High-performance compound cement retarder and preparation method thereof

A cement retarder and high-performance technology, applied in the field of cement admixtures, can solve the problems of large amount of solid retarder, unfavorable industrial production, and high cost of retarder, achieving obvious retardation effect and improving early and late strength. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A high-performance composite cement retarder and a preparation method thereof, comprising the following components: a cationic surfactant, a silane coupling agent, glacial acetic acid, glucose, an organic solvent, and deionized water.

[0023] The preparation method of described high-performance composite type cement retarder comprises the following processing steps:

[0024] (1) Add silane coupling agent, organic solvent, and deionized water into the reaction kettle to form a hydrolysis system of silane coupling agent, the mass ratio of the silane coupling agent to the organic solvent is 0.1 to 1.0, and the The mass ratio of the silane coupling agent to the deionized water is 0.1-1.0.

[0025] (2) Carry out the hydrolysis reaction of the silane coupling agent at a temperature of 40-120° C., and the hydrolysis time is 0.5-4 hours.

[0026] (3) After the hydrolysis reaction of the silane coupling agent is completed, add glacial acetic acid to adjust the pH of the hydrol...

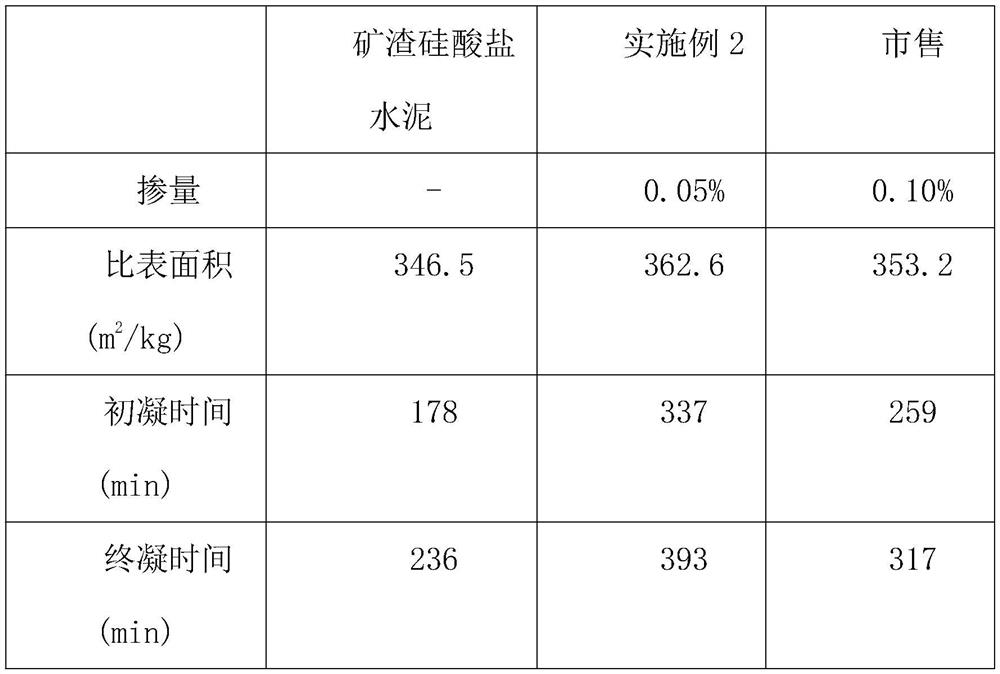

Embodiment 2

[0043] A high-performance composite cement retarder and a preparation method thereof, comprising the following components: a cationic surfactant, a silane coupling agent, glacial acetic acid, glucose, an organic solvent, and deionized water.

[0044] The preparation method of described high-performance composite type cement retarder comprises the following processing steps

[0045](1) 50 parts of silane coupling agent KH570, 50 parts of isopropanol and 150 parts of water were added to the reaction kettle to carry out the hydrolysis reaction of the silane coupling agent at 80°C, the hydrolysis time was 40min, and the pH of the hydrolyzed solution was adjusted by adding glacial acetic acid To 3-6, a silane coupling agent hydrolyzate is obtained. 50 parts of N-methyl-N-decylaminoethyl trimethyl ammonium bromide, 500 parts of glucose, 195 parts of deionized water were added to the stirring tank and stirred until a homogeneous phase, and then the silane coupling agent hydrolyzed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com