Ceramic cutting tool with ultrahigh strength and ultrahigh toughness, and preparation method thereof

A ceramic knife and ultra-high toughness technology, which is applied in the field of ceramic products, can solve the problems of inability to achieve mechanical properties and material density, and achieve the effects of small friction, safe and environmentally friendly production materials, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

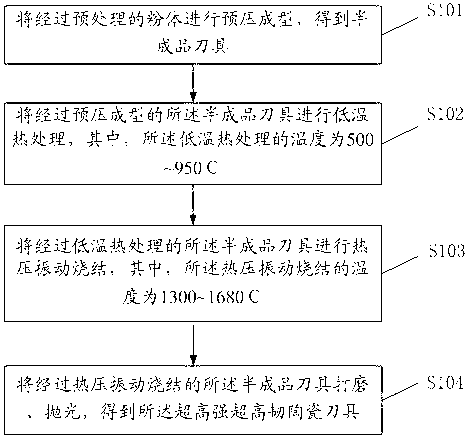

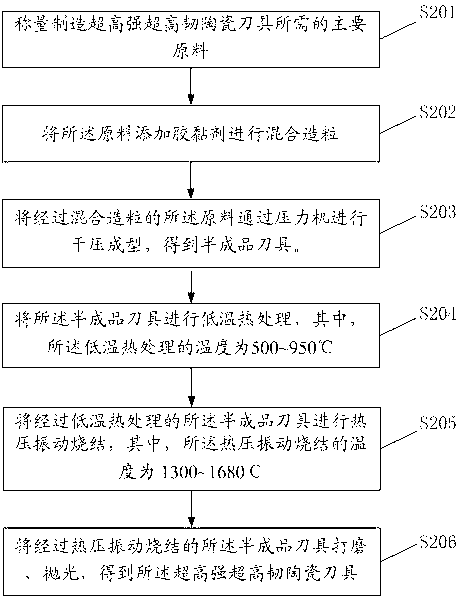

[0055] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing an ultra-high-strength ultra-high-toughness ceramic cutting tool, including:

[0056] S101, pre-pressing the pretreated powder to obtain a semi-finished tool.

[0057] During the pre-press molding process of the pretreated powder, the pre-press molding pressure is 30-200T.

[0058] Preferably, the pre-press molding pressure is 38T.

[0059] S102, performing low-temperature heat treatment on the pre-pressed semi-finished tool, wherein the temperature of the low-temperature heat treatment is 500-950°C.

[0060] Preferably, the temperature of the low temperature heat treatment is 600°C to 800°C.

[0061] S103, performing hot-press vibration sintering on the semi-finished tool that has undergone low-temperature heat treatment, wherein the temperature of the hot-press vibration sintering is 1300-1680°C.

[0062] Preferably, the temperature of hot-press vibration sintering i...

Embodiment 1

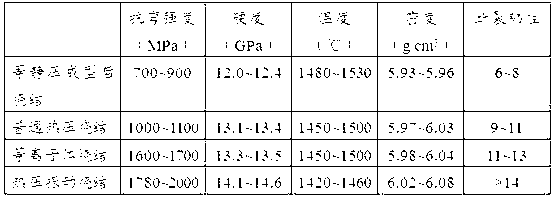

[0109] Mix 91% zirconia, 6% yttrium oxide, and 3% rare earth oxide, and add an adhesive polyvinyl alcohol aqueous solution for mixing and granulation. The mixed and granulated raw materials are dry-pressed by a press. The nominal pressure is 38T, and the semi-finished tool is obtained. The semi-finished tool is subjected to low-temperature heat treatment at 760°C. The above-mentioned semi-finished tool that has undergone low-temperature heat treatment is subjected to hot-press vibration sintering. The temperature of the hot-press vibration sintering is 1400°C, the pressure is 30MPa, the vibration amplitude is 1T, and the frequency is 1 time / s. Grinding and polishing the above-mentioned semi-finished tool that has been sintered by hot pressing and vibration to obtain a finished tool.

Embodiment 2

[0111] Mix 92% zirconia, 5% yttrium oxide, and 3% rare earth oxide, and add an adhesive polyvinyl alcohol aqueous solution for mixing and granulation. The mixed and granulated raw materials are dry-pressed by a press. The nominal pressure is 38T, and the semi-finished tool is obtained. The semi-finished tool is subjected to low-temperature heat treatment at 800°C. The above-mentioned semi-finished tool that has undergone low-temperature heat treatment is subjected to hot-press vibration sintering. The temperature of the hot-press vibration sintering is 1470°C, the pressure is 40MPa, the vibration amplitude is 2T, and the frequency is 1 time / s. Grinding and polishing the above-mentioned semi-finished tool that has been sintered by hot pressing and vibration to obtain a finished tool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com