Patents

Literature

139results about How to "Large cutting area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

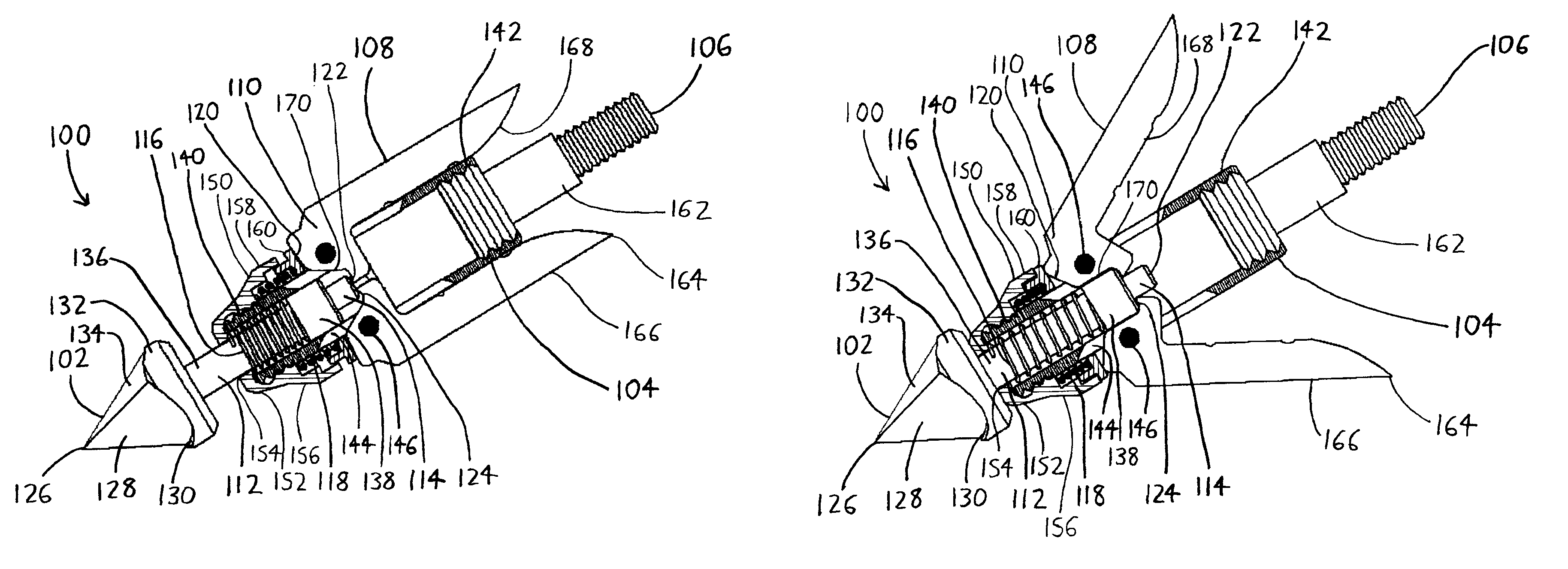

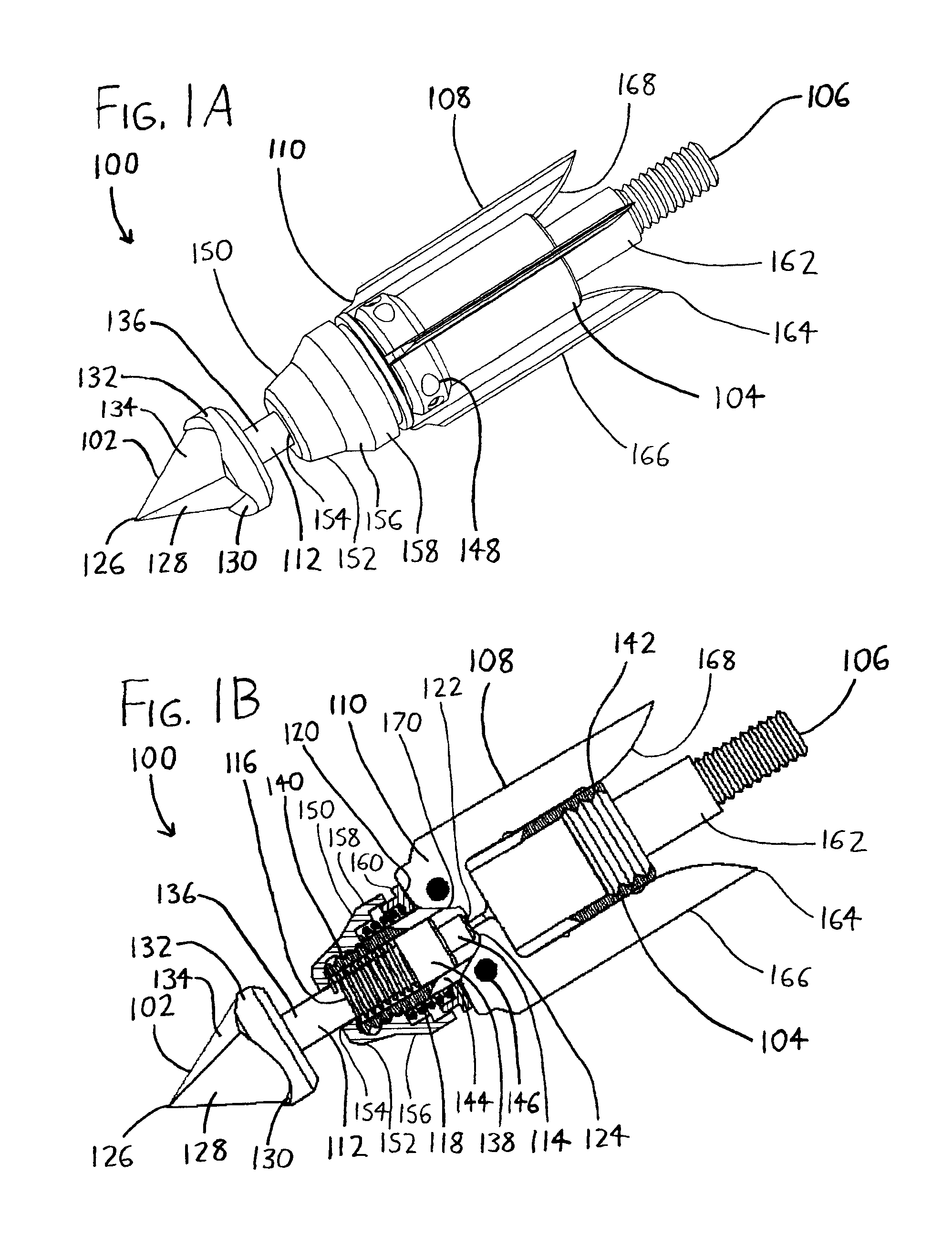

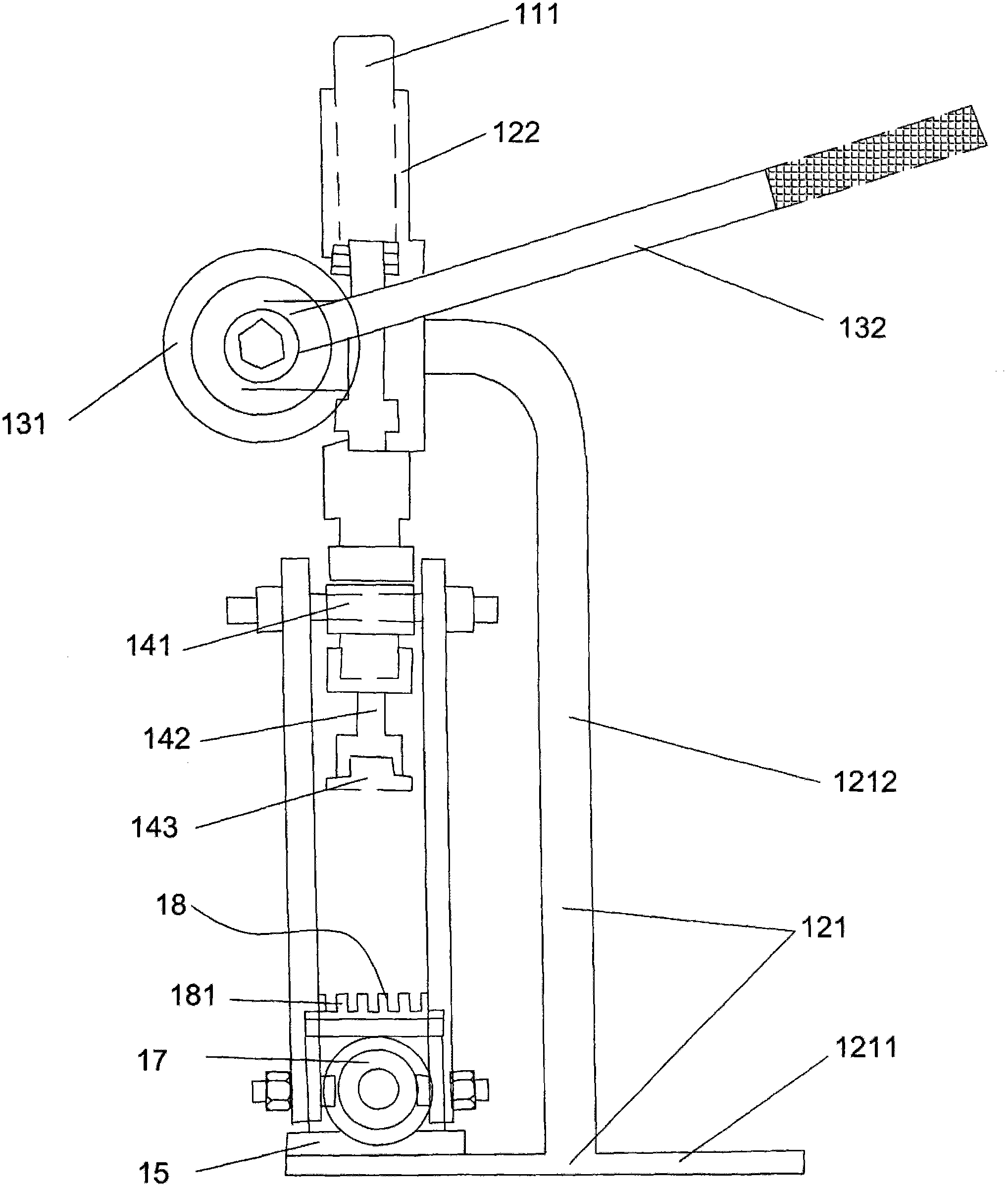

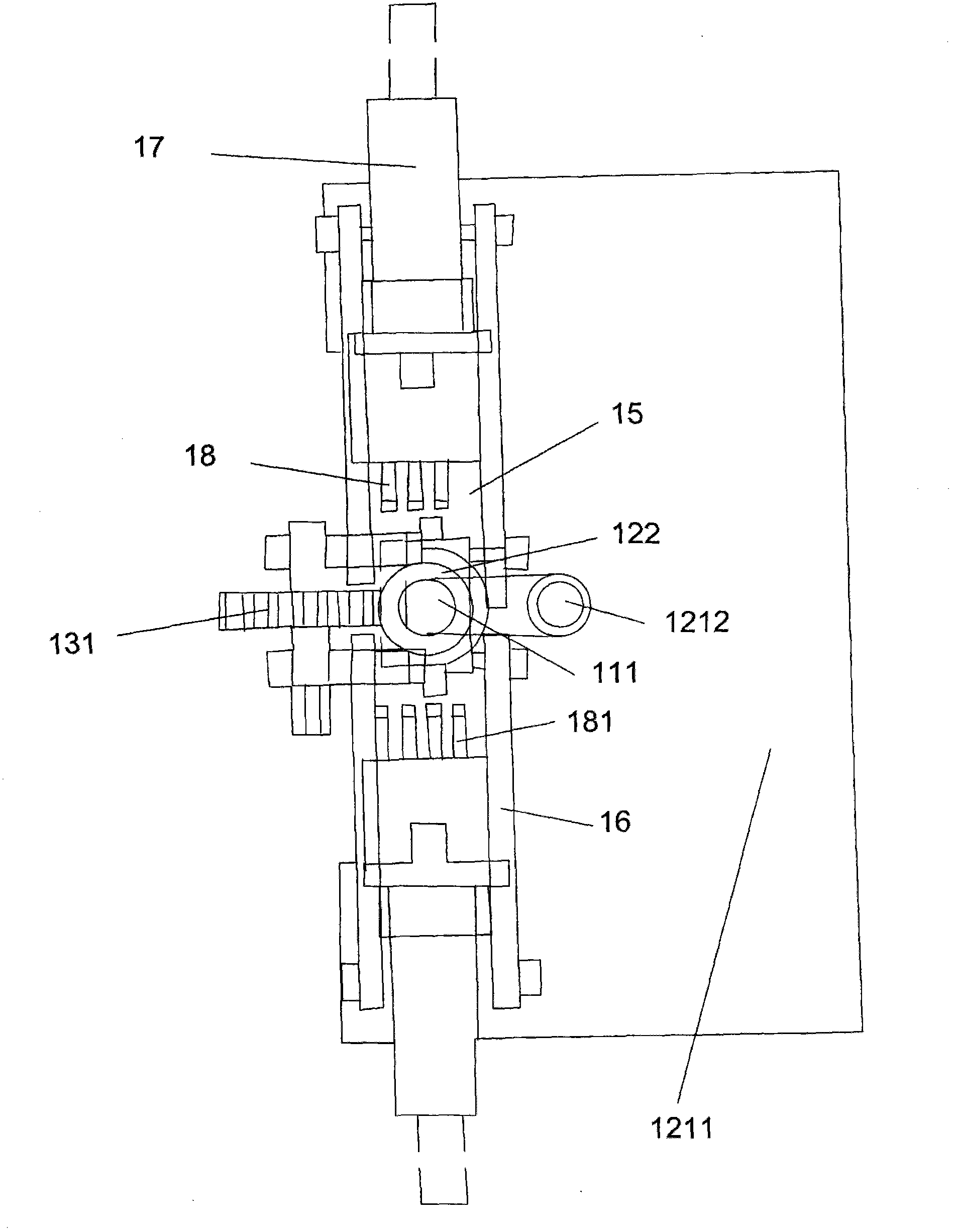

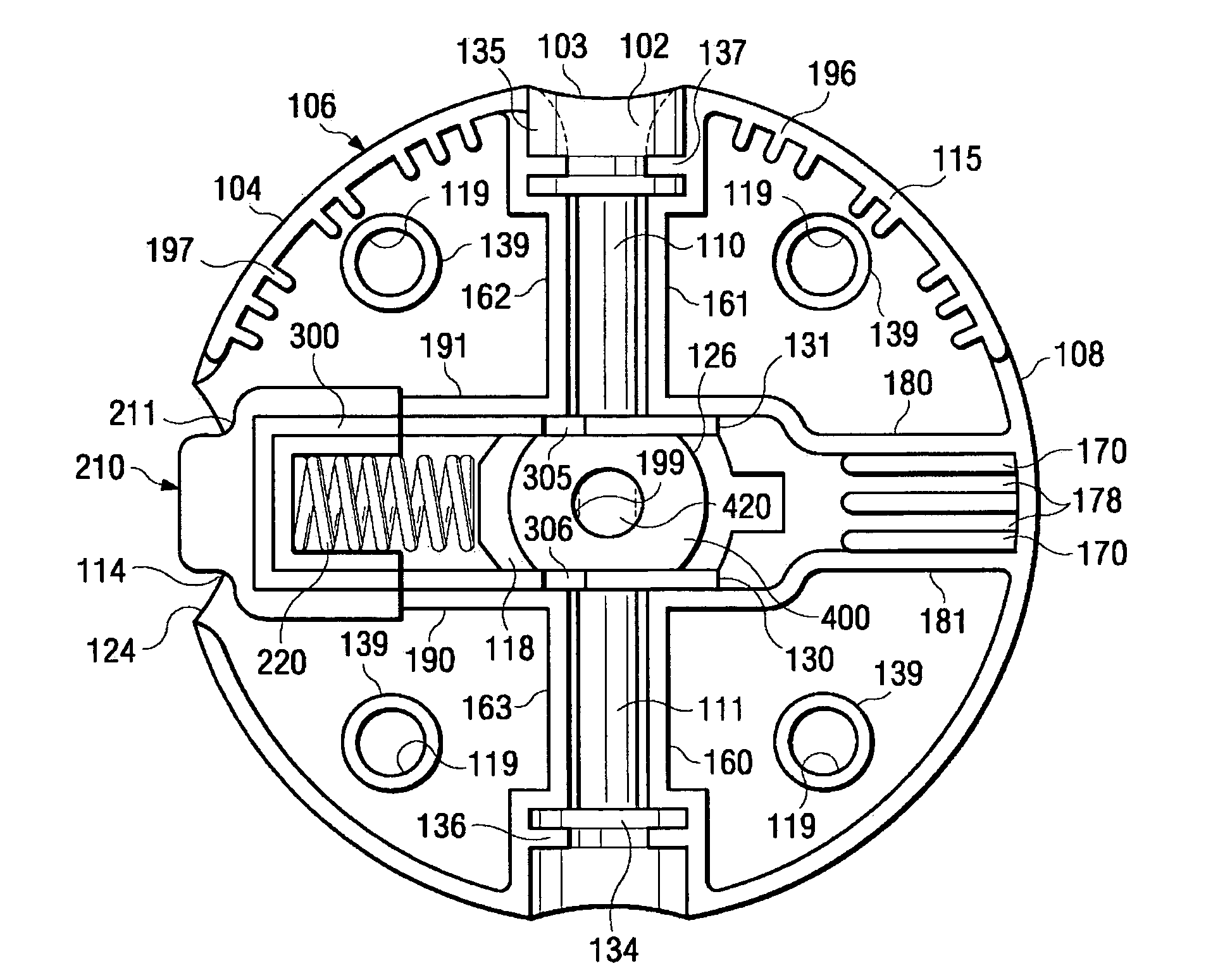

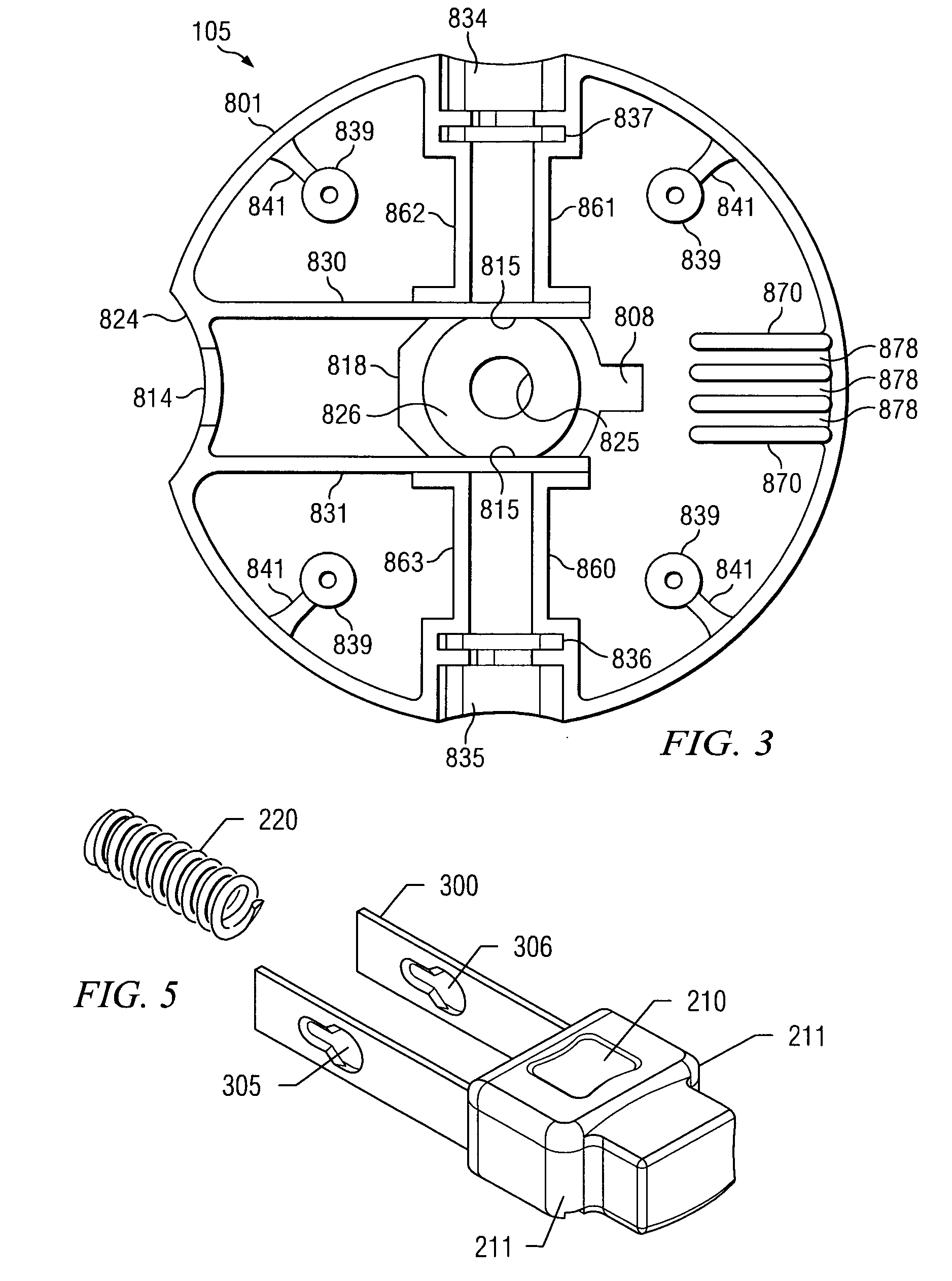

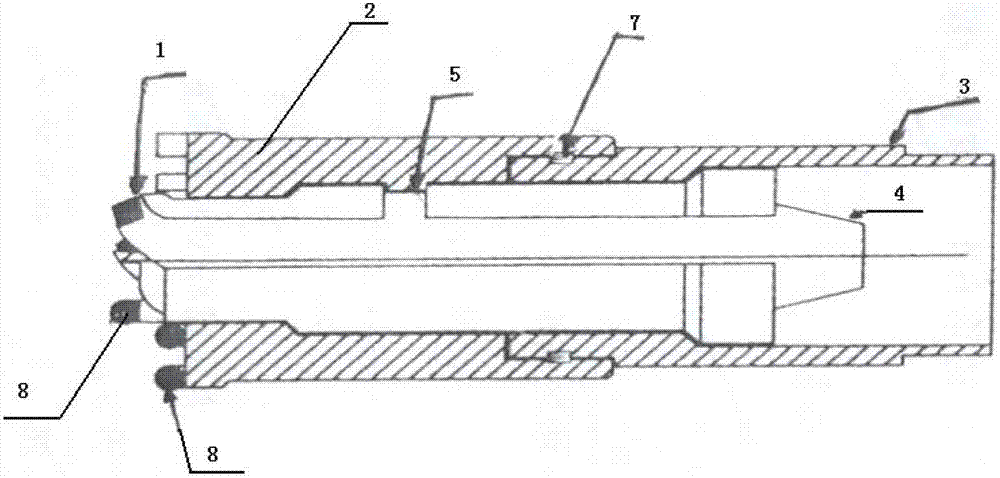

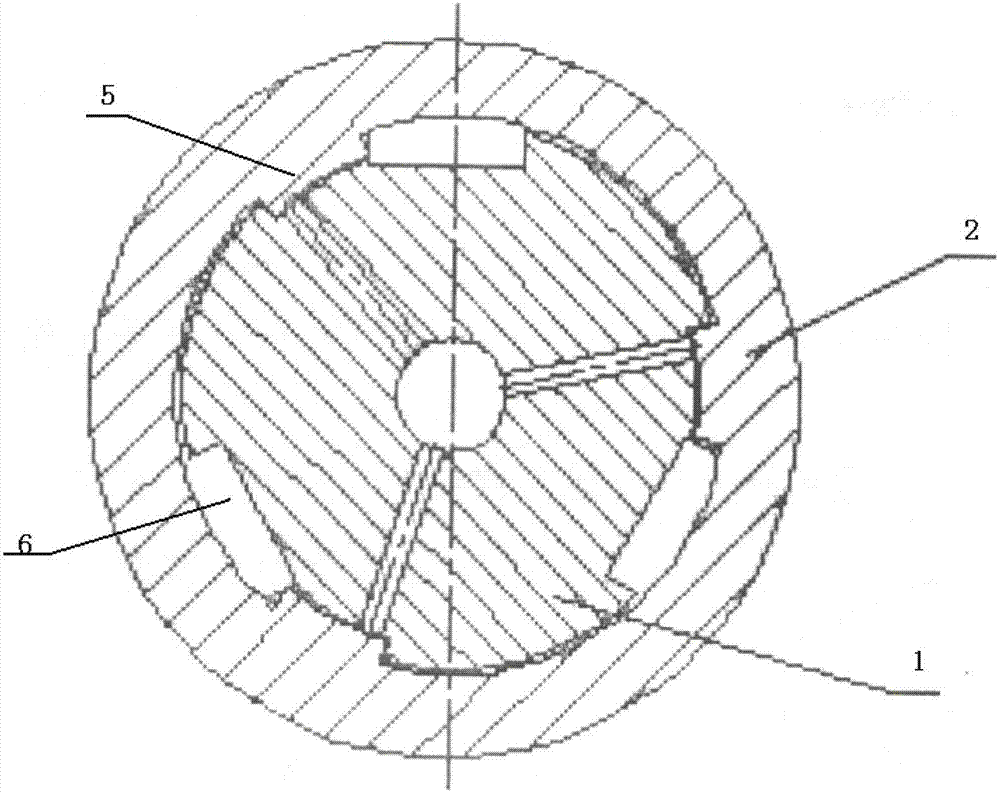

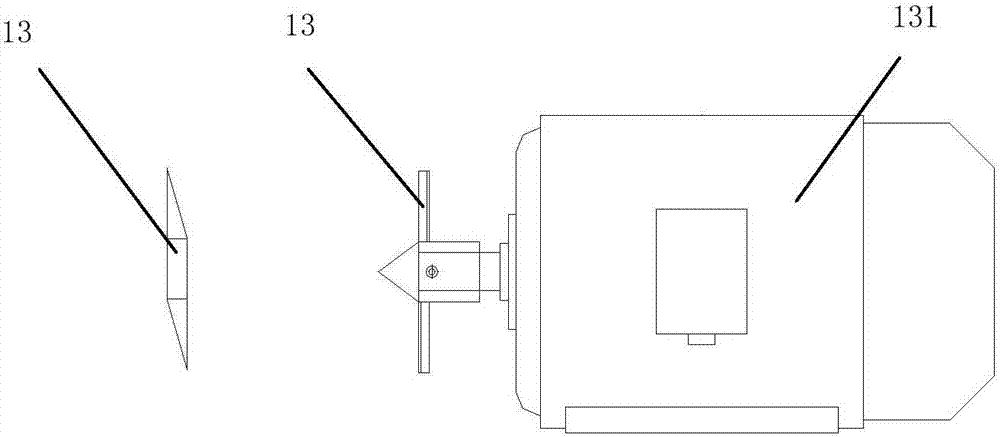

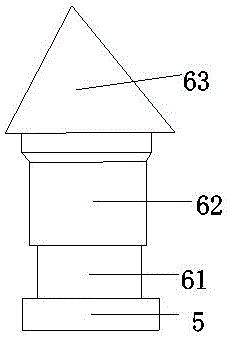

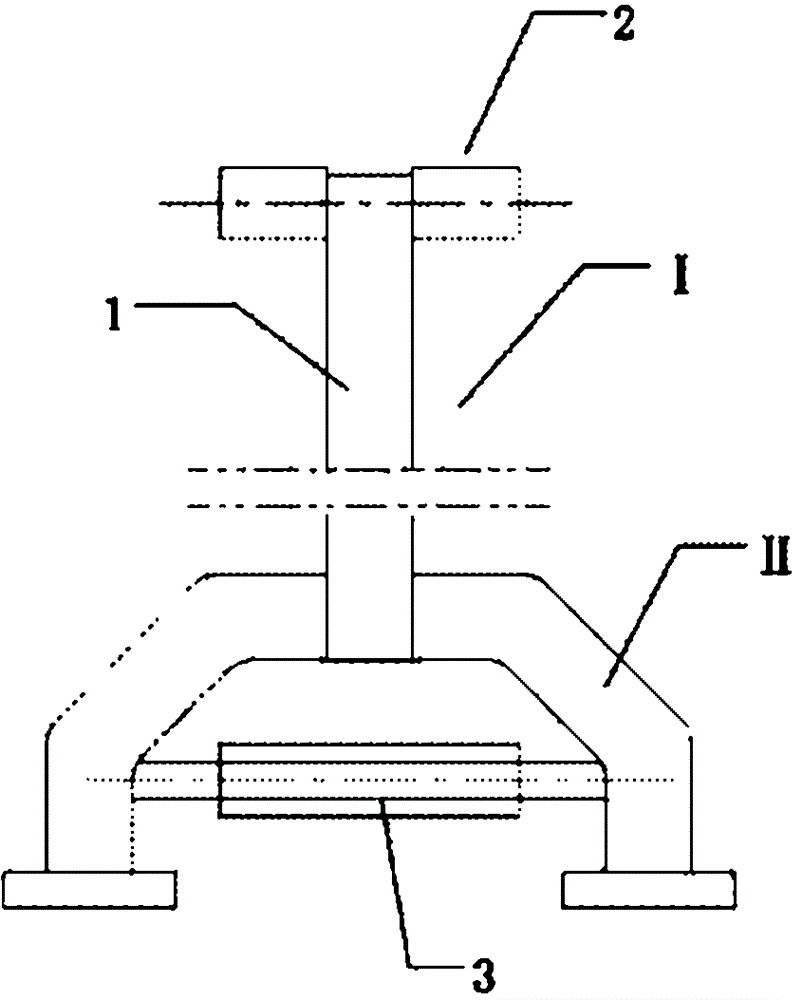

Arrowhead with unfolding blades

An arrowhead of the expandable or mechanical broadhead type, i.e., having blades which unfold to increase the effective cutting area of the arrowhead, includes a tip with a rearwardly-extending actuating member which triggers one or more blades into an open state when the tip strikes a target game animal. The blades are pivotable with respect to a body into which the actuating member extends, and they include ears against which the actuating member presses upon tip impact to trigger the blades open. A latching spring maintains the blades in a closed state until the tip and actuating member are driven rearwardly by tip impact, and the tip and actuating member are preferably maintained in a forward and ready-to-trigger state by an opening spring. The actuating member may extend between the blade ears after the blades are triggered open to fix the blades in the open state until the tip is pulled forwardly to withdraw the actuating member from the ears.

Owner:TENTLER LYNN A

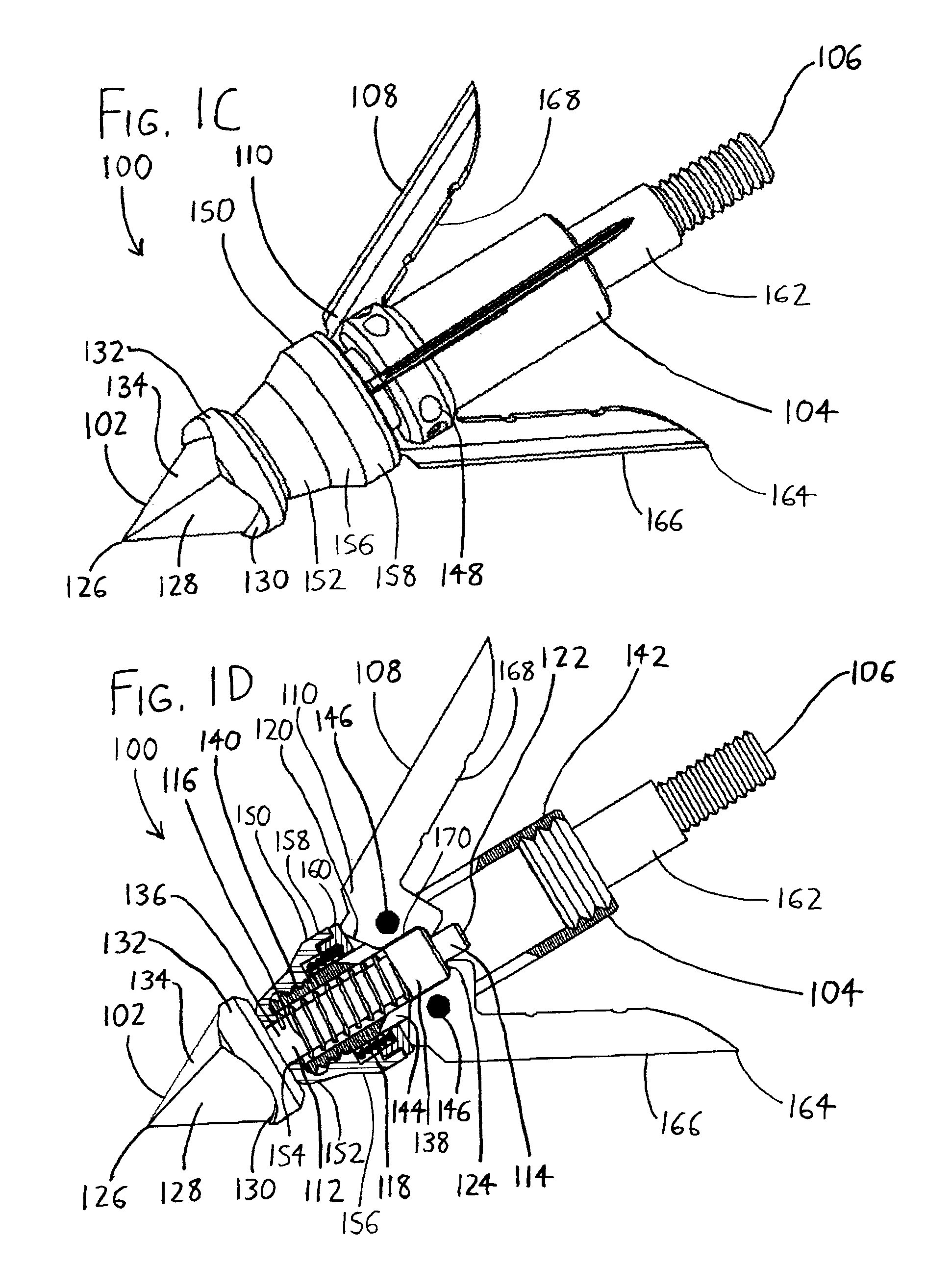

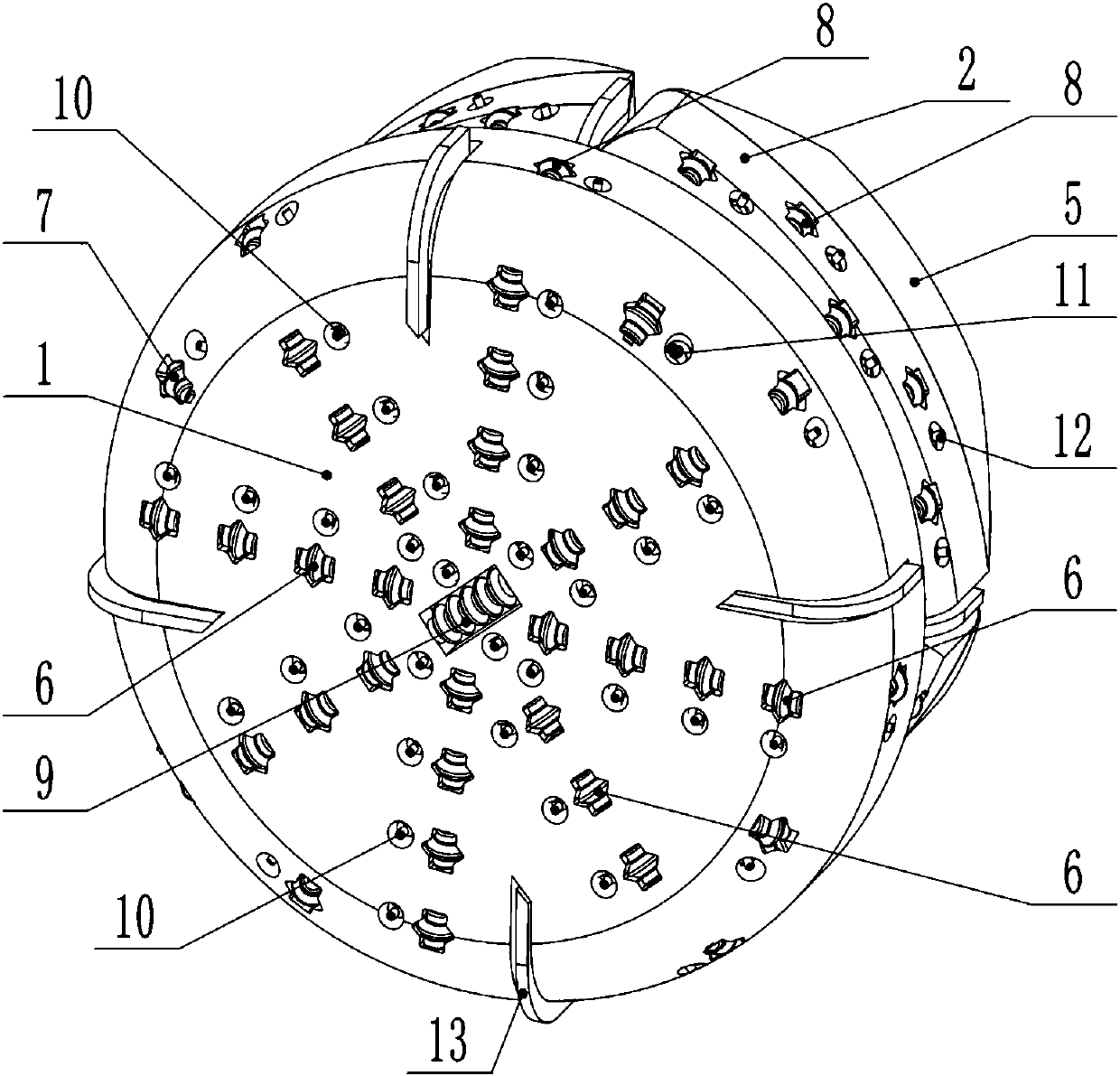

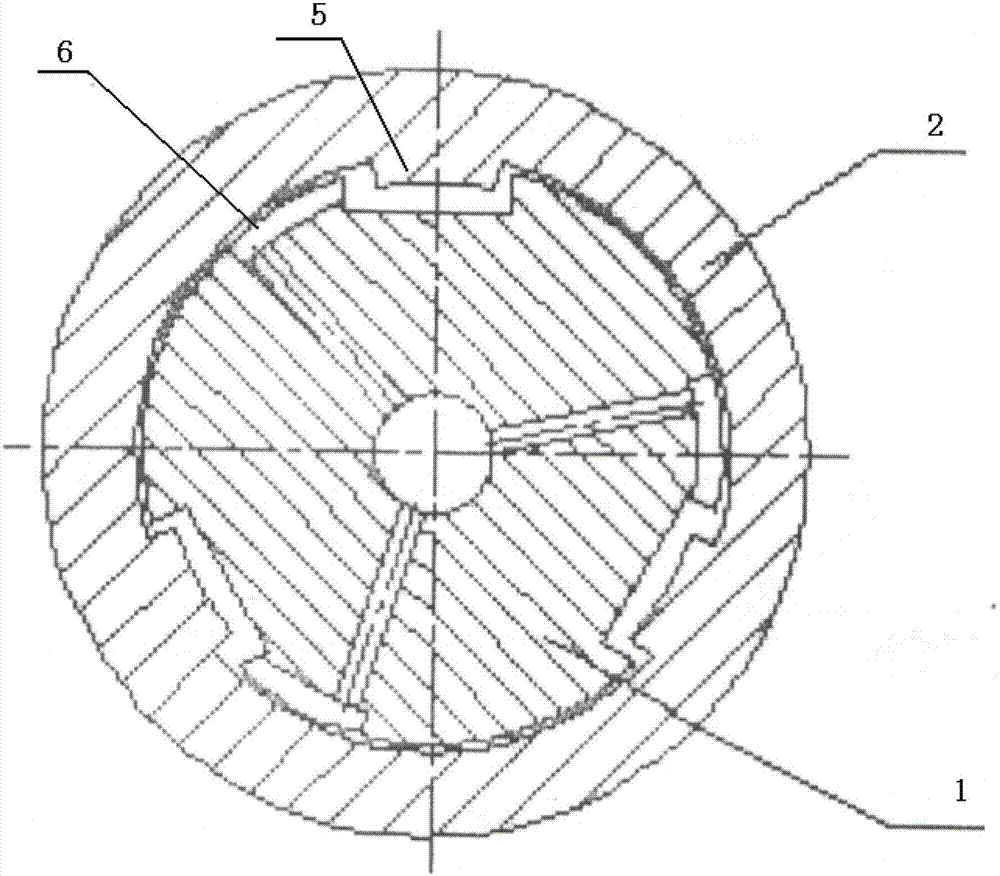

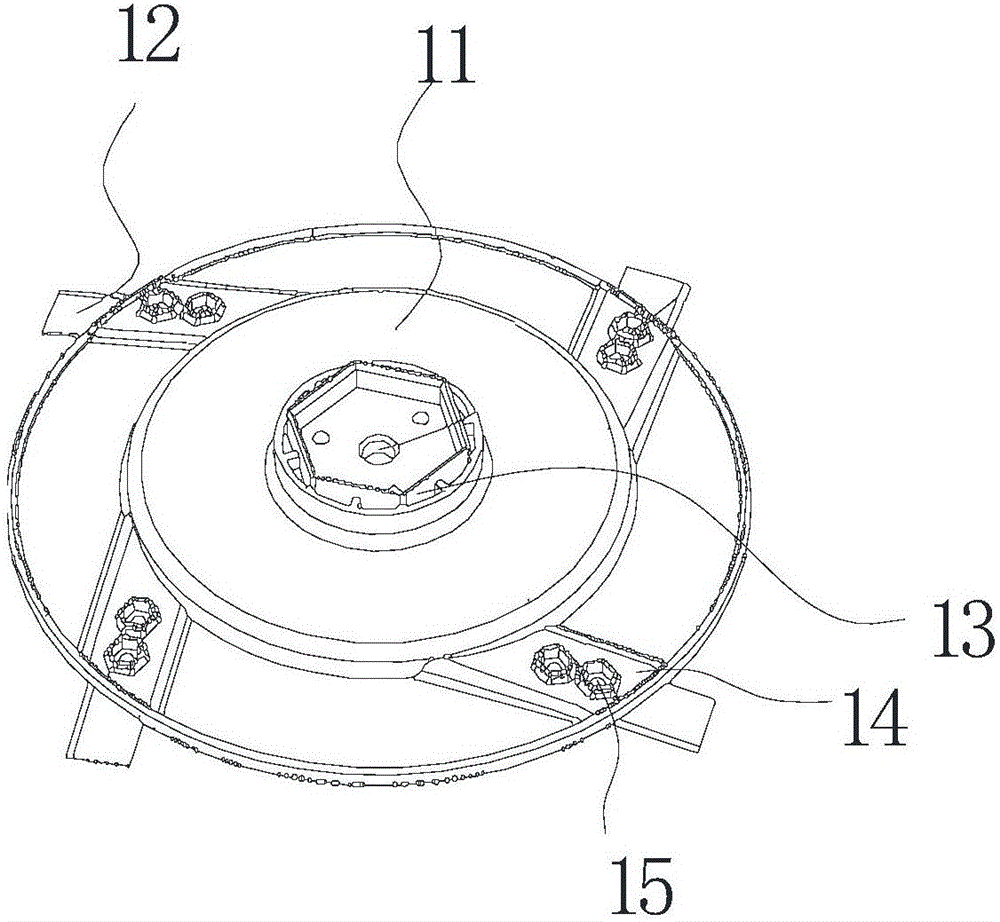

Full-fracture-surface hard-rock tunneling machine cutter disc and tunneling method

The invention belongs to the technical field of engineering machinery, and particularly discloses a full-fracture-surface hard-rock tunneling machine cutter disc and a tunneling method. The tunnelingmachine cutter disc comprises a main cutter disc mechanism, an expansion cutter disc mechanism and a connector; the connector is provided with connector mounting holes for connecting a cutter disc driving mechanism; the main cutter disc mechanism comprises a main cutter disc, a first slag removing cutter, a first hob assembly and a first water jet cutter assembly; the expansion cutter disc mechanism includes multiple auxiliary cutter disc mechanisms; each auxiliary cutter disc mechanism includes an auxiliary cutter disc, an auxiliary cutter disc mounting frame and a retractable mechanism; thecutting end of each auxiliary cutter disc is provided with a second hob assembly, a second water jet cutter assembly and a second slag removing cutter. The water jet cutter assembles of the cutter disc can carry out hydraulic incision on tunnel rock, the tunnel rock subjected to hydraulic incision is much looser, then the hob assemblies can roll and crush the much looser tunnel rock, the tunnelingstress is effectively reduced, and hobs are protected; the retractable mechanisms connected with the auxiliary cutter discs can change the cutting diameter of the auxiliary cutter discs, and the full-fracture-surface hard-rock tunneling machine cutter disc is capable of meeting demands of tunnels different in diameter.

Owner:陈南南

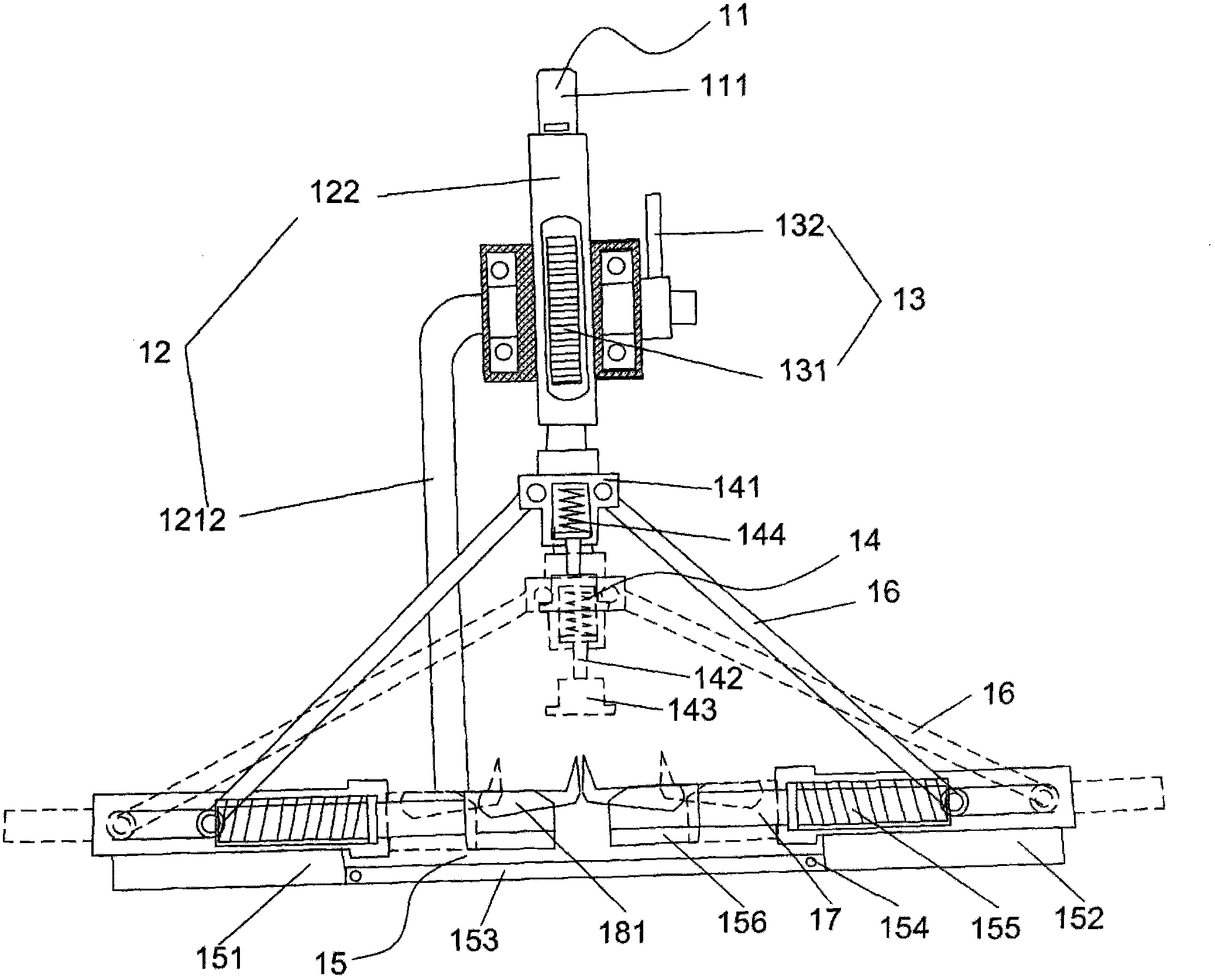

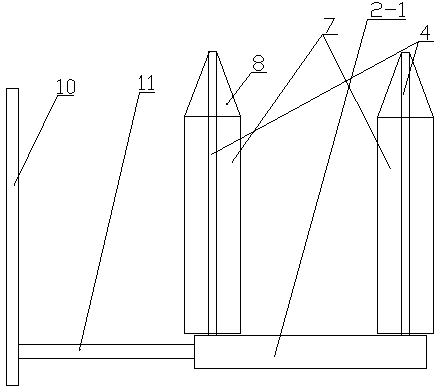

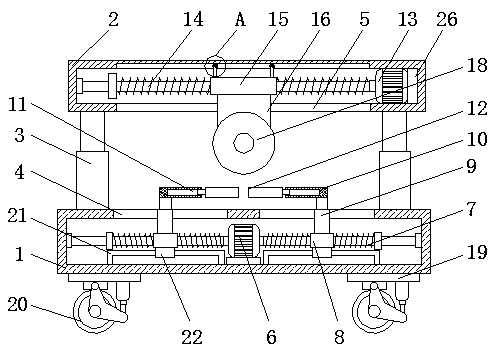

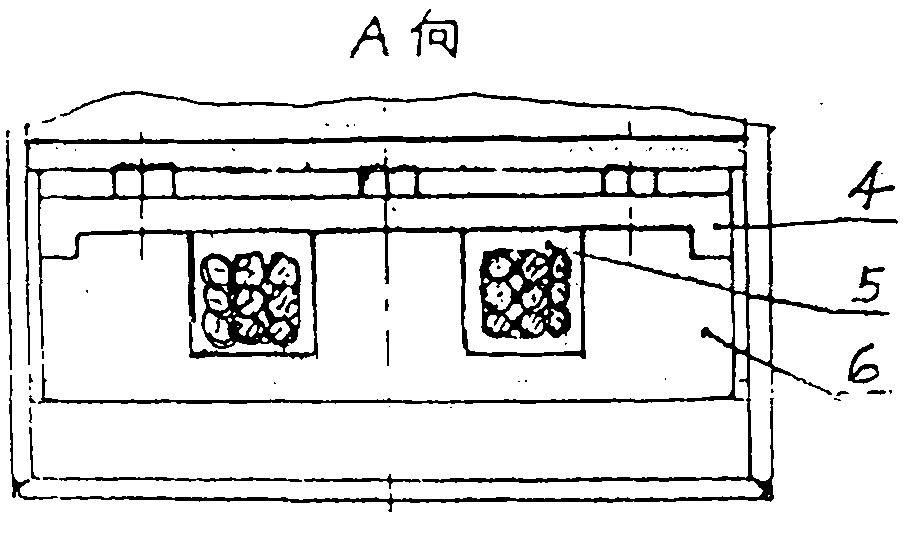

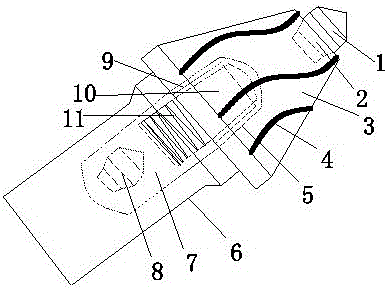

Hand-operated Chinese chestnut shucking machine

ActiveCN103230082AGood removal effectSimple structureHuskingHullingEngineeringMechanical engineering

The invention relates to a hand-operated Chinese chestnut shucking machine which comprises a compression bar assembly, a support assembly, a transmission assembly, a sliding chute, two slide bars and an inclined connecting bar, wherein the compression bar assembly reciprocates vertically; the support assembly is used for supporting the compression bar assembly to reciprocate vertically; the transmission assembly drives the compression bar assembly to reciprocate vertically; the sliding chute is horizontally placed and fixed with the support assembly; the two slide bars slide relatively and horizontally in the sliding chute; the inclined connecting bar drives the slide bars to move horizontally by the aid of the vertical reciprocation of the compression bar assembly; at least one hooked blade is connected to the opposite end parts of the two slide bares respectively; the shucking machine further comprises a material pressing assembly which is elastically pressed against Chinese chestnuts under the drive of the compression bar assembly; hook tips of the hooked blades are upward; and the hook tips of the hooked blades which are arranged at the end parts of the two slide bars encounter right below the material pressing assembly. The hand-operated Chinese chestnut shucking machine is simple in structure, low in cost and simple to operate and can very conveniently remove both Chinese chestnut hair bulbs and hulls.

Owner:启东市天汾电动工具技术创新中心

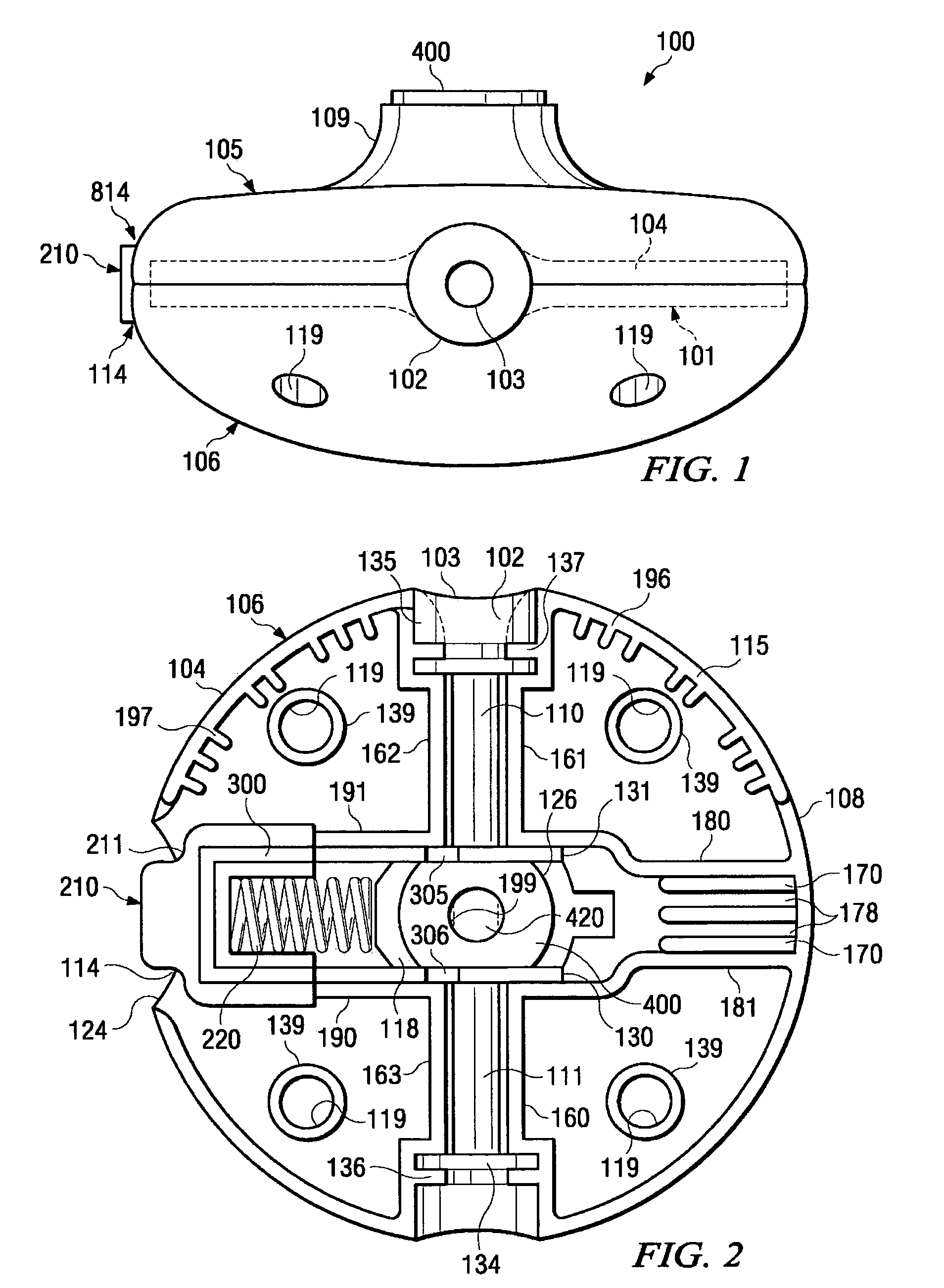

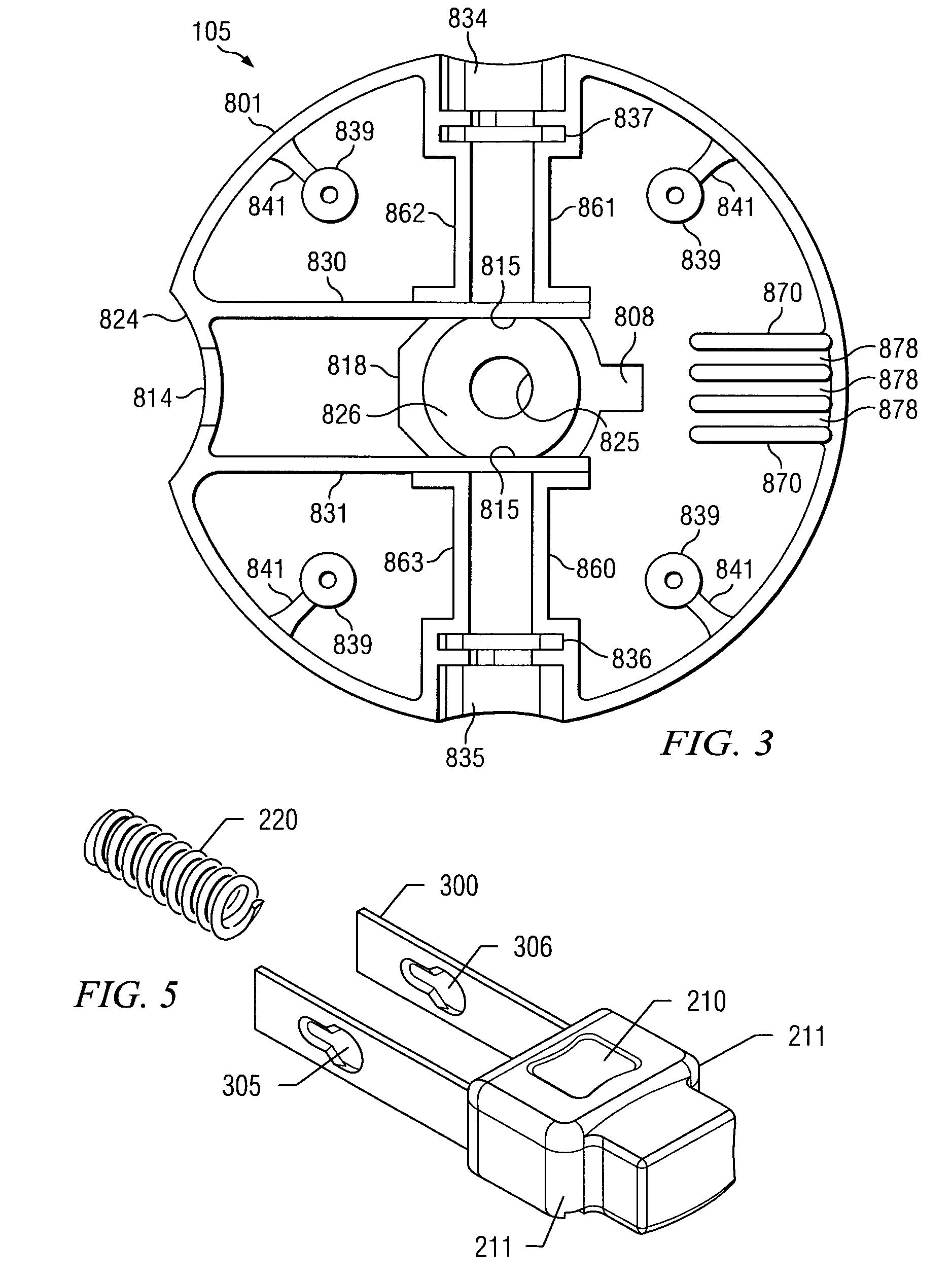

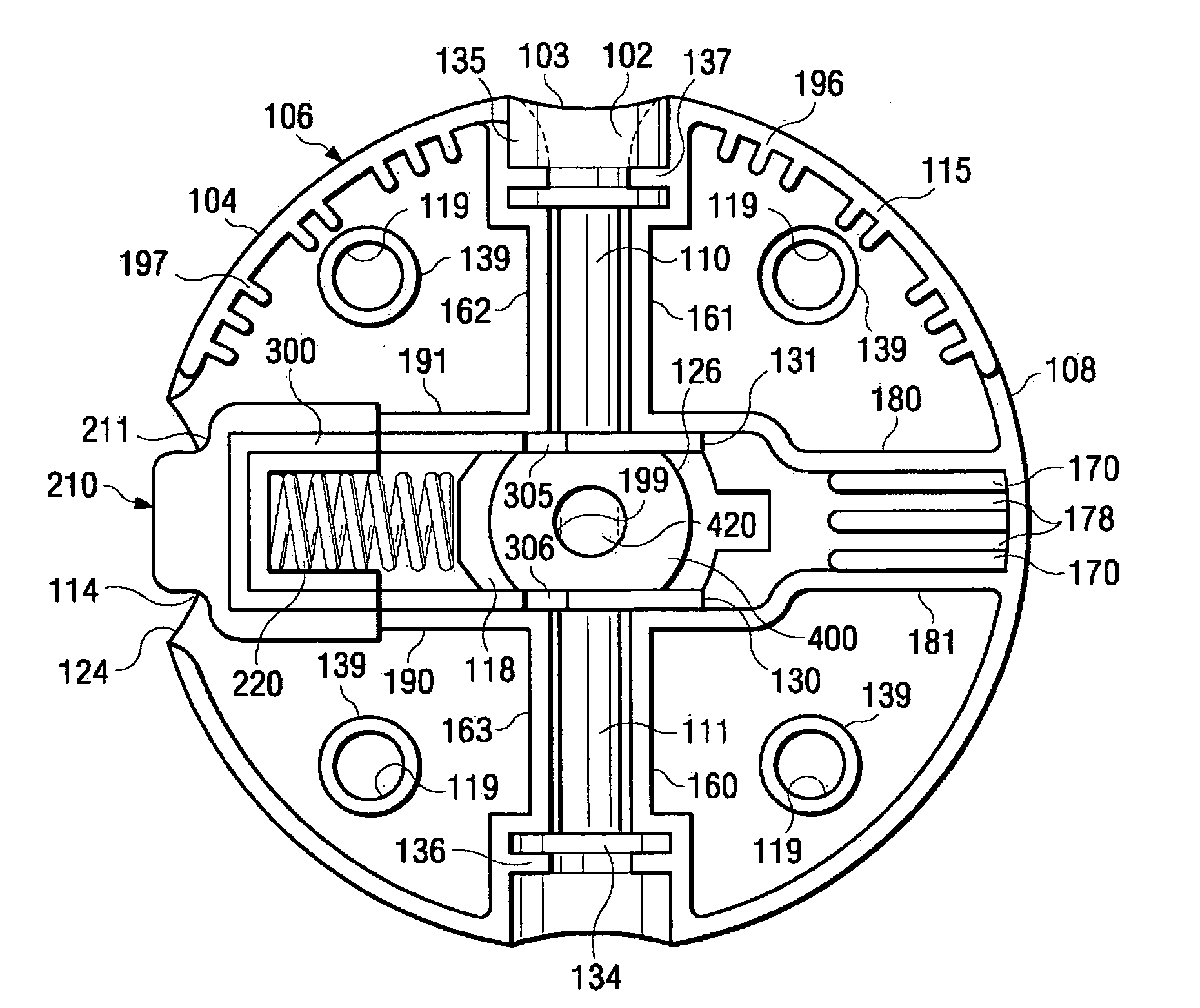

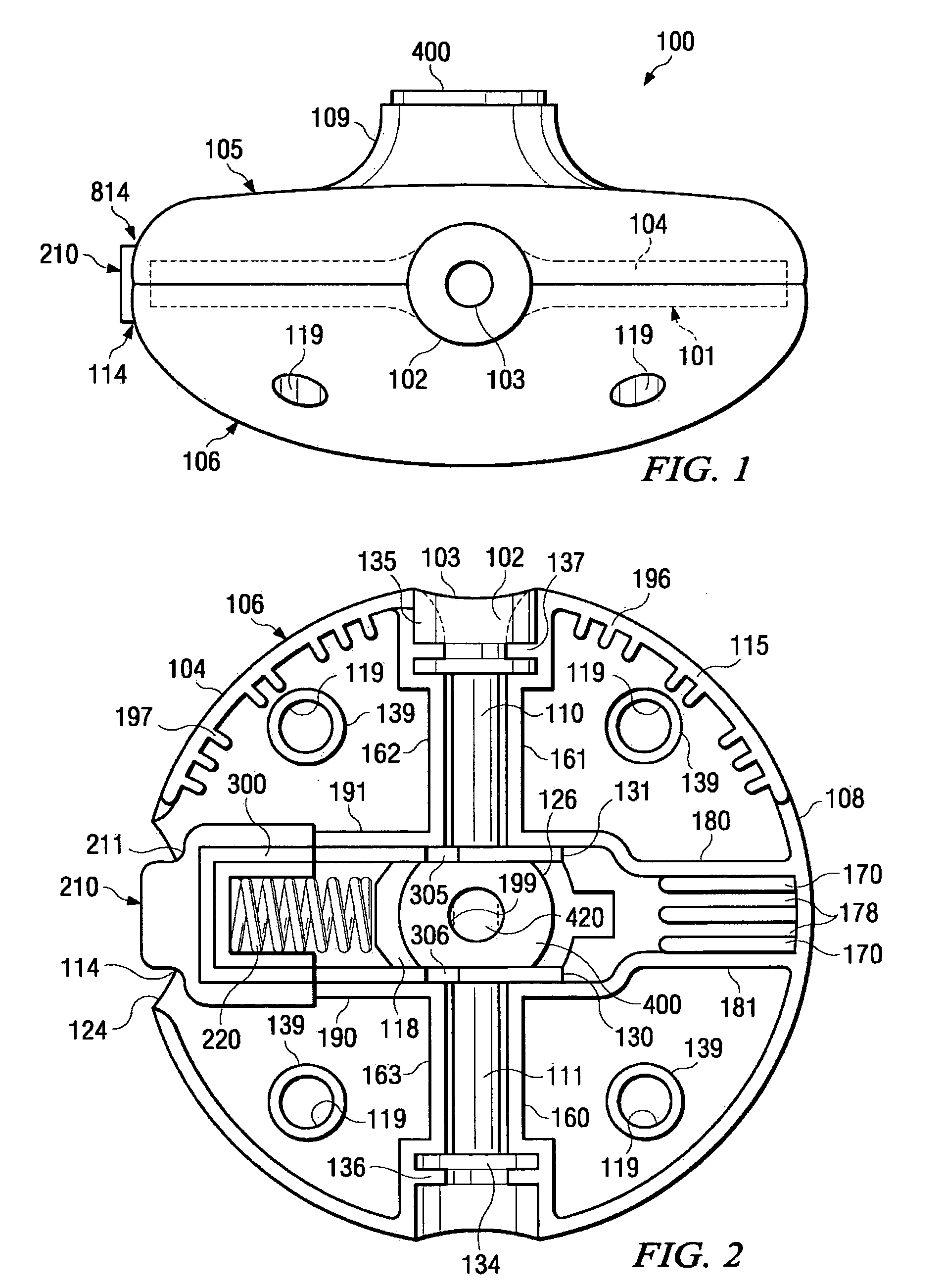

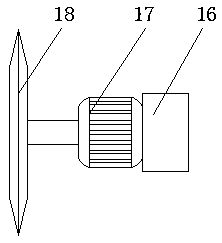

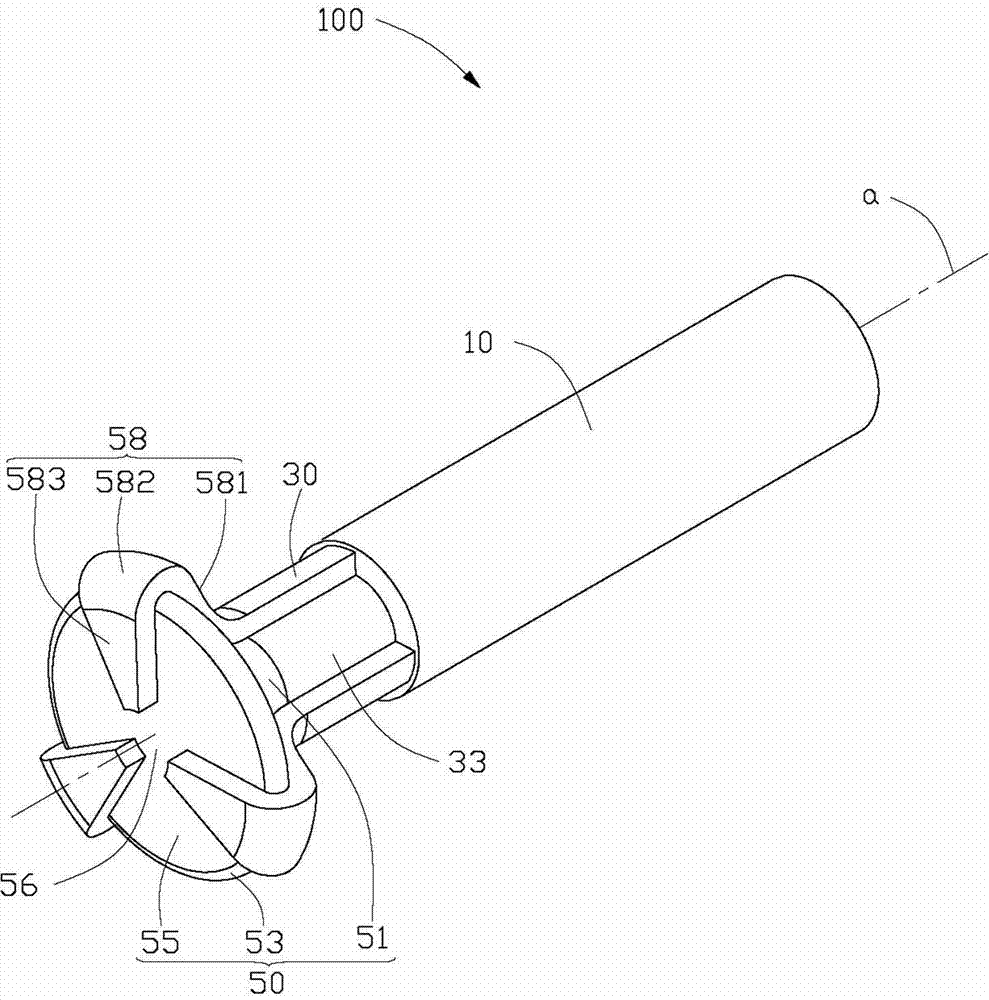

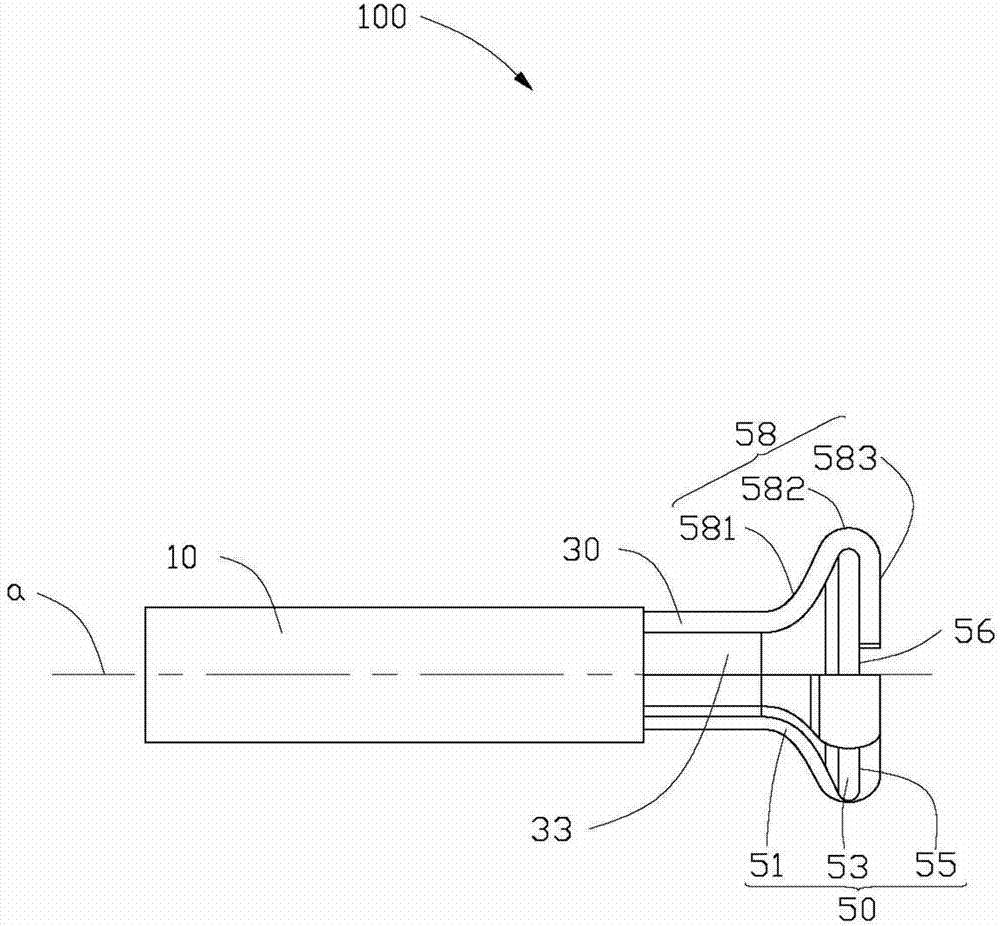

Head for a rotary line trimmer apparatus

InactiveUS7536792B2Prevents excessively acute and sharp bendingPremature damageMowersMetal working apparatusMechanical engineeringKinetic energy

An improved head for a flexible line trimmer apparatus is provided. The improved head includes a metal tubing that extends through the head and surrounds a cutting line of selected length. The tubing is provided with a flared exit portal increasing the efficiency of the head. The contact surface eliminates the possibility of the cutting line fusing to plastic surfaces due to heating caused by friction. The head is surrounded with an interior perimeter counterweight to store kinetic energy on each end having a parabolic surface of revolution concentric with the axis of the tubing. A replaceable cartridge is provided to increase the ease of maintenance and the useful life of the head.

Owner:MOORE MARK R

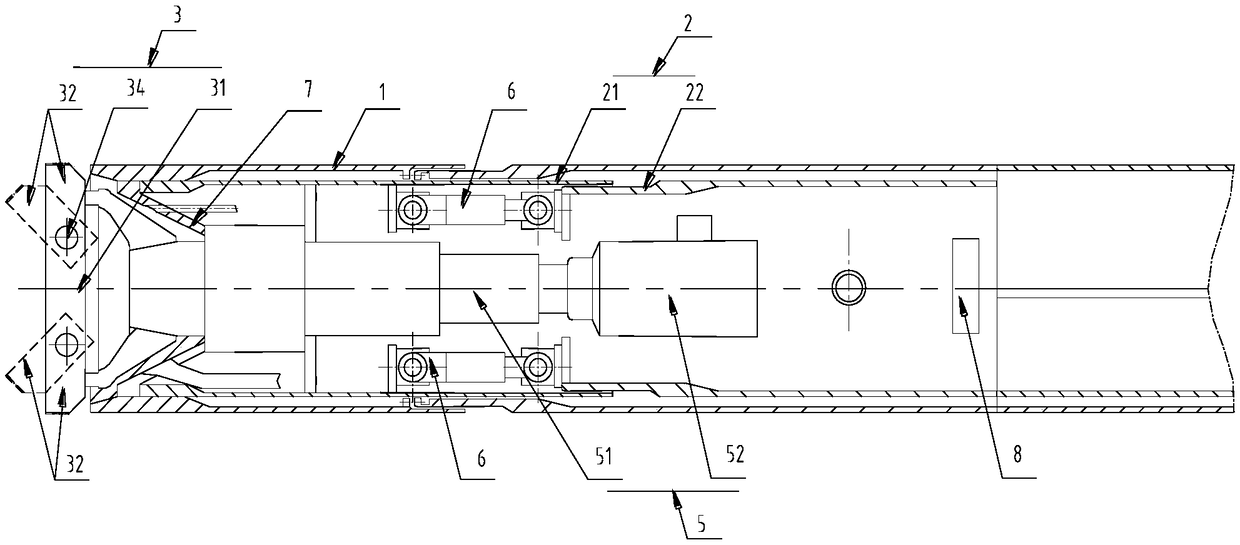

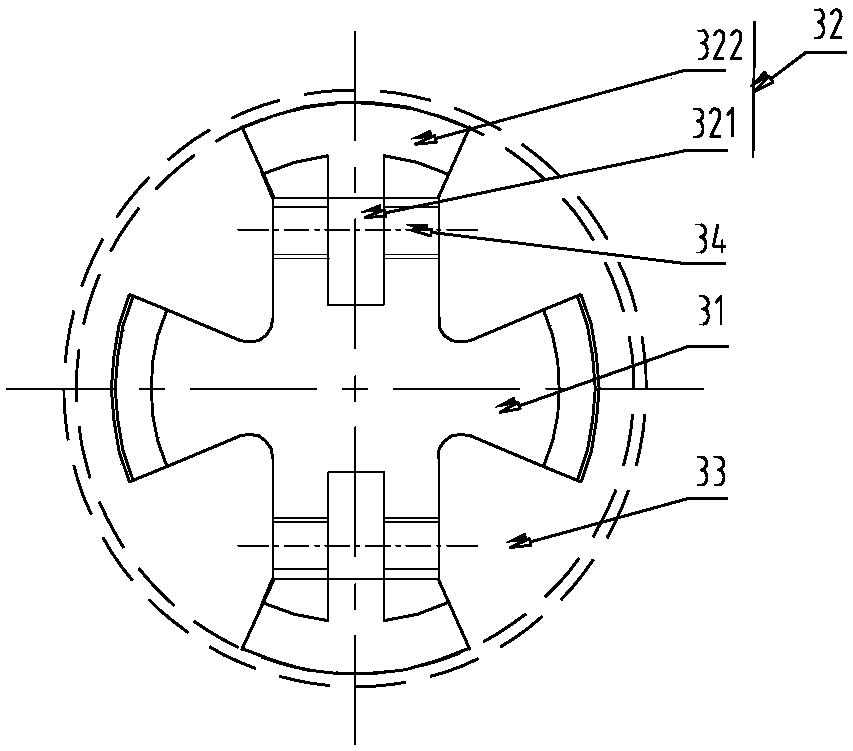

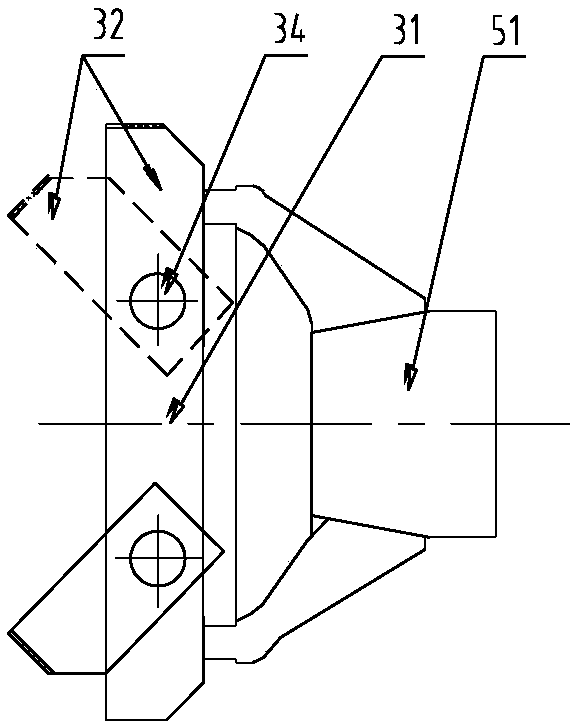

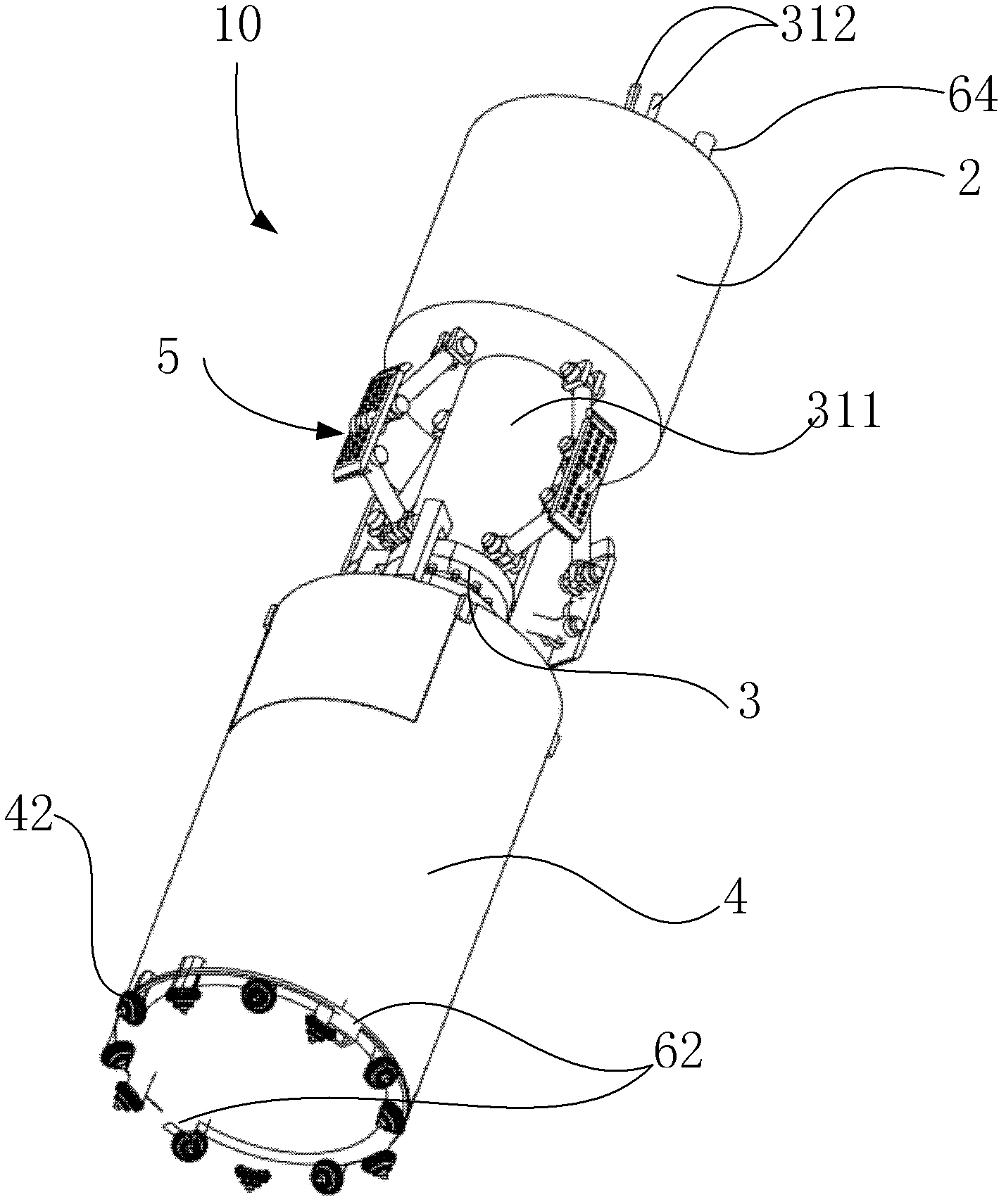

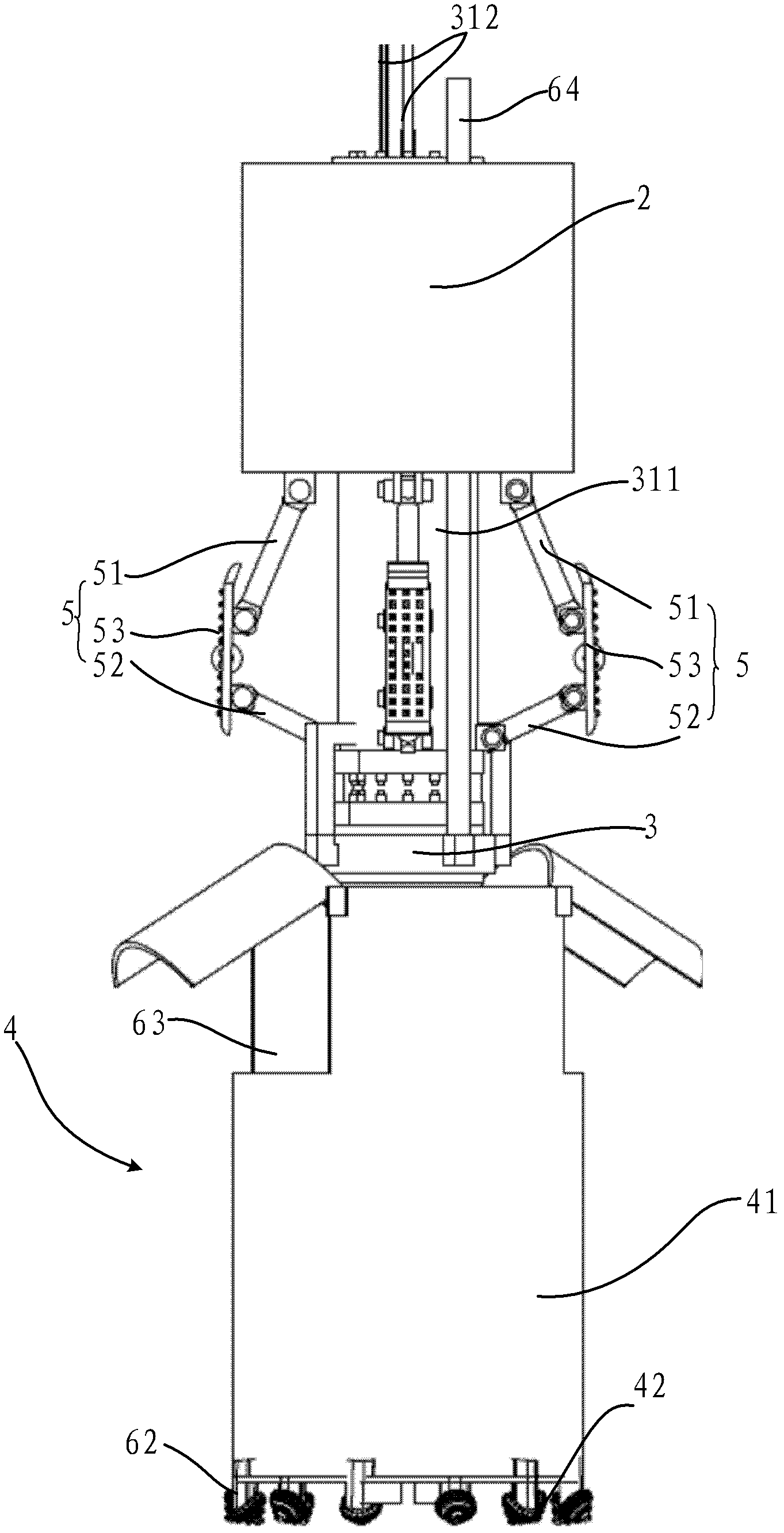

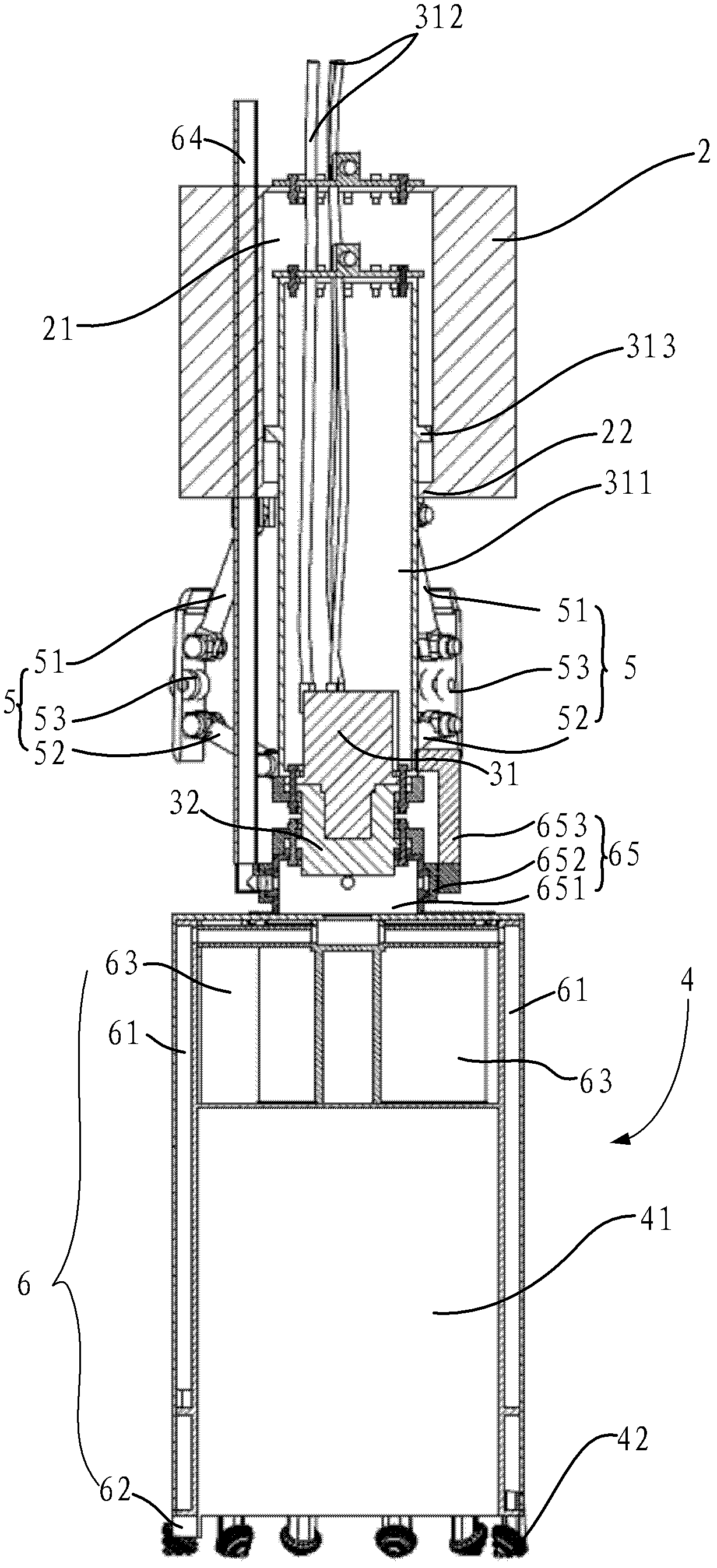

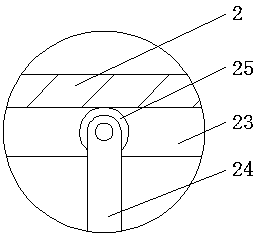

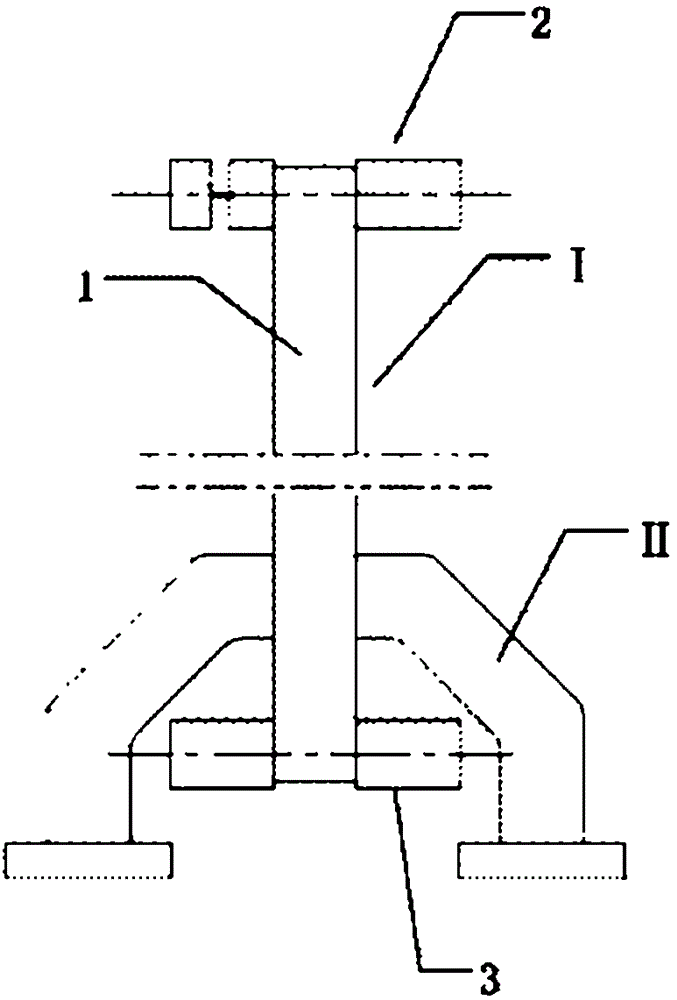

A pipe jacking machine and a returnable pipe jacking construction method

PendingCN108895201ALarge cutting areaImprove tunneling efficiencyPipe laying and repairEngineeringKnife holder

A pipe jacking machine includes a cutter head fixedly connected to the inner housing and capable of entering the central cavity, and a folding cutter holder having a first end hinged to the cutter head and a second end foldable about the first end into the central cavity. The cutter head includes an outer housing and an inner housing, and a cutter assembly and a retractor fixedly connected to theinner housing at an end remote from the cutter assembly. The cutting area of the folding cutter holder is free from the influence of the shell, and can avoid manual overturning, which is favorable forimproving the tunneling efficiency and realizing automatic retraction. In addition, the inner shell is dragged by the back dragging device so that the inner shell drives the cutter assembly to be dragged from the central cavity of the outer shell into the originating well, thereby avoiding manual disassembly of the connection between the outer shell and the inner shell and facilitating further automatic retraction. Therefore, the pipe jacking machine provided by the invention is not only conducive to improving the tunneling efficiency, but also conducive to realizing automatic retraction. Theinvention also discloses a returnable pipe jacking construction method applied to the pipe jacking machine as described above.

Owner:CHINA RAILWAY CONSTR HEAVY IND

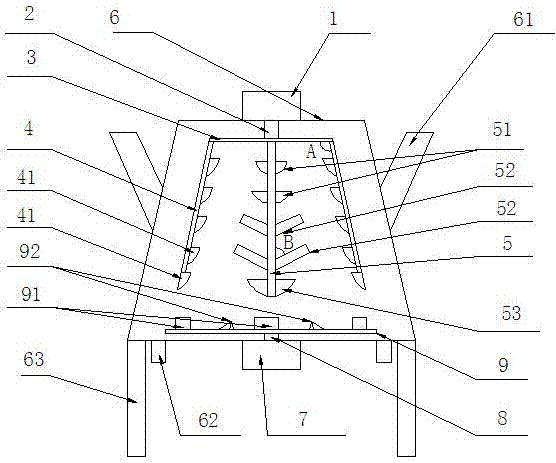

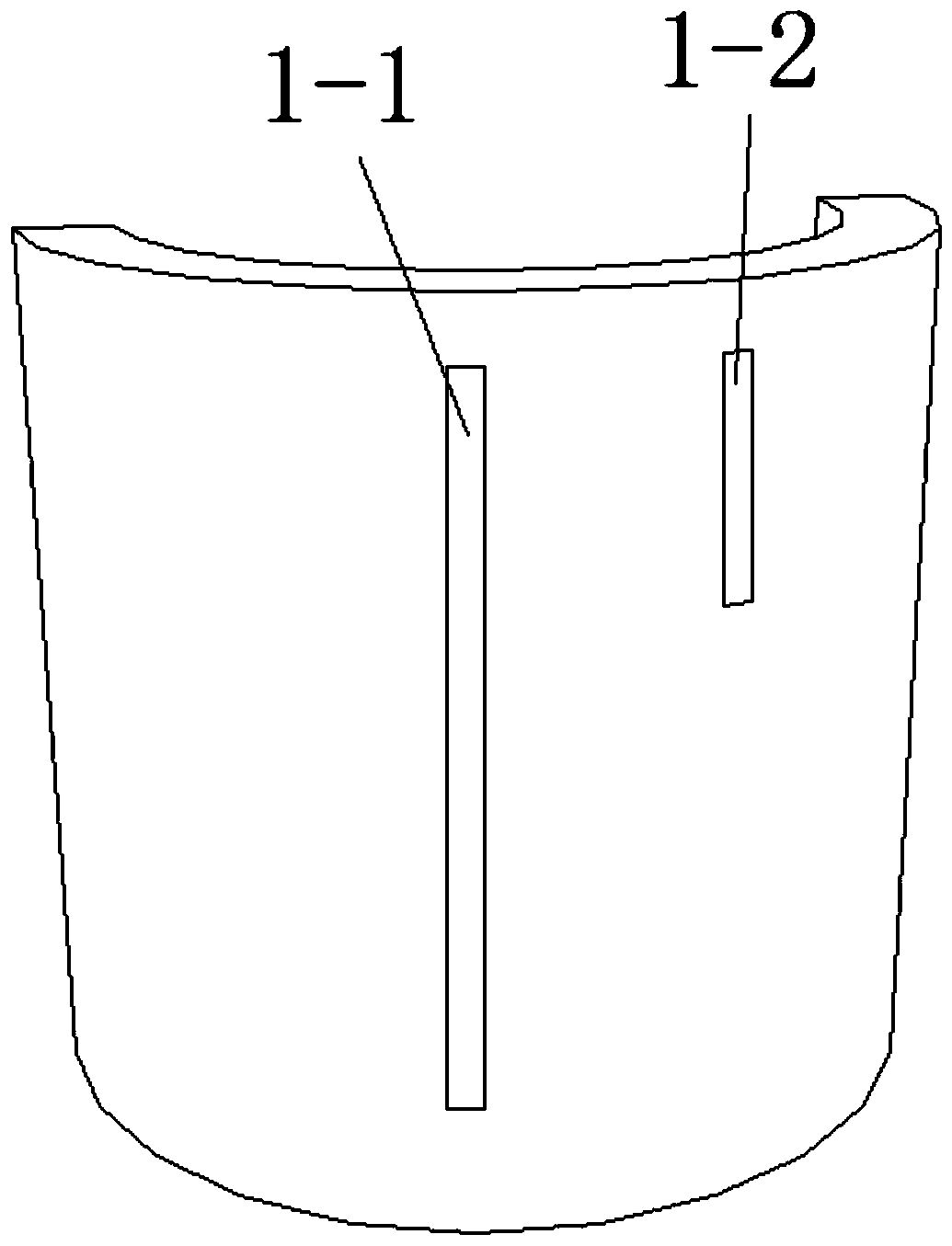

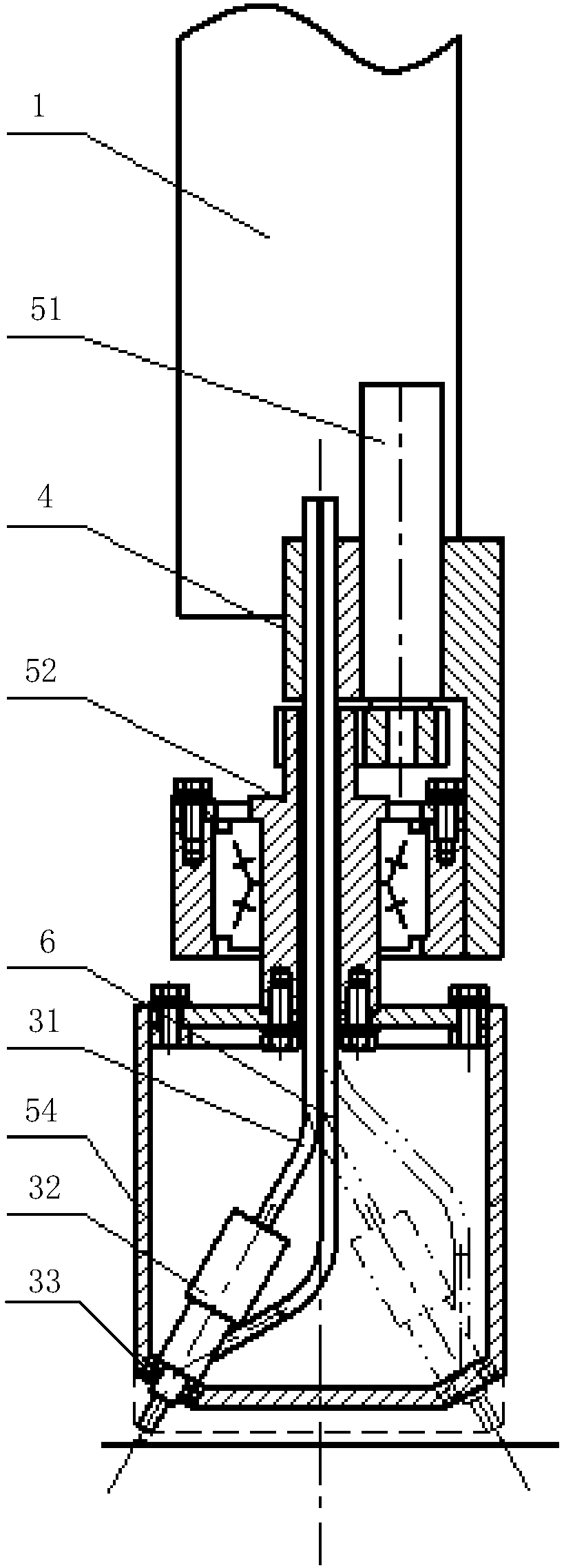

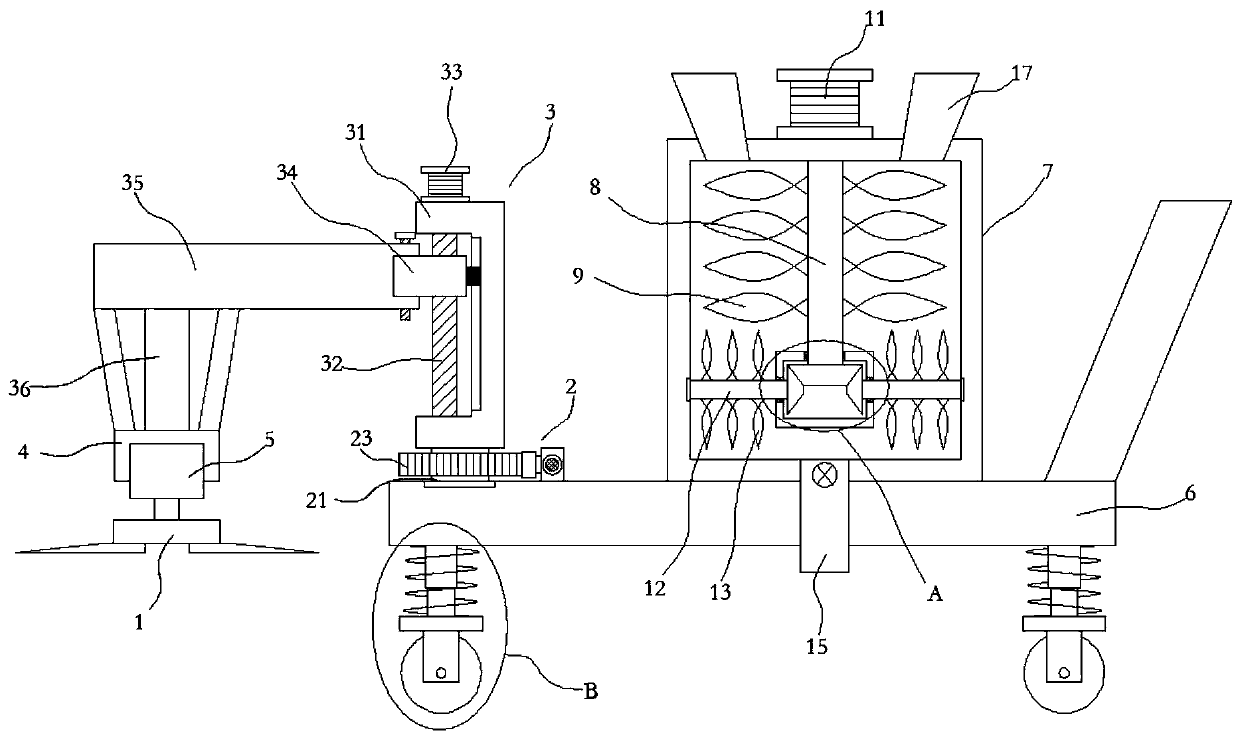

Special high-efficiency stirrer for conductive slurry

InactiveCN106975388AImprove efficiencyLarge cutting areaTransportation and packagingRotary stirring mixersMotor shaftEngineering

A special high-efficiency stirrer for conductive slurry is characterized in that a first motor is arranged in the center of the top of a stirrer shell, and a second motor is arranged in the center of the bottom of the stirrer shell; and a first motor shaft, a transverse stirring rod, tilting stirring rods, a vertical stirring rod, a second motor shaft and a bottom rotating disc are arranged in the stirrer shell. The design of multiple stirring rods is adopted to improve the multi-angle stirring efficiency, various blades are cooperated to effectively scatter large agglomerates in the slurry from all angles, and the bottom rotating disc is especially arranged to effectively prevent the deposition phenomenon in the stirrer body, so the use efficiency is improved.

Owner:江苏昱星科技股份有限公司

Head for a rotary line trimmer apparatus

InactiveUS20080155837A1Increase temperatureHead is increasedMowersMetal working apparatusEngineeringMechanical engineering

An improved head for a flexible line trimmer apparatus is provided. The improved head includes a metal tubing that extends through the head and surrounds a cutting line of selected length. The tubing is provided with a flared exit portal increasing the efficiency of the head. The contact surface eliminates the possibility of the cutting line fusing to plastic surfaces due to heating caused by friction. The head is surrounded with an interior perimeter counterweight to store kinetic energy on each end having a parabolic surface of revolution concentric with the axis of the tubing. A replaceable cartridge is provided to increase the ease of maintenance and the useful life of the head.

Owner:MOORE MARK R

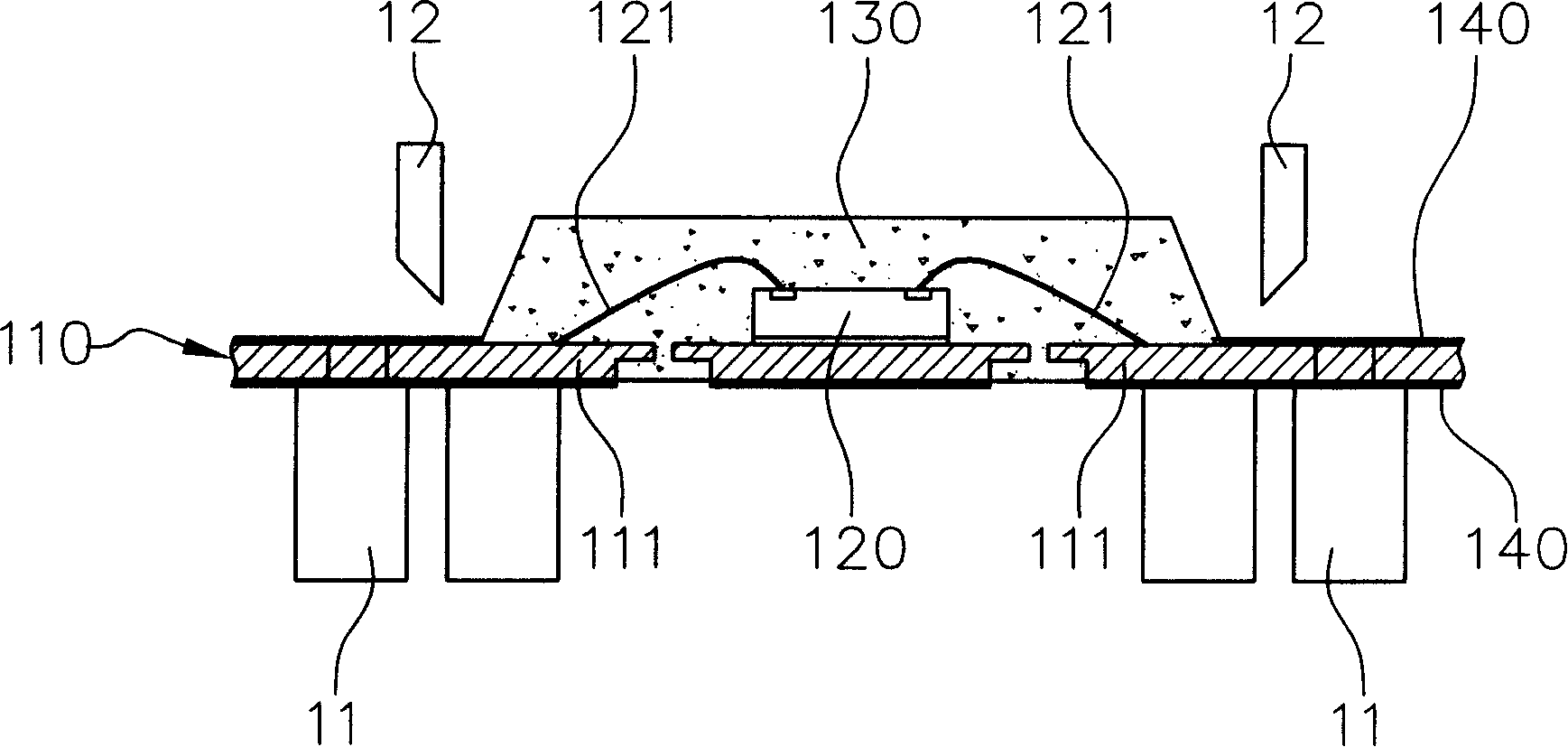

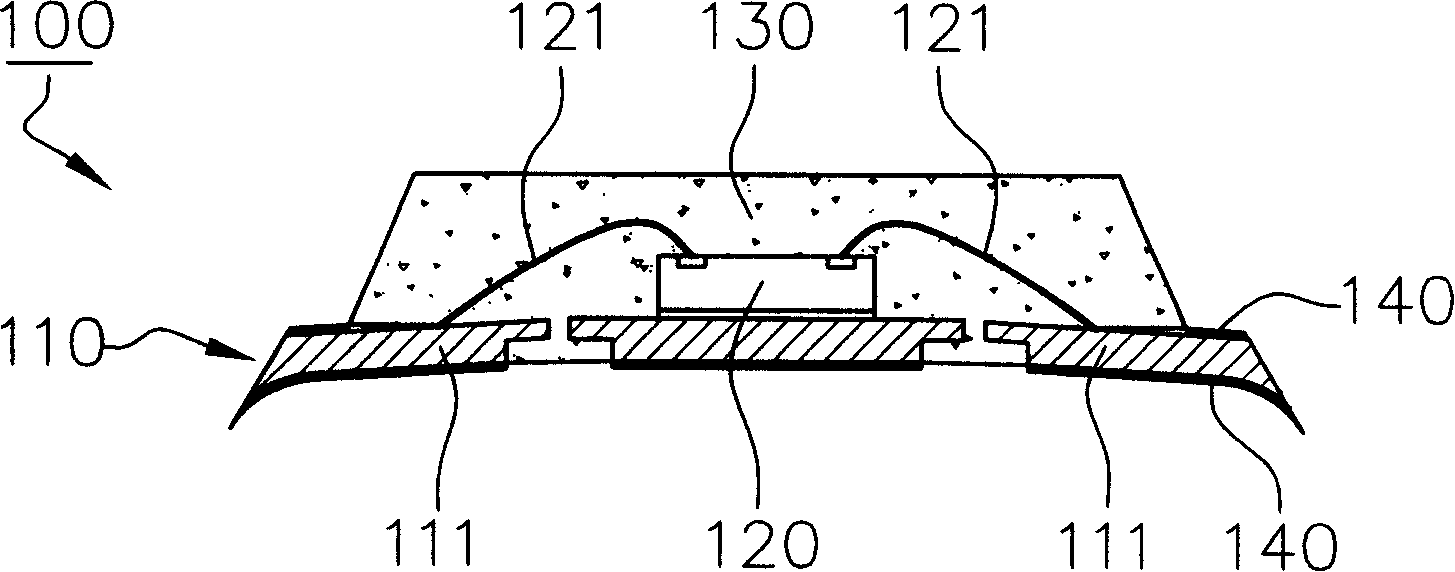

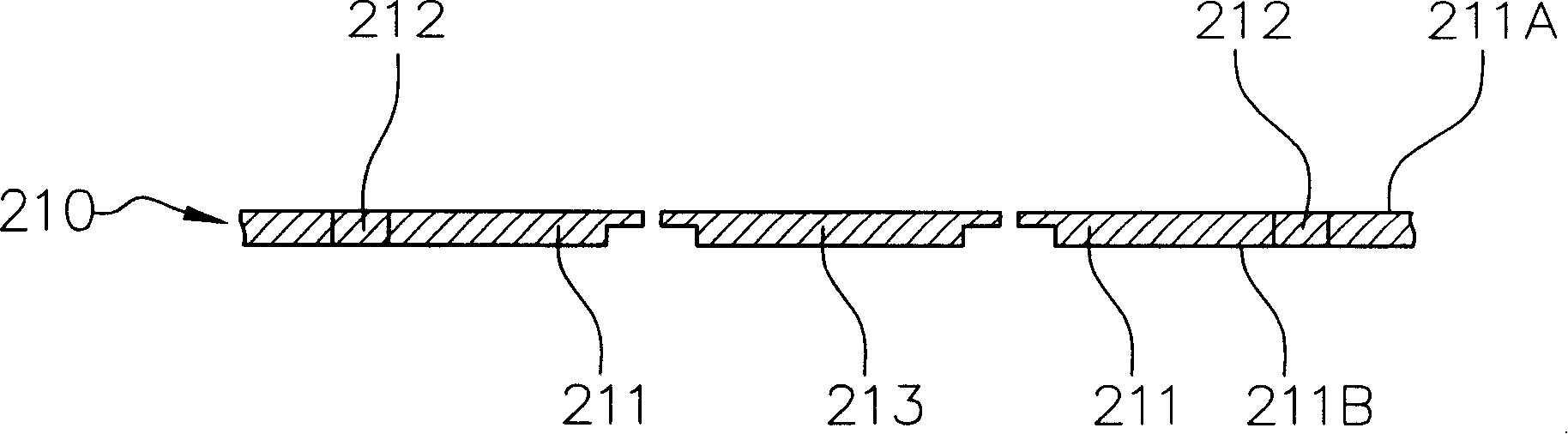

Blanking type encapsulation constitution without external pin and manufacturing method thereof

InactiveCN101226890AIncrease plating areaSolve pin strippingSemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The invention relates to a blanking-type packaging structure without outer pins and a manufacturing method thereof. The manufacturing method of the blanking-type packaging structure without outer pins comprises the following steps: providing a lead frame with a plurality of carrier units, wherein each carrier unit internally forms a plurality of pins, disposing a plurality of wafers to the lead frame, wherein the wafers are electrically connected to the pins, forming a plurality of glue sealing bodies on the carrier units and combining the pins, performing one step of semi-blanking to form a plurality of half-concave nicks on the pins along the outer periphery of the glue sealing bodies, performing one step of electric plating to form an electric plating layer on the exposed surface of the half-concave nicks of the pins and performing one step of complete plating for cutting off the pins along the half-concave nicks to be divided into individual glue sealing bodies. The invention can resolve the problems that the pins of the blanking-type packaging structure without outer pins are torn off, dropped down with rough edges and the like in the single planking process, and the invention can increase the excellent rate of the process and even increase the plating area of the pins, thereby being quite suitable for utility.

Owner:CHIPMOS TECH INC

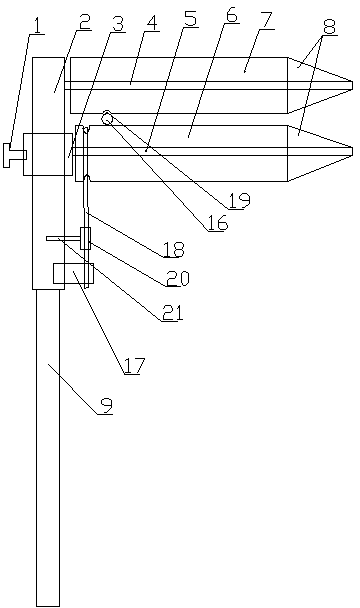

Sweeping wind on-line foreign matter removal device and debug method for overhead power transmission line

InactiveCN104184069AWon't cutPlay a limiting roleApparatus for overhead lines/cablesForeign matterEngineering

The invention discloses a sweeping wind on-line foreign matter removal device and debug method for an overhead power transmission line. The on-line foreign matter removal device comprises a rectangular rack. The two ends of an upper cross rod of the rectangular rack are respectively provided with a rotation shaft sleeved with a rolling wheel. Each vertical rod of the rectangular rack is sleeved with a sliding sleeve with a compression bolt. A lower rotation shaft sleeved with a compression rolling wheel is arranged on each sliding sleeve. The sliding sleeves are fixedly connected through a connection rod. One end of each rolling wheel is of a conical structure. An extension rod is arranged at one end of the upper cross rod. A blade parallel to the rolling wheels is arranged at the free end of the extension rod. The distance between a cutting edge of the blade and the lower planes of the rolling wheels is 0.05-0.2 mm. A telescopic insulating rod is arranged on a lower cross rod of the rectangular rack. The on-line foreign matter removal device and debug method have the advantages that cleaning is thorough, hot-line work is realized, pole climbing is not needed, and the application range is wide.

Owner:国网河南唐河县供电公司

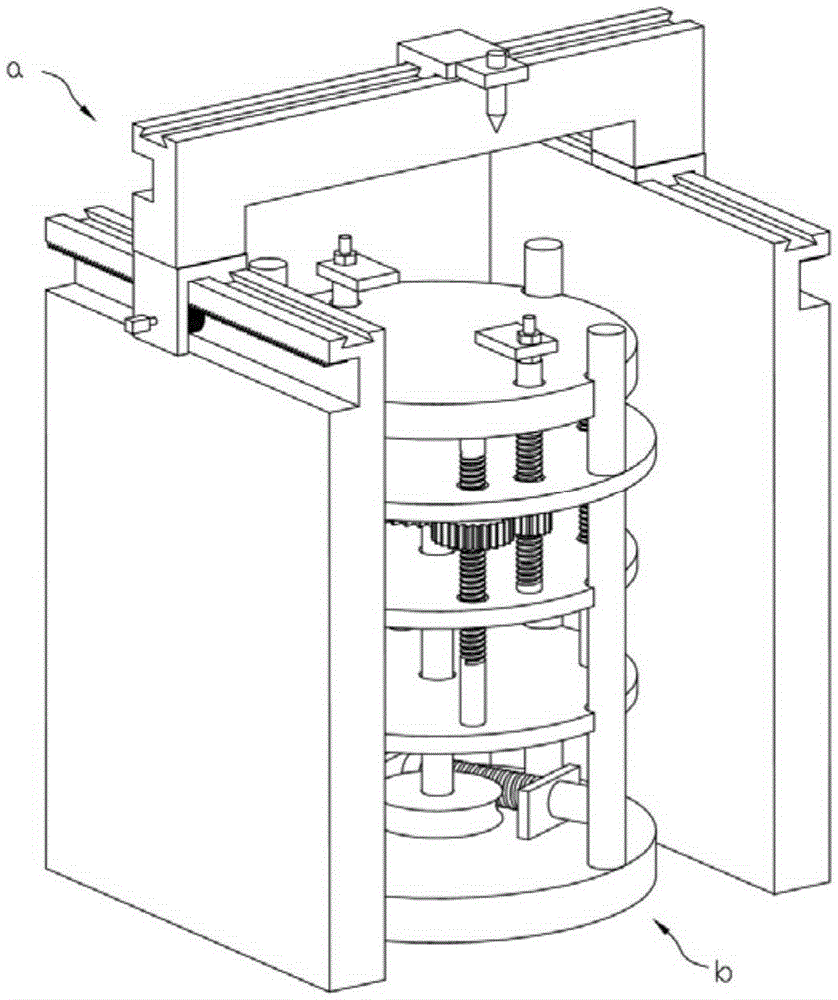

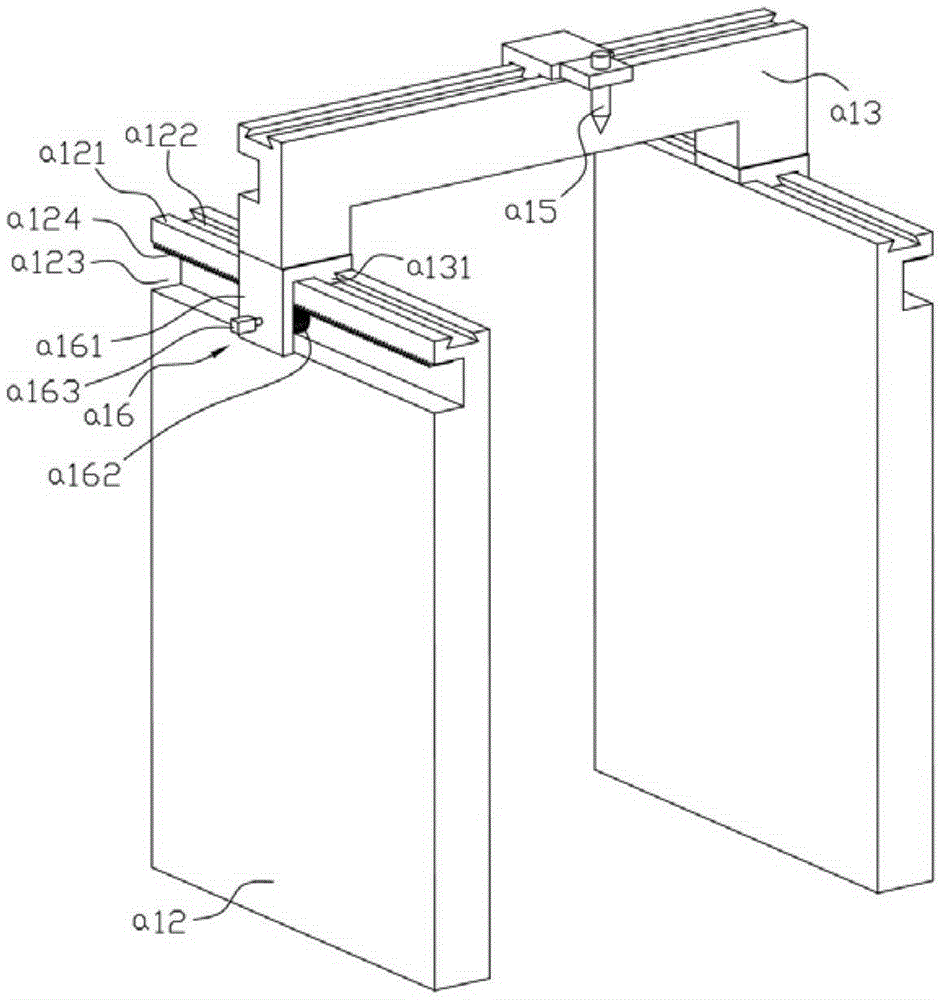

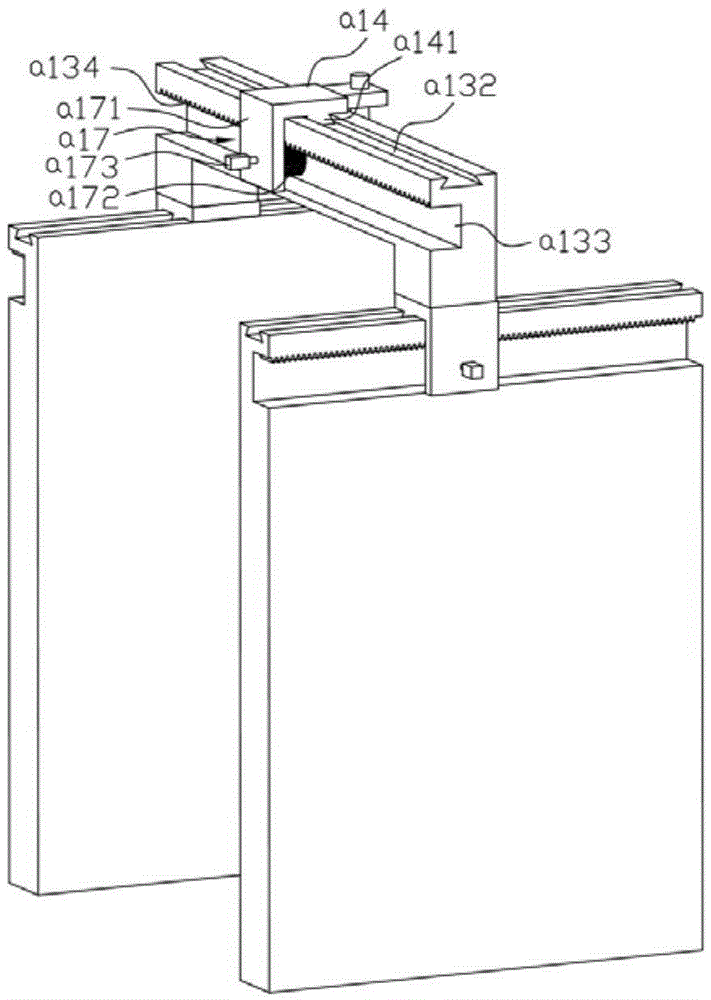

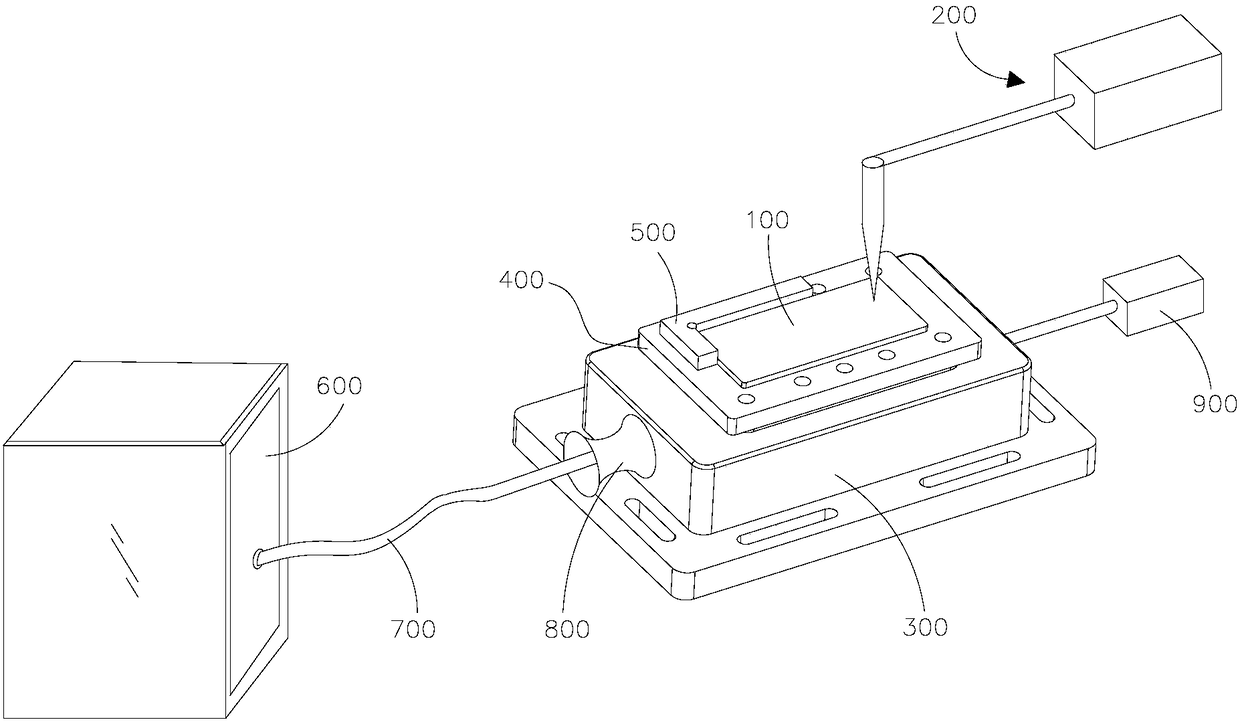

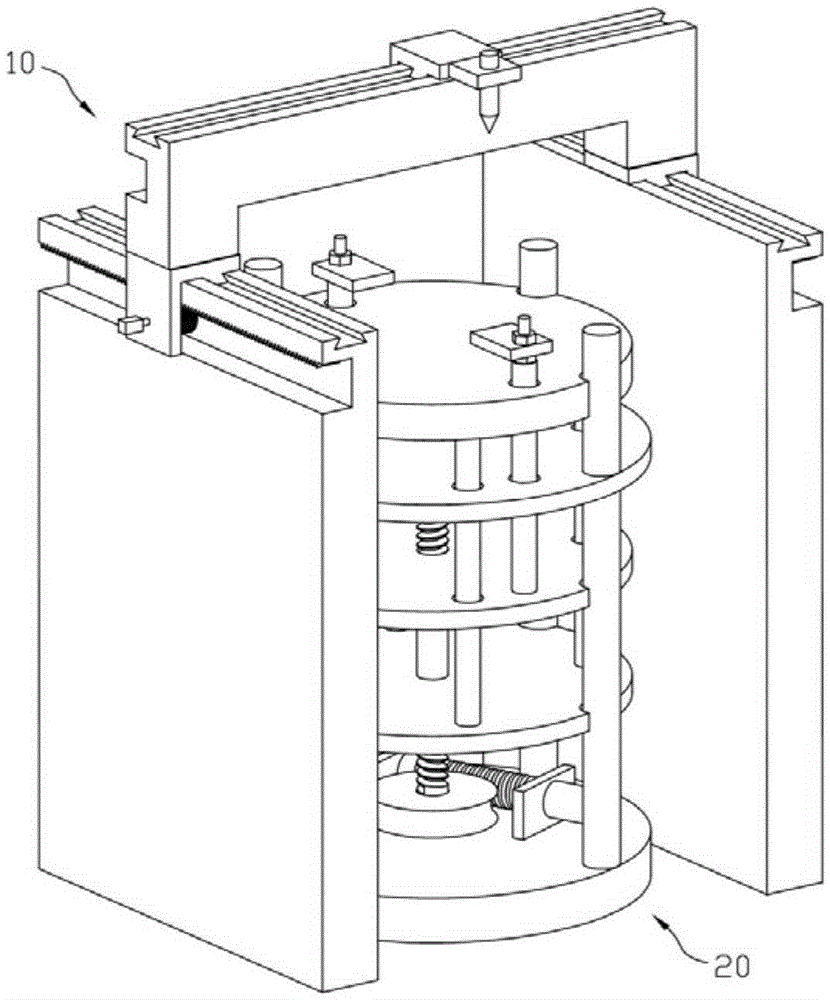

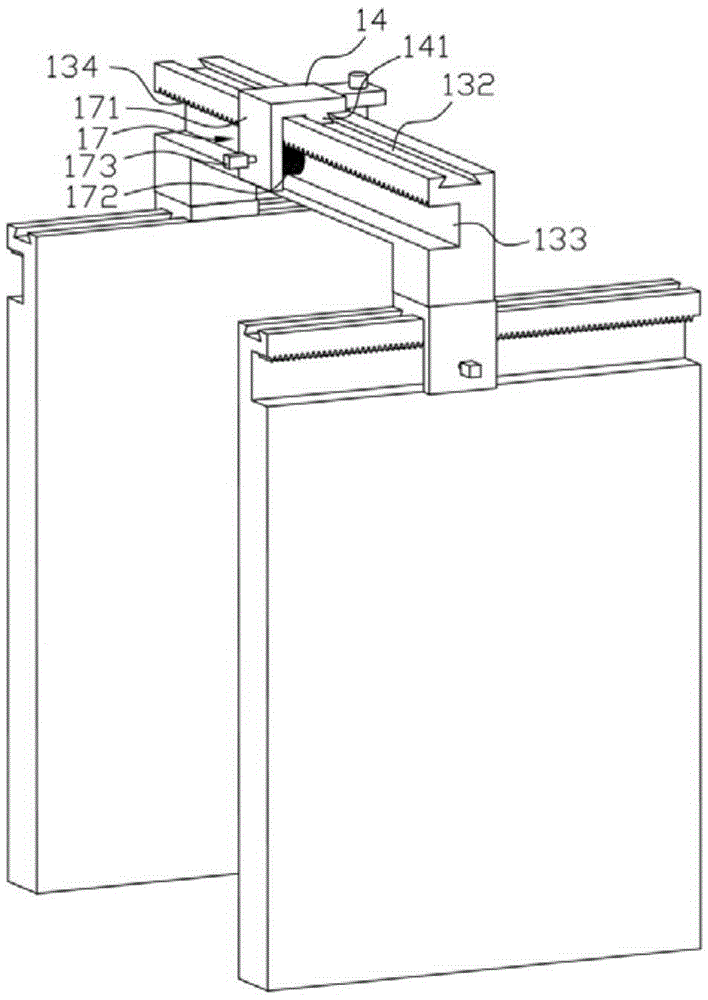

Template laser cutting equipment provided with template fixture

InactiveCN105414750AShort operating timeSimple and efficient operationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

The invention discloses template laser cutting equipment provided with a template fixture. The template laser cutting equipment comprises a cutting mechanism and the template fixture, wherein the cutting mechanism comprises a laser head; the laser head makes two-dimensional movement through an X-direction slideway and Y-direction slideways; and the template fixture is positioned between two rack plates of the cutting mechanism and is positioned below the laser head; a worm gear in the template fixture, through driving a threaded rod, drives a first chassis to descend with a locking block, and drives a second chassis to rise with a fixed disk. In this way, a workpiece on the fixed disk is clamped up and down by the fixed disk and the locking block, and the cutting of a template is completed by a laser beam. The template laser cutting equipment is high in speed and efficiency, and cuts smoothly, easily and neatly.

Owner:DONGGUAN QINZHI IND DESIGN CO LTD

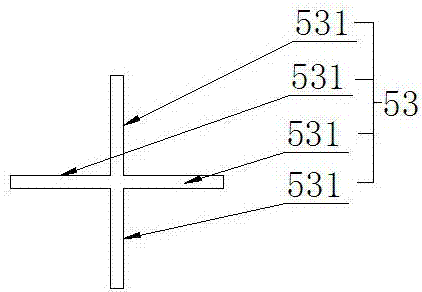

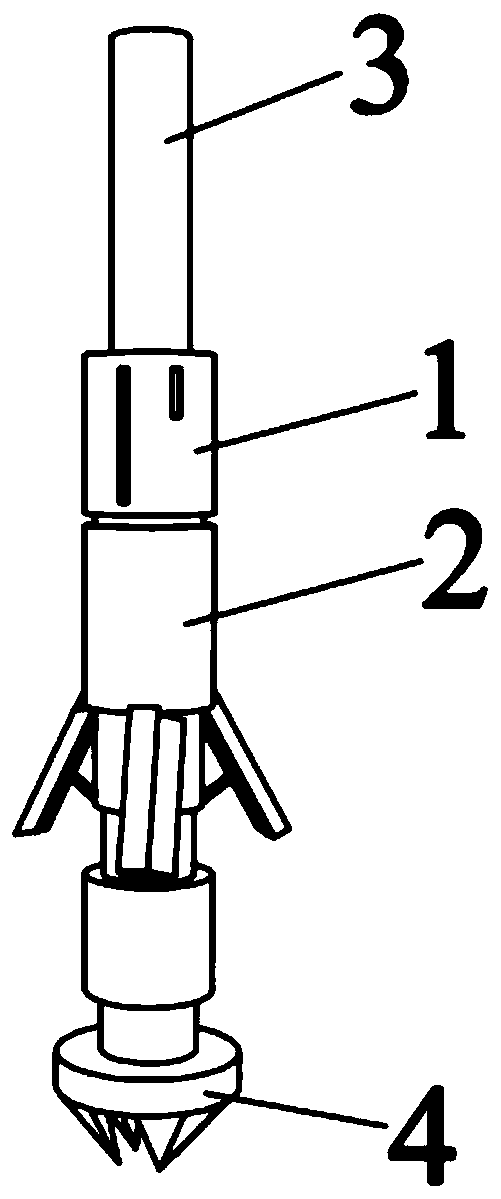

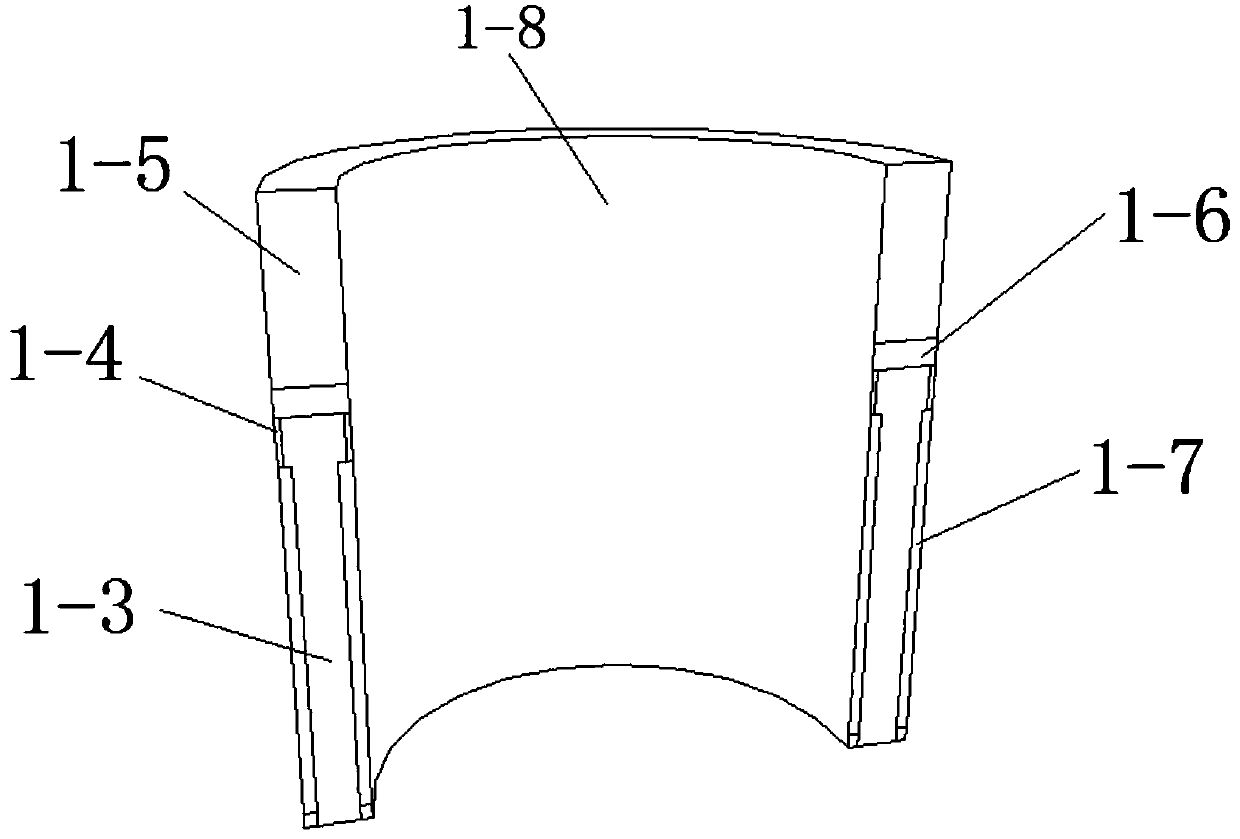

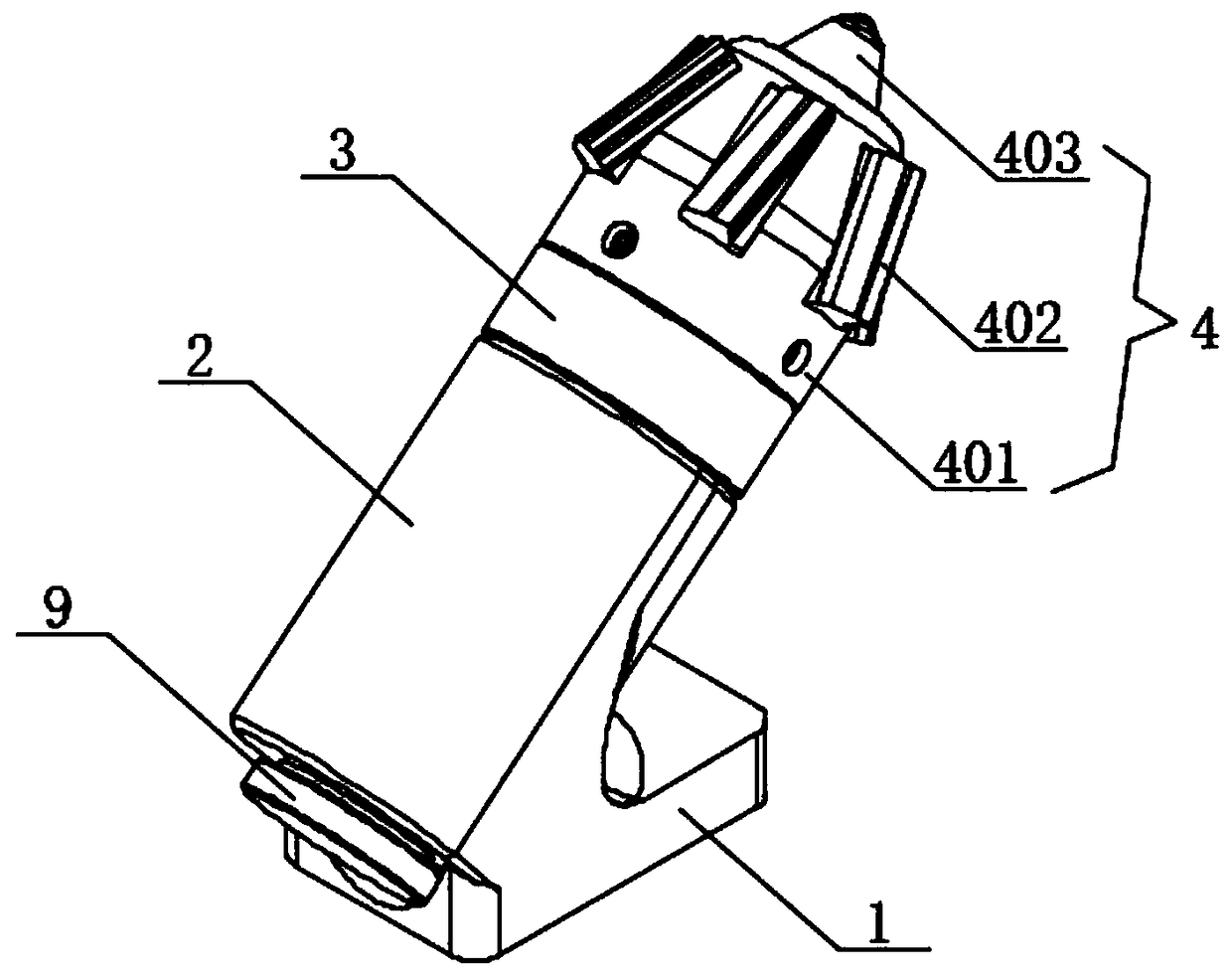

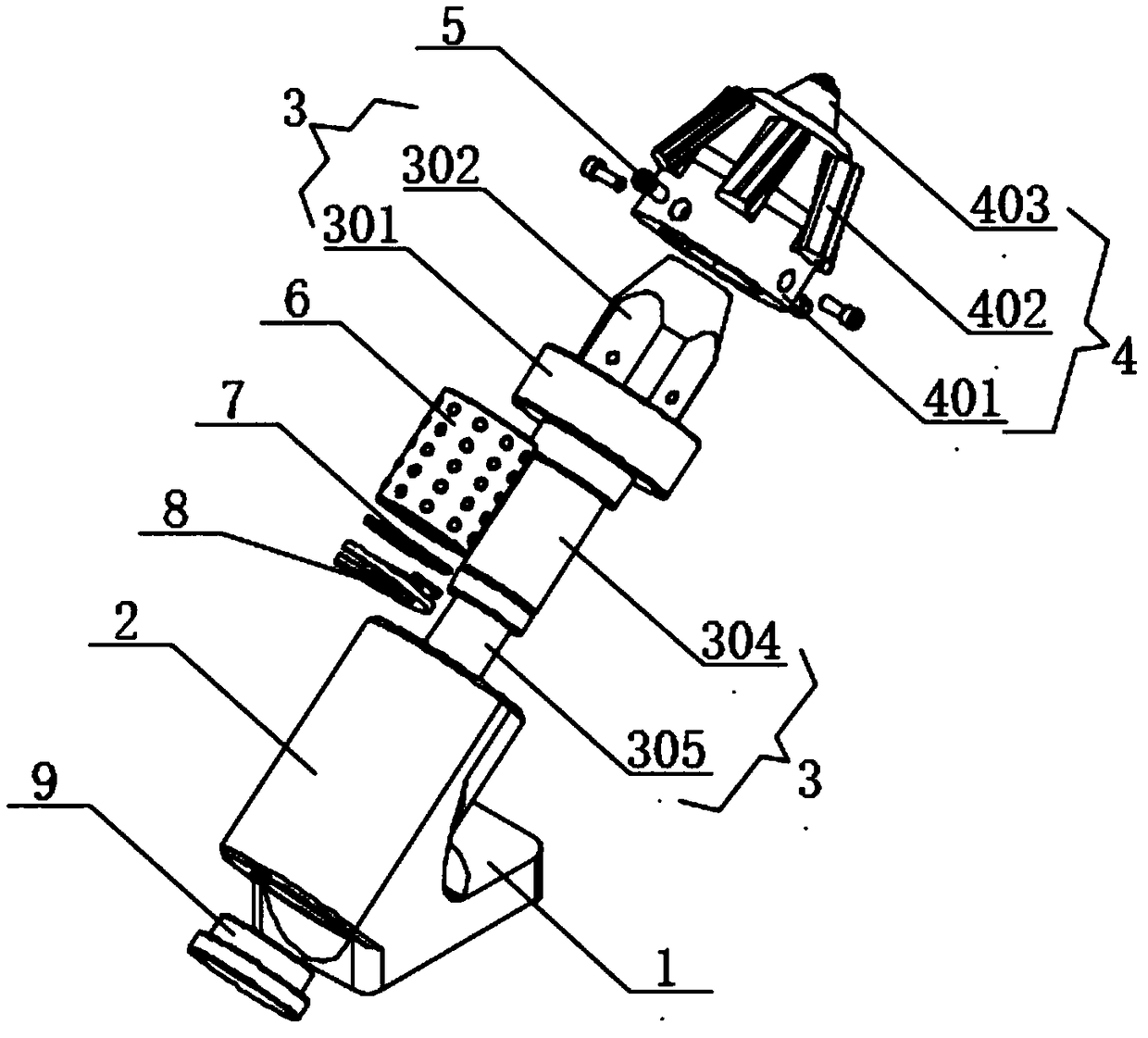

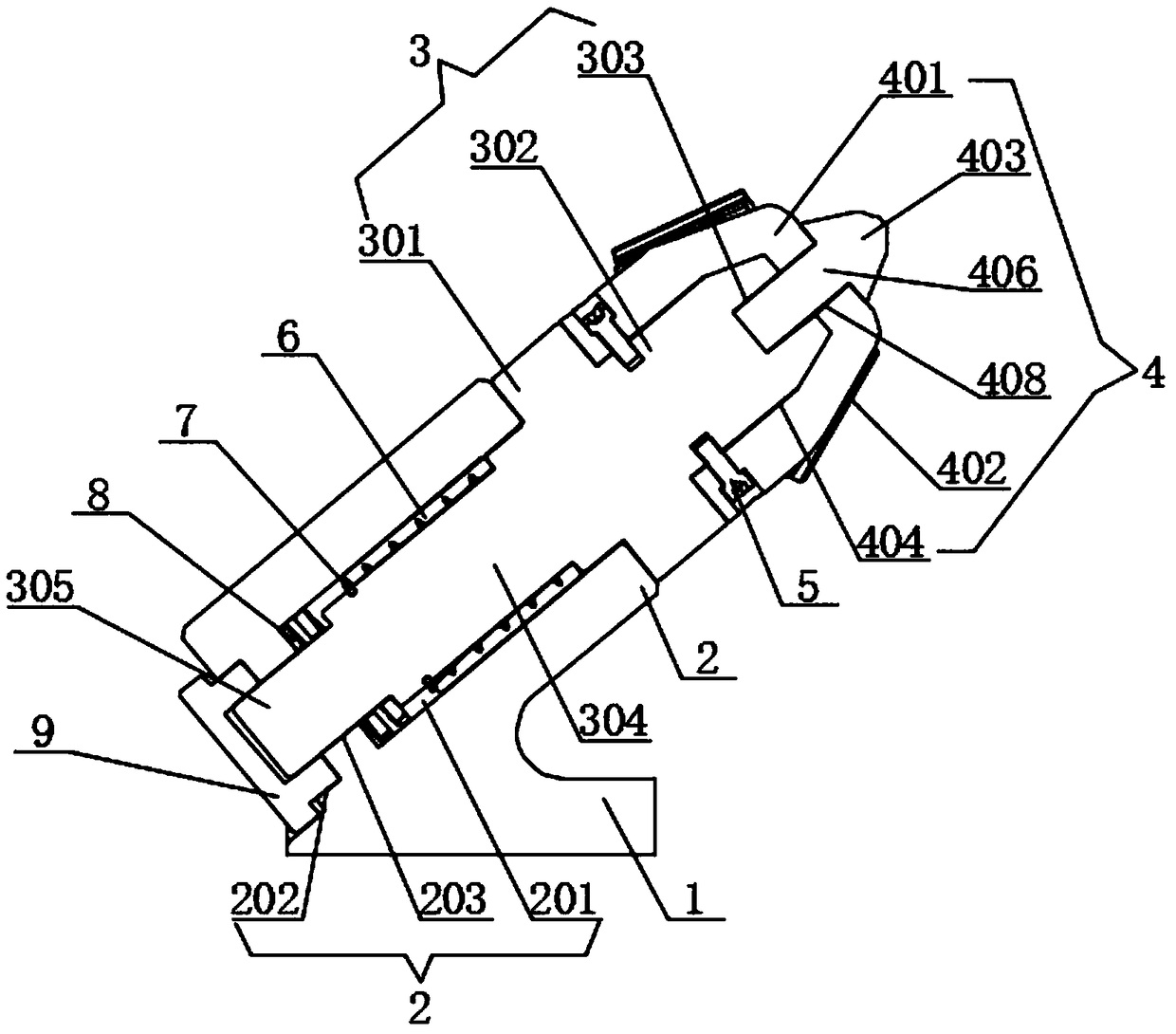

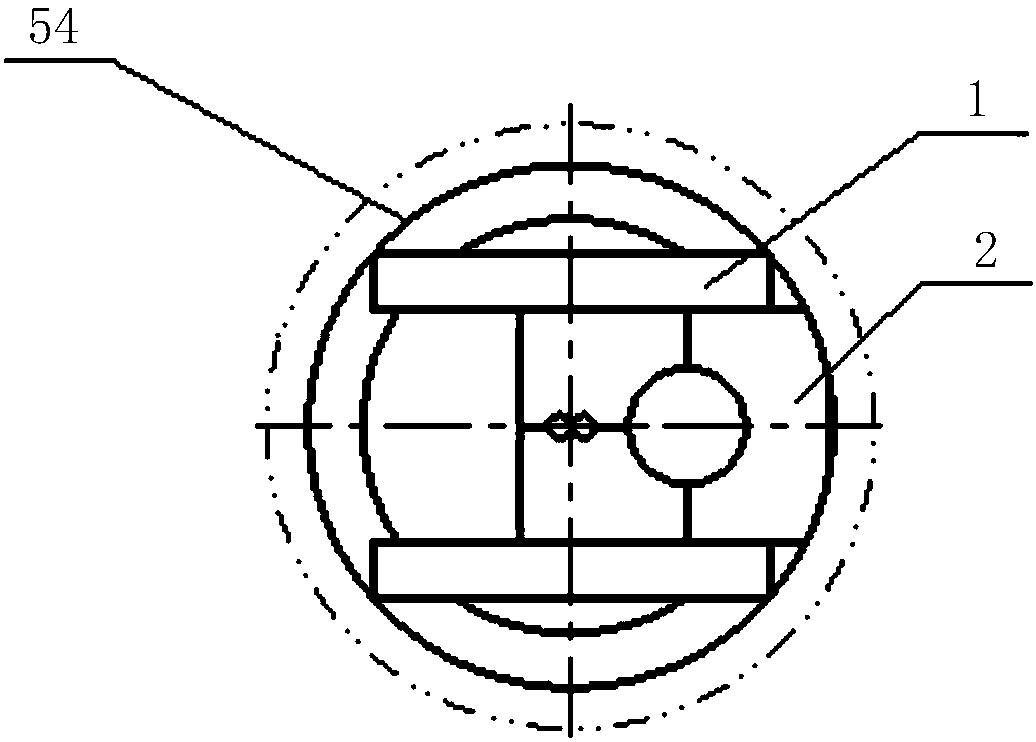

Rotary cut-expanded branch pile machine and construction method of cut-expanded branch pile

PendingCN111042738APrevent slipping outGuaranteed stabilityDrill bitsDirectional drillingDrill bitHydraulic pressure

The invention discloses a rotary cut-expanded branch pile machine and a construction method of a cut-expanded branch pile. The cut-expanded branch pile comprises a drill rod, and a rotary cut-expanding assembly is fixed to the drill rod. The rotary cut-expanding assembly comprises a first force transferring barrel, and a plurality of soil cutting steel plates are hinged to the lower end of the first force transferring barrel. First sliding grooves are formed in the inner walls of the soil cutting steel plates. The lower end of a second force transferring barrel stretches inwards to form a pressing block, and a buckle seat is fixed to a connecting barrel. A spring is mounted on the side wall of the buckle seat, the lower end of the spring and the lower end of a mounting groove are fixed, and the upper end of the spring seat and a buckle are fixedly connected. One end of each connecting rod is fixed into the corresponding first sliding groove, and the other ends of the connecting rods are mounted on the buckle. When the drill bit reaches a target position, the soil cutting steel plates work under the action of a hydraulic component, the rotary speed and angles of the soil cutting steel plates achieve stepless speed change, and finally a tree-shaped branch plate cavity is formed in the same position. Compared with a common branch pile, the formed tree-shaped branch pile has the advantages that the size is larger, and the vertical and transverse axial bearing capacity of a pile foundation is remarkably improved.

Owner:CHANGAN UNIV

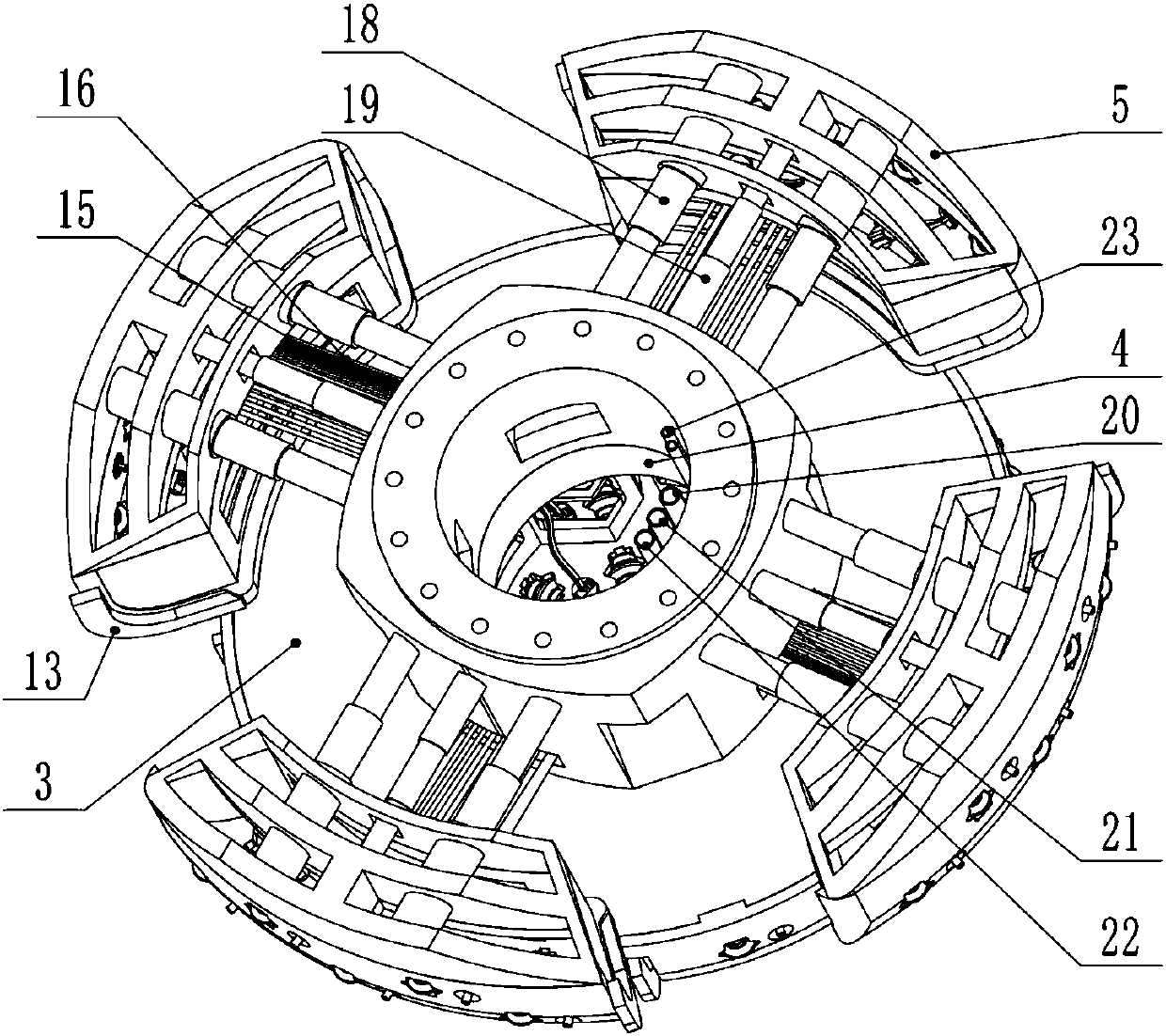

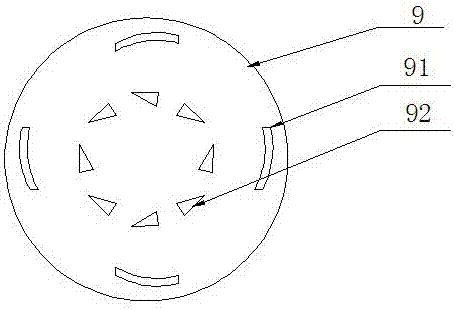

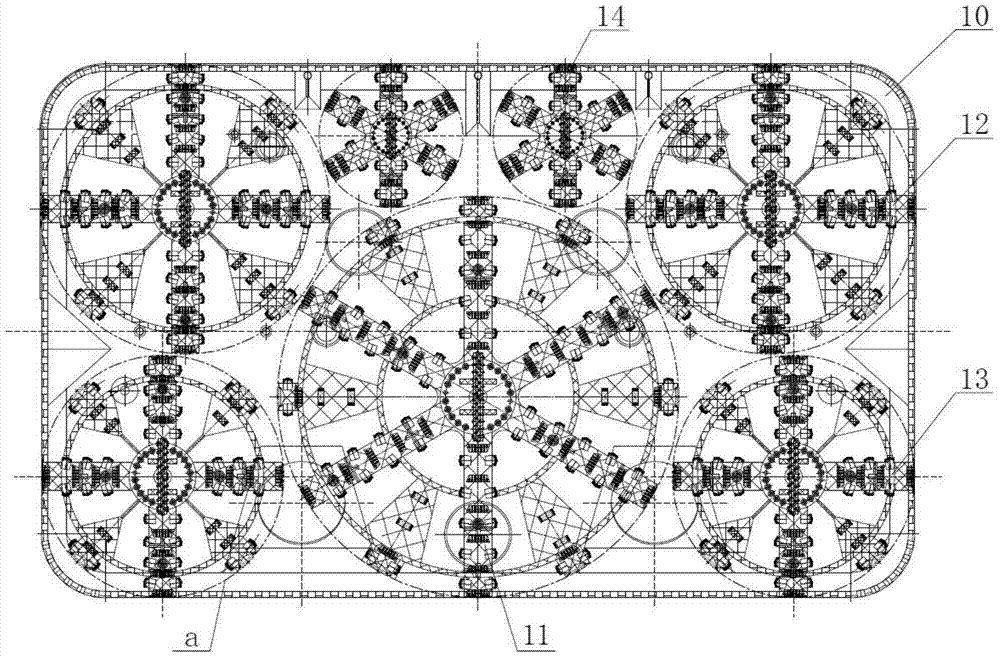

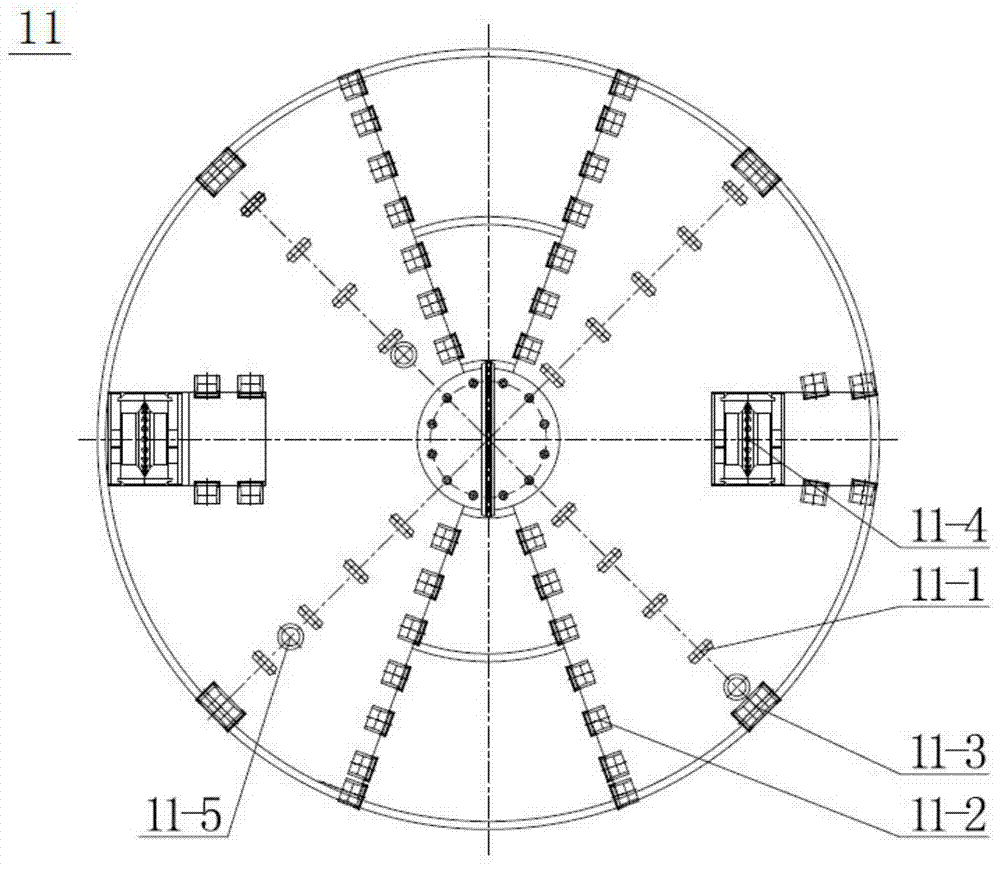

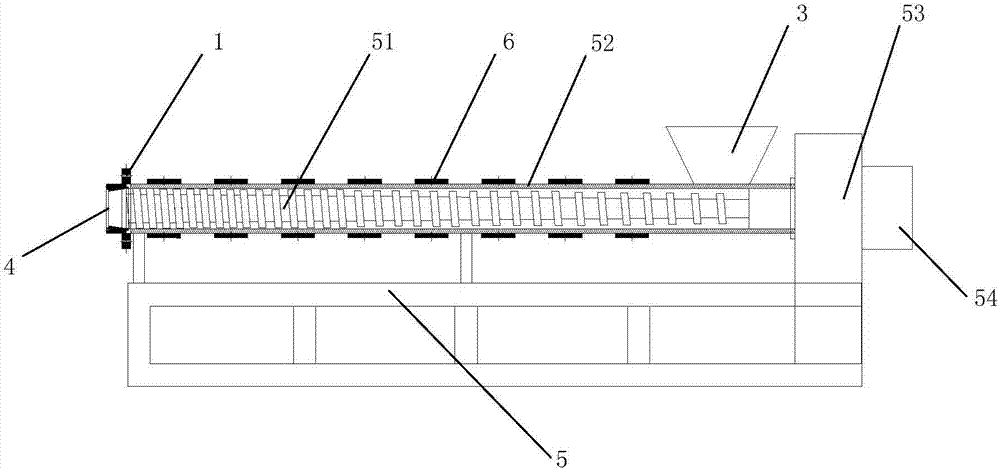

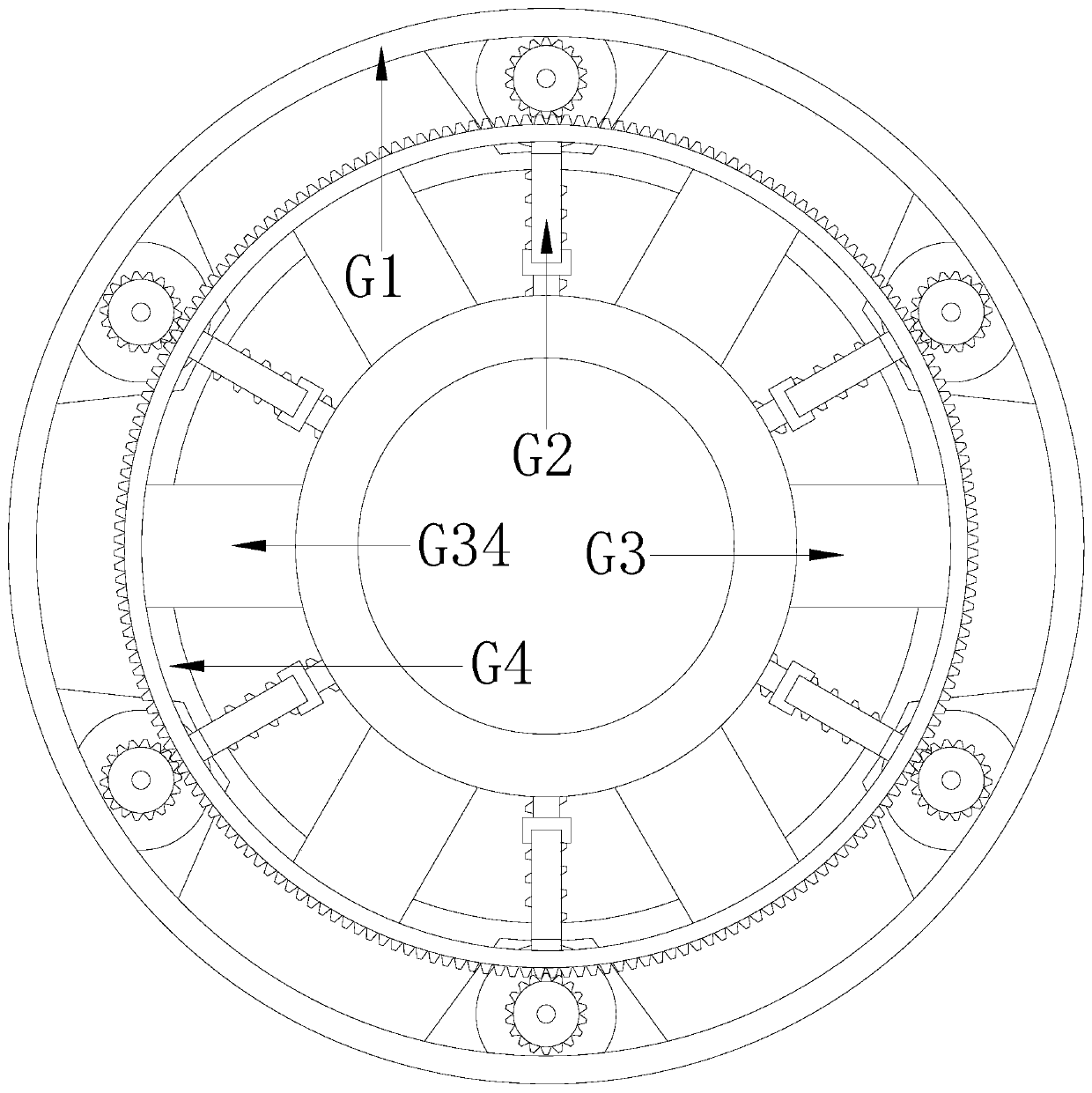

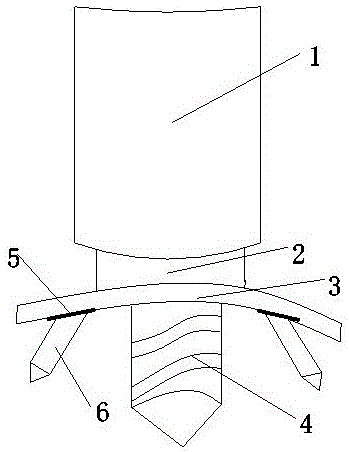

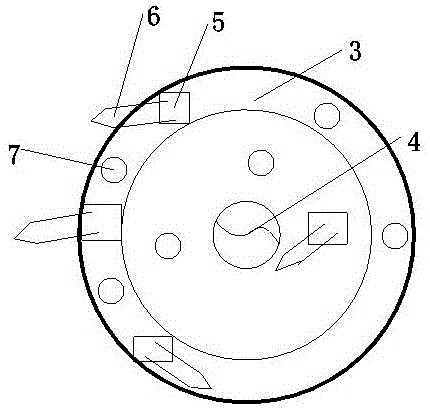

Multi-cutter head combined type cutting system for rectangular pipe pushing machine

The invention provides a multi-cutter head combined type cutting system for a rectangular pipe pushing machine, relates to the technical field of construction equipment, and aims at solving the problems that when an existing combined type cutter head carries out construction in a sandy land layer, sandy soil on the tunnel face is easy to collapse, the cutter head is easy to clamp in a soil body, and even a cutter head bearing is fractured. The multi-cutter head combined type cutting system for the rectangular pipe pushing machine comprises multiple cutter heads which are symmetrically distributed on a shield of the rectangular pipe pushing machine and a driving device used for driving the cutter heads. Circumferences of cutting tracks of every two adjacent cutter heads are tangent. According to the multi-cutter head combined type cutting system for the rectangular pipe pushing machine, the cutting area of the cutter heads is enlarged, stratum full-face cutting can be achieved, the cutter heads are prevented from being trapped, and the working efficiency is improved.

Owner:SHANGHAI MUNICIPAL CONSTR

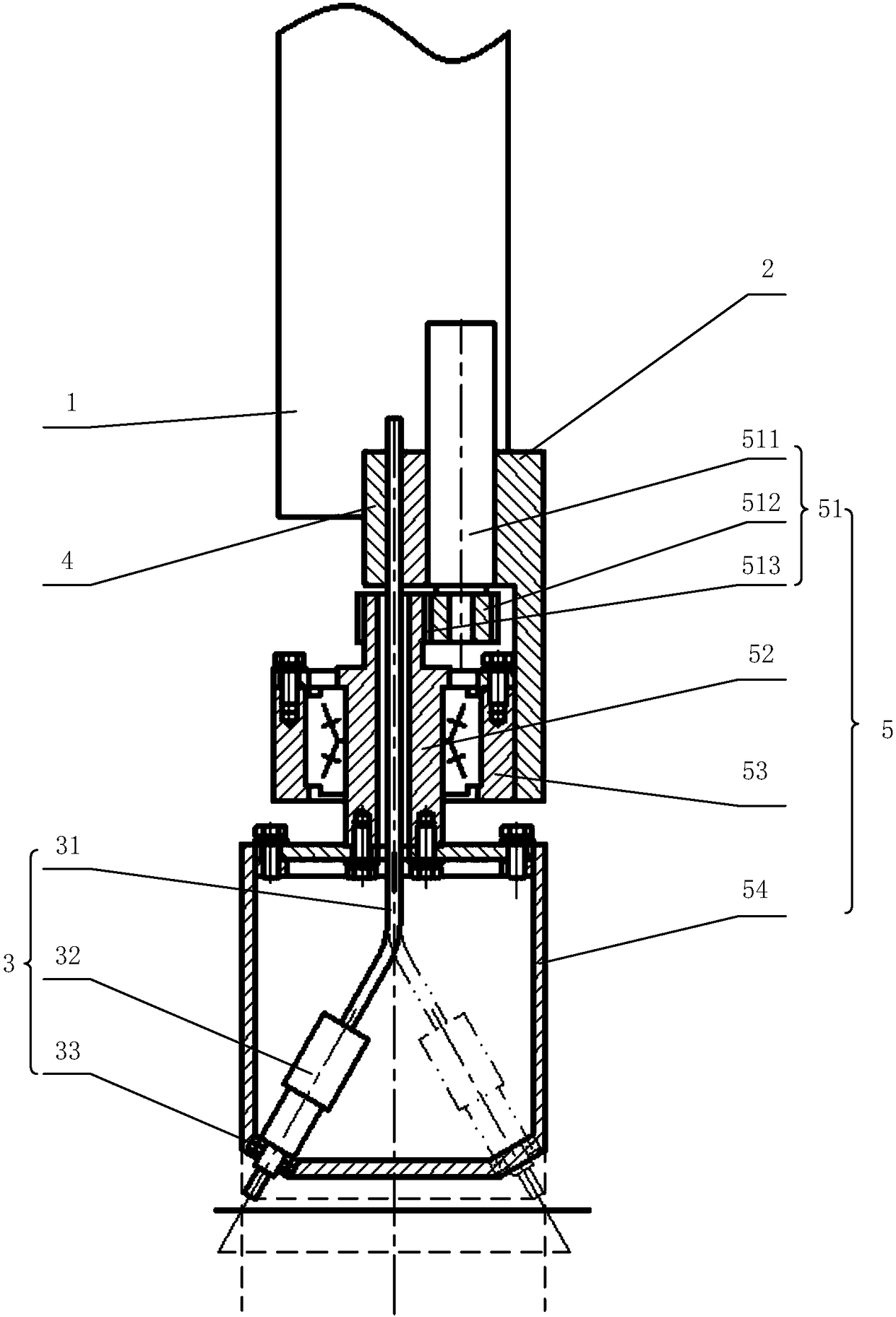

Drilling tool and piling machinery

ActiveCN102587834AImprove drilling efficiencyQuality improvementEarth drilling toolsDrill bitsSlagPetroleum engineering

The invention provides a drilling tool, comprising a drill bit and a swing mechanism which is used for driving the drill bit to rotate; and the drilling tool also comprises a slag removal mechanism which is arranged in the drill bit and capable of collecting broken slag generated during the drilling of the drill bit. The invention also provides piling machinery comprising the drilling tool. As the slag removal mechanism is arranged on the drill bit, the drilling slag generated during the drilling of the drill bit can be collected, the cutting area of native rock surface is increased, and the drilling efficiency is improved; and at the same time, through a suspension sling and a weight, the drilling requirement of deeper and harder stratums can be met, the damage caused by vibration to the machine can be effectively decreased, and the service life of the machine and the drilling tool can be prolonged.

Owner:BEIJING SANY HEAVY MASCH CO LTD

Diamond compact annular concentric simultaneous casing drilling bit and working method thereof

InactiveCN103114812AImprove drilling efficiencyImprove coaxialityDrill bitsDrilling rodsPetroleum engineeringRock breaking

The invention relates to a diamond compact annular concentric simultaneous casing drilling bit. The diamond compact annular concentric simultaneous casing drilling bit comprises a center drilling bit, a casing drilling bit and a casing shoe. The center drilling bit is connected with a drilling rod through a drilling rod connector, and the casing shoe is in threaded connection with a casing pipe. The casing drilling bit and the casing shoe are sleeved on the center drilling bit, and the drilling bit end surface of the casing drilling bit is flush with the drilling bit end of the center drilling bit in a stamping mode. The center drilling bit and the casing drilling bit are in a bonding structure, and the center drilling bit rotates around the axis in a unidirectional and limiting mode in the casing drilling bit. The casing drilling bit and the casing shoe are connected in a relative rotation mode around the axis through a sleeved installation method. According to the diamond compact annular concentric simultaneous casing drilling bit, the advantage of efficient rock breaking is fully used, in the process of efficient rock breaking and pushing of the center drilling bit, the casing drilling bit is also efficiently pushed, stratum pushing can be assisted, besides, the center drilling bit and the wall of a drill hole can be protected, coaxiality of the two-step drilling bits is good, guiding and righting supplement each other, bending of the drill hole can not be caused, efficiency of stratum hole drilling can be improved, and service life of the whole drilling tool can be prolonged.

Owner:SHANDONG TOPS DIAMOND BIT CO LTD

Cutting device for processing of new materials

InactiveCN109226863AEasy to cutLarge cutting areaShearing machinesFeeding apparatusEngineeringForward backward

The invention discloses a cutting device for processing of new materials. The cutting device comprises a base and a box body, first electric retractable rods are fixedly connected to the two sides ofthe top of the base respectively, the tops of the first electric retractable rods are fixedly connected to the bottom of the box body, through holes are formed in the two sides of the top of the baserespectively, a long hole is formed in the bottom of the box body, and a forward-backward motor is fixedly connected to the bottom of an inner cavity of the base through a fixing block. Through the cooperation among the base, the box body, the first electric retractable rods, the through holes, the long hole, the forward-backward motor, a forward-backward threaded rod, first threaded sleeves, casing pipes, third electric retractable rods, clamping plates, a first motor, a threaded rod, a second threaded sleeve, a support plate, a second motor and a cutter for use, the problems are solved thatexisting cutting devices are monotonous in structure, the new materials cannot be clamped, the cutting height cannot be adjusted, the cutting devices are very limited during use, and the practicalityof the cutting devices is reduced.

Owner:郑州杏坛电子科技有限公司

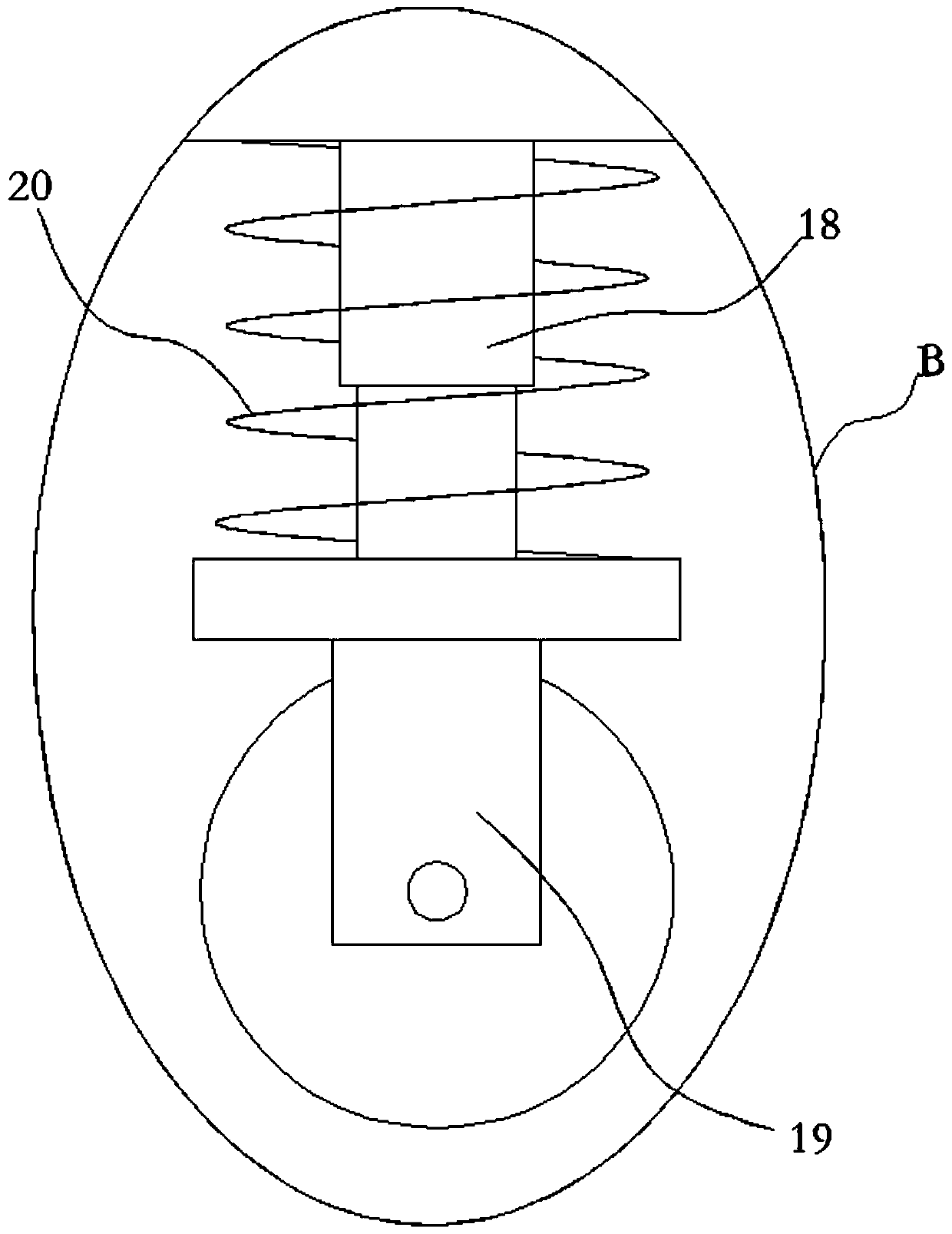

Abrasion-resisting cutting tooth with damping function

InactiveCN108825231AAvoid overexposureLarge cutting areaSlitting machinesCutting machinesDamping functionEngineering

The invention discloses an abrasion-resisting cutting tooth with a damping function. The abrasion-resisting cutting tooth comprises a cutting seat, a core shaft body arranged at the upper end of the cutting seat, and a cutting tooth head matched with the upper end of the core shaft body to be mounted. A main body of the cutting seat is composed of a connecting base of an integrally-formed platy structure and a sleeve seat which is obliquely arranged at the upper end of the connecting base and is of a cylindrical structure. When the cutting tooth head and the core shaft body make contact with arock stratum, generated instant high impact force is buffered and absorbed through a strong spring arranged at the lower end of the core shaft body in a sleeving mode and is downwards released to thecutting tooth head connected with the cutting seat. When the whole cutting tooth makes contact with the rock stratum, the first contact part is a main tooth body, second contact parts are a vice tooth body and a vice tooth sleeve on the cutting tooth head, and thus abrasion to the core shaft body on the cutting tooth due to excessive contact with the rock stratum is avoided; the main tooth body is arranged at the front end of the cutting tooth head, and the vice tooth body is arranged on the outer circle of the cutting tooth head; and when the cutting tooth makes contact with the rock stratum, the main tooth body and the vice tooth body making contact with the rock stratum cut the rock stratum simultaneously, the whole cutting area of the cutting tooth is increased, and the cutting efficiency is improved.

Owner:许国梁

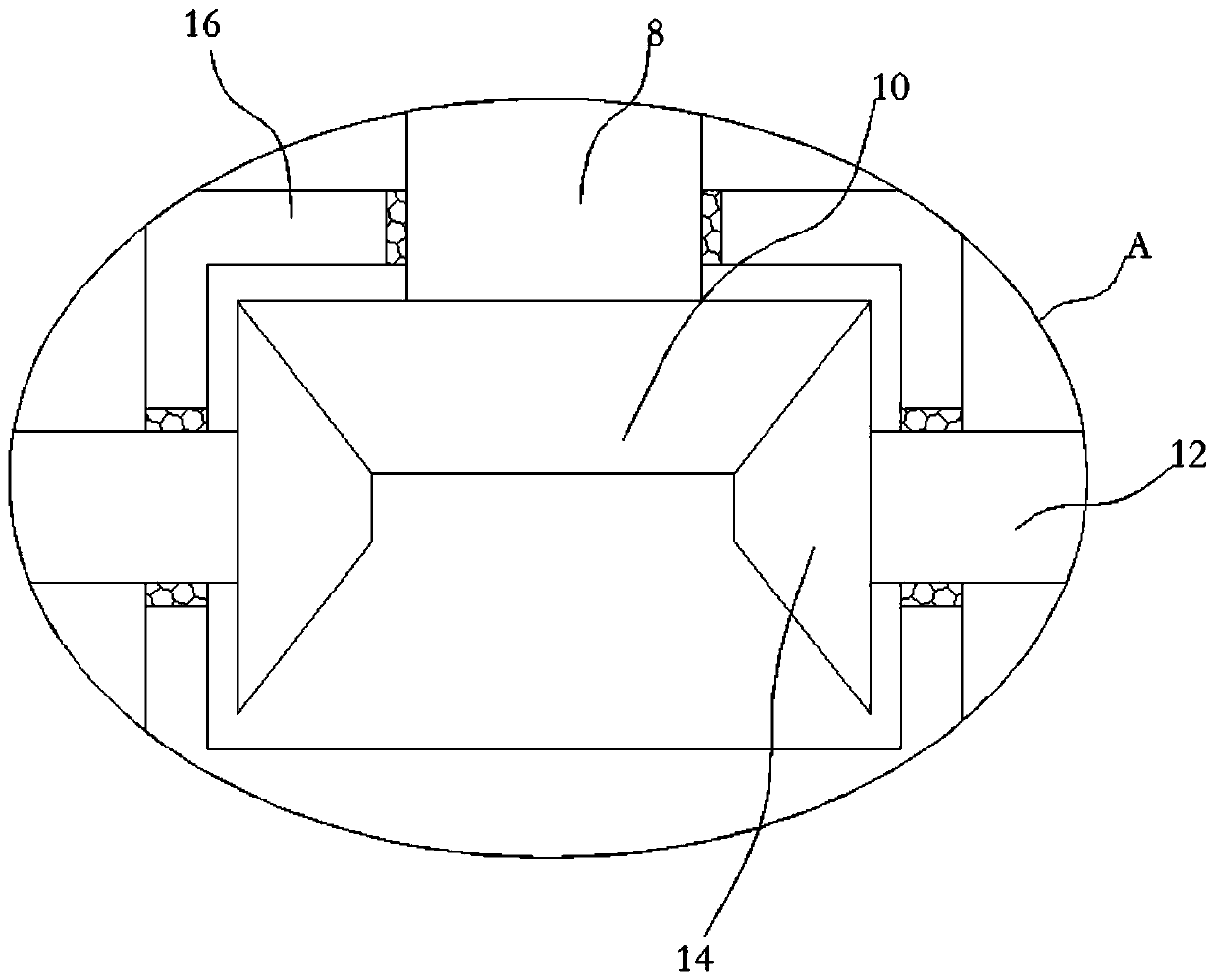

Cutter assembly and garbage granulator

ActiveCN106985305ARealize the function of material cuttingLarge cutting areaPlastic recyclingWaste based fuelHigh volume manufacturingEngineering

The invention relates to the technical field of garbage disposal, in particular to a cutter assembly and a garbage granulator. The cutter assembly comprises multiple cutting blades, a cutter holder and a drive device. The cutter holder is provided with a hollow structure. The cutting blades are evenly distributed in the peripheral direction of the section of the hollow structure of the cutter holder. Each cutting blade is connected with the drive device. The drive device drives the cutting blades to rotate relative to the cutter holder. The cutting blades are hinged to the cutter holder. The drive device drives the cutting blades to rotate relative to the cutter holder, and the rotating faces formed by rotation of the cutting blades are parallel to the cutting section; and as feeding of cutting materials, the rotating cutting blades can achieve the cutting function. The cutting blades distributed in the axial direction of the section of the hollow structure are mutually matched, the cutting area is enlarged, the working efficiency is improved, and the cutter assembly is suitable for the requirements of industrial large-scale production. The garbage granulator with the cutter assembly is good in granulation effect and suitable for industrial production.

Owner:孙庆根

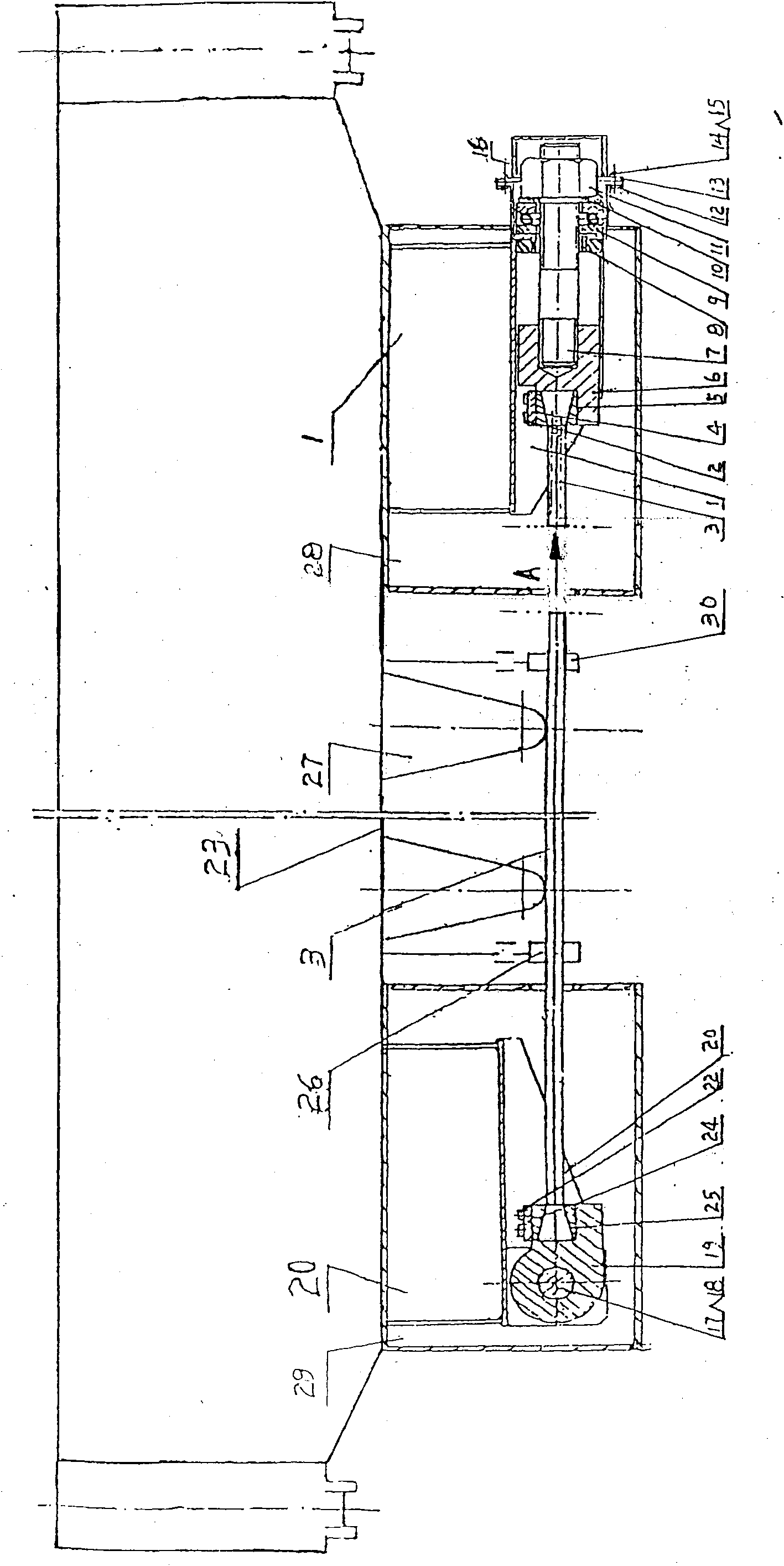

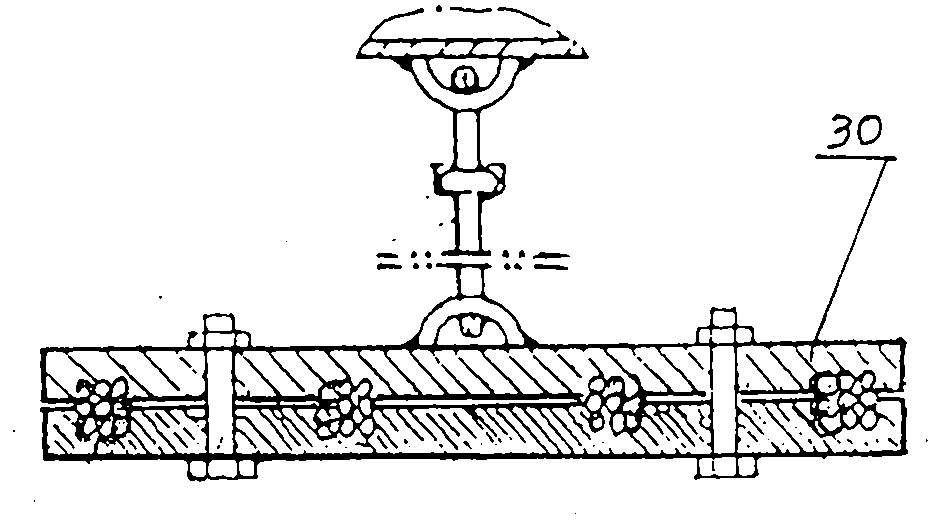

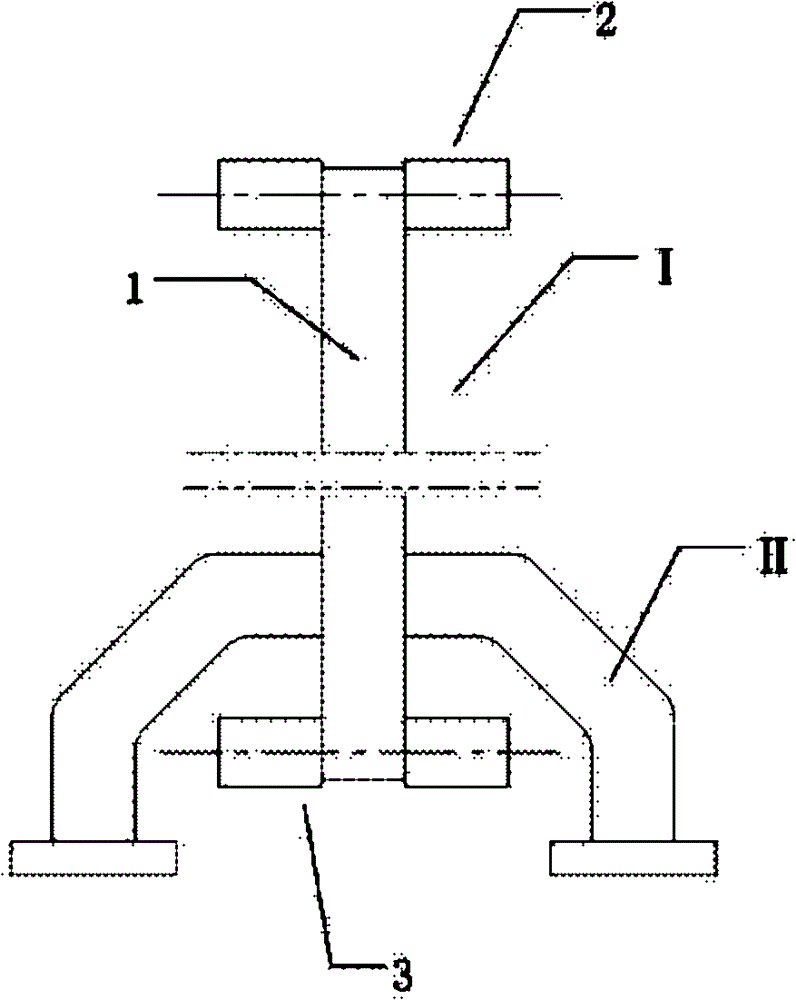

Manufacturing process of girder of overhead or gantry crane

The invention discloses a manufacturing process of a girder of an overhead or gantry crane, a threaded pull rod 7 in a box body 1 of a tensioning device is connected with a connecting seat 6, and the manufacturing process is characterized in that two wedge-shaped grooves are formed on the connecting seat 6, two rope head casting ports 5 with wedge-shaped outer shapes and square cone-shaped inner cavities are mounted in the grooves, two wedge-shaped grooves are formed on a fixed hinge 19 at the other end of a steel wire rope 3, and the rope head casting ports 25 with the wedge-shaped outer shapes and the square cone-shaped inner cavities are mounted in the grooves. The manufacturing process adopts the two groups for tensioning, the two groups are mounted on the same girder, and the ultimate tensioning force is great, thereby being applicable to manufacturing the girders of the cranes with the hoisting capacity of below 400 tons. The manufacturing process has the advantages of easy manufacturing, low cost and convenient construction, and is particularly applicable to manufacturing the gantry cranes with the span of above 60m in ports and the shipbuilding industry. The arch difference of the girder of the crane manufactured by adopting the invention can be controlled within 0-1mm, which is better than the international standard; furthermore, the manufacturing process can increase the cutting area of the girder structure, improve the strength, the static stiffness and the hoisting capacity of the girder, save steel, reduce the cost by 15-20%, be in line with the policies of energy conservation and emission reduction and prolong the service life of equipment.

Owner:傅萍 +2

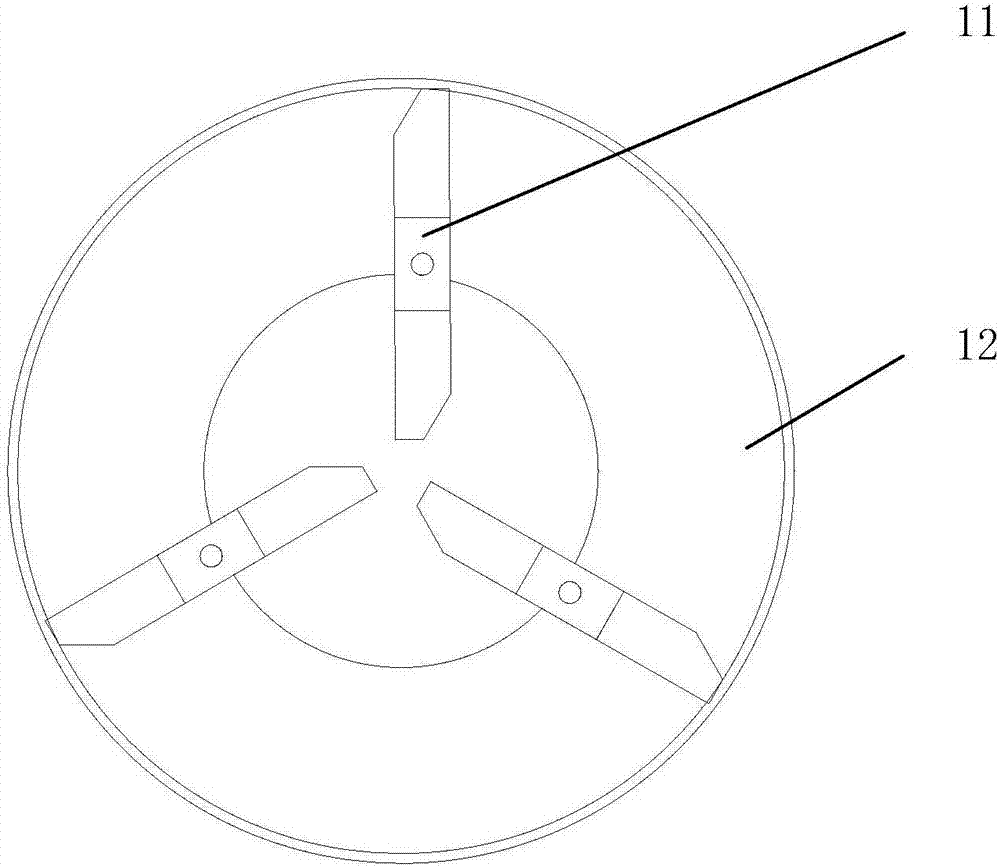

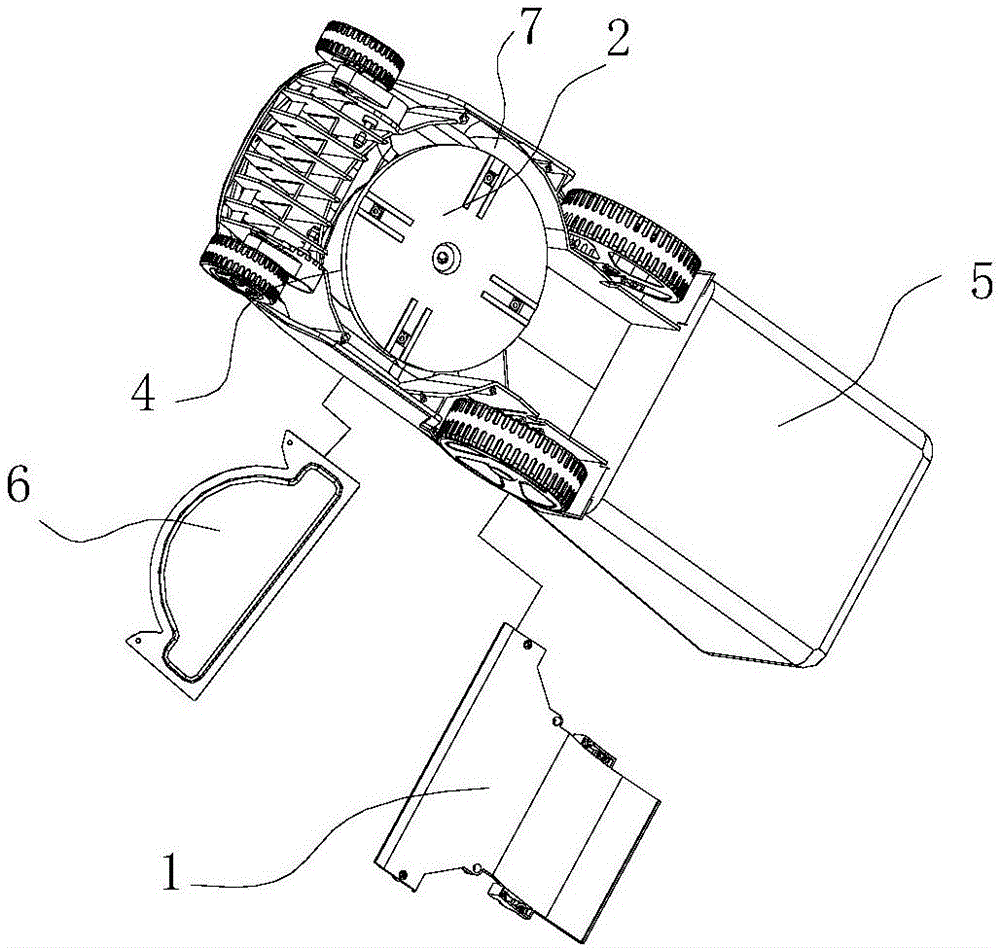

Turntable type mower

The invention relates to a turntable type mower. The mower is provided with a cutter table base and a grass-collecting box, a cutter table is arranged on the cutter table base and comprises a circular table body and a plurality of bar-type blades, a limit groove matched with the bar-type blades is formed in the table body, the bar-type blades are inserted in the limit groove, springs extending along the limit groove is arranged between the ends of the bar-typed blades inserted in the limit groove and the table body, a closed grass inlet connected with the mower and a blade protection cover is arranged above the cutter plate, a grass clipping conveyor channel of the grass-collecting box is formed between a machine shell of the mower, the cutter plate base and the blade protection cover. The mower adapts to different mowing spaces and can improve the mowing efficiency.

Owner:SUZHOU RUNHONG TRADING

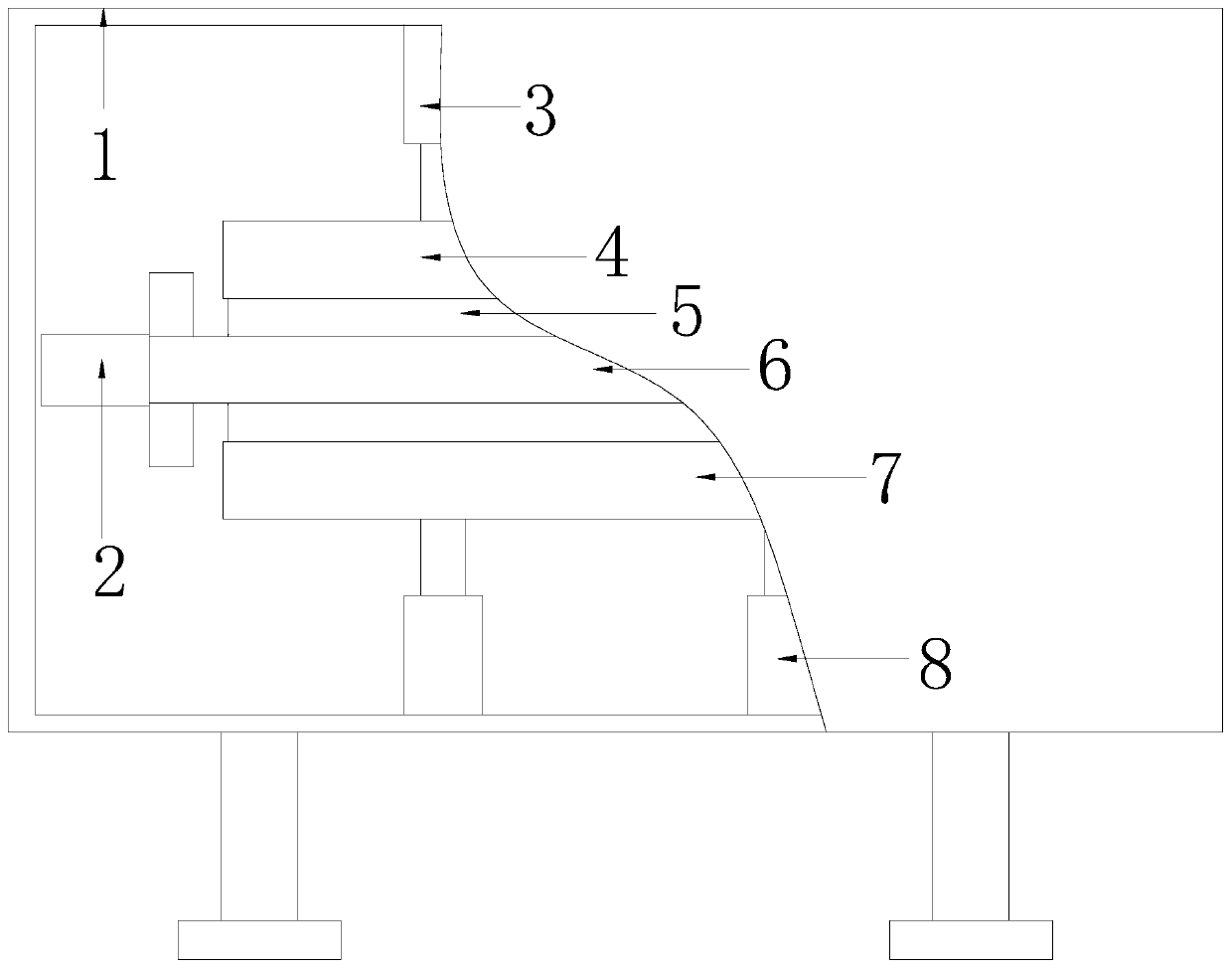

Inner cutting type numerical control cutting machine tool for hollow pipes

ActiveCN110732715APrevent splashAvoid harmMilling equipment detailsPositioning apparatusNumerical controlHydraulic cylinder

The invention discloses an inner cutting type numerical control cutting machine tool for hollow pipes. The structure of the machine tool comprises a numerical control milling lathe body, an inner cutting type device, an upper hydraulic cylinder, an upper clamping device, the hollow pipes, a linear transmission device, a lower clamping device and a lower hydraulic cylinder. The upper hydraulic cylinder is vertically connected to the inner top face of the numerical control milling lathe body. Compared with the prior art, the machine tool has the beneficial effects that the hollow pipes can be clamped and cut conveniently, meanwhile, the machine tool can adapt to clamping of the hollow pipes with different opening diameter sizes, is wide in application range, and can cut the hollow pipes in asegmented manner, after cutting is finished, the inner cutting type device can push out the cut hollow pipes under the drive effect of the linear transmission device, in the cutting process, cut scraps can be effectively prevented from splashing everywhere, the situation that the cut scraps harm operators is avoided, the high safety supportability is achieved for the operators, meanwhile, multiple cutting wheels cut the hollow pipes synchronously, the cutting area is increased, the cutting efficiency is improved, and cutting time is shortened.

Owner:ZHEJIANG NADIC CNC EQUIP CO LTD

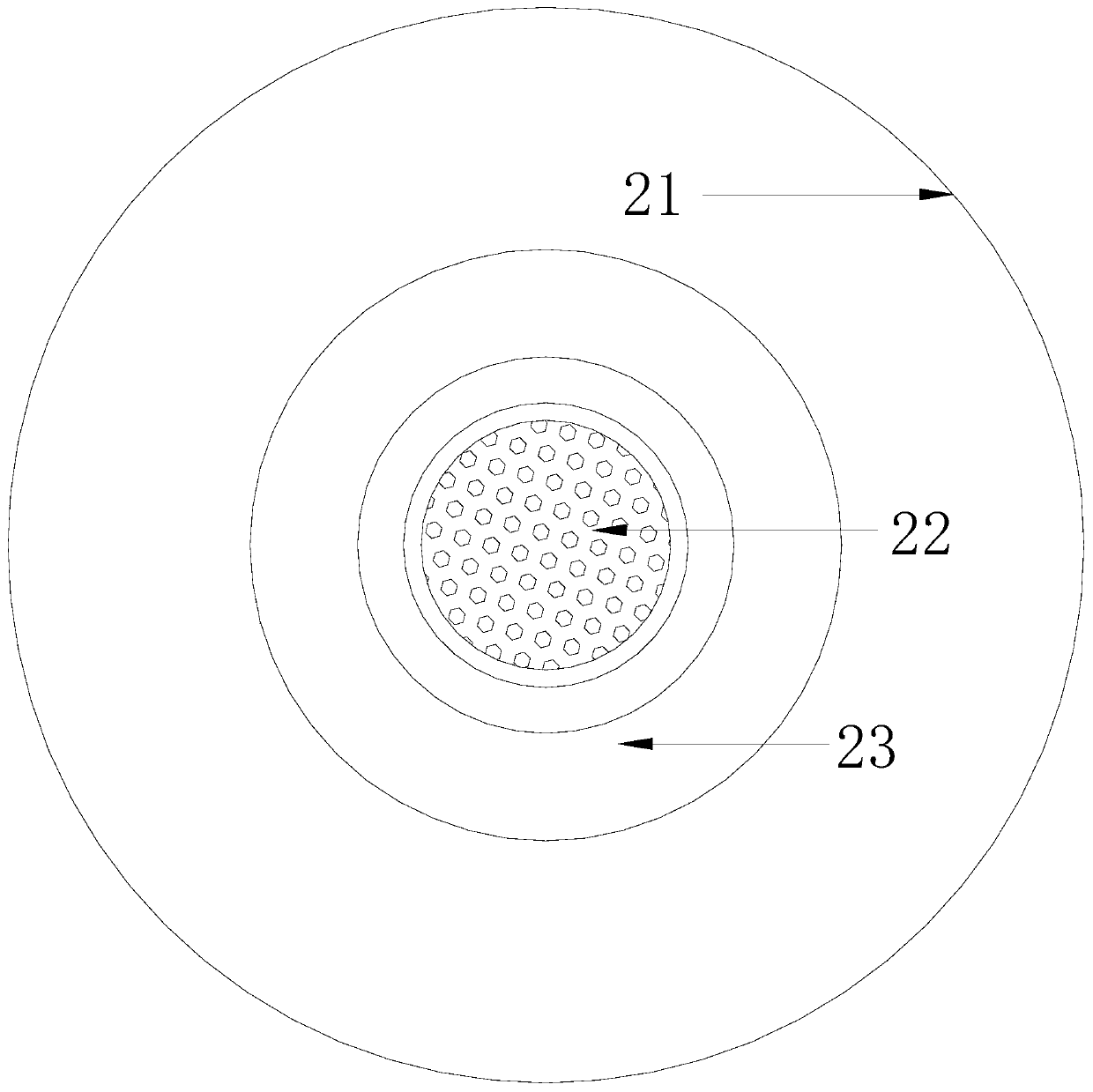

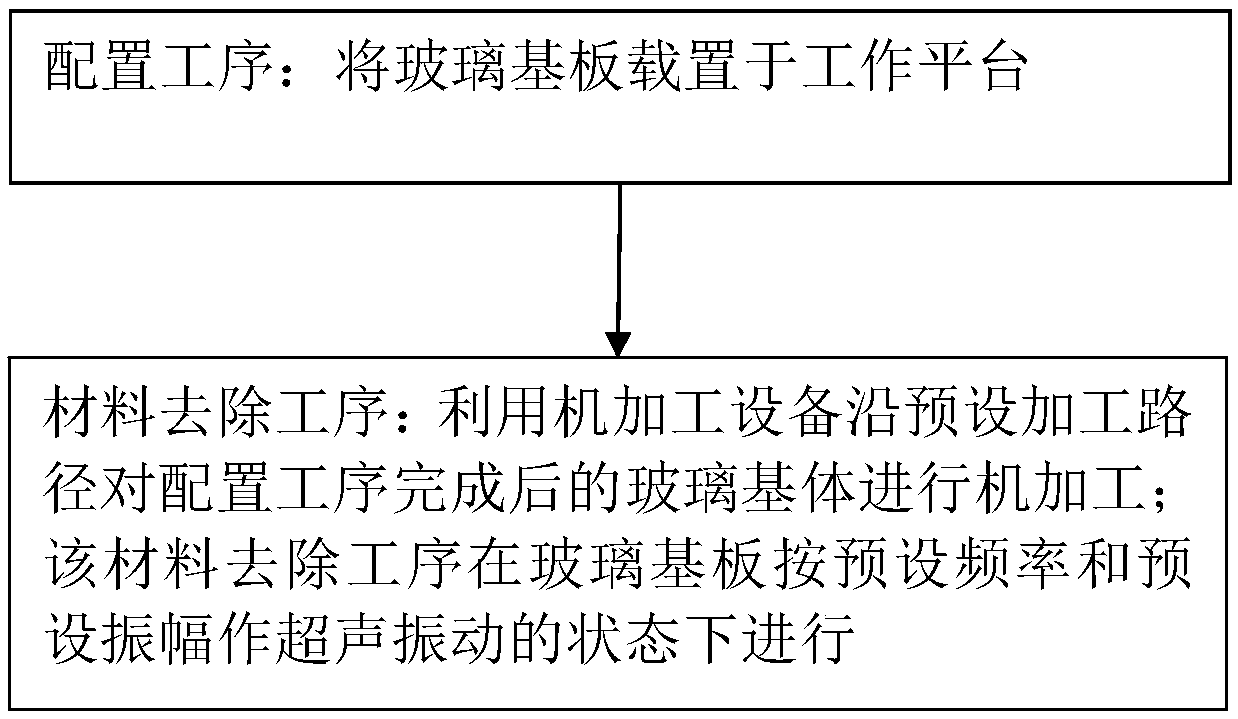

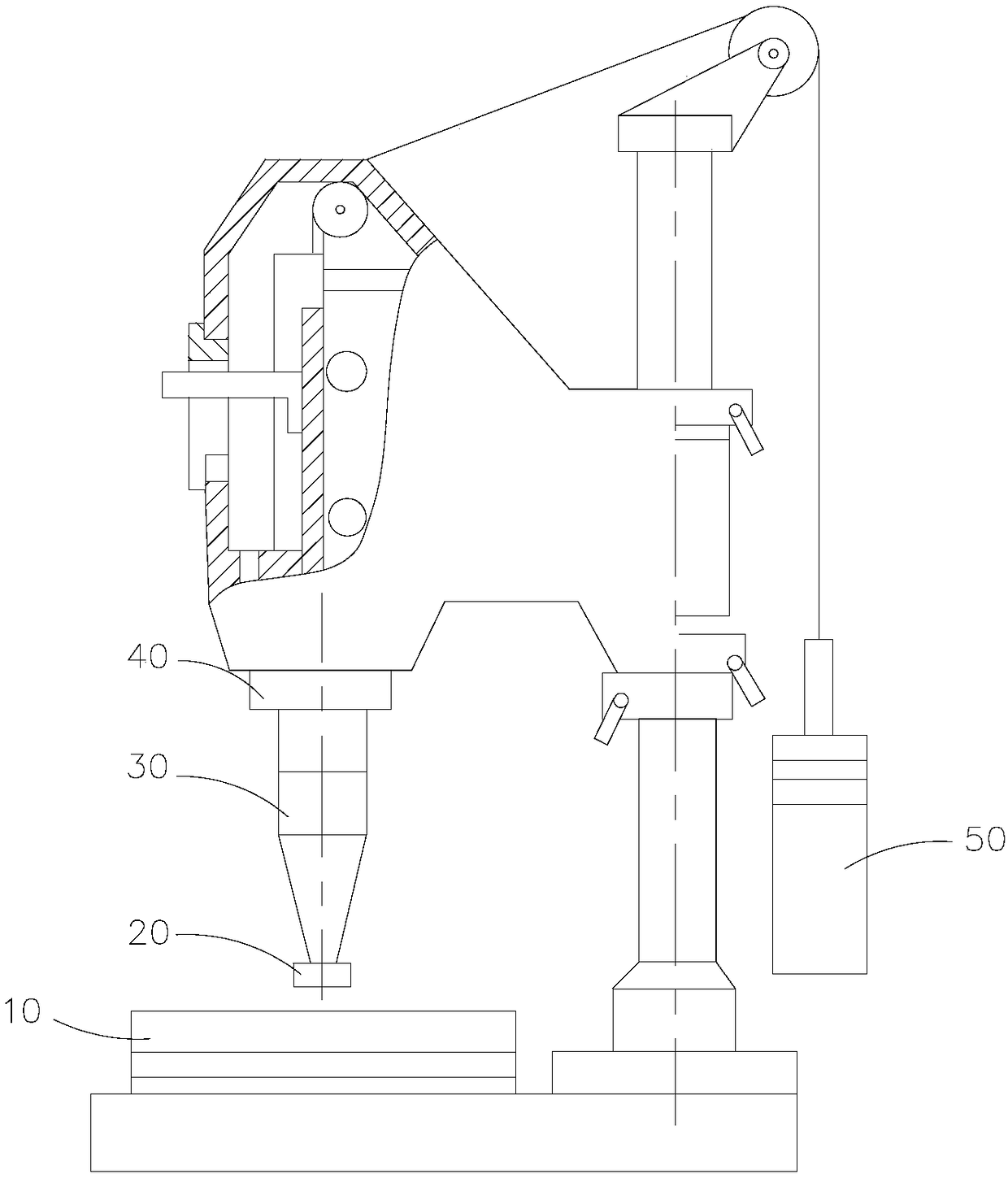

Ultrasonic machining method and device for glass substrates

InactiveCN108326640AReduce cutting forceImprove removal efficiencyGrinding work supportsStone-like material working toolsUltrasonic machiningEngineering

The invention provides an ultrasonic machining method for glass substrates. The method comprises a preparation step in which a glass substrate is placed on a worktable and a material removing step inwhich the glass substrate which is subjected to the preparation step is machined by utilizing machining equipment along a preset machining path; and the material removing step is performed at a statethat the glass substrate does ultrasonic vibration according to a preset frequency and preset amplitude. According to the method, vibration impact is formed between the glass substrate and a tool of the machining equipment by virtue of ultrasonic vibration of the glass substrate, and miniature cracks can be formed at a contact surface between the glass substrate and the tool; then machining is performed with the rotary tool; not only is cutting force greatly lowered, but also machining efficiency is improved; and surface quality of the product can also be improved through the effects of hammering, cavitation, uncontinuous cutting and the like of ultrasonic vibration, and notches, edge burning, cracking and other defects are reduced, so that the yield of the product is improved, and the service life of the tool is prolonged. The invention further provides a glass substrate ultrasonic machining device which can be applied in the method.

Owner:雷索智能科技(苏州) 有限公司

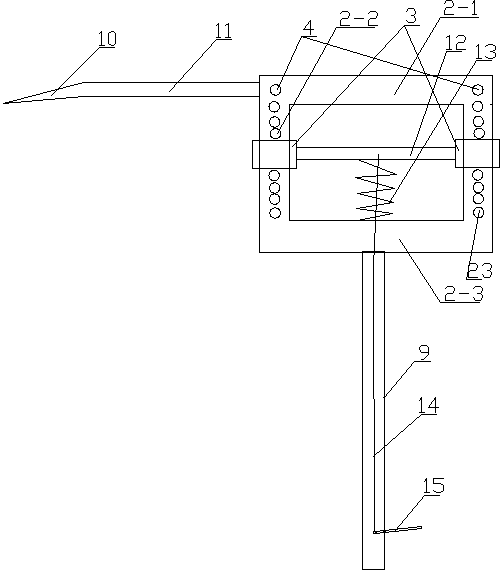

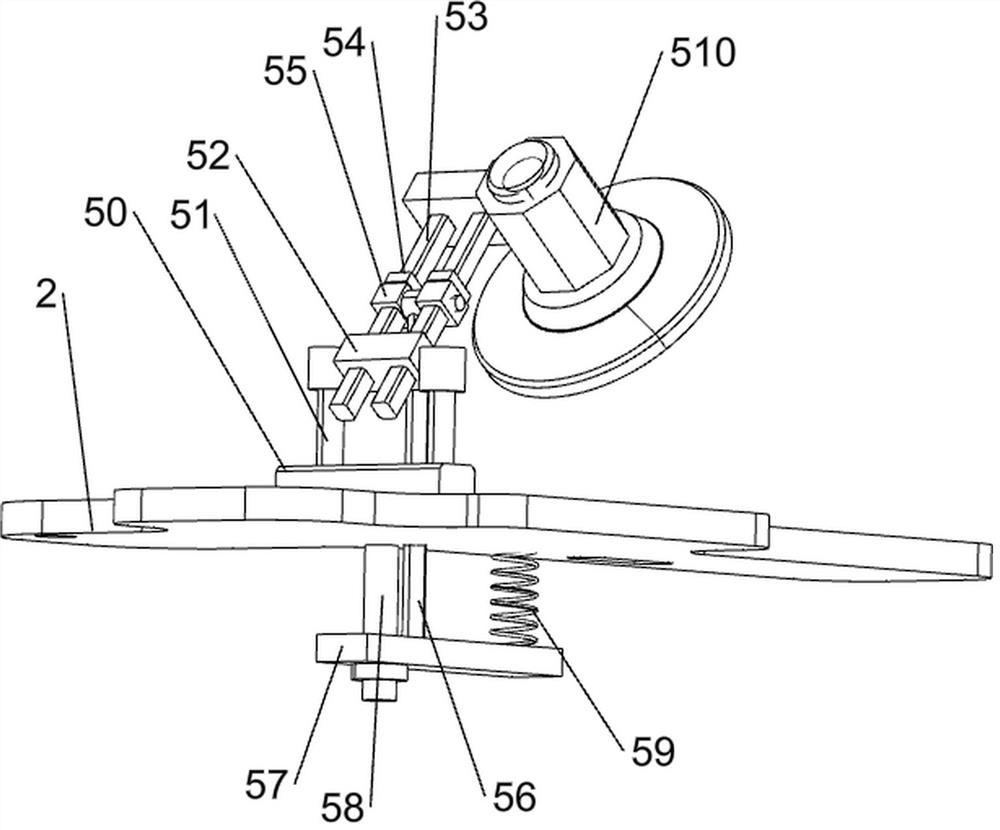

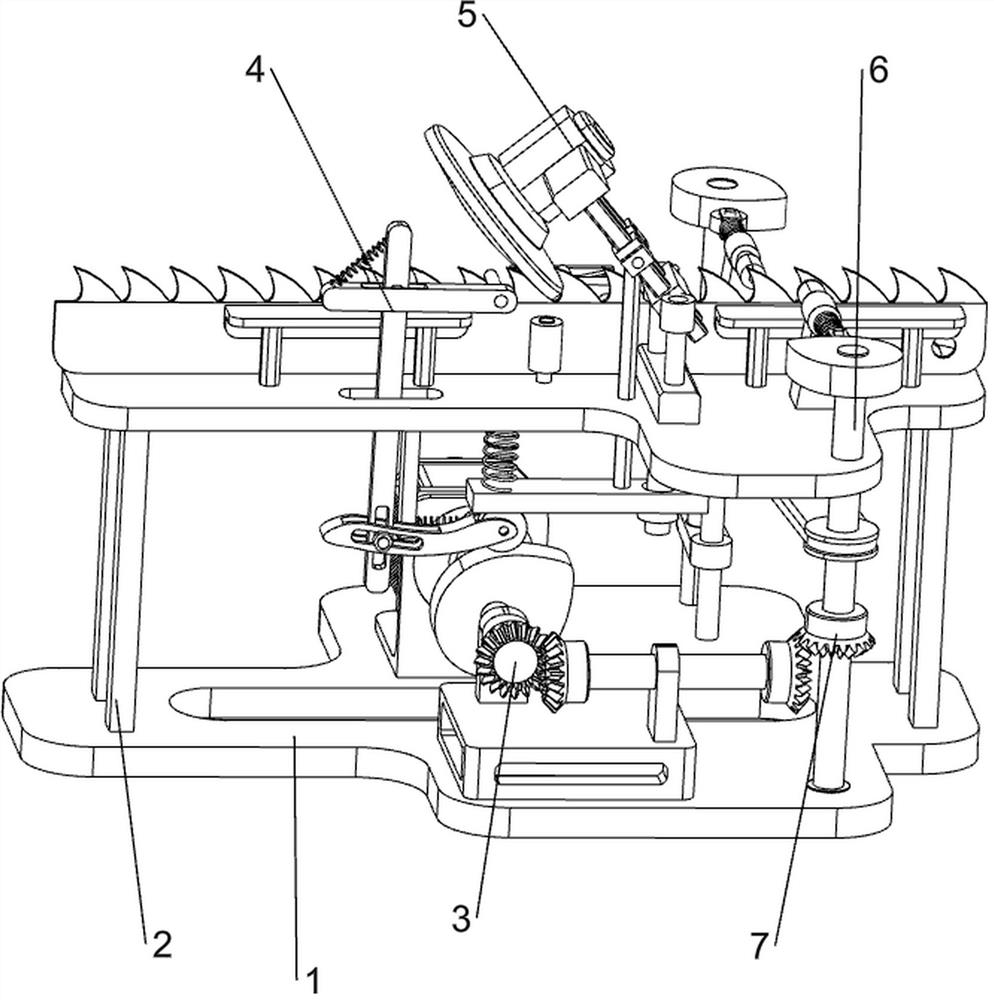

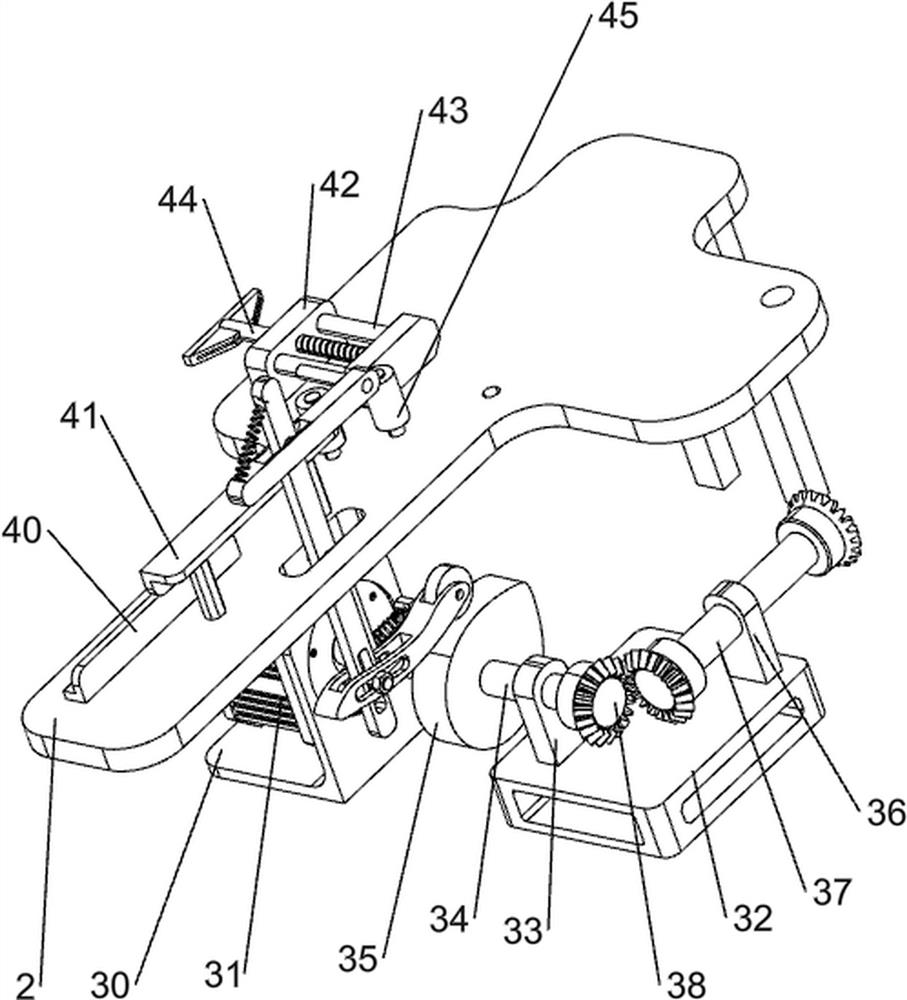

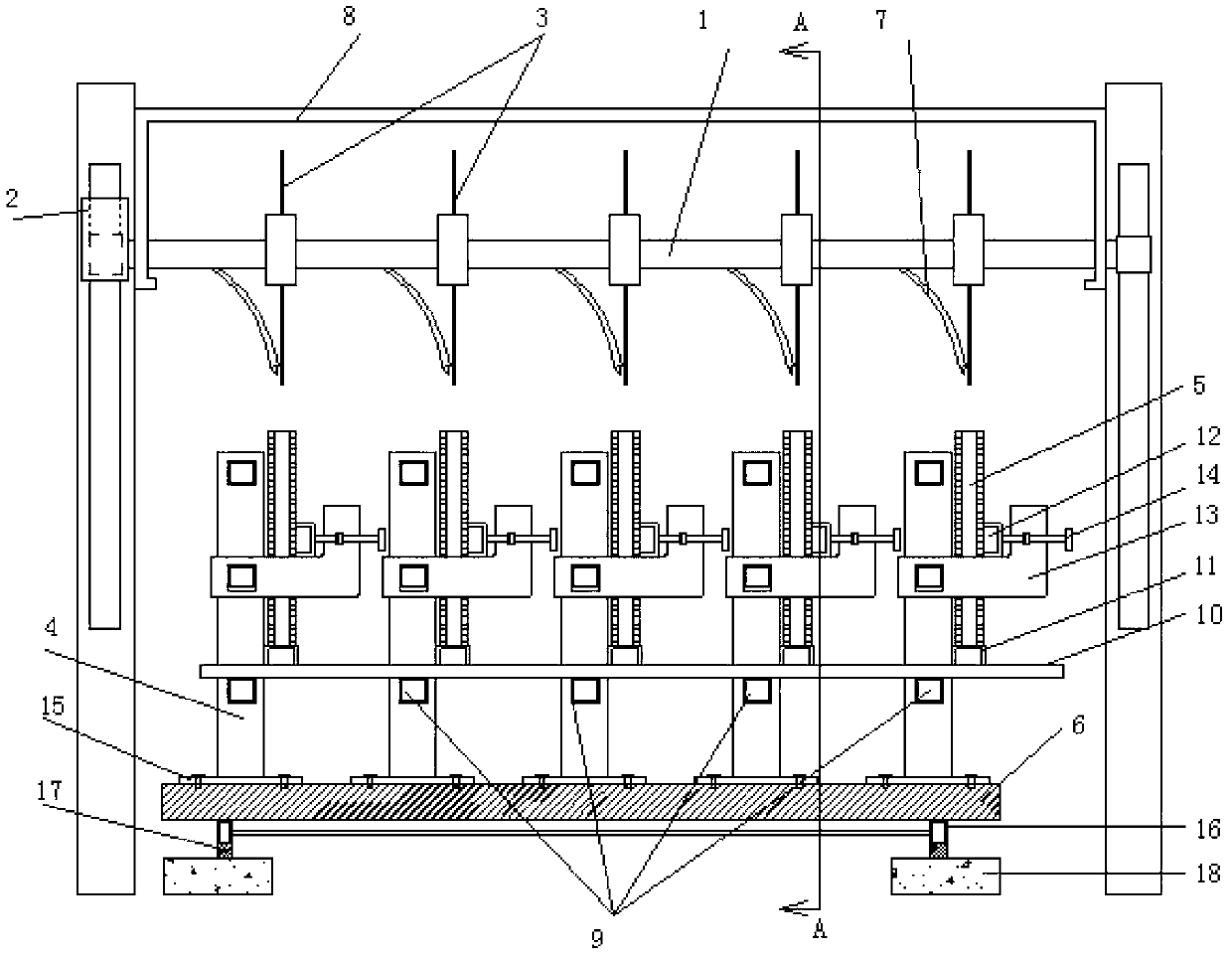

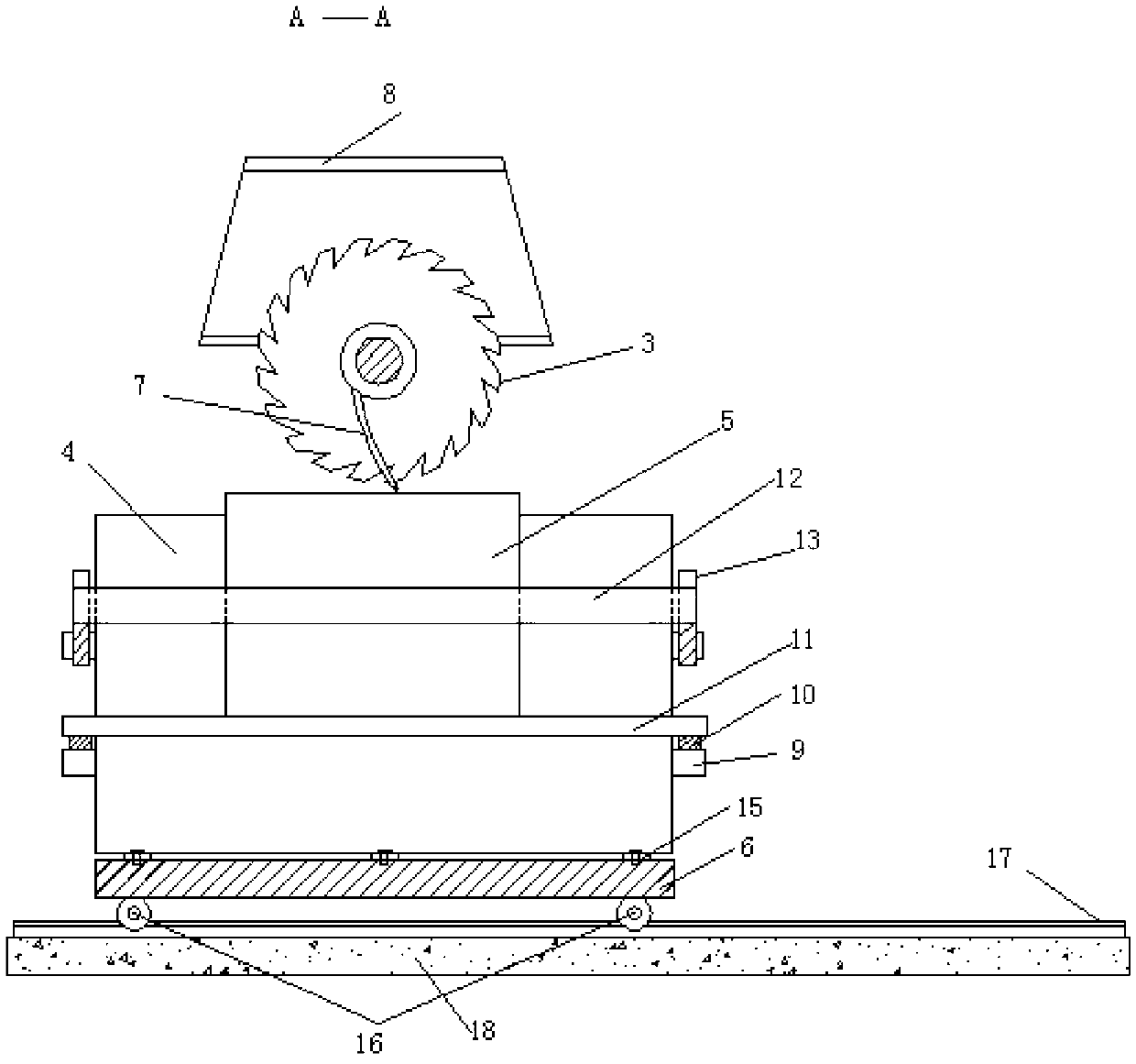

Woodworking saw blade sawtooth machining equipment

PendingCN112317871AQuick sandingSave time at workSawing tools dressing arrangementsEngineeringMachining

The invention relates to machining equipment, in particular to woodworking saw blade sawtooth machining equipment. The woodworking saw blade sawtooth machining equipment is safe, reliable, capable ofautomatically pushing materials and rapid in grinding. The woodworking saw blade sawtooth machining equipment provided by the invention comprises a bottom plate, a transmission mechanism, a material pushing mechanism and a grinding mechanism; a workbench is arranged at the top of the bottom plate; the transmission mechanism is arranged in the middle of the top of the bottom plate, and the transmission mechanism is located below the workbench; the material pushing mechanism is arranged on one side of the top of the workbench; and the grinding mechanism is arranged on the other side of the top of the workbench. According to the invention, the material pushing mechanism and the grinding mechanism are controlled by the transmission mechanism to operate, a saw blade can be conveyed at intervalsand matched with the grinding mechanism for rapid grinding; therefore, the working time is saved, and the grinding speed and safety are improved.

Owner:徐青美

Formed cutter

InactiveCN102764910AImprove work efficiencyLarge cutting areaMilling cuttersShaping cuttersEngineeringSurface structure

A formed cutter comprises a handle, a cutter neck attached to the handle and a cutterhead arranged at the end of the cutter neck. The cutterhead comprises a joint face which faces one side of the cutter neck and is connected with the end of the cutter neck, an outer circumferential surface and an end surface which is arranged opposite to the joint face and far from the side of the cutter neck. At least one cutting groove, which extends from the position wherein the joint face is connected to the cutter neck to the end surface of the cutterhead, is concavely arranged on the cutterhead. According to the formed cutter provided by the invention, a product's curved surface, flat surface and transition surface of the curved surface and the flat surface can be moulded by primary processing. The cutting edge of the formed cutter is shaped as an arc curved surface, thereby effectively increasing cutting area and raising work efficiency of the formed cutter. In addition, as the cutter edge's curved surface structure for milling matches the product's curved surface structure, machining accuracy can effectively raised, and the product quality is guaranteed.

Owner:FU TAI HUA IND SHENZHEN +1

Tunneling machine and water jet nozzle thereof

PendingCN108590691AMeet the requirements of cutting pressure changesImprove adaptabilityTunnelsHigh pressure waterHigh pressure

The invention discloses a water jet nozzle. The water jet nozzle comprises a connecting frame, and further comprises a support frame, a rotating driving portion and a high-pressure water pipeline. Thesupport frame is fixed to the lower side of the connecting frame, the rotating driving portion is mounted on the support frame, one end of the high-pressure water pipeline is fixed to the support frame through a pipe clamp, and the other end of the high-pressure water pipeline penetrates from the interior of the rotating driving portion and can swing relative to the support frame. By using the water jet nozzle, rotary cutting of high-pressure water inside the high-pressure water pipeline is realized under the action of the pipe clamp and the rotating driving portion, the cutting area is increased, the cutting efficiency is improved, and the cutting requirement of higher efficiency is met; and at the same time, the high-pressure water flows out directly through the high-pressure water pipeline, setting of rotary sealing is not required, the limitation of a rotary sealing structure and the strength on the pressure and flow of the high-pressure water is eliminated, and the cutting requirement of greater pressure is met. Therefore, the water jet nozzle has better adaptability. The invention further discloses a tunneling machine including the water jet nozzle, and the tunneling efficiency is improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Rotating drill bit with multiple drill sub-bits

InactiveCN105134085AAdapt to various geological conditionsLarge cutting areaDrill bitsConstructionsPetroleum engineeringDrill bit

The invention relates to the field of mining equipment, in particular to a rotating drill bit with multiple drill sub-bits. According to the rotating drill bit with the multiple drill sub-bits, the multiple drill sub-bits are added on the basis of a traditional rotating drill bit, the number, the installation positions, the directions of the drill sub-bits can be adjusted according to actual conditions, so that convenience and versatility of the rotating drill bit are greatly improved. The drill bit is diversified; due to the arrangement of the main and sub drill bits, the rotating drill bit is suitable for various geologic conditions; the cutting area is increased, and the mining efficiency is improved; the number of nozzles is increased, so that the dust generation amount in the mining process can be effectively decreased.

Owner:ZHENGZHOU SHENLIDA DRILLING & PRODION EQUIP

Detachable drill bit

ActiveCN105064927AEasy to useIncrease the cutting areaDrill bitsConstructionsInterior spaceDrill bit

The invention relates to the field of mining devices, in particular to a detachable drill bit. The detachable drill bit adopts modular design, the integrated drill bit is divided into a drill blade, a drill shoulder and a drillstock which are detachable, the drill blade, the drill shoulder and the drillstock can be individually replaced when one portion is damaged, a standby drill blade is arranged in the internal space of the drillstock, and the detachable drill bit is more convenient to use. The drill bit is modular, and the mining cost is reduced. The drill bit can be detached into several portions and is convenient to use. A standby drill bit is provided so that the mining devices can work continuously. The cutting area is enlarged, and mining efficiency is improved.

Owner:济宁高新科达科技项目服务有限公司

Multi-cutter vertical-type stone material sheet cutting machine

InactiveCN103341917AImprove precise controlIncrease flexibilityStone-like material working toolsEngineeringElectric motor

The invention provides a multi-cutter vertical-type stone material sheet cutting machine. The multi-cutter vertical-type stone material sheet cutting machine comprises a cutter wheel shaft (1), a plurality of cutters (3), and a plurality of props (4). The two ends of the cutter wheel shaft (1) are connected on a support in an up-down moving mode, one end of the cutter wheel shaft is connected with an electric motor (2), the cutters (3) and the cutter wheel shaft (1) are arranged coaxially, the cutters (3) are sleeved on the cutter wheel shaft (1) at equal intervals, the props are of multiple flat-plate structures which are vertically arranged, one sides of the props (4) are all provided with stone material sheet positioning parts, stone material sheets (5) are tightly attached to one sides of the flat-plate structures and vertically arranged on the stone material sheet positioning parts, and the props (4) are arranged parallel to the cutters (5) and arranged correspondingly one to one. A sheet conveying platform (6) which moves in the direction perpendicular to the arranging direction of the props (4) is located under the props (4). Cutting paths which are generated by the cutters (3) along with downward-moving of the cutter wheel shaft (1) make an interference with the thickness planes of the stone material sheets (5).

Owner:SUZHOU XINGDA STONE

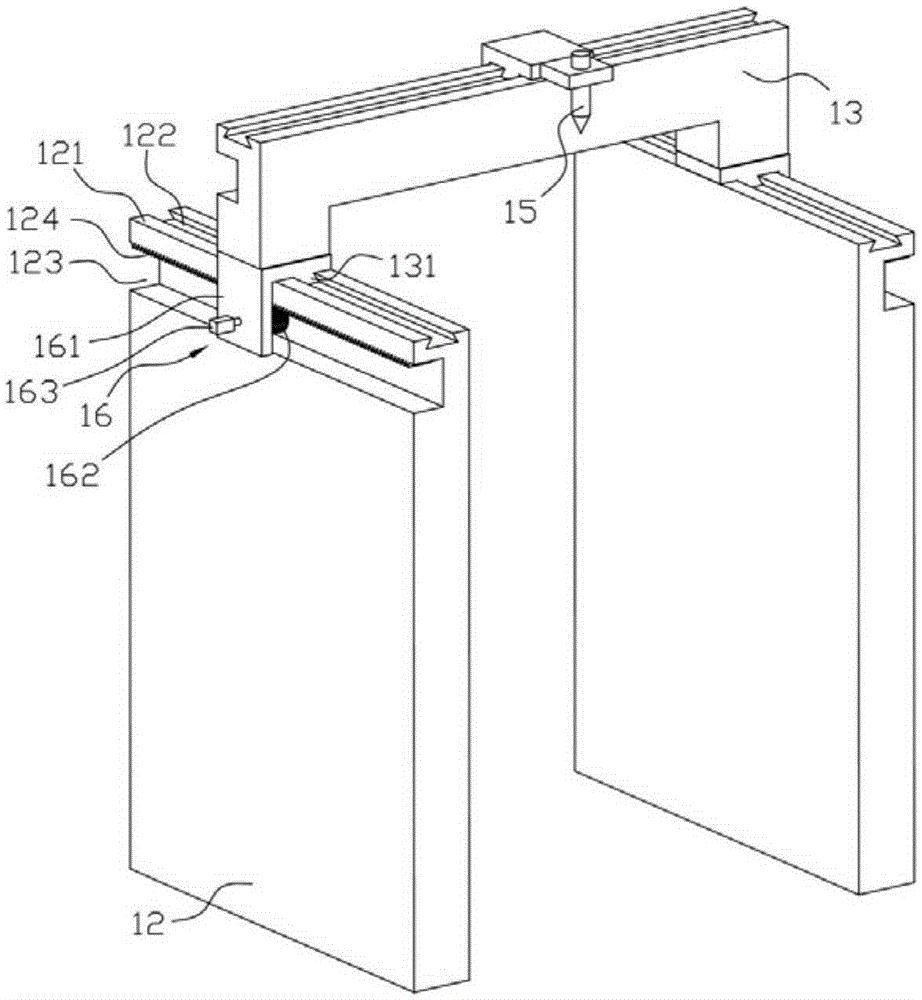

Laser template cutting machine

InactiveCN105397309AShort operating timeSimple and fast operationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser beams

The invention discloses a laser template cutting machine which comprises a cutting mechanism and a template fixture, wherein the cutting mechanism comprises a laser head; the laser head performs two-dimensional motion through an X-direction slide and Y-direction slides; and the template fixture is positioned between a pair of rack plates of the cutting mechanism and is positioned below the laser head. According to the laser template cutting machine, workpieces to be cut are located through the template fixture, and templates are cut through laser beams, so that the speed is high, the efficiency is high, and the cutting is smooth, fluent and neat.

Owner:苏州市众鑫激光科技有限公司

Coal mining excavation saw

InactiveCN102748020AReduce contact surfaceIncrease cooling areaSlitting machinesCutting machinesCoal briquetteDrive wheel

The invention belongs to the field of cutting machinery, and in particular relates to a coal mining excavation saw. The invention aims to puts forward a coal mining excavation saw with deep excavating function, ability to realize a variety of cutting functions, small energy loss, long service life, and high cutting efficiency. The technical scheme is as the following: a coal mining excavation saw comprises a body and a sawing mechanism, etc. The sawing mechanism includes a driving wheel, a driven wheel, saw blades, a cooling device and a supporting frame, etc. The driven wheel is composed of at least one wheel. The saw blades are wound on the driving wheel and the driven wheel in a tensioning state, and the supporting frame is disposed between the driving wheel and the driven wheel. When there exists one driven wheel, the driven wheel is disposed on one side of the supporting frame, and when there exist a plurality of driven wheels, they are symmetrically arranged on two sides of the supporting frame. The spray nozzle of the cooling device is arranged on the supporting frame. The saw surface width is not less than the width sum of the driven wheel and the supporting frame. The excavation saw of the invention has the advantages of good excavation function, small energy loss, long service life, and multiple cutting functions, thus being able to greatly improve the mining efficiency of coal briquettes.

Owner:刘素华

Pineapple leaf smashing device and pineapple leaf smashing machine

The invention relates to the technical field of agricultural equipment and discloses a pineapple leaf smashing device. The pineapple leaf smashing device comprises a cutting disc, a rotating mechanismand a lifting mechanism, the rotating mechanism is used for rotating the cutting disc, and the lifting mechanism is used for lifting the cutting disc. The rotating mechanism comprises a rotating rodand two clamping plates, a gear fixedly sleeves the rod wall of the rotating rod, a reciprocating screw rod is rotationally connected between opposite side walls of the two clamping plates through a ball bearing, the rod wall of the reciprocating screw rod is in threaded connection with a moving block, a rack meshed with the gear is fixedly connected to the side wall of the moving block, a rotating motor is fixedly connected to the outer wall of one of the clamping plates, and an output shaft of the rotating motor penetrates the side wall of the corresponding clamping plate to fixedly connectwith one end of the reciprocating screw rod. The pineapple leaf smashing device and a pineapple leaf smashing machine have advantages that preliminary rapid clearing and smashing of pineapple leaves can be realized, labor saving is realized, and convenience in use is provided for people.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com