Patents

Literature

762 results about "Microwave sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave sintering

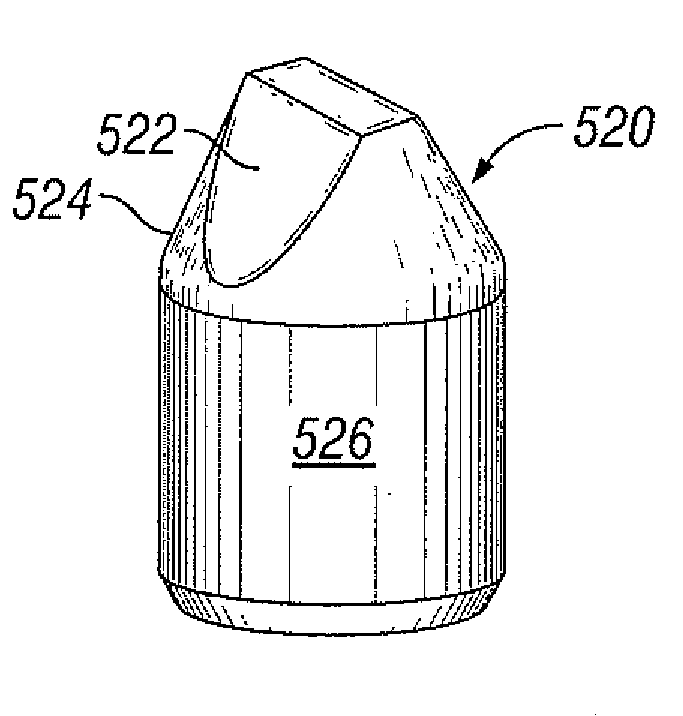

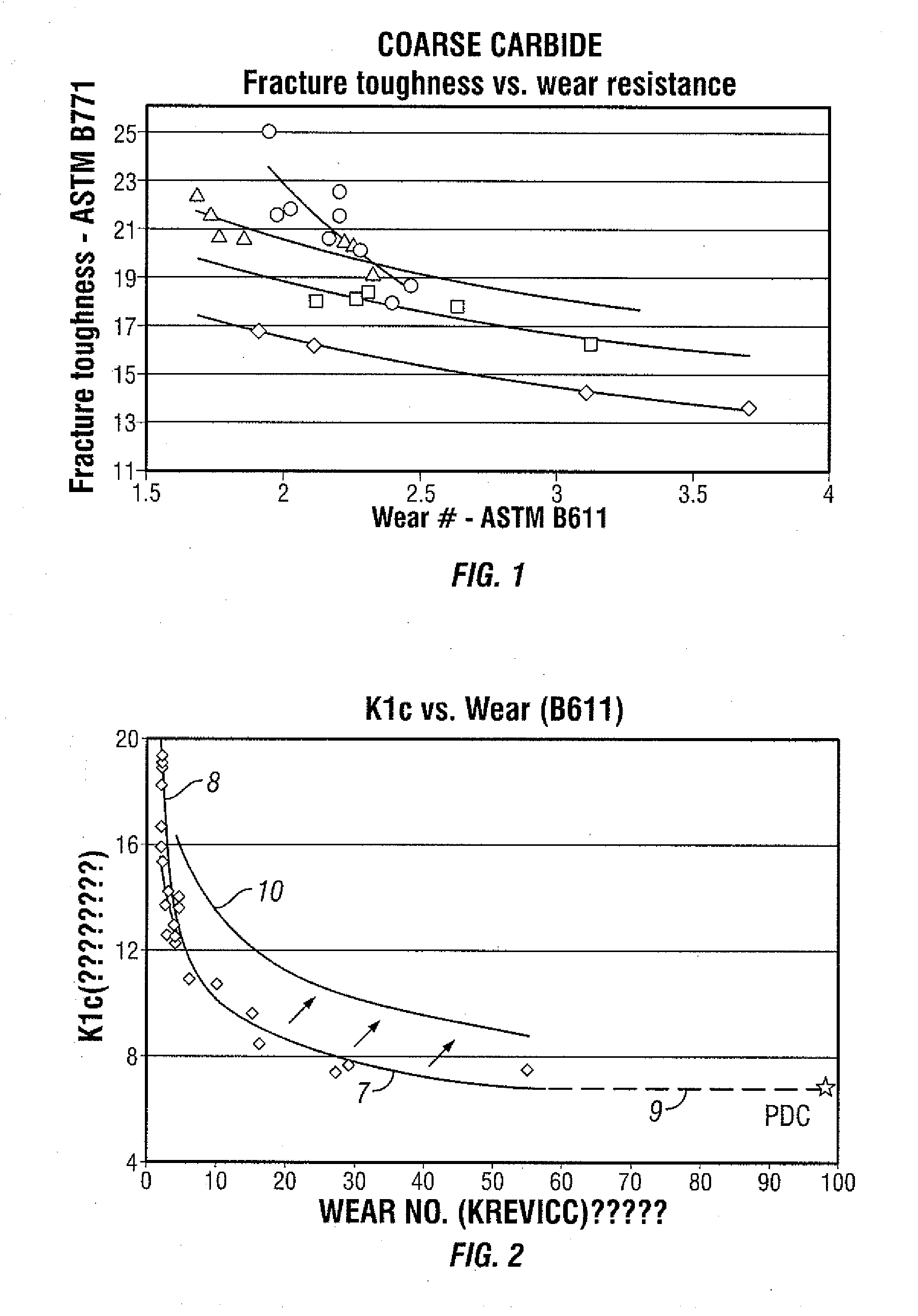

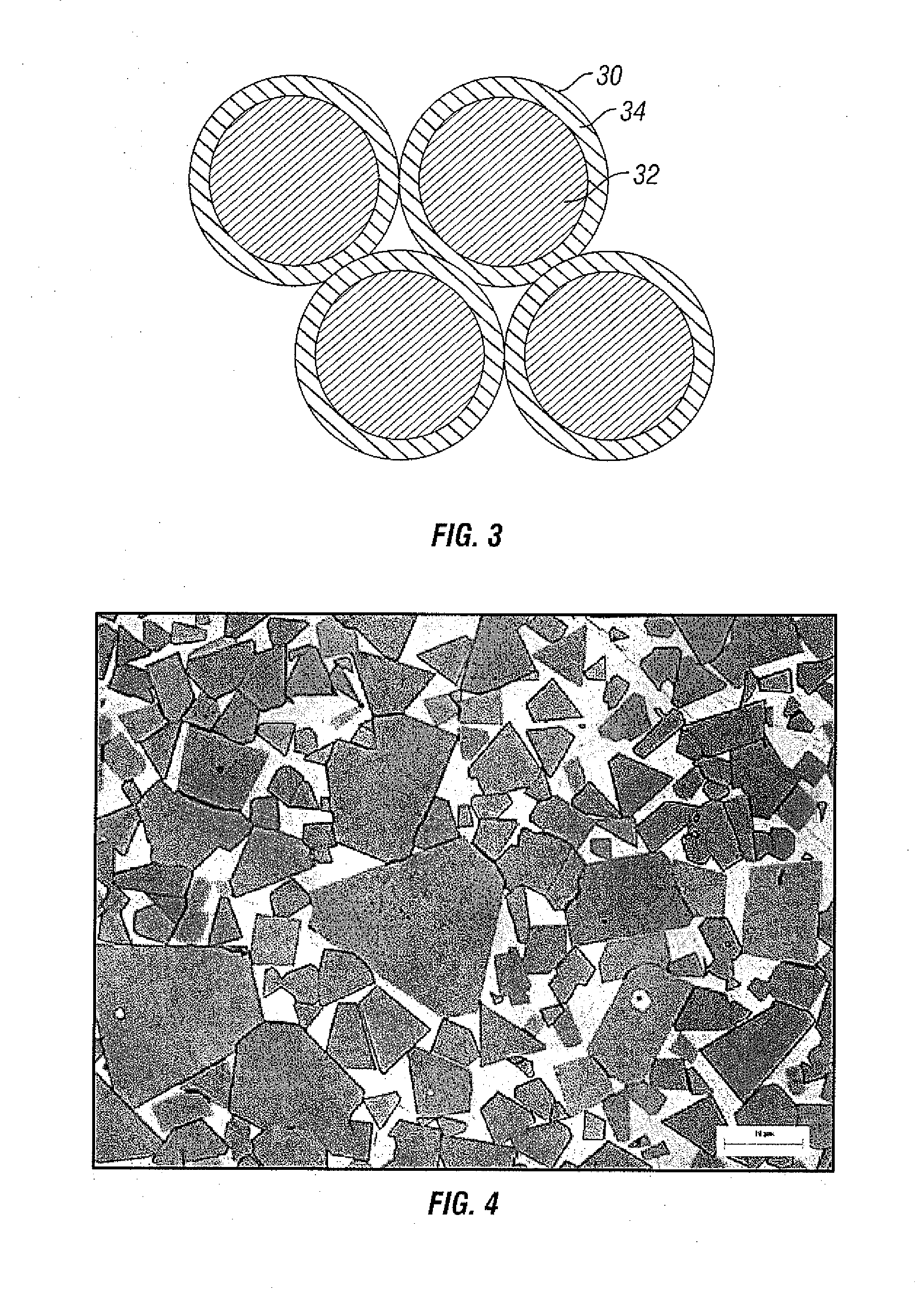

A carbide composite that includes carbide particles having an average particle size of less than about 100 nanometers and a metallic binder disposed around the carbide particles is disclosed. The carbide composite may also include carbide particles having an average particle size ranging from 3 to 10 microns.

Owner:SMITH INT INC

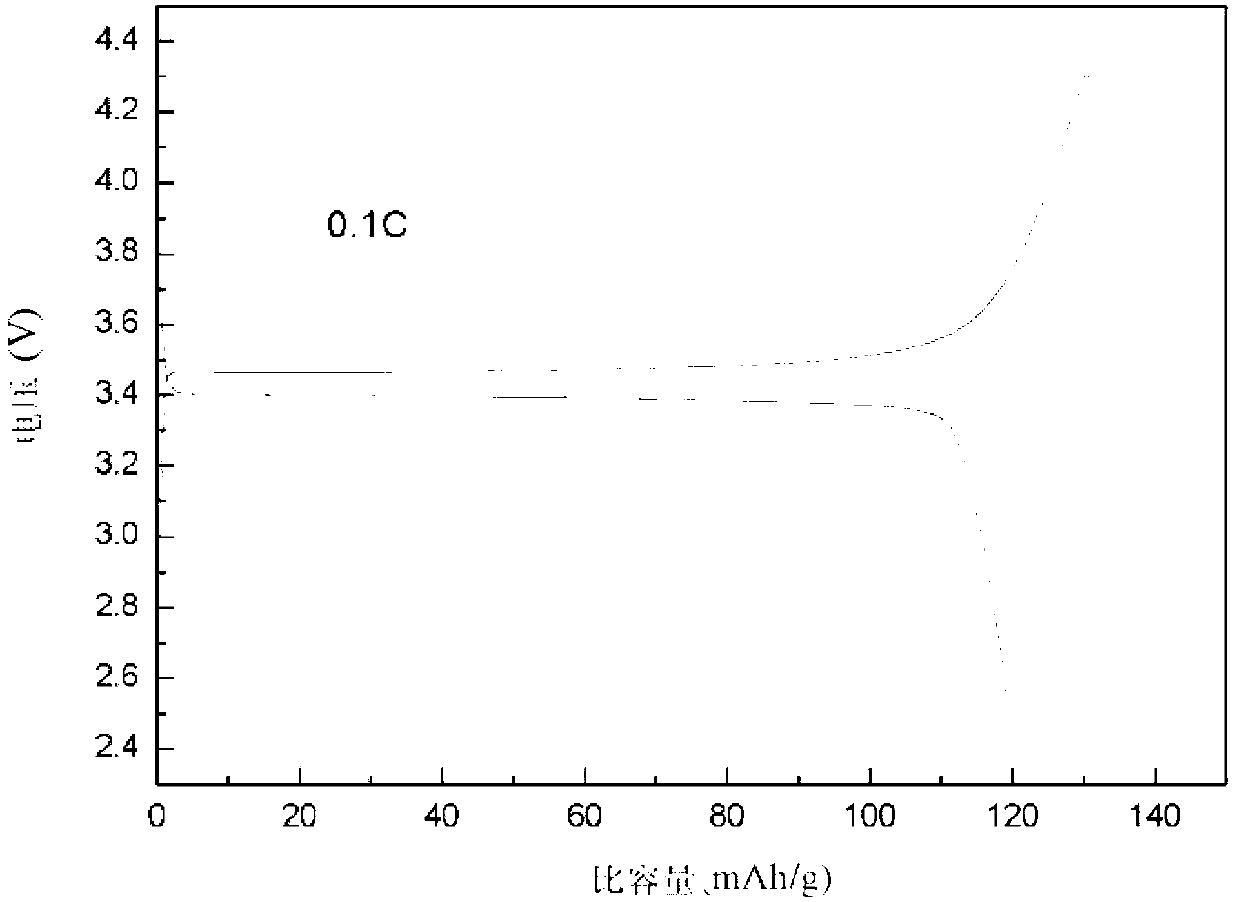

Method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate battery

ActiveCN102751548AEasy to separateImprove electrochemical performanceWaste accumulators reclaimingPhosphorus compoundsLithium iron phosphateHigh energy

The invention discloses a method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate batteries. The method comprises: 1) dismantling the recovered waste lithium iron phosphate batteries, stripping battery cases, immersing the batteries, separating the electrode plates from the powder material of positive and negative terminals through a method of alternation of ultrasonic and mechanical stirring, taking out the electrode plates and diaphragms, and obtaining mixed liquor; 2) performing a preliminary ball milling to the mixed liquor, and drying the uniformly mixed slurry obtained by the preliminary ball milling; 3) calcining the dried material in oxidizing atmosphere to obtain a recovered material, adding iron source, phosphorous source and optionally new lithium iron phosphate, then adding carbon source, high energy ball milling the obtained material, drying the material to obtain a pre-burning material of the recovered material; 4) microwave sintering or solid state sintering the pre-burning material of the recovered material in protective atmosphere to obtain the product of lithium iron phosphate. The preparation method has the advantages of environmental protection, no pollution, simpleness and practicality, high production utilization rate, simple

Owner:ZHEJIANG UNIV

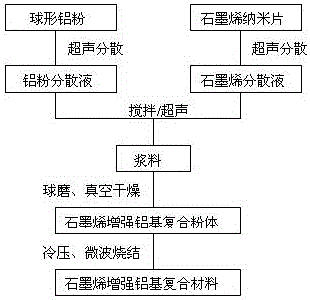

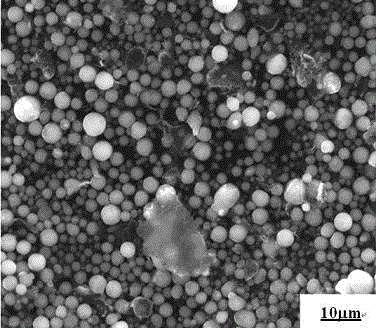

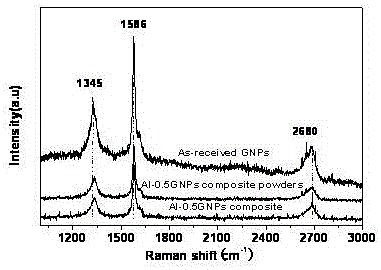

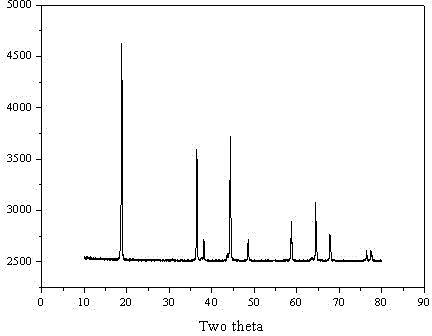

Method for preparing graphene reinforced aluminum matrix composite material by microwave sintering

The invention discloses a method for preparing a graphene reinforced aluminum matrix composite material by microwave sintering, comprising the steps of: taking graphene nano microchips and aluminum powder as raw materials, carrying out ultrasonic treatment to respectively prepare graphene dispersion liquid and aluminum powder dispersion liquid; mixing the two kinds of dispersion liquid, and carrying out low temperature ball milling, vacuum drying, press forming and microwave sintering to obtain the graphene reinforced aluminum matrix composite material with high density, high strength and high thermal conductivity. The method adopts an ethanol ultrasonic dispersion and ball milling combined method to enable the graphene to evenly disperse in the aluminum matrix, and adopts a microwave sintering technology, thus shortening the preparation time and being highly efficient and energy-saving; the production process is safe and pollution-free, and simultaneously the prepared graphene reinforced aluminum matrix composite material has high density and good heat-conducting property.

Owner:NANCHANG HANGKONG UNIVERSITY

Preparation method of medical porous titanium and titanium alloy

InactiveCN102747245AImprove efficiencyGood mechanical propertiesProsthesisThermal insulationRepair material

The invention discloses a preparation method of medical porous titanium and titanium alloy, which comprises the following steps: proportionally preparing titanium powder, alloy element powder and pore forming agent powder according to needs; carrying out ball milling, mixing and mechanical pressing by a powder metallurgy blank making technique to obtain a blank; putting the blank in a thermal insulation barrel, and putting the thermal insulation barrel into a microwave sintering furnace; and after vacuumizing the furnace chamber to a vacuum degree of 0.1Pa, charging argon with the purity of 99.999% to form cyclic protection, controlling the output power of the microwave sintering furnace at 0.5-3kW, heating to the sintering temperature of 800-1200 DEG C at the heating rate of 5-40 DEG C / minute, keeping the temperature for 5-30 minutes, shutting down the microwave source, and carrying out furnace cooling to obtain the medical porous titanium and titanium alloy. The invention has the advantages of simple preparation method, short sintering period, high efficiency, low sintering temperature and low energy consumption; and the sintered porous titanium and titanium alloy have excellent mechanical properties, and can be used as alternate repair material for bones, joints, artificial radix dentis and other hard tissues.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

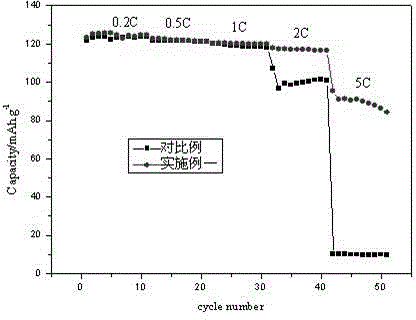

Lithium manganate composite positive electrode material, a preparing method thereof and a lithium-ion battery

ActiveCN104347853AHigh specific capacityCapacity decaySecondary cellsPositive electrodesManganeseManganate

The invention provides a lithium manganate composite positive electrode material, a preparing method thereof and a lithium-ion battery. The composite positive electrode material is of a core-shell structure. The inner layer of the composite positive electrode material is an in-situ composite of lithium manganate and nickel-rich concentration gradient type nickel cobalt manganese / lithium aluminate LiMn2O4-LiNi1-x-yCox(Al / Mn)yO2, wherein x is more than 0 and less than or equal to 0.25, and y is more than 0 and less than or equal to 0.15; the outer shell of the composite positive electrode material is a metal oxide coated layer. According to the lithium manganate composite positive electrode material and the preparing method thereof, the in-situ composite of lithium manganate and nickel-rich concentration gradient type nickel cobalt manganese / lithium aluminate is obtained after in-site sintering of a manganese source, a nickel-rich concentration gradient type nickel cobalt manganese / lithium aluminate precursor, and a lithium source, then shell-layer metal oxide is cladded by using spray drying, and finally the composite positive electrode material is obtained by combining a microwave sintering process. The composite positive electrode material provided by the invention has relatively high specific capacity, and excellent high temperature cycling and storage performances.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

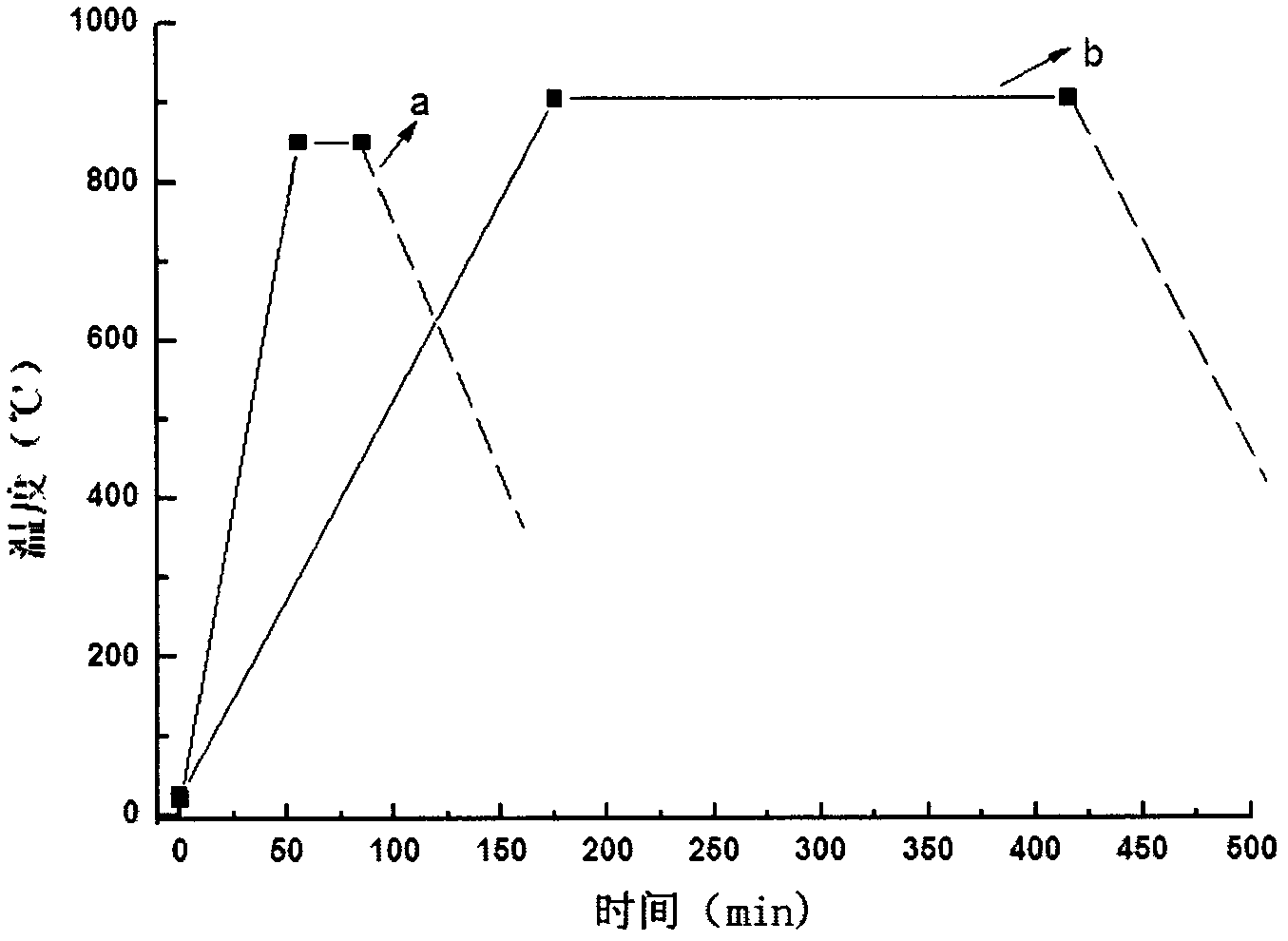

Method for preparing medical porous NiTi shape memory alloy by microwave sintering

The invention relates to a method for preparing a medical porous NiTi shape memory alloy by microwave sintering. The method comprises the following steps of: (1) compounding powder: compounding titanium powder, nickel powder and pore-forming agent powder according to certain mass percentage; (2) performing ball milling: putting the compounded powder body into a stainless steel ball milling pot for ball milling; (3) pressing billets: performing mold pressing on the powder materials after the ball milling at the pressure of between 50 and 500 MPa into pressed billets; (4) charging in a furnace:putting the obtained pressed billets and a microwave auxiliary heating material into a polycrystalline mullite fiber heat insulation barrel, and putting the heat insulation barrel into a microwave sintering furnace; and (5) performing microwave sintering. The method has the advantages that: the preparation method is simple and convenient, the sintering cycle is short, the energy consumption is low, the method is suitable for industrialized production, the porous NiTi shape memory alloy obtained by sintering has good mechanical properties, a pore structure is in three-dimensional communication, the pore ratio is controllable between 20 and 80 percent, the pore sizes are uniform and are controllable between 30 and 600 mu m, and the medical porous NiTi shape memory alloy can be used as materials for repairing and replacing hard tissues such as bones, joints, artificial tooth roots and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

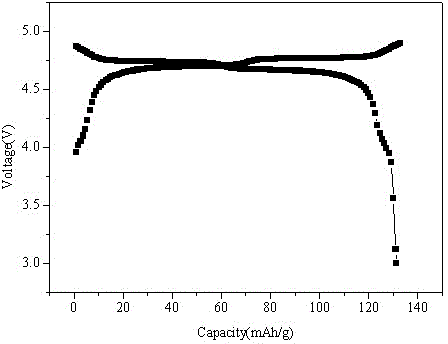

High voltage lithium ion battery cathode material and preparation method thereof

InactiveCN103332754AImprove uniformityImprove electrochemical performanceCell electrodesNickel compoundsNickel saltManganese

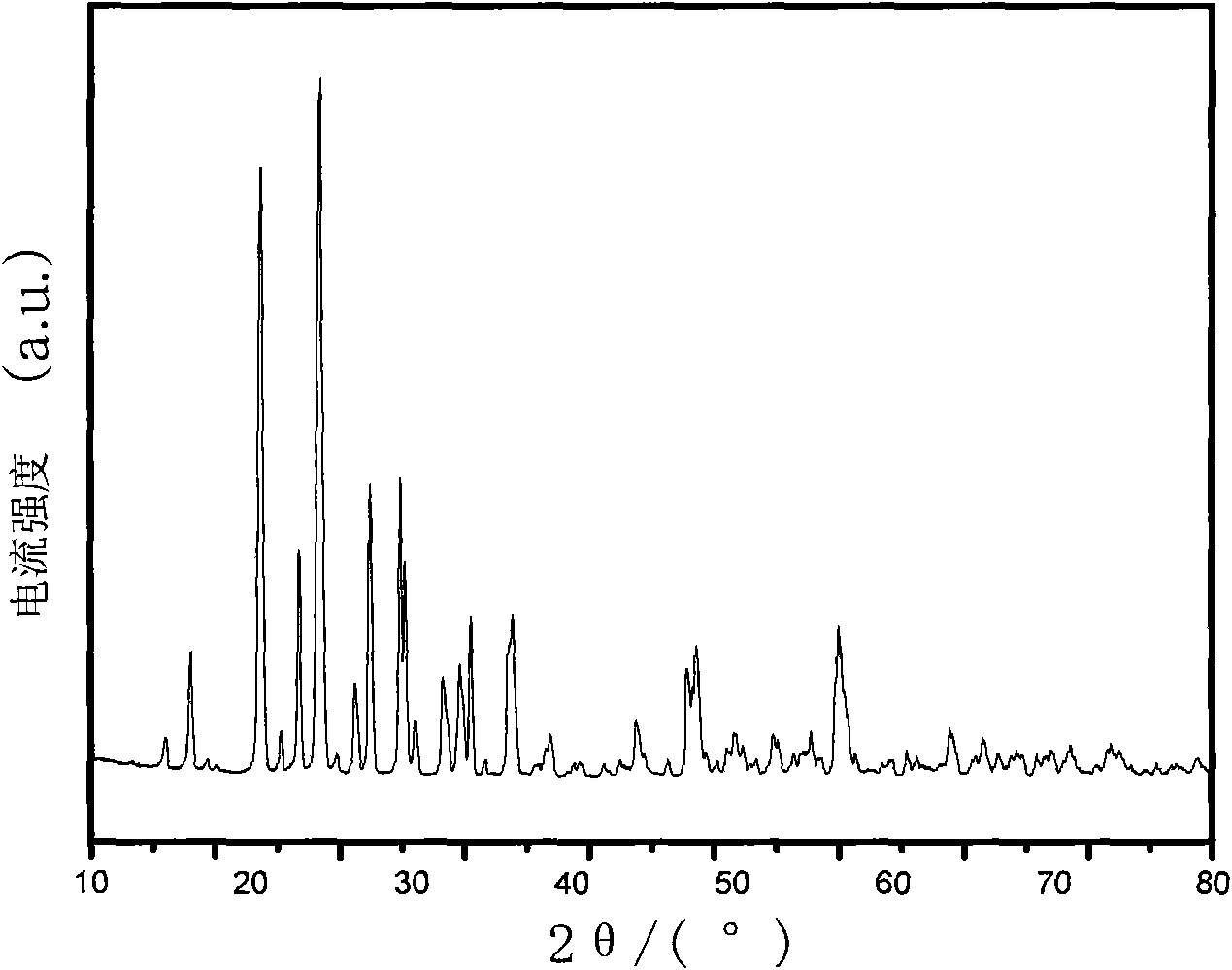

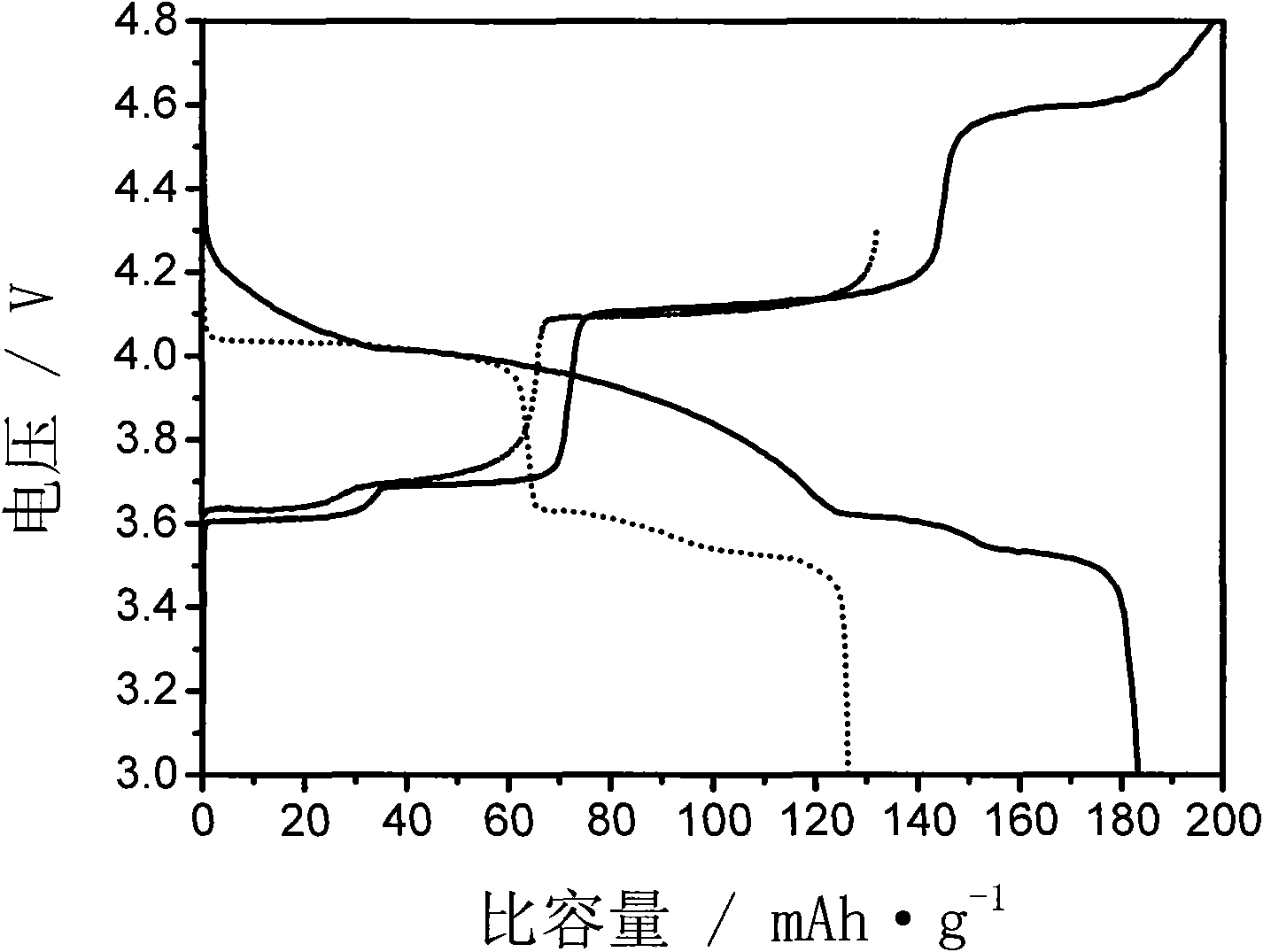

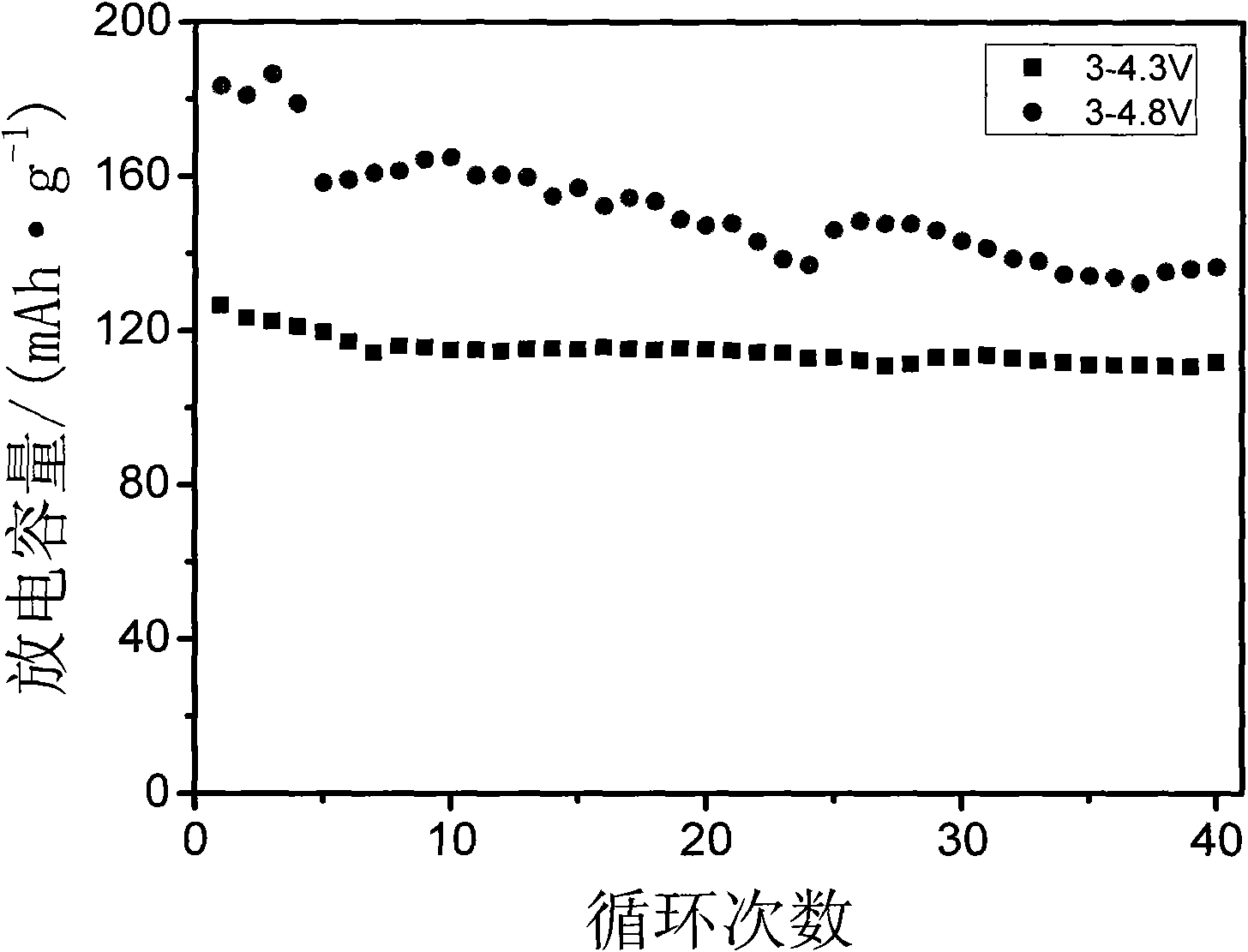

The invention provides a high voltage lithium ion secondary battery cathode material, which is represented by a general formula LiNi0.5-xMn1.5-yMx+yFzO4-z. Specifically, M is one or several elements of Mg, Cr, Ti, Co, Al, Fe, Zn and Cu, x is greater than or equal to 0 and smaller than or equal to 0.1, y is greater than or equal to 0 and smaller than or equal to 0.2, Z is greater than or equal to 0 and smaller than or equal to 0.2. The invention also provides a preparation method of the cathode material. The method includes: firstly employing a coprecipitation technique to generate a carbonate precursor of a nickel salt, a manganese salt and an M salt, then mixing the precursor with a lithium salt and LiF, performing ball milling, and carrying out fast microwave sintering to obtain the sample LiNi0.5-xMn1.5-yMx+yFzO4-z. The preparation method has the advantages of simple and controllable production process, short heating time, and low energy consumption, thus being suitable for large-scale industrial production. In the invention, an anion-cation composite doping way is adopted, the advantages of anions and cations are utilized comprehensively, and simultaneously their disadvantages can mutually offset, and the generated synergistic effect can improve the battery performance. The material prepared by the invention has completely developed crystal grains with moderate and uniform size, and has the advantages of high voltage, high capacity, excellent rate performance and high temperature cycle performance, etc.

Owner:WHOLE WIN BEIJING MATERIALS SCI & TECH

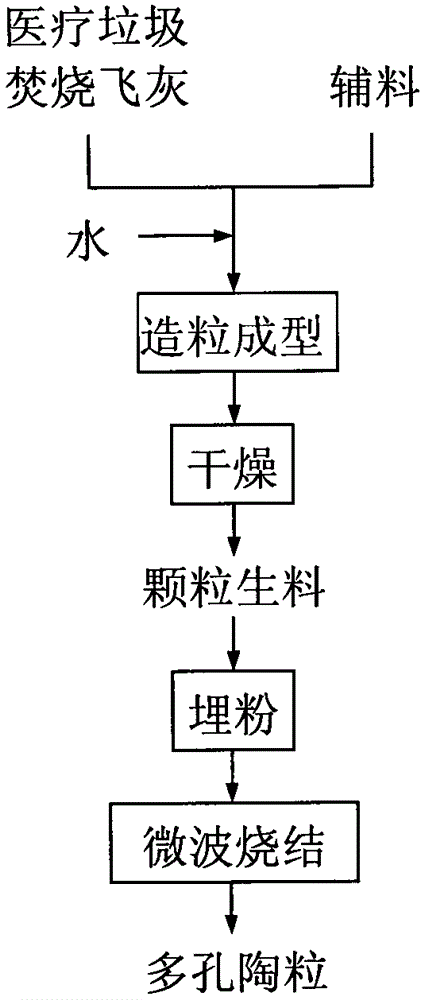

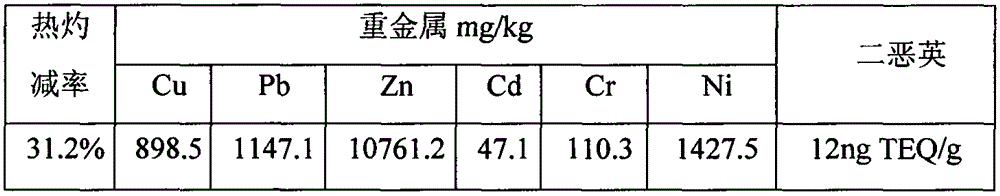

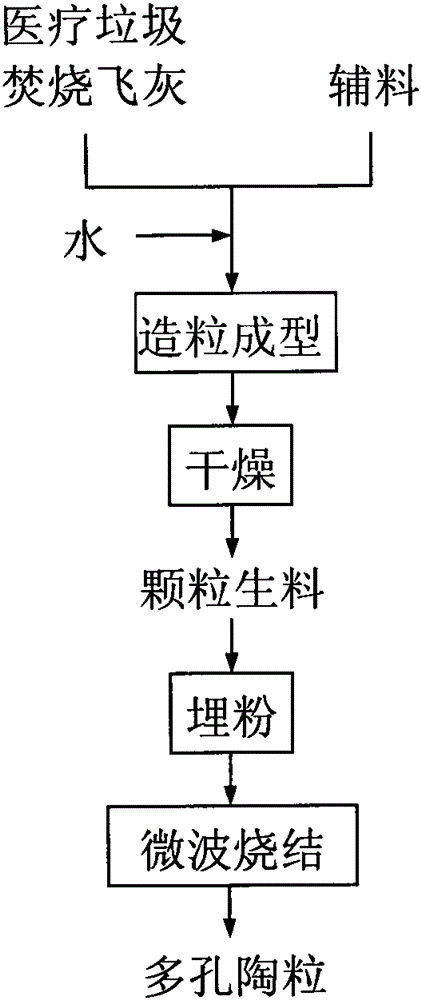

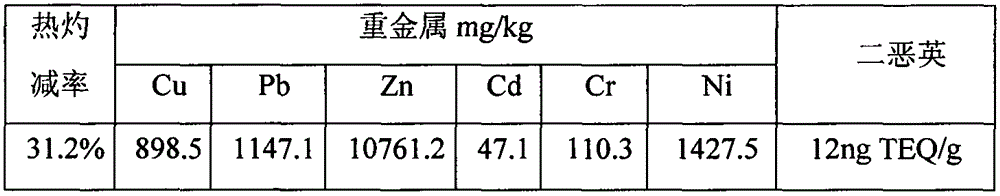

Method for microwave firing of porous ceramsites by adopting medical waste incineration fly ash

The invention discloses a method for microwave sintering of porous ceramsites by adopting medical waste incineration fly ash. The method comprises the following steps: (1) fully mixing the medical waste incineration fly ash with an auxiliary material, adding a small amount of water into the mixture, and carrying out granulation molding by a molding machine; (2) carrying out granulation molding, drying to obtain a particle raw material, filling the periphery of the particle raw material with a microwave coupling agent powder; and (3) carrying out microwave sintering of the particle raw material filled with the powder, and after sintering, cooling to the room temperature to obtain the porous ceramsites. The method can utilize a 'hot spot' effect of fly ash high-content active carbon in a microwave field to instantly completely decompose dioxins in the fly ash, at the same time, allows most heavy metals to be wrapped and cured in grids of the sintered product, and rapidly sinters the fly ash into the porous ceramsites; and the ceramsites can be used for building aggregates or wastewater filter materials, achieves further resource utilization while achieving harmlessness treatment of the medical waste incineration fly ash, and achieves many things at one stroke.

Owner:TIANJIN CHENGJIAN UNIV

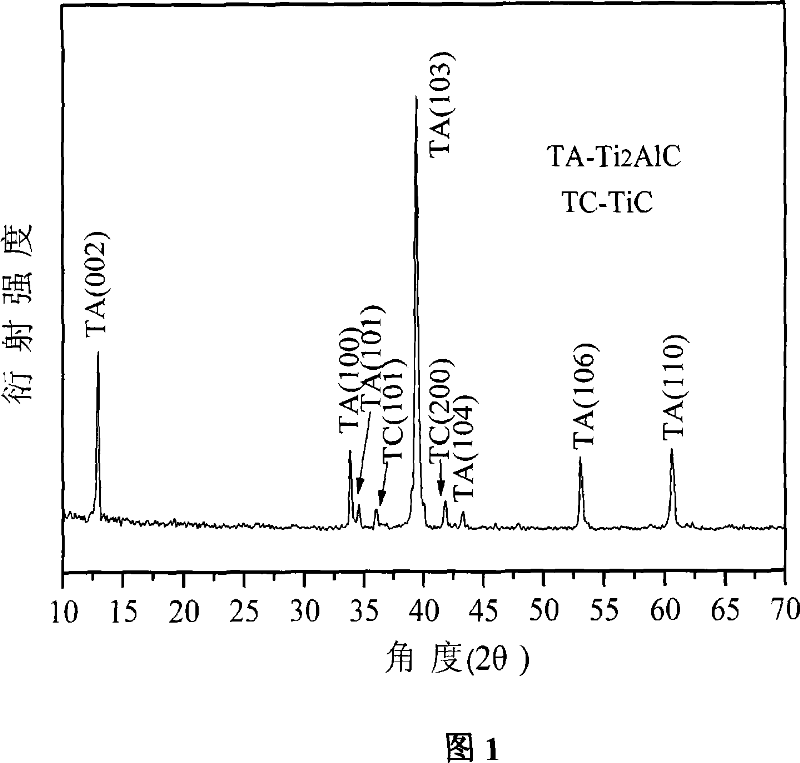

High-purity Ti2AlC powder material and preparing method thereof

The present invention discloses a high pure Ti2AlC powder material and a preparation method of the same. The powder material comprises Ti powder, TiC powder, Al powder and active carbon powder, wherein the mol ratio of which is n(Ti):n(TiC):n(Al):n(C)=(1.15~1.95):(0.5~0.95):1:(0.15~0.95). The preparation method comprises the steps of: feed weighing according to compounding ratio; mixing the raw material powder evenly; tabletting the mixed raw material and putting into the chamber of the microwave sintering device, and sintering in the presence of argon gas; obtaining the powder material after natural cooling. The powder material of the present invention has high purity and small crystal grain. The preparation process has simple raw material, adequately uses the characteristics of microwave sintering technology and the advantages of self-propagating reaction, and has a short synthesis time; besides the Ti2AlC powder material has a high purity, is adapted to industrial production. The application of the material is greatly improved.

Owner:WUHAN UNIV OF TECH

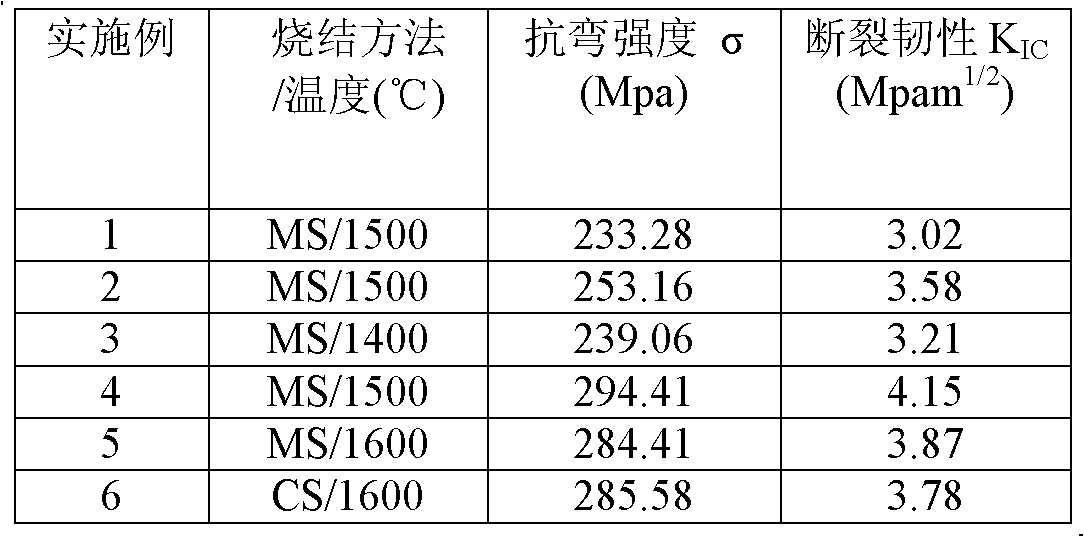

High strength and toughness 3Y-TZP composite ceramic and preparation method thereof

The invention discloses a high strength and toughness 3Y-TZP composite ceramic and a preparation method thereof. The 3Y-TZP composite ceramic consists of 3Y-TZP, a SiC crystal whisker and Sr2Nb2O7; and the preparation method of the 3Y-TZP composite ceramic comprises the steps of preparing and mixing Sr2Nb2O7 powder, ball milling, profiling, degumming and sintering. The composite ceramic is obtained by sintering the SiC crystal whisker and a Sr2Nb2O7 ferroelectric material second-phase addictive which are introduced into the 3Y-TZP. The ceramic material with high strength and toughness can be obtained by adjusting the contents of the SiC crystal whisker and the Sr2Nb2O7 and optimizing a microwave sintering process under the synergistic effect of reinforcing by the SiC crystal whisker and toughening by the Sr2Nb2O7 piezoelectric second phase. The invention has reasonable components and simple preparation process and simultaneously achieves the effects of strengthening and toughening by adopting a synergistic technology of reinforcing by the SiC crystal whisker and toughening by the Sr2Nb2O7 piezoelectric second phase. In addition, the invention is applicable for industrial production, effectively improves the mechanical property of the 3Y-TZP ceramic and widens the application field of the 3Y-TZP ceramic.

Owner:CENT SOUTH UNIV

Fast microwave sintering process of combined silicon nitride-silicon carbide refractorg material

The present invention relates to refractory material technology. By means of the fast homogeneous heating of microwave to material and reaction promoting effect of microwave field on nitriding reaction, homogeneously mixed silicon nitride, silicon powder and small amount of organic adhesive pressed into blank, stoved and defatted are heated with microwave of industrial microwave source of 900-3000 MHz frequency to 1100-1500 deg.c under the nitrogen atmosphere for nitriding reaction and sintering to densify. After cooling naturally to room temperature, combined refractory silicon nitride-silicon carbide material in specific shape and with bulk weight 2.65-2.80 g / cu cm, compression strength higher than 250 MPa, bending strength higher than 60 MPa, porosity lower than 15 % and excellent heat shock resistance is prepared.

Owner:TSINGHUA UNIV +1

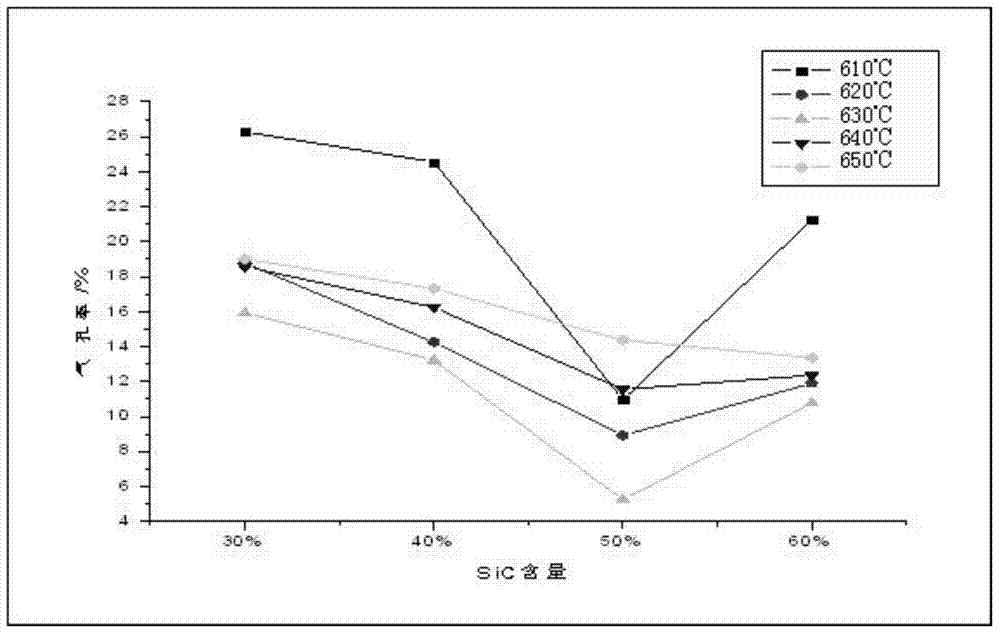

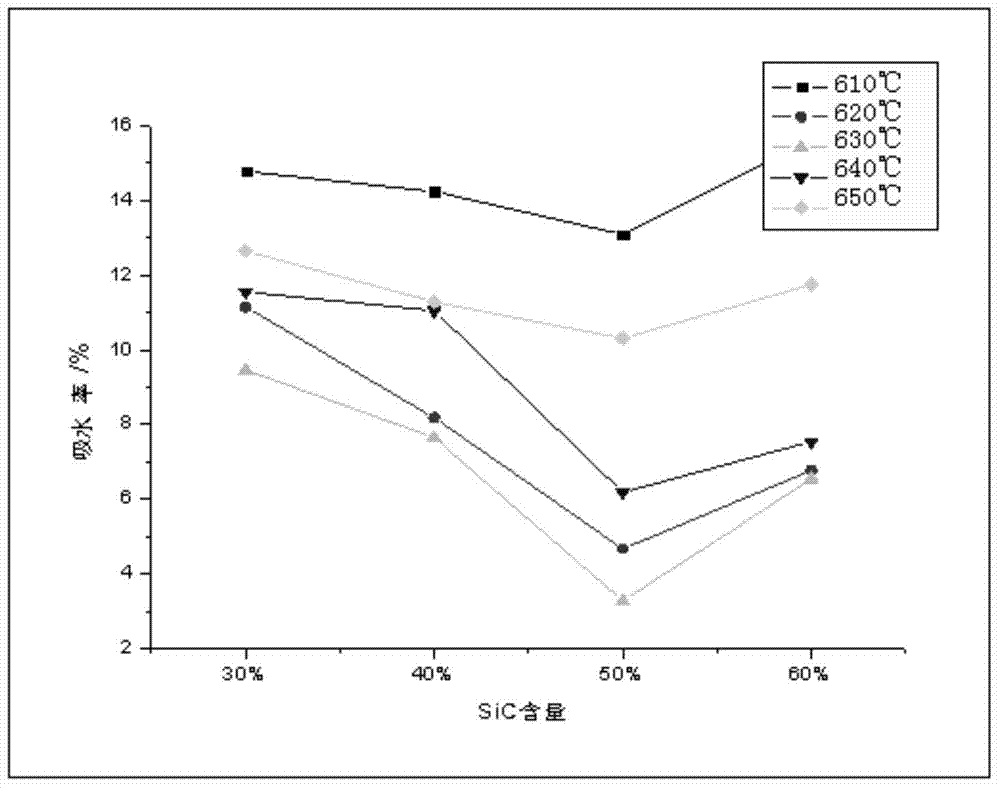

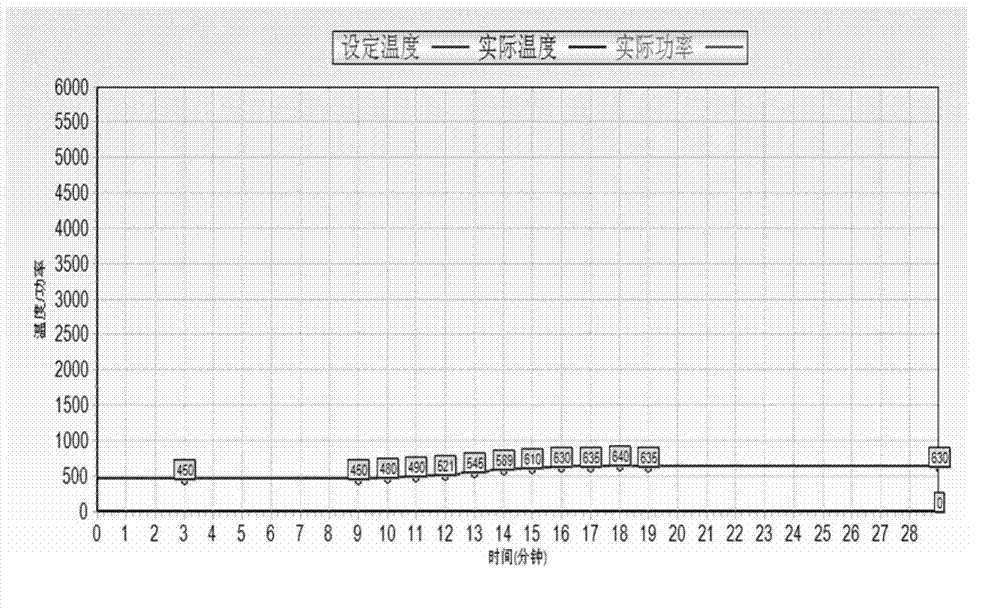

Aluminium-based composite material with high silicon carbide content and preparation method of composite material

The invention relates to an aluminium-based composite material with high silicon carbide content. The aluminium-based composite material with high silicon carbide content is characterized in that the aluminium-based composite material comprises the following components in percentage by mass: 40-60% of silicon carbide and 40-60% of aluminium. The invention also relates to a preparation method of the aluminium-based composite material. A preparation method of the aluminium-based composite material comprises the following steps: burdening, preparing mixed powder, moulding an aluminium silicon carbide composite material, degassing and degreasing under the vacuum condition, carrying out microwave sintering, and carrying out hot pressing deformation. The prepared aluminium-based composite material with high silicon carbide content is high in relative density, stable in performance and good in tissue uniformity and has high strength, modulus and hardness, excellent abrasion resistance and corrosion resistance and excellent high temperature performance. The preparation method of the aluminium-based composite material is simple in process, low in cost and high in efficiency, and the defects of composition segregation and poor wettability of SiC particles with aluminium alloy solution in the prior art are overcome.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

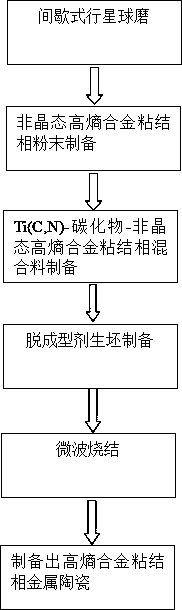

Preparation method for Ti(C,N)-based cermet with high-entropy alloy bonder phase

ActiveCN109022990AGood for maintaining relative contentKeep the relative contentWear resistantHigh entropy alloys

The invention discloses a preparation method for a Ti(C,N)-based cermet with a high-entropy alloy binder phase. The preparation method is characterized in that firstly, an amorphous high-entropy alloybinder phase powder with Co:Ni:Fe:Cu:Mn = 1:1:1:1:(0.3-1) is prepared by using an intermittent planetary ball mill; then, the amorphous high-entropy alloy binder phase powder is mixed with a hard phase powder by using a drum-type ball mill, and the prepared mixture is still in an amorphous state; lastly, microwave sintering at 1400-1450 DEG C is performed to allow the amorphous high-entropy alloybonder phase in the cermet to be crystallized, a transition process from the amorphous state to the crystalline state and the hysteretic element diffusion effect of the high-entropy alloy restrain the dissolution of the hard phase into the binder phase, and the binder phase of the cermet is the single-phase high-entropy alloy with a face-centered cubic structure; and thus, the cermet with the high-entropy alloy bonder phase is prepared. The preparation method overcomes the problem that during the existing preparation process of a cermet with a high-entropy alloy binder phase, a Ti(C,N) hard phase dissolves in a bonder phase, so that the relative content decreases and the grains of the hard phase are prone to abnormal growth, and finally insufficient mechanical properties of a hard alloy are caused. The preparation method can be used in cutting tools, wear-resistant parts and other fields.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

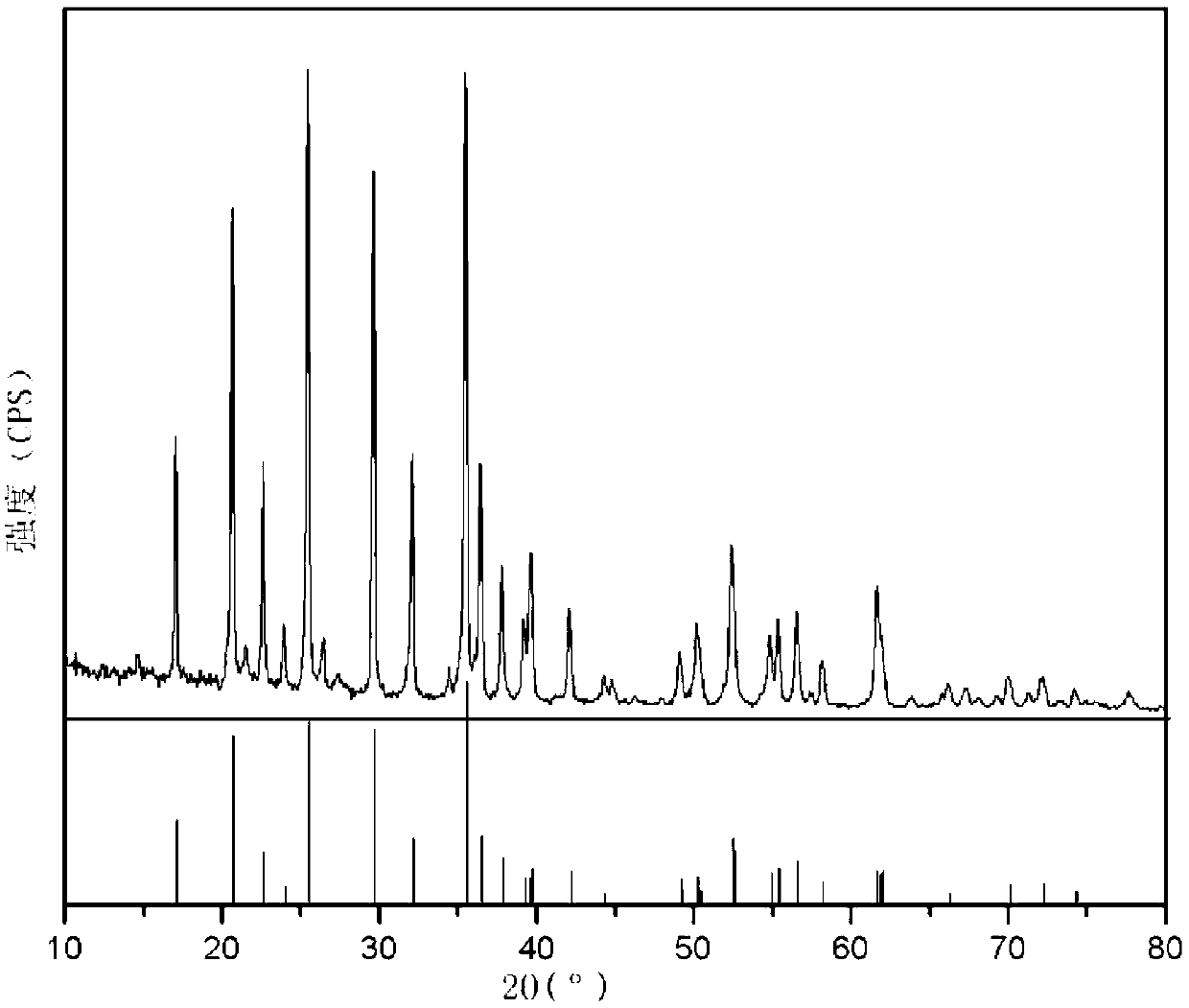

Low-temperature sintered microwave dielectric ceramic and sintering method thereof

The invention discloses low-temperature sintered microwave dielectric ceramic and a sintering method thereof. The low-temperature sintered microwave dielectric ceramic comprises Li2MTi3O8 and N, wherein an M element is Zn, Ni, Co or Mg, and N is B2O3, V2O5, CuO or Bi2O3. The performance of a product prepared by adopting a microwave sintering method disclosed by the invention is superior to that of a traditional solid-phase sintered product, the high-frequency dielectric constant (epsilonr) of the product reaches 20 to 30, a Q*f value reaches up to 6000 to 59000GHz, and the temperature coefficient (tauf) of a resonance frequency is small. Moreover, the presintering time and the sintering time can be shortened, and the sintering temperature is decreased, so that the requirements of LTCC (Low Temperature Co-fired Ceramic) production can be met, the performance of the product is improved, energy sources are saved, the production cost is lowered, the low-temperature sintered microwave dielectric ceramic can be used for the manufacture of microwave devices, such as an LTCC system, a multilayer dielectric resonator, a microwave antenna, a filter and the like, the volatilization of low-melting-point substances is inhibited, the environment is protected, and the low-temperature sintered microwave dielectric ceramic has an important industrial application value.

Owner:GUANGXI NEW FUTURE INFORMATION IND

The method for preparing high-entropy oxide ceramic material is simple and low in consumption

ActiveCN112723862AThe primary particle size is fine and uniformHigh activityOxide ceramicPlasma activation

The invention relates to the technical field of high-entropy ceramic preparation, and discloses a simple and low-consumption method for preparing a high-entropy oxide ceramic material, which comprises the following steps: S1, weighing raw materials: weighing the raw materials required for preparation according to a set ratio; s2, performing particle refinement: adding the raw materials weighed in the step S1 and a dispersing agent into a ball milling tank of a planetary ball mill together for particle refinement grinding to prepare uniformly mixed slurry, then drying the slurry, and grinding again to obtain refined powder; s3, performing spark plasma treatment: performing spark plasma activation on the refined powder obtained in the step S2 to obtain a ceramic raw material; and S4, performing microwave sintering: carrying out microwave sintering on the ceramic raw material obtained in the step S3 to obtain the high-entropy oxide ceramic material.

Owner:TAIYUAN UNIV OF TECH

Method for preparing lithium vanadium phosphate as lithium ion battery anode material

InactiveCN101651205AUniform particle size distributionHigh specific capacityElectrode manufacturing processesMuffle furnacesLithium vanadium phosphate batteryMicrowave sintering

The invention discloses a method for preparing lithium vanadium phosphate as a lithium ion battery anode material, which comprises the following steps: (1) preparing reaction precursor gel of an anodematerial by a sol-gel method; (2) presintering the reaction precursor gel prepared in the step (1); and (3) placing a material obtained by presintering into a microwave sintering furnace to sinter. The invention combines the sol-gel method with a microwave sintering method and can prepare a product with favorable electrode plate processing ability, electrical conductivity and electrochemical performance by sintering in tens of minutes. The method has high production efficiency, low energy consumption, easy control of technical parameter, favorable batch stability and low production cost and is suitable for mass industrial production.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Permanently magnetic strontium ferrite material and preparation method thereof

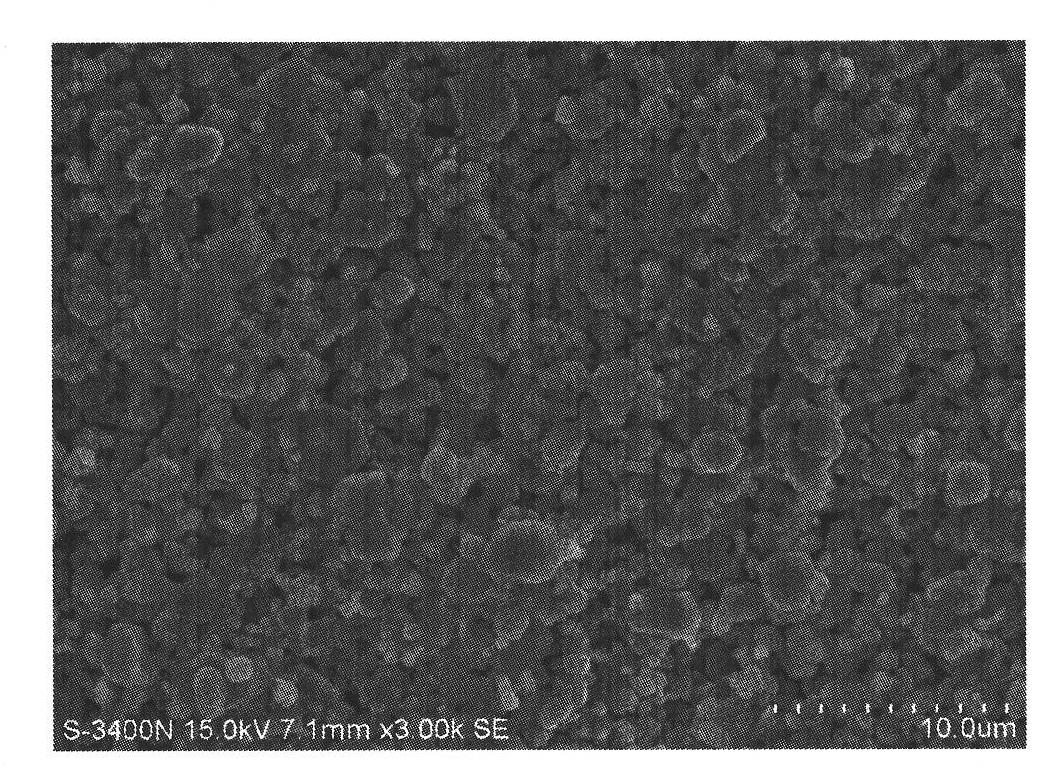

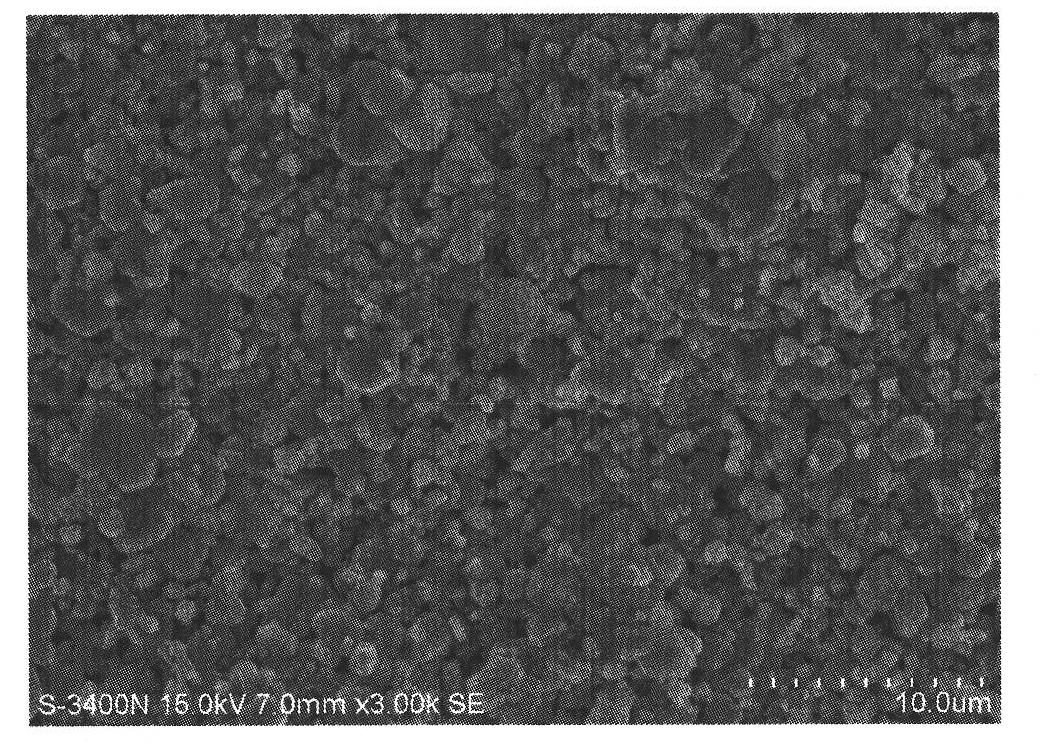

InactiveCN101870579AImprove structural propertiesExcellent magnetic propertiesMicro structureProcess systems

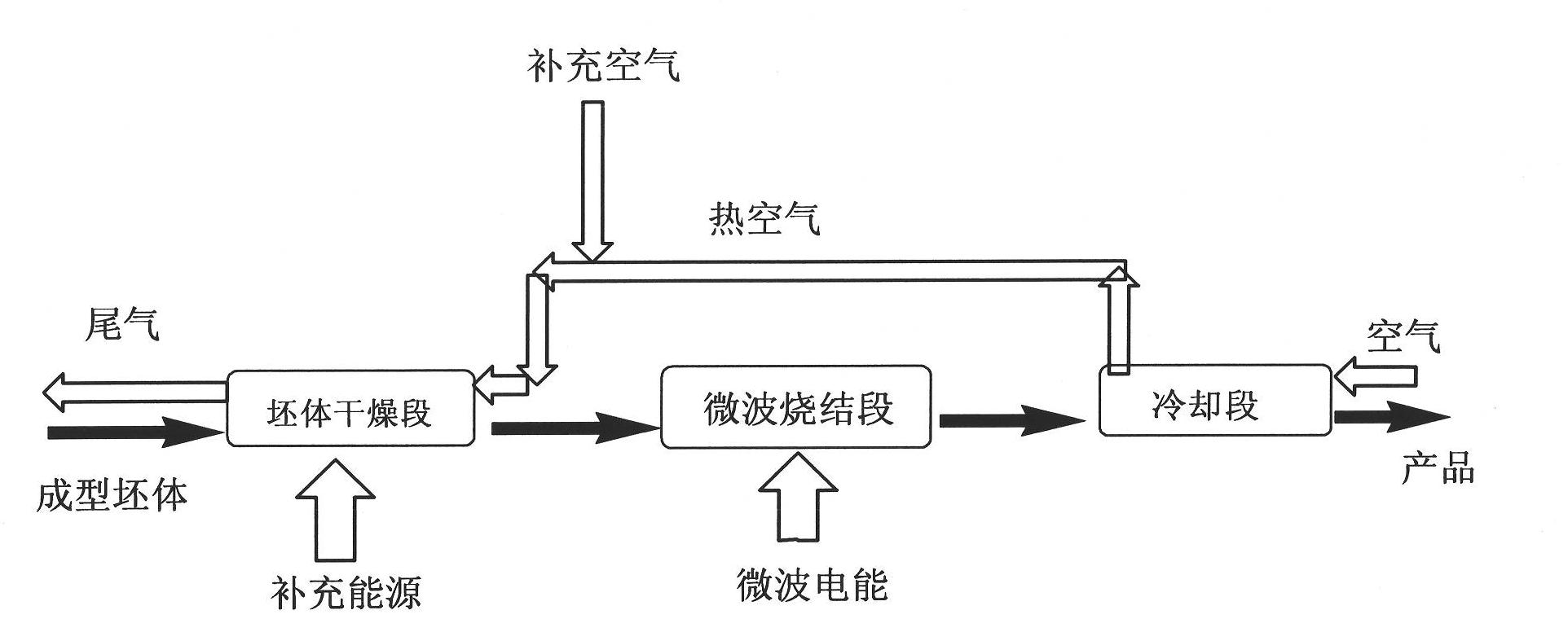

The invention discloses a permanently magnetic strontium ferrite material and a sintering method thereof. The method comprises: mixing and milling a presintered material of strontium-containing ferrite and a secondarily added assistant in a ball mill; separating dehydrated slurry and preparing a blank by using wet-method forming; dehydrating and drying the formed blank at room temperature and the temperature of 400 DEG C first, and sintering the blank in a microwave sintering furnace by a certain process system; and thus obtaining the high-performance permanently magnetic strontium ferrite magnetic material. The main magnetic property parameters of the product include: the Br of 420 to 427mT, the Hcj OF 309 TO 362.8kA / m, and the BH(MAX) of 32.6 to 34.88kJ / m<3>. The method is characterized by obviously improving the structure and magnetic property of the permanently magnetic strontium ferrite through the controlled sintering, which is realized by setting reasonable sintering process conditions, of micro structures of magnetic materials, along with quick sintering, low energy loss and high production efficiency.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Low-temperature quick sintered high-strength aluminum oxide ceramic and preparation method thereof

The invention discloses low-temperature quick sintered high-strength aluminum oxide ceramic and a preparation method thereof. The low-temperature quick sintered high-strength aluminum oxide ceramic consists of coarse crystal Al2O3 powder, nano Al2O3 powder and a sintering auxiliary agent serving as raw materials, wherein the sintering auxiliary agent consists of SiO2 powder, talc powder and limestone powder. The preparation method comprises the following steps of: partially replacing coarse crystal aluminum oxide by using the nano aluminum oxide powder, mixing, dispersing, pre-pressing and molding, performing 200 to 300MPa cold isostatic pressing molding, performing dumping on a molded test sample in a muffle furnace at a temperature of between 400 and 600 DEG C for 30 to 60 minutes, and finally performing low-temperature quick sintering by adopting a microwave sintering method to obtain the high-strength aluminum oxide ceramic. Quick sintering of the aluminum oxide ceramic can be realized at a lower temperature in short time by partially replacing the coarse crystal aluminum oxide powder by using the nano aluminum oxide powder and combining a microwave sintering process, and therefore, the energy consumption is low, and the cost is saved.

Owner:ANHUI UNIV OF SCI & TECH

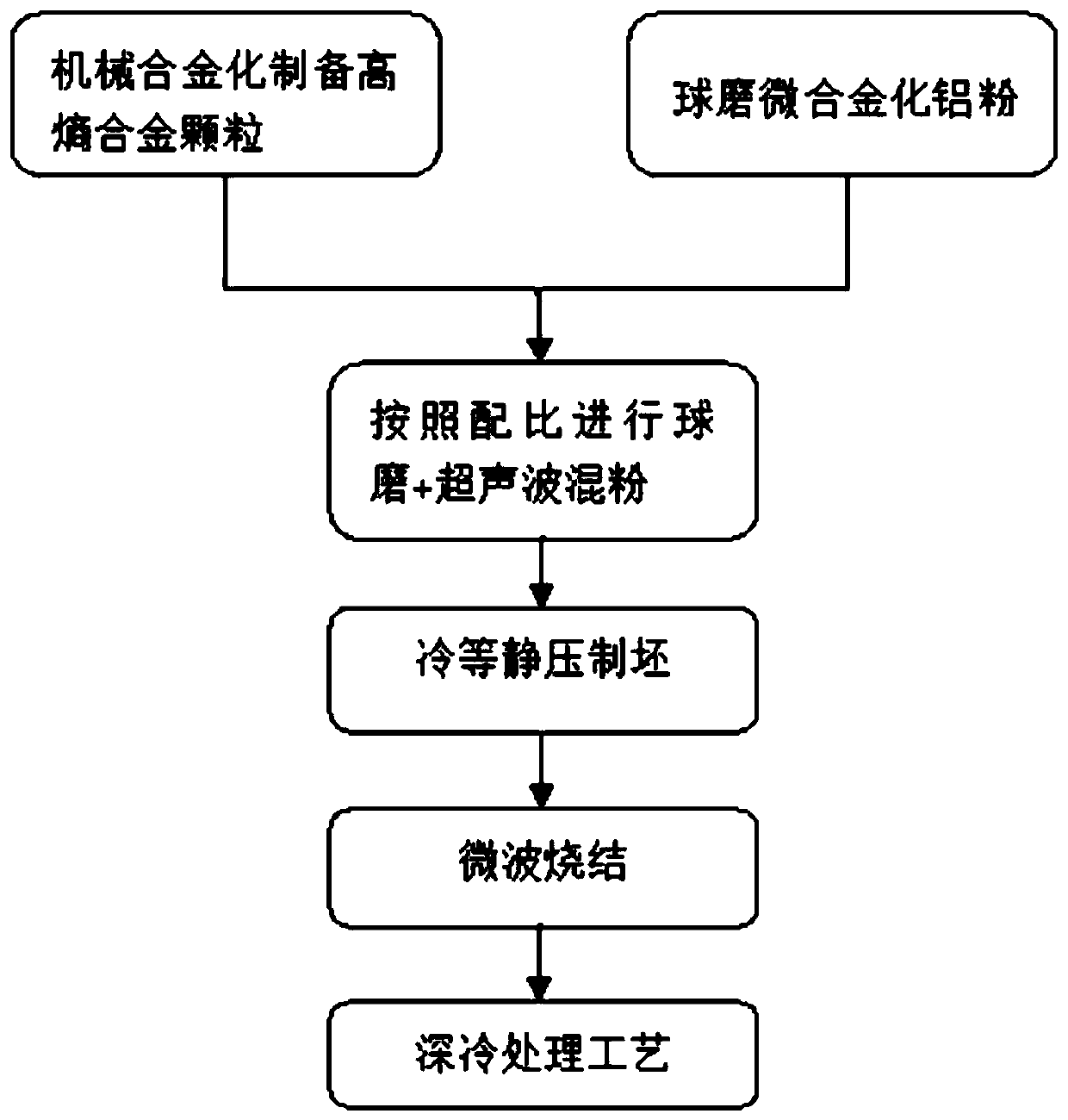

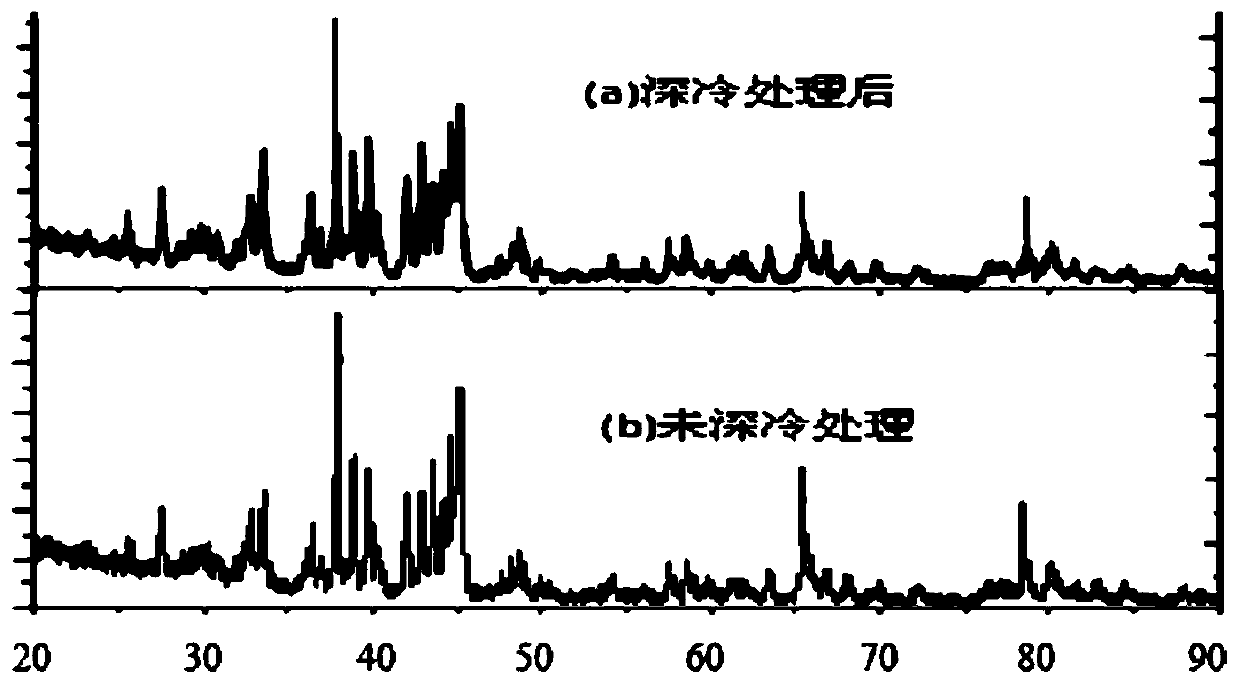

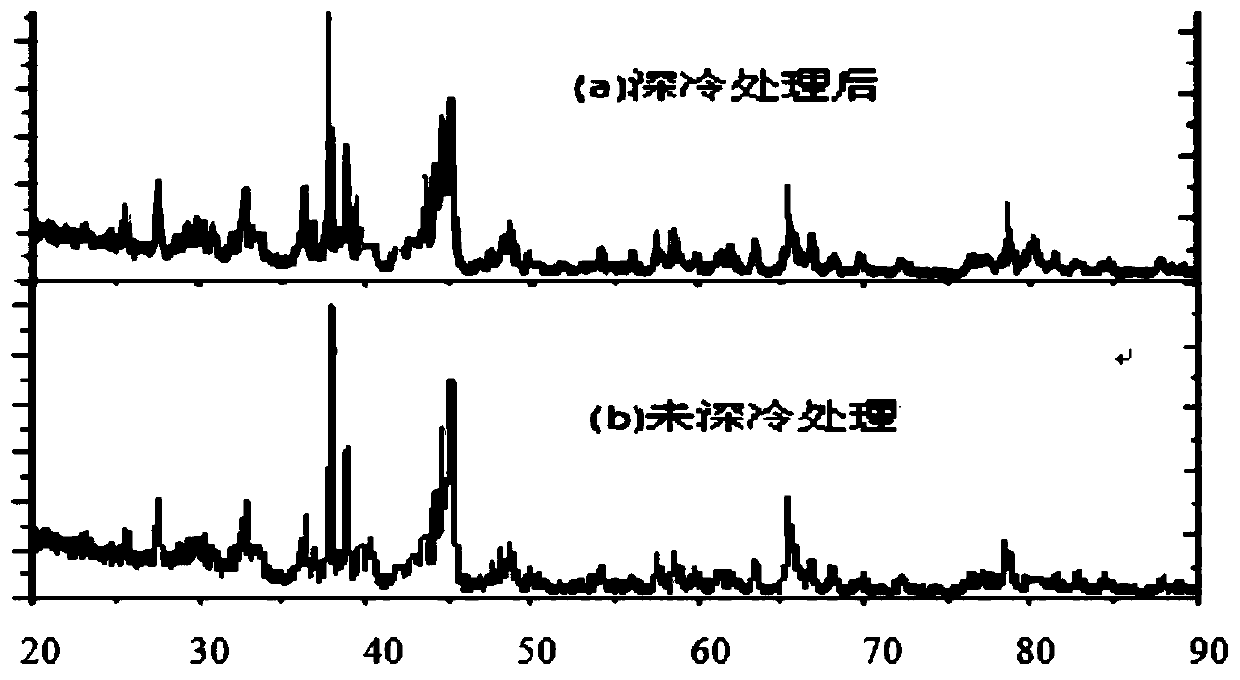

High-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and preparation method thereof

ActiveCN110523997AHigh strengthEvenly distributedTransportation and packagingMetal-working apparatusCompression moldingMaterials preparation

The invention belongs to the technical field of composite material preparation, and particularly relates to a high-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and a preparation method thereof. High-entropy alloy components are optimally designed, then vacuum ball milling is conducted to prepare high-entropy alloy, and high-entropy alloy powder and microalloyed aluminum matrix powder are evenly mixed in proportion and dried to obtain mixed powder; compression molding is performed by utilizing isostatic cool pressing to obtain a composite billet; a microwave sintering process is adopted to obtain a high-entropy alloy particle reinforced aluminum-based composite material; and finally, cryogenic treatment is performed on the aluminum-based compositematerial. According to the high-entropy alloy particle reinforced aluminum-based composite material, the strength and plasticity of the aluminum-based composite material are improved, and meanwhile the aluminum-based composite material can have good magnetic performance.

Owner:JIANGSU UNIV

Graded transmitted wave structure in microwave sintering and method for preparing ceramic material using the same

The invention relates to a gradient wave-transmitting structure used for microwave sintering and a method used for preparing ceramic materials, which are characterized in that: (1) when a material with high dielectric property is sintered, at least a transition layer is added into the exterior of the material and the transition layer is composed of high-efficient wave absorption material with certain concentration and a microwave transparent thinner; when a multilayered structure is used as the transition layer, the concentration of the high-efficient wave absorption material increases from exterior to interior in sequence; (2) when a material with low dielectric and relatively poor wave absorption properties is sintered, the multilayered structure is adopted for an exothermic material ora coat, wherein, the concentration of the high-efficient wave absorption material increases from exterior to interior in sequence and then decreases so as to be favorable for transmitting microwave. In the invention, energy consumption caused by a plurality of times of reflection and wave-absorbing and heat-emitting of a thermal insulating layer are reduced by improving the efficiency of being sintered and wave absorption, thus being capable of effectively realizing the purpose of increasing sintering temperature. In addition, the gradient thermal insulating structure can help materials sintered to obtain an even temperature field and better sintering quality.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A method of microwave firing porous ceramsite from medical waste incineration fly ash

ActiveCN103601526BPromote formationGood consolidationSolid waste disposalCeramicwarePrillResource utilization

The invention discloses a method for microwave sintering of porous ceramsites by adopting medical waste incineration fly ash. The method comprises the following steps: (1) fully mixing the medical waste incineration fly ash with an auxiliary material, adding a small amount of water into the mixture, and carrying out granulation molding by a molding machine; (2) carrying out granulation molding, drying to obtain a particle raw material, filling the periphery of the particle raw material with a microwave coupling agent powder; and (3) carrying out microwave sintering of the particle raw material filled with the powder, and after sintering, cooling to the room temperature to obtain the porous ceramsites. The method can utilize a 'hot spot' effect of fly ash high-content active carbon in a microwave field to instantly completely decompose dioxins in the fly ash, at the same time, allows most heavy metals to be wrapped and cured in grids of the sintered product, and rapidly sinters the fly ash into the porous ceramsites; and the ceramsites can be used for building aggregates or wastewater filter materials, achieves further resource utilization while achieving harmlessness treatment of the medical waste incineration fly ash, and achieves many things at one stroke.

Owner:TIANJIN CHENGJIAN UNIV

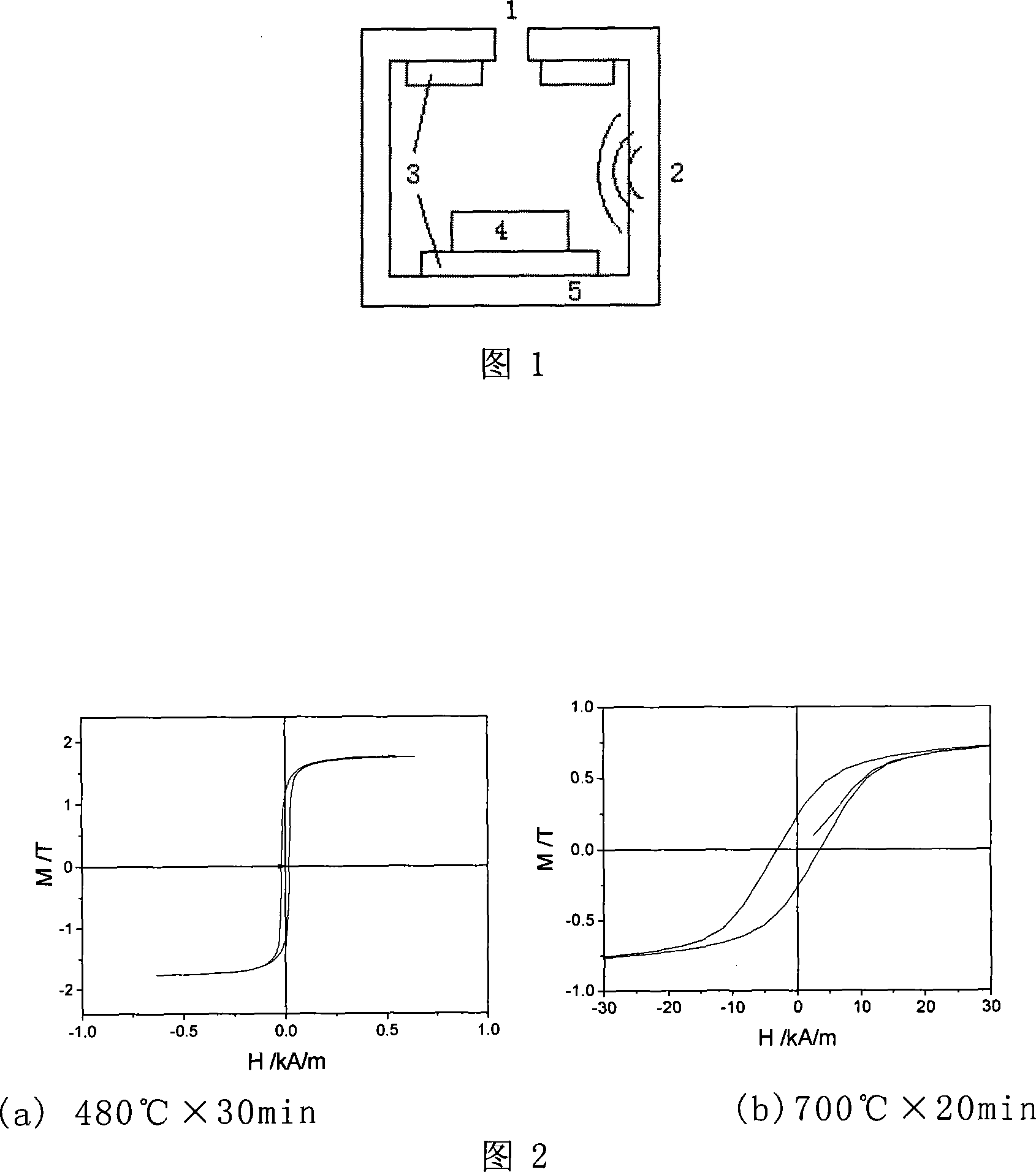

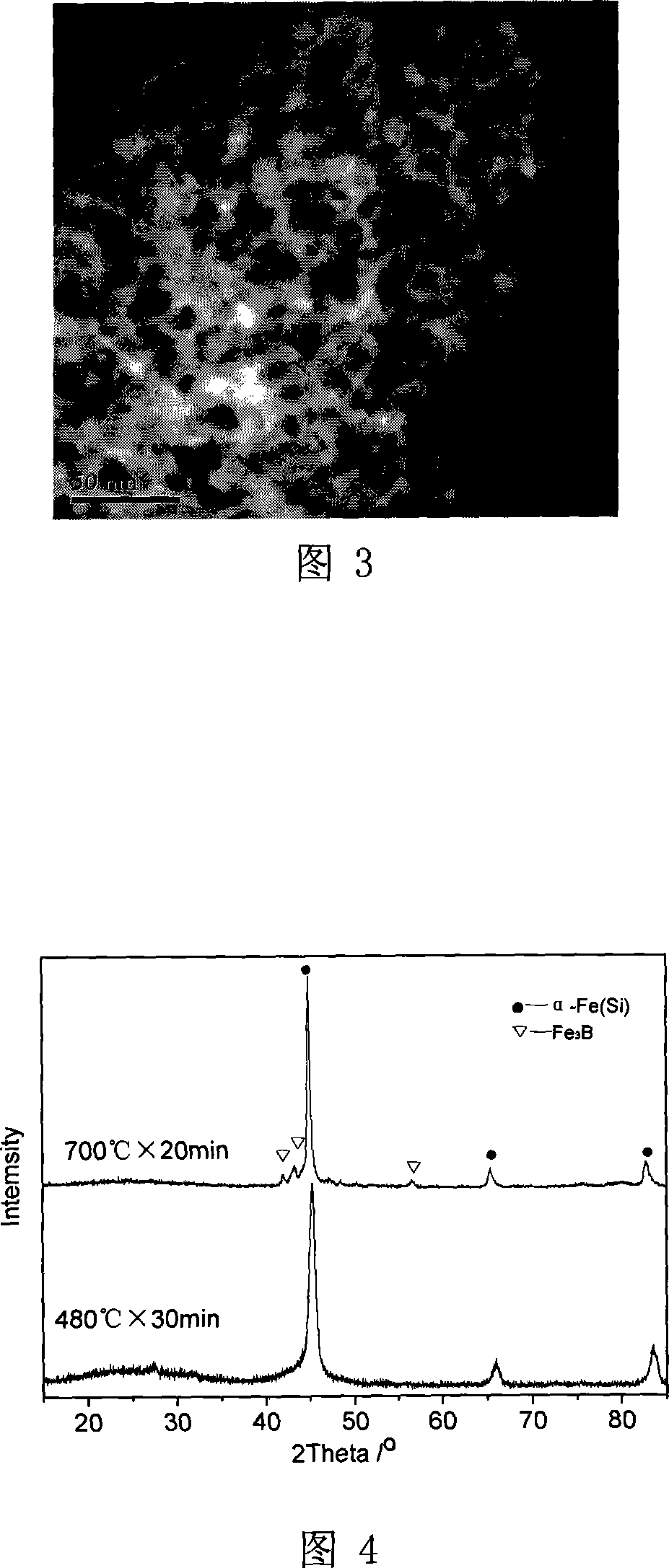

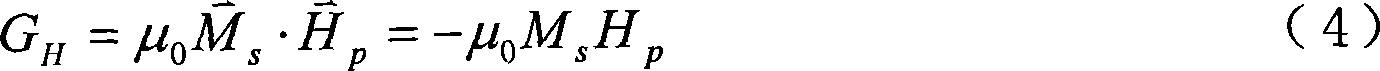

Fast microwave crystallizing process for preparing nanometer crystalline iron-base soft magnetic alloy

The present invention discloses fast microwave crystallizing process for preparing nanometer crystalline iron-base soft magnetic alloy. The technological process includes the following steps: 1. smelting alloy with Fe, Cu, Nb, Si and B in the ratio of Fe73.5Cu1Nb3Si13.5B9 in an induction furnace at vacuum 3-10 Pa in high purity Ar; 2. setting coarsely crushed alloy inside quartz pipe with nozzle in the bottom, setting the quartz pipe inside induction coil in a belt spinning machine, and melting the mother alloy in protecting Ar atmosphere; 3. spraying the alloy liquid under the pressure of Ar to the surface of rotating copper roller to form non-crystalline alloy belt; and 4. sealing the thin belt in quartz tube and crystallizing treatment in a microwave sintering furnace at 400-900 deg.c for 10-180 min to obtain ideal nanometer crystal structure.

Owner:CENT SOUTH UNIV

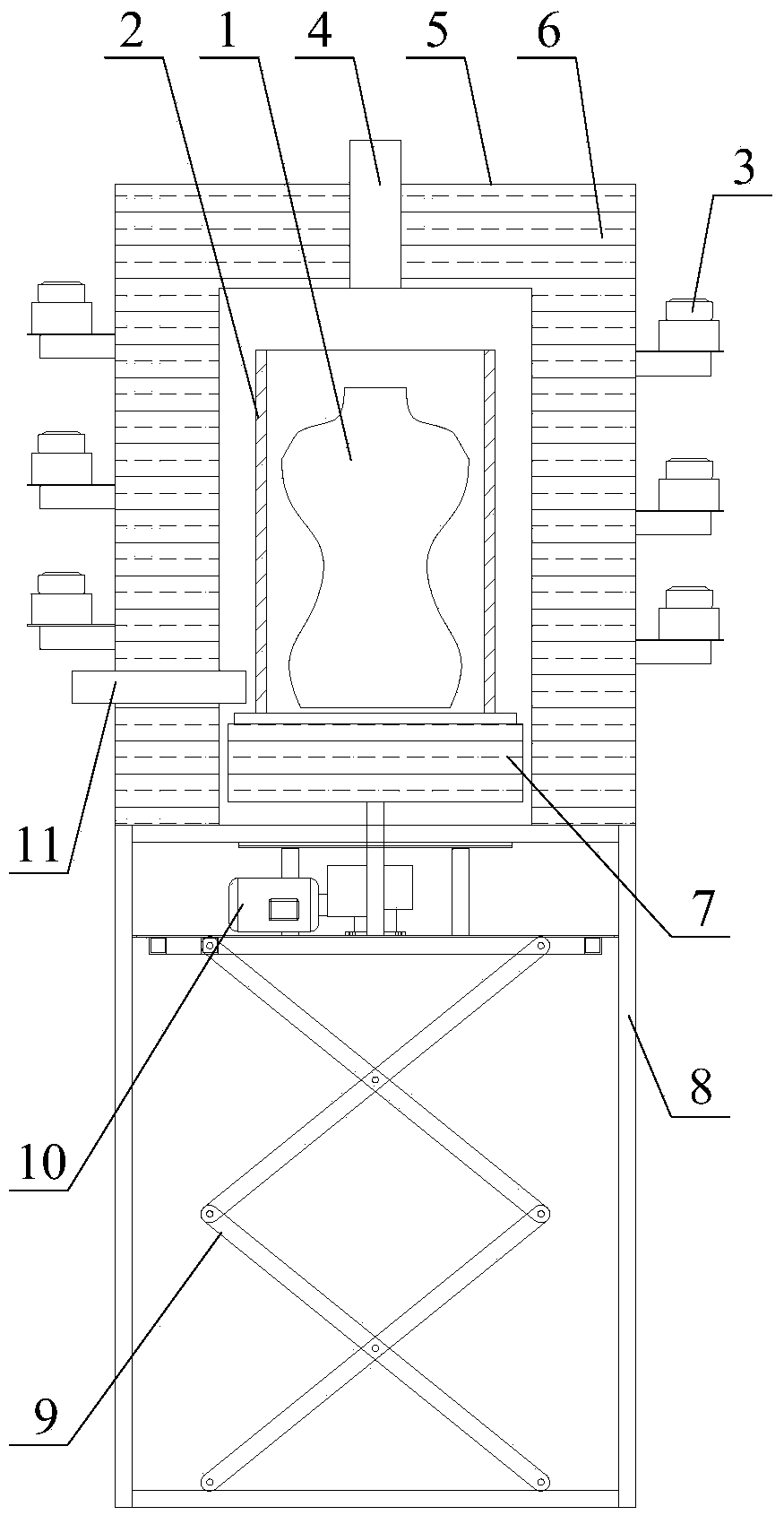

Art ceramics microwave sintering furnace

InactiveCN103411428AEnhanced ability to absorb microwaveEvenly heatedFurnace typesWaveguideMicrowave sintering

The invention discloses an art ceramics microwave sintering furnace which comprises a furnace body, a microwave heating device, an object carrying platform, a lifting device, an atmosphere system and a material rotating device, wherein the furnace body comprises a furnace casing and a furnace lining installed in the furnace casing; the atmosphere system is used for providing reducing gas required by art ceramics; the material rotating device is used for driving the object carrying platform to rotate in the horizontal direction; the microwave heating device comprises a microwave source, a magnetron, a waveguide tube and a microwave guiding body, wherein the microwave guiding body is used for absorbing microwaves, the magnetron is installed on the waveguide tube which is installed on the furnace casing, the microwave guiding body is installed in the furnace body, a microwave guiding body heating cavity is formed by the microwave guiding body, and the art ceramics is positioned in the microwave guiding body heating cavity; the lifting device is installed below the object carrying platform, and the lifting end of the lifting device is installed on the object carrying platform. By using the art ceramics microwave sintering furnace provided by the invention, the sintering quality of the art ceramics can be improved.

Owner:湖南阳东微波科技有限公司

Microwave sintering and heat treatment method for preparing high-performance tungsten-based high-density alloy

A microwave sintering and heat treatment method for preparing high-performance tungsten-based high-density alloy comprises the following steps: preparing a powder compact by a traditional powder metallurgy method, putting the compact in a microwave high-temperature furnace with atmosphere protection and a vacuum pump, controlling the atmosphere in the furnace chamber to be reducing atmosphere at a heating phase below 1200 DEG C; sintering the product at low vacuum at a high-temperature phase of 1200-1400 DEG C, and vacuumizing the furnace to obtain a high vacuum of 10-2 Pa at a cooling phase after sintering. The obtained alloy has a uniform fine grain structure, and high mechanical properties. The invention adopts low vacuum at the sintering phase, and adopts high vacuum at the cooling phase, which allow the hydrogen content of the alloy to be reduced, and effectively avoid the hydrogen embrittlement phenomenon. Additionally, the tungsten-based high-density alloy is prepared by microwave sintering technology and equipment, which is rapid, high-efficient, simple, and low in cost; the tungsten-based high-density alloy is prepared by microwave sintering-heat treatment technology; theprocess is easy to control; the technology is mature, and is applicable to industrial production.

Owner:CENT SOUTH UNIV

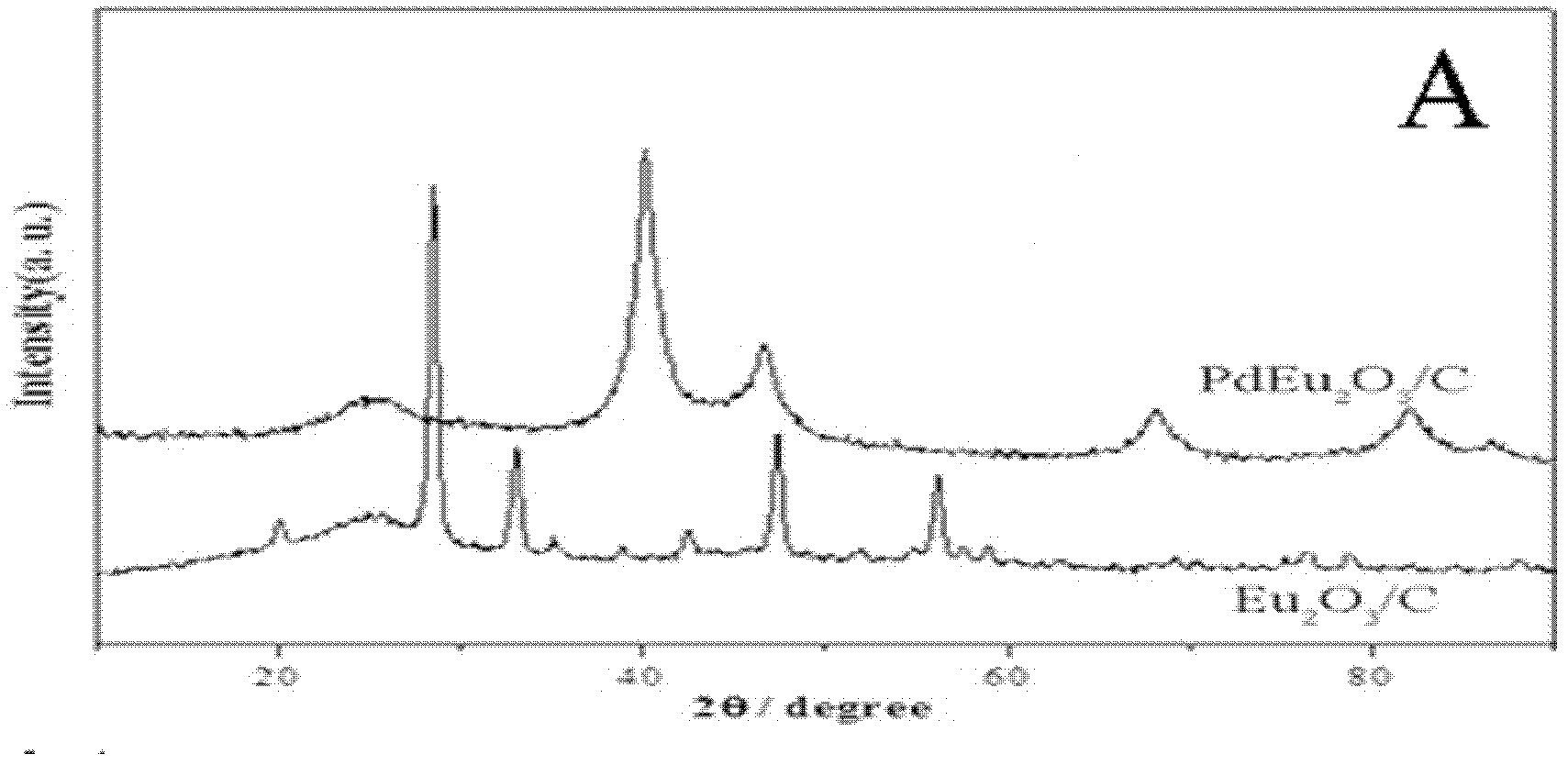

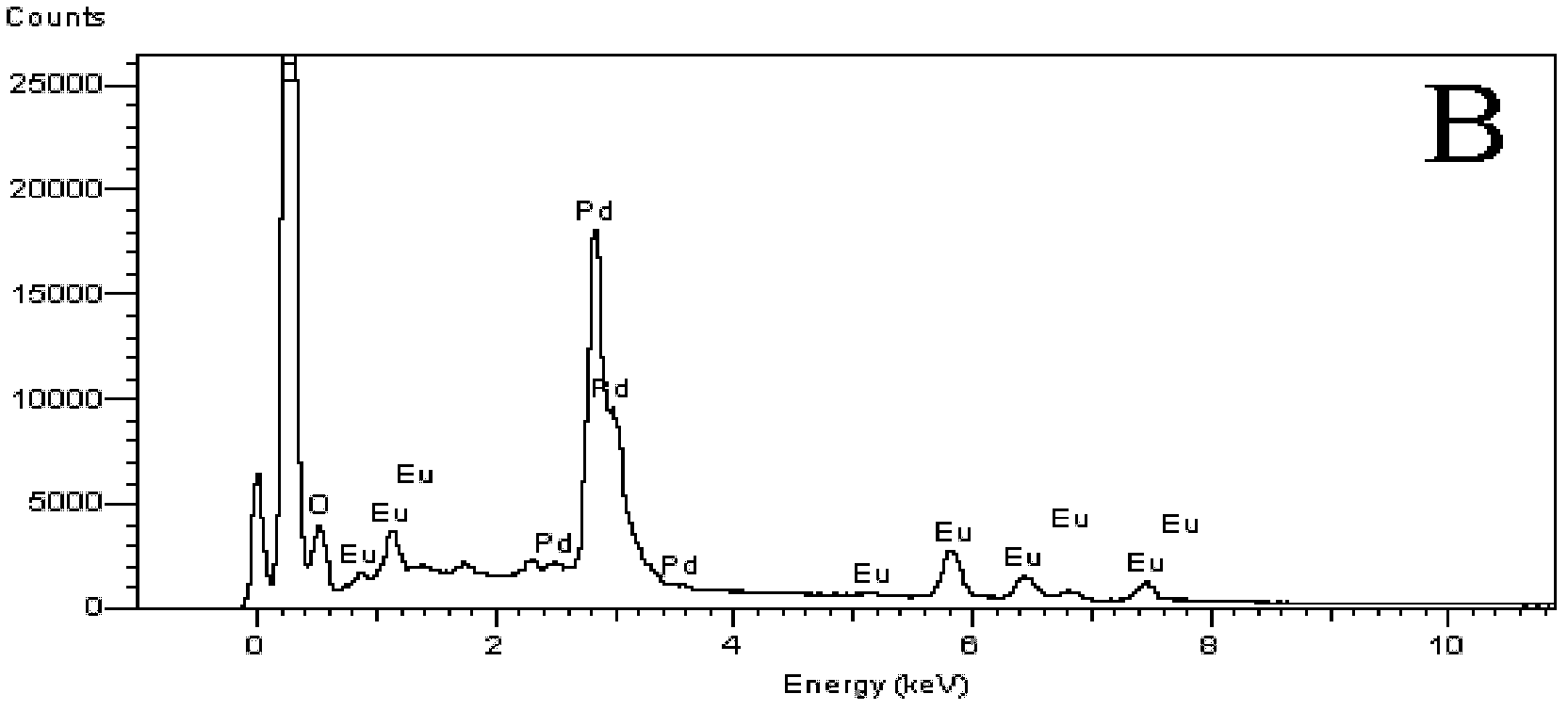

Fuel cell catalyst and preparation method thereof

InactiveCN102593473AImprove anti-toxic performanceImprove conductivityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementFuel cells

The invention provides a fuel cell catalyst, which comprises a composite carrier and a noble metal, wherein the composite carrier is prepared by a rare earth oxide and a carbon carrier, and the noble metal is loaded on the composite carrier. The catalyst provided by the invention has excellent poisoning resisting capability. The invention also provides a preparation method of the fuel cell catalyst. The preparation method comprises the steps of: (1) mixing the carbon carrier with an acid salt solution containing rare earth element to obtain a suspension; (2) precipitating the rare earth element in the suspension with an alkaline matter to obtain a rare earth element hydroxide compounded carbon carrier; (3) sintering the rare earth element hydroxide compounded carbon carrier to obtain the composite carrier; and (4) mixing a noble metal precursor with the composite carrier, and carrying out microwave sintering to obtain the fuel cell catalyst. The preparation method provided by the invention is simple, controllable and high in production efficiency.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

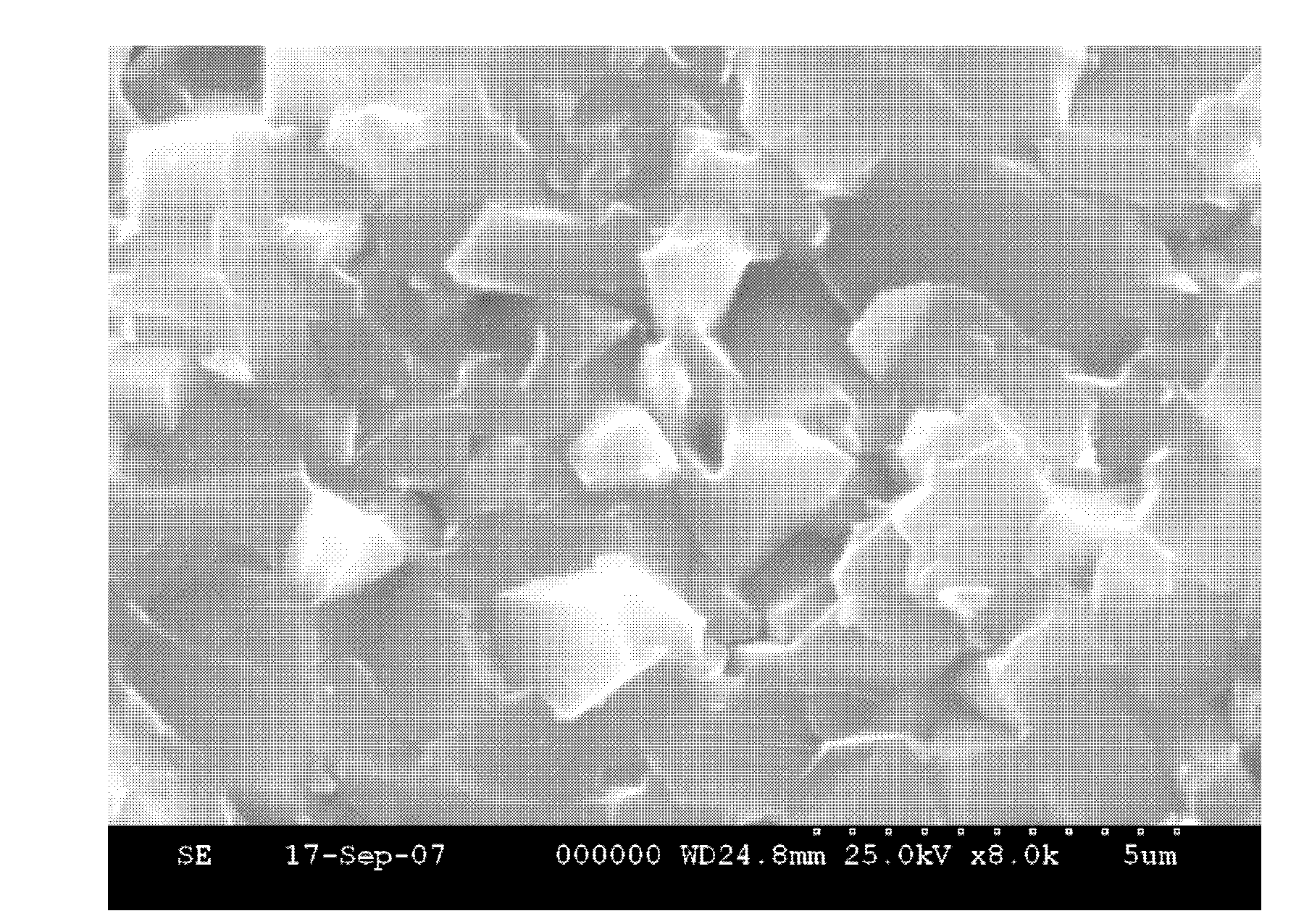

Method for preparing WC-Co cemented carbide through microwave sintering

The invention provides a method for preparing WC-Co cemented carbide through microwave sintering. The method comprises the steps of WC powder and Co powder batching and mixing, compacting and sintering, wherein in the step of sintering, compacts, SiC chips, carbon black and alumina powder are put in an alumina fiber insulating bag sleeve and then the alumina fiber insulating bag sleeve is put in a microwave high temperature furnace, the products in the furnace are heated to 500-600 DEG C at a heating speed of 5-10 DEG C / min and the heat is preserved and then the products are heated to 1400-1500 DEG C at a heating speed of 30-80 DEG C / min and the heat is preserved, thus obtaining the WC-Co cemented carbide. The method has the advantages of simple process, convenience in operation, short sintering period and low energy consumption, can replace the existing WC-Co cemented carbide processes, is used for producing the WC-Co cemented carbide by adopting the intermittent or continuous microwave sintering mode and is suitable for industrial application. The prepared WC-Co cemented carbide has excellent performances.

Owner:CENT SOUTH UNIV

Porous insulating decorative material prepared by utilizing iron tailings and preparation method thereof

InactiveCN103342578AEasy to solveSolve complexityGlass/slag layered productsCeramicwareFoaming agentThermal insulation

The invention relates to a porous insulating decorative material prepared by utilizing iron tailings and a preparation method thereof. The porous insulating decorative material is prepared by mixing and pelleting solid mixed powder and water and performing microwave sintering, and comprises a porous insulating layer and a glass surface decoration layer, wherein the porous insulating layer comprises the following raw materials in percent by mass: 75-85 percent of iron tailings powder, 2-10 percent of foaming agent, 0.1-1 percent of fluxing agent, 0.1-9 percent of foam stabilizer and 1-5 percent of wave-absorbing material; the glass surface decoration layer comprises the following raw materials in percent by mass: 45-75 percent of iron tailings powder, 20-50 percent of waste glass powder, 1-10 percent of thickening agent, 1-5 percent of expanding agent, 1-5 percent of color adjusting material and 1-3 percent of wave-absorbing material. The porous insulating decorative material has the beneficial effects that the defects of easy drop, complex process and the like caused by distribution and installation of the thermal insulation material and facing material are overcome; moreover, the utilization rate of the iron tailings is over 85 percent, and the emission reduction benefits are obvious.

Owner:WUHAN UNIV OF TECH

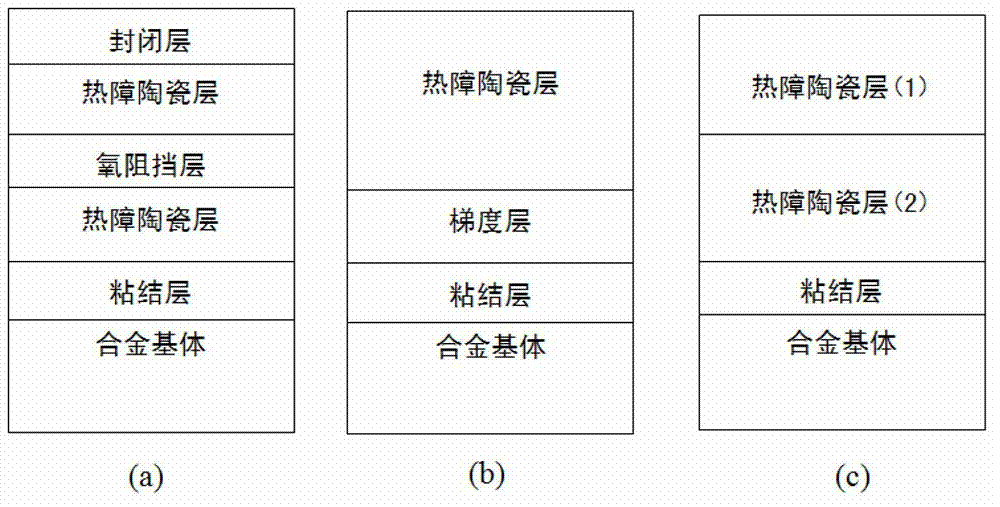

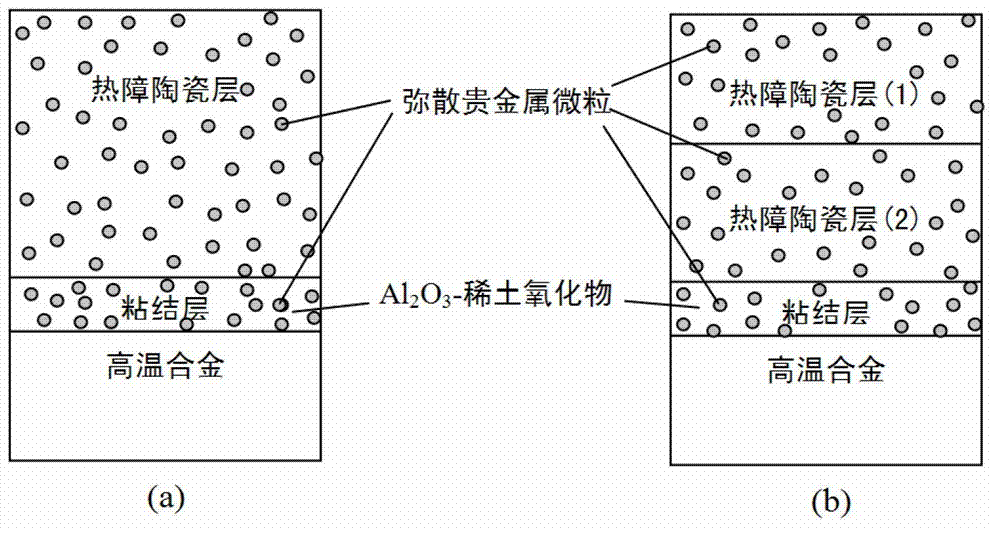

Precious metal particle dispersed toughened composite thermal barrier coating and its preparation method

InactiveCN102732883AExcellent thermal barrier effectGood mechanical propertiesBlade accessoriesEfficient propulsion technologiesThermal insulationAlloy

The invention which relates to a precious metal particle dispersed toughened composite thermal barrier coating and its preparation method belongs to the composite material field. The composite thermal barrier coating comprises a composite adhesion layer formed by a precious metal particle dispersed Al2O3-rare earth oxide, and a thermal insulation layer formed by various low-thermal-conduction ceramic single or double layers toughened by the dispersed precious metal particles. The dispersed precious metal particles comprise Au, Pt, a Pt-Au alloy, and a Pt-Rh alloy, and account for 0.5-3% of the composite thermal barrier coating. The preparation method adopts a composite sol-gel hot press filter sintering technology, a composite sol-gel pressurizing microwave sintering technology or a plasma spray technology to prepare the precious metal particle dispersed toughened composite thermal barrier coating, so the composite thermal barrier coating has the advantages of excellent thermal barrier performance, excellent high temperature oxidation resistance, excellent cracking resistance, excellent stripping resistance, excellent thermal shock resistance, stable structure, wide use temperature range, and long service life.

Owner:UNIV OF SCI & TECH BEIJING

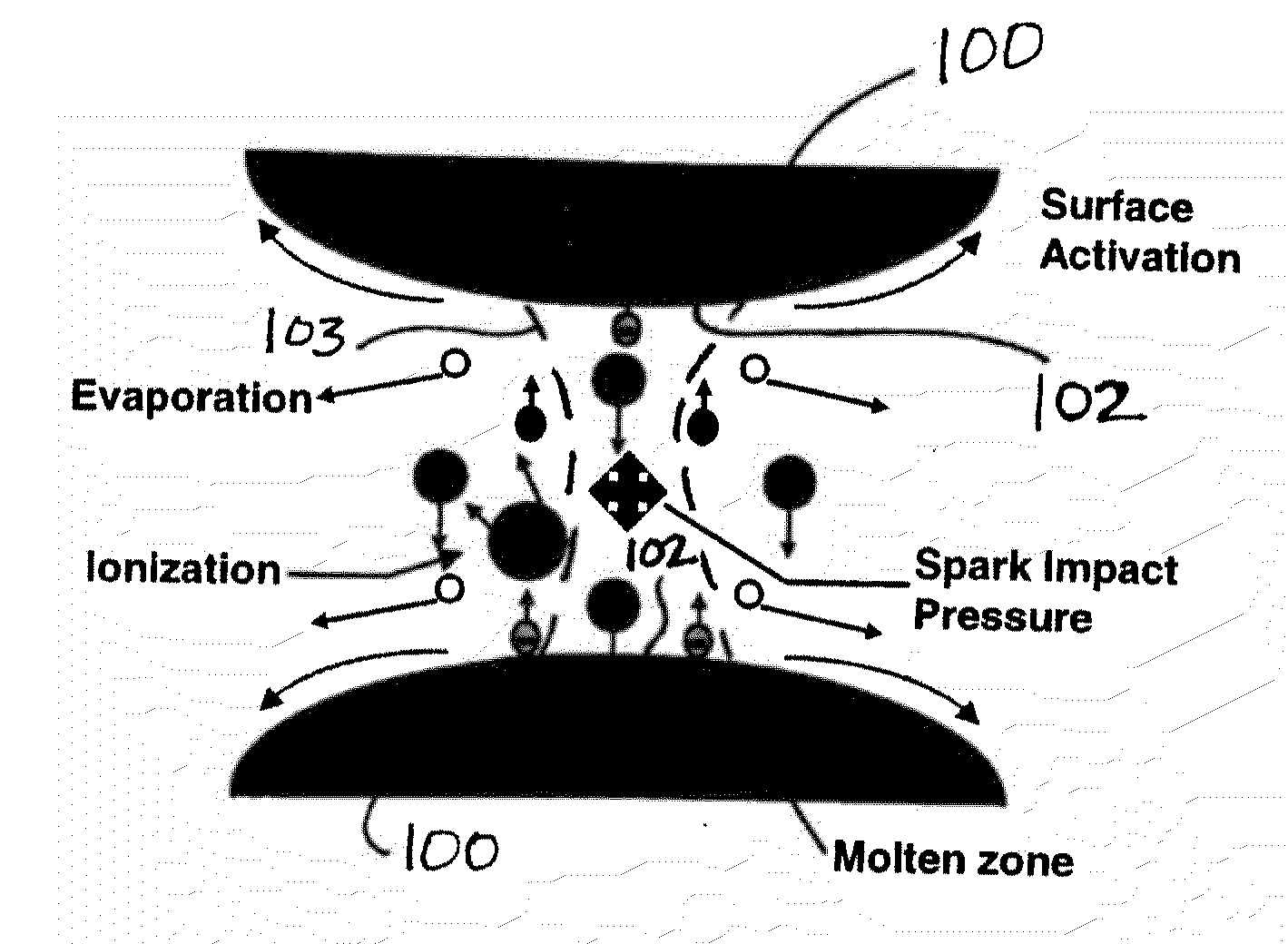

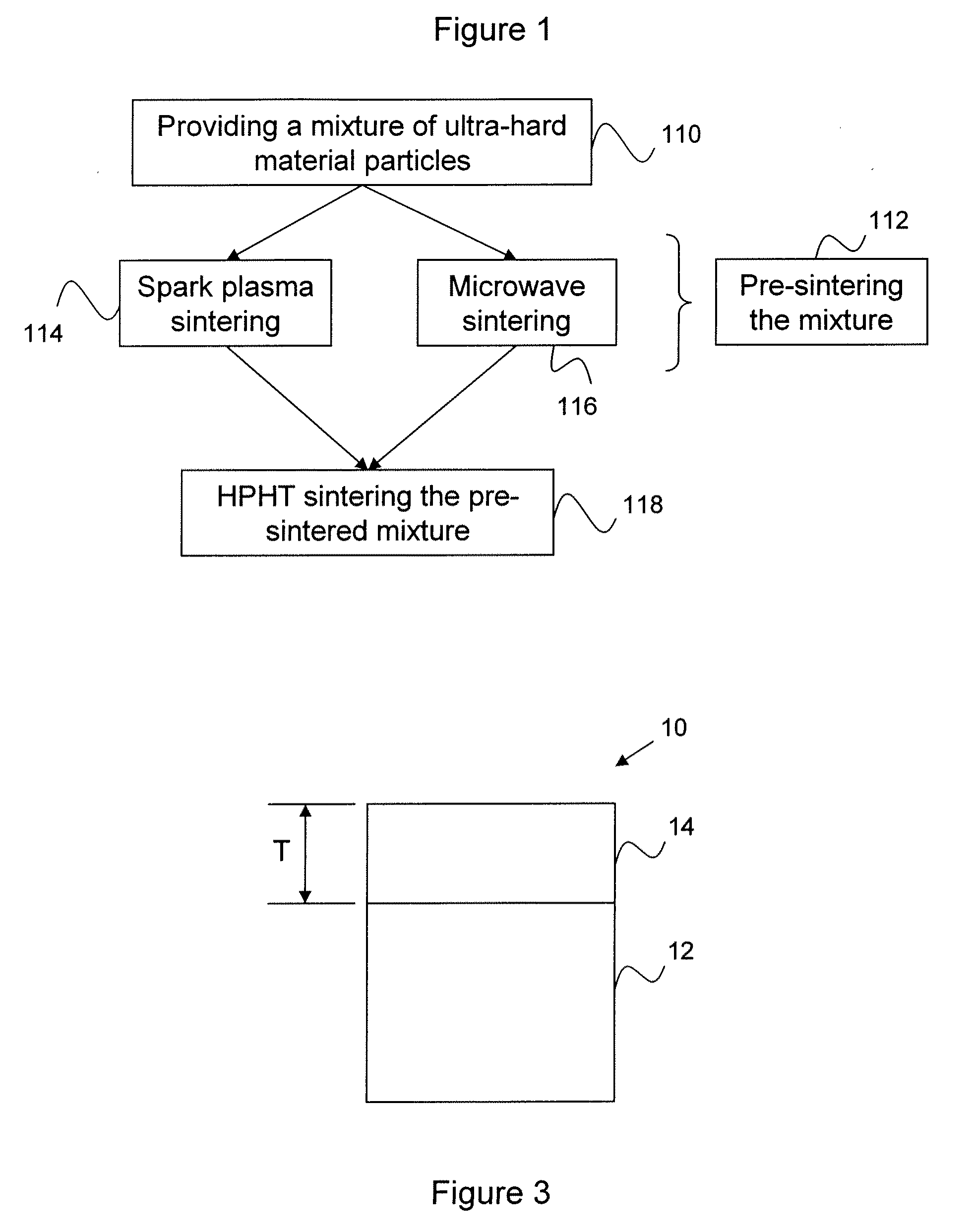

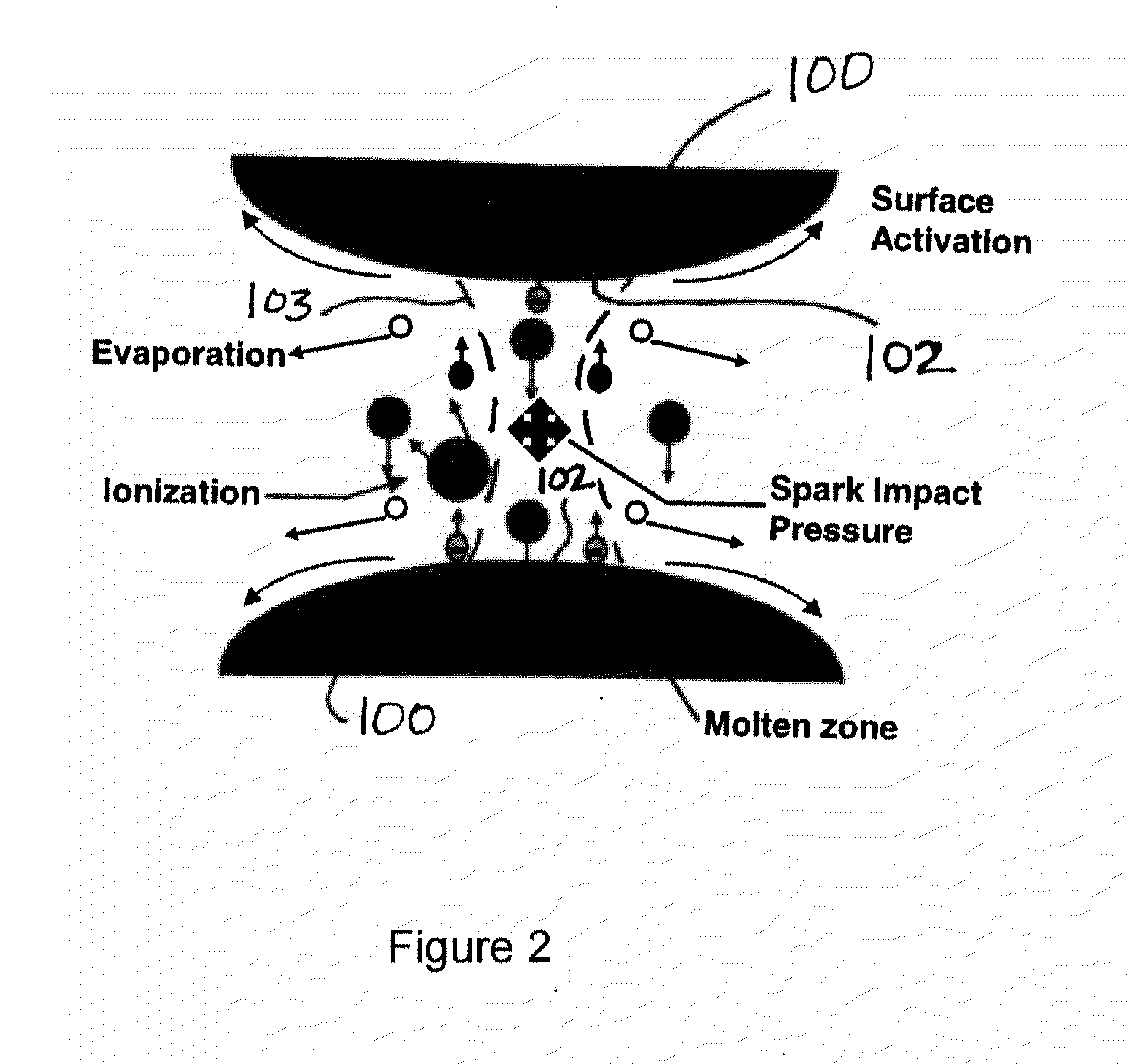

Method for making composite abrasive compacts

The present invention relates to polycrystalline ultra hard material cutting elements, and more particularly to a method of forming a polycrystalline ultra hard material cutting element with a thicker ultra hard layer than cutting elements formed by prior art methods. In an exemplary embodiment, such a method includes pre-sintering the ultra hard material powder to form an ultra hard material layer that is partially or fully densified prior to HPHT sintering, so that the ultra hard layer is pre-shrunk. This pre-sintering in an exemplary embodiment is achieved by means of a spark plasma process, or in another exemplary embodiment by a microwave sintering process.

Owner:SMITH INT INC

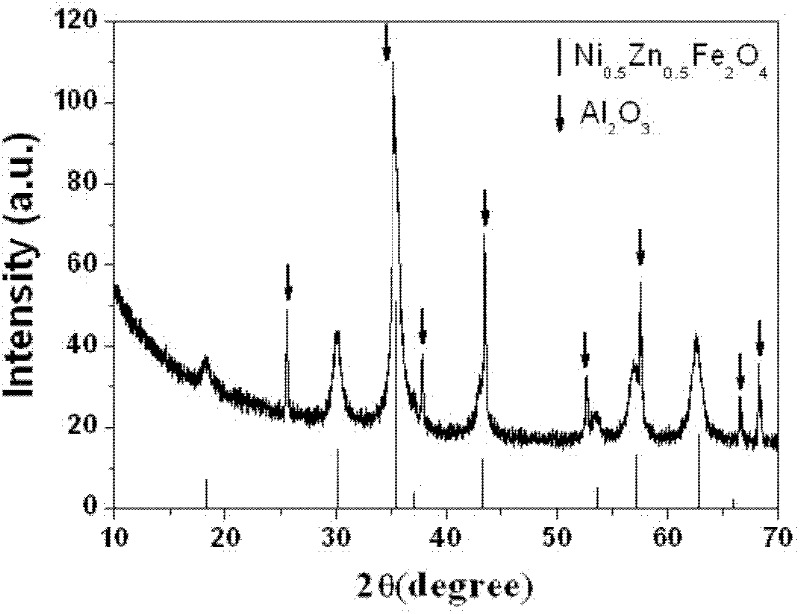

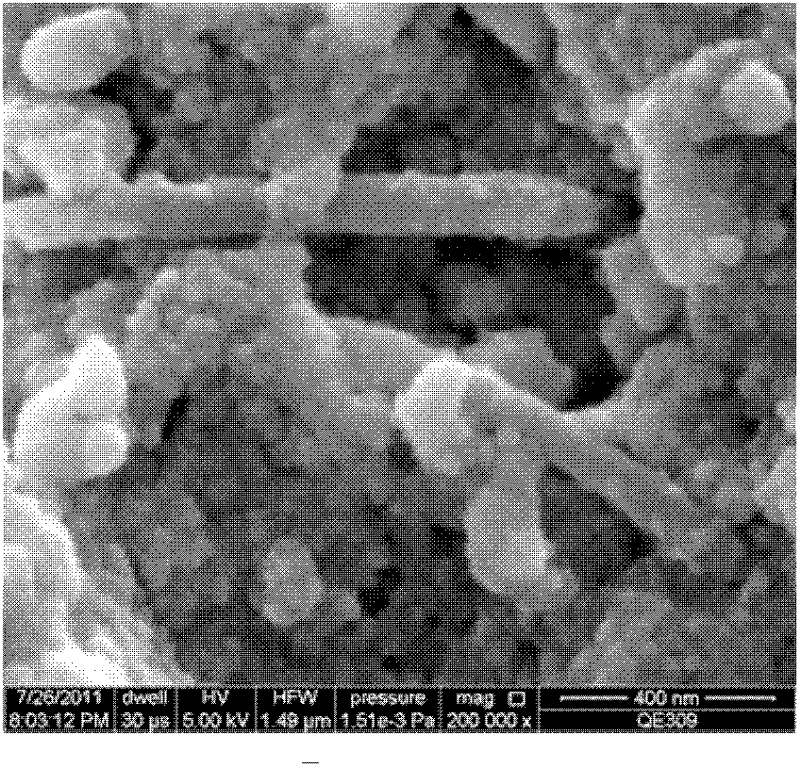

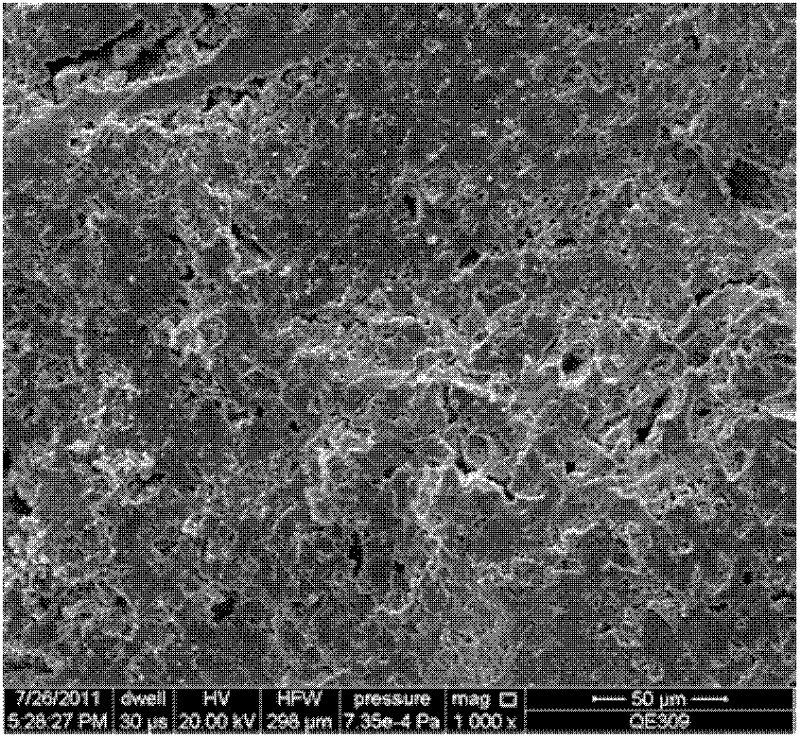

Ferrite-based ceramic composite material as well as preparation method and application thereof

ActiveCN102390989AMeet low temperature requirementsRealize the structureCeramic compositeStructure and function

The invention discloses a ferrite-based ceramic composite material as well as a preparation method and application thereof. The composite material is composed of ferrite, a carbon nanotube and a ceramic material, wherein the ferrite and the ceramic material are cladded on the tube wall of the carbon nanotube, and the ceramic material is one or several kinds of aluminum oxide, aluminum nitride, and silicon nitride. The three phases of materials, namely, the ferrite, the carbon nanotube and the ceramic, are compounded to make the advantages and disadvantages of all phases of materials complementary, so that the electrical conductance of the composite material is increased, the impedance matching performance of the composite material is improved, the wave absorption performance of the composite material is made adjustable, the structure and function integration of the ferrite-based ceramic material is realized, and thus, the application range of the composite material in the high-tech field is expanded. In addition, the powder of the composite material is prepared by adopting a coprecipitation hydrothermal method and is further prepared into a block material by adopting a microwave sintering method, and the ferrite-based ceramic composite material has the advantages that all phases are dispersed uniformly, the densification degree of the sintered material is high, the production cost is low, and the large-scale industrialization is easy to realize.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com