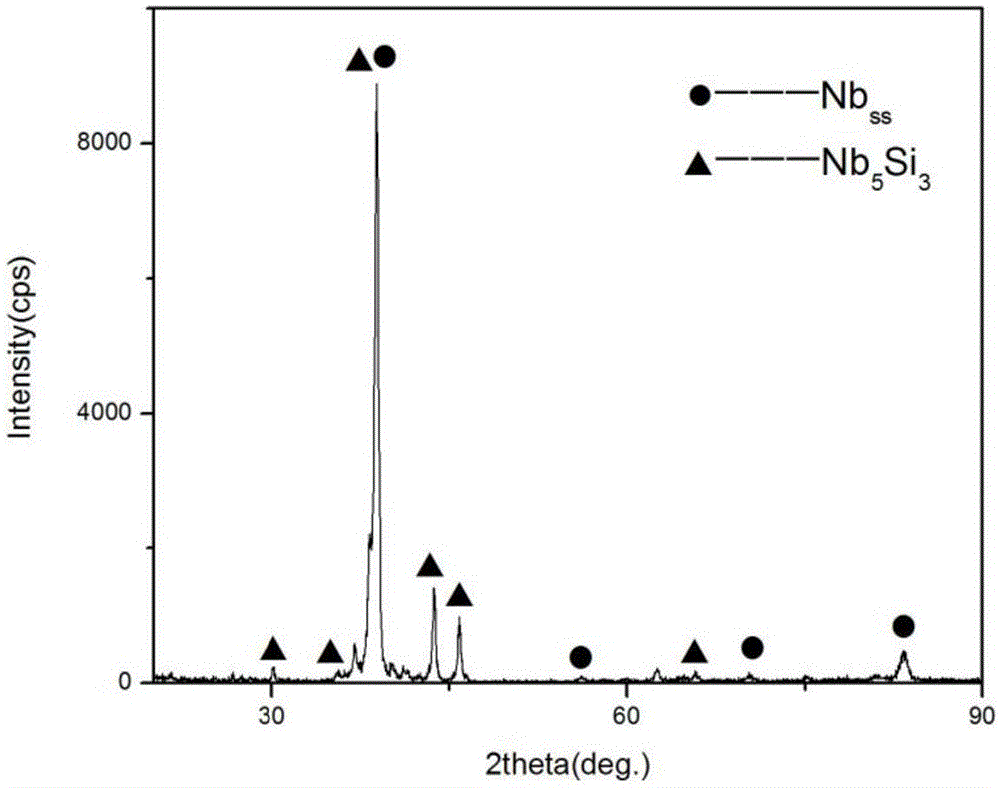

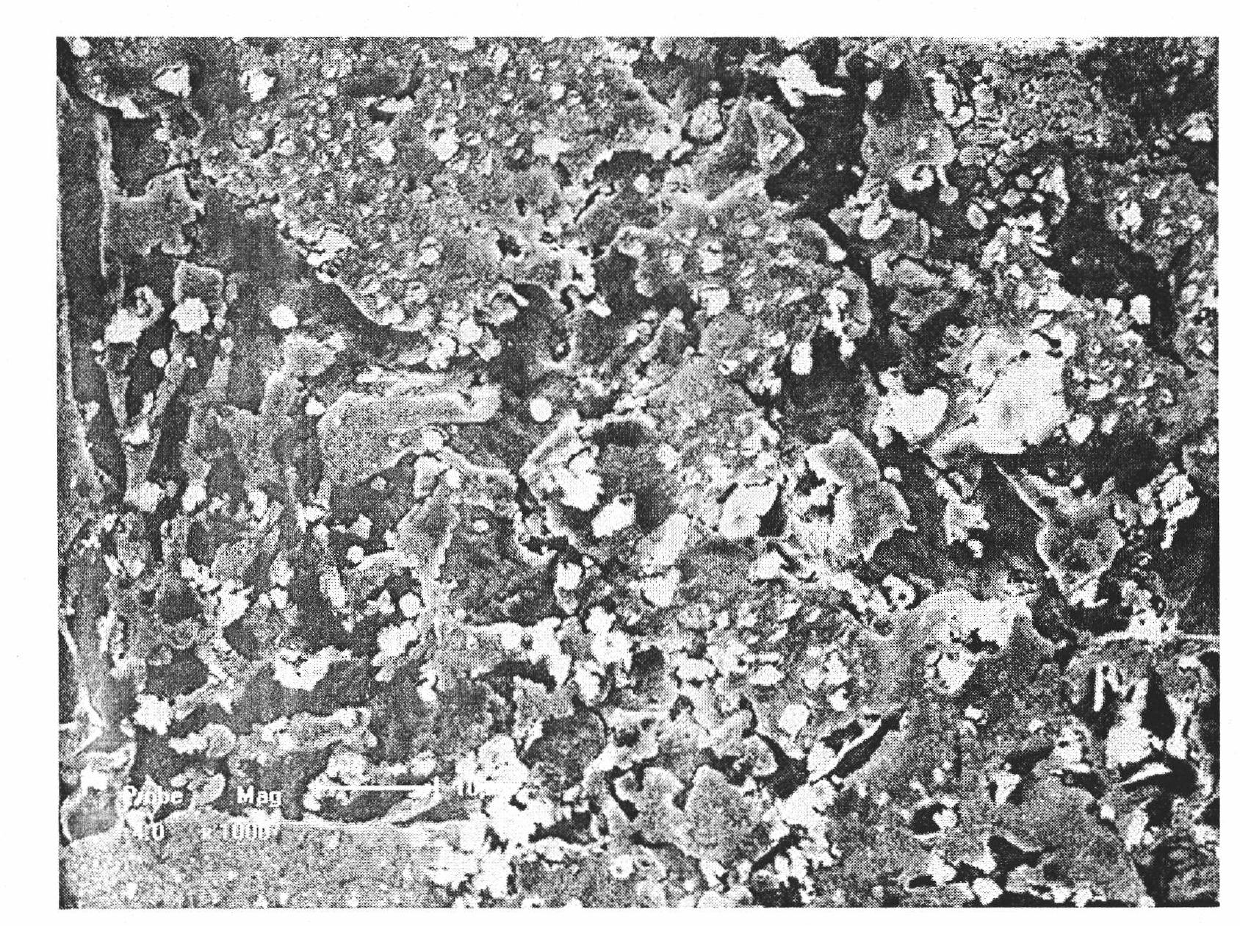

Method for improving high-temperature oxidation resistance of Nb-Si-based multicomponent alloy

The invention discloses a method for improving the high-temperature oxidation resistance of Nb-Si-based multicomponent alloy and belongs to the field of ultrahigh-temperature alloy materials. According to the method, high-energy laser beams are made to act on the surface of an Nb-Si-based multicomponent alloy sample under the protection of argon gas by means of a laser melting device by conducting preheating and setting melting technological parameters reasonably, so that the surface of the alloy is molten and solidified rapidly, and a surface remelting layer with fine, a uniform and compact structure is formed, and thus the high-temperature oxidation resistance of the Nb-Si-based multicomponent alloy is improved by refining the structure. According to the method, the phenomenon that cracks are generated easily in the rapid solidification process of brittle alloy is avoided effectively by adding the preheating procedure; meanwhile, the surface remelting layer and a base body are combined in a metallurgy mode, falling is unlikely to happen when the alloy is in service, and the practicability is high.

Owner:BEIHANG UNIV

Laser cutting method for printed circuit board and working equipment

InactiveCN1449884APromote absorptionReduce absorptionPrinted circuit detailsLaser beam welding apparatusLaser technologyEngineering

The present invention relates to a method for laser cutting printed circuit board and its working equipment, and is characterized by that it utilizes the laser sent by YG laser to form high-energy laser beam after the laser is focussed, and makes the high-energy laser beam be projected on the copper sheet of broad blank of the printed circuit board and makes the copper sheet quickly melt and oxidate so as to implement cutting. Its working equipment mainly is formed from machine frame, longitudinal moving mechanism containing longitudinal screw rod and longitudinal nut and transverse moving mechanism containing transverse screw rod and transverse nut. Said invention can make YG laser implement straight line motion with different slope and curved motion with different curvatures so as to can make predefined cutting.

Owner:徐建平

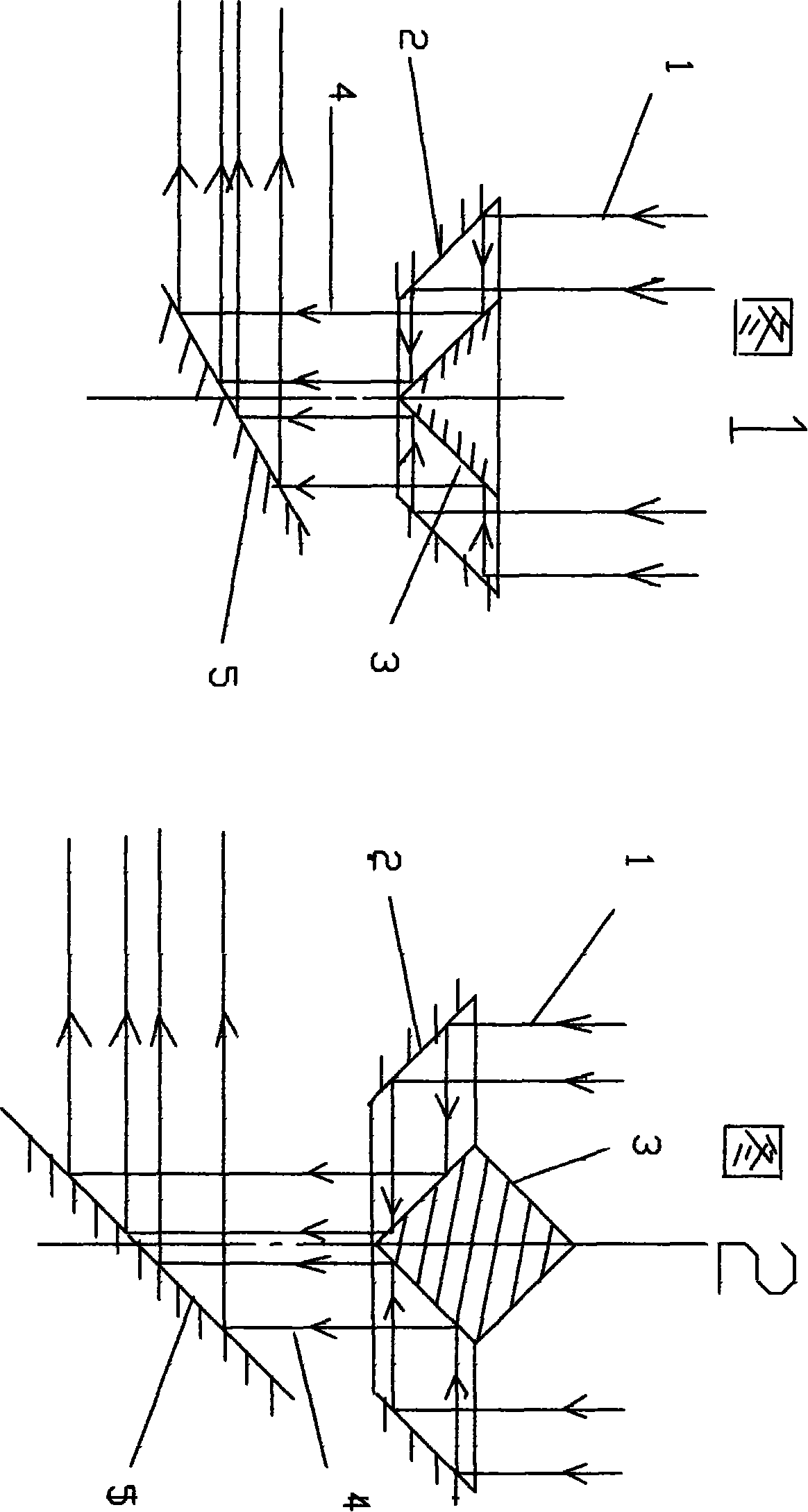

Method for parallel light directly beaming parallel light or focusing light and high-energy high stream intensity device

InactiveCN101196612ASimple methodSimple Optical Surface ShapesOptical elementsHigh energyPlane mirror

The invention discloses a method for bundling the parallel light to parallel light or focusing light, and a device for gaining high energy and high beam current, which belongs to the technical field of optics, especially the field of solar application. The method is to realize direct bundling from the parallel light to parallel light or focusing light by the direct bundling function of the reflective panel combination of double positive cones which are appropriately fixed and form a direct bundling (parallel light or focusing light) device of the parallel light with the sunshine tracking system and output transmission directional system controlled by plane mirror, which is used for heating, food and beverage, disinfection, etc. A re-bundling system is formed by the appropriate combination of the bundling method provided in the invention and other bundling methods (parabolic mirror and lens, large lens and small lens, large and small parabolic mirror, etc.) to gain a high energy and high beam current device used for welding, cutting and blinding by scanning or functioned as other military attack, etc. Simultaneously inject a plurality of parallel light directly bundling devices into a fixed (without tracking system) parallel light directly bundling device from parallel light, and gain the high energy by rebuilding used for metallurgy and power generation, etc. In the same way, simultaneously inject a plurality of laser beam into a fixed (without tracking system) parallel light or focusing light directly bundling device from parallel light to gain high-energy laser beam by rebuilding used for industry or national defense.

Owner:吴荣久

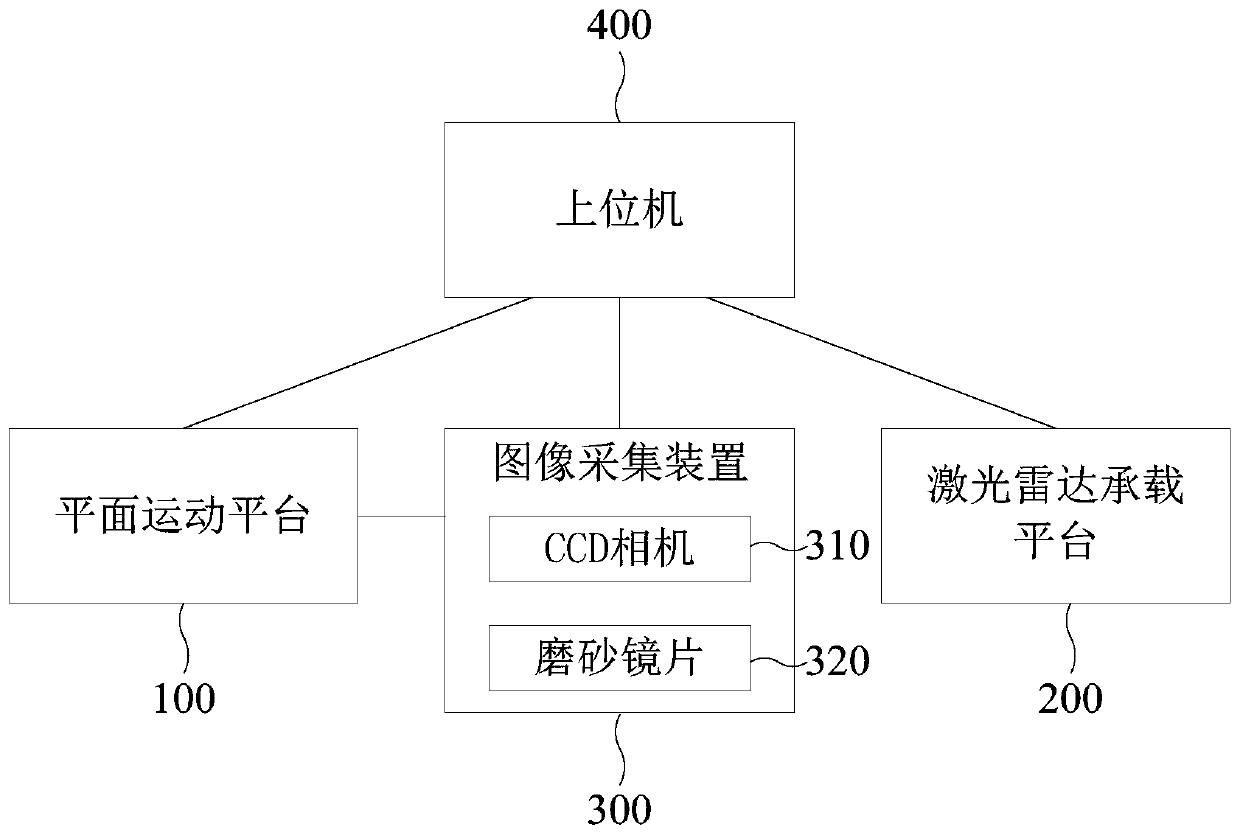

System and method for measuring deflection angle error of laser radar

ActiveCN110553605ASave energyAvoid damage phenomenonWave based measurement systemsUsing optical meansMeasurement deviceLight spot

The invention discloses a system and method for measuring a deflection angle error of a laser radar. The system comprises a planar motion platform, a laser radar bearing platform, an image acquisitiondevice and an upper computer, wherein the planar motion platform is used for driving the image acquisition device to move on a track plane; the laser radar bearing platform is used for bearing a laser radar to be measured and calibrating the position of the laser radar to be measured; the image acquisition device comprises a CCD camera and a frosted lens; a laser beam emitted by the laser radar to be measured forms a light spot on the first surface of the frosted lens, and the CCD camera is used for acquiring an image of the light spot; and the upper computer is connected with the planar motion platform, the laser radar bearing platform and the image acquisition device. According to the technical scheme provided by the embodiment of the invention, a phenomenon that damage is caused by direct incidence of a high-energy laser beam into a measuring device is avoided, the improvement of the precision of a measurement result is facilitated, and the measurement process of the deflection angle error is simple and easy to realize.

Owner:SUZHOU HUAXING YUANCHUANG TECH CO LTD

Method for assisting in laser engineered net shaping of Al2O3-based eutectic ceramic cutter through ultrasound

The method provides a method for assisting in laser engineered net shaping of an Al2O3-based eutectic ceramic cutter through ultrasound. Al2O3 and another kind of ceramic powder are placed in two powder cylinders of a powder feeder, inert gas serves as powder feeding and protective gas, and high-energy laser beams melt ceramic powder injected into a molten pool. By means of pre-adjustment of an ultrasonic device and real-time change of assisting ultrasound power, the equivalent effect of ultrasound on the molten pool is achieved. By means of the cavitation phenomenon of ultrasound, micro-bubbles in the molten pool float and are separated from the molten pool, and the porosity of a eutectic ceramic cutter material is effectively reduced. Due to the ultrasonication theory and the supercooling nucleation theory, a eutectic fiber structure is influenced to grow opposite to the heat flux direction, so thick dendritic crystal is converted into afterbirth-like crystal, and the eutectic spacing of the eutectic ceramic cutter material can reach nanoscale. The method can effectively inhibit material performance degradation caused by cracks and slow growth of a ceramic cutter material at high temperature, and an ultrasonic-assisted system can effectively refine grains, reduce porosity and effectively prevent cracks.

Owner:DALIAN UNIV OF TECH

Method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion

InactiveCN101906572AIncrease profitImprove performanceSelf-propagating high-temperature synthesisIron powder

The invention discloses a method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion, belonging to the technical field of materials. The in-situ formed ceramic particle reinforced iron-aluminum-based composites are prepared by the following steps of: putting tungsten ore powder, iron powder, aluminum powder and carbon powder in a ball mill for milling to obtain a mixed powder material; and compressing the mixed powder material into a pressed compact, transmitting a high-energy laser beam by employing a CO2 laser processing machine to ignite the surface of the pressed compact and trigger self-propagating high temperature synthesis of the pressed compact. By the invention, two ceramic particle reinforced phases are simultaneously formed on one substrate, which shortens the preparation process of the composites, lowers material manufacture cost and facilitates large-scale production and application.

Owner:LIAONING TECHNICAL UNIVERSITY

Car steel-aluminum splicing joint welding method and system

InactiveCN107971650AImprove connection strengthIncrease binding areaWelding/soldering/cutting articlesWelding apparatusLaser cuttingEngineering

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com