Patents

Literature

2436 results about "Sodium gluconate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

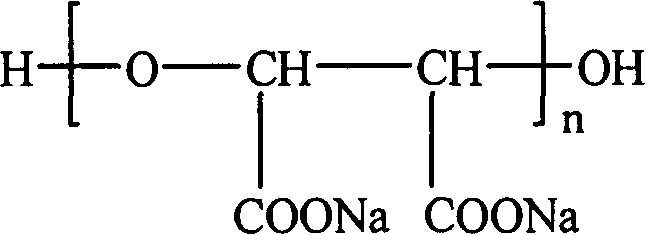

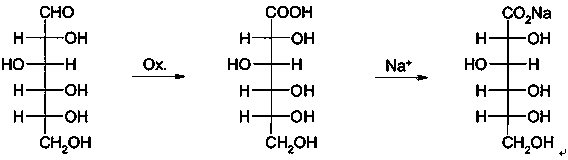

Sodium gluconate is a compound with formula NaC₆H₁₁O₇. It is the sodium salt of gluconic acid. Its E number is E576. Sodium gluconate is widely used in textile dyeing, printing and metal surface water treatment. It is also used as a chelating agent, a steel surface cleaning agent, a cleaning agent for glass bottles, and as a chelating agent for cement, plating and alumina dyeing industries. It is a white powder that is very soluble in water.

Green environment-protective composite slow-corrosion scale resistor for circulated cooling-water treatment

InactiveCN1850661AGood scale inhibition and dispersibilityObvious synergistic effect of corrosion inhibitionTreatment using complexing/solubilising chemicalsGreen environmentWater quality

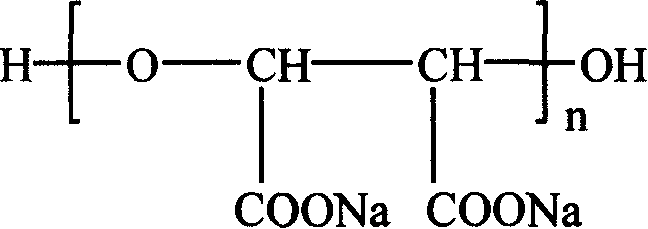

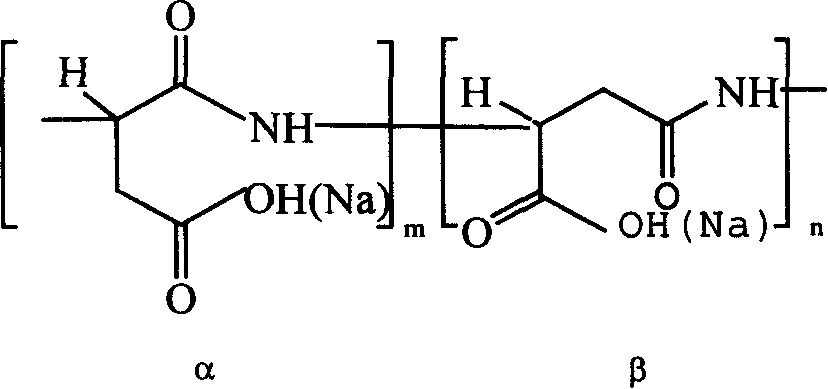

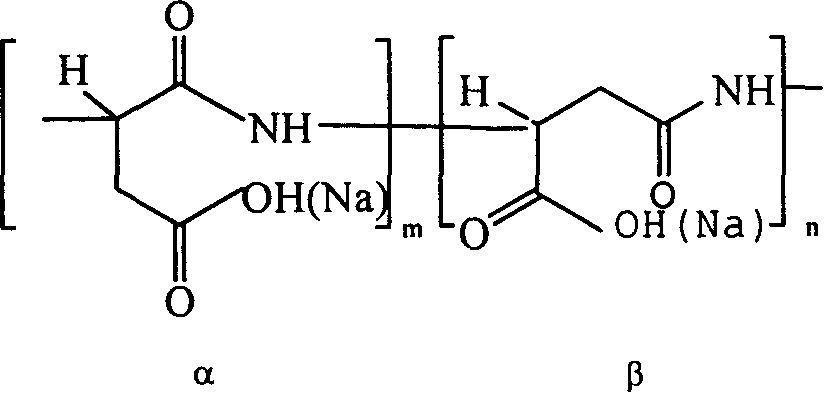

The invention belongs to the environmental protection field, concretely relating to a green environmental-protection composite corrosion inhibition antifouling agent for water circulating cooling, compounded of antifouling dispersants and corrosion inhibitors: polyepoxy sodium succinate, polymerized sodium aspartate, hydrolyzed polymaleic anhydride, sodium gluconate, zinc salt, in the mass ratio of 1-6 to 1-4 to 2-6 to 1-2 to 1-2. And it has characters of no phosphorus and biodegradability, an environment-friendly water quality stabilizer, used in a water-circulating cooling system to play the role in corrosion inhibition and antifouling.

Owner:TONGJI UNIV

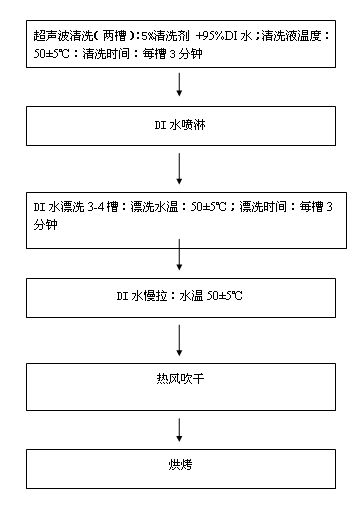

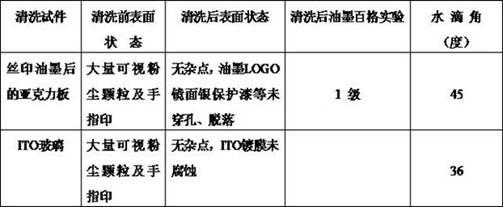

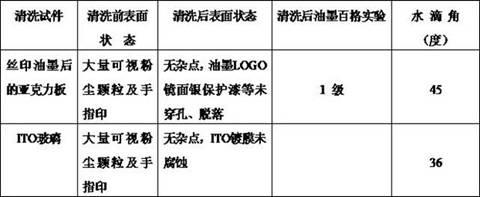

Cleaning agent for optical glass

ActiveCN102604751AEasy to cleanPromote wettingOrganic detergent compounding agentsNon-ionic surface-active compoundsOrganic baseCarbon chain

The invention discloses a cleaning agent for optical glass, which comprises the following components in weight percentage: 2-4% of long carbon chain dibasic acid; 6-10% of an anionic surfactant; 2-4% of an inorganic base; 2-6% of a nonionic surfactant; 2-4% of a special surfactant; 6-12% of a chelator; 10-20% of an organic base; and 40-70% of deionized water, wherein the long carbon chain dibasic acid is dicarboxylic acid with 21 carbon atoms, the anionic surfactant is dodecylbenzene sulfonic acid, the inorganic base is industrial NaOH, the nonionic surfactant is primary alcobol ethoxylate AEO9, the special surfactant is sodium POE nonylphenol ether sodiosulfosuccinate, the chelator is a mixture of Tetrasodium Ethylenediamine Tetraacetate and sodium gluconate, and the organic base is diethanol amine. The cleaning agent for optical glass provided by the invention has low corrosivity and good cleaning effect.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Highly durable high slump loss resistant no-bleeding concrete pump delivering agent

InactiveCN101244909AImprove appearance qualityEffectively change performanceCarboxymethyl celluloseMetallurgy

The invention relates to a non-bleeding concrete pumping admixture with high durability and high slump retaining, the raw material weight percentage composition of which is: 25 to 45 percent of naphthalene series water reducer, 2 to 6 percent of polycarboxylic series of water reducer, 1 to 4 percent of sodium lignosulfonate, 0.5 to 2 percent of sodium gluconate, 0.2 to 2 percent of triterpenoid saponin, 0.5 to 3 percent of carboxymethyl cellulose, 0.2 to 1 percent of silicon oil, and 40 to 65 percent of water; the non-bleeding concrete pumping aid with high durability and high slump retaining has the advantages of low slump loss and low cost, no bleeding, restraining the shrinkage of concrete, and controlling the fissure of concrete.

Owner:HUNAN CONSTR ENG GRP COR

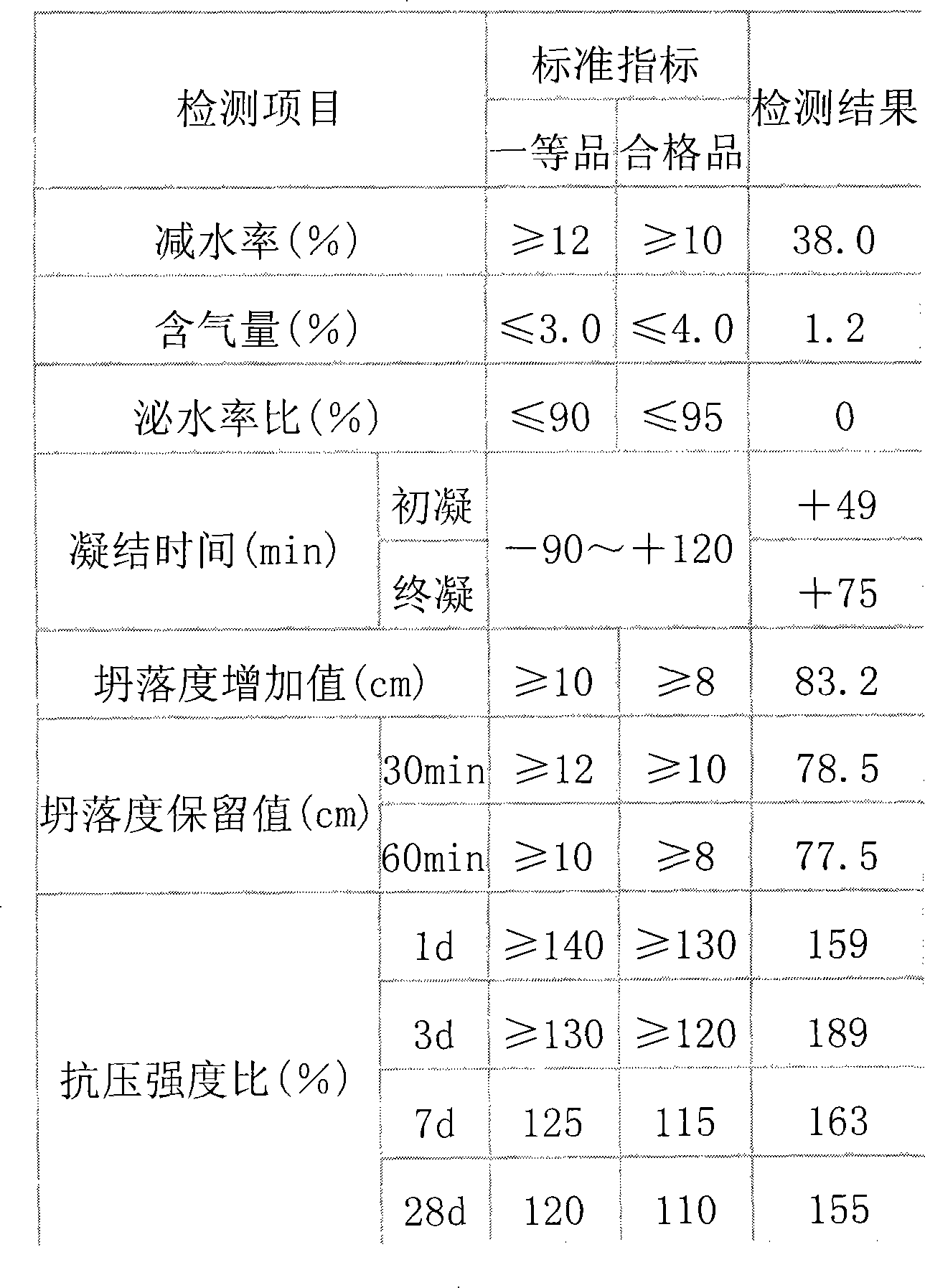

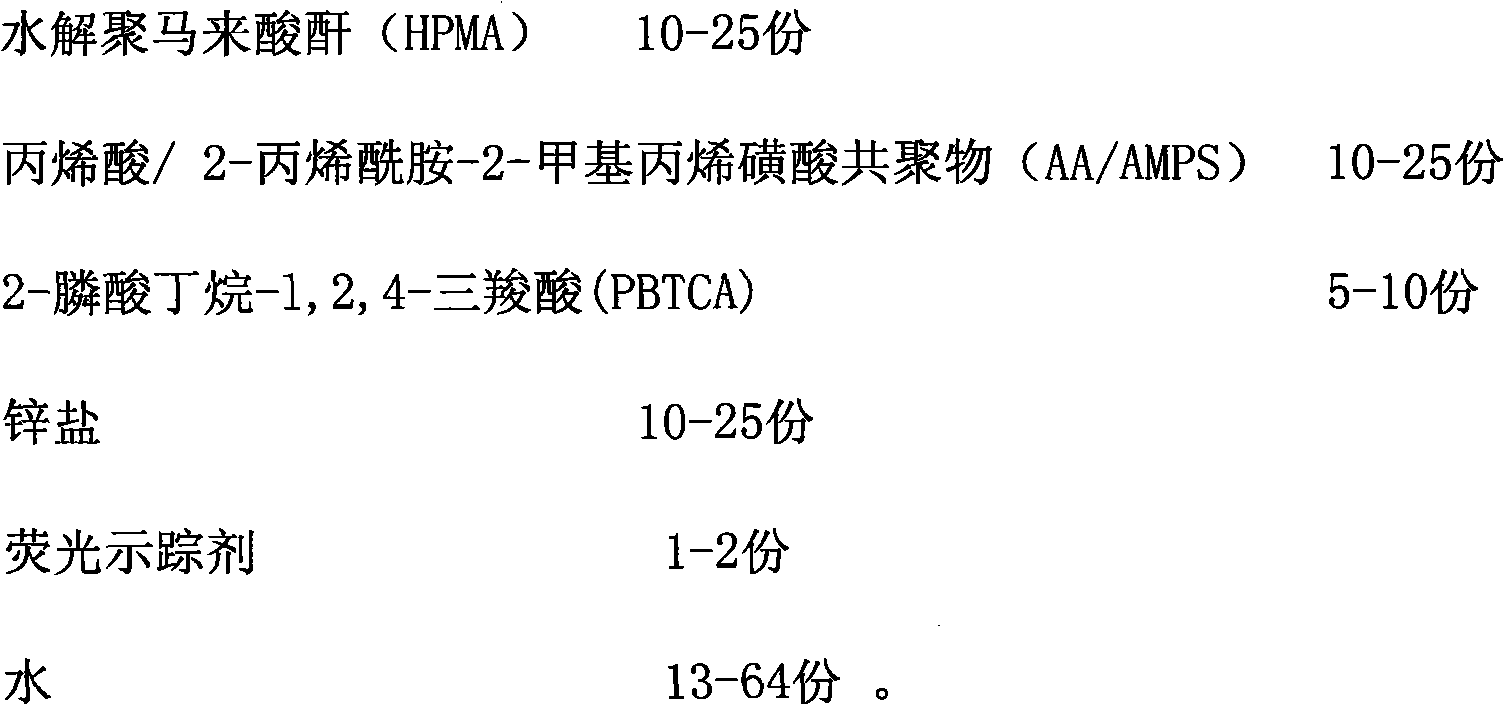

Composite low-phosphorus corrosion and scale inhibitor and application thereof

InactiveCN102674570ALow A phosphorus contentReduce dosageScale removal and water softeningTricarboxylic acidGluconic acid

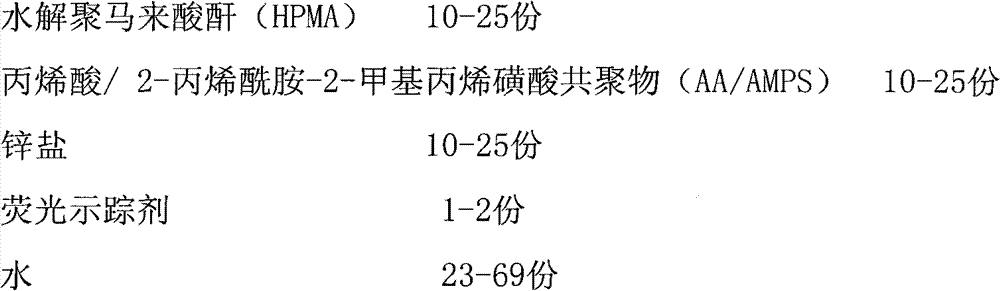

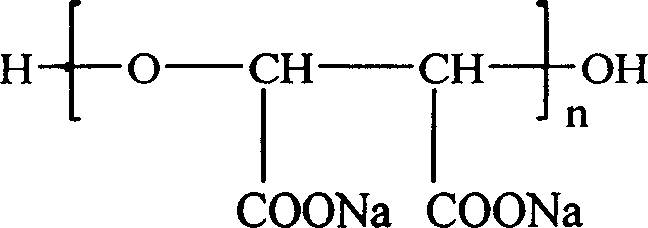

The invention provides a composite low-phosphorus corrosion and scale inhibitor and application thereof. The composite low-phosphorus corrosion and scale inhibitor is prepared from a corrosion and scale inhibitor A and a corrosion and scale inhibitor B, wherein the corrosion and scale inhibitor A is prepared from 20-40 parts of polyepoxysuccinic acid (PESA), 20-40 parts of sodium gluconate and 20-60 parts of water; and the corrosion and scale inhibitor B is prepared from 10-25 parts of hydroxypropyl methacrylate (HPMA), 10-25 parts of acrylic acid / 2-acrylamido-2-methylacrylsulfonic acid copolymer (AA / AMPS), 5-10 parts of 2-phosphonobutyl-1,2,4-tricarboxylic acid (PBTCA), 10-25 parts of zinc salt, 1-2 parts of fluorescent tracer and 13-64 parts of water. The technical scheme is as follows: the corrosion and scale inhibitor A and the corrosion and scale inhibitor B in a weight ratio of 1:2 are compounded with water. The composite low-phosphorus corrosion and scale inhibitor has excellent corrosion and scale inhibition effects, and thus, the phosphorus content in the product is low, thereby reducing the phosphorus discharge and having favorable environmental protection performance.

Owner:CHINA PETROLEUM & CHEM CORP

Biodegradable chelant compositions for fracturing fluid

InactiveUS7078370B2Improved fracture propertyImprove propertiesFluid removalFlushingFracturing fluidAlcohol sugars

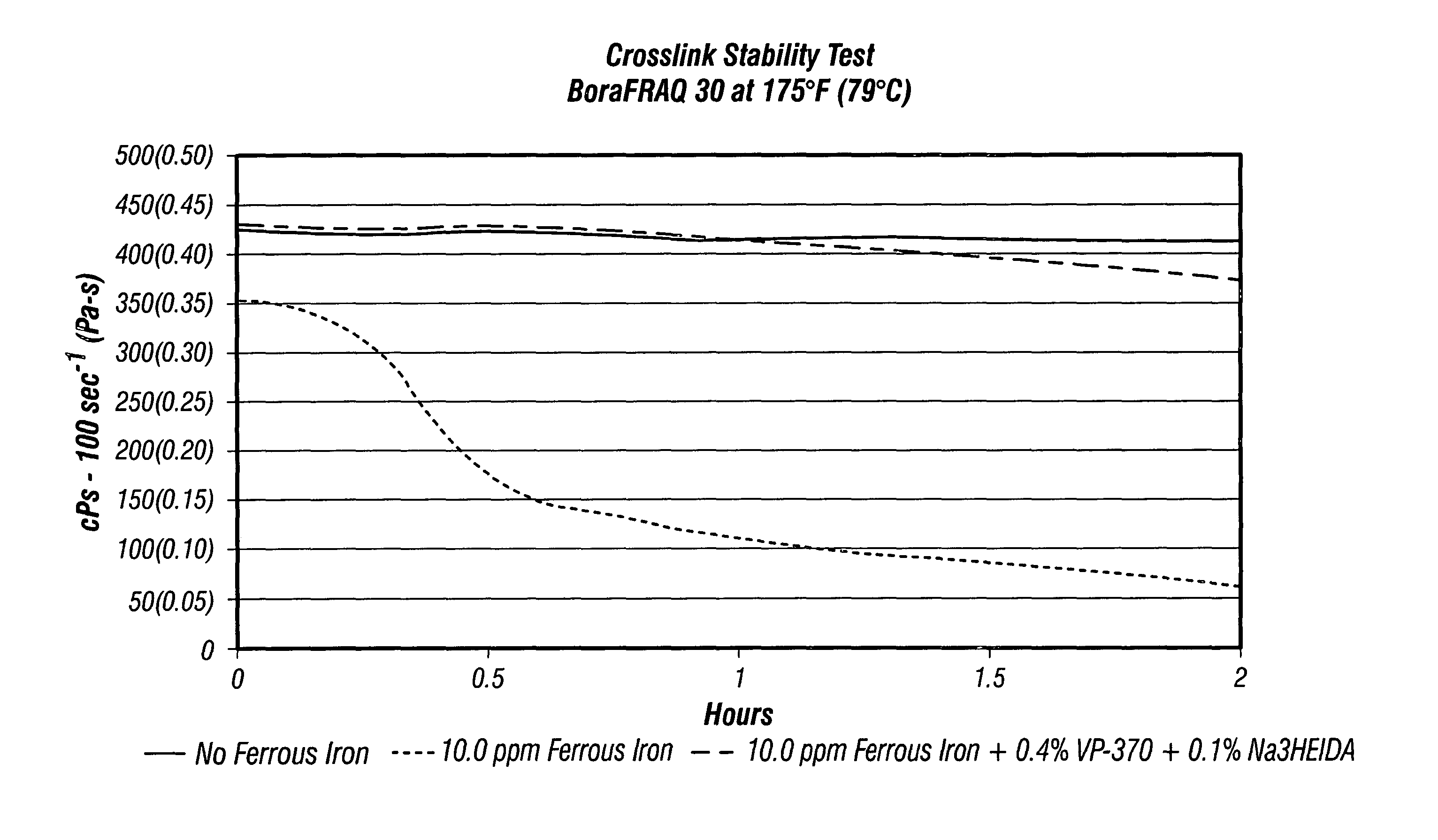

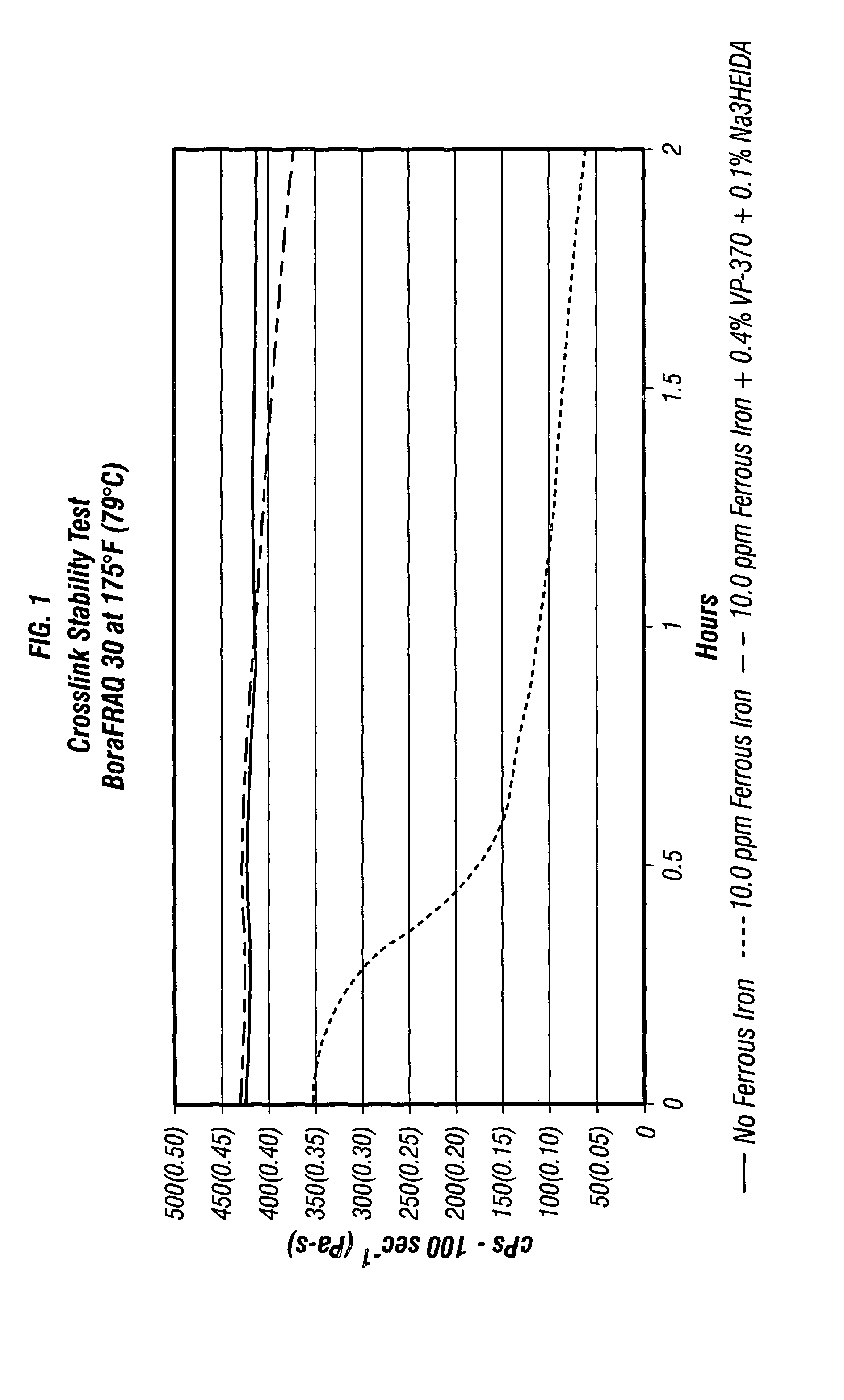

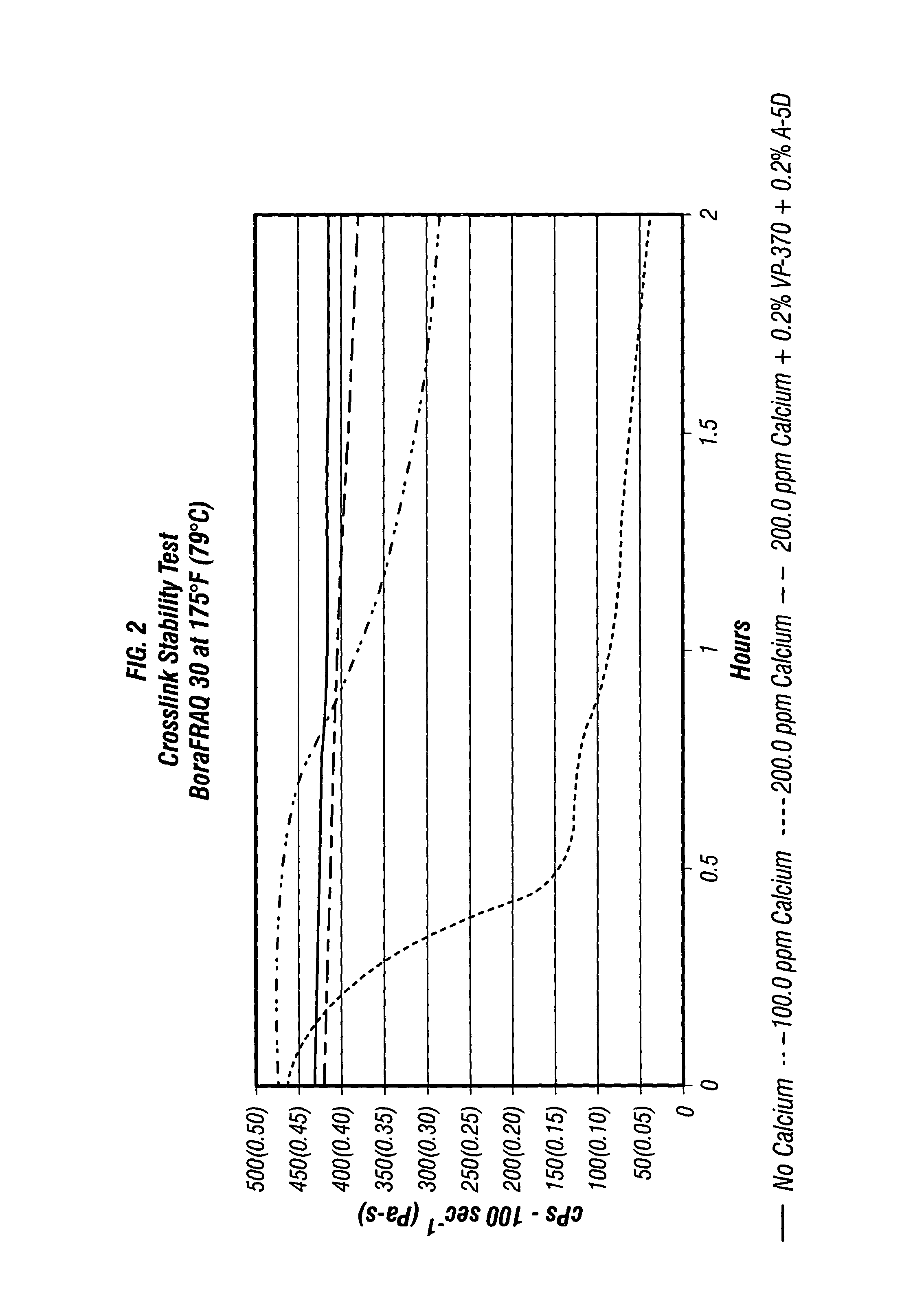

It has been discovered that biodegradable and non-toxic chelant compositions can perform multiple beneficial functions in an aqueous fracturing fluid through the chelation of ions. Some of the multiple functions include various combinations of the following: demulsifier, demulsifier enhancer, scale inhibitor, crosslink delay agent, crosslinked gel stabilizer, enzyme breaker stabilizer, and the like. Some of the chelants used in the compositions include, but are not necessarily limited to, sodium polyaspartate; sodium iminodisuccinate; disodium hydroxyethyleneiminodiacetate (Na2HEIDA); sodium gluconate; sodium glucoheptonate; sugar alcohols; monosaccharides; disaccharides; and mixtures thereof.

Owner:SUPERIOR ENERGY SERVICES LLC

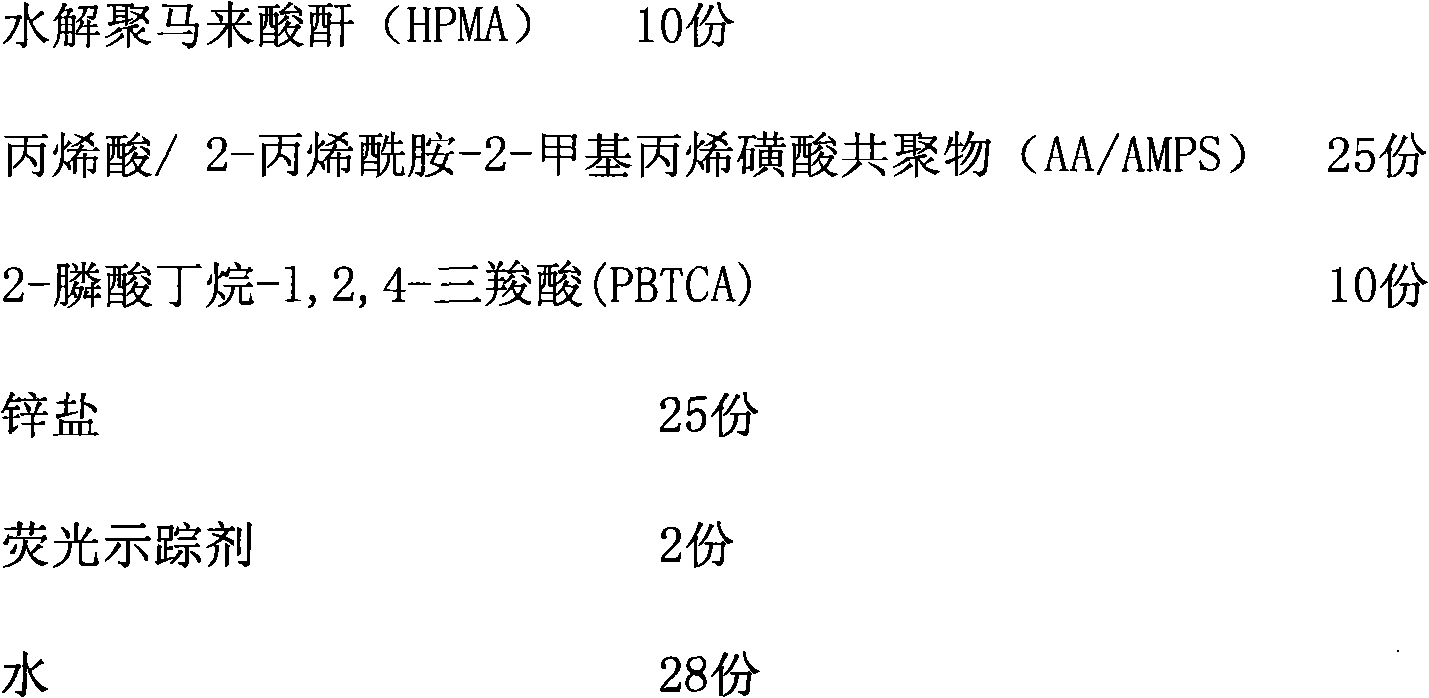

Composite phosphorus-free corrosion and scale inhibitor and its application

InactiveCN102815796AReduce pollutionAvoid water eutrophicationTreatment using complexing/solubilising chemicalsEutrophication2-methylpropene

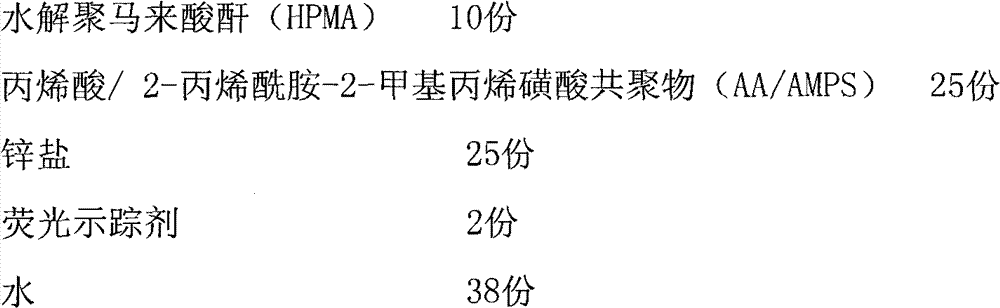

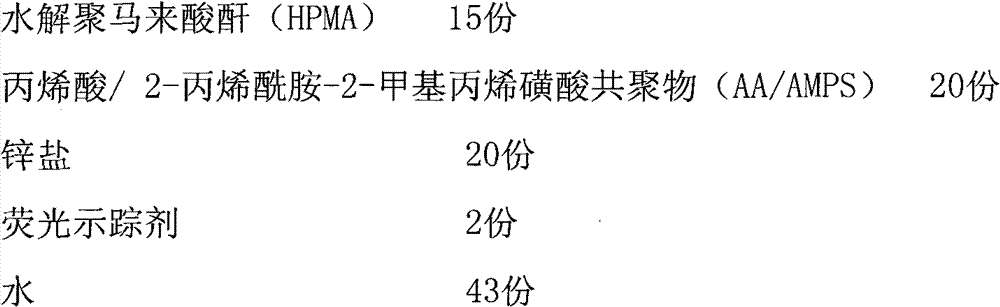

The invention provides a composite phosphorus-free corrosion and scale inhibitor and its application. The composite phosphorus-free corrosion and scale inhibitor is composed of a corrosion and scale inhibitor A and a corrosion and scale inhibitor B, wherein the corrosion and scale inhibitor A is obtained through mixing polyepoxysuccinic acid (PESA), sodium gluconate and water; and the corrosion and scale inhibitor B is obtained through mixing hydrolytic polymaleic anhydride (HPMA), an acrylic acid / 2-acrylamide-2-methylpropanesulfonic acid copolymer (AA / AMPS), a zinc salt, a fluorescent tracer and water. The composite phosphorus-free corrosion and scale inhibitor, which compounds the corrosion and scale inhibitor A and the corrosion and scale inhibitor B according to a weight ratio of the corrosion and scale inhibitor A to the corrosion and scale inhibitor B of 1:2, has the advantages of excellent corrosion and scale inhibition effects, avoiding of a water eutrophication problem caused by phosphorus discharge, environmental pollution mitigation, and good environmental protection property.

Owner:CHINA PETROLEUM & CHEM CORP

Low phosphate green composite corrosion and scale inhibitor for treating circular cooling water and its usage

InactiveCN1931745ACausing eutrophication pollutionGood scale inhibition and dispersibilityScale removal and water softeningPhosphateSewage

The present invention belongs to the field of circular cooling water treating technology, and is especially one kind of low phosphate green composite corrosion and scale inhibitor for treating circular cooling water and its usage. The green composite corrosion and scale inhibitor is compounded with polyepoxy sodium succinate, polysodium asparate, polymaleic acid, organic phosphonic acid, imidazoline type corrosion inhibitor, sodium gluconate, zinc salt and other antiscaling dispersant and corrosion inhibitor. When it is used, the green composite corrosion and scale inhibitor is added directly into circular cooling water. The green composite corrosion and scale inhibitor features its low phosphate content, biodegradability and environment friendship.

Owner:TONGJI UNIV

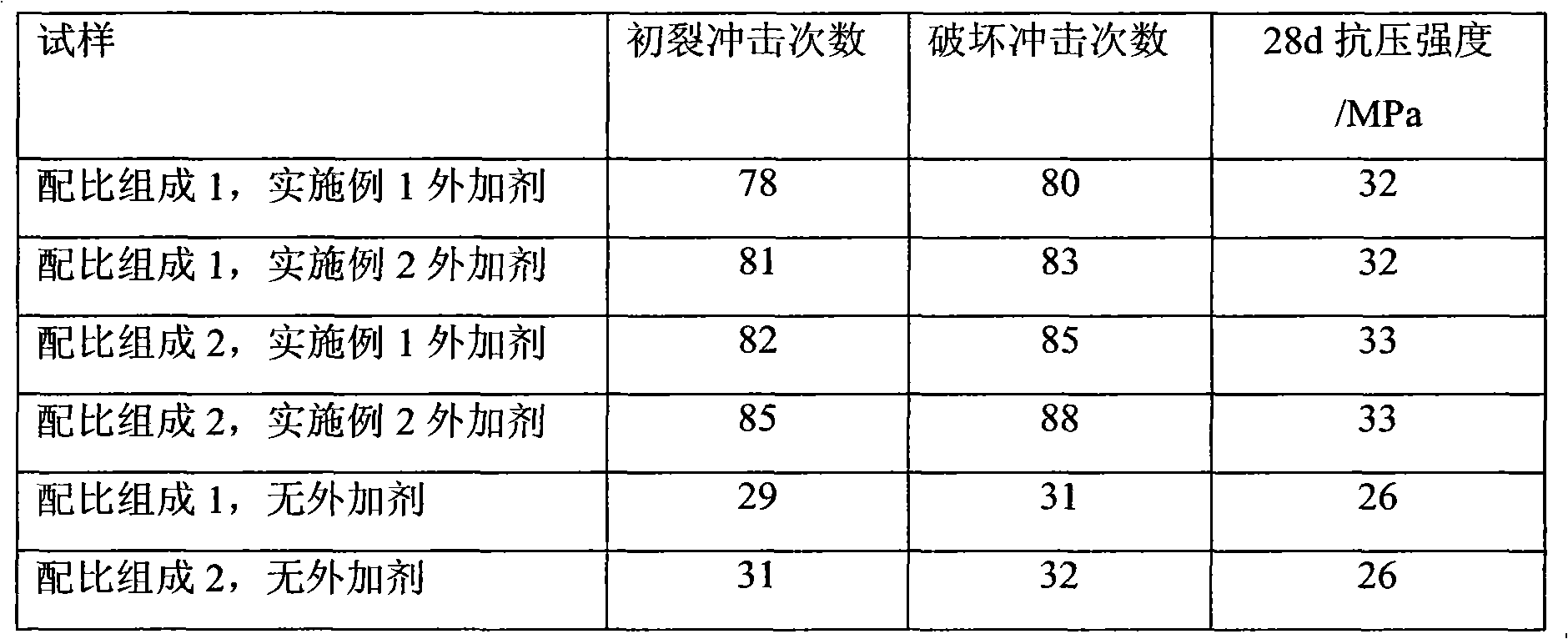

Concrete complex additive

The invention provides a concrete complex additive which comprises the following components by weight percent: 17.5-58.0% of efficient water reducing agent, 0.5-5.5% of organosilicon waterproofing agent, 0.2-2.5% of organosilicon reinforcing agent, 3.5-25% of polyacrylamide, 1.2-2.8% of triethanolamine, 3.2-6.3% of sodium nitrite, 0.3-1.2% of glycol, 0.6-1.3% of glycerol, 2.8-5.5% of sodium gluconate and the balance of water. The impact resistance, crocking resistance, impermeability and waterproofness of the concrete material can be obviously improved by using the complex additive provided by the application in the preparation process of the concrete, thus the concrete complex additives is especially suitable for the requirement on high-performance concrete for construction of airfield runways or highway bridges.

Owner:JIANGSU FENGTAI TOOLS

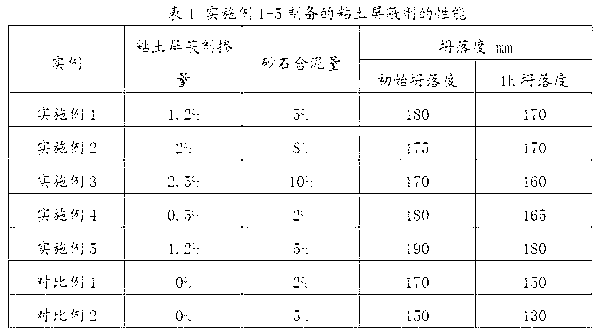

High-strength micro-expansive grouting material and its preparation method

The invention provides a high-strength micro-expansive grouting material and its preparation method. Raw materials of the high-strength micro-expansive grouting material comprise Portland cement having a compressive strength of above 42.5MPa, sulphoaluminate cement or aluminous cement having a compressive strength of above 42.5MPa, a calcium sulphoaluminate expanding agent, quartz sand or corundum or iron tailings, an organic silicon antifoaming agent, a polycarboxylate superplasticizer, calcium formate or lithium carbonate, sodium gluconate, and methyl cellulose ether or hydroxypropyl methyl cellulose ether or hydroxyethyl methyl cellulose ether. Compared with present cement-based grouting materials treating the sulphoaluminate cement and the aluminous cement as main cementing materials, the high-strength micro-expansive grouting material, which is obtained through treating the Portland cement as a main cementing material component, carrying out ultrafine crushing of the cementing material component via an ultrafine crushing technology, and processing, has the characteristics of high early-stage strength, excellent fluidity, increased long-term strength, and good durability; and compared with traditional epoxy mortars, the high-strength micro-expansive grouting material has the characteristics of micro-expansion, simple and fast construction, non-toxicity, and harmlessness.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Neutral blockage removing agent composition used for oil recovery formation in oilfield and preparation method thereof

ActiveCN104194759AImprove cleanlinessNo pollutionDrilling compositionActivated attapulgitePolythylene glycol

The invention relates to a neutral blockage removing agent composition used for an oil recovery formation in an oilfield. The neutral blockage removing agent composition is prepared from the following raw materials in parts by weight: 30-36 parts of disodium polyepoxysuccinicate, 18-25 parts of sodium gluconate, 2-3 parts of polyethylene glycol, 2-4 parts of triethanolamine, 9-12 parts of ethyl lactate, 7-10 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 8-12 parts of amino acid sodium, 10-15 parts of activated attapulgite, 0.1-0.2 part of vanadium pentoxide, 5-7 parts of lipase, 5-8 parts of sorbitan fatty acid ester, 15-18 parts of P-hydroxy sodium sulfonate, 3-7 parts of tert-butyl hydroperoxide and 0.1-0.3 part of diethylene glycol monolaurate. The neutral blockage removing agent composition has high blockage removing speed, is neutral, is free of corrosion and can quickly dissolve material scales, asphalt sediment scales, carbonate scales, silicate scales and the like generated by an ASP flooding system; waste liquid for blockage removal can be degraded and does not need to be discharged onto the ground to be subjected to sewage treatment, the formation in the oilfield is cleaned to remove the blockage, no corrosion, dead angle, precipitation or secondary well blockage is generated, and the blockage removal time does not exceed 24 hours.

Owner:GANSU HEIMA PETROCHEM ENG

Surface anodization coloring treatment method for titanium and titanium alloy

InactiveCN102115902AReduce process stepsEasy to operateSurface reaction electrolytic coatingPhosphoric acidDistilled water

The invention discloses a surface anodization coloring treatment method for titanium and titanium alloy, comprising the following technological process: firstly, putting titanium and titanium alloy sample pieces into an acetone solution and a caustic soda solution in sequence for cleaning oil stain, then cleaning with distilled water, drying, and putting the titanium and titanium alloy sample pieces into electrolyte for treatment, wherein the electrolyte is a mixed solution of phosphoric acid and sodium gluconate. The invention has the characteristics of simple technology, good binding force between an oxide film and a substrate, bright and uniform color and lower cost.

Owner:沈阳天贺新材料开发有限公司

Phosphate-free environment-friendly cleaning agent

InactiveCN101597547AReduce cleaning costsRelieve pressureInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsGluconic acidCleansing Agents

The invention discloses a phosphate-free environment-friendly cleaning agent which has non-toxic, innocuous, noncombustible, non-explosive, non-volatile, nonflammable, inodorous and phosphate-free. The cleaning agent mainly comprises the following raw material formulations in portion by weight: group A: 3 portions of sodium citrate, 2 portions of sodium gluconate, 4 portions of sodium hydroxide, 3 portions of sodium silicate, and 1 portion of sodium carbonate; group B: 3 portions of fatty alcohol-polyoxyethylene ether-AEO9, 4 portions of octylphenol-polyethoxylate OP-10, and 3 portions of triethanolamine; and group C, 60 to 80 portions of purified water.

Owner:陈安友

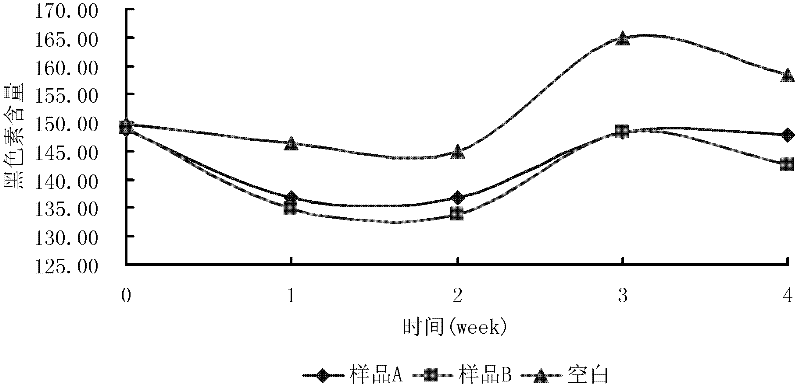

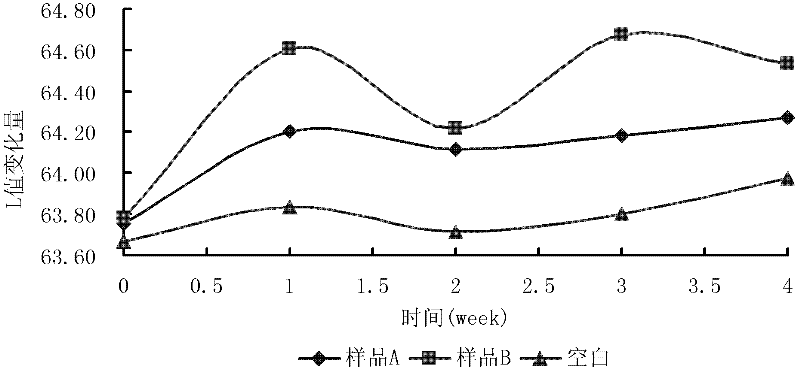

Skin-whitening chloasma-reducing skin-brightening composition, skin care product therewith, and preparation method thereof

ActiveCN102366397ASuppress or prevent generationNutritional supplementsCosmetic preparationsToilet preparationsSodium lactateWhitening Agents

The invention relates to a skin-whitening chloasma-reducing skin-brightening composition comprising raw materials of, by weight: 0.5 to 20 parts of nicotinamide, 0.1 to 15 parts of L-ascorbic acid 2-glucoside, 0.1 to 10 parts of an yeast extract, 0.05 to 10 parts of sodium lactate / sodium gluconate, 0.01 to 3.5 parts of sodium hydroxide, and 10 to 60 parts of water. With the composition provided by the invention, appearing and transferring of skin melanin can be inhibited or prevented from various perspectives; skin collagen protein synthesizing can be promoted, skin nutrients can be supplemented, such that skin aging can be retarded; and whitening effects can be achieved rapidly. Whitening active components are likely to be decomposed, oxidized, and discolored. With the composition, the problems can be solved; influences of lights and heat on the effective components are reduced. The product produced by the invention is safer than other whitening agents. With the product produced by the invention, nutrients required by skins can be provided. With a sustained-releasing technology, the whitening effect is more durable.

Owner:宝健(中国)有限公司

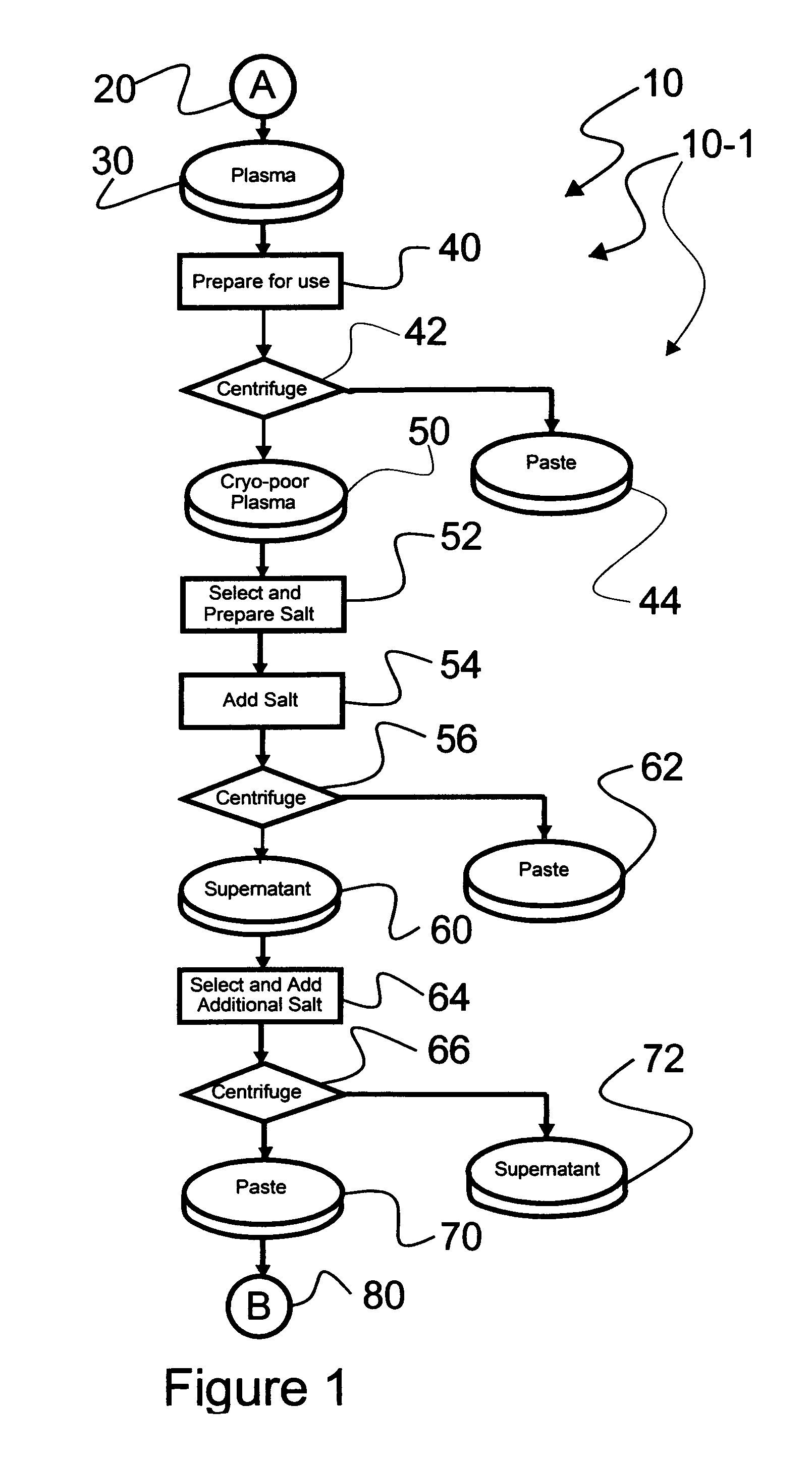

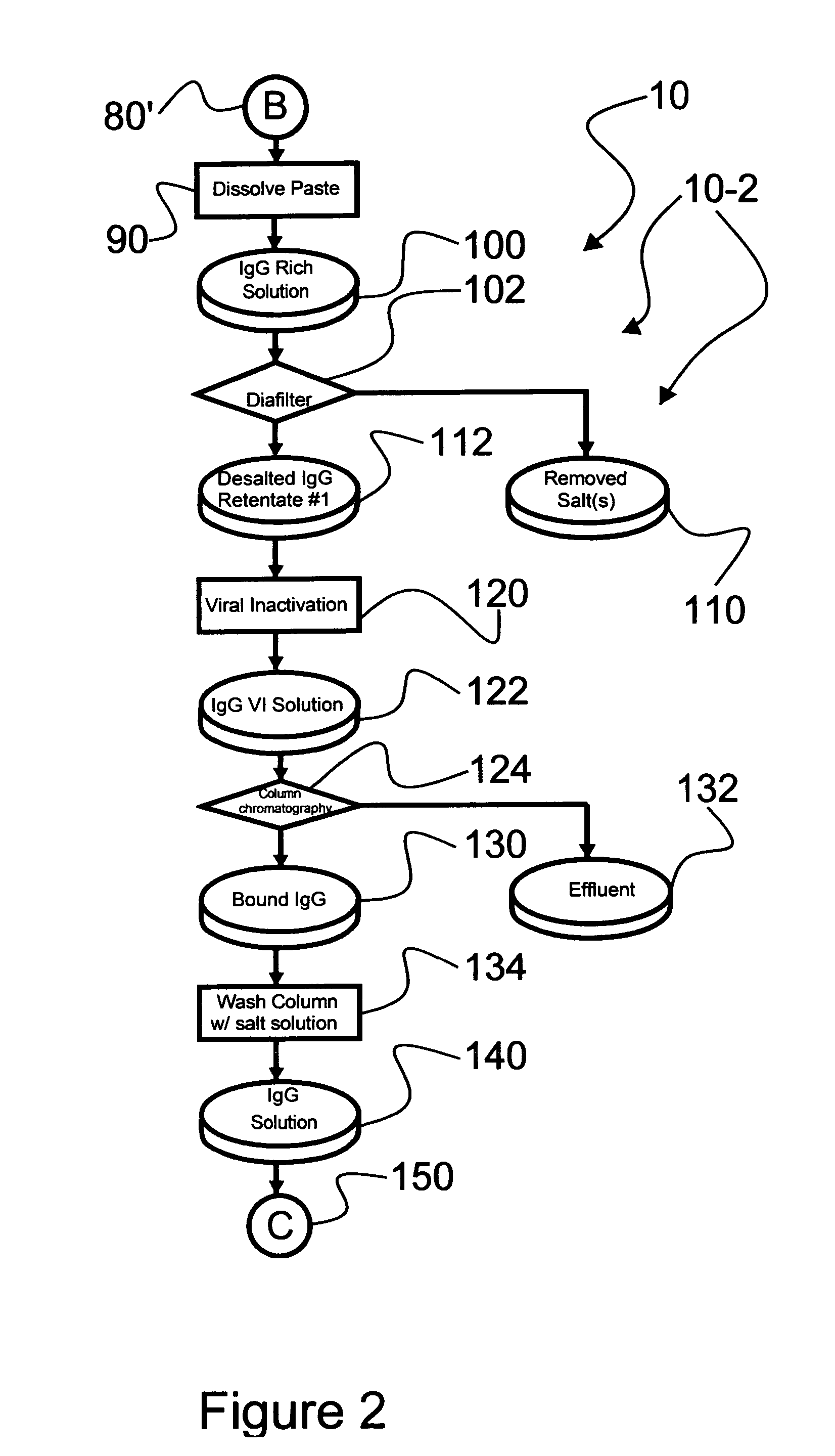

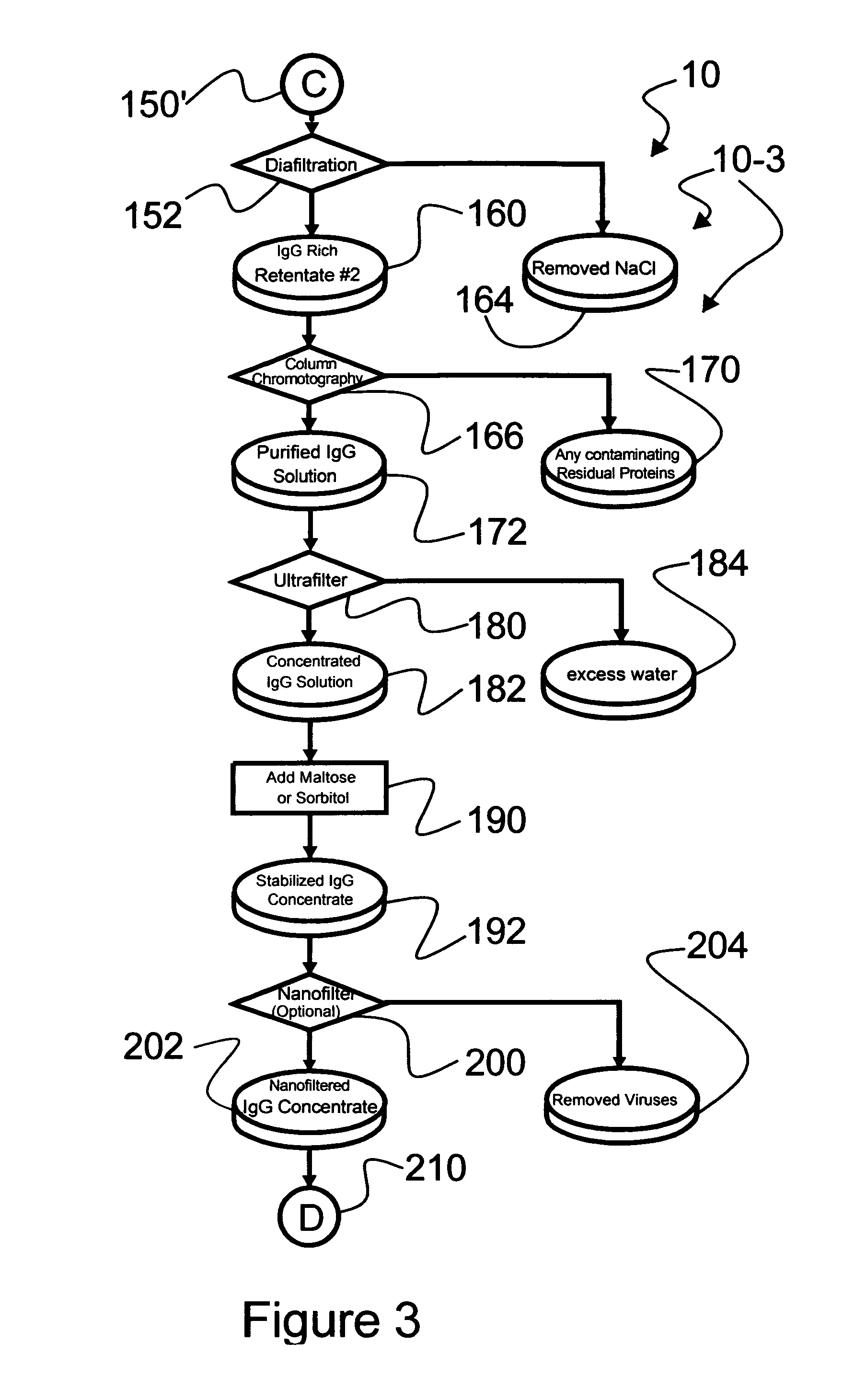

Ultra-high yield intravenous immune globulin preparation

ActiveUS7879332B2Quick restoration of the internal water moleculeReduce formationBiocideMedical devicesSodium acetateAlcohol free

An efficacious large-scale alcohol-free plasma fractionation production process which produces a high-yielding, non-denatured, double viral-inactivated intravenous human immune gamma globulin (IgG) product. The process employs one or more salts from a group of salts comprising sodium citrate, sodium acetate, sodium gluconate, ammonium sulfate, sodium chloride, sodium sulfate and ammonium chloride in two initial fractionation steps, followed by diafiltration to remove those salts employed. A process which employs alcohol via the process of the disclosed inventive method is also disclosed.

Owner:PLASMA TECH LLC

Preparation of corrosion and scale inhibitor used for high alkaline high chlorine circulating cooling water

ActiveCN101607766AStrong chelating abilityStrong corrosion inhibitorScale removal and water softeningEpoxyPhosphoric acid

The invention provides a preparation of a corrosion and scale inhibitor used for high alkaline high chlorine circulating cooling water which is prepared according to the following parts by weight: 23-25 parts of PESA, 23-25 parts of 2-phosphonic acid butane-1, 2, 4-tricarboxylic acid, 12-15 parts of corrosion and scale inhibitor, 10-15 parts of sodium gluconate, 5-8 parts of alkyl epoxy carboxylate, 2-3 parts of BTA, and 10-20 parts of pure water. The preparation comprises the following steps: adding industrial phosphoric acid of 400-420kg into a reaction kettle for stirring, adding triethanolamine of 140-160kg slowly within 30-35min, stirring for 50-60min, keeping the temperature at 40-80 DEG C, adding pure water of 385-400kg and stirring for 20-30min; adding zinc oxide of 45-55kg under stirring, stirring for 90-120min, and keeping the temperature at 40-80 DEG C to obtain the corrosion inhibition potentiating agent, adding PESA into the 2-phosphonic acid butane-1, 2, 4-tricarboxylic acid to mix with the solution of the corrosion inhibition potentiating agent, sequentially adding alkyl epoxy carboxylate, pure water and sodium gluconate to stir for 30-40min, keeping the temperature at 20-35 DEG C, then adding BTA, stirring for 30-60 min, and keeping the temperature at 20-35 DEG C to obtain the composite corrosion and scale inhibitor.

Owner:XINJIANG DELAND

Soil improvement biofertilizer and preparation method of soil improvement biofertilizer

The invention discloses a soil improvement biofertilizer and a preparation method of the soil improvement biofertilizer. The soil improvement biofertilizer is characterized by being prepared from the following raw materials in parts by weight: 200-350 parts of turf, 100-150 parts of clay, 5-10 parts of composite microbial agent, 5-7 parts of polyacrylamide, 60-80 parts of ammonium sulfate, 50-65 parts of monopotassium phosphate, 70-80 parts of calcium chloride, 20-25 parts of sodium borate, 15-25 parts of zinc sulfate, 20-25 parts of acetic acid, 2-3 parts of 1,2,3-glycerol, 6-10 parts of sodium gluconate, 80-100 parts of oyster shell powder and 9-12 parts of a soil conditioner. The soil conditioner contains a jade component which is beneficial to a human body by crop absorption; meanwhile, toxic heavy metal elements in soil can be effectively adsorbed and solidified; absorption of the heavy metal elements by the crops is reduced; and the crop yield can be increased. A plurality of microorganisms with the effects of fixing nitrogen, and resolving phosphor and potassium are added to the fertilizer, so that improvement of the soil structure is facilitated, and the yield and the quality of the crops are improved.

Owner:HEFEI SIFANG PHOSPHATE COMPOUND FERTILIZER

Concrete nano water-reducing super high-early-strength agent

The invention discloses a concrete nano water-reducing super high-early-strength agent which is capable of remarkably increasing early and late strength of concrete and shortening construction period and simultaneously has good water-reducing performance, plastic retaining performance, corrosion inhibiting performance and stability. The agent comprises the following ingredients: 46-52 wt% of early strength components, 26-32 wt% of water reducing components, 6-15 wt% of corrosion inhibiting components, 4-5 wt% of retarding components, and 6-8 wt% of adjustment components, wherein the early strength components comprise three or four selected from magnesium sulfate, sodium sulfate, sodium nitrite, triethanolamine, sodium thiosulfate, triisopropanolamine, and calcium formate, the water reducing components comprise one selected from naphthalene sulfonic acid high-efficiency water reducer and carboxylic acid water reducer, the corrosion inhibiting components comprise one selected from calcium nitrite, calcium nitrate, potassium chromate, and stannous chloride, the retarding components comprise one selected from sodium gluconate and citric acid, and the adjustment components comprise nano ground calcium carbonate.

Owner:DALIAN KEYKOWN TECH CO LTD +1

Clay screening agent and preparation method thereof

The invention discloses a clay screening agent. The clay screening agent comprises the following materials in percentage by weight: 0-50% of silicate, 0-50% of phosphate, 1%-5% of sodium gluconate, 1%-5% of lauryl sodium sulfate and 10%-50% of water. The preparation method of the clay screening agent disclosed by the invention comprises the following steps of: (1), firstly, weighing the materials in the percentage by weight; and (2), then, mixing and stirring the materials to obtain the clay screening agent, wherein the stirring temperature is 20 DEG C-50 DEG C, the stirring speed is 50 revolutions / minute-500 revolutions / minute, and the stirring time is 10 minutes-30 minutes. The clay screening agent disclosed by the invention can be used for preferably adsorbing the clay in a concrete gravel material, so that the bad influences of the clay are screened, and therefore, the acting effect of a polycarboxylic acid water reducing agent is improved. The clay screening agent is wide in material resource, not needed to be synthesized by chemical reaction, simple in preparation method, remarkable in acting effect and suitable for large-scale industrial production.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

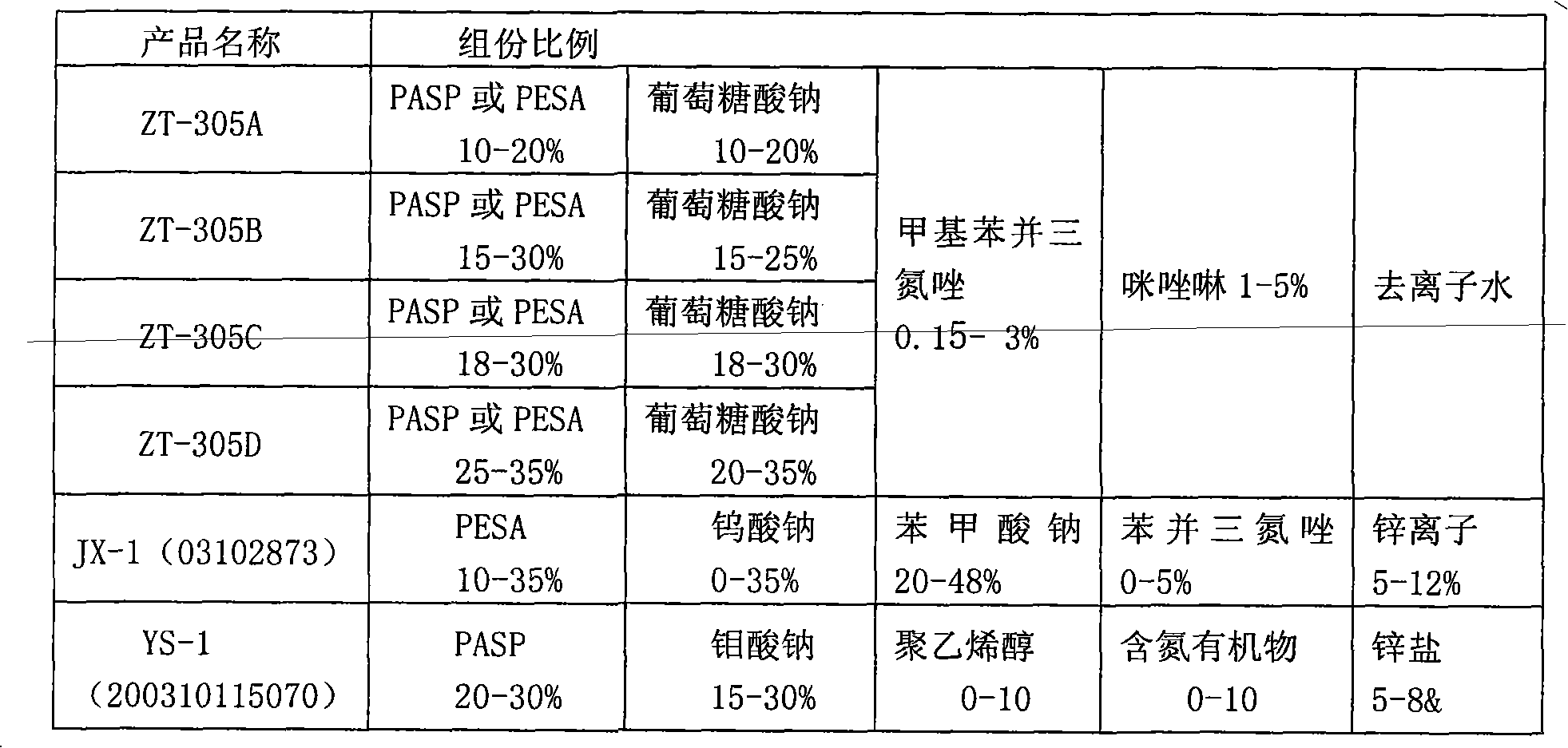

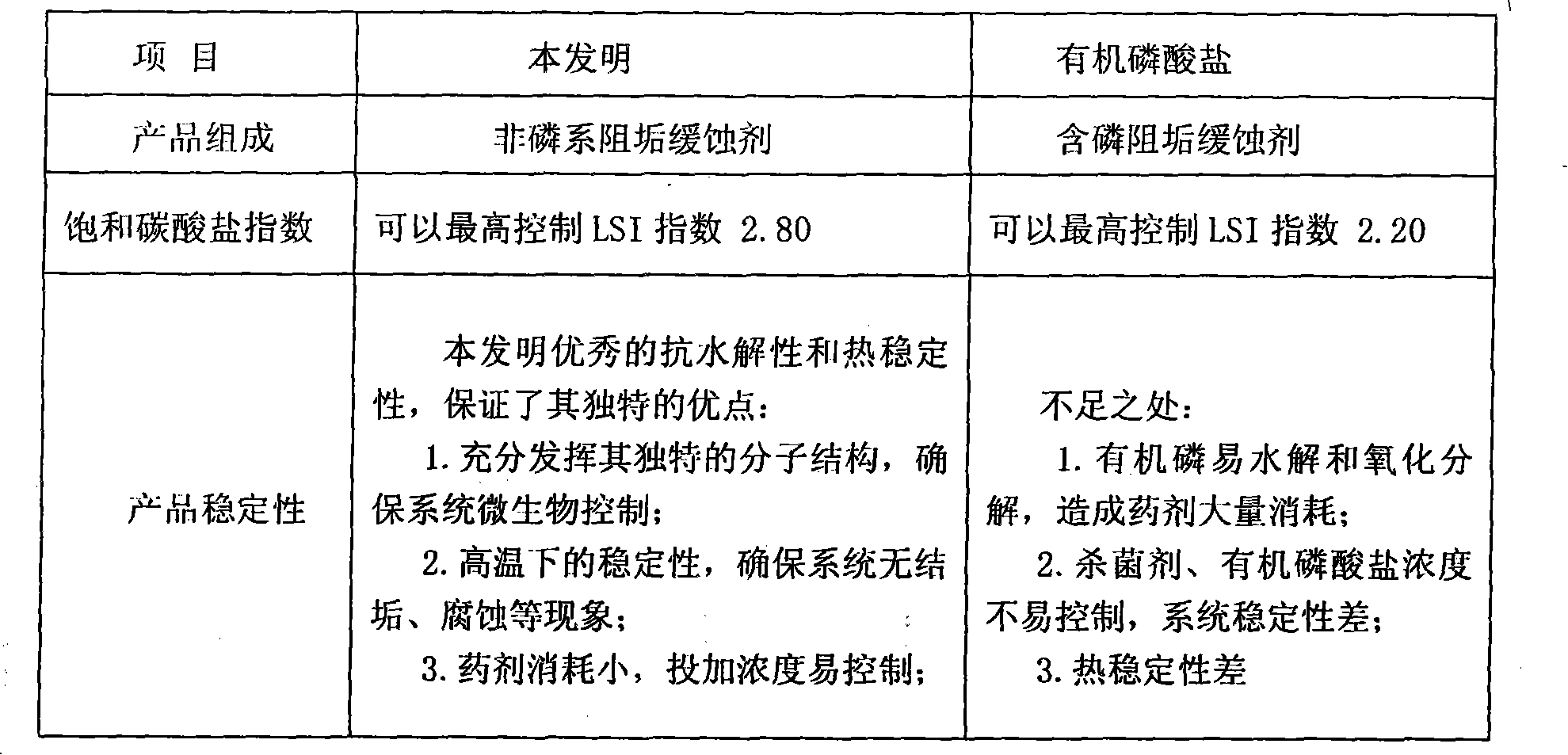

Scale and corrosion inhibitor for treating circulating cooling water

InactiveCN102134130AReduce deliveryLow costScale removal and water softeningPolyaspartic acidWater quality

The invention relates to a scale and corrosion inhibitor for treating circulating cooling water, which is prepared from the following components in percentage by weight: 10 to 35 percent of polyaspartic acid (PASP) or polyepoxysuccinic acid, 10 to 35 percent of sodium gluconate, 0.15 to 3 percent of methyl benzotriazole, 1 to 5 percent of imidazoline and deionized water. The polyaspartic acid (PASP) or the polyepoxysuccinic acid (PESA) with biodegradability serving as a main body is compounded with the deionized water, the methyl benzotriazole, the sodium gluconate and the imidazoline to form a phosphorus-free product; the sodium gluconate has good synergy with the methyl benzotriazole and the imidazoline, so the scale and corrosion inhibiting effect is good, and scale formation, corrosion and bacteria and algae propagation of the circulating water can be effectively prevented; and when the added mass concentration is 20mg / L, the corrosion rate is 0.0561mm / a. Under the same water quality condition, the scale and corrosion inhibitor has low adding concentration, low adding quantity and low cost compared with other like products; and the scale and corrosion inhibitor is stable at a high temperature, has certain chlorine resistance and oxidation resistance, can ensure that a system has no scale or corrosion or the like, and can be adapt to the water quality of various complex severe working conditions.

Owner:HUBEI ZO TAI ENVIRONMENT TECH

Liquid cement grinding additive

InactiveCN101696096AImprove early and late strengthReduce the amount of clinkerEthylenediamineDiethylenetriamine

The invention provides a liquid cement grinding additive, which comprises the following components in percentage by weight: 10 to 20 percent of tetrahydroxyethyl-ethylenediamine, 10 to 20 percent of ethoxyl-diethylenetriamine, 10 to 15 percent of diethylene glycol, 5 to 10 percent of polyethylene glycol, 2 to 5 percent of sodium tripolyphosphate, 3 to 5 percent of calcium lignosulphonate, 0 to 10 percent of tri-isopropanolamine, 0 to 8 percent of sodium gluconate, and the balance of water, wherein the molecular weight of the polyethylene glycol is between 200 and 400. As a preferred scheme of the invention, the content of the tri-isopropanolamine is between 5 and 10 percent, and the content of the sodium gluconate is between 5 and 8 percent. A cement and concrete admixture using the liquid cement grinding additive has good adaptability, can significantly improve the grinding efficiency of a grinding machine and improve the strengths of the cement in an early period and a later period by 2 to 4 MPa, or can reduce the clinker dosage by 4 to 8 percent and increase the adding volume of a mixed material by 4 to 8 percent in the cement under a condition of keeping the same cement strength grade.

Owner:NANJING YONGNENG MATERIALS

Recycled aggregate concrete and preparation method thereof

InactiveCN105174852AImproves microscopic stress-strain performanceWide variety of sourcesSolid waste managementEpoxySodium sulfate

The invention discloses recycled aggregate concrete and a preparation method thereof. The recycled aggregate concrete comprises the following raw materials by weight percent: 15 to 20 percent of cement, 5 to 15 percent of water, 15 to 25 percent of third mixed additive, 38 to 63 percent of coarse aggregate, 0.3 to 1 percent of modified wood fiber-containing polyurethane modified epoxy resin flexibilizing emulsion, 0.1 to 0.5 percent of lauryl sodium sulfate, 0.1 to 0.5 percent of sodium gluconate, 0.1 to 0.5 percent of water glass, 0.5 to 1 percent of polyacrylate, and the sum of weight percent of the raw materials is 100 percent; and the coarse aggregate is the waste concrete renewable coarse aggregate or a mixture of waste concrete renewable coarse aggregate and natural coarse aggregate. The renewable aggregate concrete has good impact resistance, earthquake resistance and crack resistance, the pressure resisting strength of the recycled aggregate concrete in 28 days can reach 80 to 100 MPa, and the recycled aggregate concrete is applicable to a load-bearing structure.

Owner:FUJIAN JIANGXIA UNIV

Low slump loss concrete pumping agent

The low slump loss concrete pumping agent has the composition of: naphthalene water reducing agent 35-65 wt%, calcium lignosulfonate 1.0-3.0 wt%, FEA sweller 30-60 wt%, saccharide retarder 1.0-3.0 wt%, sodium gluconate 0.5-4.5 wt% and air entraining agent lower than 0.03 wt%. Adding it in the amount of 3.5-5.0% of cement and other additive at 30-42 deg.c results in concrete solidifying time adjustable in 10-24 hr and 3H slump constant greater than 140 mm pumpable. Its use can avoid cold seam and delayed hydration heat peak. It has important application significence, especially in large volume and large area concrete engineering and concrete conveyance for long distance and at high environment temperature.

Owner:李乃珍

High-strength recycled concrete and preparation method thereof

The invention discloses a high-strength recycled concrete and a preparation method thereof, and relates to the field of building materials. The high-strength recycled concrete is prepared from the following components in parts by weight: 75 to 85 parts of ordinary Portland cement, 50 to 60 parts of natural fine aggregate, 90 to 100 parts of modified recycled coarse aggregate, 8 to 10 parts of flyash, 6 to 10 parts of micro-silicon powder, 1 to 2 parts of polycarboxylate water reduction agent, 8 to 12 parts of sodium gluconate, 5 to 6 parts of nanometer carbon fiber, 8 to 10 parts of stainlesssteel fiber, and 35 to 45 parts of water. The high-strength recycled concrete has the advantages that the compressive strength is high, and the anti-seepage property is good.

Owner:曙光装配式建筑科技(浙江)有限公司

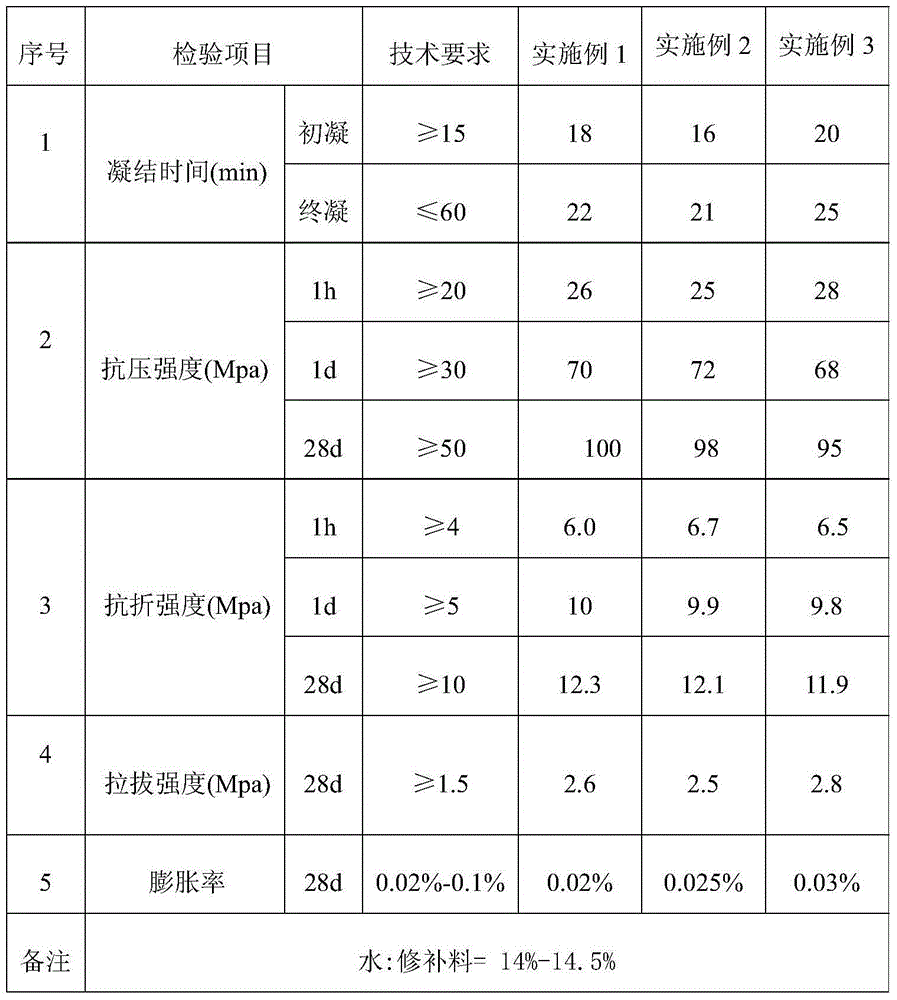

Pavement/bridge deck concrete fast mending material and application thereof

The invention relates to a pavement / bridge deck concrete fast mending material and application thereof. The mending material comprises the following raw materials by weight: 20 to 30 parts of sulphoaluminate cement, 8 to 10 parts of ordinary Portland cement 52.5, 5 to 10 parts of polymer powder, 0.5 to 1.5 parts of aluminium sulphate, 1 to 2 parts of water glass, 0.1 to 1 part of organic silicon, 1 to 2 parts of gypsum, 2 to 3 parts of slag, 0.1 to 0.5 part of silica micropowder, 0.5 to 1 part of an HPCA high-performance concrete expansive material, 3 to 5 parts of fly ash, 20 to 30 parts of washed-out and dried sand, 25 to 30 parts of corundum, 3 to 5 parts of composite fiber, 1 to 3 parts of a polycarboxylate superplasticizer, 0.1 to 0.5 part of boric acid, 0.1 to 0.3 part of sodium gluconate, and 0.2 to 1 part of lithium carbonate. The mending material is high in early strength, and has the advantages that traffic can be opened fast only 1 to 2 hours after mending is completed, so as to reduce traffic jams, and effectively reduce the generation of traffic accidents.

Owner:HENAN HUINENG ROAD & BRIDGE TECH CO LTD

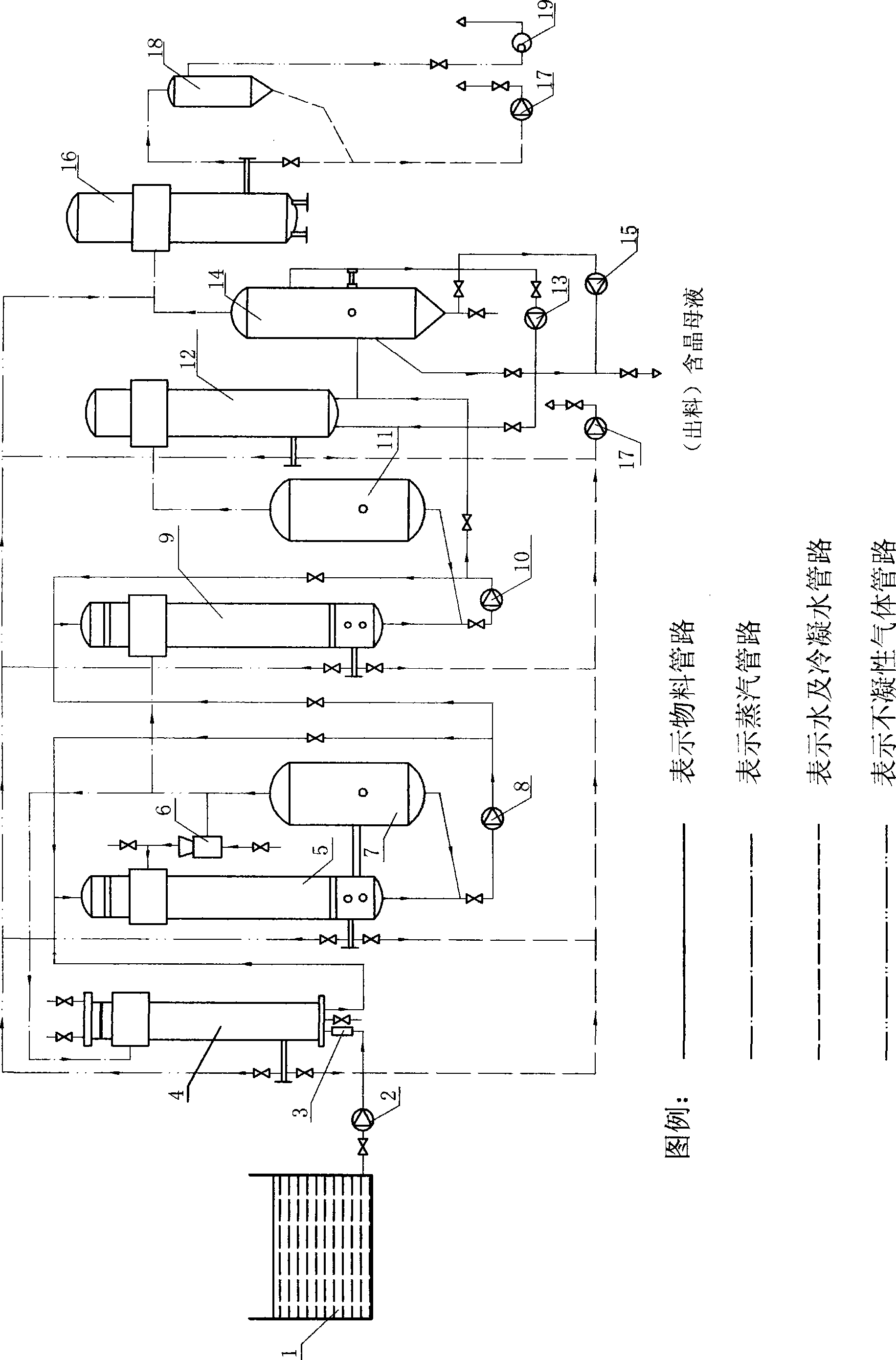

Production method and device for sodium gluconate energy-saving triple effect concentration and crystallization

InactiveCN101445449AIncrease production capacityImprove product qualityCarboxylic compound separation/purificationMoistureTriple effect

The invention discloses a production method and a device for sodium gluconate energy-saving triple effect concentration and crystallization. The continuity of sodium gluconate concentration and crystallization can be realized, that is, a raw material liquid enters a preheater continuously; the moisture can be evaporated after passing through 1st, 2nd and 3rd effect heating evaporators and 1st, 2nd and 3rd effect separators; the 2nd steam is separated continuously to heat and evaporate materials in the 1st, the 2nd and the 3rd effect heating evaporators; the crystal of sodium gluconate is separated out in the 3rd effect heating evaporator and pumped out continuously; therefore, the process of feeding, concentration and crystallization, and crystal separation at the same time is formed continuously, the 2nd steam is fully utilized, the steam consumption for evaporating moisture is 0.28 Tsteam / Twater, the crystallization rate achieves 65%, and materials can form a large amount of crystal in the 3rd effect heating evaporator. The invention can improve the productivity, reduce the steam consumption and improve the quality of products.

Owner:山东凯翔生物科技股份有限公司

Composite material toughened ceramisite concrete and preparation method thereof

ActiveCN105541212AImprove toughnessImprove isotropic performanceSolid waste managementFiberAggregate (composite)

The invention belongs to the field of preparation of concrete, and in particular relates to composite material toughened ceramisite concrete and a preparation method thereof. The composite material toughened ceramisite concrete comprises the following components in parts by weight: 320-360 parts of cement, 40-80 parts of lithium slagpowder, 20-40 parts of silica fume, 700-900 parts of recycled coarse aggregates, 500-800 parts of ceramisites, 3-4 parts of a water reducing agent, 100-200 parts of water, 10-20 parts of polyacrylate, 20-30 parts of a toughening composite material, 0.05-0.1 part of sodium gluconate, and 10-15 parts of triethanolamine, wherein the toughening composite material is prepared from the following raw materials in parts by weight: 1.2-1.8 parts of modified silicon dioxide nanotubes, 22-28 parts of a styrene-butadiene-styrene block copolymer, 46-50 parts of activated wood powder fibers, 3.5-5 parts of a silane coupling agent, 3.0-3.5 parts of a solubilizing agent, 4-6 parts of a filler and 180-220 parts of water. The concrete has good toughness, isotropy, fatigue resistance, compactness, crack resistance, shock resistance and permeability resistance, and is a high-performance concrete toughening material, and the 28-day compression strength of the prepared concrete can reach 30-60MPa, so that the concrete is suitable for building bearing structures.

Owner:福建省东霖建设工程有限公司

Sponge municipal high-strength high-toughness regenerated aggregate concrete and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to a sponge municipal high-strength high-toughness regenerated aggregate concrete and a preparation method thereof. The concrete comprises the following raw materials in parts by weight: 320-360 parts of cement, 40-80 parts of lithium slag powder, 20-40 parts of silica fume, 700-900 parts of regenerated coarse aggregate, 500-400 parts of natural coarse aggregate, 20-30 parts of superfine microbead, 3-4 parts of water reducing agent, 100-120 parts of water, 10-20 parts of polyacrylate, 10-20 parts of adhesive, 20-30 parts of toughening material, 1-1.2 parts of triethanolamine and 0.05-0.1 part of sodium gluconate. The toughening material can be sufficiently dispersed in the concrete, effectively displays the synergic toughening effect of the material, and endows the integral concrete with favorable toughness, isotropy and fatigue resistance.

Owner:ZHONGHUAN BUILDING FUJIAN CO LTD

Chemical process

This invention provides a process for preparing sodium ferric gluconate complex in sucrose using the following steps: a) combining a ferric salt solution with a weak alkali chosen from the group consisting of alkaline earth metal and ammonium salts, such as sodium carbonate, sodium bicarbonate, lithium carbonate, potassium carbonate, potassium bicarbonate, ammonium carbonate, ammonium bicarbonate and mixtures thereof, to form the ferric oxyhydroxide; b) combining ferric oxyhydroxide and sodium gluconate in solution to yield the sodium ferric gluconate complex; c) isolating the sodium ferric gluconate complex; and d) combining the sodium ferric gluconate with sucrose in solution to yield the desired sodium ferric gluconate complex in sucrose.

Owner:GENEVA PHARMA INC

Ferrous sulfide dirt neutral complexing cleaning agent and preparation method thereof

ActiveCN103194325ATo achieve the purpose of safe productionImprove anti-corrosion performanceNon-ionic surface-active compoundsOrganic detergent compounding agentsChemical industrySodium acetate

The invention relates to an equipment cleaning agent which is used in the field of petroleum and chemical industry, in particular to a ferrous sulfide dirt neutral complexing cleaning agent which is used for washing a synthesized ammonia low-temperature methanol washing unit system in the petroleum chemical industry and the coal chemical industry. The ferrous sulfide dirt neutral complexing cleaning agent is prepared from the following raw materials in parts by weight: 5 to 8 parts of sodium gluconate, 7 to 11 parts of sodium salicylate, 20 to 26 parts of gadoliniam diethylene triamine pentaacetic acid, 20 to 26 parts of sodium ethylene diamine tetracetate, 40 to 46 parts of propenoic acid-itaconic acid copolymer, 25 to 32 parts of disodium polyepoxysuccinicate, 12 to 15 parts of sodium hydroxyphenylace, 3 to 7 parts of triethanolamine, 3 to 7 parts of hydrogen peroxide, 0.1 to 0.3 part of lauryl sodium sulfate, 0.1 to 0.3 part of polydimethyl siloxane fluid and 40 to 45 parts of water. The ferrous sulfide dirt neutral complexing cleaning agent is free from generating hydrogen sulfide when cleaning the ferrous sulfide dirt and corroding the equipment and has strong capacity for complexing the iron ions, the removal speed is fast, the decontamination rate is more than 98 percent, the neutralization and passivation are unnecessary to carry out after the chemical washing, and the equipment can be put into operation immediately.

Owner:GANSU HEIMA PETROCHEM ENG

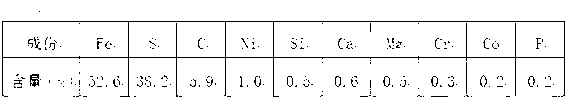

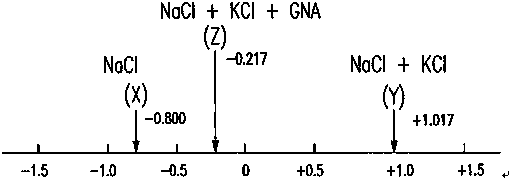

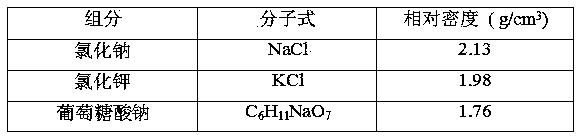

Novel low-sodium salt containing sodium gluconate and preparation method thereof

ActiveCN103404834AReasonable compositionMask bitternessFood preparationSpray driedChloride potassium

The invention discloses a novel low-sodium salt containing sodium gluconate and a preparation method thereof. The novel low-sodium salt is specifically prepared from the following ingredients in percentage by weight: 15-25% of sodium gluconate, 40-70% of sodium chloride, 15-25% of potassium chloride and 0.5-2% of maltodextrin. The preparation method comprises the steps of mixing sodium chloride, potassium chloride and sodium gluconate according to the ratio, dissolving a mixture into deionized water, heating and stirring until the mixture is completely dissolved, adding 1.5% of maltodextrin into a solution, stirring for certain time, and then, immediately carrying out spray drying. The finally prepared low-sodium salt product is powdery, and the moisture granularity is within a specific range. The sodium content of the product is at least 25% lower than that of the traditional edible salt; and compared with the ordinary low-sodium salt, due to the innovation of the preparation manners for the product, the product has the advantages that the homogeneity is improved, and the taste is pure and is not bitter on the premise that the salinity is guaranteed.

Owner:SHANDONG XIWANG SUGAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com