Patents

Literature

230 results about "Ceramic knife" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A ceramic knife is a knife designed with a ceramic blade typically made from zirconium dioxide (ZrO₂; also known as zirconia). These knife blades are usually produced through the dry-pressing and firing of powdered zirconia using solid-state sintering. It is 8.5 on the Mohs scale of mineral hardness, compared to 4.5 for normal steel and 7.5 to 8 for hardened steel and 10 for diamond. The resultant blade has a hard edge that stays sharper for longer when compared to conventional steel knives. Whilst the edge is harder than a steel knife, it is less tough and thus more brittle. The ceramic blade is sharpened by grinding the edges with a diamond-dust-coated grinding wheel.

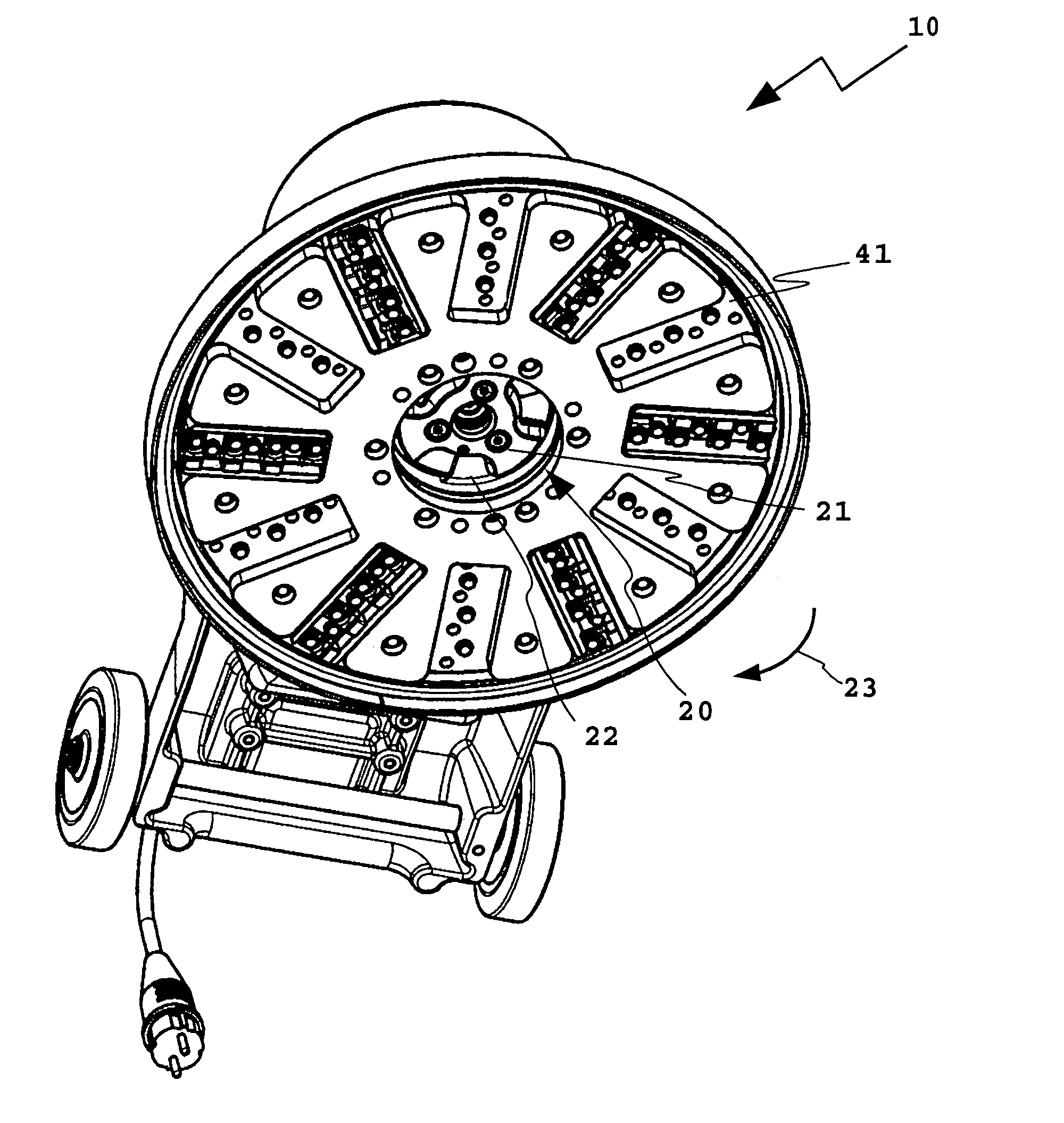

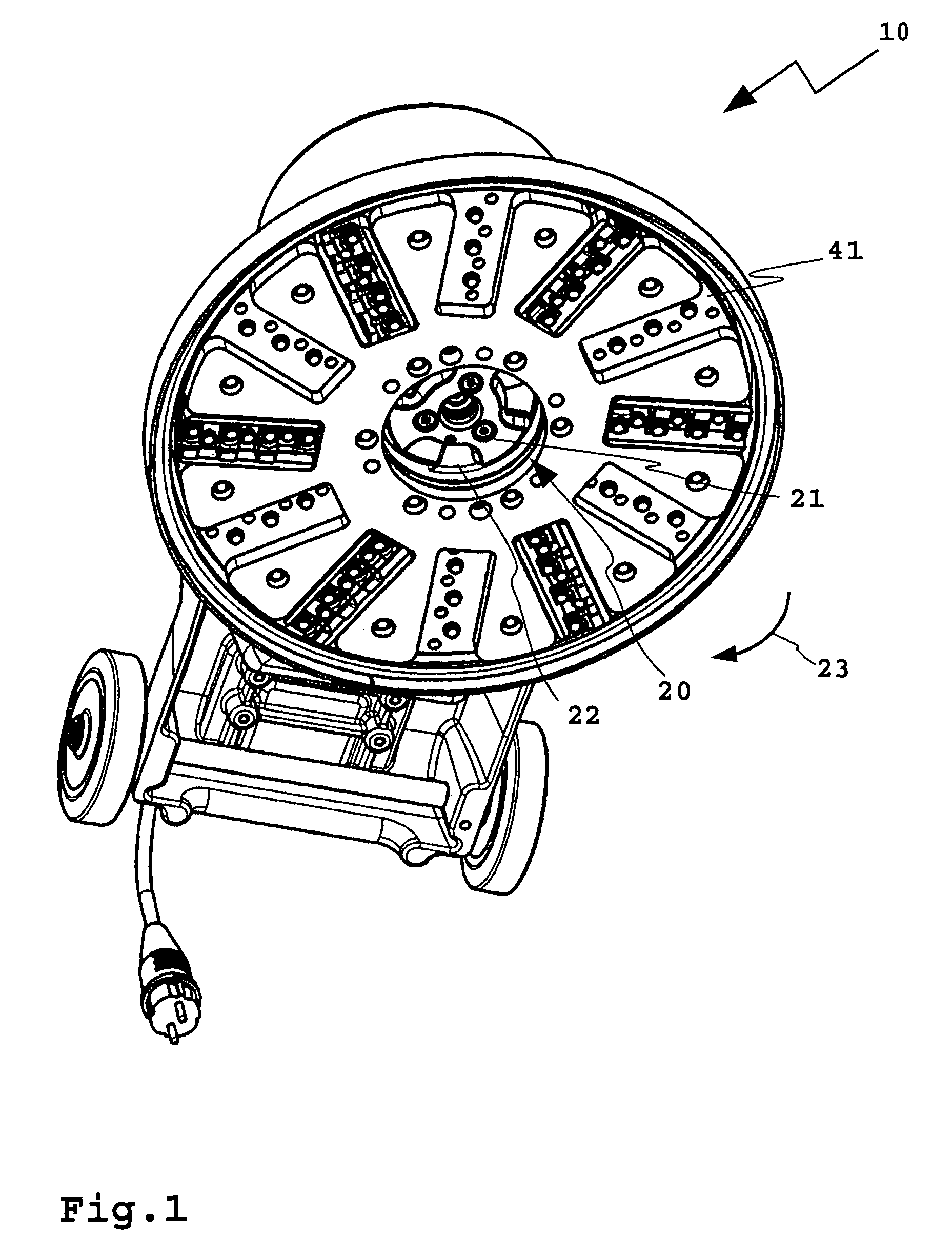

Milling disk for a floor machining appliance

ActiveUS7104739B2Avoid excessive wearHeavy loadMilling cuttersAttachable milling devicesEngineeringSubstructure

A milling disk for a floor machining appliance has a plurality of mounts for holding interchangeable plate-like milling tips, the milling disk being driven for rotation by the floor machining appliance and being held substantially parallel to the substructure to be machined so that the milling tips may bite into the substructure and remove matter from the surface thereof. The milling tips are constituted by ceramic cutting tips.

Owner:EUGEN LAEGLER

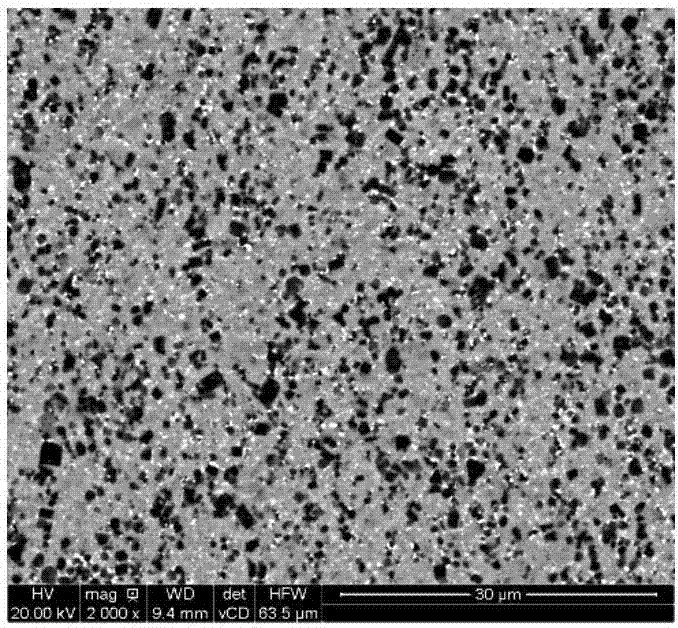

Al2O3/ZrO2 (Y2O3) nano composite ceramic tool material and its preparing method

This is a kind of Al2O3 / ZrO2(Y2O3) nanometer compound ceramics knife material and its producing method. The material components include substance material and tenacity increasing phase. The substance material is Al2O3, and its grain granularity is 60 - 200 nm; according to volume percentage, its content is 65% - 90%, and the tenacity increasing phase ZrO2(Y2O3) nanometer powder containing 1.5% - 3.5% Y2O3 according to mol percentage; its grain granularity is 50 - 100 nm, and according to volume percentage, its content is 10% - 35%; its producing craft steps include producing substance material and nanometer powder of tenacity increasing phase by hydrochemistry method, produce grains, prepare material, ball mill to mix material, flan equal static pressure molding and sinter. The anti-bending strength of the prepared ceramics knife material ªÊ= 750 - 950 MPa, the fracture toughness KIC = 7.8 - 9.6 MPaíñm1 / 2, Weibull modulus m = 10 - 11.7, and durable intensity can get to 4 - 6 hours.

Owner:NORTHEASTERN UNIV

Special ceramic cutter material for wire-board or circuit board and preparation method thereof

InactiveCN101157554AImprove impact toughnessImprove wear resistanceTitanium carbideCeramic cutting tool

The invention discloses a ceramic cutting tool and the preparation method thereof special for a smashing line board or a circuit board, and belongs to the art of the smashing equipment. The ceramic cutting tool takes crystal whisker as the plasticizing material; tungsten carbide as the substrate material; titanium carbide as anti-friction agent; carbon as deoxidizing agent; and chromic compound, lanthanum oxide and cerium oxide as additive. The ingredients are evenly blended and directly molded by heat pressing. The raw material is not taken out until being fully mixed, and is then positioned into the sample heat pressing groove of a hot-press machine. The thermo-compression intensity of pressure is 10-40MPa, and the hot-press temperature ranges from 1,480 to 1,600DEG C. The flexible ceramic cutting tool of the invention is provided with good resilience, wearlessness, high rigidity and chemical stability. The technique of the cutting tool is quite simple and the production period is far shorter than the production period of the conventional preparation method that carries the compression molding of the evenly mixed raw materials first and then the sinter molding. The cutting tool material is fit for the cutting tool special for the making of a waste line board and the smashing equipment of the circuit board.

Owner:TSINGHUA UNIV

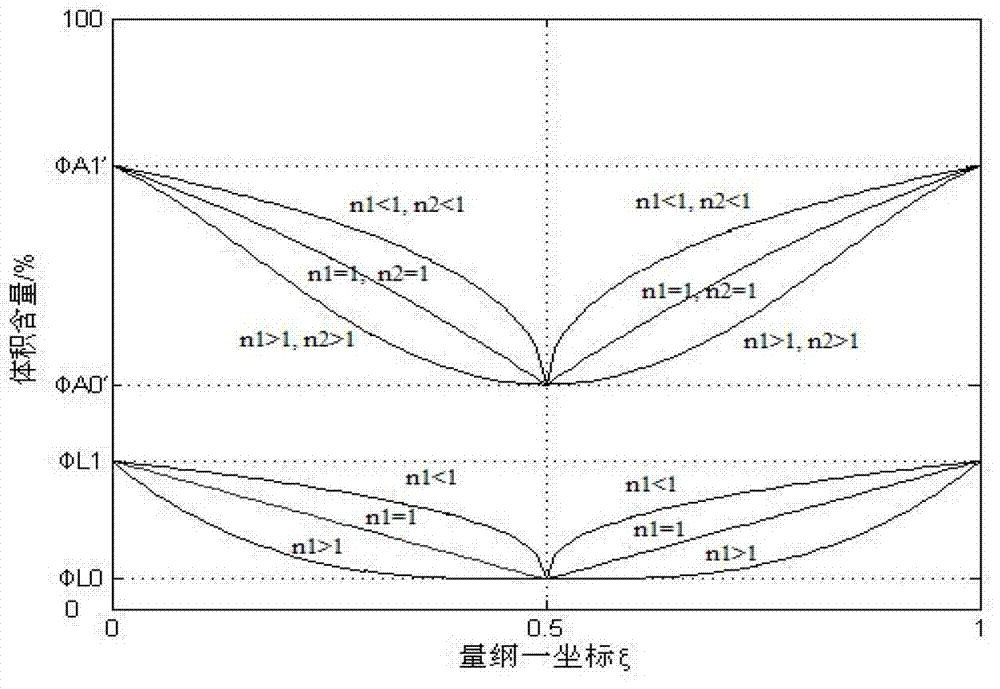

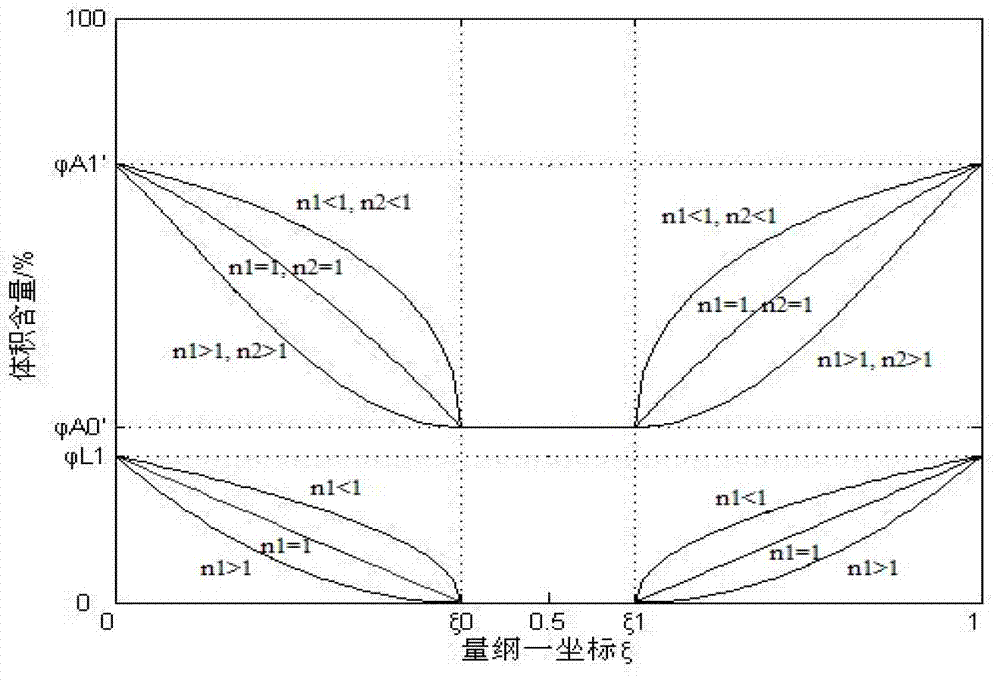

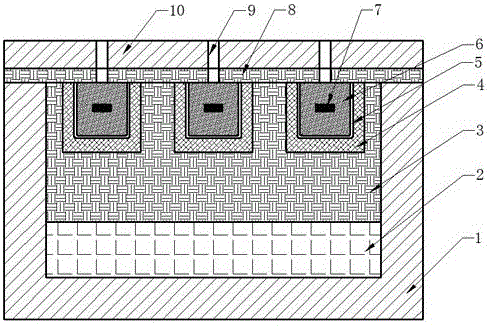

Multivariate gradient self-lubricating ceramic cutting tool material with surface having residual compressive stress and preparation method of multivariate gradient self-lubricating ceramic cutting tool material

The invention relates to a multivariate gradient self-lubricating ceramic cutting tool material with a surface having residual compressive stress and a preparation method of the multivariate gradient self-lubricating ceramic cutting tool material. The multivariate gradient self-lubricating ceramic cutting tool material subjected to composition gradient design by applying a multivariate gradient composition distribution function, and is formed by being subjected to layered paving and hot pressed sintering by taking alpha-Al2O3 as a basal body, adding (W, Ti) as wild phase, taking calcium fluoride as a solid lubricant and taking magnesium oxide and nickel oxide as sintering aids. The cutting tool material has (2K-1) layers of gradient structures components of which are symmetrical relative to a middle layer. The highest 8-12% of calcium fluoride content on the surface layer is reduced to be zero of the calcium fluoride content on the middle layer. The residual compressive stress exists between two surface layers of the cutting tool material. Various mechanical performance indexes of the ceramic cutting tool material are all higher than those of homogeneous self-lubricating ceramic cutting tool materials with the same material system, and the multivariate gradient self-lubricating ceramic cutting tool material has high antifriction and high friction-resistant properties at the same time and can be used for dry cutting and cutting processing of materials difficult to process.

Owner:QILU UNIV OF TECH

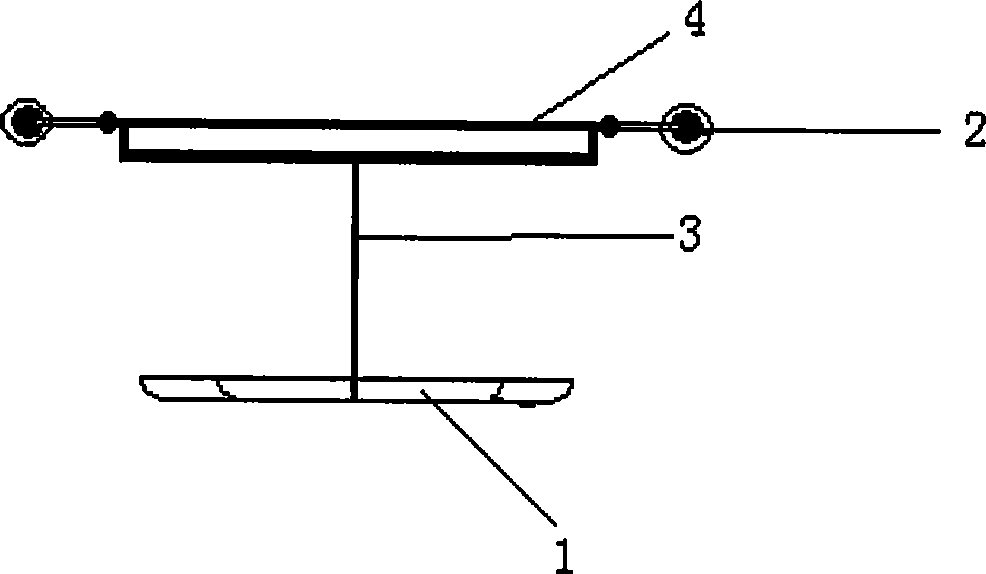

Precision sharpener for ceramic knife blades

InactiveUS20130165021A1Inexpensive techniqueEdge grinding machinesRevolution surface grinding machinesMotor driveKnife sharpener

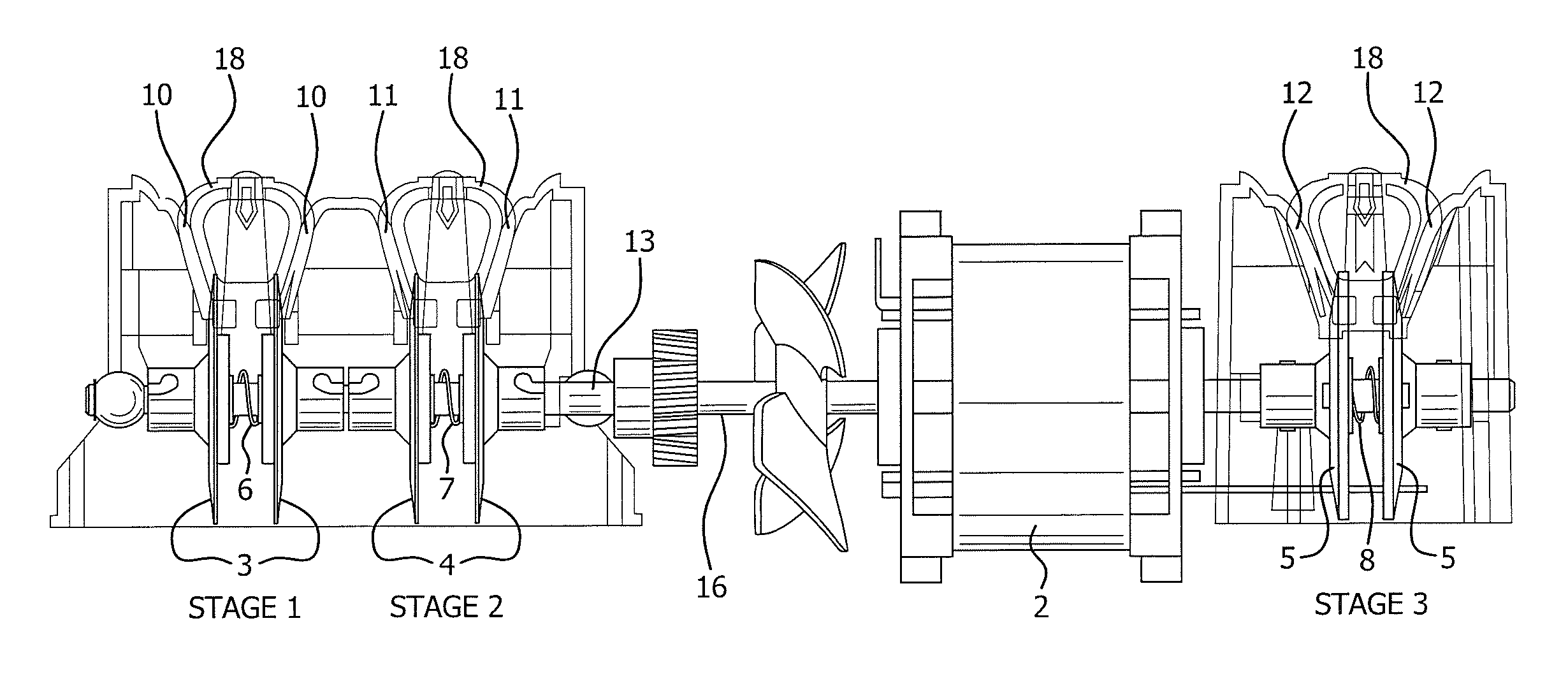

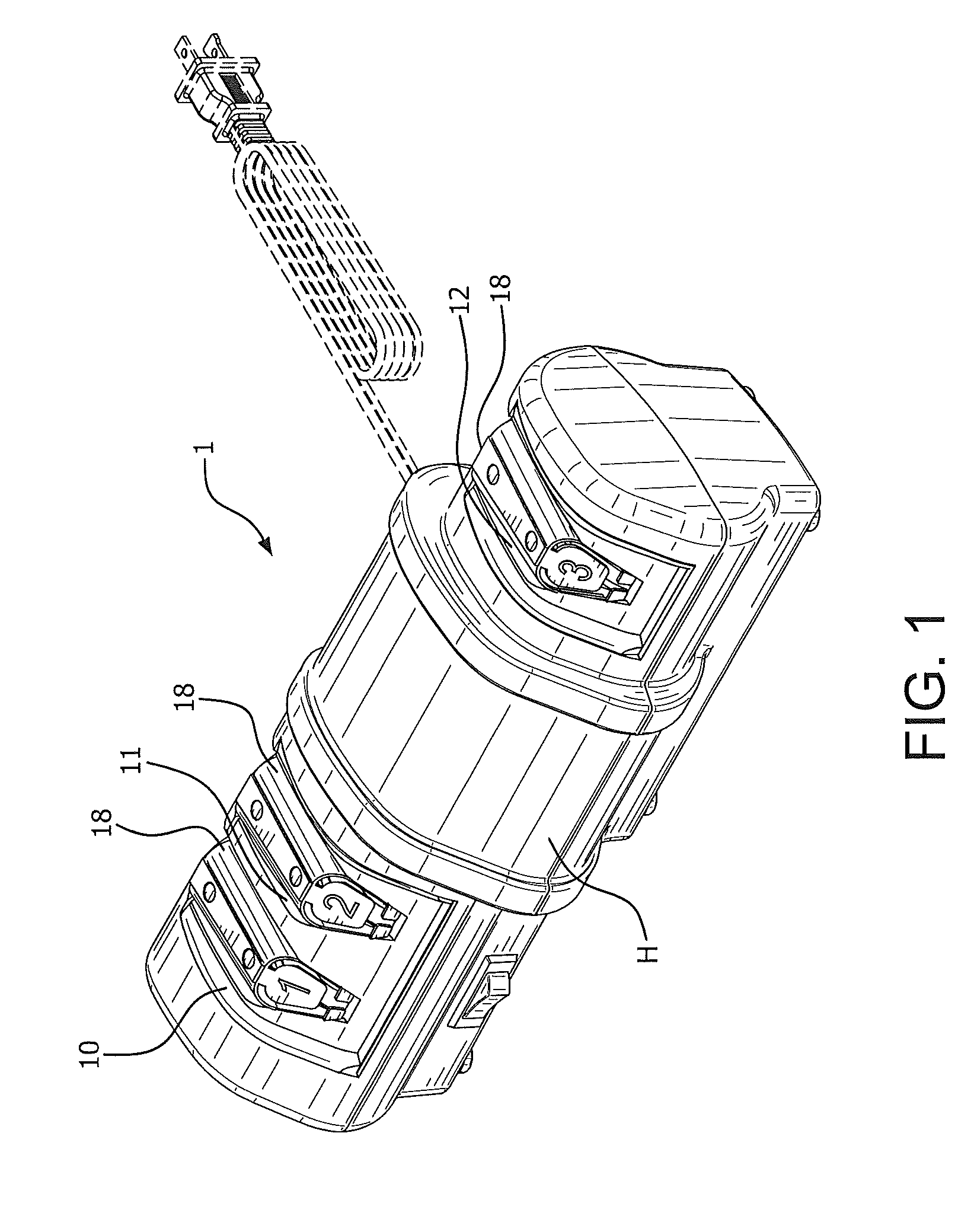

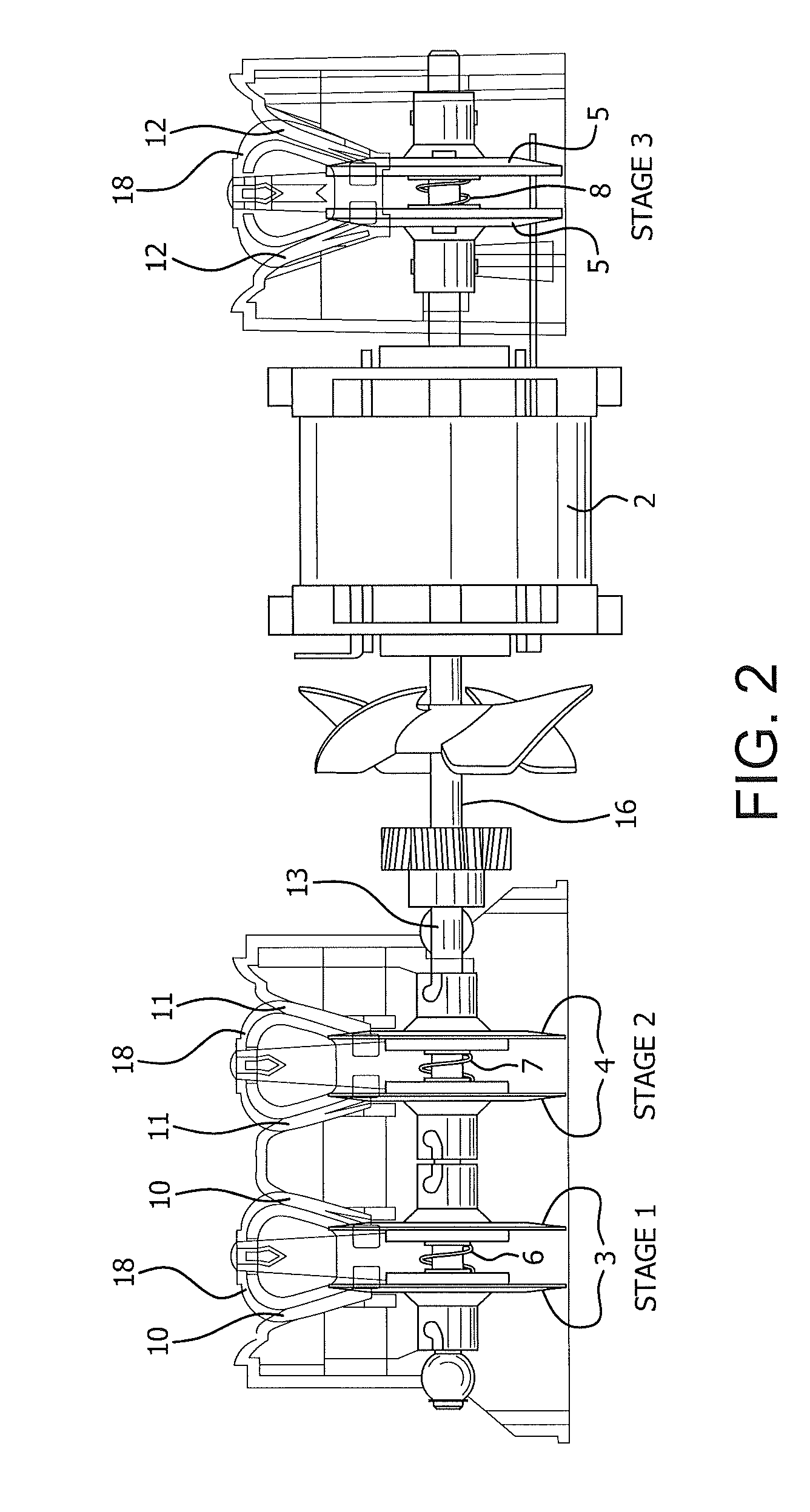

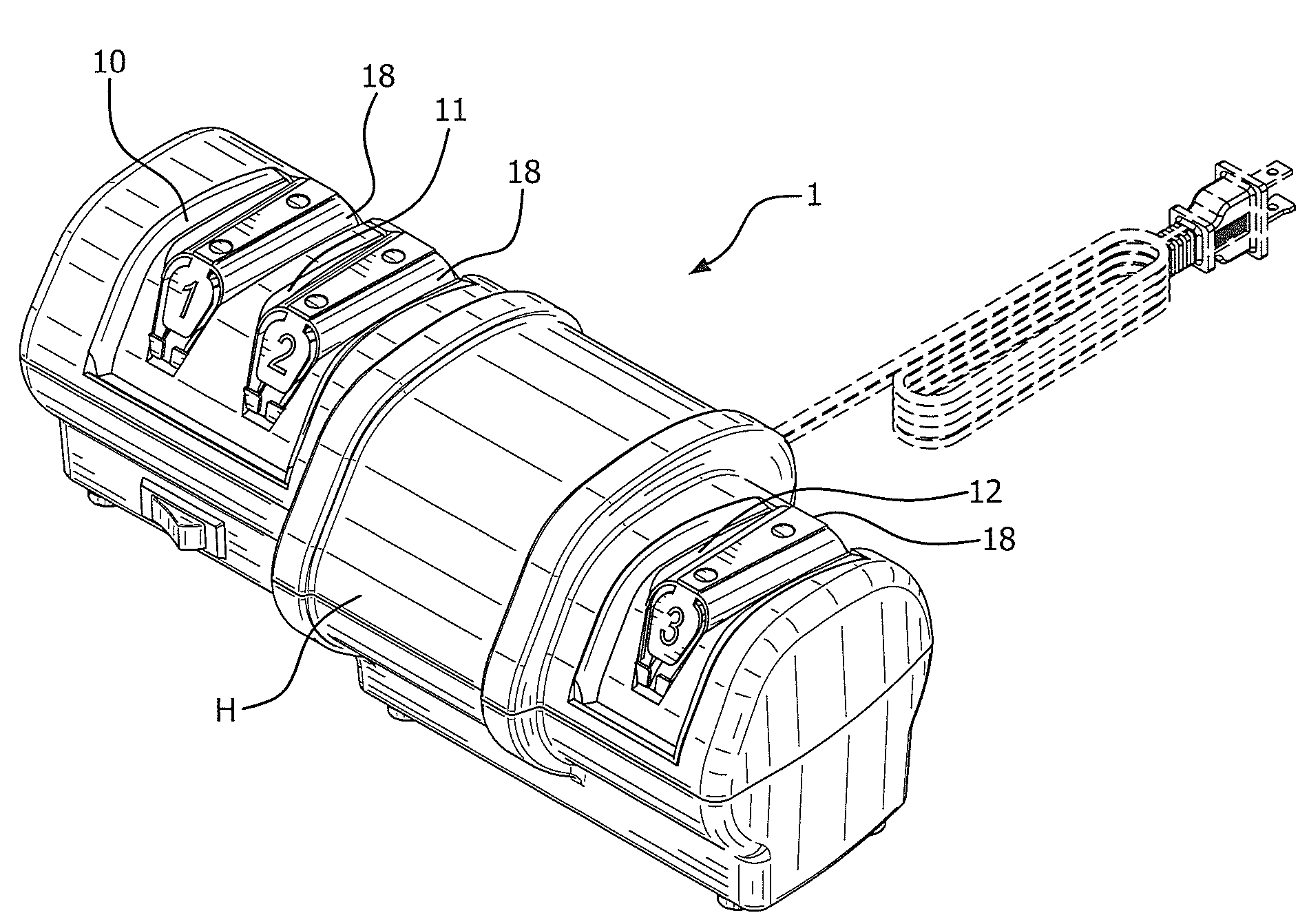

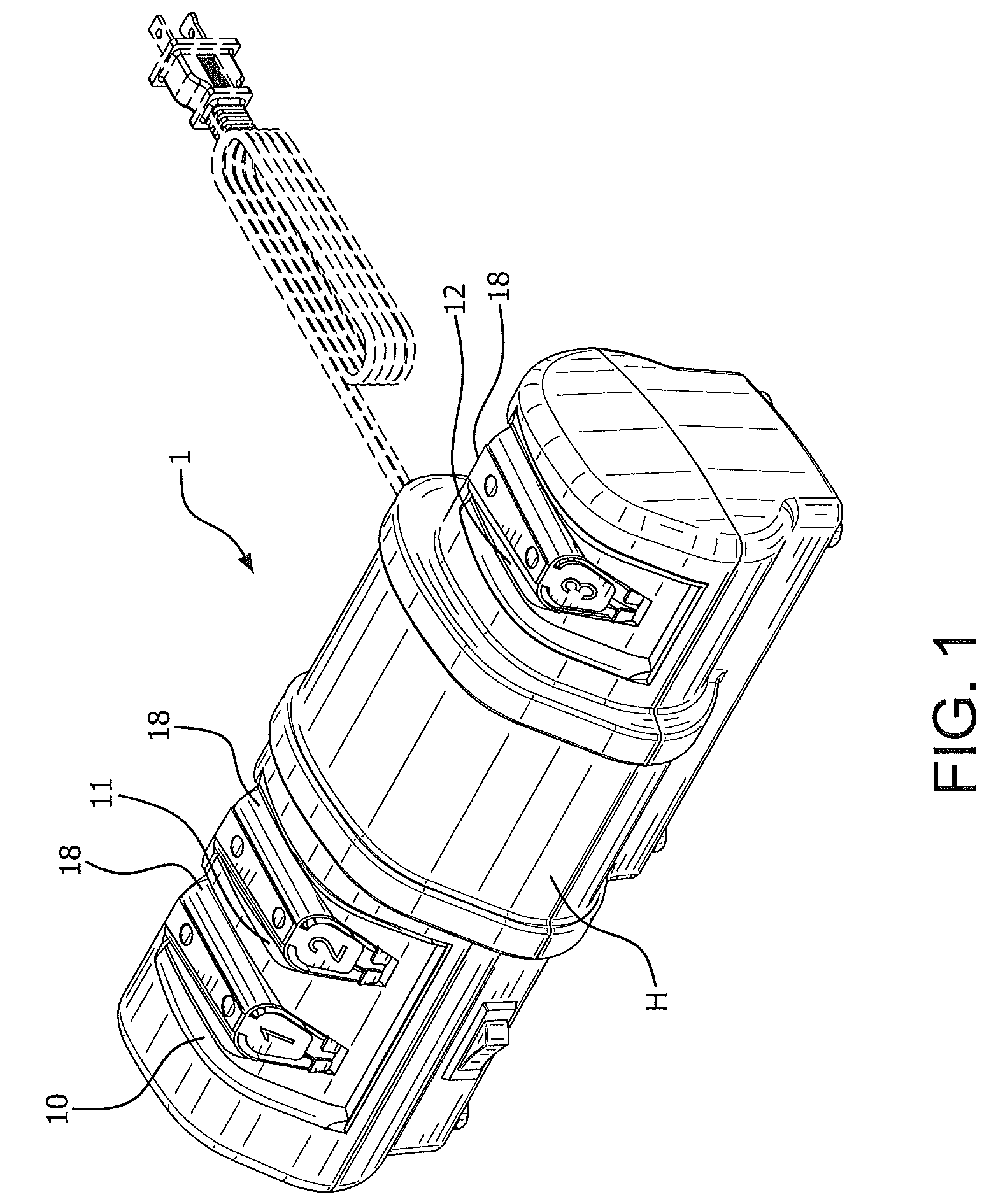

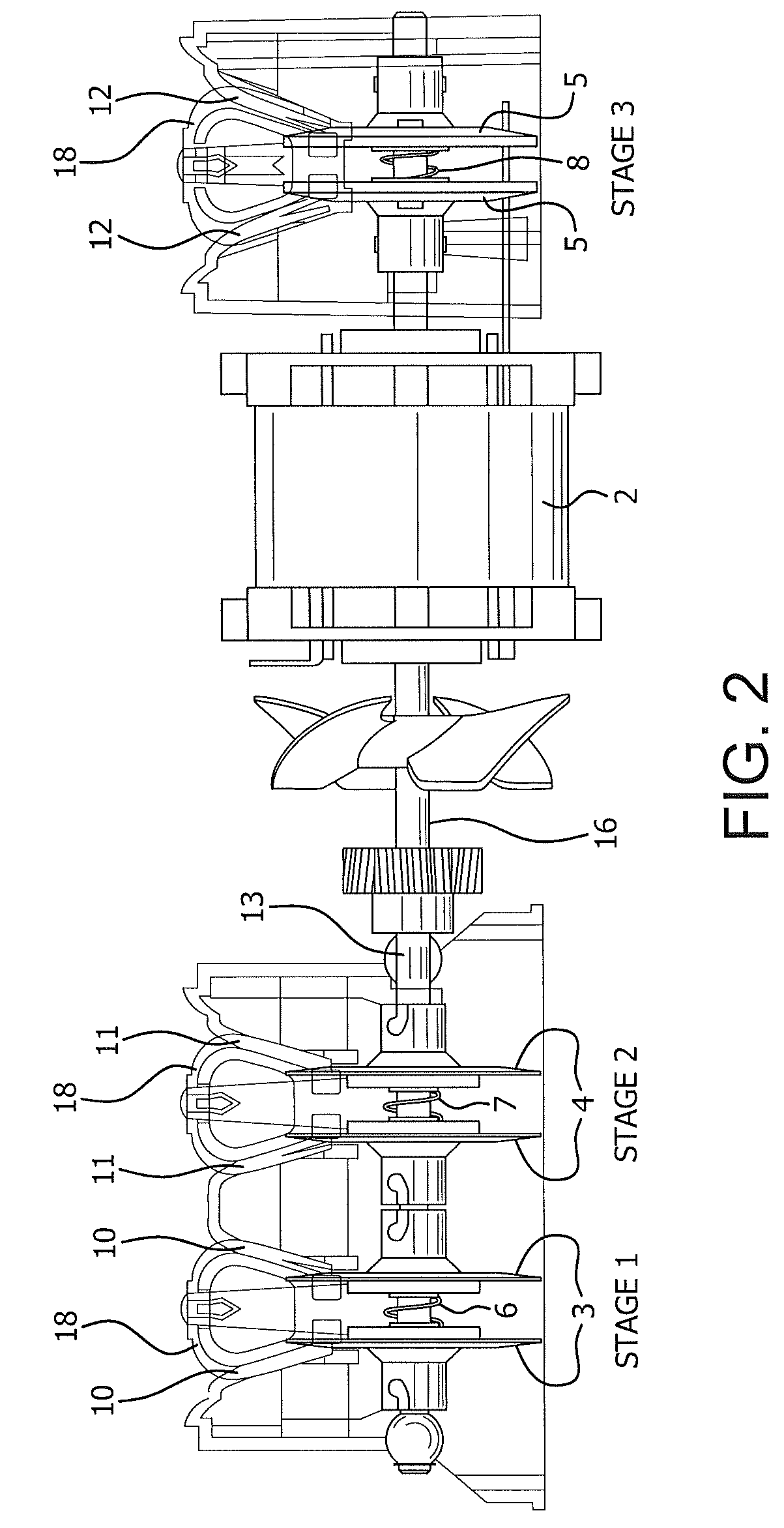

An electrically powered knife sharpener for ceramic (or other brittle, crystalline or amorphous media which could be used for blades) knives includes at least one pre-sharpening stage with a sharpening member(s) and includes a final stage with a sharpening member(s). There are one or more motor driven shafts on which the abrasive surfaced sharpening members, such as disks, are mounted. Guide structure is provided to guide the knife for aligning and positioning the knife facet precisely at a defined location on the abrasive surface of each rotating sharpening member. The pre-sharpening stage sharpening member(s) moves in a first direction. The final stage sharpening member(s) moves in a second direction which differs from the first direction.

Owner:EDGECRAFT

Precision sharpener for ceramic knife blades

InactiveUS8585462B2Inexpensive techniqueEdge grinding machinesRevolution surface grinding machinesMotor driveKnife sharpener

An electrically powered knife sharpener for ceramic (or other brittle, crystalline or amorphous media which could be used for blades) knives includes at least one pre-sharpening stage with a sharpening member(s) and includes a final stage with a sharpening member(s). There are one or more motor driven shafts on which the abrasive surfaced sharpening members, such as disks, are mounted. Guide structure is provided to guide the knife for aligning and positioning the knife facet precisely at a defined location on the abrasive surface of each rotating sharpening member. The pre-sharpening stage sharpening member(s) moves in a first direction. The final stage sharpening member(s) moves in a second direction which differs from the first direction.

Owner:EDGECRAFT

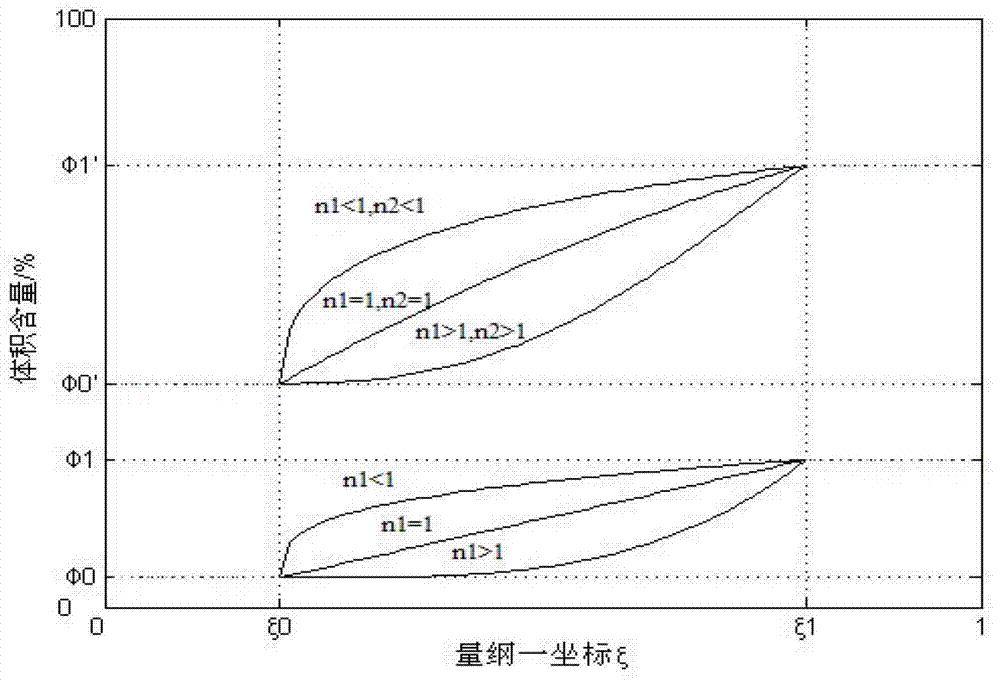

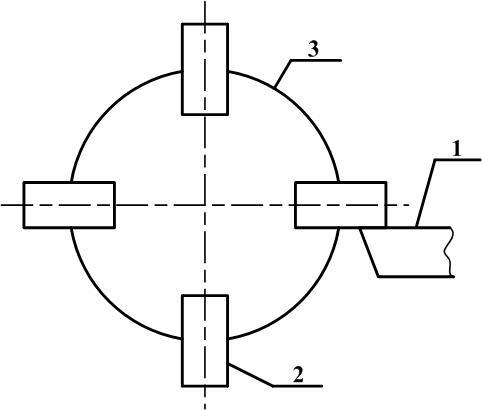

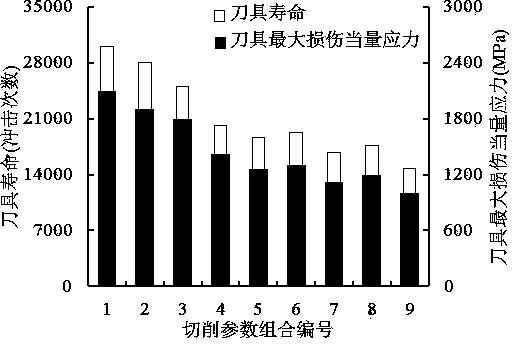

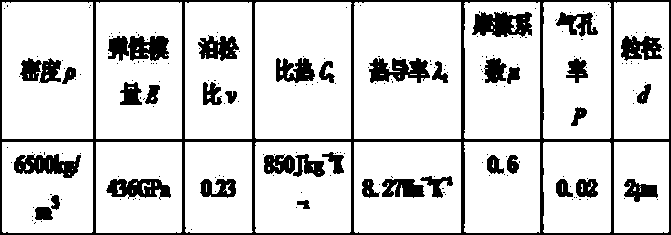

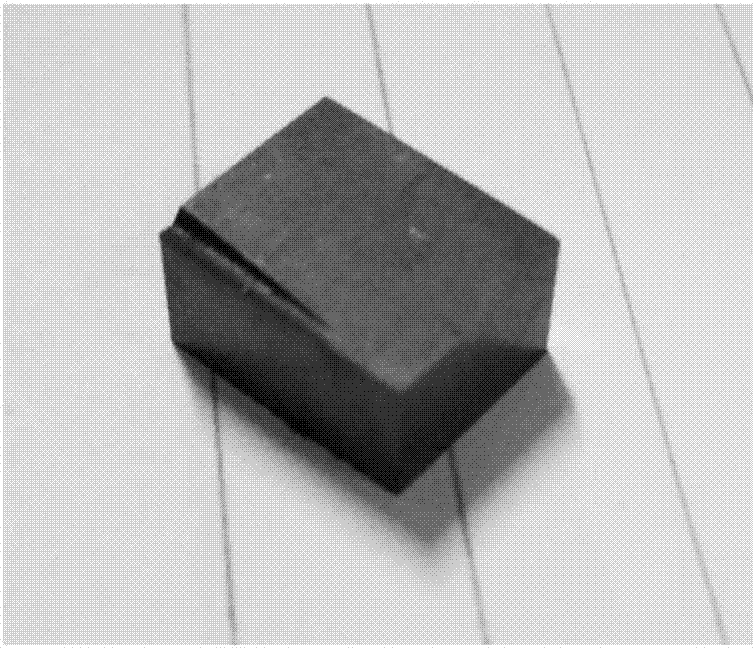

Ceramic cutting tool cutting parameter optimization method on interrupted cutting conditions

InactiveCN104050322AExtend your lifeReduce optimization costsSpecial data processing applicationsStructural engineeringCeramic knife

The invention discloses a ceramic cutting tool cutting parameter optimization method on interrupted cutting conditions. The method comprises the steps that parameters of a ceramic cutting tool are determined; the initial state value and the critical state value of microscopic damage to the ceramic cutting tool are determined; parameters of workpiece materials are determined; geometrical shapes of the cutting tool and workpieces are set in finite element simulation software, and all the relevant parameters of cutting tool materials and the workpiece materials are imported; cutting parameter combinations adopted in the finite element simulation process are determined through an orthogonal experimental design method; the maximum damage equivalent stress value is calculated; the cutting parameter combination with the minimum value is selected. According to the ceramic cutting tool cutting parameter optimization method, the influences of the cutting tool microscopic damage state and external loads on invalidation of the cutting tool are considered, and meanwhile the orthogonal experimental design method is adopted, so that the optimization precision of the cutting parameter combinations is higher; the cutting parameter combinations are optimized, and the cutting parameter optimization cost is greatly reduced; the ceramic cutting tool cutting parameter optimization method can be widely applied to optimization of the cutting parameter combinations on the various interrupted cutting conditions, and the purpose of prolonging the service life of the cutting tool is achieved finally.

Owner:HENAN POLYTECHNIC UNIV

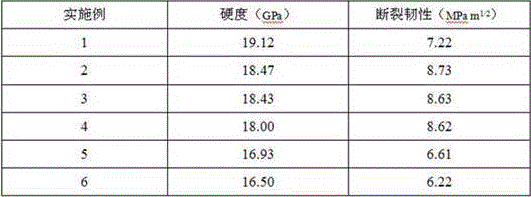

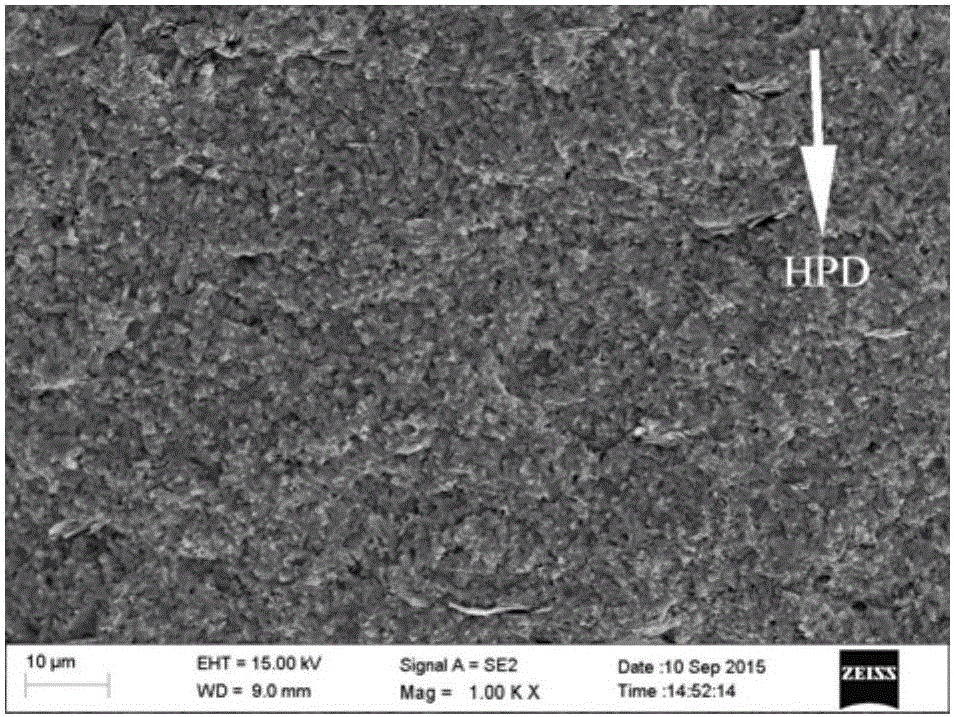

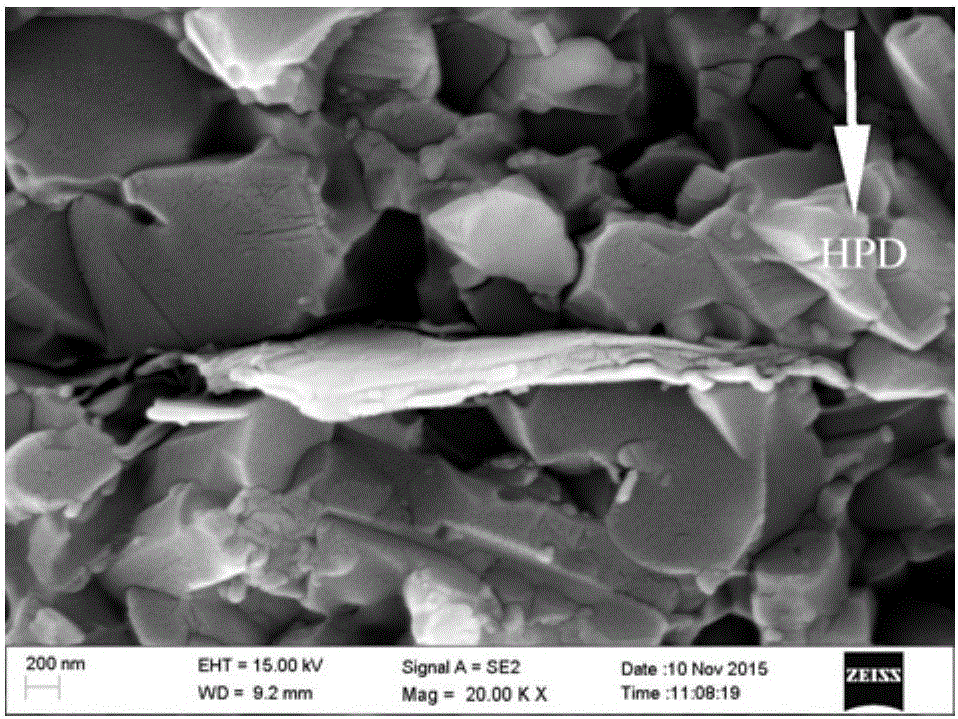

Composite ceramic tool with toughness reinforced by graphene nanosheets and microwave preparation technology of composite ceramic tool

InactiveCN106187259AGive full play to the role of toughening and strengtheningImprove mechanical propertiesComposite ceramicArgon atmosphere

The invention discloses a composite ceramic tool with the toughness reinforced by graphene nanosheets and a microwave preparation technology of the composite ceramic tool, and belongs to the technical field of machining tool manufacturing. The ceramic tool is prepared from, by mass, 50.2-60.2% of Al2O3, 20-40% of TiC, 3-5% of Ni, 3-5% of Mo, 0.5-1% of MgO, 0.5-1% of Y2O3 and 0.1-0.8% of graphene nanosheets with Al2O3 as the base body and TiC and graphene nanosheets as the reinforcing phases by adding a certain amount of metal adhesives and sintering aids. The composite ceramic tool is prepared through the microwave sintering technology with a microwave medium as the heat source under the protection of argon atmosphere through the optimum mixture ratio, the sintering temperature, the heat preservation time and other technological parameters. The graphene nanosheets in the prepared composite ceramic tool are uniformly distributed, the fracture toughness property of the tool is greatly improved, the highest hardness is 19.12 GPa, the fracture toughness property is 8.73 MPa m<1 / 2>, and the composite ceramic tool is good in comprehensive mechanical property and simple in preparation technology.

Owner:NANJING UNIV OF SCI & TECH

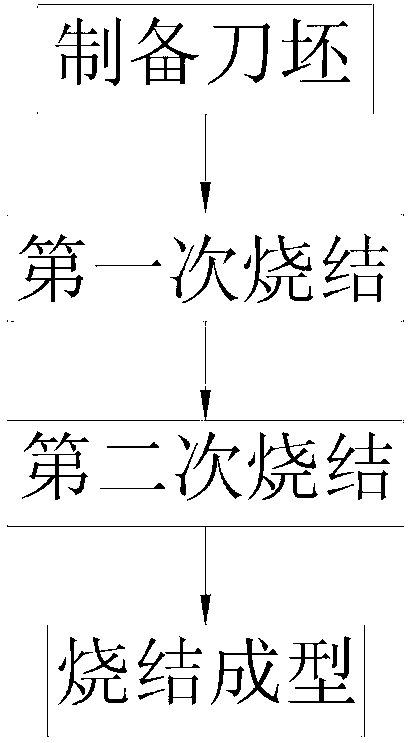

High-performance ceramic knife and preparation method thereof

The invention aims to provide a high-performance ceramic knife which has high strength and high toughness and has high sharpness after putting the first edge on the knife as well as a method for preparing the ceramic knife. The high-performance ceramic knife comprises the following components in percentage by weight: 93-94 percent of mixture of ZrO2 and HfO2, 5-6 percent of Y2O3 and 0.2-1 percent of Al2O3. The method for preparing the ceramic knife comprises the following steps: (1) preparing a cutter blank; (2) sintering at the first stage; (3) sintering at the second stage; and (4) sintering and forming. According to the ceramic knife prepared by utilizing the method, the bending strength is improved from the original 900MPa to the 1100MPa, toughness is obviously improved, the initial sharpness of the ceramic knife is improved from the original 80mm to 95mm, and the durable sharpness is improved from 1100mm to 1500mm. The method can be applied to the field of manufacturing of ceramic knives.

Owner:ZHUHAI LUCKYMAN TECH CO LTD

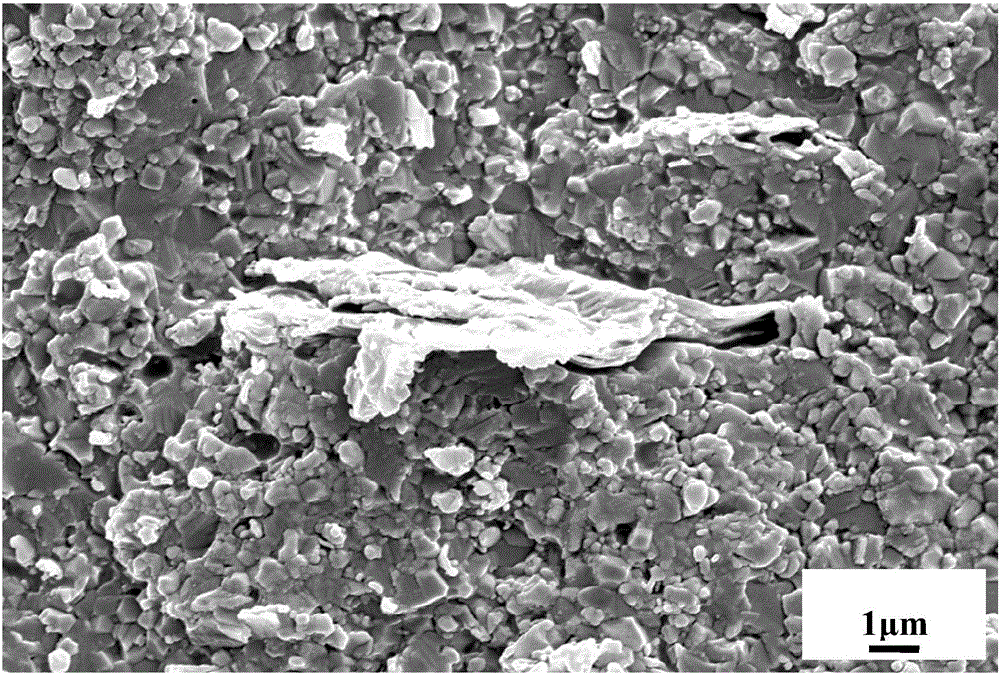

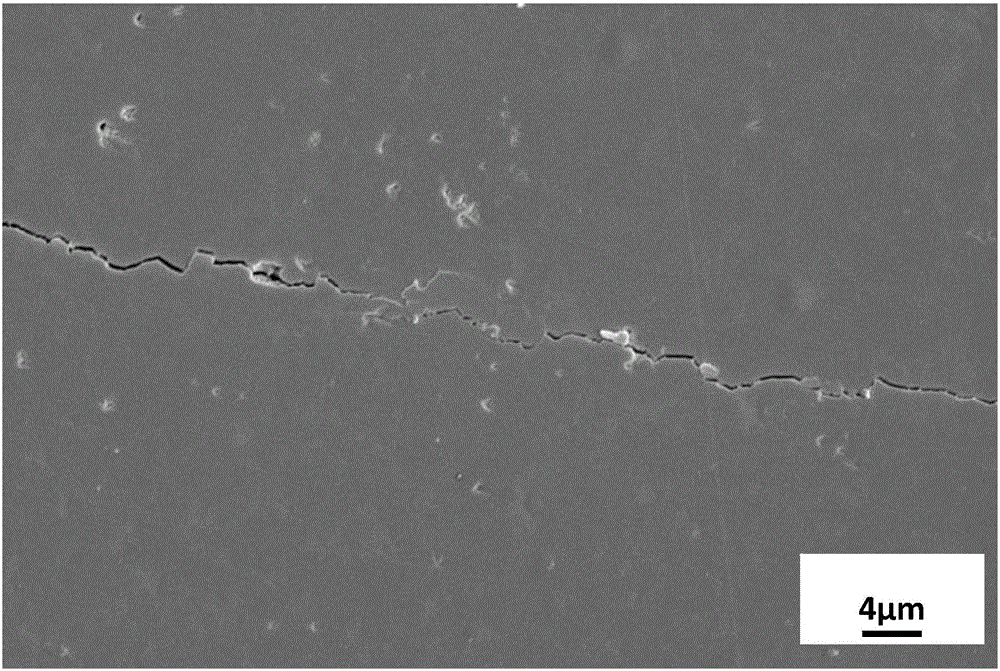

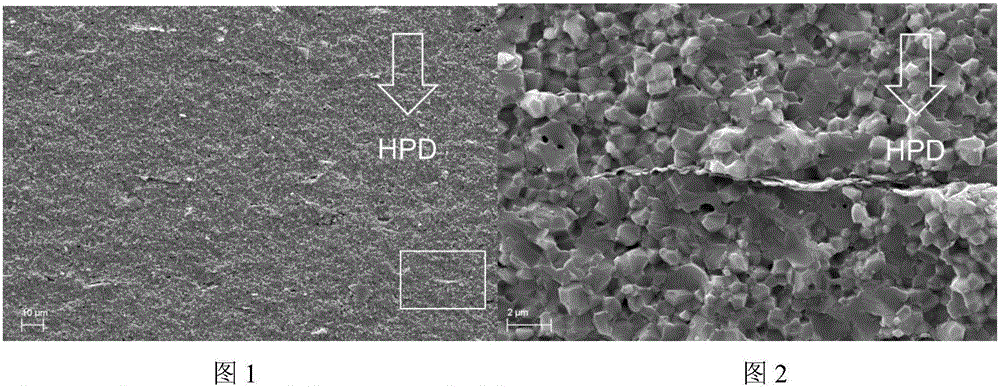

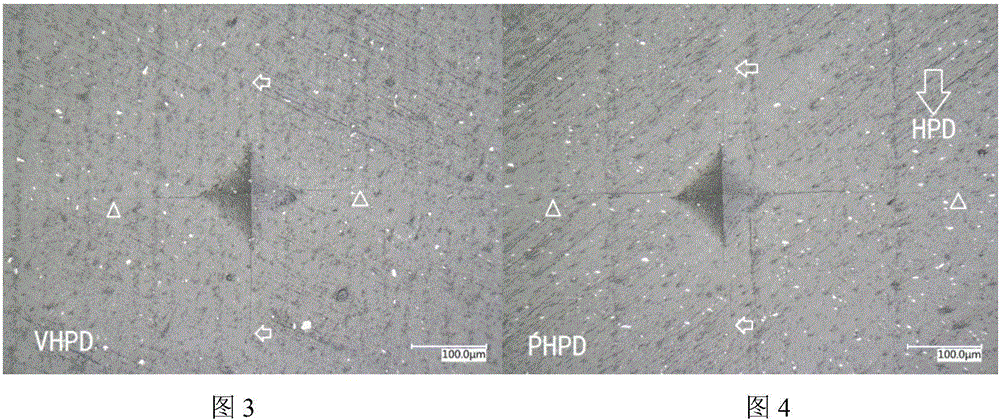

Anisotropic graphene-toughened Al2O3 nano composite ceramic cutting tool material and preparation method thereof

The invention relates to an anisotropic graphene-toughened Al2O3 nano composite ceramic cutting tool material and a preparation method thereof. According to the ceramic cutting tool material, Al2O3 is used as the matrix, graphene nanosheets are used as a reinforcement phase, and MgO, Mo and Ni are used as sintering aids. The preparation method of the ceramic cutting tool material comprises the following steps: graphene dispersion, composite powder preparation, drying and screening, cold-pressed mold filling and hot-pressed sintering. In the graphene toughened Al2O3 nano composite ceramic material, the graphene has obvious graphene toughening effects, and has obvious orientation in the matrix. The mechanical properties of the ceramic cutting tool have obvious anisotropy in the directions which are perpendicular and parallel to the hot pressing direction.

Owner:QILU UNIV OF TECH

Zirconium oxide-based ceramic tool material and preparation method thereof

The invention provides a zirconium oxide-based ceramic tool material, which is prepared from the following raw materials in parts by weight: 50-60 parts of zirconium oxide, 30-35 parts of aluminium oxide, 1-2 parts of borax, 4-5 parts of barium carbonate, 1-2 parts of sodium humate, 2-4 parts of carboxymethylcellulose, 2-3 parts of carbonyl nickel powder, 3-5 parts of LiSbO3, 4-6 parts of potassium-sodium niobate, 2-3 parts of cerium oxide, 1-1.5 parts of lanthanum nitrate, a proper amount of deionized water, 1-1.4 parts of polyacrylic acid, 0.7-1.2 parts of polyethylene glycol, a proper amount of ethanediol and 3-4 parts of an anti-abrasion aid. Due to addition of carbonyl nickel powder to the ceramic, the thermal conductivity of the ceramic is increased, a tool is prevented from overheating, the ceramic has very high hardness and abrasive resistance, the ceramic tool is suitable for cutting and chipping a high-hardness material and is hardly aged or broken off; due to use of the anti-abrasion aid, the surface smoothness, abrasive resistance and heat resistance of the ceramic are improved.

Owner:安徽上阡科技信息咨询有限公司

Ceramic kitchen knife

InactiveCN101204816AImprove HRCNovel materialMetal working apparatusMetal-working hand toolsHardnessCeramic knife

The invention relates to a ceramic knife. By adopting advanced ceramic (zirconia) technology in domestic, the invention is to balance high hardness and abrasion resistance and characteristics of being easy to be broken and frangibility of ceramic materials to further improve sharpness and tool life of products and achieve Rockwell hardness of the ceramic materials up to HRC 80 degrees, which is much better than HRC 60 degrees of the present most excellent carbon steel and stainless knife. As the ceramic knife is made of novel and fine materials and the surface of the materials is similar to glass, the invention is uneasy to be polluted and is clean and sanitary, and can be cleaned quite conveniently.

Owner:上海张小泉刀剪制造有限公司

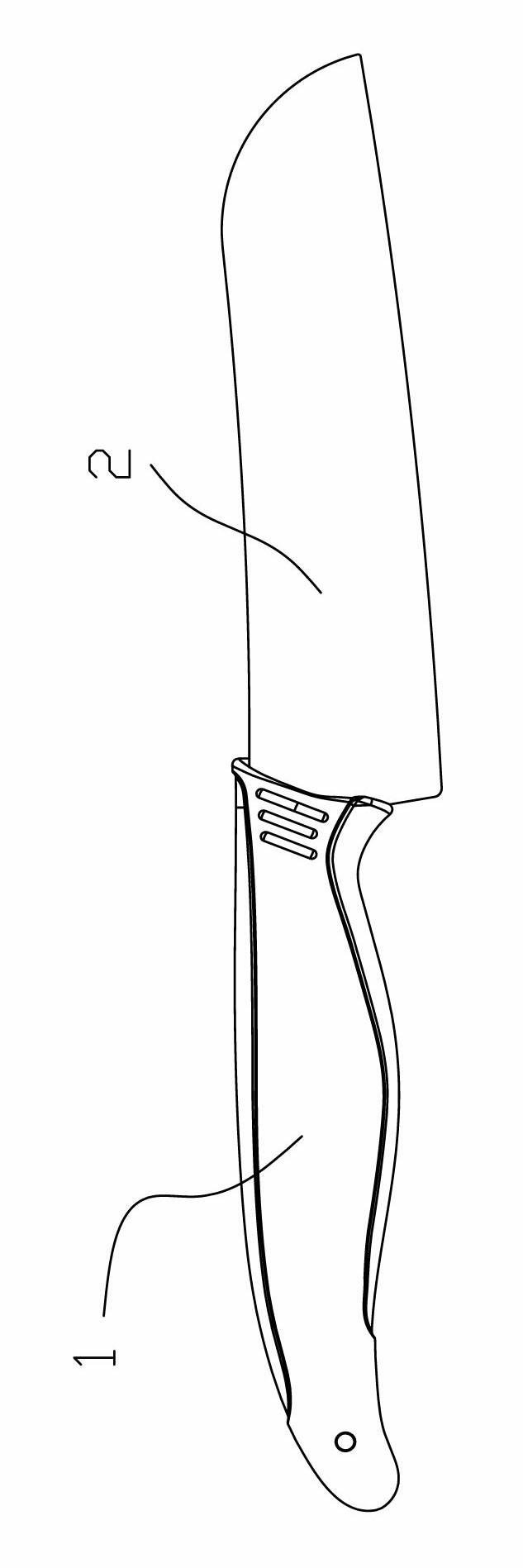

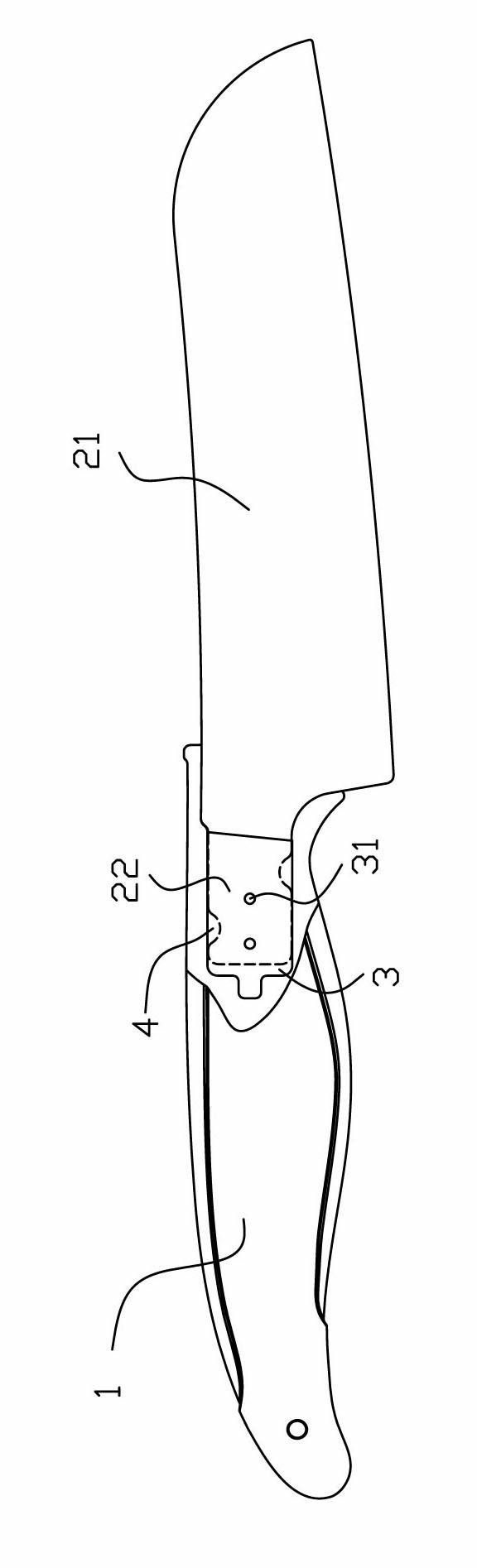

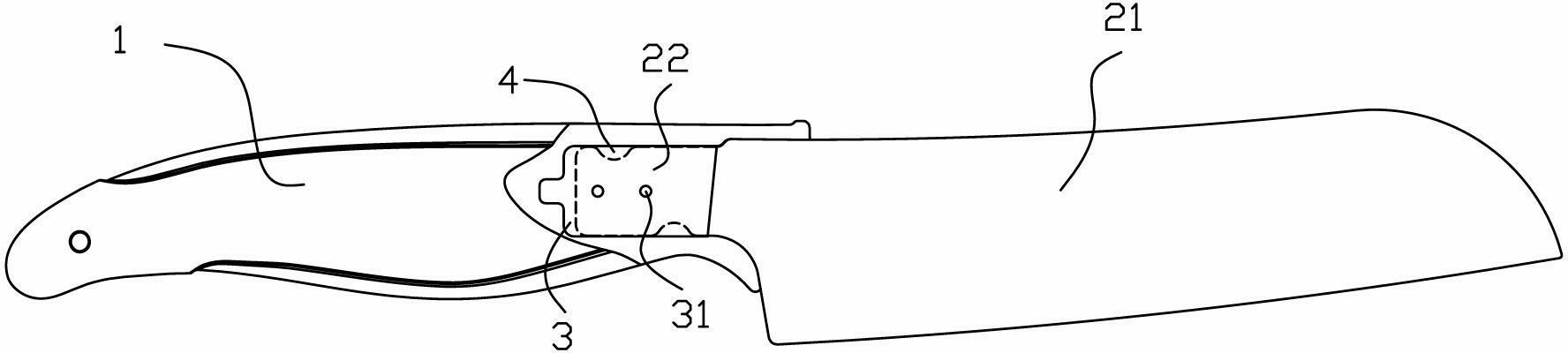

Ceramic knife and manufacturing method thereof

InactiveCN102114638ASimple structureImprove the heating effectMetal working apparatusMetal-working hand toolsPlastic materialsCeramic knife

The invention discloses a ceramic knife and a manufacturing method thereof. The ceramic knife comprises a plastic hilt, a ceramic blade and a metal piece, wherein, the ceramic blade is spliced in the plastic hilt through a connecting sheet; the metal piece is arranged in the outer position of the connecting sheet; a position equipped with the metal piece on a structure to be heated is heated through a thermatron when the ceramic knife is manufactured, molten plastic material is welded on the metal piece and the connecting sheet, and the ceramic knife is obtained after the molten plastic material is cooled down. The ceramic knife has a simple structure, the connection stability between the ceramic blade and the plastic hilt is easy to control, the finished product ratio is high, the manufacture effect can be controlled effectively, the manufacturing cost can be lowered greatly, the firm degree of formed structure is improved greatly by compared with the gluewater connection, the ceramic knife also has the advantage of compact and beautiful appearance, and the installing and fixing speed of the ceramic knife can be increased greatly; in addition, the metal piece in the ceramic knife can be detected through a metal detector when security inspection is carried out, so that safety accidents caused by the ceramic knife can be avoided.

Owner:ZHUHAI YUEKE JINGHUA TECH

TiCN/Al2O3 metal ceramic cutter and microwave preparation process thereof

The present invention discloses a TiCN / Al2O3 metal ceramic cutter and a microwave preparation process thereof, wherein the TiCN / Al2O3 metal ceramic cutter comprises, by weight, 40-60% of TiCN, 5-15% of alpha-Al2O3, 5-15% of Mo2C, 5-15% of WC, and 15-25% of No and Co. According to the present invention, the metal ceramic cutter adopts the 2.45 GHz frequency microwave dielectric as the heat source, and under the protection of the nitrogen atmosphere, the material ratio, the heating rate, the sintering temperature and other process parameters are optimized and the microwave sintering technology is used to prepare the metal ceramic cutter at the rapid heating rate; and the prepared metal ceramic cutter material has characteristics of high hardness and good toughness.

Owner:NANJING UNIV OF SCI & TECH

Si3N4/TiC/graphene composite ceramic cutter material with mechanical aeolotropy and preparation method thereof

The invention relates to a Si3N4 / TiC / graphene composite ceramic cutter material with mechanical aeolotropy and a preparation method thereof. In the ceramic cutter material, silicon nitride serves as a matrix, TiC is a hard phase while graphene is a toughening phase, and MgO, Al2O3 and Y2O3 are adopted as composite sintering aids; and the ceramic cutter material is prepared by the processes of independent dispersion, composite dispersion, ball milling, drying and screening and hot-pressing sintering of the raw materials. According to the invention, in the prepared Si3N4 / TiC / graphene composite ceramic cutter material, the graphene realizes an obvious toughening and reinforcing effect on the ceramic cutter material; and due to the oriental distribution of the graphene in the material, the mechanical properties of the Si3N4-based composite ceramic cutter material have aeolotropy. Moreover, by adding graphene, the friction coefficient of the composite ceramic cutter material is reduced, and the wear resistance is improved.

Owner:QILU UNIV OF TECH

Processing method for antibacterial ceramic knife

The invention discloses a processing method for an antibacterial ceramic knife. The processing method comprises the following steps that zirconium oxide powder with stable yttrium oxide, an antibacterial agent, a dispersing agent and deionized water are mixed and then prepared into slurry through ball milling, wherein the particle size of the zirconium oxide powder is 10-30 nm, and the particle size of the antibacterial agent is 10-50 nm; a binding agent is added into the slurry, the materials are stirred to be uniform, and granulating is performed to obtain zirconium oxide ceramic granulation powder; the zirconium oxide ceramic granulation powder is processed through preforming pressing and then processed through isostatic pressing treatment, and a green body is obtained; the green body is sintered to obtain a blank; the blank is polished, burnished and edged to obtain the antibacterial ceramic knife. According to the processing method for the antibacterial ceramic knife, the made ceramic knife is uniform in internal structure, higher in density and bending strength and better in tenacity, and the processed knife edge is sharp; in addition, due to the fact that the antibacterial agent is added, the antibacterial ceramic knife can have the better antibacterial property.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

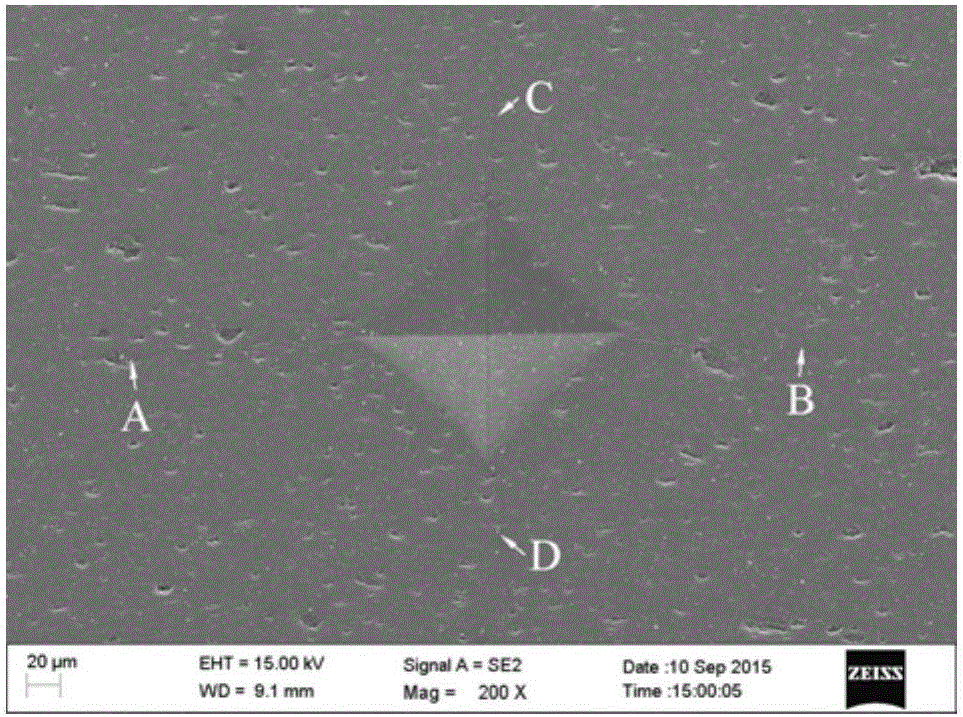

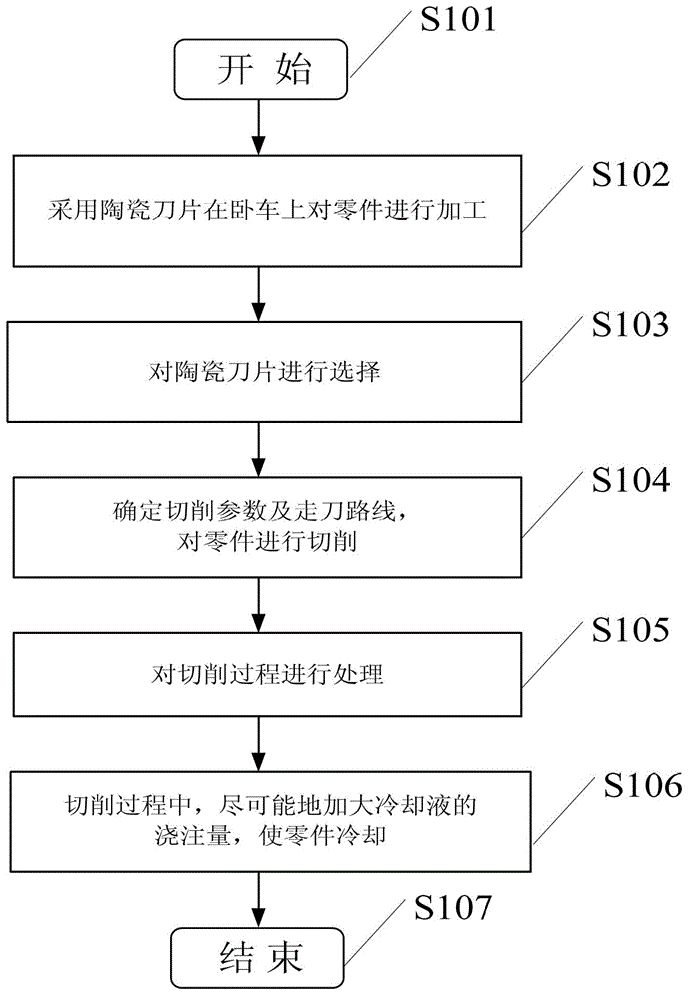

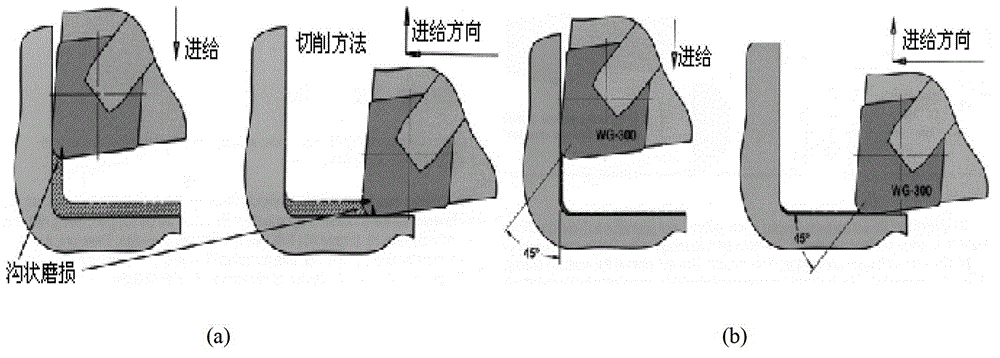

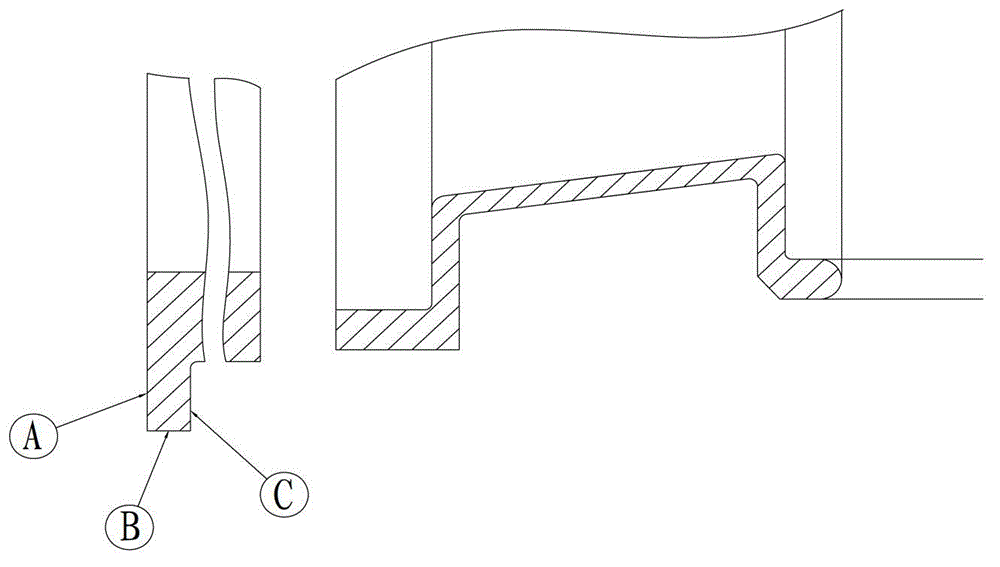

Machining method through ceramic blades

InactiveCN103056393ASolve bottlenecksImprove processing efficiencyTurning toolsNumerical controlMachine parts

The invention relates to a machining method through a ceramic blade and belongs to the technical field of machining. Ceramic blades are selected to machine parts on a sleeping car when high temperature alloys are difficult to machine. Selection of the ceramic blades includes firstly matching the ceramic blades with parts; selecting a large-diameter round blade to cut if machining space permits; selecting a negative rake blade to cut if external circles, end faces or inner holes of large-diameter parts are to be turned; and using the round blade to cut most allowance and then using a sharp knife or a slot blade to remove the allowance at fillet positions if molded surfaces of parts have bosses or grooves with fillet radiuses smaller than that of the round blade. According to the method, how to select cutting parameters and how to determine moving paths correctly are provided, so that the ceramic blades are applied to numerical control sleeping cars. The machining efficiency can be improved by more than 60% if ceramic tools are applied to continuous cutting of high temperature alloys and machining efficiency can be improved by more than 80% if ceramic tools are applied to interrupted cutting of high temperature alloys.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

High-performance ultra-fine grain Ti(C,N)-TiB2-WC composite metal ceramic tool and preparation method thereof

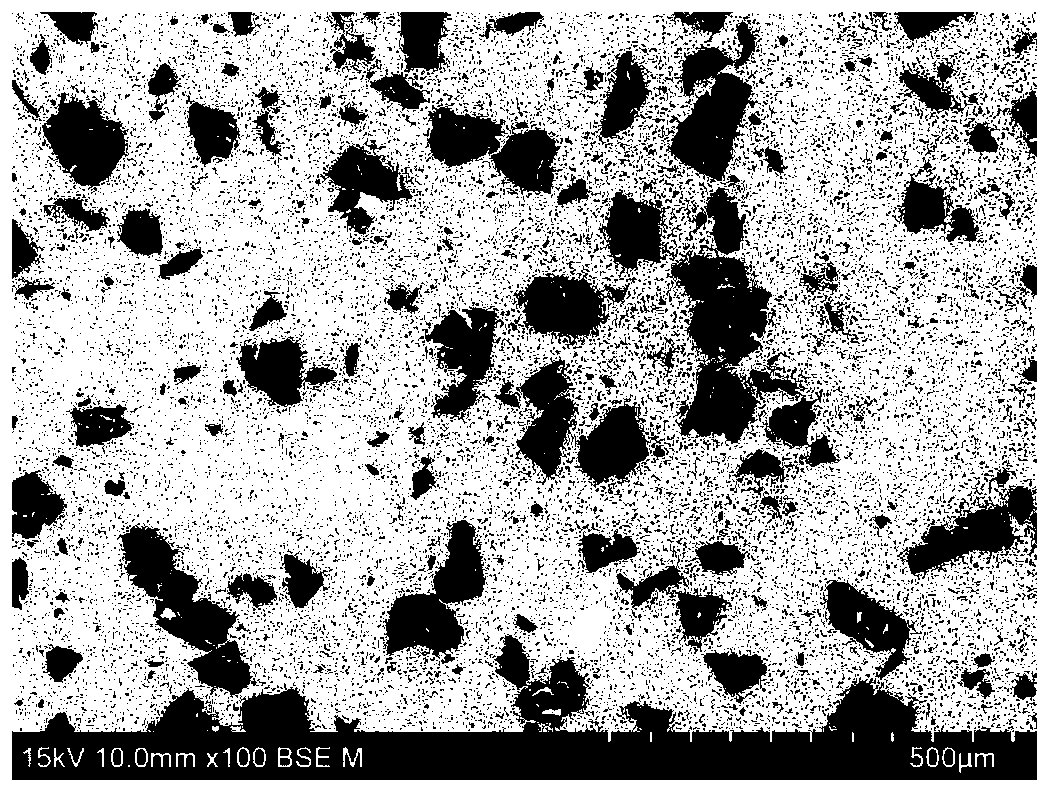

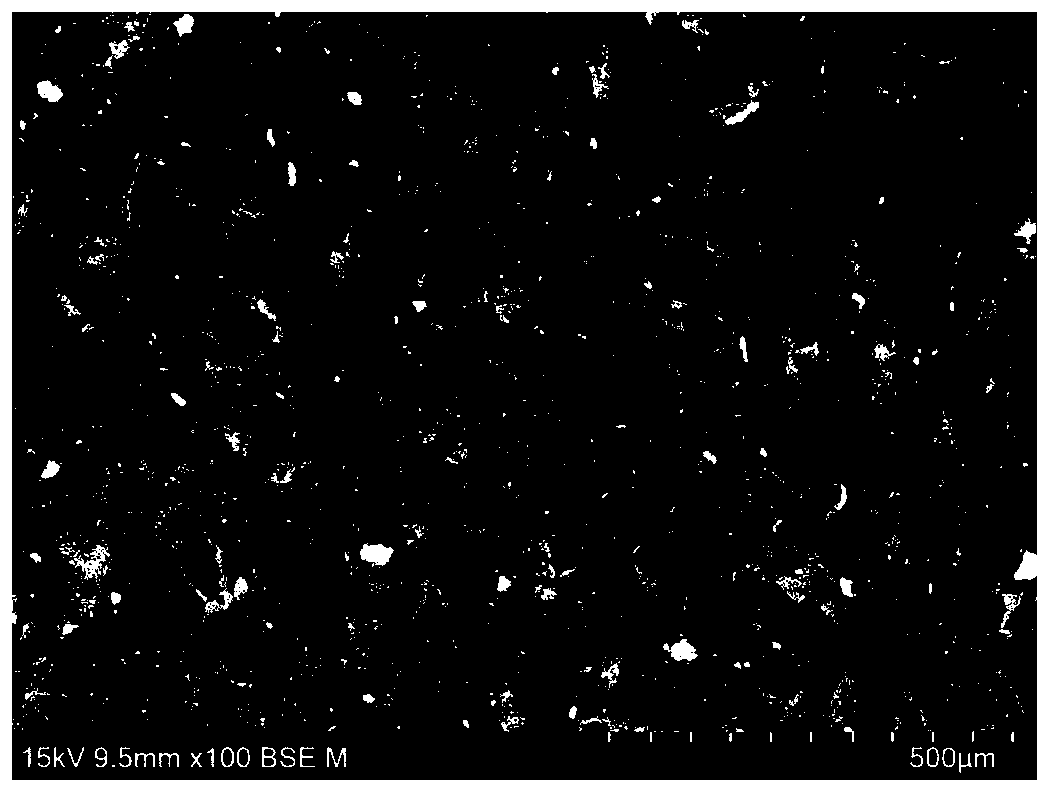

ActiveCN107164679ADensely distributed evenlyLow costTurbinesOther manufacturing equipments/toolsUltra fineCermet

The invention belongs to the technical field of new materials, and discloses a high-performance ultra-fine grain Ti(C,N)-TiB2-WC composite metal ceramic tool and a preparation method thereof. The high-performance ultra-fine grain Ti(C,N)-TiB2-WC composite metal ceramic tool is synthesized in-situ through a one-step method, and the grain size of the tool is smaller than 700 nm. The high-performance ultra-fine grain Ti(C,N)-TiB2-WC composite metal ceramic tool mainly comprises 8wt.% of Co (with the purity of 99wt.% and the granularity smaller than 1 [mu]m), 53-69wt.% of Ti (with the purity of 99.9wt.% and the granularity smaller than 0.8 [mu]m), 1-4wt.% of C (with the purity of 98wt.% and the granularity smaller than 1 [mu]m), 10-14wt.% of BN (with the purity of 99 wt.% and the granularity smaller than 0.5 [mu]m) and 5-25wt.% of WC (with the purity of 99.9wt.% and the granularity smaller than 0.4 [mu]m). The preparation method of the tool comprises the steps that powder is prepared through grinding, pre-pressing is conducted under the pressure of 8 MPa, a blank is formed through vacuum reacting, hot-pressing and sintering, a blade is ground, and finally, the Ti(C,N)-TiB2-WC composite metal ceramic tool is obtained. Compared with a traditional metal ceramic tool, the metal ceramic tool prepared through the method and added with carbide has higher hardness and abrasion resistance and has obvious advantages on the aspects of thermal stability, abrasion resistance, thermal conductivity, oxidation resistance, high-temperature hardness, high-temperature strength and cutting performance.

Owner:TAIZHOU UNIV

Environment-friendly type nanometer ceramic knife and manufacture method thereof

The invention discloses an environmental-protective nanometer ceramic knife and preparing method, which comprises the following steps: adopting tetragonal ZrO2 powder of nanometer grade stable 3mol% Y2O3 and little tetragonal ZrO2 powder of nanometer grade stable 12mol% CeO as raw material; moulding; sintering to produce the product.

Owner:景德镇市新纪元精密陶瓷有限公司

Al2O3-TiC-TiN micron composite ceramic cutter material and microwave sintering method thereof

The invention belongs to the technical field of microwave sintering materials, and relates to an Al2O3-TiC-TiN micron composite ceramic cutter material and a microwave sintering method thereof. The Al2O3-TiC-TiN micron composite ceramic cutter material and the microwave sintering method thereof are characterized in that material dosing is conducted by the materials, by weight, 55%-75% of submicrons, 10%-15% of microns, 15%-20% of submicrons, 5%-10% of molybdenum powder and nickel powder, and the balance MgO and Y2O3; through protection of high-purity argon atmosphere, the microwave sintering process is conducted, and the Al2O3-TiC-TiN micron composite ceramic cutter material is successfully prepared. The Al2O3-TiC-TiN micron composite ceramic cutter material is high in compactness, high mechanical property is achieved, and the material is suitable for being using for manufacturing and processing cutters of materials difficult to process. The Al2O3-TiC-TiN micron composite ceramic cutter material prepared by the microwave sintering method is high in material performance, simple in process, saving in energy and time, low in cost, and prone to industrialization.

Owner:NANJING UNIV OF SCI & TECH

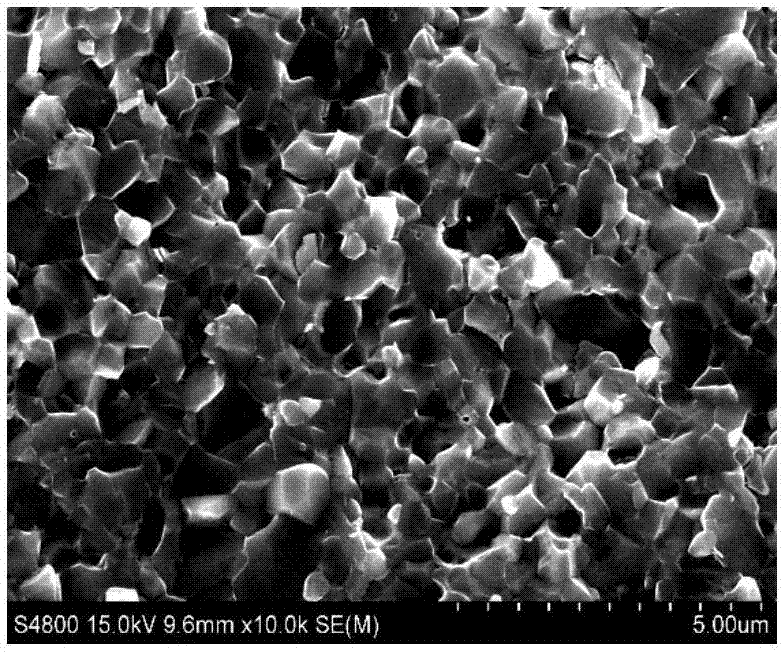

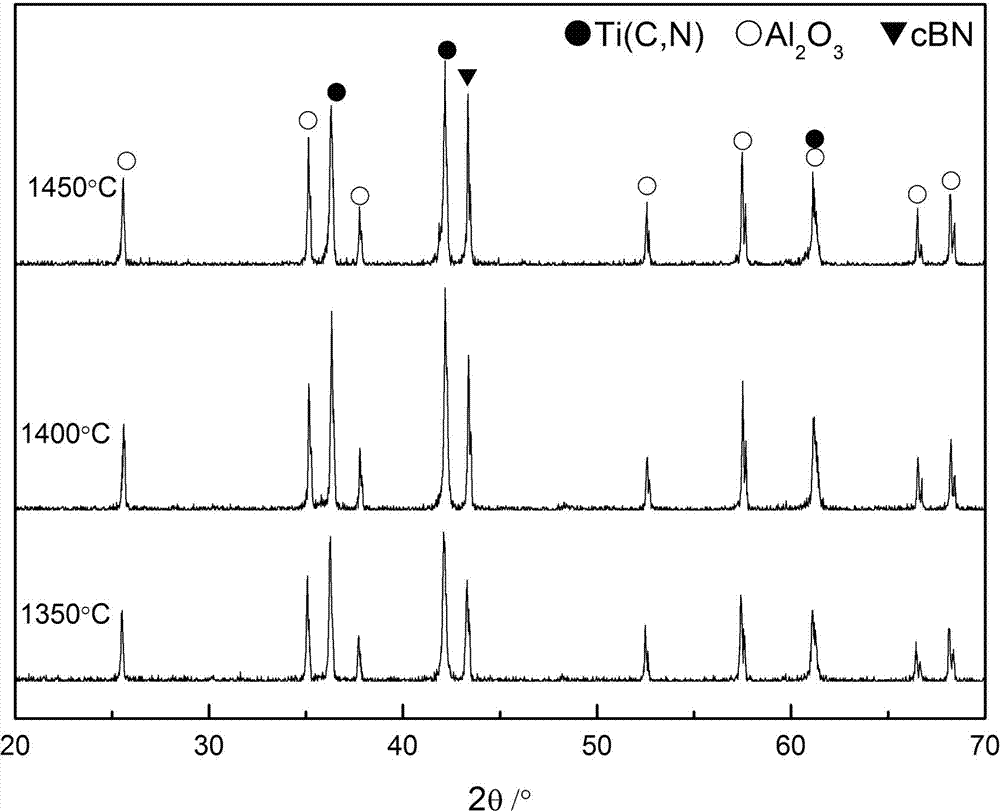

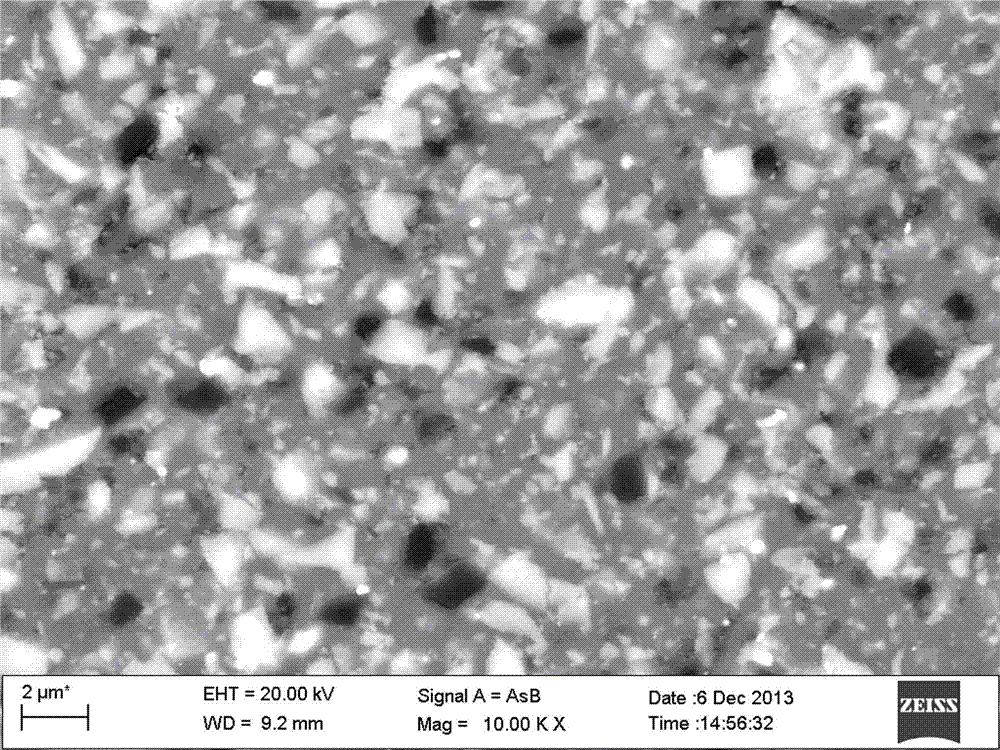

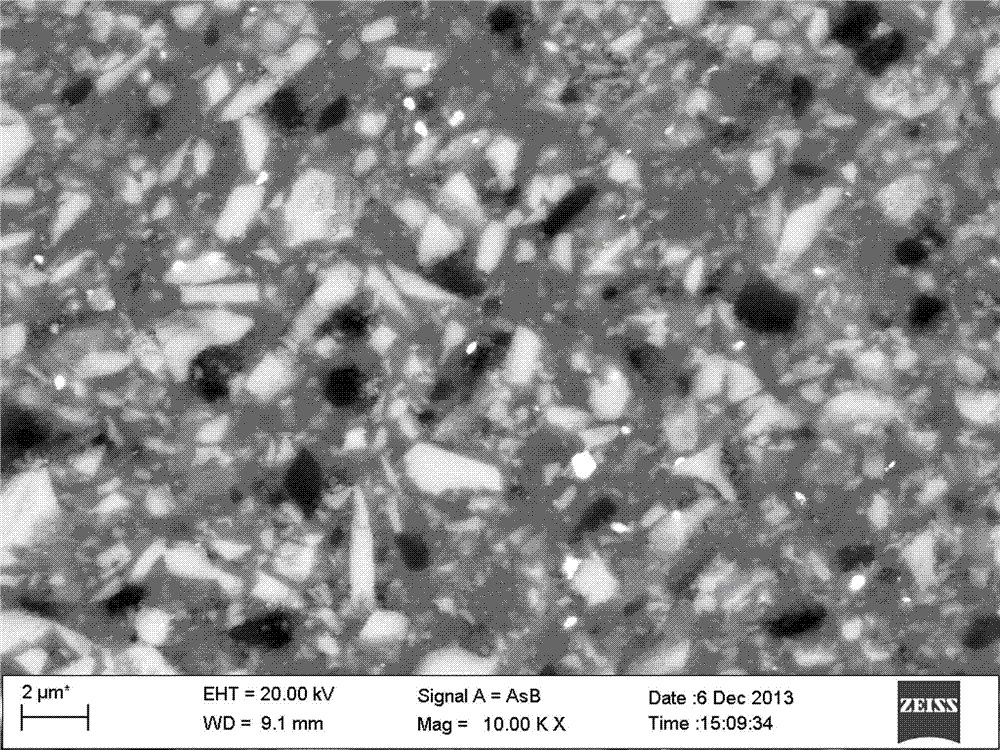

Al2O3-Ti(C,N)-cBN ceramic tool material and preparation method thereof

Owner:NORTHEASTERN UNIV

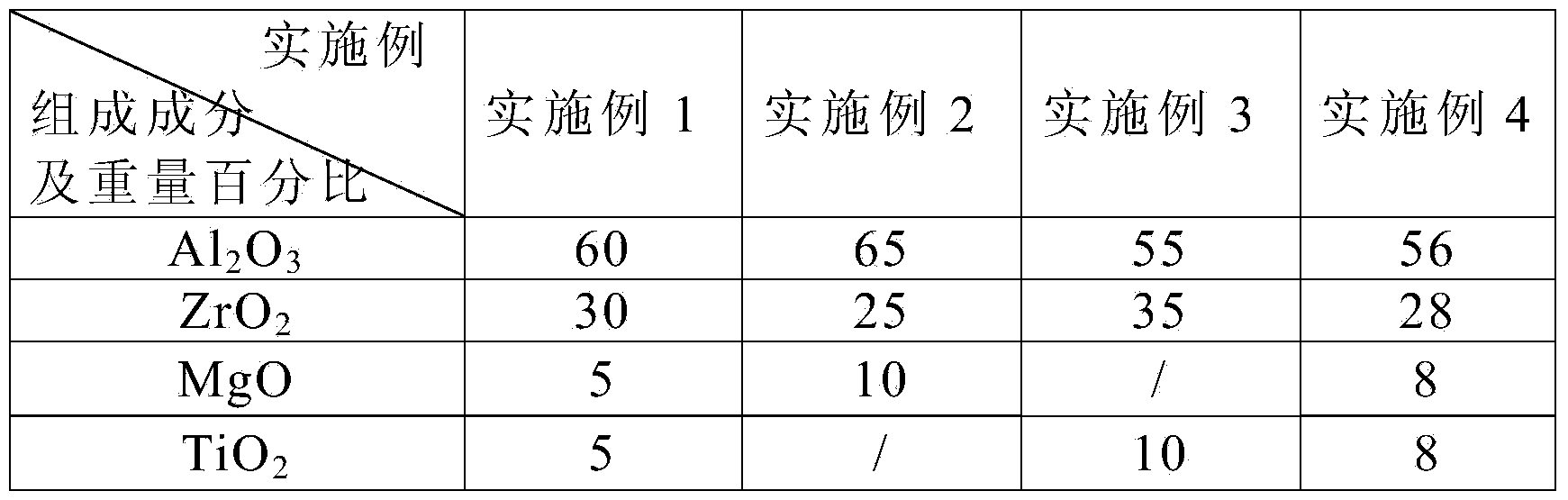

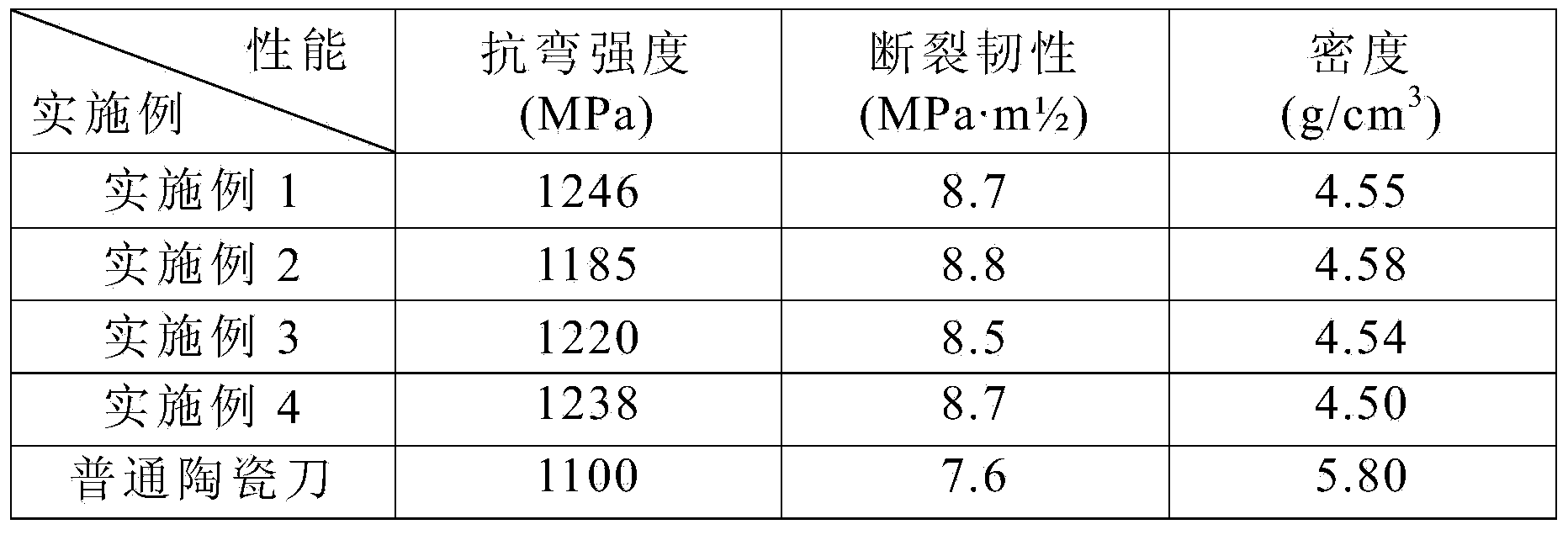

Ceramic knife and preparation method thereof

The invention relates to a ceramic knife and a preparation method thereof, and belongsto the technical field of new materials. The ceramic knife comprises the following materials by weight percentage: 50-70% of Al2O3, 15-40% of ZrO2, and 5-20% of a sintering aid. The sintering aid is one or two selected from MgO and TiO2, the ZrO2 is stabilized by Y2O3 or CeO2, and mass fraction of Y2O3 or CeO2 in ZrO2 is 2-4%. The preparation method of the ceramic knife comprises the following steps: weighing the raw materials according to the mass percentage and mixing; compacting the raw materials into a ceramic knife blank; placing the ceramic knife blank into a vacuum furnace for sintering and insulating by segment; and finally cooling with the furnace to obtain the ceramic knife. The ceramic knife provided by the invention has reasonable compatibility of materials and is prepared from a specific energy-saving and environment-friendly method with easy operations; and the ceramic knife has the advantages of light weight, high precision, high hardness, high bending strength, high fracture toughness, wear resistance and chemical corrosion resistance.

Owner:宁波晶天新材料有限公司

Antibacterial ceramic fruit paring knife and manufacturing method thereof

The invention relates to an antibacterial ceramic fruit paring knife and belongs to the technical field of production of functional ceramic knives. The antibacterial ceramic fruit paring knife comprises a ceramic knife body and a plastic handle. The antibacterial ceramic fruit paring knife is characterized in that a special ceramic with higher strength is adopted as the knife body, so that mechanical strength, thermal stability and dielectric strength of the ceramic knife are enhanced, corrosion caused by liquid and gas can be prevented, and the ceramic knife is durable; a negative ion layer is arranged on the outer surface of the ceramic knife body, an antibacterial effect can be achieved, and a common ceramic knife is upgraded into a functional high-grade kitchen utensil.

Owner:嘉善县临沪新城实业有限公司

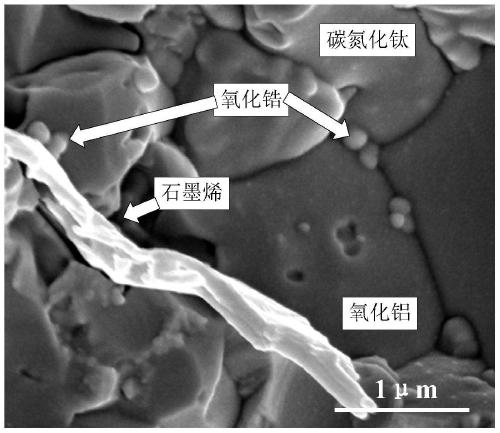

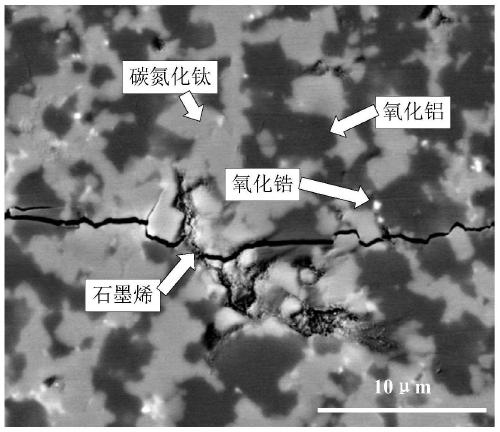

Method for synergistically toughening ceramic material by graphene and nano zirconia and application thereof

The invention relates to the technical field of ceramic cutter materials, and in particular relates to a method for synergistically toughening a ceramic material by graphene and nano zirconia and application thereof. The method comprises the following steps: (1) preparing the graphene and the nano zirconia into graphene / nano zirconia suspension with uniform dispersion; (2) mixing the suspension inthe step (1) with alumina powder, titanium carbonitride powder, a sintering aid and a stabilizer, and performing ball milling to obtain a mixed material; (3) drying the mixed material in the step (2), screening, and performing vacuum hot pressing sintering on the obtained target material to obtain the product. The addition of zirconia strengthens the interface between the graphene and matrix crystal grains. Graphene-induced crack deflection, crack bridging and crack bifurcation, crack deflection caused by the nano zirconia and pull-out of graphene sheets, stress-induced phase transformation and compressive stress formed on the surface of a matrix due to phase transformation produce synergistic effects to significantly improve the fracture toughness of the multiphase ceramic material.

Owner:SHANDONG UNIV

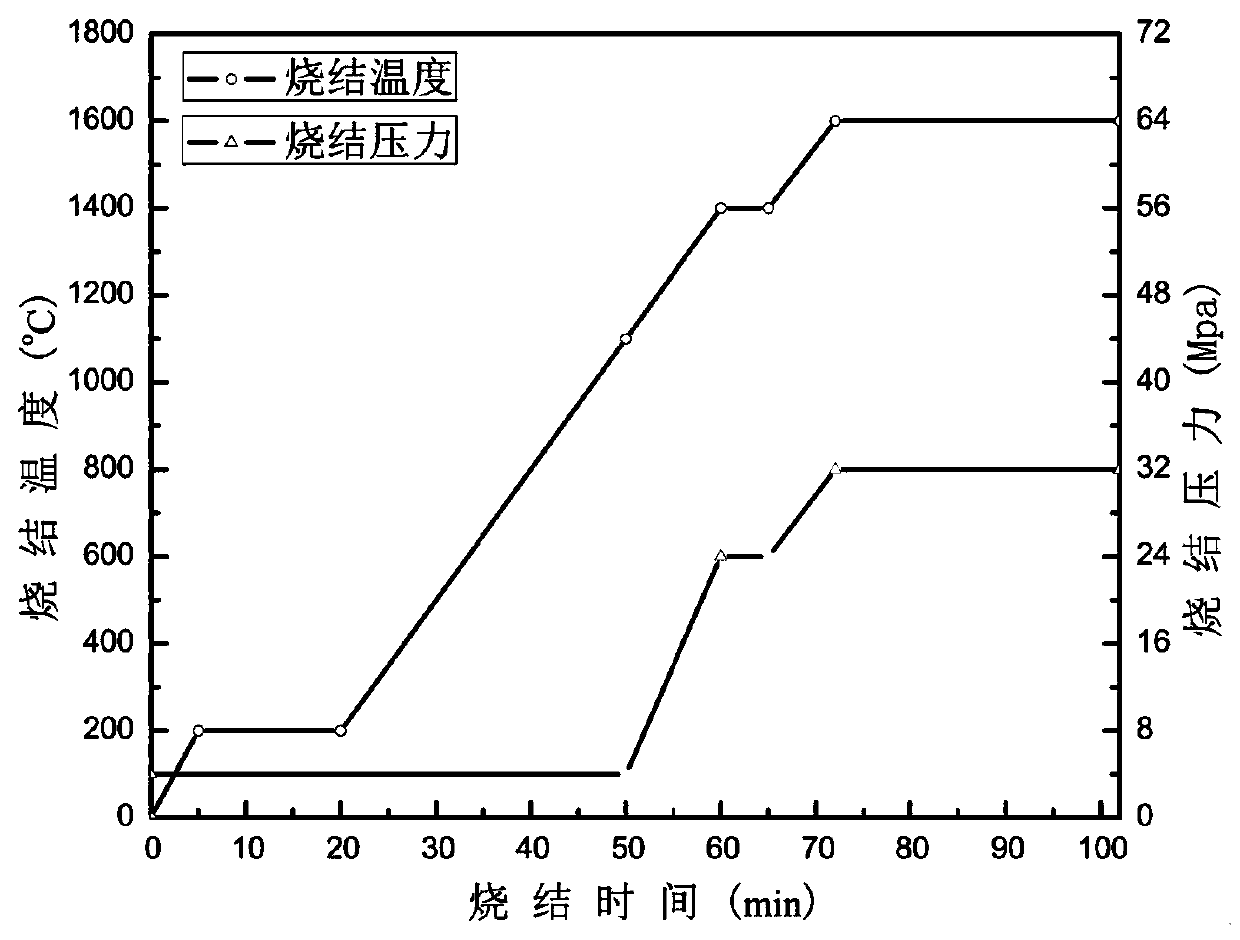

High-thermal-conductivity and high-wear-resistance silicon nitride ceramic as well as preparation method and application thereof

The invention belongs to the technical field of ceramics, and discloses high-thermal-conductivity and high-wear-resistance silicon nitride ceramic as well as a preparation method and application thereof. The preparation method of the silicon nitride ceramic comprises the following steps: adding diamond with a metal coating, Si3N4, a sintering aid MgO and Yb2O3 powder into ethanol and a Si3N4 ball-milling medium, carrying out ball-milling and mixing, and carrying out ball-milling and drying to obtain mixed powder; and heating the mixed powder to 1600-1700 DEG C under the axial pressure of 30-100 Mpa and under a protective atmosphere, conducting heat preservation, and carrying out spark plasma sintering. The silicon nitride ceramic provided by the invention has high thermal conductivity andwear resistance, good cutting performance and long cutting life, and can be applied to the field of ceramic cutters.

Owner:GUANGDONG UNIV OF TECH

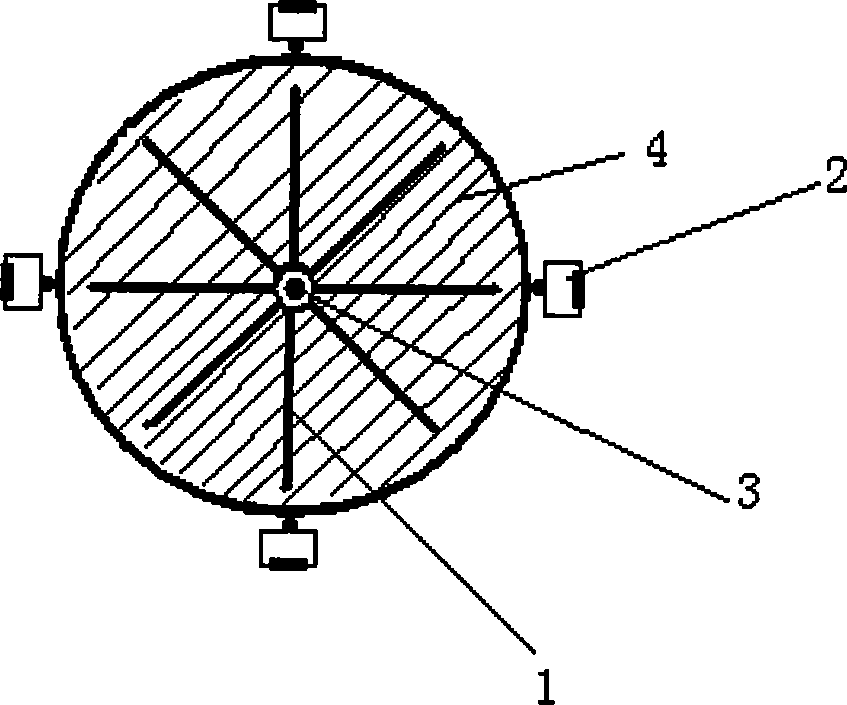

Device facilitating cake cutting

InactiveCN104162905APrevent unhappinessEasy to use and very practicalMetal working apparatusBaked article cutting/slicingCircular discChinese characters

A device facilitating cake cutting comprises a disc. A center shaft is perpendicularly fixed to the center of the disc. The bottom end of the center shaft is fixedly provided with a blade. The side of the periphery of the disc is fixedly provided with four handles. The blade is in the shape like a Chinese character 'mi'. The center of the blade shaped like the Chinese character 'mi' is fixed to the bottom end of the center shaft. The four handles are evenly fixed to the circumference of the periphery of the disc, and the included angle formed between every two adjacent handles is 90 degrees. When the device is used, a user holds two handles with the left and right hands, the blade shaped like the Chinese character 'mi' is placed on a cake, the center shaft is aligned to the center of the cake, the user cuts the cake with the strength of the two hands, the cake can be cut into eight pieces at a time, the cut cake pieces are orderly and uniform, attractiveness is achieved, and unnecessary unhappiness caused by non-uniform distribution is avoided, so that the device is convenient to use and practical. The disc is made of transparency organic glass, the blade can be made of stainless steel materials or ceramic knife materials, the center shaft is made of stainless steel materials, and therefore the device is beautiful and safe.

Owner:张煜尧

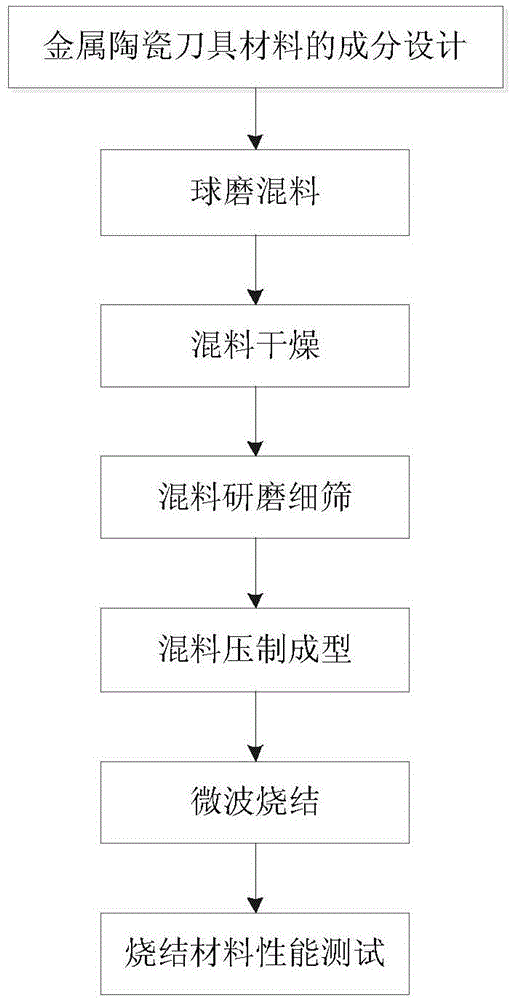

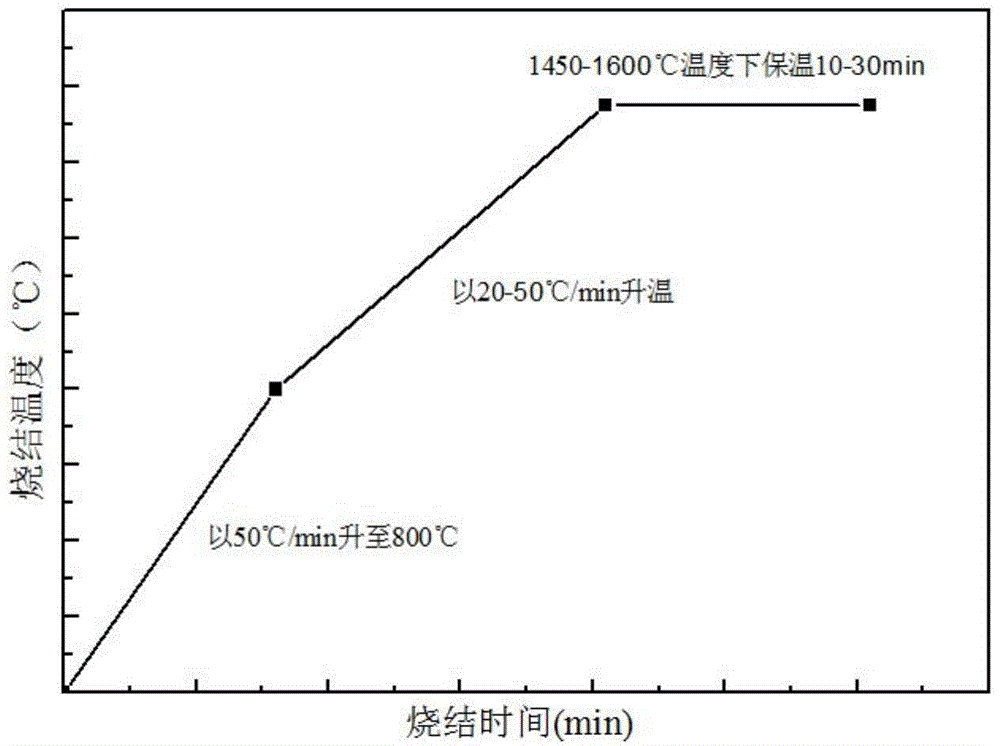

Alumina-based composite ceramic knife material and microwave preparation method thereof

The invention belongs to the field of microwave sintering material science and relates to an Al2O3 / TiC composite ceramic knife material and microwave preparation method thereof. The microwave preparation method is characterized by including: determining content according to mass percent, wherein Al2O3 which is a matrix phase is 61.4-81.4%, TiC which is a reinforcement phase is 10-30%, Mo and Ni which are additives are 4-6%, MgO and Y2O3 are 1-1.5%, and Cr3C2 is 1-2.5%. The microwave preparation method includes: blending according to the above formula, utilizing a QM-3SP2 planetary ball mill for material mixing to prepare mixed powder, and pressing to form a biscuit; utilizing a microwave sintering temperature-holding device to successfully prepare the Al2O3 / TiC composite ceramic knife material through high-purity argon protection and microwave sintering process. The composite material is high in compactness, and the microwave preparation method is suitable for manufacturing knives made of materials difficult to process and high in preparation efficiency. The material prepared by the method is good in performance and low in energy source consumption.

Owner:NANJING UNIV OF SCI & TECH

Raw material powder for composite-grain zirconia ceramics with high wear resistance and preparation process of raw material powder

The invention discloses raw material powder for composite-grain zirconia ceramics with high wear resistance and a preparation process of the raw material powder. The raw material powder comprises a main material and a yttrium-stable zirconia clinker, wherein the weight ratio of the yttrium-stable zirconia clinker to the main material is 1: (5-20); the main material is a mixture of zirconium oxychloride and yttrium nitrate; and the molar ratio of zirconium oxychloride to yttrium nitrate is 97:3. The raw material powder disclosed by the invention is high in wear resistance and hardness and corrosion-resistant. A ceramic part made of the raw material powder disclosed by the invention is high in wear resistance and beneficial to continuous and durable application; and the raw material powder is particularly suitable for ceramic knives and can be widely applied to other ceramic equipment or tools with high wear-resistant requirements.

Owner:厦门智中精密研磨科技有限公司

Wear-resistant carbide-based metal ceramic knife and manufacturing method thereof

The invention discloses a wear-resistant carbide-based metal ceramic knife and a manufacturing method thereof. The wear-resistant carbide-based metal ceramic knife is manufactured by, by weight, 40-50 parts of titanium carbide, 45-60 parts of silicon carbide, 20-30 parts of copper powder, 3-11 parts of asbestos powder, 3-6 parts of maldonite powder, 1-5 parts of diaspore powder, 3-8 parts of graphene, 3-6 parts of potassium oxide, 10-15 parts of glass fiber and 11-15 parts of paraffin. Compared with conventional metal ceramic knives, the wear-resistant carbide-based metal ceramic knife manufactured by the method has higher wear resistance and heat resistance and excellent cutting performance; through optimization of components and content, compactness and bending resistance of metal ceramic tissue are improved remarkably, and the wear-resistant carbide-based metal ceramic knife can be widely used for high-speed cutting of low-medium-carbon steel and low-alloy steel.

Owner:陈林美

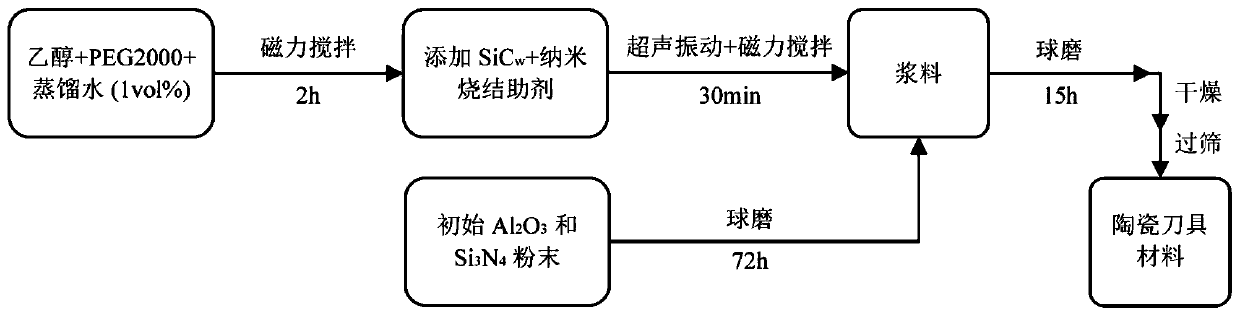

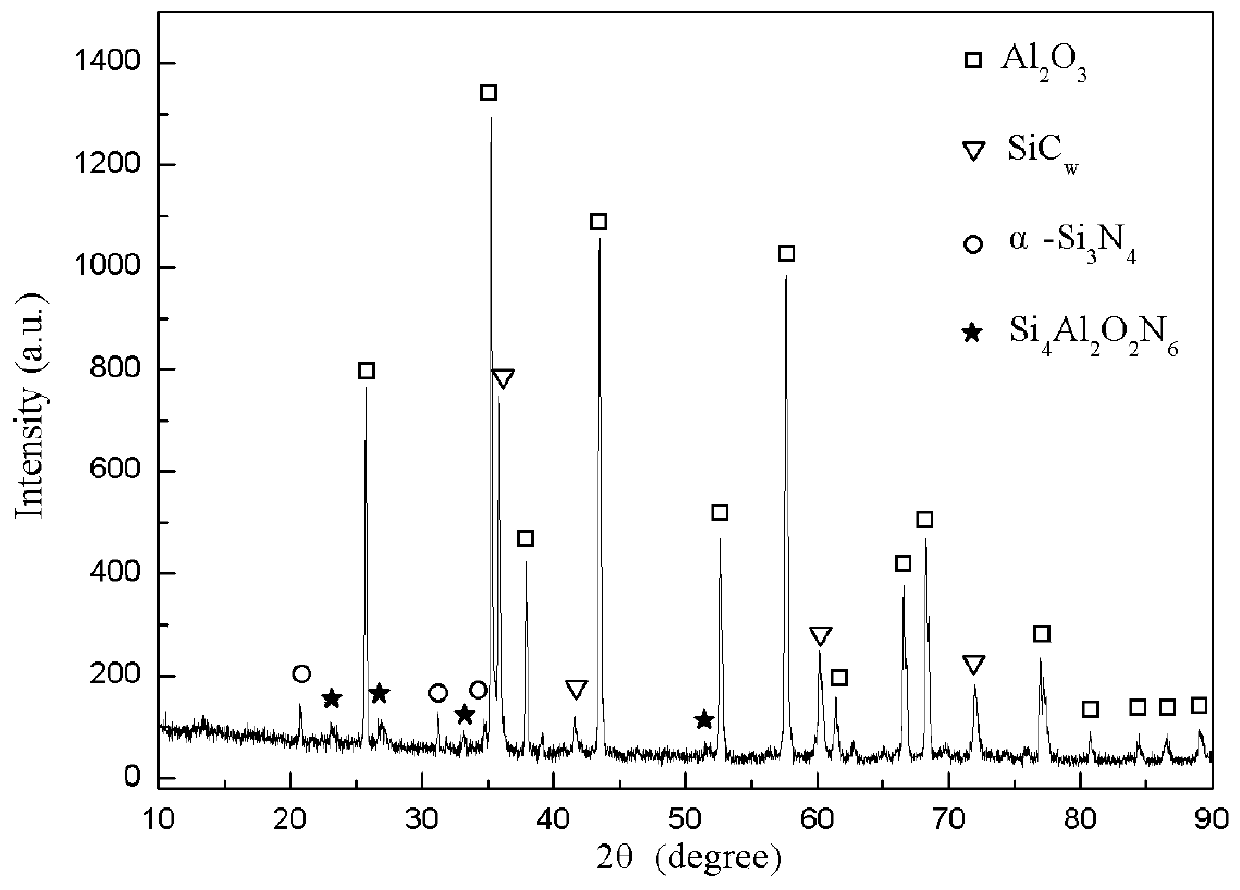

SiC whisker synergistic silicon nitride particle toughened alumina-based ceramic cutter material and preparation process thereof

ActiveCN110818395AImprove corrosion resistanceHigh processing compatibilityComposite ceramicCeramic knife

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com