Water-based mortar modifier, its preparation method and application

A modifier and mortar technology, which is applied in the field of water-based mortar modifier and its preparation, can solve the problems of inaccurate measurement, the inability of mortar modifier to maintain mortar construction performance for a long time, and inconvenient use, so as to increase the Workability and plasticity, improving mortar workability, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

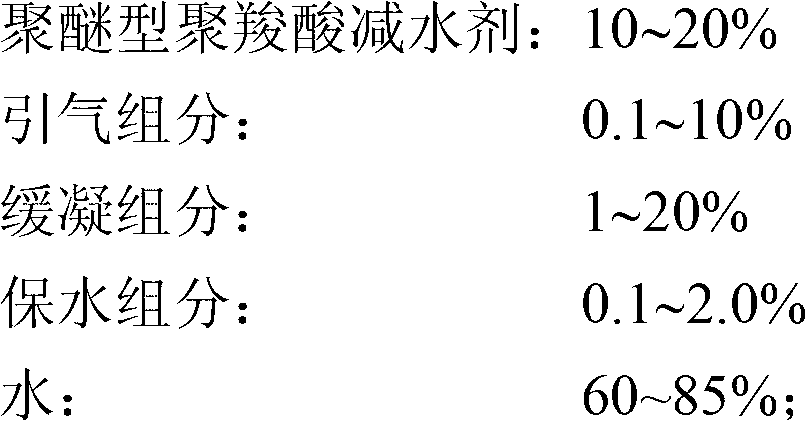

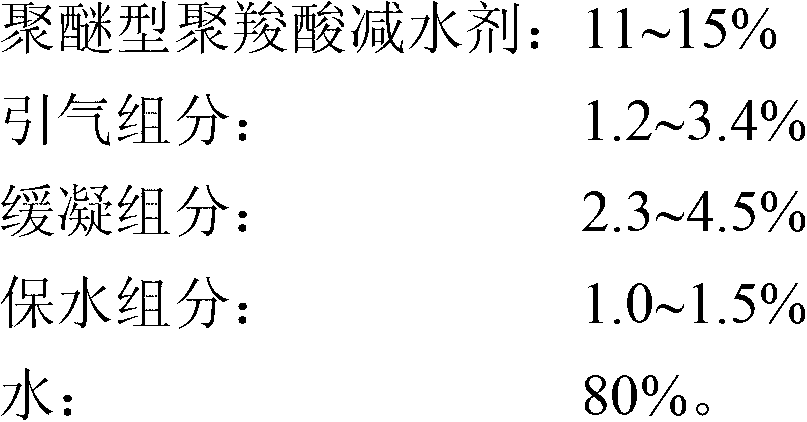

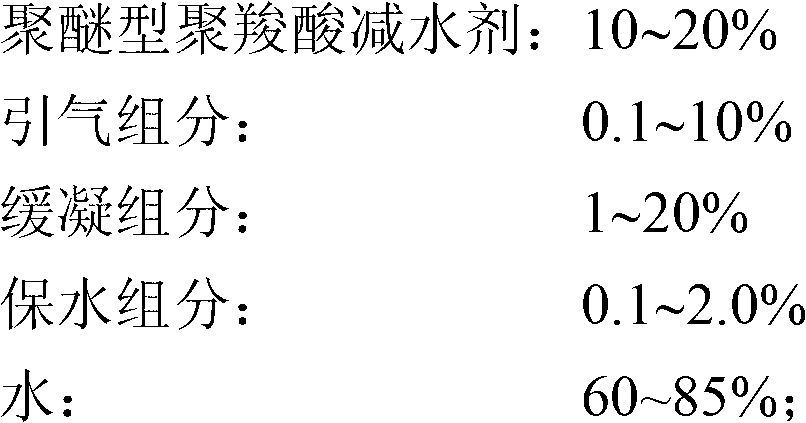

Method used

Image

Examples

Embodiment 1

[0033] A water-based mortar modifier, prepared by the following steps:

[0034] (1) Preparation of polyether-type polycarboxylate superplasticizer: Dissolve 100 grams of acryl alcohol polyoxyethylene ether (molecular weight: 2400), 9.5 grams of acrylic acid, and 2.0 grams of maleic anhydride in 105 grams of water. Add 25 grams of ammonium persulfate aqueous solution (mass concentration 4.5%) dropwise, finish dropping within 120 minutes, keep warm at 65°C for 3 hours after the dropwise addition, then cool down to 45°C, add an appropriate amount of NaOH to neutralize, and adjust the pH of the system to 7 -8, to prepare a polyether polycarboxylate water reducer.

[0035] (2) Add 13% polyether polycarboxylate superplasticizer, 1% sodium lauryl sulfate, 0.5% sodium α-allyl sulfonate, 1.5% sodium gluconate, 3.0% three Sodium polyphosphate, 0.5% polyethylene glycol, 0.5% hydroxypropyl cellulose and 80% water are mixed and stirred evenly to obtain a water-based mortar modifier; The ...

Embodiment 2

[0037] A water-based mortar modifier, prepared by the following steps:

[0038] (1) Preparation of polyether-type polycarboxylate superplasticizer: Dissolve 100 grams of isobutylene alcohol polyoxyethylene ether (molecular weight 1200), 18 grams of acrylic acid, and 5 grams of maleic anhydride in 105 grams of water, and heat up to 70 ° C to evenly Add 30 grams of ammonium persulfate aqueous solution (mass concentration 6.0%) dropwise, and finish dropping within 150 minutes. After dropping, keep warm at 60°C for 4 hours, then cool down to 45°C, add an appropriate amount of NaOH to neutralize, and adjust the pH of the system to 7 -8, to prepare a polyether polycarboxylate water reducer.

[0039] (2) Add 11% polyether polycarboxylate superplasticizer, 3.0% sodium rosinate, 0.4% sodium fatty alcohol polyoxyethylene ether sulfonate, 1.5% sodium gluconate, 3.0% lignin sulfonate Sodium phosphate, 0.5% polyvinylpyrrolidone, 0.6% hydroxypropyl starch are mixed with 80% water, stirred ...

Embodiment 3

[0041] A water-based mortar modifier, prepared by the following steps:

[0042] (1) Preparation of polyether-type polycarboxylate superplasticizer: Dissolve 100 grams of isobutylene alcohol polyoxyethylene ether (molecular weight 3600), 7.5 grams of acrylic acid, and 1.2 grams of maleic anhydride in 105 grams of water, and heat up to 62 ° C to uniformly Add 32 grams of potassium persulfate aqueous solution (mass concentration 5.0%) dropwise, and finish the drop within 150 minutes. After the dropwise addition, keep warm at 60°C for 2 hours, then cool down to 45°C, add appropriate amount of NaOH to neutralize, and adjust the pH of the system to 7 -8, to prepare a polyether polycarboxylate water reducer.

[0043] (2) Add 11.0% polyether polycarboxylate superplasticizer, 1.0% sodium rosinate, 2.4% sodium fatty alcohol polyoxyethylene ether sulfonate, 1.8% sodium gluconate, 2.5% lignin sulfonate Sodium phosphate, 0.5% polyvinylpyrrolidone, 0.8% hydroxypropyl starch and 80% water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com