Patents

Literature

98results about How to "Improve static stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

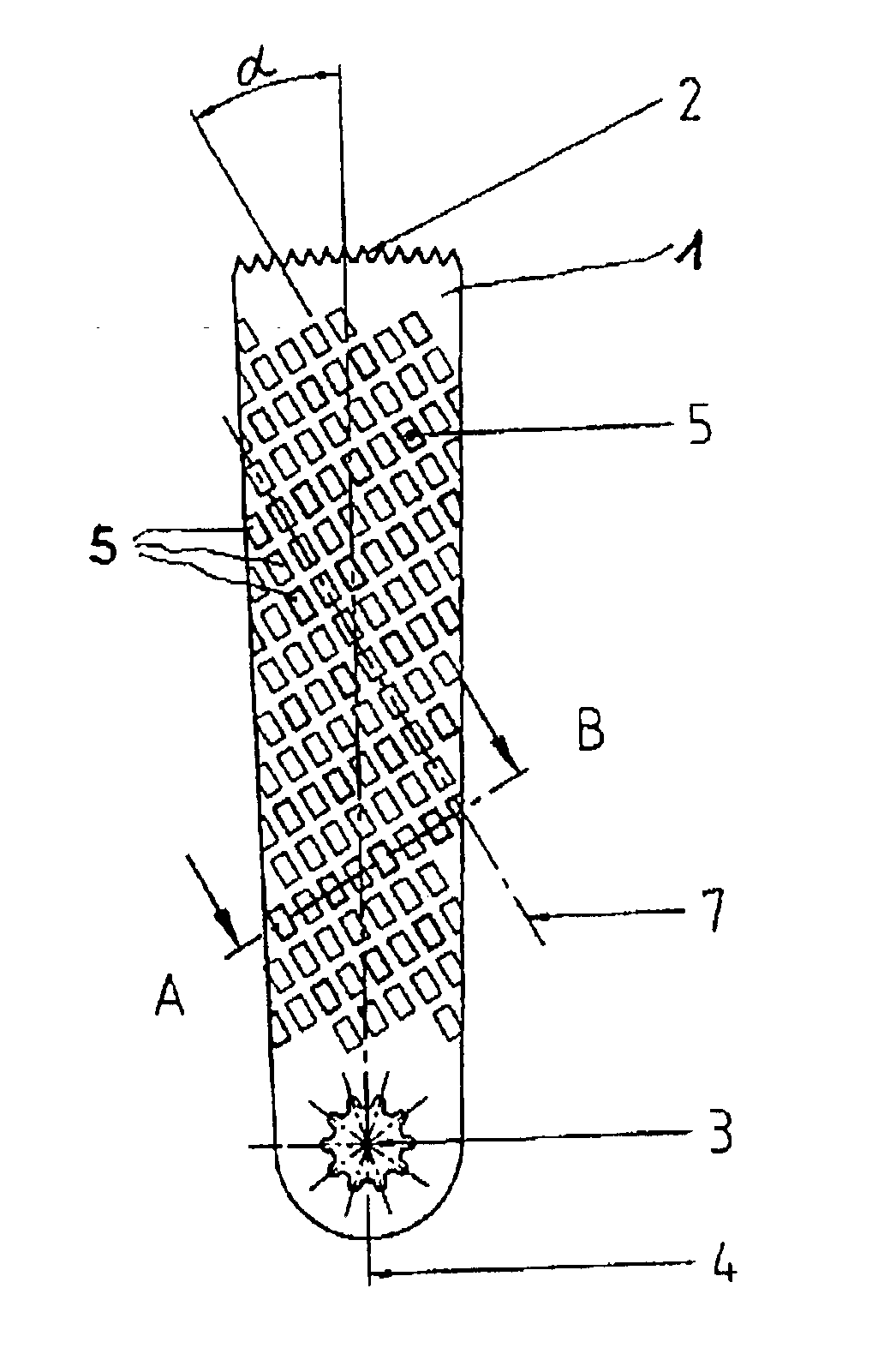

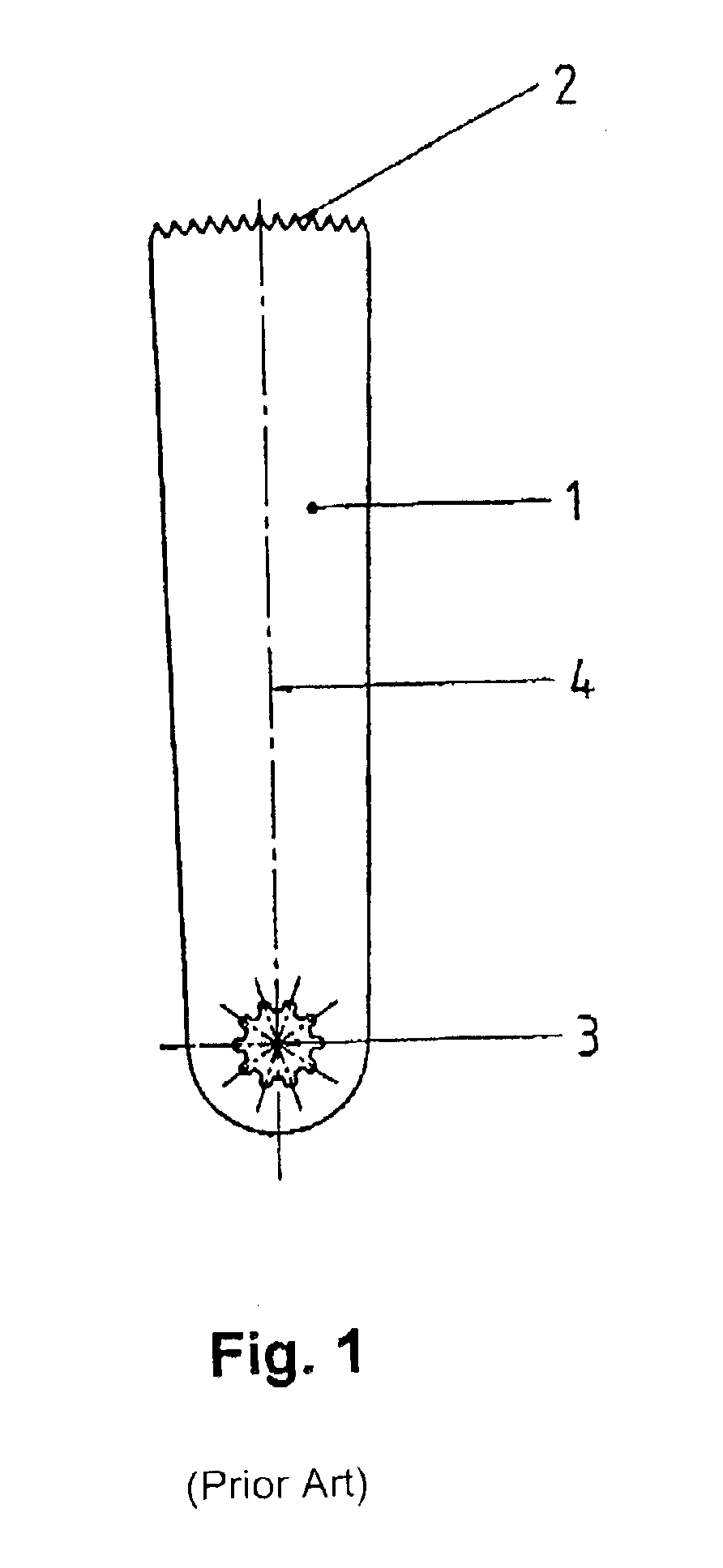

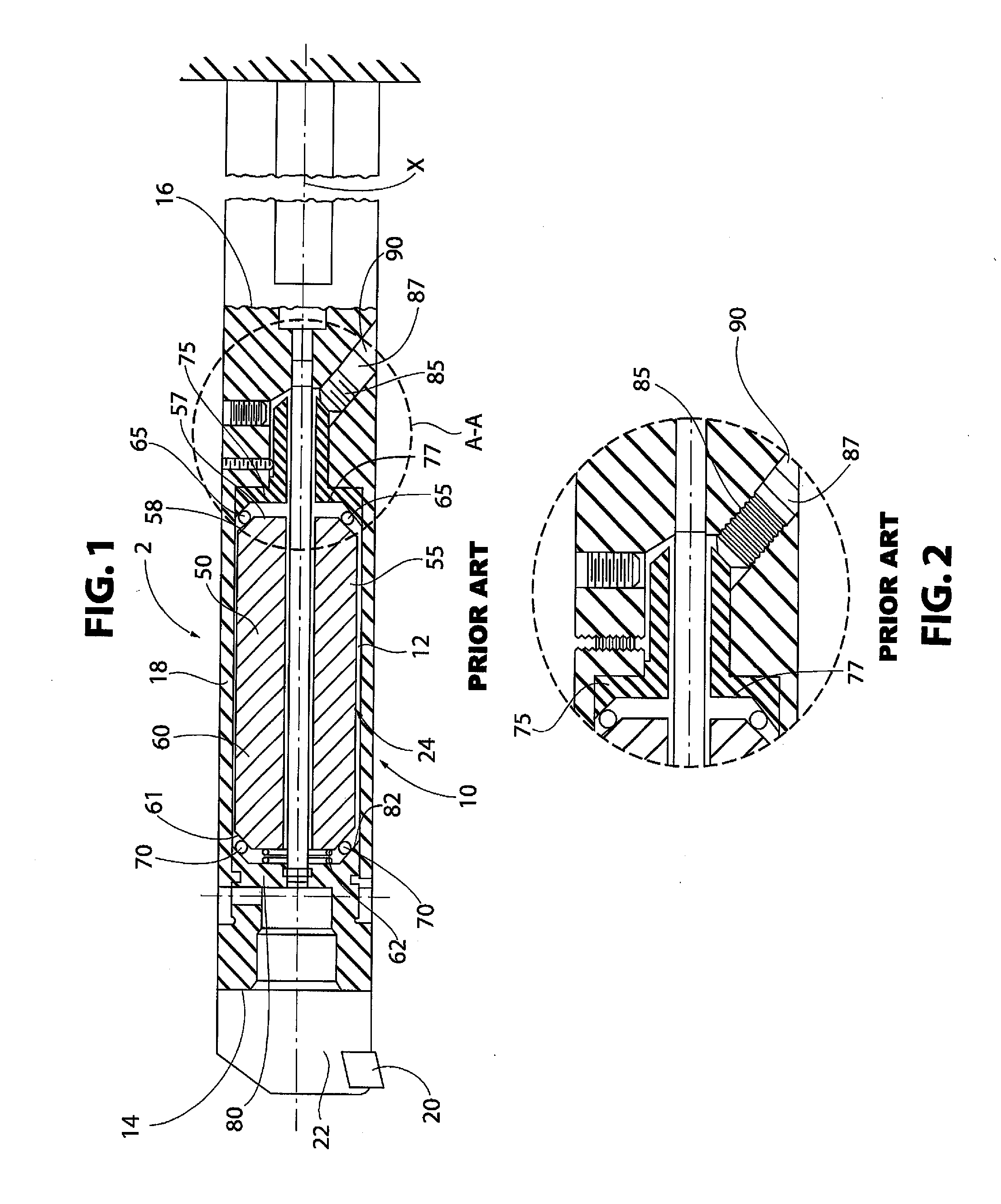

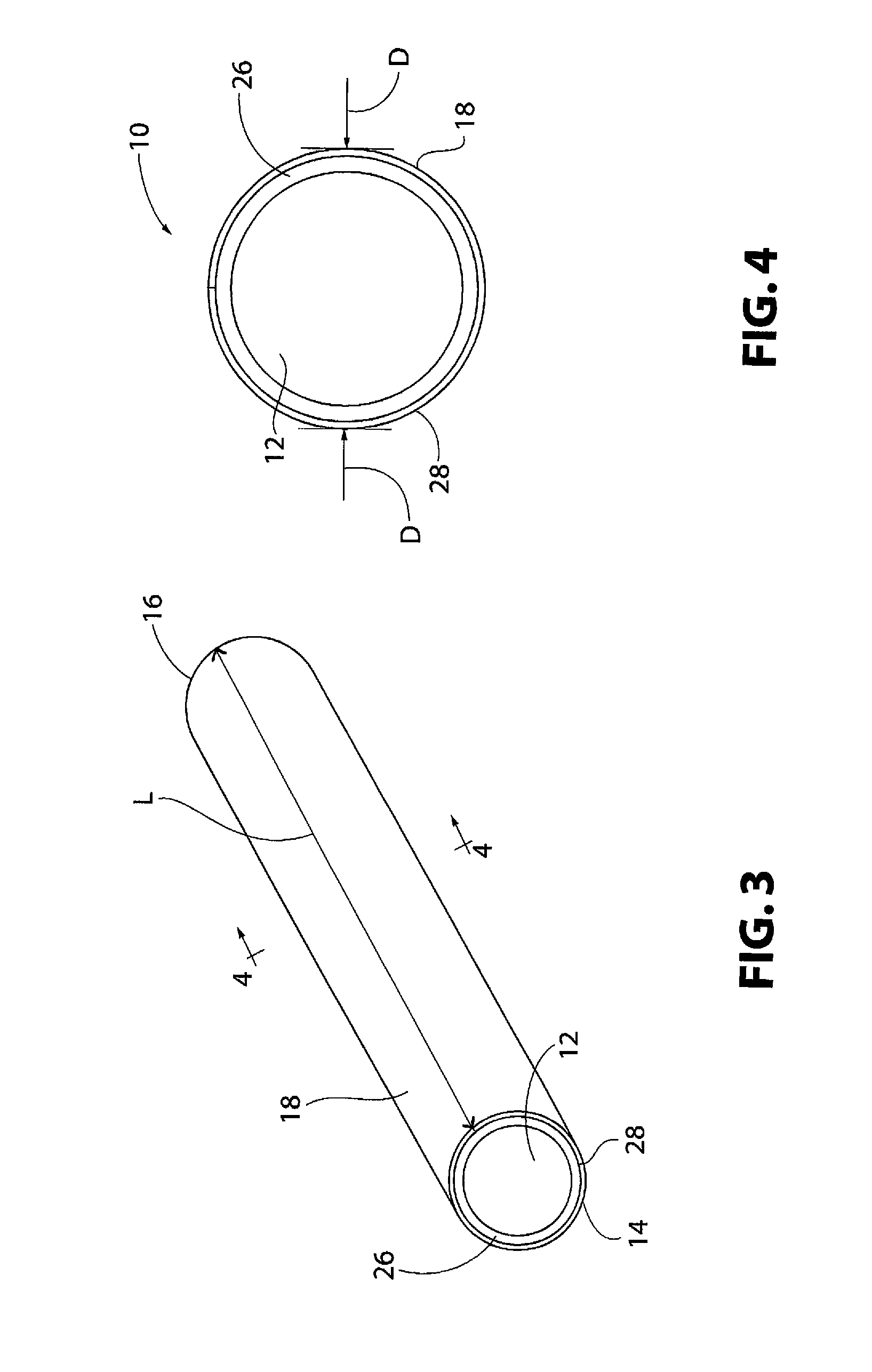

Saw blade for medical applications

InactiveUS7001403B2Precise cuttingDamped reliablyMetal sawing devicesNon-rotary toothed toolsMechanical engineeringMedical treatment

Owner:HAUSMANN THOMAS +1

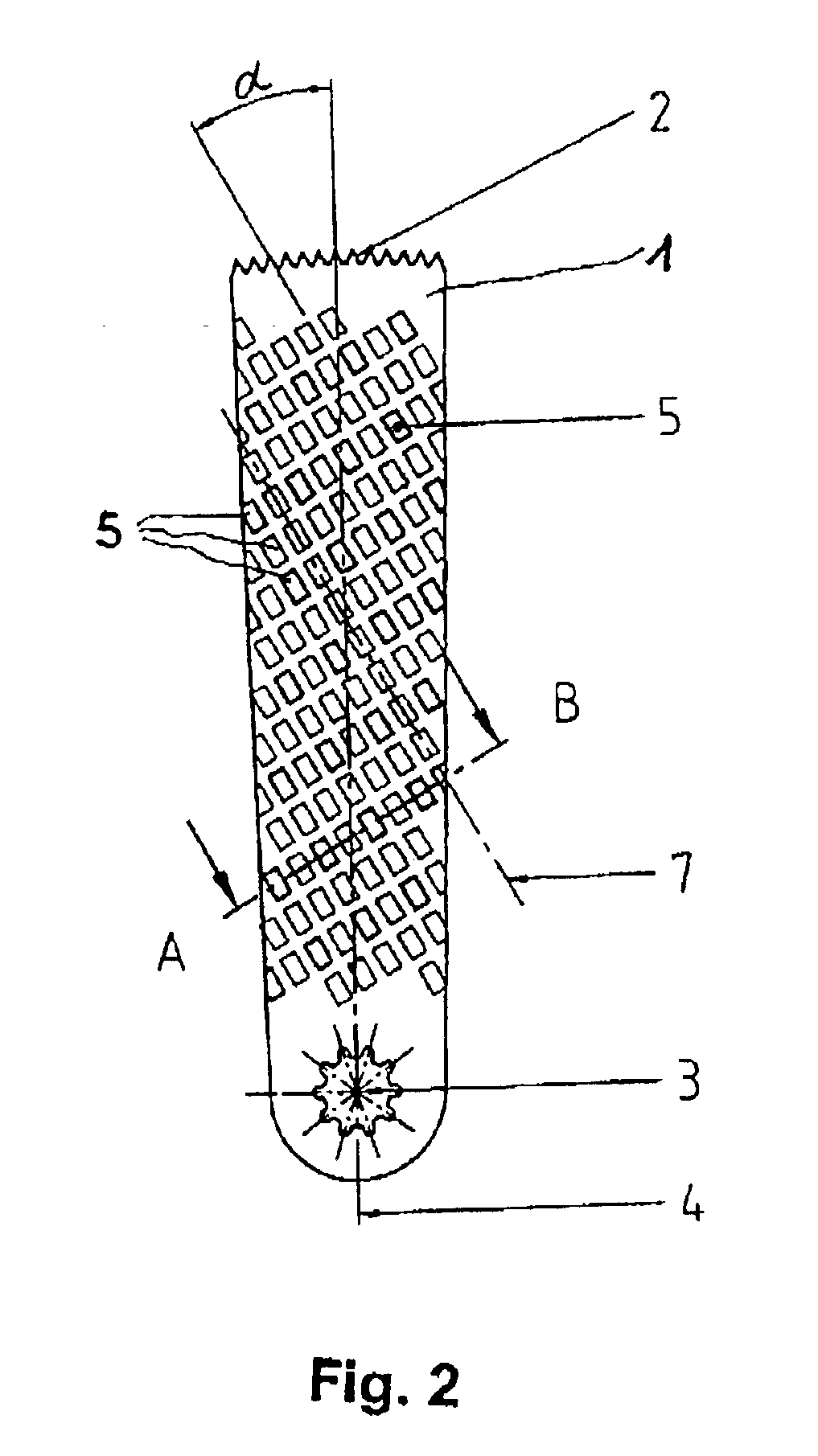

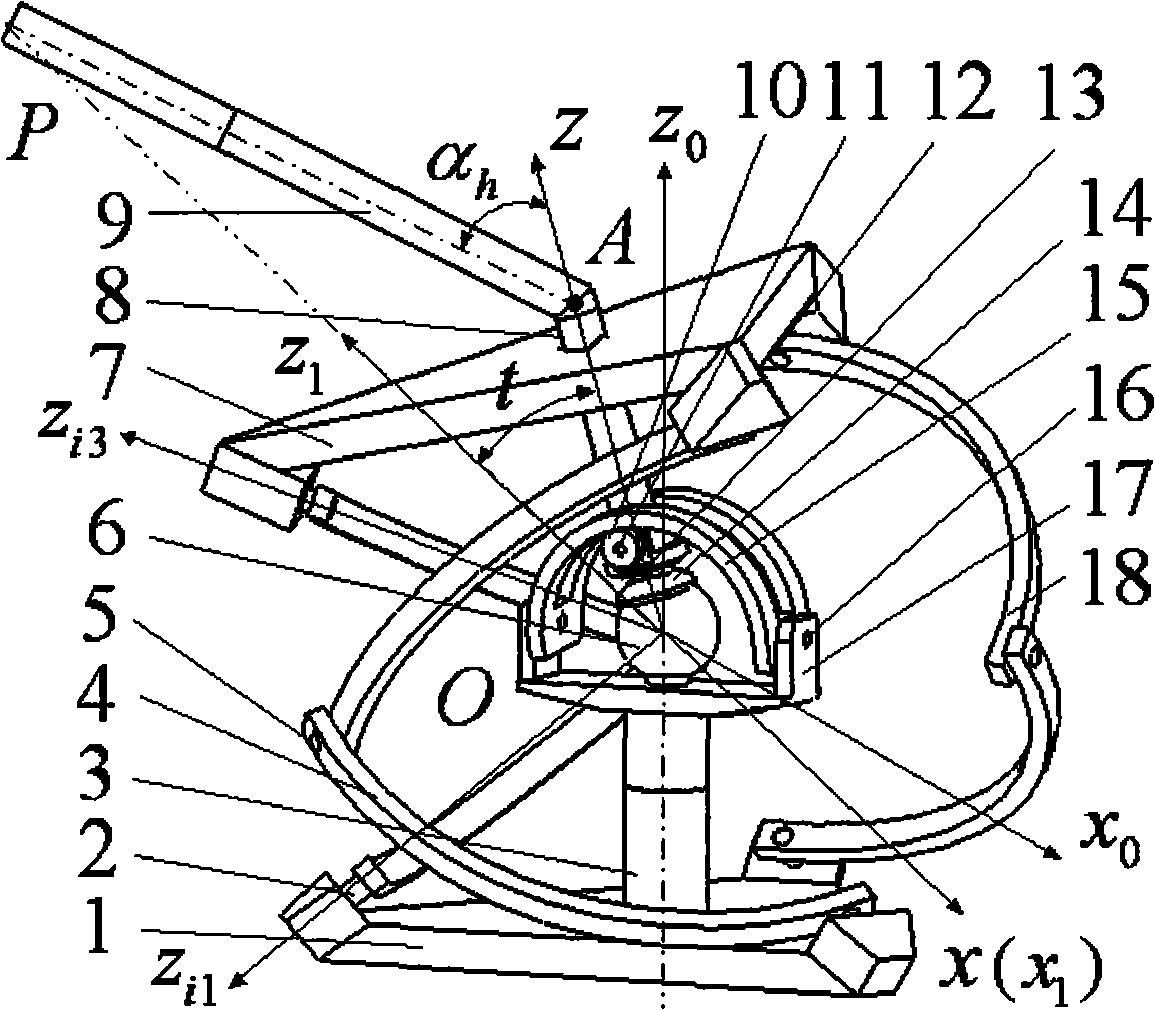

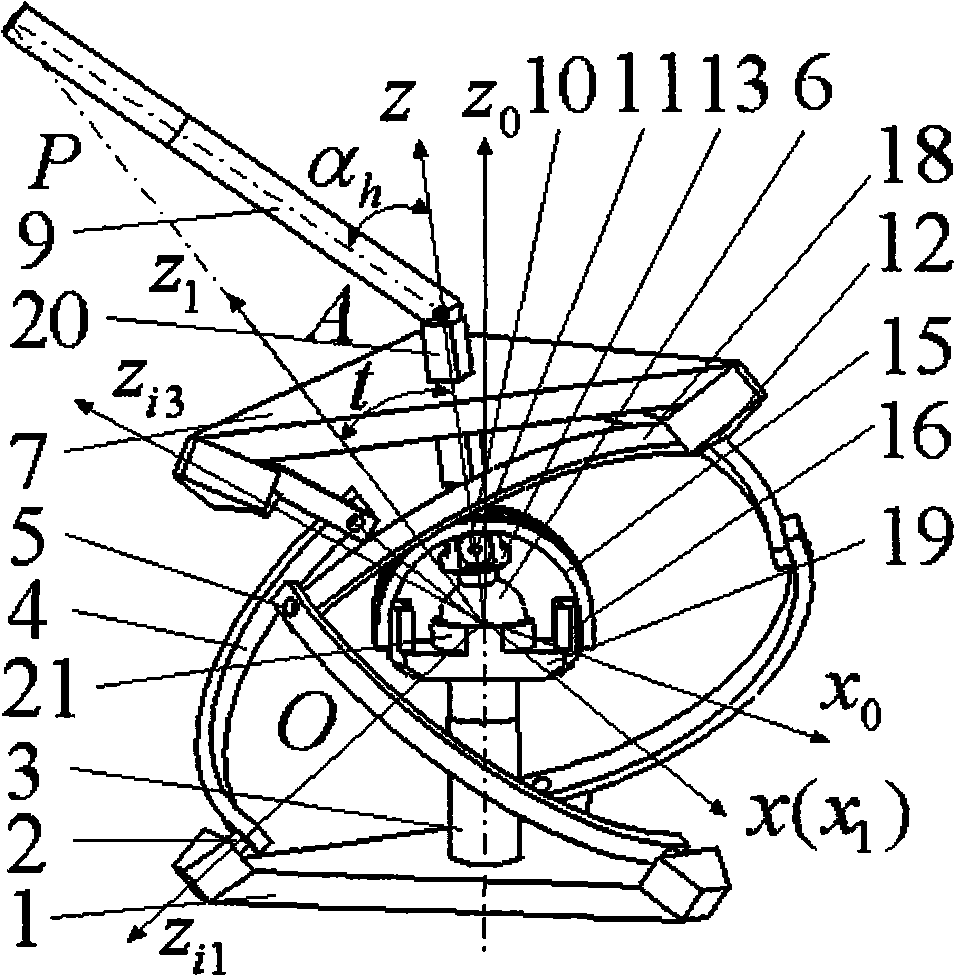

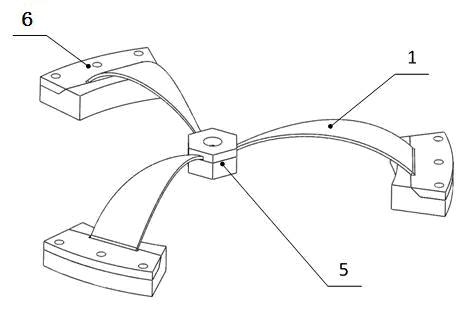

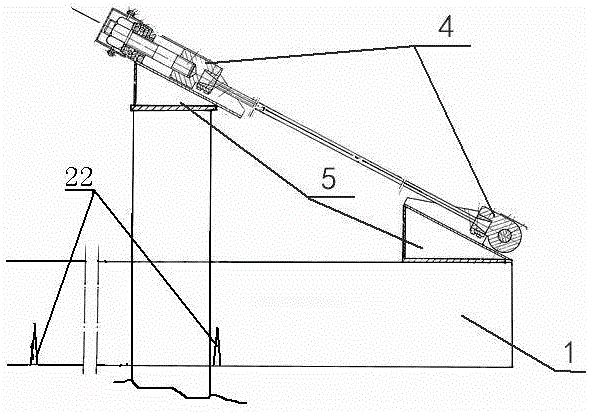

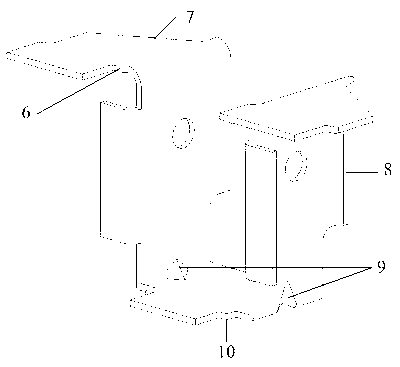

Off-set output 3-dof spherical surface parallel mechanism articulated with center spherical surface

InactiveCN101306534AImprove mechanical propertiesIncrease exerciseProgramme-controlled manipulatorAngle alphaMechanical property

The invention discloses a bias output three freedom spherical parallel mechanism with a central spherical hinge, which consists of a three freedom spherical parallel mechanism, the central spherical hinge and a bias output link unit, and is characterized in that the lower end of a lower support bar (3) of the central spherical hinge is fixed to a fixed platform (1); the axis of the lower support bar (3) passes through the central point of the fixed platform (1); a cylindrical straight output link (8) passes through the center of a moving platform (7), is fixed to the moving platform or connected with the moving platform through a prismatic pair; the upper end of the straight output link (8) is fixedly connected with a bias output link (9) at the point of intersection (A) of central lines; the axial included angle alpha h of the cylindrical straight output link (8) and the bias output link (9) ranges from 0 DEG to100 DEG; and the bias direction is random. The bias output three freedom spherical parallel mechanism has the advantages of high restriction, high rigidity, large working space, unloading function and greatly improved mechanical property of mechanism.

Owner:YANSHAN UNIV

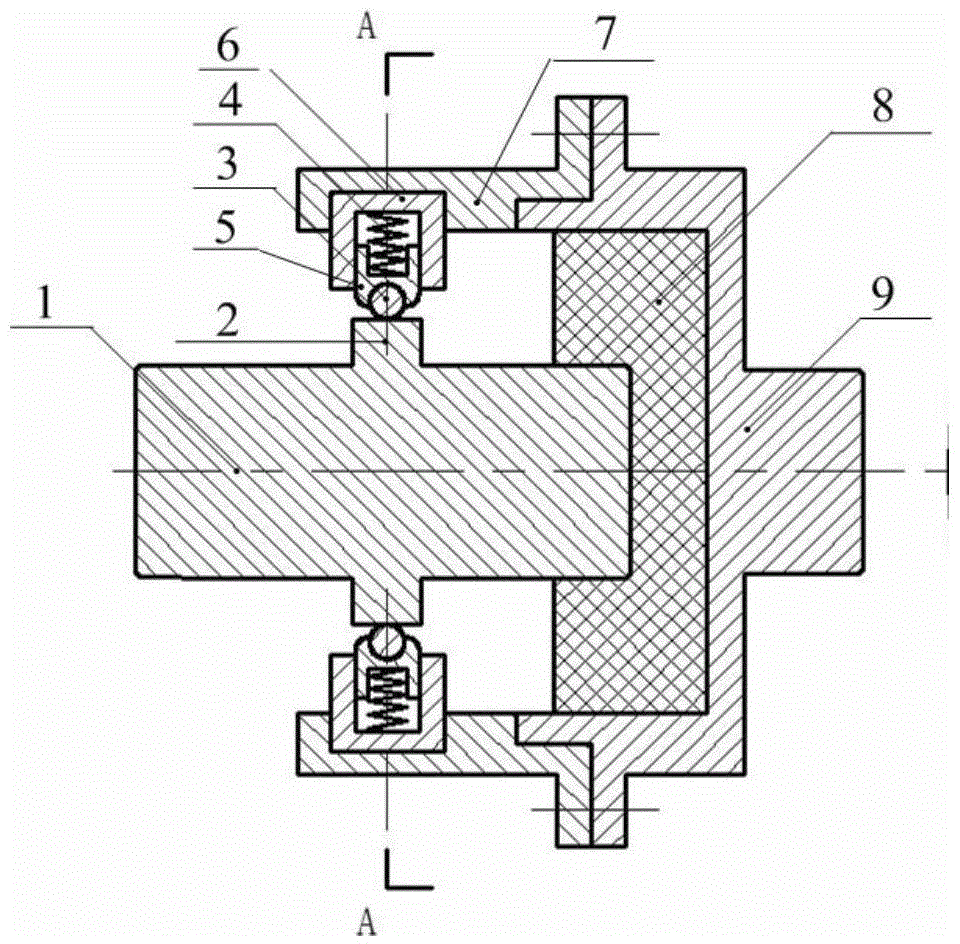

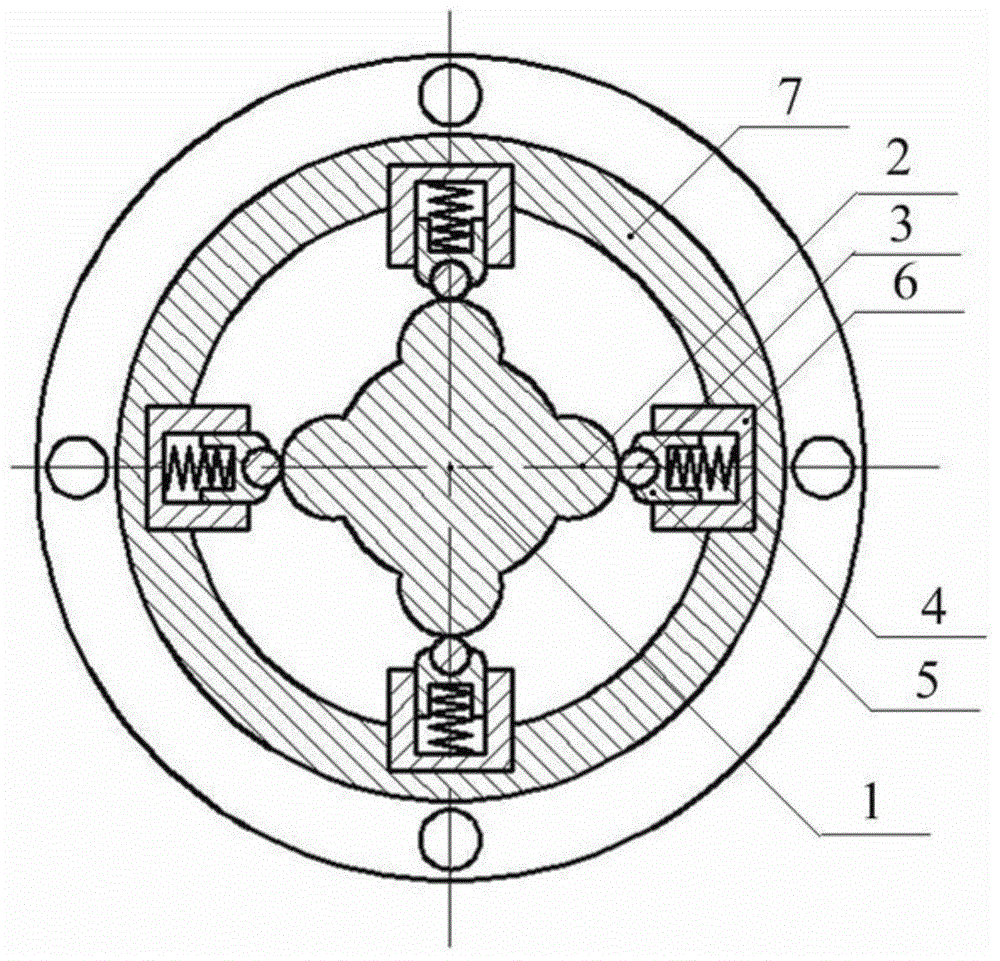

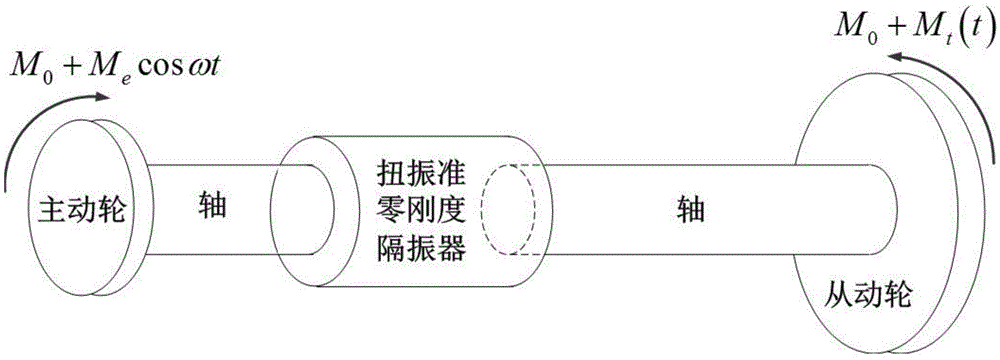

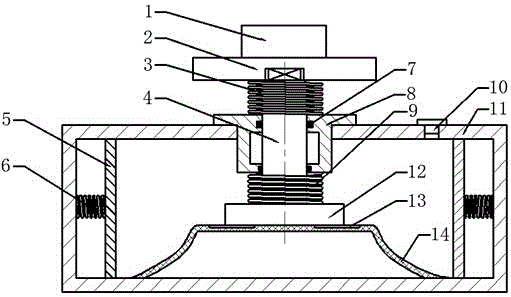

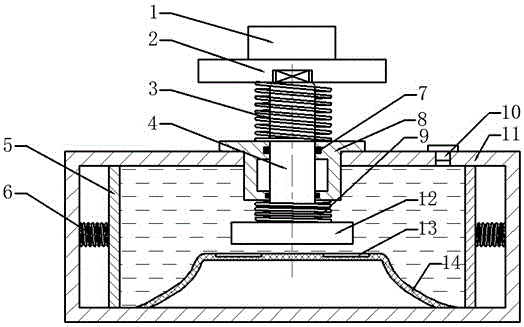

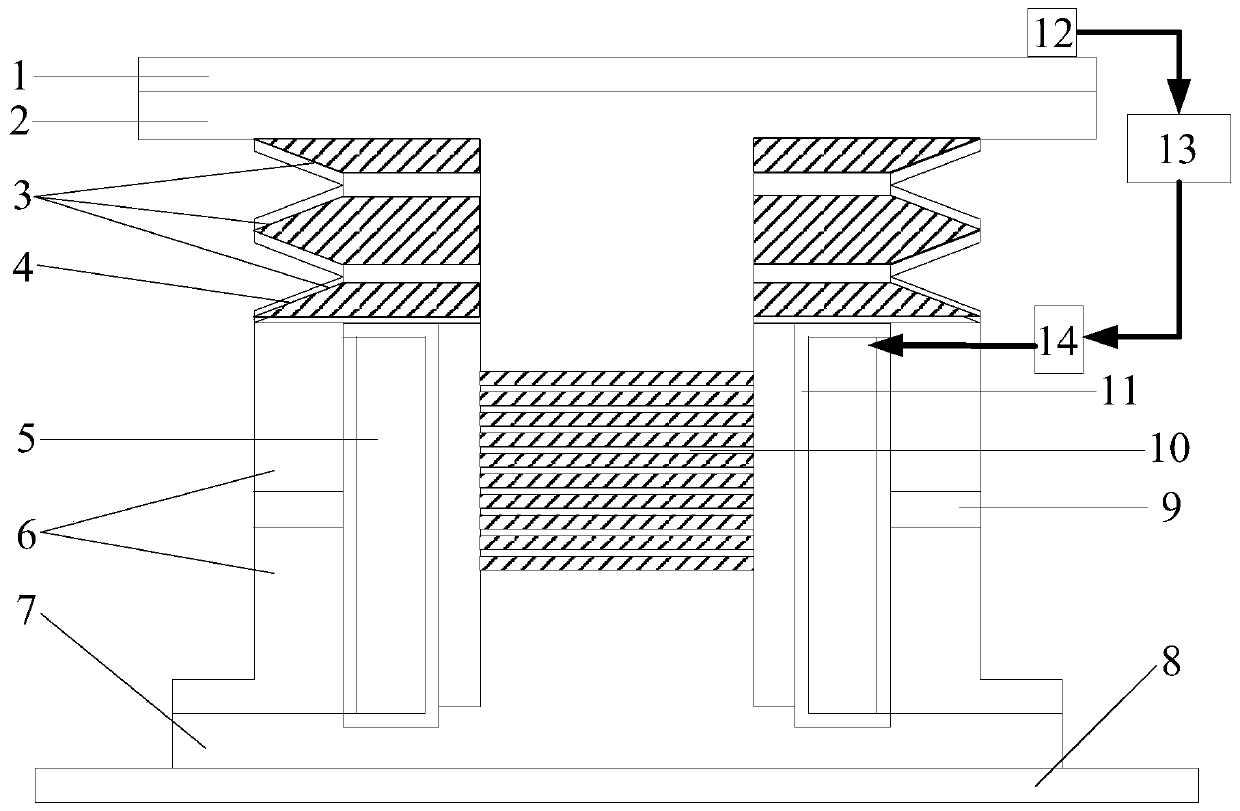

Torsion quasi-zero stiffness vibration isolator

ActiveCN104455199AImprove static stiffnessPositive torsional stiffnessVibration suppression adjustmentsDynamic stiffnessCoupling

The invention discloses a torsion quasi-zero stiffness vibration isolator. The torsion quasi-zero stiffness vibration isolator is mainly composed of a negative-stiffness cam-roller-radial spring mechanism and a positive-stiffness rubber spring vulcanized on a first coupling and a second coupling, and is further provided with a radial spring supporting component used for supporting a radial spring and guaranteeing that the radial spring only deforms in the radial direction. When the first coupling and the second coupling rotate relative to each other, the cam-roller-radial spring mechanism generates negative torsion stiffness, the rubber spring has positive torsion stiffness; under the parallel combination of the positive-stiffness element and the negative-stiffness element, the vibration isolator has the high static stiffness and low dynamic stiffness characteristic that the vibration isolator can bear large static loads, namely, the vibration isolator can transmit large static torque. The stiffness is zero at the static balance position, and the micro stiffness characteristic is shown near the static balance position. Thus, the vibration isolator can isolate ultralow-frequency torsion vibration of a shaft system.

Owner:HUNAN UNIV

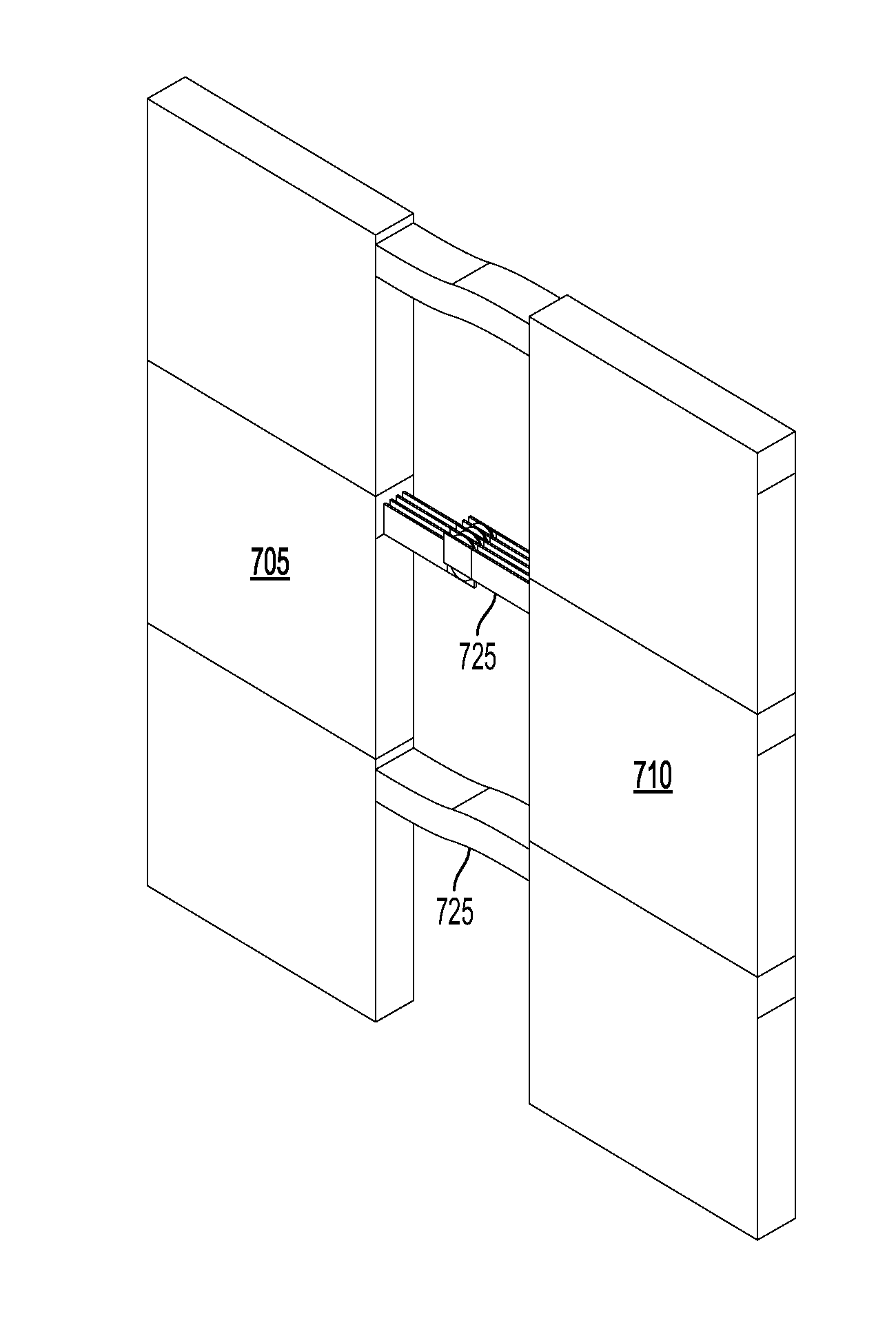

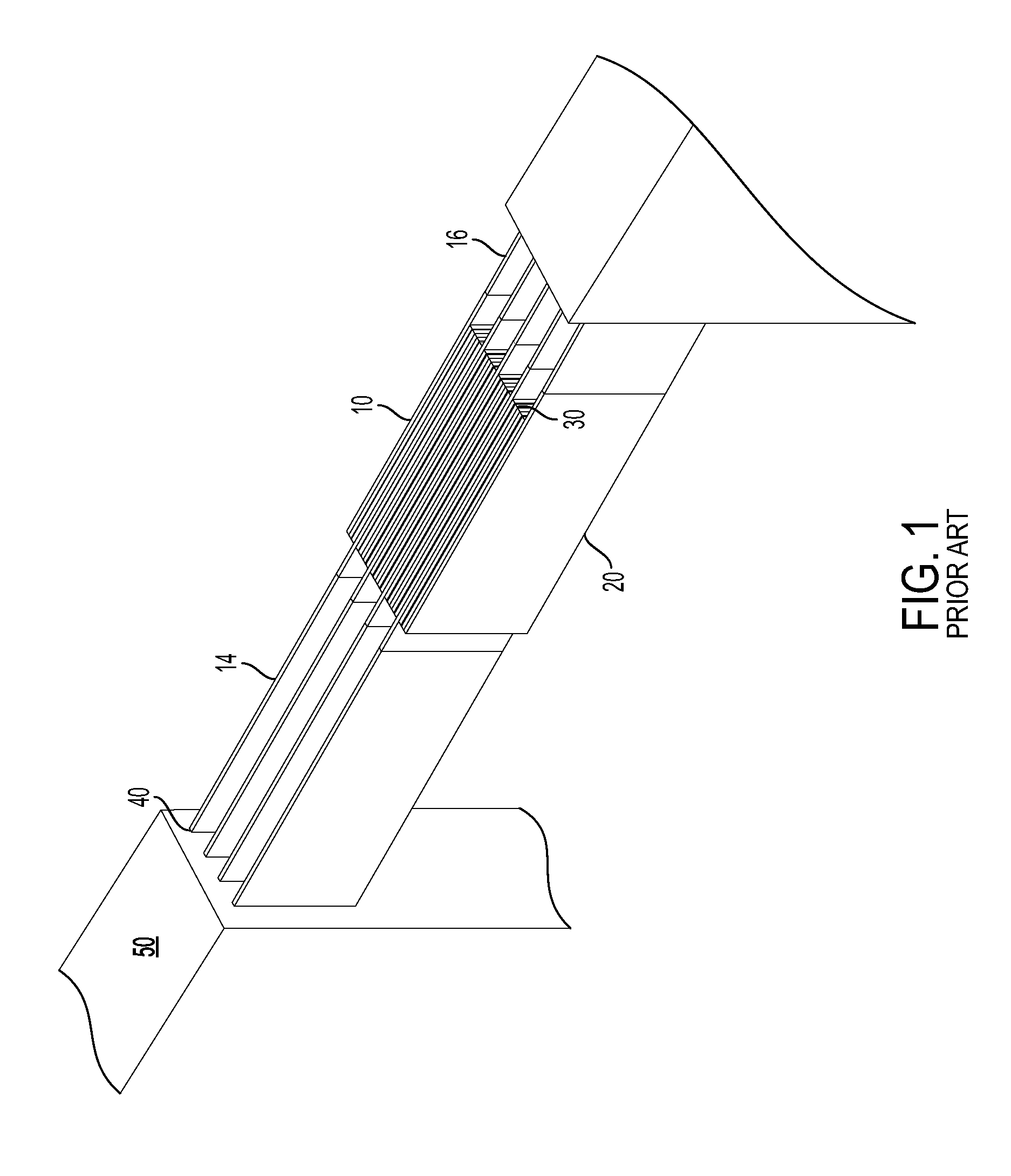

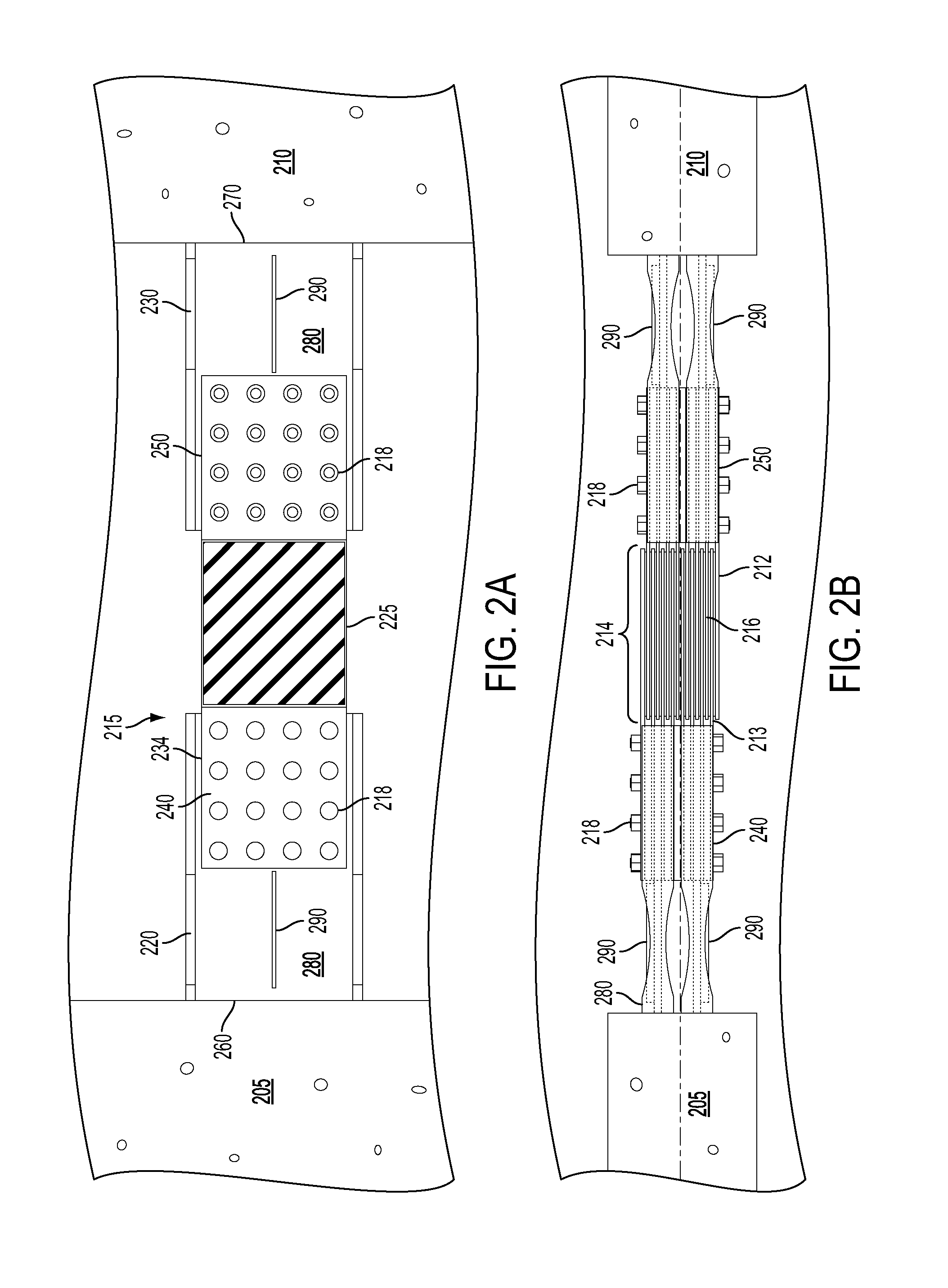

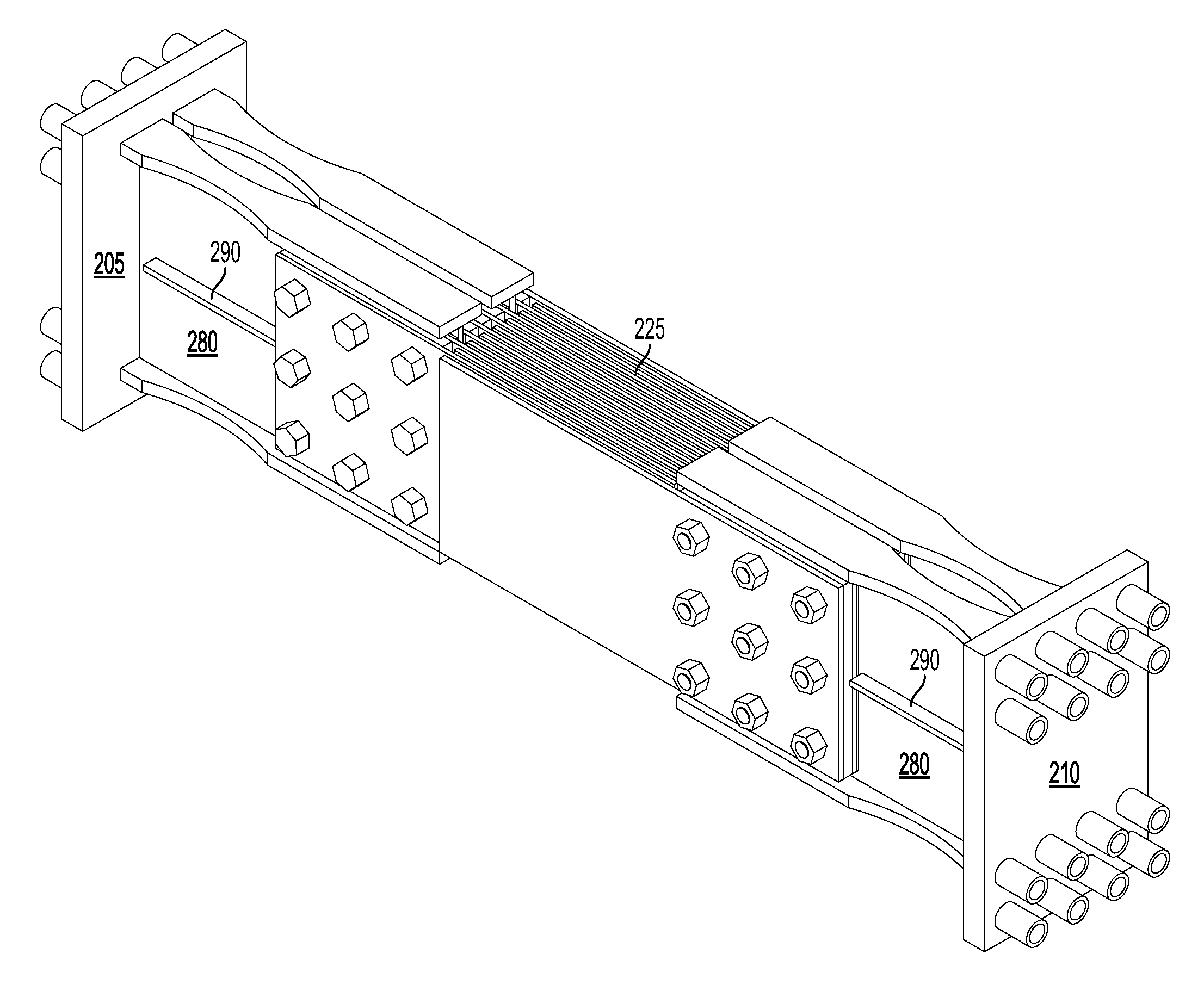

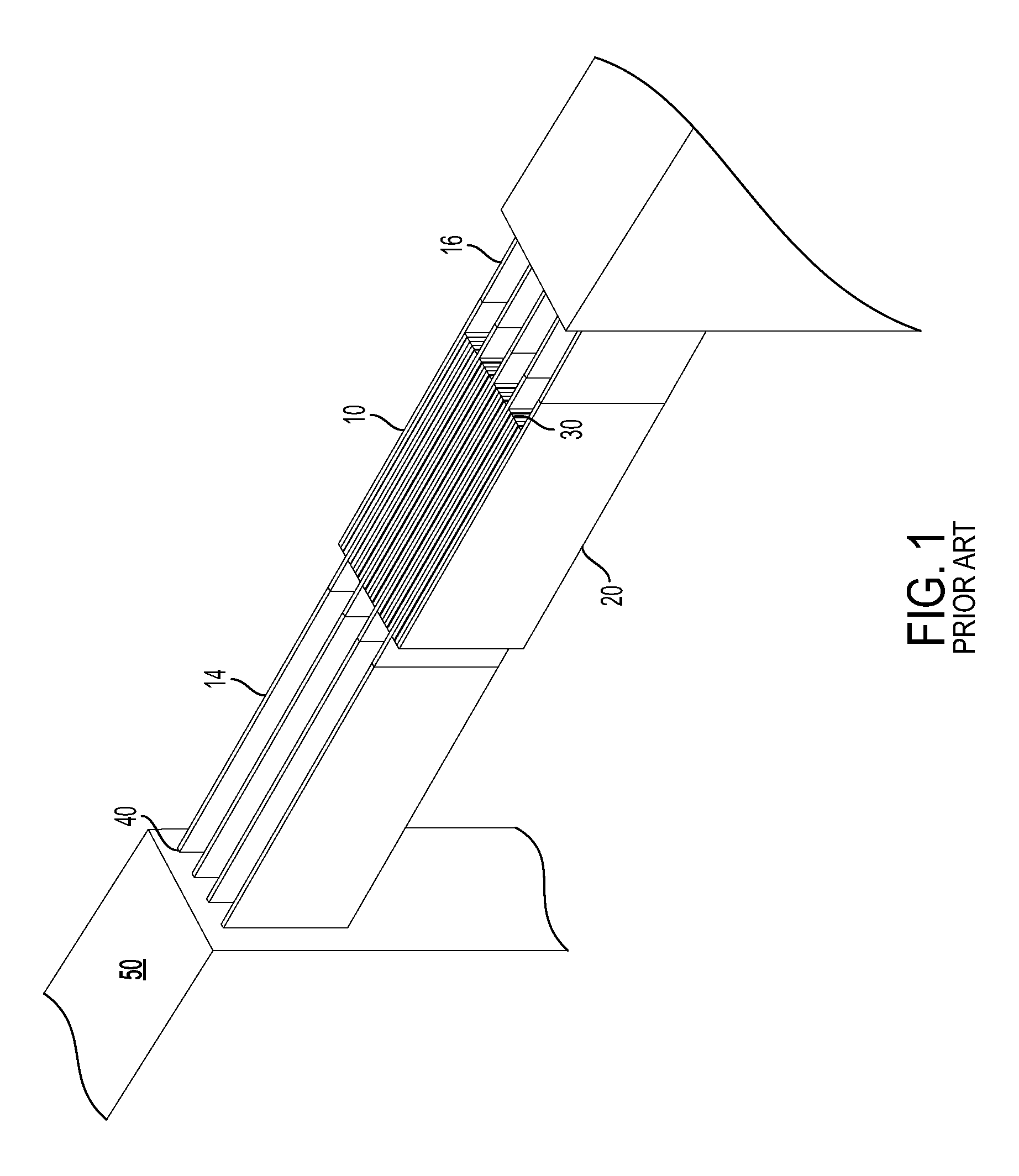

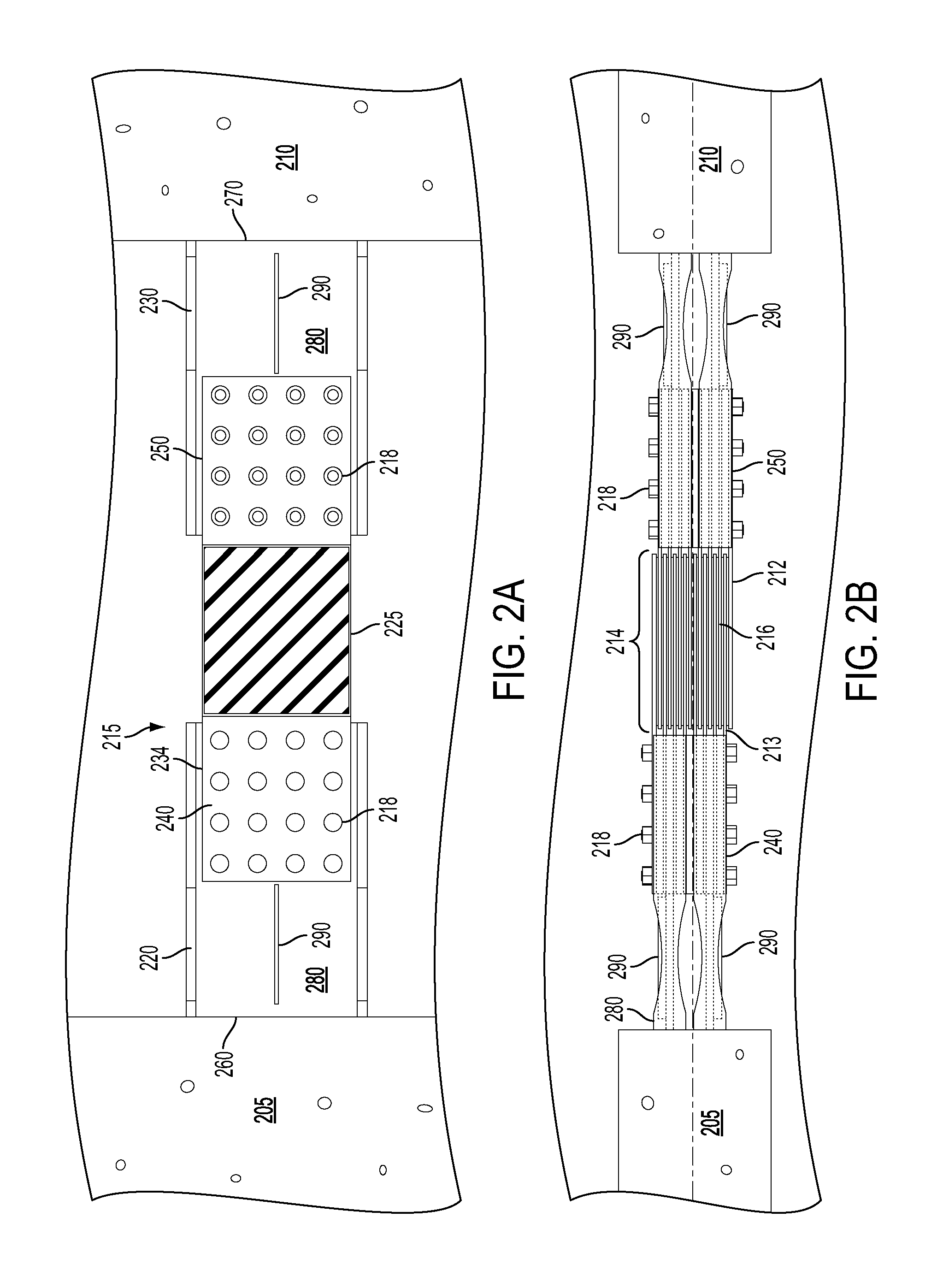

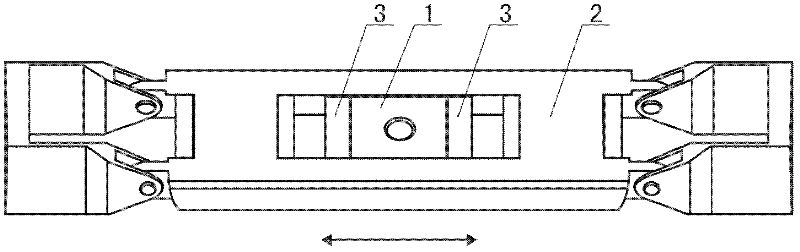

Coupling member for damping vibrations in building structures

ActiveUS20130283709A1Prevent slippingControl loadBuilding repairsProtective buildings/sheltersRelative motionControl theory

A building structure including a plurality of vertical elements extending from a ground surface with at least a first of the vertical elements connected to a second of the vertical elements by a coupling member, the coupling member includes a damping element for damping vibrations in the building structure resulting from relative movement between the first and second vertical elements due to lateral loads applied to the building structure. The damping element undergoes deformation due to the relative movement between the vertical elements causing the damping material to be activated in shear. At least one of a first and second fuse member is connected to at least one of first and second ends of the damping element respectively. The fuse member is selected from a material, and otherwise sized and dimensioned to exhibit semi-rigid behavior when the damping element undergoes deformation due to loads below a predetermined load limit and to undergo deformation without substantially increasing the load in the fuse and in the damping element when loads exceed the predetermined load limit, such that the damping element is prevented from deforming beyond its predetermined deformation limit and therefore avoiding any occurrence of damage that would reduce its ability to provide damping to the structure. First and second connecting means are also provided for rigidly connecting the first and second fuse members to the first and second vertical elements, respectively.

Owner:CHRISTOPOULOS CONSTANTIN +1

Coupling member for damping vibrations in building structures

ActiveUS8881491B2Reduce vibrationAvoid deformationBuilding repairsProtective buildings/sheltersControl theoryEngineering

A building structure including a plurality of vertical elements extending from a ground surface with at least a first of the vertical elements connected to a second of the vertical elements by a coupling member, the coupling member includes a damping element for damping vibrations in the building structure resulting from relative movement between the first and second vertical elements due to lateral loads applied to the building structure. The damping element undergoes deformation due to the relative movement between the vertical elements causing the damping material to be activated in shear. At least one of a first and second fuse member is connected to at least one of first and second ends of the damping element respectively. The fuse member is selected from a material, and otherwise sized and dimensioned to exhibit semi-rigid behavior when the damping element undergoes deformation due to loads below a predetermined load limit and to undergo deformation without substantially increasing the load in the fuse and in the damping element when loads exceed the predetermined load limit, such that the damping element is prevented from deforming beyond its predetermined deformation limit and therefore avoiding any occurrence of damage that would reduce its ability to provide damping to the structure. First and second connecting means are also provided for rigidly connecting the first and second fuse members to the first and second vertical elements, respectively.

Owner:CHRISTOPOULOS CONSTANTIN +1

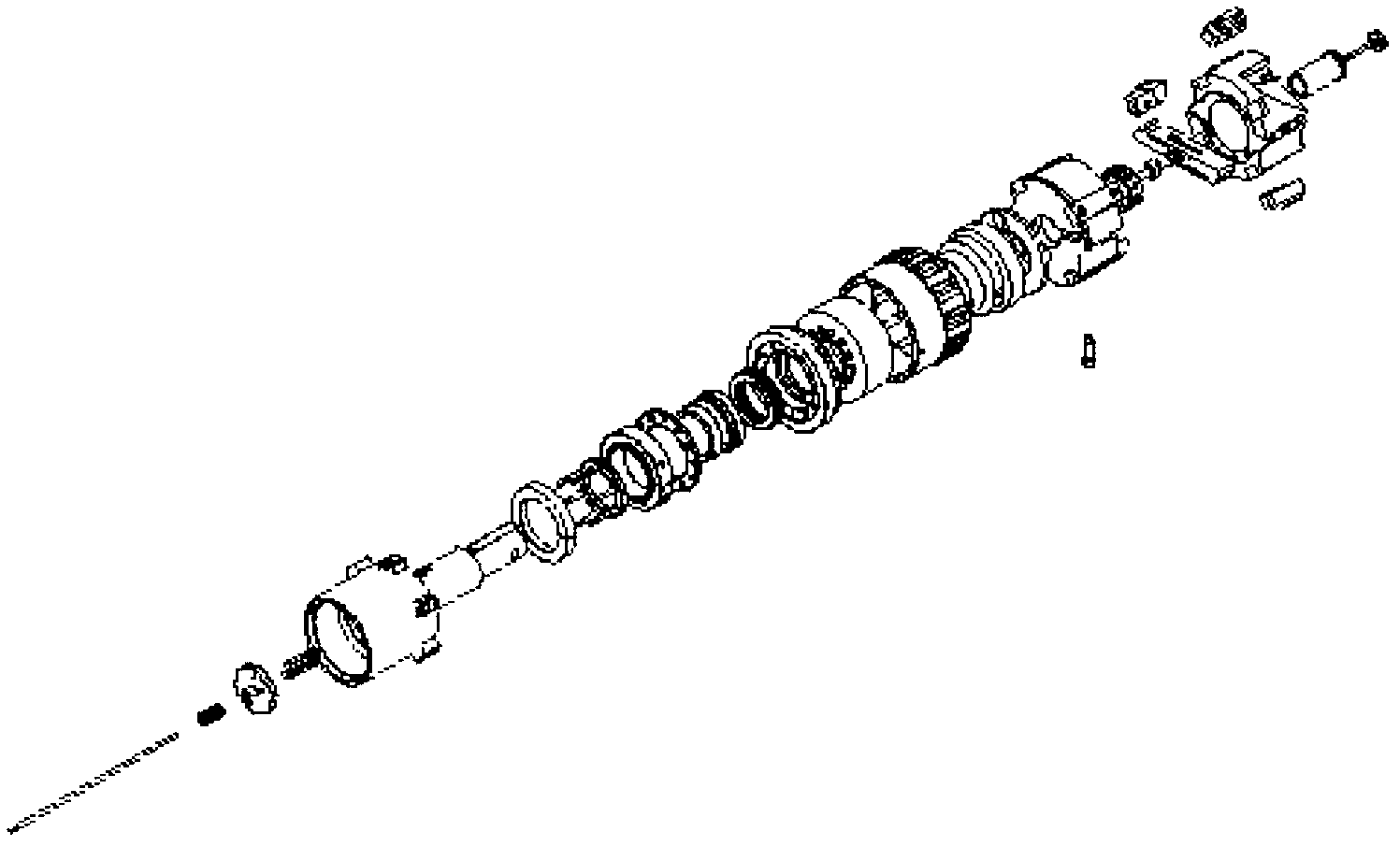

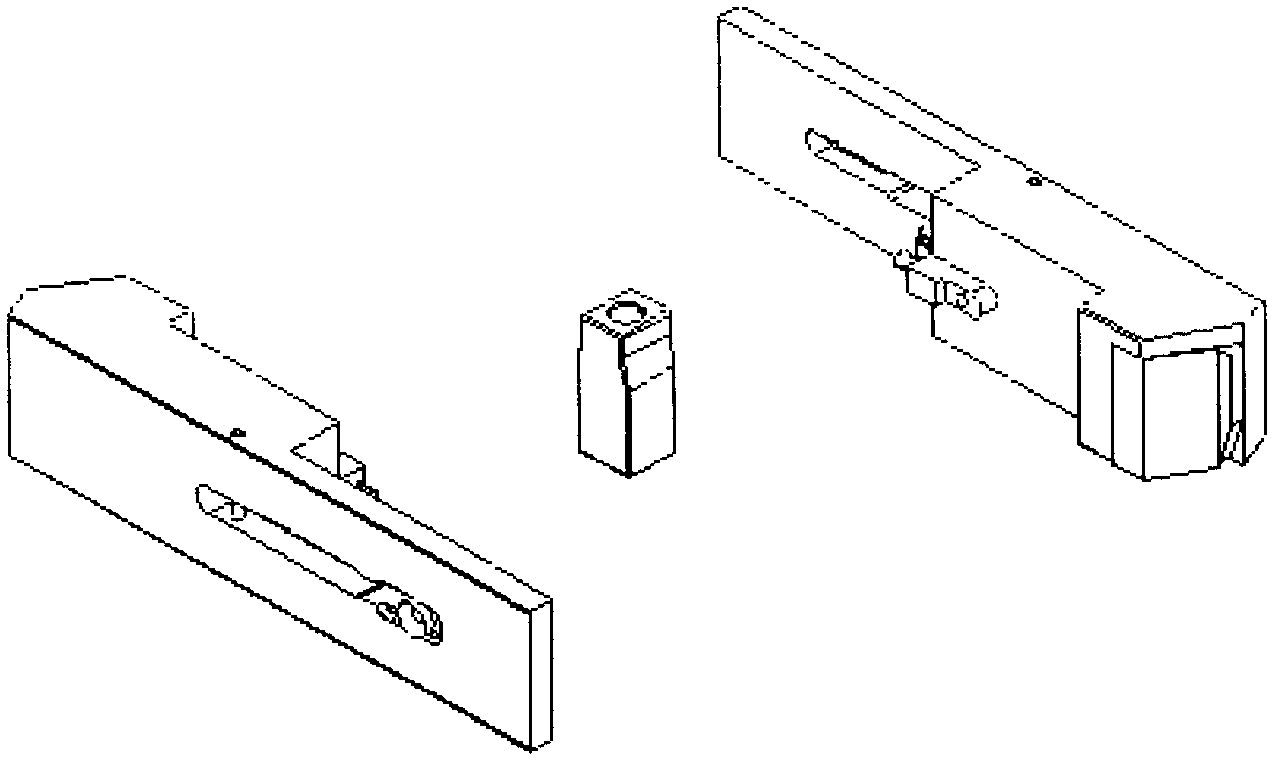

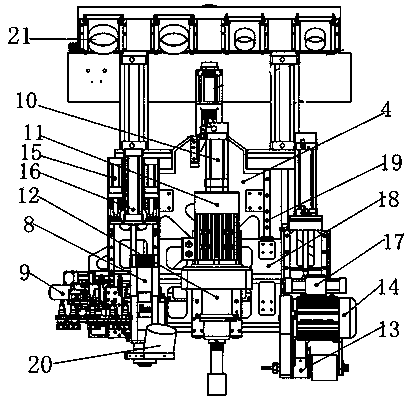

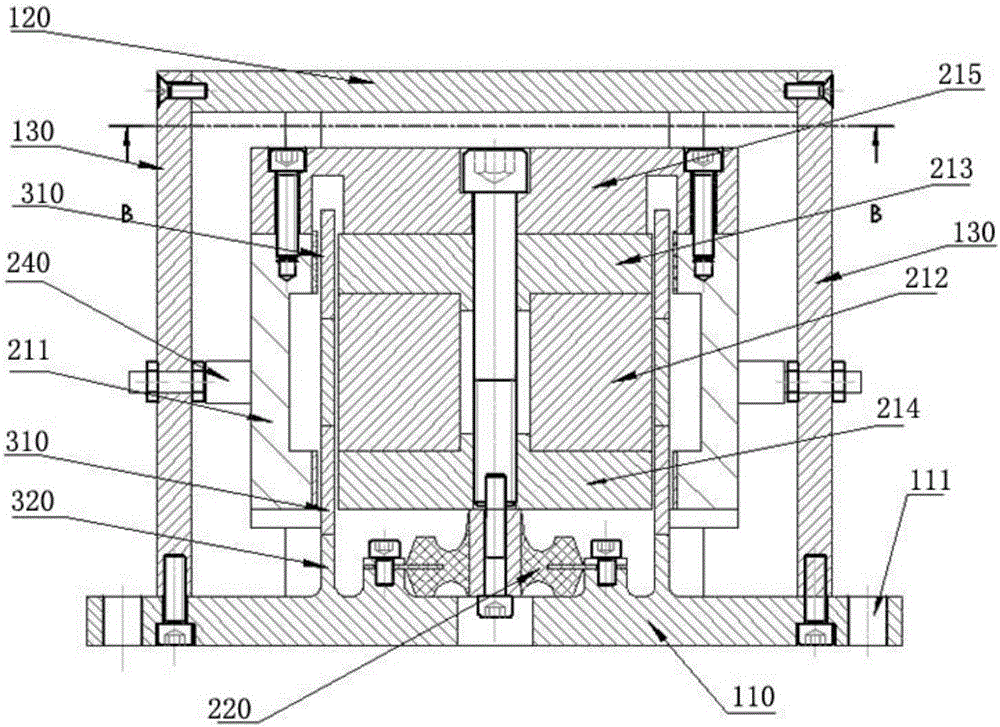

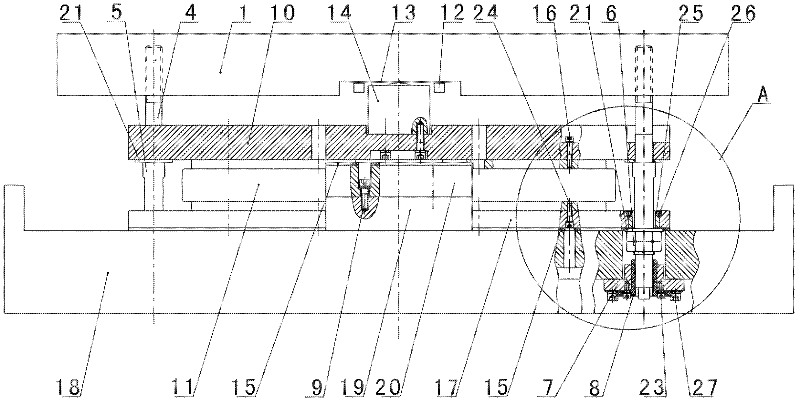

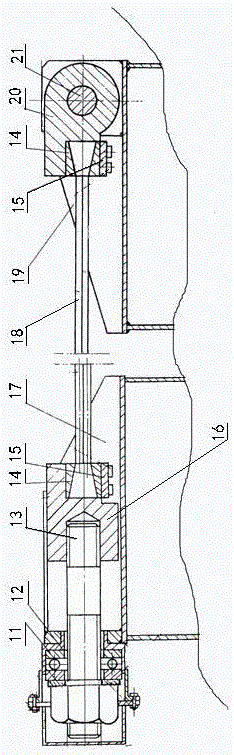

Automatically expanding and shrinking scraping-rolling combined deep hole cutter

ActiveCN102152118AImprove static stiffnessImprove dynamic stiffnessOther manufacturing equipments/toolsBoring headsMatched pairEngineering

The invention discloses an automatically expanding and shrinking scraping-rolling combined deep hole cutter. A scraping part of the cutter comprises at least one pair of scrapers, a top block, and a reset device; the top block is positioned in the centre of a thick boring head body and is provided with a taper structure, and a corresponding conical surface is jacked by an endocentric end of the scraper; and the reset device is arranged between each matched pair of scrapers for resetting the scrapers; and a rolling part of the cutter comprises a rolling path and a keeper. The combined boring head also comprises a manipulating device which comprises a first driving part and a second driving part, wherein the first driving part drives the keeper to move axially along a spindle, and the second driving part penetrates a centre hole and acts on the top block in order to drive the top block to move axially along the spindle. The cutter disclosed by the invention is compact in structure, high in processing precision, convenient to use, and can expand and shrink automatically.

Owner:德州普利森机床有限公司

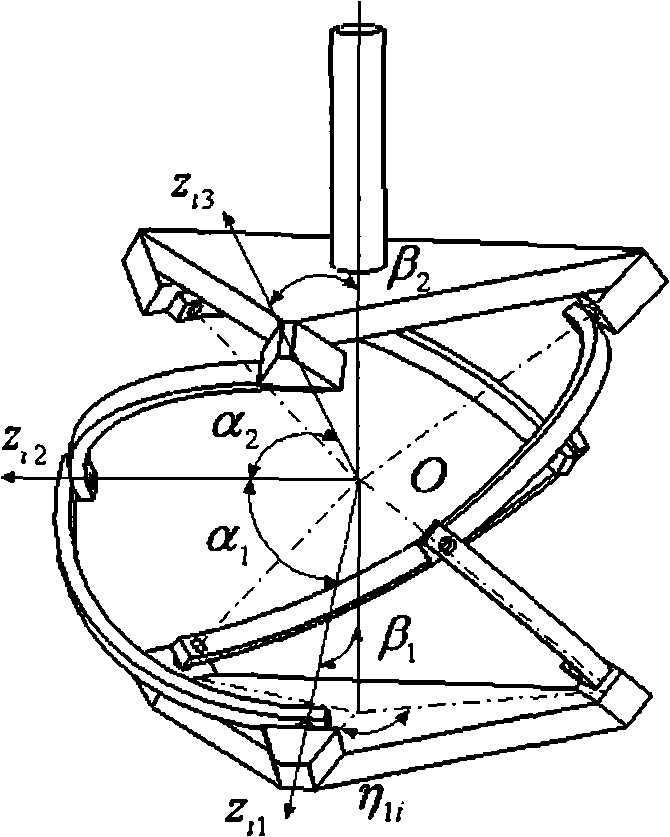

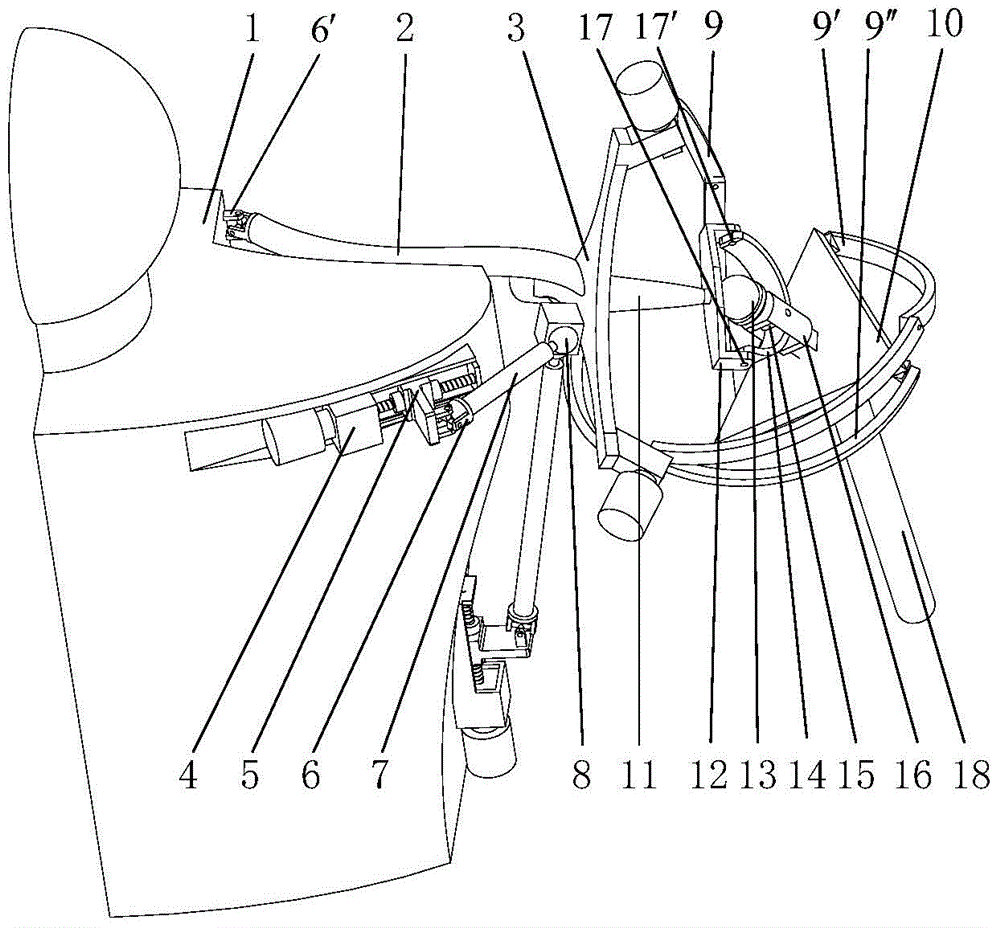

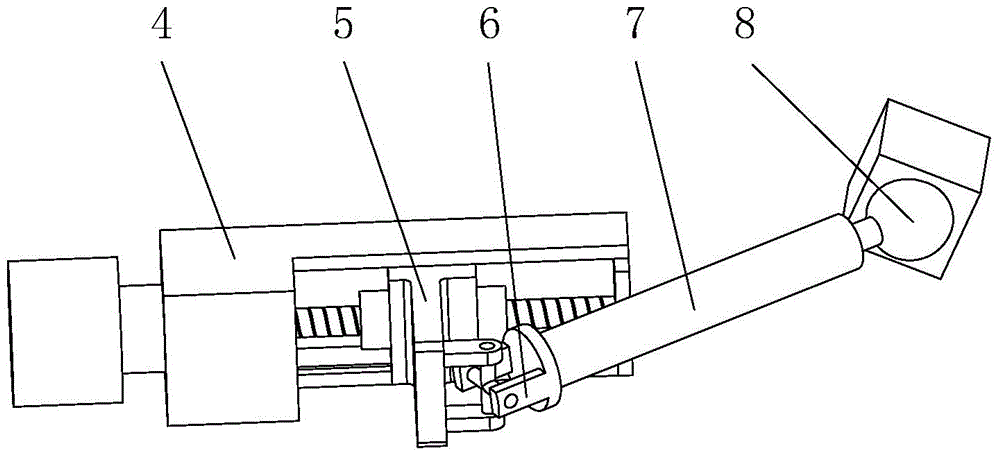

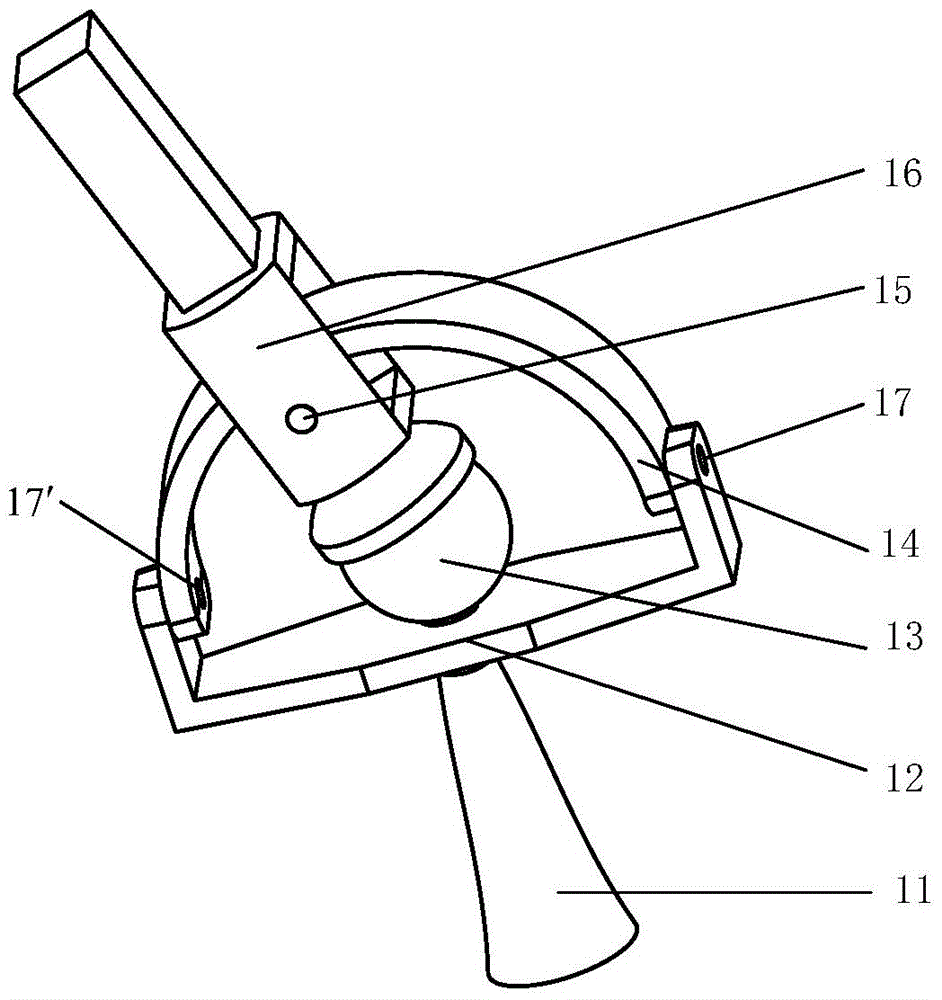

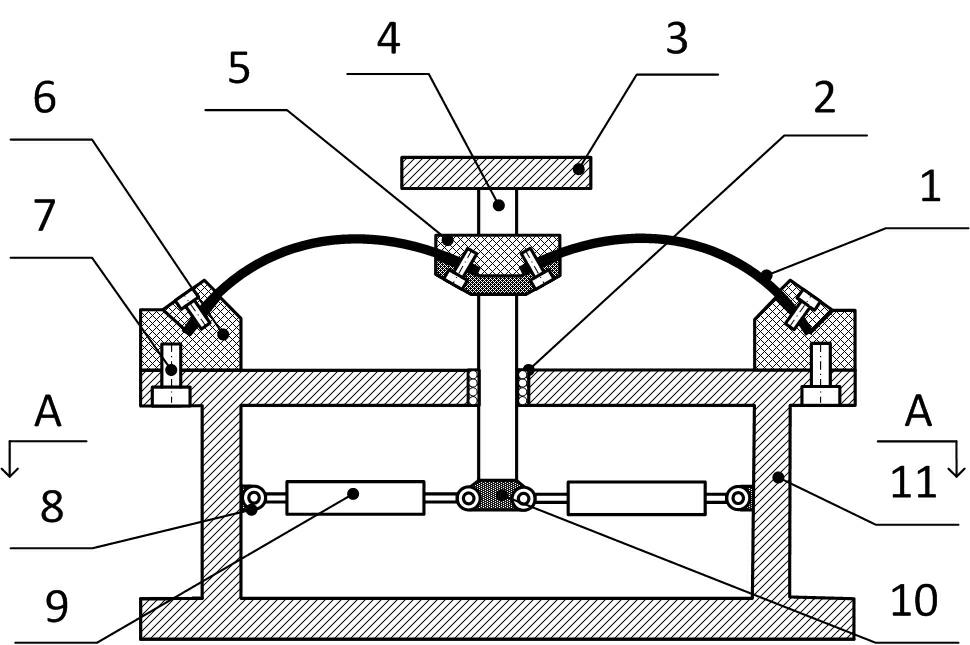

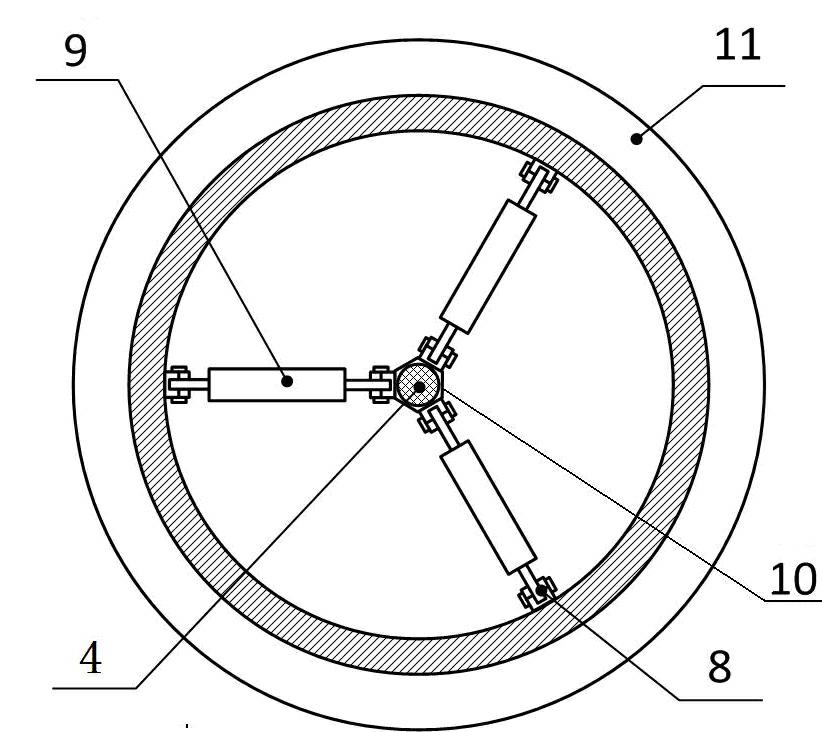

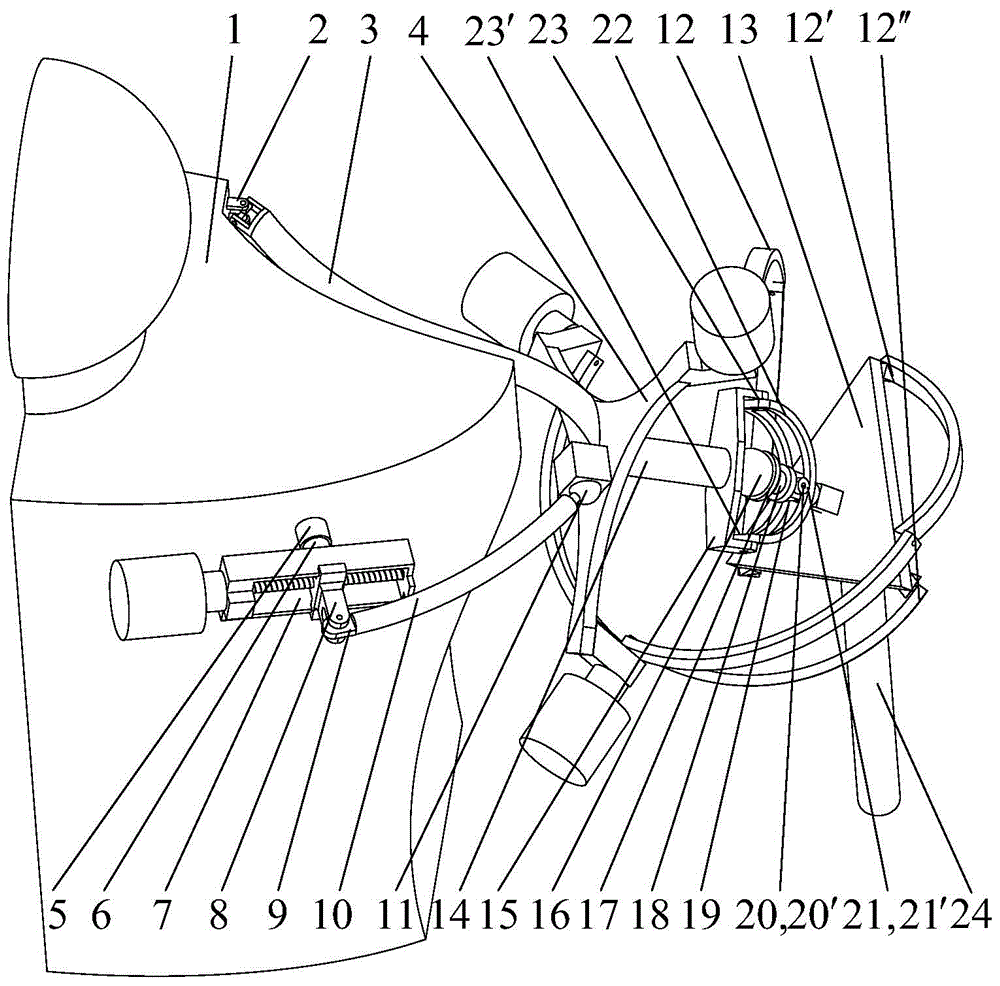

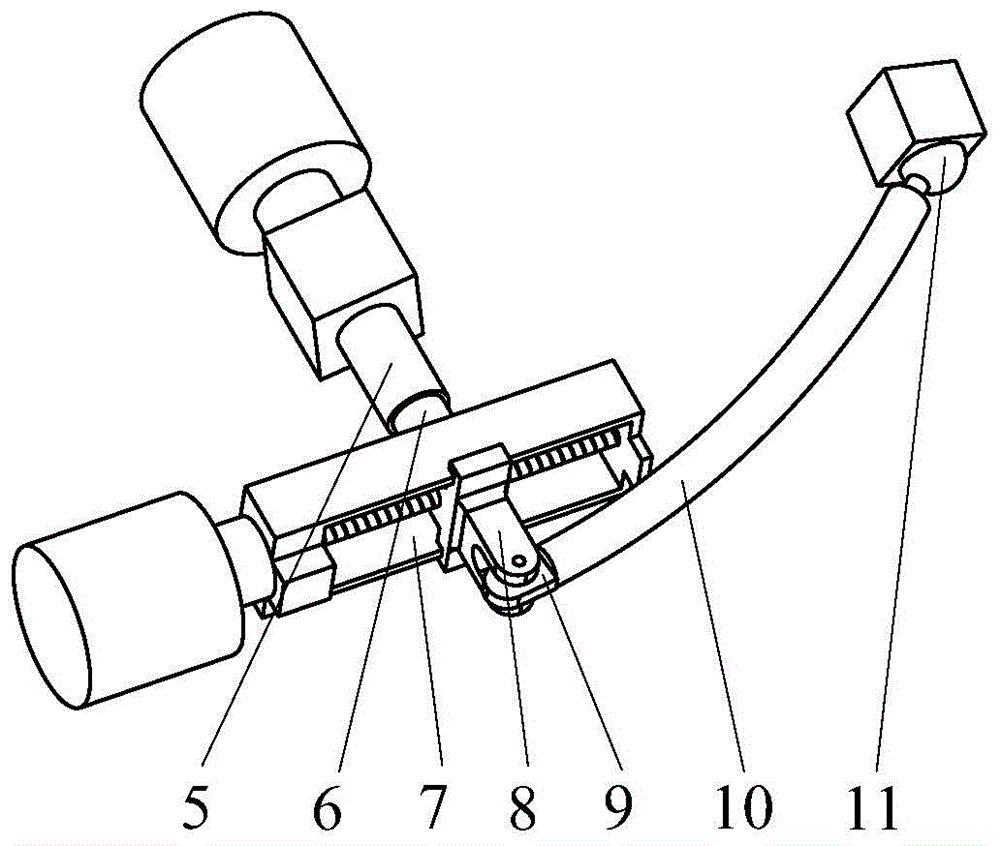

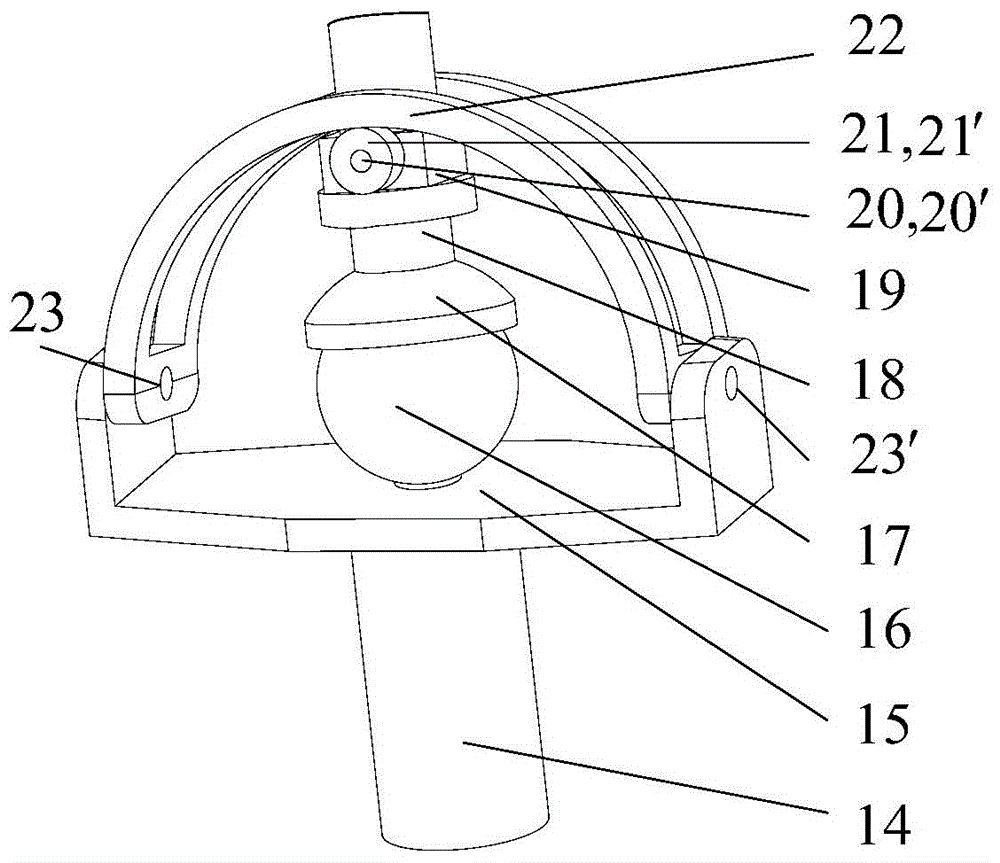

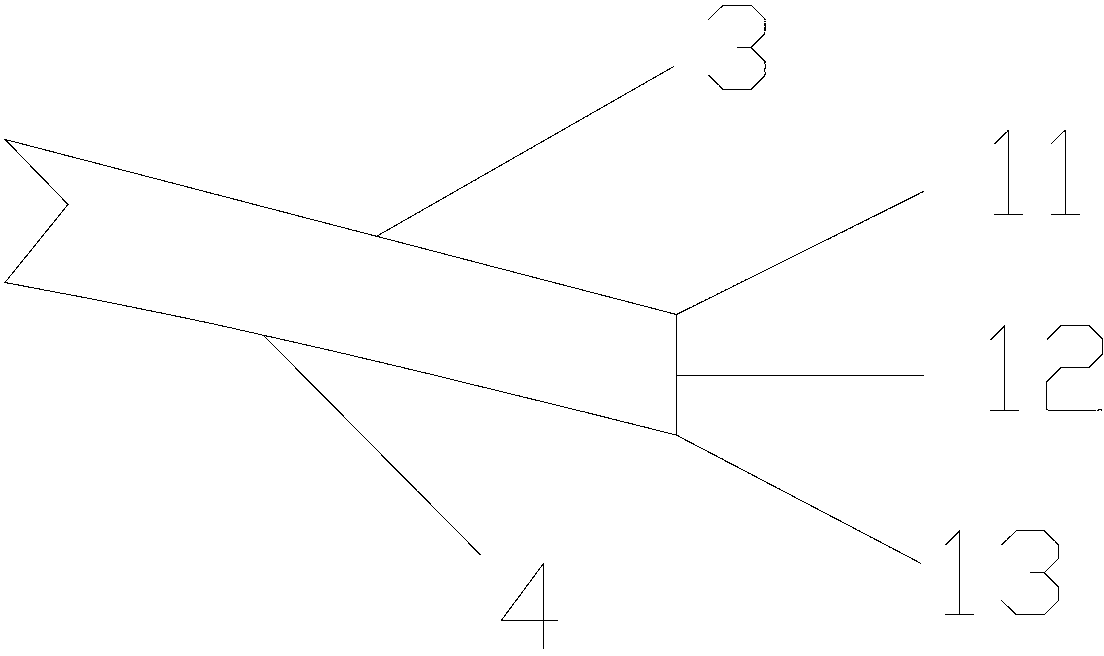

Five-degree-of-freedom parallel-series bionic shoulder joint

InactiveCN104908060AImprove static stiffnessLarge working spaceJointsThree degrees of freedomEngineering

The invention discloses a five-degree-of-freedom parallel-series bionic shoulder joint. A 2-PUS+U two-degree-of-freedom parallel mechanism comprises a bionic rack, an intermediate moving platform, an S-shaped connecting rod between the bionic rack and the intermediate moving platform and two moving branch chains with the same structure, wherein each moving branch chain sequentially consists of a linear guide rail moving pair, a driving sliding block, a hook joint, a driven rod and a spherical pair; a 3-RRR three-degree-of-freedom spherical parallel mechanism comprises an intermediate moving platform, three rotating branch chains and a tail moving platform; a spherical hinge with a large working space comprises a support rod, a double-lug bracket, a ball head, a U-shaped stirring fork, an intermediate support roller, a hollow output rod and a pin shaft; a bias output unit comprises an output rod and a bias output rod. According to the bionic shoulder joint, the bias output rod can move in five degrees of freedom, and the bionic shoulder joint is maximally close to the actual state of a human shoulder joint in terms of structure, movement and function.

Owner:YANSHAN UNIV

Passive low-frequency vibration isolator

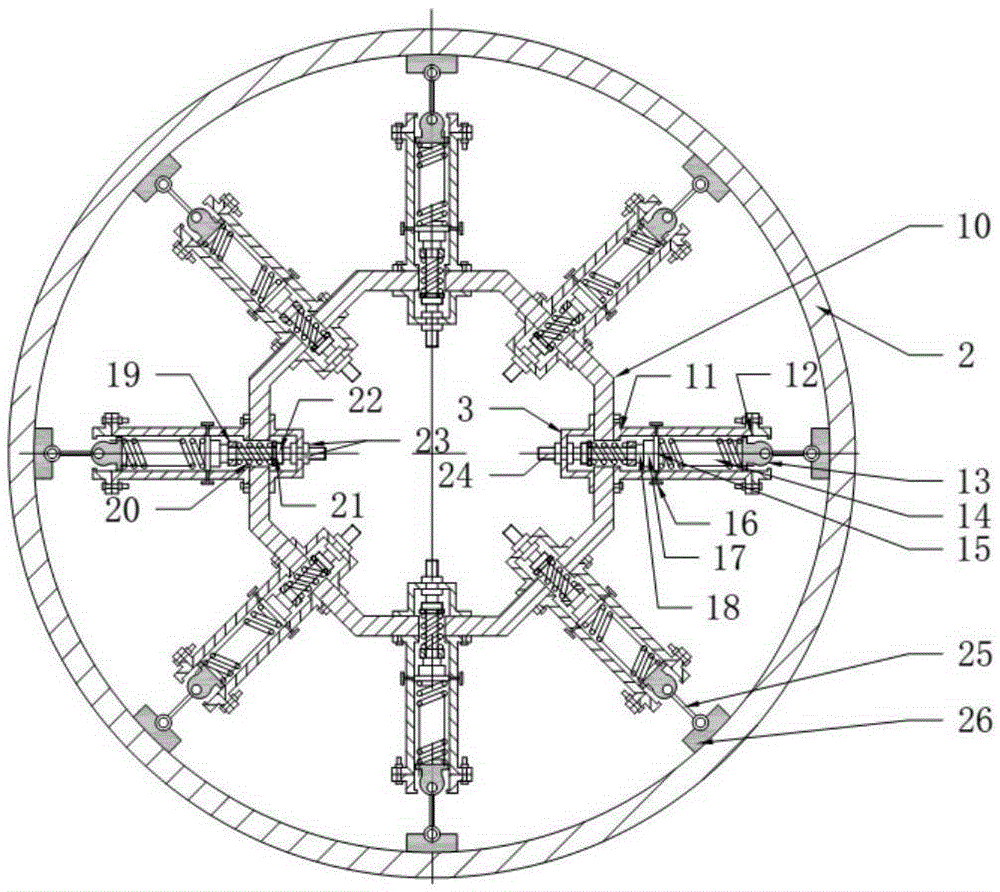

InactiveCN102518741AImprove static stiffnessAchieve low frequency and even ultra-low frequency vibration isolationSpringsNon-rotating vibration suppressionLow frequency vibrationEngineering

The invention relates to a passive low-frequency vibration isolator, which comprises an enclosed cylindrical base, wherein the top of the enclosed cylindrical base is provided with a through hole, and the inner side wall of the enclosed cylindrical base is uniformly provided and movably connected with cylinder bodies of three dampers; a center connecting rod is inserted into the through hole in the base, and the lower end of the center connecting rod is moveably connected with piston rods of the three dampers; the top of the base is uniformly provided with three mounting fixtures; the upper part of the center connecting rod is provided with a hexagonal center clamping piece which is uniformly provided and connected with one ends of three flat springs; the other ends of the three flat springs are connected with the three mounting fixtures respectively; and the top of the center connecting rod is provided with a bearing table. The passive low-frequency vibration isolator has obvious high static stiffness and low dynamic stiffness, reduces initial isolation frequency, can realize low-frequency vibration isolation and ultralow-frequency vibration isolation, has high static bearing capacity and reduces deformation; meanwhile, by optimizing the damping structure, the vibration isolator can automatically adjust damp according to working conditions to achieve effects of inhibiting resonance and resisting impact.

Owner:UNIV OF SCI & TECH OF CHINA

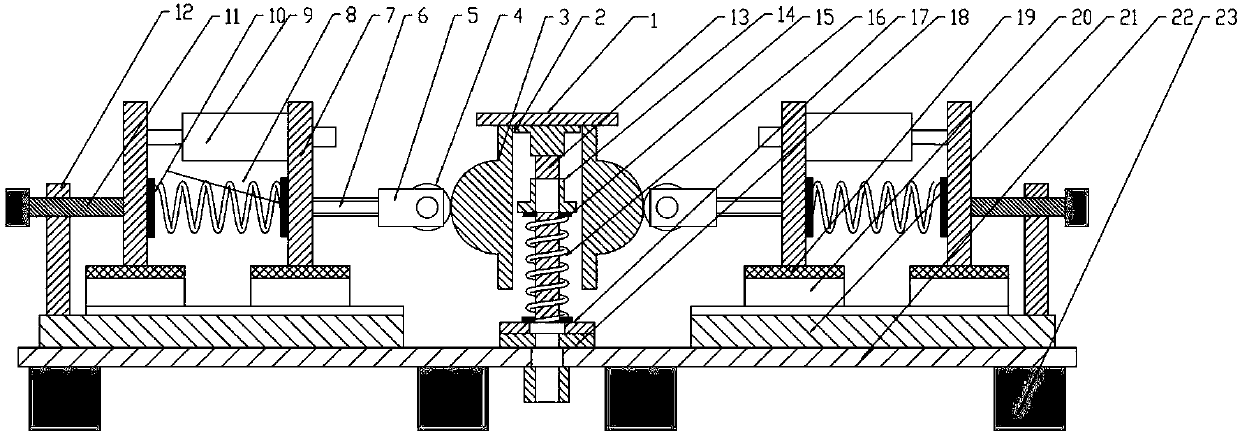

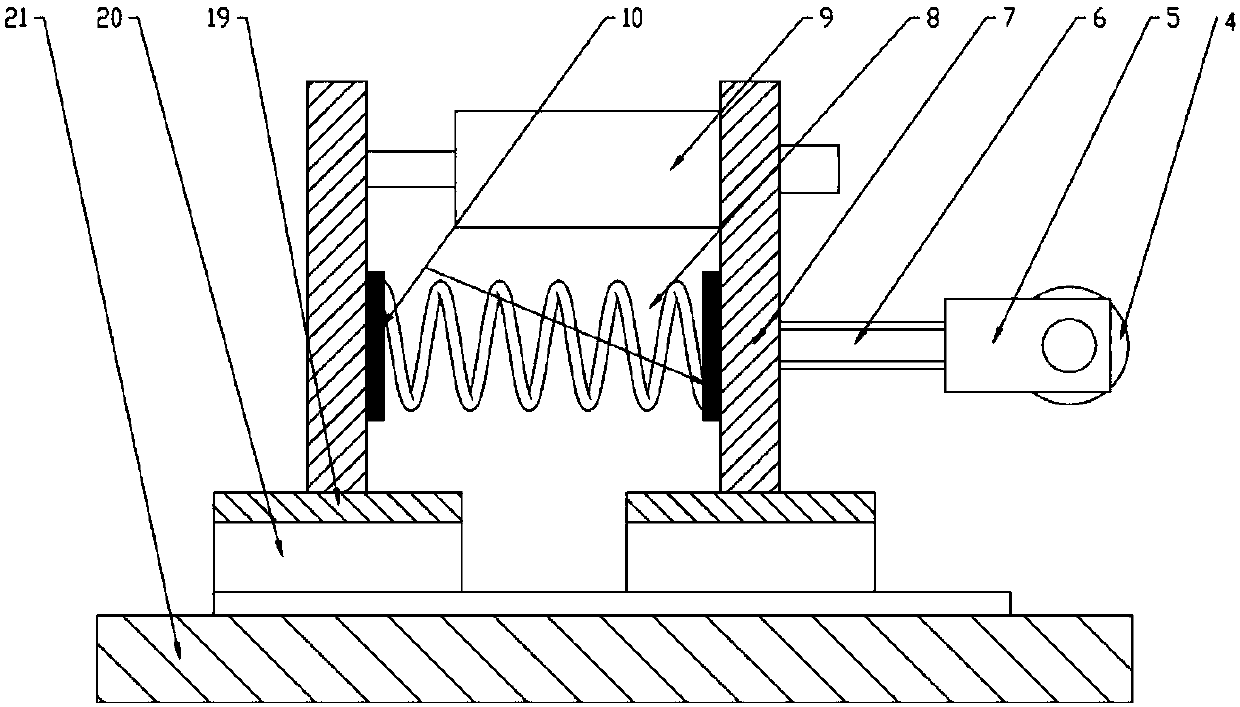

Cam roller negative stiffness structure low-frequency vibration isolator

PendingCN107740843AReduce stiffnessImprove static stiffnessNon-rotating vibration suppressionResonanceEngineering

The invention relates to a cam roller negative stiffness structure low-frequency vibration isolator. According to the low-frequency vibration isolator, a positive and negative stiffness parallel connection principle is adopted, a positive stiffness element and a negative stiffness element are connected in parallel, system resonance is restrained in combination with an added damping device, and protection is provided for drastic situations. A positive stiffness adjustment device and a negative stiffness adjustment device are used for realizing effective and accurate adjustment of the positive stiffness range and negative stiffness range to meet different bearing mass and vibration isolation requirements. The problems that an existing low-frequency vibration isolator is inconvenient to install, complex in structure, poor in work condition adaptability and the like are solved.

Owner:BEIJING MUNICIPAL INST OF LABOUR PROTECTION +1

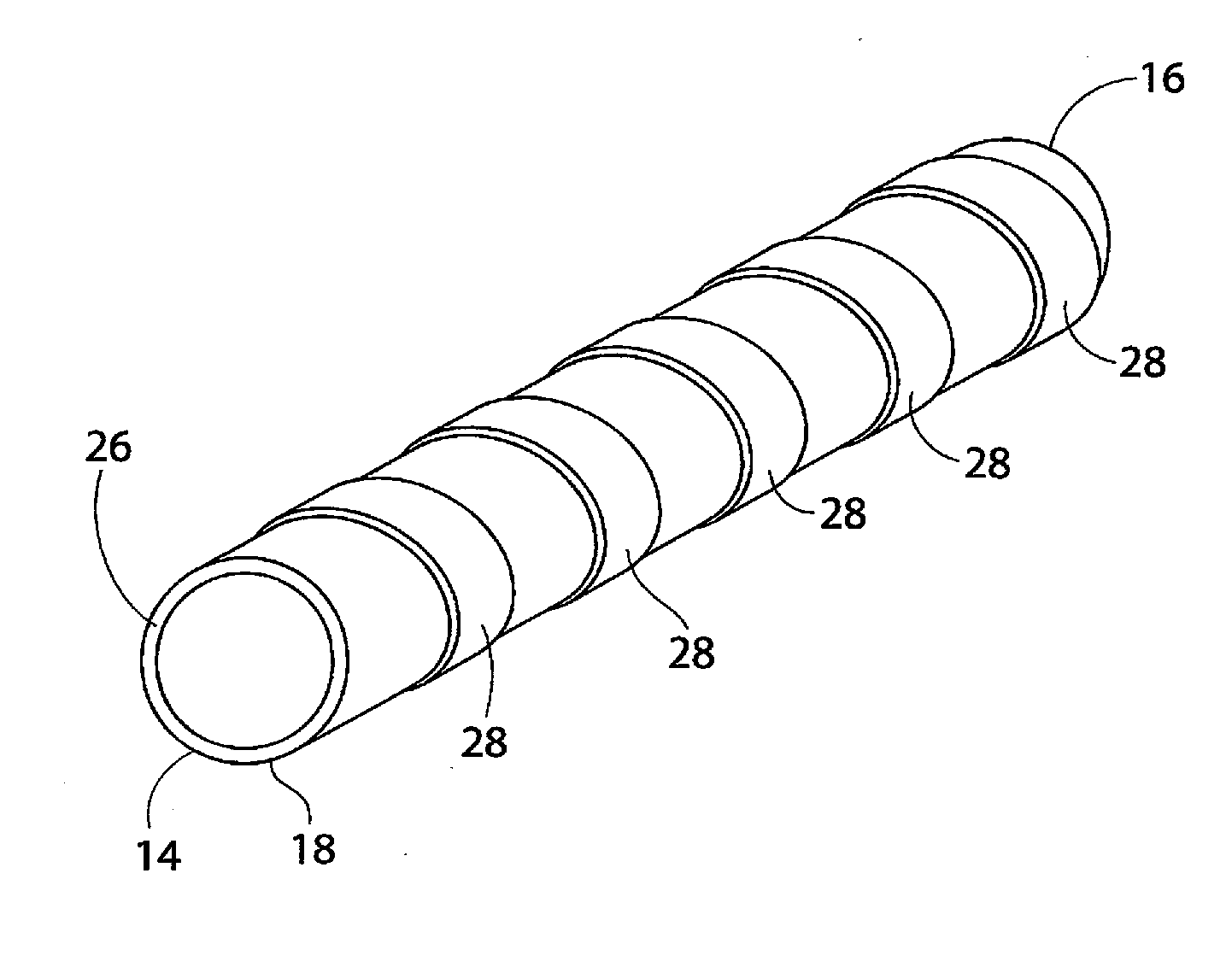

"Boring Bar with Improved Stiffness"

ActiveUS20150258612A1High dynamic stiffnessImprove dynamic stiffnessTransportation and packagingWorkpiecesDistal portionPlasma diffusion

A tunable or tuned boring bar having increased stiffness is provided. Increasing the stiffness of the bar increases the natural frequency, thereby reducing directional deformation of the bar during use. The tunable boring bar includes a distal portion configured to support a tool, a proximal portion configured for attachment to a support structure of a metalworking machine, and a body, which is at least partially tubular, extending between the proximal portion and the distal portion. The tubular portion of the body has an elongated cylindrical cavity. The body of the boring bar includes a core layer formed from a first material and a coating layer formed from a second material. The second material has a higher modulus of elasticity than the first material. In certain configurations, the coating layer is bonded to the core layer by cladding, welding, chemical adhesives, chemical vapor deposition, pulsated plasma diffusion, or combinations thereof.

Owner:KENNAMETAL INC

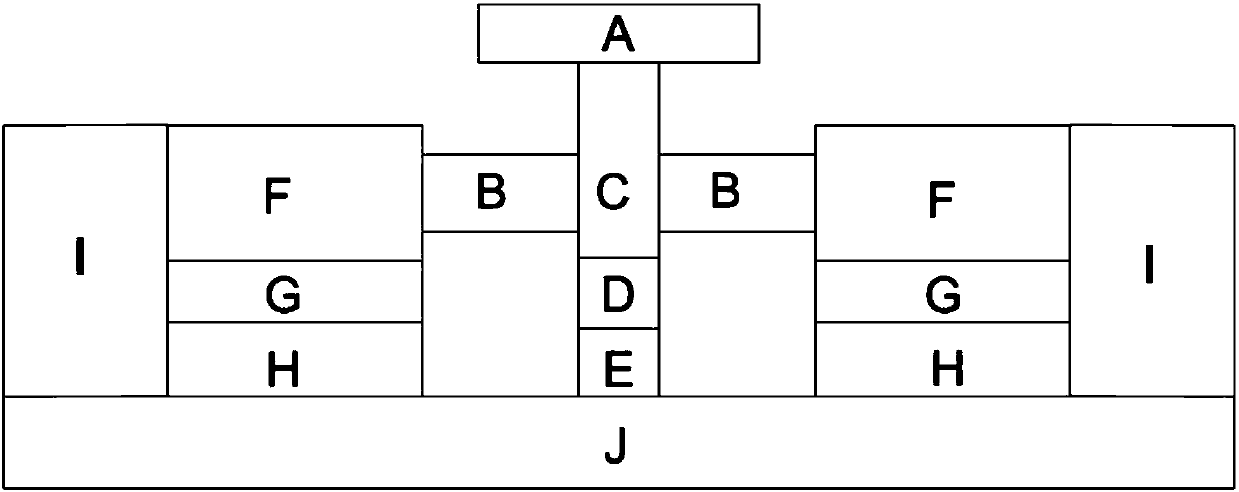

Novel positive/negative rigidity parallel low-frequency vibration isolation mechanism

InactiveCN106763466AThe overall structure is compact and reasonableEasy to install and disassembleNon-rotating vibration suppressionLow frequency vibrationEngineering

The invention discloses a novel positive / negative rigidity parallel low-frequency vibration isolation mechanism. The mechanism comprises a positive-rigidity spring adjusting device, a vertical spring body, a negative-rigidity structure, a negative-rigidity spring adjusting device, a damping structure, a bearing structure, a horizontal spring support column and a base support fixed structure, wherein the positive-rigidity spring adjusting device includes a circular sleeve, an adjusting knob and a pressure sensor 1; the negative-rigidity structure includes a horizontal spring body and a sleeve, horizontal spring slide blocks 1 and 2, a horizontal spring connecting rod and a cylinder side wall hinge device; the negative-rigidity spring adjusting device includes a stud and and an adjusting knob thereof, a stud fixed frame, a pressing spring body, a pressing adjusting nut, and a pressure sensor 2 and a fastening nut thereof; the damping structure includes an adjusting cushion plate, a damper and a connecting plate thereof; the bearing structure includes a bearing table and a cylinder side wall; and the base support fixed structure includes a support plate, a disc base, a support cushion leg, a support column and a linear bearing. The mechanism has such vibration isolation advantages as compact structure and accurate adjustment.

Owner:BEIJING UNIV OF TECH +2

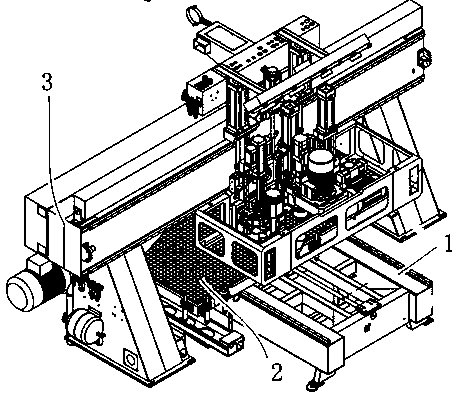

Multifunctional solid wood processing device achieving milling and planing

InactiveCN108237600ARealize multifunctional machining and cuttingRealize automatic indexing functionMulti-purpose machinesNumerical controlSolid wood

The invention discloses a multifunctional solid wood processing device achieving milling and planning, and relates to the field of wood working machine tools. The multifunctional solid wood processingdevice comprises a base, wherein a working table and a beam frame are fixedly arranged on the base, a sliding plate which freely slides in the beam frame direction is arranged on the beam frame, andan engraving milling module, a vertical-axis milling module and a rotary horizontal milling module are fixedly arranged on the sliding plate. The multifunctional solid wood processing device has the technical effects that the device is not only suitable for solid wood processing, an integrated device of integrating a numerical control engraving milling machine, a numerical control vertical millingmachine, a numerical control planing side milling machine and a numerical control circular saw is provided, and automatic tool changing can be achieved.

Owner:LAIZHOU JINHONG CNC EQUIP CO LTD

Ultralow-frequency hydraulic-pressure vibration isolation device based on shape memory alloy spring

ActiveCN105065560AIsolation of low frequency vibrationIsolation of ultra-low frequency vibrationSpringsShock absorbersPistonPre treatment

The present invention discloses an ultralow-frequency hydraulic-pressure vibration isolation device based on shape memory alloy springs. The vibration isolation device is mainly composed of a fuel tank, a rubber holder, mobile side plates, a piston, a piston rod, an installation table board, a guide sleeve, common springs, the shape memory alloy springs, a seal ring and the like. According to the ultralow-frequency hydraulic-pressure vibration isolation device provided by the present invention, the shape memory alloy springs serve as elastic elements, and through pre-treatment of a shape memory alloy, the shape memory alloy springs can work within a hyperelastic working range. Within the hyperelastic working range, large deformations of the shape memory alloy springs only cause slight restoring forces, and thus the shape memory alloy springs can obtain an ultralow dynamic stiffness. With arrangement of a differential-type hydraulic device using the shape memory alloy springs as the elastic elements, ultralow-frequency vibrations can be effectively isolated.

Owner:ZHEJIANG UNIV

Quasi-zero rigidity inertia actuator

ActiveCN106594169AHigh static low dynamic stiffnessLower natural frequencyNon-rotating vibration suppressionDynamic stiffnessPower flow

The invention discloses a quasi-zero rigidity inertia actuator which comprises a shell, a movable component and a driving component. The movable component is provided with a first supporting component and second supporting components, the first supporting component elastically supports the movable component in the vertical direction, the movable component transmits force to a base through the first supporting component, and the driving component transmits force to the base; and the at least two second supporting components are elastically connected with the movable component in the horizontal direction and are evenly arranged in the circumferential direction of the movable component, the first supporting component is in a static compression state or dynamic compression and stretching alternative state in the vertical direction, and the second supporting components are in a static compression state or dynamic compression state in the horizontal direction. The first supporting component forms a high-static low-dynamic rigidity supporting assembly, the inherent frequency of an assembly formed by the movable component, the first supporting component and the second supporting components can be reduced, the frequency can be close to zero frequency in the ideal state, and the low-frequency even ultra-low-frequency output of the actuator can be increased under the condition that the size and the input current are not increased.

Owner:苏州东菱智能减振降噪技术有限公司

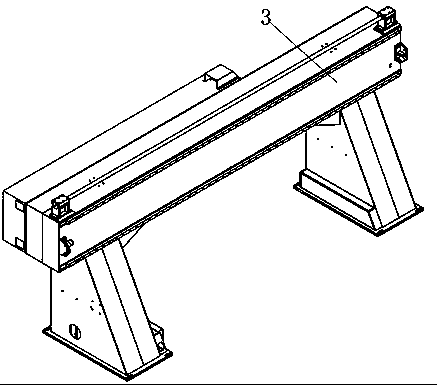

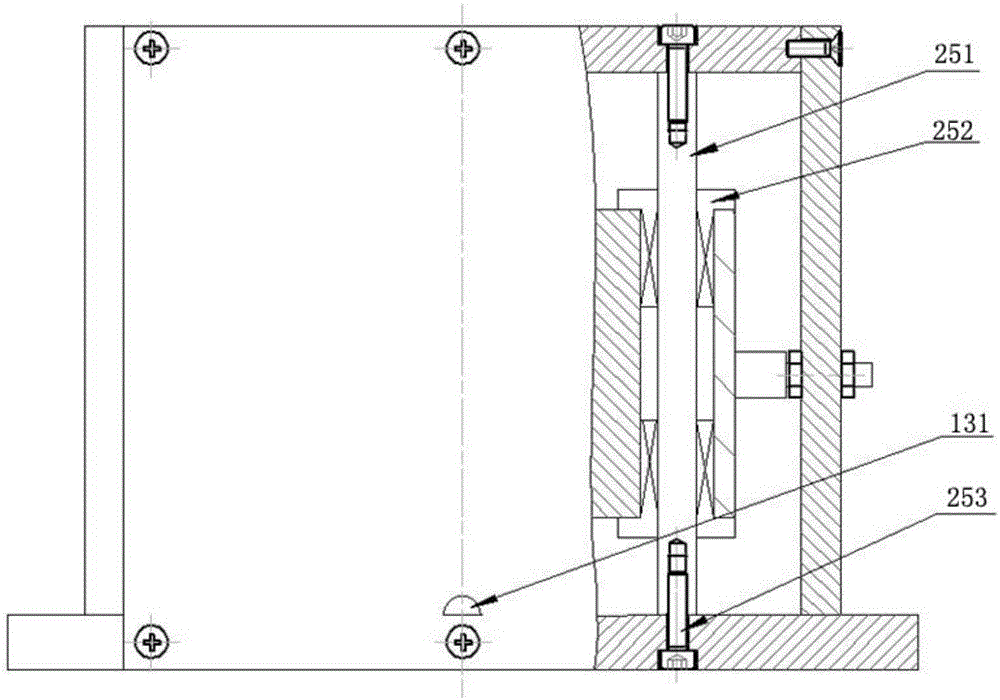

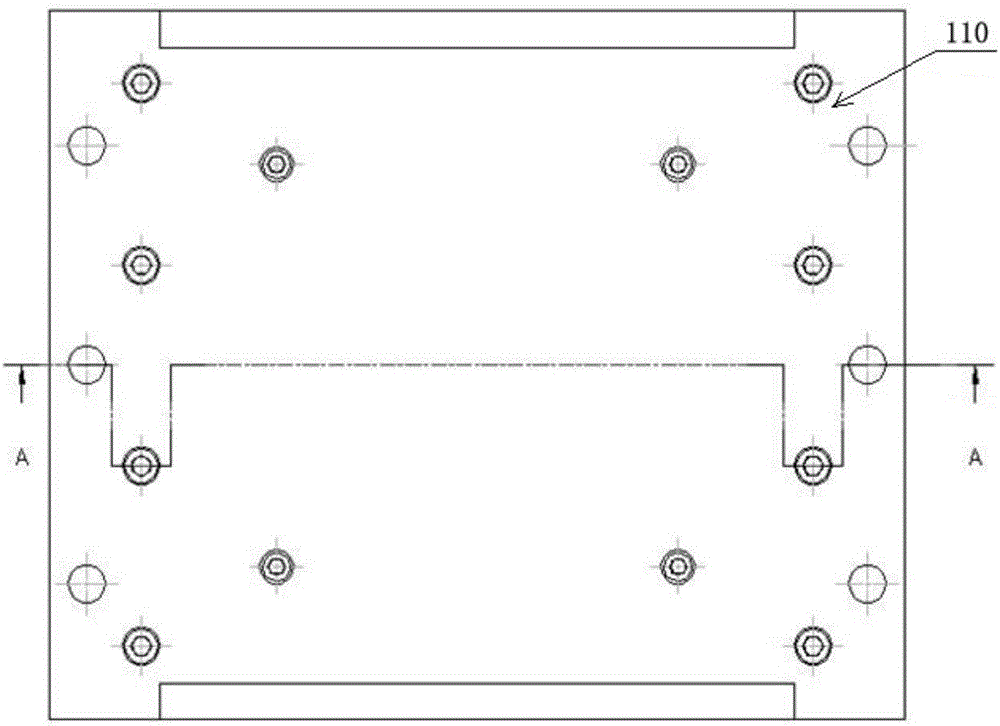

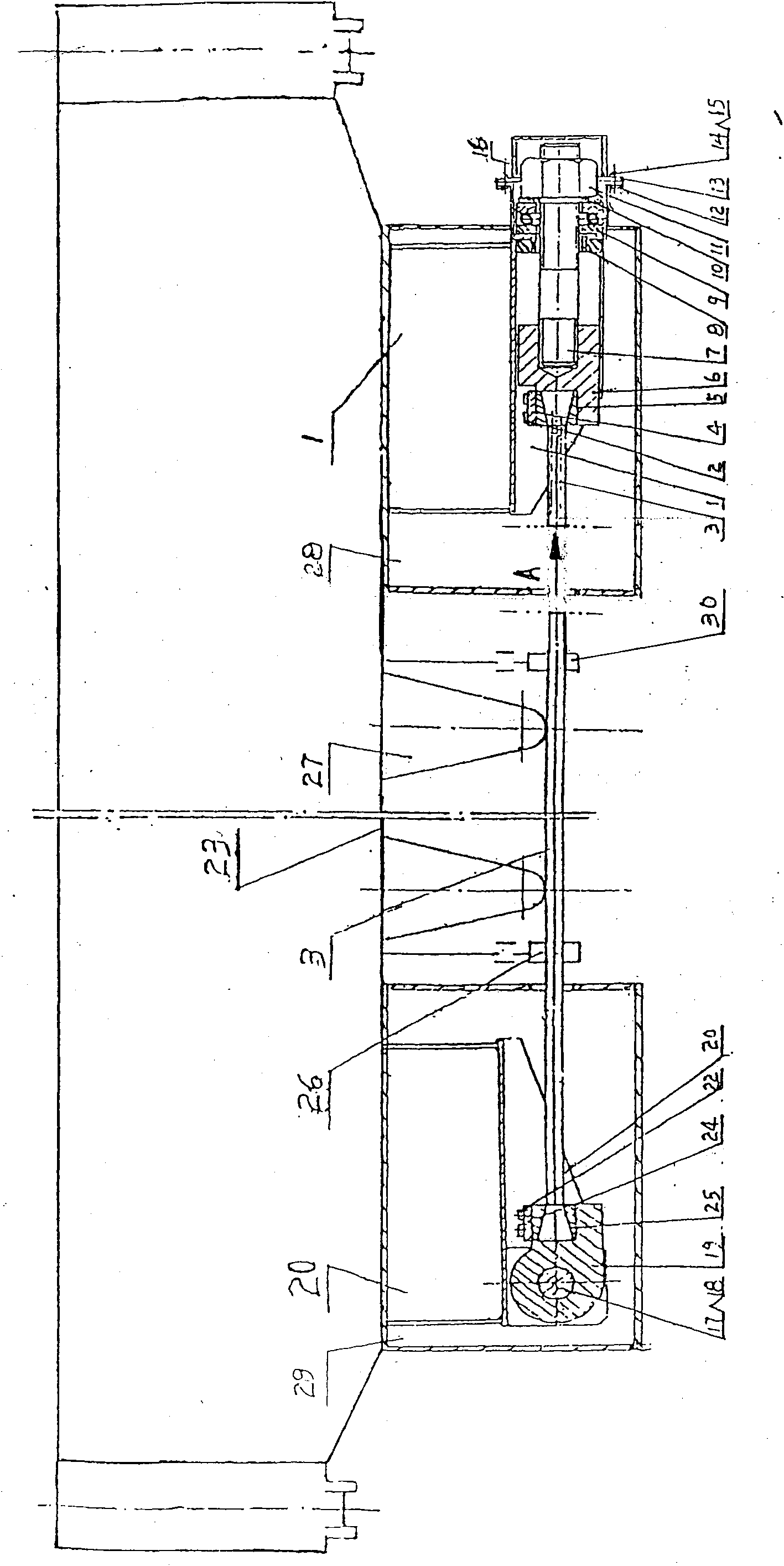

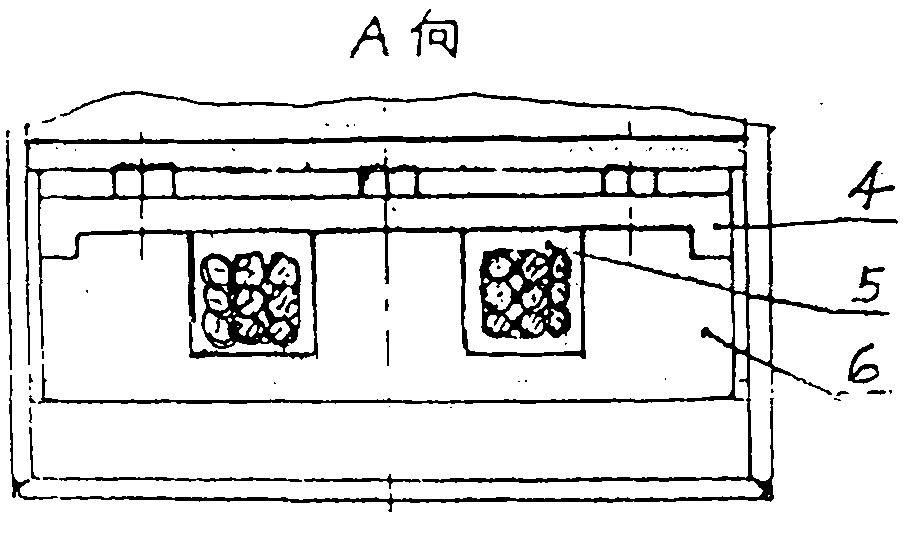

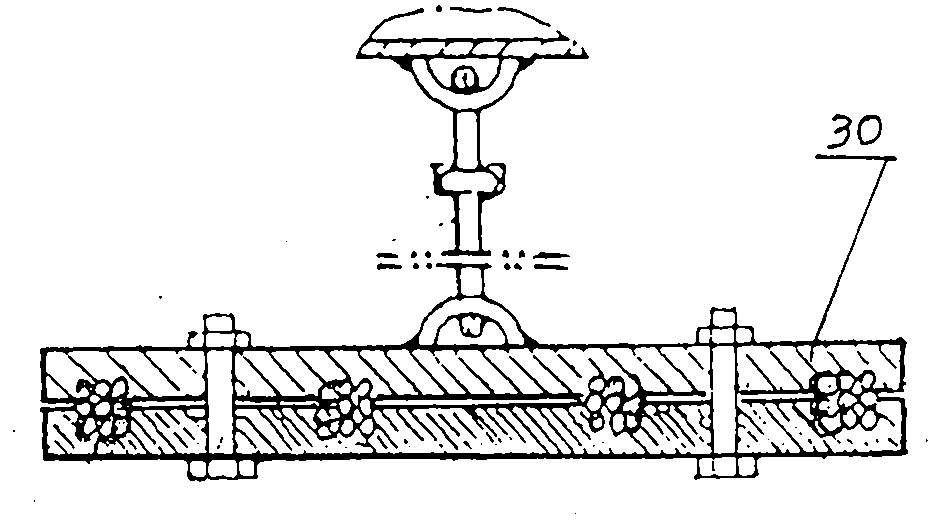

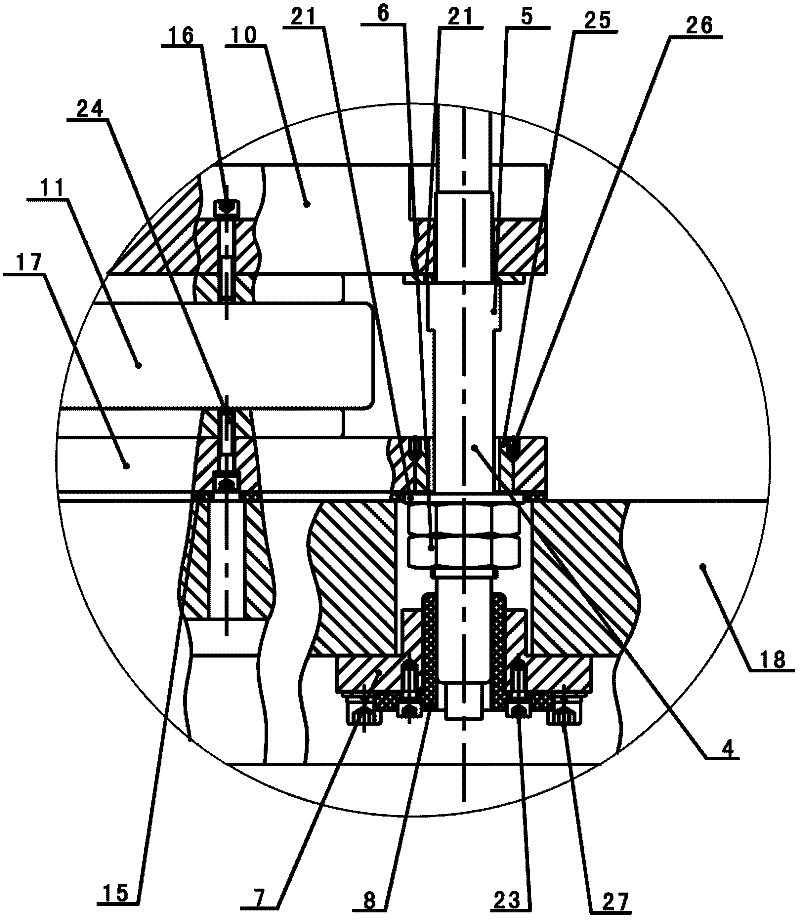

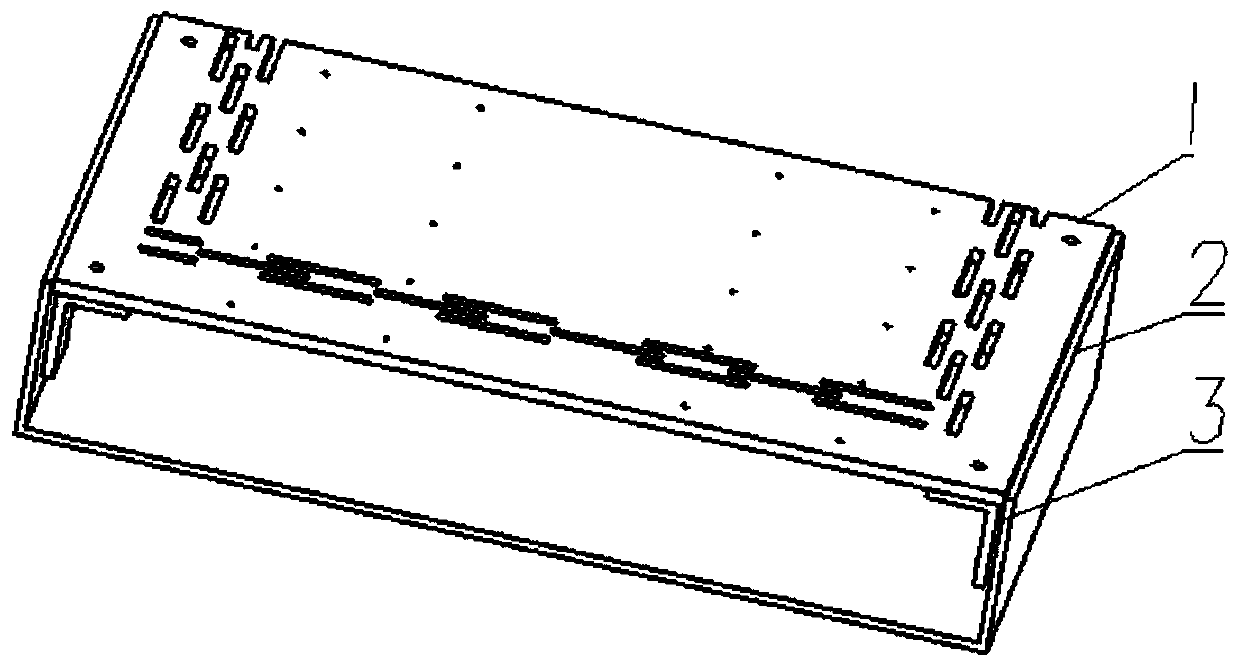

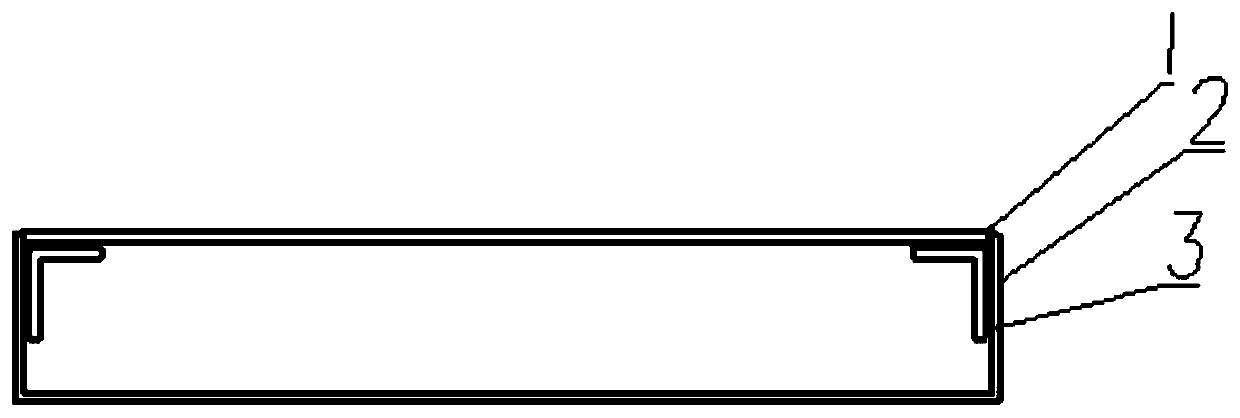

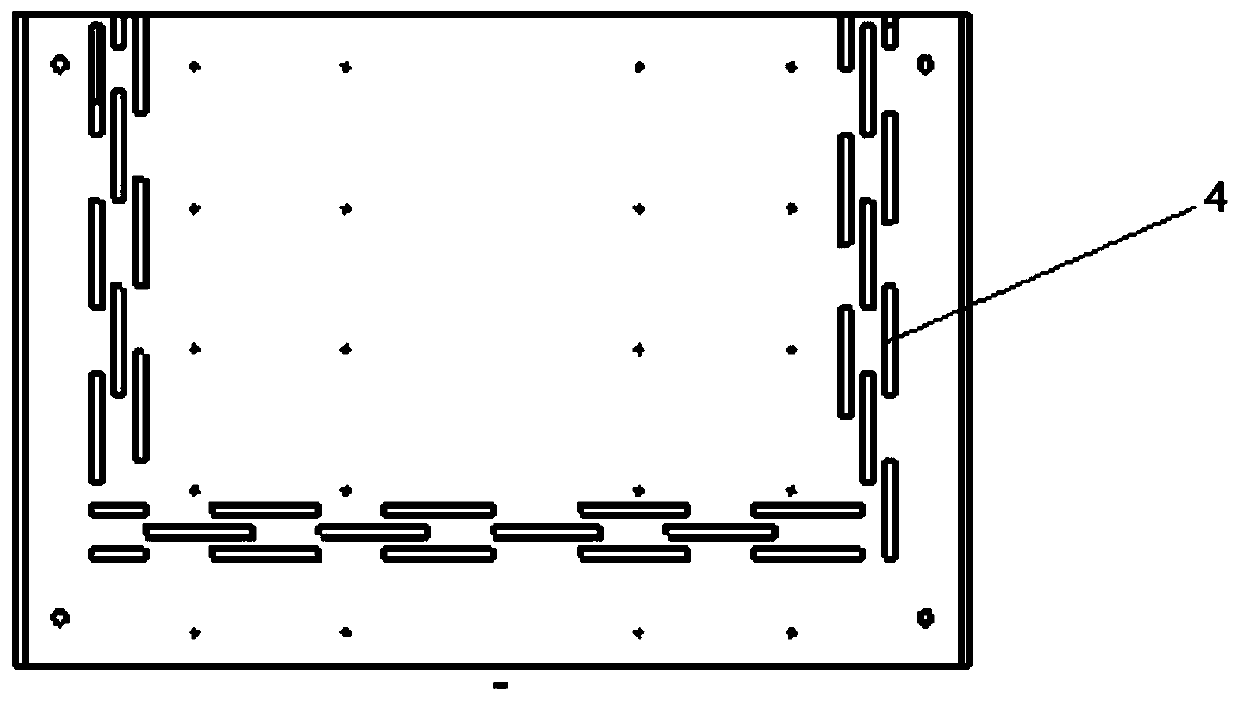

Manufacturing process of girder of overhead or gantry crane

The invention discloses a manufacturing process of a girder of an overhead or gantry crane, a threaded pull rod 7 in a box body 1 of a tensioning device is connected with a connecting seat 6, and the manufacturing process is characterized in that two wedge-shaped grooves are formed on the connecting seat 6, two rope head casting ports 5 with wedge-shaped outer shapes and square cone-shaped inner cavities are mounted in the grooves, two wedge-shaped grooves are formed on a fixed hinge 19 at the other end of a steel wire rope 3, and the rope head casting ports 25 with the wedge-shaped outer shapes and the square cone-shaped inner cavities are mounted in the grooves. The manufacturing process adopts the two groups for tensioning, the two groups are mounted on the same girder, and the ultimate tensioning force is great, thereby being applicable to manufacturing the girders of the cranes with the hoisting capacity of below 400 tons. The manufacturing process has the advantages of easy manufacturing, low cost and convenient construction, and is particularly applicable to manufacturing the gantry cranes with the span of above 60m in ports and the shipbuilding industry. The arch difference of the girder of the crane manufactured by adopting the invention can be controlled within 0-1mm, which is better than the international standard; furthermore, the manufacturing process can increase the cutting area of the girder structure, improve the strength, the static stiffness and the hoisting capacity of the girder, save steel, reduce the cost by 15-20%, be in line with the policies of energy conservation and emission reduction and prolong the service life of equipment.

Owner:傅萍 +2

Series-parallel type five-freedom-degree bionic shoulder joint linked with shoulder blade

Disclosed is a series-parallel type five-freedom-degree bionic shoulder joint linked with a shoulder blade. An S-shaped connecting rod in an RPRS+U two-freedom-degree series mechanism of the shoulder joint is connected with a bionic rack and an intermediate movable platform. An output shaft in an RPRS movement branch chain is connected with the bionic rack and a linear guide rail, a driving sliding block is arranged on a lead screw of the linear guide rail and is connected with a driven rod, and the driven rod is connected with the intermediate movable platform. Three rotary branch chains of the same structure in a 3-RRR three-freedom-degree spherical parallel mechanism are connected with the intermediate movable platform and a tail-end movable platform. A spherical hinge with the large work space is connected with the intermediate movable platform and a bias output unit. The bias output unit comprises a supporting rod, a double-lug support, a ball head, a movable ball socket, an output rod, rotary supports, supporting pin shafts, a supporting roller, U-shaped shifting forks and a pin shaft. The bias output unit is a bias output rod. By the adoption of the bionic shoulder joint, five-freedom-degree movement of the bias output rod can be achieved, and the state of the bionic shoulder joint is close to the actual state of the human body shoulder joint to the maximum degree in the aspects of the structure, the movement and functions.

Owner:YANSHAN UNIV

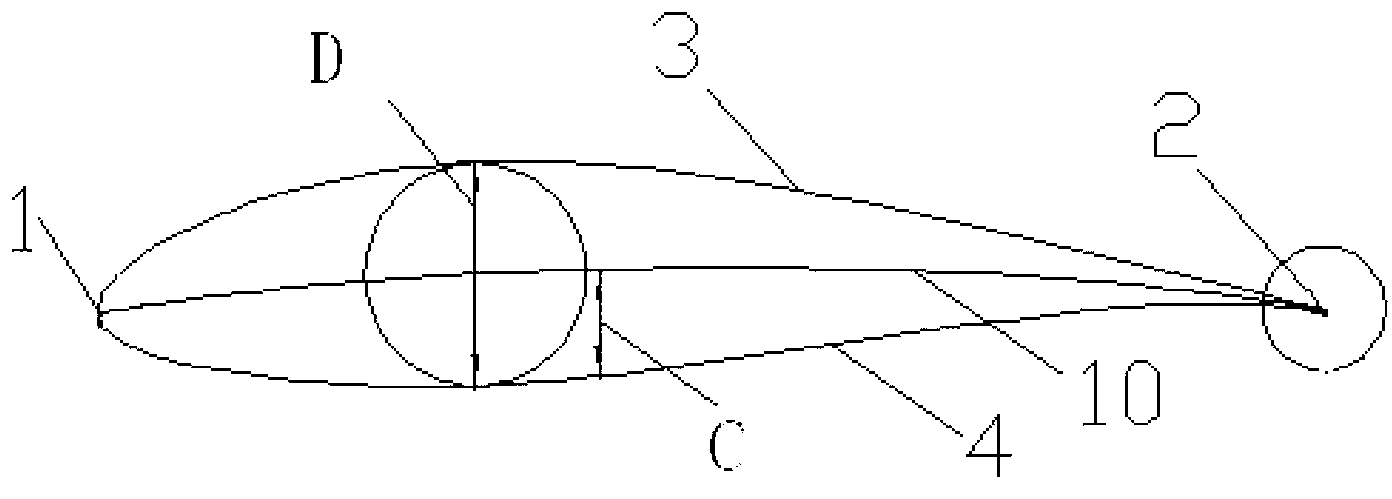

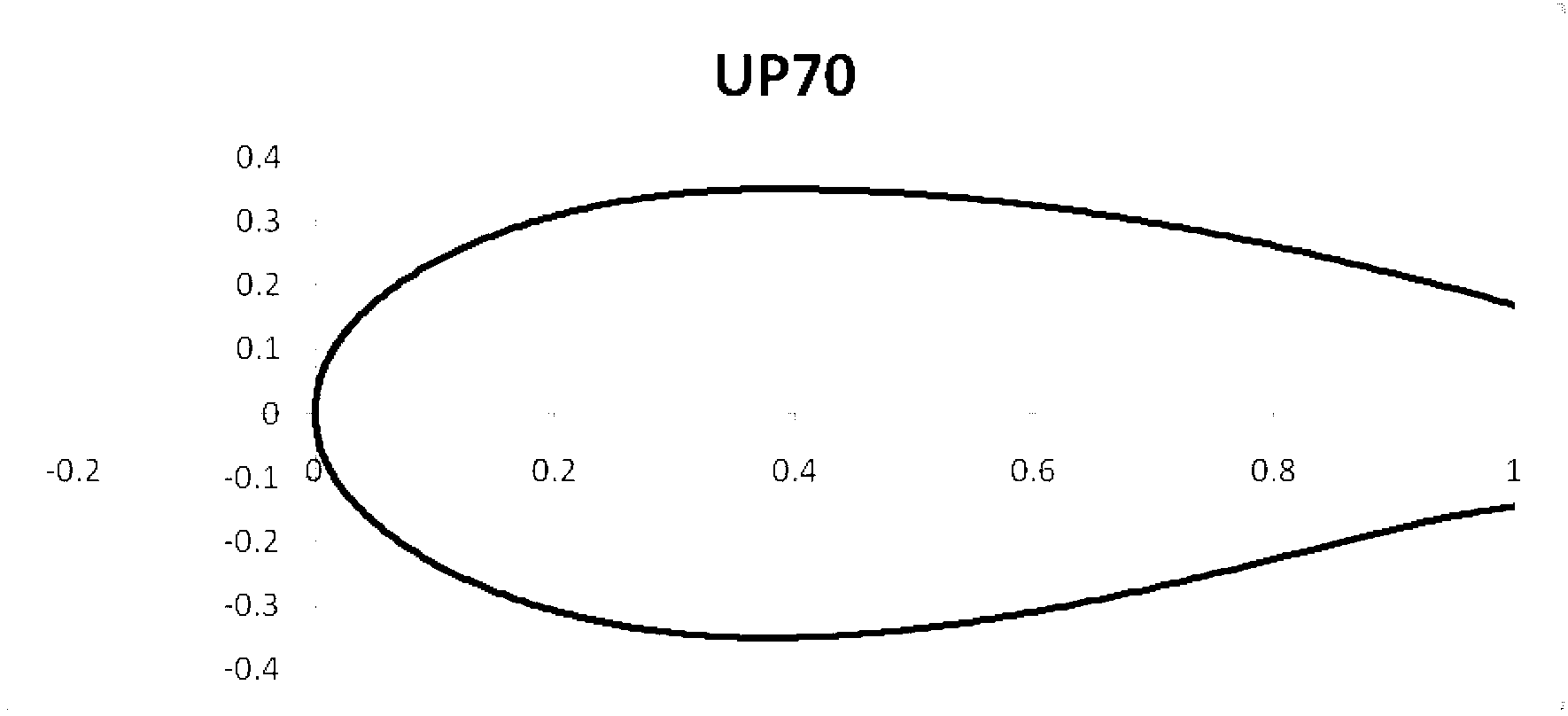

Large-thickness blunt-trailing-edge airfoil-shaped blade of large-scale wind turbine

ActiveCN103321857ASolve Thickness ProblemsImprove static stiffnessFinal product manufactureWind motor componentsLeading edgeTrailing edge

The invention relates to a large-thickness blunt-trailing-edge airfoil-shaped blade of a large-scale wind turbine. The outer contour of the cross section of a root portion of the blade is divided into a leading edge, a trailing edge, a suction-surface molded line and a pressure-surface molded line. The distance between the leading edge and the trailing edge is chord length, the maximum thickness of the cross section is 65.0%-75.0% of the chord length, and the distance between the thickest position and the leading edge is 25%-35% of the chord length. The maximum camber of the cross section is 0.1%-0.5% of the chord length, the distance between the maximum camber position and the leading edge is 85%-97% of the chord length, the radius of the leading edge is 35.0%-45.0% of the chord length, and the end-face thickness of the trailing edge is 25%-35% of the chord length. The airfoil shape is a precedent in domestic airfoil shapes, with relative thickness of over 40%, special for wind turbines; by the airfoil shape, static rigidity of the blade can be improved and structural weight can be reduced, and an important technical basis is provided to development of large-size efficient wind turbines with low costs.

Owner:国能联合动力技术(保定)有限公司

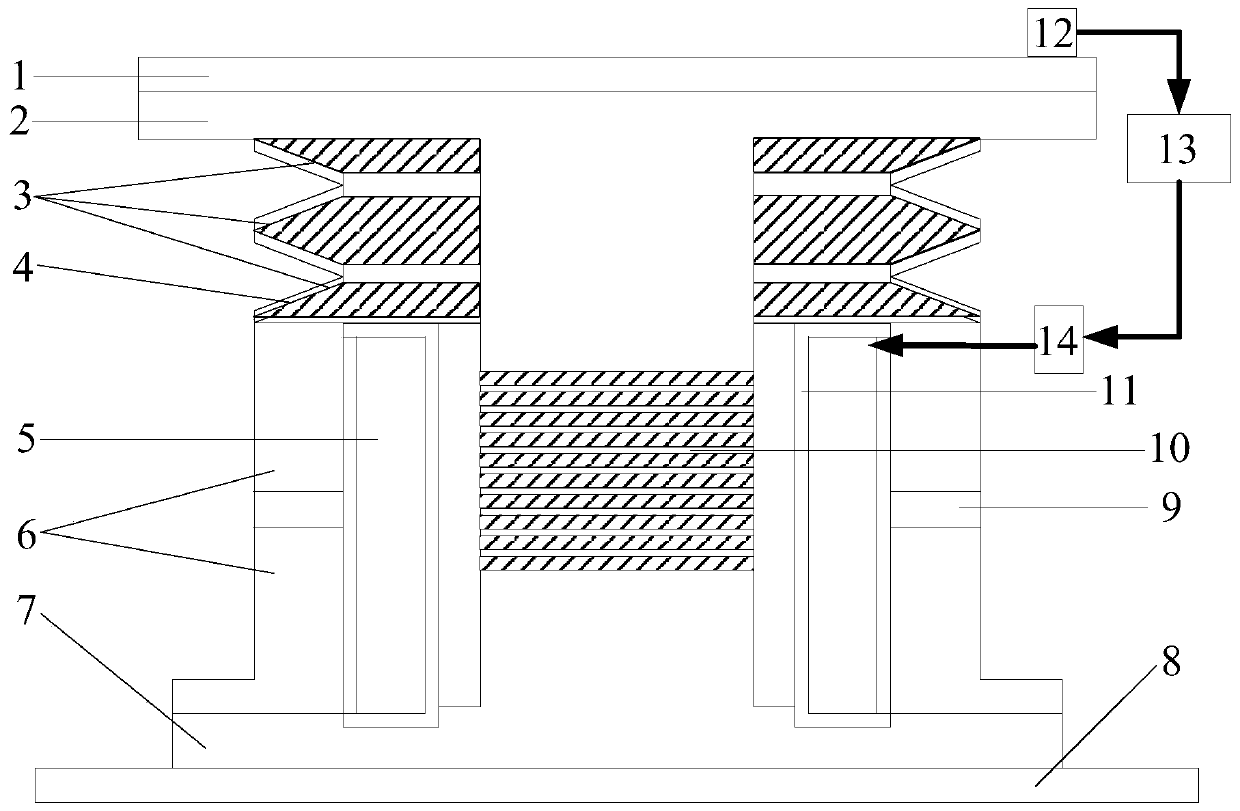

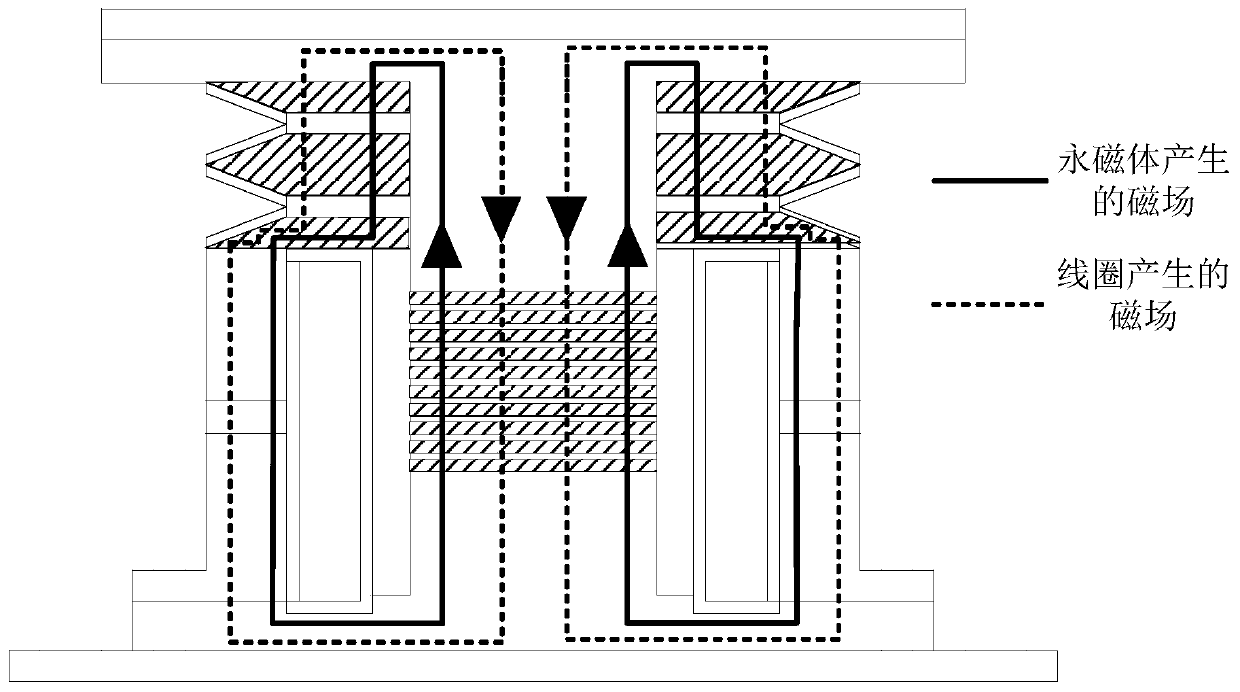

Composite structure magnetorheological elastomer negative rigidity shock isolator

ActiveCN109972667AReduce problems caused by heatReduce lossProtective foundationElastomerClassical mechanics

The invention discloses a composite structure magnetorheological elastomer negative rigidity shock isolator which comprises an upper connecting plate, an upper cover plate, an annular magnetorheological elastomer, a butterfly spring, a coil, a first sleeve, a lower connecting plate, a lower bottom plate, a permanent magnet, a laminated magnetorheological elastomer, a second sleeve, an accelerationsensor, a DSP controller and a current driver. Under normal conditions, the permanent magnet provides a strong magnetic field to ensure that the magnetorheological elastomers have large initial rigidity, that is, to ensure that a system has high static rigidity, and the stability of the structure is increased, while the butterfly spring, the annular magnetorheological elastomer and the laminatedmagnetorheological elastomer provide high bearing capacity; when an earthquake occurs, the acceleration sensor transmits a vibration signal to the DSP controller, and the DSP controller controls the current driver to supply power to the coil which provides a reverse magnetic field, the rigidity of the magnetorheological elastomers is reduced so as to reduce the rigidity of the system to enable thesystem to provide larger horizontal displacement and change the natural frequency to achieve the purpose of vibration reduction and shoke isolation.

Owner:NANJING UNIV OF SCI & TECH

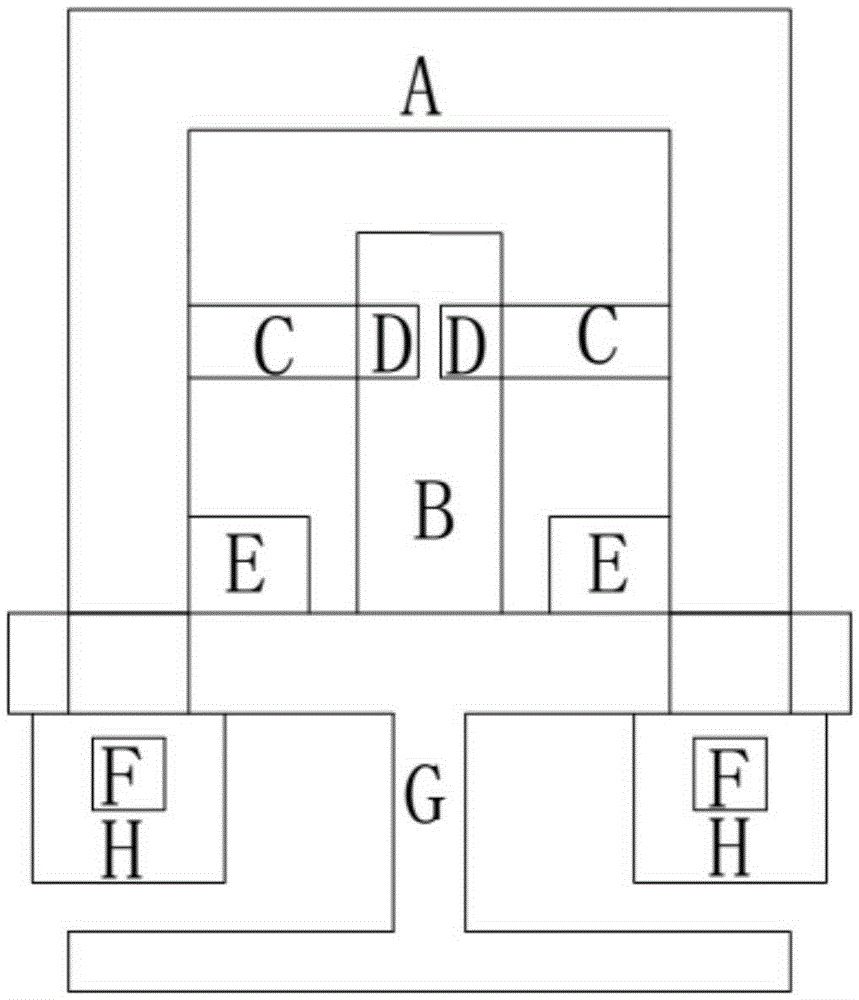

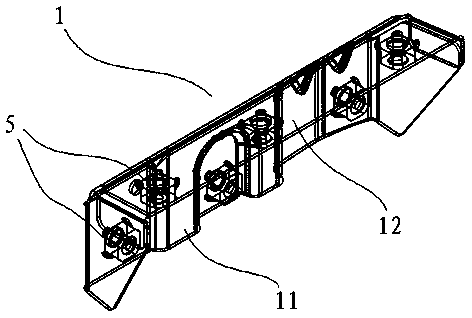

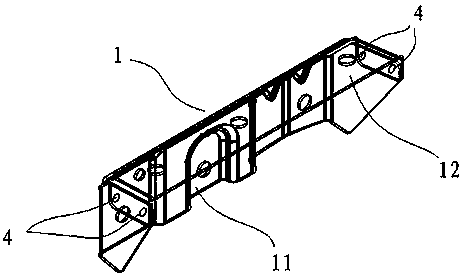

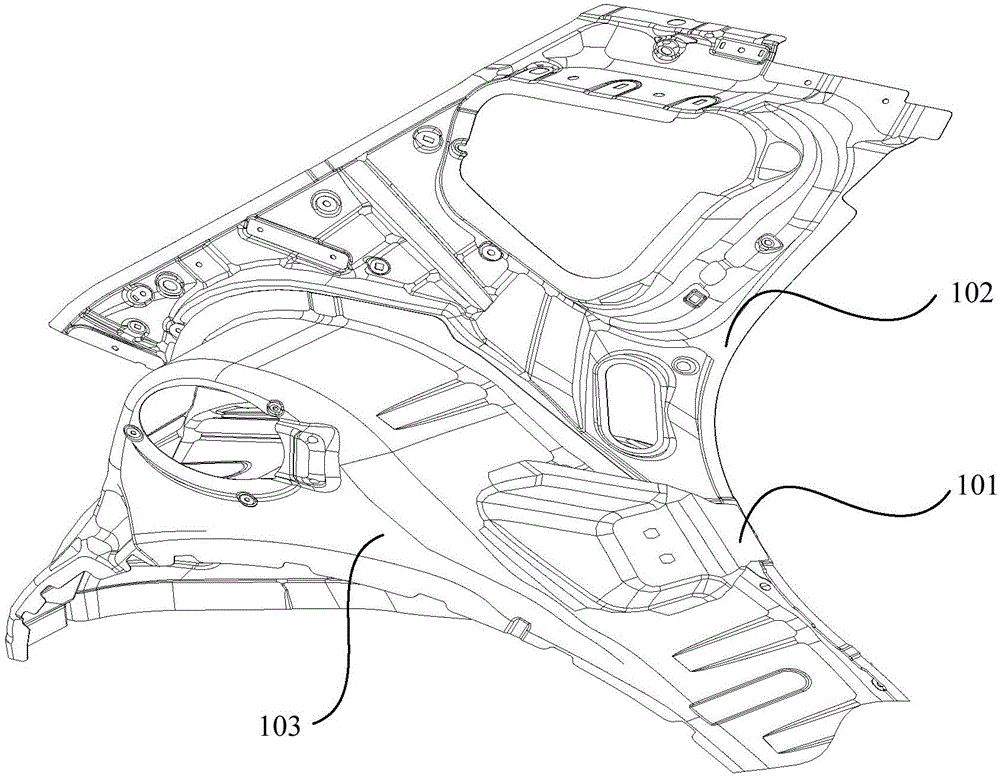

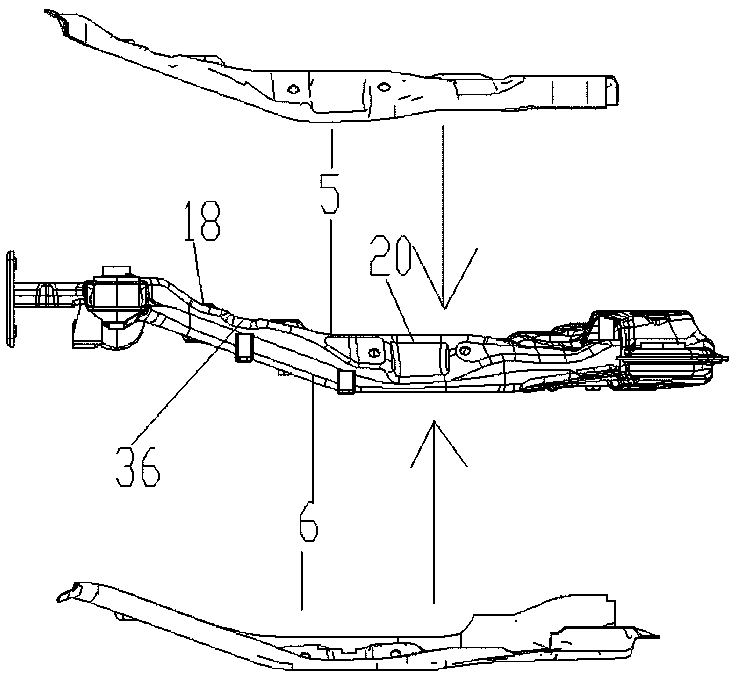

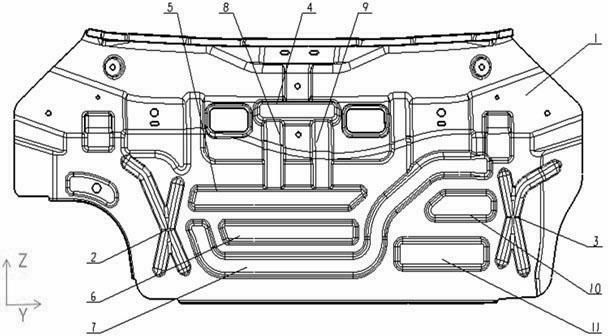

Reinforcing structure of suspension installation points for automobile

ActiveCN103738152AFirmly connectedReduce in quantityJet propulsion mountingInternal combustion mountingDynamic stiffnessResonance

The invention provides a reinforcing structure of suspension installation points for an automobile. On the premise of ensuring the installation intensity and stiffness, the achievement difficulty of the process is lowered, and the platform requirement is met. The reinforcing structure of the suspension installation points for the automobile comprises a reinforcing board of a front longitudinal beam inner board body, a suspension supporting board and the front longitudinal beam inner board body, wherein the reinforcing board of the front longitudinal beam inner board body and the suspension supporting board are welded to be a suspension reinforcing board subassembly, the suspension reinforcing board subassembly is provided with at least three full-closed or semi-closed box-shaped units; each box-shaped unit is provided with the installation points; the suspension reinforcing board subassembly and the front longitudinal beam inner board body are welded and fixed. As the box-shaped units are formed inside the structure and the multiple suspension installation points can be provided at the same time, the platform design requirement of a front longitudinal beam is met, the dynamic stiffness and the static stiffness of the suspension installation points are improved, resonance between the suspension installation points and the vibration frequency of an engine is avoided effectively, and the durability and the NVH performance of the installation points are improved; compared with the prior art, the reinforcing structure has the advantages that the number of parts is reduced, and the process is easy to implement.

Owner:CHERY COMML VEHICLE ANHUI

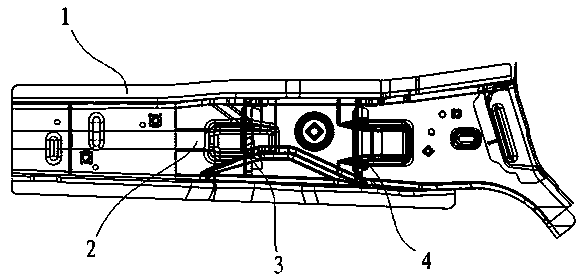

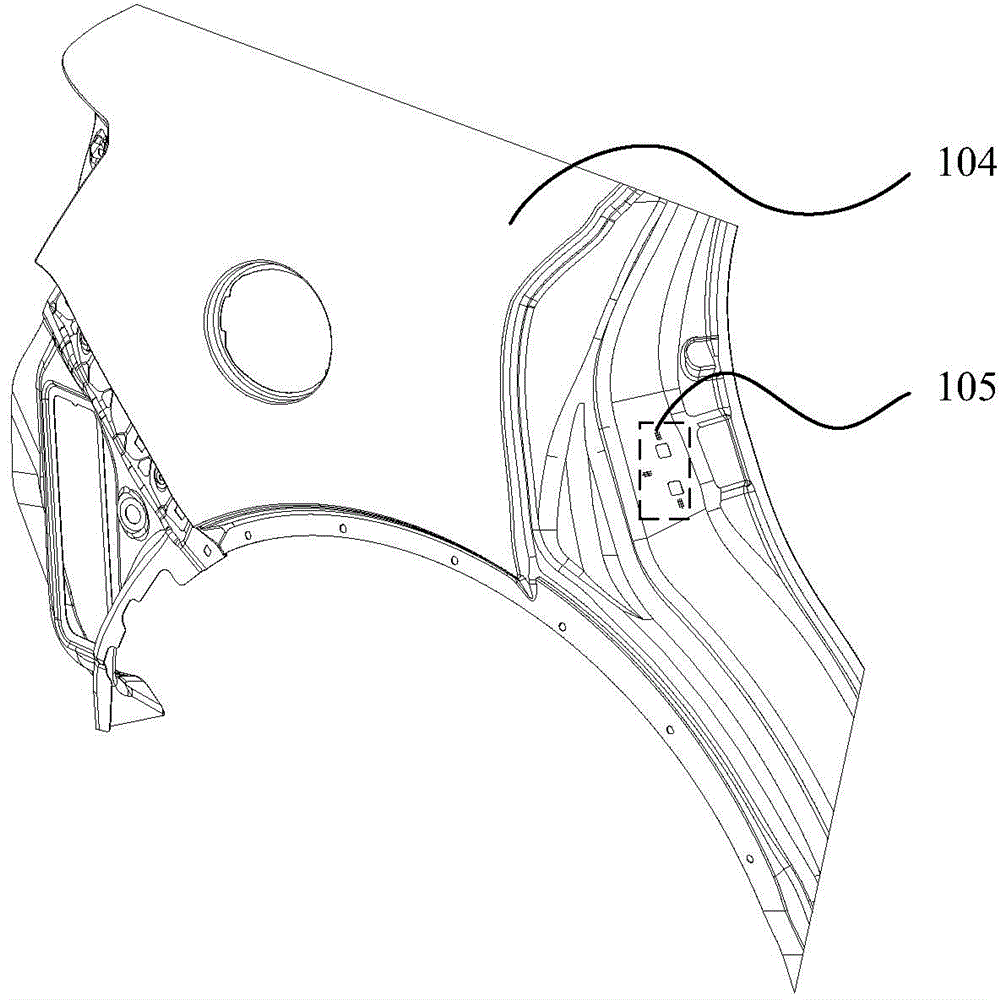

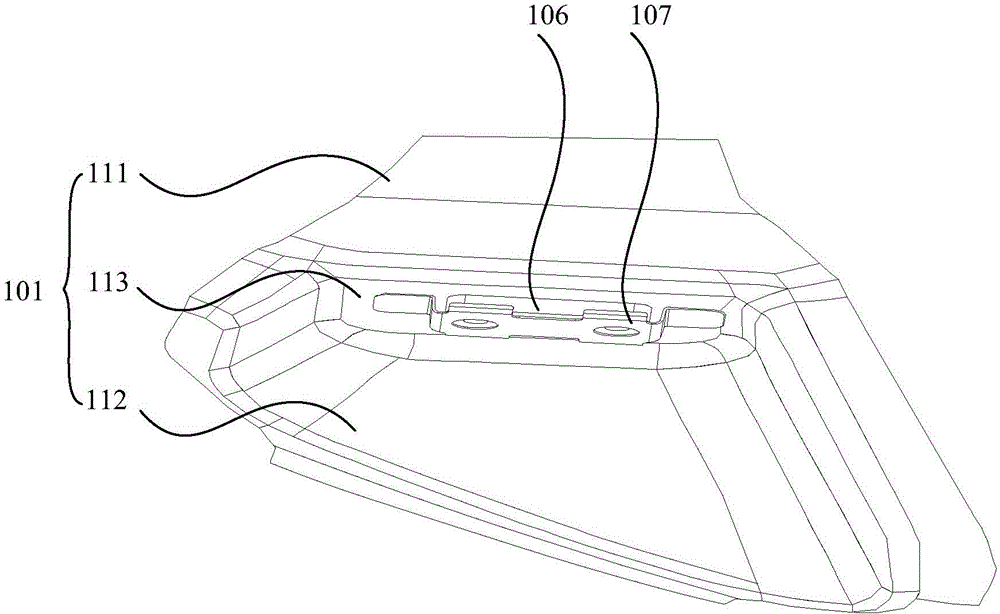

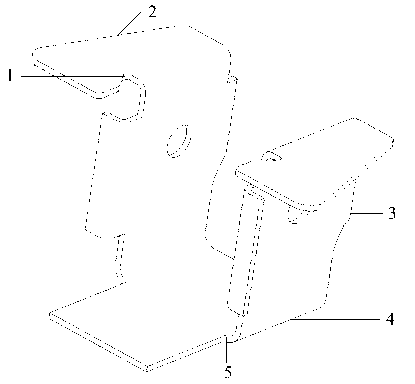

Latch component, locking mechanism and vehicle

InactiveCN104405223AImprove static stiffnessImprove dynamic stiffnessVehicle locksDynamic stiffnessLocking mechanism

The invention provides a latch component, a locking mechanism and a vehicle, and relates to the technical field of vehicle manufacturing. The latch component comprises a reinforcement plate fixedly mounted in a set area of a vehicle body, and a latch arranged in an area, opposite to the reinforcement plate, of the vehicle body and fixedly connected with the reinforcement plate through at least two bolts, wherein the reinforcement plate is positioned at the inner side of the vehicle body; and the latch is positioned at the outer side of the vehicle body. The latch component, provided by the invention, can improve static stiffness and dynamic stiffness of the connected area of the vehicle body and the latch, so that high-frequency components in door closing sound generated in the closing of a vehicle door are decreased, low-frequency components are increased, the door closing sound is deep, and the quality of the door closing sound is improved. The locking mechanism comprises the latch component provided by the invention; and the vehicle comprises the locking mechanism provided by the invention.

Owner:GREAT WALL MOTOR CO LTD

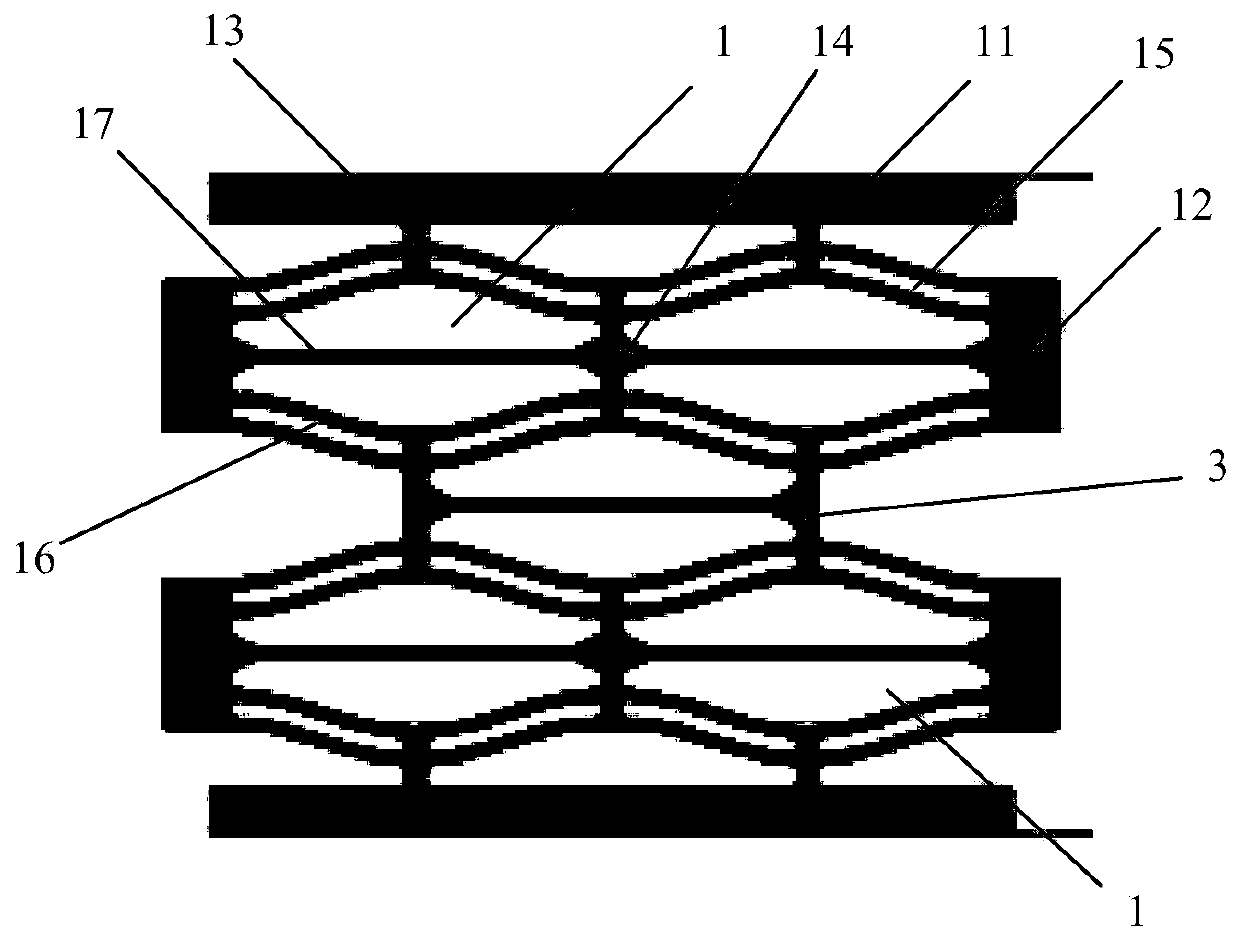

Repulsive force type magnetic force negative stiffness honeycomb structure

ActiveCN110985581AImprove static stiffnessReduce dynamic stiffnessShock absorbersMagnetic tension forceStructural engineering

The invention provides a repulsive force type magnetic force negative stiffness honeycomb structure. The structure comprises an upper structure and a lower structure, the upper structure and the lowerstructure are in a mirror image, magnetisms of magnets of the upper structure and the lower structure are arranged in the opposite direction, the upper structure and the lower structure are connectedthrough a support, the upper structure is formed by multiple single-cell structures which are connected, and each single-cell structure comprises a wall plate, joints, a first transmission rod, a second transmission rod, a first bending beam, a second bending beam and a permanent magnet plate. The wall plates are connected with the first bending beams through the first transmission rods, the first bending beams and the second bending beams are arranged in a mirror image, the joints are arranged at the two ends of the first bending beams and the two ends of the second bending beams, the secondtransmission rod is arranged at the shortest distance position of each first bending beam and the corresponding second bending beam, and the permanent magnet plates are arranged on the connecting lines of the vertical middle positions of the second transmission rods and the joints. Through positive and negative stiffness combination, high static stiffness and low dynamic stiffness can be obtained, the vibration isolation interval can be expanded, and the contradiction between the static displacement and the vibration isolation effect can be solved.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

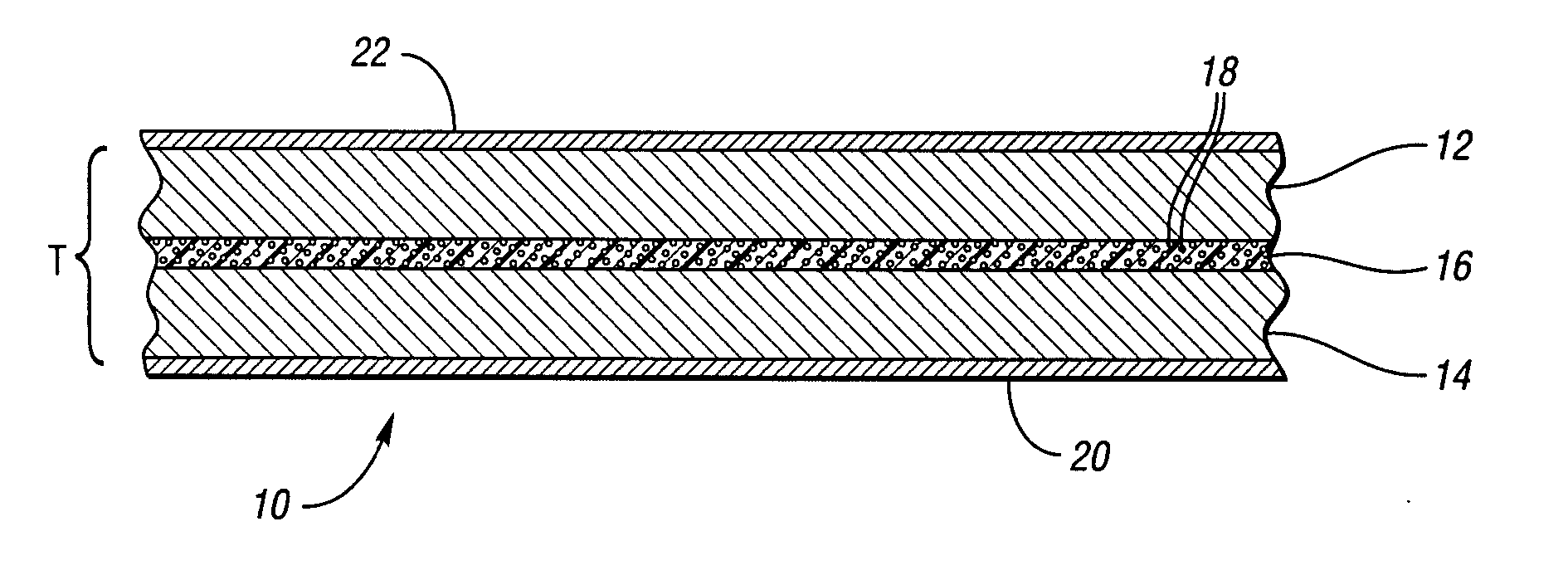

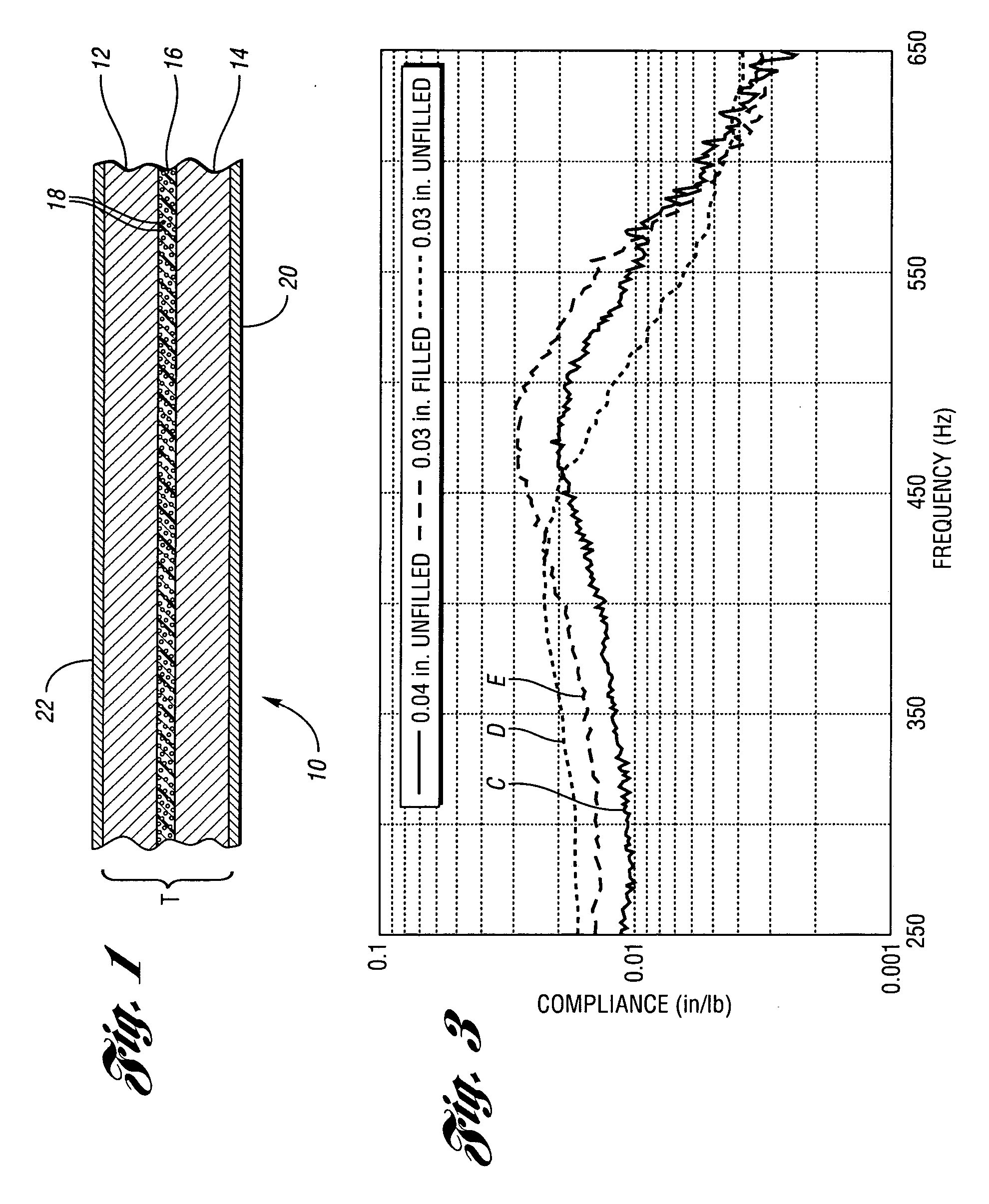

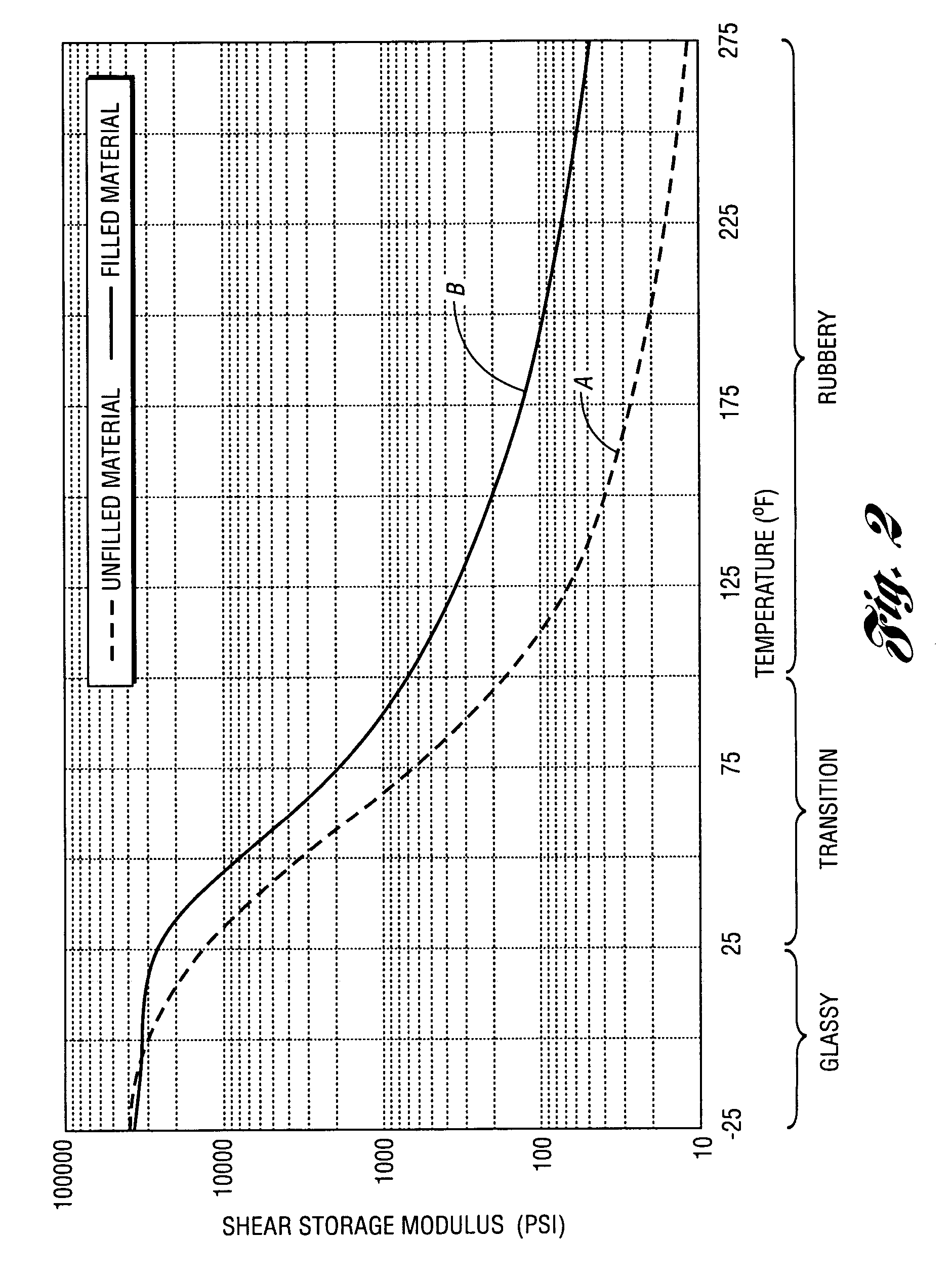

Laminated structure with a filled viscoelastic layer and method

InactiveUS20070026212A1Improve static stiffnessSame stiffnessSynthetic resin layered productsCeramic layered productsVibration attenuationFilling materials

The present invention provides a panel providing improved noise and vibration attenuation. The panel is formed from a constrained layer viscoelastic laminate material having at least two constraining layers and at least one viscoelastic layer therebetween spanning the entirety of the constraining layers. Included within the viscoelastic layer is an effective amount of filler material operable to increase the static stiffness of the panel. A method of increasing the static stiffness of constrained layer viscoelastic materials is also provided.

Owner:MATERIAL SCIENCES CORPORATION

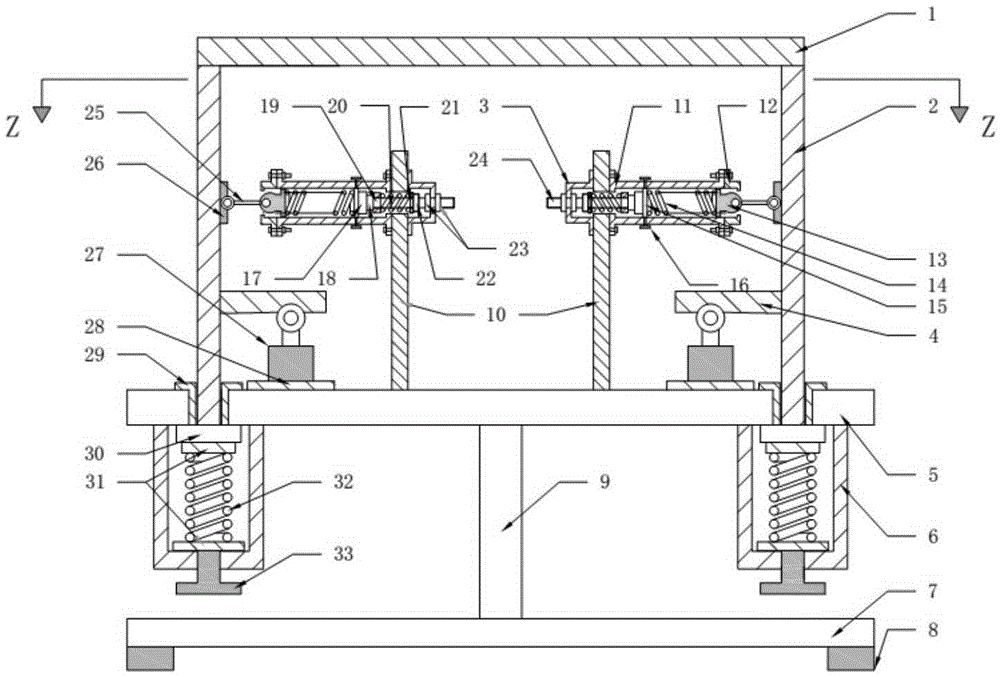

Vibration isolation system of vibrating centrifuge

InactiveCN102652930ASmall dynamic stiffness and natural frequencyImprove static stiffnessCentrifugesAir springEngineering

The invention discloses a vibration isolation system of a vibrating centrifuge. The vibration isolation system comprises a vibration isolation device, wherein the vibration isolation device comprises a guide rod, the axial direction of the guide rod is taken as the up-and-down direction, the upper end of the guide rod is connected with a rotating arm support of the vibrating centrifuge, the lower end of the guide rod sequentially penetrates through an upper-layer rigid plate, a middle-layer rigid plate and a lower-layer rigid plate, a linear bearing is connected with a regulating block, the regulating block is mounted on the lower-layer rigid plate, the lower end of the guide rod penetrates through the linear bearing, the two ends of the lower-layer rigid plate are respectively connected with the inner side of a support of a rotating arm system of the vibrating centrifuge, a force sensor is positioned between the rotating arm support and the upper-layer rigid plate, and an air spring is positioned between the upper-layer rigid plate and the middle-layer rigid plate. By adopting the structure that the air spring cooperates with the rigid plates, the imbalance force of the support of the rotating arm system relative to the rotating arm support is buffered and the vibration isolation purpose can be achieved. The vibration isolation system disclosed by the invention has the advantages of small dynamic rigidity, small inherent frequency, great static rigidity, good vibration isolation performance and capabilities of isolating vibration waves with higher frequency and bearing greater imbalance force.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

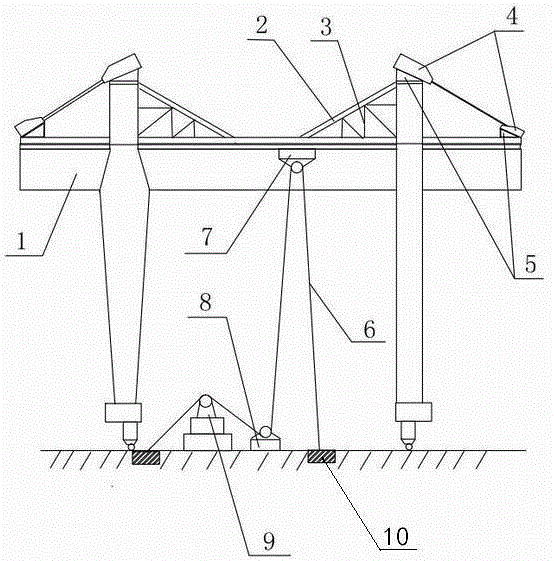

Method for manufacturing or transforming main beams of crane

Provided is a method for manufacturing or transforming main beams of a crane. An I-shaped steel support and reinforcing ribs are welded between a main beam midspan beam and supporting frames; tensioners are mounted at the top ends of the supporting frames and the tail end of a main beam cantilever through connecting seats, and are tensioned through a tensioning system, so that the camber of the main beam midspan beam meets the standard requirement, and the upwarping degree of the effective cantilever position of the main beam cantilever ranges from 0.9 / 350 to 1.4 / 35. According to the method for manufacturing or transforming the main beams of the crane, processing and manufacturing are easy, cost is low, and construction is convenient; the method is suitable for being used for manufacturing or transforming main beams of cranes of any tonnage, and especially suitable for manufacturing and transforming of portal cranes in the port and shipbuilding industry. The camber difference of the two manufactured or transformed main beams of the crane is kept between 0 to 1 mm, the main beams of the crane are always kept at any value within the international range, steel is saved, and cost is reduced by 15% to 20 %; the method conforms to the national energy saving and emission reducing policy, and the service life of the crane is prolonged.

Owner:傅欣荣 +7

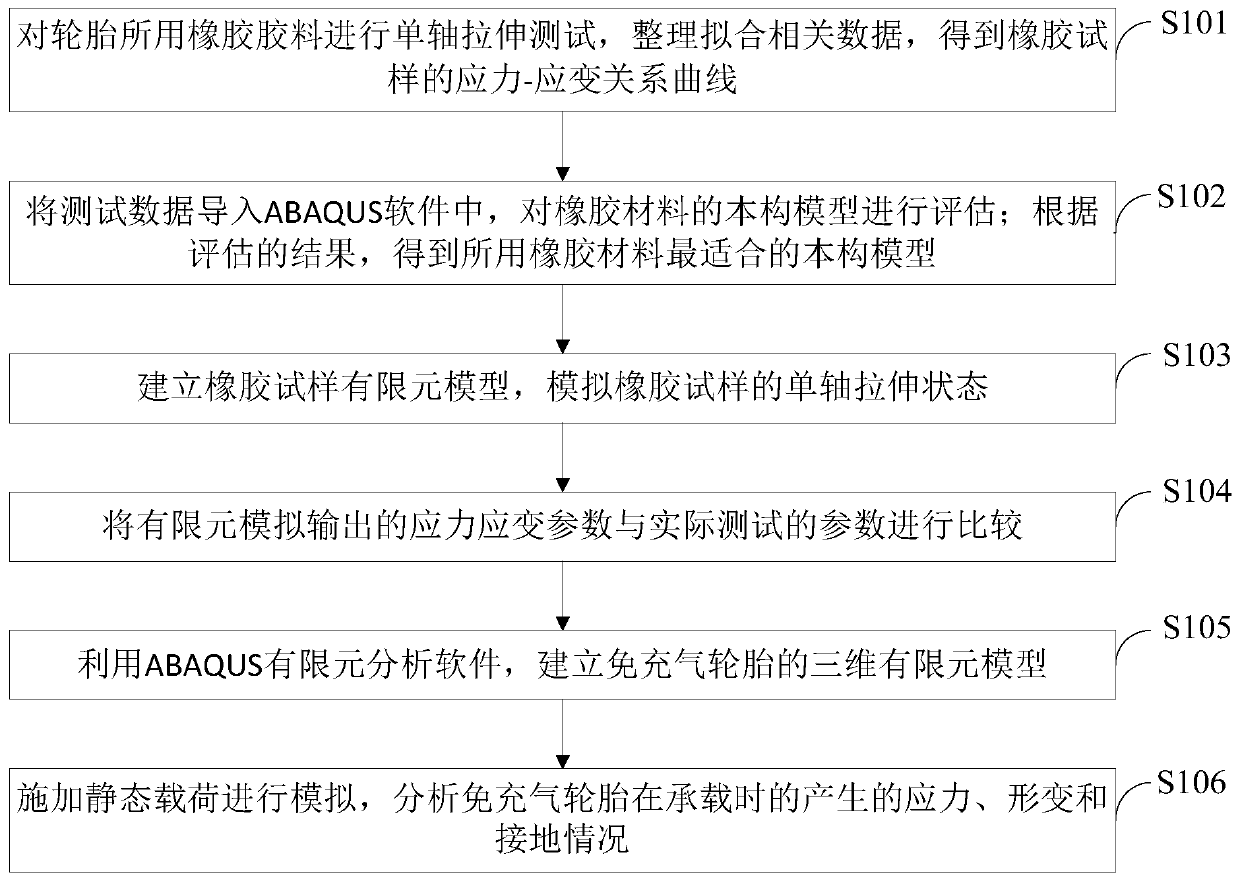

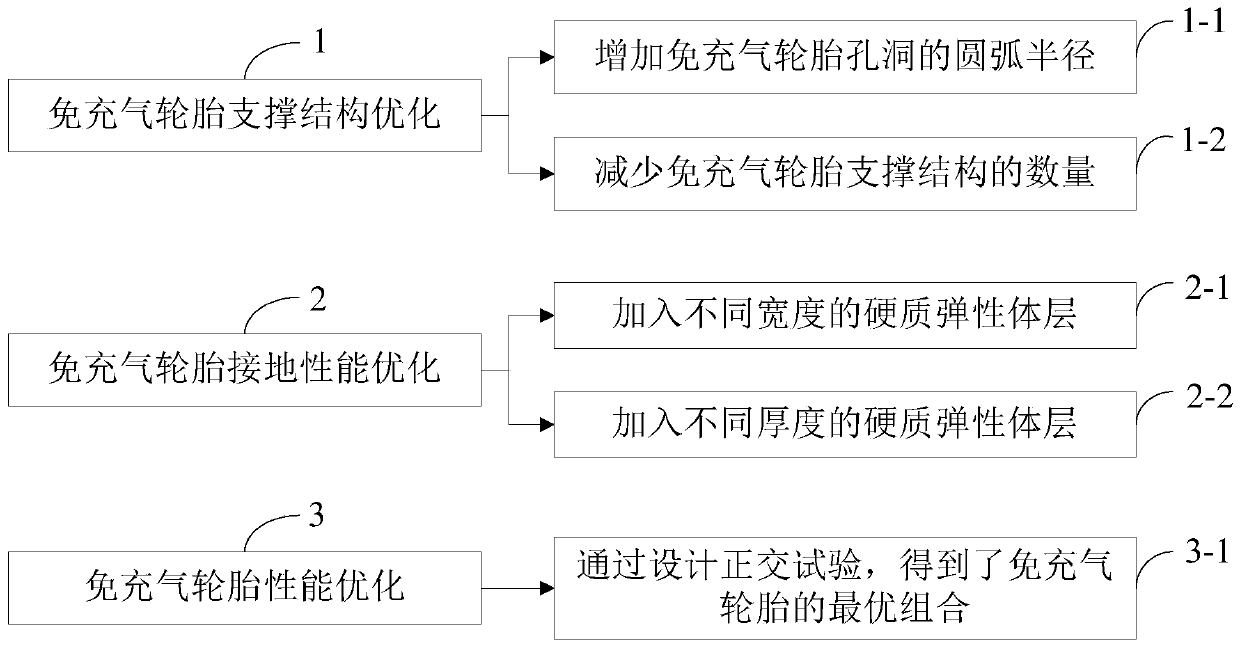

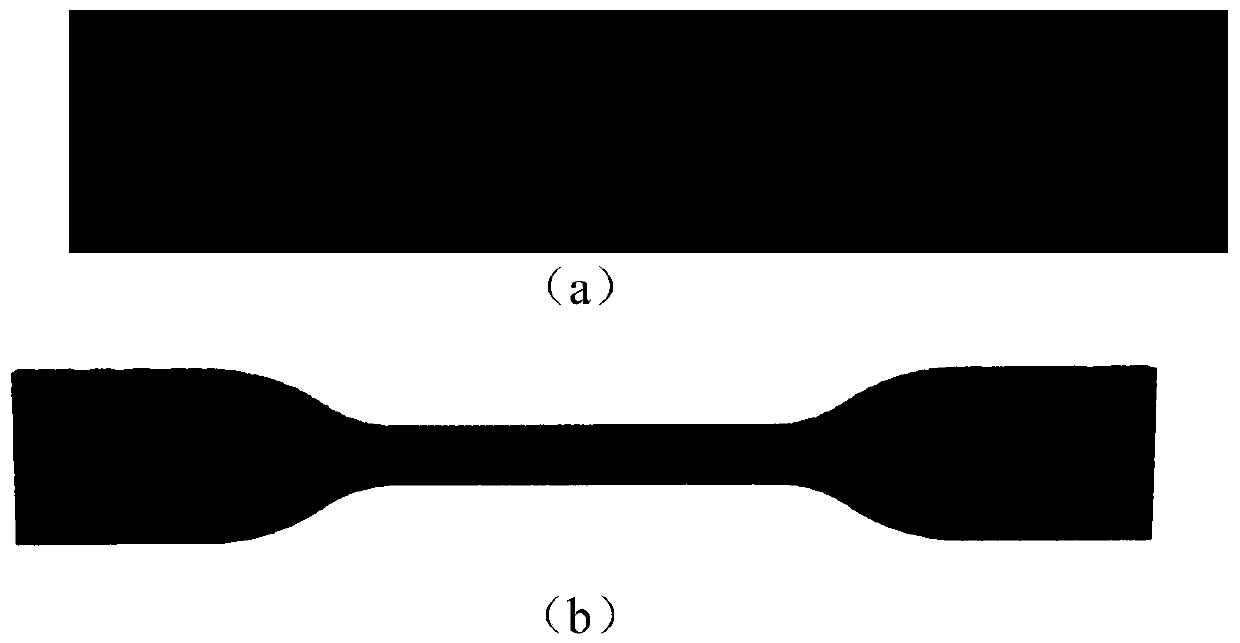

Finite element simulation analysis and performance optimization method for non-pneumatic tire

ActiveCN110688794AReduce stressReduce strainSustainable transportationDesign optimisation/simulationElastomerFatigue damage

The invention belongs to the technical field of tire performance optimization, and discloses an inflation-free tire finite element simulation and performance optimization method which comprises the following steps: fitting tire rubber uniaxial tensile test data based on ABAQUS professional software, establishing a finite element model of an inflation-free tire, and carrying out finite element analysis on a supporting structure and a tread part of the tire. By increasing the arc radius of the non-pneumatic tire hole and reducing the number of the non-pneumatic tire supporting structures, the stress-strain concentration phenomenon can be effectively weakened, the fatigue damage probability of the supporting structures is reduced, and the performance of the non-pneumatic supporting structuresis improved. The hard elastomer layer with certain width and thickness is added between the supporting structure and the tread, so that the performance of the supporting structure of the non-pneumatic tire can be improved, the ground contact stress is uniformly distributed, and the ground contact performance of the non-pneumatic tire is improved. The optimal combination of the non-pneumatic tireis obtained by designing an orthogonal test, and the supporting structure and the grounding performance of the optimal combination non-pneumatic tire are greatly improved.

Owner:QINGDAO UNIV OF SCI & TECH

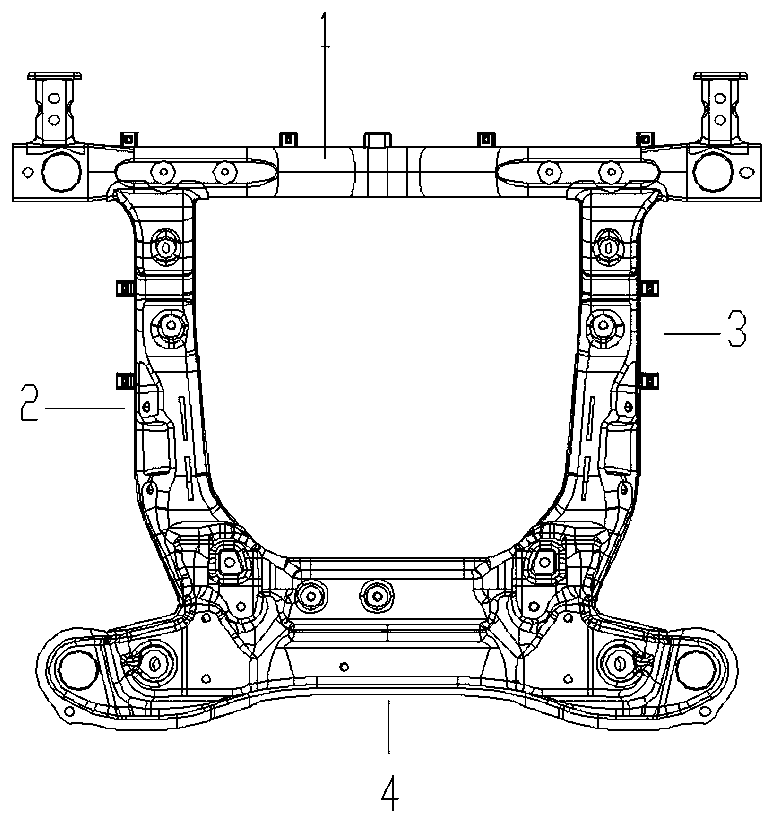

#-shaped front sub frame

The invention relates to the field of automobile manufacturing and design, specifically to a #-shaped front sub frame. The rigidity of each mounting point is higher so that the controllability of thewhole automobile is improved. The sub frame and an automobile body are flexibly connected with each other through a bushing; and therefore, the shock from a pavement is effectively blocked, and the comfort of the whole automobile is improved. The #-shaped front sub frame comprises a front cross beam, a left side beam, a right side beam and a rear cross beam; a left side beam and a right side beamare correspondingly arranged on the two sides of the front cross beam downwards; the tail end of the left side beam and the tail end of the right side beam are inserted into the tops of the head and the top of the rear cross beam to be integrally connected to form a square shape or # shape, wherein the left side beam and the right side beam have same structures and acting as mirror images of eachother; the left side beam and the right side beam comprise side beam upper plates and side beam lower plates; the side beam upper plates and the side beam lower plates are arranged to cover each otherin the up-and-down direction; after the side beam upper plates and the side beam lower plates are arranged to cover each other in the up-and-down direction, side beam cavities are formed inside; therear cross beam comprises a rear cross beam upper sheet and a rear cross beam lower sheet; the rear cross beam upper sheet and the rear cross beam lower sheet are connected with each other in a covering manner; a rear cross beam cavity is formed inside; and connecting ports are formed in positions, matched with the left side beam and the right side beam, on the rear cross beam.

Owner:ZHEJIANG TUOWEI AUTOMOBILE PARTS CO LTD

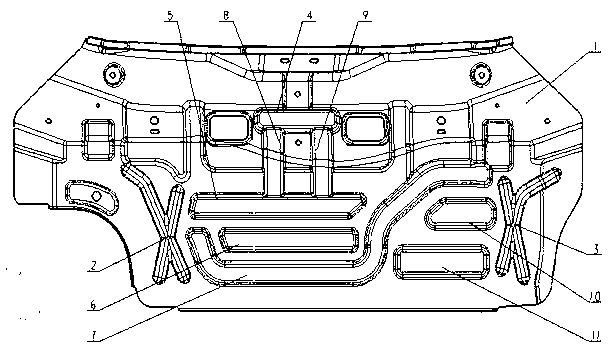

Rear apron board of automotive body

InactiveCN102700616AReduce weightImprove local stiffnessSuperstructure subunitsEngineeringSquare Shape

The invention relates to a rear apron board of an automotive body. The rear apron board comprises a board body and is characterized in that the left lower part of the board body is provided with a first X-shaped reinforcing rib, and the right lower part of the board body is provided with a second X-shaped reinforcing rib; the middle upper part of the board body is provided with a first horizontal reinforcing rib, the middle lower part of the board body is sequentially provided with a second horizontal reinforcing rib, a third horizontal reinforcing rib and an S-shaped reinforcing rib from top to bottom; and a first vertical reinforcing rib and the second vertical reinforcing rib are arranged between the first horizontal reinforcing rib and the second horizontal reinforcing rib. Because the rear apron board is provided with the first X-shaped reinforcing rib and the second X-shaped reinforcing rib, local rigidity of the point of the reinforcing ribs is improved, the additional arrangement of a reinforcing plate at the reinforcement point is avoided, the weight of the automotive body is reduced, and the cost is saved. Because the two horizontal reinforcing ribs and the two vertical reinforcing ribs are connected in a square shape, the static rigidity and the dynamic rigidity of a metal plate at the point are obviously improved, and the vibration resistance is improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

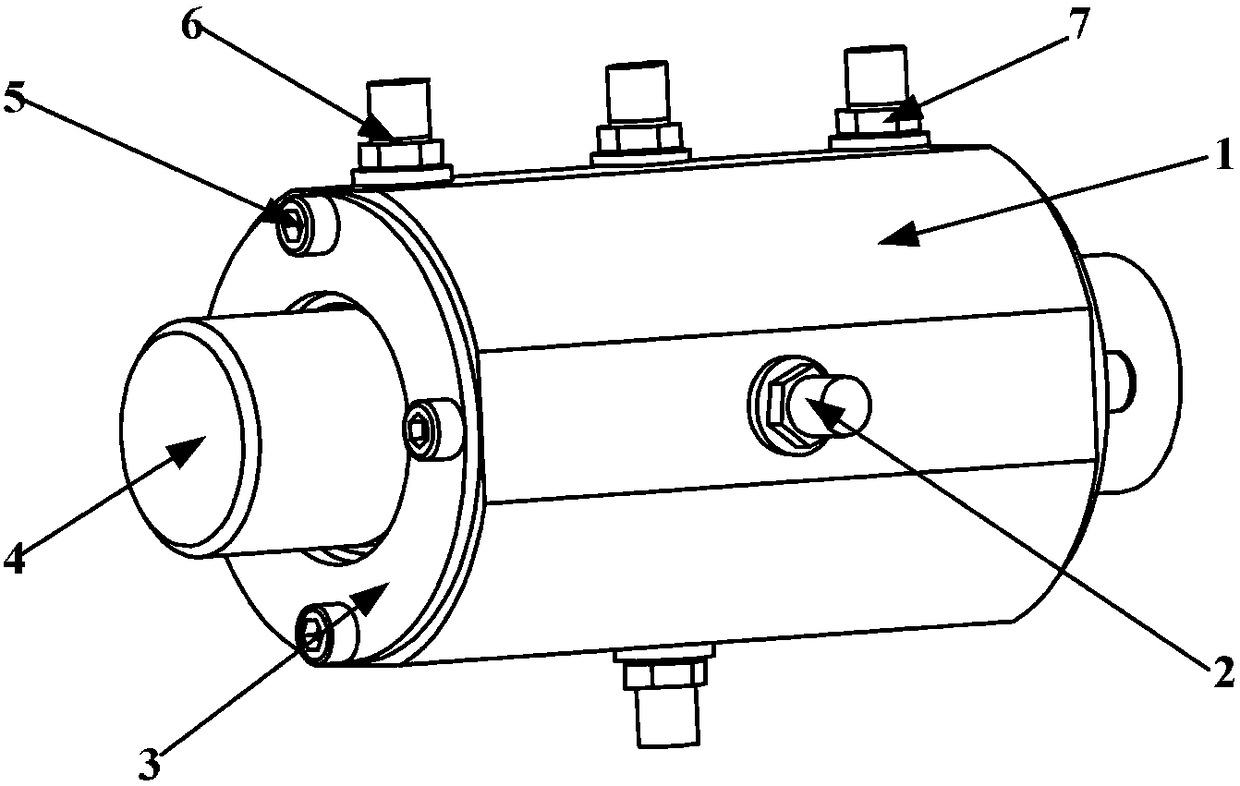

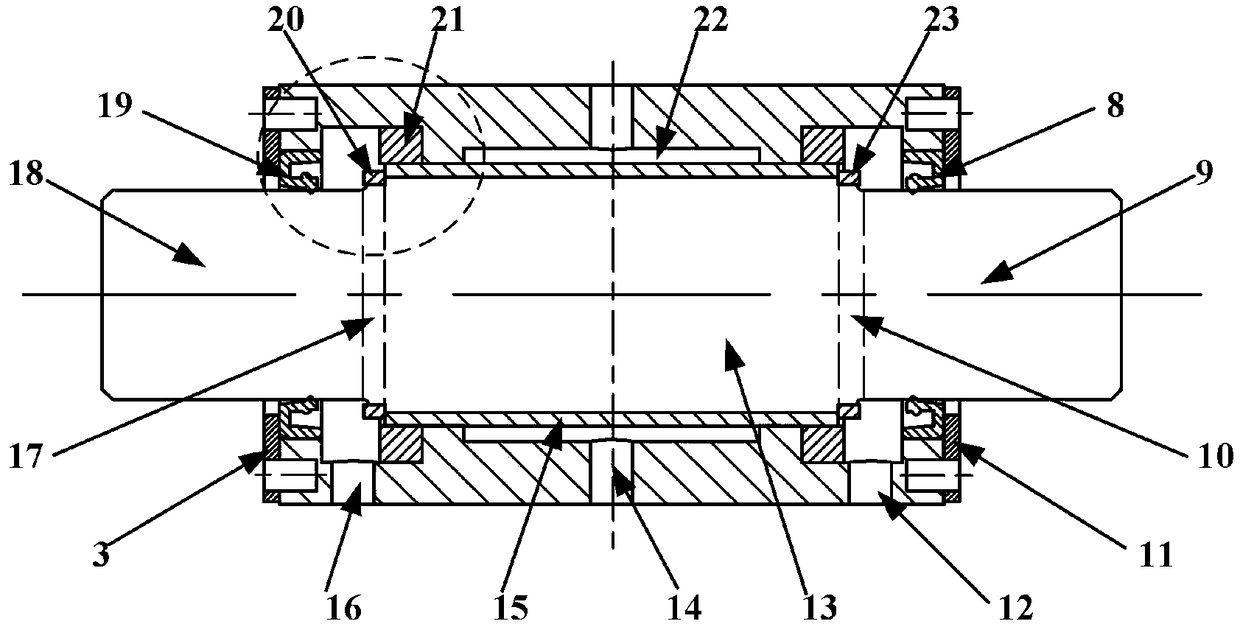

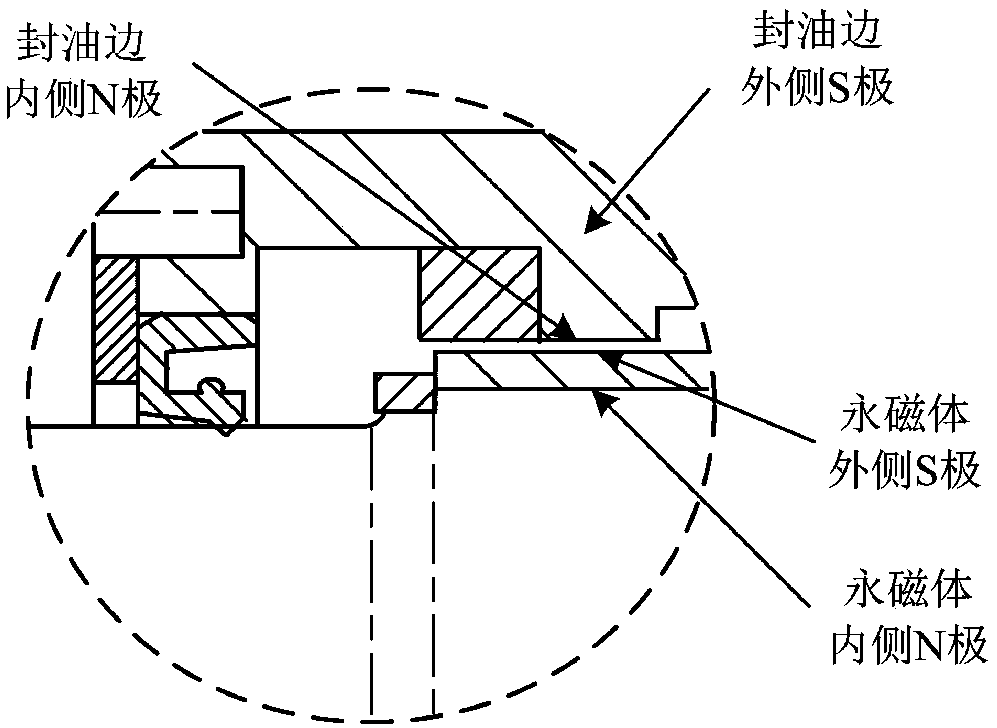

Active-type magnetorheological fluid hydrostatic bearing

The invention discloses an active-type magnetorheological fluid hydrostatic bearing. The active-type magnetorheological fluid hydrostatic bearing comprises a stepped shaft, a first shaft end check ring, a shaft sleeve, a second shaft end check ring, a permanent magnet, four enameled coils, a first skeleton seal, a second skeleton seal, a first axial nut and a second axial nut. Five journals are machined on the stepped shaft; the shaft sleeve is a rotating body, four radial oil inlet holes are evenly machined in the axial center of the shaft sleeve along the circumference of the rotating body,and an inwards-protruded hydrostatic supporting cavity is formed in each radial oil inlet hole in the inner circumference of the rotating body; and the oil sealing edge on the periphery of each hydrostatic supporting cavity is provided with the corresponding enameled coil in a glued mode. Magnetorheological fluid is adopted as a lubricating medium, when the magnetorheological fluid flows through amagnetic field generated between the permanent magnet and an electromagnet, flowing resistance is increased, the supporting pressure of the supporting cavities is forced to be increased, thus the bearing capacity of the bearing is effectively improved, and the active-type magnetorheological fluid hydrostatic bearing has the characteristics of high bearing capacity and high stiffness accordingly.

Owner:YANSHAN UNIV

Military vehicle flexible antimine ground plate

PendingCN109895872AImprove static stiffnessImprove machinabilitySuperstructure subunitsEngineeringGround plate

Owner:NANJING UNIV OF SCI & TECH

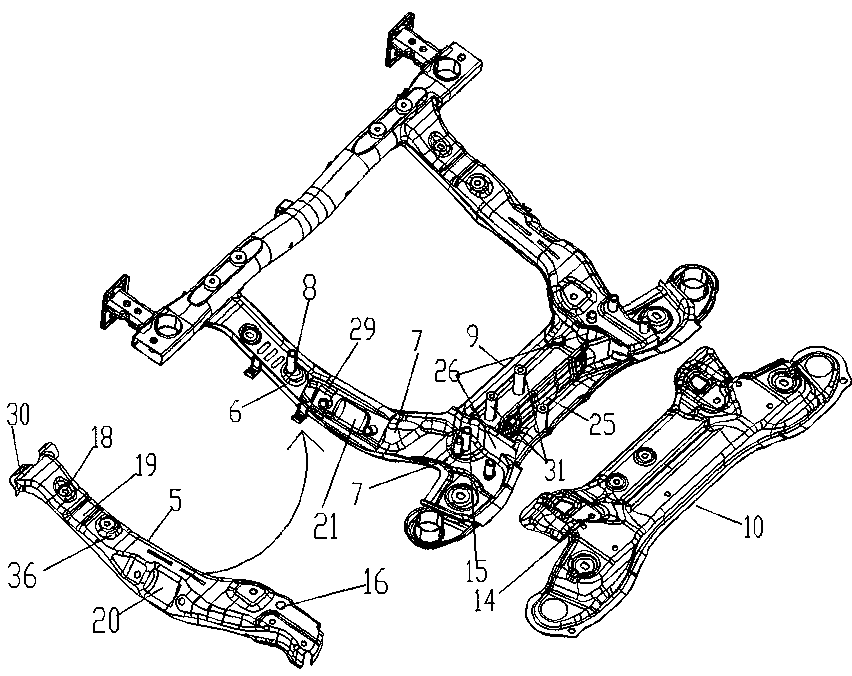

Front support of passenger car chassis control arm

InactiveCN103101414AReduce stress concentrationImprove self-stiffnessPivoted suspension armsStress concentrationVehicle frame

The invention discloses a front support of a passenger car chassis control arm, which is fixed on an auxiliary frame of a passenger car chassis when being used. The front support is mainly characterized in that a right-angle opening is processed in the upper side in the front support of the control arm, the flanging of the front support of the control arm is beveled to form a bevel edge of 45 degrees, the outer side edge of the front support of the control arm stretches upwards to the top the height of which is one third of the height from the top to the bottom of the front support, a triangular rib plate is processed in the middle part of the bottom edge of the front support of the control arm, and the inner side of the bottom edge of the front support of the control arm is processed to be in the shape of a stair-step. According to the structure of the front support, the stiffness of the front support is improved, and stress concentration is eliminated, so that the front support is more suitable for working in a complicated vibration environment and can be applied to the manufacturing field of passenger-car chassis installation kits.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com