Method for assisting in laser engineered net shaping of Al2O3-based eutectic ceramic cutter through ultrasound

A technology of laser near-net shaping and ceramic cutting tools, which is applied in the field of cutting tool manufacturing, can solve problems such as poor fracture toughness, achieve the effect of reducing porosity and avoiding pseudo-eutectic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

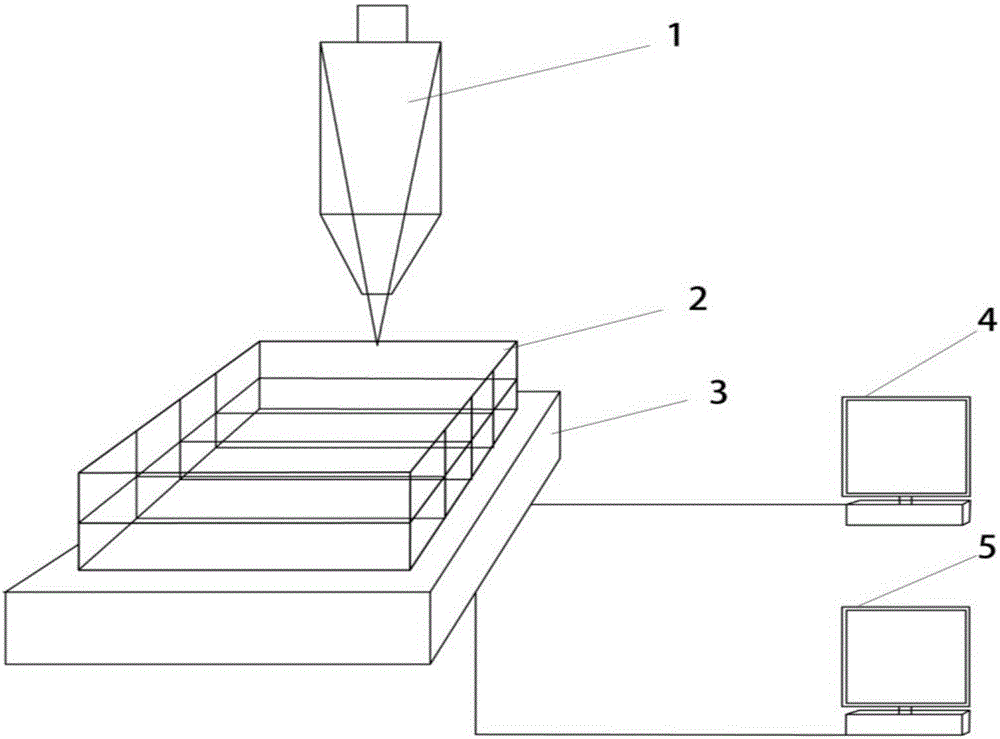

[0022] Using Nd:YAG solid-state continuous laser and ultrasonic auxiliary device 2 o 3 and ZrO 2 The powder is subjected to laser near-net forming, and the specific forming steps are as follows:

[0023] A. Polish the platform 3 of the ultrasonic generating device with sandpaper, clean it with acetone, ethanol, and deionized water in sequence, and dry it, and select Al with a diameter of 40-90 μm 2 o 3 and ZrO 2 Powder, put the powder in an electric blast drying oven and dry at 100°C for 4 hours, adjust the ultrasonic platform 3 so that the powder flow focus of the coaxial powder feeding is on the surface of the substrate, and at the same time ensure that the powder flow focus coincides with the laser spot to maximize To improve the powder utilization rate, and then Al 2 o 3 and ZrO 2 The powder is put into the two powder cylinders of the powder feeder respectively;

[0024] B. Turn on the ultrasonic generator 4, search for the resonance frequency of the ultrasonic vib...

Embodiment 2

[0028] Using Nd:YAG solid-state continuous laser and ultrasonic auxiliary device 2 o 3 Laser near-net forming with SiC powder, the specific forming steps are as follows:

[0029]A. Before the experiment, the platform 3 of the ultrasonic generating device was polished with sandpaper, washed with acetone, ethanol, and deionized water in sequence, and dried, and Al with a diameter of 40-90 μm was selected. 2 o 3 and SiC powder, put the powder in an electric blast drying oven and dry at 100°C for 5 hours, adjust the ultrasonic platform 3 so that the powder flow focus of the coaxial powder feeding is on the surface of the substrate, and at the same time ensure that the powder flow focus coincides with the laser spot, so as to Maximize powder utilization, then put the ceramic powder into the powder cylinder of the powder feeder;

[0030] B, turn on the ultrasonic generator 4, search the resonance frequency of the ultrasonic vibration system in the 20~22kHz frequency range, observ...

Embodiment 3

[0034] Using Nd:YAG solid-state continuous laser and ultrasonic auxiliary device 2 o 3 and Si 3 N 4 The powder is subjected to laser near-net forming, and the specific forming steps are as follows:

[0035] A. Before the experiment, the platform 3 of the ultrasonic generating device was polished with sandpaper, washed with acetone, ethanol, and deionized water in sequence, and dried, and Al with a diameter of 40-90 μm was selected. 2 o 3 and Si 3 N 4 Powder, put the powder in an electric blast drying oven and dry at 100°C for 4 hours, adjust the ultrasonic platform 3 so that the powder flow focus of the coaxial powder feeding is on the surface of the substrate, and at the same time ensure that the powder flow focus coincides with the laser spot to maximize Maximize the powder utilization rate, and then put the ceramic powder into the powder cylinder of the powder feeder;

[0036] B. Turn on the ultrasonic generator 4, search for the resonance frequency of the ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com