Liquid cement grinding additive

A cement grinding aid and liquid technology, applied in the field of cement manufacturing, can solve problems such as cost increase, cement water consumption increase, mixing, etc., to achieve good adaptability and improve the effect of grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

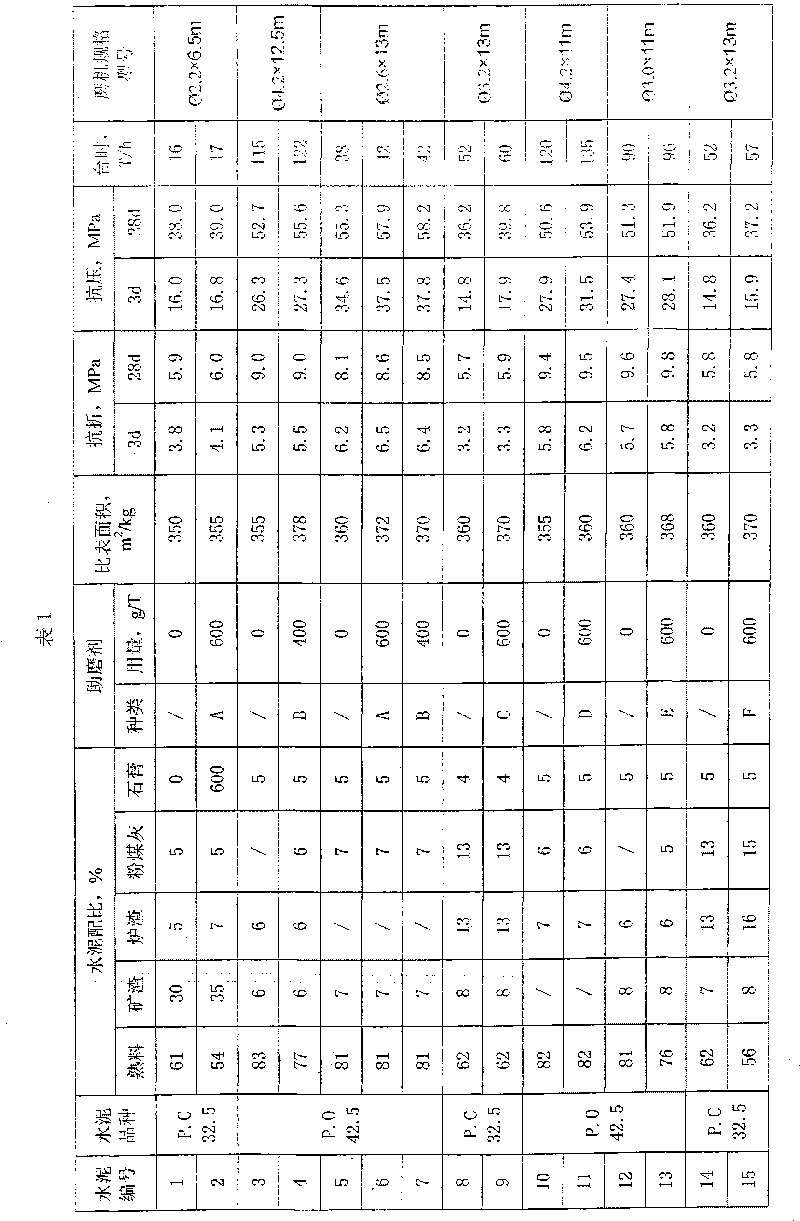

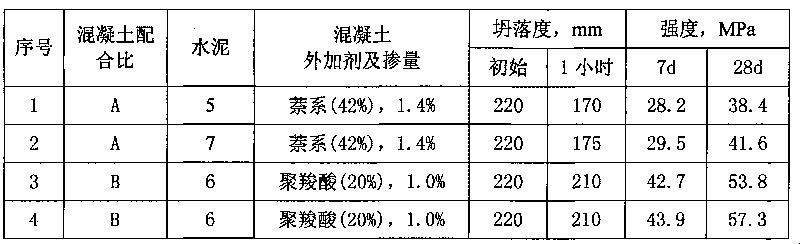

Examples

preparation Embodiment 1

[0021] A kind of liquid cement grinding aid A, composition is as follows:

[0022] Tetrahydroxyethylethylenediamine 10%,

[0023] Hydroxyethyldiethylenetriamine 10%,

[0024] Diethylene glycol 15%,

[0025] Polyethylene glycol (molecular weight 200) 5%,

[0026] Sodium Tripolyphosphate 5%,

[0027] Calcium lignosulfonate 5%,

[0028] The balance is water.

[0029] The preparation process of this liquid cement grinding aid is as follows:

[0030] Inject hot water at 30-40°C into the reaction kettle, add sodium tripolyphosphate and calcium lignosulfonate into it and stir evenly, then filter the materials in the reaction kettle with a 150-mesh screen; then add tetrahydroxyethyl Ethylenediamine, hydroxyethyldiethylenetriamine, diethylene glycol, and polyethylene glycol are stirred evenly to obtain a liquid cement grinding aid product.

preparation Embodiment 2

[0032] A liquid cement grinding aid B, composed as follows:

[0033] Tetrahydroxyethylethylenediamine 20%,

[0034] Hydroxyethyldiethylenetriamine 20%,

[0035] Diethylene glycol 10%,

[0036] Polyethylene glycol (molecular weight 200) 10%,

[0037] Sodium Tripolyphosphate 2%,

[0038] Calcium Lignosulfonate 3%,

[0039] The balance is water.

[0040] Its preparation process is the same as Preparation Example 1.

preparation Embodiment 3

[0042] A liquid cement grinding aid C, composed as follows:

[0043] Tetrahydroxyethylethylenediamine 10%,

[0044] Hydroxyethyldiethylenetriamine 10%,

[0045] Diethylene glycol 10%,

[0046] Polyethylene glycol (molecular weight 200) 5%,

[0047] Sodium Tripolyphosphate 5%,

[0048] Calcium Lignosulfonate 5%,

[0049] Triisopropanolamine 5%,

[0050] Sodium Gluconate 5%,

[0051] The balance is water.

[0052] The preparation method of this liquid cement grinding aid is as follows:

[0053] Inject hot water at 30-40°C into the reaction kettle, add sodium tripolyphosphate, calcium lignosulfonate, and sodium gluconate into it and stir evenly, then filter the materials in the reaction kettle with a 150-mesh screen; then add Tetrahydroxyethylethylenediamine, hydroxyethyldiethylenetriamine, diethylene glycol, polyethylene glycol, and triisopropanolamine are mixed evenly to obtain a liquid cement grinding aid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com