TiCN-base metal ceramic tool material and its microwave sintering process

A ceramic tool and microwave sintering technology, which is applied in the field of microwave sintering material science, can solve problems such as insufficient hardness, achieve the effects of improving strength and fracture toughness, inhibiting decomposition, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

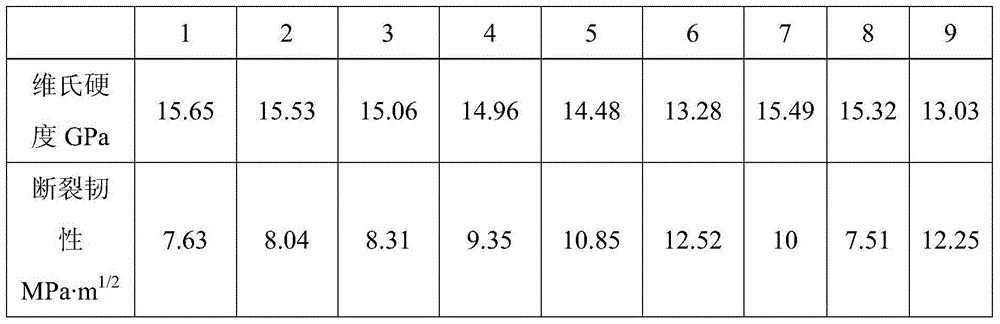

Embodiment 1

[0022] According to the mass percentage of TiCN 69%, Co and Ni 12%, WC 15%, Mo 4%, the prepared mixed powder was mixed by ball milling with absolute ethanol for 48 hours, and the concentration of 5wt% poly Ethylene alcohol aqueous solution granulation, the mass ratio of ball to material is 8:1; after ball milling, drying and grinding, the ground powder is dry-pressed, the pressure is 250MPa, and the holding time is 3min; the formed sample is placed in a microwave sintering furnace During the process, turn on the vacuum pump, evacuate the air pressure in the furnace to a vacuum state, and then fill it with 30kPa nitrogen. Turn on the microwave power supply for heating, heat the sample to 650°C at a heating rate of 80°C / min and hold it for 10 minutes, then heat it to 1550°C at a heating rate of 30°C / min, keep it at this temperature for 10 minutes, and then heat it with the furnace Cool to room temperature. After testing, the Vickers hardness of the material is 15.65GPa (HV20), ...

Embodiment 2

[0024] By mass percentage TiCN 62%, Co and Ni 15%, WC 15%, Mo 2 C 8% for batching, the prepared mixed powder was ball milled with absolute ethanol as the medium for 40 hours, and 5 wt% polyvinyl alcohol aqueous solution was added to granulate 2 hours before the end of ball milling, and the mass ratio of ball to material was 8:1; after ball milling Drying and grinding, the ground powder is dry-pressed, the pressure is 300MPa, and the holding time is 2min; the formed sample is placed in the microwave sintering furnace, the vacuum pump is turned on, the air pressure in the furnace is pumped to a vacuum state, and then filled with 30kPa of nitrogen. Turn on the microwave power supply for heating, heat the sample to 650°C at a heating rate of 80°C / min and hold it for 10 minutes, then heat it to 1550°C at a heating rate of 30°C / min, keep it at this temperature for 10 minutes, and then heat it with the furnace Cool to room temperature. After testing, the Vickers hardness of the mat...

Embodiment 3

[0026] According to the mass percentage of TiCN 62%, Co and Ni 15%, WC 15%, Mo 8%, the prepared mixed powder was mixed by ball milling with absolute ethanol for 36 hours, and 5 wt% poly Ethylene alcohol aqueous solution granulation, the mass ratio of ball to material is 9:1; after ball milling, dry and grind, dry press the ground powder, the pressure is 300MPa, and the pressure holding time is 2min; the formed sample is placed in a microwave sintering furnace During the process, turn on the vacuum pump, evacuate the air pressure in the furnace to a vacuum state, and then fill it with 30kPa nitrogen. Turn on the microwave power supply for heating, heat the sample to 800°C with a heating rate of 100°C / min and keep it for 10 minutes, then heat it to 1550°C at a heating rate of 30°C / min, keep it at this temperature for 0 min, and then heat it with the furnace Cool to room temperature. After testing, the Vickers hardness of the material is 15.06GPa (HV20), and the fracture toughne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com