Patents

Literature

35results about How to "Uniform fine grain structure" patented technology

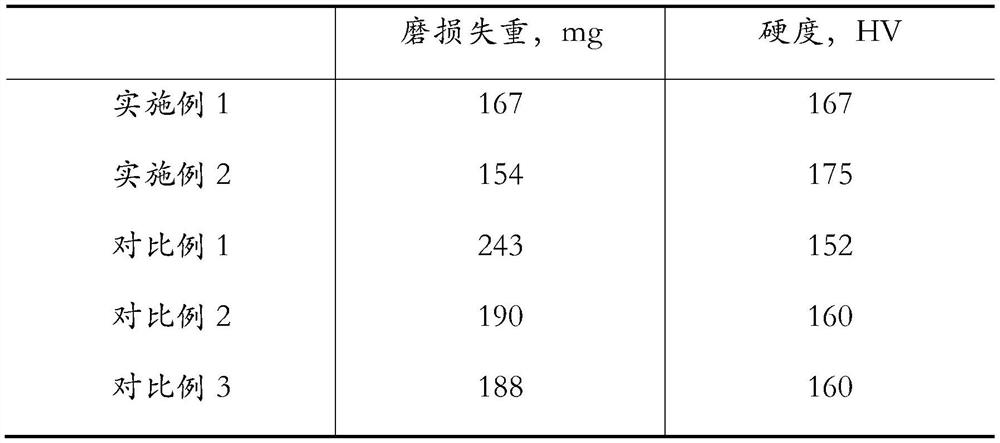

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite molybdenum wire used for linear cutting and manufacturing method

ActiveCN105772877AReduce the probability of crackingEasy to processElectrical-based machining electrodesRare earthSolid solution

The invention discloses a composite molybdenum wire used for linear cutting and a manufacturing method. The composite molybdenum wire is made of molybdenum powder containing solid solution metal elements and rare earth oxide. The solid solution metal elements are selected from at least one of Co, W, Ni, Hf or Re, and the weight content of the solid solution metal elements is 0.01%-0.30%. The rare earth oxide is selected from at least one of La2O3 or Y2O3, and the weight content of the rare earth oxide is 0.005%-0.20%. The manufacturing method comprises the following steps that secondary solid-liquid mixing is conducted, and uniform mixed molybdenum powder is obtained; then a molybdenum rod billet is obtained through pressing; the sintered molybdenum rod billet is rolled into a molybdenum coil rod; then the composite molybdenum wire used for linear cutting is obtained through drawing by repeatedly conducting a hot draw technique and a cold draw technique; and annealing is conducted repeatedly in the process, and the composite molybdenum wire is obtained. According to the composite molybdenum wire used for linear cutting, the abrasion resistance can be substantially improved, the service life is longer during cutting, the cutting speed is higher, and the rate of finished products is larger.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

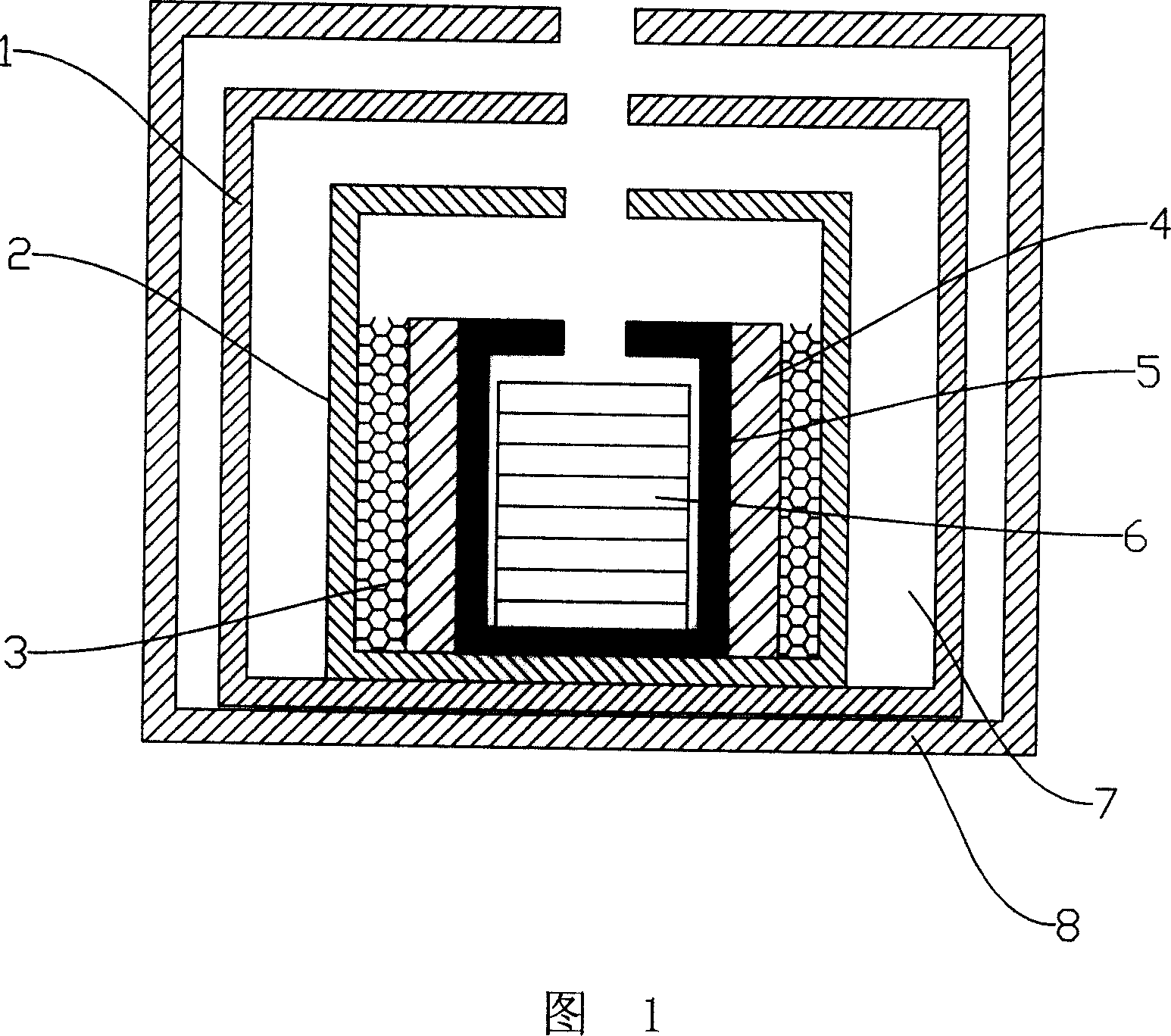

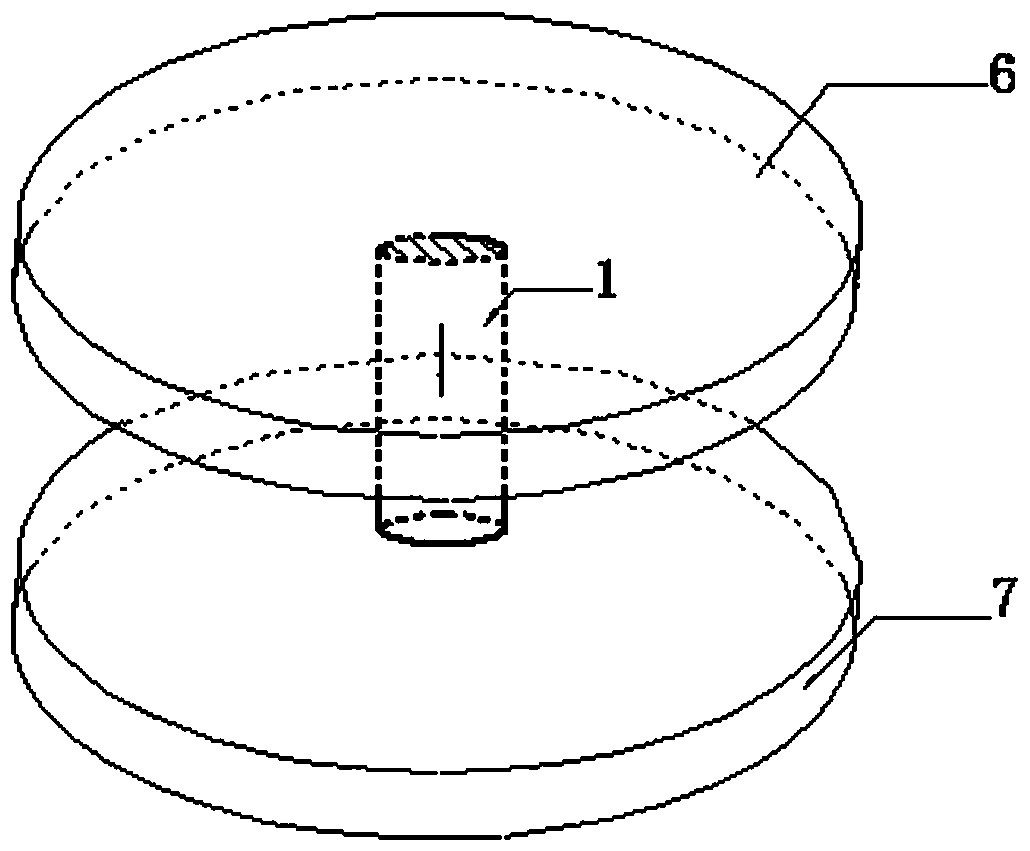

Microwave oven sintering method of producing silicon nitride ceramics heater and special equipment thereof

A microwave oven sintering preparation method of silicon nitride ceramic heating body and the special equipment belong to the field of preparation process of electric heating body and the special equipment. The present invention is characterized in that the special equipment comprises a microwave oven body, a crucible, a fiber insulation body on the outside layer and an insulation body on a secondary outer layer, a special insulation body for sintering consisting of an assistant heating plate and a fiber insulation ball filling layer. The preparation method is as follows: a ceramic green compact is put into a crucible; then the corundum crucible filled with the ceramic green compact and the special insulation bodies for sintering are together put into a microwave sintering device for sintering. The sintering process is as follows: the inside of the microwave oven is first vacuumed; the N2 of quality percent of more than 90 percent is filled; the procedures are repeated a plurality of times; the temperature-raising program is arranged to be adjustable between 5 DEG C per minute to 50 DEG C per minute; the temperature is raised to be 1300 plus or minus 50 DEG C and kept for 10 to 60 minutes; then the temperature is raised to be between 1600 and 1750 DEG C and kept for 5 to 60 minutes; the microwave source is closed and the product is naturally cooled.

Owner:SHENZHEN JINKE SPECIAL MATERIALS CO LTD

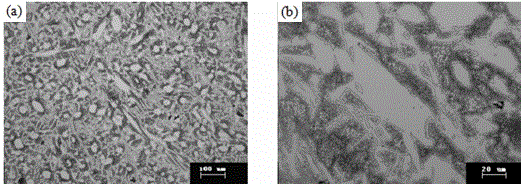

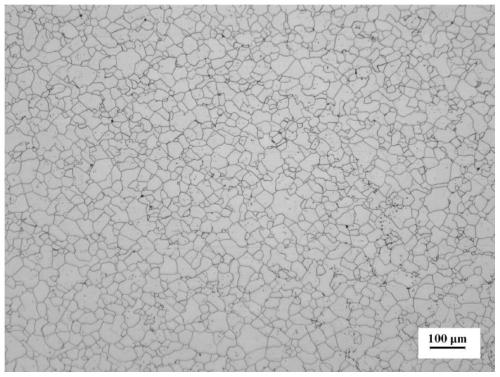

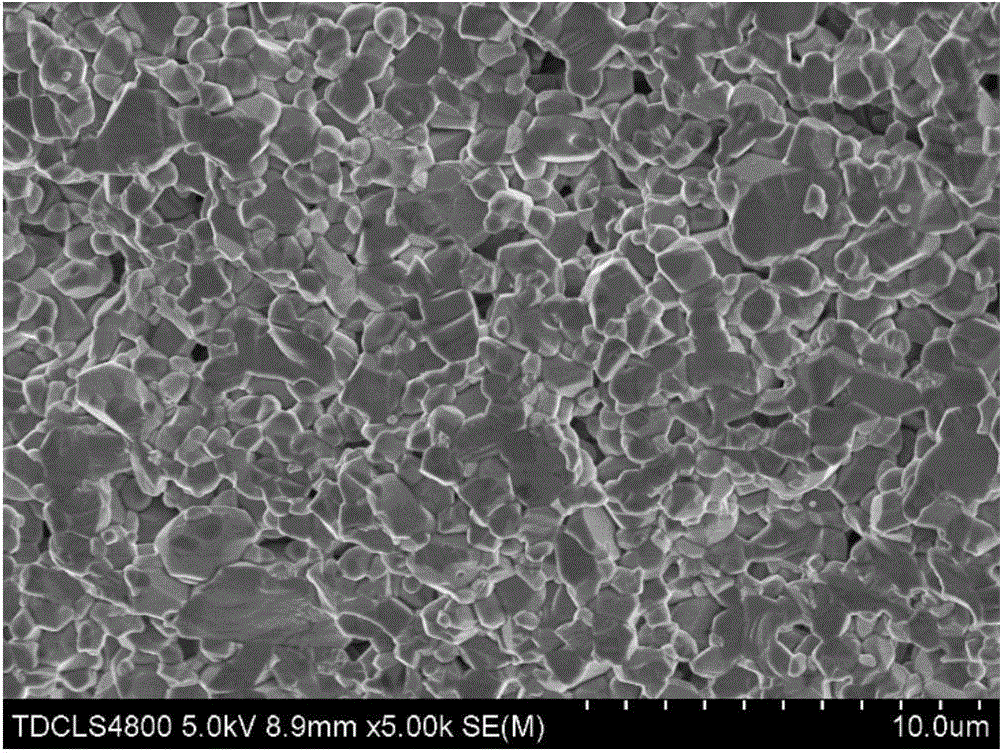

Preparation method of nano zirconia-toughened high-chromium refractory material

The invention discloses a preparation method of a nano zirconia-toughened high-chromium refractory material, which can produce a high-chromium material which has the advantages of favorable thermal shock resistance and low cracking tendency and can stably operate inside the kiln for a long time. The method comprises the following steps: by using 91-97 wt% of pigment-grade chrome oxide micropowder as a base, 1-6 wt% of nano zirconia powder as an additive and 3 wt% of titanium dioxide micropowder as a combustion assistant, dispersing by ball milling to form a uniformly dispersed slurry, drying the slurry to obtain powder, and carrying out binding molding to obtain the Cr2O3-ZrO2-TiO2 material. The Cr2O3-ZrO2-TiO2 high-chromium refractory material is a fine crystalline structure formed by distributing nano zirconia powder among the chrome oxide crystal grains or coating the nano zirconia powder among the chrome oxide crystal grains; and after the refractory material is sintered, the volume density is 3.52-4.68 g / cm<3>, and the porosity is 9.8-33.2%. The high-chromium refractory material has the advantages of higher compactness and higher thermal shock resistance.

Owner:TIANJIN UNIV

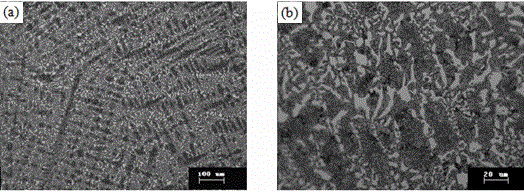

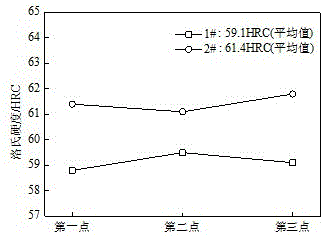

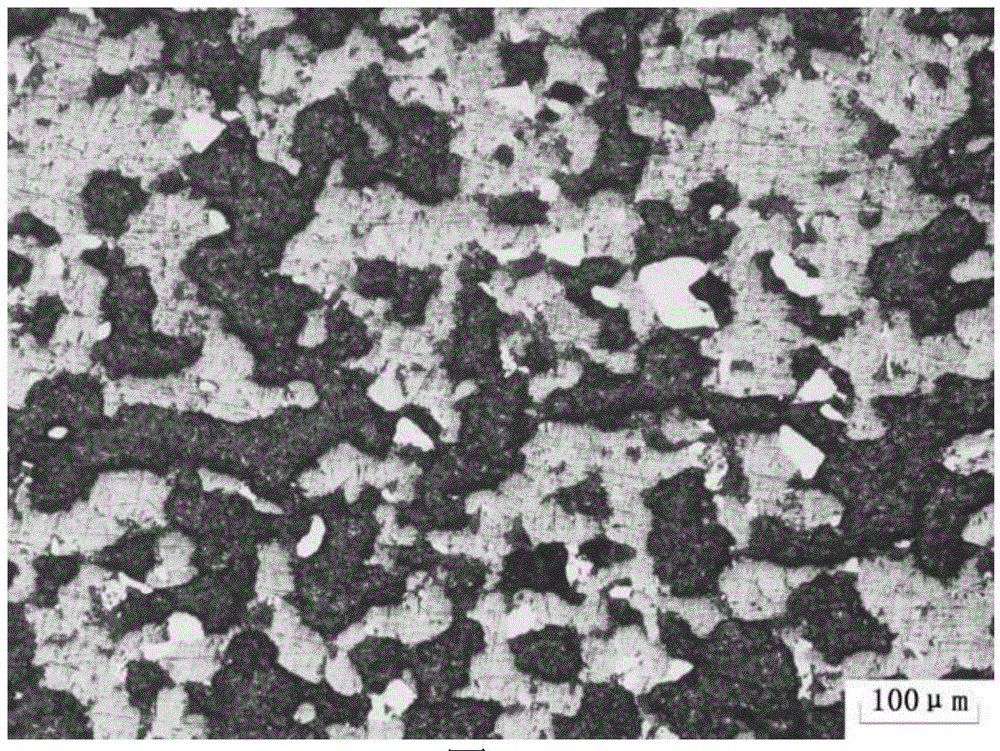

Wear-resisting hammer head for hammer type breaking machine and production method of wear-resisting hammer head

The invention provides a wear-resisting hammer head for a hammer type breaking machine. The wear-resisting hammer head comprises a high-manganese-steel lifting lug and a high-chrome iron hammer head body. The production method comprises smelting, modification treatment, casting and heat treatment. The hammer head produced through the method has the higher hardness and wear resistance, and wear of the hammer head in the using process is reduced; toughness of the hammer head can be obviously improved, and good bonding of hardness and the toughness is ensured; and the phenomenon that due to higher brittleness, the hammer head is broken in the using process is avoided.

Owner:NANJING MEISHAN METALLURGY DEV +2

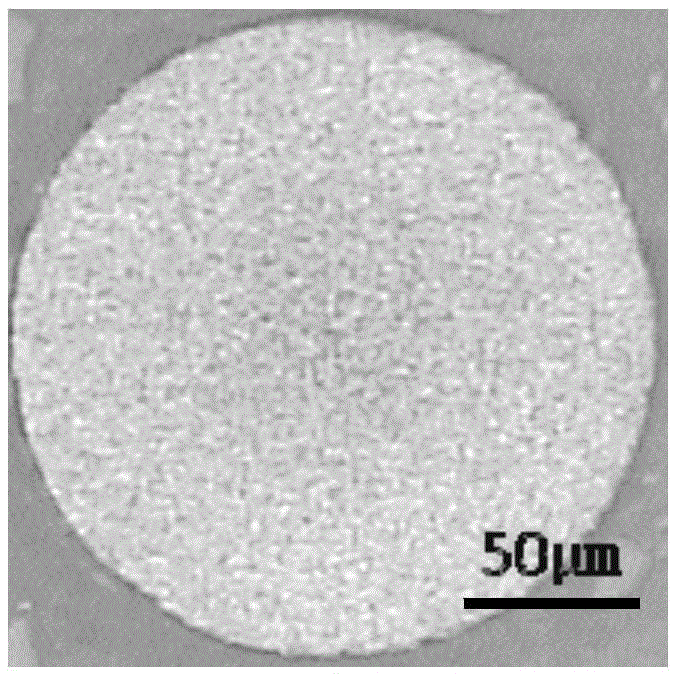

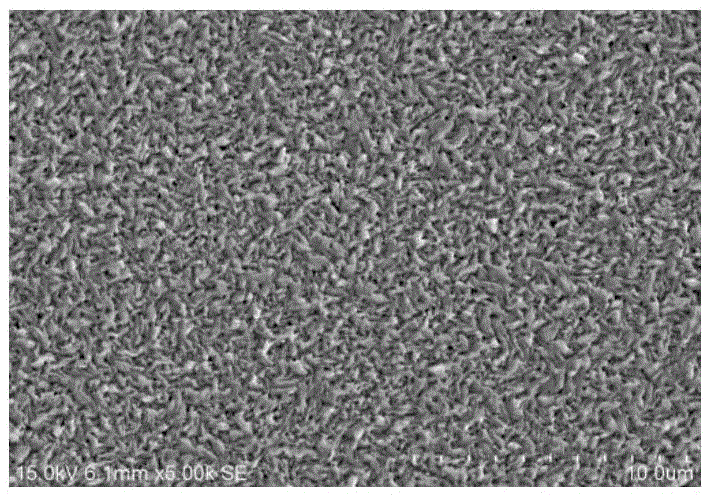

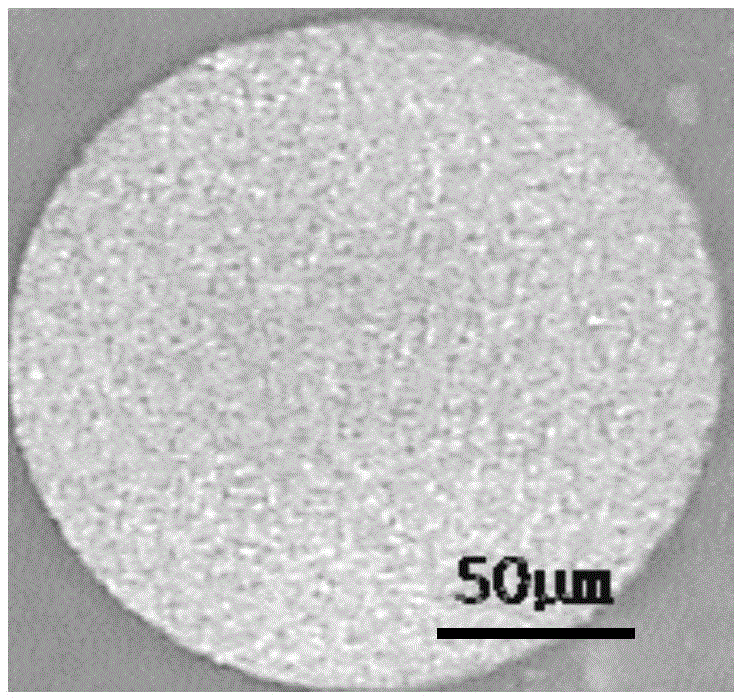

Preparation method for titanium, aluminum and silicon alloy target

ActiveCN104416157AHigh densityUniform fine grain structureVacuum evaporation coatingSputtering coatingHot isostatic pressingTitanium

The invention provides a preparation method for a titanium, aluminum and silicon alloy target. The method comprises the steps: alloy powder preparation, cold isostatic pressure treatment, degassing treatment, thermal isostatic pressure treatment and machining. The titanium, aluminum and silicon alloy target prepared by the preparation method disclosed by the invention has the advantages of high compactness, no gas hole and segregation, uniform tissue, small crystalline grain and the like, and is suitable for sputtering coating layers of various cutters and dies.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

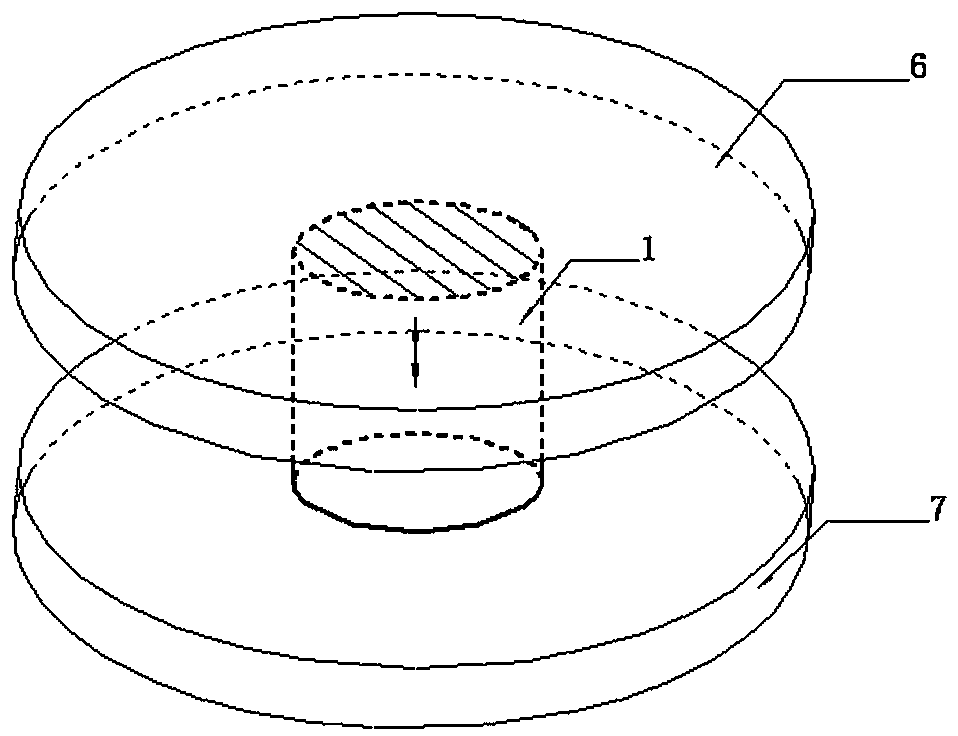

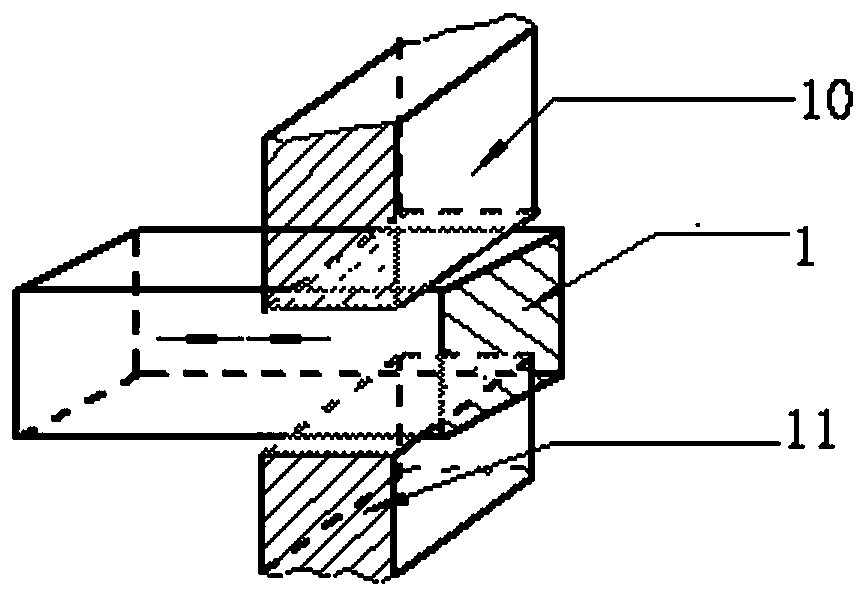

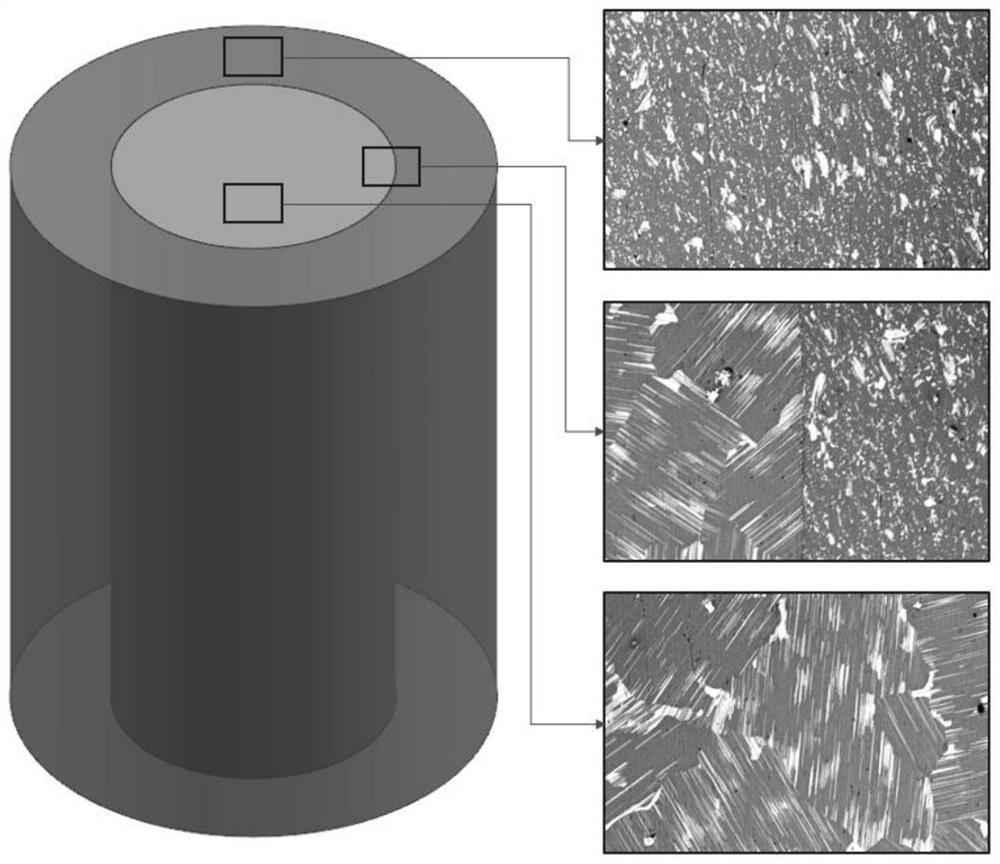

Forging method capable of efficiently, integrally and uniformly compacting deformation

InactiveCN108465762AImprove forgeabilityImprove forging efficiencyMetal-working apparatusIngotDeformation Problem

The invention relates to a forging method capable of efficiently, integrally and uniformly compacting deformation, and the forging method can uniformly refine compacting deformation and the structureof a large forged piece product. The forging method is characterized in that special upper and lower wide plates are adopted for upsetting and forging a forged piece, so that forging main deformationis completed; then, finishing forming is performed on upper and lower anvils; a special wide plate is utilized for integrally forging, so that forging permeability is greatly improved, and the problemthat forging deformation is uneven at positions such as each hammer head, and a joint of the hammer heads during upper and lower anvil forging is also overcome, and therefore, the inner part of the forged piece is forged thoroughly and compacted, and a uniform fine grain structure is obtained; upset electroslag ingots are mainly deformed on upper and lower wide plates, and integral once formationis performed until design dimensions at every pass in a wide plate forging process, and reduction is controlled to be 25%-40%; the electroslag ingots are integrally forged until deformed to the designed dimensions between upper and lower flat plates after being turned over by 90 degrees, and 700mm-wide upper and lower nails are adopted for forging and forming so as to conveniently erecting angles, so that the uneven forging deformation problem of the hammer head during main deformation is avoided, forging permeability is improved, anvil replacing times are reduced, forging time is saved by about 1 / 2, forging production efficiency is improved, production cost is reduced, and product quality stability is high.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Method for preparing large-specification difficult-to-deform high-temperature alloy fine crystal bar

InactiveCN110394410ALarge amount of deformationConducive to complete recrystallization and refinementMetal-working apparatusIngot castingHot working

The invention discloses a method for preparing a large-specification difficult-to-deform high-temperature alloy fine crystal bar, and belongs to the technical field of high-temperature alloy hot machining. The method comprises the following steps of ingot casting machining; ingot upsetting; intermediate billet sheathing; hot extruding; and extrusion bar machining. According to the method, a billetmaking method that the cogging deformation is enabled to be increased through the upsetting and extruding and optimizing deformation distribution is provided, the method can be used for preparing thelarge-specification difficult-to-deform high-temperature alloy uniform and fine crystal rod, and meet the development requirements of a difficult-to-deform nickel-based high-temperature alloy turbinedisc forging piece.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation method of ultralow-temperature TA7ELI titanium alloy plate

ActiveCN109013738AImprove ultra-low temperature deformation performancePromote homogenizationMetal rolling arrangementsAcid washingRoom temperature

The invention discloses a preparation method of an ultralow-temperature TA7ELI titanium alloy plate. The method comprises the following steps: (1) a TA7ELI titanium alloy plate blank is heated for thefirst time; (2) the TA7ELI titanium alloy plate blank is rolled as a first semi-finished plate blank after primary heating; (3) the first semi-finished plate blank is formed to a second semi-finishedplate blank through polishing, acid washing and cutting in sequence; (4) the second semi-finished plate blank is heated for the second time; (5) the second semi-finished plate blank is rolled as a second semi-finished plate blank after secondary heating; and (6) the second semi-finished plate blank is straightened after insulation, and is cooled in air to reach the room temperature to obtain theTA7ELI titanium alloy plate. The high-temperature heating treatment and the reversing rolling method are adopted to provide larger deformation space for twin deformation, in the leading deformation role, of the plate under ultralow temperature; and the plate blank structure uniformity is promoted to obtain the ultralow-temperature TA7ELI titanium alloy plate.

Owner:WESTERN TITANIUM TECH

Isothermal die forging technology for large-size high-strength aluminum alloy parts

InactiveCN105964849AImprove plasticityImprove malleabilityMetal-working apparatusLarge deformationLarge size

The invention relates to an isothermal die forging technology for large-size high-strength aluminum alloy parts, and belongs to the technical field of aluminum alloy machining. According to the isothermal die forging technology, large-size aluminum alloy forging cake blanks undergo isothermal die forging formation in one step after being heated and thermally insulated for obtaining forge pieces, the forge pieces are taken out and cooled, and finally finished products are obtained; in the isothermal die forging process, the descending speed of upper dies is 0.1-0.2 mm / s. By selecting raw materials and strictly controlling forging parameters, continuous large deformation is realized on the condition that alloy crystal grains do not grow, and the large-size and high-performance aluminum alloy parts can be prepared with high efficiency and low cost. The isothermal die forging technology has the advantages that the operation is easy, the production efficiency is high, the product quality is high and the practicability is high, thereby being suitable for industrialized use and popularization.

Owner:SHANDONG NANSHAN ALUMINUM

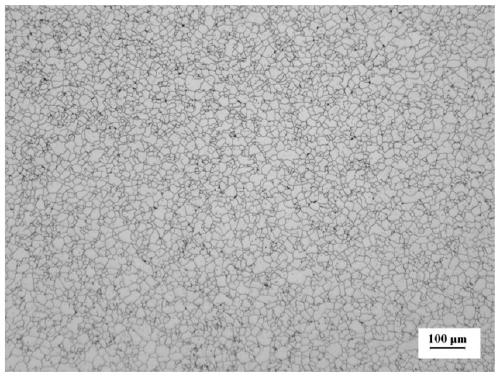

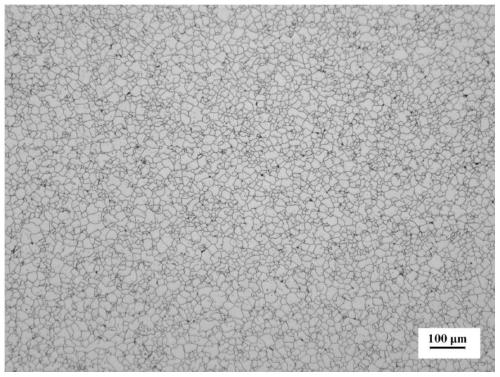

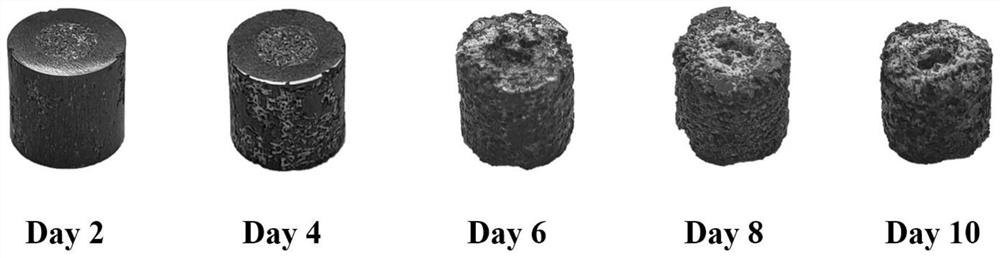

GH4282 nickel-based high-temperature alloy bar and preparation method thereof

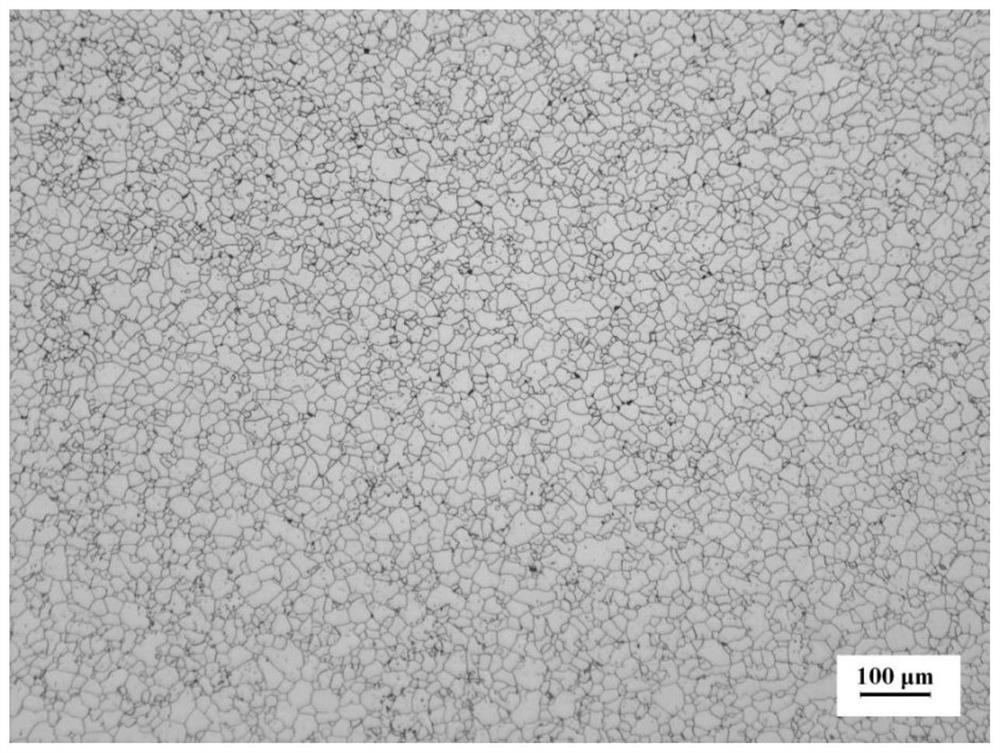

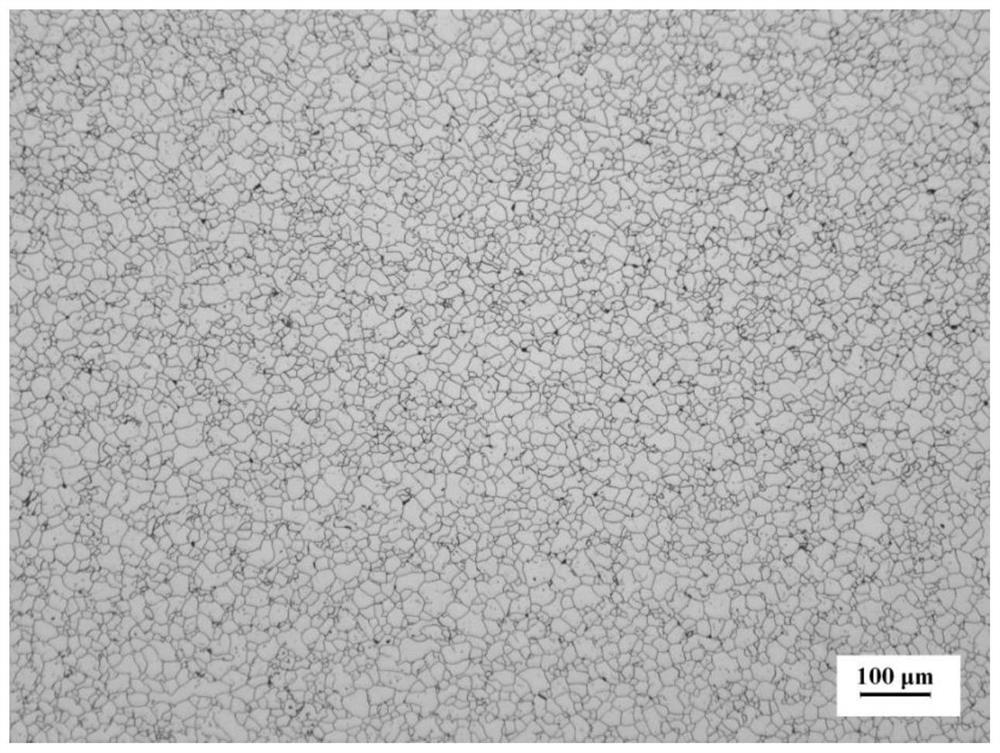

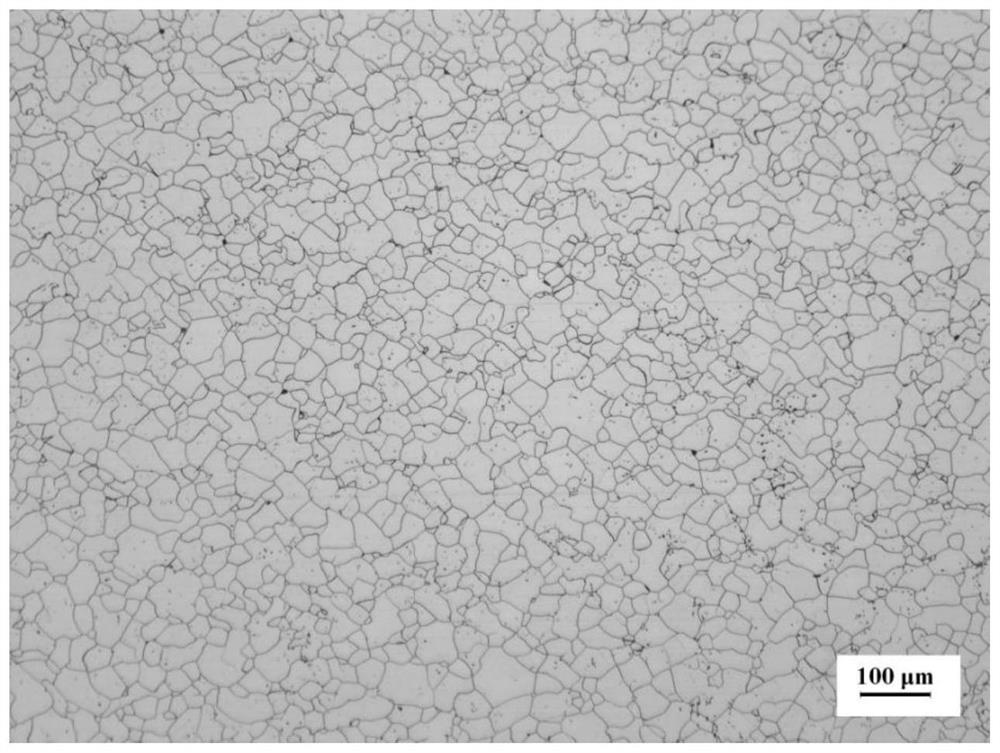

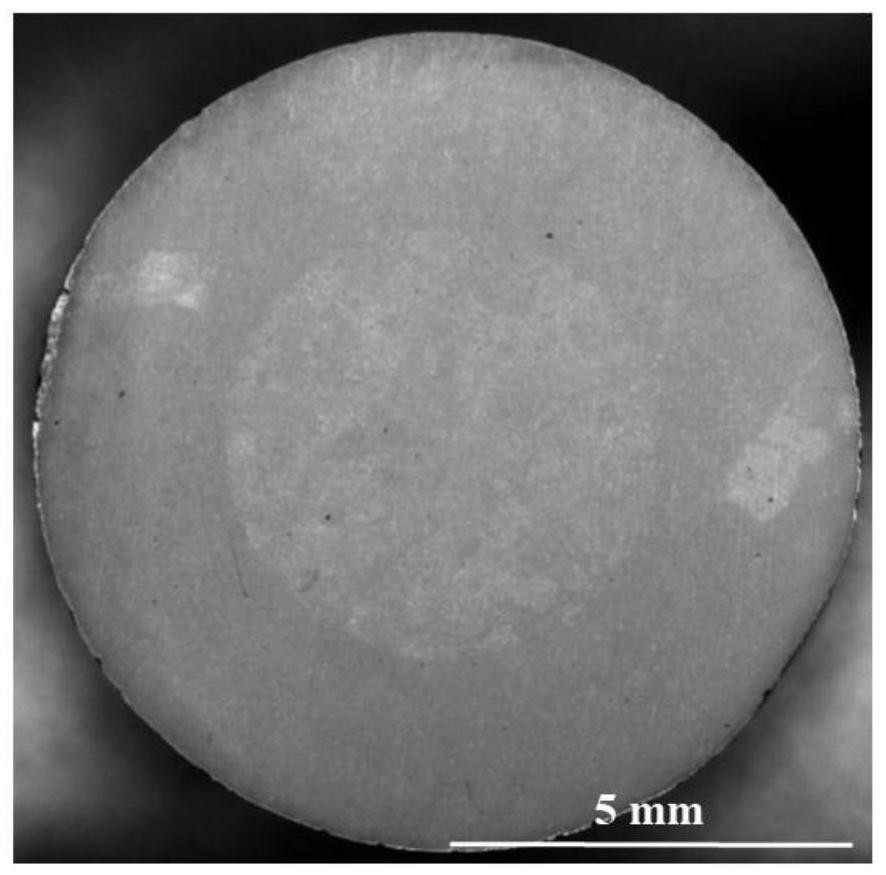

ActiveCN111118423AUniform fine grain structureImprove tissue performance uniformityTemperingIngot casting

The invention discloses a GH4282 nickel-based high-temperature alloy bar and a preparation method thereof, and solves the technical problems of coarse grain size and poor uniformity of an existing GH4282 alloy bar. The preparation method comprises the following steps: S1, heating a GH4282 nickel-based high-temperature alloy ingot casting; S2, carrying out primary upsetting and tempering on the ingot casting in the axial direction to obtain a blank, and carrying out primary hot drawing and tempering on the blank in the direction perpendicular to the axial direction; S3, carrying out secondary upsetting and tempering on the blank in the axial direction, and then carrying out secondary hot drawing and tempering in the direction perpendicular to the axial direction; S4, carrying out three-timeupsetting and tempering on the blank in the axial direction, and then carrying out three-time drawing and tempering in the direction perpendicular to the axial direction to obtain a bar blank; and S5, tempering the bar blank in the step S4, and then performing one-fire-diameter forging forming to obtain the GH4282 nickel-based high-temperature alloy bar. The invention further discloses the GH4282nickel-based high-temperature alloy bar prepared by the method. The GH4282 nickel-based high-temperature alloy bar has the advantage that the structure uniformity of the GH4282 nickel-based high-temperature alloy bar can be effectively improved, so that the performance of the GH4282 nickel-based high-temperature alloy bar is improved.

Owner:BEIJING CISRI GAONA TECH +1

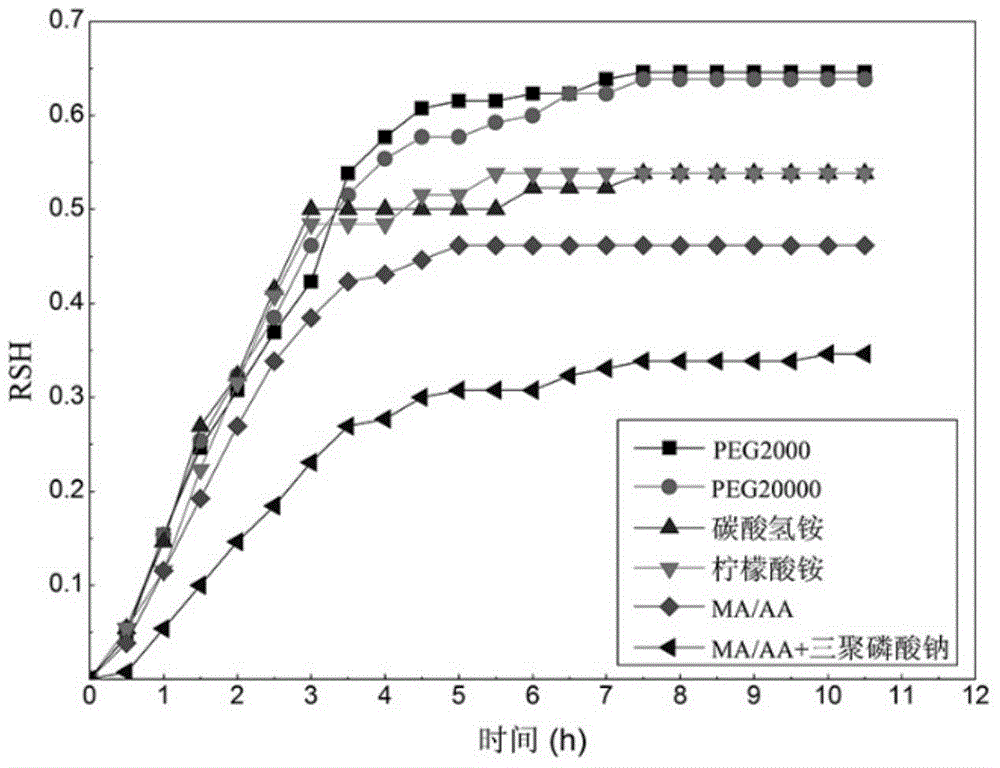

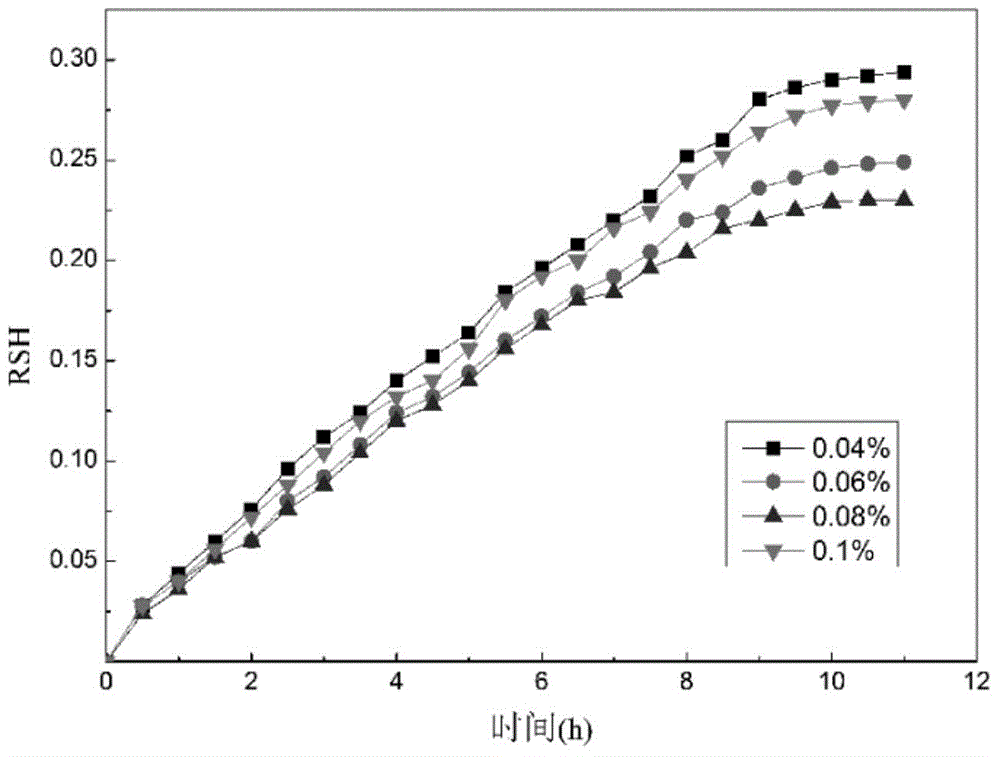

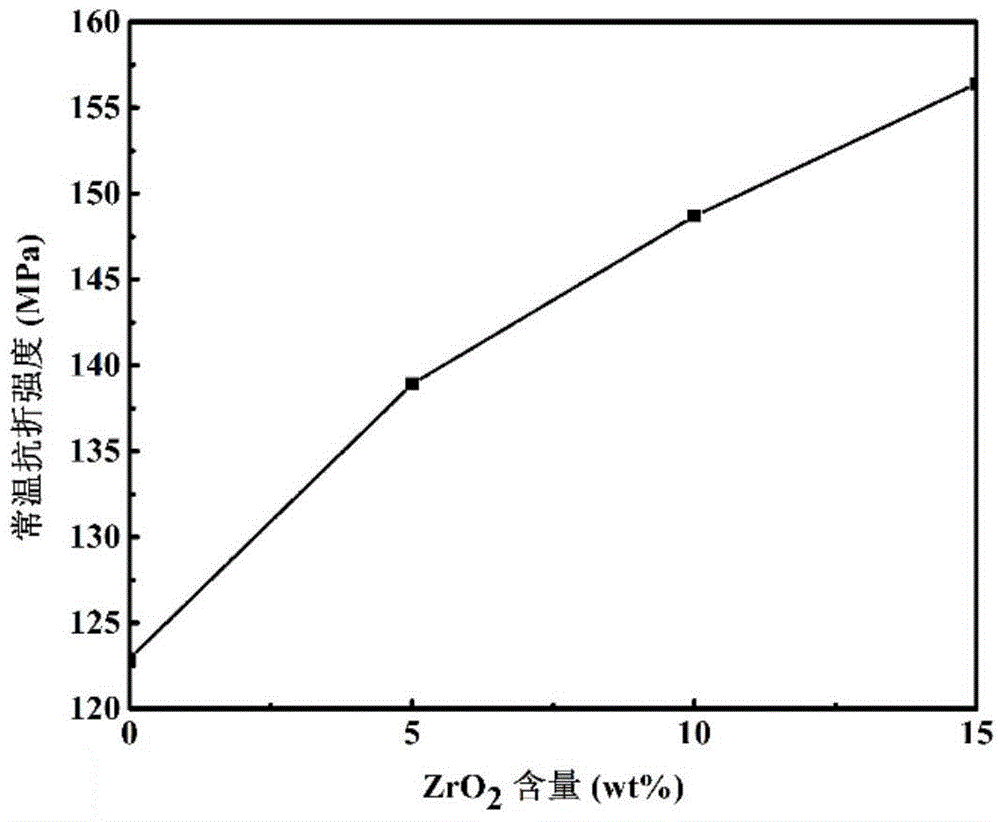

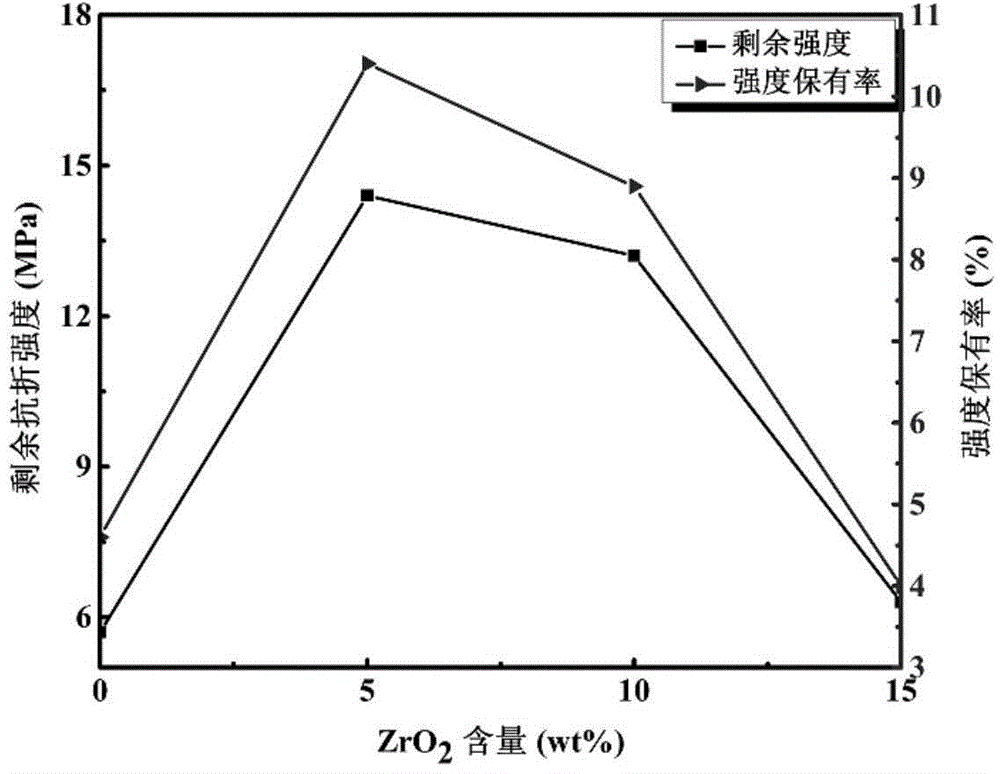

Preparation method of nano zirconium oxide and chromium oxide composite material

The invention discloses a preparation method of a nano zirconium oxide and chromium oxide composite material. The preparation method comprises the following steps: performing ball-milling dispersion to form uniformly dispersed slurry by taking 82-97wt% of pigment-grade chromium oxide micro powder as a matrix, 1-15wt% of nano zirconium oxide as a complexing agent and 3wt% of titanium dioxide micro powder as a sintering aid; and drying the slurry into powder, and then performing bonding forming to finally prepare the nano zirconium oxide and chromium oxide composite material. The nano zirconium oxide and chromium oxide composite material has a fine crystalline structure in which nano zirconium oxide is distributed among chromium oxide crystalline grains or wrapped in the chromium oxide crystalline grains, the volume density after sintering is 4.39-5.11g / cm<3>, and the porosity is 0.9-16.7%. By adopting the preparation method disclosed by the invention, the production of a composite material which has high strength, high compactness and good thermal impact resistance and can be stably operated in a furnace for a long time can be ensured.

Owner:TIANJIN UNIV

Manufacturing technology of arc-shaped molybdenum plate for long-service-life heat shield

A manufacturing technology of an arc-shaped molybdenum plate for a long-service-life heat shield specifically comprises the steps of preparing powder A which is of a rhenium-doped nanometer aluminum oxide structure, preparing nanometer lanthanum oxide, preparing the molybdenum plate, preparing a molybdenum blank through the molybdenum plate, and pressing the molybdenum blanket to obtain the targeted arc-shaped molybdenum plate. According to the manufacturing technology, the outward dispersing and oxidizing capacity of molybdenum is reduced through compound elements, so that the oxidizing resistance of molybdenum can be improved, and the service life can be prolonged by more than 30%; in addition, powder metallurgy and mechanical rolling are combined, so that the relative density of the manufactured arc-shaped molybdenum plate is high, and the plasticity is improved, and as a result, cracks can be avoided; an uniform fine grain structure is obtained, and thus physical performance and the mechanical performance can be improved.

Owner:LUOYANG KEWEI MOLYBDENUM & TUNGSTEN

Microwave sintering and heat treatment method for preparing high-performance tungsten-based high-density alloy

A microwave sintering and heat treatment method for preparing high-performance tungsten-based high-density alloy comprises the following steps: preparing a powder compact by a traditional powder metallurgy method, putting the compact in a microwave high-temperature furnace with atmosphere protection and a vacuum pump, controlling the atmosphere in the furnace chamber to be reducing atmosphere at a heating phase below 1200 DEG C; sintering the product at low vacuum at a high-temperature phase of 1200-1400 DEG C, and vacuumizing the furnace to obtain a high vacuum of 10-2 Pa at a cooling phase after sintering. The obtained alloy has a uniform fine grain structure, and high mechanical properties. The invention adopts low vacuum at the sintering phase, and adopts high vacuum at the cooling phase, which allow the hydrogen content of the alloy to be reduced, and effectively avoid the hydrogen embrittlement phenomenon. Additionally, the tungsten-based high-density alloy is prepared by microwave sintering technology and equipment, which is rapid, high-efficient, simple, and low in cost; the tungsten-based high-density alloy is prepared by microwave sintering-heat treatment technology; theprocess is easy to control; the technology is mature, and is applicable to industrial production.

Owner:CENT SOUTH UNIV

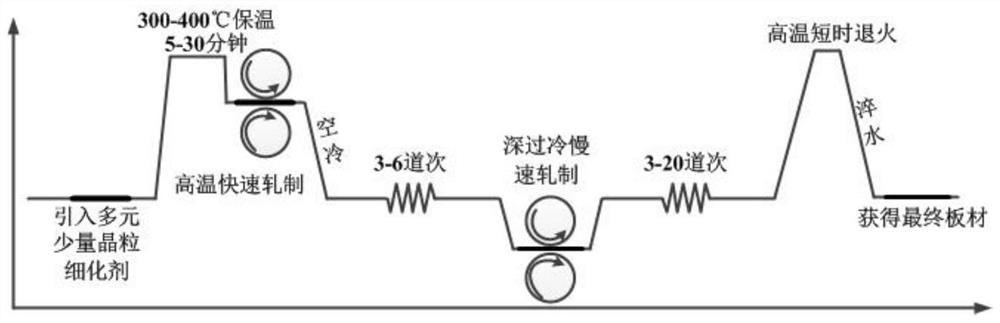

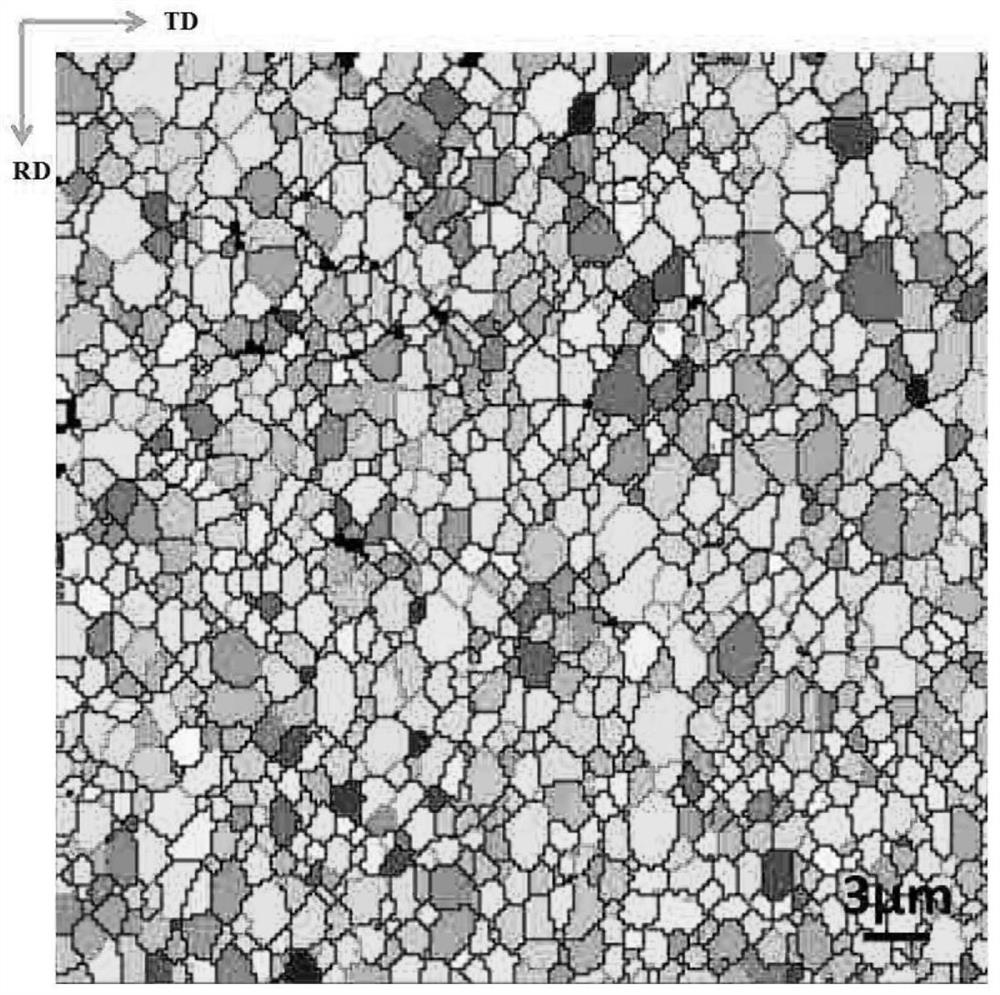

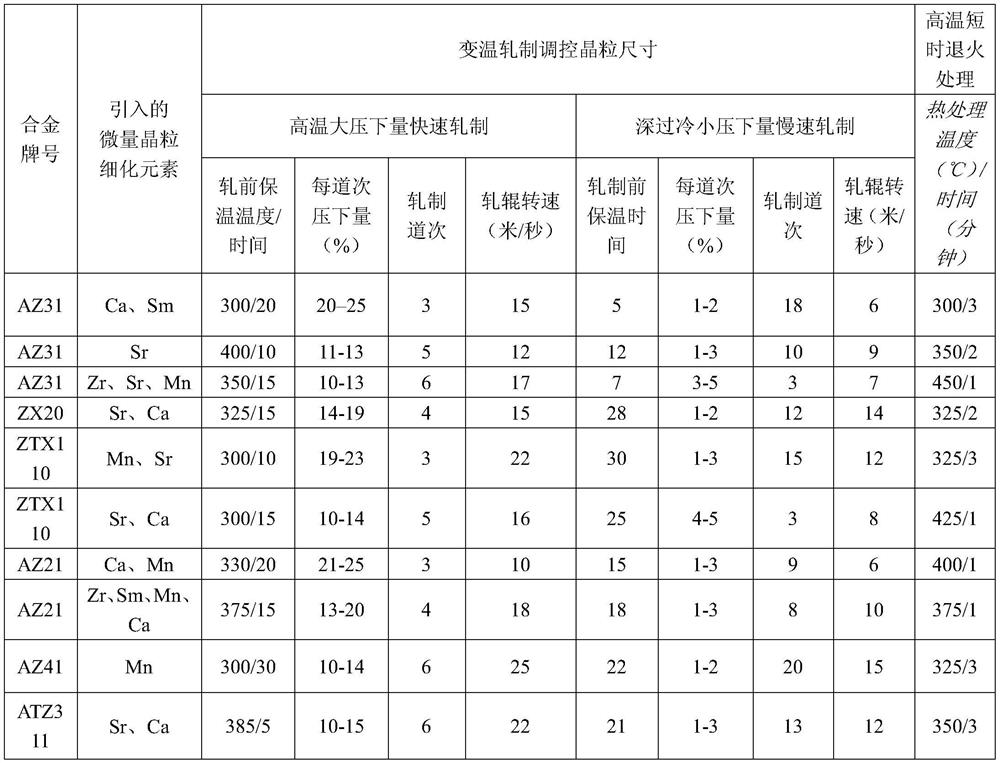

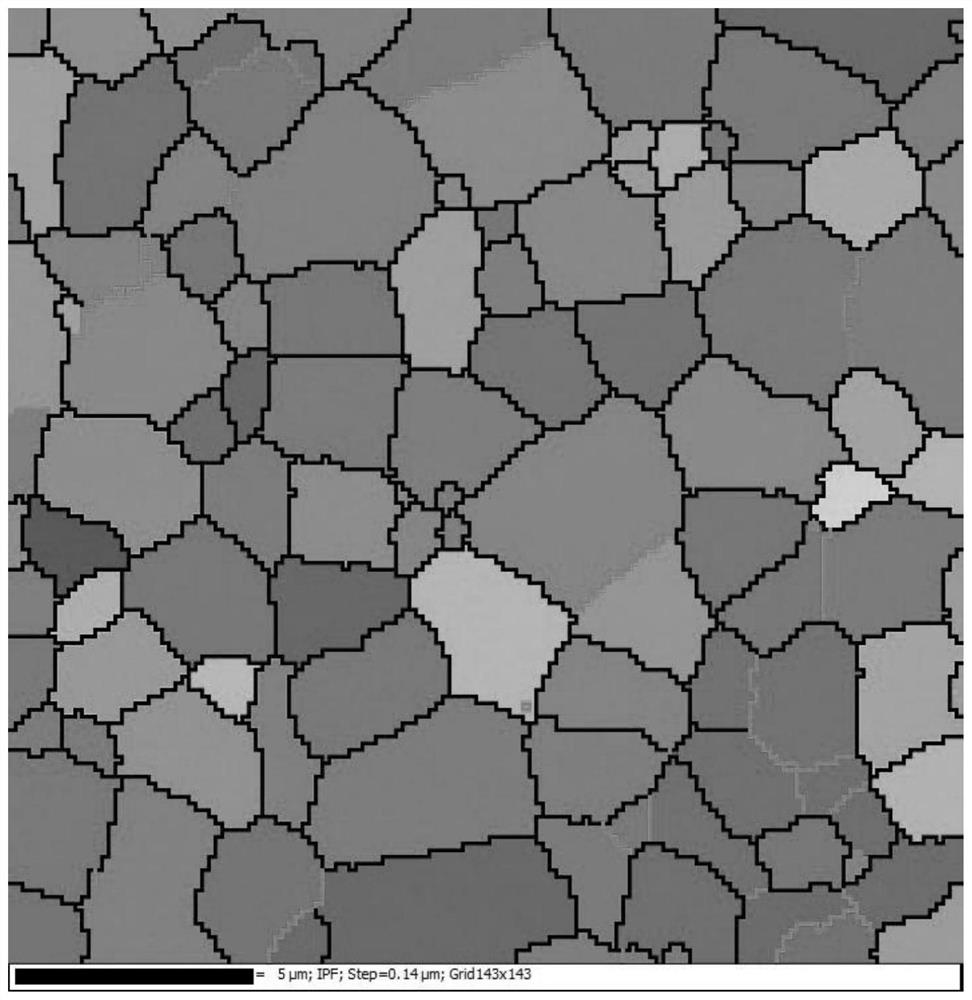

A method for preparing low-content magnesium alloys with uniform and fine-grained variable temperature controlled rolling

ActiveCN109837437BOmit high temperature solution treatmentShort production processTemperature control deviceMetal rolling arrangementsTemperature controlMicron scale

The invention relates to a variable temperature controlled rolling preparation method for makinglow-content magnesium alloys with uniform fine grains. The low-content magnesium alloys are magnesium alloys with the chemical composition mass percentage less than or equal to 5%, such as AZ31, ZX20, ZX10 and AZ21. The variable temperature controlled rolling preparation method for making the low-content magnesium alloys with the uniform fine grains includes three steps of adding trace amounts of grain refining elements, adjusting the grain size through variable temperature rolling and high-temperature short-term recrystallization treatment. According to the variable temperature controlled rolling preparation method for making the low-content magnesium alloys with uniform fine grains, by introducing the trace amounts of refining elements, combined with a variable temperature controlled rolling method, the technical problems that the low-content magnesium alloys are difficult to refine and difficult to deform at the room temperature or below the room temperature are solved, low-content magnesium alloy sheets with the average grain size less than 3 micron are prepared, and an idea is provided for preparation of novel high-performance magnesium alloy plates with the micron grain size in short process and low cost.

Owner:JILIN UNIV

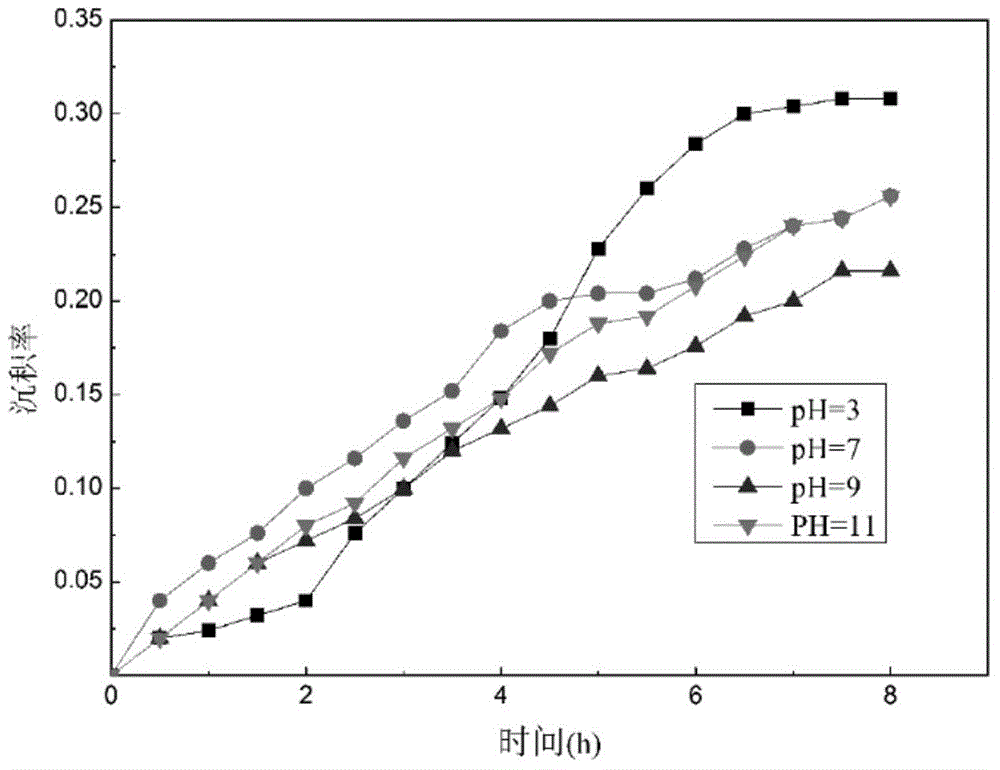

Method for preparing nano zircite combining aluminium titanate composite material

InactiveCN101423389BInhomogeneous fine grain structureUniform fine grain structureZirconium oxychlorideDysprosium titanate

The invention relates to a method for preparing a composite material of the combination of nano-zirconia and aluminium titanate, which belongs to the field of ceramic materials. The method comprises the following steps: dispersing aluminium titanate powder the grain size of which is less than 0.01 millimeter into a zirconium oxychloride aqueous solution the concentration of which is between 0.02 and 0.06 mol per liter; dripping ammonia into the mixture while stirring until the pH value is between 8.7 and 9.5 to obtain a soliquid deposition; calcining the soliquid deposition at a temperature of more than 600 DEG C for 2 hours after dehydration and drying to obtain composite material powder of the combination of the nano-zirconia and the aluminium titanate, wherein the diameter of the powder is less than 100 nanometers, and the components of the powder in weight percentage are: 2 to 10 percent of zirconia and 90 to 98 percent of the aluminium titanate; performing pressure molding on the powder to form a blank with the pressure of more than or equal to 100 MPa; and keeping the temperature of the blank at 1,500 DEG C for 2 hours and sintering the blank to obtain the composite material of the combination of the nano-zirconia and the aluminium titanate. The strength of the material is higher than that of the common aluminium titanate material, thus the composite material is a promising updating material for a continuous casting water gap for metallurgy of iron and steel or a nonferrous metallurgy liquid-raising tube.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of copper alloy material and preparation method thereof

The invention provides a copper alloy material for a large-expanded-hole shaped charge liner and a preparation method thereof. Copper powder, zinc powder and aluminum powder are adopted as raw materials, powder-compacting sintering smelting is adopted, vacuum electron-beam smelting is adopted, and the vacuum degree is not lower than 2*10<-3> Pa. The density of the prepared copper alloy material is6-7 g / cm3, the ductility is high, and compared with a traditional pure-copper shaped charge liner material, the high penetration depth is kept, the diameter of expanded holes is enlarged, and penetration power of the shaped charge liner is improved.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

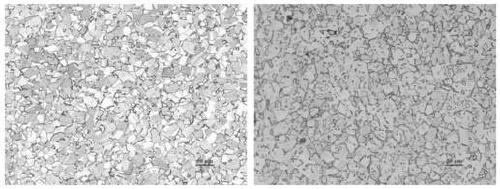

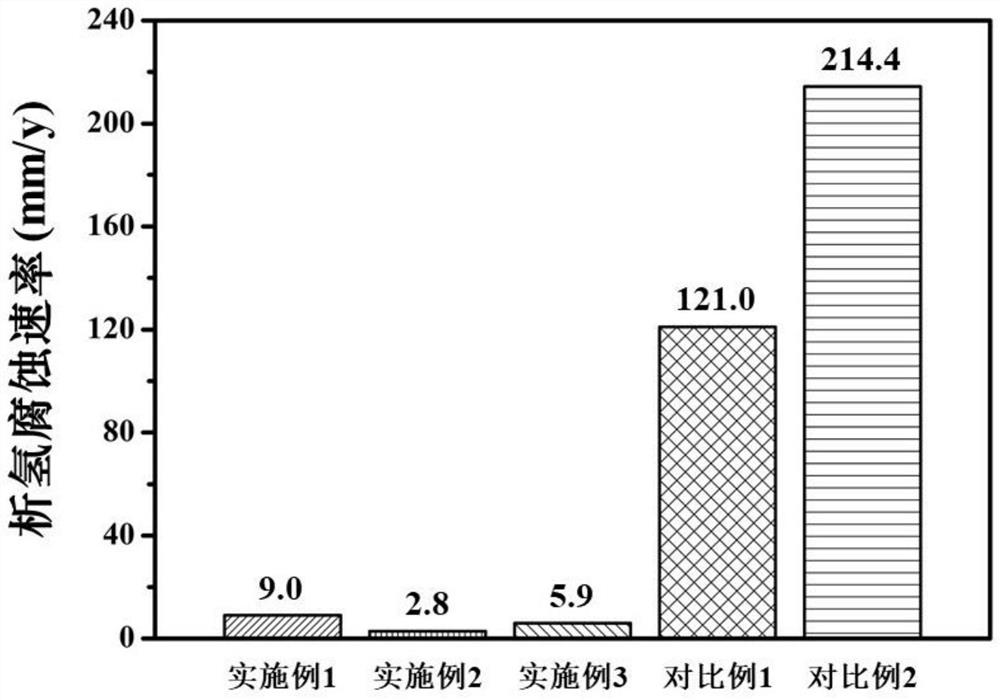

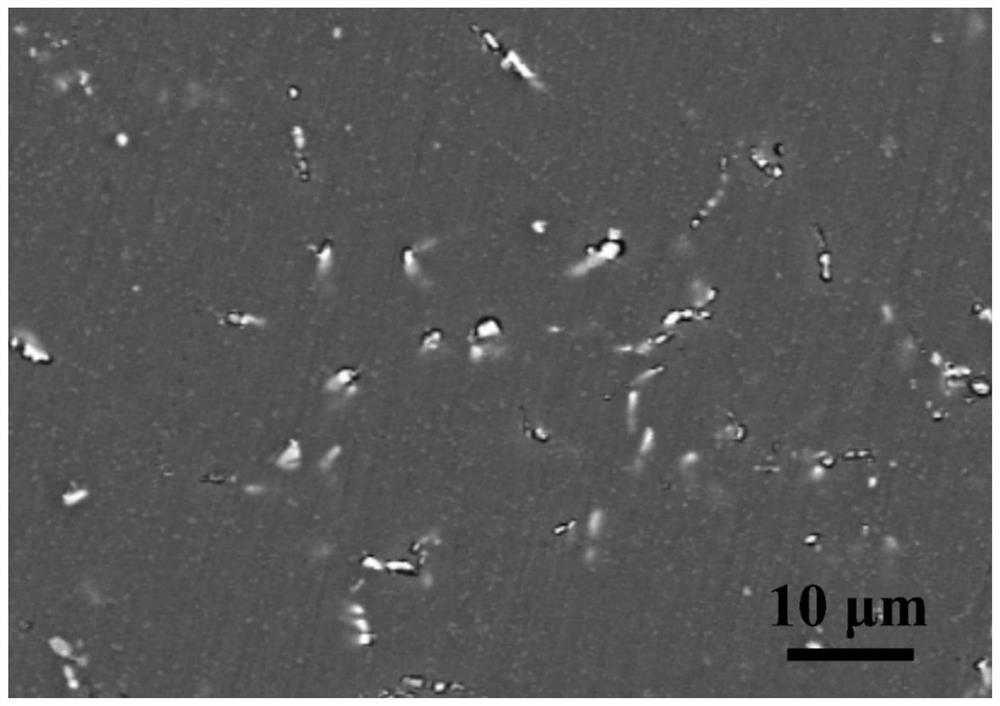

A kind of corrosion-resistant high-strength plastic magnesium alloy and preparation method thereof

The invention provides a corrosion-resistant high-strength plastic magnesium alloy and a preparation method thereof. The magnesium alloy is composed of the following components according to the mass percentage of the components: 4-6% of aluminum, 1-3% of tin, and 0.1% of calcium ‑2%, manganese 0.01‑0.5%, rare earth 0.01‑0.2%, unavoidable impurities ≤ 0.02%, and the balance magnesium. The magnesium alloy preparation method includes five steps of sub-rapid solidification, pre-rolling, gradient solid solution, cross-rolling and stress relief annealing. Compared with the conventional magnesium alloy, the invention improves the stability and compactness of the corrosion product film by adding trace amounts of rare earth elements cerium and samarium, hinders the erosion of chloride ions on the alloy surface, suppresses localized corrosion, and improves the corrosion resistance of the alloy. In addition, the preparation method of the present invention can effectively control the size and distribution of the second phase in the magnesium alloy, and refine the crystal grains, thereby successfully preparing a corrosion-resistant high-strength plastic magnesium alloy.

Owner:JILIN UNIV

A preparation method of ta7eli titanium alloy plate for ultra-low temperature

ActiveCN109013738BImprove ultra-low temperature deformation performancePromote homogenizationMetal rolling arrangementsRoom temperatureAcid washing

Owner:WESTERN TITANIUM TECH

Wear-resistant aluminum alloy and preparation method thereof

ActiveCN114774728AHigh hardnessImprove wear resistanceIncreasing energy efficiencyManganeseCryogenic technology

The invention relates to a wear-resistant aluminum alloy and a preparation method thereof, and belongs to the technical field of non-ferrous metals. The aluminum alloy is prepared from the following chemical components in percentage by mass: 10.4 to 11.8 percent of Si, 1.5 to 2.5 percent of Zr, 1.2 to 2.2 percent of Ti, 0.05 to 0.1 percent of Cu, 1.2 to 1.7 percent of Sn, 0.5 to 0.7 percent of Mn, 1.4 to 2.4 percent of Nb, 0.07 to 0.2 percent of Fe, 0.03 to 0.15 percent of Ni, 0.05 to 0.15 percent of Cr, 0.14 to 0.22 percent of V, 0.2 to 0.25 percent of Mo and the balance of Al. The preparation method comprises the following steps: firstly, carrying out mechanical alloying through a high-energy ball mill, and then carrying out microwave sintering, low-temperature rolling, vacuum annealing treatment and magnetic field subzero treatment. By optimizing the contents of elements such as silicon, zirconium, copper, nickel and manganese and adding chromium, vanadium, molybdenum and tin, forced solid solution between atoms of different elements is realized by means of mechanical alloying, and a microwave sintering technology, a low-temperature rolling technology and a magnetic field cryogenic technology are applied to refine crystal grains, improve compactness and form deformation stress strengthening, so that the high-strength and high-toughness alloy is obtained. And the hardness and wear resistance of the aluminum alloy are improved.

Owner:JIANGSU UNIV

Composite molybdenum wire for wire cutting and production method thereof

ActiveCN105772877BImprove wear resistanceReduce the probability of crackingElectrical-based machining electrodesRare earthWire cutting

The invention discloses a composite molybdenum wire used for linear cutting and a manufacturing method. The composite molybdenum wire is made of molybdenum powder containing solid solution metal elements and rare earth oxide. The solid solution metal elements are selected from at least one of Co, W, Ni, Hf or Re, and the weight content of the solid solution metal elements is 0.01%-0.30%. The rare earth oxide is selected from at least one of La2O3 or Y2O3, and the weight content of the rare earth oxide is 0.005%-0.20%. The manufacturing method comprises the following steps that secondary solid-liquid mixing is conducted, and uniform mixed molybdenum powder is obtained; then a molybdenum rod billet is obtained through pressing; the sintered molybdenum rod billet is rolled into a molybdenum coil rod; then the composite molybdenum wire used for linear cutting is obtained through drawing by repeatedly conducting a hot draw technique and a cold draw technique; and annealing is conducted repeatedly in the process, and the composite molybdenum wire is obtained. According to the composite molybdenum wire used for linear cutting, the abrasion resistance can be substantially improved, the service life is longer during cutting, the cutting speed is higher, and the rate of finished products is larger.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

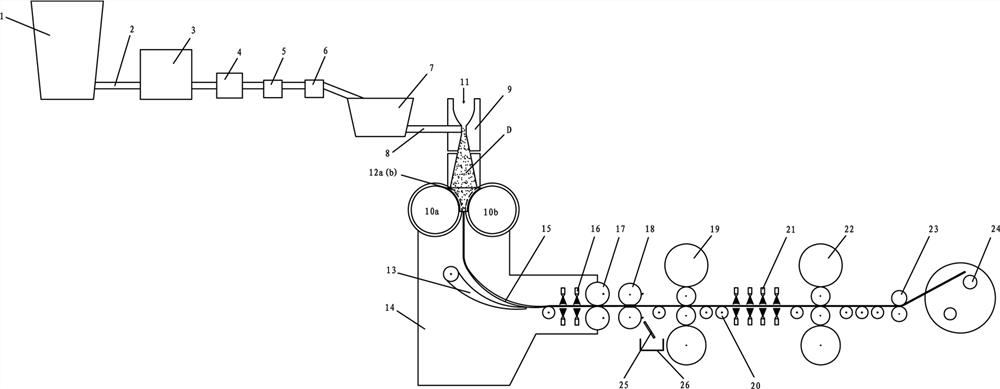

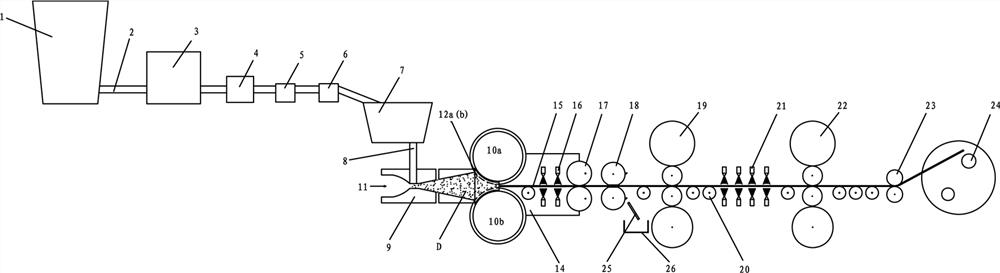

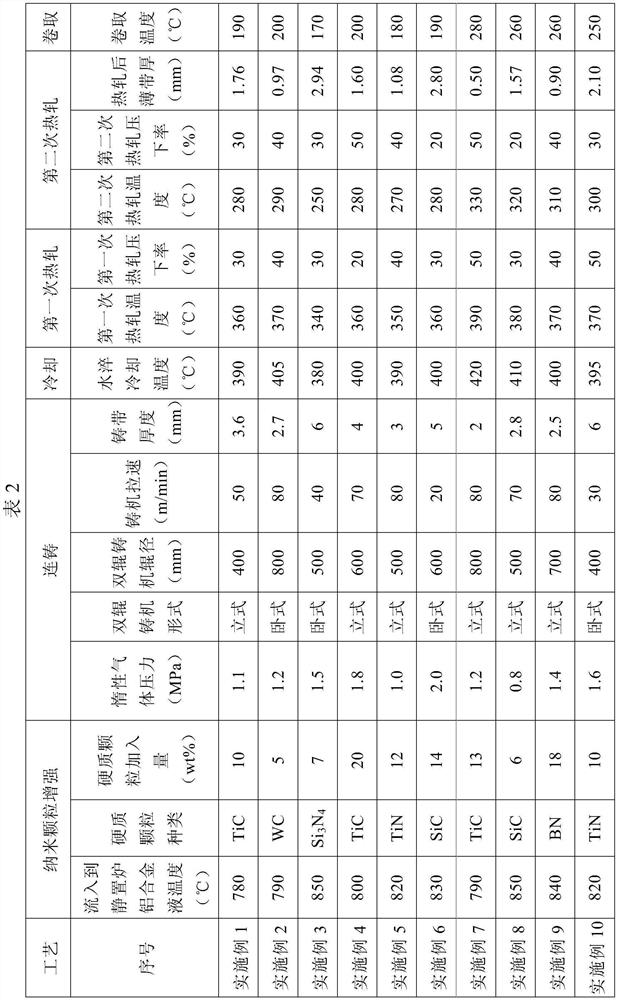

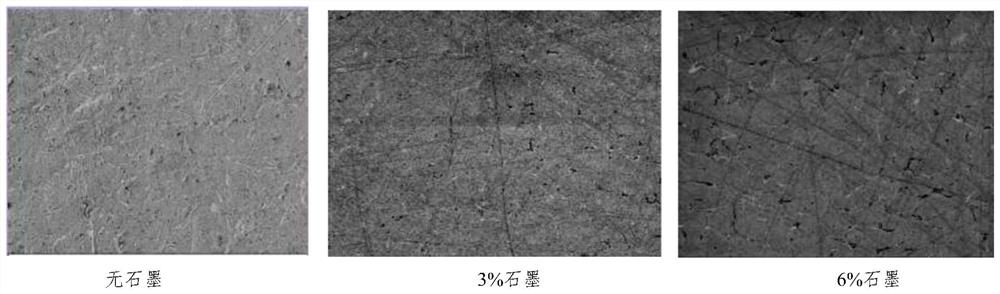

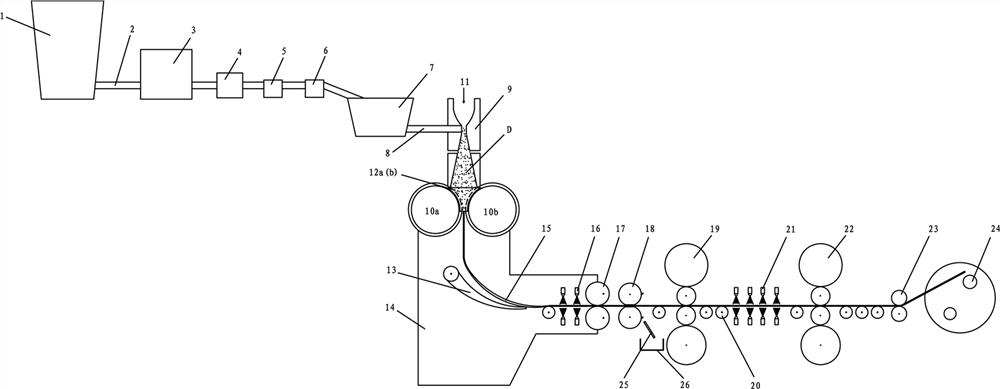

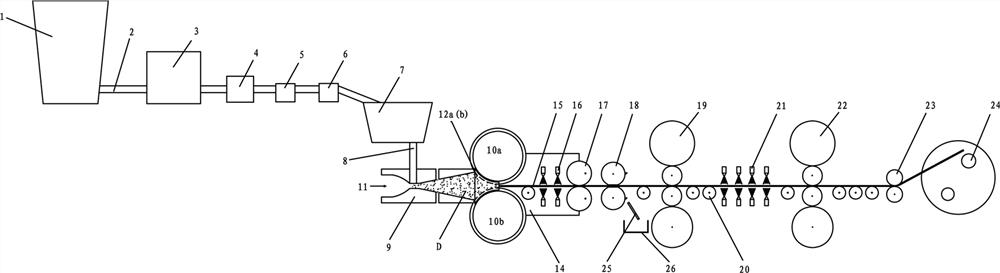

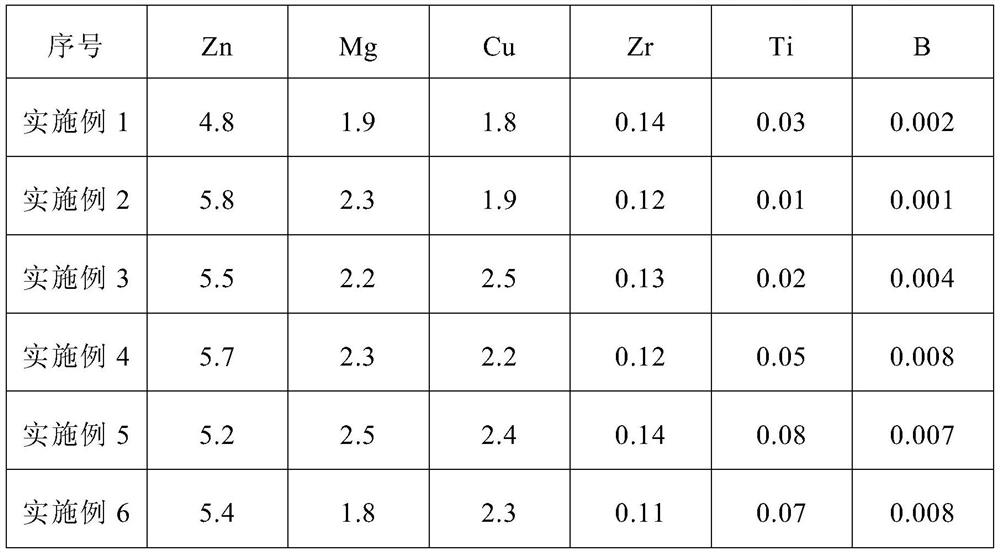

Preparation method of novel 7XXX aluminum alloy thin strip with high performance through jet casting and rolling

The invention relates to a preparation method of a novel 7XXX aluminum alloy thin strip with high performance by jet casting, which comprises the following steps of: 1) smelting according to the following chemical components in percentage by weight: 4.8 to 6.3 percent of Zn, 1.6 to 2.5 percent of Mg, 1.6 to 2.5 percent of Cu, 0.1 to 0.15 percent of Zr and the balance of Al and other inevitable impurities; the single impurity content is less than or equal to 0.1%, and the total impurity content is less than or equal to 0.2 (2) nano-particle enhancement; 3) spray deposition and continuous casting; 4) cooling; 5) primary hot rolling; (6) cooling and secondary hot rolling; (7) coiling; and 8) post-processing. Compared with an existing 7XXX aluminum alloy, the 7XXX aluminum alloy thin strip cast and rolled through the spray deposition combined double-roller thin strip cast rolling technology has the advantages that the strength is improved by 25% or above, and the ductility is improved by 35% or above; compared with a steel plate, the weight is reduced by 50% or more.

Owner:BAOSHAN IRON & STEEL CO LTD

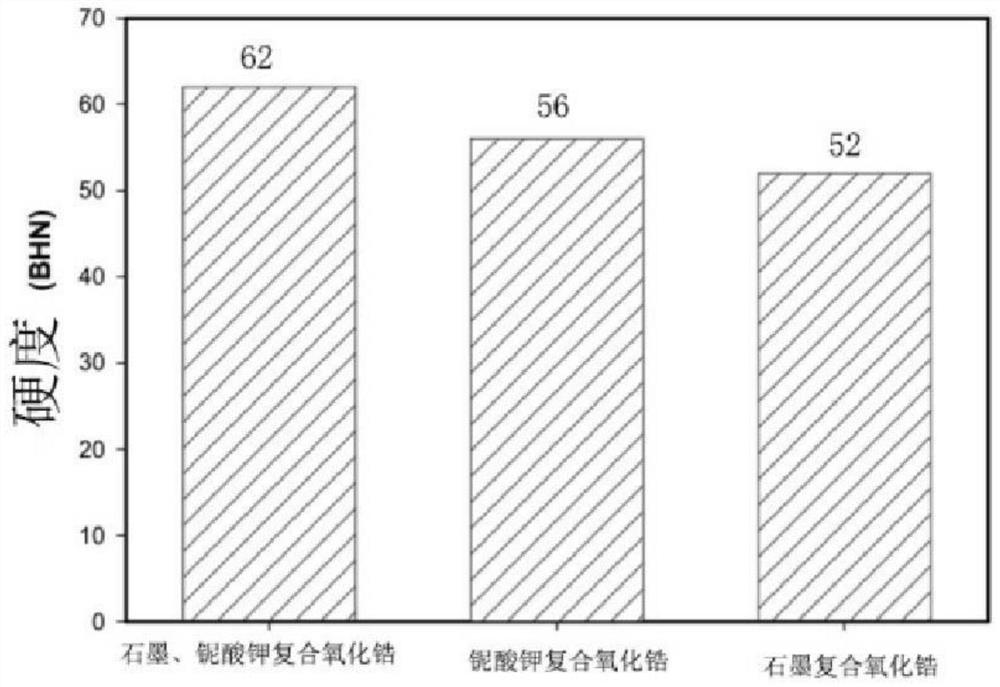

Mobile phone rear cover material and preparation method thereof

The invention relates to a mobile phone rear cover material and a preparation method thereof. The mobile phone rear cover material is formed by compounding graphite micro-particles, potassium niobateand zirconium oxide, wherein the graphite microparticles can be uniformly dispersed in the potassium niobate composite zirconium oxide ceramic mobile phone rear cover material through a melting method, the KNbO3 synthesis raw materials are K2CO3 and Nb2O5, and bismuth oxide is added in the calcination process of the KNbO3 synthesis raw materials and a zirconium oxide raw material. The KNbO3 synthetic raw material and the zirconium oxide raw material are subjected to composite calcination, so that a uniform fine-grain structure is shown, and meanwhile, the KNbO3 synthetic raw material also hasthe characteristics of very high Curie temperature (about 420 DEG C), high frequency constant and the like. Due to no lead, the pollution to the environment can be reduced, and the volatilization of potassium and sodium in the sintering process can be avoided or reduced through hot-pressing sintering, so that a compact product is obtained. The preparation method disclosed by the invention is simple and convenient to operate and has an extremely wide application prospect.

Owner:HANGZHOU XINKANG NEW MATERIAL CO LTD

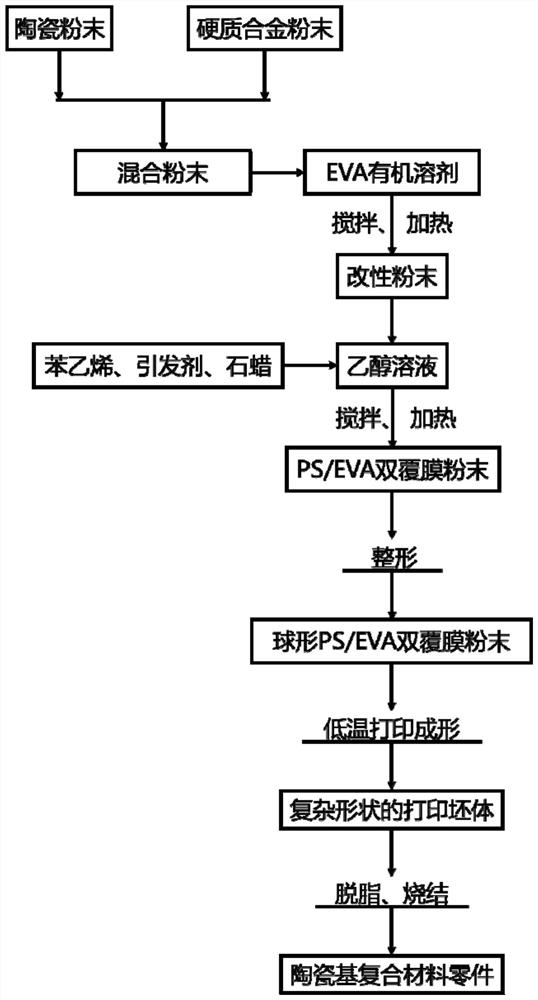

Complex-shaped ceramic matrix composite part and preparation method thereof

ActiveCN113770375AImprove liquidityHigh bulk densityAdditive manufacturing apparatusIncreasing energy efficiencyParaffin waxAlloy

The invention belongs to the field of advanced composite preparation research, and particularly provides a complex-shaped ceramic matrix composite part and a preparation method thereof. The method comprises the steps that firstly, ceramic powder and hard alloy powder are evenly mixed according to the proportion, the surface of the mixed powder is evenly coated with an ethylene-vinyl acetate copolymer layer, and modified powder is obtained; then, the modified powder is uniformly dispersed in an ethanol solution, styrene, an initiator and paraffin are added, heating is conducted, stirring is conducted uniformly, after drying, grinding and sieving are conducted to obtain PS / EVA double-coating powder, and the double-coating powder is subjected to shaping by adopting suspended shaping; and low-temperature printing is conducted, a printing blank with a complex shape is obtained, and the hard alloy reinforced ceramic matrix composite part with the complex shape is obtained through degreasing and sintering. The method has the beneficial effects that the possibility is provided for preparing the ceramic matrix composite part with the complex shape, and the method has the advantages of flexible design, near-net forming, low-cost preparation of large-size parts and the like.

Owner:UNIV OF SCI & TECH BEIJING

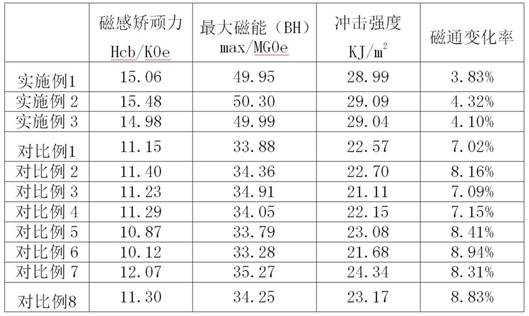

A kind of high performance neodymium iron boron material and preparation method thereof

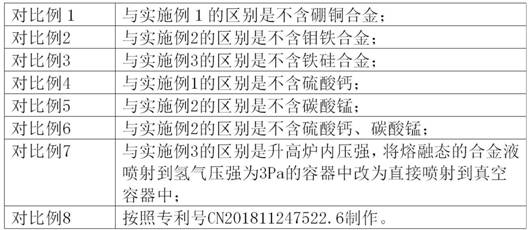

ActiveCN112481543BImprove strength propertiesImprove magnetic propertiesMagnetic materialsContinuous useSilicon alloy

The invention relates to the technical field of rare earth permanent magnet materials, in particular to a high-performance NdFeB material and a preparation method thereof. The magnet is prepared from the following raw materials: magnesium-neodymium alloy, zirconium-tin alloy, iron-cobalt alloy, boron-copper alloy, Ferro-cerium alloy, ferro-zinc alloy, ferro-molybdenum alloy, iron-silicon alloy, iron powder, calcium sulfate, manganese carbonate. The magnetic material of the present invention constitutes a composite crystal with higher adhesion, so that the material has more excellent magnetic properties, effectively prevents the increase of pores caused by surface wear during magnet processing, further reduces the performance of the magnet, and then improves the continuous use effect of the magnet in unfavorable environments. Especially in a high temperature environment, the magnetic properties of the magnet decay more slowly, significantly improve the impact resistance of the magnet, strengthen the mechanical properties of the magnet, and reduce the mechanical damage of the magnet in the assembly and use of various accessories.

Owner:东阳市科力达电子器材有限公司

A preparation method of high chromium refractory material toughened by nano zirconia

The invention discloses a preparation method of a nano zirconia-toughened high-chromium refractory material, which can produce a high-chromium material which has the advantages of favorable thermal shock resistance and low cracking tendency and can stably operate inside the kiln for a long time. The method comprises the following steps: by using 91-97 wt% of pigment-grade chrome oxide micropowder as a base, 1-6 wt% of nano zirconia powder as an additive and 3 wt% of titanium dioxide micropowder as a combustion assistant, dispersing by ball milling to form a uniformly dispersed slurry, drying the slurry to obtain powder, and carrying out binding molding to obtain the Cr2O3-ZrO2-TiO2 material. The Cr2O3-ZrO2-TiO2 high-chromium refractory material is a fine crystalline structure formed by distributing nano zirconia powder among the chrome oxide crystal grains or coating the nano zirconia powder among the chrome oxide crystal grains; and after the refractory material is sintered, the volume density is 3.52-4.68 g / cm<3>, and the porosity is 9.8-33.2%. The high-chromium refractory material has the advantages of higher compactness and higher thermal shock resistance.

Owner:TIANJIN UNIV

A kind of gh4282 nickel-based superalloy bar and its preparation method

ActiveCN111118423BUniform fine grain structureImprove tissue performance uniformityTemperingIngot casting

The invention discloses a GH4282 nickel-based high-temperature alloy bar and a preparation method thereof, and solves the technical problems of coarse grain size and poor uniformity of an existing GH4282 alloy bar. The preparation method comprises the following steps: S1, heating a GH4282 nickel-based high-temperature alloy ingot casting; S2, carrying out primary upsetting and tempering on the ingot casting in the axial direction to obtain a blank, and carrying out primary hot drawing and tempering on the blank in the direction perpendicular to the axial direction; S3, carrying out secondary upsetting and tempering on the blank in the axial direction, and then carrying out secondary hot drawing and tempering in the direction perpendicular to the axial direction; S4, carrying out three-timeupsetting and tempering on the blank in the axial direction, and then carrying out three-time drawing and tempering in the direction perpendicular to the axial direction to obtain a bar blank; and S5, tempering the bar blank in the step S4, and then performing one-fire-diameter forging forming to obtain the GH4282 nickel-based high-temperature alloy bar. The invention further discloses the GH4282nickel-based high-temperature alloy bar prepared by the method. The GH4282 nickel-based high-temperature alloy bar has the advantage that the structure uniformity of the GH4282 nickel-based high-temperature alloy bar can be effectively improved, so that the performance of the GH4282 nickel-based high-temperature alloy bar is improved.

Owner:BEIJING CISRI GAONA TECH +1

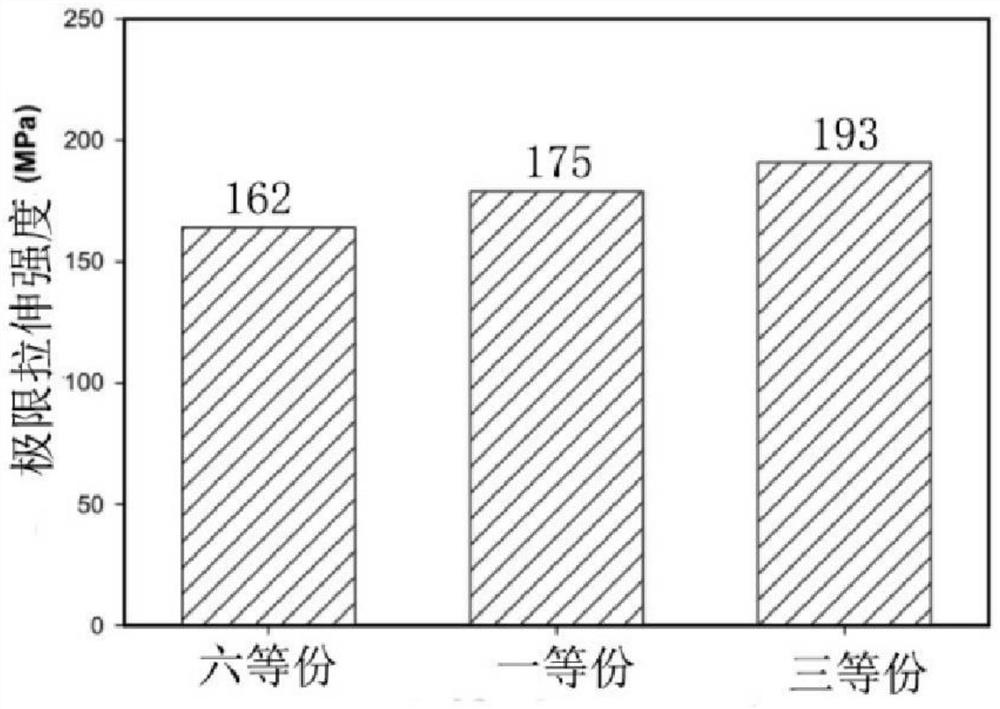

Medical composite magnesium alloy and preparation method thereof

ActiveCN114807708AAchieve different strengthsImprove plasticityUltimate tensile strengthImplantation Site

The invention discloses a medical composite magnesium alloy and a preparation method thereof, the composite magnesium alloy comprises a bar and a sleeve which are nested together, the bar is made of an annealed Mg-Y-Zn alloy, the sleeve is made of an extruded Mg-Y-Zn alloy, and the bar and the sleeve form the composite magnesium alloy through a hot press molding process. The composite magnesium alloy has great directivity and flexibility of microstructure and macrostructure design. The preparation method is simple in process, magnesium alloy materials of different size series can be prepared in batches, and the requirements for different strength and degradation rates of different implantation parts in a human body and different periods after implantation can be met.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

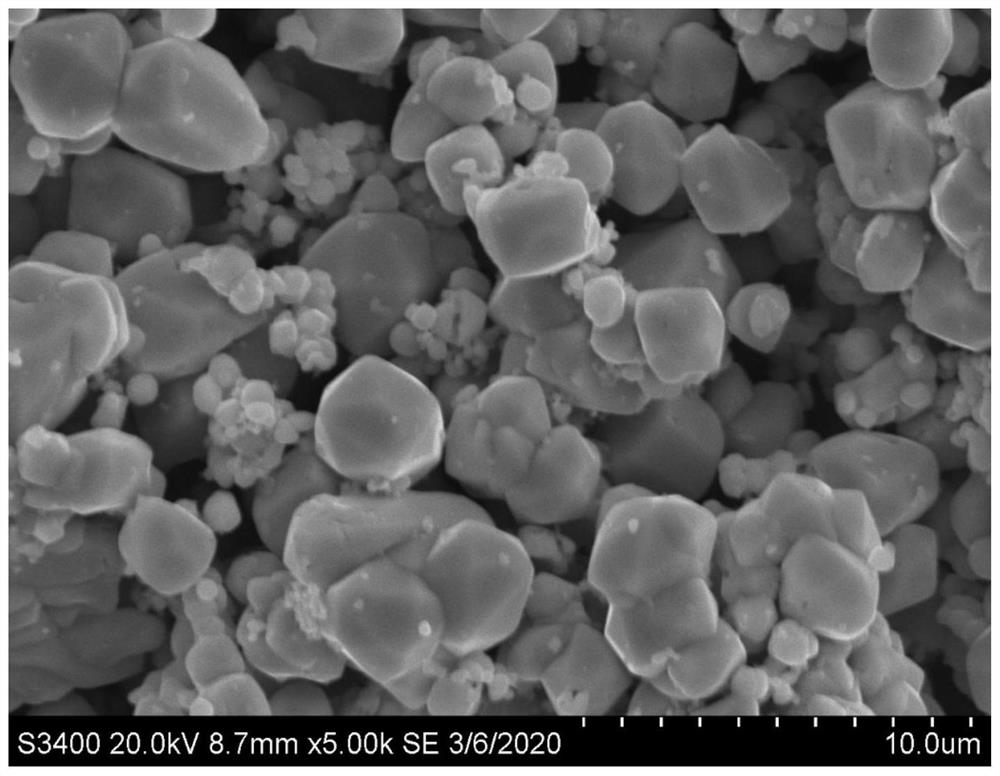

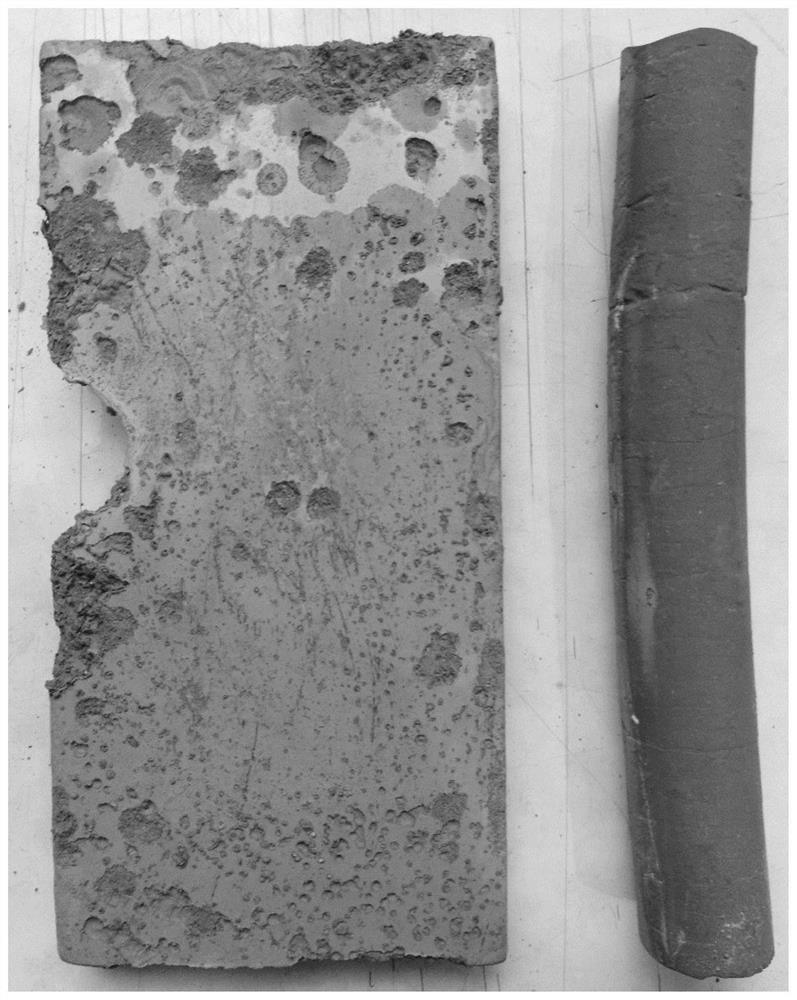

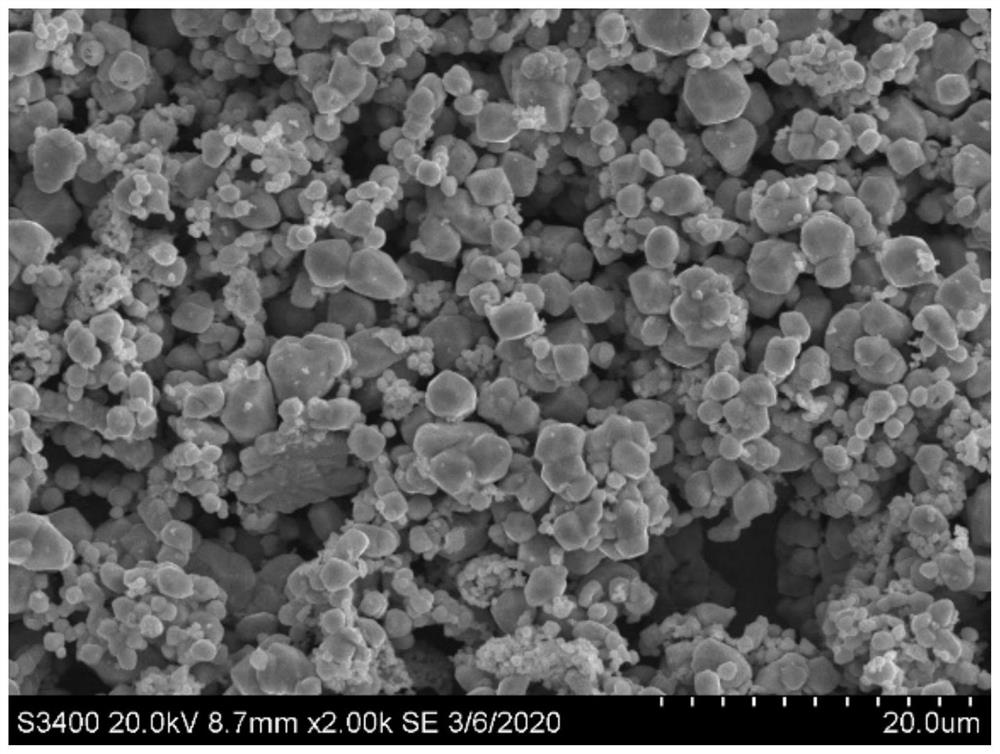

Jet cast rolling high-performance 7XXX aluminum alloy thin strip and preparation method thereof

ActiveCN114107764AImprove mechanical propertiesReduced hot cracking tendencyMetal rolling arrangementsNacelleFlight vehicle

The invention relates to a jet cast rolling high-performance 7XXX aluminum alloy thin strip and a preparation method thereof, the aluminum alloy thin strip comprises the following components in percentage by mass: 4.8-6.3% of Zn, 1.6-2.5% of Mg, 1.6-2.5% of Cu, 0.1-0.15% of Zr, 0.01-0.08% of Ti, 0.001-0.008% of B, and the balance of Al and other inevitable impurities, the content of a single impurity is less than or equal to 0.1%, and the content of total impurities is less than or equal to 0.2%. Compared with an existing 7XXX aluminum alloy, the 7XXX aluminum alloy thin strip prepared through the spray deposition and double-roller thin strip cast rolling combined technology has the advantages that the strength is higher by 20% or above, and the ductility is higher by 30% or above; compared with a steel plate, the weight is reduced by more than 40%. The produced aluminum alloy thin strip can be widely applied to the field of aerospace, such as various aircraft fuselages, wing beams, cabin wallboards, aircraft high-stress structural parts, aircraft skins, high-strength structural parts in aircraft rockets and the like, and a wide space can be provided for aerospace high strengthening, light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

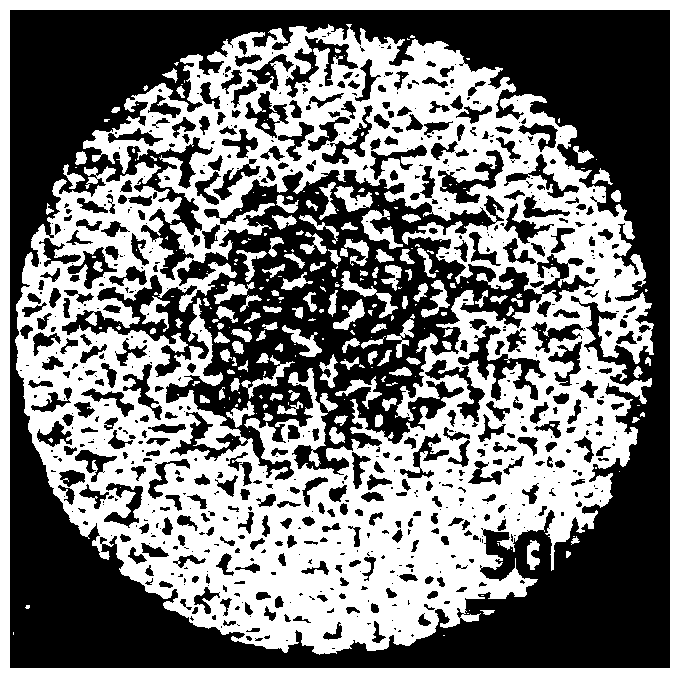

Molybdenum and molybdenum alloy material sintering method and application thereof

The invention discloses a molybdenum and molybdenum alloy material sintering method and application thereof.The molybdenum and molybdenum alloy material sintering method comprises the steps that after molybdenum and molybdenum alloy powder is pressed into a blank and put into a sintering furnace, hydrogen is introduced for heating sintering, the molybdenum and molybdenum alloy powder is subjected to passivating treatment before sintering, and the passivating treatment comprises the step that the molybdenum and molybdenum alloy powder is put into a ball mill for ball milling; the heating sintering comprises the following steps: heating for 2-3 hours, 2.5-3.5 hours and 6 hours, sequentially heating to 800 DEG C, 1100 DEG C and 1500 DEG C from room temperature, then heating to 1740 DEG C after 6-8 hours, and keeping the temperature for 6 hours; the passivating treatment comprises the steps that molybdenum grinding balls with the diameter of 5-20 mm and molybdenum and molybdenum alloy powder are put into a ball mill with the rotating speed larger than or equal to 30 rpm according to the ball-to-material ratio of (1-1.5): 1 to be subjected to ball milling, and the total ball milling time is 8-15 h. According to the sintering method, the highest sintering temperature is reduced, the total sintering time is shortened, the overall working efficiency is improved, and meanwhile it is guaranteed that a sintered product or billet has a microscopic structure with the average grain size being 15-20 microns.

Owner:JINDUICHENG MOLYBDENUM CO LTD

A manufacturing process of arc-shaped molybdenum plate for high-life heat shield

A manufacturing technology of an arc-shaped molybdenum plate for a long-service-life heat shield specifically comprises the steps of preparing powder A which is of a rhenium-doped nanometer aluminum oxide structure, preparing nanometer lanthanum oxide, preparing the molybdenum plate, preparing a molybdenum blank through the molybdenum plate, and pressing the molybdenum blanket to obtain the targeted arc-shaped molybdenum plate. According to the manufacturing technology, the outward dispersing and oxidizing capacity of molybdenum is reduced through compound elements, so that the oxidizing resistance of molybdenum can be improved, and the service life can be prolonged by more than 30%; in addition, powder metallurgy and mechanical rolling are combined, so that the relative density of the manufactured arc-shaped molybdenum plate is high, and the plasticity is improved, and as a result, cracks can be avoided; an uniform fine grain structure is obtained, and thus physical performance and the mechanical performance can be improved.

Owner:LUOYANG KEWEI MOLYBDENUM & TUNGSTEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com