Patents

Literature

425 results about "Tool material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Many types of tool materials, ranging from high carbon steel to ceramics and diamonds, are used as cutting tools in today’s metalworking industry.

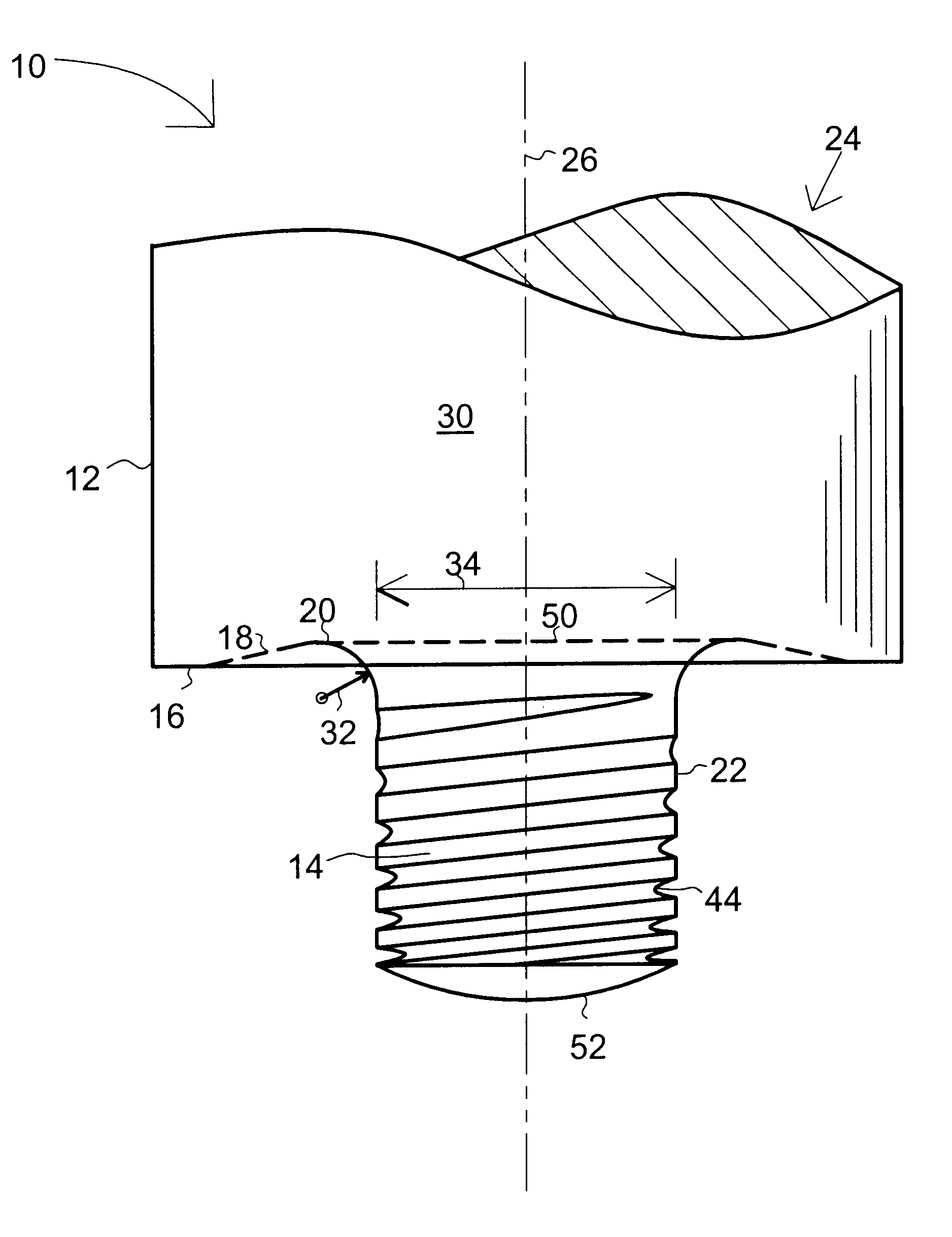

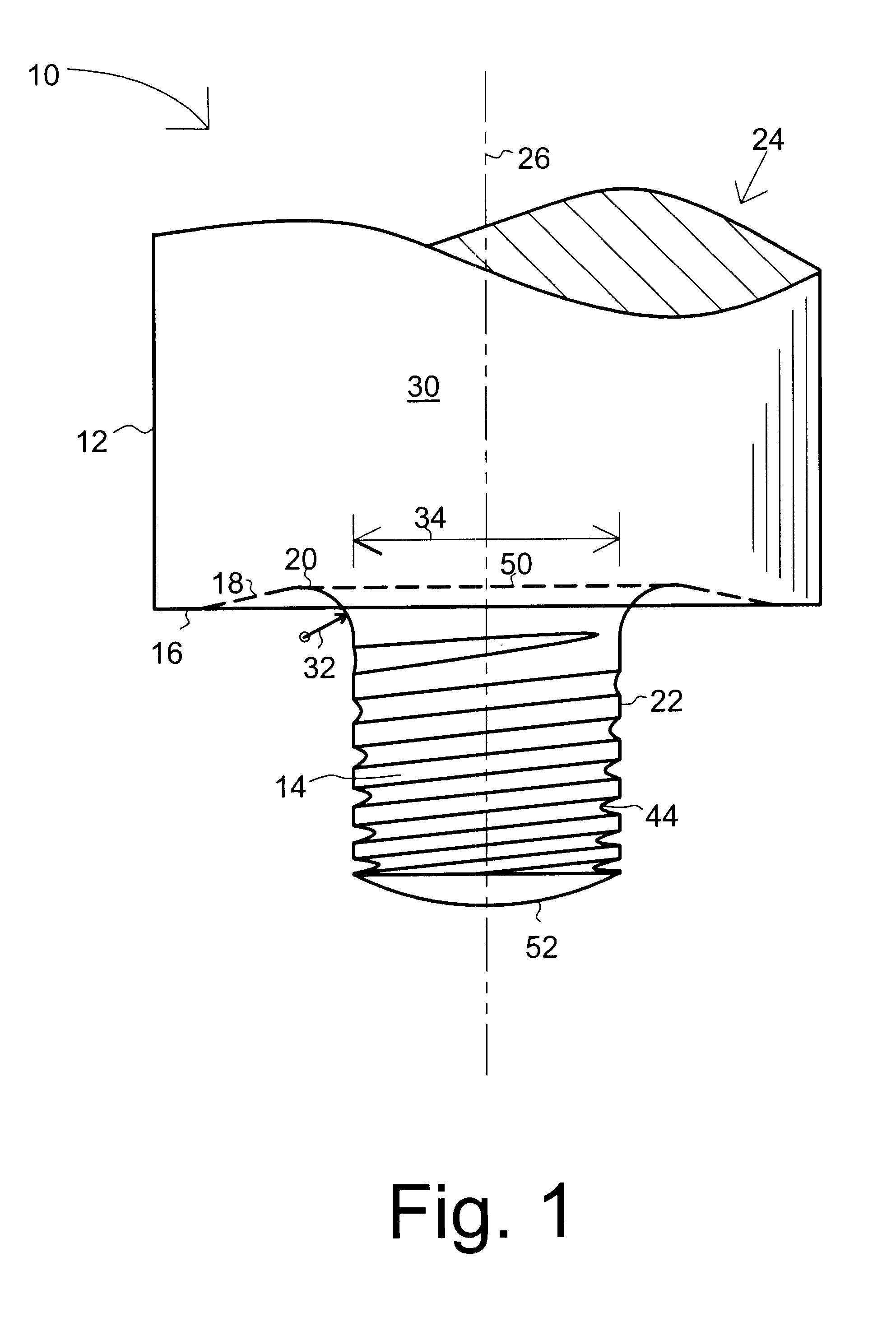

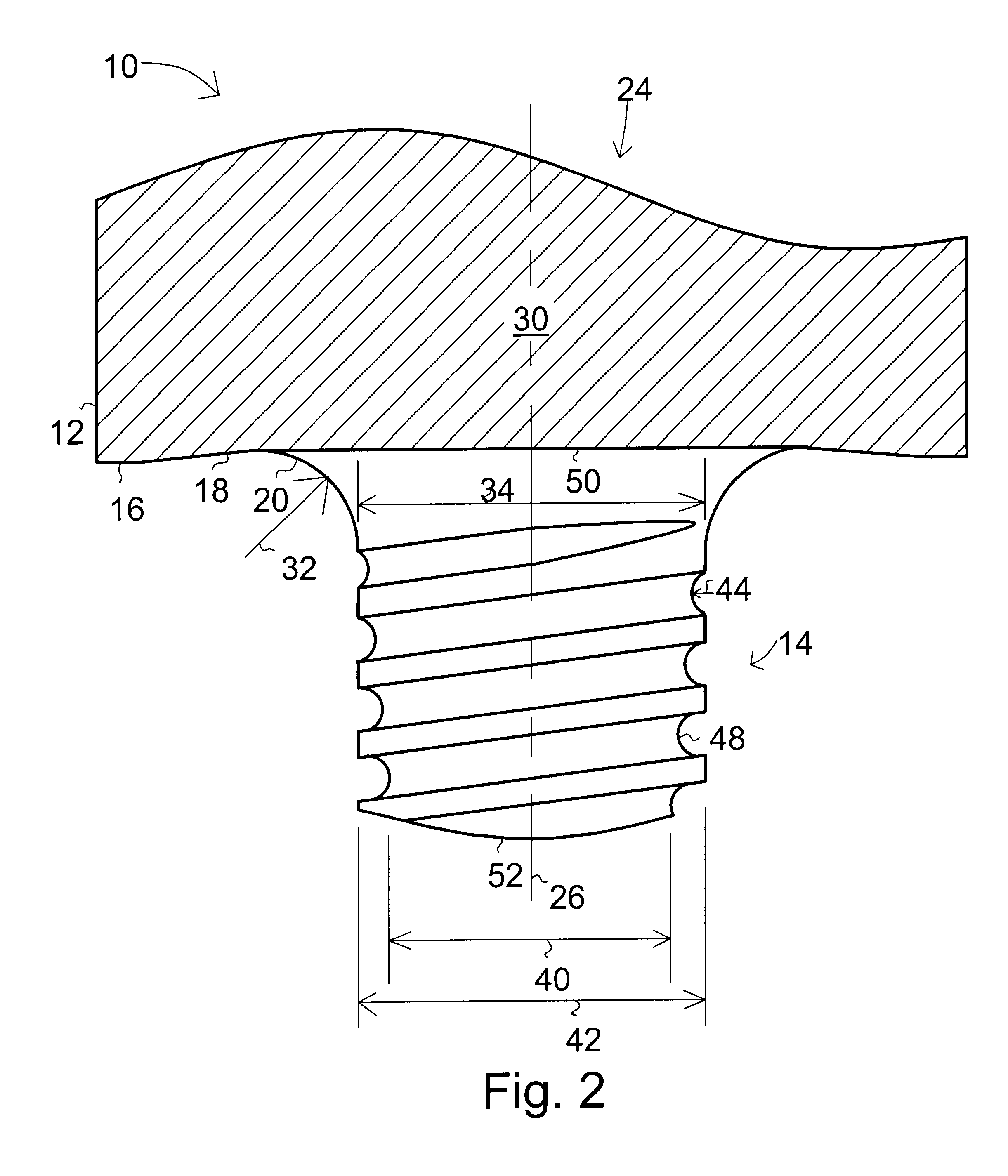

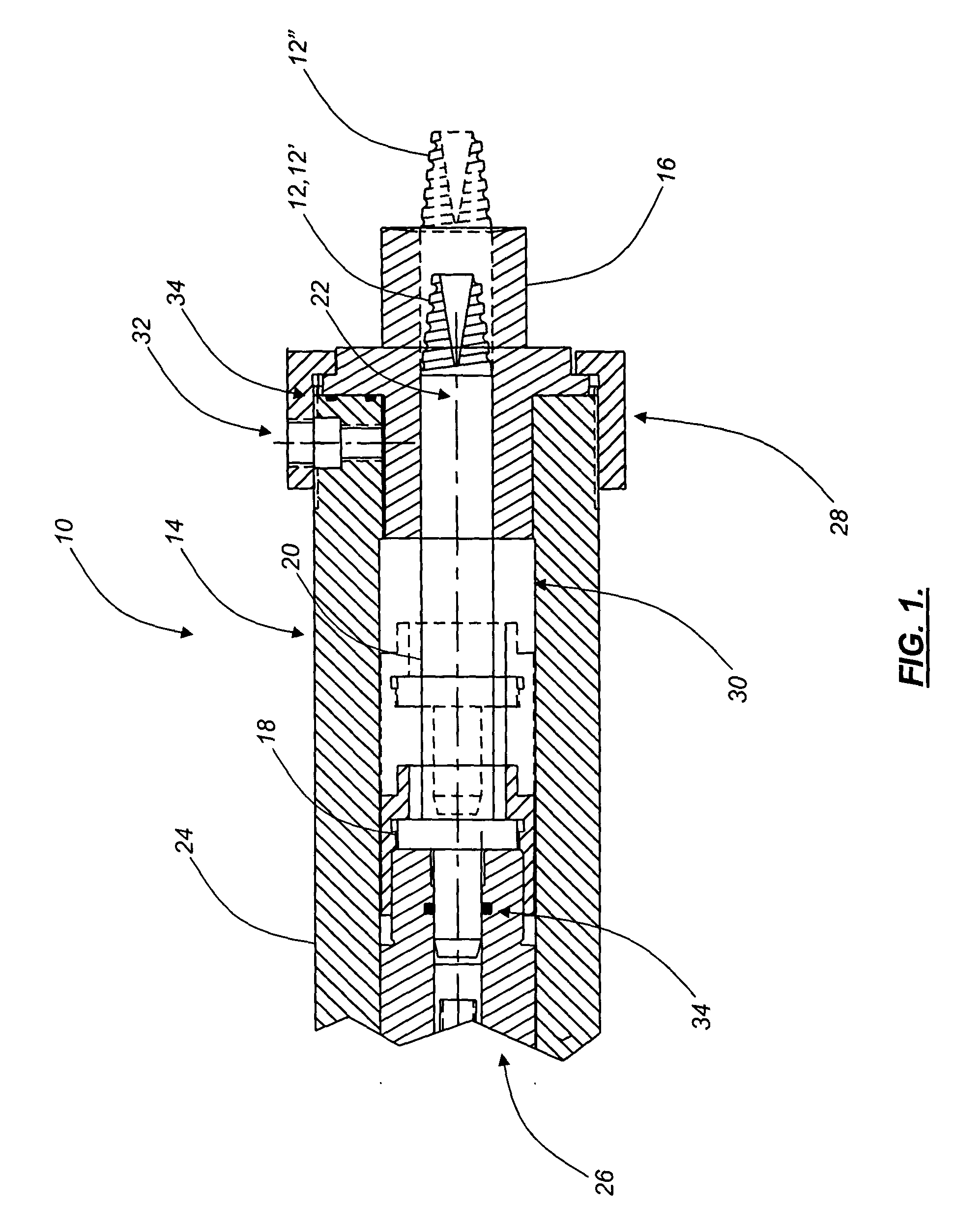

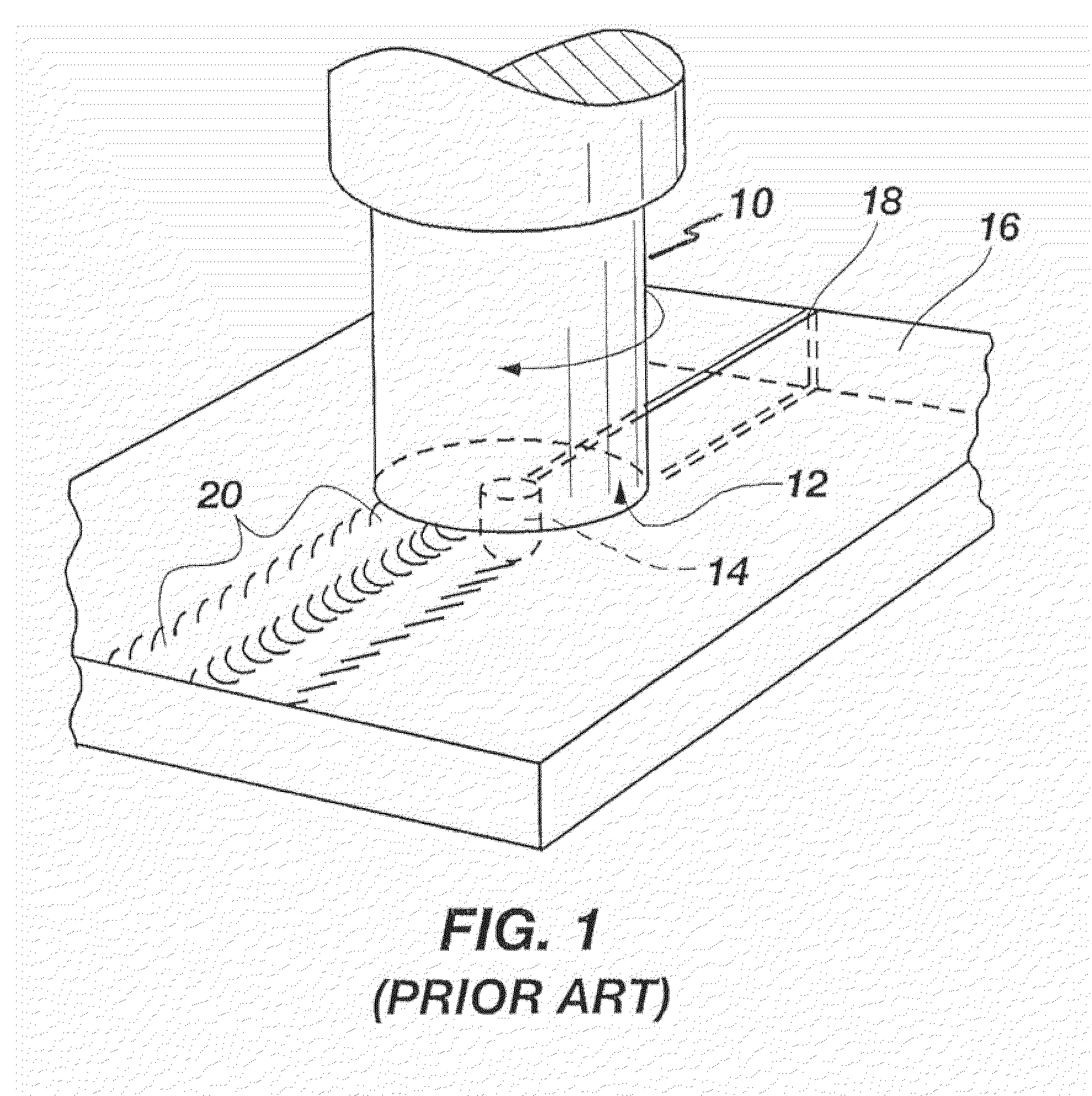

Tool for friction stir welding

InactiveUS6676004B1Low costImprove joint efficiencyWelding/cutting auxillary devicesAuxillary welding devicesUltimate tensile strengthScrew thread

A friction stir welding tool for welding high-strength materials with one or more of the following features: 1) a curved transition geometry structure at the shoulder face and probe interface; 2) a tool material selected on the basis of an ultimate tensile strength determined at or above the temperature of the tool processing temperature; 3) a compressive stress at the point of crack fatigue introduced by mechanical or chemical means; and 4) a threaded probe with a) a major to minor thread diameter ratio that increases toward the distal end of the probe and / or b) with a curved thread root.

Owner:EDISON WELDING INSTITUTE INC

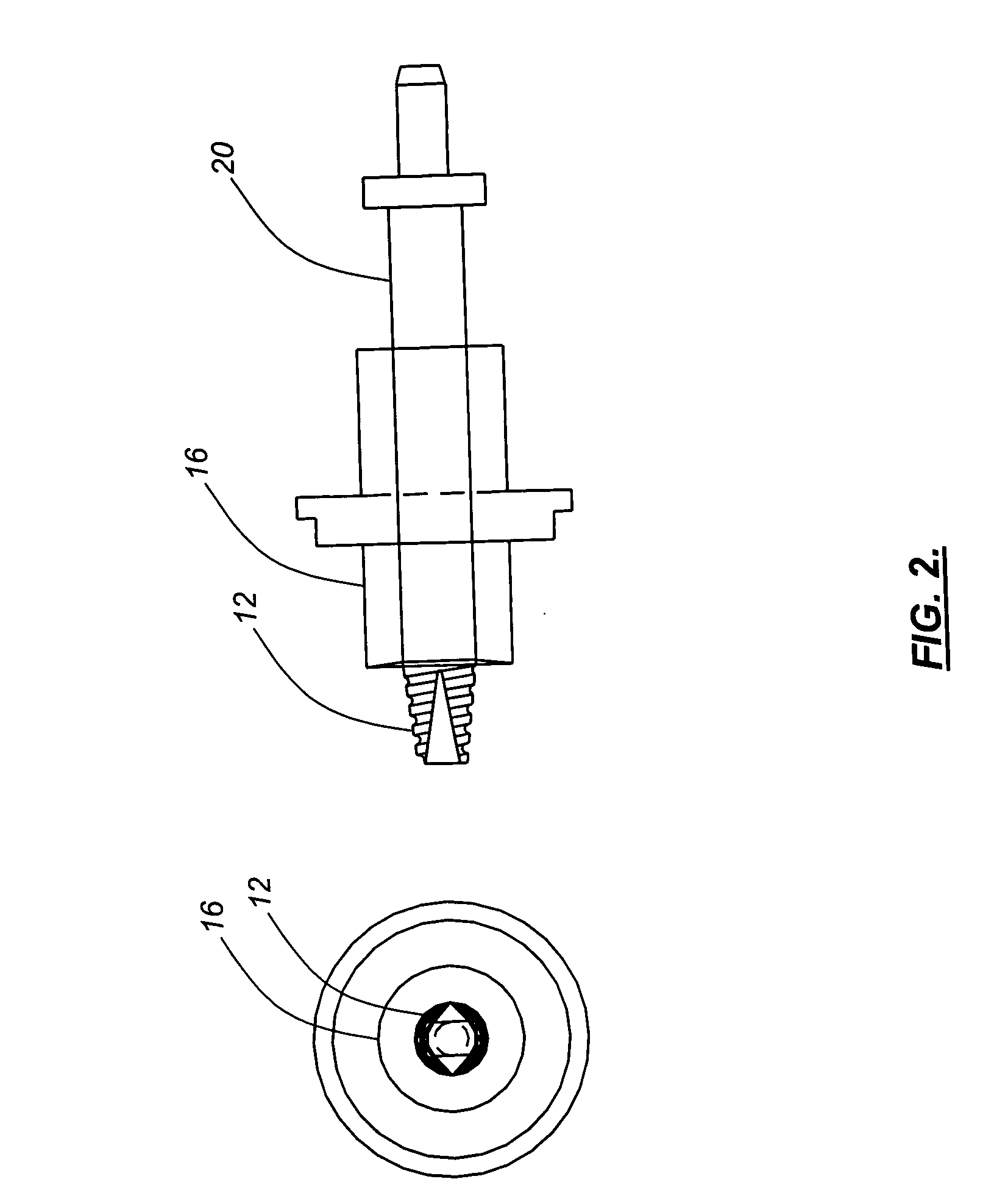

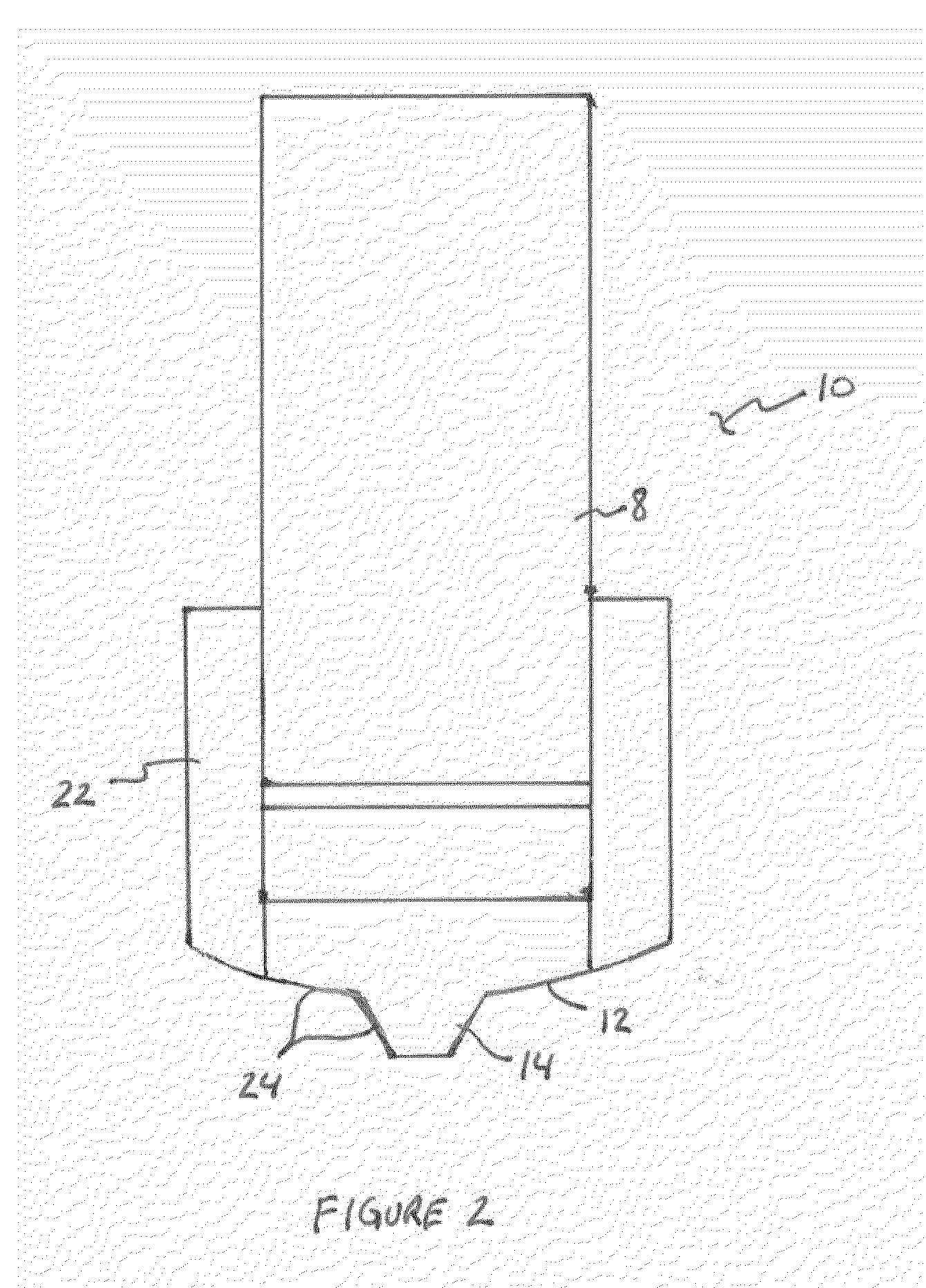

Apparatus and method for friction stir welding using a consumable pin tool

InactiveUS20050045695A1Improve mechanical propertiesImprove joint efficiencyNon-electric welding apparatusMulti materialMetal alloy

The present invention provides a friction stir welding apparatus operable for welding one or more metals, metal alloys, or other materials. The friction stir welding apparatus includes a pin tool holder, a shoulder having a surface coupled to the pin tool holder, and a pin tool coupled to the pin tool holder, the pin tool at least partially protruding from the surface of the shoulder, wherein the pin tool is made of a consumable pin tool material. Optionally, the shoulder rotates at a predetermined rotational speed and is retractable into / extendable from the pin tool holder at a substantially constant rate. Optionally, the shoulder is also made of a consumable shoulder material that is at least partially incorporated into the volume of a joint to be welded. The consumable shoulder material comprises a material that is the same as, similar to, or dissimilar from one or more materials comprising a workpiece to be friction stir welded. Preferably, the pin tool rotates at a predetermined rotational speed and is retractable into / extendable from the surface of the shoulder at a substantially constant rate. The consumable pin tool material is at least partially incorporated into the volume of the joint to be welded. The consumable pin tool material comprises a material that is the same as, similar to, or dissimilar from one or more materials comprising the workpiece to be friction stir welded.

Owner:GENERAL ELECTRIC CO

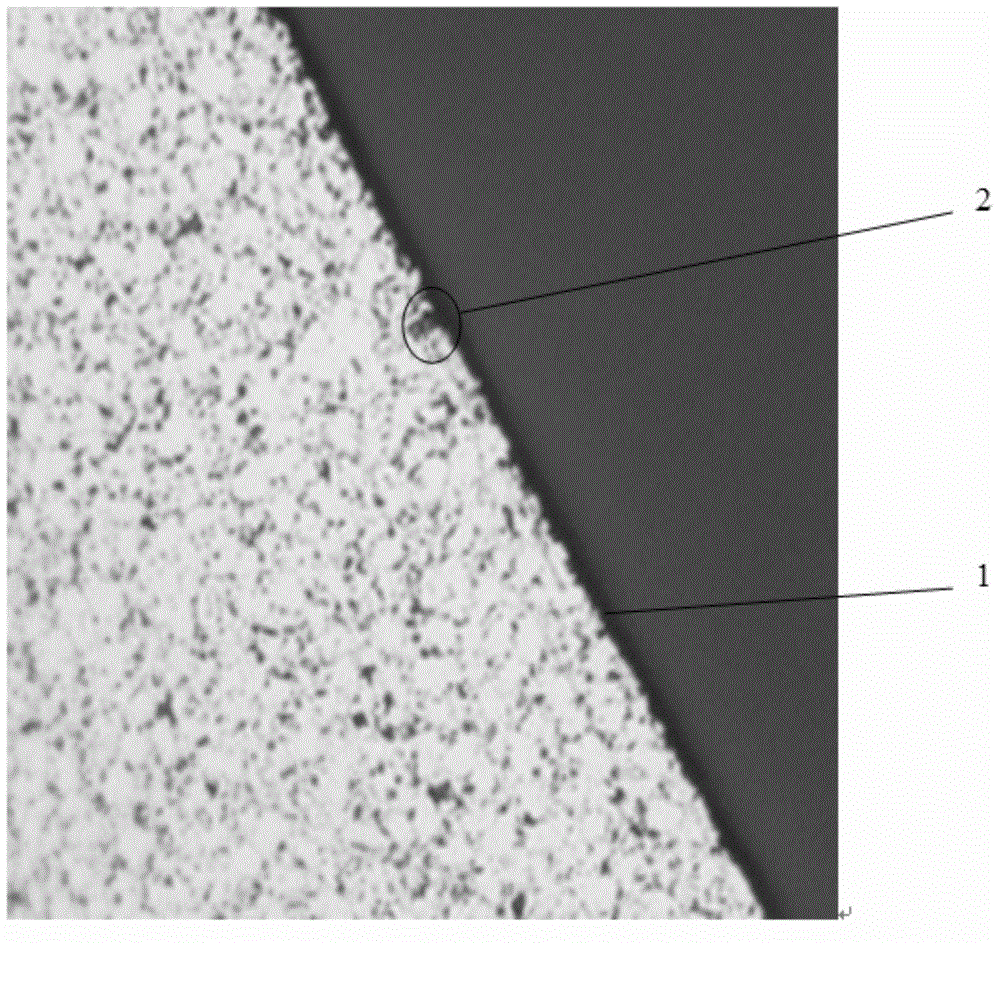

Tungsten carbide particle-enhanced iron-based powder metallurgy material and preparation method thereof

The invention relates to plastic forming technology and powder metallurgy technology, in particular to a tungsten carbide particle-enhanced iron-based powder metallurgy material and a preparation method thereof. According to a specific formula, the iron-based powder metallurgy material comprises the following components in percentage by mass: 85.0 to 90.0 percent of matrix material and 10.0 to 15.0 percent of enhanced phase tungsten carbide, wherein the matrix material comprises the following components in percentage by mass: 1.4 to 2.0 percent of copper, 1.7 to 2.0 percent of nickel, 0.9 to 1.2 percent of molybdenum, 0.7 to 1.6 percent of carbon and the balance of iron. In the invention, quick spark plasma sintering is adopted; and the obtained material has the characteristics of nearly full densification, high hardness, high indoor temperature bending strength, high high-temperature mechanical property and the like, can be used as a wear-resistant material, a tool material and the like, and can reduce the dependency of Chinese tool material production on import of precious metals such as vanadium, chromium and the like. The material has high cost performance and a good industrial production prospect.

Owner:SOUTH CHINA UNIV OF TECH

Apparatus and method for friction stir welding using a consumable pin tool

InactiveUS20060163328A1Improve mechanical propertiesImprove microstructureWelding/cutting auxillary devicesAuxillary welding devicesMulti materialMetal alloy

The present invention provides a friction stir welding apparatus operable for welding one or more metals, metal alloys, or other materials. The friction stir welding apparatus includes a pin tool holder, a shoulder having a surface coupled to the pin tool holder, and a pin tool coupled to the pin tool holder, the pin tool at least partially protruding from the surface of the shoulder, wherein the pin tool is made of a consumable pin tool material. Optionally, the shoulder rotates at a predetermined rotational speed and is retractable into / extendable from the pin tool holder at a substantially constant rate. Optionally, the shoulder is also made of a consumable shoulder material that is at least partially incorporated into the volume of a joint to be welded. The consumable shoulder material comprises a material that is the same as, similar to, or dissimilar from one or more materials comprising a workpiece to be friction stir welded. Preferably, the pin tool rotates at a predetermined rotational speed and is retractable into / extendable from the surface of the shoulder at a substantially constant rate. The consumable pin tool material is at least partially incorporated into the volume of the joint to be welded. The consumable pin tool material comprises a material that is the same as, similar to, or dissimilar from one or more materials comprising the workpiece to be friction stir welded.

Owner:GENERAL ELECTRIC CO

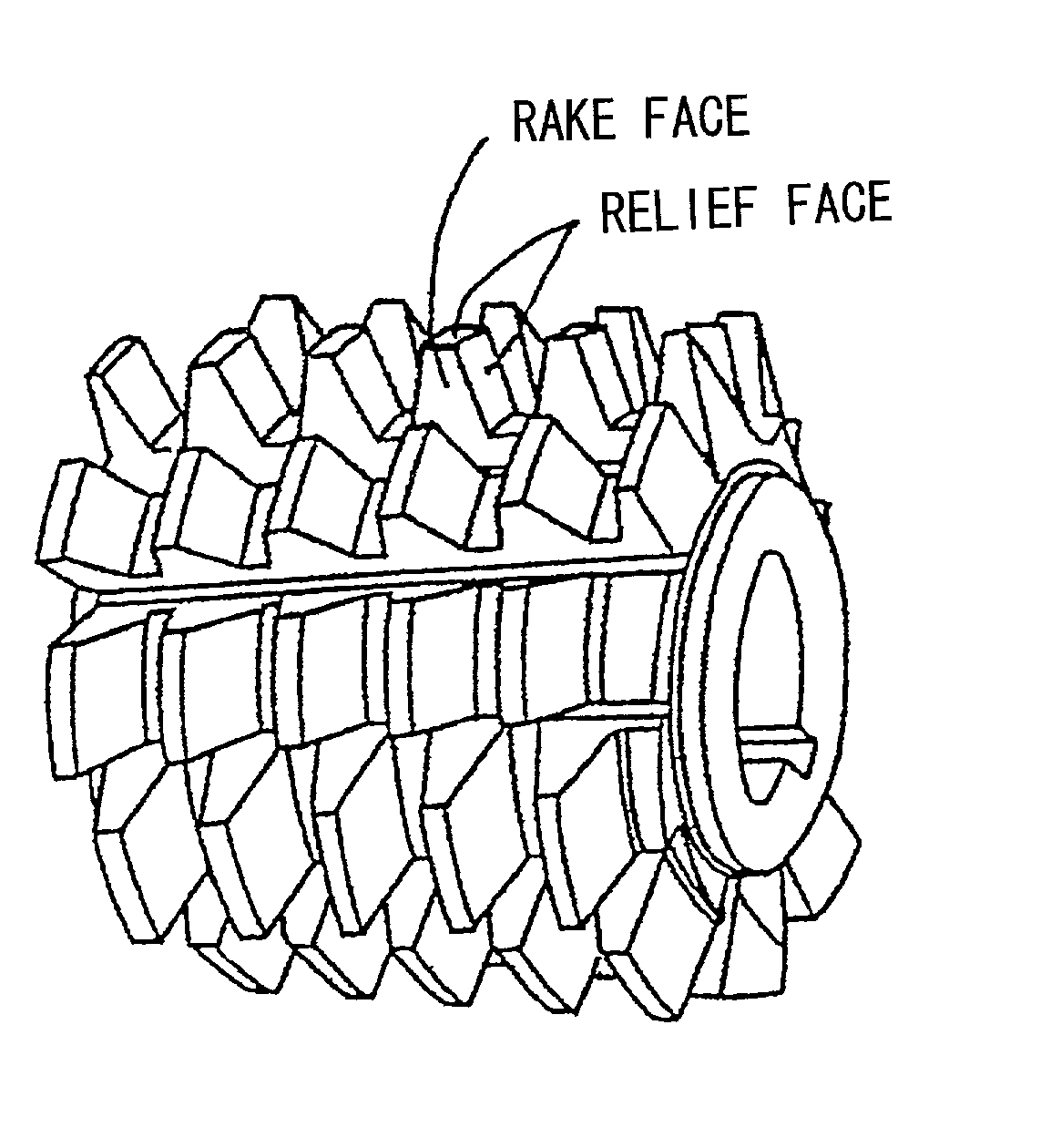

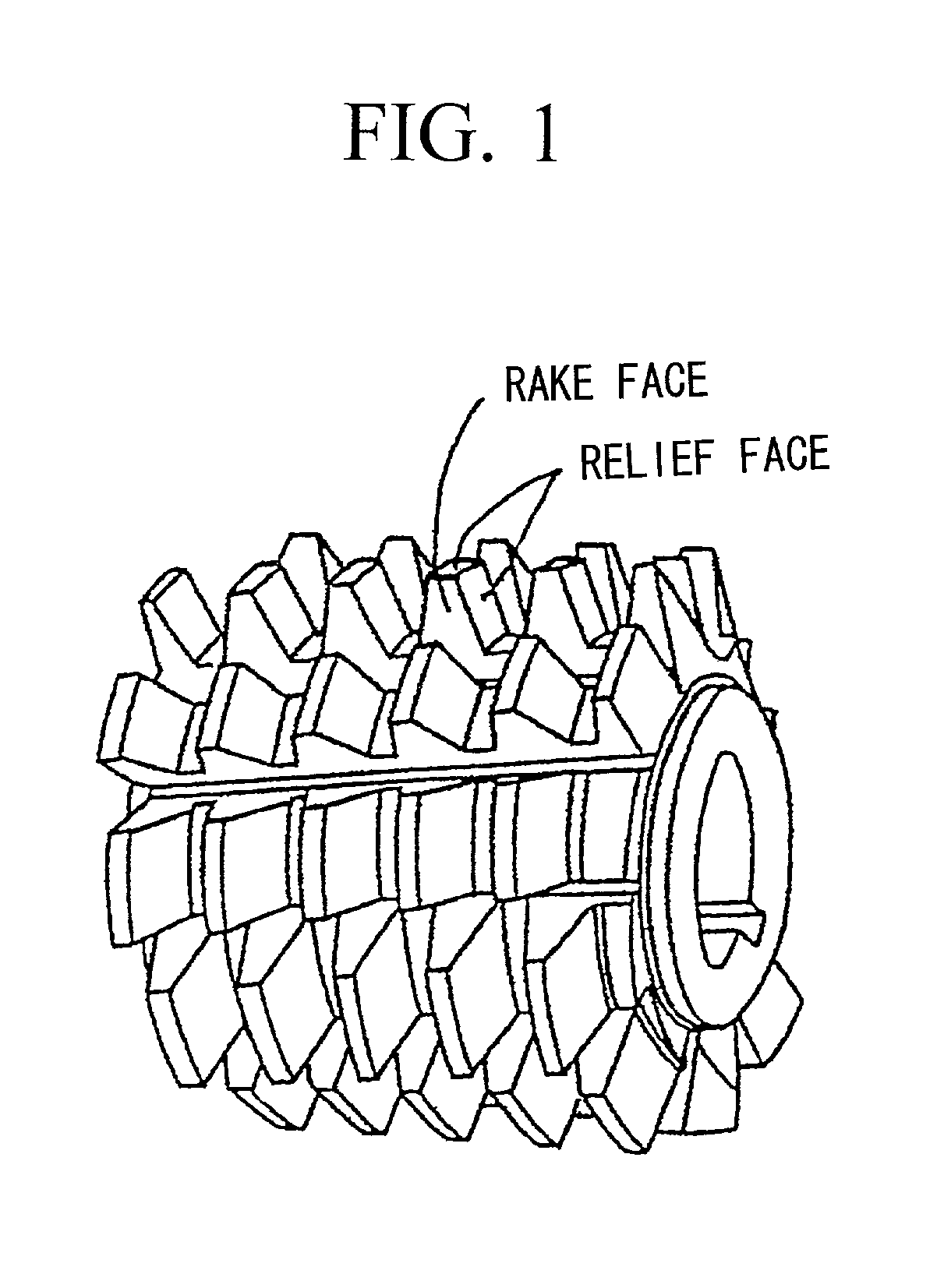

High-speed tool steel gear cutting tool and manufacturing method therefor

The invention provides a high-speed tool steel gear cutting tool in which fracture or chipping does not occur at the cutting edge, and which realizes excellent cutting performance over long periods. Moreover, a method of manufacturing a gear cutting tool including: a step for quenching a tool material comprising high-speed tool steel and which has been rough processed to a shape corresponding to a final shape of a gear cutting tool, to transform a structure of the tool material into martensite, a step for temperling the tool material after quenching to transform any residual austenite dispersingly distributed throughout a matrix of the martensite structure formed by the quenching, into martensite, and a step for finishing the tool material after tempering to a final shape, is characterized in that the tool material after quenching is subjected to sub-zero treatment involving cooling and holding at a temperature of less than -150° C.

Owner:MITSUBISHI MATERIALS CORP

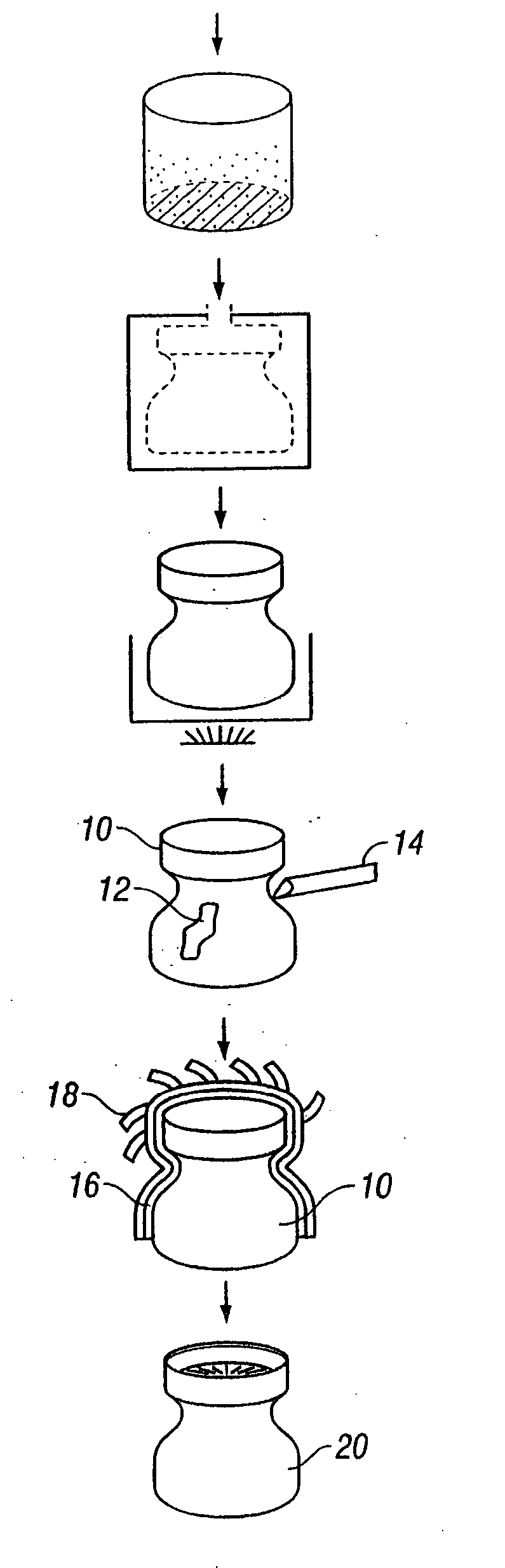

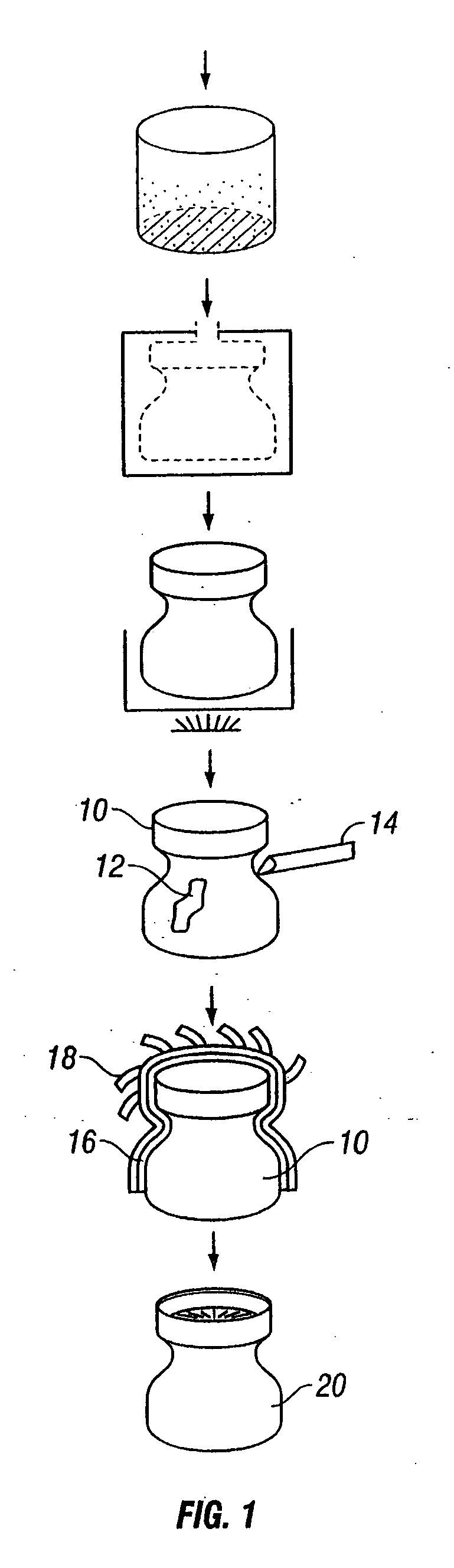

Water soluble tooling materials for composite structures

InactiveUS20050116136A1Readily soluble in waterEasy to splitFoundry mouldsSpecial tyresWater solubleThermal expansion

The present invention relates to a low density, water-soluble coring and tooling material used for the fabrication of composite parts. One aspect of the present invention relates to a lightweight, strong composite coring material that can be easily shaped and removed from cured composite parts. Another aspect of the present invention relates to a lightweight, strong composite tooling material that is easily tailored to provide a specific coefficient of thermal expansion and thermal conductivity, thus providing a tooling material that can be matched to the composite structure and material being fabricated.

Owner:ADVANCED CERAMICS

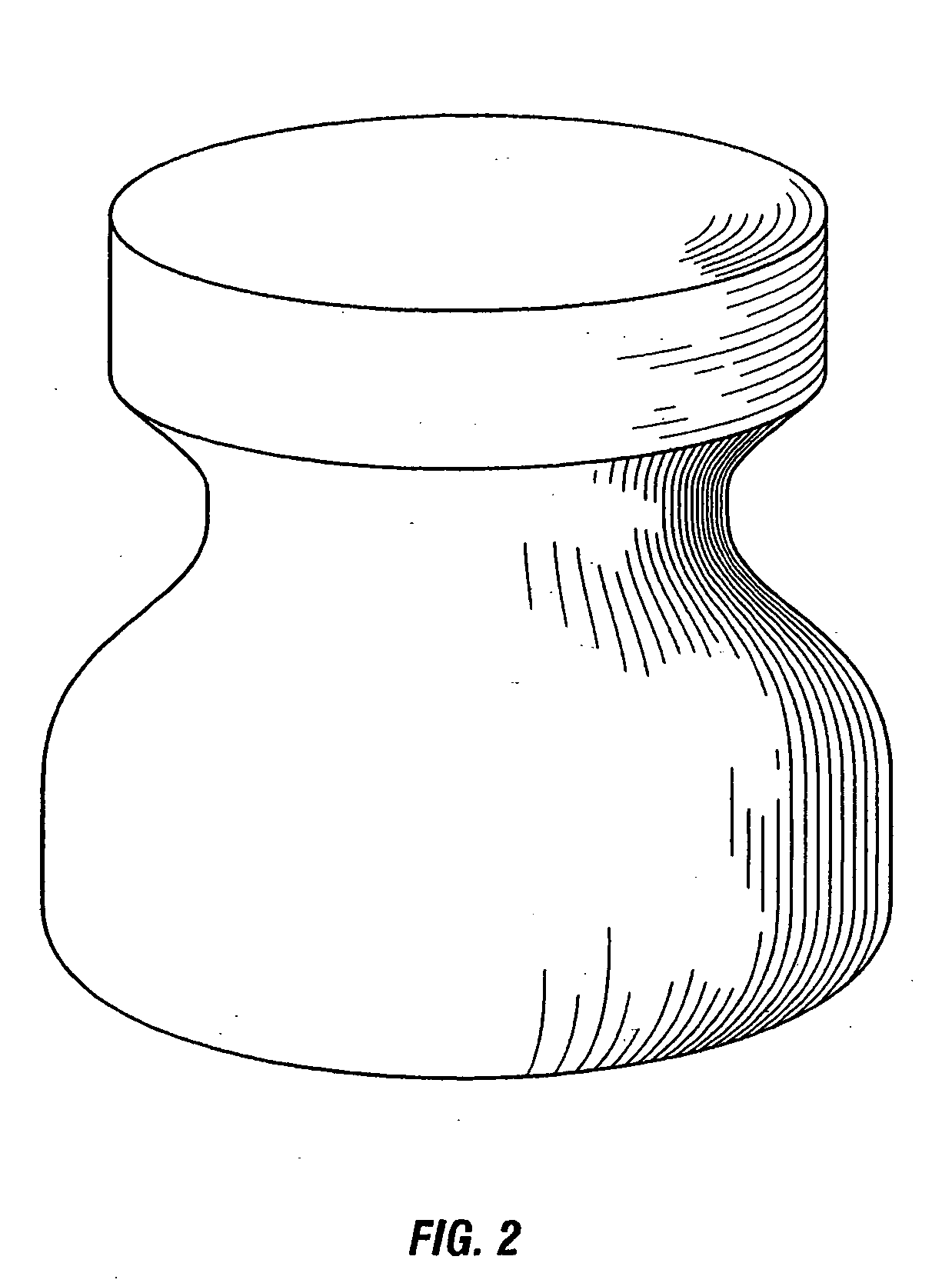

Wood cutting tool material of Ti(CN) cermet and preparation method thereof

The invention provides a wood cutting tool material of Ti(CN) cermet and a preparation method thereof, relating to the technical field of wood cutting tool materials. The Ti(CN) cermet comprises 50 to 65% of Ti(CN) powder, 5 to 10% of cobalt powder, 5 to 10% of nickel powder, 8 to 15% of molybdenum powder, 10 to 20% of tungsten carbide powder, 4 to 8% of tantalum carbide powder and 0 to 1.0% of chromium carbide and vanadium carbide powder. The preparation method comprises the steps of preparation of materials, ball milling, spray drying, compacting, pressure sintering and obtainment of a finished product. Compared to other cutter materials, a cutter prepared in the invention has durability and a service life increased by 1 to 10 times, a cutting speed increased by 1.5 to 3 times and cost for cutting processing reduced by 20% to 40%, and has a wide application prospect in processing of wood composite materials by using cermet cutters.

Owner:CHENGDU BANGPU CUTTING TOOLS CO LTD

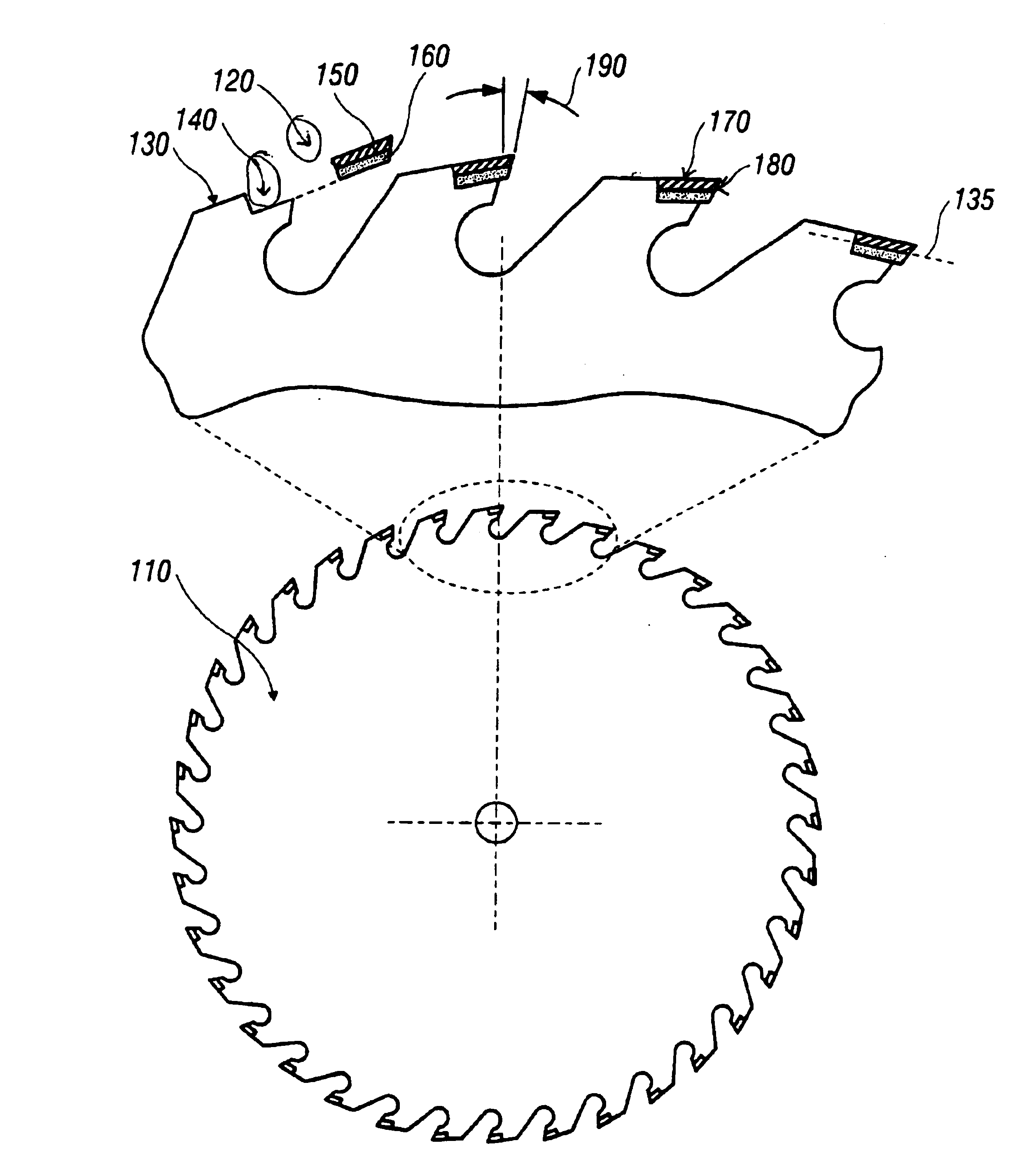

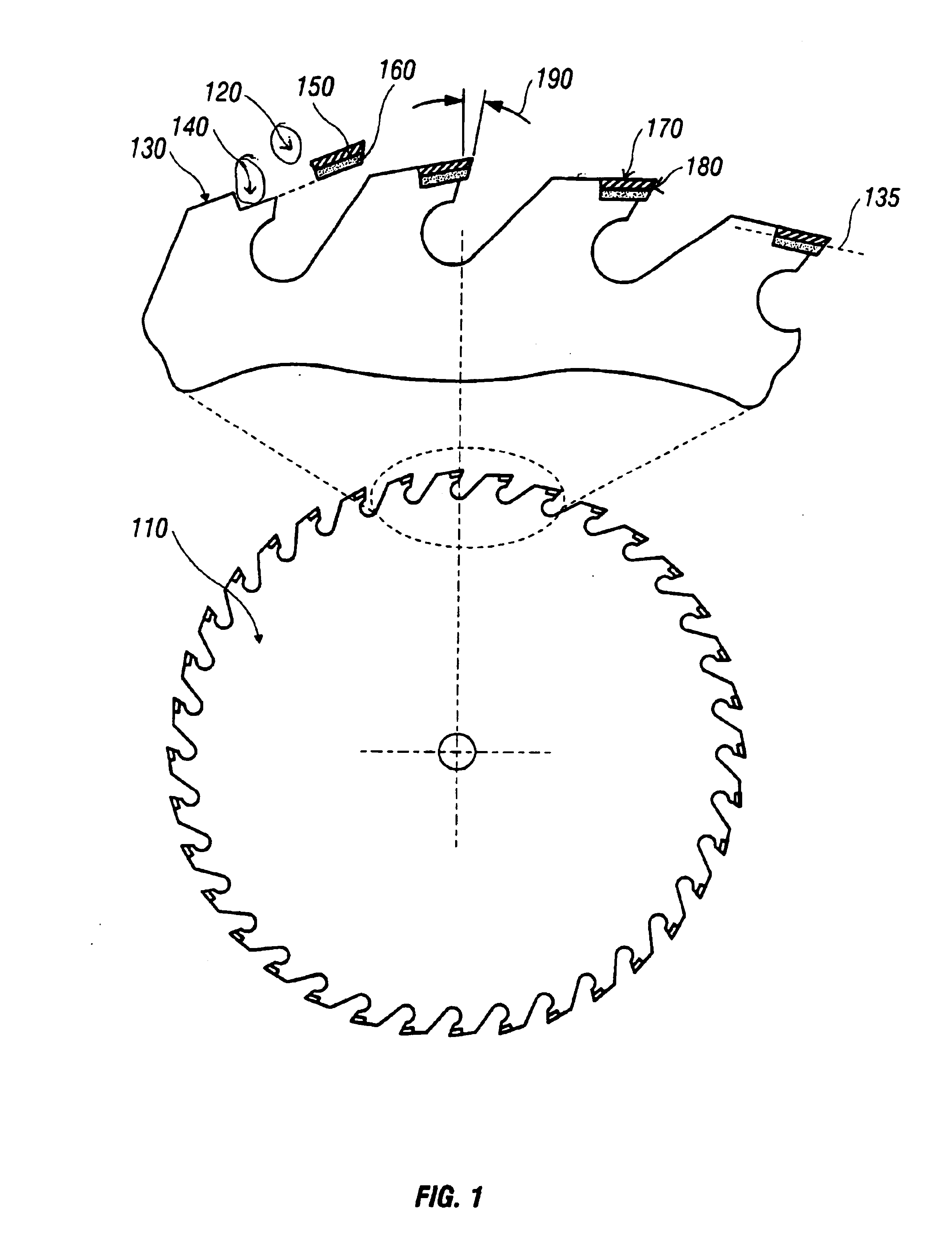

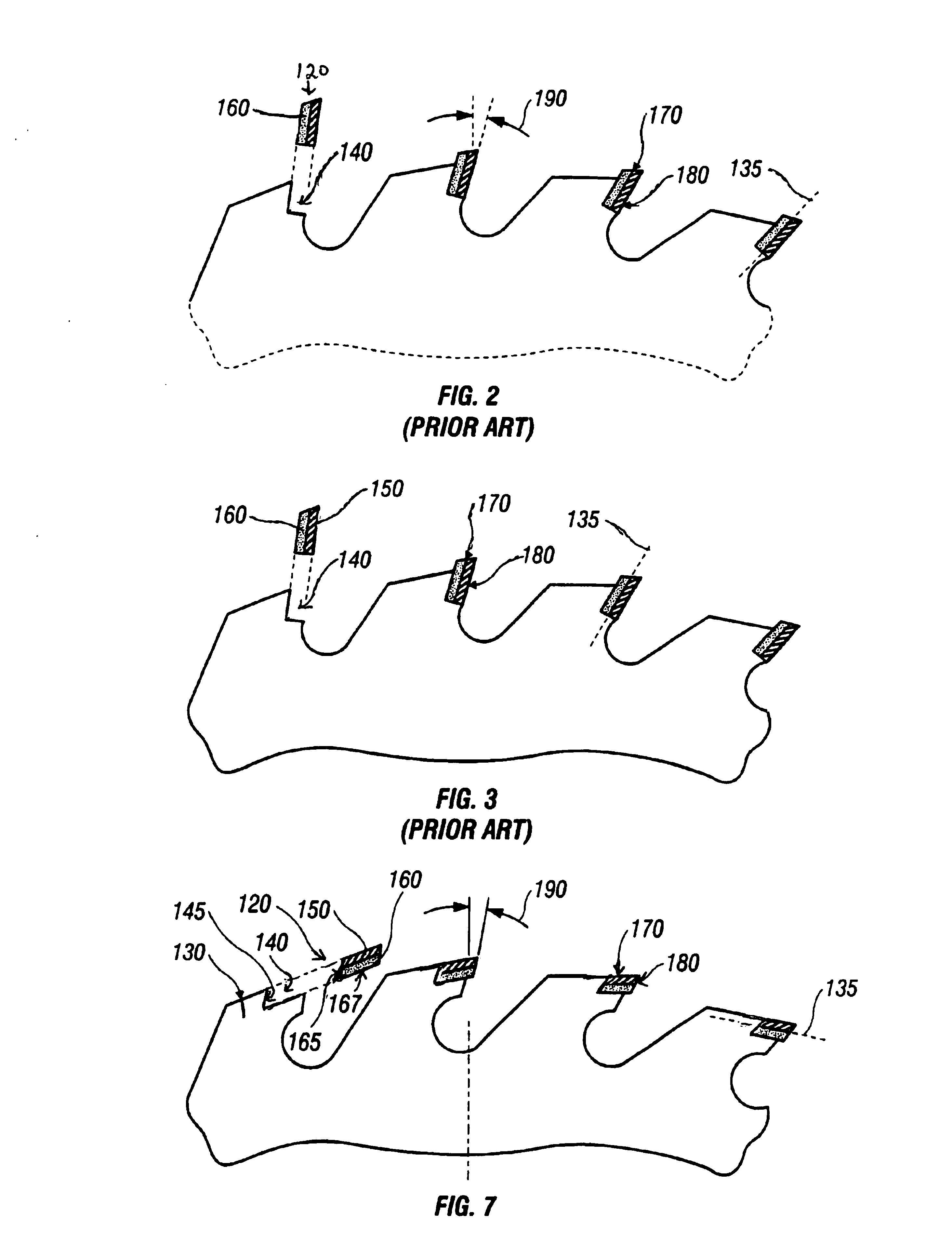

Method of fabricating circular saw blades with cutting teeth composed of ultrahard tool material

InactiveUS6883412B1Relieve pressureImprove rigidityMetal sawing devicesMetal sawing toolsCircular sawSharpening

A cutting tool having a cutting tip partially constructed from ultrahard materials. The cutting tip is oriented on the cutting tool such that the face has a reduced surface area. This has the effect of greatly reducing cutting tool costs and of maintaining the radius of the blade essentially constant even after repeated sharpening of the cutting tip.

Owner:SHEFFIELD SAW SND TOOL CO

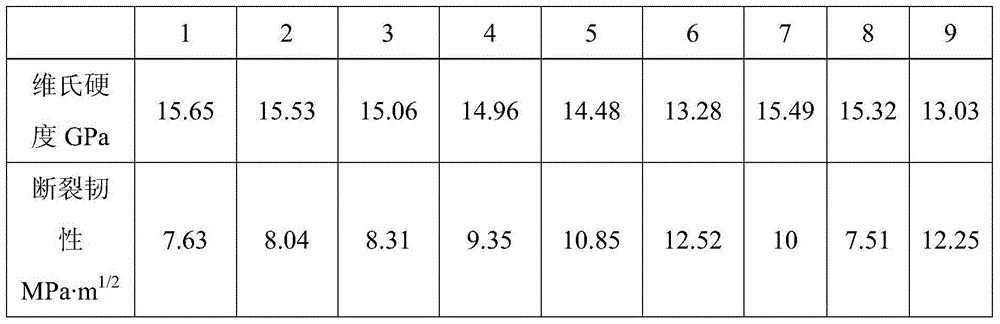

Al2O3/ZrO2 (Y2O3) nano composite ceramic tool material and its preparing method

This is a kind of Al2O3 / ZrO2(Y2O3) nanometer compound ceramics knife material and its producing method. The material components include substance material and tenacity increasing phase. The substance material is Al2O3, and its grain granularity is 60 - 200 nm; according to volume percentage, its content is 65% - 90%, and the tenacity increasing phase ZrO2(Y2O3) nanometer powder containing 1.5% - 3.5% Y2O3 according to mol percentage; its grain granularity is 50 - 100 nm, and according to volume percentage, its content is 10% - 35%; its producing craft steps include producing substance material and nanometer powder of tenacity increasing phase by hydrochemistry method, produce grains, prepare material, ball mill to mix material, flan equal static pressure molding and sinter. The anti-bending strength of the prepared ceramics knife material ªÊ= 750 - 950 MPa, the fracture toughness KIC = 7.8 - 9.6 MPaíñm1 / 2, Weibull modulus m = 10 - 11.7, and durable intensity can get to 4 - 6 hours.

Owner:NORTHEASTERN UNIV

Whisker plasticizing tungsten carbide-cobalt base hard alloy material and its preparation process

The invention discloses a crystal whisker toughened tungsten carbide cobalt-base hard alloy material and the preparing method. It takes powder metallurgy technology, employs tungsten carbide- cobalt as base material, adds titanium carbide crystal whisker and prepares toughened tungsten carbide cobalt-base hard alloy material through a certain process. It is characterized in that: (1) employs powder metallurgy technology and prepares out product with different shapes. (2) the rigidity is high, compression strength and toughness are good, the titanium carbide crystal whisker increases toughness on basis of guranteeing strength of said alloy, and it aslo can be used to replace cobalt and as adhesive phase, to improve material performance. (3) the process is simplea nd cost is low. The hard alloy material can be used in mechanics, metallurgy, mine, first-order instrument and military, and uesd to prepare kinds of blade and drilling button, and new knife tool material.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

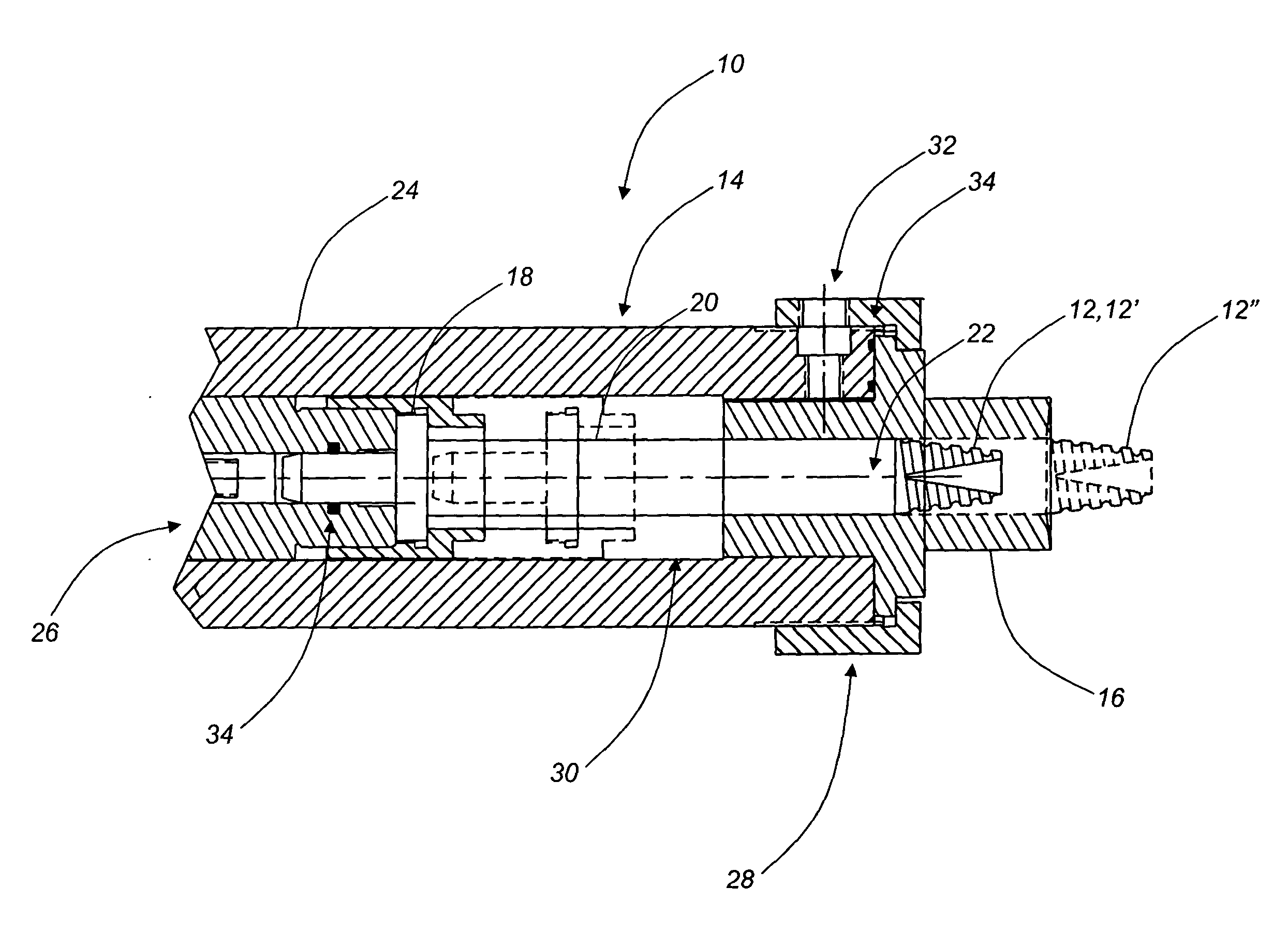

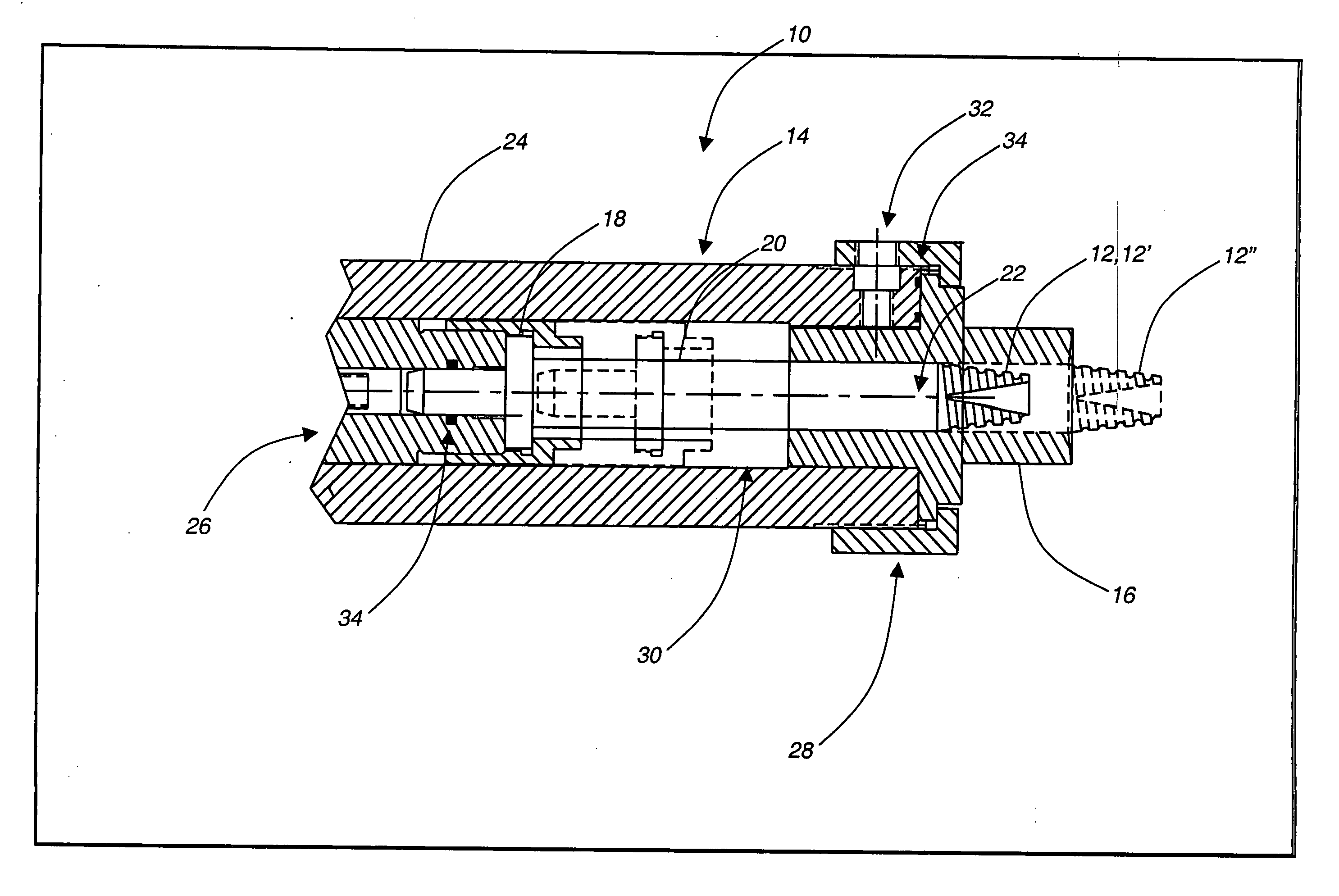

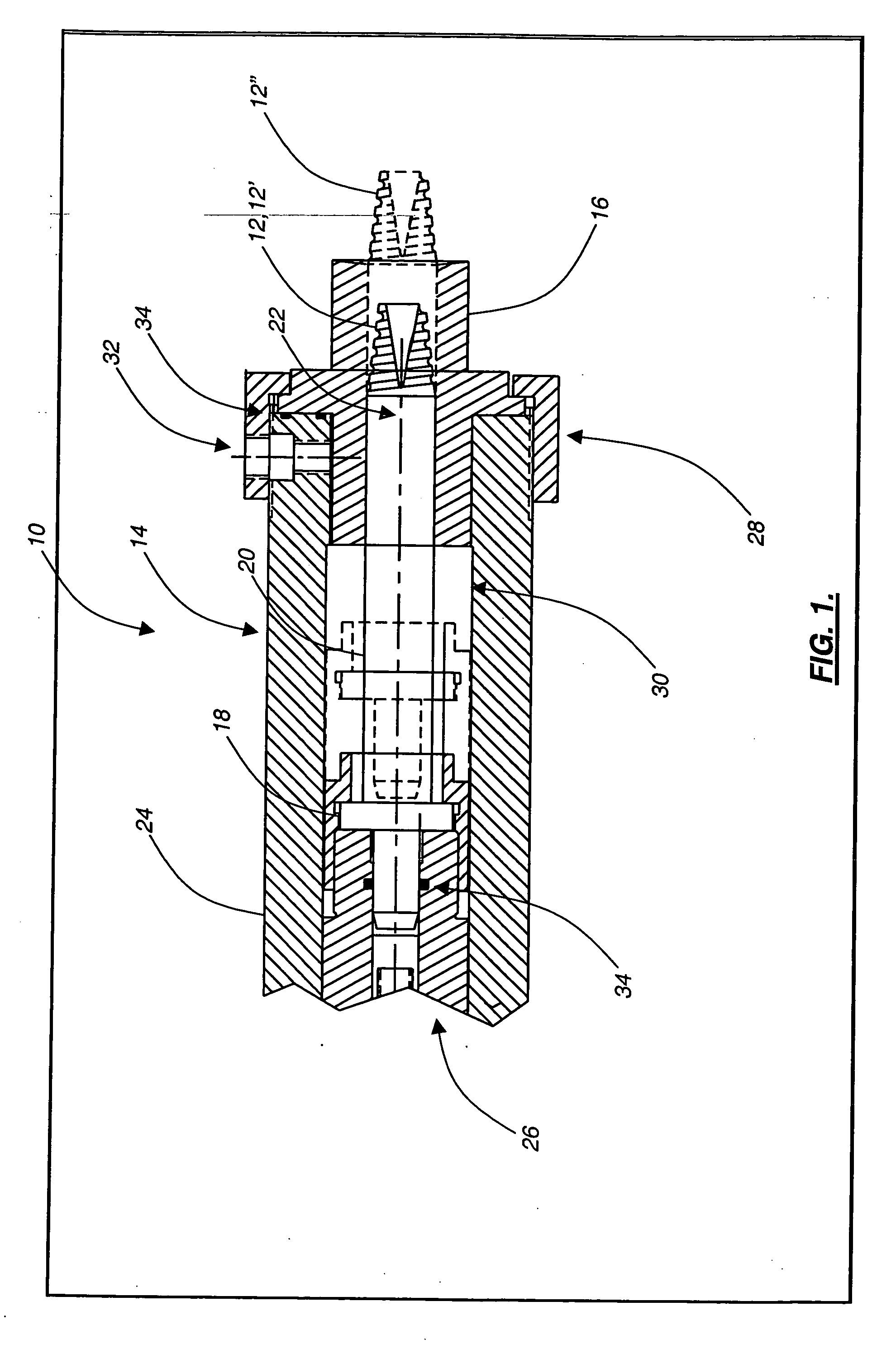

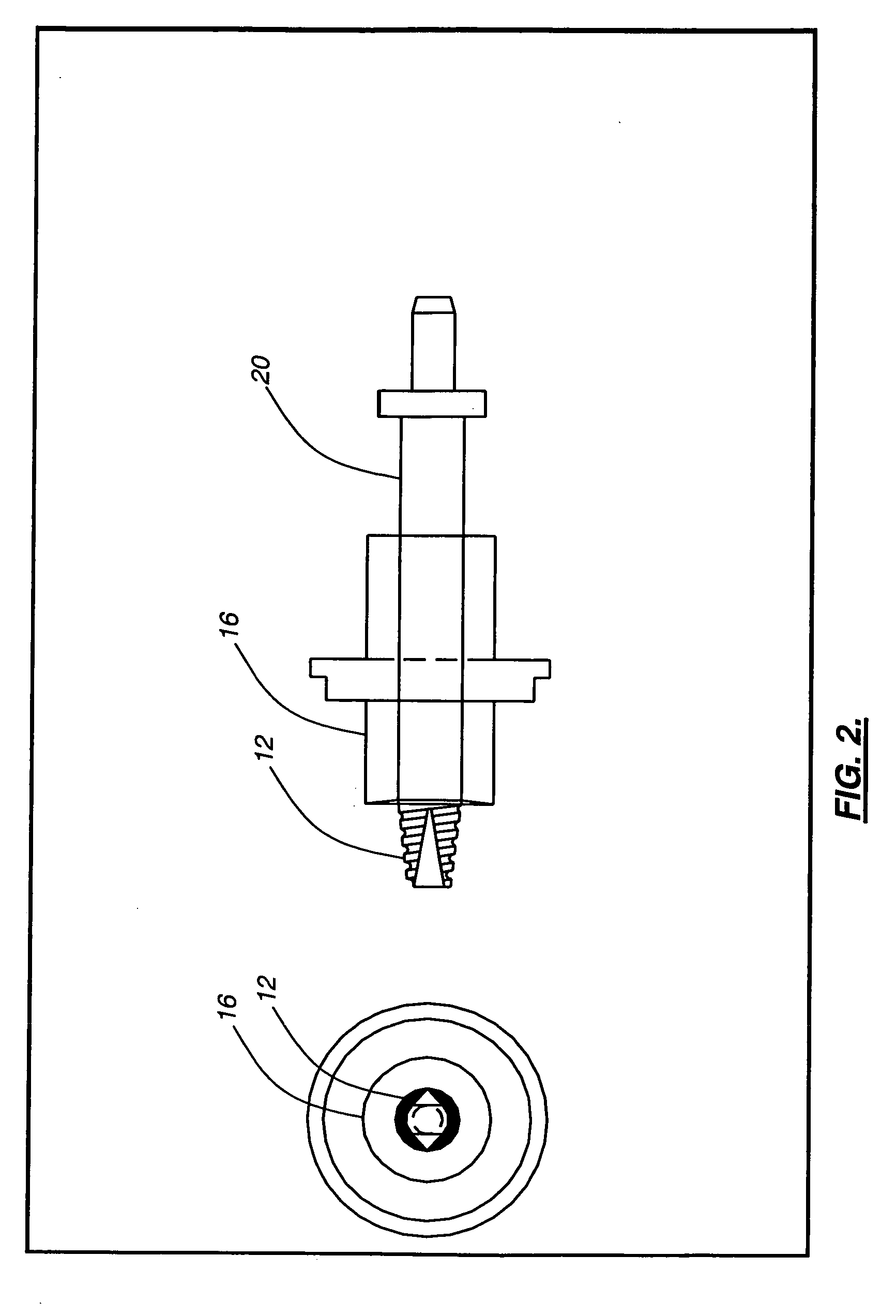

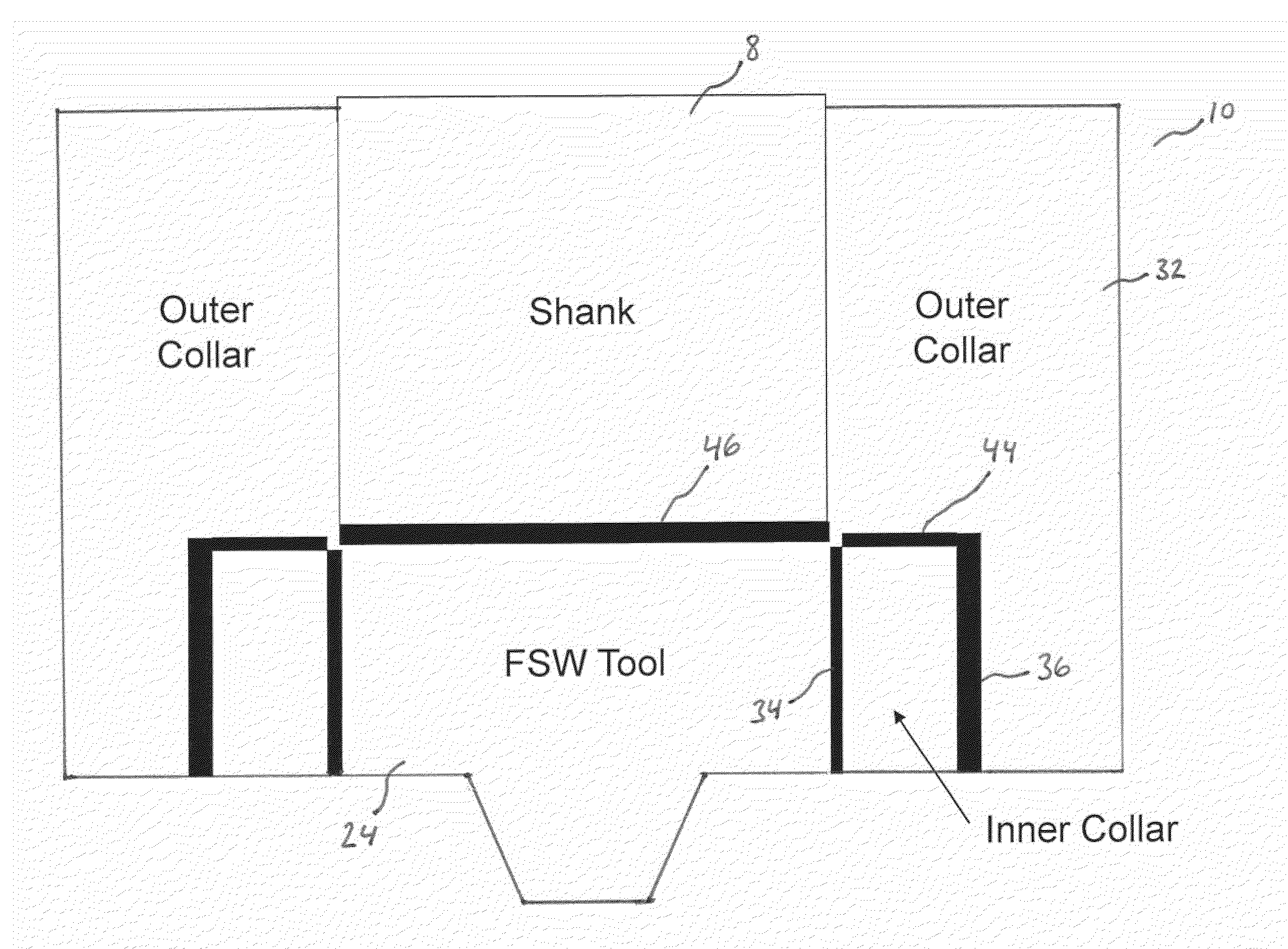

Rotary holding device for gripping tool material at elevated temperatures through multiple collar assembly

ActiveUS20100038832A1Improve stressImprove gripWelding/cutting auxillary devicesBlast furnace detailsEngineeringFriction stir processing

A tool is provided that is capable of friction stir processing, friction stir mixing, and friction stir welding of high melting temperature and low melting temperature materials, wherein the collar is now divided into at least an inner and an outer collar coupled to the shank and the FSW tip, wherein new thermal barriers enable expansion of the inner collar to be directed inward to thereby create compression on the FSW tip instead of allowing the FSW tip to become loose in the tool at elevated temperatures.

Owner:MAZAK CORP

PCD tool cutting edge processing method

ActiveCN104440004AReduce processing costsMeet high performance requirementsWorkpiecesTurning toolsLaser cuttingEngineering

The invention discloses a PCD tool cutting edge processing method which includes the following steps that firstly, PCD composite piece cutting is conducted, wherein a linear cutting method is used for cutting the whole PCD composite piece into a plurality of PDC blades; secondly, blade welding is conducted, wherein the PCD blades are welded to a tool base body, and a PCD tool is obtained; thirdly, a cutting edge of the PCD tool is processed, wherein laser cutting processing is conducted on the PCD tool through a laser cutting device according to the design requirement of the shape of the tool, and the PCD tool with a flat cutting edge is obtained. The PCD tool cutting edge processing method improves the processing rate of the cutting edge of PCD tool materials, shortens the production cycle of the tool, reduces the processing cost of the PCD tool and obtains the good quality of the cutting edge of the PCD tool, according to the PCD tool processed through the laser cutting of the cutting edge, the breaking size of the cutting edge can be controlled within 2 microns in length and 2 microns in width, the breaking number is small, and the number of broken edges in the range of 10 mm is smaller than or equal to 5.

Owner:深圳章源精密工具技术有限公司

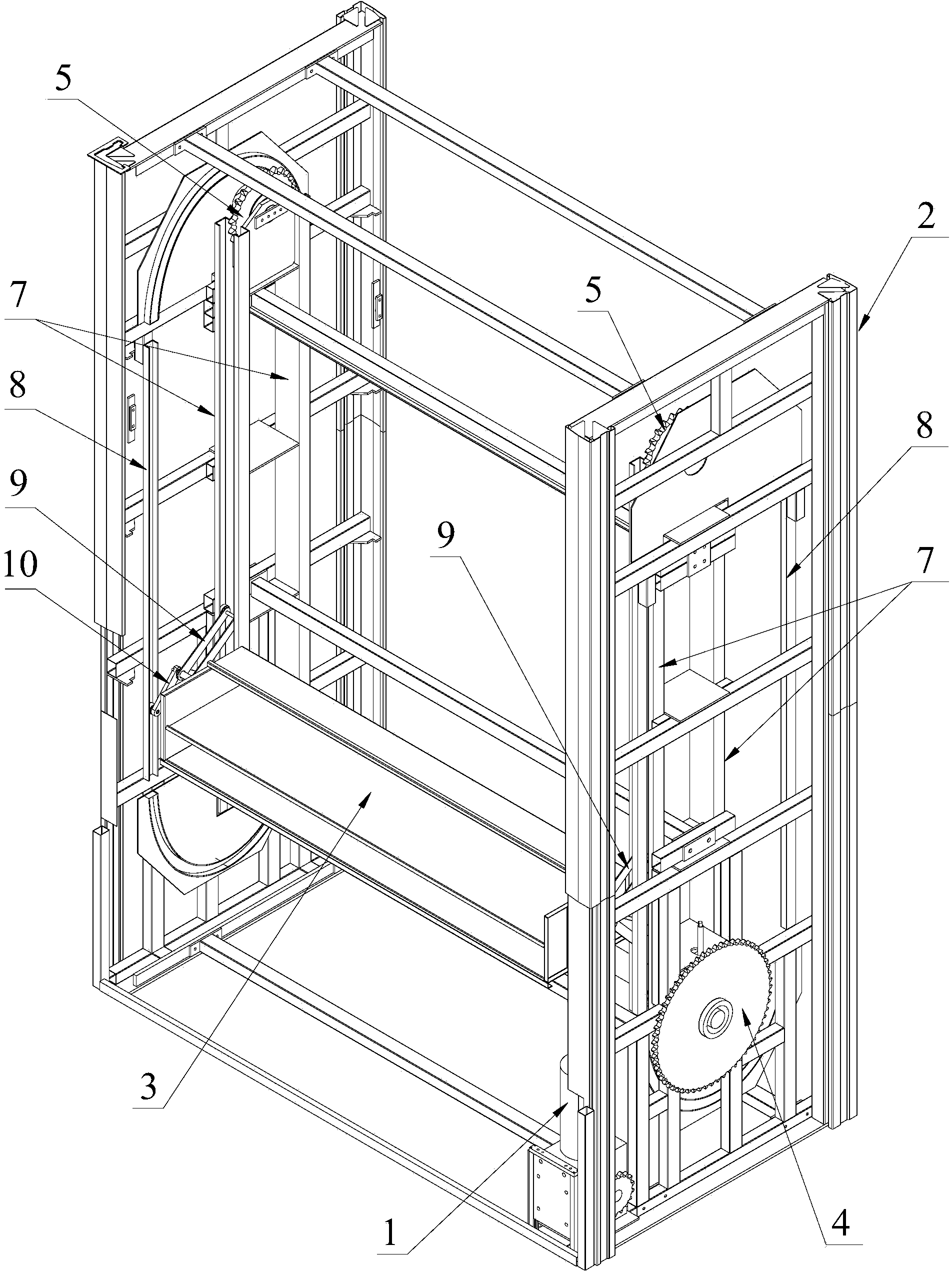

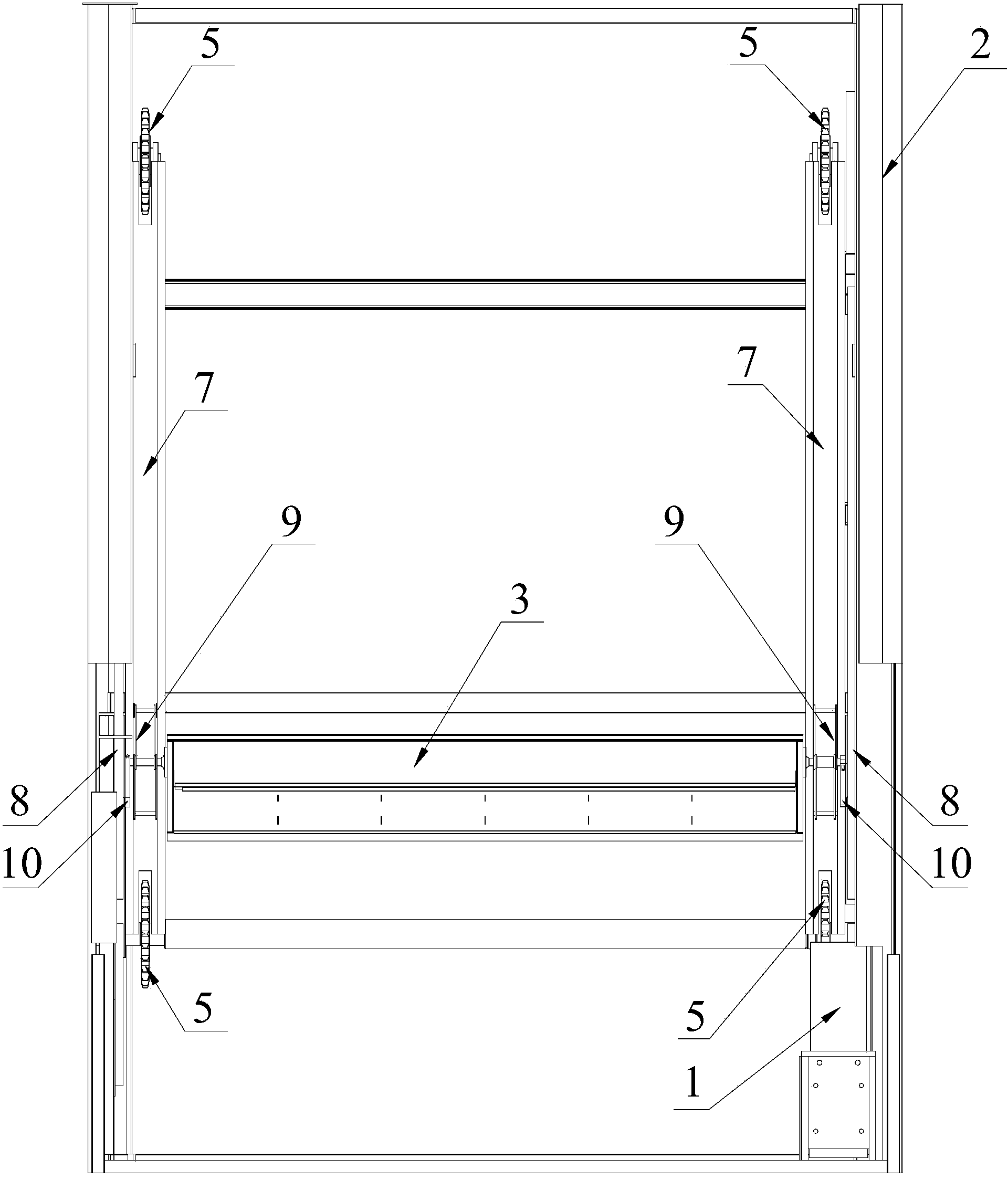

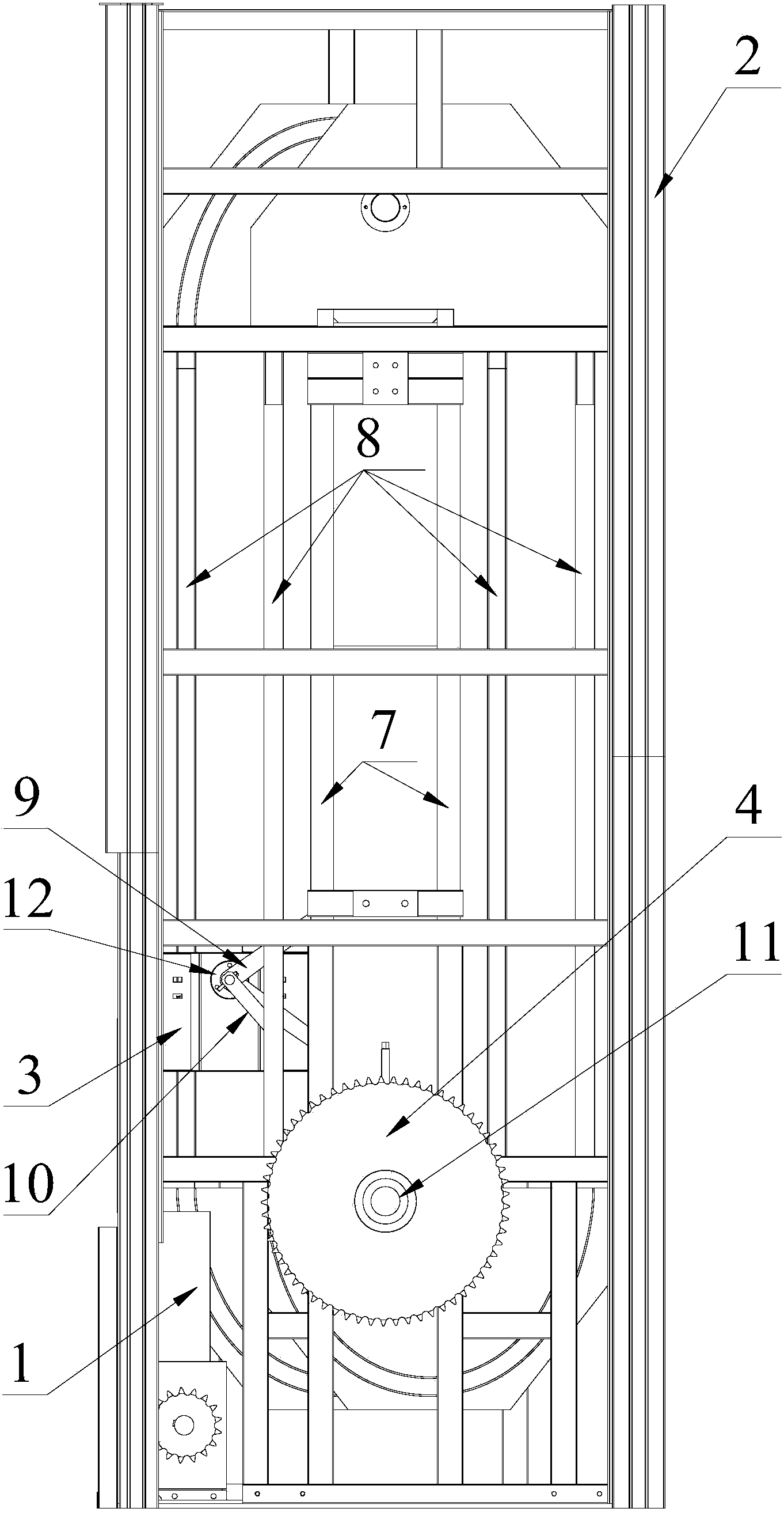

Numerical-control vertical-rotation repository

InactiveCN103662563AOccupy a large plane spaceStorage devicesNumerical controlInformation repository

The invention relates to a numerical-control vertical-rotation repository and belongs to the field of automatic storage devices. The repository comprises a motor, a transmission mechanism and an electronic control system. The electronic control system comprises a PLC industrial personal computer and a remote monitoring unit. The transmission mechanism comprises a frame (2), a plurality of material boxes (3), a transmission wheel (4), four chain gears (5), two transmission chains (6), two chain guide rails (7), two slide ways (8), a plurality of material box supports (9) and a plurality of guide rods (10). According to the numerical-control vertical-rotation repository, the multiple material storage boxes can be driven to make reciprocating motion in the vertical direction along a circulation track through the transmission chains, and thus the numerical-control vertical-rotation repository overcomes the defects that a tool material rack of a traditional fixed truss structure is large in occupied planar space, fixed in repository position, incapable of being adjusted flexibly, high in labor intensity of material storing and taking operation, low in efficiency and the like.

Owner:CHANGCHUN RAILWAY VEHICLE FACILITIES

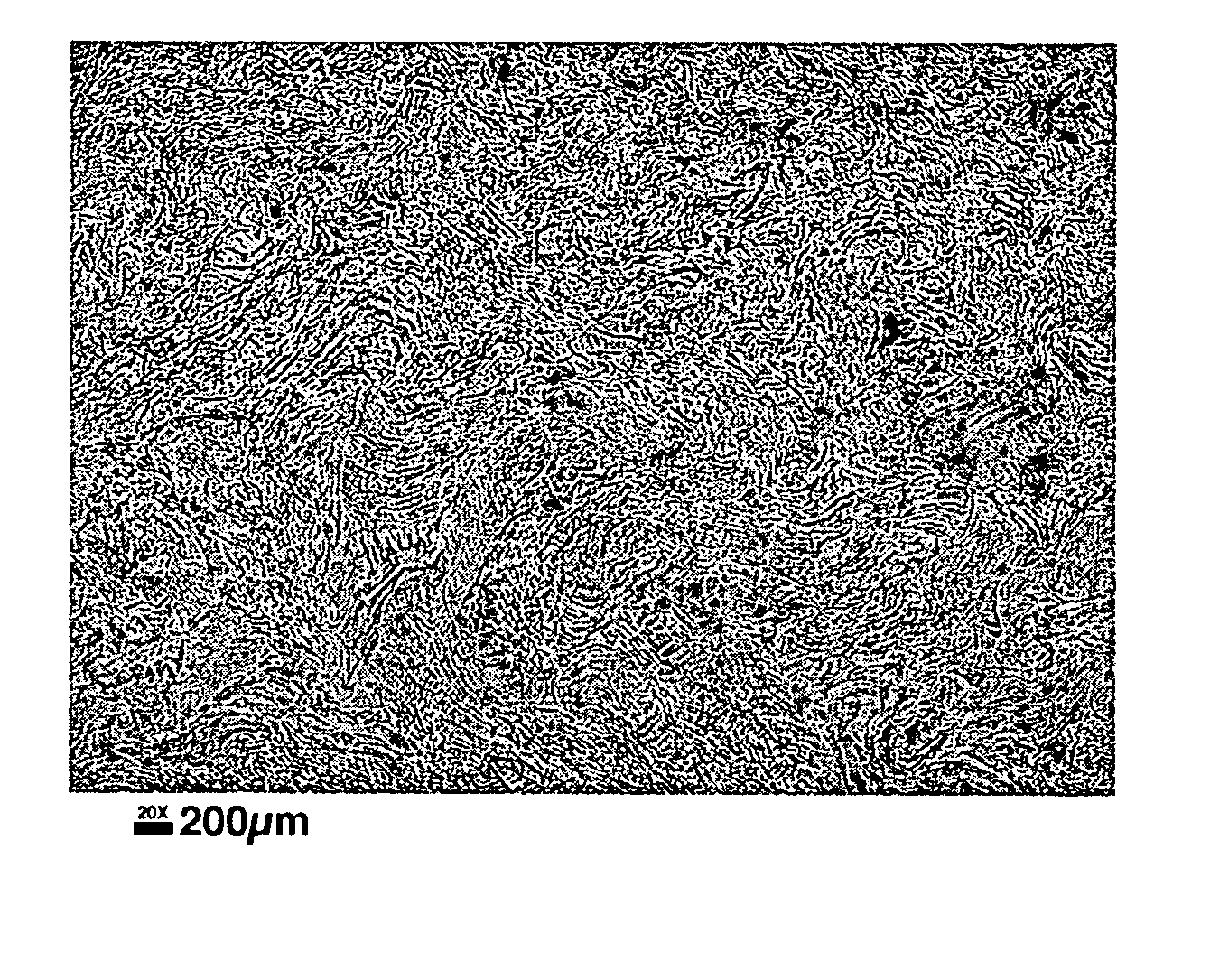

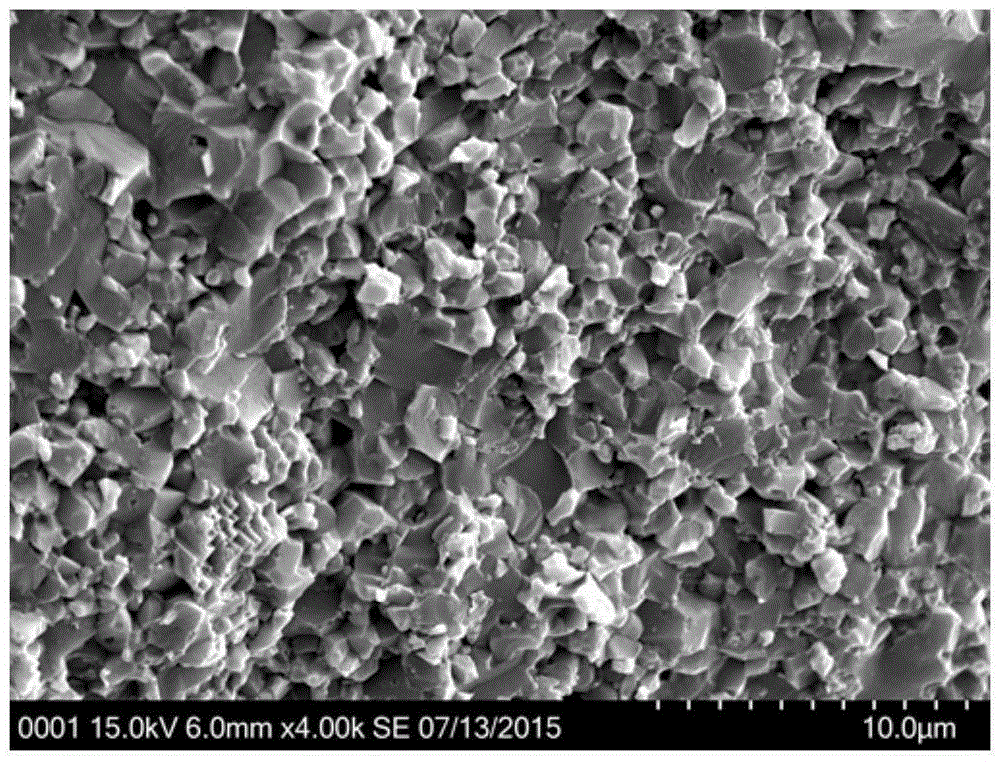

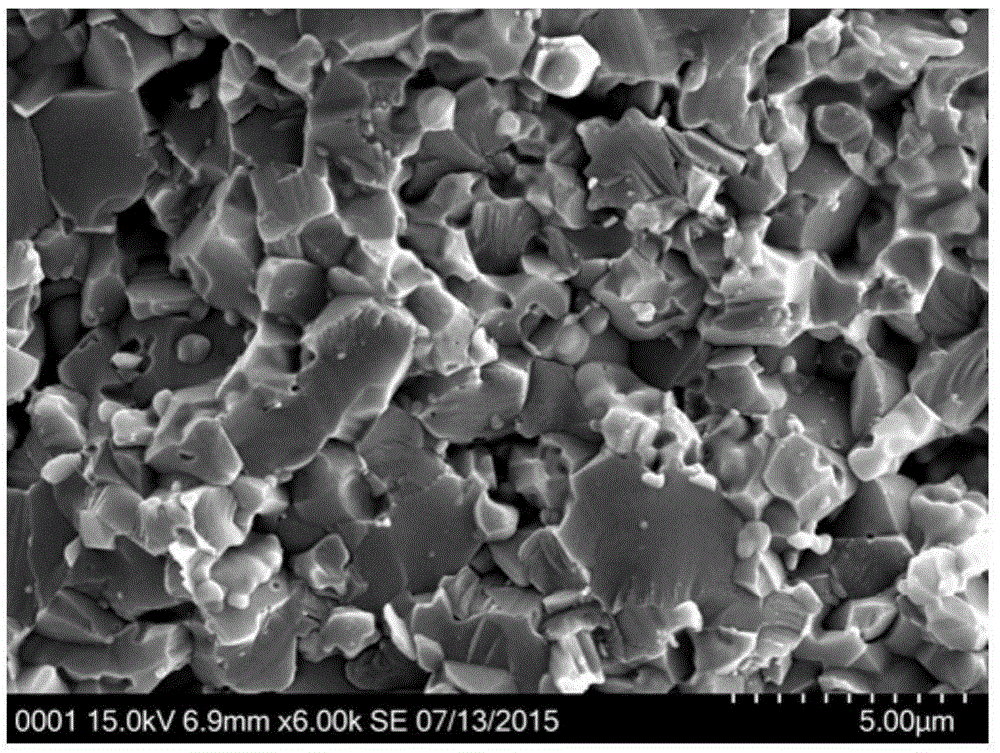

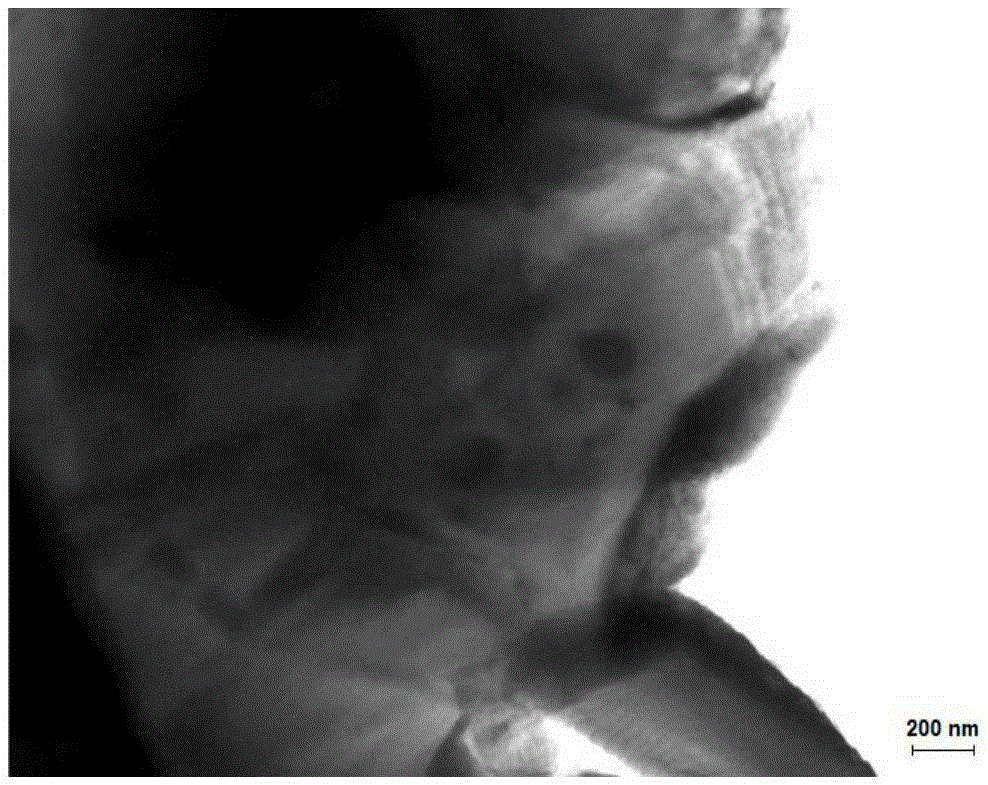

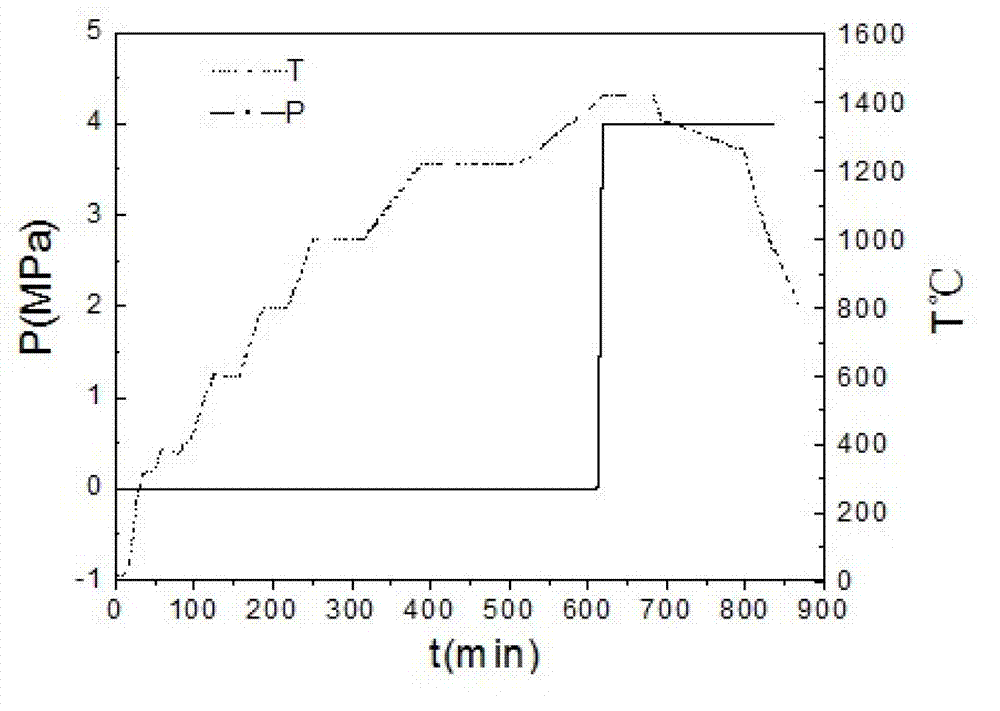

Al2O3/Ti(C,N) composite ceramic tool material and microwave sintering process thereof

The invention discloses an Al2O3 / Ti(C,N) composite ceramic tool material and a microwave sintering process thereof. The Al2O3 / Ti(C,N) composite ceramic tool material is prepared from, by mass, 61%-70% of alumina (Al2O3), 25%-35% of titanium carbonitride (Ti(C,N)), 2%-6% of nickel (Ni) and 1%-3% of molybdenum (Mo). Ceramic tool materials are sintered in a microwave sintering furnace with nitrogen as protection atmosphere through the characteristics that whole microwaves can conduct non-gradient heating, material compactness is promoted and environment friendliness is achieved, wherein the frequency of the microwave sintering furnace is 2.45 GHz. The prepared tool material is uniform in microstructure and small in crystalline grain, has high density, high fracture toughness and high harness, and the performance of the prepared tool material meets the use requirement of tools; meanwhile, the sintering process is advanced, the production efficiency is high, cost is low, large-scale production can be easily conducted, and popularization value is achieved.

Owner:NANJING UNIV OF SCI & TECH

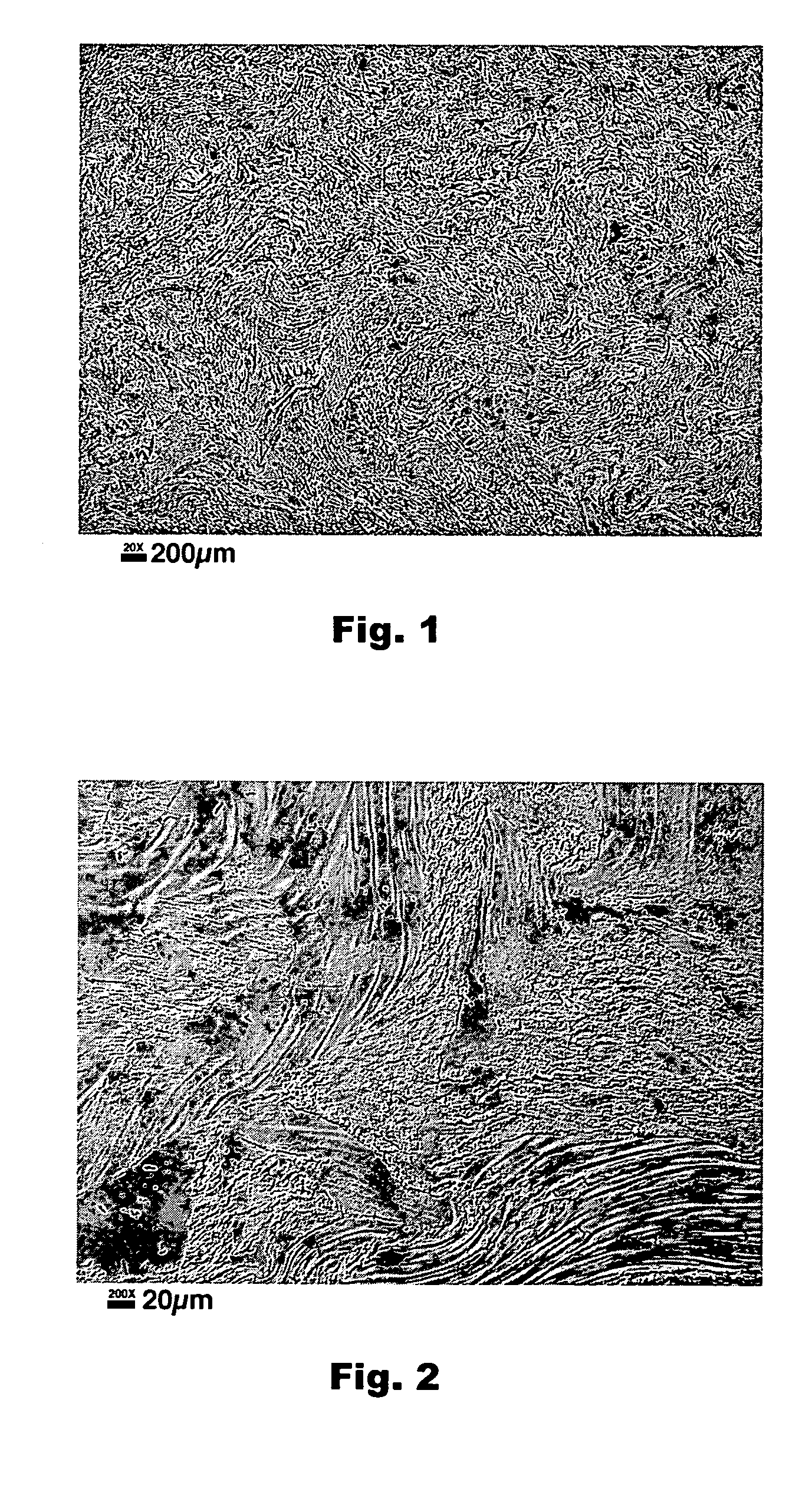

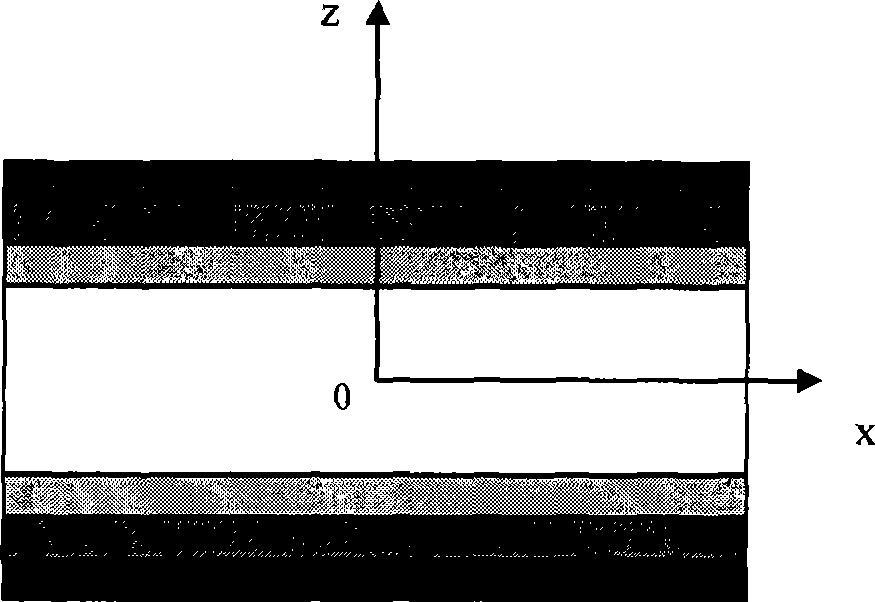

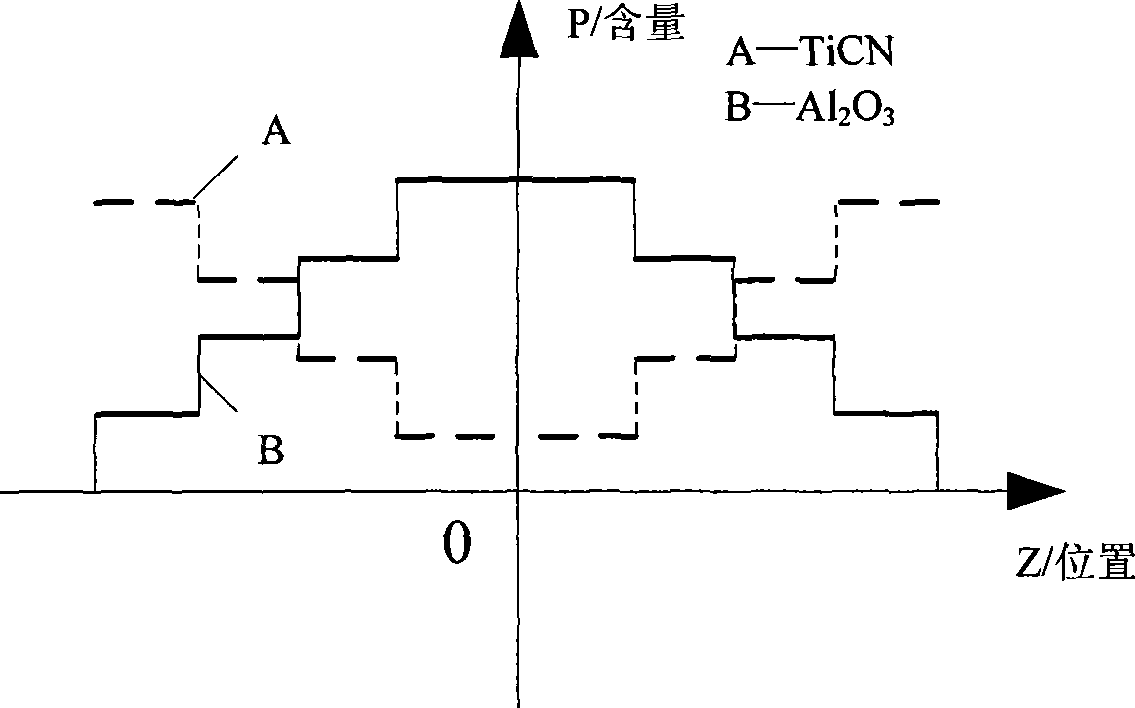

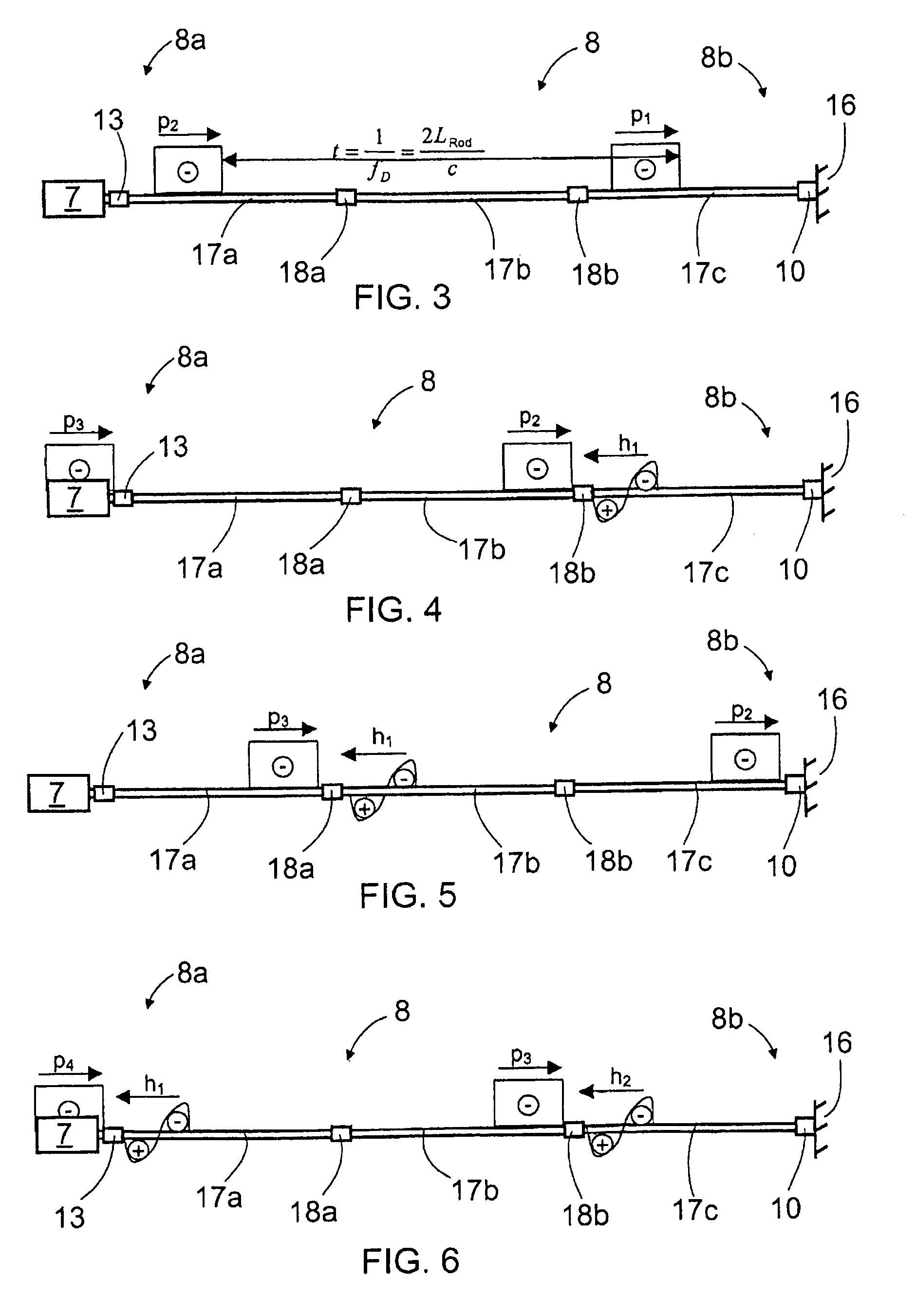

Gradient nano composite ceramic tool material and preparation method thereof

InactiveCN101391888AHigh hardnessUniform particle size distributionComposite ceramicCeramic cutting tool

The invention provides a gradient nano composite ceramic cutting tool material and a preparation method thereof, pertaining to the technical field of ceramic cutting tool materials. The cutting tool material has a symmetrical gradient layered structure, with the layer number of 3 or 5; according to volume percentage, the components of all the layers are 69 percent to 39 percent of AI2O3, 30 percent to 60 percent of micro TiCN, and 1 percent of micro MgO, micro Y2O3 and micro NiO; the layers which are symmetrical relative to the central layer have the same content of the components, and the thickness is symmetrically distributed, wherein, the AI2O3 of two surface layers is the mixture of nano AI2O3 and micro AI2O3, the volume content of the nano AI2O3 takes up 10 percent to 30 percent of the total AI2O3 volume content of the layer, and the AI2O3 of all the other layers is micro AI2O3; the TiCN content of each layer steadily increases layer by layer by 10 percent from the central layer to the outer layers, and the AI2O3 content steadily decreases layer by layer by 10 percent from the central layer to the outer layers. Powder layered filling in a laying way and hot pressed sintering technologies are adopted to prepare the material. The cutting tool material is characterized by uniform grain size distribution, high hardness, high bending strength, and good fracture toughness property and thermal shock resistance.

Owner:SHANDONG UNIV

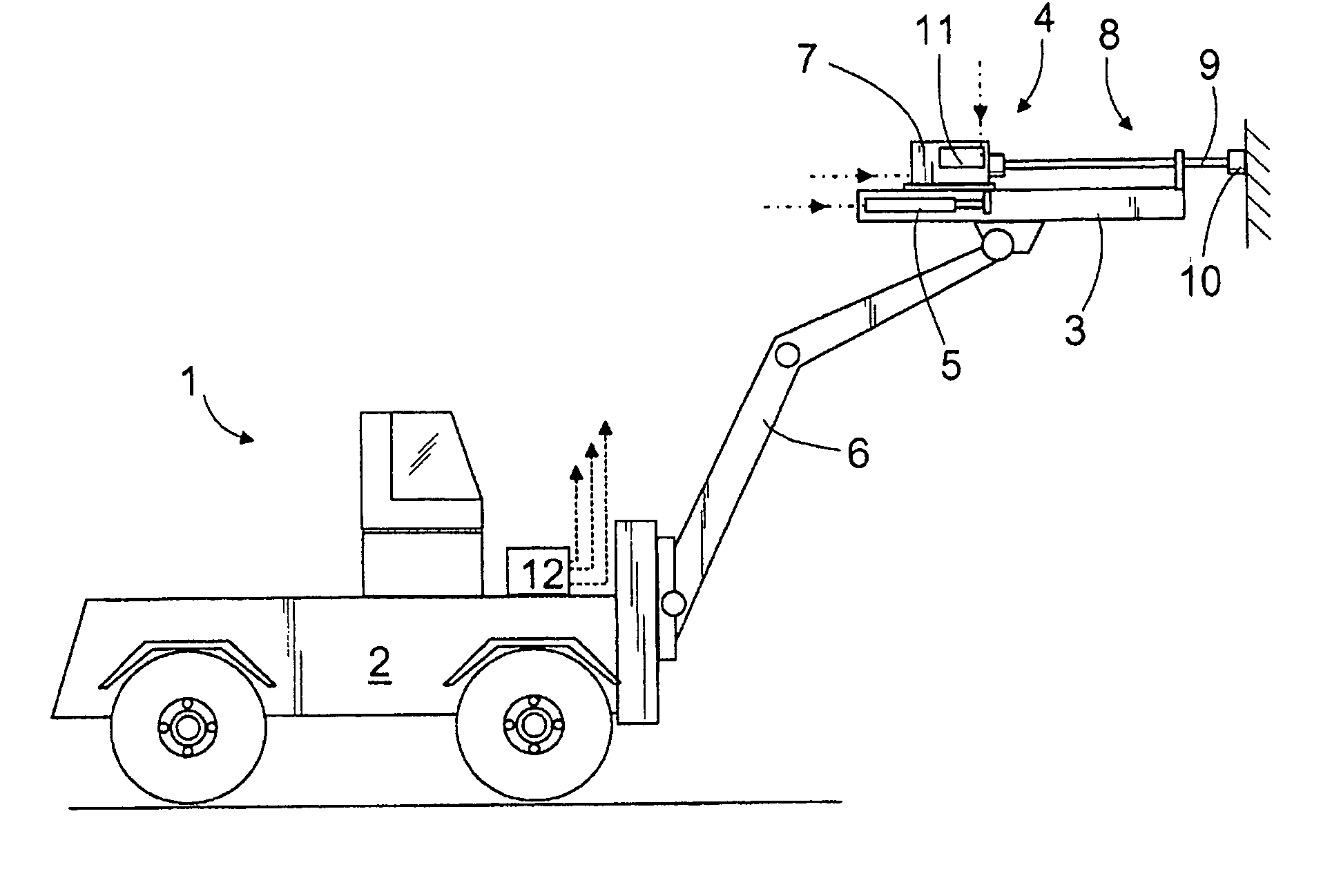

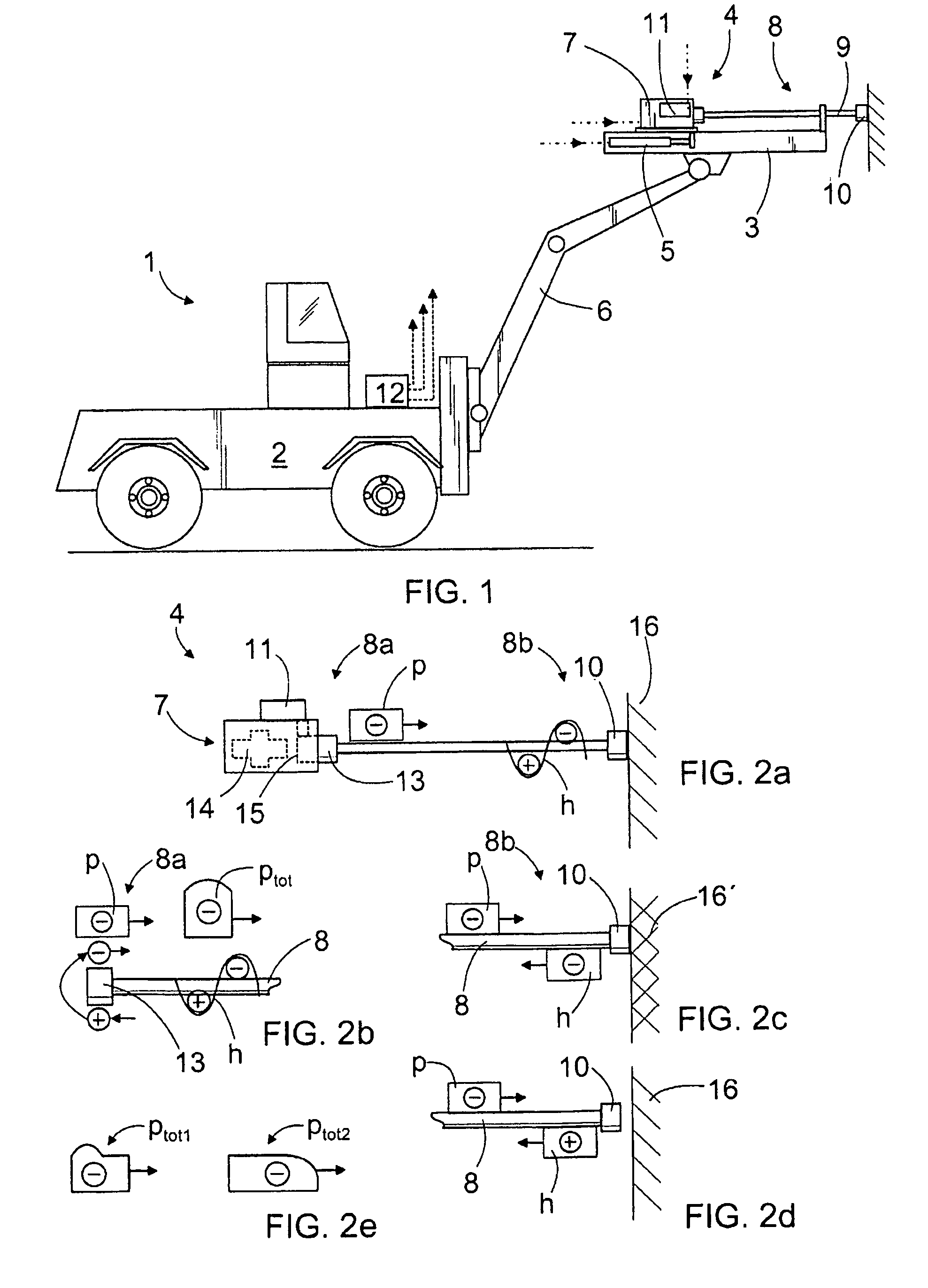

Method for controlling percussion device, software production, and percussion device

InactiveUS7717190B2Improve overall utilizationIncrease energy contentReciprocating drilling machinesConstructionsDevice formPropagation time

Owner:SANDVIK MINING & CONSTR OY

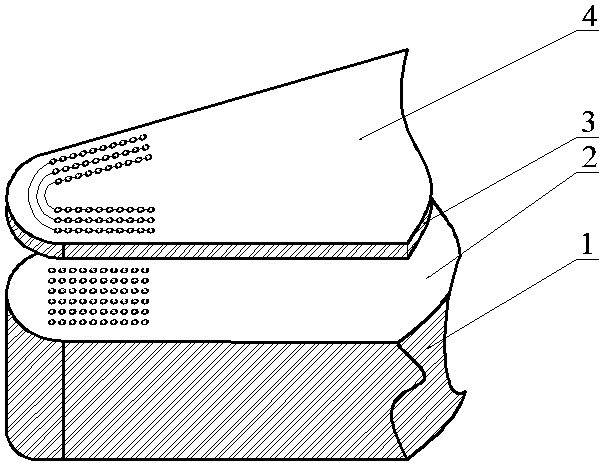

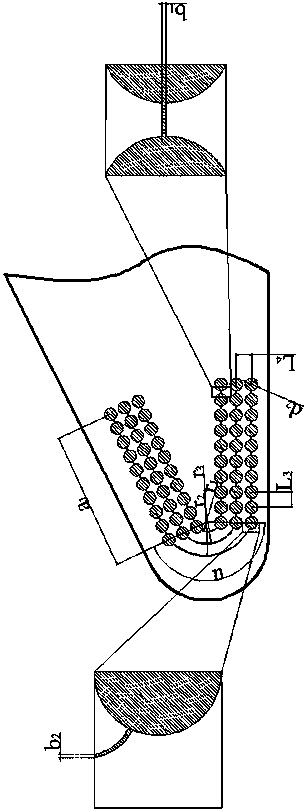

Silicon nitride based nano complex gradient function ceramic tool material and preparation thereof

The invention provides a silicon nitride-based nano composite functionally gradient ceramic cutter material and a preparation method thereof. The ceramic cutter material is provided with a five-layer symmetrical gradient level structure; the component contents of the symmetrical layers relative to a central layer are the same and the thickness of each layer is consistent; the components of each layer are all micron Si3N4, nano Si3N4, nano TiC, nano TiN, Al2O3 and Y2O3. The preparation method thereof is as follows: (1) preparing materials according to the content of each component in each layer; (2) dispersing the nano materials in each layer; (3) mixing the other materials in each layer with the dispersed nano materials to obtain the powder material of a composite ceramic material which disperses excellently; and (4) employing a powder layering paving method and a hot pressing sintering technique to carry out loading and sintering. The invention improves the anti-bending intensity and the fracture toughness property of the materials, and improves the fracture toughness property of the materials; while the gradients of the nano TiC and the nano TiN are arranged in layers, thus leading the mechanical property of the cutter material to be changed in stagewise gradient, and being capable of effectively easing the residual heat stress.

Owner:SHANDONG UNIV

Surface cross-scale composite micro-modeling tool and preparation method

The invention discloses a surface cross-scale composite micro-modeling tool and a preparation method, and belongs to the technical field of machine manufacturing. The surface of a tool material is subjected to micro-modeling treatment of a recessed cavity morphology, a micron-size recessed cavity and a nanoscale groove are machined in a friction and abrasion sensitive area on the surface of a hardcoating, a combined way that the groove communicates with the cavity is adopted for distribution, and the cross-scale composite micro-modeling coating tool is obtained. In this way, the film-base combined strength of the coating tool is improved, and the wettability and lubrication performance of the surface of the coating tool are improved.

Owner:JIANGSU UNIV

Preparation method of nano calcium fluoride for self-lubricating tool material

InactiveCN102583486AHigh purityComplete crystal formCalcium/strontium/barium fluoridesNanotechnologyAlcoholSolvent

The invention relates to a preparation method of nano calcium fluoride for a self-lubricating tool material. According to the preparation method, an ultrasonic reduction method is adopted. The preparation method comprises the following steps of: preparing calcium nitrate and ammonium fluoride serving as raw materials into aqueous or alcohol solution respectively; adding PEG 6000-abslute ethyl alcohol composite solvent; performing ultrasonic dispersion; mixing the dispersed calcium nitrate solution and the ammonium fluoride solution under ultrasonic and stirring conditions; and reacting, aging, centrifuging, cleaning and drying to obtain nano calcium fluoride powder. The prepared nano calcium fluoride has the particle size of 15-50 nm and has high purity, complete crystal form, high crystallinity, uniform size distribution and high dispersion. The preparation method also has the advantages of simple technical process, convenience for operation and low equipment requirements.

Owner:QILU UNIV OF TECH

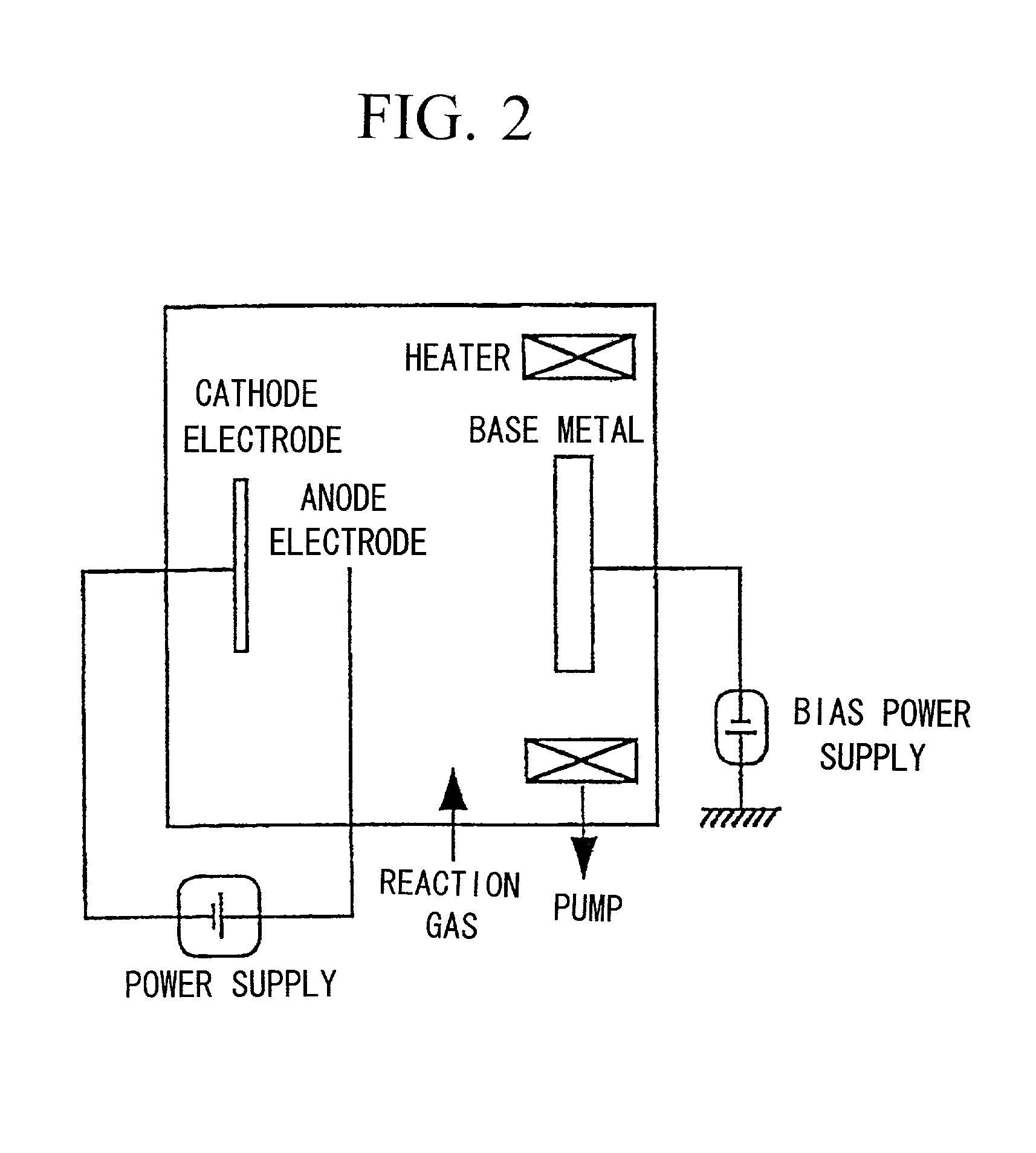

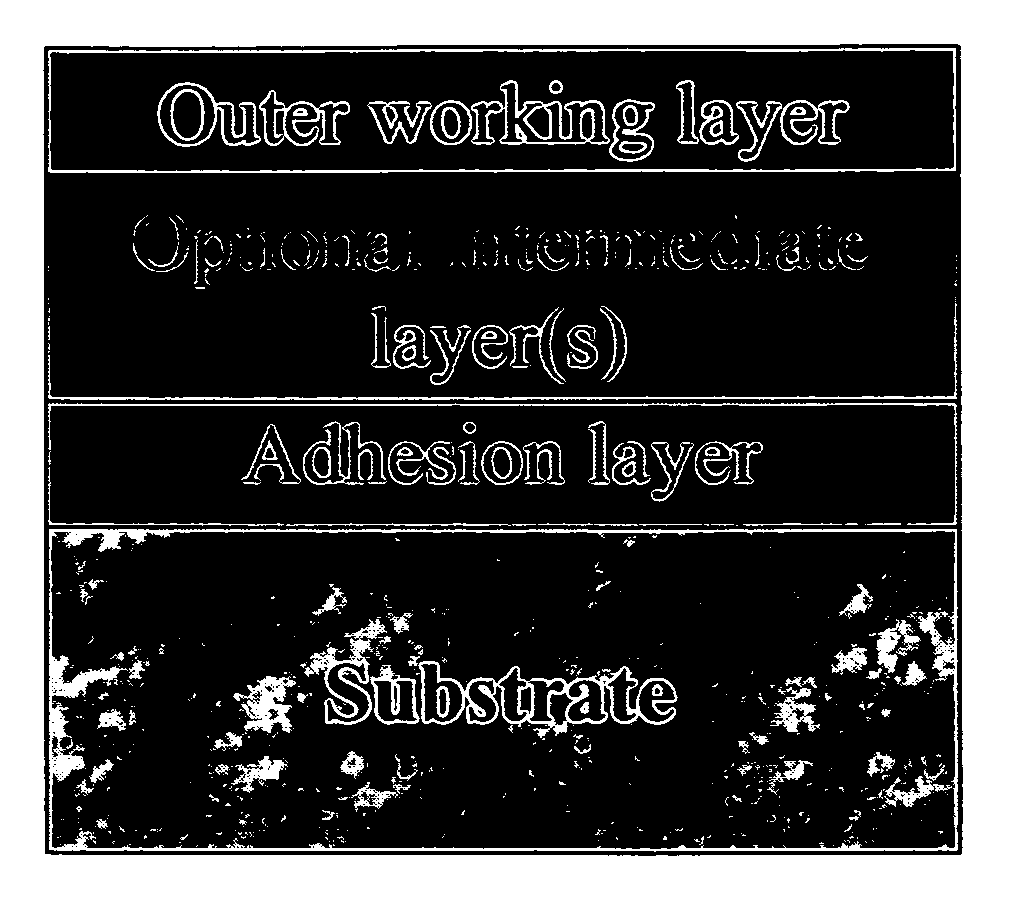

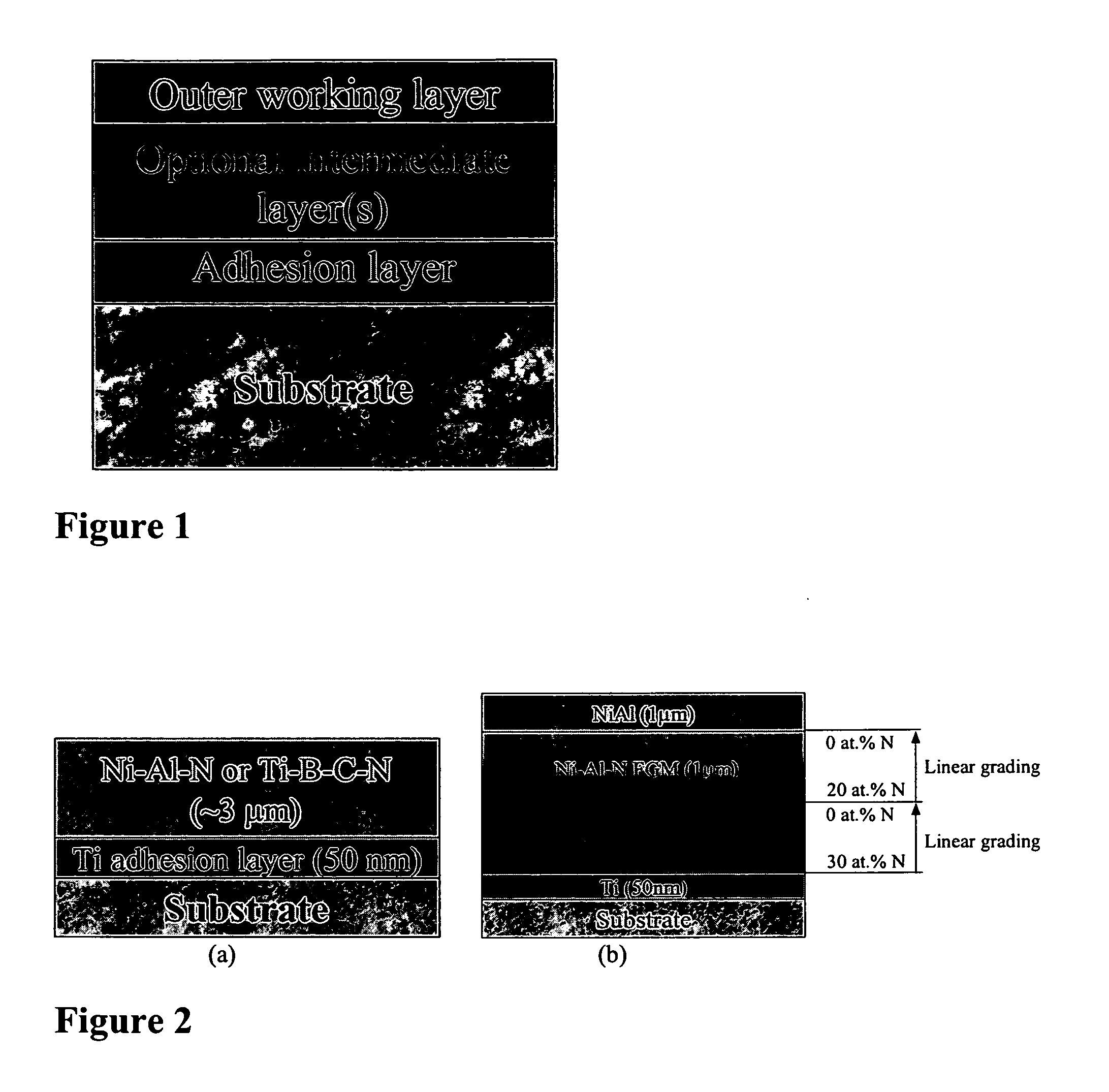

Coatings for glass molding dies and forming tools

InactiveUS20050268662A1Protecting enhancing desirable physical characteristicPigmenting treatmentVacuum evaporation coatingPlatinumCompound (substance)

The invention provides coatings to achieve the best accommodation of chemical, physical, and mechanical properties desired in high performance and reliable glass molding and forming tools. The substrate material can be any ordinary die or tool material such as cast iron, stainless steel, platinum, tungsten carbide and silicon. A simple coating architecture consisting of a titanium adhesion layer and a Ni—Al—N or Ti—B—C—N working layer is provided. A NiAl working layer can meet the requirements of wear resistance in which abrasive and / or erosive wear is relatively low, while a Ti—B—C—N working layer is sufficient for processes operating at relatively low temperature or in vacuum or a protective environment. The coating architectures, from the coating / substrate interface to the outer most surface of the coating include an inner adhesion layer, an outer working layer and, optionally, one or more finctionally graded material layers. The invention also provides methods of making these coatings.

Owner:COLORADO SCHOOL OF MINES

Graphene oxide coated Si3N4 composite powder added Al2O3-based ceramics cutting tool material and preparation method thereof

The invention relates to a graphene oxide coated Si3N4 composite powder added Al2O3-based ceramics cutting tool material and a preparation method thereof. The ceramics cutting tool material is characterized in that Al2O3 is used as a substrate; graphene oxide coats Si3N4 to be used as a reinforcement phase; and MgO, Ni and Mo are used as sintering additives. The preparation method of the ceramicscutting tool material comprises steps such as the step of preparing graphene oxide coated Si3N4 powder, the step of mixing cutting tool material powder, the step of drying and sieving, the step of cold pressing and die filling, and the step of thermally pressing and sintering. The graphene oxide coated SI3N4 composite powder is added into the nano composite ceramics cutting tool material, thus obviously improving the fracture toughness and the flexure strength of the material. According to the ceramics cutting tool material, the defect problems on microstructure, such as air pores which are caused by non-uniform dispersing and particle conglomerating of graphene oxide and nanoparticles in a composite ceramic substrate and other phenomena, and untight combination with the substrate, can beeffectively solved; and meanwhile, the problem of orientation of graphene in the ceramics substrate can be avoided.

Owner:QILU UNIV OF TECH

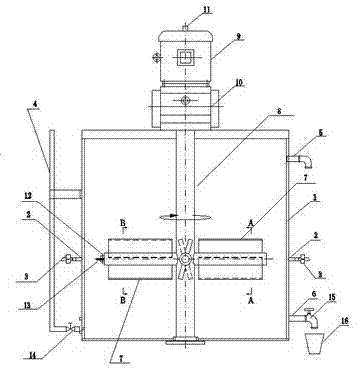

Residue soil improvement experimental device for shield method tunnel construction

InactiveCN102445395AConvenient Quantitative DetectionHigh reference valueFlow propertiesMaterial strength using steady shearing forcesCross connectionEngineering

The invention discloses a residue soil improvement experimental device for shield method tunnel construction, belonging to the technical field of shield method tunnel construction. The experimental device comprises a steel cylinder, stirring blades, a stirring shaft, a motor, a speed reducer, a torque meter, a test block fixing device, a test block and the like, and is partitioned into a test cylinder and a stirring device, wherein four improvement solution injection ports are formed; the stirring blades are uniformly distributed on the wall of the steel cylinder; four stirring blades are crossly connected to the stirring shaft; the tail end of one of the stirring blades is provided with a tool material test block fixing device; the test block is fixed at the tail end of the stirring blade of the test block fixing device; the left lower parts of a connector pipe and a connector pipe valve are connected with the steel cylinder; and the right lower part of a drain pipe valve is connected with the steel cylinder. In the device, the flow plasticity and shearing resistance of residue soil are quantitatively described by measuring the rotary torques of the stirring blades, the permeability coefficient of residue soil is measured by performing a permeation experiment, and the abrasiveness of residue soil on a tool is detected by measuring the abrasion loss of a tool material.

Owner:SHENYANG HEAVY MACHINERY GROUP

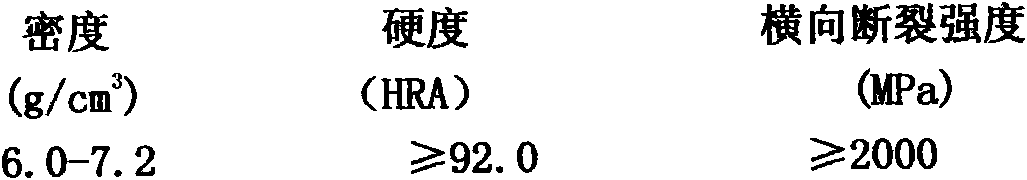

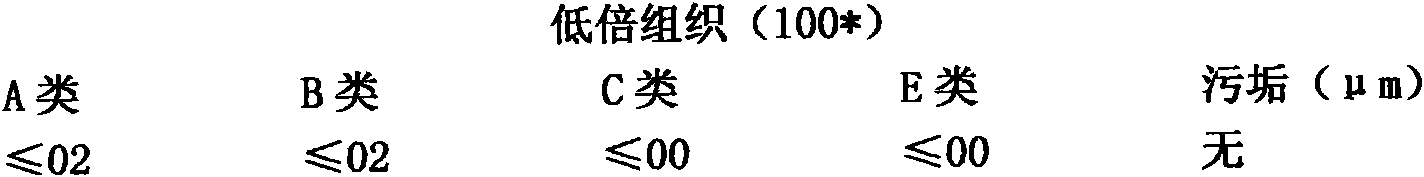

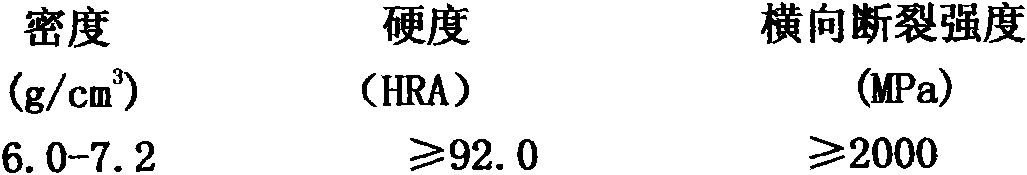

TiCN-base metal ceramic tool material and its microwave sintering process

The invention discloses TiCN-base metal ceramic tool material and its microwave sintering process. The TiCN-base metal ceramic tool material comprises, by weight, 55% to 75% of TiCN, 6% to 24% of Ni, 8% to 15% of WC, and 4% to 15% of Mo2C or Mo4. The 2.45GHz frequency microwave medium is used as a heating source; under the nitrogen atmosphere, the material is sintered. The TiCN-base metal ceramic tool material is higher in compactness, rigidity and breaking tenacity, meets the application requirements and is simple to sinter, high in productivity and low in cost.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing tungsten carbide-zirconium oxide-aluminum oxide composite knife material

The invention belongs to the technical field of material science and relates to a preparation method of a tungsten carbide-zirconia-alumina composite cutting tool material. In the invention, submicron-scale ZrO2 particles and nano-scale Al2O3 powder are added to the sub-micron-scale WC matrix, and the micro-scale VC and TaC particles are used as inhibitors. A new type of composite tool material with ZrO2 and Al2O3 as the matrix as the matrix. By adding submicron ZrO2 particles and nano-Al2O3, the high temperature stability and oxidation resistance of the WC matrix are improved. The composite tool material has high comprehensive mechanical properties, and its hardness, flexural strength, and fracture toughness can reach: 18GPa , 880MPa and 13MPa.m1 / 2.

Owner:SHANDONG UNIV

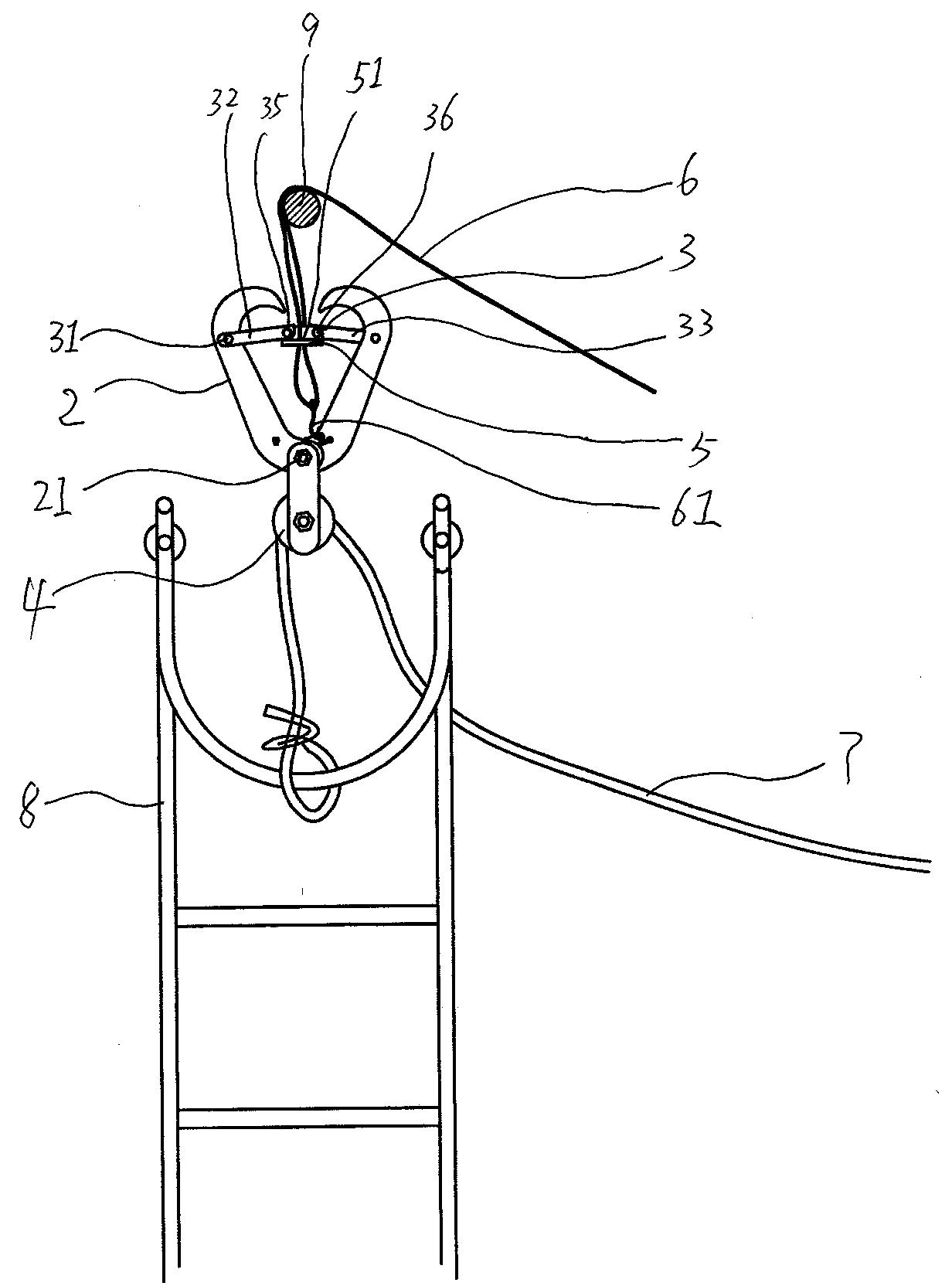

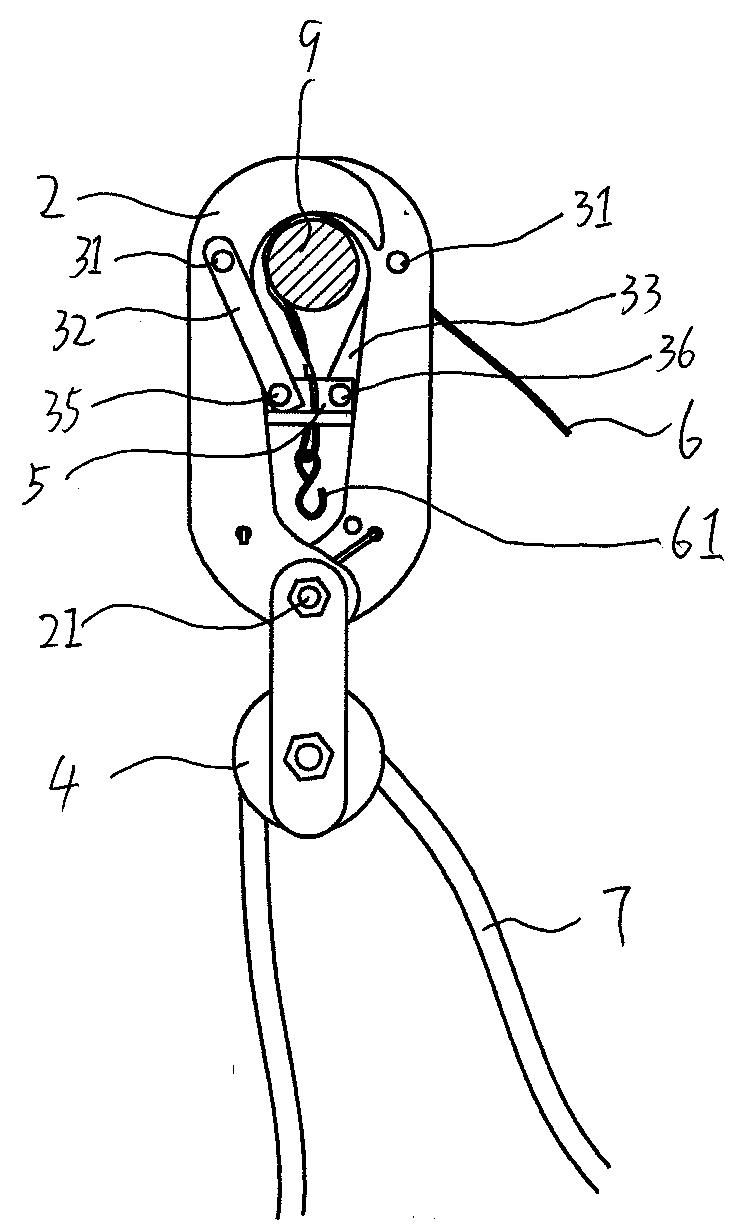

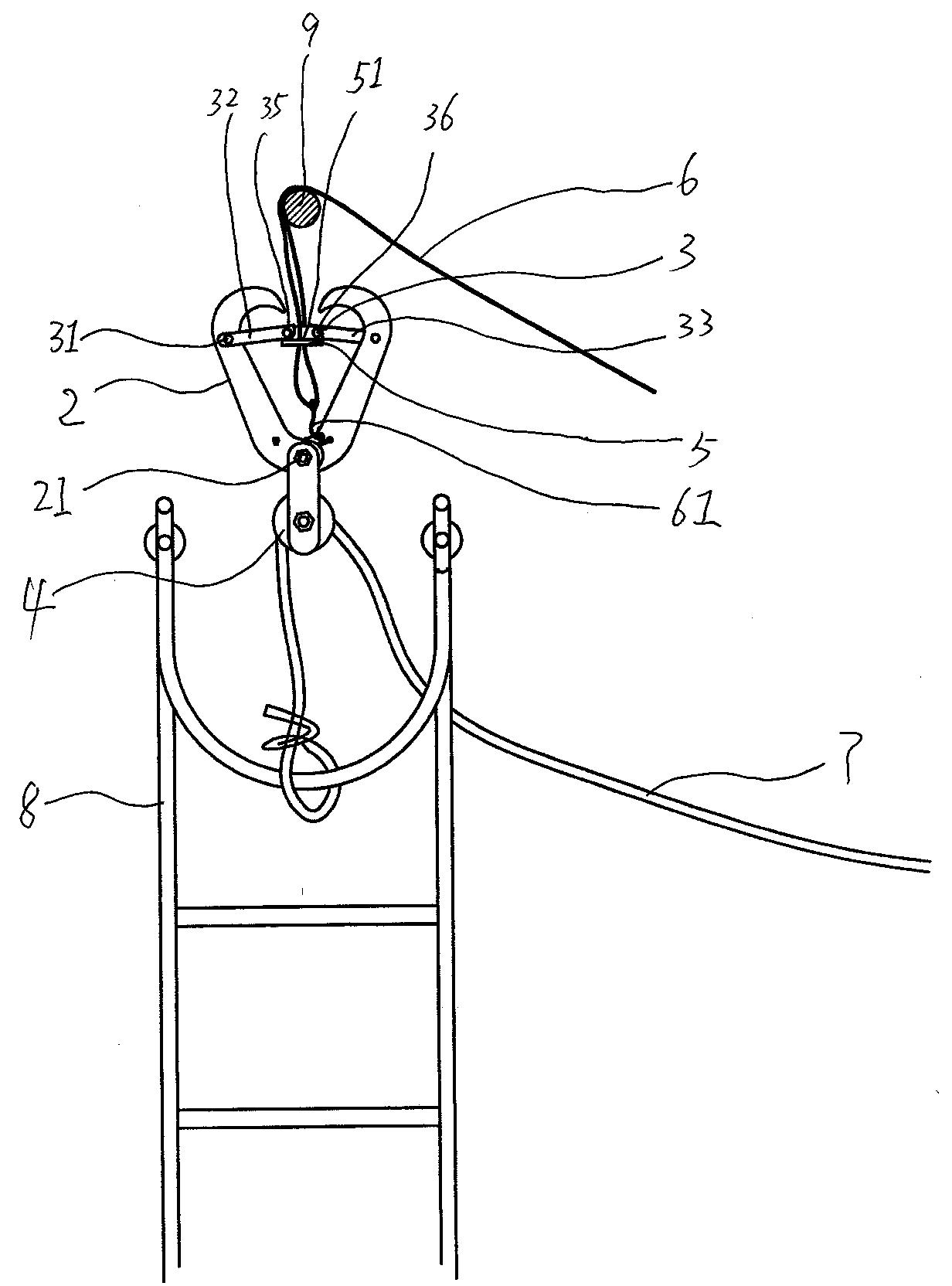

Special pulley for automatic suspension and method for suspending insulating flexible ladder using the same

ActiveCN102064497AEasy to take off and hangUnhook safetyApparatus for overhead lines/cablesTraveling blockPulley

The invention belongs to the technical fields of maintenance accessory appliance used in lead live working and a method for suspending an insulating flexible ladder, and discloses a special pulley for automatic suspension and a method for suspending an insulating flexible ladder using the same. The pulley is mainly characterized by comprising two insulated hooks, a blocking mechanism and an insulating pulley wheel positioned below the insulated hooks, wherein, the two insulated hooks are fixed together by a pin shaft and are oppositely arranged; the blocking mechanism comprises two support rods of which the tail ends are fixed with the inner pin shaft of the insulated hooks; free ends of the two support rods are respectively connected with two ends of a connection rod though pin shafts; the connection rod is equipped with through holes, and a first insulating rope passes through the through holes; the upper end of the first insulating rope is connected with the insulated hooks through a hanger; and a second insulating rope is wound on the insulating pulley, thus more convenience and highersafety can be provided for picking off and suspending. The special pulley for automatic suspension can be applied to suspending the flexible ladder in the case of live working and is also suitable for transferring tool materials in the case of lead working.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

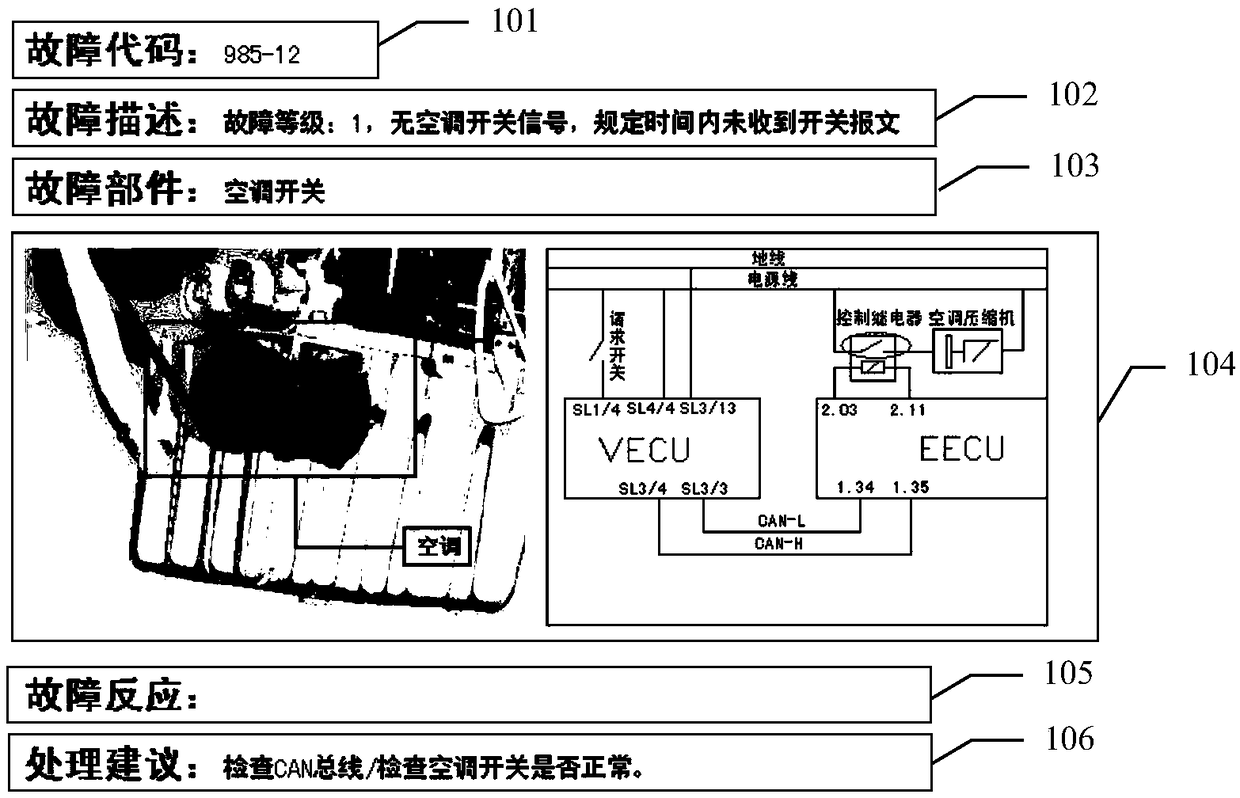

Car diagnostic instrument fault and maintenance suggestion information association and display method

InactiveCN109062191AExpand and enrich expression schemesReduce interpretationElectric testing/monitoringProcess complexityComputer science

The invention relates to the technical field of car diagnosis and discloses a car diagnostic instrument fault and maintenance suggestion information association and display method. On the basis of themethod provided by the invention, a mapping relationship of associated data such as fault information, maintenance information and vehicle models is established; types of the associated data are expanded; expression schemes of a car diagnostic instrument for the fault information can be expanded and enriched; efficiency of the car diagnostic instrument is improved; dependence of a diagnostic instrument user on other tool materials is reduced; online updating and issuing of the fault maintenance information are realized; processing complexity of multi-vehicle model and multi-batch fault information is improved; and fault information reading and fault positioning misjudgment probabilities are reduced.

Owner:WUHAN EUREKA CONTROL SYST CO LTD

Metal ceramic cutting tool material and preparation method thereof

The invention discloses a metal ceramic cutting tool material and a preparation method thereof. The material is prepared from the following powdery raw materials in percentage by weight: 13 to 22 percent of Ni, 10 to 16 percent of Mo, less than or equal to 1.0 percent of Cr2C3, 0.8 to 1.5 percent of C, 5 to 12 percent of WC and the balance of Ti(C,N). The particle sizes of particles of the powdery raw materials for the metal ceramic cutting tool material are matched in an optimal combination way. High-vacuum sintering is adopted in early stages of a preparation process, and low-pressure sintering is adopted within a sintering temperature range. The obtained metal ceramic cutting tool material is high in yield, stable in quality and high in comprehensive performance.

Owner:湖北麦拓新材料科技股份有限公司

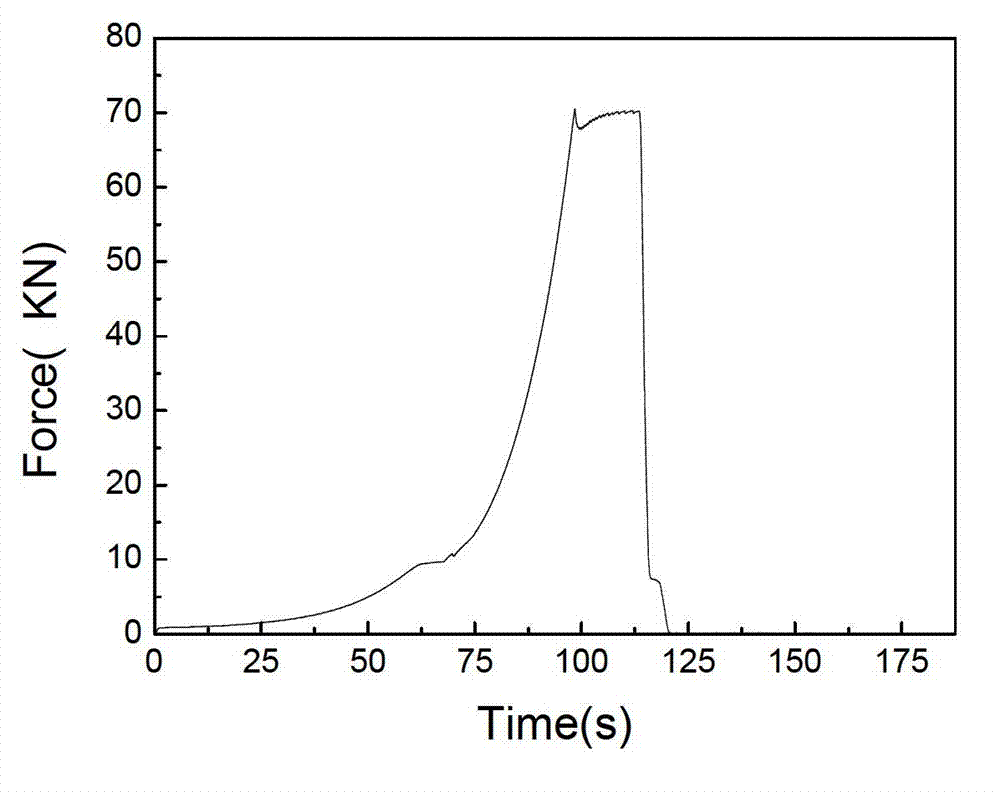

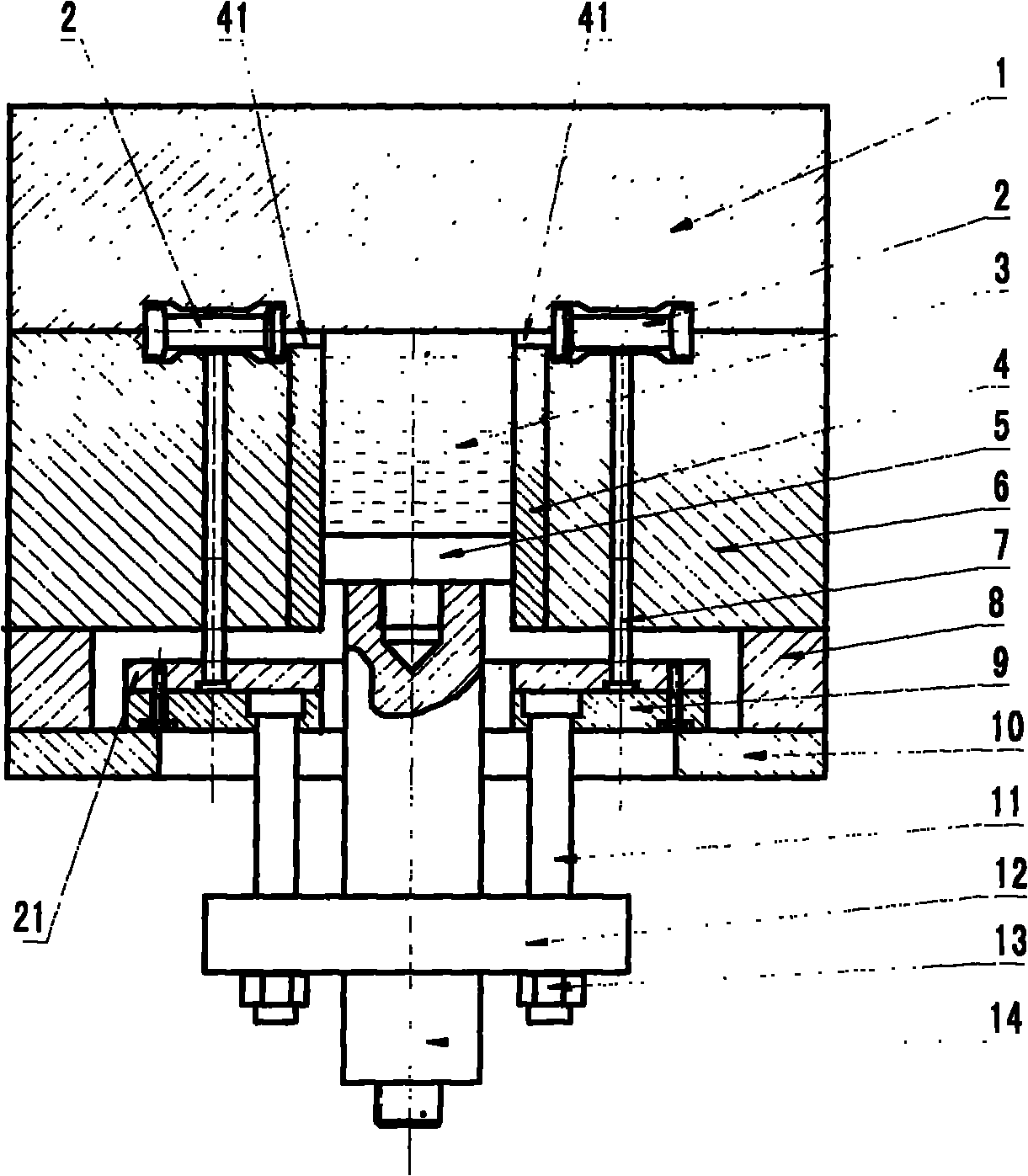

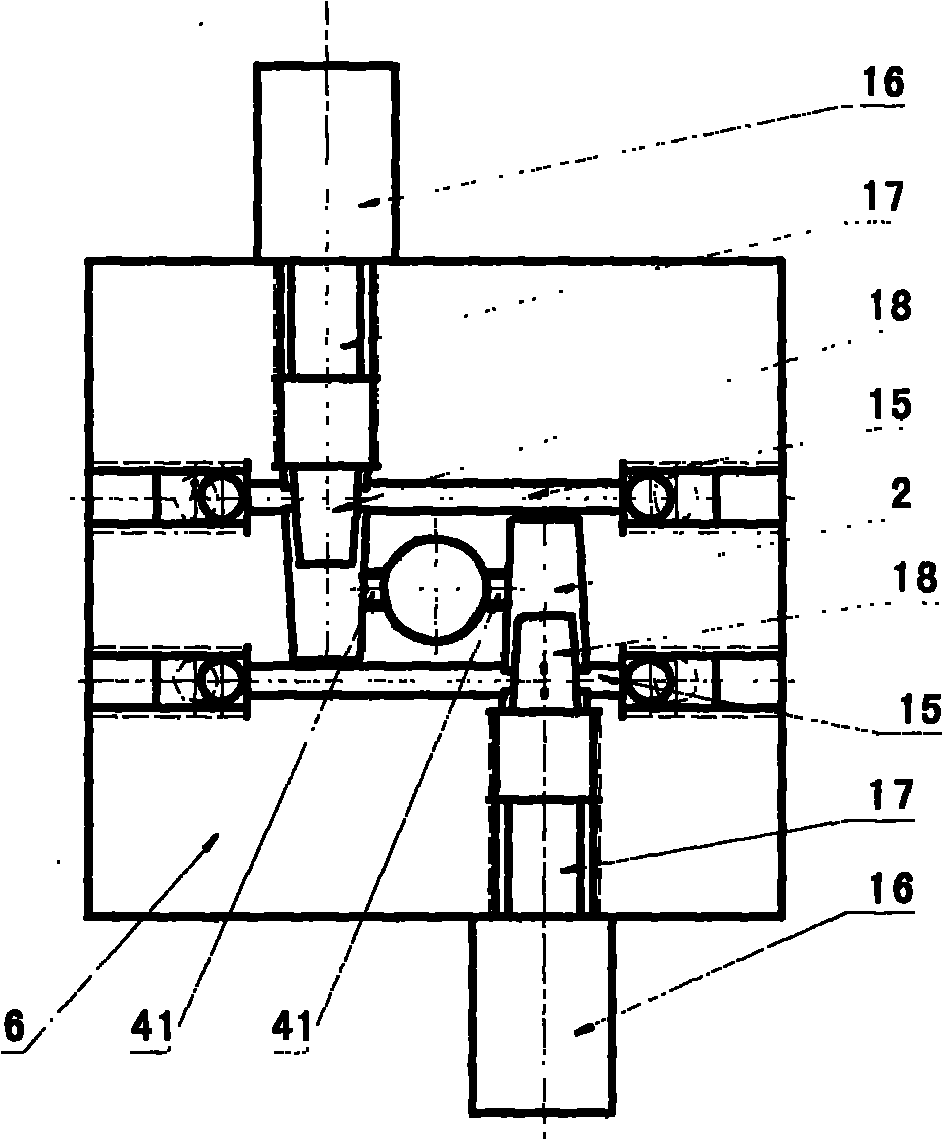

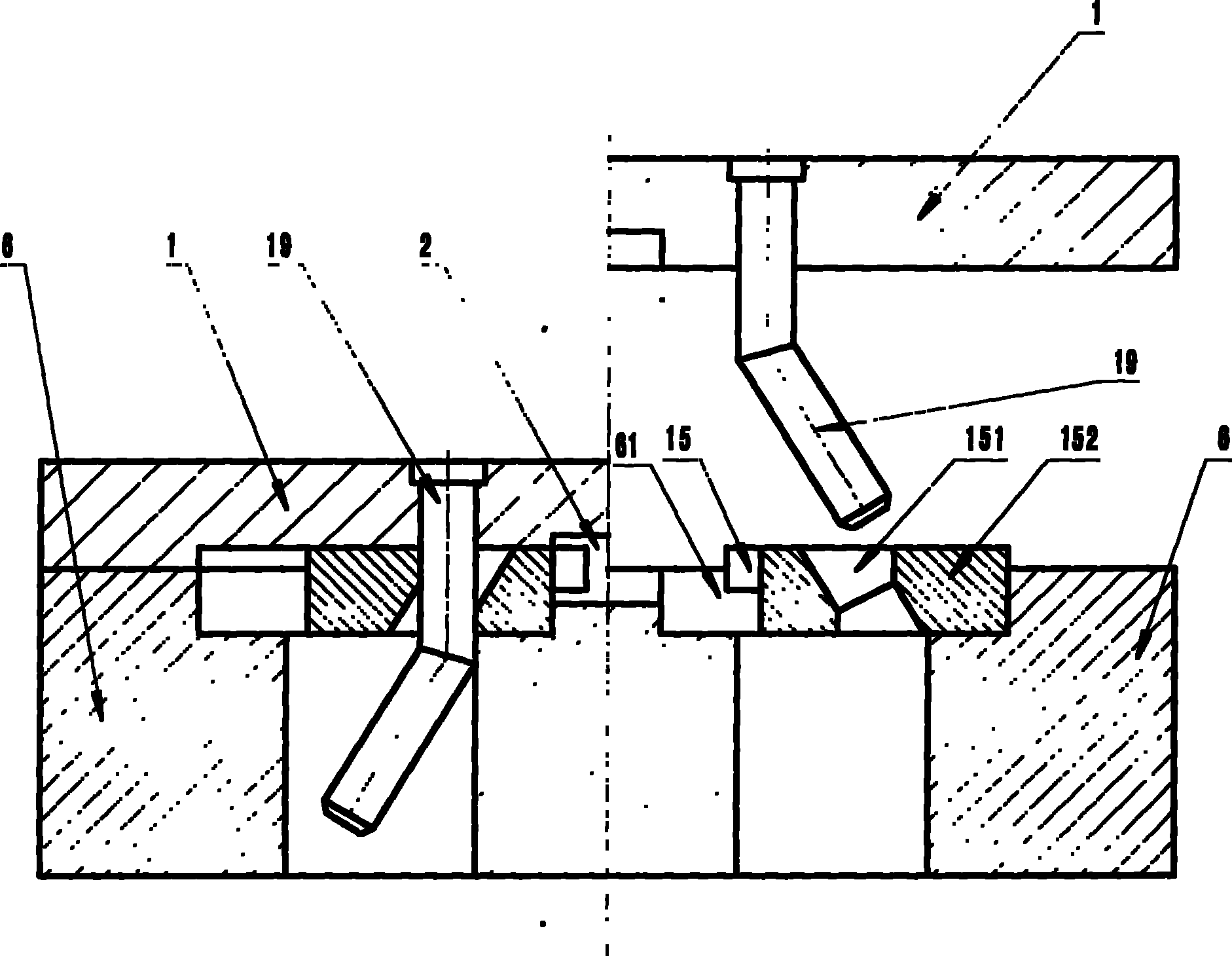

Manufacturing method of bucket tooth and applied mould thereof

The invention provides a manufacturing method of bucket tooth and an applied mould thereof. Liquid bucket tool material is poured into a material storage cavity, a core puller is utilized to push a tooth cavity core and a pin hole core into a bucket tooth mould cavity; an upper mould and a lower mould are closed, and pressure is maintained to be 3000-15000kN; the lower cylinder of a hydraulic cylinder drives a pressure head to push the liquid bucket tooth material in the material storage cavity to be filled with the bucket tooth mould cavity at the linear speed of 10-100m / s, pressure is increased to be 500-5000kN, and pressure is maintained until the material is completely solidified. The core puller is utilized to pull out the tooth cavity core and the pin hole core; the lower cylinder drives a material tray to push an ejector rod to eject the bucket tooth and residue material, heat treatment is carried out, thus obtaining the bucket tooth of the invention; the lower cylinder returns, the material tray pulls the ejector rod and the pressure head to be descended and reset, and next operating cycle is executed. Material utilization is 85-95%, strength is improved by 20-30% compared with a sand-cast bucket tooth, impact toughness is improved by 15-25%, energy consumption is reduced by 20-30%, cost is reduced by 15-30%, and hour output can reach 150 pieces. Qualified bucket tooth can be manufactured without a dead head or sand mould.

Owner:BEIJING JIAOTONG UNIV +1

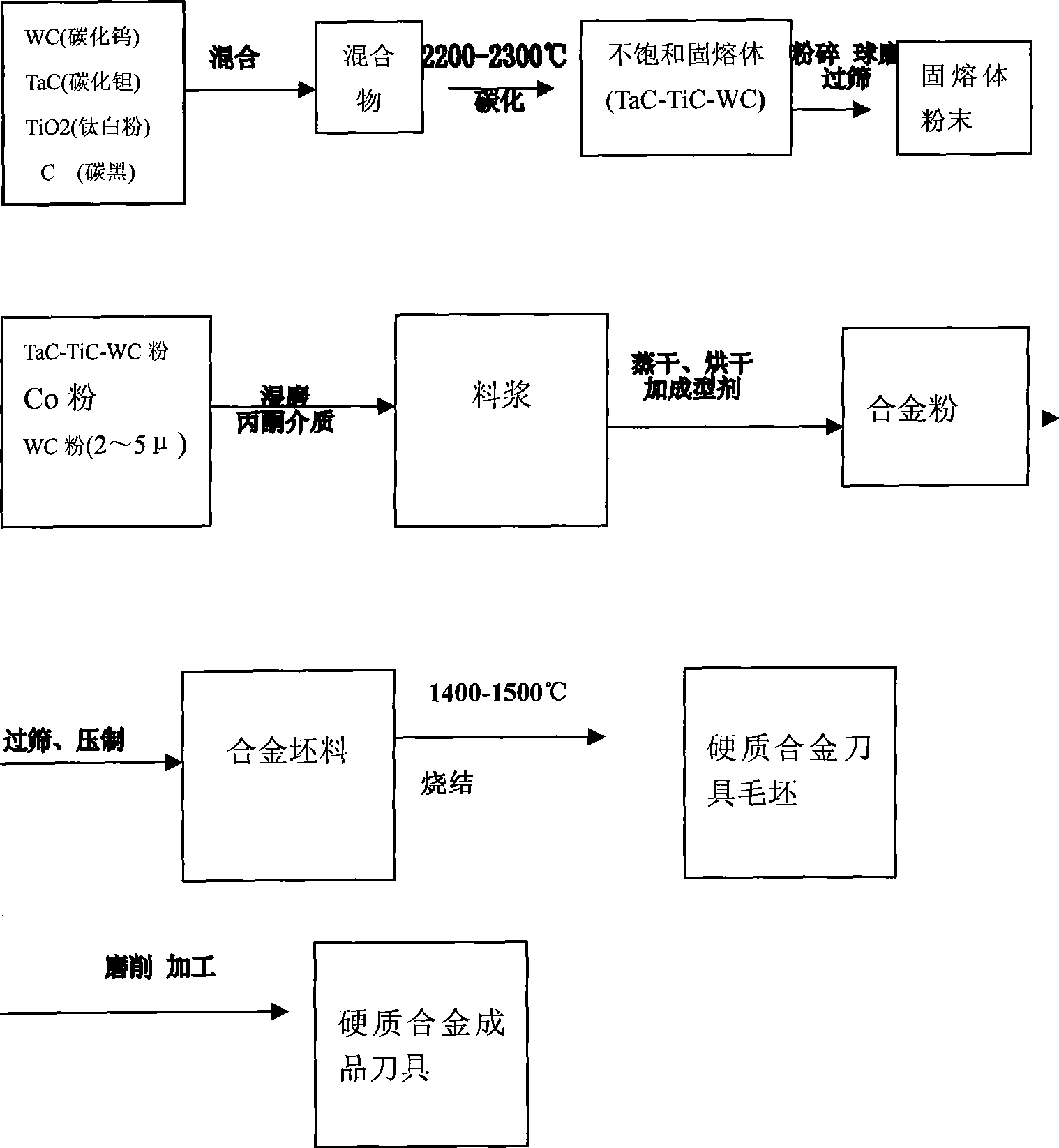

Sintered carbide tool material for processing manganese steel, preparation and use thereof

The invention relates to a hard alloy tool material used for manganese steel processing, a preparation method and applications thereof. The hard alloy tool material contains 6.5 to 20 percent wt of titanium carbide, 6.5 to 20 percent wt of tantalum carbide, 8 to 13 percent wt of cobalt and the balance of 1 to 5 Mu of tungsten carbide. Compared with the existing tool material, the invention has higher thermal fatigue resistance and shock resistance, simultaneously has better front abrasion resistance as well as longer service life when processing manganese steel rails and can improve the durability by 50 to 100 percent compared with the alloy of YW and YT.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com