Patents

Literature

132 results about "Ceramic cutting tool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

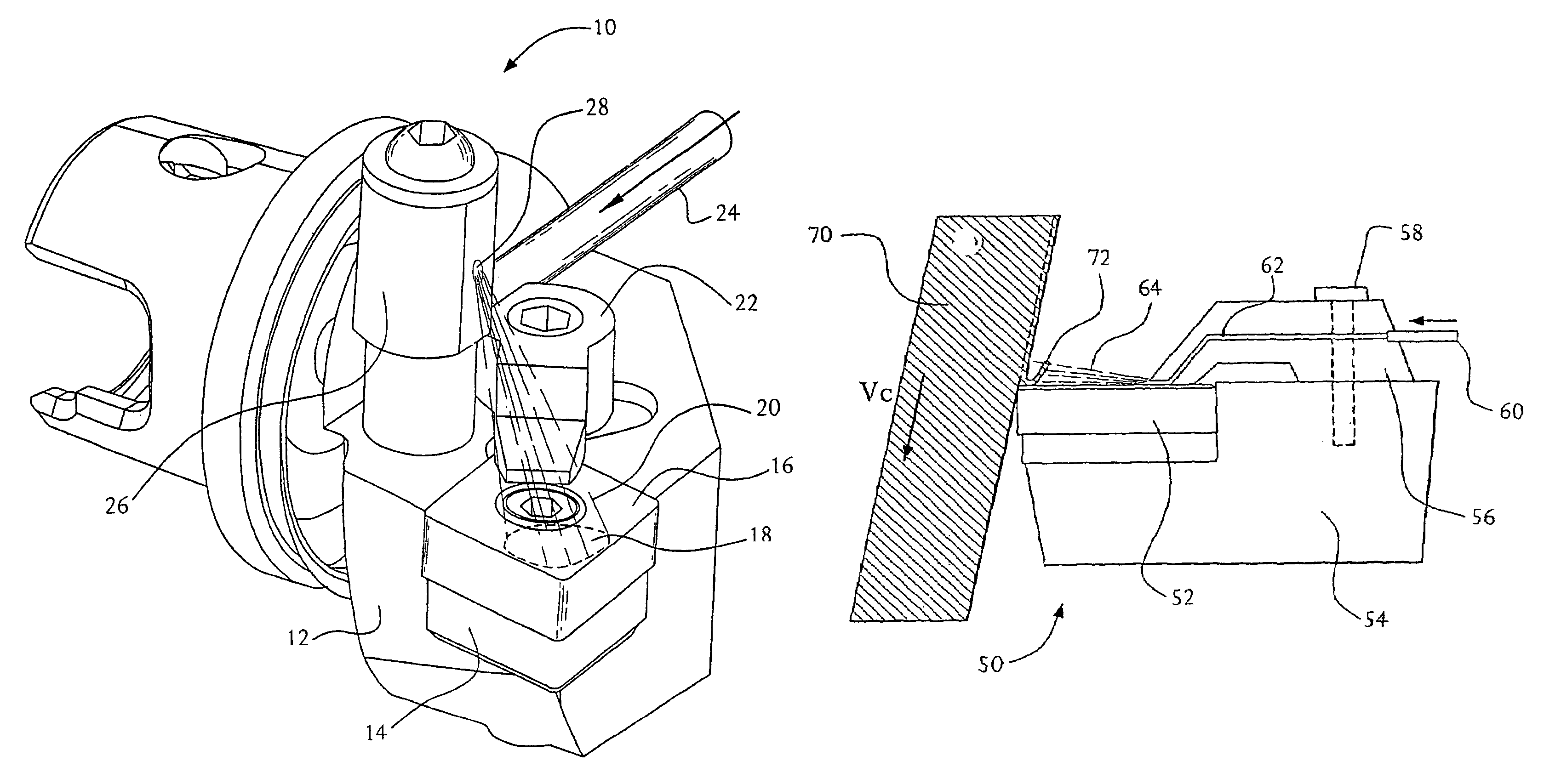

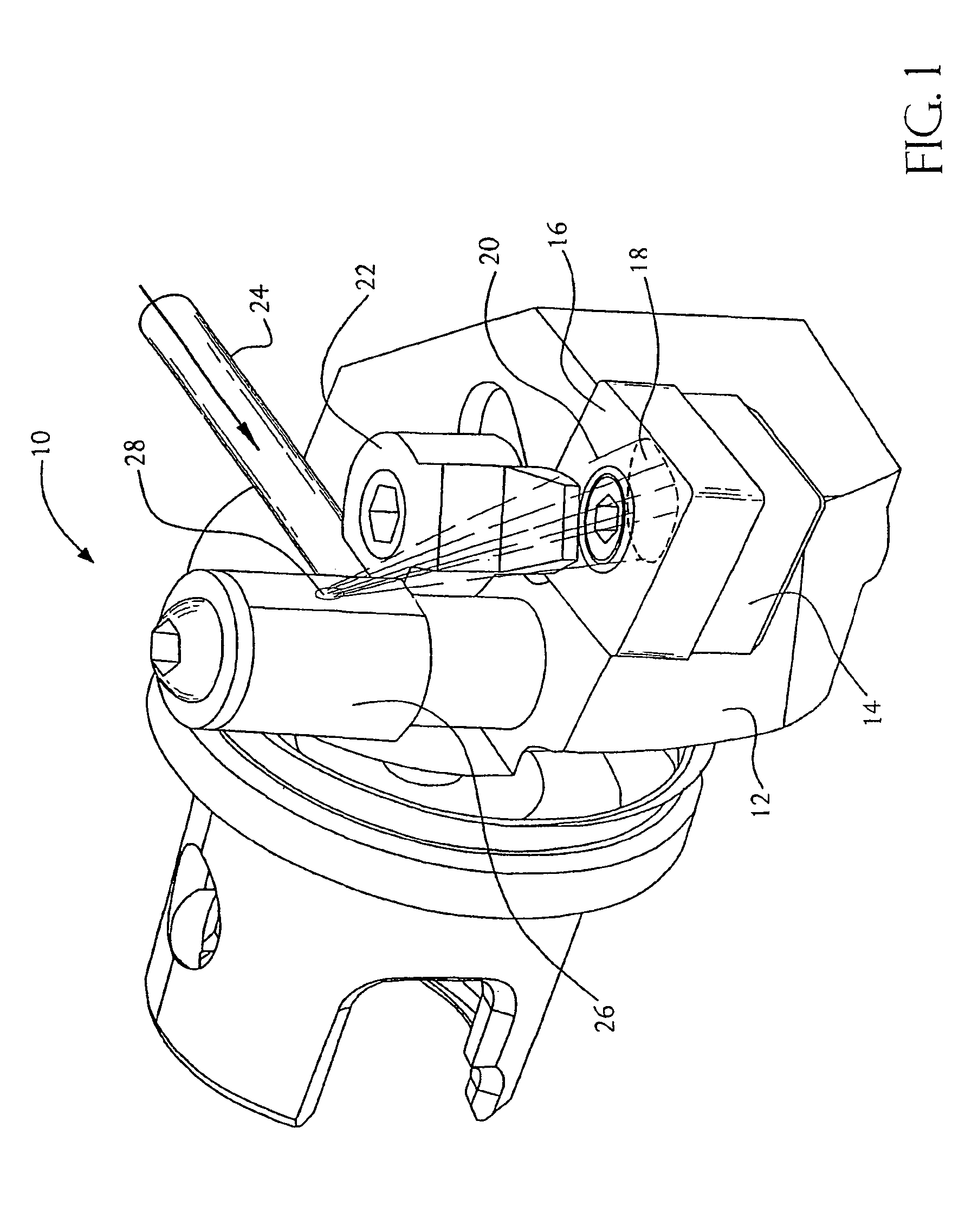

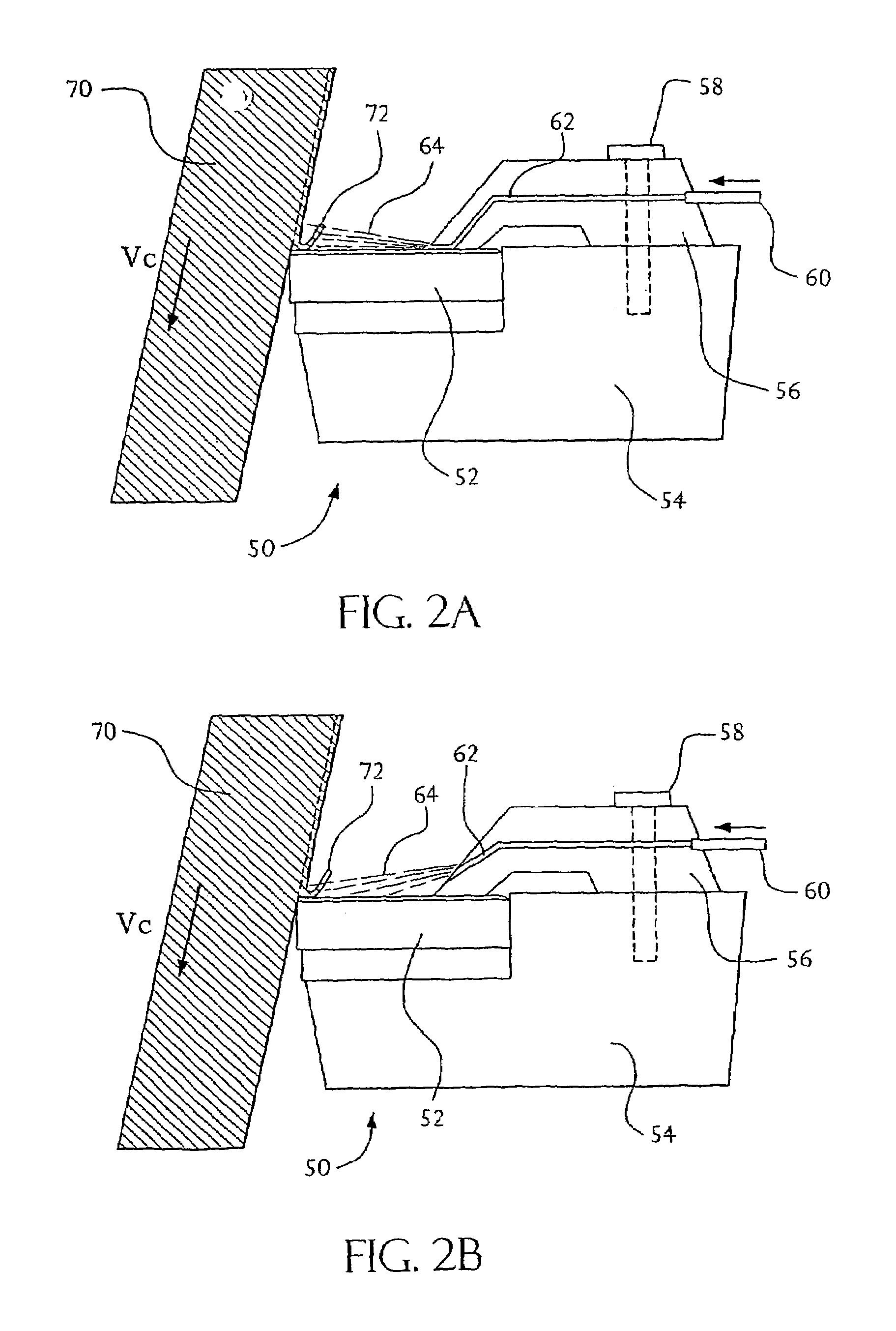

Apparatus and method for machining with cryogenically cooled oxide-containing ceramic cutting tools

A method and an apparatus or machining a workpiece include the use of a cryogenically cooled oxide containing ceramic cutting tool. The method involves cryogenic cooling of the cutting tool during a cutting operation, which cooling results in enhanced wear resistance and fracture resistance of the cutting tool. A preferred embodiment involves jetting a cryogenic fluid directly at the cutting tool.

Owner:AIR PROD & CHEM INC

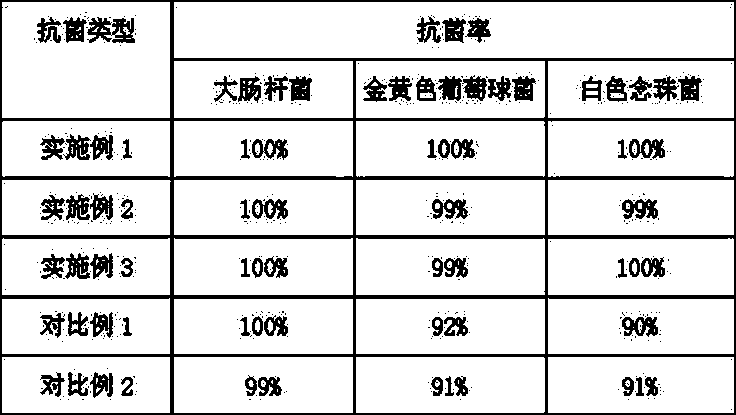

Antimicrobial ceramic cutting tool and its manufacturing method

InactiveCN101269961AImprove antibacterial propertiesGood antibacterial effectTitanium nitrideUltra fine

The present invention provides an antibacterial ceramic cutting tool and belongs to the technological field of fine ceramics. The present invention comprises ingredients and is characterized in that the ceramic cutting tool is essentially made of fine ceramic material that is used as the main raw material, and 1.5 to 5 weight percent of antibacterial material. The fine ceramic material can be selected from ultra-fine zirconia powder, ceylon ceramic materials, alumina or silicon nitride that is used for plasticizing the ceramic materials, and metal ceramic materials such as titanium carbide or titanium nitride. The application of antibacterial ingredients in the fine ceramic material has resulted in the antibacterial and bacteriostatic properties of fine ceramic products. Further the ceramic cutting tool of the antibacterial function can be prepared.

Owner:淄博博纳科技发展有限公司

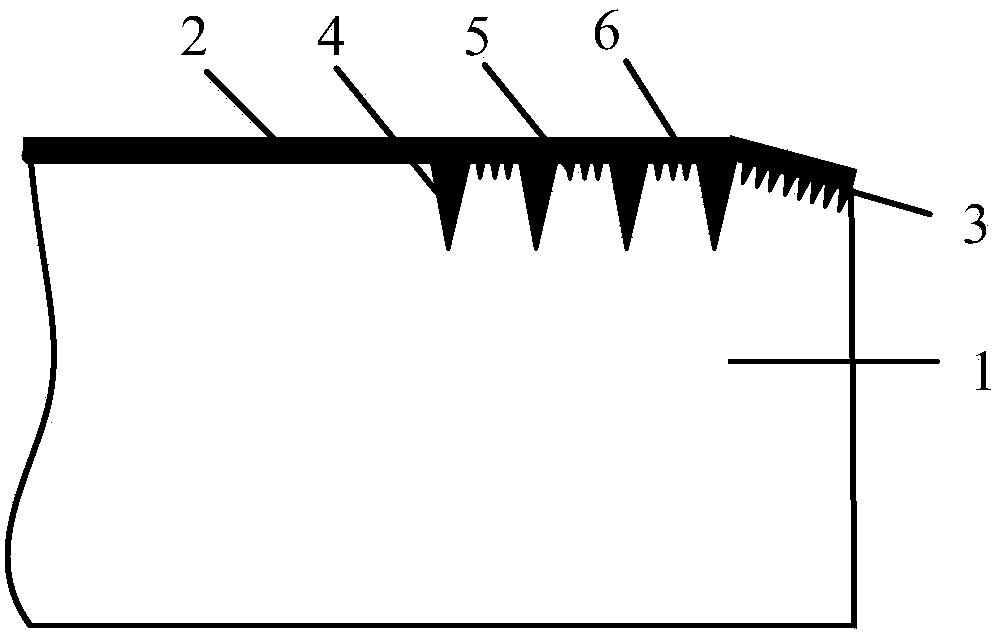

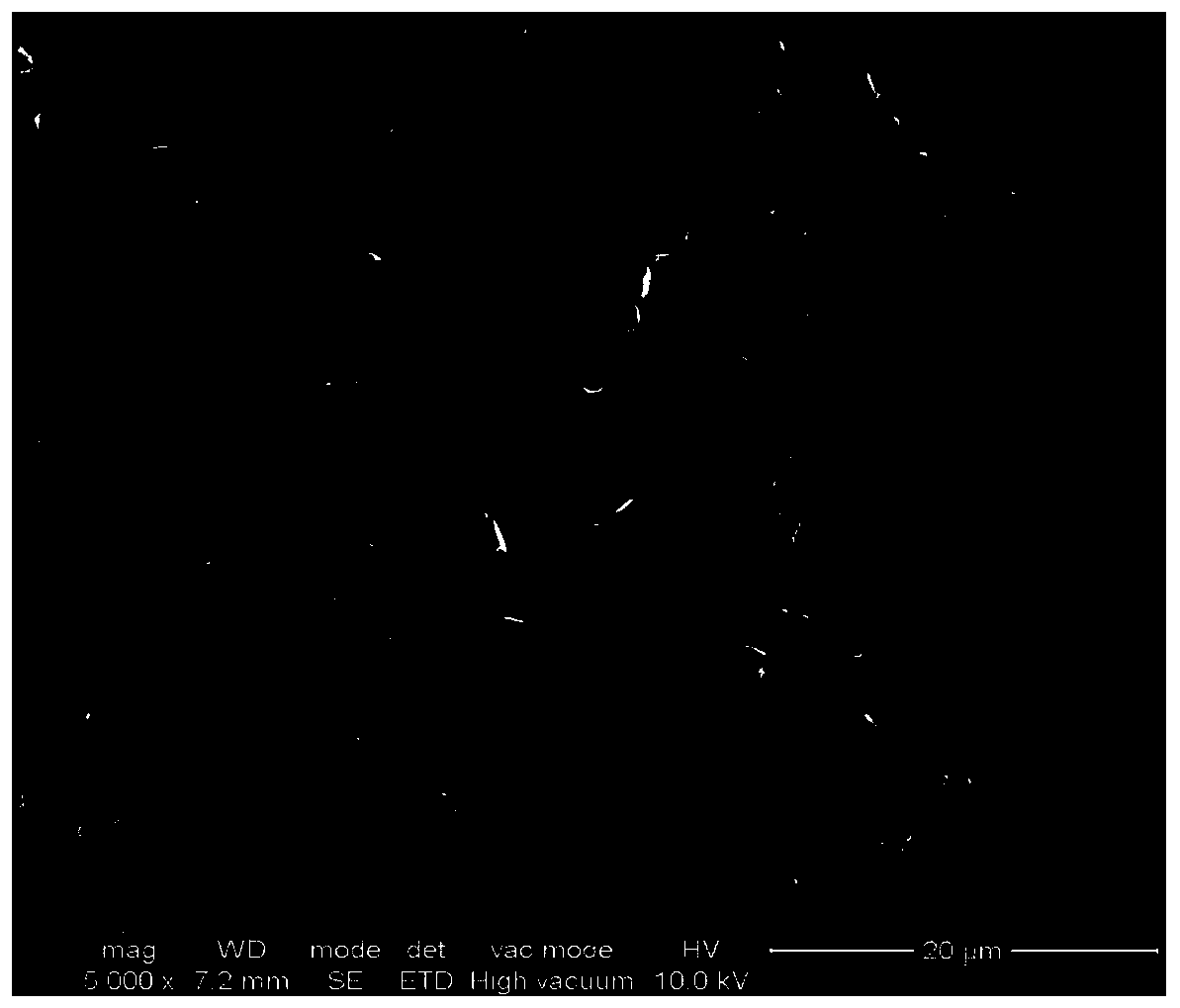

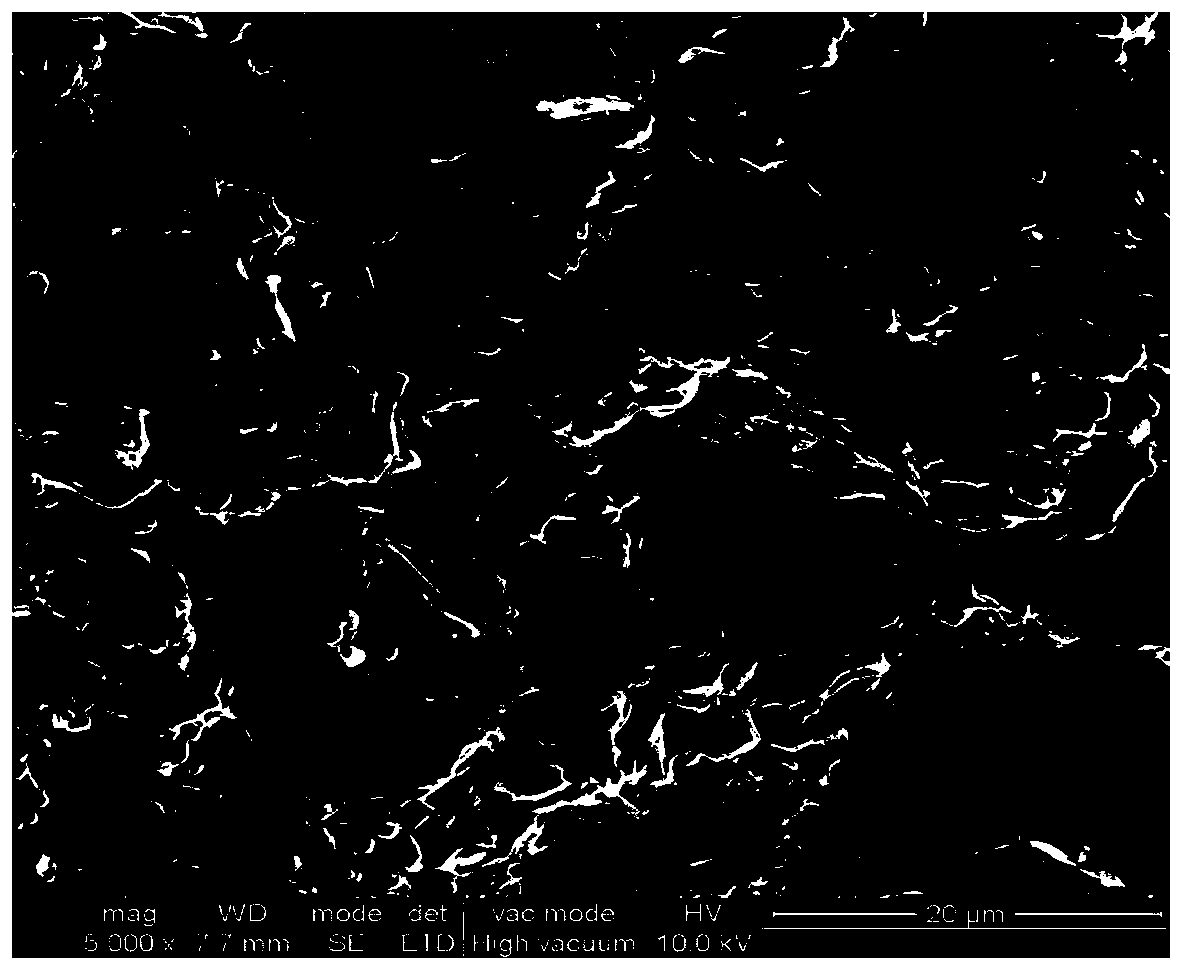

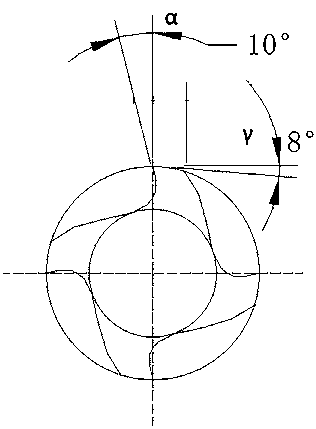

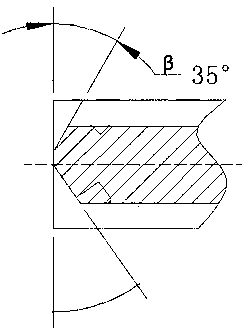

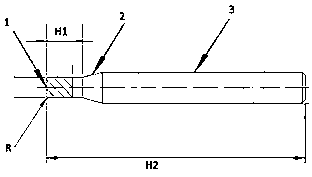

WS2/Zr soft coating micro-nano composite texture ceramic cutting tool and preparing method thereof

InactiveCN104014828AHigh hardnessImprove cutting performanceVacuum evaporation coatingSputtering coatingMicro nanoMicrometer

The invention belongs to the field of mechanical cutting tool manufacturing, and relates to a preparing method for a WS2 / Zr soft coating micro-nano composite texture ceramic cutting tool. Base materials of the cutting tool are ceramic. The method comprises the steps that firstly, the laser machining technology is adopted to machine micrometer textures of different morphologies and sizes on the front tool face of the ceramic cutting tool, then the laser machining technology is adopted to machine nanometer textures on a negative chamfer and the front tool face, and finally the medium frequency magnetron sputtering deposition plus multi-arc ion plating method is adopted to deposit a WS2 / Zr soft coating on the surface of the cutting tool, wherein the WS2 / Zr soft coating is arranged on the surface of the cutting tool, and a Zr transition layer is arranged between the soft coating and a base body. According to the ceramic cutting tool, friction between tool chips can be effectively reduced during cutting, the cutting force and the cutting temperature are reduced, and the abrasion resistance capacity of the cutting tool is improved, so that the service life of the cutting tool is prolonged. The ceramic cutting tool can be widely applied to dry cutting and cutting machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

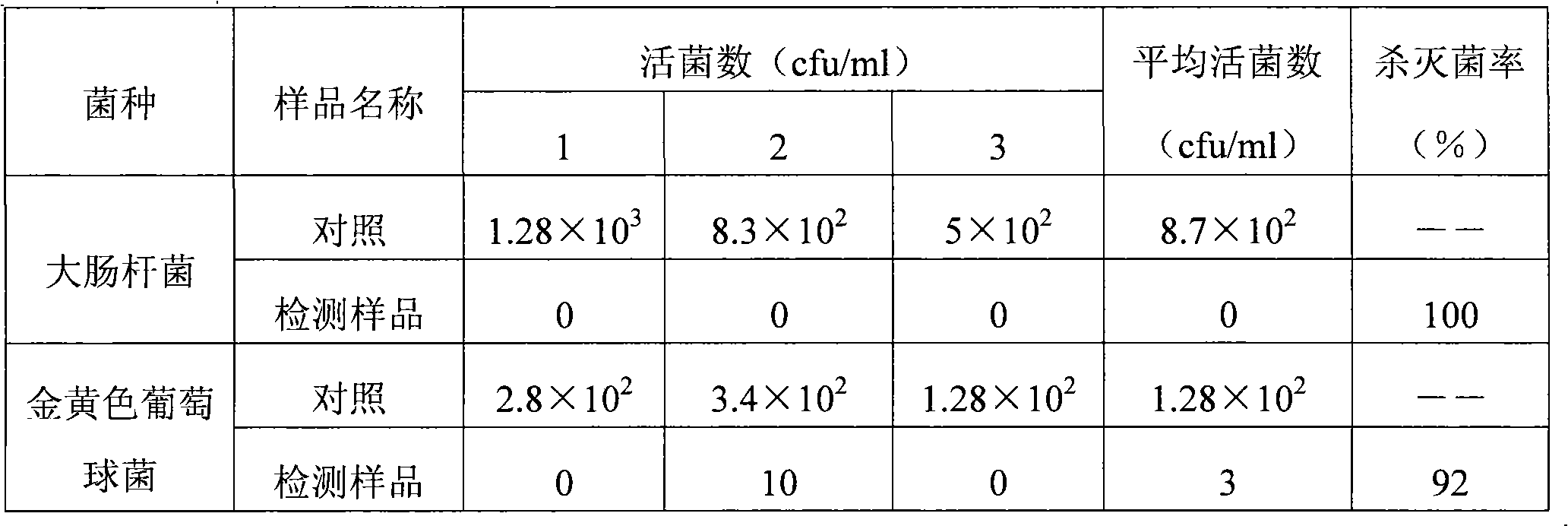

Antibacterial ceramic cutting tool and preparation method thereof

ActiveCN103848633AImprove antibacterial propertiesGood antibacterial effectAlkali metal oxideTitanium nitride

The invention provides an antibacterial ceramic cutting tool which is prepared from a ceramic material and an antibacterial active material. Based on the total weight of the ceramic material and the antibacterial active material, the addition of the antibacterial active material is 3-10wt% and the balance is the ceramic material. The ceramic material comprises one or more than one of zirconium oxide, aluminum oxide, silicon nitride, titanium carbide or titanium nitride. The antibacterial active material comprises silver oxide, copper oxide, titanium oxide, silicon oxide, aluminum oxide, alkali metal oxide, alkaline earth metal oxide and inevitable impurities. The grain size of the antibacterial active material is 10-100nm. Meanwhile, the invention further provides a preparation method of the antibacterial ceramic cutting tool. The antibacterial ceramic cutting tool provided by the invention is good in antibacterial and bacteriostatic effect, and particularly has a good capability of resisting and inhibiting staphylococcus aureus and tritirachium album.

Owner:BYD CO LTD

Cutting tool having high toughness and abrasion resistance

ActiveUS20060127671A1Improve toughnessIncrease the residual compressive stressPigmenting treatmentMolten spray coatingGas phaseCeramic cutting tool

Disclosed herein is a cutting tool having high toughness and abrasion resistance, in which a coated cutting tool including a cemented carbide substrate, a cermet substrate or a ceramic substrate coated with a hard coating film by means of chemical vapor deposition, moderate temperature-chemical vapor deposition or physical vapor deposition, and / or a cemented carbide cutting tool, a cermet cutting tool or a ceramic cutting tool are subjected to wet blasting using 10-300 μm sized particles to decrease residual tensile stress or increase residual compressive stress, thereby improving toughness, and also, reducing surface roughness of the cutting tool, thus remarkably increasing chipping resistance and flaking resistance.

Owner:KORLOY

Cutting tool having high toughness and abrasion resistance

ActiveUS7691496B2Improve toughnessIncrease the residual compressive stressPigmenting treatmentMolten spray coatingGas phaseSurface roughness

Disclosed herein is a cutting tool having high toughness and abrasion resistance, in which a coated cutting tool including a cemented carbide substrate, a cermet substrate or a ceramic substrate coated with a hard coating film by means of chemical vapor deposition, moderate temperature-chemical vapor deposition or physical vapor deposition, and / or a cemented carbide cutting tool, a cermet cutting tool or a ceramic cutting tool are subjected to wet blasting using 10-300 μm sized particles to decrease residual tensile stress or increase residual compressive stress, thereby improving toughness, and also, reducing surface roughness of the cutting tool, thus remarkably increasing chipping resistance and flaking resistance.

Owner:KORLOY

Self-lubricating ceramic cutting bits

InactiveCN1583660ARealize self-lubricating functionReduce coefficient of frictionMetallurgyWorking temperature

Owner:SHANDONG UNIV

Preparation method of silicon nitride-based conductive ceramic and molding method of silicon nitride-based conductive ceramic cutting tool

The invention relates to the technical field of ceramic preparation, and in particular relates to a preparation method of silicon nitride-based conductive ceramic and a molding method of a silicon nitride-based conductive ceramic cutting tool. A microstructure of the silicon nitride-based conductive ceramic can be effectively optimized by adding a certain amount of a sintering aid prepared from MO and a rare earth oxide, so that the toughness and the strength of the silicon nitride-based conductive ceramic are significantly improved; improvement of the electric conductivity of the silicon nitride-based conductive ceramic is facilitated by adding a certain amount of conductive phase; the silicon nitride-based conductive ceramic can be processed by an electric spark machining technique; the ceramic cutting tool prepared from the silicon nitride-based conductive ceramic is suitable for a PVD coating technology; in addition, the ceramic cutting tool also plays toughening and strengthening roles; the improvement of the overall performance of the silicon nitride-based conductive ceramic is facilitated by adding a certain amount of a metal phase binder; the cutting tool is fabricated from the silicon nitride-based conductive ceramic through the molding method; the cutting tool with a complicated shape can be prepared; and the silicon nitride-based conductive ceramic cutting tool with relatively excellent performance can be obtained.

Owner:GUANGDONG UNIV OF TECH

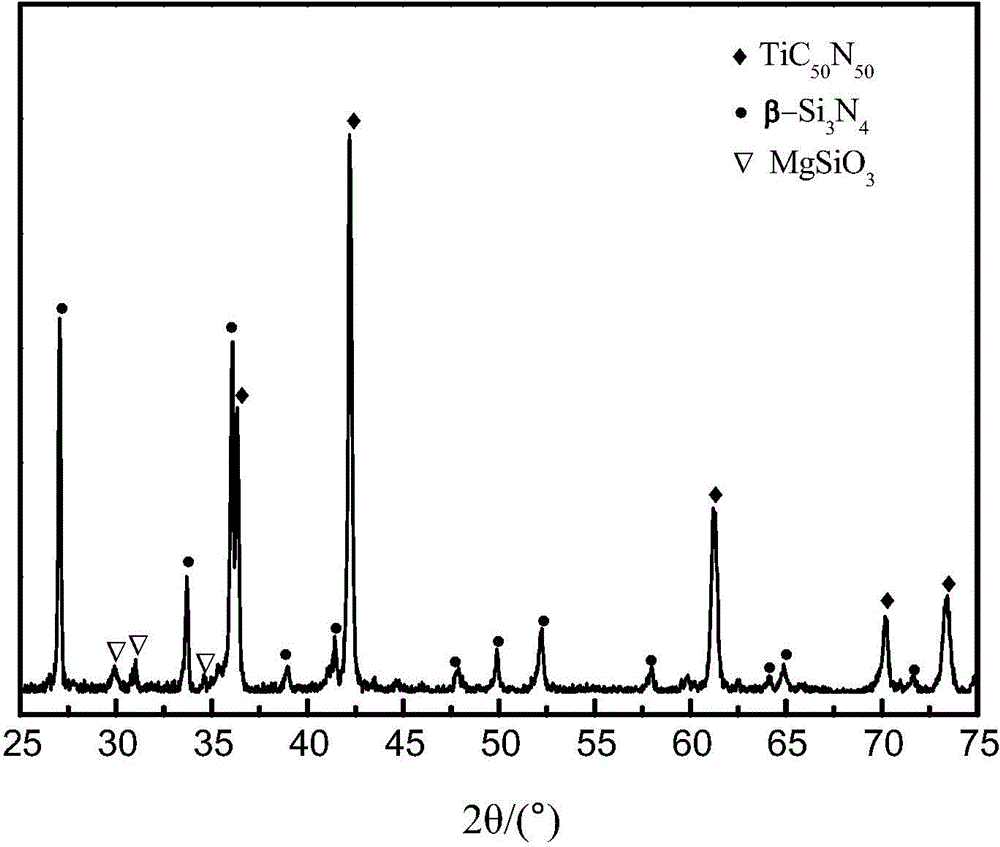

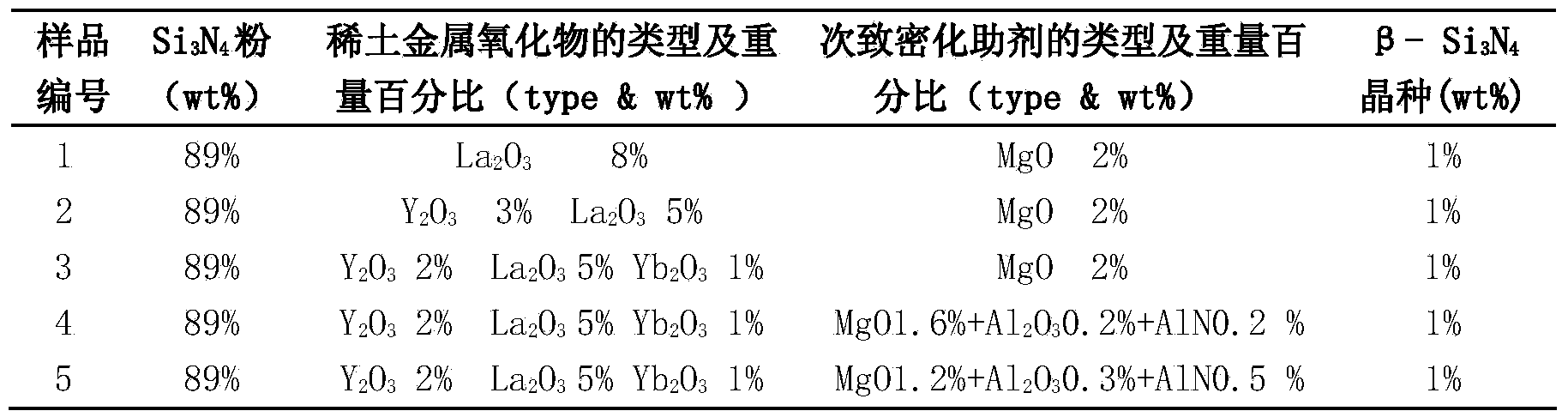

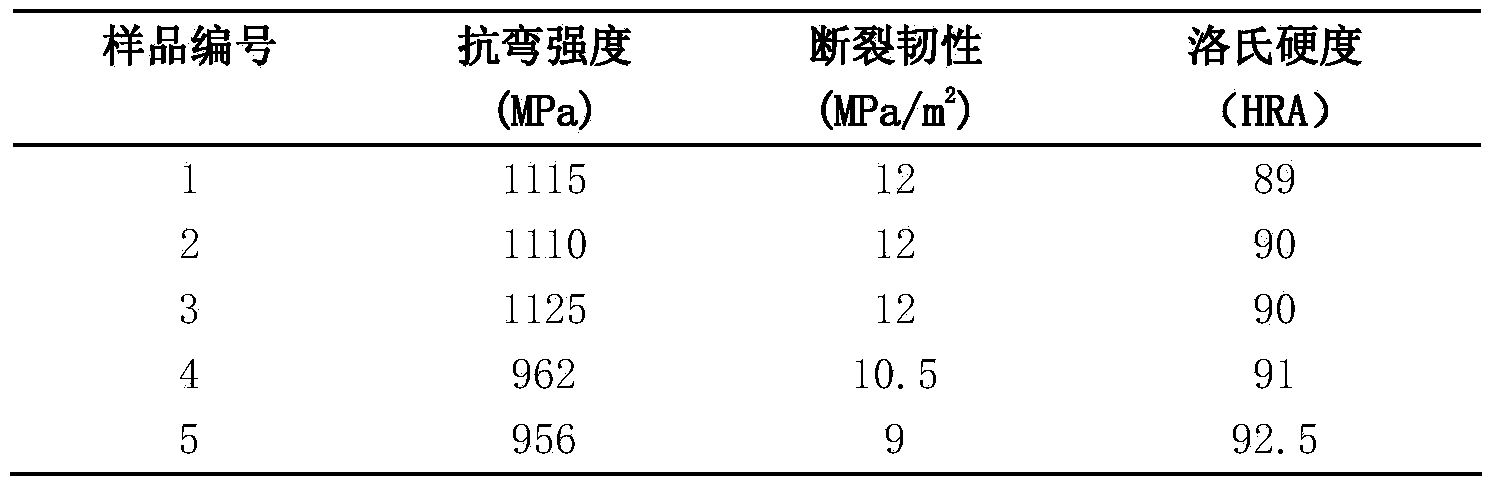

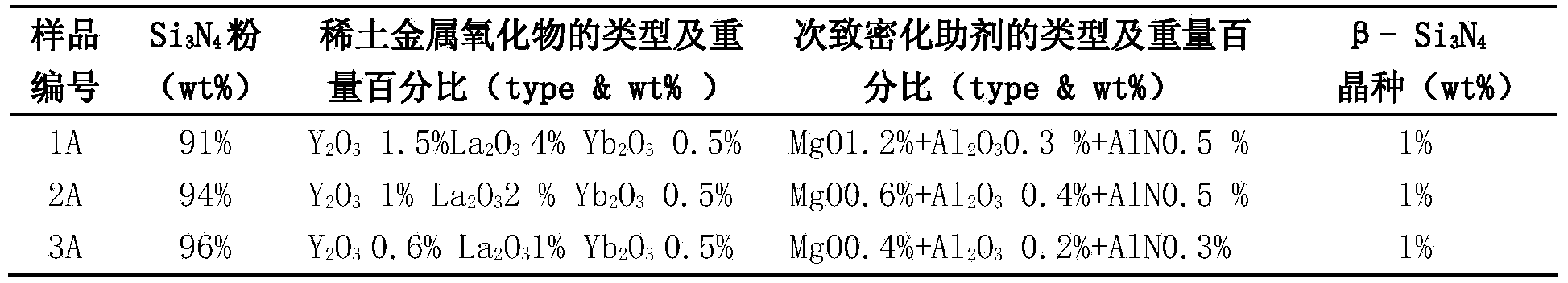

Silicon nitride based ceramic cutting tool material and preparation method thereof

The invention relates to the technical field of ceramic cutting tool materials, and in particular relates to a silicon nitride based ceramic cutting tool material and a preparation method thereof. The method comprises the following steps of: adding a dispersing agent to deionized water to prepare a dispersing agent solution; mixing the raw materials of the silicon nitride based ceramic cutting tool material and the dispersing agent solution by weight percentage: 80%-95% of Si3N4, 1%-8% of Ti(C1-XNX) with the X between 0.3 and 0.9, 2%-8% of Y2O3 and 1%-4% of Al2O3; ball-milling, drying and sieving by a 40-mesh sieve to obtain mixed powder; and subjecting the mixed powder to hot-pressing at the temperature between 1650 and 1750 DEG C and under the pressure between 20 and 40MPa to obtain the silicon nitride based ceramic cutting tool material. The material has higher mechanical property and the Vickers hardness, the bending strength and the fracture toughness are respectively 90-92GPa, 950-1219MPa and 10-16MPa.m1 / 2.

Owner:NORTHEASTERN UNIV

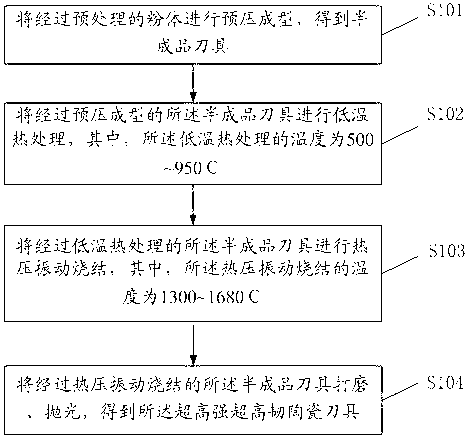

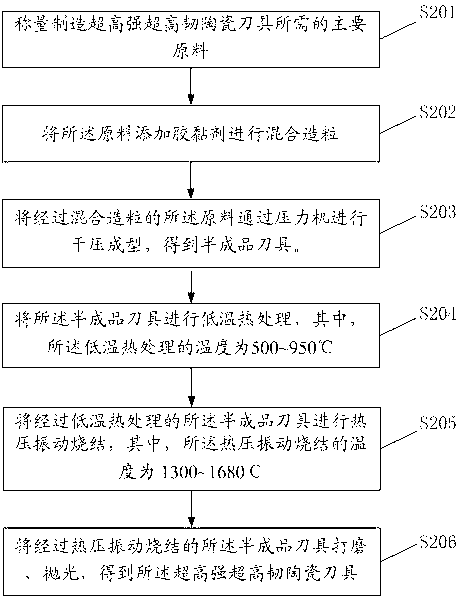

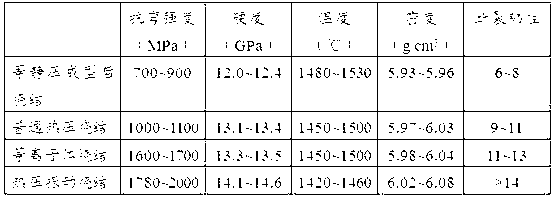

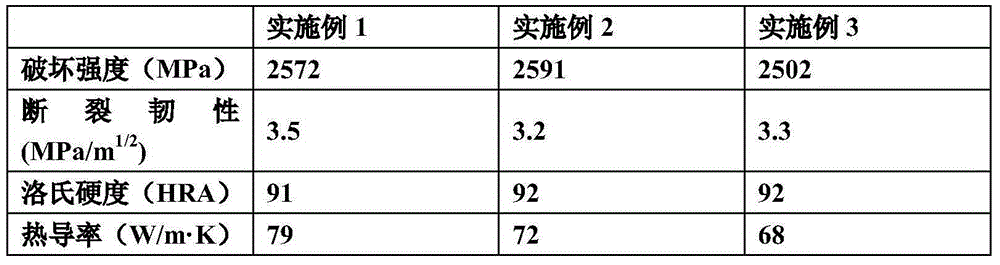

Ceramic cutting tool with ultrahigh strength and ultrahigh toughness, and preparation method thereof

The invention discloses a ceramic cutting tool with ultrahigh strength and ultrahigh toughness. The ceramic cutting tool with ultrahigh strength and ultrahigh toughness is prepared by a hot-press vibratory sintering process by using zirconium oxide, yttrium oxide and a rare earth oxide as main raw materials. Accordingly, the invention also discloses a preparation method of the ceramic cutting tool with ultrahigh strength and ultrahigh toughness. The preparation method comprises the steps of prepressing molding preprocessed powder to obtain a semi-finished cutting tool; performing low temperature heat treatment on the semi-finished cutting tool; hot-press vibratory sintering the semi-finished cutting tool processed by the low temperature heat treatment; and polishing and burnishing the semi-finished cutting tool processed by the hot-press vibratory sintering process to obtain the ceramic cutting tool with ultrahigh strength and ultrahigh toughness. Due to the adoption of the preparation method, the cutting toll has high hardness, good wear resistance and excellent thermal shock resistance, high bending strength and high fracture toughness. The cutting tool has obvious advantages in thermal conductivity, corrosion resistance, antioxidant activity, high temperature hardness, high temperature strength, etc.

Owner:FOSHAN CERAMICS RES INST GRP CO LTD +1

High-entropy boride-based ceramic, preparation method and applications thereof

The invention belongs to the field of ceramic cutting tools, and discloses a high-entropy boride-based ceramic, a preparation method and applications thereof. The preparation method comprises: carrying out ball milling mixing on high-entropy boride ceramic powder (A0.2B0.2C0.2D0.2E0.2)B2, an additive B4C and SiC, and drying to obtain mixed powder, wherein A, B, C, D and E respectively are different elements selected from Ti, Zr, Hf, V, Nb, Ta, C, Mo and W; heating the mixed powder to 1000-1500 DEG C in vacuum through a spark plasma method; and axially pressurizing to 25-50 MPa in an argon atmosphere, heating to 1800-2000 DEG C, and sintering to obtain the high-entropy boride-based ceramic. The high-entropy boride-based ceramic of the invention is high in hardness and good in chemical stability, has good wear resistance and good cutting performance, and can be used in the field of cutting tools for difficult-to-process materials.

Owner:GUANGDONG UNIV OF TECH

Preparation method of multifunctional gradient composite ceramic cutting tool material

The invention belongs to the field of mechanical manufacturing, more particularly relates to a preparation method of a multifunctional gradient composite ceramic cutting tool material. The method takes hard alloy with high strength, high tenacity and high elastic modulus as reinforced materials, wherein an upper layer is WC-based nano composite powders including WC, ZrO2 and Al2O3 (WZA), and a bottom layer is hard alloy powders including WC and Mo(WM); or the upper layer and the lower layer are WC-based nano composite powders (WZA), and a middle layer is hard alloy powders(WM); and the reinforced materials are hot-pressed and sintered at the atmosphere of nitrogen. The flexural strength, the fracture toughness property, the wear-resisting property, and the like of the cutting tool material are improved by utilizing the high hardness, the high chemical stability and the high wearing-resisting property of the WC-based nano composite material and the high strength and the high fracture toughness of the hard alloy. Compared with the general hard alloy cutting tool, the hardness of the multifunctional gradient composite ceramic cutting tool material is improved by 15-20 percent; and compared with the ceramic cutting tool, the flexural strength and the fracture toughness of the multifunctional gradient composite ceramic cutting tool material are respectively improved by 30-40 percent and 25-40 percent.

Owner:SHANDONG UNIV

Special ceramic cutter material for wire-board or circuit board and preparation method thereof

InactiveCN101157554AImprove impact toughnessImprove wear resistanceTitanium carbideCeramic cutting tool

The invention discloses a ceramic cutting tool and the preparation method thereof special for a smashing line board or a circuit board, and belongs to the art of the smashing equipment. The ceramic cutting tool takes crystal whisker as the plasticizing material; tungsten carbide as the substrate material; titanium carbide as anti-friction agent; carbon as deoxidizing agent; and chromic compound, lanthanum oxide and cerium oxide as additive. The ingredients are evenly blended and directly molded by heat pressing. The raw material is not taken out until being fully mixed, and is then positioned into the sample heat pressing groove of a hot-press machine. The thermo-compression intensity of pressure is 10-40MPa, and the hot-press temperature ranges from 1,480 to 1,600DEG C. The flexible ceramic cutting tool of the invention is provided with good resilience, wearlessness, high rigidity and chemical stability. The technique of the cutting tool is quite simple and the production period is far shorter than the production period of the conventional preparation method that carries the compression molding of the evenly mixed raw materials first and then the sinter molding. The cutting tool material is fit for the cutting tool special for the making of a waste line board and the smashing equipment of the circuit board.

Owner:TSINGHUA UNIV

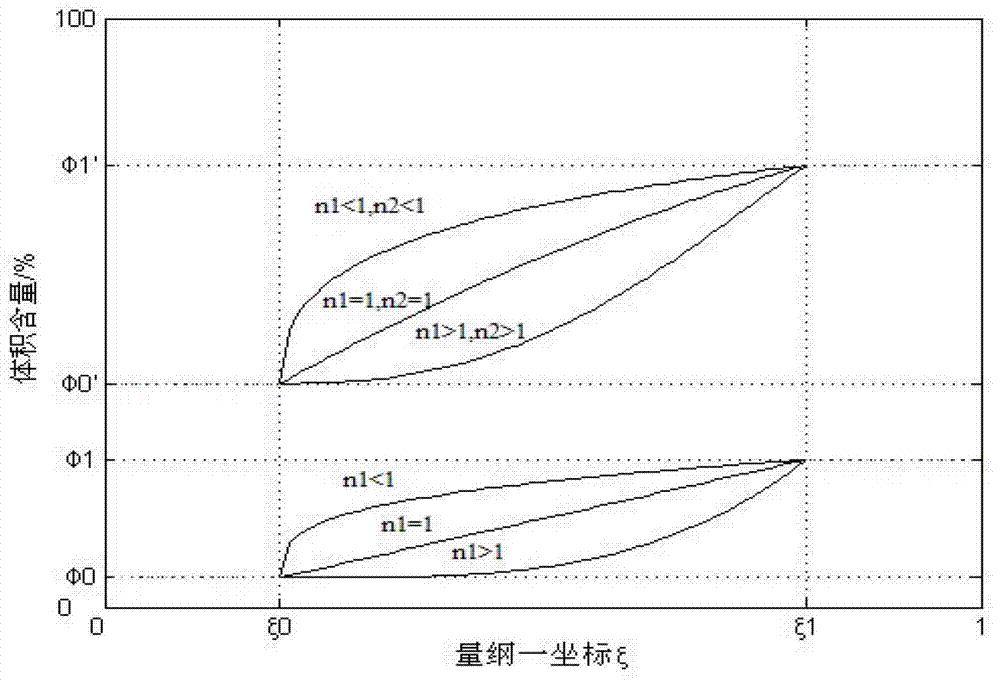

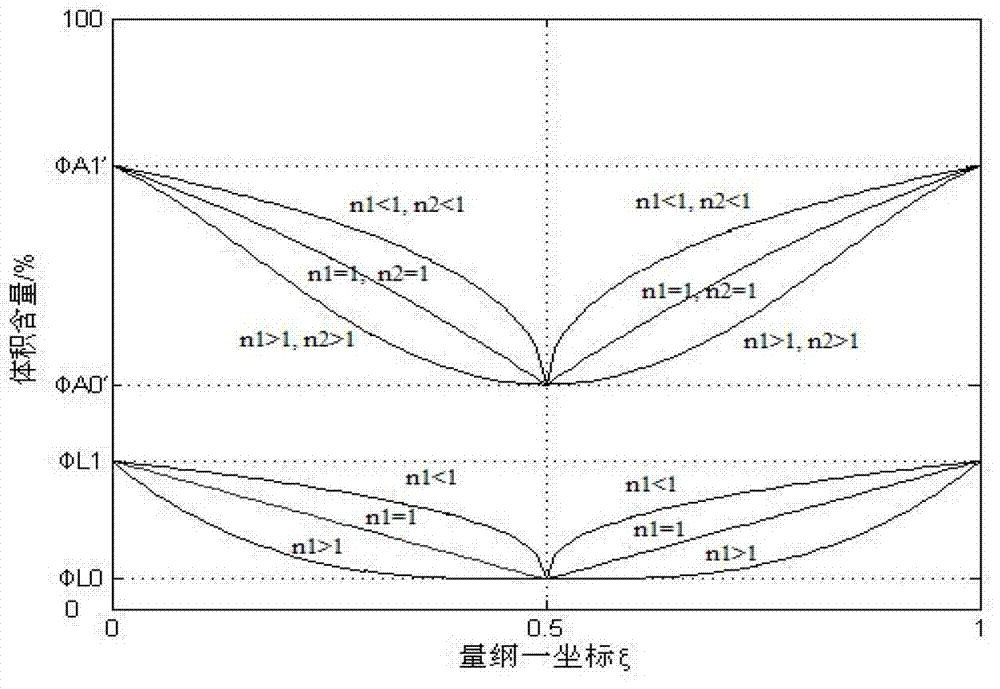

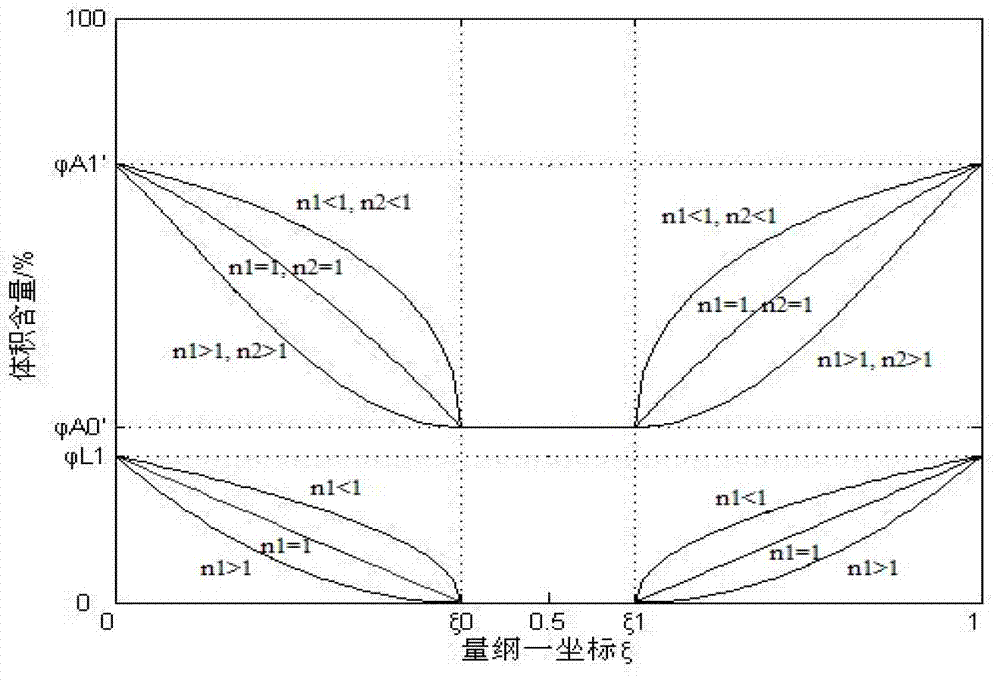

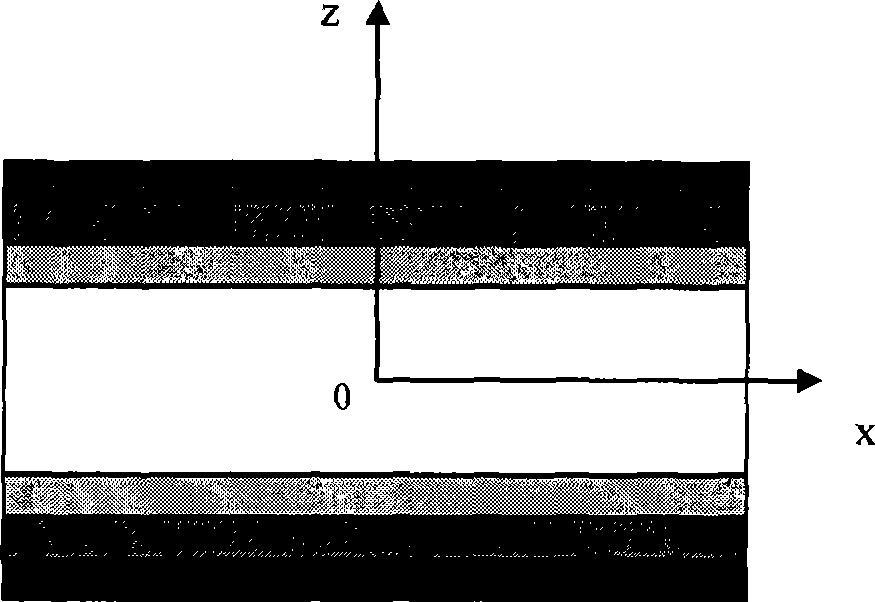

Multivariate gradient self-lubricating ceramic cutting tool material with surface having residual compressive stress and preparation method of multivariate gradient self-lubricating ceramic cutting tool material

The invention relates to a multivariate gradient self-lubricating ceramic cutting tool material with a surface having residual compressive stress and a preparation method of the multivariate gradient self-lubricating ceramic cutting tool material. The multivariate gradient self-lubricating ceramic cutting tool material subjected to composition gradient design by applying a multivariate gradient composition distribution function, and is formed by being subjected to layered paving and hot pressed sintering by taking alpha-Al2O3 as a basal body, adding (W, Ti) as wild phase, taking calcium fluoride as a solid lubricant and taking magnesium oxide and nickel oxide as sintering aids. The cutting tool material has (2K-1) layers of gradient structures components of which are symmetrical relative to a middle layer. The highest 8-12% of calcium fluoride content on the surface layer is reduced to be zero of the calcium fluoride content on the middle layer. The residual compressive stress exists between two surface layers of the cutting tool material. Various mechanical performance indexes of the ceramic cutting tool material are all higher than those of homogeneous self-lubricating ceramic cutting tool materials with the same material system, and the multivariate gradient self-lubricating ceramic cutting tool material has high antifriction and high friction-resistant properties at the same time and can be used for dry cutting and cutting processing of materials difficult to process.

Owner:QILU UNIV OF TECH

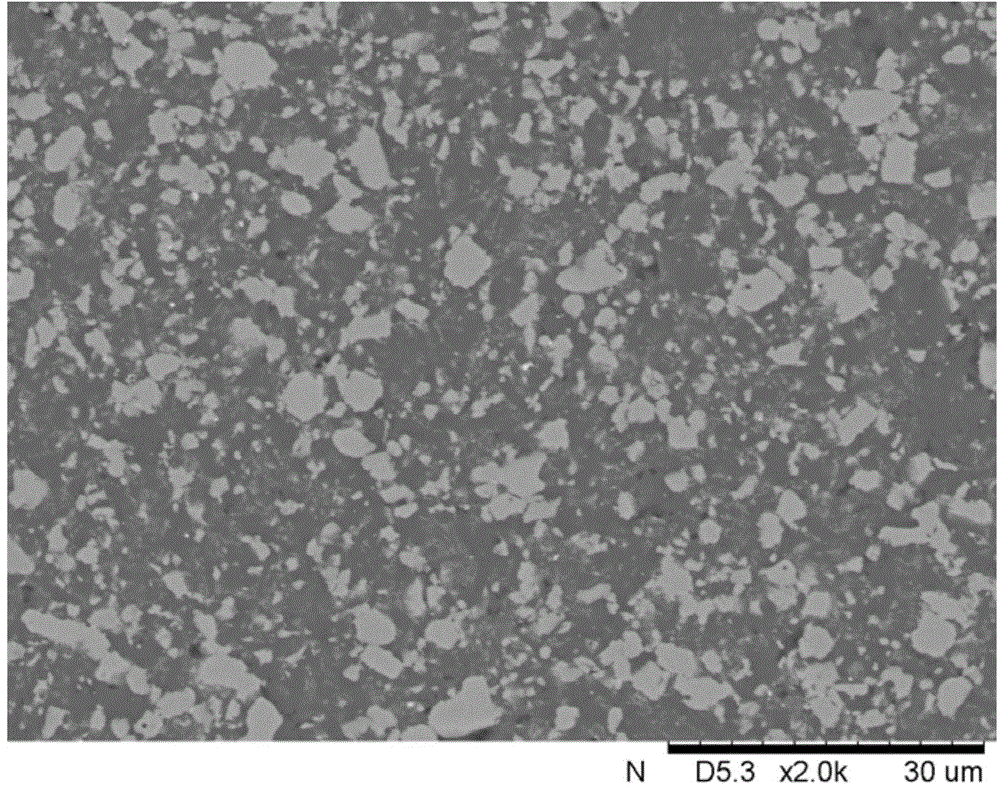

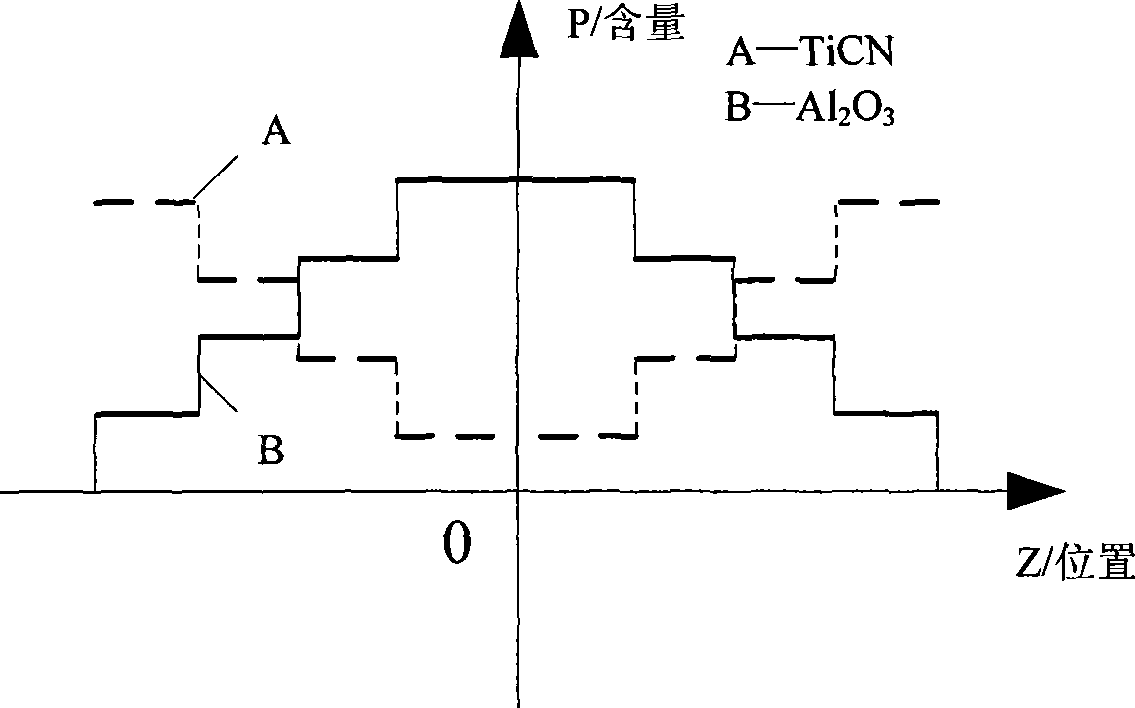

Gradient nano composite ceramic tool material and preparation method thereof

InactiveCN101391888AHigh hardnessUniform particle size distributionComposite ceramicCeramic cutting tool

The invention provides a gradient nano composite ceramic cutting tool material and a preparation method thereof, pertaining to the technical field of ceramic cutting tool materials. The cutting tool material has a symmetrical gradient layered structure, with the layer number of 3 or 5; according to volume percentage, the components of all the layers are 69 percent to 39 percent of AI2O3, 30 percent to 60 percent of micro TiCN, and 1 percent of micro MgO, micro Y2O3 and micro NiO; the layers which are symmetrical relative to the central layer have the same content of the components, and the thickness is symmetrically distributed, wherein, the AI2O3 of two surface layers is the mixture of nano AI2O3 and micro AI2O3, the volume content of the nano AI2O3 takes up 10 percent to 30 percent of the total AI2O3 volume content of the layer, and the AI2O3 of all the other layers is micro AI2O3; the TiCN content of each layer steadily increases layer by layer by 10 percent from the central layer to the outer layers, and the AI2O3 content steadily decreases layer by layer by 10 percent from the central layer to the outer layers. Powder layered filling in a laying way and hot pressed sintering technologies are adopted to prepare the material. The cutting tool material is characterized by uniform grain size distribution, high hardness, high bending strength, and good fracture toughness property and thermal shock resistance.

Owner:SHANDONG UNIV

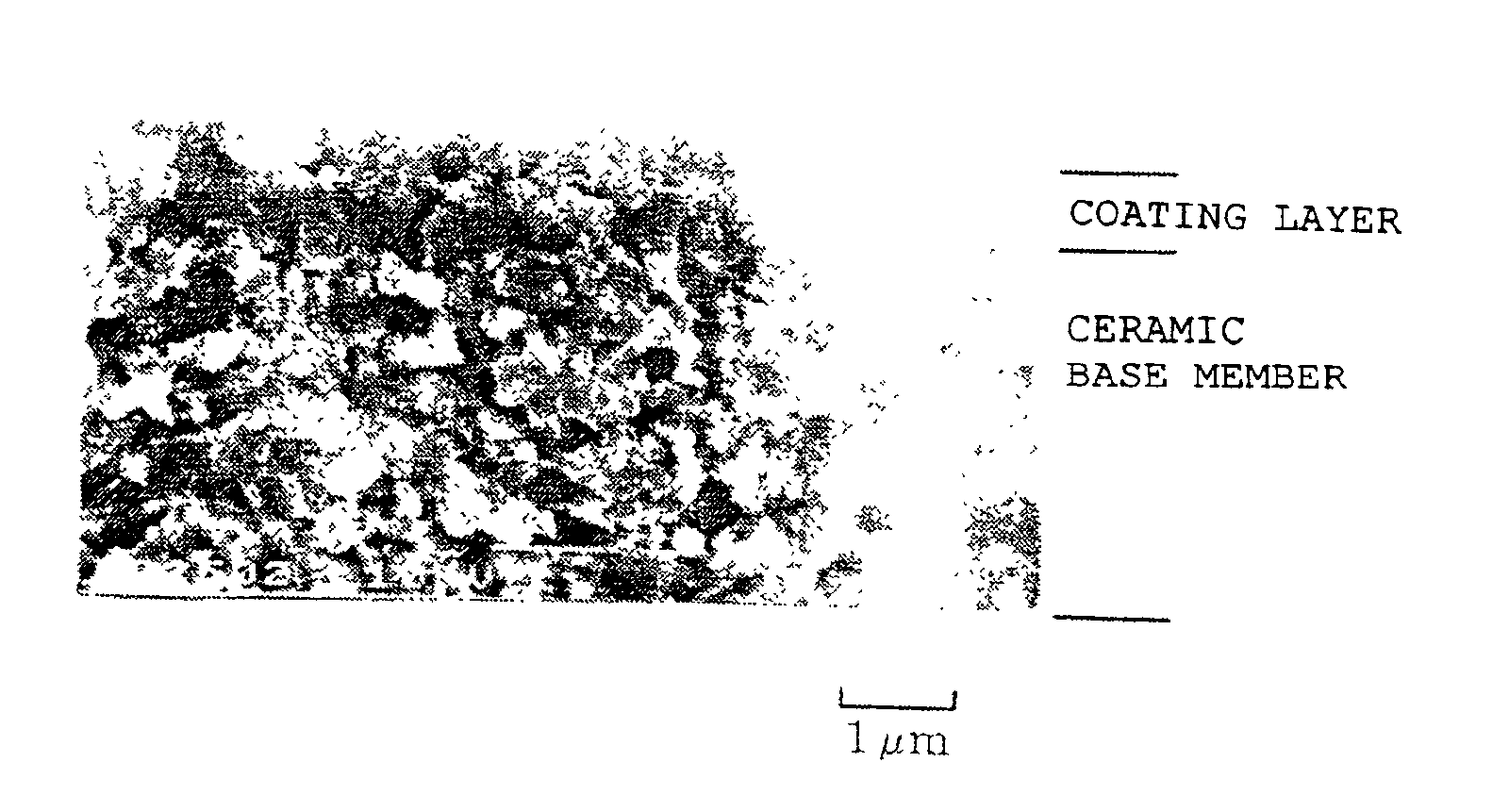

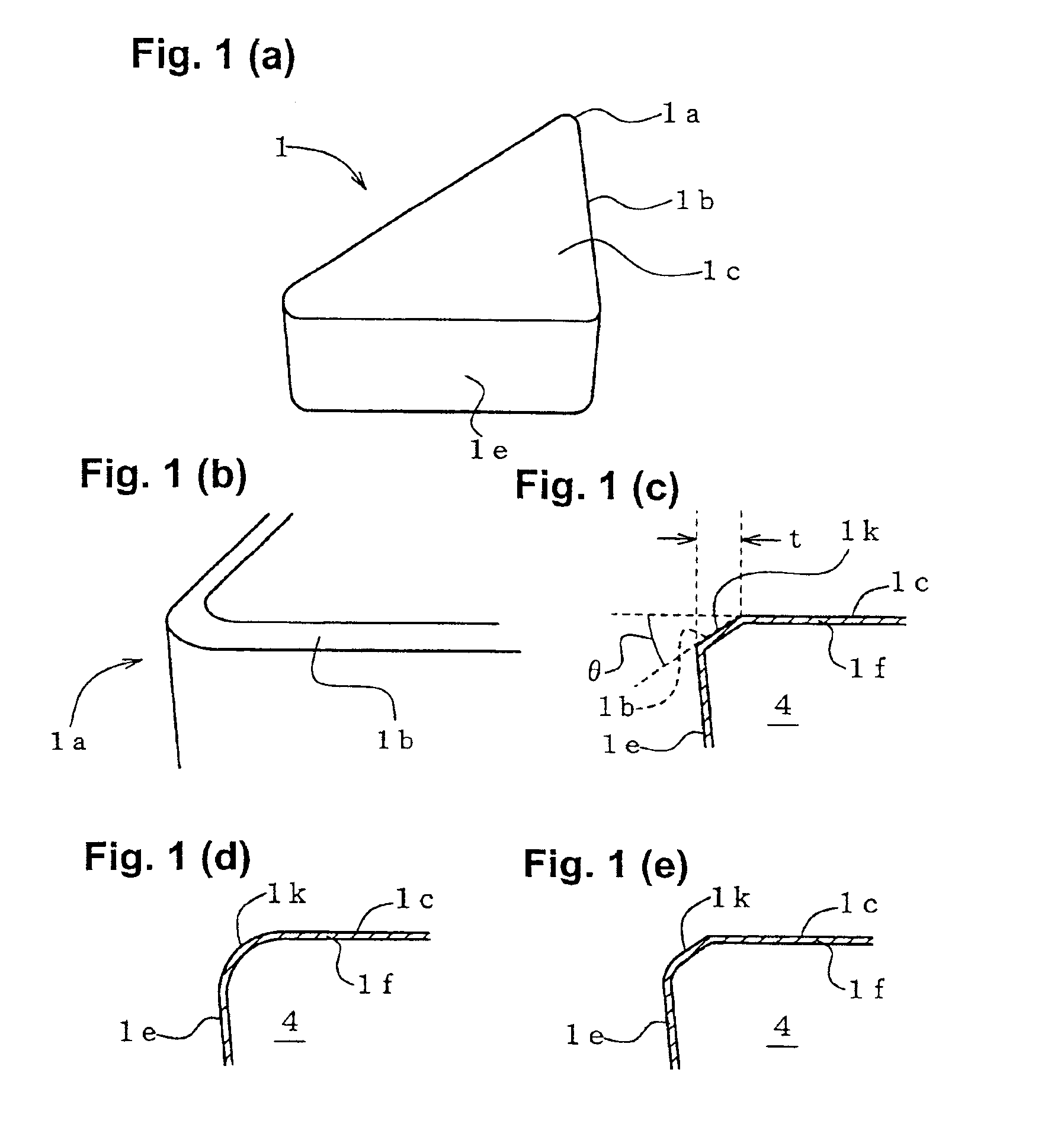

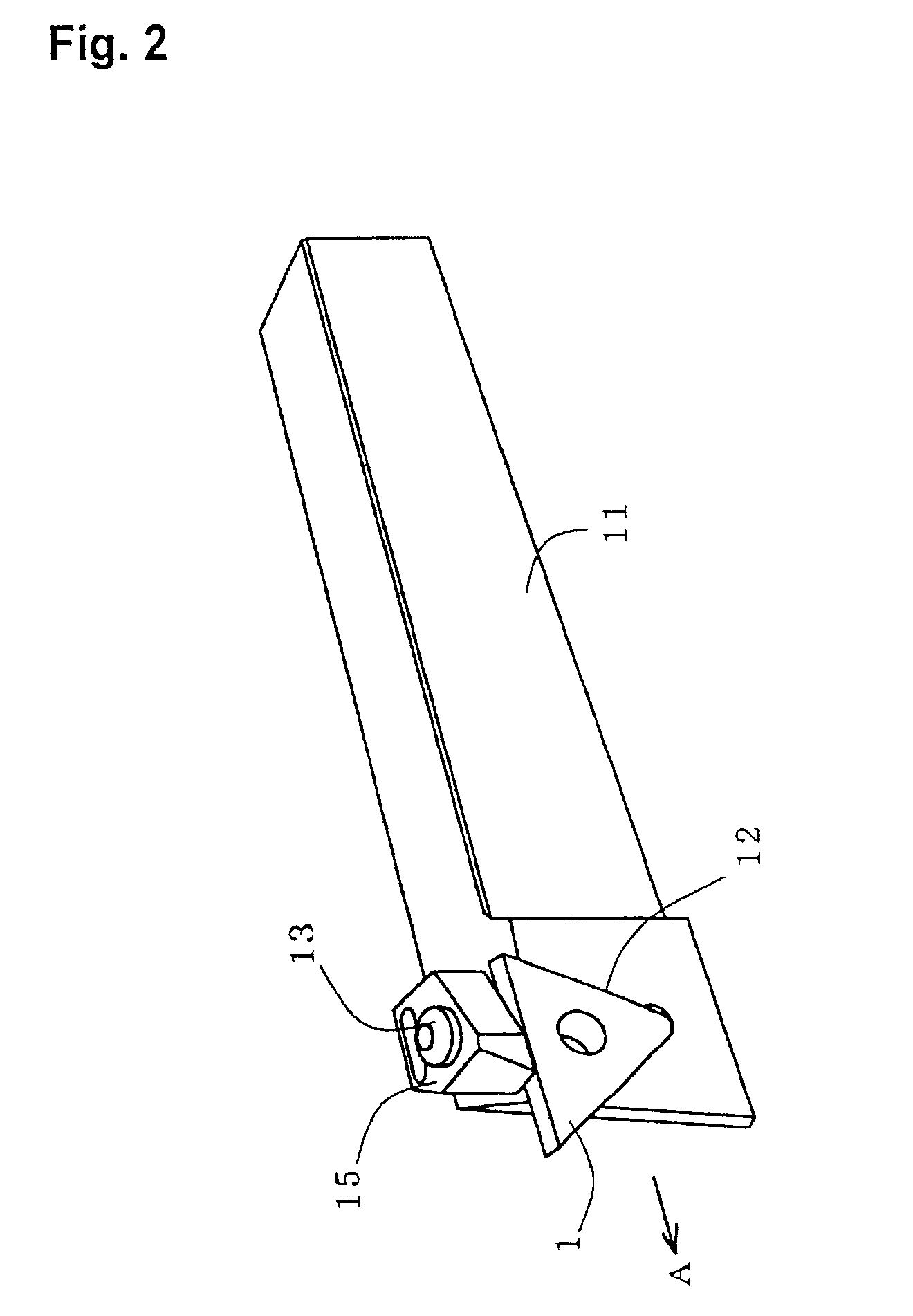

Cutting tool

InactiveUS6939607B2Low costImprove cutting performancePigmenting treatmentCutting insertsBorideComposite ceramic

A ceramic cutting tool including a ceramic base member 4 of a tool main body 1 which is formed of a composite ceramic which contains a hard phase dispersed within an alumina matrix phase. The hard phase contains, as a predominant component, one or more elements selected from hard-phase-forming metal elements M in the form of at least one of a carbide, nitride, or boride, or in the form of a solid solution of at least two selected from the carbide, nitride and boride. The hard-phase-forming metal elements M include Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W and Si. The surface of the ceramic base member 4 is covered with a coating layer 1f, which contains titanium carbonitride or titanium nitride as a predominant component. The coating layer 1f has an average crystal-grain size of 0.1 to 0.5 μm as observed on the surface, and an average thickness of 0.5 to 2 μm. The coating layer 4f is formed by a CVD at a low to medium temperature range of 750 to 900° C. The ceramic cutting tool can be fabricated at low cost and can secure stable cutting performance over a long period even when the tool is used under severe cutting conditions under which large thermal and mechanical loads act on the tool.

Owner:NGK SPARK PLUG CO LTD

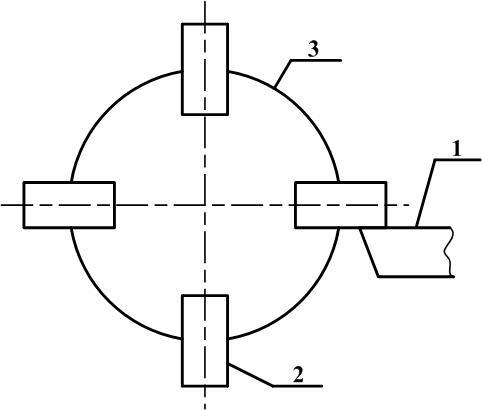

Cryogenic treatment method for ceramic/metal ceramic cutting tool

InactiveCN102329151AAddress resilienceSolve the problem of longevityRoom temperatureCryogenic treatment

The invention provides a cryogenic treatment method for ceramic / metal ceramic cutting tools, which can be especially used by cutting tool users to improve the service life of all kinds of finished ceramic / metal ceramic cutting tools. The cryogenic treatment method is suitable for metal ceramic / ceramic cutting tool series such as alumina-based ceramic cutting tool series, silicon-nitride-based ceramic cutting tool series, coating ceramic cutting tool series, TiC-based metal ceramic cutting tool series and Ti(C, N)-based metal ceramic cutting tool series. The cryogenic treatment method is characterized in that when the finished ceramic / metal ceramic cutting tools are in a program-controlled cryogenic box, cooling and heating programs are strictly controlled, firstly the finished ceramic / metal ceramic cutting tools are cooled to liquid nitrogen temperature, i.e. negative 150 DEG C to negative 196 DEG C, heat preservation is conducted for 2-24 hours, then finished ceramic / metal ceramic cutting tools are tempered in the cryogenic box to 150-200 DEG C, heat preservation is conducted for 1-4 hours and finally the finished ceramic / metal ceramic cutting tools are cooled to room temperature together with a furnace. The cryogenic treatment method for ceramic / metal ceramic cutting tools has the advantages that the cost is low, the industrialized production is easy to realize and the overall service life of the treated finished ceramic / metal ceramic cutting tools is prolonged.

Owner:CHONGQING UNIV OF ARTS & SCI +1

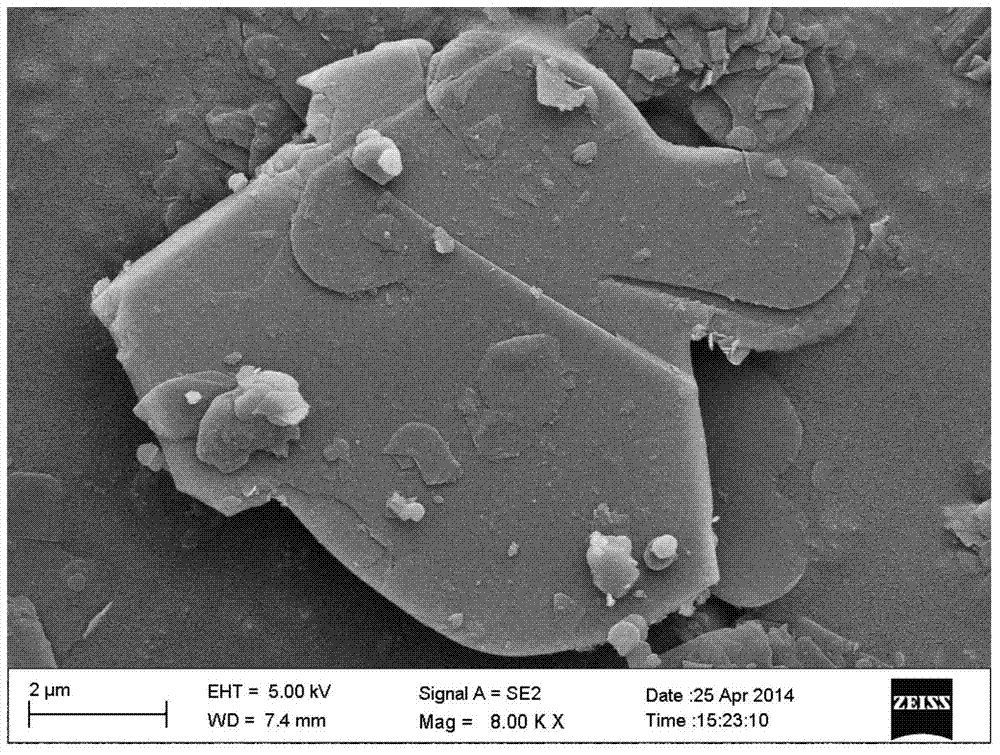

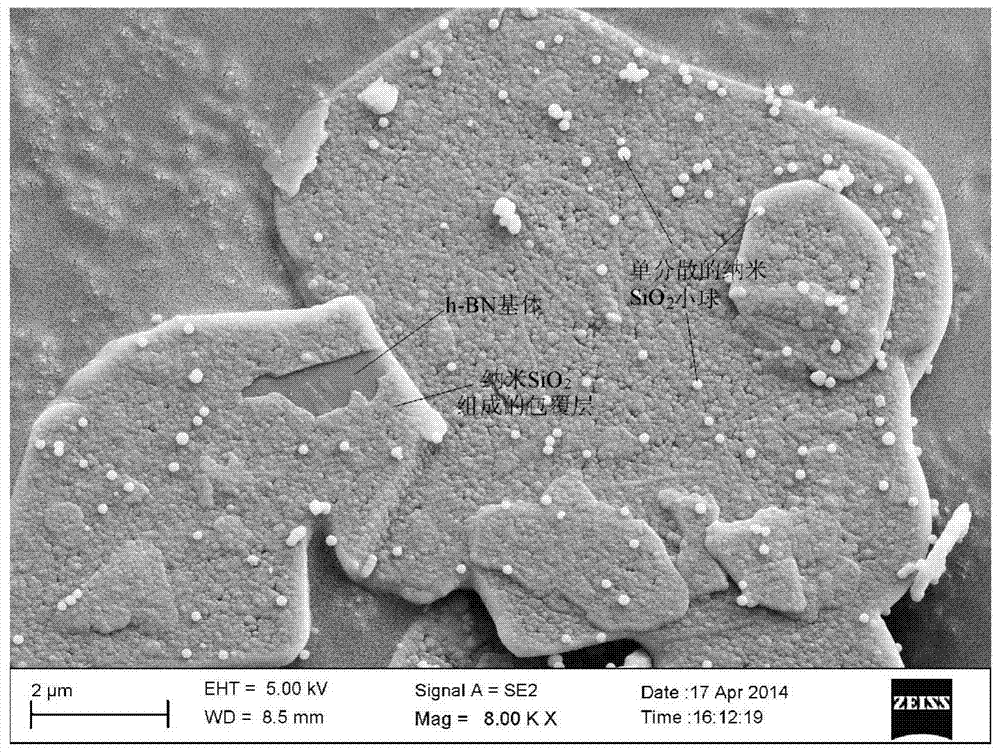

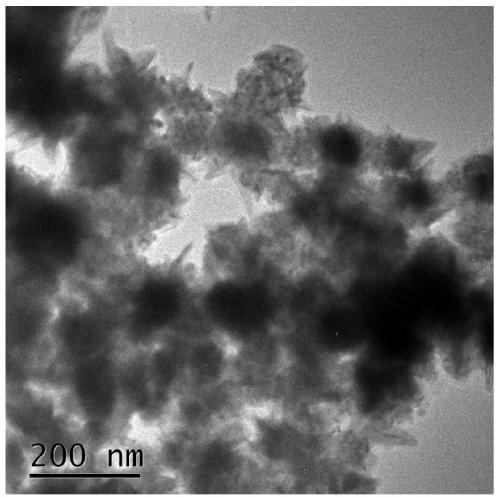

Preparation method of self-lubricating ceramic cutting tool material comprising spherical nanometer silicon dioxide coated hexagonal boron nitride composite powder

ActiveCN104844178AImprove mechanical propertiesTightly boundHexagonal boron nitrideCeramic cutting tool

The invention relates to a preparation method of self-lubricating ceramic cutting tool material comprising spherical nanometer silicon dioxide coated hexagonal boron nitride composite powder. The self-lubricating ceramic cutting tool material comprises the following raw material components in percentage by volume: 15-75% of TiC, 2-20% of h-BN@SiO2, 0.2-2.5% of MgO and the balance of Al2O3, wherein the h-BN@SiO2 is the spherical silicon dioxide coated hexagonal boron nitride composite powder which is obtained by dispersing h-BN powder in absolute ethyl alcohol and dropwise adding tetraethyl orthosilicate at the temperature of 30-70 DEG C. The invention also provides the preparation method of the self-lubricating ceramic cutting tool material. The added h-BN@SiO2 can improve the wettability of h-BN@SiO2 and a matrix and the mechanical property of the cutting tool material when the excellent lubricating property of the cutting tool material is remained, and reduce the agglomeration of air holes and the h-BN@SiO2 and the negative influence of the added h-BN on the mechanical property of the self-lubricating ceramic cutting tool material. The self-lubricating ceramic cutting tool material is suitable for application in manufacturing of self-lubricating ceramic cutting tools and can also be used for manufacturing ceramic molds, bearings and other wear-resisting anti-corrosion components and parts.

Owner:QILU UNIV OF TECH

Metal-ceramic cutting tool material and its preparation method

The invention discloses the Ti(C,N) based metal ceramics and its preparation method. The weight ratio of each constituent of the metal ceramics is as following Ti30-65, W8-25, Ta1.0-15.0, Zr0.1-5.0, Nb0-10, Cr0-1.0 etc as well as C and N as the rest. The powder of ceramics of carbonitride with Multiple elements in duplex type of two or more different element combinations is mixed with the powdersof carbide of Ti, W, Ta, Nb, V, Zr etc. and / or powders of carbide of their solid solution as well as the powders of Co, Ni, Mo. The metal ceramics are made from the admixture through the procedures of ball mill crushing, pressure moulding, vacuum dewaxing and vacuum sintering. With the good wear resistance being kept, the metal ceramics possesses high intensity and toughness.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

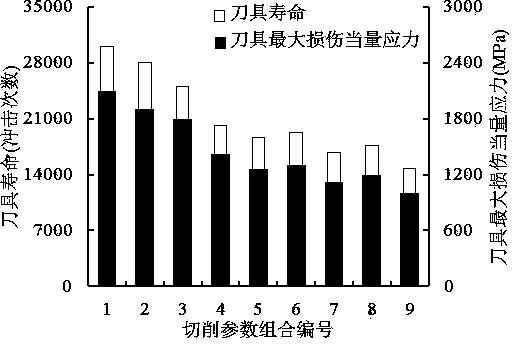

Ceramic cutting tool cutting parameter optimization method on interrupted cutting conditions

InactiveCN104050322AExtend your lifeReduce optimization costsSpecial data processing applicationsStructural engineeringCeramic knife

The invention discloses a ceramic cutting tool cutting parameter optimization method on interrupted cutting conditions. The method comprises the steps that parameters of a ceramic cutting tool are determined; the initial state value and the critical state value of microscopic damage to the ceramic cutting tool are determined; parameters of workpiece materials are determined; geometrical shapes of the cutting tool and workpieces are set in finite element simulation software, and all the relevant parameters of cutting tool materials and the workpiece materials are imported; cutting parameter combinations adopted in the finite element simulation process are determined through an orthogonal experimental design method; the maximum damage equivalent stress value is calculated; the cutting parameter combination with the minimum value is selected. According to the ceramic cutting tool cutting parameter optimization method, the influences of the cutting tool microscopic damage state and external loads on invalidation of the cutting tool are considered, and meanwhile the orthogonal experimental design method is adopted, so that the optimization precision of the cutting parameter combinations is higher; the cutting parameter combinations are optimized, and the cutting parameter optimization cost is greatly reduced; the ceramic cutting tool cutting parameter optimization method can be widely applied to optimization of the cutting parameter combinations on the various interrupted cutting conditions, and the purpose of prolonging the service life of the cutting tool is achieved finally.

Owner:HENAN POLYTECHNIC UNIV

High-entropy metal ceramic and preparation method and application thereof

The invention belongs to the field of metal ceramic cutting tools, and discloses high-entropy metal ceramic and a preparation method and application thereof. The high-entropy metal ceramic is preparedby the following steps: ball-milling and mixing high-entropy boride ceramic powder (A0.2B0.2C0.2D0.2E0.2) B2 and binders Ni, Co and Mo, wherein ABCDE is a different element in Ti, Zr, Hf, V, Nb, Ta,Cr, Mo or W; drying to obtain mixed powder; dry-pressing the mixed powder into blocks; heating to 800-1200 DEG C in vacuum in a normal pressure atmosphere; and heating to 1500-1800 DEG C in a protective atmosphere, and calcining. The high-entropy metal ceramic has the advantages of high hardness, favorable toughness, favorable chemical stability, favorable wear resistance and favorable impact resistance, and can be used for intermittent cutting of difficult-to-machine materials.

Owner:GUANGDONG UNIV OF TECH

Aluminum oxide reinforced high-entropy boride ceramic as well as preparation method and application thereof

The invention belongs to the field of ceramic cutting tools, and discloses aluminum oxide reinforced high-entropy boride ceramic as well as a preparation method and application thereof. The alumina-reinforced high-entropy boride ceramic is prepared by the following steps: carrying out ball milling and mixing on high-entropy boride ceramic powder (A<0.2>B<0.2>C<0.2>D<0.2>E<0.2>) B2 and a reinforcing phase Al2O3; drying the mixture to obtain mixed powder; heating the mixture powder to 900-1200 DEG C in vacuum; then under argon protection and axial pressurization of 30-50 MPa, heating the mixed powder to 1700-1900 DEG C; and performing spark plasma sintering, wherein the A, B, C, D, and E are different elements selected from Ti, Zr, Hf, V, Nb, Ta, Cr, Mo or W. The alumina-reinforced high-entropy boride ceramic has the advantages of high hardness, favorable chemical stability, favorable wear resistance and favorable cutting property, and can be applied to the field of cutting tools for difficult-to-machine materials.

Owner:GUANGDONG UNIV OF TECH

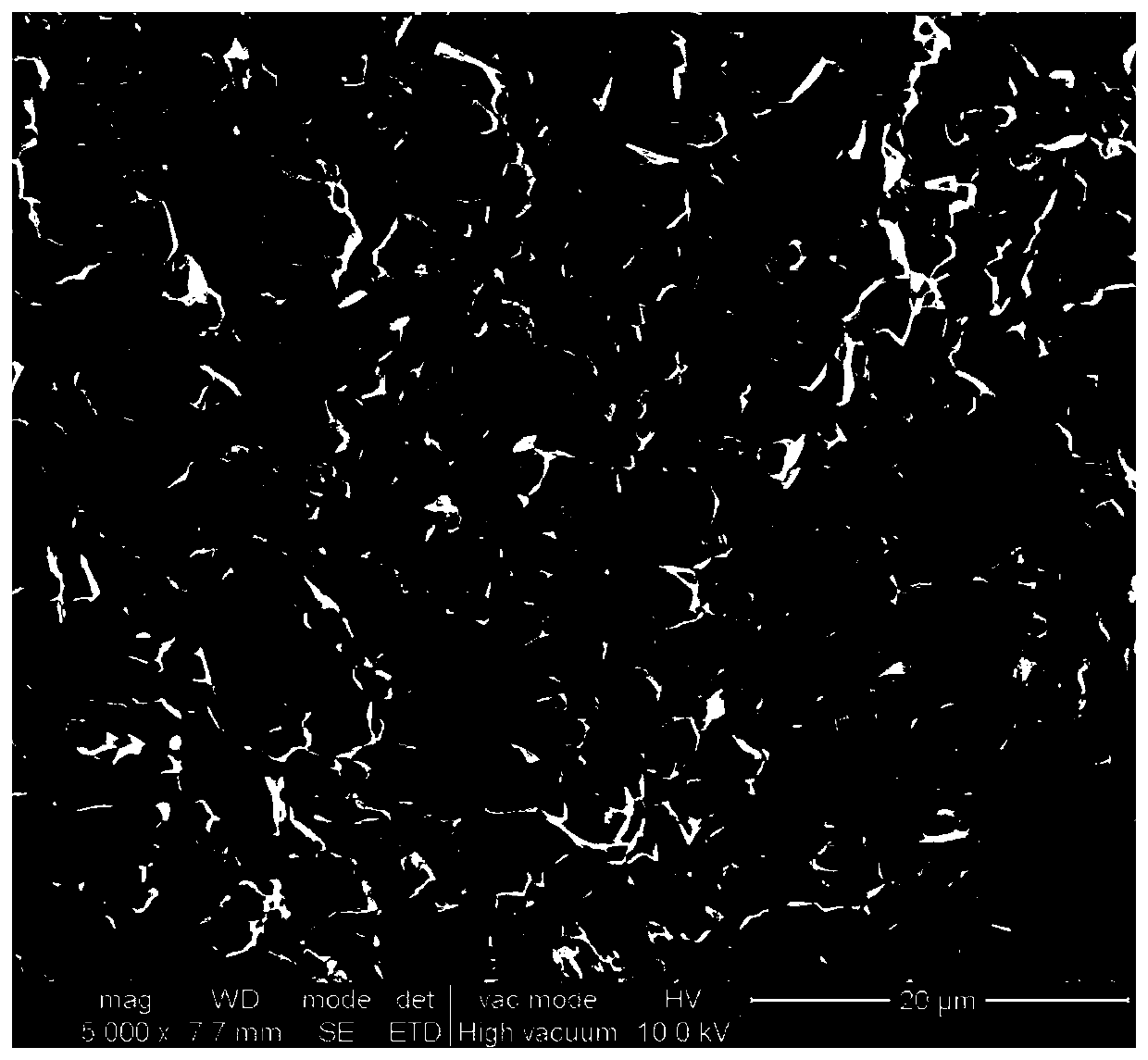

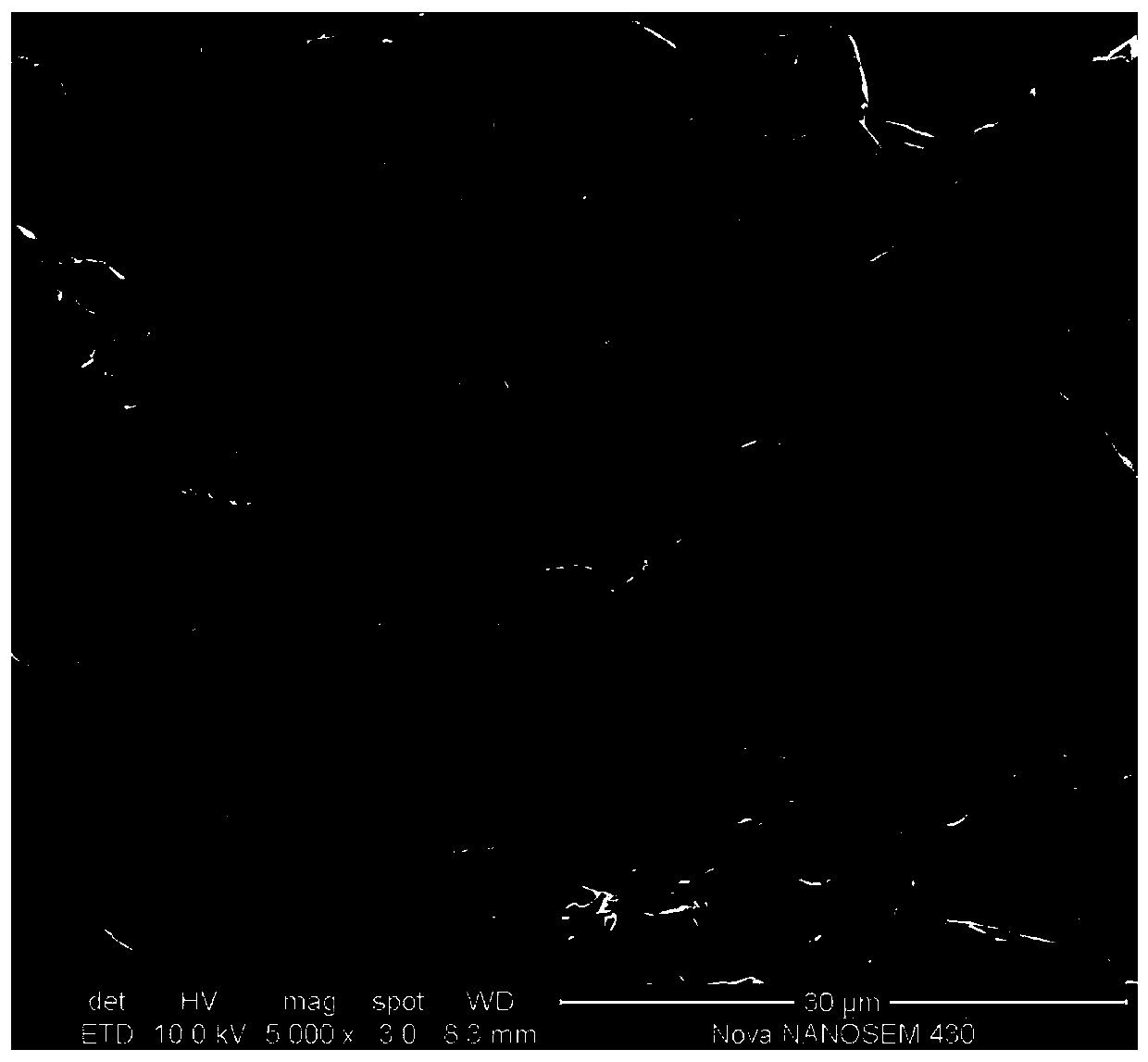

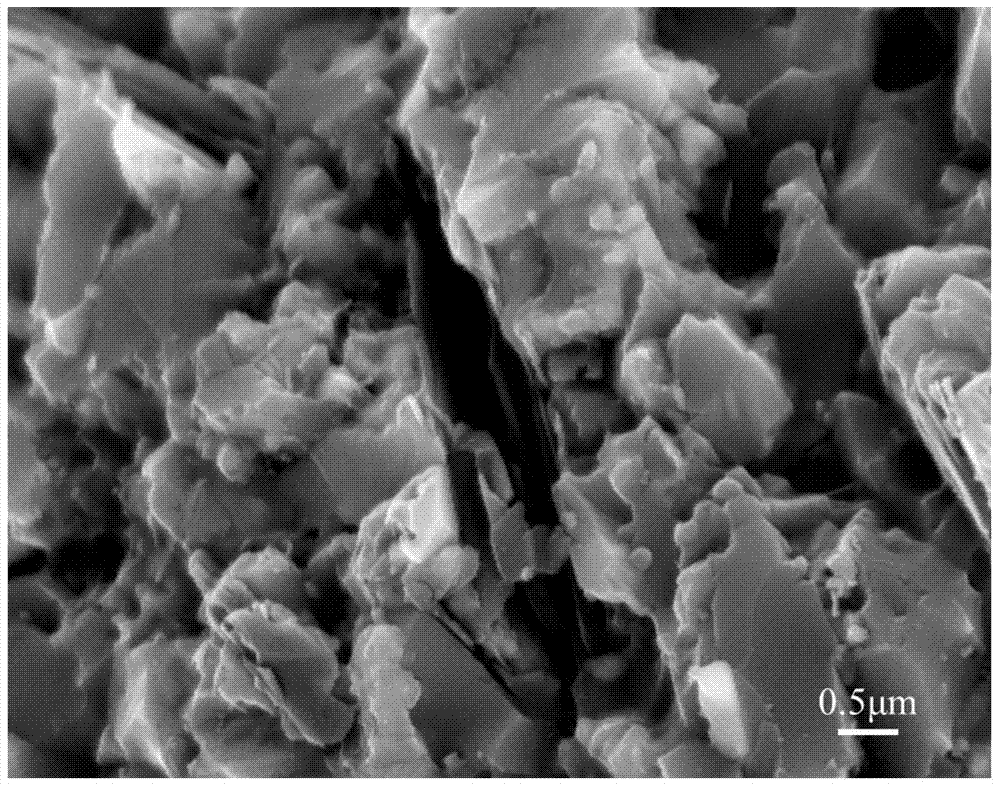

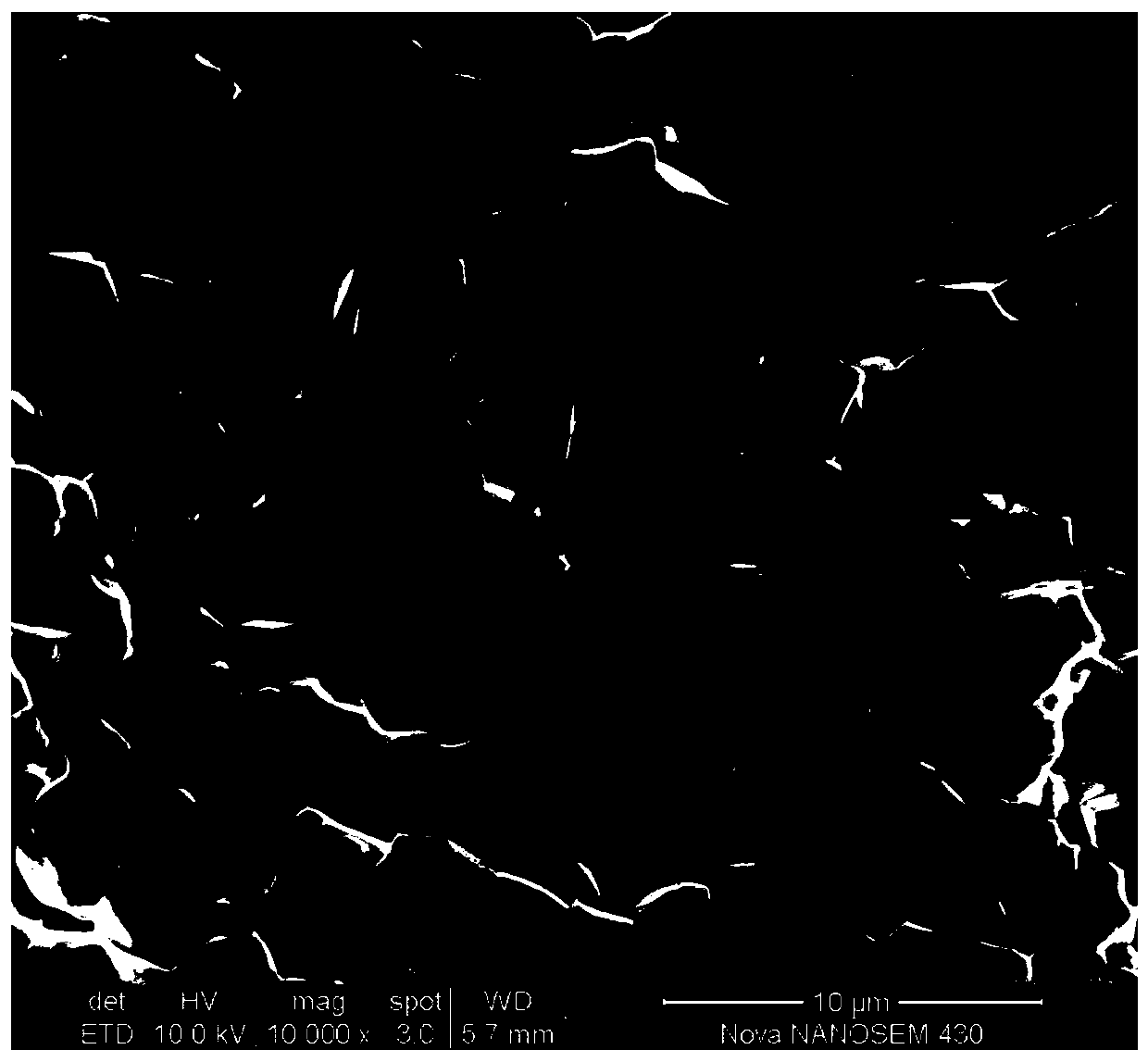

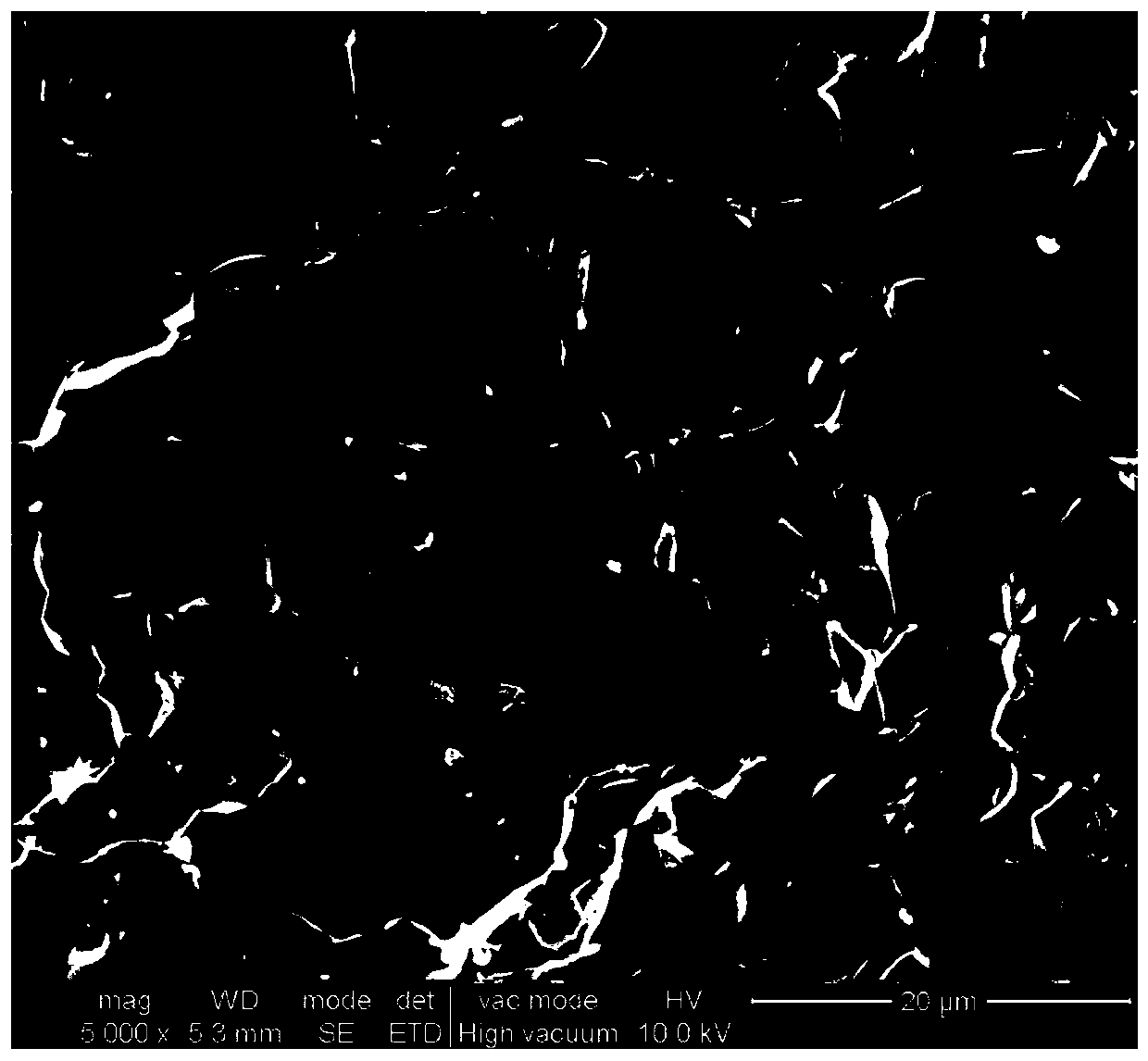

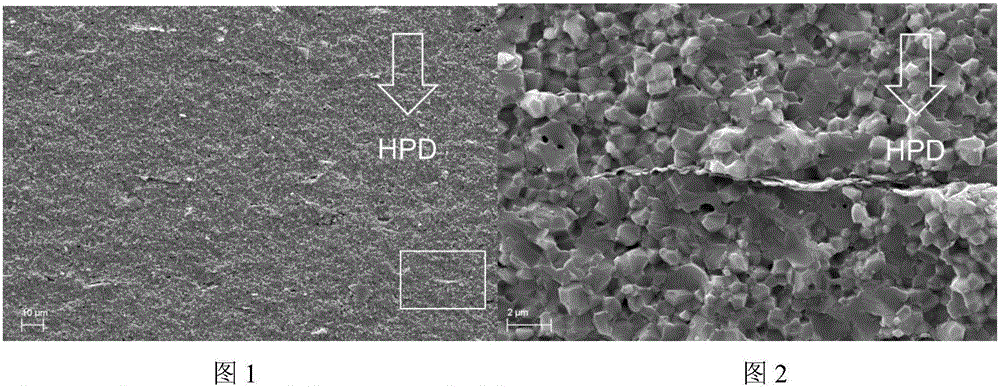

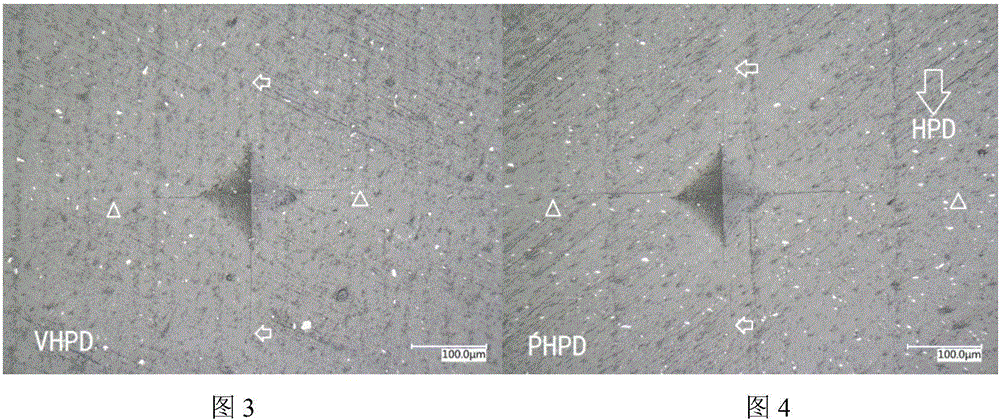

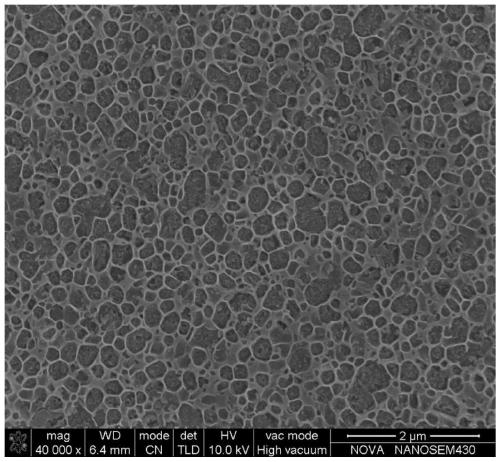

Anisotropic graphene-toughened Al2O3 nano composite ceramic cutting tool material and preparation method thereof

The invention relates to an anisotropic graphene-toughened Al2O3 nano composite ceramic cutting tool material and a preparation method thereof. According to the ceramic cutting tool material, Al2O3 is used as the matrix, graphene nanosheets are used as a reinforcement phase, and MgO, Mo and Ni are used as sintering aids. The preparation method of the ceramic cutting tool material comprises the following steps: graphene dispersion, composite powder preparation, drying and screening, cold-pressed mold filling and hot-pressed sintering. In the graphene toughened Al2O3 nano composite ceramic material, the graphene has obvious graphene toughening effects, and has obvious orientation in the matrix. The mechanical properties of the ceramic cutting tool have obvious anisotropy in the directions which are perpendicular and parallel to the hot pressing direction.

Owner:QILU UNIV OF TECH

Metal-based ceramic cutting tool and preparation method

InactiveCN105861901AHigh grinding purityHigh surface finishTurbinesOther manufacturing equipments/toolsCeramic cutting toolChemical stability

The invention discloses a metal-based ceramic cutter and a preparation method thereof, the main components of which are composed of the following materials: TiN: 7‑15%, TiC: 40‑60%, Mo 2 C: 8‑20%, WC: 8‑20%, ZrC: 1‑2%, Al 2 o 3 : 1‑2%, Si 3 N 4 : 3‑5%, BN: 0.1‑0.5%, C: 1‑2%, Ni: 8‑15%, Co: 3‑8%, Cr: 4‑8%, La 2 o 3 : 1‑3%, CeO 2 : 0‑1%, Pr 6 o 11 : 0‑1%, Nd 2 o 3 : 0-1%, by grinding and preparing powder, pressurized granulation, initial molding, pressure sintering, post-treatment, etc., reasonable control of process parameters, and finally ceramic tool material, the invention is simple to operate, and the tool material has chemical stability and It has the advantages of anti-cutting fusion, capable of cutting refractory metals, and small friction coefficient against steel.

Owner:程叙毅

Diamond coating silicon nitride ceramic integral cutter, preparation method thereof and application of cutter in graphite

ActiveCN109397549AHigh hardnessImprove wear resistanceChemical vapor deposition coatingStone-like material working toolsThermal expansionCeramic cutting tool

The invention provides a diamond coating silicon nitride ceramic integral cutter, a preparation method thereof and an application of the cutter in graphite, and relates to the field of ceramic cutters. The cutter is composed of a silicon nitride ceramic substrate and a diamond film coating, the diamond film coating coats the surface of the silicon nitride ceramic substrate, the thickness of the diamond film coating is 7 um-12 um. Due to the fact that a chemical vapor deposition (CVD) diamond film has excellent chemical and physical properties and has extremely high hardness, excellent wear resistance and chemical stability, the CVD diamond film can be widely applied to various cutters. The method combines the advantages of a coating material and a silicon nitride ceramic cutting tool basebody, the coating cutter has good cutting performance, high hardness, wear resistance, low thermal expansion coefficient and the like, and the abrasion resistance and the service life of the cutter are improved.

Owner:GUANGDONG UNIV OF TECH

Ceramic cutting tool material with high mechanical strength and preparation method therefor

The present invention discloses a ceramic cutting tool material with high mechanical strength and a preparation method therefor. The ceramic cutting tool material is prepared from the following raw materials in parts by weight: 50-70 parts of silicon dioxide, 10-12 parts of nanometer aluminium oxide, 6-8 parts of Huangxiu Stone (a type of China's granite), 1-2 parts of sodium fluoride, 1-2 parts of polyacrylic acid, 2-4 parts of magnesium borate whiskers, 15-25 parts of coal ash, 2-3 parts of glycerin, 3-5 parts of triglycidyl ester, 4-6 parts of a borate coupling agent, 2-4 parts of antimony trichloride, 1-2 parts of phosphorus pentoxide, 2-3 parts of phenolic resin emulsion, 2-4 parts of butanediol, and 6-7 parts of an auxiliary agent. According to the present invention, the ceramic cutting tool material takes silicon dioxide as a main raw material; the raw materials such as magnesium borate whiskers, Huangxiu Stone, and nanometer aluminium oxide, are added, so that the integral mechanical strength of the ceramic cutting tool material is improved and the corrosion resistance and the heat resistance of the ceramic cutting tool material can be further improved. Moreover, the ceramic cutting tool material is long in service life, and the using cost is reduced.

Owner:广东好来客集团有限公司

Preparation process for nanometer modified Ti(C&N)-based metal ceramic cutting tool

InactiveCN104690273AImprove wettabilityReduce porosityTurbinesOther manufacturing equipments/toolsPorosityLiquid metal

The invention discloses a preparation process for a nanometer modified Ti(C&N)-based metal ceramic cutting tool. According to the technical scheme, a nanometer modified Ti(C&N)-based metal ceramic material is prepared by an optimized dispersion process and optimized nanometer addition, and the cutting tool is prepared by a liquid sintering method. A nanometer TiN modified TiC-based metal ceramic cutting tool consists of the following basic components: 54 percent of TiC, 10 percent of TiN(nm), 15 percent of Mo, 20 percent of Ni and 1 percent of C. The preparation process has the characteristics that TiC, TiN and WC form a hard phase of the metal ceramic cutting tool, and Ni forms a main adhesive phase; Co has higher toughness and hardness than Ni, and is well wetted with the hard phase, so that alloy porosity is reduced; by Mo, the wettability of liquid metal for the hard phase can be remarkably improved.

Owner:QINGDAO PINGDU JIUDIAN GOLD MINE

Methods for preparing multiphase high-strength highly-wear-resistant silicon nitride ceramic cutting tool material and tool

The invention discloses a method for preparing a multiphase high-strength highly-wear-resistant silicon nitride ceramic cutting tool material for processing cast iron and alloys as well as a method for preparing a ceramic tool made of the material. According to the method, alpha-sialon is grown in situ, the intergranular phase is reduced, the ceramic material is reinforced and toughened, and the obtained material has the bending strength of 900-1000MPa at room temperature, the breaking tenacity of 8-10MPa / m<2> and the hardness of 92-94.5HRA. Moreover, the ceramic material is processed into a tool by adopting the method, when the speed is 600m / in and the cutting length is 1000meters in the process of cutting nodular cast iron QT450-10, the flank wear is less than 0.4mm, and the cutting level of the tool is higher than that of a commercial tool in the conventional market.

Owner:广州腾亚工艺品有限公司

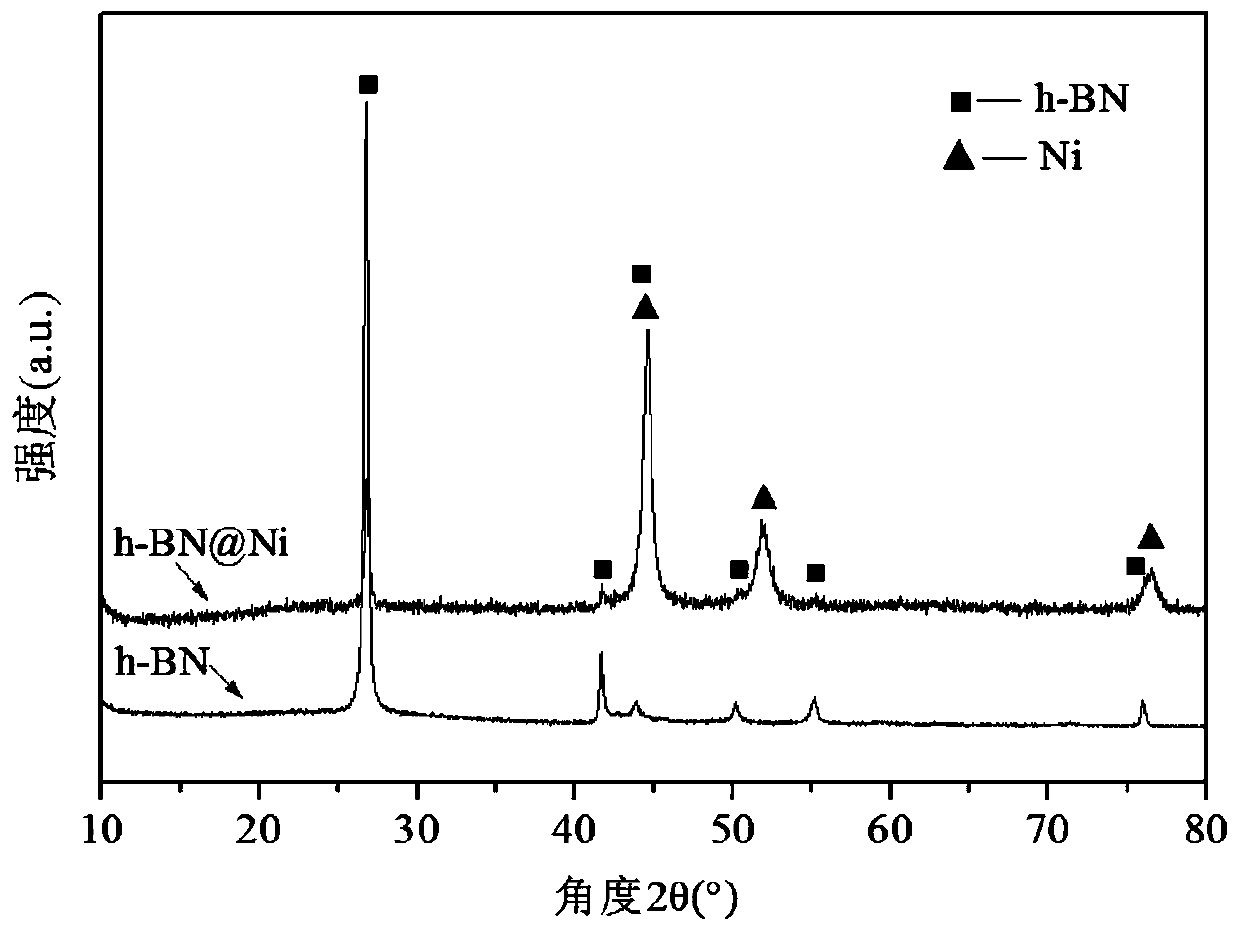

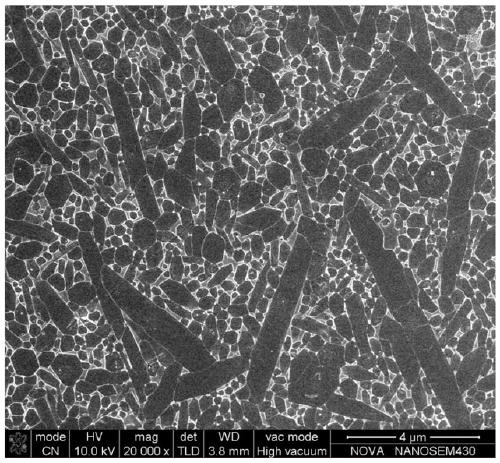

Self-lubricating ceramic cutting tool material added with metal-coated nano-solid lubricant composite powder and preparation method thereof

ActiveCN109721361AGood sintered densityImprove mechanical propertiesLiquid/solution decomposition chemical coatingLubricant compositionChemical platingVolumetric Mass Density

The invention relates to a self-lubricating ceramic cutting tool material added with metal-coated nano-solid lubricant composite powder and a preparation method thereof. The self-lubricating ceramic cutting tool material is prepared by: taking h-BNn@Ni composite powder as the solid lubricant, adopting alpha-Al2O3 as the matrix, using (W, Ti)C as the reinforcement phase, and employing magnesium oxide and yttrium oxide as the sintering aids, and conducting wet ball-milling mixing and vacuum hot pressing sintering. Specifically, the h-BNn@Ni composite powder is obtained by: coarsening h-BNn powder in a coarsening liquid, then performing treatment in a sensitizing-activating solution, and then conducting plating in a chemical plating solution. The self-lubricating ceramic cutting tool materialprovided by the invention has good sintering density, h-BNn and the ceramic matrix have high bonding strength, thus toughening and reinforcing the self-lubricating ceramic cutting tool material, andthe synergistic effect can improve the mechanical properties and wear resistance of the self-lubricating ceramic cutting tool material.

Owner:QILU UNIV OF TECH

High-hardness high-wear-resistance silicon nitride ceramic and preparation method and application thereof

The invention belongs to the field of ceramic cutting tools, and discloses high-hardness high-wear-resistance silicon nitride ceramic and a preparation method and application thereof. The silicon nitride ceramic is prepared by mixing Si3N4 powder and a sintering aid that is Al2O3-Re2O3; bal-milling and mixing the mixture by adopting ethanol as a solvent and adopting Si3N4 balls as a ball milling medium; drying to obtain mixture powder of Si3N4-Al2O3-Re2O3; heating the mixture powder in vacuum at a speed I to 700-900 DEG C; then axially pressurizing the powder to 25-50 MPa under nitrogen protection; heating the powder at a speed II to 1600-1800 DEG C and maintaining the temperature; and performing spark plasma sintering. The ceramic has good wear resistance and cutting performance and can be applied to the field of cutting tools.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com