Active-type magnetorheological fluid hydrostatic bearing

A magneto-rheological fluid and hydrostatic bearing technology, which is applied to bearings, shafts, bearings, mechanical equipment, etc., can solve the problems of bearing load capacity reduction, bearing chamber pressure reduction, viscosity reduction, etc., to achieve static stiffness improvement, fluid The effect of large resistance change and viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

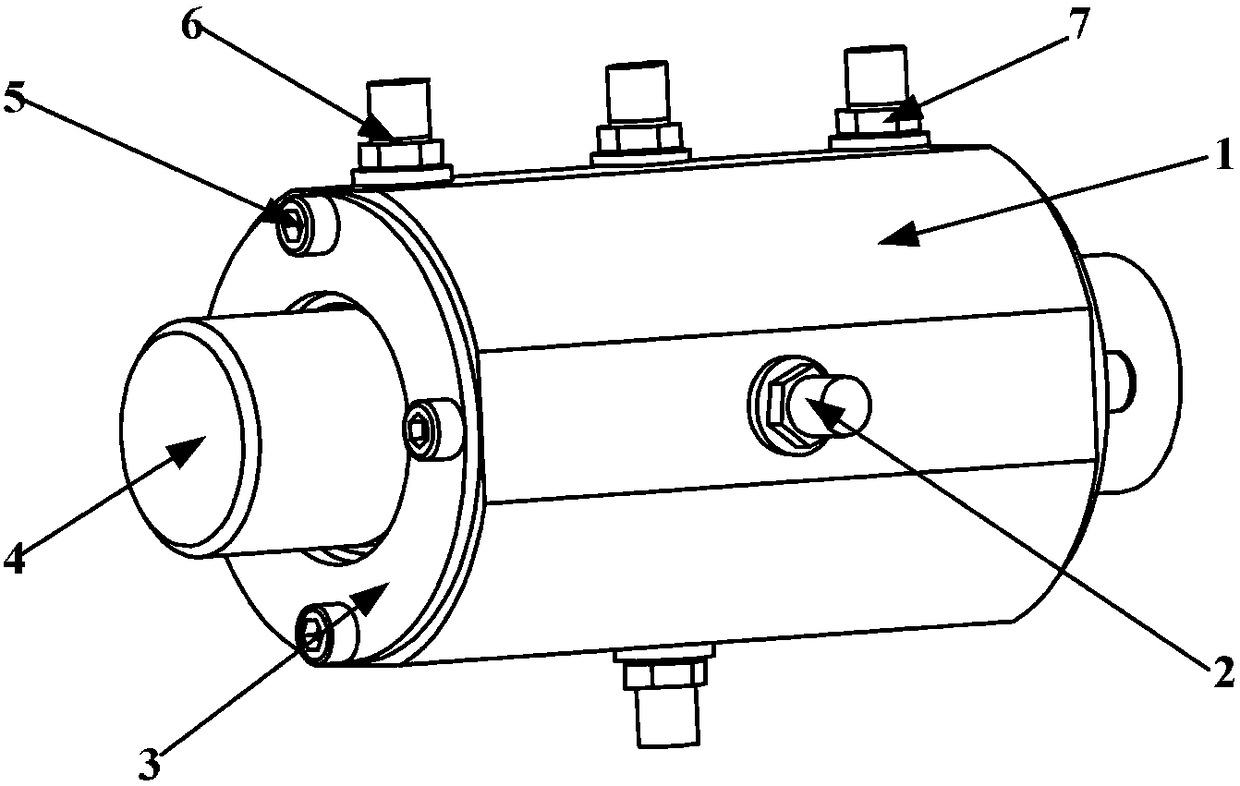

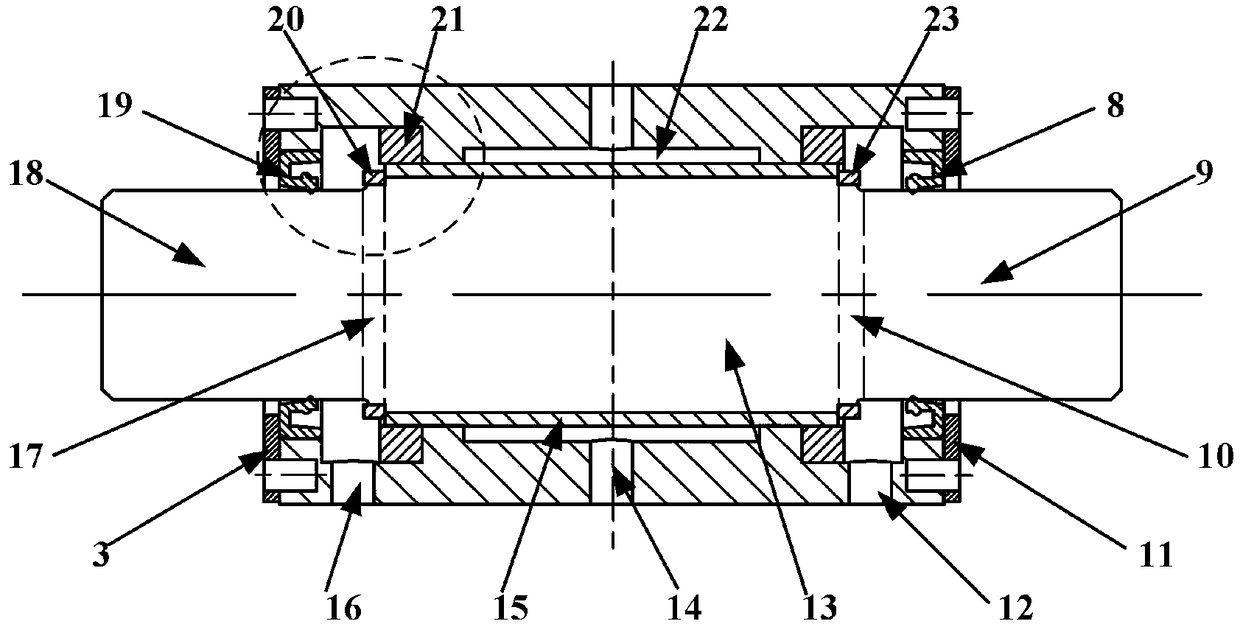

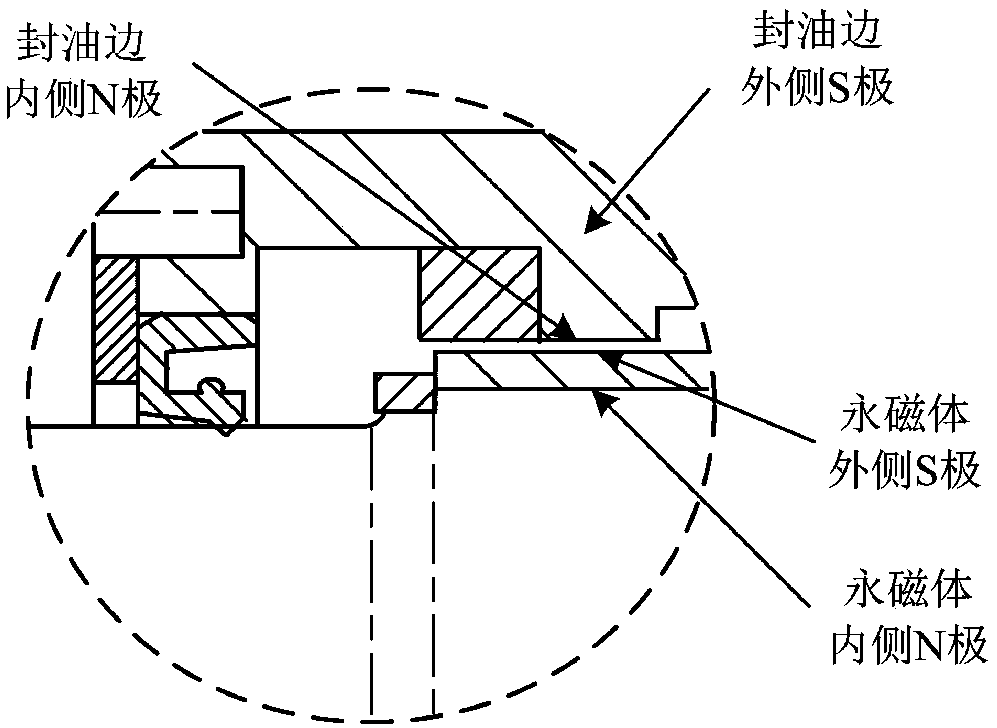

[0022] An embodiment of an active magnetorheological hydrostatic bearing of the present invention: as figure 1 , 2 As shown, it includes a stepped shaft 4, a first shaft end retaining ring 3, a shaft sleeve 1, a second shaft end retaining ring 11, a permanent magnet 15, four enameled coils 21, a first skeleton seal 19, a second skeleton seal 8, The first axial nut 20 and the second axial nut 23 .

[0023] The stepped shaft 4 is processed with five journals, which are the first shaft section 18, the second shaft section 17, the third shaft section 13, the fourth shaft section 10 and the fifth shaft section 9 from left to right; The diameters of the shaft section 18 and the fifth shaft section 9 are both 40mm and 50mm in length; the diameters of the second shaft section 17 and the fourth shaft section 10 are both 42mm and 5mm in length; the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com