Sintered carbide tool material for processing manganese steel, preparation and use thereof

A technology of cemented carbide and tool materials, which is applied in the field of cemented carbide tool materials for manganese steel processing and its preparation, which can solve the problems of large cutting force, wear of the front of the tool, and temperature rise, so as to increase the strength and improve the wettability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

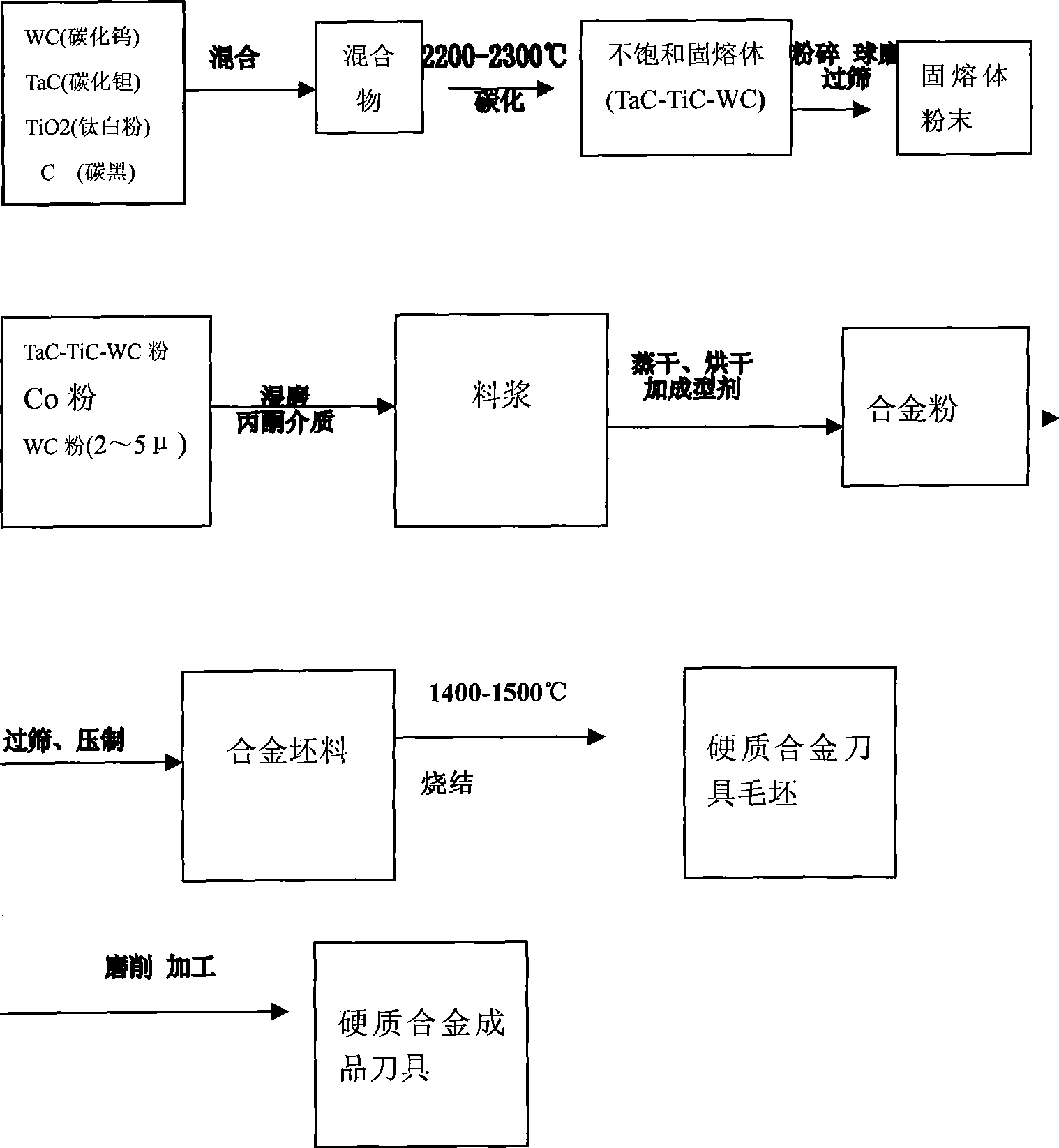

Image

Examples

Embodiment 1

[0019] The rail shaping machine manufactured by GEISMAR company imported from France is equipped with TN35M blades from Vidia, a world-renowned cemented carbide company, and can repair and mill 15-20 standard rails with a length of 25m on average with a single edge.

[0020] The ratio is 20%-40%wt of titanium carbide, 20%-40%wt of tantalum carbide, and 20%-40%wt of tungsten carbide. Mix 150kg of tungsten carbide, tantalum carbide, titanium dioxide (titanium dioxide), and carbon black mixture in a dry ball mill for 5 hours, (the ratio of ball to material is 2:1); carbonize the material in a carbon tube furnace after being loaded into a boat. The carbonization temperature is 2250°C, hydrogen (H 2 ) protection, the speed of pushing the boat is 40min / boat, and then the WC-TiC-TaC ternary solid solution powder is obtained after cooling out of the furnace, crushing, ball milling and sieving.

[0021] According to the final composition ratio (weight) of the alloy: 6.5 to 20% TiC; 6....

Embodiment 2

[0027] A cemented carbide sawtooth for manganese steel processing, according to the final composition (weight) of the alloy: 6.5-20% TiC; 6.5-20% TaC; Ternary solid solution powder, cobalt powder, and tungsten carbide powder are prepared into an alloy according to the proportion of ternary solid solution powder 30%wt, cobalt powder 6%wt, and tungsten carbide powder 59%wt, adding medium acetone 5%wt, and inserting Mix and ball mill in a ball mill (wet type) for 72 hours, discharge, distill, dry and add paraffin wax molding agent. Forming with a mold on a press, and sintering (vacuum furnace, 1430°C, heat preservation for 50 minutes) to obtain a sawtooth blank, and its performance indicators are as follows:

[0028] Grade Density (g / cm 3 ) Hardness (HRA) Flexural Strength (MPa) Porosity

[0029] Five# alloy 12.0~13.0 89.0~92.0 1600~2500 A02B00C00

[0030] After welding and sharpening, the service life is equivalent to that of imported products.

Embodiment 3

[0032] A kind of processing manganese steel carbide milling cutter:

[0033] The ratio is 30%-35%wt of titanium carbide, 30-40%wt of tantalum carbide, and 25-45%wt of tungsten carbide. Thoroughly stir the mixture of tungsten carbide, tantalum carbide, titanium dioxide (titanium dioxide) and carbon black in a dry ball mill for 5 hours (the ratio of ball to material is 2:1); The temperature is 2250°C, under the protection of hydrogen, the speed of pushing the boat is 40 minutes / boat, it is cooled out of the furnace, crushed, ball milled, and sieved to obtain the WC-TiC-TaC solid solution.

[0034] According to the final composition ratio (weight) of the alloy: 8-25% TiC, 8-25% TaC, 9-13% Co, and the balance WC (1-5μ), the ternary solid solution powder, cobalt powder and tungsten carbide powder Prepare the alloy according to the ratio of ternary solid solution powder 20%wt, cobalt powder 13%wt, tungsten carbide powder 47%wt, add medium acetone 20%wt, put into ball mill (wet type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com